A through-tube fin type cylindrical battery module

A cylindrical battery and fin technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of uneven temperature field distribution, non-specific area overheating, etc., to improve performance and service life, The effect of preventing thermal runaway, high volume and weight specific energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

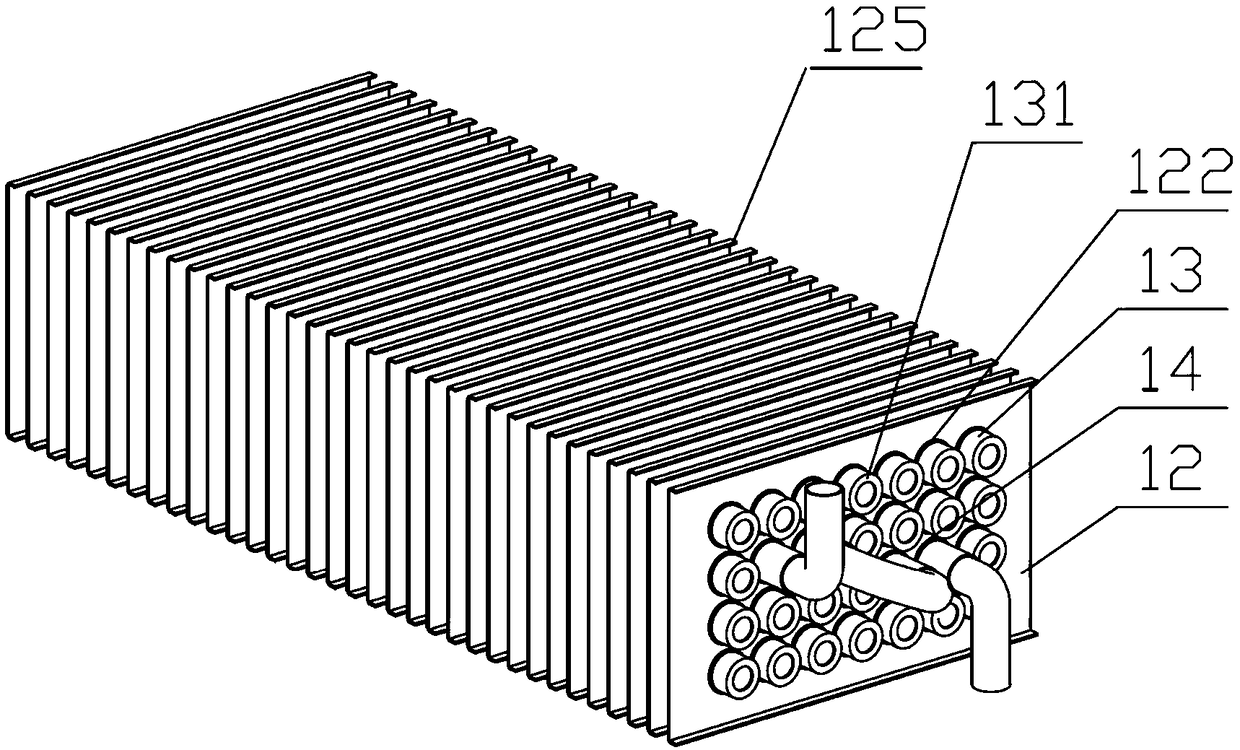

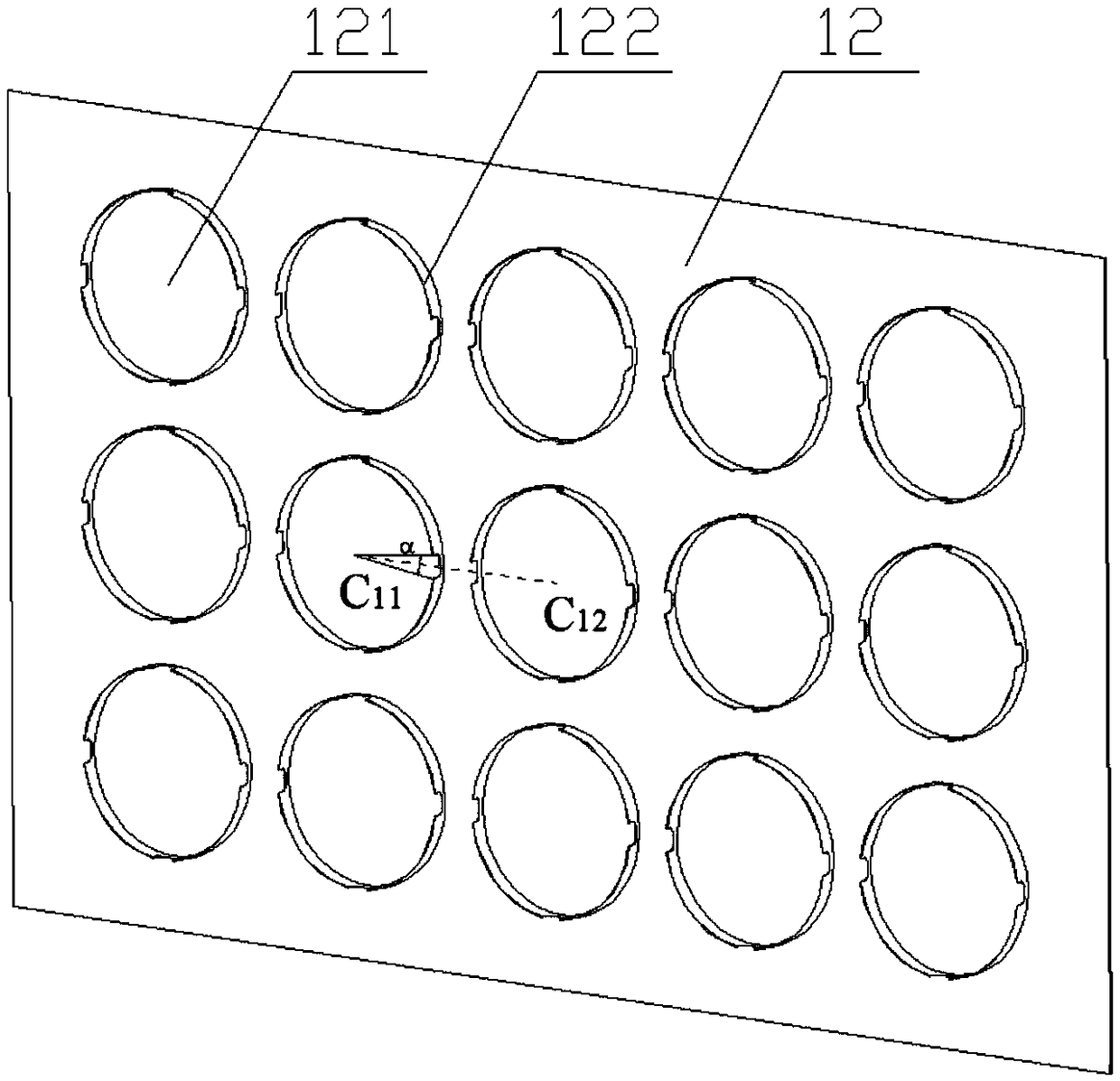

[0039] see Figure 1-3 , this embodiment provides a technical solution: a tube-through-finned cylindrical battery module, including a battery sleeve 13, a cylindrical battery 11 and a fin group, the fin group is composed of a number of fins 12 arranged in parallel, the fins The sheet 12 is provided with an assembly hole 121 matching the battery casing 13, and the edge of the assembly hole 121 extends outward to form a flange 122; the battery casing 13 is vertically mounted on the assembly hole 121 on each fin 12 and cooperate with the fins 12, the inner diameter of the battery casing 13 matches the outer diameter of the cylindrical battery 11. Each battery casing 13 is equipped with one or more cylindrical batteries 11; when the battery casing 13 is equipped with a plurality of cylindrical batteries 11, the plurality of cylindrical batteries 11 are installed end to end in series. The battery module can effectively control local overheating in non-specific areas of the battery...

Embodiment 2

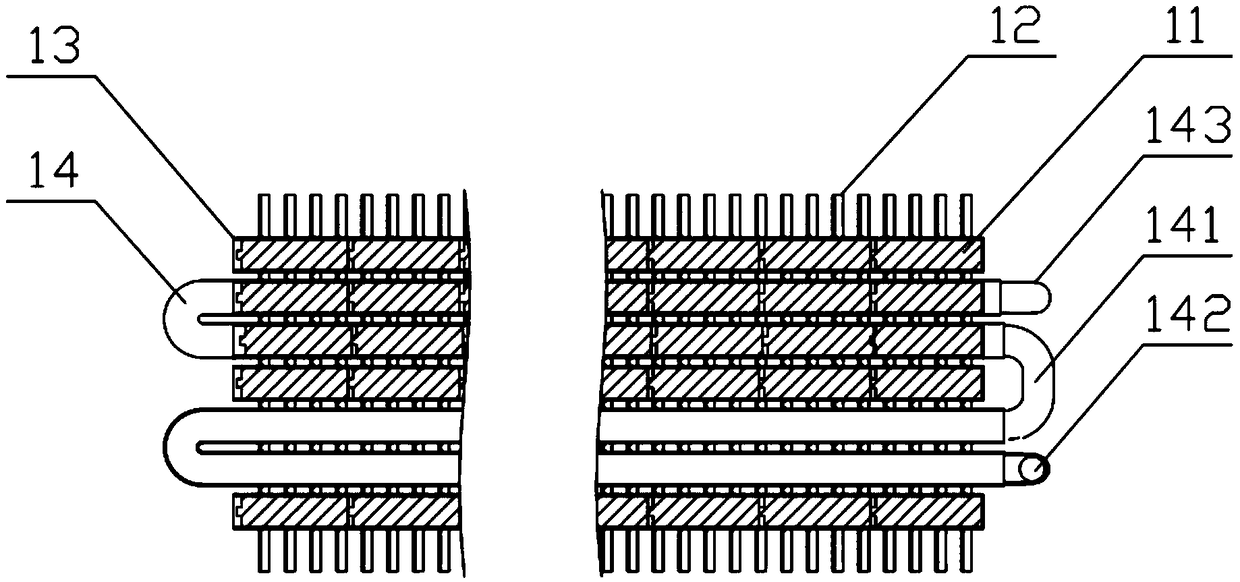

[0056] see Figure 4-7, this embodiment provides a technical solution: a tube-through-finned cylindrical battery module, including a cylindrical battery 21, a battery sleeve 23 and a fin group, the fin group is composed of a number of parallel fins 22, the fins The sheet 22 is provided with an assembly hole 221 that matches the battery sleeve 23, and the edge of the assembly hole 221 extends outward to form a flange. The battery sleeve 23 is vertically mounted on the assembly hole 221 of each fin 22 and Cooperating with the fins 22 , the inner diameter of the battery sleeve 23 matches the outer diameter of the cylindrical battery 21 . The fins 22 are also provided with some heat transfer tube holes 224 for assembling the heat transfer tubes 24. The apertures of the heat transfer tube holes 224 match the heat transfer tubes 24 so that the fins 22 are sleeved on the heat transfer tubes 24. . Each battery casing 23 is equipped with one or more cylindrical batteries 21; when the...

Embodiment 3

[0067] see Figure 8-9 , this embodiment provides a technical solution: a through-tube finned cylindrical battery module, including a battery casing 33, a cylindrical battery 31 and a fin group. The fin group is composed of several fins 32 arranged in parallel. The fins 32 are provided with assembly holes 321 matching the battery sleeves 33 , and the edges of the assembly holes 321 extend outwards to form flanges. The battery sleeve 33 is vertically mounted on the assembly hole 321 of each fin 32 and fits with the fin 32 . The fins 32 of the battery module are also provided with a number of heat transfer tube holes 324 for assembling the heat transfer tubes 34. The apertures of the heat transfer tube holes 324 are matched with the heat transfer tubes 34 to cover the fins 32 On the heat transfer tube 34.

[0068] In this embodiment, the battery casing 33 is made of metal or plastic or a thin-walled tube of composite insulating material, which is processed and deformed by extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com