Coal-fired electricity generation-CO2 capture-heat supply integrating system and method

A CO2, coal-fired power plant technology, applied in heating systems, chemical instruments and methods, hot water central heating systems, etc., can solve problems that do not involve the rational utilization of low-temperature waste heat, and achieve reasonable and efficient utilization and high comprehensive energy utilization. Efficiency and techno-economic performance, the effect of reducing energy consumption and CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

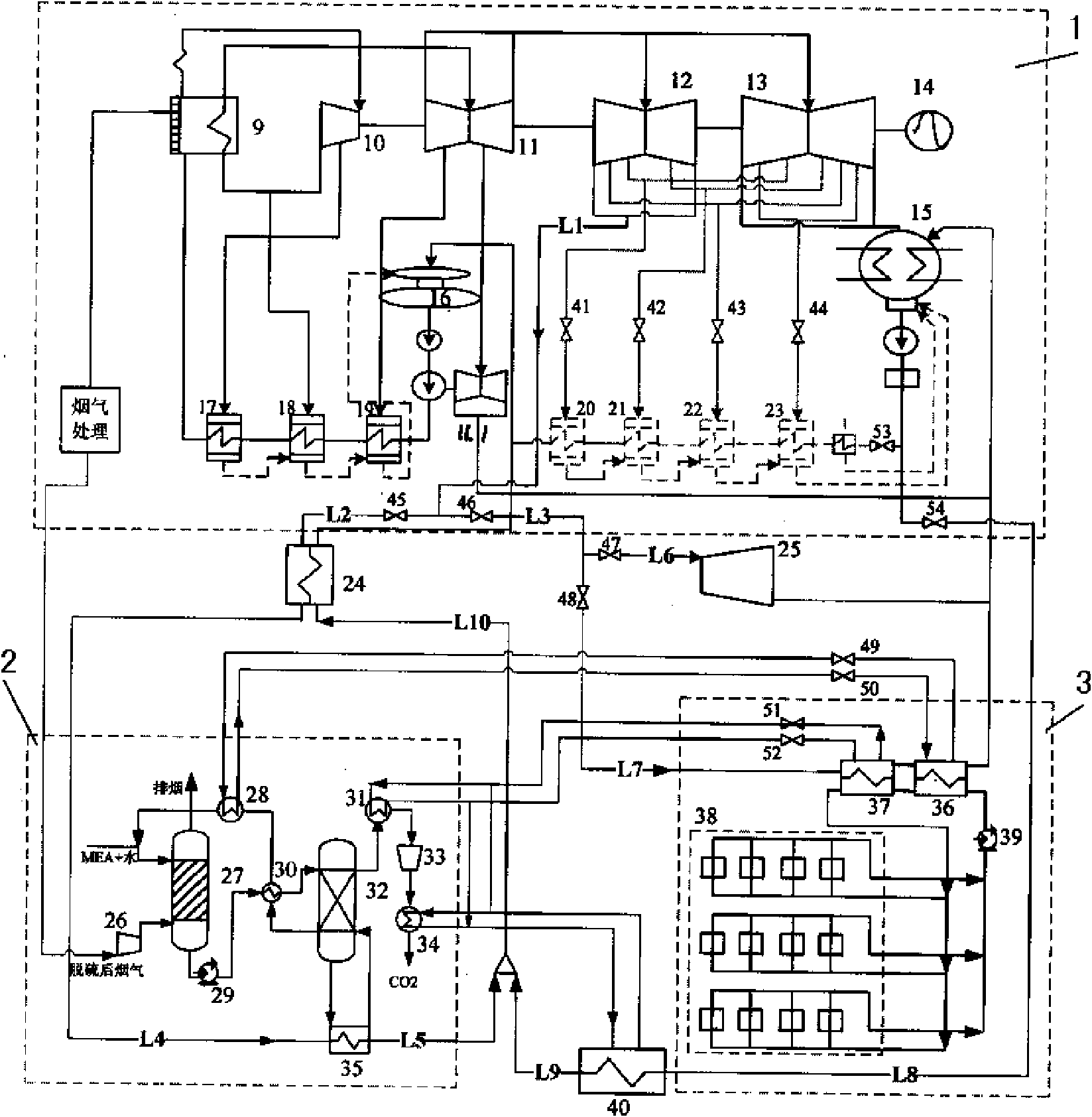

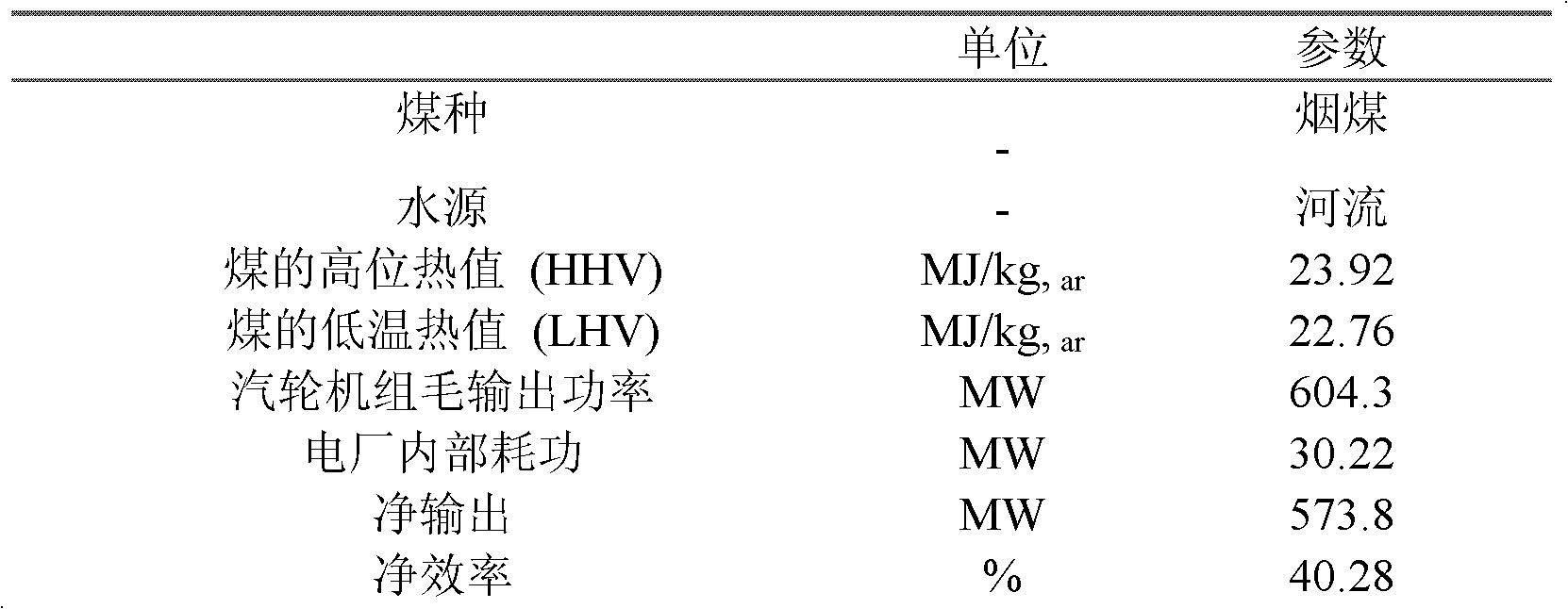

[0030] A typical 600MW coal-fired power plant in China was selected as the reference object, and monoethanolamine (MEA) was selected as the CO 2 Capture chemical absorbent; where Table 1 gives the parameters of a typical 600MW power plant.

[0031] Table 1 Parameters of a typical 600MW coal-fired power plant in China

[0032]

[0033]

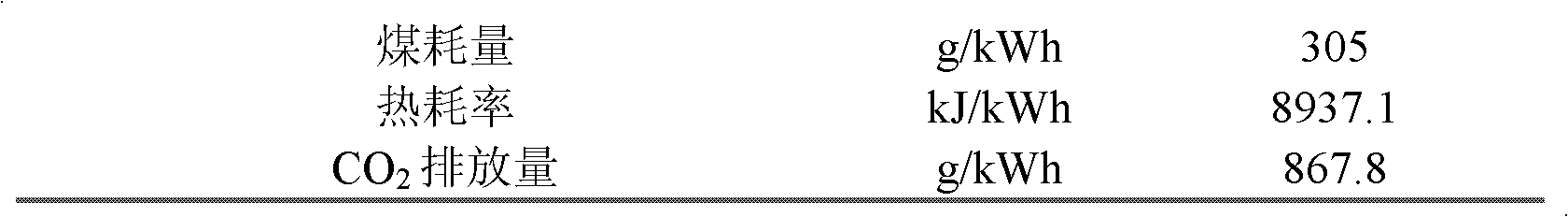

[0034] Table 2 presents the coal-fired power generation-CO 2 CO capture-heat integration scheme (i.e. basic scheme) 2Capture system performance, . It is assumed that the power plant burns the design coal, and the boiler works under the rated conditions, and at the same time in the calculation of the present invention, it is assumed that the designed new CO 2 The capture thermal power plant has the same coal feed as the reference typical 600MW coal-fired power plant in China.

[0035] Table 2 CO2 capture system parameters

[0036]

[0037] The cooling release heat of the poor liquid MEA in the capture system is used as the heat sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com