Patents

Literature

281results about How to "Avoid taking away" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

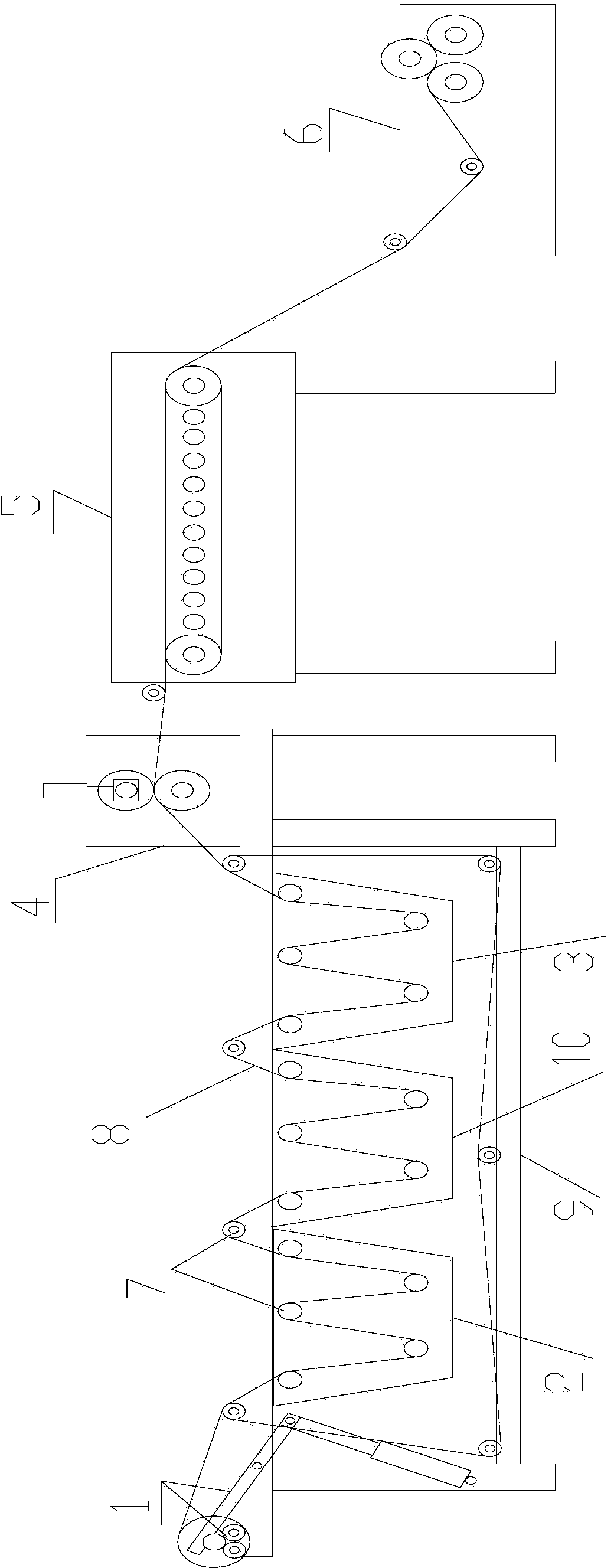

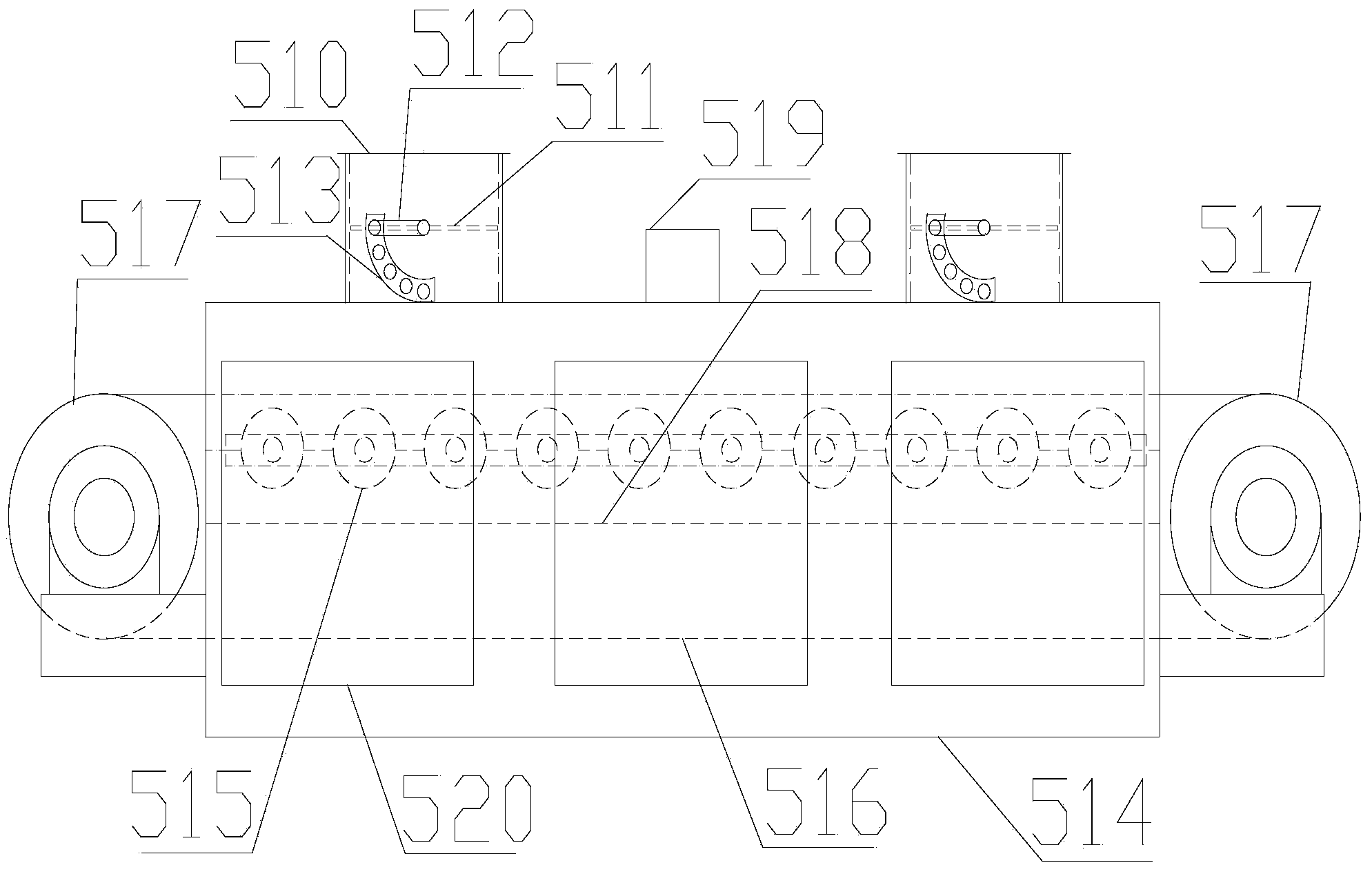

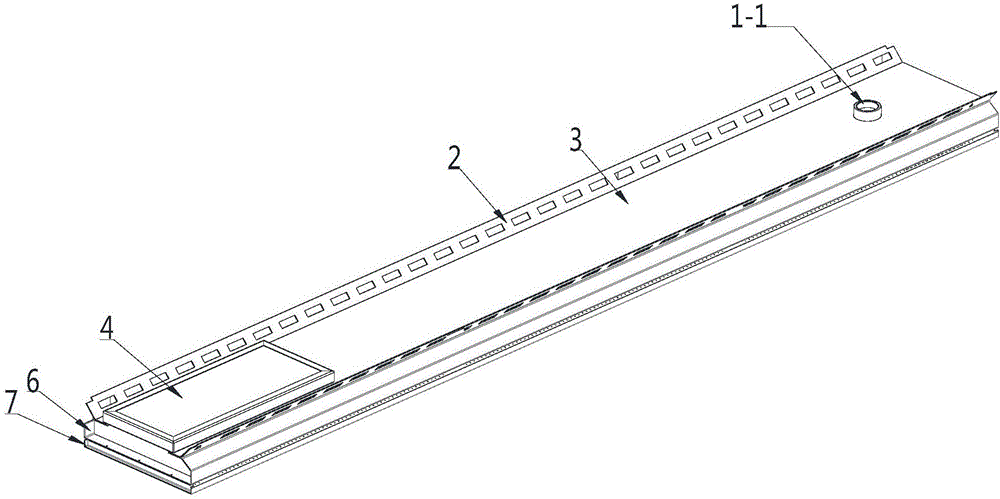

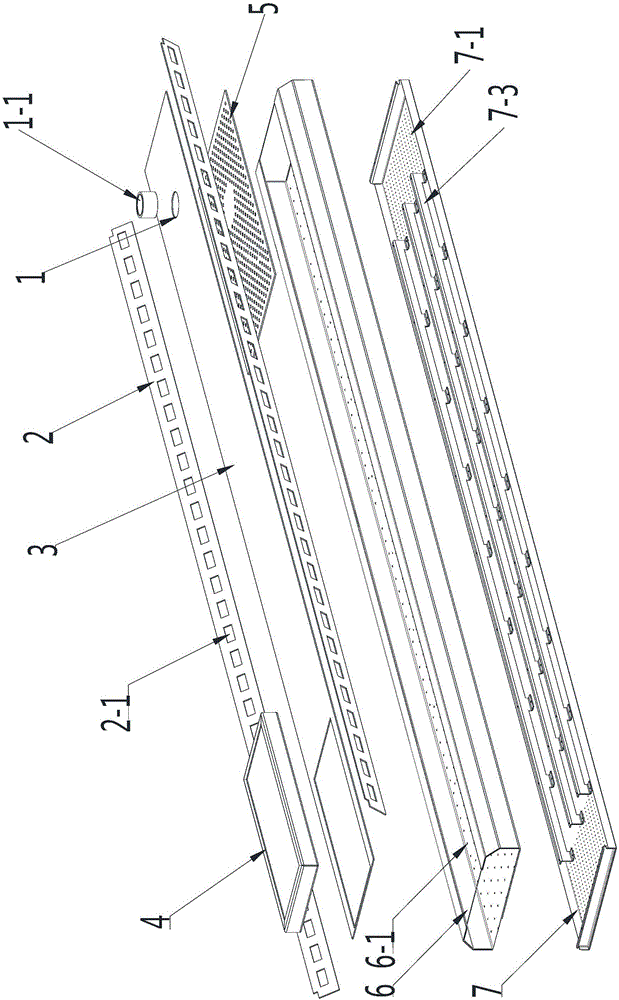

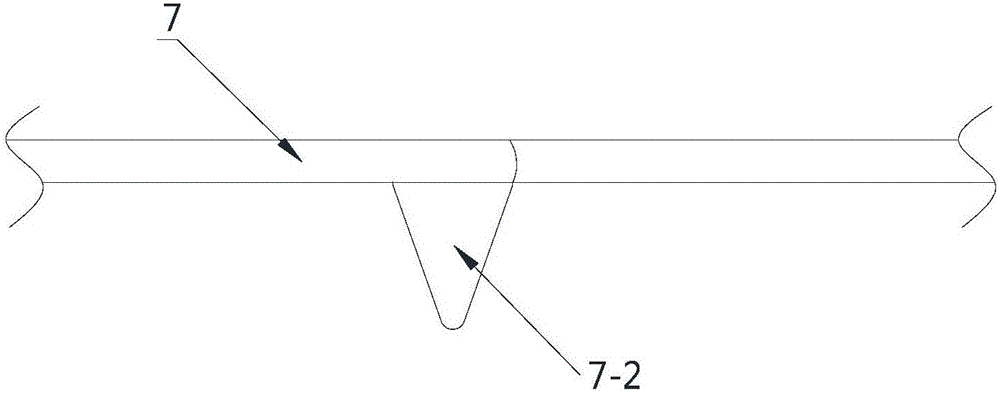

Non-woven fabric dying production line

InactiveCN103820962AAvoid shakingPrevent fallingSucessive textile treatmentsTextile treatment machine arrangementsEngineeringNonwoven fabric

The invention discloses a non-woven fabric dying production line which comprises an uncoiling device, a dying cylinder, a cleaning cylinder, dry-rolling device, a drying device, a coiling device, a plurality of guide rollers, net belts and a first frame body. The uncoiling device, the dying cylinder, the cleaning cylinder and the dry-rolling device are arranged on the first frame body in sequence. The coiling device is arranged in rear of the drying device, and the dying cylinder, the cleaning cylinder and the first frame body are provided with the guide rollers. The net belts are arranged on the guide rollers in a tensioning mode. Compared with the prior art, the good cleaning effect can be achieved, the dying quality of a product is not affected, the size of an exhaust opening can be adjusted, the normal temperature in drying non-woven fabric in a drying oven and the coherence of the whole production process are guaranteed, production efficiency is not affected, crimples are avoided, the overall attractiveness and the coiling quality of the non-woven fabric are ensured, slippage in transmission can also be avoided, the transmission rate is guaranteed, the uncoiling speed can be prevented from being higher than the belt supporting speed of the net belts, water removing is even, the normal water removing effect is achieved, and the drying effect is not affected.

Owner:HANGZHOU AOKE GARMENT ACCESSORIES

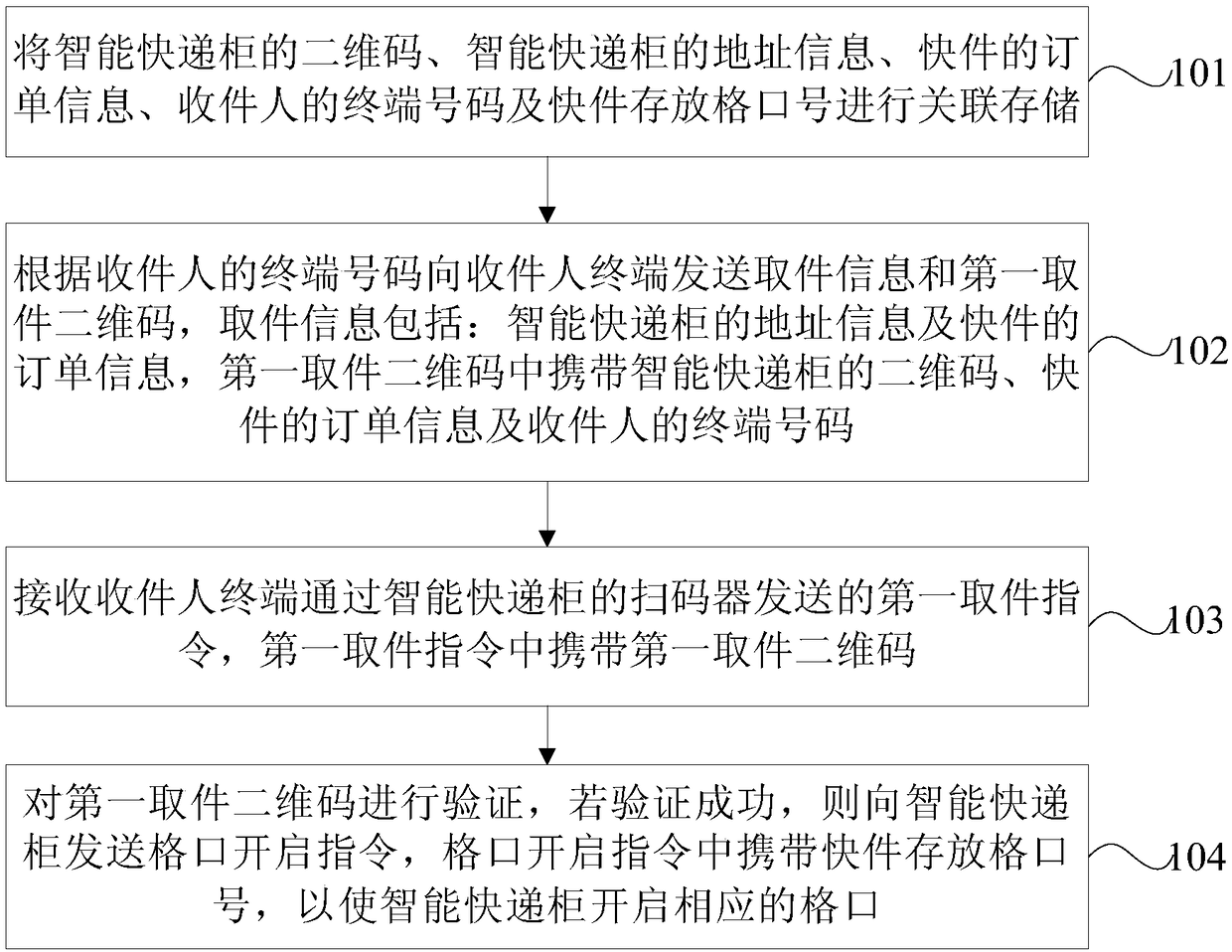

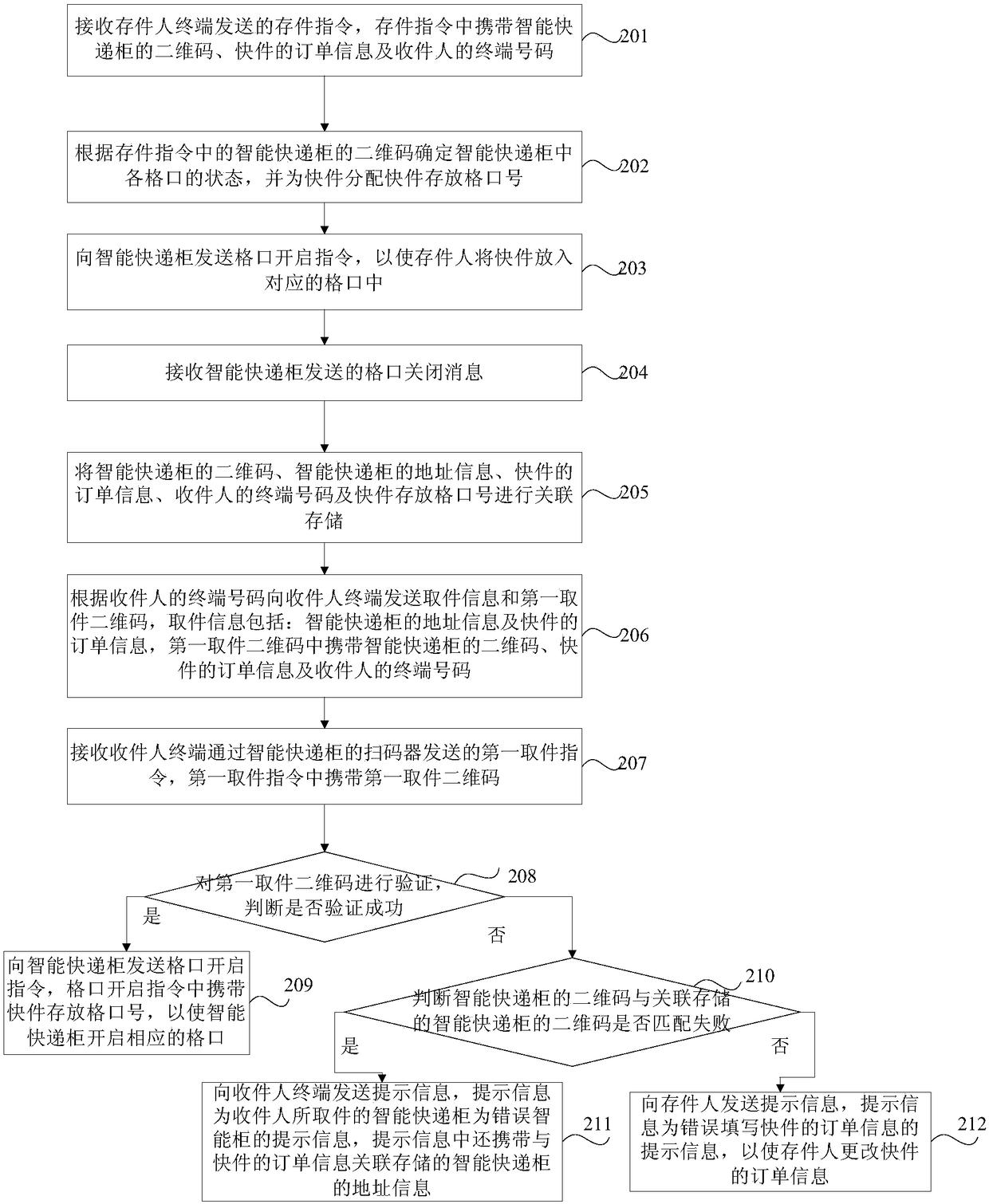

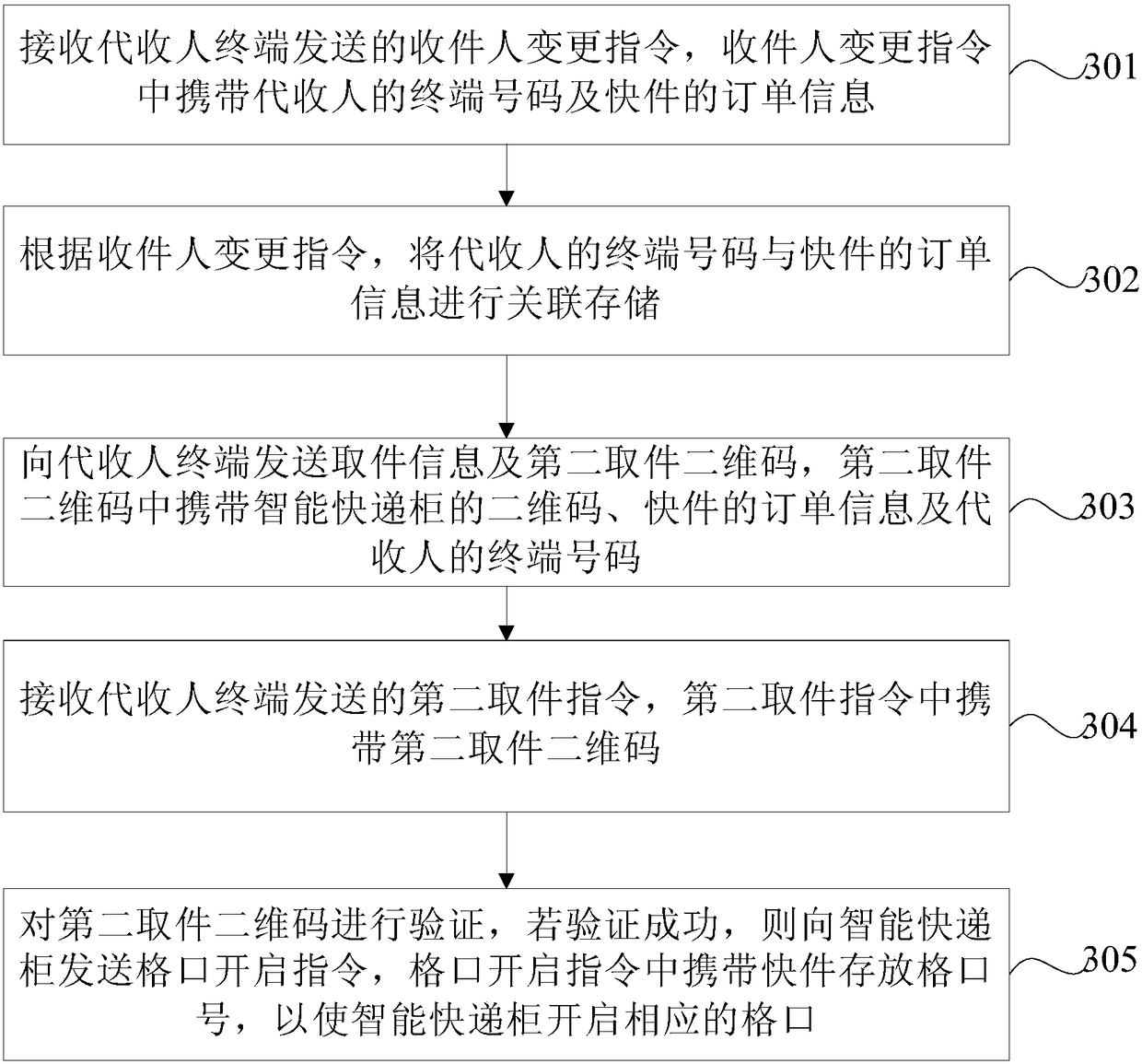

An express item processing method and device based on intelligent express delivery cabinets

ActiveCN108269363ATake out accuratelyImprove securityApparatus for meter-controlled dispensingIndividual entry/exit registersComputer scienceStorage cell

The invention provides an express item processing method and device based on intelligent express delivery cabinets. The method comprises the steps of: storing two-dimensional codes of intelligent express delivery cabinets, address information of the intelligent express delivery cabinets, order information of express items, terminal numbers of recipients and express item storage cell numbers in a correlated manner; sending item fetching information and first item fetching two-dimensional codes to the terminals of recipients according to the terminal numbers of the recipients, wherein the item fetching information includes the address information the intelligent express delivery cabinets and the order information of the express items and the first item fetching two-dimensional codes carry the two-dimensional codes of the intelligent express delivery cabinets, the order information of the express items and the terminal numbers of the recipients; receiving first item fetching instructionssent by the terminals of the recipients through code scanners of the intelligent express delivery cabinets, wherein the first item fetching instructions carry the first item fetching two-dimensional codes; verifying the first item fetching two-dimensional codes and sending cell opening instructions to the intelligent express delivery cabinets if the codes pass the verification, wherein the cell opening instructions carry the express item storage cell numbers so that the intelligent express delivery cabinets can open corresponding cells.

Owner:NEW FOUNDER HLDG DEV LLC +1

Aluminum alloy for subway station ceiling and preparing method of aluminum alloy

The invention relates to an aluminum alloy for a subway station ceiling and a preparing method of the aluminum alloy. The aluminum alloy is characterized by comprising chemical components, including by mass percent, 0.45% to 0.6% of Mg, 0.3% to 0.5% of Si, 0.1% to 0.3% of Mn, 0.1% to 0.2% of Cr, 0.1% to 0.3% of Zr, 0.1% to 0.3% of Hf, 0.05% to 0.2% of Ta, 0.05% to 0.15% of Cu, not larger than 0.05% of Zn, not larger than 0.20% of Fe, not larger than 0.05% of Ti, and the balance Al, wherein the single content of other impurity elements is not larger than 0.05%, and the total content of other impurity elements is not larger than 0.15%. The aluminum alloy is obtained through the preparing method of smelting, refining, casting and homogenizing. Through optimizing of alloy components, adjustment is carried out, the trace of Zr, Hf and Ta is added, and the strength, the heat dissipation, corrosion resistance, humidity resistance, fatigue resistance, static electricity resistance, recrystallization resistance capacity and breaking resistance performance of the aluminum alloy can be obviously improved.

Owner:ALNAN ALUMINIUM CO LTD

Aluminum alloy welding wire for high speed train and preparation method of aluminum alloy welding wire for high speed train

InactiveCN105772981AHigh tensile strengthImprove plasticityWelding/cutting media/materialsSoldering mediaCrack resistanceAlloy

The invention relates to an aluminum alloy welding wire for a high speed train and a preparation method of the aluminum alloy welding wire for the high speed train. The aluminum alloy welding wire for the high speed train is characterized by comprising the following chemical components in percentages by mass: 4.0-6.5% of Mg, 0.06-0.2% of Ti, 0.1-0.3% of Cr, 0.05-0.2% of Mn, 0.05-0.2% of La, 0.05-0.2% of Te, 0.01-0.05% of Bi, less than or equal to 0.25% of Si, less than or equal to 0.2% of Fe, less than or equal to 0.20% of Zn, less than or equal to 0.05% of single content of other impurity elements, less than or equal to 0.15% of total content of other impurity elements and the balance of Al. The preparation method of the aluminum alloy welding wire for the high speed train comprises the following steps: smelting, refining, casting, homogenization, extrusion, drawing, and surface treatment. The aluminum alloy welding wire for the high speed train provided by the invention is fine in weld microstructure and good in crack resistance; the tensile strength, the plasticity and the toughness of welded joints are remarkably higher than those of common ER5356 and ER5183 welding wires.

Owner:GUILIN UNIV OF AEROSPACE TECH

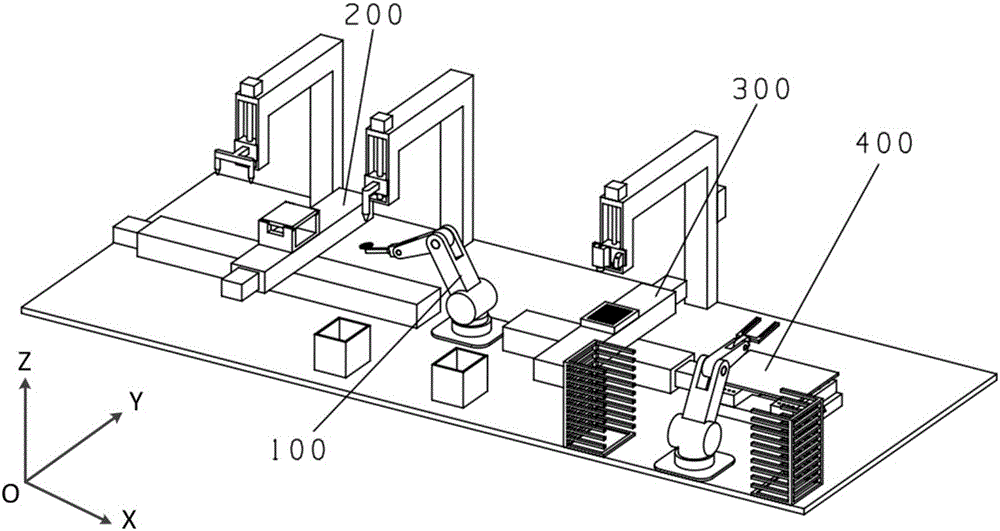

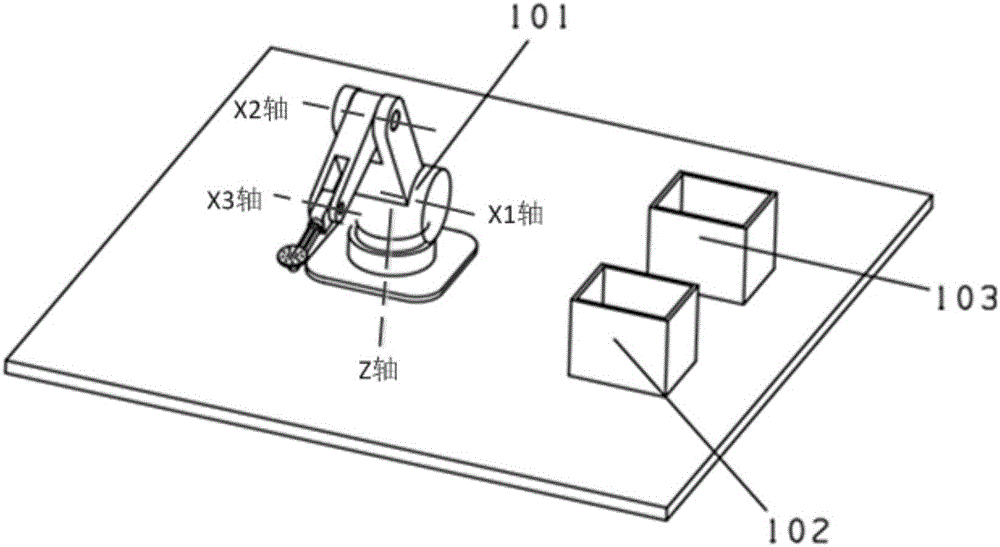

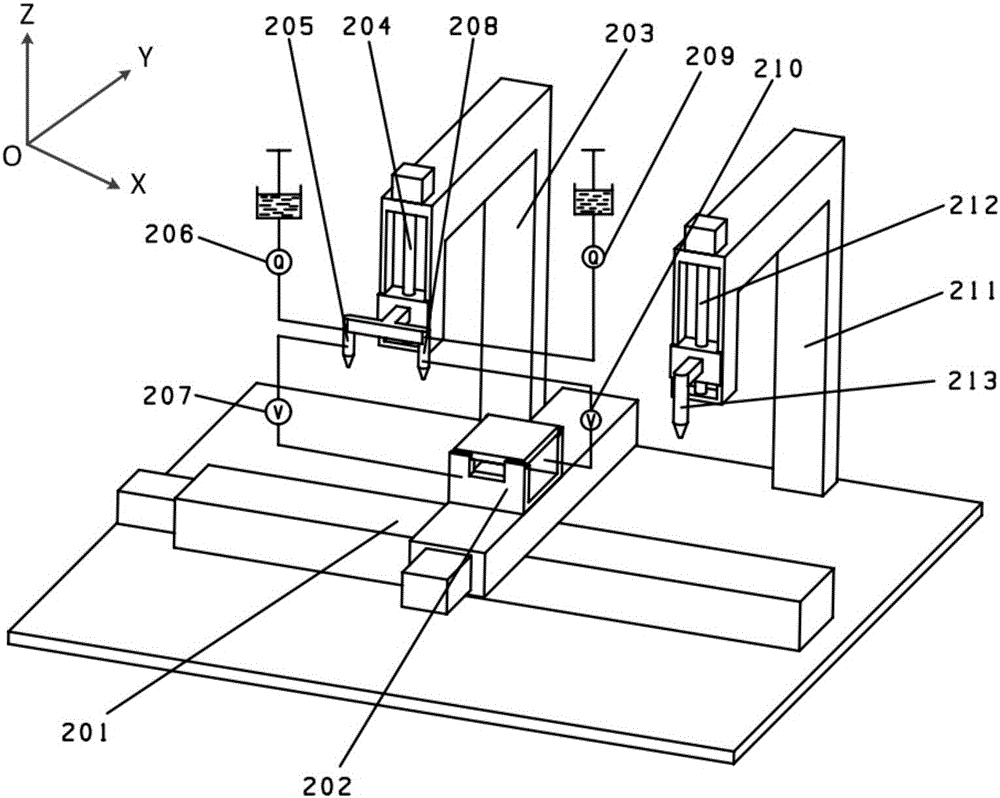

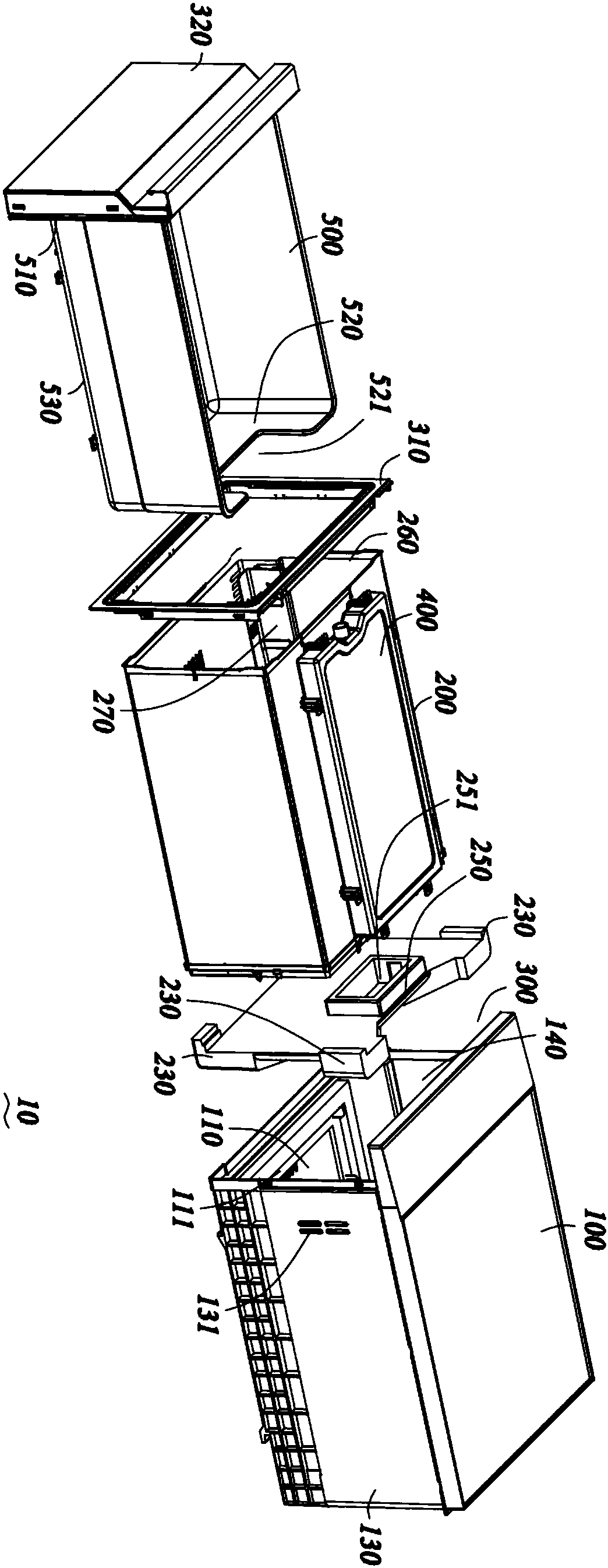

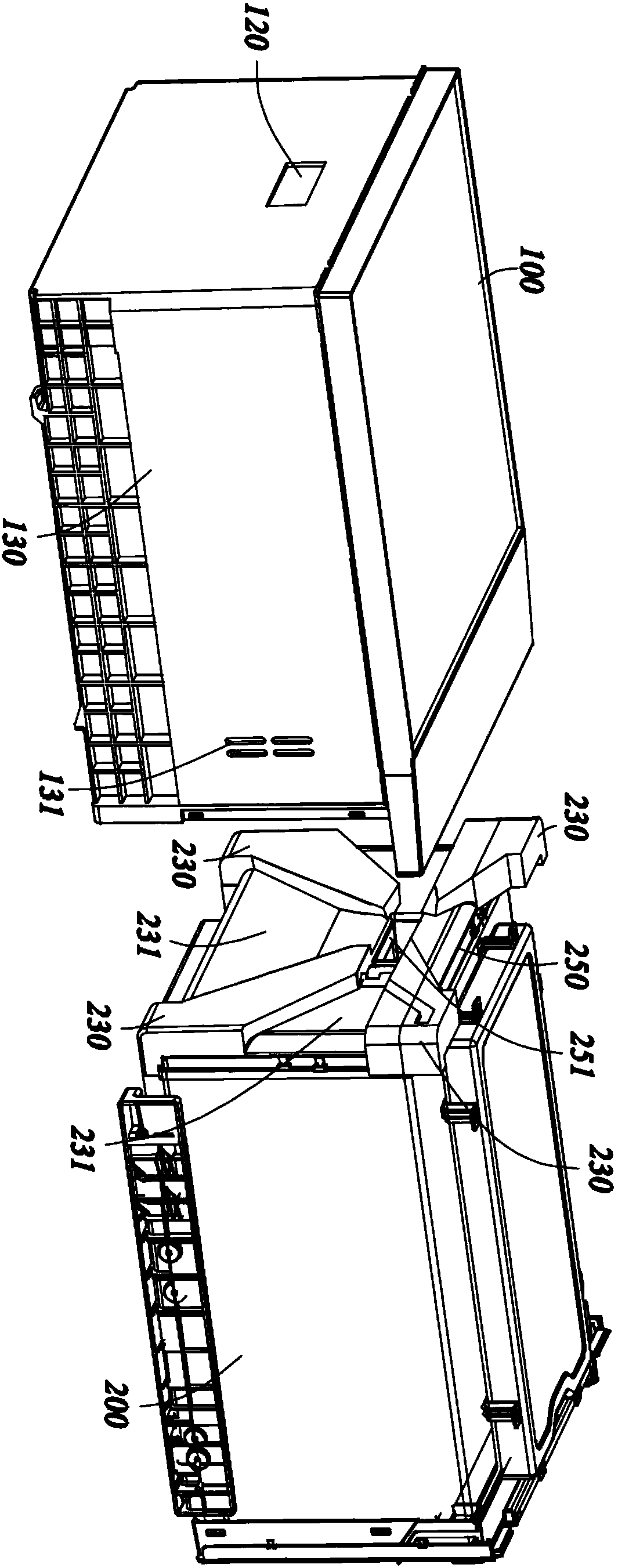

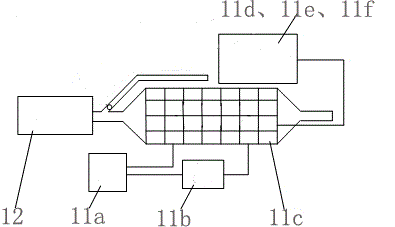

Flexible electronics preparing, transferring, and packaging system and method

ActiveCN105762096AIncrease productivityReduce volumeSemiconductor/solid-state device manufacturingConveyor partsEngineeringFlexible electronics

The invention discloses a flexible electronics preparing, transferring, and packaging system and method. The system comprises a substrate transferring module, a flexible electronics preparing module, a laser stripping module, and a packaging, loading and unloading module. The substrate transferring module is used for picking up a substrate and placing the substrate on the flexible electronics preparing module, and transferring prepared flexible electronic device and the substrate to the laser stripping module, and finally reclaims the stripped substrate from the laser stripping module. The flexible electronics preparing module is used for preparing the flexible electronic device on the substrate. The laser stripping module is used for stripping the prepared flexible electronics off the substrate. The packaging, loading and unloading module is used for placing a product to be packaged on a packaging module, packages the flexible electronics stripped from the substrate on the product, and taking down the packaged product. The method prepares, transfers, and packages the flexible electronic device by using the system. The system is greatly decreased in size, reduces intermediate links, saves space, and increases production efficiency.

Owner:武汉国创科光电装备有限公司

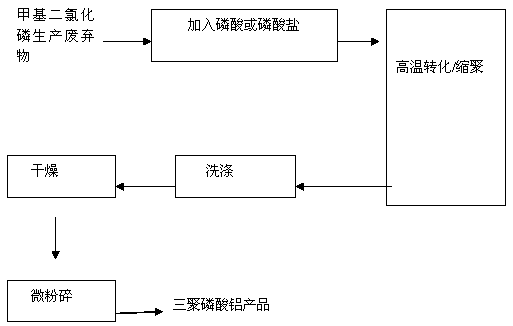

Method for producing aluminum triphosphate by utilizing methyl phosphorus dichloride production waste

ActiveCN105502326ARealize resource utilizationAvoid pollutionPhosphorus compoundsTernary complexPhosphate

The invention provides a method for producing aluminum triphosphate by utilizing methyl phosphorus dichloride production waste. With methyl chloride, aluminum trichloride and phosphorus trichloride as raw materials, a complex generated through reaction is reduced under the catalysis of aluminum powder, phosphoric acid or phosphate is added into the waste left after a product methyl phosphorus dichloride is evaporated out, condensation reaction is performed at the high temperature of 250-450 DEG C, and after the reaction is completed, washing, drying and micro-grinding are performed to obtain the aluminum tripolyphosphate product. Resource utilization that methyl phosphorus dichloride production waste is utilized to prepare ternary complexes is achieved.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

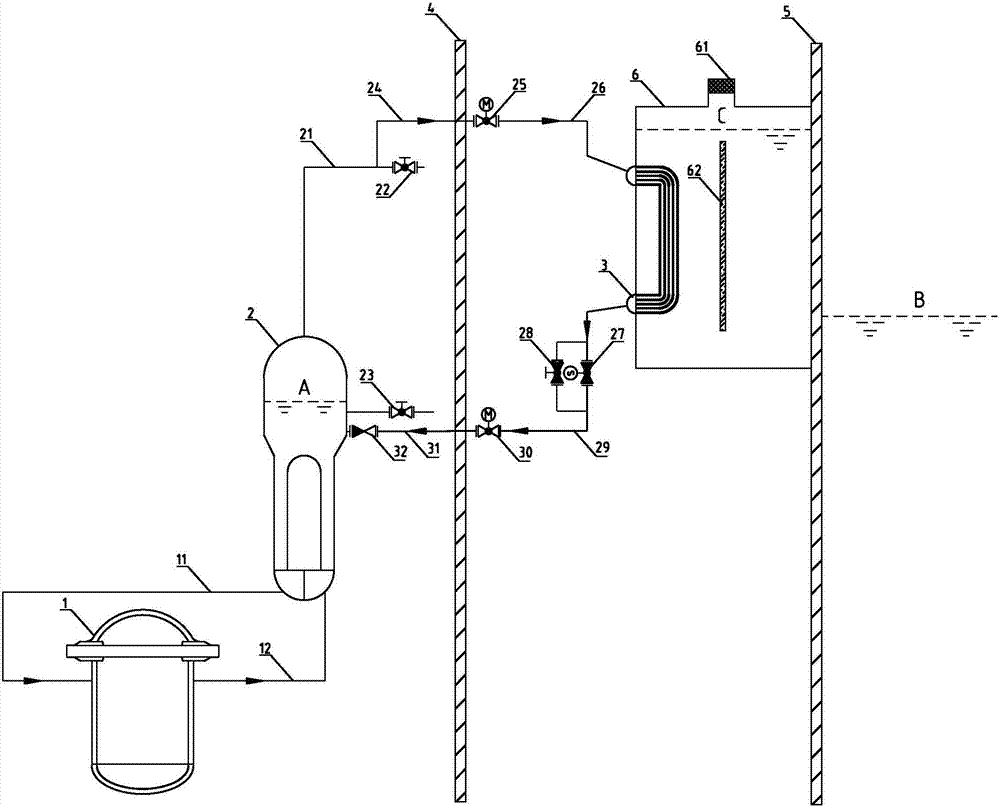

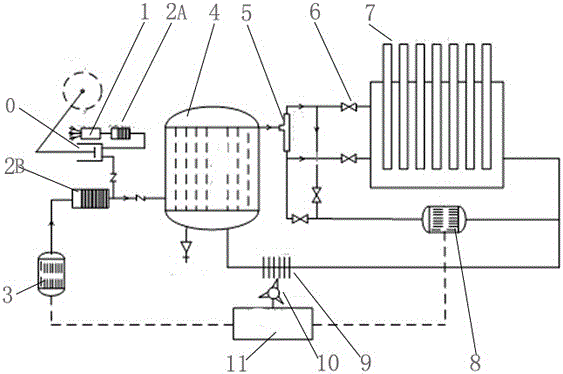

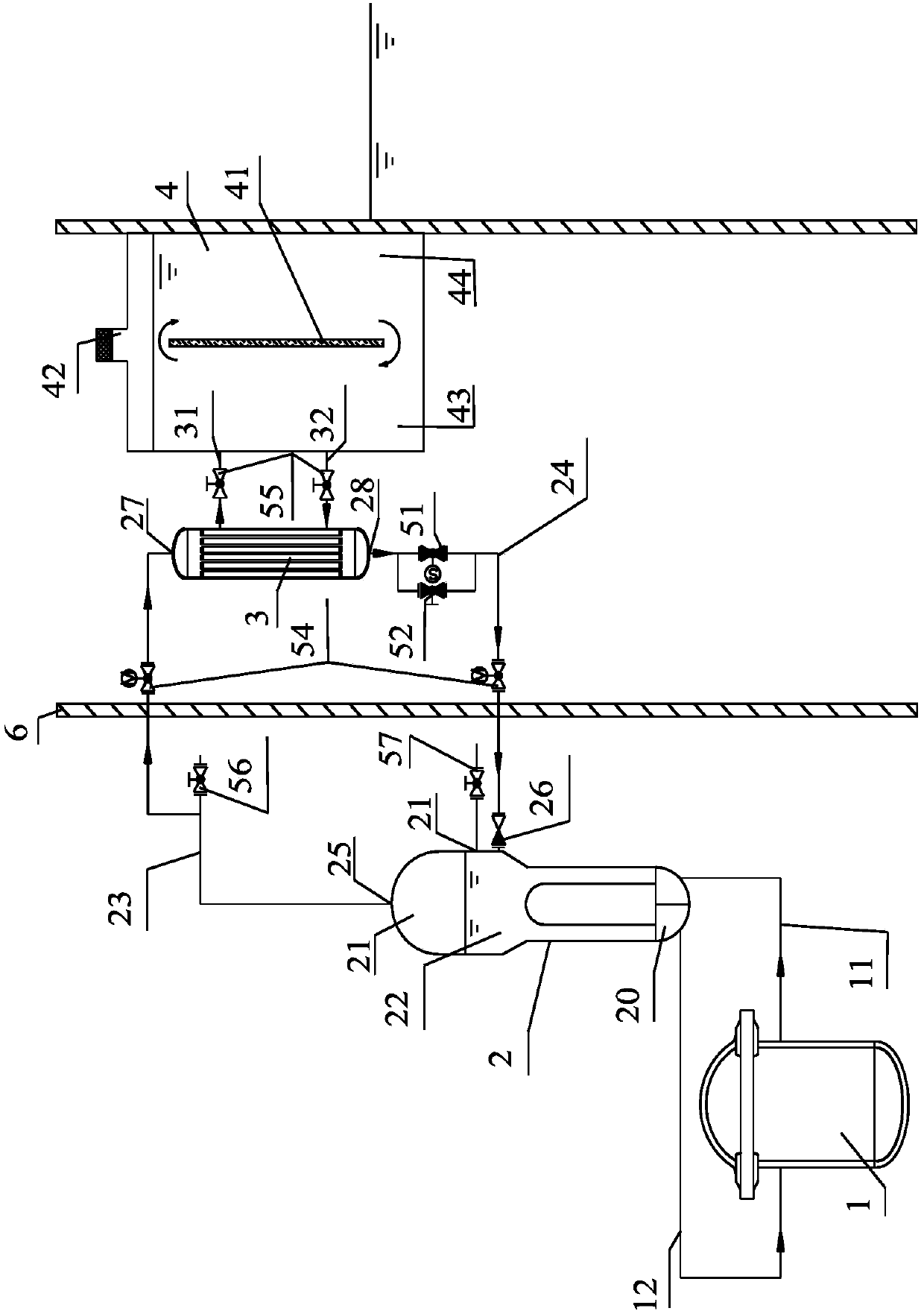

Secondary-side passive waste heat discharging system for ship pressurized water reactor

PendingCN107464590AAvoid stressReduce riskNuclear energy generationCooling arrangementPressurized water reactorWater source

The invention relates to a secondary-side passive waste heat discharging system for a ship pressurized water reactor. The system comprises a safety shell, and a high-altitude water tank arranged outside the saftey shell and in a wall face of a ship body, and the system also comprises a reactor pressure container, a steam generator and a passive waste heat discharging condenser, wherein the steam generator is higher than the reactor pressure container in position, and a primary side of the steam generator is communicated with the reactor pressure container respectively by virtue of a main pipeline cooling section and a main pipeline hot section; the passive waste heat discharging condenser is soaked in a water source of the high-altitude water tank, and the bottom of the passive waste heat discharging condenser is higher than a liquid surface in the steam generator; and the passive waste heat discharging condenser is communicated with a secondary side of the steam generator respectively by virtue of a steam pipeline and a condensation pipeline. When a whole ship is in power failure, the waste heat of a ship pressurized water reactor core can be led out by virtue of the natural circulation of a system loop, the advantage of higher natural circulation capacity can be realized, and the safety, the reliability and the economic performance of the ship pressurized water reactor can be improved.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

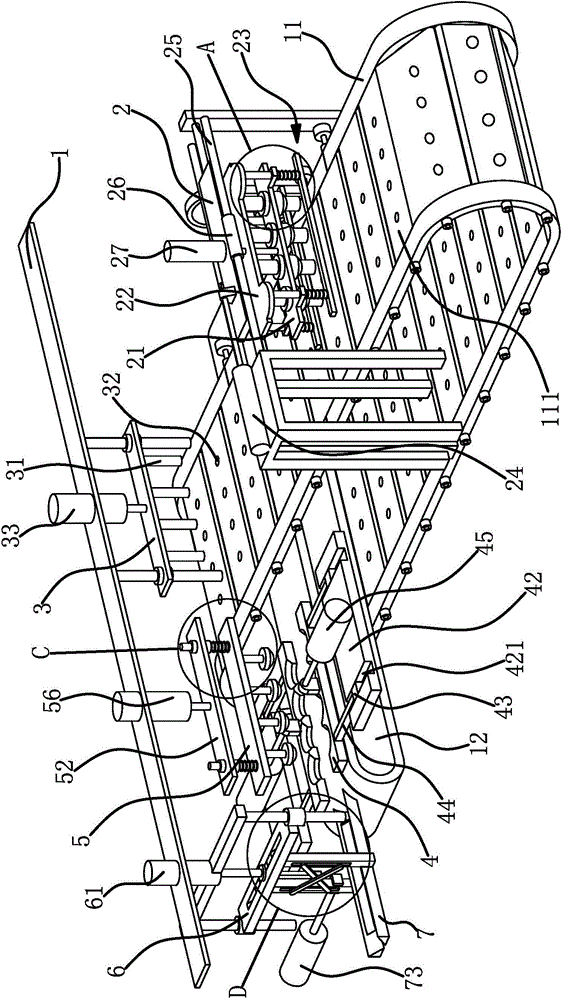

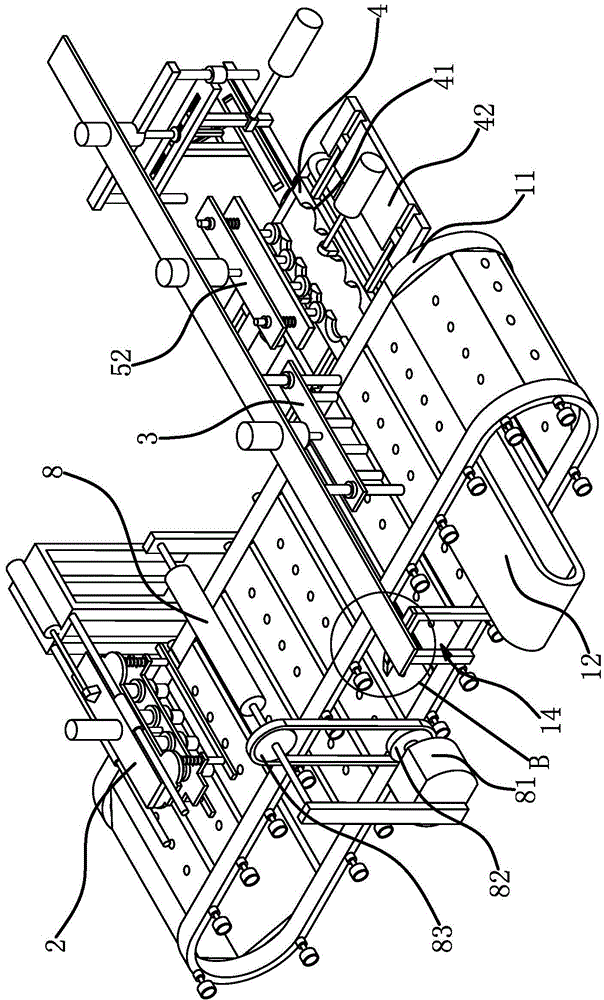

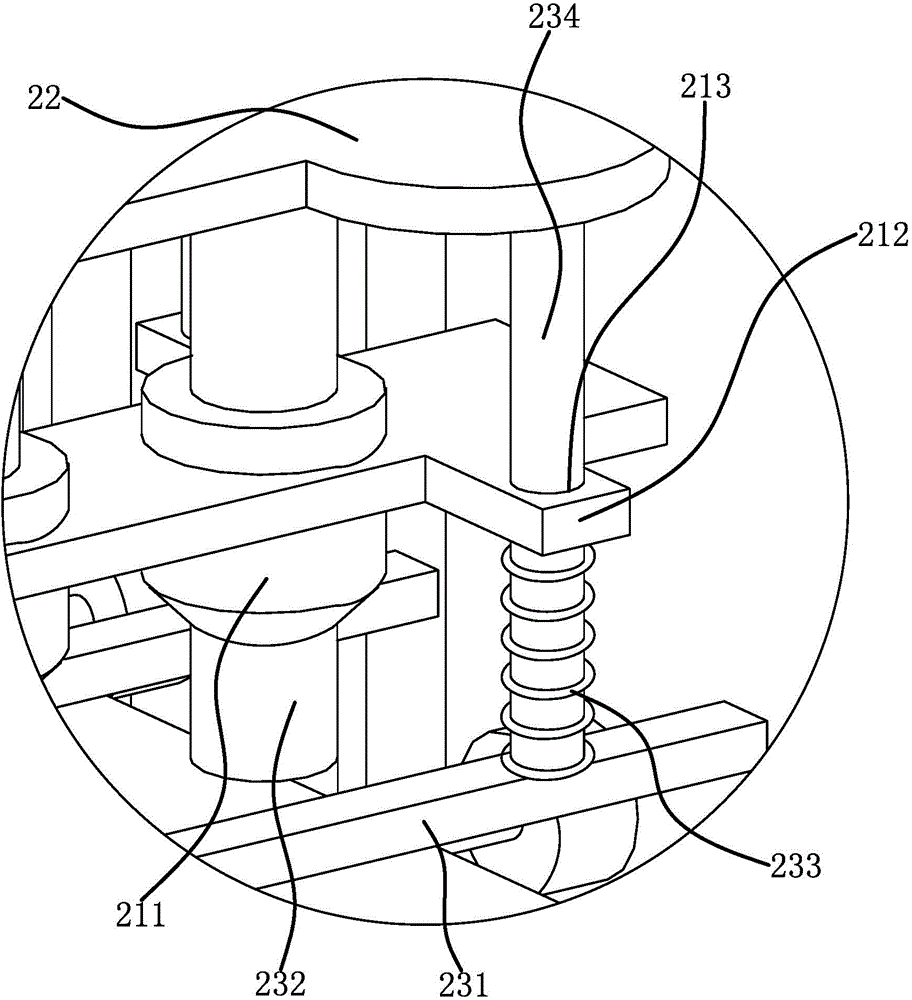

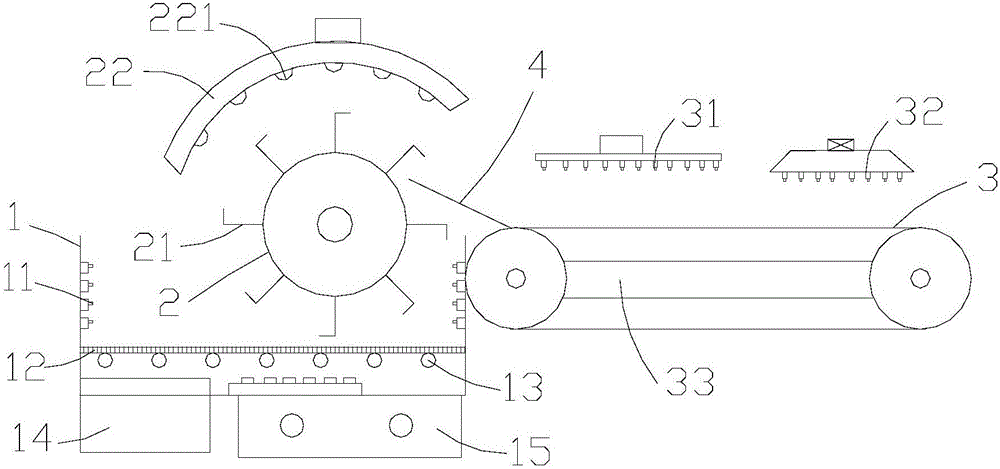

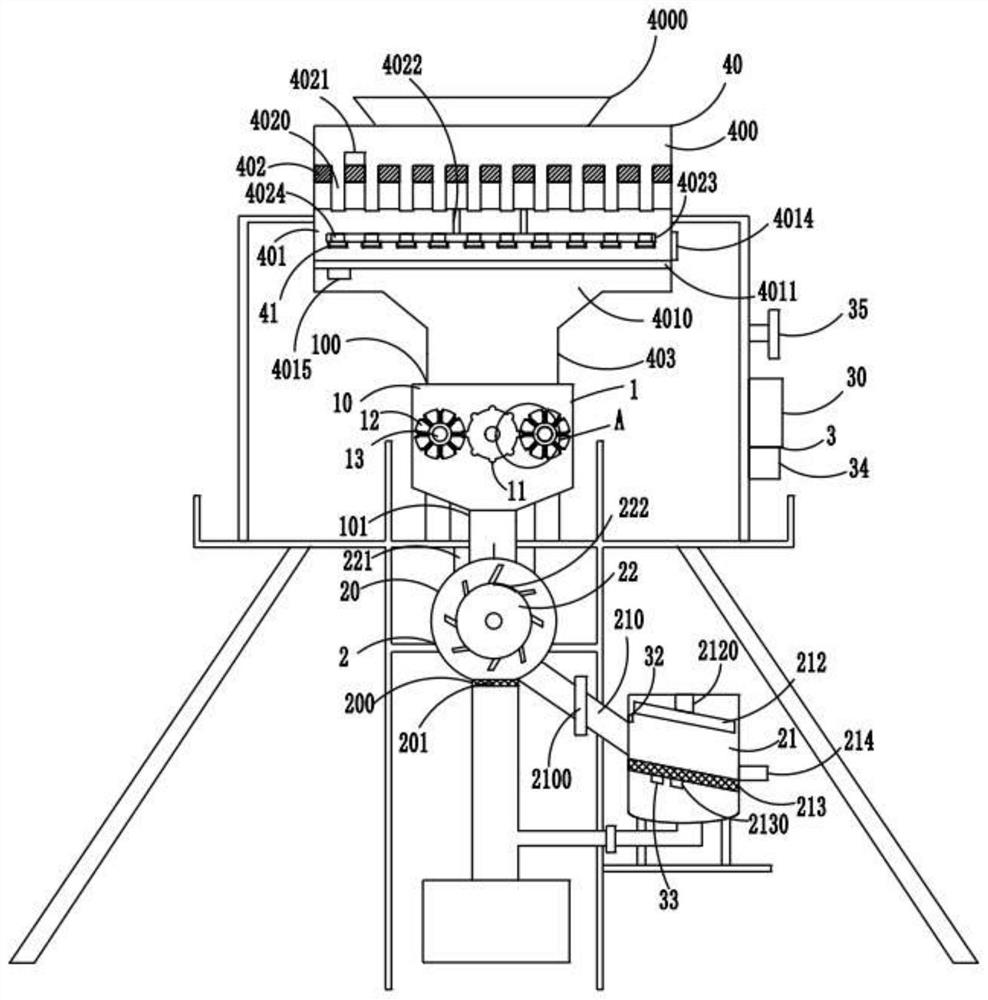

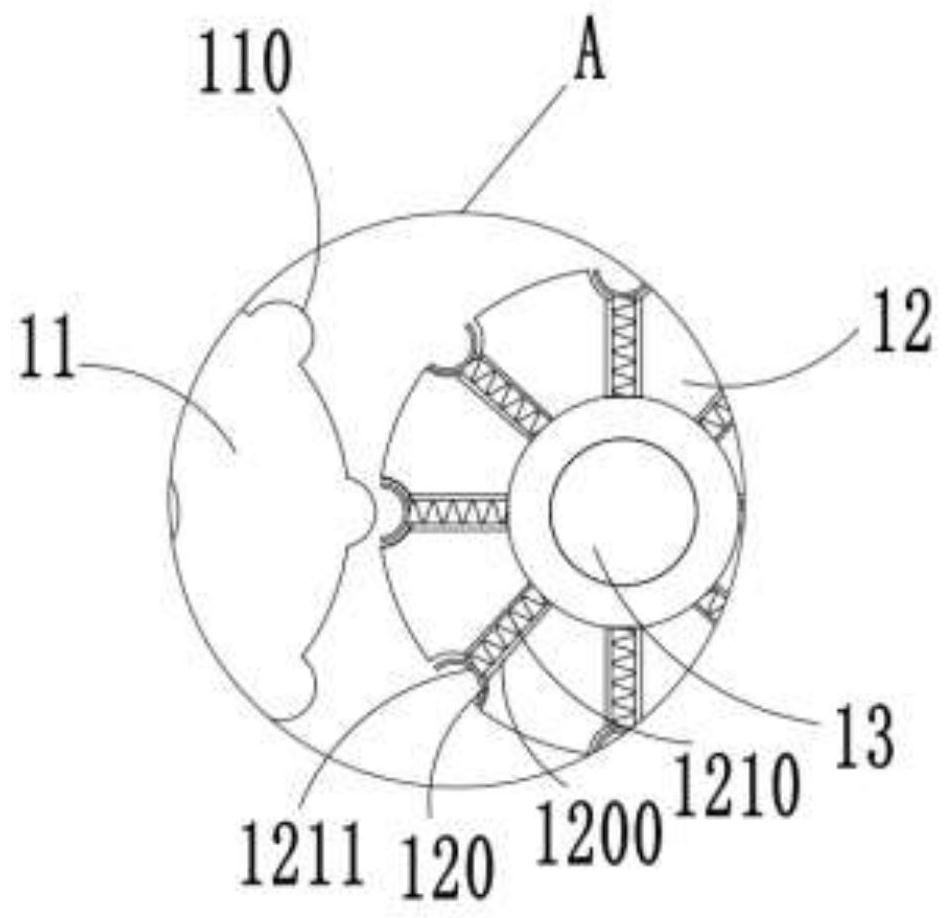

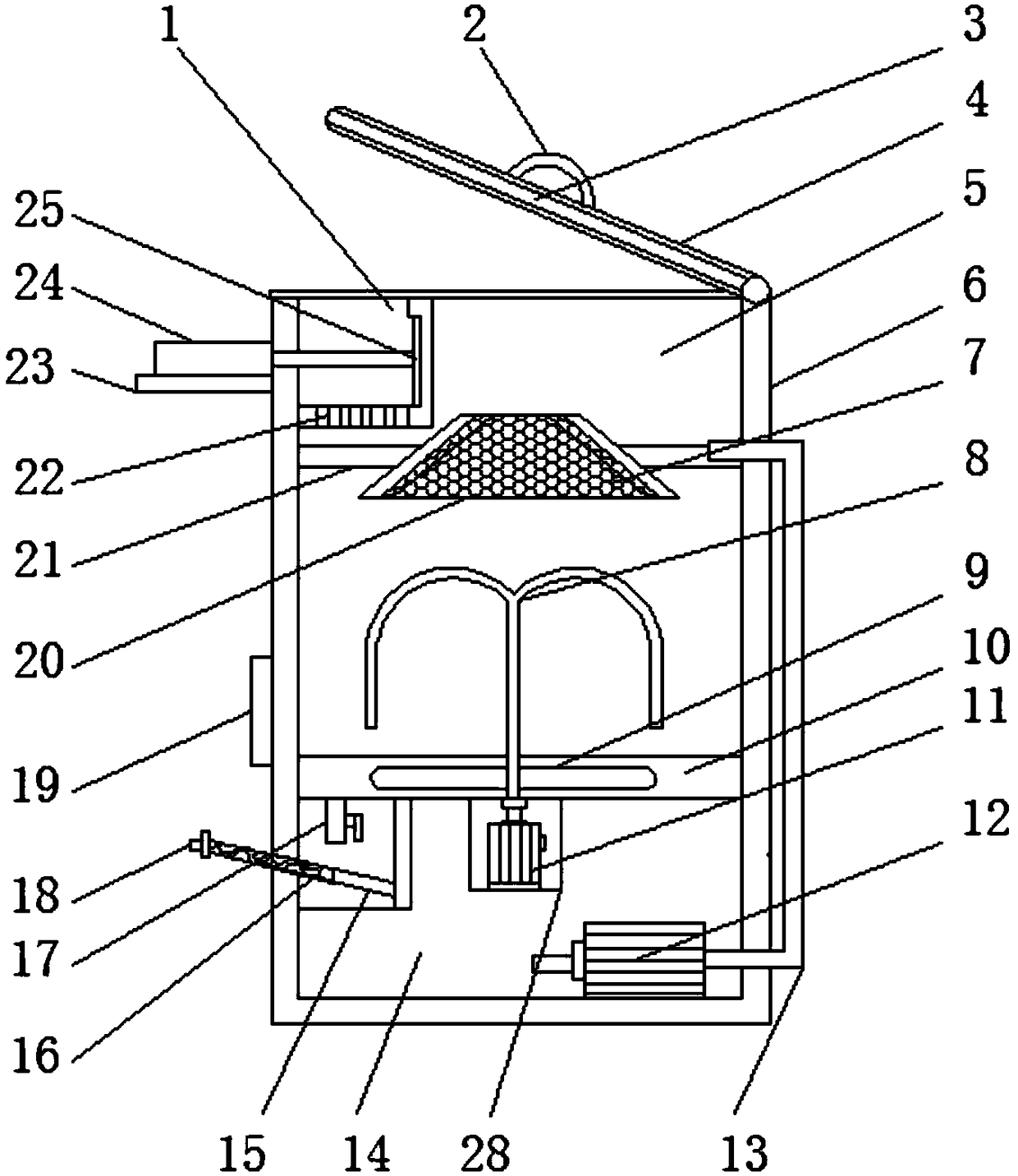

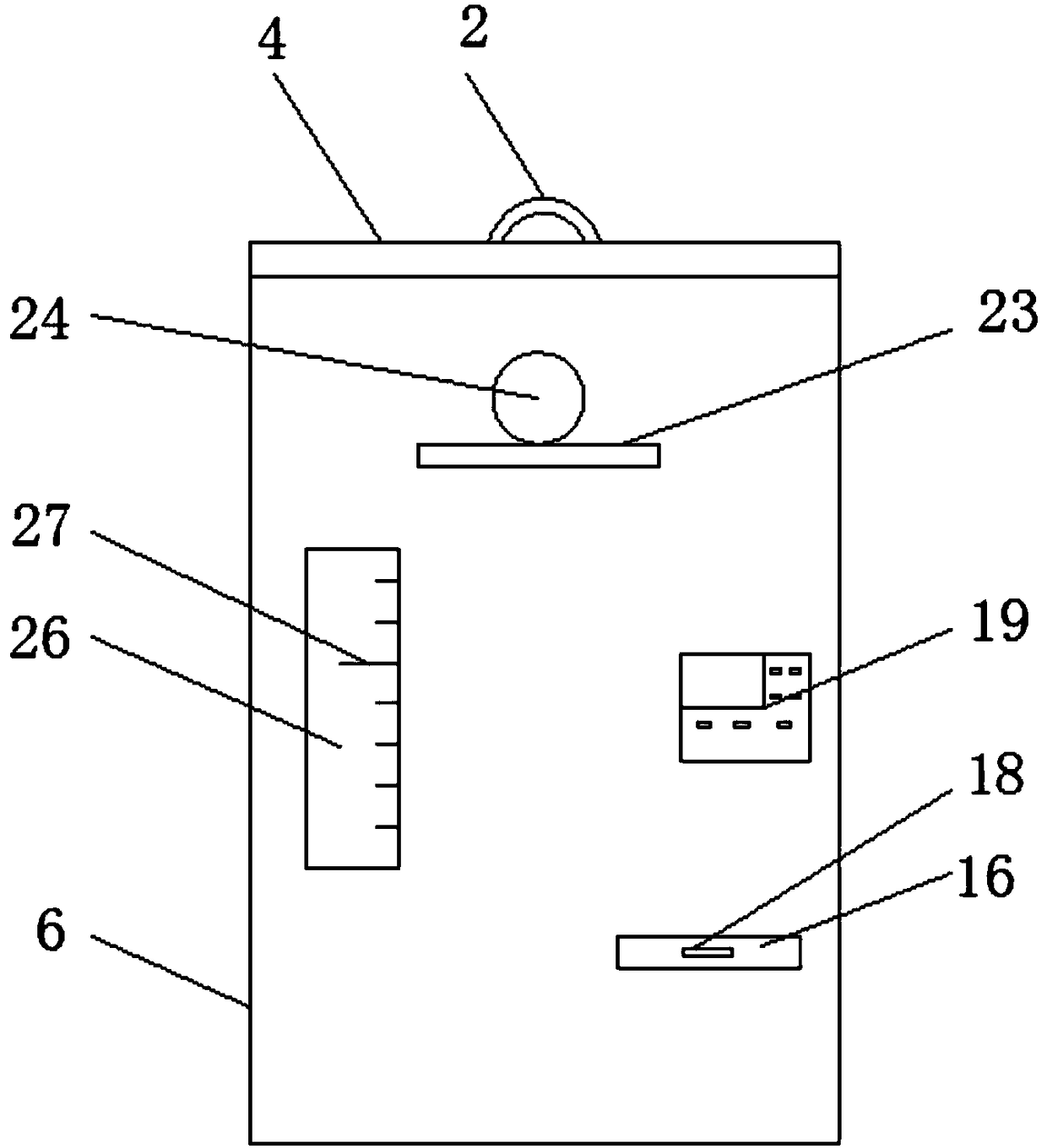

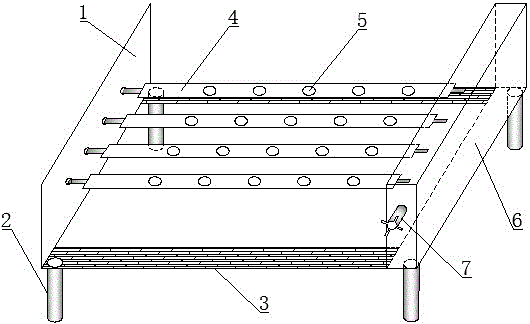

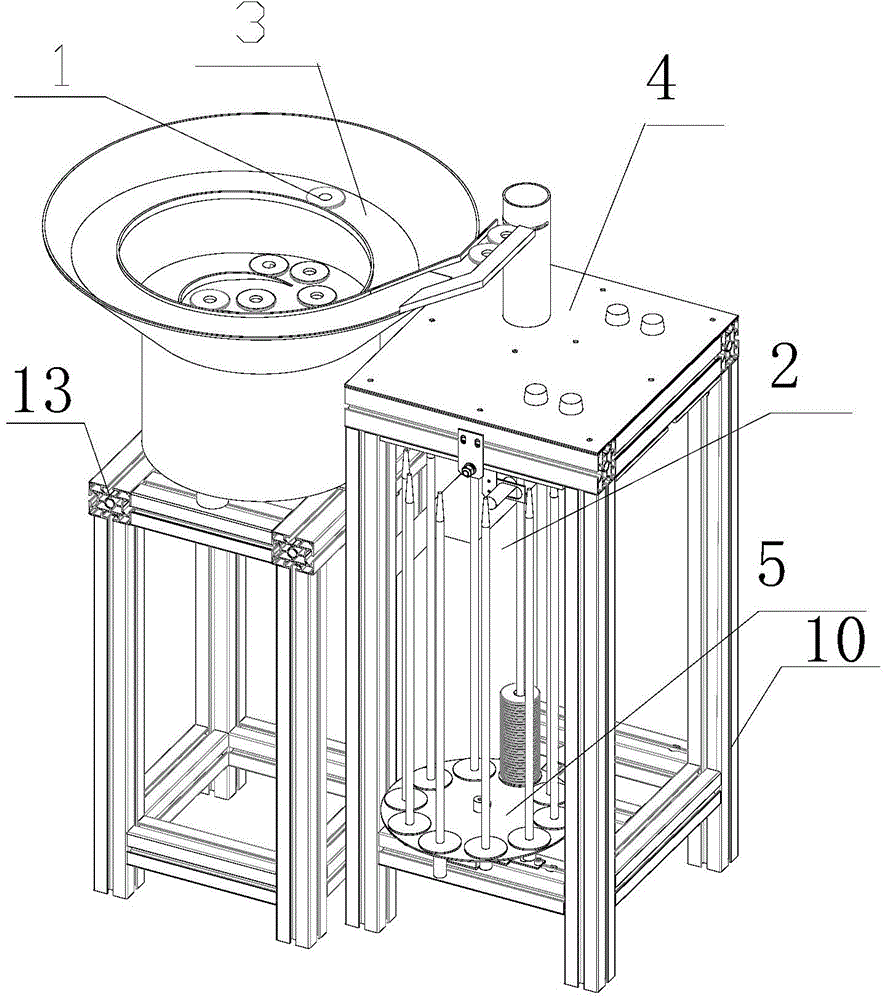

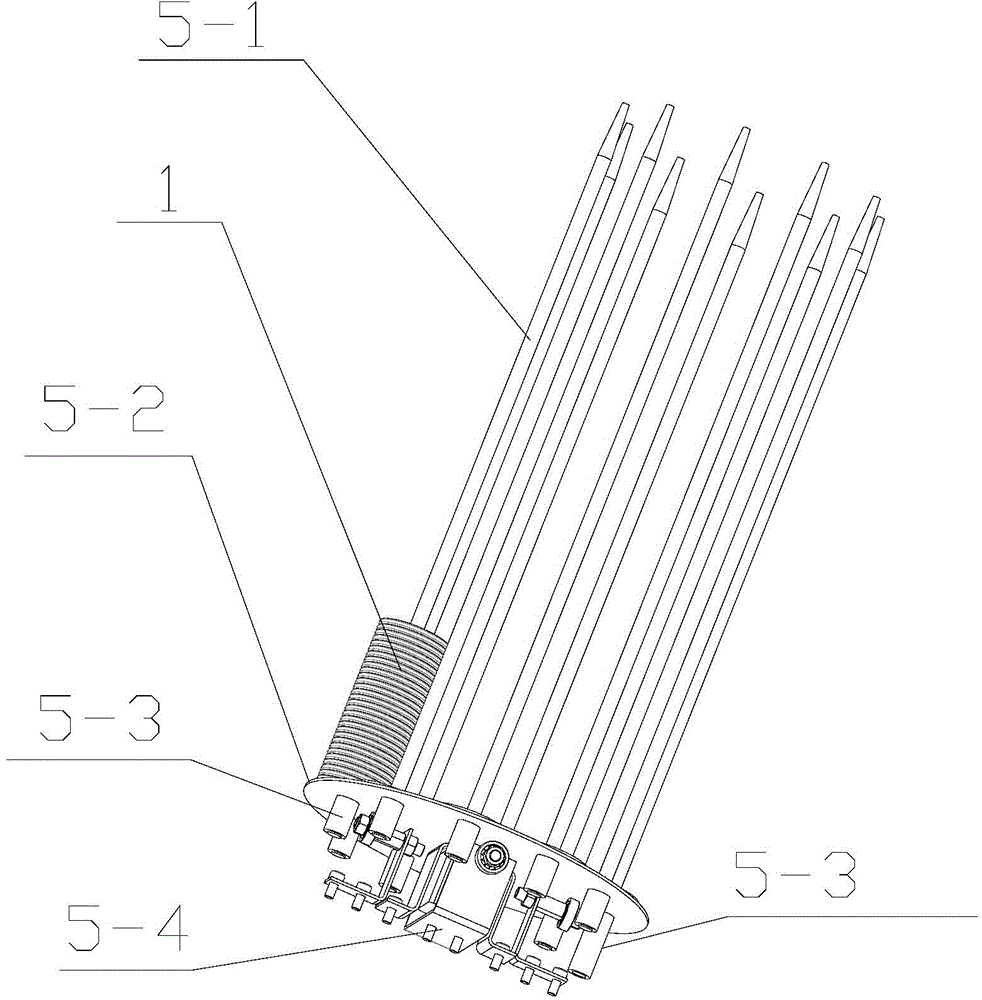

Automatic egg tart skin processing machine

InactiveCN104957204AAvoid taking awayImprove cut qualityDough dividingDough processingEngineeringFood processing

The invention provides an automatic egg tart skin processing machine, and belongs to the technical field of food processing equipment. The problem of lower egg tart skin processing efficiency in the prior art is solved. The automatic egg tart skin processing machine comprises a machine frame, wherein two longitudinal conveying belts and a transverse conveying belt are arranged on the machine frame; the machine frame is slidably connected with a moving plate; the moving plate is slidably connected with a lifting plate; a plurality of cutters are fixedly connected to the lifting plate; the machine frame is slidably connected with a stripper plate; a stripper column is fixedly connected to the stripper plate; a plurality of stripper holes are formed in a supporting plate; the machine frame is slidably connected with two positioning plates; a positioning groove is formed in each positioning plate; the machine frame is slidably connected with a material pressing plate; a material pressing mold head is connected to the material pressing plate; the machine frame is slidably connected with a blanking plate; two blanking rods are slidably connected to the blanking plate. According to the automatic egg tart skin processing machine, dough can be automatically cut into a circular egg tart skin, and the egg tart skin can be automatically pressed into an egg tart mold, so that the processing efficiency is high.

Owner:南通盛净环保设备有限公司

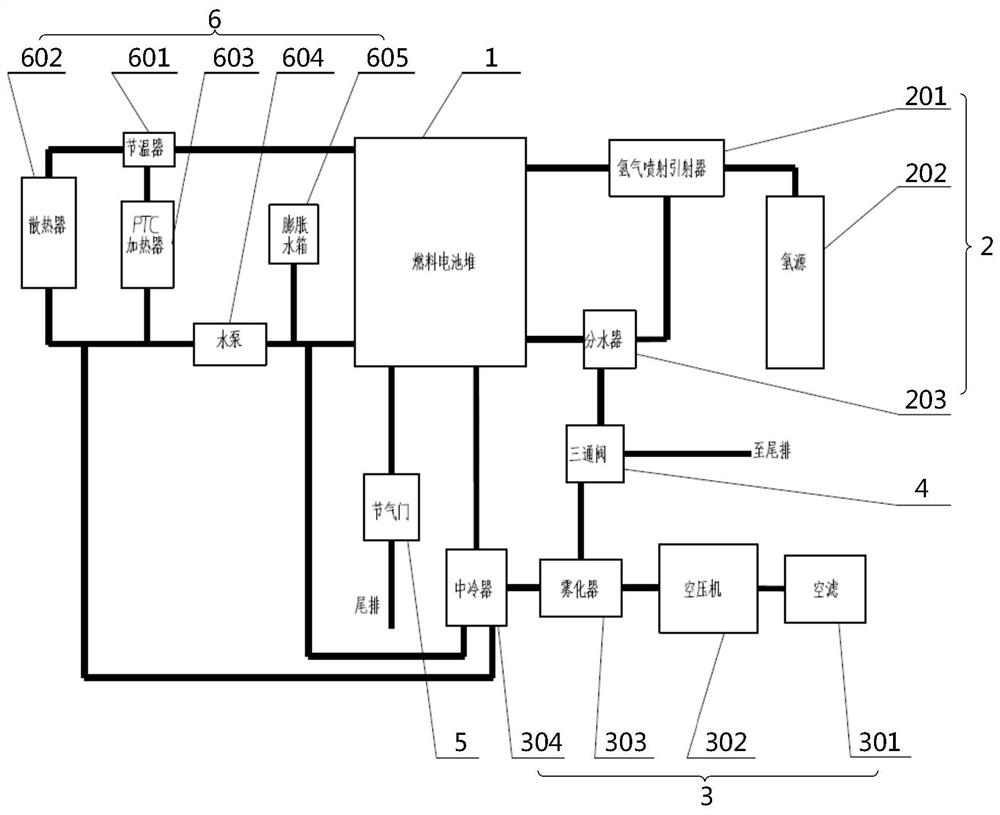

Fuel cell system and humidity control method thereof

The invention relates to a fuel cell system and a humidity control method thereof. The fuel cell system comprises a fuel cell stack, a hydrogen loop and an air loop, the hydrogen loop comprises a hydrogen circulating device and a water segregator, and a hydrogen source is connected with a hydrogen inlet of the fuel cell stack through the hydrogen circulating device; a gas inlet of the water distributor is connected with a hydrogen outlet of the fuel cell stack, and a gas outlet of the water distributor is connected with the hydrogen circulating device; the air loop comprises an air filter, anair compressor, an atomizer and an intercooler which are sequentially connected in series, an outlet of the intercooler is connected to an air inlet of the fuel cell stack, and a water outlet of the water distributor is connected with the atomizer; according to the fuel cell system, the atomizer is arranged at the rear end of the air compressor of the air loop, moisture discharged by the anode ofthe galvanic pile can be added into the air in time to humidify the galvanic pile, an external water source is not needed, and therefore the purposes of increasing the humidity of the air and the moisture in the galvanic pile and reducing the internal resistance of the galvanic pile are achieved.

Owner:风氢扬氢能科技(上海)有限公司

Method and apparatus for prededusting

InactiveCN102240486AEasy to handlePrevent roll upDispersed particle separationDust controlEngineering

The invention discloses a method and an apparatus for prededusting. The method allows a dusty gas to enter into the prededusting apparatus at a tangent from an inlet. Dust in an airflow moves along the inner wall of a cylinder body, slides into a dust collector and is discharged from a dust discharge port because of centrifugal force generated by airflow rotation. A conical reflection screen is arranged in the cylinder body, most of the airflow entering into the cylinder body is reflected upward because of the effect of the reflection screen, and only a small amount of the gas enters into the dust collector with dust particles, so a case that the dust which has been already separated is rewinded up and taken away by a secondary gas can be prevented, thereby the dedusting effect is improved. A certain gap between the reflection screen and the cylinder body is kept, so the dust can enter into the dust collector through the gap; and simultaneously an air-vent is arranged on the top of the reflection screen, so the small amount of the gas entering into the dust collector can enter into the cylinder body through the air-vent. So the apparatus has the characteristics of low equipment cost, stable working condition, and simple and convenient maintenance.

Owner:GUIYANG AL-MG DESIGN & RES INST

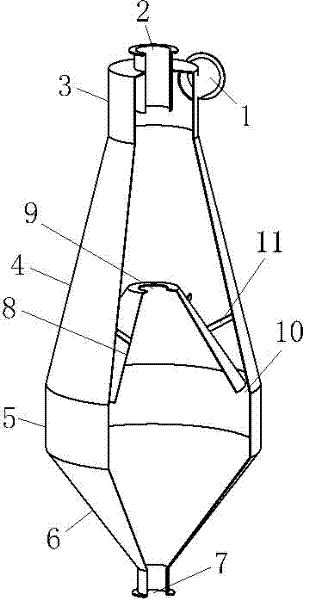

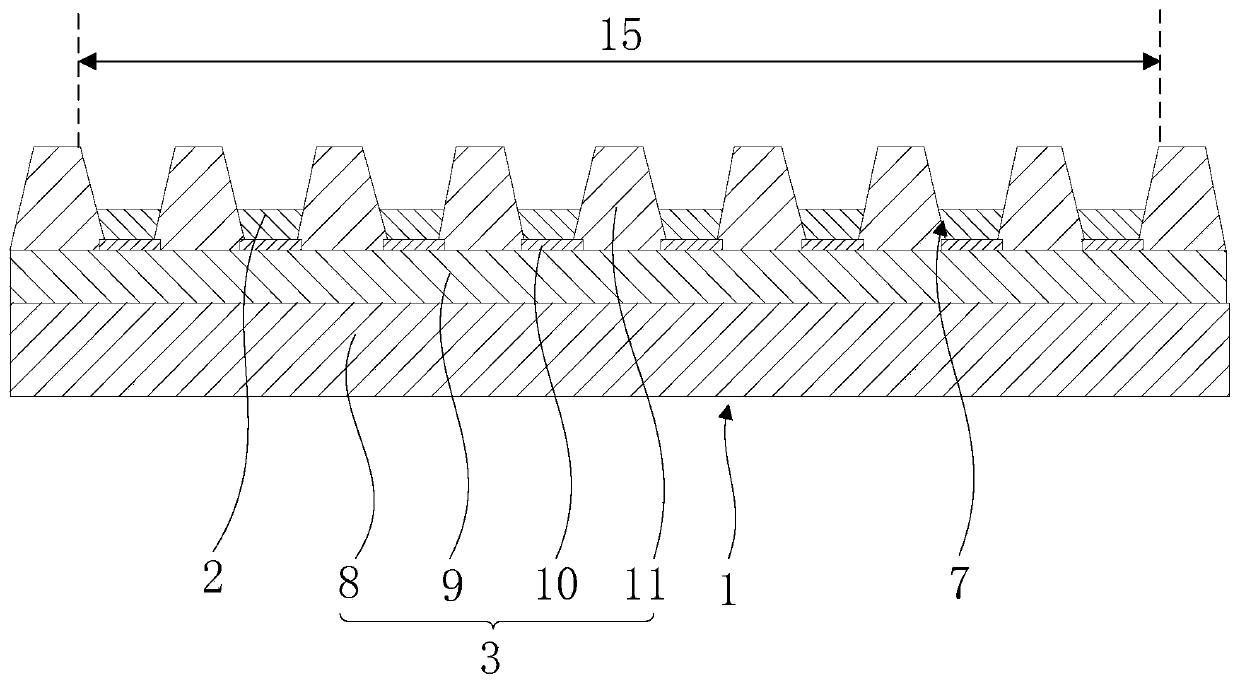

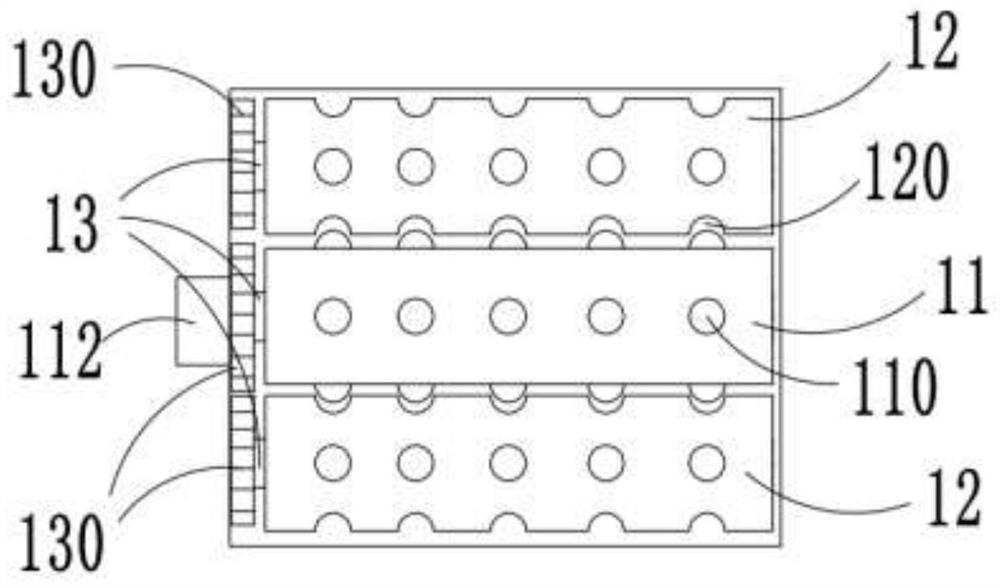

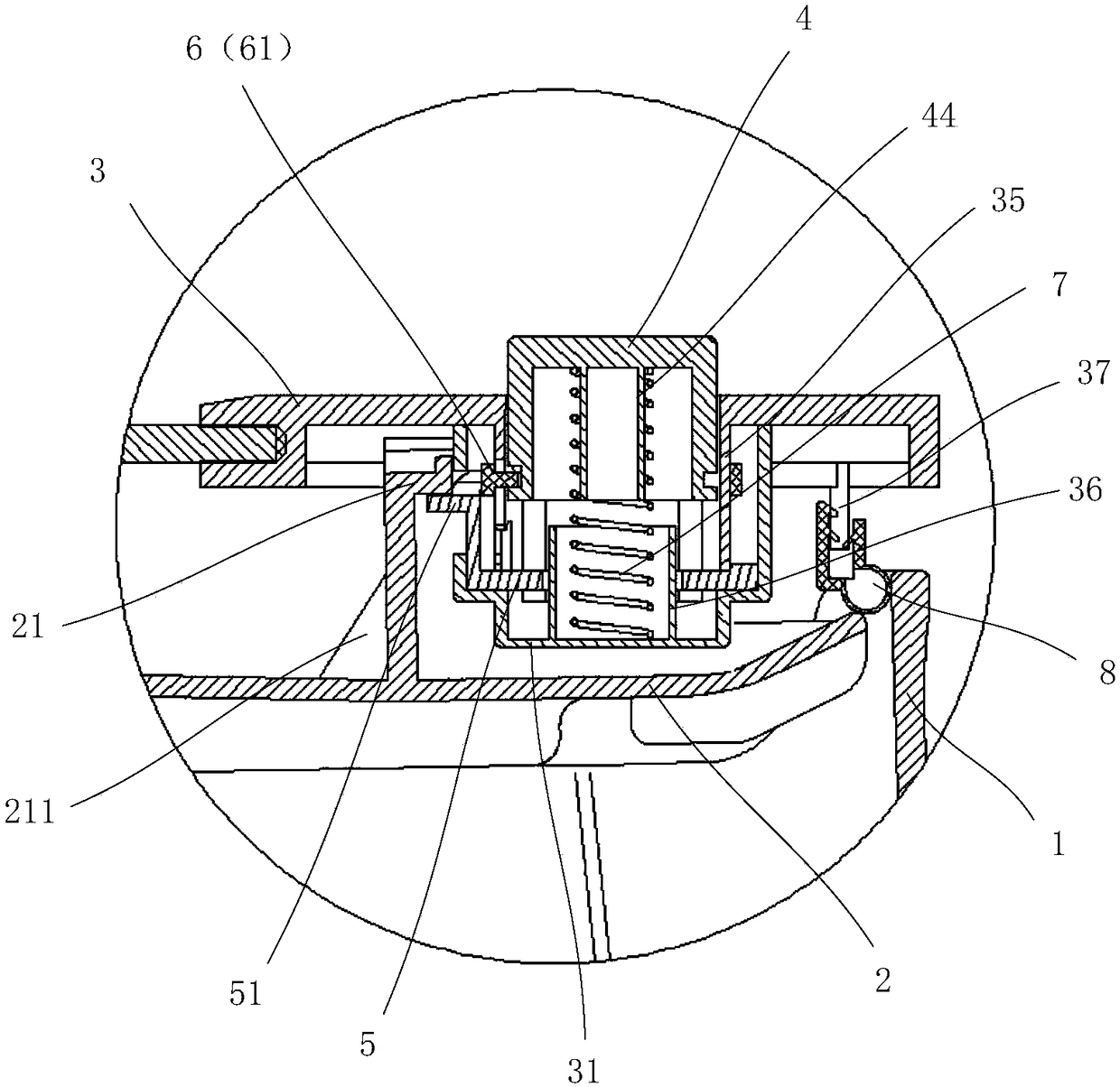

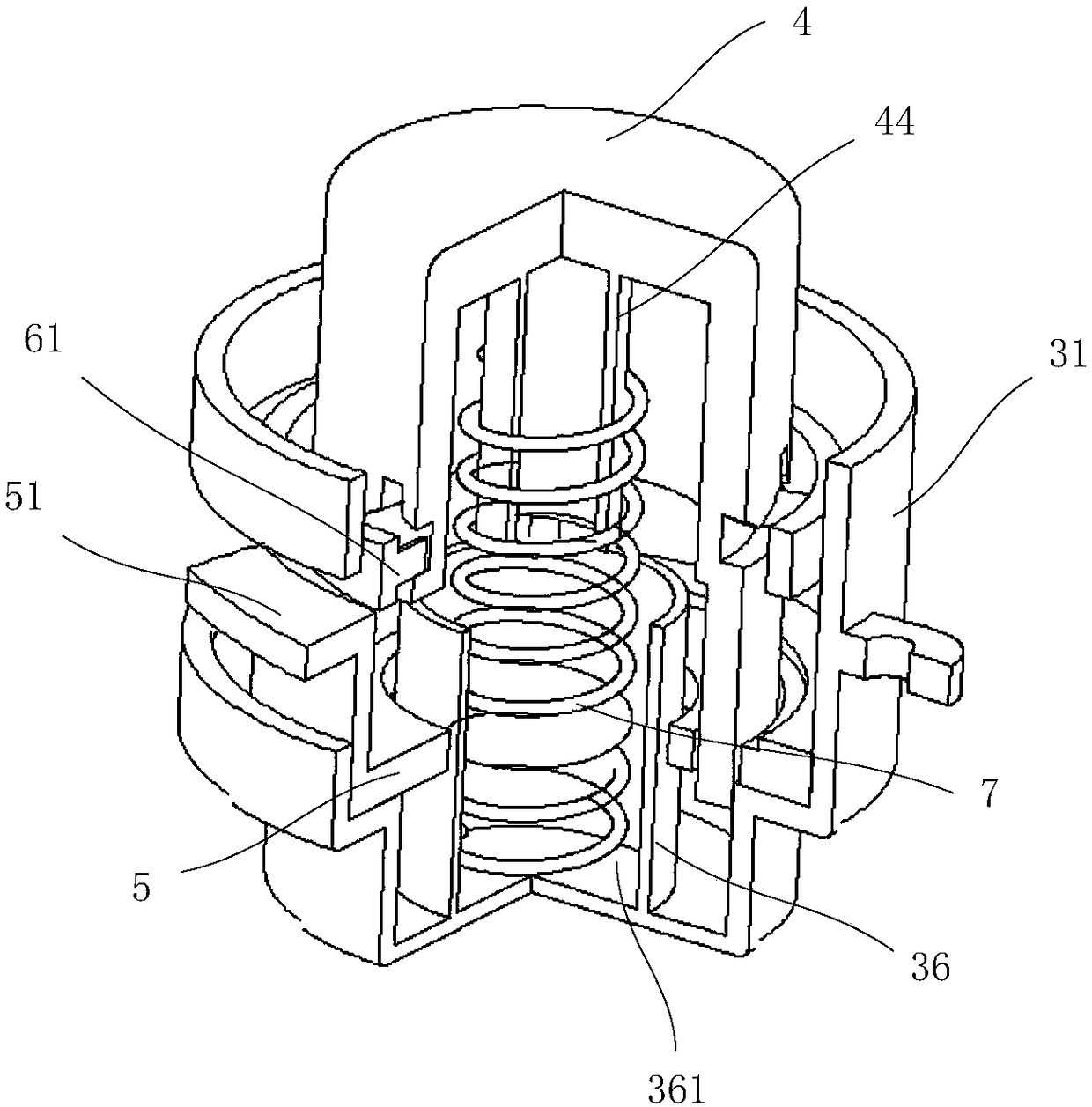

Distributor in falling film evaporator

ActiveCN106482400AAvoid taking awayEven and effective dischargeEvaporators/condensersFluid circulation arrangementEngineeringRefrigerant

The invention relates to evaporator accessories in refrigerating equipment, in particular to a distributor in a falling film evaporator. The distributor comprises a cover plate, a gas-liquid separation disc and a gravity drop-leaching disc, wherein water holes are uniformly and densely distributed and a plurality of partition plates are arranged at the bottom of the gravity drop-leaching disc; the gas-liquid separation disc is connected with the top end of the gravity drop-leaching disc; pressure holes are uniformly distributed on a baseplate at the bottom of the gas-liquid separation disc; the cover plate is fixedly connected onto the gas-liquid separation disc; the gas-liquid separation disc and the cover plate are combined to form an enclosed gas-liquid separation cavity; and a liquid inlet and a demister are arranged on the cover plate. The distributor provided by the invention has the following beneficial effects: a gaseous refrigerant in a gas-liquid two-phase refrigerant can be separated out, and liquid drops can be prevented from being entrained by the gaseous refrigerant, thereby achieving uniform and effective gas exhaust; and meanwhile, uniform dropping of a liquid can be guaranteed, thereby reducing the adverse impact of gas flow in an evaporation process.

Owner:顿汉布什(中国)工业有限公司

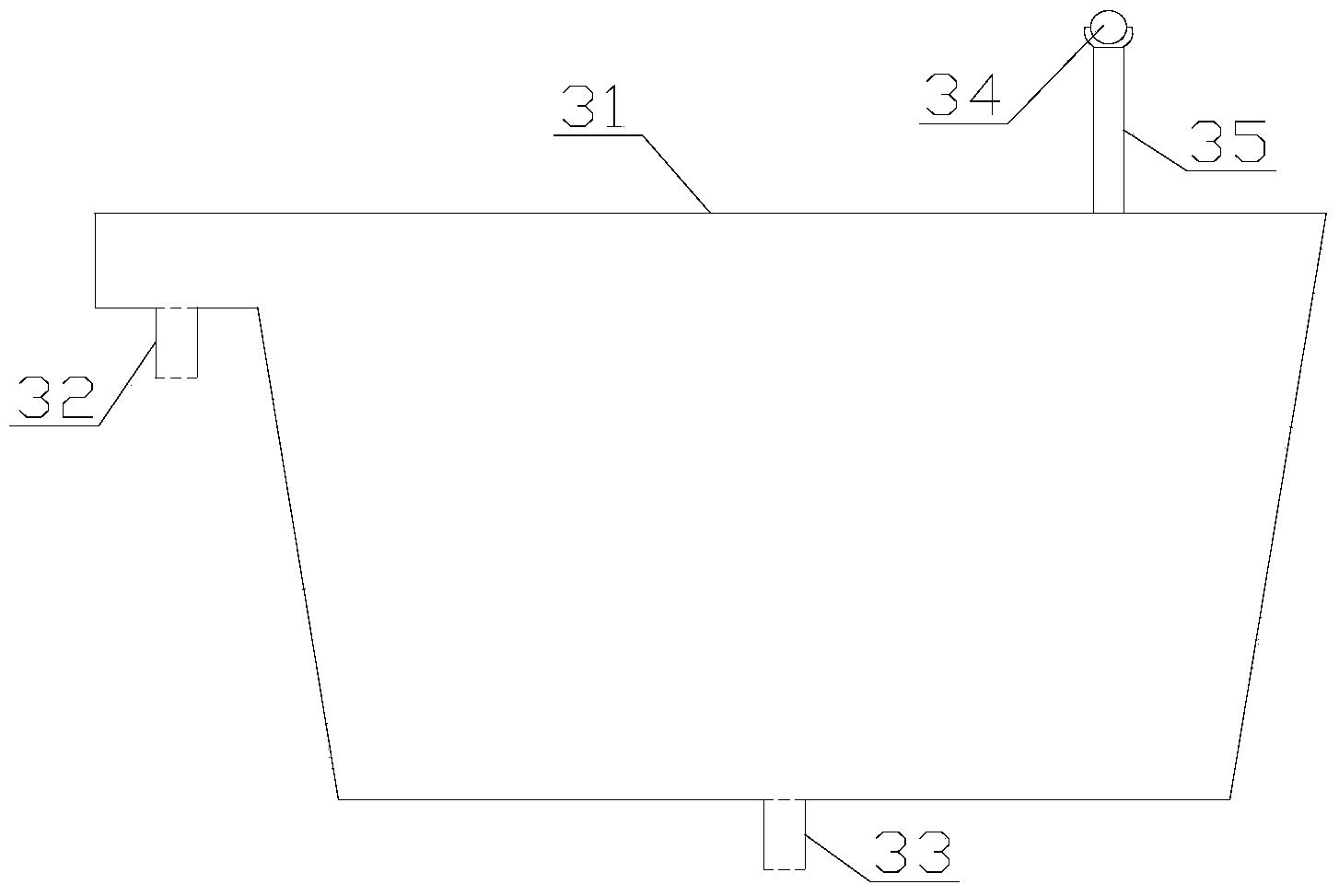

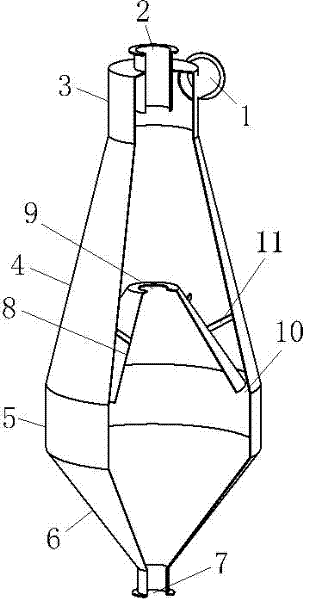

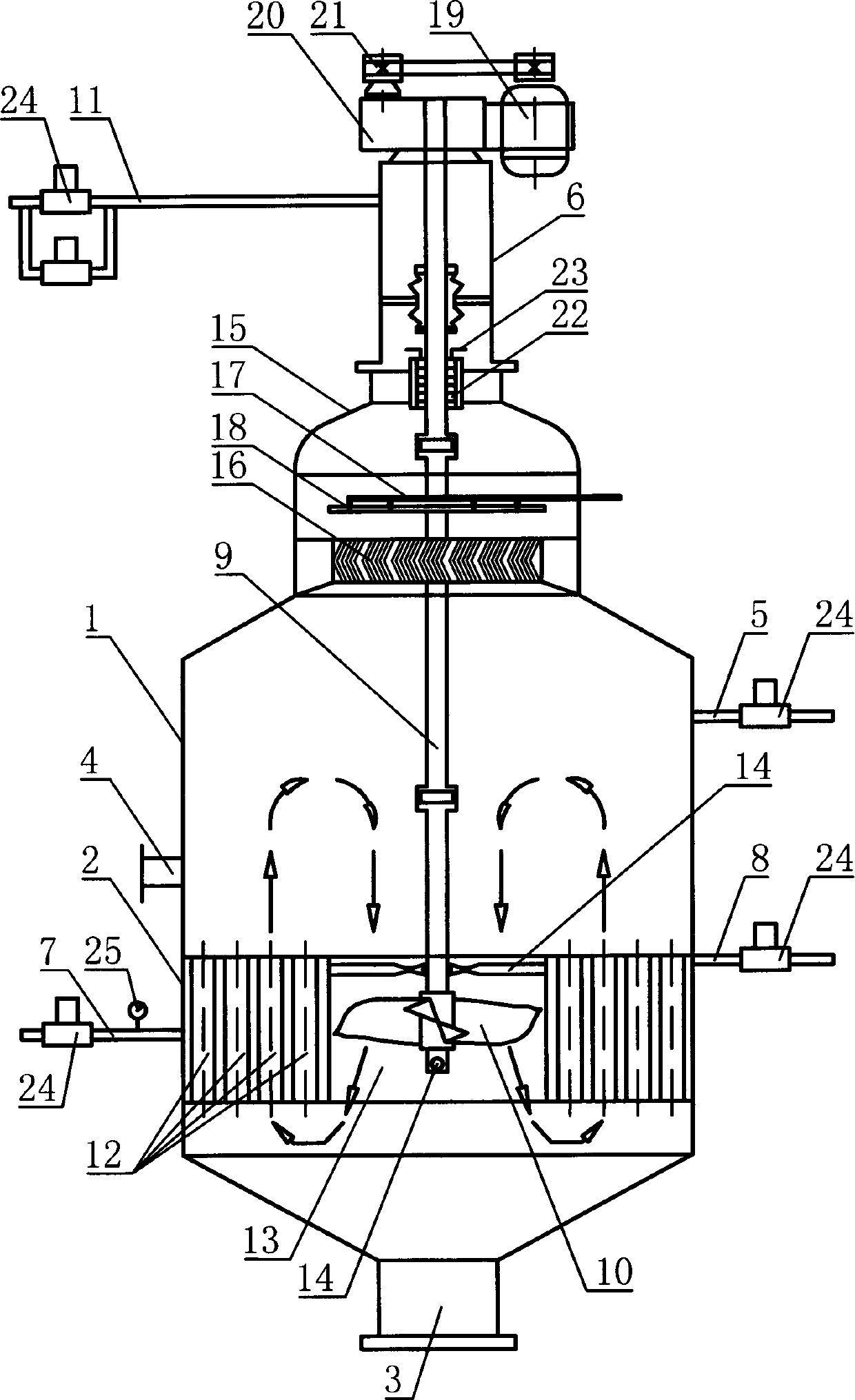

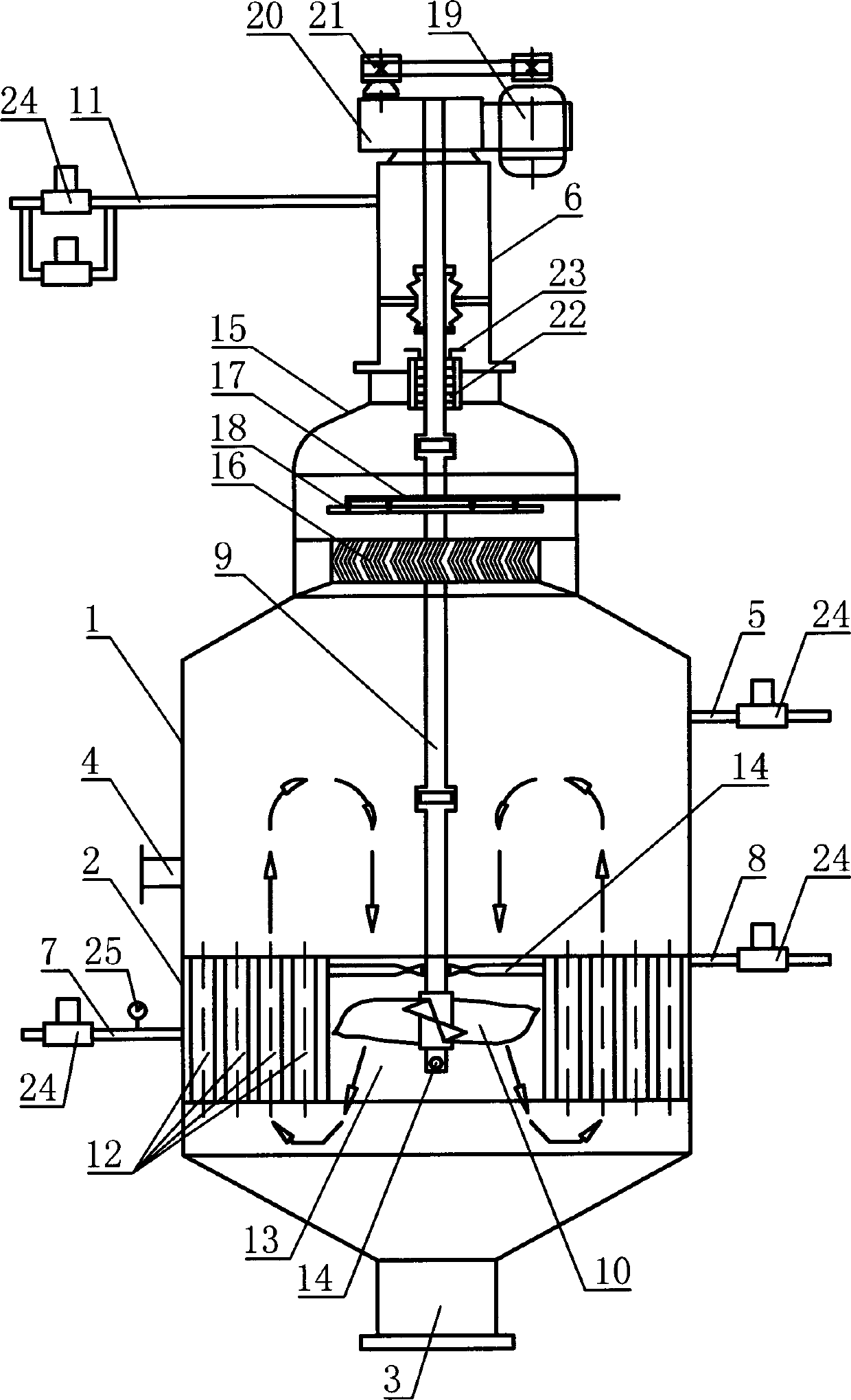

Crystallizing tank for boiling sugar

InactiveCN102676704AAvoid wear and tearLarge design angleSugar crystallisationBiochemical engineeringSugar

The invention relates to the field of sugar-producing devices and particularly relates to a crystallizing tank for boiling sugar which is smooth in operation, good in sealing performance, good in massecuite circulation, uniform in concentration, little in sugar crystal grain abrasion and capable of effectively saving the time of sugar boiling. The crystallizing tank comprises a tank body (1), wherein an evaporator (2) is arranged inside the tank body (1), a discharging port (3) is arranged at the bottom of the tank body (1), a feeding port (4) and a blow-down pipe (5) are arranged on the side wall of the tank body (1), and a driving device is arranged on the upper portion of the tank body (1) through a supporting seat (6); a heating chamber is arranged on a position inside the tank body (1), the position corresponds to the evaporator (2), and an evaporating chamber is arranged on the upper portion of the evaporator (2); the heating chamber is provided with and respectively communicated with a steam input pipe (7) and a seed input pipe (8); the driving device is connected with a main shaft (9) extending to the inside of the tank body (1); a forced-circulation blade (10) arranged inside the center of the evaporator (2) is installed at the end of the main shaft (9) which extends to the inside of the tank body (1); and one side of the supporting seat (6) is connected with a vacuum tube (11).

Owner:郑凯锋

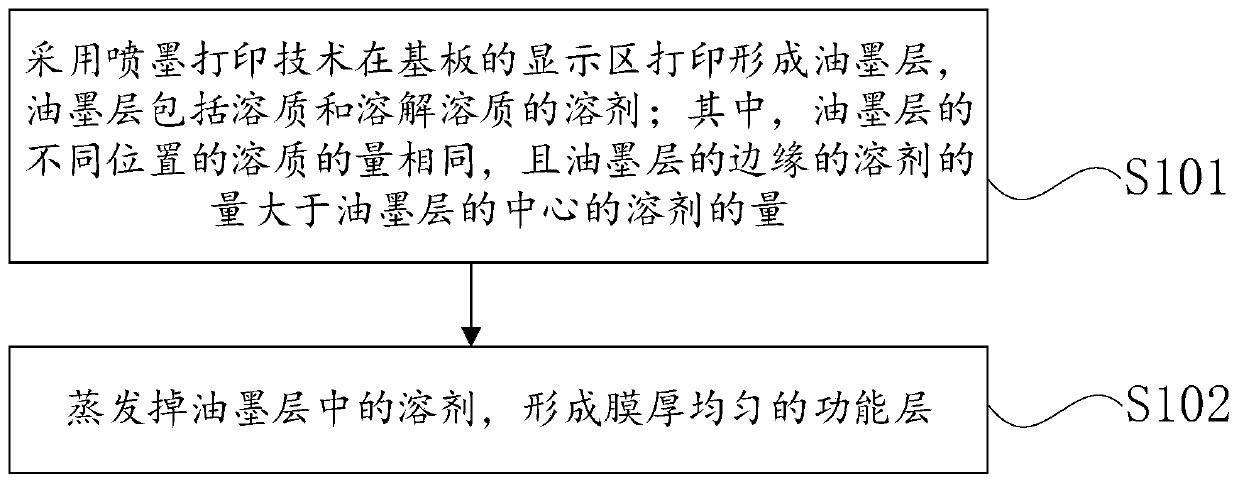

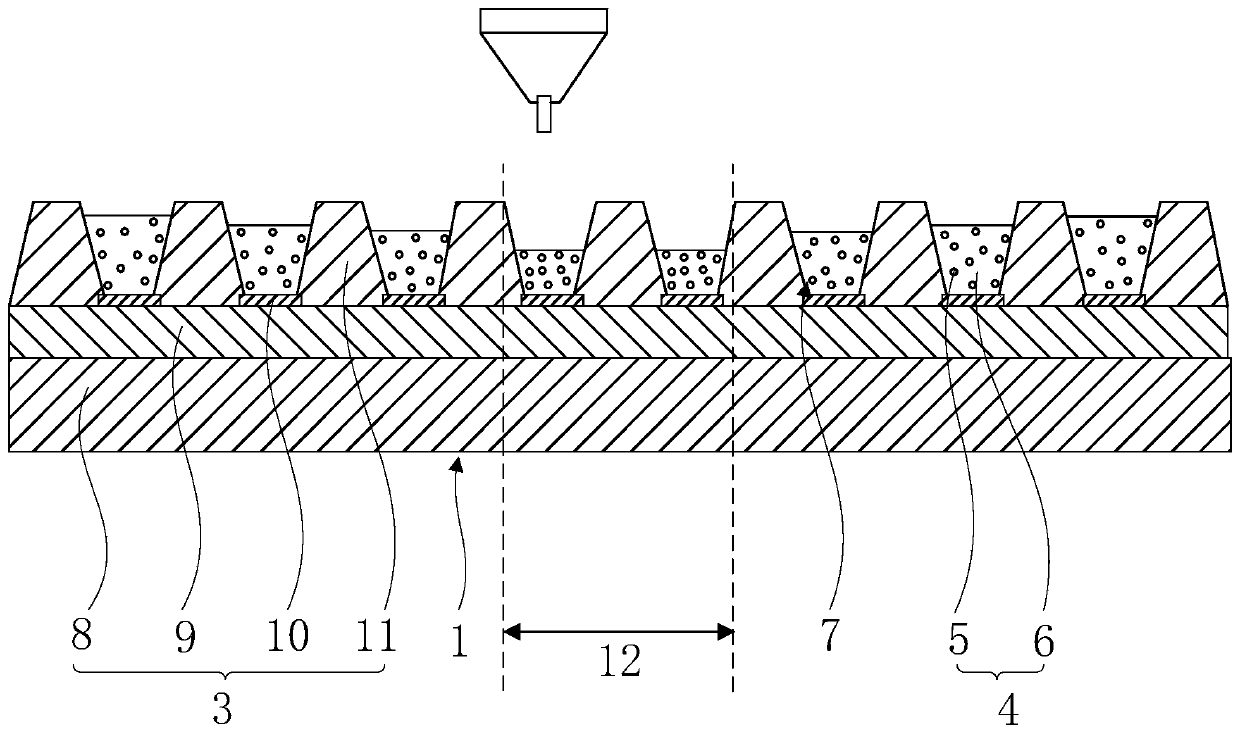

Preparation method for display panel and preparation method for functional layer thereof

ActiveCN110611053AAchieve narrow bordersAvoid taking awaySolid-state devicesSemiconductor/solid-state device manufacturingSolvent evaporationSolvent

The invention discloses a preparation method for a display panel and a preparation method for a functional layer thereof. The display panel comprises a substrate. The preparation method for the functional layer comprises the steps that an inkjet printing technology is used to print on a display area of the substrate to form an ink layer, wherein the ink layer comprises a solute and a solvent whichdissolves the solute; the amount of the solute at different positions of the ink layer is the same, and the amount of the solvent at the edge of the ink layer is greater than the amount of the solvent at the center of the ink layer; the solvent in the ink layer is evaporated to form the functional layer with uniform film thickness. The invention provides the method for preparing the functional layer with uniform film thickness. According to the invention, in the process of solvent evaporation, the solvent atmosphere above the display area of the substrate is substantially the same; the film thickness of the formed functional layer is uniform; and the design of the narrow frame of the display panel is realized.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Vegetable washing and drying system

InactiveCN106490647ASpeed up water removalKeep dryClimate change adaptationFood treatmentOzone generatorWater insoluble

The invention discloses a vegetable washing and drying system which comprises a washing tank, a rotation transfer shaft and a reticular conveying belt, wherein a middle sloping plate is arranged between the rotation transfer shaft and the reticular conveying belt, a vegetable selecting rod through groove is formed in the middle sloping plate, a water spraying pipe is arranged on a side wall in the washing tank, a perforated plate is mounted at the lower part in the washing tank, a magnetic bar is mounted at the lower part of the perforated plate, a water spraying device is mounted at the upper part of the front segment of the reticular conveying belt, a compressed air blowpipe is mounted at the upper part of the rear segment of the reticular conveying belt, an ultrasonic wave generator is mounted at the bottom of the washing tank, an ozone generator is mounted at the bottom of the washing tank, the upper part of the rotation transfer shaft is covered with an arc-shaped ultraviolet disinfection lampshade, an ultraviolet disinfection lamp is mounted in the arc-shaped ultraviolet disinfection lampshade, and a chloride solution is placed in the washing tank. The vegetable washing and drying system disclosed by the invention has the advantages that the structure is simple, the use is convenient, water insoluble impurities such as scrap iron in vegetables can be effectively removed, the washing efficiency is high, the disinfection effect is obvious, the fresh preservation time is long, water is saved, and the drying time is shortened.

Owner:苍溪县峻绿食品有限公司

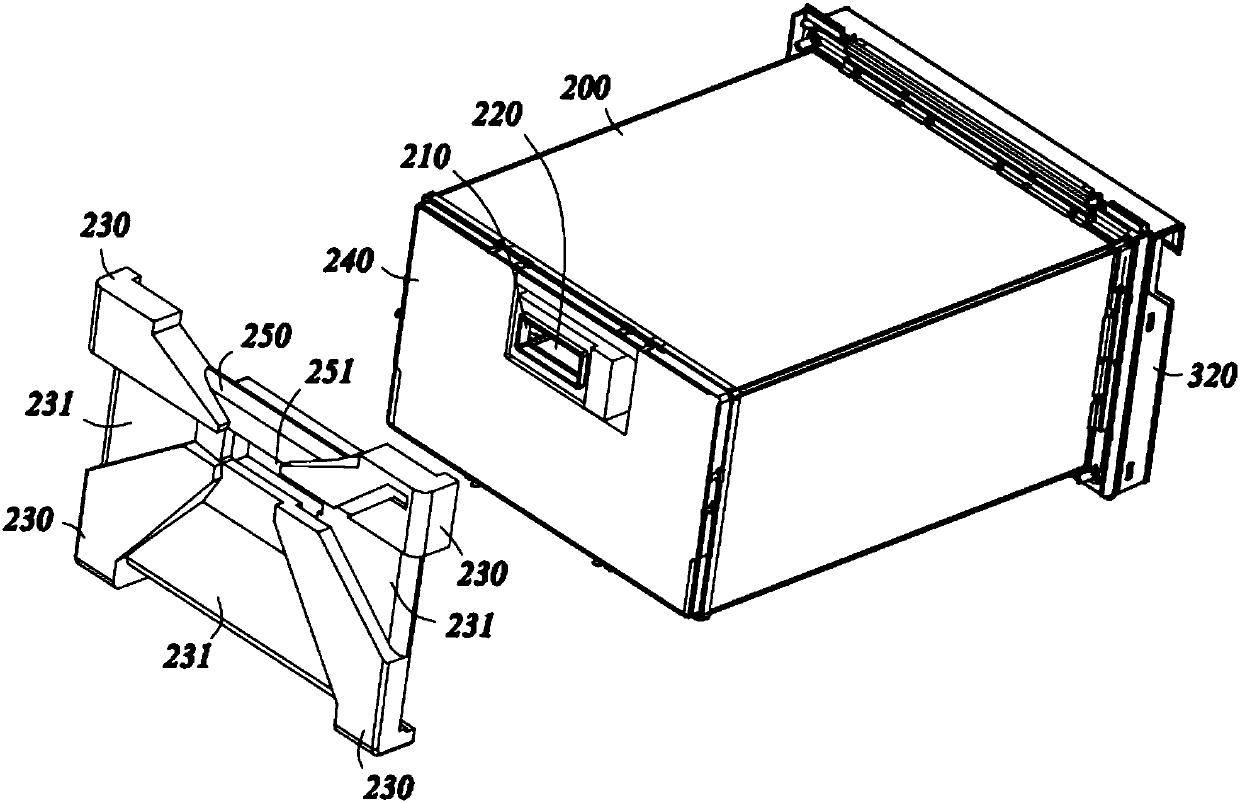

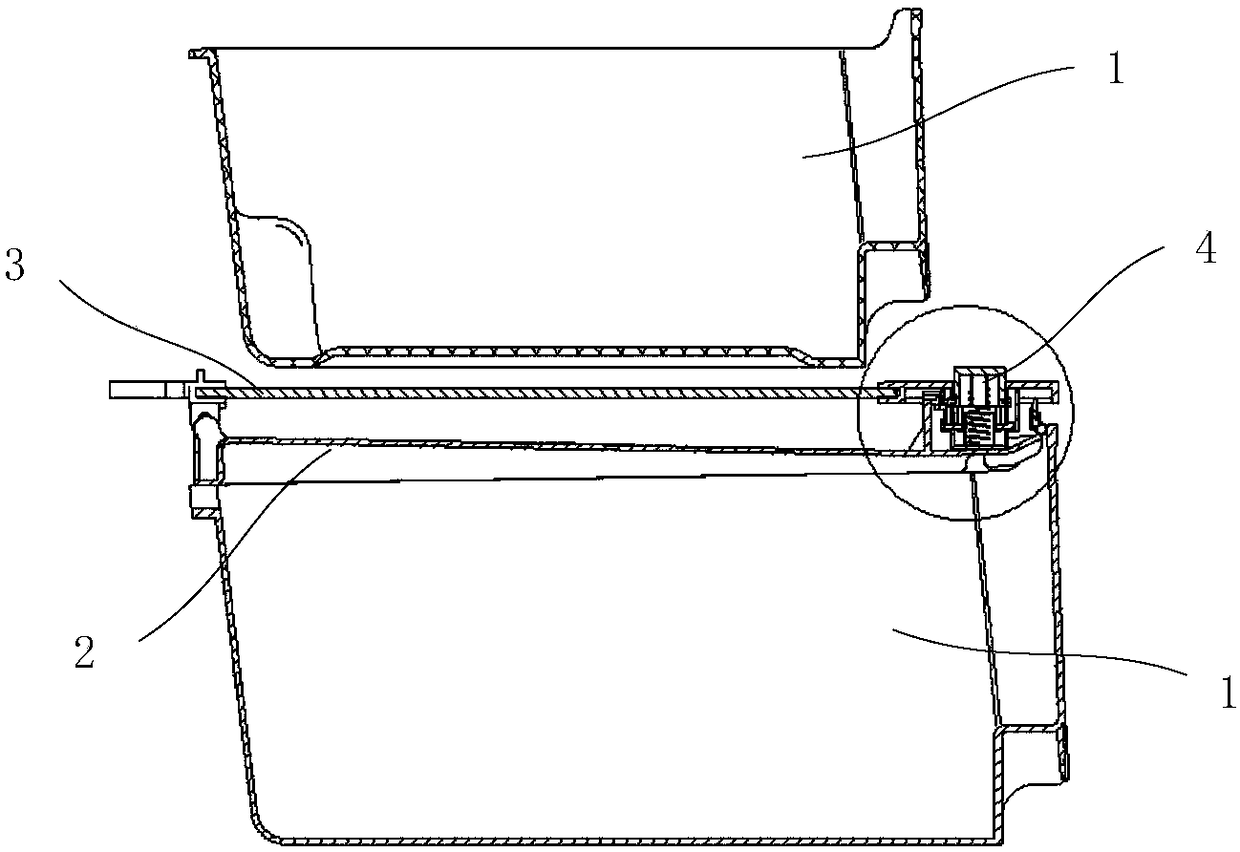

Preservation chamber and refrigerator with preservation chamber

ActiveCN107782040AGuaranteed freshAvoid taking awayLighting and heating apparatusDomestic refrigeratorsEngineeringCold blast

The invention provides a preservation chamber arranged in a compartment of a refrigerator and the refrigerator with the preservation chamber. The preservation chamber comprises a shell and an inner container, wherein the inner container is held in the shell; a supporting frame is arranged in the shell; the inner container is arranged on the supporting frame, so that an accommodating space is formed between the inner container and the shell; the shell is provided with a first air inlet; the inner container is provided with a second air inlet corresponding to the first air inlet; cold-blast aircan enter the inner container from the second air inlet to quickly cool food; the preservation chamber also comprises an air door used for opening or closing the second air inlet and an air guiding element arranged in the accommodating space; the air guiding element is arranged along the peripheral side of the second air inlet, so that at least two air-guiding air passages extending in different directions are formed on the periphery of the second air inlet; the cold-blast air is circulated along the air passages and around the inner container; the inner container is maintained at a low temperature for a long time; the condition that the rapid change of the temperature of the inner container occurs is avoided; the moisture of the food in the preservation chamber is also prevented from being taken away due to the circulation of the cold-blast air and further, the freshness of the food is ensured.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

Aluminum alloy for pedestrian bridges and preparation method thereof

The invention relates to an aluminum alloy for pedestrian bridges and a preparation method thereof. The invention is characterized in that the aluminum alloy is composed of the following chemical components in percentage by mass: 0.55-1.0% of Mg, 0.55-0.8% of Si, 0.18-0.55% of Mn, 0.1-0.2% of Cr, 0.05-0.2% of Ta, 0.10-0.3% of Ni, 0.10-0.50% of V, 0.1-0.3% of Cu, at most 0.05% of Zn, at most 0.20% of Fe, at most 0.05% of Ti, at most 0.15% of other impurity elements (at most 0.05% of each of other impurity elements), and the balance of Al. The preparation method comprises the following steps: smelting, refining, casting and uniformizing. By optimizing the alloy composition, trace amounts of Ta, Ni and V are added to obviously enhance the strength, toughness, fatigue resistance, corrosion resistance and processability of the aluminum alloy.

Owner:ALNAN ALUMINIUM CO LTD

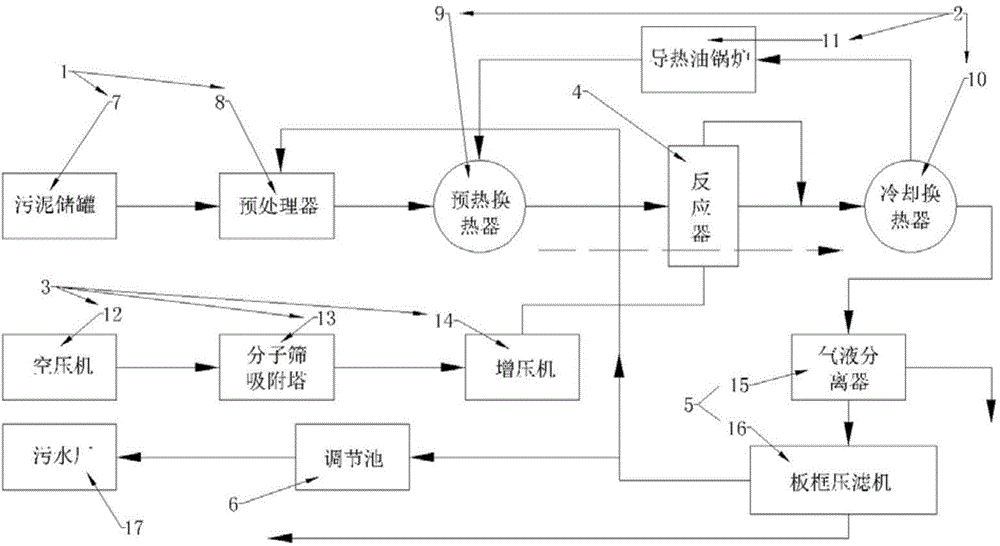

Low water consumption sludge treatment system and method

ActiveCN105645702AReduce lossesReduce generationSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationWater vaporSludge

The present invention relates to a low water consumption sludge treatment system and method, an efficient heat exchanger is used for preheating a starting material with a reacted material, a closed heat exchanger structure is used,the low water consumption sludge treatment system can prevent a lot of water vapor from being taken away during direct discharge of a gas, the loss of water is reduced, the generation of vapor is reduced, water phase change heat consumption energy is reduced, energy investment is reduced, and operating cost is saved. Further, by heat transfer of the gas, the loss of water entrained by high temperature is effectively reduced, and defogging arrangement in gas-liquid separation can effectively reduce the loss of the water vapor. At the same time, by adding of a conditioning tank, the water is further treated, and by adding of a base, most of heavy metals form complex precipitates, so that the water can be returned directly to a wastewater treatment plant for reuse, water sources are saved, and the operation cost of the system is reduced.

Owner:北京首创大气环境科技股份有限公司

Deseeding and squeezing device for wine processing and production and processing method thereof

ActiveCN112175762AAvoid affecting post-cleaning workAvoid Interfering with Cleaning WorkJuice extractionWine preparationGrape seedProcess engineering

The invention provides a deseeding and squeezing device for wine processing and production and a processing method thereof, and belongs to the technical field of grape processing. The deseeding and squeezing device comprises a pulp squeezing element, a seed filtering element, a control element, a peeling element and a power supply. The deseeding and squeezing device has the advantages that the cleaned grape particles can be peeled, squeezed and deseeded, so as to meet the requirement of wine brewing; when the pulp squeezing element works, because a buffer press sheet is arranged on an auxiliary squeezing roller, the pressure between the auxiliary squeezing roller and a main squeezing roller can be partially buffered, so as to avoid the influence to the mouth feel of the brewed wine due tocrushing of grape seeds and difficulty in separation from grape juice; and when the seed filtering element works, the grape seeds can be quickly separated, and the pulp which is not thoroughly squeezed can be secondarily squeezed, so as to ensure the low content of grape juice in the filtered pulp, avoid the waste of grape juice, and increase the output of wine.

Owner:ZUNYI NORMAL COLLEGE

Method for planting suaeda heteroptera in silty tidal beach

InactiveCN103563594AReduce adverse effectsImprove germination rateSeed coating/dressingHorticultureVegetationTidal flat

The invention relates to restoration technology for salt-tolerant vegetation of estuarine wetlands and coastal tidal beaches, in particular to a method for planting suaeda heteroptera in a tidal environment. The method specifically includes at 15-20 DEG C, adding fresh water in suaeda heteroptera seeds according to a weight ratio of 1:3-1:5 for soaking for 20-25h until the seeds open mouths; adding clay or clayey slit in the seeds after being soaked according to a weight ratio of 1:1-1:5, wherein grain size ranges from 0.001mm to 0.03mm, and uniformly stirring; selecting March-June, during ebb tide, splashing the seeds hanging mud on the tidal beaches, wherein seeding quantity is 0.5-1.0kg / hm2. Seed germination is promoted through fresh water soaking, so that germination percentage of the suaeda heteroptera seeds is increased; the soaked seeds are sowed after mud hanging, so that the suaeda heteroptera seeds are enabled to be quickly pasted on the surfaces of the wetlands and the tidal beaches and covered by the clay or clayey slit, the suaeda heteroptera seeds are avoided from being brought away by high wind and tide water, planting rate of seedlings is increased, and utilization efficiency of the seeds is improved. By the method, unfavorable effect, of the tidal environment, on suaeda heteroptera planting is overcome, and technical reserve is provided for suaeda heteroptera vegetation restoration and ecological environment improvement of the estuarine wetlands and the coastal tidal beaches.

Owner:LIAONING OCEAN & FISHERIES SCI RES INST

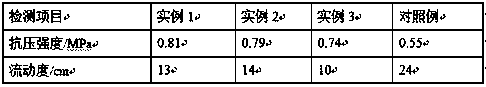

Preparation method of tailings paste filling material

The invention relates to a preparation method of a tailings paste filling material and belongs to the technical field of filling materials. The tailings paste filling material is prepared by adding limestone powder; the limestone powder which has good filling effect enables the paste structure to be compacted, so that pore size distribution is improved, and compressive strength of concrete is improved; the limestone power features low water adsorption; compared with fly ash, mineral residue and other active mineral mixtures, the limestone powder can evidently improve pumpability of concrete under same mixing amount. The mineral residue powder is added to prepare the tailings paste filling material; the mineral residue powder is an industrial byproduct made by treating a melt formed at 1350-1450 DEG C during mineral extraction, and is a high-quality concrete admixture; the mineral residue powder has high potential activity, helps improve late strength of a mix, has high activity, and can partly replace cement, reduce hydration heat, inhibit alkali-aggregate reaction and improve durability of concrete.

Owner:雷江容

Anti-splashing textile dyeing vat

InactiveCN108385316AStir wellImprove the heating effectTextile treatment containersLiquid/gas/vapor removal by squeezing rollersTextile dyeingWater pipe

The invention discloses an anti-splashing textile dyeing vat. The anti-splashing textile dyeing vat comprises a cover, a dyeing chamber, a vat body, a filtering chamber and an anti-splashing plate, wherein the internal bottom end of the vat body is provided with the filtering chamber; the dyeing chamber is arranged above the filtering chamber and inside the vat body; one side of the internal bottom end of the filtering chamber is provided with a water pump, and the output end of the water pump is connected with a water pipe extending inside the dyeing chamber; a separating plate is arranged between the dyeing chamber and the filtering chamber, the inside of the separating plate is provided with a heating pipe in a ring shape, and the middle of the bottom of the separating plate is providedwith a motor; the output end of the motor extends into the dyeing chamber and is fixedly provided with a stirring shaft, the inside of the dyeing chamber above the stirring shaft is provided with theanti-splashing plate, and connecting rods are uniformly fixed between the anti-splashing plate and the inner wall of the vat body. By means of the anti-splashing plate which is in a conical shape andis provided with an internal leakage mesh, the anti-splashing textile dyeing vat can reduce impact force between dye and the anti-splashing plate and further avoid splashing of the dye.

Owner:XIANGSHUI COUNTY XINHONG TEXTILE CO LTD

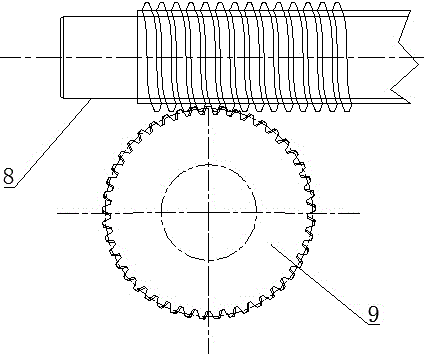

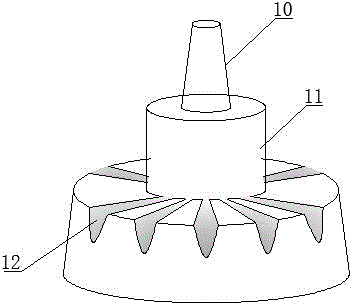

Coral reef transplanting repairing device applicable to South China Sea

InactiveCN106538445AImprove restoration qualityImprove repair efficiencyClimate change adaptationPisciculture and aquariaCoral reef fishEngineering

The invention provides a coral reef transplanting repairing device applicable to South China Sea. The coral reef transplanting repairing device comprises a lateral wall, bottom feet, a rigid support, a base plate, a control box, a cross rotary knob, a worm, a bevel gear and a coral cultivation device. By the arrangement, the coral reef transplanting repairing device has the advantages that during a coral spawning period, the coral reef transplanting repairing device fixed on the outer slope in front of a coral reef attracts and fixes drifting coral larvae, and a hole is drilled in the degenerated coral reef and the coral cultivation device attached with coral is inserted and fixed into the hole after the coral is mature so as to complete the ecologic repairing of the coral reef. By the coral reef transplanting repairing device, the problems that a traditional coral reef transplanting repairing device is low in coral transplanting survival rate and difficult in underwater coral transplanting and fixing, the coral larvae are preyed easily and covered by sediments, and the like are solved, and coral reef transplanting repairing efficiency and quality are increased.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

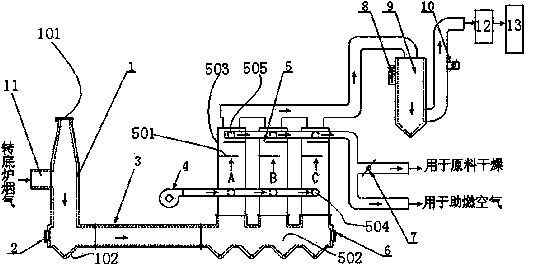

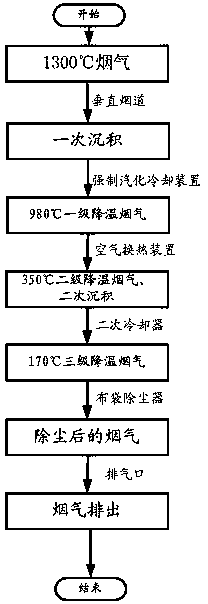

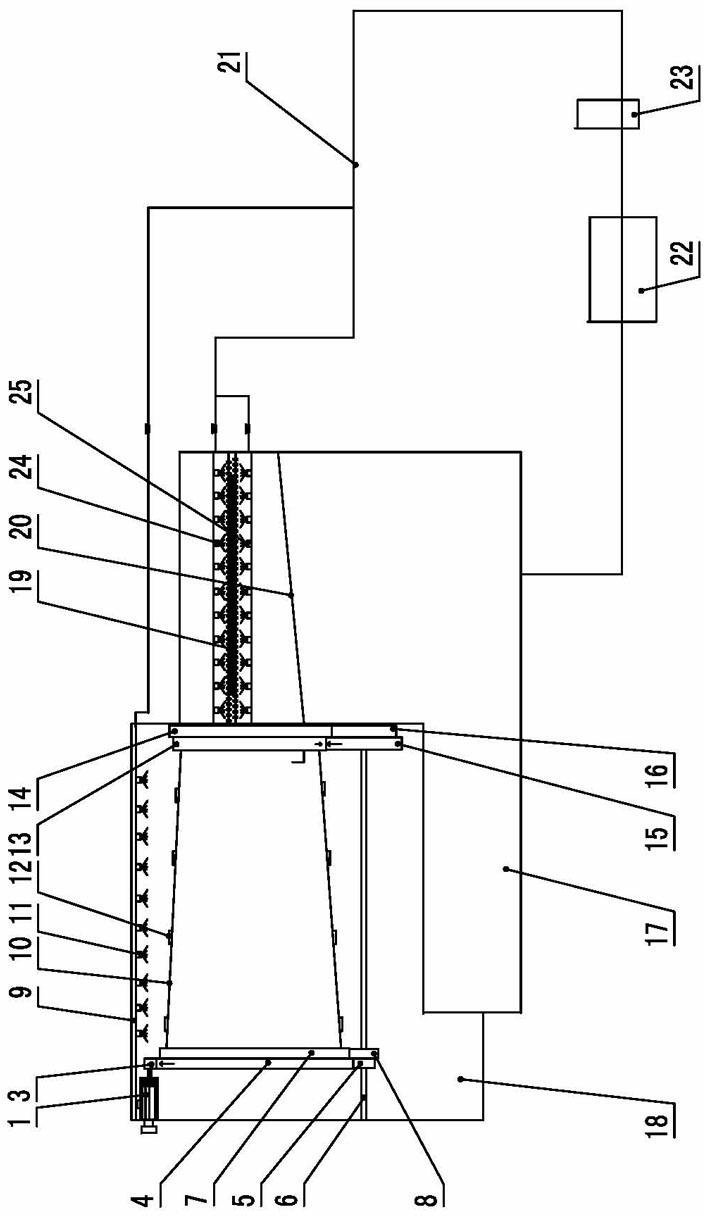

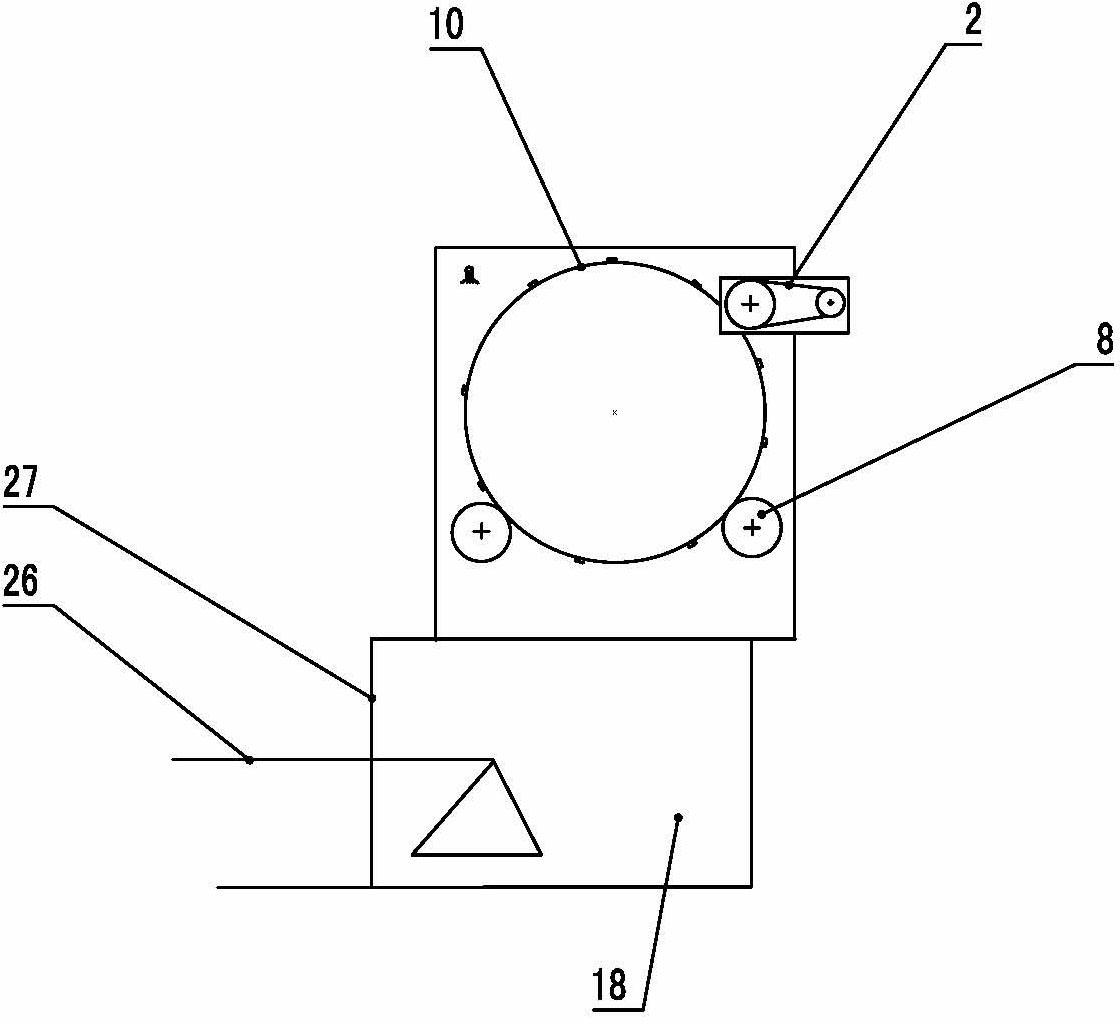

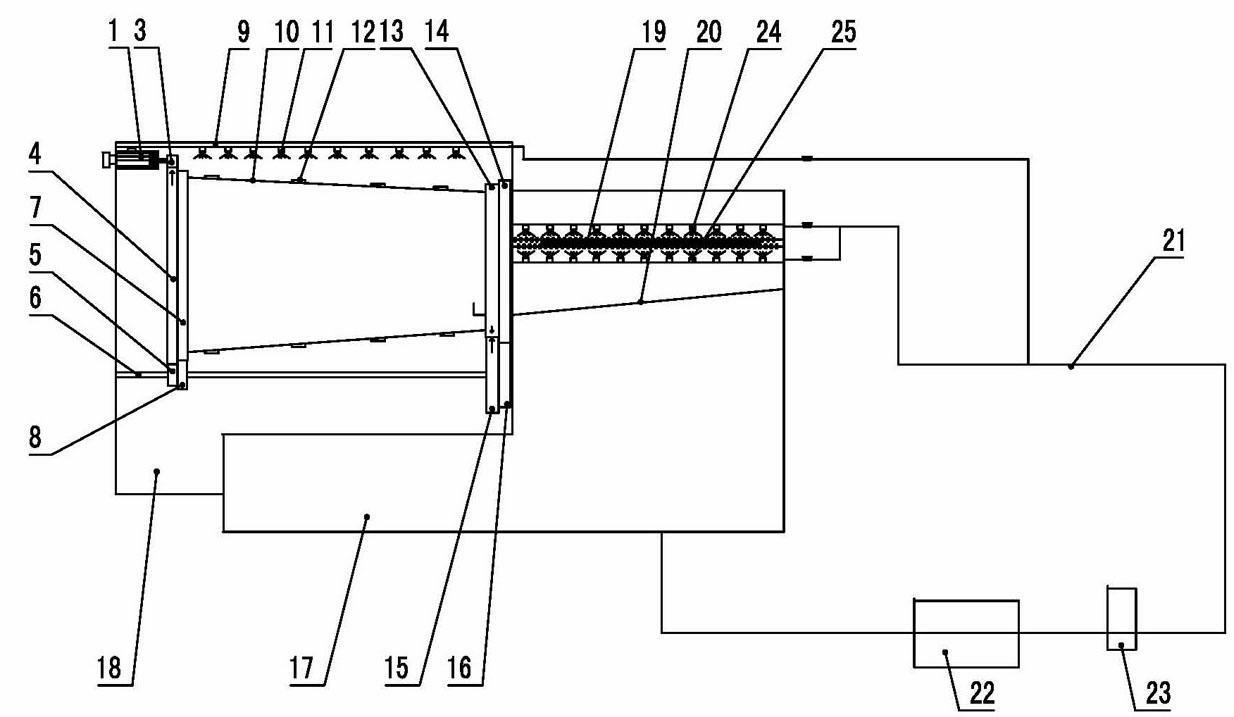

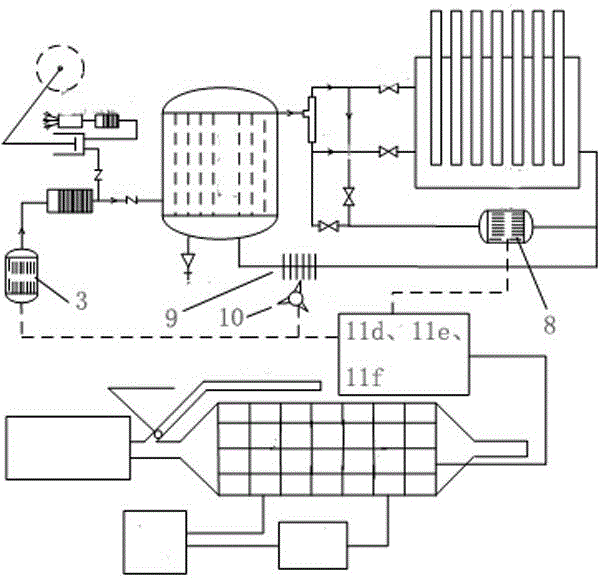

Anti-blockage rotary hearth furnace smoke processing system and method

The invention provides an anti-blockage rotary hearth furnace smoke processing system and method. The anti-blockage rotary hearth furnace smoke processing system comprises a smoke inlet (11), a vertical flue (1), a forcing evaporative cooling device (3), an air heat exchanging device (5), a secondary cooler (9), a cloth bag dust removing device (12) and an exhaust port (13), all of which are connected in sequence. According to the anti-blockage rotary hearth furnace smoke processing method, the temperature of the smoke inlet (11) is set to be 1,200 DEG C or higher, smoke enters the vertical flue (1) from the smoke inlet (11) to enter the forcing evaporative cooling device (3) along the flue so that one-level cooled smoke with the temperature controlled to be 600 DEG C or higher can be obtained; the one-level cooled smoke enters the air heat exchanging device (5) to be cooled, and two-level cooled smoke with the temperature of 300 DEG C or higher is obtained; the two-level cooled smoke enters the secondary cooler (9), and three-level cooled smoke with the temperature ranging from 150 DEG C to 190 DEG C is obtained; the three-level cooled smoke is exhausted out of the exhaust port (13) after entering the cloth bag dust removing device (12).

Owner:SHANGHAI BAOSTEEL ENERGY TECH

Tumbling filter device

InactiveCN102166447AEfficient separationPrevent immersionMoving filtering element filtersDrive shaftEngineering

The invention relates to a filter device, particularly relates to a tumbling filter device, which belongs to a filter device. The tumbling filter device provided by the invention comprises a support, and the support is provided with a motor, a transmission shaft and a tumbling filter screen with two opened ends; the tumbling filter screen is in the shape of conical platform, the two ends of the tumbling filter screen are respectively an inlet end and an outlet end, and the opening diameter of the outlet end is greater than that of the inlet end; the motor is connected with the tumbling filter screen, and the inlet end of the tumbling filter screen is connected with a ramp drainage plate; and the support is provided with a storage tank for separate matters and a drain tank for medicinal liquids, the storage tank is arranged below the outlet end of the tumbling filter screen, and the drain tank is arranged below the middle part of the tumbling filter screen. The tumbling filter device provided by the invention has the beneficial effects that dry film scraps and the medicinal liquid can be effectively separated, and the situation that the dry film scraps are immersed into the medicinal liquid can be avoided; and meanwhile, in the process of rotating filter, the medicinal liquid in the dry film scraps can be thrown off, therefore, the medicinal liquid can be saved.

Owner:崇达技术股份有限公司

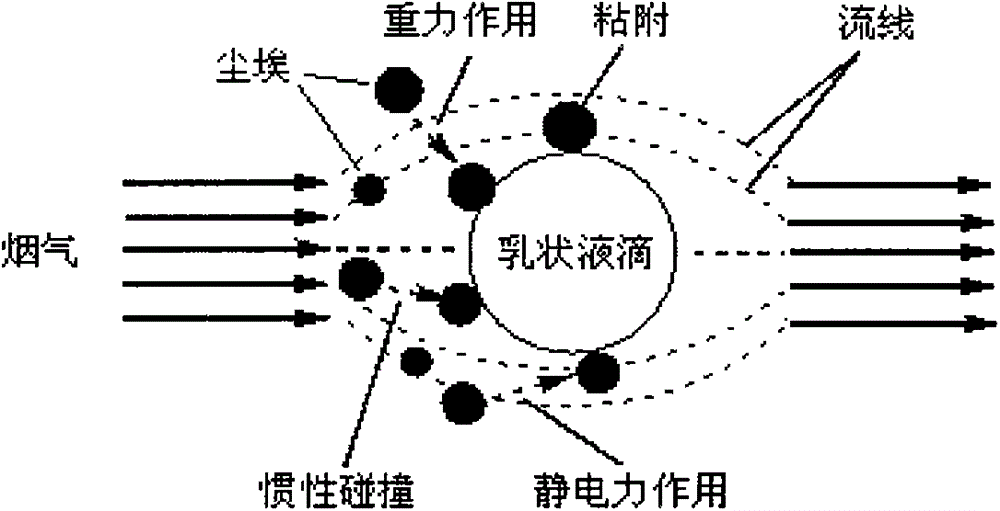

Method for removing dust out of smoke

InactiveCN104014210AFully contactedImprove dust removal effectSemi-permeable membranesLiquid separation by electricityBoiling pointSlurry

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

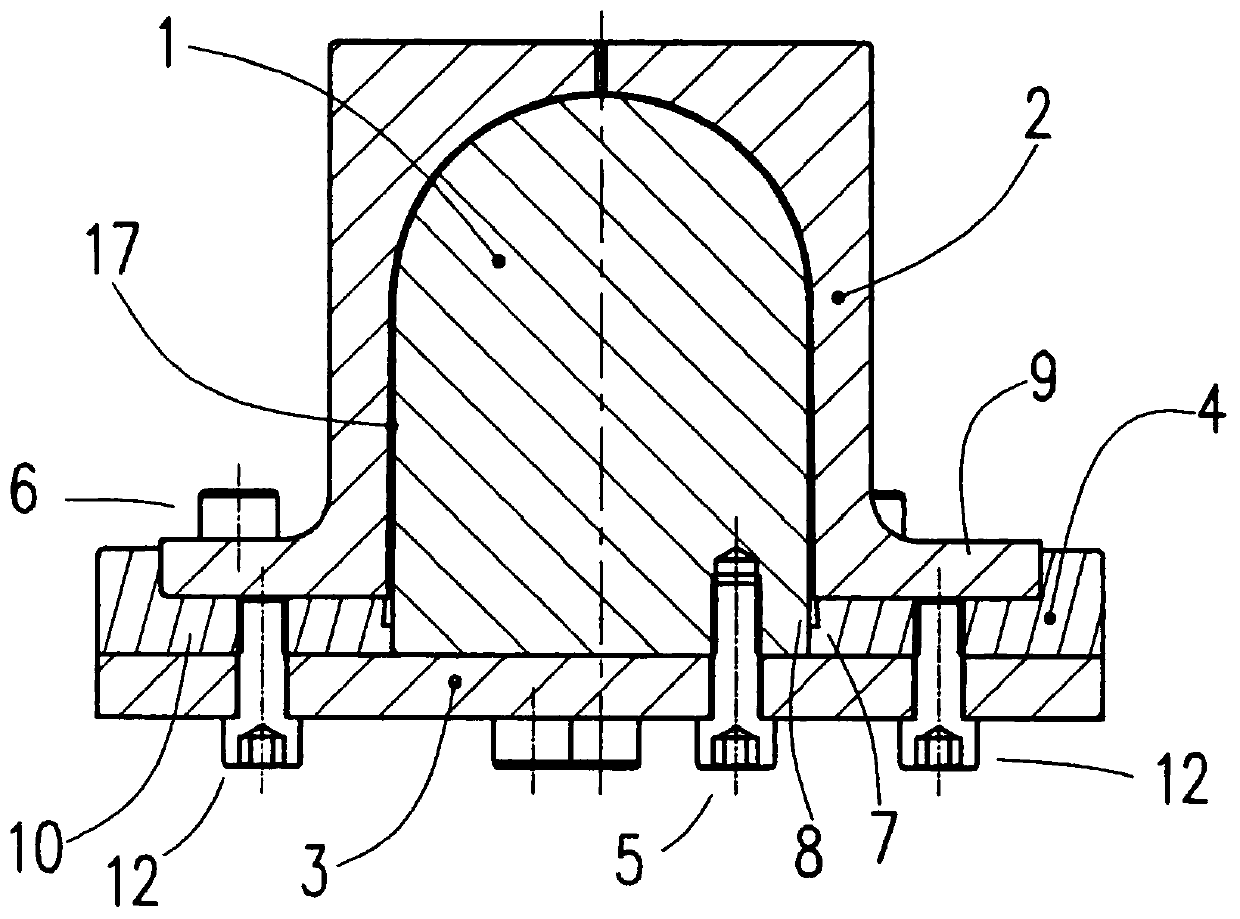

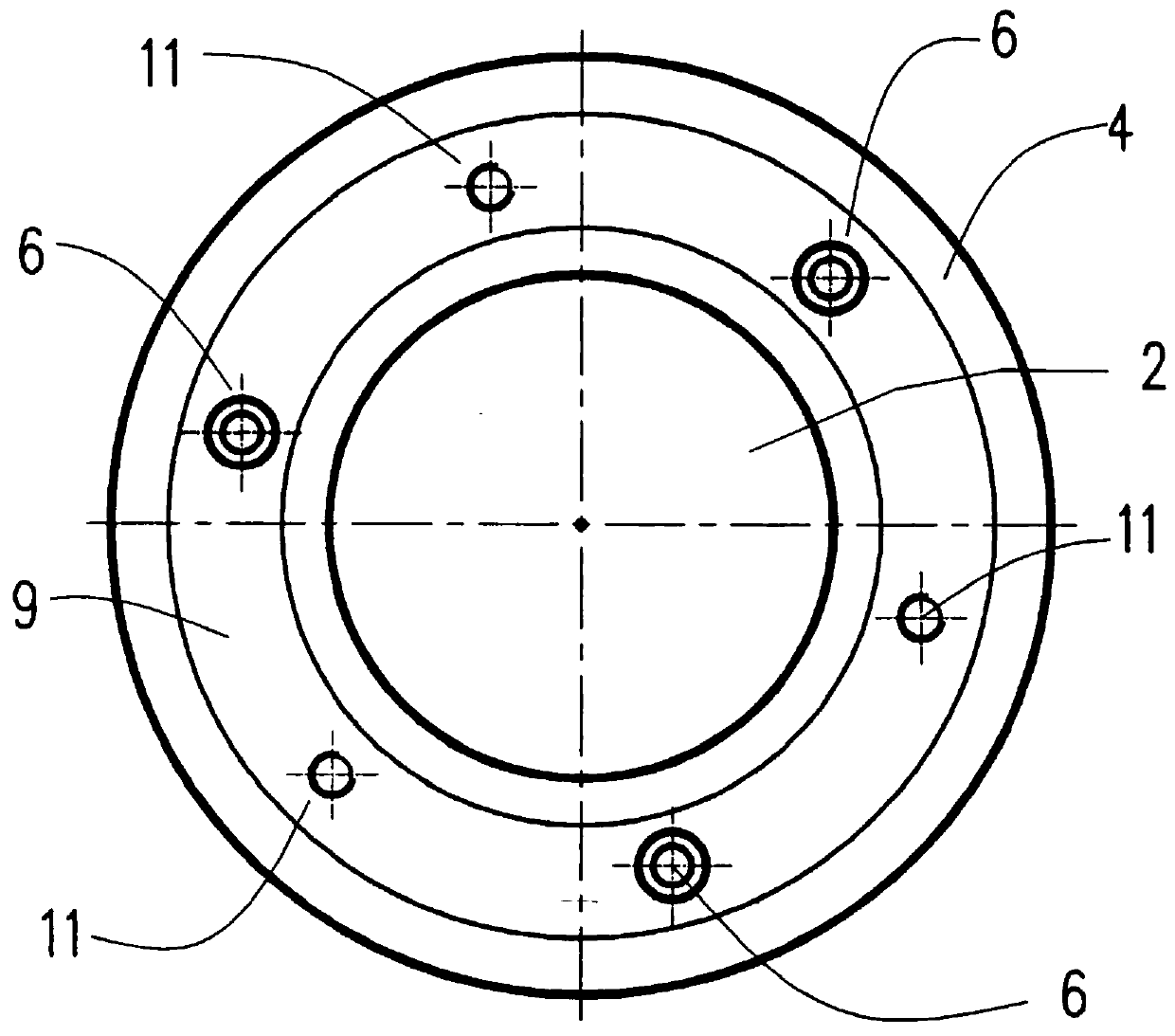

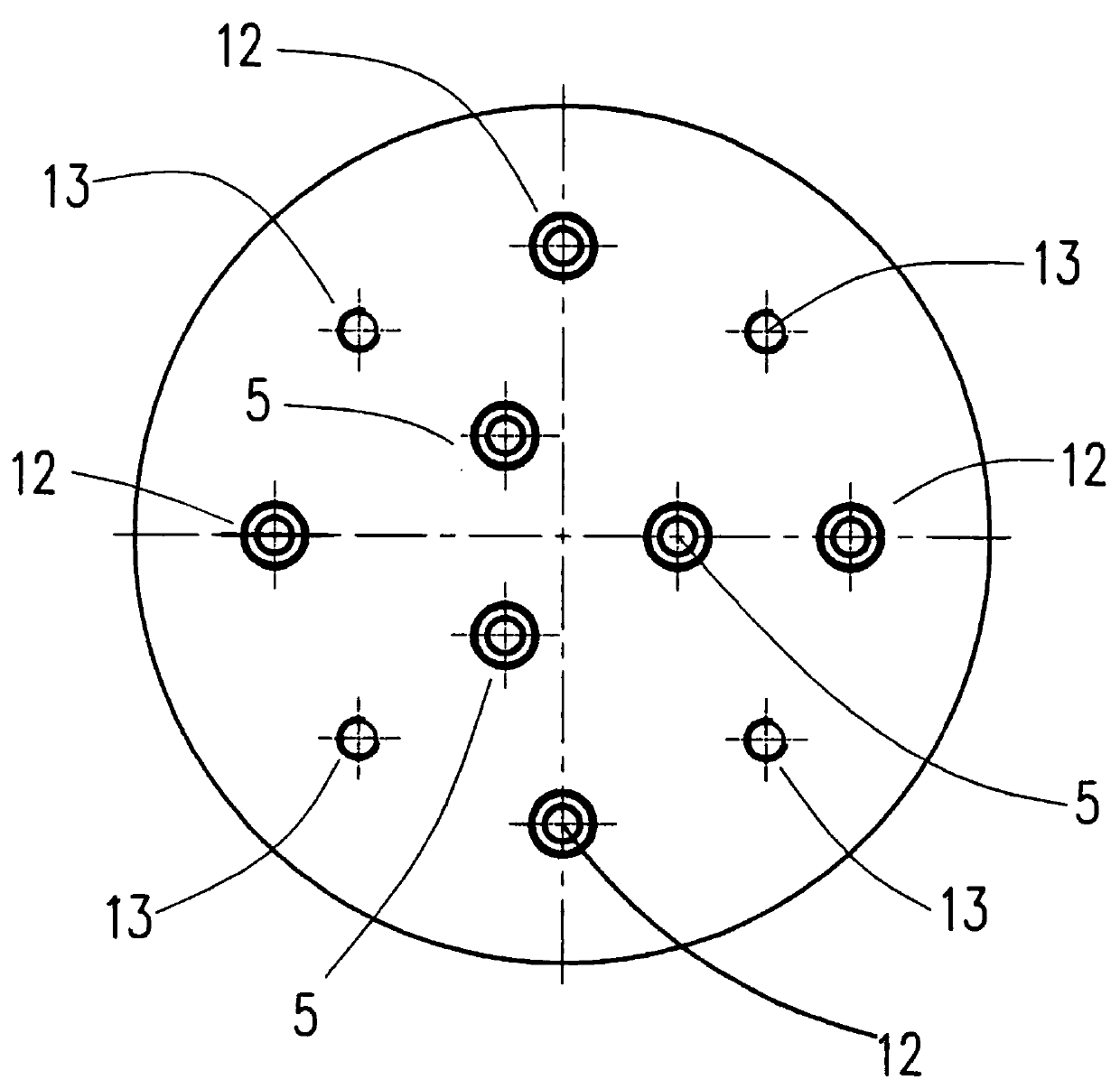

Molding die of resin-based composite radome

The invention relates to a molding die of a resin-based composite radome. The molding die comprises a male die, a female die, a bottom plate and a demolding ring; an inner circle edge opening of the demolding ring is matched with an outer circle edge opening of the male die in shape and size; the lower end of the female die is provided with a positioning ring piece, the upper end surface of the demolding ring is provided with a ring-shaped groove seat matched with the positioning ring piece in shape and size, and the female die can be clamped into the ring-shaped groove seat through the positioning ring piece; and the positioning ring piece is provided with a first demolding screw matched with a first demolding screw hole, the bottom plate is provided with a second demolding screw matched with a second demolding screw hole, the inner circle edge opening is a stepped hole, the stepped hole includes an upper hole opening and a lower hole opening, and the upper hole opening is of a horn mouth structure small in top and larger in bottom. The molding die has the following advantages that 1, the structure is simple, and demolding operation is convenient and quick; 2, a stress part of the demoulding process is designed reasonably, and protection of a main body part of a radome product is facilitated; 3, and the product yield rate is above 98%.

Owner:SICHUAN TIANYUAN MACHINERY CO LTD OF 081 ELECTRONICS GRP

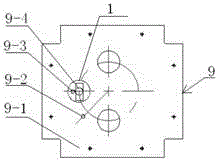

Intelligent card issuing machine and control method thereof

ActiveCN104598945AImprove work efficiencyReduce labor intensityConveying record carriersCo-operative working arrangementsEngineeringSmart card

The invention provides an intelligent card issuing machine comprising a feed mechanism and a screening and separating mechanism. The screening and separating mechanism comprises a card reader, a base plate and a separating disc, the card reader is installed on the base plate or a frame, and the base plate is installed on the frame and is provided with a discharging hole; the separating disc is located above the base plate and is driven to rotate through a drive device, and a gap is formed between the separating disc and the base plate; the separating disc is provided with an intelligent card drive hole; a collection mechanism is located below the discharging hole; after intelligent card are fed into the intelligent card drive hole through the feed mechanism, the card reader reads the intelligent cards, after the card reading operation, the intelligent cards fall into the discharging hole from the intelligent card drive hole and enter the collection mechanism through the discharging hole. The invention further provides a control method of the intelligent card issuing machine. The intelligent card issuing machine is simple in structure, convenient to assemble and high in reliability and is adaptive to hanger production companies for fed intelligent card detection and textile and garment companies for intelligent card sequence.

Owner:ZHEJIANG RESISTING INTELLIGENT TECH CO LTD +1

Refrigerator with humidity control drawer

ActiveCN108592509ARegulate humidityReduce the temperatureLighting and heating apparatusCooling fluid circulationRefrigerated temperatureSliding contact

The invention discloses a refrigerator with a humidity control drawer, and relates to the technical field of refrigerators. The humidity in the object storage drawer can be adjusted, and operation issimple and convenient. The refrigerator with the humidity control drawer comprises a refrigerating chamber, the object storage drawer is arranged in the refrigerating chamber, an opening of the objectstorage drawer is covered with a drawer cover plate, a fixing support fixed to the refrigerating chamber is arranged above the drawer cover plate, an adjusting button is rotationally connected to thefixing support in the vertical direction, a spiral adjusting device is connected to the lower portion of the adjusting button, a fan-shaped spiral ring is arranged in the circumferential direction ofthe spiral adjusting device, the heights of the fan-shaped spiral ring in the vertical direction are gradually changed, the fan-shaped spiral ring is in a shape of an inclined slope, the upper portion of the drawer cover plate extends to the fixing support to form a hook part, and the upper surface of the fan-shaped spiral ring is in sliding contact with the lower surface of the hook part; and when the adjusting button is rotated, the fan-shaped spiral ring can be driven to rotate, and the drawer cover plate is lifted up or put down accordingly. The refrigerator is used for storing objects.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

Vehicle energy saving system combining temperature difference power generation and vortex tube principle

InactiveCN106150631AReduce fuel consumptionImprove comfortAir-treating devicesInternal combustion piston enginesAir pumpEngineering

The invention discloses a vehicle energy saving system combining temperature difference power generation and a vortex tube principle. The vehicle energy saving system comprises a gas supply device, a gas storage tank, a vortex tube, a first heat exchanger, a second gas pump, a second heat exchanger and a temperature difference power generation system. The gas supply device supplies gas to the gas storage tank. The input end of the vortex tube is connected with the gas storage tank. A cold gas output pipe of the vortex tube is divided into two branches to be connected with the first heat exchanger and the second gas pump correspondingly. A hot gas output pipe of the vortex tube is divided into two branches to be connected with the first heat exchanger and the second gas pump correspondingly. A stop valve is arranged on each branch. An output pipe of the first heat exchanger and an output pipe of the second gas pump are connected with the input end of the second heat exchanger together. The output end of the second heat exchanger is connected with the gas storage tank. A temperature difference power generation system supplies power to the gas supply device and the second gas pump. According to the vehicle energy saving system, heat in vehicle tail gas is converted into electric energy through the temperature difference power generation system, and noise and temperature of vehicle tail gas emission can be lowered, and because an air conditioner system based on the vortex tube principle is simple in structure, low in power consumption and can be completely self-sufficient, the oil consumption is lowered, and energy conservation and environment protection are achieved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Passive residual heat removal system with heat exchanger located at exterior of water tank for secondary side of marine pressurized water reactor

PendingCN107833642AIncrease stressReduce risk of leakageNuclear energy generationCooling arrangementReactor pressure vesselPlate heat exchanger

The invention discloses a passive residual heat removal system with a heat exchanger located at the exterior of a water tank for the secondary side of a marine pressurized water reactor, and relates to the field of nuclear reactor safety facilities. The passive residual heat removal system comprises a reactor pressure vessel, a containment and at least one heat removal subsystem, wherein the heatremoval subsystem comprises a steam generator, a condenser, a water tank, a main coolant pipeline, a steam pipeline, a condensate water pipeline and a cooling water circuit; and the steam generator comprises a steam generating part and a heat exchanging part. After an accident, residual heat in a reactor is discharged through the main coolant pipeline between the reactor pressure vessel and the heat exchanging part, the steam pipeline and the condensate water pipeline between the steam generating part and the condenser, and the cooling water circuit between the condenser and the water tank. According to the invention, by utilization of device position difference and medium density difference, a heat transfer medium in the system provided by the invention can passively flow, so the purposeof safe and passive residual heat removal is achieved.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com