Patents

Literature

89results about How to "Improve charge and discharge rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

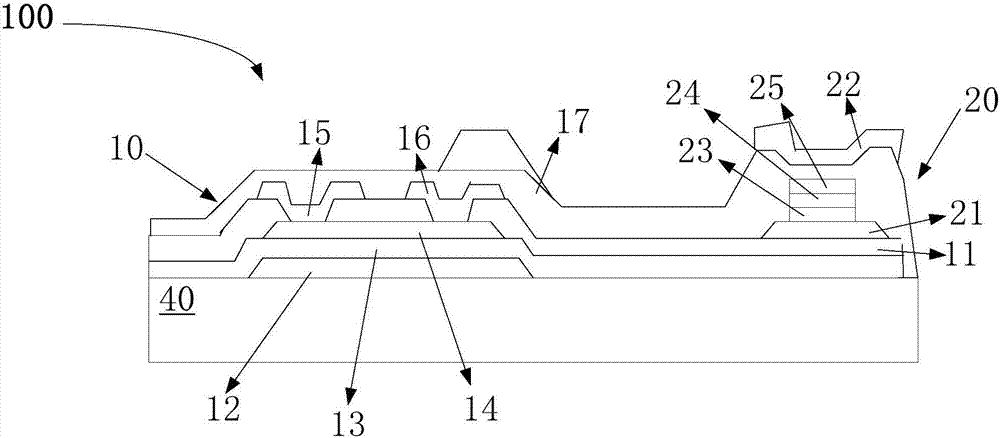

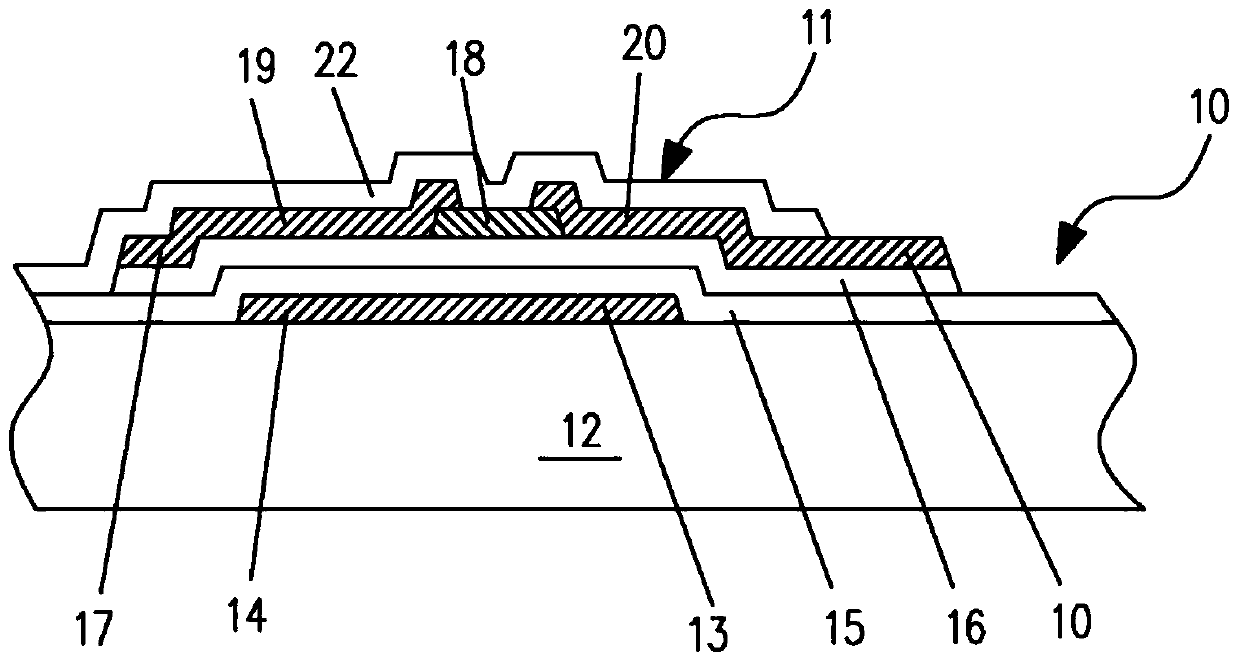

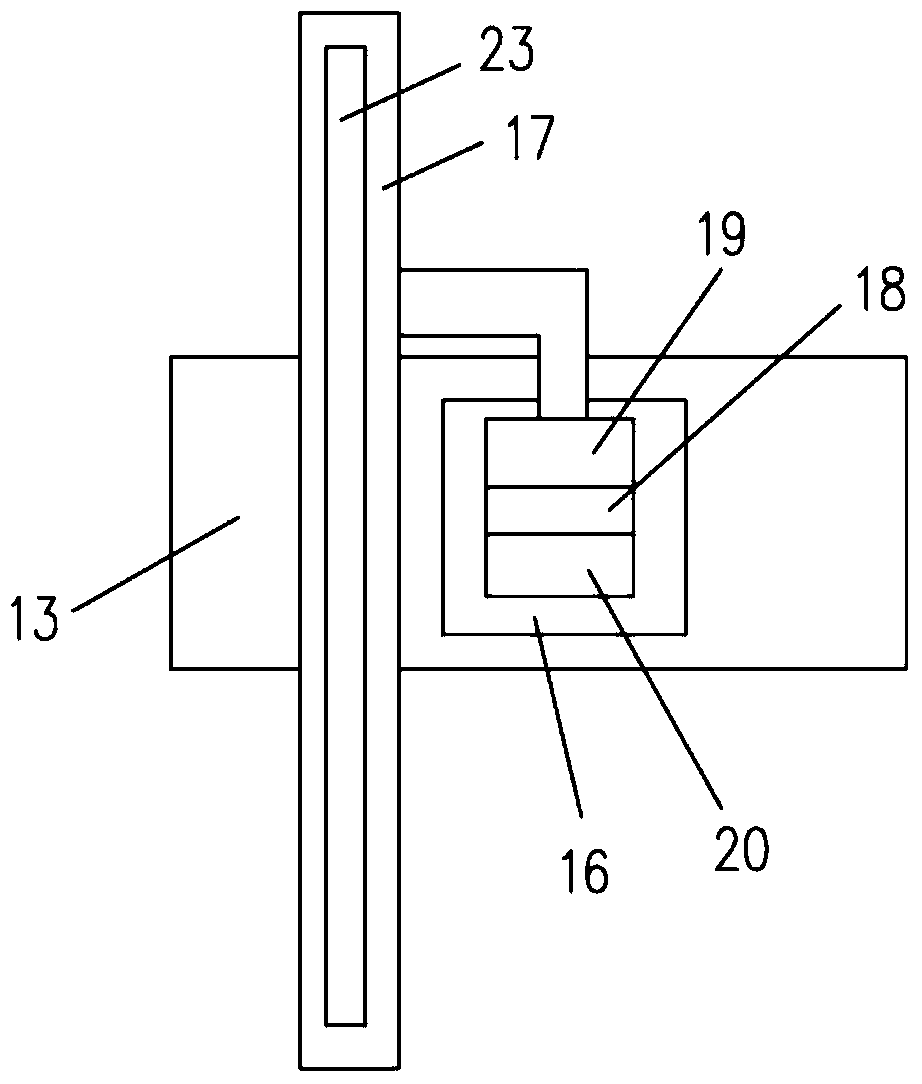

Array substrate and display device

ActiveCN104656334AImprove image qualityImprove charge and discharge rateTransistorSolid-state devicesDisplay deviceEngineering

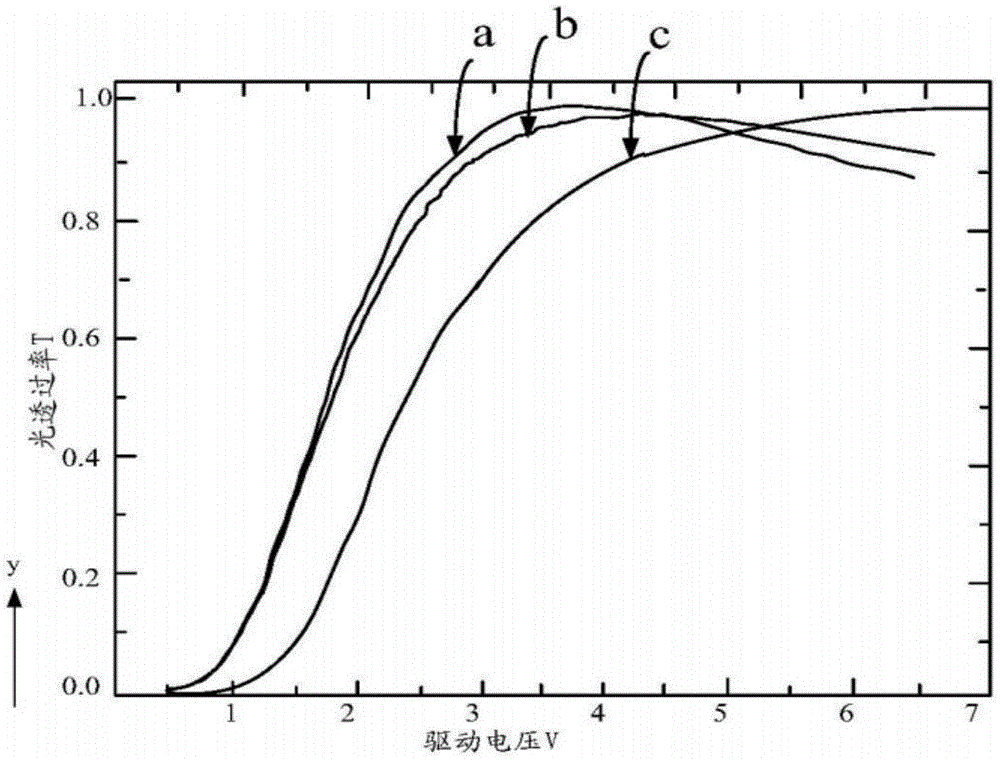

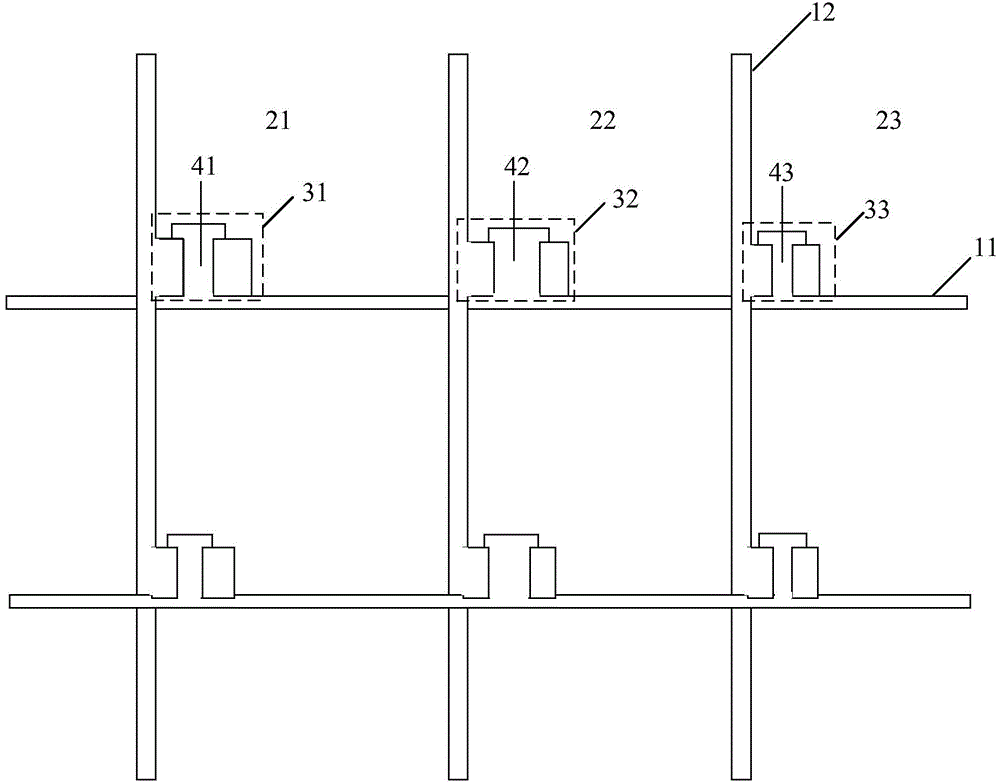

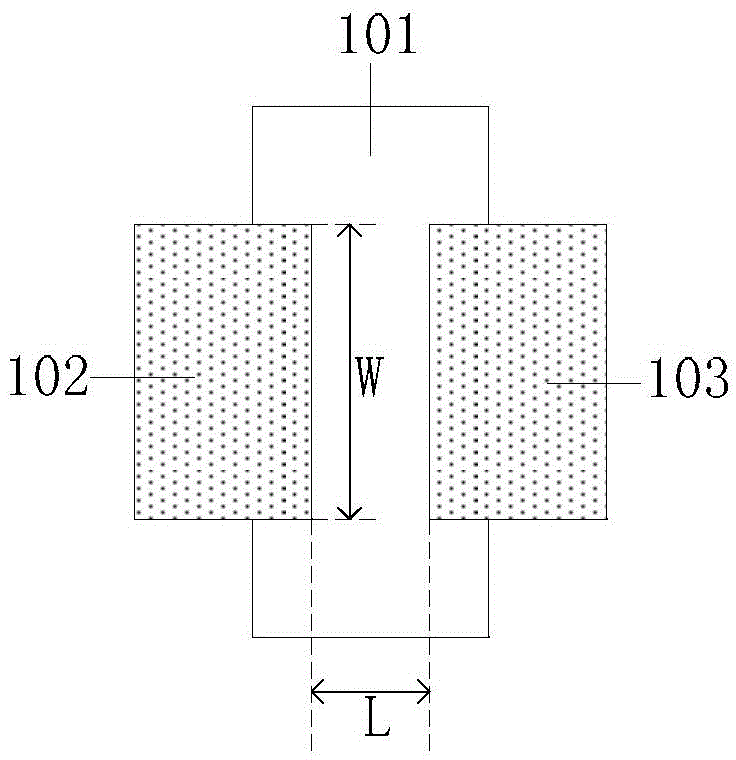

The embodiment of the invention provides an array substrate and a display device, relating to the technical field of electronics. The problem of color offset generated by a display device is reduced to a certain degree. According to the scheme, a first pixel unit corresponds to a red resistor and comprises a first TFT channel formed between the source and drain of a first TFT; a second pixel unit corresponds to a green resistor and comprises a second TFT channel formed between the source and drain of a second TFT; a third pixel unit corresponds to a blue resistor and comprises a third TFT channel formed between the source and drain of a third TFT; and the ratio of the width to length of the third TFT channel is higher than that of the second TFT channel, or the ratio of the width to length of the third TFT channel is higher than that of the first TFT channel. The scheme is used for the array substrate and the display device.

Owner:BOE TECH GRP CO LTD +1

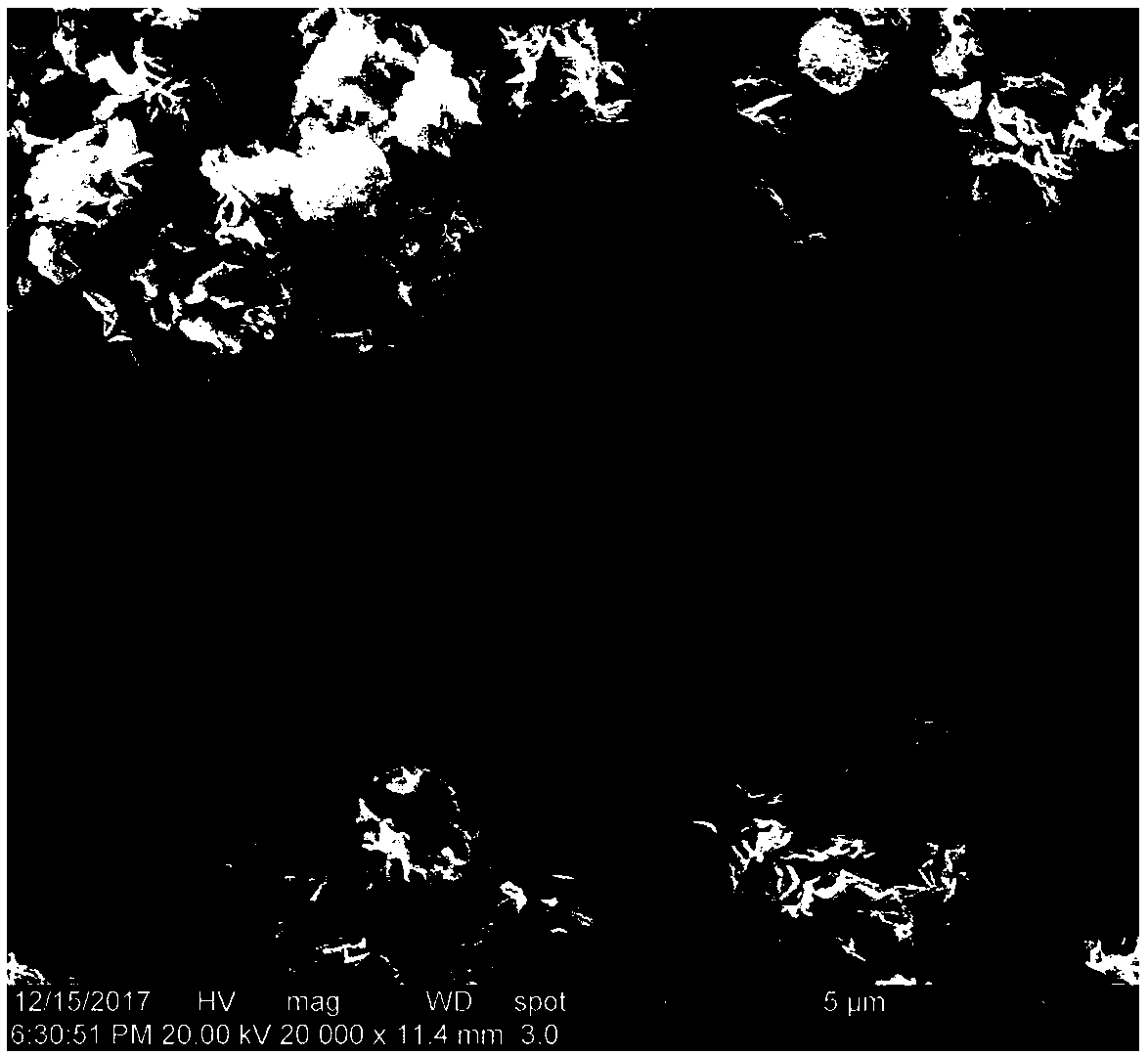

Graphene-bismuth oxide composite material as well as preparation method thereof, lead carbon battery cathode diachylon as well as preparation method thereof and lead carbon battery cathode plate

InactiveCN103811763AInhibitionGuaranteed lifeLead-acid accumulator electrodesHydrogenOxide composite

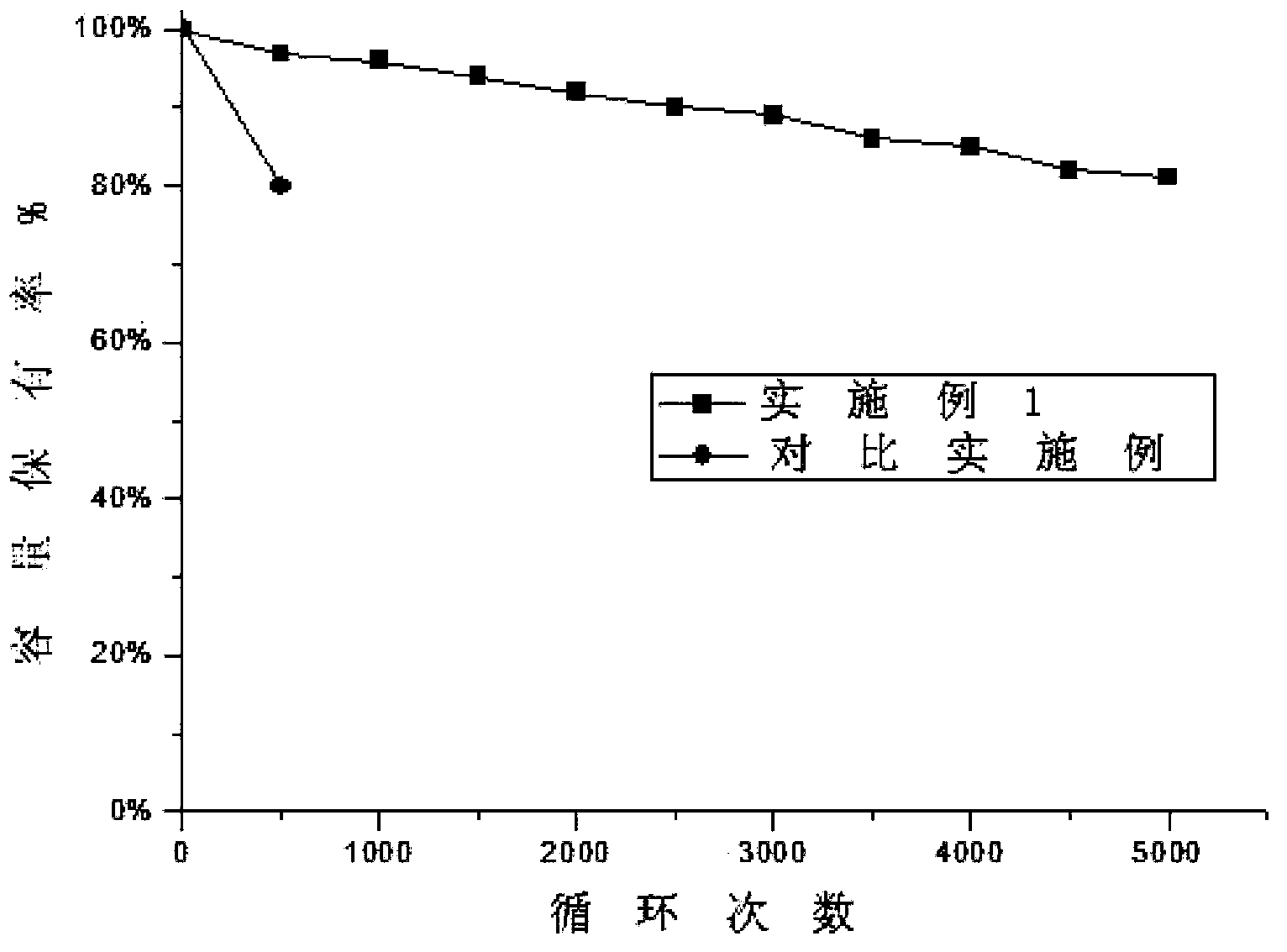

The invention discloses a graphene-bismuth oxide composite material. The graphene-bismuth oxide composite material comprises graphene as well as bismuth oxide loaded on a graphene sheet layer, wherein the mass ratio of bismuth oxide to graphene is (0.005-0.25):1. The invention also discloses a preparation method of the composite material as well as lead carbon battery cathode diachylon comprising the composite material as well as a preparation method of the lead carbon battery cathode diachylon and a lead carbon battery cathode plate. According to the invention, the generation of hydrogen on the surface of graphene is inhibited by loading bismuth oxide on the sheet layer of graphene, so that the hydrogen evolution phenomenon of the lead carbon battery cathode plate is inhibited; the reduction of lead carbon battery current efficiency and the battery water loss phenomenon are prevented effectively; the service life of the lead carbon battery is ensured.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

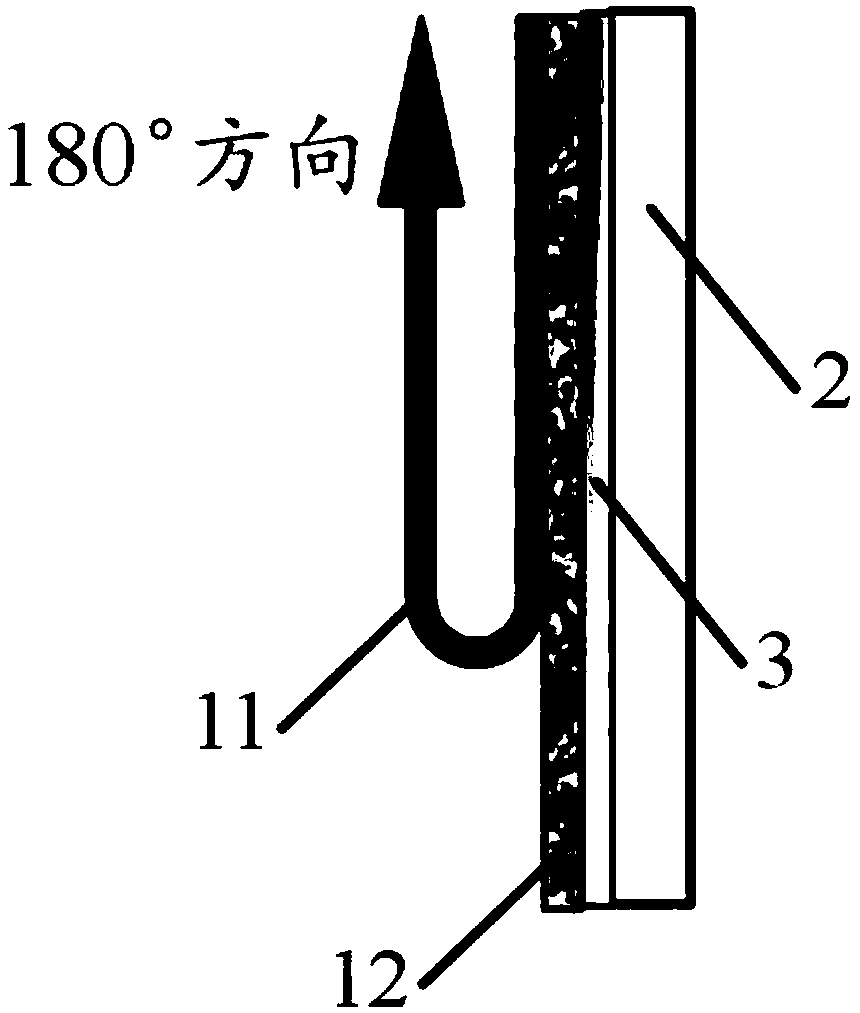

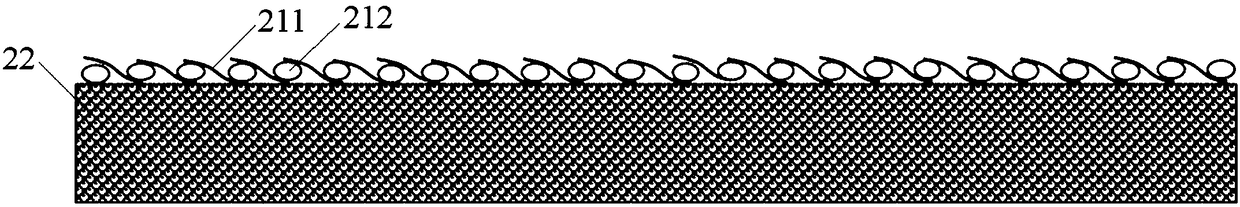

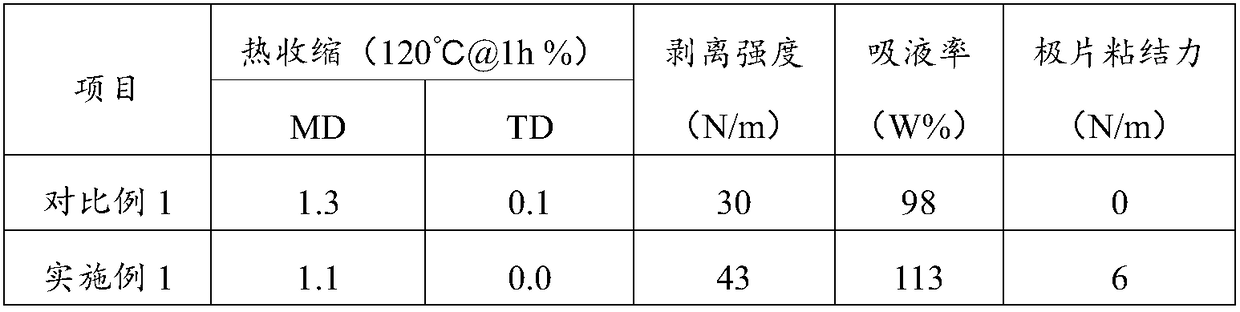

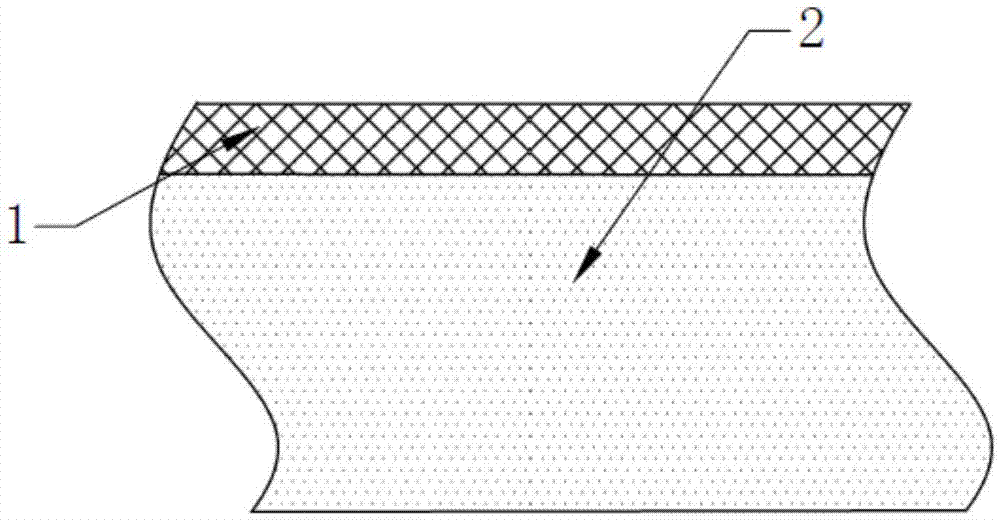

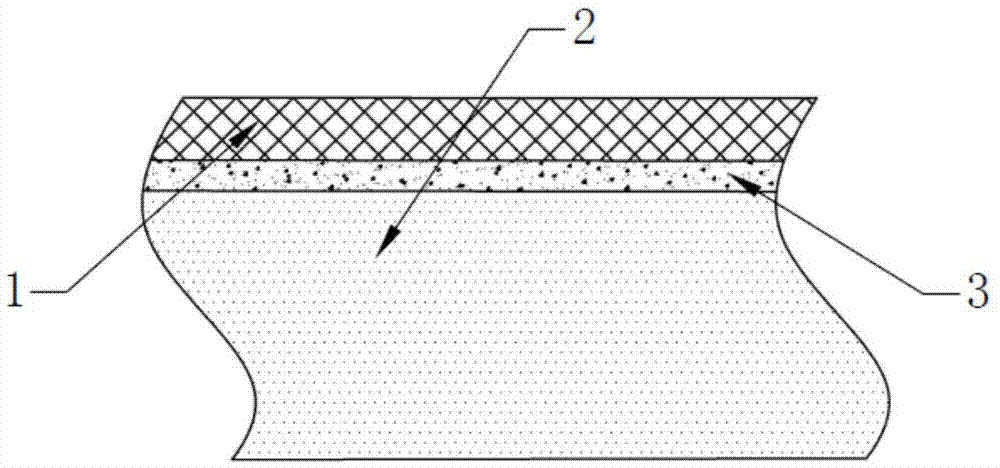

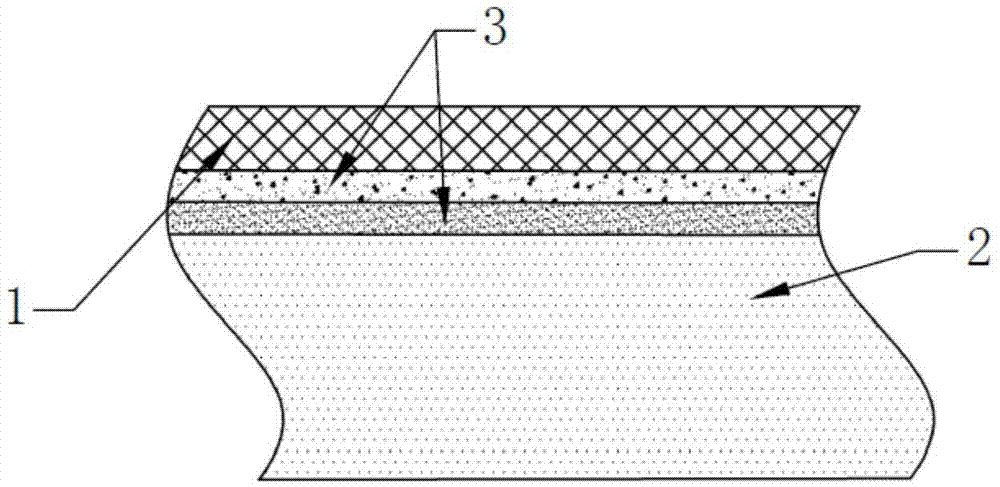

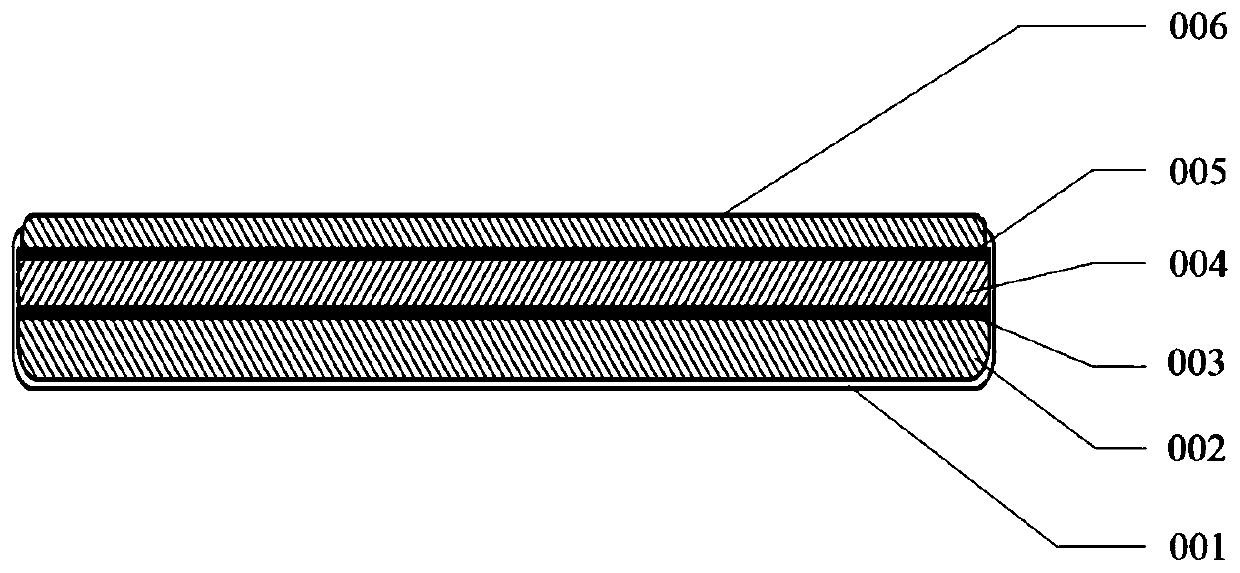

High-temperature resistant composite battery separator and preparation method thereof

ActiveCN108281592AGood thickening effectImprove hydrophilicityCell component detailsInorganic particleInorganic particles

The invention discloses a high-temperature resistant composite battery separator and a preparation method thereof. The high-temperature resistant composite battery separator comprises a base film anda high-temperature resistant coating layer, wherein the high-temperature resistant coating layer is coated on at least one surface of the base film and is formed by coating inorganic particles containing nanometer cellulose as a binding agent. In the composite battery separator, the nanometer cellulose is creatively used as the binding agent to prepare the high-temperature resistant coating layer,the interface bonding force of the coating layer and the base film is improved, the stripping strength of the composite battery separator is further improved, and the problems of falling and powder dropping of the coating layer are solved very well; with the addition of the nanometer cellulose, the inorganic particles are better in dispersion effect in water; moreover, the nanometer cellulose isused as the binding agent to form the coating layer, the high-temperature resistant composite battery separator is rapid in liquid conductivity and high in liquid absorption capability, gel is easilyformed after the electrolyte is absorbed, so that the composite battery separator can be attached onto a surface of an electrode very well, and the integral performance of the lithium ion battery is improved.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

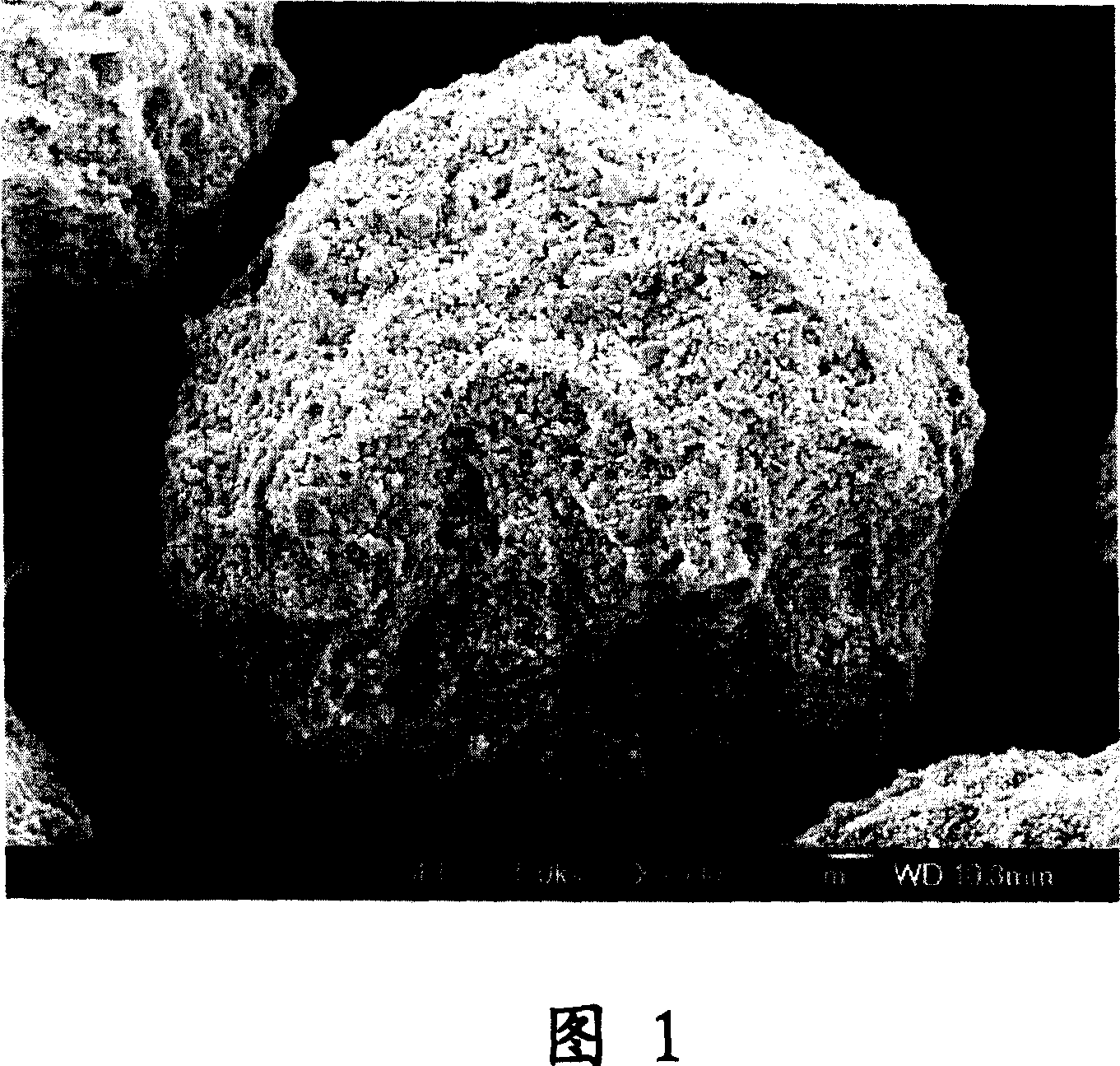

Compound material of anode fit for producing secondary battery and its produced battery

ActiveCN101064367AGood adhesionSimplify the process stepsMaterial nanotechnologyActive material electrodesHigh rateElectrical battery

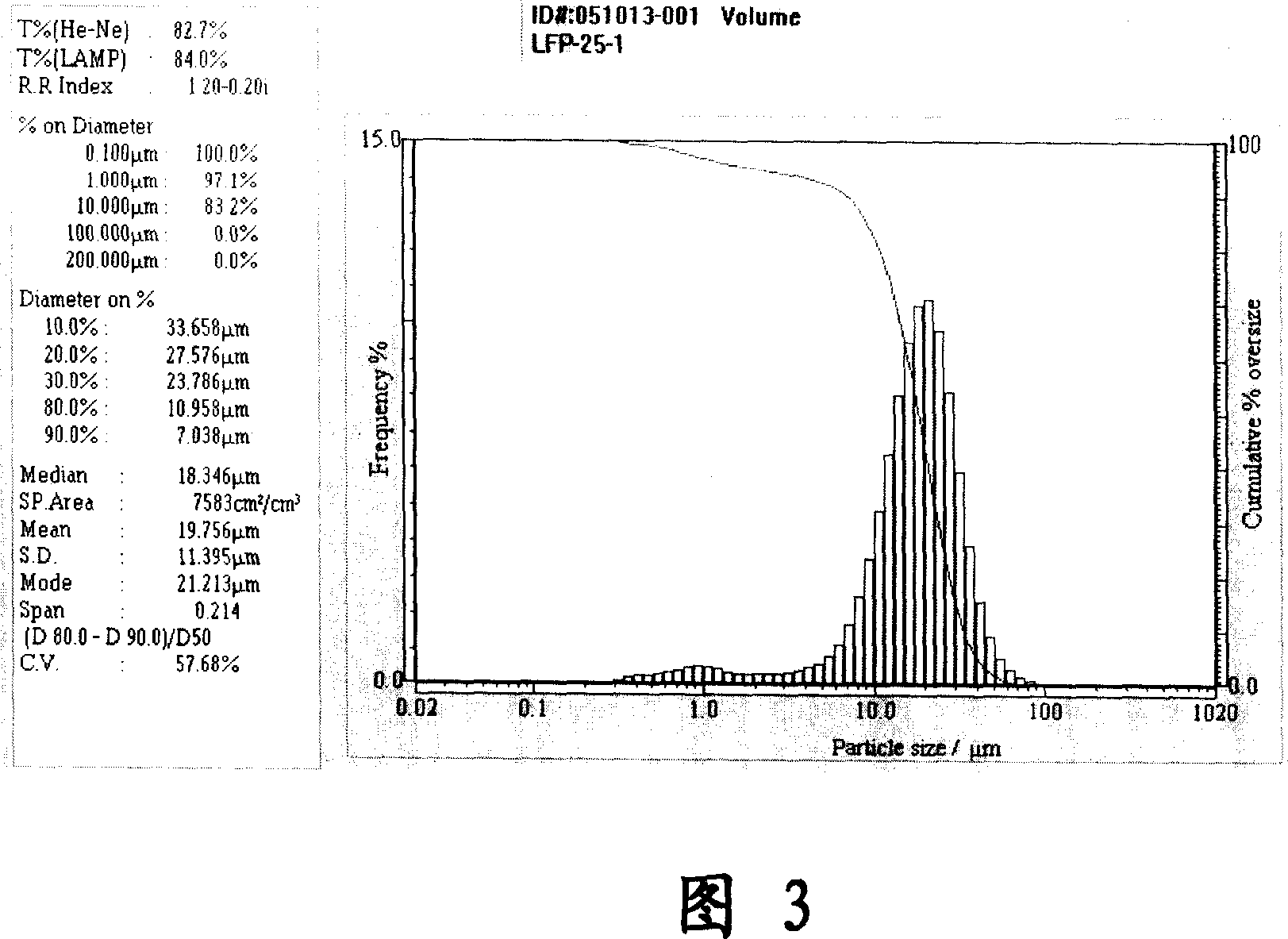

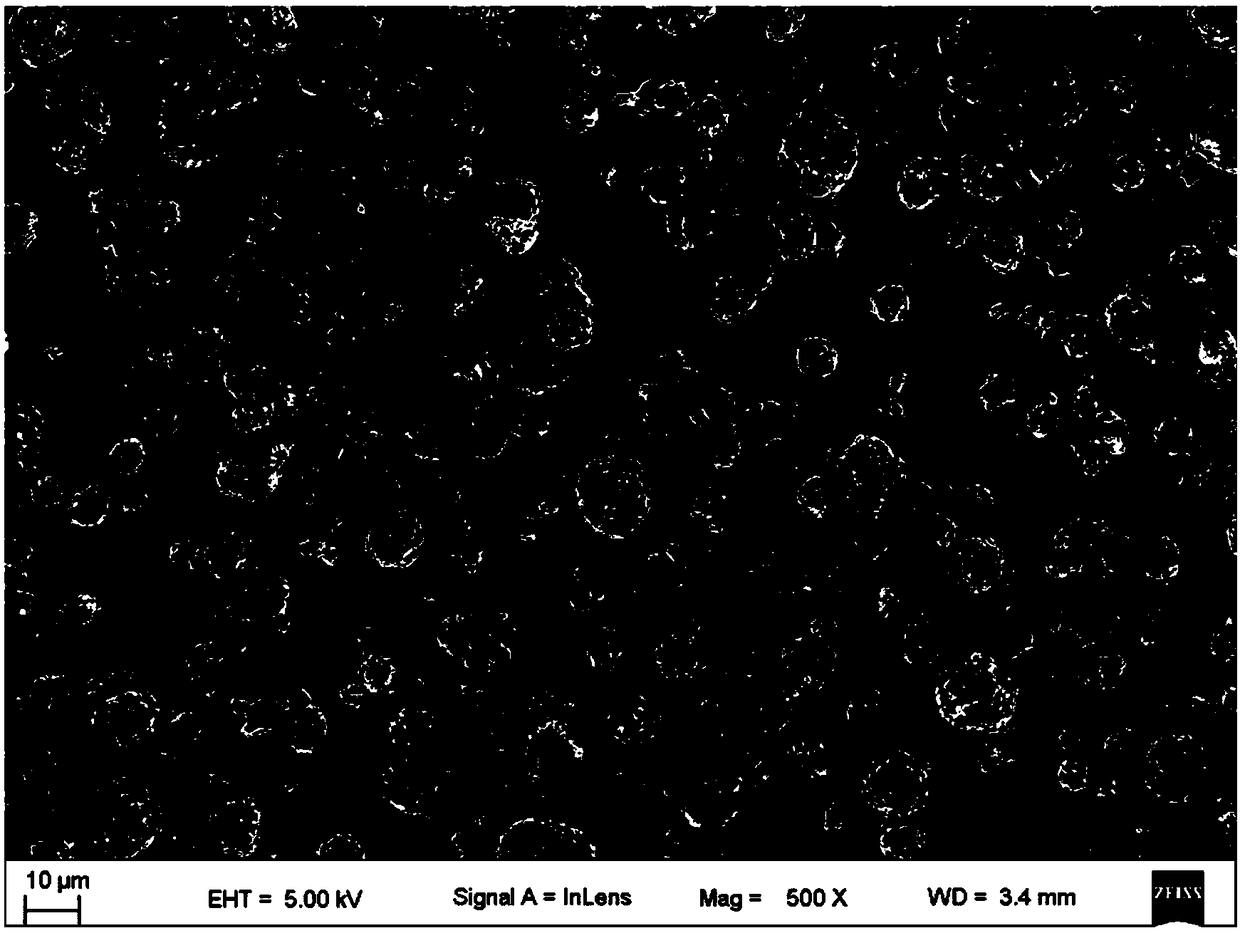

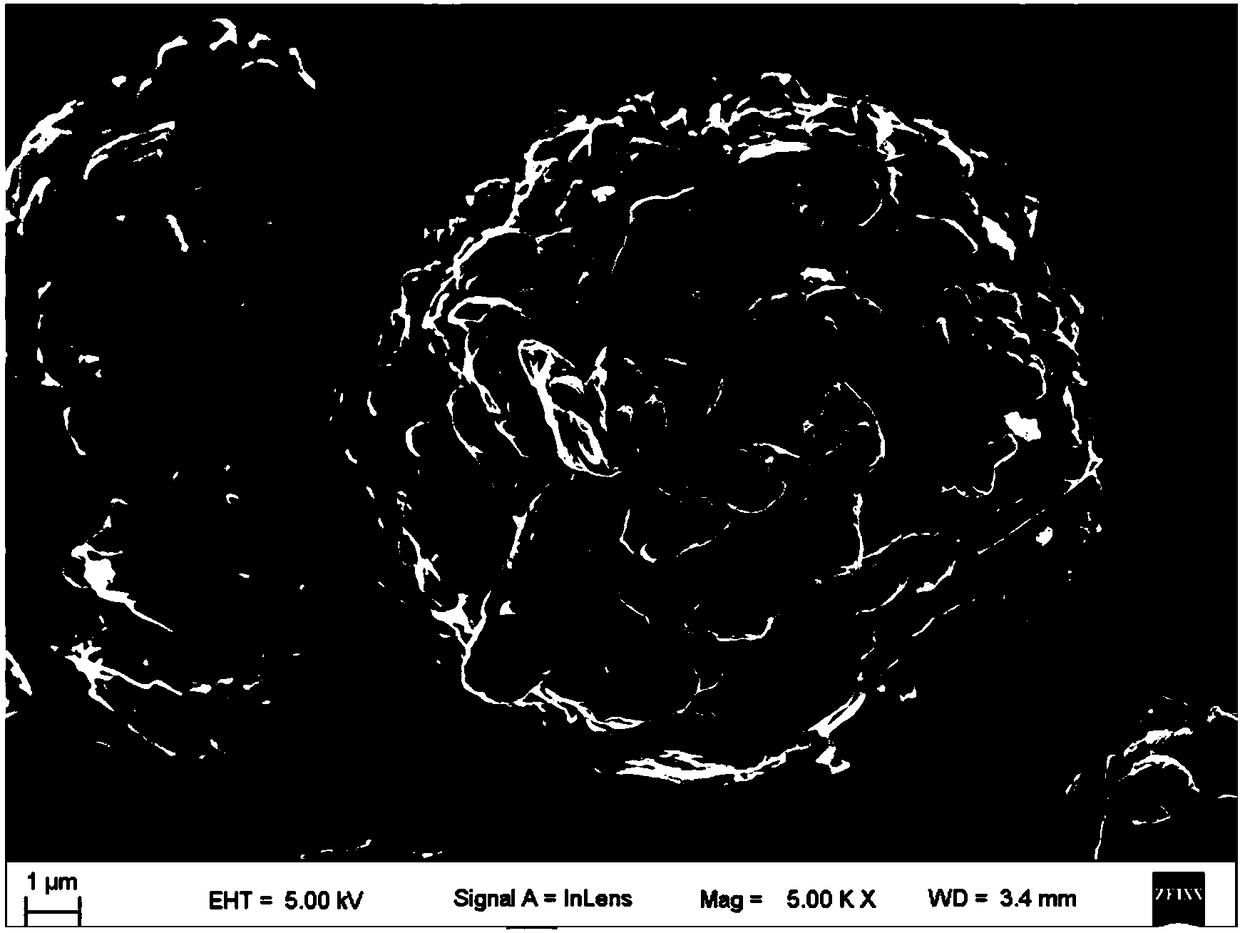

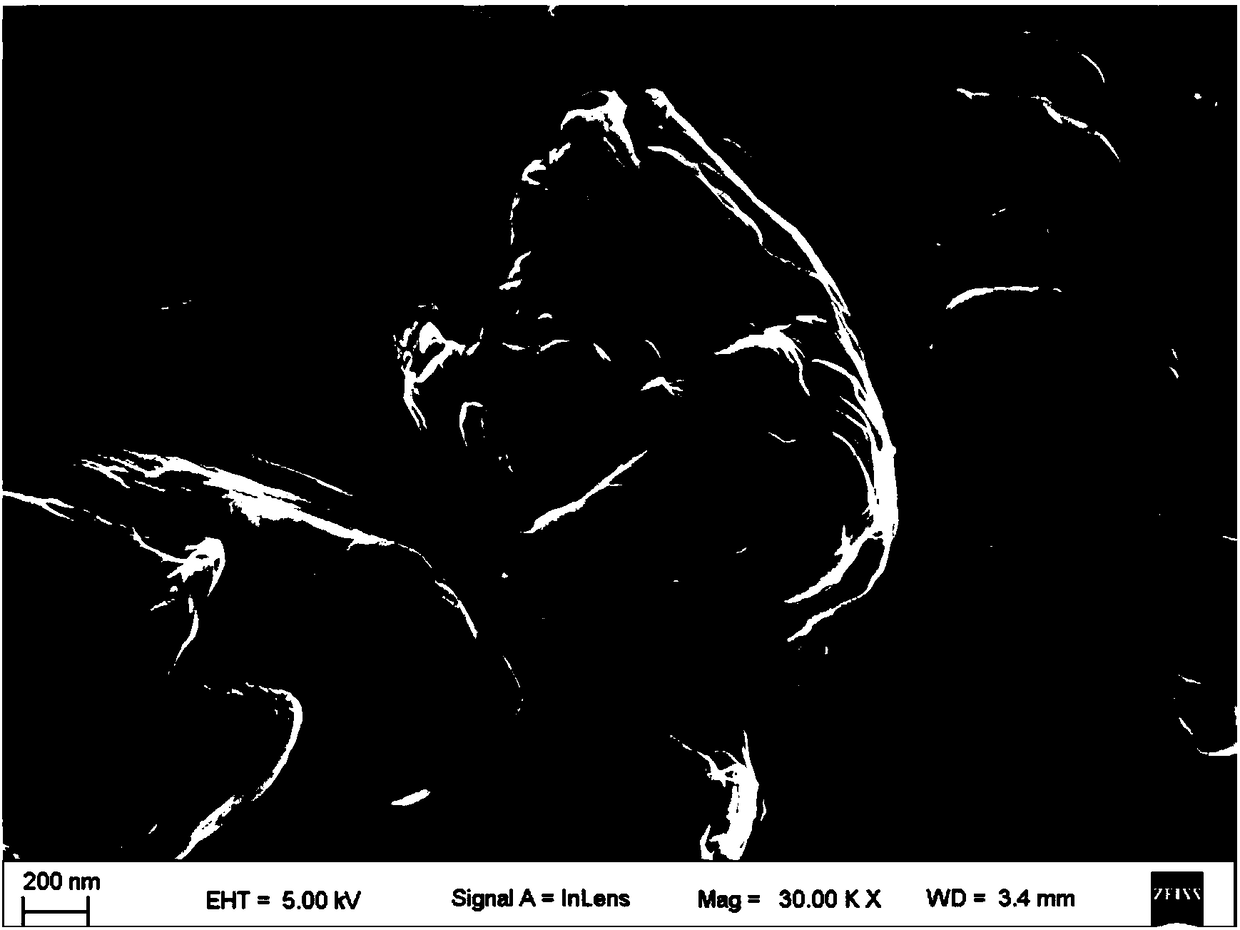

The invention relates to composite material which is used to produce positive pole of second battery and the produced battery. The composite material which is used to produce positive pole of second battery is powder and with olivine structure or NASICON structure, the powder of composite material is primary particle with 10-500 nanometer, and the secondary particle with 1 mm consists of the primary particle. The second battery includes negative pole, electrolyte, and positive pole produced by composite material, and composite material is powder and with olivine structure or NASICON structure, the powder of composite material is primary particle with 10-500 nanometer, and the secondary particle with 1 mm consists of the primary particle. The invention can improve the surface area of material, and increase the capacity, and easy to be produced, and the formed battery has high rate of charge and discharge, high capacity, and reduce the overcharge or overdischarge to increase the battery life.

Owner:ADVANCED LITHIUM ELECTROCHEMISTRY CO LTD

Negative electrode material of lithium-ion battery, preparation method thereof, negative electrode and lithium-ion battery

InactiveCN108232173AImprove charge and discharge rateIncreased total surface areaElectrode thermal treatmentSecondary cellsSilicon monoxideGraphite particle

The invention relates to a negative electrode material of a lithium-ion battery, a preparation method thereof, a lithium-ion battery negative electrode comprising the negative electrode material and the lithium-ion battery. The negative electrode material is prepared from silicon monoxide particles, graphite particles and a carbon-coated layer, wherein the graphite particles and the silicon monoxide particles are doped with each other to form silicon monoxide / graphite composite particles; the carbon-coated layer covers the outer surfaces of the silicon monoxide / graphite composite particles toform the negative electrode material with a pomegranate structure.

Owner:GP BATTERIES INT LTD

Power battery pack

ActiveCN102005603AUniform temperatureUniform temperature fieldFinal product manufactureCell temperature controlElectricityElectrical resistance and conductance

A power battery pack consists of a plurality of storage batteries, wherein bulges are arranged on the outer surfaces of the terminals of each storage battery, the adjacent terminals of each two adjacent storage batteries are connected through the bulges on the outer surfaces of the storage batteries; a three-dimensional grid structure is formed by connecting all the bulges; the three-dimensional grid structure is used as the thermally conductive bridge of each storage battery to intensify heat exchange; all or part of the holes and gaps in the three-dimensional grid are communicated to form a criss-cross networked runner; the heat-exchange medium flows to the outer surface of each terminal through the networked runner to perform effective heat exchange to the power battery pack; the overlapped points and lines of the three-dimensional grid structure form electric connection points and electric connection bands between the terminals of the adjacent storage batteries; and the raised sharp tops are deformed under the pretightening force to be embedded mutually, thus the electric connection points and electric connection bands can form reliable contacts. The heat flow lines and current lines of the power battery pack can not gather, thus the electrical connection can be strengthened and the heat exchange problem can be solved so as to reduce the thermal resistance and the electric resistance.

Owner:马洪沛

Electrode active material for lead-acid storage battery

InactiveCN106876667AHigh porosityInhibition of agglomeration and cloggingLead-acid accumulatorsCell electrodesSpecific energyMixed type

The invention discloses an electrode active material for a lead-acid storage battery. The electrode active material comprises lead powder and composite material granules; the lead powder comprises one or more kinds of metal lead powder, ball-milling lead powder, Barton lead powder, Pb<2>O powder, PbO powder, Pb<2>O<3> powder, Pb<3>O<4> powder and PbO<2> powder; and the composite material granules comprise one or more kinds of coating type composite material granules and mixed type composite material granules. By virtue of the electrode active material for the lead-acid storage battery with an improved formula, the specific power, specific energy, active material utilization rate, charging-discharging efficiency, cycle life, low-temperature performance and the like of the applied lead-acid storage battery can be obviously improved.

Owner:杨春晓

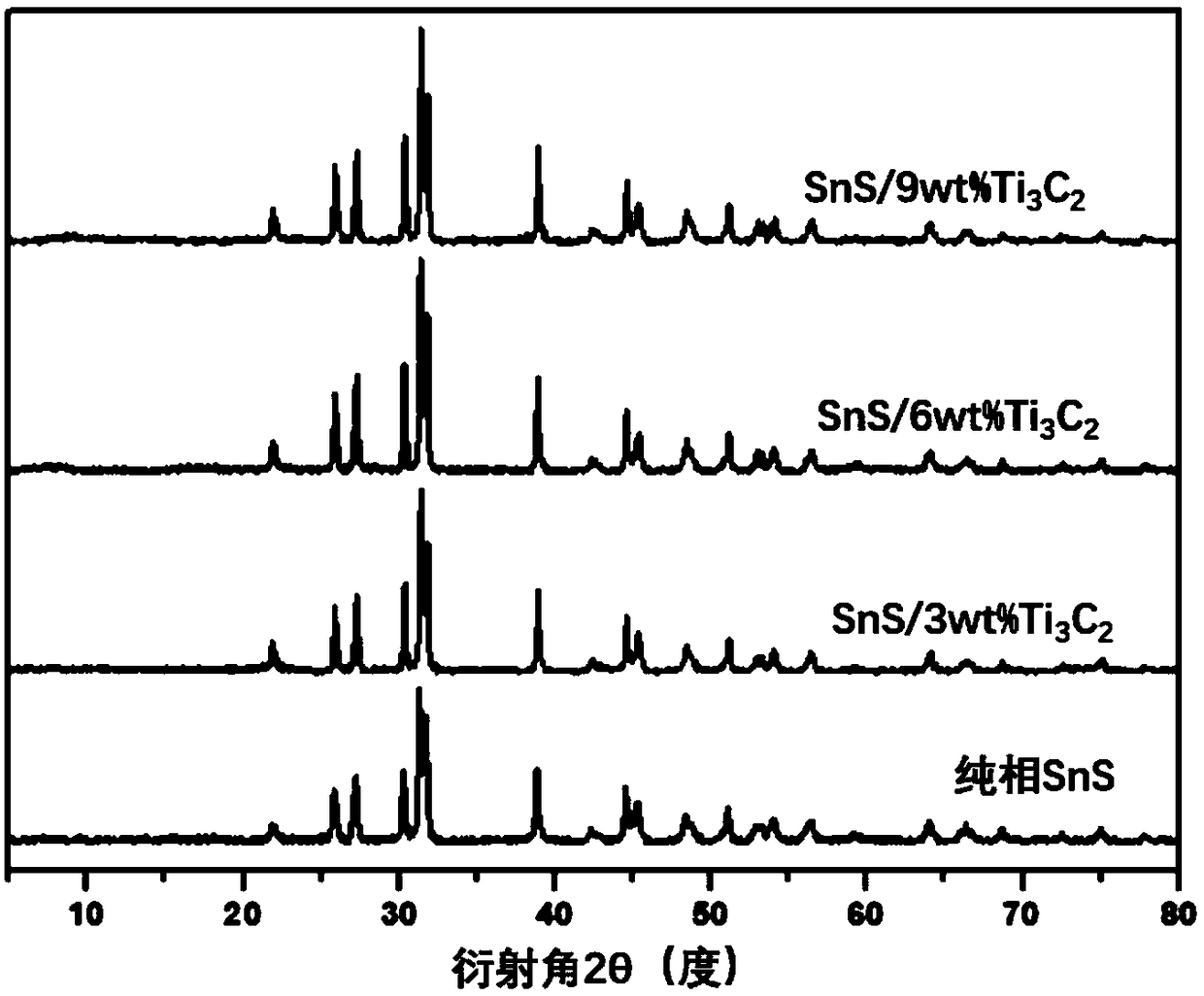

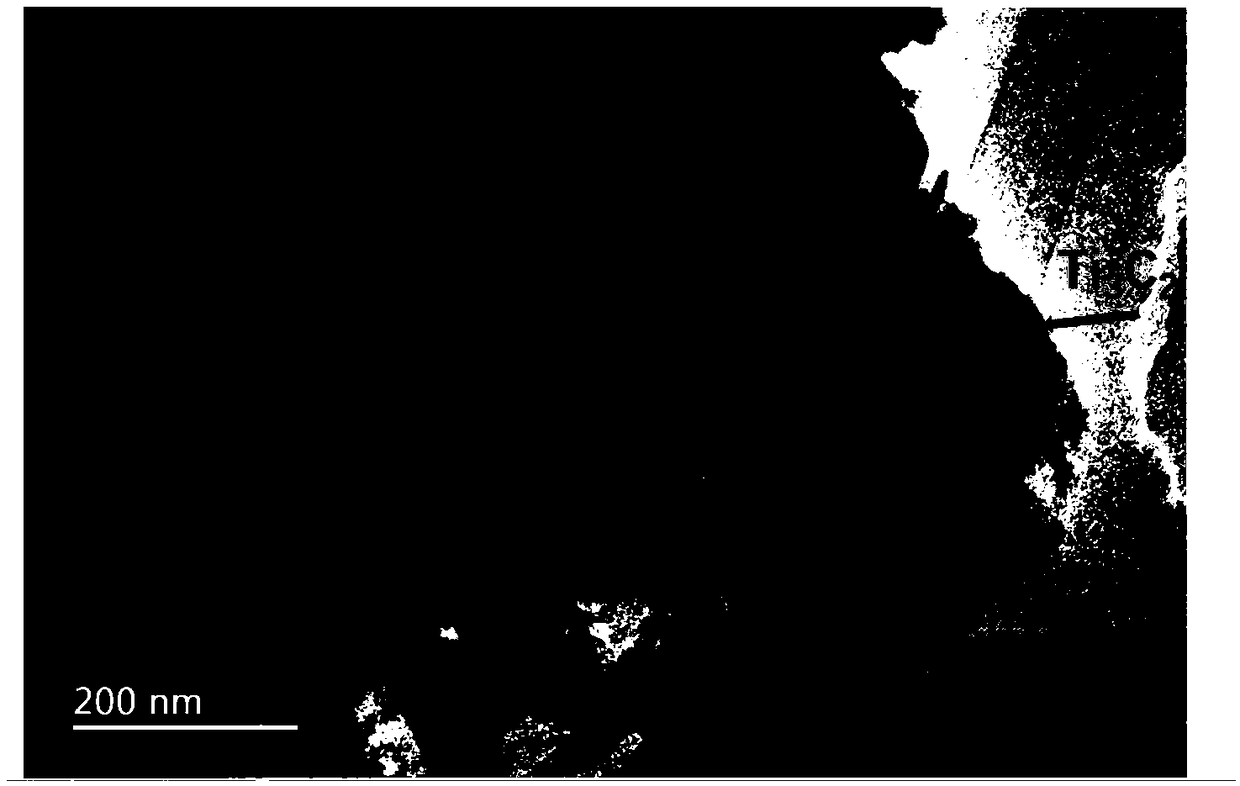

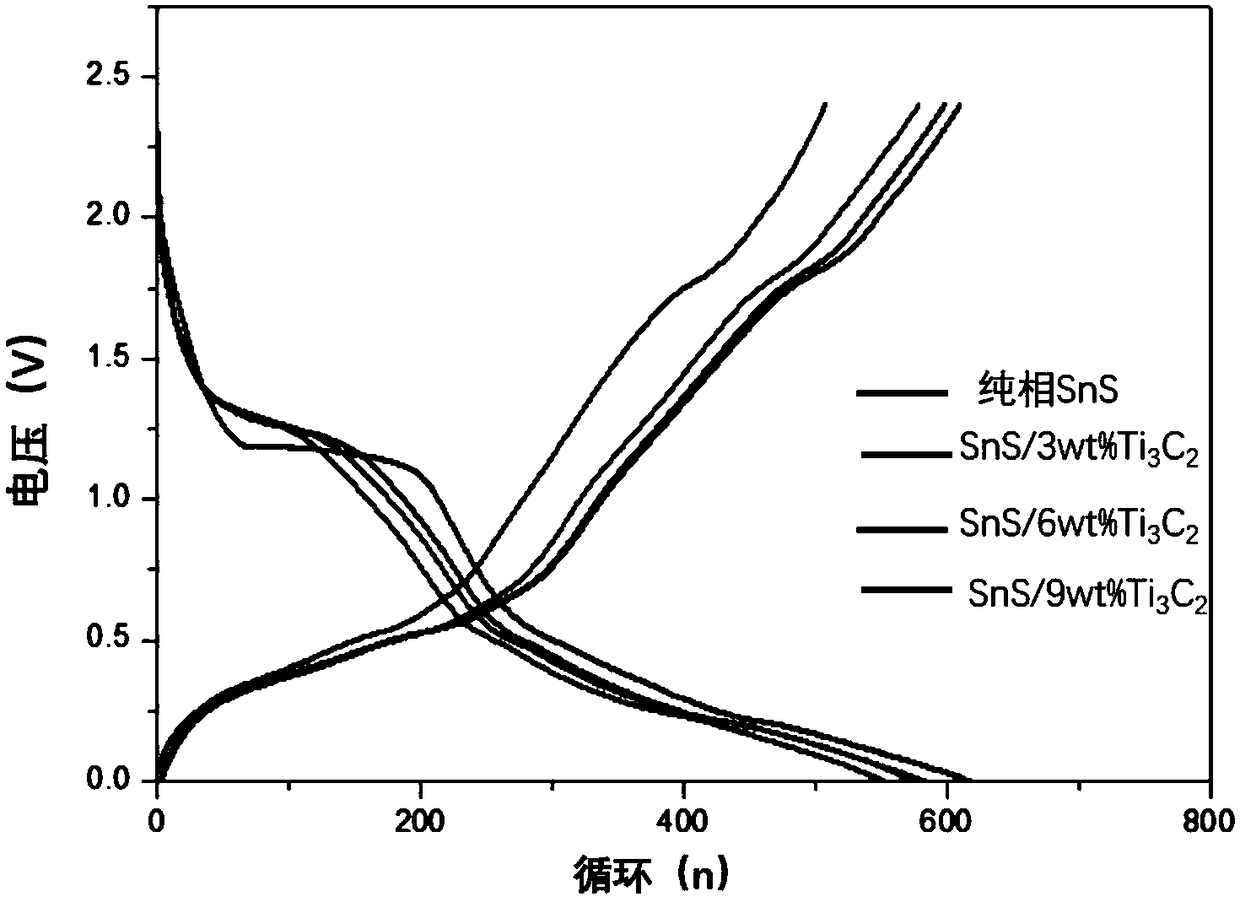

Titanium carbide-loaded stannous sulfide composite anode material

InactiveCN108963211AGood cycle performance and rate performanceImproved cycle performance and rate performanceCell electrodesSecondary cellsSolventUltrasonic oscillation

The invention relates to a titanium carbide-loaded stannous sulfide composite anode material. The composite anode material is a stannous sulfide anode material loaded with titanium carbide, wherein the loading capacity of titanium carbide is 3-9% of the mass of stannous sulfide. The composite anode material is prepared by the following specific method: mixing a sulfur source and a tin source, adding a solvent and stirring until the above substances are completely dissolved so as to obtain a sulfur-tin mixed solution; taking titanium carbide, adding a surfactant and deionized water, and carrying out ultrasonic oscillation until the substances are completely dissolved so as to obtain a titanium carbide dispersion; adding the titanium carbide dispersion into the sulfur-tin mixed solution, andtransferring the mixed solution into a reaction kettle to carry out a hydrothermal reaction; successively centrifuging, washing and drying the product after the reaction, and finally grinding to obtain a powder product; calcining the powder product in an inert gas atmosphere, cooling to room temperature with a furnace, and grinding the powder to obtain a product. This material shows better cycleperformance and rate performance than pure-phase stannous sulfide.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

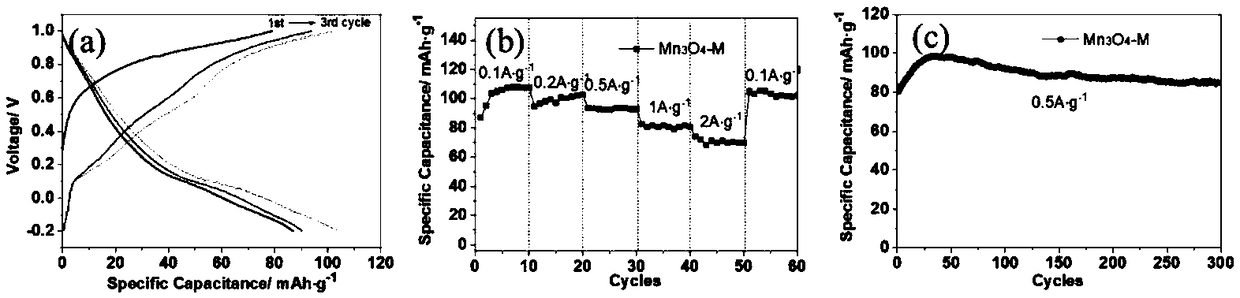

Environmentally-friendly aqueous battery and preparation method thereof

InactiveCN109449437AIncrease energy densityImprove cycle lifeFinal product manufactureCell electrodesHigh energyAqueous electrolyte

The present invention relates to an environmentally-friendly aqueous battery and a preparation method thereof, pertaining to the technical field of batteries. The environmentally-friendly aqueous battery comprises a positive electrode, an aqueous electrolyte, a negative electrode and a membrane, wherein the material of the positive electrode is Mn3O4. The environmentally-friendly aqueous battery has higher energy density and longer cycle life. According to the preparation method of the environmentally-friendly aqueous battery, the environmentally-friendly aqueous battery can be prepared simply, low costly and pollution-freely.

Owner:PEKING UNIV

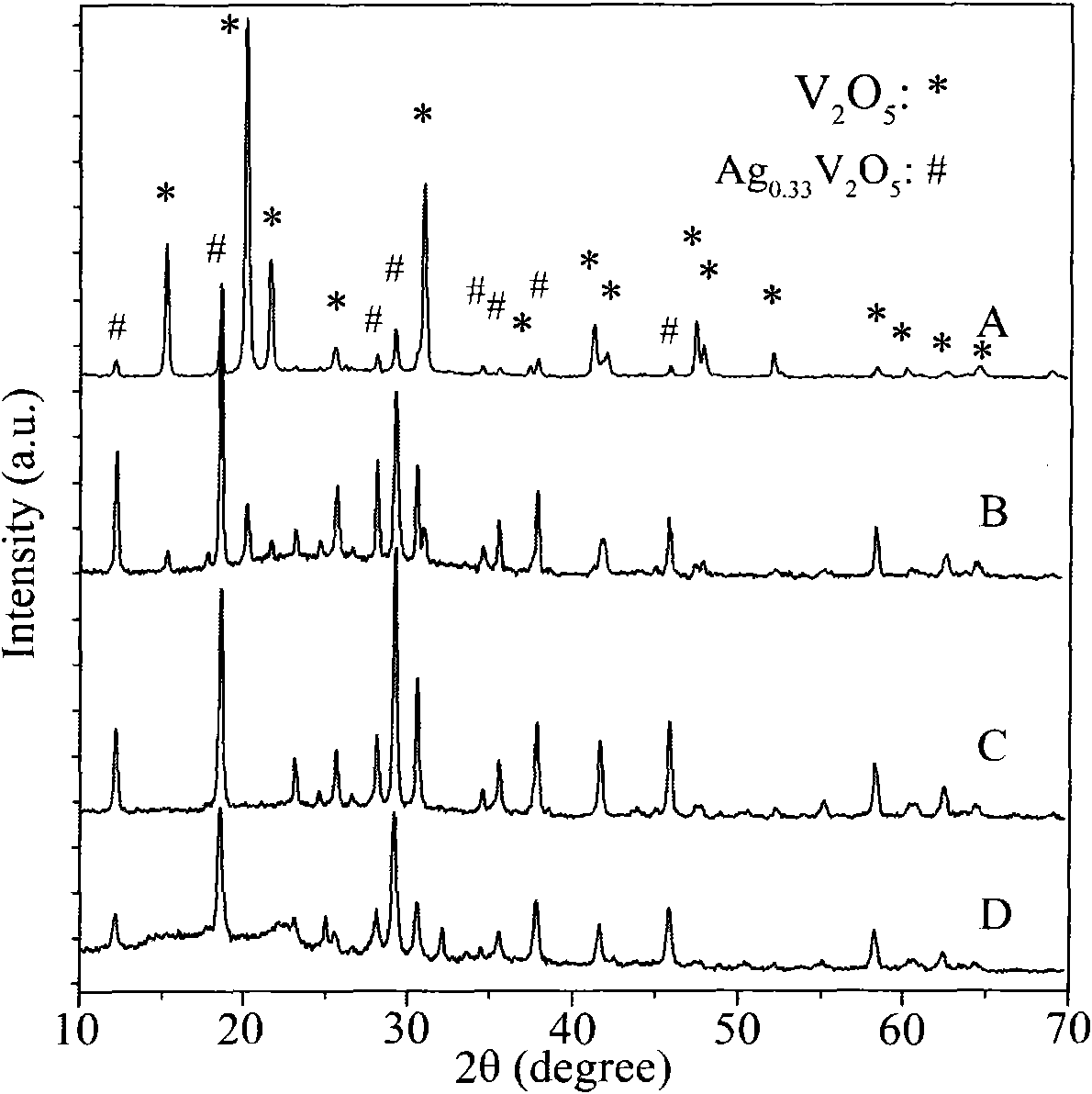

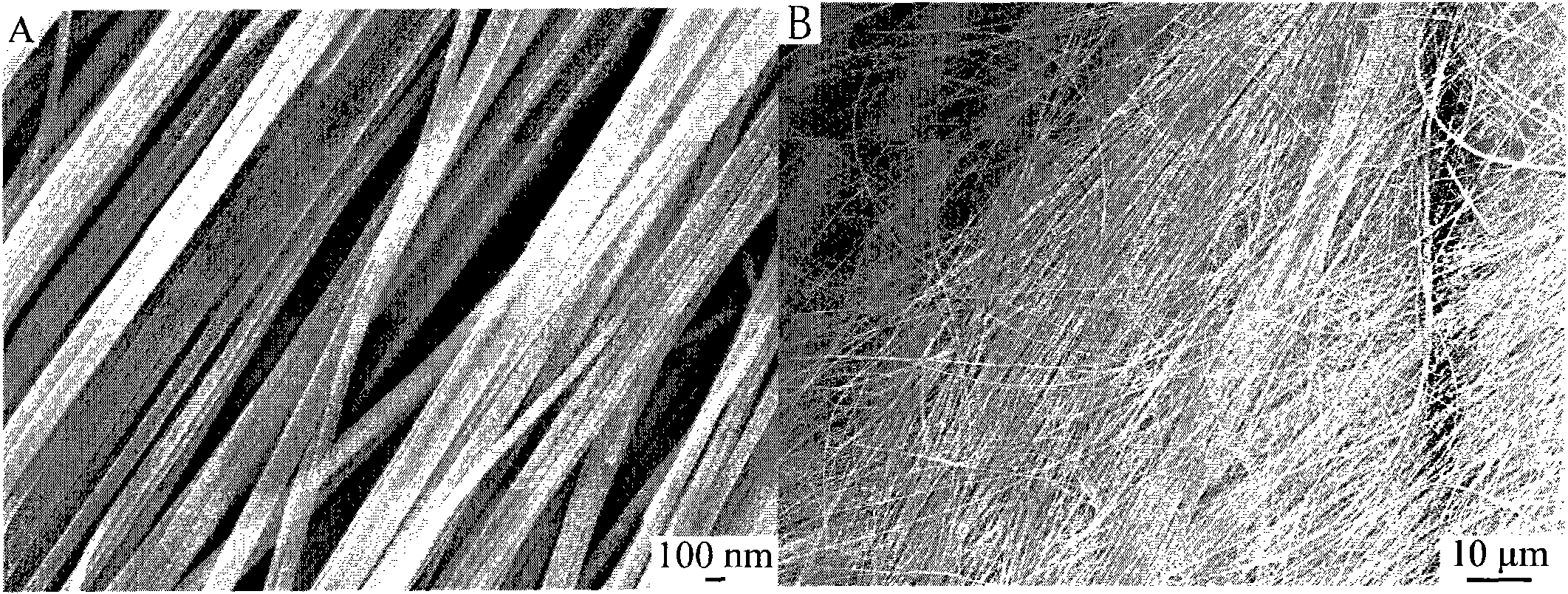

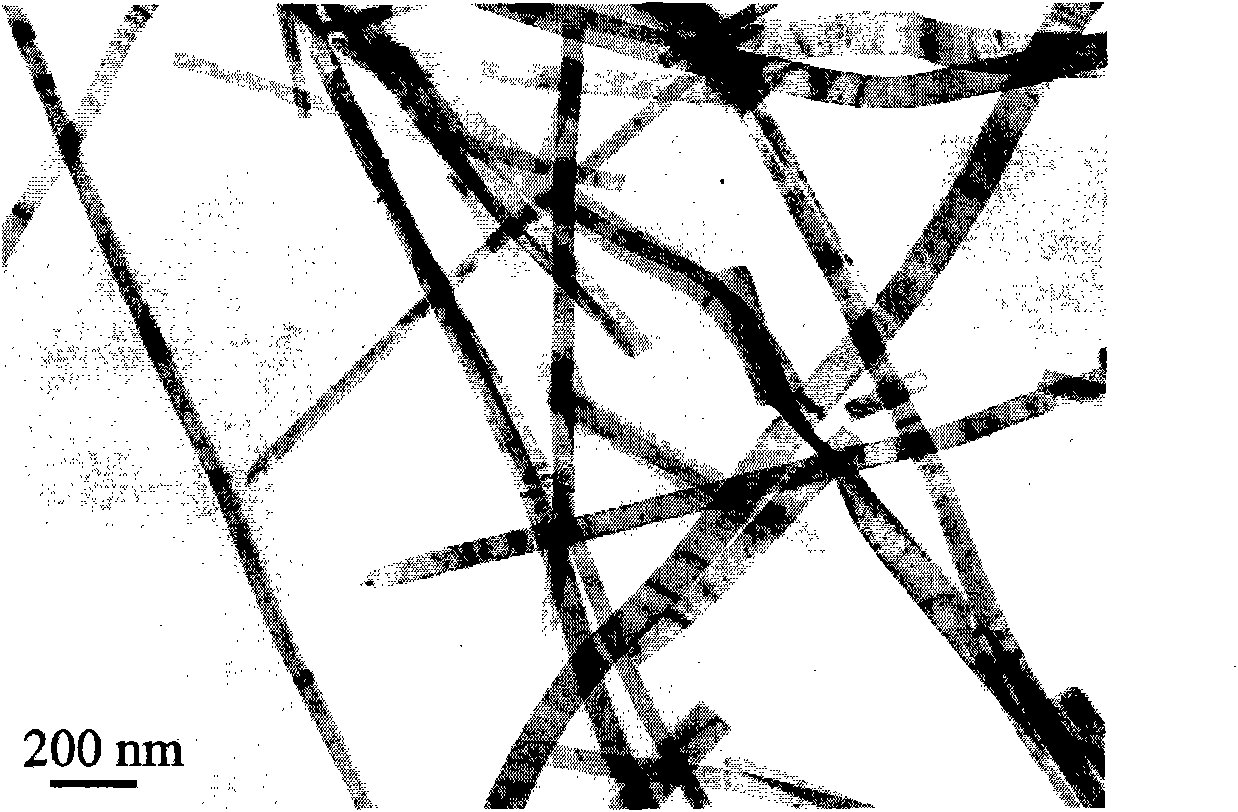

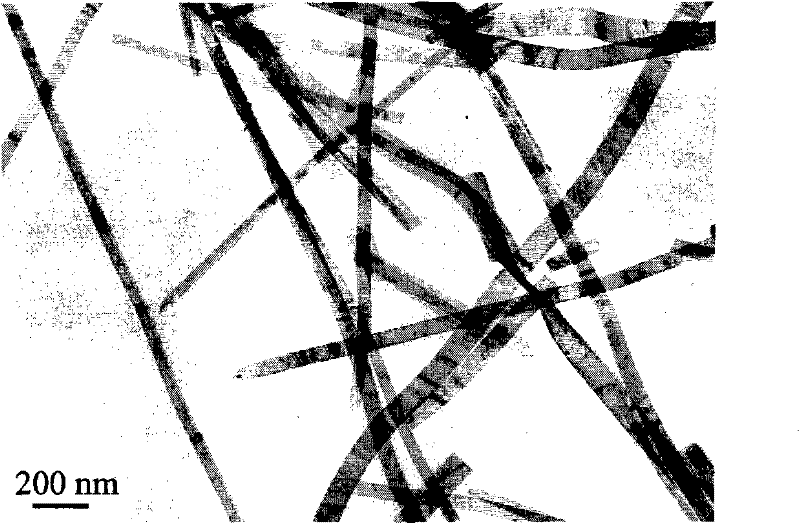

Preparation method and application of silver vanadate/vanadium oxide one-dimensional composite nano-electrode material

InactiveCN101807685AIncreased intercalation/deintercalation ratesImprove charge and discharge rateCell electrodesSecondary cellsHigh energyVanadium oxide

The invention provides a preparation method and application of a silver vanadate / vanadium oxide one-dimensional composite nano-electrode material, which can solve the problems of high energy consumption, difficult control of components, grain diameter and appearance of a product, low electrical conductivity and poorer cyclical stability of a traditional lithium battery anode material. The invention adopts a one-step hydrothermal method which comprises the following steps of: 1. dissolving vanadium salt into 10-30 percent hydrogen peroxide to obtain a transparent peroxovanadate solution; 2. dispersing the vanadium salt into deionized water; 3. pouring a vanadium salt mixture into the peroxovanadate solution, mixing, fully stirring and pouring into a hydrothermal reaction kettle for hydrothermal reaction to obtain a product; and 4. obtaining the silver vanadate / vanadium oxide one-dimensional composite nano-electrode material through centrifugalizing, washing and drying the product. The preparation process of the invention is simple, the size of the product and the doping amount of silver are easy to control, the product has larger yield and is pure, and both the specific capacity and the cyclical stability of the silver vanadate / vanadium oxide one-dimensional composite nano-electrode material as the lithium battery anode material are markedly improved.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method for mixture of nano silicon particles coated with silicon monoxide net-shaped structure and graphene lithium battery negative electrode material

ActiveCN103811729ASimple preparation processReduce contact resistanceCell electrodesLi-accumulatorsNano siliconSilicon monoxide

The invention provides a preparation method for a mixture of nano silicon particles coated with a silicon monoxide net-shaped structure and a graphene lithium battery negative electrode material. The preparation method comprises the following steps: (1) mixing a silicon compound with graphene to prepare a soluble mixture solution; (2) preparing the silicon compound and the graphene in the soluble mixture solution into nano particles; adding the nano particles into a cavity of microwave hot cracking equipment; and (3) controlling the oxygen partial pressure in the cavity to be 5-10000ppm and controlling the temperature to be 200-500 DEG C; reacting for 10-300 seconds and collecting powder in the microwave hot cracking cavity; and drying to obtain the mixture. According to the method, the process is simple; the nano silicon particles and the nano graphene particles in the prepared mixture of the nano silicon particles coated with the silicon monoxide net-shaped structure and the graphene lithium battery negative electrode material have good dispersibility and high purity.

Owner:福建省诺希科技园发展有限公司

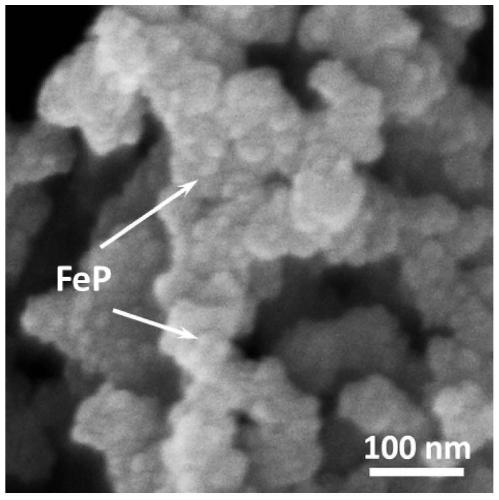

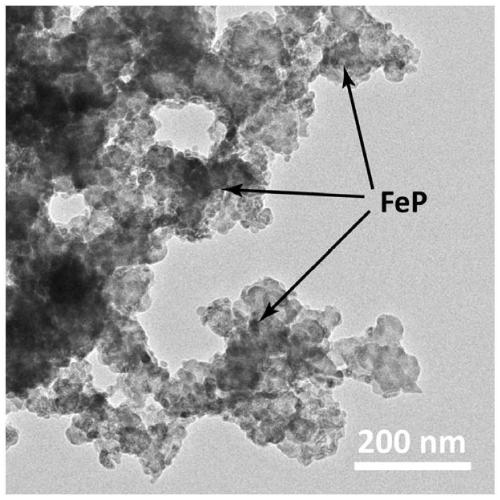

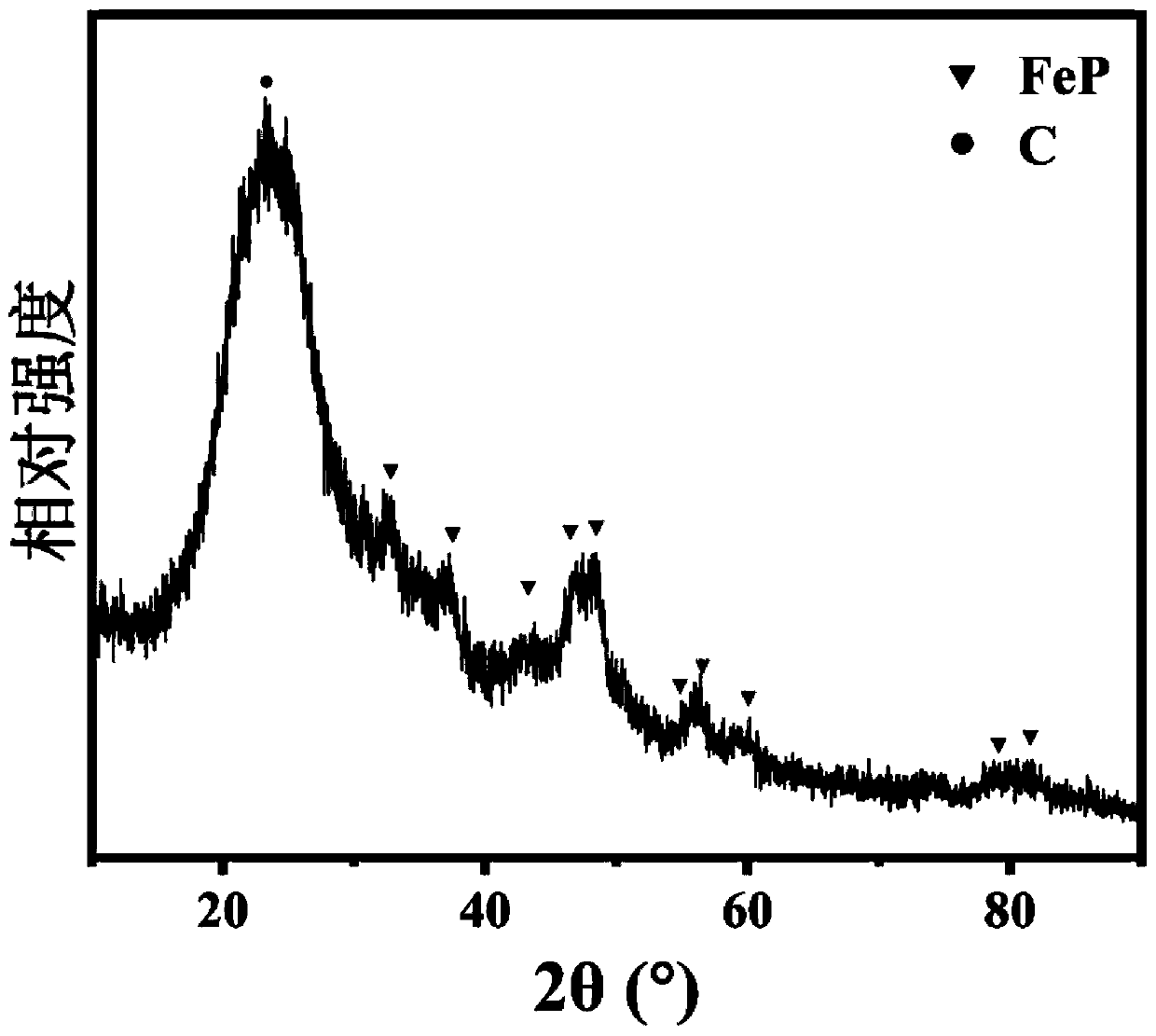

Lithium-sulfur battery conductive agent based on nano transition metal phosphide/carbon composite material as well as preparation method and application of lithium-sulfur battery conductive agent

InactiveCN111477873AImprove stabilityConductiveMaterial nanotechnologyCell electrodesCarbon compositesLithium–sulfur battery

The invention relates to the technical field of lithium-sulfur battery conductive agents, and in particular relates to a lithium-sulfur battery conductive agent based on a nano transition metal phosphide / carbon composite material as well as a preparation method and application of the lithium-sulfur battery conductive agent. The conductive agent comprises a conductive agent body and nano transitionmetal phosphide particles growing on the conductive agent body in situ, and the conductive agent body is a conductive carbon material. According to the invention, the conductive nano transition metalphosphide is compounded on the conductive carbon material to form the lithium-sulfur battery conductive agent with a new structure; the conductive performance of the lithium-sulfur battery conductiveagent is superior to that of a traditional conductive agent, shuttling of polysulfide can be effectively prevented, and a certain catalytic effect is generated; due to the existence of the catalyticaction of the transition metal phosphide, the reaction time of converting soluble lithium polysulfide into a liquid state in the charging and discharging process can be effectively shortened, and nucleation of lithium polysulfide is accelerated; the charging and discharging rate of a positive electrode material is increased; the utilization rate of active substances of the positive electrode material is increased; and the specific capacity and the cycling stability of the lithium-sulfur battery are improved.

Owner:SHANDONG UNIV

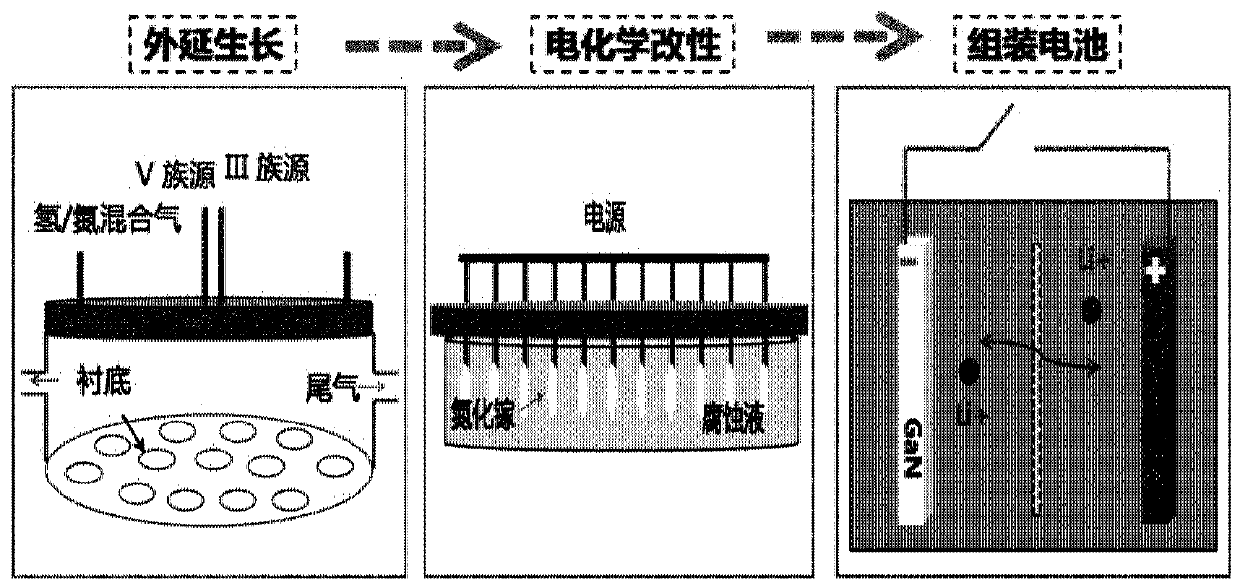

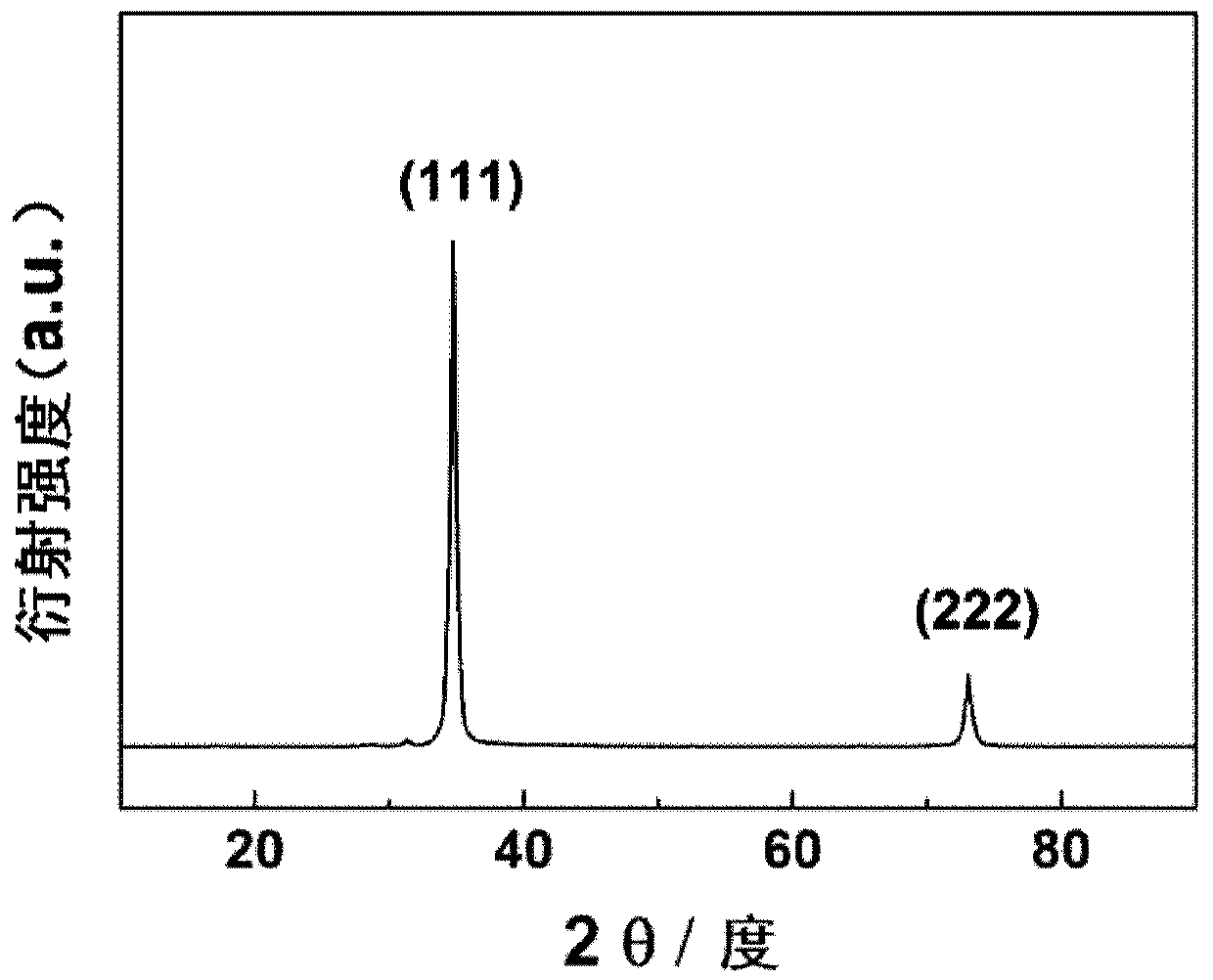

Battery anode material and preparation method thereof and lithium battery

ActiveCN110336028AIncrease capacityGood cycle stabilityCell electrodesSecondary cellsGallium nitrideCyclic stability

The invention provides a battery anode material and a preparation method thereof and a lithium battery. The preparation method of the battery anode material comprises the following steps: epitaxiallygrowing a high-quality gallium nitride thin film on a conductive crystal substrate to obtain an epitaxial structure; and modifying the epitaxial structure through electrochemical corrosion, forming holes in the surface of the high-quality gallium nitride thin film and making the holes run through the epitaxial structure and forming a crystal gallium nitride material serving as the battery anode material. The crystal gallium nitride material is first used as the battery anode material and is directly used as an electrode in the lithium battery; the preparation method overcomes the technical challenge that the preparation technique of the crystal gallium nitride material is not compatible with the traditional electrode technique; and through adoption of the high-conductivity homogeneous substrate, epitaxial growth of the gallium nitride materials with different properties and structures and modification of the material through the electrochemical corrosion process, the high-quality gallium nitride electrode material is obtained, wherein the material has good cycle stability and high capacity, and has a good application prospect.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

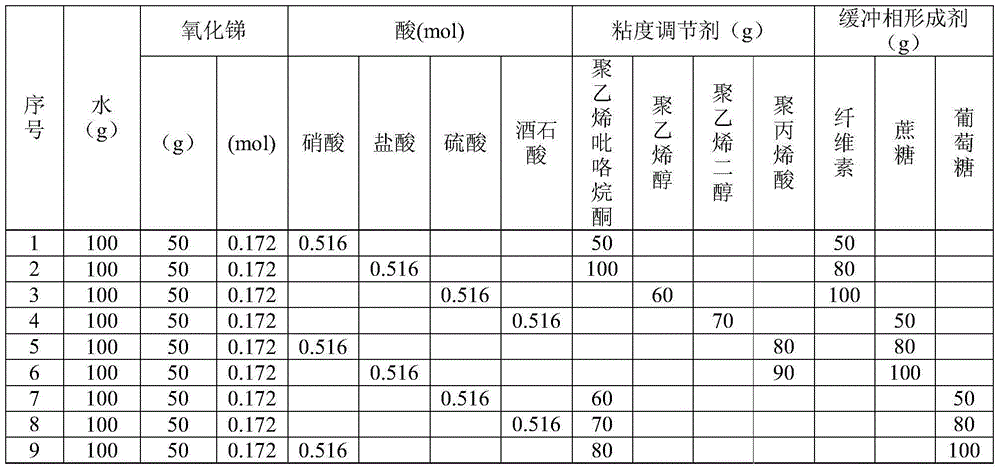

Preparation process of composite fiber electrode material for sodium-ion battery

InactiveCN104157841ASimple processStress reliefNon-aqueous electrolyte accumulatorsCell electrodesFiberSodium-ion battery

The invention discloses a preparation process of a composite fiber electrode material for a sodium-ion battery. The process is characterized by comprising the steps of: adding antimony oxide in water, and adding acid to dissolve antimony oxide, so as to obtain a solution containing antimony; adding a viscosity conditioning agent and a buffer phase forming agent into the solution to obtain a precursor solution; pouring the precursor solution into a centrifugal spinning machine, and conducting a centrifugal spinning method to obtain fiber electrode precursors; drying and calcining the precursors to obtain an antimony oxide and buffer phase composite fiber electrode material. The fiber is used for sodium-ion batteries, and has the characteristics of high capacity and good cycle performance.

Owner:SHAANXI UNIV OF TECH

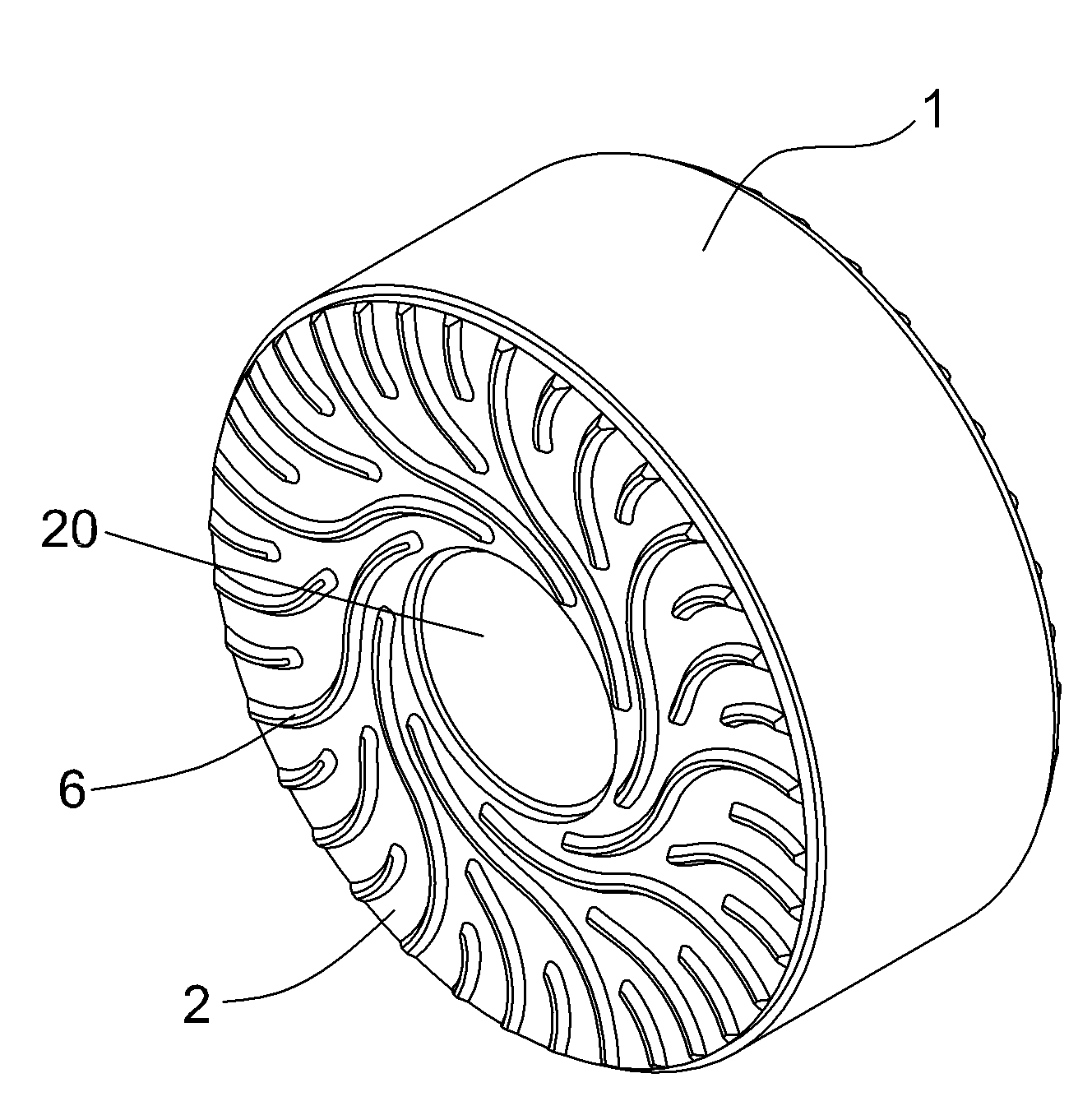

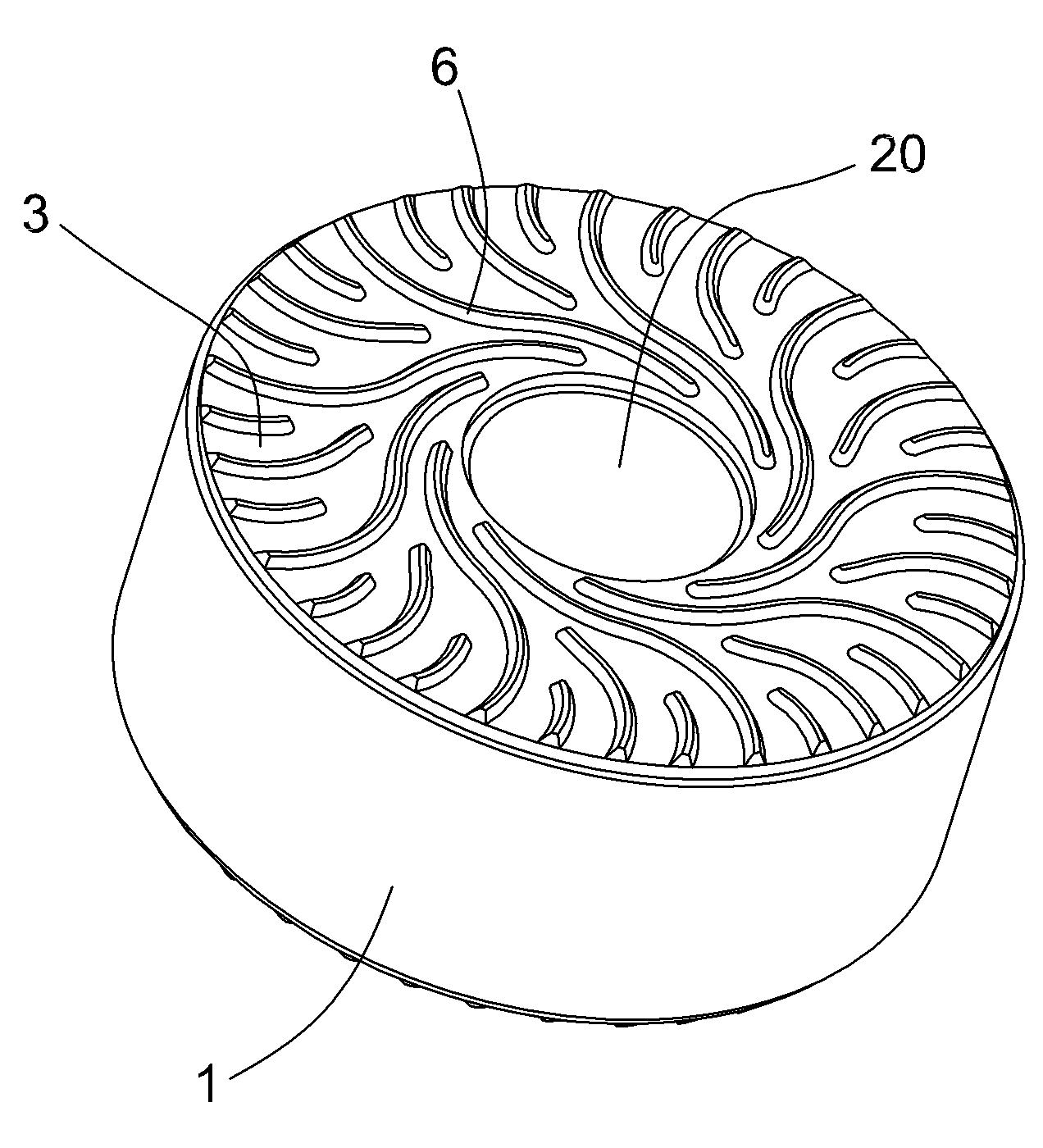

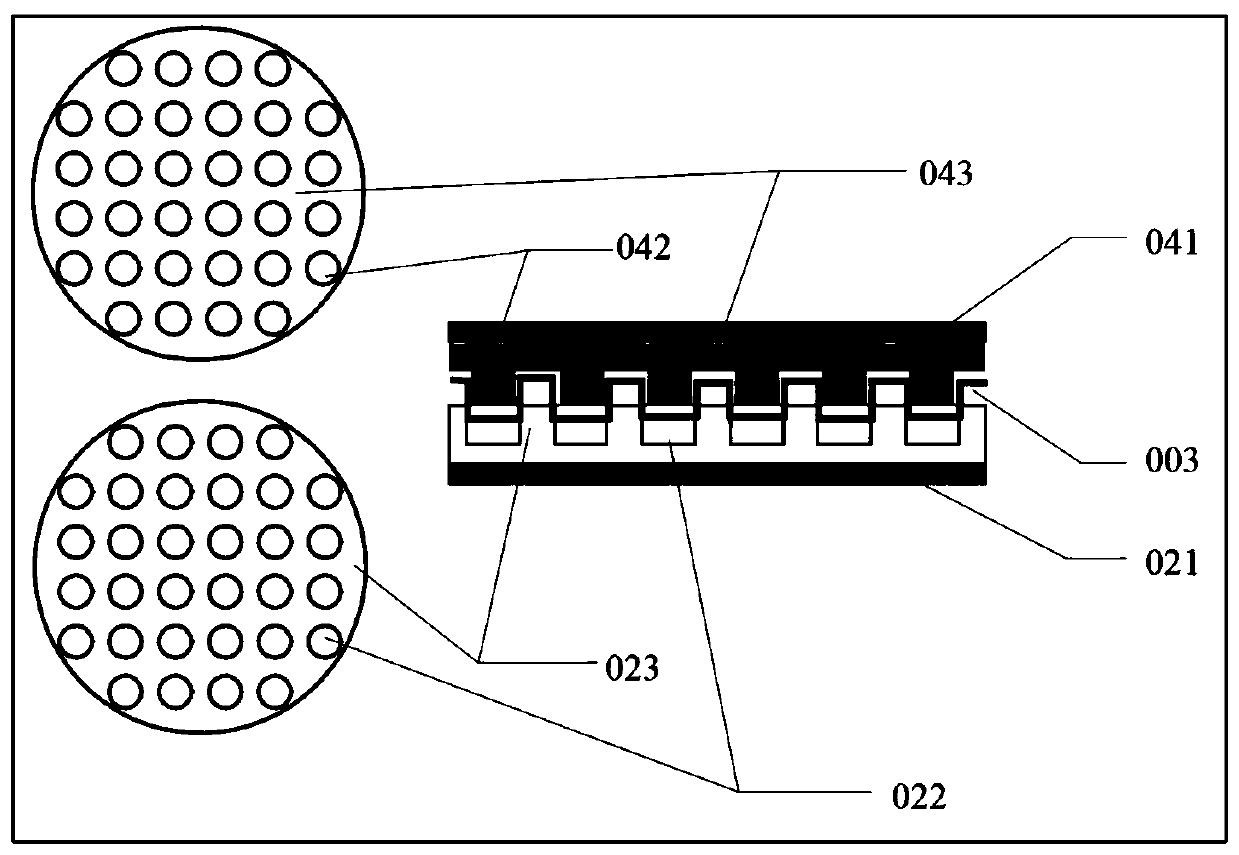

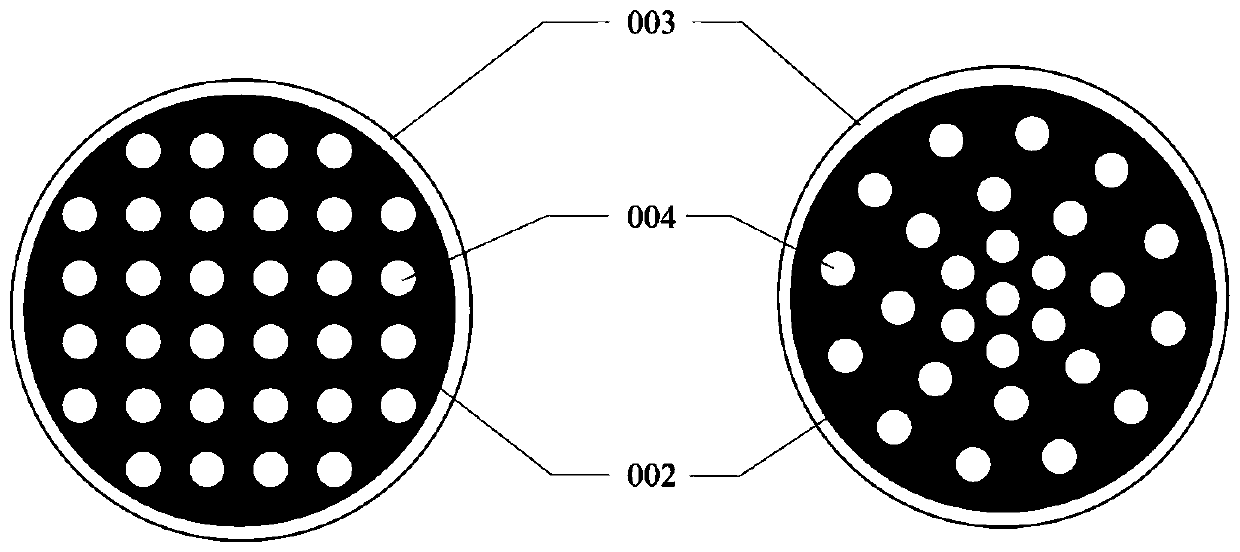

High-performance honeycomb-shaped lithium ion button battery

InactiveCN109817885AIncrease capacityImprove cycle lifeElectrode manufacturing processesFinal product manufactureCarbon compositesButton battery

The invention relates to a high-performance honeycomb-shaped lithium ion button battery. The honeycomb-shaped lithium ion button battery consists of a positive electrode shell, a positive plate, an electrolyte, a separator, a negative plate, a foam nickel gasket and a negative electrode shell, wherein the positive plate has a honeycomb porous structure, honeycomb pores of the positive plate are filled with the negative plate, and the positive plate and the negative plate are in close contact through the separator; the active substance of the positive plate is a high-nickel ternary material, and the active substance of the negative plate is a nano silicon-carbon composite material. And the honeycomb-shaped lithium ion button battery is assembled according to the sequence of the positive electrode shell->the positive plate->the electrolyte->the separator->the electrolyte->the negative plate->foam nickel->the negative electrode shell. The lithium ion button battery provided by the invention has a honeycomb porous structure, so that the wettability of the electrolyte is remarkably improved, and the rate capability of the battery is improved; the porous structure can alleviate the charge-discharge volume expansion stress of the silicon-carbon negative electrode and obviously improve the cycle performance of the battery; in addition, honeycomb holes of the positive plate and the negative plate are matched to realize self-positioning, battery short circuit caused by dislocation of the positive plate, the negative plate and the separator in the battery assembling process is effectively avoided, and the button battery is simple in assembling process, good in consistency and high in production efficiency.

Owner:湖北锂诺新能源科技有限公司

Polypyrrole, mesoporous carbon and sulfur composite electrode material and secondary cell

InactiveCN104362313AFacilitated DiffusionIncrease transfer rateNon-aqueous electrolyte accumulatorsCell electrodesComposite electrodeSulfur

The invention relates to a secondary aluminum cell adopting a polypyrrole, mesoporous carbon and sulfur composite electrode material as a positive electrode. A preparation method of the polypyrrole, mesoporous carbon and sulfur composite material comprises the following steps: ordered mesoporous carbon is prepared with a template method; the activated ordered mesoporous carbon is taken as a carrier to prepare a polypyrrole and mesoporous carbon composite material with a three-dimensional porous structure with a chemical in-situ polymerization method; and then the surface and pores of the polypyrrole and mesoporous carbon composite material are coated with sulfur through heat treatment so as to obtain the polypyrrole, mesoporous carbon and sulfur composite electrode material. The prepared secondary aluminum cell has high specific capacity, good circulating stability and low cost, the preparation method is simple, and the polypyrrole, mesoporous carbon and sulfur composite electrode material is suitable for industrial production.

Owner:NANJING ZHONGCHU NEW ENERGY

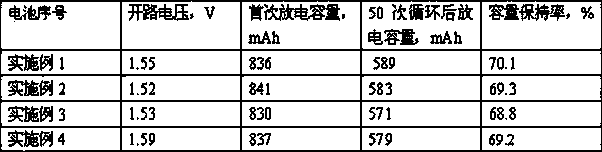

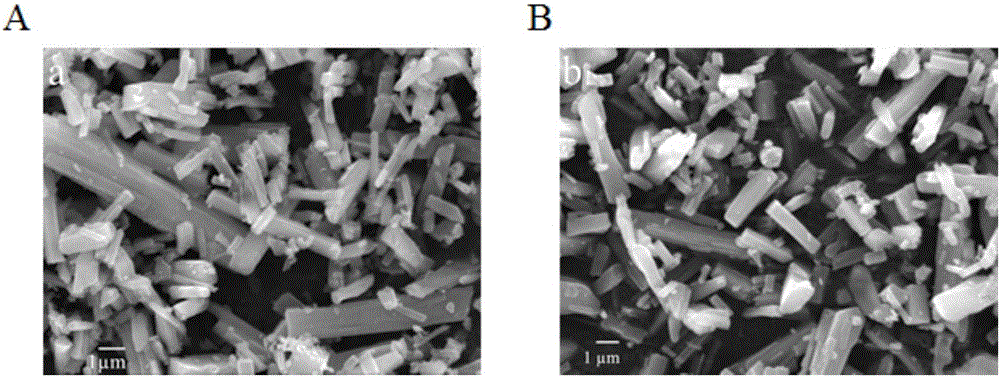

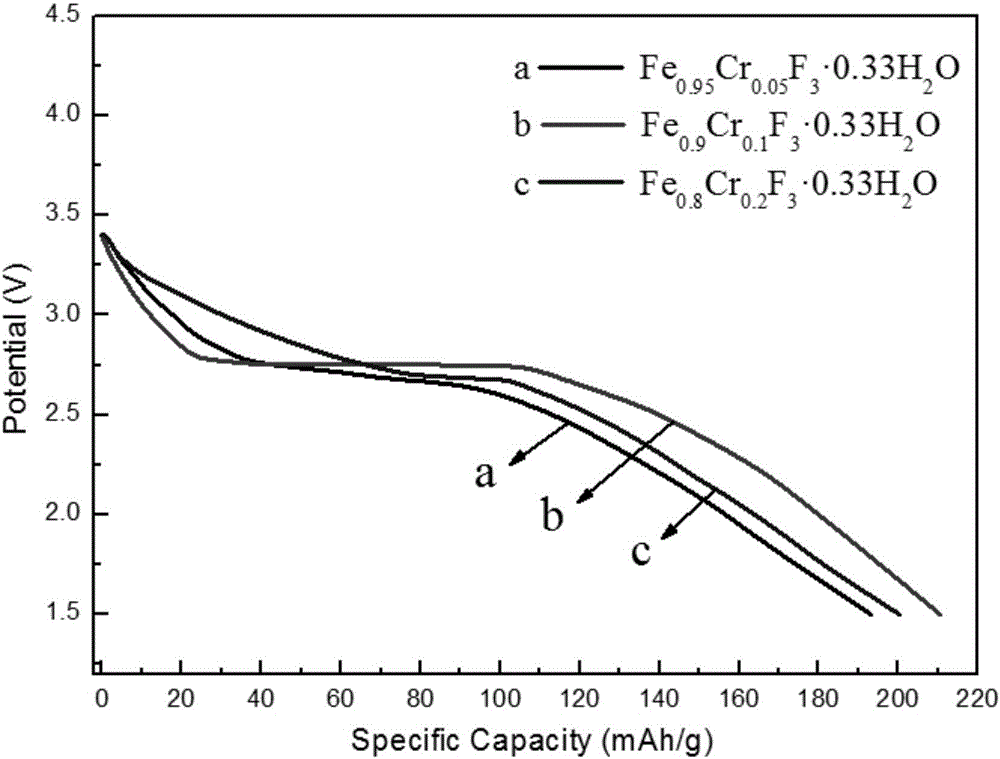

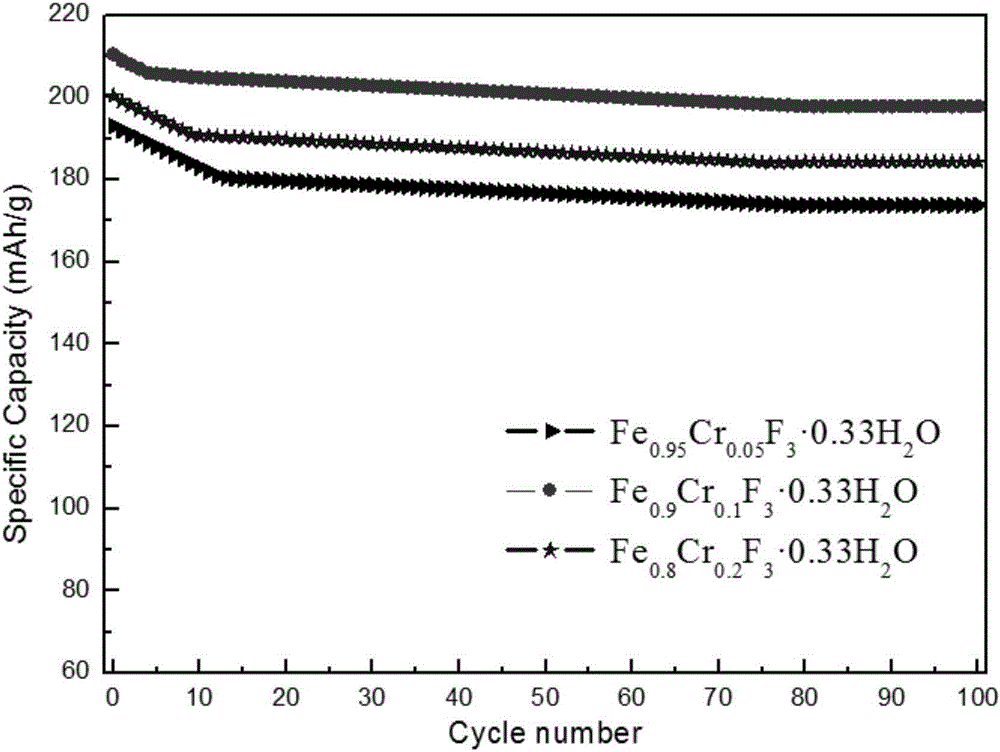

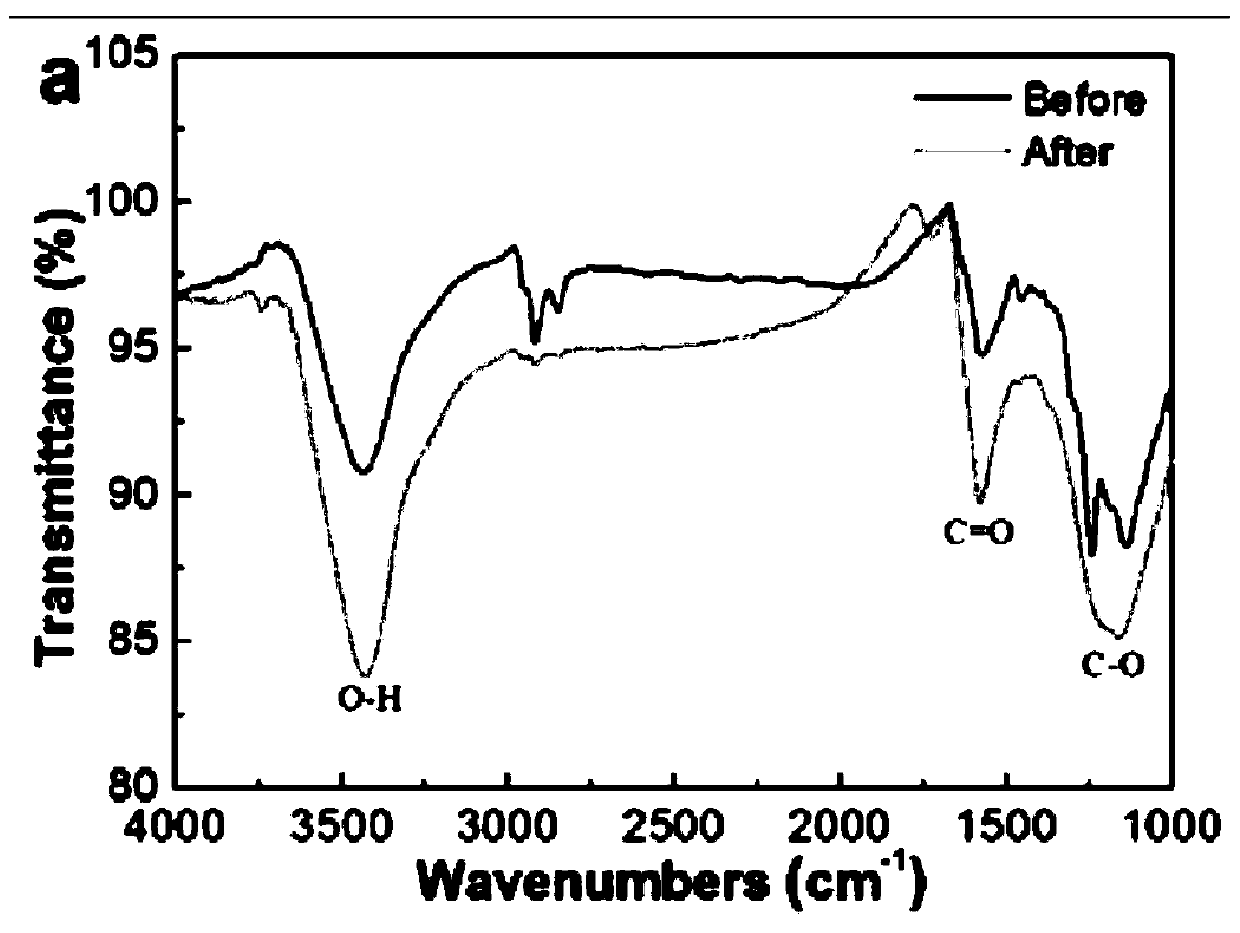

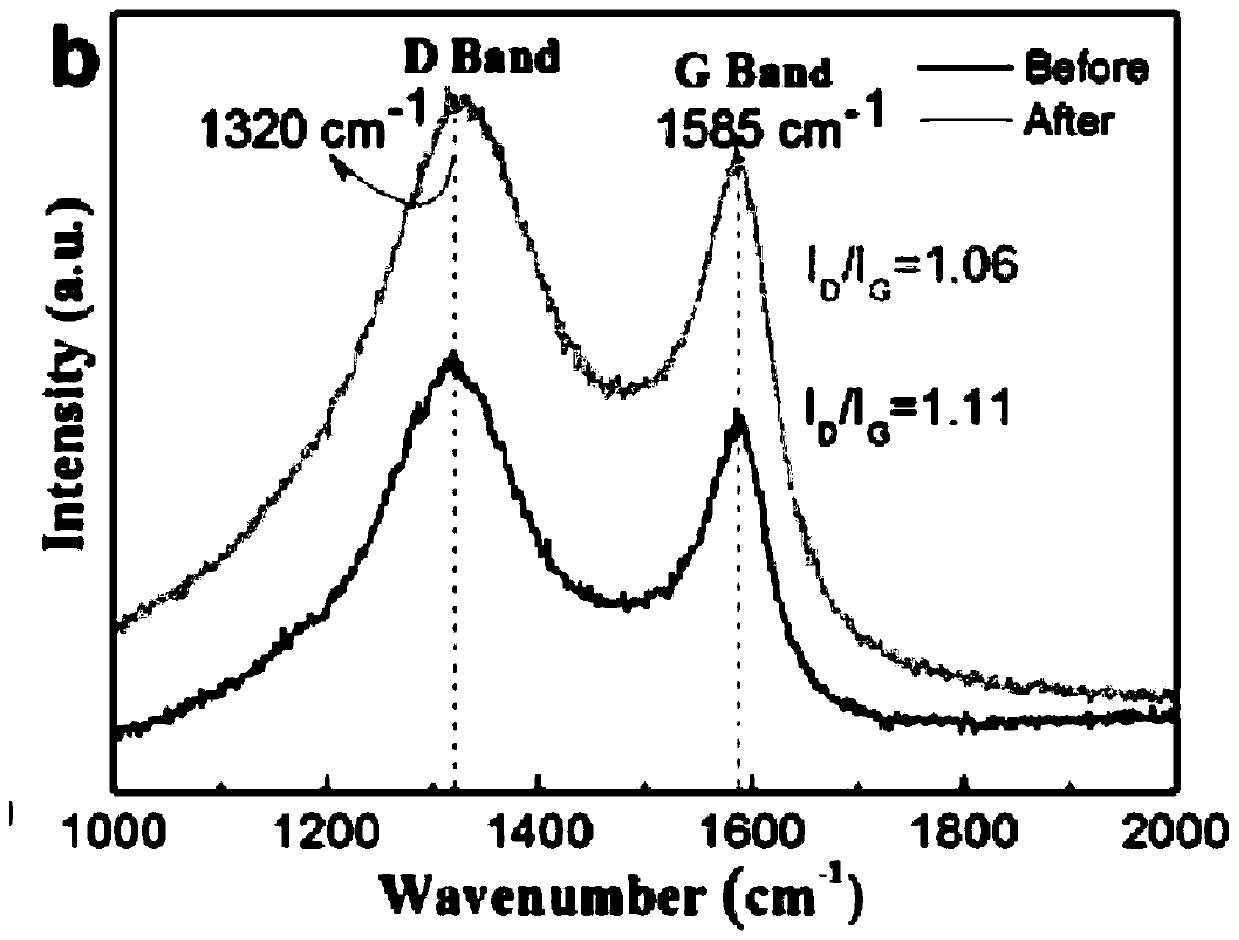

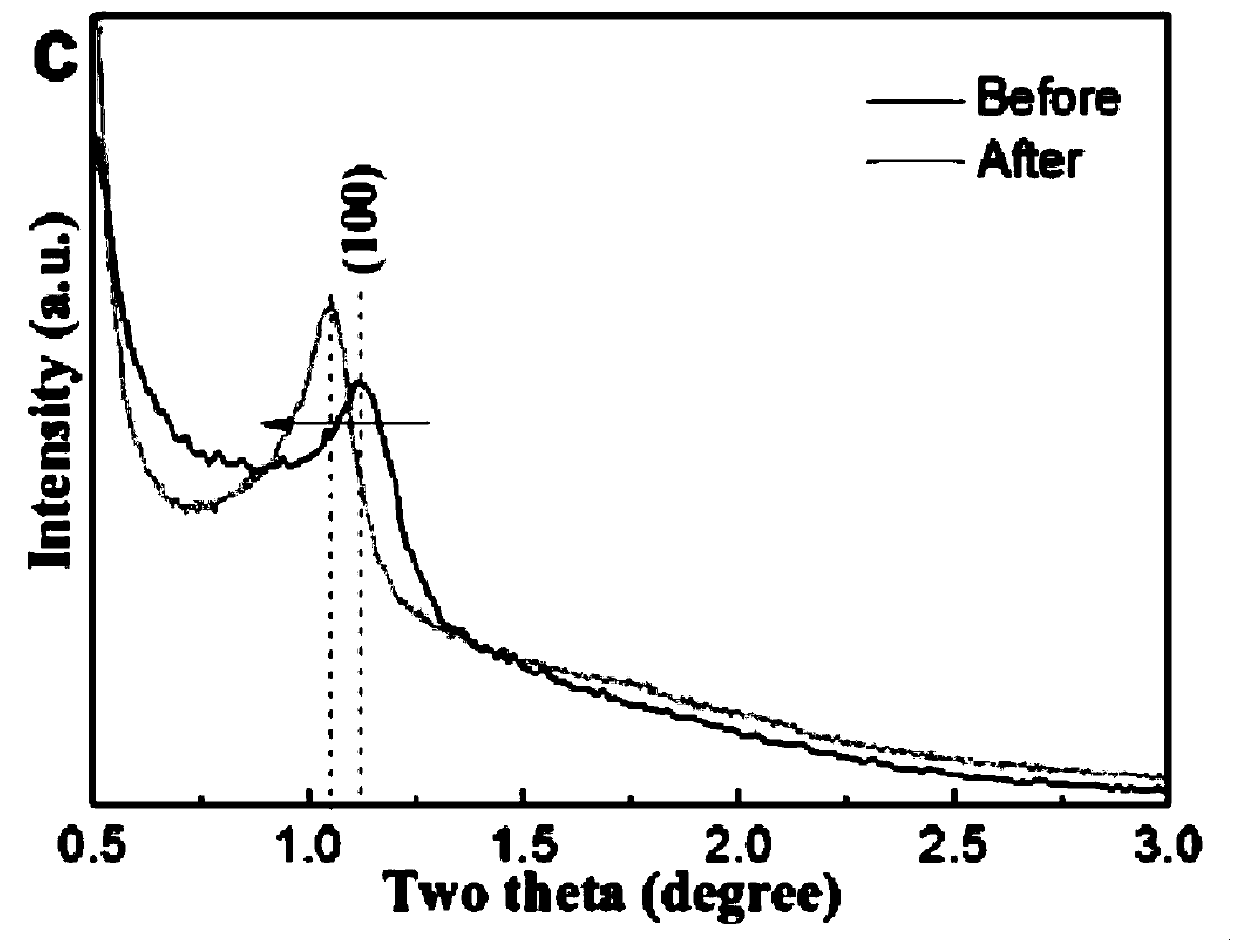

Modified ferric fluoride nano-composite anode material and preparing method and application thereof

ActiveCN106099074AImprove conductivityImprove diffusion abilityMaterial nanotechnologyCell electrodesPhysical chemistrySpecific discharge

The invention relates to the field of battery anode materials and discloses a modified ferric fluoride nano-composite anode material and a preparing method and application thereof. The modified ferric fluoride nano-composite anode material is prepared from a molysite alcohol solution, a villiaumite alcohol solution and chromic salt. The preparing method of the modified ferric fluoride nano-composite anode material comprises the following steps that firstly, the molysite alcohol solution is prepared; secondly, the villiaumite alcohol solution is prepared; third, the molysite alcohol solution and the villiaumite alcohol solution are mixed; fourthly, chromic salt is added, centrifuging is carried out after a mixing and stirring reaction, and precipitate is obtained and washed and centrifuged with absolute ethyl alcohol; fifthly, high-temperature drying is carried out, then a high-temperature reaction is carried out under the protection of inert gas, cooling is carried out, and the product is obtained. The modified ferric fluoride nano-composite anode material is high in specific discharge capacity, multiplying power and circulation stability. The preparing method of the modified ferric fluoride nano-composite anode material is simple in process, low in cost and beneficial to industrial production.

Owner:深圳鑫茂新能源技术股份有限公司

OMC-based composite electrode and lead-acid battery

InactiveCN110391401ALarge specific surface areaImprove adsorption capacityLead-acid accumulatorsNegative electrodesComposite structureLarge capacity

The present invention provides an OMC (Ordered Mesoporous Carbon)-based composite electrode and a lead-acid battery. The OMC-based composite electrode comprises a negative plate grid and lead plasterof an OMC / sponge Pb composite structure material, wherein the lead plaster of the OMC / sponge Pb composite structure material coats the negative plate grid, and the OMC-based composite negative electrode is prepared after solidification and drying. The OMC-based composite negative electrode is prepared by coating lead plaster of the OMC / sponge Pb composite structure material on the negative plate grid for curing and drying. The OMC-based composite electrode and the lead-acid battery are favorable for improving the specific capacity and the service life of the lead-acid battery. The technology of the traditional lead-acid battery negative electrode and the technology of the super capacitor are fused, so that the energy advantage of the battery characteristic is achieved, and the instant power high-capacity charging characteristic of the double electric layer capacitor is achieved, so that the specific capacity and the service life of the traditional lead-acid battery are improved.

Owner:ZHAOQING LEOCH BATTERY TECH

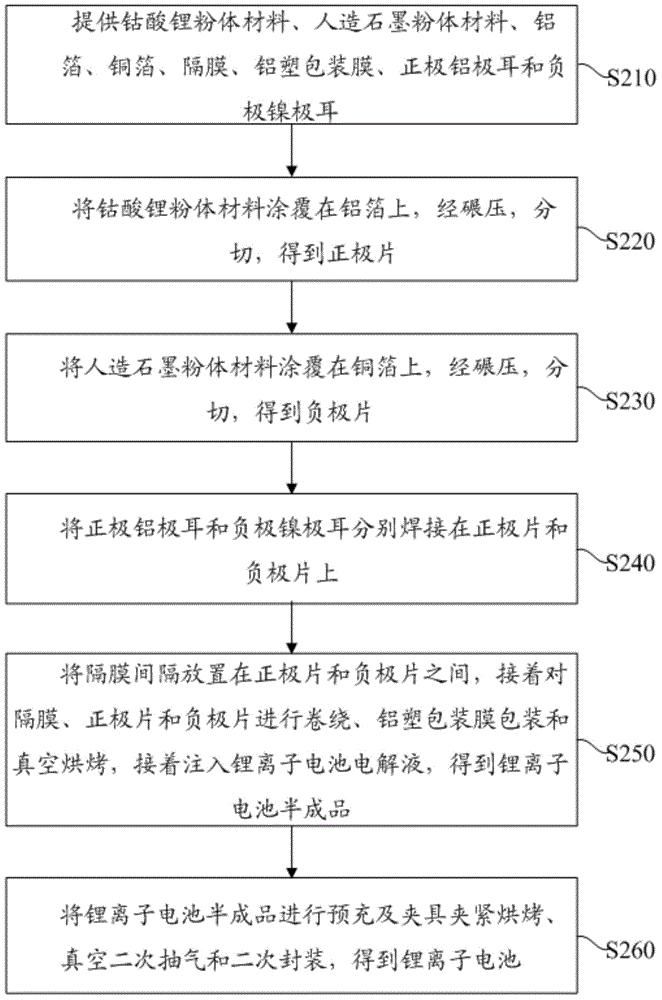

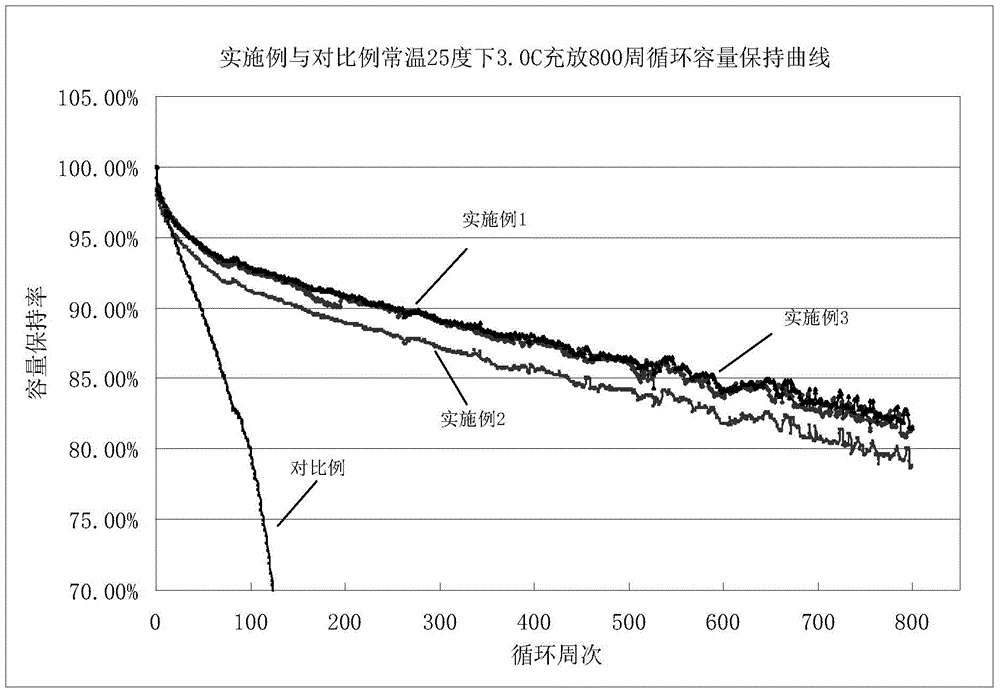

A production method of a power type lithium ion battery anode material

ActiveCN107293697AApplicable useImproved magnification performanceCell electrodesCarbon disulfideAsphalt

A production method of a power type lithium ion battery anode material is provided. Needle coke is adopted as a main raw material. The method includes a step of crushing and grading the needle coke into micron-size particles; a step of adding asphalt into carbon disulfide liquid, stirring the mixture to dissolve the asphalt, then adding the needle coke micron-size particles, fully stirring the mixture, and performing evaporation to dryness at 70 DEG C; a step of adding graphene into an ethanol solution having a concentration of 70%, fully stirring the ethanol solution, then adding phenolic resin into the ethanol solution, stirring the mixture to obtain a suspension, filtering the suspension and performing evaporation to dryness; a step of subjected to two dried materials to mixing, heating and modification at 300-400 DEG C according to a certain ratio; and a step of performing carbonization at 1300-1400 DEG C, or performing carbonization at 1300-1400 DEG C, and then performing graphitization at 2800-3000 DEG C, or directly performing graphitization at 3000-3200 DEG C. The material prepared by the method has advantages of a high charge-discharge rate, good cyclic performance, good charge-discharge reaction reversibility, a high capacity, and the like.

Owner:大连宏光锂业有限责任公司

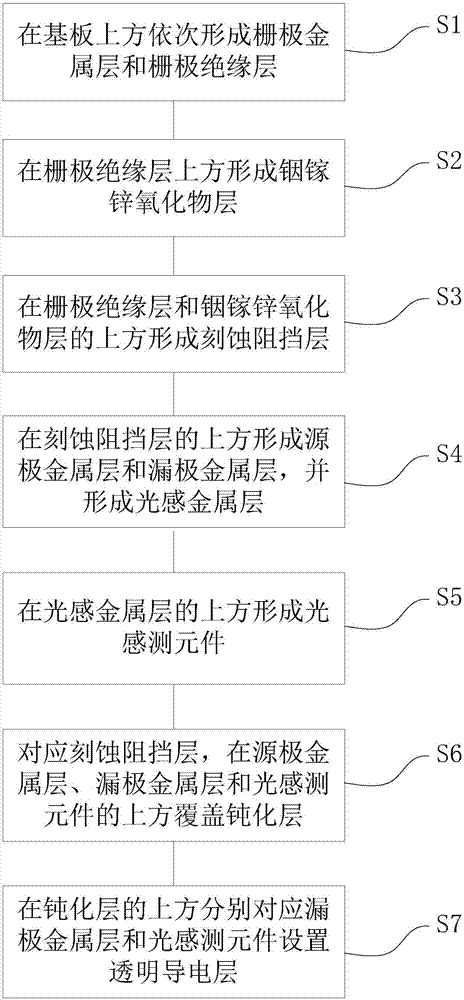

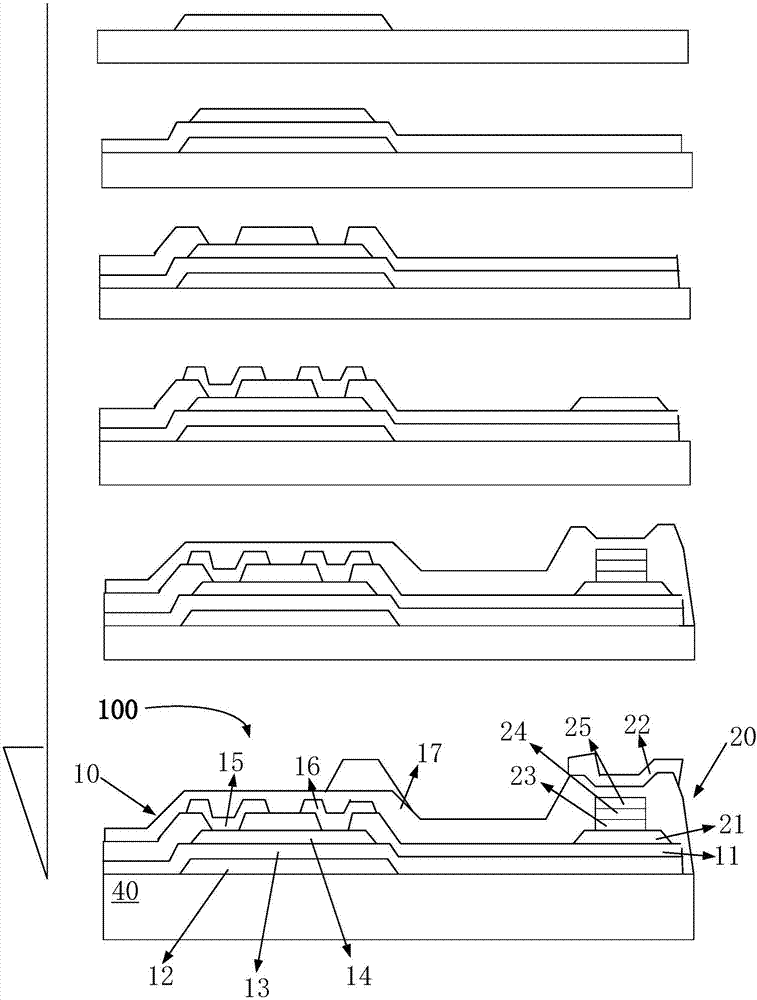

Display panel, manufacture method for display panel, and display device

ActiveCN107390406AIncrease brightnessImprove charge and discharge rateTransistorStatic indicating devicesLight sensingIndium gallium zinc oxide

The invention discloses a display panel, a manufacture method for the display panel and a display device. The display panel comprises a baseplate, a switch assembly and a light sensing component, wherein the switch assembly is disposed on the baseplate; the switch assembly comprises an indium gallium zinc oxide layer; and the light sensing component is disposed on one side of the switch assembly. According to the invention, automatic luminance adjustment of the display panel can be conducted according to external environments.

Owner:HKC CORP LTD +1

A preparation method of a mixture of nano-silicon particles and graphene lithium battery negative electrode materials coated with a silicon monoxide network structure

ActiveCN103811729BSimple preparation processReduce contact resistanceCell electrodesLi-accumulatorsNano siliconSilicon monoxide

The invention provides a method for preparing a mixture of coated silicon monoxide network structure nano-silicon particles and graphene lithium battery negative electrode material, comprising the following steps: (1) mixing silicon compound and graphene to prepare a soluble mixture solution; (2) ) The silicon compound and graphene in the soluble mixture solution are both made into nanoparticles, and then added into the chamber of the microwave pyrolysis equipment; (3) The oxygen partial pressure in the chamber is controlled at 5~10000ppm, and the temperature is 200~500℃ , after reacting for 10-300s, collect the powder in the microwave pyrolysis chamber and dry to obtain the product. The method not only has simple process, but also has good dispersion and high purity of nano-silicon particles and graphene particles in the obtained mixture of nano-silicon particles coated with silicon monoxide network structure and graphene lithium battery negative electrode material.

Owner:福建省诺希科技园发展有限公司

Graphene-coated lithium battery anode material and preparation method thereof

InactiveCN108807914ARegulatory performanceSimple methodCell electrodesSecondary cellsSulfideGraphene

The invention discloses a graphene-coated lithium battery anode material and a preparation method thereof. The preparation method has the advantages that a graphene-coated lithium battery anode is prepared by a hydrothermal method; the preparation method is simple; compared with the method for preparing the nanometer structure type lithium battery anode under the high vacuum condition or high temperature condition, the vacuum degree is not required, the high temperature is not required, and the preparation cost is obviously reduced; the requirement on equipment is low, the reaction material iseasy to obtain, the preparation temperature is lower, the reaction conditions are easy to control, and the like; the lithium battery anode is coated by the graphene with higher conductivity, and thecuprous sulfide treated by carbon disulfide is used as the lithium battery anode material, so that the charging and discharging rates of the battery are effectively improved, and the transmission of electrons at the surface of the material is enhanced; in the embedding and deembedding process of lithium ions, the volume change of the material can be adjusted, the influence to the material propertyby the volume change is decreased, and the electrochemical property of the material is improved.

Owner:SHANGQIU NORMAL UNIVERSITY

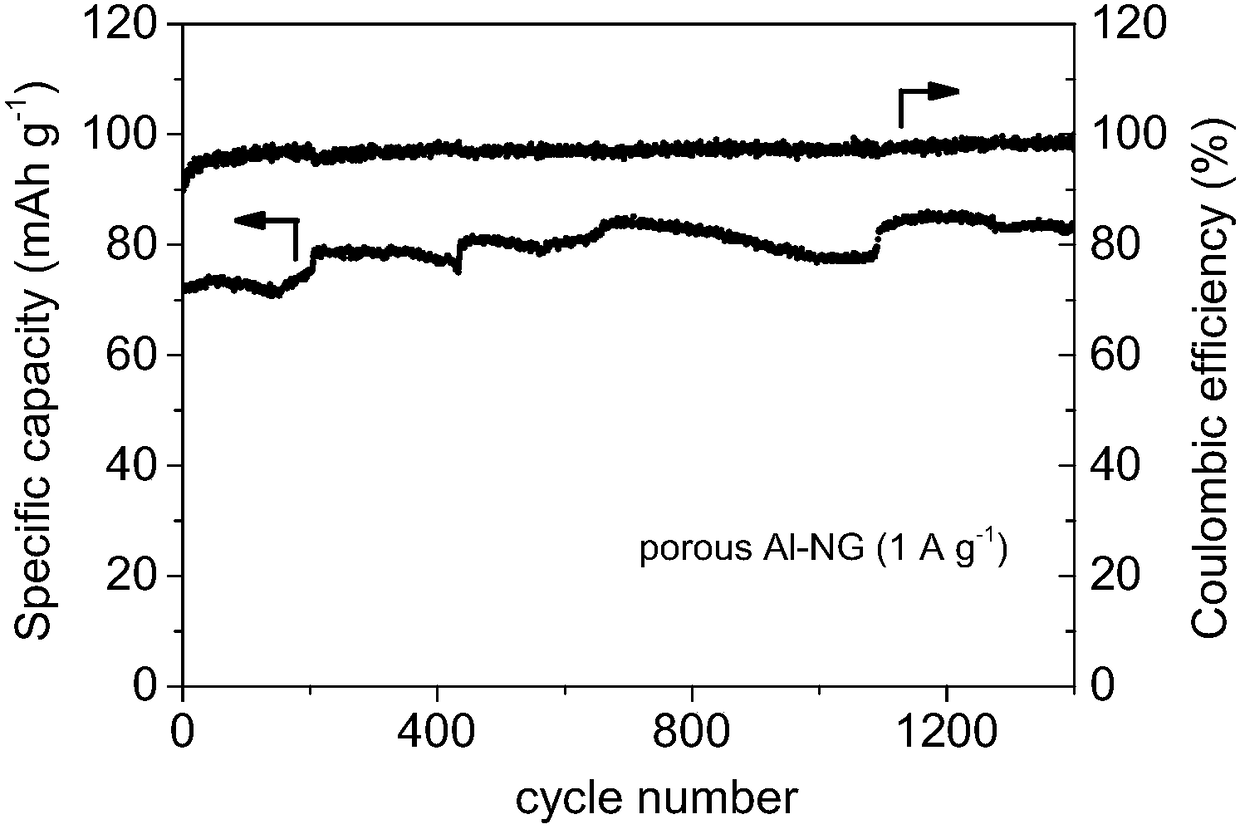

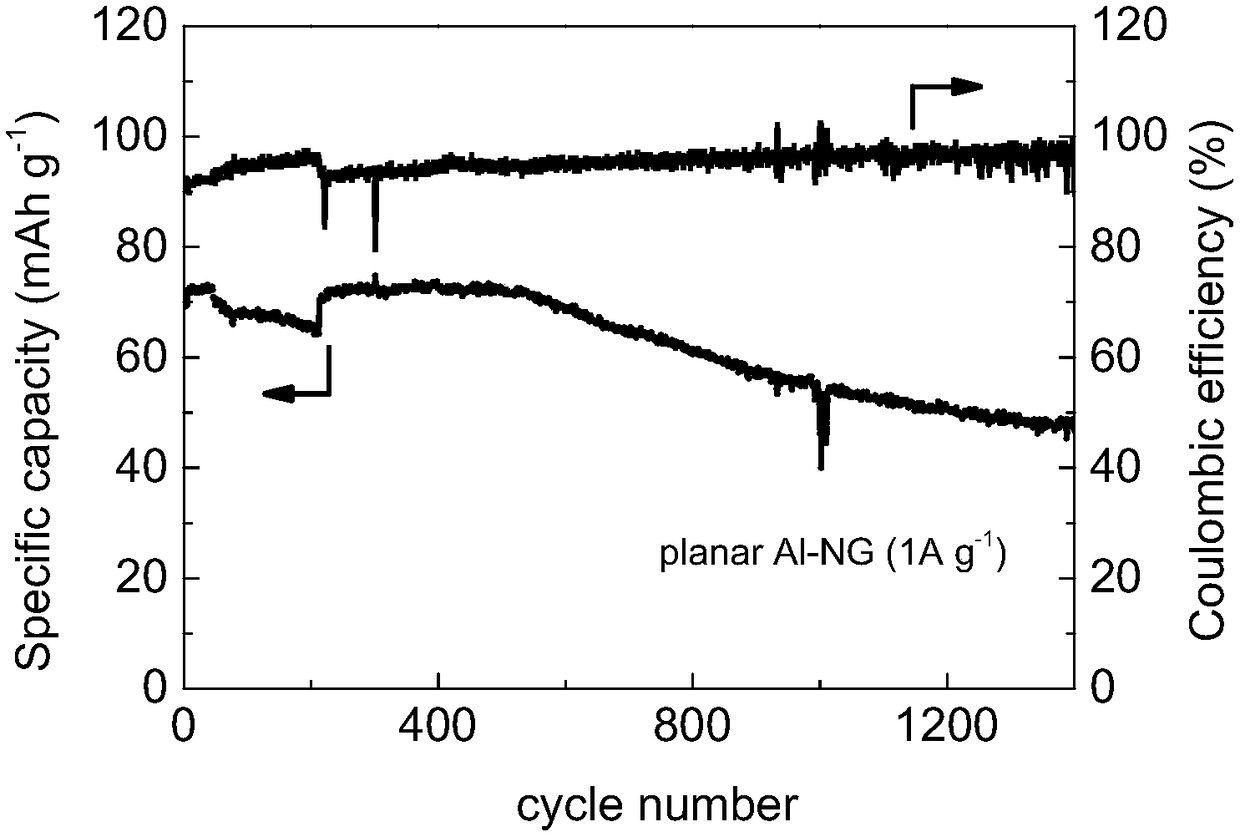

Dendrite-free and high-rate aluminum ion battery

ActiveCN108376795ALarge specific surface areaIncrease roughnessNegative electrodesSecondary cellsAluminum IonHigh rate

The invention belongs to the technical field of energy storage batteries and particularly relates to a dendrite-free and high-rate aluminum ion battery. The aluminum ion battery comprises an anode, acathode, electrolyte and an isolating membrane, wherein the isolating membrane is arranged between the anode and the cathode; and the cathode is a porous aluminum foil, an included angle between a pore channel direction of the porous aluminum foil and an aluminum ion transmission direction is gamma, and gamma is more than or equal to 0 and less than or equal to 90 degrees. Compared with the priorart, the problem that a dendrite is produced by taking a plane aluminum foil as a cathode of an aluminum ion battery under a large-current long cycle condition is effectively inhibited, and the cycling stability and rate capability of a device are effectively improved; and the technical problems of poor rate capability and cycling stability of the aluminum ion battery caused by the production of the dendrite in the prior art are solved.

Owner:TIANJIN UNIV

Preparation method of graphite-ferroferric oxide composite cathode material

InactiveCN103219494AIncrease capacityImprove charge and discharge rateCell electrodesNano siliconCarbon layer

The invention relates to a preparation method of graphite-ferroferric oxide composite cathode material, and the method comprises the following steps of: (1) preparing an active substance Fe3O4; (2) uniformly coating a carbon layer on the surface of nano-silicon particle powder via the chemical vapor deposition method, then ball-milling and mixing the nano-silicon particle powder coated with the carbon layer, and graphite to obtain a high-reversible-capacity graphite mixture; and (3) weighing a specified amount of the active substance Fe3O4; adding dysprosium oxide, the high reversible capacity graphite mixture and PVA (polyvinyl alcohol) binder; and mixing substances uniformly to obtain the graphite-ferroferric oxide composite cathode material. The graphite-ferroferric oxide composite cathode material prepared according to the preparation method disclosed in the invention has the characteristics of integration of high capacity, high charge and discharge rate and high cycling stability due to combination of the ferroferric oxide composite cathode material with high specific capacity and the high reversible capacity graphite material.

Owner:马军昌

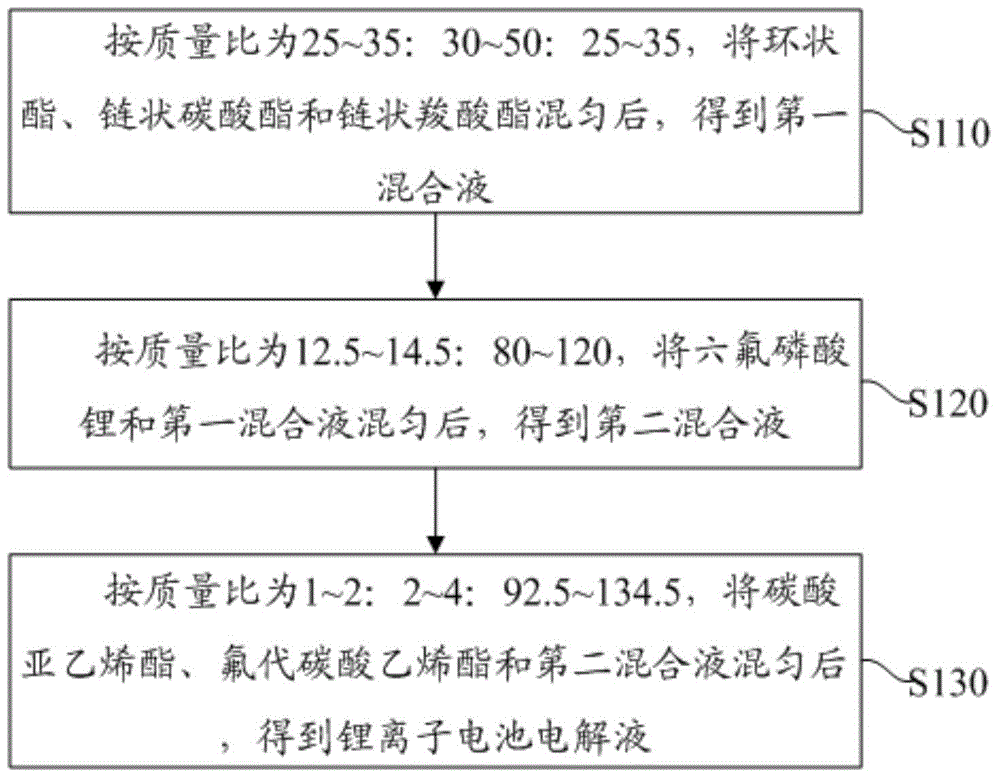

Lithium ion battery electrolyte and preparation method thereof, and lithium ion battery

InactiveCN105489933AImprove charge and discharge rateInhibition of decomposition reactionsSecondary cellsVinylene carbonateLithium electrode

The invention relates to a lithium ion battery electrolyte, which comprises, by mass, 25-35 parts of a cyclic ester, 30-50 parts of a chain carbonate, 25-35 parts of chain carboxylic acid ester, 12.5-14.5 parts of lithium hexafluorophosphate, 1-2 parts of vinylene carbonate, and 2-4 parts of fluoroethylene carbonate. According to the present invention, with the application of the lithium ion battery electrolyte in the lithium ion battery, vinylene carbonate and fluoroethylene carbonate can form the SEI film with characteristics of high density and stable structure on the electrode material, such that the adsorption of the lithium ions migrating between the positive electrode and the negative electrode on the electrode material surface during the charging and discharging process can be avoided to increase the concentration of the migrating lithium ions so as to improve the number of the charges moving between the positive electrode and the negative electrode within the per unit time of charge and discharge so as to improve the charging and discharging rate of the lithium ion battery. The present invention further discloses a preparation method of the lithium ion battery electrolyte, and a lithium ion battery using the lithium ion battery electrolyte.

Owner:EVE HYPERPOWER BATTERIES INC

Method for manufacturing display device, repairing method and liquid crystal display panel

ActiveCN103995378AReduce RC hysteresisReduce Line DefectsNon-linear opticsElectrical conductorLiquid-crystal display

The invention relates to a method for manufacturing a display device, a repairing method and a liquid crystal display panel. The method for manufacturing the display device comprises the steps that firstly, a grid electrode, a scanning line, a first insulating layer and a semiconductor layer are sequentially arranged on a substrate; secondly, the position of a data line is determined on the semiconductor layer, and an etching preventing layer is arranged at the position, deviating from the data line, on the semiconductor layer; thirdly, the part, in the position of the data line, of the semiconductor layer is modified into a conductor; fourthly, a source electrode, a drain electrode, the data line and a second insulating layer are arranged on the semiconductor layer. According to the repairing method, when the data line is broken, broken data line segments are connected with a conductor layer below the data line respectively in a melting mode. The display device manufactured through the method is high in display quality and easy to repair.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

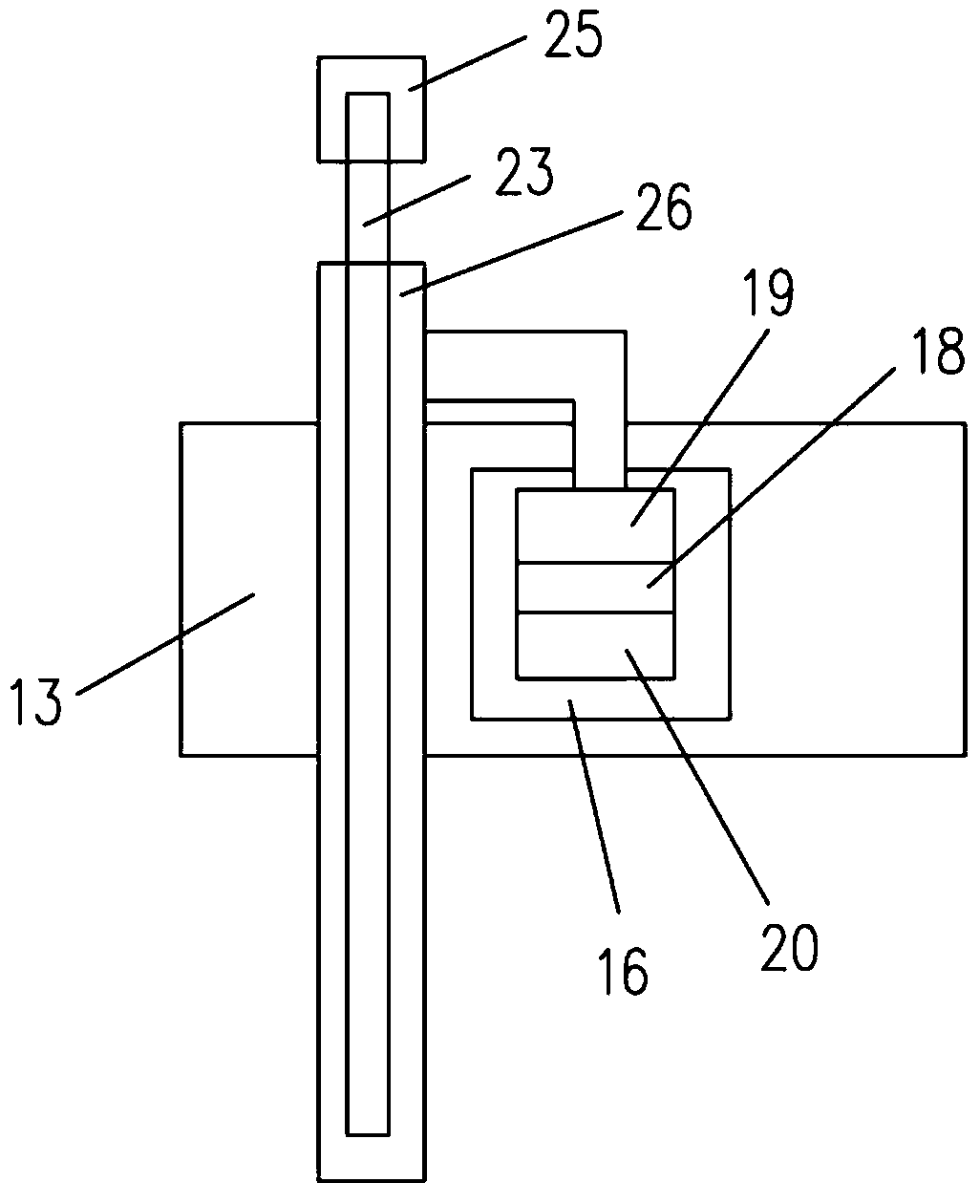

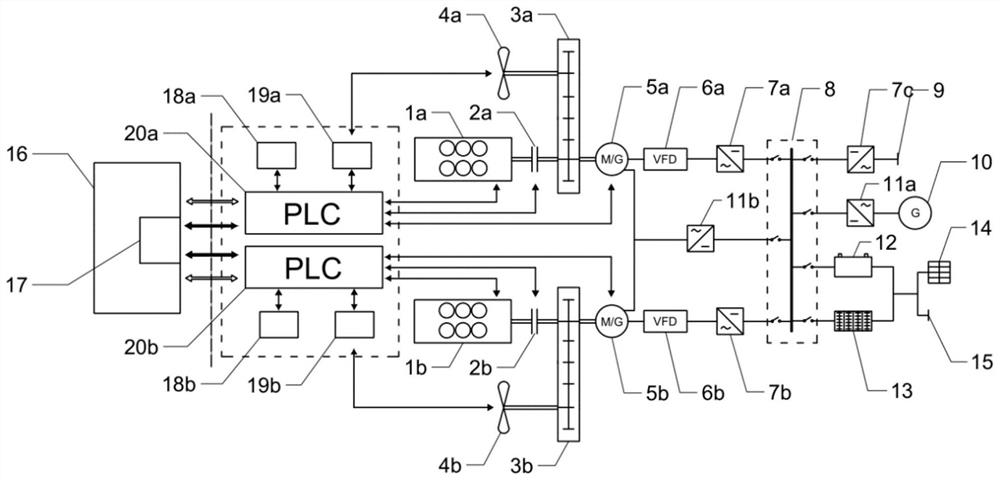

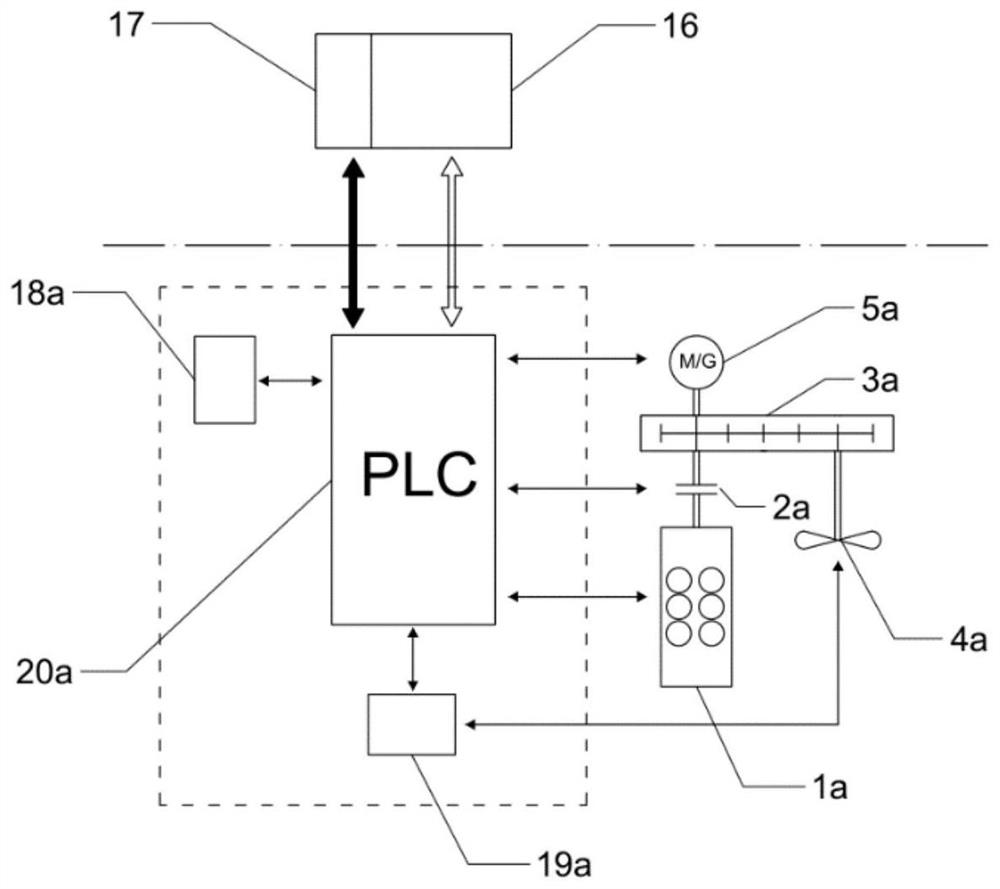

Double-shaft four-machine type ship hybrid power system and propulsion control method thereof

InactiveCN112572744AImprove reliabilityWide power coveragePower plants using propulsion unit combinationsPropulsive elementsControl theoryPower apparatus

The invention relates to a double-shaft four-machine type ship hybrid power system and a propulsion control method thereof. The hybrid power system comprises two sets of independent power devices. Theoutput end of a main push diesel engine is connected with the input end of a gearbox through a clutch; the input / output end of a propulsion motor is connected with the input / output end of the gearbox; the output end of the gearbox is connected with the input end of a full-revolving steering oar; a first group of power transmission lines of the propulsion motor are connected with a first group ofterminals of a distribution board through a propulsion motor end rectifier; a second group of terminals of the distribution board are connected with an energy storage unit; and a third group of terminals of the distribution board are connected with a second group of power transmission lines of the propulsion motor through a propulsion motor end inverter and a frequency converter in sequence. The power system is wide in power coverage range, on the one hand, power redundancy is increased, the reliability of the power system is improved, and on the other hand, multiple working modes are provided, and the requirements of various ship environments and working conditions are met.

Owner:WUXI DONGFANG HIGH PERFORMANCE SHIP ENG

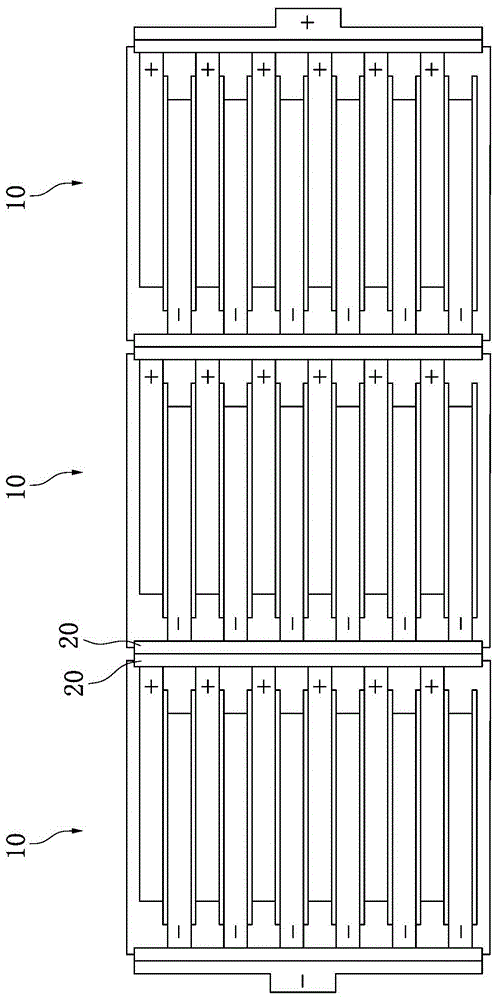

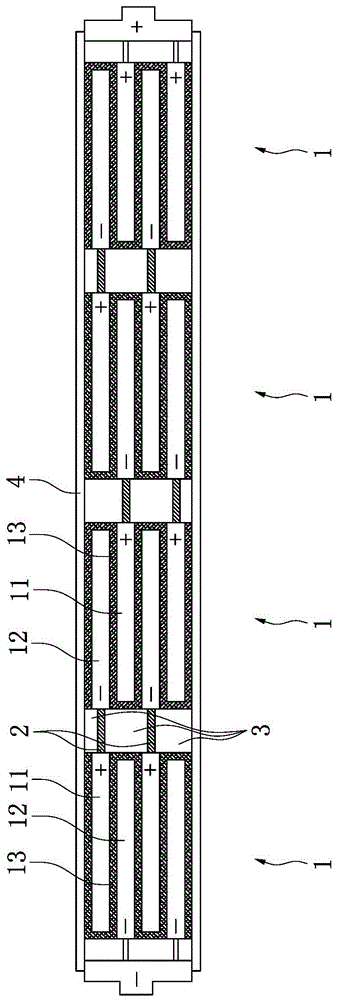

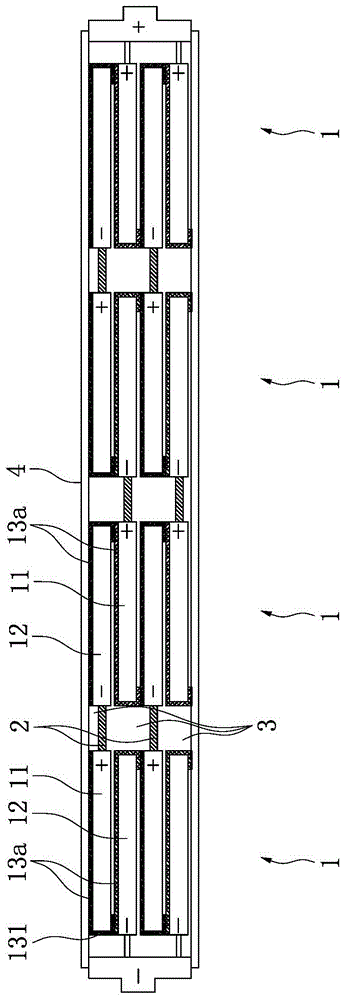

Series-connection structure of square battery and square nickel-hydrogen battery

InactiveCN106410105ALower internal resistanceImprove charge and discharge rateCell component detailsNickel accumulatorsInternal resistanceEngineering

The invention discloses a series-connection structure of a square battery and a square nickel-hydrogen battery. The series-connection structure of the square battery comprises more than two single power cores, wherein each single power core comprises at least one cathode plate, at least one anode plate and at least one diaphragm; each diaphragm is used for isolating the corresponding cathode plate from the corresponding anode plate; the single power cores are successively assembled in the same shell in the front-back direction in the horizontal direction; the cathode plates of the former single power core and the anode plates of the latter single power core are in one-to-one correspondence and are fixedly connected integrally directly through conductive plates; and partitions for isolating an electrolytic solution are respectively mounted between the conductive plates of each two front and back adjacent single power cores and between each conductive plate and the shell. The series-connection structure of the square battery is compact in structure, good in connection stability and small in internal resistance; and the charging and discharging speed of the battery is high, and the service life of the battery is long.

Owner:杨清文

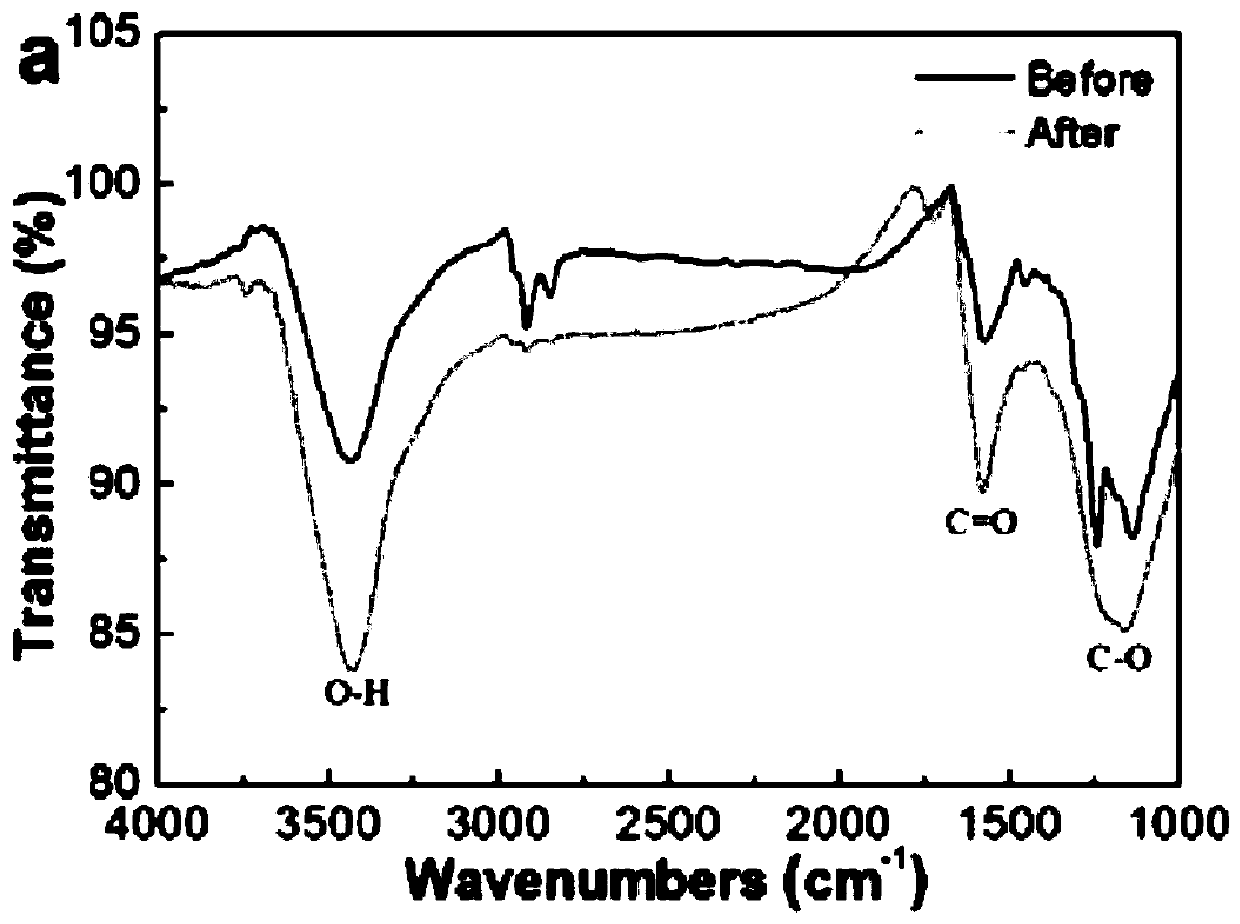

OMC/sponge Pb composite structure material lead plaster and preparing method and application thereof

InactiveCN110416502AGood dispersionUniform dispersionLead-acid accumulatorsCell electrodesMaterials scienceHydrogen peroxide

An OMC / sponge Pb composite structure material lead plaster and a preparing method and an application thereof are provided. The preparing method comprises the following steps: performing passivation modification processing on OMC by using hydrogen peroxide, to obtain hydrophilic OMC; configuring the hydrophilic OMC into OMC dispersion liquid by using deionized water, wherein a mass ratio of the hydrophilic OMC to the deionized water is 1:2000 to 1:3500; mixing and stirring the OMC dispersion liquid and lead powder at the mass ratio of 0.1:1 to 0.11:1, to obtain a mixture; and adding sulfuric acid to the mixture, and performing mechanical agitation and mixing to prepare the OMC / sponge Pb composite structure material lead plaster. Therefore, OMC and lead powder can be mixed uniformly, and robustness of negative OMC / sponge Pb composite material pasting and a bonding capability of a polar plate and lead plaster can be ensured.

Owner:ZHAOQING LEOCH BATTERY TECH

Preparation method and application of silver vanadate/vanadium oxide one-dimensional composite nano-electrode material

InactiveCN101807685BIncreased intercalation/deintercalation ratesImprove charge and discharge rateCell electrodesSecondary cellsHigh energyVanadate

The invention provides a preparation method and application of a silver vanadate / vanadium oxide one-dimensional composite nano-electrode material, which can solve the problems of high energy consumption, difficult control of components, grain diameter and appearance of a product, low electrical conductivity and poorer cyclical stability of a traditional lithium battery anode material. The invention adopts a one-step hydrothermal method which comprises the following steps of: 1. dissolving vanadium salt into 10-30 percent hydrogen peroxide to obtain a transparent peroxovanadate solution; 2. dispersing the vanadium salt into deionized water; 3. pouring a vanadium salt mixture into the peroxovanadate solution, mixing, fully stirring and pouring into a hydrothermal reaction kettle for hydrothermal reaction to obtain a product; and 4. obtaining the silver vanadate / vanadium oxide one-dimensional composite nano-electrode material through centrifugalizing, washing and drying the product. The preparation process of the invention is simple, the size of the product and the doping amount of silver are easy to control, the product has larger yield and is pure, and both the specific capacity and the cyclical stability of the silver vanadate / vanadium oxide one-dimensional composite nano-electrode material as the lithium battery anode material are markedly improved.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com