High-temperature resistant composite battery separator and preparation method thereof

A composite battery, high temperature resistant technology, applied in the direction of battery pack components, circuits, electrical components, etc., can solve the problems of limited adhesive bonding effect, decreased mechanical strength of the diaphragm, high self-discharge probability, etc., to ensure various performances , The conduction rate is fast, the effect of increasing the dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

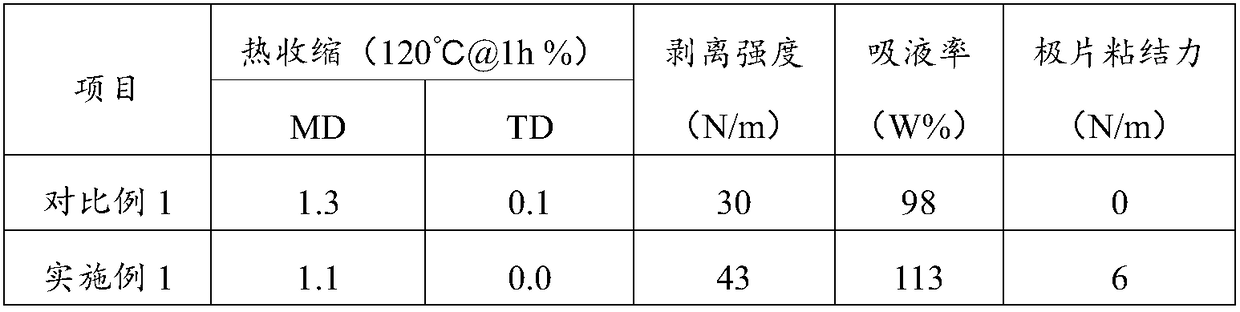

[0030] The base membrane of this example is a polypropylene microporous membrane with a thickness of 16 μm, a porosity of 40%, and a pore size of 0.02-0.03 μm from Shenzhen Zhongxing Innovative Materials Technology Co., Ltd.; this example uses aluminum oxide inorganic particles bonded with nano-cellulose The high-temperature-resistant coating is prepared with a high-temperature-resistant coating, wherein the particle size of the aluminum oxide inorganic particles is D50 0.50-0.82 μm; the length of the nanocellulose is 300-3000 nm, the diameter is 1-80 nm, and the crystallinity is greater than 50%. The preparation method of nanocellulose refers to Kun.Y, ACSAppl.Mater.Interfaces, 2017, 9, 20169. The preparation method of the high temperature resistant coating composite diaphragm of this example is as follows:

[0031] First, prepare nanocellulose suspension, the preparation method refers to Kun.Y, ACS Appl. Mater. Interfaces, 2017, 9, 20169. Specifically, the pulp is added int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com