Patents

Literature

121 results about "Specific energy density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The specific energy density (which is energy density, E divided by the weight of the cell) is the product of the specific capacity and the operating voltage in one full discharge cycle. The values are often quoted for an average voltage and less frequently for the maximum voltage in the discharge sequence.

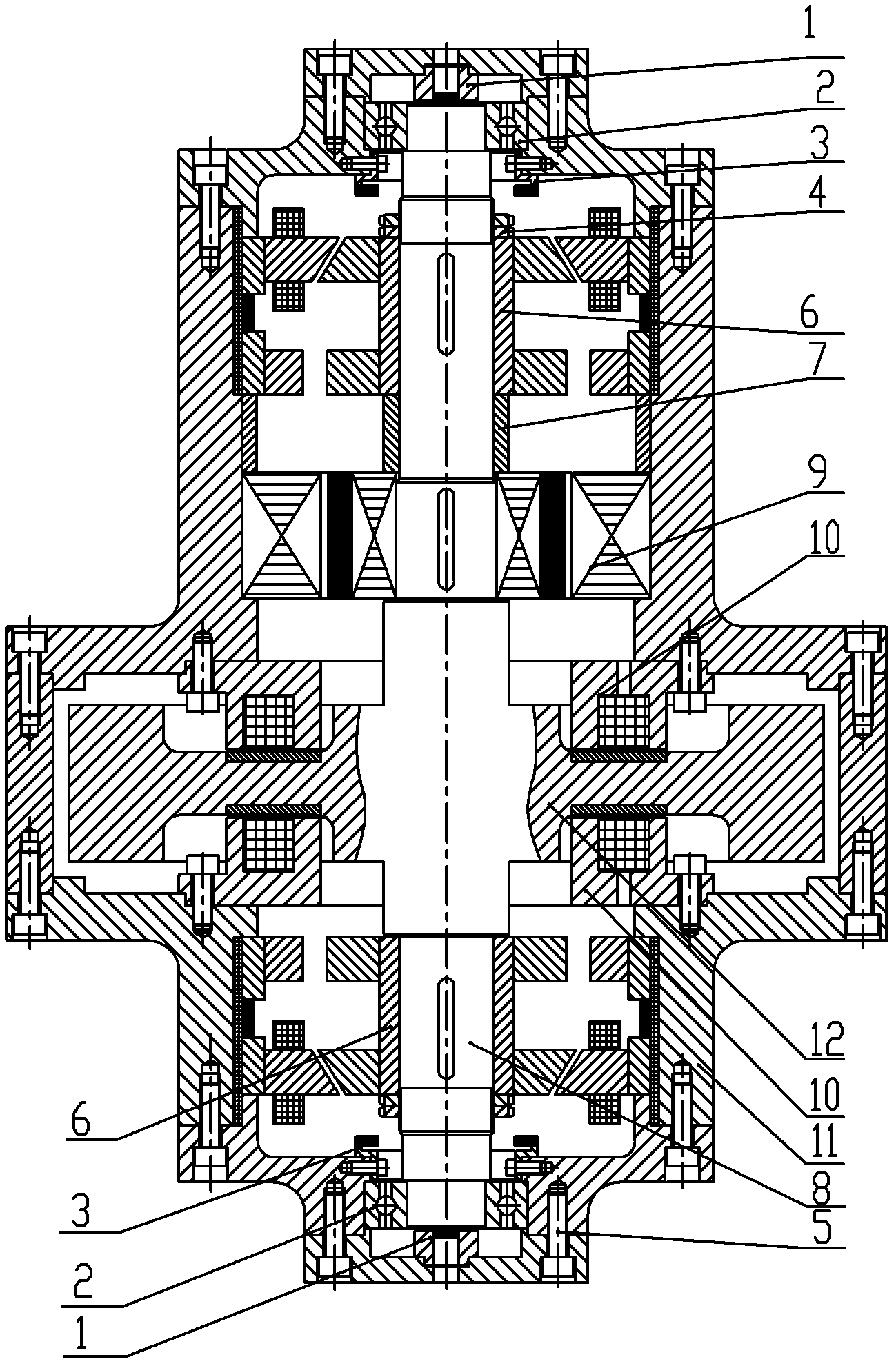

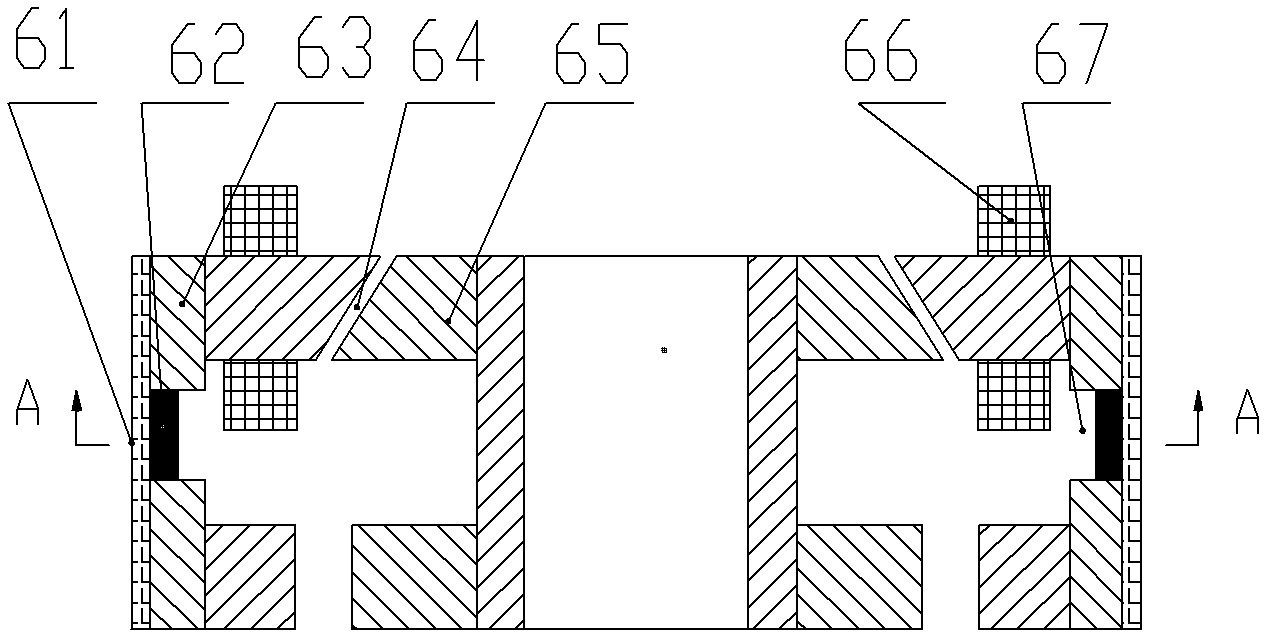

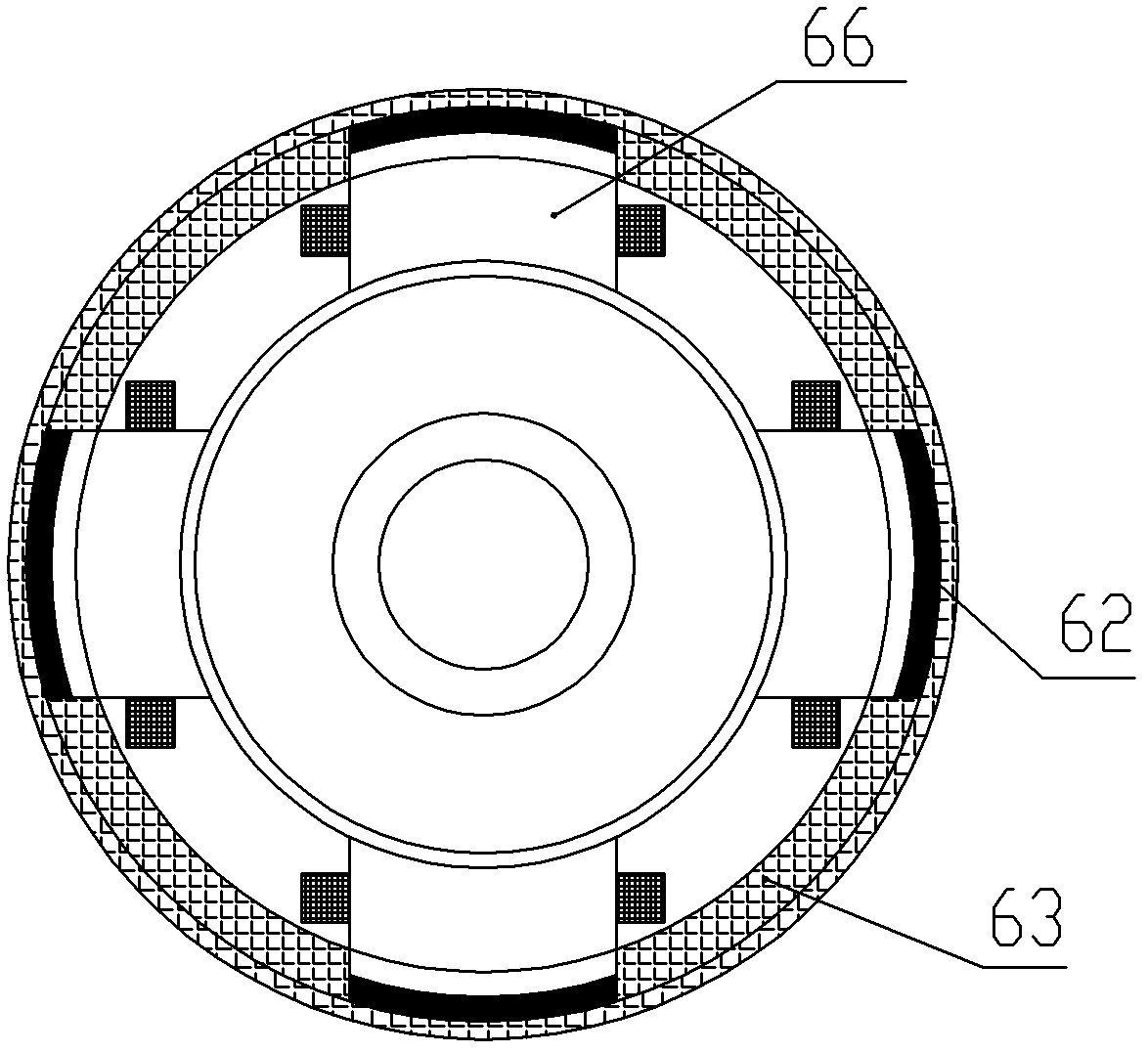

Energy storage device of magnetic suspension flywheel

InactiveCN102437675AReduce the burden onImprove reliabilityMechanical energy handlingMagnetic holding devicesMagnetic bearingEngineering

The invention discloses an energy storage device of magnetic suspension flywheel, comprising an energy storing and converting part, a magnetic suspension supporting part and an auxiliary part, wherein the energy storing and converting part includes a flywheel, a rotor of the motor / generator and a stator part; the magnetic suspension supporting part comprises a radial magnetic bearing, an axial magnetic bearing, an axial sensor, a radial sensor and a protection bearing; the auxiliary part includes a shell and a mounting shaft; the radial magnetic bearing is a radial mixed conical magnetic bearing; the suction disk of each axial magnetic bearing is respectively installed on two side wheel surfaces of the flywheel; the radial mixed conical magnetic bearing and the axial magnetic bearing are non-mechanically contacted magnetic suspension bearings; the mounting shafts of the energy storing and converting part, the magnetic suspension supporting part and the auxiliary part are sealed in the shell of the auxiliary part; the inside of the shell is in vacuum state. The invention has the characteristics of compact structure, high specific energy density and discharge depth, long service life, low power consumption and stable performance without pollution.

Owner:SHANDONG UNIV OF SCI & TECH

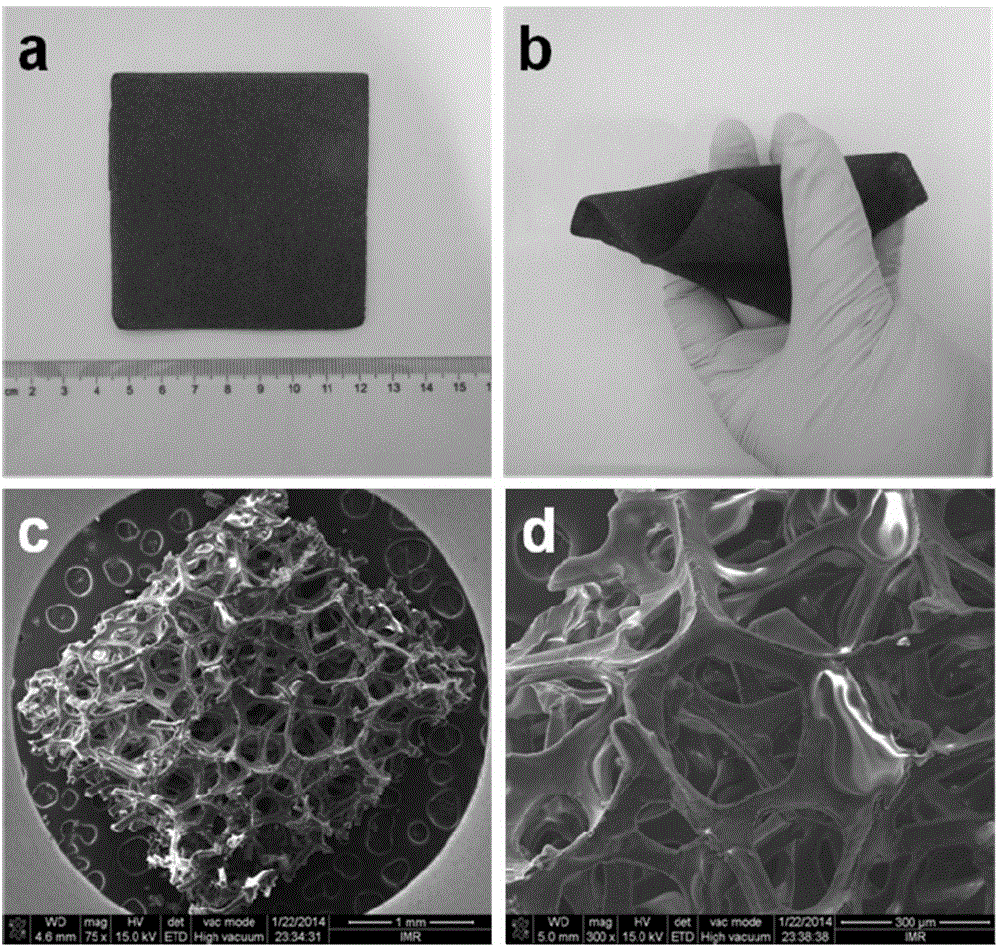

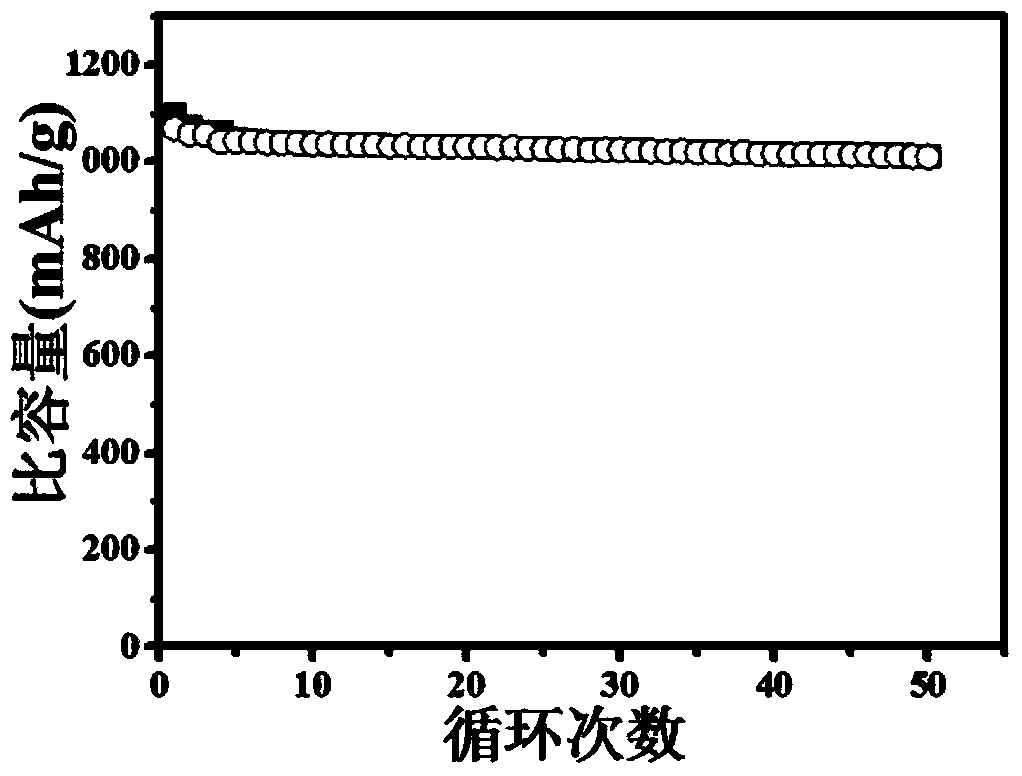

Flexible high-sulfur load self-repairing cathode structure for lithium-sulfur battery and preparation method of flexible high-sulfur load self-repairing cathode structure

ActiveCN105098143AEasy to makeThe preparation process is simple and controllableNon-aqueous electrolyte accumulator electrodesSulfurLithium–sulfur battery

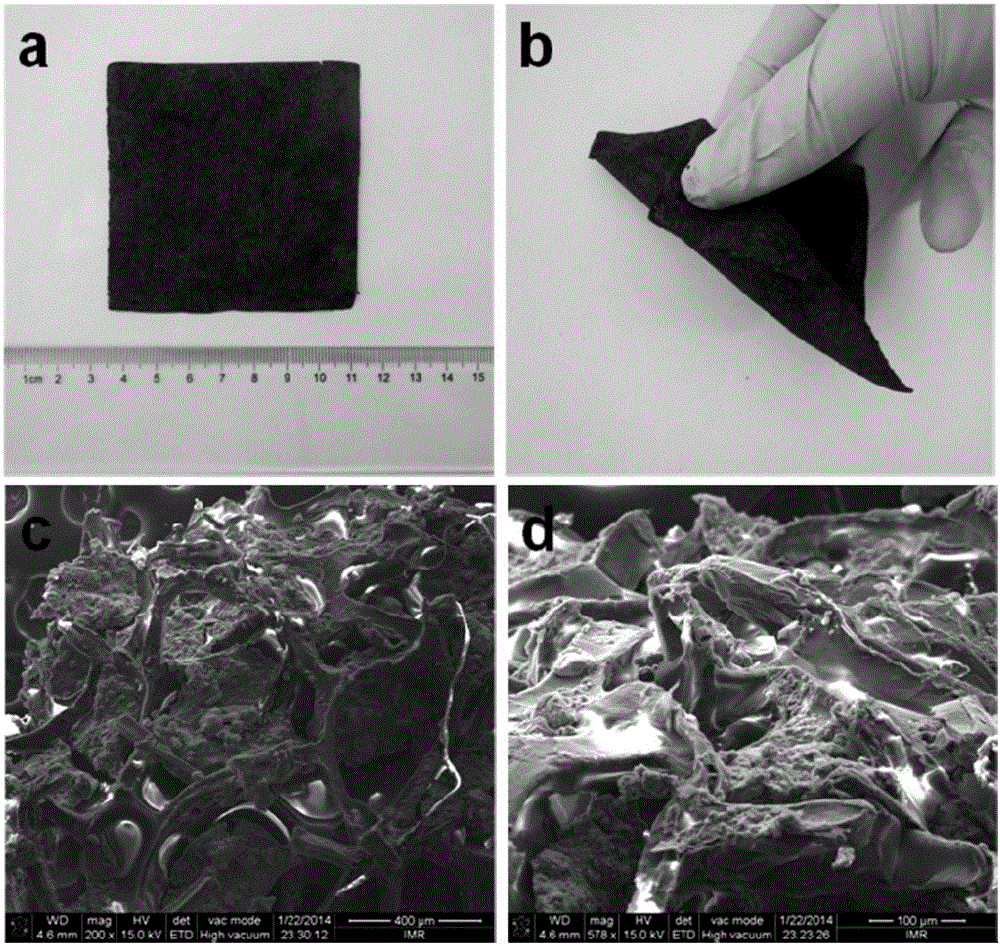

The invention discloses a flexible high-sulfur load self-repairing cathode structure for a lithium-sulfur battery and a preparation method of the flexible high-sulfur load self-repairing cathode structure, and belongs to the field of electrochemical batteries. The lithium-sulfur battery cathode structure disclosed by the invention is composed of graphene / high-molecular polymer flexible foam and a carbon / sulfur active material layer, wherein the active material is sulfur; and the graphene / high-molecular polymer flexible foam provides strength and a self-repairing function. The flexible high-sulfur load self-repairing cathode structure has the characteristics that a multicomponent integrated design of the lithium-sulfur battery is realized; the electrochemical property is ensured; meanwhile, the content of sulfur is increased; high active material surface density of the battery is realized; the obtained lithium-sulfur battery has the advantages of high specific capacity and high specific energy density, and simultaneously has flexibility and self-healing characteristics; the preparation process of the flexible high-sulfur load self-repairing cathode structure is simple and easy to control; large-scale and low-cost preparation can be realized; and the application value is wide.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

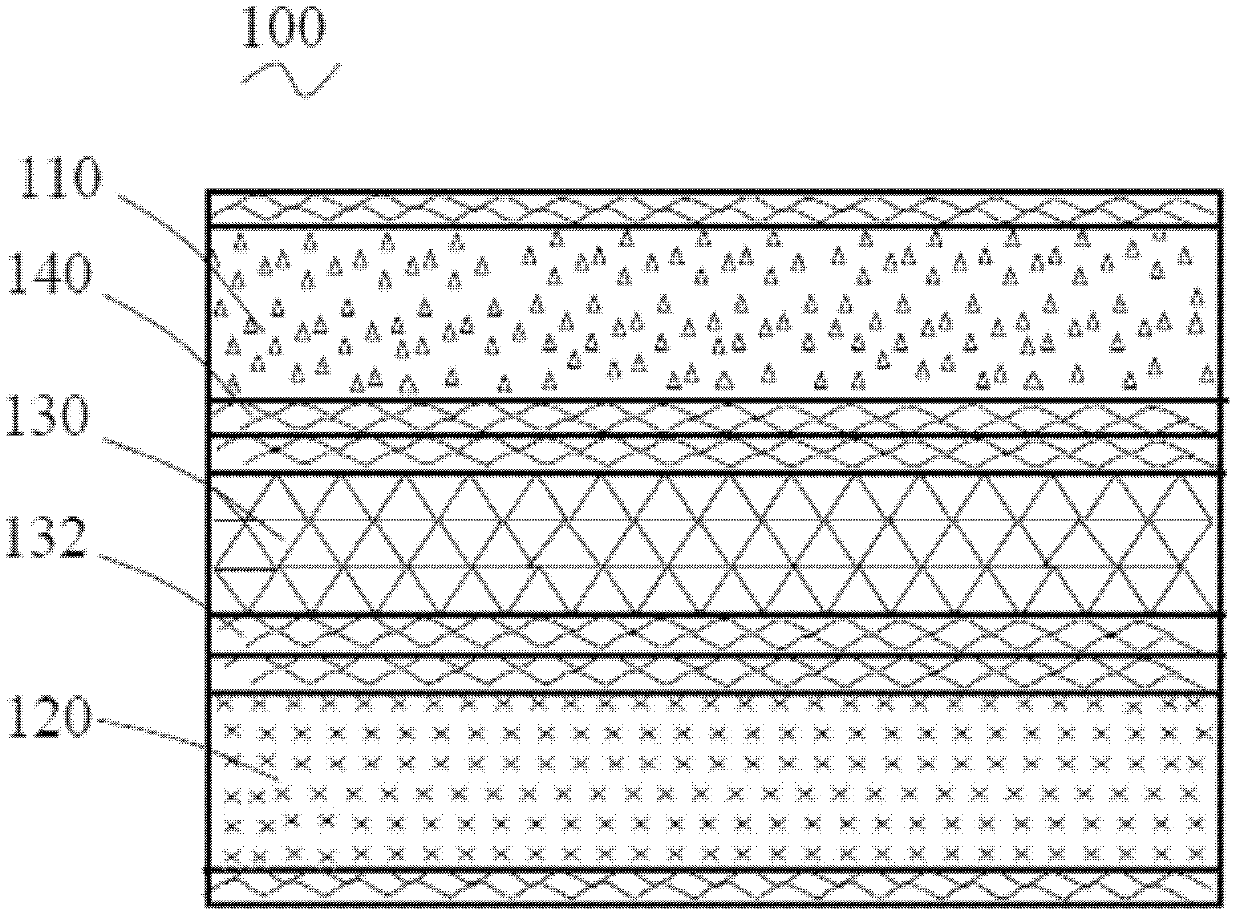

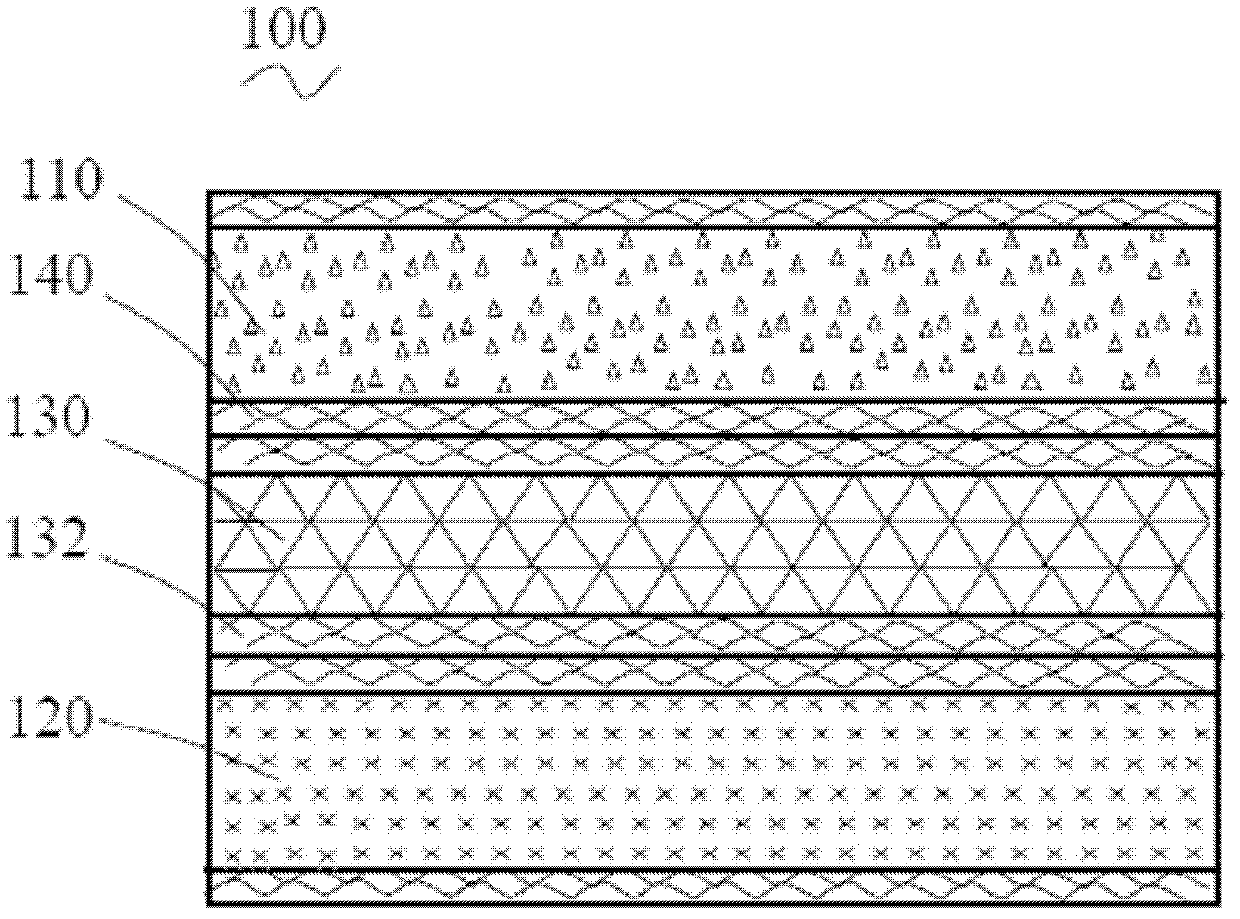

Lithium ion battery

ActiveCN102610830AIncrease energy densityLow costElectrode carriers/collectorsElectrode collector coatingElectricityElectrical battery

Owner:LONG POWER SYST SUZHOU

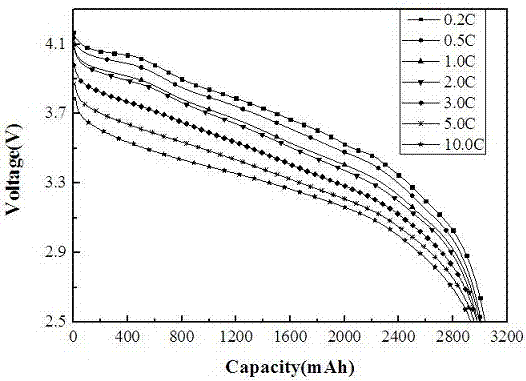

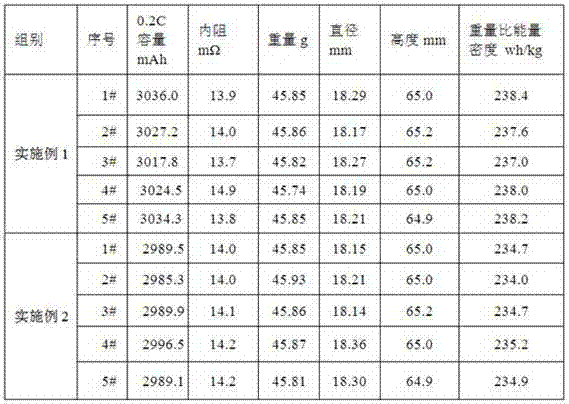

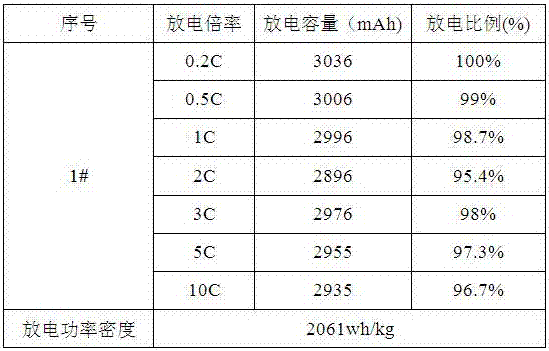

Novel lithium ion battery with high power and high energy density

InactiveCN107248592AIncrease gram capacityIncrease energy densityCell electrodesSecondary cellsHigh energyCarbon nanotube

The invention provides a novel lithium ion battery with high power and high energy density. The novel lithium ion battery comprises a positive plate, a negative plate, a diaphragm, electrolyte, a lug and a shell; the negative plate is mixed by negative electrode active materials, a negative electrode conductive agent and a negative electrode binder; the negative electrode active materials are composed of SiO, soft carbon and / or artificial graphite; the negative electrode conductive agent is at least one of superconductive carbon black and a single-walled carbon nanotube; and the negative electrode binder is at least two combinations of styrene butadiene rubber, acrylate and sodium carboxymethyl cellulose. The battery provided by the invention has excellent rate discharge capacity and high energy density; and besides, the weight specific energy density reaches 230wh / kg, the volume specific energy density is above 650wh / L, the power density is above 1,500w / kg, the rate discharge performance reaches 10C, and the cycle performance can reach more than 500 times.

Owner:鹤壁市诺信电子有限公司

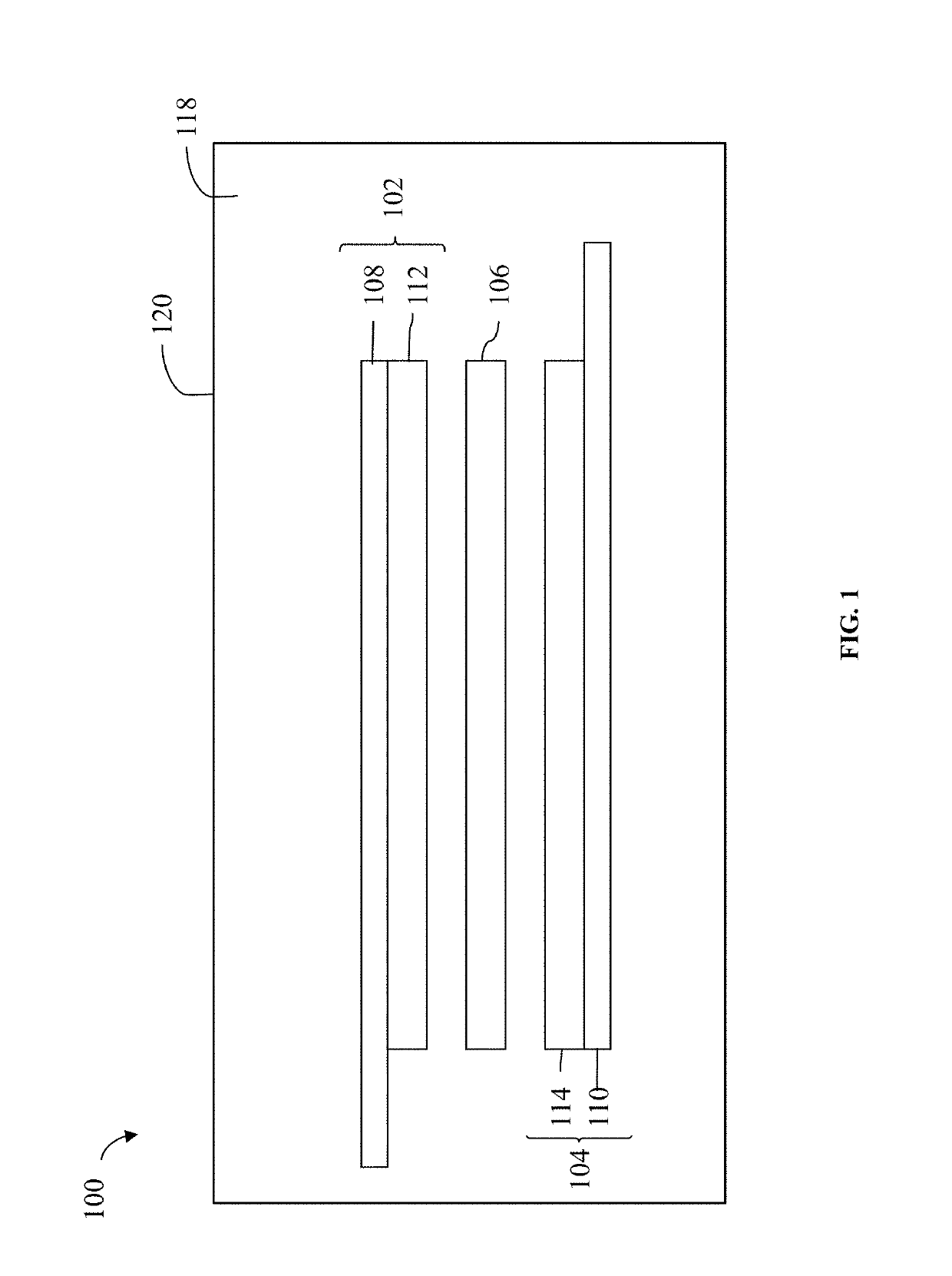

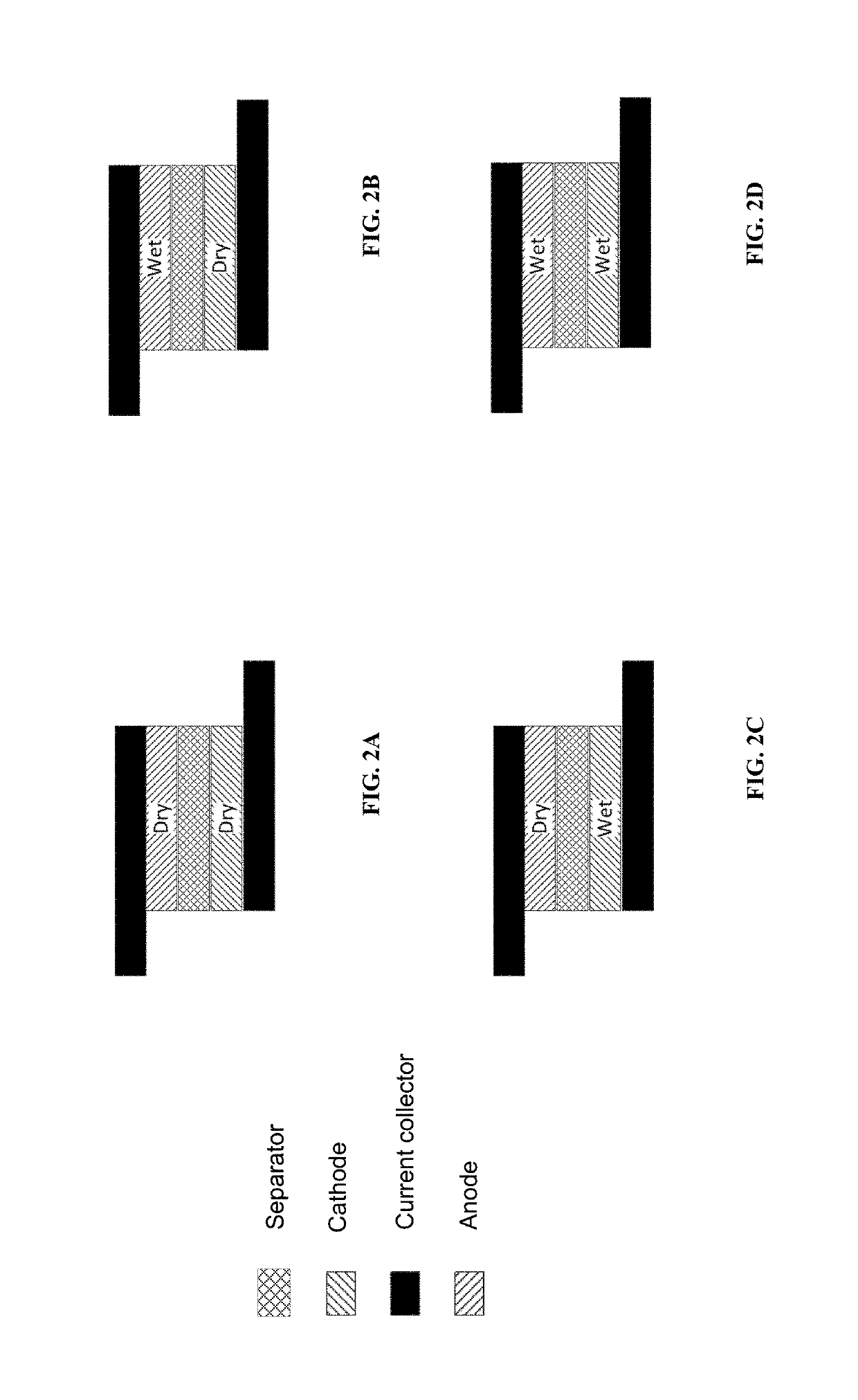

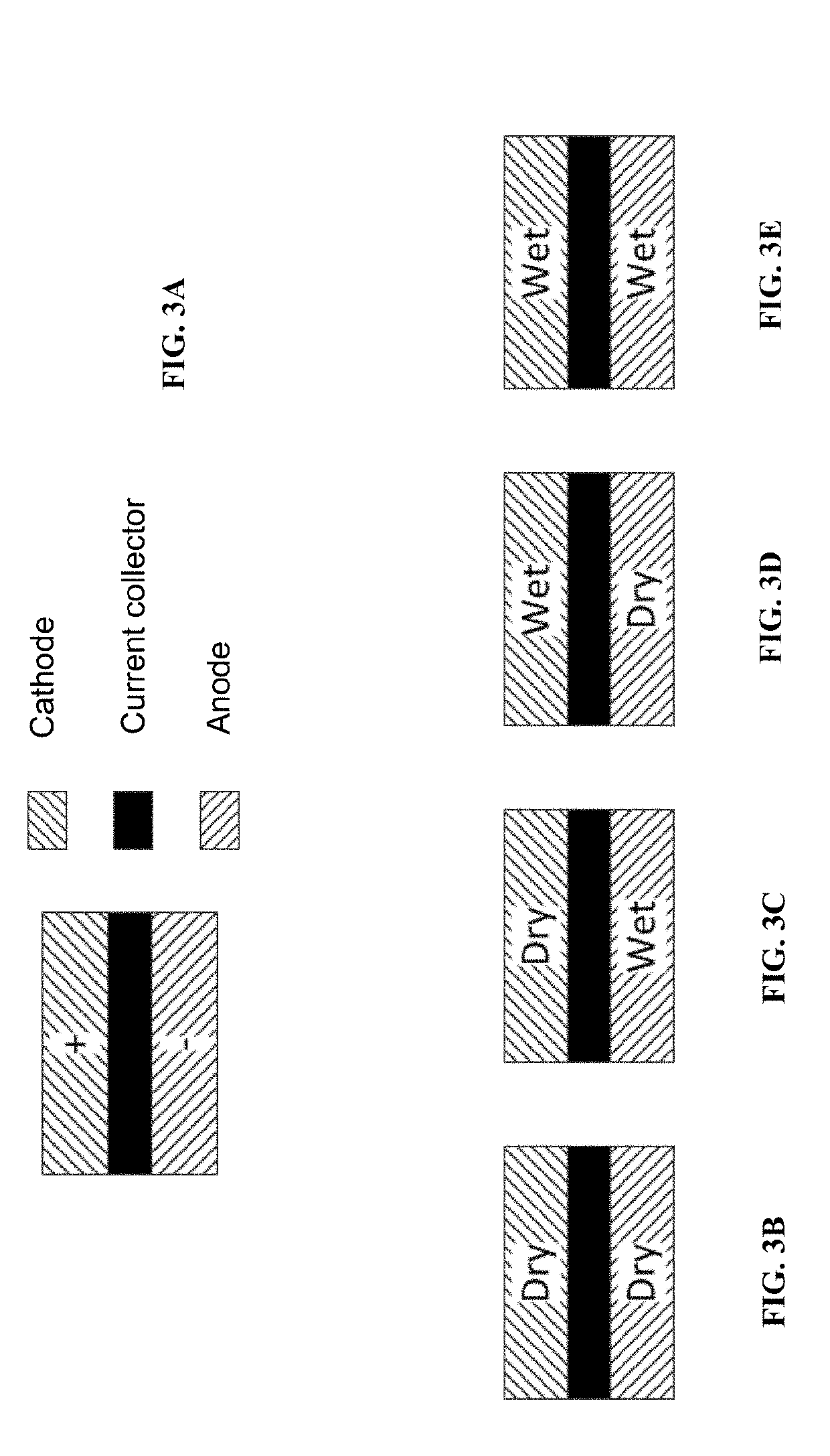

Compositions and methods for energy storage devices having improved performance

PendingUS20190237748A1Improve performanceIncrease capacityElectrode rolling/calenderingElectrode thermal treatmentAreal capacitySpecific energy density

Provided herein are energy storage devices comprising at least one dry process, self-supporting electrode film having improved performance. The improved performance may be realized as improved electrode material loading, improved active material loading, improved active material density, improved areal capacity, improved specific capacity, improved areal energy density, improved energy density, improved specific energy density, or improved Coulombic efficiency.

Owner:TESLA INC

Mesoporous carbon loaded sulfur/selenium flexible electrode based on three-dimensional graphite alkene self-supporting structure as well as preparation method and application thereof

ActiveCN103825000AHave mechanical strengthIncrease energy densityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsLithium sulfurSe element

The invention discloses a mesoporous carbon loaded sulfur / selenium flexible electrode based on a three-dimensional graphite alkene self-supporting structure. The invention further discloses a preparation method of the electrode, and application of the mesoporous carbon loaded sulfur / selenium flexible electrode based on the three-dimensional graphite alkene self-supporting structure in preparing a lithium ion secondary battery. The invention further discloses a lithium-sulfur battery and a lithium-selenium battery both comprising the electrode. The mesoporous carbon loaded sulfur / selenium flexible electrode based on the three-dimensional graphite alkene self-supporting structure, provided by the invention, has good mechanical performance and electrical performance, can effectively improve the specific energy intensity of the electrode; the lithium-sulfur(selenium) battery manufactured by adopting the electrode has the advantages of small size, high capacity, long service life and high efficiency, and has very high application potential and commercial value.

Owner:SOUTHEAST UNIV

Negative plate used for lithium ion battery and preparation method thereof

ActiveCN105098138ARegulated contentImprove conductivityCell electrodesMetallic lithiumLithium-ion battery

The invention provides an integrative negative plate used for a lithium ion battery. The integrative negative plate is prepared from negative electrode materials and metal powder, wherein the metal powder does not form alloy with metal lithium. The invention also provides a preparation method of the integrative negative plate and the lithium ion battery which contains the above integrative negative plate. The integrative negative plate has good comprehensive performance and excellent negative plate conductivity, and the specific energy density of the unit volume or the unit mass of the battery is greater than the specific energy density of a common lithium ion battery.

Owner:微宏先进材料公司

A silicon-carbon composite negative electrode material and a preparation method thereof

ActiveCN109004203AHigh mechanical strengthImprove conductivityMaterial nanotechnologyCell electrodesCarbon compositesSilanes

Owner:INNER MONGOLIA SANXIN IND

Aluminum batteries comprising metal-oxide, metal-fluoride, metal-sulfide, or sulfur cathodes

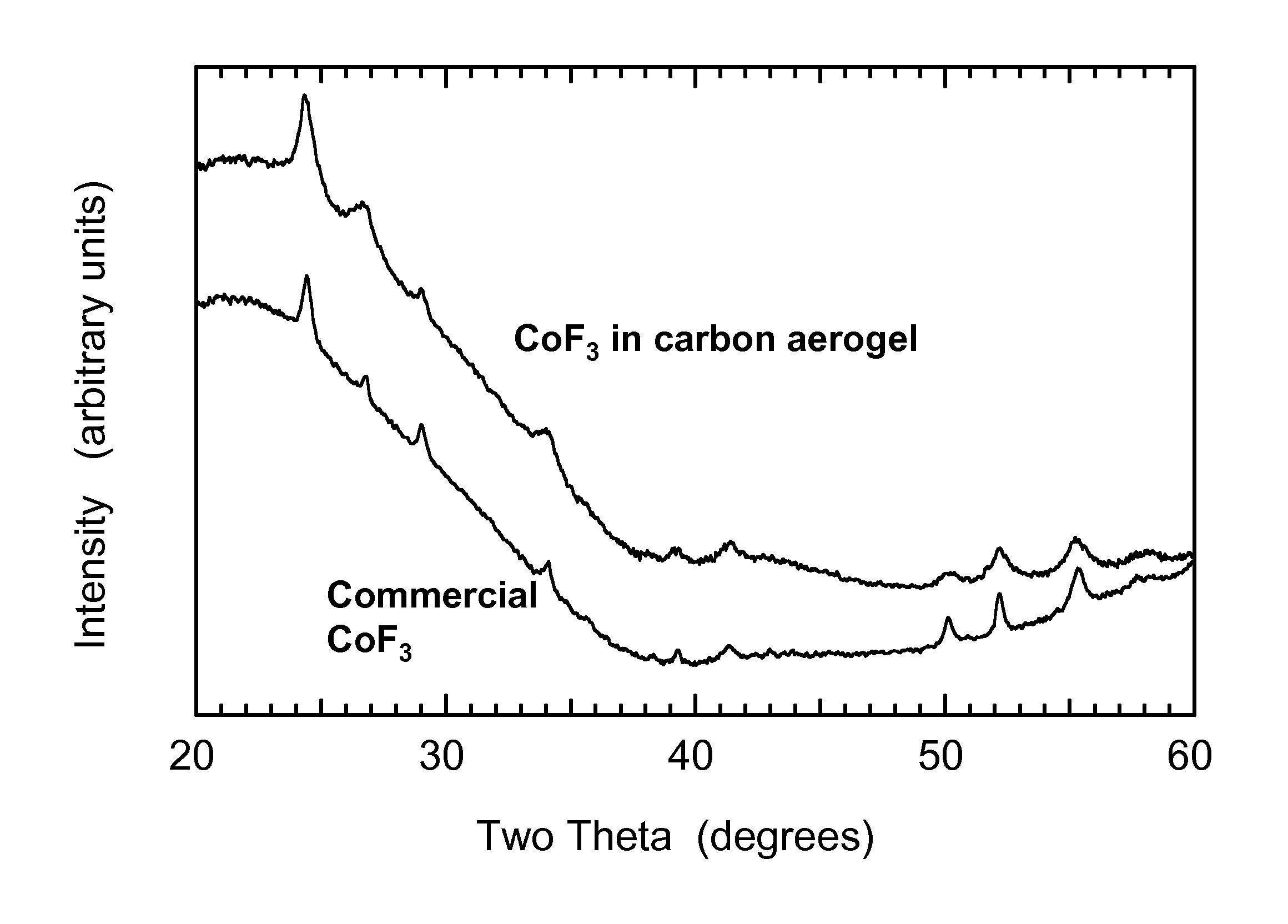

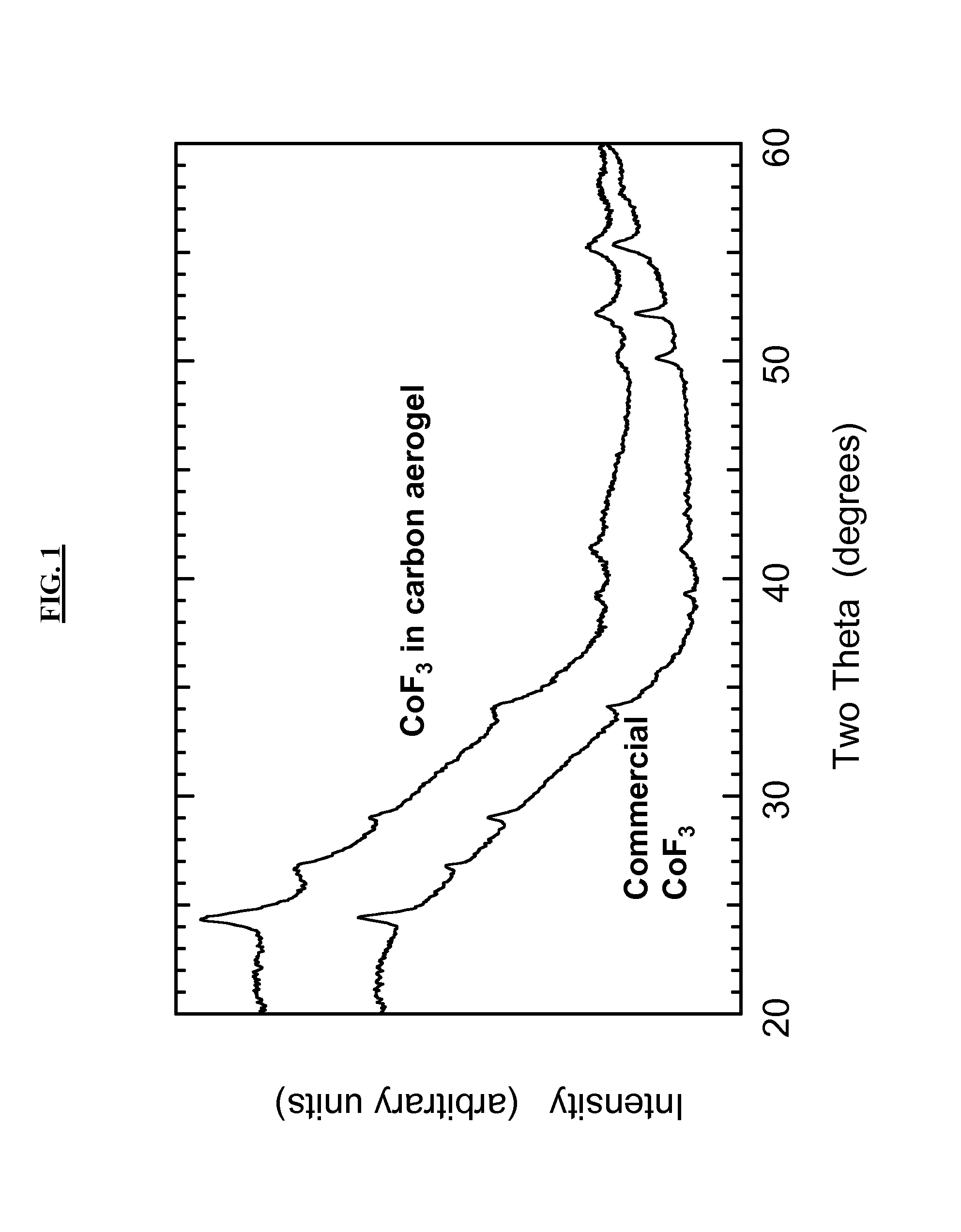

InactiveUS8715853B1Silver accumulatorsElectrochemical processing of electrodesMetallic sulfideElectron

Variations of the invention provide an improved aluminum battery consisting of an aluminum anode, a non-aqueous electrolyte, and a cathode comprising a metal oxide, a metal fluoride, a metal sulfide, or sulfur. The cathode can be fully reduced upon battery discharge via a multiple-electron reduction reaction. In some embodiments, the cathode materials are contained within the pore volume of a porous conductive carbon scaffold. Batteries provided by the invention have high active material specific energy densities and good cycling stabilities at a variety of operating temperatures.

Owner:HRL LAB

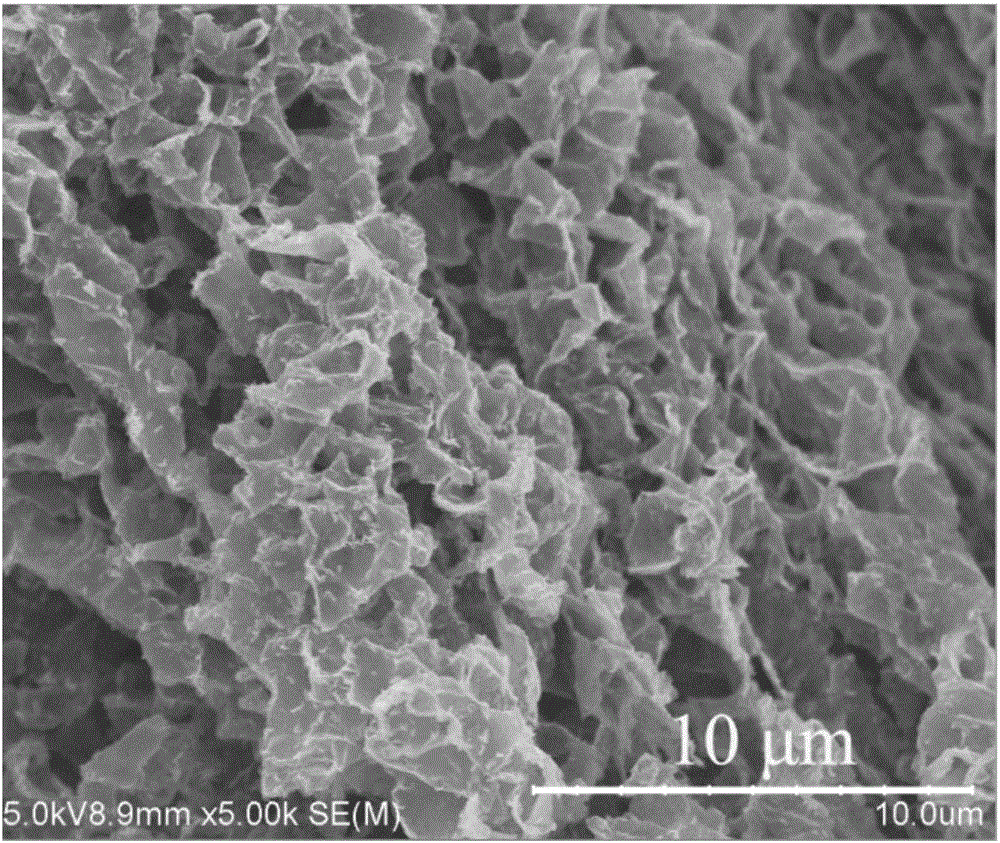

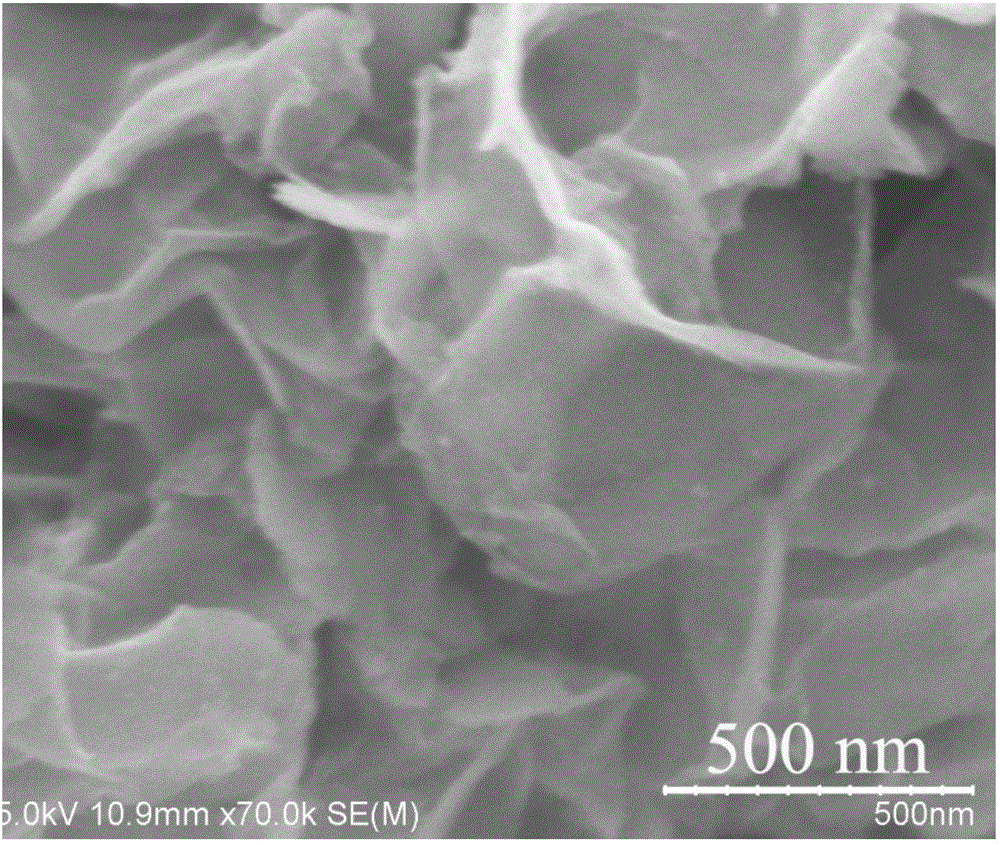

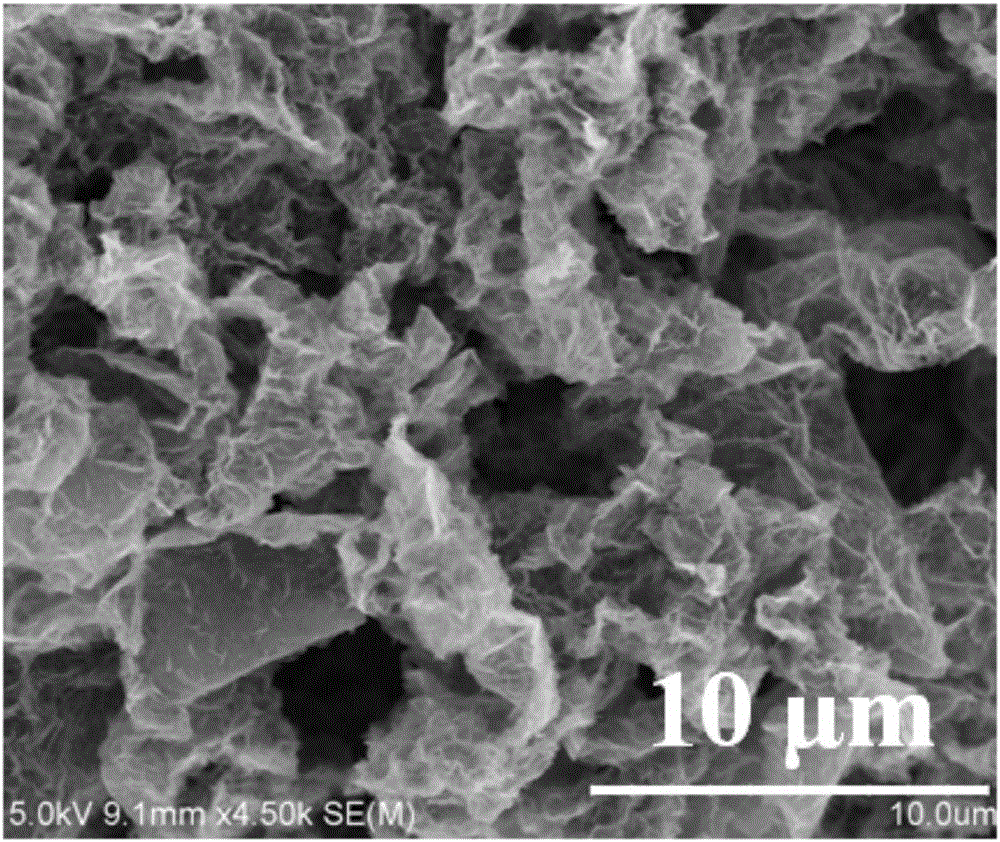

Preparation method for stannic disulfide/graphene nanocomposite, negative electrode of lithium ion battery, and lithium ion battery

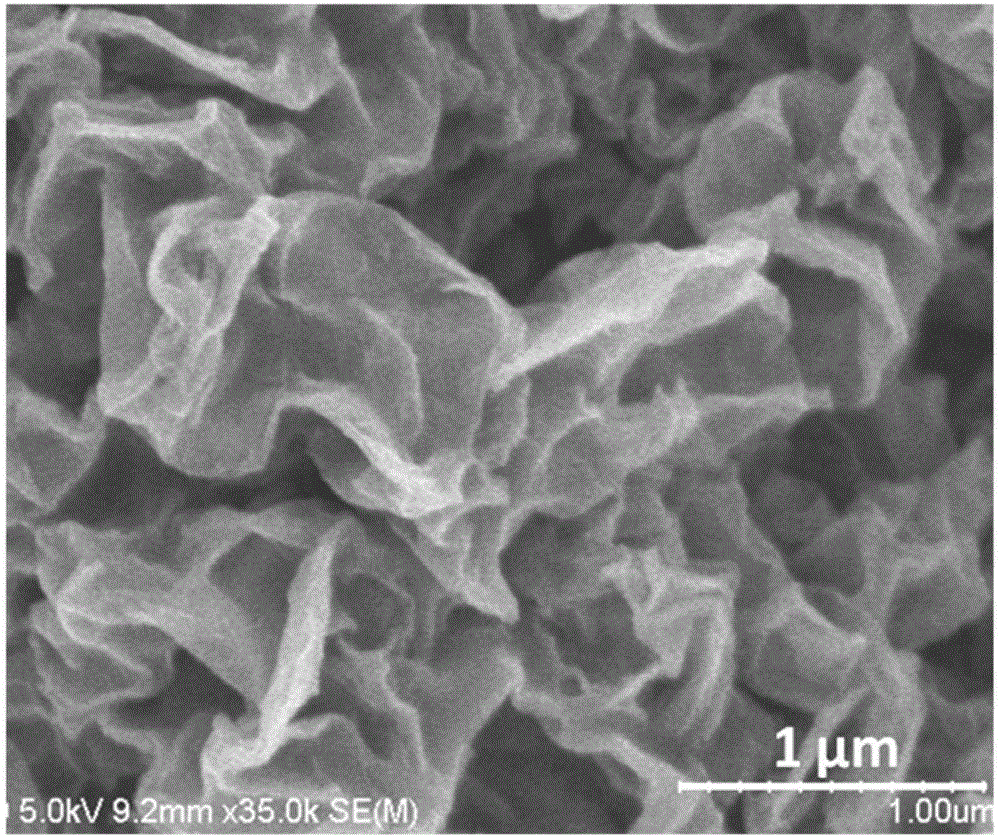

InactiveCN106129378AEvenly distributedImprove performanceCell electrodesSecondary cellsGraphene nanocompositesCvd graphene

The invention discloses a preparation method for a stannic disulfide / graphene nanocomposite, a negative electrode of a lithium ion battery, and the lithium ion battery. The preparation method comprises the following steps of performing a hydrothermal process and a compounding process. By adoption of the preparation method, the stannic disulfide is subjected to direct in-situ growth on the surface of graphene; then the obtained stannic disulfide is washed and dried to obtain the sheet-shaped stannic disulfide / graphene nanocomposite; the material is applied to the negative electrode material of the lithium ion battery; the stability and the conductivity of the material are effectively improved; the performance of the battery is improved; and the stannic disulfide / graphene nanocomposite has the advantages of high cycling stability, high specific energy density and the like.

Owner:ANHUI NORMAL UNIV

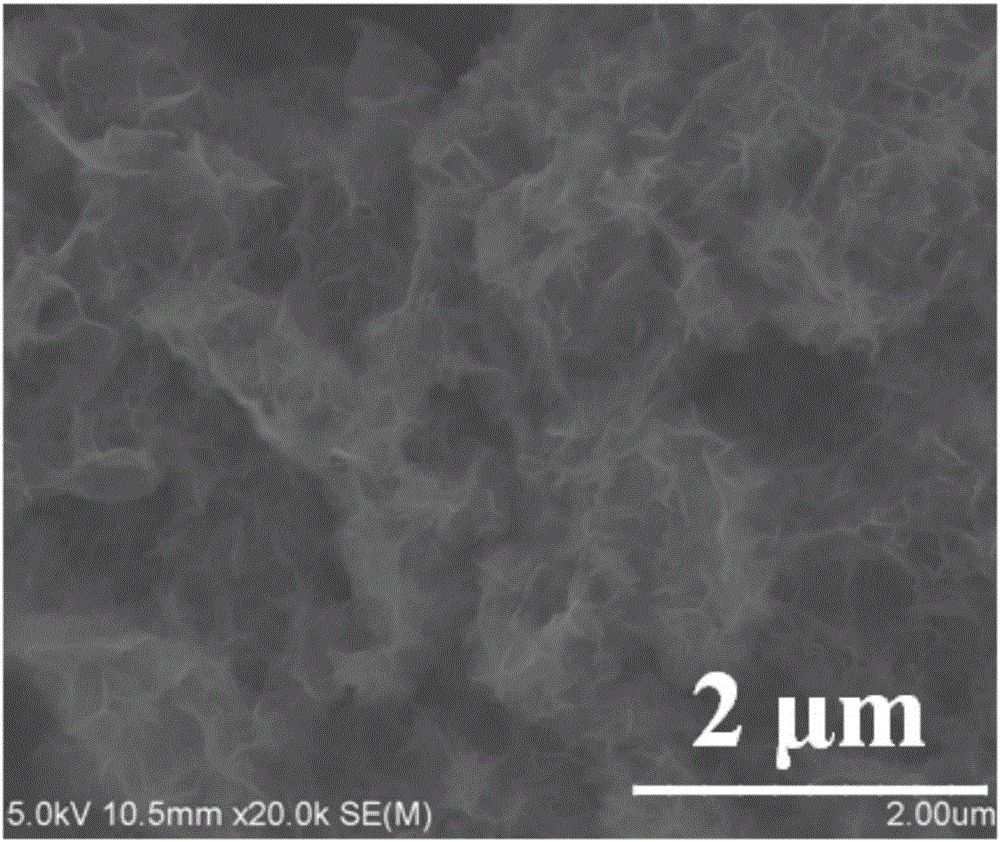

Preparation method of manganese sulfide/graphene nano composite material, negative electrode of lithium ion battery and lithium ion battery

ActiveCN106159239AEvenly distributedImprove performanceMaterial nanotechnologyCell electrodesNano compositesGraphene nanocomposites

The invention discloses a preparation method of a manganese sulfide / graphene nano composite material, a negative electrode of a lithium ion battery and the lithium ion battery. The preparation method comprises the steps of a hydrothermal procedure and a compounding procedure. By virtue of the preparation method, in-situ growth of manganese sulfide is directly carried out on the surface of graphene; after washing and drying steps are carried out, the manganese sulfide / graphene nano composite material is obtained; the disadvantages such as poor stability caused by volume change are overcome through compounding of the manganese sulfide and three-dimensional reduced graphene oxide are overcome and the conductivity is enhanced, so that the properties of the lithium ion battery are improved; the material is applied to a negative electrode material of the lithium ion battery and has the advantages of good circulating stability, high specific energy density and the like.

Owner:ANHUI NORMAL UNIV

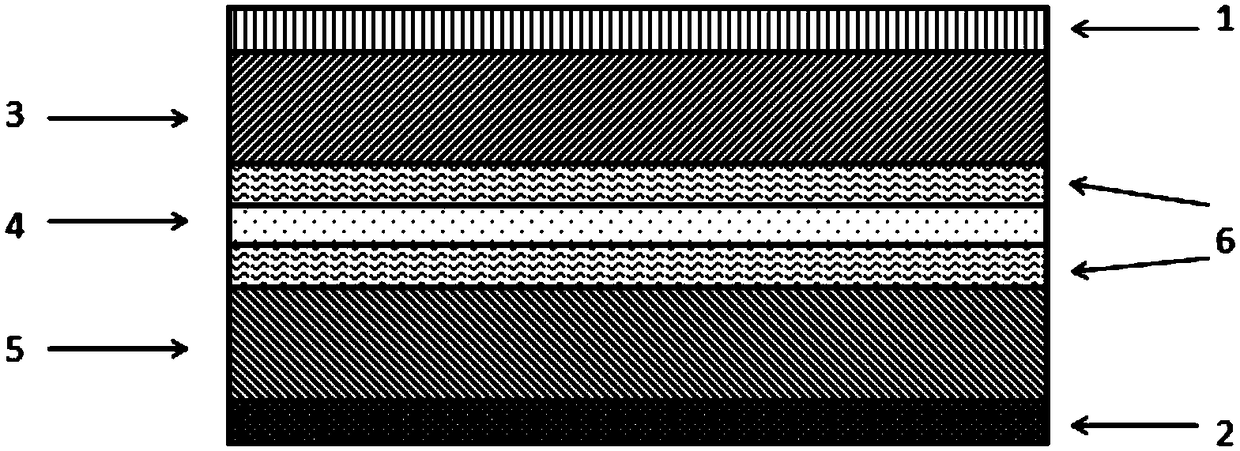

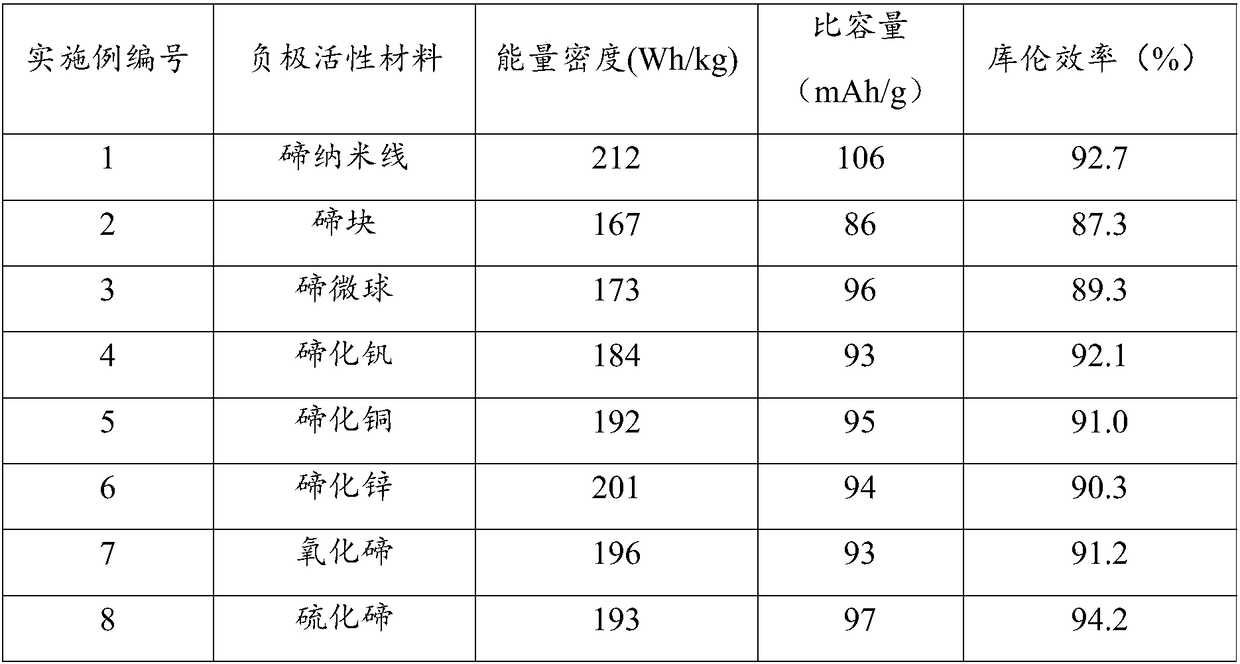

Application of tellurium based material serving as negative electrode active material in sodium-based dual-ion cell, sodium-tellurium dual-ion cell and preparation method thereof

InactiveCN108321387AImprove securityImprove cycle performanceCell electrodesSecondary cellsTellurium compoundsSodium-ion battery

The invention discloses application of a tellurium based material serving as a negative electrode active material in a sodium-based dual-ion cell, the sodium-tellurium dual-ion cell and a preparationmethod thereof and relates to the field of electrochemical energy storage devices. The invention further discloses application of tellurium, a tellurium compound or a tellurium composite material serving as the negative electrode active material in the sodium-based dual-ion cell. The sodium-tellurium dual-ion cell comprises a negative electrode, a positive electrode, a diaphragm and electrolyte; the negative electrode active material comprises tellurium, the tellurium compound or the tellurium composite material; the positive electrode active material comprises a material capable of being reversibly embedded and dis-embedded into negative ions in the electrolyte; the electrolyte comprises a sodium salt and a non-aqueous solvent. The safety problems existing in the conventional sodium-ion battery taking a carbon material as the negative electrode material that the potential is low, sodium is easily separated out and a tinfoil serving as the negative electrode is simple in volume expansion and is easily powdered are solved. According to the sodium-tellurium dual-ion cell disclosed by the invention, the sodium ion and the tellurium negative electrode can carry out an alloying reaction, the reaction potential is high, and the sodium-tellurium dual-ion cell has the characteristics of being high in safety, high in specific energy density and stable in cycle.

Owner:SHENZHEN INST OF ADVANCED TECH +1

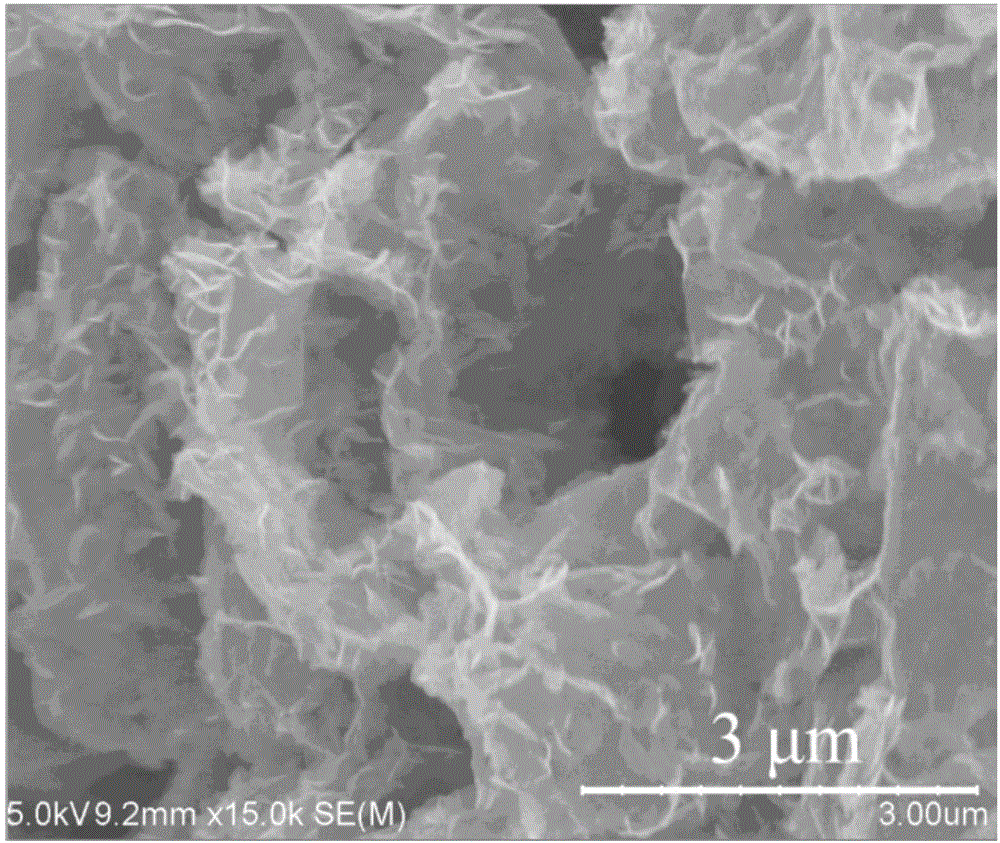

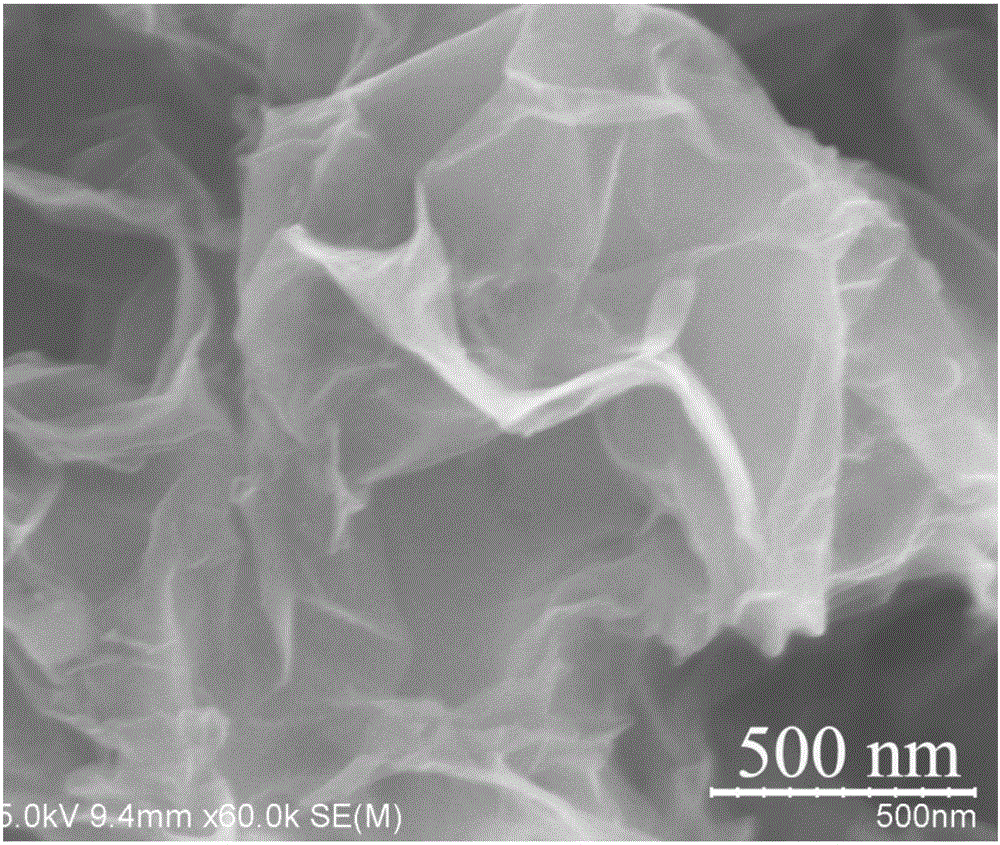

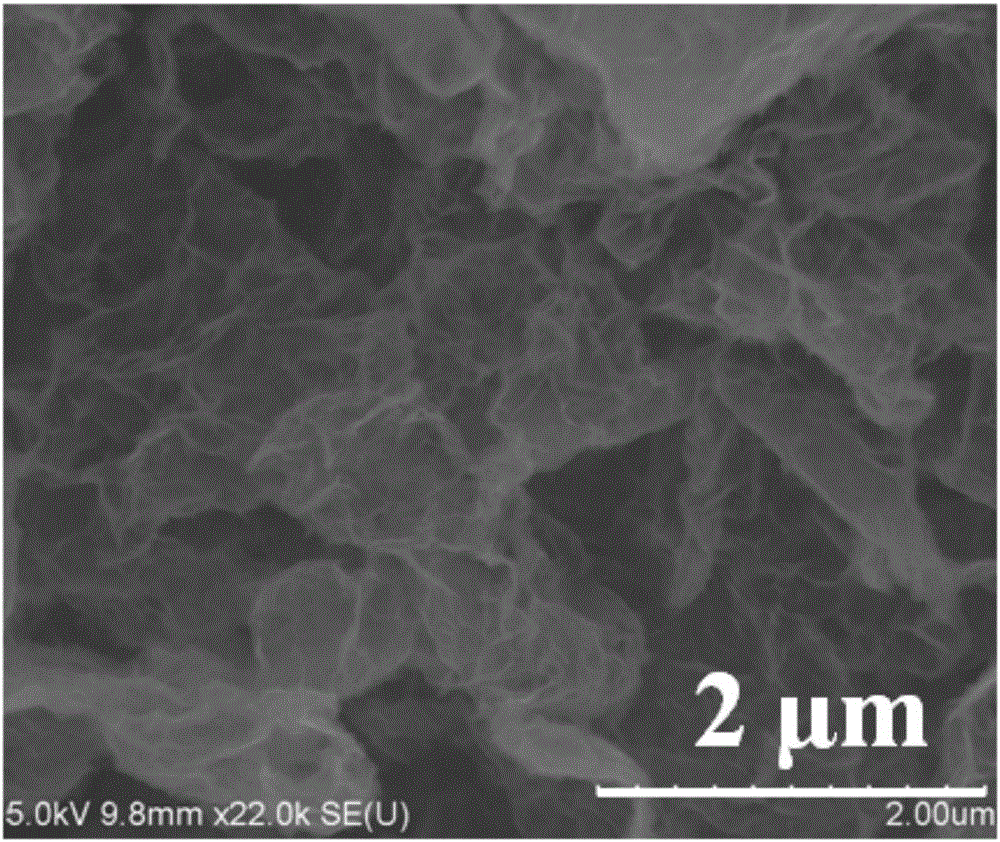

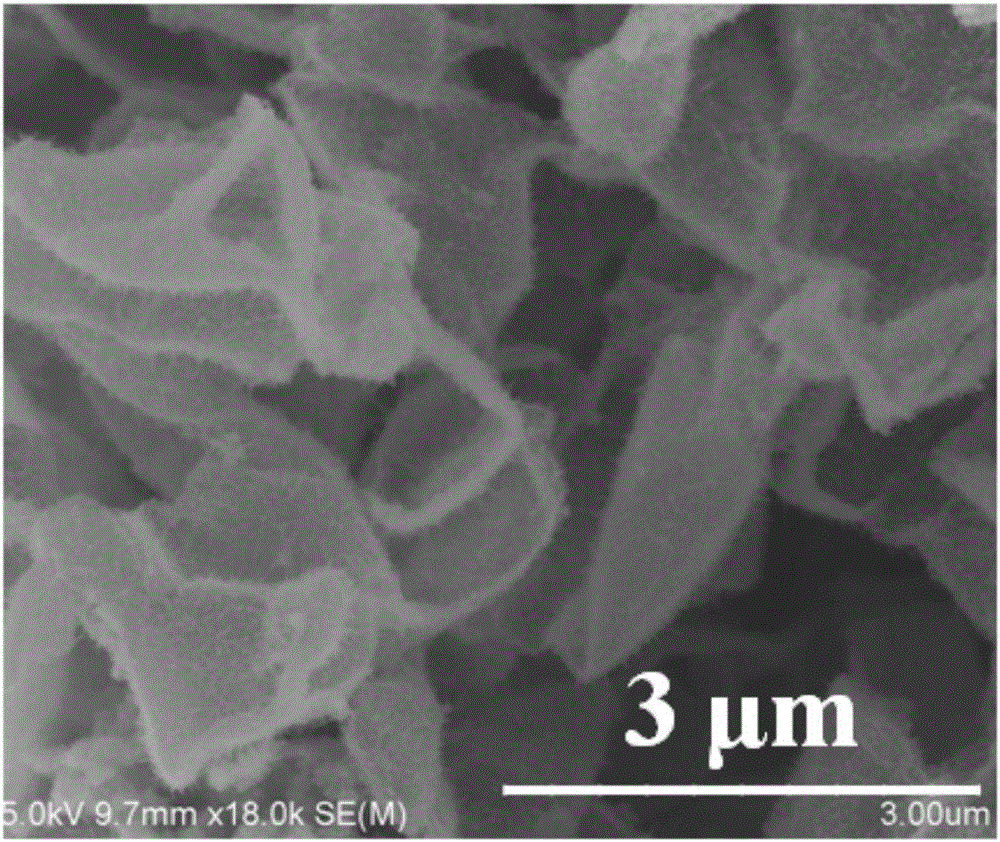

Method for preparing molybdenum disulfide/graphene nanometer composite materials, lithium ion battery and cathode thereof

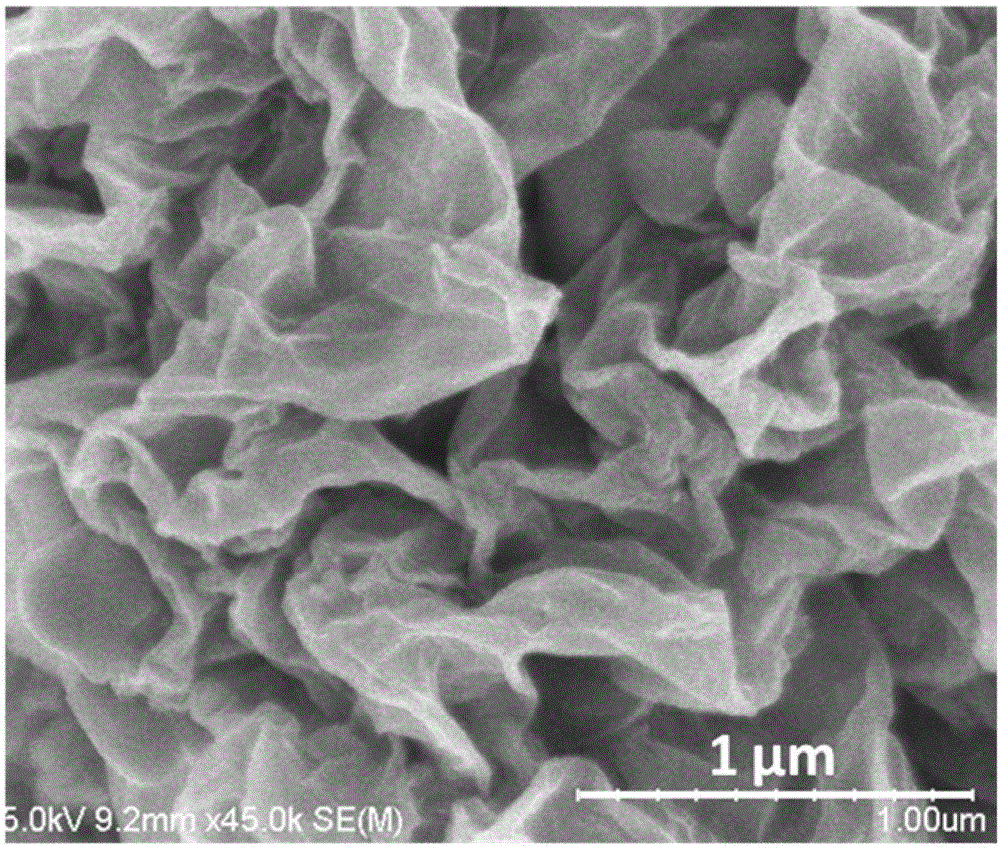

ActiveCN106207171AEvenly distributedImprove performanceMaterial nanotechnologyCell electrodesNano compositesGraphene nanocomposites

The invention discloses a method for preparing molybdenum disulfide / graphene nanometer composite materials, a lithium ion battery and a cathode thereof. The method includes a hydrothermal working procedure and a composite working procedure. The method, the lithium ion battery and the cathode have the advantages that lamellar molybdenum disulfide can directly grow on the surfaces of graphene in an in-situ manner, and accordingly the molybdenum disulfide / graphene nanometer composite materials are unique in morphology and have large specific surface areas, and the problem of graphene and molybdenum disulfide agglomeration can be solved; the molybdenum disulfide / graphene nanometer composite materials applied to cathode materials for the lithium ion battery are good in cycle stability and high in specific energy density, and the like.

Owner:ANHUI NORMAL UNIV

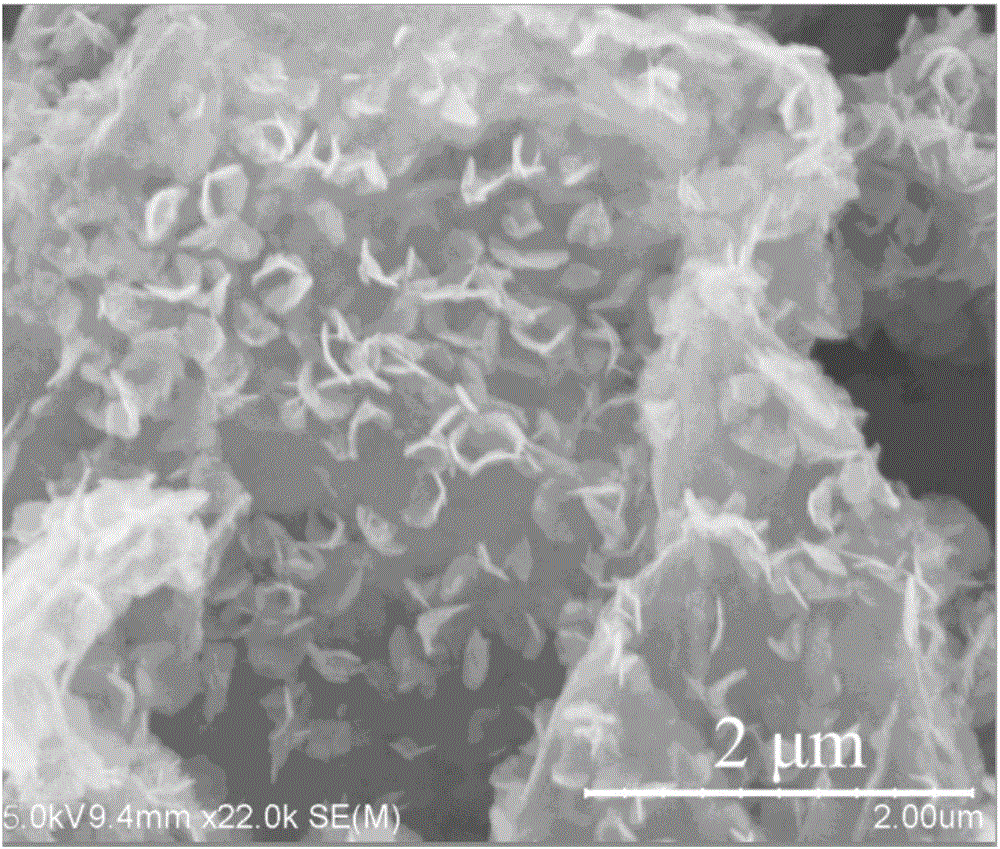

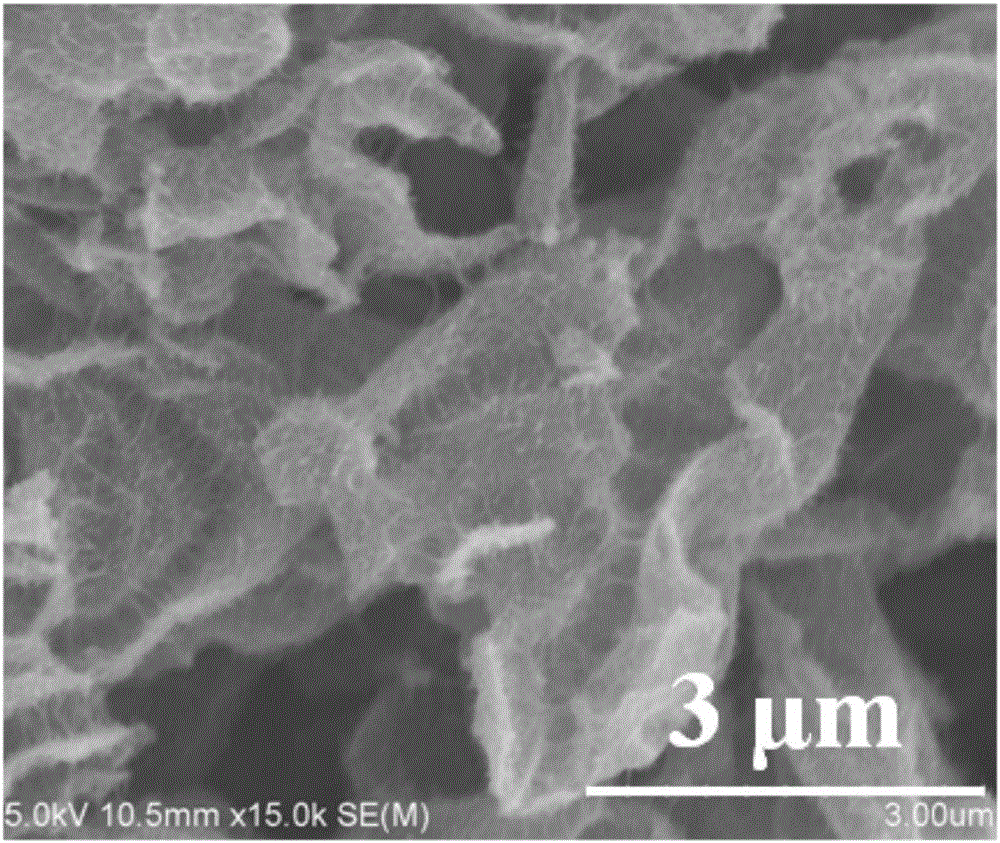

Preparation method for nickel oxide/graphene nanocomposite, negative electrode of lithium ion battery and lithium ion battery

ActiveCN106229503AEvenly distributedImprove performanceMaterial nanotechnologyCell electrodesGraphene nanocompositesOxide composite

The invention discloses a preparation method for a nickel oxide / graphene nanocomposite, a negative electrode of a lithium ion battery and the lithium ion battery. The preparation method comprises the following steps of a hydrothermal process, a compound process and a roasting process. According to the preparation method, nickel hydroxide directly carries out in-situ growth on the surface of graphene, so that a three-dimensional reduced graphene oxide composite with the specific morphology is formed and has a large specific surface area, a black flaky nickel oxide and graphene composite is obtained through washing, drying and roasting, a problem of aggregation of the graphene and the nickel oxide is solved, and the defects of poor stability, poor electrical conductivity and the like of the negative electrode material are well solved, and thus a purpose of improving the performance of the lithium ion battery is realized; the material is applied to the negative electrode material of the lithium ion battery and has the advantages of good cycling stability, high specific energy density and the like.

Owner:中森联合科技有限公司

Preparation method of manganese oxide/graphene nano-composite material, lithium ion battery negative electrode and lithium ion battery

ActiveCN106252628AEvenly distributedImprove performanceCell electrodesSecondary cellsNano compositesGraphene nanocomposites

The invention discloses a preparation method of a manganese oxide / graphene nano-composite material, a lithium ion battery negative electrode and a lithium ion battery. The preparation method comprises the steps of: a hydrothermal process, a compounding process and a roasting process. The preparation method provided by the invention enables direct in-situ growth of hydroxyl manganese oxide on a graphene surface, hydroxyl manganese oxide is compounded on graphene to form a three-dimensional reduced graphene oxide composite material with unique appearance and large specific surface area, and after washing, drying and roasting, a colorless linear manganese oxide and three-dimensional reduced graphene oxide composite material can be obtained. The material solves the agglomeration problem of three-dimensional reduced graphene oxide and manganese oxide nanowire, and well solves the poor stability, poor electrical conductivity and other shortcomings in itself, thus reaching the purpose of enhancing battery performance. The material can be applied to a lithium ion battery negative electrode material, and has the advantages of good cyclic stability and high specific energy density, etc.

Owner:ANHUI NORMAL UNIV

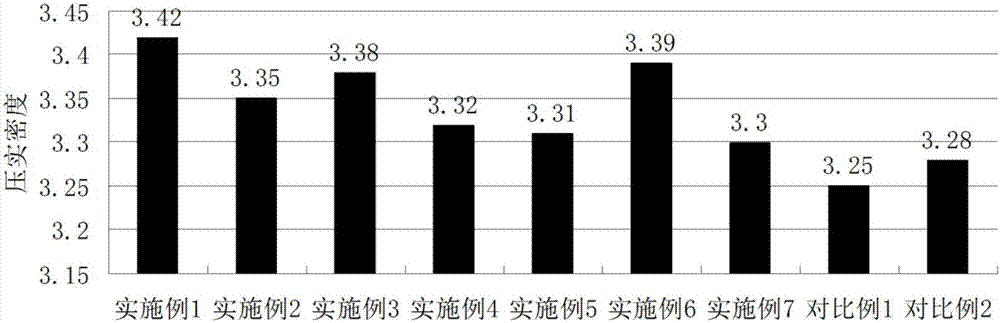

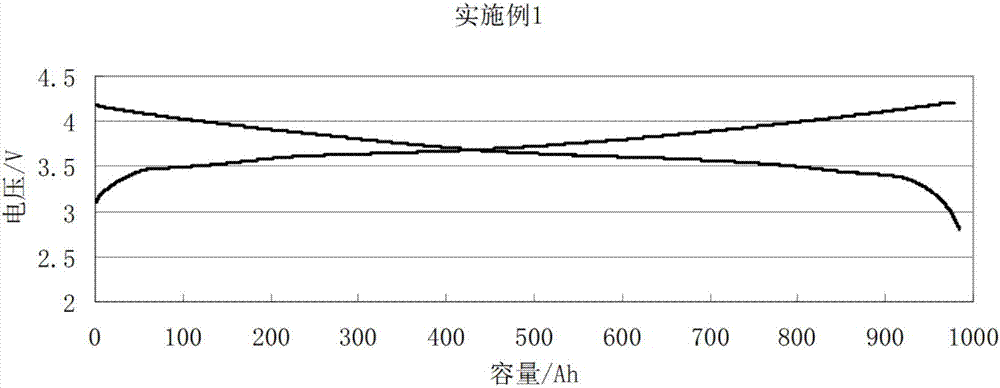

Lithium ion battery, positive paste, positive pole plate and preparation method of positive pole plate

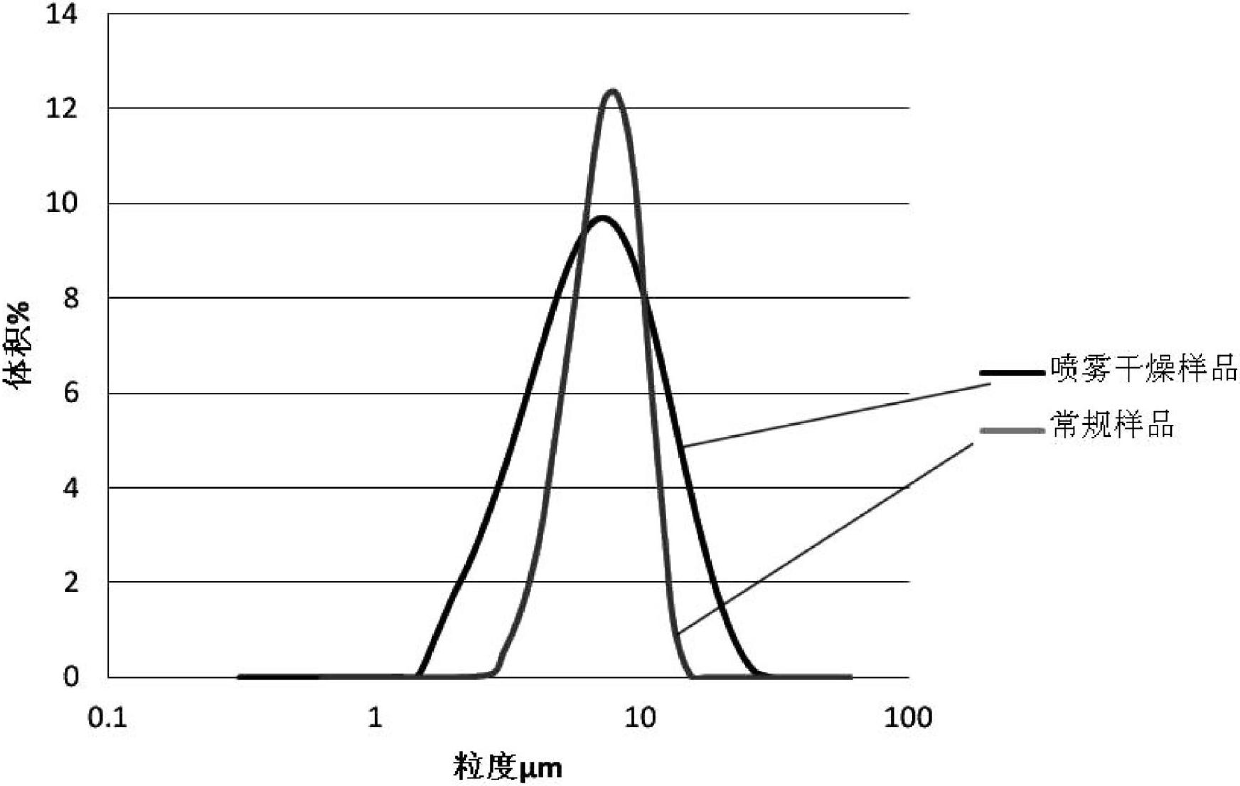

InactiveCN107195858AIncrease compaction densityHigh specific energy densityElectrode manufacturing processesSecondary cellsMicrometerManganese

The invention provides a lithium ion battery positive paste, a preparation method thereof, a lithium ion battery and a positive pole plate. The positive paste provided by the invention comprises a lithium nickel manganese cobalt material, a binding agent, a conductive agent and a solvent, wherein the lithium nickel manganese cobalt material comprises a lithium nickel manganese cobalt material A with D50 being 7.5-9.5 micrometers and a lithium nickel manganese cobalt material B with D50 being 10.5-11.5 micrometers, and the mass ratio of the lithium nickel manganese cobalt material A and the lithium nickel manganese cobalt material B is (0.2:0.8)-(0.8:0.2). The lithium nickel manganese cobalt material with different grain sizes are used for preparing the positive paste according a certain proportion, the positive paste is used for preparing the battery positive pole plate, thus, the compaction density of the positive electrode material obtained by preparation is improved, and meanwhile, the specific energy density of the battery obtained by preparation is finally improved.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Preparation method of positive electrode material (carbon-coated iron-manganese-lithium phosphate) of lithium ion battery

InactiveCN104037413AHigh reactivityIncrease working voltageCell electrodesSecondary cellsManganesePerformance index

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

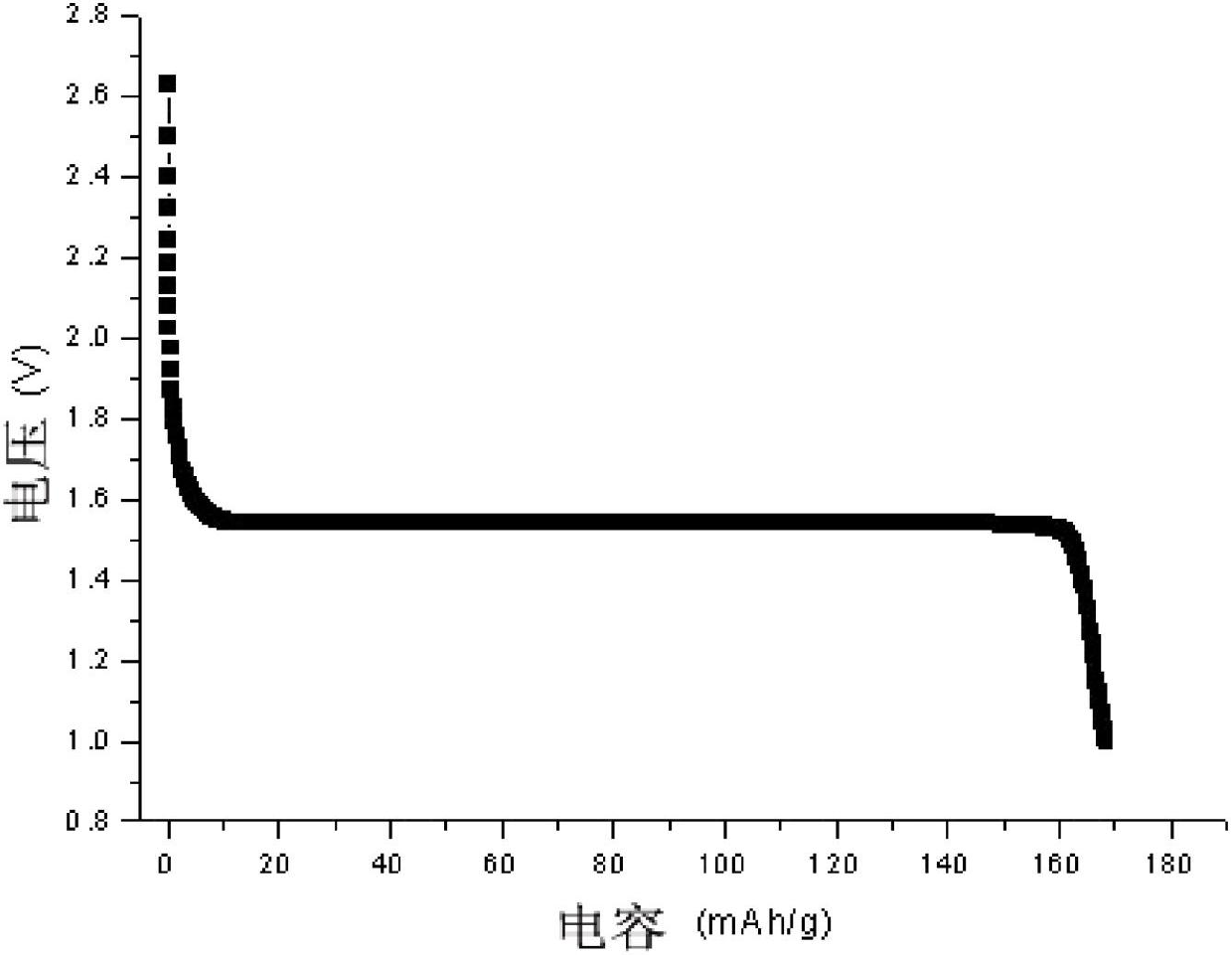

Method for synthesizing spheroidal lithium phosphate

The present invention provides process of synthesizing spherical or spheriodal lithium phosphate. The compounds of lithium ion, transition metal ion and phosphate radical ion are mixed, ground and pyrolyzed in inert atmosphere to obtain the intermediate product; the intermediate product is mixed with certain amount of melting alkali salt and sintered at high temperature to obtain initial product; and the initial product is washed, filtered and dried to obtain spherical or spheriodal lithium phosphate grains of diameter 1-5 microns, with the grain size being controllable by means of the synthesis conditions. The process has short sintering time, low power consumption, and the spherical or spheriodal lithium phosphate product has small specific surface area, excellent processing performance, great tap density, high energy density and high safety, and may be used widely in power battery for electrically driven tool, electric bicycle, etc.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

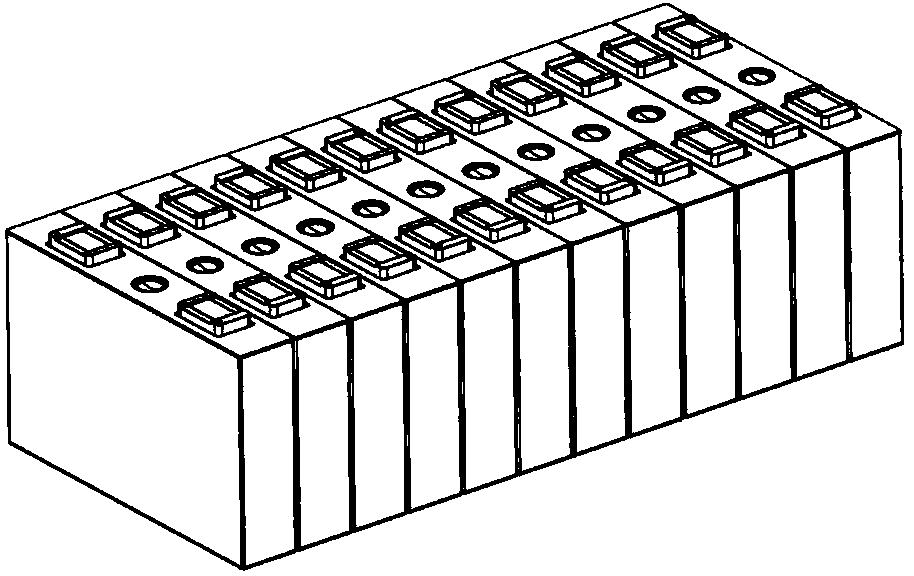

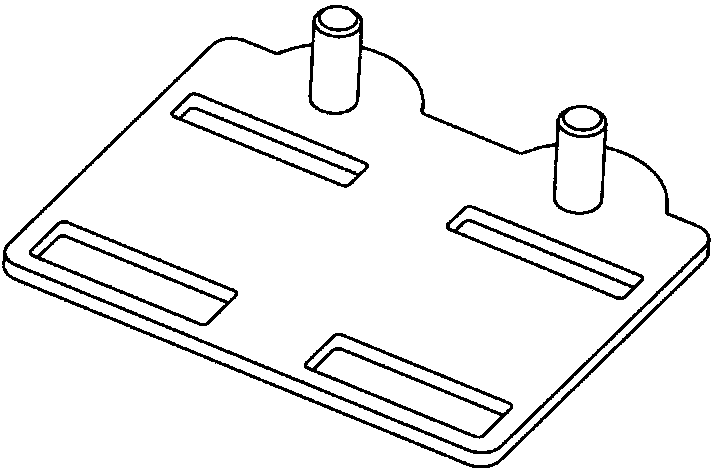

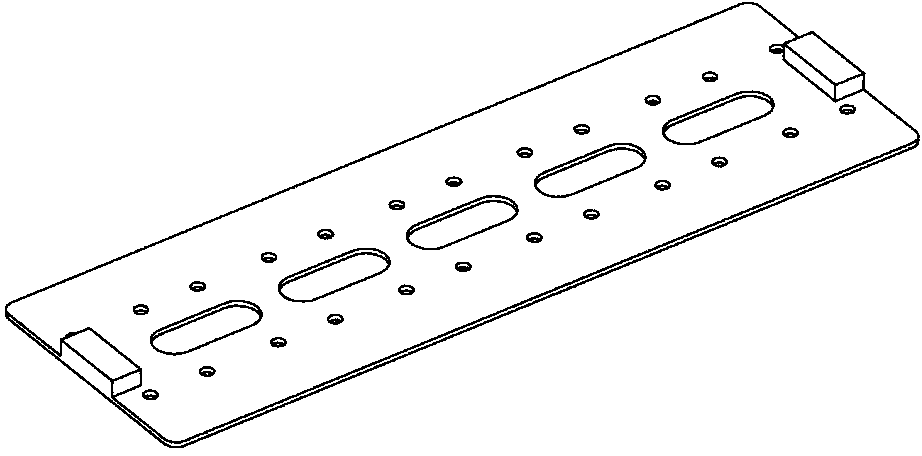

Novel lithium ion power battery module design method and battery module

InactiveCN104103800AHigh densityImprove environmental adaptabilityCell seperators/membranes/diaphragms/spacersCells structural combinationPower batteryElectrical battery

The invention discloses a novel lithium ion power battery module design method and a battery module, which are applied to an aluminum shell square battery module. By designing and developing the battery module according to the method, the gravimetric specific energy and volumetric specific energy of the battery module can be increased remarkably under the condition of constant energy density of a battery monomer, thereby remarkably increasing the overall energy density of a battery system. The method is of great significance to the development of the electric vehicles. Moreover, the battery module developed according to the method has high assembly performance and interchangeability, the assembly performance of the battery system is improved, and the production efficiency is increased.

Owner:TIANJIN LISHEN BATTERY

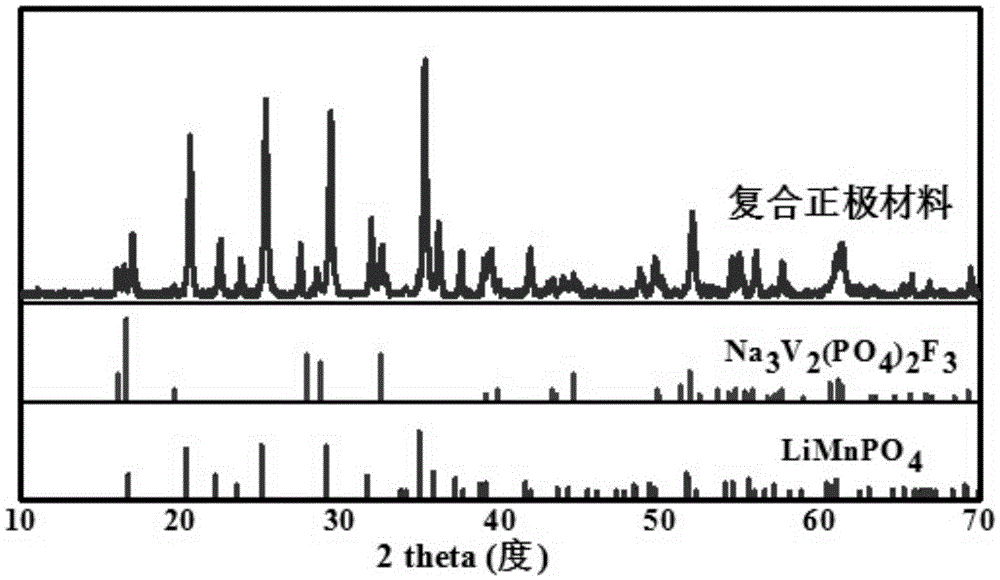

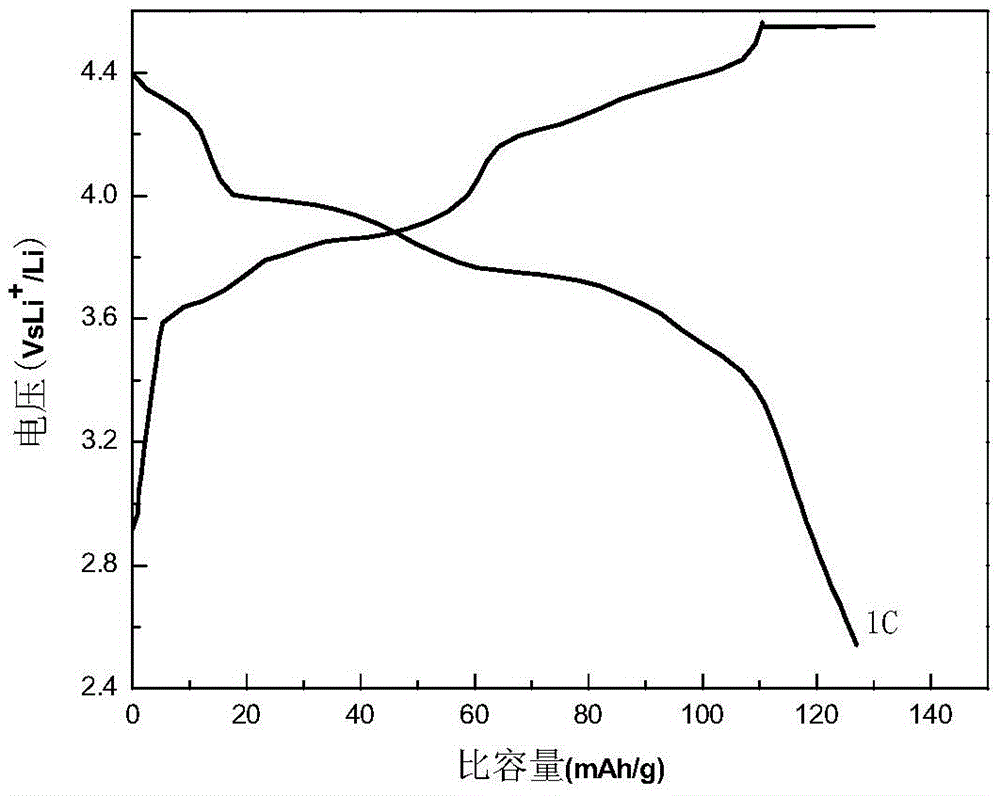

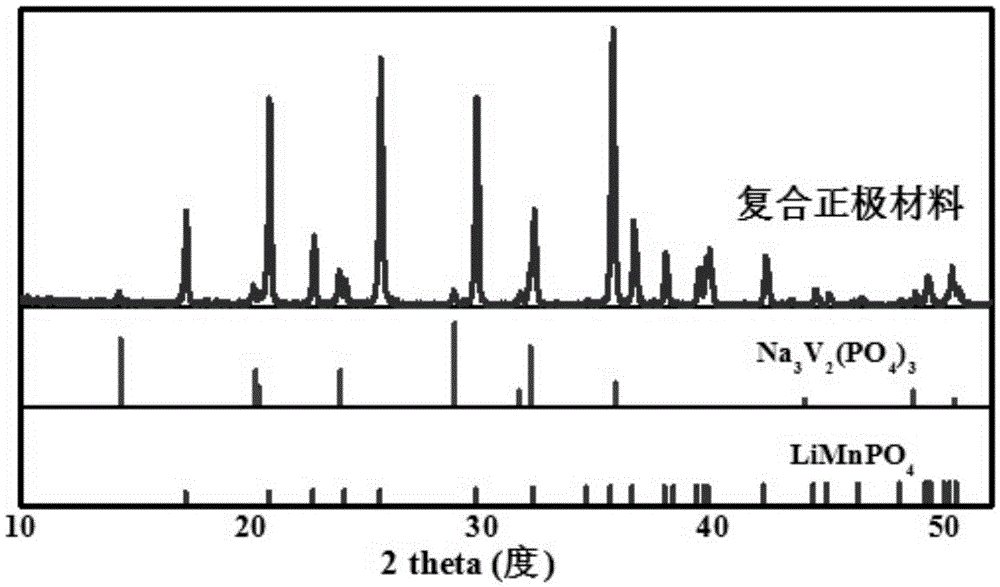

Modified lithium manganese phosphate composite anode material and preparation method thereof

ActiveCN105470479AHigh specific capacityImprove cycle performanceCell electrodesSecondary cellsCarbon compositesPhosphate

The invention discloses a modified lithium manganese phosphate composite anode material and a preparation method thereof. The problem that an existing lithium manganese phosphate anode material is poor in conductivity, poor in rate capability and unstable in circulation is solved. The nominal molecular formula of the composite anode material disclosed by the invention is yLiMnPO4.(1-y)Na3V2(PO4)3-xF3x / C, wherein x is greater than or equal to 0 and smaller than or equal to 2; and y is greater than or equal to 0.75 and smaller than 1. The preparation method comprises the following steps: (1) carrying out mechanical activation dispersion of LiMnPO4 powder and modified precursor raw materials; (2) controlling to prepare a lithium manganese phosphate / vanadium-containing colloid precursor; and (3) carrying out a one-step calcination method to prepare a lithium manganese phosphate / sodium (fluoro)phosphate vanadium / carbon composite material. The modified lithium manganese phosphate composite anode material has the beneficial effects that the material is simple in technological process, uniform in dispersion and easy to control, and the synergistically modified LiMnPO4-based composite material is high in specific energy density, good in cycle performance and excellent in rate capability.

Owner:深圳市费特森新能源有限责任公司

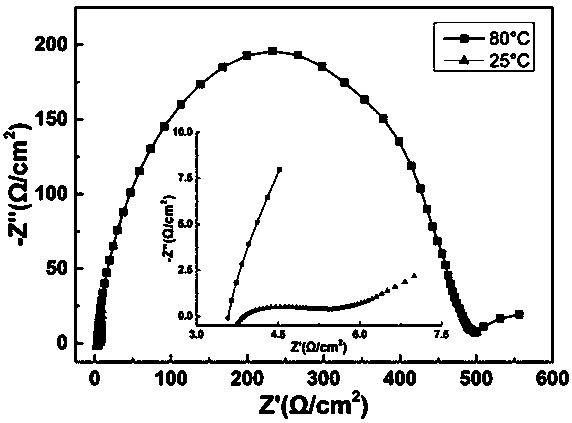

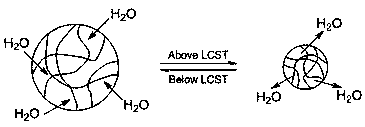

Temperature-sensitive polymer electrolyte as well as preparation method and application thereof

ActiveCN107759726AMild conditionsReduce system viscosityHybrid capacitor electrolytesOil phaseElectrochemistry

The invention relates to a temperature-sensitive polymer electrolyte as well as a preparation method and application thereof. The preparation method of the temperature-sensitive polymer electrolyte comprises the following steps: stably dispersing an aqueous phase component containing an electrolyte in an oil phase component to form an emulsion under the condition of strong stirring, and then raising the temperature to carry out a reversed phase suspension polymerization reaction under the condition of continuous strong stirring and inert gas filling, so as to obtain the temperature-sensitive polymer electrolyte, wherein the volume ratio of the aqueous phase component to the oil phase component is (0.1-1.0):1. The temperature-sensitive polymer electrolyte is obtained through a reaction of areversed phase suspension polymerization method, and the electrolyte is green and environmentally-friendly and can be cycled reversibly; and the application of the electrolyte in an electrochemical energy storage device can effectively solve the safety problem hindering the wide application of high specific energy density and high-power energy storage devices in commercialization.

Owner:SUN YAT SEN UNIV +1

Lithium titanate negative electrode material and preparation method thereof

InactiveCN102683664AIncrease volume specific energy densityImprove performanceCell electrodesImpuritySpecific energy density

The invention provides a lithium titanate negative electrode material and a preparation method thereof. The lithium titanate negative electrode material is prepared from LiOH.H2O and TiO2 based on mole ratio of (0.7-0.9):1. The preparation method comprises the following steps of: uniformly mixing the LiOH.H2O and TiO2 to obtain a first material; adding the first material to a defined amount of deionized water and crushing to obtain a second suspension material; drying the second material to obtain a precursor; sintering the precursor at high temperature being 600-900 DEG C for 5-20h to obtain a third material; and sieving the third material in 400 meshes to obtain the lithium titanate negative electrode material in a shape of a sphere. The lithium titanate negative electrode material prepared by the method disclosed by the invention has the advantages of wide grain size distribution range, no impurities and high volumetric specific energy density, and solves a problem that the tap density of a negative electrode material of a lithium battery is hard to increase; and the tap density of the lithium titanate negative electrode material is as high as 1.4g / cm<3>.

Owner:HUNAN RESHINE NEW MATERIAL

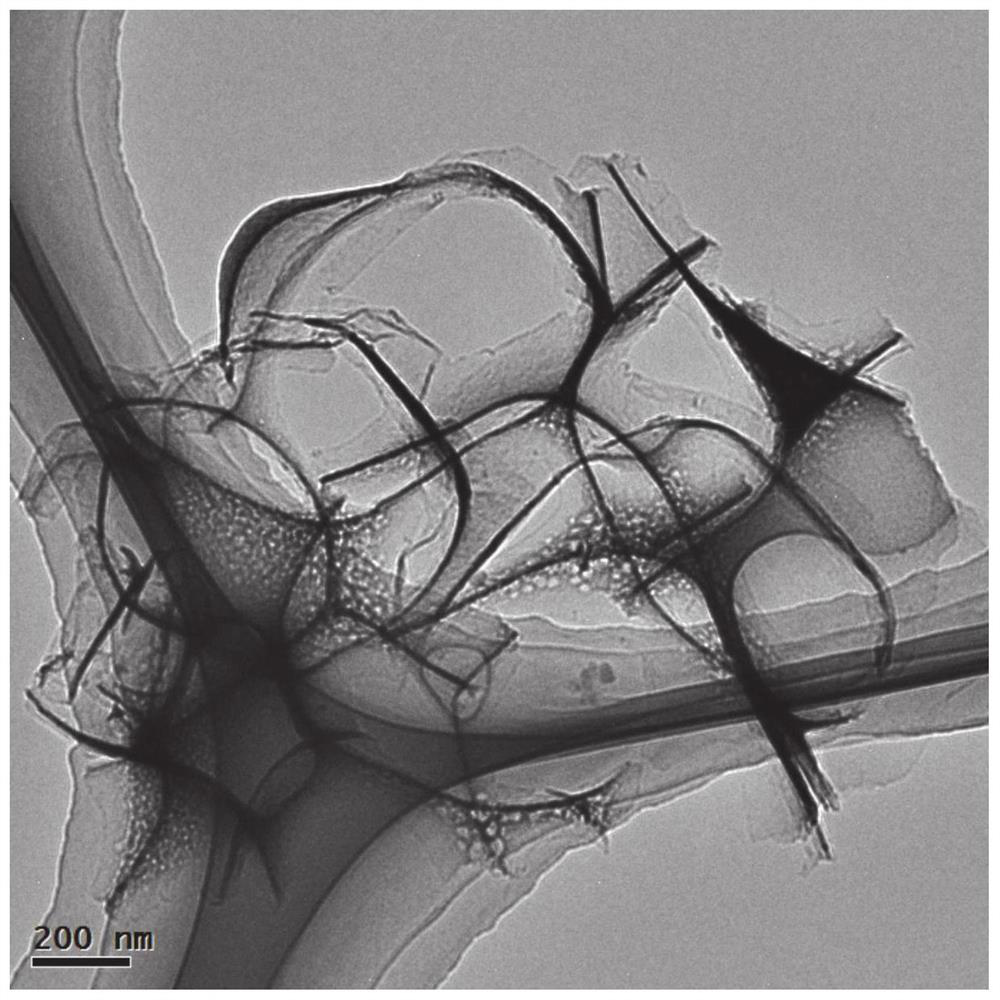

Carbon nano-tube net/Ni(OH)<2>/PPY composite electrode, preparation method and application

InactiveCN106169377AImprove specific energy density characteristicsHigh specific energy density characteristicsMaterial nanotechnologyHybrid capacitor electrodesCapacitanceHigh rate

The invention discloses a carbon nano-tube net / Ni(OH)<2> / PPY composite electrode, a preparation method and application, belonging to the technical field of super capacitors. The carbon nano-tube net / Ni(OH)<2> / PPY composite electrode is a core-shell structure; a core is composed of Ni(OH)<2> and a carbon nano-tube net doped therein; and a shell is uniform and compact PPY formed through an electrochemical deposition method. The composite electrode exerts a double-electrode-layer effect by utilizing the carbon nano-tube net having high specific surface area; with the help of the pseudocapacitance characteristic of the nano metallic oxide Ni(OH)<2>, the specific capacity is increased; simultaneously, depending on the high electric conductivity and the high specific energy density of the polymeric conductive polymer PPY, the discharge capability of the super capacitors under a high rate can be improved; the carbon nano-tube net with a connection point in a composite pole piece is doped in Ni(OH)<2>; therefore, the electric conductivity and the liquid sucking and keeping capability of the material are easily improved; and furthermore, the structural stability of the material can be improved through a net type structure.

Owner:深圳博磊达新能源科技有限公司

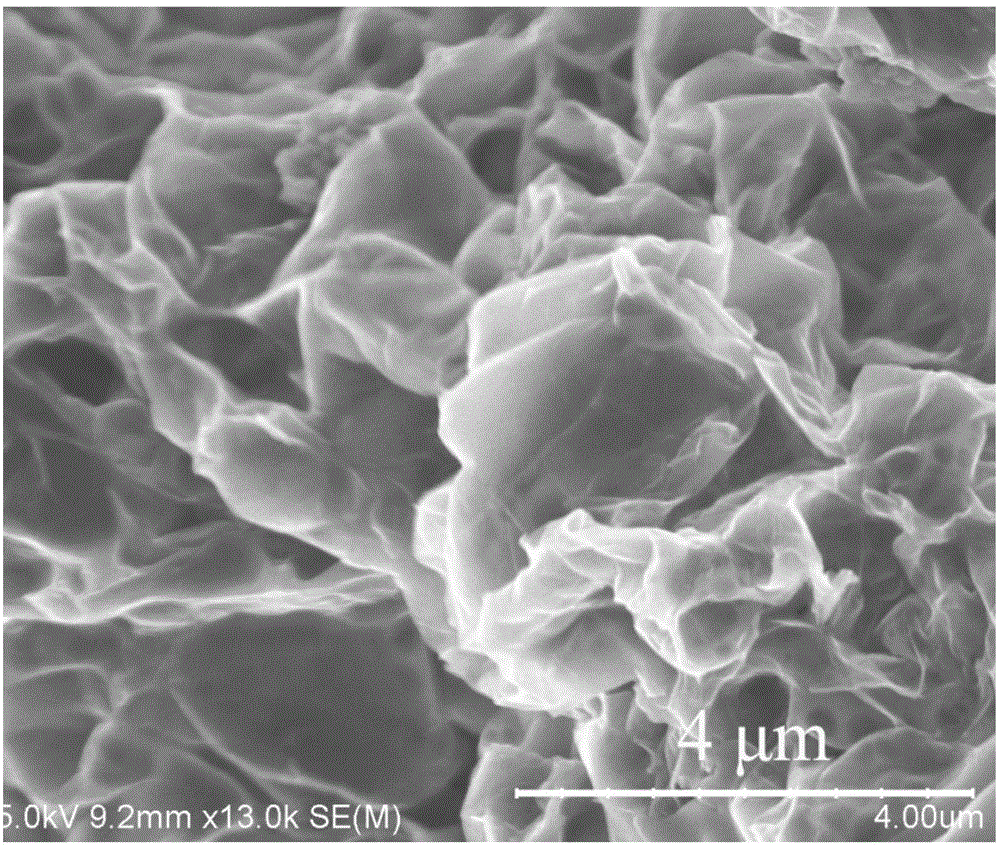

Preparation method of sulfur/graphene nano composite material, positive electrode of lithium ion battery and lithium ion battery

ActiveCN106159240AUniform shapeStable in natureMaterial nanotechnologyCell electrodesNano compositesGraphene nanocomposites

The invention discloses a preparation method of a sulfur / graphene nano composite material, a positive electrode of a lithium ion battery and the lithium ion battery. The preparation method comprises the steps of a hydrothermal procedure and a compounding procedure. A monomer sulfur and three-dimensional reduced graphene oxide composite material obtained by the preparation method greatly represents the advantages of two-dimensional graphene compounding in the prior art; all groups of a monomer sulfur and three-dimensional reduced graphene oxide have very strong chemical bonding forces and the monomer sulfur is not easy to fall off, so that the stability of the material is greatly increased; the material is applied to a positive electrode material of the lithium ion battery and has the advantages of good circulating stability, high specific energy density and the like.

Owner:信骅(上海)器材有限公司

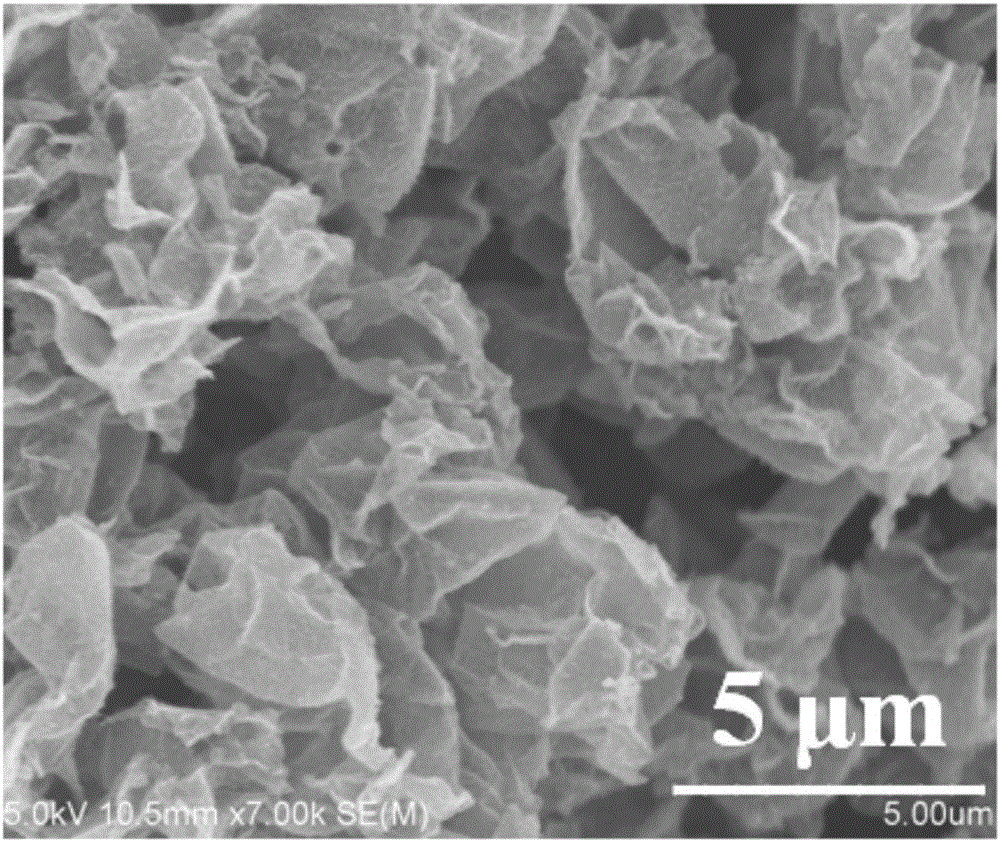

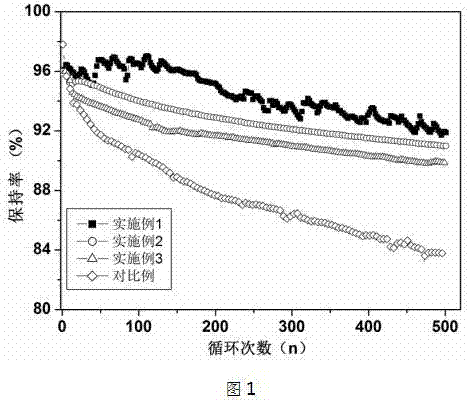

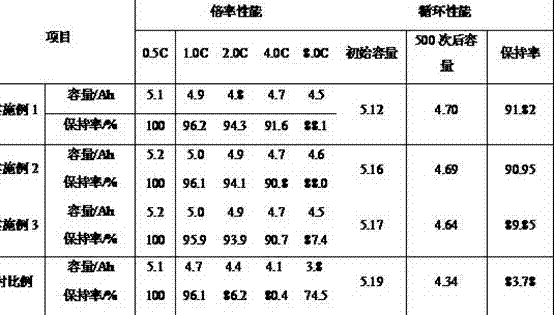

Sr-and-H3BO3-doped LiNi0.5Co0.2Mn0.3O2 cathode material and preparation method thereof

InactiveCN106910873AImprove performanceIncrease compaction densityCell electrodesSecondary cellsLithium-ion batterySpecific energy density

The invention relates to a cathode material of a lithium ion battery and preparation of the cathode material, in particular to a Sr-and-H3BO3-doped LiNi0.5Co0.2Mn0.3O2 cathode material and a preparation method thereof. The Sr-and-H3BO3-doped LiNi0.5Co0.2Mn0.3O2 cathode material is prepared from the following raw materials: a ternary precursor Ni0.5Co0.2Mn0.3(OH)2, Li2CO3, Sr(OH)2.8H2O and H3BO3, wherein the stoichiometric ratio of the ternary precursor Ni0.5Co0.2Mn0.3(OH)2 to the Li2CO3 is m(Li<+>) / m(Ni<2+>+Co<2+>+Mn<2+>) which is equal to 1.04 to 1; the Sr doping content is 0.06 to 0.18 percent by mass; the H3BO3 doping content is 0.5 to 1.2 percent by mass; all the raw materials are prepared into the cathode material through high temperature solid phase sintering. Compared with a conventional ternary cathode material, the cathode material prepared through the preparation method is higher in compaction density, and the specific energy density is substantially increased, so that the full battery performance is effectively improved.

Owner:宁夏科捷锂电池股份有限公司

Lithium ion battery and negative electrode composite electrode plate thereof

InactiveCN106972151AReduce expansionImprove securityCell electrodesNanotechnologyCarbon compositesElectrical battery

The invention discloses a lithium ion battery and a negative electrode composite electrode plate thereof. A preparation method for the negative electrode composite electrode plate comprises the steps of 1) preparing a solution A; 2) preparing a material B; and 3) preparing a silicon / titanium dioxide / carbon composite electrode plate. According to the prepared composite negative electrode plate, based on the zero-strain characteristic of the titanium dioxide material and a relatively high voltage platform, the expansion rate of the material in a charging-discharging process is lowered and the safety performance of the battery is improved; meanwhile, by virtue of a TiO<2> / C coating layer, the electrical conductivity of the composite material is improved, and volume change in a silicon cycling process can be effectively suppressed by virtue of a porous structure; in addition, TiO<2> / C, used as framework support, can provide a three-dimensional space transmission channel for lithium ion transfer; meanwhile, the negative electrode plate can be directly used without requiring a binder and a conductive agent; and the prepared composite negative electrode plate has the characteristics of high gram volume, excellent rate capability and strong liquid absorption and retention capability and the like, so that requirement of the high-specific-energy-density battery on the negative electrode material can be satisfied particularly.

Owner:JIANGSU LENENG BATTERY INC

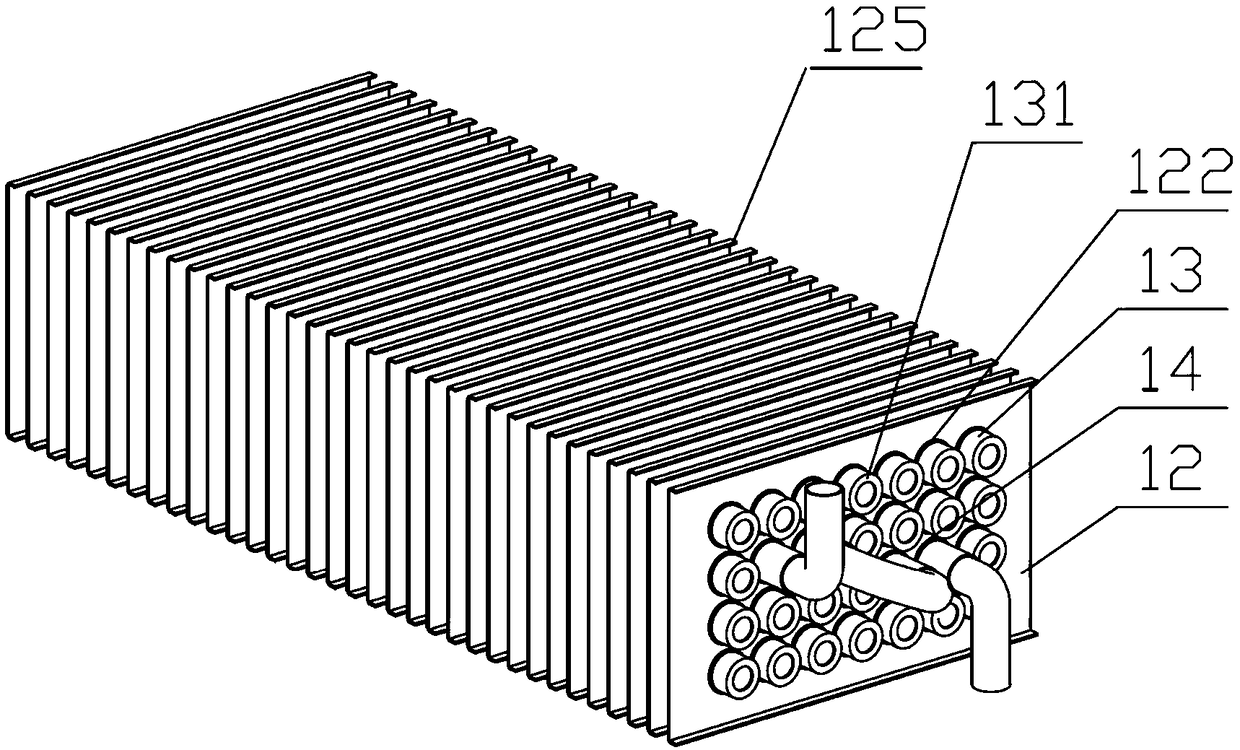

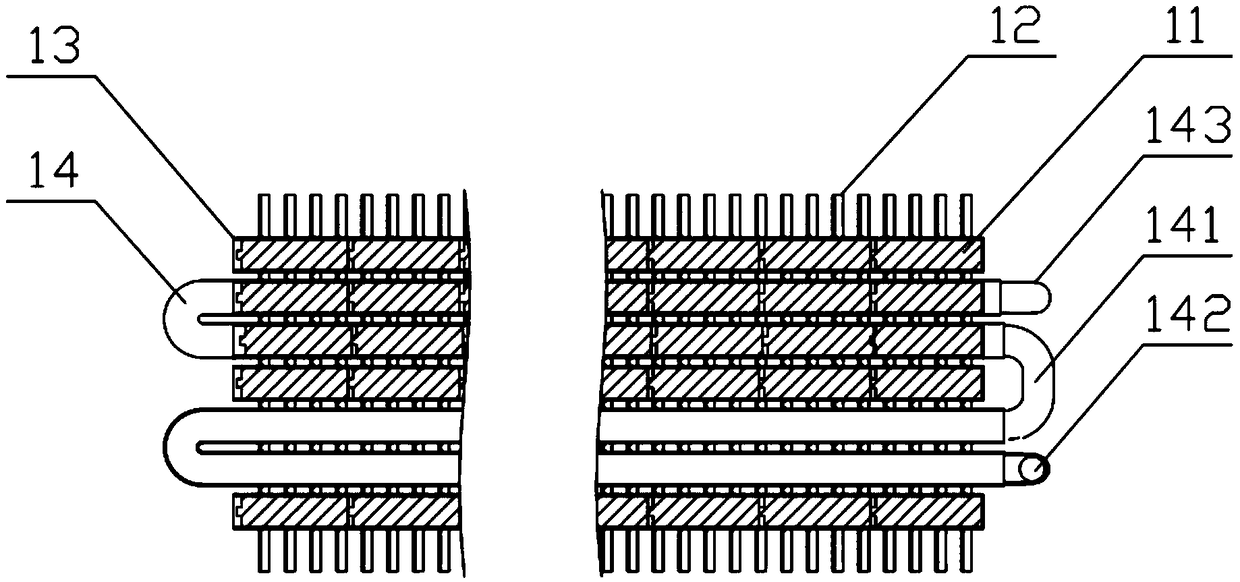

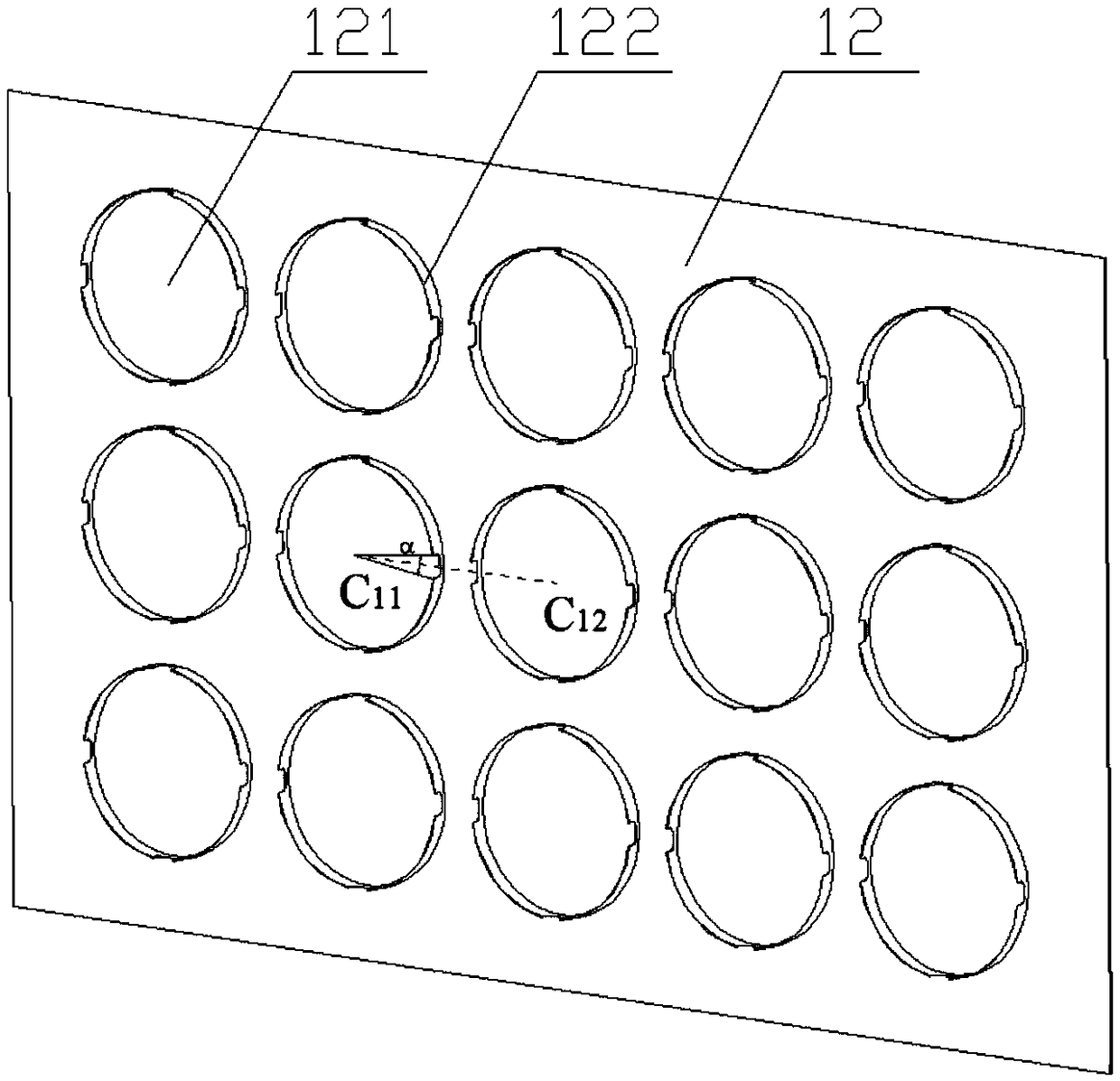

A through-tube fin type cylindrical battery module

PendingCN109004245AGuaranteed cooling effectSolve uneven temperature distributionFuel cell heat exchangeTemperature controlBattery thermal management

The invention relates to the technical field of battery thermal management, in particular to a tube-through fin type cylindrical battery module, including a battery sleeve, a cylindrical battery and afin group, the fin group is composed of a plurality of fins arranged in parallel, The fin is provided with an assembly circular hole matched with the battery sleeve, the battery sleeve vertically passes through and is mounted in the assembly circular hole of each fin and is matched with the fin, the inner diameter of the battery sleeve is matched with the outer diameter of the cylindrical battery, and the cylindrical battery is connected end to end in series and installed in the battery sleeve. The invention can solve the problems that the temperature field distribution of a cylindrical battery pack arranged horizontally and connected in series to form a pack is uneven and part of the non-specific area is overheated in the prior art. The battery module has higher specific energy density,and can meet the requirements of good temperature uniformity, temperature control performance and low cost, light weight and manufacturability.

Owner:马海云

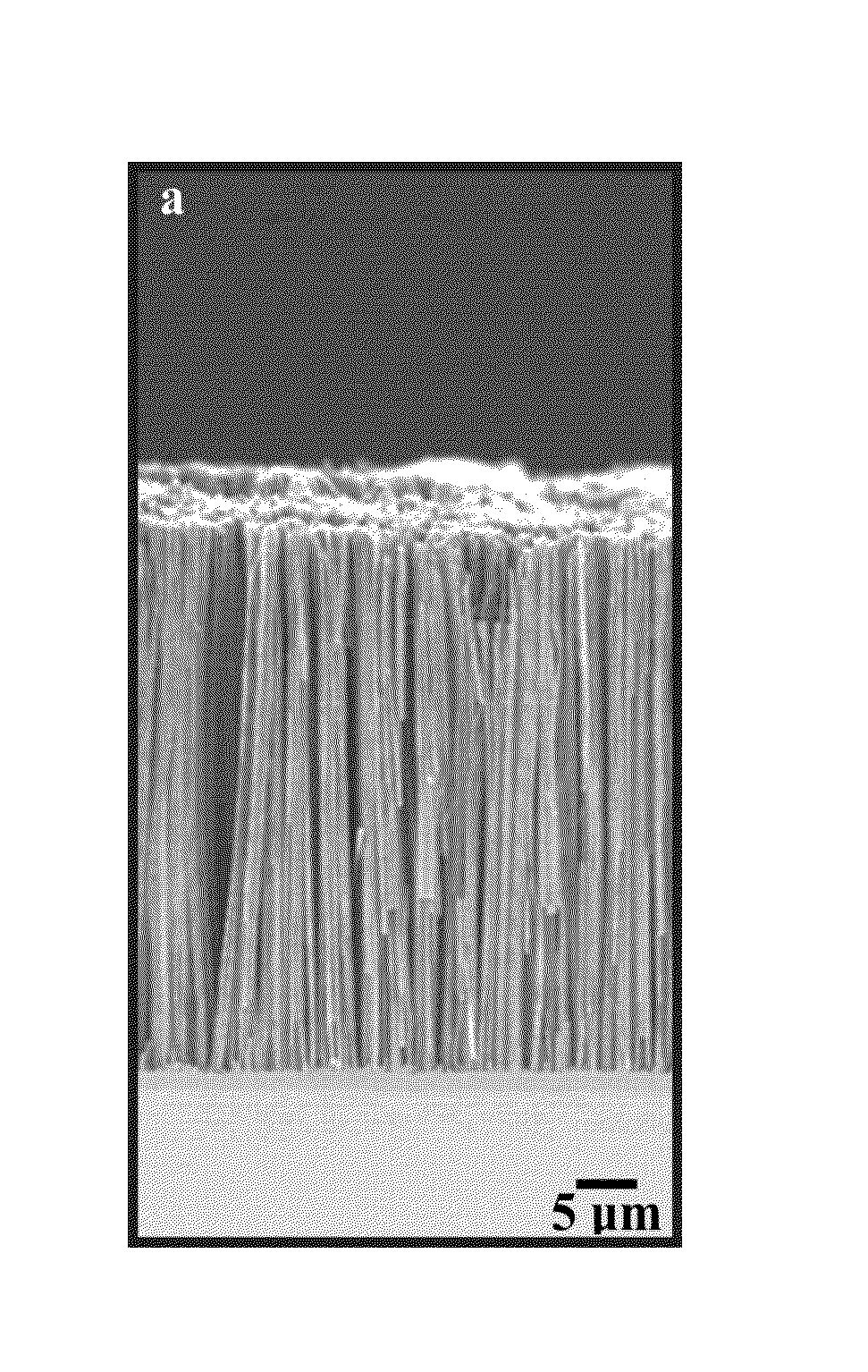

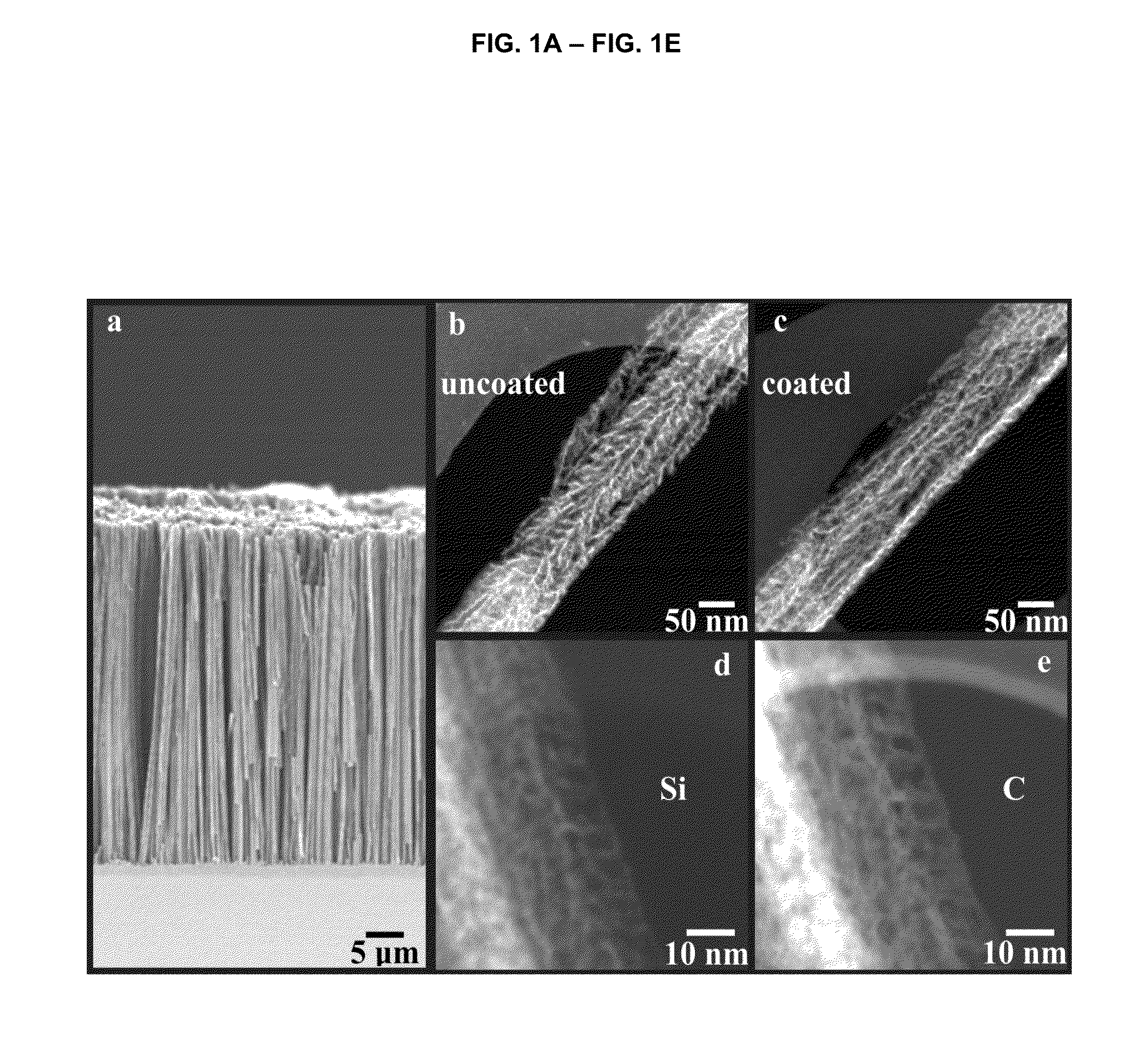

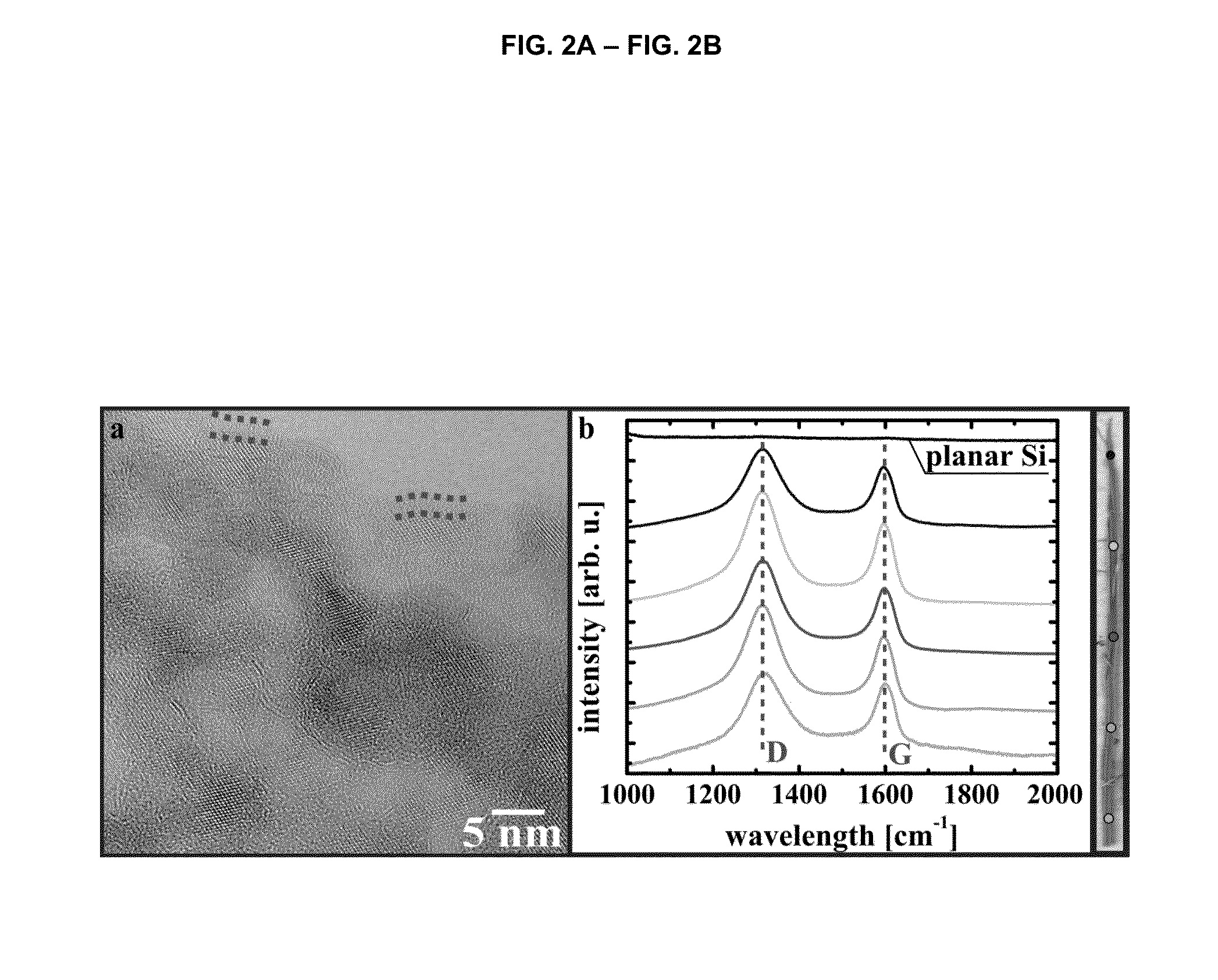

Passivated porous silicon nanowires

InactiveUS20150364267A1Mitigating Si degradationFull accessHybrid capacitor electrodesElectrolytic capacitorsCapacitanceCarbon coating

In exemplary embodiments, there is provided a scalable process for producing supercapacitor electrodes with very high specific capacitance and specific energy density, and very high capacitance retention after thousands of charge discharge cycles. The electrode material consists of a thin, electrically conductive carbon coating deposited onto nanoporous silicon nanowires. The coating prevents degradation of the silicon nanowires in aqueous solutions, while leaving the pore area fully accessible, enabling application as a supercapacitor electrode with the highest capacitance per projected area to date. The nanowires also are of use as a water splitting electrode and aqueous fuel cell electrode.

Owner:RGT UNIV OF CALIFORNIA

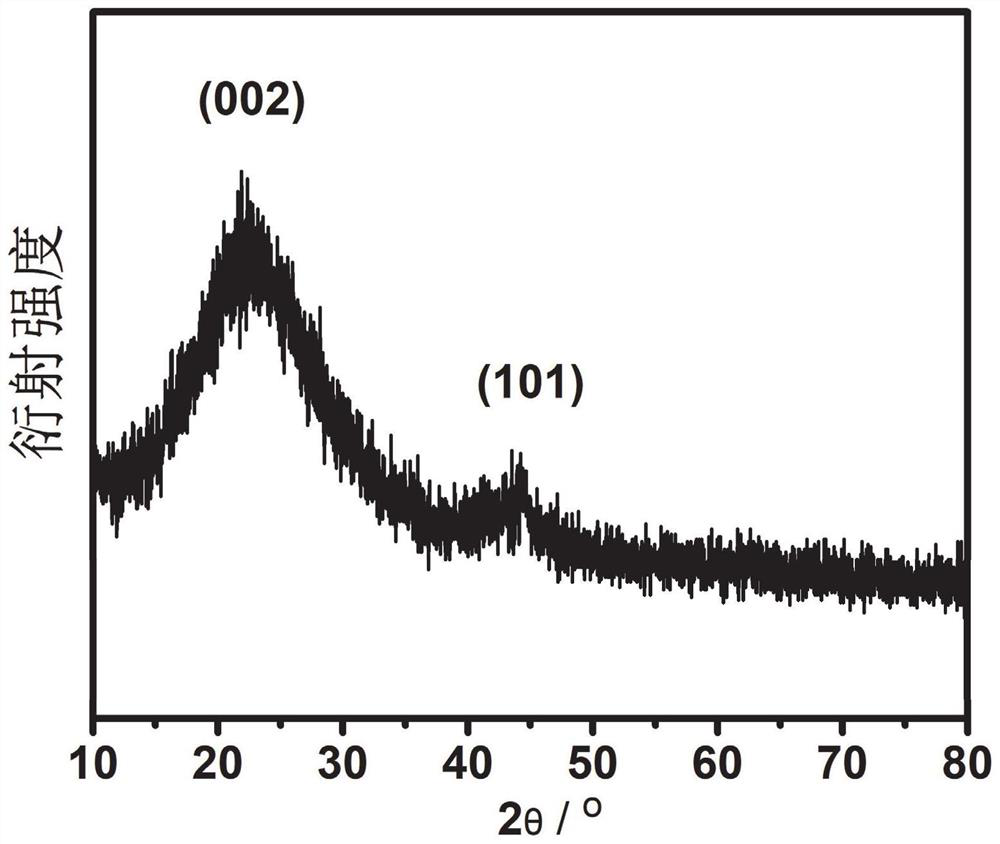

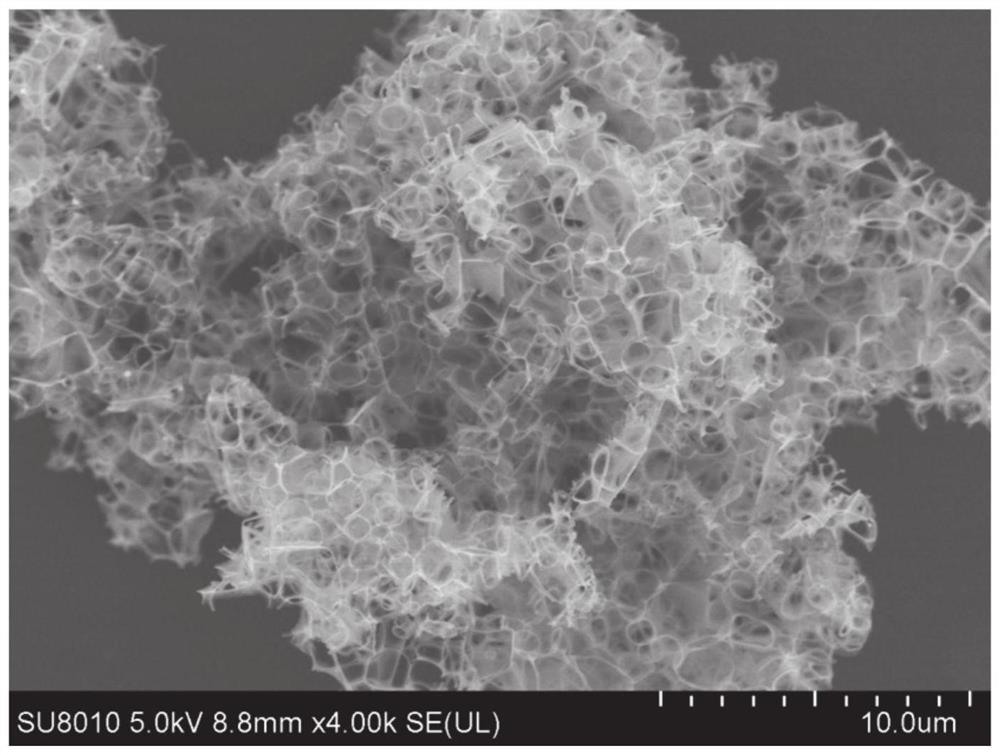

Preparation method and application of sulfur-nitrogen co-doped three-dimensional porous carbon nanosheet

PendingCN111825074AIncrease layer spacingEasy to embedMaterial nanotechnologyHybrid capacitor electrodesInorganic saltsPorous carbon

The invention discloses a preparation method of a sulfur-nitrogen co-doped three-dimensional porous carbon nanosheet, and the method comprises the following steps: calcining and washing a mixture containing a carbon source, a sulfur source, a nitrogen source and an inorganic salt template agent to obtain the sulfur-nitrogen co-doped three-dimensional porous carbon nanosheet. The sulfur-nitrogen co-doped three-dimensional porous carbon nanosheet prepared by the method has the advantages of large specific surface area, good conductivity, multiple active sites and the like, and excellent performances of high specific energy density and power density are obtained when the nanosheet is applied to a negative electrode of a potassium ion hybrid supercapacitor.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

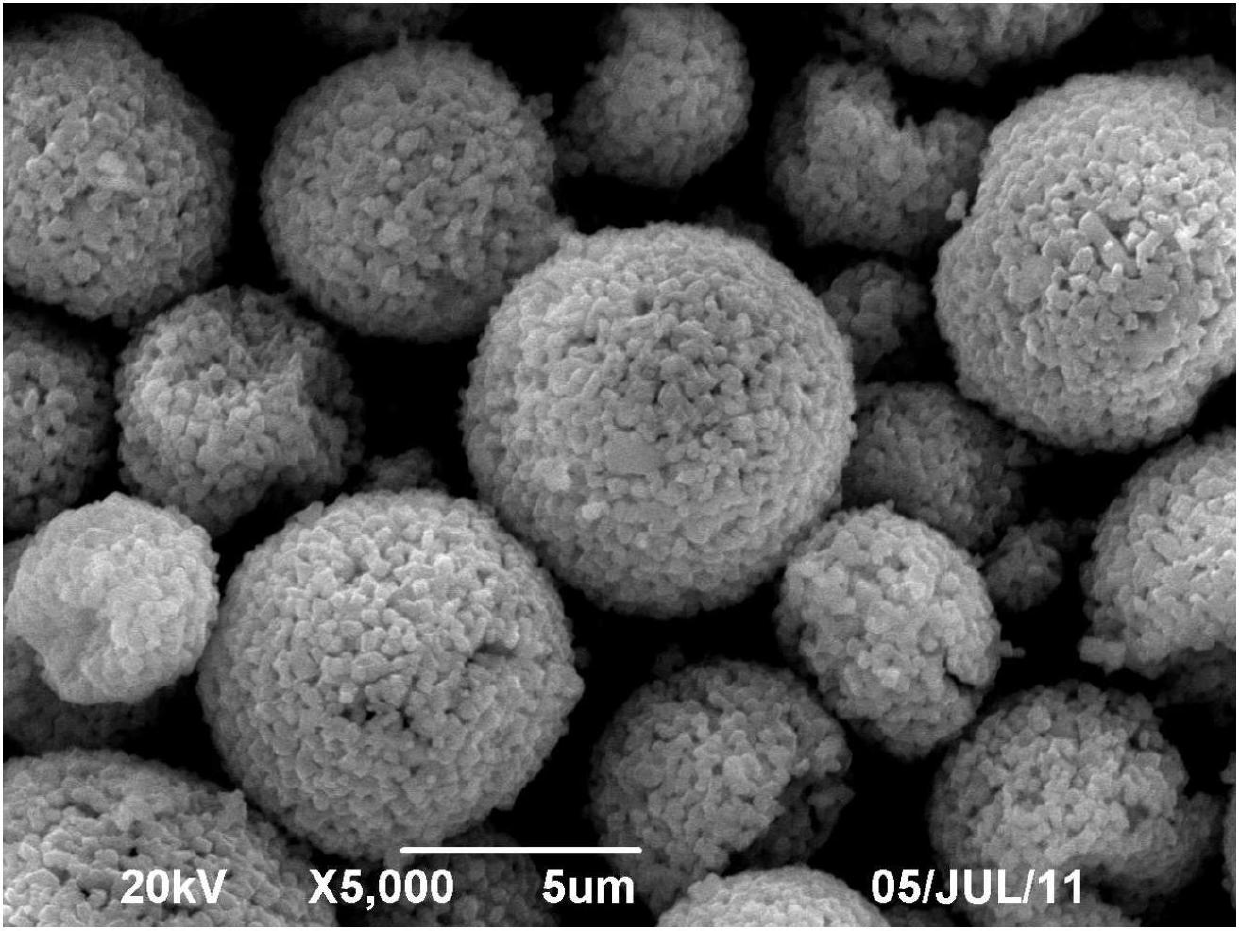

Preparation method of high-density lithium battery anode material spinel lithium manganate

InactiveCN103367737AIncrease electrode densityIncrease volume specific energy densityCell electrodesManganates/permanganatesManganateManganese

The invention discloses a preparation method of high-density lithium battery anode material spinel lithium manganate. The preparation method comprises the following steps of: step 1, dripping a water solution containing manganese ions into an alkaline solution under the condition of agitating by strong force to obtain sediment product MnOOH; separating the sediment product MnOOH, washing and drying; 2, mixing the prepared MnOOH with a lithium salt or mixing the lithium salt with other metal oxides; and carrying out high-temperature calcination to prepare the spherical or sphere-like-shaped spinel lithium manganate, wherein the grain diameter of obtained spinel lithium manganate grains is in a range of 1-10 microns. If the spherical or sphere-like-shaped spinel lithium manganate LiMn2O4 prepared by the method disclosed by the invention or a monobasic or polybasic compound LiMxMn2-xO4 doped with other metal elements is applied to an ion battery, the density of electrodes of the battery can be improved and the volumetric specific energy density of the battery is increased, so that the whole performance of the battery is obviously improved.

Owner:GUANGZHOU LIBODE NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com