Patents

Literature

138results about How to "High mineralization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

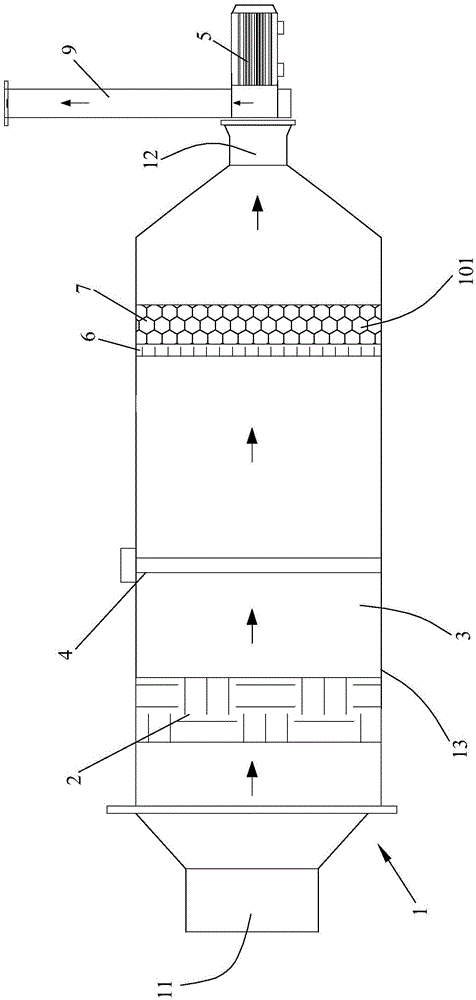

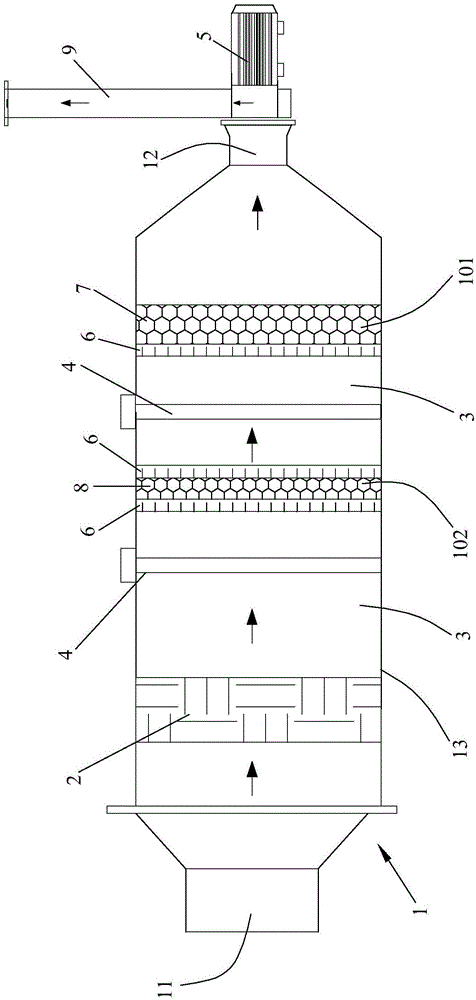

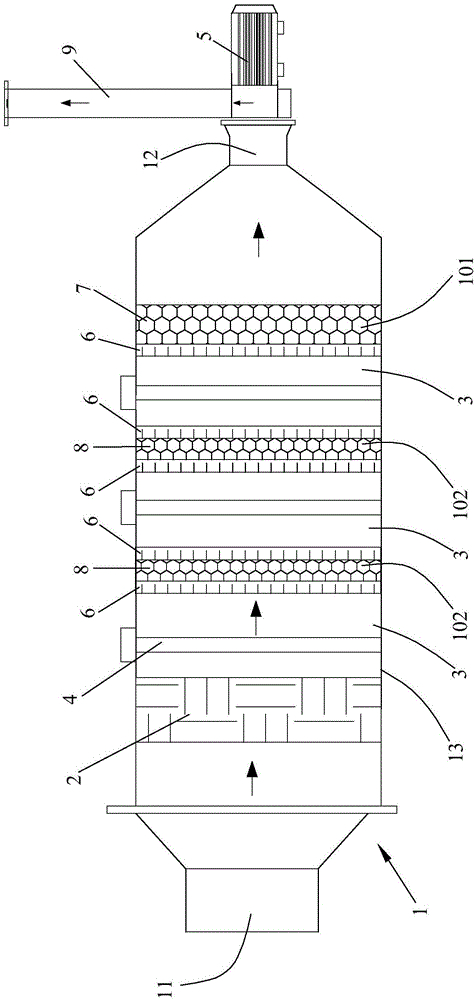

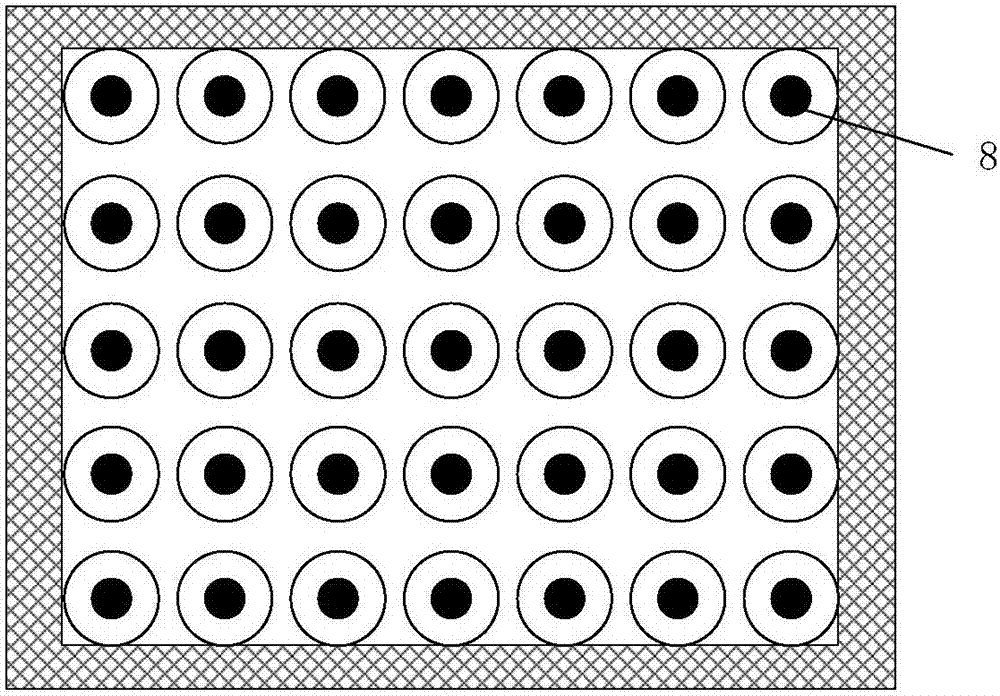

Waste gas processing method and device collaborating vacuum ultraviolet light catalysis and ozone catalytic oxidation

ActiveCN104857824AAvoid wastingHigh mineralization rateDispersed particle filtrationParticulatesCompound a

The invention discloses a waste gas processing method and device collaborating vacuum ultraviolet light catalysis with ozone catalytic oxidation. The waste gas processing method comprises the following steps: after particulate impurities in waste gas are removed, the waster gas enters a vacuum ultraviolet light catalysis chamber; a pollutant is directly split by the ultraviolet light emitted by an ultraviolet lamp, and free radicals with high oxidizability and ozone substances are generated at the same time so as to further oxidize the pollutant; in a composite catalyst structure formed by compounding a photocatalyst layer and an ozone catalyst layer, the residual pollutant is further purified through the collaboration of vacuum ultraviolet light catalysis and ozone catalytic oxidation, and the ozone is totally utilized and eliminated at the same time. The waste gas processing device comprises a reactor, wherein an efficient filter and the composite catalyst structure are arranged in the reactor; the composite catalyst structure is formed by compounding the photocatalyst layer and the ozone catalyst layer; the light catalysis chamber is formed at the inner cavity zone between the efficient filter and the composite catalyst structure, and the ultraviolet lamp is arranged in the light catalysis chamber. The waste gas is purified by utilizing the collaboration of vacuum ultraviolet light catalysis and ozone catalytic oxidation.

Owner:深圳科莱环保科技有限公司

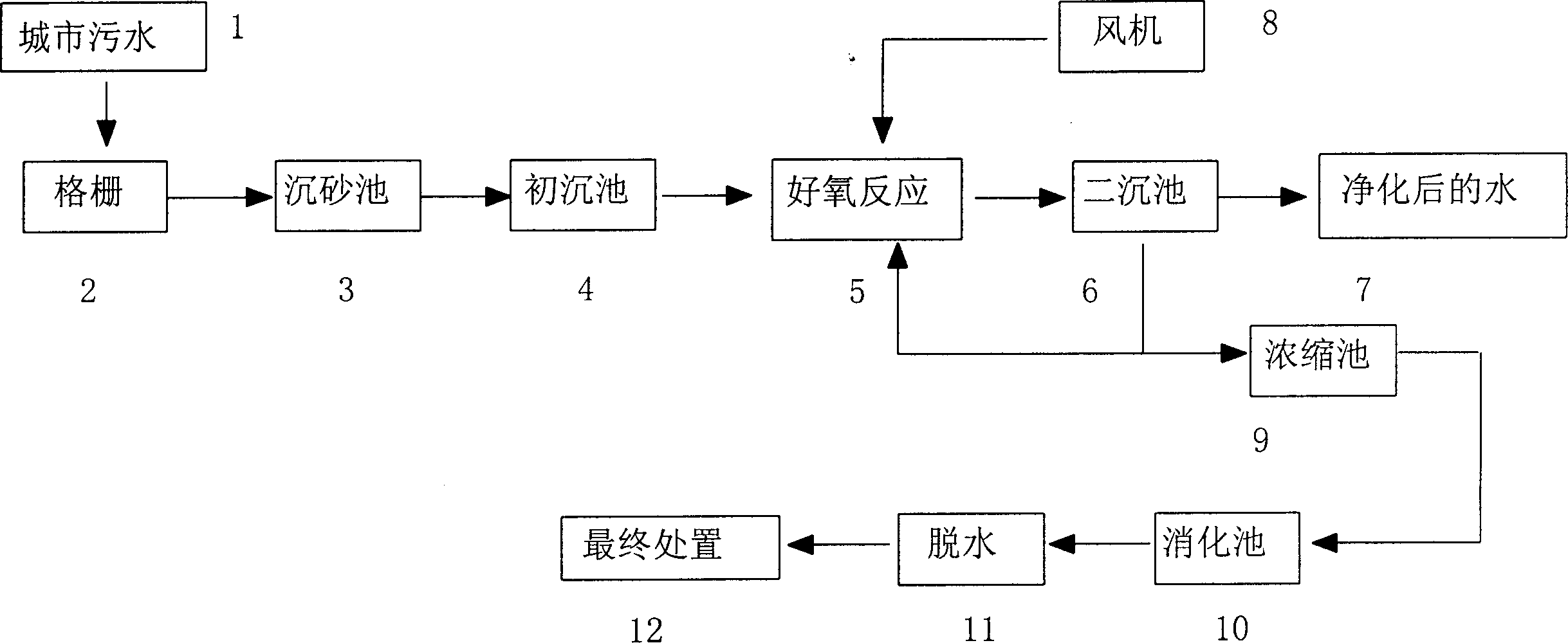

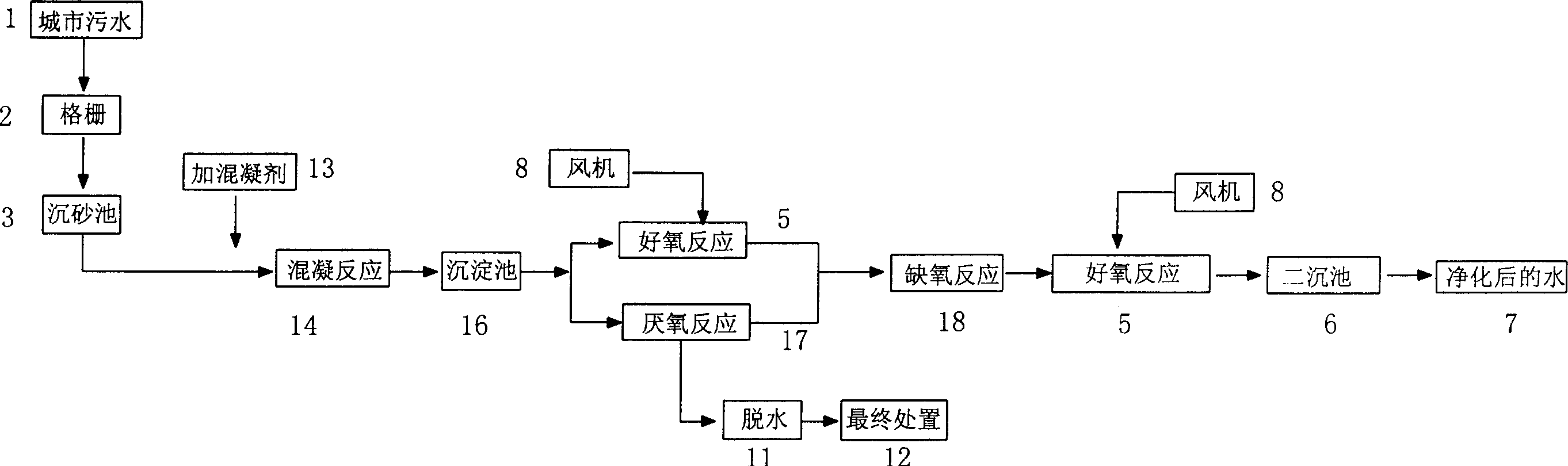

Urban domestic sewage treatment process and its method

InactiveCN1412134AReduce contentReduce concentrationWater/sewage treatmentMultistage water/sewage treatmentWater qualitySmall footprint

The city sewage treatment process includes the following steps: utilizing grile and desilting basin to pretreat sewage, adding coagulating agent to make the phosphorus, heavy metal and orgnaic matters existed as colloid and suspended substances feed into anaerobic reactor in the form of sludge to make organic matter convert into impure methane, making the supernatant fluid pass through the next aerobic treatment reactor to remove organic matter and convert the ammoniacal nitrogen into nitric nitrogen, mixing anaerobic discharged water and aerobic discharged water, and making the mixture waterundergo the process of anaerobic treatment to make denitrifcation, finally utilizing secondary aeration and precipitation to completely remove organic matters from sewage so as to attain the goal of cleaning the sewage.

Owner:NANKAI UNIV

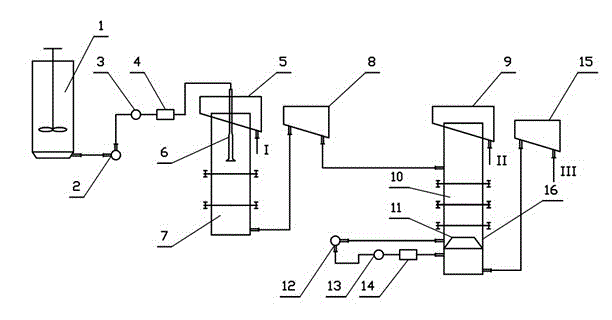

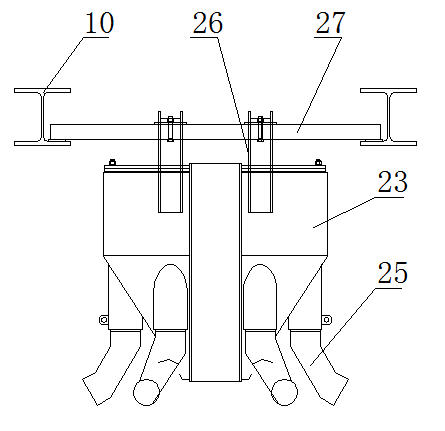

Novel flotation column serial connection test system for improving flotation granularity upper limit

The invention relates to a novel flotation column serial connection test system for improving the flotation granularity upper limit. The equipment of the system comprises a fed material stirring barrel, a feeding pump, a feeding pressure meter, a froth generator, a primary-section foam enriching chamber, a lower catheter, a spray type flotation column chamber, a primary-section tailing box, a secondary-section foam enriching chamber, a column flotation chamber, a rotary flow sorting chamber, a circulation ore pulp pump, a circulation pressure meter, a froth generator, a secondary-section tailing box and an FCMC cyclo-microfroth flotation column, wherein a spray type flotation column and the FCMC cyclo-microfroth flotation column are connected in series by the system, and the primary-section tailing is used as secondary-section fed materials. The system is favorable for the static fast flotation of preference flotation of coal with good flotation performance and the strong power efficient recovery of difficult-to-sort coal, in addition, the problem of high-concentration coal slime flotation can be perfectly solved, the recovery rate of coarse particle coal slime can be improved, and the problem of coarse particle running of coarse particle flotation can be solved.

Owner:CHINA UNIV OF MINING & TECH

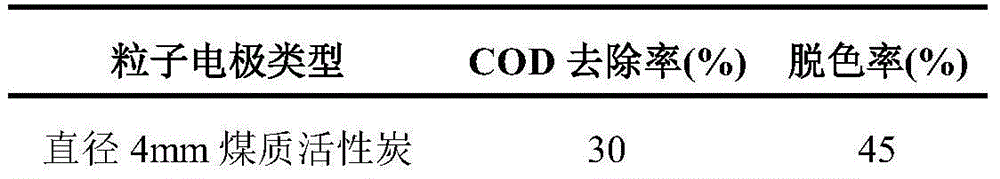

Catalytic particle electrode used for removing refractory organics and ammonia nitrogen from wastewater and preparation method and application thereof

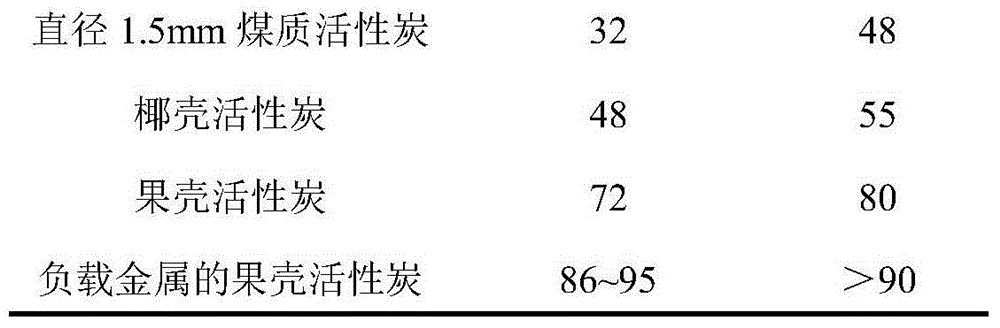

ActiveCN104925913AEasy to prepareFast adsorption rateWater/sewage treatment using germicide/oligodynamic-processChemistryActivated carbon

The invention relates to the field of wastewater treatment, in particular to a catalytic particle electrode used for synchronously removing refractory organics and ammonia nitrogen from wastewater and a preparation method and application thereof. The electrode comprises shell activated carbon and metal components loaded on the shell activated carbon, wherein the particle size of the shell activated carbon is 1mm-5 mm, and the content of the metal components is 0.8wt%-2.5wt% the total mass of the activated carbon. Packing of the catalytic particle electrode has the advantages of being high in catalytic activity, low in price, easy to obtain, simple in preparation, high in COD and ammonia nitrogen degradation and removal efficiency, high in produced water mineralization degree, low in unit COD energy consumption and capable of being used continuously. Accordingly, the electrode is suitable for treatment of wastewater which is difficult to degrade biologically and contains high-concentration organic pollutants and high ammonia nitrogen.

Owner:BEIJING FORESTRY UNIVERSITY

Preparation method of nickel foam supported bimetal MOF base ozone catalyst, production thereof and application

ActiveCN110302841ASolve separation and recyclingSimple and fast operationWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSynthesis methodsDecomposition

The invention relates to a preparation method of nickel foam supported bimetal MOF base ozone catalyst, a production thereof and application. The preparation method comprises the steps that a metal organic framework ZIF-67 is taken as a template, nickel foam serves as a carrier, an in-situ hydrothermal-impregnation synthesis method is adopted to prepare a supported porous Mn / Co bimetal MOF base ozone catalyst, bimetal Mn / Co oxide in situ grows on a nickel foam base through a hydrothermal method, the supported bimetal oxide is modified by ZIF-67 through a impregnation method, and thus the nickel foam supported bimetal MOF base ozone catalyst is prepared. According to the preparation method, the crystal size and morphology of the catalyst are regulated effectively and accurately, evenly-distributing of active sites is facilitated, the decomposition rate on ozone and the mineralization rate on organic matter of the nickel foam supported bimetal MOF base ozone catalyst are greatly improved, the problems of separating and recycling of suspended catalysts can be effectively solved, the operation cost of water treatment is lowered, and large application prospects are achieved.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Method for catalytically degrading adsorbed organic pollutants through microwave ultraviolet coupled radiation

ActiveCN102701310ASave microwave timeSave energyWater/sewage treatment by irradiationDispersed particle separationSorbentUltraviolet lights

The invention relates to a method for catalytically degrading adsorbed organic pollutants through microwave ultraviolet coupled radiation, belonging to the technical field of pollution control technologies. The invention solves the problems that the consumption level of the traditional adsorbent is high and secondary solid pollutants are produced by using an adsorption method, and overcomes the defects that the microwave-assisted photocatalytic oxidation water treatment and waste gas treatment method is high in energy consumption, easy for generation of thermal pollution and incomplete in degradation of pollutants. In the method, an adsorbent is used to enrich organic matters in waste water and waste gas; a porous wave-adsorbing catalyst for adsorbing the organic matters is placed in a quartz reactor; air with the humidity being 30-100% is introduced into the quartz reactor via an air intake pipe, the microwave ultraviolet reaction time is adjusted to be 10-60 min, and the microwave power is 100-2000 W; and a microwave oven is started, a non-polar ultraviolet lamp is excited by microwaves to generate ultraviolet light, and organic matters are thoroughly mineralized under the combined action of the microwaves, the ultraviolet light and the catalyst. The method is used for treating the organic matters in the waste water and the waste gas.

Owner:HARBIN INST OF TECH

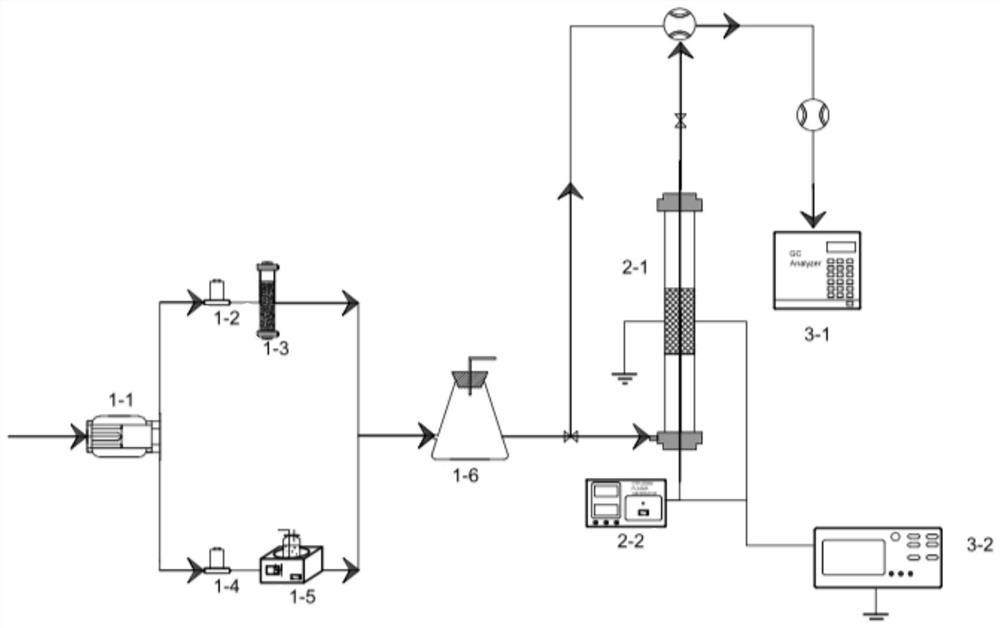

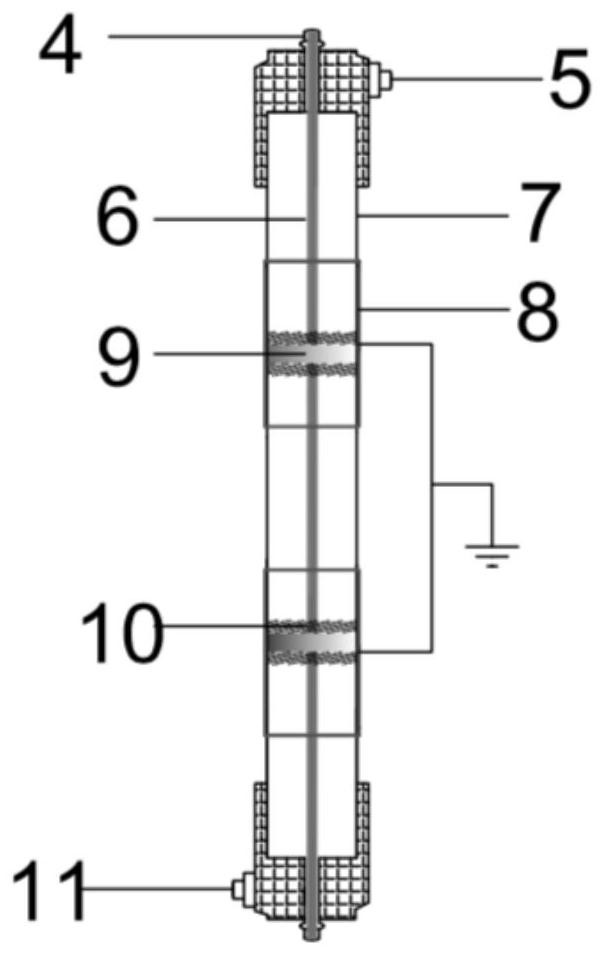

Device and treating method for treating organic waste gas through concerted catalysis of dielectric barrier discharge and low-temperature plasma

InactiveCN107042039AAvoid direct contactSuitable for engineering applicationsDispersed particle filtrationHigh energyEngineering

The invention discloses a device and a treating method for treating organic waste gas through concerted catalysis of dielectric barrier discharge and low-temperature plasma and belongs to the technical field of organic gas treatment. Organic waste gas enters a reaction cavity through a gas inlet device after being filtered by a filter bed layer, a low-temperature plasma generation device inhales external air through a fan at the same time, high-energy active particles and ozone generated by dielectric barrier discharge stimulation enter the reaction cavity to oxidize and decompose the organic waste gas, gas flow in the reaction cavity passes through an absorbing catalytic bed layer at the upper portion of the device to be further reinforced and decomposed under catalyst action to generate harmless gas of CO2, H2O and the like which can be emitted on standard. The device disclosed by the invention has the advantages that the low-temperature plasma generation device is separated from waste gas, so that the problems of discharge device corrosion and the like caused by direct contact are avoided, and low-temperature plasma and catalysis are effectively combined to reinforce organic waste gas treatment.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST +1

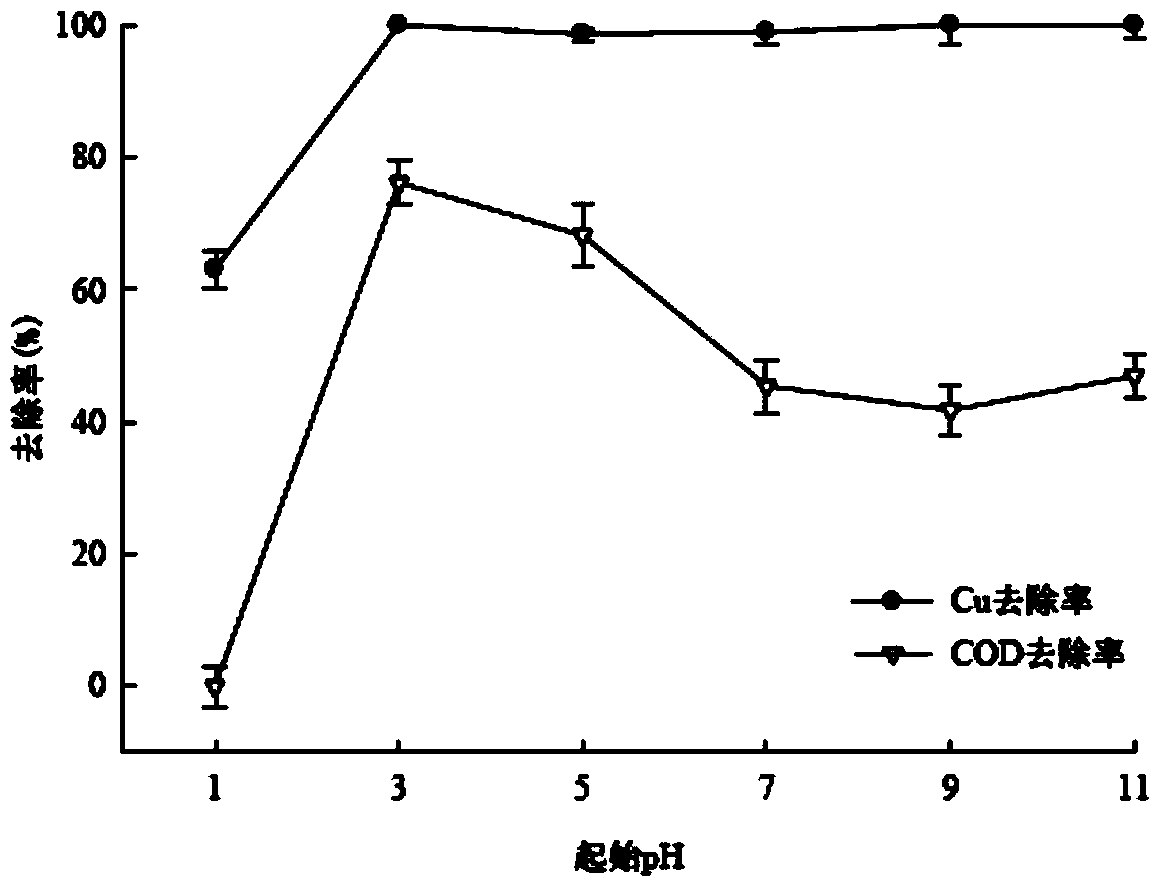

Processing method of Cu(II)-EDTA (Ethylene Diamine Tetraacetic Acid) wastewater

InactiveCN102910762AHigh mineralization rateImprove recycling ratesMultistage water/sewage treatmentCopper oxides/halidesEthylene diamineEconomic benefits

The invention discloses a processing method of Cu(II)-EDTA (Ethylene Diamine Tetraacetic Acid) wastewater, for solving the problems that the conventional wastewater processing method is high in cost and easily causes secondary pollution and has a trivial process. The processing method comprises the following steps of: measuring the concentration of COD and Cu<2+> in the Cu(II)-EDTA wastewater before processing; adjusting the pH value of Cu(II)-EDTA wastewater in a reaction tank I to 3-6, adding catalysts and an oxidant into the reaction tank I, and stirring and reacting for 0.5 hour to 3 hours, thus obtaining the reacted Cu(II)-EDTA wastewater; and standing the reacted Cu(II)-EDTA wastewater, discharging supernatant liquor of the wastewater into a reaction tank II, adding NaOH into the supernatant liquor of the wastewater to adjust the pH value of the supernatant liquor to 11-12, standing for getting sediments, and filtering, washing and calcining the sediments to obtain copper oxide, wherein sediments in the reaction tank I are recycled as the catalysts after being dried. The processing method has the advantages of degrading organic matter and recycling copper, and has environment-friendly and economic benefits.

Owner:HANGZHOU DIANZI UNIV

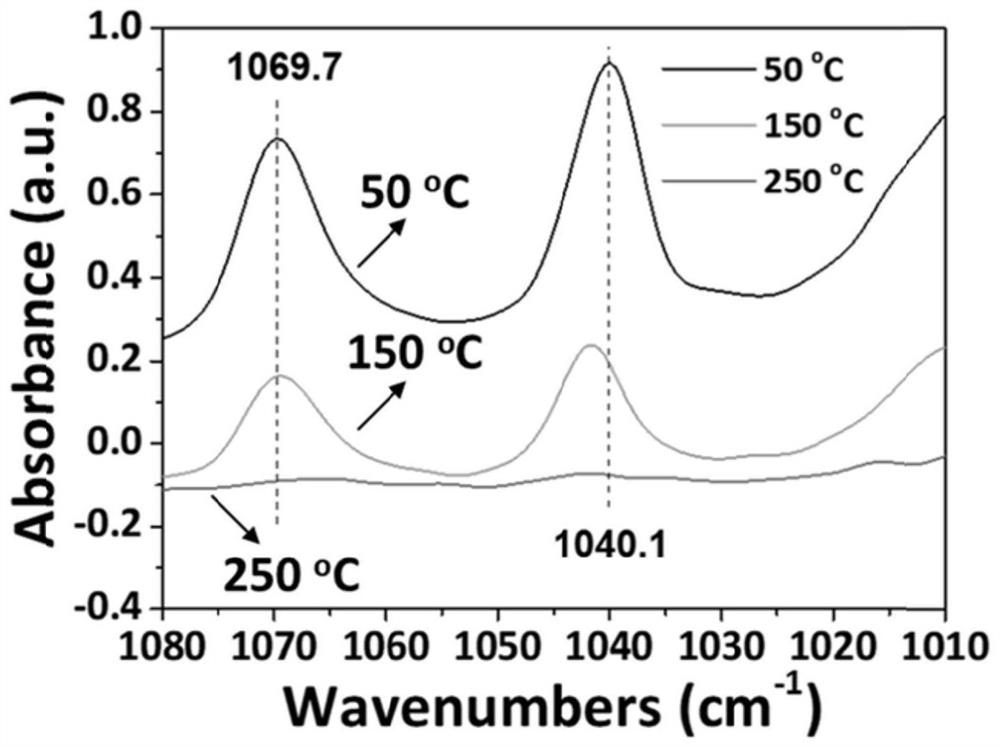

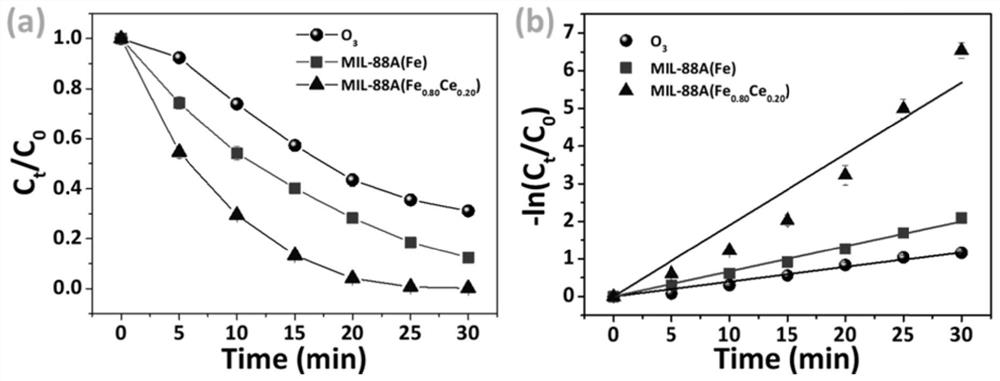

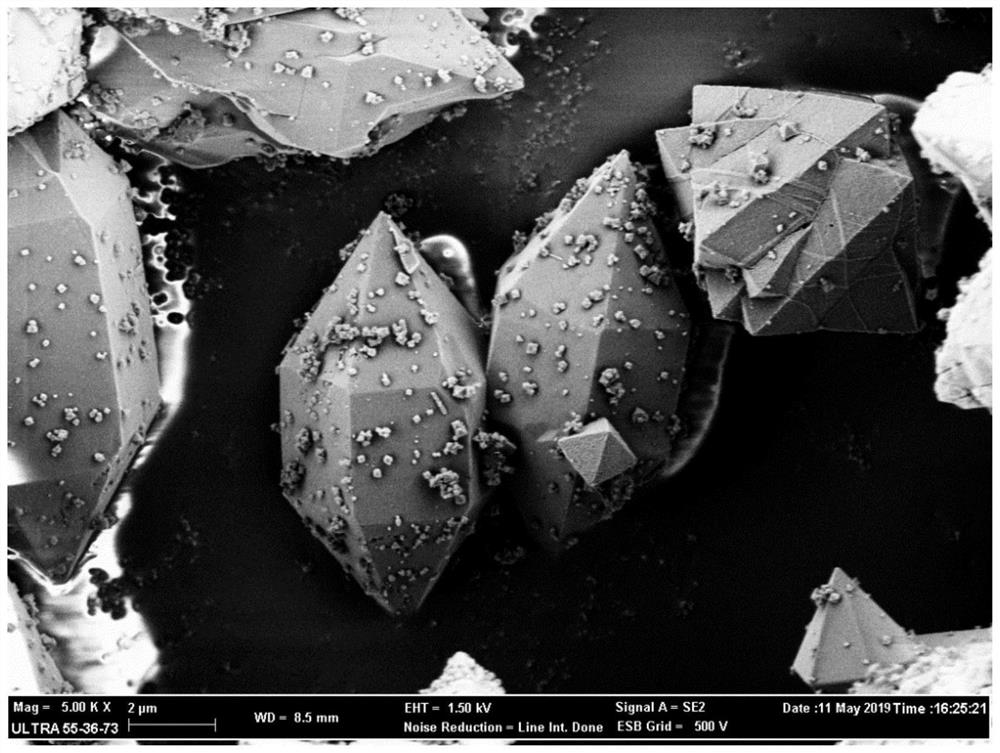

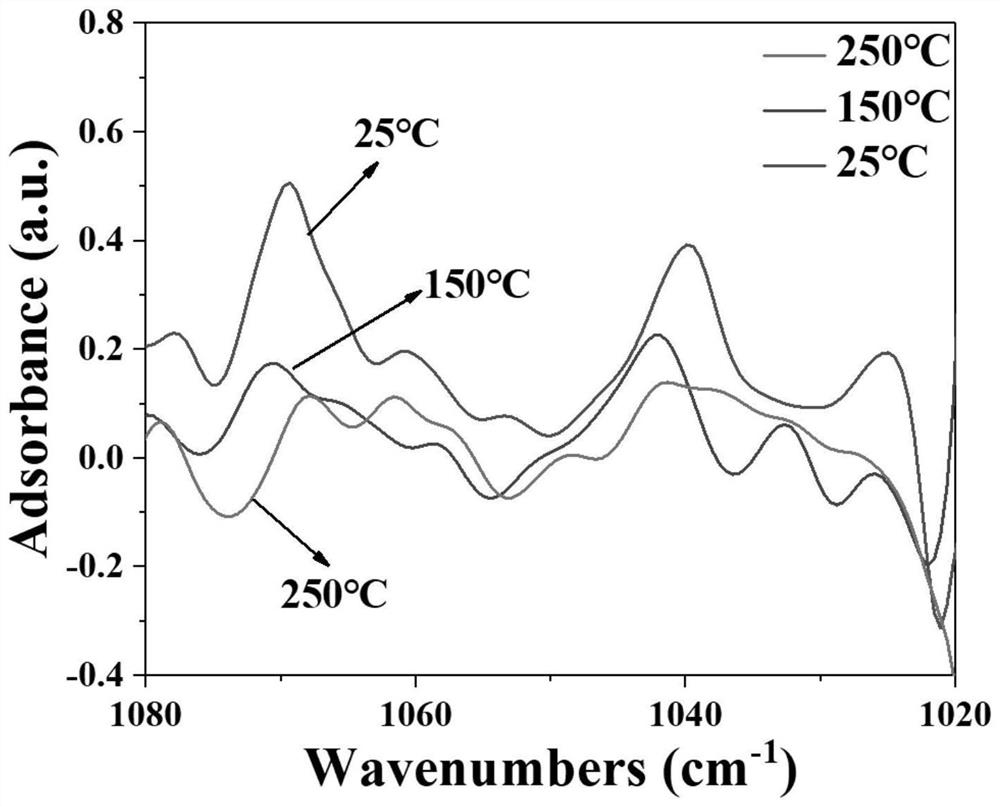

Ce-doped Fe-MOF ozone catalyst, and preparation and application thereof

PendingCN111715294AImprove catalytic ozone activityHigh degree of mineralizationOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsPtru catalystCatalytic decomposition

The invention discloses a preparation method of a Ce-doped Fe-MOF ozone catalyst. The Ce-doped Fe-MOF ozone catalyst is formed by cerium ion-doped Fe-MOFs through hydrothermal or solvothermal self-assembling, wherein Fe-MOF is an iron-based metal organic framework material. According to the invention, Lewis acid site density of the surface of the Fe-MOF ozone catalyst is effectively adjusted by utilizing hetero-metal Ce, so the catalytic ozonation activity of the Fe-MOF is improved, the ozone adsorption and catalytic decomposition rate of a Fe-MOF catalytic material is promoted, more active oxygen species such as hydroxyl radicals are further generated, oxidative degradation of organic pollutants in water is enhanced, and the mineralization degree of the organic pollutants is remarkably improved.

Owner:ZHEJIANG SCI-TECH UNIV

Pretreatment technology for high-concentration refractory organic petrochemical wastewater

ActiveCN105461135AImprove oxidation efficiencyEfficient processingWater/sewage treatment by irradiationWater contaminantsChemistryHigh concentration

The invention discloses a pretreatment technology for high-concentration refractory organic petrochemical wastewater. The technology comprises steps as follows: (1) the organic petrochemical wastewater is acidized until the pH ranges from 4 to 5, then the organic petrochemical wastewater is heated to the temperature of 80-95 DEG C, and wastewater A is obtained through solid-liquid separation after precipitation of silicate; (2) iron and copper plates are added to the wastewater A for microelectrolysis for 0.5-2 h, then wastewater B is obtained through solid-liquid separation, the pH of the wastewater B is adjusted to range from 2.0 to 2.5, a hydrogen peroxide solution accounting for 0.5%-3% of the wastewater B in volume is added, the mass fraction of the hydrogen peroxide solution is 25%-40%, a reaction is performed for 1-3 h, and wastewater C is obtained; (3) after the pH of the wastewater C is adjusted to range from 2.5 to 3.5, the wastewater C is subjected to three-dimensional electro-Fenton treatment for 1-3 h, then a flocculating agent is added after the pH is adjusted to range from 9.5 to 10.5 by alkaline liquor, and wastewater D is obtained after solid-liquid separation; (4) the pH of the wastewater D is adjusted to range from 1.5 to 3.5, a catalyst and persulfate are added, the mixture is irradiated by ultraviolet light and aerated for photocatalytic oxidation for 1-2 h, and the pretreatment of the wastewater is completed. With the adoption of the technology, the COD (chemical oxygen demand) value of the wastewater is effectively decreased, and the biodegradability of the wastewater is improved.

Owner:HUNAN YONKER ENVIRONMENTAL PROTECTION RES INST

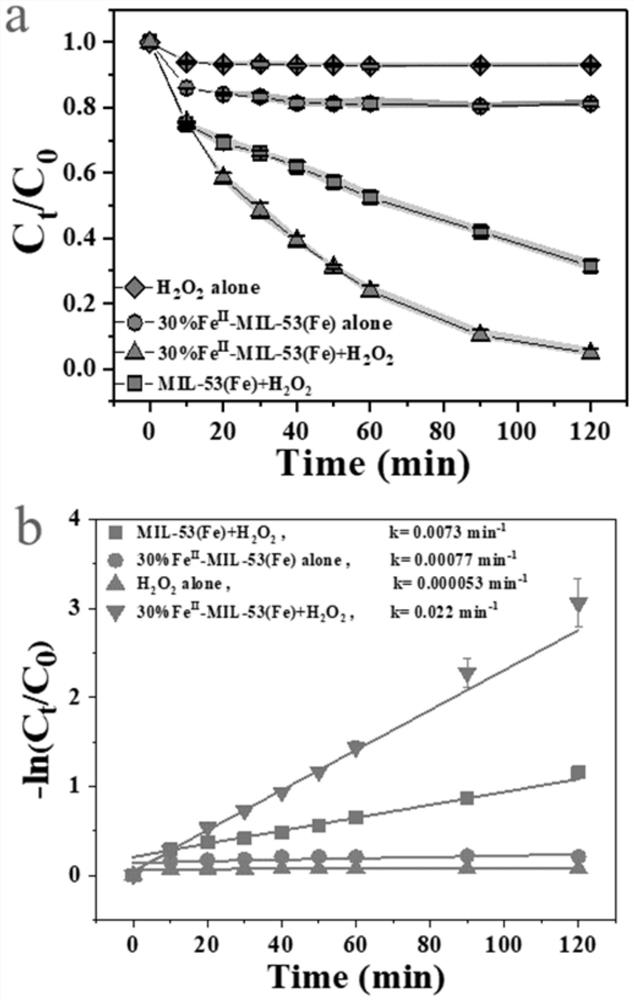

Preparation method, product and application of ferrous doped Fe-MOFs Fenton-like catalyst

PendingCN112206828AHigh heterogeneous Fenton performanceQuick activationWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystFerrous salts

The invention provides a preparation method, a product and application of a ferrous doped Fe-MOFs Fenton-like catalyst. The preparation method comprises the following steps: dissolving an organic ligand in a solvent to obtain an organic ligand solution; adding a mixed metal salt of a ferric salt and a ferrous salt into the organic ligand solution, and conducting uniform stirring to obtain a ferrous doped Fe-MOFs Fenton-like catalyst precursor mixed solution; and carrying out a solvothermal reaction on the mixed solution, and then carrying out solid-liquid separation and solid-phase drying to obtain the ferrous doped Fe-MOFs Fenton-like catalyst. The ferrous doped Fe-MOFs Fenton-like catalyst can improve Fenton-like mass transfer adsorption and catalytic decomposition rate and the efficiency of catalyzing Fenton-like oxidative degradation and mineralizing organic pollutants in water. The catalyst is applied to the field of organic wastewater pollution treatment, the catalytic Fenton-like activity of Fe-MOFs can be improved, the decomposition rate of Fenton-like reactions is promoted, and removal of organic pollutants in water is enhanced.

Owner:ZHEJIANG SCI-TECH UNIV

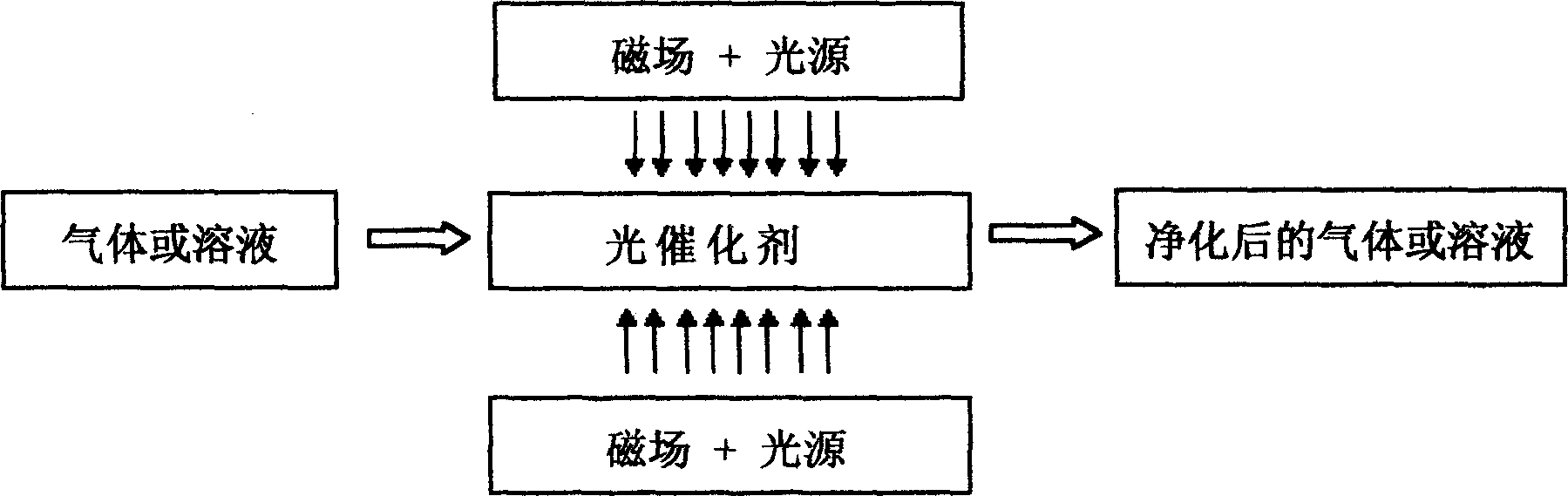

Photo-magnetic synergistic catalytic technique and its application for degrading organic pollutant

InactiveCN1460542AImprove efficiencyHigh mineralization rateWater/sewage treatment by irradiationDispersed particle separationPhotocatalytic reactionUltraviolet

On the basis of original photocatalytic reactor an external magnetic field of added to form said invented magnetic field-photocatalytic coupling reaction equipment, sand invention utilizes the influence of the magnetic field on the catalyst and intermediate body of photocatalytic process to produce photocatalytic-magnetic field synergistic action so as to greatly raise the photocatalytic conversion efficiency of organic pollutant and mineralization rate and attain the goal of high-effectively degradating organic pollutants being in waste water and waste gas.

Owner:FUZHOU UNIV

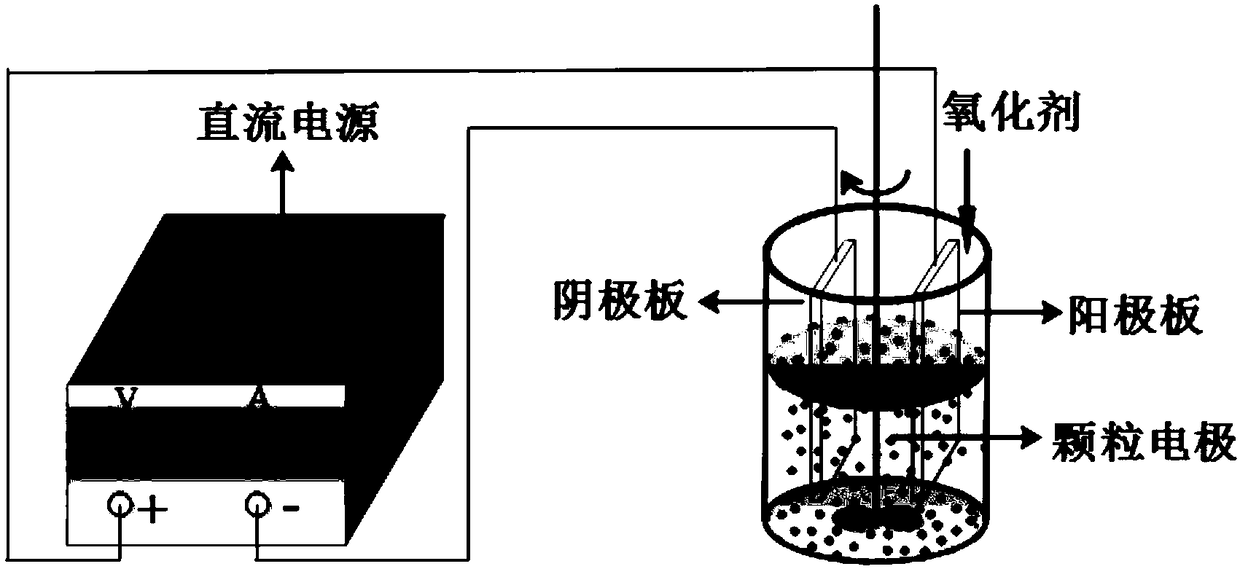

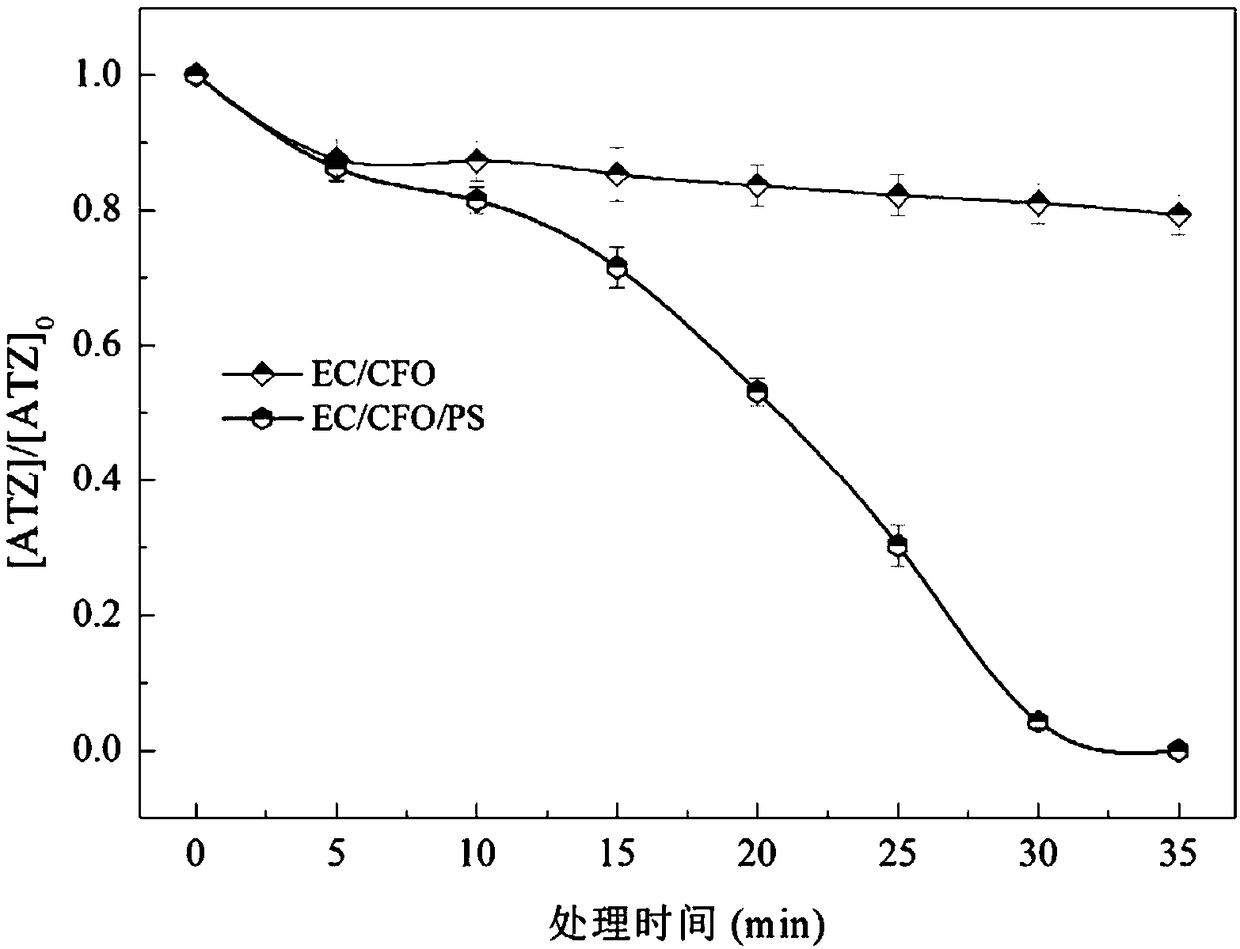

Method for processing refractory wastewater by three-dimensional electrode coupled with oxidant

ActiveCN108928890AImprove activation efficiencyImprove processing efficiencyWater contaminantsWater/sewage treatment by neutralisationPersulfateMaterials science

The invention belongs to the field of refractory wastewater treatment, and provides a method for processing refractory wastewater by a three-dimensional electrode coupled with an oxidant. The method comprises the following operation: adding the refractory wastewater with a pH value of 3-11 to be processed into a wastewater processing container provided with a slab anode and a slab cathode, addingthe oxidant and a particle electrode into the wastewater processing container, performing stirring to make the particle electrode in a fluidized state, starting a direct-current power supply connectedwith the slab anode and the slab cathode, and performing treatment for 15-60 min under the condition of a current density of 2-20 mA / cm<2> to complete the treatment of the refractory wastewater, wherein the particle electrode is magnetic spinel type ferrite MFe2O4 nanoparticles, and the oxidant is at least one selected from the group consisting of a persulfate, hydrogen peroxide and ozone. The method provided by the invention can effectively improve the degradation efficiency and degradation effect of the refractory wastewater while reducing the treatment costs of the wastewater.

Owner:SICHUAN UNIV

Treating method and electric flocculation device for Cu-EDTA complex wastewater

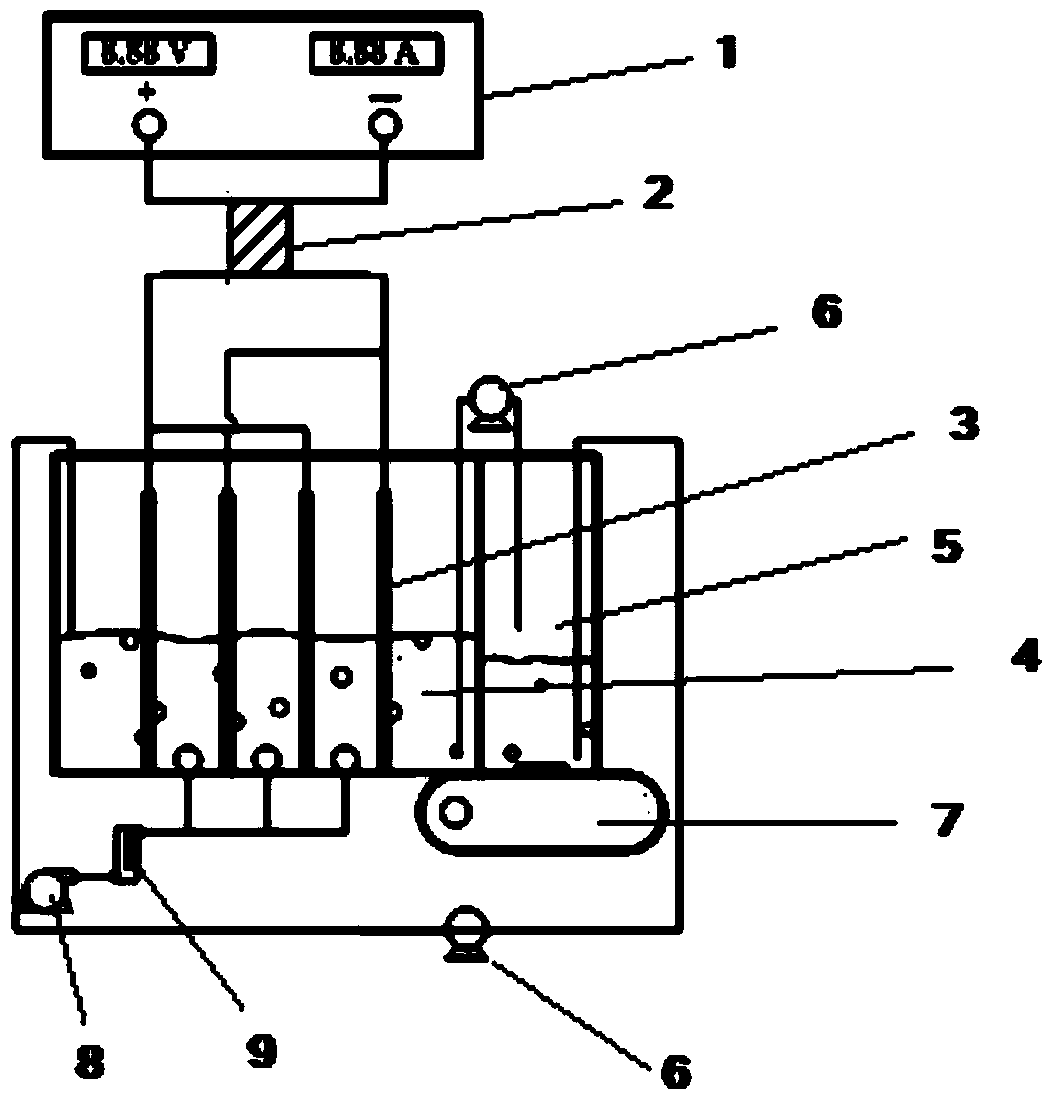

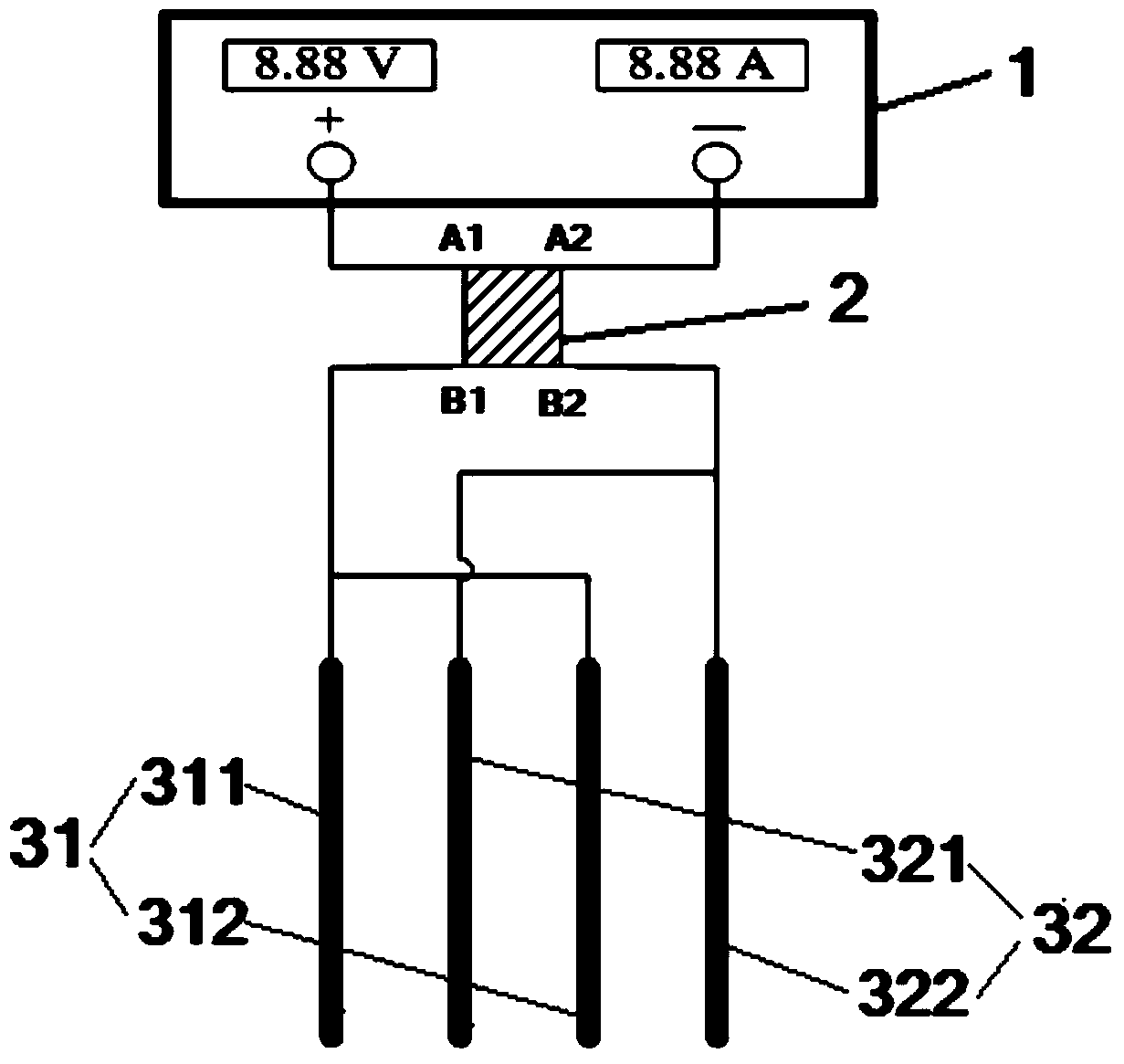

ActiveCN104071932AHigh mineralization rateMild reaction conditionsWater/sewage treatmentMultistage water/sewage treatmentSorbentEngineering

The invention provides a treating method and electric flocculation device for Cu-EDTA complex wastewater. The treating method comprises the following steps: placing the Cu-EDTA complex wastewater into a reaction tank for 30 to 50 minutes of electric flocculation reaction, wherein an aluminum electrode is taken as the anode, and an iron electrode is taken as the cathode; changing the current direction by taking the aluminum electrode as the anode while taking the iron electrode as the cathode, and carrying out electric flocculation reaction for 30 to 50 minutes, so as to fulfill treatment of the Cu-EDTA complex wastewater. The electric flocculation device comprises a power supply, a relay, the electrodes and the reaction tank, wherein the electrodes comprise the aluminum electrode and the iron electrode; one ends of the aluminum electrode and the iron electrode are connected in series with the power supply through the relay; the other ends of the aluminum electrode and the iron electrode are arranged in the reaction tank. The Cu-EDTA complex wastewater is treated due to the cooperation of the aluminum electrode and the iron electrode without addition of chemical agents and adsorbents. The method has the advantages that the operation is simple; the treating cost is low; the removal rates of copper ions and COD are high.

Owner:HUNAN UNIV

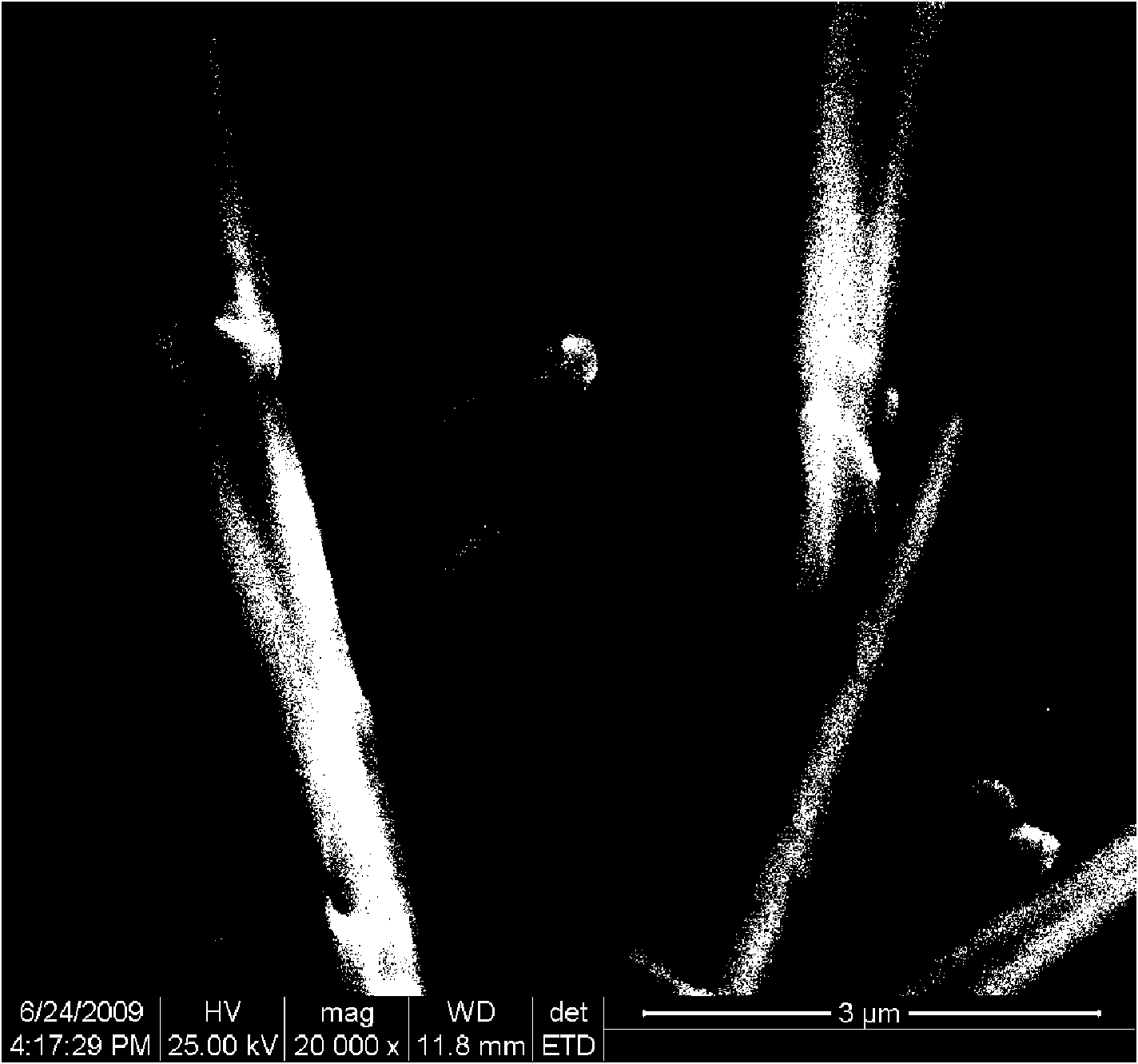

Preparation method of zinc oxide/zinc titanite nucleocapsid nanowire composite photocatalyst and application thereof

InactiveCN101632921ASimple processEasy to makeWater/sewage treatment by irradiationWater contaminantsTitanitesPhotocatalytic degradation

The invention discloses a preparation method of a zinc oxide / zinc titanite nucleocapsid nanowire composite photocatalyst and application thereof, belonging to the technical field of environment pollution disposal. The preparation method of the catalyst comprises the following steps: 1) preparing a zinc oxide nanowire template by using a water heat process, wherein the diameter of the nanowire is about 200 nm, and the length of the nanowire is about a plurality of microns; 2) adopting a sol-gel wet chemical process to uniformly wrap a layer of titanium dioxide outside the zinc oxide nanowire template; and 3) sintering at a high temperature so as to generate solid phase reaction and then obtaining the zinc oxide / zinc titanite nucleocapsid nanowire. The method has the advantages of simple operation, room temperature implementing, stable performance, green synthesis process and the like. The composition of the zinc titanite not only expands the photoresponse scope of the zinc oxide nanowire and improves the separation efficiency of electron holes but also improves the photocatalyst degradation efficiency of organic pollutants, thereby having high practical value and great application prospect.

Owner:DALIAN UNIV OF TECH

Preparation and application of Sb-Ni-Nd co-doping SnO2 high catalytic activity positive electrode

ActiveCN104016449AImprove stabilityImprove adsorption capacityWater/sewage treatment using germicide/oligodynamic-processMetal/metal-oxides/metal-hydroxide catalystsOrganic matter mineralizationElectrochemistry

The invention discloses preparation and application of a Sb-Ni-Nd co-doping SnO2 high catalytic activity positive electrode, and belongs to the technical field of electrochemical water treatment. A micropore titanium (mp-Ti) plate is used as a matrix, and a SnO2-Sb-Ni-Nd composite oxide coating is immobilized on the mp-Ti plate. (1) A modified sol using citric acid and ethylene glycol as matrixes and containing SnCl4, SbCl3, NiSO4 and NdCl3 is prepared; (2) after pretreatment of the mp-Ti plate, the mp-Ti plate is impregnated in the modified sol of the step (1), brushed and dried, then is calcined at high temperature, finally is rinsed with water, and dried for stand-by use. The Sb-Ni-Nd co-doping SnO2 high catalytic activity positive electrode is used for electrocatalytic oxidation of phenol which is a pollutant difficult to biodegrade in water, results show that the remove phenol ability is strong, and the organic matter mineralization rate is significantly higher than that of electrodes in the prior art. The prepred Sb-Ni-Nd co-doping SnO2 high catalytic activity electrode is high in catalytic activity and good in stability, and has a good industrial application prospect.

Owner:BEIJING UNIV OF TECH

Method for renovating polycyclic aromatic hydrocarbon contaminated soil with ultrasound wave

InactiveCN101195122AFast removal rateHigh mineralization rateContaminated soil reclamationCavitationSlurry

The invention belongs to the surgical repair field of contaminating soil, and discloses a method for restoring soil which is polluted by polycyclic aromatic through supersonic waves. Soil slurry with a dampness 5%-95%, which is polluted by the polycyclic aromatic whose concentration of the polycyclic aromatic is 10-10000 g / kg is treated under a condition of supersonic wave irradiations, supersonic frequency is 20kHz-100kHz, the output power of the supersonic waves is 100W-2.0kw, and the duration of the supersonic wave irradiations is 5min-4h. The polycyclic aromatic is one of 16 polycyclic aromatics compounds with priority control, and the 16 polycyclic aromatics compounds are regulated in American EPA610. The invention mainly adopts cavitations effects of the supersonic waves to degrade or subtract organic contaminants with durability as the polycyclic aromatic and the like. Compared with a soil restoring technique which is adopted commonly at present, and the method isn't affected by the condition of contaminant species and environment, and the method has a wide applying field. The invention has high efficiency, low energy consumption, non-secondary pollutions, good social profits and environmental benefits.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

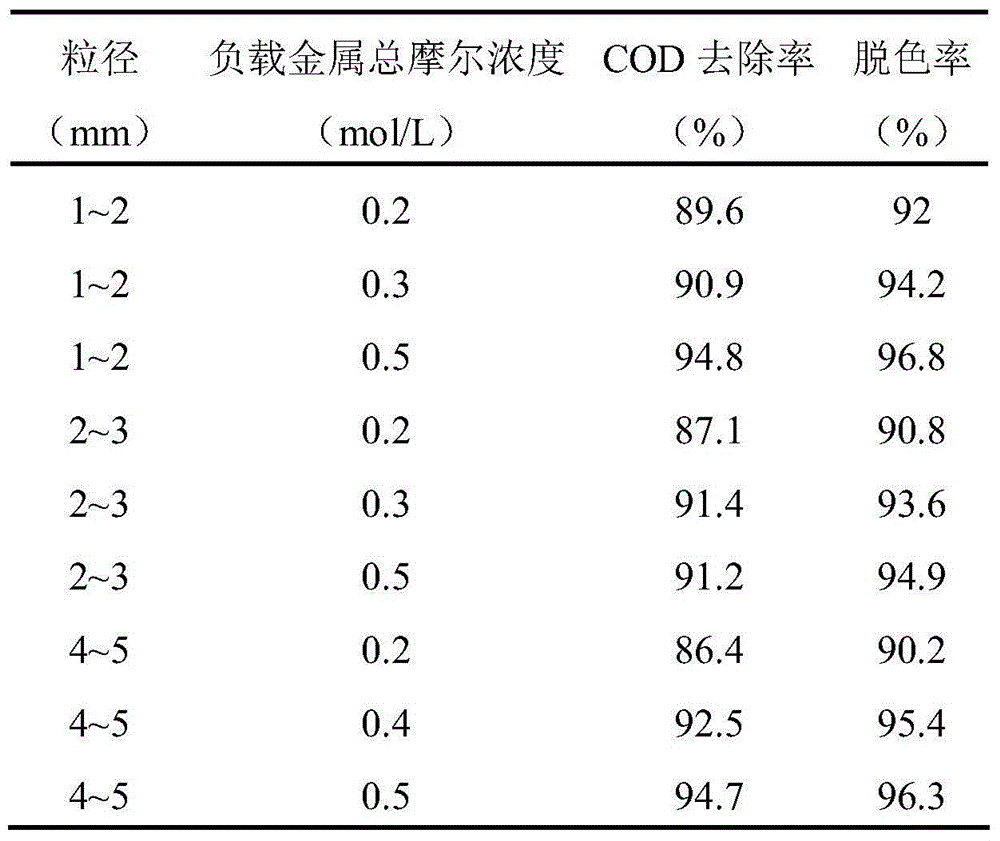

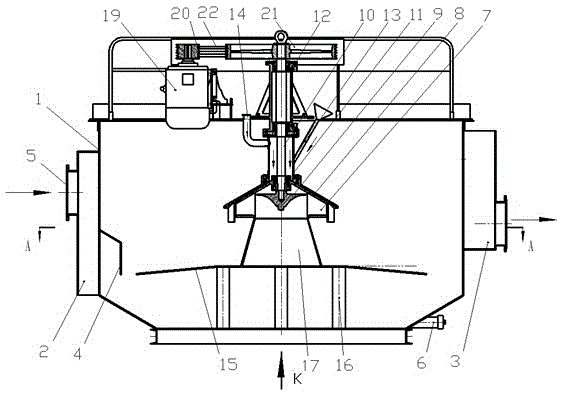

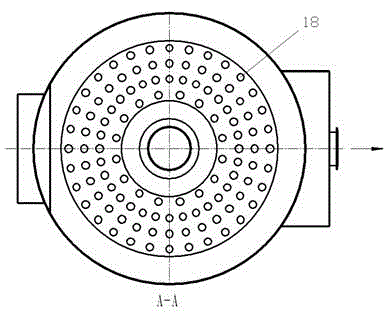

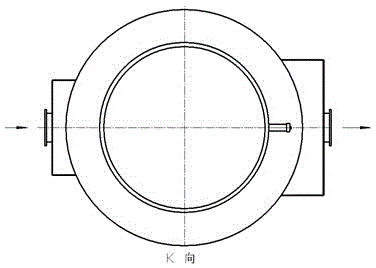

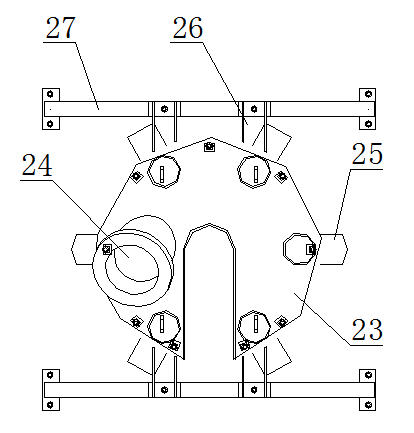

Pretreatment equipment for coal slime before floatation feed

The invention relates to pretreatment equipment for coal slime before floatation feed, belongs to the technical field of flotation equipment for the coal slime, and is used for pretreatment of the coal slime before entering flotation equipment for sorting. The pretreatment equipment adopts the technical scheme that a feeding box and a discharging box are respectively arranged on two sides of a cylinder body of a casing; a motor is fixed at the upper part of the casing, and is connected with the upper end of a stirring shaft through a leather belt; a vane wheel is mounted at the lower end of the stirring shaft, a sleeve sleeves the stirring shaft, the upper end of the sleeve is fixedly connected with the casing, and the lower end of the sleeve is connected with a stator; the lower end of a chemical dosing pipe is connected to the wall of the sleeve; the lower end surface of the stator and the upper end surface of the vane wheel are in clearance fit; a false bottom plate is a flat plate, a gap is reserved between the false bottom plate and the bottom plate of the casing, and a plurality of circular holes are uniformly distributed in the plate surface of the false bottom plate. The equipment disclosed by the invention is low in electricity consumption, the service life of the vane wheel is long, the flow state of ore pulp is reasonable, and medicament and the ore pulp are sufficiently mixed during operation; the equipment has the characteristics of high volume utilization rate, large ore pulp treatment quantity, wide particle size treatment ranges and high adaptability to coal properties.

Owner:TIANDI TANGSHAN MINING TECH

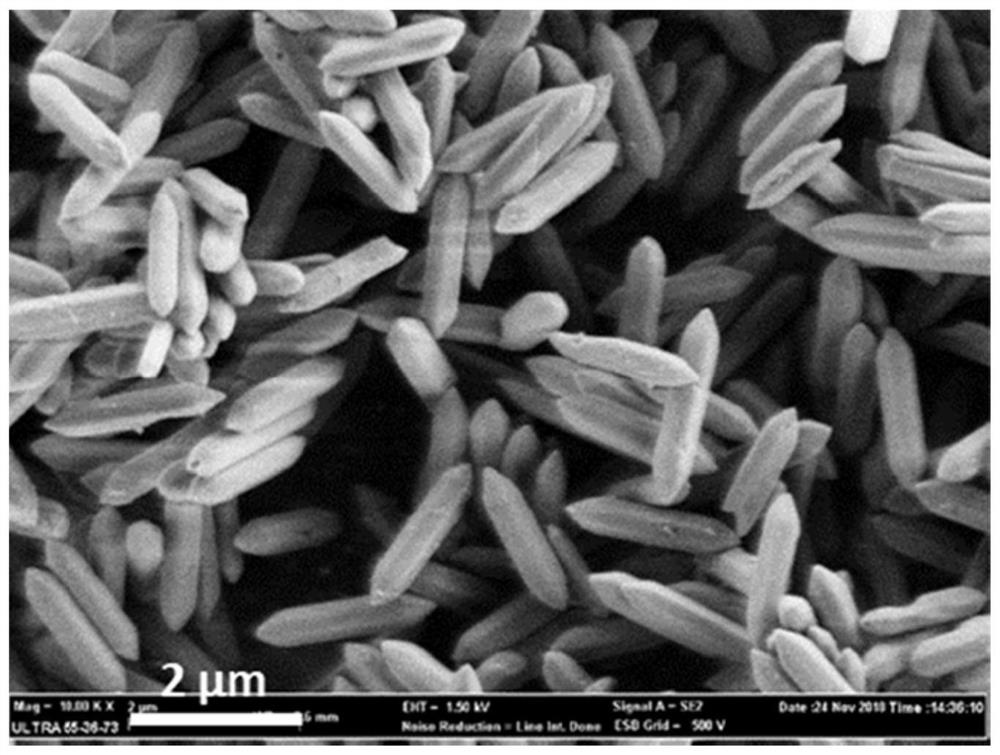

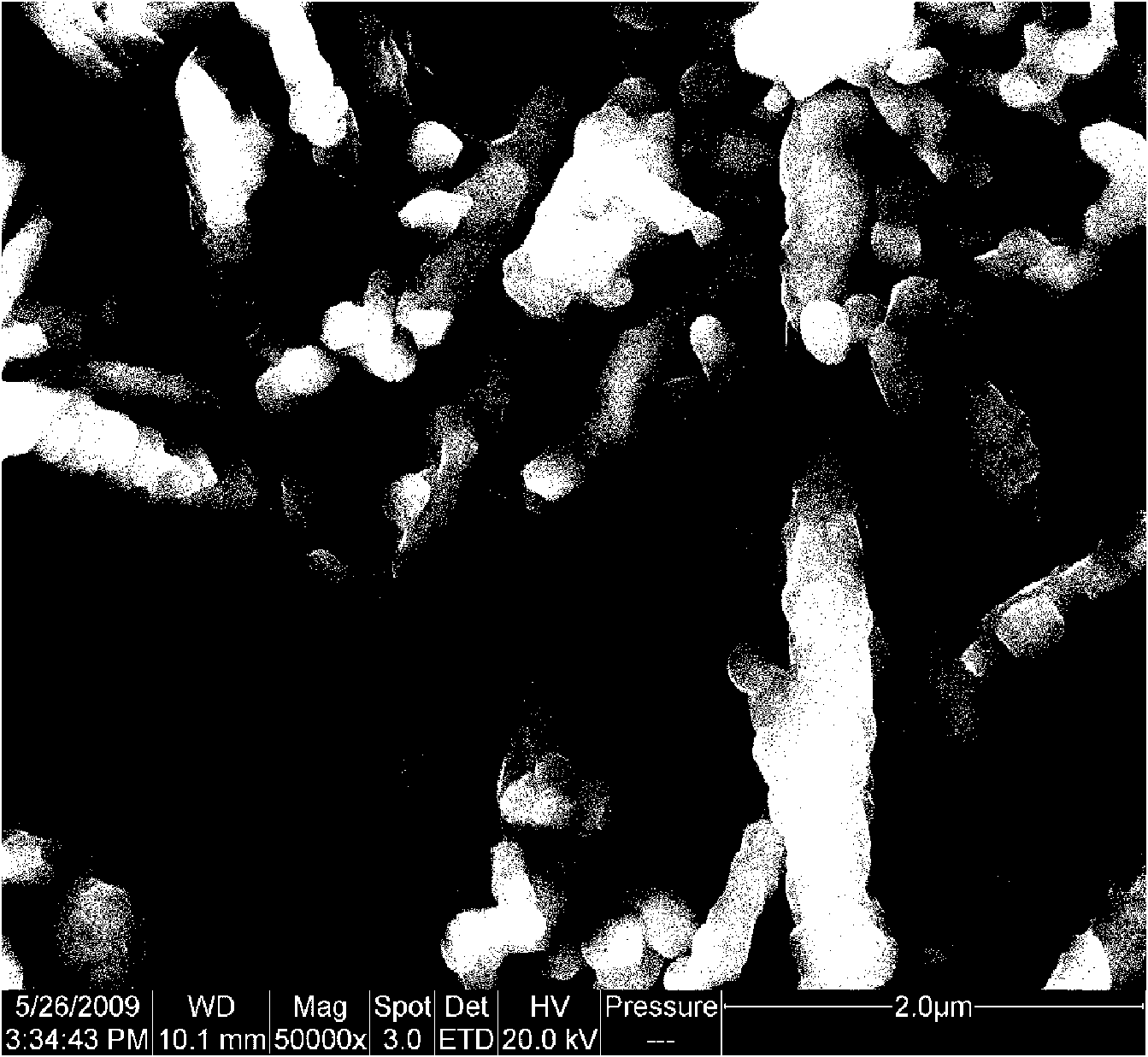

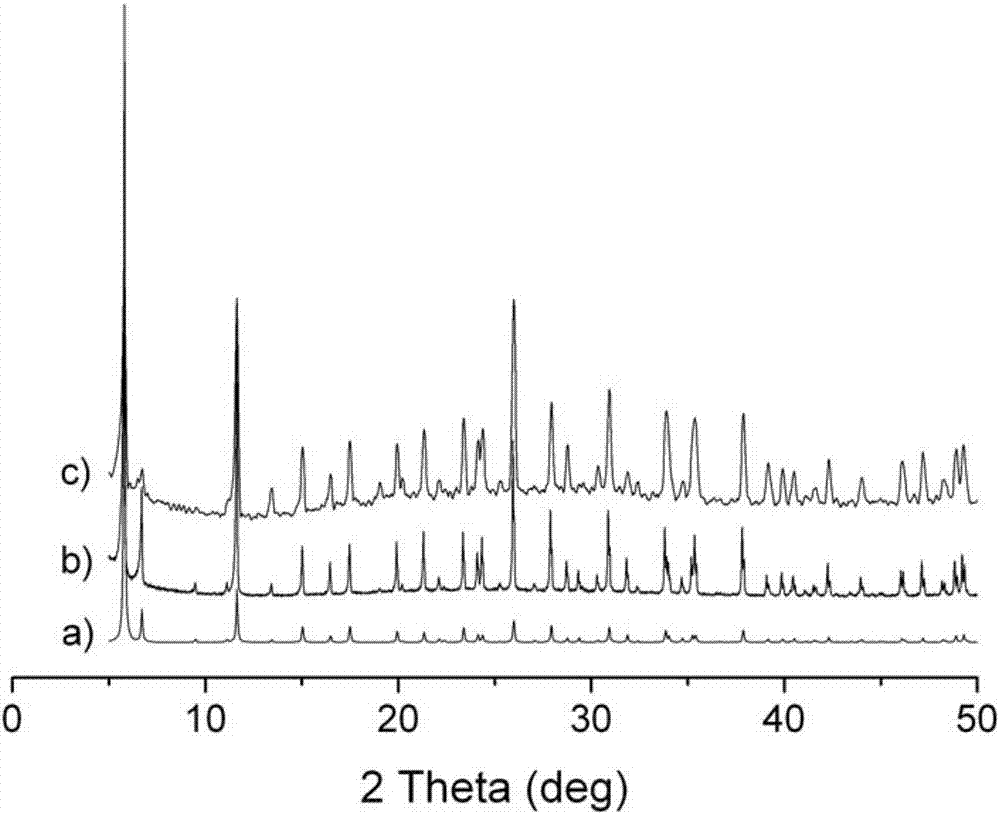

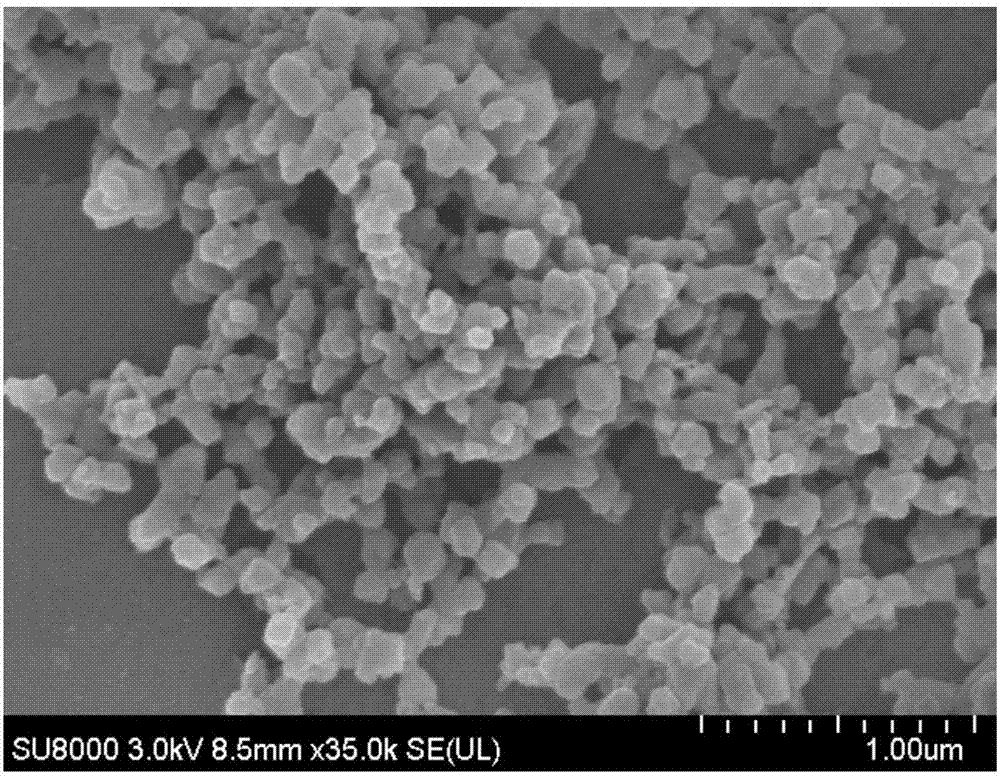

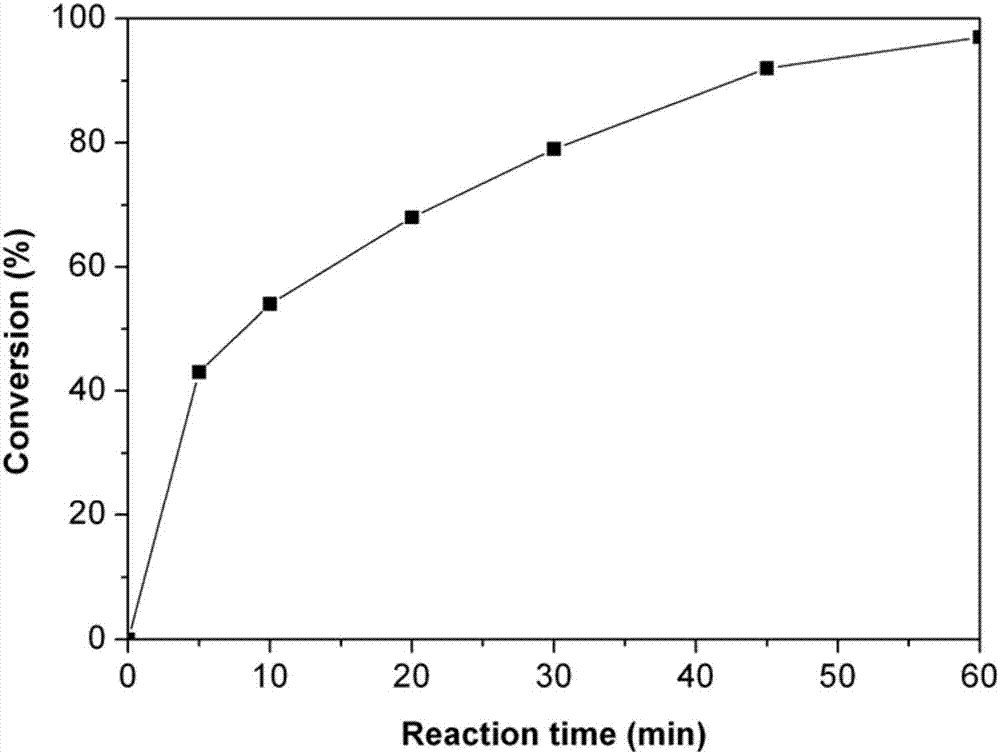

Preparation method and application of polyacid-based metal organic framework nanocrystalline catalyst

ActiveCN107243361ASmall scaleUniform shapeOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsMetal-organic frameworkCarbon deposit

The invention provides a preparation method and application of a polyacid-based metal organic framework nanocrystalline catalyst. The nanocrystalline catalyst can be synthesized by a liquid-assisted grinding method, the obtained nanocrystalline catalyst has small particle dimension, and the grain size of the nanocrystalline catalyst is 50 to 200 nanometers; furthermore, the nanocrystalline catalyst has uniform morphology and size; meanwhile, the catalyst has determined component and structure. Under moderate condition, hydrogen peroxide is utilized as an oxidizing agent, the nanocrystalline can catalyze phenol to be degraded in high efficiency, and high phenol conversion rate and high mineralization rate are achieved. The catalyst can be completely separated and recycled through simple centrifugal operation, can be used repeatedly after being dried and can still keep good catalytic activity after being repeatedly utilized for multiple times. The preparation method of the polyacid-based metal organic framework nanocrystalline catalyst disclosed by the invention is simple and can effectively reduce the particle size of the catalyst; thus, phenomena of diffusional limitation and carbon deposit in catalytic reaction are reduced, and a material catalyzing efficiency is improved.

Owner:NORTHEAST NORMAL UNIVERSITY

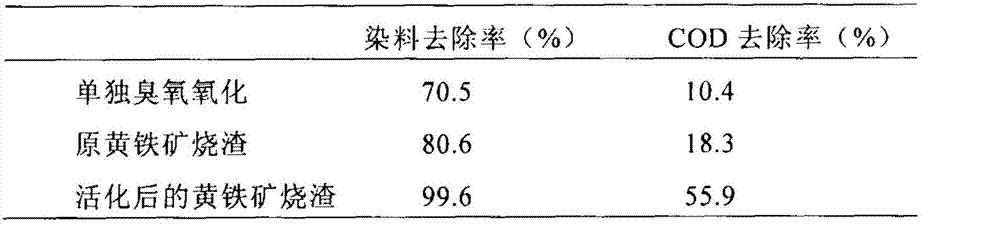

Method of treating wastewater by catalyzing ozone to oxidize by using pyrite cinder

ActiveCN103787488AEasy to prepareReduce manufacturing costWater/sewage treatment by oxidationPyriteHomogeneous catalysis

The invention relates to a method of treating wastewater by catalyzing ozone to oxidize by using pyrite cinder, wherein the oxidizing efficiency of ozone is improved, the economic cost of preparing an ozone catalyst is lowered, and the economic and efficient catalytic ozonation technology is developed. The core of the method provided by the invention is as follows: chemical cinder, namely pyrite cinder is used and after being subjected tosimple activating treatment, the pyrite cinder is used for catalyzing ozone to oxidize, so that treatment of wastes with processes of wastes against one another is carried out. The pyrite cinder is developed to a novel ozone catalyst with high catalytic activity for heterogeneous catalytic ozonation treatment of wastewater by virtue of an activating method of controlling critical process parameters and inventing the catalyst. Compared with the prior art, according to the method provided by the invention, pyrite cinder is simply activated to use, so that the preparation process is simple, the catalytic activity is high, and no other metals are loaded additionally, thereby greatly lowering the economic cost of the catalyst while improving the catalytic efficiency.

Owner:TONGJI UNIV

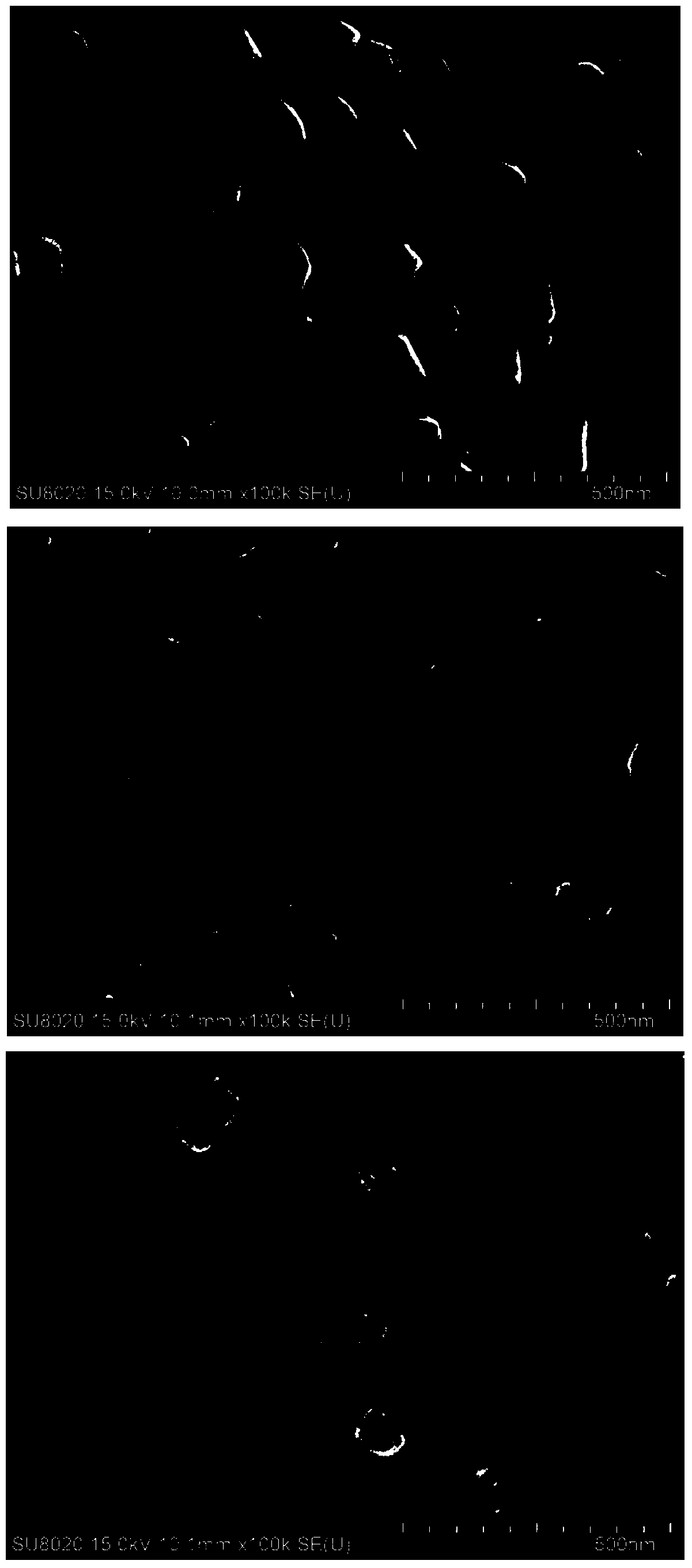

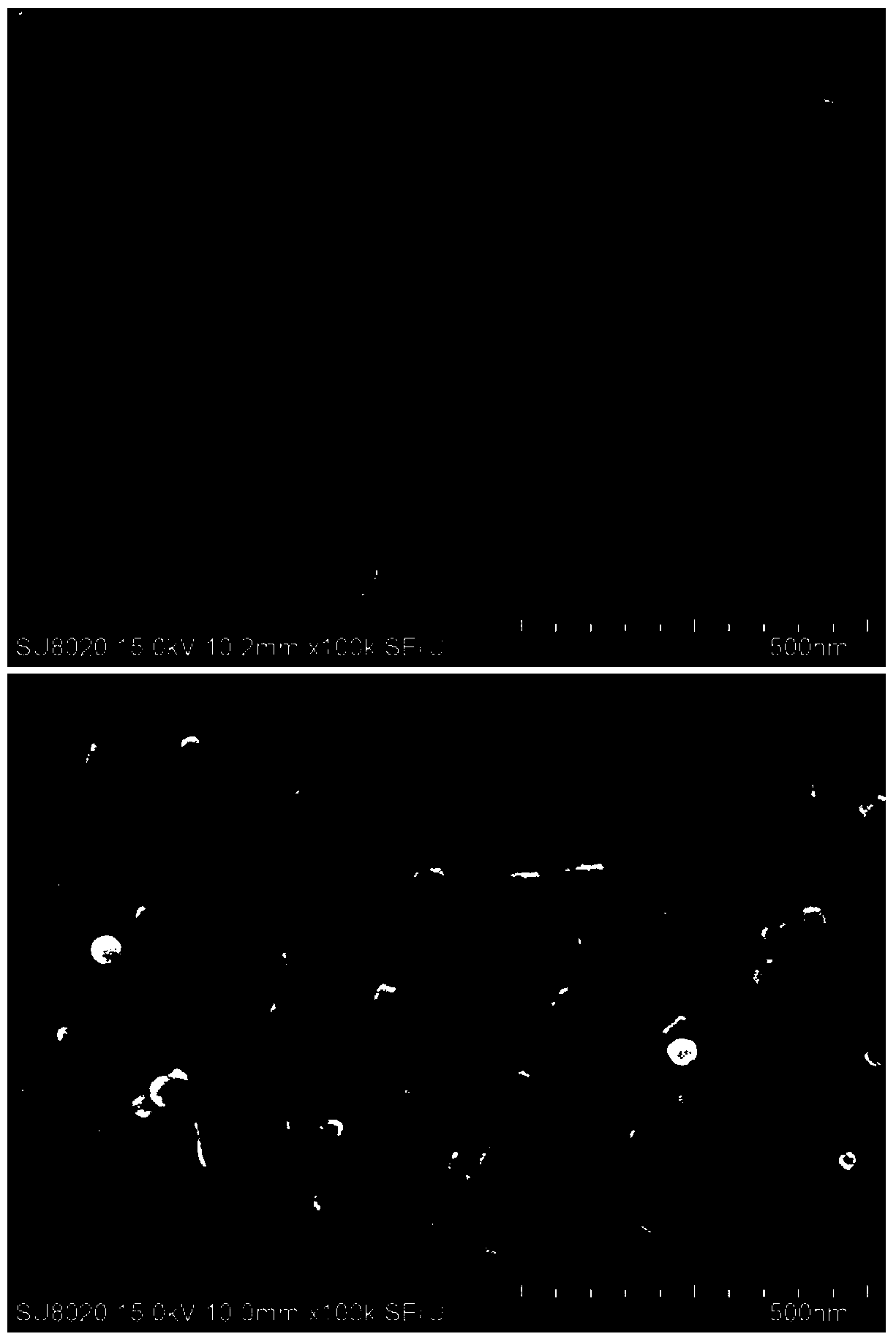

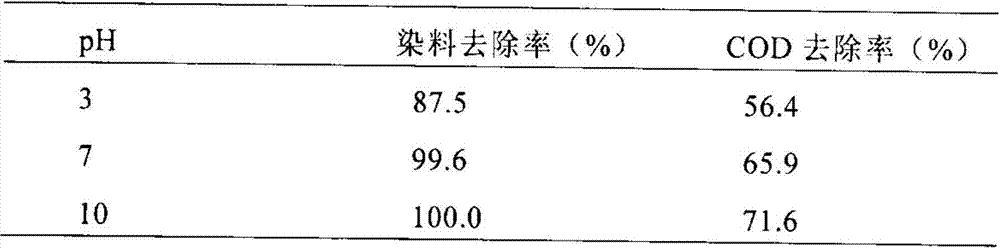

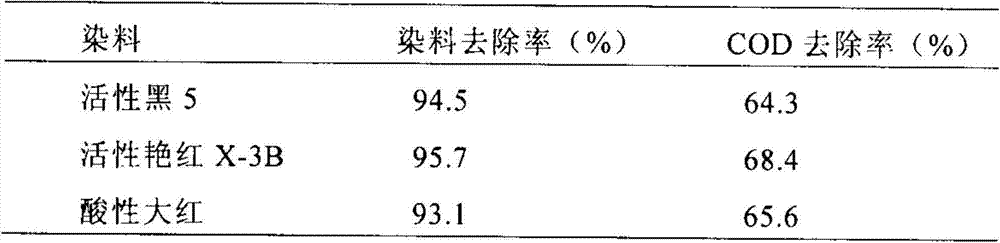

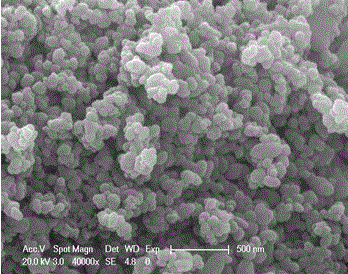

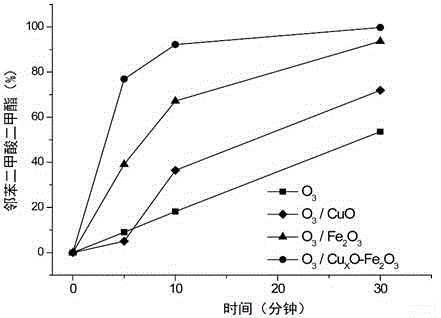

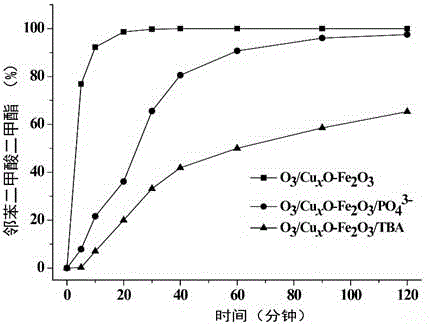

Preparation method and application of magnetic CuxO-Fe2O3 nano ozone catalyst

ActiveCN105797728AOvercoming repetitivenessOvercoming pollutionWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsDispersityCatalytic effect

The invention relates to a preparation method and application of a CuxO-Fe2O3 nano material, and belongs to the technical field of advanced waste water treatment and environmental catalysis.The CuxO-Fe2O3 nano material is prepared through an impregnation method, the CuxO-Fe2O3 nano material serves as a catalyst and is added into organic waste water which is difficult to degrade to catalyze an ozone reaction, degradation of organic contaminants is promoted, and the mineralization rate of organic matter is greatly increased; the CuxO-Fe2O3 nano material is small in size and good in dispersity in a nano material system, CuxO-Fe2O3 has magnetism, the catalyst subjected to the reaction can be effectively separated from water and recycled by means of an external magnetic field, the catalyst is good in stability, and the high catalytic activity can still be maintained after the catalyst is repeatedly used three times.The added CuxO-Fe2O3 catalyst can obviously improve the the removal efficiency of ozone to the contaminants, a good catalytic effect can be achieved on the condition that the pH ranges from 3 to 11, and the catalyst is small in dosage and stable in repeatedly used performance and has a wide prospect in water treatment.

Owner:TONGJI UNIV

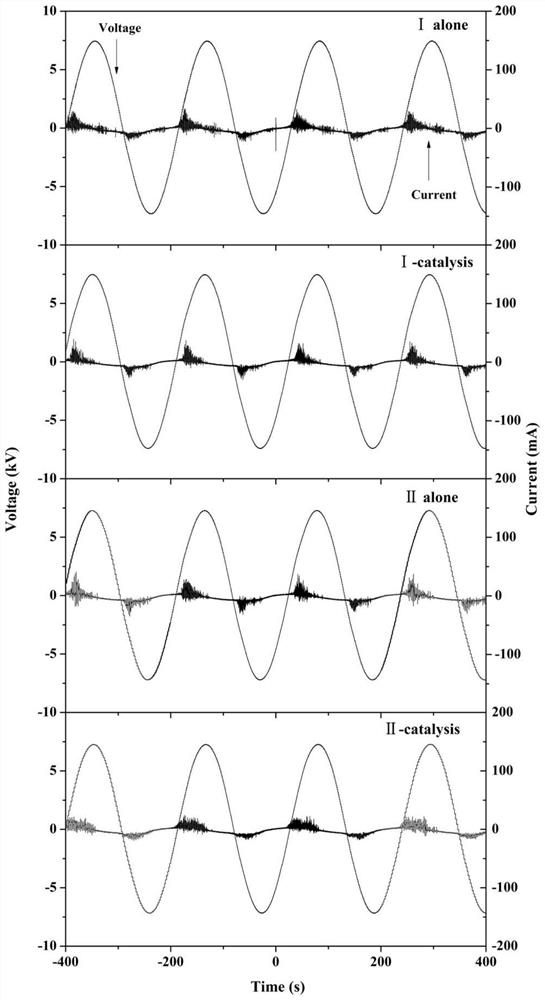

Method for catalytically degrading chlorobenzene by double-stage discharge plasma and preparation method of used catalyst

InactiveCN111921374AReduce energy consumptionFacilitate chemical reactionsGas treatmentDispersed particle separationEnvironmental chemistryChemical reaction

The invention relates to a method for degrading chlorobenzene, and provides a method for catalytically degrading the chlorobenzene by using double-section discharge plasma aiming at the problem of incomplete decomposition when the chlorobenzene is removed by using low-temperature plasma. The discharge interval distance of the double-section discharge plasma is less than or equal to 10cm, 0.1-0.3 gof a catalyst is placed in each of two discharge areas of a reactor, the chlorobenzene is entrained in air at the concentration of 200-400 mg / m < 3 > and introduced into the reactor, a power supply of the reactor is turned on for discharging, the peak voltage is 13-17 kV, and the chlorobenzene stays in the discharge areas for 1-3 s for degradation. The advantages of low energy consumption, rapidchemical reaction, thorough purification, wide applicability and the like of the low-temperature plasma are utilized, the defect that the low-temperature plasma lacks selectivity for treated pollutants is overcome, by-products are effectively reduced, and the CO2 selectivity and the pollutant removal rate are increased. The invention also provides a preparation method of the catalyst.

Owner:ZHEJIANG UNIV OF TECH

Combustion device for volatile organic composites and simulating detection device and method of combustion device

ActiveCN109579033AIncrease heating speedImprove energy conversion efficiencyGas analyser construction detailsIncinerator apparatusCombustion chamberFixed bed

The invention discloses a combustion device for volatile organic composites and a simulating detection device and method of the combustion device. The combustion device comprises a microwave emittingsystem, a catalysis combustion chamber and a catalysis bed; a waste gas inlet and a waste gas outlet are formed in the catalysis combustion chamber; a catalyst is arranged on the catalysis bed; the catalysis bed is fixedly arranged in the catalysis combustion chamber; the waste gas inlet and the waste gas outlet are located on two sides of the catalysis bed; the microwave emitting system comprisesa microwave emitting device which is arranged on the catalysis combustion chamber; the microwave emitting device communicates with the catalysis combustion chamber through a waveguide pipe; and microwave emitted by the microwave emitting device can enter the catalysis combustion chamber through the waveguide pipe. According to the combustion device, the catalyst fixing bed is heated by microwave;VOCs waste gas is catalyzed, oxidized and mineralized high-efficiently; the degradation and mineralization rate can be improved; and reaction energy consumption is lowered.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

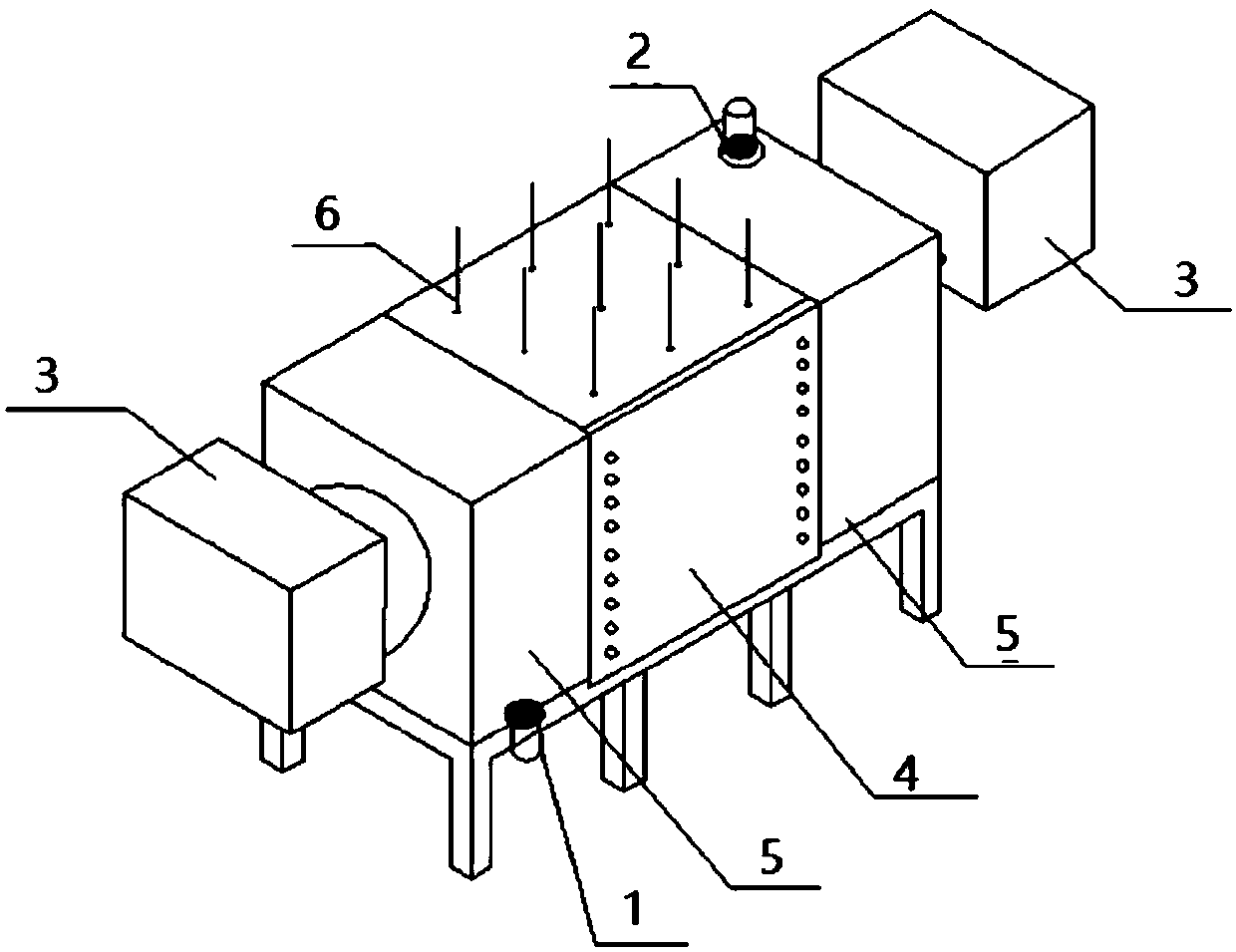

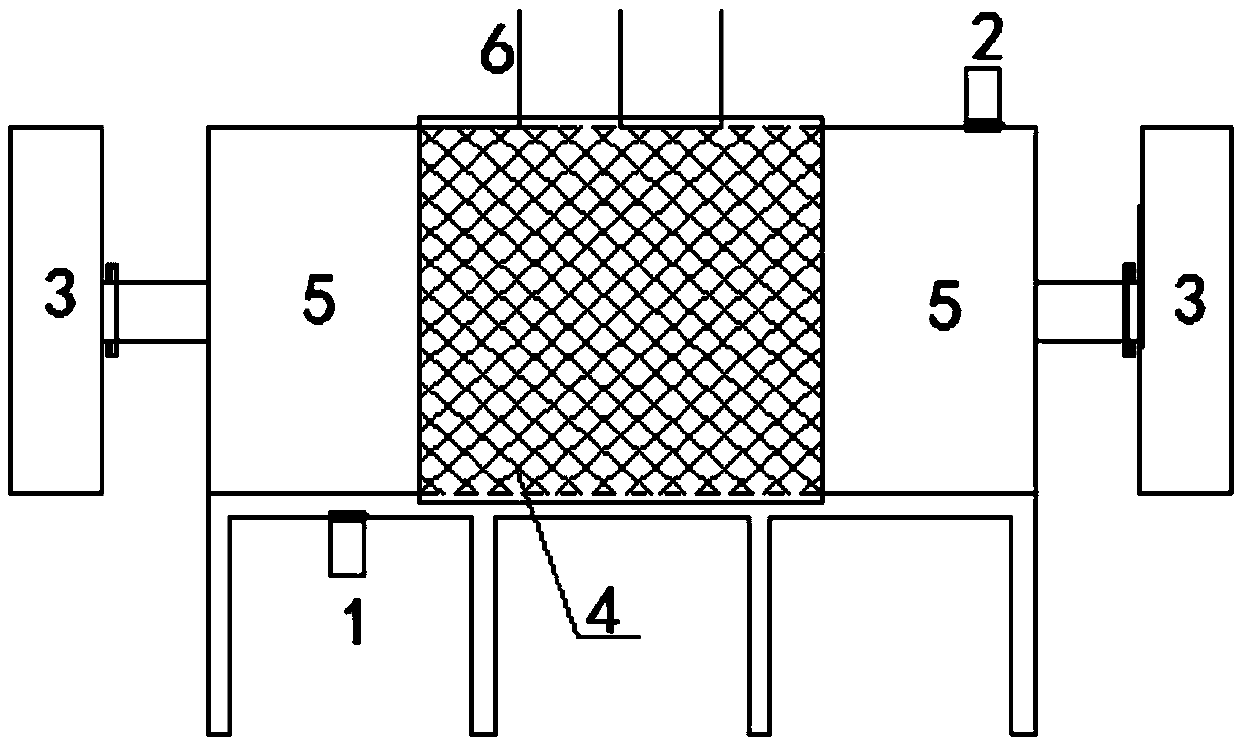

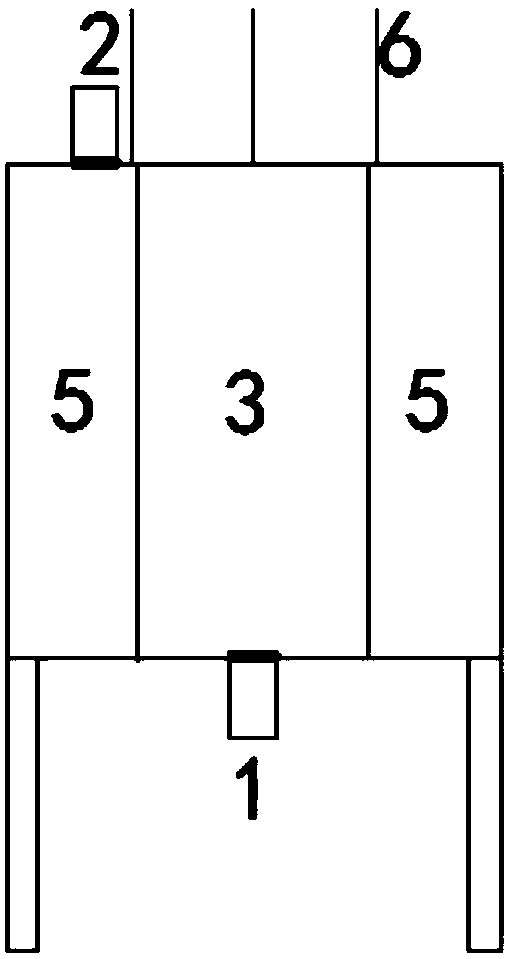

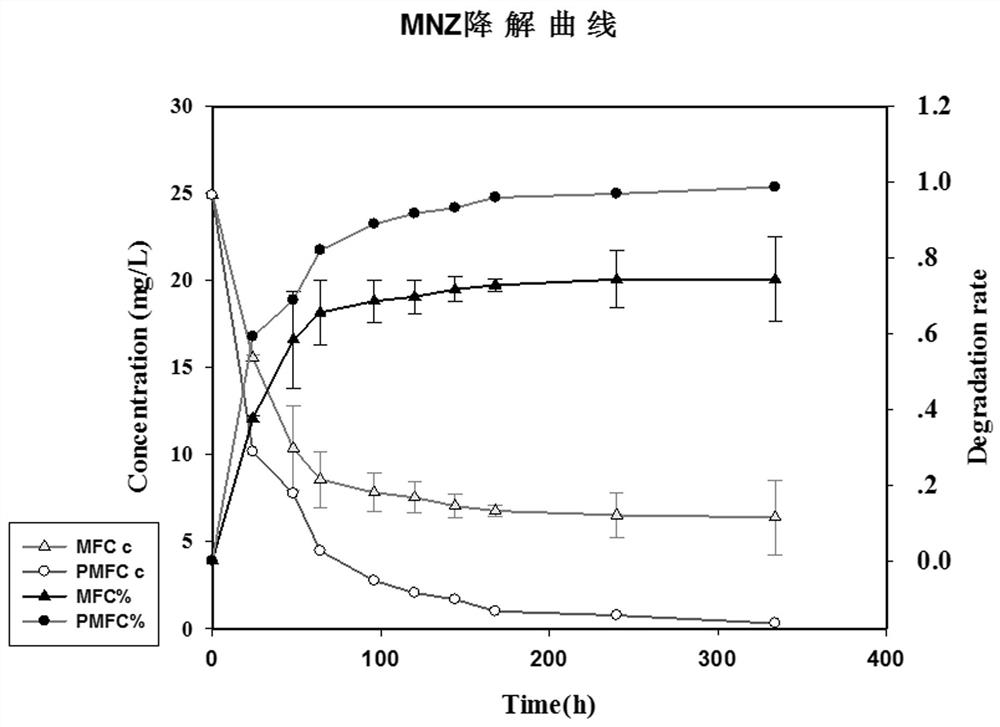

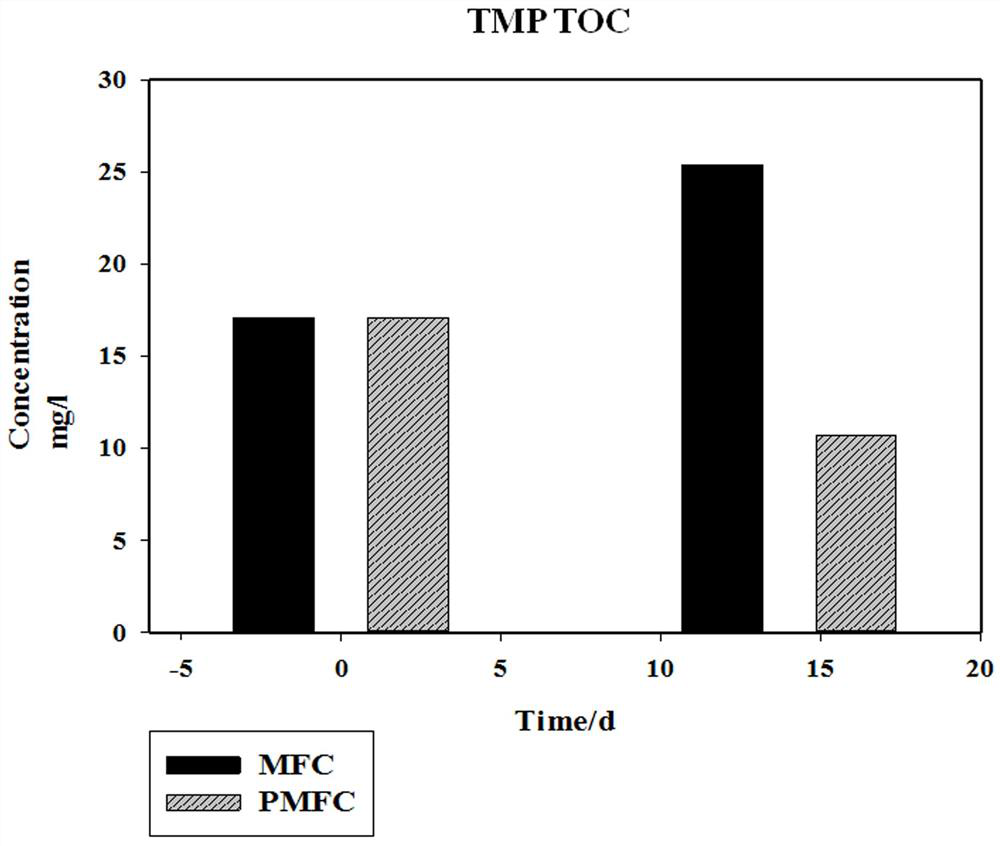

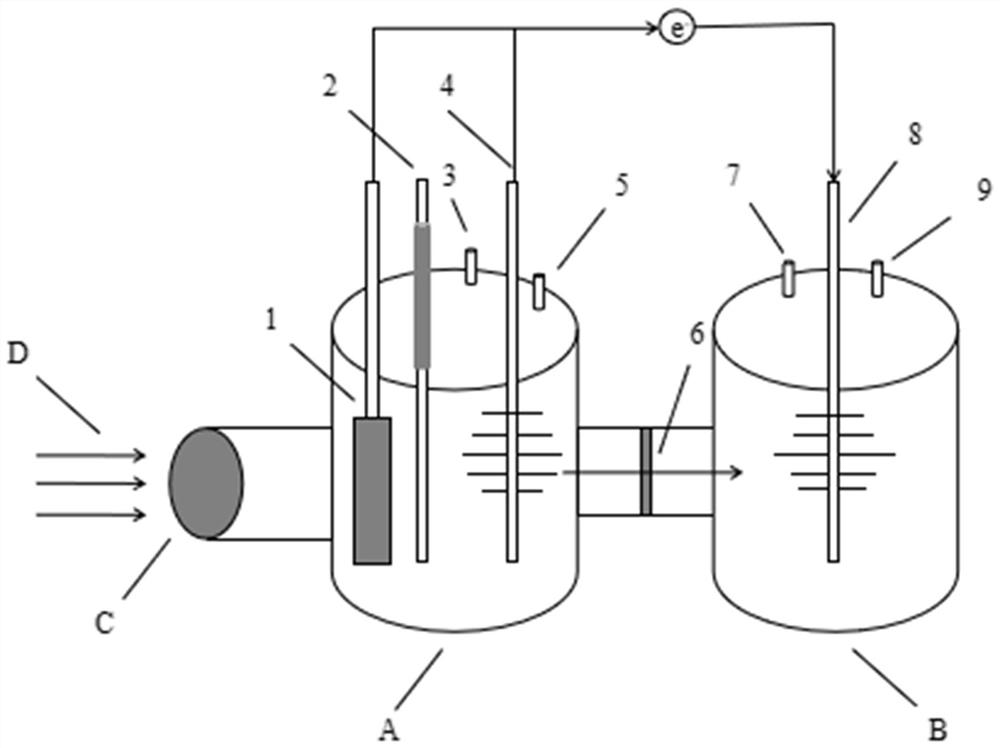

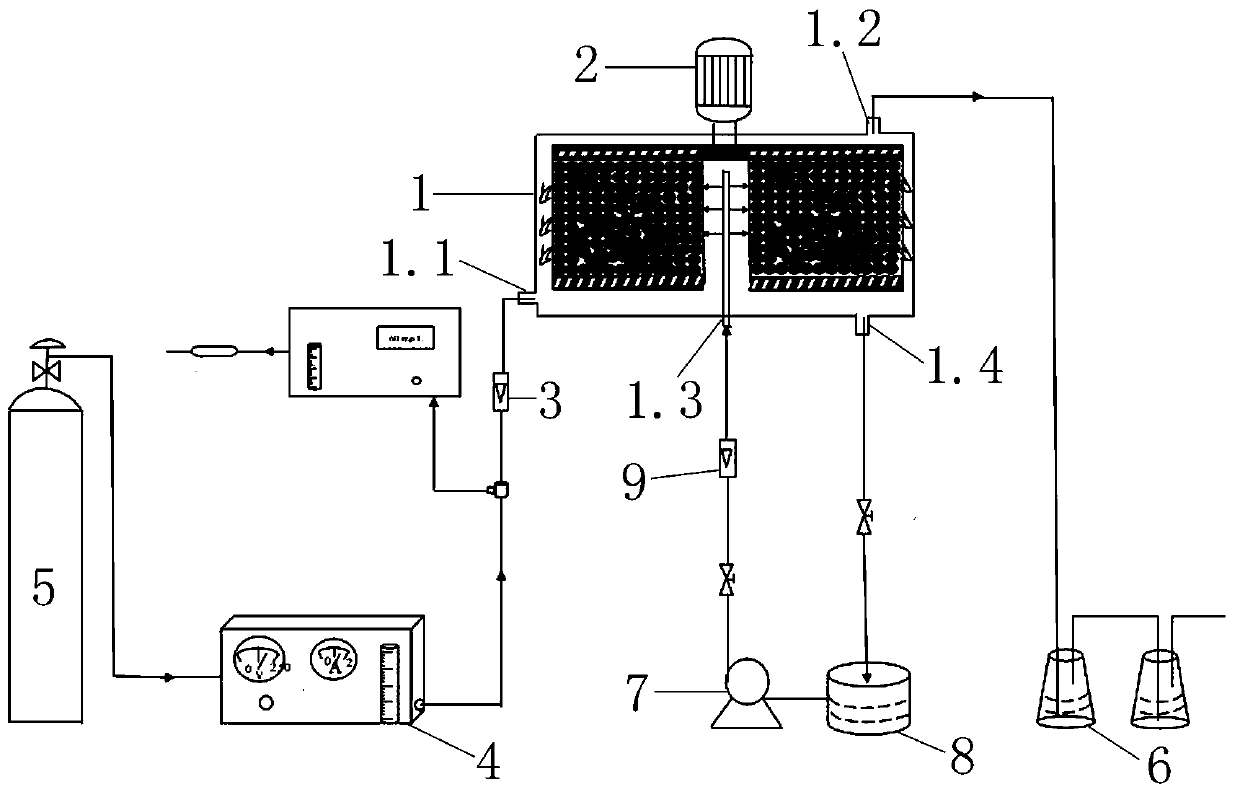

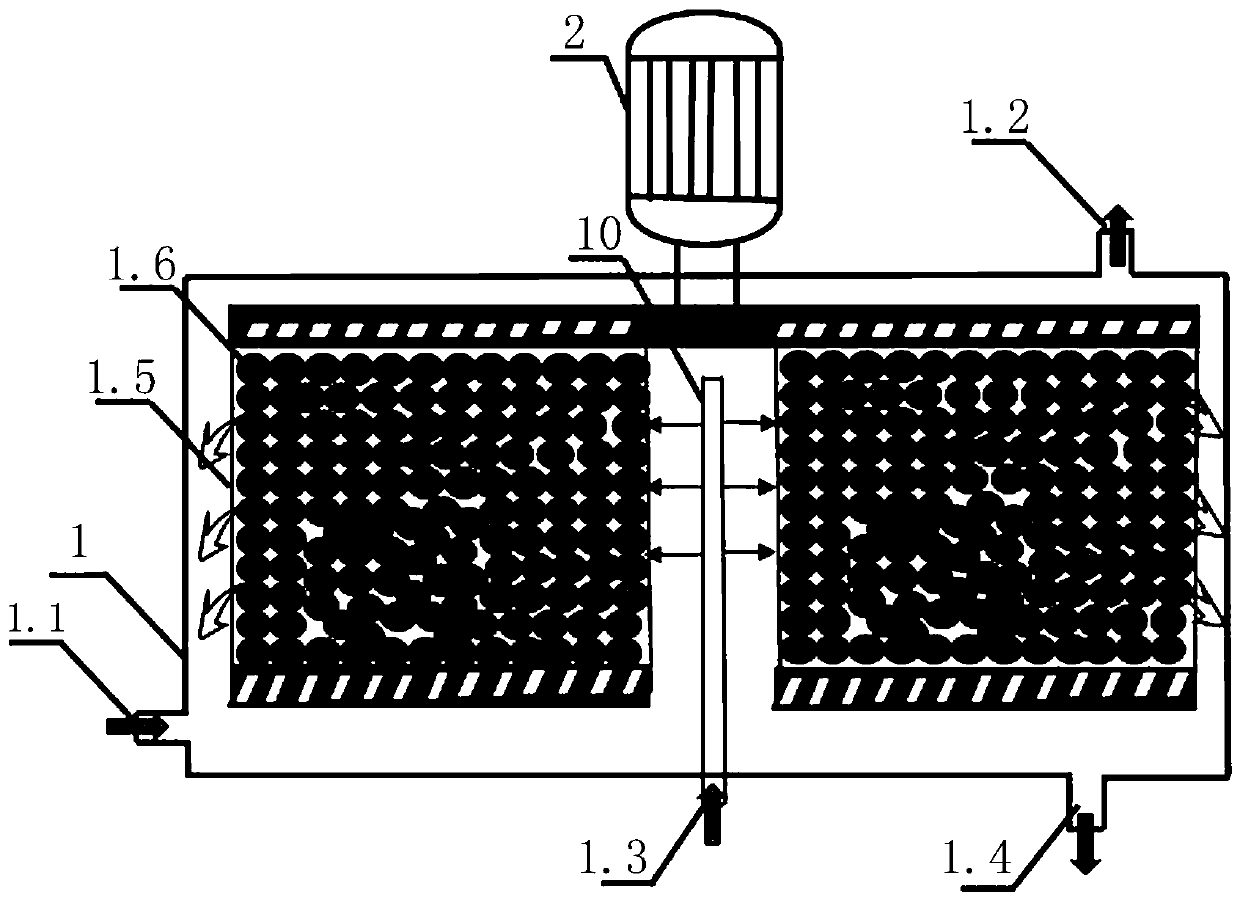

Device for degrading antibiotics by adopting photocatalysis-assisted enhanced biological anode

ActiveCN112125390AImprove degradation efficiencyIncrease production capacityTreatment by combined electrochemical biological processesBiological treatment apparatusPtru catalystBiology

The invention provides a photoelectrocatalysis and microbial fuel cell coupling system for treating antibiotics, and belongs to the technical field of difficult-to-degrade pollutant treatment and energy recovery and utilization. An electrogenesis biological anode of a microbial fuel cell (MFC) is coupled with a photoelectrocatalysis anode to form a coupled electrogenesis catalytic degradation antibiotic system; a photocatalysis anode of the system is of a net structure with a nickel net loaded with a hydrothermal TiO2 catalyst; the biological anode of the system is a carbon brush loaded with electrogenesis microorganisms; and a cathode of the system is a common carbon brush; the cathode and the anode are separated by an ion exchange membrane. The effect of the system in the degradation ofdifficult-to-degrade antibiotics by an anode is obviously superior to that of a traditional microbial fuel cell or a photoelectrocatalysis system; and degradation reaction of the traditional microbialfuel cell is carried out under the condition of the absence of light. According to the advantages of the device, the MFC system and the photocatalysis system are coupled, the problems that an existing MFC is low in degradation efficiency and low in power generation can be solved, and the degradation efficiency of the antibiotics is higher, and the degradation of the antibiotics is more thorough.

Owner:TAIYUAN UNIV OF TECH

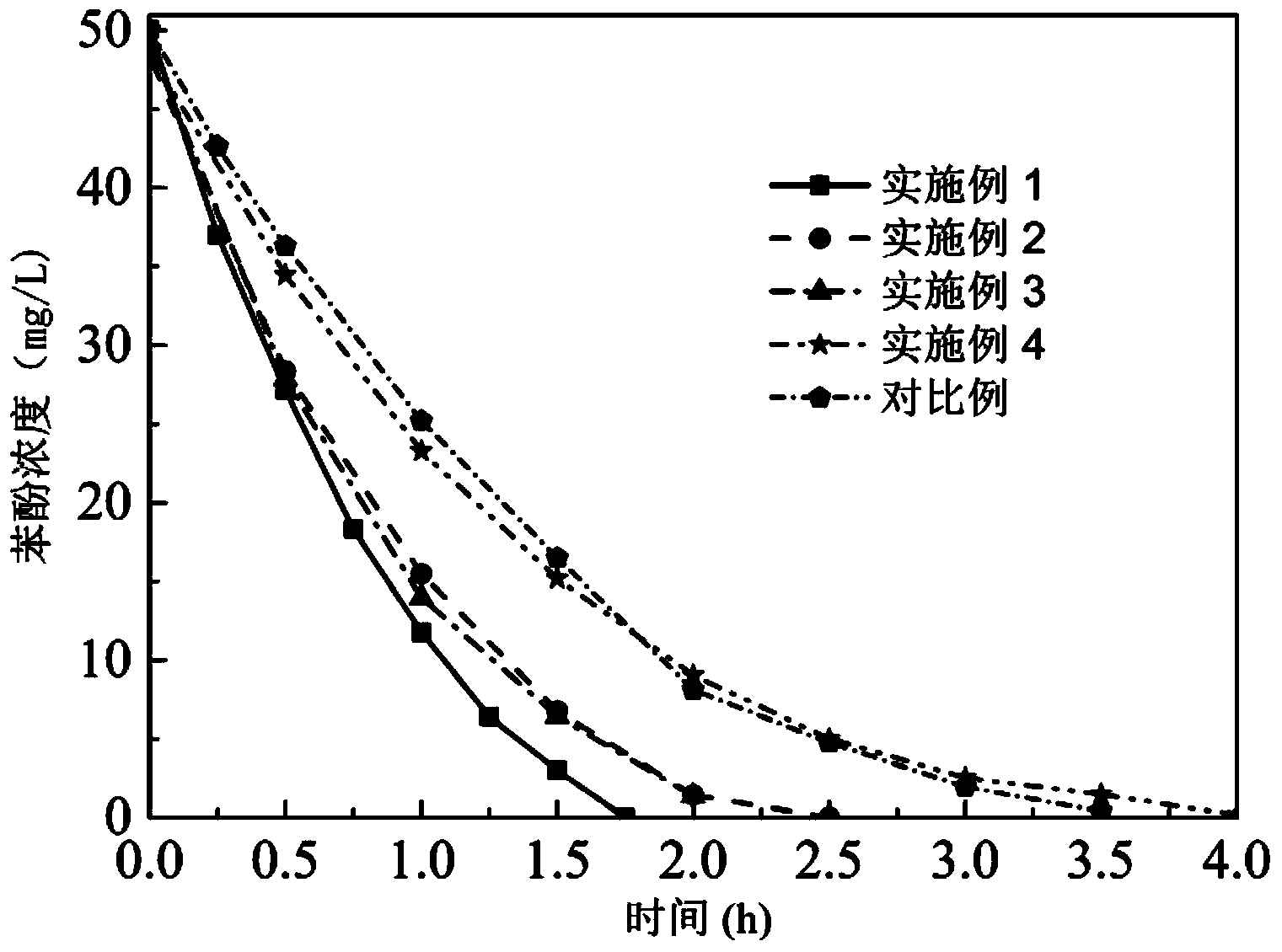

Method and device for degrading phenol wastewater by heterogeneous catalysis of ozone in high gravity field

InactiveCN110436603ASolve the problem of reuse and recycling difficultiesIncrease mass transfer rateWater contaminantsWater/sewage treatment by oxidationPeristaltic pumpLiquid storage tank

The invention belongs to the technical field of phenol wastewater treatment, and provides a method and a device for degrading phenol wastewater by heterogeneous catalysis of ozone in a high gravity field in order to solve the problems of loss of metal ions, difficulty in separation, easiness in causing secondary pollution to the environment and low ozone mass transfer efficiency in a method for degrading phenol wastewater by homogeneous catalysis of ozone. The method comprises the following steps: with a supergravity rotating packed bed as a reactor and a heterogeneous solid catalyst as a filler, adding phenol wastewater into a liquid storage tank in a semi-intermittent feeding manner; under the action of a peristaltic pump, uniformly spraying the phenol wastewater on the inner side of theheterogeneous catalyst filler, and enabling the phenol wastewater to move outwards along the radial direction of the filler layer under the action of supergravity, at this time, the phenol wastewateris in cross-flow contact with ozone gas entering in the axial direction, and the heterogeneous catalyst catalyzes ozone and decomposes the ozone to generate hydroxyl radicals, so that the phenol wastewater is degraded. The process realizes repeated utilization of the catalyst, improves the degradation capability of organic matters, reduces post-treatment procedures, reduces the industrial cost, and has a wide application prospect in the field of treatment of degradation-resistant organic wastewater.

Owner:ZHONGBEI UNIV

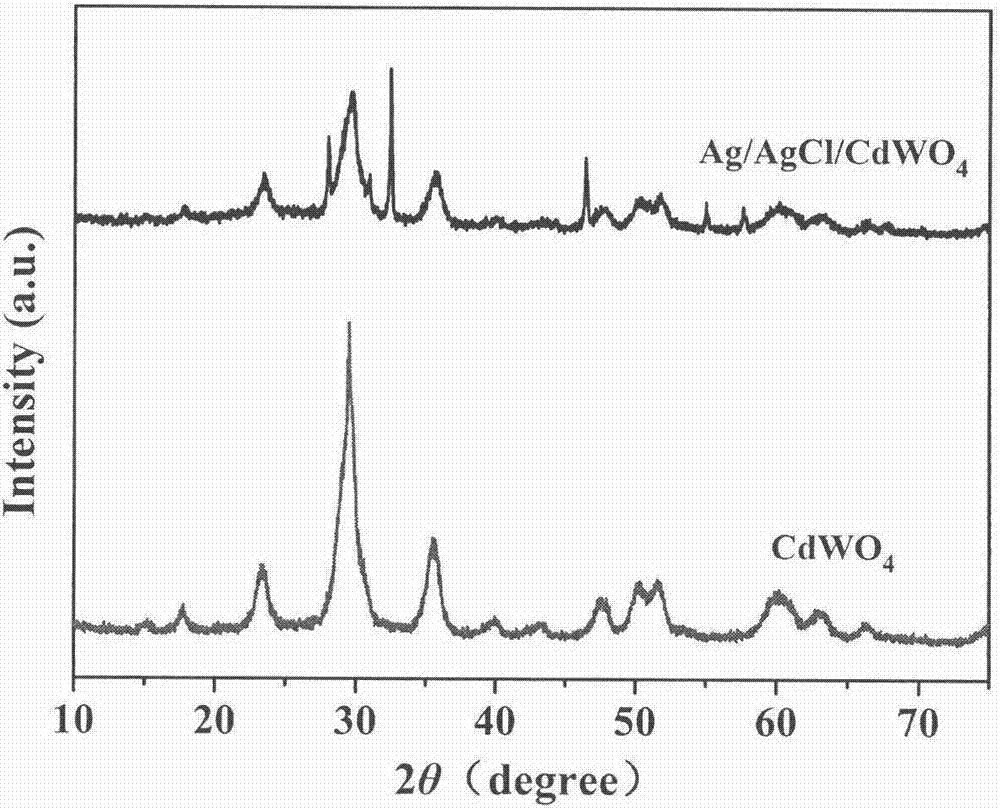

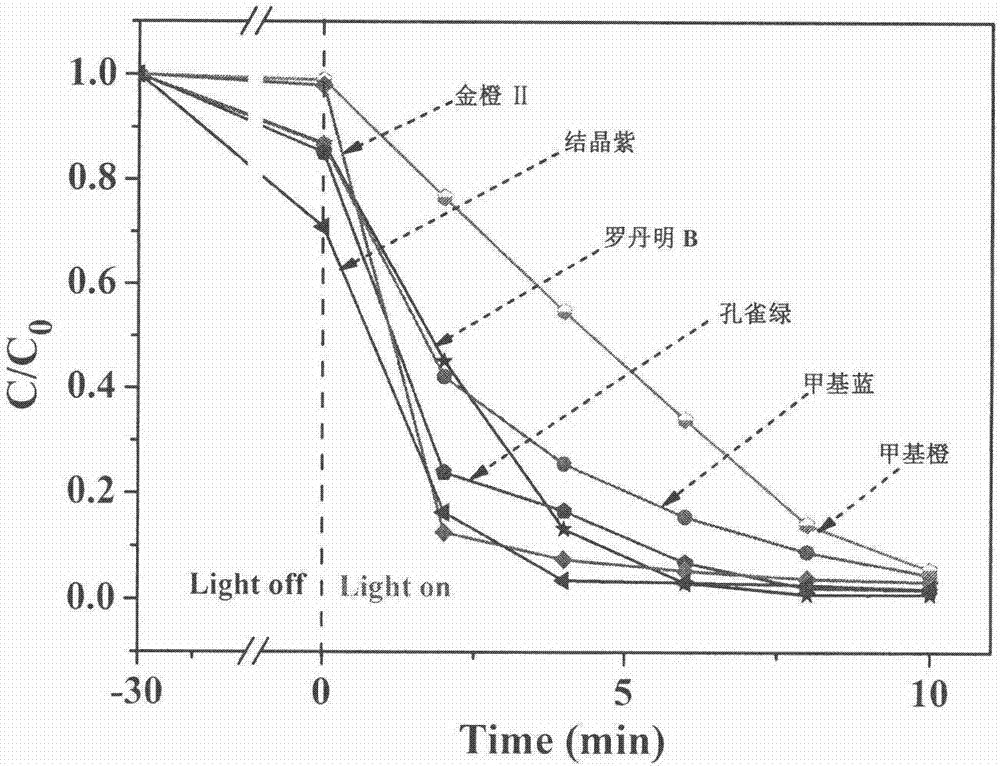

Ag/AgCl/CdWO4 catalyst with efficient visible-light catalytic activity

InactiveCN106890655AImprove photocatalytic degradation performanceHigh mineralization rateWater/sewage treatment by irradiationWater contaminantsMethyl blueSolvent

The invention provides a preparation method for an Ag / AgCl / CdWO4 catalyst with an efficient visible-light catalytic activity and an application in various dyes capable of catalytically degrading under visible light. The method comprises the following steps: by taking sodium tungstate and chromic nitrate as main raw materials and taking water and glycol as a mixed solvent, adopting a hydrothermal method for preparing a CdWO4 material, and then adopting a dipping and photo-reduction method for preparing the Ag / AgCl / CdWO4 photocatalyst with a plasma resonance effect. The catalyst prepared according to the method has excellent photocatalytic degradation property to various dyes, such as gold orange II, methyl orange, methyl blue, peacock green, crystal violet and rhodamine B under the irradiation of visible light; the degradation rate within 10 minutes can reach up to 95% or above; the mineralization rate is high; the catalyst is reusable. The production process conditions are simple, the raw materials are easily acquired and the acquired material has efficient photo-response and wide industrial application prospect.

Owner:NANJING UNIV OF TECH

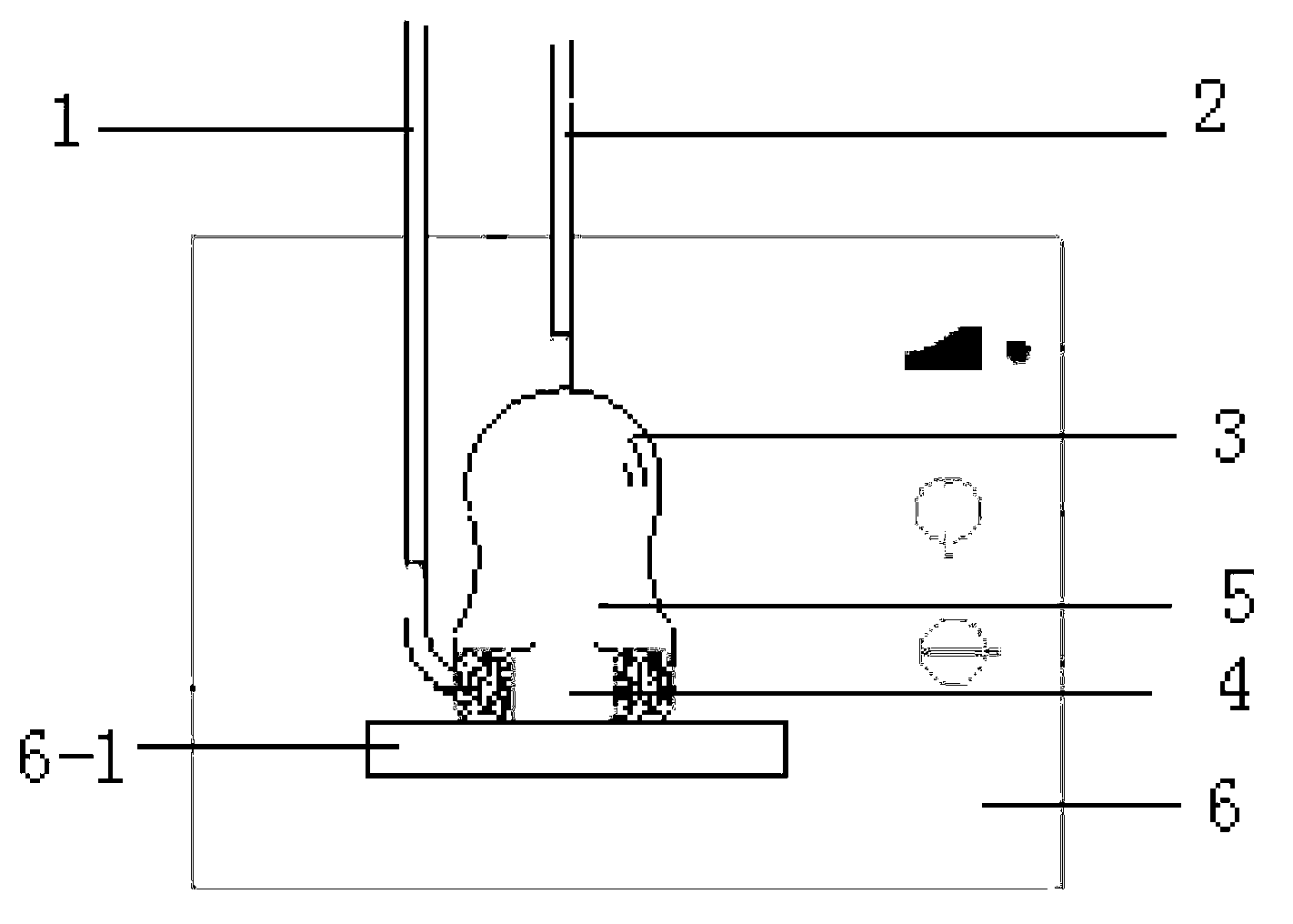

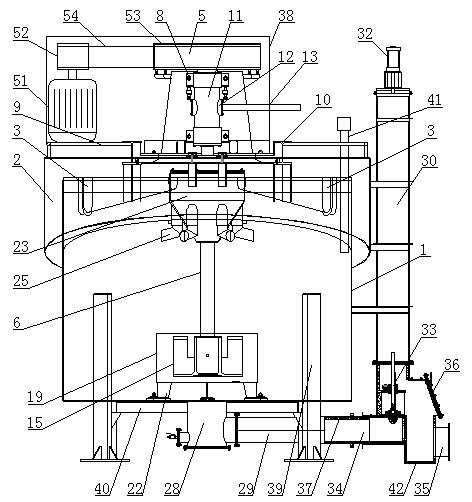

Pneumatic flotation machine with mechanical stirring

The invention discloses a pneumatic flotation machine with mechanical stirring, which comprises a cylindrical tank body flotation chamber, wherein a foam product collecting chute is closely fastened on the outer side of the upper end of the flotation chamber, and the outer side of the foam product collecting chute is connected with a concentrate pipe; a hollow shaft connected with a driving device is arranged in the flotation chamber, and the hollow shaft is fixed on the support through a bearing and bearing blocks, a bearing housing is arranged between the bearing blocks, an air inlet formedon the bearing housing is connected with an air inlet pipe, and an air inlet is formed on a hollow shaft corresponding to the bearing housing; the lower end of the hollow shaft is connected with a rotor which has an air outlet, and a stator is arranged on the outer side of the rotor; a feed tank is hoisted on the upper part of the flotation chamber, the feed tank is a tank body with an annular cavity, the annular tank body surrounds the outside of the hollow shaft, a feed inlet is formed on the upper part of the feed tank, and discharging nozzles are uniformly arranged on the lower part of the feed tank; and a tailing chamber is formed at the bottom part of the flotation chamber, and the tailing chamber is communicated with a tailing tank through a pipe. The machine is efficient, energy-saving and very adaptable and is long in service life and low in production cost.

Owner:张玮

Enhanced disposal method applicable to wastewater of water-based cutting fluids

InactiveCN110104836AEfficient removalImprove biodegradabilityWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesWater basedDecomposition

The invention relates to an enhanced disposal method applicable to wastewater of water-based cutting fluids. The method can effectively achieve removal of organic pollutants and ammonia nitrogen in the wastewater. According to the method, a combined process of physical oil separation, demulsification coagulation, ozone catalysis and flocculation sedimentation is adopted, a cationic demulsificationcoagulant is utilized to fully neutralize the surface charges of emulsified oil droplets, destroy hydration membranes of the emulsified oil droplets, compress an electric double layer, increase the collision probability among the oil droplets and thus accelerate the destabilization and demulsification of emulsified oil, and more free radicals of active hydroxyl are generated in combination with the decomposition rate of ozone under the action of a heterogeneous ternary composite ozone catalyst. In this way, catalyzation of organic pollutants in ozonized water is facilitated, the mineralization rate of organic matter is greatly increased, and the biodegradability of the wastewater is improved significantly.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

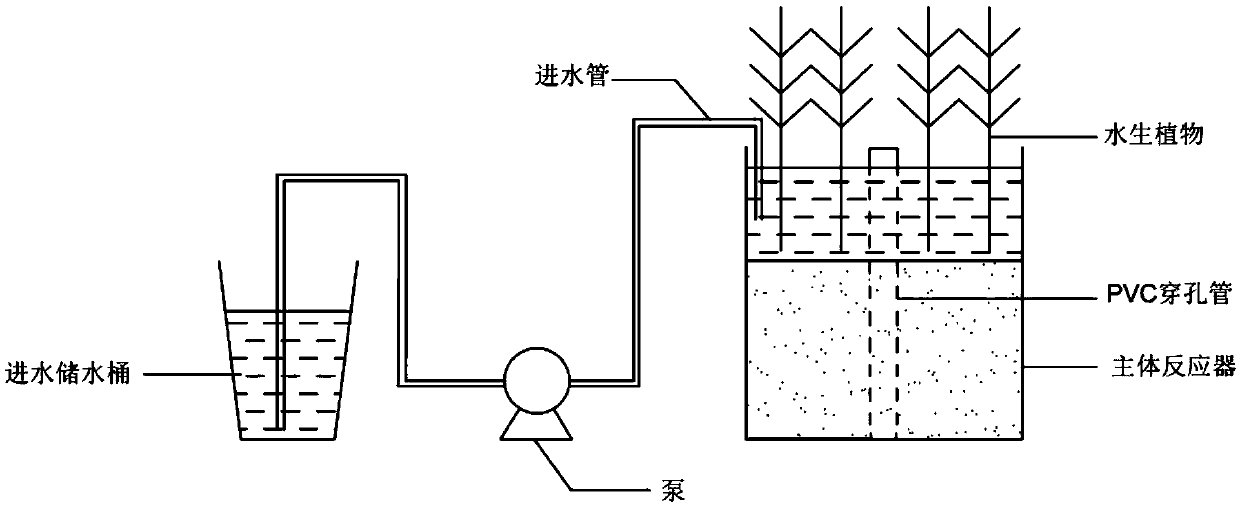

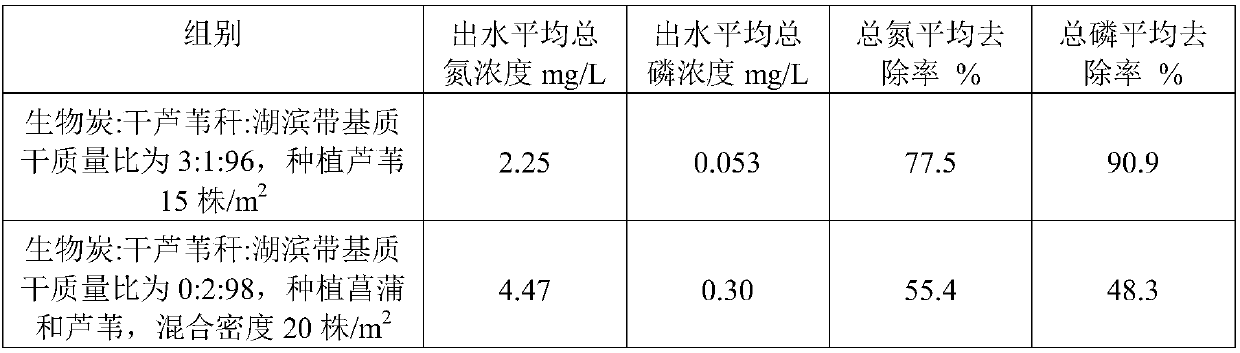

Technology for lakeside matrix to strengthen nitrogen and phosphorus removal

InactiveCN109626585AImprove adsorption capacityImprove stabilityWater contaminantsBiological water/sewage treatmentVascular bundleNitrogen

The invention relates to a technology for conditioning a lakeside matrix through biochar and dry reed stems conditioning to strengthen nitrogen and phosphorus removal. The dry mass percent of the charcoal, the dry reed high-temperature cracking stems and the lakeside matrix is (1-5):(0.5-2):(93-98.5). The dry reed stems are subjected to high-temperature cracking to prepare the charcoal, then the charcoal and the dry reed stems are mixed into the lakeside matrix, vascular bundle type aquatic plants are planted on the mixed matrix, and effective removal of lakeside nitrogen and phosphorus is achieved through the synergistic effect of the three. The raw materials, namely the dry reed stems, adopted in the method are cheap and easy to obtain, the technical operation is simple and feasible, andthe technology has the advantages of being low in investment cost, low in energy consumption and the like.

Owner:BEIJING FORESTRY UNIVERSITY +1

Application of nano metal oxide in catalyzing persulfate to degrade organic dyes

ActiveCN112138661ALow costSimple processWater contaminantsEnergy based wastewater treatmentPeroxydisulfateOrganic dye

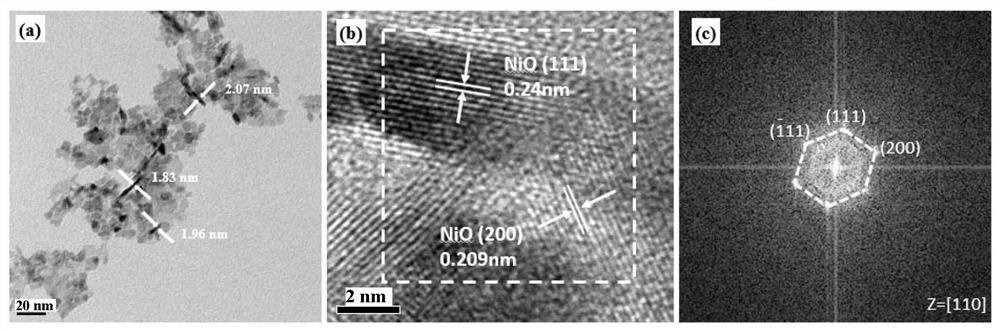

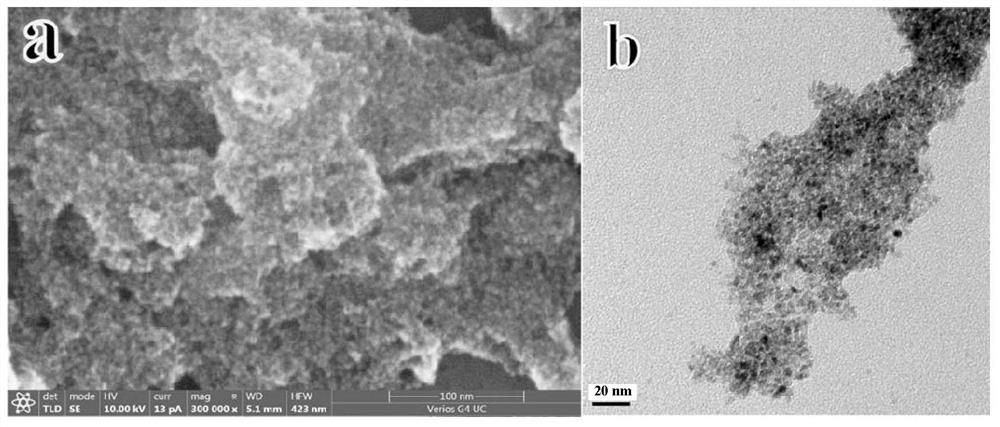

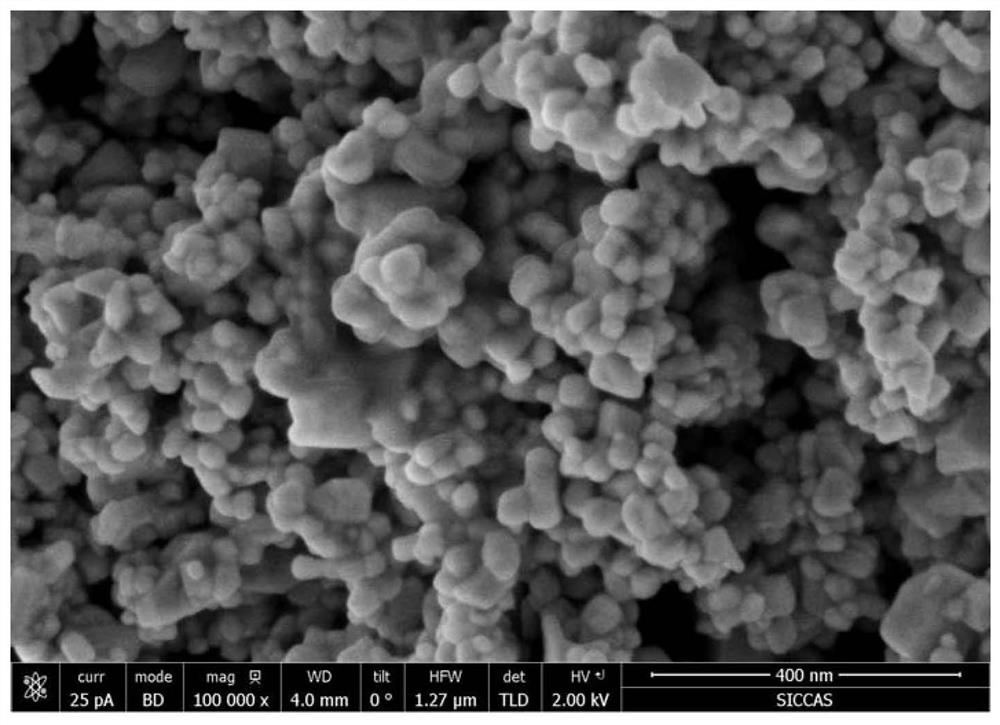

The invention relates to an application of nano metal oxide in catalyzing persulfate to degrade organic dyes; the nano metal oxide and the persulfate are added into wastewater containing the organic dyes to catalyze the persulfate to generate an active substance so as to realize degradation of the organic dyes, and the persulfate comprises peroxymonosulfate or / and peroxydisulfate; the nano metal oxide is at least one of nano CuO, nano NiO and nano Fe3O4, and the size of the nano metal oxide is smaller than 100 nm; the nano metal oxide has a high-energy crystal face, the high-energy crystal face of the nano CuO is a (110) crystal face, the high-energy crystal face of the nano NiO is a (110) or (111) crystal face, and the high-energy crystal face of the nano Fe3O4 is a (311) crystal face.

Owner:中国科学院上海硅酸盐研究所苏州研究院 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com