Manufacturing method of ultrathin heat-reinforced glass

A heat-strengthened glass and manufacturing method technology, applied to glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the problems of no temperature transfer, few convection points, and difficult re-cutting, etc., to achieve enhanced heating speed and balanced temperature, Effect of increasing radiation area and avoiding unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

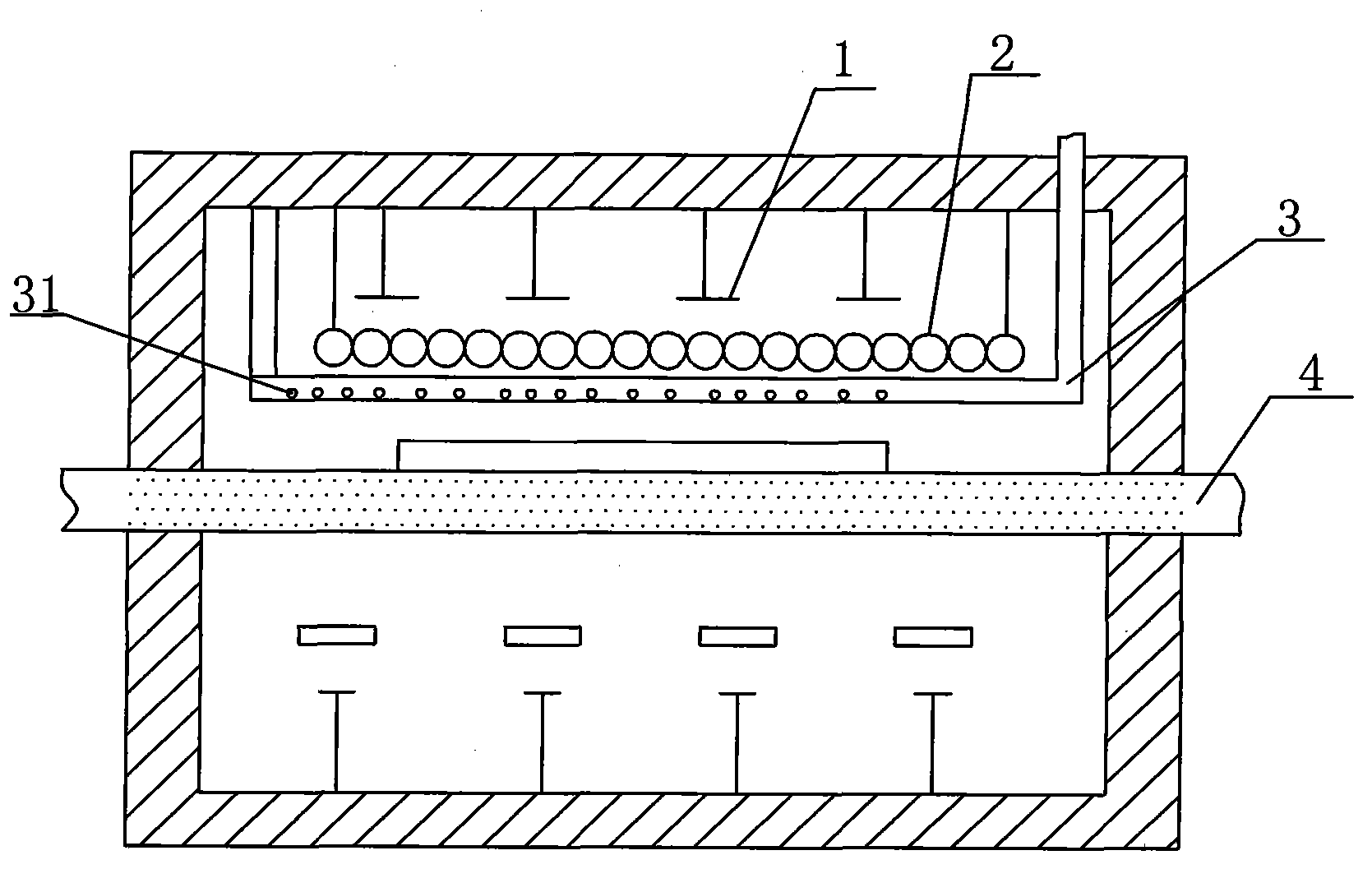

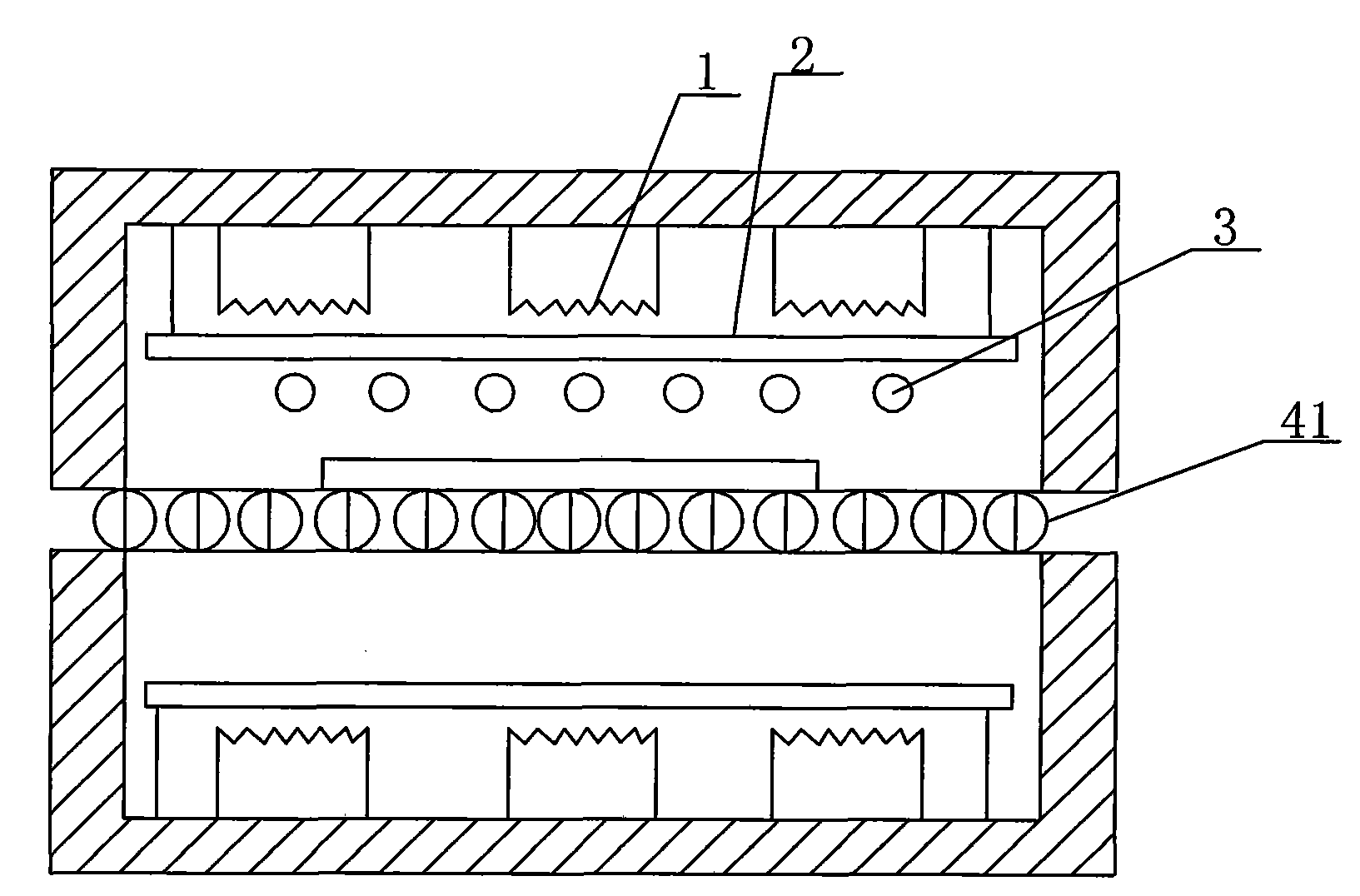

Method used

Image

Examples

Embodiment 1

[0035] Put the ultra-thin glass with a thickness of 1.8-2.2mm flat on the roller table, the glass is transported to the tempering furnace for heating, and the pressure of the convection air in the tempering furnace is adjusted to 2000pa / cm 2, the convection time is 30s, and the roller table drives the glass to reciprocate in the tempering furnace at a speed of 20mm / s. until the glass is heated to 623°;

[0036] The ultra-thin glass heated to 623° is conveyed to the quenching zone through the roller table, and the roller table drives the glass to reciprocate in the quenching zone at a speed of 130mm / s. to 460°, then stop blowing, and the glass continues to reciprocate for 5S;

[0037] The glass after quenching treatment for 5S is blown again, and the wind pressure is controlled at 1500pa until the glass is completely cooled and reaches room temperature to form ultra-thin heat-strengthened glass.

Embodiment 2

[0039] Put the ultra-thin glass with a thickness of 1.8-2.2mm flat on the roller table, the glass is transported to the tempering furnace for heating, and the pressure of the convection air in the tempering furnace is adjusted to 3000pa / cm 2 , the convection time is 40s, and at the same time, the roller table drives the glass to reciprocate in the tempering furnace at a speed of 25mm / s. until the glass is heated to 626°;

[0040] The ultra-thin glass heated to 626° is conveyed to the quenching zone through the roller table, and the roller table drives the glass to reciprocate in the quenching zone at a speed of 190mm / s. Drop to 430°, then stop blowing, and the glass continues to reciprocate for 10S;

[0041] The glass after quenching treatment for 10 seconds is blown again, and the wind pressure is controlled at 2000pa until the glass is completely cooled and reaches room temperature, forming ultra-thin heat-strengthened glass.

Embodiment 3

[0043] Put the 1.8-2.2mm thick ultra-thin glass flat on the roller table, the glass is sent to the tempering furnace for heating, and the pressure of the convection air in the tempering furnace is adjusted to 4000pa / cm 2 , the convection time is 50s, and at the same time, the roller table drives the glass to reciprocate in the tempering furnace at a speed of 30mm / s. until the glass is heated to 630°;

[0044] The ultra-thin glass heated to 630° is conveyed to the quenching zone through the roller table, and the roller table drives the glass to reciprocate in the quenching zone at a speed of 250mm / s. to 400°, then stop blowing, and the glass continues to reciprocate for 15S;

[0045] The glass after quenching treatment for 15S is blown again, and the air pressure is controlled at 2500pa until the glass is completely cooled and reaches normal temperature to form ultra-thin heat-strengthened glass.

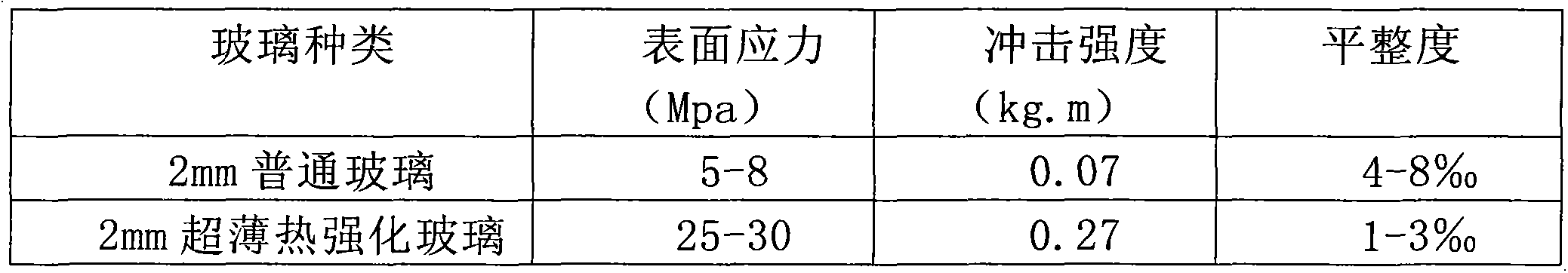

[0046] It is determined by tests that the surface stress intensity of the glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com