Dual-layer hot air distribution pipe

A hot air distribution, double-layer technology, applied in the direction of pipes, branch pipelines, pipes/pipe joints/pipe fittings, etc., can solve the problems of low temperature on both sides, uneven temperature distribution, obvious thermal deformation, etc., and achieve the goal of improving the quality of hot air difference, solve the effect of uneven temperature distribution and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

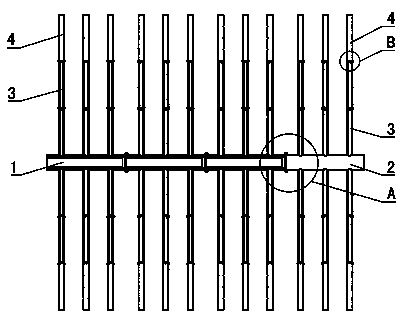

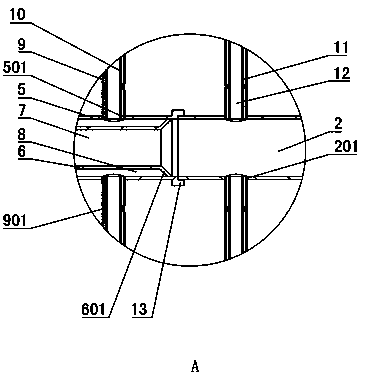

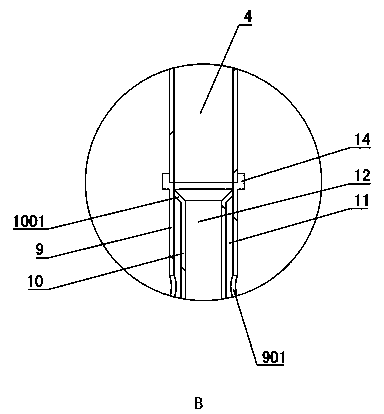

[0046] Such as Figure 1~5 As shown: in this embodiment, the main pipe 1 is provided with three sections connected head to tail along the axial direction, and the left end of each section of the main pipe 1 is the air inlet end, and the right end is the air outlet end. 2. Three branch pipes 3 are evenly distributed on the upper and lower sides of each section of the main pipe 1. The branch pipes 3 are arranged along the radial direction of the main pipe 1. The right end of the main pipe end pipe 2 is closed, and the upper and lower sides of the main pipe end pipe 2 are also symmetrically arranged. Three branch pipes 3. The end of each branch pipe 3 close to the main pipe 1 or the end pipe 2 of the main pipe is the air inlet end, and the end of each branch pipe 3 far away from the main pipe 1 or away from the main pipe end pipe 2 is the gas outlet end, and each branch pipe 3 is provided with a head-to-tail connection in the axial direction In the two sections, the gas outlet e...

Embodiment 2

[0058] Such as Figure 6~7 As shown: the difference between embodiment 2 and embodiment 1 is that the delivery main pipe docking cover 601 of the main delivery main pipe 6 is spaced apart from the inner wall of the corresponding distribution main pipe 5 of this section, that is, both ends of the main pipe distribution chamber 8 are open. The delivery branch pipe docking cover 1001 of the delivery branch pipe 10 is spaced apart from the inner wall of the corresponding distribution branch pipe 9 , that is, both ends of the distribution chamber 11 of the branch pipe are open. Ensure that the hot air flow is more stable.

Embodiment 3

[0060] Such as Figure 8~12 As shown: the difference between embodiment 3 and embodiment 1 is that a pre-allocation main pipe 16 is arranged between the distribution main pipe 5 and the conveying main pipe 6 of each section of main pipe 1, and the pre-allocation main pipe 16 is connected with the corresponding distribution main pipe 5 and the conveying main pipe 6 They are evenly spaced so that a main pipe distribution cavity 8 is formed between the pre-distribution main pipe 16 and the distribution main pipe 5, and a main pipe pre-distribution chamber 18 is formed between the delivery main pipe 6 and the pre-distribution main pipe 16. The intake end of the conveying main pipe 6 is arranged within the intake end of the pre-distribution main pipe 16, so that the air inlet for connecting the pre-distribution main pipe 16 intake end and the conveying main pipe 6 intake end is formed at the pre-distribution main pipe 16 intake end. The main pipe communicates with the chamber 17. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com