Titanium carbide-loaded stannous sulfide composite anode material

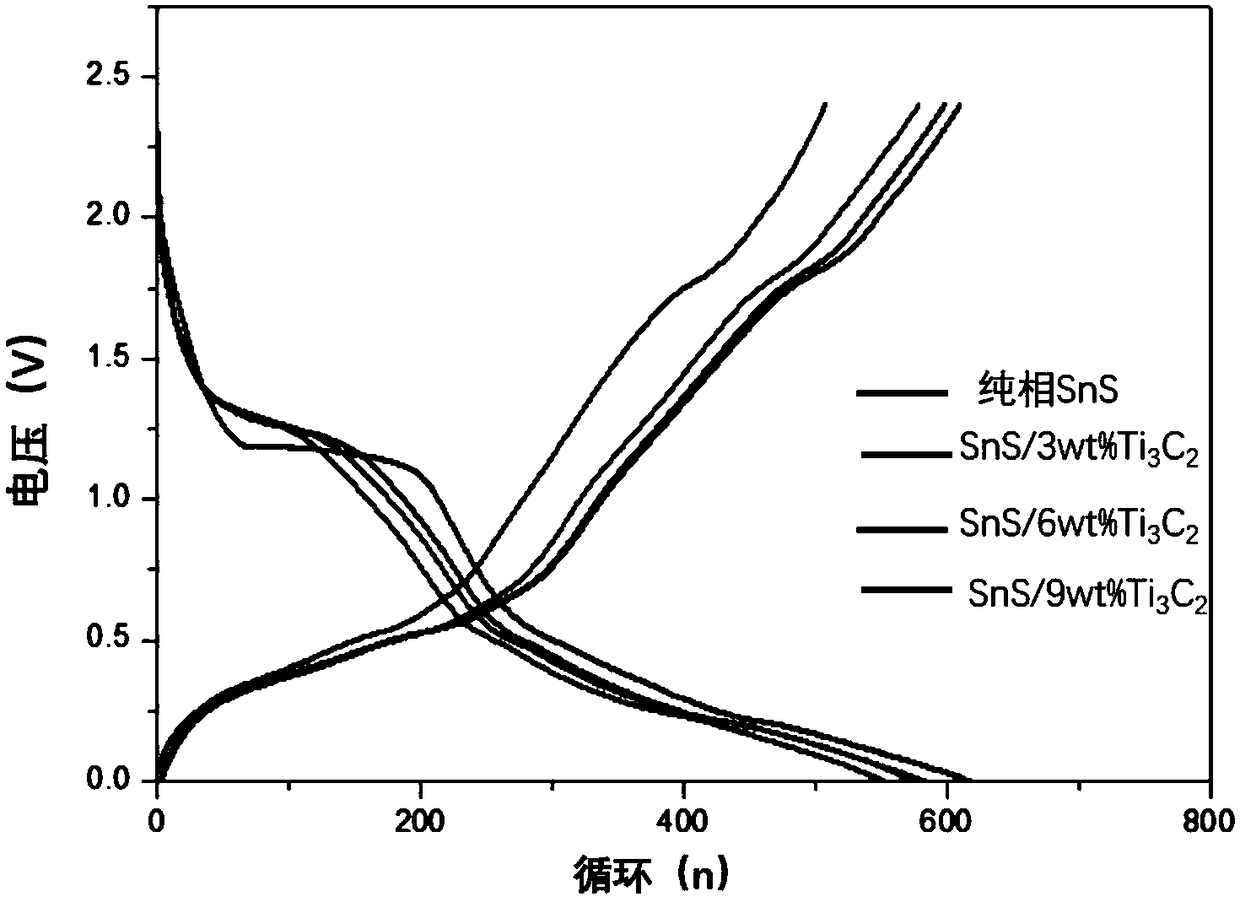

A stannous sulfide and negative electrode material technology, applied in battery electrodes, electrochemical generators, electrical components, etc., can solve the problems of poor cycle performance, poor cycle stability, poor rate performance, etc., and achieve the improvement of cycle performance and rate performance , good structural stability, good cycle performance and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

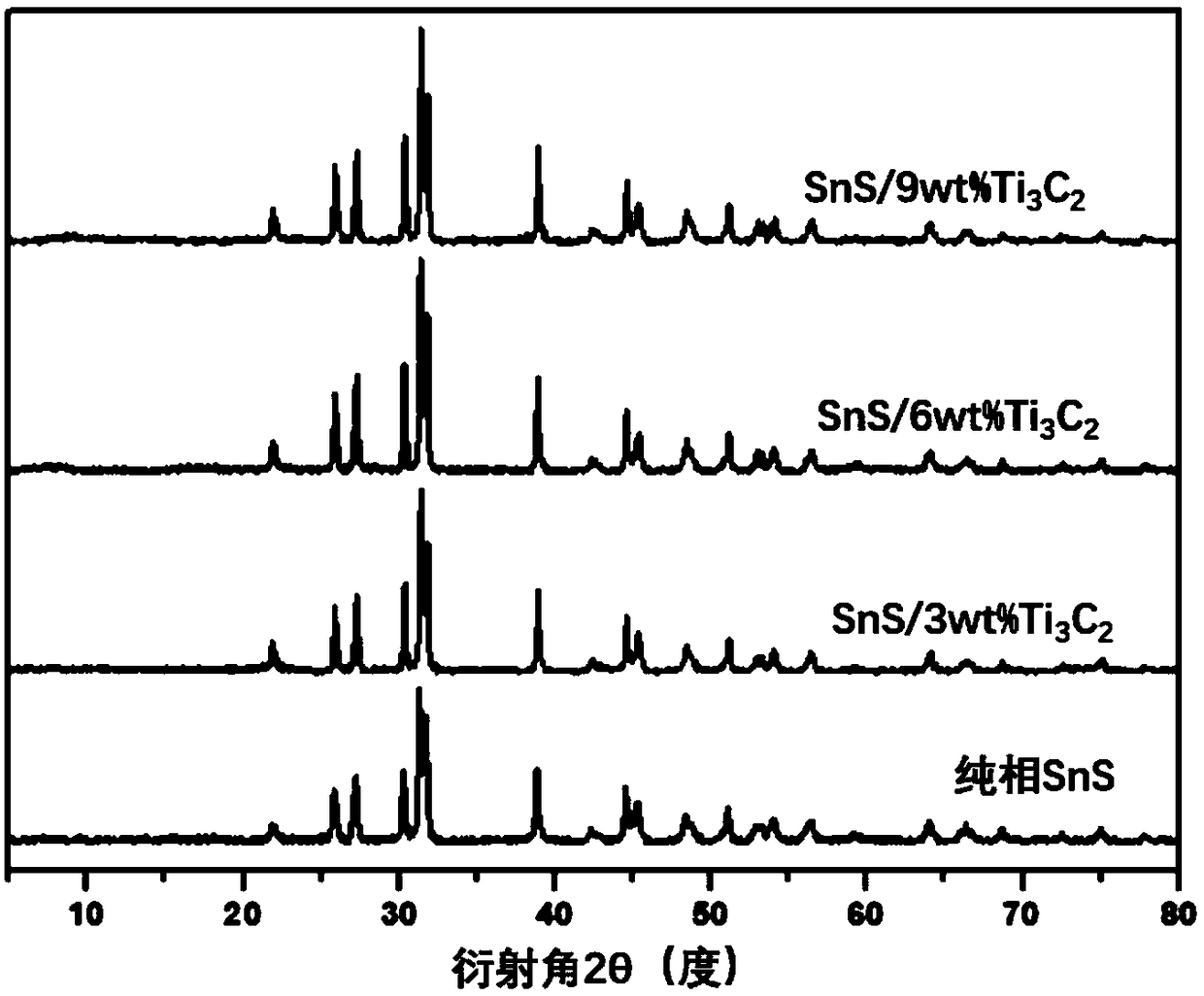

[0033] A kind of titanium carbide loaded tin sulfide composite anode material, namely Ti 3 C 2 The upper loading tin sulfide SnS composite negative electrode material, composite negative electrode material SnS / Ti in the present embodiment 3 C 2 , the mass ratio of pure-phase stannous sulfide anode material to titanium carbide is 1:0.03.

[0034] Prepared by:

[0035] Weigh 0.528g of L-cysteine and 0.364g of potassium stannate and mix in a beaker, add deionized water and magnetically stir until completely dissolved (solution A), at the same time, weigh 0.045g of titanium carbide and place it in another beaker Add 1ml of diethylene glycol diacrylate (PDDA) phthalate (PDDA) and deionized water and ultrasonically shake until completely dissolved (solution B), slowly add solution B to solution A to form black suspension C, and dissolve the black The suspension C was poured into a high-temperature reaction kettle in a polytetrafluoroethylene inner village, and then the reactio...

Embodiment 2

[0037] A kind of titanium carbide loaded tin sulfide composite anode material, namely Ti 3 C 2 The upper loading tin sulfide SnS composite negative electrode material, composite negative electrode material SnS / Ti in the present embodiment 3 C 2 , the mass ratio of pure-phase stannous sulfide anode material to titanium carbide is 1:0.06.

[0038] Specifically prepared by the following steps:

[0039]Weigh 0.528g of L-cysteine and 0.364g of potassium stannate and mix them in a beaker, add deionized water and magnetically stir until completely dissolved (solution A), at the same time, weigh 0.09g of titanium carbide and place it in another beaker Add 1ml of diethylene glycol diacrylate (PDDA) phthalate (PDDA) and deionized water and ultrasonically shake until completely dissolved (solution B), slowly add solution B to solution A to form black suspension C, and dissolve the black The suspension C was poured into a high-temperature reaction kettle in a polytetrafluoroethylene...

Embodiment 3

[0041] A kind of titanium carbide loaded tin sulfide composite anode material, namely Ti 3 C 2 The upper loading tin sulfide SnS composite negative electrode material, composite negative electrode material SnS / Ti in the present embodiment 3 C 2 , the mass ratio of pure-phase stannous sulfide anode material to titanium carbide is 1:0.09.

[0042] Specifically prepared by the following steps:

[0043] Weigh 0.528g of L-cysteine and 0.364g of potassium stannate and mix them in a beaker, add deionized water and magnetically stir until completely dissolved (solution A), at the same time, weigh 0.135g of titanium carbide and place it in another beaker Add 1ml of diethylene glycol diacrylate (PDDA) phthalate (PDDA) and deionized water and ultrasonically shake until completely dissolved (solution B), slowly add solution B to solution A to form black suspension C, and dissolve the black The suspension C was poured into a high-temperature reaction kettle in a polytetrafluoroethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com