Waste gas processing method and device collaborating vacuum ultraviolet light catalysis and ozone catalytic oxidation

A technology of ozone catalytic oxidation and waste gas treatment device, which is applied to organic waste gas and stench, can solve the problems of residual ozone, ozone secondary pollution, improper control of ozone concentration, etc., and achieve the effect of avoiding waste of resources, avoiding waste, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

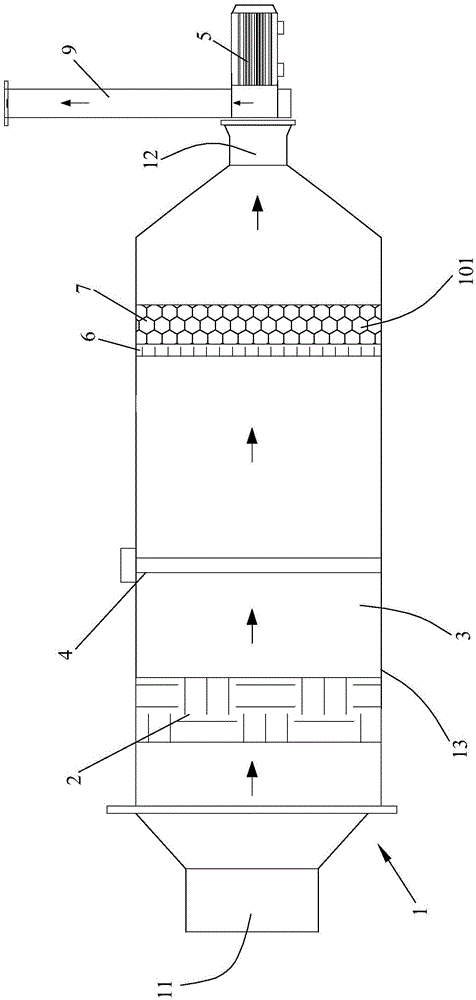

[0046] The embodiment of the exhaust gas treatment device of vacuum ultraviolet photocatalysis and ozone catalytic oxidation of the present invention is as follows figure 1 As shown, the device includes a reactor 1, the reactor 1 has an air inlet 11, an air outlet 12 and a rectangular cylinder 13 in cross section, and a high-efficiency filter 2 and a composite catalyst structure are built in the cylinder 13 along the direction of gas flow , the gas flow direction is also the axial direction of the cylinder 13, the high efficiency filter 2 and the composite catalyst structure are arranged radially along the cylinder 13, and the composite catalyst structure is formed by compounding the photocatalyst layer 6 and the ozone catalyst layer, and the cylinder 13 is in the A photocatalytic chamber 3 is formed in the cavity region between the high-efficiency filter 2 and the composite catalyst structure. In the photocatalytic chamber 3, an ultraviolet lamp 4 is arranged radially along th...

Embodiment 2

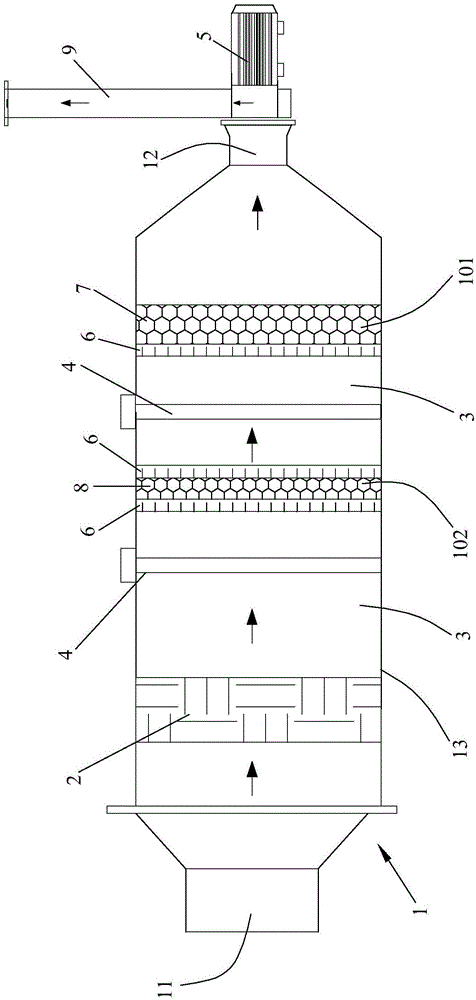

[0057] Embodiment 2 of the exhaust gas treatment device of vacuum ultraviolet light photocatalysis and ozone catalytic oxidation of the present invention is as follows figure 2 As shown, different from Embodiment 1, the composite catalyst structure also includes a middle section composite catalyst unit 102, which is located between the high efficiency filter 2 and the end composite catalyst unit 101, and the cylinder body 13 is positioned at The cavity area between the high-efficiency filter 2 and the terminal composite catalyst unit 101 is divided into two photocatalytic chambers 3, and each photocatalytic chamber 3 is provided with an ultraviolet lamp 4 along the radial direction of the cylinder body 13, and the ultraviolet lamp 4 selects a wavelength It is a 185nm vacuum ultraviolet lamp, and the middle composite catalyst unit 102 is arranged radially along the cylinder body 13. The middle composite catalyst unit 102 is composed of two layers of photocatalyst layers 6 and o...

example 1

[0070] Exhaust gas parameters: flow rate 800-1000m 3 / h, the pollutant components are benzene and benzene series, the concentration is 30-50ppm, the relative humidity is 50%, and the temperature is 25-35°C.

[0071] When the exhaust gas treatment device is running, the fan and vacuum ultraviolet lamp are turned on by controlling the electric control box. After the organic waste gas passes through the high-efficiency filter layer to remove impurities such as particulate matter, it enters the vacuum ultraviolet photocatalytic chamber. In the gas phase reaction, benzene and benzene series are completely degraded into CO 2 And water, and form ozone. When the undegraded benzene and benzene series and ozone pass through the photocatalyst-ozone catalyst-photocatalyst layer, they are further oxidized into CO by photocatalytic oxidation and ozone catalytic oxidation. 2 And water, and finally pass through the ozone catalyst layer again, further complete ozone catalytic oxidation of rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com