A method and device capable of increasing the capture rate of carbon dioxide in oilfield carbon dioxide flooding produced gas

A carbon dioxide and capture rate technology, applied in chemical instruments and methods, gas fuels, inorganic chemistry, etc., can solve the problems of low capture yield, high unit capture energy consumption, high venting ratio, etc., to achieve capture energy consumption The effect of reducing, increasing the capture rate, and increasing the capture rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention provides a method and device that can increase the capture rate of carbon dioxide in oilfield carbon dioxide flooding produced gas. The specific implementation will be described below with specific examples. It should be understood that the specific examples described here are only used to explain the present invention , and are not intended to limit the present invention.

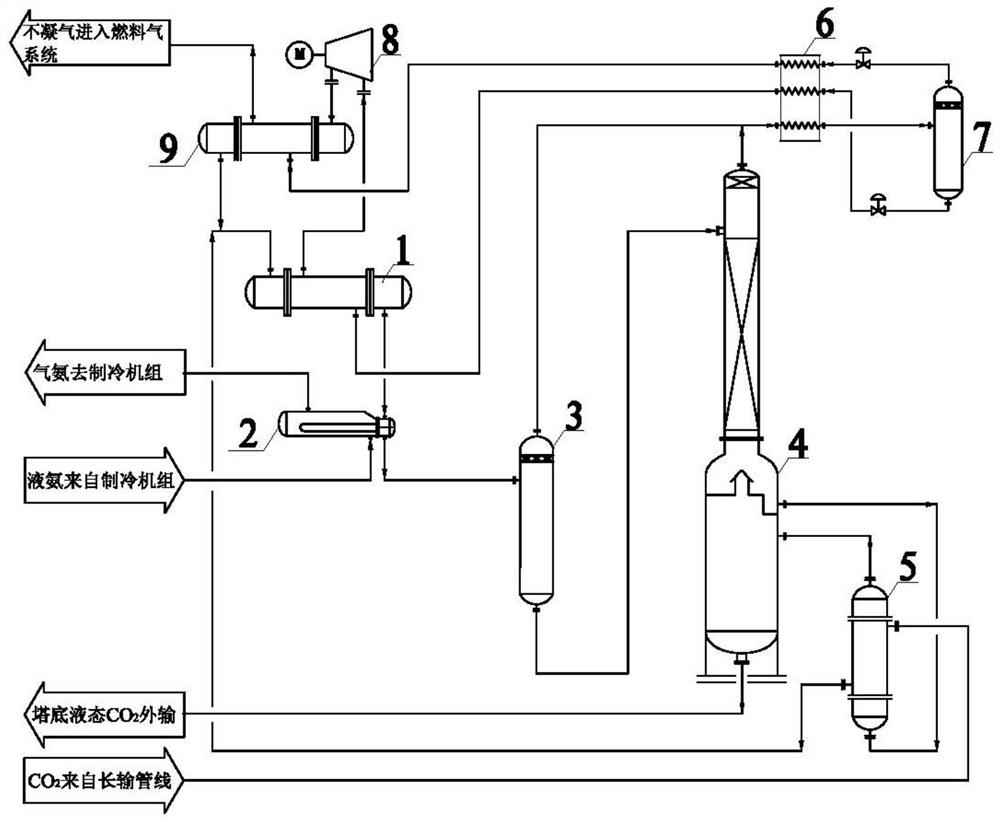

[0034] Such as figure 1 As shown, the method provided by the present invention that can improve the carbon dioxide capture rate in the oilfield carbon dioxide flooding produced gas comprises the following steps:

[0035] 1) Raw material gas precooling: the raw material gas entering the device requires CO 2 Content is 90%, water content is lower than 200ppm, pressure 4MPa, at first pass through tower bottom reboiler 5 to provide heat for stripping operation (wherein the liquid CO at the bottom of tower 2 external transport), while reducing the temperature of the feed gas to 8°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com