Patents

Literature

316results about How to "Increase heating speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

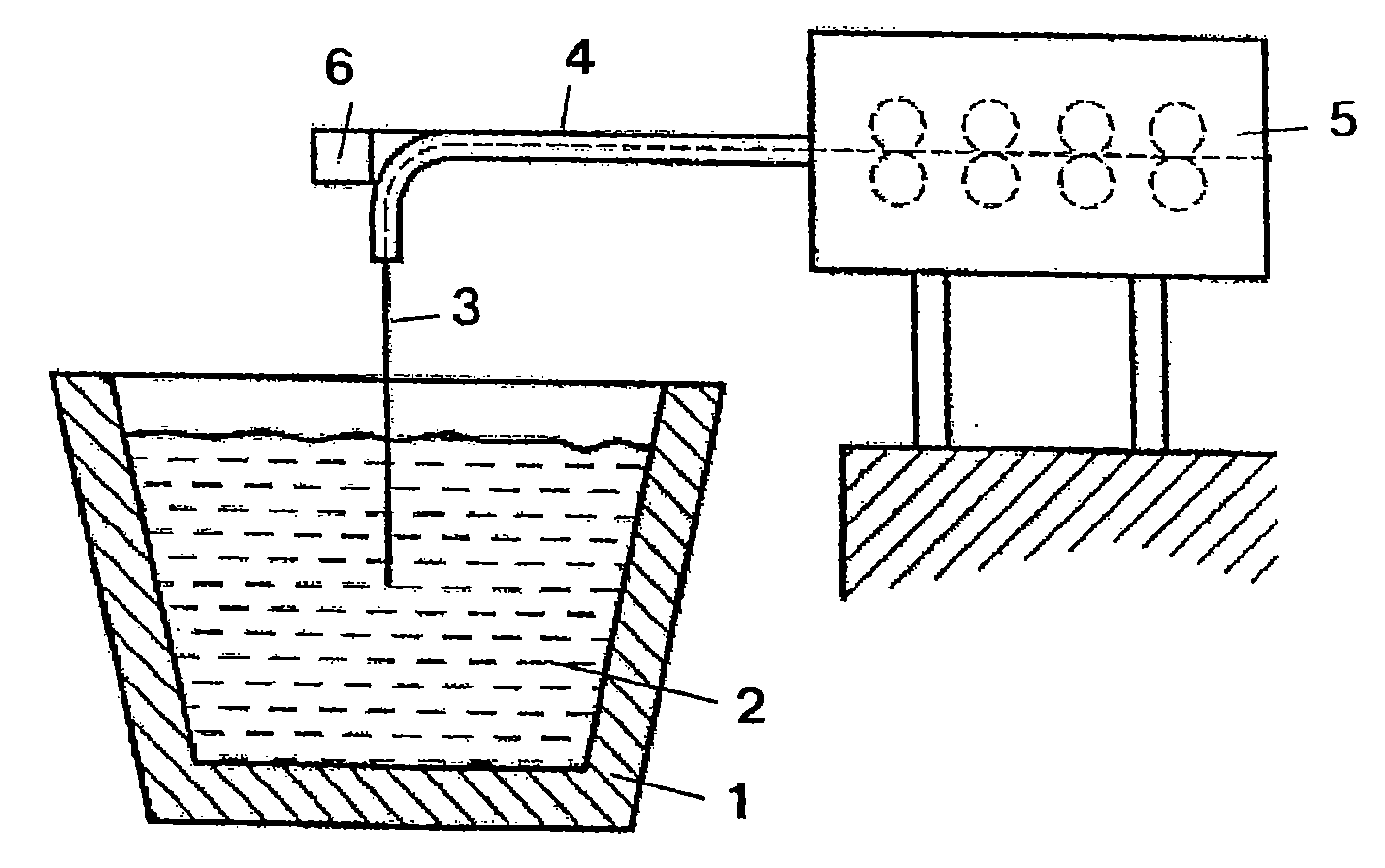

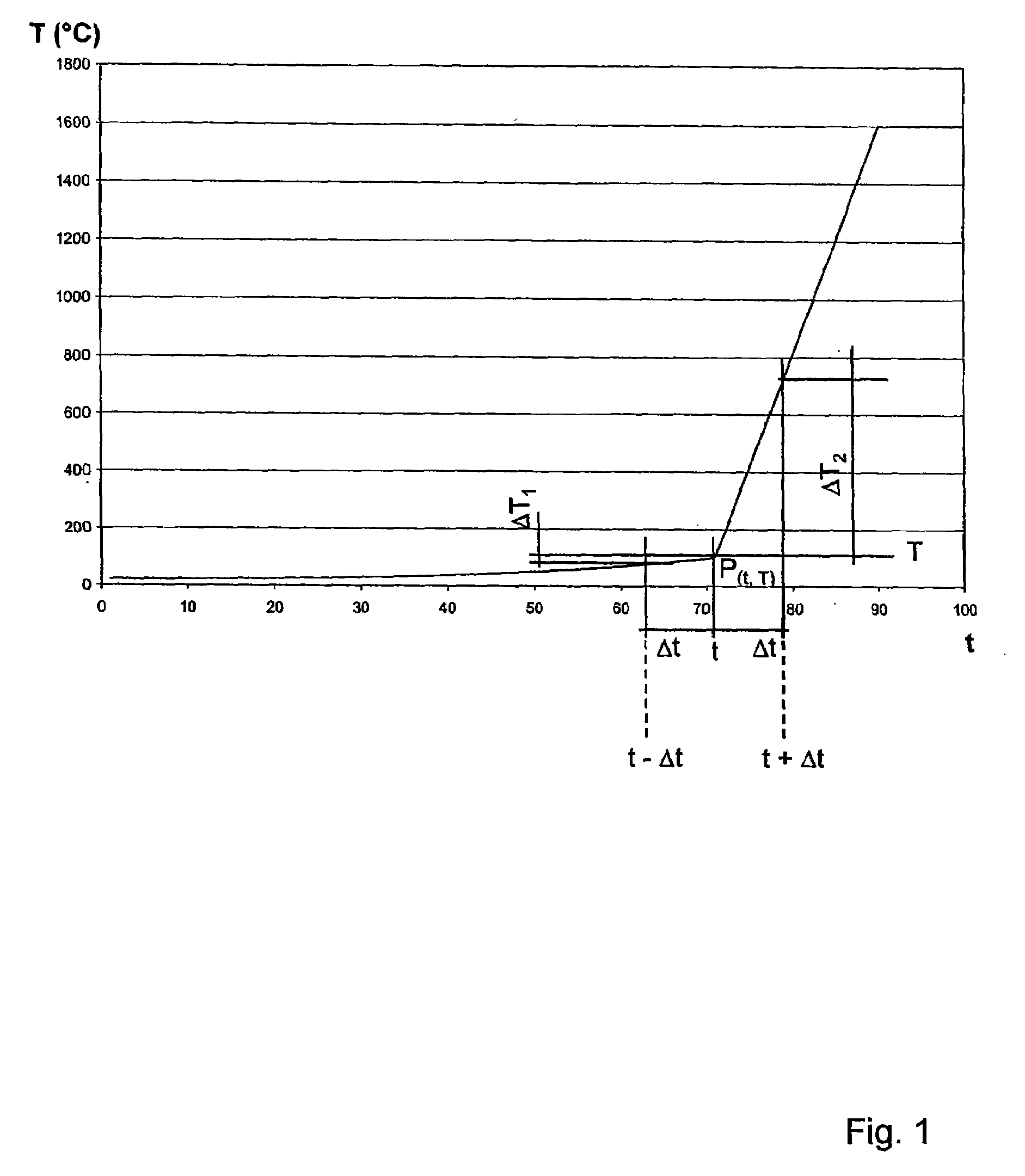

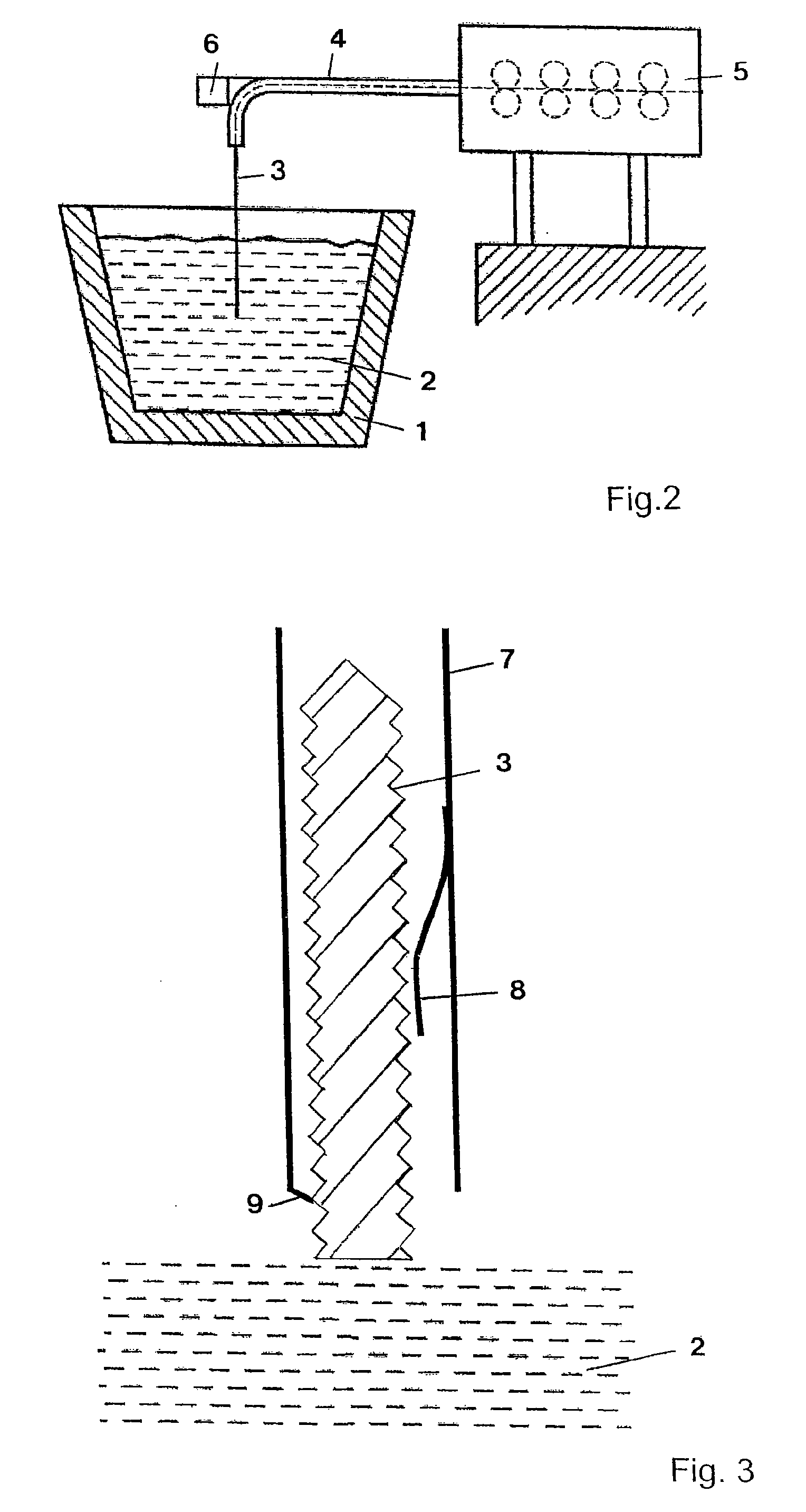

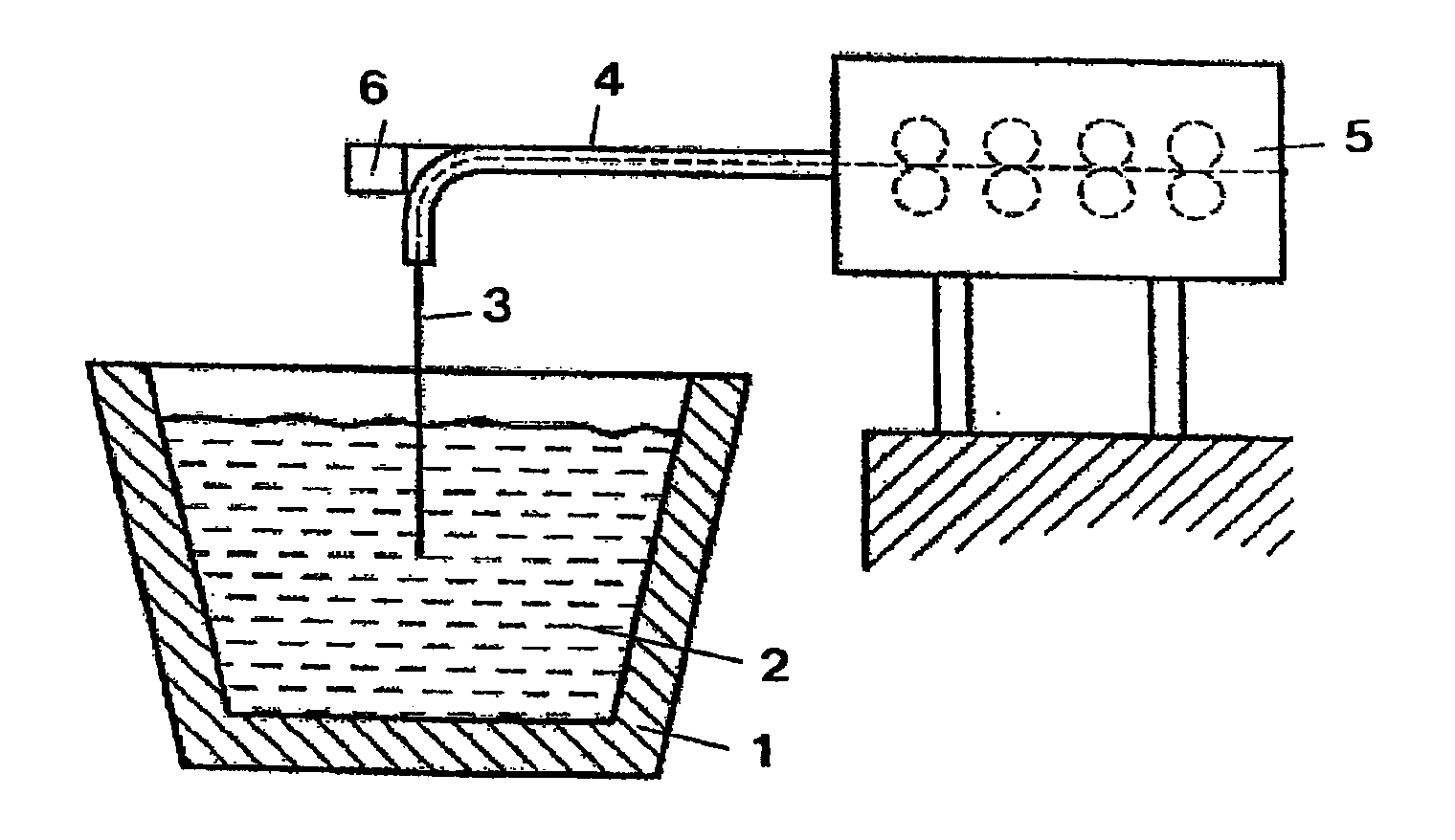

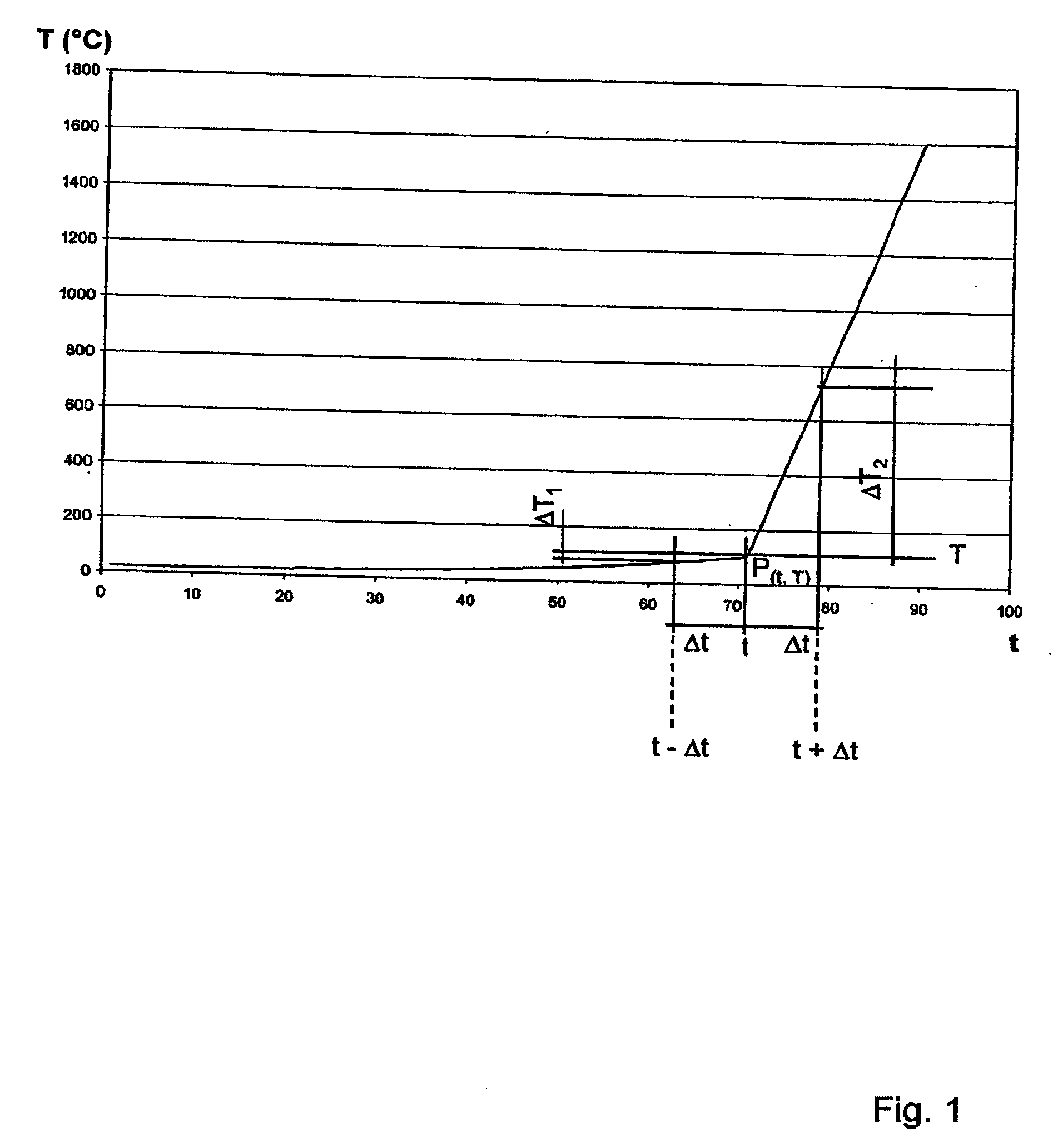

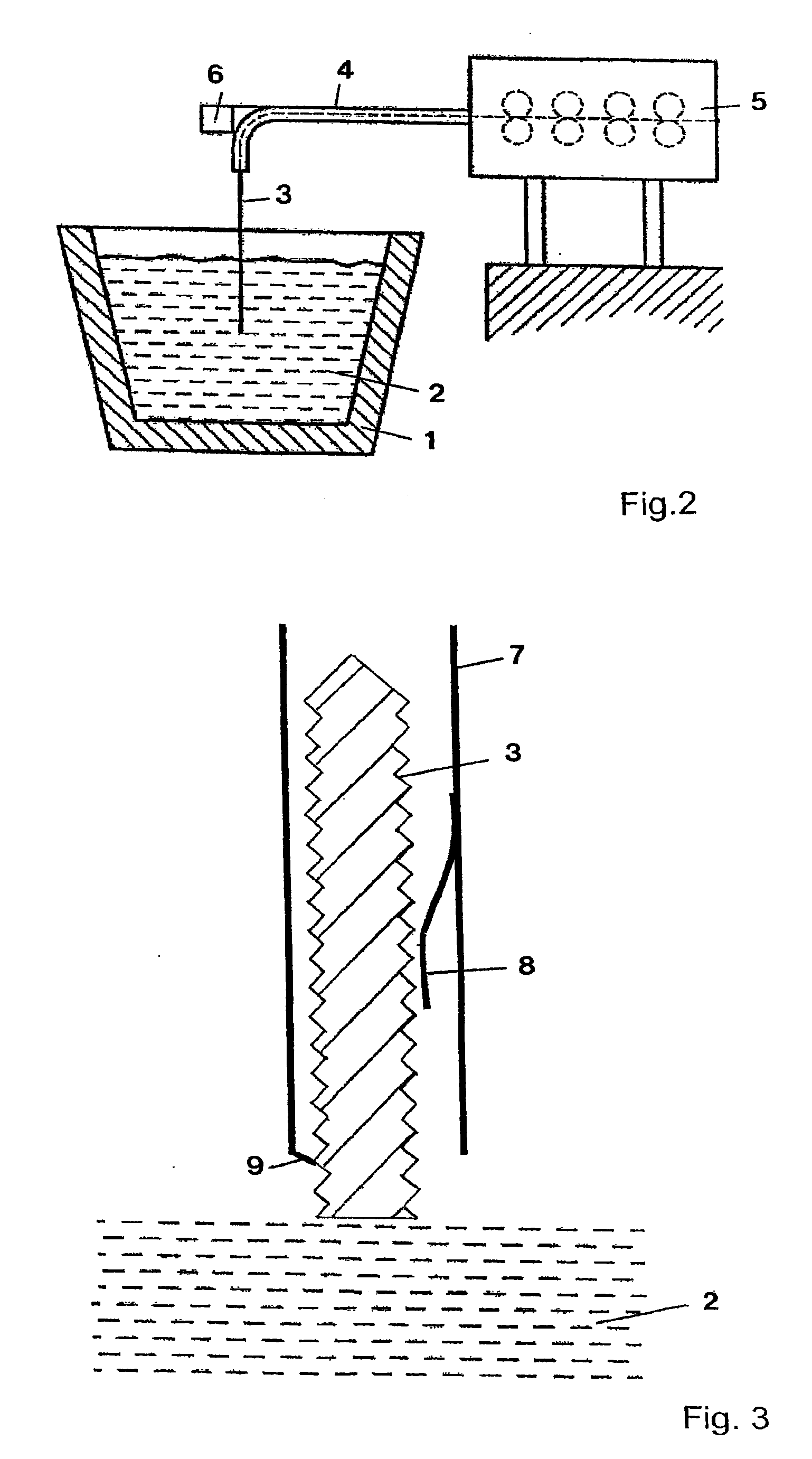

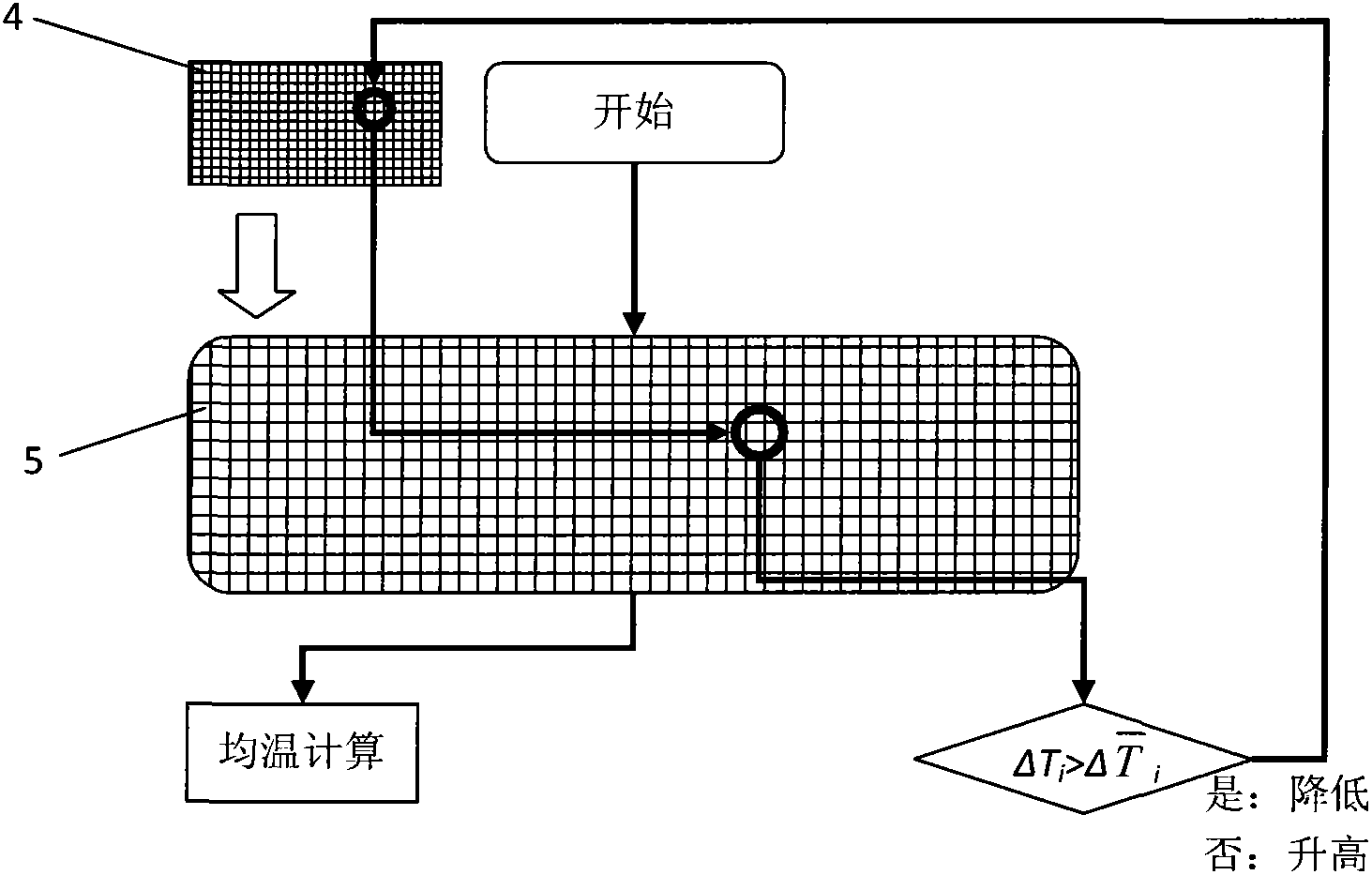

Method and device for measuring the temperature of a molten metal bath

ActiveUS20070268477A1Strong and effective changeIncrease heating speedThermometer detailsThermometers using physical/chemical changesMolten bathMolten metal

A method is provided for measuring a temperature of a molten metal bath by an optical fiber surrounded by a cover. The optical fiber is immersed in the molten bath, and the radiation absorbed by the optical fiber in the molten bath is fed to a detector, wherein the optical fiber is heated when immersed in the molten bath. The heating curve of the optical fiber has at least one point P(t0, T0), wherein the increase ΔT1 in the temperature T of the optical fiber over the time Δt in a first time interval t0−Δt up to the temperature T0 is smaller than the increase ΔT2 in the temperature of the optical fiber over the time Δt in an immediately following second time interval t0+Δt.

Owner:HERALUS ELECTRO NITE INT NV

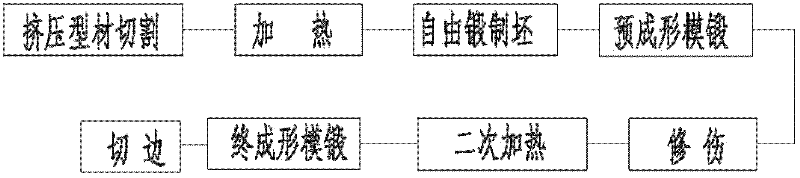

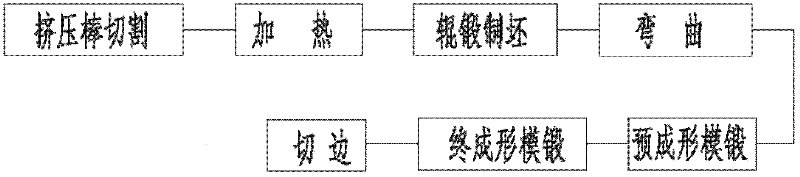

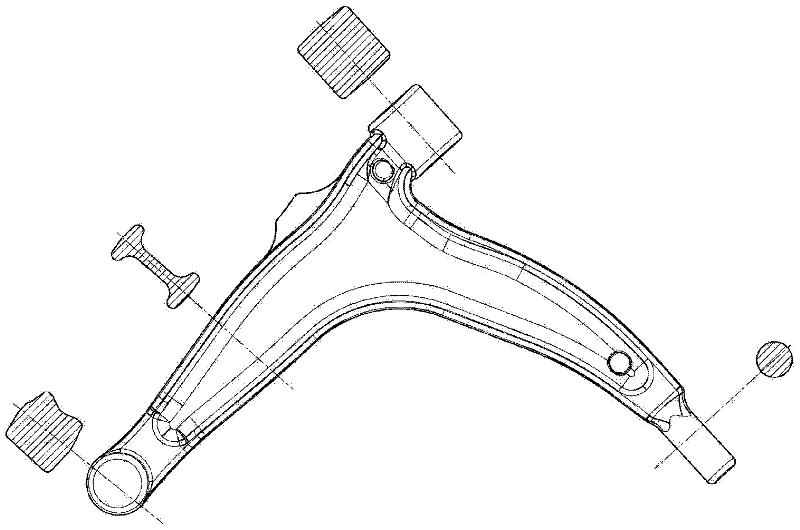

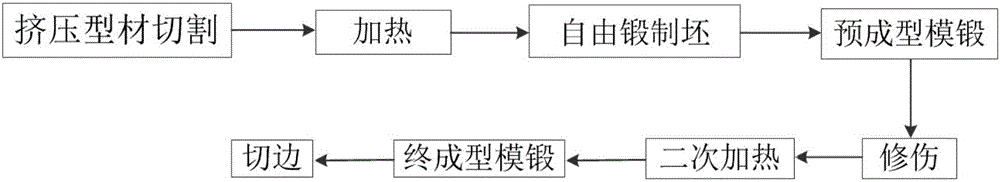

Manufacturing process for lambdoidal control arm

InactiveCN102500740AReduce preprocessing timeIncrease profitRailway componentsMetal-working apparatusProduction rateControl arm

The invention discloses a manufacturing process for a lambdoidal control arm. The manufacturing process comprises the following steps of: sawing an extruded bar; heating the extruded bar; rolling and forging the extruded bar to form a blank; bending to form the blank; preforming a forged die; finally forming the forged die; and trimming the forged die. In the manufacturing process, the extruded bar is taken as a raw material; the blank is heated to 440 DEG C-480 DEG C through electric induction; the blank is rolled and forged twice by a forging roll to realize volume distribution; the processes of bending to form the blank, preforming the forged die and finally forming the forged die are carried in sequence; and the trimming process is carried out in a thermal cutting manner. Compared with the prior art, a repairing process and a secondary heating process are reduced, the processing steps for the lambdoidal control arm are simplified, production cost for the product can be lowered, production rate can be increased, and product performances can be ensured.

Owner:芜湖禾田汽车工业有限公司

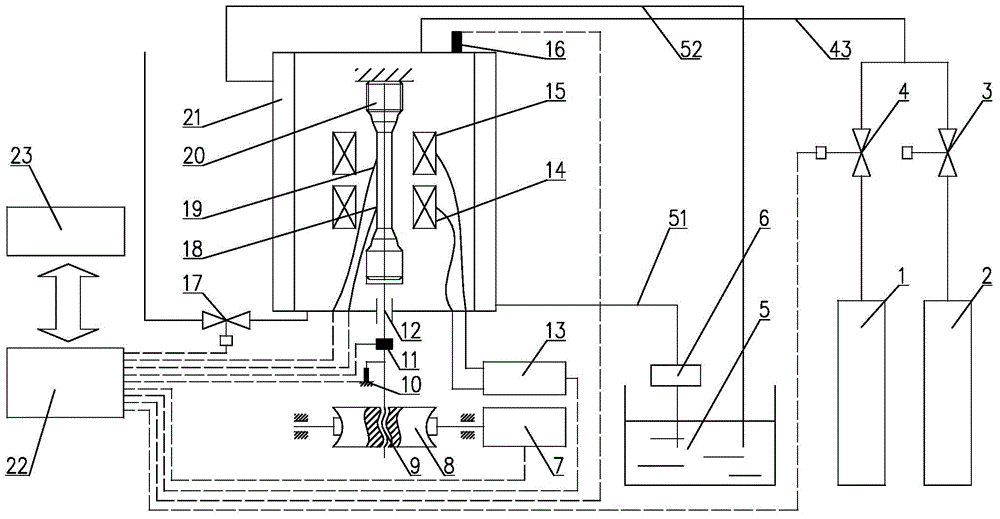

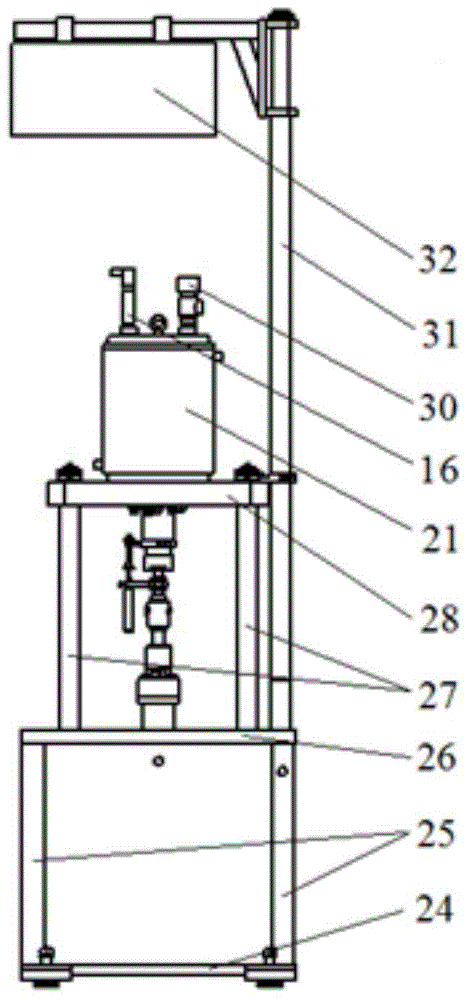

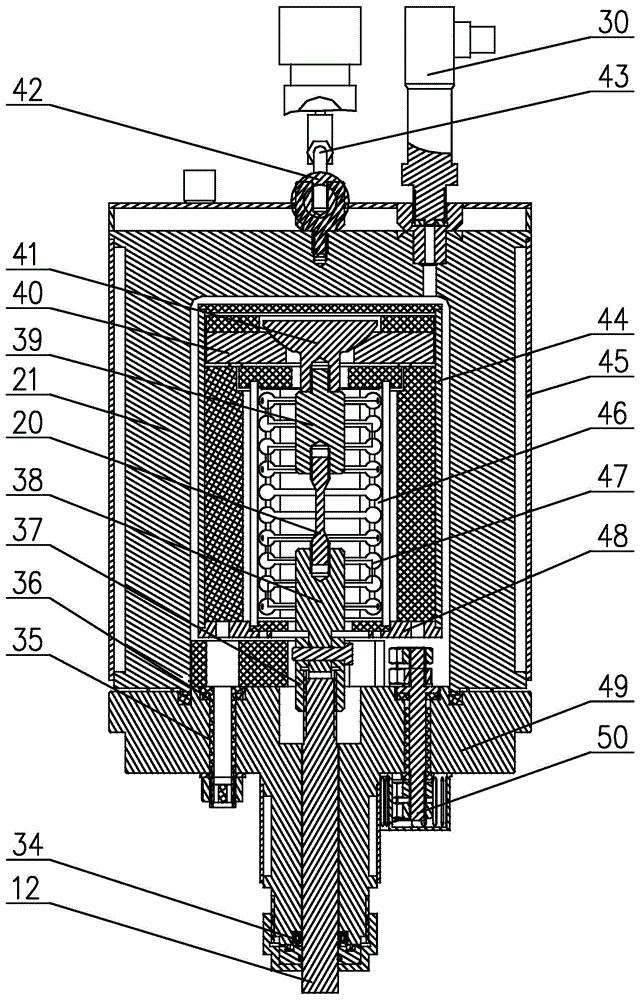

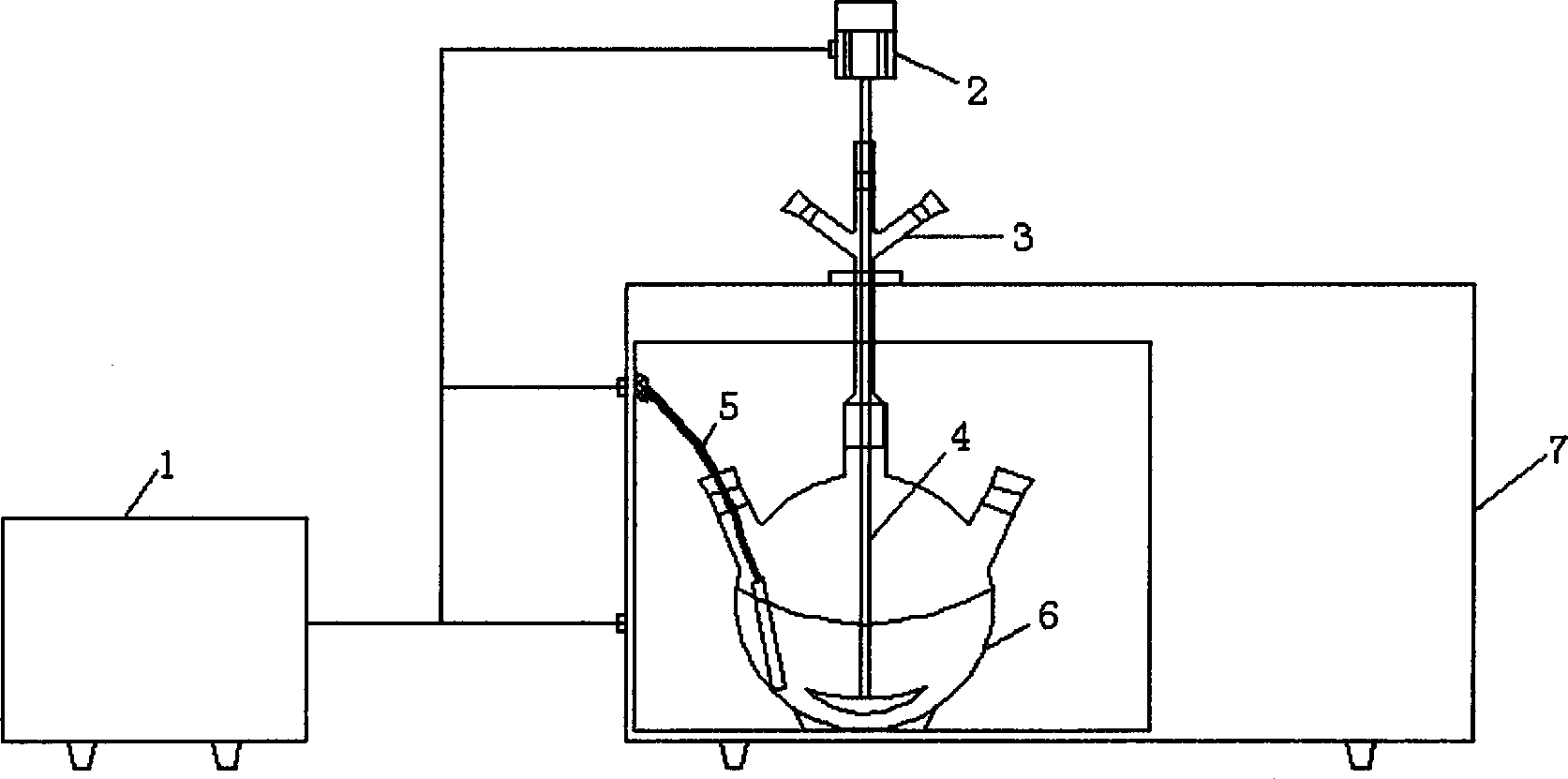

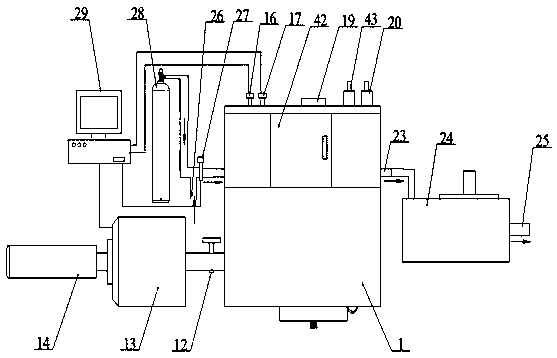

Device for testing material properties in high-temperature hydrogen environment

ActiveCN104897476AReasonable and reliable device structureShort heat transfer chainWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesProcess engineeringHydrogen supply

The invention relates to a device for testing material properties in a high-temperature hydrogen environment. The device comprises a hydrogen environment box and a host machine loading framework, wherein a test sample is arranged in the hydrogen environment box; a pull rod is mounted on the host machine loading framework; the hydrogen environment box is arranged on the host machine loading framework; an upper clamping part, a lower clamping part and an electrical heating component are arranged in the hydrogen environment box; the pull rod penetrates through the hydrogen environment box and is fixedly connected with the lower clamping part; the hydrogen environment box is connected with a hydrogen supply pipe; an air-relief solenoid valve is arranged on the hydrogen environment box. The device further comprises sensors and a control component, wherein the sensors are used for monitoring test sample stress load, test sample deformation, test sample environment temperature and test sample ambient hydrogen pressure; the control component is used for monitoring and processing the information collected by the sensors. The device can be used for testing the creep property, stress rupture property and tension-tension alternating load fatigue property of a metal material in the hydrogen environment, can ensure the accuracy of testing results, works reliably and stably and has high efficiency.

Owner:HEFEI GENERAL MACHINERY RES INST +1

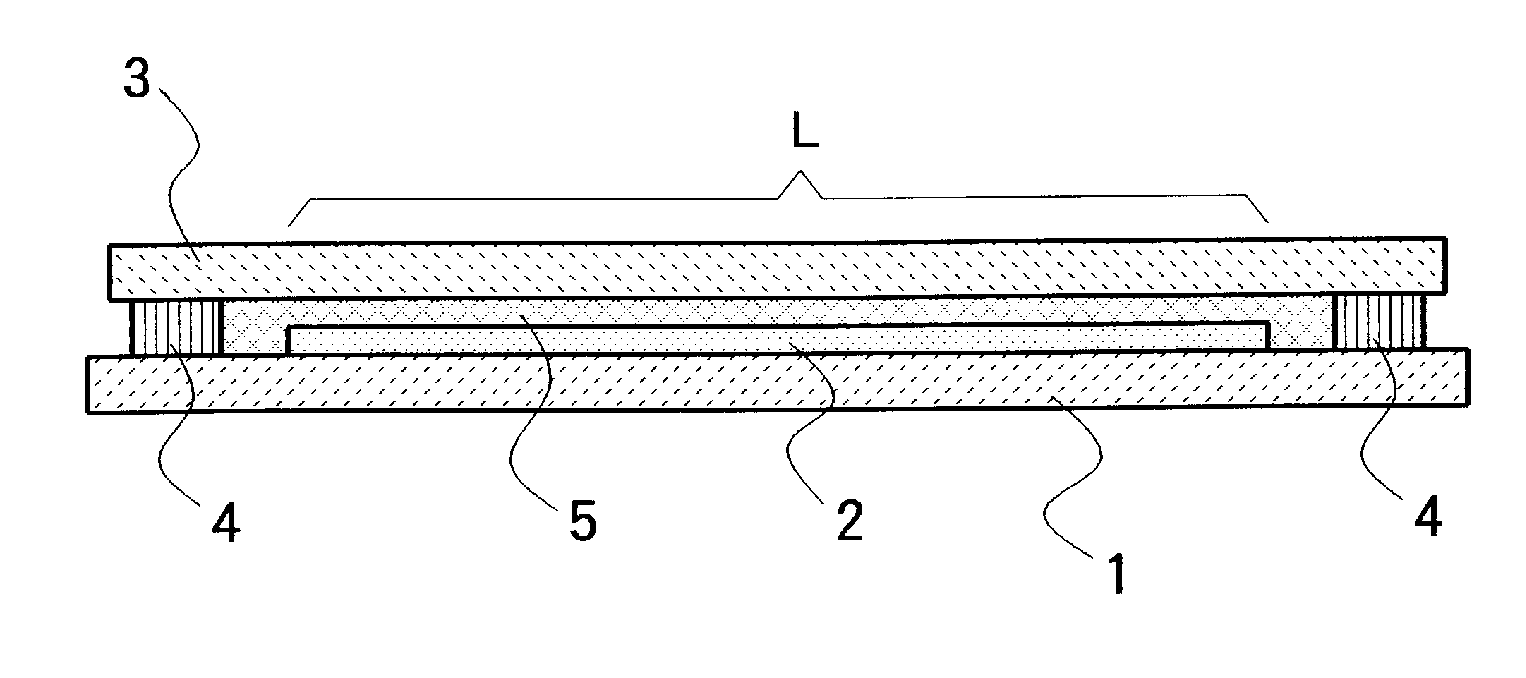

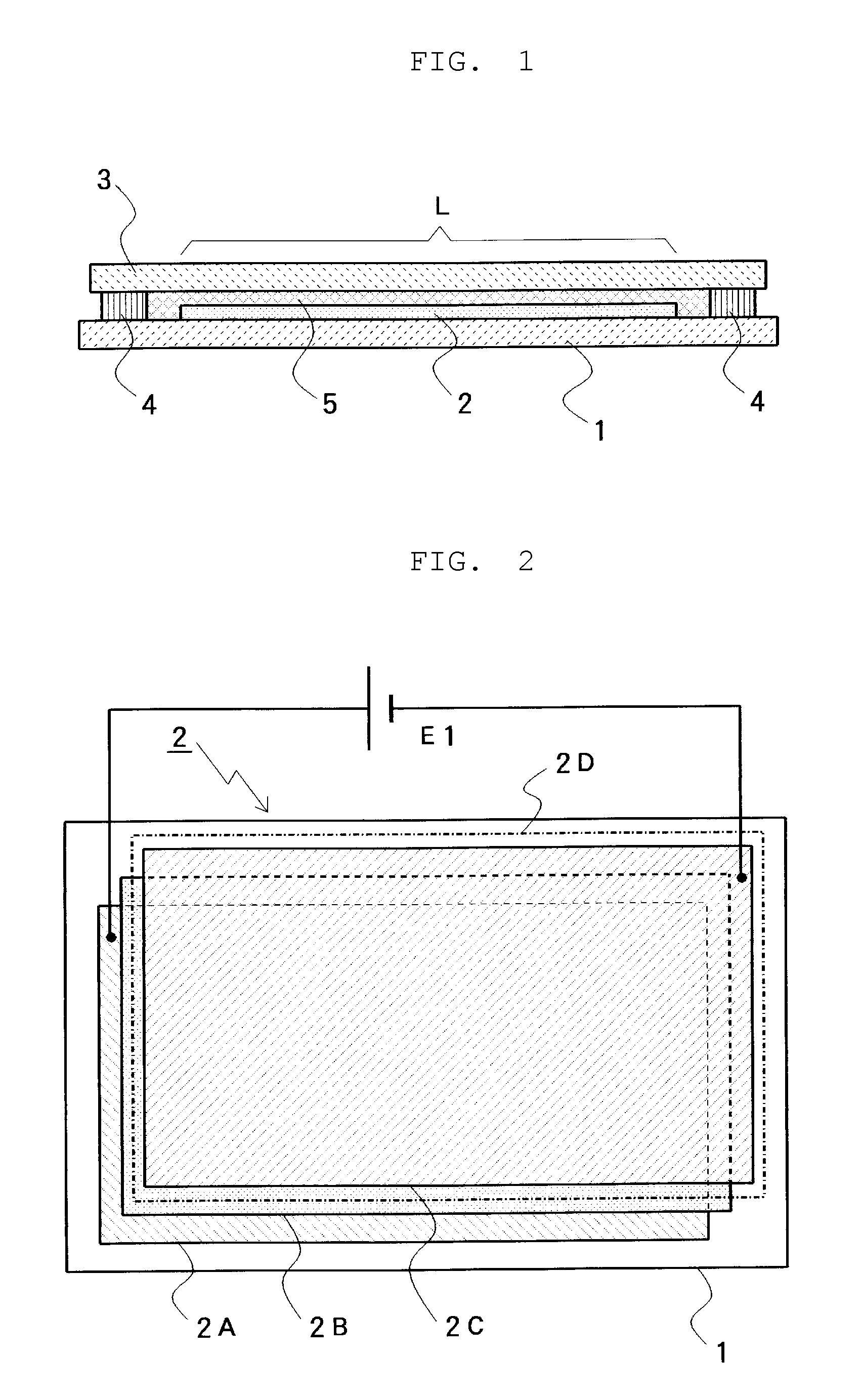

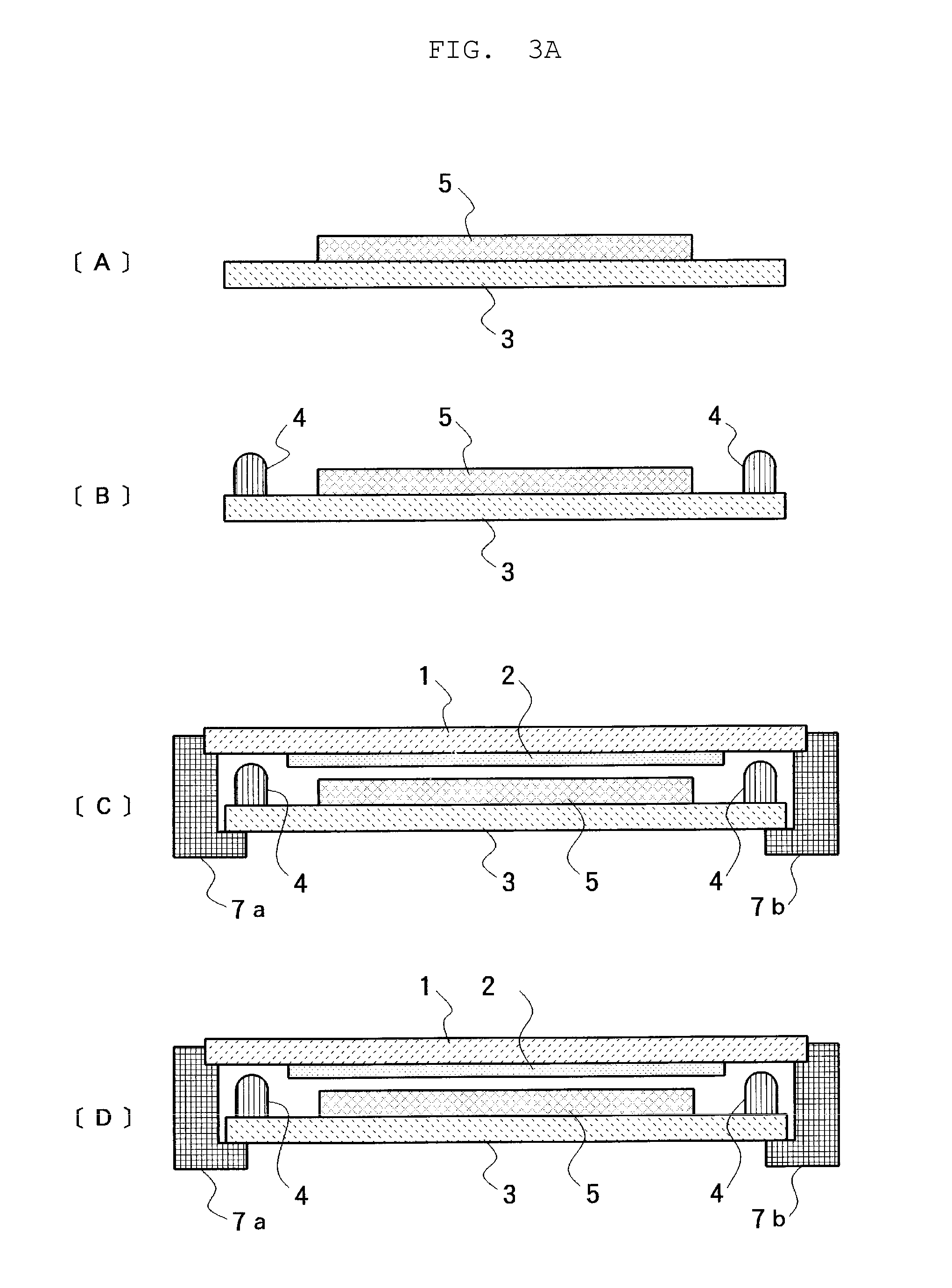

Organic el light-emitting device and method for manufacturing the organic el light-emitting device

InactiveUS20110052857A1Increase thermal conductivityIncrease speed of heatingElectroluminescent light sourcesSolid-state devicesEngineeringAdhesive

This invention provides an organic EL light-emitting device, which can prevent the occurrence of brightness unevenness due to resistance of a transparent electrode, in a large surface light-emitting panel of an organic EL element.The organic EL light-emitting device includes an element formation substrate 1, on which an organic EL element 2 including an organic light-emitting layer is stacked, and a sealing substrate 3 for sealing the organic EL element so as to accommodate the organic EL element between the element formation substrate and the sealing substrate. A sealing portion 4 formed of an adhesive is formed in the peripheral edge portion between the element formation substrate 1 and the sealing substrate 3, and a grease layer 5 or a gel layer 5 is accommodated in between the element formation substrate, on which the organic EL element surrounded by the sealing portion is formed, and the plate-shaped sealing substrate so as to adhere to the element formation substrate and the sealing substrate. The grease layer 5 or the gel layer 5 contains an oligomer or a polymer having organosiloxane bond(—R2SiO—) or fluorinated polyether (—CF2CFYO—) as a skeleton.

Owner:YAMAGATA PROMOTIONAL ORG FOR INDAL TECH +1

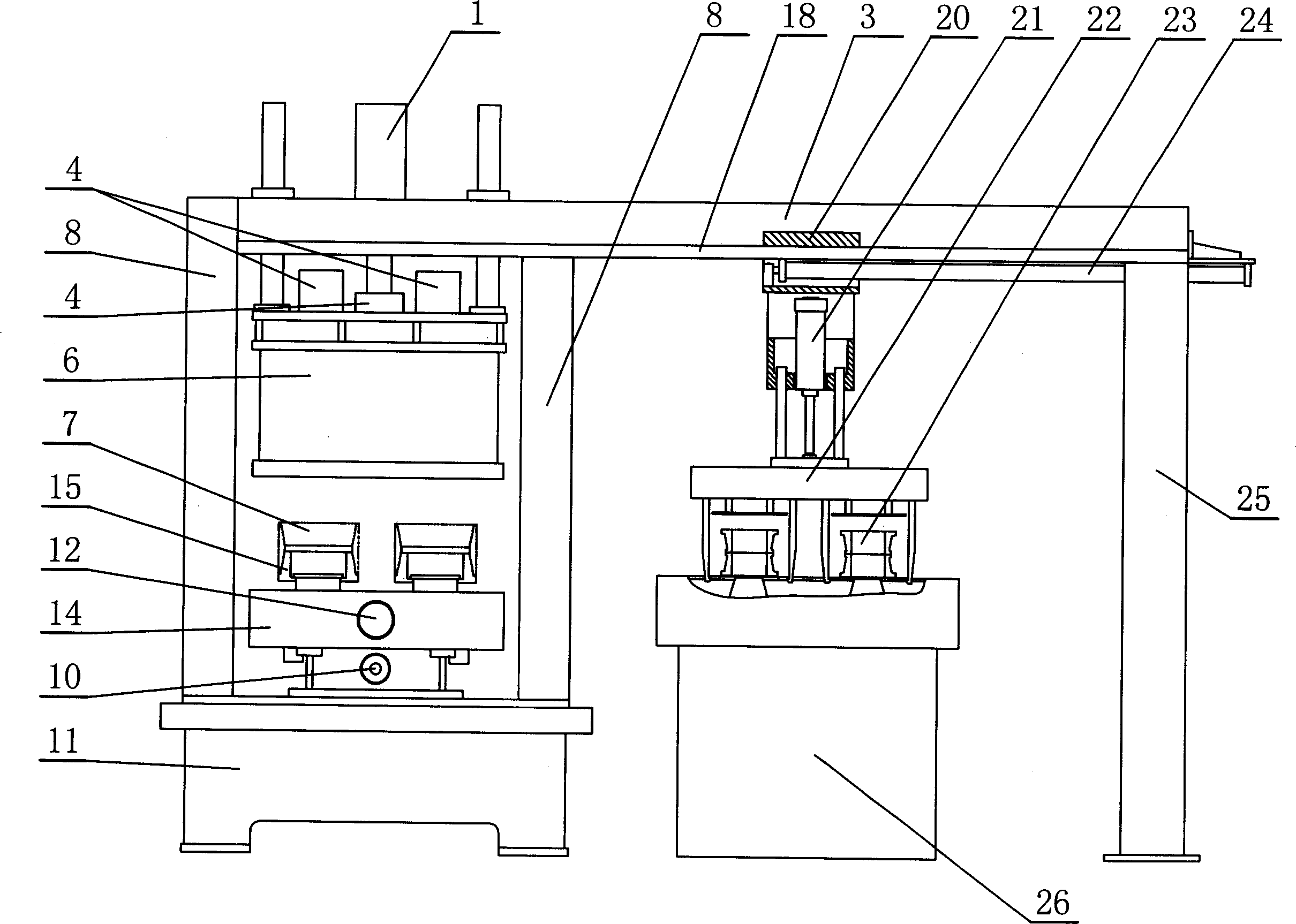

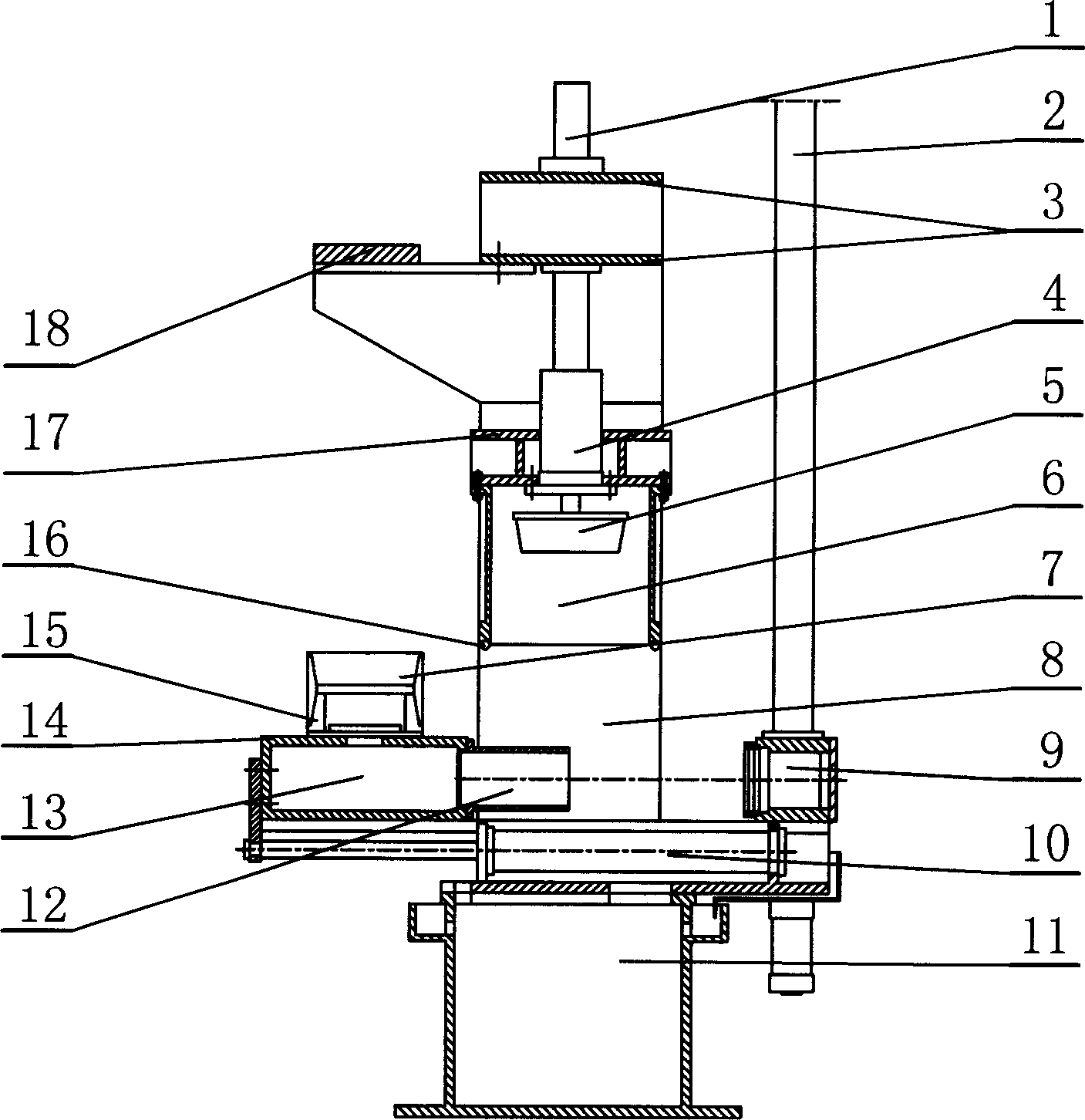

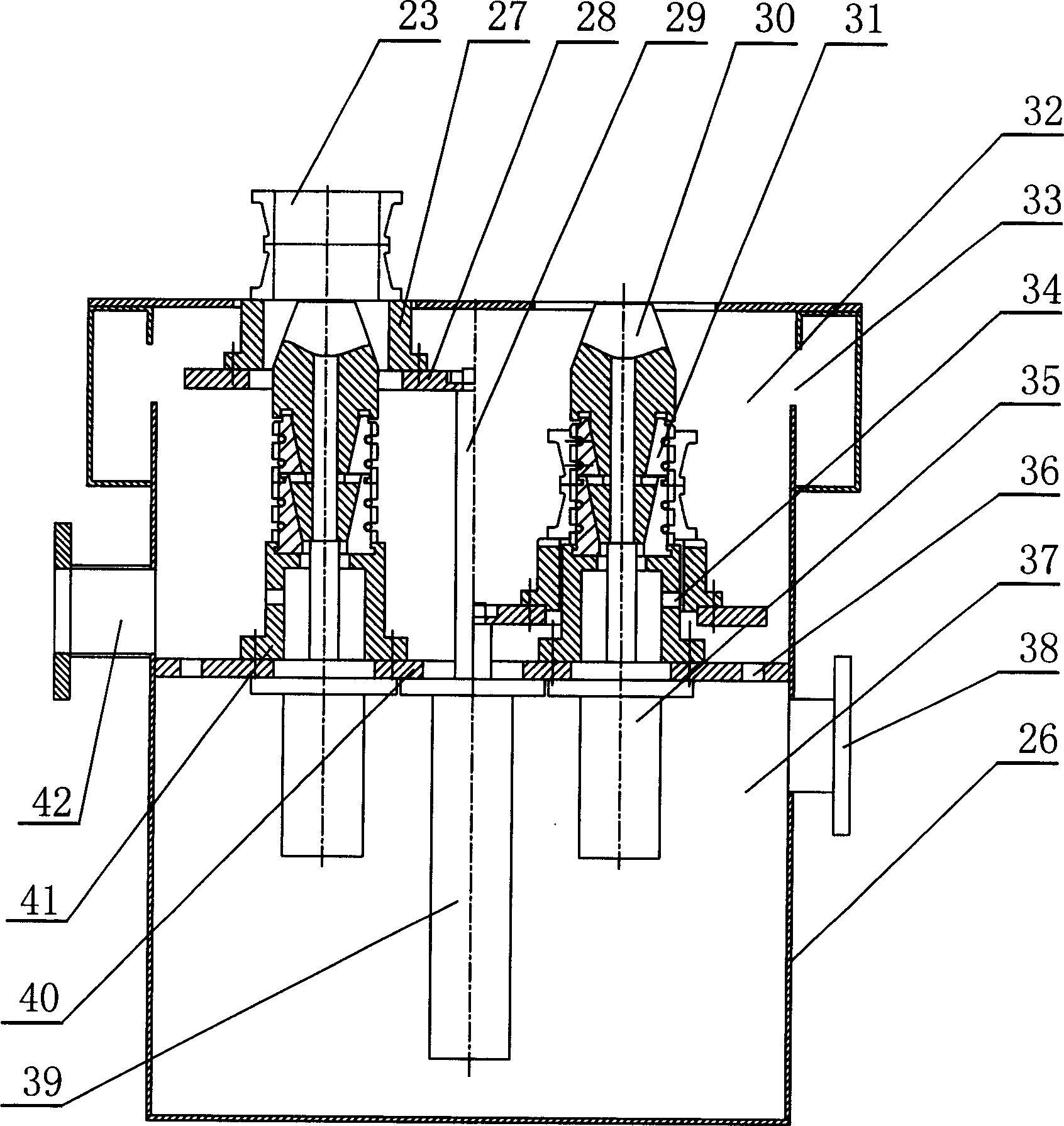

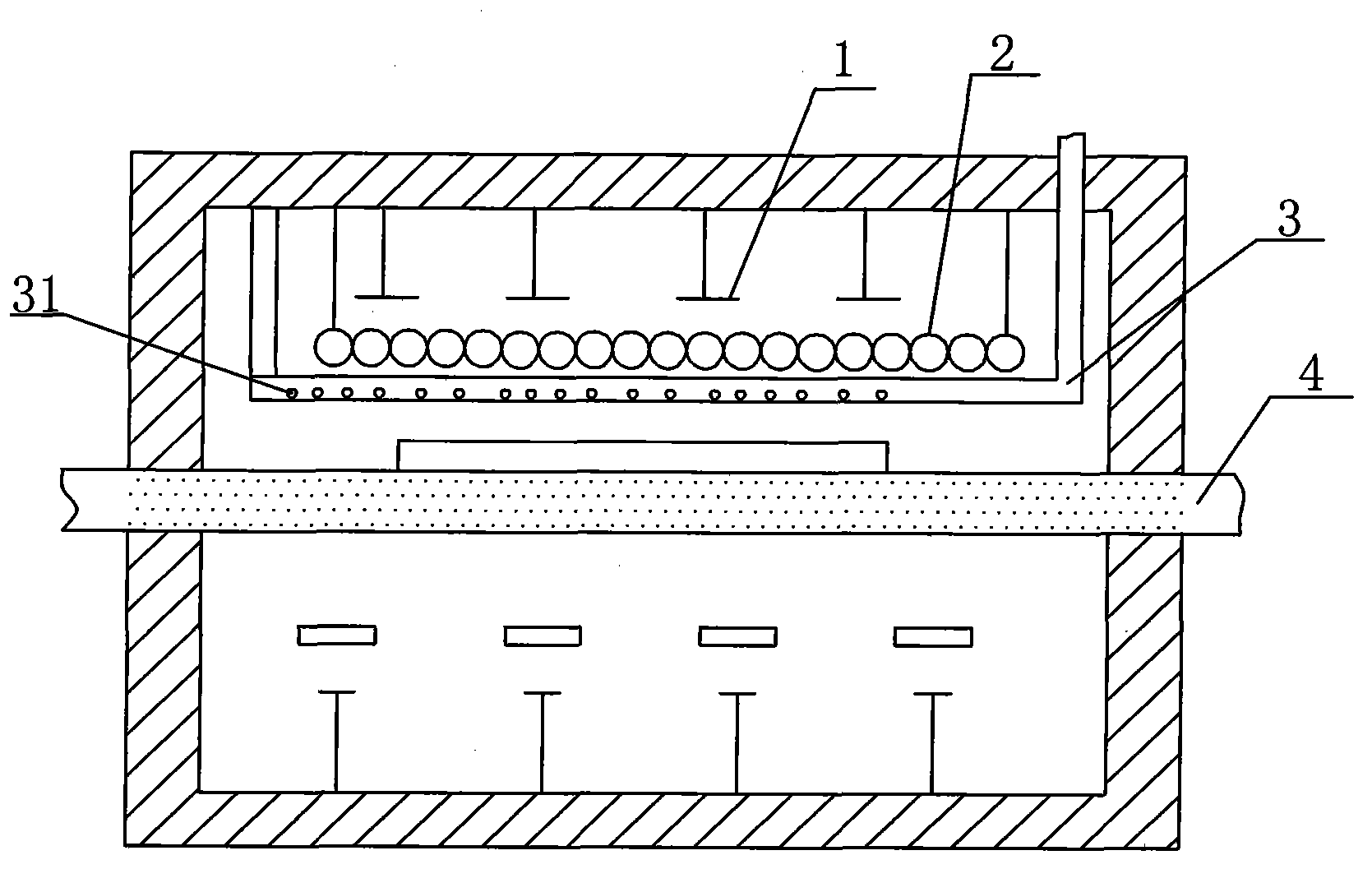

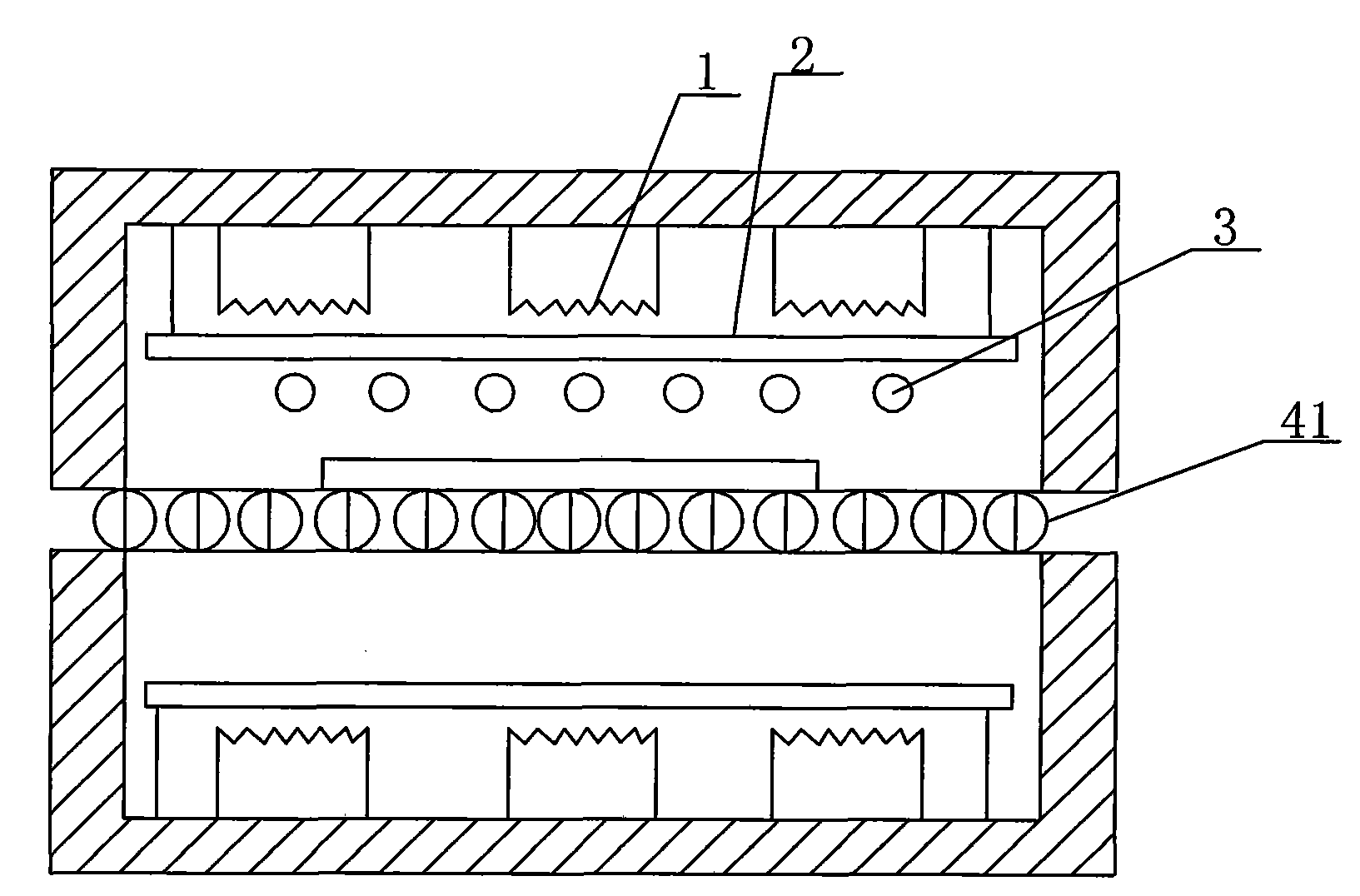

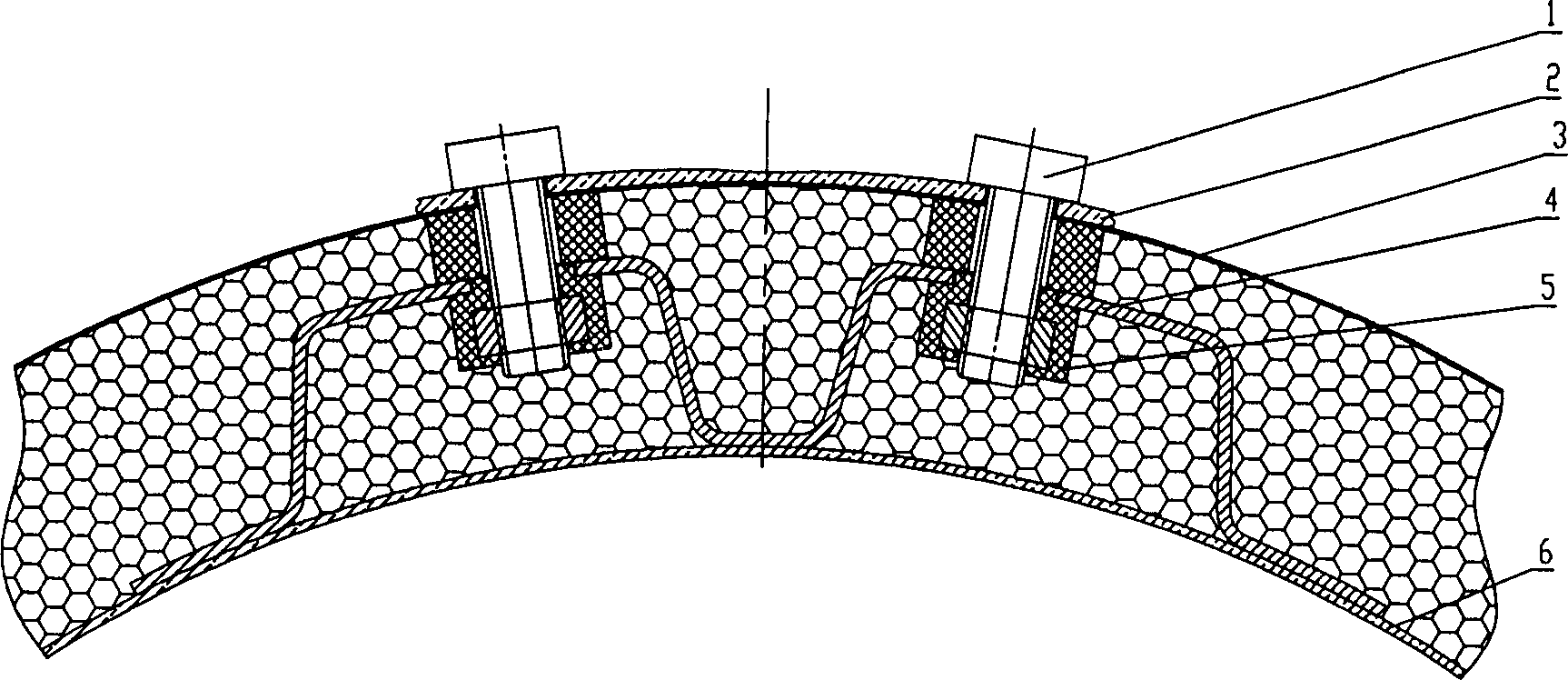

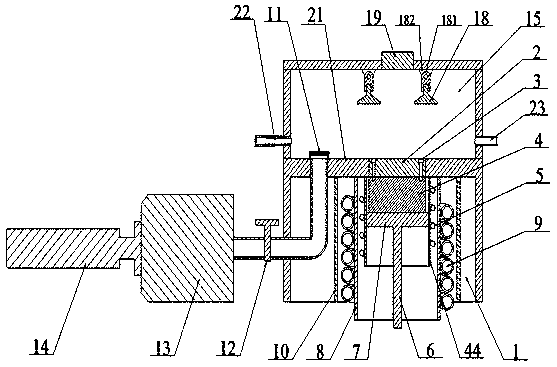

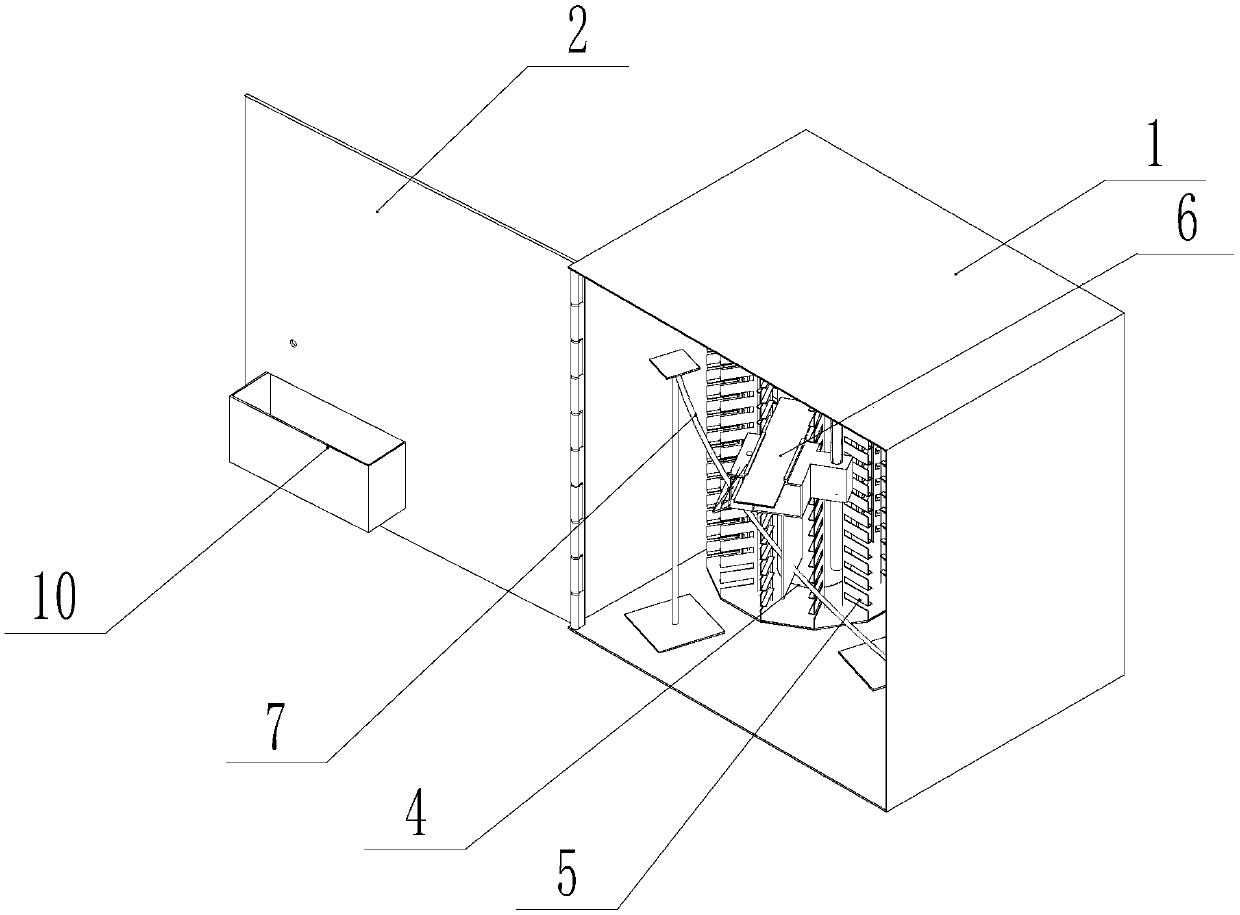

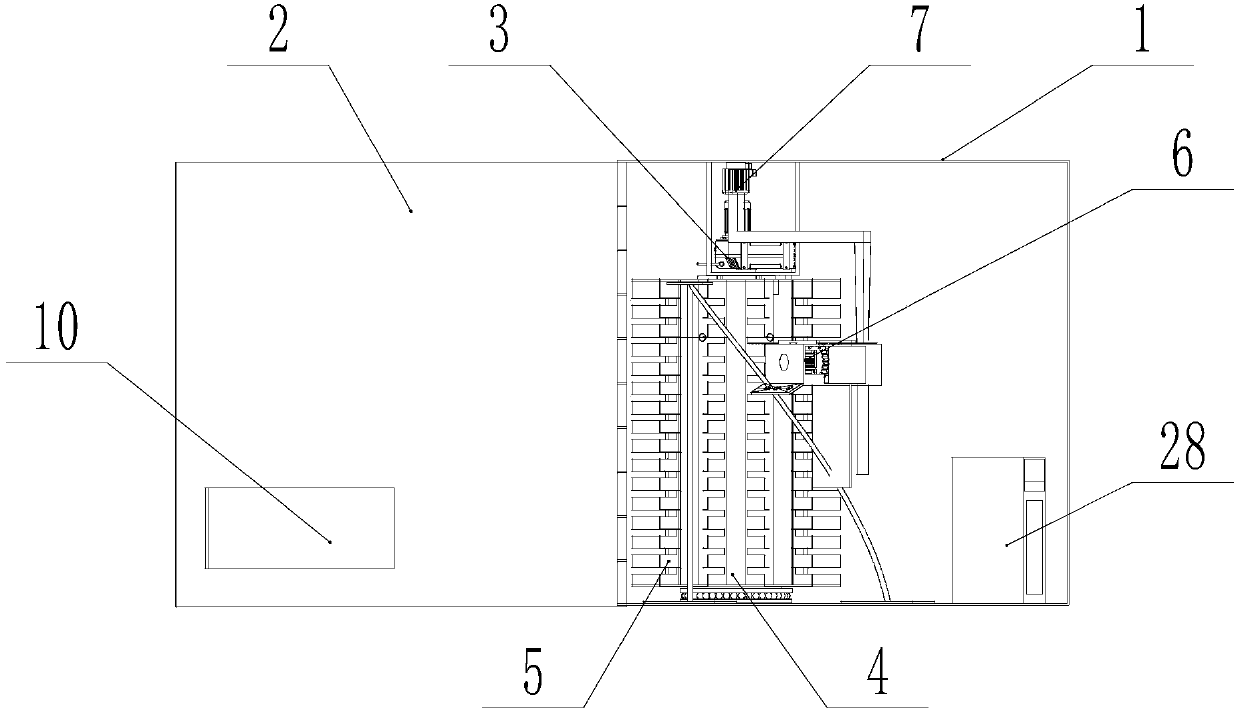

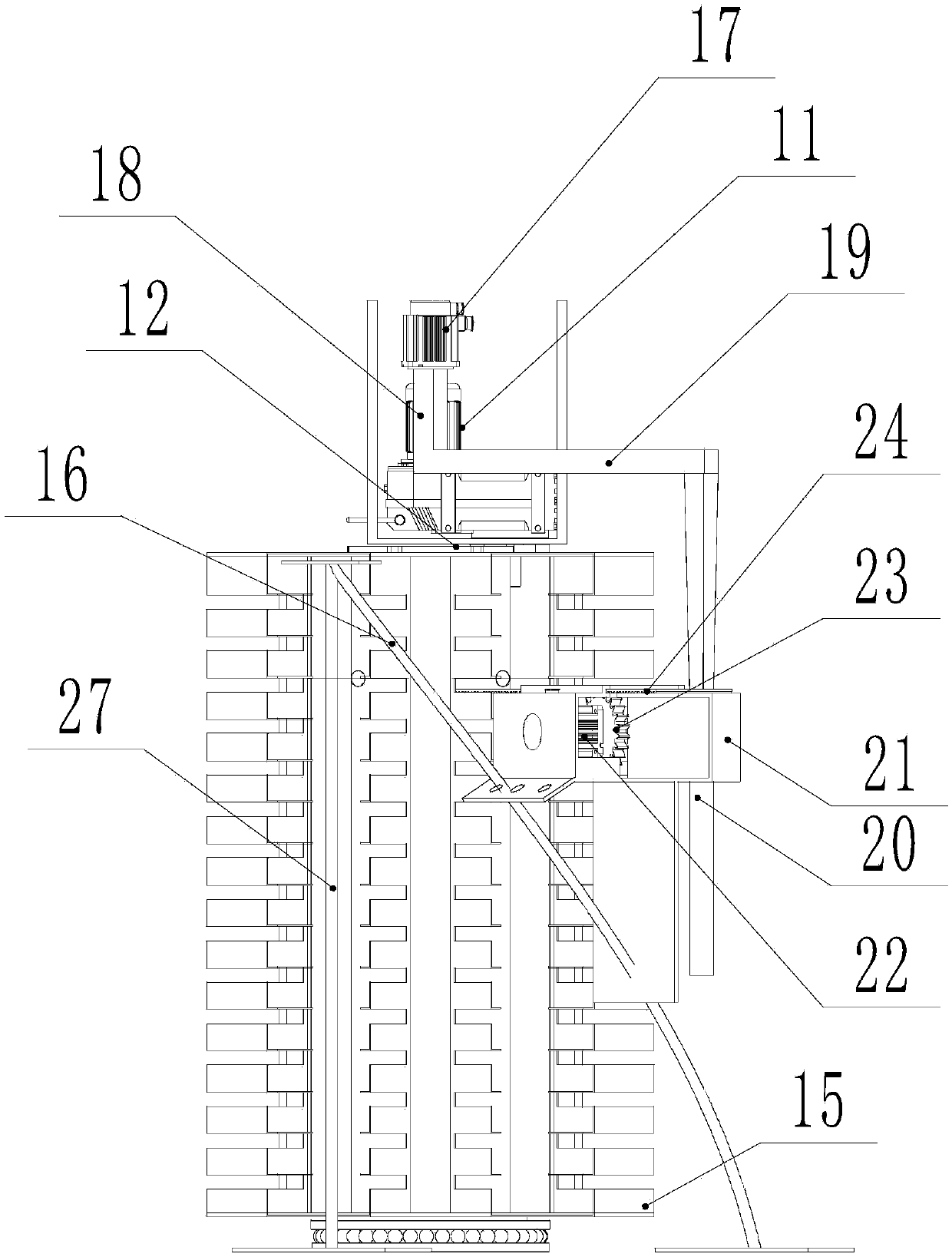

Quenching process and its quenching device for bearing internal and external rings

ActiveCN1858268ASimple structureImprove work efficiencyFurnace typesHeat treatment furnacesSmall footprintManipulator

The present invention relates to heat treatment, and is especially internal and external bearing ring quenching process and quenching press. The quenching process includes the steps of mounting and heating, feeding quenching material, simultaneous quenching of the internal bearing ring and the external bearing ring, and discharging. The special quenching apparatus includes internal bearing ring quenching apparatus, external bearing ring quenching apparatus and manipulator for grabbing the outer bearing ring. The external bearing ring quenching press is provided with fixing mold, the internal bearing ring quenching apparatus is provided with expanding mold, and the quenching process is one closed immersing process. The present invention has homogeneous quenching and is suitable for batch heat treatment.

Owner:NINGXIA MACHINERY RES INST

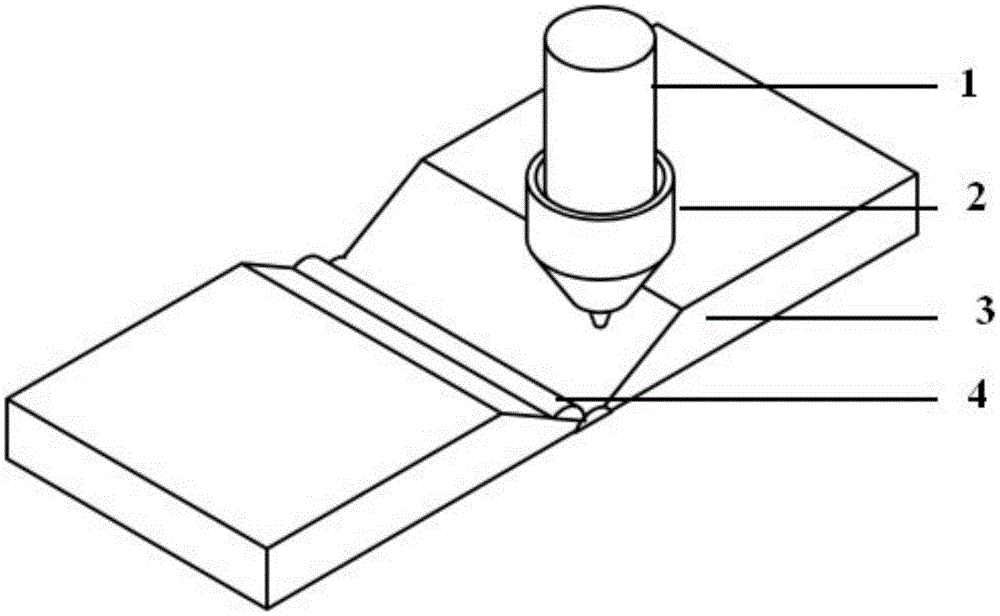

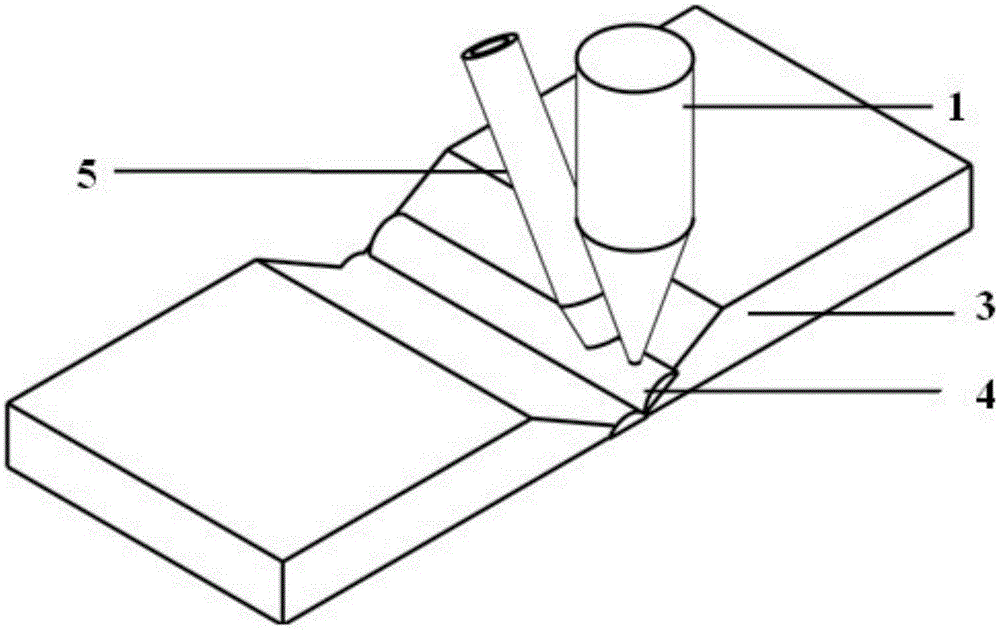

Laser connection method based on laser material additive manufacturing technology

InactiveCN105414762AImprove performanceControl deficienciesLaser beam welding apparatusManufacturing technologyWeld seam

A laser connection method based on the laser material additive manufacturing technology relates to a welded connection method of a special material. According to the laser material additive manufacturing principle, and by utilizing the laser depositing method and the layer-by-layer piling method, a new material shaped like the welding seam between two base materials is formed between the welding seam of two connecting materials and the formed new material is further utilized to connect the two base materials. According to the laser connection method based on the laser material additive manufacturing technology, provided by the invention, the metallurgical composition of the welding seam and the joint performance are improved, near-net forming connection is realized, materials are greatly saved, the cost is reduced, weld defects are controlled, the degree of automation is high, and the operation is easy; besides, a fiber laser, a YAG solid laser, a semiconductor laser or CO2 laser are taken as the core, and a powder feed device, a protective gas system and a cooling system are taken as auxiliary appliances, therefore the overall system is high in automation level, can realize whole-process computer control, and is simple in operation processes and further easy to implement.

Owner:HARBIN INST OF TECH

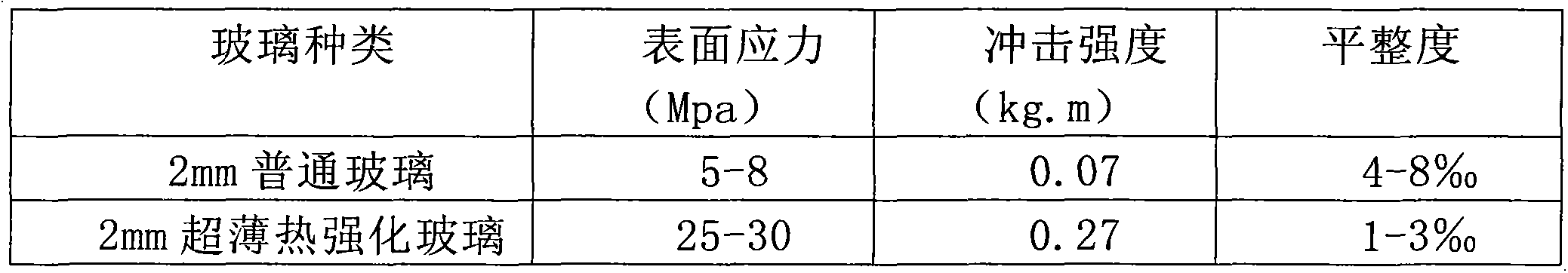

Manufacturing method of ultrathin heat-reinforced glass

InactiveCN103319082AHeating fastRadiation area is largeGlass tempering apparatusGlass manufactureToughness

The invention discloses a manufacturing method of ultrathin heat-reinforced glass. The manufacturing method comprises the following steps of: flatly placing ultrathin glass with the thickness of 1.8-2.2mm on a rolling way, adjusting the pressure of convection air in a toughening furnace to be 2000-4000pa / cm<2> with the convection time of 30-50s, simultaneously using the rolling way to drive the glass to do reciprocating movement for 40-50S in the toughening furnace at a speed of 20-30mm / s, and then adjusting the operating speed of the rolling way to be 160-175mm / s till the glass is heated to be 623-630 degrees. The glass manufactured by utilizing the method has the advantages that the generation of 'white mist' is avoided, and the glass is good in flatness, high in strength and good in toughness.

Owner:CHANGZHI SHENGLONG IND

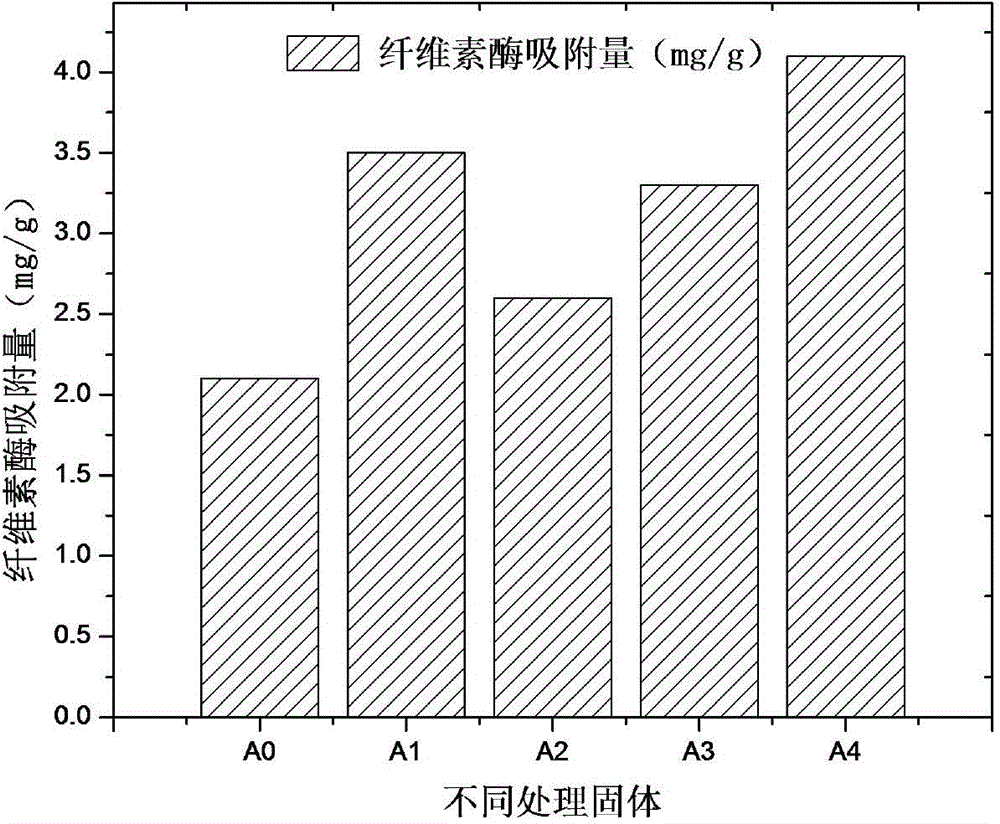

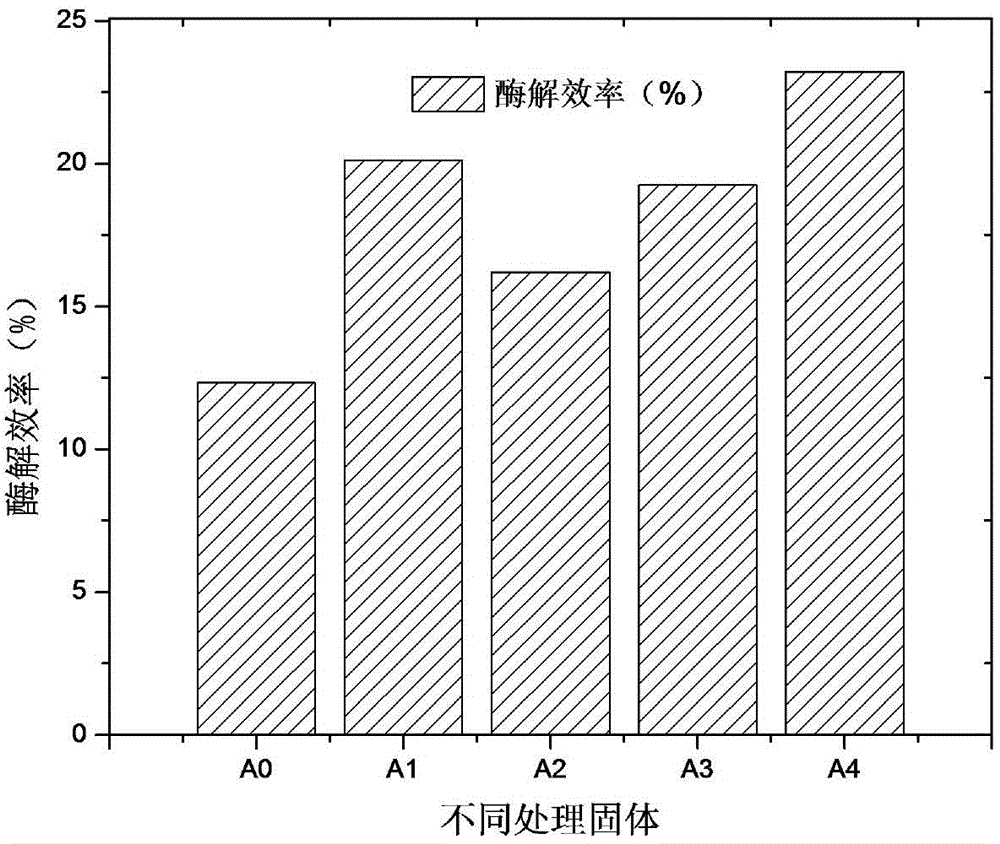

Pretreatment method of lignocellulose by using microwave-assisted alkaline sodium sulfite

The invention discloses a pretreatment method of lignocellulose by using microwave-assisted alkaline sodium sulfite, belonging to the technical fields of biomass resource utilization and agricultural waste comprehensive utilization. The method comprises the following steps: by using lignocellulose as a raw material, pulverizing, screening, and pretreating by using microwave-assisted alkaline sodium sulfite to lower the alkali consumption and enhance the pretreatment effect of the alkaline sodium sulfite; and carrying out solid-liquid separation, flushing the solid residue with an alkaline sodium sulfite solution, and washing with water to obtain the lignocellulose pretreatment product with favorable enzymolysis effect. The method can better remove lignin and reduce the inhibition effect of lignin on cellulose degradation, thereby effectively enhancing the conversion efficiency from lignocellulose to monosaccharide. The method reduces the chemical reagent consumption, is beneficial to environmental protection, and lowers the production cost, thereby generating higher economic value.

Owner:JIANGNAN UNIV

Wollastonite powder surface wet modification method assisted by microwave

InactiveCN101531835AGood modification effectImprove efficiencyChemical industryMicrowave heatingFiltrationHydrolysate

The invention relates to a wollastonite powder surface wet modification method assisted by microwave, which belongs to the technical field of powder surface modification. KH550 is used as coupling agent. The method comprises the processes of hydrolysate solution preparing, microwave-assisted coupled reaction, extraction and drying. The process of the microwave-assisted coupled reaction is as follows: wollastonite powder and ethanol are prepared into slurry to be put a constant-temperature microwave oven and stirred and heated to 50-80 DEG C; the hydrolysate solution is dripped into the slurry slowly and is stirred to react for 15 to 60 minutes; and a sample is dried in the constant-temperature microwave oven under the temperature of 90-130 DEG C after suction filtration. Compared with the prior wollastonite powder surface wet modification method, the invention uses the characteristic of heating by the microwave completely and realizes the goals of being assisted by microwave radiation and intensifying modification; the invention does not change the wollastonite crystal structure and the molecular structure of the coupling agent; and the invention can control the temperature exactly and ensures that the thermal efficiency and the heating speed during the modifying process are improved greatly.

Owner:JILIN UNIV

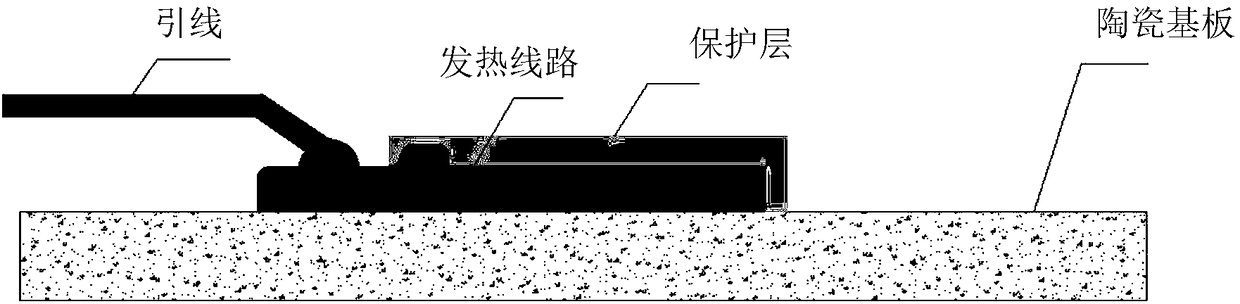

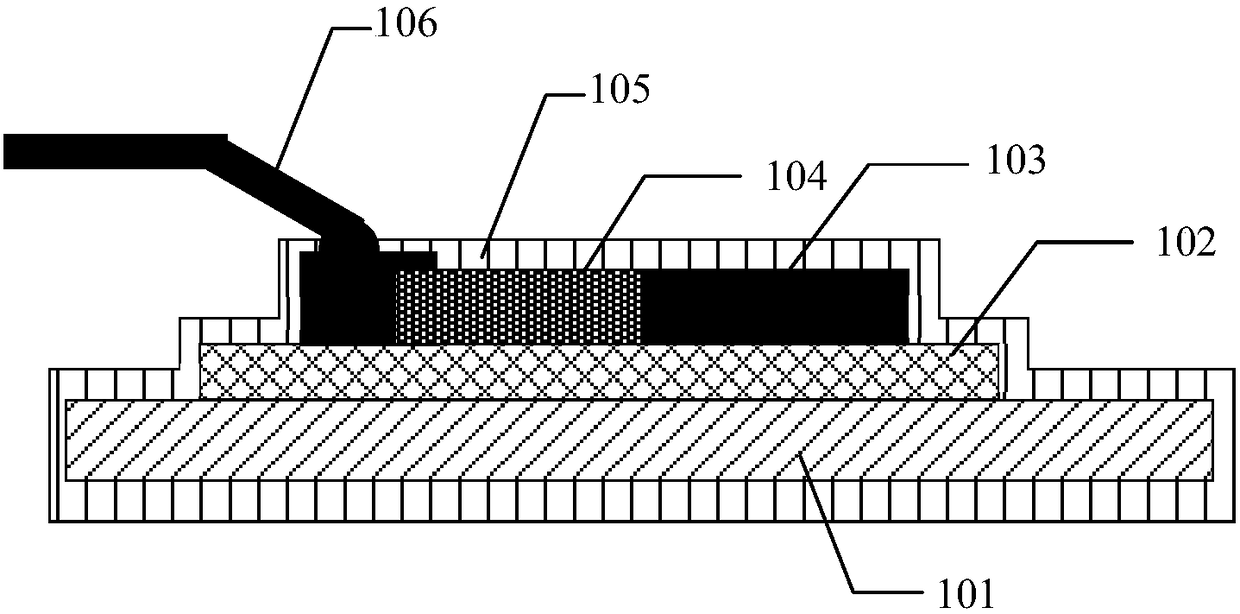

Chip type electronic cigarette heater, preparation method thereof and electronic cigarette

PendingCN108451044AImprove heating efficiencyIncrease heating speedTobacco devicesElectrical resistance and conductanceElectrical conductor

The invention discloses a chip type electronic cigarette heater which comprises a protection anti-fouling layer. The protection anti-fouling layer comprises a metal substrate, an insulating layer covering the surface of the metal substrate, a heating layer which covers the insulating layer and is used for heating the metal substrate, and a conductor layer which covers the insulating layer and is connected with the heating layer and used for conducting the heating layer. The substrate is set as the metal substrate, and the problem that the service life of an instrument is affected due to the characteristic that ceramics is hard and crisp is avoided; the metal substrate has the good thermal conductivity, the heat conducting speed is high, the heating efficiency of the chip type electronic cigarette heater is improved, and the heating response speed of the chip type electronic cigarette heater is increased; meanwhile, by arranging the insulating layer on the surface of the metal substrate, the thick film circuit heating layer formed by sintering resistance paste is arranged on the insulating layer, the advantages of high heating speed and high power density are achieved, and energy consumption is lowered; the invention further provides a preparation method of the chip type electronic cigarette heater and an electronic cigarette having the advantages.

Owner:ZHUZHOU LEEDINK ELECTRONICS TECH CO LTD

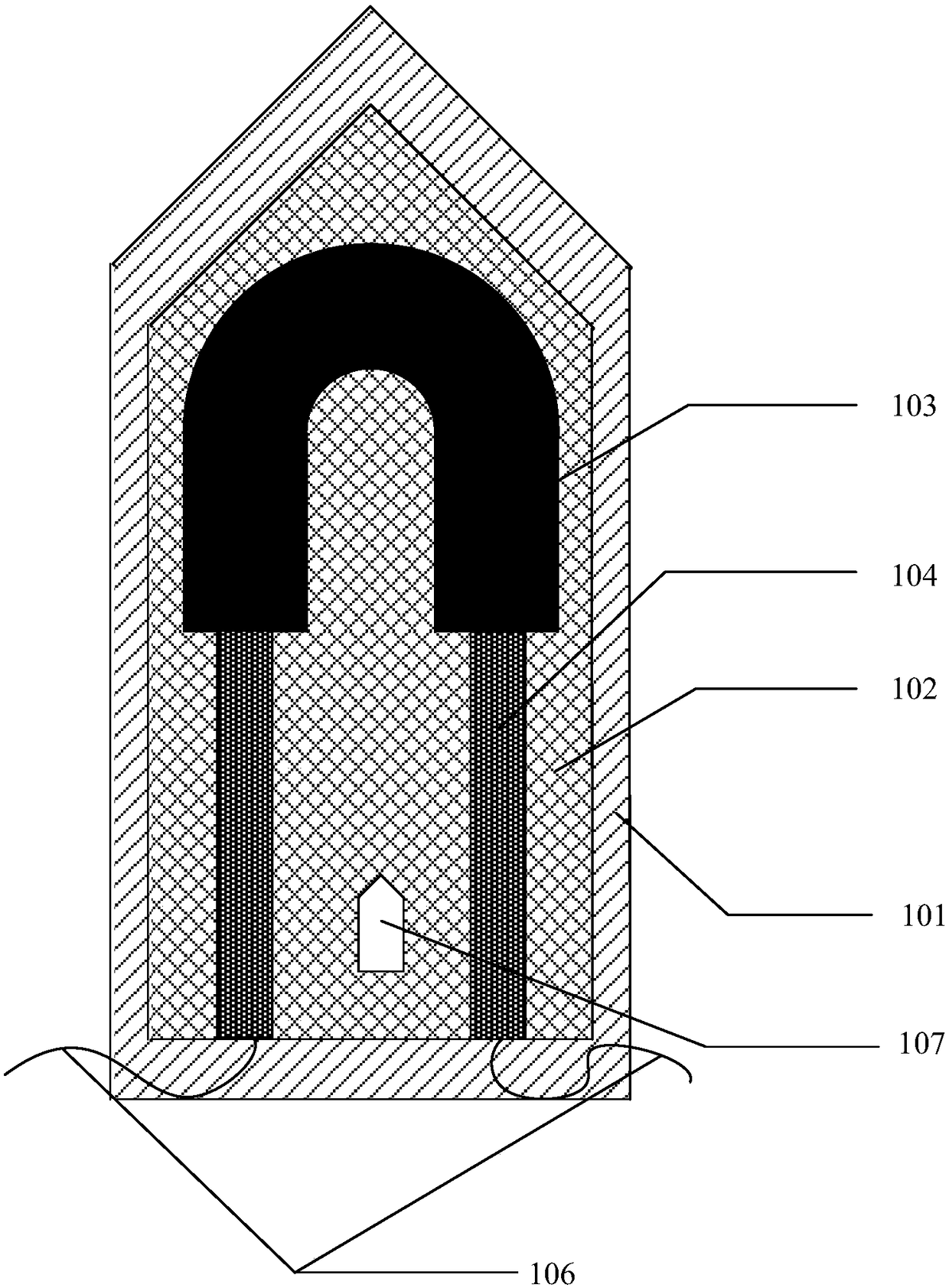

Downhole electric heating horizontal production well string structure

ActiveCN106168119AIncrease heating speedImprove oil recovery efficiencyDrilling rodsFluid removalCoiled tubingTransmission channel

The embodiment of the invention provides a downhole electric heating horizontal production well string structure. The string structure comprises a casing pipe, a horizontal liner pipe and oil pipes located in a cavity formed by the casing pipe and the horizontal liner pipe in a defined mode, the oil pipes include the first metal oil pipe and the second metal oil pipe which are used for forming an electromagnetic wave energy transmission channel, the first metal oil pipe is sleeved with the second metal oil pipe, and the cavity between the second metal oil pipe and the first metal oil pipe is filled with an insulating material; the casing pipe and the horizontal liner pipe are insulated and isolated, the horizontal liner pipe is horizontally divided into two parts which are insulated and isolated to serve as two arms of a radio frequency antenna, and the first metal oil pipe and the second metal oil pipe are correspondingly coupled with the two arms of the radio frequency antenna respectively. The structure further comprises a continuous oil pipe for forming an oil and gas transmission channel, the continuous oil pipe is located in the cavity formed by the casing pipe and the horizontal liner pipe in the defined mode, and a hot fluid injecting pipe is installed in the continuous oil pipe. The embodiment can be used for collaborative development of electromagnetic waves and hot fluid.

Owner:PETROCHINA CO LTD

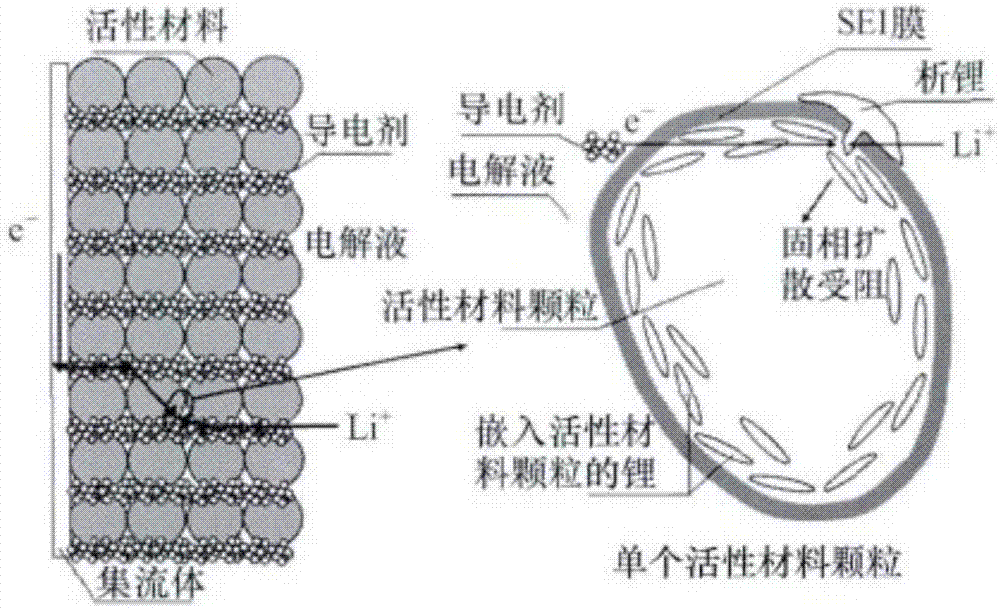

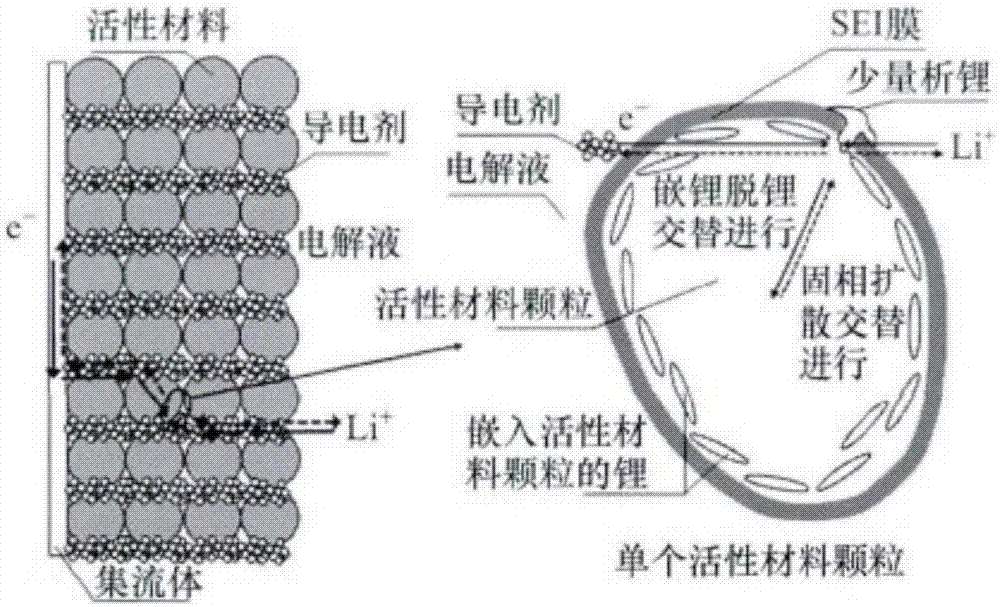

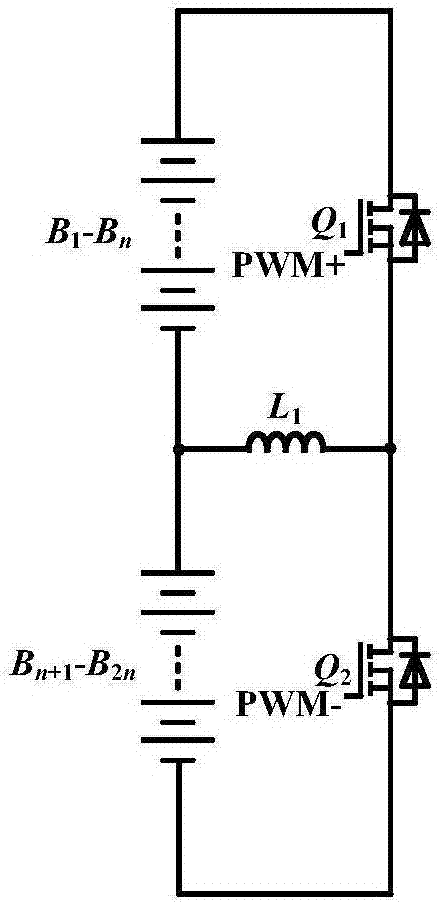

Vehicle-mounted power battery low-temperature full-time interleaving heating topology circuit and application thereof

The invention discloses a vehicle-mounted power battery low-temperature full-time interleaving heating topology circuit and application thereof. The circuit comprises a first battery pack and a secondbattery pack, wherein two Buck-Boost inverter circuits which are connected in parallel are connected in parallel with a to-be-heated battery pack; the Buck-Boost inverter circuits are respectively controlled by two pairs of PWM (Pulse-Width Modulation) signals of which phase angles are different for a set angle; when a single battery of the first battery pack is heated by a first Buck-Boost inverter circuit, a single battery of the second first battery pack is heated by the second Buck-Boost inverter circuit, and thus full-time battery heating is achieved. By adopting the interleaving heatingtopology circuit disclosed by the invention, under the condition that a battery pack is not further damaged, the heating speed can be remarkably increased, and the heating efficiency can be remarkably improved.

Owner:SHANDONG UNIV

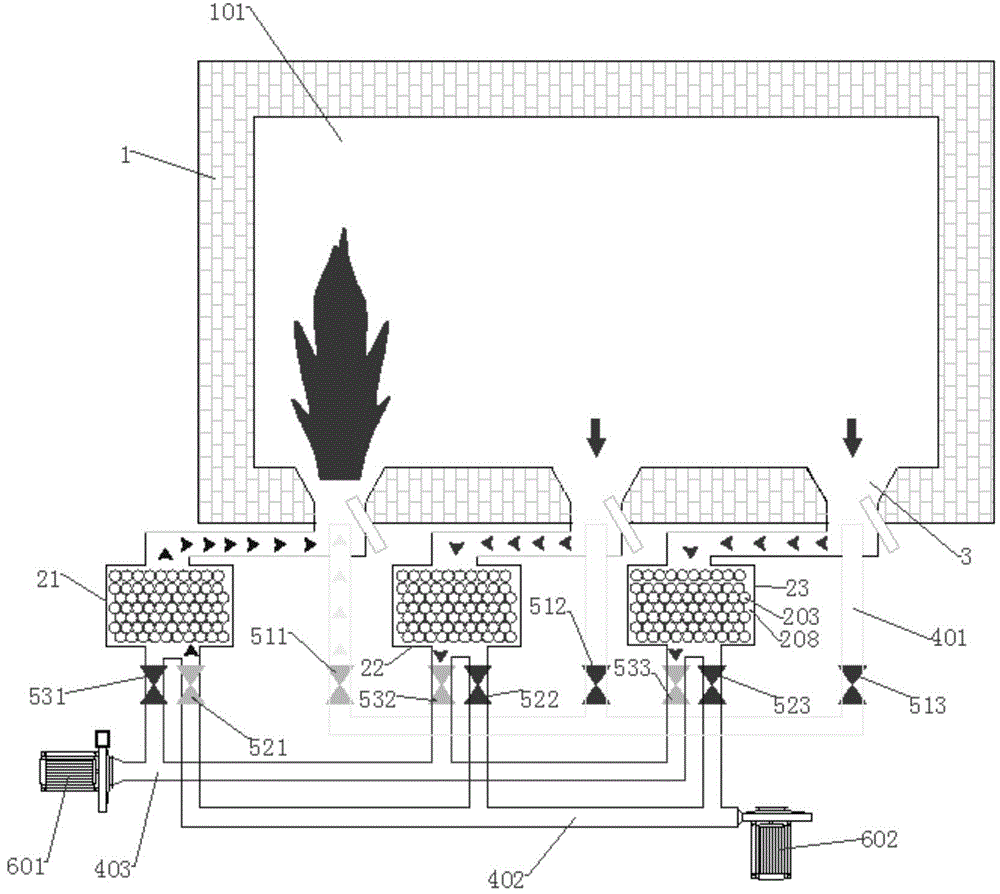

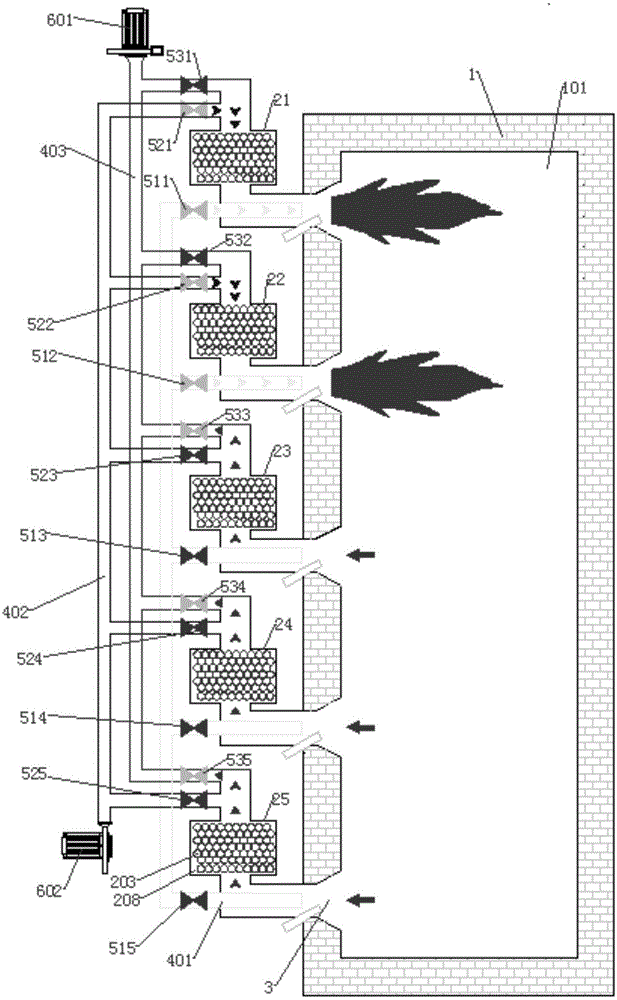

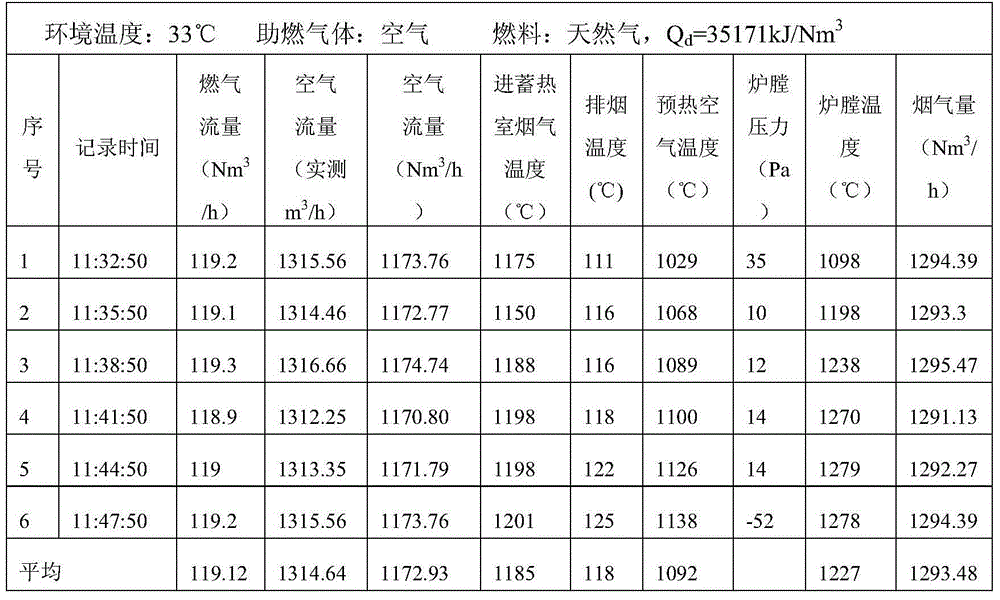

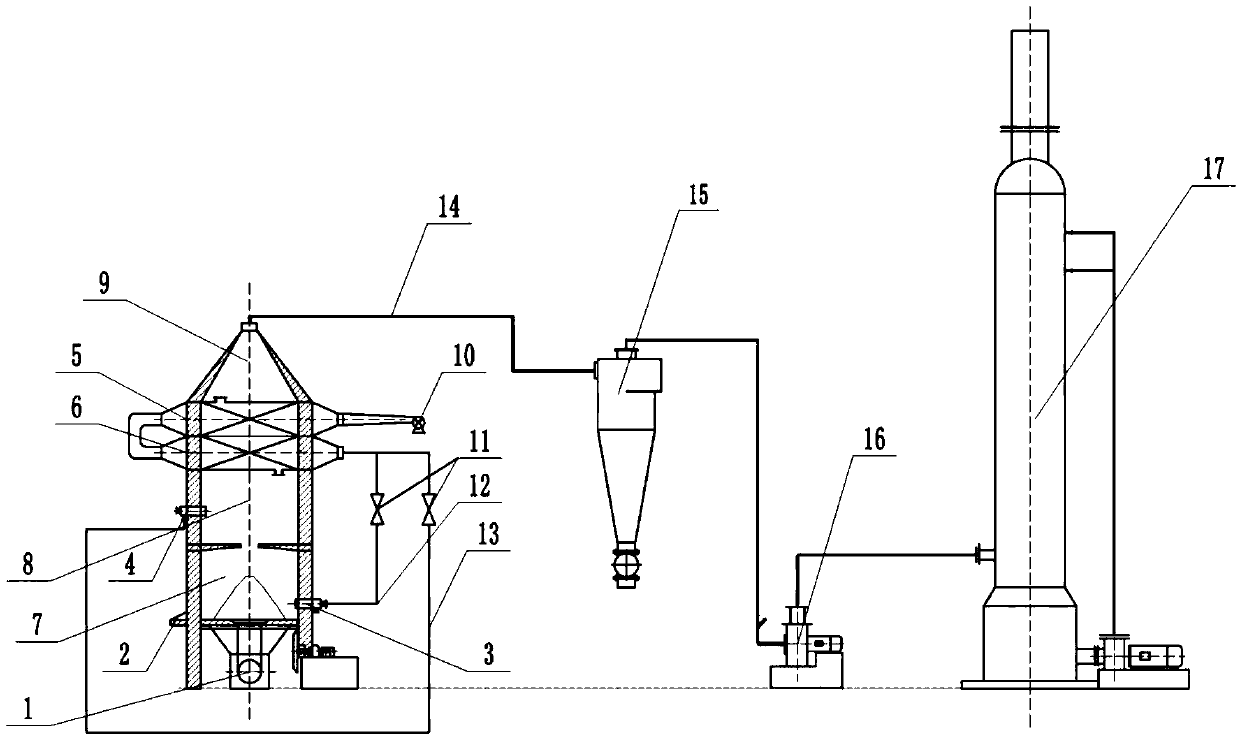

Regenerative combustion device

InactiveCN104457302ASmooth exhaustStable furnace pressureEnergy industryIndirect carbon-dioxide mitigationCombustorLow nitrogen

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

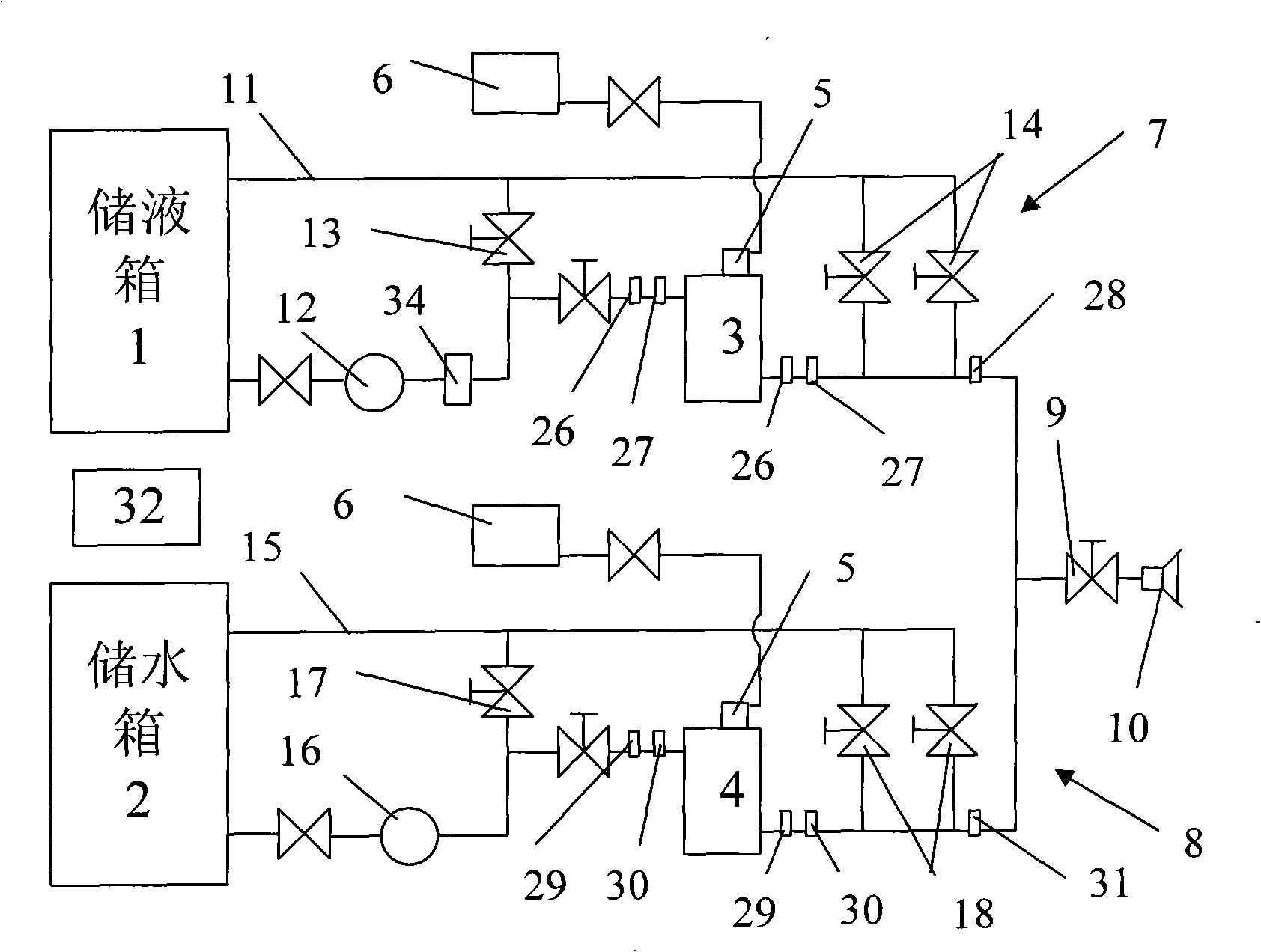

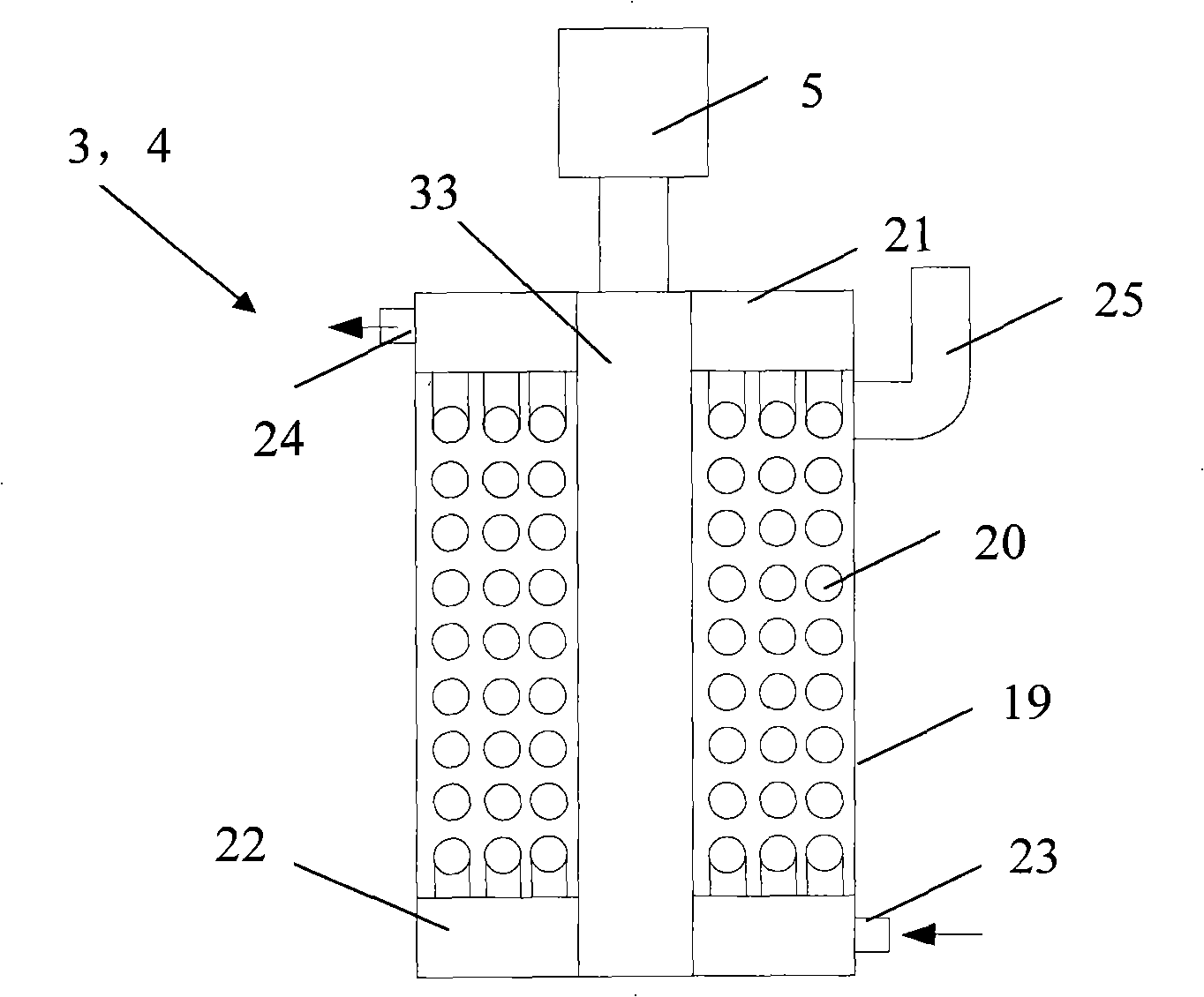

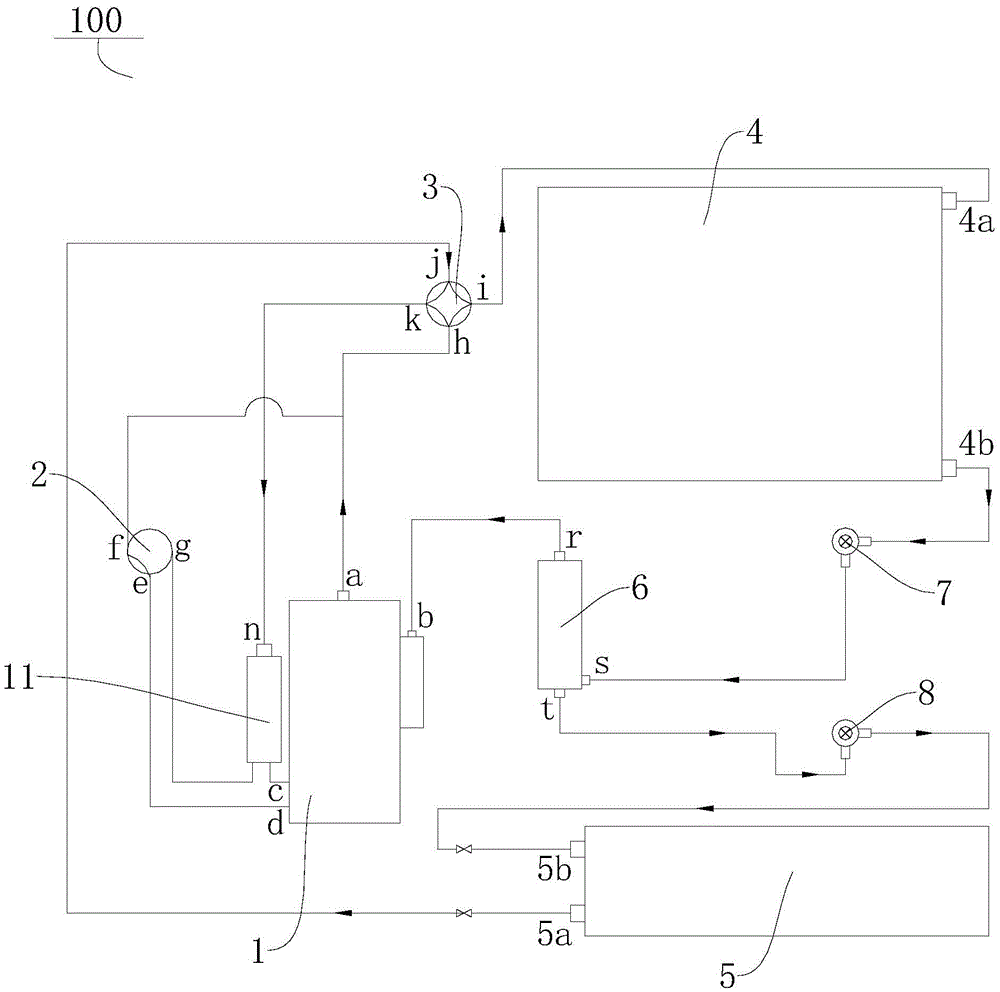

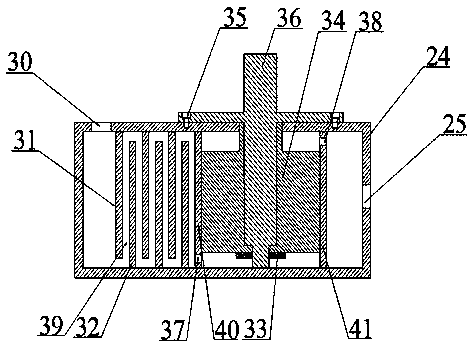

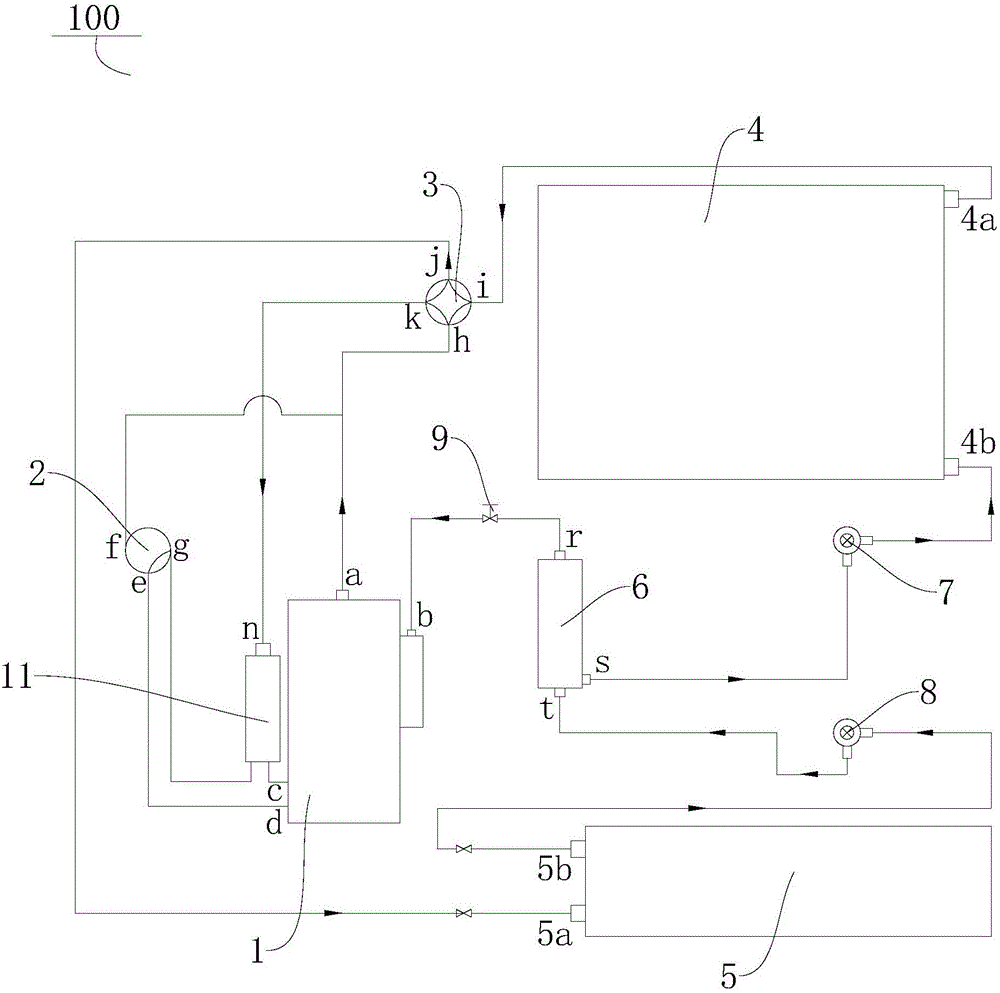

Rapid heating and automatic liquid supply mixing apparatus for deice liquid for airplane

ActiveCN101492096AReduce flight safety accidentsGuaranteed safe operationDe-icing equipmentsComputer control systemHeating time

The invention discloses an automatic proportioning device for flash heat and feed liquid of a plane, which comprises a liquid reserve tank, a water tank, a deicing liquid heater, a water heater, two fuel oil type burners, two fuel oil supply devices, a deicing liquid pipeline control system, a water pipeline control system, a general export valve, a spray gun and a computer control system. The automatic proportioning device for flash heat and feed liquid of a plane provided by the invention adopts a plurality of heaters to heat the deicing liquid and water simultaneously, and then the deicing liquid and the water are mixed fully and then are exported. Therefore, the heating rate and the deicing operating efficiency are improved. In addition, the proportion and the outlet temperature of the deicing liquid and the water can be set flexibly by airport staff according to the intraday weather condition, and the fluid production and the heating time are worked out accurately by the computer control system, thereby the safe operation and punctual take off of airport flight are guaranteed effectively, the regional flight delay is reduced, and plane flight safety accidents caused by the flight delay are reduced.

Owner:CIVIL AVIATION UNIV OF CHINA

Temperature measuring method in molten metal bath

ActiveUS20100020845A1Increase heating speedStrong and effective changeThermometer detailsThermometers using physical/chemical changesMolten bathMolten metal

Owner:HERAEUS ELECTRO NITE INT NV

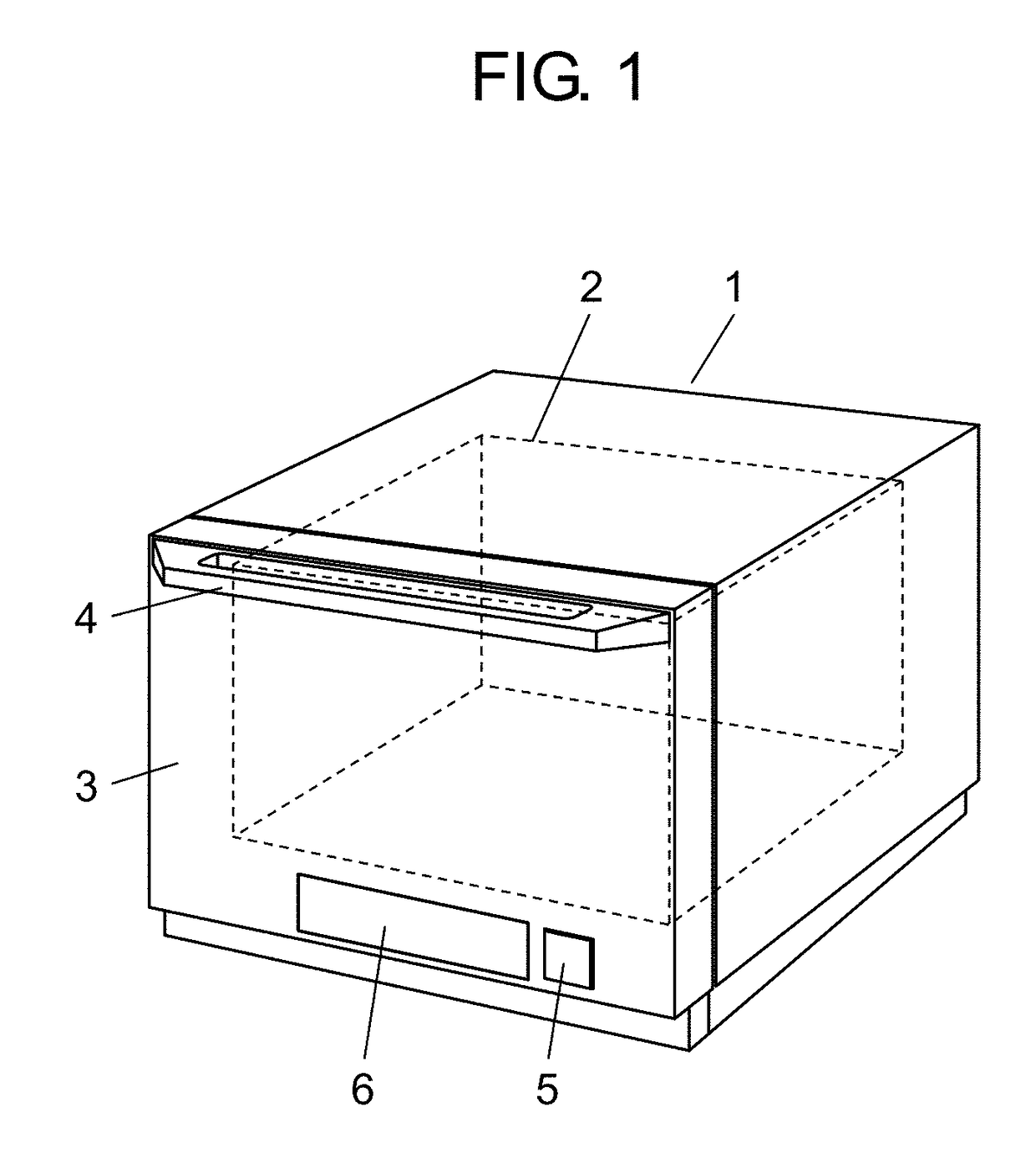

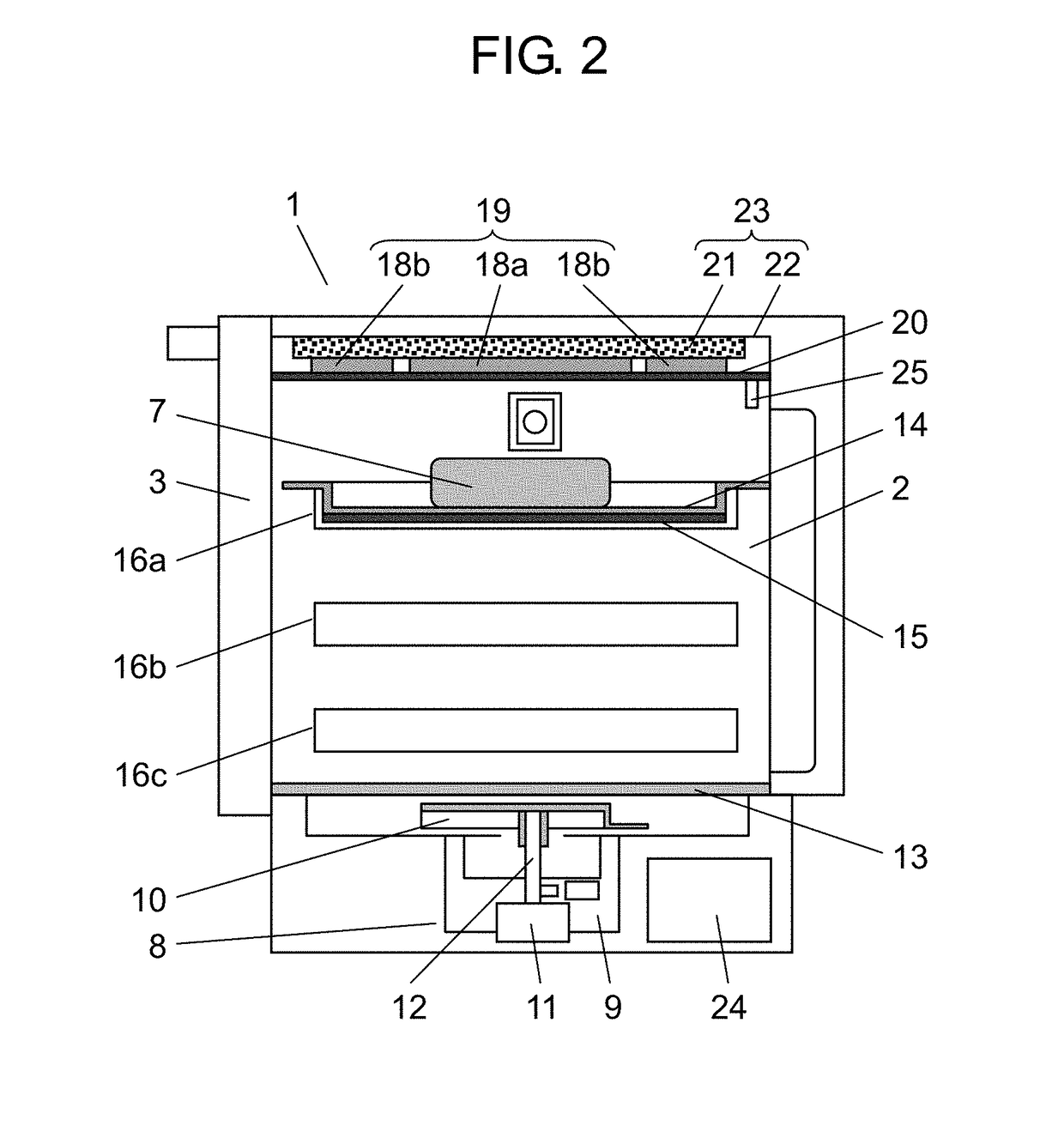

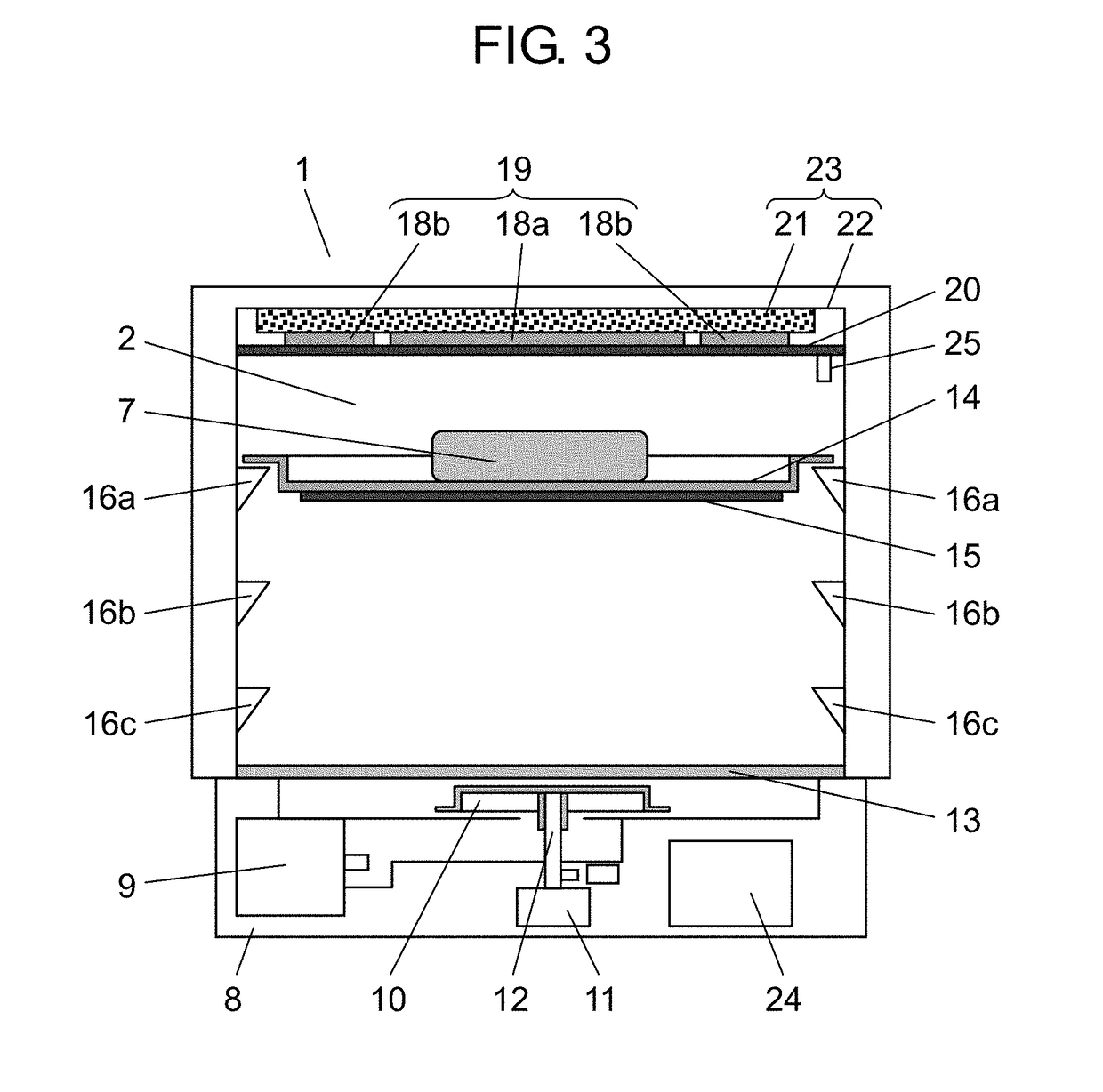

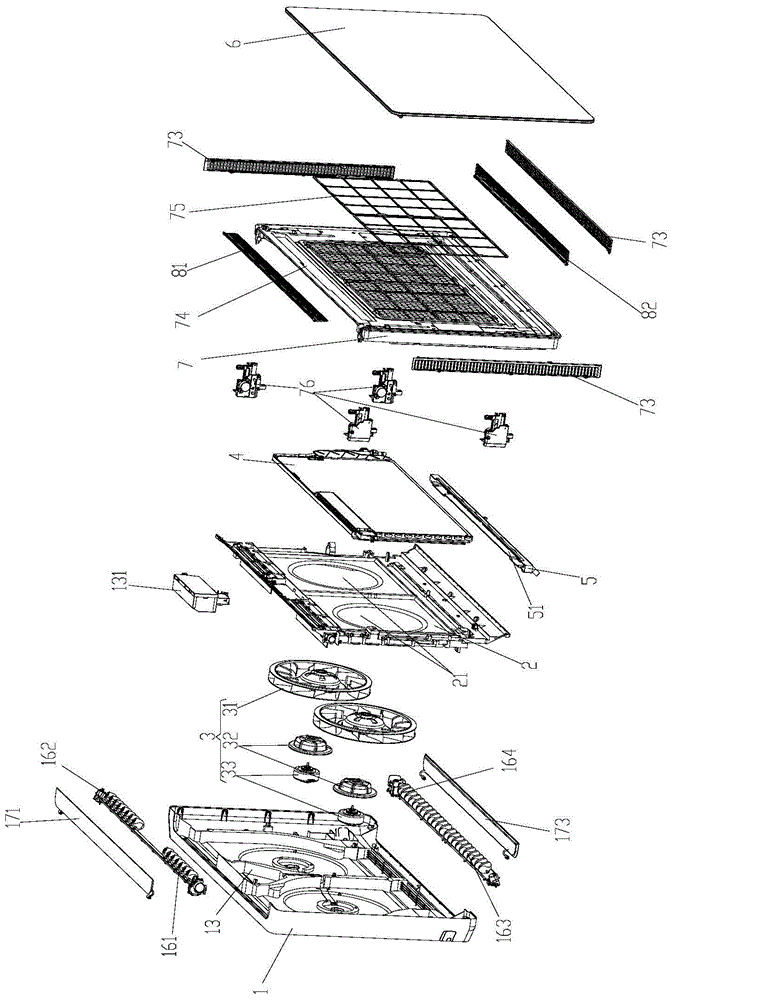

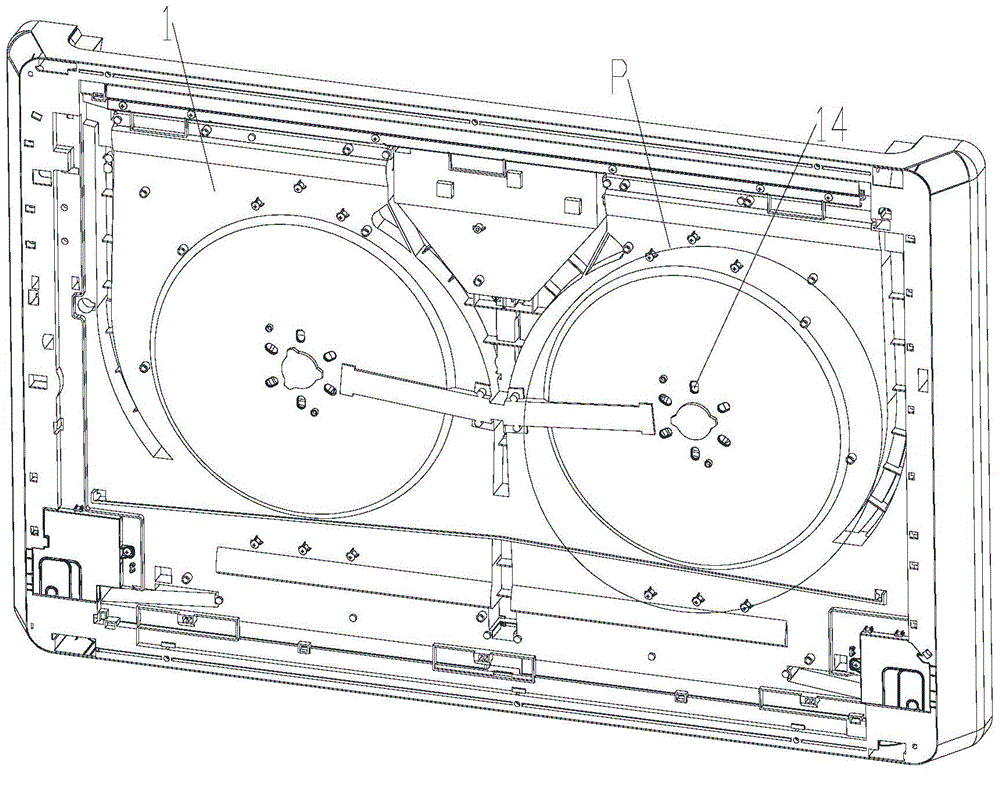

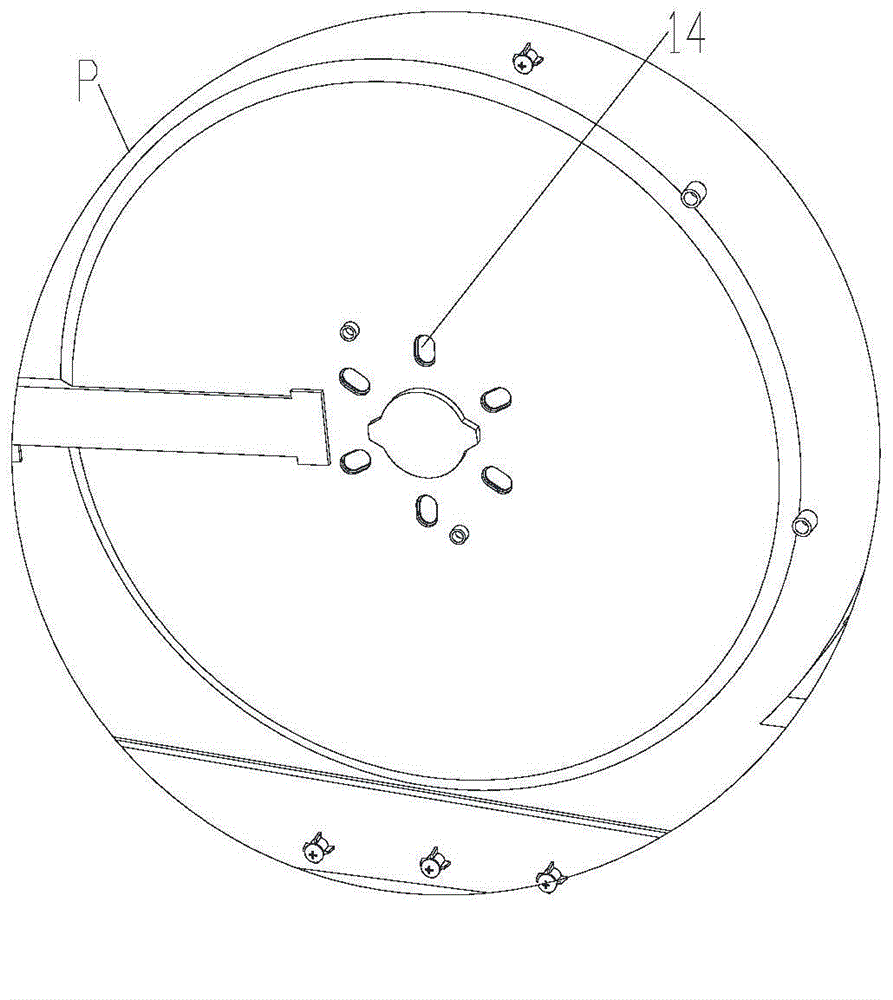

Heating cooker

ActiveUS20190045590A1Suppression of distortionImprove reliabilityDomestic stoves or rangesLighting and heating apparatusSuppressorEngineering

The heating cooker includes a first heater disposed below a tray to heat the tray, and second heater disposed over the tray to heat the tray. In addition, the heating cooker includes a controller that controls output of the first heater and switches energization of second heater in accordance with a kind of object to be heated and a quantity of object to be heated. Furthermore, second heater includes two plane-shaped insulators and a plurality of planar heat generators that are sandwiched between insulators, and the controller heats regions that are disposed over and below the tray to be opposed to each other by controlling energization of the first heater and second heater. Furthermore, second heater has a distortion suppressor between the plurality of planar heat generators, and the distortion suppressor suppresses internal distortion of insulators caused by heating of the plurality of planar heat generators of second heater.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

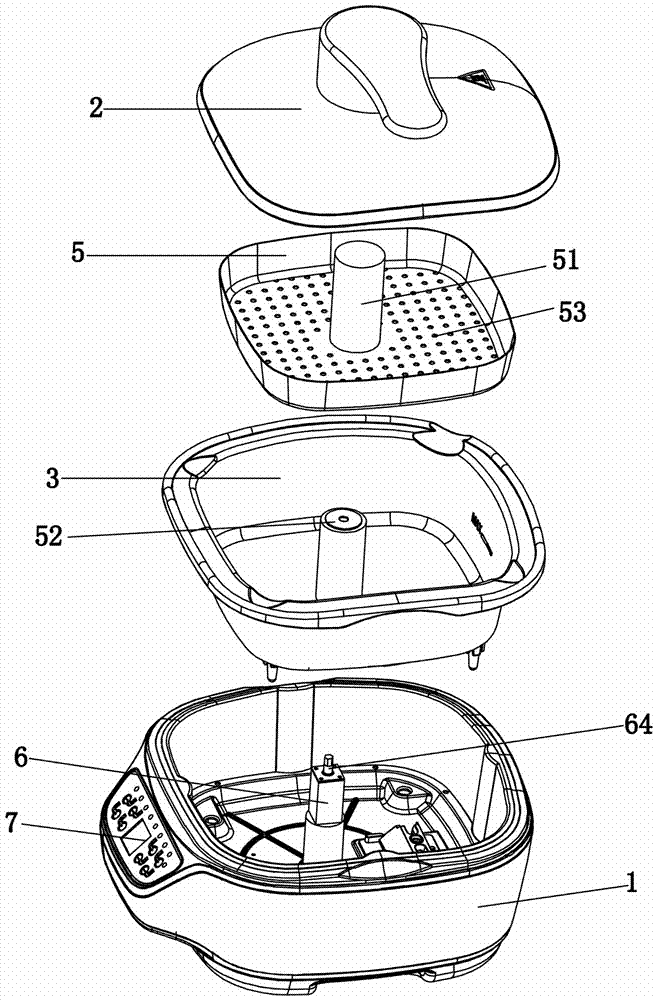

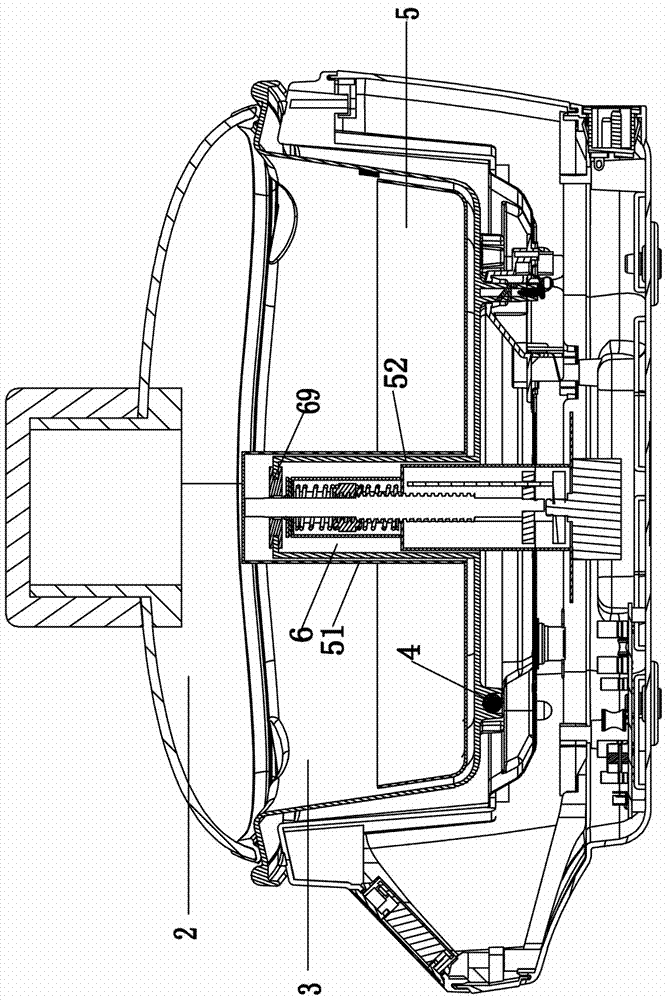

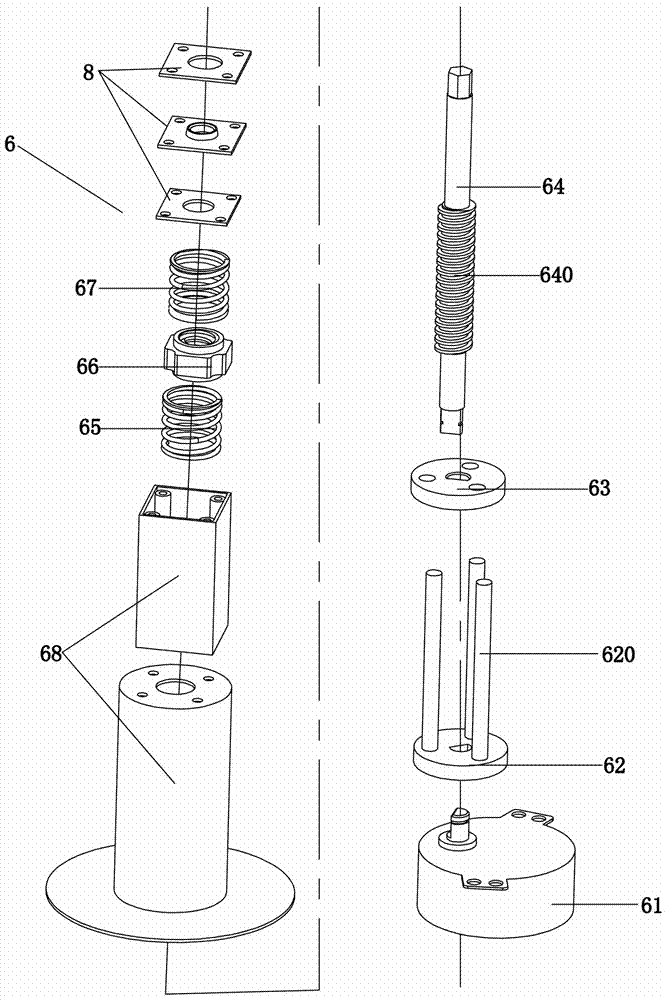

Multifunctional cooking pot

PendingCN107048998AEasy to grabEasy to placeWater-bath cooking vesselsCooking insertsEngineeringHigh heat

The invention relates to a multifunctional cooking pot. The multifunctional cooking pot comprises a pot boy, the pot body is provided with a main pot body, a draining tray is arranged in the main pot body, the pot body is provided with a tray-lifting driving device for driving the draining tray to ascend and descend, the tray-lifting driving device comprises a lifting motor, a driving turntable, a screw rod turntable, a lifting screw rod, a lifting nut and a fixation column, the lifting motor is in driving connection with the driving turntable, and the lifting screw rod is in transmission connection with a screw of the lifting nut to lift or lower the draining tray. According to the multifunctional cooking pot, the pot body and the main pot body are provided with the tray-lifting driving device and the draining tray respectively to lift or lower food in the pot body, so that the food is separated from soup in the pot body, a user picks up and places the food conveniently, and therefore the situation is avoided that the user is scalded by the splashed soup with high temperature when the user adds food into the main pot body. Soup on the food is drained through the draining tray, the user eats the food conveniently, the food is separated from the main pot body, and the heating efficiency and heating speed of the multifunctional cooking pot are improved.

Owner:ZHONGSHAN CITY O BEKO ELECTRICAL APPLIANCES

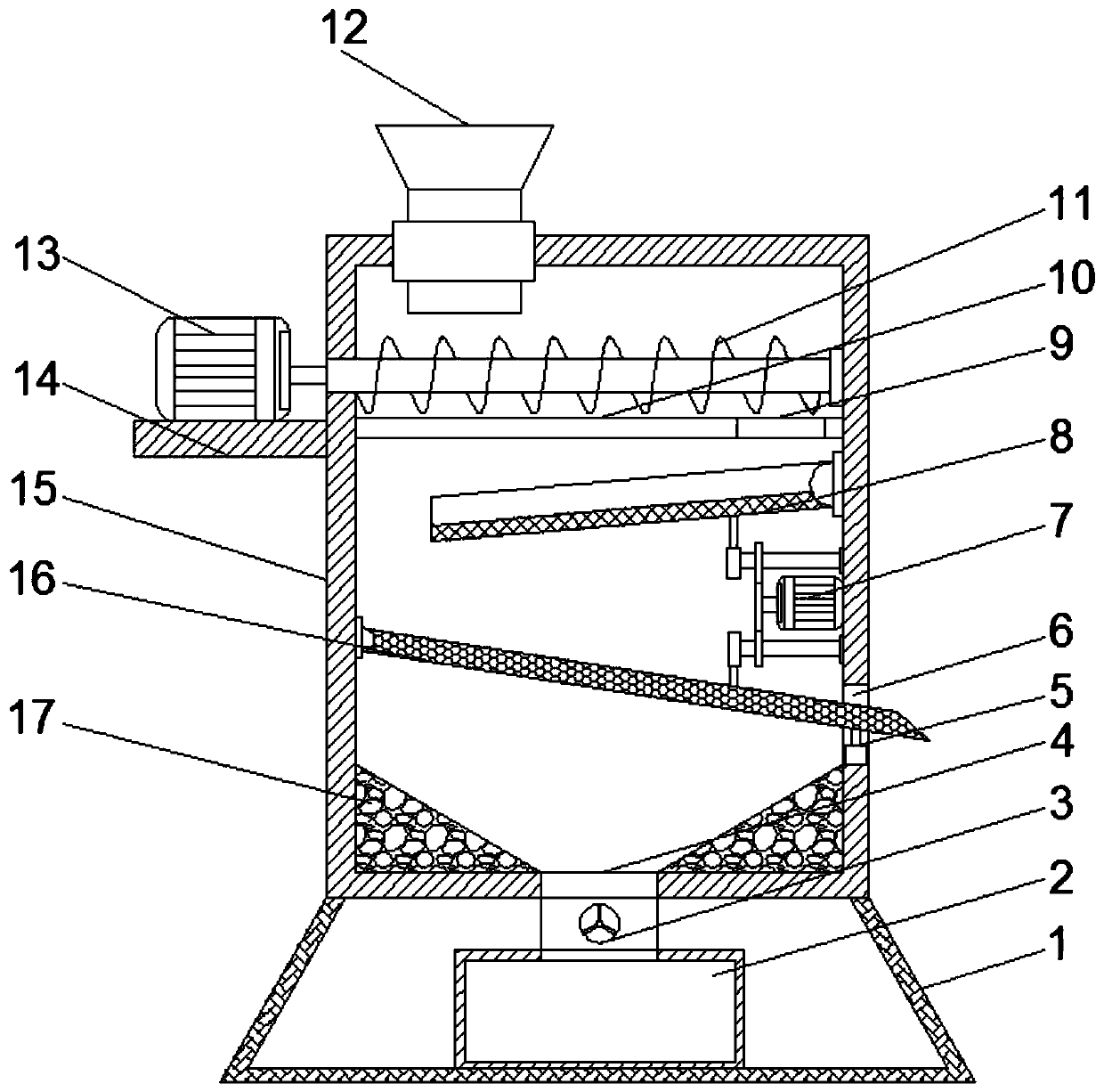

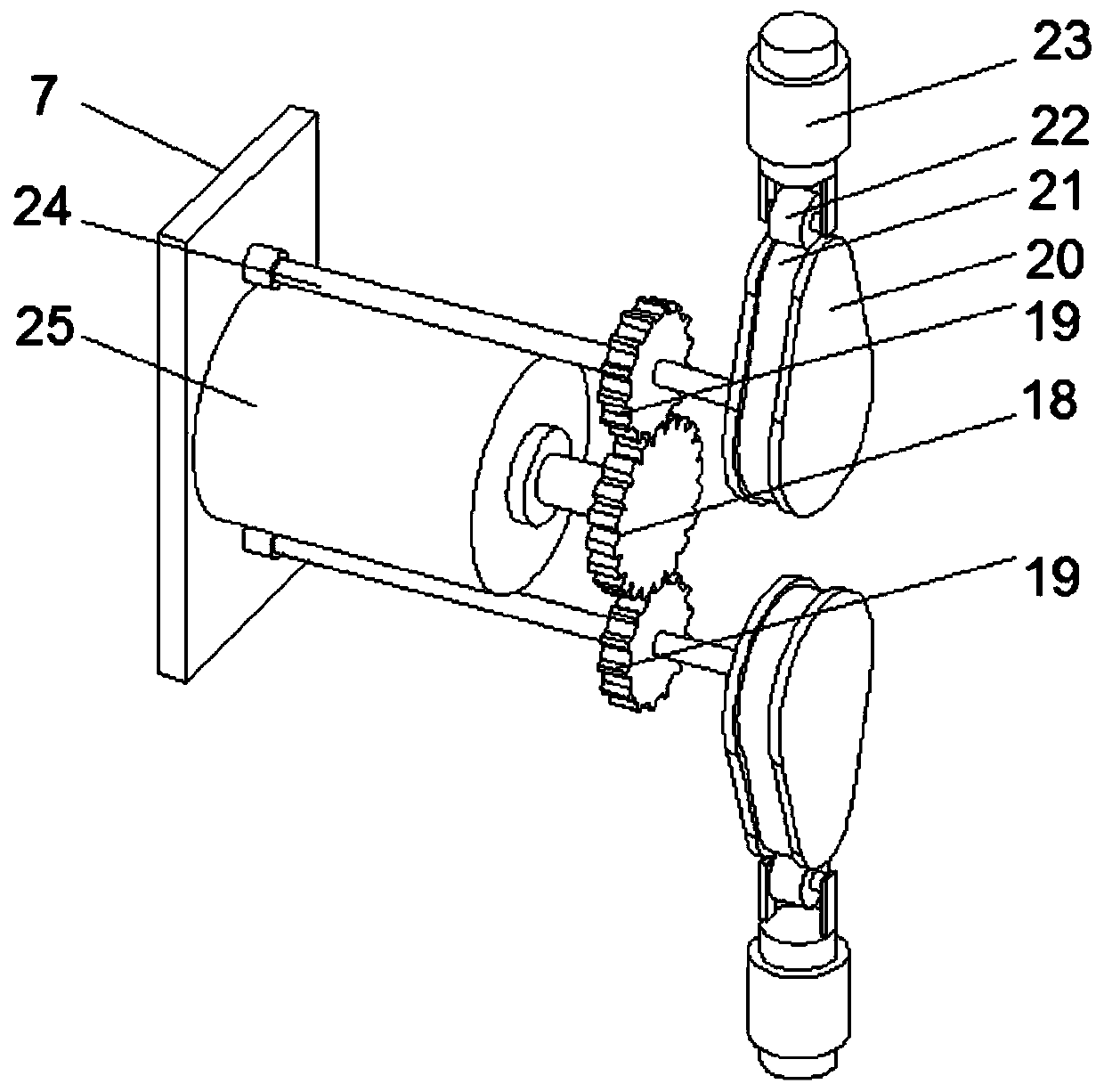

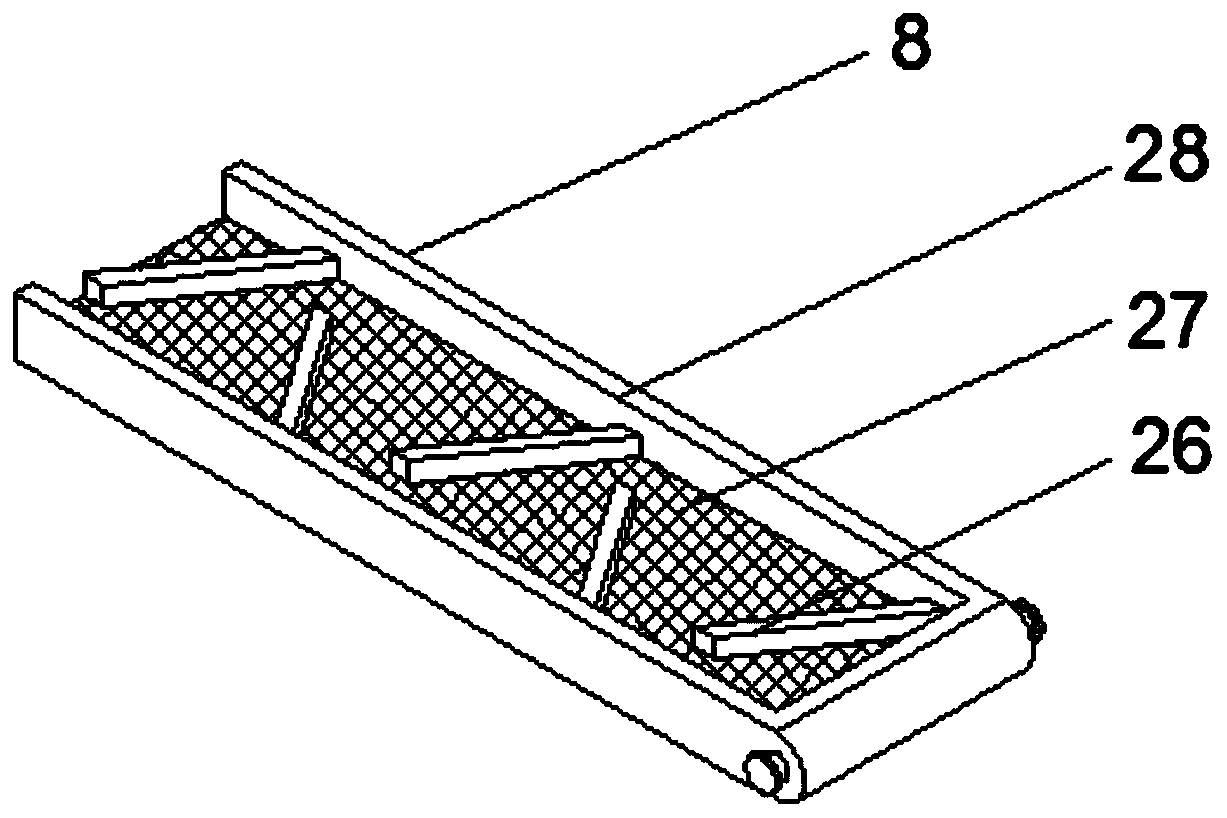

Sand accelerated drying and screening device based on cam transmission structure

The invention relates to the technical field of sand screening, and discloses a sand accelerated drying and screening device based on a cam transmission structure. The sand accelerated drying and screening device comprises a box body, wherein a discharging opening is formed in the bottom of the interior of the box body; and a base is fixedly connected to the bottom of the box body. According to the sand accelerated drying and screening device based on the cam transmission structure, sand in a lump is smashed through a stirring roller, and heating and screening of the sand are facilitated; through a gear transmission structure, two sets of cams can be driven by a second motor to synchronously rotate, and therefore synchronous vibration of a heating plate and a filtering plate is achieved, the heating and screening speed of the sand is increased, and the screening efficiency is improved; the flow speed of the sand on the heating plate is reduced through a gear rod, the heating time of the sand is prolonged, and the drying performance of the sand is enhanced; and a buffering base buffers vibration generated by the filtering plate, the situation that the filtering plate is damaged dueto too large amplitude is prevented, and the service life of the machine is prolonged.

Owner:杭州鑫赐贸易有限公司

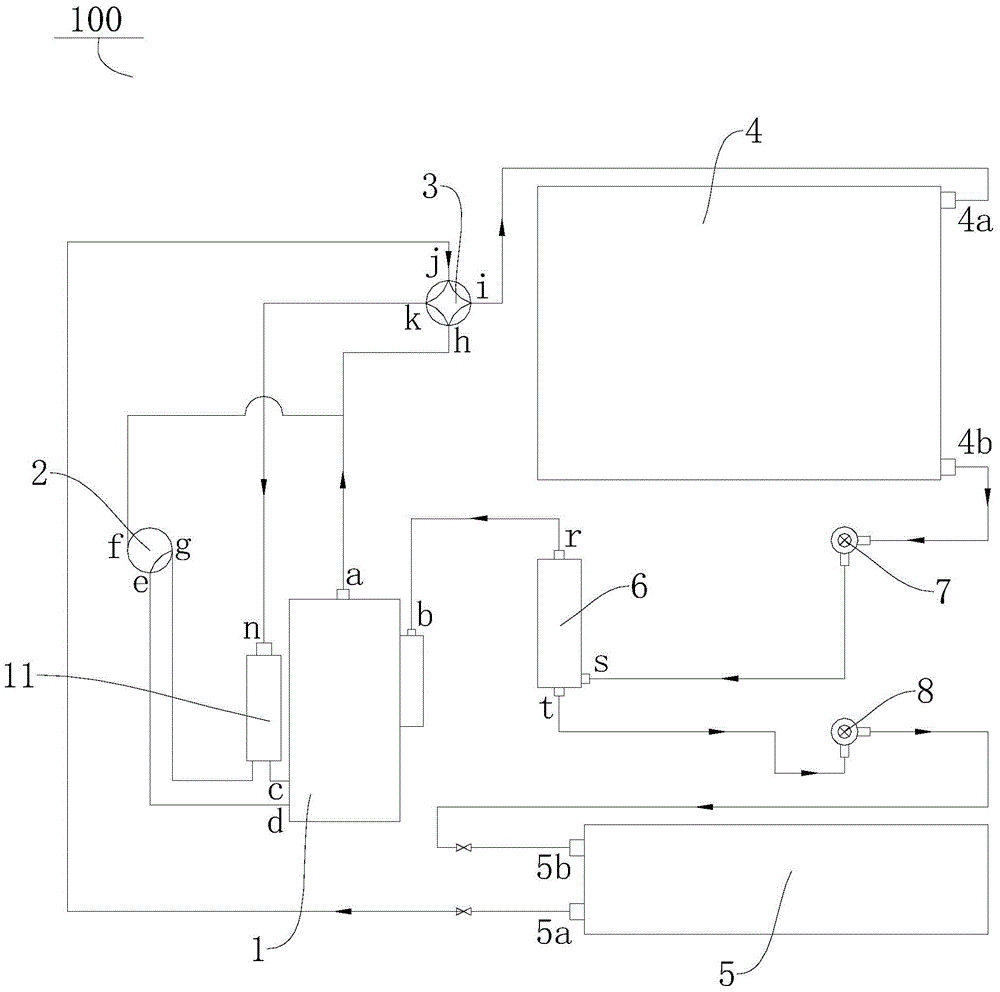

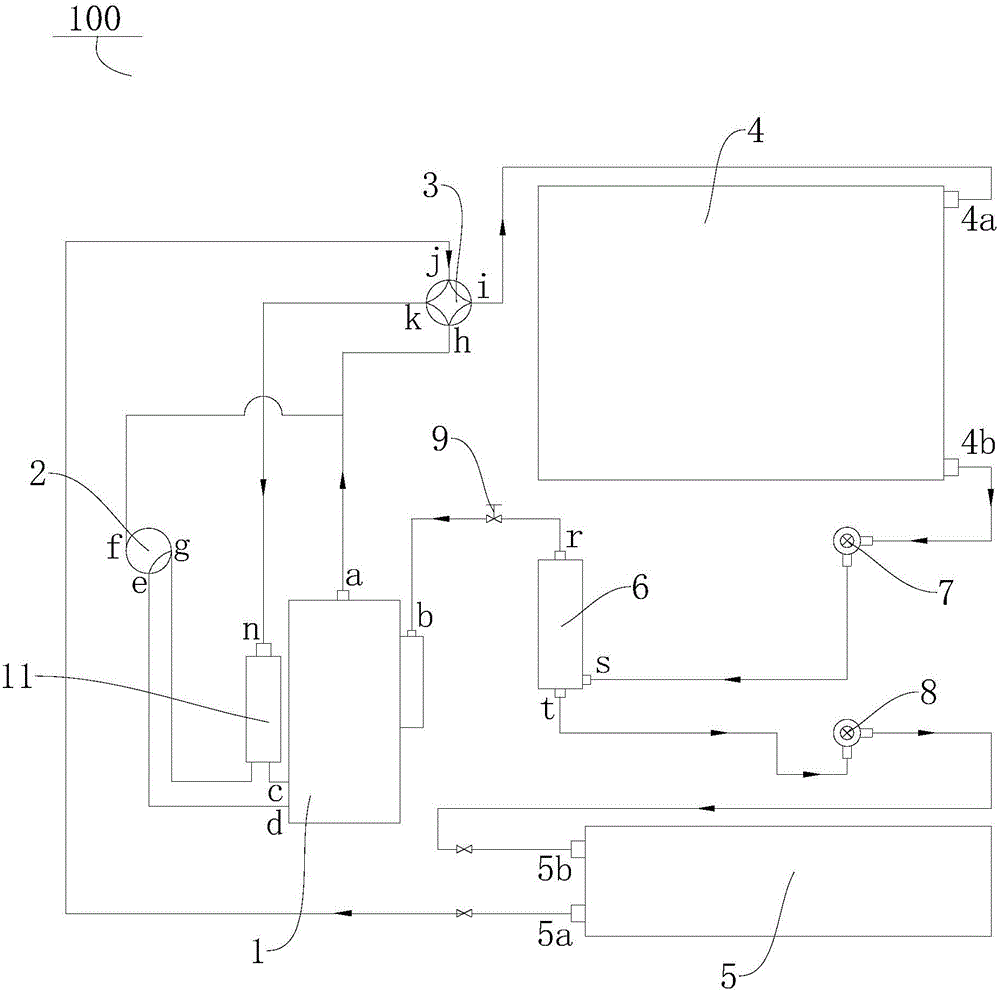

Air conditioner system and control method thereof

ActiveCN105627615AIncrease powerImprove energy efficiencyMechanical apparatusSpace heating and ventilation safety systemsEngineeringRefrigeration

The invention discloses an air conditioner system and a control method thereof. The air conditioner system comprises an enhanced vapor injection compressor, a first reversing assembly, a second reversing assembly, two heat exchangers and a flash evaporator, wherein the enhanced vapor injection compressor is provided with an air exhausting port, an air supplementation port, a first air sucking port, a second air sucking port and an air return port; the pressure of a slide piece cavity of an air cylinder corresponding to the second air sucking port is equal to the air exhausting pressure of the air exhausting port; a first pipe port of the first reversing assembly is connected with the second air sucking port, a second pipe port of the first reversing assembly is connected with the air exhausting port, a third pipe port of the first reversing assembly is connected with a liquid storage device, and the first pipe port communicates with the second pipe port or the third pipe port; an air outlet of the flash evaporator communicates with the air supplementation port. The air conditioner system can use a double-rotor mode when large-capacity output is needed during refrigeration at high temperature and heating at low temperature and use a single-rotor mode during refrigeration at low temperature and heating at high temperature.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

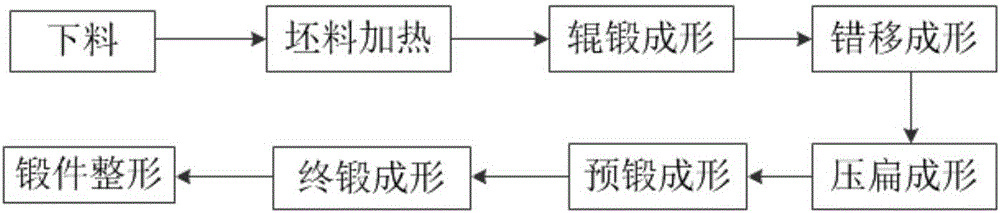

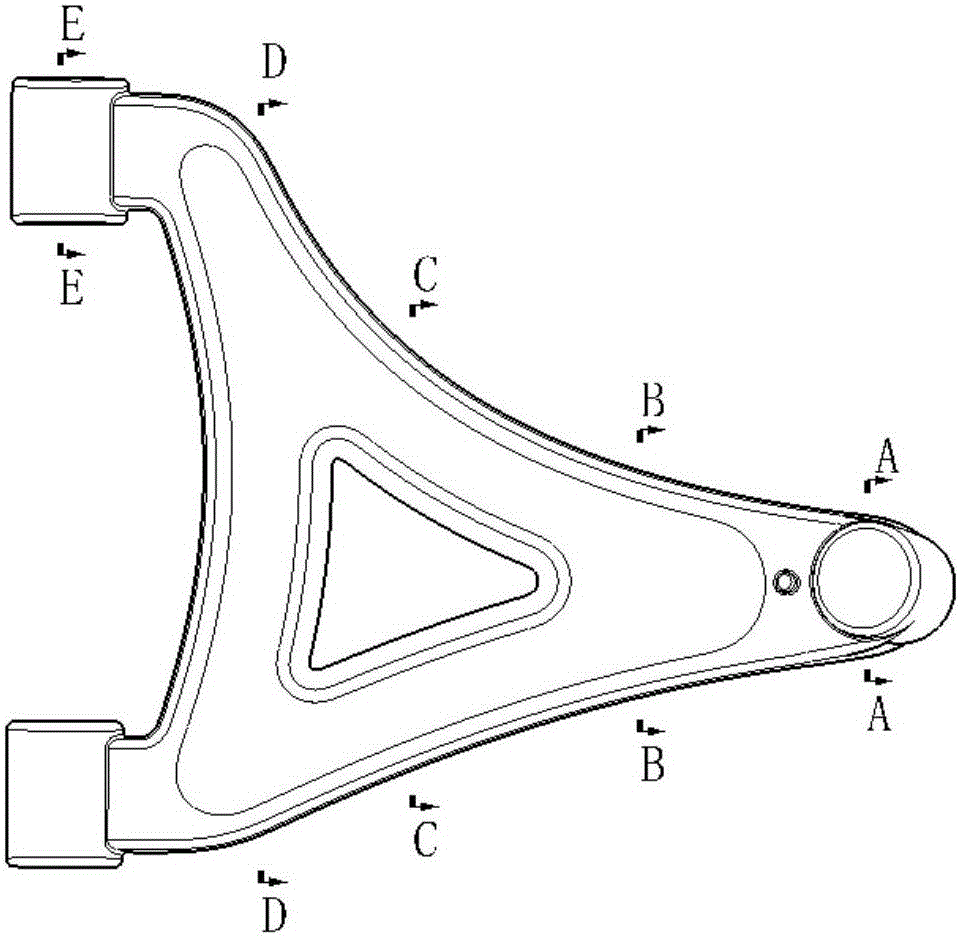

Forging forming method of triangular aluminum alloy control arm

ActiveCN106424529AAvoid Folding DefectsReduce repair workRailway componentsForging/hammering/pressing machinesControl armHeating furnace

The invention discloses a forging forming method of a triangular aluminum alloy control arm and aims at solving the problems in the prior art of low quality of a product, low material utilization ratio and low production efficiency. The forging forming method comprises the following steps: 1, blanking; 2, heating a blank: heating the blank in the first step in an electric induction heating furnace at the heating temperature of 420-480 DEG C, keeping the temperature for 5-8min to enable the blank to be uniformly heated, and finishing dynamic recrystallization after finishing forging to obtain uniform microstructures; 3, roll forgingforming: 1) calculating a roll forging pass n; 2) roll forging forming: comprising the following steps: from (1) first-pass roll forgingforming to (4) fourth-pass roll forging forming; 4, mis-shifted forming; 5, flattening forming; 6, pre-forging forming; 7, finish forging forming: carrying out finish forging forming on the basis of pre-forging forming, designing a die according to a hot forging drawing during finish forging forming, putting a pre-forging into a mold cavity of the finish forging die, and then obtaining a part in finish forging forming under the action of a press; and 8, shaping the forging.

Owner:JILIN UNIV

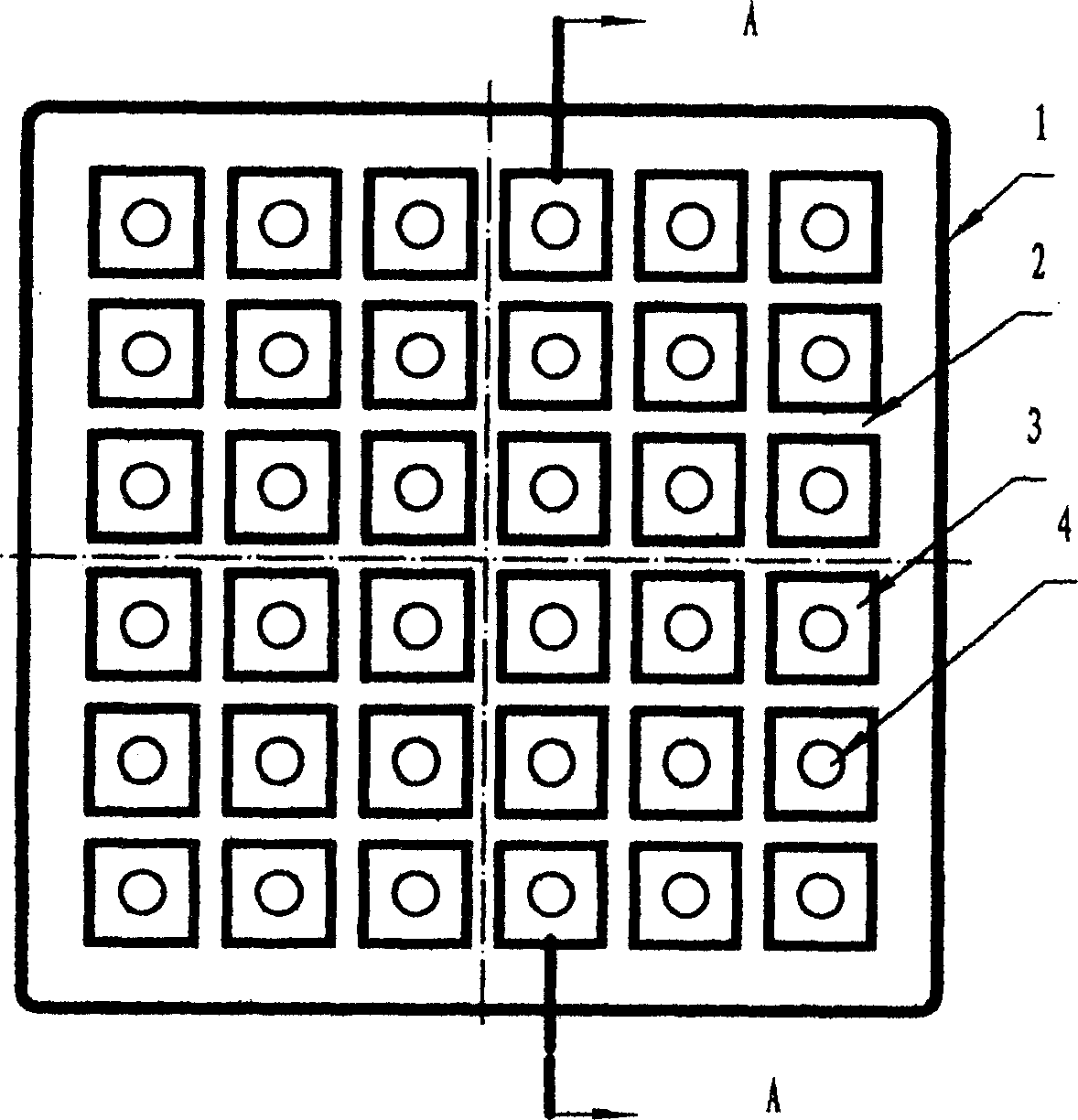

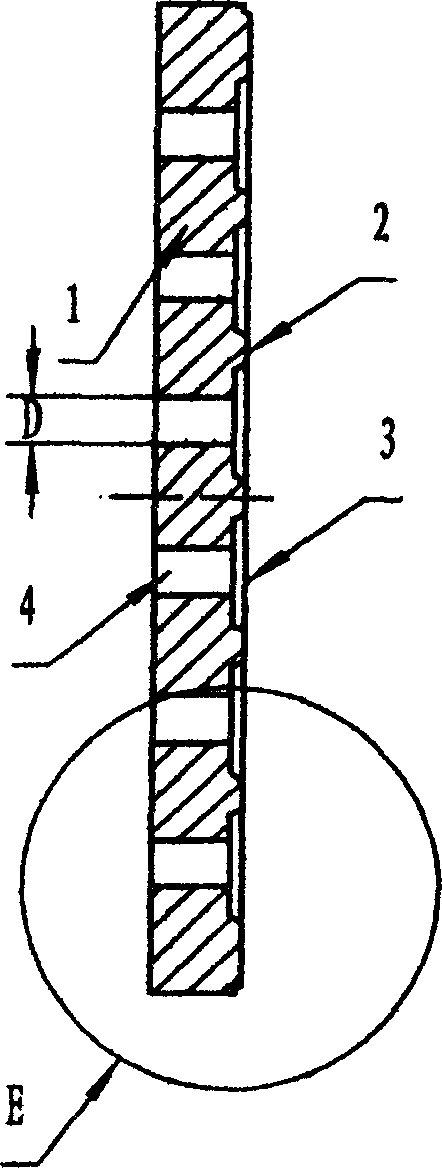

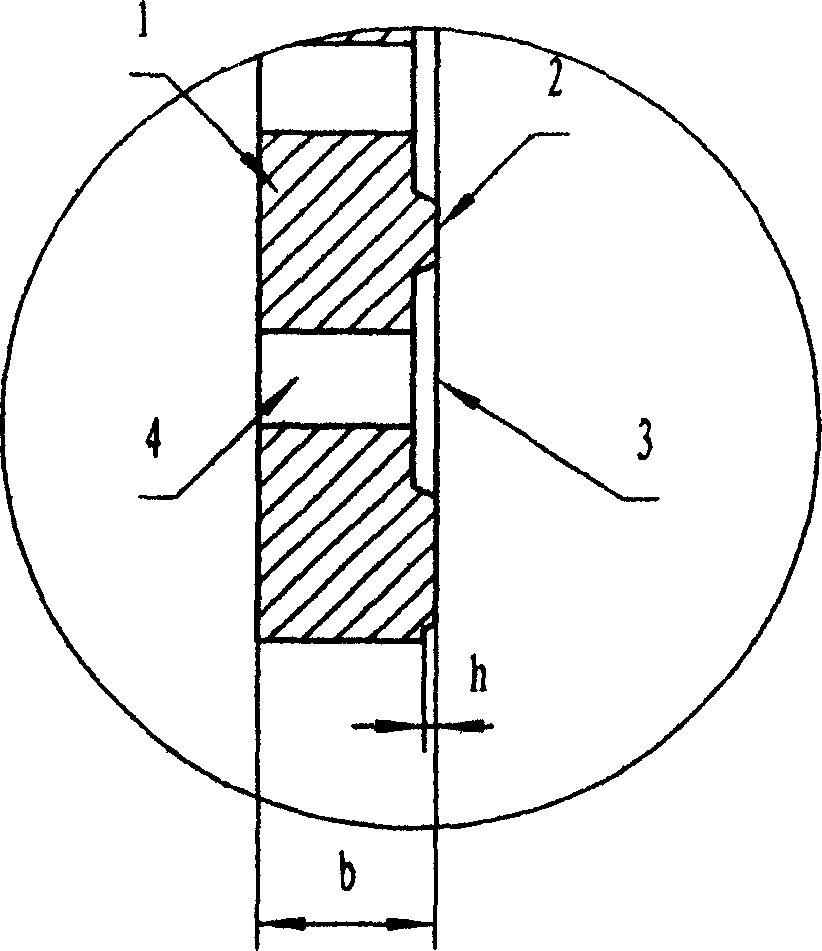

Energy-saving ceramic fire resistant bearing board

InactiveCN1724964AChange the heating methodChange the state of heatingCharge supportsBrickCombustion chamber

The invention is an energy-saving ceramic flame-resistant bearing firing plate, for solving the technical problem of making the glazed outside wall bricks fired by the same kiln have no obvious color difference but small deformation, thus improving the quality of finished products, and besides, for strengthening the intensity of bearing firing plate, reducing its breakage rate. For this, the invention fills ribs and blanks at the bottom of the bearing firing plate, where a through hole is equipped within each blank. The blanks and holes can be regularly shaped or irregularly shaped. The invention is mainly used in ceramic kiln to bear and transport the fired ceramic blanks in the course of firing and especially applied to the glazed outside wall blanks.

Owner:康健伟

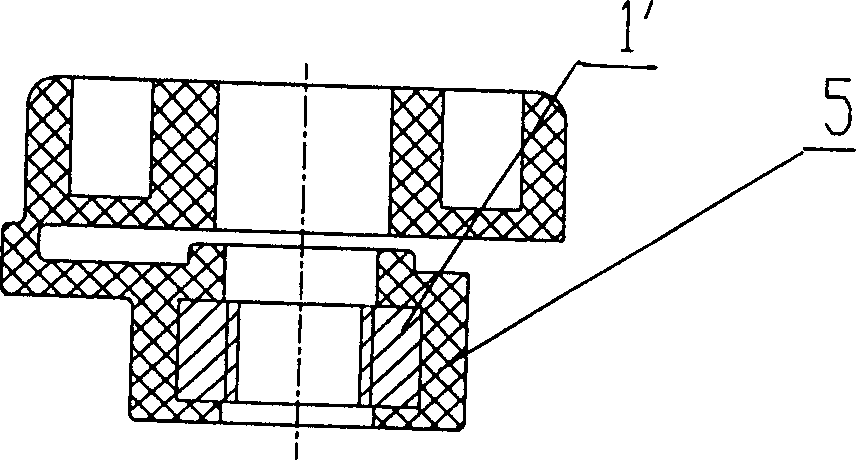

Total obstructing insulation device and electric water heater employing the same

ActiveCN1800743AFully meet the requirements of safety standardsMeet the requirements of safety standardsInsulated cablesWater heatersHome applianceSafety standards

The invention relates to an improvement of insulated device, and an electric water heater with said device, belonging to the household appliance technique. The inventive all-baffle insulated device comprises a first connected element near the electric appliance, a outwards second connected element, a separation insulated element between said two connected elements and a connection element. Said separation insulated element can at least separate the first connected element from the connection element; said connection element is through the first connected element, the separation insulated element and the second connected element to connect them. Therefore, if the first connected element is electrified by electric leakage, the other elements will not be electrified to confirm the safety. Compared to present technique, the invention can avoid the electric leakage to reach the safety standard of household appliance.

Owner:A O SMITH CHINA WATER HEATER CO LTD

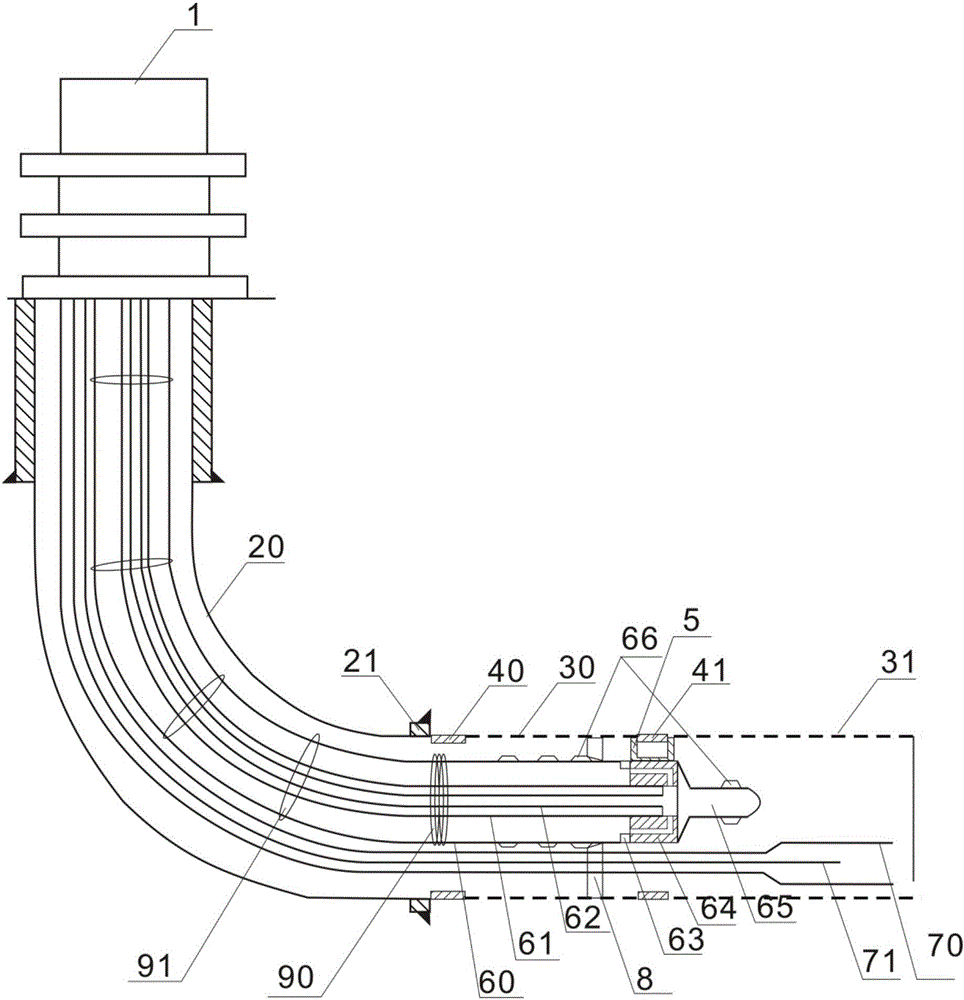

Multifunctional SLM device

ActiveCN108394099AEnsure accumulationIncrease heating speedAdditive manufacturing apparatus3D object support structuresEngineeringService efficiency

The invention discloses a multifunctional SLM device, and belongs to the technical field of laser 3D printing. The multifunctional SLM device is composed of four parts including a preheating module, avacuumizing module, a gas circulating and filtering module and a programmable logic controller (PLC).According to the multifunctional SLM device, firstly, a forming chamber is repeatedly vacuumized,and inert gas is introduced, so that the oxygen content is quickly reduced within a limit range; two modes of induction heating and infrared heating are combined, so that the heating speed is high, the material application range is wide, the heating time can be greatly shortened, the workpiece quality is obviously improved, and the temperature gradient of a forming piece is reduced; and after heating is completed, the inert gas is continuously introduced, and a secondary circulating and filtering structure is adopted, so that impurity particles in the gas are effectively filtered, the secondary service efficiency of the gas is obviously improved, and the economic cost is reduced.

Owner:KUNMING UNIV OF SCI & TECH

Air conditioner

InactiveCN104807165AImprove heating effectIncrease heating speedPump componentsLighting and heating apparatusEngineeringCavity conditioner

The invention provides an air conditioner. The air conditioner comprises a bottom shell, a first centrifugal fan and a second centrifugal fan, wherein an upper side and a lower side are arranged on the bottom shell and are oppositely arranged; a first air duct and a second air duct are arranged on the bottom shell, extend from the upper side to the lower side and are symmetrically arranged; a first upper air outlet corresponding to the upper side and a first lower air outlet corresponding to the lower side are formed in the first air duct; a second upper air outlet corresponding to the upper side and a second lower air outlet corresponding to the lower side are formed in the second air duct; a first upper volute tongue is arranged on the first upper air outlet; a first lower volute tongue is arranged on the first lower air outlet; a second upper volute tongue is arranged on the second upper air outlet; a second lower volute tongue is arranged on the second lower air outlet; the first lower volute tongue and the second lower volute tongue are respectively protruded toward a mutually closing direction, and the first upper volute tongue and the second upper volute tongue are respectively protruded toward a mutually departing direction; the first centrifugal fan is arranged in the first air duct; the second centrifugal fan is arranged in the second air duct. The air conditioner has high heating speed.

Owner:GREE ELECTRIC APPLIANCES INC

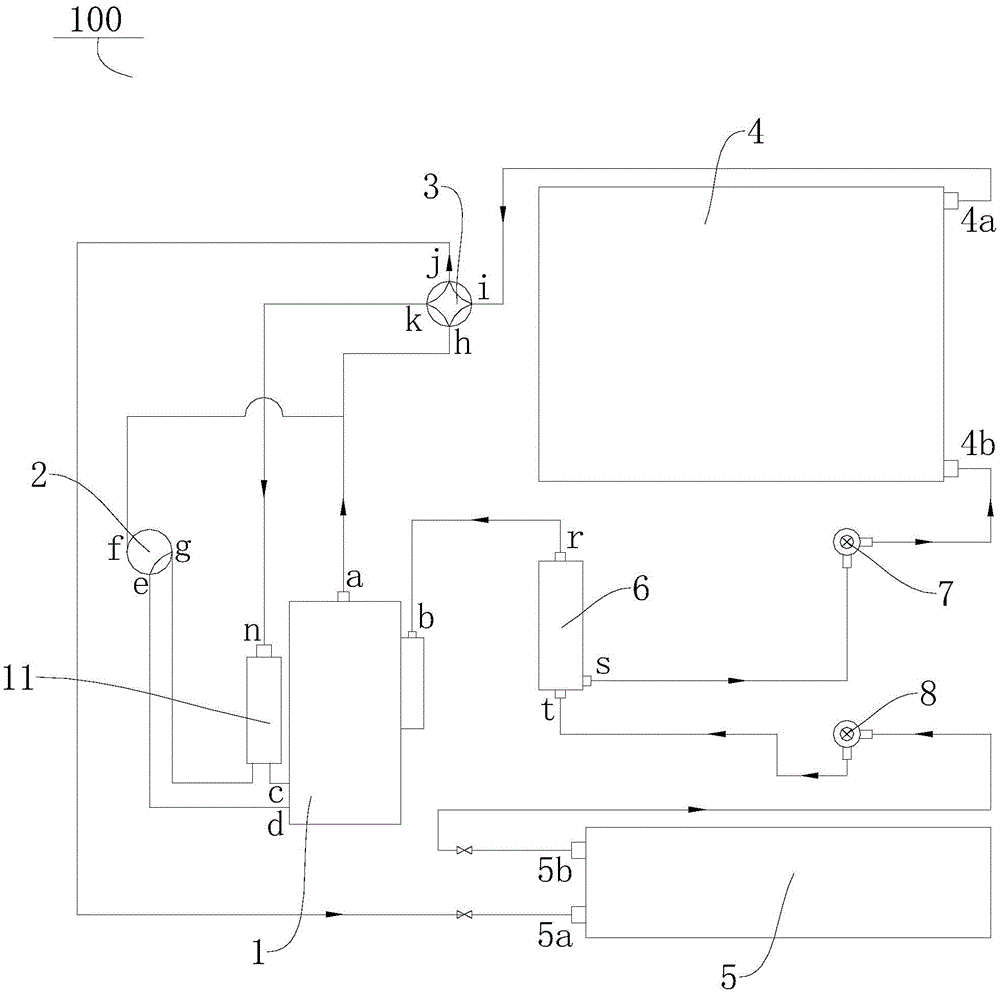

Air-conditioning system and control method of air-conditioning system

ActiveCN105757798AIncrease powerImprove energy efficiencyMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir conditioning

The invention discloses an air-conditioning system and a control method of the air-conditioning system. The air-conditioning system comprises an enhanced vapor injection compressor, a first commutating assembly, a second commutating assembly, two heat exchangers and a flash evaporator, wherein the enhanced vapor injection compressor is provided with an exhaust hole, an air supplementing hole, a first air suction hole, a second air suction hole and an air returning hole; the pressure of a slide sheet cavity of an air cylinder corresponding to the second air suction hole is the same as exhausting pressure of the exhaust hole; a first pipe opening of the first commutating assembly is connected with the second air suction hole; a second pipe opening is connected with the exhaust hole; a third pipe opening is connected with a liquid storage device; one of the first pipe opening, the second pipe opening and the third pipe opening is communicated; and a control valve is connected between a gas outlet of the flash evaporator and the air supplementing hole in series. According to the air-conditioning system disclosed by the invention, a double-rotor mode is utilized when high-temperature refrigeration and low-temperature heating need great energy output; and a single-rotor mode is utilized when low-temperature refrigeration and high-temperature heating are carried out.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP

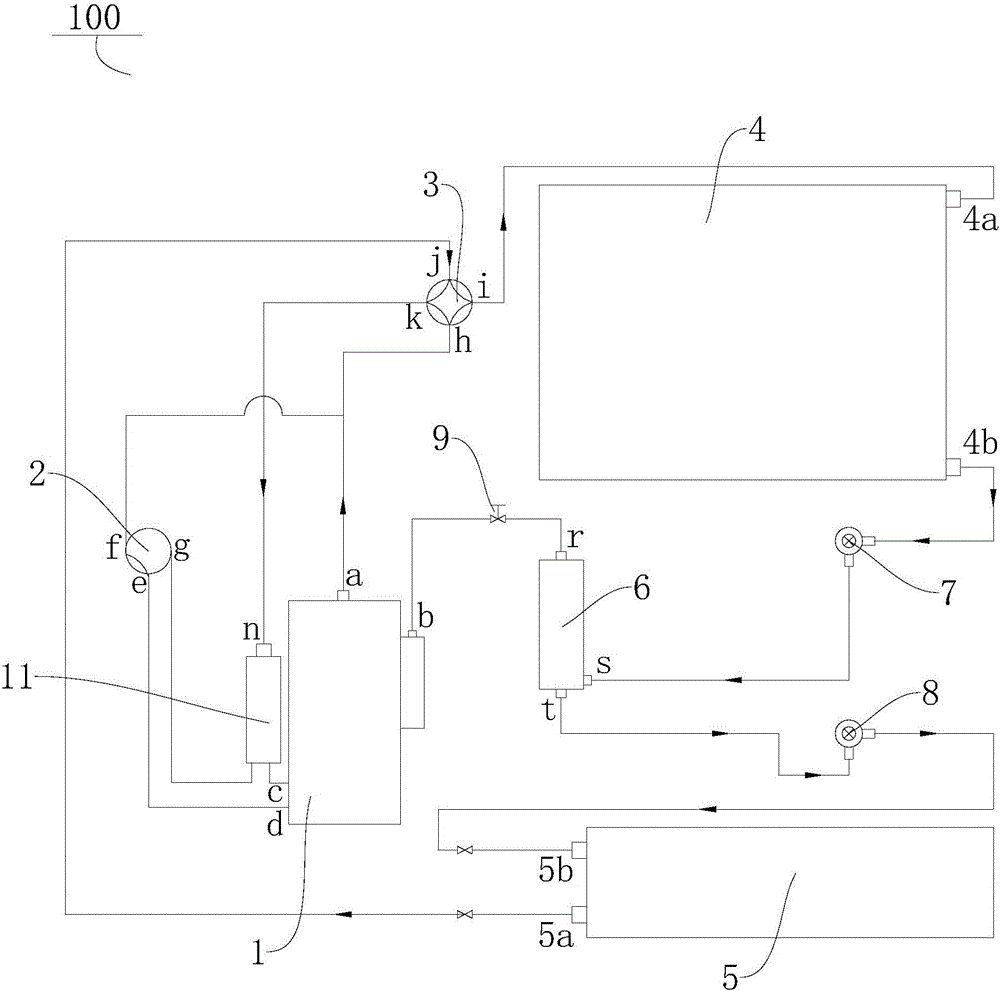

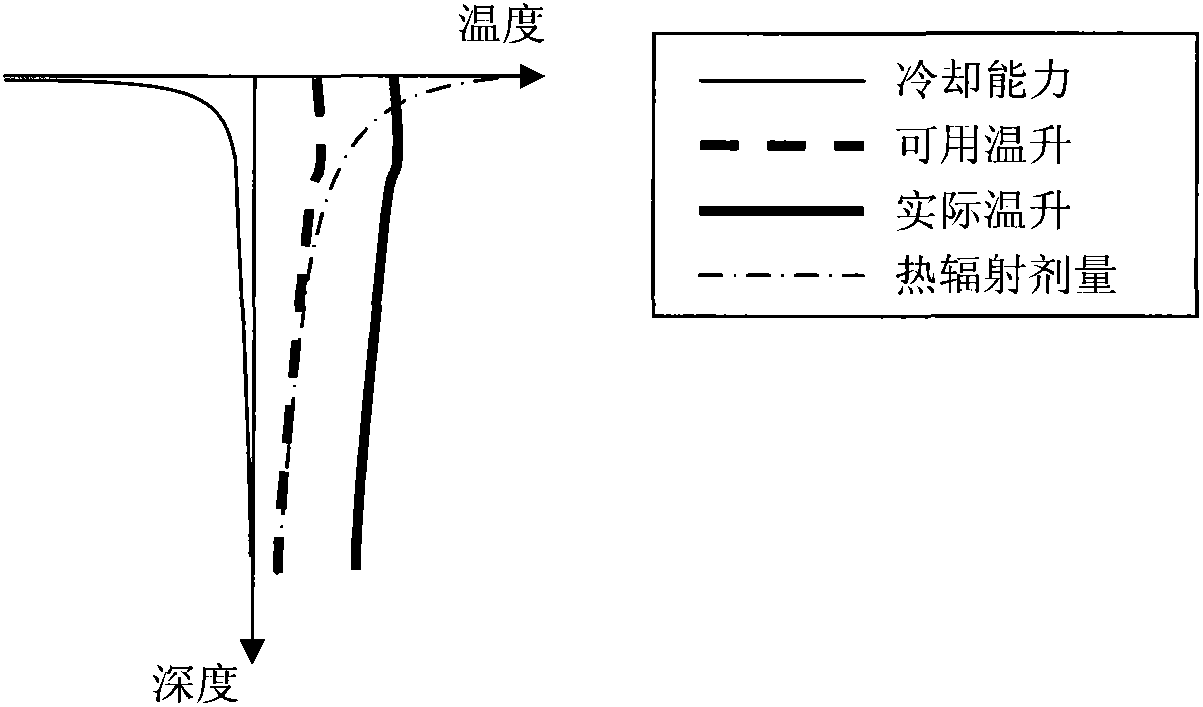

Surface-cooling non-invasive radiation whole-body thermocuring method

The invention relates to a surface-cooling non-invasive radiation whole-body thermocuring method, in particular to a non-invasive radiation whole-body thermocuring method by introducing a large amount of radiation power into the deep issues of human bodies quickly through surface-cooling technology to prevent surfaces from being burned and increase radiation power. In the method, a radiation heating system is combined with a surface-cooling system, so that low-attenuation electromagnetic radiation on the surfaces is taken away, and high dose of infrared, microwaves, radio frequency and energyradiation of electromagnetic wave probes of each frequency range are radiated to the deep parts of the human bodies for heating to realize the non-invasive radiation whole-body thermocuring. The method breaks through the technical route that improvement is performed through aspects of a heating mode, heat source control and the like in the prior art technically, introduces ultralow-temperature cooling for the first time to offset the local radiation of the surfaces and prevent overheating and empyrosis; simultaneously, the non-invasive radiation whole-body thermocuring is performed by utilizing a deep radiation heating source so as to improve power which can be accepted by organisms and prevent the surfaces from being burned substantially.

Owner:TSINGHUA UNIV

Restocking method for food vending machine

ActiveCN109615779AEasy replenishmentTake it accuratelyCoin-freed apparatus detailsApparatus for dispensing discrete articlesFood vending machinesEngineering

The invention discloses a restocking method for a food vending machine, which is used for carrying out restocking for the vending machine. The method comprises the steps of: designing a unique two-dimensional code for each food placing cavity; in each time the vending machine needs restocking, a staff reading the two-dimensional code on the food placing cavity where a meal box to be placed by using a camera in the vending machine to acquire the position information of the storage cavity; then reading the two-dimensional code of the box meals to be placed to acquire food information; the vending machine binding the food information of the meal box to be placed in the current food placing cavity, sending the information to the cloud server; and the cloud server storing the information in a database and updating original food information and inventory of the food placing cavity. According to the restocking method for the food vending machine, by means of twice code scanning of the staff,each box meal stored in the vending machine corresponds to an accurate food placing cavity position, so that it is easy for the staff to replenish, and utilization rate of the storage cabinet is improved.

Owner:ZHEJIANG UNIV OF TECH

Combustion device for volatile organic composites and simulating detection device and method of combustion device

ActiveCN109579033AIncrease heating speedImprove energy conversion efficiencyGas analyser construction detailsIncinerator apparatusCombustion chamberFixed bed

The invention discloses a combustion device for volatile organic composites and a simulating detection device and method of the combustion device. The combustion device comprises a microwave emittingsystem, a catalysis combustion chamber and a catalysis bed; a waste gas inlet and a waste gas outlet are formed in the catalysis combustion chamber; a catalyst is arranged on the catalysis bed; the catalysis bed is fixedly arranged in the catalysis combustion chamber; the waste gas inlet and the waste gas outlet are located on two sides of the catalysis bed; the microwave emitting system comprisesa microwave emitting device which is arranged on the catalysis combustion chamber; the microwave emitting device communicates with the catalysis combustion chamber through a waveguide pipe; and microwave emitted by the microwave emitting device can enter the catalysis combustion chamber through the waveguide pipe. According to the combustion device, the catalyst fixing bed is heated by microwave;VOCs waste gas is catalyzed, oxidized and mineralized high-efficiently; the degradation and mineralization rate can be improved; and reaction energy consumption is lowered.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

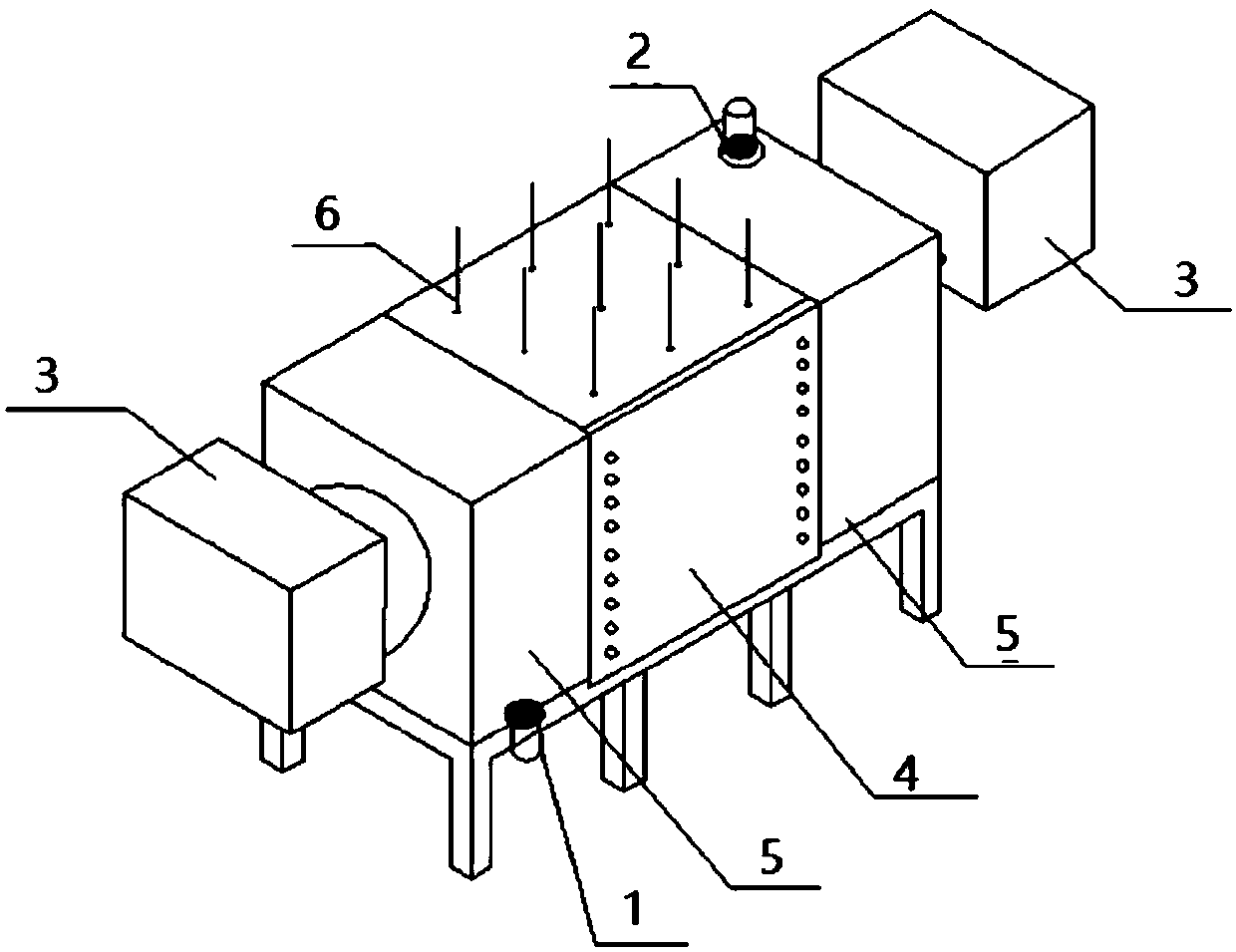

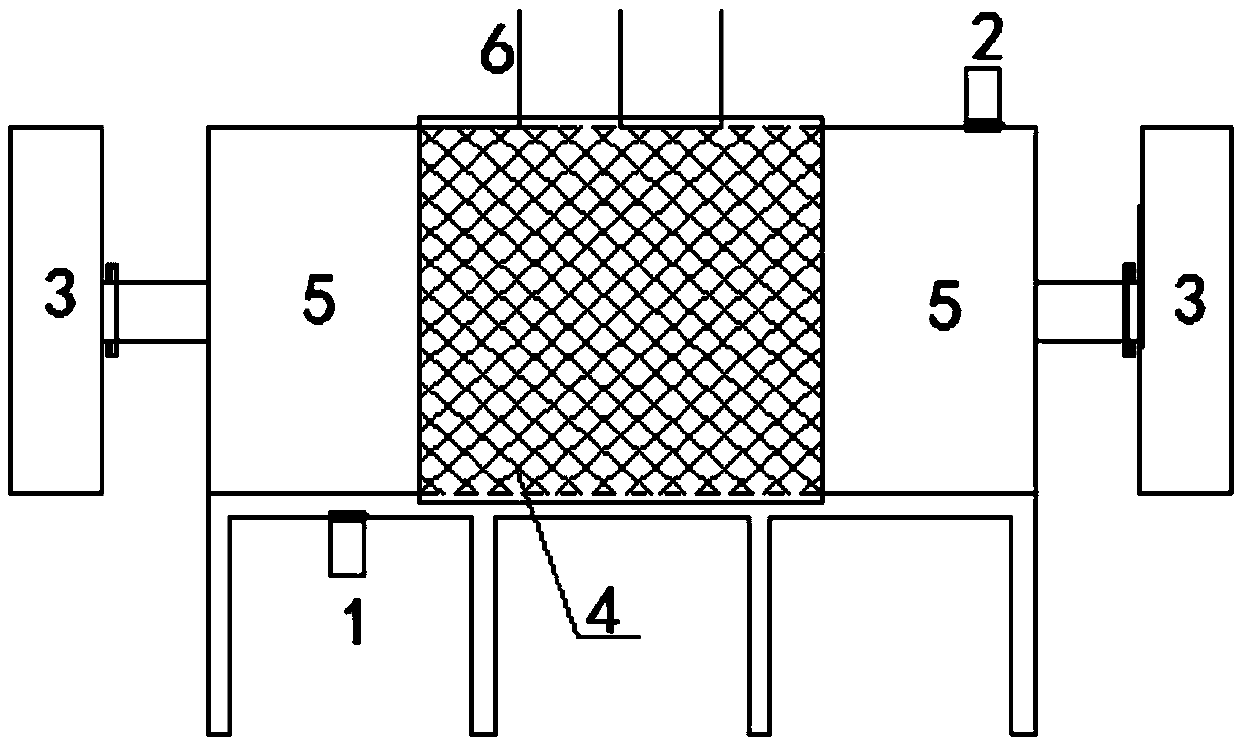

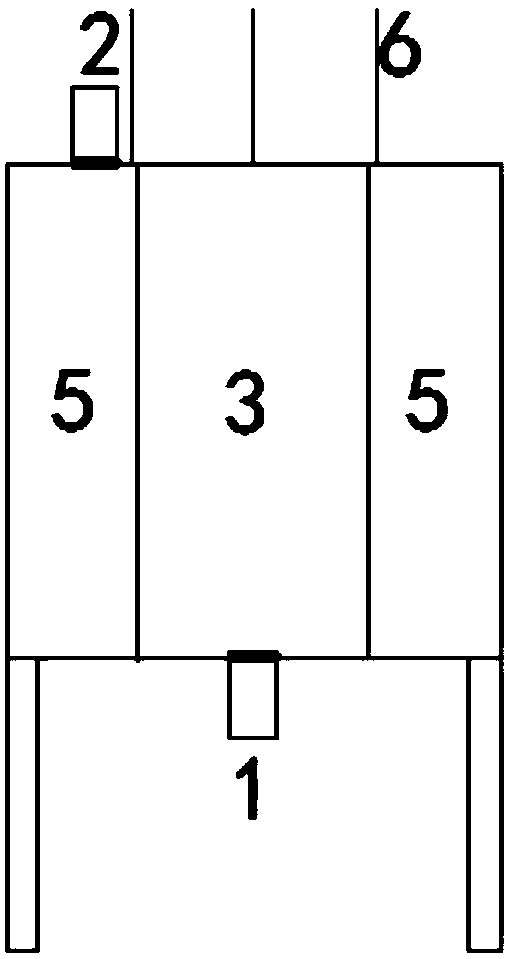

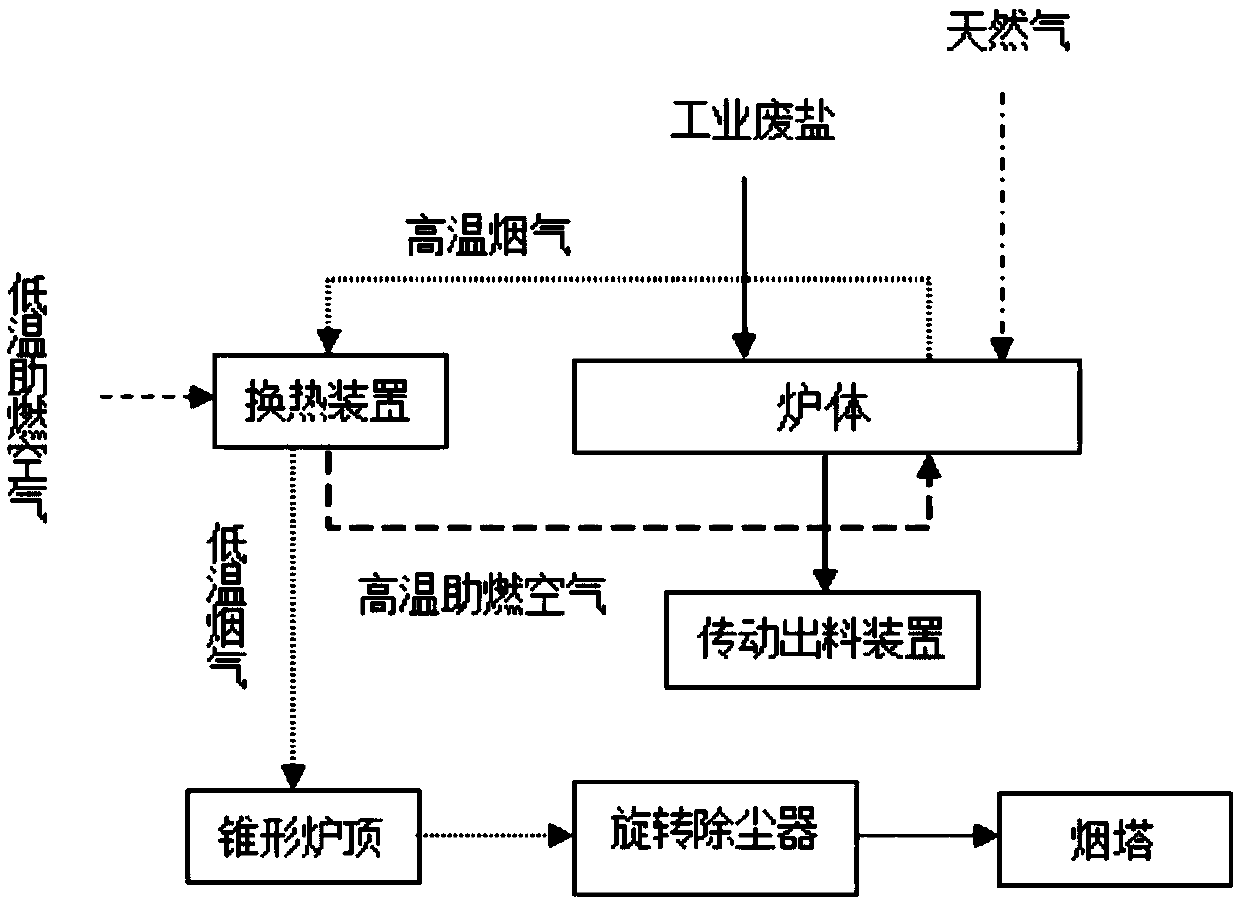

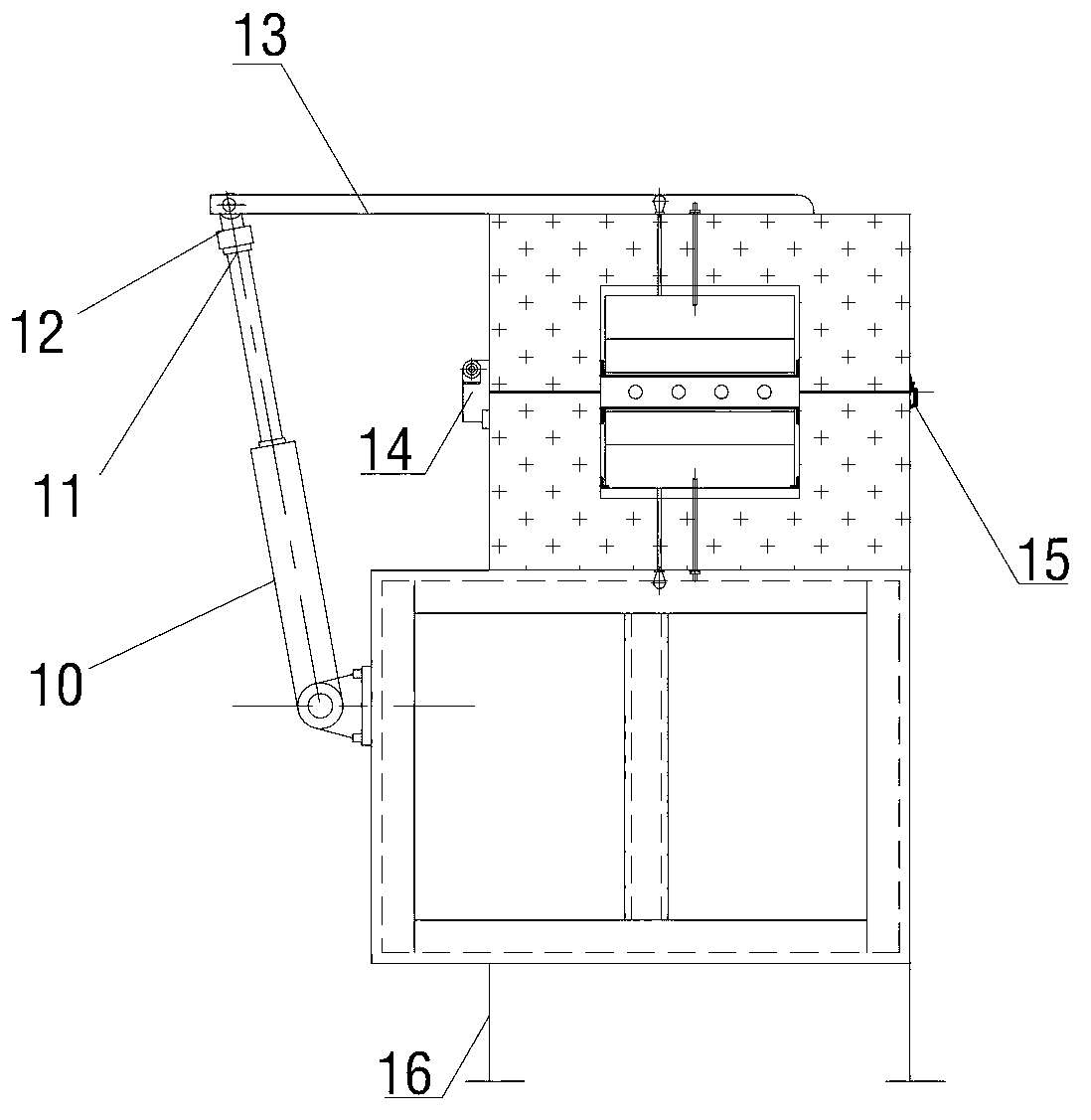

High-efficiency melting and incineration device for industrial waste salt

InactiveCN109579025AEfficient removalAvoid secondary pollutionIncinerator apparatusSimple Organic CompoundsCombustion

The invention belongs to the technical field of environmental protection and industrial waste treatment and particularly relates to a high-efficiency melting and incineration device for industrial waste salt. The high-efficiency melting and incineration device for industrial waste salt comprises a melting incinerator body, a waste heat recovery device, a burner A, a burner B, a combustion air pipeline A, a combustion air pipeline B, a flue gas pipeline, a blower, an induced draft fan, an electric control valve, a lifting feeder, a furnace bottom transmission mechanism and a transmission discharging device. According to the high-efficiency melting and incineration device for industrial waste salt, toxic organic compounds in secondary high-temperature incineration flue gas are utilized, andthe waste heat recovery device is utilized, so that the flue gas temperature is reduced, combustion-supporting air is preheated, and meanwhile the effects of protecting the environment and improving the thermal efficiency of a furnace can be achieved.

Owner:NORTHEASTERN UNIV

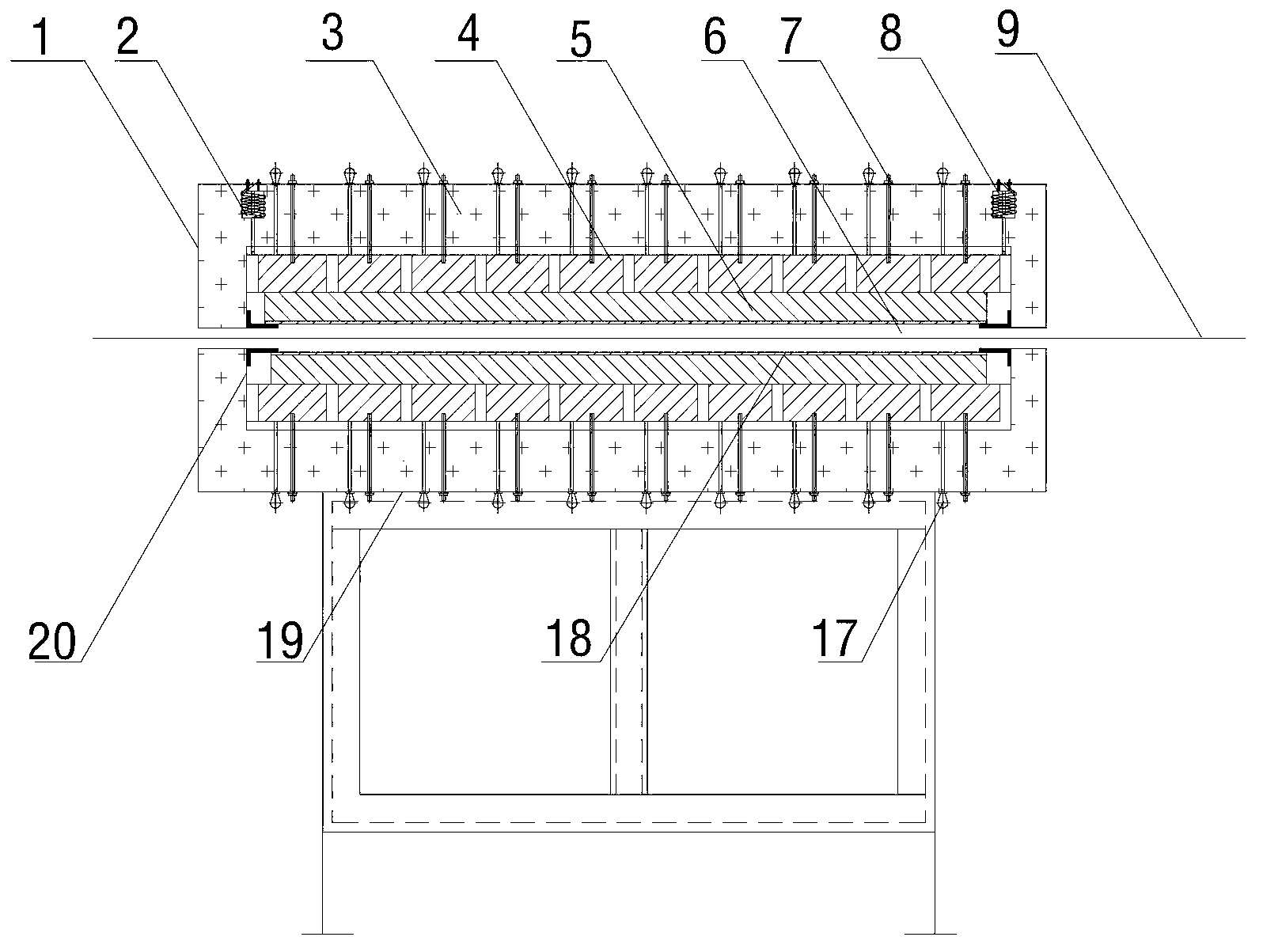

High-temperature heat setting device

ActiveCN103276490AImprove uniformityUniform temperature distributionTextiles and paperEngineeringHeat setting

The invention provides a high-temperature heat setting device. The high-temperature heat setting device comprises a box body, frames and heating devices. The box body comprises an upper casing body, a lower casing body and inner cavity bodies, wherein the inner cavity bodies comprise an upper cavity body arranged on the upper casing body and a lower cavity body arranged on the lower casing body. The frames comprise a first frame arranged on the upper cavity body and a second frame arranged on the lower cavity body, wherein the first frame body and the second frame body are correspondingly arranged. The heating devices comprise a first heating device arranged inside the first frame body and a second heating device arranged inside the second frame body, and both the first heating device and the second heating device comprise a plurality of plate-type heaters which are sequentially arranged in the length direction of the frames. According to the technical scheme of the high-temperature heat setting device, the heating devices are divided into the plurality of plate-type heaters to enlarge contact areas, improve heating efficiency and heating speed, reduce energy consumption and improve the uniformity degree of the temperature distribution of the box body, and the box body is of a frame type structure so that heat deformation of the box body due to long-time operation under high temperatures can be effectively avoided.

Owner:CHINA PETROLEUM & CHEM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com