Patents

Literature

115 results about "Blowpipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term blowpipe refers to one of several tools used to direct streams of gases into any of several working media.

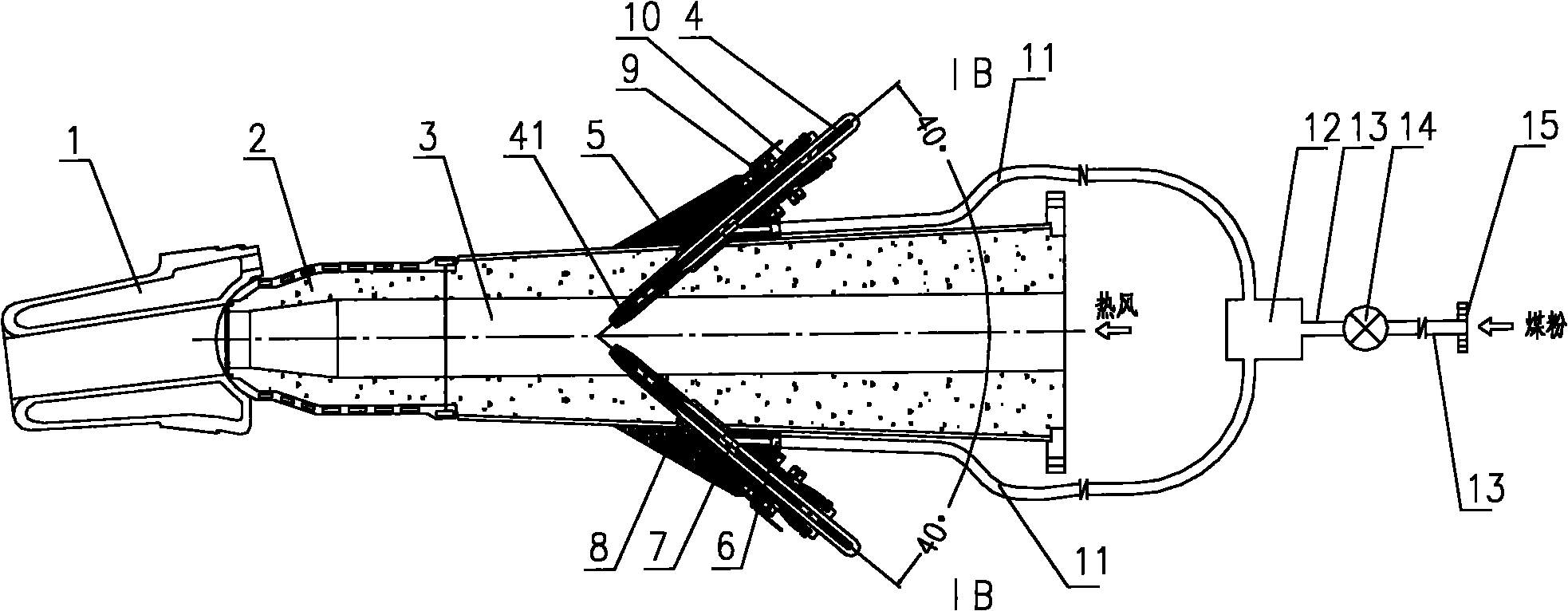

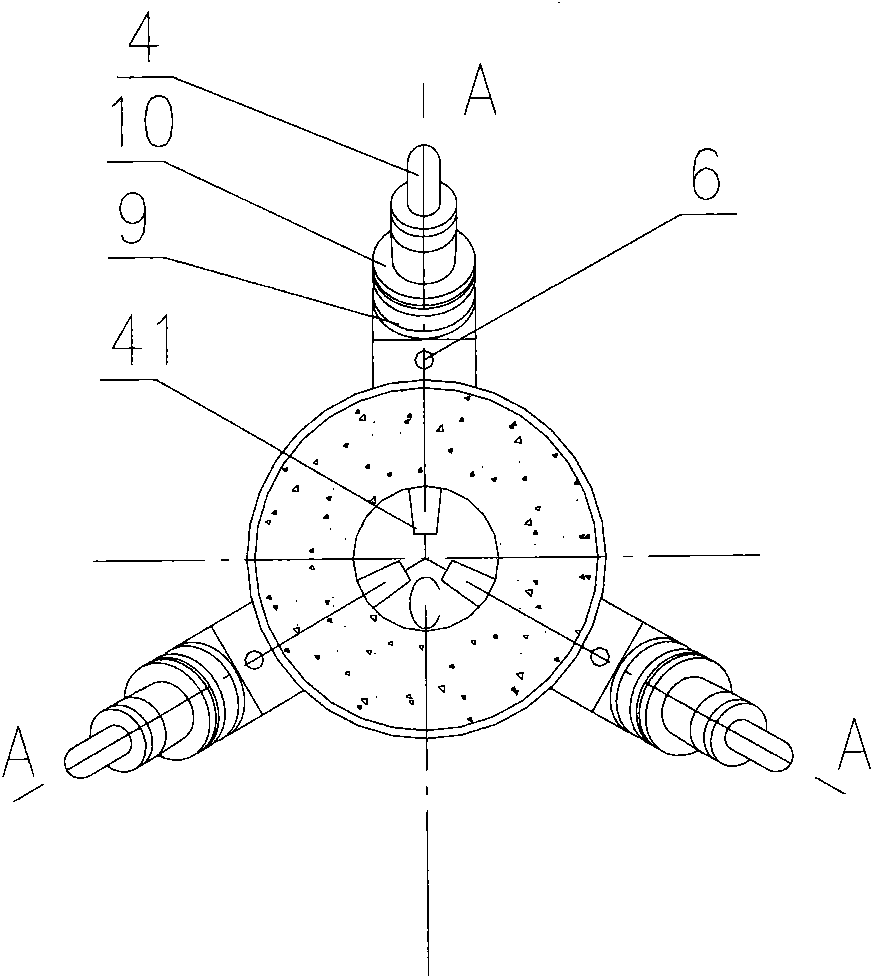

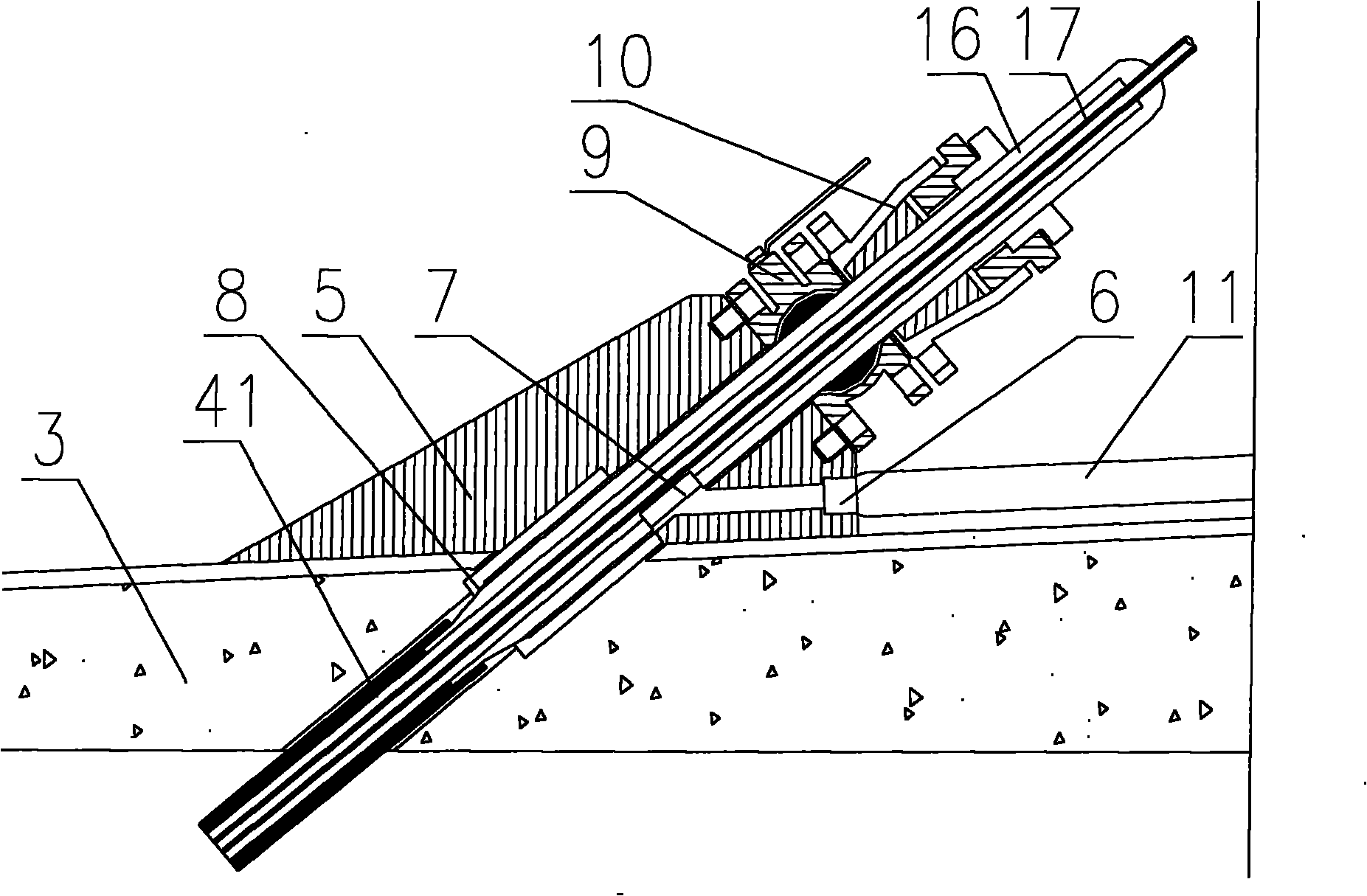

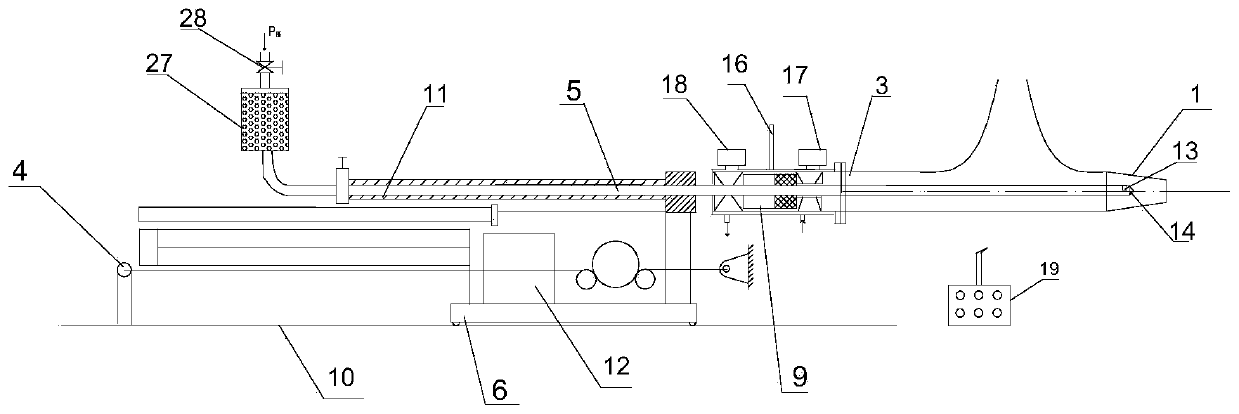

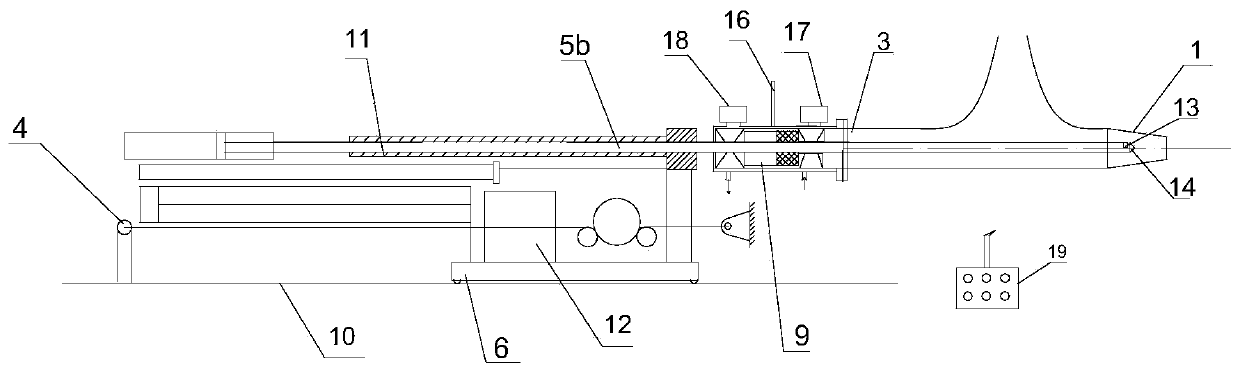

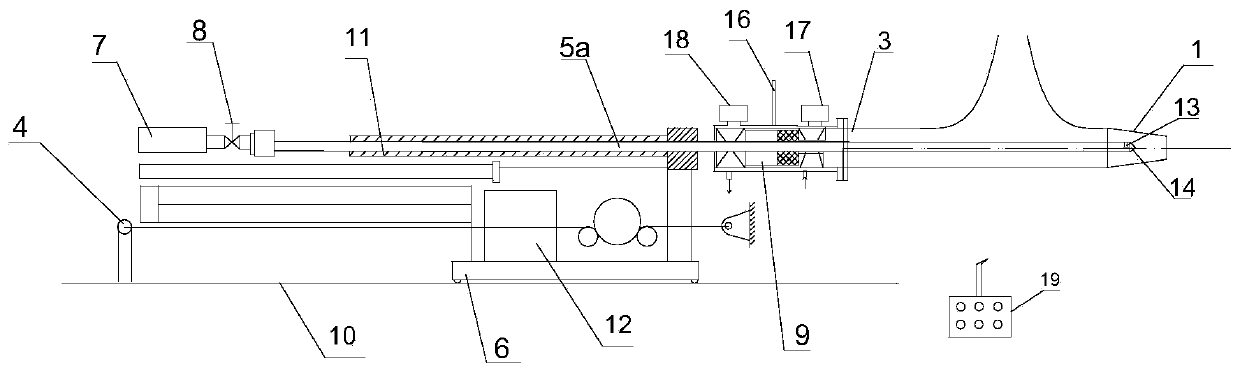

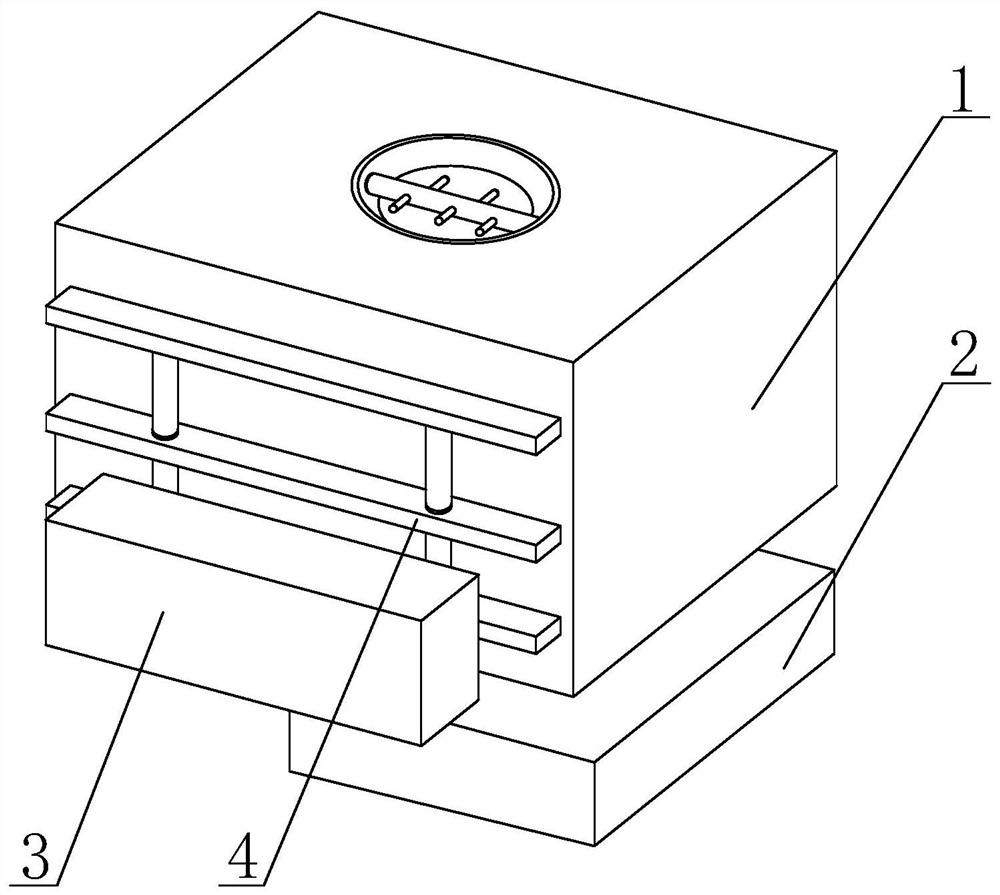

Method and device for blast furnace to blow coal powder

InactiveCN102485913AEnhance heat and mass transferExtended stayTuyeresBlast furnace detailsBall valveNew device

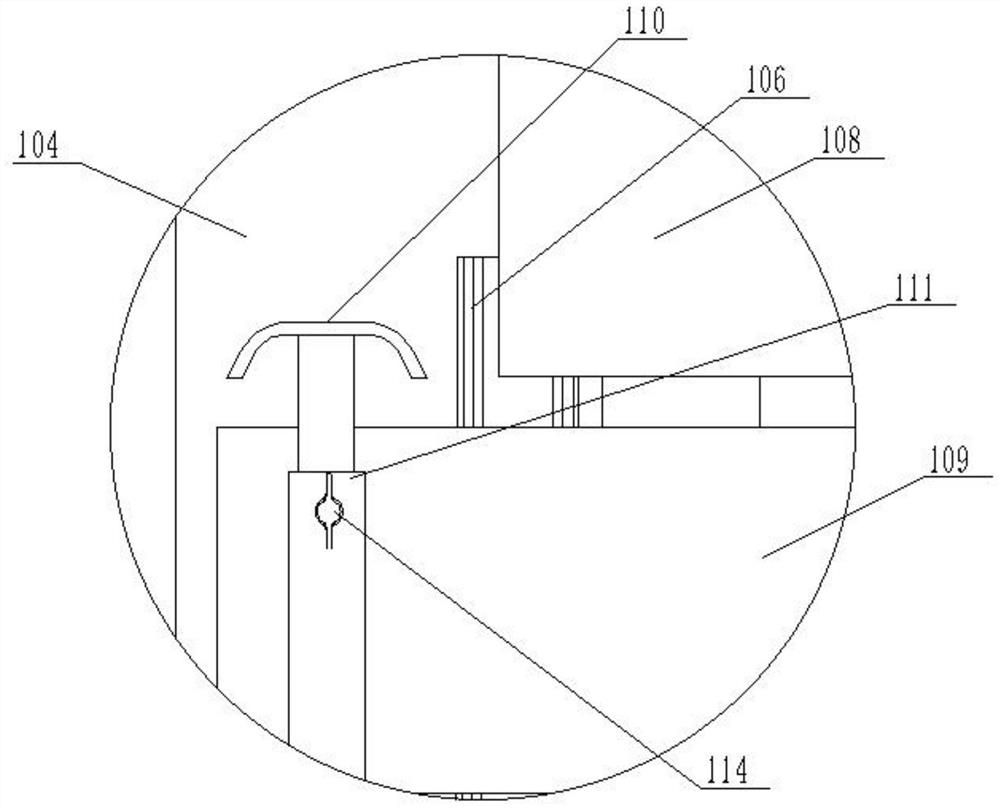

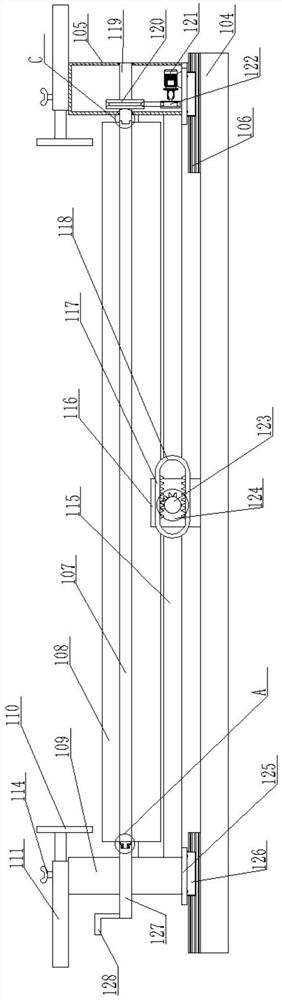

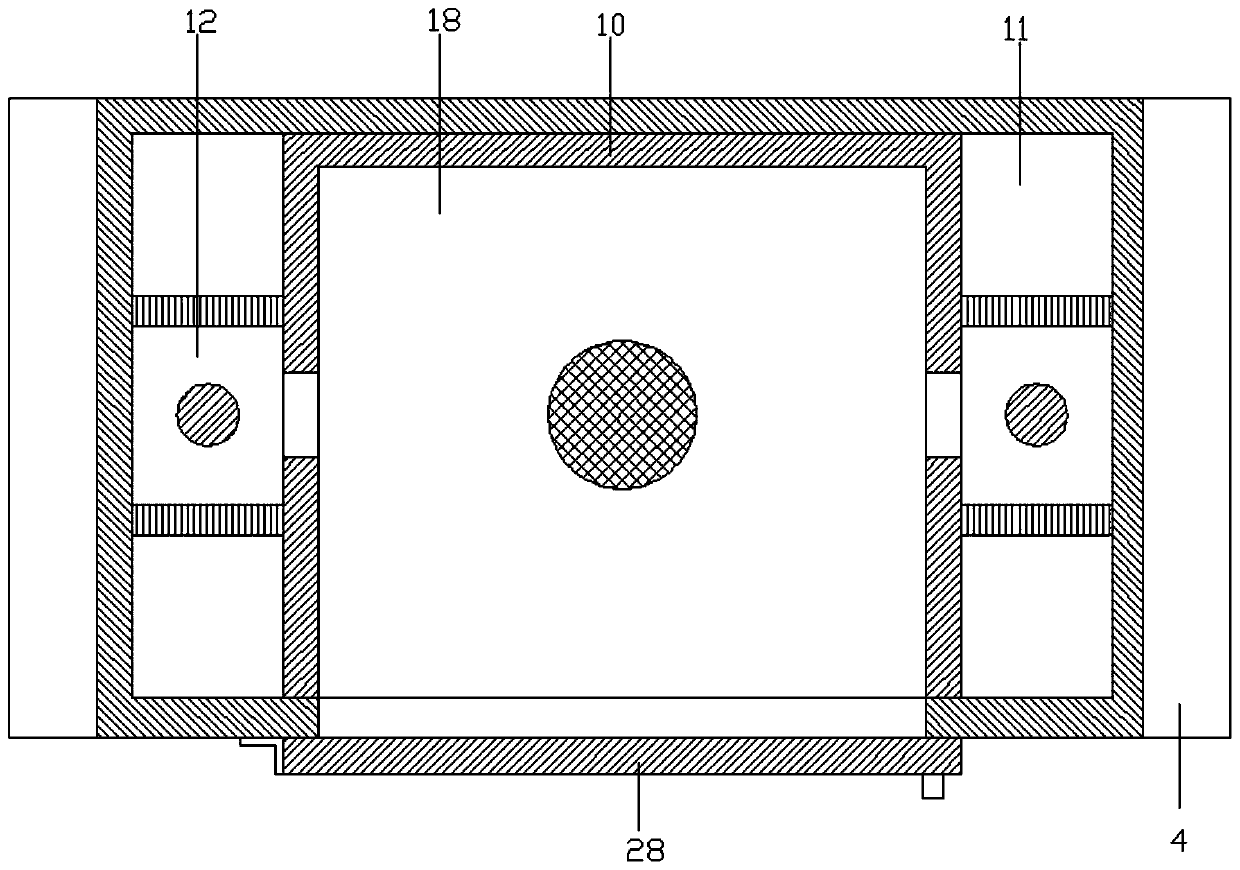

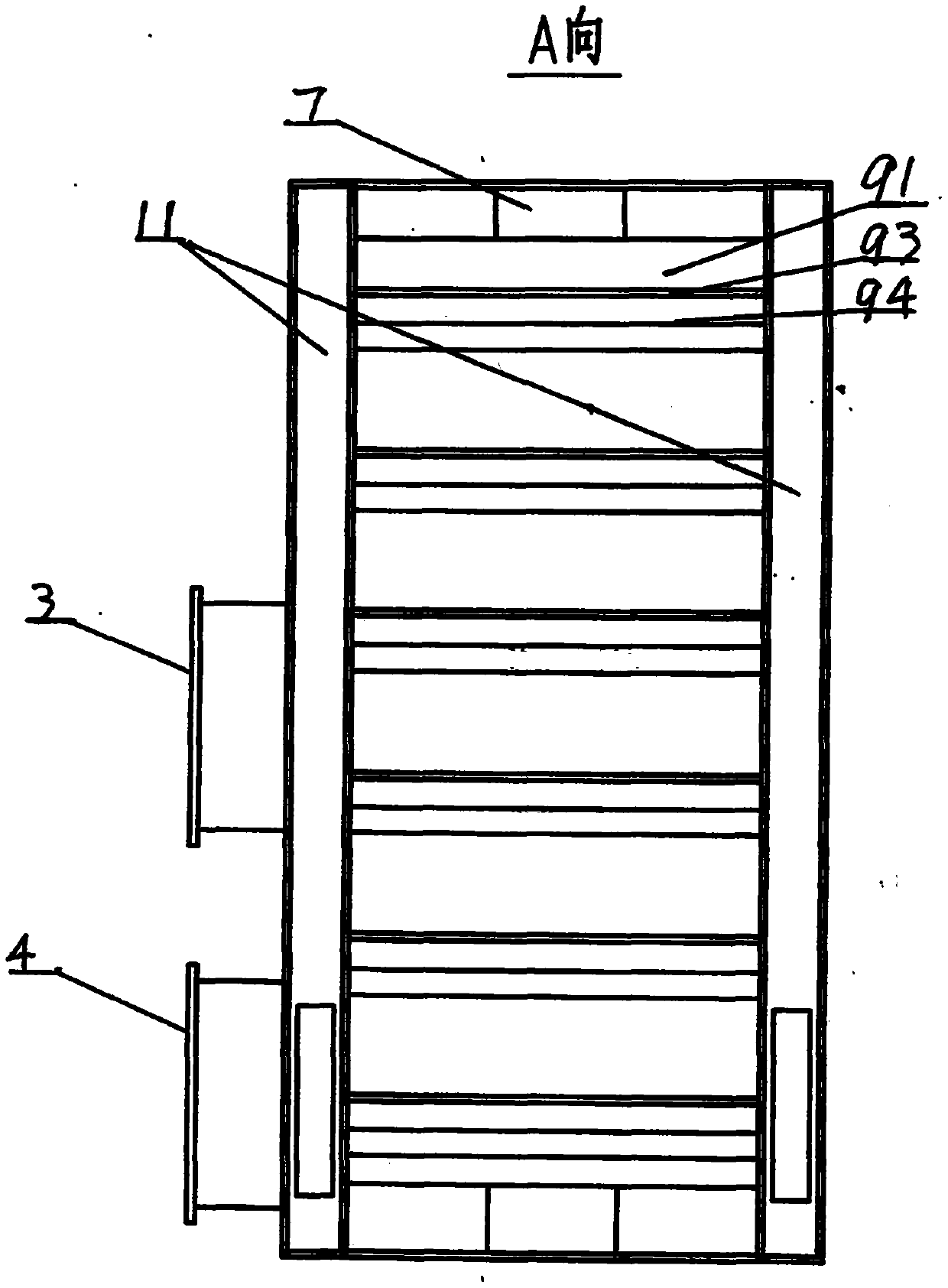

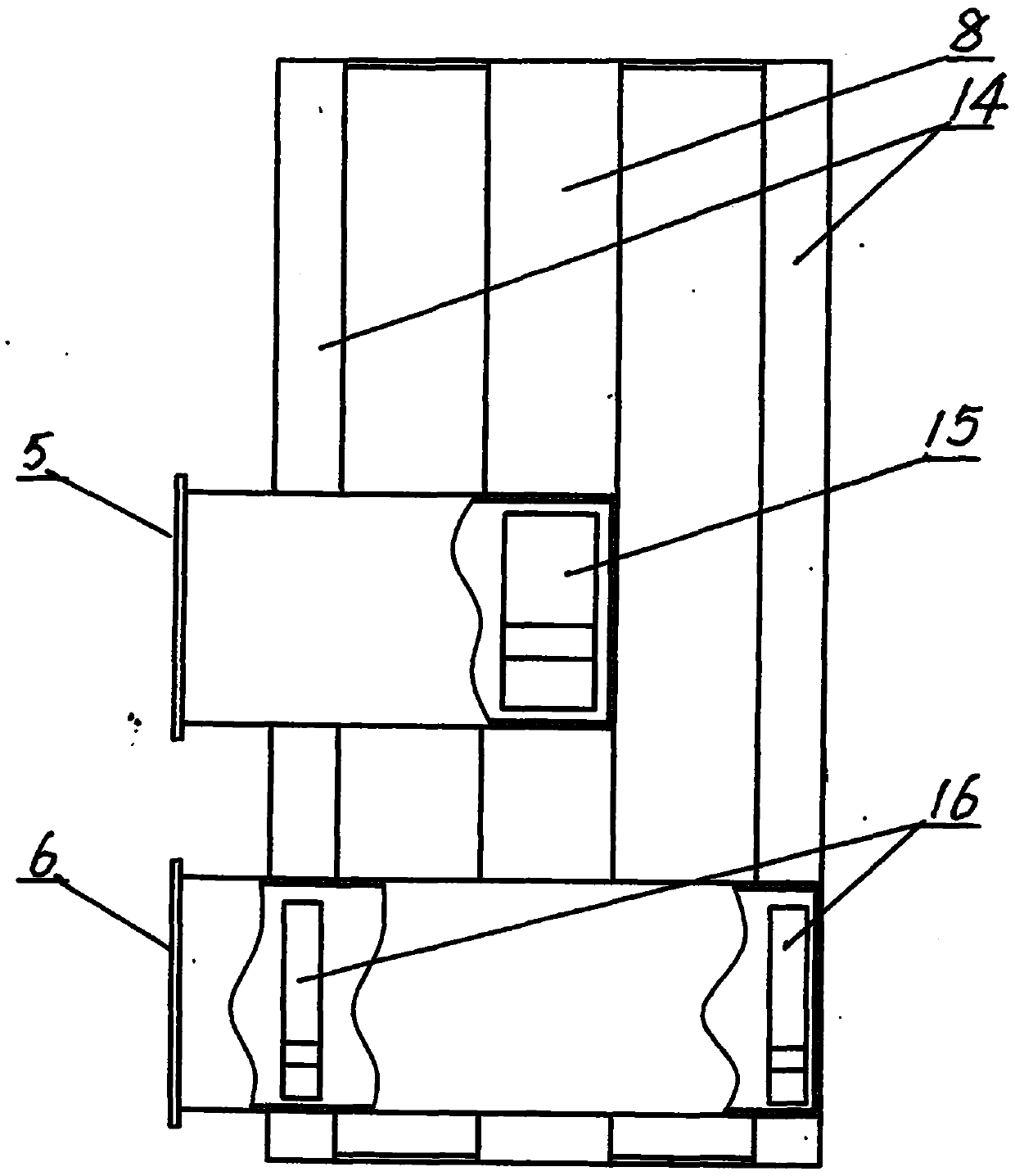

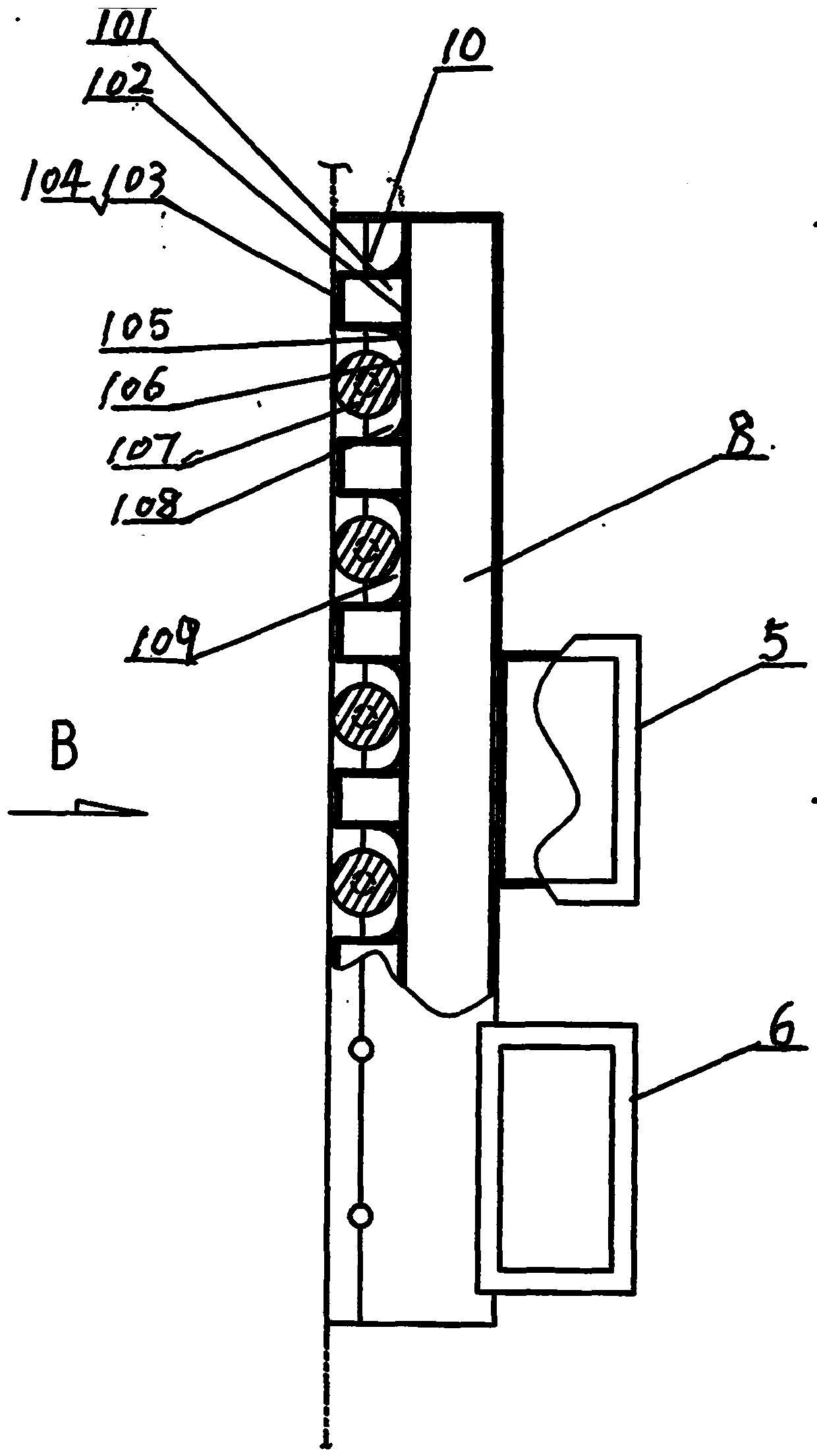

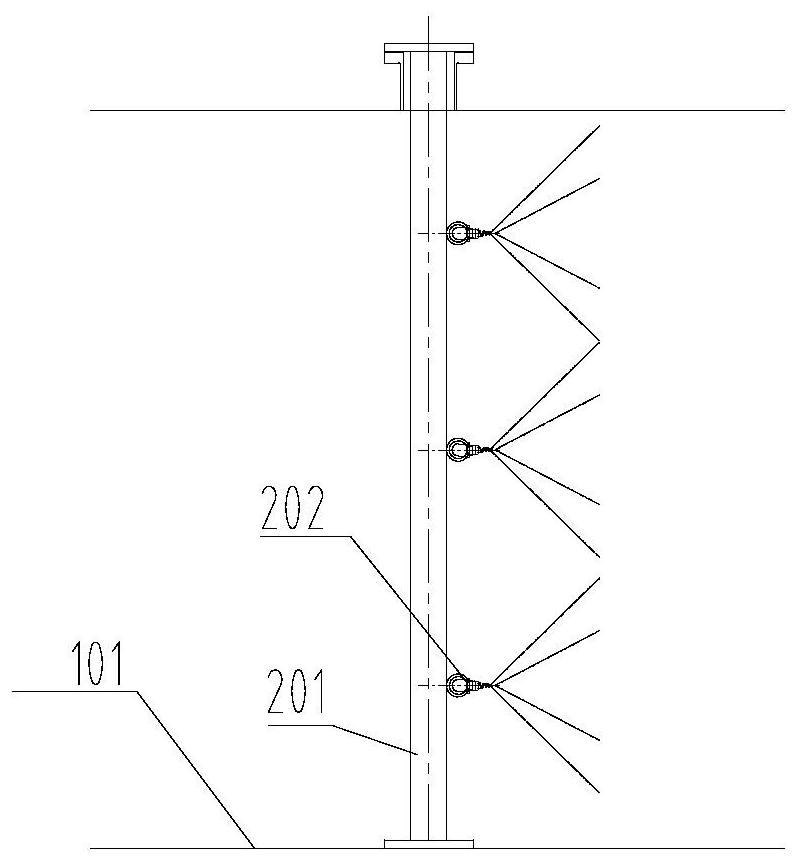

The invention puts forward a method and device for a blast furnace to blow coal powder. Characterized by employment of several short spray guns, a large incidence angle, accurate positioning of spray guns, small heat radiation and long life of blowpipes, and adoption of ceramic nozzles, the new method and new device of the invention aims to eliminate various defects in prior art, such as small coal powder incidence angle, restriction by high speed hot airflow, inadequate mixing with hot air, long length and long service life of spray guns, large heat radiation and short service life of blowpipes, and hard use of oxygen-coal lances, etc. According to the invention, on the blowpipes of each air ports, each short spray gun is inserted into each installation seat, and coal powder blown into a blast furnace enters from blowing inlets positioned on a lateral side of each installation seat, then reaches the inside of each short spray gun through coal spraying holes that are disposed on tube walls of the short spray guns and are over against the blowing inlets, and is finally blown into the furnace through each short spray gun. The device of the invention at least comprises: a blowpipe with a coal powder precombustion function, short spray guns, installation seats, ball valves, locking devices, coal conveying branch pipes, a distributor, a small ball valve, a coal conveying pipe, and an inlet connecting piece.

Owner:张昭贵

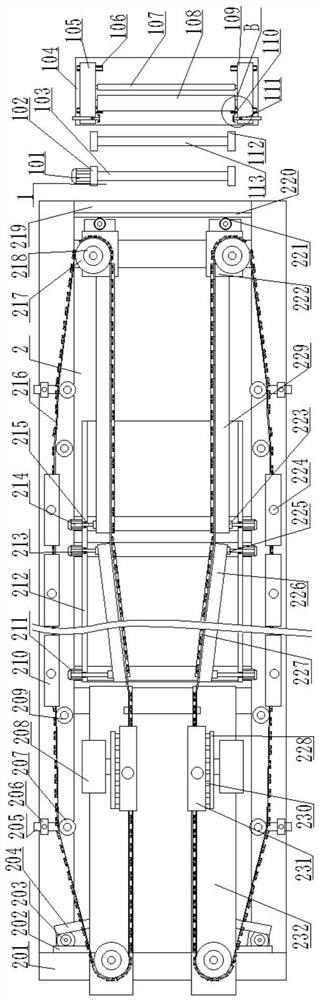

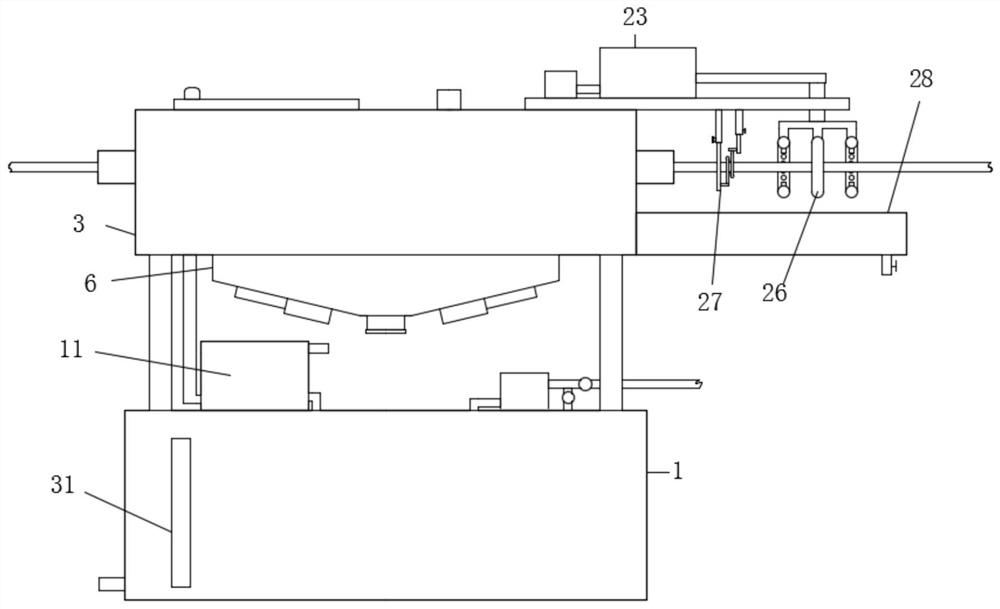

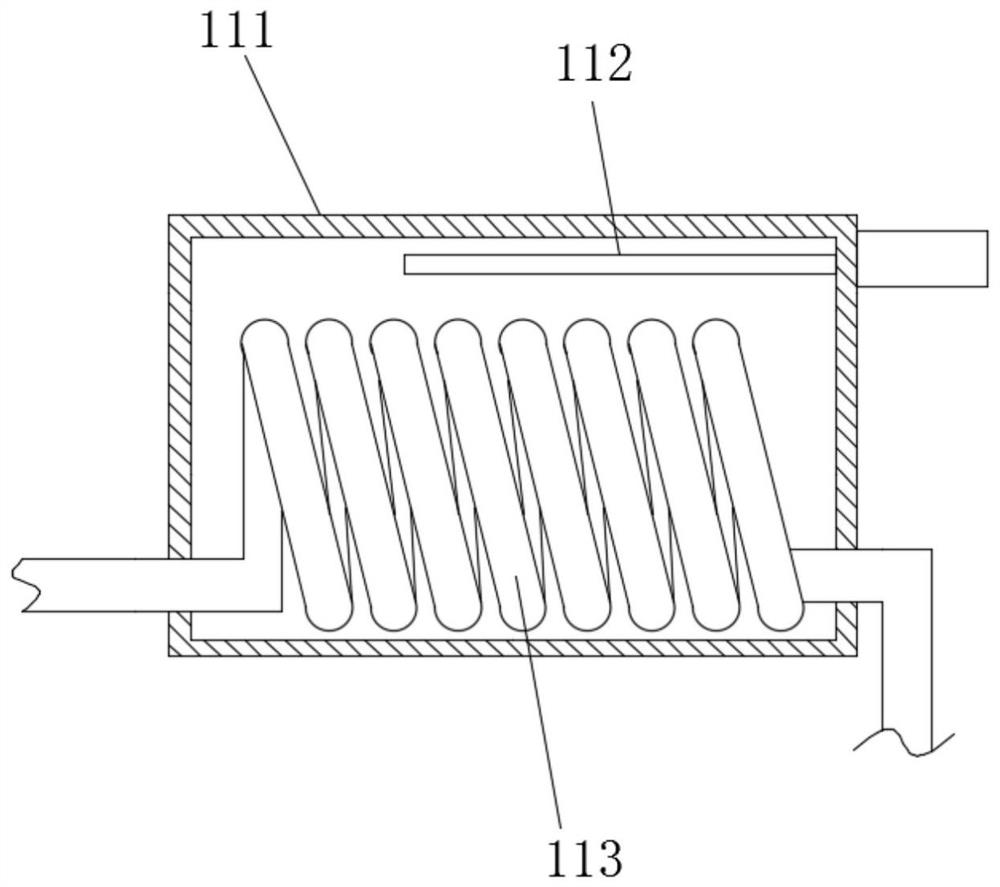

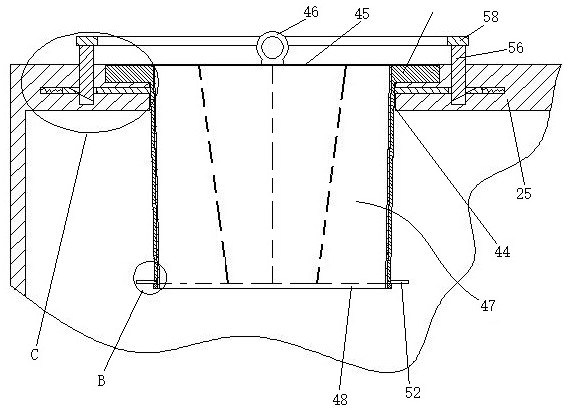

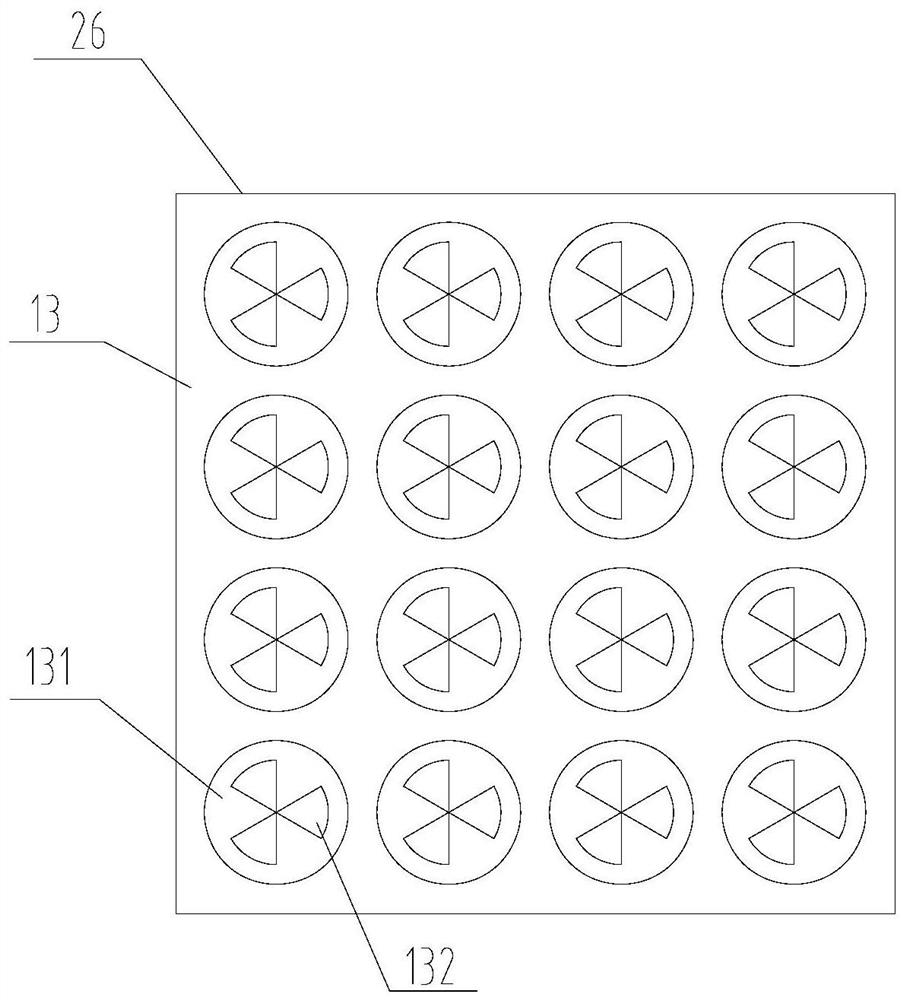

Two-way stretching equipment for PTFE ultra-fine filtering membrane production

The invention relates to two-way stretching equipment for PTFE ultra-fine filtering membrane production. The two-way stretching equipment comprises an expanding machine and a winding mechanism arranged at the discharging end of the expanding machine, the expanding machine comprises a machine frame and a drying oven, the machine frame is provided with a pair of conveying chains clamping the two sides of a film to convey the film to penetrate through the drying oven, the return stroke ends of the conveying chains are located on the outer side of the drying oven, a plurality of sections of cooling boxes are arranged on the outer sides of the return stroke ends of the conveying chains, each section of cooling box is connected with a suction pipe, the suction pipes are connected with cooling fans, a secondary cooling box is arranged on the outer side of the forward stroke end of the conveying chain at the front end of the drying oven, blowpipes blowing towards the conveying chain are arranged on the front side and the rear side of the secondary cooling box, and the blowpipes are connected with blowing fans. The return stroke ends of the conveying chains on the expanding machine are arranged on the outer side of the drying oven, and then the cooling boxes arranged at the return stroke ends of the conveying chains are matched, so that the temperature of the conveying chains can be reduced through air suction cooling, and the expanding quality of products is improved.

Owner:SHANDONG SENRONG PLASTIC IND TECH

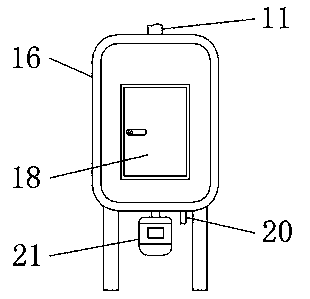

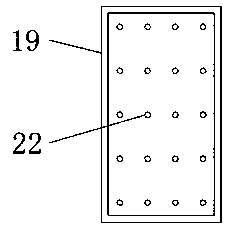

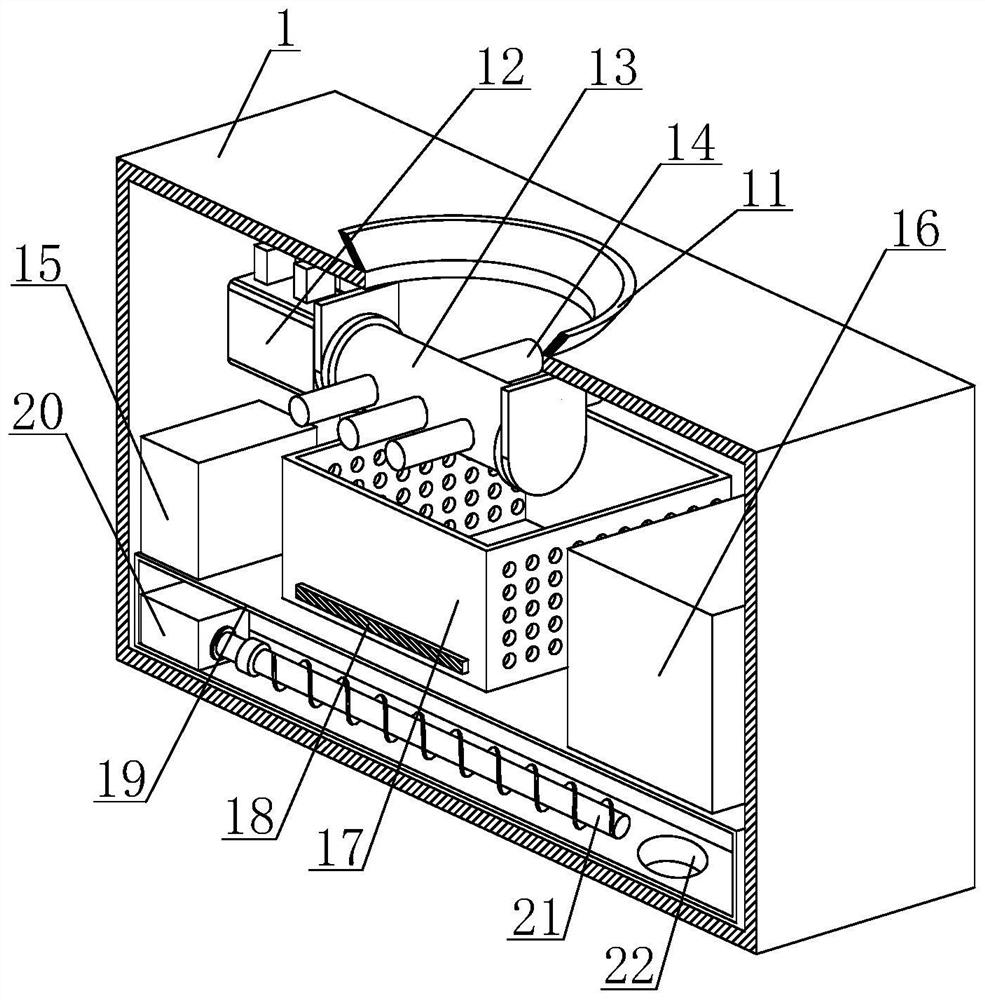

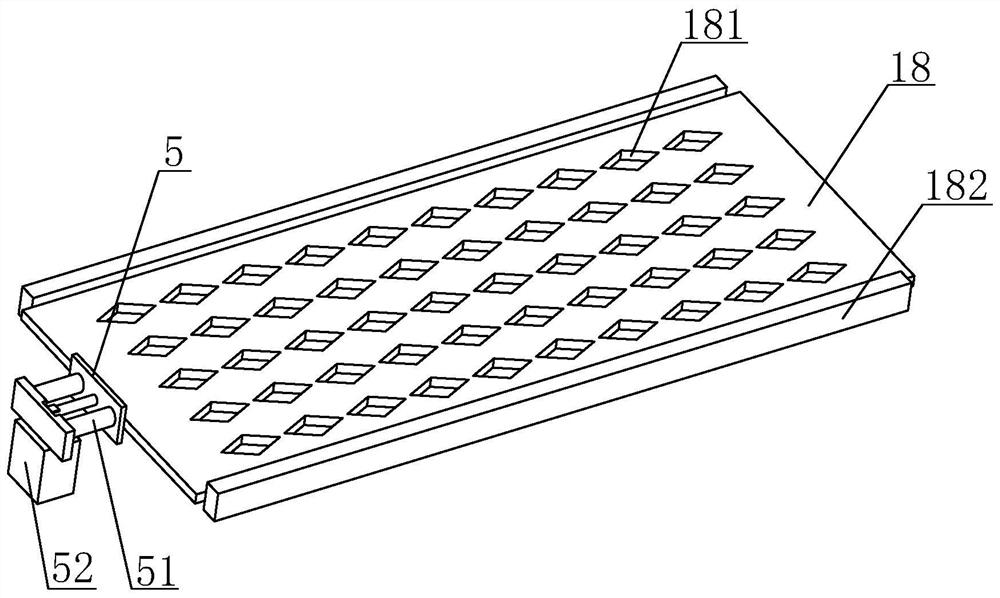

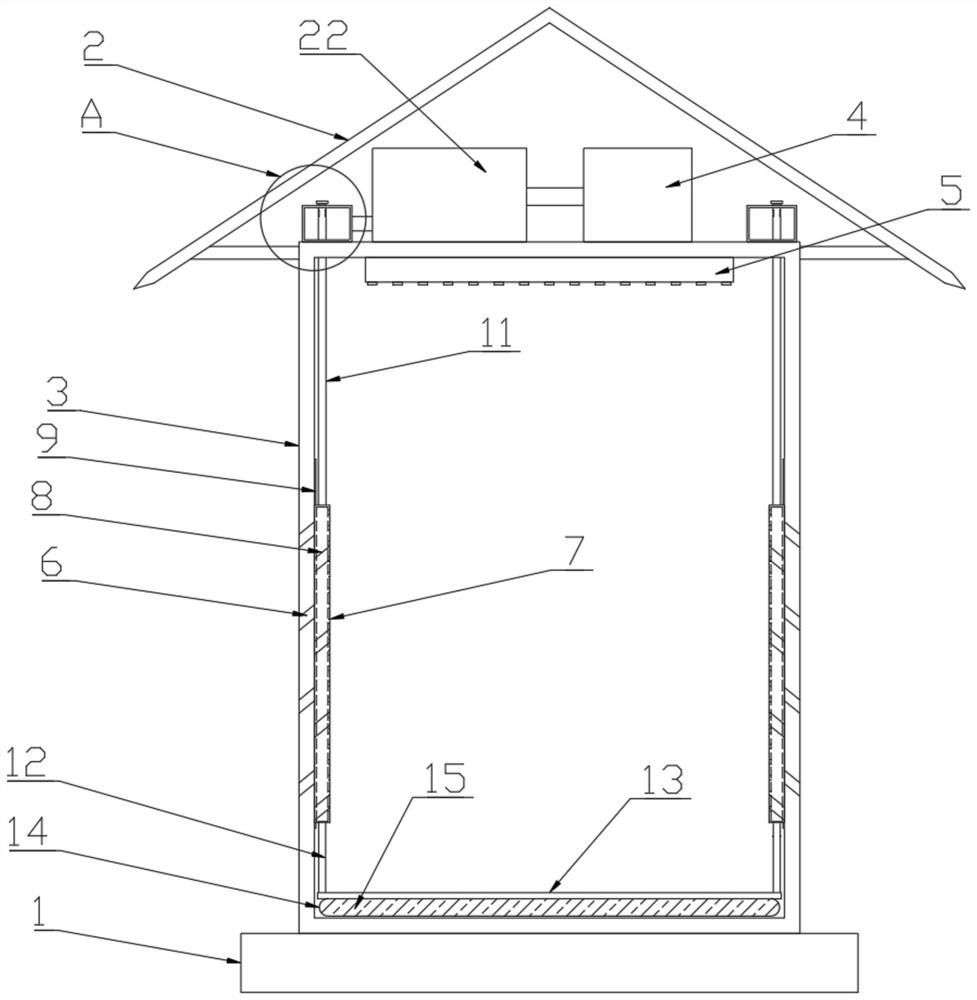

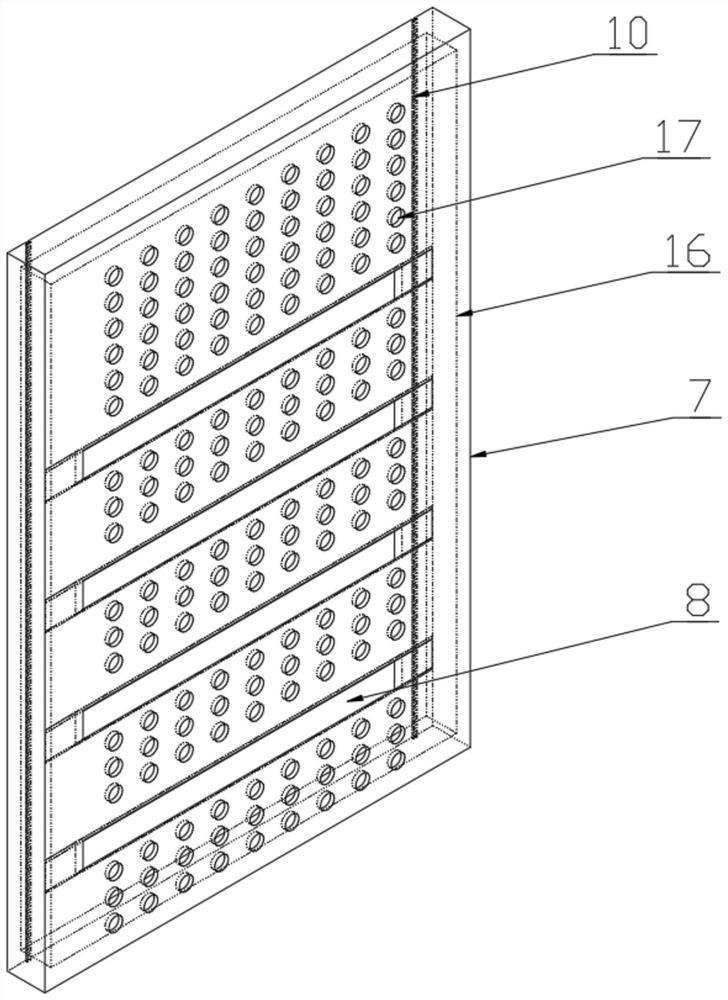

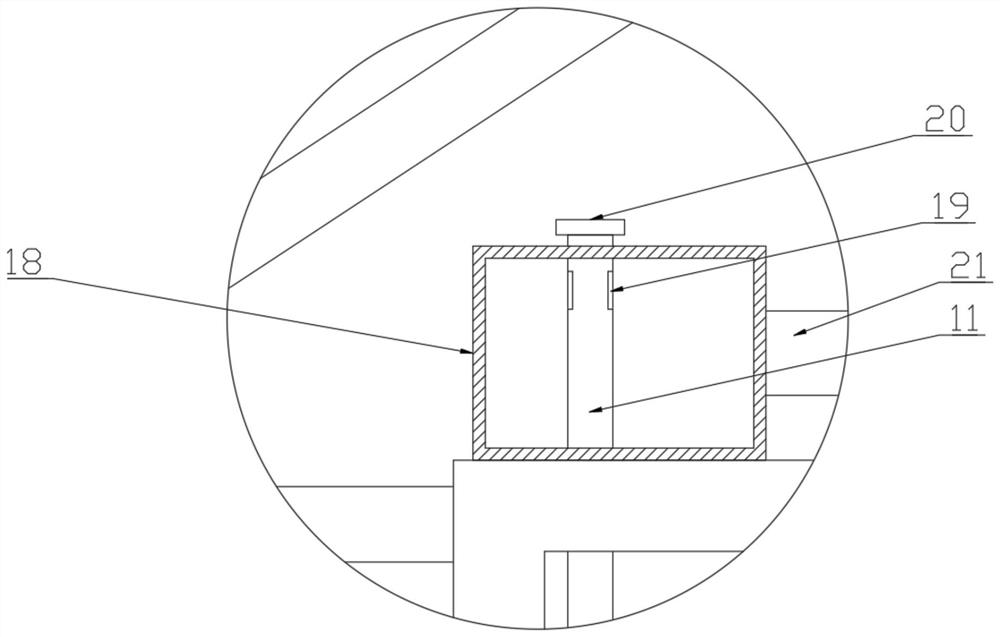

Big data computer network security protection device

InactiveCN111050499AAdjustment spaceReasonable useCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsStructural engineeringExhaust pipe

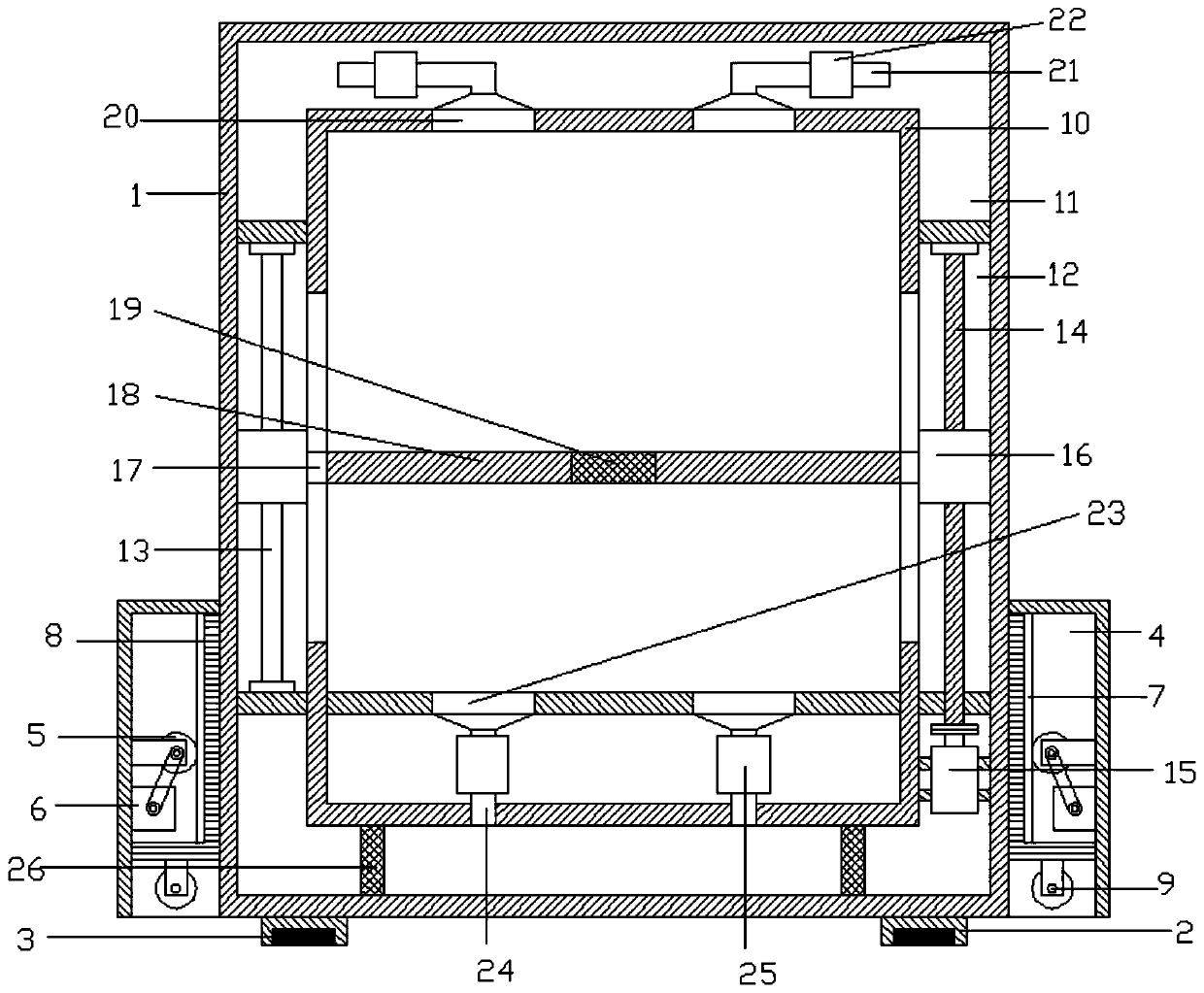

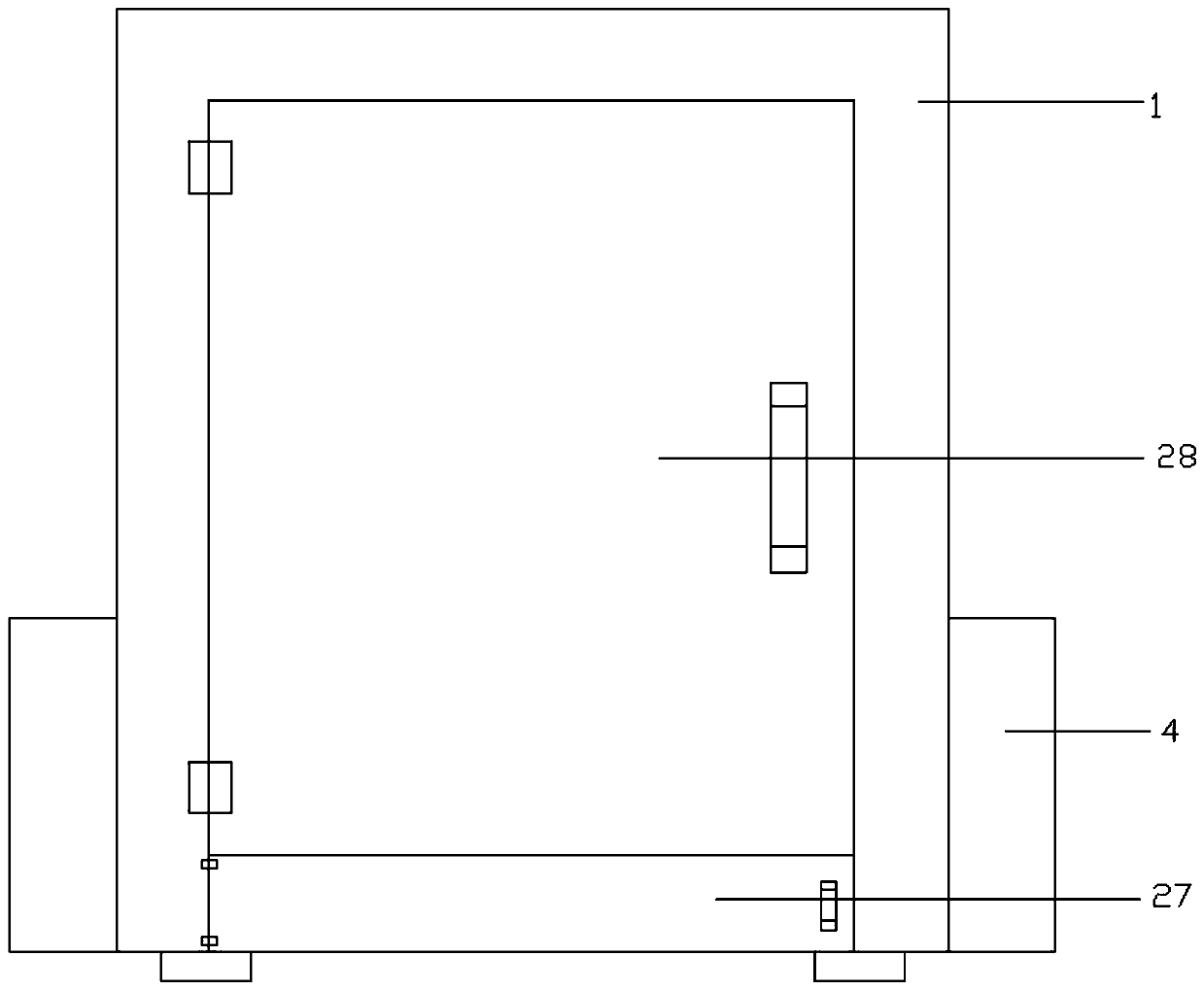

The invention relates to the field of computer network security protection, and particularly relates to a big data computer network security protection device. The device comprises an outer box body,wherein the middle end in the outer box body is provided with an inner box body; cavities are formed in the upper and lower ends of the left and right sides of the inner box body; a sliding grooves are formed in the cavities; a limiting rod is fixedly mounted in the sliding groove in the left end; a lead screw is mounted in the sliding groove in the right end through a bearing seat; sliding blocksare mounted on the lead screw and the limiting rod; connecting blocks are fixedly mounted on the inner sides of the sliding grooves; a placement plate is arranged between the connecting blocks; blowing covers are arranged at left and right ends of the top of the inner box body; a blowpipe is arranged on the upper side of each blowing cover; a blowing pump is arranged on each blowpipe; exhaust hoods are arranged at the left end and the right end of a partition plate at the lower end of the inner box body; an exhaust pipe is arranged on the lower side of each exhaust hood; an exhaust pump is fixedly mounted on each exhaust pipe; and filter screens are fixedly mounted at the left end and the right end of the lower side of the inner box body. According to the invention, the interior of the equipment can be effectively and conveniently ventilated, and the safe use of the equipment is ensured.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Countercurrent suspension type oven

PendingCN111319351ANo jitterGuaranteed overprint accuracyPrinting press partsPhotogravureExhaust fumes

The invention discloses a countercurrent suspension type oven, relates to printing equipment and coating machine and laminating machine equipment, and mainly relates to a countercurrent suspension type oven of a photogravure press. The countercurrent suspension type oven comprises two parts including a left half oven and a right half oven, wherein the left half oven and the right half oven are integrally folded relatively during operation, and a printing film passes through a gap between the two half ovens; the left half oven structurally comprises a main air inlet pipe and a main exhaust pipe, a middle air inlet pipe and two side exhaust pipes are arranged inside, and a blowpipe air chipper, an air deflector and an exhaust gas diversion pipe which are engaged to each other are arranged inthe innermost position; and the right half oven structurally comprises a main air inlet pipe and a main exhaust pipe, a middle air inlet pipe and two side exhaust pipes are arranged inside, and a suspension air pipe, a top suspension support plate and an air nozzle which are engaged to each other are arranged in the innermost position. The countercurrent suspension type oven has the beneficial effects that the printing film is in suspension and cannot shake under the combined action of the air chipper and the air deflector of the left half oven as well as the suspension air pipe and the suspension support plate of the right half oven, so that the overprint of the press is accurate, and the front and back sides of the printing film are blown at the same time, so that the drying efficiencyis greatly improved.

Owner:青岛成盛林环保设备有限公司

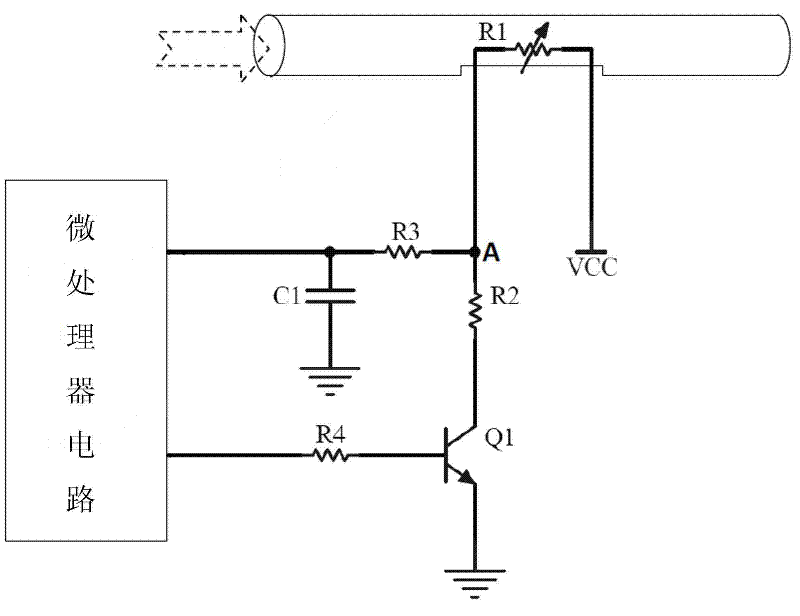

Blowing behavior detection method and detector for alcohol content of exhaled gas

ActiveCN102305877AOutstanding FeaturesHighlight significant progressIndication/recording movementBiological testingCapacitanceAlcohol content

The invention provides a blowing behavior detection method and a detector for the alcohol content of exhaled gas. The method comprises the following steps of: connecting a sampling resistor and a thermistor arranged in a blowpipe in series to obtain a voltage-dividing sampling circuit; applying fixed voltage to two ends of the voltage-dividing sampling circuit, and continuously acquiring voltage U2 at two ends of the sampling resistor; blowing gas into the blowpipe; and if the voltage U2 is continuously reduced, regarding the blowing behavior as an effective blowing behavior, and if the voltage U2 is not continuously reduced, continuously blowing gas into the blowpipe. The detector comprises a microprocessor circuit, a blowing behavior detection circuit and the blowpipe, wherein the blowing behavior detection circuit comprises a thermistor, a sampling resistor, a direct-current power supply, a resistor and a capacitor; one end of the thermistor is connected with the direct-current power supply, and the other end of the thermistor is connected with one end of the sampling resistor and one end of the resistor; the other end of the sampling resistor is grounded; the other end of the resistor is connected with one end of the capacitor and an input / output (I / O) port of an analog-to-digital conversion module of the microprocessor circuit; and the other end of the capacitor is grounded. The method has high practicability; and the detector has low cost and accurate detection results.

Owner:HENAN HANWEI ELECTRONICS

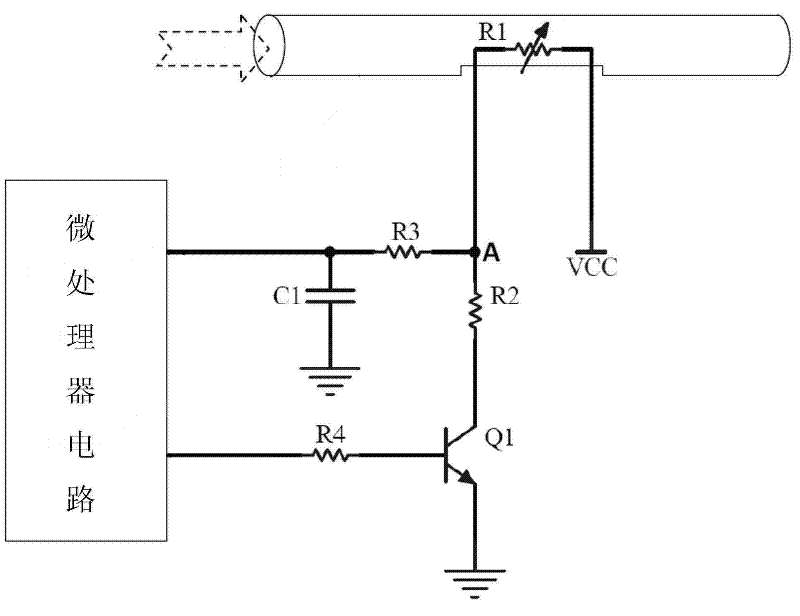

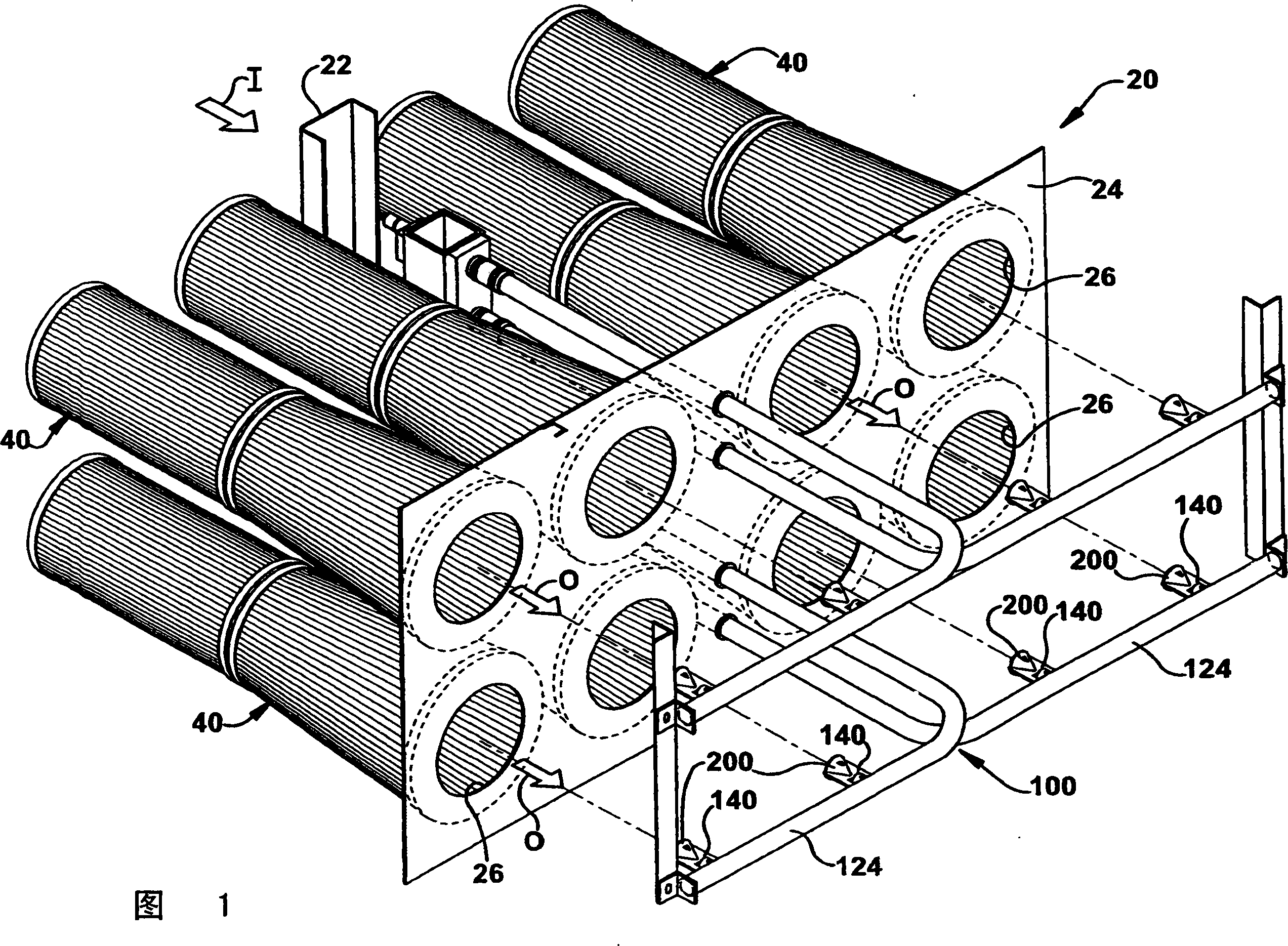

Filter cleaning system and method

InactiveCN101134149AEasy to cleanDispersed particle filtrationTransportation and packagingParticulatesAspirator

Owner:BHA GROUP HLDG

Automatic folding machine

The invention discloses an automatic folding machine, comprising an upper platform arranged on a Y axis guide rail, a lower platform which is arranged in an up-down staggered way with the upper platform and is arranged on an X axis guide rail, a base die fixture arranged on the lower platform, a rolling head base connected with the upper platform by virtue of a Z axis guide rail, a rolling head connected with the rolling head base by virtue of a 360-degree rotating shaft, a heating device communicated with the rolling head by virtue of a gas blowpipe, a control system connected with the upperplatform, the lower platform and the rolling head base, the X axis guide rail, the Y axis guide rail and the Z axis guide rail, wherein the two ends of the Y axis guide rail are connected with a machine column, a product is fixed on the base die fixture by virtue of a product fixing device, and the heating device is communicated with the rolling head by virtue of the gas blowpipe. By applying theautomatic folding machine provided by the invention, the degree of automation is obviously improved, the working efficiency is improved, the manpower cost is saved, and the edge of the rolled productis uniform in thickness and is smooth, the product can not be crushed or scratched, and the quality of the product is ensured.

Owner:KAEDAR ELECTRONICS KUNSHAN

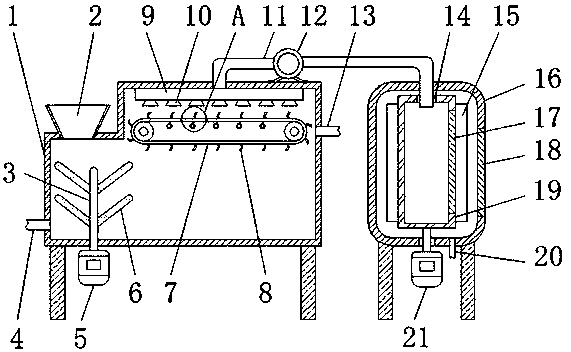

A cleaning and drying device for down production and processing that is convenient for removing impurities

ActiveCN108168222BFacilitate subsequent processingProcessing effectDrying solid materials without heatWool fibre washing/scouringTransmission beltElectric machinery

The invention discloses a cleaning and drying device conveniently removing impurities for down feather production and processing. The cleaning and drying device includes a cleaning device, a water inlet pipe, a stirring rod, a transmission belt, a suction opening, a fan, a first water outlet, a protective cover, a protective door, an air-tight door, a spin-dry revolving drum, a second air hose anda blowpipe; the upper of the cleaning device is provided with a feed inlet, the lower of the feed inlet is provided with a rotating rod, the water inlet pipe is located below the left side of the cleaning device, and the cleaning device is internally connected with a first motor through the rotating rod; and the stirring rod is located at the outer side of the rotating rod, the second air hose isarranged in the transmission belt which is provided with through holes, and the through holes are connected with scraping plates. According to the cleaning and drying device conveniently removing theimpurities for the down feather production and processing, the cleaning device is arranged to clean down feather, subsequent processing can be prevented from affection due to impurities in the down feather, and the cleaning of the down feather is facilitated.

Owner:ZHANJIANG ZIJIN DOWN PROD

Cleaning machine for spring steel wire

The invention discloses a cleaning machine for a spring steel wire in the technical field of spring production. The cleaning machine is characterized by comprising a water tank, wherein steel pipes are correspondingly arranged at the left and right sides of the top end of the water tank; a cleaning box is connected to the top ends of the steel pipes; channel pipes are correspondingly arranged in the middles of the left and right side walls of the cleaning box; one end of the steel wire penetrates through the two sets of channel pipes from left to right and extends outwards; a settling impurity collecting box is arranged in the middle of the bottom end of the cleaning box and is of a funnel-shaped shell structure; a detachable sealing cover is arranged on a bottom discharging pipe of the settling impurity collecting box; and right-angle blocks are arranged at the bottom end of an inner cavity of the cleaning box in a left-right corresponding mode. By means of the structures such as an air pump, an air heater and staggered arc-shaped blowpipes, hot air blow-drying and drying operation can be conducted on the steel wire, and by means of a wiping mechanism, wiping treatment can be conducted on the steel wire, part of impurities attached to the steel wire can be wiped away, water on the surface layer can also be removed, the functions are rich, and the cleaning effect is good.

Owner:常熟市琴川钢丝制品有限责任公司

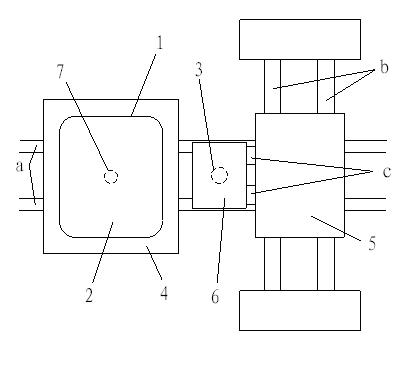

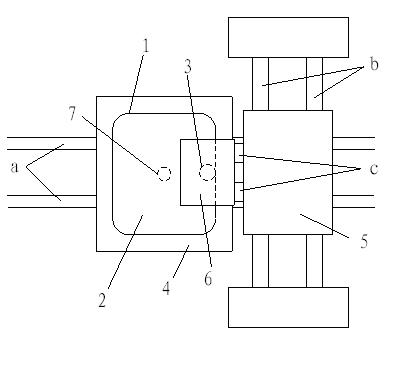

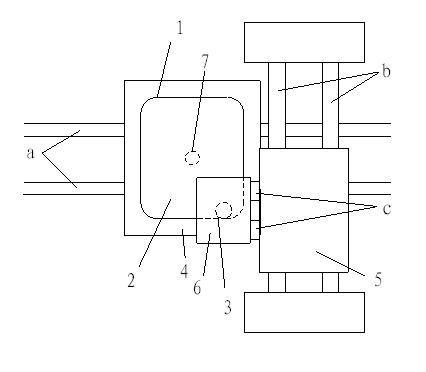

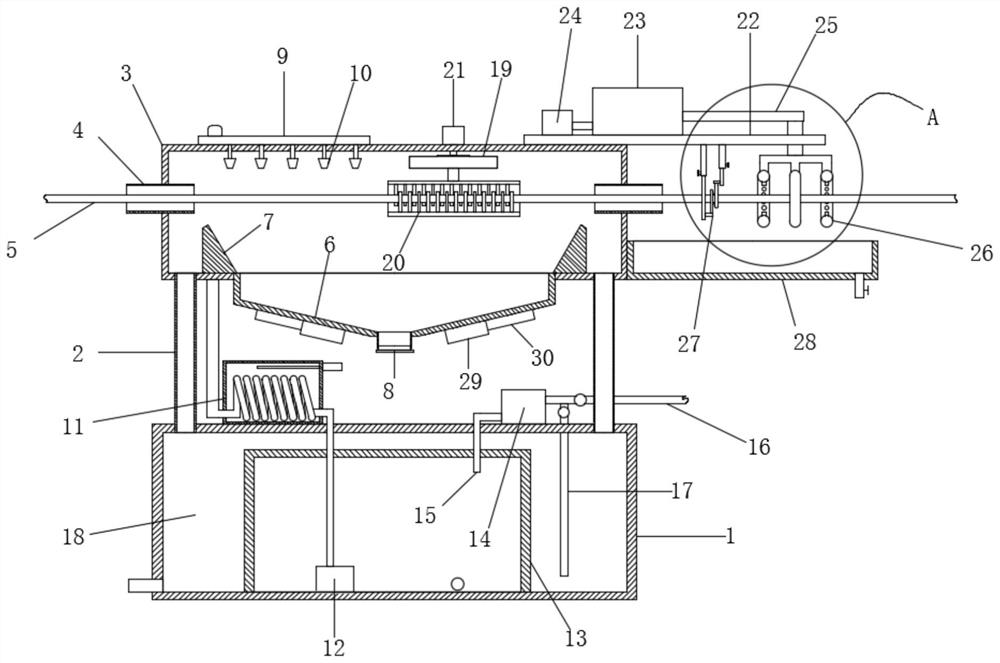

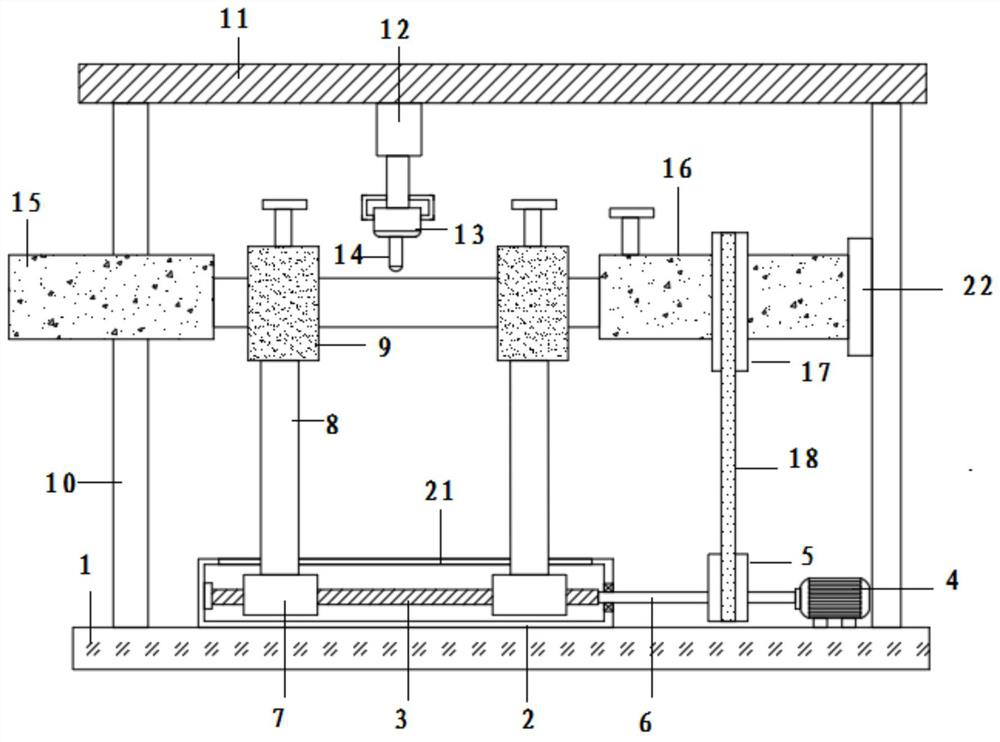

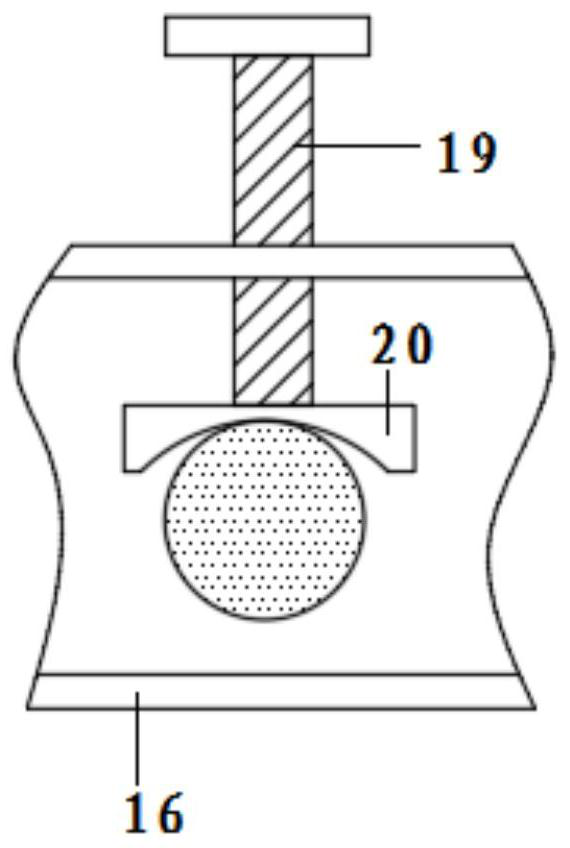

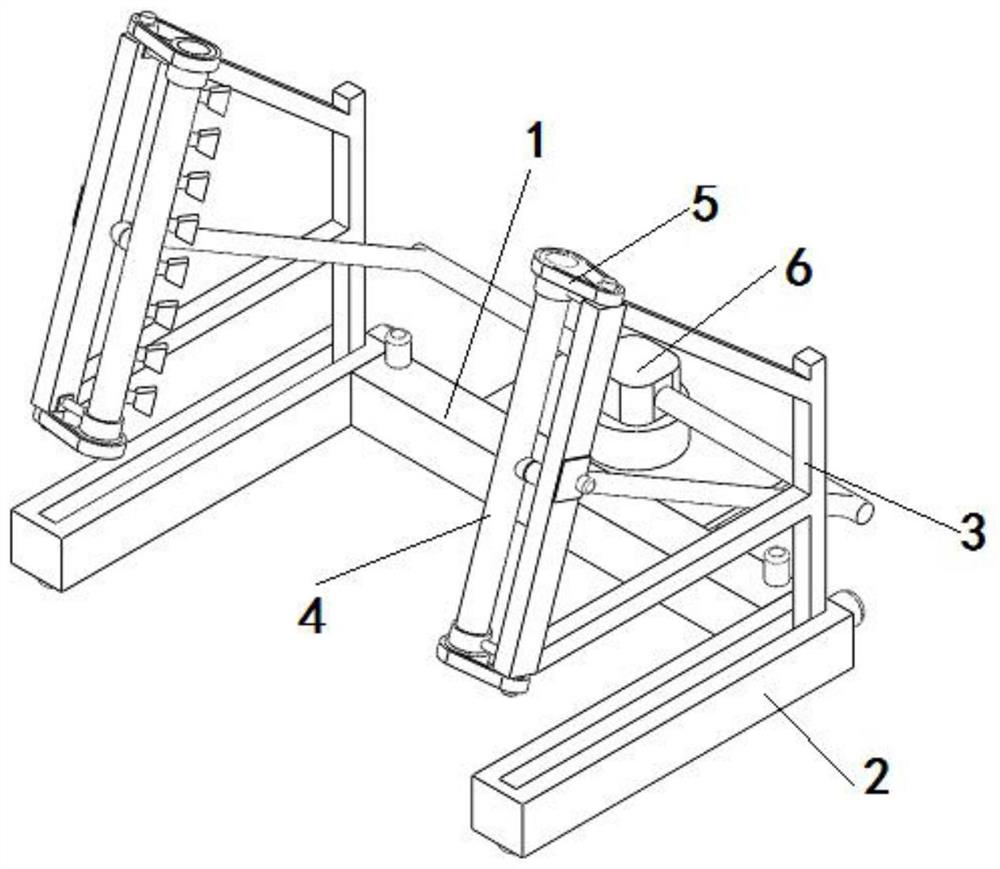

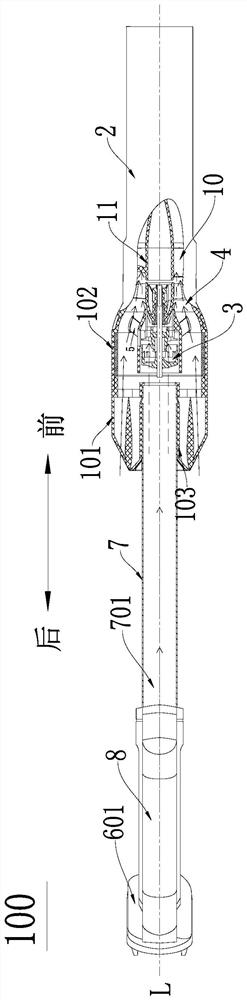

Drilling equipment for Li nationality blowpipe instrument

The invention provides drilling equipment for Li nationality wind instrument. The drilling equipment comprises a drilling supporting table, a position adjusting box is fixed to the top of the drilling supporting table, a rotating lead screw is horizontally arranged in an inner cavity of the position adjusting box, a servo motor is installed at the position, located on the right side of the position adjusting box, of the top of the drilling supporting table, and the output end of the left side of the servo motor is sleeved with a driving rotating wheel; the driving rotating wheel is sleeved with a connecting rotary rod, the left side of the connecting rotary rod rotationally penetrates through the side wall of the right end of the drilling supporting table and is fixed to the right side of a rotary lead screw, the outer wall of the rotary lead screw is sleeved with two sets of movable sliding sleeves in a threaded connection mode, and movable adjusting rods are fixed to the tops of the two sets of movable sliding sleeves and located above the position adjusting box to be sleeved with movable fastening sleeves; according to the invention, a movable sliding sleeve drives a movable adjusting rod and a movable fastening sleeve at the top to move horizontally, then different positions of the Li nationality blowpipe are punched, a second rotating sleeve is driven to rotate, the Li nationality blowpipe is driven to rotate, and then different angle positions of the Li nationality blowpipe are punched.

Owner:HAINAN NORMAL UNIVERSITY

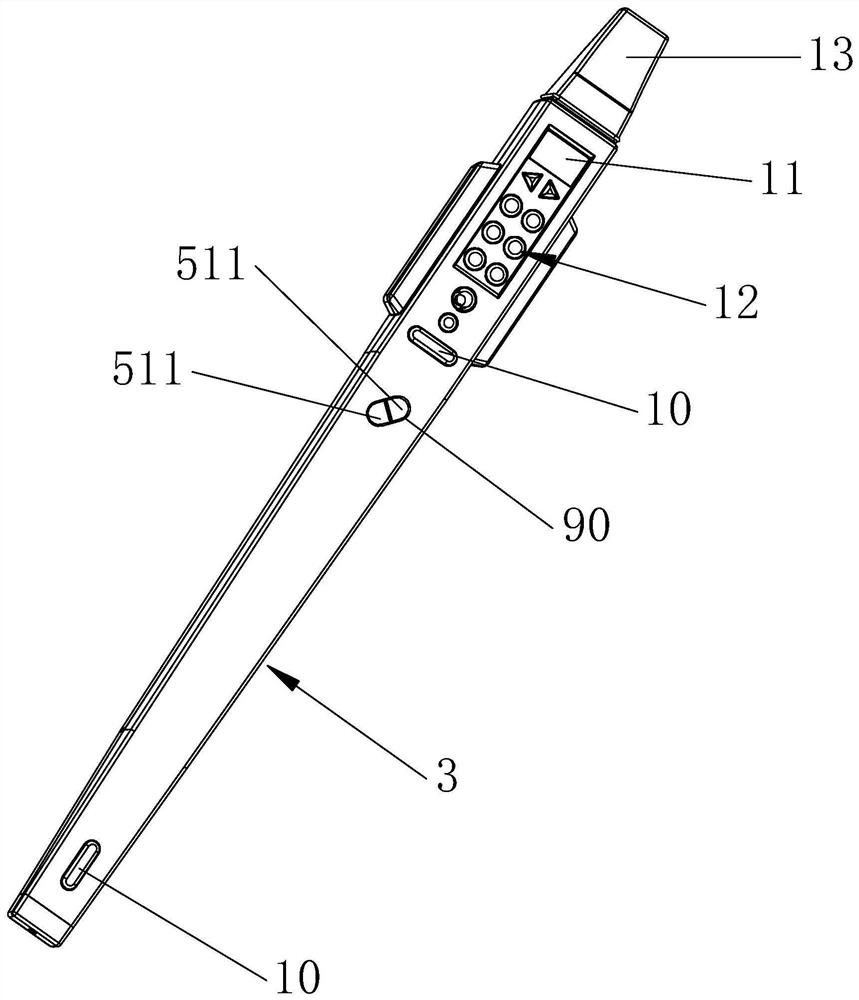

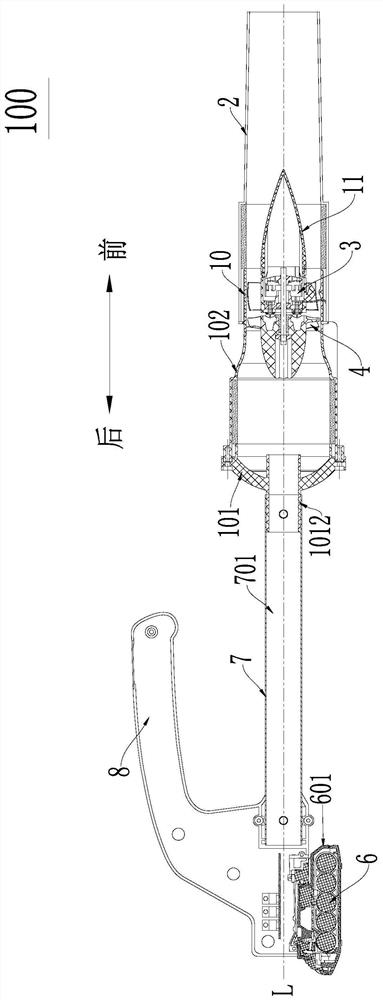

Smart handheld wind and reedless wind instruments, performing system and method

PendingCN105825842AEasy to carryEasy to useElectrophonic musical instrumentsWind musical instrumentsAtmospheric sciencesComputer science

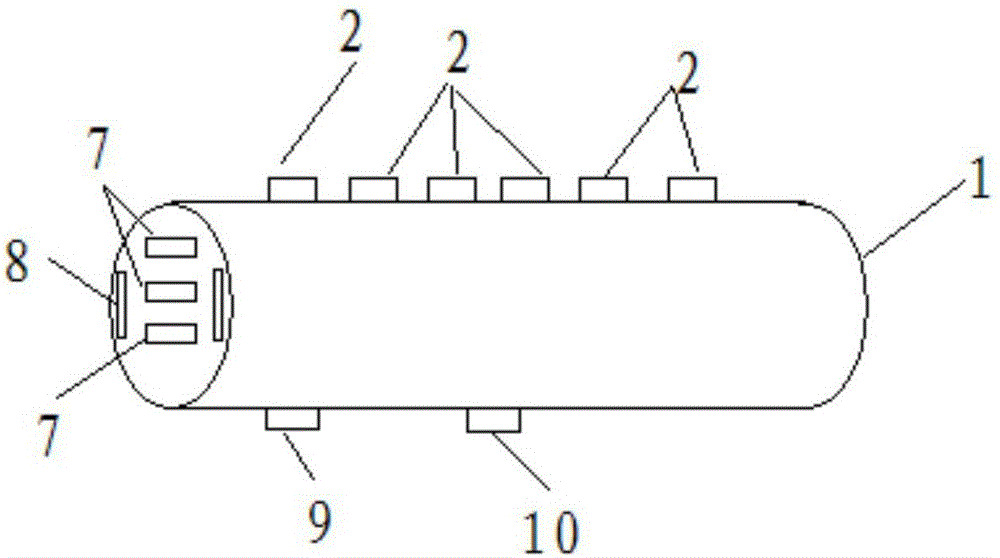

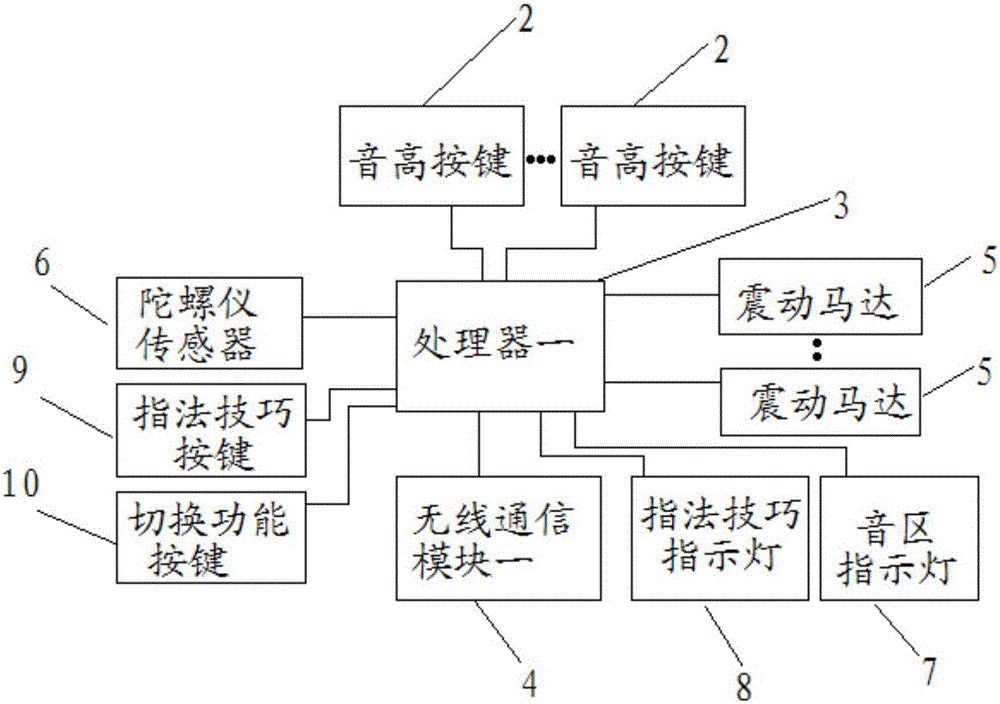

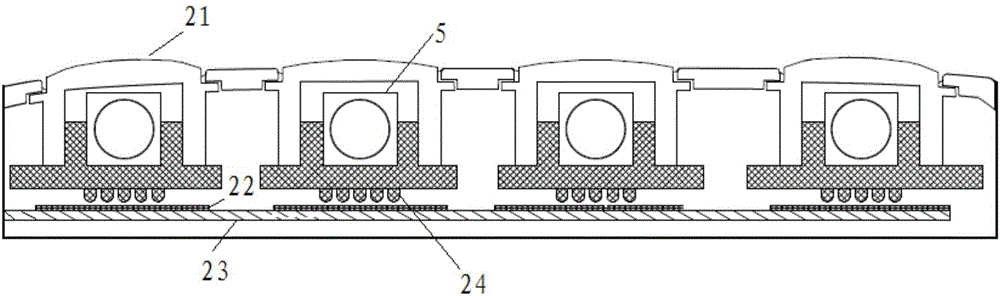

The invention discloses a blowpipe which belongs to smart handheld wind and reedless wind instruments. The blowpipe includes a pipe body which is provided with a plurality of pitch keys thereon. The pipe is provided with a processor 1 therein. The processor 1 is separately connected to each pitch key. The processor 1 is also connected to a communication lead 1 and / or a wireless communication module 1. The invention also discloses a blowtorch which belongs to smart handheld wind and reedless wind instruments. The blowtorch includes an air bag which is provided therein with a processor 2 and an air pressure sensor 1. The processor 2 and the air pressure sensor 1 are connected. The processor 2 is also connected to a communication lead 2 and / or a wireless communication module 2. The invention also discloses a smart handheld wind and reedless wind instrument, a performing system of the smart handheld wind and reedless wind instrument, and a performing method of the smart handheld wind and reedless wind instrument. The technical solution of the invention realizes simulation of the wind and reedless wind instruments, which enables users who do not understand instruments or music theory to play music and is easy to carry.

Owner:北京千音互联科技有限公司

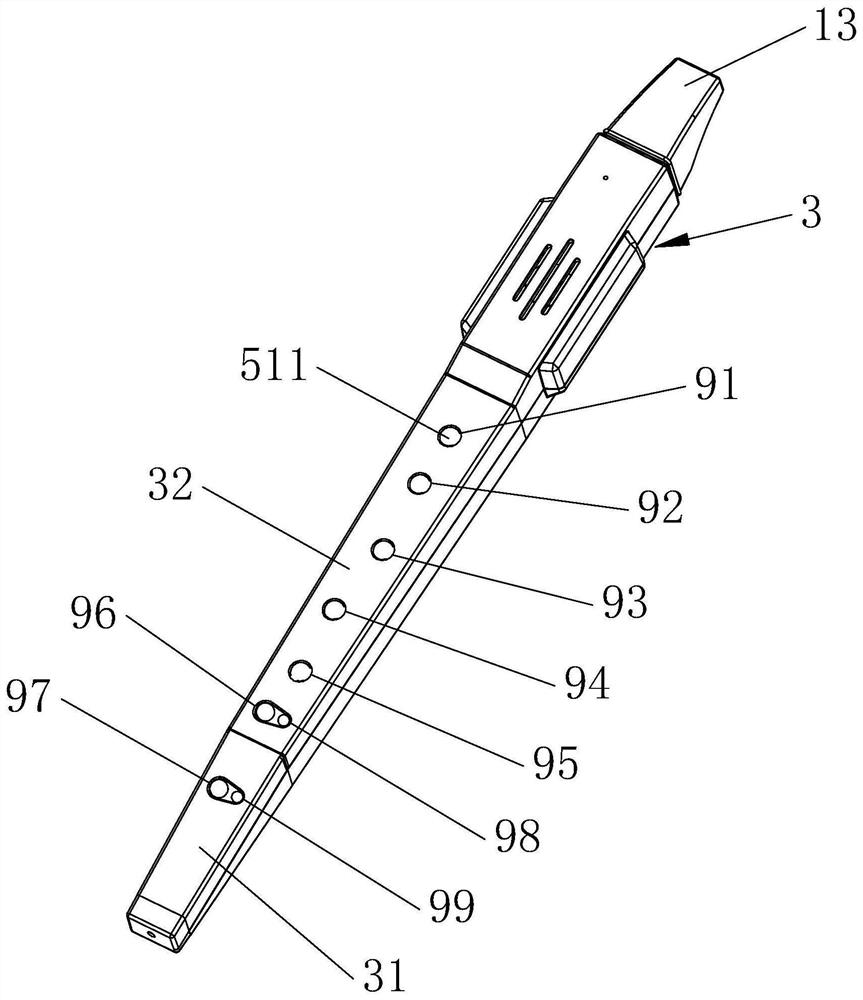

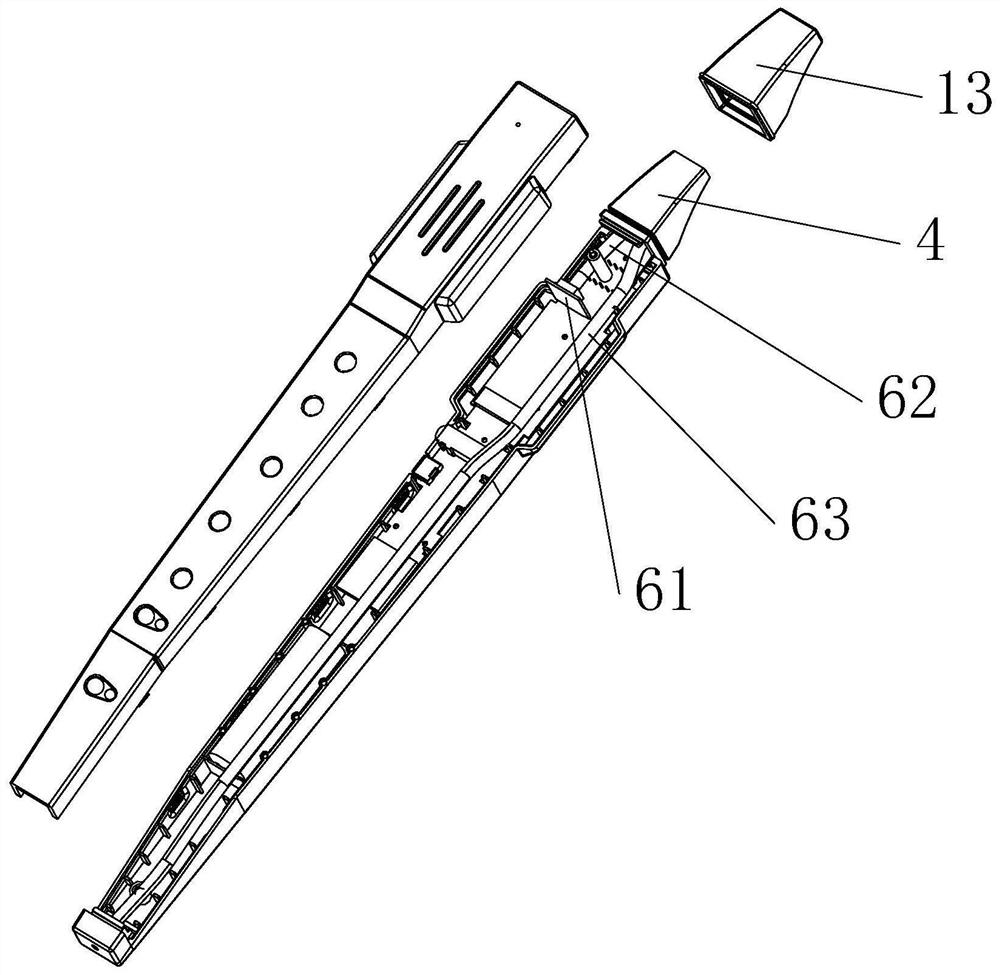

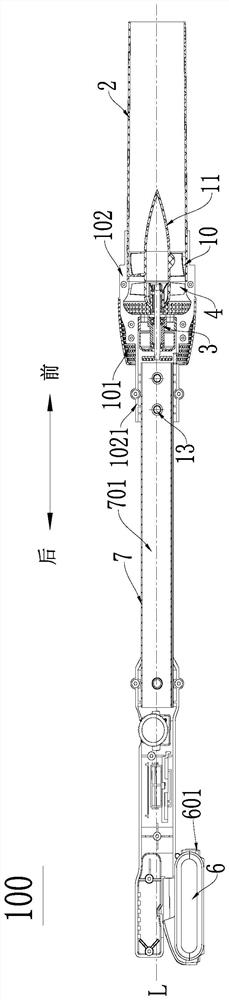

Electric blow pipe

PendingCN112150993AImprove playing skillsImprove the level ofElectrophonic musical instrumentsWireless transmissionEngineering

The invention relates to the technical field of electric blowpipes, in particular to an electric blow pipe which comprises a processor, a power supply, a pipe body, a blowing nozzle arranged at one end of the pipe body, a plurality of sound holes formed in the pipe body, a sound hole pressing detection device, an air blowing detection device, an audio output module and a wireless transmission module. The power supply, the sound hole pressing detection device, the air blowing detection device, the audio output module and the wireless transmission module are electrically connected with the processor. The blowing nozzle is detachably connected with a nozzle sleeve in a sleeving manner; the electric blow pipe not only can replace a traditional clarinet for playing, but also can be in wirelesscommunication connection with an intelligent terminal, playing works can be uploaded, and the playing skill and level can be improved.

Owner:东莞市美派电子科技有限公司

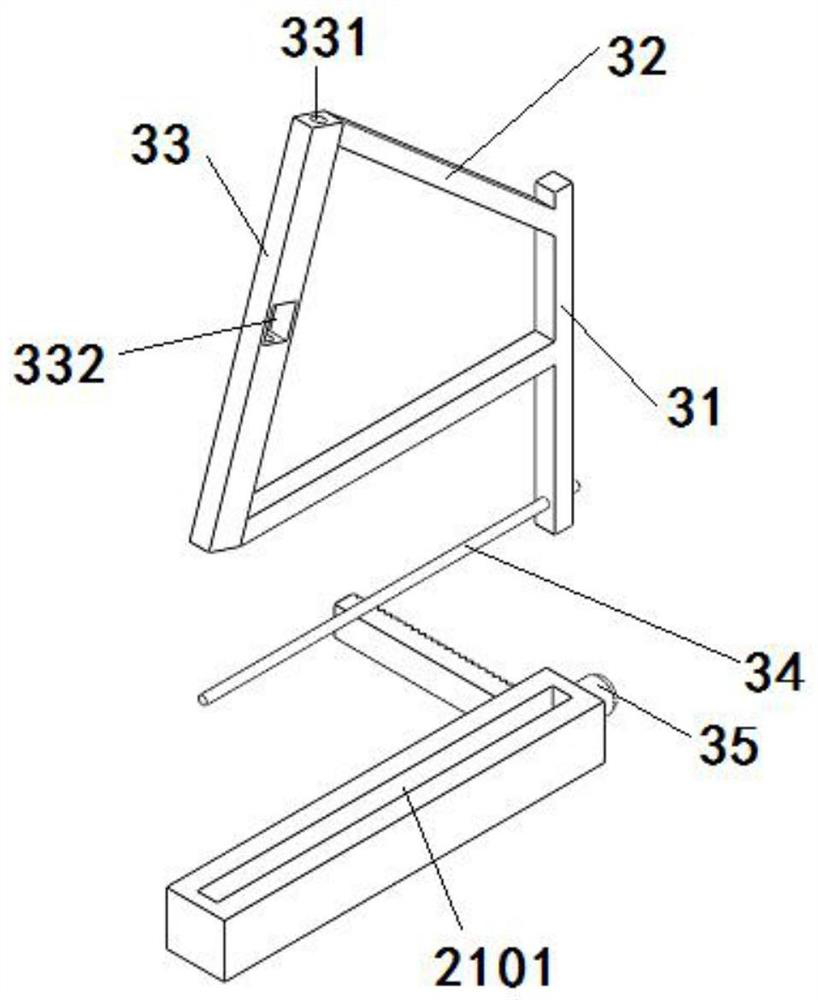

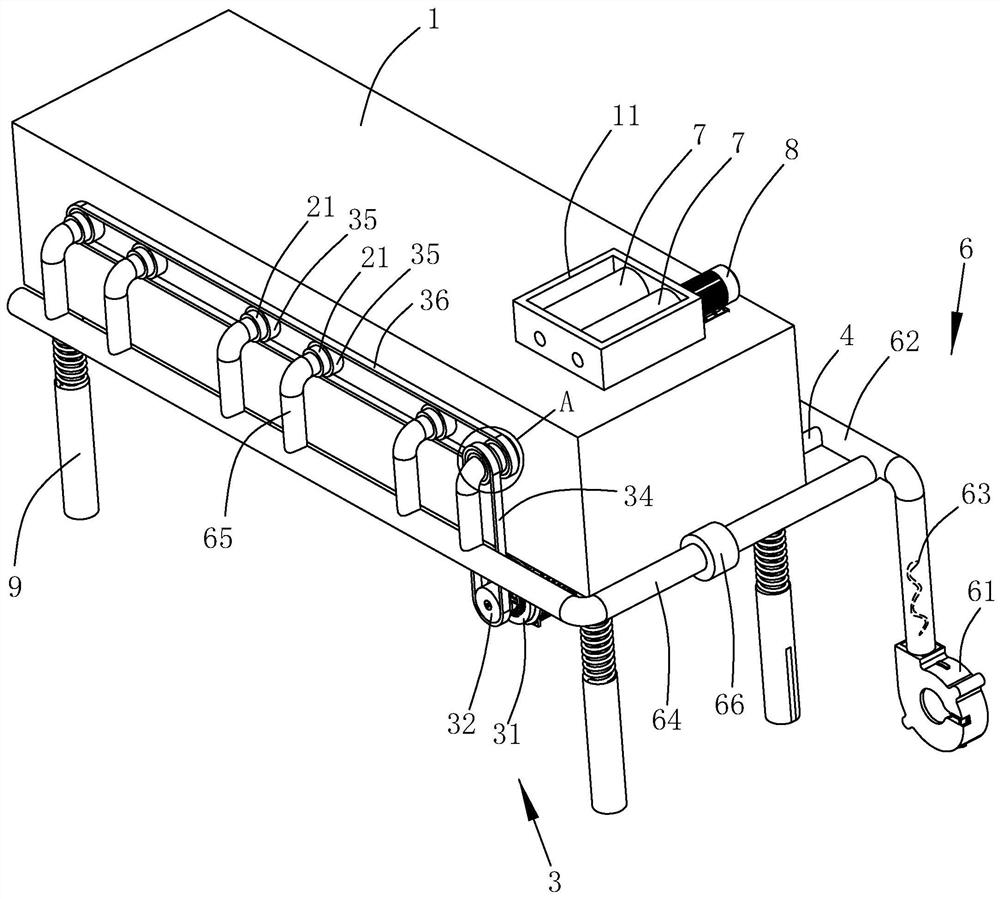

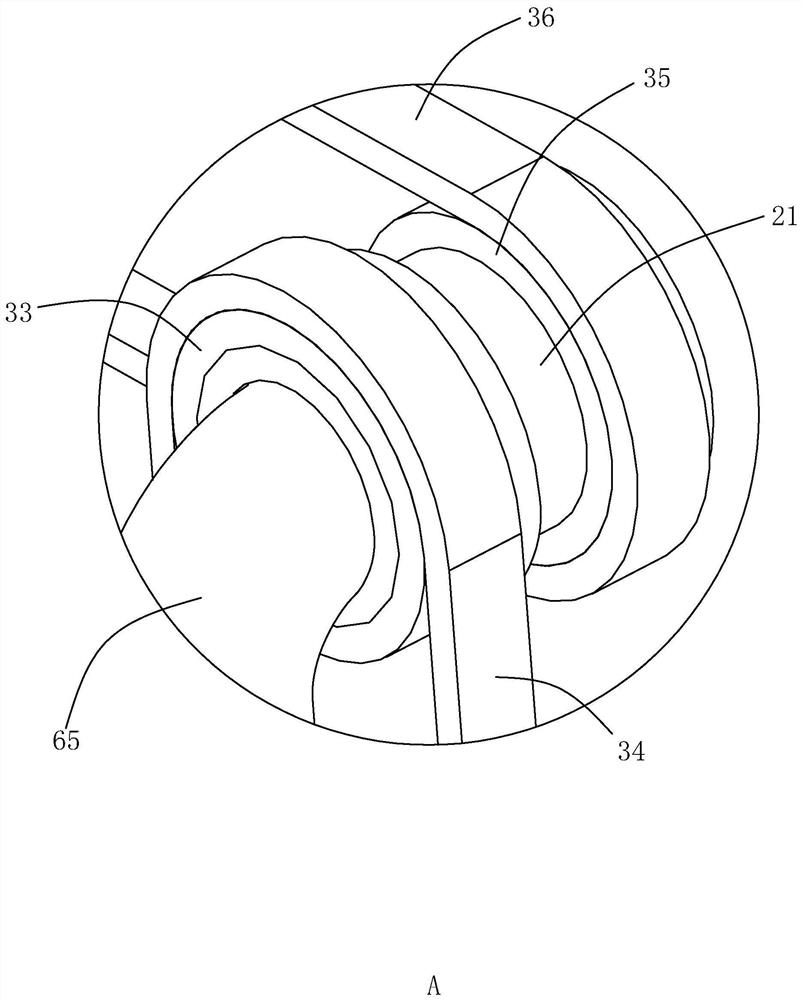

Device for separating glass substrate from spacing packing paper on A-shaped frame

The invention discloses a device for separating a glass substrate from spacing packing paper on an A-shaped frame. The device comprises a square connecting transverse column, wherein longitudinal supporting structures are symmetrically connected to the front sides of the left side and the right side of the square connecting transverse column correspondingly, a movable supporting frame is connectedto the upper ends of the longitudinal supporting structures, an air blowing assembly is installed on the inner side of the movable supporting frame, an angle adjusting mechanism is installed on the air blowing assembly, and an air blowing device connected with the air blowing assembly is installed on the rear side of the square connecting transverse column. According to the device, the air blowing device conveys air into blowpipes through an air outlet pipe and an air supply pipe, and the air in the blowpipes on the two sides is blown to the spacing packing paper through air blowing nozzles,so that the spacing packing paper is pressed, static electricity between the spacing packing paper and the glass substrate can be eliminated, then the spacing packing paper is separated from the glasssubstrate, a robot can take the glass substrate conveniently, the spacing packing paper does not fall onto the ground and does not need to be cleaned by a worker, the burden of the worker is reduced,and the surface of the glass substrate is not scratched when the spacing packing paper is repeatedly used.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

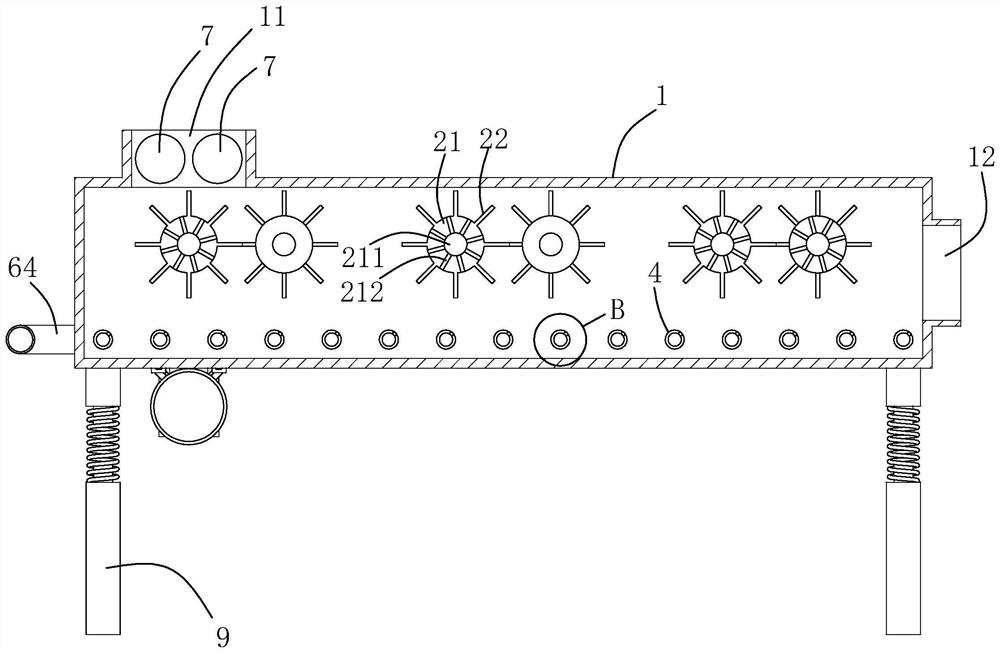

Cotton opener for bedding production line

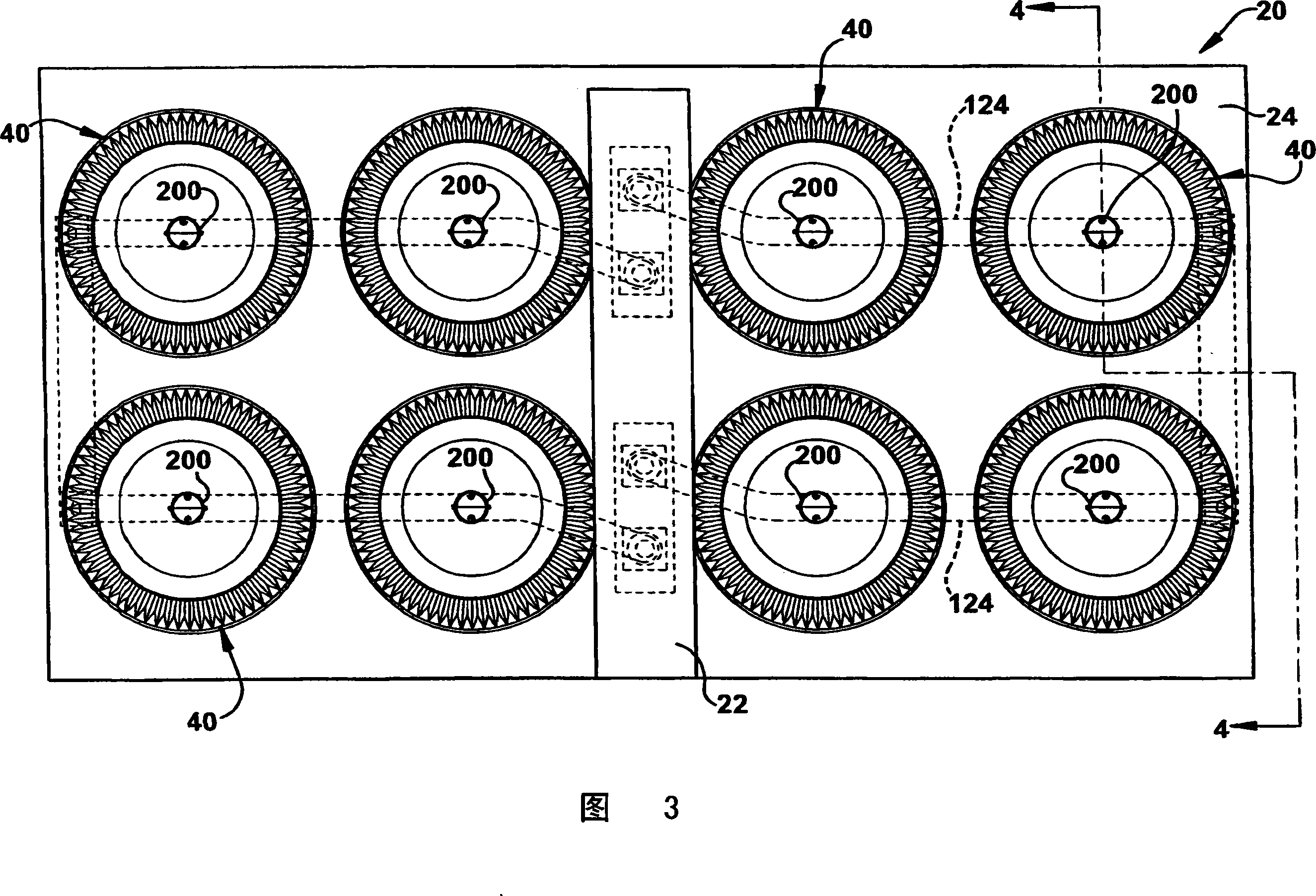

InactiveCN112080818AAvoid the phenomenon of being unable to rotateImprove opening efficiencyFibre cleaning/opening by toothed membersFibre cleaning/opening machinesAgricultural engineeringManufacturing line

Disclosed is a cotton opener for a bedding production line. The cotton opener comprises a machine shell; a feeding port is formed in one end of the machine shell, and a discharging port is formed in the other end of the machine shell; at least three opening mechanisms are arranged in the machine shell in the direction from the feeding port to the discharging port at intervals; and each opening mechanism comprises two opening rollers rotationally connected in the machine shell, and opening needles are arranged on the peripheral walls of the opening rollers. The opening needles on the two opening rollers belonging to the same opening mechanism are staggered in the axis direction of the opening rollers, and the density of the opening needles in each opening mechanism in the axis direction ofthe opening rollers is gradually increased in the direction from the feeding port to the discharging port. A driving mechanism for driving the opening rollers to rotate in the same direction is arranged on the machine shell. A plurality of blowpipes are arranged at the bottom in the machine shell at intervals in the direction from the feeding port to the discharging port, a plurality of blowing ports inclining upwards in the direction where the discharging port is located are formed in each blowpipe at equal intervals, and one end of each blowpipe is connected with an air source for continuously conveying air into the corresponding blowpipe. The cotton opener has the advantages that the opening efficiency is high, and opened cotton is fluffy and soft.

Owner:北京一锦工贸有限责任公司

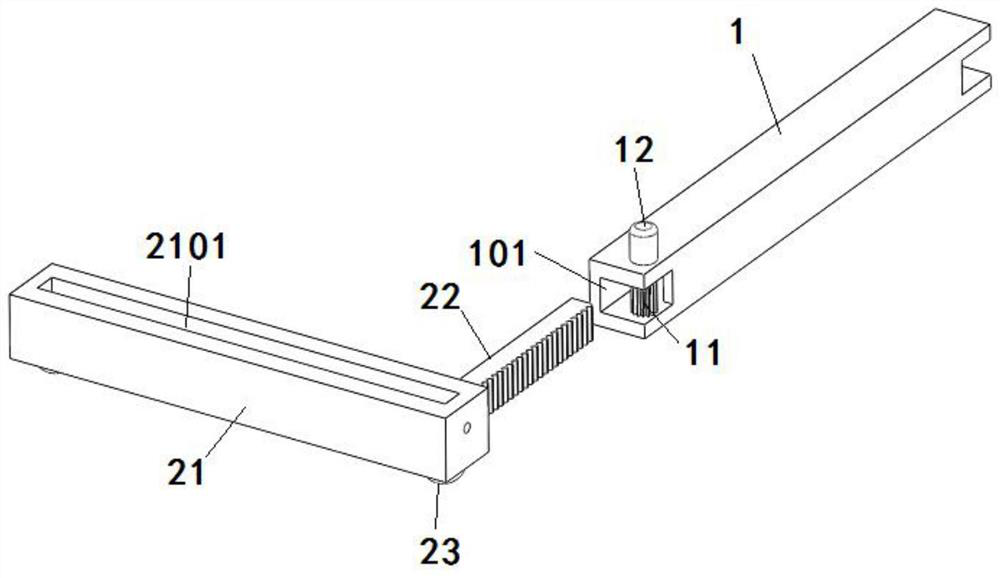

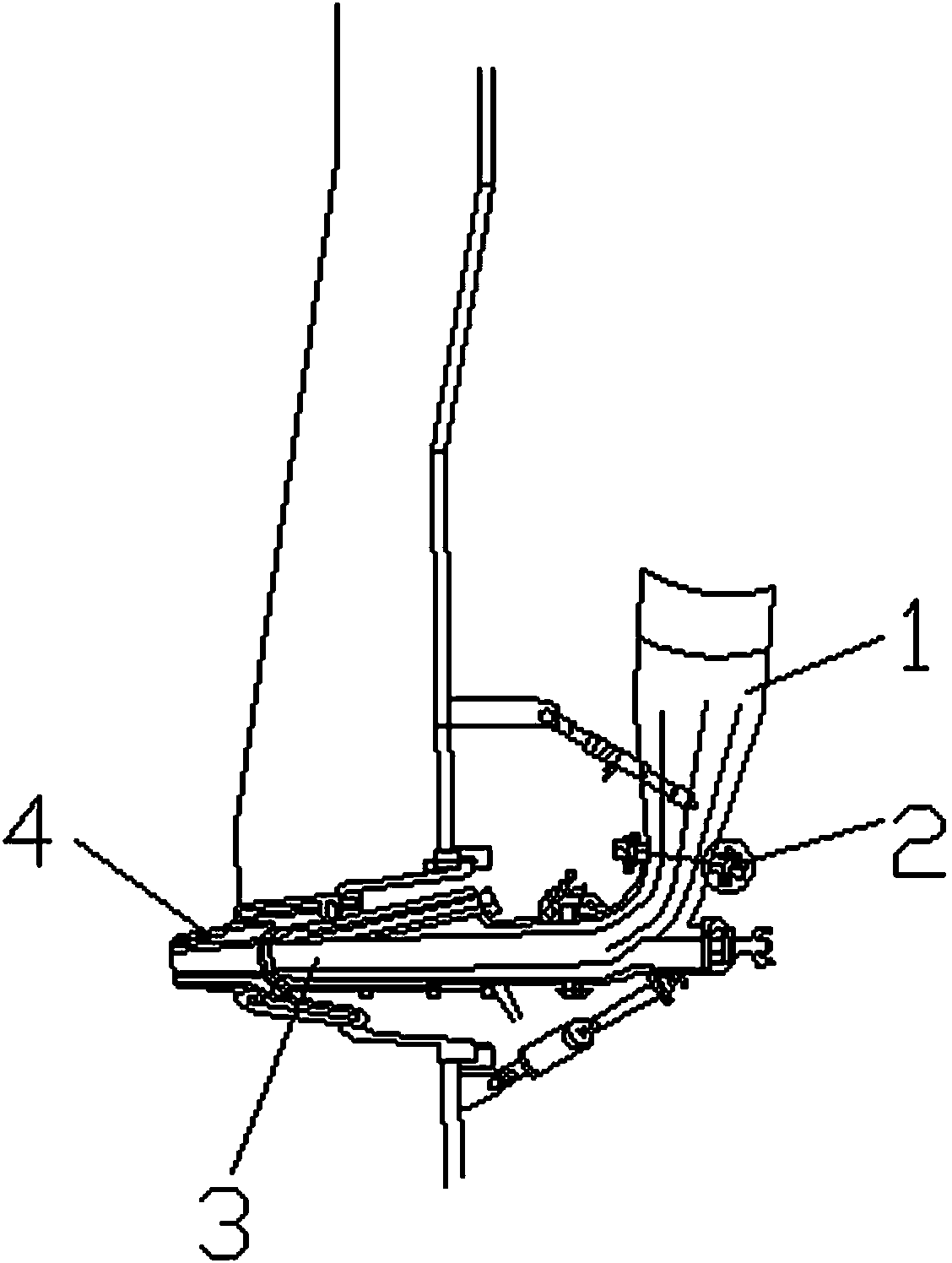

Blast-furnace tuyere with-air taking and conveying machine and taking and conveying method

ActiveCN110926885AEnable real-time analysisIncrease productivityFurnace componentsWithdrawing sample devicesReal time analysisProcess engineering

The invention relates to a real-time air taking and conveying device and method used in a blast-furnace tuyere in the metallurgical ironmaking process, and belongs to the technical field of machines.The device structurally comprises a rail, a chassis walking mechanism, front and rear chain seats, a rack and an air taking and conveying system. A temperature measurement display is arranged on achassis, the bottom of the rack is fixed on the chassis; a guide rail mechanism parallel to the rail and used for guiding the air taking and conveying system to move is arranged at the top of the rack, the air taking and conveying system comprises a taking and conveying pipe capable of moving in the guide rail mechanism, the tail end of the taking and conveying pipe is connected with a sample tank ora feeding tank through a control valve, and the top end of the taking and conveying pipe enters the blast furnace tuyere small sleeve through a smelting furnace measuring controller and a blowpipe. The method has the beneficial effects that real-time analysis of solid, gas and temperature in the furnace in the blast furnace production process is fully achieved, air blocking with wind, air openingwith wind and material spraying in the blast furnace are fully achieved, the purposes of saving energy and increasing yield are achieved, the blast furnace production efficiency is improved, the costis reduced, the domestic technical blank is filled up, and the world advanced level is achieved.

Owner:宗宁枫 +1

Wheat impurity removing and drying device for agricultural machinery

InactiveCN112845090AEasy to remove impuritiesAchieve jitterSievingGas current separationAgricultural scienceAgricultural engineering

The invention discloses a wheat impurity removing and drying device for agricultural machinery, and relates to the technical field of agricultural machine.The wheat impurity removing and drying device comprises a feeding box, a discharging box, a dust suction box and a dust suction pipe, the bottom of the feeding box is fixedly connected with the top of the discharging box, and the front face of the feeding box is fixedly connected with the back face of the dust suction box; and the top of the dust suction box is connected with a bottom pipeline of the dust suction pipe, and a first driving motor, a waste collecting box, an air blowing box, a filtering box and a drying box are arranged on the inner wall of the feeding box. Impurities in wheat are cleaned and removed by using a multi-stage blowpipe, the problem of low impurity removal efficiency caused by singly using the blowpipe at present is solved, the moisture content in the wheat is relatively high, the moisture in the wheat can be dried in the process of pushing the wheat through an arranged material pushing shaft, the wheat airing time can be shortened, the dust suction box is used in cooperation, and the dust amount in the feeding box can be reduced in the process that the wheat is poured into the feeding box.

Owner:龙利和

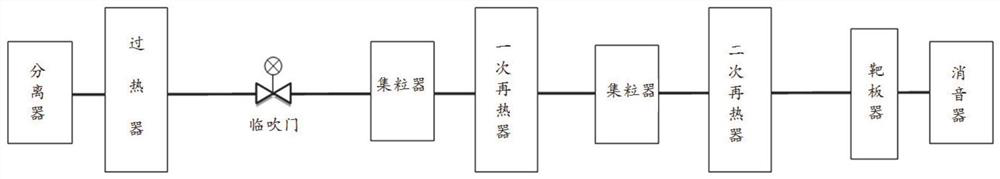

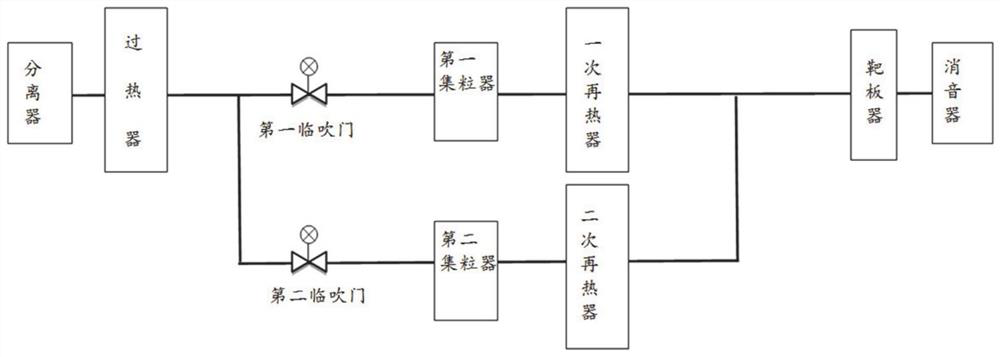

Secondary reheating boiler pressure stabilizing steam blowpipe system and method

ActiveCN112325267ASolve the problem of overheatingSolve the problem that the blowpipe coefficient is too largeBoiler cleaning apparatusSolid removalEngineeringSuperheater

The invention provides a secondary reheating boiler pressure stabilizing steam blowpipe system and method. The secondary reheating boiler pressure stabilizing steam blowpipe system comprises a separator, a superheater, a reheating system, a target plate device and a silencer which are connected in sequence, and the reheating system comprises a primary reheater system and a secondary reheater system; and the primary reheater system and the secondary reheater system are connected to the output end of the superheater in parallel. The pressure stabilizing blowpipe system is arranged to be of a parallel pressure stabilizing blowpipe system structure, a primary reheater and a secondary reheater are connected with a pressure stabilizing blowpipe in parallel, the problems that steam at an inlet ofa secondary reheating system is prone to being overheated, the blowpipe coefficient is large, and the blowpipe coefficient of a low-temperature superheater is small are solved, and obstacles are eliminated by adopting the pressure stabilizing blowpipe on a secondary reheating boiler.

Owner:SHANDONG ZHONGSHI YITONG GRP

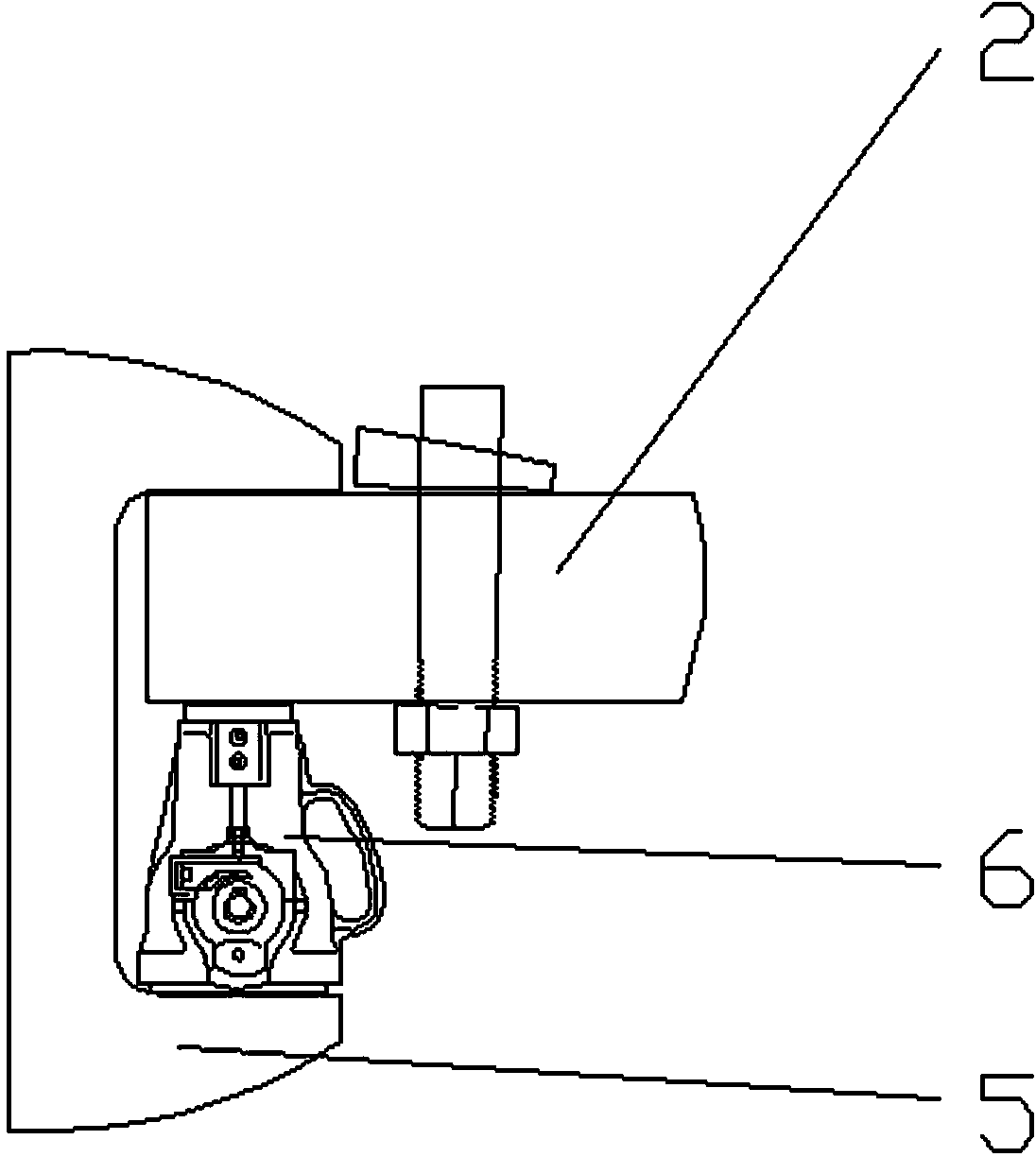

Tool for quick disassembly and assembly of blast furnace blowpipe and tight beating of tapered wedges and use method thereof

The invention relates to a tool for quick disassembly and assembly of a blast furnace blowpipe and tight beating of tapered wedges. The tool includes a tool body; the upper end and the lower end of the tool body are respectively connected with two same-direction clamps in an integration mode; a jack is mounted on the bottom clamp; the jack can press against a connection flange tightly when a blowpipe and the corrugated compensator connection flange are clampingly connected between the clamp and the jack. The tool has the characteristics of reasonable design structure and high efficiency, can avoid a phenomenon that a flange joint has wind leakage because of uneven force application when manpower is used for tight beating of the tapered wedges, avoids a rework problem, can be applicable to location, connection and tight locking of various flanges, and has relatively good popularization and application values.

Owner:GUANGDONG GUANGDONG SHAOGANG ENG TECH

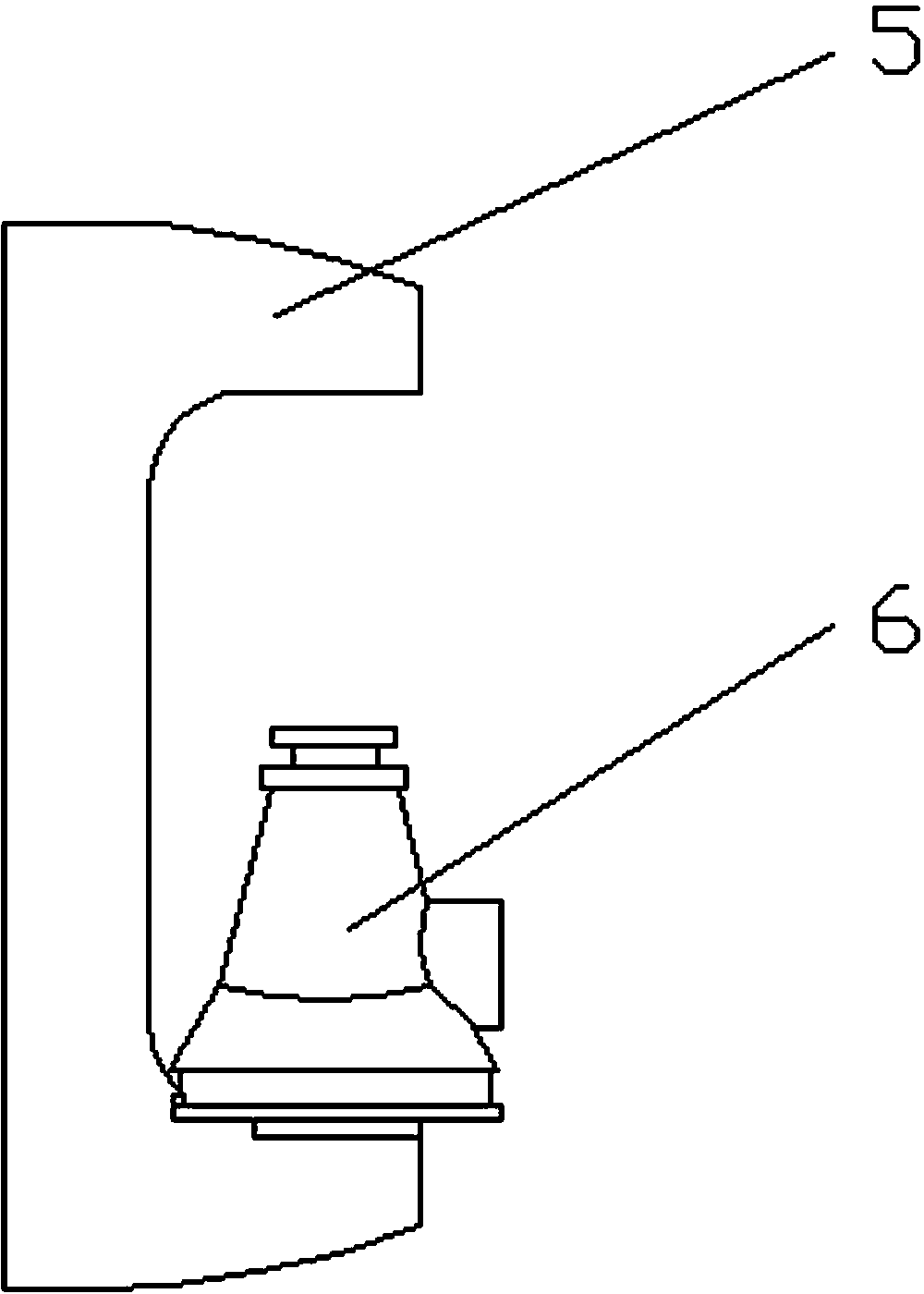

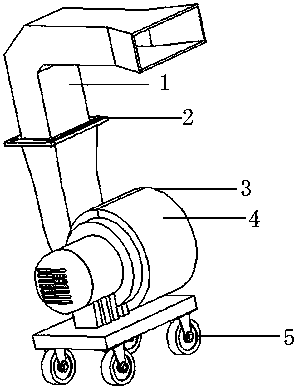

Movable fan cooling device

The invention discloses a movable fan cooling device which is used for generating cooling of a double-wall corrugated pipe. The cooling device comprises a centrifugal fan, a blowpipe, an air door, a connecting plate and omni-directional wheels, wherein the centrifugal fan is installed on one end surface of the connecting plate, the omni-directional wheels are installed on the other end surface of the connecting plate, the air door is installed on the air inlet of the centrifugal fan, and the blowpipe is connected with the air blowing port of the centrifugal fan. According to the cooling device disclosed by the invention, by moving the omni-directional wheels, polydirectional cooling is realized, and the difficulties that the fan can not be placed because a workbench is narrow and the like can be overcome, the mode of air cooling is soft, and the temperature fluctuation is relatively stable; the problems that a flaring is distortional, the wave crest of the corrugated pipe is burnt to be broken and the outer wall is coarse and the like caused by overhigh temperature of a module when the double-wall corrugated pipe is molded into a mould are solved; the cooling device has the advantages that the operation is more simple and more convenient, wind power is more moderate, the device does not occupy the narrow space of a machine and can be moved freely, and the production efficiency is effectively improved.

Owner:长春联塑实业有限公司

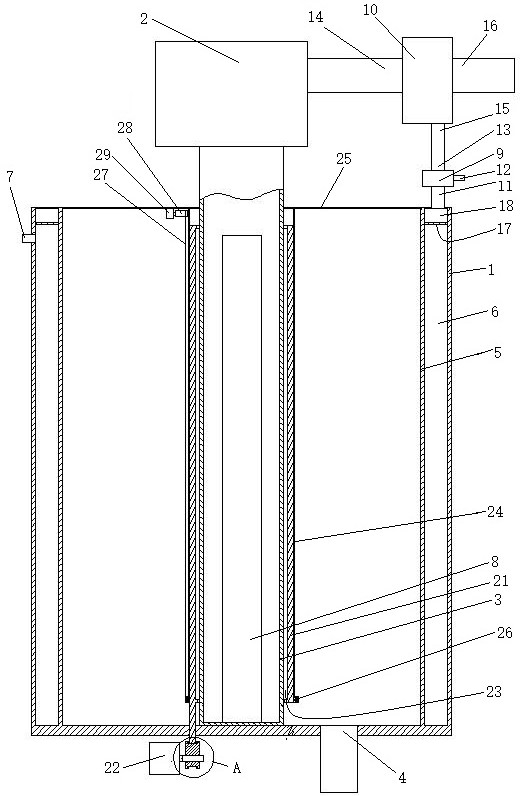

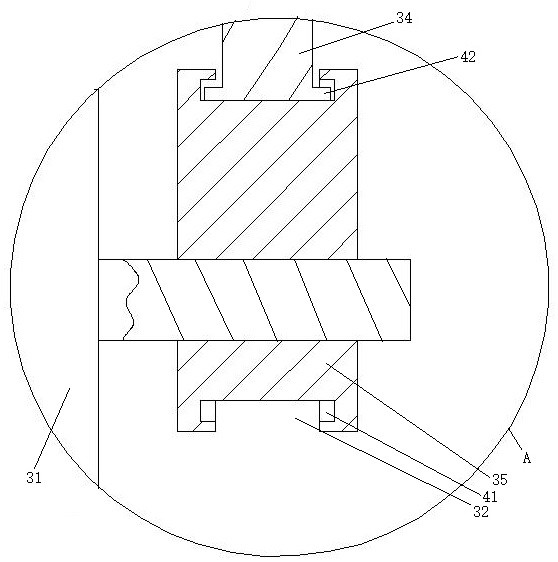

Ramming mass for air-supplying blowpipe of blast furnace and forming method thereof

ActiveCN105254232AImprove uniformityImprove compactnessSolid waste managementCeramic shaping apparatusSlagThermal insulation

The invention discloses a ramming mass for an air-supplying blowpipe of a blast furnace and a forming method thereof. The ramming mass is prepared from the following raw materials in parts by weight: 65-75 parts of water granulated slag, 20-24 parts of high-temperature cement, 6-10 parts of fire-resistant clinker powder and 5-12 parts of water. The forming method for the ramming mass comprises the following steps: inclining a to-be-prepared blowpipe for 40-50 degrees, closing the lower end of the blowpipe and putting the blowpipe into a mould, wherein the taper at 0.5-1 degree on the mould is required and the surface of the mould is wrapped with the separation material; weighing the water granulated slag, the high-temperature cement and the fire-resistant clinker powder at the ratio of formula, adding the water granulated slag, the high-temperature cement and the fire-resistant clinker powder into water and mixing and stirring for 3-5min until the mixture is uniform; feeding the uniformly mixed materials into the blowpipe, ramming the material to be compact while feeding, till forming the whole blowpipe, extracting the mould and repeating the preparation for the next blowpipe; standing by the formed blowpipe for 5-9 days at room temperature. The blowpipe prepared according to the forming method provided by the invention has the advantages of excellent thermal insulation property, easy removal after slag pouring, convenience in manufacturing, no requirement for baking, low production cost, short period and higher popularization and application value.

Owner:WUKUN STEEL

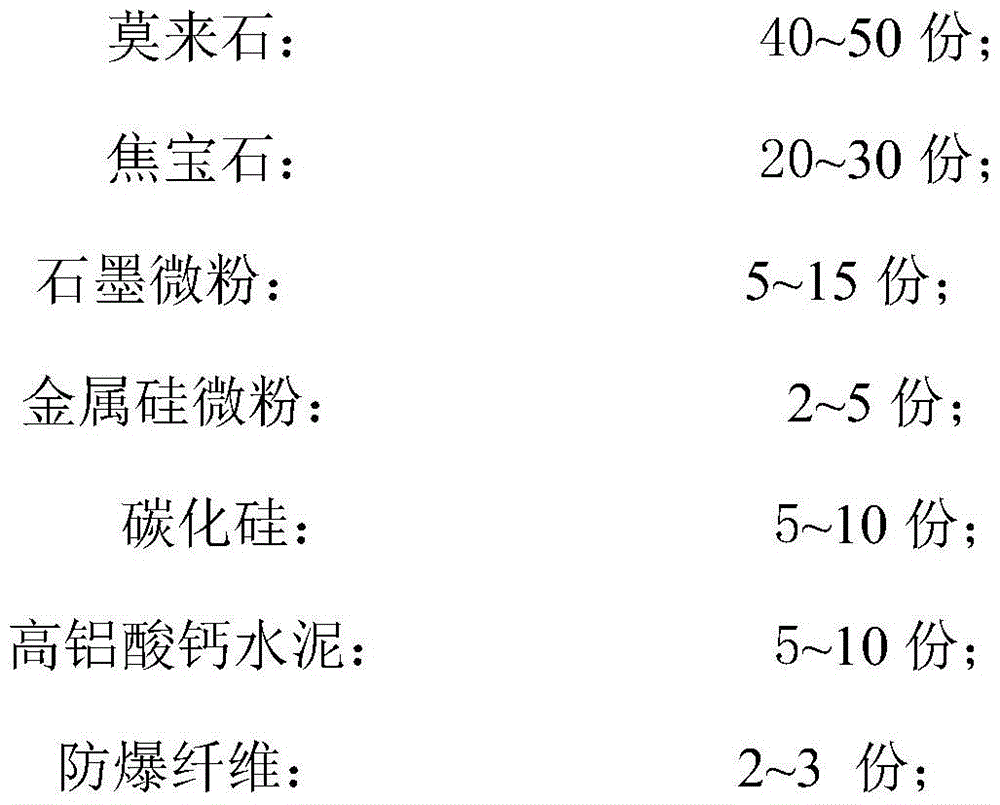

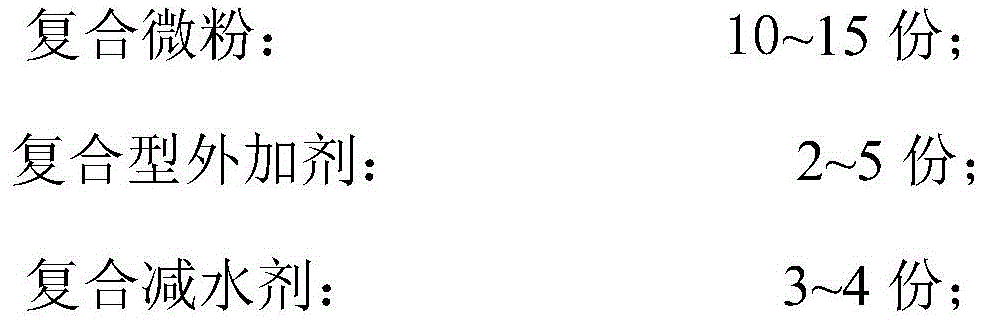

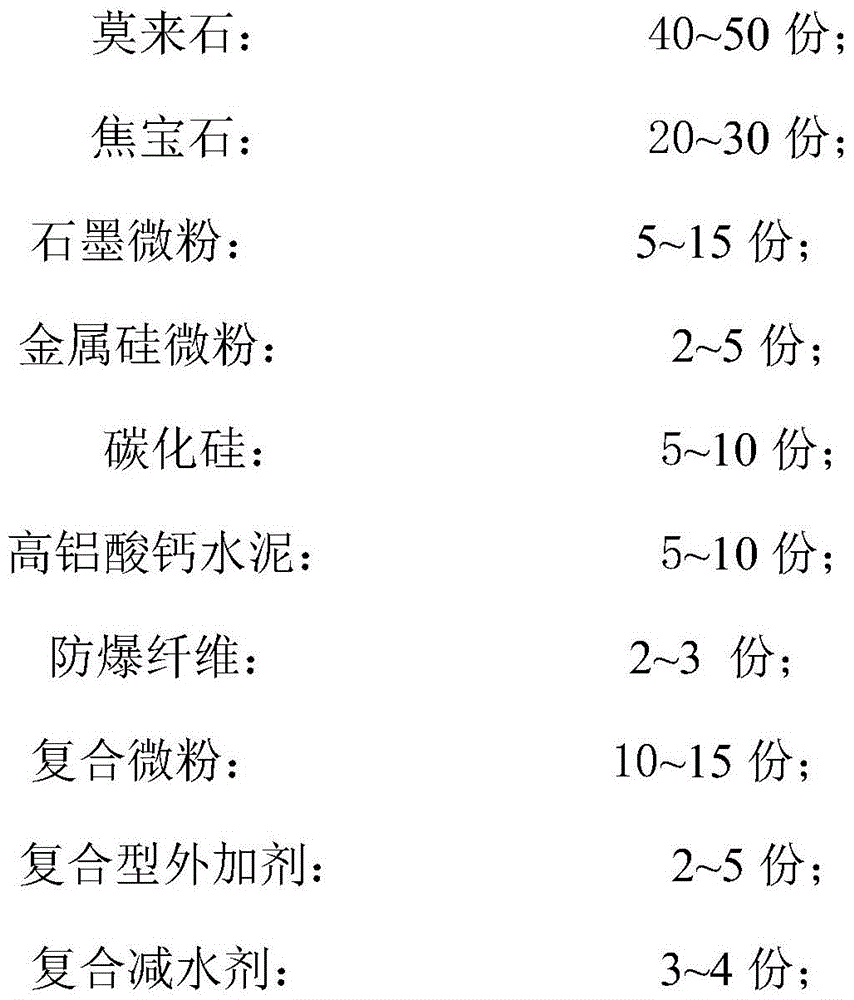

Durable blowpipe material

The invention discloses a durable blowpipe material. Through improving a formula and introducing carbon powder and silicon powder, of which the particle size is 10 microns, and compounded admixtures into the blowpipe material, the introduced special carbon powder and silicon powder with the particle size of about 10 microns produce SiC whiskers during firing, the SiC whiskers are uniformly distributed in gaps between a matrix and particles, the expansion resulting from the firing of the material is filled up, and SiC is bonded with a ceramic phase so as to improve the density and thermal shock stability of the material; and meanwhile, relatively high strength is obtained, so that the probability of burn-through of blowpipes during use is lowered. Compound sodium hexametahposphate, sodium tripolyphosphate and the like are adopted as the admixtures, so that the fluidity during the manufacturing of the blowpipes is improved and is relatively good, the hardening time for the blowpipe material is shortened, and the production schedule of the material is guaranteed; and on the other hand, bonding strength is generated during the manufacturing of the blowpipes, and the internal bonding mode of the blowpipes is changed into ceramic bond after baking and firing, so that the strength of the material is improved, and the service lives of the blowpipes are prolonged.

Owner:长兴云峰炉料有限公司

Blowing dust removal device for electronic product

InactiveCN112958543AAffect the effect of dust removalEasy to placeDirt cleaningCleaning using gasesDust controlAir pump

The invention relates to a dust removal device, in particular to a blowing dust removal device for an electronic product. The technical problem to be solved by the invention is to provide the blowing dust removal device for the electronic product, which can automatically and efficiently clean and has a good cleaning effect. The blowing dust removal device for the electronic product comprises a placing frame, a first placing screen plate arranged on the placing frame, an air pump arranged on the first placing screen plate at one side, an air inlet cover arranged on the placing frame and connected to the air pump, an air blowpipe arranged on the air pump, a gas ejector pipe arranged on the placing frame in a sliding manner, and a connecting cover arranged on the gas ejector pipe and connected to the air blowpipe. The dust removal device is provided with a dust collection component, and dust can be discharged into a collection frame under the action of a dust collection pump, so that the dust is prevented from staying in the placing frame to affect the dust removal effect of the electronic product.

Owner:抚州盛宏电子有限公司

Self-adaptive adjustment high-voltage switch complete device

InactiveCN112736675AReduce internal temperatureGuaranteed accuracySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsThermal dilatationThermodynamics

The invention relates to the field of electric power, and particularly discloses a self-adaptive adjustment high-voltage switch complete device which comprises a base, a rain baffle, a cabinet body, a fan, a blowpipe and outer heat dissipation holes. The inner wall of the cabinet body is provided with a vertical movable shielding seat which moves in the vertical direction. Inner heat dissipation holes corresponding to the outer heat dissipation holes in a one-to-one manner are formed in the movable shielding seat, the inclination angle of the inner heat dissipation holes is same as that of the outer heat dissipation holes, and the lower fixed connecting rods below the movable shielding seat at the two sides are fixedly connected to a horizontal connecting plate. The lower side of the connecting plate is fixedly connected with an elastic expansion part covering the bottom of the cabinet body, and the elastic expansion part is filled with thermal expansion fillers. When heat dissipation is needed, the outer heat dissipation holes directly correspond to the inner and outer heat dissipation holes, so that the internal hot air is directly exhausted, and the internal temperature is rapidly reduced; the heat dissipation function is started through thermal expansion filling and elastic expansion part driving and directly adapts to the internal temperature.

Owner:龙四学

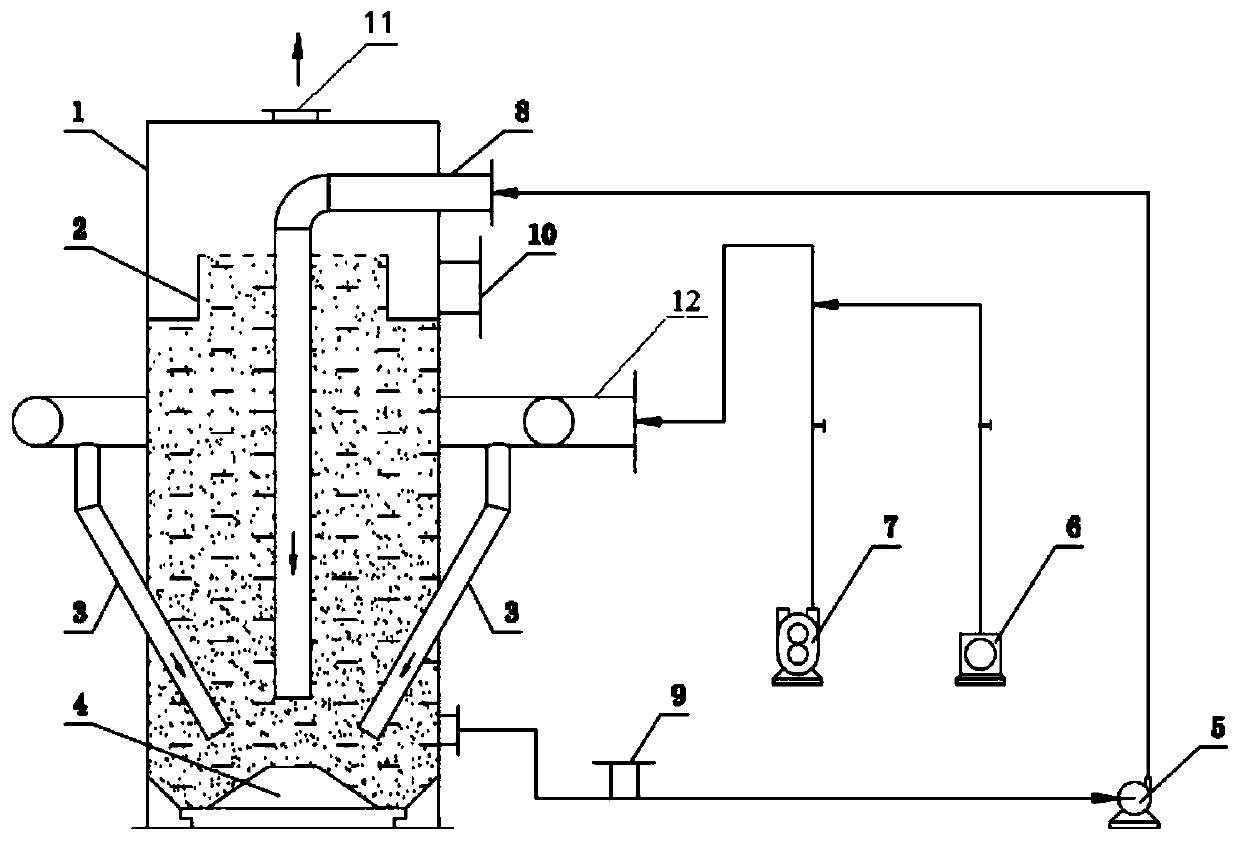

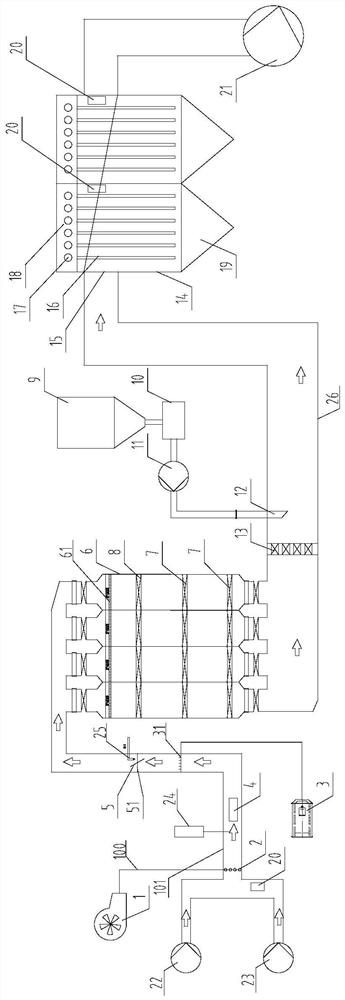

A method for reducing the content of soluble impurities in wastewater by utilizing a gas-liquid impact mixing reaction system

ActiveCN106608673BLow chemical oxygen demand (COD) contentIncrease surface areaBiological water/sewage treatmentWater/sewage treatment by oxidationAmmoniacal nitrogenWater flow

The invention discloses a method for reducing the content of soluble impurities in waste water by using an air-liquid impact mixing reaction system. The air-liquid impact mixing reaction system is used for treating waste water containing COD, BOD, ammonia-nitrogen, S<2-> and other impurities; the reaction system comprises a circulation solution storage case, a liquid impact tube, an air blowpipe, a circulating water pump, an air supplying device, etc.; the circulating water pump and the air supplying device are started, and the waste water is introduced from a water inlet and ejected from the lower end of the liquid impact tube at a high speed and impacts a baffle plate; air or ozone-containing air is ejected from a branch air blowpipe at a high speed and impacts the baffle plate; a foam reaction zone is formed due to high-speed impact mixing of the air and the liquid; reacted clear water flows into an overflow groove and is discharged from a water outlet; and reacted gases are directly discharged from a gas outlet. The method is easy, low in cost, capable of highly efficiently reducing the contents of COD, BOD, ammonia-nitrogen, S<2-> and other impurities in the waste water, free of secondary pollution, simple in used devices and suitable for large-scale application.

Owner:湖南西林环保材料有限公司

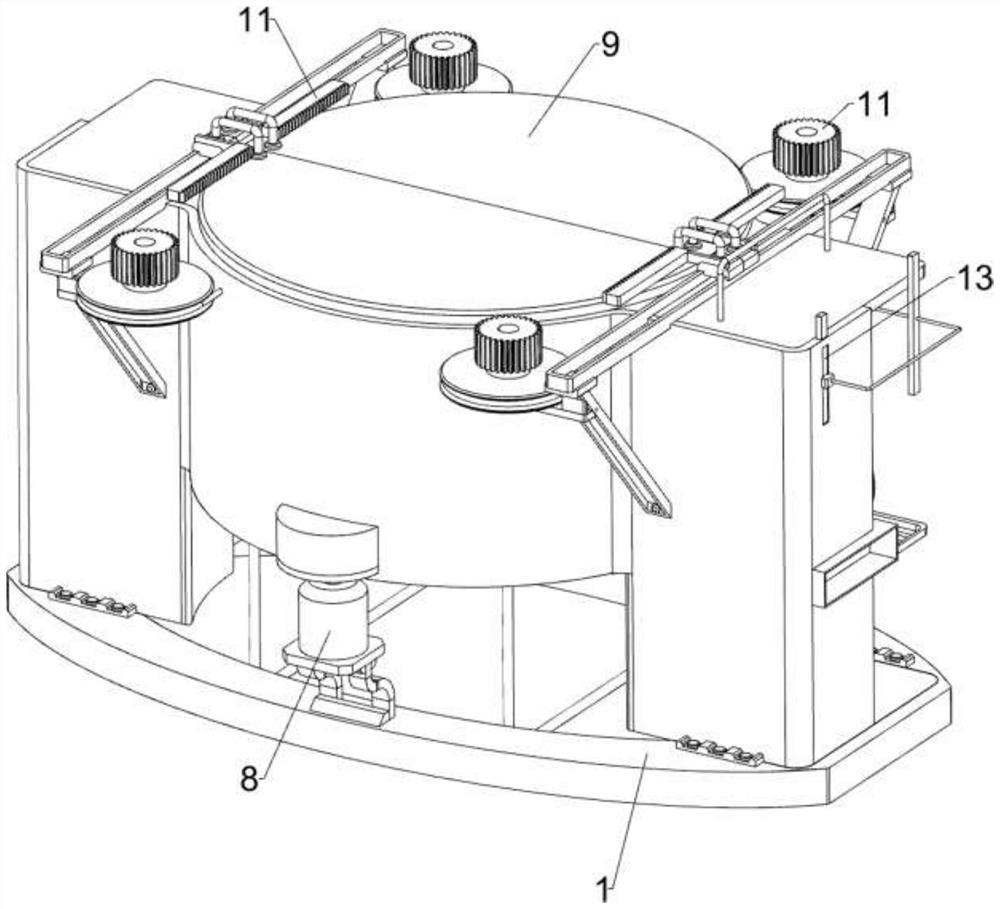

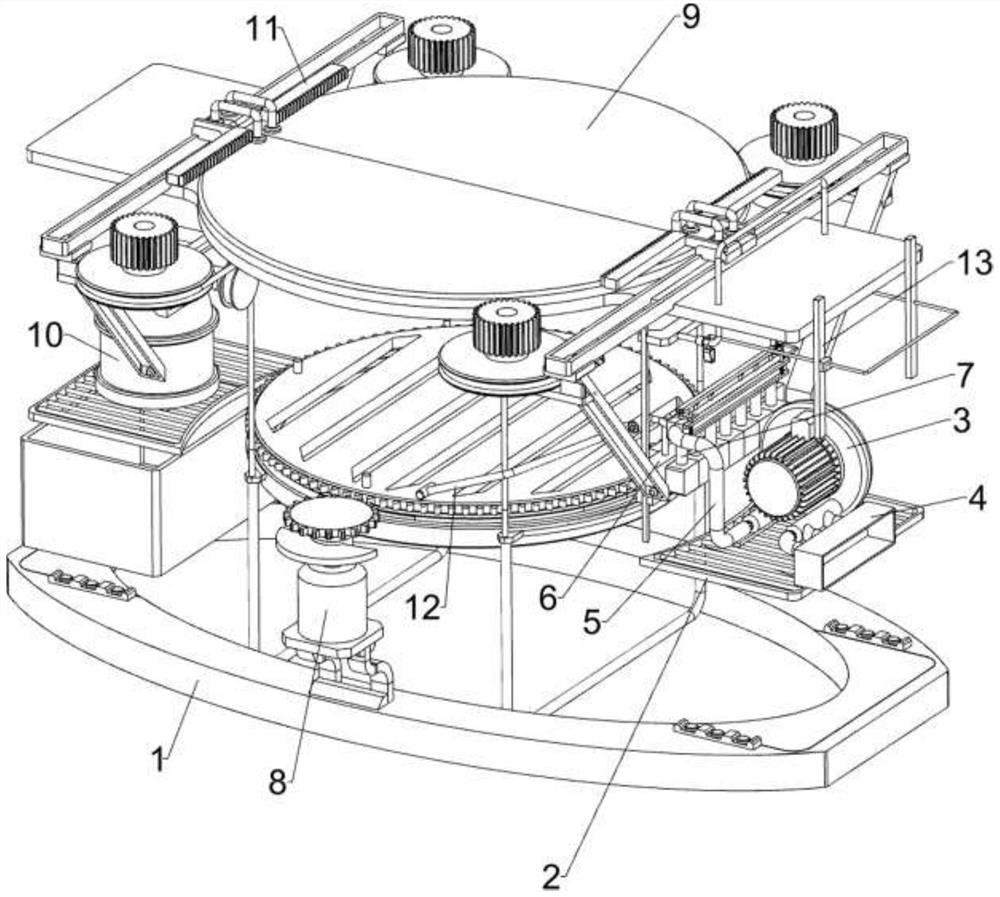

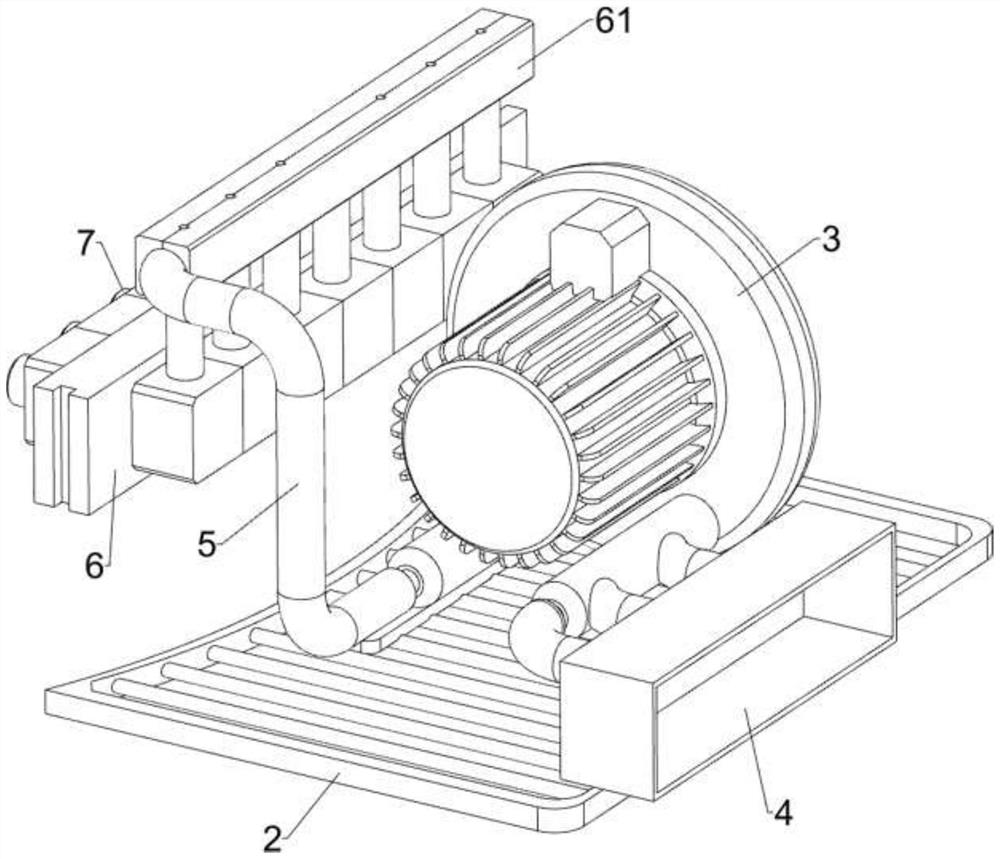

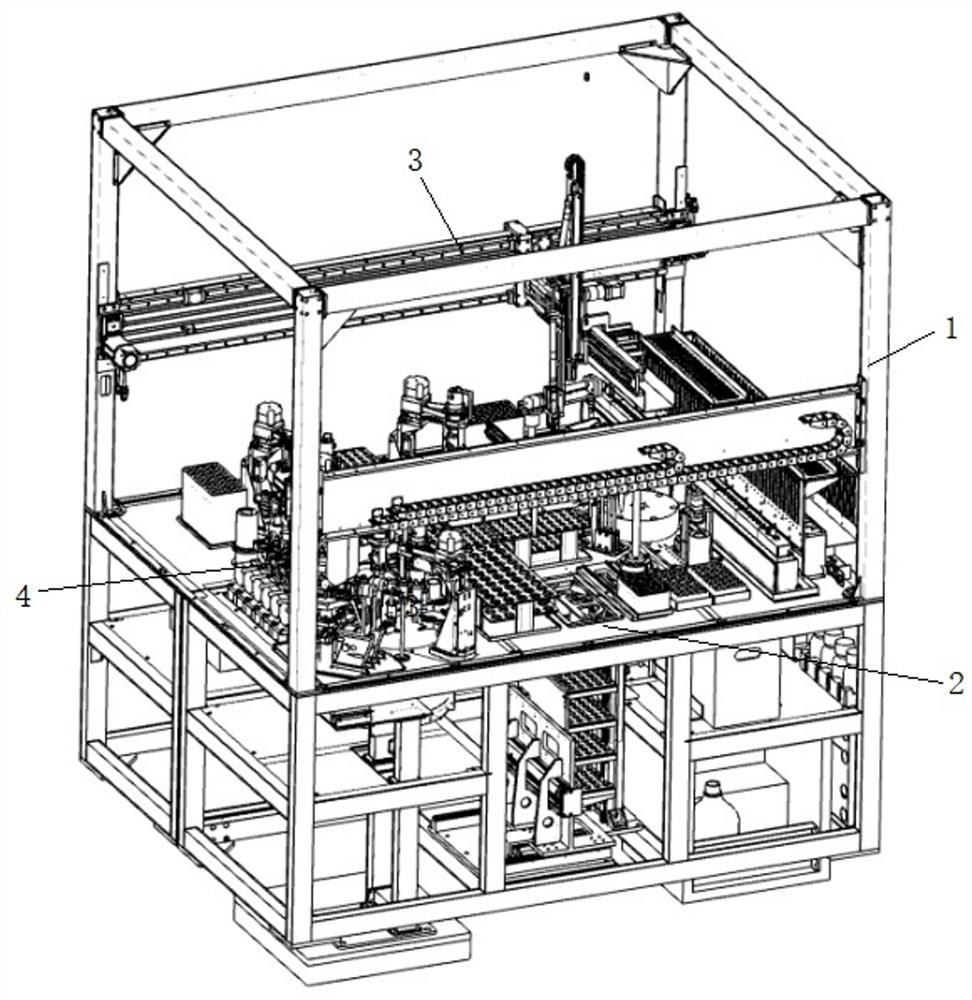

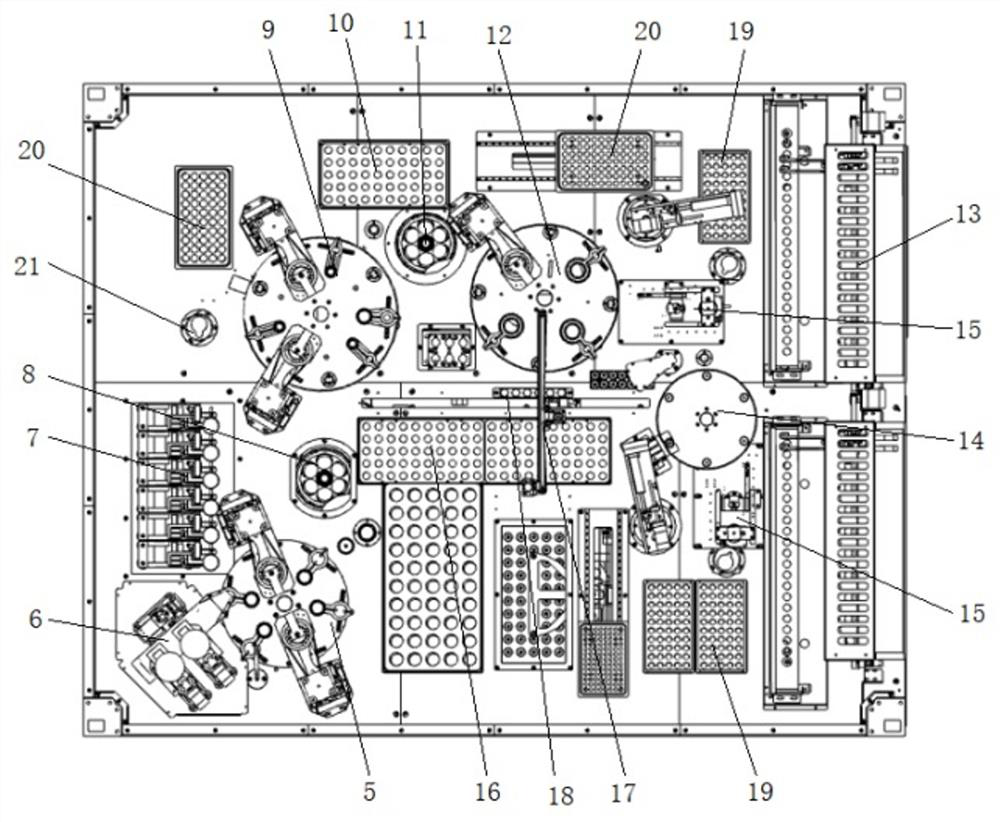

Pesticide residue detection pretreatment system

PendingCN112684195ACompact structureMeet different testing needsMaterial analysisPesticide residueControl cell

The invention relates to the technical field of automatic equipment, and discloses a pesticide residue detection pretreatment system. The system comprises functional units and a control unit which are arranged on a workbench of a rack, each functional unit comprises a sample feeding cover opening and closing unit, a liquid and salt adding unit, a weighing oscillation unit, a first centrifugal unit, a first nitrogen blowpipe transferring unit, a nitrogen blowing unit, a solvent adding unit and a filtering unit, the control unit comprises a mechanical arm unit and an electric control unit, the functional units are sequentially arranged on a workbench of the rack along the periphery, and the control unit controls the functional units and the mechanical arm unit to carry out processing work. Automatic operation of pesticide residue detection pretreatment work is achieved, manual operation is reduced, and the working efficiency and the sample consistency are improved.

Owner:SHANGHAI HUI X IMAGING INFORMATION TECH

Novel rearview mirror

The invention discloses a novel rearview mirror which comprises a shell body and a mirror face embedded on the front face of the shell body. The mirror is characterized in that a round hole is formed in the mirror face, and a convex mirror fitted with the round hole passes through the round hole and is installed between the mirror face and the shell; an annular blowpipe fixed on a rearview mirror base is disposed on peripheries of a lens of the rearview mirror, vent holes which are arranged at equal intervals and aligned with the mirror face are formed in the inner side of the blowpipe, and a ventilation pipe connected to the annular blowpipe passes through the fixation base of the rearview mirror and then communicates with an automobile fan heater pipe; and a wiper blade is closely adhered to the mirror face and is connected to a drive device disposed in the shell body. The rearview mirror disclosed by the invention has the advantages that water stains on the rearview mirror can be effectively removed, and universal use in multiple car types is realized; hot wind of the automobile fan heater is effectively used to dry the rearview mirror in time; and a view angle can be adjusted at will, so that a driver can better observe road conditions of an intended position.

Owner:QINGDAO ALLITE AUTO TECHNIC

Method for drying pig feed in pig feed raw material storage tank

The invention relates to a method for drying pig feed in a pig feed raw material storage tank. The method comprises the following steps that a vertically arranged blowpipe which penetrates through a storage tank and is inserted into the pig feed raw material in the storage tank is arranged, the blowpipe is butted with the outlet end of an air blower, an inner sleeve which is sleeved on the blowpipe in the storage tank in a penetrating manner is arranged, an annular air outlet cavity which is located outside the inner sleeve and extends in the circumferential direction of the inner sleeve is isolated by the inner sleeve in the storage tank, the annular air outlet cavity is provided with an air outlet cavity portion air outlet valve, the inner sleeve is provided with a plurality of inner sleeve portion air holes communicated with the inner space of the inner sleeve and the annular air outlet cavity, a plurality of blowpipe part air holes are formed in the side wall of the part, located in the storage tank, of the blowpipe, and a blowpipe part electric heating pipe is arranged in the blowpipe. The invention aims to provide the method for drying the pig feed in the pig feed raw material storage tank, so that the problem that the existing pig feed raw material storage tank is easy to mildew due to high internal humidity when storing the pig feed raw material is solved.

Owner:ZHEJIANG NATUFEED LIVESTOCK

Air blower

PendingCN111749174AReduce volumeImprove portabilityAssociation with control/drive circuitsWindingsElectric machineryAir blower

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

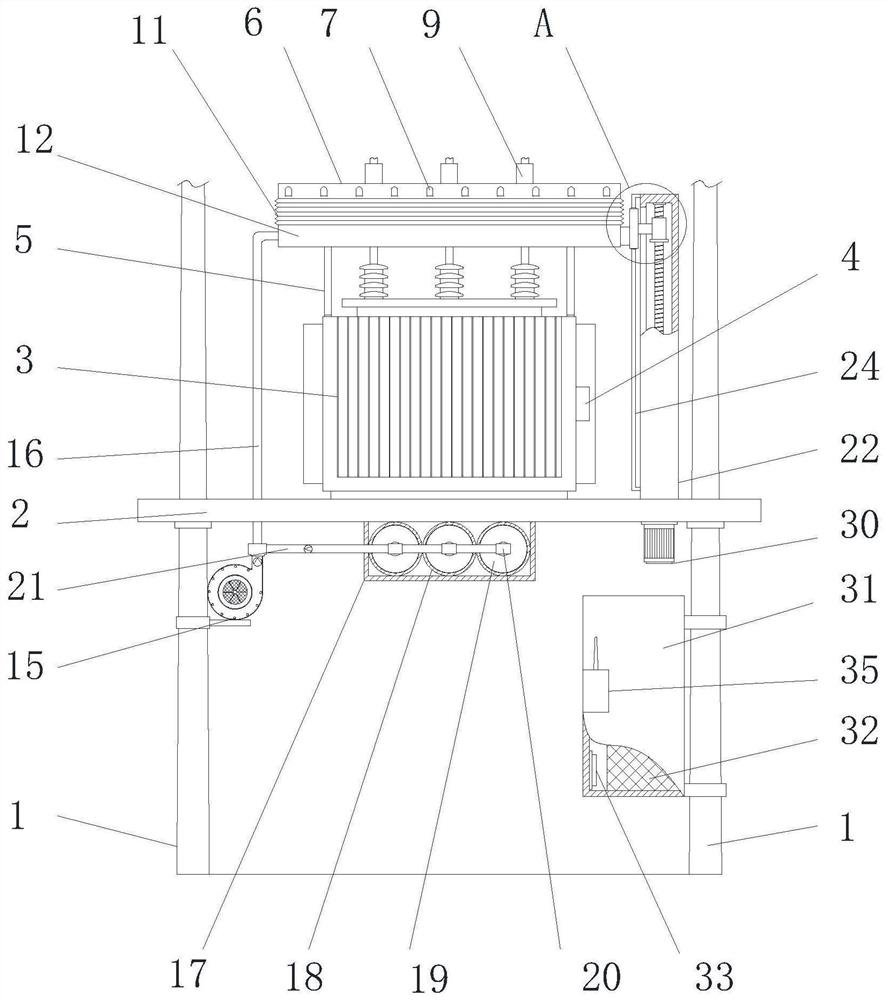

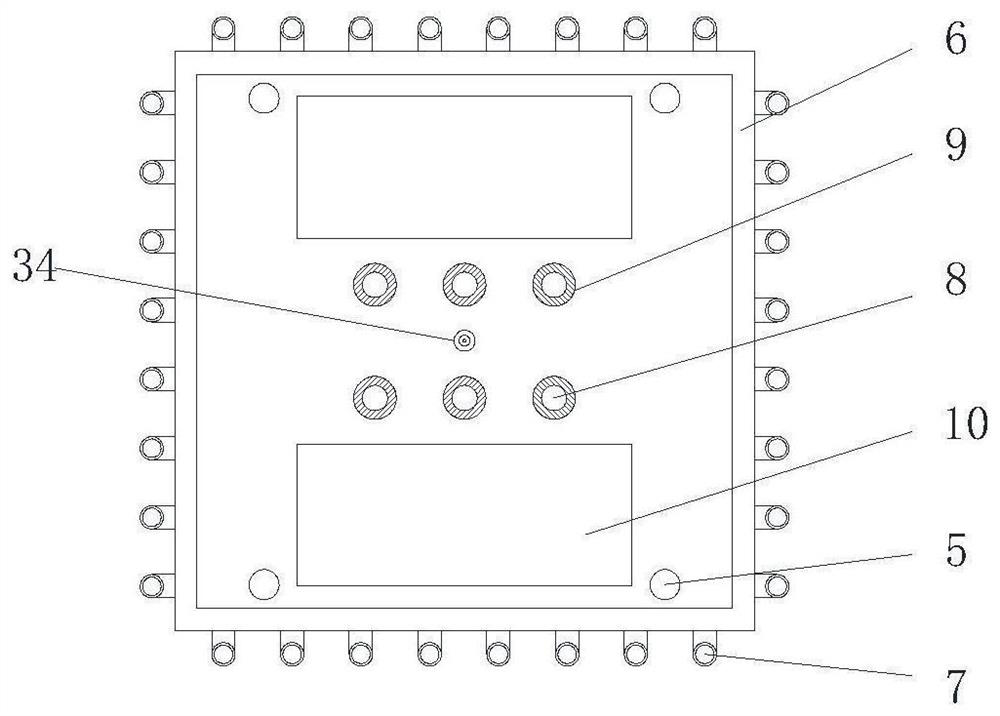

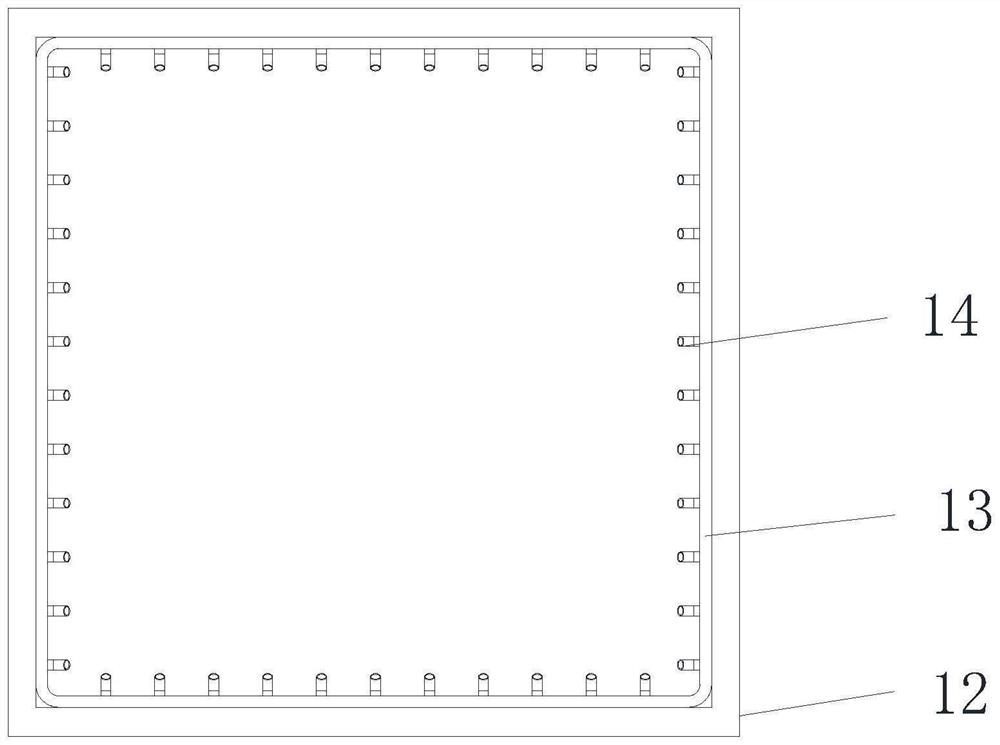

Novel transformer protection control device

ActiveCN112103047AFunction normallyGuarantee the safety of lifeTransformers/inductances coolingTransformers/inductances casingsTransformerStructural engineering

A novel transformer protection control device comprises a stand column set, a vertical sliding plate and a fire extinguishing module; wherein the stand column set comprises a left stand column and a right stand column, the lower portions of the left stand column and the right stand column are both buried in the ground, and the lower portions of the left stand column and the right stand column arejointly connected with an installation bottom plate in a supporting mode. Supporting columns are arranged on the left side and the right side of the upper end of the transformer body, and the upper ends of the supporting columns are jointly connected with a top cover in a supporting mode. Four-side air cooling can be carried out through the Y-shaped blowpipe, so that the coverage area is larger and the heat dissipation effect is better; the Y-shaped blowpipe can move up and down to discharge air to clean pollutants, so that the operation safety of equipment and the life safety of staff are guaranteed, the protection performance is good in extreme weather, and dry powder can be conveyed to the Y-shaped blowpipe to be blown out after the electric control valve is opened, thus extinguishing the fire timely and efficiently; in addition, the fire extinguishing device is ingenious and reasonable in structure, and is more energy-saving and environment-friendly.

Owner:江苏诺盛电气科技有限公司

Comprehensive treatment device for tail gas of heating furnace

PendingCN113019095AReduce construction costsSimple structureGas treatmentDispersed particle filtrationThermodynamicsFlue gas

The invention provides a comprehensive treatment device for tail gas of a heating furnace. The device comprises a mixing flue, a low-temperature SCR reactor, a desulfurization flue and a bag-type dust collector which are sequentially arranged in the flue gas conveying direction. The input end of the mixing flue is provided with two flue branches, and the junction of the two flue branches is connected with a dilution fan. A homogenizing device and an ammonia gas spraying pipe are arranged in the mixing flue, the dilution fan is connected with the homogenizing device through a blowpipe, and the ammonia gas injection pipe is arranged on the upstream of the homogenizing device and connected with a reducing agent spraying system. The mixing flue is further connected with a tail gas heating device. The output end of the mixing flue is connected into an inlet of the low-temperature SCR reactor, an outlet of the low-temperature SCR reactor is connected with the bag-type dust collector through the desulfurization flue, and the desulfurization flue is connected with a desulfurizing agent spraying and flow equalizing device which is used for spraying a desulfurizing agent into the desulfurization flue. The device is compact in overall structure, uniform mixing can be ensured, and the desulfurization efficiency is improved.

Owner:浙江菲达环保科技股份有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com