T2 type lithium cobalt oxide positive electrode material with space group of Cmca and preparation method of T2 type lithium cobalt oxide positive electrode material

A cathode material, lithium cobalt oxide technology, which is applied in the field of lithium ion battery materials and electrochemistry, can solve the problems of limited specific energy density of batteries, has not been widely used, and cannot be well solved, and achieves uniform particle size and method. Simple and easy, high crystallinity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

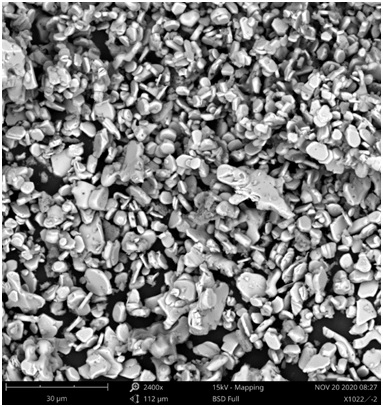

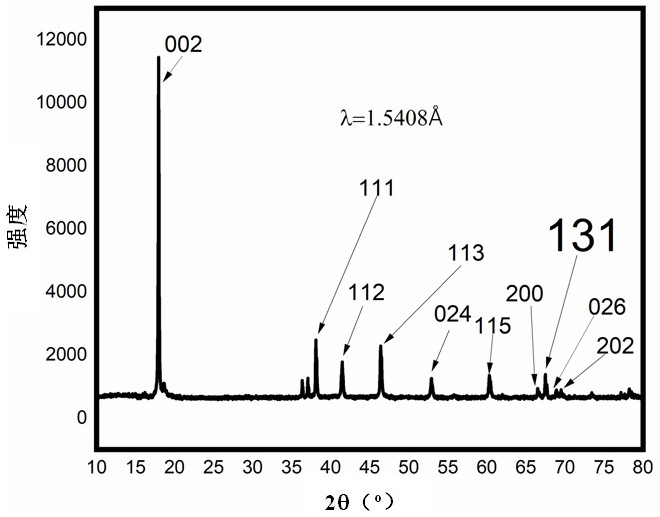

[0033] Example 1 Synthesis of T2 configuration binary lithium-rich material Li by ball milling method + ion exchange method 0.7 Na 0.02 CoO 2

[0034] Take 1.8732 g of cobaltous oxide and 0.954 g of sodium carbonate, add 5 mL of ethanol, ball mill and mix at 300 rpm for 4 h, and then dry. Take out the dried mixed precursors, grind them evenly, and place them in a tube furnace at 450°C for 4 hours, followed by calcination at 800°C for 8 hours to obtain a sodium-containing precursor product—Na 0.72 CoO 2 .

[0035] The sodium-containing precursor was combined with a 5-fold molar amount of the lithium salt LiNO 3 After ion exchange at 280 °C for 0.5 h, the obtained sample was washed twice with deionized water and then dried in a blast oven at 100 °C to obtain the final sample T2-Li 0.7 Na 0.02 CoO 2 .

[0036] T2-Li prepared by the above method 0.7 Na 0.02 CoO 2 Mixed with carbon black and PVDF (polyvinylidene fluoride) in a mass ratio of 8:1:1, ground evenly with N-m...

Embodiment 2

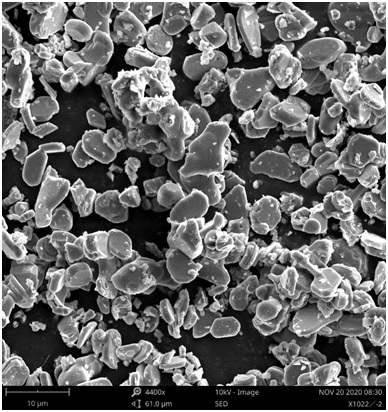

[0038] Example 2 T2 configuration binary lithium-rich material Li synthesized by co-precipitation method + ion exchange method 0.7 Na 0.02 CoO 2

[0039] Take 0.12 mol CoSO 4 ·6H 2 Dissolve O in 60 mL of deionized water and stir to form a salt solution, then take 0.12 mol of Na 2 CO 3 Mix it with 2 mL of ammonia solution with a concentration of 18.4 mol / L and add water to make 60 mL of alkaline solution. The prepared alkaline solution and salt solution were simultaneously added dropwise to deionized water using a peristaltic pump to maintain pH between 7.5 and 8.5, and heated in a water bath at a temperature of 60 °C with constant stirring at a stirring speed of 500 rpm.

[0040] After the dropwise addition, the obtained suspension was left to stand for more than 12 hours, then filtered with a Buchner funnel, and washed with deionized water for more than 3 times. The precipitation material obtained by filtration was dried in a vacuum oven at 80 °C for more than 8 h, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com