Patents

Literature

249results about How to "Efficient and reasonable use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Streamlined acceleration system of FPGA-based depth convolution neural network

ActiveCN106875012AProcessing speedHighly integratedPhysical realisationNeural learning methodsComputer science

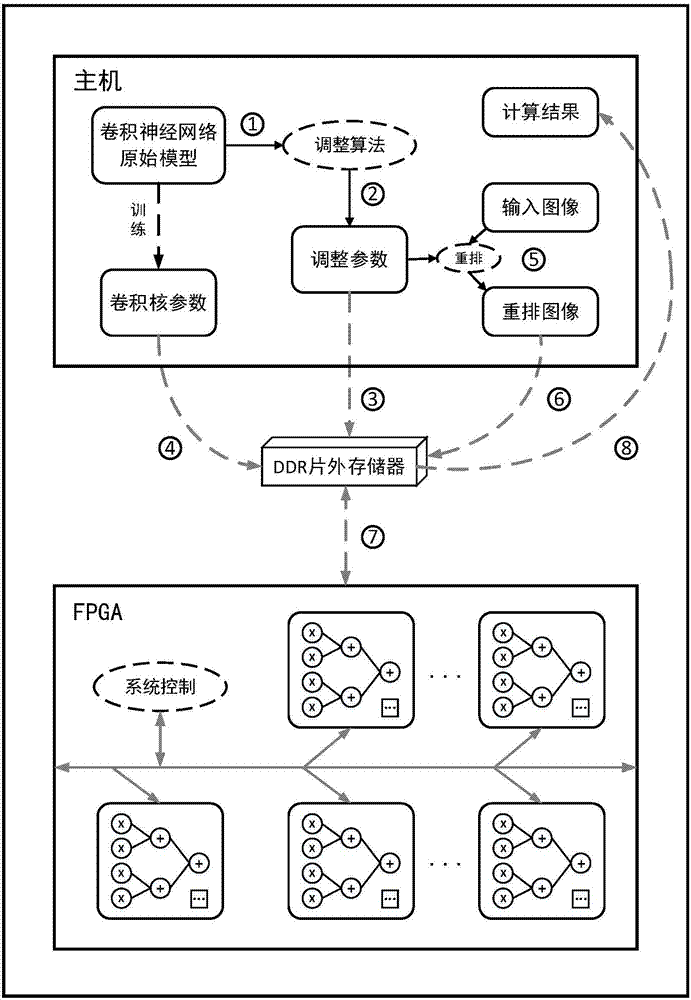

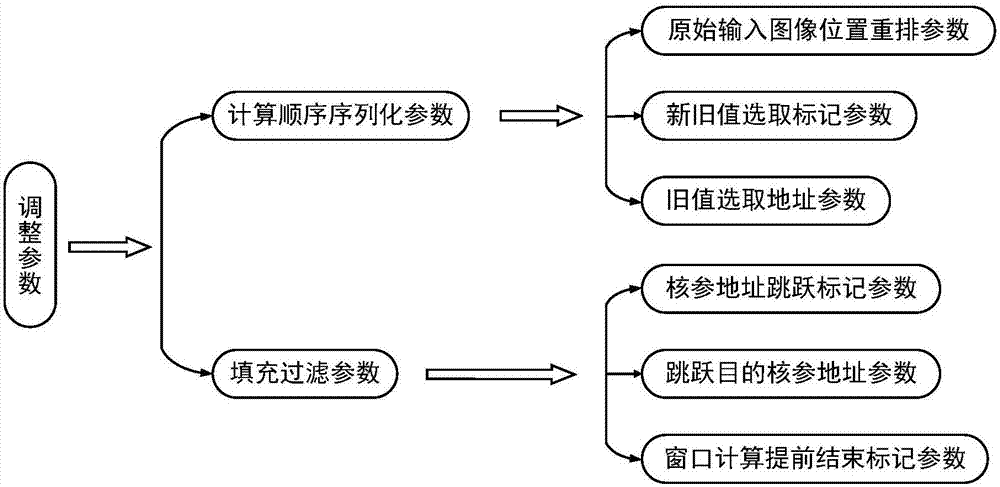

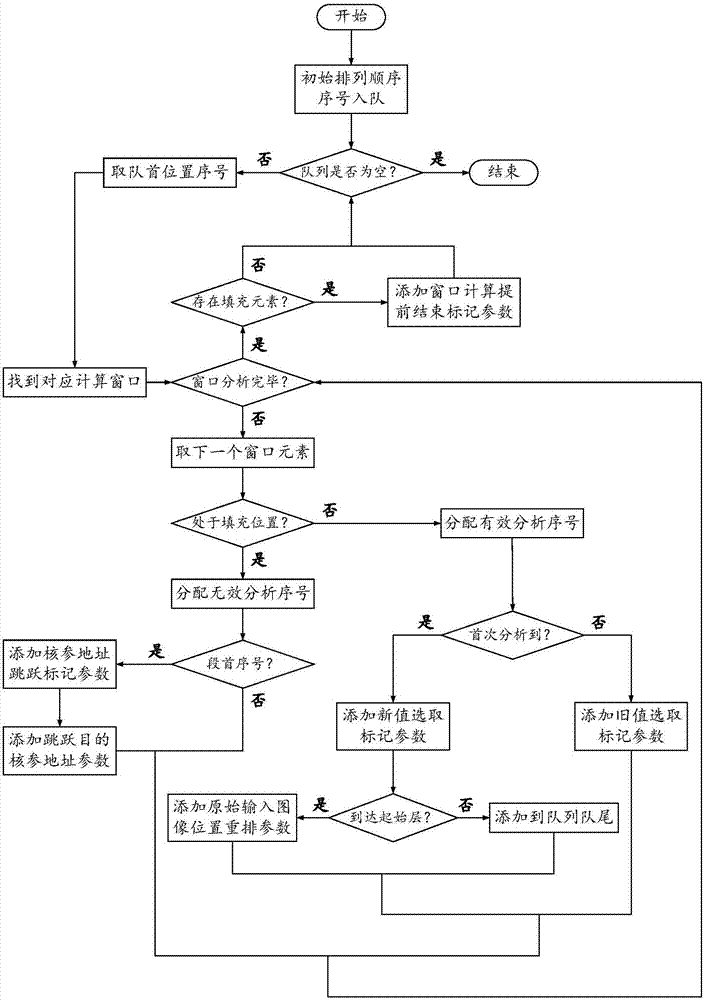

The invention brings forward a streamlined acceleration system of an FPGA-based depth convolution neural network. The streamlined acceleration system is mainly formed by an input data distribution control module, an output data distribution control module, a convolution calculating sequence serialization realizing module, a convolution calculating module, a pooling calculating sequence serialization realizing module, a pooling calculating module, and a convolution calculating result distribution control module. Moreover, the streamlined acceleration system comprises an internal system cascade interface. Through the streamlined acceleration system designed by the invention, highly efficient parallel streamlined realization can be conducted on an FPGA, problems of resource waste and effective calculation delays caused by filling operations during calculation are effectively solved, the power consumption of the system is effectively reduced, and the operation processing speed is greatly increased.

Owner:武汉魅瞳科技有限公司

Bicycle management system as well as control method and control device thereof

InactiveCN105046827AEasy to useImprove experienceAnti-theft cycle devicesReservationsEngineeringReport status

Owner:BEIJING MOBIKE TECH CO LTD

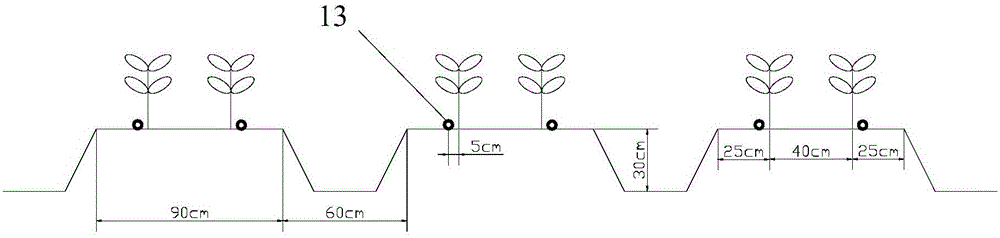

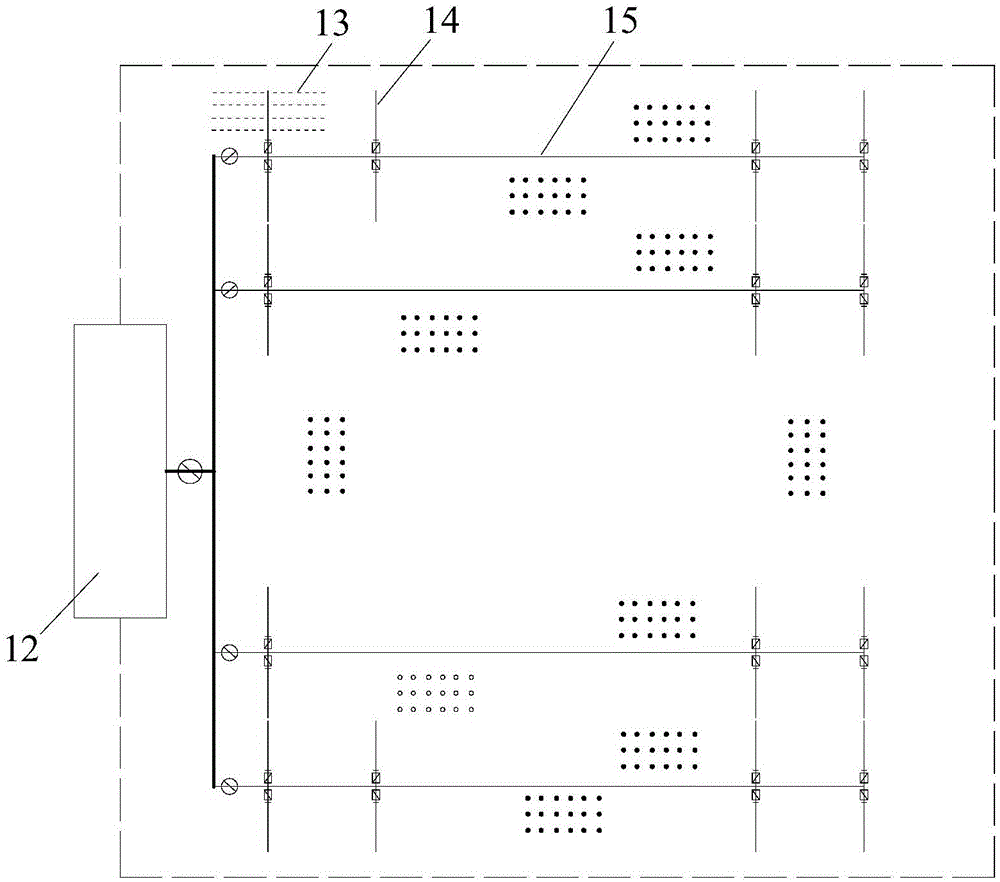

Saline-alkali soil brackish water film mulching drip irrigation processing tomato planting method

ActiveCN105103857AEasy to mineReduce evaporationClimate change adaptationWatering devicesAridAlkali soil

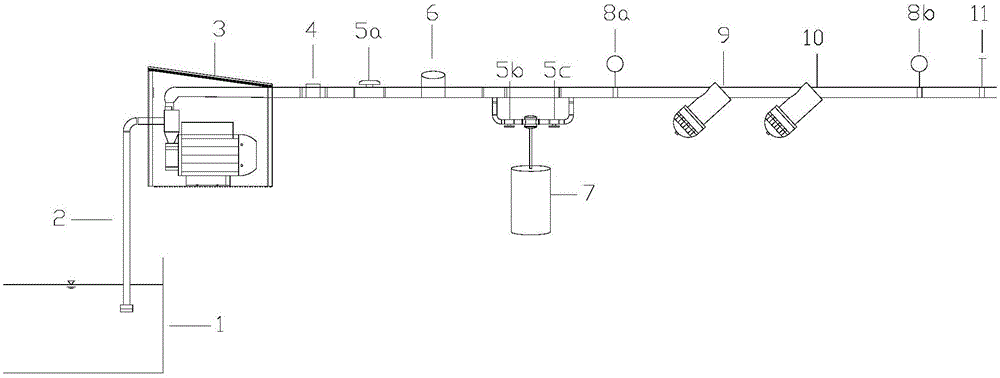

The invention provides a saline-alkali soil brackish water film mulching drip irrigation processing tomato planting method, which comprises the following steps: (1) planting processed tomatoes: planting the processed tomatoes by adopting a manner of wide rows and high ridges, and mulching a white film above plants; (2) laying out a drip irrigation system, wherein an interval b between the drip irrigation systems is 48 to 52 cm; an interval a between drip emitters is 0.25 to 0.35 m; (3) carrying out high-frequency and small fixed amount water irrigation in a growing period of the processed tomatoes: alternatively irrigating brackish water and fresh water, and adopting the fresh water for irrigation in a seedling stage, and no irrigation in a red-mature period. The invention puts forward a cultivation method taking the brackish water and saline-alkali soil as targets in combination with the realities of shortage of fresh water resources, abundant underground brackish water resources and serious soil salinization in an arid region and a semi-arid region, and not only moisture is enabled to be held up within a field microcirculation of soil-and-film, deep seepage losses of the moisture are greatly reduced, but also under-film soil evaporation is remarkably lowered, sources of soil secondary salinization are cut off and the surface accumulation of salt is eliminated.

Owner:CHINA AGRI UNIV

Method for extracting, separating and purifying Astragaloside IV from Astragalus mongholicus

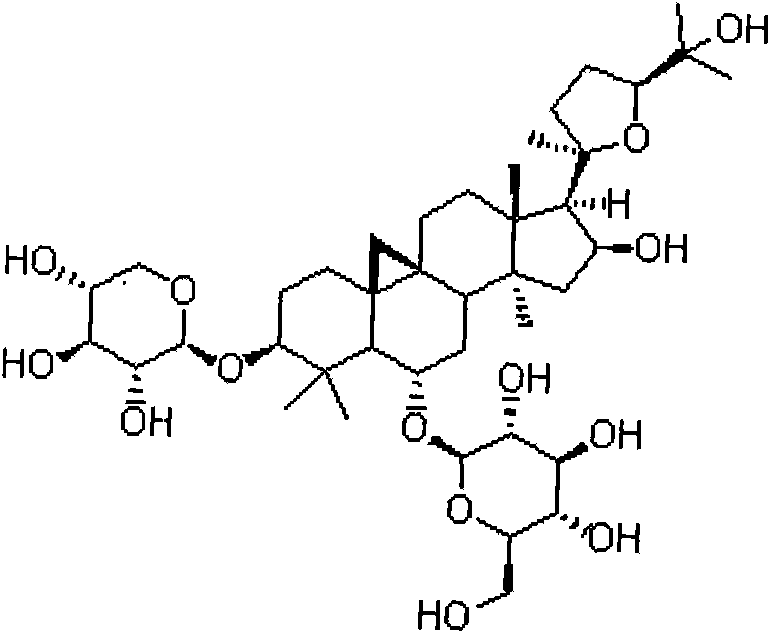

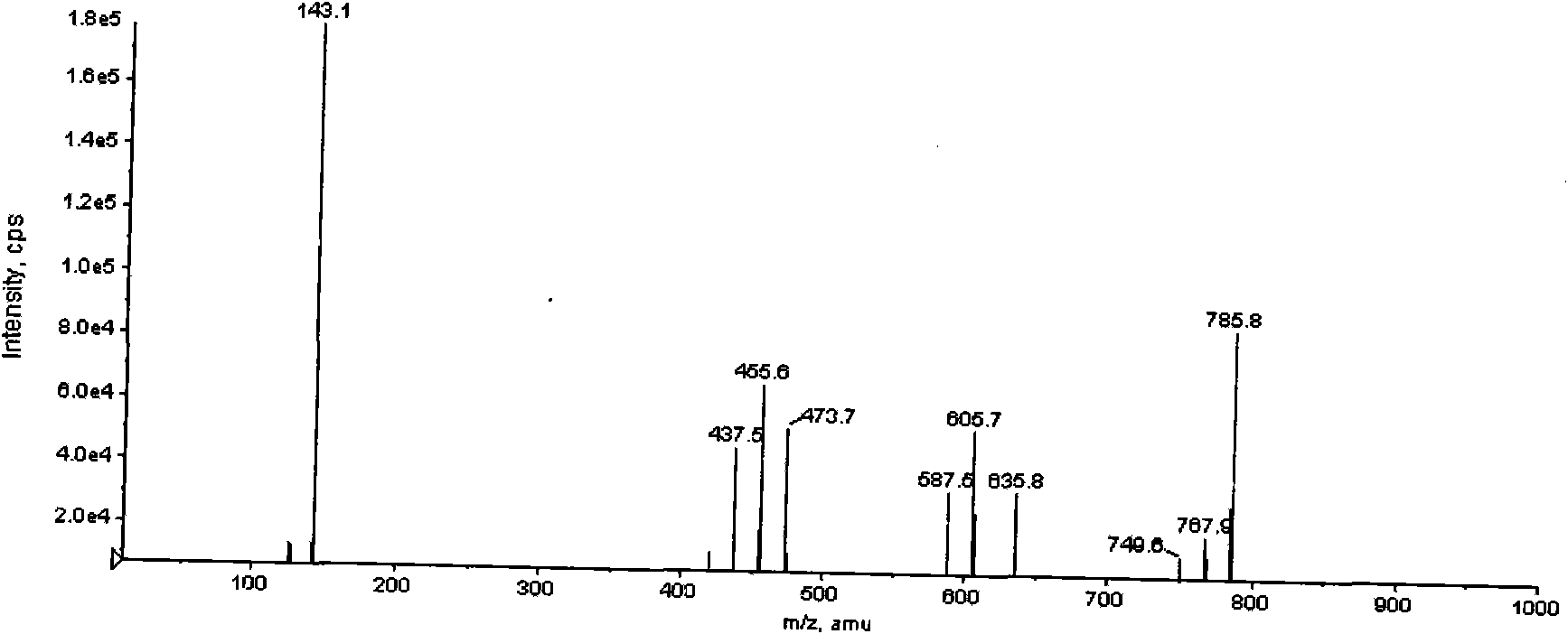

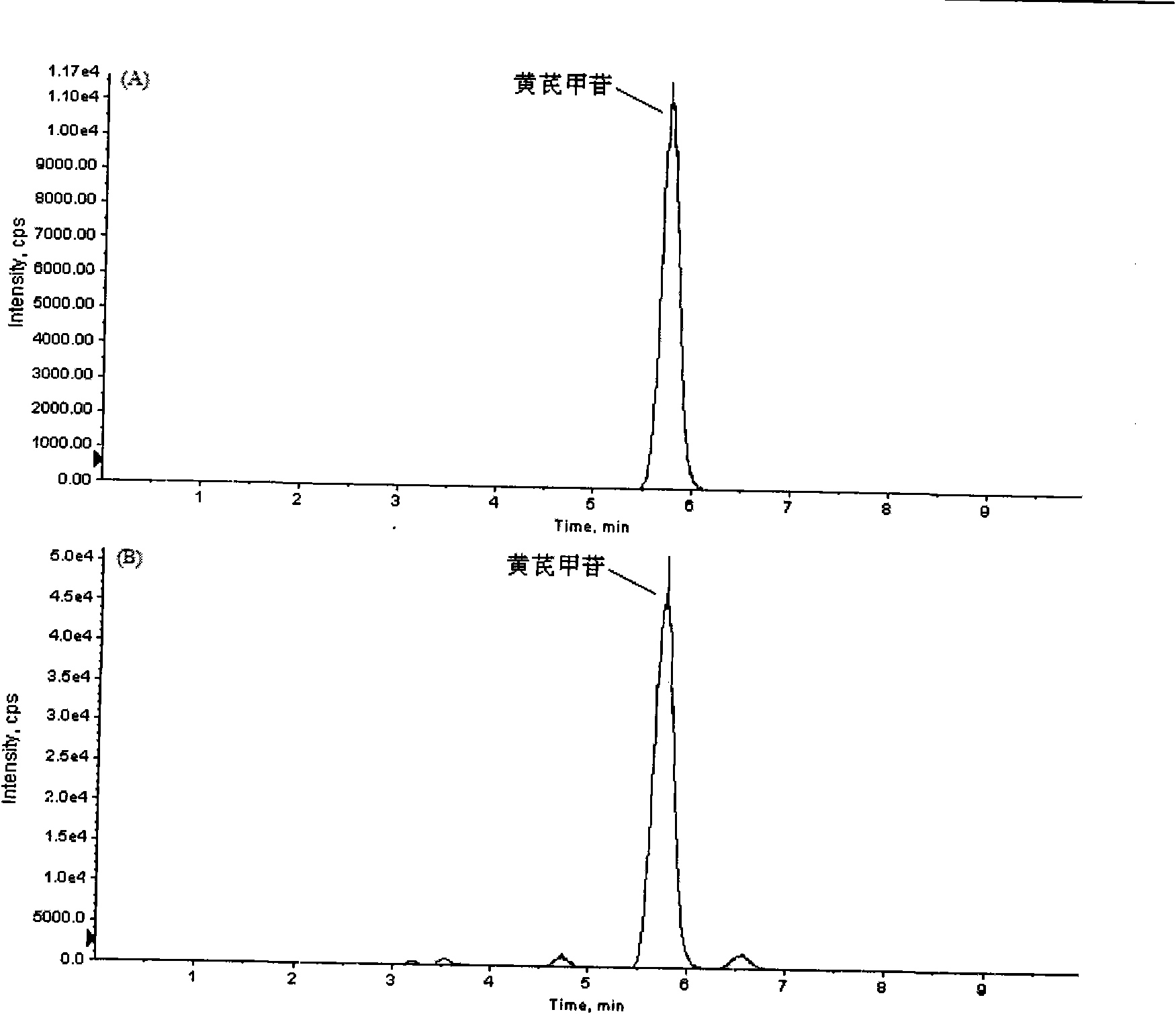

The invention relates to a method for extracting, separating and purifying a functionality active component Astragaloside IV from a common used traditional Chinese medicine Astragalus mongholicus, and aims to provide a simple, safe, economic and effective method for extracting, separating and purifying the Astragaloside IV from the Astragalus mongholicus with high purity. The adopted technical scheme is as follows: taking traditional Chinese medicine Astragalus mongholicus as a raw material; and adopting a series of original and efficient technologies for extracting, separation and purifying such as homogenate extraction-mixing enzyme induction biotransformation technology, negative pressure cavitation suspension extraction technology, saponin derivant hydrolysis converting technology, liquid-liquid extraction technology, macroporous absorption resin enrichment technology, normal phase silica gel medium pressure column chromatography technology and devitrification at a low temperature, recrystallization technology and the like to obtain the Astragaloside IV with high purity and yield, wherein the yield thereof can be more than 0.08% and the purity can be more than 95%. The raw material used in the invention is the common used traditional Chinese medicine Astragalus mongholicus, and has abundant resources; the production process of the Astragaloside IV is simple and practicable; the target compound has high yield and purity; and the method is suitable for the industry production and application, has high additional value and excellent market application prospective.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

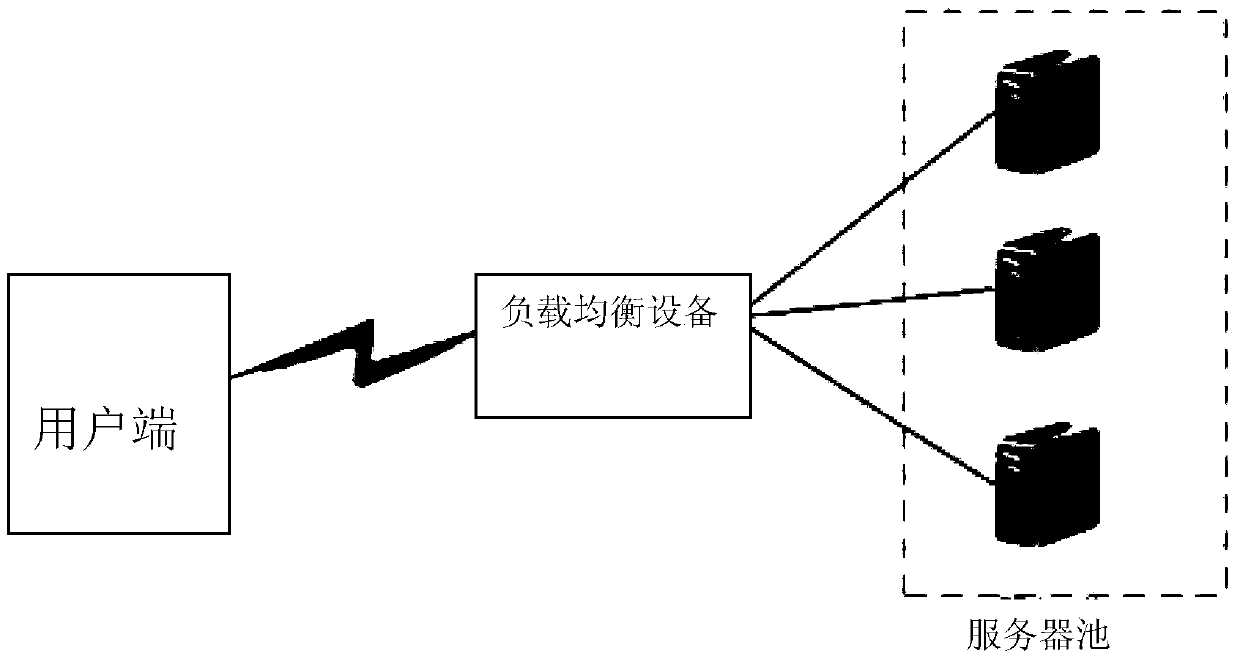

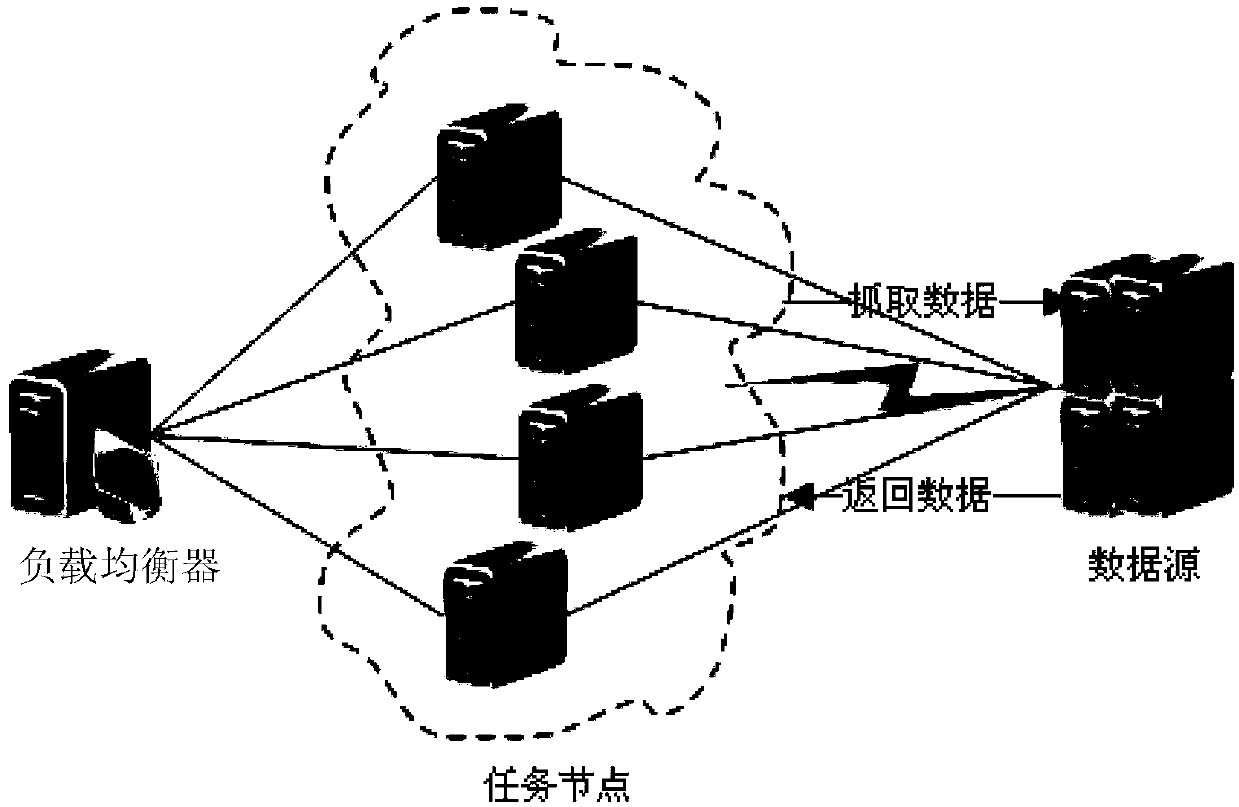

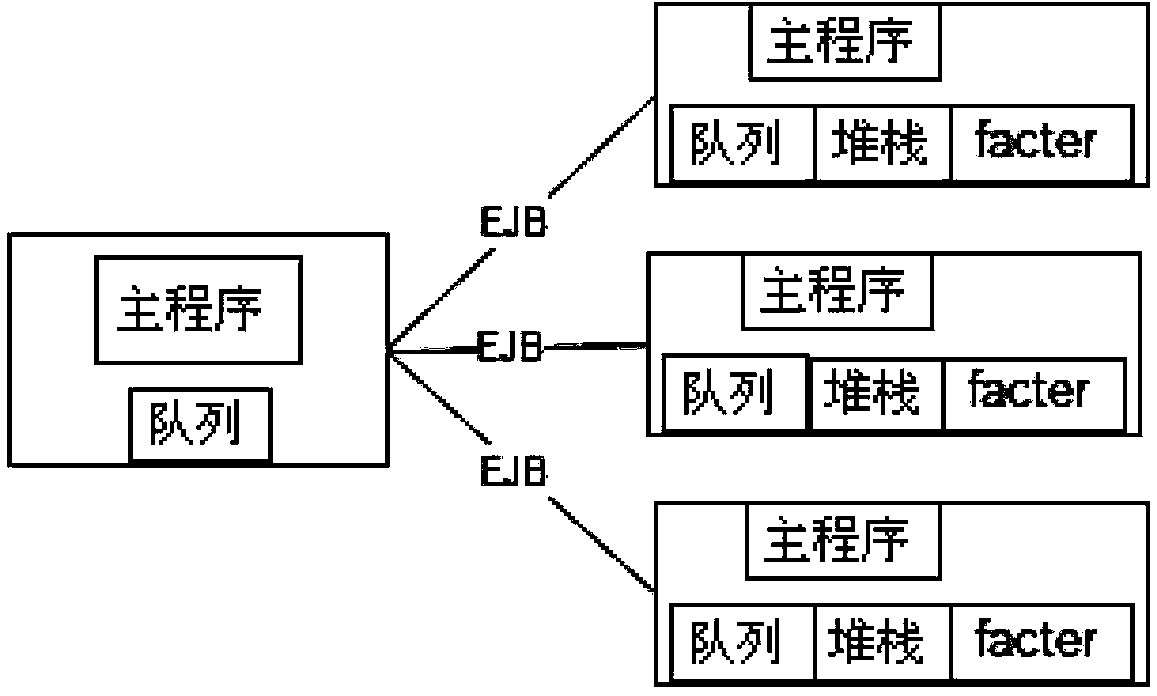

Intelligent load balancing method based on c/s (Client/Server) architecture

InactiveCN103368864AEfficient and reasonable useSolve stressData switching networksStructure of Management InformationDistributed computing

The invention discloses an intelligent load balancing method based on a c / s (Client / Server) architecture. The method comprises the following steps that: (1) a communication connection is established between all task nodes and a load balancer by employing a c / s star structure, wherein the task nodes and the load balancer are initialized, and a long connection is maintained; (2) the task nodes periodically transmit node information to the load balancer; (3) the load balancer calculates a performance value of each task node according to the node information and determines distribution of the tasks according to the variation tendency of the performance value of each task node, if the performance of a certain task node is improved, tasks in a total task queue are distributed to the task nodes, and if the performance of a certain task node is reduced, the tasks in the total task queue are paused to be distributed to the task nodes; (4) the task nodes receive the distributed tasks and feed back a task execution log to the load balancer. According to the method, dynamic regulation of the tasks can be realized, and fine intelligent load balancing is achieved.

Owner:华易互动科技(北京)有限公司

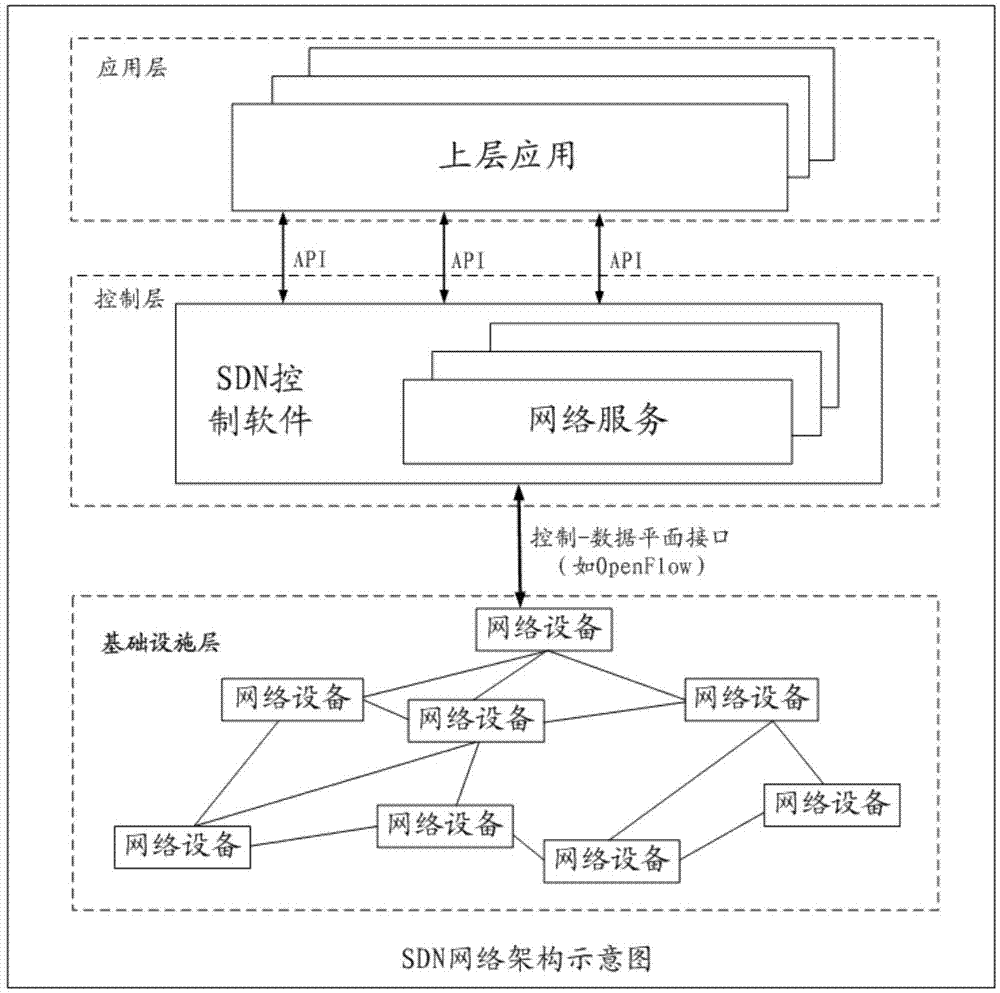

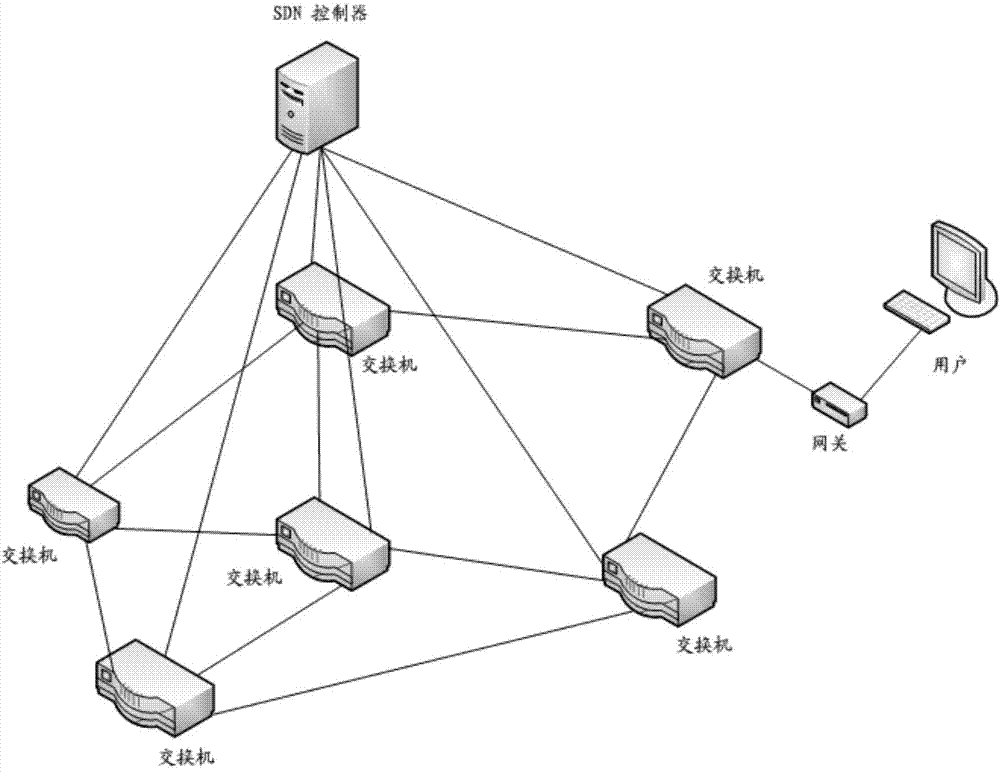

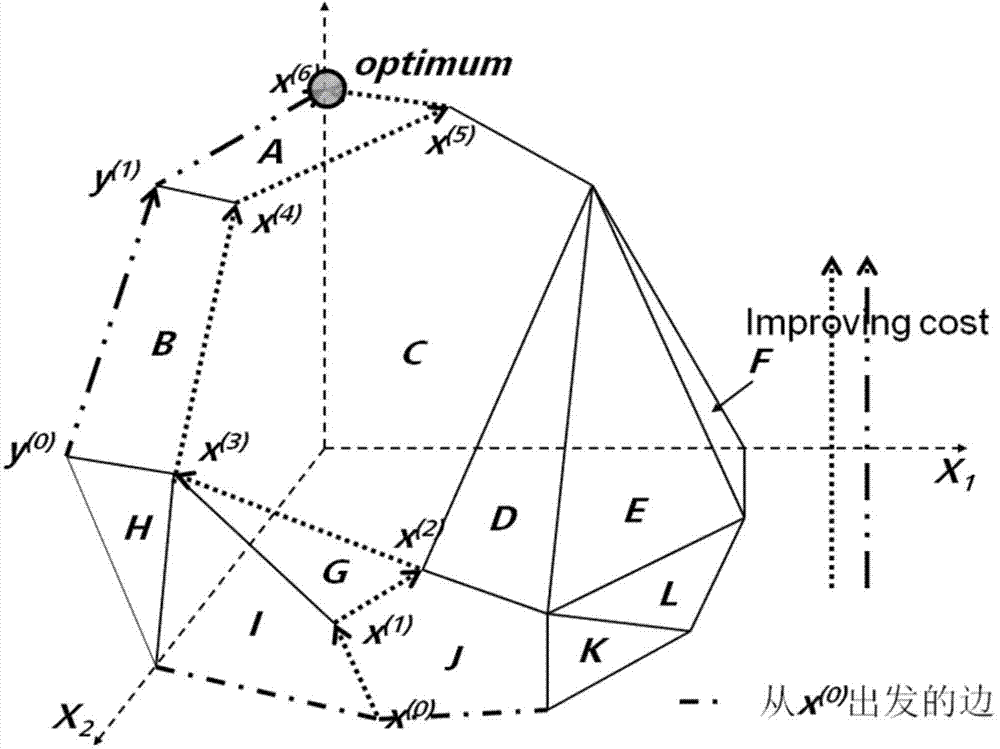

Routing determination method and device used for software defined network (SDN)

InactiveCN104734954AImprove computing efficiencyEfficient and reasonable useData switching networksMathematical modelComputation process

The embodiment of the invention discloses a routing determination method and device used for a software defined network (SDN). The method comprises the steps that at least two starting points are determined, wherein the starting points are computation starting points of at least two iterative computation processes, the iterative computation processes are used for solving a linear programming mathematical model so that a target path can be obtained, and each starting point exclusively corresponds to a set of bases of the linear programming mathematical model; according to a computation result of at least one of the iterative computation processes, the target path is determined. In this way, the iterative steps of the iterative computation processes can be simplified, and therefore the efficiency of SDN routing computation is improved.

Owner:南京友偌信息技术有限公司

Hazard-free treatment and utilization method for aluminium electrolysis waste slot liner

ActiveCN106565120AEfficient and reasonable useAvoid wasting timeSolid waste managementAluminium electrolysisBrick

The invention relates to a hazard-free treatment and utilization method for an aluminium electrolysis waste slot liner. The hazard-free treatment and utilization method is characterized by comprising the steps of (1) performing sorting and separating on the aluminium electrolysis waste slot liner based on an aluminium electrolysis waste negative electrode carbon material and a waste fireproof material; (2) performing smashing separately; (3) performing powder grinding separately; (4) measuring content values of cyanogen and fluorine;(5) adding a solid cyanogen removal agent and a solid fluorine removal agent, and performing material mixing; (6) performing a cyanogen removal and fluorine removal and neutral reaction on the waste fireproof material; (7) performing a cyanogen removal and fluorine removal reaction on the waste negative electrode carbon material; (8) pressing and filtering material slurry obtained in the step (6), recycling the filtering liquid, and taking filtering slag for road pavement; and (9) pressing and filtering material slurry obtained in the step (7), recycling the filtering liquid, and taking filtering slag as carbon brick for manufacturing a blast furnace. By adoption of the hazard-free treatment and utilization method, different kinds of waste materials in the waste slot liner are processed, respective optimal technological parameters specific to different kinds of waste materials are selected, and the hazard-free slag can be sorted and reasonably recycled.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Finger vein identification method based on fusion of multiple characteristic thresholds

ActiveCN108256456AImprove rejection rateEfficient and reasonable useSubcutaneous biometric featuresBlood vessel patternsCorrelation coefficientVein

The invention discloses a finger vein identification method based on fusion of multiple characteristic thresholds. A 2D Gaussian template based on multiple standard deviations is used to calculate a curvature of a finger vein image, a background-area curvature grayscale characteristic, a vein-area curvature grayscale characteristic and a curvature fine line characteristic of the image are extracted; a correlation coefficient method is used to calculate a matching threshold of the background-area curvature grayscale characteristic and the vein-area curvature grayscale characteristic, an MHD algorithm is used to calculate a matching threshold of the curvature fine line characteristic, and a multi-characteristic-threshold fusion decision algorithm is provided to fuse independent identification thresholds of the three characteristics and further to carry out verification and decision. According to the algorithm based on fusion of the thresholds of the three characteristics, background areaavailable information included by the background-area curvature grayscale characteristic is combined, the fuzzy finger vein image identification performance is not decreased obviously, the false rejection rate under a low false accept rate is substantially lower than that of a traditional identification algorithm based on the fine line characteristic only, and the identification algorithm can beutilized reasonably and highly efficiently.

Owner:HANGZHOU DIANZI UNIV

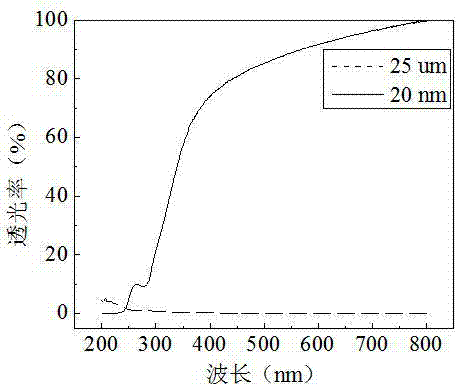

Method for preparation of nano-cellulose whiskers from garlic skins

ActiveCN103643577AAvoid harmEfficient and reasonable usePaper material treatmentFreeze-dryingPolysaccharide

The invention relates to a method for preparation of nano-cellulose whiskers from garlic skins. Taking garlic skins as raw materials, the method includes the steps of: 1) conducting dipping swelling in a sodium carbonate solution; 2) performing cooking degumming by an alkali solution; 3) carrying out polysaccharide extraction; 4) implementing bleaching treatment; 5) conducting sanding treatment; 6) performing acidification hydrolysis; and 7) carrying out washing dialysis and freeze drying, etc. The garlic skin raw materials undergo component separation and conversion to be made into a nano-cellulose dispersion liquid with certain concentration, and the dispersion liquid is subjected to freeze drying to remove water, thus obtaining the nano-cellulose whiskers. The nano-cellulose whiskers prepared by the method provided by the invention is needle-shaped, presents good dispersion, and has a high length-diameter ratio, a diameter of 20nm-30nm, and a length of 300nm-2micrometers. The method provided by the invention adopts garlic skins as the raw materials to remove pectin and other impurities. After functional compounding, the prepared nano-cellulose whiskers have wide application value in the fields of optics, electrics, magnetics, biology and semiconductors, etc.

Owner:SHANGHAI UNIV

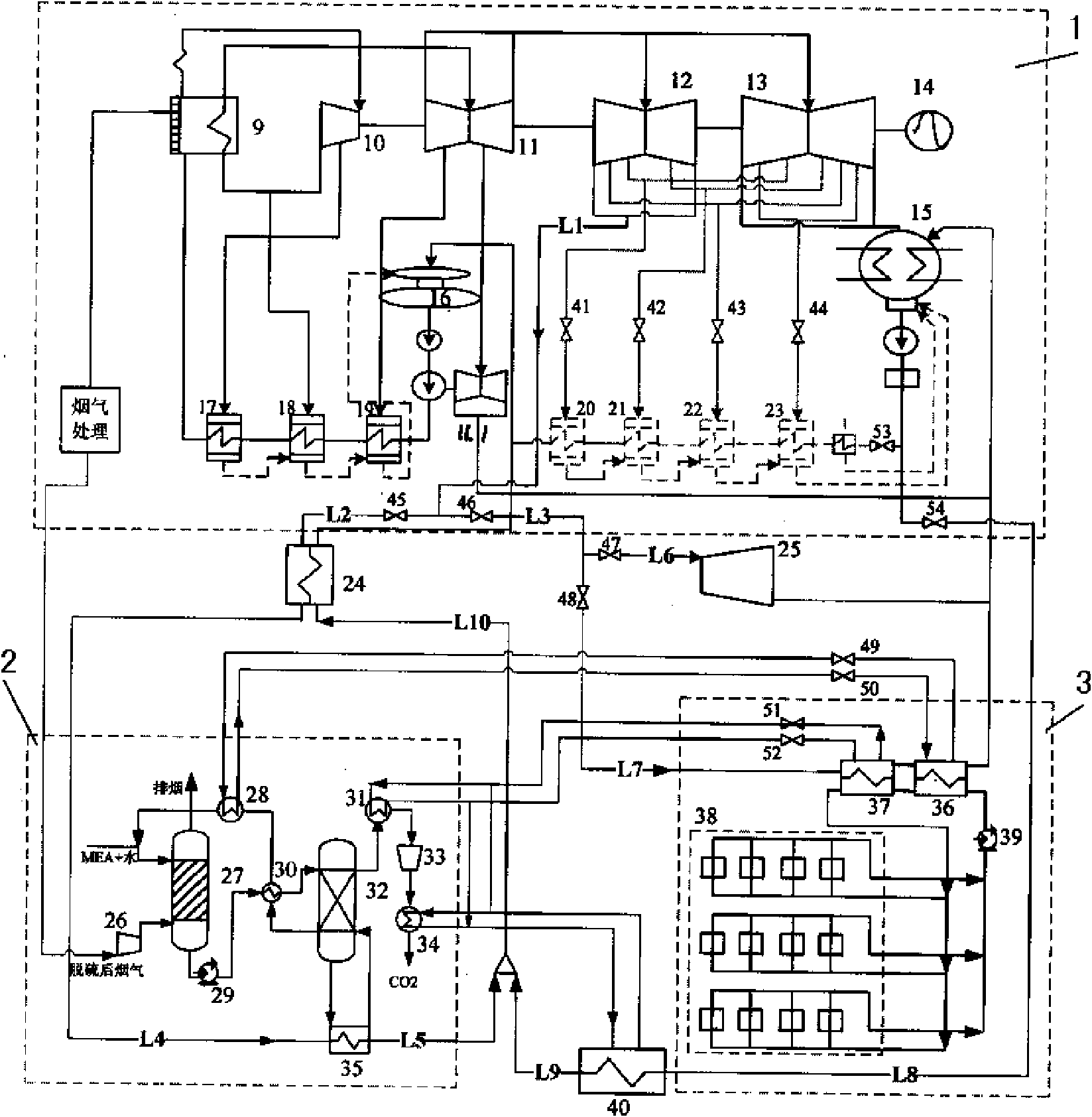

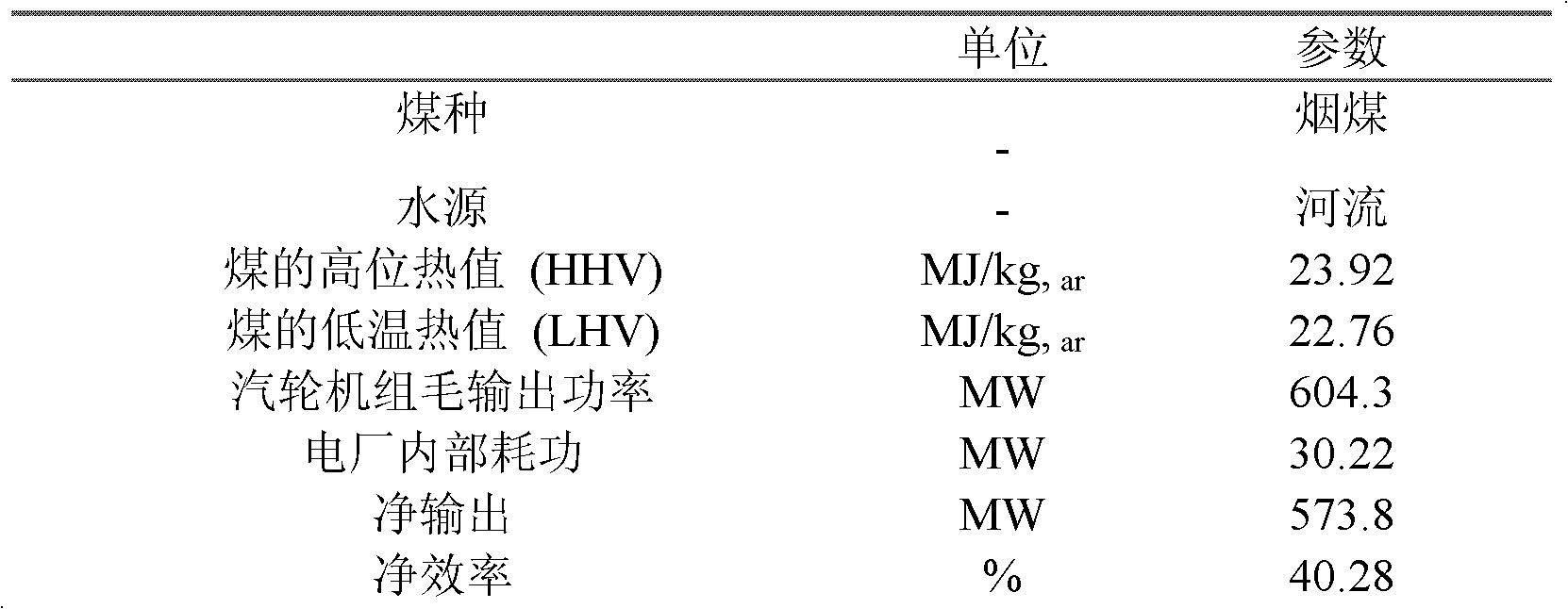

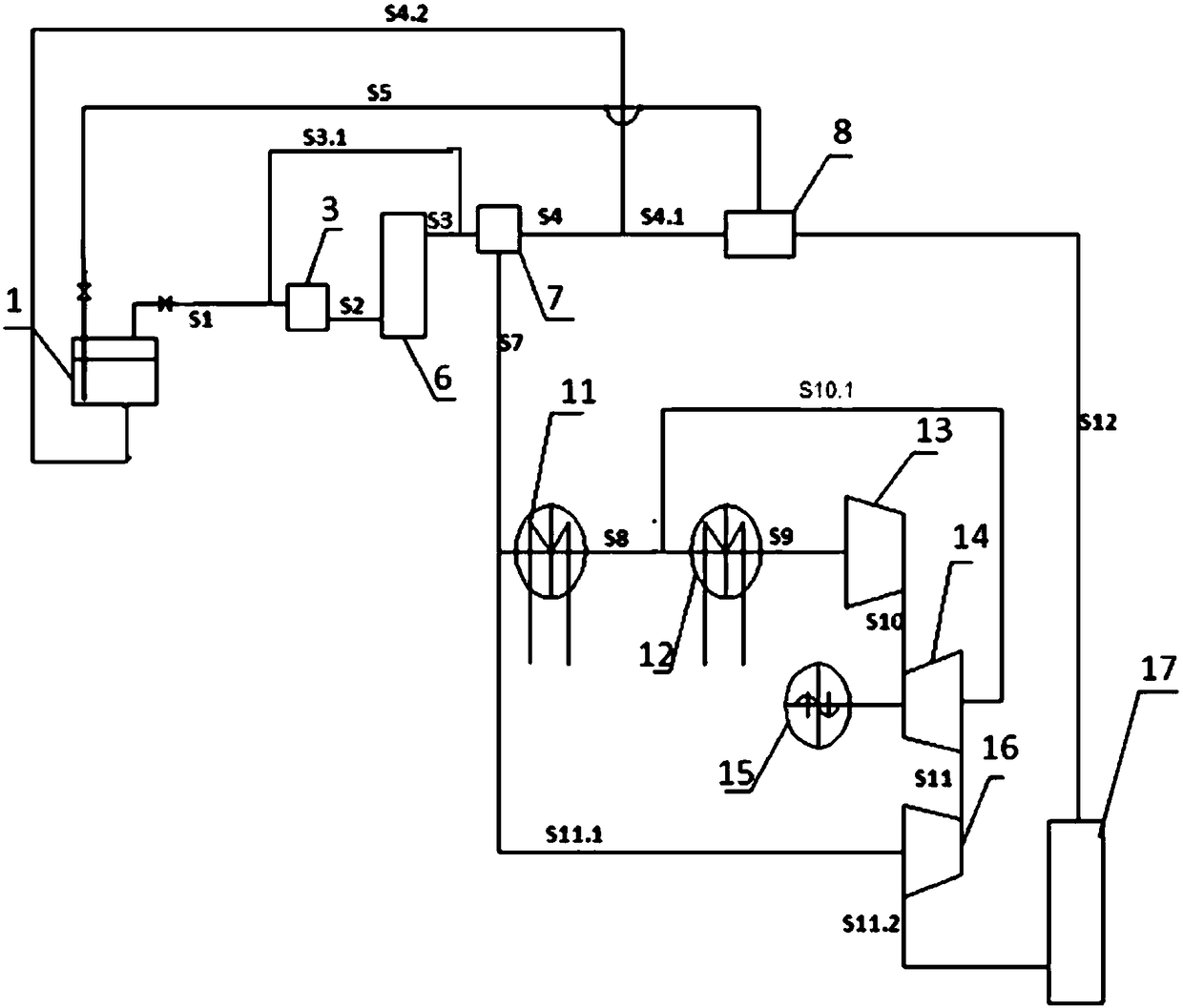

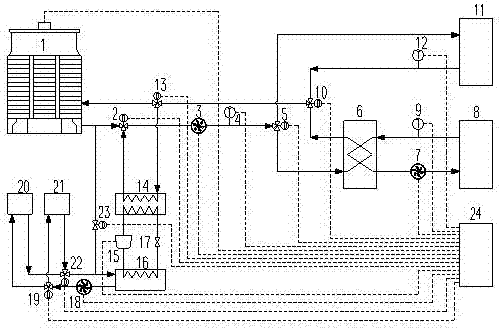

Coal-fired electricity generation-CO2 capture-heat supply integrating system and method

InactiveCN102322301AReduce capture energy consumptionReasonable useCarbon compoundsLighting and heating apparatusElectricityCogeneration

The invention discloses a coal-fired electricity generation-CO2 capture-heat supply integrating method, belonging to the field of energy saving and emission reduction. The system mainly comprises three large parts which are a steam electricity generating subsystem, a CO2 capture unit and a heat supply subsystem. The three subsystems are communicated with other another by mainly using an interviewing heat exchanger, a low-temperature heater, a 45th valve and a 46th valve to form the coal-fired electricity generation-CO2 capture-heat supply integrating system. An electricity plant vapor water flow, a CO2 capture flow and a heat-supply system are reasonably integrated in the coal-fired electricity generation-CO2 capture-heat supply integrating system for the first time so that the energy consumption for the CO2 capture is substantially reduced and the cascade utilization of energy is realized; the coal-fired electricity generation-CO2 capture-heat supply integrating system has the advantages of being capable of effectively reducing the energy consumption for discharging carbon and the CO2 discharging, restraining the reduction of electricity generating efficiency caused by the carbon emission reduction, meanwhile obtaining a higher utilization ratio of comprehensive energy and technical economy performance. The invention provides an important technical support for carbon emission reduction of a combined heat and electricity machine unit.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

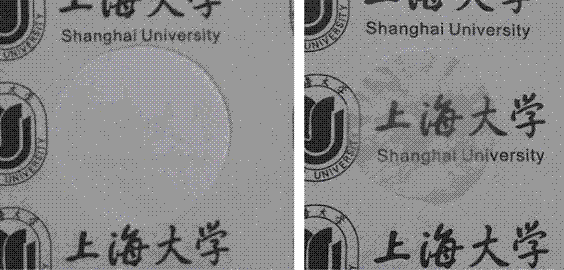

Method for preparing flexible transparent nano paper by utilizing bamboo fibers

ActiveCN103757986AReasonable and efficient use of natural resourcesEco-friendlySpecial paperPulp bleachingThin membraneElectrical battery

The invention provides a method for preparing flexible transparent nano paper by utilizing bamboo fibers. The flexible transparent nano paper is prepared by using the bamboo fibers as raw materials and carrying out five treatment processes including swelling and degumming, delignification, bleaching treatment, nano fibrillation treatment and paper forming. The method has the advantages that a film is formed by adopting high-pressure filtration, the process is simple, and the film thickness is controllable; the prepared transparent nano paper has the characteristics of micropore structure, large specific surface area, transparency and flexibility; the transparent nano paper has good application prospects in the fields such as thin film solar batteries, super-capacitors, lithium-ion battery separators, catalytic carriers, environmental management, antistatic electricity and the like.

Owner:SHANGHAI UNIV

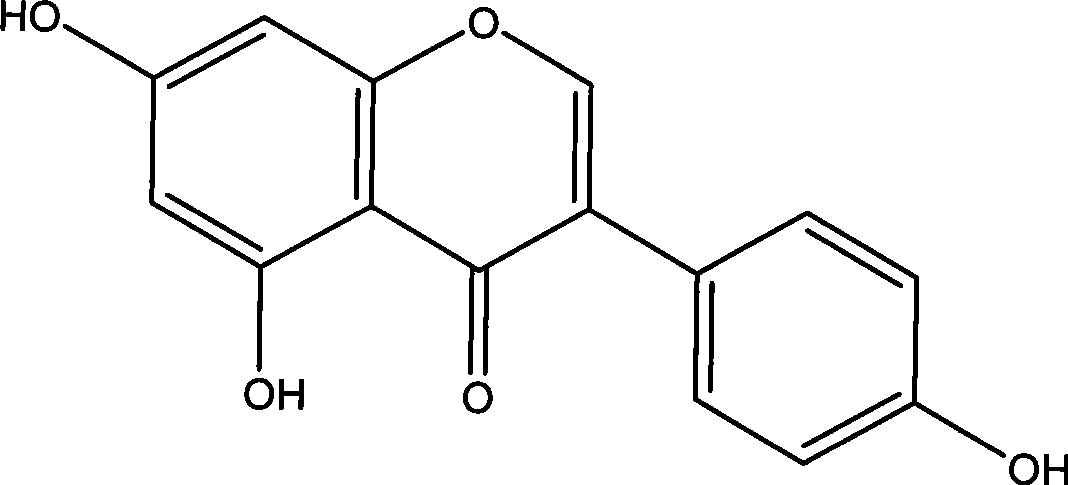

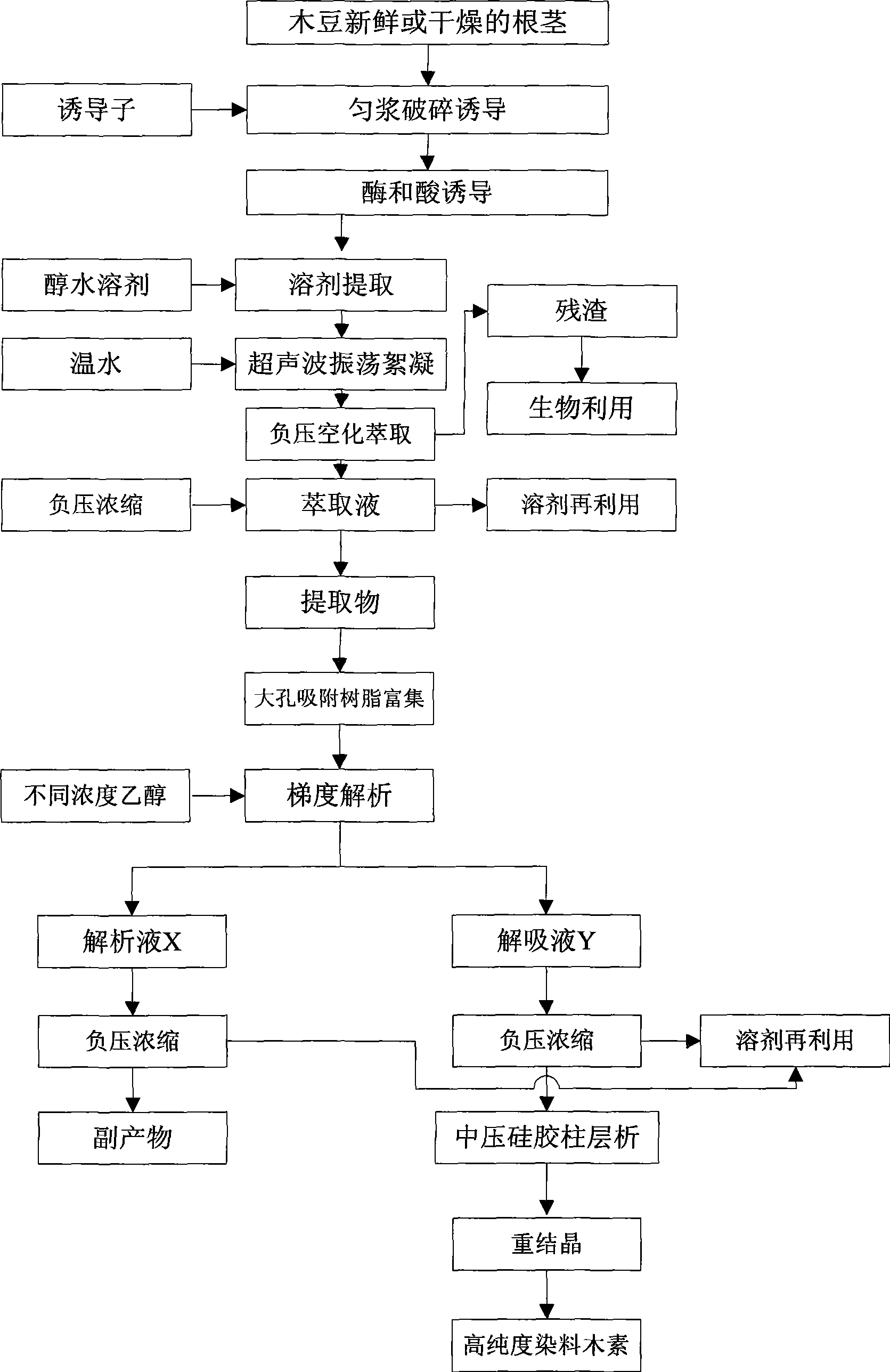

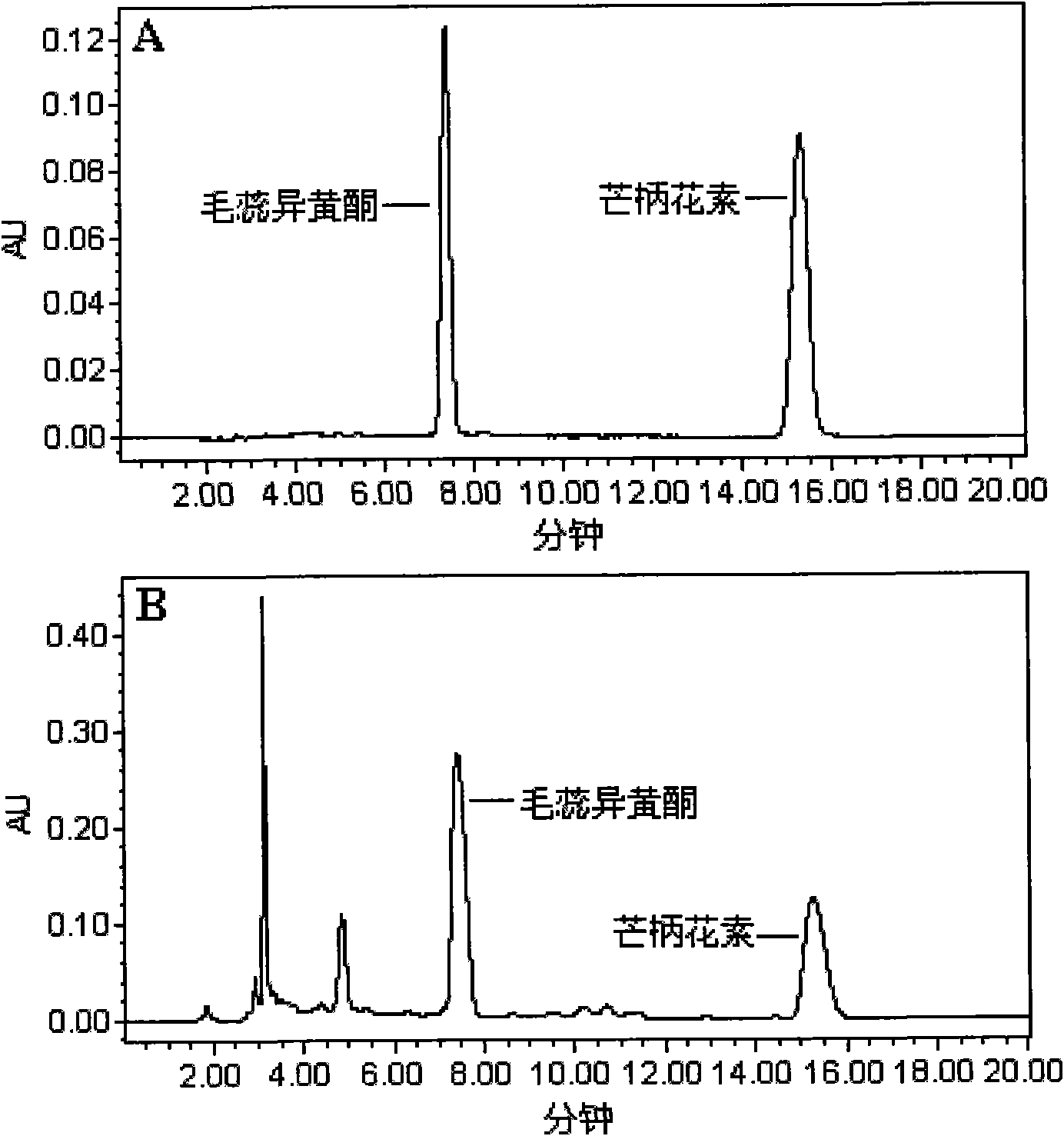

Method for extracting, separating and purifying genistein from pigeon pea rhizome

ActiveCN101497594AMaintain ecological balanceEfficient and reasonable useOrganic chemistryCrystallization separationCavitationSilica gel

The invention relates to a method for extracting, separating and purifying an active component of Chinese herbal medicine, namely genistein from roots and stems of pigeon pea, and aims at providing a method for easily, safely, economically and effectively extracting, separating and purifying the high-purity genistein from roots and stems of the pigeon pea. The adopted technical proposal comprises that: fresh or dry roots and stems of the pigeon pea are used as raw materials, and by adopting the homogenate induction technique, the enzyme and acid induction technique, the solvent extraction technique, the ultrasonic oscillation flocculation technique, the negative pressure cavitation suspension solid extraction technique, the macroporous absorbent resin enriching technique, the positive phase silica gel medium-pressure column chromatography separation technique and the low-temperature crystallization and re-crystallization technique, the refined genistein is obtained, and the purity of the genistein reaches more than 95 percent. The method has the advantages of abundant and easily obtained raw materials, simple and convenient process, high yield and purity of the obtained genistein, suitability for industrialized production and high added value of products.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

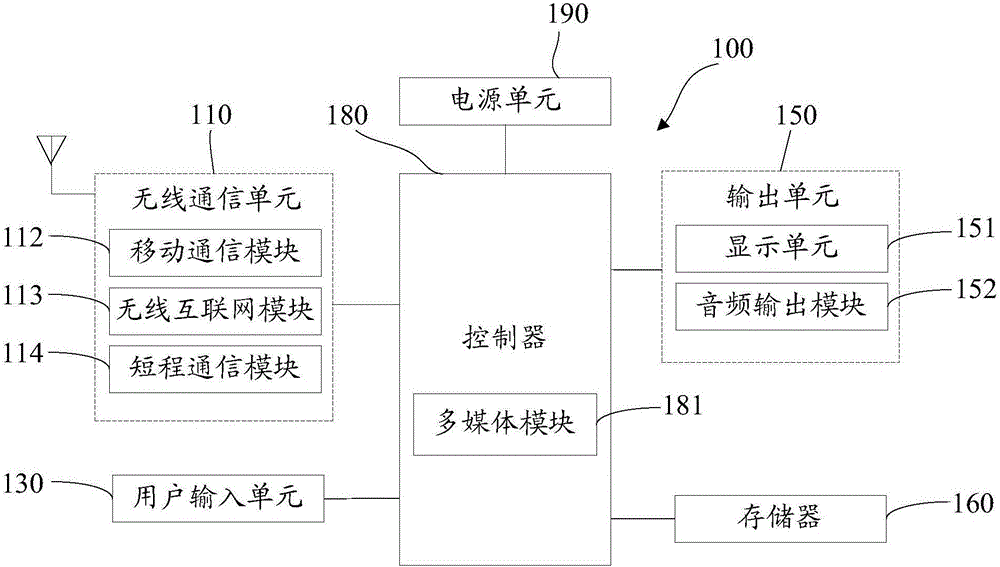

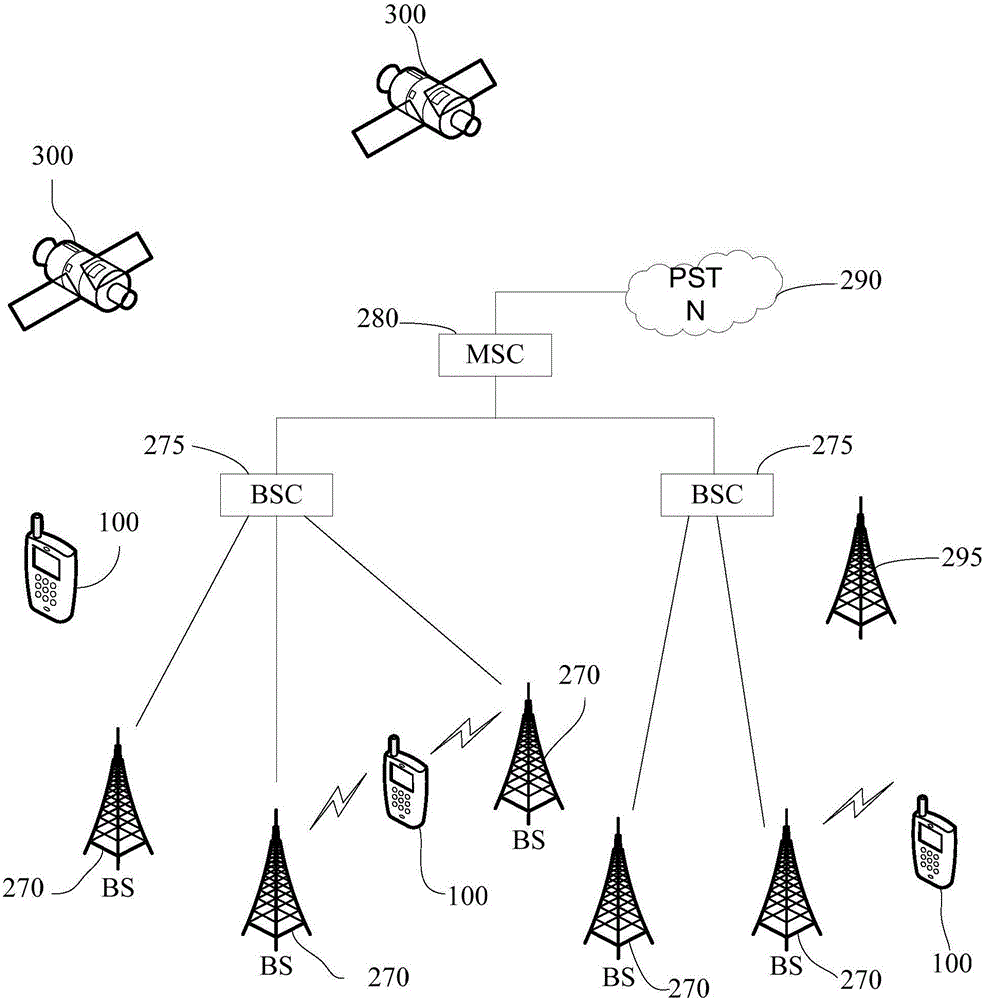

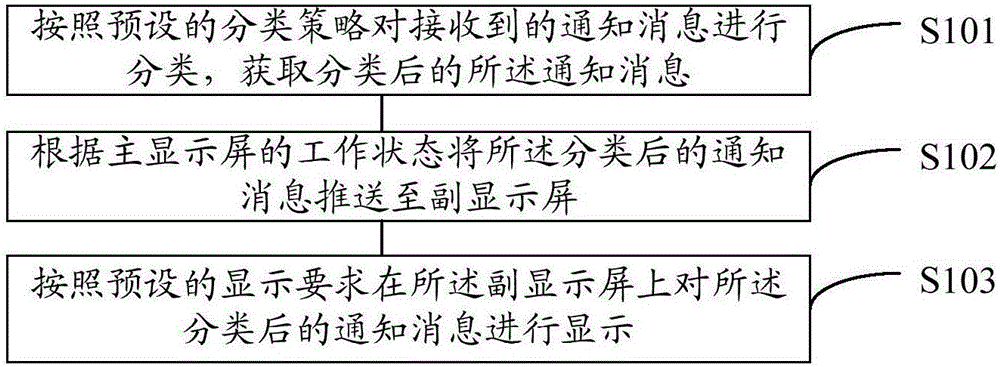

Notification message display method and terminal

InactiveCN106201474AReduce power consumptionEfficient and reasonable usePower supply for data processingExecution for user interfacesTerminal equipmentReal-time computing

Owner:NUBIA TECHNOLOGY CO LTD

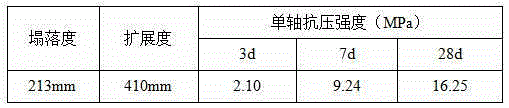

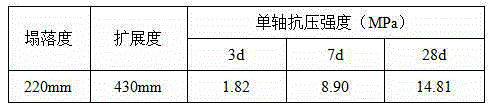

Preparation method of gangue base mine cemented filling material

ActiveCN105152601AImprove utilizationEfficient and reasonable useSolid waste managementMaterials scienceGangue

The invention discloses a preparation method of a gangue base mine cemented filling material, and belongs to the field of mine filling materials. Cementing activity hidden in gangue is stimulated in a compound stimulation way, cement is partially replaced with the cementing activity to serve as a cementing material for cemented filling mining, and then the material is mixed with fine particle size gangue to be prepared into the mine cemented filling material. The process for preparing the mine cemented filling material is simple, large proportion dosage of gangue powder and cement is realized, the filling material has excellent mechanical property and stable conveying property, no segregation or no bleeding exists, the application of gangue in mine filling is broadened, the mine filling cost is reduced, the material conveying property is improved, at the same time, the purpose of effective use of gangue is realized, and mine filling is promoted to develop forward.

Owner:TAIYUAN UNIV OF TECH

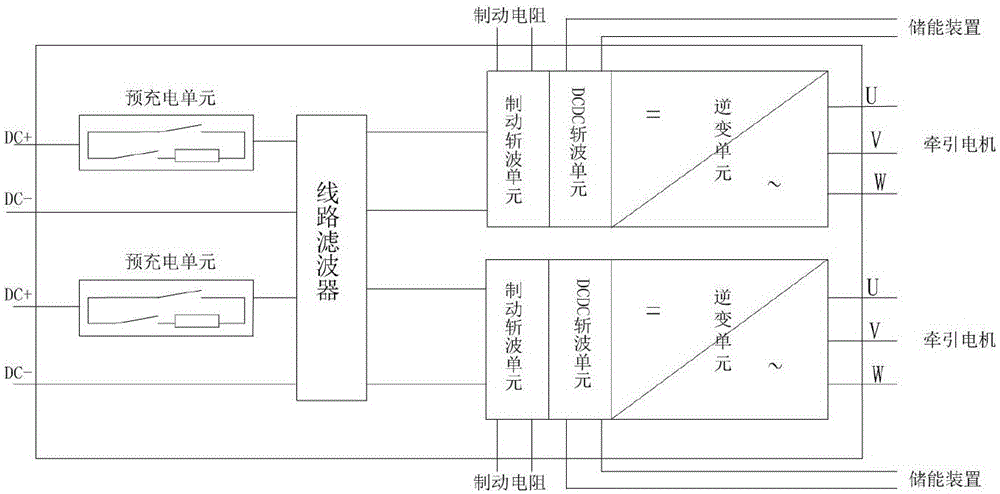

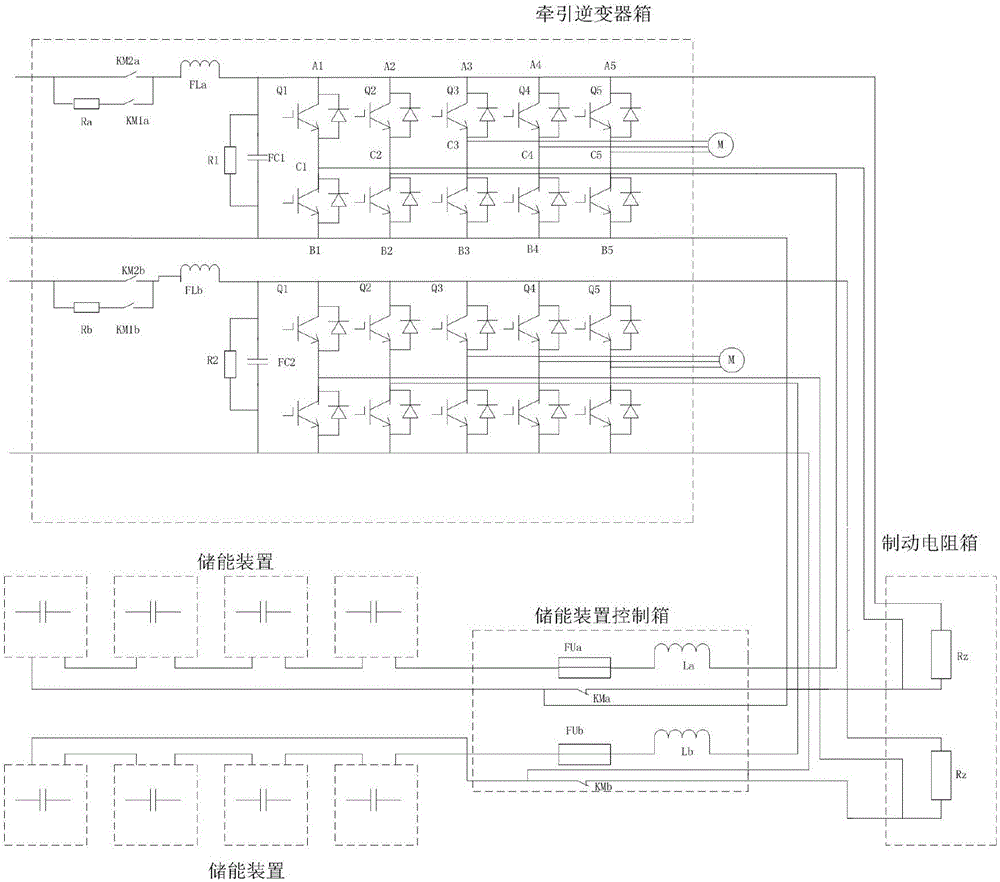

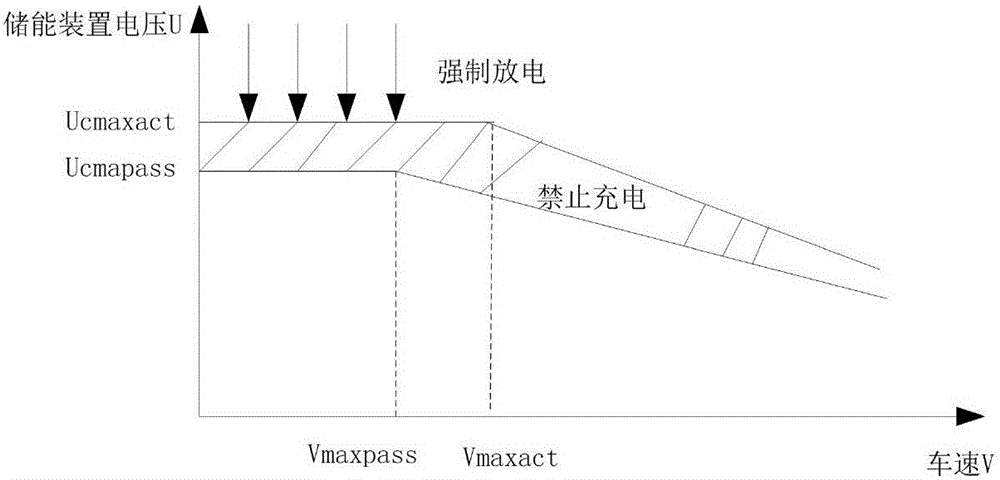

Rail vehicle traction inverter system and method for integrated energy storage device charging and discharging control

ActiveCN105774569AAchieve integrationRealize centralized controlElectrodynamic brake systemsConverter typesElectrical resistance and conductanceEngineering

Disclosed is a rail vehicle traction inverter system for integrated energy storage device charging and discharging control. The rail vehicle traction inverter system comprises precharging units, a circuit filter unit, a current and voltage detection unit, two sets of traction inverter units and a traction control unit. Current and voltage signals are collected by the current and voltage detection unit, signal conversion is conducted, and the current and voltage signals are sent to the traction control unit. Direct current wire sides are connected to the input end of the set of circuit filter unit through the two sets of precharging units. Each set of traction inverter unit comprises a wave chopping module and an inverter module which are integrated, wherein the wave chopping module comprises a braking wave chopping unit and a DCDC wave chopping unit. The braking wave chopping units are connected with the output end of the circuit filter unit, a braking resistor and the DCDC wave chopping units correspondingly. The DCDC wave chopping units are connected with an energy storage device and an inverter unit correspondingly. The traction inverter units of the rail vehicle traction inverter system are of an integrated structure, so that integration of the DCDC wave chopping units is achieved, a hardware circuit is simplified, and the cost is reduced.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

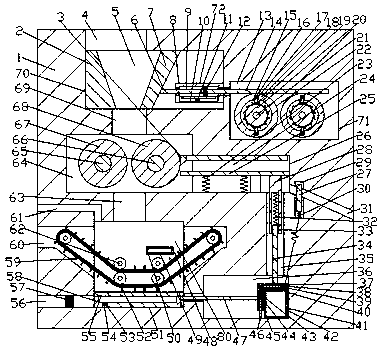

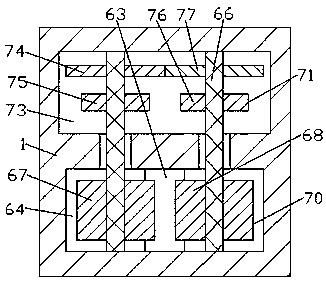

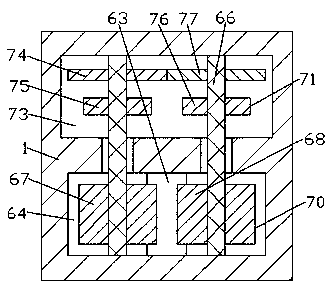

Solid waste reutilization device

InactiveCN109289972AIncrease the degree of fragmentationEasy to handleMagnetic separationGrain treatmentsResource utilizationComminution

The invention discloses a solid waste reutilization device which comprises a crushing box. A crushing mechanism is arranged in the crushing box and comprises a smashing cavity and a comminution cavity. A transmission mechanism is arranged on the right side of the smashing cavity and comprises a hydraulic mechanism located in the smashing cavity to drive the crushing mechanism located in the smashing cavity to move left and right. The transmission mechanism further comprises a transmission cavity, and two ratchet mechanisms moving through the hydraulic mechanism are arranged in the transmissioncavity. According to the solid waste reutilization device, during work, the device can separate and collect crushed products well, and therefore it is guaranteed that resources are utilized more efficiently and reasonably, solid waste is smashed and separated more thoroughly, and reutilization of operators to the solid waste is more convenient, and the resource utilization rate is increased; andthrough machine transmission, utilization of the device to a power source is more reasonable and efficient, and energy utilization is improved.

Owner:台州市路桥跃盛环保科技有限公司

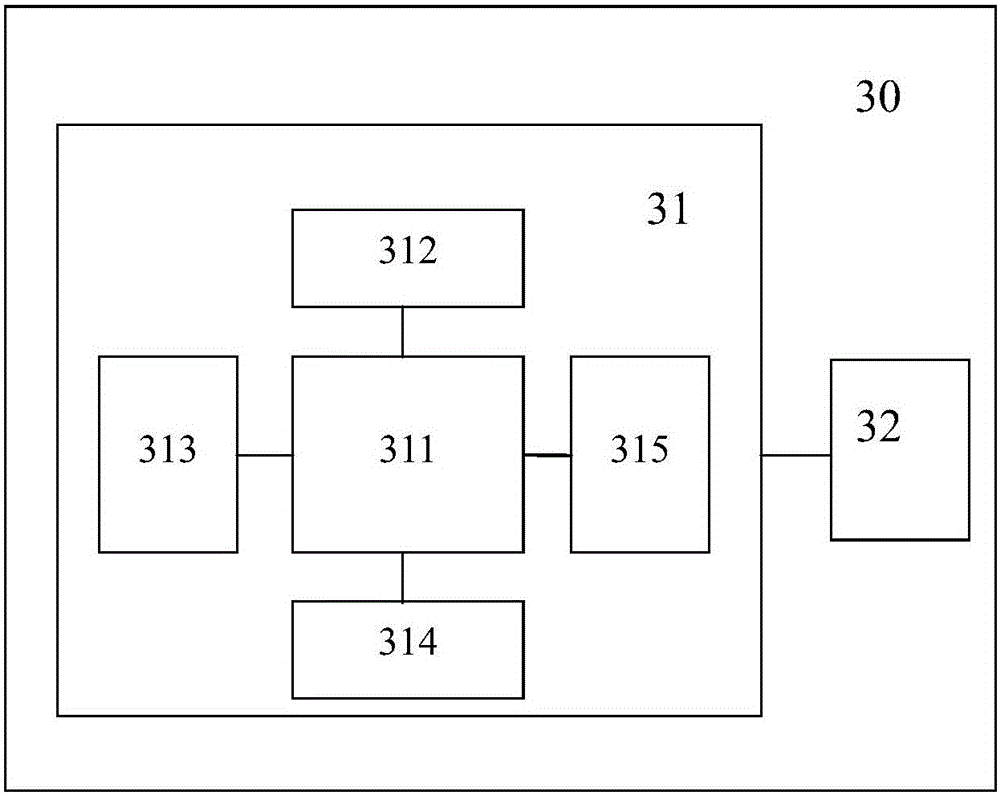

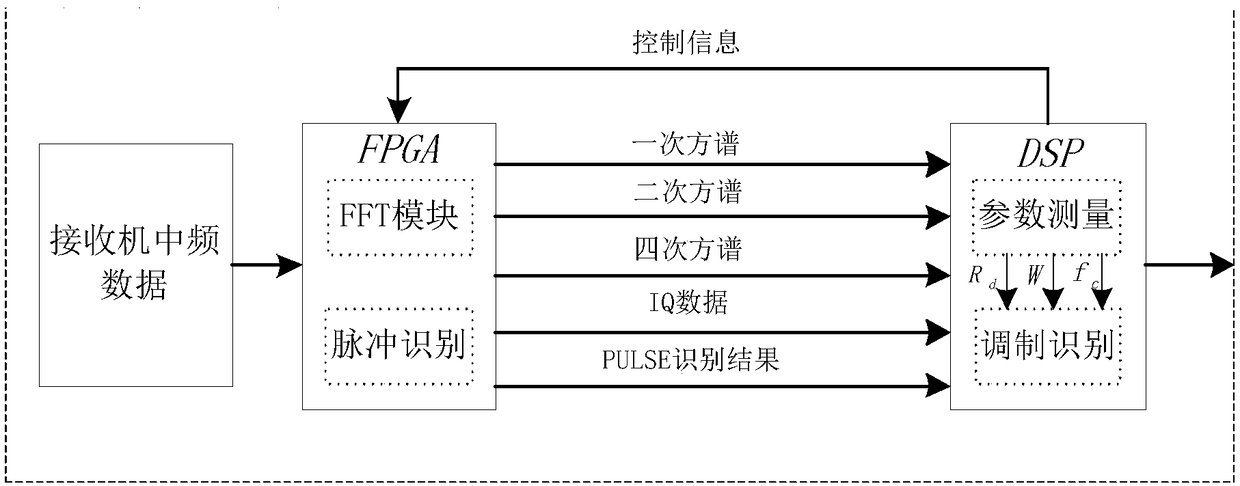

Fast identification device for continuous wave and pulse signals

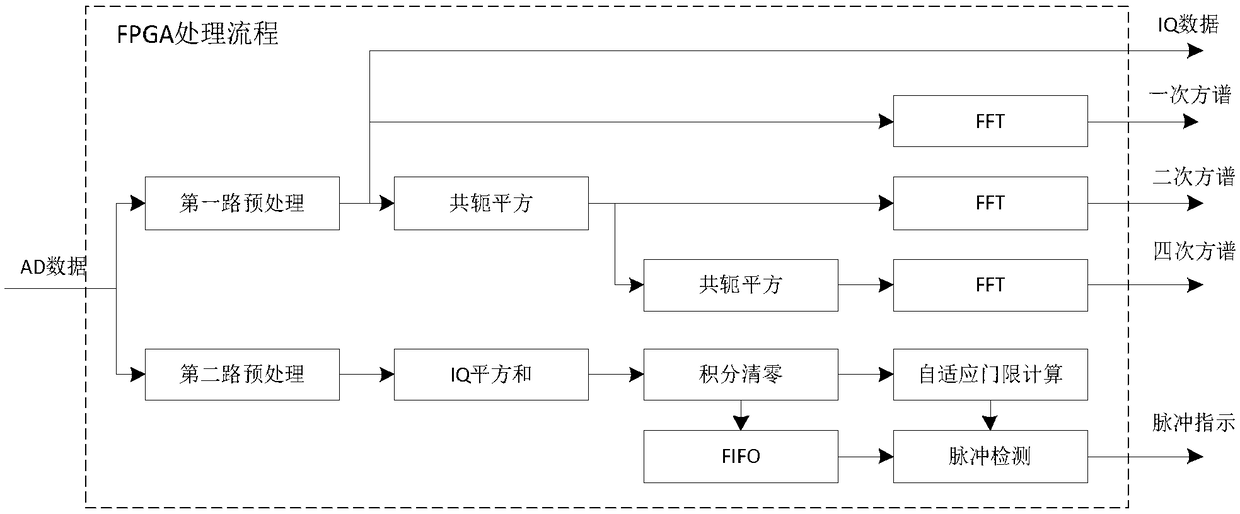

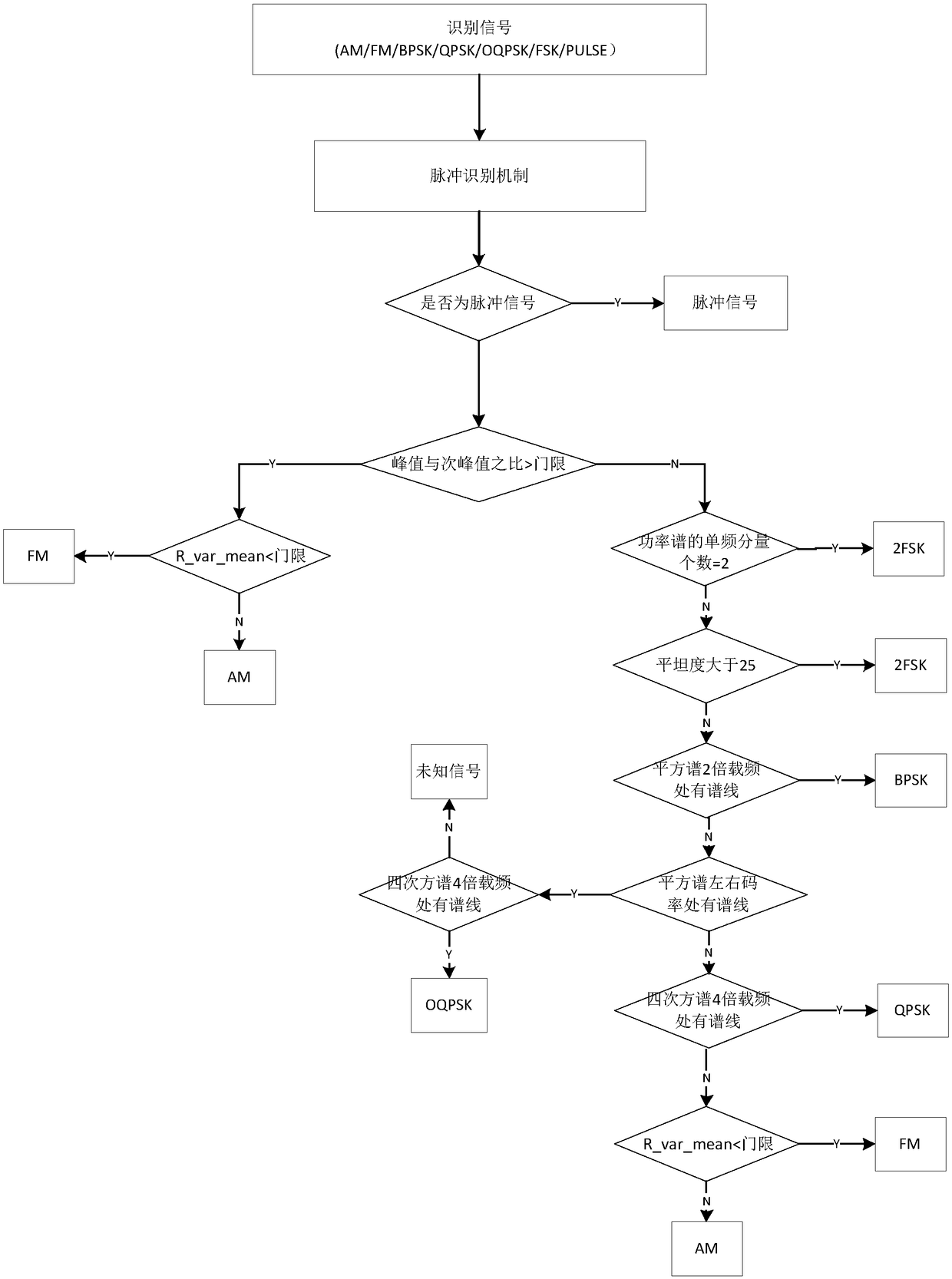

ActiveCN109167746AEfficient and reasonable useFast recognitionModulation type identificationModulation patternDigital signal processing

The invention discloses a fast identification device for a continuous wave and pulse signals, which can quickly identify continuous wave modulated signals and pulse signals such as AM, FM, BPSK, QPSK,OQPSK, 2FSK, etc. The invention is realized by the following technical scheme: the FPGA preprocessing module constructs a calculation model to complete the real-time preprocessing of the digital signal, and transmits a plurality of high-order spectral components and characteristic parameters calculated in parallel to the digital signal processor DSP. the FPGA preprocessing module realizes the real-time preprocessing of the digital signal. When the DSP receives the preprocessed FPGA, frequency domain data, At that time of calculation, the characteristic parameter in the frequency domain, A tree classifier is designed based on the time and frequency domain characteristic parameters of the pulse signal. A group of time and frequency domain characteristic parameters are extracted from the high order spectral components of the pulse signal or the continuous wave signal and the time domain IQ data. The modulation patterns of the input signal are judged according to the pulse attributes, andthe parameters of the continuous wave and the pulse signal are identified and measured.

Owner:10TH RES INST OF CETC

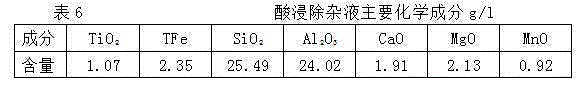

Method for extracting titanium from vanadium-titanium magnetite

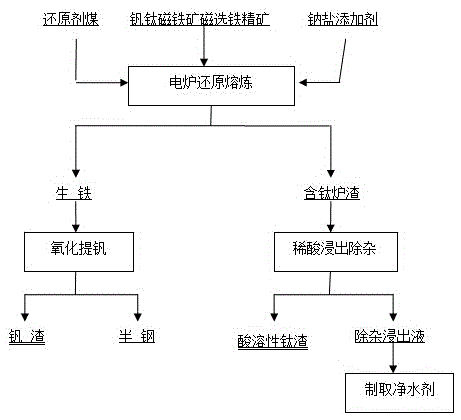

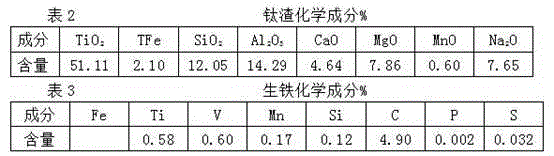

InactiveCN105112689AEfficient and reasonable useSolve the technical problems of efficient separation and extractionProcess efficiency improvementElectric furnaceAluminateSmelting process

The invention discloses a method for extracting titanium from vanadium-titanium magnetite. The method comprises the following steps: adding sodium or potassium salt additive in the reduction smelting of an iron ore concentrate electric stove to obtain liquid iron and titanium-containing slag, wherein vanadium and iron are reduced to enter liquid iron, under a smelting high temperature condition, silicon and aluminum impurities form sodium aluminosilicate capable of being dissolved in dilute acid with the sodium or potassium salt additive, and enabling the sodium aluminosilicate and titanium and aluminum magnesium impurities to remain in the titanium-containing slag; purifying the titanium-containing slag by virtue of a wet-method metallurgical impurity removal method, to acquire a titanium slag product with TiO2 content more than 75 percent. For the application problem of titanium in the iron ore concentrate, the slag modification additive is added in the reduction smelting process, so that not only is the mobility of the slag improved, but also a condition is created for removing the later silicon-aluminum impurities of the slag, the high-efficiency separation and extraction problem of the titanium in the iron ore concentrate can be well solved, the resource utilization rate of the iron, titanium and vanadium is greatly increased, and the utilization rate of the titanium is increased about 3 times compared with the flow of a blast furnace.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

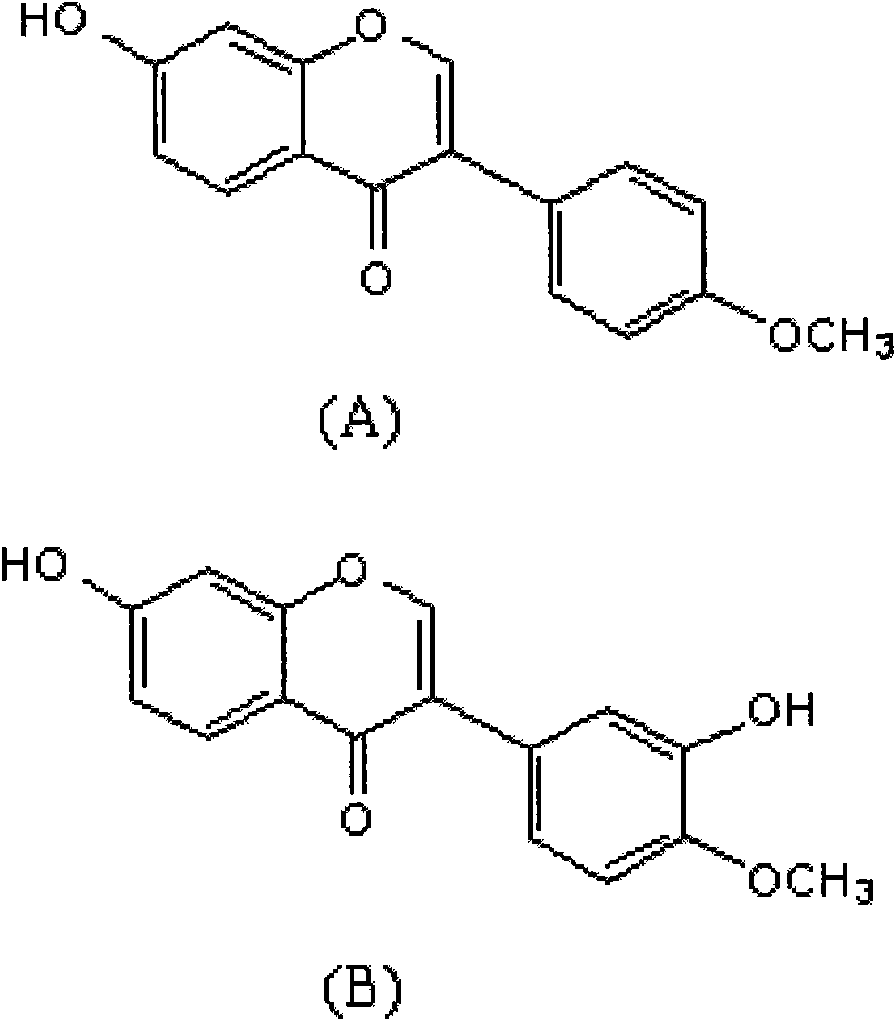

Method for extracting, separating and purifying formononetin and calycosin from Astragalus mongholicus waste residue

InactiveCN101775418AReduce pollutionEfficient and reasonable useOrganic chemistryFermentationDevitrificationCavitation

The invention provides a method for extracting, separating and purifying formononetin and calycosin from Astragalus mongholicus waste residue. The technical scheme adopted in the invention is as follows: taking waste residue after the production and process of astragalus injection as a raw material; adopting a series of original and efficient technologies for extracting, separation and purifying such as homogenate extraction-mixing enzyme induction biotransformation technology, negative pressure cavitation extract technology, liquid-liquid extraction technology, macroporous absorption resin enrichment technology, normal phase silica gel medium pressure column chromatography technology and devitrification at a low temperature, recrystallization technology and the like to obtain the formononetin and calycosin with high purity, wherein the purity thereof can be more than 95%, and the yield is 80-95%. The raw material used in the invention is the waste residue in the industry production, and the process of the method is simple and practicable, has small pollution to the environment; the obtained formononetin and calycosin have low production cost, high purity and yield, good repeatability, high utilization effect of Astragalus mongholicus resources and the like; and the method is suitable to scaled industrial production.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

Whitening anti-ageing eye cream

InactiveCN105816392AEfficient and reasonable useCosmetic preparationsToilet preparationsMelaninAnti ageing

The invention discloses whitening anti-ageing eye cream .The eye cream is mainly prepared from, by mass, 0.2-0.8% of French lavender extract, 1-5% of 3-o-ethyl ascorbic acid, 0.02-0.08% of glycyrrhiza flavonoids, water and other components .The eye cream has the advantages that by means of the synergistic effect of the components, the eye cream inhibits melanin while promoting repair and regeneration of eye skin, supplements skin bottom water and has the effects of whitening and tendering the skin, resisting ageing and removing wrinkles.

Owner:CANTON DAMEKISS DAILY CHEM FACTORY LIMITED

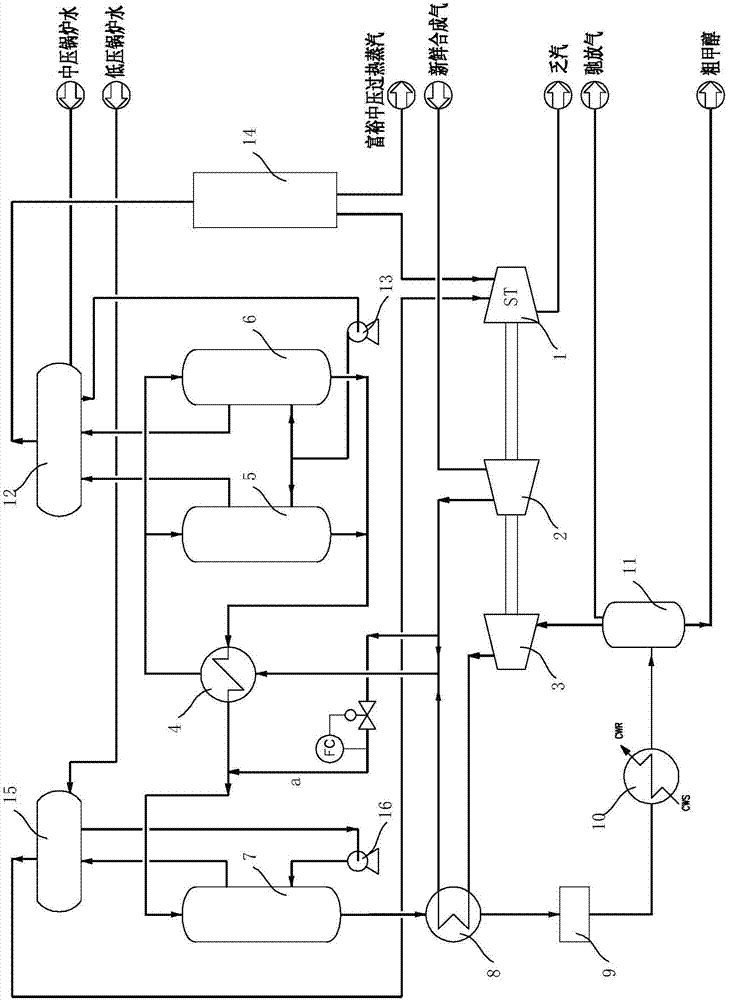

Low-pressure methanol synthesizing process

ActiveCN107162872ASmall sizeLower height requirementOrganic compound preparationHydroxy compound separation/purificationSyngasGas compressor

The invention relates to a low-pressure methanol synthesizing process. In the low-pressure methanol synthesizing process, both a primary reactor and a secondary reactor adopt a boiler feed water forced circulating heat transfer technology, heat transfer is fast and efficient, the device layout can be effectively simplified, the project investment of a device frame is reduced, and the problems of circulating ratio decrease, a non-ideal heat effect and the like, which are caused by inaccurate calculation of the layout height of a steam pocket, do not appear; through forced circulation, the circulating ratio can be effectively increased, reaction heat can be efficiently and reasonably utilized, and the heat transfer effect is enhanced; a jumper wire is arranged between an outlet of a synthetic gas compressor and an inlet of the secondary reactor, so that stable operation of catalysts in the two stages of reactors in different stages of the service life is achieved, and through the jumper wire, loads of the reactors are conveniently and forcibly adjusted, so that the production ratio of medium-pressure steam to low-pressure steam is flexibly adjusted; a connection position of fresh synthetic gas is arranged behind a synthetic gas thermostat, so that the heat transfer area and the specification of the synthetic gas thermostat can be reduced and the project investment is reduced.

Owner:SINOPEC NINGBO ENG +2

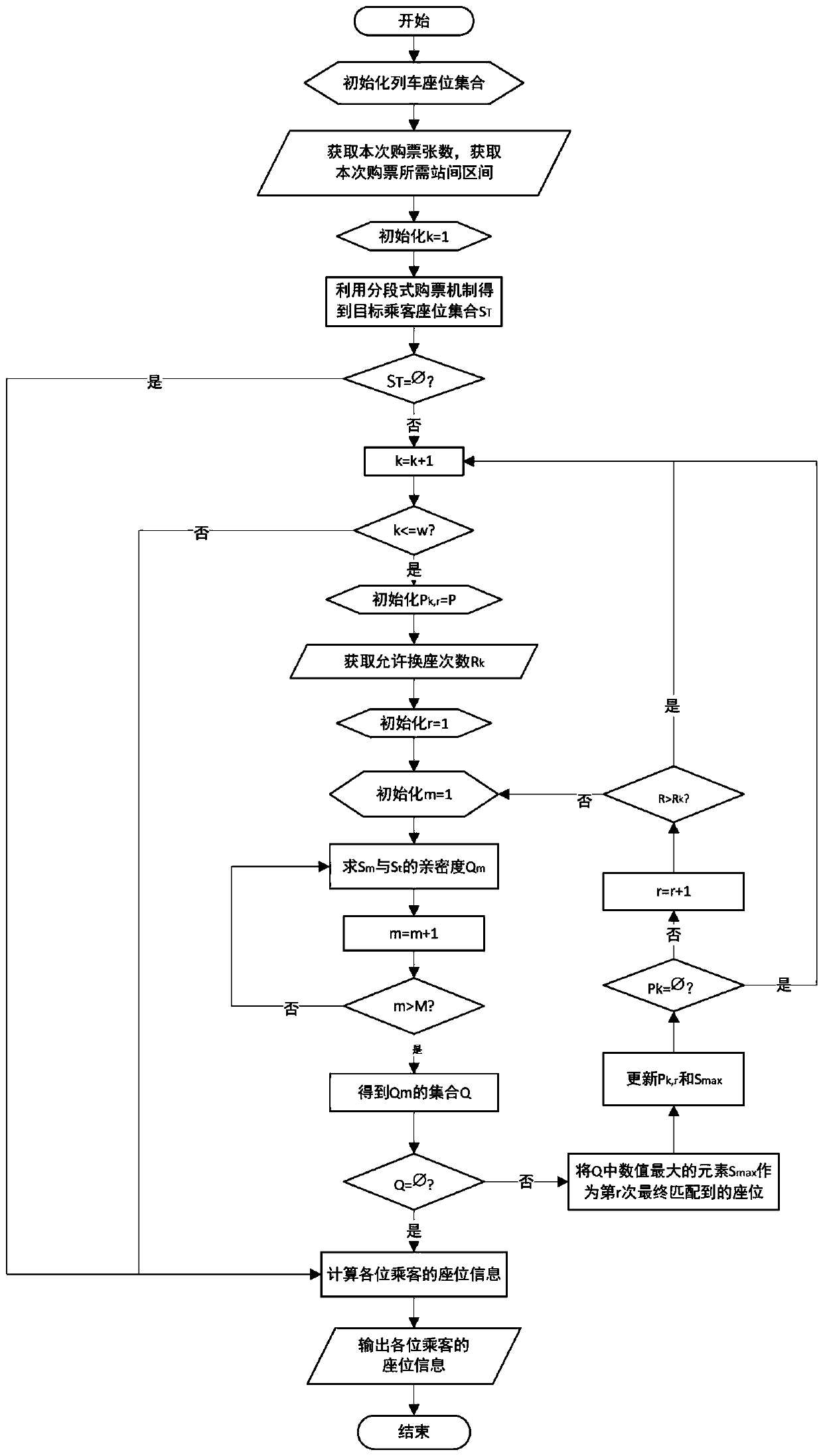

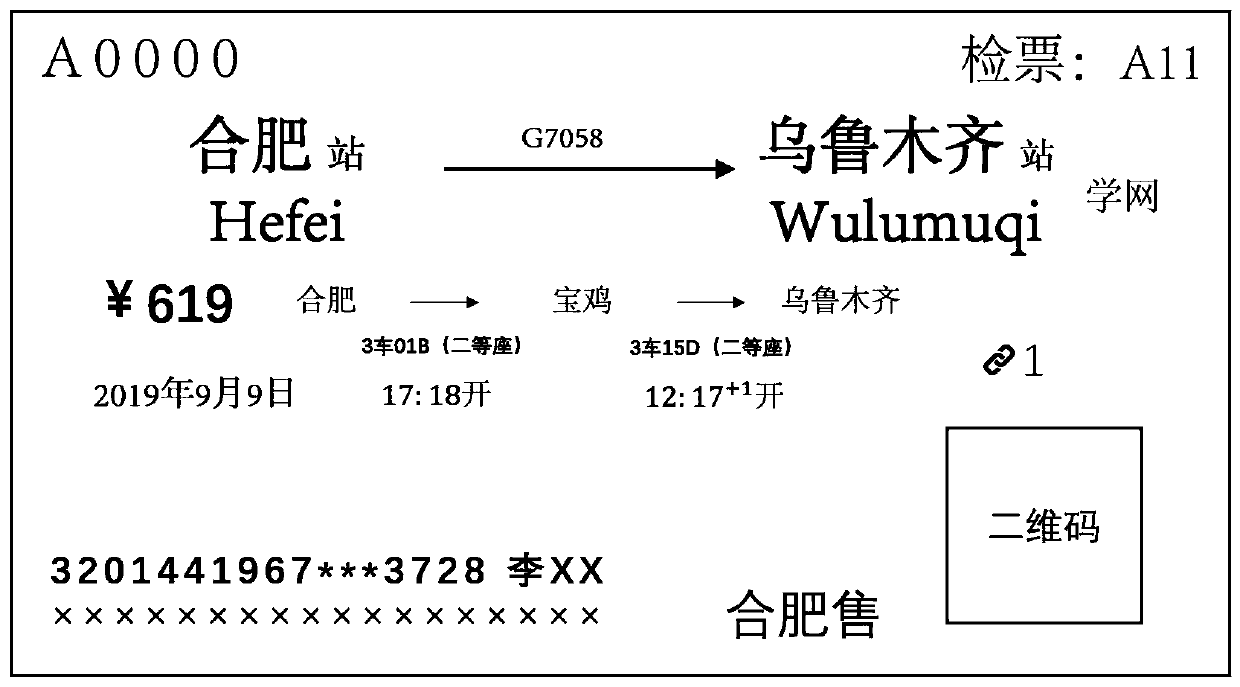

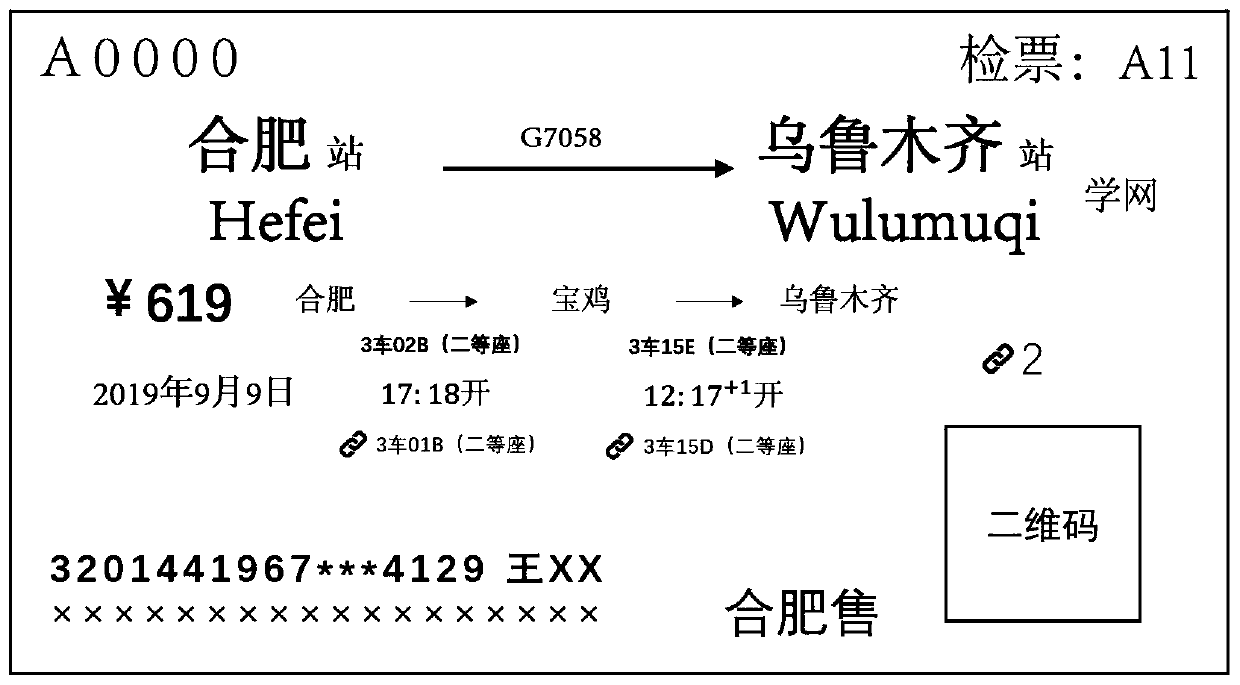

Segmented seat-associated ticket-selling method for train

ActiveCN110648407ASolve the disadvantages of the random allocation ticket sales modelEfficient and reasonable useMachines for printing and issuing ticketsTicketSeating capacity

The invention discloses a segmented seat-associated ticket-selling method for a train. The ticket-selling method comprises steps: 1, establishing a database about total numbers of seats in a train; 2initializing seat information in the train and information of a plurality of passengers participating in ticket purchase in which a first passenger who buys a ticket is set as a target passenger and remaining passengers are set as related passengers; 3, acquiring ticket-buying information of the target passenger and the related passengers in the related ticket purchase, including numbers of passengers, boarding interval, and number of seat changes allowed; 4, matching the target passenger to the most suitable seat in the seat database and updating the seat information; 5, matching the relatedpassengers to the seat most close to the target passenger in the seat database and updating the seat information; 6, outputting ticket information of each passenger. The segmented seat-associated ticket-selling method for the train can further improve segmented ticket-buying mode to obtain a plurality of tickets with seats as close to each other as possible for a long time, providing more convenience for passengers traveling with a group or buying tickets in a group, and making the ticket-selling system more user-friendly.

Owner:HEFEI UNIV OF TECH

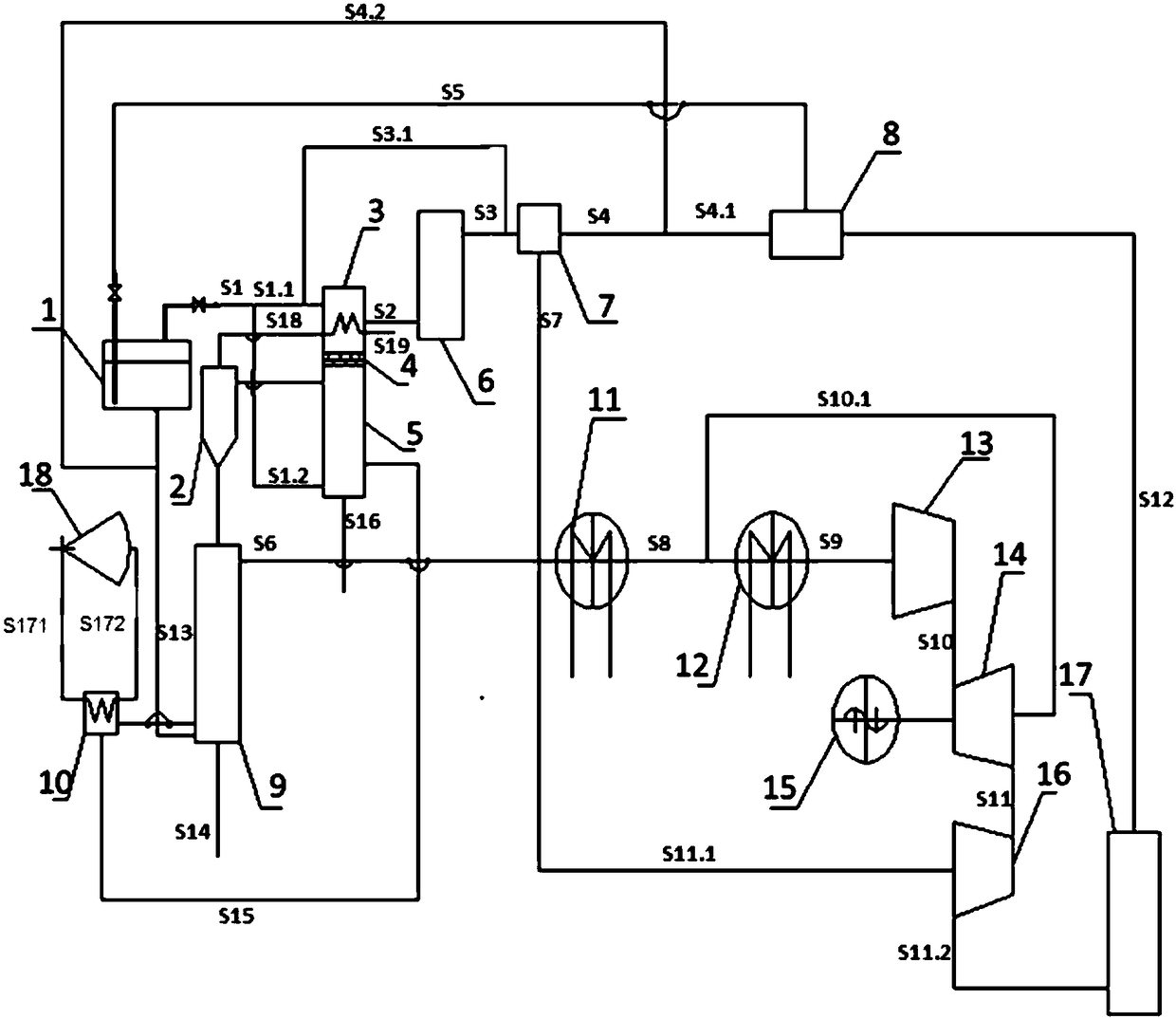

Combined heat and power generation system based on solar energy integrated oxygen-enriched combustion and chemical looping combustion and working method thereof

InactiveCN108507188AReduce sinteringBig investmentBioreactor/fermenter combinationsSolar heating energyHigh energyPower cycle

The invention discloses a combined heat and power generation system based on solar energy integrated oxygen-enriched combustion and chemical looping combustion and a working method thereof. A solar thermal chemistry process and a fuel power cycle are organically coupled by the system, so that the step utilization of the solar energy is realized; on one hand, a reduced oxygen-carrying body is usedfor converting the solar energy into chemical energy to be stored in an oxygen-carrying body heat accumulator, necessary heat energy is provided for the chemical looping combustion; and on the one hand, the characteristic that the CO2 is released by absorbing CO2 through the photosynthesis of microalgae under light illumination is utilized, pure O2 is provided for the oxygen-enriched combustion, and secondary air is provided for an air reactor; in addition, by complementary integration of the oxygen-enriched combustion system and the chemical looping combustion system, and the reasonable and efficient utilization of the fuel is realized; and meanwhile, the pure CO2 generated through oxygen-enriched combustion and chemical looping combustion is used for pushing a turbine to generate electricity for heat supply, so that the problem of high energy consumption and high cost due to the fact that CO2 is trapped and separated is solved, the CO2 flue gas waste heat can be effectively utilized.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

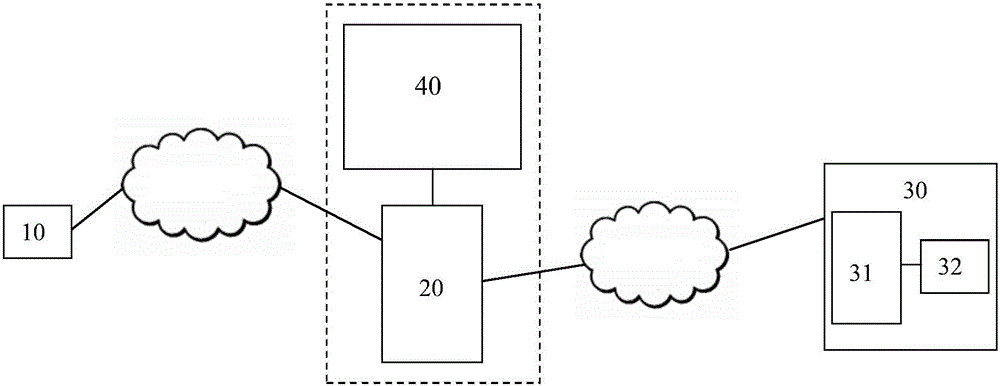

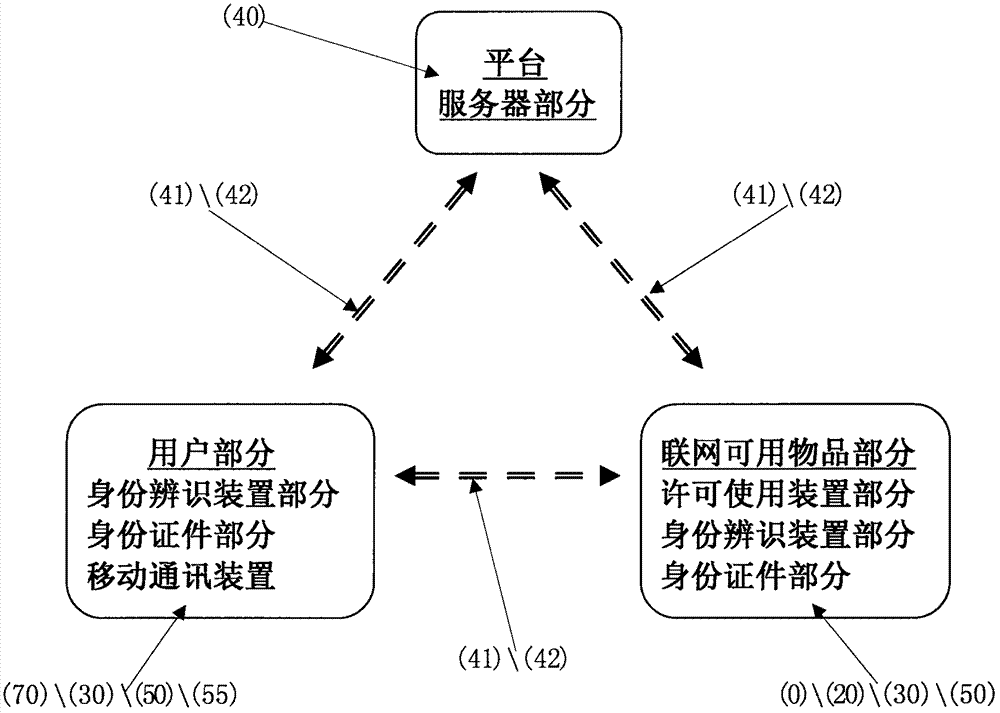

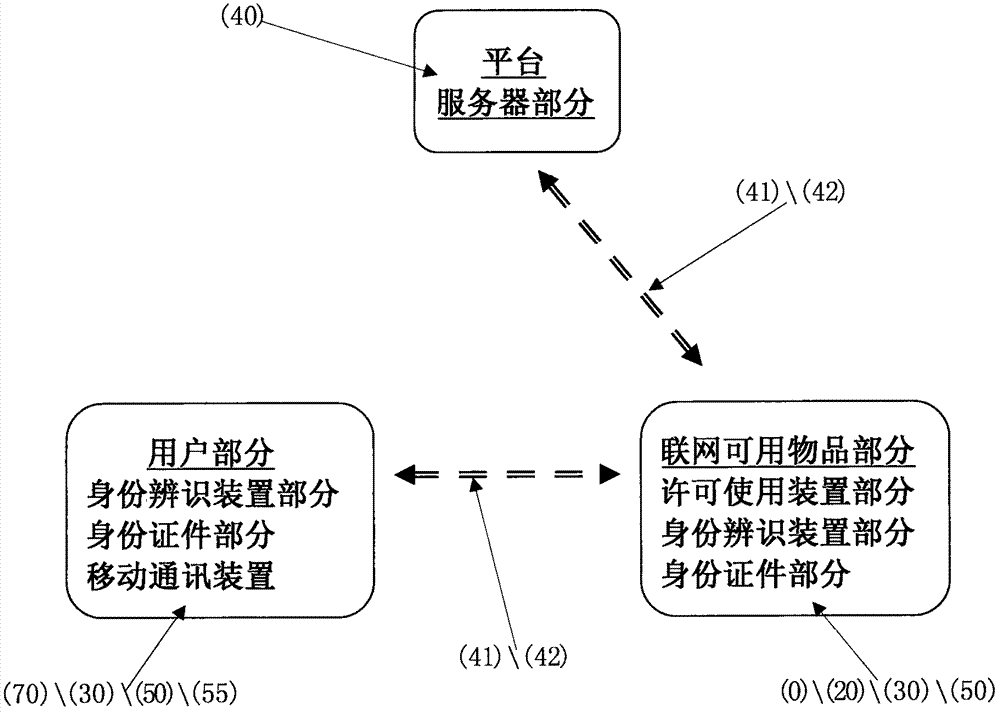

Networking usage method, networking available article part, network-permission-based usable device and purpose thereof

InactiveCN107507048AReduce returnsSave resourcesDigital data authenticationApparatus for meter-controlled dispensingPaymentThe Internet

The invention relates to the fields of information, Internet, Internet of Things, e-commerce and electromechanical engineering, especially e-commerce, Internet sharing system, network-available items, and network-controlled devices. Features include a network available item section and / or available item or person or living thing (0), a licensed use device section (20), a platform server section (40), an identification device section (30) and / or an identity document section ( 50); wherein the network available item part includes available items or personnel or living things (0), permitted use device part (20), identification device part (30) and / or identity certificate part (50); also includes steps : Step 1 - Registration or login, Step 2 - Provision of items, Step 5 - Permission to use, and Step 6 - Delivery, inspection and pickup, Step 7 - Payment and settlement before use, Step 9 - Return to storage, Step 11 - 12 steps such as payment and settlement after use. It solves the problem of information exchange between people and things (Internet function + Internet of Things function), and Internetizes available items and commodities.

Owner:吕怀民

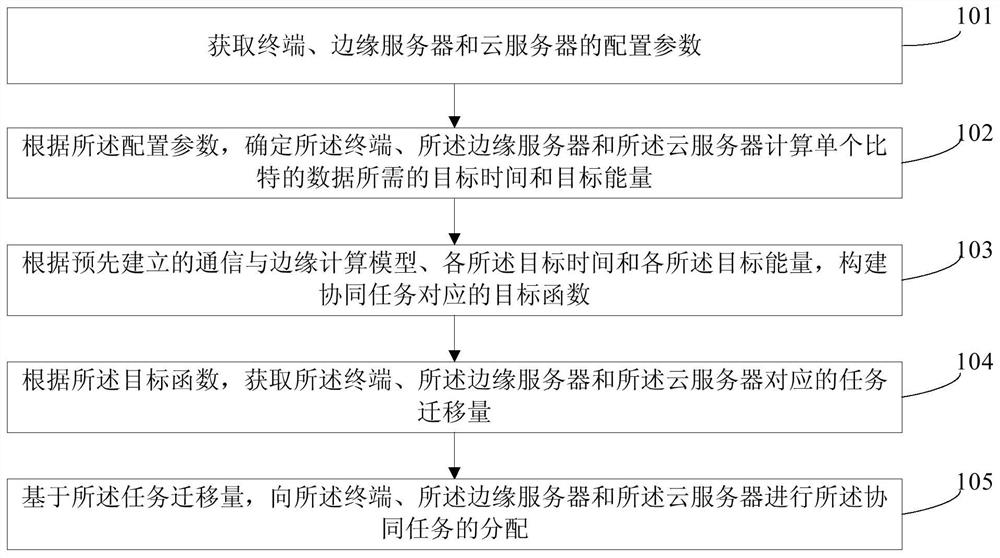

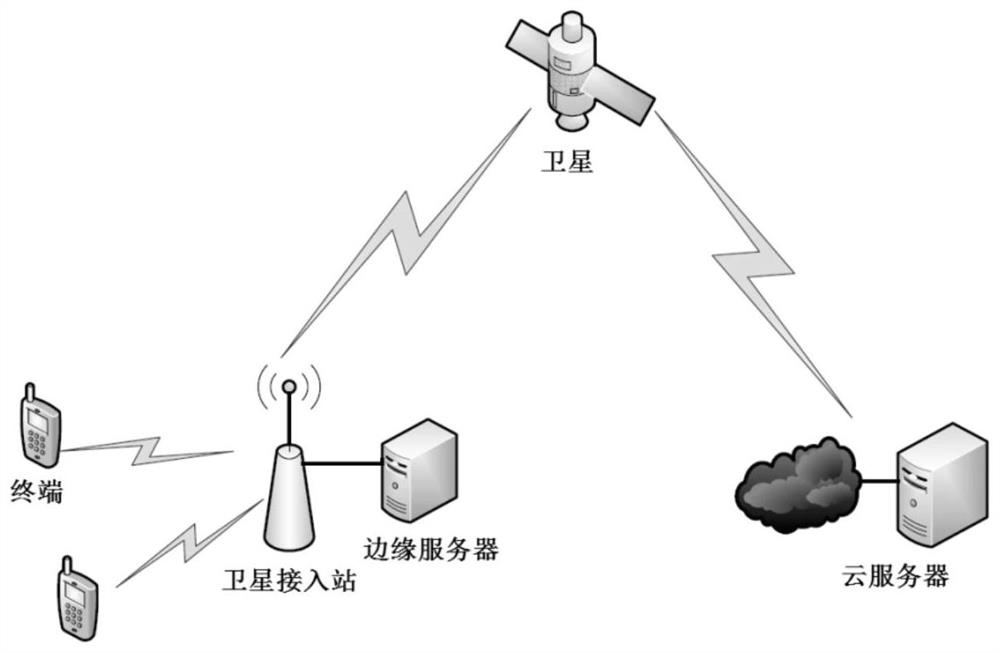

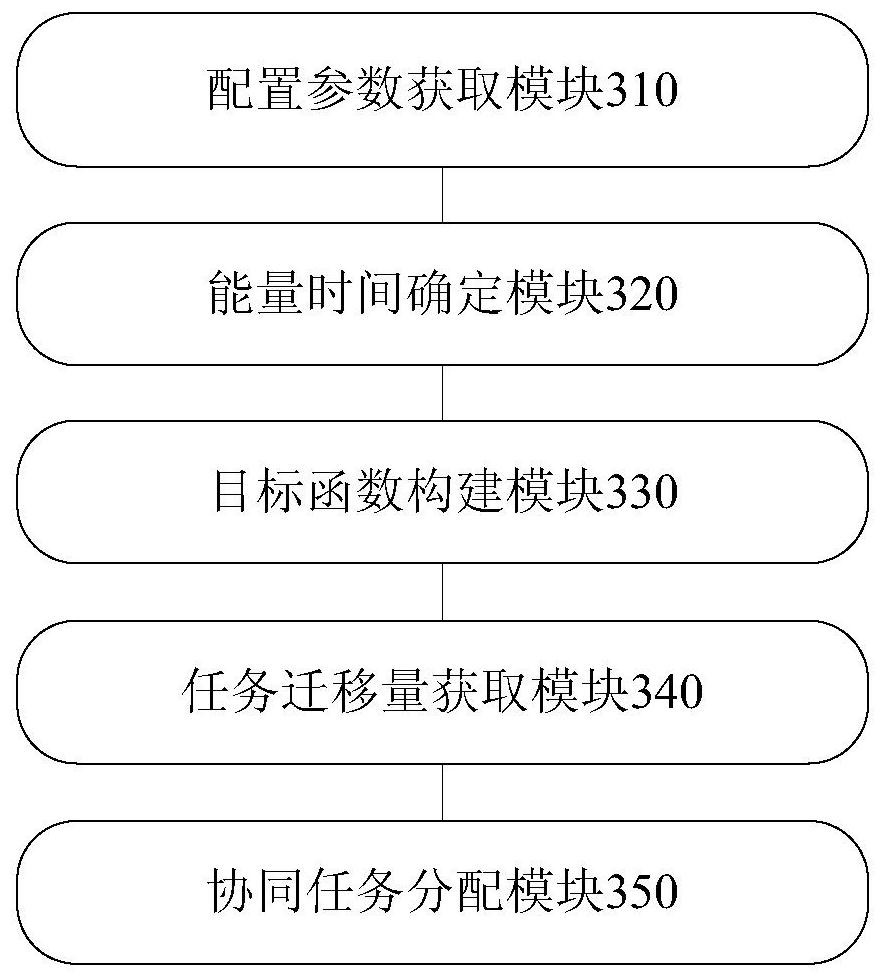

Cooperative computing task migration method and device for satellite network

PendingCN112272198AImprove service qualityEfficient and reasonable useRadio transmissionHigh level techniquesQuality of serviceEdge server

The invention provides a cooperative computing task migration method and device for a satellite network. The method comprises steps that configuration parameters of a terminal, an edge server and a cloud server being acquired; determining target time and target energy required by the terminal, the edge server and the cloud server to calculate single-bit data according to the configuration parameters; constructing a target function corresponding to the cooperative task according to a pre-established communication and edge calculation model, each target time and each target energy; according tothe target function, obtaining task migration amounts corresponding to the terminal, the edge server and the cloud server; and based on the task migration amount, allocating the collaborative task tothe terminal, the edge server and the cloud server. According to the method, the service quality of the satellite to the terminal is enhanced, and resources including power, frequency spectrum and server computing frequency are reasonably and efficiently utilized so as to provide support for space-ground integration, satellite internet and other communication satellite systems.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

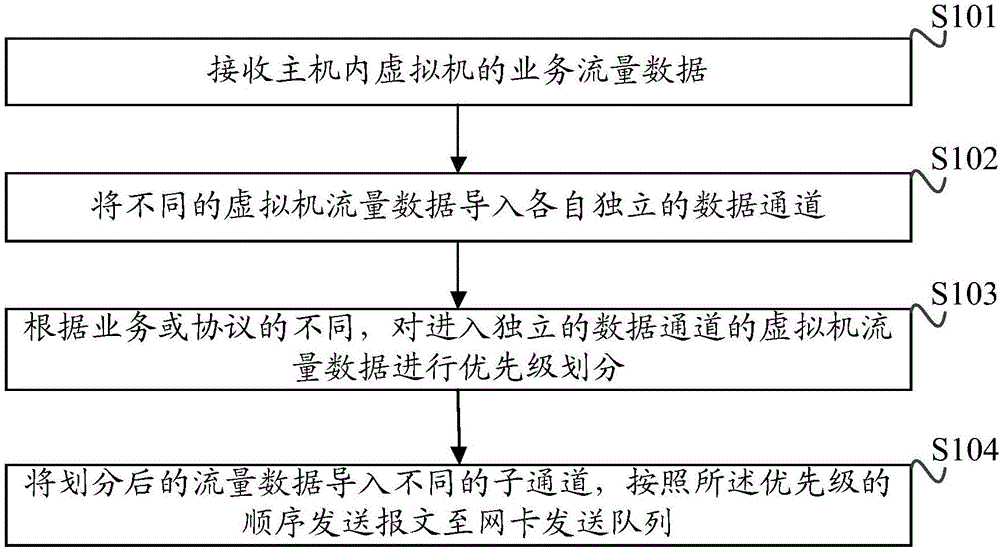

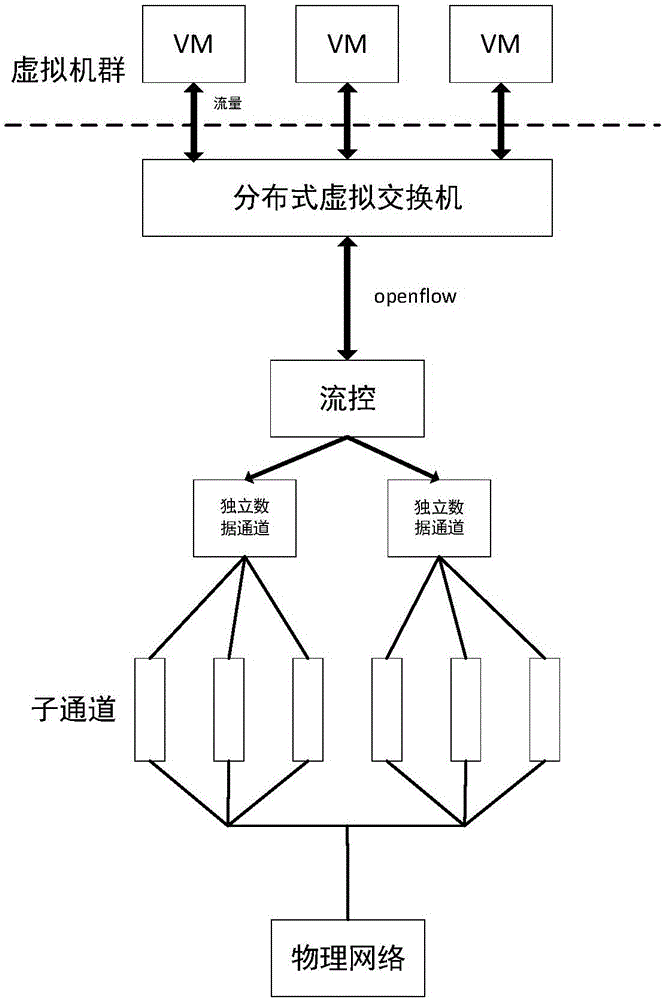

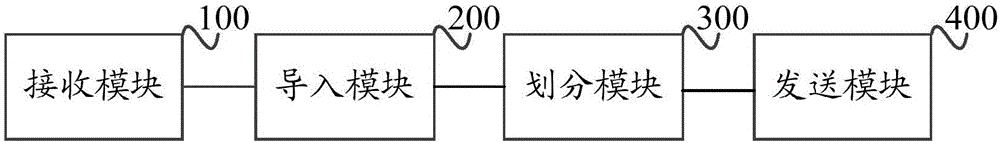

Virtual machine traffic control method and device

InactiveCN106453126AControl business traffic rateDoes not affect accessData switching networksTraffic capacityNetwork interface controller

The invention discloses a virtual machine traffic control method and device. The method comprises the steps of receiving service traffic data of a virtual machine in a host machine; importing different virtual machine traffic data into respective independent data channels; according to different services or protocols, dividing the priorities of the virtual machine traffic data entering the independent data channels; importing the divided traffic data into different sub channels, and sending messages to a network card sending queue according to the sequence of the priorities. The virtual machine traffic control method and device have the advantages that the priorities can be divided according to the service traffic of the virtual machine in the host machine, and the service traffic rate of the virtual machine is effectively controlled according to different priorities, so that the network access of other virtual machines in the host machine is not influenced, and the network resources in the host machine are reasonably and efficiently utilized.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

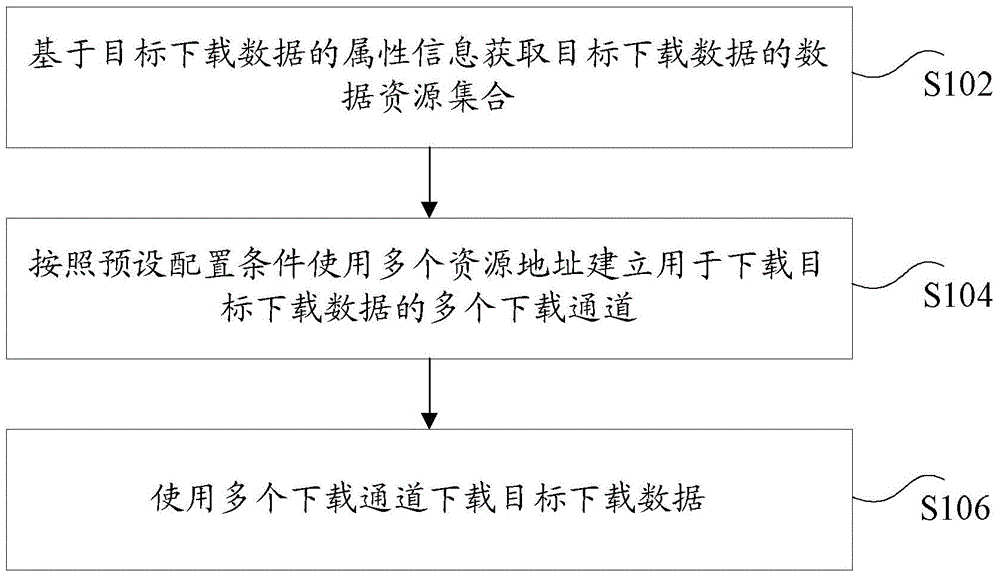

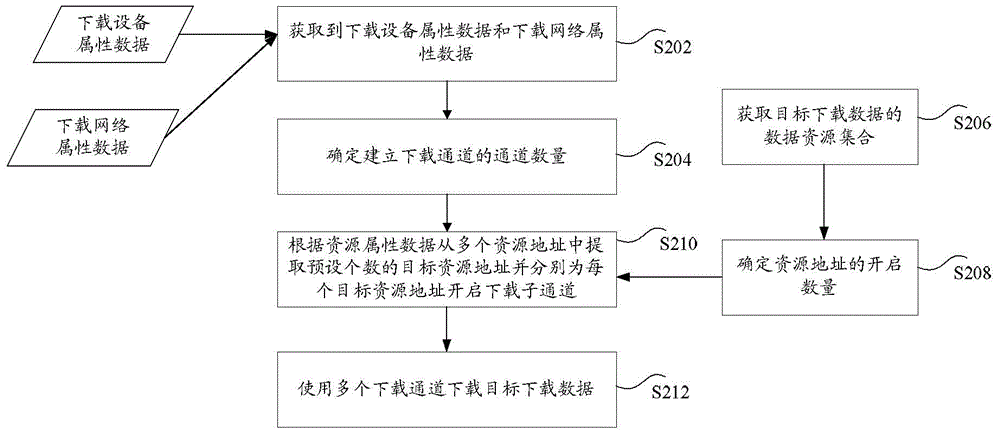

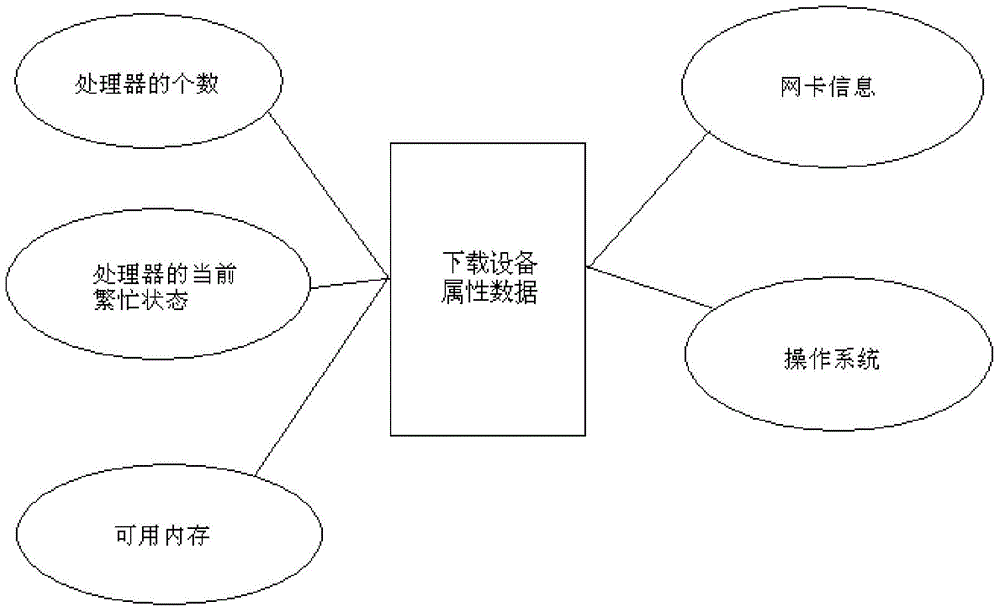

Network data downloading method and apparatus

ActiveCN105025068AEfficient and reasonable useHigh speedSubstation equipmentTransmissionNetwork dataComputer science

The invention discloses a network data downloading method and apparatus, wherein the method comprises: obtaining the data resource set of target downloading data based on the attribute information of the target downloading data, wherein the data resource set comprises a plurality of resource addresses pointing to the target downloading data; according to preset configuration conditions, using the plurality of resource addresses to establish a plurality of downloading channels used for downloading the target downloading data; and using the plurality of downloading channels to download the target downloading data. The network data downloading method and apparatus solve the problem that in the prior art, the downloading speed of network resources of a mobile terminal is slow, reasonably and efficiently utilize resource addresses, and increase the speed of a terminal of downloading network resources.

Owner:TENCENT TECH (SHENZHEN) CO LTD

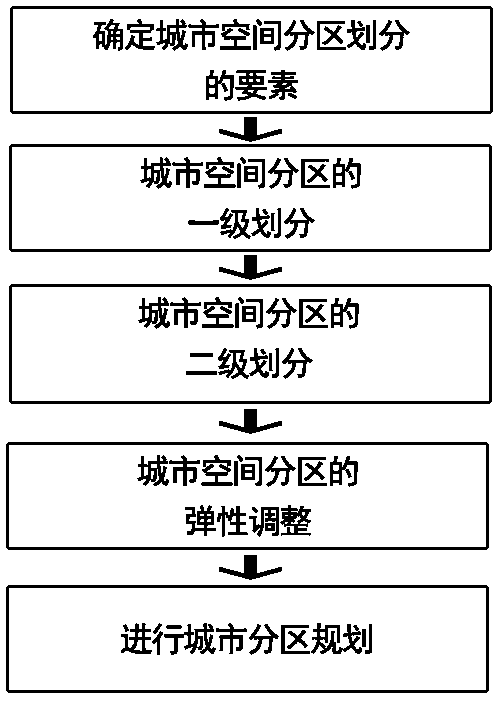

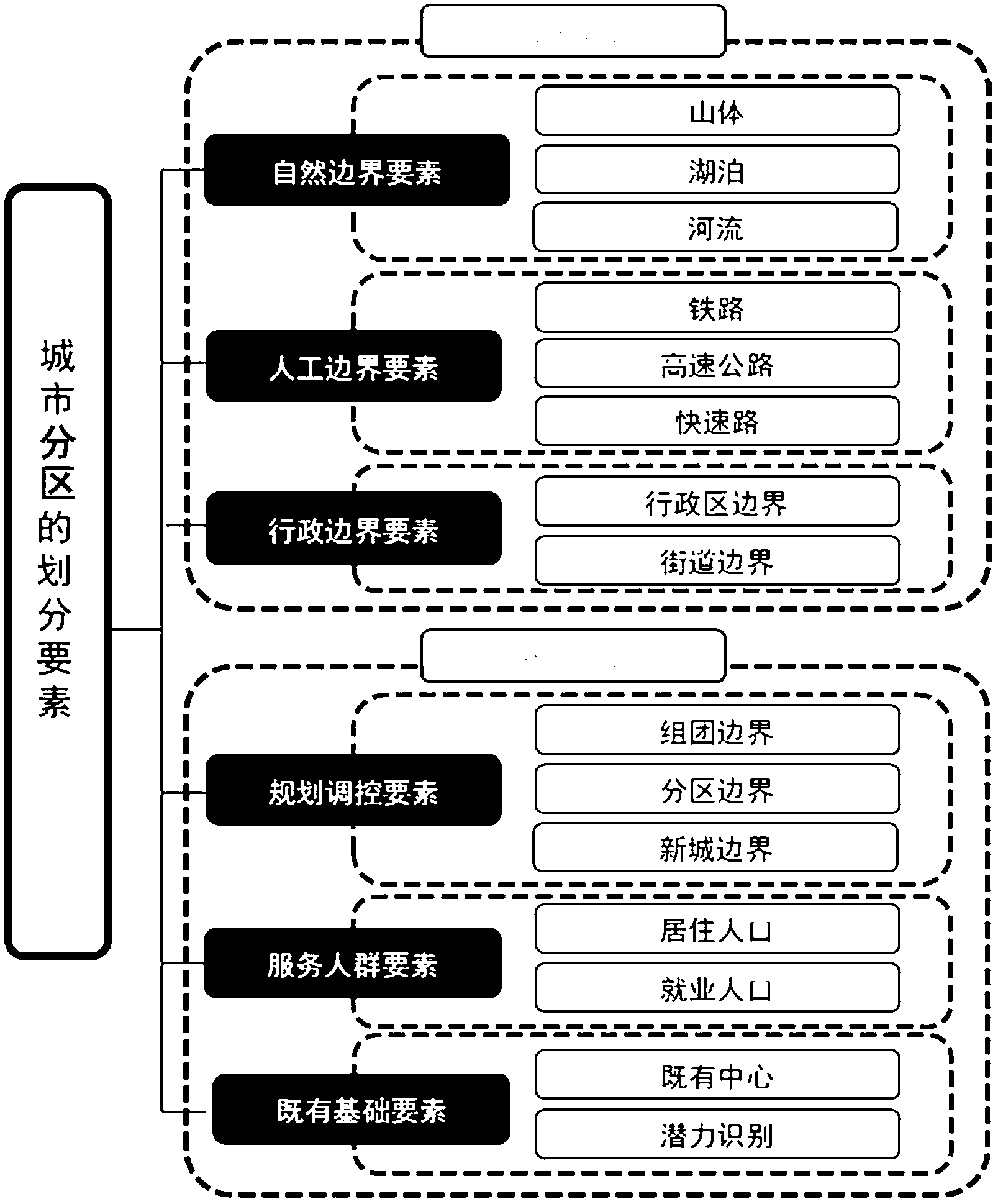

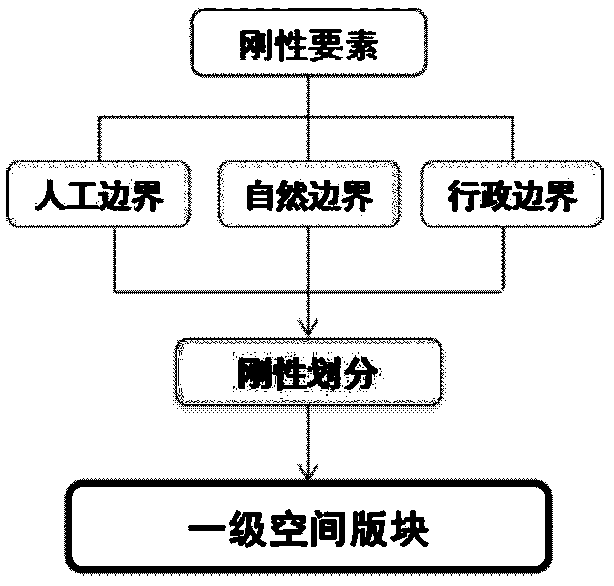

Space dividing method facing city zoning plan

The invention discloses a space dividing method facing a city zoning plan. The method comprises the following steps of: drawing an evaluation base map which only comprises main urban area data information according to city plan topographic data, confirming elements and dividing modes which can influence the city space dividing, and zoning and secondarily zoning a city; and adjusting according to changeable elements. According to the space dividing method, the completely-quantized surveying, counting and computing methods are adopted, so that the space dividing method has the characteristics of being objective, rigorous and sole. After public service facilities are distributed by using the space dividing method, the balanced coverage of a public service resource can be promoted, the bases for the city zoning plan, the city strategy development project, the city commercial network plan and the related building can be provided, the implementation effect of the city planning and building can be improved, and the valuable city building resource can be effectively and reasonably used.

Owner:SOUTHEAST UNIV

Machine room heat dissipation system with heat recovery/full natural cooling and control method of machine room heat dissipation system

PendingCN106895526AAir supply requirements relaxedImprove utilization efficiencyFluid heatersEnergy recovery in ventilation and heatingWater source heat pumpWater source

The invention provides a machine room heat dissipation system with heat recovery / full natural cooling. The machine room heat dissipation system comprises a full natural cooling system, a heat recovery system and a control system. The full natural cooling system comprises a cooling unit, a cooling water pump, a liquid cooling system and a gas cooling system. The liquid cooling system and the gas cooling system are connected in parallel through a pipeline and are connected with the cooling unit. The heat recovery system comprises a water source heat pump unit, a heat source pump and a heat utilization device, all of which are connected with the cooling unit in parallel. The heat utilization device, the heat source pump and the water source heat pump unit are sequentially connected to form a circulation loop. The heat utilization device comprises an absorption refrigerator and a heating tail end which are connected in parallel. The control system is used for controlling the full natural cooling system and the heat recovery system to work. The invention further provides a control method of the above machine room heat dissipation system. According to the machine room heat dissipation system and the control method of the machine room heat dissipation system, a liquid-gas double-channel refrigerating technology is used for achieving data center natural cooling, the heat recovery system is used for recovering liquid-gas double-channel dissipated heat, and data center energy can be reasonably, efficiently and flexibly used.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

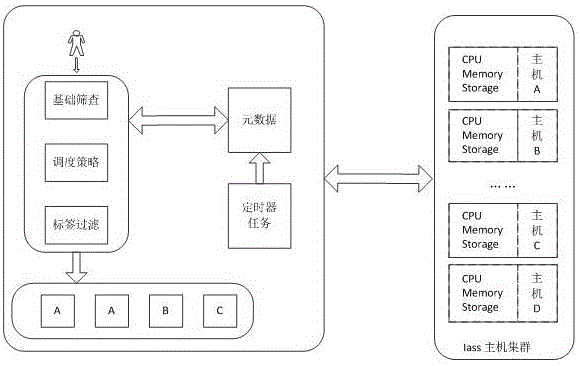

Method for effectively achieving host cluster resource scheduling under cloud platform

InactiveCN106126347AGuaranteed functional stabilityEfficient schedulingResource allocationMetadataHost machine

The invention discloses a method for effectively achieving host cluster resource scheduling under a cloud platform, belongs to the field of cloud platforms, and aims at solving the technical problem of how to reasonably utilize Iass layer physical resources to be large platforms. According to the technical scheme, the method comprises the following steps that 1, a cloud platform synchronously obtains metadata information of all physical resources of a corresponding Iass platform through an Iass platform interface, and the metadata information is saved to the platform side; 2, all the physical resources of the Iass platform are classified and labeled correspondingly, labels serve as the basis of resource scheduling, all resource application tasks initiated through the Iass platform are subjected to distribution through scheduling policies, and final resources are obtained; 3, after scheduling is completed through the scheduling policies, updating is conducted on the metadata of the platform side.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com