Movable fan cooling device

A fan-cooled, mobile technology, applied in the field of double-wall corrugated pipe cooling, can solve the problems of high scrap rate, high temperature of molding mold modules, affecting production efficiency, etc., achieve elegant appearance, convenient installation and disassembly, and simple processing technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings, but the embodiments of the present invention are not limited to this.

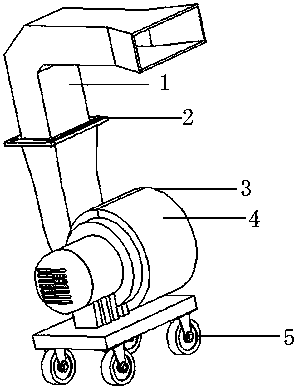

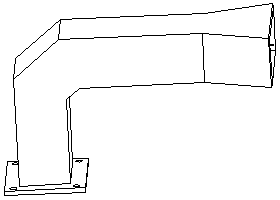

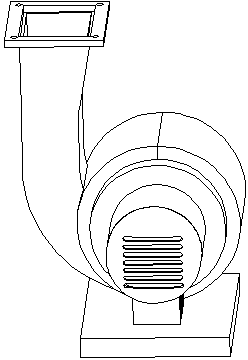

[0019] Such as Figure 1-4 , A mobile fan cooling device, used to generate double-wall corrugated pipe cooling, including centrifugal fan 4, blowing pipe 1, air door 3, connecting plate and universal wheel 5, centrifugal fan 4 is installed on the connecting plate The universal wheel 5 is installed on the other end of the connecting plate. In this embodiment, the connecting plate is equipped with four universal wheels 5 in a rectangular distribution, and the air door 3 is installed at the air inlet of the centrifugal fan 4 , The blowing pipe 1 is connected with the blowing port of the centrifugal fan 4 through the bolt 2. In this embodiment, the blower pipe 1 is welded with a white iron plate. The air door 3 includes two blades that are rotatably connected to each other. Through the two blades on the air door 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com