Patents

Literature

247results about How to "Scale adjustable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

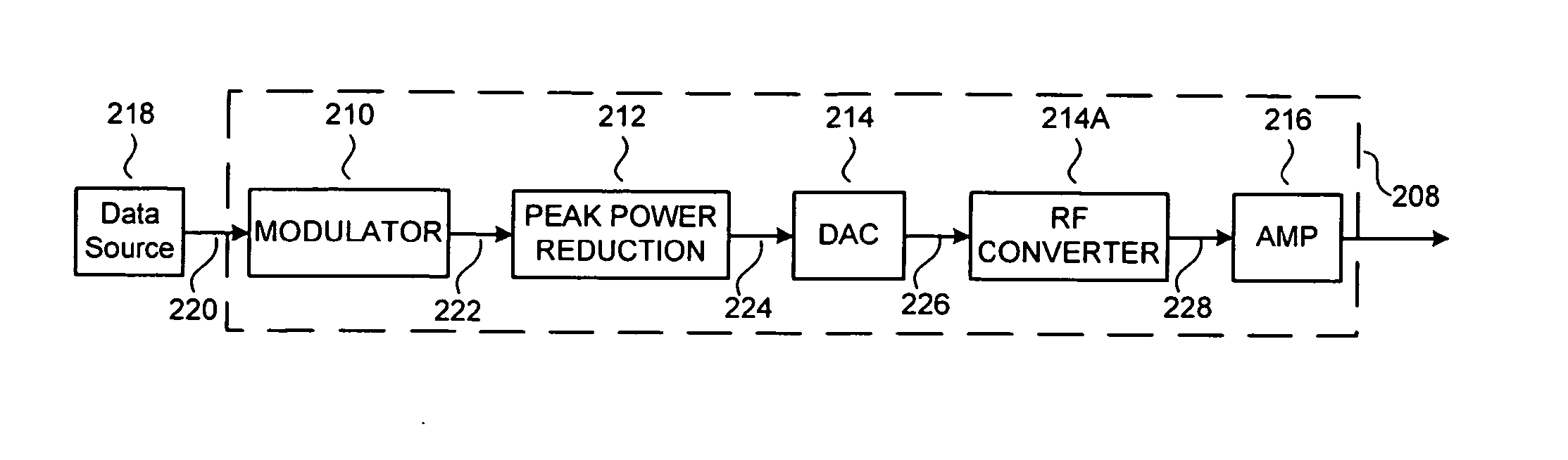

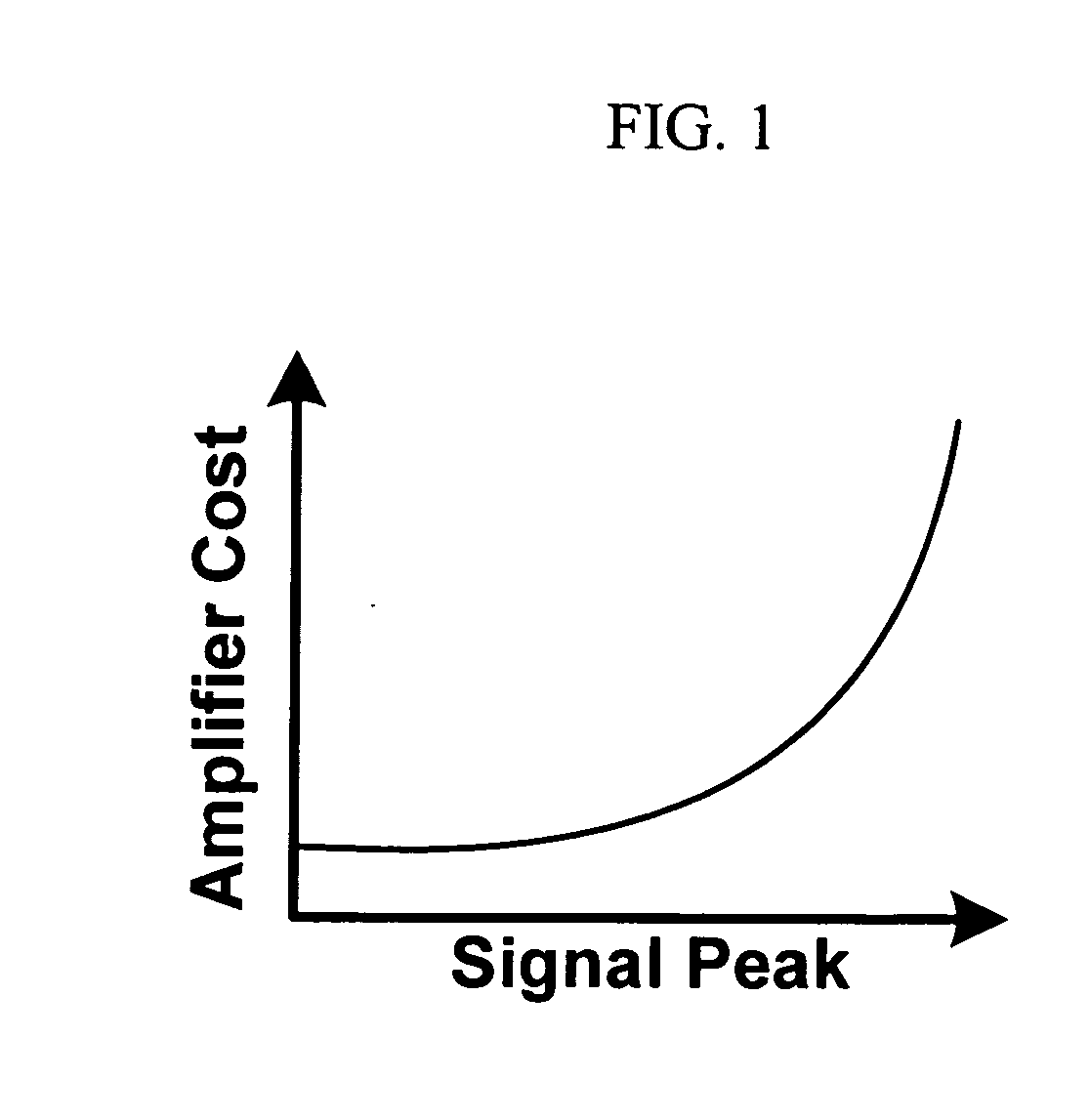

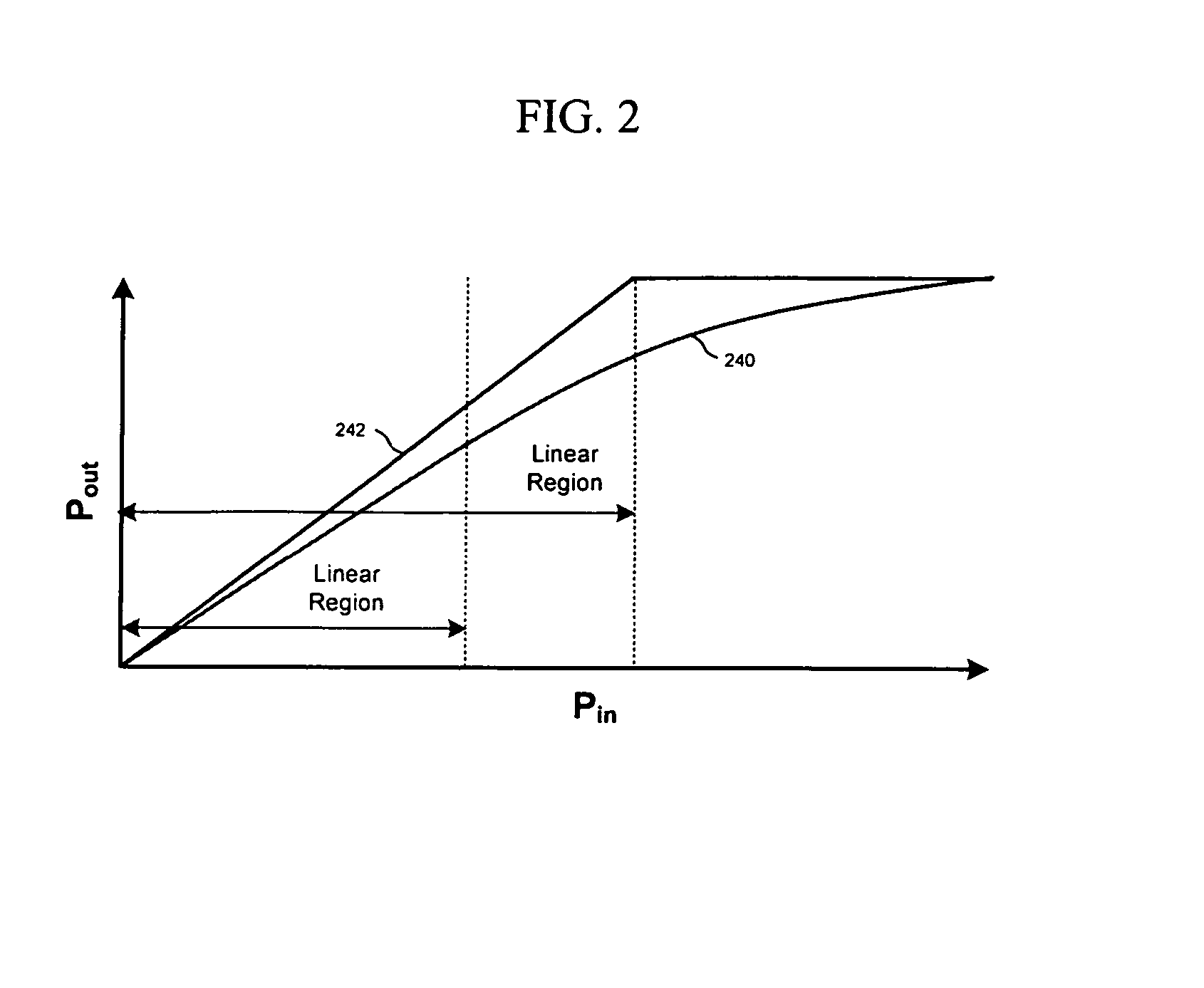

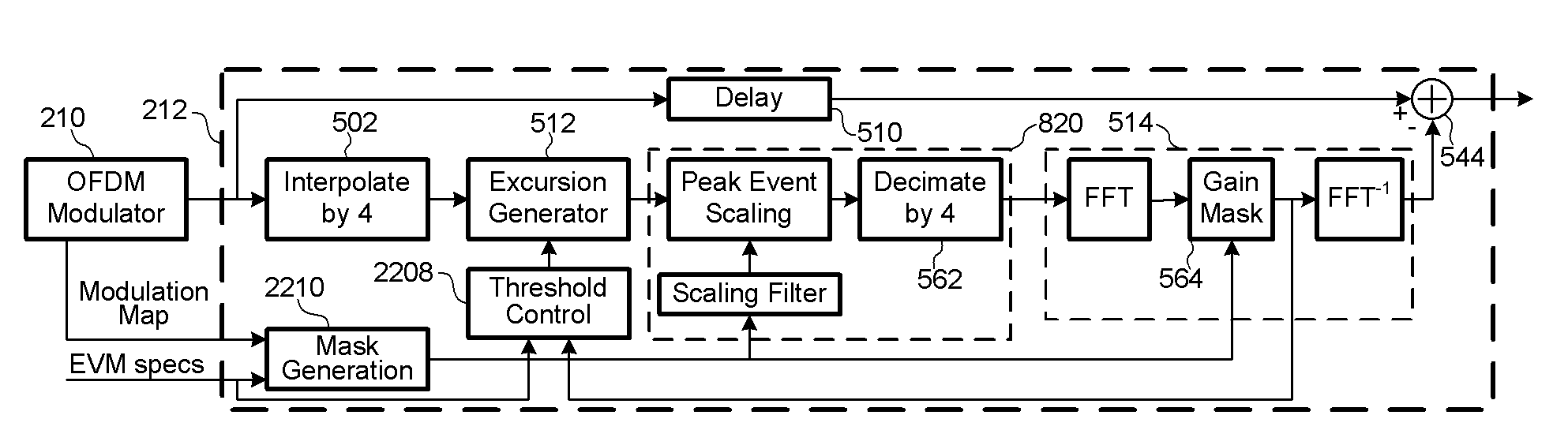

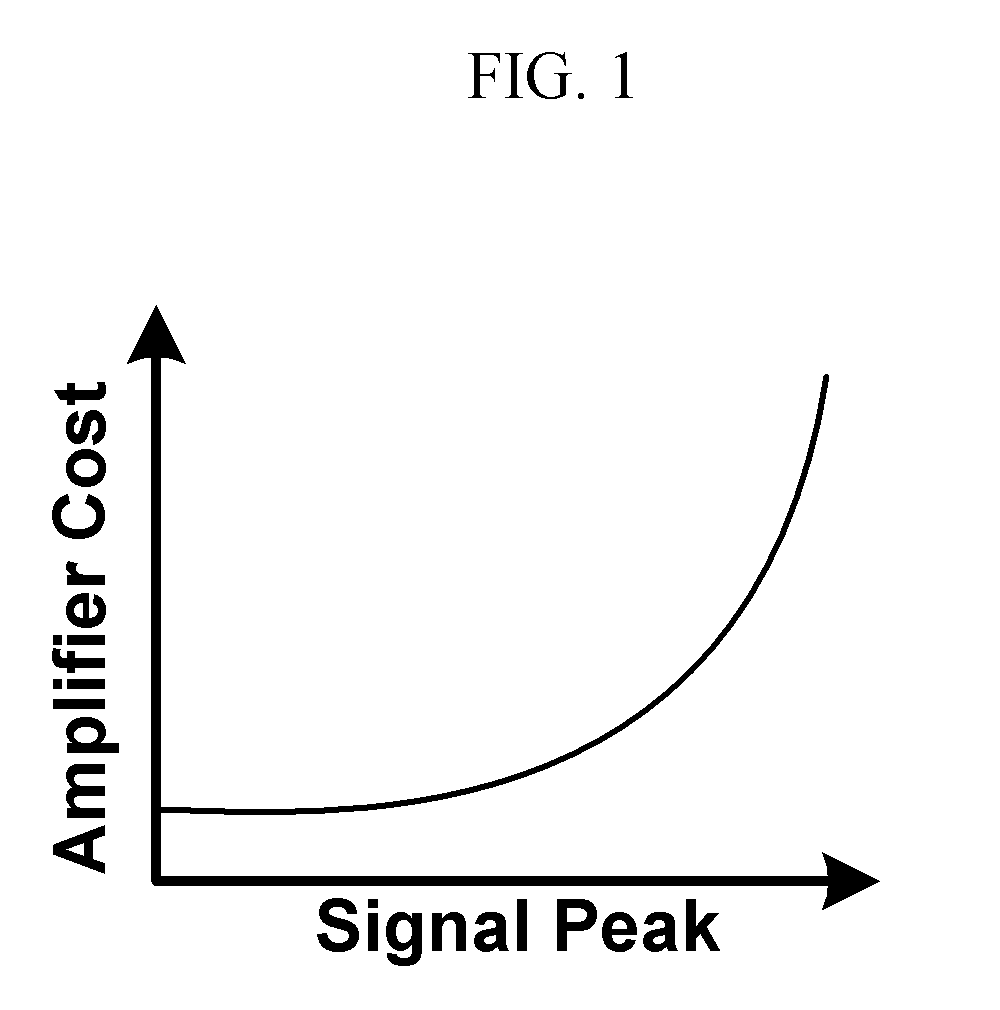

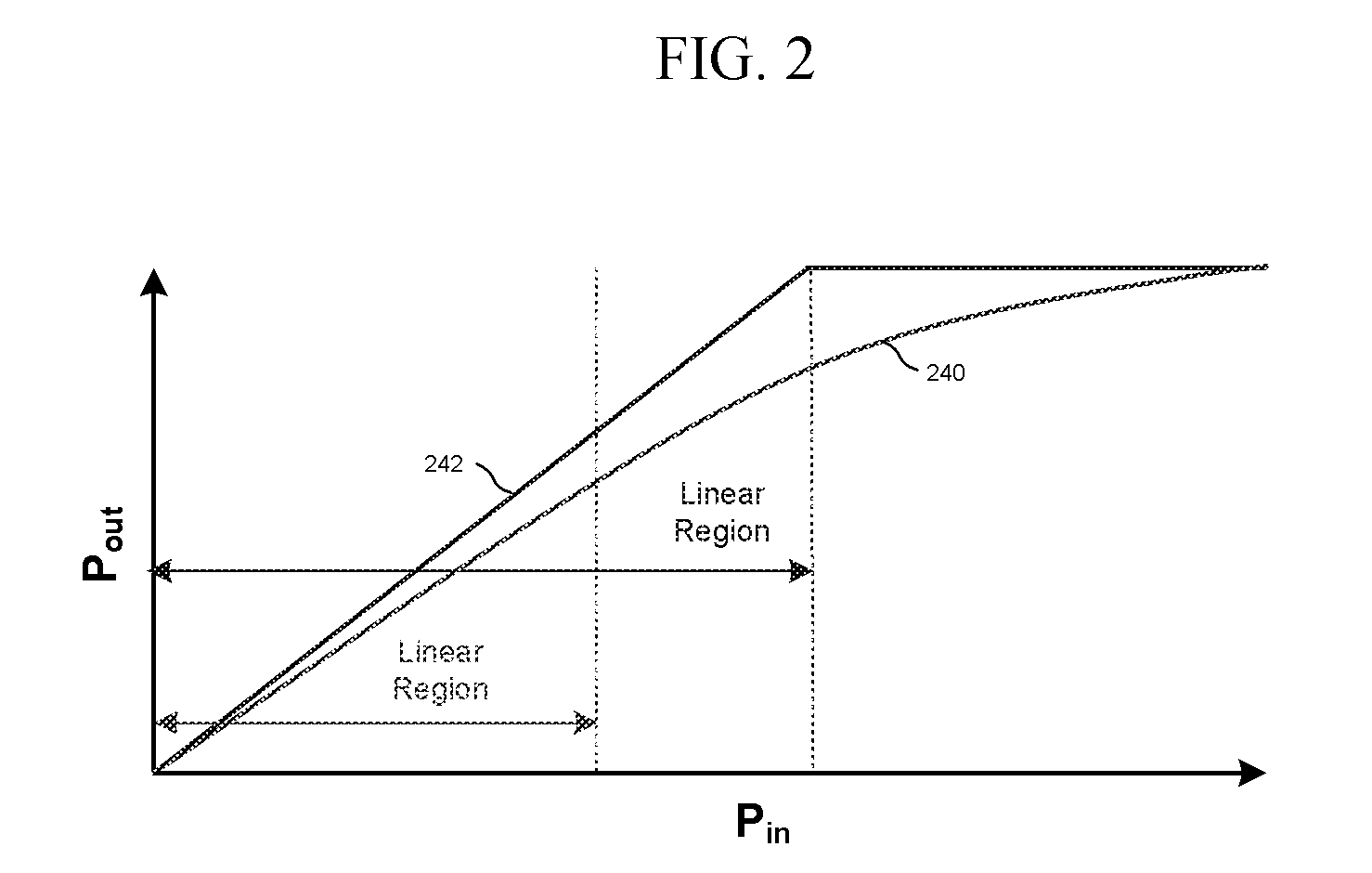

Method and apparatus for adaptively controlling signals

ActiveUS20070254592A1Enhance peak reductionReduce peakModulated-carrier systemsGain controlSignal qualityFrequency spectrum

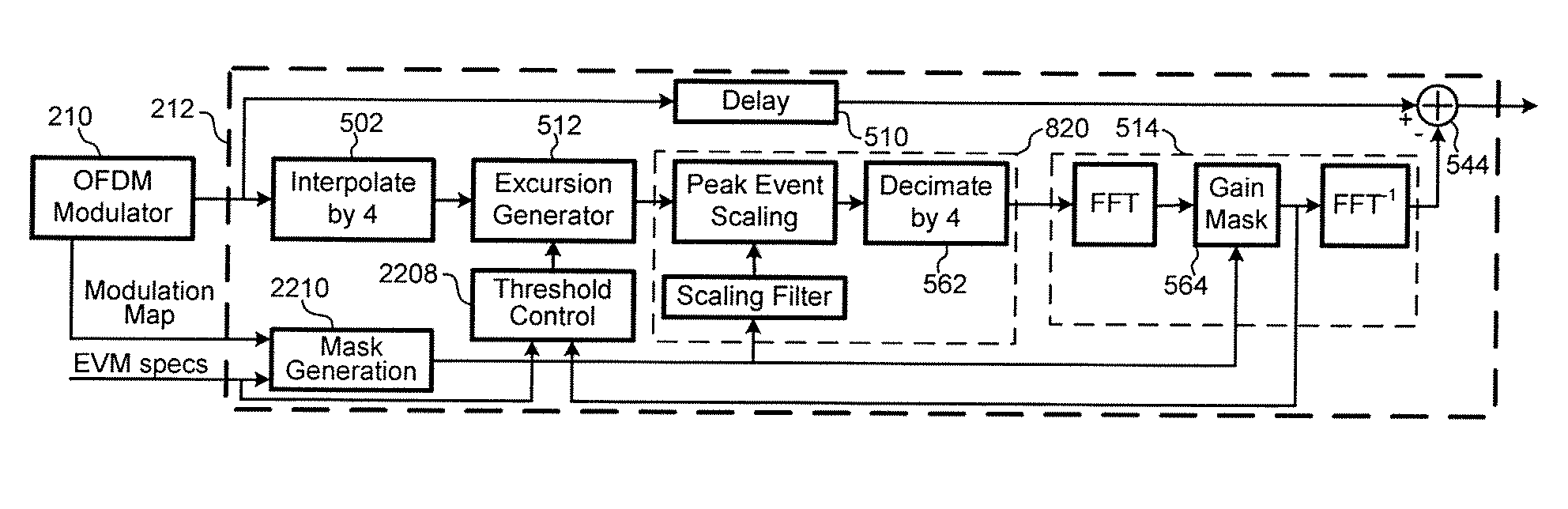

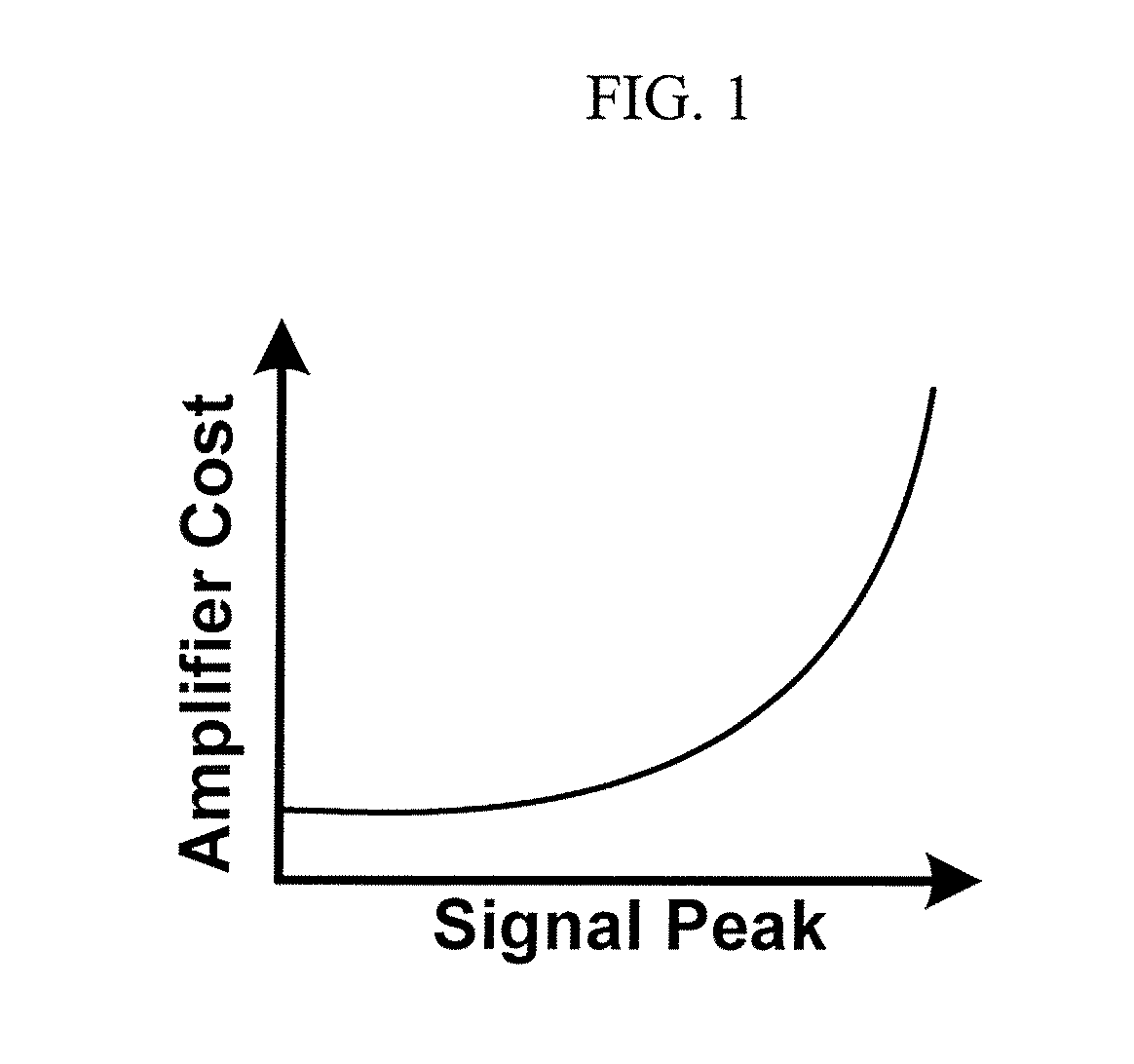

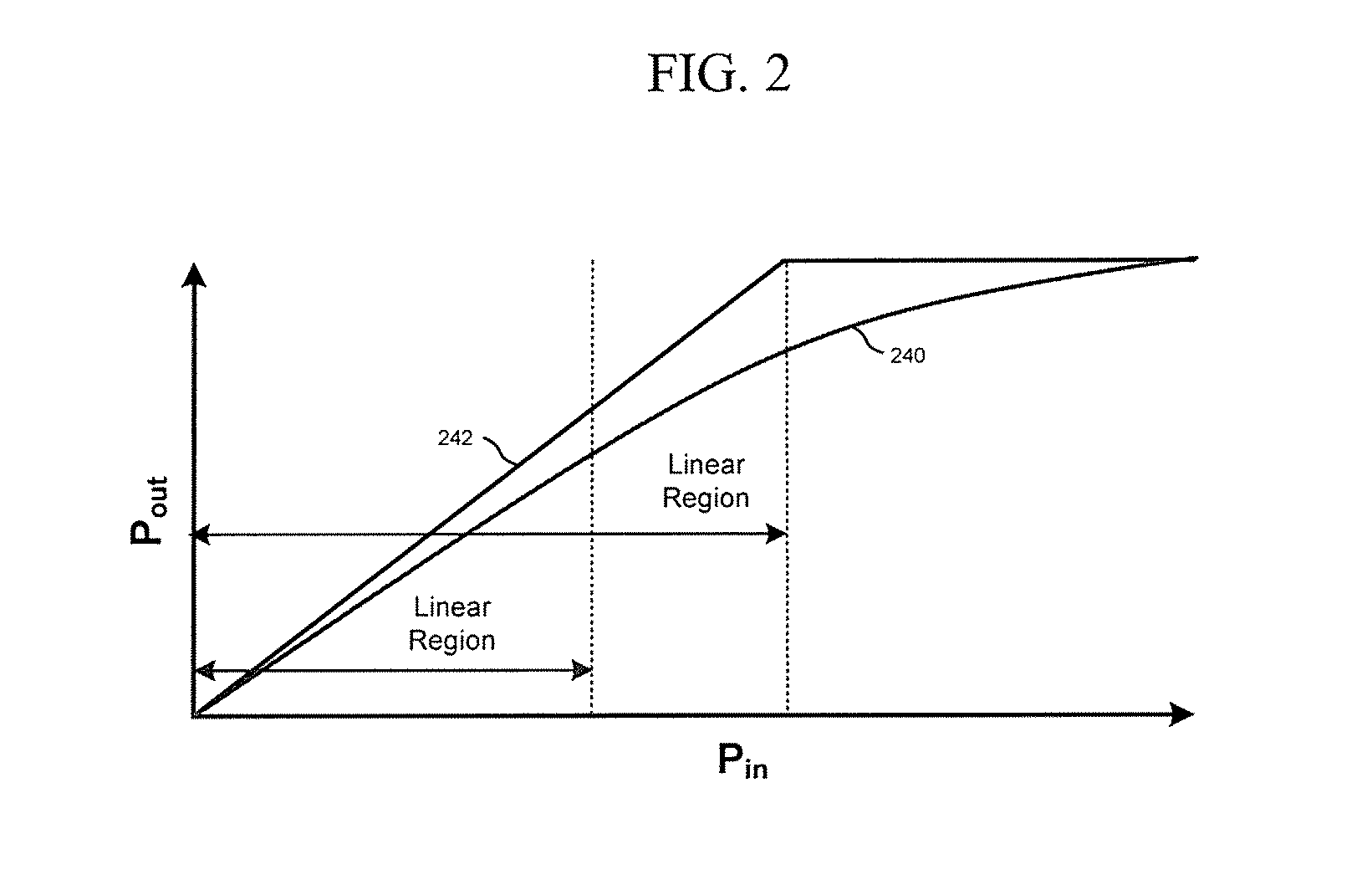

A signal processing system according to various aspects of the present invention includes an excursion signal generator, a scaling system and a filter system. The excursion signal generator identifies a peak portion of a signal that exceeds a threshold and generates a corresponding excursion signal. The scaling system applies a real scale factor to contiguous sets of excursion samples in order to optimize peak-reduction performance. The filter system filters the excursion signal to remove unwanted frequency components from the excursion signal. The filtered excursion signal may then be subtracted from a delayed version of the original signal to reduce the peak. The signal processing system may also control power consumption by adjusting the threshold. The signal processing system may additionally adjust the scale of the excursion signal and / or individual channel signals, such as to meet constraints on channel noise and output spectrum, or to optimize peak reduction. The magnitude threshold, excursion signal and / or individual channel signals may also be adaptively adjusted based on, for example, a channel signal quality such as a noise level specification.

Owner:CRESTCOM INC

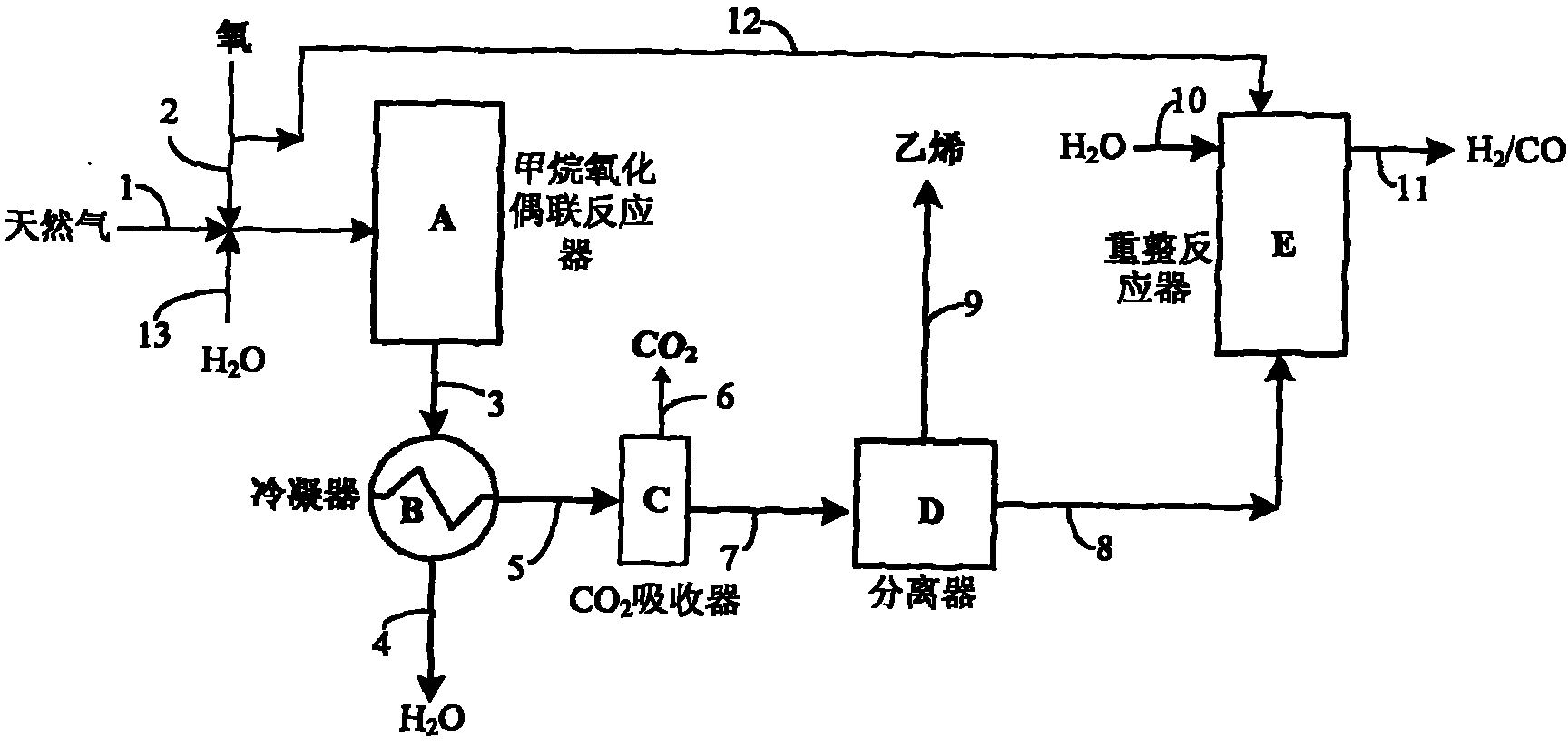

Joint process for preparing ethylene and synthesis gas by direct conversion of methane

InactiveCN102093157AScale adjustableAchieve green productionHydrogenHydrocarbon by hydrocarbon condensationEthyleneSingle product

The invention discloses a joint process for preparing ethylene and synthesis gas by direct conversion of methane. The invention provides the joint process for directly converting a methane-containing raw material into the ethylene and producing the synthesis gas at the same time. The process overcomes the limit of using single product as a target during directly preparing the ethylene from the methane in the past; and besides the methane is converted into the ethylene with high yield, the further utilization of the methane is also taken into consideration, namely, the methane can be converted into the synthesis gas with high yield.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

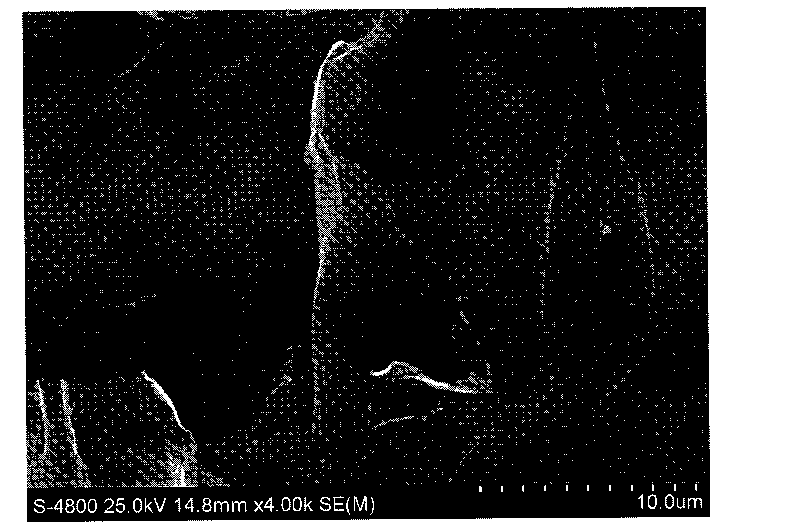

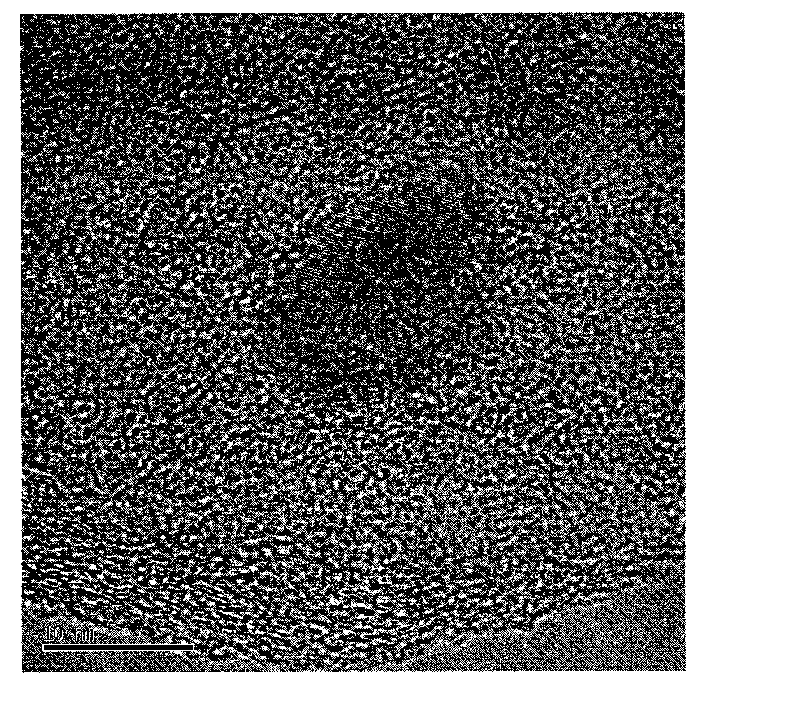

Graphene/nickel oxide laminated-structure composite film and preparation method thereof

ActiveCN101733985AImprove conductivityHigh strengthLayered productsNickel oxides/hydroxidesCapacitanceComposite film

The invention relates to a graphene / nickel oxide laminated-structure composite film and a preparation method thereof. The preparation method comprises the following steps: putting graphite oxide and a solvent in the proportion of 0.5-2:1 (mg / mL) into a beaker, and carrying out the ultrasonic treatment for 0.5-5 hours to obtain the finely disseminated graphene oxide solution; adding a nickel nitrate solution to the graphene oxide solution in the volume proportion of 1:1-10, continuing to carry out the ultrasonic treatment for 0.5-5 hours to obtain the graphene oxide / nickel nitrate solution; vacuum-drying at 70-90 DEG C to obtain the graphene oxide / nickel nitrate film; and carrying out the heat treatment on the film at 330-1000 DEG C in the protective atmosphere to obtain the graphene / nickel oxide laminated-structure composite film. The composite film has favorable electric properties and mechanical properties; and the specific capacitance can reach 180-1300 F / g, the thickness is 0.02-10 mu m, and the particle size of the nickel oxide in the film is 1-200 nm. The invention has the advantages of simple preparation process, easy operation, controllable film thickness, scalable shape, adjustable scale, low cost and easy amplification of technique.

Owner:TIANJIN UNIV

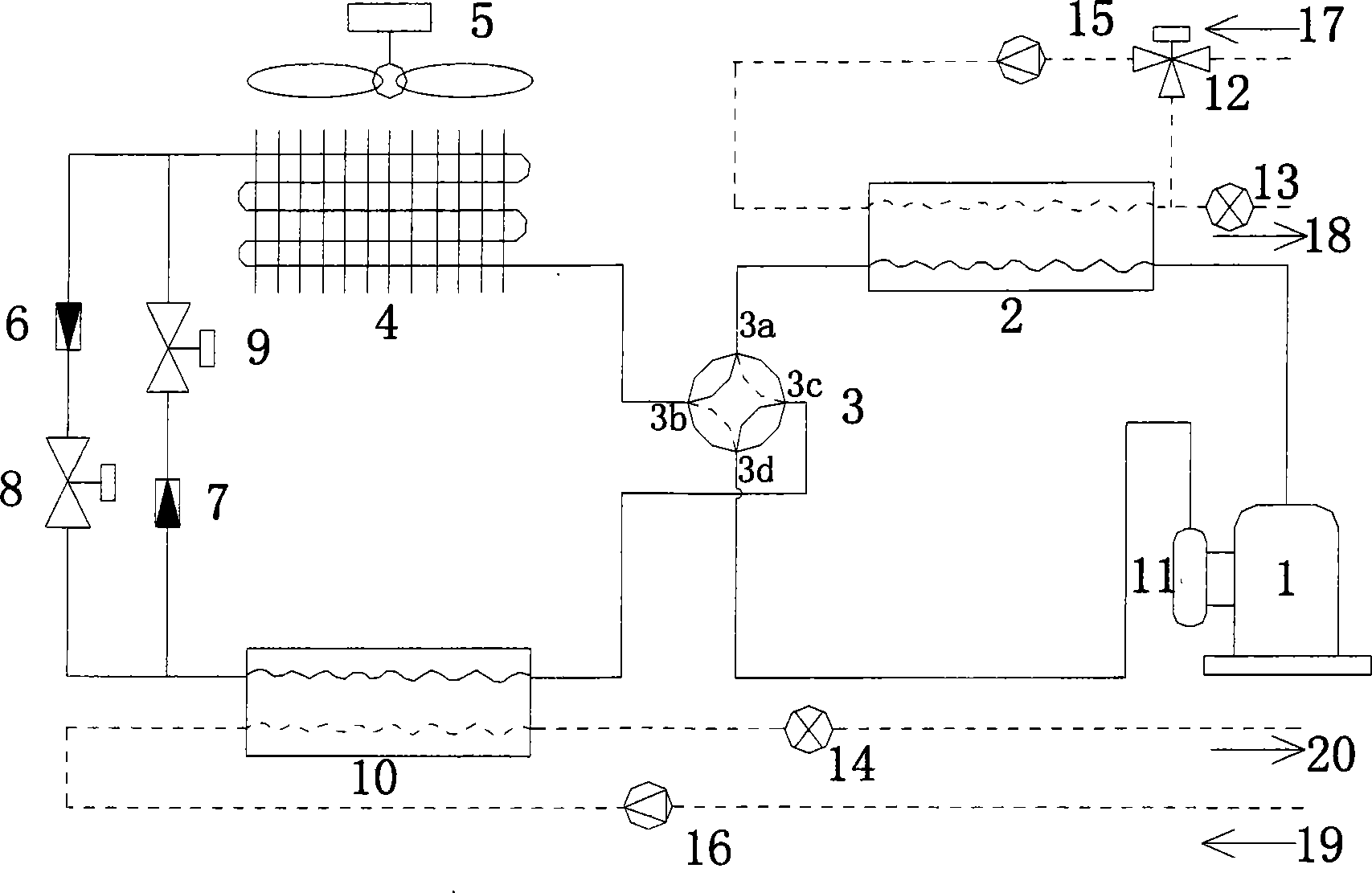

Cascade energy usable variable capacity family energy resource system

InactiveCN101240949AAvoid wet compressionRealize the supplyEnergy recovery in ventilation and heatingHeat pumpsSolenoid valveEngineering

The present invention provides an adjustable volume family energy system utilized by step energy, the invention includes a compressor, a hot water heat exchanger, a four-way reversing valve, an outdoor wind cooling pipe coil, a first check valve, a second check valve, a first electronic expansion valve, a second electronic expansion valve, an air conditioning hot and cold heat exchanger, a gas-liquid separator, a water side electric three-way control way, a first solenoid valve, a second solenoid valve, a first water pump, a second water pump. These parts form a refrigerant loop, a domestic hot-cold water loop, realize refrigerating and hot water supplying, single refrigerating, single hot water supplying, single warm supplying, warm supplying and hot water supplying five modes. The control part of the refrigerant loop only has four-way reversing valve and electronic expansion valve in traditional air conditioning system, does not exist refrigerant potential safety hazard. The function of each system is mainly realized by switch and adjustment of the water side two solenoid valves and electric three-way control way, has a simple control, credible security.

Owner:SHANGHAI JIAO TONG UNIV

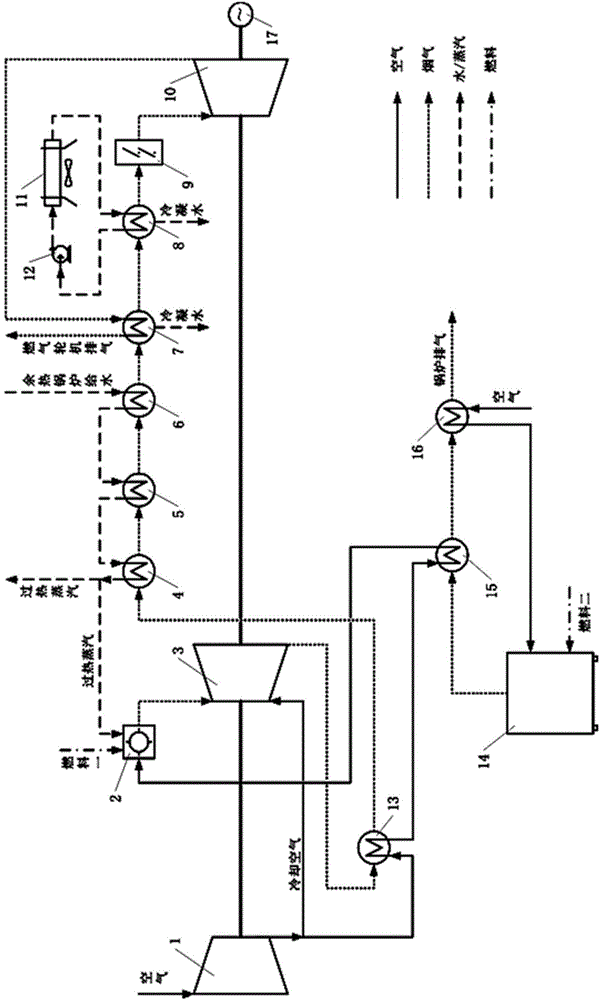

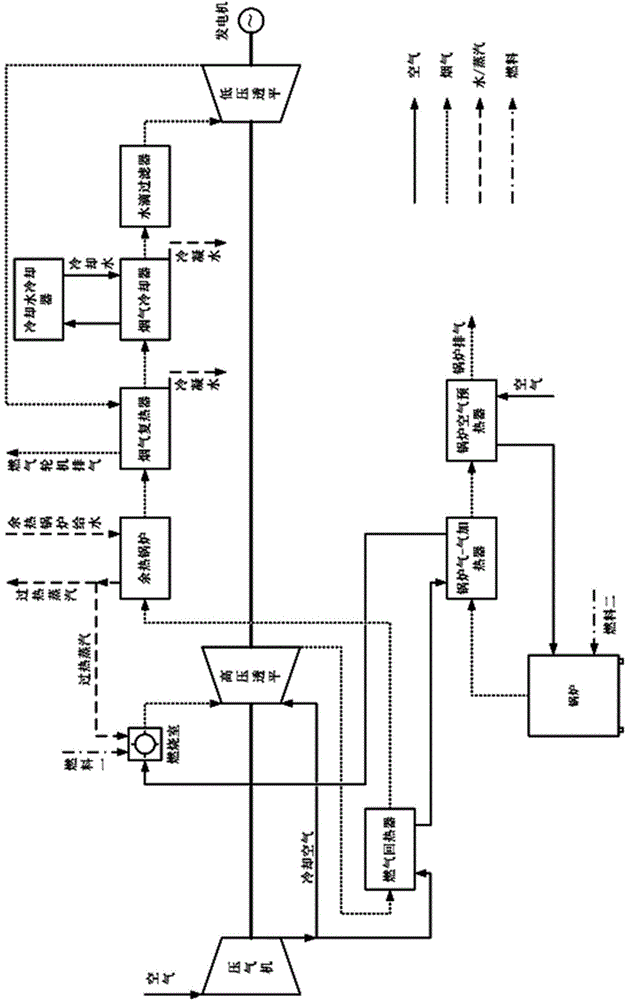

Dual-fuel steam injection direct-inverse gas turbine combined cycle

ActiveCN104533621ACombined Cycle Efficiency ImprovementEmission reductionTurbine/propulsion engine coolingGas turbine plantsSystem integrationBrayton cycle

The invention relates to a clean fuel and biomass fuel dual-fuel steam injection direct-inverse gas turbine combined cycle. A backheating type steam injection-inverse gas turbine combined cycle form is adopted for a gas turbine, and clean fuel is adopted for the gas turbine; flue gas produced when biomass fuel burns in a boiler indirectly heats the air entering a combustion chamber of the gas turbine first and then preheats the air entering the boiler, wherein the steam cyclically produced by the gas turbine can be used for supplying heat to the outside. According to the dual-fuel steam injection direct-inverse gas turbine combined cycle, the gradient utilization principle of energy is utilized, an external combustion method and the advanced steam injection direct-inverse Brayton cycle are organically combined through system integration, the energy utilization efficiency of the biomass fuel can be substantially improved, the proportion of the biomass fuel to the clean fuel is adjustable, and self-balance of water consumption and water recovery for steam injection can be achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Nano hydrogenation catalysts composition and method of producing the same

ActiveCN101172235ALarge particle sizeHigh surface areaMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsSolubilityInorganic oxide

The invention discloses nano-composite hydrogenation catalyst composition and a preparation method thereof. The catalyst composition includes active metal oxide and the composition of porous melt-resistant inorganic oxide. By utilizing the property that the precursors of the melt-resistant inorganic oxide, promoter oxide and the active metal oxide can form super-solubility nanometre micelle under the existence of surfactant with the VB value less than 1 and hydrocarbon composition, the invention facilitates the precursors and the hydroxide formed by precipitant to be in situ synthesized inside a micelle, so as to avoid the augment of the particle diameter of the oxide, and to facilitate the particle diameter to be in a single dispersed state. The catalyst of the invention has high specific surface area, large pore volume, large pore diameter, wide application range and good activity stability. The method of the invention has the advantages that the nano particle diameter is easy to be controlled, the distribution range of the particle diameter is narrow and the proportion of the carrier and the active component can be adjusted. The amount of the surfactant and the hydrocarbon component used for the method of the invention is less, and the cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and apparatus for adaptively controlling signals

ActiveUS20090097581A1Enhance peak reductionReduce peakGain controlPower amplifiersFrequency spectrumSignal quality

A signal processing system according to various aspects of the present invention includes an excursion signal generator, a scaling system and a filter system. The excursion signal generator identifies a peak portion of a signal that exceeds a threshold and generates a corresponding excursion signal. The scaling system applies a real scale factor to contiguous sets of excursion samples in order to optimize peak-reduction performance. The filter system filters the excursion signal to remove unwanted frequency components from the excursion signal. The filtered excursion signal may then be subtracted from a delayed version of the original signal to reduce the peak. The signal processing system may also control power consumption by adjusting the threshold. The signal processing system may additionally adjust the scale of the excursion signal and / or individual channel signals, such as to meet constraints on channel noise and output spectrum, or to optimize peak reduction. The magnitude threshold, excursion signal and / or individual channel signals may also be adaptively adjusted based on, for example, a channel signal quality such as a noise level specification.

Owner:CRESTCOM INC

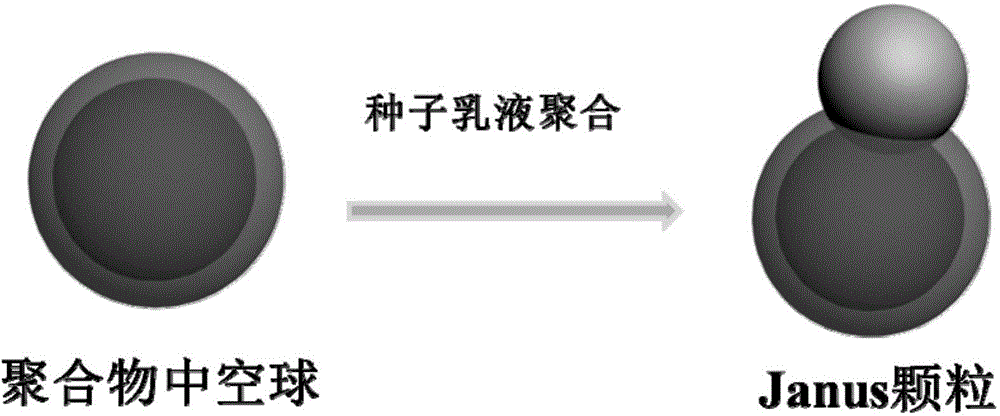

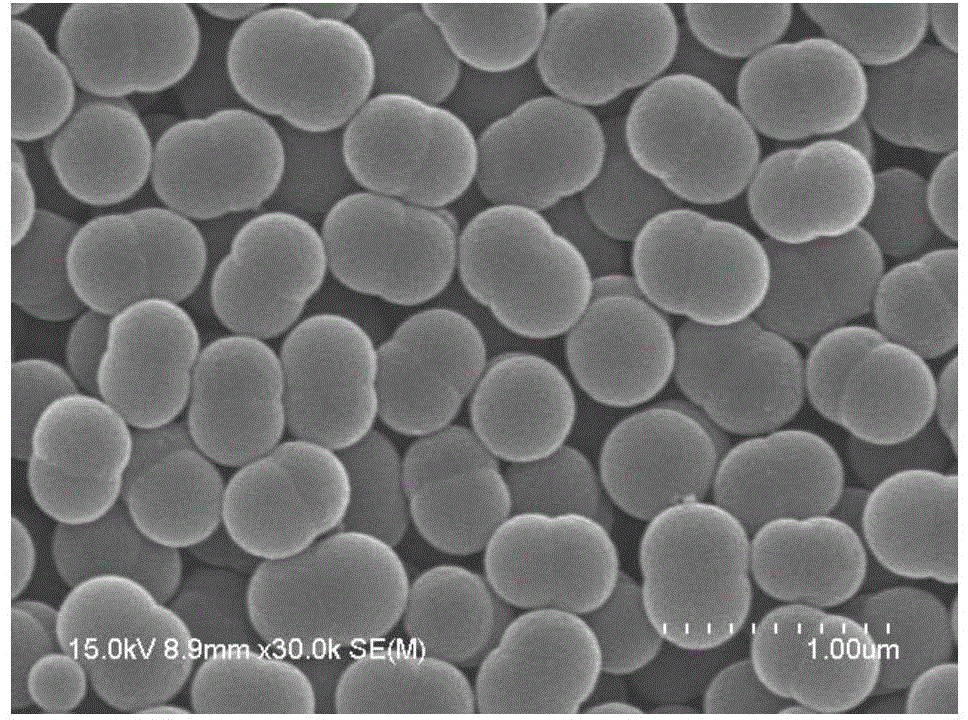

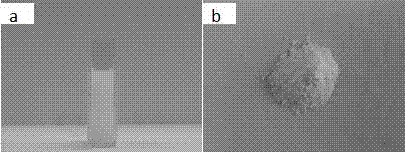

A controllable batch preparation method of organic/inorganic hybrid Janus particles

InactiveCN105440218AStructure Precise ControlScale adjustableTransportation and packagingMixingEmulsionSilane coupling

A controllable batch preparation method of organic / inorganic hybrid Janus particles is disclosed. The method includes 1) dispersing polymer hollow sphere particles into water to obtain a seed emulsion, 2) adding a silane coupling agent emulsion into the seed emulsion, polymerizing under mechanical stirring, and performing phase separation to obtain a Janus-particle emulsion, with the silane coupling agent emulsion comprising a silane coupling agent monomer and a polymerization initiator, and 3) preparing the Janus-particle emulsion obtained in the step 2) into the Janus particles with separated organic and inorganic parts by a spray drying manner or a freeze drying manner. The structure of the Janus particles prepared by the method can be accurately controlled, and the ratio of the organic part to the inorganic part is adjustable. The method is simple in reaction and can be applied to mass production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method and apparatus for adaptively controlling signals

ActiveUS20090191907A1Enhance peak reductionReduce peakModulated-carrier systemsGain controlSignal qualityFrequency spectrum

A signal processing system according to various aspects of the present invention includes an excursion signal generator, a scaling system and a filter system. The excursion signal generator identifies a peak portion of a signal that exceeds a threshold and generates a corresponding excursion signal. The scaling system applies a real scale factor to contiguous sets of excursion samples in order to optimize peak-reduction performance. The filter system filters the excursion signal to remove unwanted frequency components from the excursion signal. The filtered excursion signal may then be subtracted from a delayed version of the original signal to reduce the peak. The signal processing system may also control power consumption by adjusting the threshold. The signal processing system may additionally adjust the scale of the excursion signal and / or individual channel signals, such as to meet constraints on channel noise and output spectrum, or to optimize peak reduction. The magnitude threshold, excursion signal and / or individual channel signals may also be adaptively adjusted based on, for example, a channel signal quality such as a noise level specification.

Owner:CRESTCOM INC

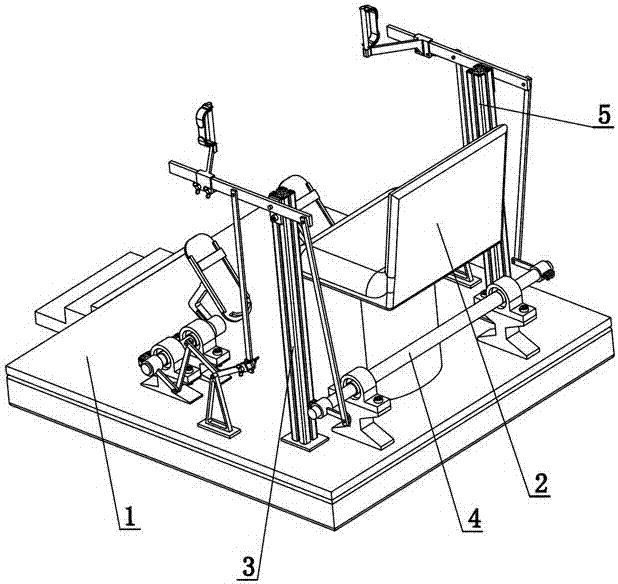

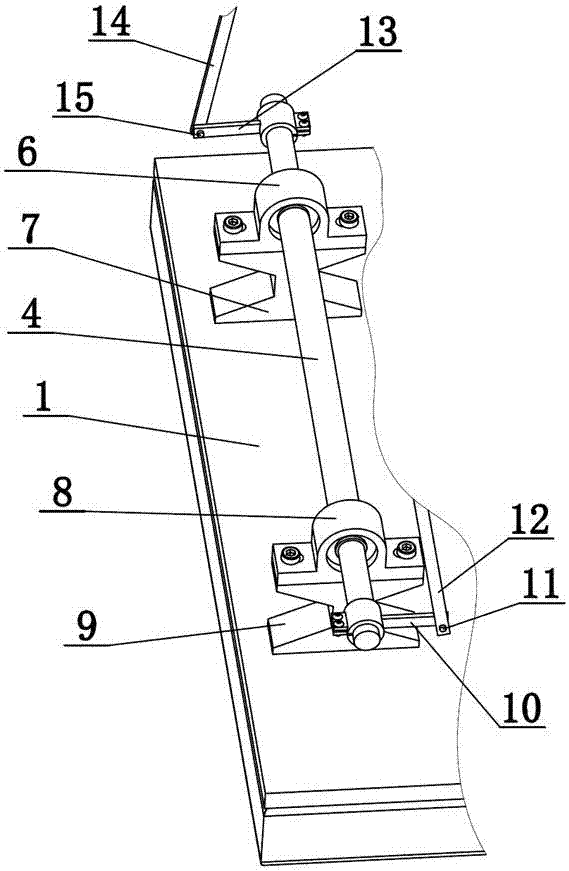

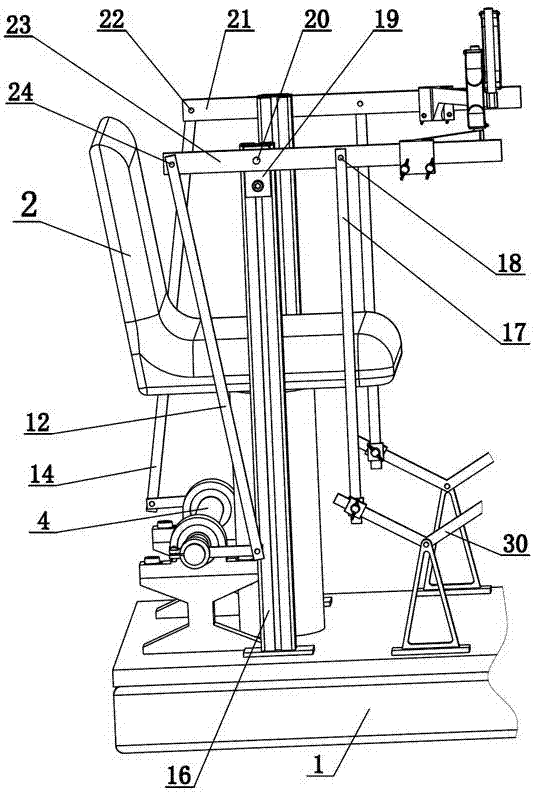

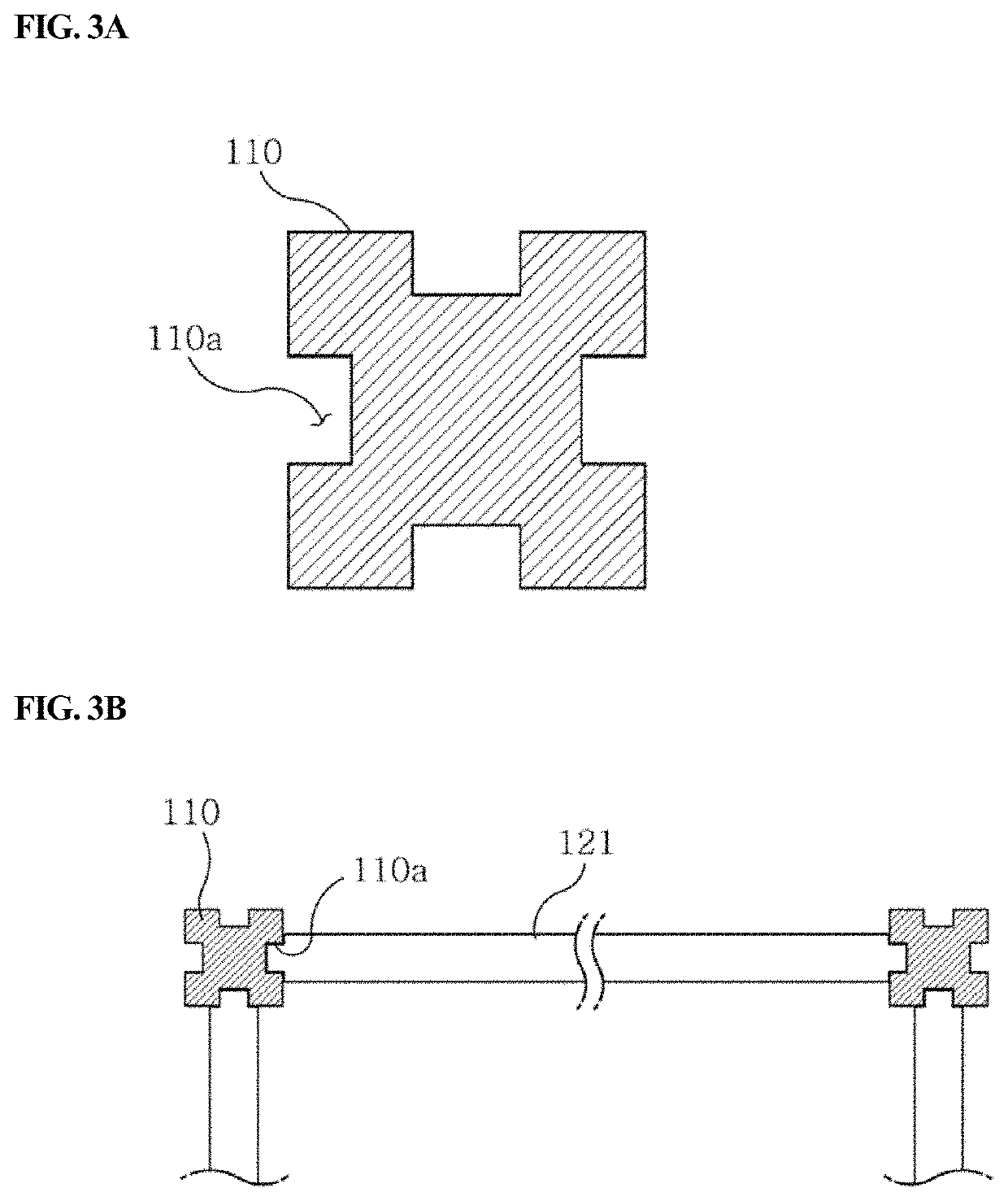

Rehabilitation trainer for simultaneous movement of four limbs of hemiplegic patient

InactiveCN106963602AImprove comfortImprove comfort and recoveryChiropractic devicesIndividual personRehabilitation training

The invention provides a rehabilitation trainer for simultaneous movement of four limbs of a hemiplegic patient. The rehabilitation trainer comprises a base, a seat, a left upper and lower limb rehabilitation training mechanism and a right upper and lower limb rehabilitation training mechanism. The left upper and lower limb rehabilitation training mechanism and the right upper and lower limb rehabilitation training mechanism achieve that the up-and-down swing directions of the upper limbs on the left side and the right side are opposite through connecting rod mechanisms and the rehabilitation movement directions of the lower limbs on the two sides are opposite through rod type transmission mechanisms, gait four-limb simultaneous rehabilitation movement is achieved, proportional adjustment of single side upper and lower limb rehabilitation movement ranges and upper and lower limb initial movement position adjustment are achieved, the comfort of the patient is improved, no power needs to be provided externally, the cost is low, and the rehabilitation trainer is conveniently used by the patient individually.

Owner:ANYANG INST OF TECH

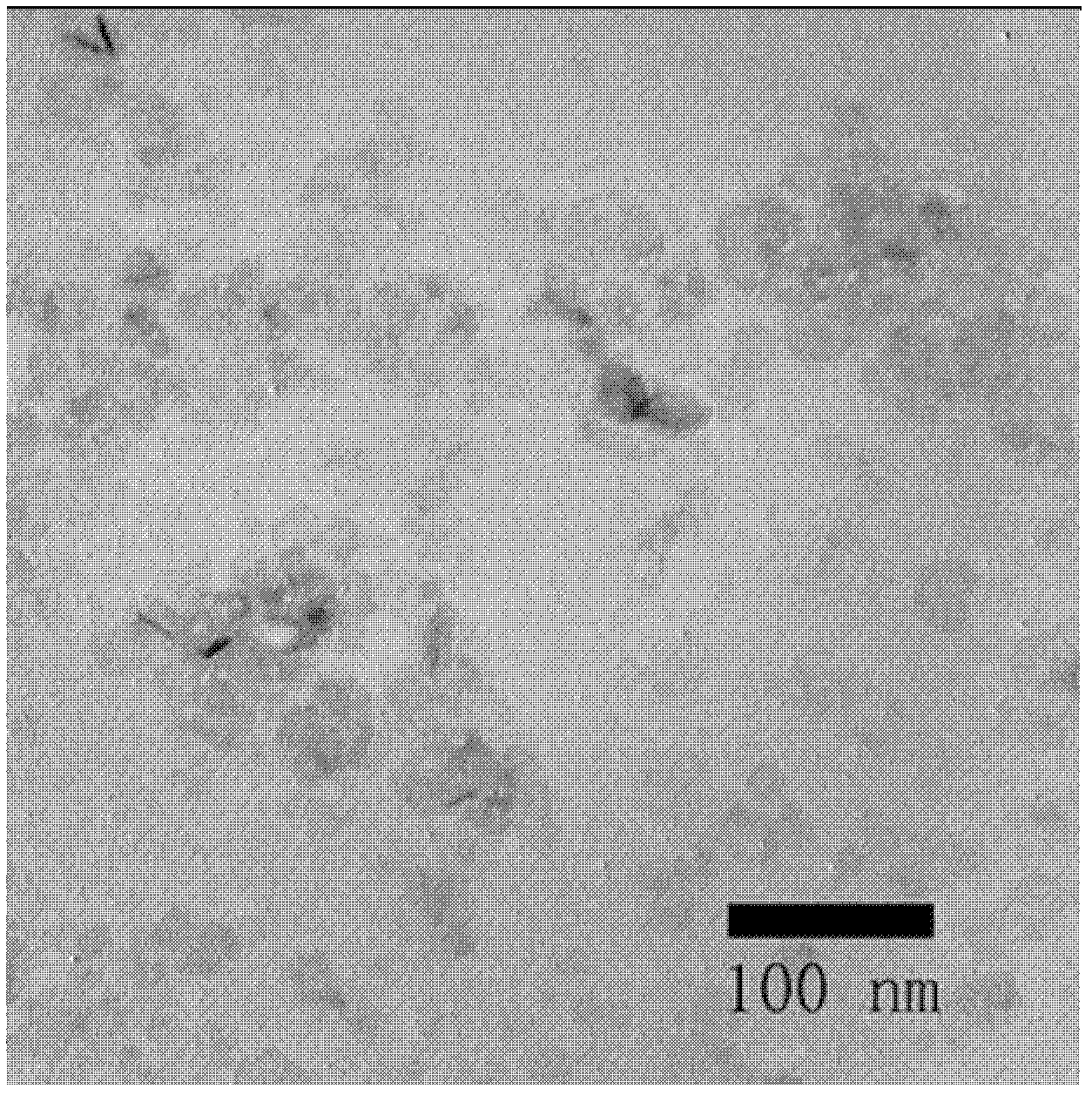

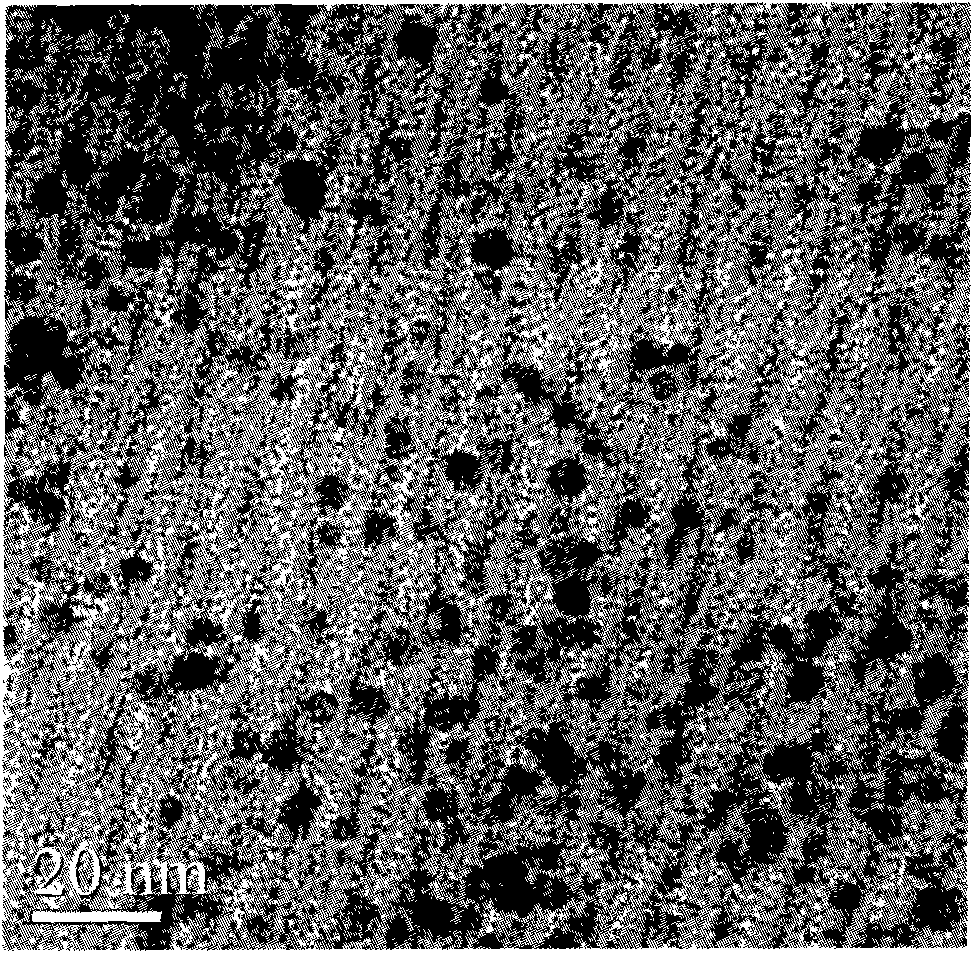

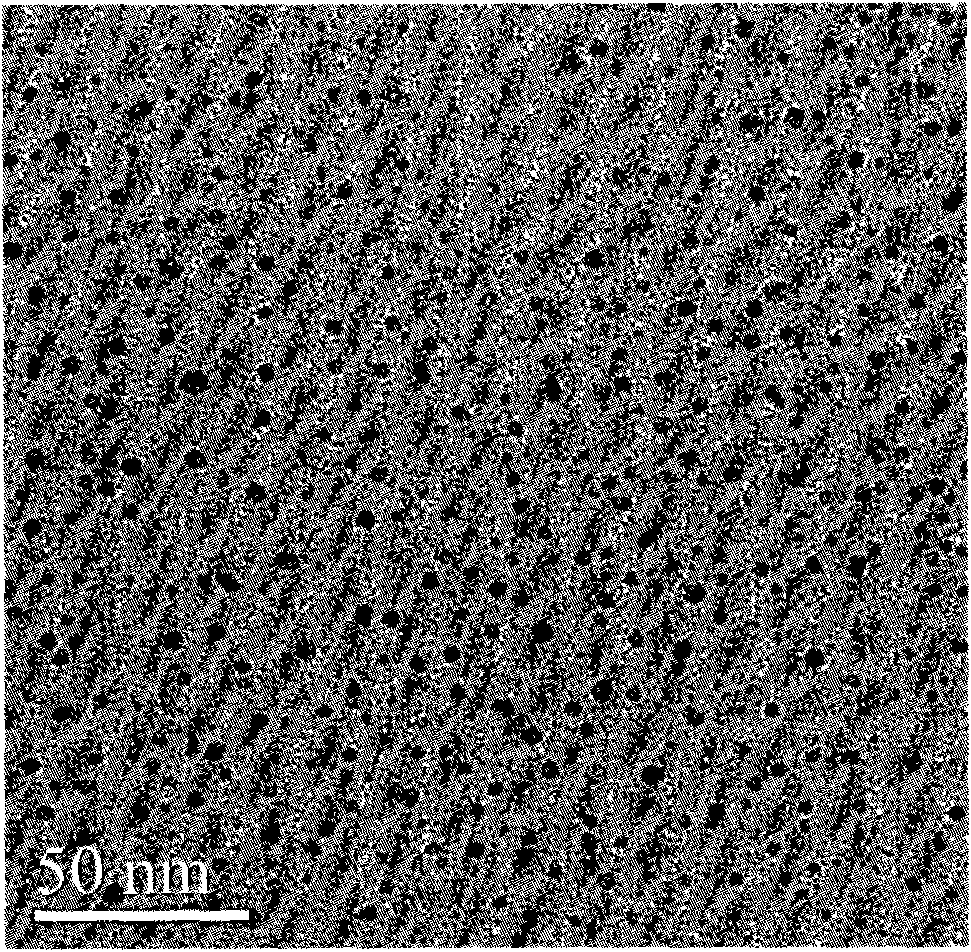

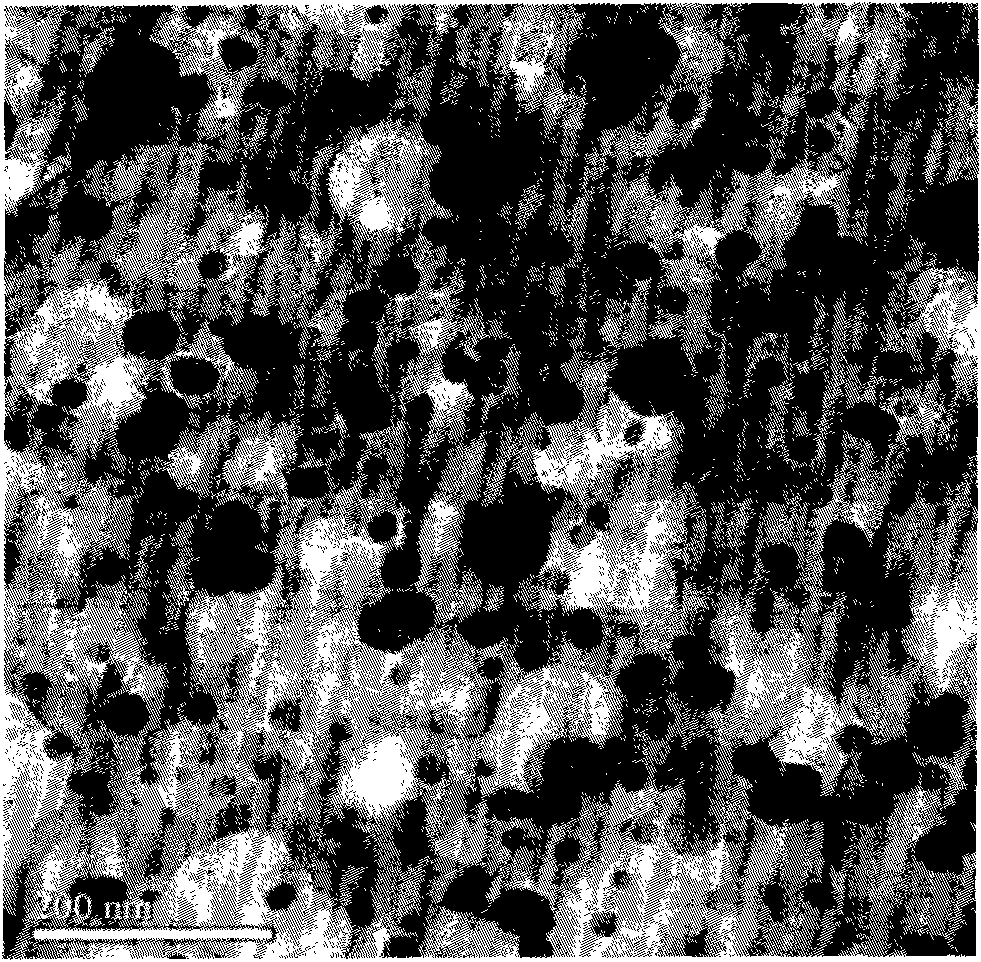

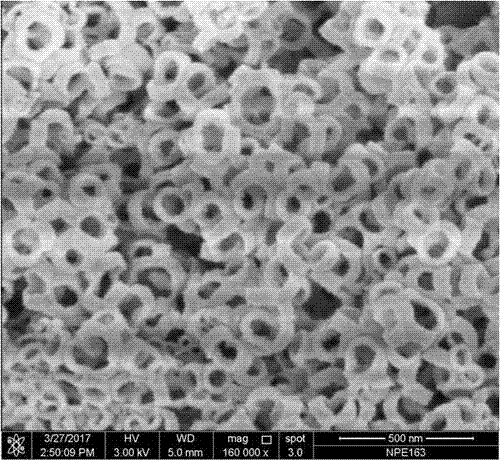

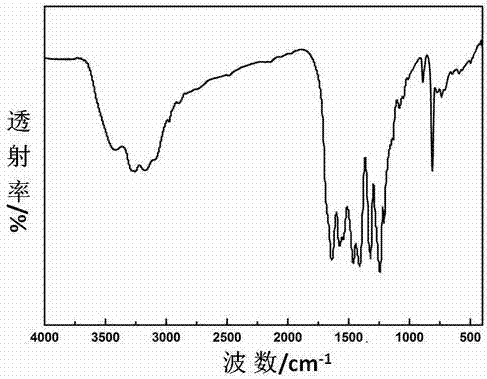

Multi-element composite metal oxide hollow nanosphere and preparation method thereof

InactiveCN102671645AScale adjustableControllable ratioMaterial nanotechnologyOther chemical processesMaterials scienceCenosphere

The invention relates to multi-element composite metal oxide hollow nanospheres and a preparation method thereof. The method comprises the following steps of dispersing carbon spheres in a hydrotalcite colloidal solution, allowing hydrotalcite flakes to be adsorbed on the surface of the carbon spheres by the action of electrostatic attraction, removing the supernatant containing non-adsorbed hydrotalcite flakes by centrifugal separation to obtain a pure hydrotalcite-coated carbon sphere material, and then calcining to obtain multi-element composite metal oxide hollow nanospheres which have uniform size and controllable metal element proportions. The general formula of the hollow nanospheres is MIIO / MIII2O3, wherein MII represents bivalent metal cations, MIII represent trivalent metal cations; and the specific surface area of the hollow nanospheres is 140 to 240 m<2> / g. The multi-element composite metal oxide hollow nanospheres have good application prospects in the fields of catalysis, adsorption and sustained release drug delivery.

Owner:BEIJING UNIV OF CHEM TECH

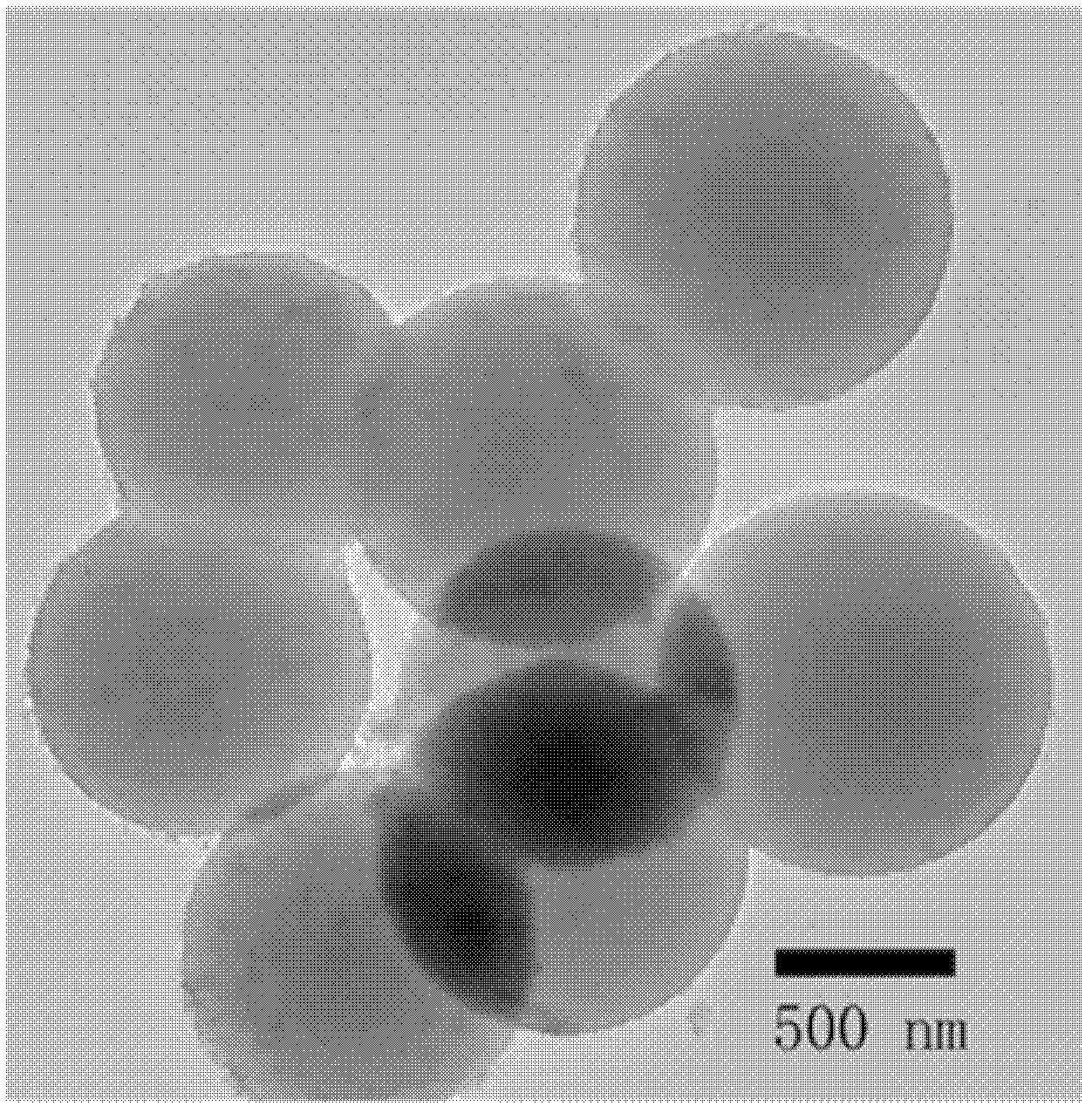

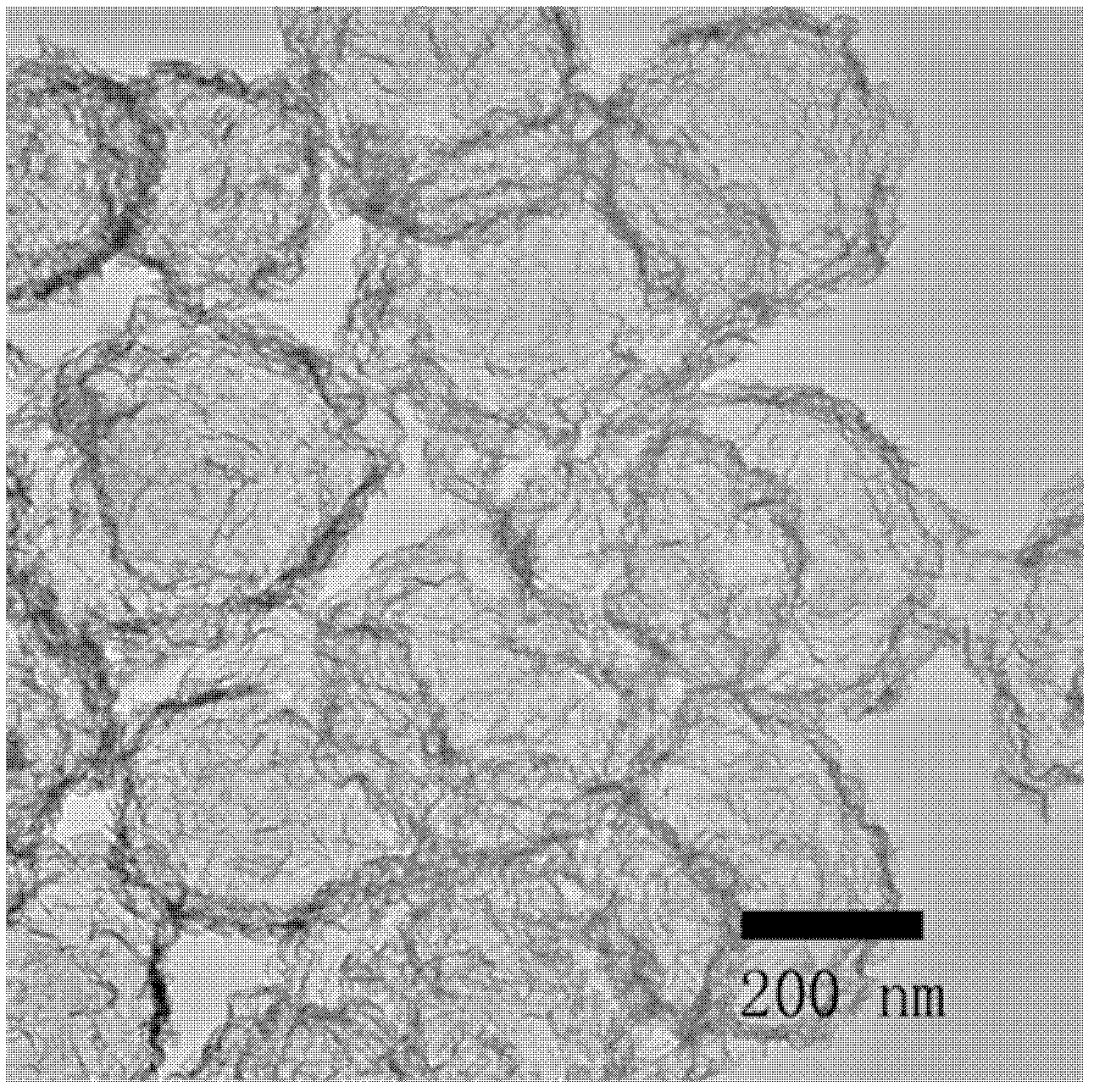

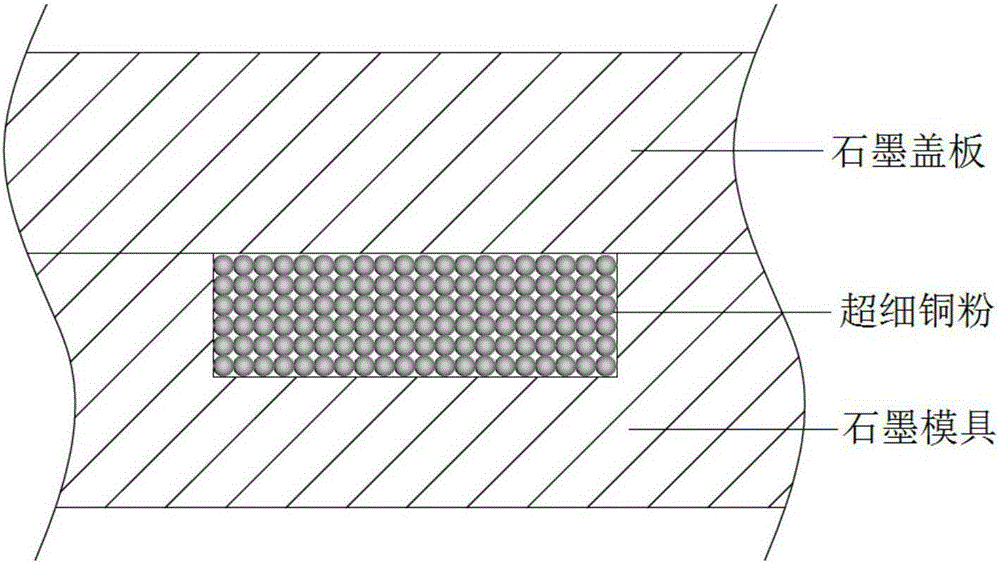

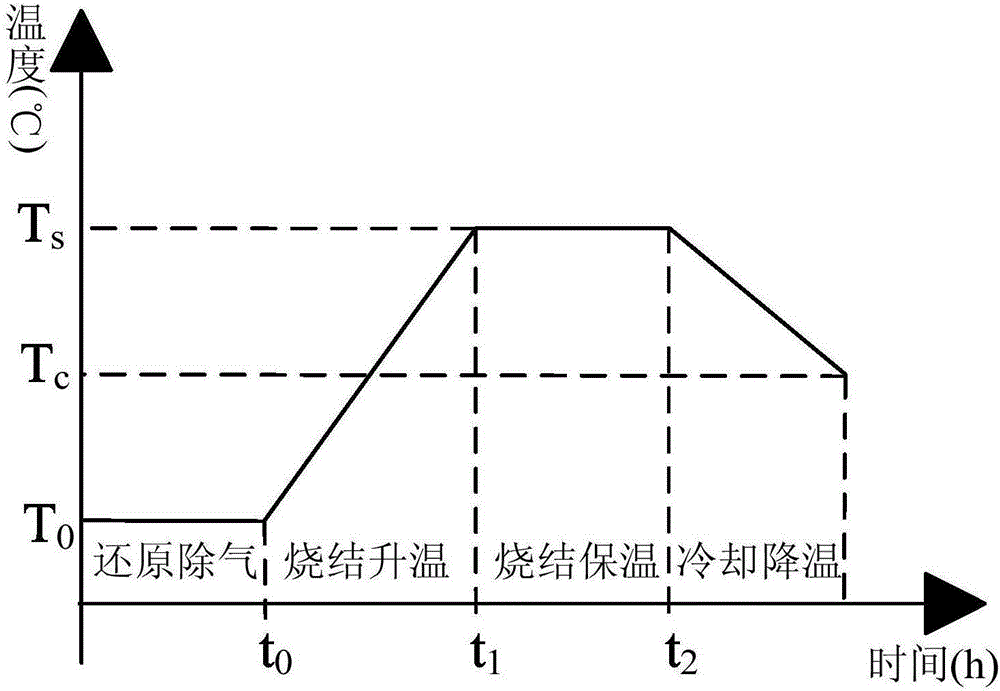

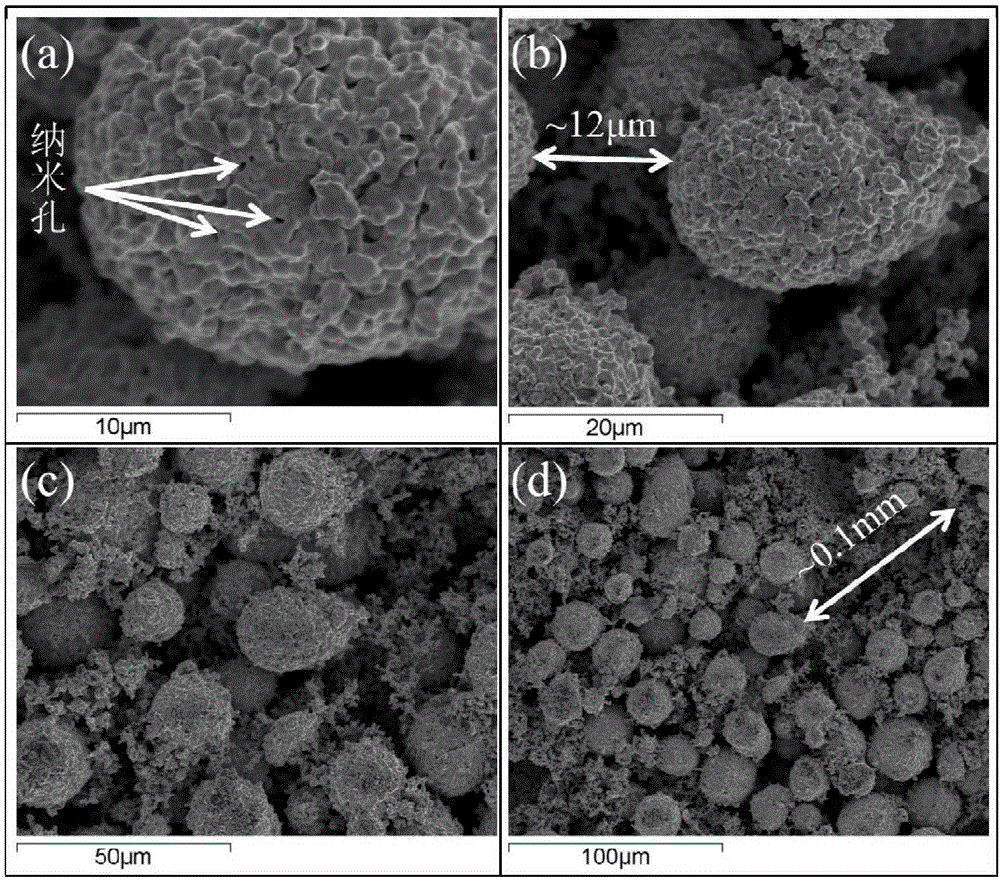

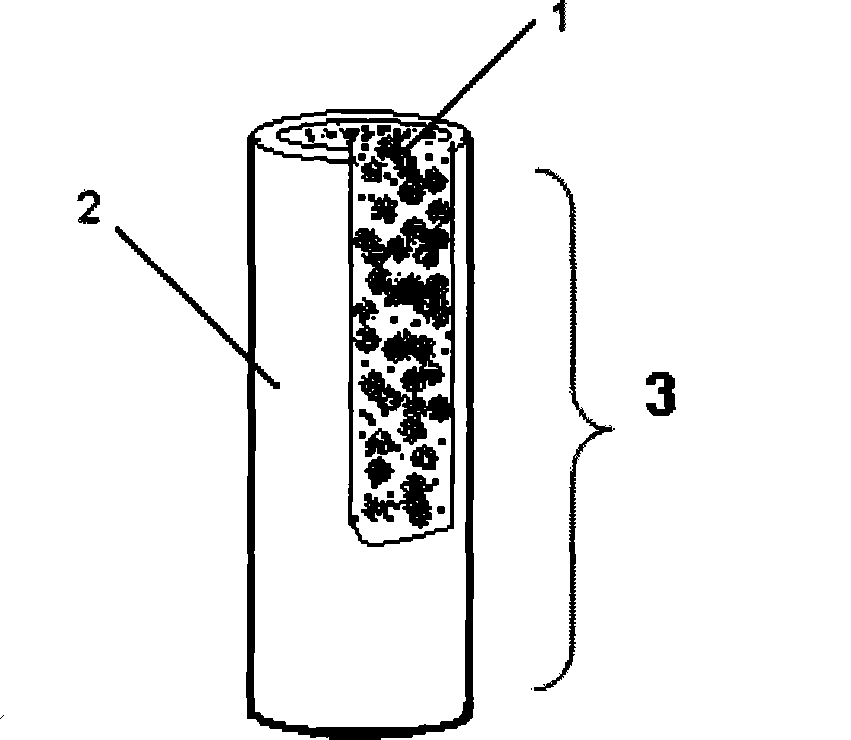

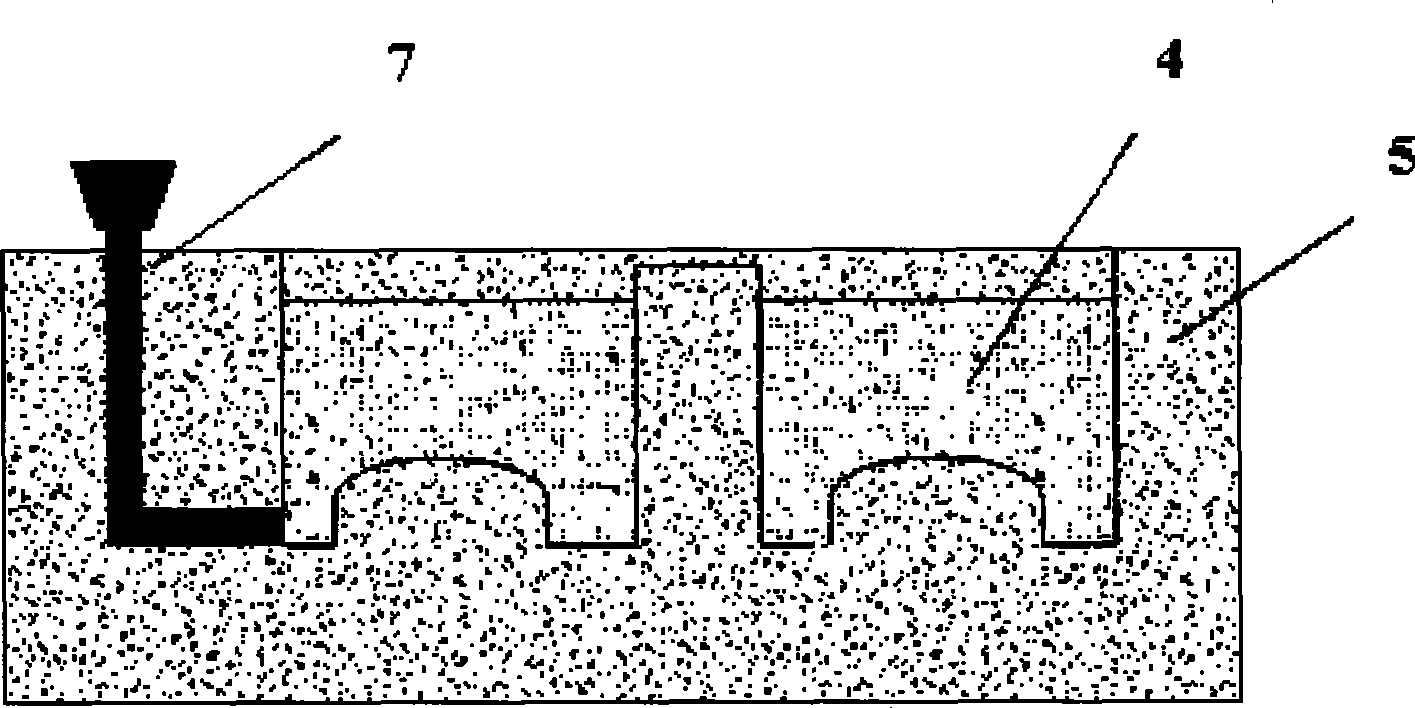

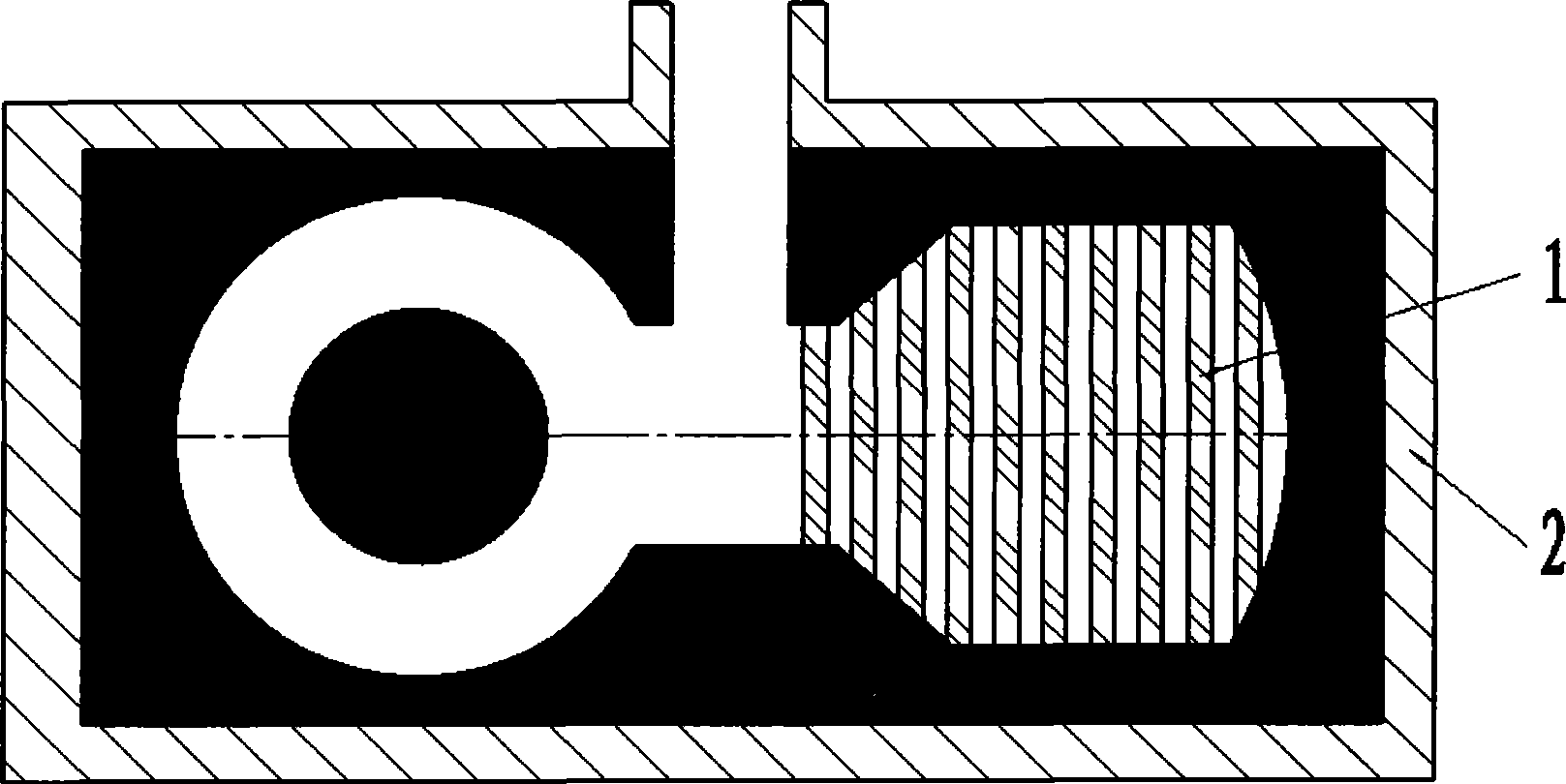

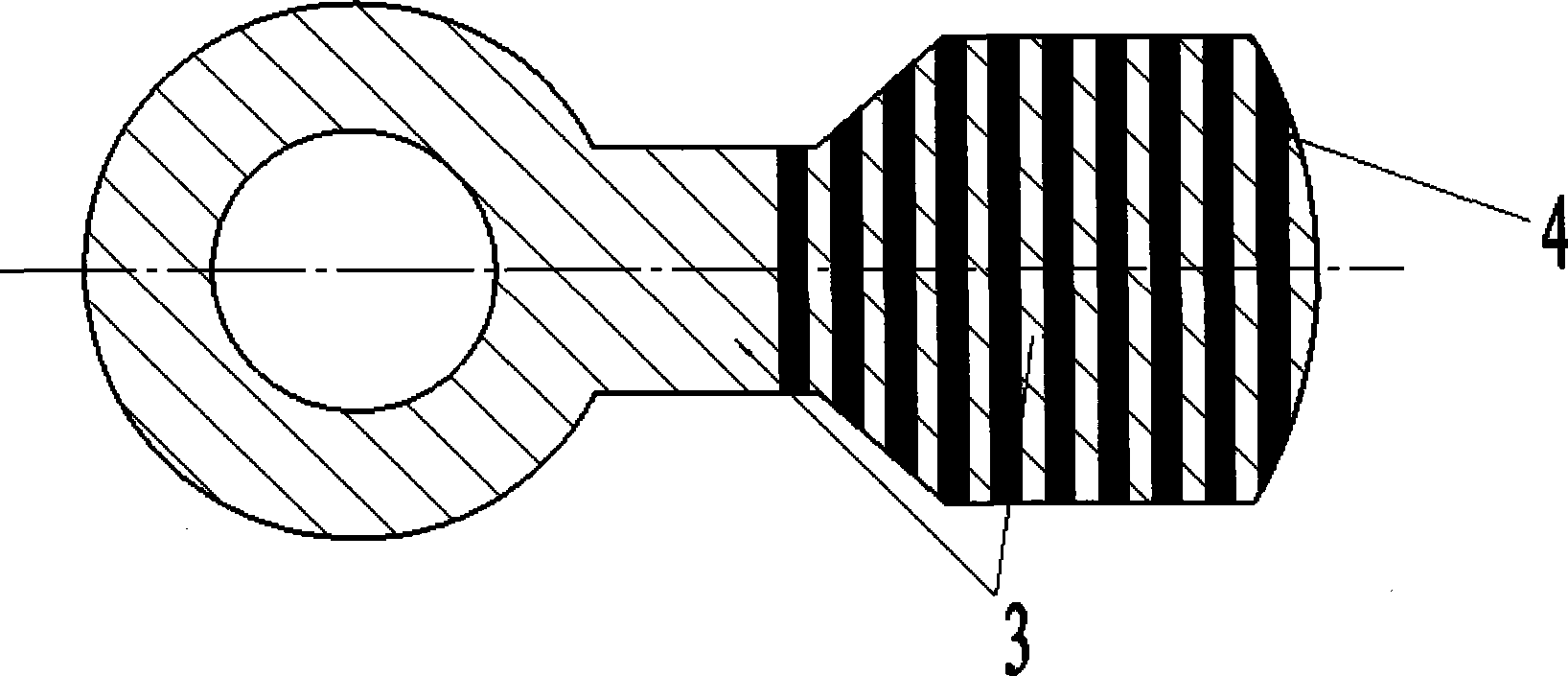

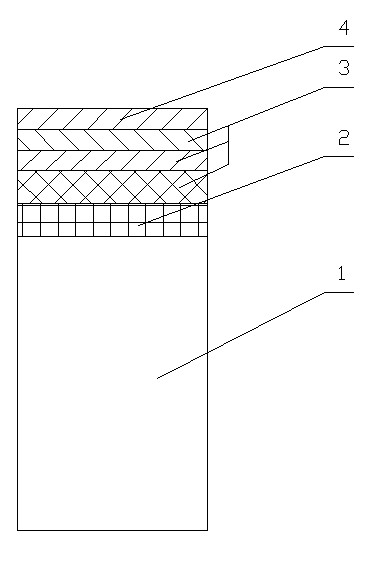

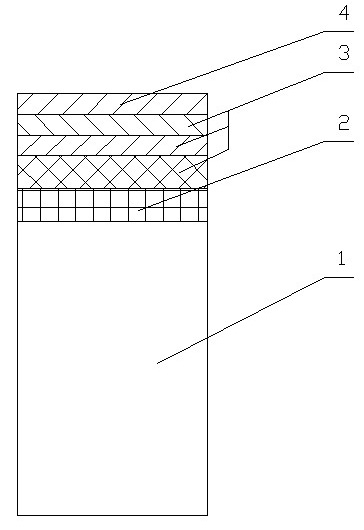

Preparation method for scale-adjustable nano porous metal material

The invention discloses a preparation method for a scale-adjustable nano porous metal material and belongs to the field of porous material preparation. A pore-forming material is added to superfine metal powder, compression molding of the superfine metal powder is conducted, and then the superfine metal powder is sintered in a vacuum sintering furnace to obtain the porous material. The interior of the porous material contains multiple pore scales of nano-micron-milli, and the dual-adjustment of the inside pore scale of the porous material and the surface roughness scale of a metallic matrix can be achieved by controlling the parameters such as the grain size of the metal powder, the content and grain size of the pore-forming material, the sintering temperature and the holding time and the follow-up treatment process, so that the porous material has super hydrophilicity, and the efficiency of boiling heat transferring is significantly improved. The preparation method for the scale-adjustable nano porous metal material is low in cost, easy to operate and reliable in technology; the product can be used for a wick of a heat pipe, the evaporating surface of an evaporator and other boiling phase-changing heat transferring devices, so that the preparation method for the scale-adjustable nano porous metal material has good application prospects.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for accelerating plant growth by LED (Light Emitting Diode) light source

ActiveCN102326491APromote growthIncrease productionGreenhouse cultivationHorticulture methodsPhysicsRed light

The invention discloses a method for accelerating plant growth by an LED (Light Emitting Diode) light source, and the method has good growth acceleration action on the whole growth process of plants. The method is characterized in that an LED light source which can emit red light and blue light is used for irradiating plants to accelerate plant growth, wherein the ratio of the red light to the blue light is adjustable, the wavelength of the red light is 610-720 nanometers, and the wavelength of the blue light is 400-500 nanometers. The method for accelerating plant growth is mainly used for irradiating plants during greenhouse planting. According to irradiation, the average growth speed of the plant is about 3 times higher than the growth speed under the natural environment, thereby satisfying the requirements on chlorophyll, anthocyanin and carotene required by photosynthesis of plants in winter; thus, the harvesting time of vegetables and fruits are advanced by 20%, and the yield isincreased by 30-50%; and in addition, the sweetness of the vegetables and fruits is improved, and plant diseases and insect pests are reduced.

Owner:ZHANGJIAGANG RADIANT TECH

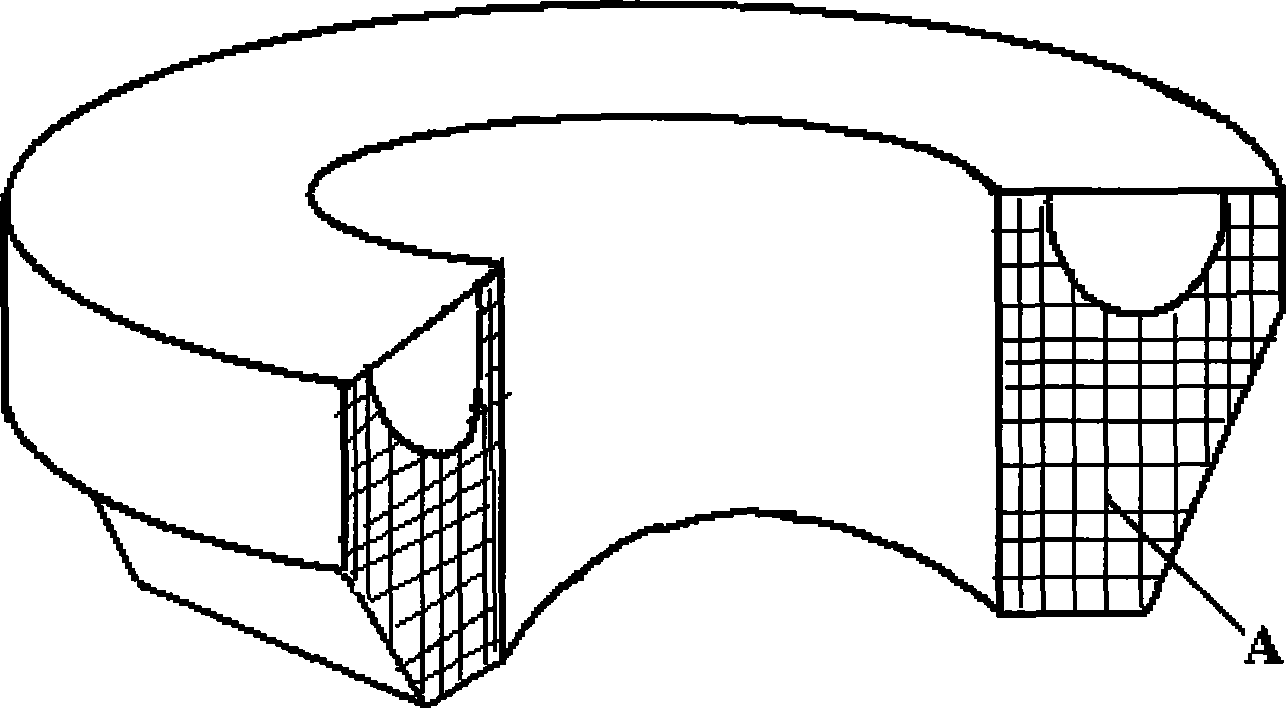

Method for preparing primary column shaped horniness phase composite wear-resistant grinder dish

The invention discloses a method for preparing a composite wear resistant abrasive disk with a protogenous columnar hard phase. The wear resistant abrasive disk prepared by the method is formed by pouring and compounding a high hardness columnar alloy hard phase and a high tenacity base metal. The method comprises the following steps: weaving an alloy powder core wire material into a framework similar to the shape of the abrasive disk, and pouring smelted high temperature base material molten steel into a die cavity of an abrasive disk casting mould; putting the woven framework similar to the shape of the abrasive disk into the casting die cavity filled with the high temperature base metal molten steel quickly, performing cast-infiltration, sintering or melting on the woven alloy powder core wire material framework by using the heat of the high temperature base metal molten steel so as to generate a highly-dispersed high hardness columnar alloy hard phase in situ; and cooling the phase at room temperature to produce the composite wear resistant abrasive disk using high-tenacity and high-strength metal as a base and containing the metallurgically-combined protogenous columnar hard phase. The composite wear resistant abrasive disk with the protogenous columnar hard phase has ultra wear resistance and good impact resistant toughness, and the service life of the abrasive disk is close to or exceeds the imported products of the same type.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

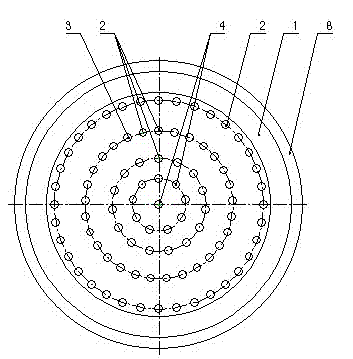

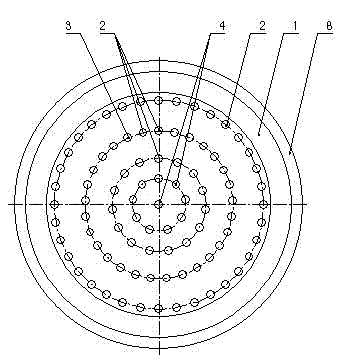

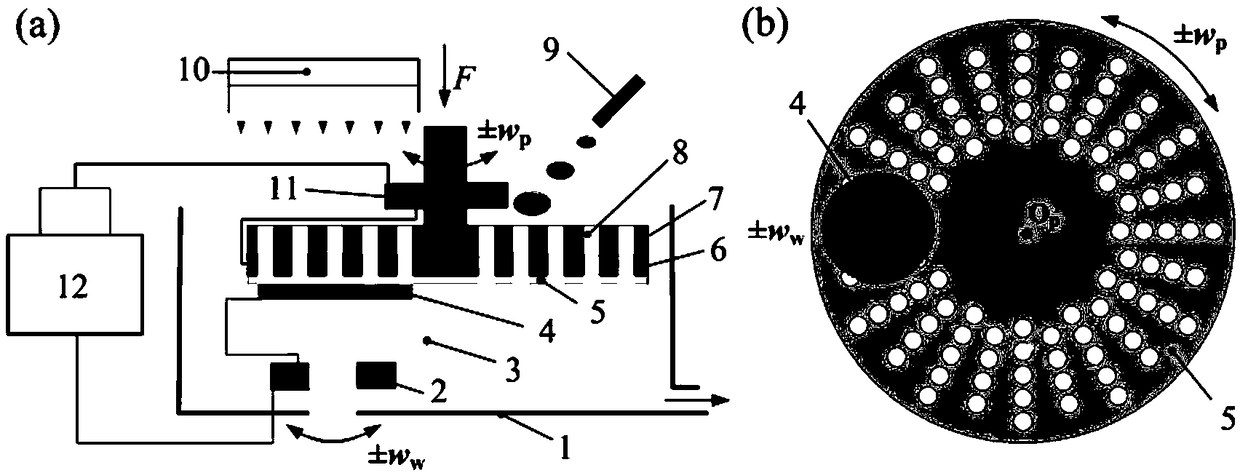

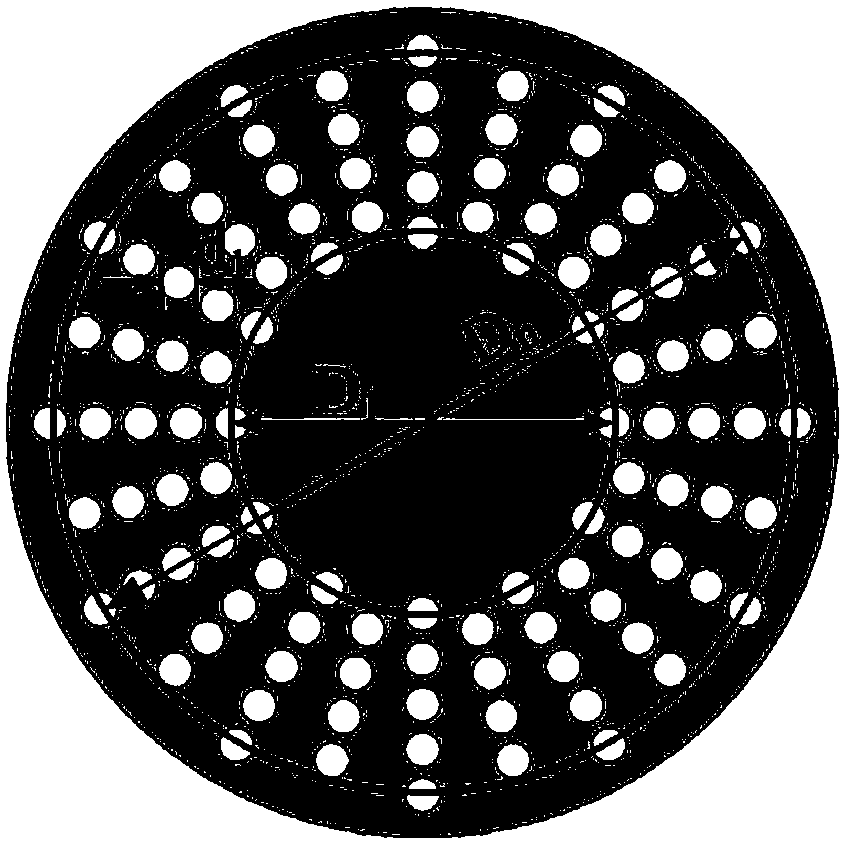

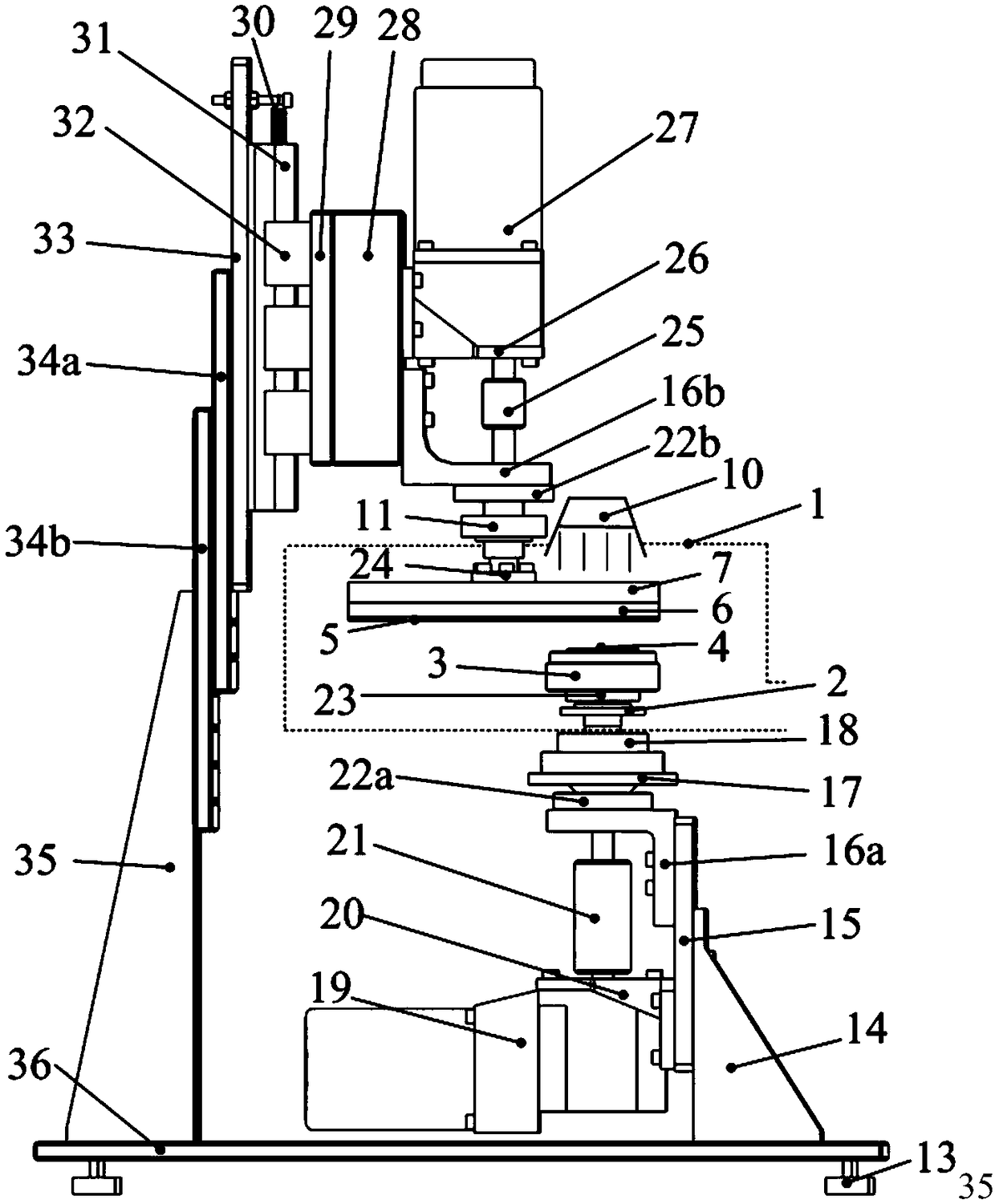

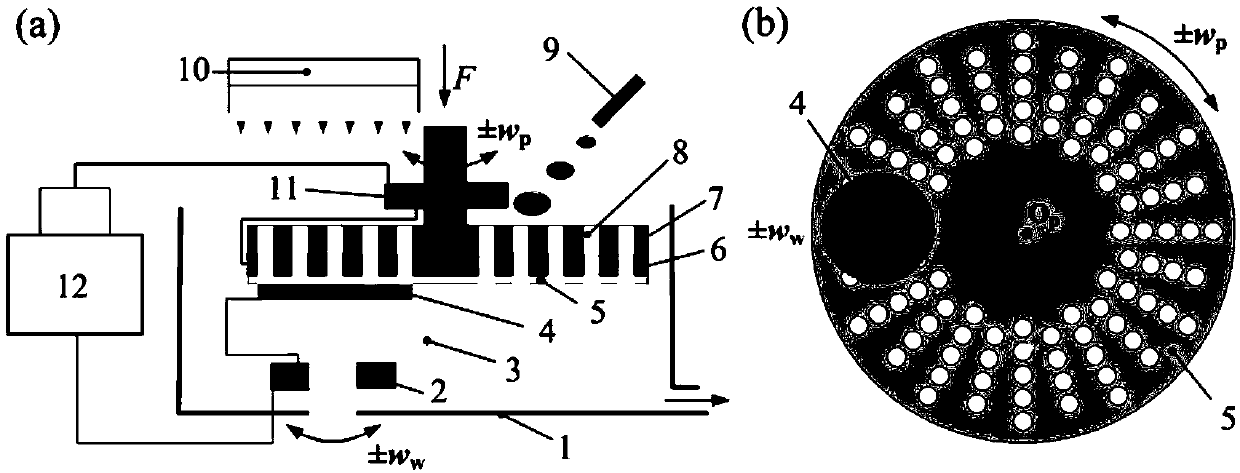

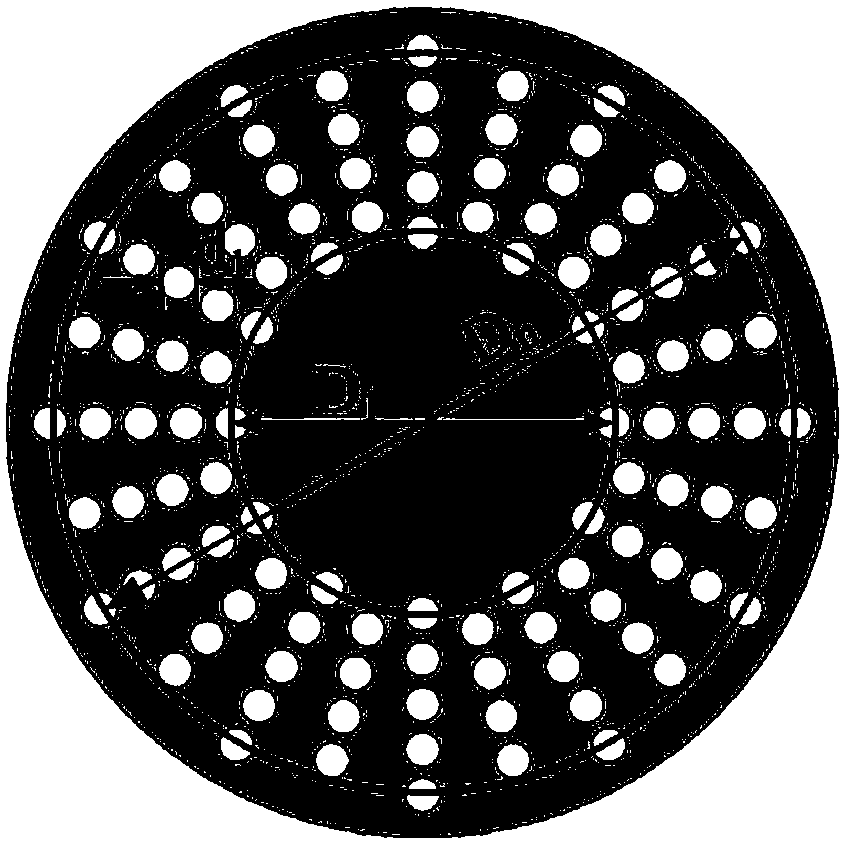

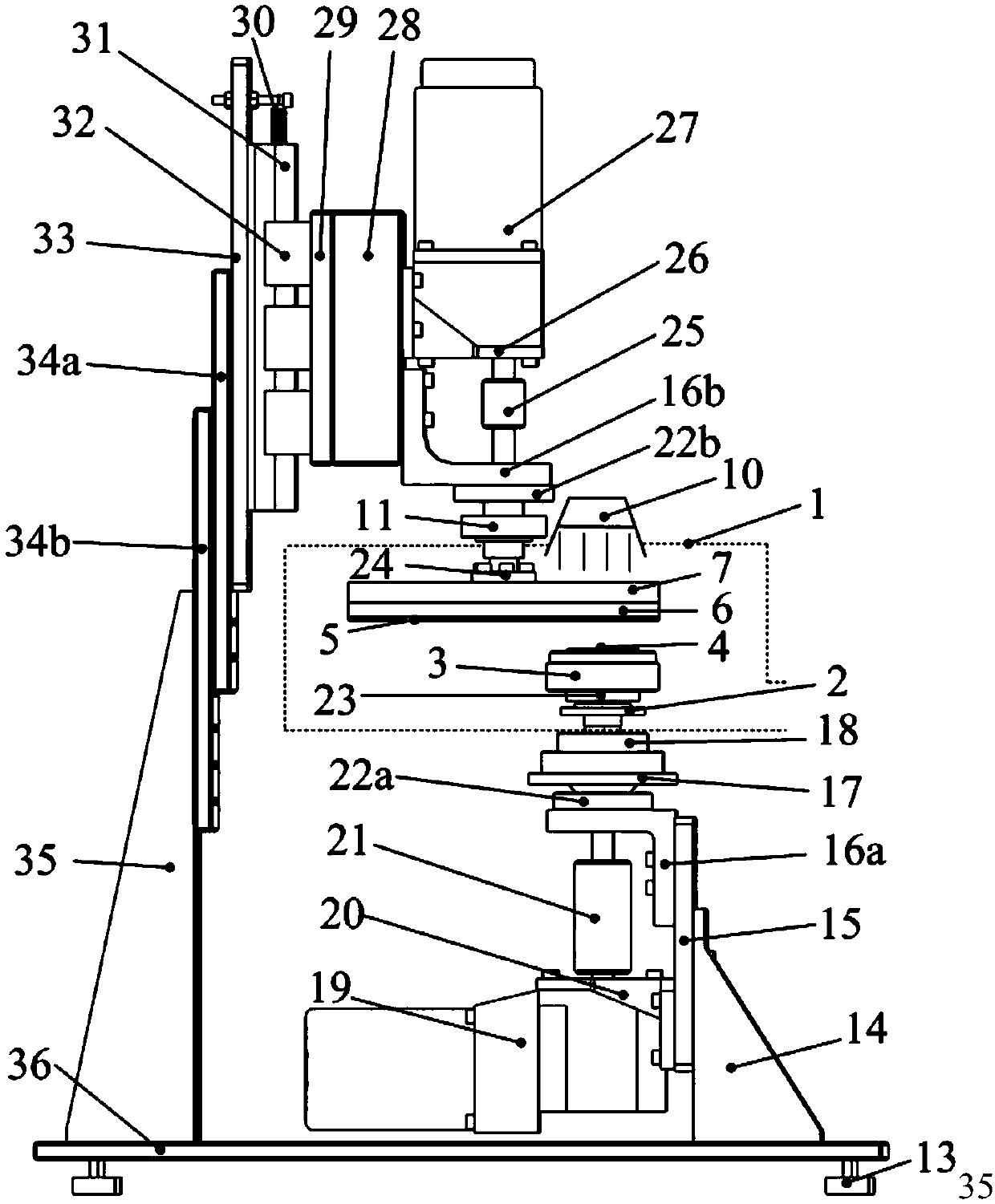

Semiconductor chip photo-electro-chemical mechanical polishing machining device

ActiveCN109465739AReduce roughnessFast removal rateGrinding machine componentsLapping machinesUltraviolet lightsSemiconductor chip

The invention discloses a semiconductor chip photo-electro-chemical mechanical polishing machining method and device. A chip is fixedly bonded to a polishing head through electrically-conductive adhesive. The lower portion of the chip is connected with a positive pole of an external power source through wires at an inner ring and an outer ring of an electrically-conductive sliding ring. A polishing pad is bonded to the bottom of a counter electrode disc. The counter electrode disc is fixed to the bottom of a polishing disc, and a through hole is machined in the position, corresponding to the polishing disc, of the counter electrode disc. The counter electrode disc is connected with a negative pole of the external power source through wires at the inner ring and the outer ring of an electrically-conductive sliding ring located above the counter electrode disc. Ultraviolet light transmitted by an ultraviolet light source can be cast to the surface of the chip through the through hole. Apolishing solution can be sprayed into the through hole and enter the contact area of the chip and the polishing pad. By means of the photo-electro-chemical mechanical polishing machining device, themachining method can be well implemented; the machining device has the advantages that the device is easy to operate and implement, and technological parameters can be flexibly adjusted; and the effects that in the practical machining process of the gallium nitride chip, the removal rate is high, and the surface quality achieved after machining is high are achieved.

Owner:DALIAN UNIV OF TECH

Method for preparing water dispersible metal nano-particles

The invention discloses a method for preparing water dispersible metal nano-particles. The method comprises the following steps of: adding metal ions or metal ion complex into nano cellulose dispersion; reducing the metal ions with a reducer under a certain temperature condition; curing the reduced metal ions in reaction liquid for a period of time; and separating the mixed solution by centrifuging and washing the separated product to obtain the water dispersible metal nano-particles. The prepared water dispersible metal nano-particles can be applied in the fields of biology, physics, chemistry, medicine and the like.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

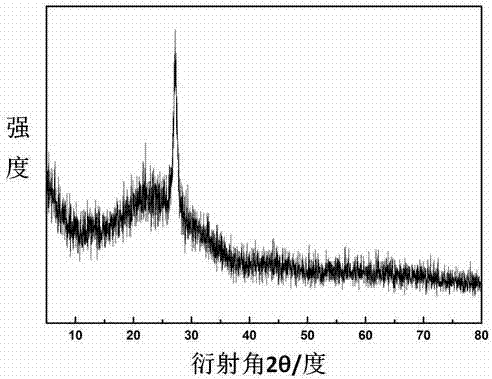

Graphite phased carbon nitride nano-ring material and its preparation method

InactiveCN107151003AUniform sizeUnique structureMaterial nanotechnologyNitrogen and non-metal compoundsPhotocatalytic degradationSilicon dioxide

The invention discloses a graphite phased carbon nitride (g-C3N4) nano-ring material and its preparation method, and belongs to the technical field of nanometer material preparation. The g-C3N4 nano-ring material is a ring structure, wherein the diameter of an outer ring is 20-1000 nm, the height of the outer ring is 20-200 nm, and the diameter of an internal circular hole is 10-800 nm. The preparation method includes steps of using melamine as a precursor and silicon dioxide nanosphere as a template; making the heated and sublimated precursor enter a high-temperature zone under the blowing of carrier gas to perform the heat polycondensation reaction; self-assembling a heat polycondensation product on the surface of the silicon dioxide nanosphere to form a g-C3N4 nano-ring; after cooling, removing the template by etching reagent, and drying the product to acquire the g-C3N4 nano-ring material. Compared with volume phase g-C3N4 formed by the heat polycondensation method, the g-C3N4 has higher specific surface area, more excellent photo-induced electron-cavity separating ability and better conductivity; thus the g-C3N4 can be used for photocatalysis hydrogen production, photocatalysis carbon dioxide reduction, and photocatalysis degraded organic matters, and other domains, and also can be used as carrier loaded catalyst or drug; therefore, the g-C3N4 nano-ring material has wide application prospect in energy source, environment and medicine domains.

Owner:DALIAN UNIV OF TECH

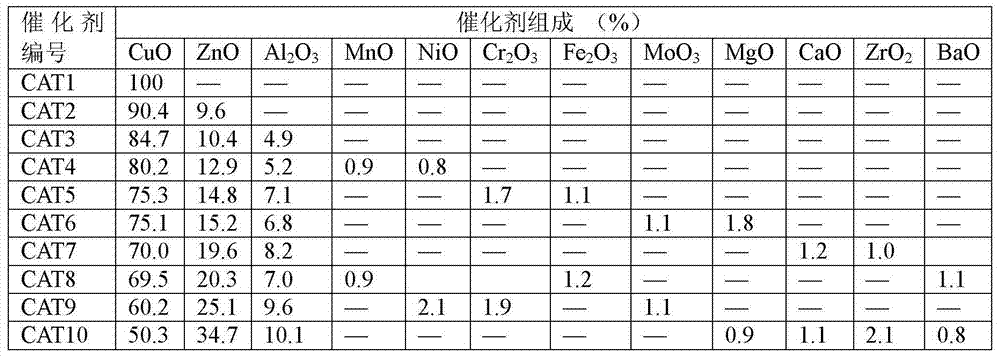

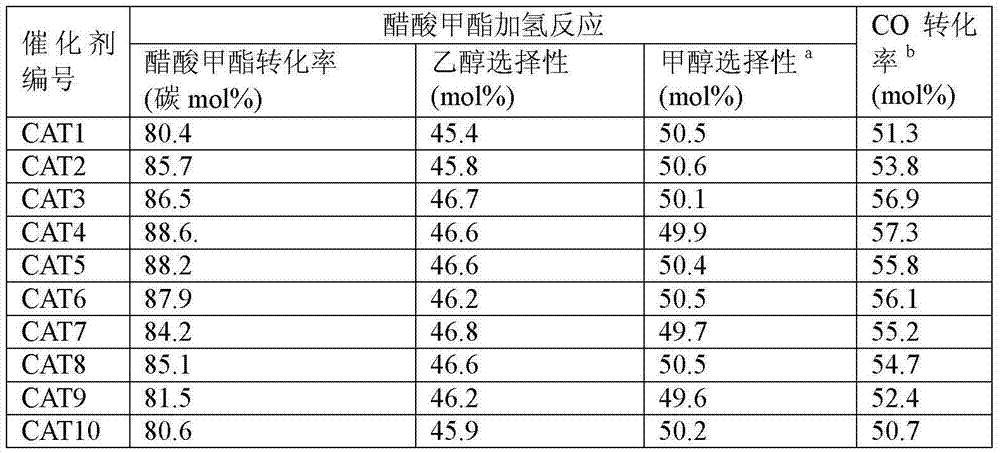

Method for production of ethanol and co-production of methanol

ActiveCN104710282AImprove hydrogenation activityBoost conversion generationOrganic compound preparationHydroxy compound preparationActive componentReaction temperature

The invention discloses a method for production of ethanol and co-production of methanol on one catalyst in a reactor by co-feeding of synthetic gas and acetic ester as the reaction raw materials. More specifically, the method for production of ethanol and co-production of methanol provided by the invention includes: passing the feed gas containing acetic ester and synthetic gas through a catalyst loaded reactor, under the conditions of a reaction temperature of 150-350DEG C, a reaction pressure of 0.1-20.0Mpa, a reaction volume space velocity of 100-45000mlg<-1>h<-1> and an acetic ester mass space velocity of 0.01-5.0h<-1>, carrying out production of ethanol and co-production of methanol. The active components of the catalyst are copper and optional zinc and / or aluminum. The method provided by the invention greatly promotes carbon monoxide conversion to generate methanol, and at the same time maintains extremely high acetic ester hydrogenation activity. Moreover, while producing ethanol, the method provided by the invention achieves co-production of a certain amount of methanol, the proportions of ethanol and methanol are adjustable, and the flexibility of the product is enhanced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Porous active artificial bone and preparation method thereof

The invention relates to a porous active artificial bone. In the porous active artificial bone, a calcium phosphate-based biological ceramic material is used as a matrix, and the porous active artificial bone comprises small pores, dense parts and directional pore channels and chelates with diphosphonate. A preparation method of the porous active artificial bone comprises the steps of preparing calcium phosphate precursor powder, compression molding a ceramic blank by using a pore-foaming agent, polyester fiber and the precursor powder, high temperature sintering into a calcium phosphate-based ceramic sintered body and forming the dense parts, the small pores distributed alternately; and immersing calcium phosphate-based ceramic sintered body in a diphosphonate solution to chelate with the diphosphonate so as to obtain the drug-loaded porous active artificial bone. The artificial bone provided by the invention has longitudinal directional pores and a porous structure suitable for osteoblast migration, propagation and growth metabolism, can slowly release small molecular drugs capable of promoting the growth of the osteoblast and inhibiting osteoclast, and is particularly suitable for the fields of treating bone defects of osteoporosis patients, dental restoration, and the like.

Owner:SHENZHEN LANDO BIOMATERIALS

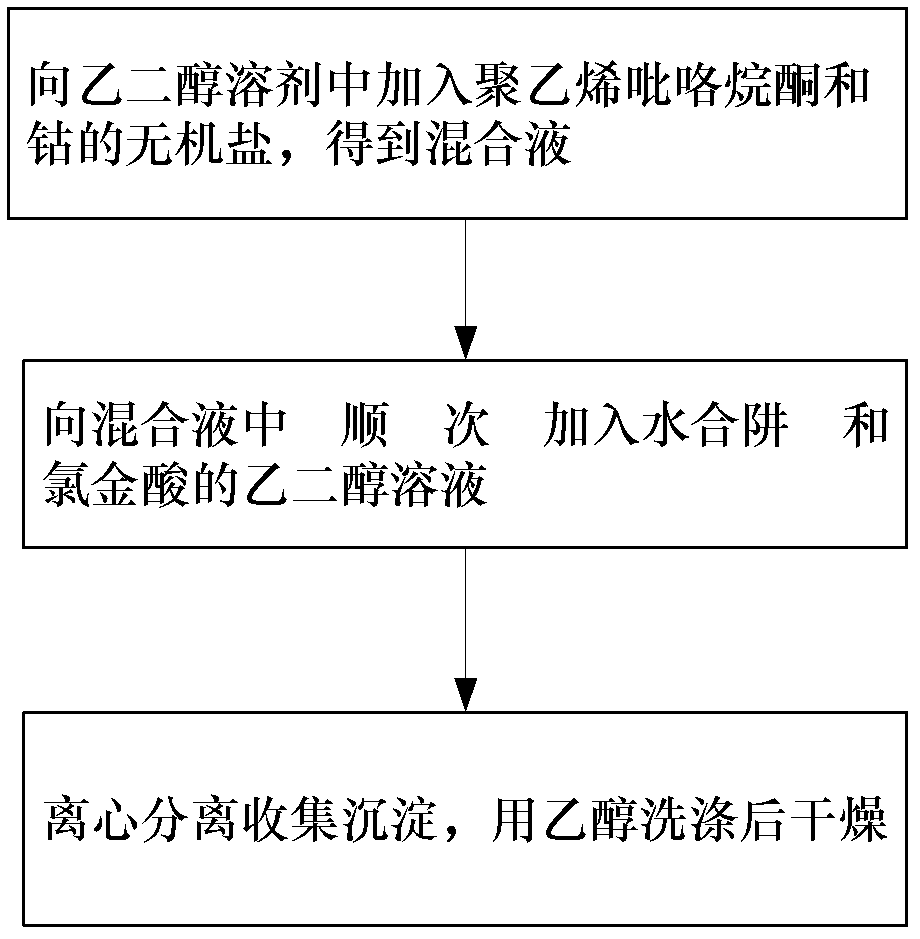

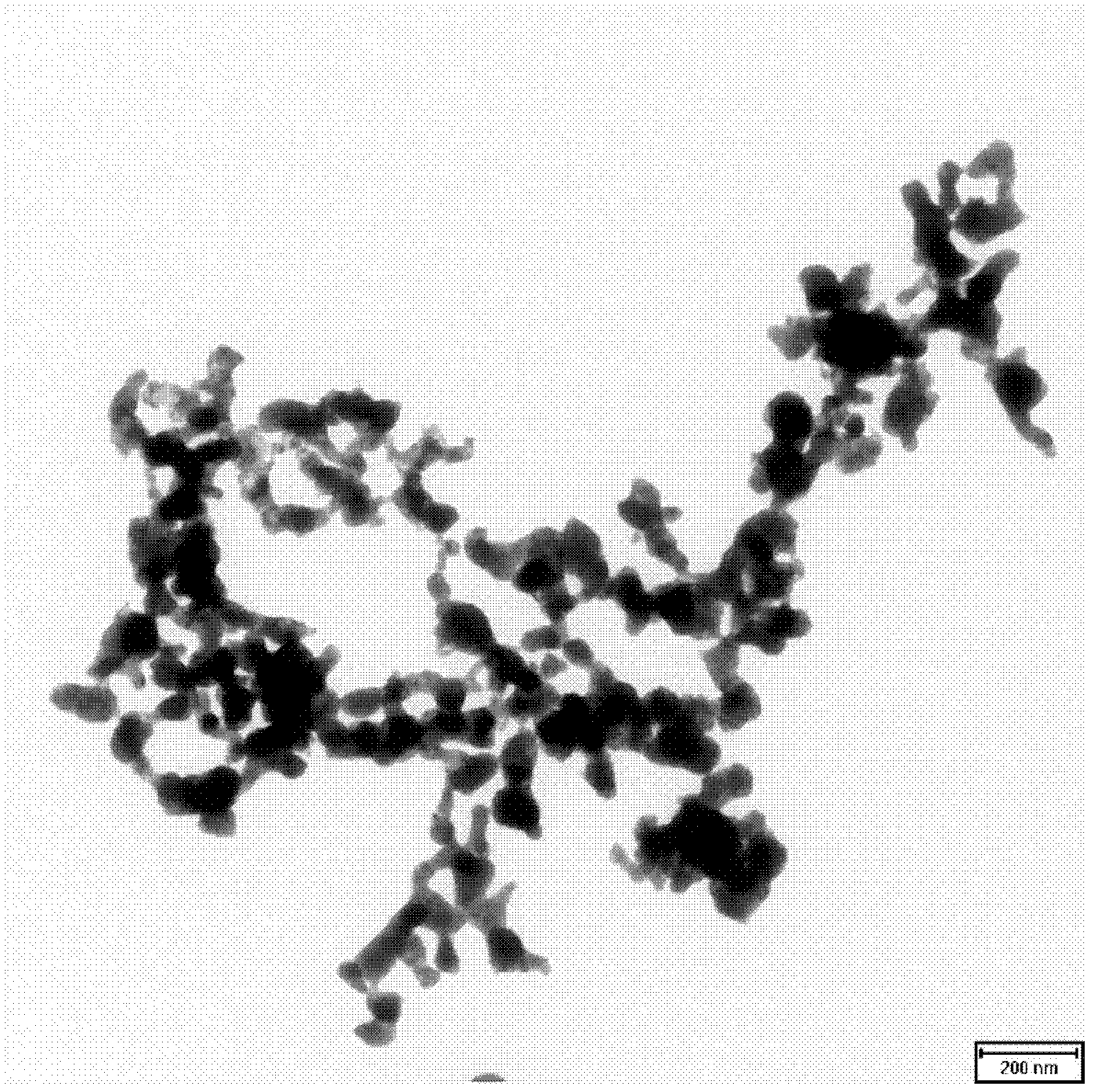

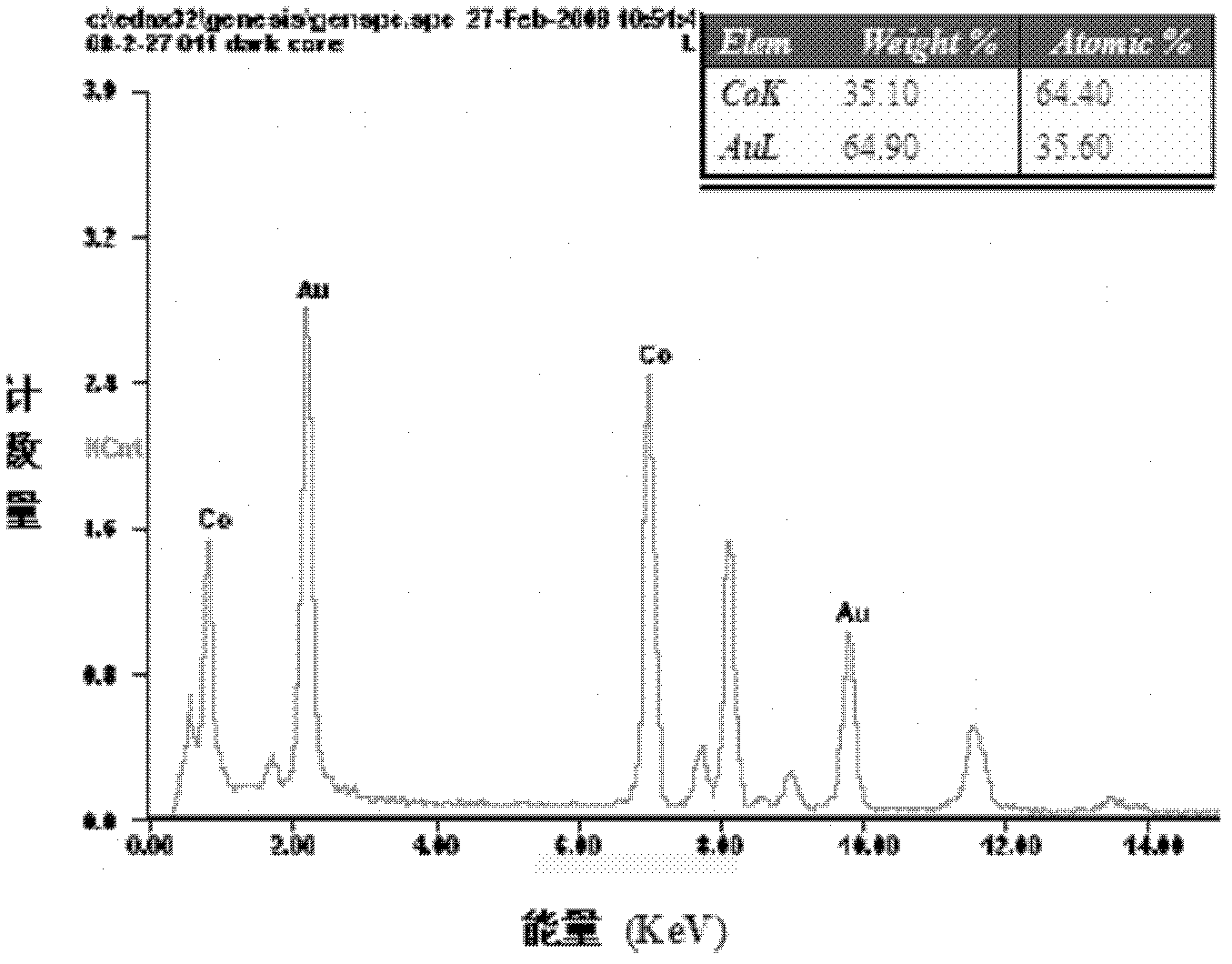

A kind of preparation method of synthetic cobalt-gold bimetallic alloy nanoparticles

The invention provides a method for preparing a synthesized cobalt-gold double-metal alloy nano particle and belongs to the technical field of inorganic material preparation processes. The method comprises the following steps of: 1, adding polyvinylpyrrolidone and inorganic salt of cobalt into an ethylene glycol solvent to obtain mixed solution; 2, under the condition of stirring, adding hydrazine hydrate and ethylene glycol solution of chloroauric acid into the mixed solution sequentially; and 3, removing a heating source after the reaction is stopped, performing centrifugal separation, collection and deposition, washing by using ethanol and drying. The cobalt-gold double-metal alloy nano particle prepared by using the method for preparing the synthesized cobalt-gold double-metal alloy nano particle has the characteristic of a chain structure. In the method, inorganic substances are used as raw materials, so the reaction is low in toxicity and the raw materials are more economical; the cobalt and the gold of the product are distributed uniformly, and a proportion of the cobalt to the gold can be regulated within a certain range; moreover, the reaction time is short, the process is simple and the production can be enlarged easily.

Owner:BEIHANG UNIV

Method for preparing composite wear-resistant hammerhead

The invention discloses a method for preparing a high-ductility and high-abrasion composite hammerhead, which comprises the following steps: alloy dust core bars are bound into bundles and arranged in a hammerhead casting mould cavity, and the volume of the alloy dust core bars accounts for 20 to 60 percent of the total volume of the hammerhead; molten matrix metal is cast into the casting mould cavity, the alloy dust core bars are melted and dissolved under the heat effect of the matrix metal, a great number of alloy elements and the molten matrix metal generate metallurgical combination reaction so as to generate a highly dispersed alloy structure on the original position; and finally the alloy structure is cooled and solidified, and the bar-shaped hard phase is metallurgically and transitionally combined into a whole with the matrix metal, thereby preparing the composite hammerhead which takes the high-strength and high-ductility metal as the matrix and contains a certain number of metallurgically combined bar-shaped hard points. The composite hammerhead has high strength and high ductility of the matrix metal and high hardness and high wear resistance of the hard phase, can simultaneously bear high pressure and strong wear, and has the characteristics of long service life, low price and so on.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

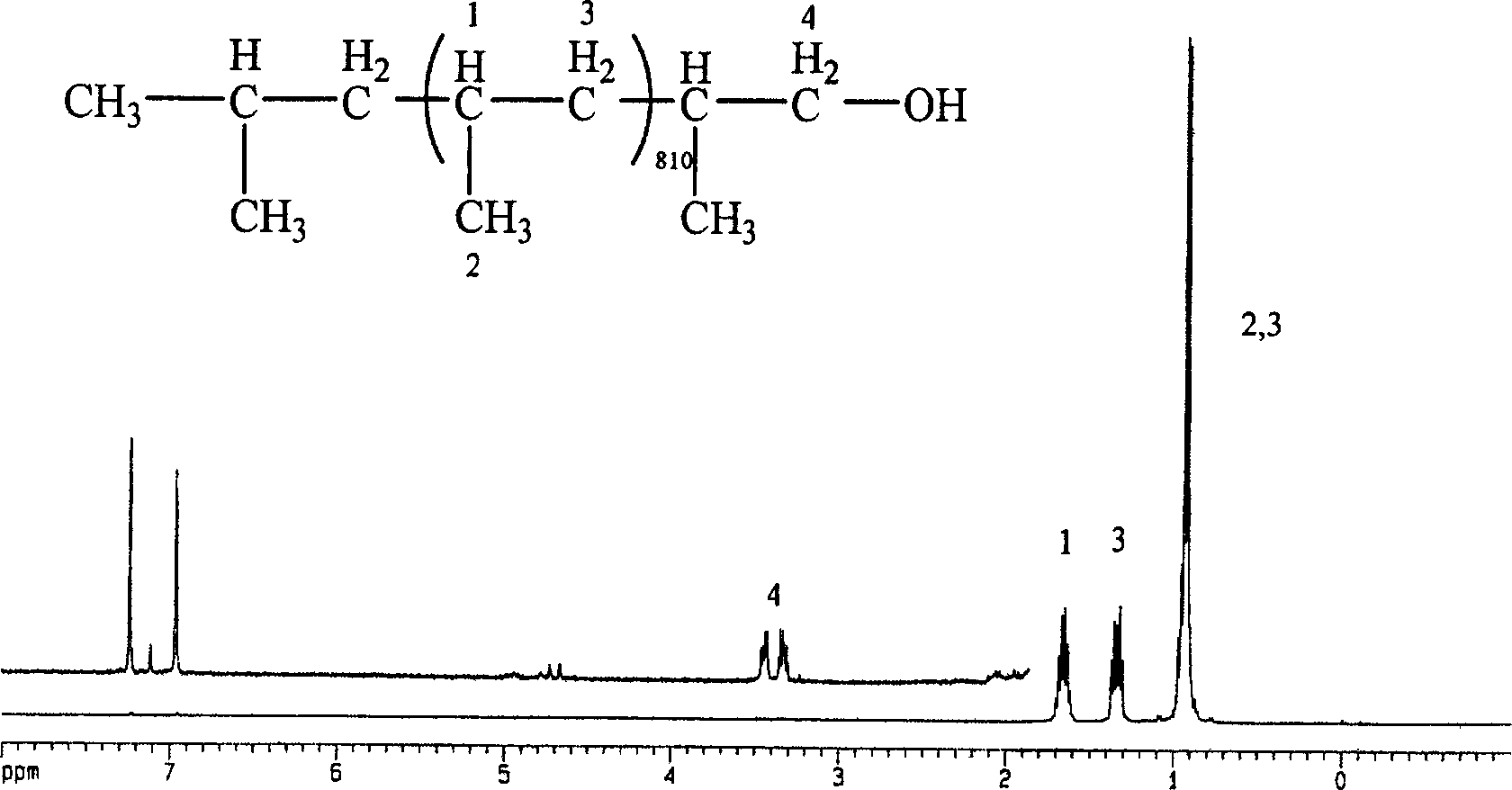

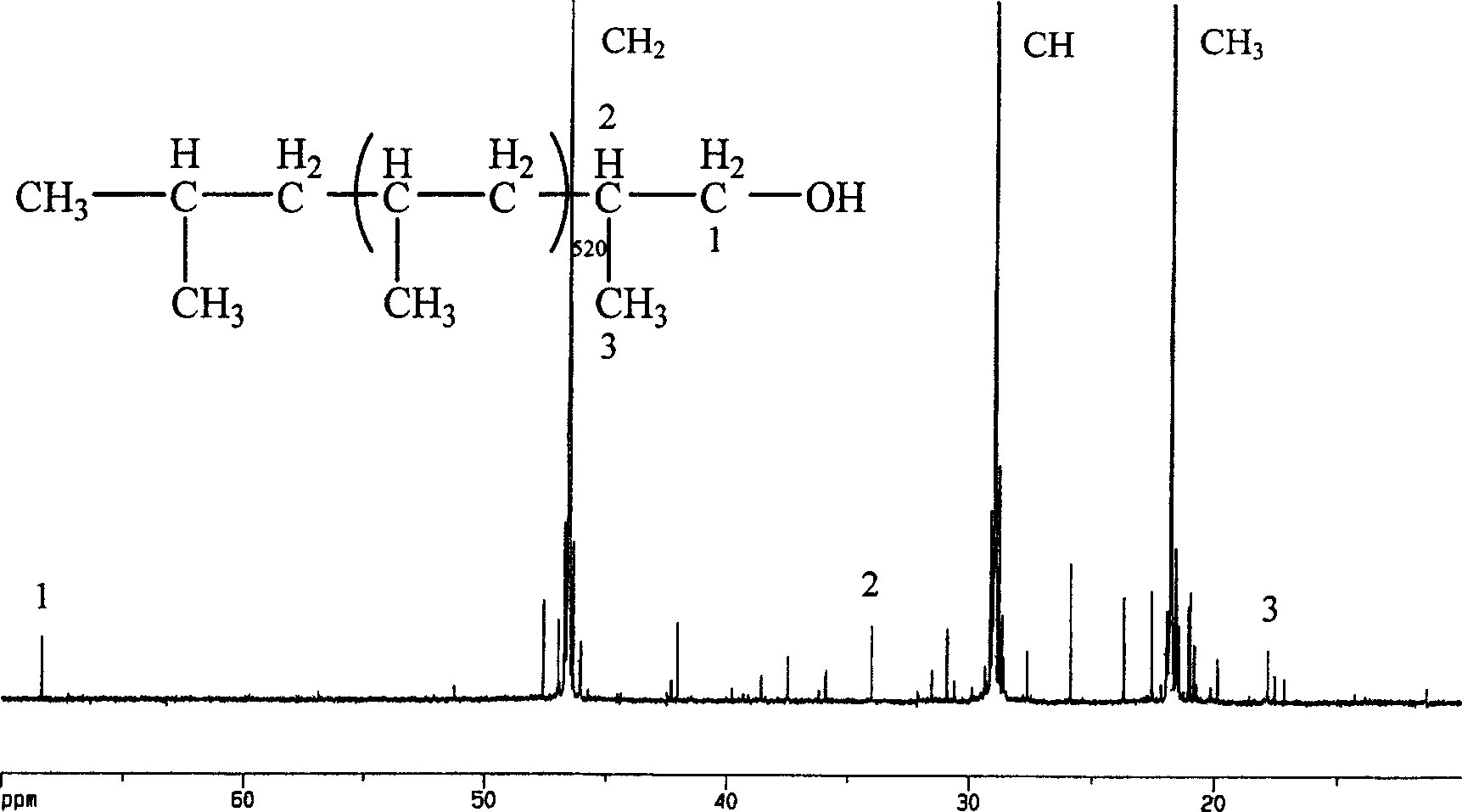

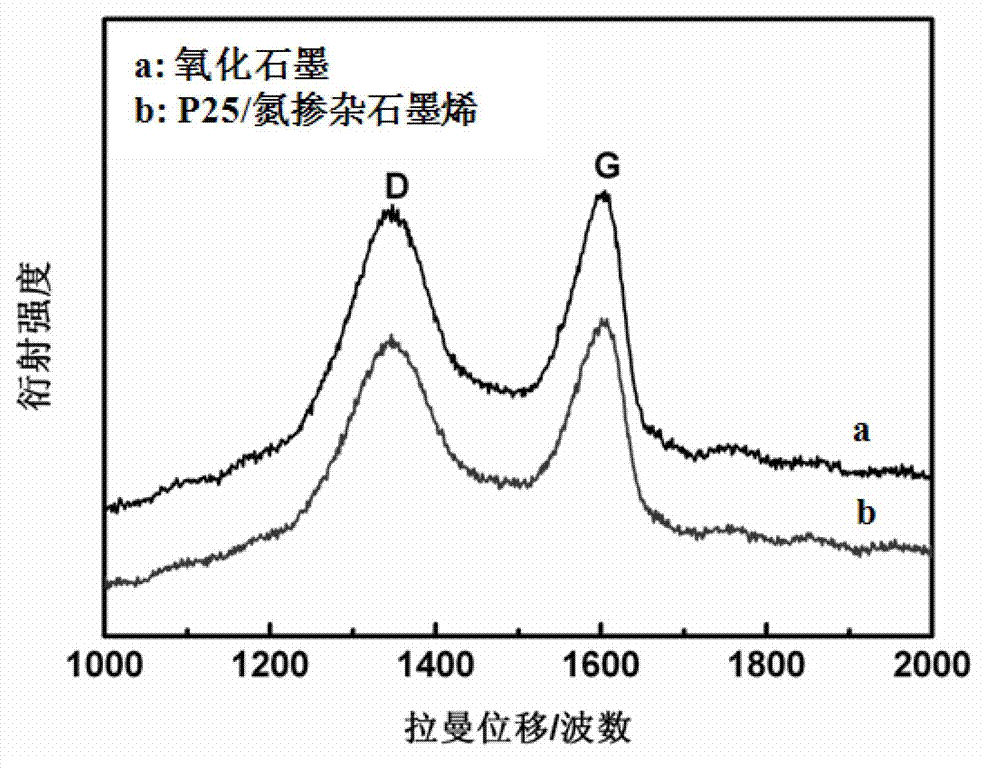

Hydroxy terminated polypropylene and its preparing method

The present invention relates to hydroxy terminated polypropylene in the structure as shown and its preparation process. The catalyst system comprising metallocene and alkyl aluminoxane catalyzes propylene polymerization reaction, dry air or oxygen is then introduced into the reacted system, and hydrogen perosxide and alkali hydroxide aqua are finally added for treating to obtain polypropylene with one hydroxy radical in one end of the macro molecular chain. The polymer of the present invention has high terminated hydroxy function degree not lower than 0.8, high isotactic configuration, high adjustable molecular weight, narrow molecular weight distribution, simple preparation process, and other advantages.

Owner:INST OF CHEM CHINESE ACAD OF SCI

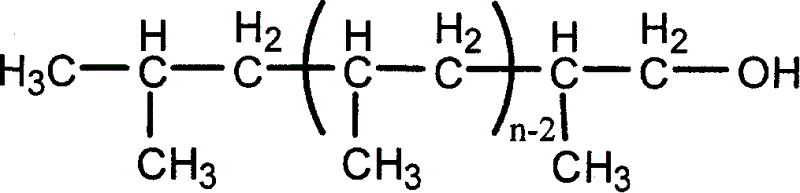

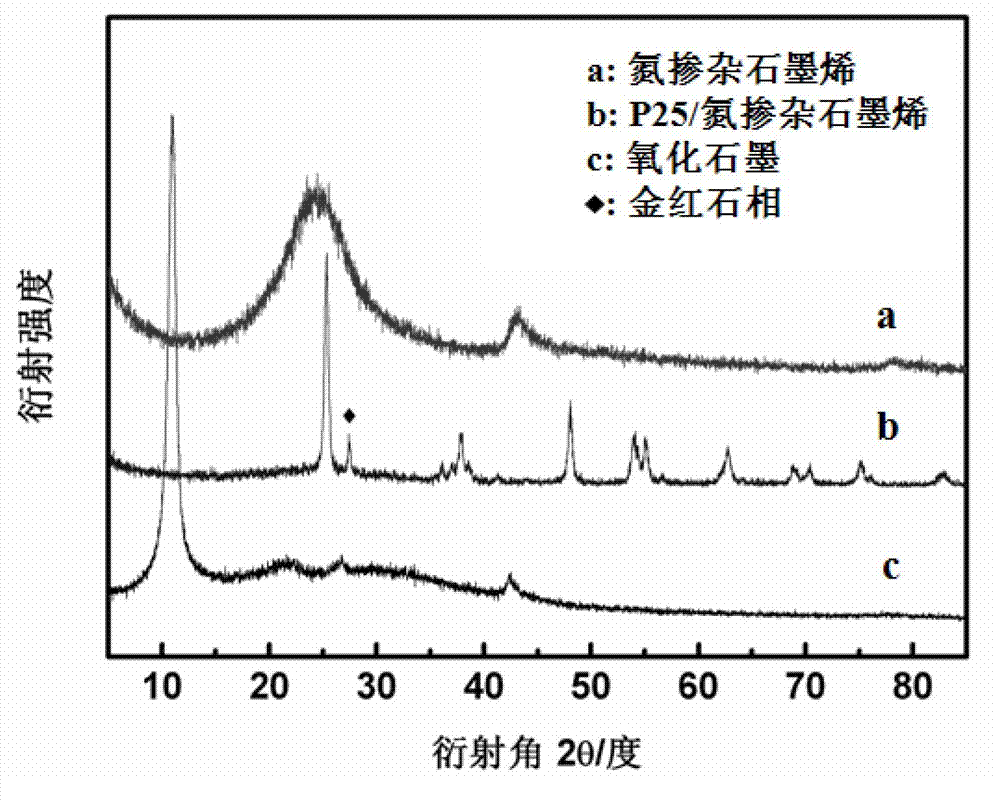

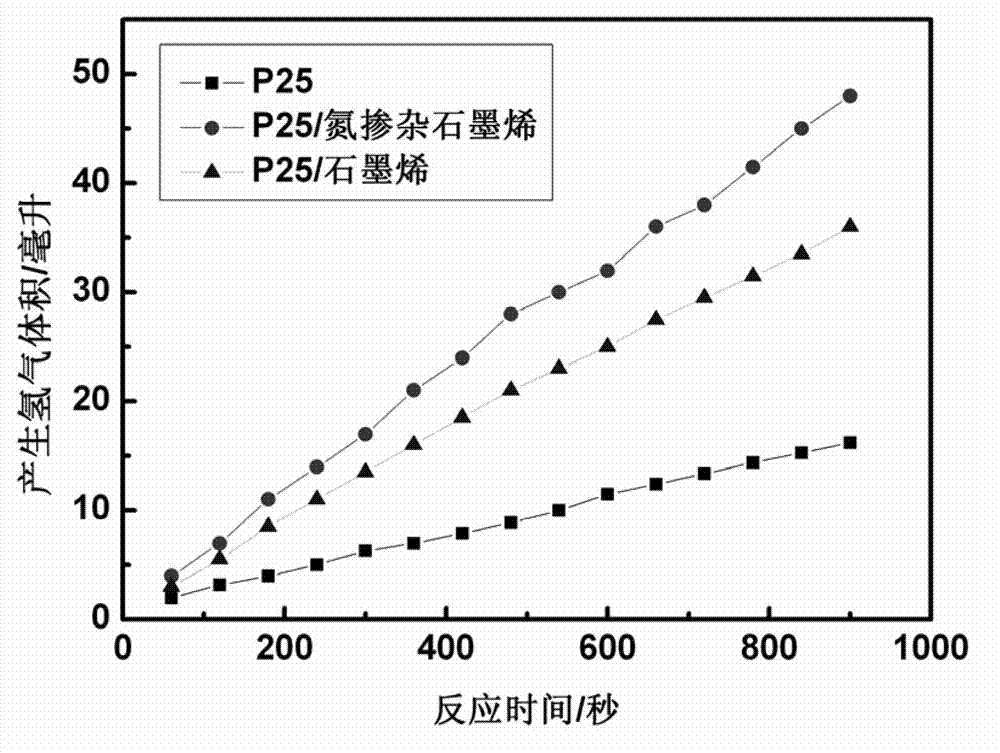

Method for preparing P25/nitrogen-doped graphene composite material

InactiveCN102921444ANo pollution in the processEasy to preparePhysical/chemical process catalystsHydrogen productionHydrazine compoundNitrogen doped graphene

The invention relates to a method for preparing a P25 / nitrogen-doped graphene composite material. The method comprises the following steps of 1, dispersing graphite oxide (GO) in deionized water at a room temperature, carrying out uniform ultrasonic dispersion of the mixed solution, adding P25-type titanium dioxide and a hydrazine hydrate solution into the mixed solution, and uniformly stirring to obtain a reaction solution, 2, heating the reaction solution to a temperature of 150 to 210 DEG C and carrying out a reaction process for 8 to 24 hours, and 3, cooling the products to a room temperature, carrying out centrifugation to collect the products, washing the products, and drying to obtain the P25 / nitrogen-doped graphene composite material. The method for preparing the P25 / nitrogen-doped graphene composite material has simple processes and a low cost, is suitable for industrial production, is environmentally friendly, has good repeatability, can be used for a lithium ion battery cathode, and can be used in the fields of photocatalysts and dye-sensitized solar cells.

Owner:DONGHUA UNIV

Photoelectrochemical mechanical polishing processing method of semiconductor wafer

ActiveCN109648463AReduce roughnessFast removal rateSemiconductor/solid-state device manufacturingLapping machinesAdhesiveUltraviolet lights

The invention discloses a photoelectrochemical mechanical polishing processing method of a semiconductor wafer and a processing device. The method comprises the following steps that the wafer is fixedon a polishing head through a conductive adhesive in a bonding mode, and the wafer is connected to the positive electrode of an external power supply through leads of an inner ring and an outer ringof a conductive slip ring below the wafer; a polishing pad is adhered to the bottom of a counter electrode plate, the counter electrode plate is fixed at the bottom of a polishing plate, a through hole is formed in the position, corresponding to the polishing plate, of the counter electrode plate, and the counter electrode plate is connected to the negative electrode of the external power supply through the leads of the inner ring and the outer ring of the conductive slip ring above the counter electrode plate; and ultraviolet light emitted by an ultraviolet light source can irradiate the surface of the wafer through the through hole, and polishing solution can also be jetted into the through hole to be entered the contact area of the wafer and the polishing pad. The photoelectrochemical mechanical polishing processing device can well realize the processing method involved in the invention, and the processing device has the advantages that the operation is simple, the implementation iseasy, and the process parameters can be flexibly adjusted; and effects of being rapid in the removal rate and good in the processed surface quality can be obtained in actual processing of the galliumnitride wafers.

Owner:XIAMEN UNIV

Preparation method of multi-scale double-interface metal ceramic powder

The invention discloses a preparation method of multi-scale double-interface metal ceramic powder. The preparation method comprises the following steps of: preparing multi-scale ceramic particles by a mechanical alloying and screening process; preparing metal or alloy-coated multi-scale metal ceramic particles by a coating process; controlling the bonding state of a coated interface by a materialcomposition and thermal treatment process; performing glomeration granulation by matching coated metal ceramic particles with different scales so as to obtain double-interface metal ceramic particles; and performing densification and scale and density double grading so as to obtain metal ceramic powder with a multi-scale double-interface structure. The multi-scale double-interface metal ceramic powder prepared by the method has a double-interface structure in which a ceramic phase is combined with a coated phase and the interface binding between coated particles is controlled and the multi-scale characteristic of controllable scale and density distributions of ceramic particles and powder particles. The powder structure provided by the invention has novel design and high controllability. A metal ceramic material prepared from the powder has high intensity, high toughness and good market application prospect.

Owner:JIUJIANG UNIVERSITY

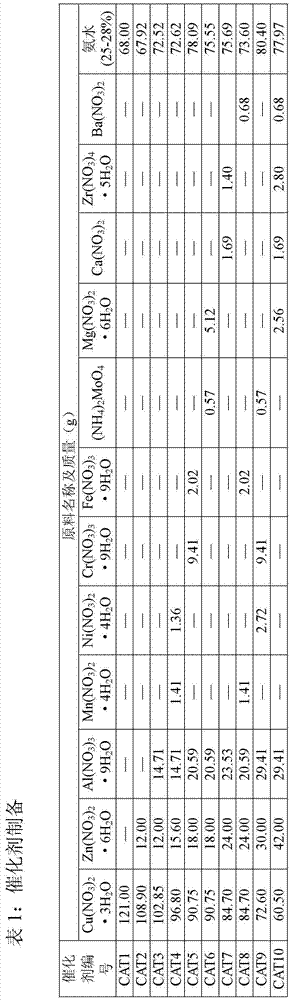

Preparation method of hierarchical porous material-loaded cobalt-based catalyst

InactiveCN104549416AAvoid Diffusion LimitationImprove thermal stabilityMolecular sieve catalystsLiquid hydrocarbon mixture productionChemistryAcid treatment

The invention discloses a preparation method of a hierarchical porous material-loaded cobalt-based catalyst. The method comprises the following steps: (1) evenly mixing a silicon source, an aluminum source, ethanol, NH3 and H2O at the ratio of 1 to (20-30) to (25-35) to (0.1-0.4) to (1-3), and adding a template agent at the mass ratio of the template agent to the aluminum source being (0.5-1) to 1; (2) putting the mixed liquid obtained from the step (1) into a crystallization kettle lined with polytetrafluoroethylene, filtering, washing, drying and removing the template agent through three-section temperature control roasting; (3) carrying out acid treatment on a carrier precursor to obtain a hierarchical porous carrier; and (4) dipping a saline solution dissolved with cobalt or a saline solution of cobalt and non-noble metal into the hierarchical porous material by adopting an equivalent-volume impregnation method for 10-48 hours, drying at 100-130 DEG C, and roasting at 300-600 DEG C for 4-10 hours, tabletting, and screening to prepare the hierarchical porous material-loaded cobalt-based catalyst.

Owner:华文蔚

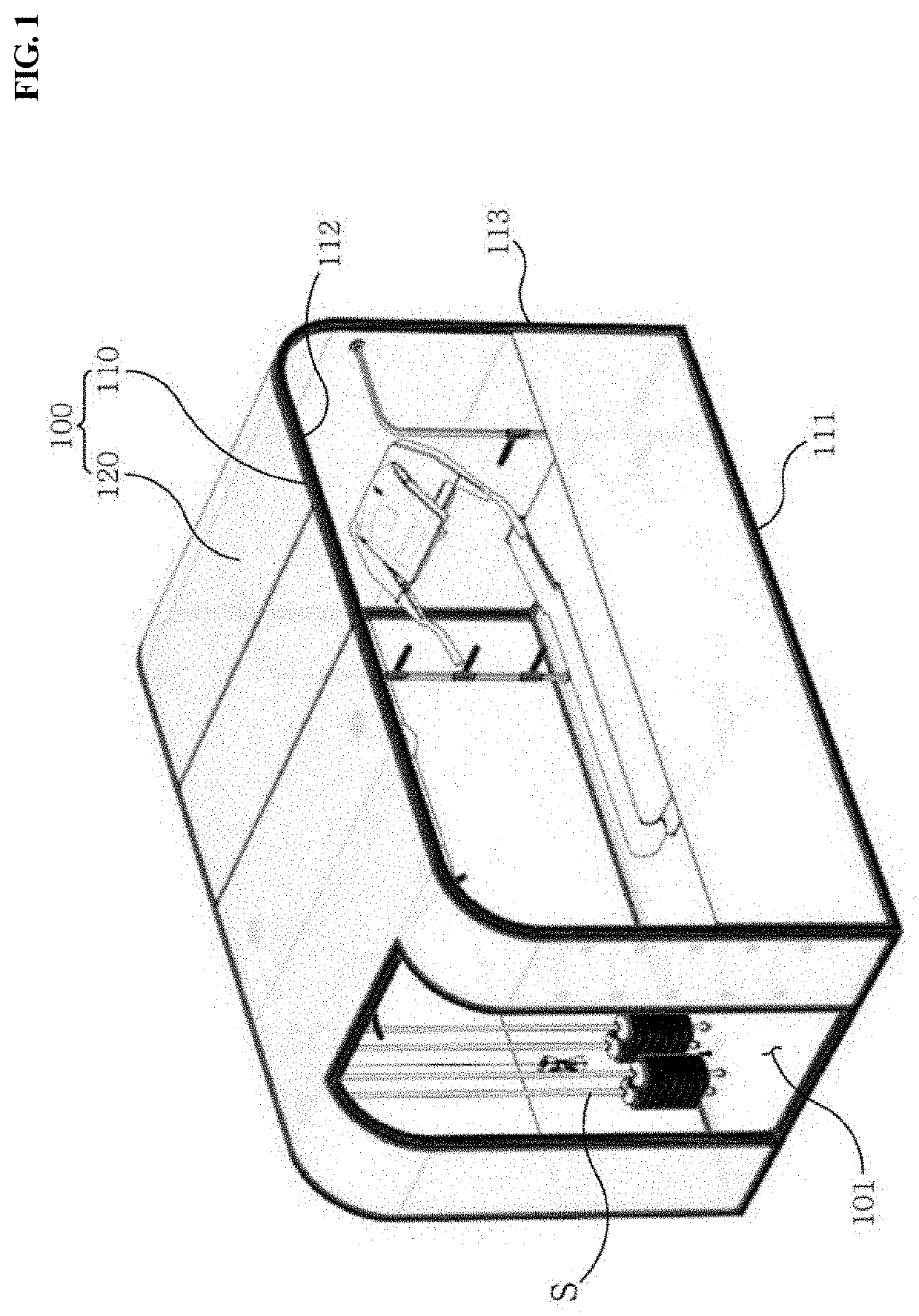

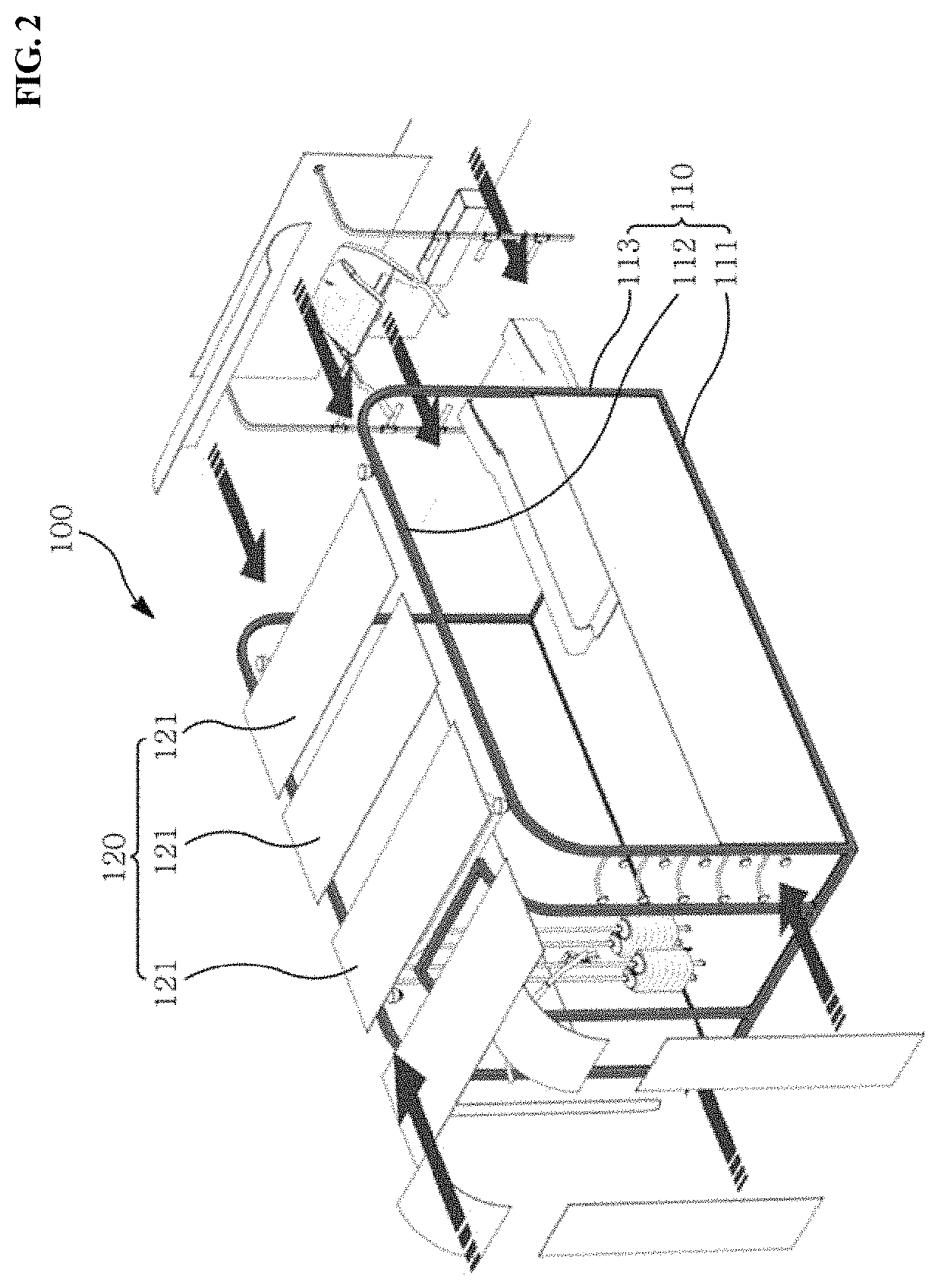

Fitness module box

ActiveUS10533333B2Scale adjustableSpecial buildingGymnasiumSoftware engineeringMechanical engineering

Owner:SHIN DONG GEON +1

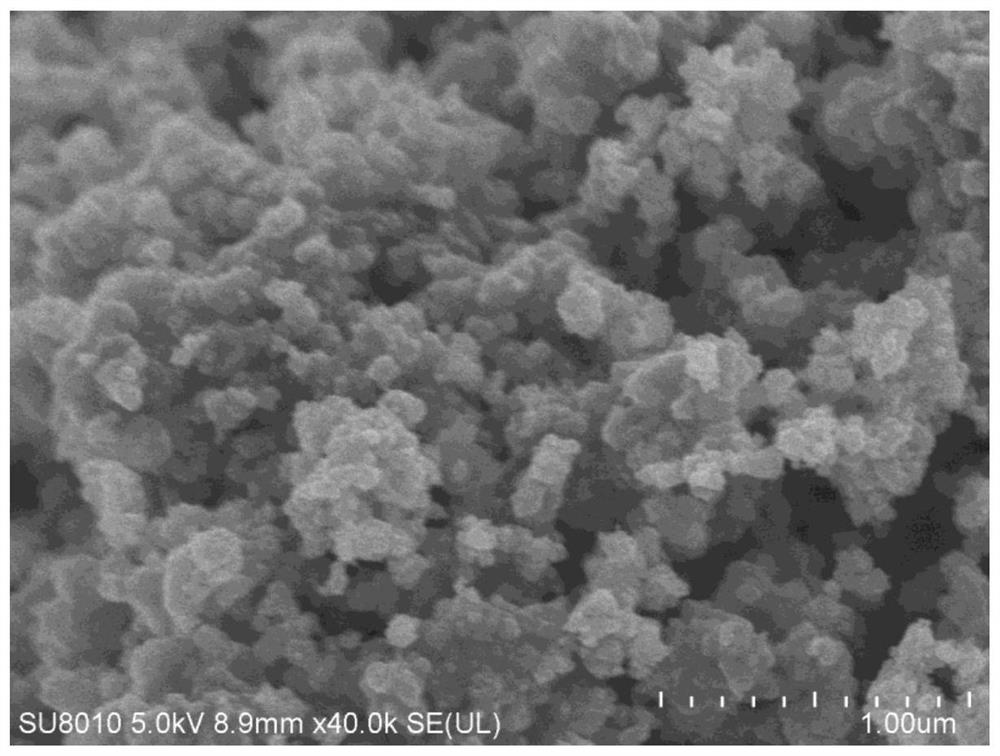

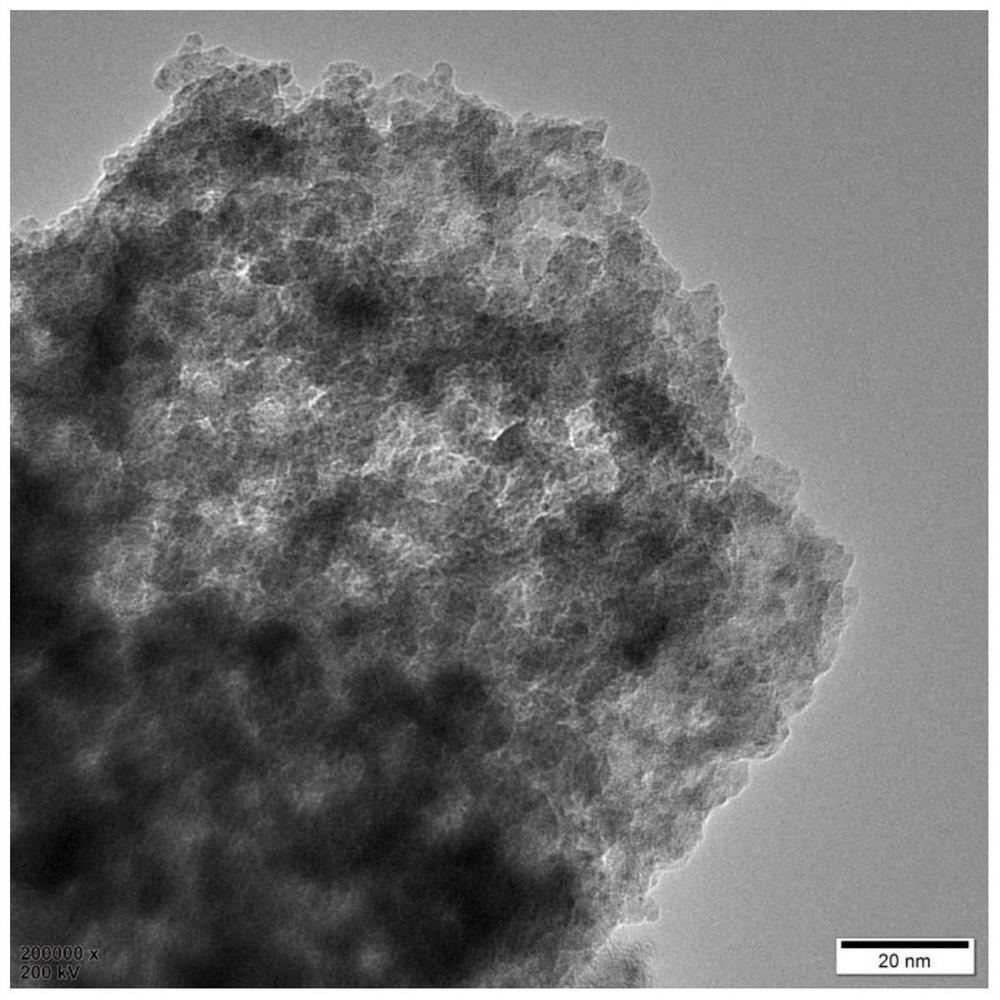

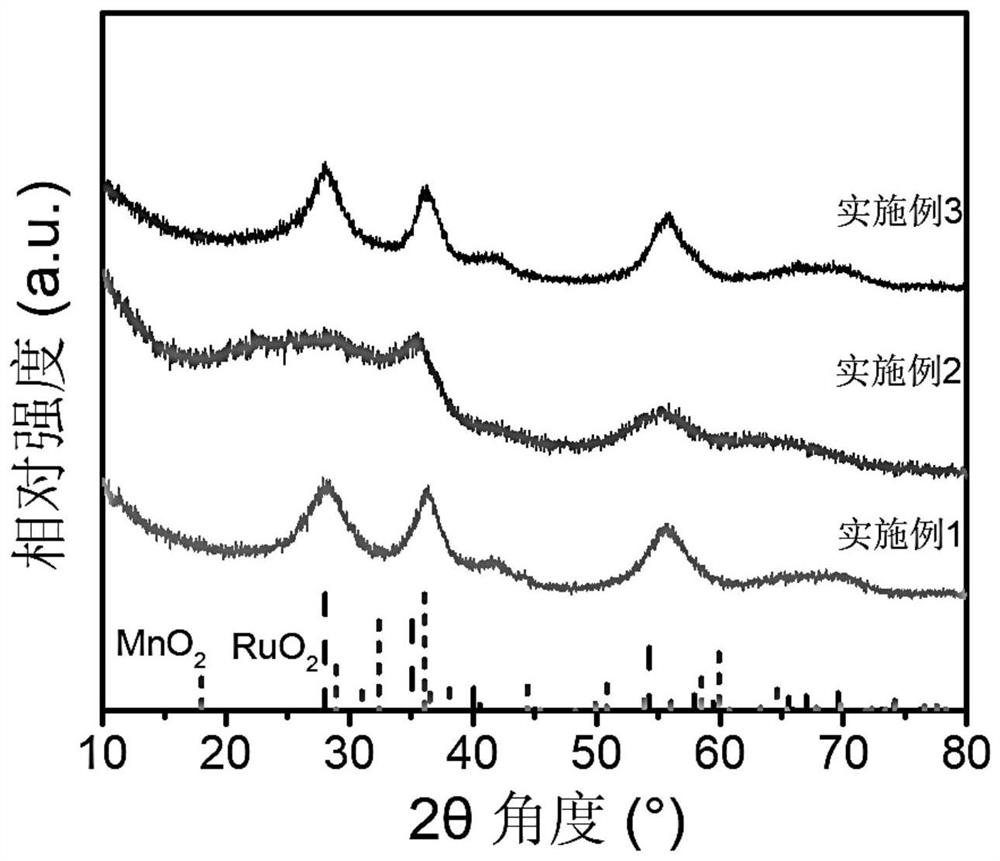

Electrocatalyst of ruthenium-based transition metal oxide solid solution as well as preparation method and application thereof

The invention relates to the technical field of energy chemical industry and nano materials, and discloses an electrocatalyst of a ruthenium-based transition metal oxide solid solution as well as a preparation method and application of the electrocatalyst. The electrocatalyst is a solid solution with a rutile type structure, the chemical formula of the electrocatalyst is M1-xRuxO2, M is manganese,vanadium or chromium, x is the number of ruthenium atoms, and x is larger than or equal to 0.2 and smaller than or equal to 0.5. The preparation method comprises the following steps: (1) adding a high-valence transition metal salt solution with strong oxidizing property and a ruthenium chloride solution into a transition metal salt solution, and reacting to obtain amorphous oxide powder; and (2)drying and roasting the oxide powder prepared in the step (1) to obtain the ruthenium-based transition metal oxide solid solution. The catalyst has high oxygen evolution reaction activity and stability when applied to water electrolysis oxygen evolution reaction.

Owner:QUZHOU RES INST OF ZHEJIANG UNIV +1

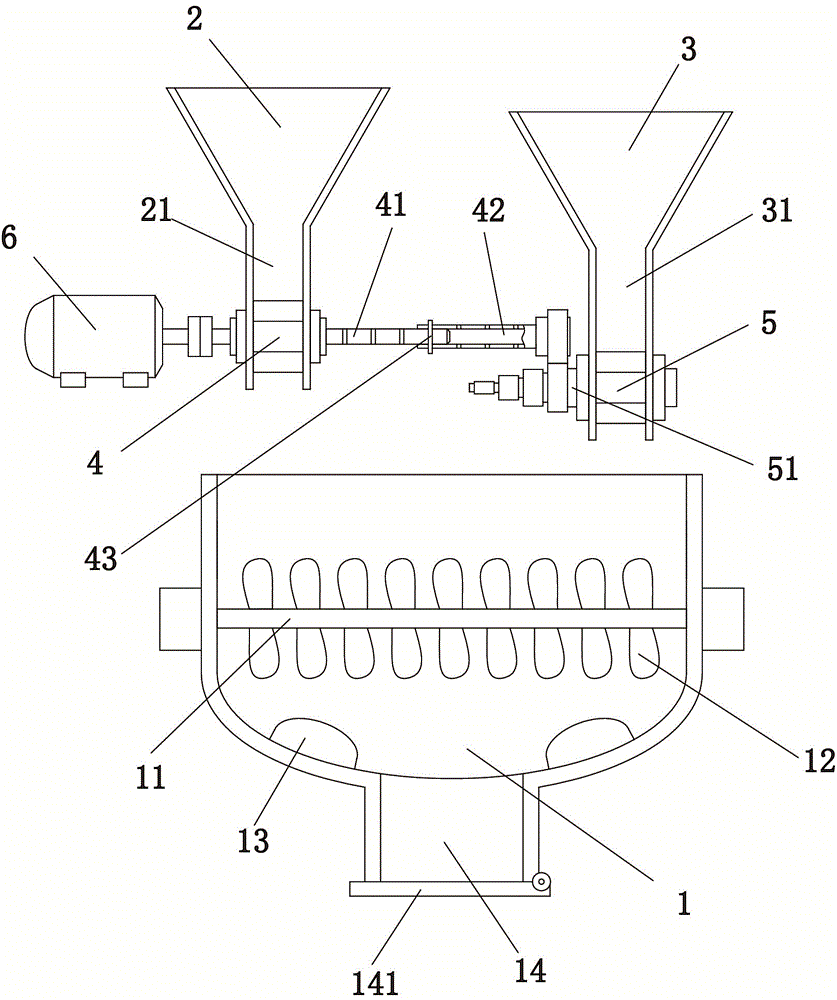

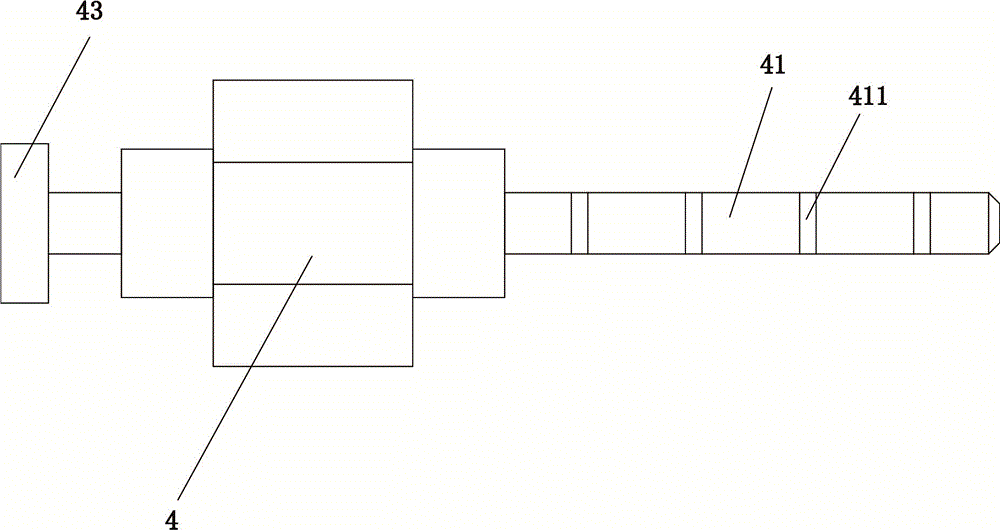

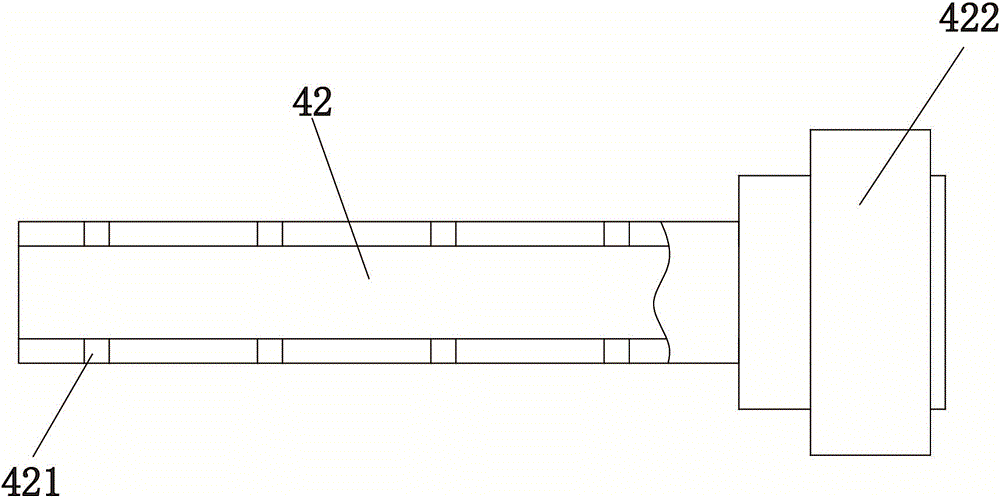

Simple and precise mixing device of injection molding machine

The invention discloses a simple and precise mixing device of an injection molding machine. The simple and precise mixing device comprises a mixing bin, wherein a fresh material hopper and an old material hopper are arranged above the mixing bin; the fresh material hopper is connected with a fresh material channel; an impeller A is rotationally arranged in the fresh material channel; one end face of the impeller A is connected with a locating rod; the locating rod is sleeved by a locating sleeve; the locating rod and the locating sleeve are connected together by a dowel pin to be capable of rotating together; a driving gear is arranged at the end part of the locating sleeve; the old material hopper is connected with an old material channel; an impeller B is rotationally arranged in the old material channel; a gear shaft is arranged at the end part of the impeller B; and the gear shaft and the driving gear are engaged and matched for transmission, so that the impeller B can rotate with the impeller A. Compared with the prior art, the device is simple in structure and low in manufacturing cost; a fixed quantity of reclaimed waste materials can be added into fresh materials; the resource usage efficiency is improved to the greatest extent; and the proportion of the fresh materials and the waste materials is adjustable.

Owner:宁波海洲机械有限公司

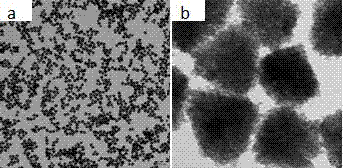

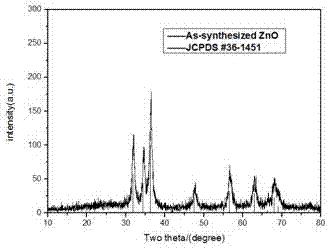

High specific surface area mesoporous zinc oxide nano-cluster and preparation method thereof

ActiveCN106986374AHigh yieldGood monodispersityZinc oxides/hydroxidesNanotechnologyZinc nitratePhotocatalytic degradation

The invention relates to a high specific surface area mesoporous zinc oxide nano-cluster and a preparation method thereof. The obtained mesoporous zinc oxide nano-cluster is characterized by being formed by assembling and stacking hollow nanoparticles with the scale of 3-5 nm and the wall thickness of 1-2nm, and has the characteristics of high specific surface area, excellent photocatalytic performance and the like. The preparation method comprises the following steps: (1) mixing and stirring deionized water and ethylene glycol solution so as to obtain a mixed solution of ethylene glycol and water; (2) adding zinc nitrate, sodium hydroxide and sodium chloride aqueous solution into the mixed solution of ethylene glycol and water under rapid stirring conditions, and obtaining a reaction precursor solution for preparing the mesoporous zinc oxide nano-cluster; (3) reacting the reaction precursor solution for 1-10 hours while stirring at a room temperature, performing high-speed centrifugal separation and ultrasonic cleaning, drying, and calcining, so as to obtain the mesoporous zinc oxide nano-cluster. The high specific surface area mesoporous zinc oxide nano-cluster disclosed by the invention has important application values on aspects of photocatalytic degradation, drug delivery, bacteria resistance, environmental governance and protection and the like.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com