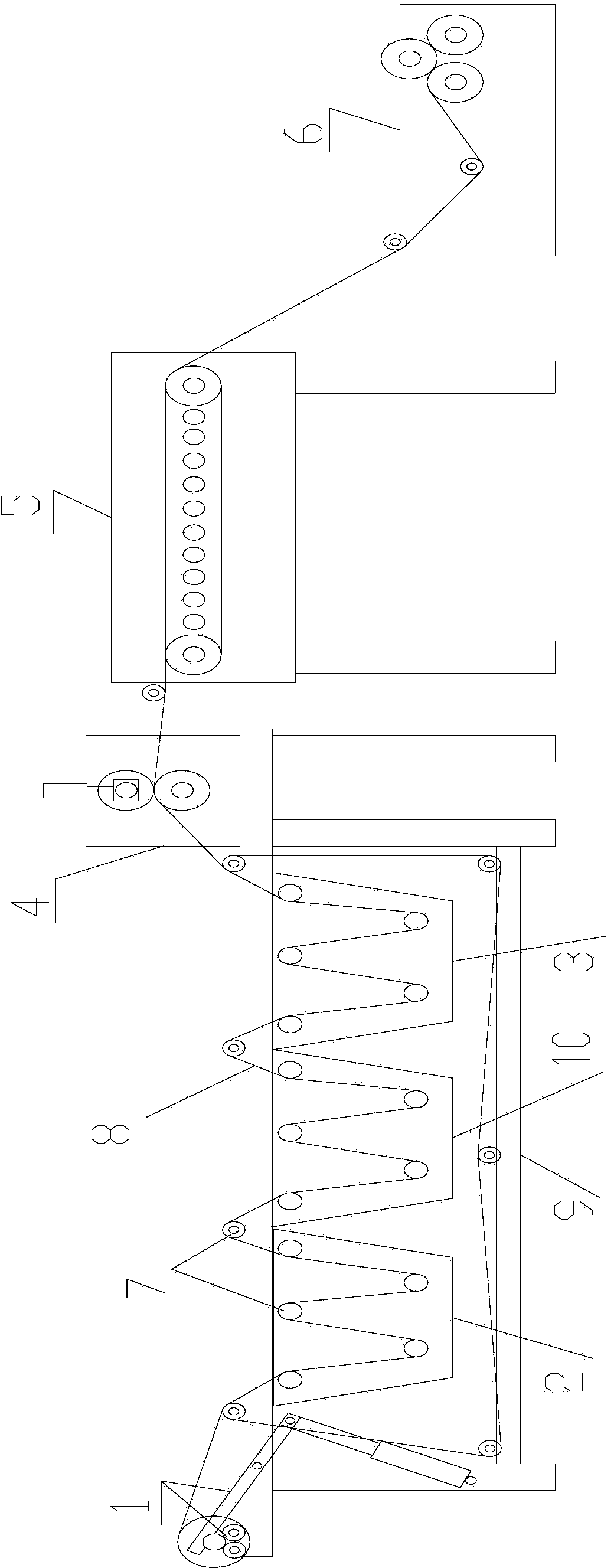

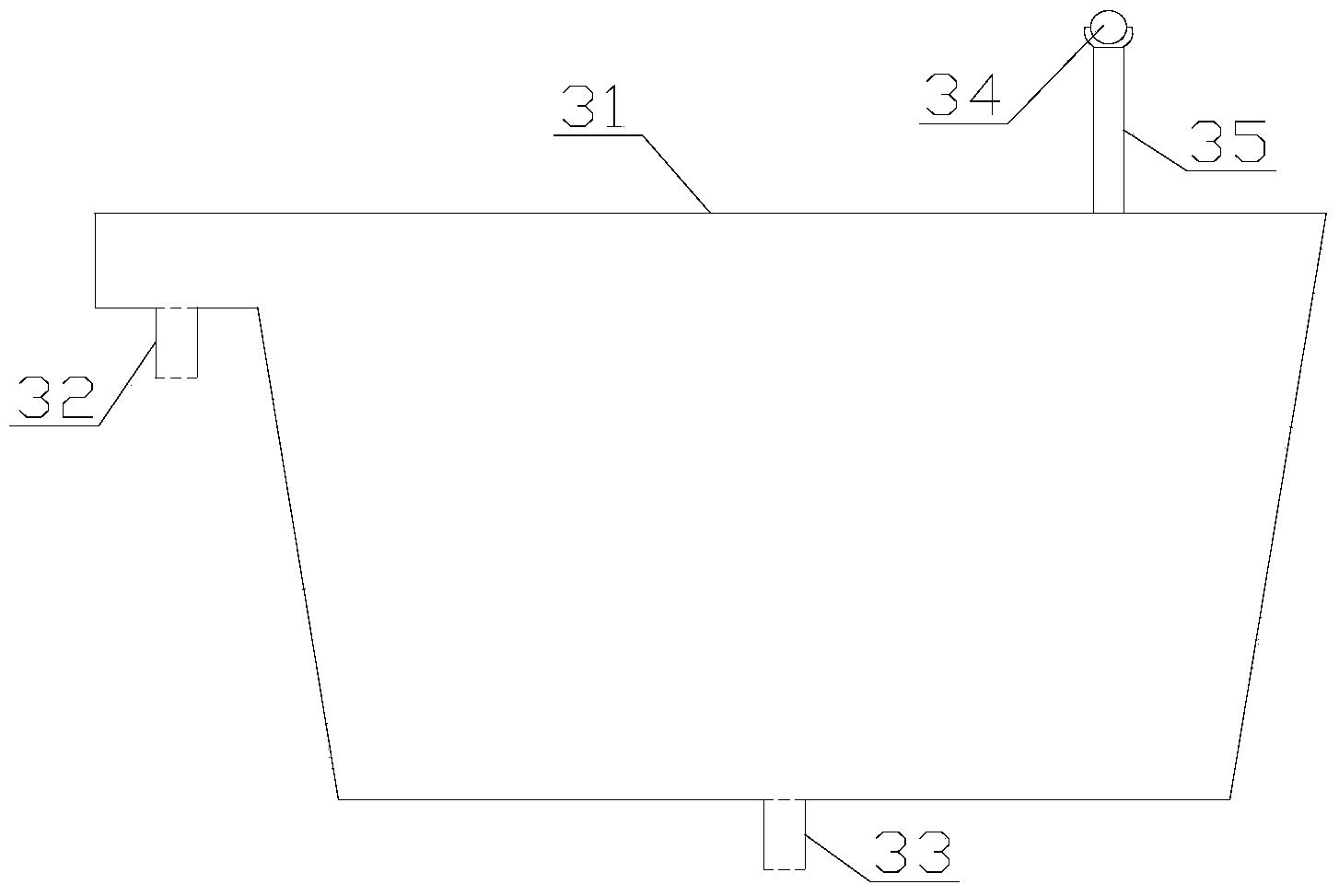

[0003] During the dyeing production process of non-woven fabrics, the non-woven fabrics are unrolled into the dye vat for dyeing, and then enter the cleaning vat for cleaning and other subsequent processes. In the prior art, the dyed non-woven fabrics enter the cleaning vat for cleaning, which is the mesh belt support. The dyed non-woven fabric passes through the cleaning tank filled with water. As the non-woven fabric passing through continues to increase, the dye contained in the water will continue to increase, and the dye will be taken away by the non-woven fabric along with the water, thereby achieving Less than a good cleaning effect will affect the dyeing quality of the product

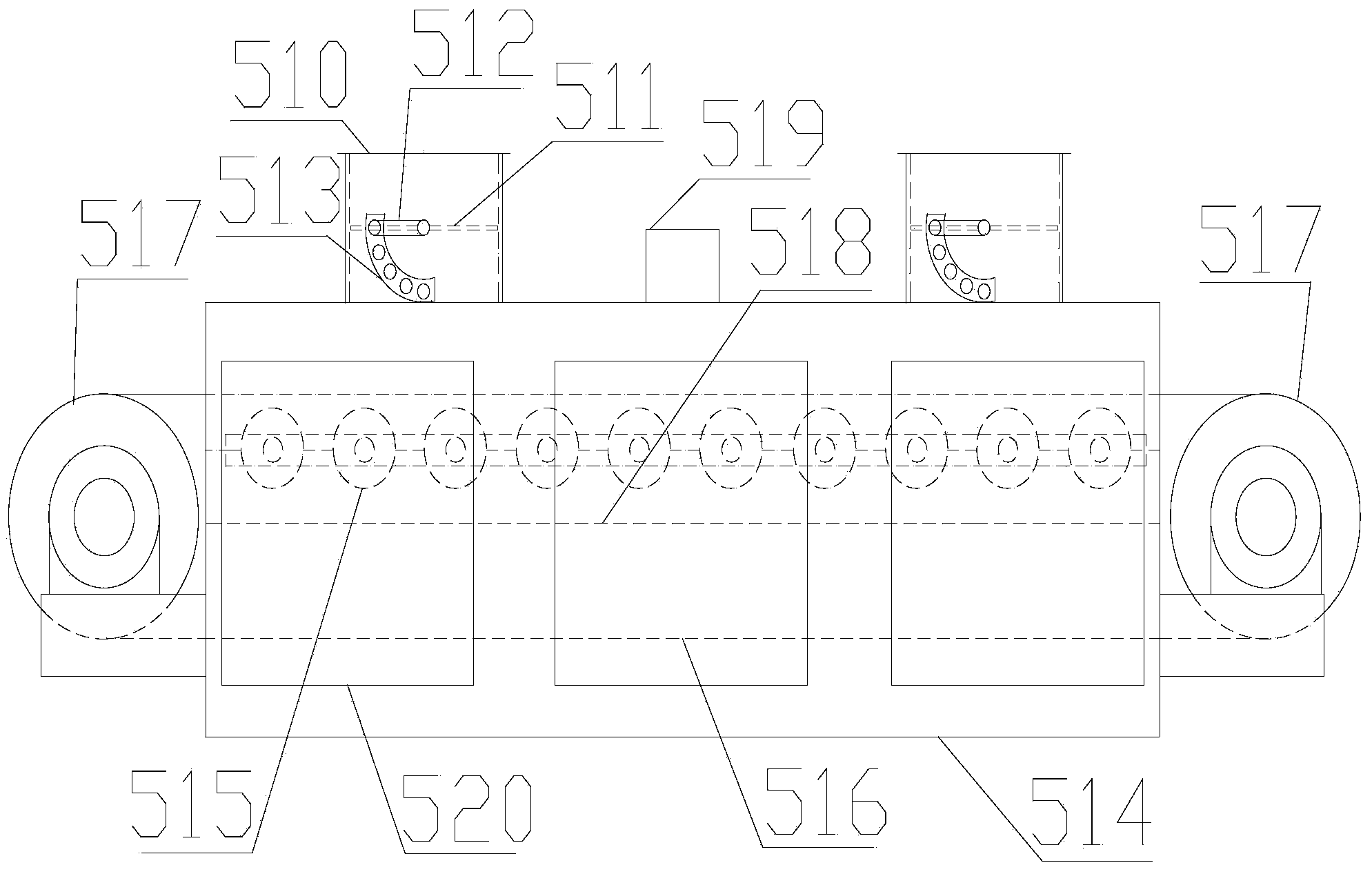

[0004] In the prior art, the size of the exhaust port of the drying device cannot be adjusted, but a large amount of heat is discharged at the same time when exhausting, causing the temperature in the oven to be unstable and drop quickly, so that the drying of non-woven fabrics cannot be achieved. normal temperature, affecting production

There are several guide rollers on the drying device, and the shafts of the guide rollers are equipped with gears, which are transmitted to the gears through the chain and drive the guide rollers to rotate. Since the chains and gears need to be lubricated, for the safety of employees, manual cleaning is required after the production is stopped. When the chain is refueled, lubricating oil needs to be added once every 3 to 5 hours, which not only leads to incoherence in the entire production process, but also seriously affects production efficiency

[0005] Due to the large width of the non-woven fabric and its own flexibility, the non-woven fabric is prone to wrinkles during the rolling process, which affects the quality of the roll.

[0006] The position height of the reel varies with the size of the non-woven fabric roll. When the reel rises to a certain height, the reel shakes due to its own weight during the roll-forming process. In the case of the position, it is easy to move the position, causing the two ends of the rolled non-woven fabric to be uneven, which will affect the rolling effect and the overall aesthetics

[0007] The driving mechanism of the coiling device in the prior art is that the motor drives the transmission to rotate, and the transmission drives the driving roller to rotate. Since the transmission and the driving roller are connected by belt transmission, when the belt is used for a certain period of time, it is prone to slipping during transmission. , the

transmission rate is reduced, causing the intermittent stop of the rolling device or the reduction of the

rolling speed, so that the non-woven fabric cannot be tightened on the rolling device, resulting in wrinkles in the rolled non-woven fabric

[0008] During the whole process from unwinding to rolling, the non-woven fabric needs to be conveyed by several guide rollers. During the conveying process, the position of the non-woven fabric is often unstable, so that the two ends of the non-woven fabric after being rolled are not neat. , which seriously affects the overall appearance of the rolled non-woven fabric

[0009] During the dyeing process of non-woven fabrics, the rolls of non-woven fabrics must first be unrolled through the unwinding device, and then carried by the mesh belt into subsequent processes such as dyeing tanks and cleaning tanks. The unwinding of non-woven fabrics in the prior art The device is equipped with two rollers on both sides of the frame body, and then the unwinding shaft passes through the non-woven fabric reel, and then the two ends of the unwinding shaft are placed between the two rollers, and the non-woven fabric roll is carried by the mesh belt. Unwinding, because the friction between the unwinding shaft and the roller is too small, the unwinding speed is prone to be greater than the speed of the mesh belt under the action of

inertia, so that the unrolled non-woven fabric touches the ground and sticks to

dirt. Can not be tiled on the surface of the mesh belt, thus affecting the dyeing quality and prone to wrinkles

[0010] During the dyeing production process of non-woven fabrics, the washed non-woven fabrics need to be rolled and dried, and then enter the drying device. In the prior art, the gap between the two rollers needs to be adjusted to apply normal pressure to the non-woven fabrics. , to achieve the normal

dewatering effect. In the prior art, the roll adjustment is adjusted by manually turning the adjustment wheels connected to the two ends of the roll. Since the two ends of the roll are moved up and down during the adjustment process, when adjusting Using

visual inspection, the distance between the two rolls will be inconsistent, and the normal

dewatering pressure on the non-woven fabric will not be satisfied, so that when the non-woven fabric is dewatered by the rolls, the

dewatering is not uniform enough or the normal dewatering effect cannot be achieved. , it is time-consuming to make repeated adjustments and the adjustment is not in place, which not only wastes time, but also affects the drying effect

Login to View More

Login to View More  Login to View More

Login to View More