Magnetic mesoporous polydopamine composite material with core-shell structure as well as preparation method and application of magnetic mesoporous polydopamine composite material

A mesoporous polydopamine, core-shell structure technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problems of slow adsorption rate of heavy metals, lack of active sites, low removal efficiency, etc., to achieve convenient The effects of large-scale industrial production and application, efficient and fast capture, and efficient and fast removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

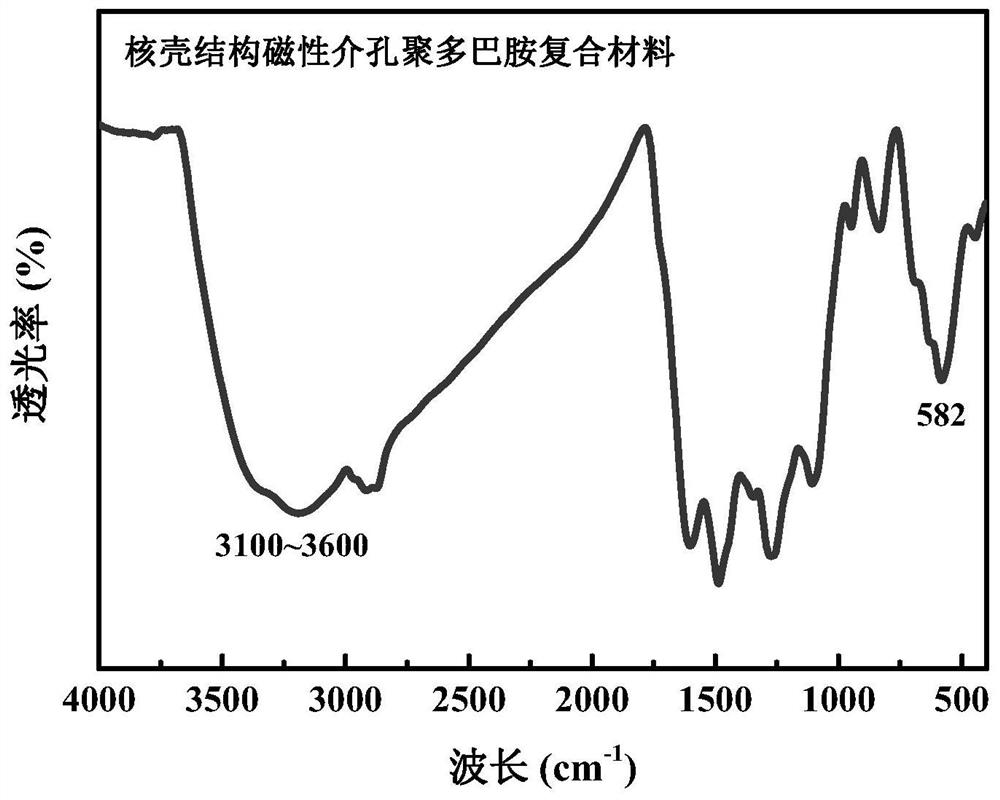

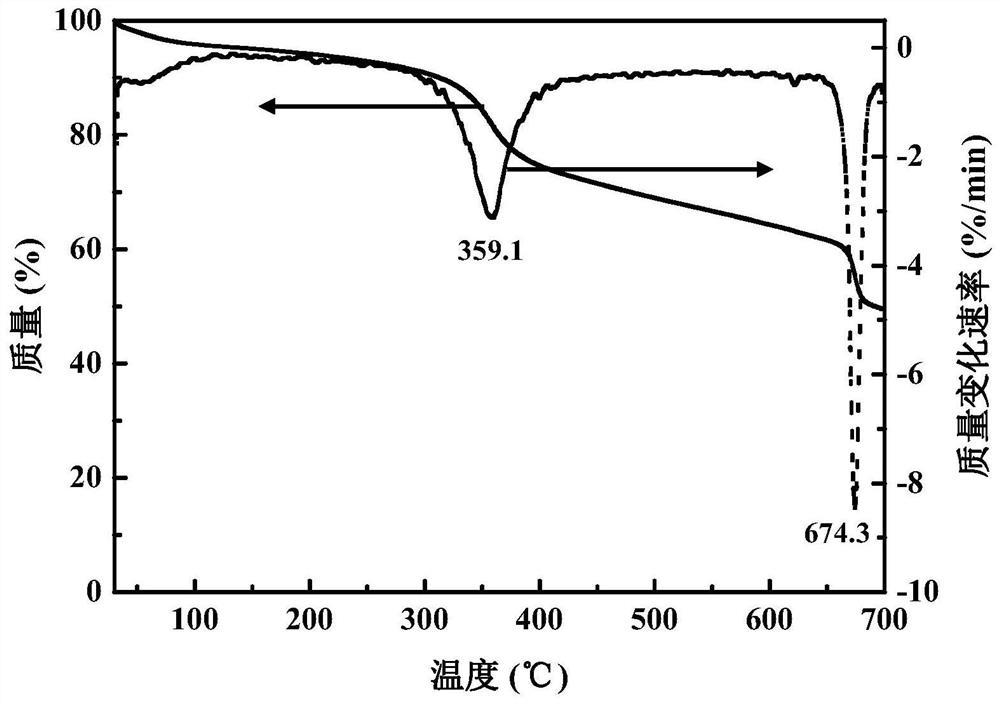

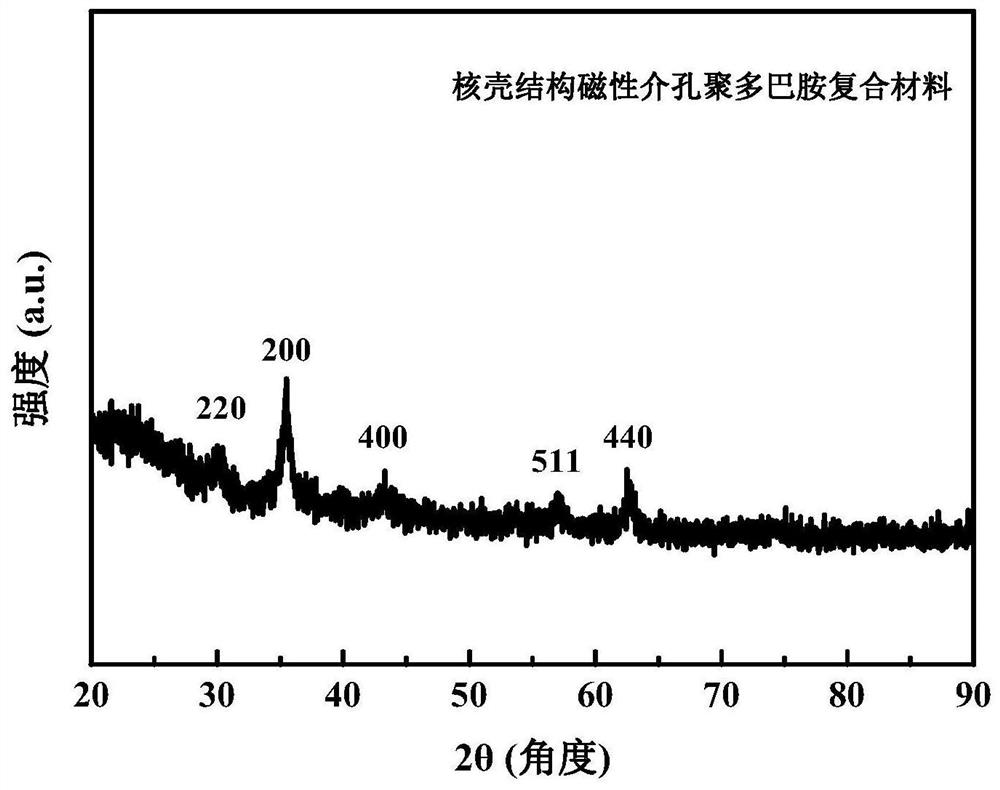

[0063] Example 1: Preparation of a magnetic mesoporous polydopamine composite with core-shell structure

[0064] (1) 1 part by mass of Fe 3 o 4 (spherical, 20nm), 5 parts by mass of Pluronic F127 and 5 parts by mass of mesitylene are dispersed in 154 parts by volume of deionized water to form a uniform emulsion;

[0065] (2) 1.2 parts by mass of dopamine hydrochloride were dispersed in 10 parts by volume of deionized water, and then added dropwise to the above-mentioned emulsion at a rate of 2 mL / min to obtain a reaction solution;

[0066] (3) Quickly add 4.1 parts by mass of 25 wt% ammonia water to the above reaction solution to promote the polymerization of dopamine monomer, react at 90°C with a mechanical stirring rate of 250rpm for 24h, magnetically separate, take the precipitate, wash with water until the template agent is completely removed, and freeze After drying for 24 hours, a magnetic mesoporous polydopamine composite material with a core-shell structure was obtai...

Embodiment 2

[0068] Example 2: Preparation of a core-shell magnetic mesoporous polydopamine composite material

[0069] (1) 1 part by mass of Fe 3 o 4 (spherical, 20nm), 1.25 parts by mass of Pluronic F127 and 1.25 parts by mass of mesitylene are dispersed in 154 parts by volume of deionized water to form a uniform emulsion;

[0070] (2) 1.2 parts by mass of dopamine hydrochloride were dispersed in 7.7 parts by volume of deionized water, and then added dropwise to the above-mentioned emulsion at a rate of 2 mL / min to obtain a reaction solution;

[0071] (3) 4.1 parts by mass of 25% ammonia water was quickly added to the above reaction solution to promote the polymerization of dopamine monomer, reacted at 70° C. with a mechanical stirring rate of 200 rpm for 36 hours, magnetically separated, washed with water until the template was completely removed, and freeze-dried for 24 hours. A magnetic mesoporous polydopamine composite material with a core-shell structure was obtained.

[0072] Us...

Embodiment 3

[0073] Example 3: Preparation of a core-shell magnetic mesoporous polydopamine composite material

[0074] (1) 1 part by mass of Fe 3 o 4 (spherical, 20nm), 5 parts by mass of Pluronic F127 and 5 parts by mass of mesitylene are dispersed in 154 parts by volume of deionized water to form a uniform emulsion;

[0075] (2) 3.08 parts by mass of dopamine hydrochloride were dispersed in 15.4 parts by volume of deionized water, and then added dropwise to the above-mentioned emulsion at a rate of 2 mL / min to obtain a reaction solution;

[0076] (3) 4.1 parts by mass of 25% ammonia water was quickly added to the above reaction solution to promote the polymerization of dopamine monomer, reacted at 80° C. with a mechanical stirring rate of 350 rpm for 12 hours, magnetically separated, washed with water until the template agent was completely removed, and freeze-dried for 12 hours. A magnetic mesoporous polydopamine composite material with a core-shell structure is obtained.

[0077]Us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com