Patents

Literature

34results about How to "Solve uneven temperature distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Physical vapor deposition equipment and physical vapor deposition process

ActiveCN103572211AImprove heating efficiencyImprove heating uniformityVacuum evaporation coatingSputtering coatingGas phaseEngineering

The invention discloses a physical vapor deposition device which comprises a reaction chamber, wherein the reaction chamber comprises a medium window arranged in the reaction chamber and used for dividing the reaction chamber into an upper chamber and a lower chamber, a substrate support component in the lower chamber, a heating component arranged on the top wall of the upper chamber and used for heating a to-be-processed substrate, a substrate sending port arranged on the side wall of the lower chamber and used for sending out the processed substrate from the lower chamber or sending the to-be-processed substrate in the lower chamber, and a heating constraint bucket arranged in the lower chamber and can be lifted in the lower chamber through a lifting mechanism. The medium window has light transmission and is used for sealing the lower chamber. The physical vapor deposition equipment disclosed by the invention is capable of greatly improving the uniformity when the substrate is heated and improving the degassing effect of the substrate. The invention further discloses a physical vapor deposition process.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

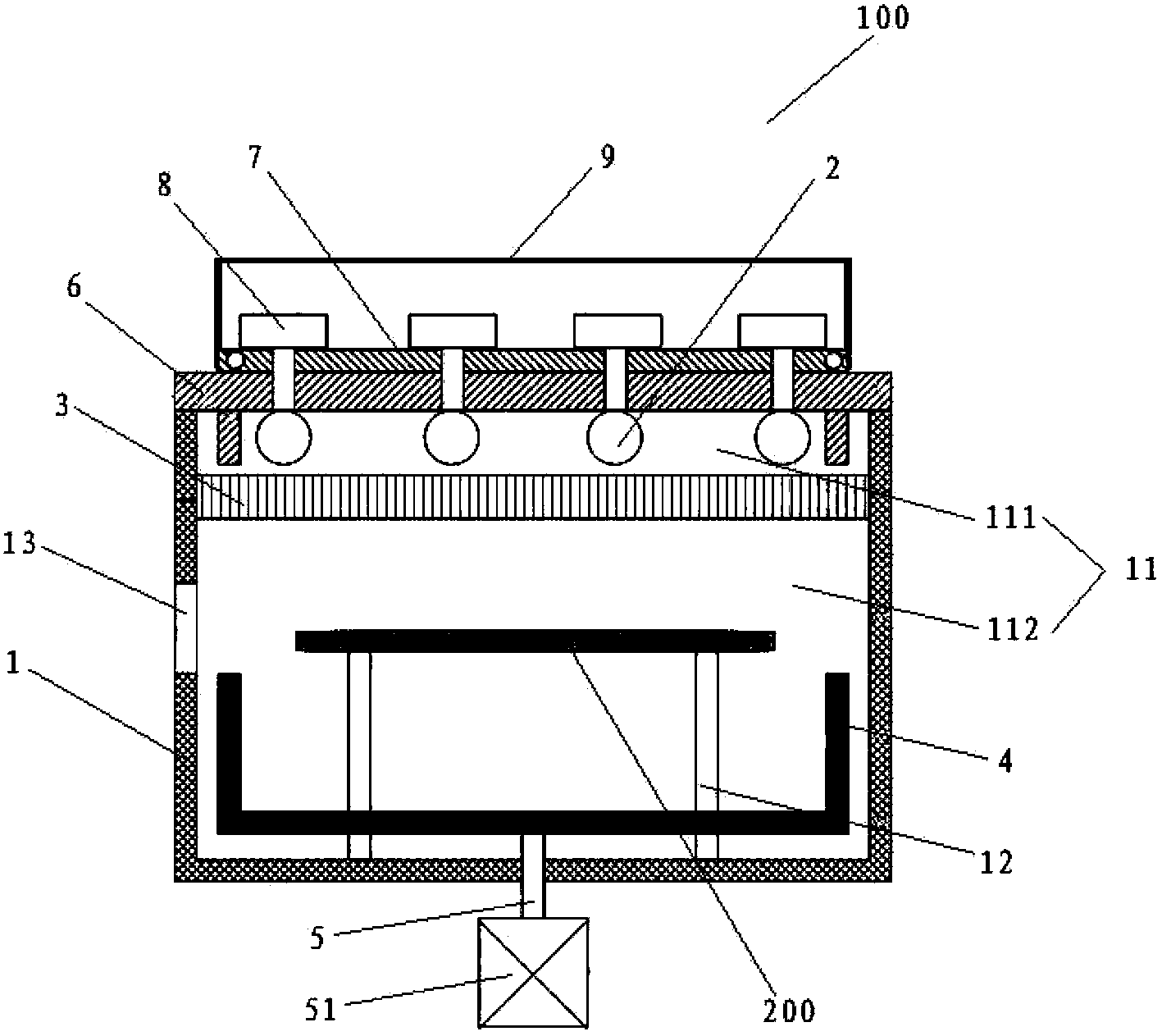

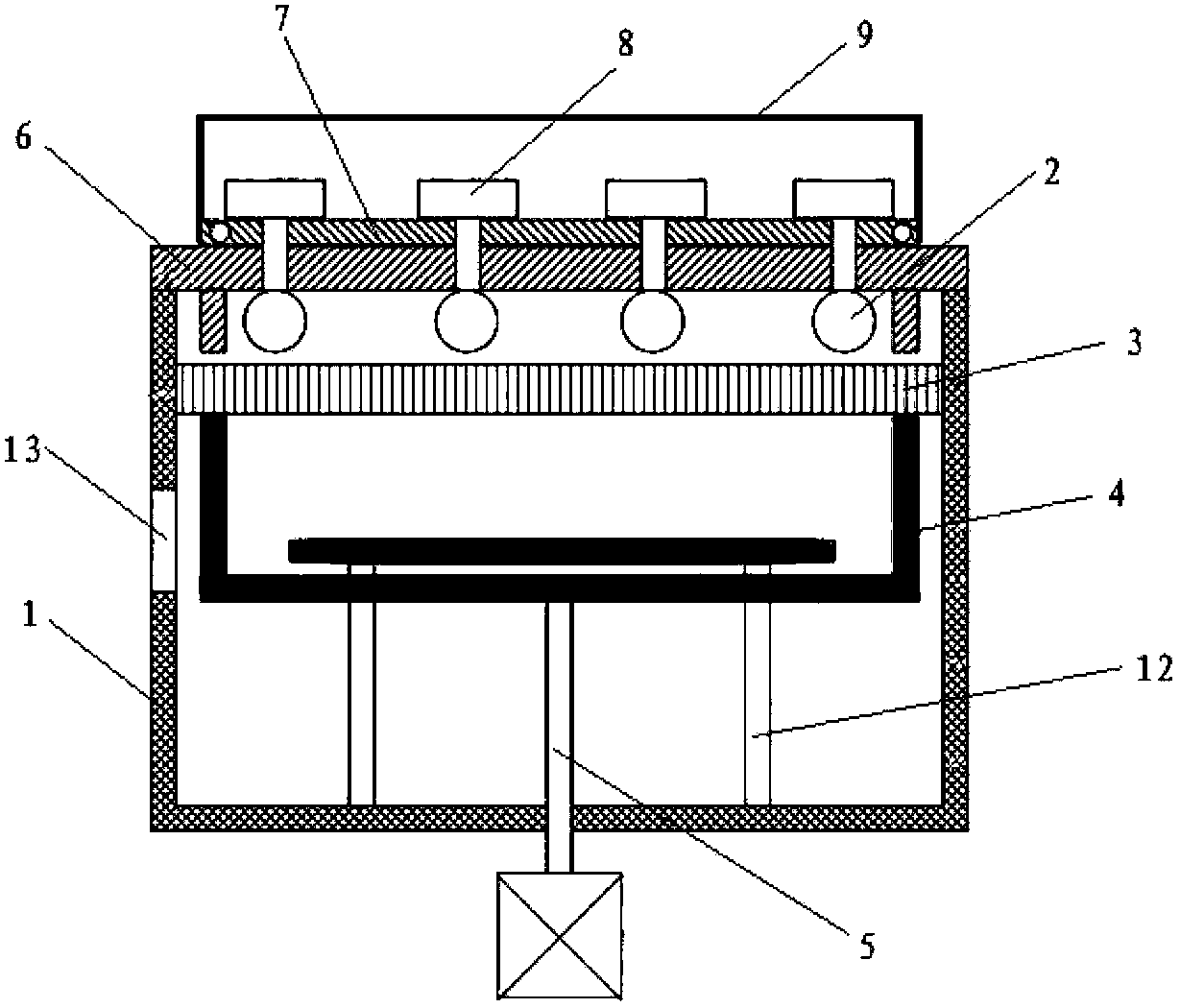

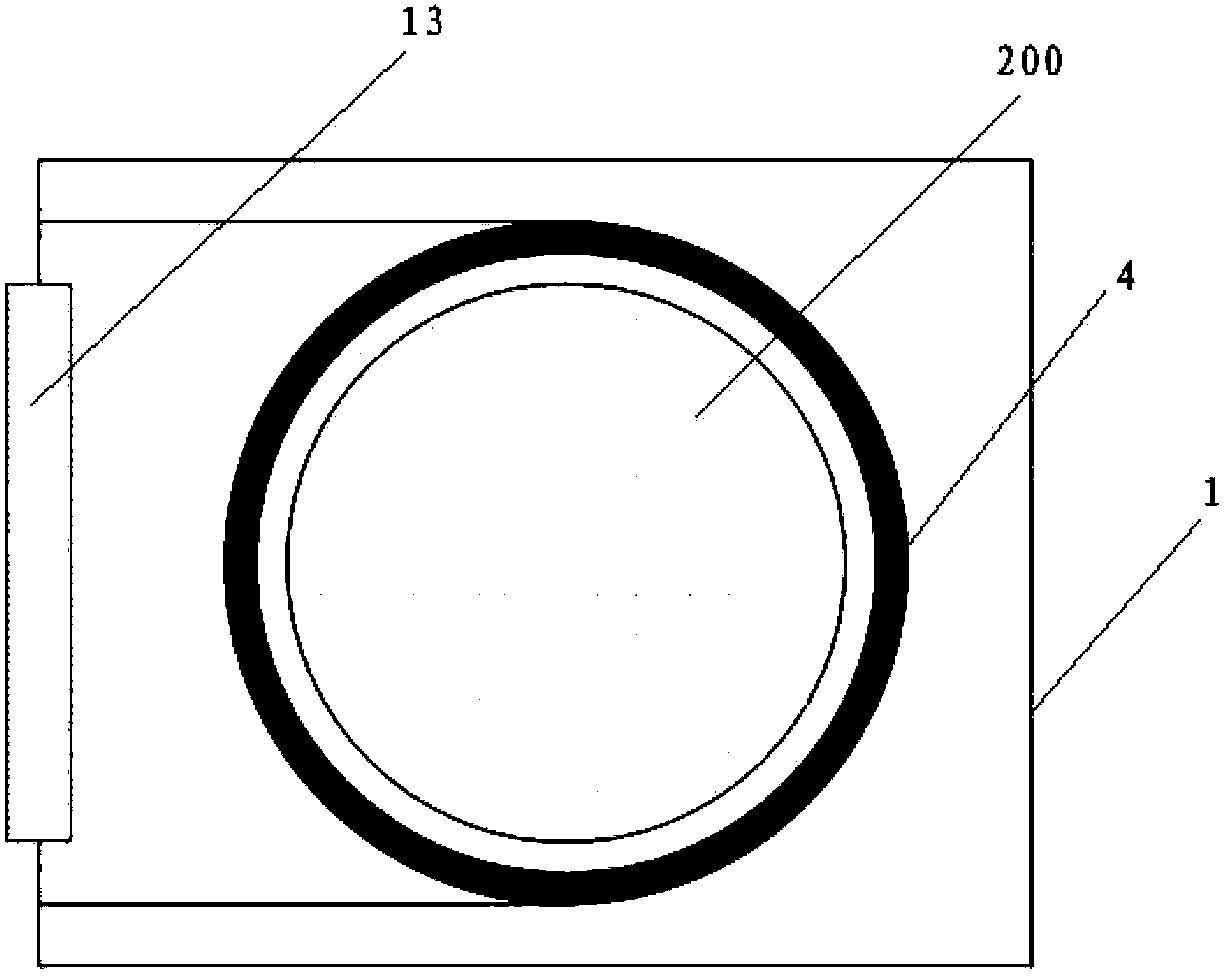

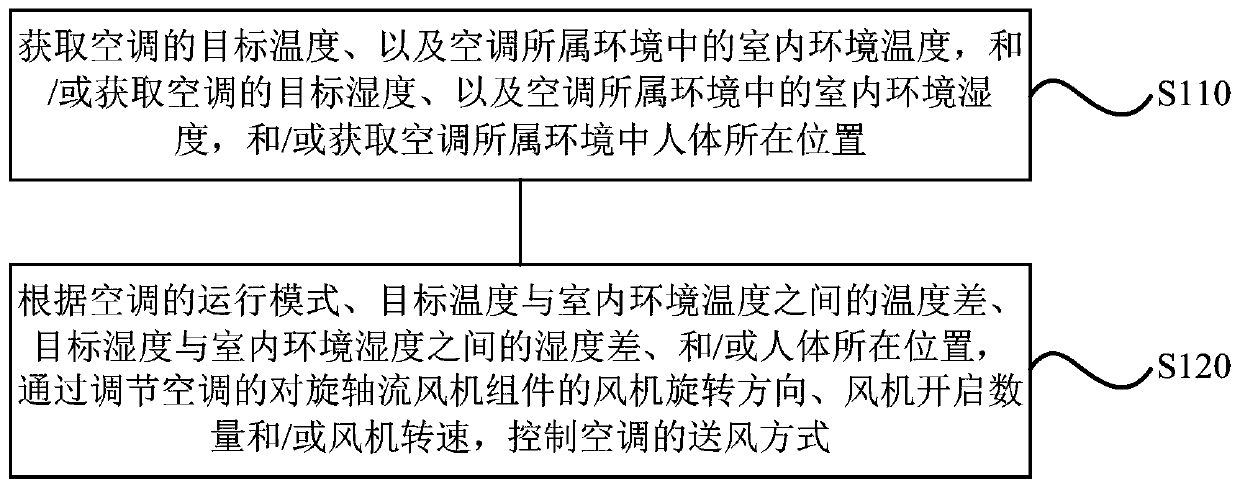

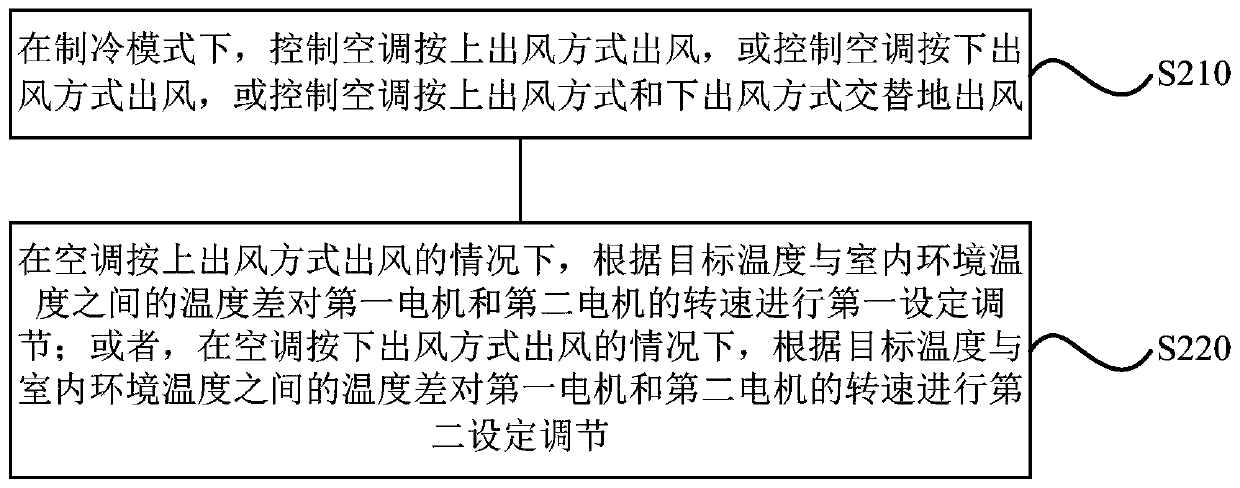

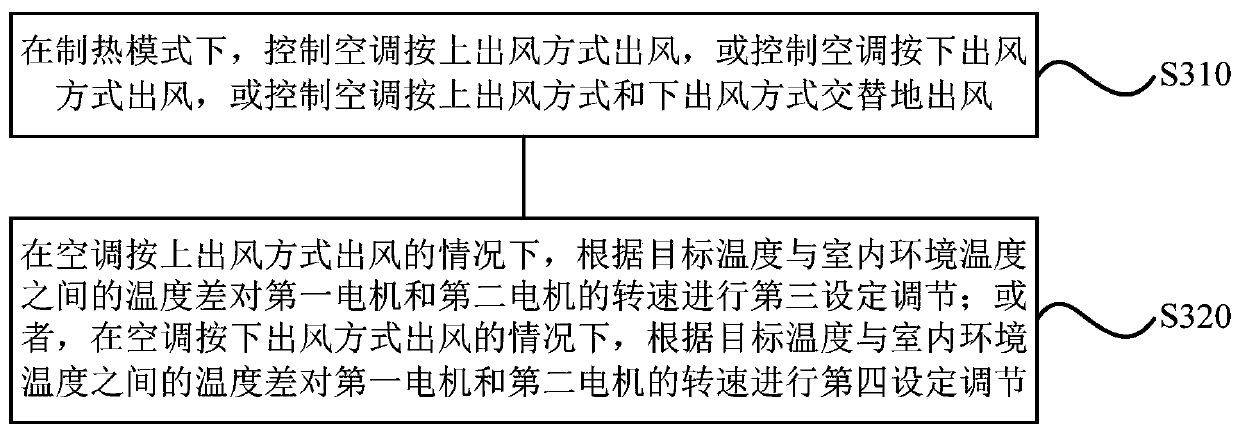

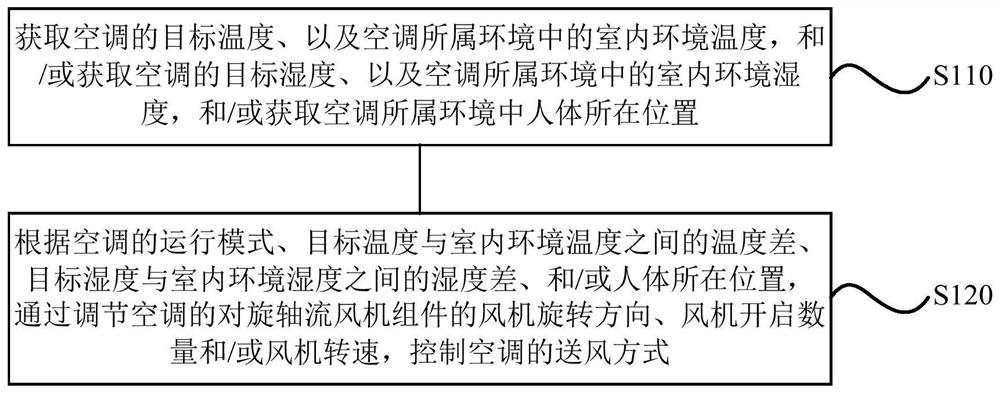

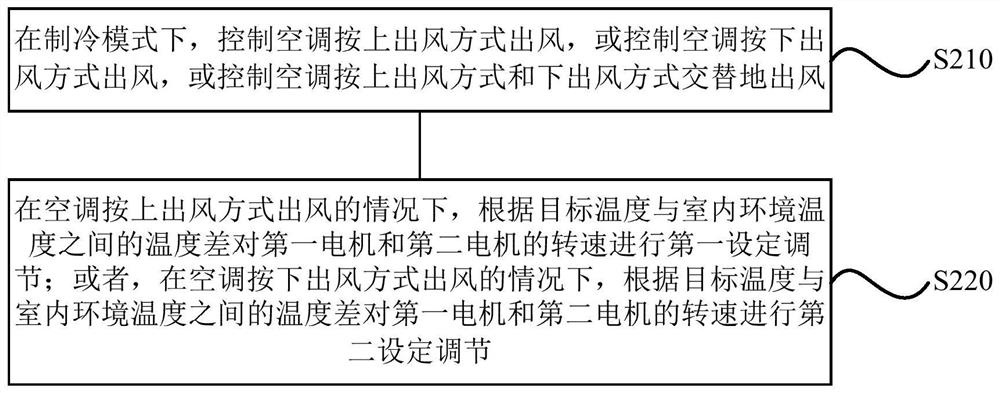

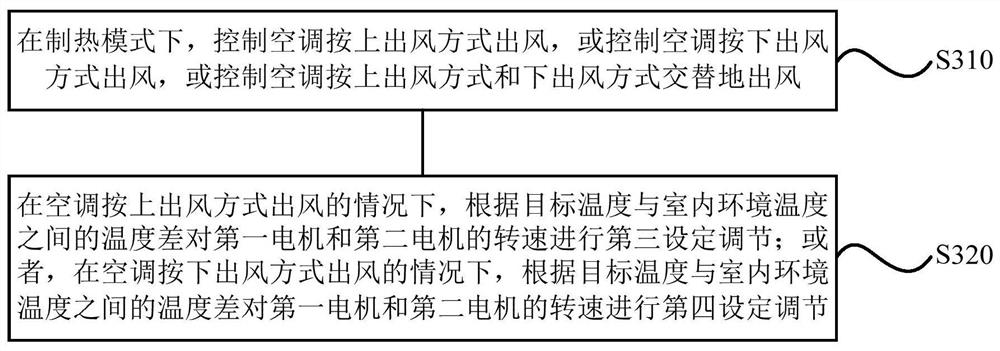

Air conditioner control method and device, computer readable storage medium and air conditioner

ActiveCN110887197ASpeed up heat exchangeUniform temperature distributionMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsProcess engineering

The invention discloses an air conditioner control method and device, a computer readable storage medium and an air conditioner. The method comprises the steps of obtaining the target temperature of the air conditioner and the indoor environment temperature in an environment to which the air conditioner belongs, and / or obtaining the target humidity of the air conditioner and the indoor environmenthumidity in the environment to which the air conditioner belongs, and / or obtaining the position of the human body in the environment to which the air conditioner belongs; according to an operation mode of the air conditioner, a temperature difference between the target temperature and the indoor environment temperature, a humidity difference between the target humidity and the indoor environmenthumidity, and / or the position of the human body, controlling an air supply mode of the air conditioner by adjusting the fan rotating direction of a double rotary axial fan assembly of the air conditioner, the number of started fans and / or the fan speed. According to the scheme, the problem that temperature distribution of a room is uneven due to the fact that the air supply mode of the cabinet airconditioner is single can be solved and the effect of improving the uniformity of the temperature distribution of the room is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

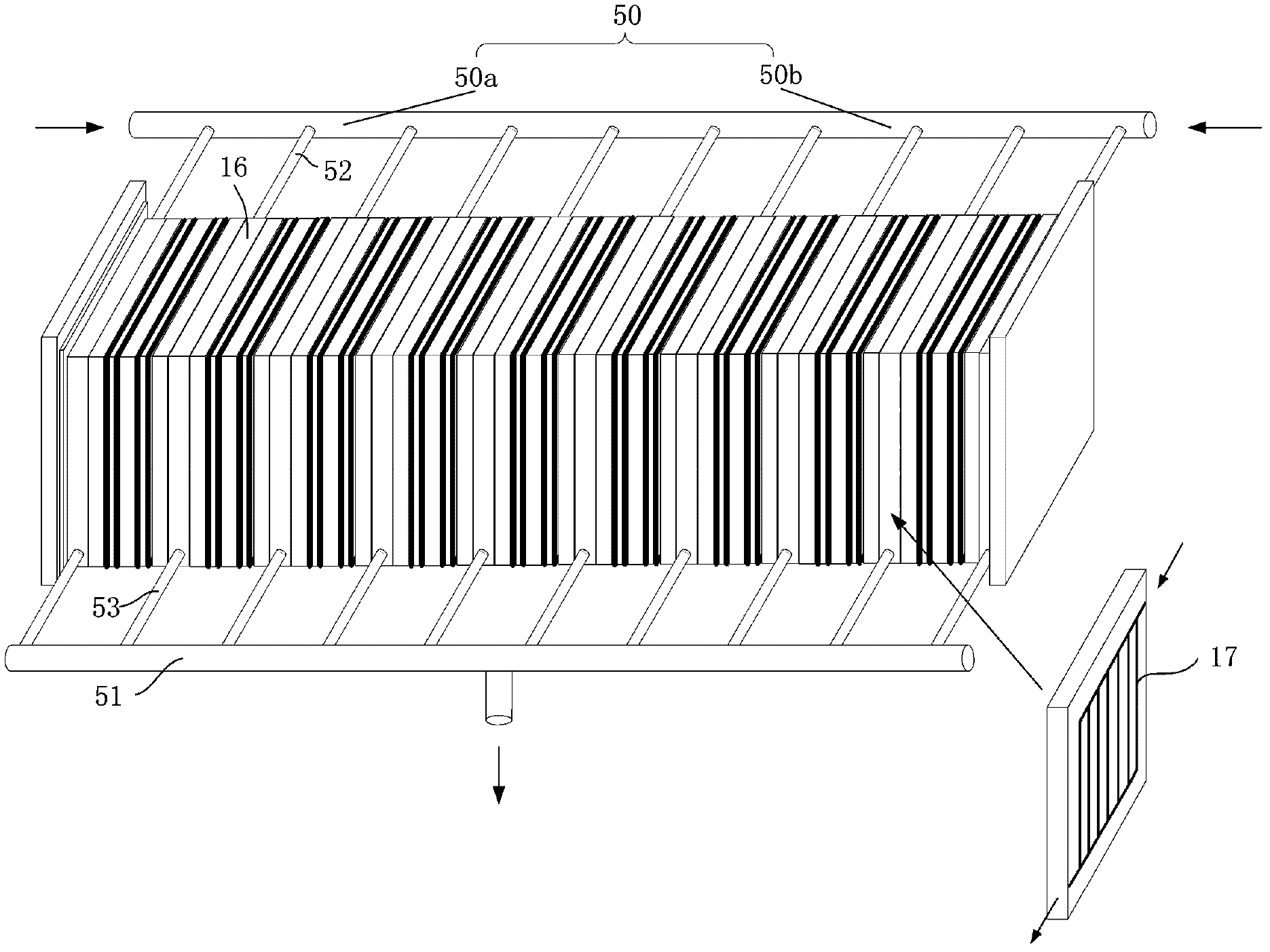

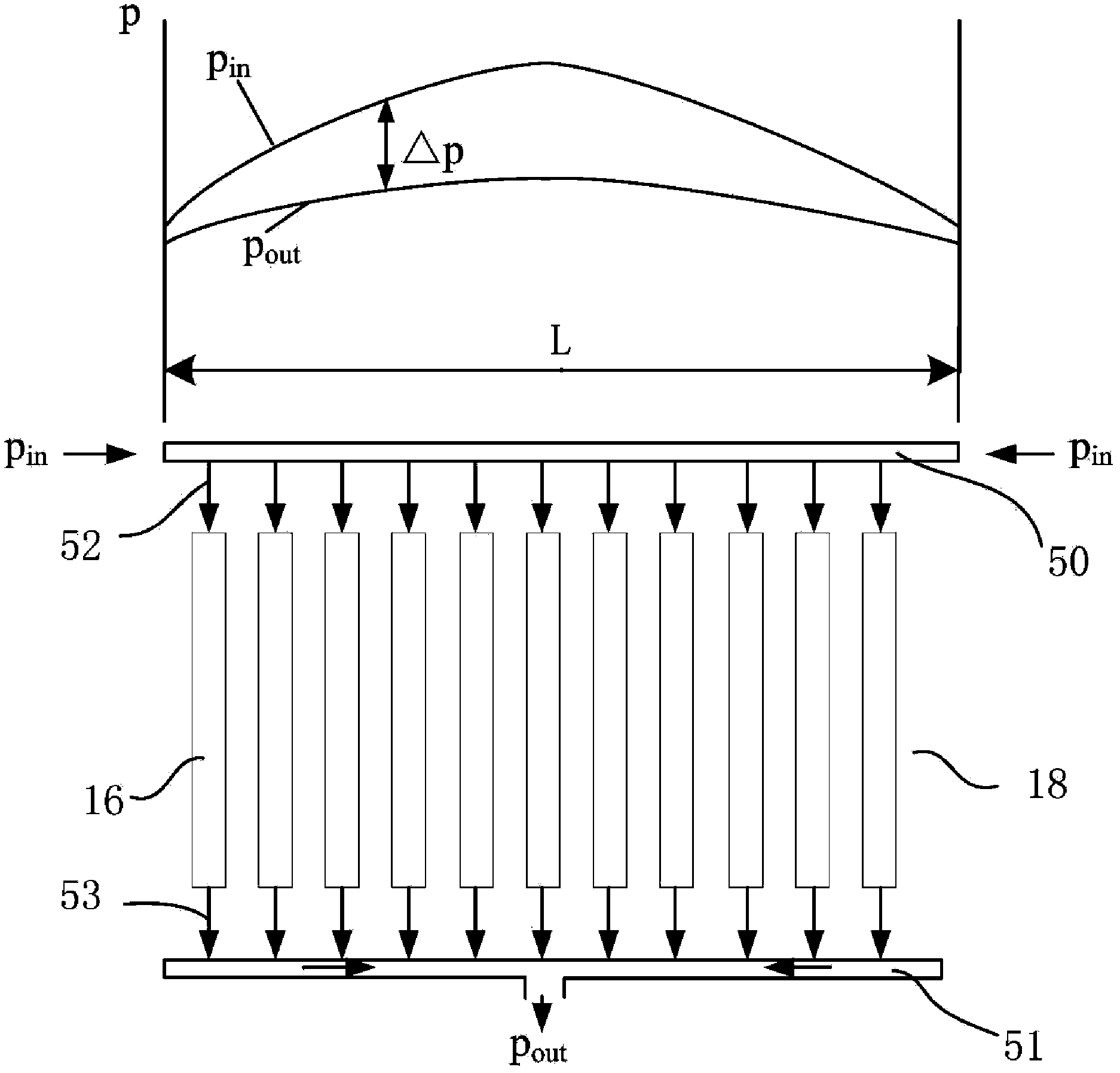

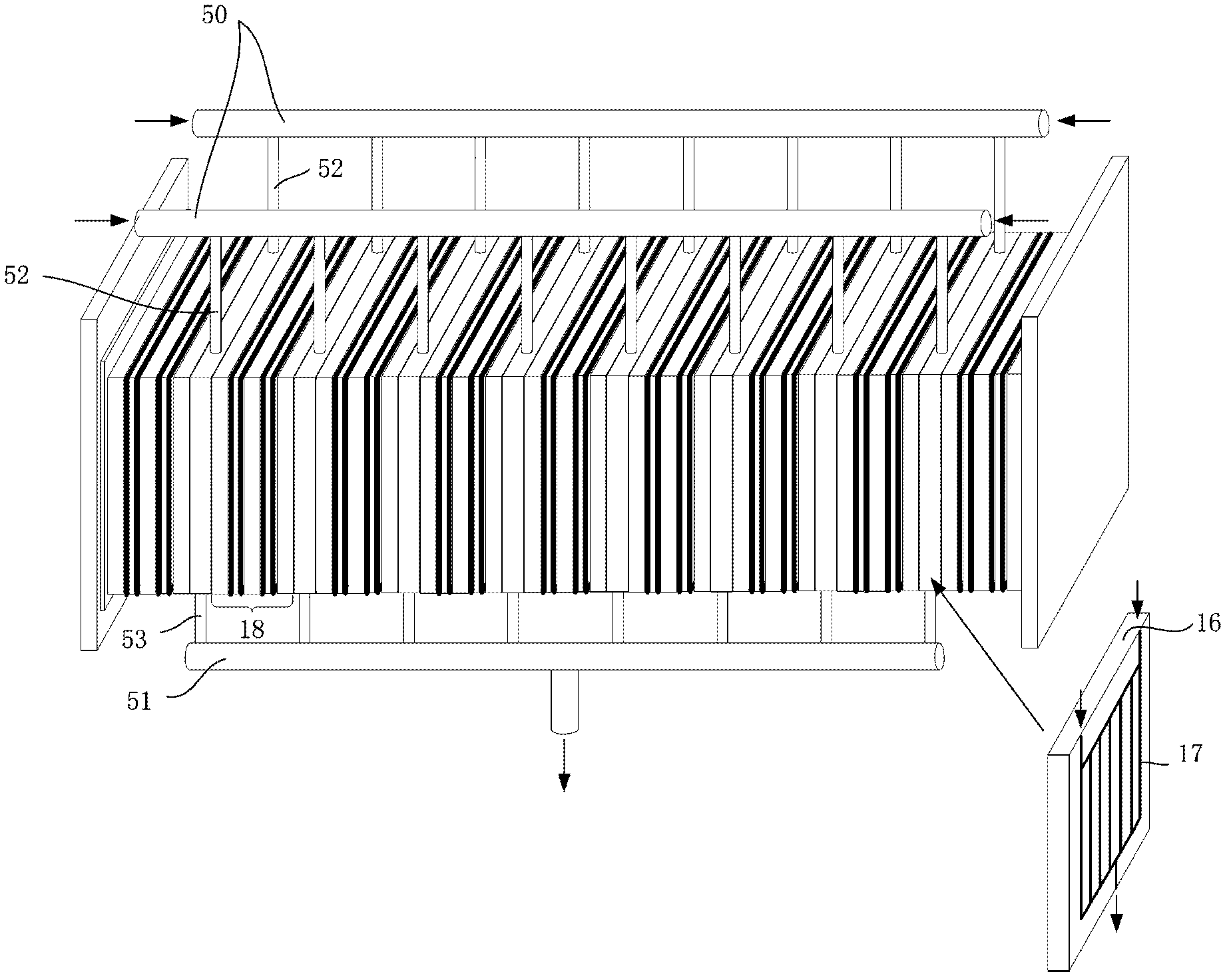

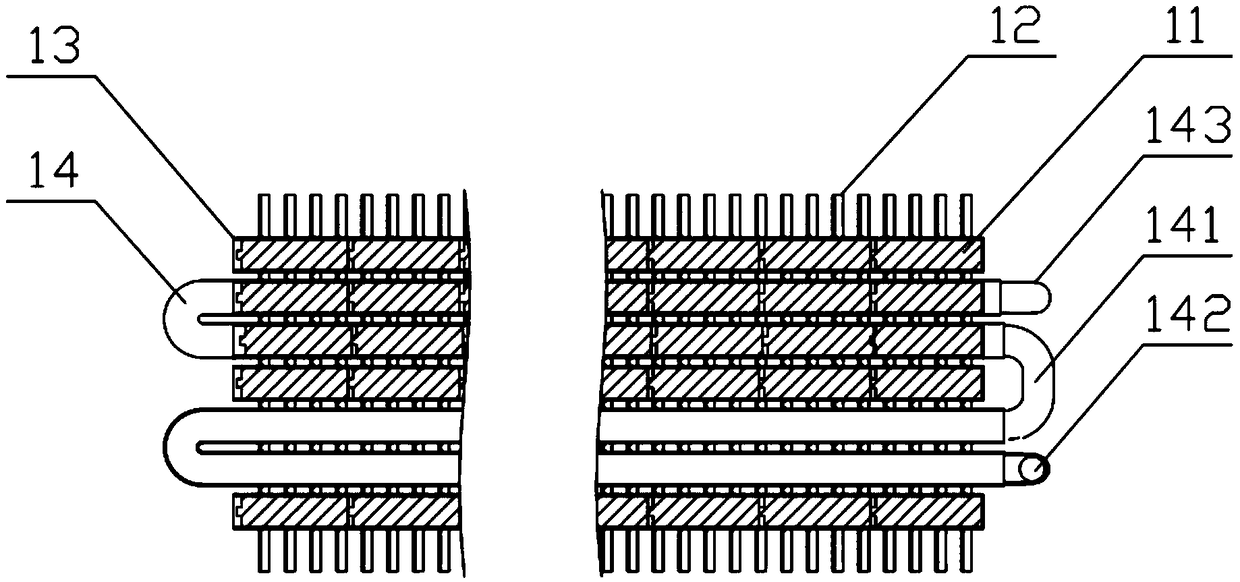

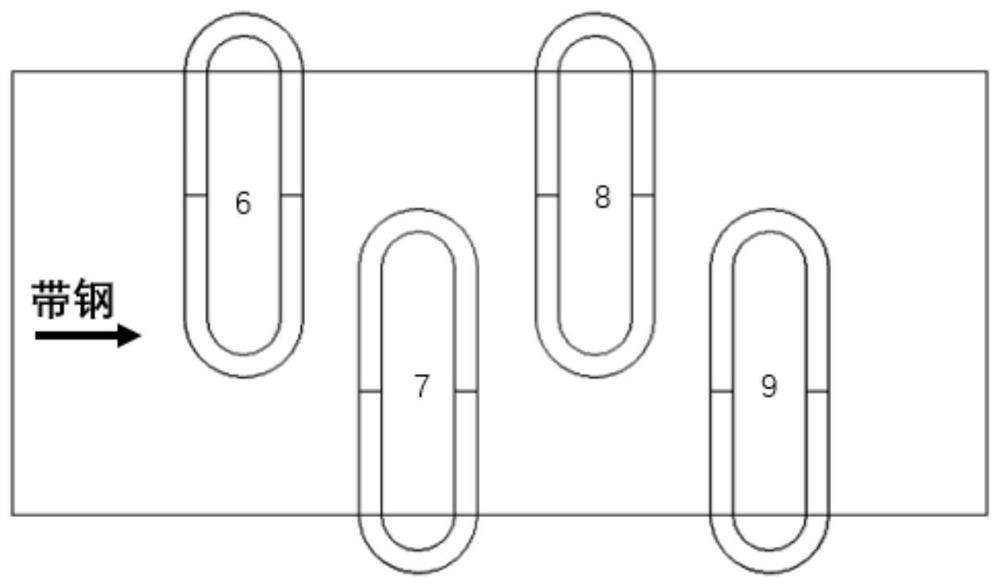

Cooling system and fuel cell stack

InactiveCN102637885AIncrease flow rateSolve uneven temperature distributionFuel cells groupingFuel cell auxillariesEngineeringFuel cells

The invention provides a cooling system and a fuel cell stack. The cooling system comprises a liquid inlet pipe, multiple liquid inlet branch pipes, a liquid outlet pipe and multiple liquid outlet branch pipes, wherein the liquid inlet pipe comprises a liquid inlet main pipe which is provided with liquid inlets at an upstream end, the liquid inlets are arranged at two ends of the liquid inlet main pipe, the multiple liquid inlet branch pipes are connected between the liquid inlet main pipe and a fuel cell stack body; the liquid outlet pipe is provided with a liquid outlet at a downstream end, the liquid outlet is arranged at the middle part of the liquid outlet pipe; and multiple liquid outlet branch pipes are connected between the liquid outlet main pipe and the fuel cell stack body, wherein the liquid outlet is connected with the liquid inlets through a circulation loop so as to form a cooling circulation loop of the fuel cell. The cooling system and the fuel cell stack provided by the invention can effectively solve the problem of uneven temperature distribution between a single battery of a fuel stack end plate and a single battery of a middle position in the prior art.

Owner:中国东方电气集团有限公司

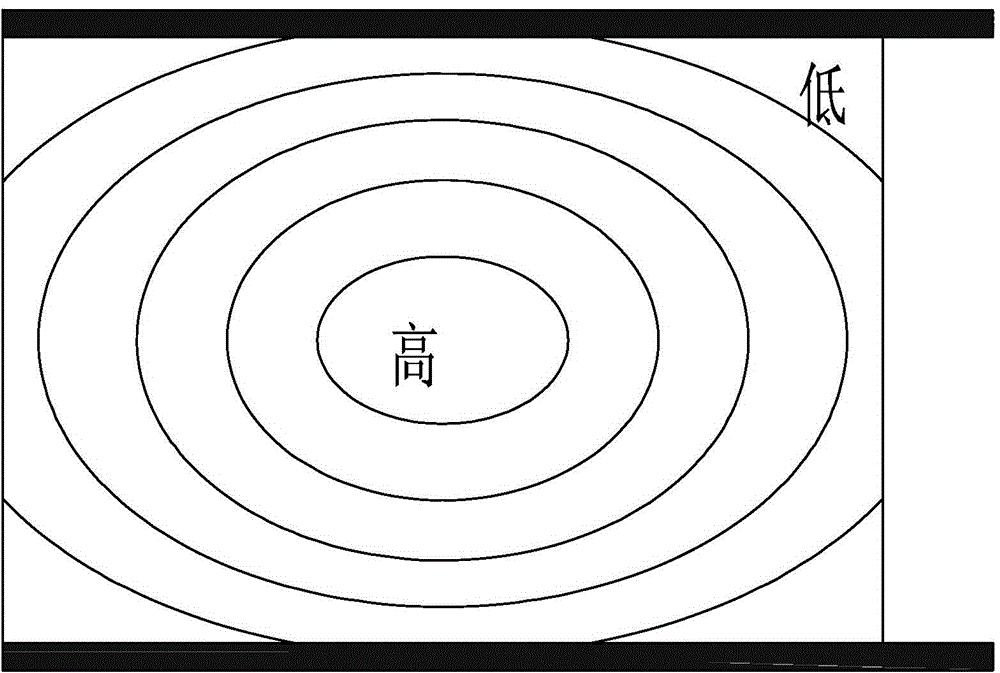

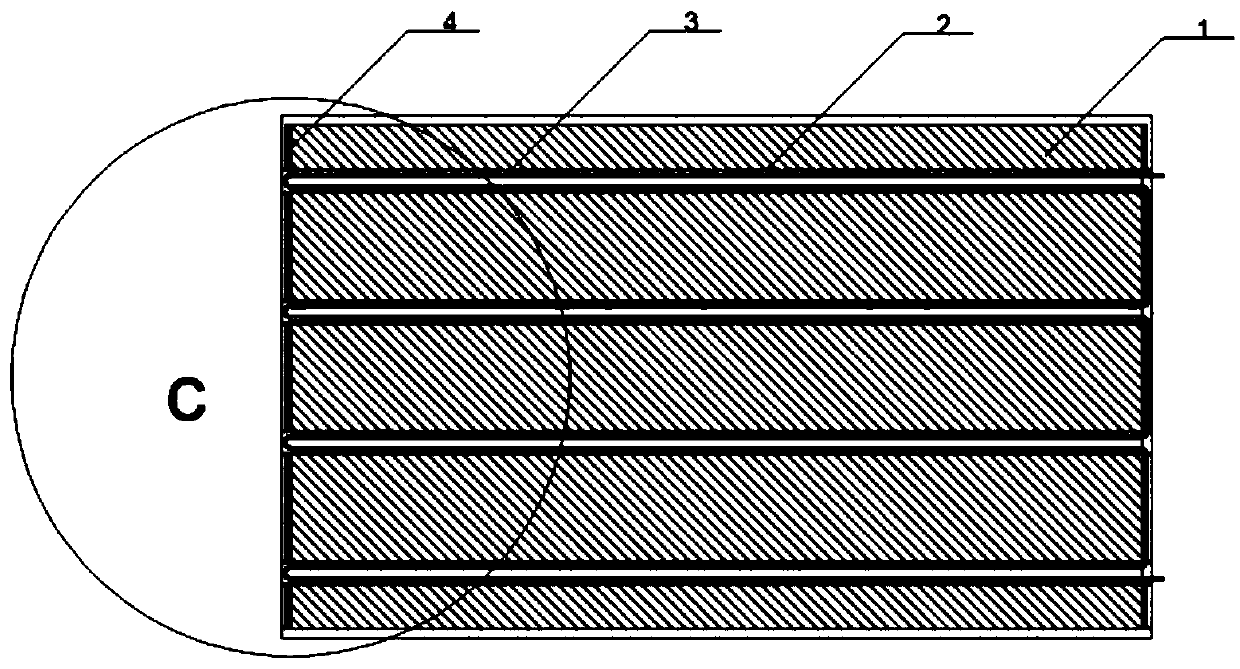

Heater made from screen mesh thin film and manufacturing method thereof

InactiveCN103607796ASolve for uniformityReduce usageHeating element materialsNon-linear opticsWire gauzeLiquid-crystal display

The invention discloses a heater made from a screen mesh thin film and a manufacturing method of the heater. The heater comprises an electrode strip, a conductive clad layer and a substrate material. The substrate material is coated with the conductive clad layer. The electrode strip is connected to the conductive clad layer. A plurality of openings are etched into the conductive clad layer so that the screen mesh thin film can be formed on the conductive clad layer, wherein the wire diameter of the screen mesh thin film ranges from 5 micrometers to 30 micrometers, and the aperture ratio of the screen mesh thin film is above 80%. The manufacturing method of the heater comprises the following steps that the substrate material is coated with the conductive clad layer, and then the multiple openings are formed in the conductive clad layer in an exposure etching mode so that the screen mesh thin film can be formed on the conductive clad layer. According to the heater made from the screen mesh thin film, the surface resistance distribution of a conductive surface of the heater is controlled through adjustment of the screen mesh thin film, so that the heating uniformity of a liquid crystal display screen at a low temperature is realized; on one hand, the usage of an auxiliary heating membrane is avoided; on the other end, the solution also can well solve the problem of temperature maldistribution for a liquid crystal display screen with a large area.

Owner:中航华东光电有限公司

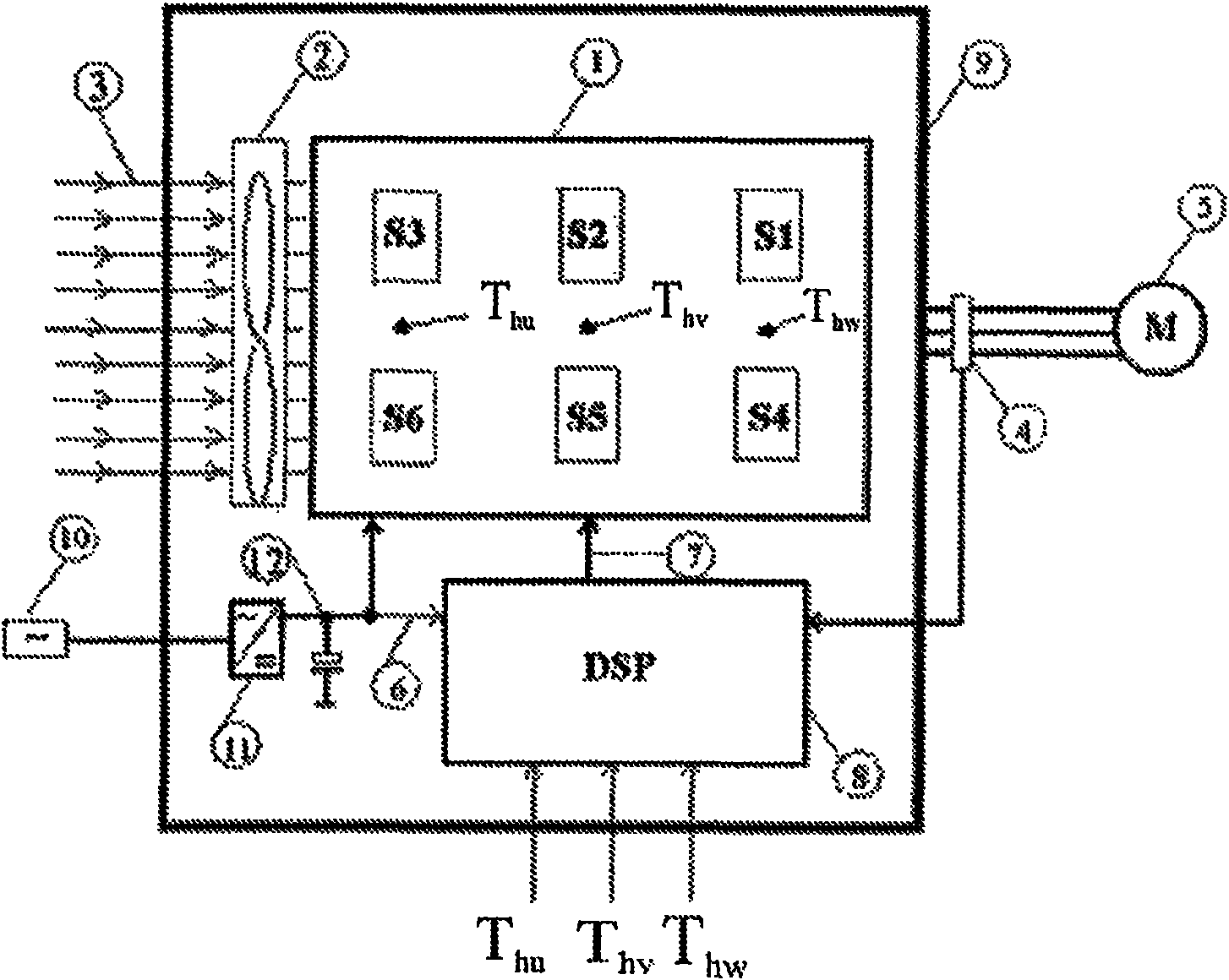

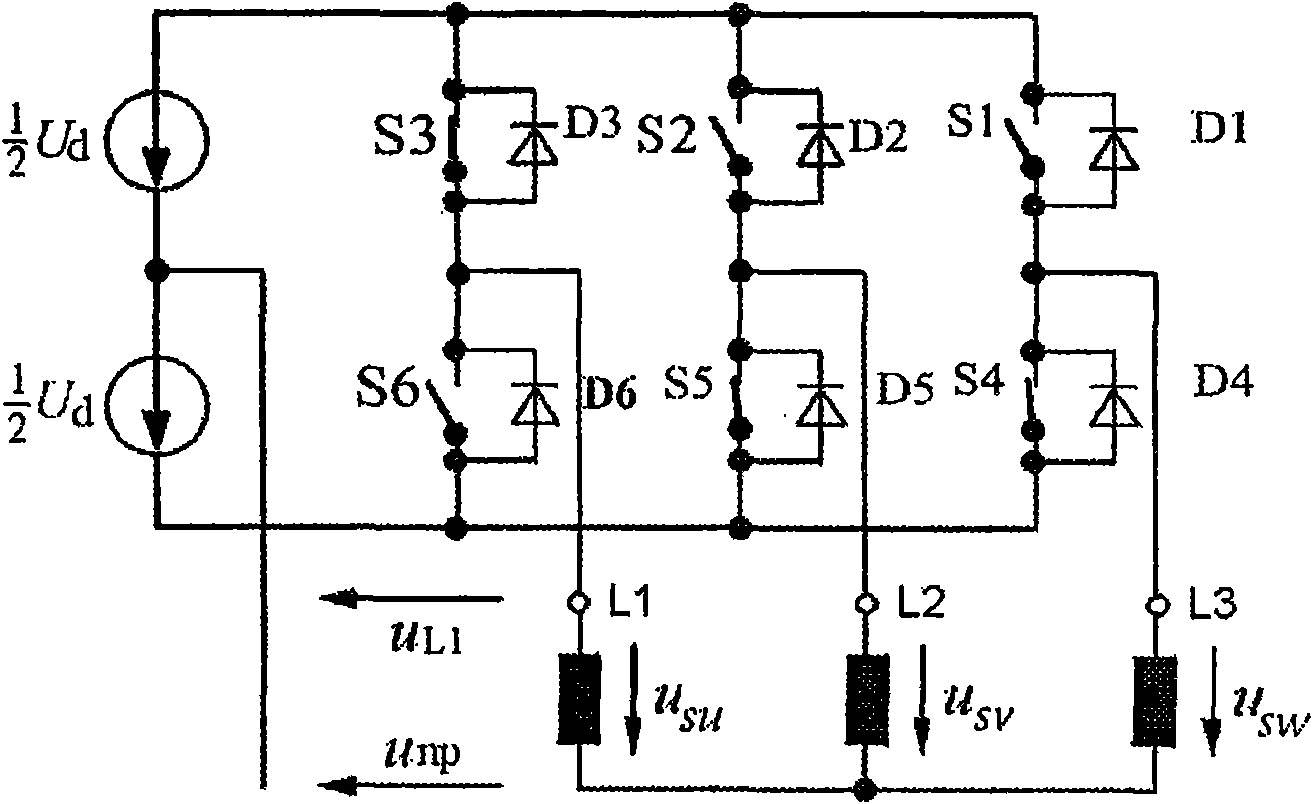

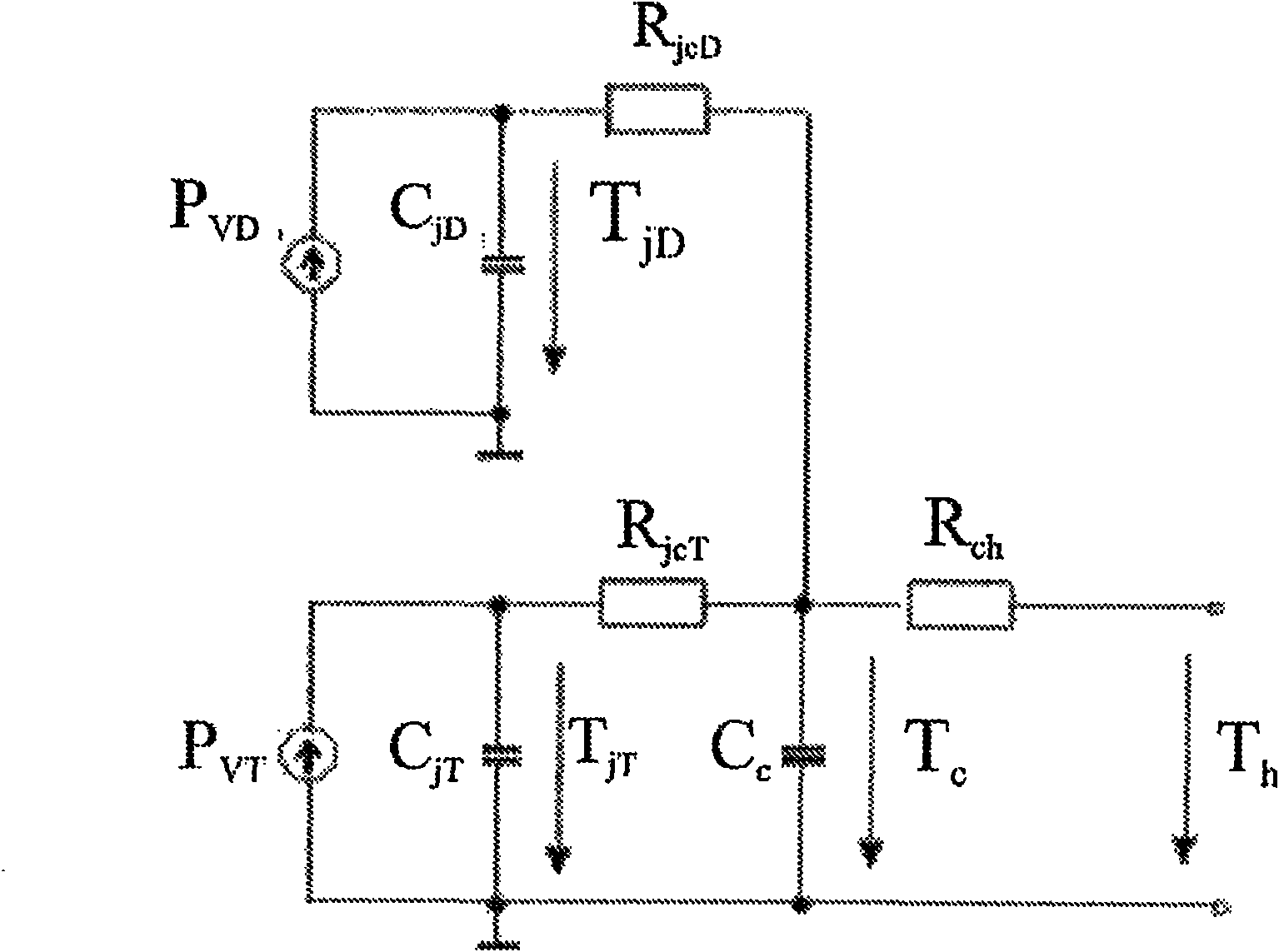

Temperature monitoring for circuit breakers

ActiveCN101681179ASolve uneven temperature distributionThe temperature is precisely determinedConversion constructional detailsTemperature control using electric meansTemperature monitoringElectric drive

The invention relates to a method for determining and / or monitoring the temperatures of at least two electronic power switches, particularly semiconductor circuit breakers, which are coupled to or arranged on a common cooling body, wherein the temperature determination and / or monitoring occurs based on a temperature model associated with a switch each, switch and operating parameters and temperature measurement values being processed in said model for calculating the temperature and / or a temperature difference inside the respective switch, wherein a temperature measurement value from a temperature sensor is used as an input parameter for the temperature model, the sensor being disposed spatially at the center between the at least two switches and having a heat-transmitting connection to the cooling body. The invention further relates to an electronic power temperature-providing switch arrangement, particularly converters for electric drives or other converters, for performing the method according to any one of the preceding claims.

Owner:BAUMULLER NURNBERG GMBH

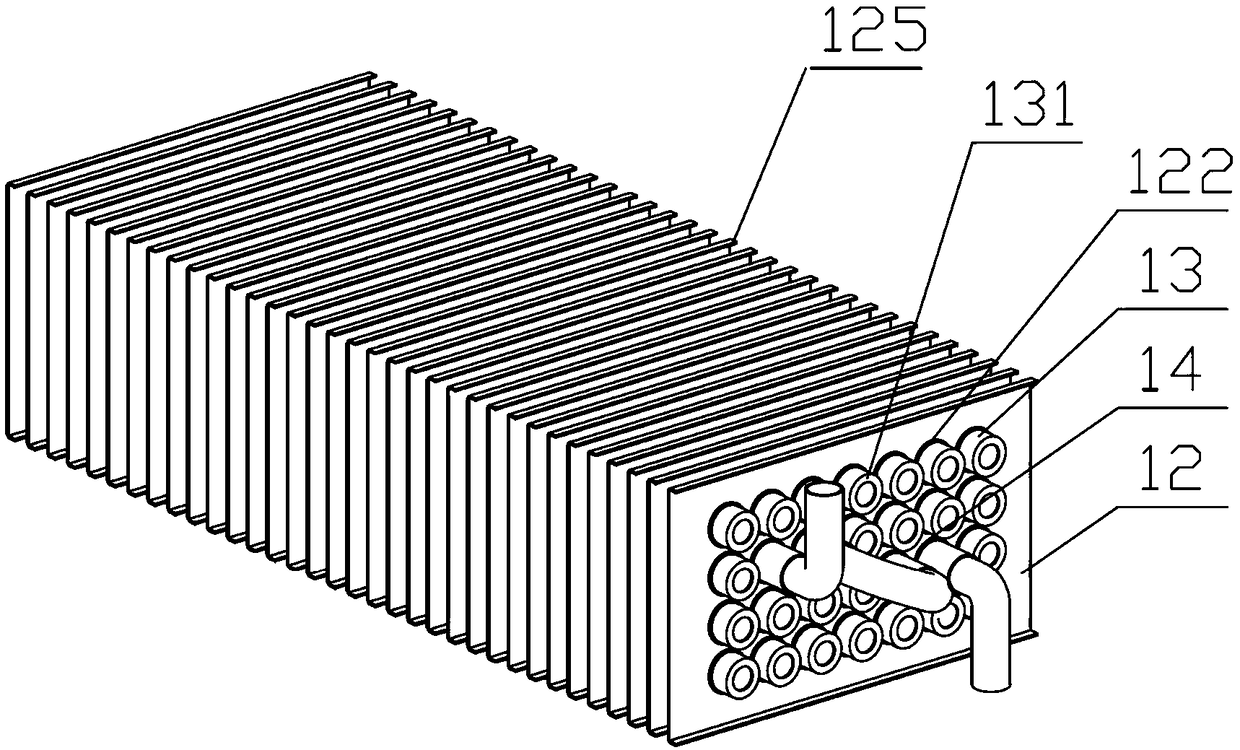

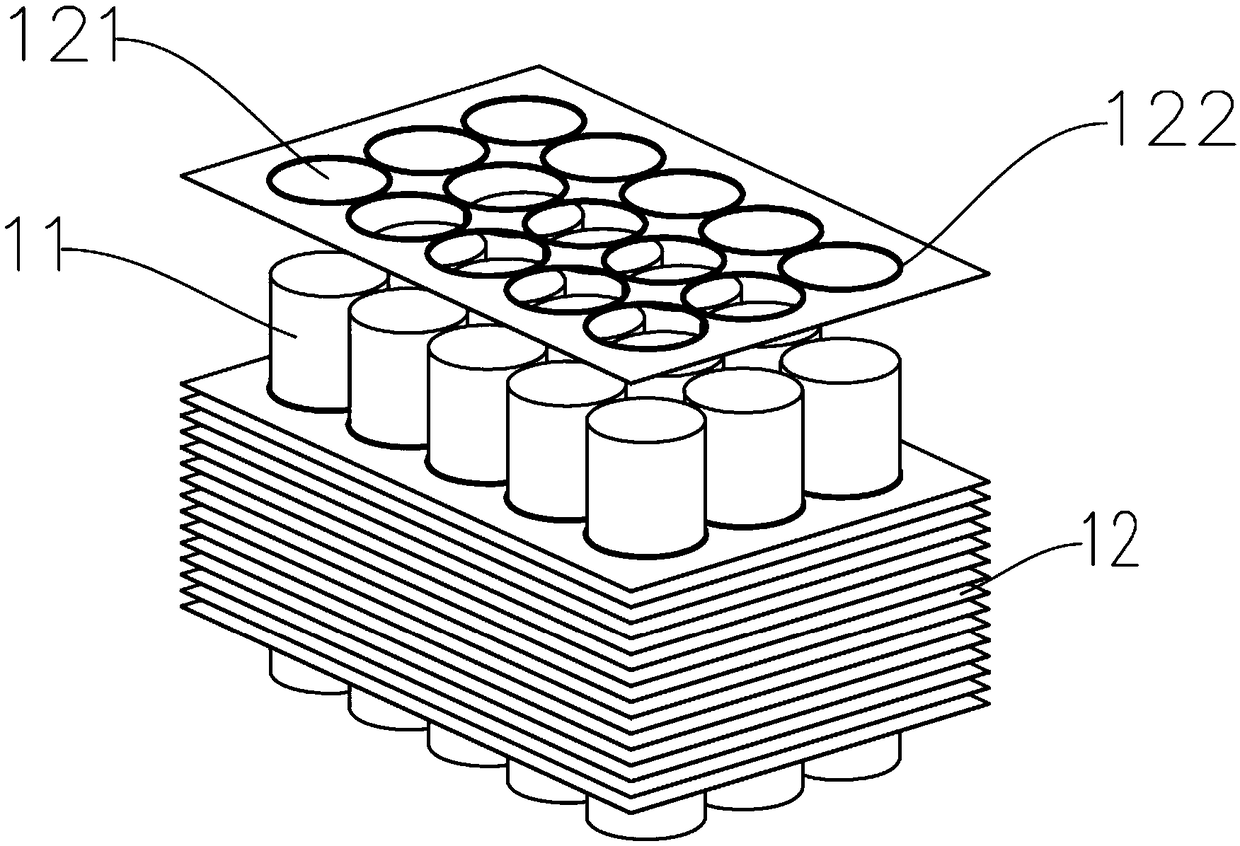

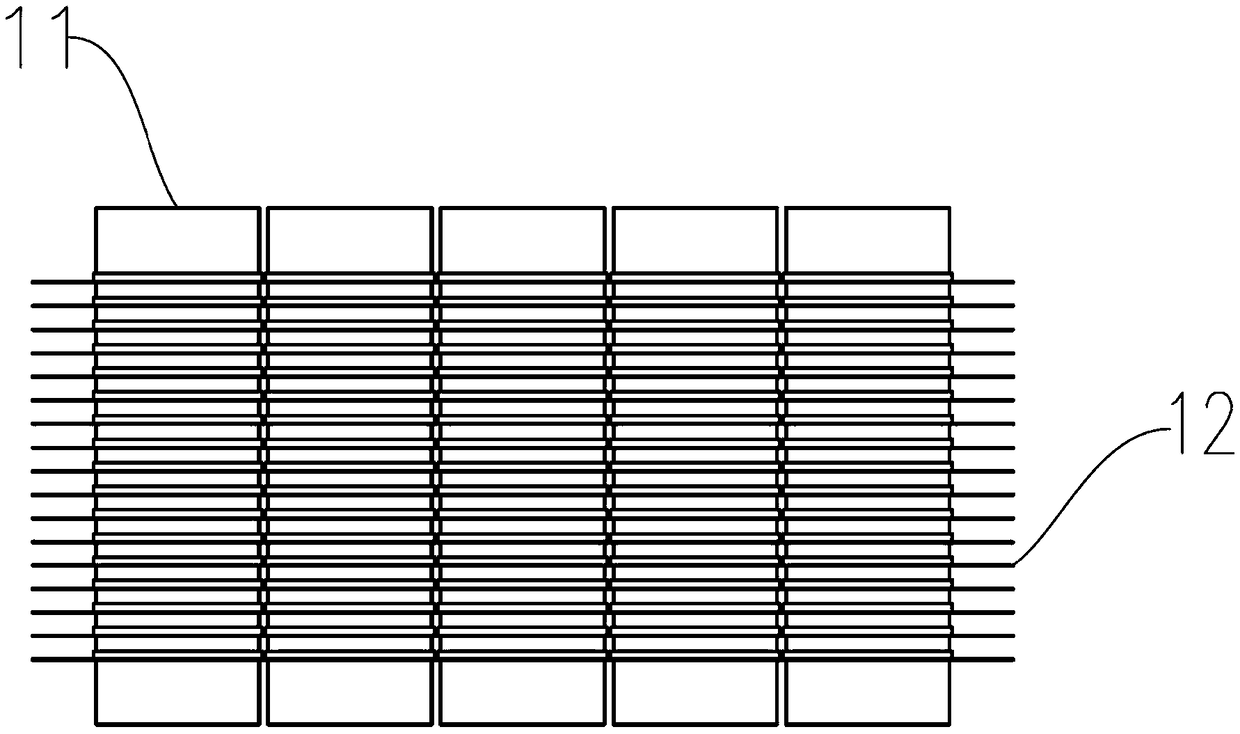

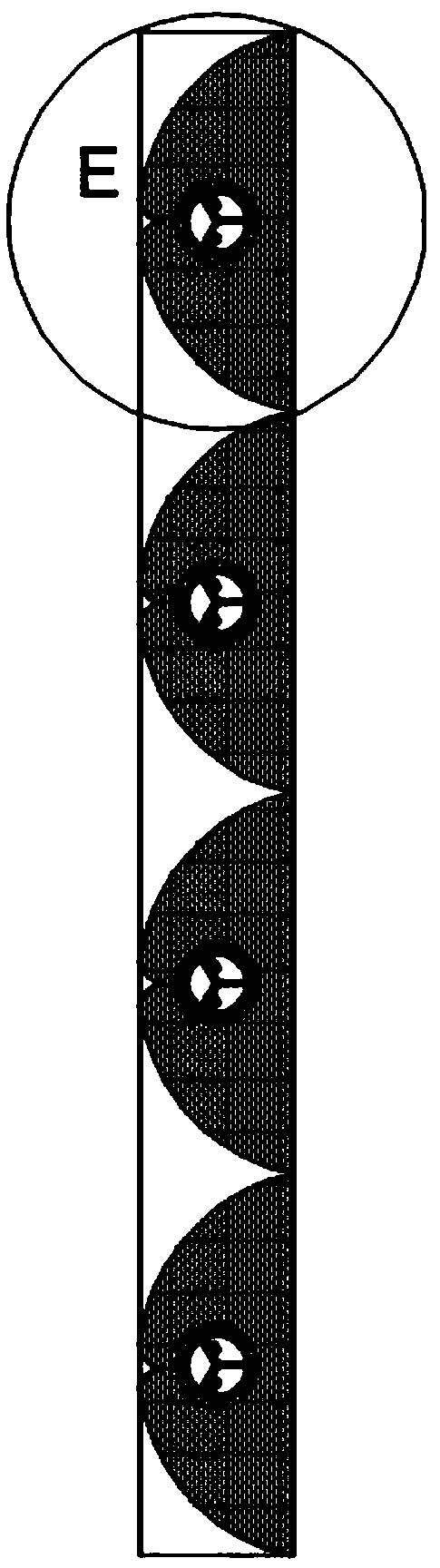

A through-tube fin type cylindrical battery module

PendingCN109004245AGuaranteed cooling effectSolve uneven temperature distributionFuel cell heat exchangeTemperature controlBattery thermal management

The invention relates to the technical field of battery thermal management, in particular to a tube-through fin type cylindrical battery module, including a battery sleeve, a cylindrical battery and afin group, the fin group is composed of a plurality of fins arranged in parallel, The fin is provided with an assembly circular hole matched with the battery sleeve, the battery sleeve vertically passes through and is mounted in the assembly circular hole of each fin and is matched with the fin, the inner diameter of the battery sleeve is matched with the outer diameter of the cylindrical battery, and the cylindrical battery is connected end to end in series and installed in the battery sleeve. The invention can solve the problems that the temperature field distribution of a cylindrical battery pack arranged horizontally and connected in series to form a pack is uneven and part of the non-specific area is overheated in the prior art. The battery module has higher specific energy density,and can meet the requirements of good temperature uniformity, temperature control performance and low cost, light weight and manufacturability.

Owner:马海云

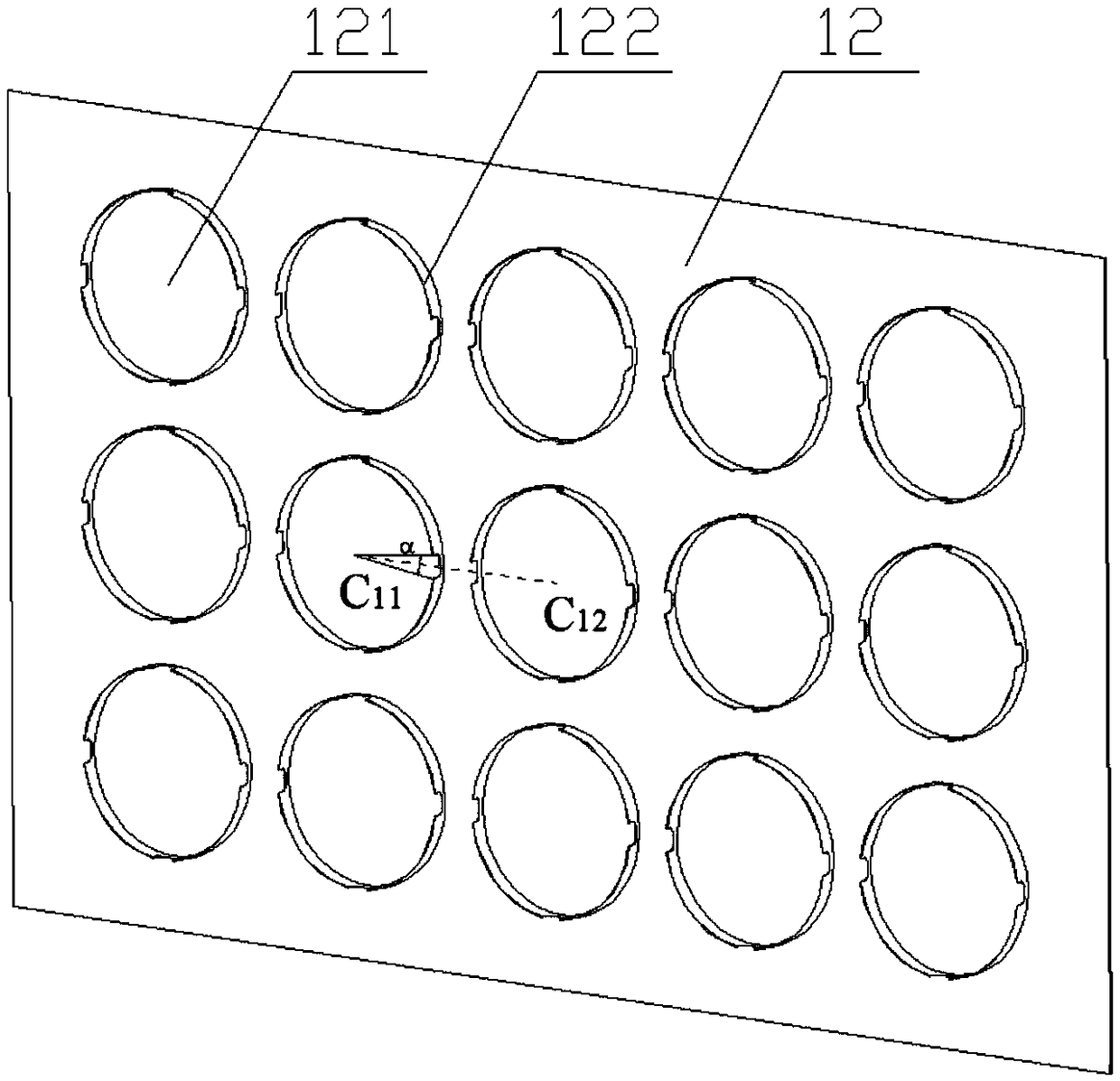

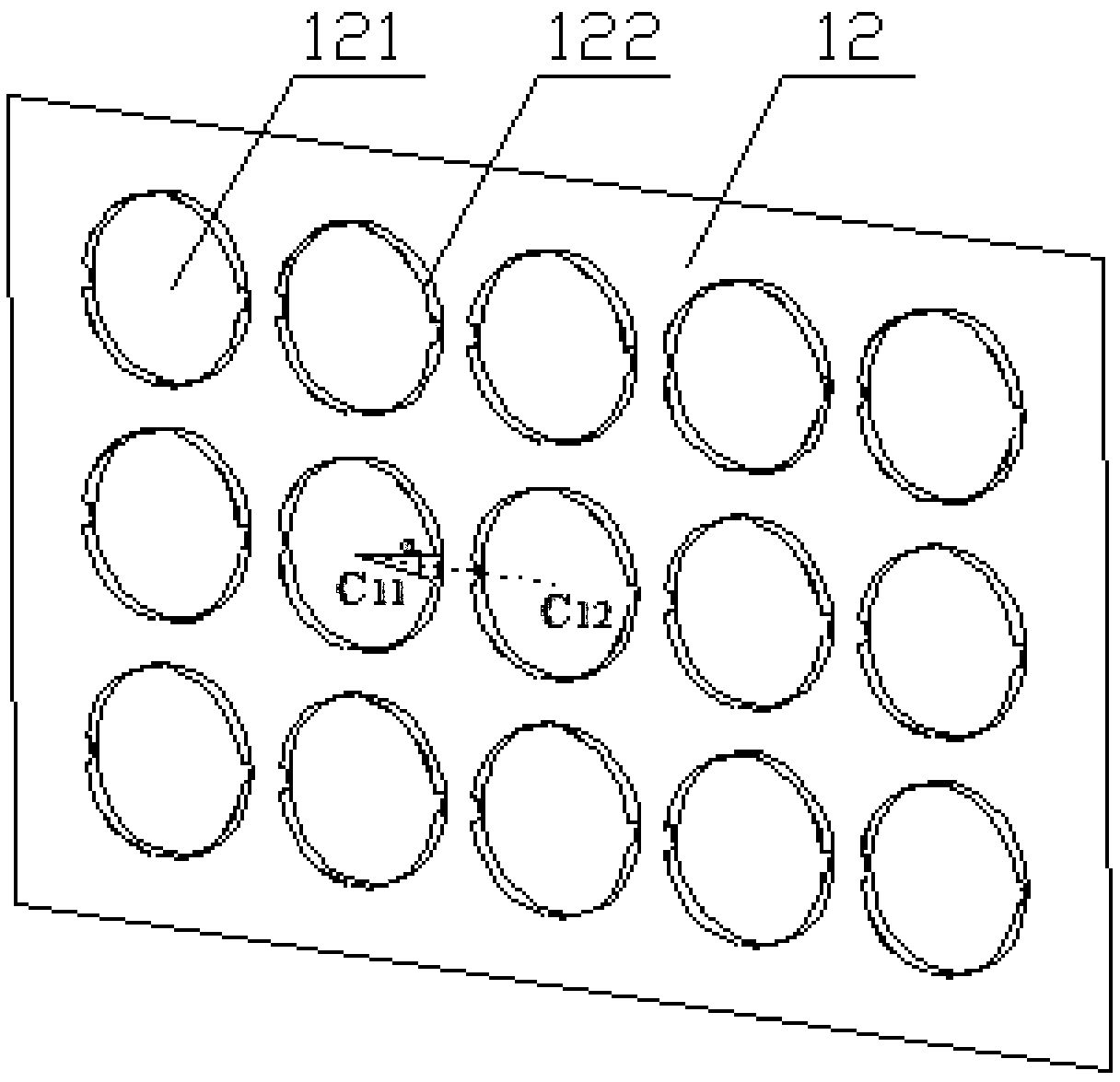

Fin perforation type cylindrical battery pack, battery pack assembly and battery pack array

PendingCN109004302AImprove performanceExtend your lifeSecondary cells servicing/maintenanceTemperature controlState of art

The invention relates to the technical field of battery thermal management, in particular to a fin perforation type cylindrical battery pack, includomg a plurality of cylindrical cells and a fin group, The fin group is composed of a plurality of fins arranged in parallel, and the fin is provided with a plurality of assembly holes matched with the shape and size of the plurality of cylindrical cells, the edges of the assembly holes extend outward to form flanged edges with a certain height, and the plurality of cylindrical cells vertically penetrate the assembly holes on the fins and are matched with the flanged edges. The invention can solve the problems that the temperature field distribution of the cylindrical battery pack in the prior art is uneven and the part of the non-specific areais overheated, and can meet the requirements of good temperature uniformity, temperature control performance and low cost, light weight and manufacturability.

Owner:马海云

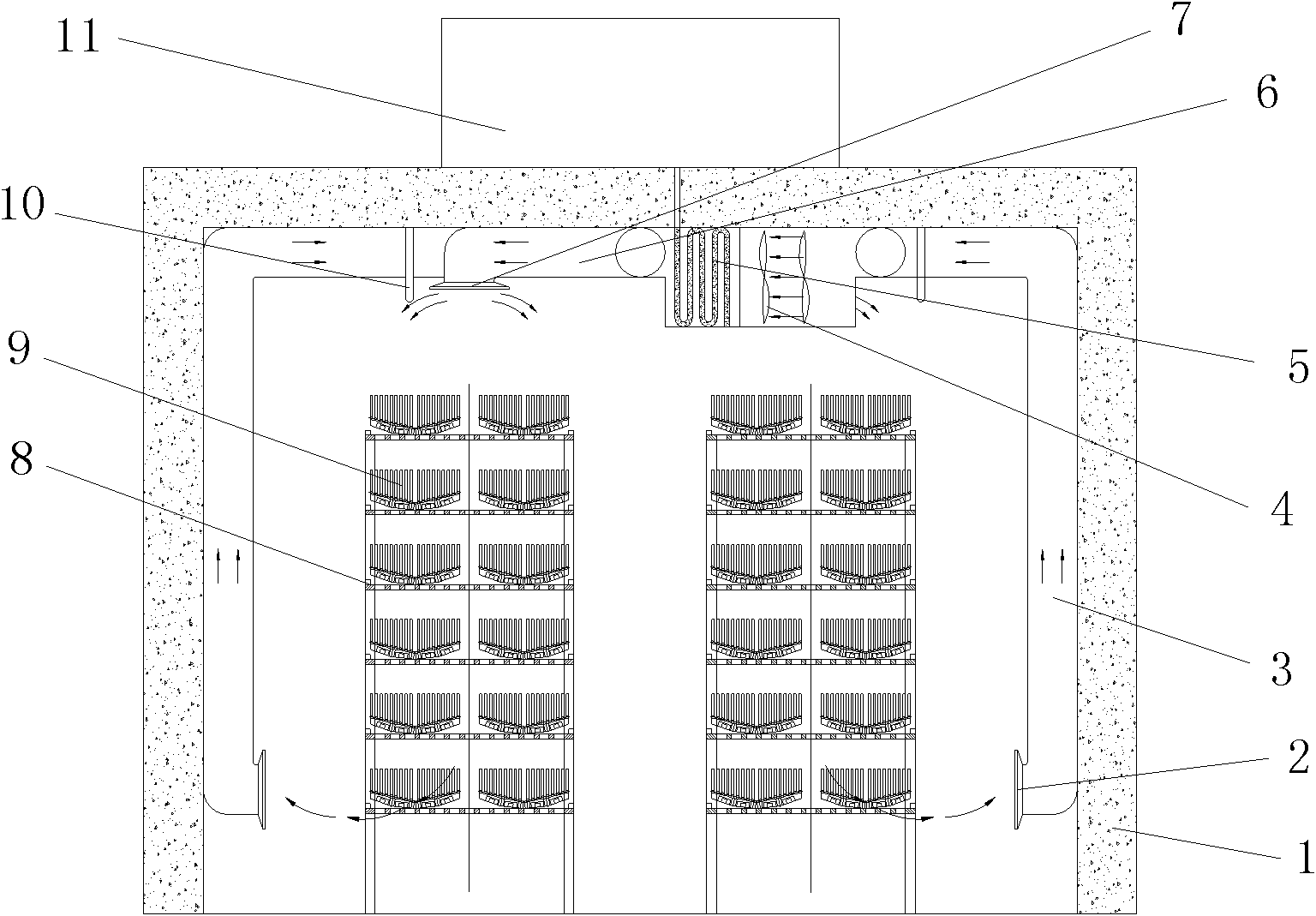

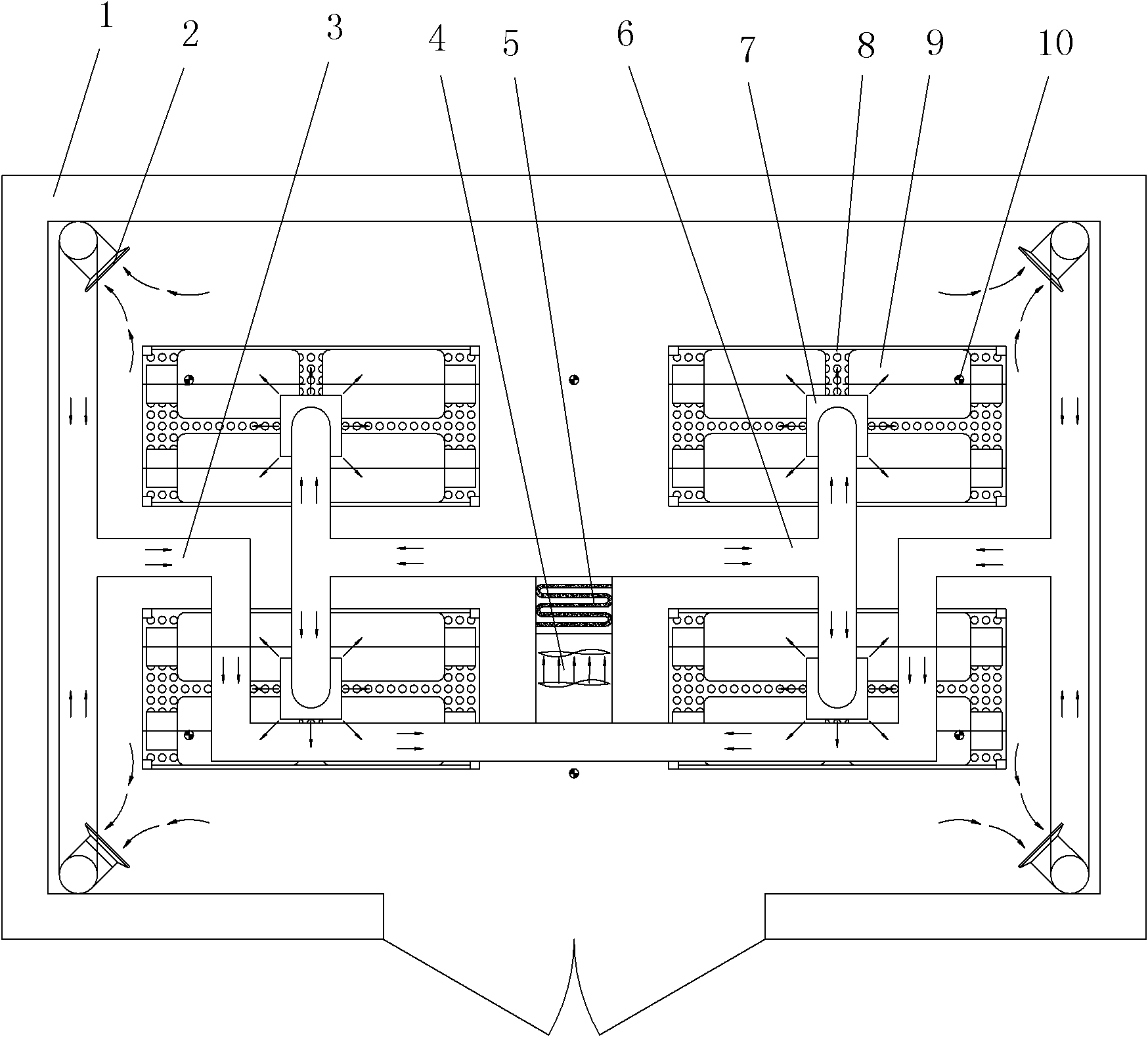

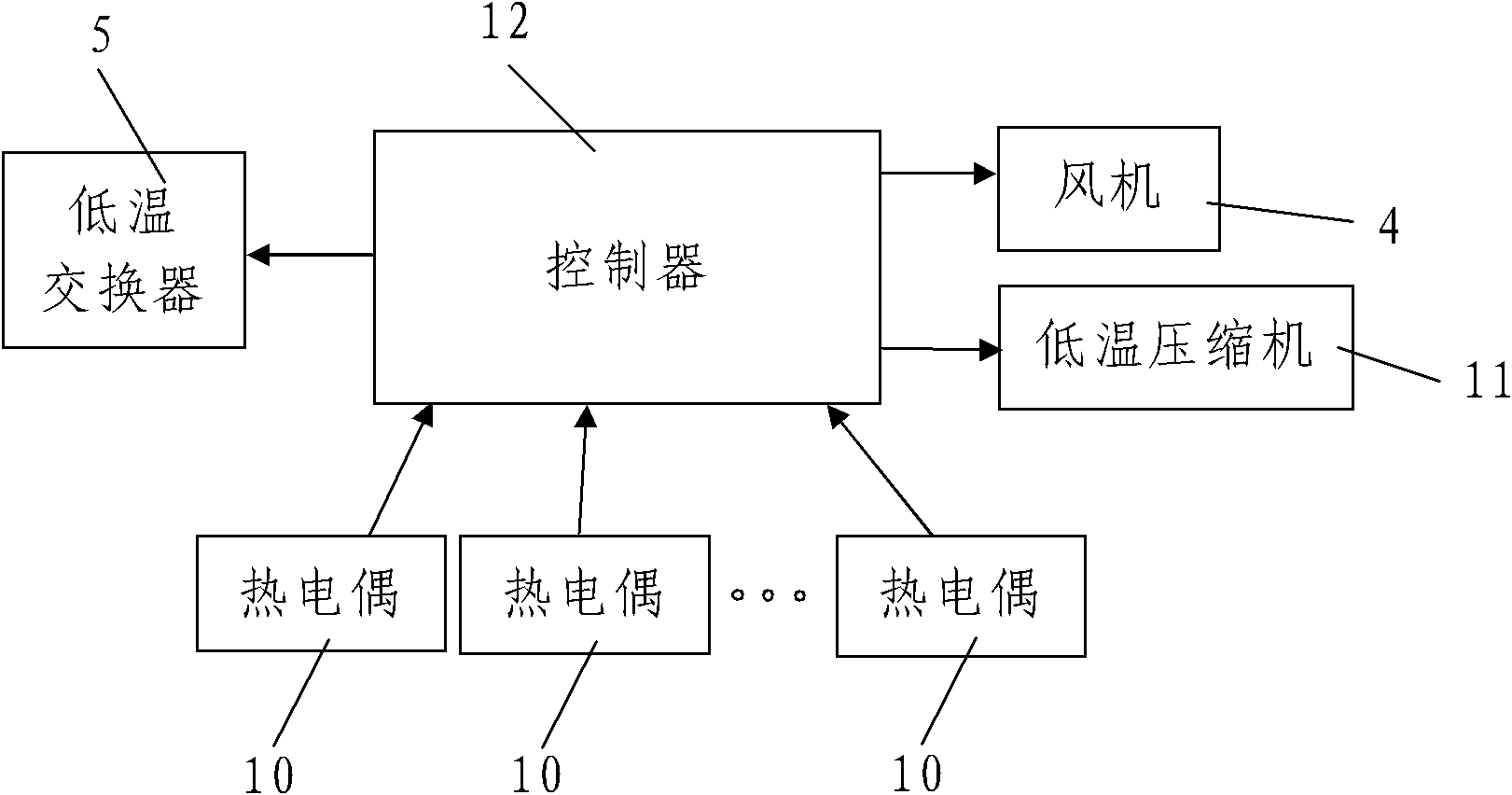

LED (light-emitting diode) street lamp low temperature environment aging room

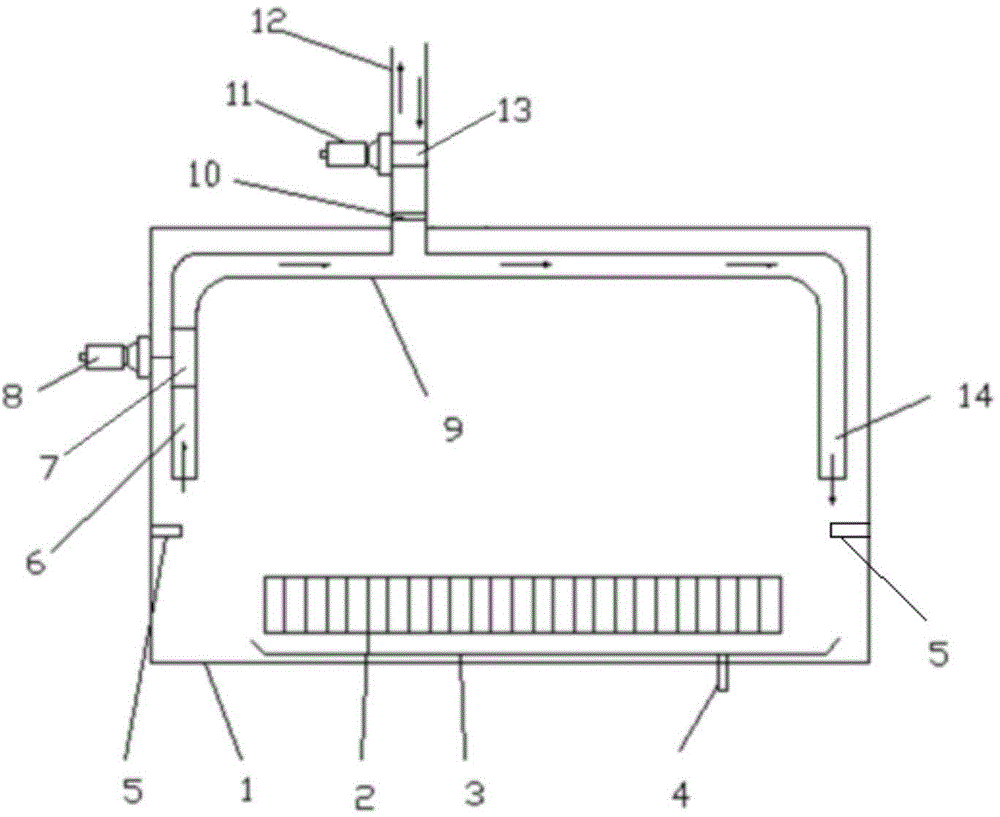

InactiveCN102486321ASimple structureLow costDucting arrangementsSpace heating and ventilation safety systemsAirflowReturn channel

The invention discloses an LED (light-emitting diode) street lamp low temperature environment aging room. The LED street lamp low temperature environment aging room comprises an aging room body, an air-circulating channel which is used for continually circulating to introduce cold air to an aging region in the aging room body, a controller and multiple temperature-detecting devices, wherein the air-circulating channel comprises a low temperature exchanger, a low temperature compressor, a fan, a cold air inlet channel, and an air return channel, wherein the low temperature exchanger is arranged above the middle of the aging room body, the low temperature compressor is connected with a low temperature exchanger, the cold air inlet channel is used for leading cooling draft acquired by the low temperature exchanger after low temperature exchange to successively introduce the aging region through multiple cold air inlets, the air return channel is used for absorbing air in the aging region under the action of the fan to the side of the low temperature exchanger so as to carry out low temperature exchange through multiple air return ports, and the cold air inlet channel is communicated with the air return channel through a communicating pipe. The low temperature environment aging room provided by the invention has the advantages of simple structure, is easy to operate, is low in cost and has good using effects, and can be used for effectively solving a temperature maldistribution problem in the aging region through adjusting the refrigeration states of the low temperature exchanger and the low temperature compressor and the shutter states of air inlets and the air return ports.

Owner:XIAN DAYU PHOTOELECTRIC TECH

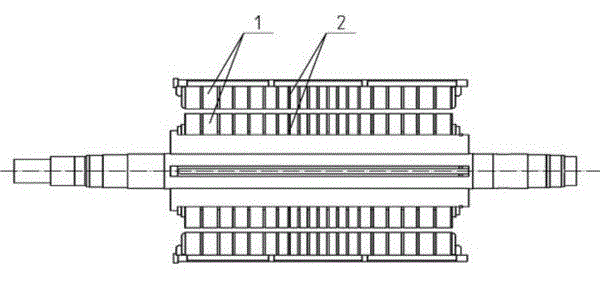

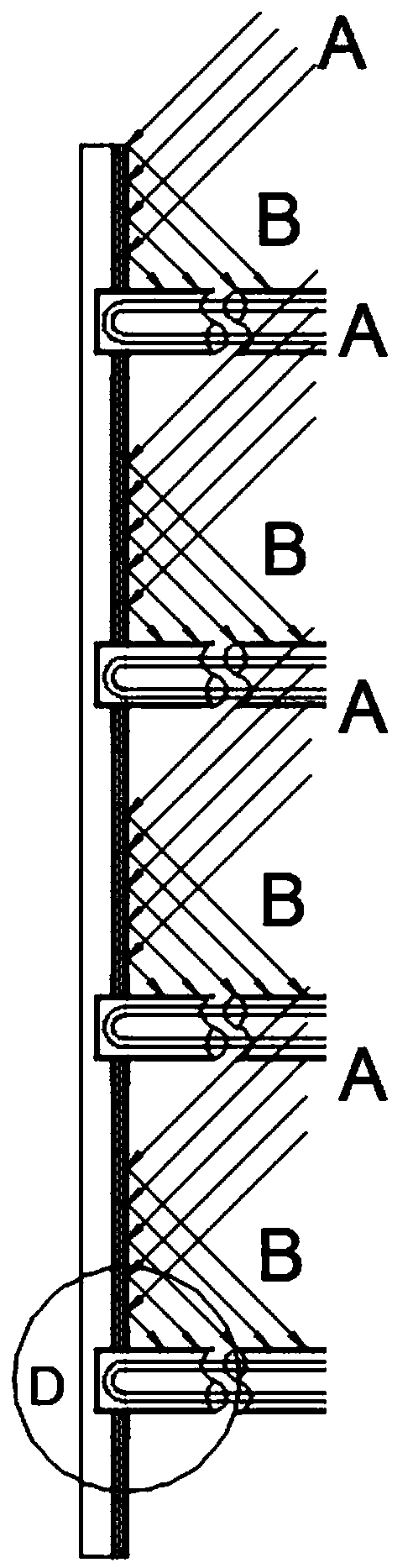

Unequal interval symmetrical ventilating ducts for stators and rotors of air and water-cooled wind driven generator

InactiveCN102983644AImprove heat transfer capacitySolve uneven temperature distributionMagnetic circuit rotating partsMagnetic circuit stationary partsWind drivenDynamo

The invention discloses unequal interval symmetrical ventilating ducts for stators and rotors of an air and water-cooled wind driven generator. Iron cores of stators and iron cores of rotors are in a segmented press fitting structure, lengths of all segments of iron cores are symmetrically distributed in such a way that lengths are shortened gradually from end portions to middle portions, ventilating groove plates are arranged among adjacent iron cores to form ventilating ducts, widths of ventilating ducts for stators and rotors are consistent, and ventilating ducts are aligned after iron cores of stators and rotors are mounted in a pressing mode. The unequal interval symmetrical ventilating ducts have the advantages that the unequal interval symmetrical ventilating duct structure is adopted, so that the heat exchange capability of middle portions of iron cores, which is poor originally, is greatly improved, and the problems that original iron cores are uneven in temperature distribution in axis directions and the temperature of middle portions is too high are solved.

Owner:DALIAN TIANYUAN ELECTRICAL MACHINERY

Method for reducing defect generation in SiC crystal growth

ActiveCN106245110ASolve uneven temperature distributionReduced hexagonal void defectsPolycrystalline material growthFrom condensed vaporsAdhesiveGas phase

The invention relates to a method for reducing defect generation in SiC crystal growth. Further improvement is made on the basis of silicon carbide single crystal growth by common physical vapor transport technique, and the method includes: (1) preparing graphite glue; (2) applying the graphite glue uniformly to a seed crystal non-growth surface and a bonding surface of a graphite plate with single-side blade, then overlapping the graphite glue coated two surfaces together, and bonding the graphite plate and the seed crystal well with as few graphite glue as possible; and (3) performing heating to cure the graphite glue. The method provided by the invention solves the problem that the thermal conductivity difference between air vents and a high temperature carbonized adhesive can result in non-uniform temperature distribution on the back of the seed crystal, reduces the hexagonal cavity defect caused by back evaporation in the process of crystal growth, and greatly improves the quality and yield of silicon carbide crystals.

Owner:HEBEI SYNLIGHT CRYSTAL CO LTD

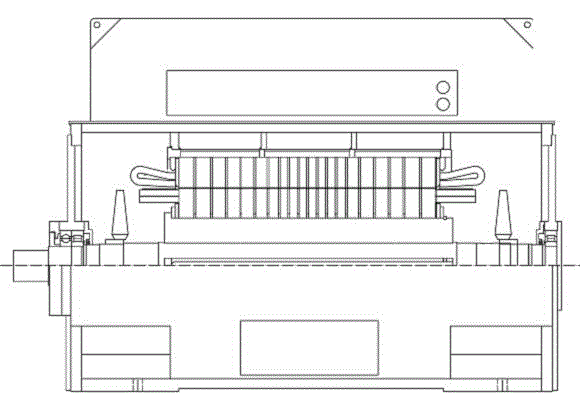

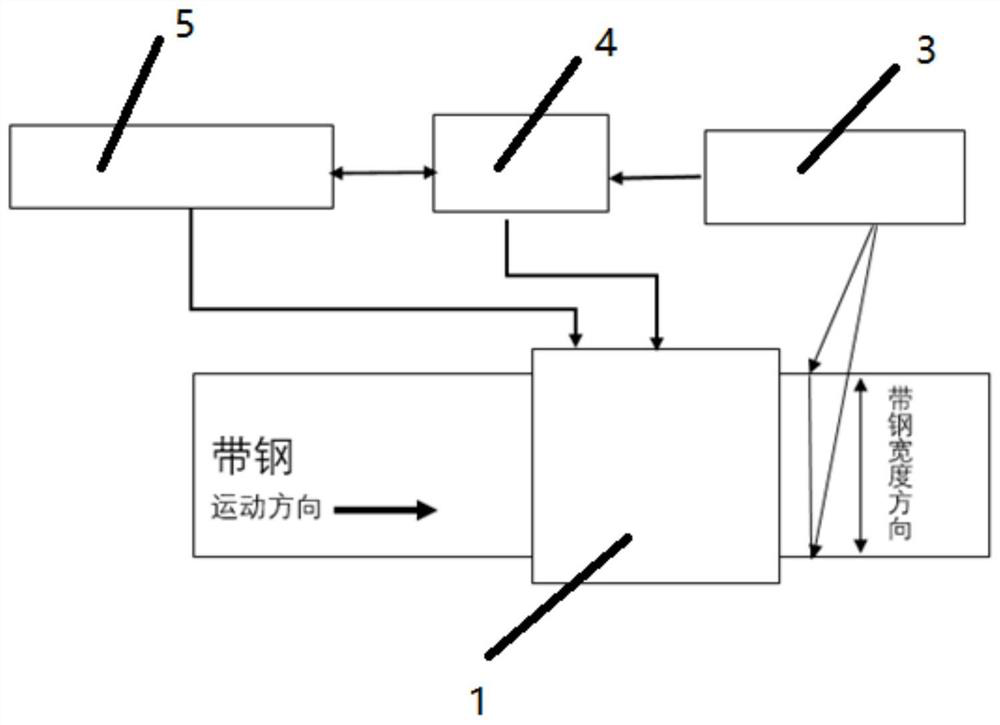

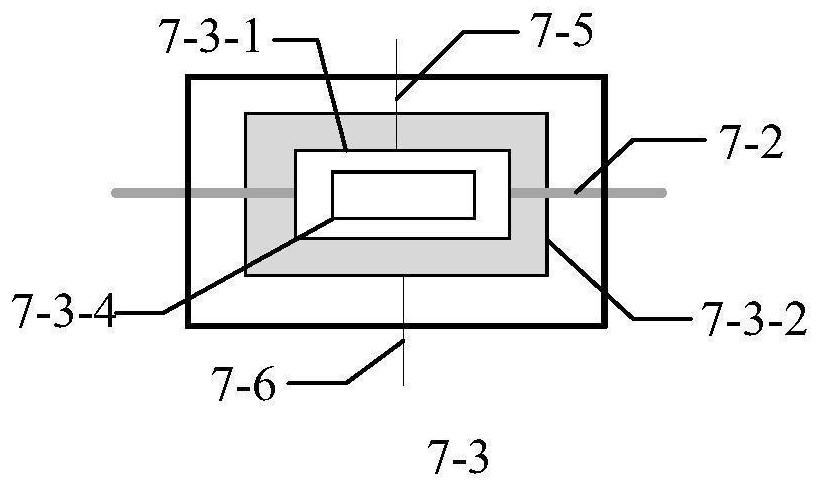

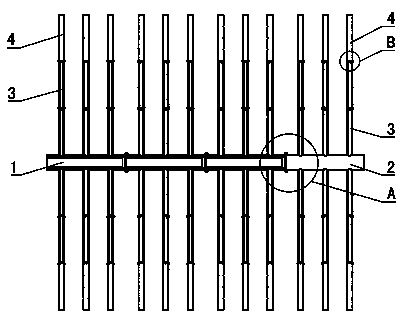

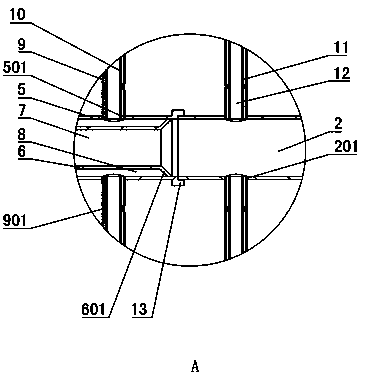

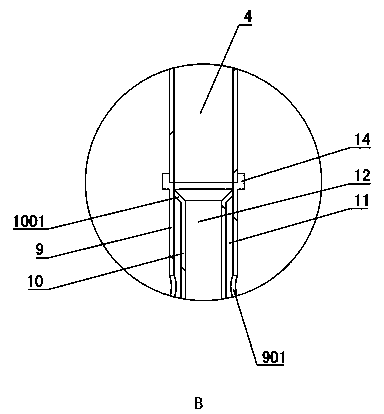

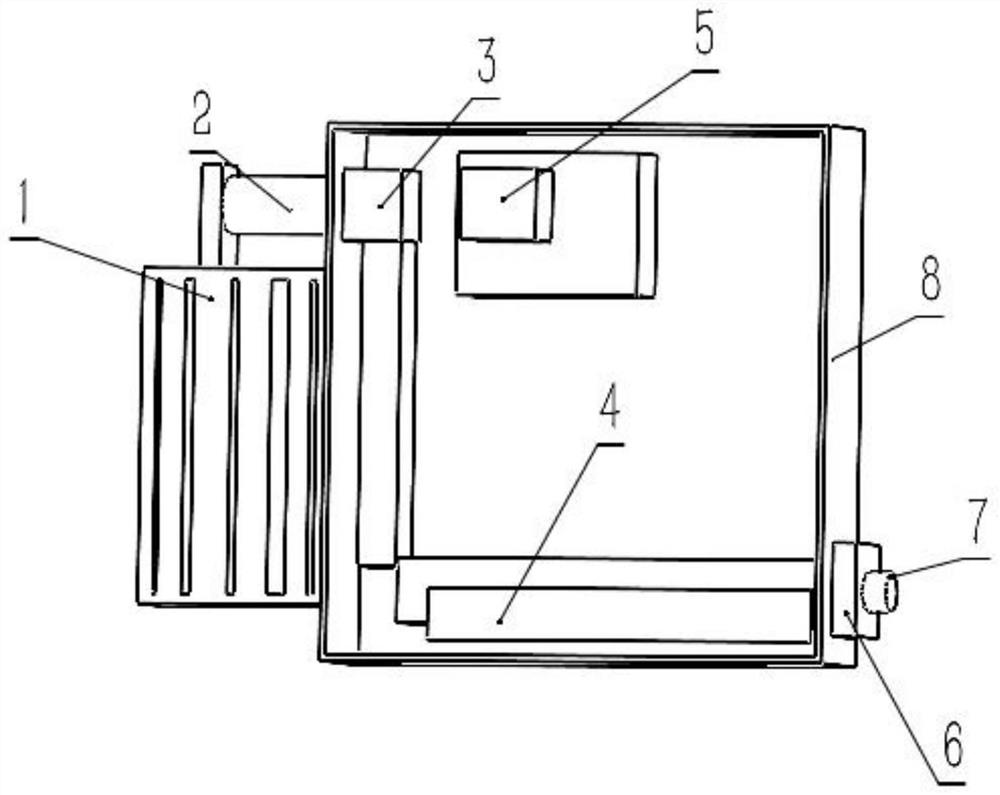

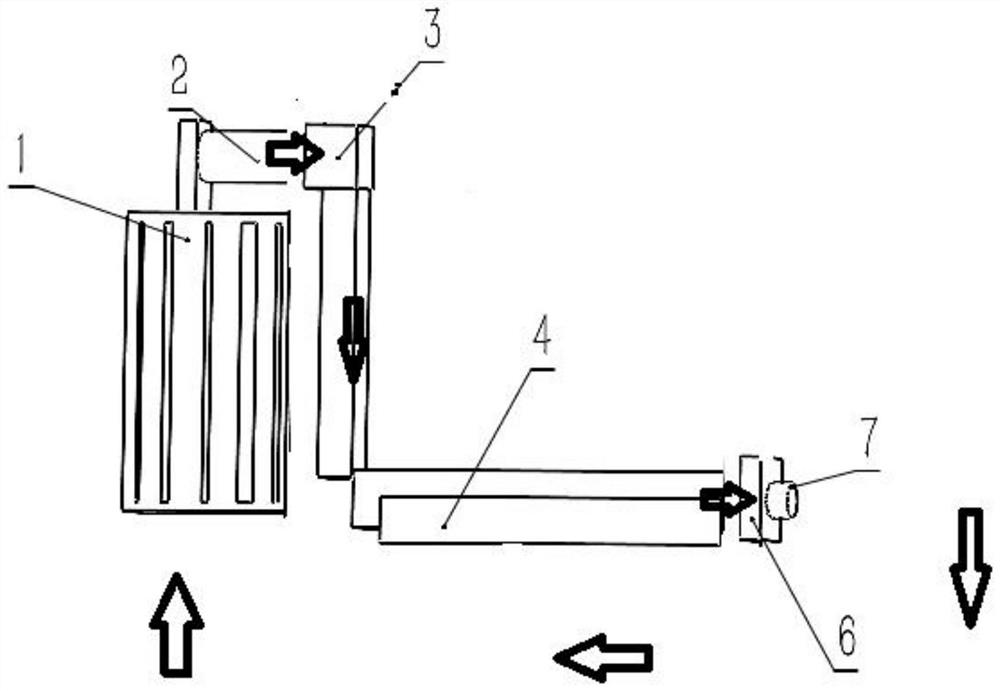

Transverse magnetic induction heating temperature uniformity automatic adjusting system and method

PendingCN113923808ASolve uneven temperature distributionSolve the problem of overheatingInduction heating controlInduction heaterContinuous production

The invention provides a transverse magnetic induction heating temperature uniformity automatic adjusting system and method. The transverse magnetic induction heating temperature uniformity automatic adjusting system comprises a transverse magnetic induction heater (1), strip steel, a temperature line scanner (3) and a transverse magnetic induction heating control cabinet (4). The transverse magnetic induction heater (1) is connected with strip steel; the temperature line scanner (3) is fastened and connected above the strip steel behind the transverse magnetic induction heater (1); and after the strip steel passes through the transverse magnetic induction heater, the temperature line scanner scans the temperature of the strip steel in the width direction, and the temperature value is recorded. The transverse magnetic induction heating control cabinet (4) is connected with the transverse magnetic induction heater (1). By adopting the automatic temperature uniformity adjusting system for transverse magnetic induction heating, the problems that in the strip steel heating process, the strip steel is overburnt and overcooled, the temperature in the width direction is uneven, and the normal continuous production is affected due to slow response of manual heating parameter adjustment are solved.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

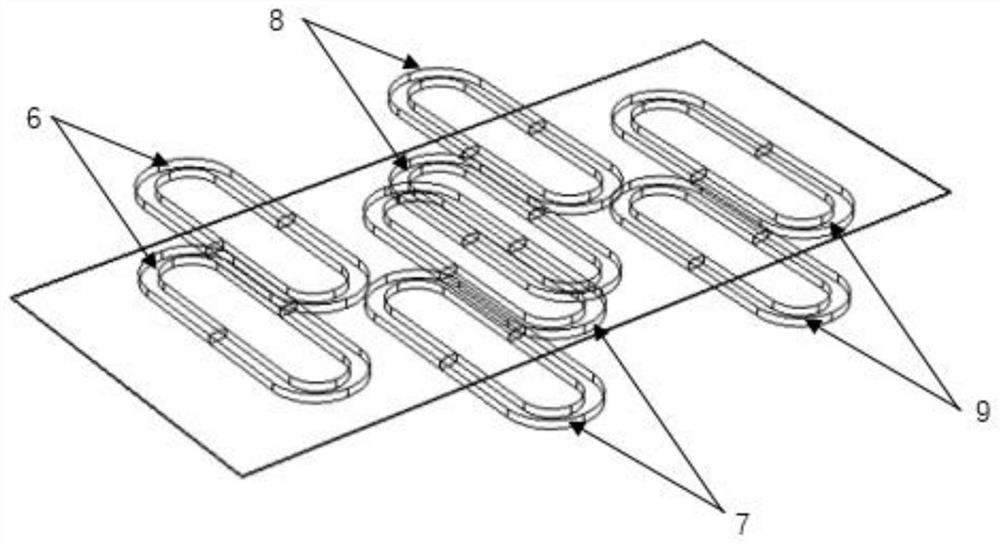

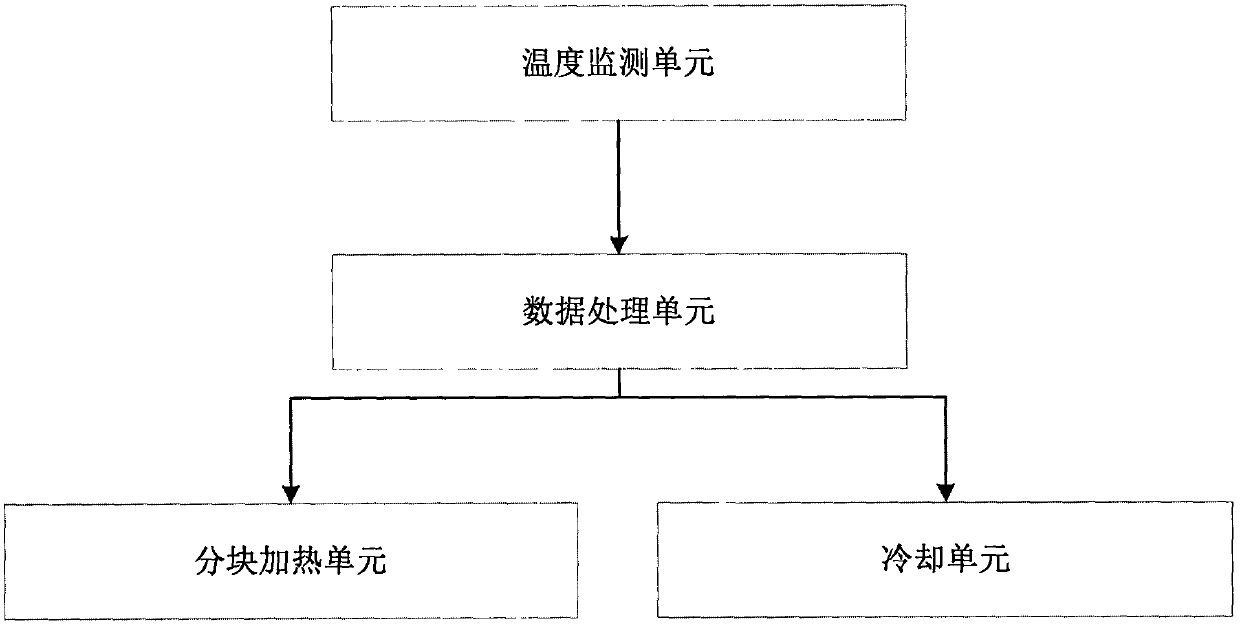

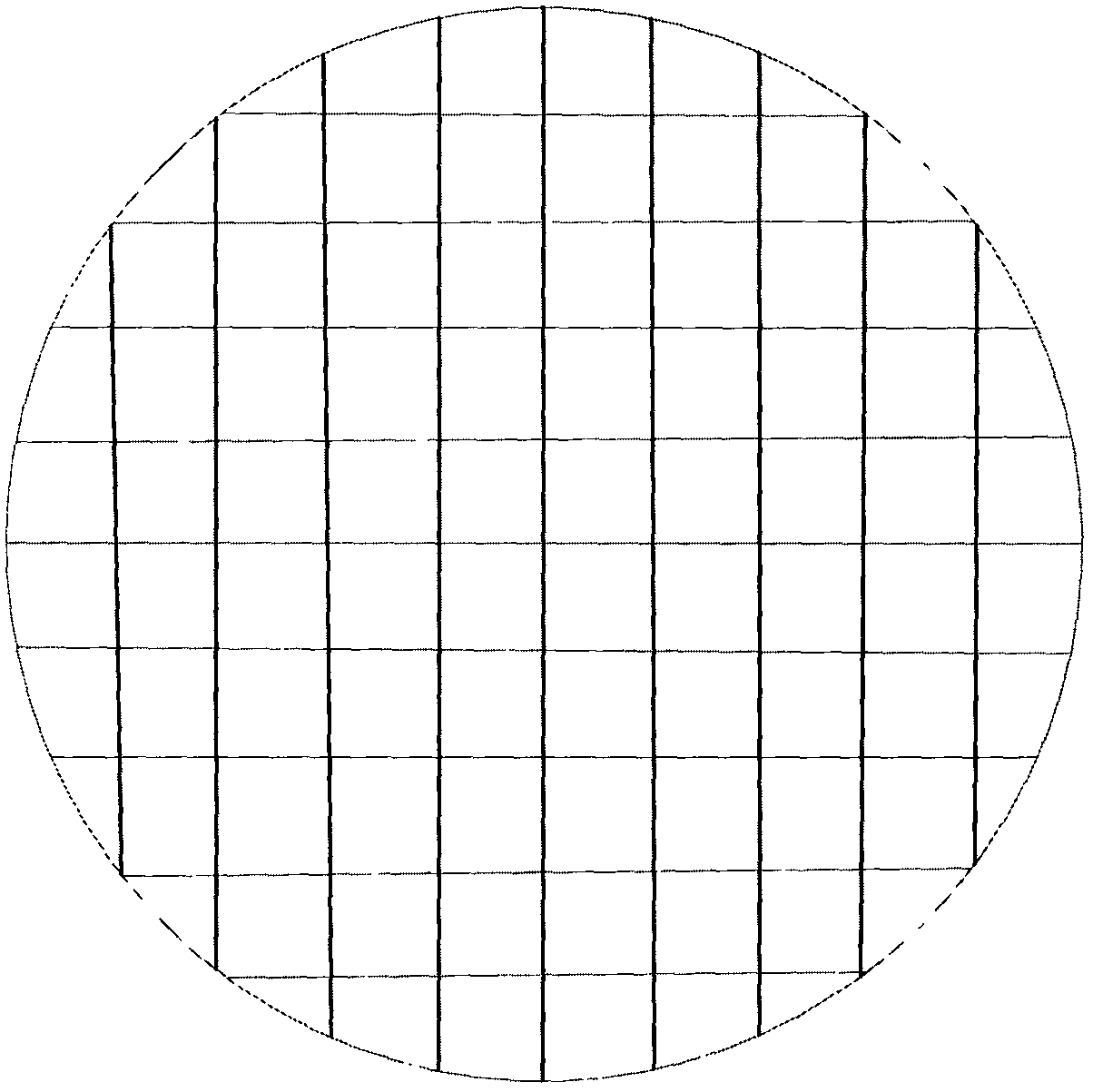

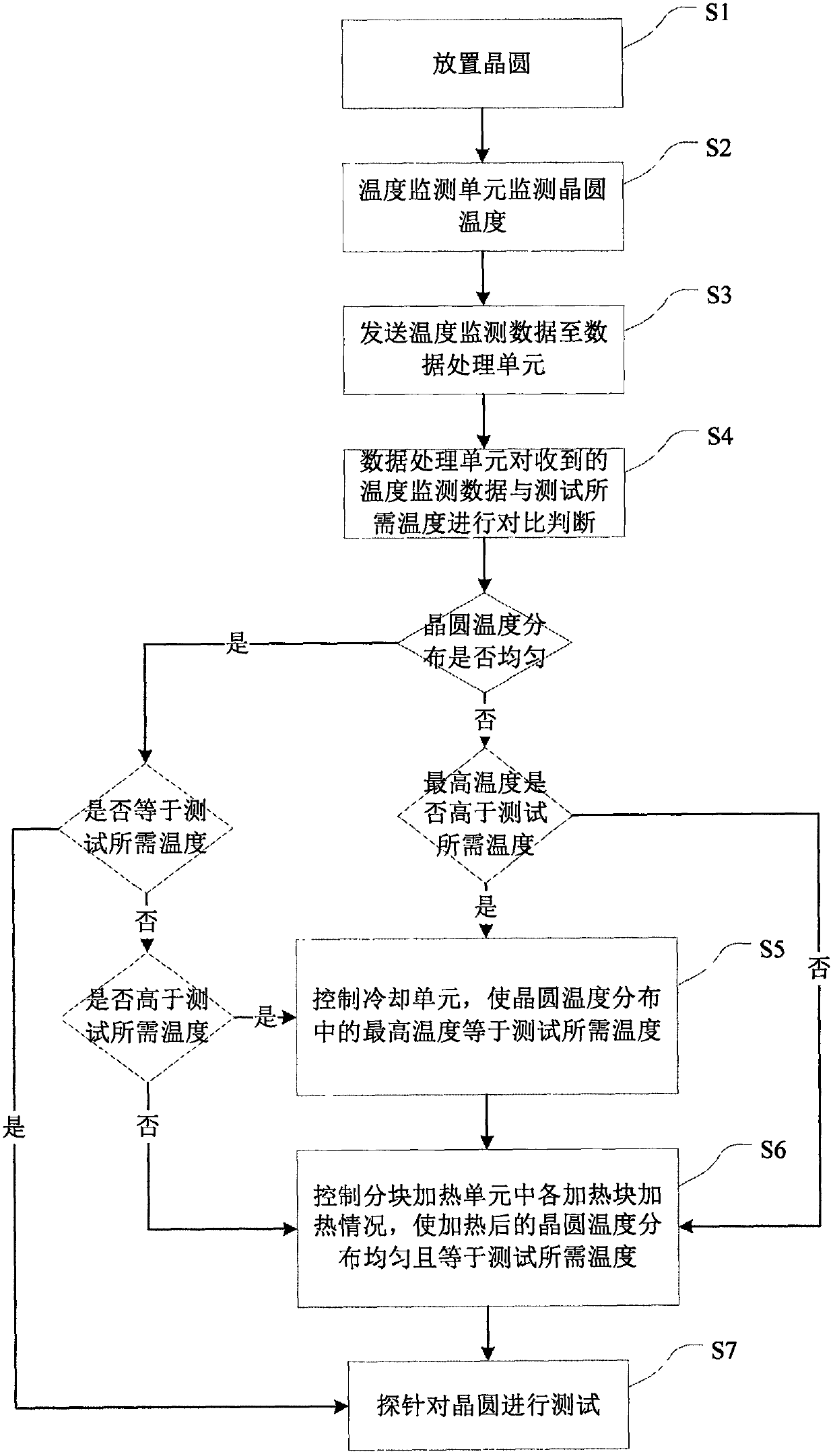

Device and method for wafer test temperature adjustment

PendingCN109659244ASolve uneven temperature distributionImprove accuracySemiconductor/solid-state device testing/measurementCooling UnitsCold test

The invention discloses a device and a method for wafer test temperature adjustment. A temperature monitoring unit monitors the temperature of a wafer in real time, and a data processing unit controlsa block heating unit and a cooling unit according to the temperature monitoring result, and changes the heating condition of each heating block through a block heating unit to achieve the temperatureadjustment of the local area of the wafer so as to solve the problem that the temperature distribution is not even when the wafer is subjected to high-low temperature test and improve the wafer testaccuracy.

Owner:BEIJING INFORMATION SCI & TECH UNIV

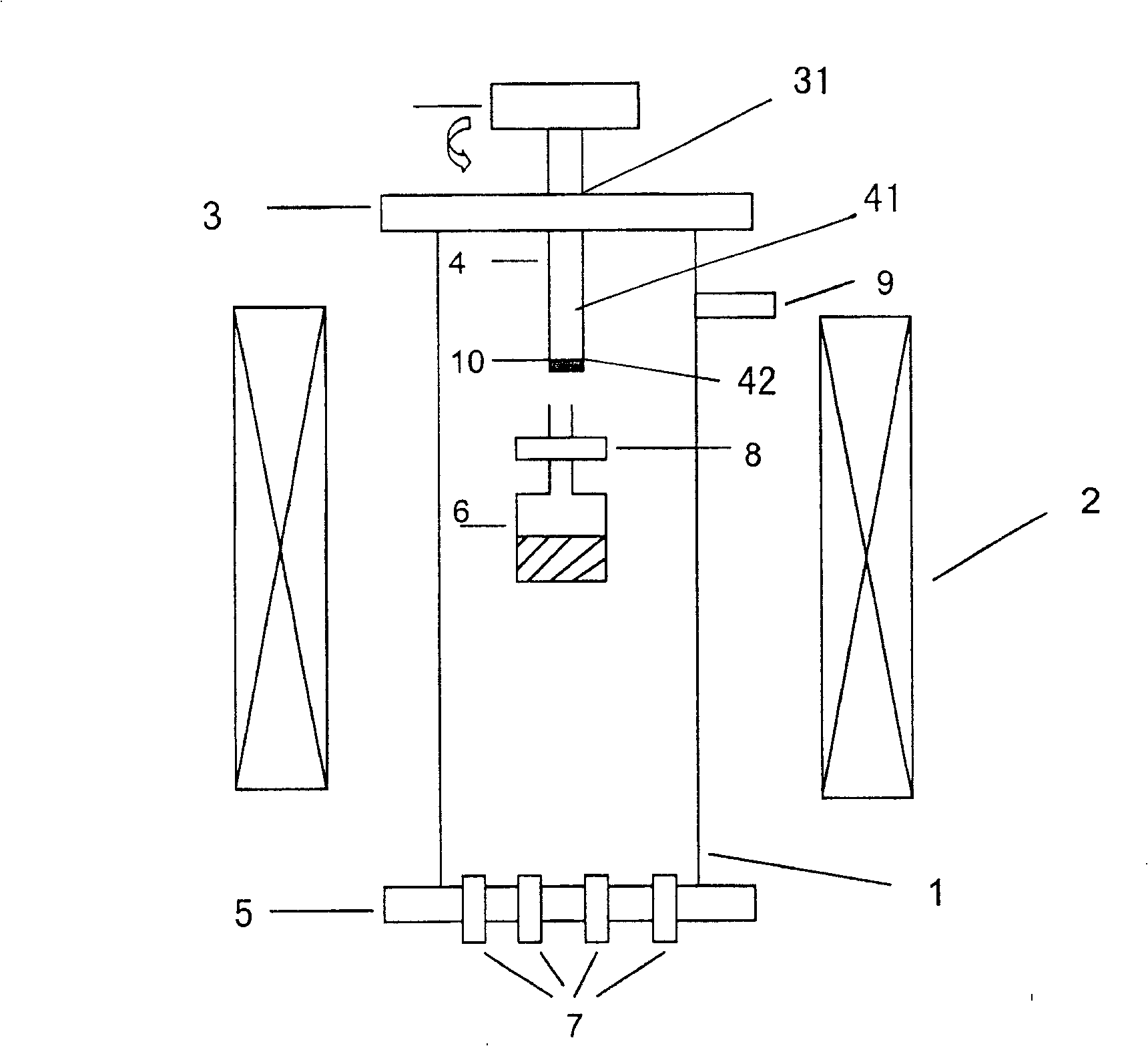

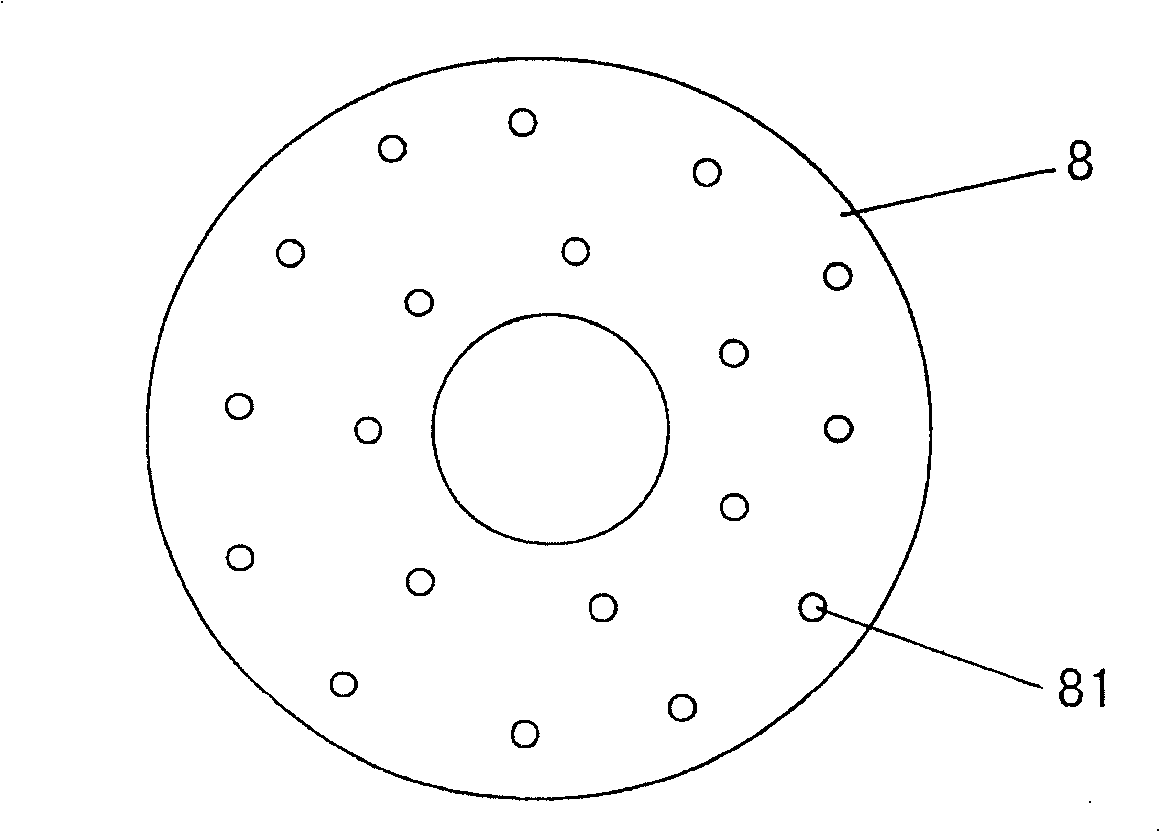

Hydride gas phase extent device for manufacturing thick film nitride material

ActiveCN100418193CSolve uneven temperature distributionEasy to adjust temperatureFinal product manufactureSemiconductor/solid-state device manufacturingGas phaseSprayer

The invention relates to a hydride gas extending device for preparing thick nitride material, which comprises: an upright quartz extending growing room in cylinder shape; a growing room heater in annular shape for sheathing the growing room; an upper cover plate fixed above the growing room with a central round hole; a substrate rotating and lifting device whose front end has one rod whose end is the substrate base, while the rod is slide matched with the central round hole of upper cover plate; a metal react source arranger inside the growing room; a chassis fixed at the lower end of growing room with several gas inlets; and an ammonia gas sprayer with several ejector nozzles, while it is connected to the ammonia gas inlets of chassis with tube.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

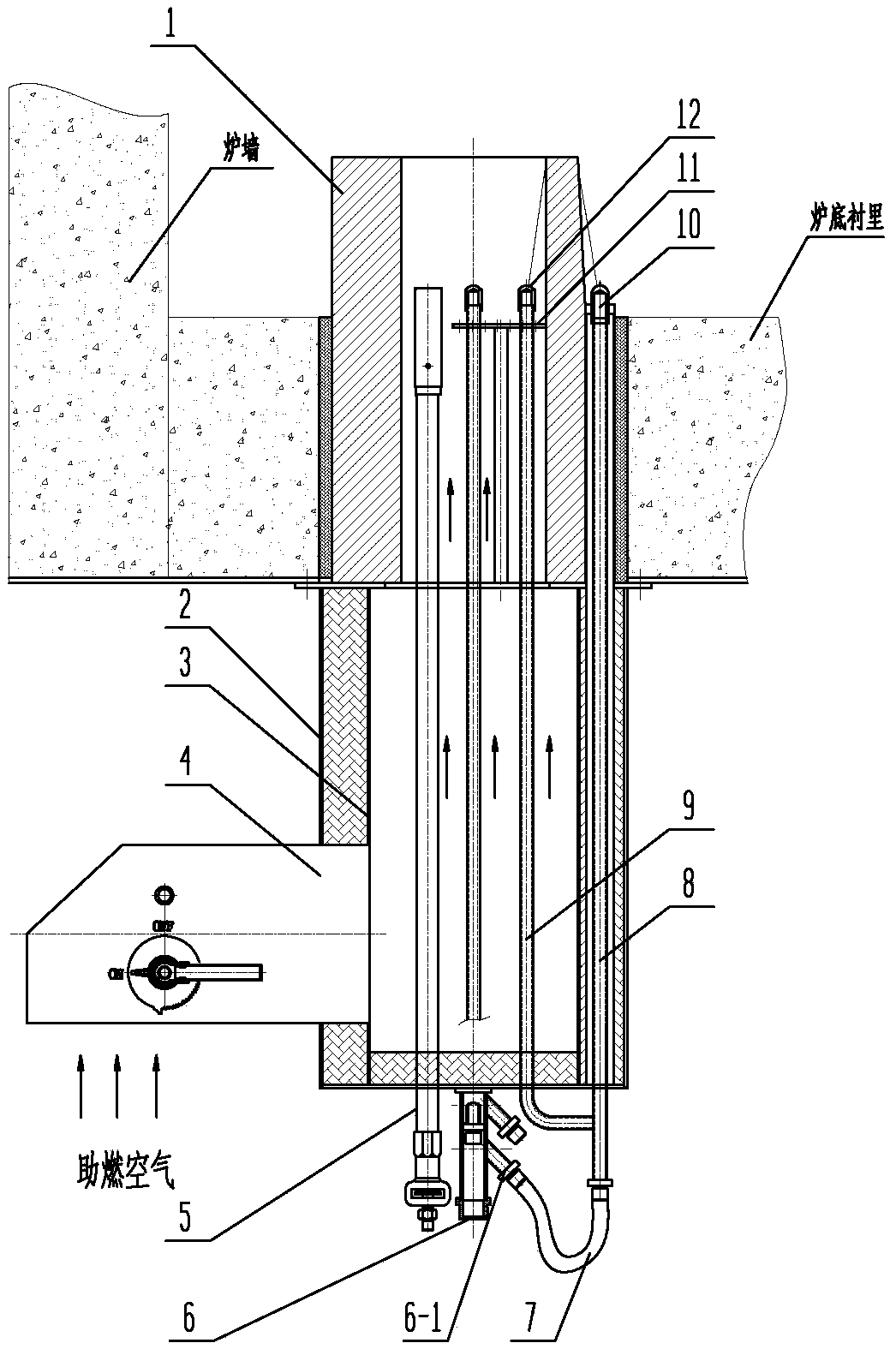

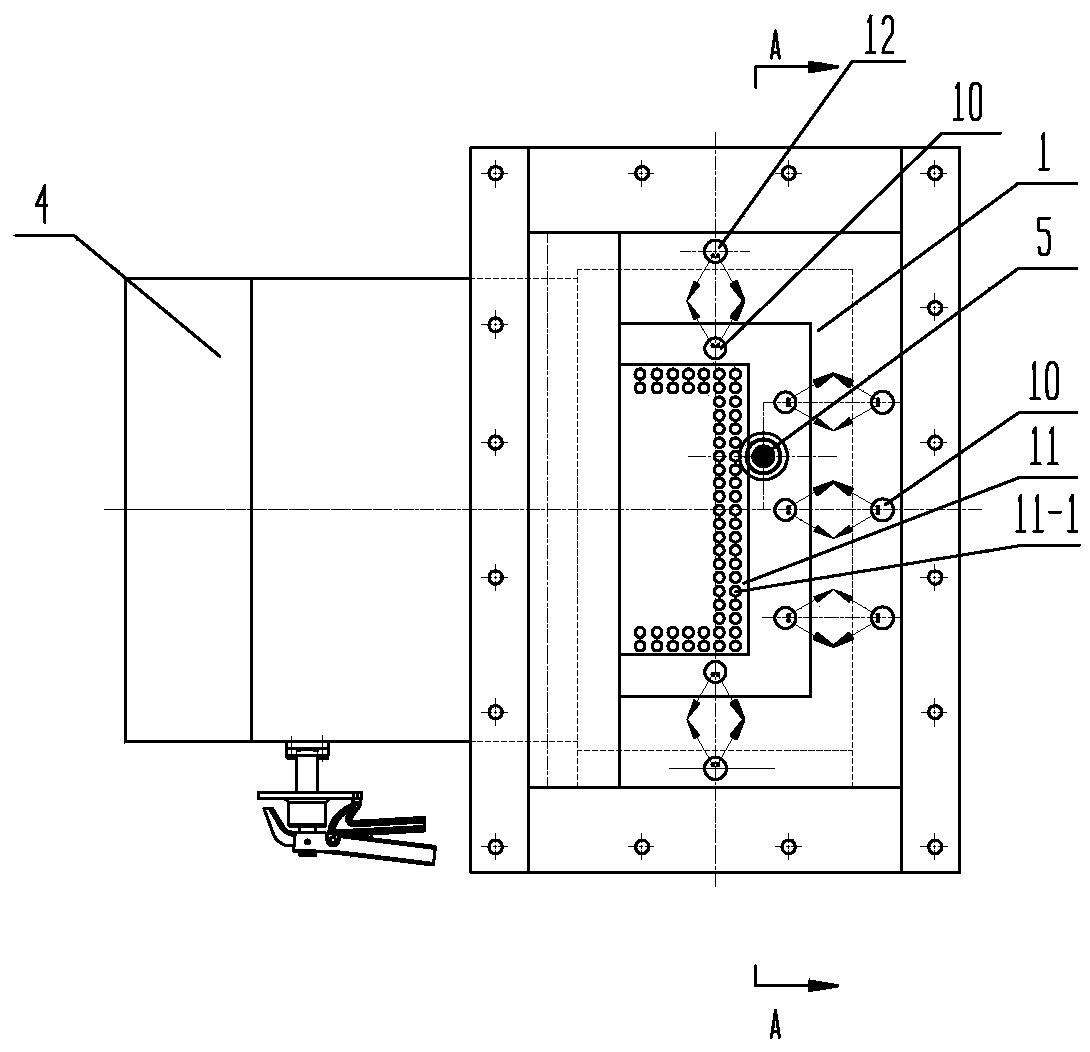

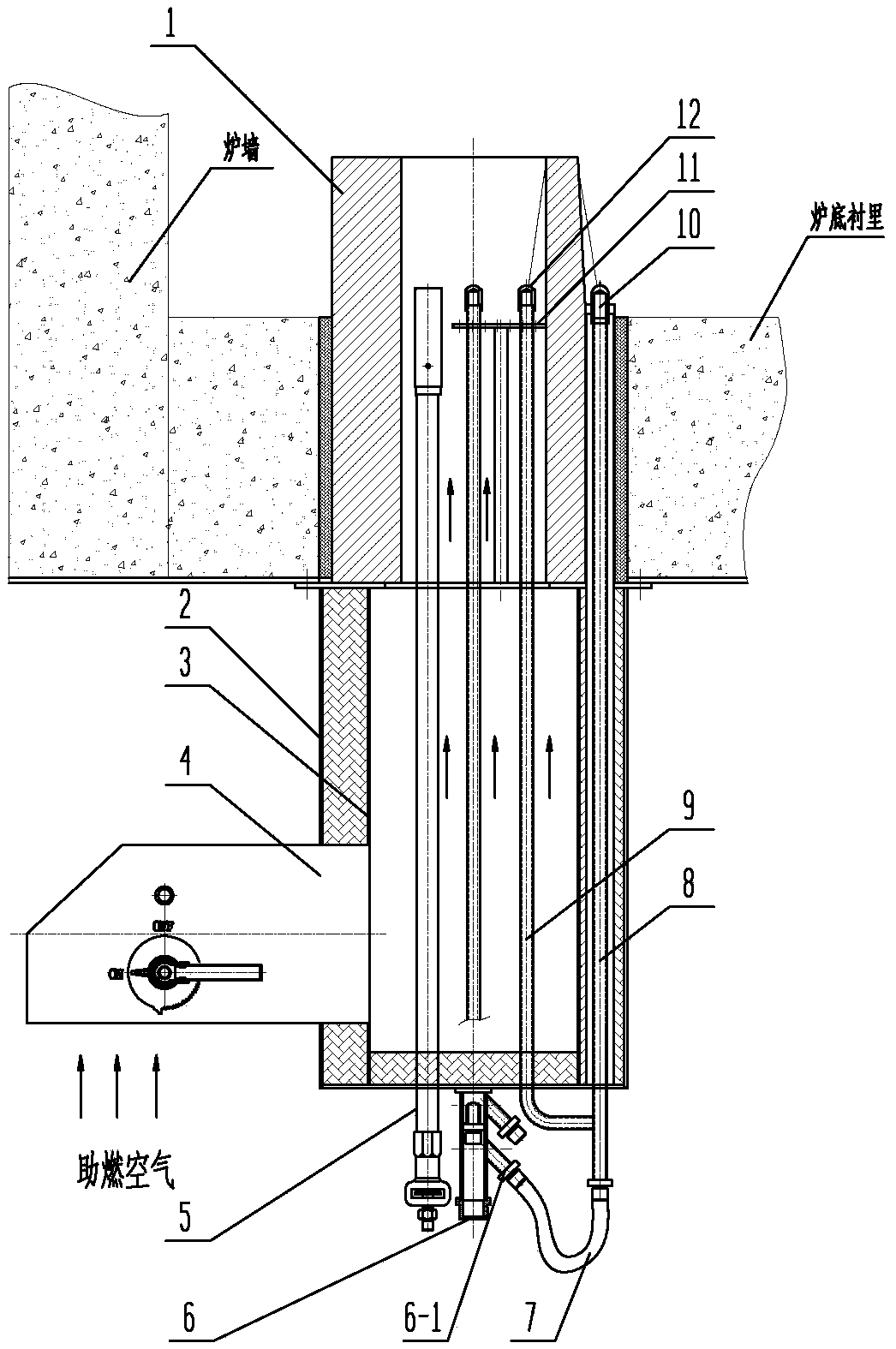

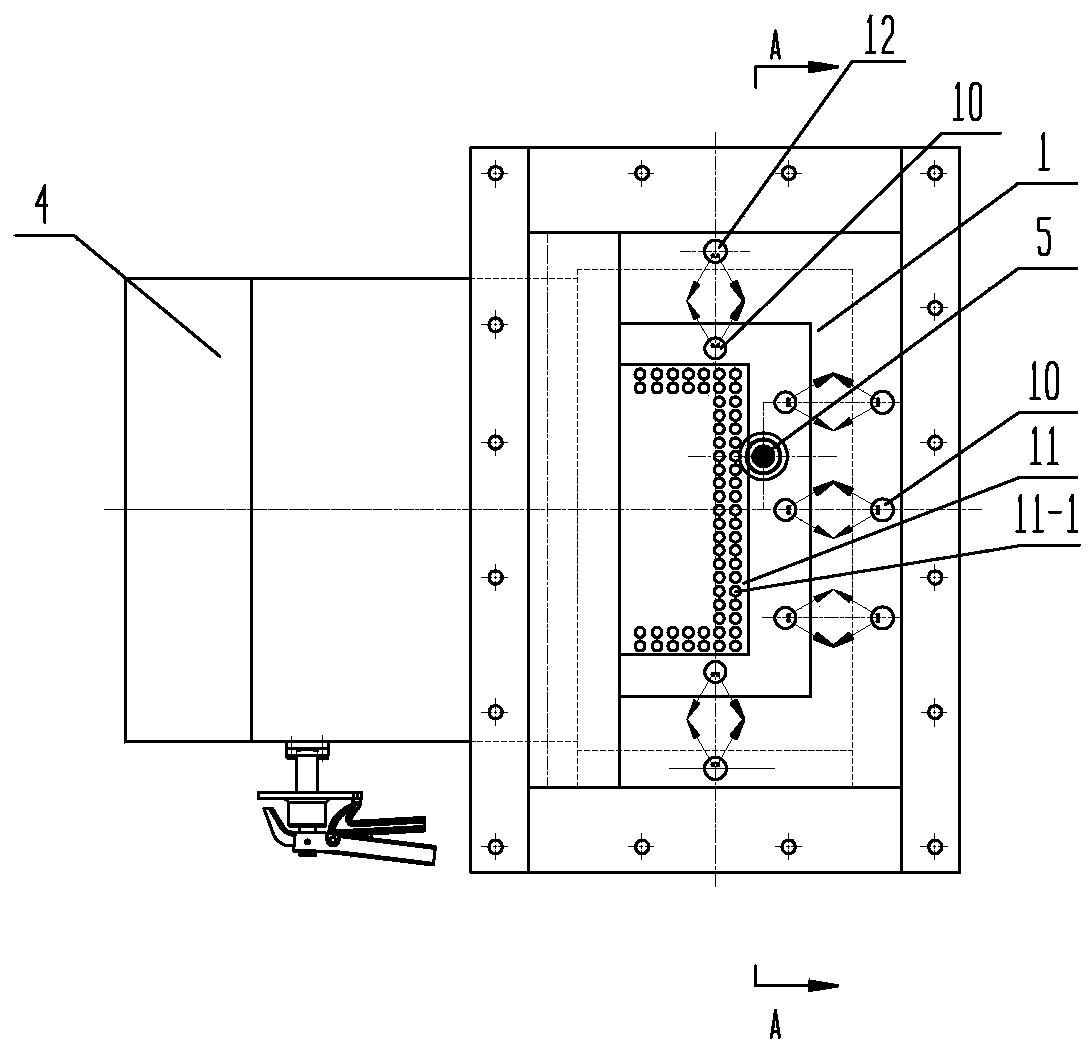

U-shaped flame low-nitric-oxide combustor for high-temperature hearth

ActiveCN109737402ASuppress generationCurb emissionsGaseous fuel burnerMonolithic liningsBrickCombustor

The invention discloses a U-shaped flame low-nitric-oxide combustor for a high-temperature hearth. A combustor steel structure body and an air and fuel gas mixing brazier brick are included. The U-shaped flame low-nitric-oxide combustor is characterized in that the brazier brick is a square rectangular brazier brick with the uneven wall thickness; the combustor steel structure body comprises an air distributor, an air channel and a fuel gas pipeline, and a flame stabilizing cover and an incandescent light are further included; the fuel gas pipeline comprises a fuel gas gathering pipe, an innergas gun and an outer gas gun, and five fuel gas branch pipes are designed on the gathering pipe; and a first-level gas sprayer is arranged on the top of the inner gas gun, and a second-level gas sprayer is arranged on the top of the outer gas gun. According to the U-shaped flame low-nitric-oxide combustor, in the combustion environment where the hearth temperature of a steam overheating furnace,an ethylene cracking furnace and the like exceeds 1,000 DEG C, through furnace wall local high temperature restraining, the flame dividing technology, thick and thin combustion and other technologies,generation of nitric oxide is restrained, and the emission of the nitric oxide in the environment where the hearth temperature exceeds 1,000 DEG C is lower than 80 mg / m<3>.

Owner:湖南一航石化设备有限公司

A method for reducing defect generation in sic crystal growth

ActiveCN106245110BSolve uneven temperature distributionReduced hexagonal void defectsPolycrystalline material growthFrom condensed vaporsGas phaseAdhesive

Owner:HEBEI SYNLIGHT CRYSTAL CO LTD

Manufacturing method for reinforcement type liquid crystal display module

InactiveCN103777394ASolve uneven temperature distributionSolve the problem of uniformity of temperature distribution in low temperature heatingOhmic-resistance heatingNon-linear opticsLiquid-crystal displayComputer module

A manufacturing method for a reinforcement type liquid crystal display module is characterized by including the following steps that firstly, glass is selected as a heater substrate to be washed; secondarily, a heating pattern shape is designed on the substrate and meets the heating requirement; thirdly, alloy material serves as heating material, and alloy material patterns are formed on the substrate through one or more combinations of a chemical vapor deposition method, a physical vapor deposition method, a mechanical rolling method and other methods; fourthly, electrodes are led out to a heating power supply from the alloy material patterns used for heating. The problem that in the process of low-temperature heating, liquid crystal screen temperature is not even in distribution is solved, so that heating efficiency is improved. The film forming technology, on substrate material poor in high-temperature performance, of the alloy material is achieved, and the application field of the alloy material is expanded. The problem that the irregular-shape liquid crystal display module is not even in temperature distribution in the process of low-temperature heating can be solved well.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

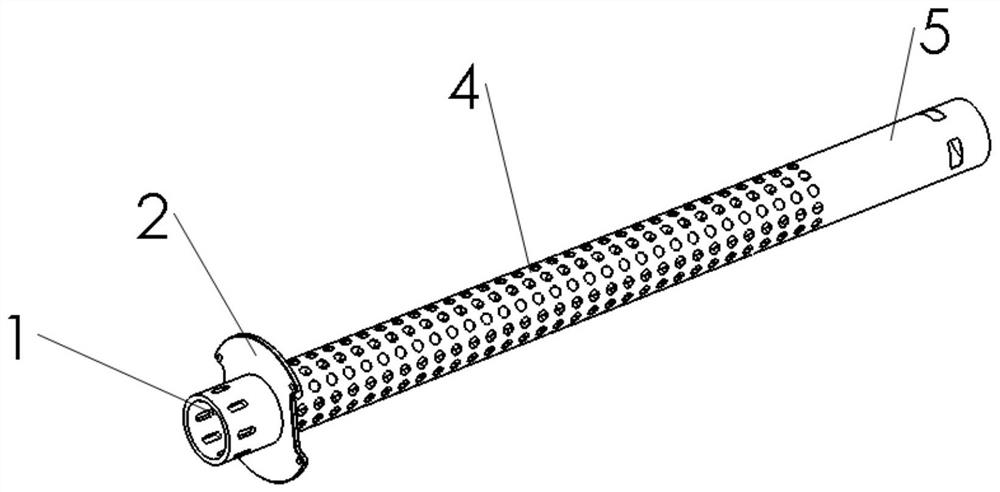

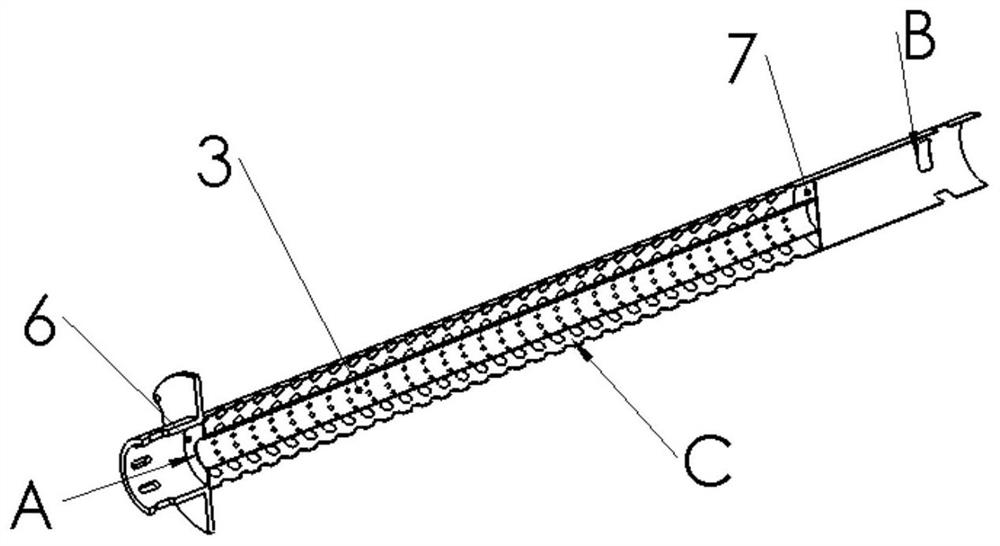

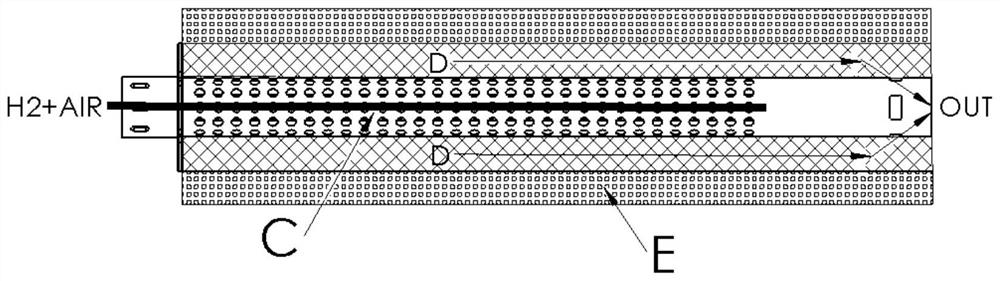

Sleeve type catalytic burner and application

InactiveCN112815316AUniform temperature distributionImprove conversion rateFuel cellsGaseous fuel burnerSteam reformingMethanol water

The invention discloses a sleeve type catalytic burner. The sleeve type catalytic burner is used for releasing heat by utilizing catalytic combustion reaction of hydrogen and oxygen, is particularly suitable for the field of methanol steam reforming hydrogen production reaction in a high-temperature proton exchange membrane fuel cell (HT-PEMFC), can be used for providing heat for a reforming reactor and adjusting the temperature distribution of a reactor bed, is arranged in the reforming reactor, is not in contact with the external environment, and reduces the loss of heat, so that the whole reforming cavity completely receives the high-temperature radiation heat of a combustion cavity; meanwhile, a channel is defined by a combustor and an external reformer, combustion tail gas flows along the channel in the combustor to conduct convective heat transfer, the heat utilization rate is increased, holes with different diameters are distributed in the inner wall and the outer wall of the sleeve type combustor, and by adjusting the hole diameter or the hole distance of the inner wall, combustion gas quantity at different positions is controlled, so that temperature distribution at all positions of the combustor is adjusted, the overall temperature distribution of the combustor tends to be consistent, or the temperature difference at all positions is small, the problem of uneven temperature distribution of a bed layer of the reforming reactor is solved, and the overall conversion rate and the heat utilization rate of the reforming reactor are effectively improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Air conditioner control method, device, computer readable storage medium and air conditioner

ActiveCN110887197BSpeed up heat exchangeUniform temperature distributionMechanical apparatusSpace heating and ventilation safety systemsAmbient humidityRoom temperature

The invention discloses an air conditioner control method, device, computer-readable storage medium, and air conditioner. The method includes: obtaining the target temperature of the air conditioner and the indoor ambient temperature in the environment to which the air conditioner belongs, and / or obtaining the target humidity of the air conditioner, And the indoor ambient humidity in the environment to which the air conditioner belongs, and / or obtain the location of the human body in the environment to which the air conditioner belongs; according to the operating mode of the air conditioner, the temperature difference between the target temperature and the indoor ambient temperature, and the humidity between the target humidity and the indoor ambient humidity The air supply mode of the air conditioner is controlled by adjusting the rotation direction of the fan of the counter-rotating axial flow fan assembly of the air conditioner, the number of fans turned on and / or the speed of the fan. The solution of the present invention can solve the problem of uneven temperature distribution in the room caused by the single air supply mode of the air conditioner cabinet, and achieve the effect of improving the uniformity of the temperature distribution in the room.

Owner:GREE ELECTRIC APPLIANCES INC

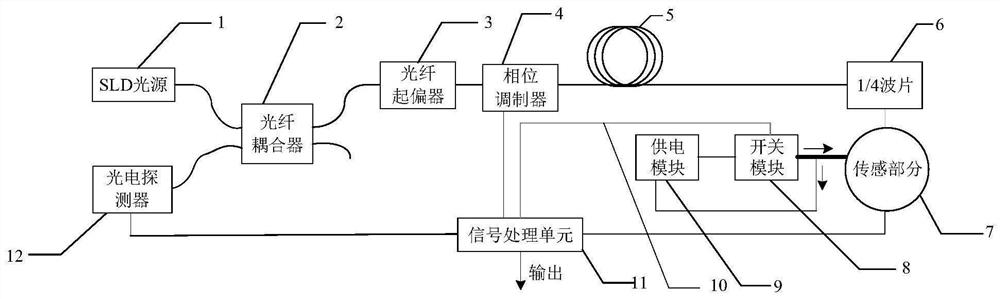

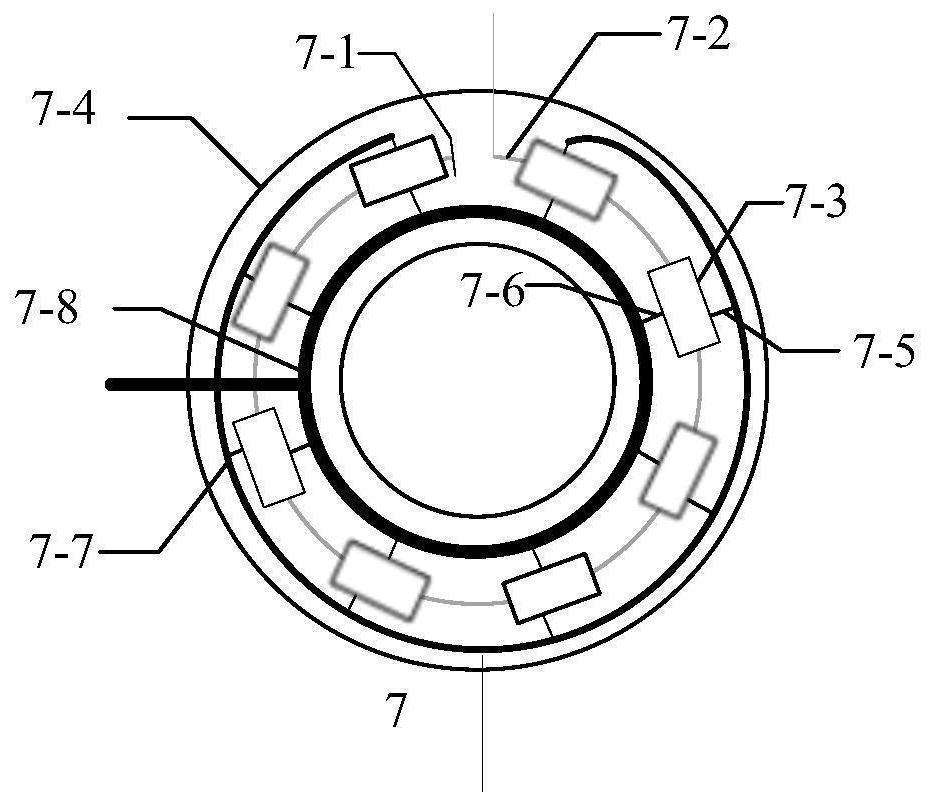

An all-fiber current transformer sensing device capable of active temperature compensation and a temperature compensation method

ActiveCN111398651BSolving Measurement ErrorsExtended service lifeCurrent/voltage measurementVoltage/current isolationPhotovoltaic detectorsPolarization-maintaining optical fiber

An all-optical current transformer sensing device capable of active temperature compensation and a temperature compensation method belong to the technical field of optical current sensing and measurement. The invention includes SLD light source, fiber coupler, fiber polarizer, switch module, power supply module, switch signal line, signal processing unit and photodetector; SLD light source and photodetector are connected with the input end of fiber coupler, and the fiber optic The polarizer is connected to the output end of the fiber coupler, the other end of the fiber polarizer is connected to the phase modulator, the phase modulator is connected to the polarization maintaining fiber delay line, and the polarization maintaining fiber delay line is connected to the 1 / 4 wave plate, 1 / 4 wave plate The other end of the power supply module is connected to the sensing part, one end of the power supply module is connected to the switch module, the switch module is connected to the sensing part, and the other end of the power supply module is connected to the sensing part; the signal processing unit is connected to the switch module through a switch signal line; the present invention can balance the sensing The temperature distribution of each point on the ring solves the problem of measurement error caused by uneven heating of the sensing ring.

Owner:HARBIN UNIV OF SCI & TECH

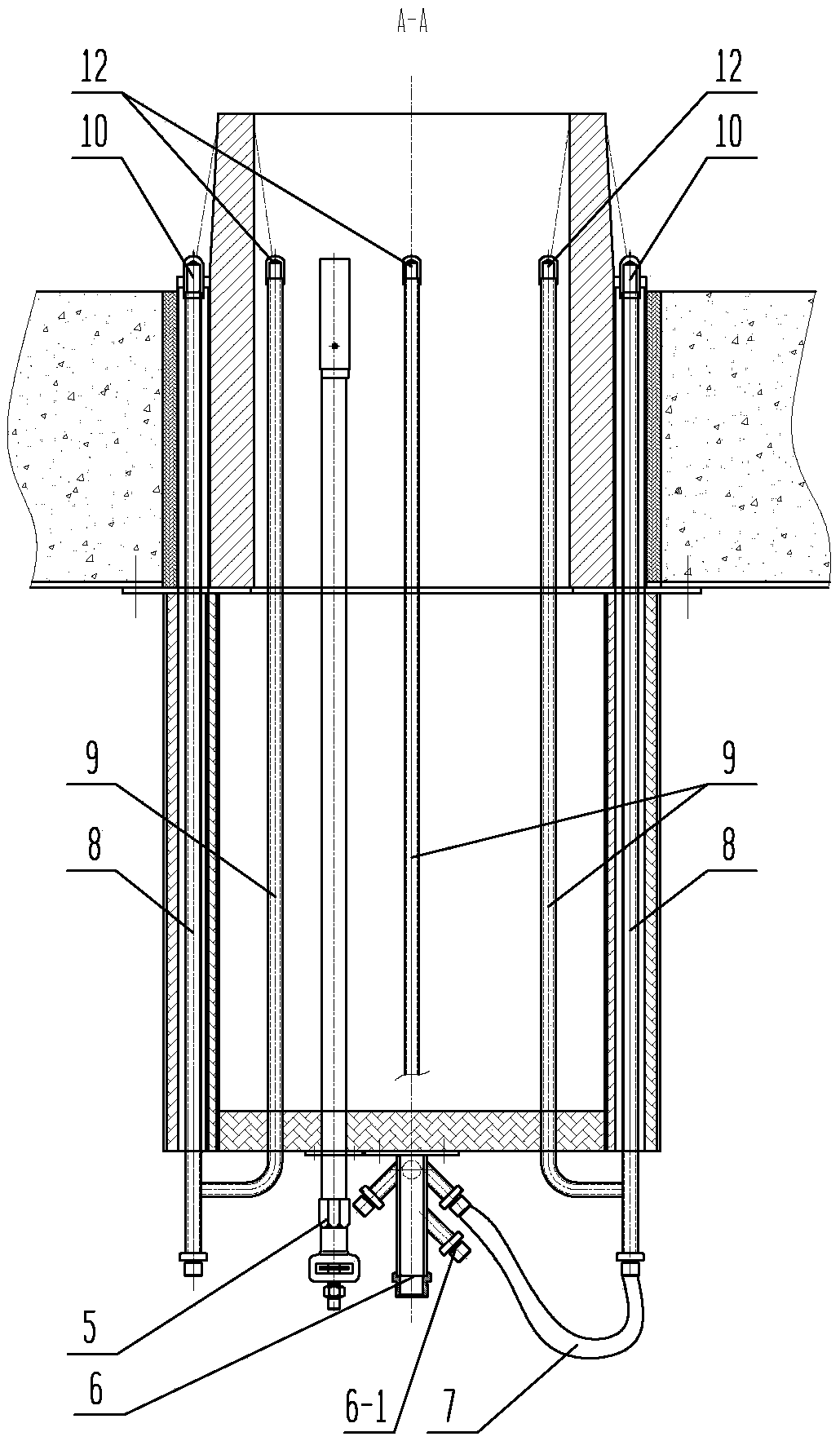

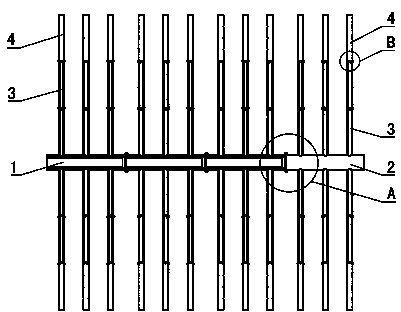

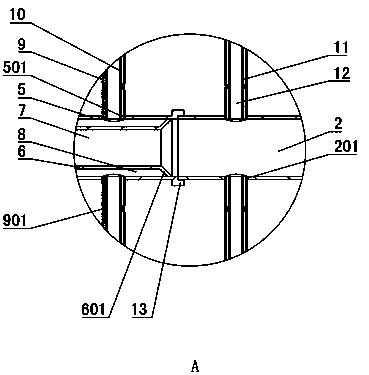

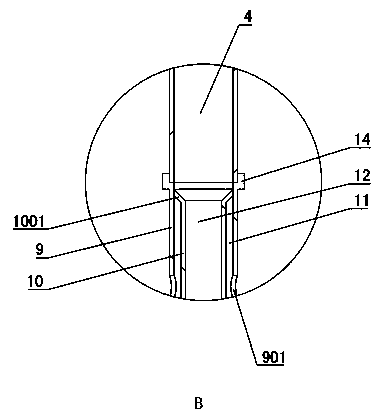

Dual-layer hot air distribution pipe

The invention discloses a dual-layer hot air distribution pipe, and belongs to the technical field of ultra-low concentration methane heat counter-current oxidation and low-density energy recycling. The pipe is characterized by comprising main pipes (1) and multiple branches (3) arranged on the two sides of the main pipes (1); and the air outlet end of each main pipe (1) is provided with a main pipe end pipe (2), each main pipe (1) comprises a conveying main pipe (6) and a distribution main pipe (5) which are sequentially arranged from inside to outside, the air outlet end of each conveying main pipe (6) communicates with the conveying main pipe (6) and a main pipe distribution cavity (8) of the next segment of the main pipe (1) at the same time, each branch pipe (3) comprises a conveyingbranch pipe (10) and a distribution branch pipe (9) which are sequentially arranged from inside to outside, and the air outlet end of each conveying branch pipe (10) communicates with the conveying branch pipe (10) and the distribution branch pipe (9) of the next segment of branch pipe (3) at the same time. The dual-layer hot air distribution pie solves the problem that temperature distribution isnot uniform thoroughly, and temperature distribution of an oxide bed on the same cross section is more uniform.

Owner:SHANDONG UNIV OF TECH

High-temperature burn-in house with automatic ventilating function

InactiveCN104654512AEasy to installSimple structureDucting arrangementsMechanical apparatusSolenoid valveAir blower

The invention discloses a high-temperature burn-in house with the automatic ventilating function. The high-temperature burn-in house with the automatic ventilating function comprises an air inlet / outlet pipeline, an air inlet and an air outlet; the air inlet and the air outlet are connected with the air inlet / outlet pipeline; the air inlet / outlet pipeline is communicated with the air inlet to form an air inlet pipeline, and the air inlet / outlet pipeline is communicated with the air outlet to form an air outlet pipeline; the air inlet pipeline and the air outlet pipeline are communicated to form a ventilating channel; a first air blower is arranged on the air inlet pipeline; a second air blower and a solenoid valve are arranged on the air inlet / outlet pipeline; the first air blower is connected with a first air blower motor, and while the second air blower is connected with a second air blower motor; a plurality of temperature and humidity sensors are uniformly distributed on the inner wall of the burn-in house; a heater is arranged at the bottom part of the burn-in housing; a water collector which is communicated with the outside through a draining pipe is arranged below the heater. The high-temperature burn-in house with the automatic ventilating function is simple in structure and reasonable in design; the problem of non-uniform temperature distribution in the burn-in house can be effectively solved through an automatic ventilating system, and thus the burn-in result of an electronic product can be improved.

Owner:XIAN LIANKONG ELECTRICAL

High-efficiency low-heat-loss non-imaging concentrating heat collector with heat storage function

PendingCN109579318AHighlight substantive featuresReduce heat lossSolar heating energySolar heat storageEngineeringHeat losses

The invention provides a high-efficiency low-heat-loss non-imaging concentrating heat collector with a heat storage function. The high-efficiency low-heat-loss non-imaging concentrating heat collectorwith the heat storage function comprises a compound parabolic mirror and vacuum heat collector tubes. Each vacuum heat collector tube is composed of double layers of vacuum glass tubes comprising aninner glass tube and an outer glass tube, wherein the interval between the inner tube and the outer tube is vacuumized. A heat-conducting fin metal tube and a U-shaped heat conducting pipe are arranged in each vacuum heat collector tube, wherein the radial section of the heat conducting finned metal tube is formed in the manner that three fins are connected into an outer circle. The included angleof the three fins is 120 degrees, the inner area of the heat conducting finned metal tube is divided into three areas by the three fins, two areas store a heat exchange medium, and the other one areais filled with a heat storage medium. The U-shaped heat conducting tube is arranged in the two areas filled with the heat exchange medium, and the U-shaped heat conducting tube is fixed to the positions tangent to the midpoints of the two adjacent fins of the heat conducting finned metal tube. The high-efficiency low-heat-loss non-imaging concentrating heat collector with the heat storage function solves the problem that heat cannot be transferred by a heat absorbing medium in the heat collector tubes in time, so that the heat exchange medium in the vacuum heat collector tubes rises to be excessively high, and then the heat collector tubes burst.

Owner:北京市热力集团有限责任公司 +1

Automatic temperature and humidity control device for electronic equipment

InactiveCN114144027AClear design ideasAvoid Data Collection ErrorsModifications using gaseous coolantsTemperature controlAutomatic control

The invention belongs to the technical field of temperature and humidity control, and discloses an electronic equipment temperature and humidity automatic control device which is provided with a control box, a controller, a TEC module, a temperature control system, an air circulation system and a sensor system. One end of the TEC module is connected with a heat dissipation system, and the other end of the TEC module is connected with a main controller; the heat dissipation system is connected with the TEC module of the internal controller, the external sensor system and the heat dissipation system; the controller is arranged in the control box, and a TEC module is welded on the controller and is connected with each system and the controller. According to the automatic temperature and humidity control device for the electronic equipment, the design thought is clear, a real-time monitoring working environment is formed by utilizing the TEC module, an external sensor system and a heat dissipation system, the problem that temperature control is not intelligent enough is solved, and meanwhile the problem that temperature distribution is not uniform is solved by additionally arranging a gas flowmeter on a pipeline.

Owner:CHONGQING CREATION VOCATIONAL COLLEGE

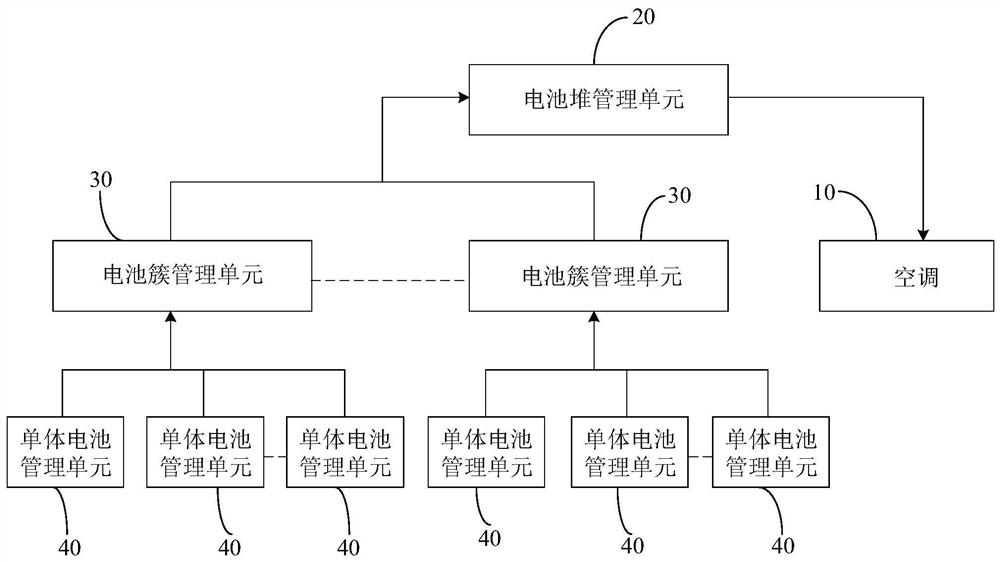

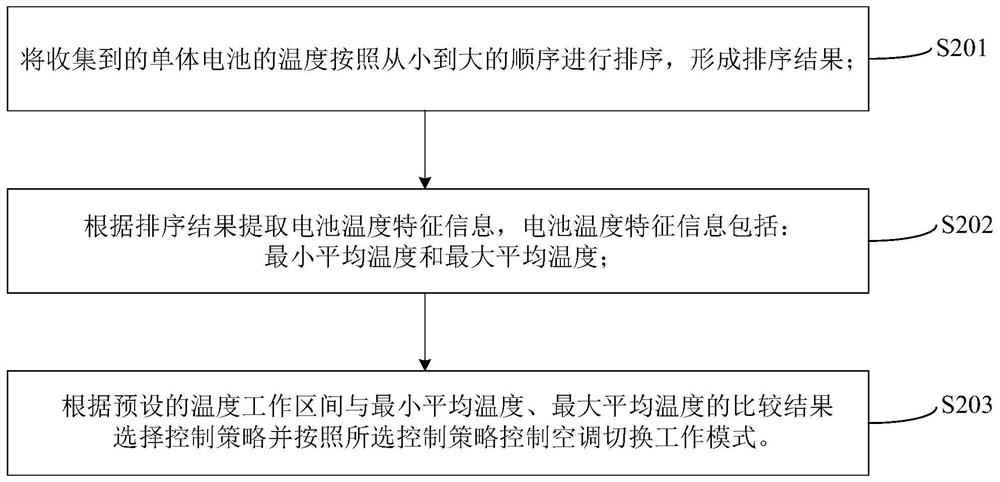

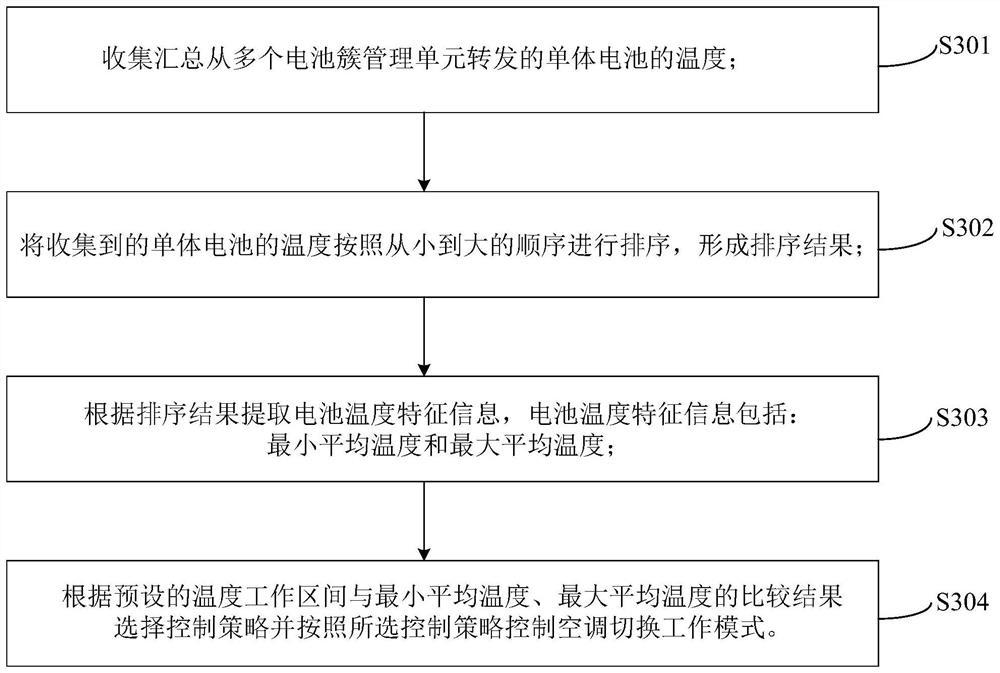

Air conditioning temperature control system and control method based on temperature difference of energy storage battery

ActiveCN109616719BEffectively adjust temperature in real timeSolve uneven temperature distributionSecondary cellsTemperature controlAir conditioning

Owner:SHENZHEN CLOU ELECTRONICS

U-shaped flame low nitrogen oxide burner for high temperature furnace

ActiveCN109737402BSuppress generationCurb emissionsGaseous fuel burnerMonolithic liningsBrickCombustor

Owner:湖南一航石化设备有限公司

Double-layer hot air distribution pipe

ActiveCN108953811BGuaranteed temperatureUniform temperatureBranching pipesEngineeringEnergy recovery

A double-layer hot air distribution pipe belongs to the technical field of ultra-low concentration methane thermal countercurrent oxidation and low-density energy recovery. It is characterized in that it includes a main pipe (1) and a plurality of branch pipes (3) arranged on both sides of the main pipe (1), and the outlet end of the main pipe (1) is provided with a main pipe end pipe (2); each section of the main pipe (1) includes The conveying main pipe (6) and the distributing main pipe (5) are arranged sequentially from the inside to the outside, and the gas outlet end of the conveying main pipe (6) is simultaneously connected with the main pipe distributing cavity (8) and the conveying main pipe (6) of the next main pipe (1); Each branch pipe (3) includes a delivery branch pipe (10) and a distribution branch pipe (9) arranged sequentially from the inside to the outside, and the gas outlet end of the delivery branch pipe (10) is connected with the delivery branch pipe (10) and The distribution branch pipe (9) is connected. The double-layer hot air distribution pipe fundamentally solves the problem of uneven temperature distribution, making the temperature distribution of the oxidation bed more uniform on the same cross section.

Owner:SHANDONG UNIV OF TECH

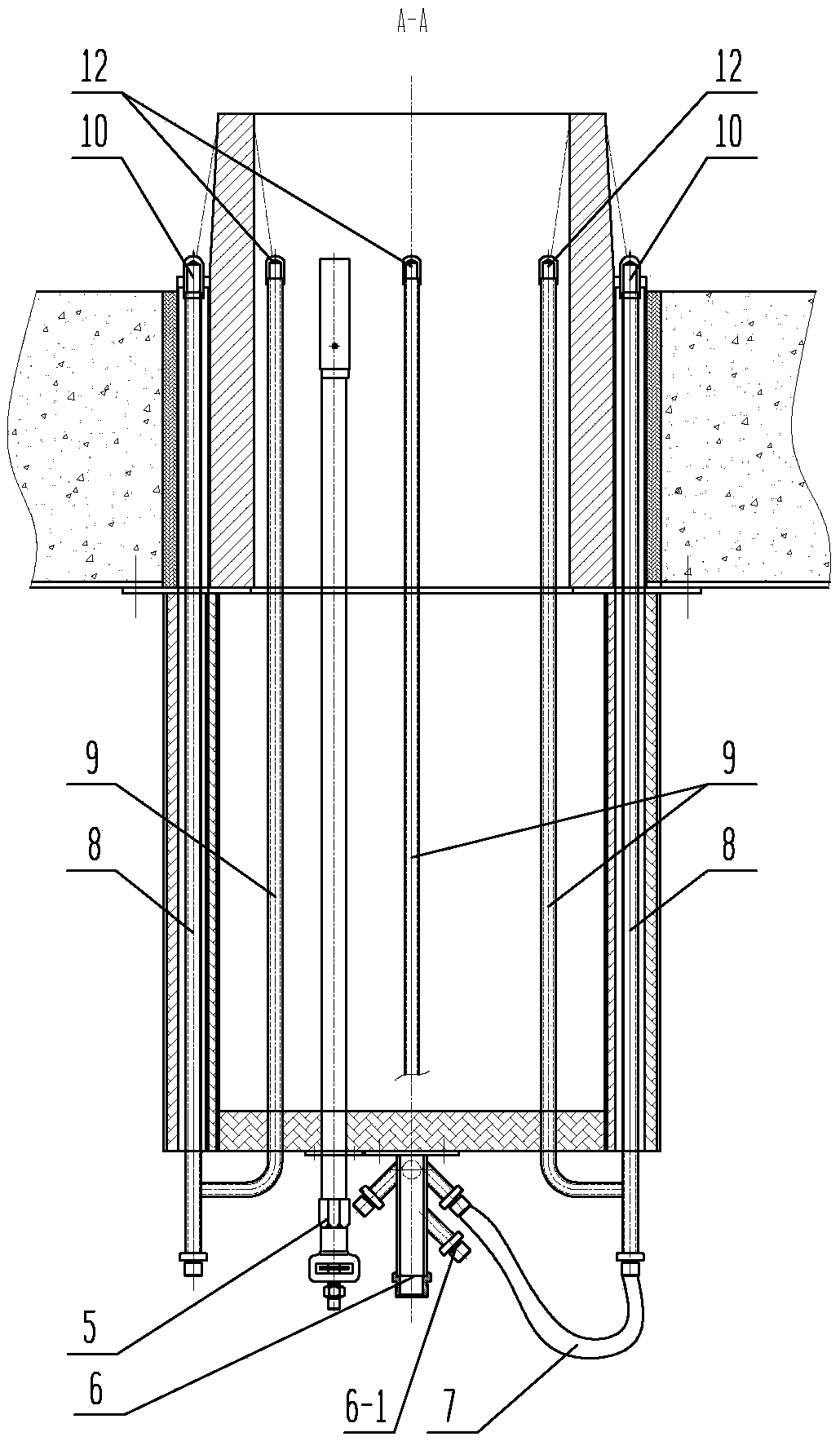

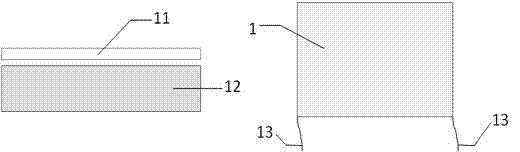

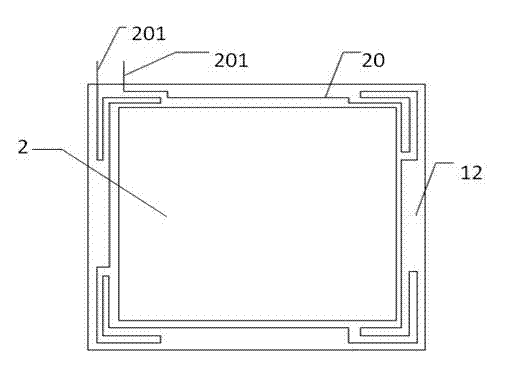

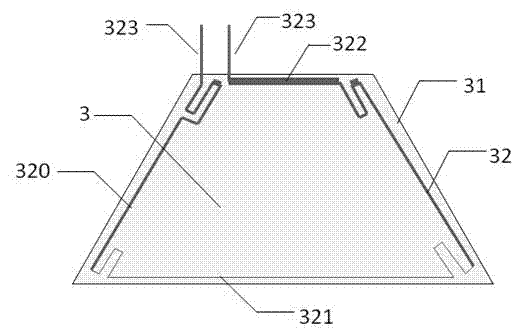

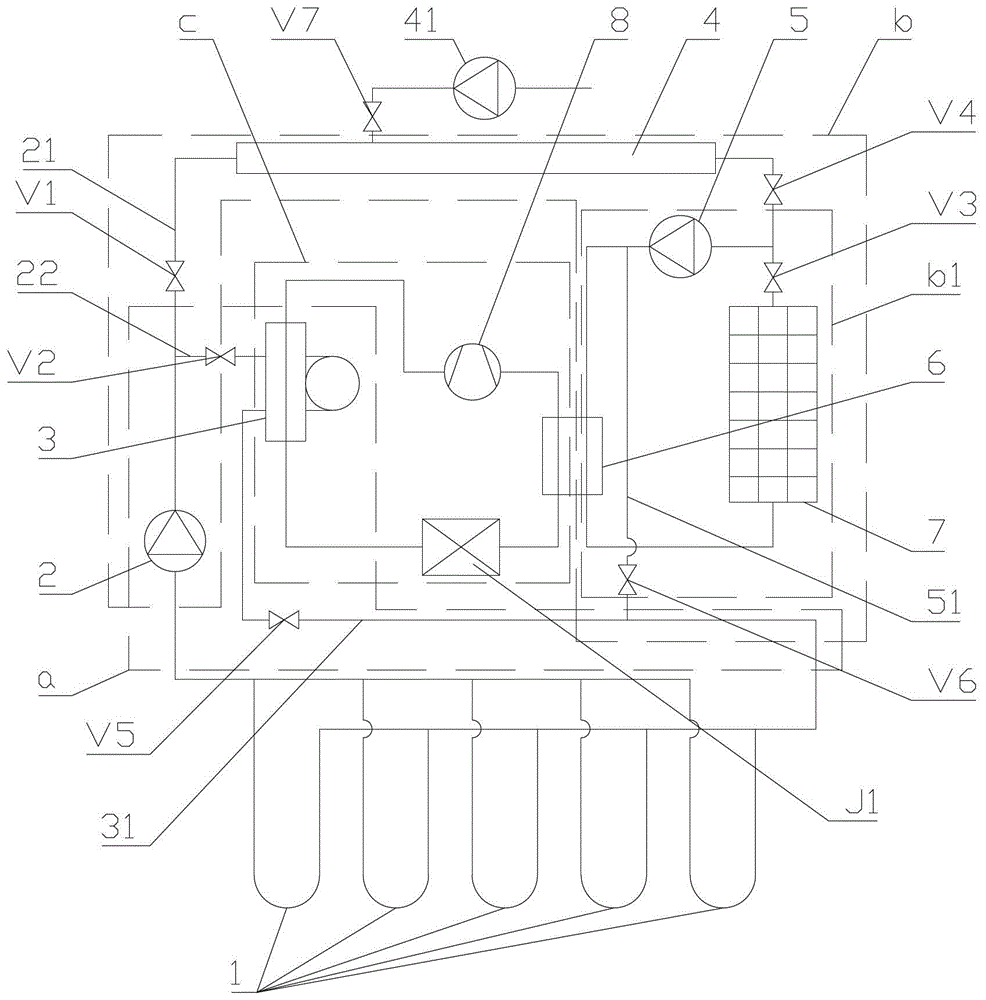

Phalaenopsis cultivation greenhouse heating and humidification soil source heat pump system

InactiveCN103486767BReliable operation in winterStable operation in winterHeat pumpsPhalaenopsisGreenhouse

The invention discloses a soil-source heat pump system for heating and humidifying phalaenopsis planting greenhouse. The soil-source heat pump system comprises a burying pipe, a heating circulation assembly, a cooling and humidifying circulation assembly and a refrigerant circulation assembly, wherein the heating circulation assembly and the cooling and humidifying circulation assembly are communicated with the burying pipe; and the refrigerant circulation assembly exchanges heat with the heating circulation assembly and the cooling and humidifying circulation assembly. The soil-source heat pump system disclosed by the invention has the advantages that the operation is reliable and stable in winter, and fuel such as coal is not needed for driving; for the system with good operation in heating in winter, the operating cost can be saved by 30-40%, and high efficiency and economical efficiency of the system are guaranteed; a great amount of land sources are saved, and pollutants such as CO2 and SO2 discharged by coal burning are reduced.

Owner:ZHEJIANG DUNAN ARTIFICIAL ENVIRONMENT

Physical vapor deposition equipment and physical vapor deposition process

ActiveCN103572211BImprove heating efficiencyImprove heating uniformityVacuum evaporation coatingSputtering coatingEngineeringMaterials science

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Stirling cold insulation equipment

PendingCN113357863AIncrease speedImprove temperature uniformityLighting and heating apparatusDomestic refrigeratorsStirling cryocoolerMechanical engineering

The invention discloses Stirling cold insulation equipment. The equipment comprises a cold insulation container and a Stirling cryocooler, wherein a cold head of the Stirling cryocooler and the cold insulation container are arranged in a spaced mode; the cold insulation equipment further comprises a heat transfer component, and the heat transfer component comprises a first thermosiphon and a second thermosiphon; the first thermosiphon and the second thermosiphon are fixedly connected to the cold head and arranged on the periphery of the cold insulation container in a surrounding mode; and the first thermosiphon is arranged at a position higher than the second thermosiphon, and a refrigerating capacity Q1 of the first thermosiphon is smaller than a refrigerating capacity Q2 of the second thermosiphon to uniformly refrigerate an object placed in the cold insulation container. The Stirling cold insulation equipment can solve the problems that the cold insulation equipment is slow in cooling and uneven in temperature distribution in the vertical direction.

Owner:RIZHAO CHINA STIRLING TECH CO LTD +1

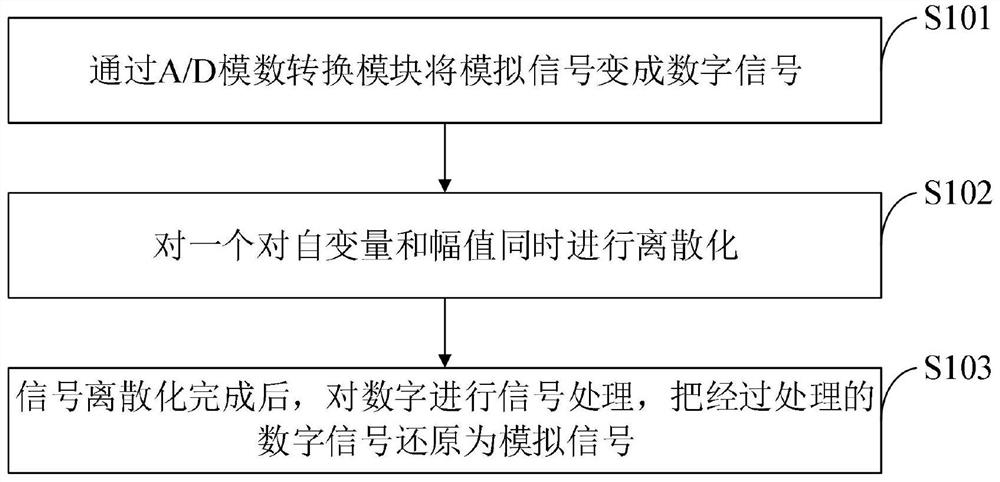

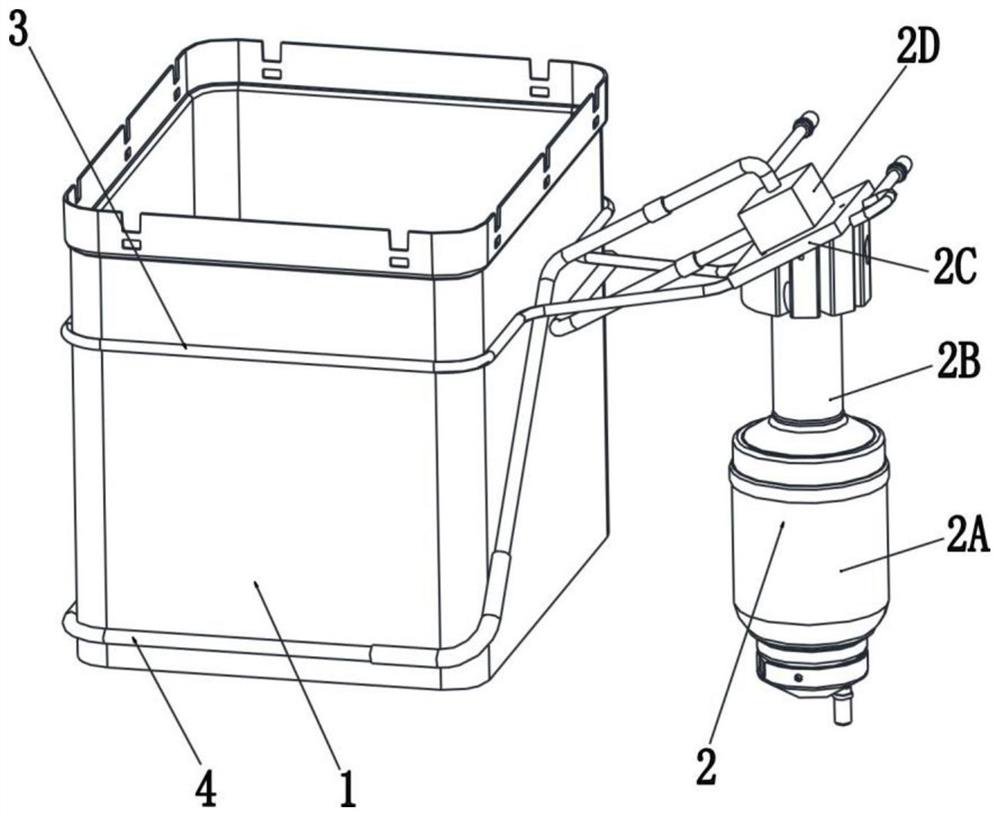

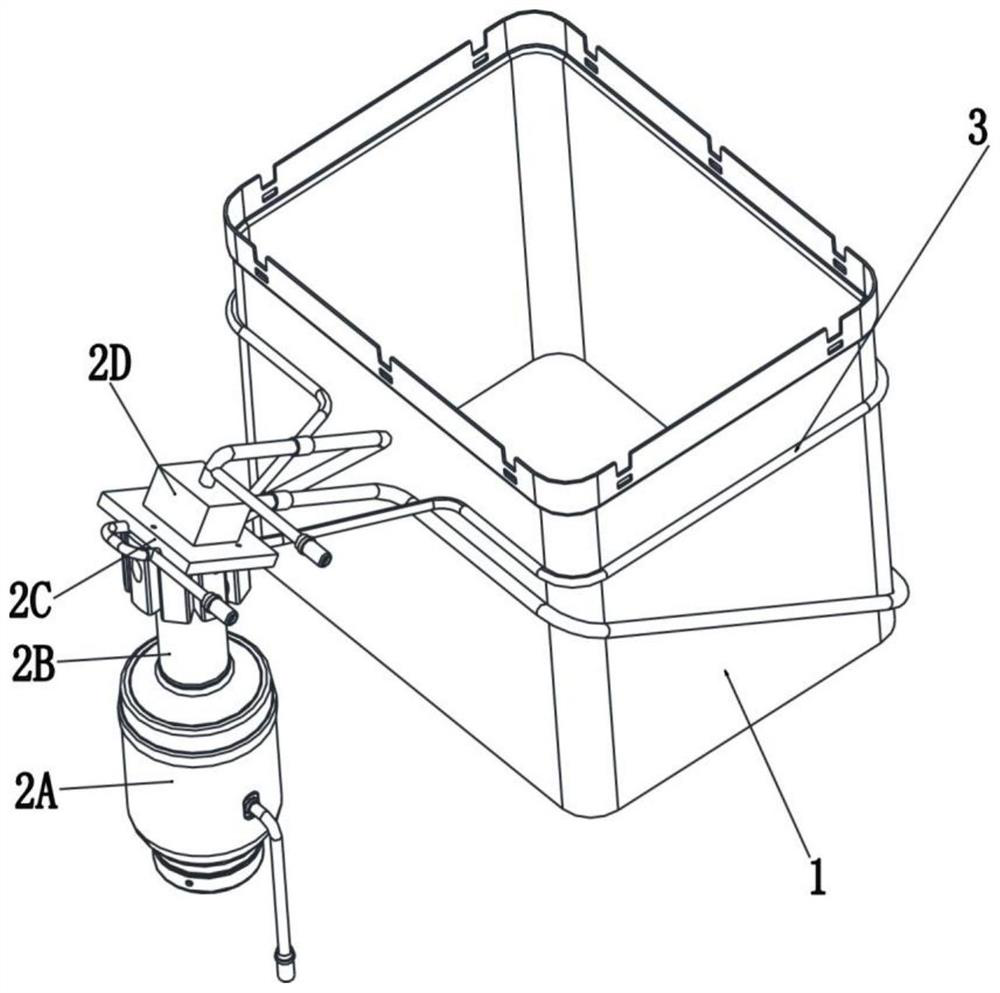

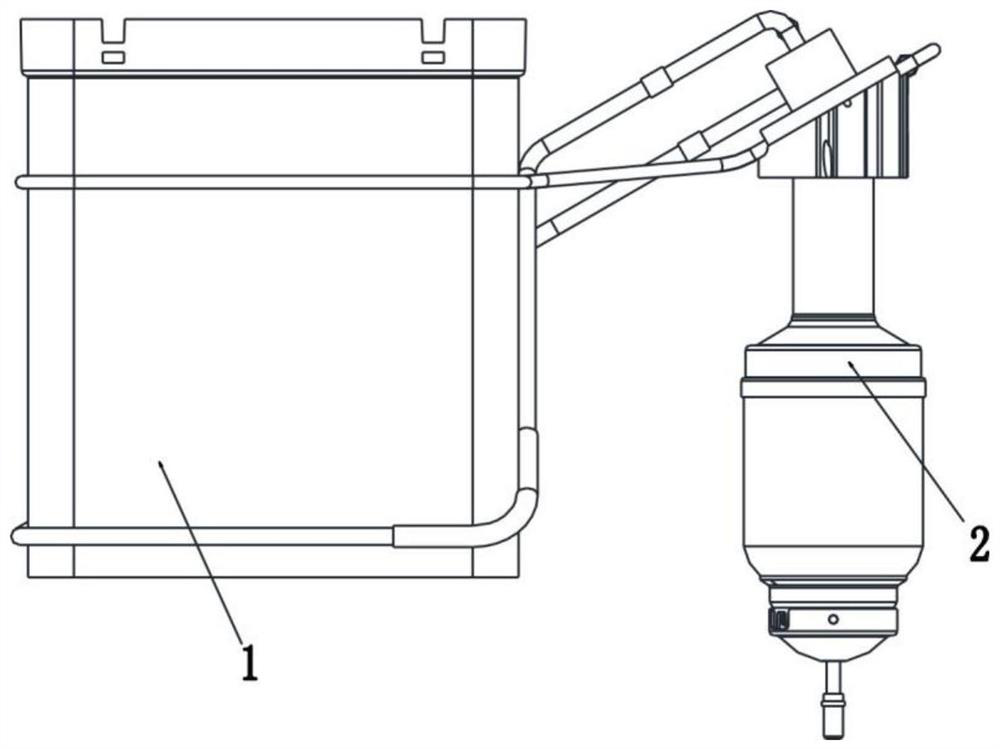

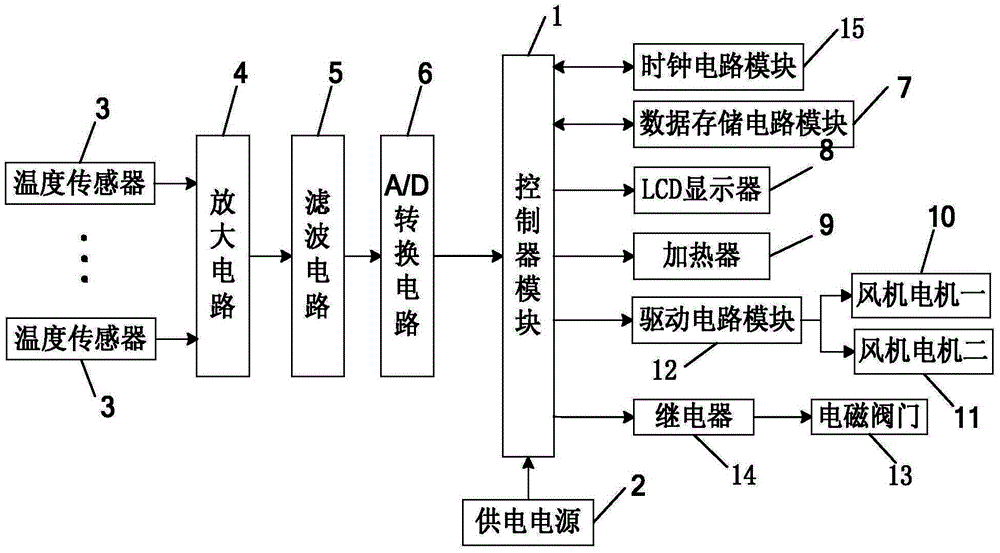

Automatic ventilation control system for high temperature aging room

InactiveCN104656712ASimple structureReasonable designSimultaneous control of multiple variablesAutomatic train controlMoisture sensor

The invention discloses an automatic ventilation control system for a high temperature aging room. The automatic ventilation control system comprises a controller module and a power supply, wherein the input end of the controller module is connected with temperature and humidity sensors; an amplifying circuit, a filter circuit and an A / D switching circuit are sequentially connected between the temperature and humidity sensors and the controller module; the controller module is connected with a data storage circuit module and a clock circuit module; the output end of the controller module is connected with an LCD display, a heater, a driving circuit module for driving a fan motor I and a fan motor II, and a relay for controlling an electromagnetic valve. The automatic ventilation control system disclosed by the invention is simple in structure, reasonable in design, low in production and usage cost, energy-saving, and convenient to operate and test, and can improve the production efficiency.

Owner:XIAN LIANKONG ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com