Subminiature minimal invasion high-temperature creep fatigue testing machine and application thereof

A fatigue testing machine and high-temperature creep technology, applied in the direction of testing the ductility of materials, etc., can solve the problems of large geometric size of the sample, the inability to sample, and the impact of high-temperature structure life, so as to prevent the oxidation of the sample, facilitate the test operation, The effect of improving accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

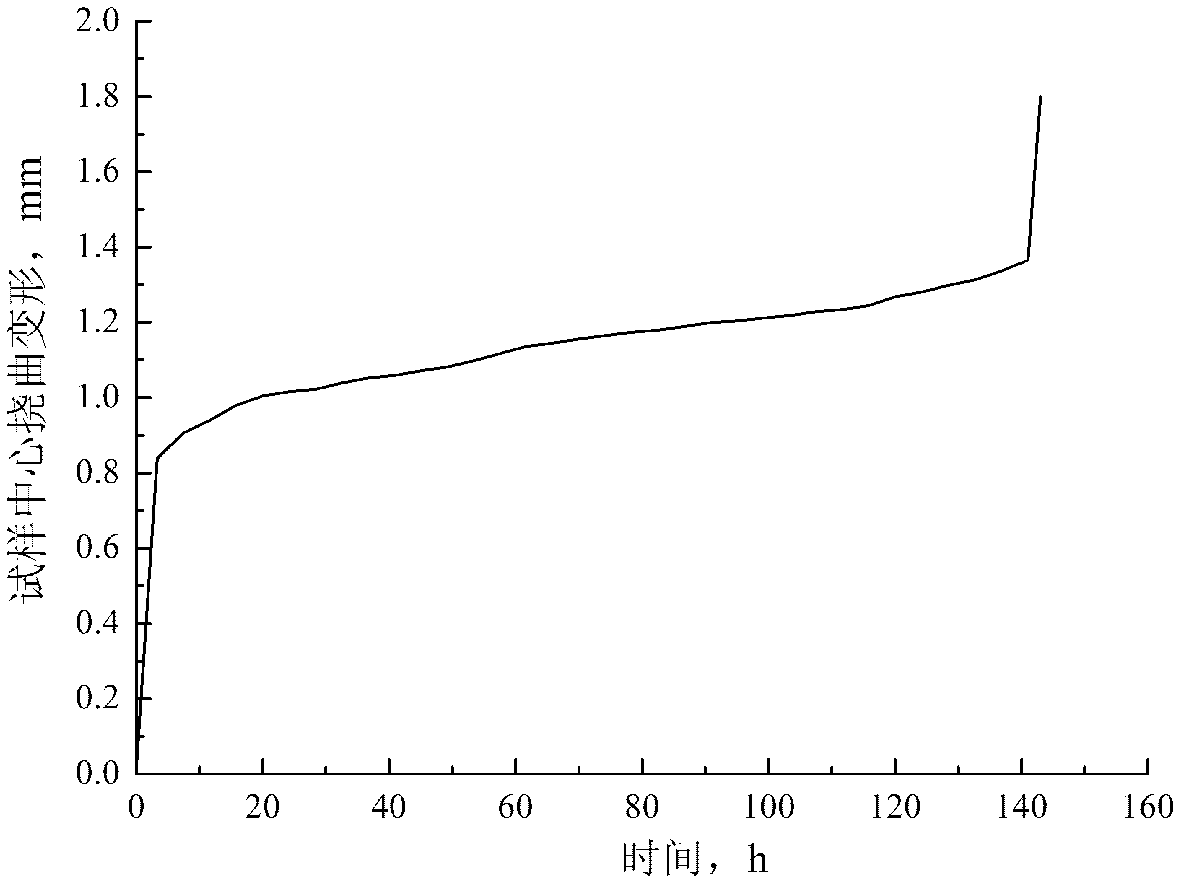

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

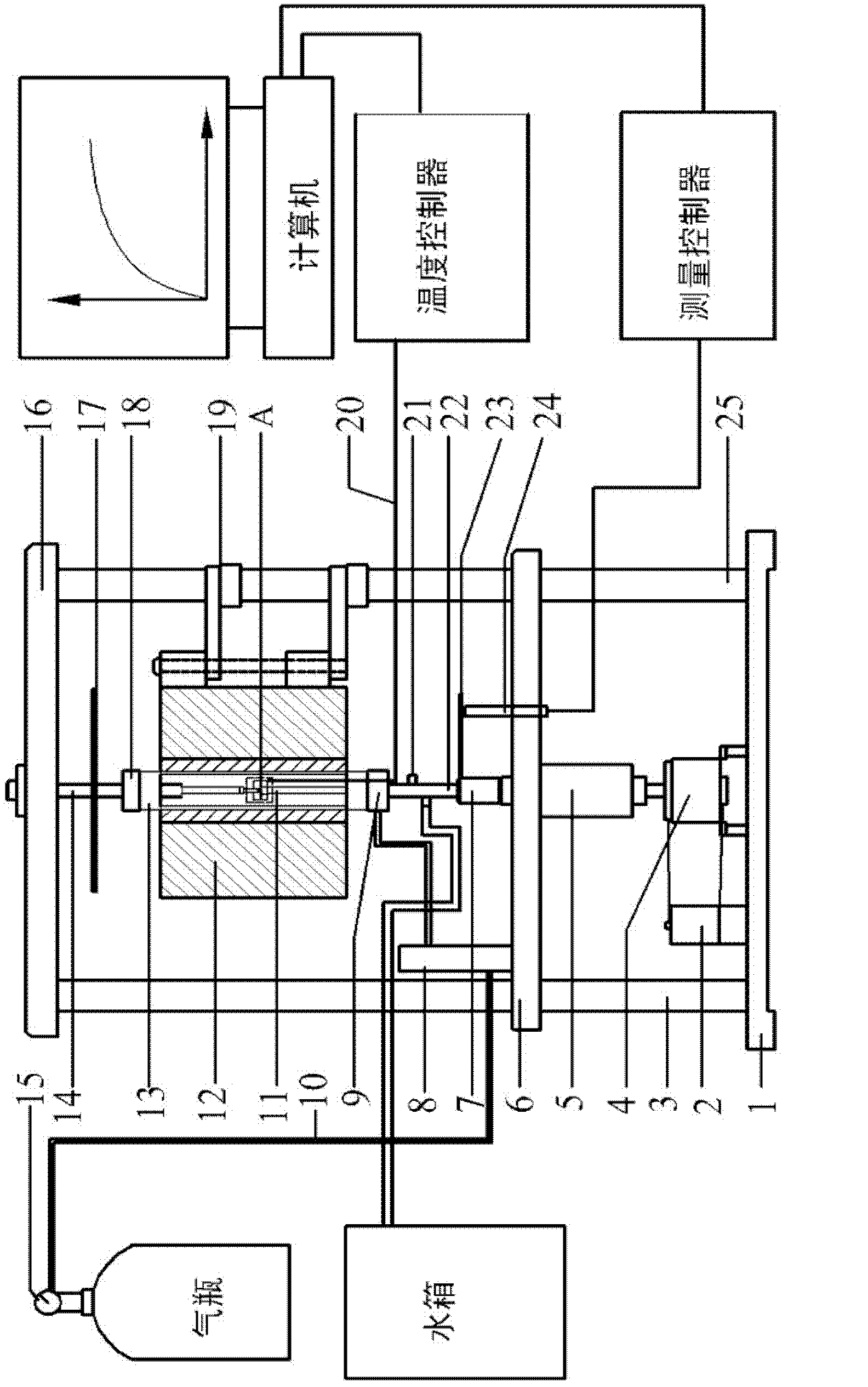

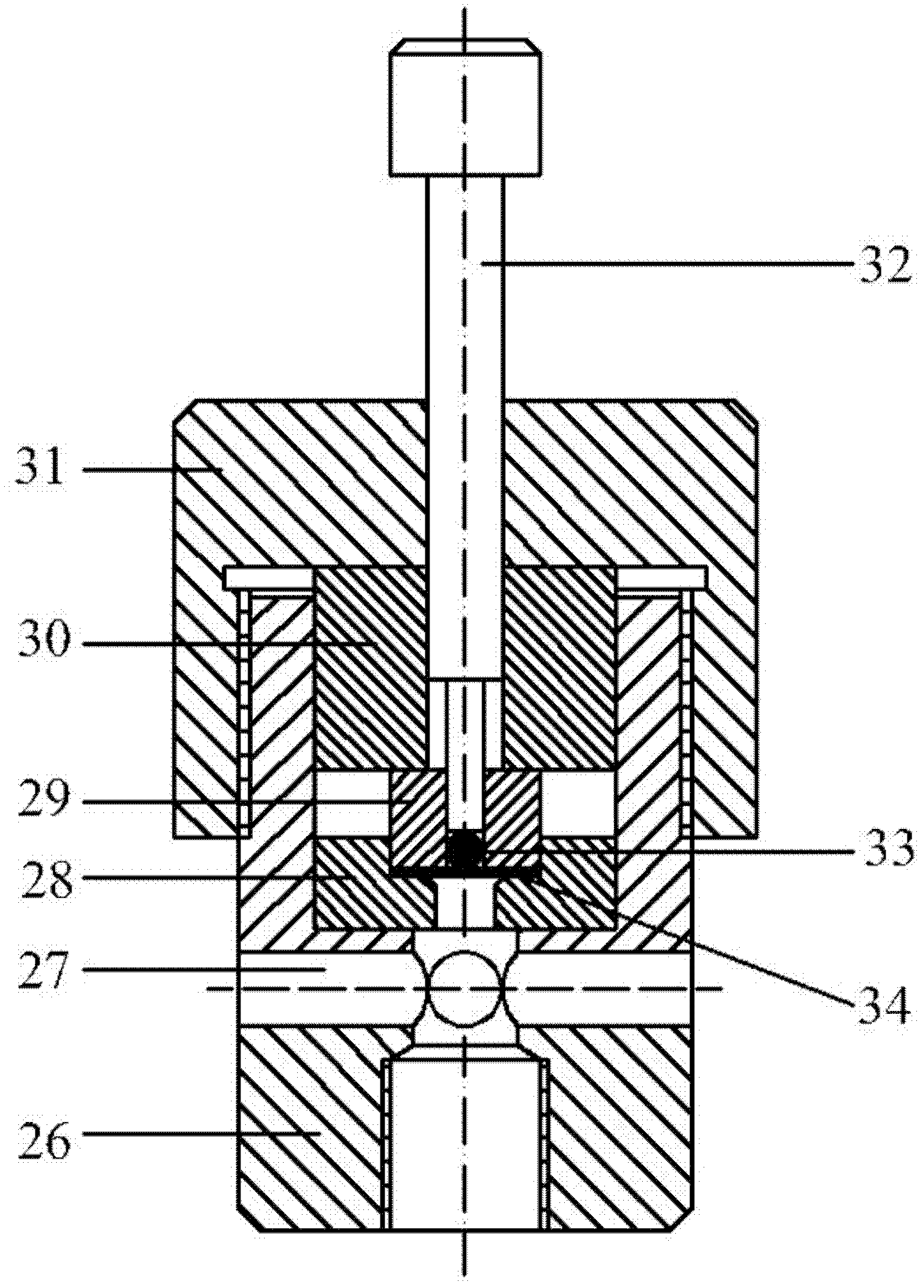

[0024] The ultra-small minimally invasive high-temperature creep fatigue testing machine of the present invention includes a frame, a drive system, a temperature control system, a high-temperature gas protection system, a measurement control system, a loading device and a water cooling system, wherein:

[0025] The frame includes a base plate 1, a middle plate 6, an upper beam 16 and column supports 3 and 25 connecting them, wherein the base plate is used to install and fix servo motors and reducers; the middle plate is used to install and fix sensors and flowmeters; The upper beam is used for fixed connection with the upper loading rod; the column support is used for connecting and reinforcing the bottom plate, middle platform and upper beam;

[0026] The drive system includes a servo motor 2, a reducer 4 and a transmission mechanism 5, wherein t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com