High-temperature heat setting device

A technology of heating and equipment, applied in the field of chemical fiber processing, can solve the problems of temperature and box temperature difference, slow speed, low efficiency, etc., and achieve the effect of preventing oxidation, increasing the heating contact area, and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

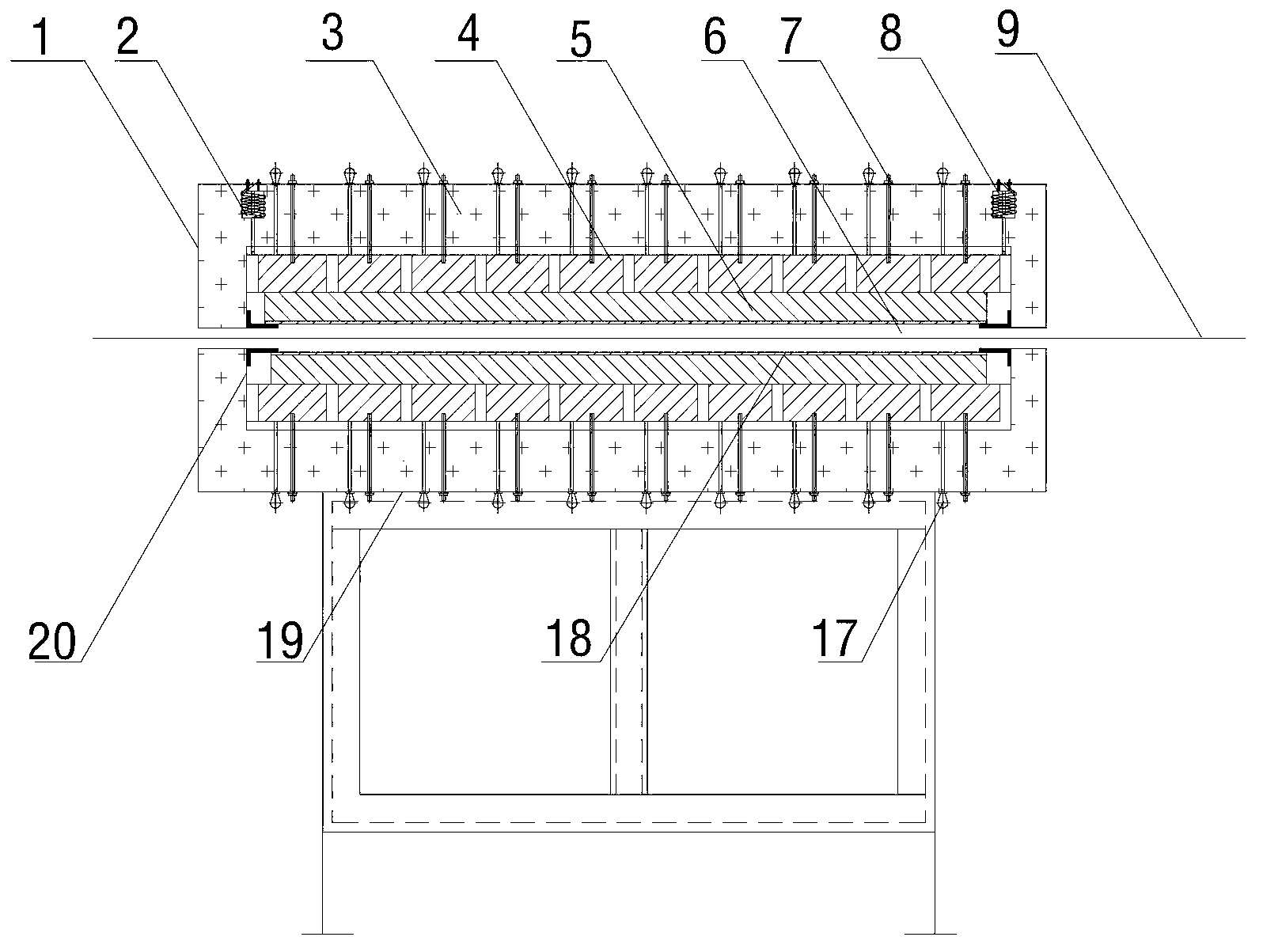

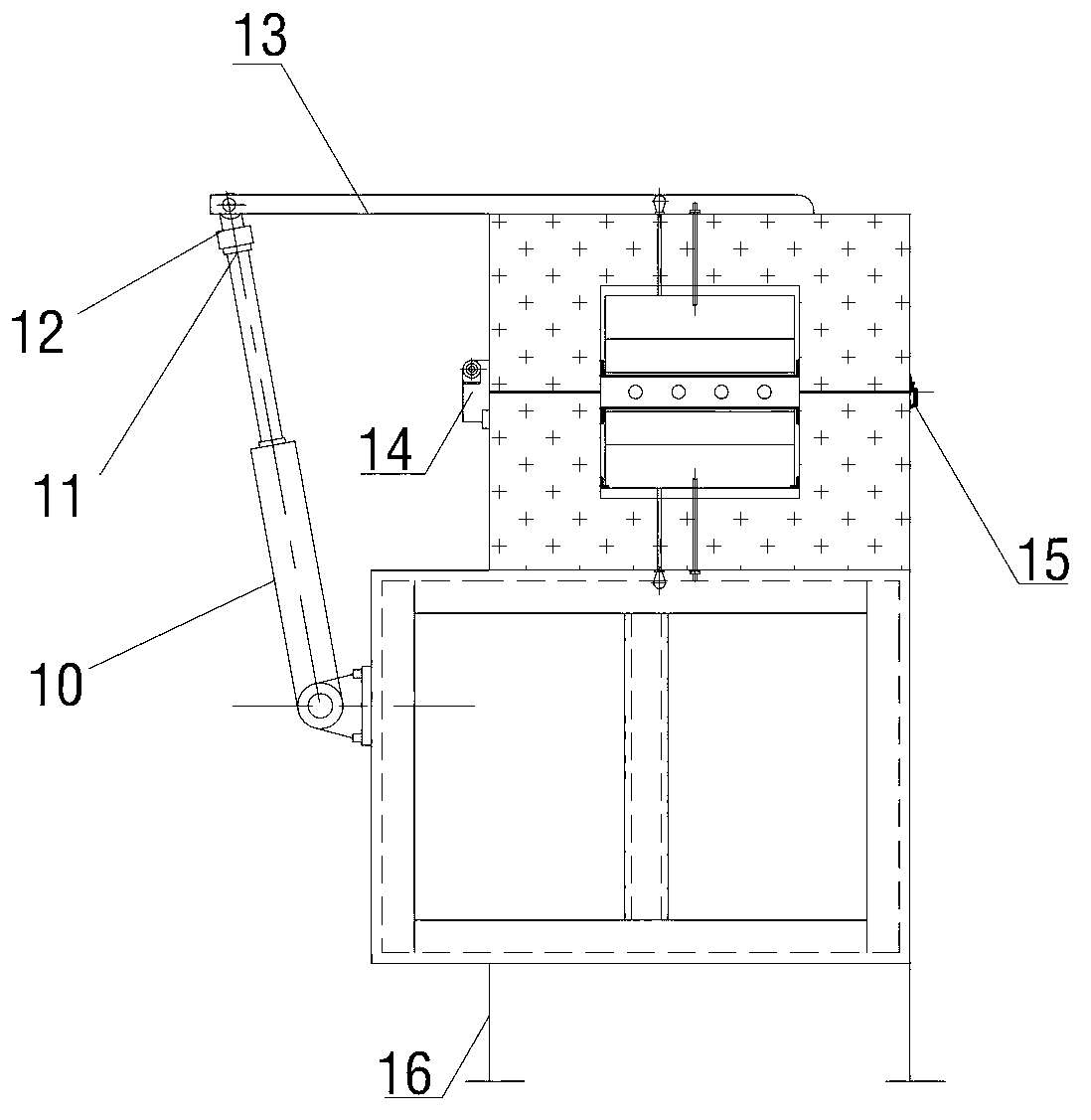

[0033] The high-temperature heat-setting equipment according to the embodiment of the present invention includes: a box body, a frame 20 and a heating device. The length of the constant temperature zone of the box body of the high temperature heat setting equipment provided by the present invention is 2000mm to 3000mm. The width of the constant temperature zone is according to the formula W=n (w x +10) +20, where W is the width of the constant temperature zone of the box, in mm, w x is the width of fibers or fabrics, in mm, and n is the number of fibers or fabrics, and the numerical units represented by the above letters are millimeters. Preferably, the constant temperature zone in this embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com