Secondary-side passive waste heat discharging system for ship pressurized water reactor

A waste heat removal system and passive waste heat technology, applied in reactors, nuclear power generation, greenhouse gas reduction, etc., can solve the problems of no commercial application and affect the heat removal function of the passive waste heat removal system, and achieve the effect of alleviating space shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

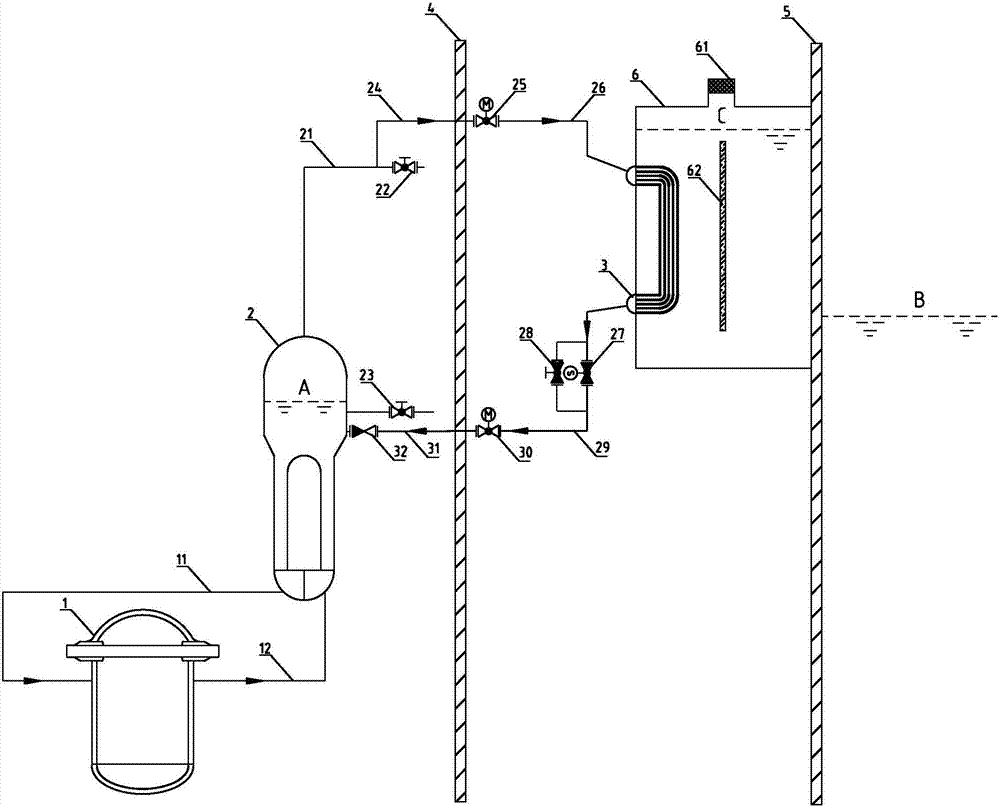

[0039] Such as figure 1 As shown, the secondary side passive waste heat discharge system of the marine PWR of the present invention comprises that the reactor pressure vessel 1 is connected to the primary side of the steam generator 2 through the cold section 11 of the main pipeline and the hot section 12 of the main pipeline, and the reactor pressure vessel 1 and the steam The generator 2 is located in the containment 4, and the thermal center of the steam generator 2 is higher than the thermal center of the reactor pressure vessel 1 by a certain distance Δh 1 .

[0040] The secondary side of the steam generator 2 is connected to the pipe side of the passive waste heat discharge condenser 3 through a steam pipeline and a condensation pipeline. In this embodiment, the steam pipeline includes a first pipeline 21, a second pipeline 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com