Patents

Literature

106results about How to "Fast removal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

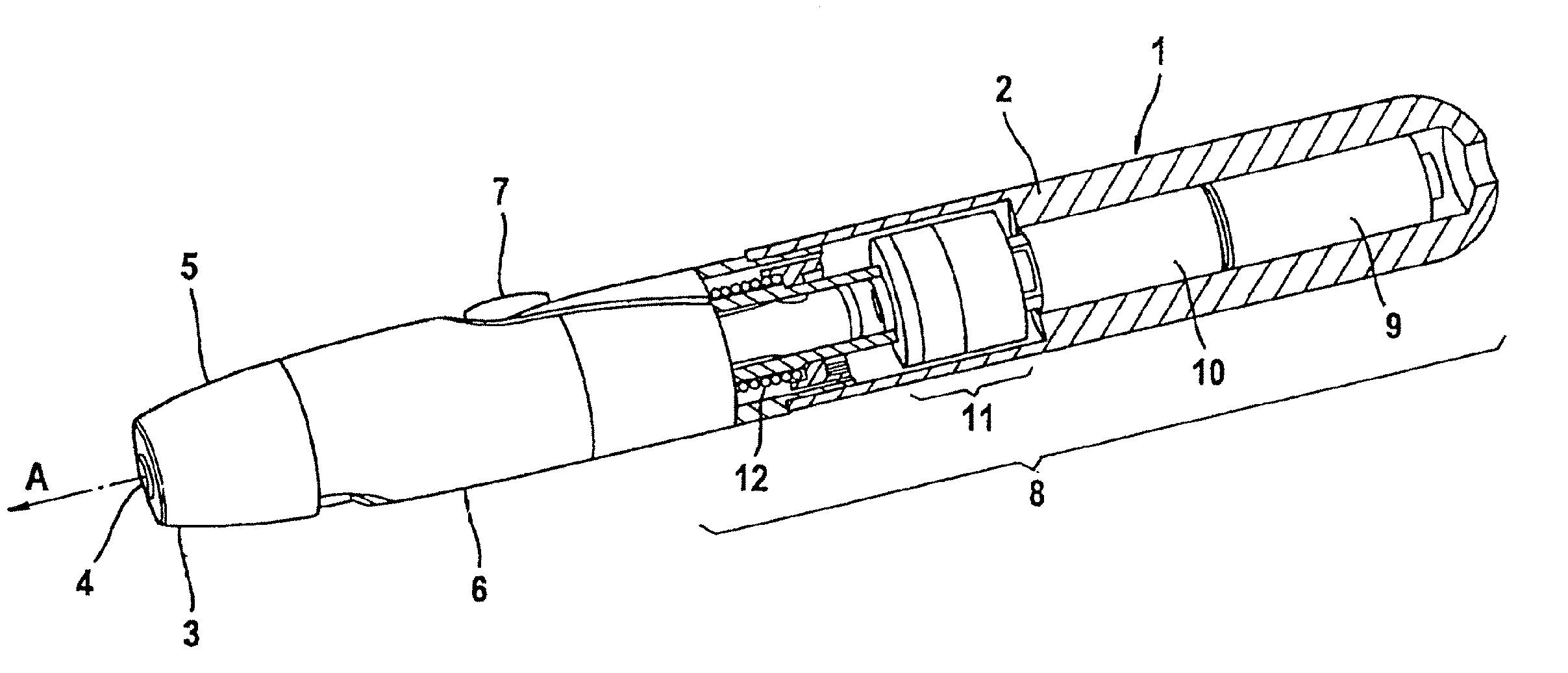

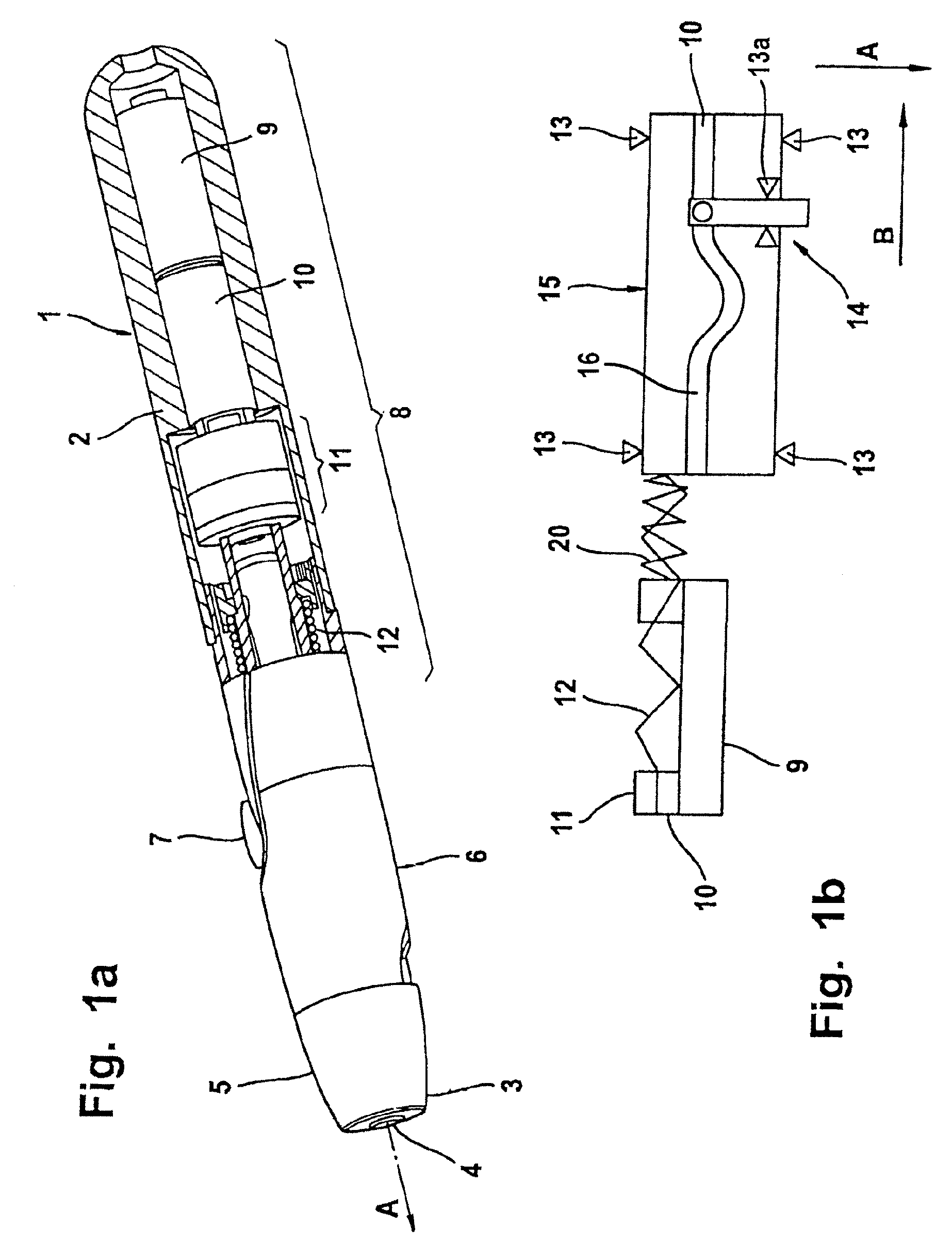

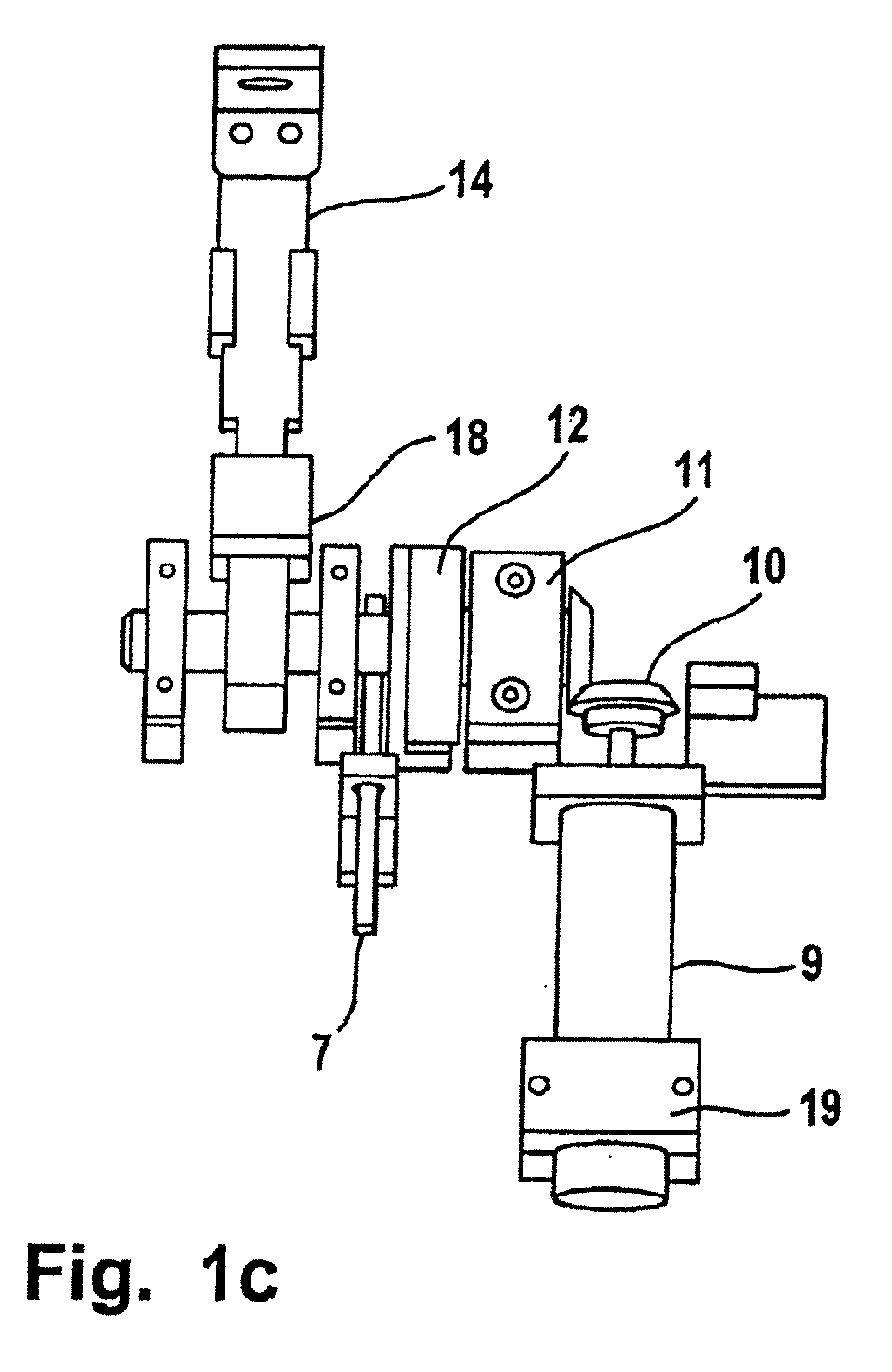

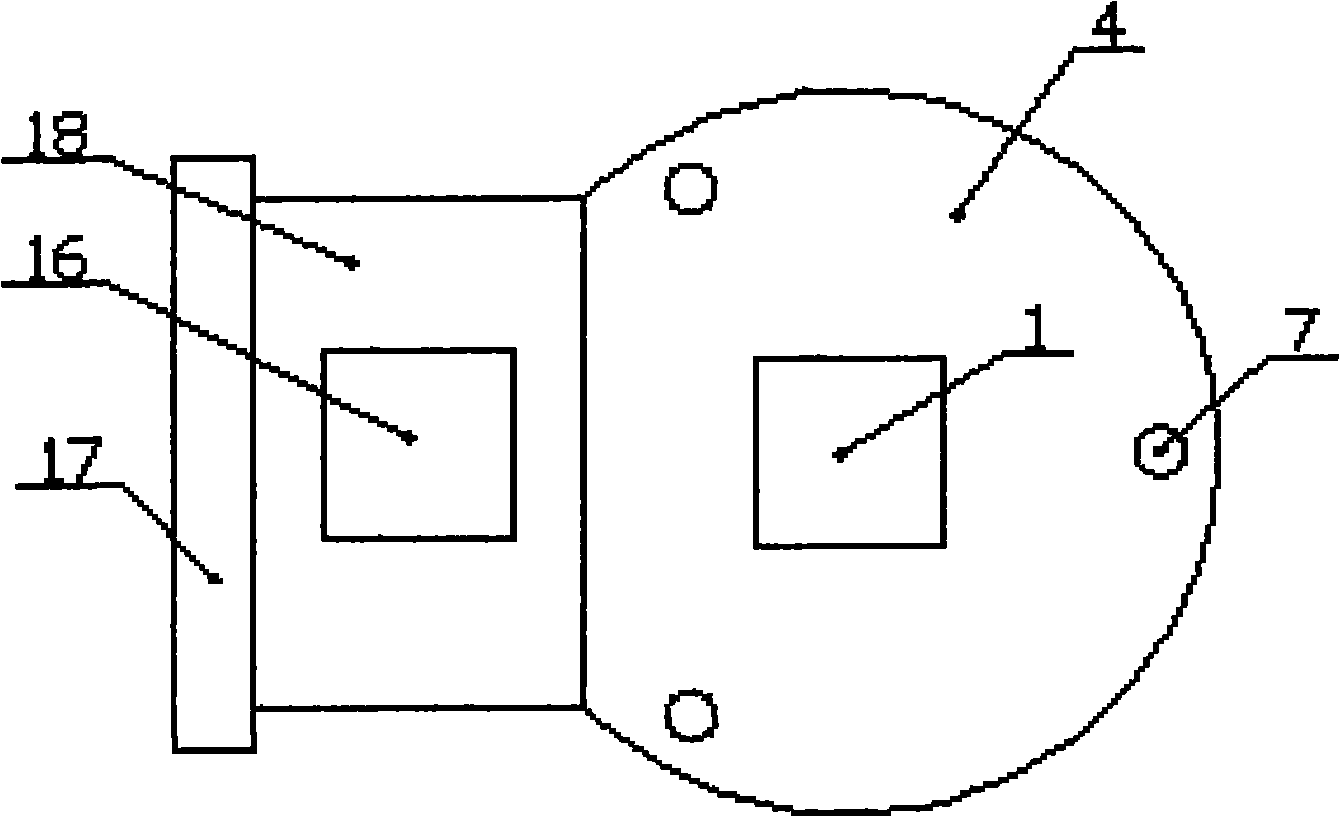

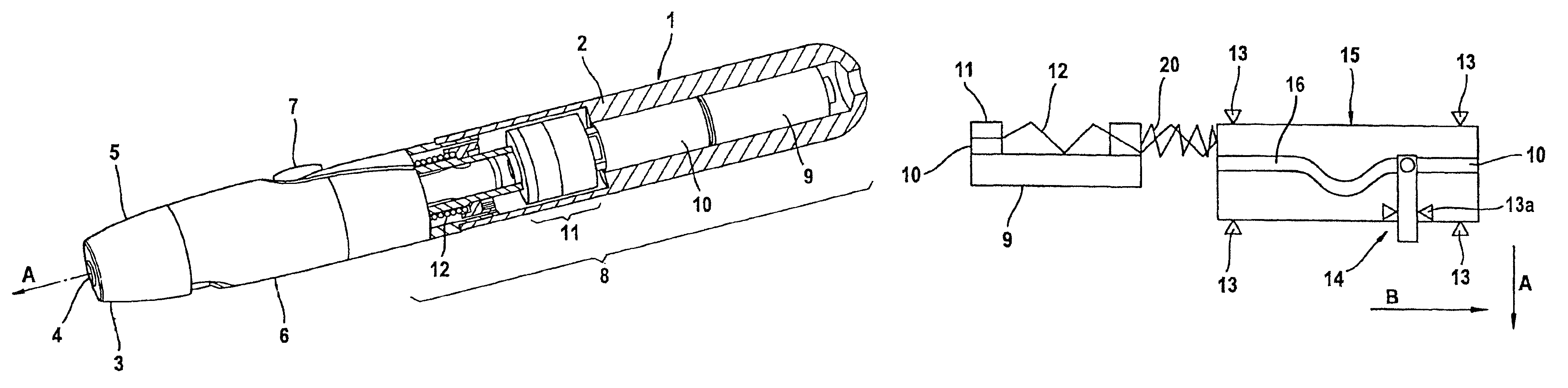

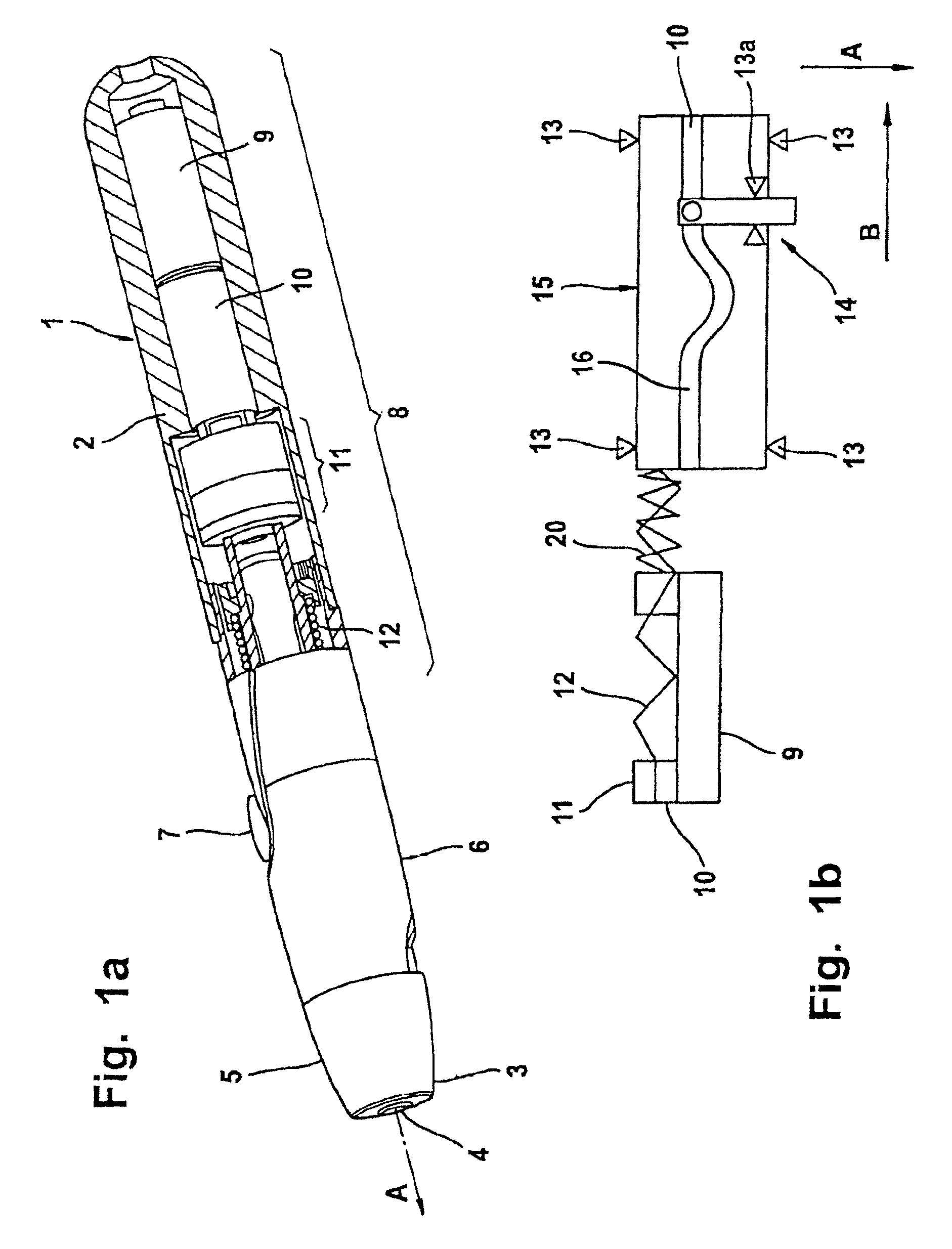

Integrated device for diagnostic purposes

The present invention provides an integrated measuring device that includes a blood collection system for collecting blood for diagnostic purposes. The blood collection system comprises an electric motor which provides energy for propelling a lancet. The blood collection system comprises a mechanical energy store in which the electric energy that is converted by the motor is stored in the form of mechanical energy. The use of a mechanical energy store allows the use of known mechanical drive elements. The blood collection system can also be electrically activated and is thus easy to use for the operator. The motor can also be coupled to another system component, such as a test strip or lancet drum, to operate it.

Owner:ROCHE DIABETES CARE INC

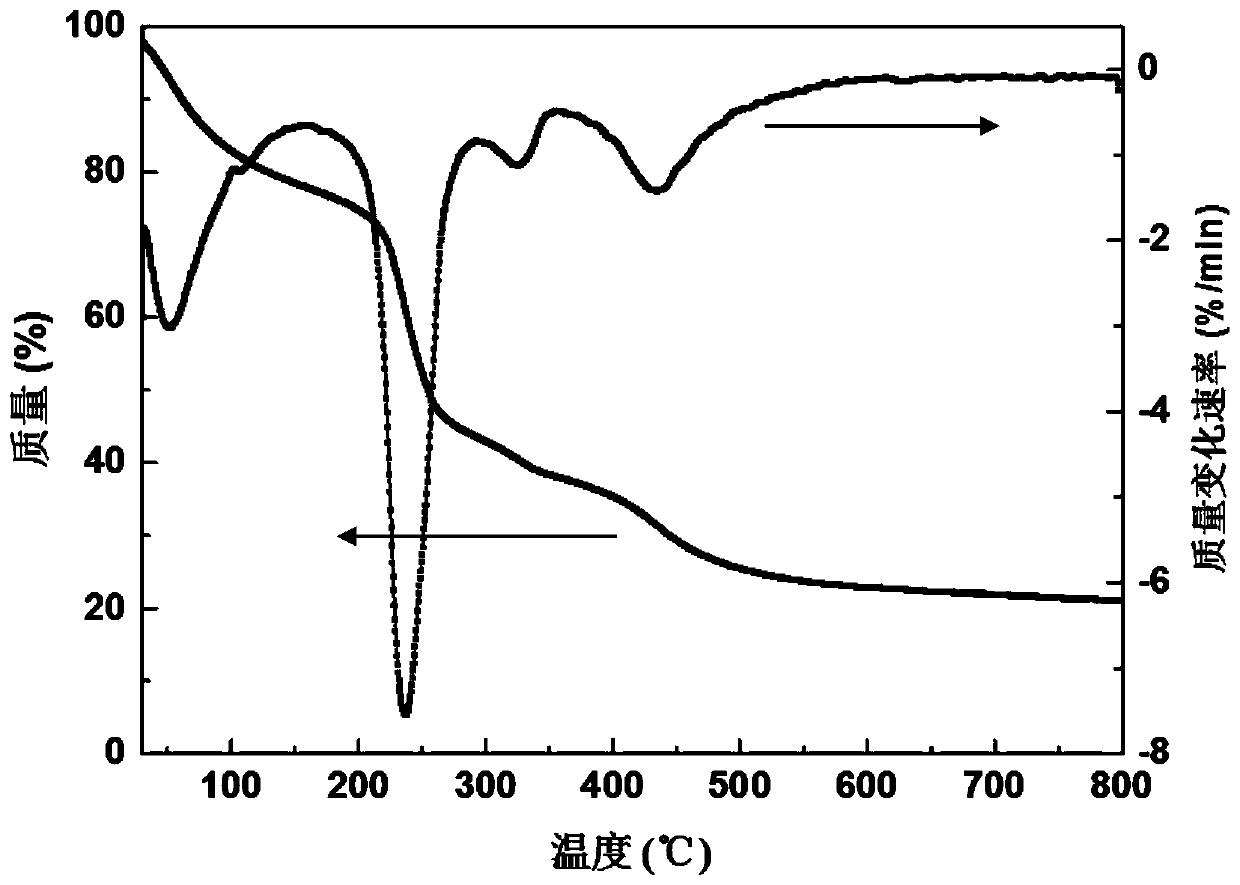

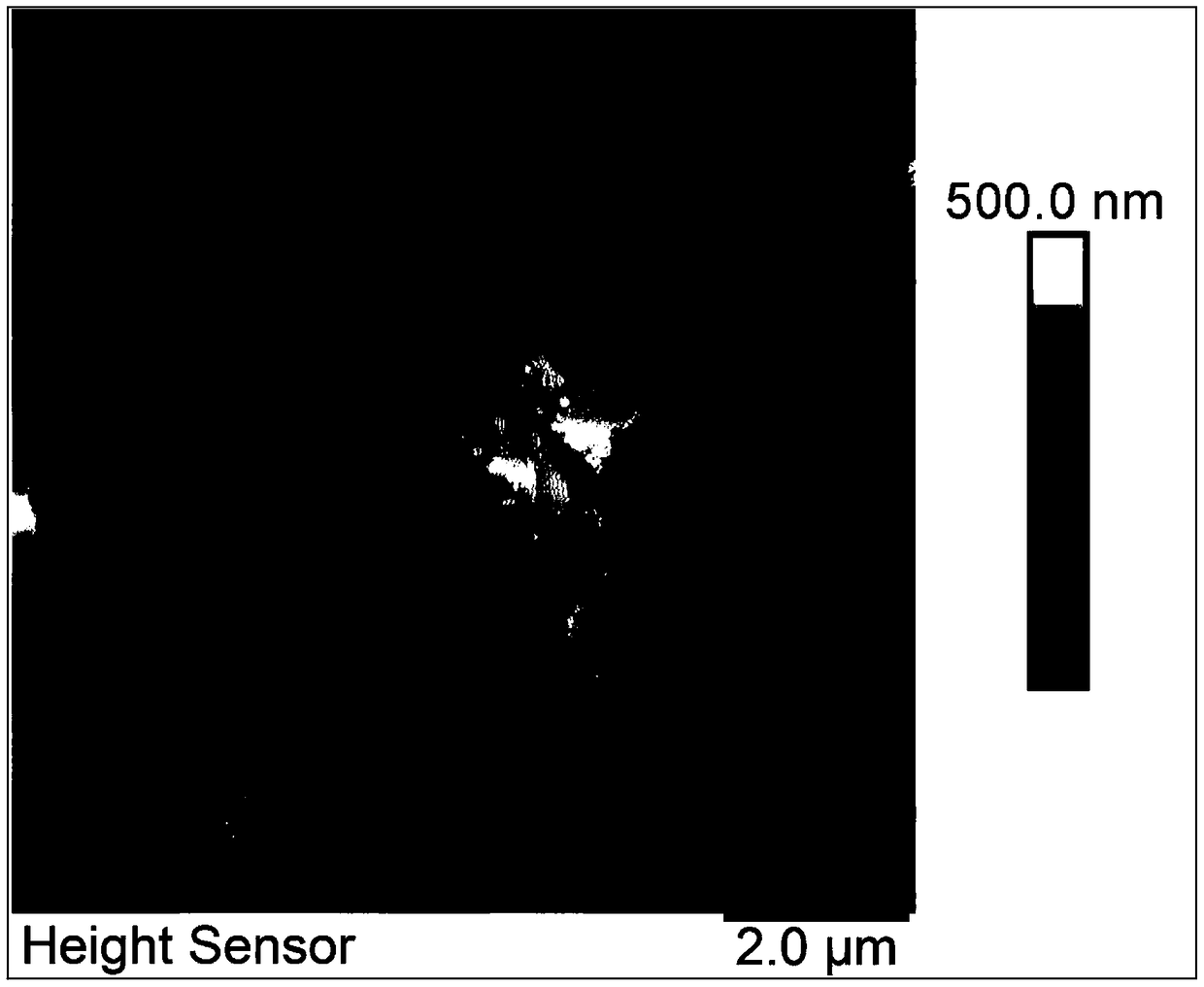

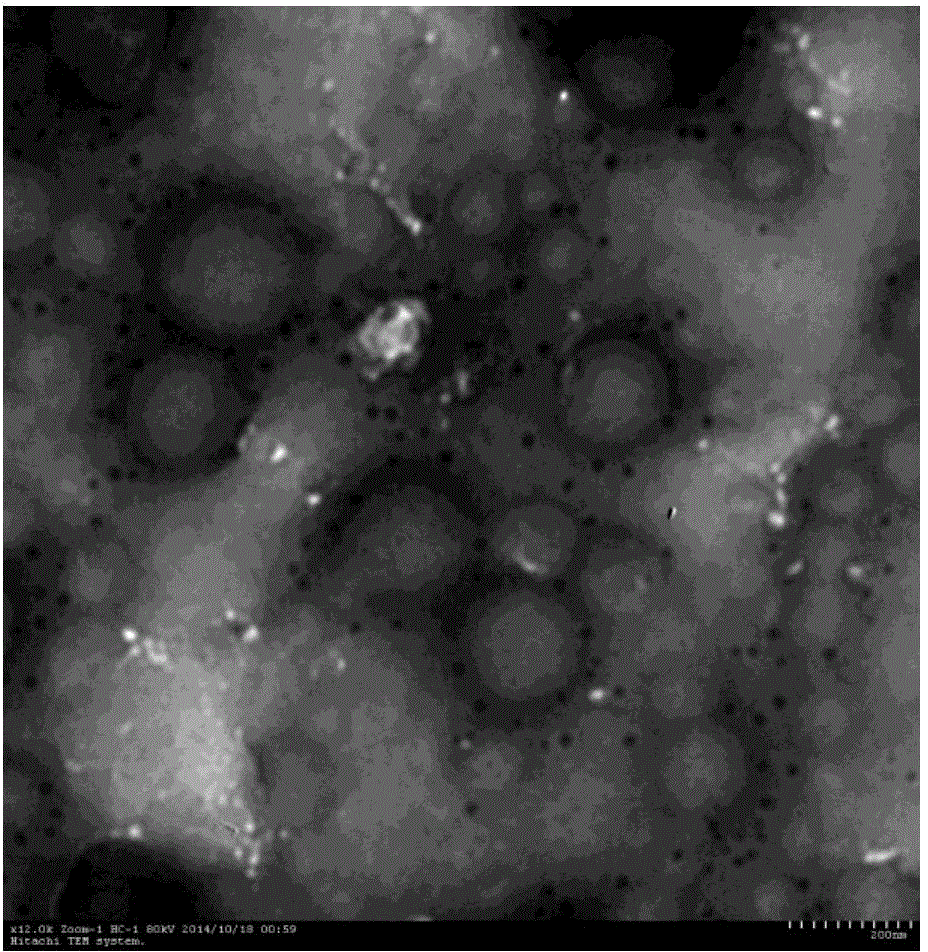

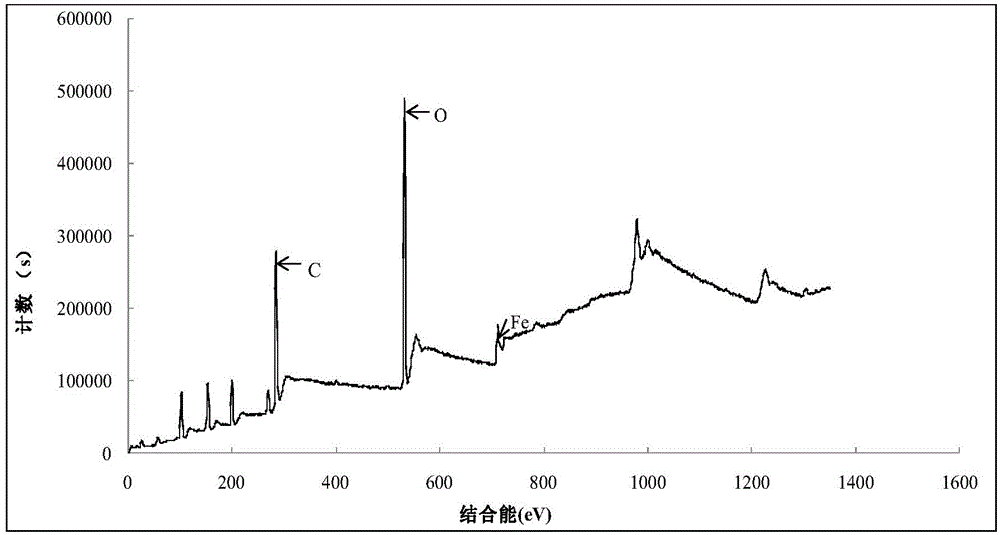

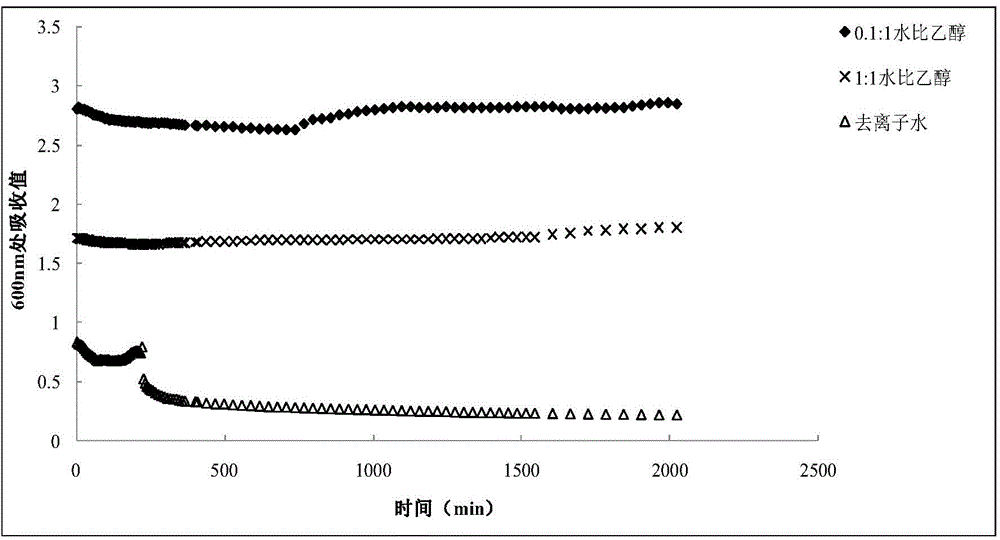

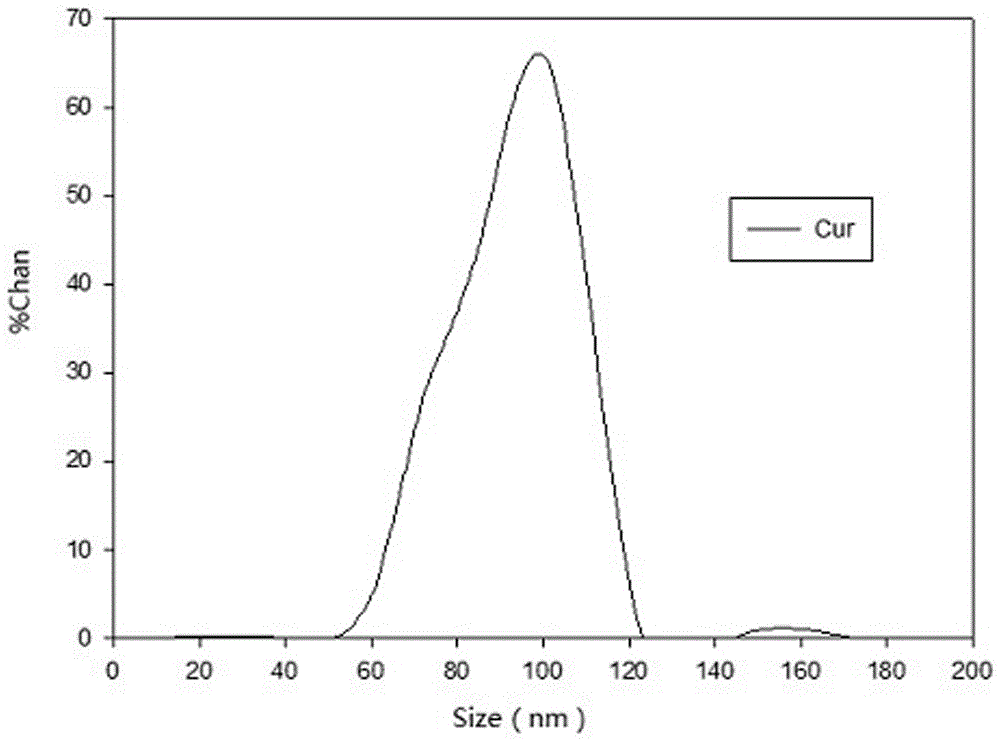

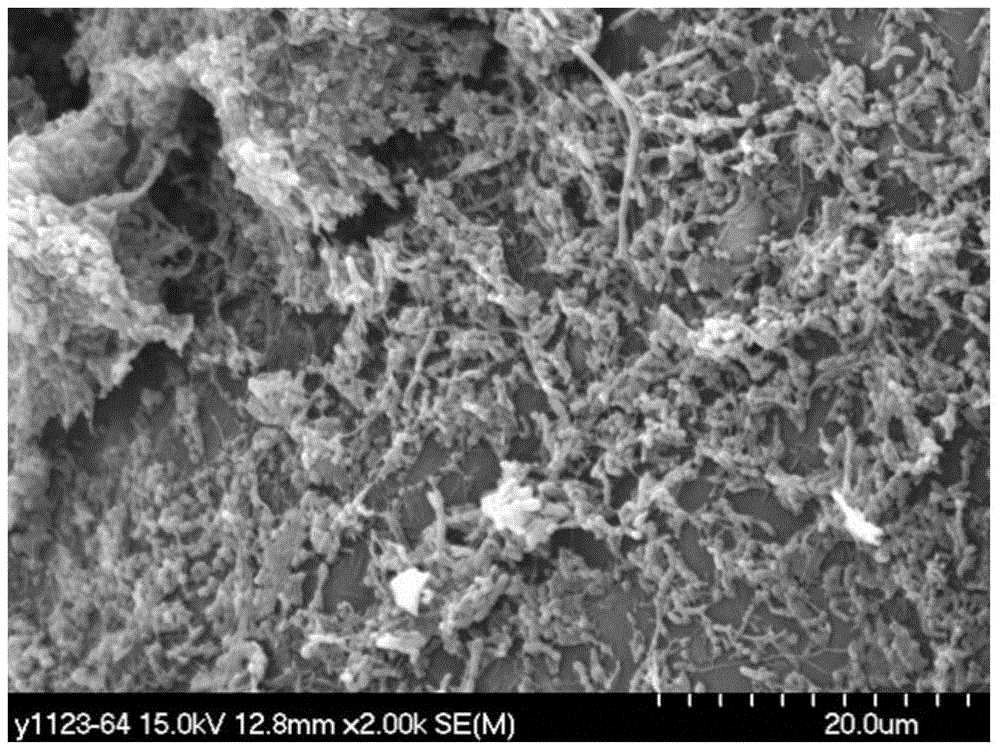

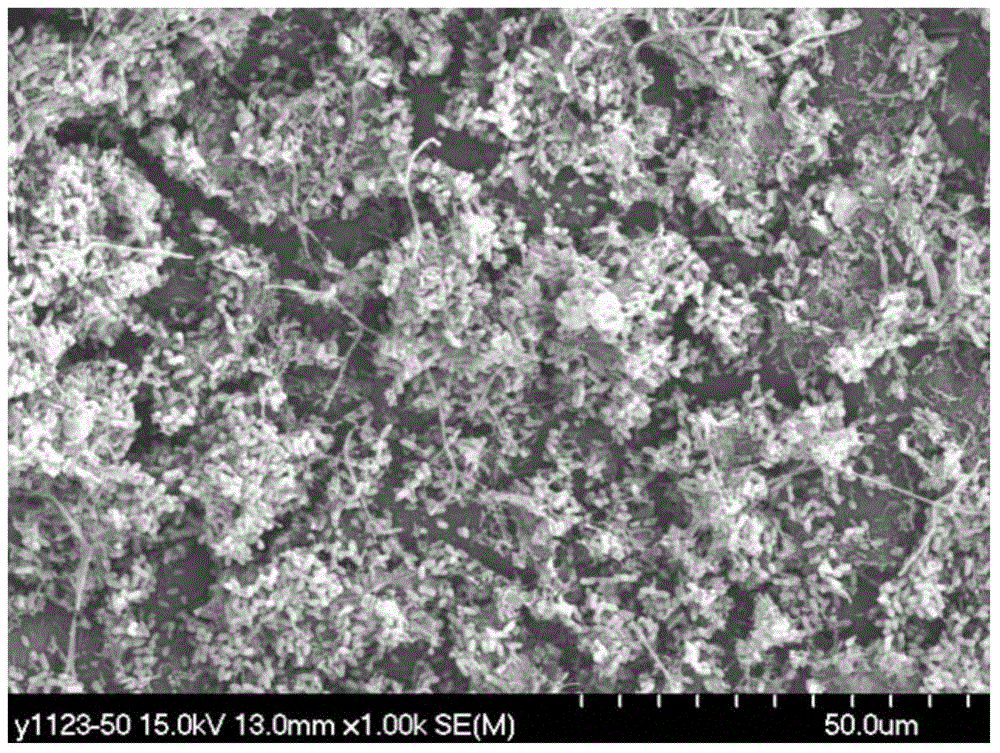

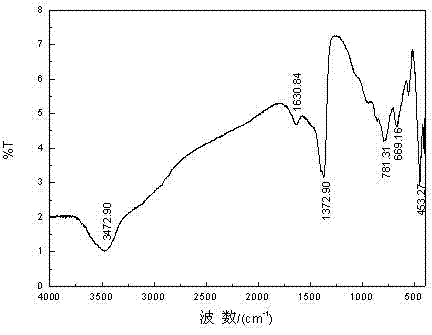

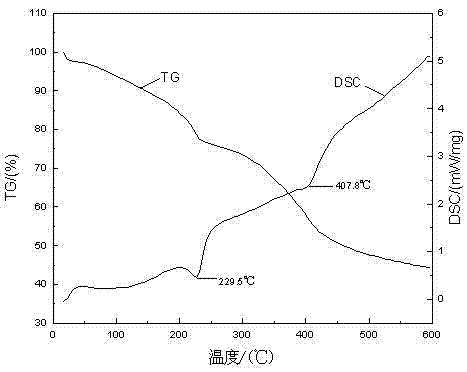

Method for preparing NZVI (nano-scale zero-valent iron) suspension from green tea as well as application of suspension

InactiveCN104857934ALarge specific surface areaImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionDissolutionSewage

The invention discloses a method for preparing NZVI (nano-scale zero-valent iron) from green tea as well as an application of a suspension of the NZVI. The method comprises technological steps as follows: A, preparing a green tea dissolution solution; B, preparing a ferric trichloride solution; C, preparing the GT-NZVI (green tea-NZVI) suspension. The prepared GT-NZVI has the advantages of good suspension stability, simple preparation technology, low cost, environment-friendliness, good stability, high penetrability in an aquifer and capability of quickly and thoroughly removing hexavalent chromium in sewage and underground water.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

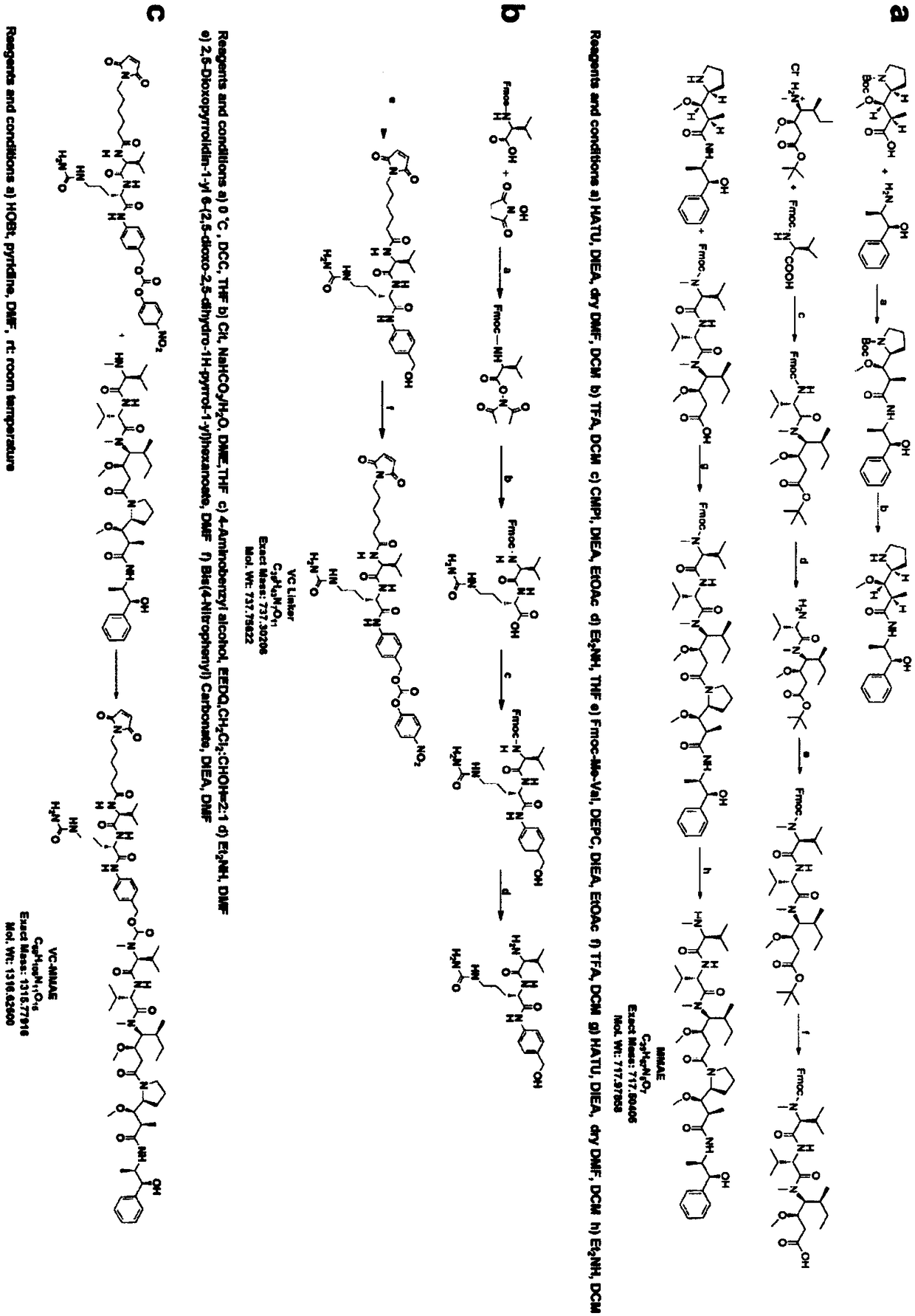

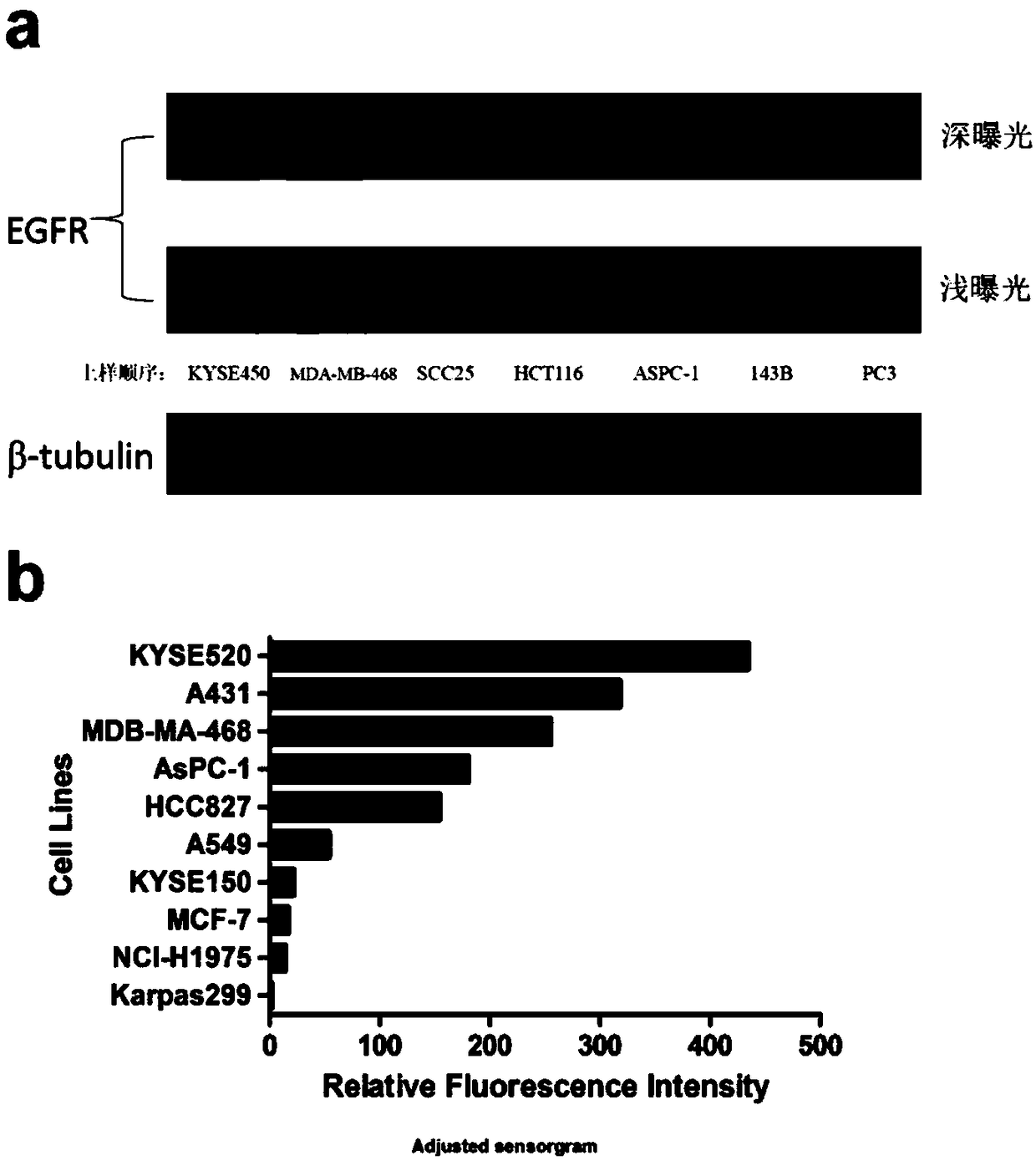

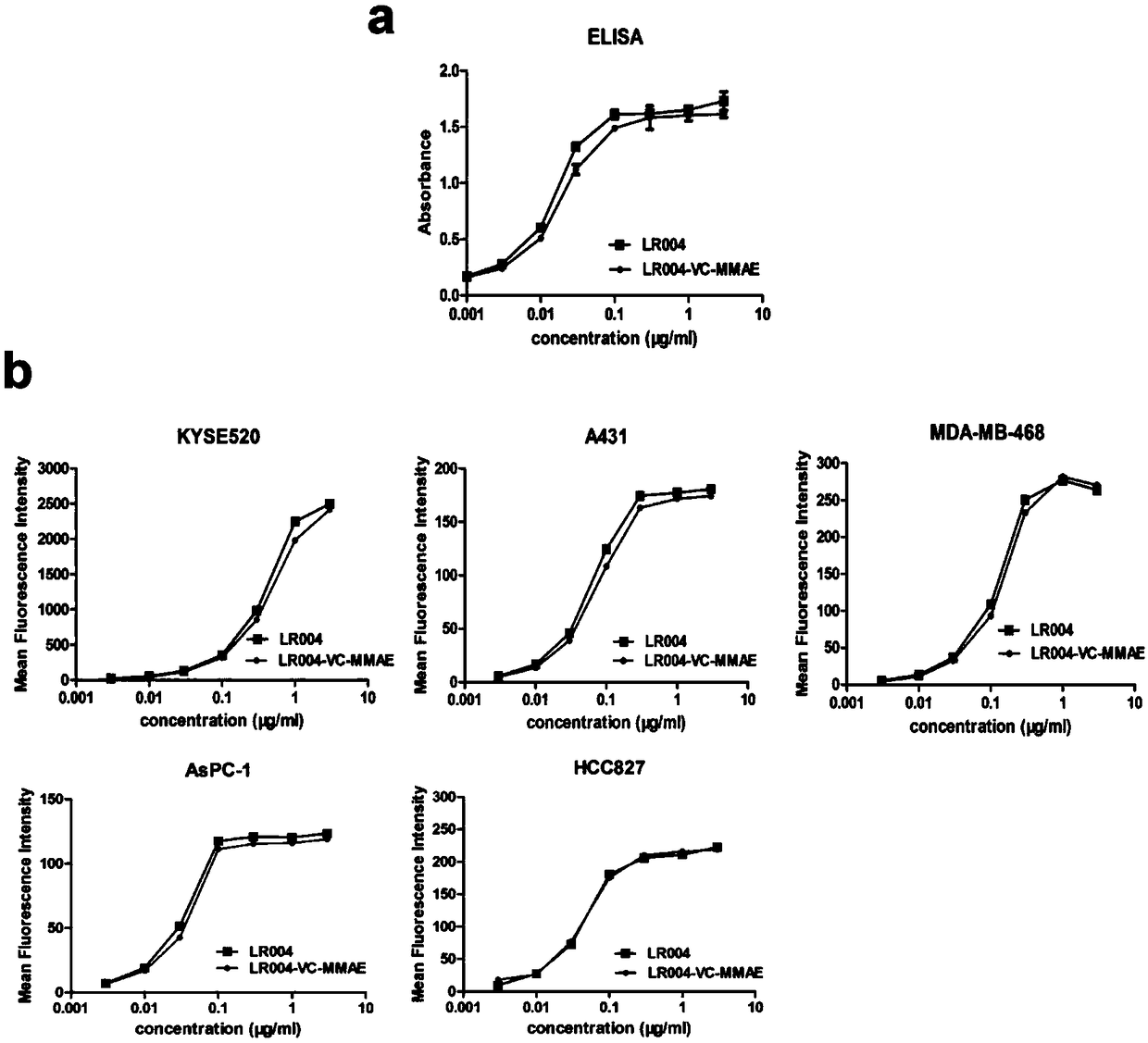

An antibody-coupled drug targeting on EGFR, a preparation method thereof, and uses thereof

ActiveCN109200291ADid not affect stabilityStable and controllable qualityTetrapeptide ingredientsAntibody ingredientsHalf-lifeAntibody conjugate

The invention discloses an antibody coupling drug targeting on EGFR, a preparation method thereof and uses thereof. The antibody-conjugated drug targeting EGFR is named LR004-VC-MMAE consisting of anantibody, a cytotoxic drug and a linker, wherein the antibody drug conjugate has a structure represented by the formula I, wherein mAb is an LR004 monoclonal antibody, n=2-8. The novel antibody-conjugated drug LR004-VC-MMAE can not only target EGFR antigen, but also has strong cytotoxicity to tumor cells. Compared with LR004 itself, it did not affect the affinity, endocytosis and targeting of theantibody, and better retained its biological function. Compared to LR004, the antitumor effect of LR004-VC-MMAE antibody-conjugated drug is significantly improved, and the tumor disappeared. Comparedto LR004, LR004-VC-MMAE antibody-conjugated total antibody showed longer half-life, slower clearance rate, lower concentration of free MMAE in plasma, shorter half-life and faster clearance rate, which is conducive to reduce toxicity.

Owner:MEDICINE & BIOENG INST OF CHINESE ACAD OF MEDICAL SCI

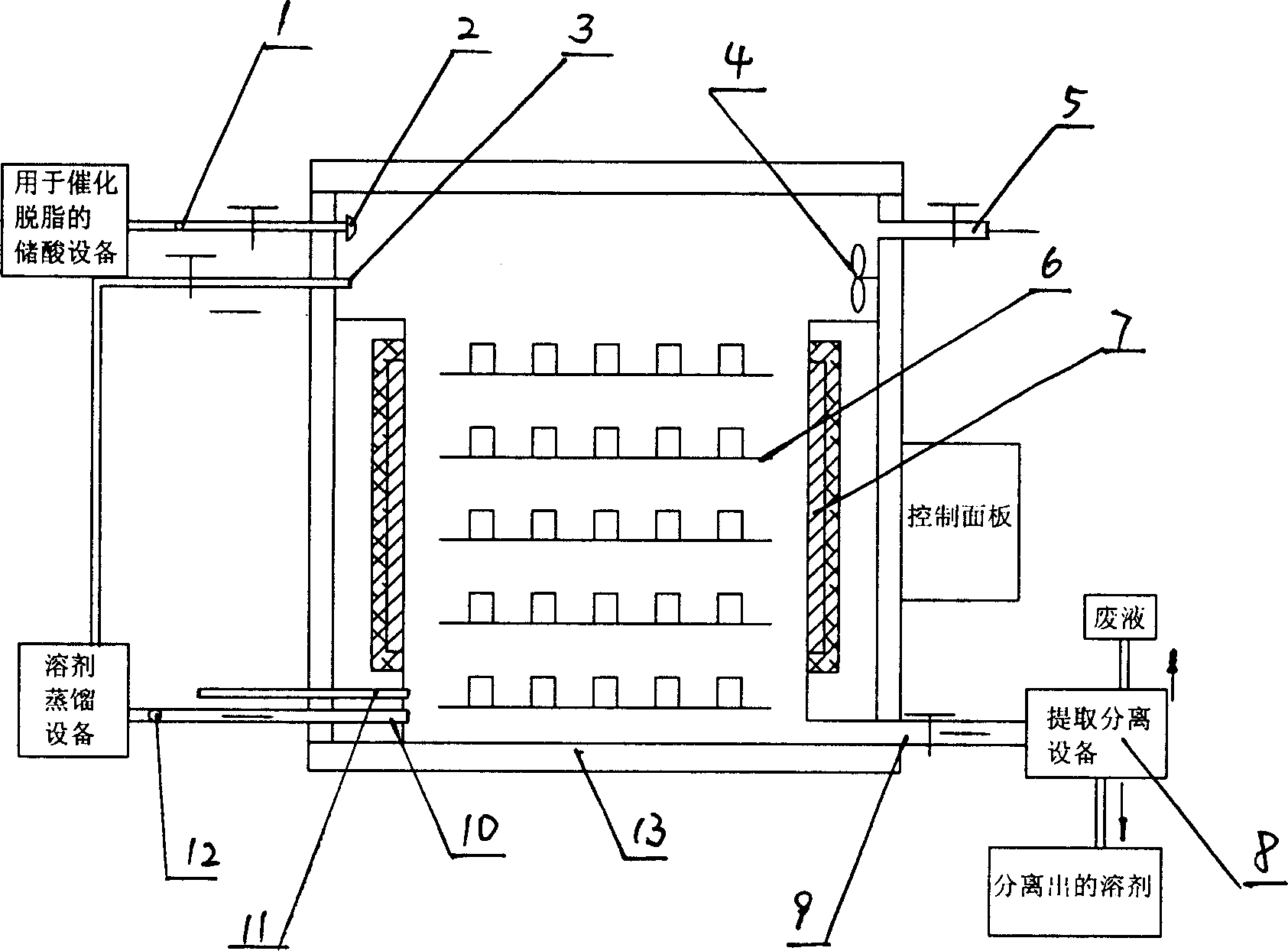

Mixed defatting stove and its mixed defatting process

The mixed defatting stove includes one stove body with a solvent inlet in the lower part and connected via a pump to a solvent storage device, a solvent outlet, a protecting gas inlet in the lower part, a gas exhaust port in the upper part, a solvent vapor inlet in the upper part and connected to solvent distiller, and has a heater on the side wall of the stove body, a blower on the upper part of the stove body to homogenize gas inside the stove, and an atomizer on the upper part of the stove and connected via a pump to a catalytic defatting acid storing device outside the stove body. The mixed defatting stove may meet the requirement of different defatting processes, including single or simultaneous solvent defatting, vapor defatting, condensed vapor defatting, catalytic defatting and siphonic defatting.

Owner:LIANYUNGANG DONGMU NEW MATERIALS CO LTD

Method for green synthesis of nanometer zero-valent iron suspension liquid with peels or seed kernels

InactiveCN105750562AHigh removal rateNo secondary pollutionTransportation and packagingWater contaminantsDispersityNitrogen gas

The invention discloses a method for green synthesis of nanometer zero-valent iron suspension liquid with peels or seed kernels. Ferric ions are reduced with plant total phenols in peels or seed kernels as a reducing agent to generate the nanometer zero-valent iron suspension liquid. The method for preparing the nanometer zero-valent iron suspension liquid from total phenols comprises the steps of extracting plant total phenols from waste peels or seed kernels, introducing nitrogen to remove dissolved oxygen in total phenol solution and ferric ion solution, and ferric ions are reduced by means of the reductibility of total phenols to generate zero-valent iron. The obtained zero-valent iron suspension liquid has high dispersity and reaction activity. The preparing method is easy to operate, the synthesized material is environment-friendly, low in cost and high in effectiveness, and equipment is simple. The zero-valent iron suspension liquid is used for removing hexavalent chromium in water, the rate of removing hexavalent chromium of 20 mg / L is 93-98%, removing speed is high, removing rate is high, secondary pollution to polluted water is avoided, and the zero-valent iron suspension liquid has broad application prospects in remediation of water polluted by hexavalent chromium.

Owner:TAIYUAN UNIV OF TECH

Electromagnetic coupling field-induced rheological polishing tool

InactiveCN101774151AExquisite structureImprove securityPolishing machinesLow voltageOptical processing

The invention belongs to the technical field of precise optical working and relates to an electromagnetic coupling field-induced rheological polishing tool. Based on electro-rheological and magneto rheological effect, the invention utilizes ferro magnetic material as a polished shaft; when direct current low voltage is applied on an electromagnetic coil, the polished shaft is magnetized to form an electromagnet with the electromagnetic coil, and a vertically distributed magnetic field is produced near the tip of the polished shaft; when direct current high voltage is applied on a taper sleeve and two ends of the polished shaft, a horizontal electric field can be provided to obtain a cross field near a polishing head; when direct current high voltage is applied on a sheet metal and the polishing shaft, a vertical electric field can be obtained, and a parallel field is obtained near the polishing head. Electromagnetic rheological liquid generates rheological effect under the action of externally applied electric and magnetic fields; liquid particles are distributed in chain and intensively attached near the polishing head to form a small-size flexible liquid polishing head which forms relative shearing movement with workpiece surface under the drive of a motor, thus finishing the ultrasmooth polishing of minor-caliber aspherical mirrors, heteromorphic mirrors and free curved mirrors.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Integrated device for diagnostic purposes

Owner:ROCHE DIABETES CARE INC

Method for rapidly and stably starting wastewater nitrite type mixotrophic desulfurization and denitrification system

InactiveCN104609548AIncrease success rateImprove maneuverabilityWater contaminantsTreatment with anaerobic digestion processesNitriteSulfur

The invention discloses a method for rapidly and stably starting a wastewater nitrite type mixotrophic desulfurization and denitrification system. The method comprises the following steps: controlling ecological factors in stages by virtue of a three-step method, respectively creating an anaerobic environment favorable for improving the activities of sulfur-autotrophic nitrate microbes, mixotrophic nitrate microbes and mixotrophic nitrite microbes, and promoting rapid formation of different functional floras, so that the complexity of the micro flora is reduced. According to the start method disclosed by the invention, stable operation of the desulfurization and denitrification process under high load conditions is promoted, the starting time is reduced, the stability of the system is enhanced, and after the system is started, the removal rate of sulfides and nitrite can rapidly reach 100 percent, the removal rate of the organic matters can be over 90 percent, the yield of elemental sulfur is high and is always over 80 percent, subsequent high-efficiency recovery of the elemental sulfur is promoted, and the wastes are recycled.

Owner:DALIAN MARITIME UNIVERSITY

Method for deeply treating micro-polluted source water through in-situ enrichment, immobilization and acclimatization of indigenous microorganisms

ActiveCN105417727AAvoid introducingNo ecological riskImmobilised enzymesMicroorganism separationStart timeWater quality

The invention provides a method for deeply treating micro-polluted source water through in-situ enrichment, immobilization and acclimatization of indigenous microorganisms. In-situ enrichment and immobilization of the indigenous microorganisms are carried out in a stuffy aeration manner under an appropriate aeration condition by inoculating underwater bed sediment to be treated and water to be treated and adding nutrient elements; then, the immobilized microorganisms are gradually adapted to the water quality to be treated by arranging automatic water intake / discharge, gradually reducing the concentration of the nutrient elements in intake water and increasing the amount of intake / discharged water. The method disclosed by the invention has the following advantages: 1) under the stuffy aeration condition, loss of the microorganisms is avoided, multiplication of the indigenous functional microorganisms is accelerated, and the start time of the process is greatly shortened; 2) the multiplication of autotrophic nitrobacteria flora is preferably promoted by inoculating the underwater bed sediment having nitrobacteria flora of high abundance, adding ammonia nitrogen and reducing a carbon nitrogen ratio, and the diversity of the inoculated nitrobacteria flora is ensured by inoculating the underwater bed sediment having an appropriate depth, and therefore the operation stability of a system is promoted.

Owner:NANJING FRONTIER ENVIRONMENTAL TECH

Processing method for ultrathin plain glass based on consolidated abrasive

InactiveCN102172859AUniform thicknessImprove flatnessPolishing compositionsPlane surface grinding machinesGranularityMicrometer

The invention discloses a processing method for ultrathin plain glass based on consolidated abrasive, which is characterized by comprising the following steps: firstly, taking ground plain glass of which the thickness is less than or equal to 0.5mm as a raw material; secondly, adopting a polishing pad of diamond consolidated abrasive of which the granularity is less than or equal to 28 micrometers, controlling the polishing temperature to 20-40oC, polishing pressure of 100-1000g / cm<2>, pH value of a polishing solution of 8-11, flow velocity of 100-500ml / min and polishing rotation speed of 10-500r / min to obtain a middle glass product of which the thickness is 0.2-0.3mm; thirdly, polishing the polishing pad of diamond consolidated abrasive of which the granularity is less than or equal to 10 micrometers, controlling the polishing temperature to 20-40oC, polishing pressure of 100-500g / cm<2>, pH value of a polishing solution of 8-11, flow velocity of 100-500ml / min and polishing rotation speed of 10-300r / min; and putting the middle glass product onto a polisher to polish to obtain ultrathin glass of which the thickness is less than or equal to 0.15mm. The processing method has the advantages of simple process, no pollution, high efficiency and low cost, and size material with a larger length or width and thickness ratio can be processed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

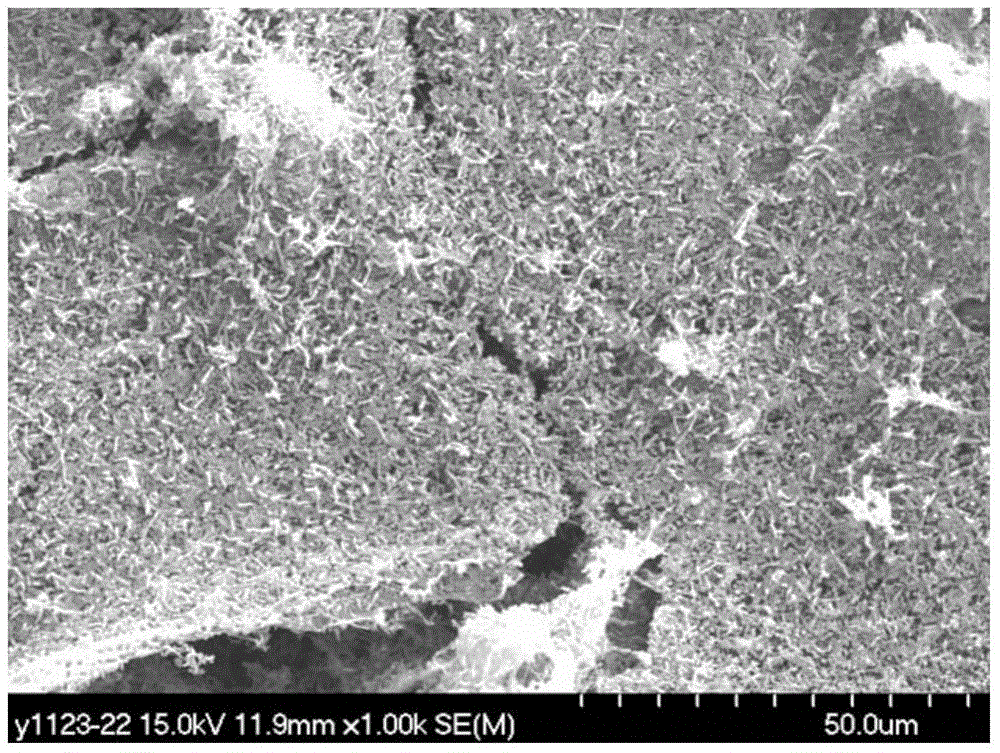

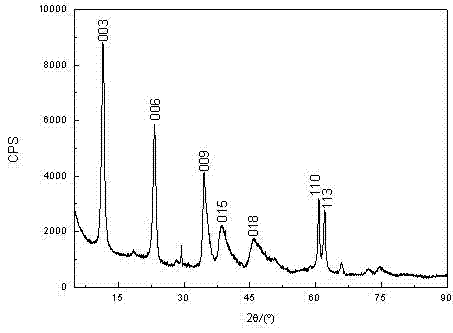

Method for preparing hydrotalcite by adopting brucite

InactiveCN102219248AWide variety of sourcesAbundant resource reservesAluminium oxides/hydroxidesWater bathsAluminium hydroxide

The invention relates to the technical field of hydrotalcite preparation, in particular to a method for preparing hydrotalcite by adopting brucite. In the method, brucite is adopted as a magnesium source, aluminum hydroxide is adopted as an aluminum source, and two main process steps of de-crystallization of brucite and aluminum hydroxide and recrystallization of de-crystallization substances areadopted. The method comprises the following steps: combining the brucite with the aluminum hydroxide according to the mole ratio of magnesium to aluminum being 2:4 to obtain mixture, mixing the mixture with zirconium oxide balls uniformly according to the ball-material ratio being 50:1, arranging the mixture and the zirconium oxide balls into a zirconium oxide ball milling tank for ball milling, then adding deionized water accounting for 10-20% of the total amount of brucite and aluminum hydroxide for ball milling continuously; mixing the material after ball milling and sodium carbonate solution according to the mole ratio being Mg2+:CO32-=1.5-6, stirring and crystallizing the mixture for 1-5h under water bath with the temperature being 60-80 DEG C, and the stirring rotation speed being 500r / min, and finally washing and drying to obtain the final product hydrotalcate.

Owner:NORTHEASTERN UNIV +1

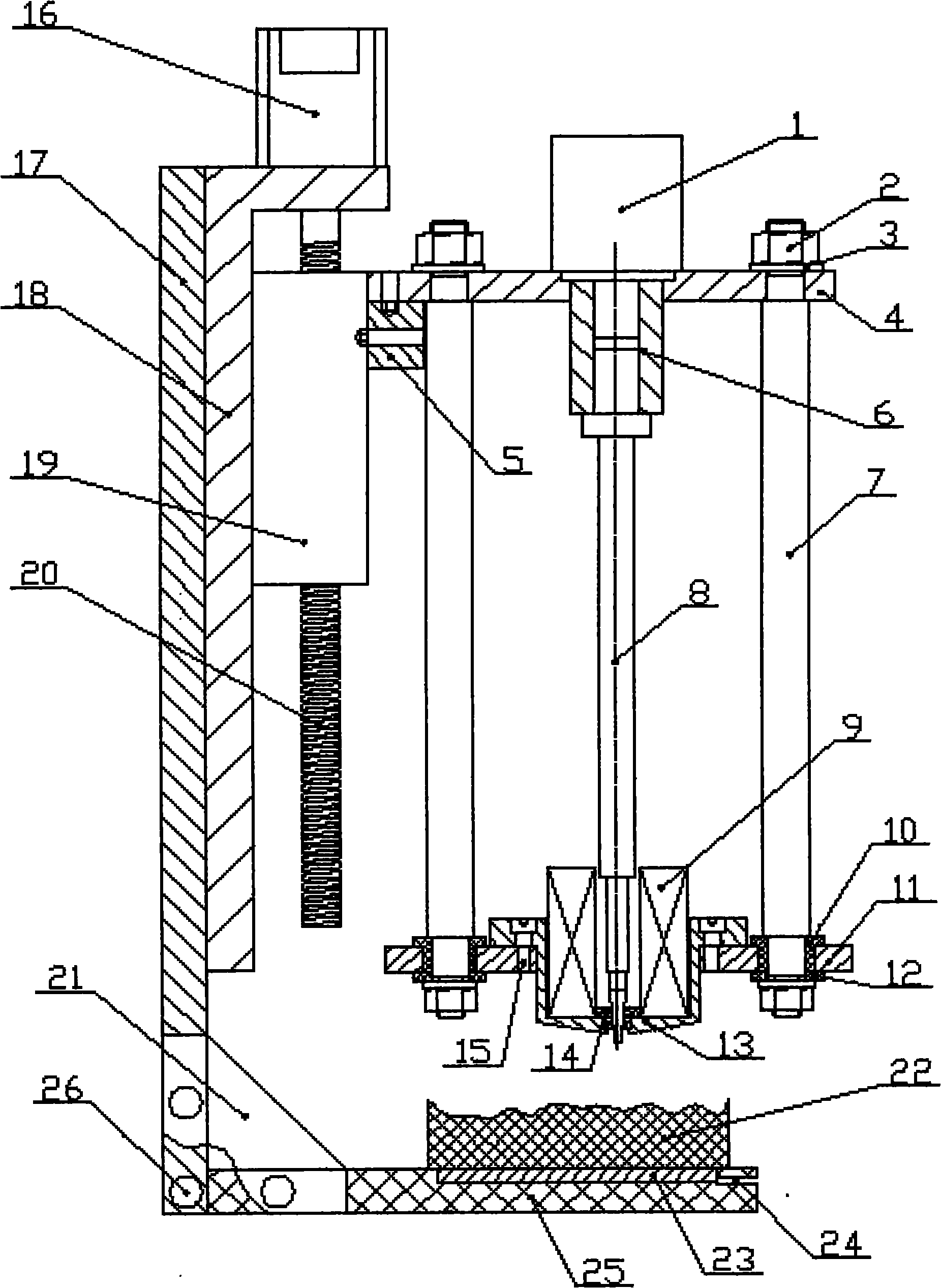

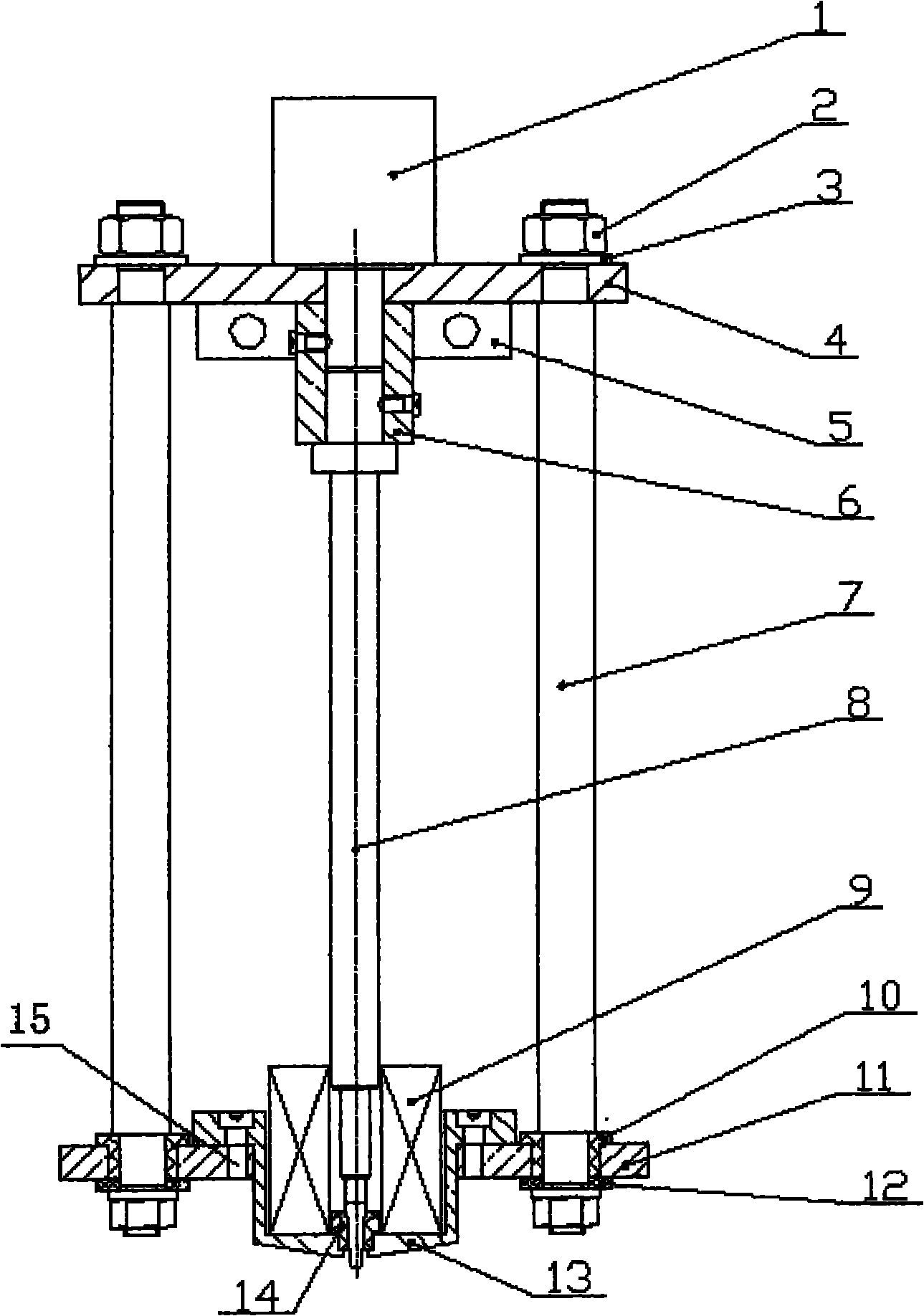

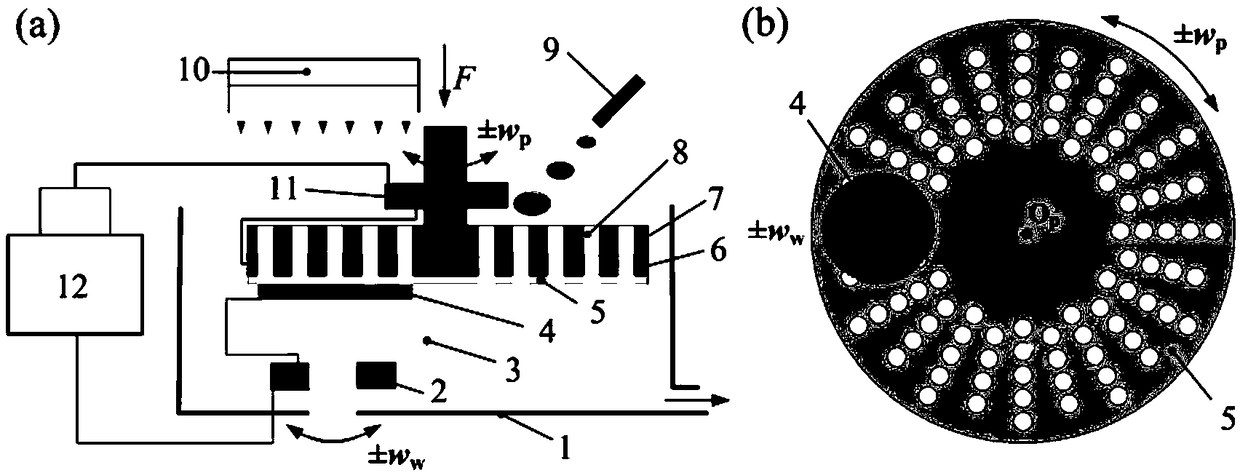

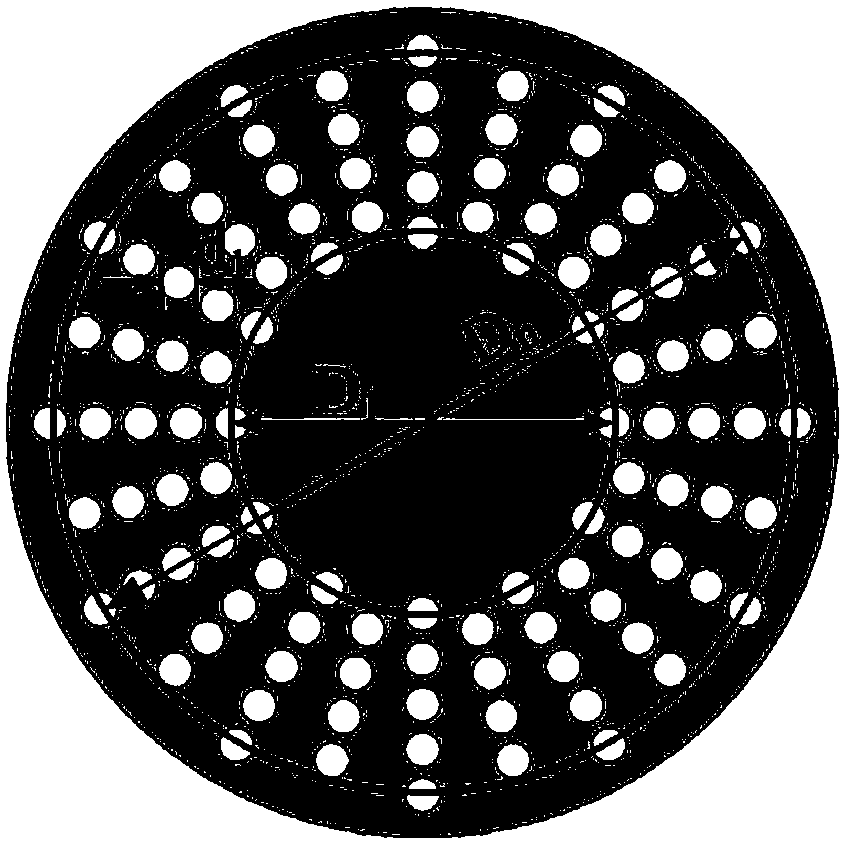

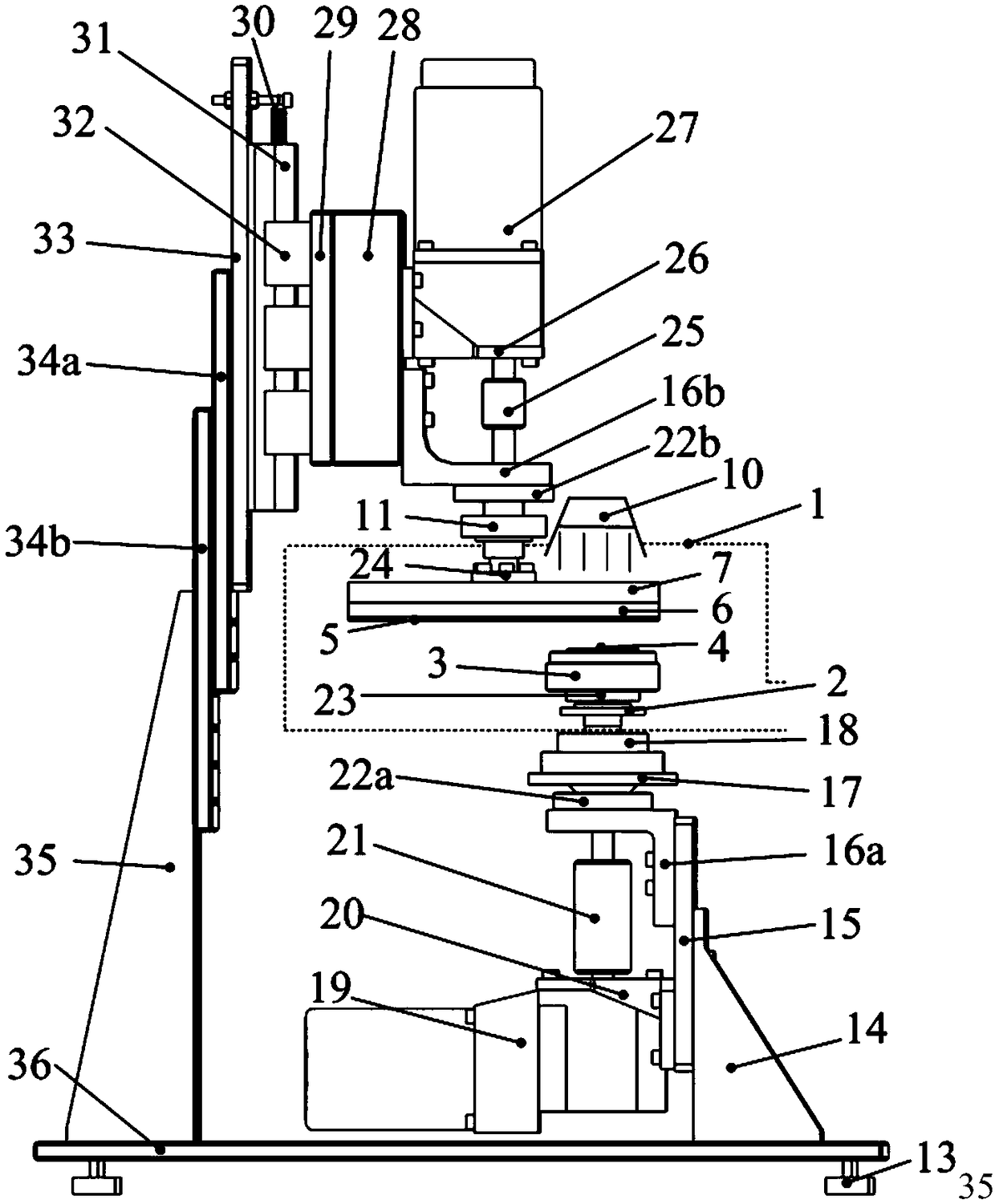

Semiconductor chip photo-electro-chemical mechanical polishing machining device

ActiveCN109465739AReduce roughnessFast removal rateGrinding machine componentsLapping machinesUltraviolet lightsSemiconductor chip

The invention discloses a semiconductor chip photo-electro-chemical mechanical polishing machining method and device. A chip is fixedly bonded to a polishing head through electrically-conductive adhesive. The lower portion of the chip is connected with a positive pole of an external power source through wires at an inner ring and an outer ring of an electrically-conductive sliding ring. A polishing pad is bonded to the bottom of a counter electrode disc. The counter electrode disc is fixed to the bottom of a polishing disc, and a through hole is machined in the position, corresponding to the polishing disc, of the counter electrode disc. The counter electrode disc is connected with a negative pole of the external power source through wires at the inner ring and the outer ring of an electrically-conductive sliding ring located above the counter electrode disc. Ultraviolet light transmitted by an ultraviolet light source can be cast to the surface of the chip through the through hole. Apolishing solution can be sprayed into the through hole and enter the contact area of the chip and the polishing pad. By means of the photo-electro-chemical mechanical polishing machining device, themachining method can be well implemented; the machining device has the advantages that the device is easy to operate and implement, and technological parameters can be flexibly adjusted; and the effects that in the practical machining process of the gallium nitride chip, the removal rate is high, and the surface quality achieved after machining is high are achieved.

Owner:DALIAN UNIV OF TECH

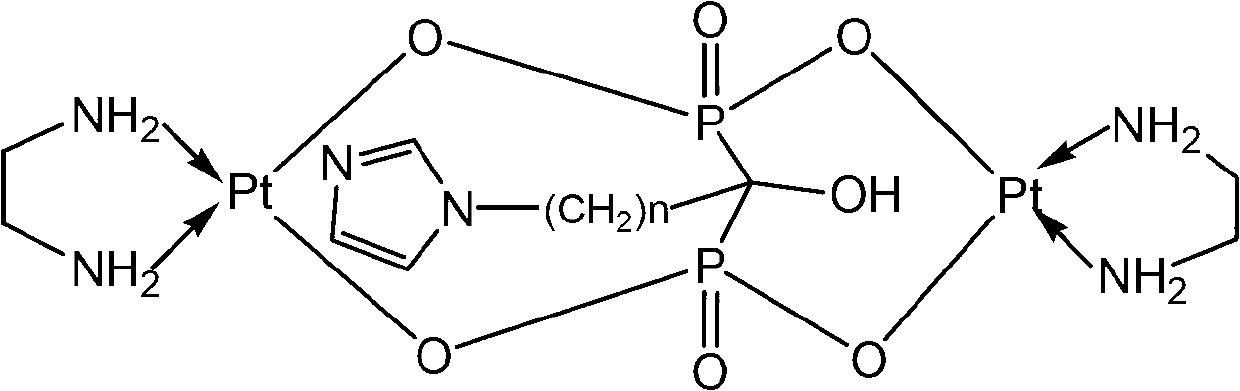

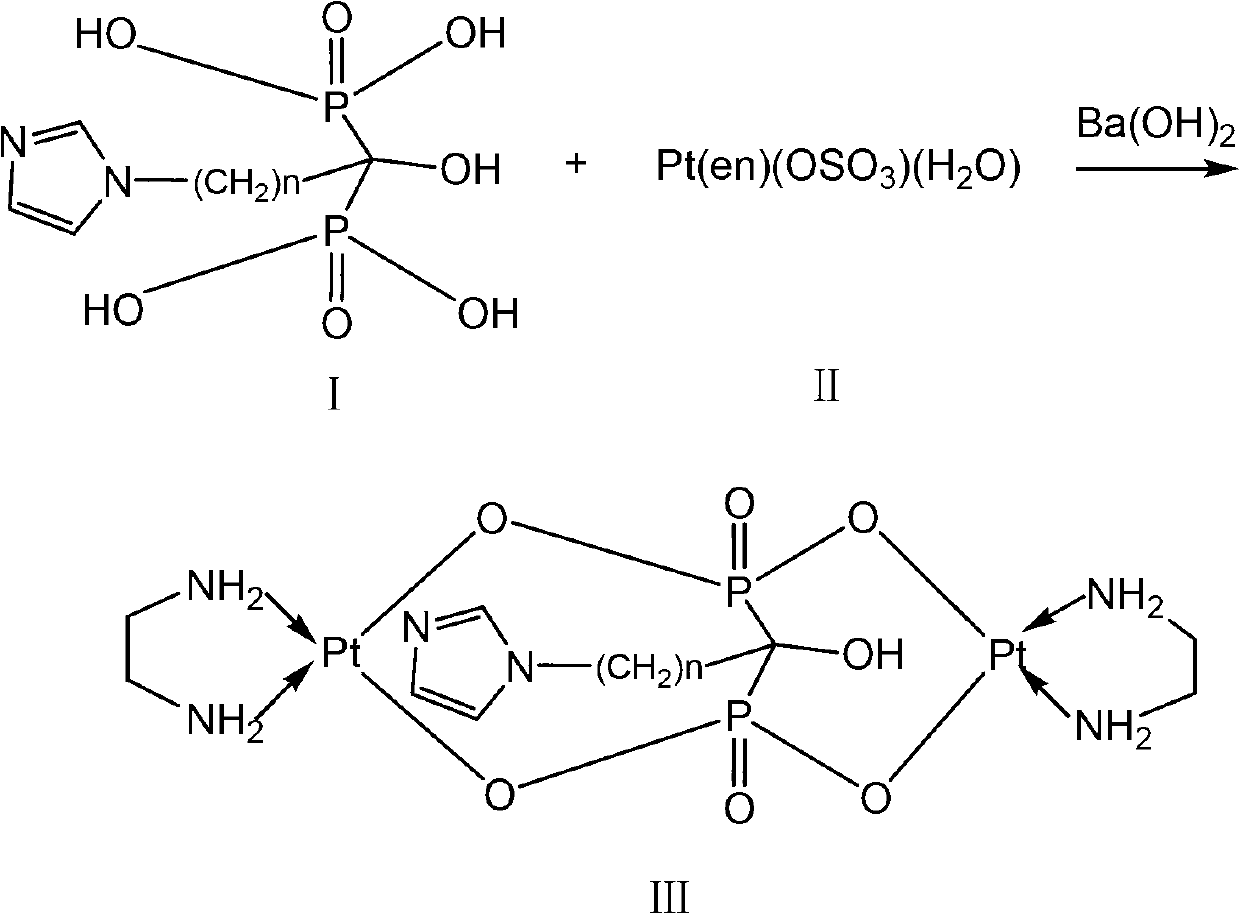

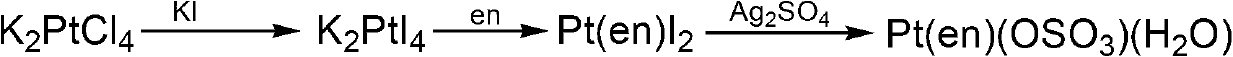

Binuclear platinum (II)-diphosphonic acid coordination compound, preparation method and application thereof

ActiveCN102731580AIncrease intakeExtended stayOrganic active ingredientsOrganic chemistryPlatinumDiphosphonates

The invention provides a binuclear platinum (II)-diphosphonic acid coordination compound, a preparation method and an application thereof, and belongs to the field of anti-cancer drugs. The binuclear platinum (II)-diphosphonic acid coordination compound has the structural formula shown in the description, wherein n is 2, 3, 4 or 5. The preparation method of the binuclear platinum (II)-diphosphonic acid coordination compound comprises the following steps: diphosphonic acid derivative and Pt(en)(OSO3)(H2O) are reacted under the function of Ba(OH)2 to obtain the binuclear platinum (II)-diphosphonic acid coordination compound. According to the compound, a link arm of C between diphosphonates is expanded; quinary aromatic amine (namely imidazole) is introduced in, so that at the initial usage stage of the coordination compound, the coordination compound has high intake in tumour cells and long residence time; and the aggregation concentration of the coordination compound in other non-targeted tissues is greatly reduced.

Owner:JIANGSU INST OF NUCLEAR MEDICINE

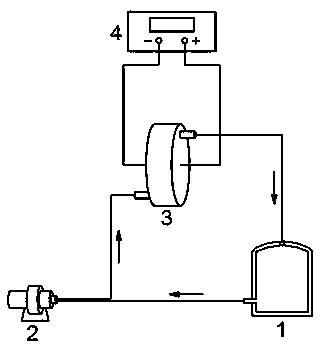

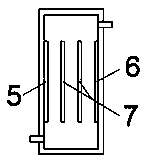

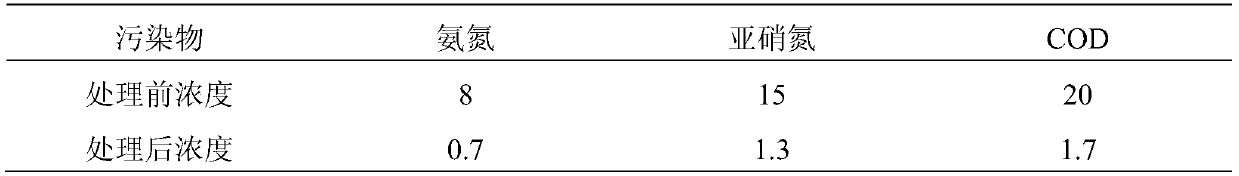

Device and method for removing ammonia nitrogen, nitrite nitrogen and COD in marine culture wastewater

InactiveCN105502584AReduce processing costsImprove securitySeawater treatmentWater contaminantsElectrochemical responsePeristaltic pump

The invention discloses a device and method for removing ammonia nitrogen, nitrite nitrogen and COD in marine culture wastewater. A water inlet is formed in the top end of an impounding reservoir of the device and communicated with a water outlet in the upper end of an electrochemical reactor, and a water outlet is formed in the lower end of the impounding reservoir and connected with a water inlet in the lower end of the electrochemical reactor. An anode, a bipolar electrode and a cathode are sequentially arranged in the electrochemical reactor through a peristaltic pump, the anode is connected with a positive electrode of a direct-current stabilized power supply, and the cathode is connected with a negative electrode of the direct-current stabilized power supply. A chemical agent does not need to be added, and thus treatment cost can be greatly reduced; free chlorine is constantly generated in situ at the anode, and thus safety performance is improved; the treatment process is clean and quick, and sludge and secondary pollution are avoided; the ammonia nitrogen, nitrite nitrogen and COD removing speed is high, and efficiency is high; only the current size needs to be controlled, and thus control is easy; the device is simple and convenient to operate and maintain.

Owner:ZHEJIANG UNIV

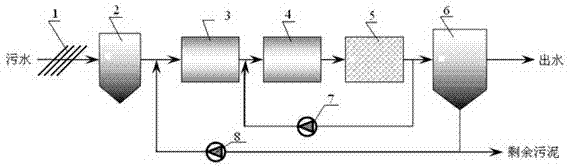

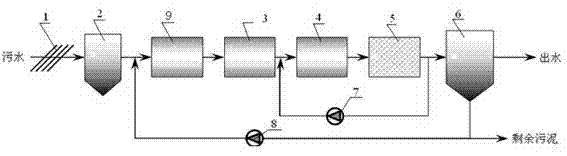

Sewage treatment system and application thereof

InactiveCN102765857AFast nitrification rateIncrease nitrification rateTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentAmmoniacal nitrogenWater discharge

The invention discloses a sewage treatment system which comprises a grating, a grit tank, a preaeration tank, an anaerobic tank, an anoxia tank, an aerobic tank and a secondary sedimentation tank. Sewage enters the grit tank after being treated by the grating, water discharged from the grit tank sequentially enters a biological treatment unit composed of the anaerobic tank, the anoxia tank and the aerobic tank to be treated, obtained mixed liquid enters the secondary sedimentation tank, two outlets are arranged on the secondary sedimentation tank, one outlet is a discharging port of treated sewage, and the other outlet is a discharging port of surplus sludge. A bypass is arranged on the discharging port of the surplus sludge, and one part of the surplus sludge discharged from the secondary sedimentation tank flows back to the preaeration tank through a sewage backflow pump. Simultaneously, one part of the mixed liquid from the aerobic tank flows back to the anoxia tank through a mixed liquid backflow pump on the bypass. The sewage treatment system has the advantages of being high in nitrobacterium activity, high in nitrification rate, high in ammonia nitrogen removing rate and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

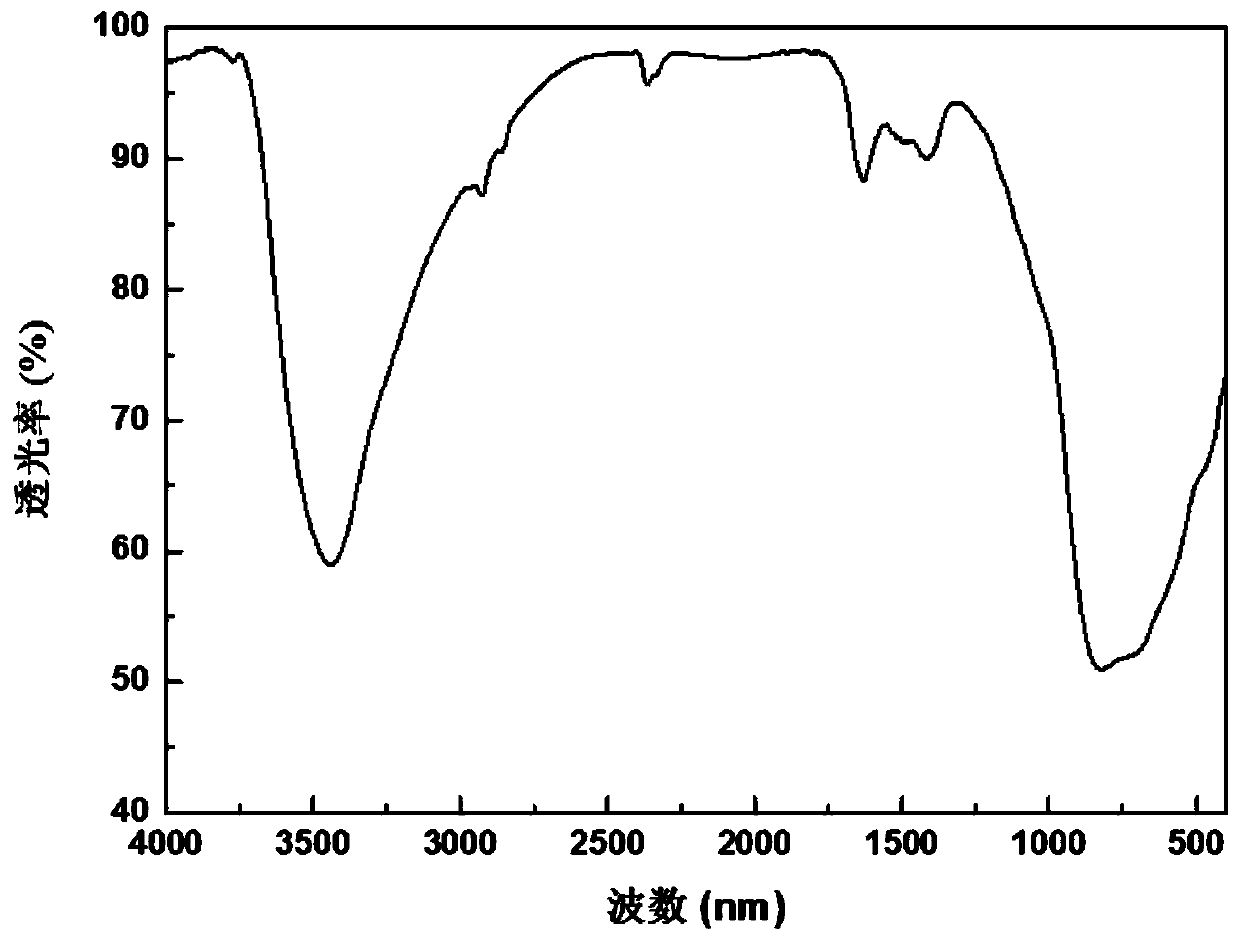

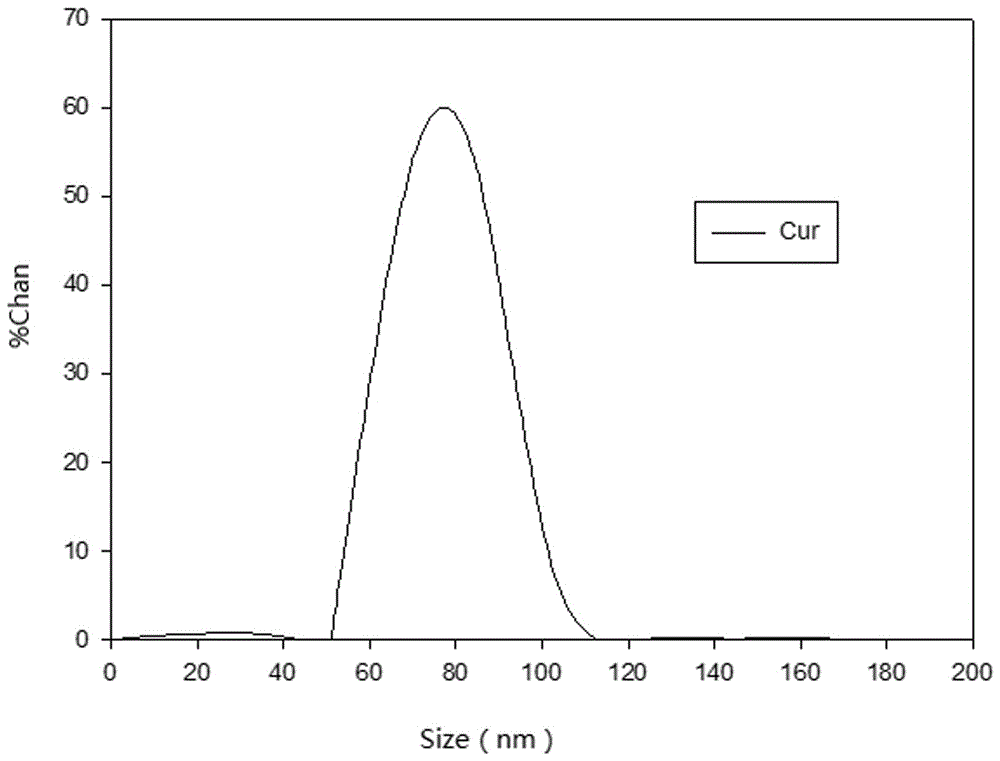

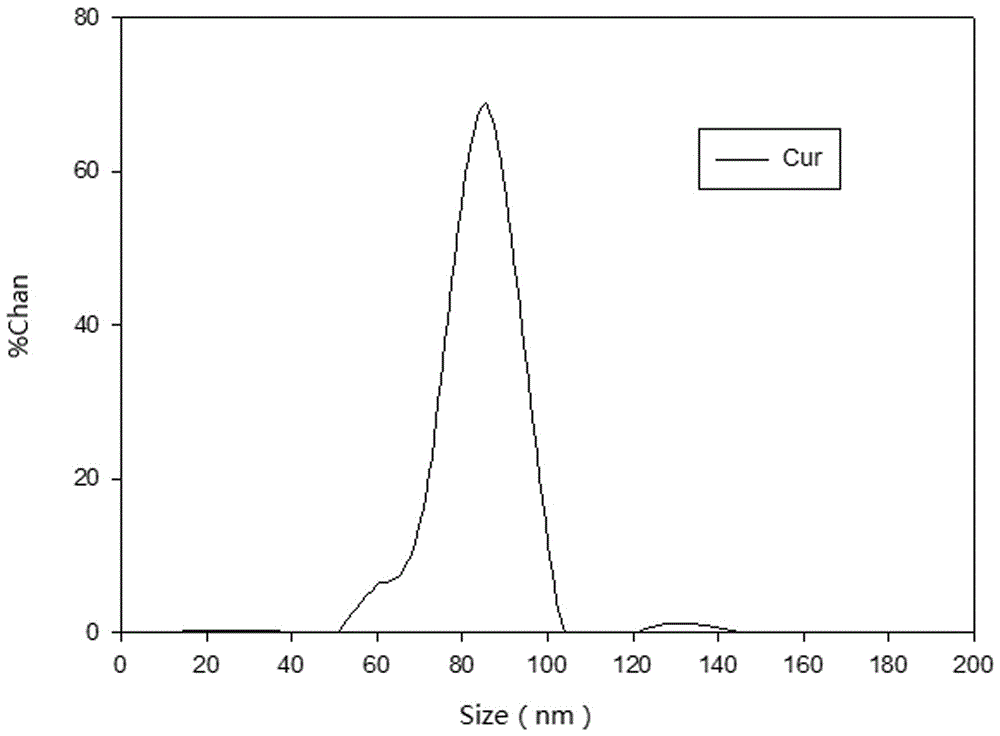

[<18>F] AlF marked positron emission tomography (PET) polypeptide probe and preparation method thereof

InactiveCN104725473ADoes not affect biological activityDoes not affect pharmacokinetic propertiesPeptide preparation methodsIn vivoStructural formula

The invention discloses a [<18>F] AlF marked positron emission tomography (PET) polypeptide probe and a preparation method thereof. The probe comprises TMTP1 polypeptide and NOTA, which are connected together, and the structural formulae of the TMTP1 polypeptide and the NOTA are shown in the description. According to the [<18>F] AlF marked positron emission tomography (PET) polypeptide probe and the preparation method thereof, a glycine is added to the TMTP1, and a G-TMTP1 polypeptide is designed, so that the polypeptide does not influence the biological activity after being radioactively marked; furthermore, 18F is taken as a radionuclide, and the G-TMTP1 polypeptide is marked by utilizing a [<18>F] AlF-NOTA method, so that the obtained [<18>F] AlF-marked PET polypeptide probe has excellent pharmacokinetics properties, the background cleaning rate is high, the liver uptake rate is low, in-vivo stability is good, the uptake rate of tumor site is high, highly metastatic tumor can be diagnosed specifically, and the polypeptide probe can be applied to diagnosis or therapeutic evaluation of highly metastatic malignant tumor.

Owner:THE FIRST AFFILIATED HOSPITAL OF XIAMEN UNIV +1

Anti-cleavage suspended grinding fluid for gallium oxide wafer and preparation method thereof

ActiveCN105273638AInhibition of cleavage defectsFast removal ratePolishing compositions with abrasivesAlkaneMaterial removal

The invention discloses an anti-cleavage suspended grinding fluid for a gallium oxide wafer and a preparation method thereof. The fluid is prepared from aluminium oxide micropowder, a dispersing thixotropic agent, a surfactant, kerosene, an alkane, a pH value conditioning agent, an antifoaming agent, a bactericide and a cleaning auxiliary agent. The anti-cleavage suspended grinding fluid is preferably obtained through a large amount of experiments. The grinding fluid is good in stability, and is applicable to rough grinding and smooth grinding of the gallium oxide wafer. The material removal speed is fast, and the wafer surface is smooth and does not have obvious scratches or pits. The grinding fluid is capable of reducing mechanics expansion effect during grinding on surface micro cracks, stress damage layers and other defects left after cutting is performed , is capable of effectively inhibiting cleavage defects during grinding of the gallium oxide wafer, also is low in cost and beneficial for popularization application, and overcomes many disadvantages in the prior art.

Owner:YANCHENG INST OF TECH

Method for renovating polycyclic aromatic hydrocarbon contaminated soil with ultrasound wave

InactiveCN101195122AFast removal rateHigh mineralization rateContaminated soil reclamationCavitationSlurry

The invention belongs to the surgical repair field of contaminating soil, and discloses a method for restoring soil which is polluted by polycyclic aromatic through supersonic waves. Soil slurry with a dampness 5%-95%, which is polluted by the polycyclic aromatic whose concentration of the polycyclic aromatic is 10-10000 g / kg is treated under a condition of supersonic wave irradiations, supersonic frequency is 20kHz-100kHz, the output power of the supersonic waves is 100W-2.0kw, and the duration of the supersonic wave irradiations is 5min-4h. The polycyclic aromatic is one of 16 polycyclic aromatics compounds with priority control, and the 16 polycyclic aromatics compounds are regulated in American EPA610. The invention mainly adopts cavitations effects of the supersonic waves to degrade or subtract organic contaminants with durability as the polycyclic aromatic and the like. Compared with a soil restoring technique which is adopted commonly at present, and the method isn't affected by the condition of contaminant species and environment, and the method has a wide applying field. The invention has high efficiency, low energy consumption, non-secondary pollutions, good social profits and environmental benefits.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Etching Solution for Tungsten Word Line Recess

ActiveUS20190284704A1High selectivityLong processing timeSemiconductor/solid-state device manufacturingSurface treatment compositionsOrganic solventSURFACTANT BLEND

Described herein is an etching solution suitable for both tungsten-containing metals and TiN-containing materials, which comprises: water; and one or more than one oxidizers; and one or more than one of the components selected from the group consisting of: one or more fluorine-containing-etching compounds, one or more organic solvents, one or more chelating agents, one or more corrosion inhibitors and one or more surfactants.

Owner:VERSUM MATERIALS US LLC

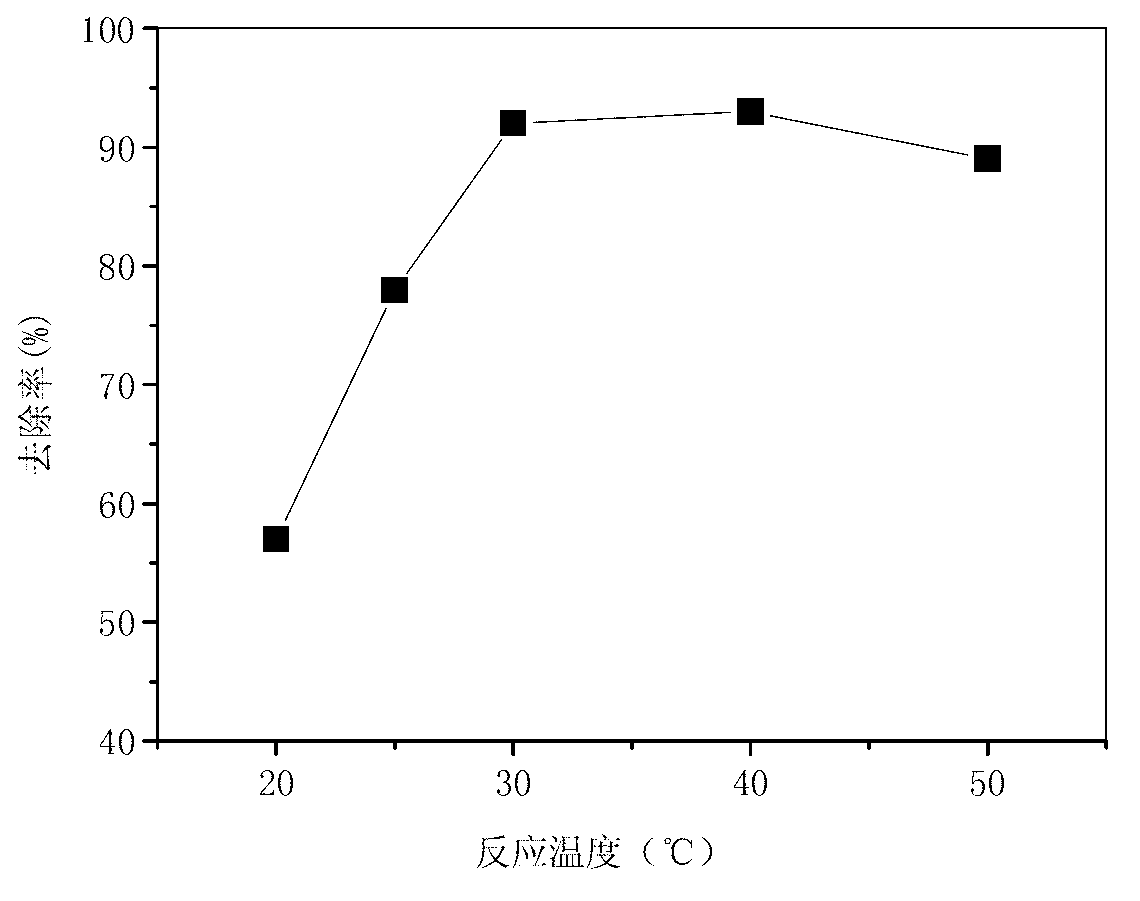

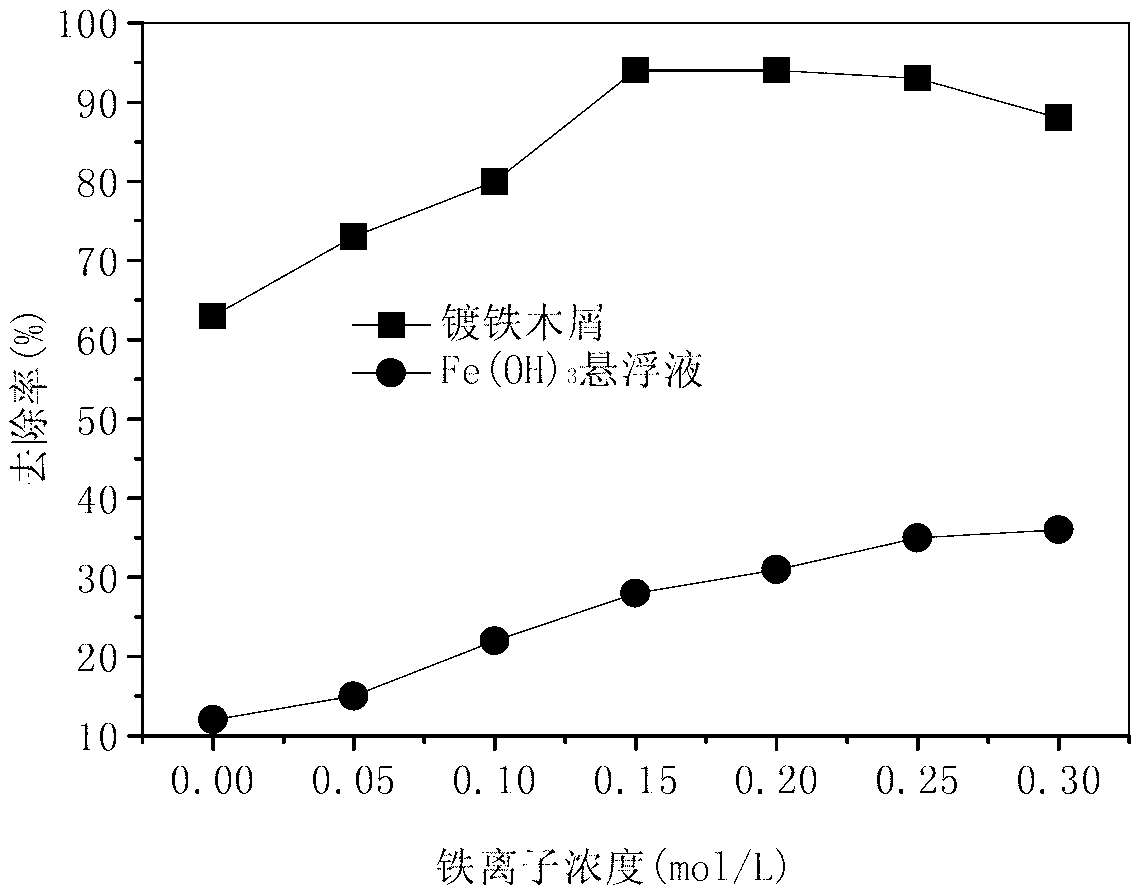

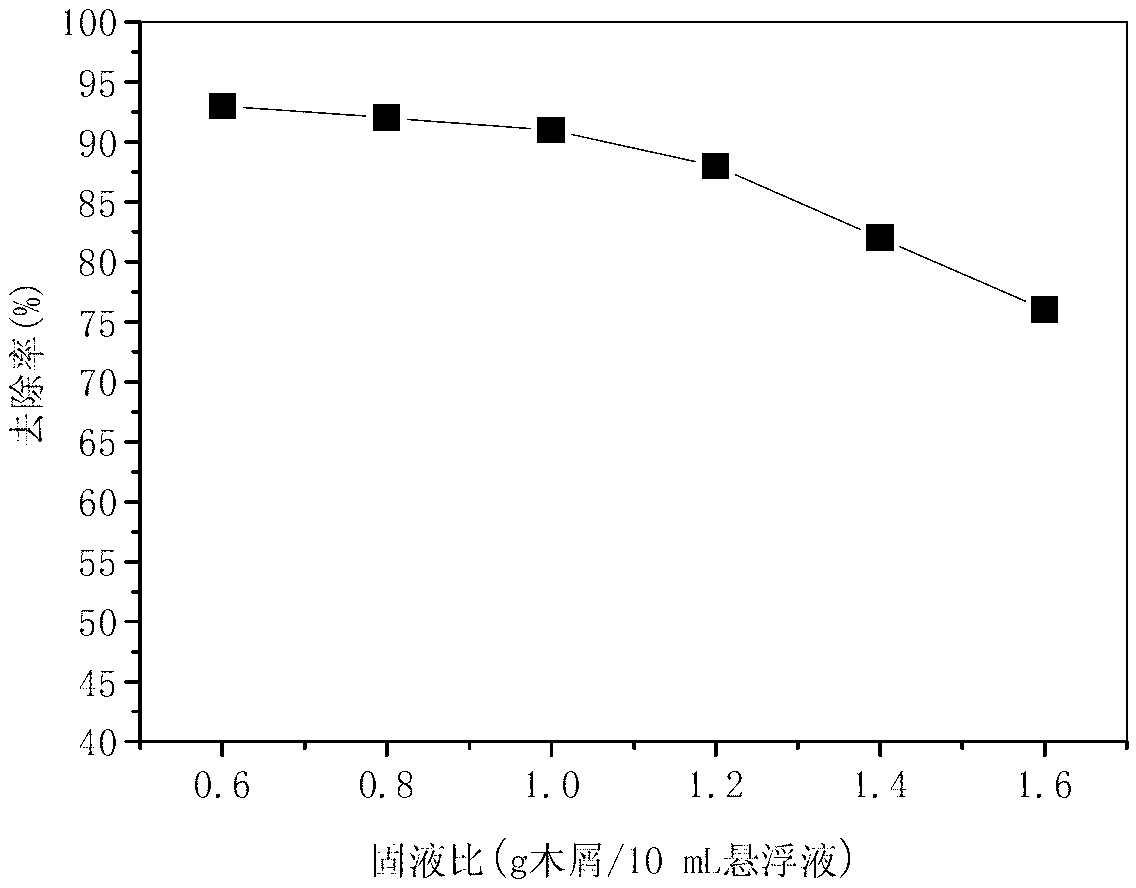

Adsorbent, preparation process thereof and application of adsorbent to purification of ammonia-nitrogen wastewater with medium-low concentration

InactiveCN103252216AImprove performanceUniform particle distributionOther chemical processesWater contaminantsDissolved organic carbonFiltration

The invention relates to a technology for purifying and treating ammonia-nitrogen wastewater by using an adsorption method and particularly relates to an adsorbent, a preparation process thereof and an application of the adsorbent to the purification of ammonia-nitrogen wastewater with medium-low concentration. An iron-plated woodchip adsorbent provided by the invention is composed of woodchips and Fe(OH)3. The preparation process comprises the following steps of: washing woodchips by using water for 1-3 times to remove impurities, drying, crushing and screening to ensure that the mass percentage of the woodchips with the particle sizes of 198-350mum is larger than or equal to 80%; subjecting a FeCl3 solution with the concentration of 0.15-0.25mol / L and a NaOH solution to reaction to generate a Fe(OH)3 suspension liquid; and then, sufficiently mixing the screened woodchips and the Fe(OH)3 suspension liquid according to the solid-to-liquid ratio of 0.6-1.0g / 10mL, carrying out hydrothermal treatment at the temperature of 30-50 DEG C for 1.5-3h, washing a product by using water until the product is neutral, carrying out suction filtration, and drying the product. When the adsorbent is used for purifying the ammonia-nitrogen wastewater with medium-low concentration, the removal rate of NH4<+>-N is larger than or equal to 90%, and the removal rate of COD (Dissolved Organic Carbon) is larger than or equal to 75%.

Owner:JIANGXI UNIV OF SCI & TECH

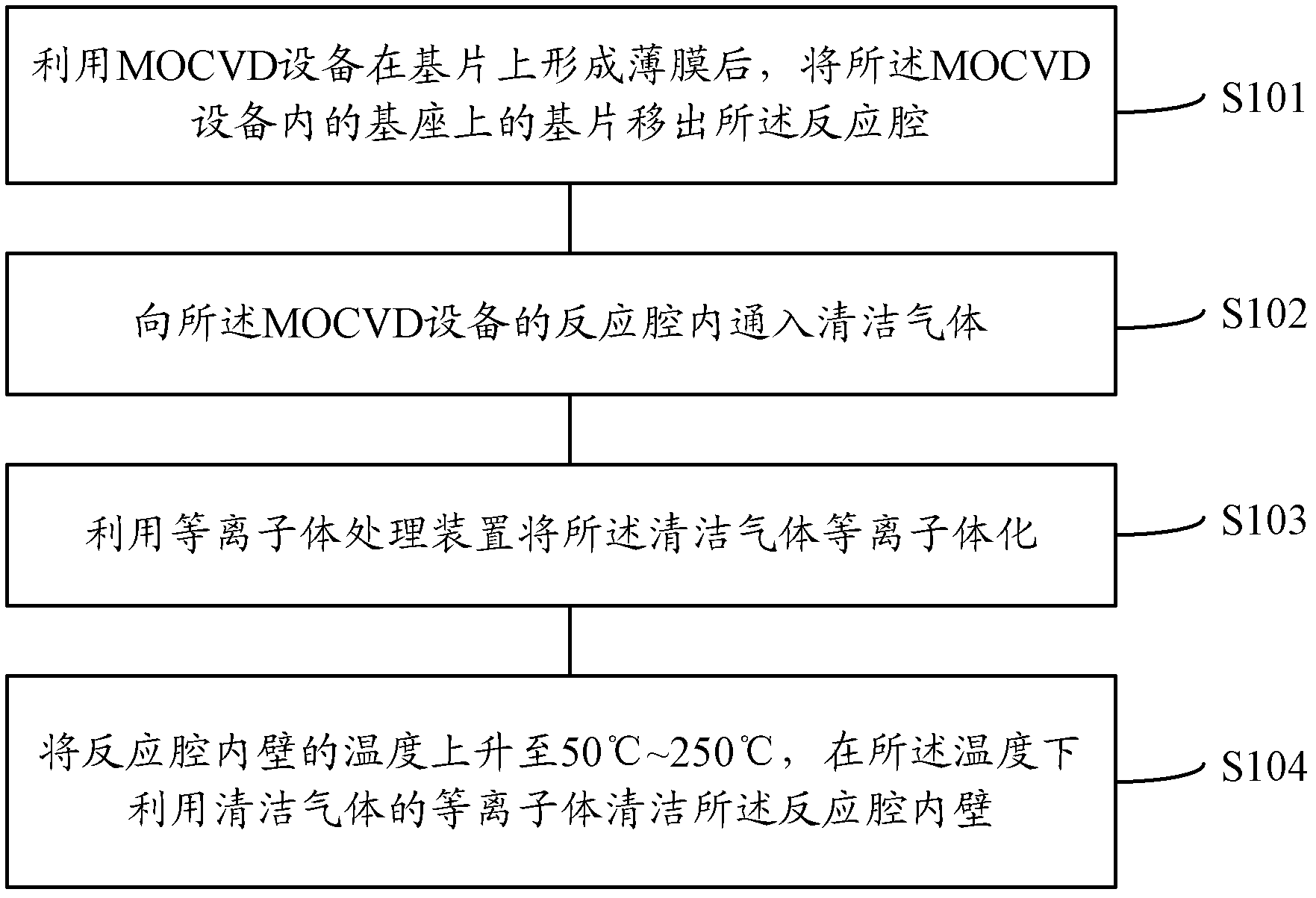

Cleaning method for MOCVD equipment

ActiveCN102615068AFast removal rateShorten the timeCleaning processes and apparatusCleaning methodsGas plasma

A cleaning method for MOCVD (Metal Organic Chemical Vapor Deposition) equipment comprises the following steps: feeding cleaning gas to a reaction chamber of the MOCVD equipment; processing the cleaning gas into plasma through a plasma processing device; increasing the temperature of the inner wall of the reaction chamber to 50 to 250 DEG C; and utilizing the plasma of the cleaning gas to clean the inner wall of the reaction chamber at the temperature of 50 to 250 DEG C. When the cleaning method is adopted, residual sediment on the inner wall of the MOCVD reaction chamber can be removed automatically, the plasma of the cleaning gas causes no damage to the inner wall of the MOCVD reaction chamber, and less time is spent in cleaning.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

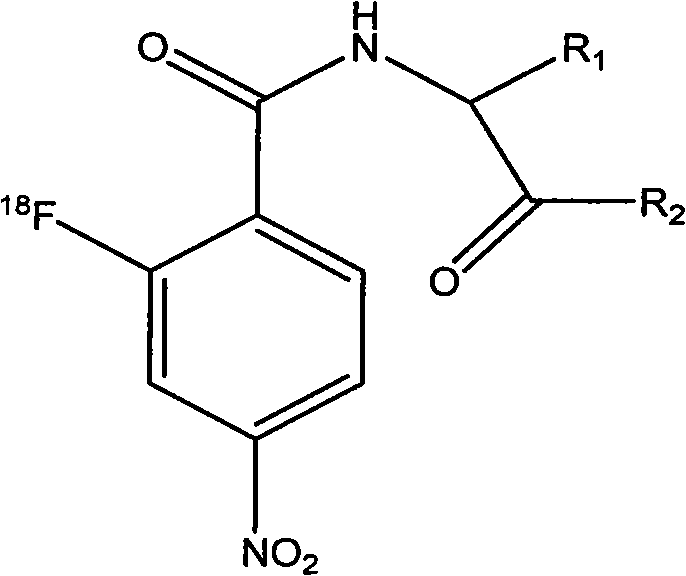

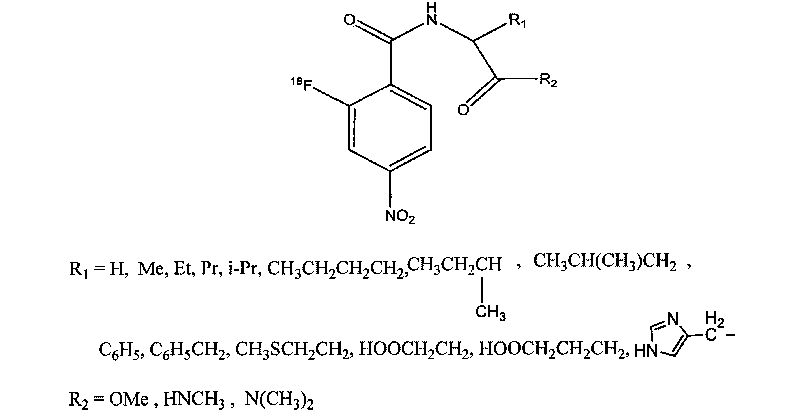

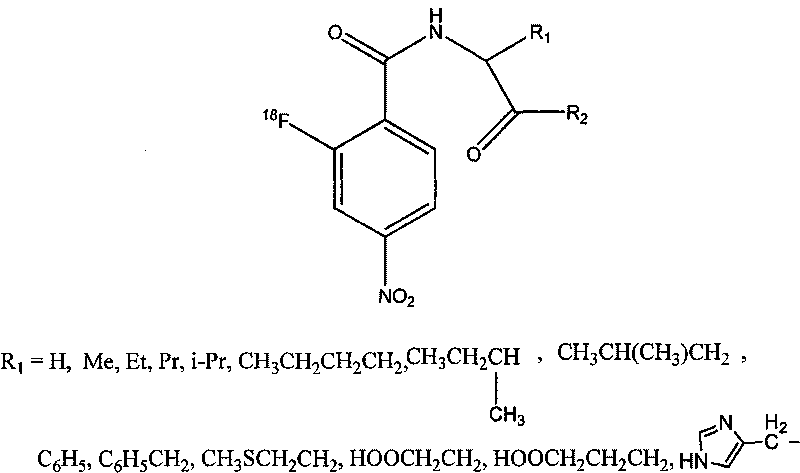

Novel 18F labeled p-nitro benzoyl amino acid derivatives, preparation method and application thereof in tumor imaging

InactiveCN101723846AImprove featuresEasy to synthesizeOrganic compound preparationRadioactive preparation carriersImaging agentEthyl group

The invention designs novel 18F labeled p-nitro benzoyl amino acid derivatives. The derivatives are characterized in that one end of the derivatives is provided with 2-fluorine 18-4-nitro benzoyl structure, and the other end of the derivatives is provided with alpha-amino acid derivative structure (derived group R2 is methoxyl group, methylamino group and N,N-dimethylamino group respectively); and substituent R1 is positioned on an alpha site of carbonyl group and is hydrogen, methyl group, ethyl group, propyl group, isopropyl group, butyl group, isobutyl group, benzyl group, 2-methylthio-ethyl group, carboxyethyl group, carboxypropyl group, phenyl or imidazole methyl group. The structures at two ends are directly connected through amido bond. The structure of the derivatives is shown in a formula A. The compounds are simple to synthesize, fast to label, large in the amount of initial absorption and slow to clear in tumor tissue, low in uptake or fast to clear in other normal tissue and blood and high in degree of distinguishing tumor from background. The invention also relates to the application of the compounds serving as a PET brain tumor imaging agent. R2=OMe, HNCH3.

Owner:BEIJING NORMAL UNIVERSITY

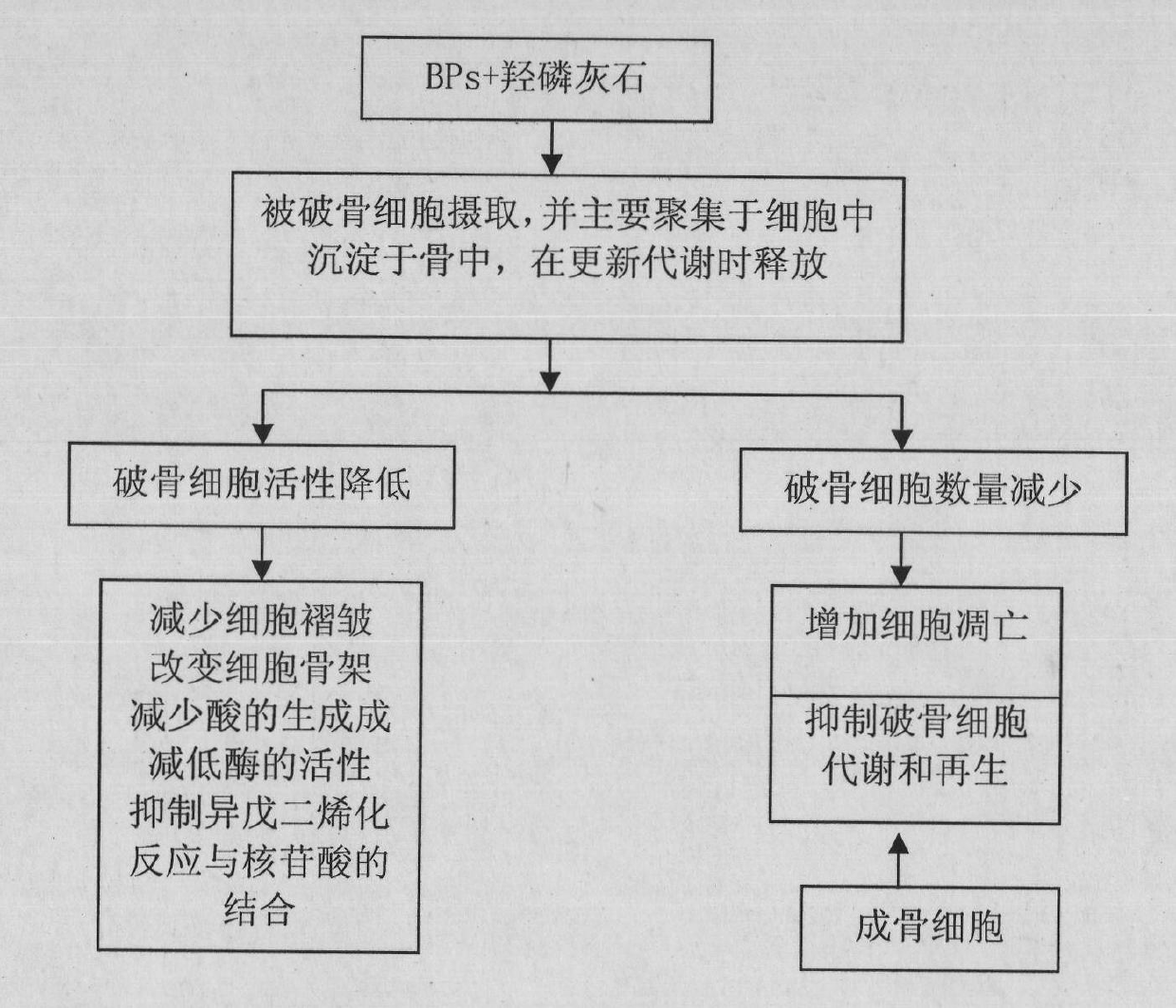

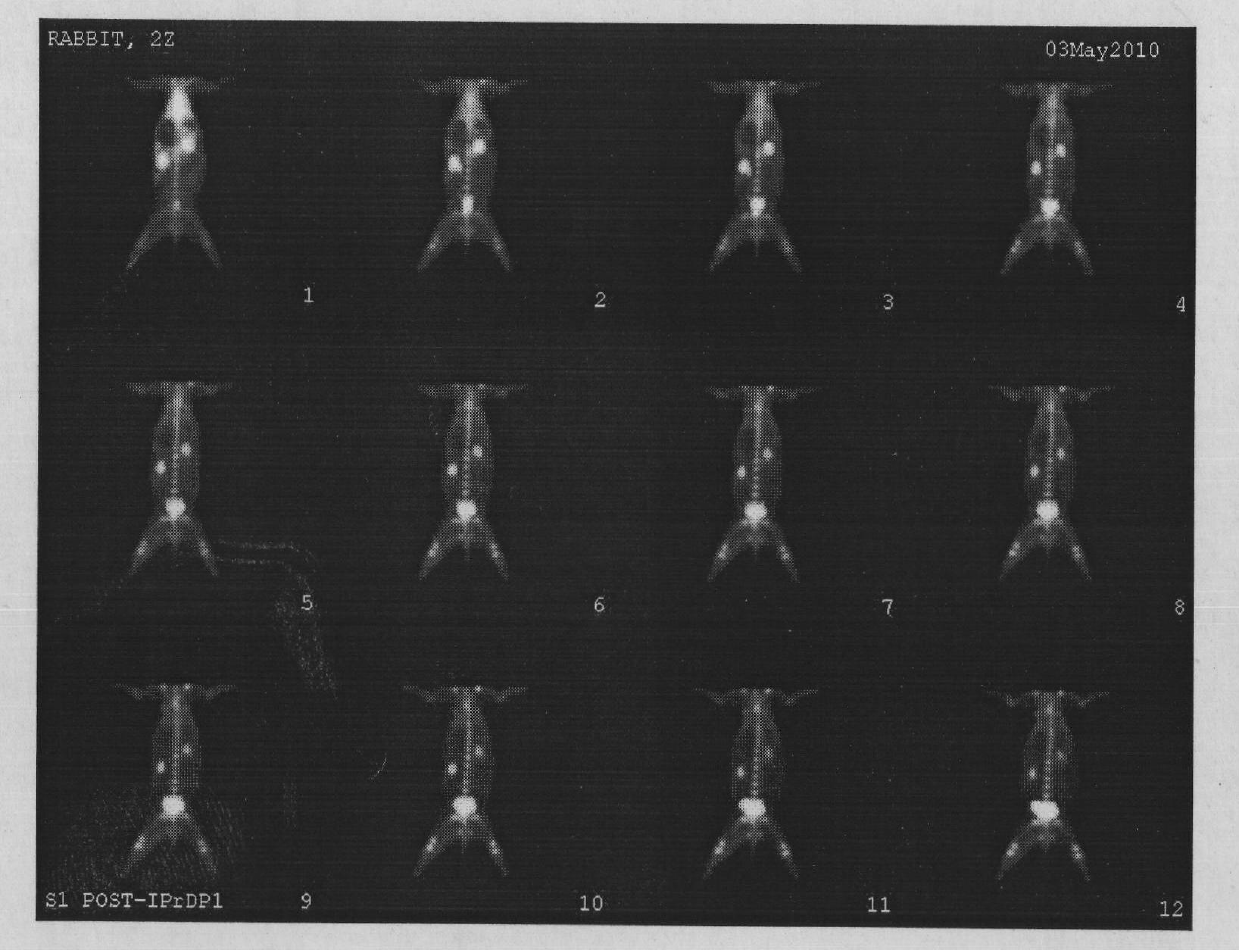

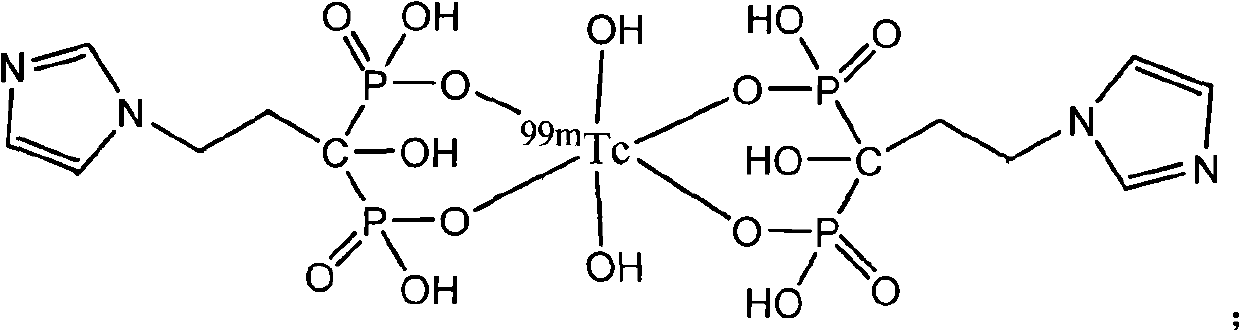

Bone-seeking 99mTc-IPrDP coordination compound as well as preparation method and application thereof

InactiveCN101985456AImprove performanceExtension armRadioactive preparation carriersGroup 7/17 element organic compoundsClearance rate99mTc-IPrDP

The invention relates to a bone-seeking 99mTc-IPrDP coordination compound, belonging to the fields of radiopharmaceuticals and nuclear medicine. The structural formula of the bone-seeking 99mTc-IPrDP coordination compound is shown in the specification. The preparation method of the coordination compound is as follows: mixing ligand IPrDP, reducing agent, pH buffer solution and pertechnetic acid (99mTcO<4->) solution to react to obtain an IPrDP coordination compound labeled by technetium-99m. The 99mTc-IPrDP coordination compound is used for nuclear medical diagnostic imaging. Through comparison, the product provided by the invention has the advantages of good product specificity, high bone / tissue intake (Am, bone) (% ID / g) and (Am, bone / Am, blood) and good tissue clearance rate, thus being expected to become novel bone imaging agent.

Owner:JIANGSU INST OF NUCLEAR MEDICINE

Filter material having phosphor adsorbing and biological membrane function and its preparing method

InactiveCN1587103AEfficient removalWide variety of sourcesSustainable biological treatmentWater/sewage treatment by sorptionEutrophicationPhosphate

The filter material with phosphor adsorbing and biological membrane hanging functions is prepared with flyash with CaO content of 5-20 % as material, and through stoving, sieving, mixing with water and small amount of curing agent via stirring, pelletizing in a high speed turntable pelletizer, and naturally cured for 2-7 days while spraying water to maintain the water content of 10-40 % to form the spherical filter material. The filter material has irregular rough surface with microporous structure for biological membrane to grow easily. The filter material has the advantages of fast absorbing phosphate in great amount, and eliminating SS, BOD and other soluble organic matter from sewage. The present invention may be used widely in water treating industry, especially in directly purifying rich nutrients water.

Owner:SHANGHAI JIAO TONG UNIV

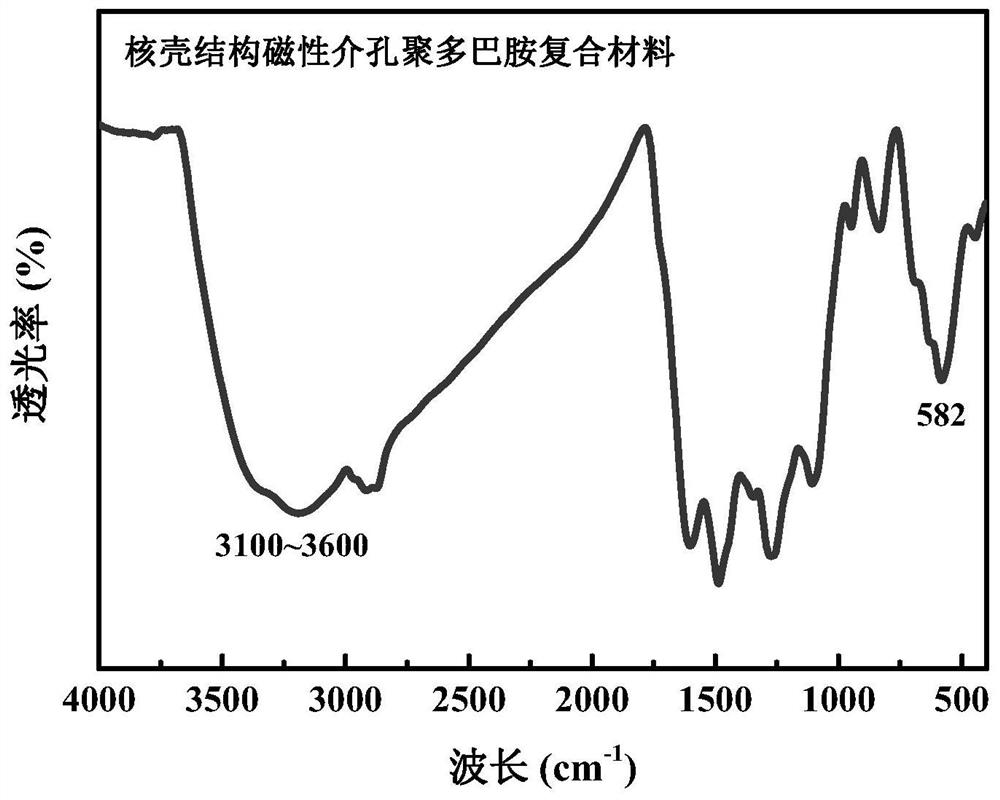

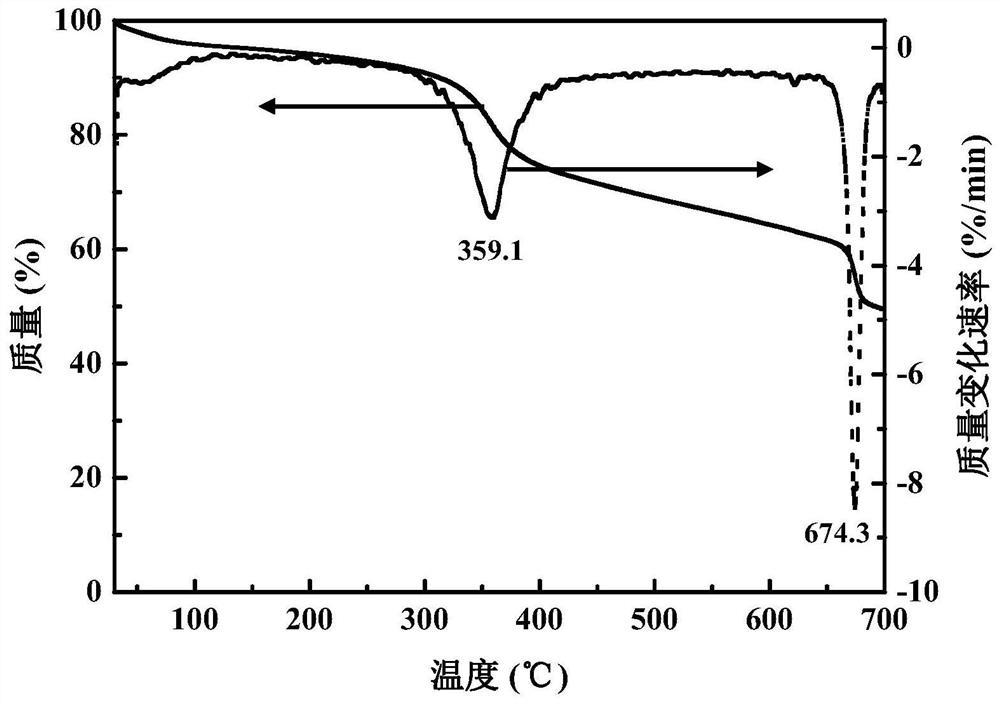

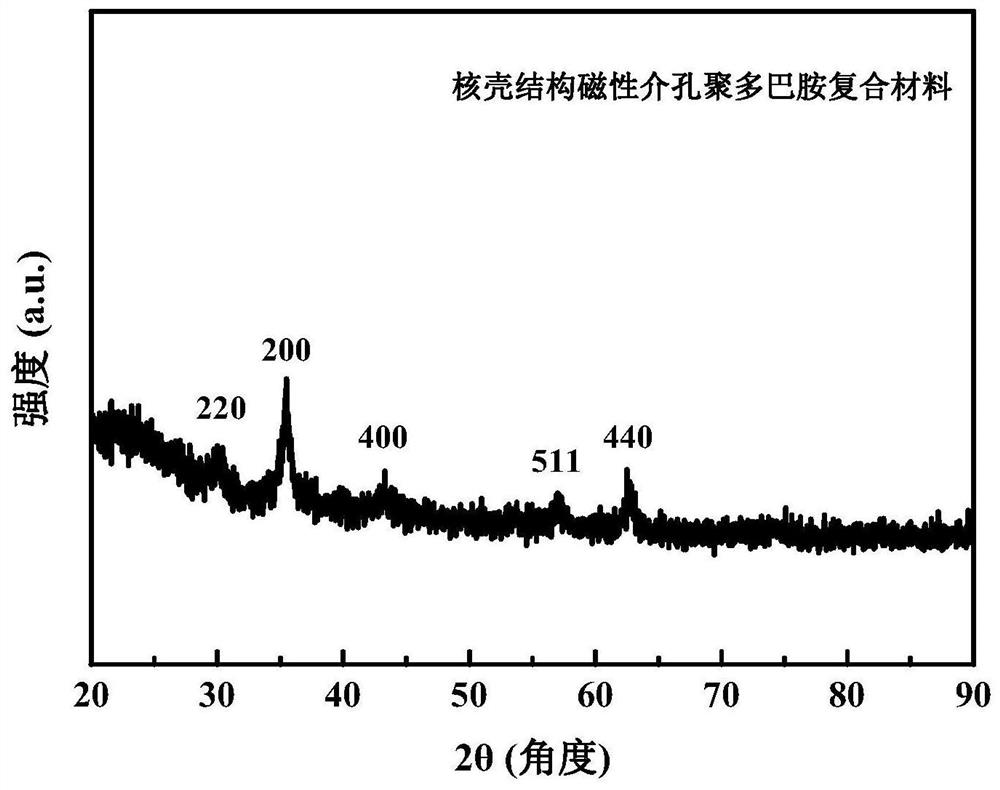

Magnetic mesoporous polydopamine composite material with core-shell structure as well as preparation method and application of magnetic mesoporous polydopamine composite material

ActiveCN112275263AReduce dosageSimple preparation processOther chemical processesWater contaminantsMagnetite NanoparticlesBiocompatibility

The invention belongs to the technical field of environmental functional nano materials, and discloses a magnetic mesoporous polydopamine composite material with a core-shell structure as well as a preparation method and application of the magnetic mesoporous polydopamine composite material. The preparation method comprises the steps of by taking magnetic nanoparticles as an inner core, a triblockpolymer as a template agent and an organic pore-enlarging agent as an auxiliary template agent, carrying out in-situ oxidative polymerization on dopamine monomers on the surfaces of the magnetic nanoparticles under a weakly alkaline condition to form the magnetic mesoporous polydopamine composite material with the core-shell structure. The preparation method is simple in process, the obtained nano composite material has high specific surface area and pore volume, a large-size mesoporous structure, biocompatibility and strong magnetism, the adsorption capacity of the nano composite material toheavy metal chromium can reach 522.74 mg / g when the nano composite material is used as an adsorption material, and the nano composite material has the characteristics of high adsorption rate, high removal rate and the like, can be recycled, and can be widely applied to the field of environmental governance.

Owner:SOUTH CHINA UNIV OF TECH

Flexible aluminum-magnesium composite oxide nanofiber membrane and preparation method and application thereof

ActiveCN110528173AImprove toughness and strengthHigh mechanical strengthOther chemical processesInorganic material artificial filamentsPorosityFiber

The invention belongs to the technical field of inorganic nanofiber materials, discloses a flexible aluminum-magnesium composite oxide nanofiber membrane, a preparation method thereof and an application thereof in the field of environmental treatment and repair, and particularly suitable for the field of heavy metal adsorption. According to the flexible aluminum-magnesium composite oxide nanofibermembrane, an aluminum source and a magnesium source are used as raw materials, yttrium salt is used as a doping agent, acid is used as a hydrolysis catalyst, at least one of polyvinylpyrrolidone andpolyoxyethylene is used as a spinning assistant, and xerogel fibers are obtained in a solvent system by combining a sol-gel method with an electrostatic spinning technology and then subjected to segmental calcination to obtain the membrane. The flexible aluminum-magnesium composite oxide nanofiber membrane prepared by combining the sol-gel method with the electrostatic spinning technology has theadvantages of large specific surface area, high porosity, excellent mechanical property and good flexibility, has the characteristics of high adsorption rate, high removal rate and the like as an adsorption material, avoids the defects of easy agglomeration, difficult recovery and the like of a powder adsorbent, and can be applied to the field of environmental treatment and repair.

Owner:SOUTH CHINA UNIV OF TECH

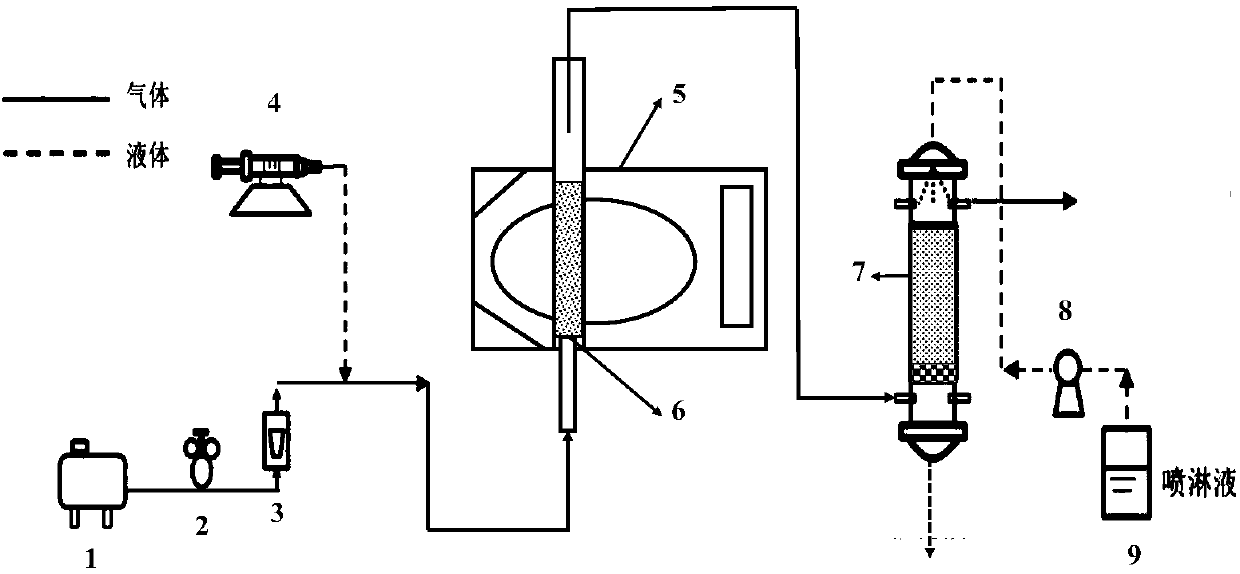

Method for removing VOCs (Volatile Organic Chemicals) through microwave radiation synergistic double-liquid phase biological filtering tower

InactiveCN107694307AHigh removal rateGood removal effectGas treatmentDispersed particle separationBiological filterAir compressor

The invention relates to a method for removing VOCs (Volatile Organic Chemicals) through a microwave radiation synergistic double-liquid phase biological filtering tower. According to the method, a microsyringe and an electromagnetic air compressor are respectively connected with a microwave radiation device inlet through pipelines; a thermocouple is accessed to an Fe3O4 wave absorption material of a microwave radiation device; a biological tower bottom gas inlet is connected with a microwave radiation device outlet; one end of a double-liquid phase spraying system is connected with a sprayingliquid inlet at the top of a biological filtering tower; nutrient substances are provided to microorganisms in the biological filtering tower from a double-liquid phase spraying liquid flowing in; acontainer in which the double-liquid phase spraying liquid is stored and a metering pump for providing power to a double-liquid phase spraying pipeline are arranged at the other end of the double-liquid phase spraying system; the microsyringe and the air compressor are powered on, then VOCs are mixed with the air, and at the same time a vacuum air sucking pump is powered on. By adopting the method, the biological filtering removal capacity is increased, and waste gases with relatively large VOC concentrations can be relatively rapidly removed.

Owner:TIANJIN UNIV

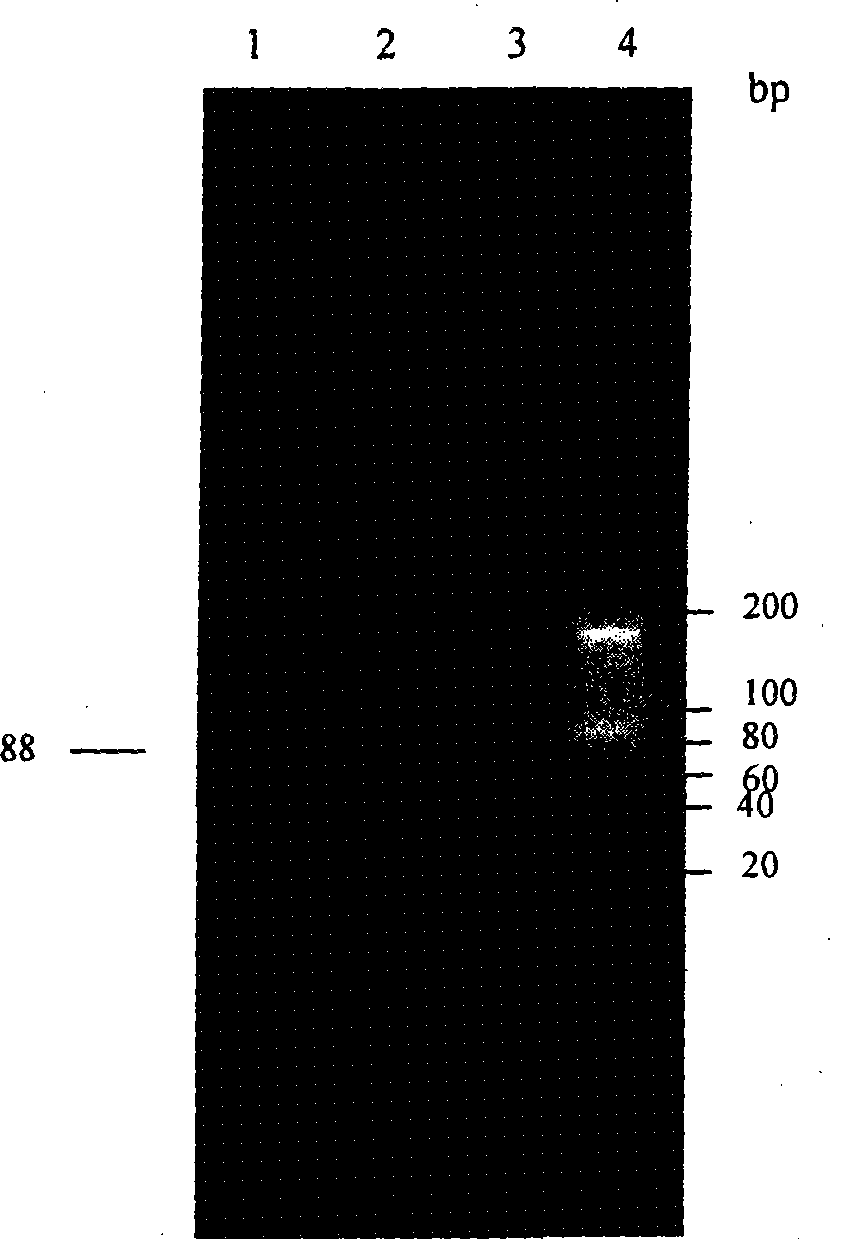

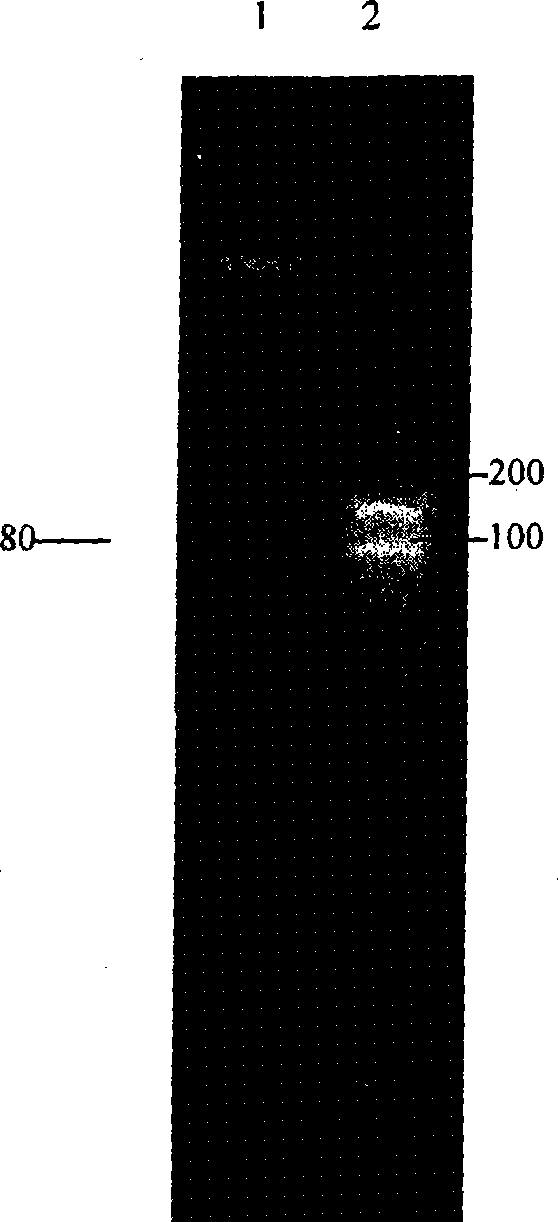

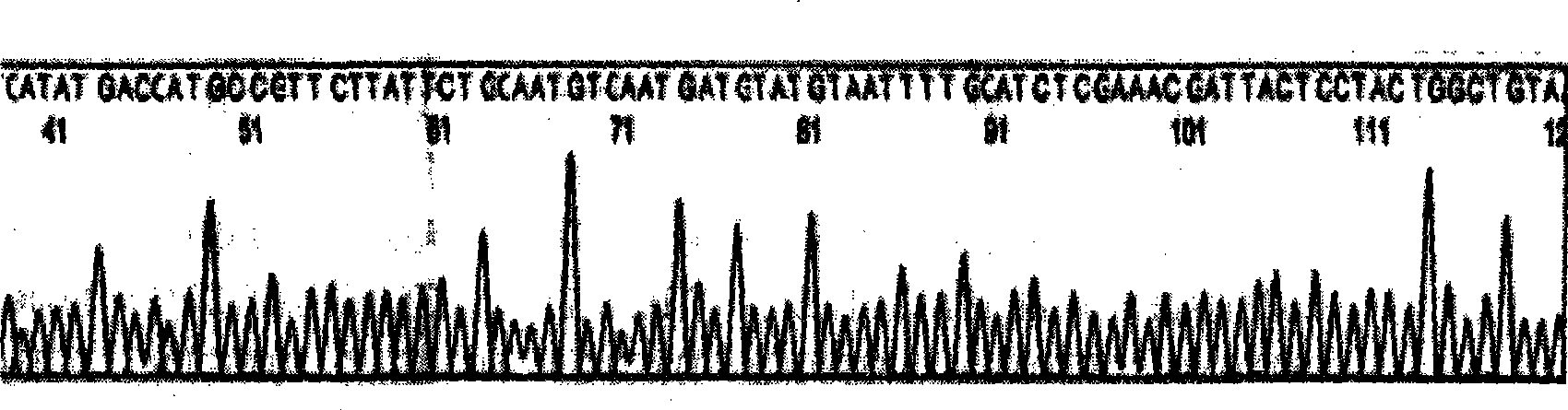

Construction and expression of vector of tumstatin T7 of tumstatin T7 peptide and derivative T7-NGR thereof

InactiveCN101519658ASmall molecular weightStrong penetrating powerConnective tissue peptidesPeptide/protein ingredientsWestern blotTumstatin

The invention constructs recombinant plasmid vector containing tumstatin T7 peptide and gene sequence of derivative T7-NGR thereof and obtains recombinant T7 peptide and T7-NGR fusion protein. The amino acid sequence of the derivative T7-NGR is TMPFLFCNVNDVCNFASRNDYSYWLGSCNGRCVSGCAGRC. The invention combines the generation activity of tumstatin T7 peptide for restricting the tumor neovascularization effectively and high specificity of NGR guide peptide, so as to lead the generation activity of T7 peptide for restricting the tumor neovascularization to be greatly strengthened. The recombinant cloned vectors are respectively identified by sequencing: the direction, position and sequence of integration are correct. The expression vector is transformed into competent E.coli BL21 (DE3) and then is expressed by the induction of IPTG; electrophoresis is carried out on the thalli after cracking; and by Western-Blot identification, the expression product is in accordance with the expected. The pET7N expression vector fusion protein T7-NGR has potential application prospect in the diagnosis and treatment of tumor.

Owner:INST OF RADIATION MEDICINE CHINESE ACADEMY OF MEDICAL SCI

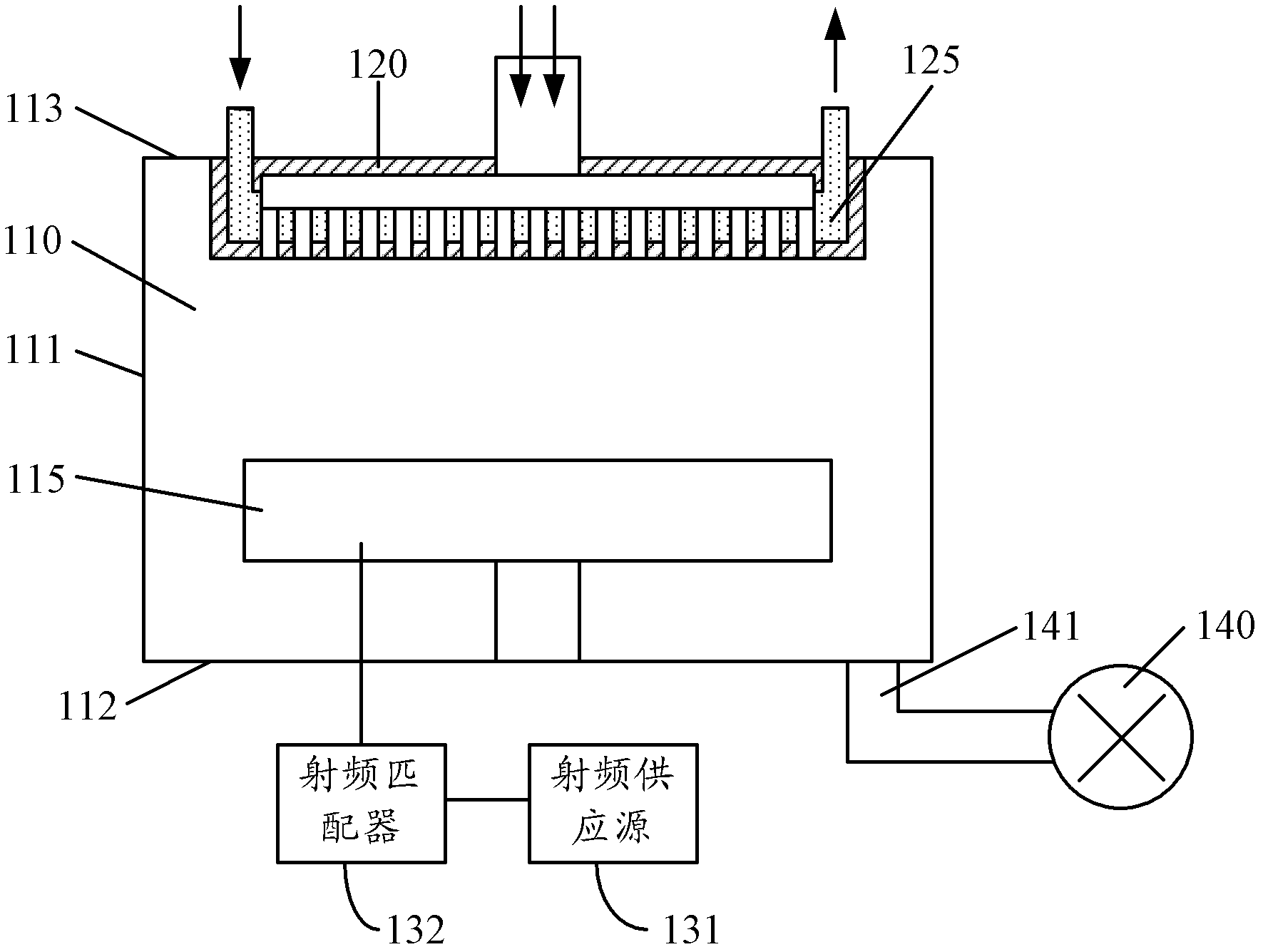

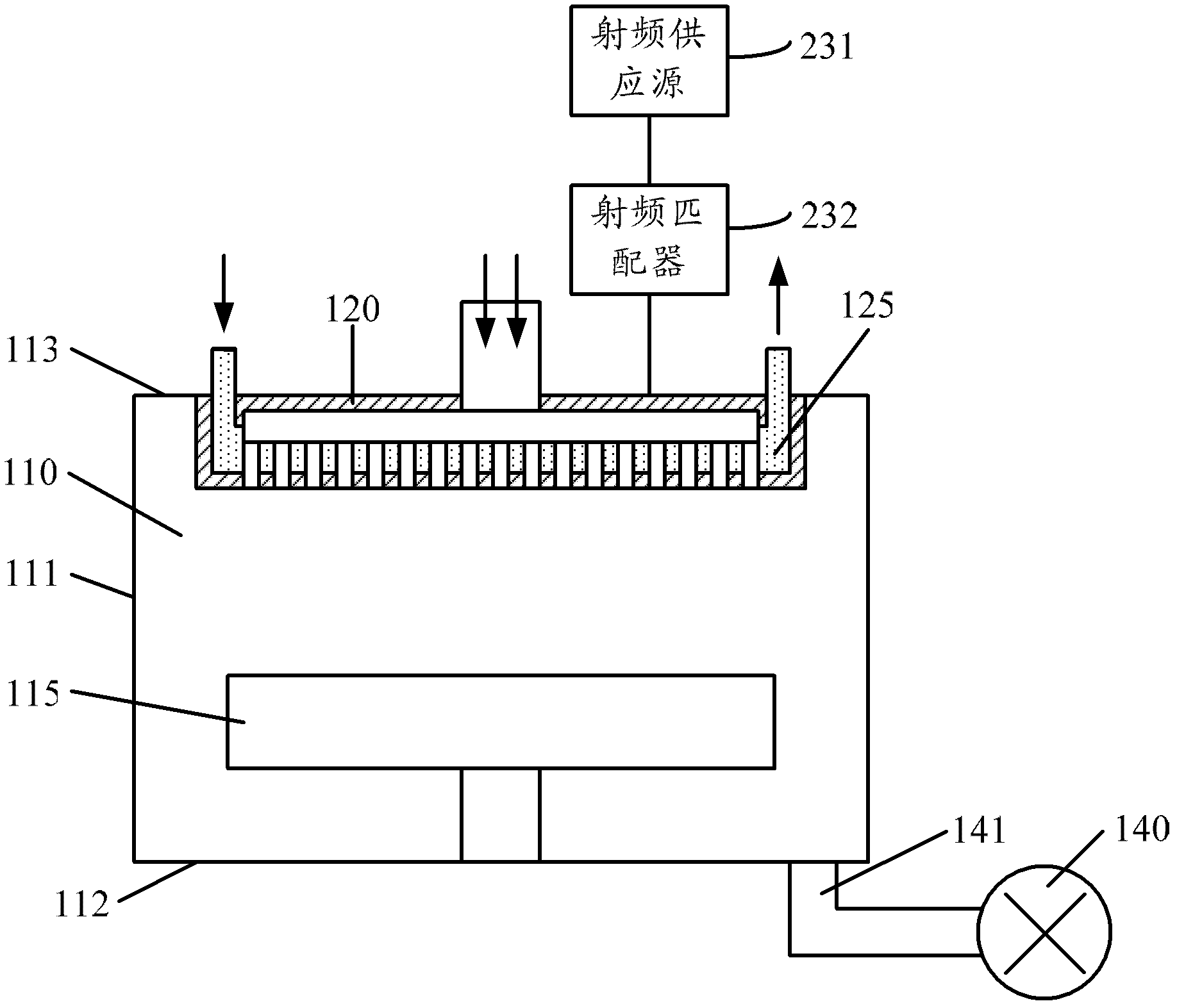

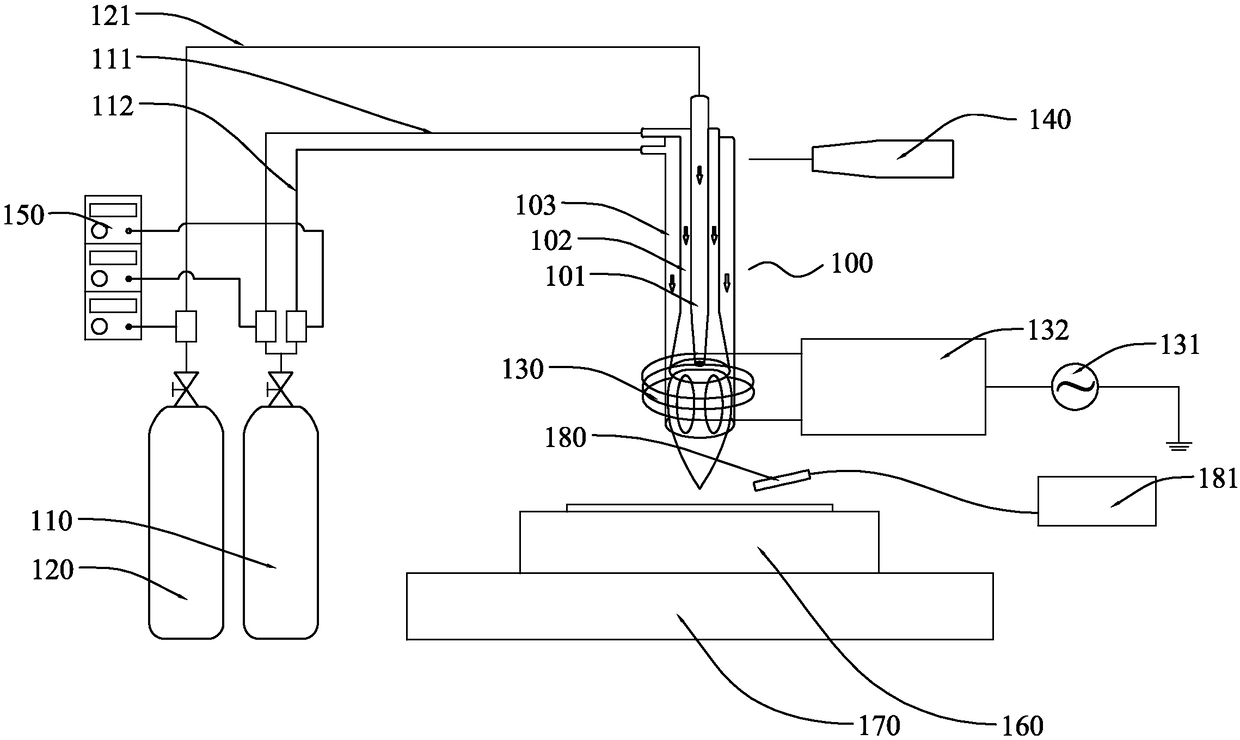

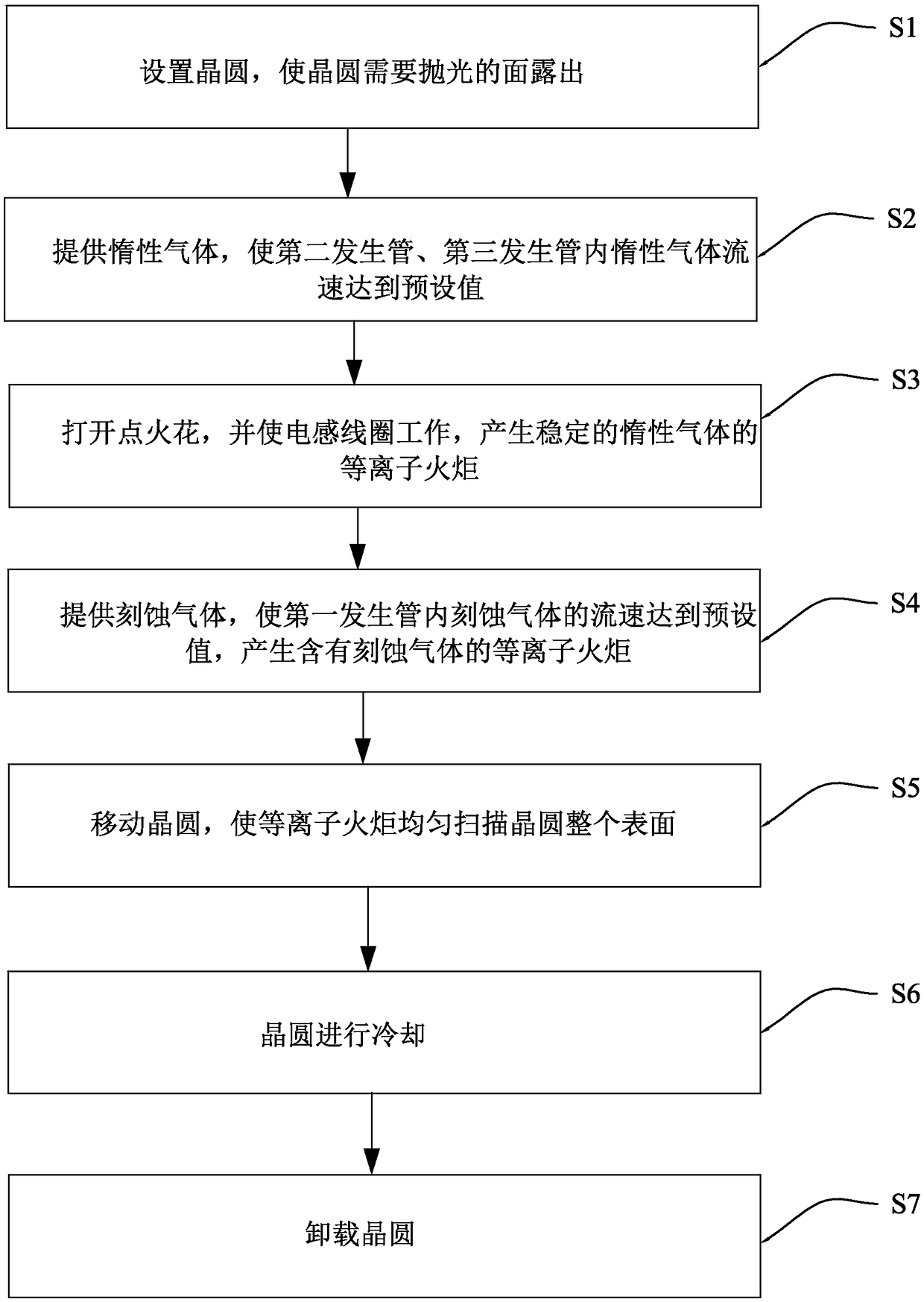

Single crystal material polishing device and polishing method based on inductively coupled plasma

The invention relates to the technical field of single crystal material polishing, and discloses a single crystal material polishing device and polishing method based on inductively coupled plasma. The single crystal material polishing device based on inductively coupled plasma comprises: a rectangular tube, wherein the rectangular tube comprises a first generating tube, a second generating tube arranged outside the first generating tube and a third generating tube arranged outside the second generating tube; an inert gas supply device in communication with the second generation pipe and the third generation pipe; an etching gas supplying device in communication with the first gas generating tube; a spark generator in communication with the torque tube; an inductor coil, wherein an outletof a torque tube is arranged in the inductor coil and is connected with a radio frequency power supply. The single crystal material polishing method based on inductively coupled plasma of the presentinvention is based on the polishing device. The single crystal material polishing device and polishing method based on the inductively coupled plasma body of the invention have the advantages of fastremoval rate, no introduction of sub-surface damage, no need for grinding slurry and no need for post-cleaning.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Novel pyrazolo[1,5-a]pyrimidines compound for labeling 18F instead of p-benzenesulfonyloxy and preparation and application

InactiveCN101967148AImprove featuresEasy to synthesizeOrganic chemistryRadioactive preparation carriersHigh concentrationMuscle tissue

The invention relates to a novel pyrazolo[1,5-a]pyrimidines compound for labeling 18F with p-benzenesulfonyloxy as the label locus, which is characterized in that the compound has matrix structure 3-cyanopyrazolo[1,5-a]pyrimidines; the fifth position of the matrix structure has substituents R which are respectively methyl and chloromethyl; and the amino on the seventh position is connected with fluorine-18 by a carbon chain with carbon atom number of n and has structure shown in the formula A. The compound is simple to synthesize and label and easy to operate. The compound maintains higher concentration and longer time in the tumor tissues, while the compound absorbs less or is fast in elimination in the normal tissues and blood, and especially has high tumor / blood ratio and tumor / muscle tissue ratio. The invention also relates to application of the compound as the PET brain tumor imaging agent.

Owner:BEIJING NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[<18>F] AlF marked positron emission tomography (PET) polypeptide probe and preparation method thereof [<18>F] AlF marked positron emission tomography (PET) polypeptide probe and preparation method thereof](https://images-eureka.patsnap.com/patent_img/13785fee-f1d4-4334-9714-3e2e39f3ae96/HDA0000568632230000011.PNG)

![[<18>F] AlF marked positron emission tomography (PET) polypeptide probe and preparation method thereof [<18>F] AlF marked positron emission tomography (PET) polypeptide probe and preparation method thereof](https://images-eureka.patsnap.com/patent_img/13785fee-f1d4-4334-9714-3e2e39f3ae96/HDA0000568632230000012.PNG)

![[<18>F] AlF marked positron emission tomography (PET) polypeptide probe and preparation method thereof [<18>F] AlF marked positron emission tomography (PET) polypeptide probe and preparation method thereof](https://images-eureka.patsnap.com/patent_img/13785fee-f1d4-4334-9714-3e2e39f3ae96/HDA0000568632230000021.PNG)