Patents

Literature

160 results about "Glass strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tempered glass strength detecting device

ActiveCN106568663APrevent splashAvoid harmMaterial strength using tensile/compressive forcesInvestigating material hardnessHydraulic cylinderAgricultural engineering

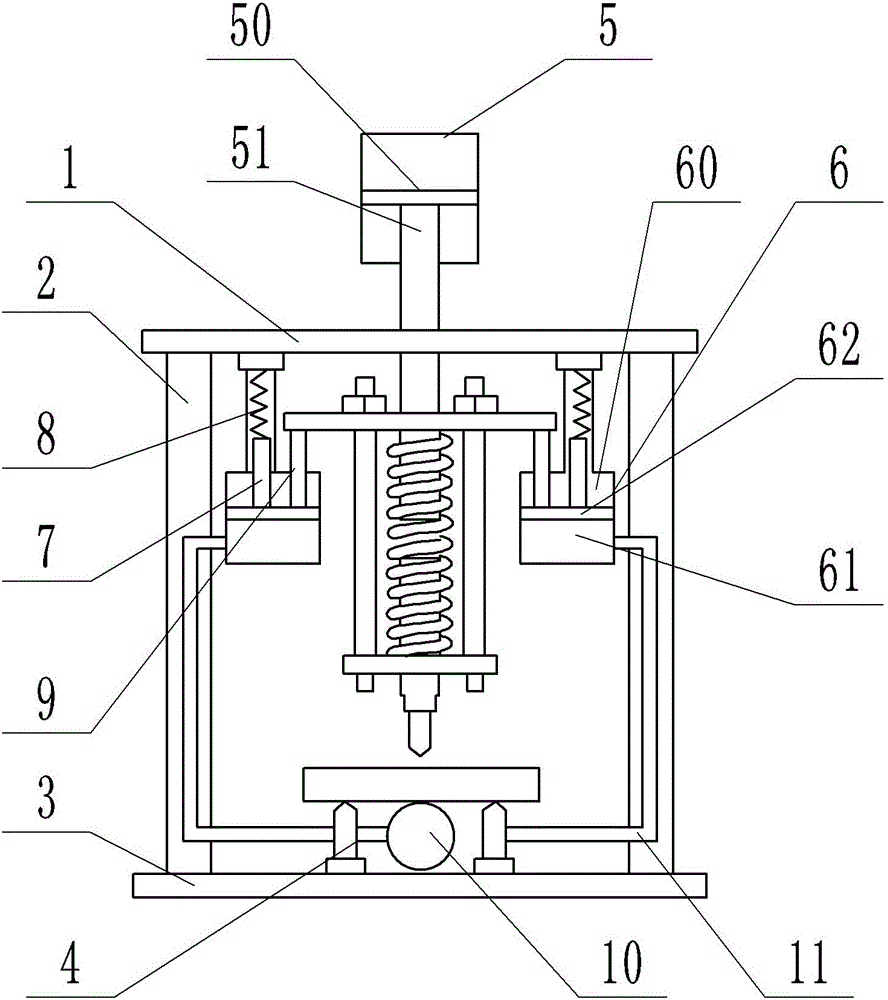

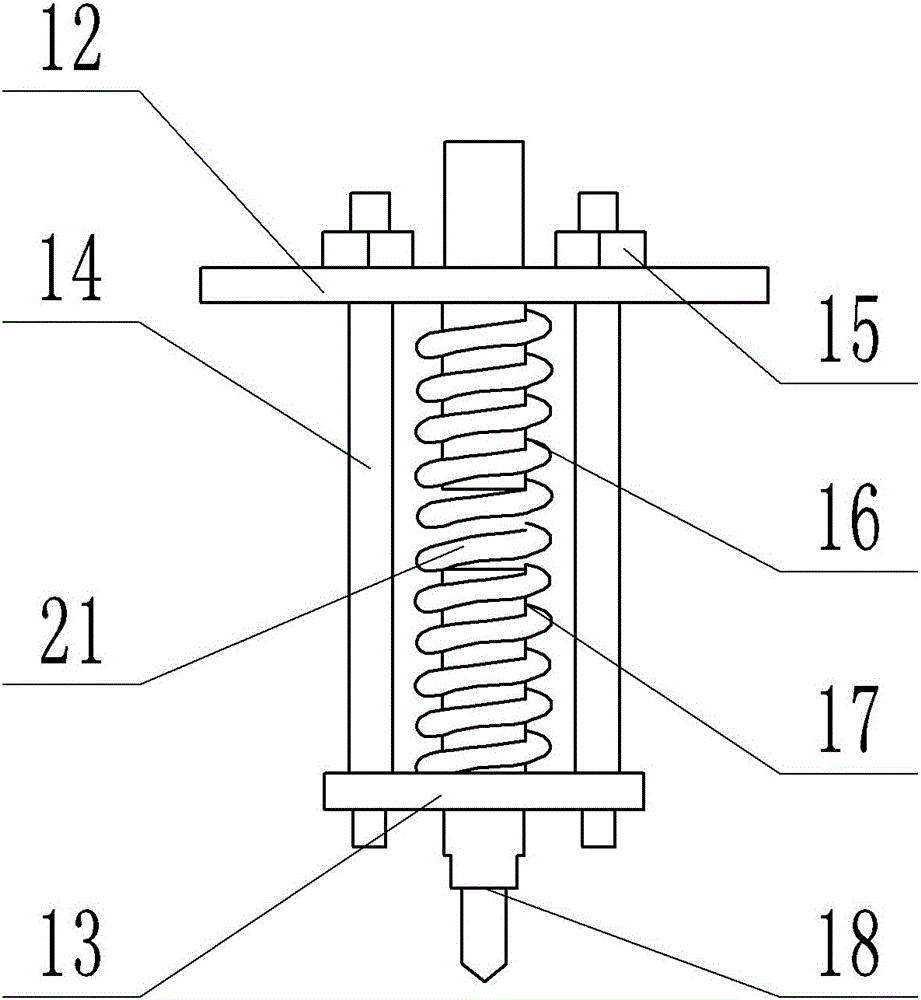

The invention discloses a tempered glass strength detecting device. The tempered glass strength detecting device comprises a machine frame and a detection component, a spring, an air cylinder, a deformation component, and liquid drainage pipes; the detecting component is arranged on the machine frame and comprises an upper fixing plate; each of the two ends of the lower part of the upper fixing plate is slidingly connected with a subordinate guide rod, the middle part of the upper fixing plate is fixedly connected with a principal guide rod, and the lower part of the principal guide rod is provided with a pressure rod; the principal guide rod and the pressure rod are sleeved with the spring; the air cylinder comprises a piston and a piston rod; the lower end of the piston rod is connected with the principal guide rod; a hydraulic cylinder is arranged between the principal guide rod and each subordinate guide rod; each hydraulic cylinder comprises an upper cylinder, a lower cylinder, a push plate, and a first connecting rod; one end of each first connecting rod is connected with the corresponding push plate; a second connecting rod is connected with the upper part of each push plate; the second connecting rods are fixedly connected with the upper fixing plate; a hydraulic air bag is arranged below a test block; and the hydraulic air bag is connected with the two lower cylinders via the two liquid drainage piles respectively.

Owner:CHONGQING XINGBAOXING GLASS PROD CO LTD

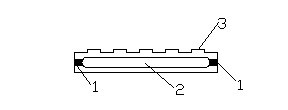

Universal clamp suitable for detecting glass strength of mobile phones in various sizes

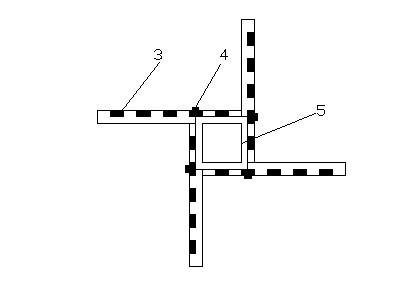

The invention relates to a universal clamp suitable for detecting glass strength of mobile phones in various sizes, which comprises four supporting blocks. Side surfaces at both ends of each supporting block are provided with screw holes respectively and the end surface of each supporting block is provided with a concave-convex table. The side surface of each supporting block is provided with a through groove hole. The screw holes and through groove holes on the four supporting blocks are penetrated through by bolts respectively to fixedly connect the four supporting blocks so as to form a product supporting surface combined by the concave-convex tables on the four supporting blocks. The size of the clamp can be changed by moving the position of the bolt in the through groove hole and the glass strength of products in various sizes can be detected by the clamp. The clamp is convenient and practical and reduces the cost.

Owner:TIANJIN ZHONGHUAN HI TECH

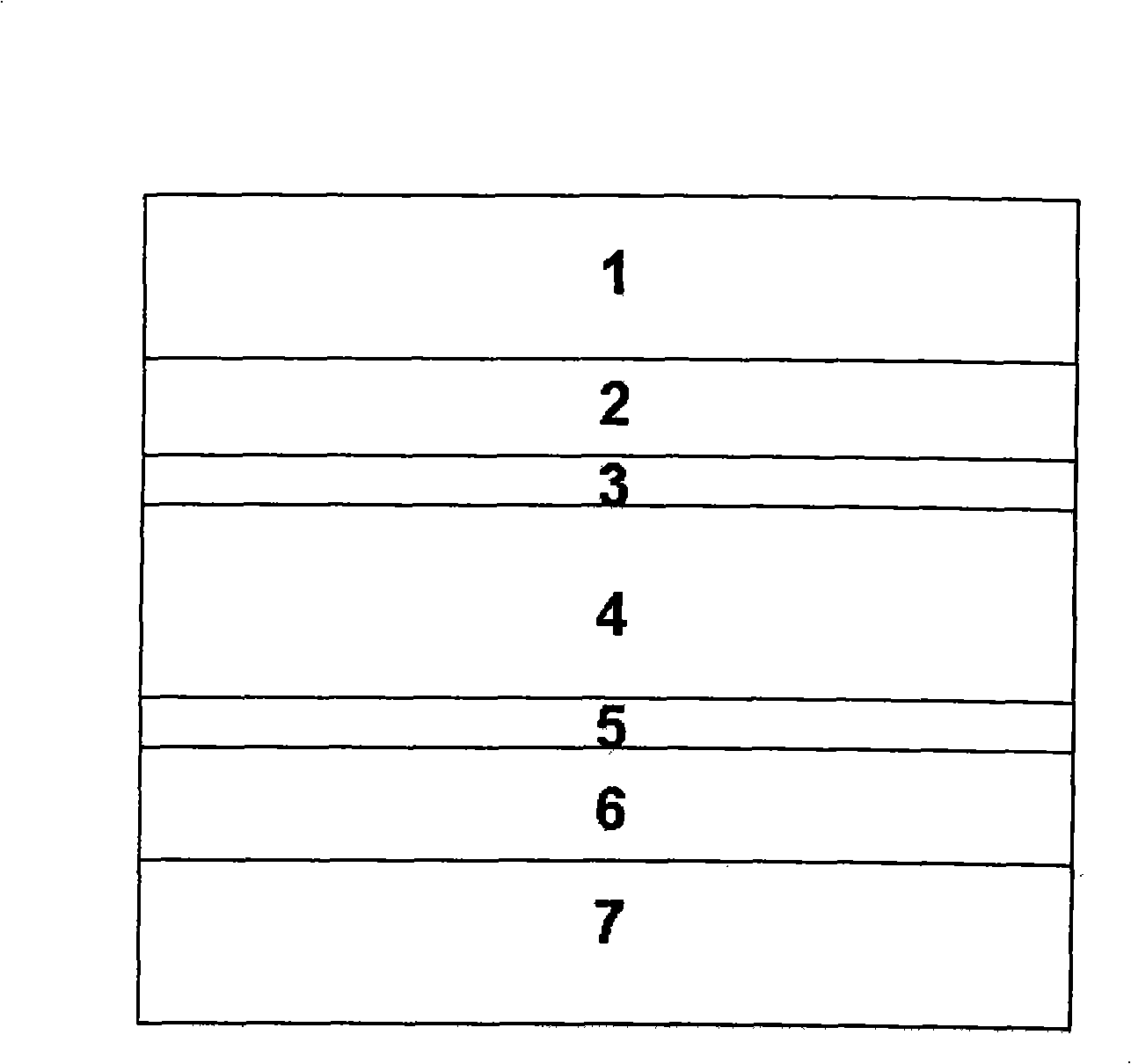

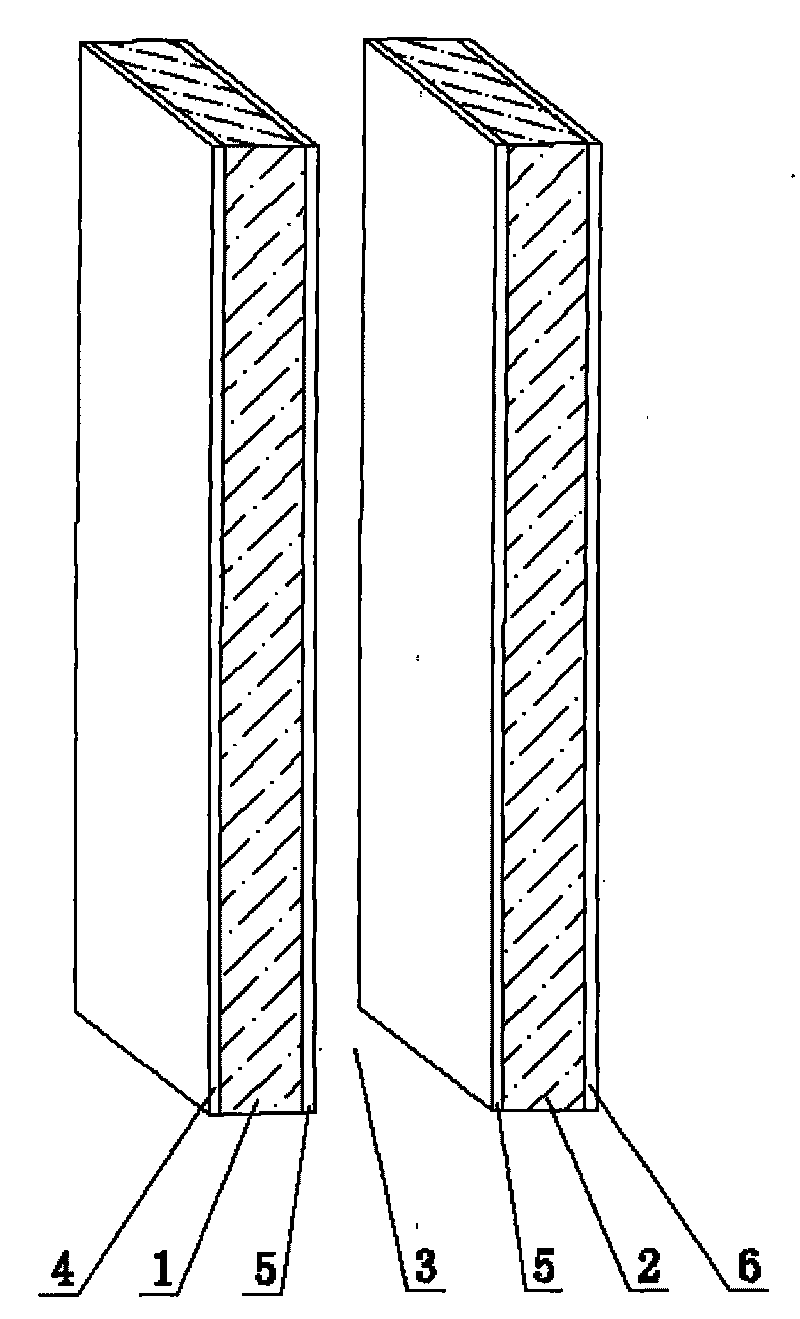

Viewing glass for radio frequency electromagnetic screen and method for preparing same

InactiveCN101289287AImprove transmittanceImprove permeabilityMagnetic/electric field screeningScreening apparatusEvaporationElectromagnetic shielding

The invention discloses a sight glass for shielding radio frequency electromagnetic wave, which consists of a first white glass layer, a first transparent and conductive ITO metallic oxide film layer, a first metal film layer with silver and titanium alloy, a PU doubling layer, a second metal film layer with silver and titanium alloy, a second transparent and conductive ITO metallic oxide film layer and a second white glass layer in sequence. By combining with the glass doubling technology, the sight glass of the invention is prepared by adopting electron beam evaporation to deposit an ITO / Ag-Ti alloy bilayer film in situ. The sight glass for shielding radio frequency electromagnetic wave of the invention has high intensity, low cost and the shielding efficiency of more than 30dB on the radio frequency electromagnetic wave of 30MHz-5GHz. Meanwhile, the sight glass of the invention has good permeability against visible light while the permeability rate is more than 70 percent, solving the technical problem that the transmittance of light and the electromagnetic shielding of the existing ITO coated glass and wire mesh interlayer shielding glass products can not be realized at the same time.

Owner:杭州百高实业有限公司

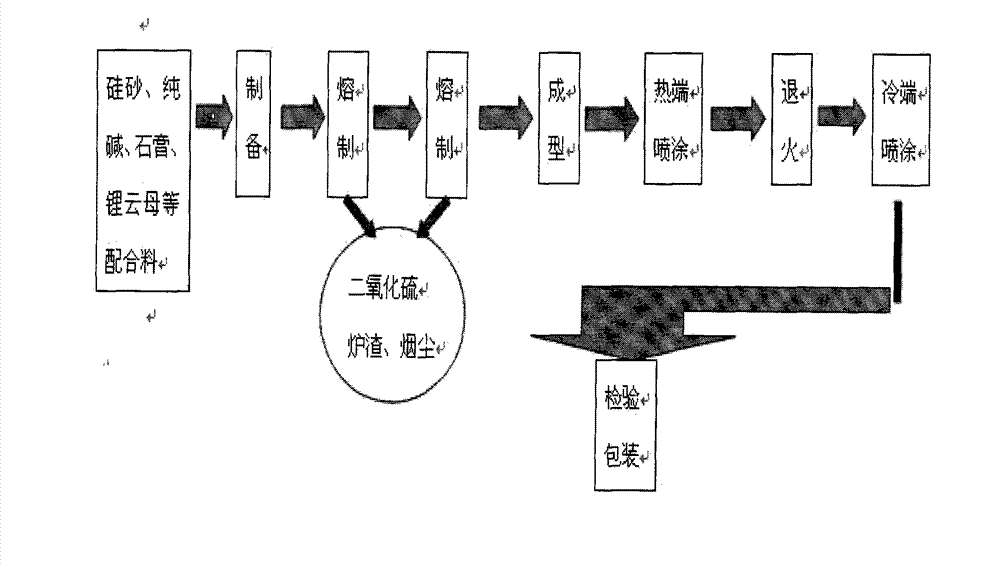

Fabrication method of beer bottle

The invention relates to a beer bottle and a fabrication method thereof. The beer bottle is fabricated by taking desulfurization gypsum of a thermal power plant as a raw material. According to the beer bottle and the fabrication method, a by-product, namely the desulfurization gypsum, for flue gas desulfurization of the thermal power plant serves as a clarifying agent to substitute fluorite and anhydrous sodium sulphate, so that the cost is lowered effectively, corrosion to fire-resisting materials is reduced, the service life of a kiln is prolonged, emission of fluoride is decreased, and pollution to an atmosphere is reduced. The desulfurization gypsum of the thermal power plant substitutes partial toxic raw materials, including fluoride such as the fluorite, so that the glass melting and clarification capacity can be improved, the glass component structure can be changed, the melting temperature and melt viscosity can be reduced, the thermal expansion coefficient can be reduced, the glass transparency can be enhanced, the thermal shock resistance and acid resistance of a product can be improved, and the glass strength can be improved; in addition, the corrosion of the clarifying agent such as the fluorite to the kiln is eliminated, volatilization of fluoride is reduced, atmosphere pollution is avoided, and an environment is protected.

Owner:青岛崂玻玻璃制品有限公司

Etching method for OGS (One Glass Solution) glass subjected to secondary chemical enhancement

The invention relates to an etching method for OGS (One Glass Solution) glass subjected to secondary chemical enhancement, and the etching method comprises the following steps of: etching an OGS glass sheet in an etching bath for 6-15 minute, wherein an acid-resisting film is respectively adhered to the forward surface and back surface of the OGS glass sheet, the etching bath is filled with etching acid liquor, and the temperature of the etching bath is 30-35 DEG C, the etching acid liquor is prepared by mixing a hydrofluoric acid solution, auxiliary acid liquor and water at a volume ratio of (4-5):(1.5-2.5):(3-4), the auxiliary acid liquor is a mixture of one or more of a salpeter solution, a sulfuric acid solution or a hydrochloric acid solution, the mass concentration of the hydrofluoric acid solution is 40%, the mass concentration of the salpeter solution is 68%, the mass concentration of the sulfuric acid solution is 86%, and the mass concentration of the hydrochloric acid solution is 31%; bubbling the etching acid liquor in an etching process, wherein the bubbling amount is 50-150 l / min. According to the invention, the occurrence of irregular edge and sawteeth phenomena caused by the poor etching of OGS glass can be avoided, the glass strength is improved, and the problem of bad appearance caused by edge BM falling off and corrosion of an ITO circuit is avoided; micro cracks at the edges of glass can be effectively eliminated, so that the mechanical compressive resistance amplitude can be enhanced, and the strength and yield of the OGS glass can be significantly enhanced.

Owner:HUIZHOU TRUST IND

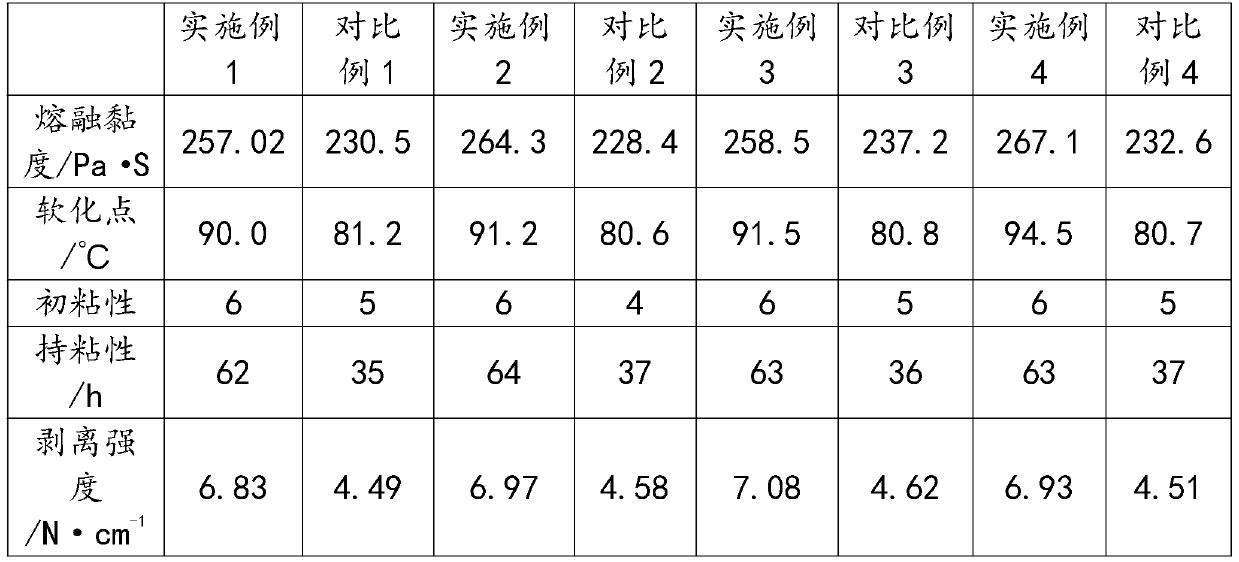

Environmentally-friendly hot-melt pressure sensitive adhesive and preparation method thereof

PendingCN110093128AUniform molecular weightGood solubilityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesEnvironmental resistanceAntioxidant

The invention discloses an environmentally-friendly hot-melt pressure sensitive adhesive. The environmentally-friendly hot-melt pressure sensitive adhesive is prepared from, by weight, 25-35 parts ofa thermoplastic elastomer, 28-36 parts of modified petroleum resin, 6-10 parts of natural tackifying resin, 12-20 parts of a plasticizer, 2-3 parts of a modifying filler, 0.2-0.3 part of a coupling agent and 0.2-0.3 part of an antioxidant. The present invention also discloses preparation method of the hot-melt pressure sensitive adhesive. The thermoplastic elastomer is used as a matrix for the hot-melt pressure sensitive adhesive, the modified petroleum resin and the natural tackifying resin are used as tackifying resins, and no organic solvent is needed, so the raw materials are safe and environmentally friendly; the petroleum resin is modified, so the compatibility of the petroleum resin and the thermoplastic elastomer is improved, and the thermal stability of the hot-melt pressure sensitive adhesive is improved; and the reinforcing effect of the modifying filler improves the initial viscosity, the glass strength and the thermal stability of the hot-melt pressure sensitive adhesive are improved, so the environmentally-friendly hot-melt pressure sensitive adhesive with excellent performances is prepared.

Owner:黄敏

Manufacturing technology for glass panel of electronic products

A disclosed manufacturing technology for a glass panel of electronic products comprises the following steps: 1) performing patterning transferring, specifically printing an anticorrosive membrane resisting corrosion of hydrofluoric acid on an A surface and pre-drying, printing an anticorrosive membrane on B surface and completely drying; 2) performing chemical etching forming; 3) engraving glass edges and hole interiors; 4) performing secondary strengthening; 5) employing a sodium hydroxide solution to remove the anticorrosion membranes; 6) detecting appearance; and 7) packaging and delivering. The manufacturing technology for the glass panel of the electronic products can help to perform various model manufacturing on glass on the basis without destroy the glass strength and guarantee the precision, and also the production efficiency is effectively improved. The beneficial effects comprise that the technology substantially reduces the production process, substantially improves the production efficiency and the yield, substantially reduces the production cost and improves the processing precision, improves the chemical-strengthening strength and the bending strength of the glass, effectively prevents ITO lines and silkscreen patterns from being damaged.

Owner:KUNSHAN RUIYONGCHENG PRECISION EQUIP

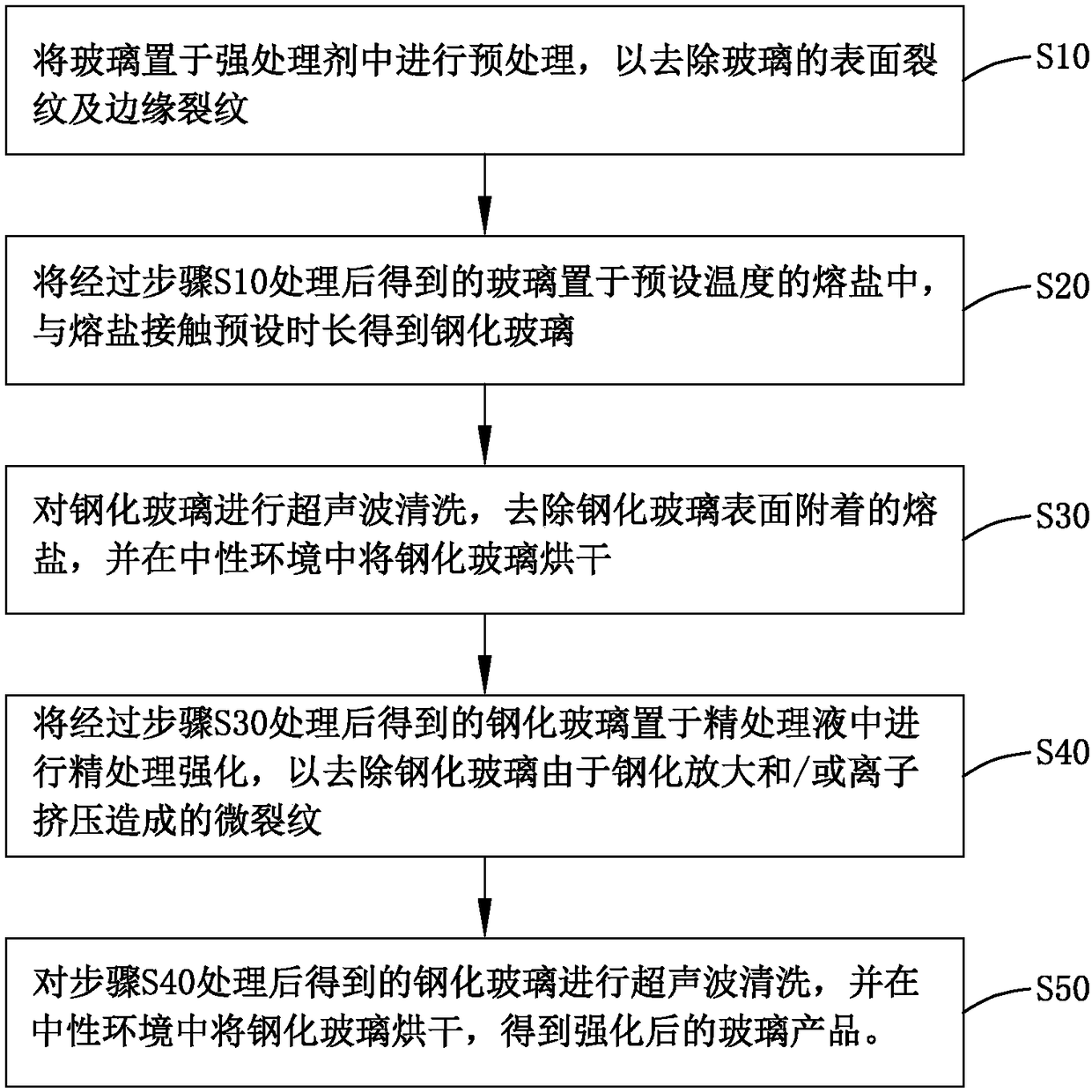

Glass toughening method and toughened glass

The invention provides a glass toughening method and toughened glass. The glass toughening method comprises the following steps: placing glass in a strong treating agent for pretreatment; placing theglass treated in step 1 in molten salt at preset temperature and enabling the glass to make contact with the molten salt for preset duration to obtain the toughened glass; placing the toughened glasstreated in step 2 in a fine treating agent for fine treatment to remove microcracks, caused by tempering amplification and / or ion extrusion, of the toughened glass. The invention further provides thetoughened glass prepared with the glass toughening method. According to the glass toughening method and the toughened glass, the microcracks are removed by the strong treating agent and the fine treating agent respectively before and after tempering, so that the microcracks in all areas of the glass can be removed uniformly, shape and dimension of the glass are not limited, the method is simple, easy to operate and high in efficiency, influence on a temper stress layer is small, and glass strength is improved greatly.

Owner:AAC TECH PTE LTD

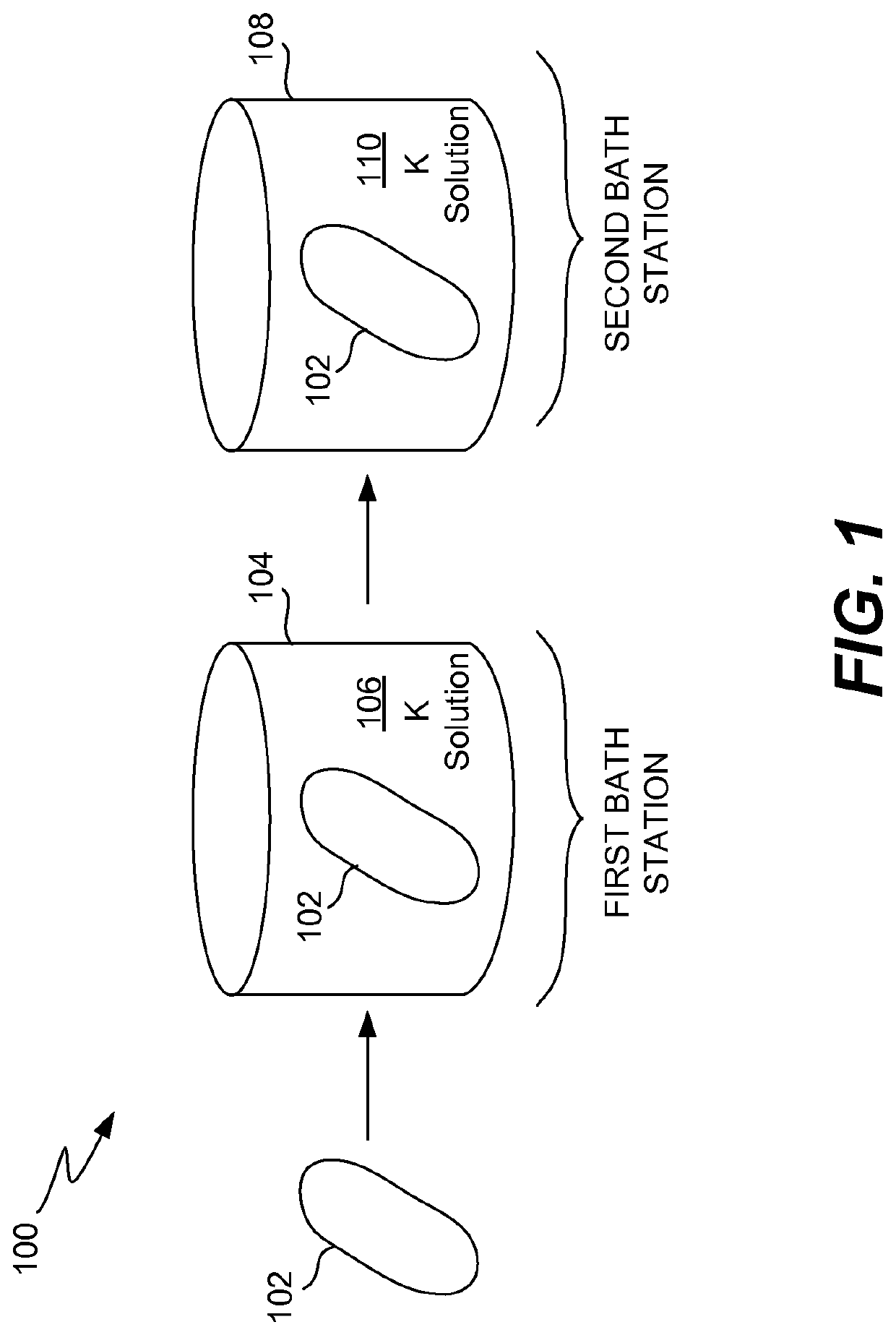

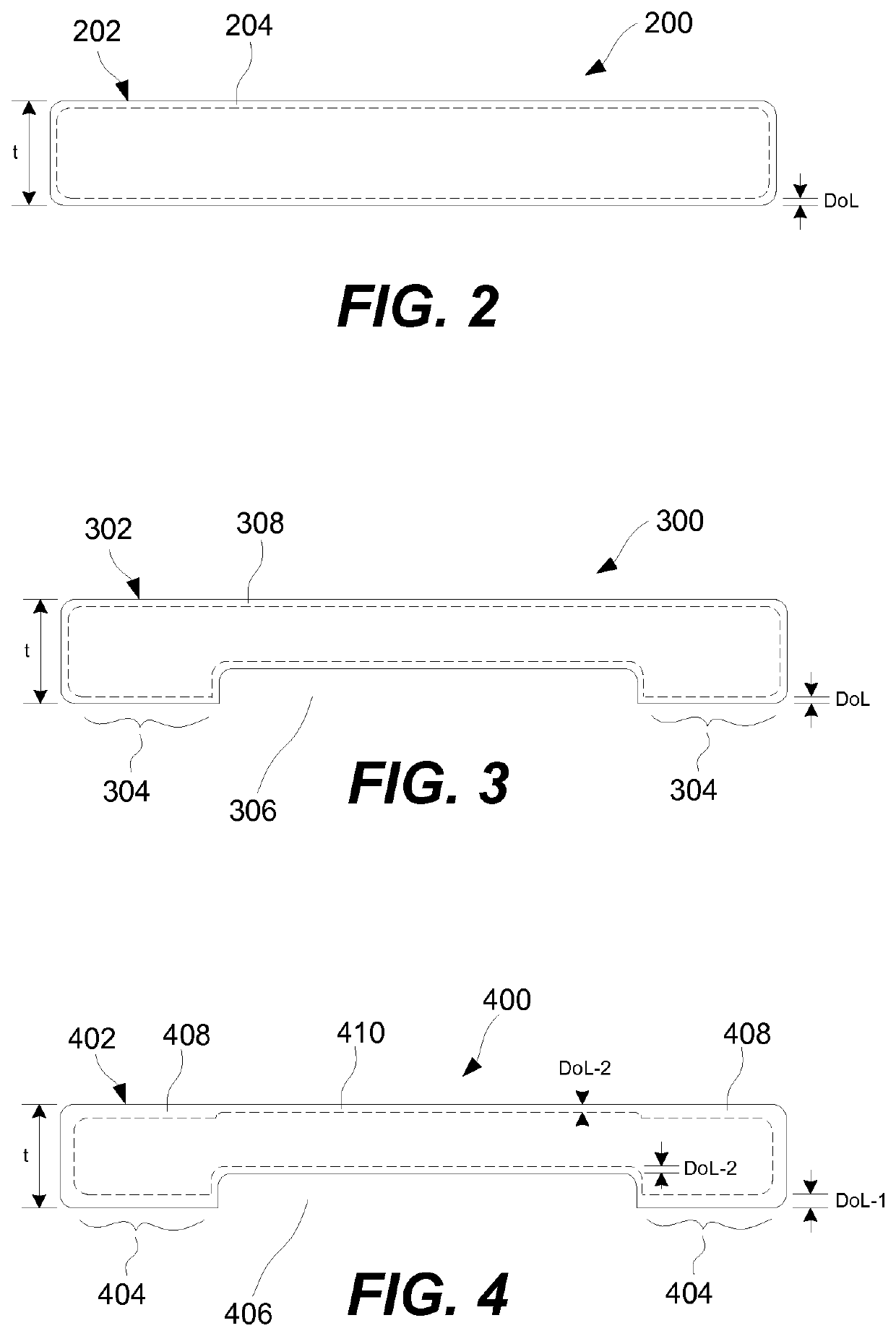

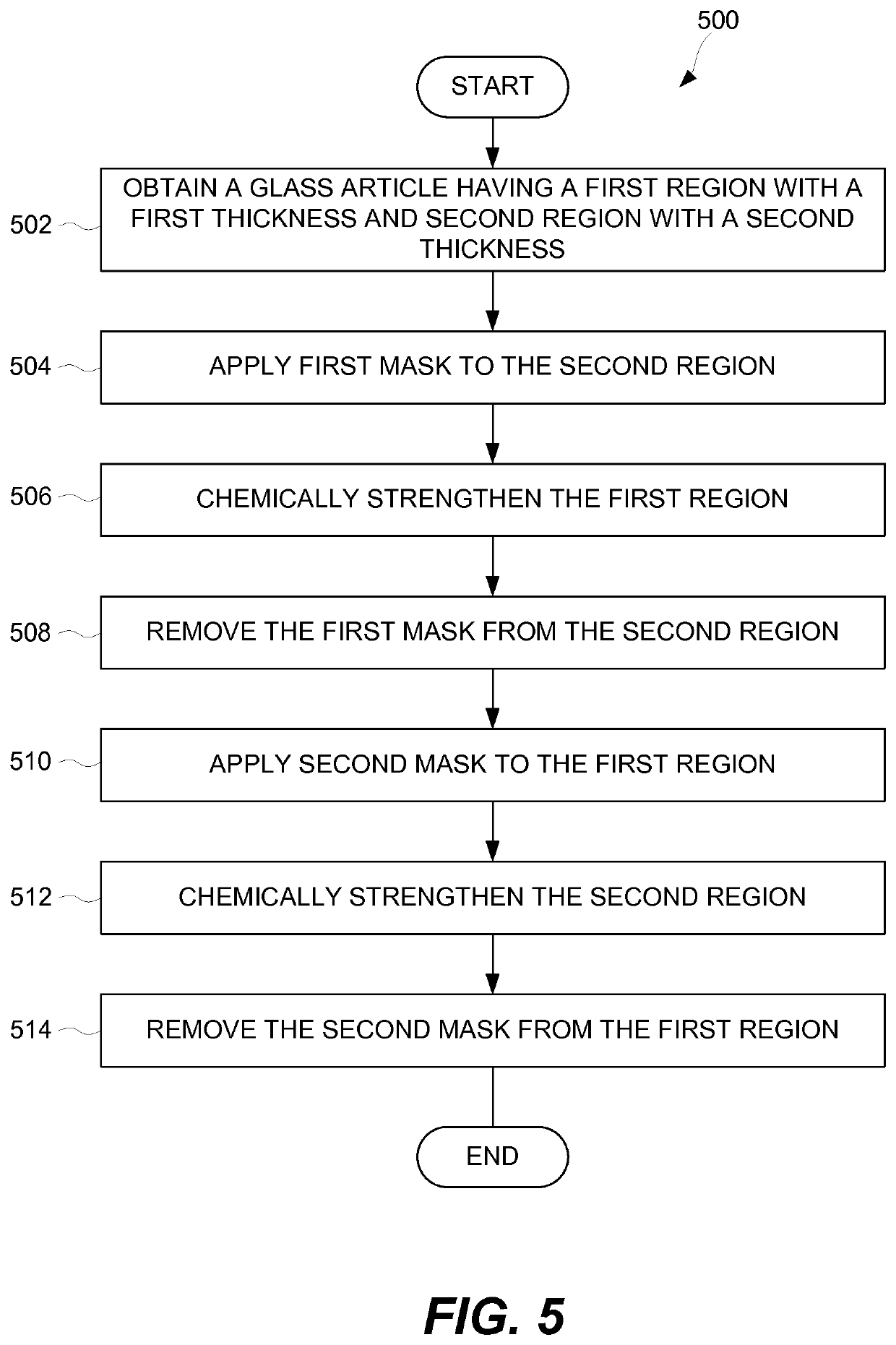

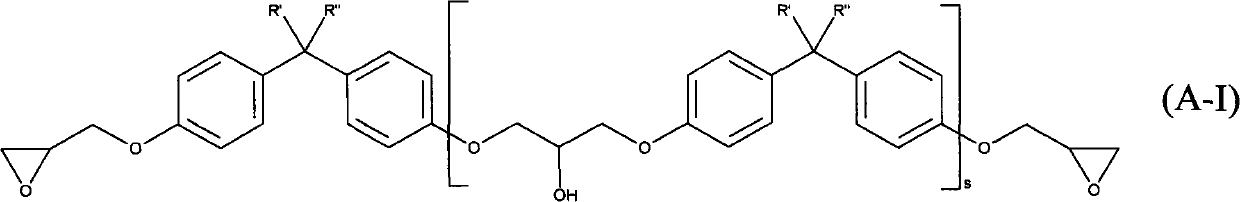

Strengthening variable thickness glass

ActiveUS10781135B2Improve glass strengthEasy to controlCircuit arrangements on conductive chasisChemical treatmentGlass cover

Apparatus, systems and methods for increasing the strength of glass are disclosed. The use of multi-bath chemical processing for a glass article can facilitate controlled chemical strengthening. Through multi-bath (or multi-step) chemical processing, differing levels of strengthening can be achieved for different portion of glass articles. The multi-bath chemical processing can be achieved through the use of successive chemical baths. Accordingly, glass articles that have undergone multi-bath chemical processing are able to be not only thin but also sufficiently strong and resistant to damage. The strengthened glass articles are well suited for use in consumer products, such as consumer electronic devices (e.g., portable electronic devices). In one embodiment, the glass member can pertain to a glass cover for a housing of an electronic device.

Owner:APPLE INC

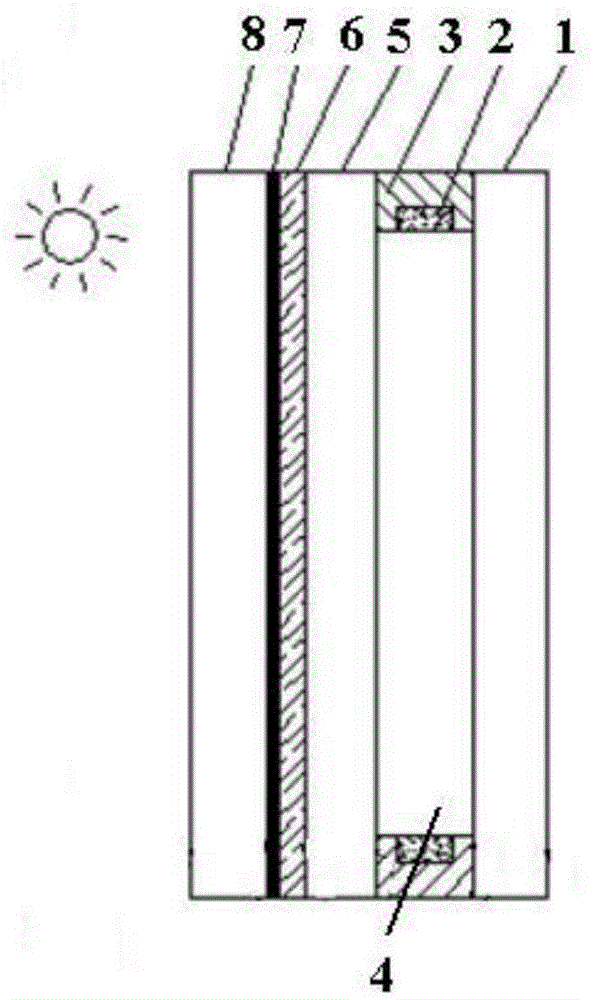

Intelligent heat-color light-dimming energy-saving glass and manufacturing method thereof

ActiveCN106150290ADelay agingExtended service lifeUnits with parallel planesNon-linear opticsComposite filmBuilding energy

The invention relates to intelligent heat-color light-dimming energy-saving glass. The intelligent heat-color light-dimming energy-saving glass is characterized by comprising a first glass layer, a frame and a glass complex which are adhered in sequence, wherein the first glass layer is boned with the glass complex through the frame to form a hollow glass structure. The glass complex is selected from single-layer glass or interlayer glass structures. The glass complex comprises an intelligent heat-color film layer having a phase-change function. The intelligent heat-color light-dimming energy-saving glass achieves heat adjustment with environment temperature change and can be widely applied to the field of building energy-saving door windows and vehicle and ship windows. By the adoption of the structure, impact resistance and other safety properties of the glass can be improved, the service life of a vanadium oxide composite film layer can be prolonged, and the demands for different environmental glass strength can be met by selecting multiple substrate materials.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

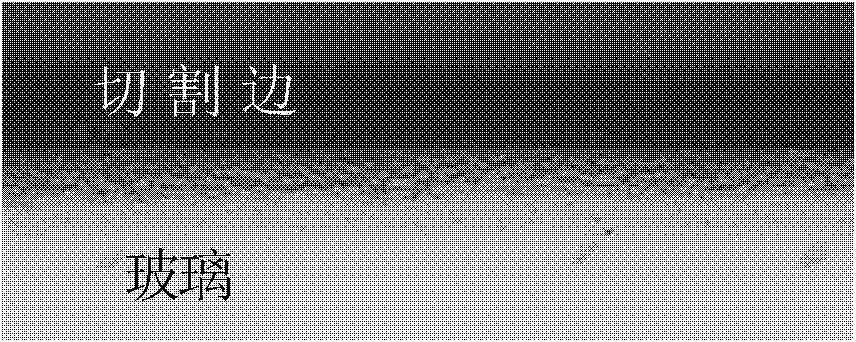

Method for increasing compressive strength of cut toughened glass

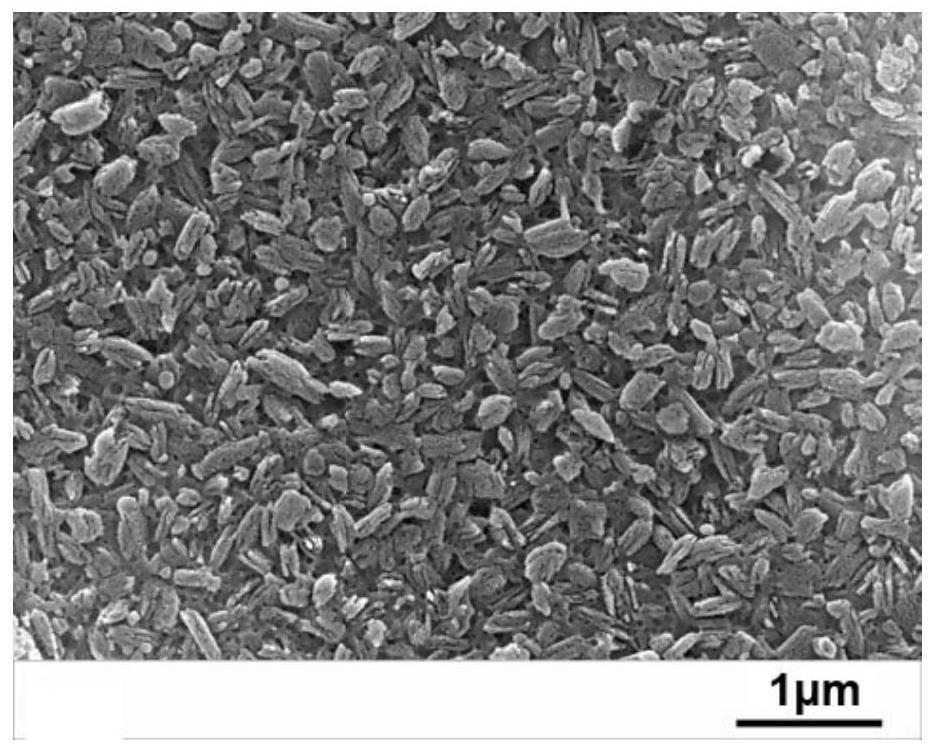

InactiveCN102424530ARealize blockbuster processChange the microstructureHydrofluoric acidCompressive strength

The invention discloses a method for increasing the compressive strength of cut toughened glass, characterized by corroding the edge of the cut toughened glass through using a chemical corrosive agent, wherein, the chemical corrosive agent is a hydrofluoric acid solution. According to the invention, by processing the cut edge of the cut toughened (tempered) glass through chemical corrosion, the glass edge defect point (point breakage, edge breakage) is narrowed down from 0.05 mm to less than 0.01 mm, the edge sawtooth turns into smooth, the edge appearance turns into uniform regular crystals from irregular serration, thus the microstructure of the toughened glass edge is changed, the crushing stress thin spots are eliminated, the consistency of the compressive strength is achieved, and the glass strength reaches more than 350 MPa. By adopting the method of chemically corroding the edge of the cut toughened glass to increase the compressive strength, the advantages of realization of sheet process, high efficiency, greatly reduced operation staff, and high yield rate are achieved, thus the invention has huge advantages of production cost, and realizes the sheet process of the toughened (tempered) glass.

Owner:TRULY OPTO ELECTRONICS

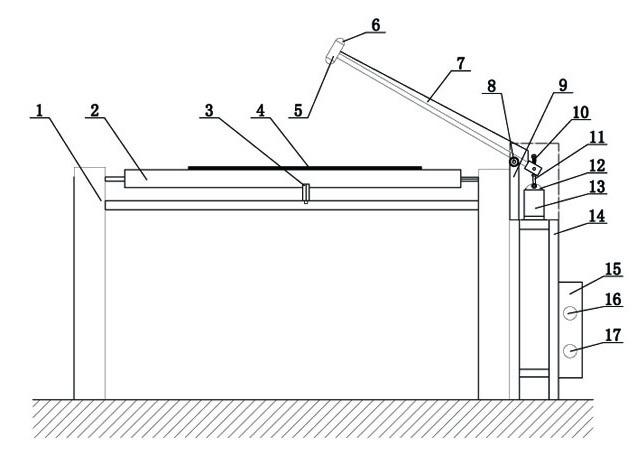

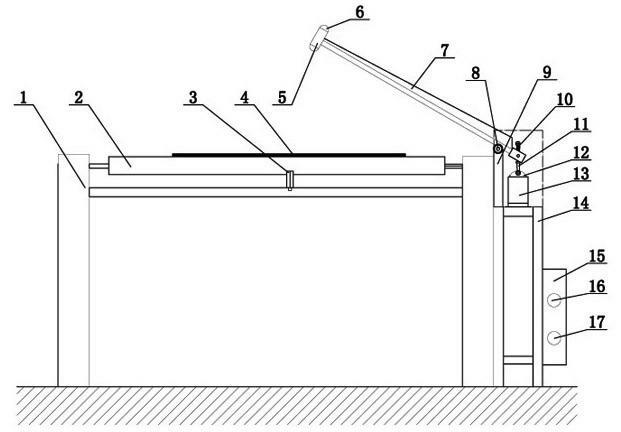

Device for online detection of photovoltaic glass strength

ActiveCN102147344ARealize online detectionLess cost increaseStrength propertiesEngineeringElectric control

The invention relates to a device for online detection of photovoltaic glass strength. A carrier roller is arranged on a carrier roller bracket, photovoltaic glass moves on the carrier roller, the carrier roller bracket is provided with a photoelectric sensor, the photoelectric sensor is arranged below the photovoltaic glass, corresponds to the longitudinal axis of the photovoltaic glass, and is connected with a first timer arranged inside an electric control cabinet, the electric control cabinet is further provided with a second timer and is fixed on a support, the support is provided with an electromagnet and a supporting rod, the electromagnet corresponds to an armature fixed on one end of a connecting rod, the other end of the connecting rod is fixedly provided with a hammer body, the connecting rod is articulated with the supporting rod, and the first timer and a second timer are both connected with the electromagnet. In the invention, a lever principle is utilized for realizing the online detection of the photovoltaic glass strength, a photoelectron sensor and electromagnetic induction principle is used for realizing automatic control of online detection of the photovoltaic glass strength so as to realize the automatic online detection of the photovoltaic glass strength, and repetitive manual work and batch spot-check destructive tests are replaced so that the cost is reduced.

Owner:河南华美新材料科技股份有限公司

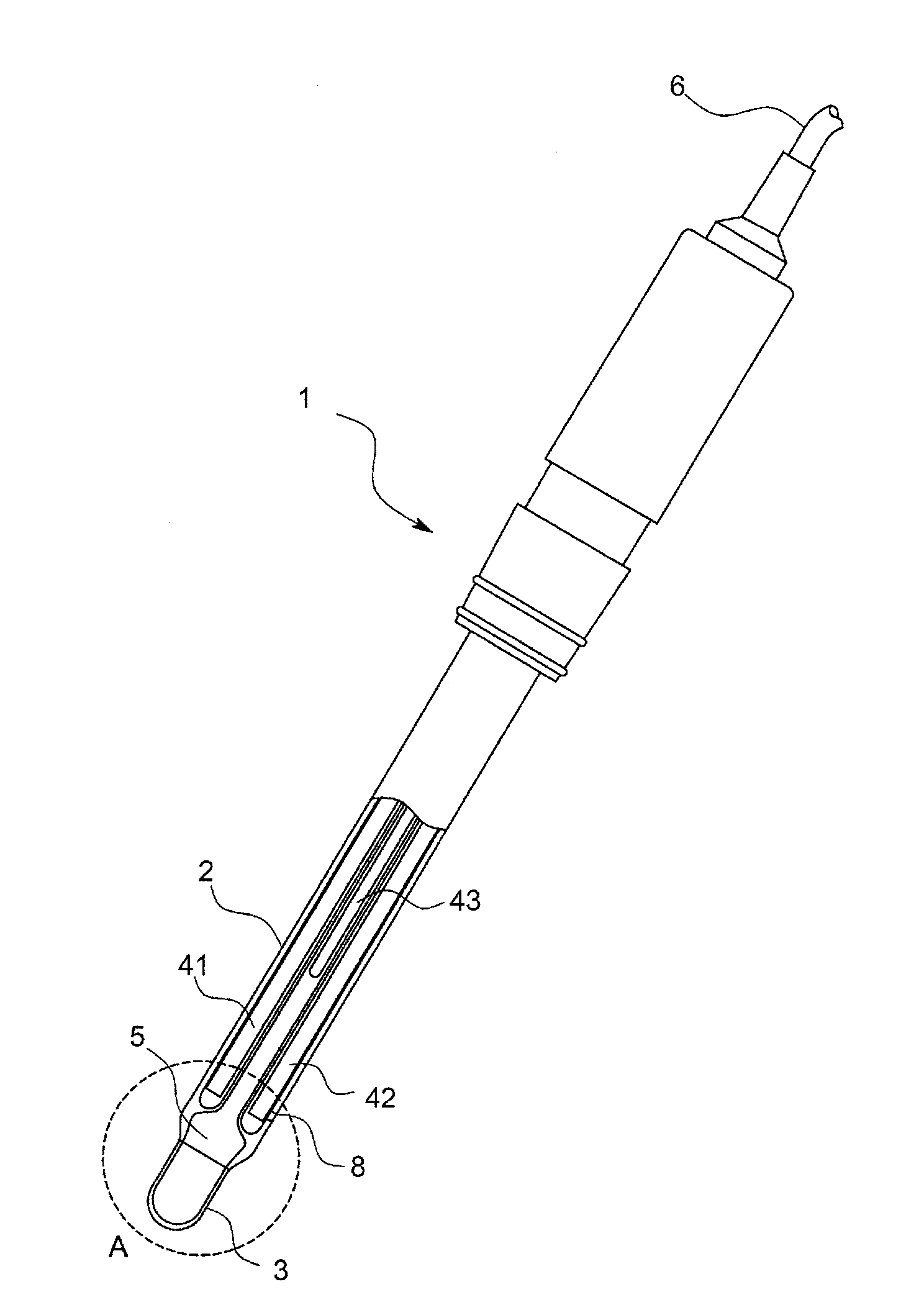

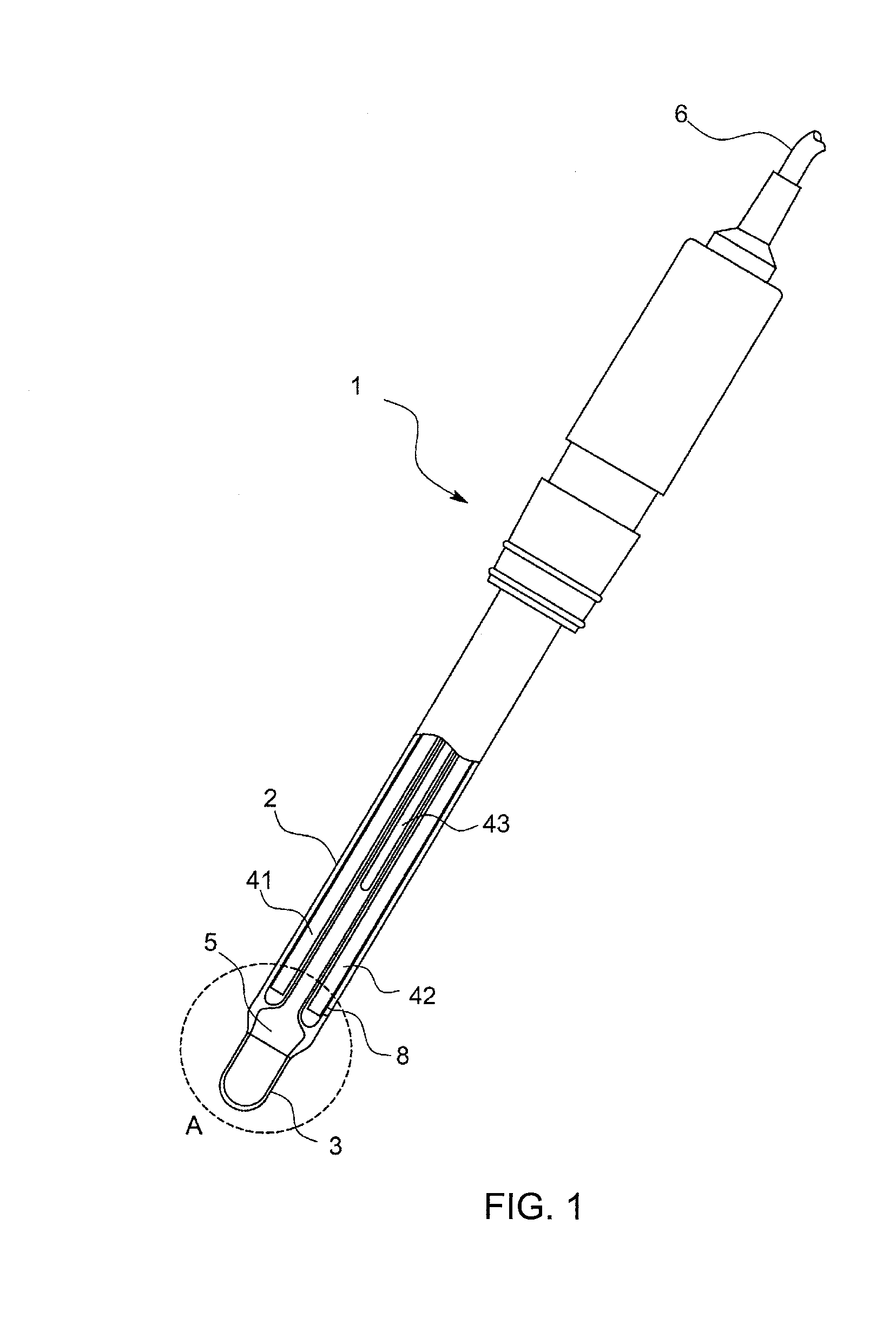

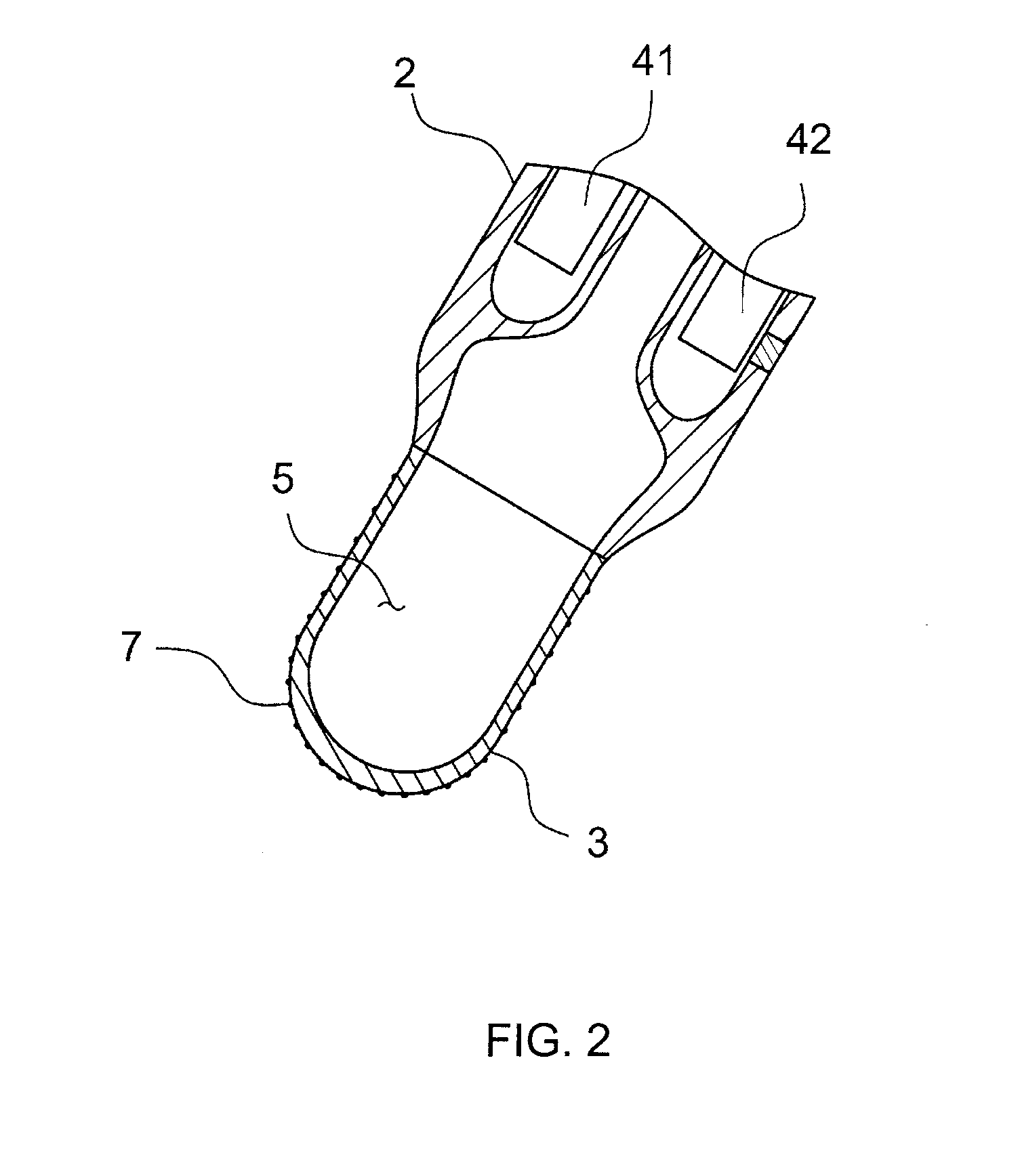

Method for production of responsive glass membrane for ion electrode, responsive glass membrane for ion electrode, and ion electrode

ActiveUS20100025235A1Reduce in quantityAccurate measurementGlass drawing apparatusGlass forming apparatusBrookiteMicroparticle

Disclosed is a sensitive glass film for a pH electrode, which is not deteriorated in its glass strength or pH-measuring function, which is hardly stained, and from which any stain can be removed easily. Also disclosed is a pH electrode having the sensitive glass film. A microparticle comprising rutile-type or brookite-type titanium dioxide or a microparticle comprising amorphous titanium dioxide is adhered directly on the glass film surface of a sensitive glass film for a pH electrode.

Owner:HORIBA ADVANCED TECHNO +1

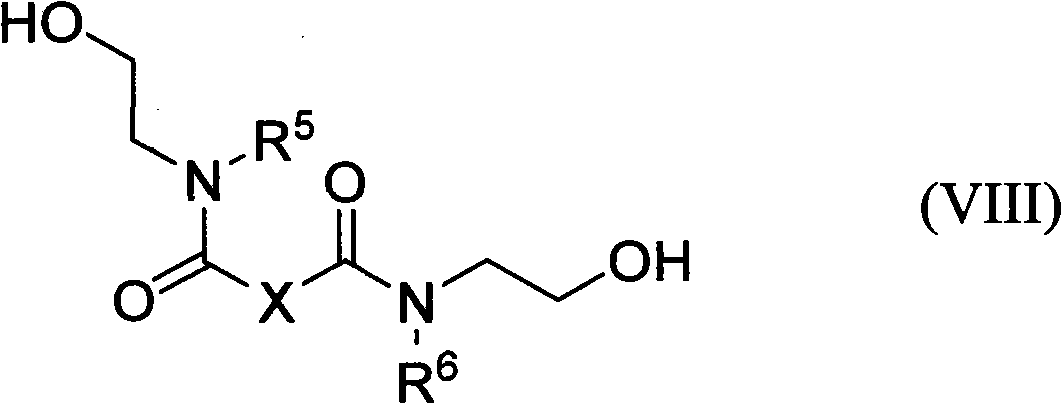

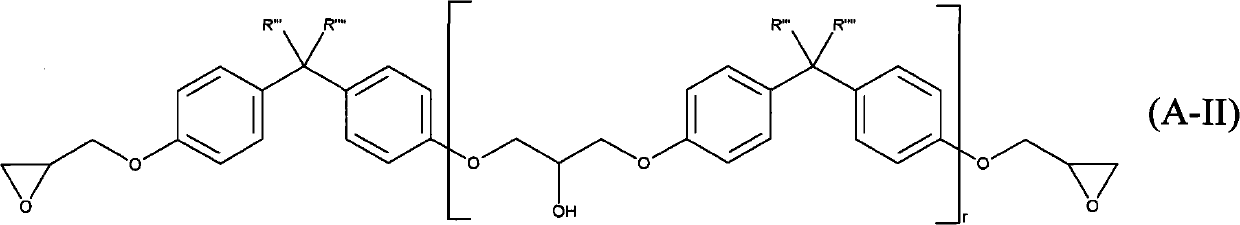

Heat curable epoxy resin composition with water as foaming agent

InactiveCN102399358AHigh mechanical strengthImprove glass strengthEpoxynovolac adhesivesEpoxyCarboxylic acid

Heat-curable epoxy resin compositions and the use thereof, for example, in motor vehicle construction and sandwich panel construction, are disclosed. Exemplary heat-curable epoxy resin compositions include, in addition to epoxy resin components A1, optionally A2, a hardener component B, a carboxylic acid C and a hydroxyalkylamide or hydroxyalkylurea H, an accelerator E for activation of the conversion of components A1, A2 and B. The compositions and the structural foams produced therefrom are notable for high mechanical strength, high glass strength and good adhesion capacity on metallic and nonmetallic substrates, and it is possible at the same time to dispense with the use of toxic or inflammable blowing agents.

Owner:SIKA TECH AG

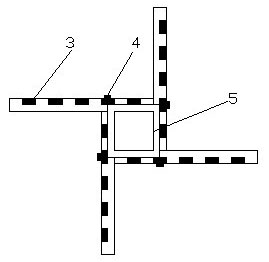

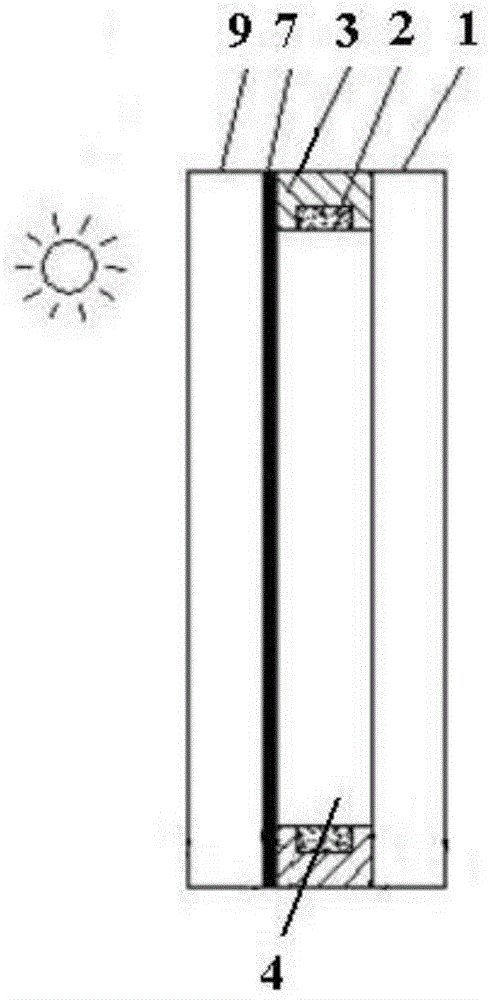

Piece type OGS touch screen and manufacturing method therefor

InactiveCN105335026AImprove glass strengthImprove yieldInput/output processes for data processingPrinting inkEngineering

The present invention discloses a piece type OGS touch screen. The OGS touch screen comprises a transparent substrate (1), an ink layer (2), an ITO electrode layer (3) and an ITO protective layer (4) which are successively stacked. The present invention also provides a manufacturing method for a piece type OGS touch screen. The method comprises: printing ink on a transparent substrate (1) to form an ink layer (2); applying a piece type ITO coating to the ink layer (2), and performing laser dry etching to form an ITO electrode layer (3); and printing ink on the ITO electrode layer(3) to form an ITO protective layer (4). The method provided by the present invention can significantly improve glass strength of the OGS touch screen, and reduce and optimize OGS process steps, thereby reducing production costs, improving the yield rate of the OGS touch screen, and facilitating environmental protection.

Owner:深圳市合力泰光电有限公司

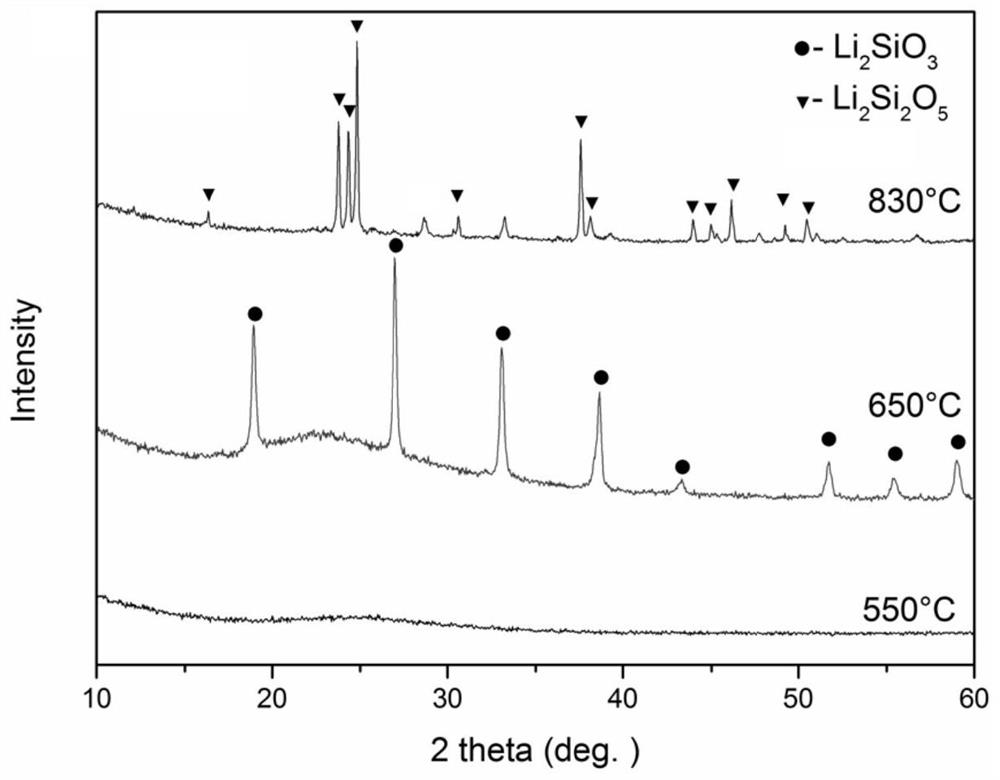

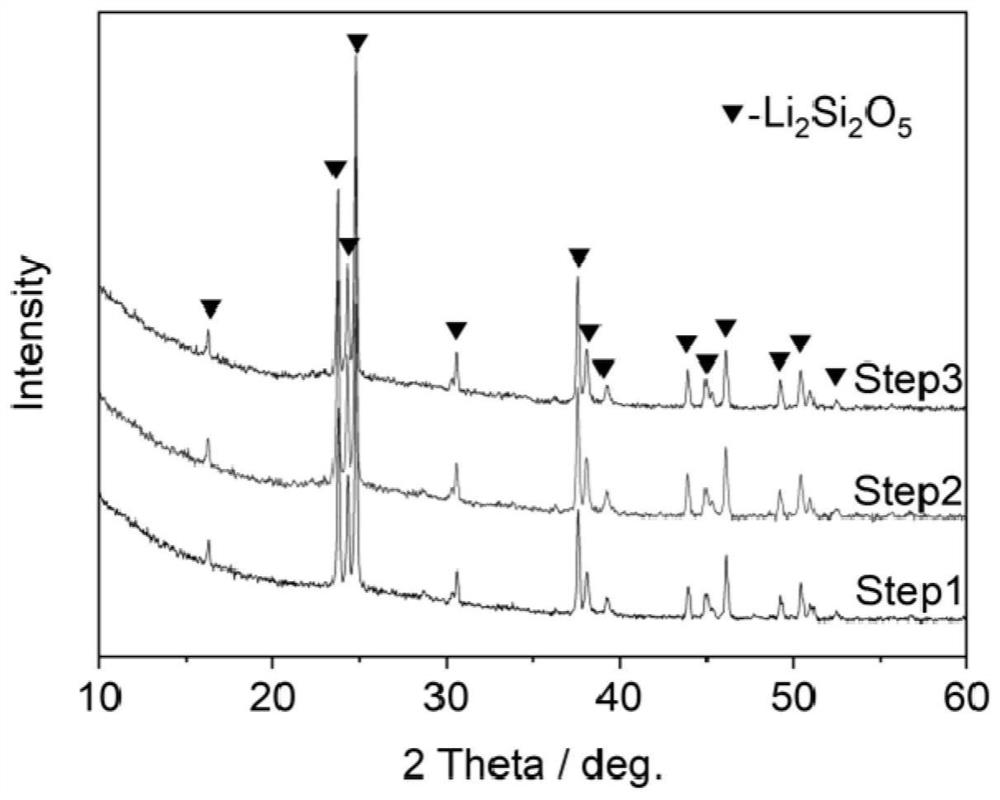

Lithium disilicate microcrystalline glass and preparation method thereof

The invention discloses lithium disilicate microcrystalline glass and a preparation method thereof, belonging to the technical field of microcrystalline glass preparation processes. According to the preparation method, transparent hard glass with a lithium disilicate component is used as a glass matrix, and a microstructure in which multiple scales of lithium disilicate grains with different sizescoexist is obtained through three-step heat treatment. In the first step of heat treatment, common lithium disilicate crystals with fine and uniform crystal grains are obtained; in the second step ofheat treatment, coarse crystal grains playing a toughening role are obtained through crystal remelting and secondary recrystallization; and in the third step of heat treatment, small lithium disilicate crystals are separated out again, a length-diameter ratio is larger, and glass strength is improved. With the three-step heat treatment, fine and uniform lithium disilicate crystals are differentiated into two crystals with obvious size and form difference, so homogeneous toughening effect is achieved, the fracture toughness of the lithium disilicate microcrystalline glass is effectively improved, a heterogeneous phase is not introduced, the transparency and appearance of a material are not influenced, and the use stability and reliability of the material are guaranteed.

Owner:SHAANXI UNIV OF SCI & TECH

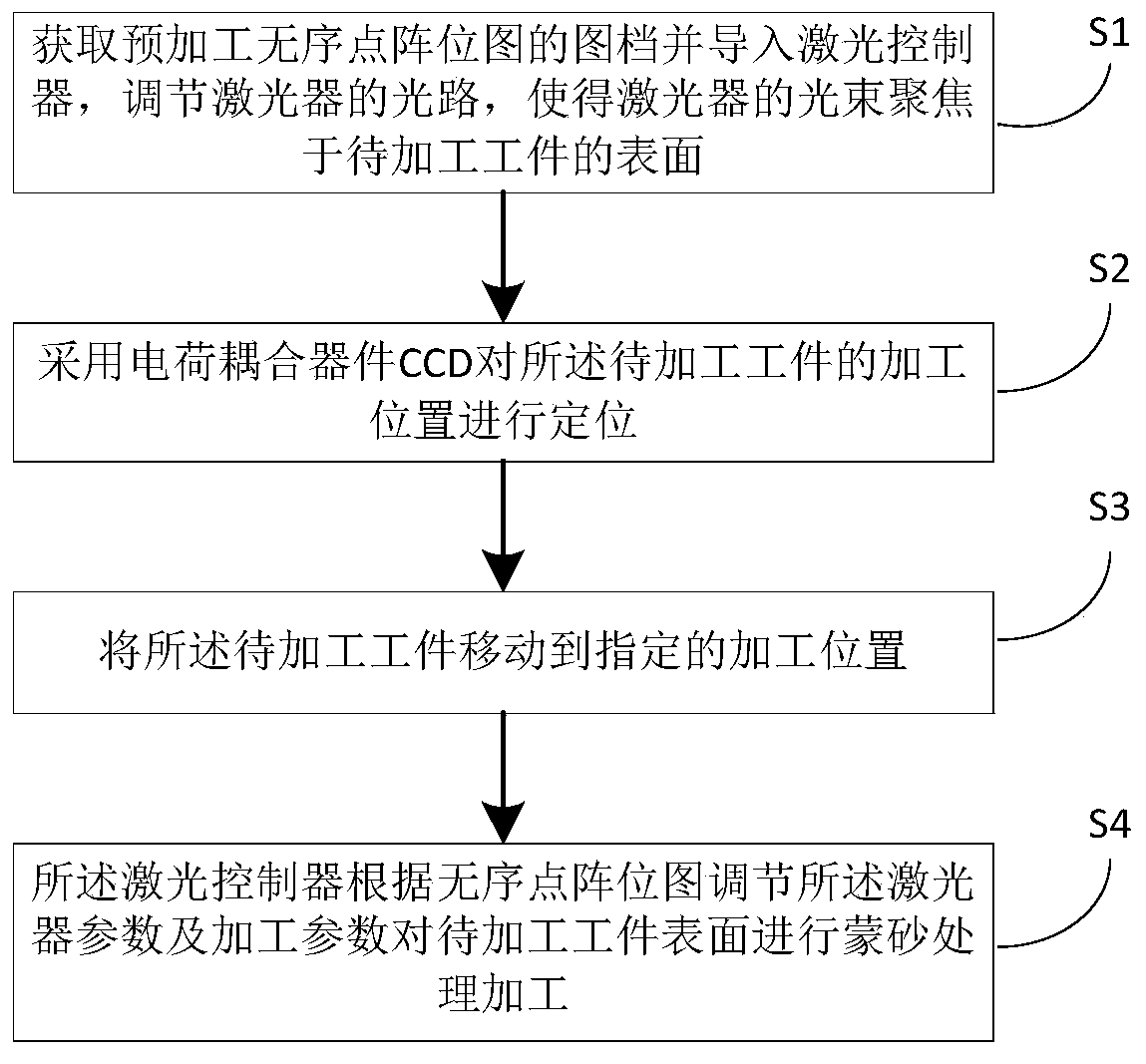

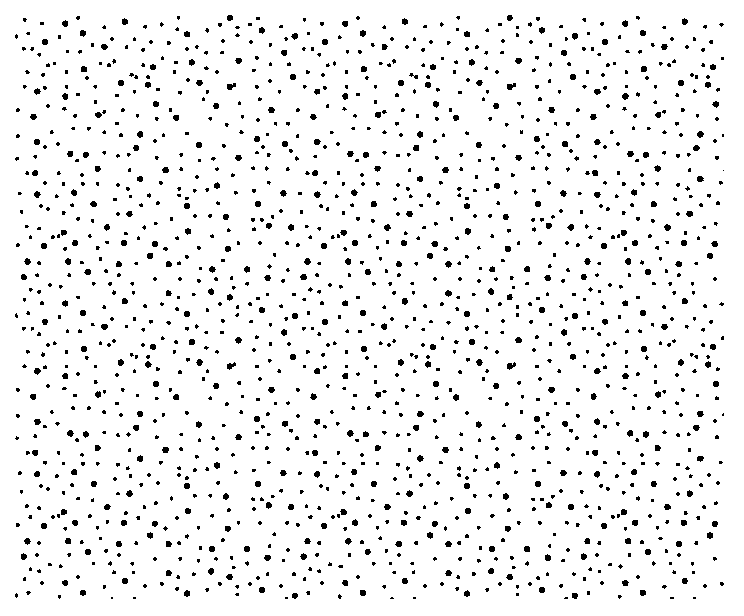

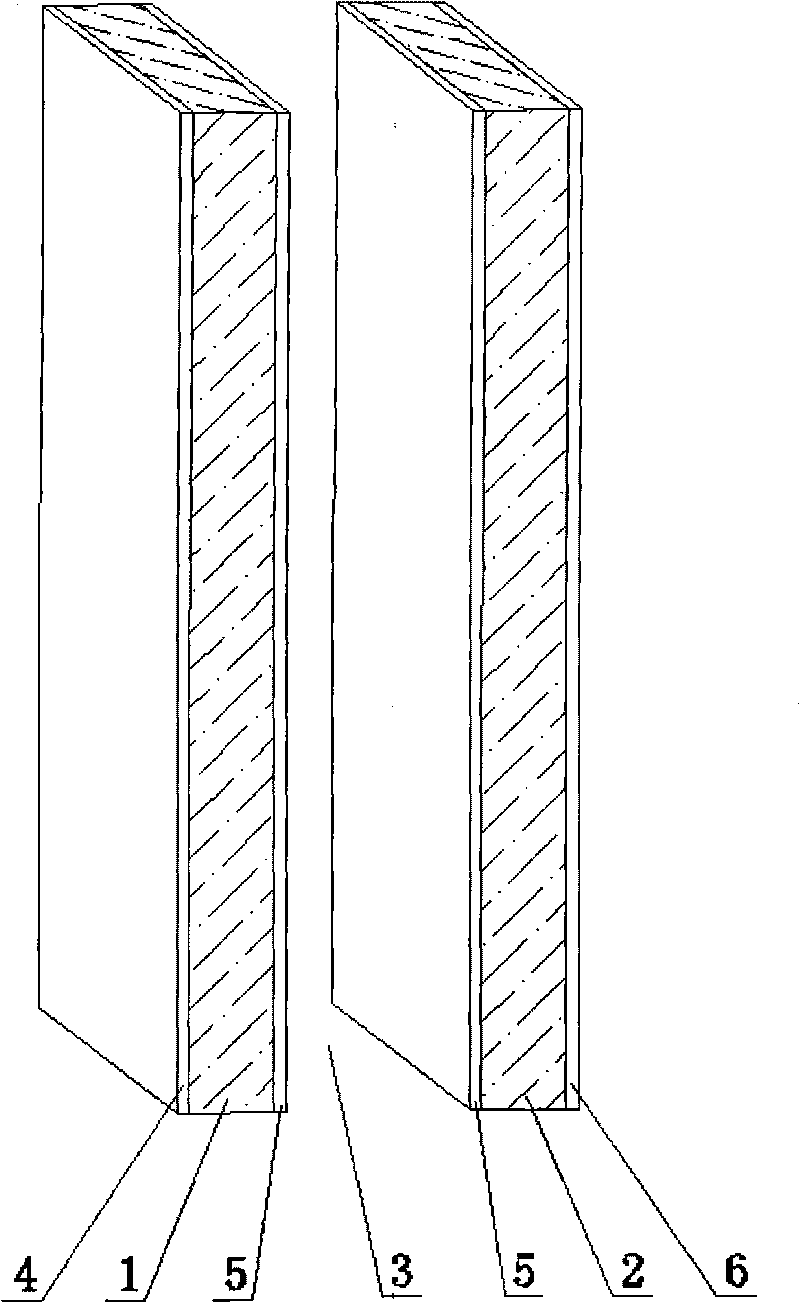

Laser processing method for sand covering of surface of glass material

ActiveCN109848564AReduced impact strengthEffective control of laser textureLaser beam welding apparatusDot matrixGlass strength

The invention belongs to the technical field of laser microprocessing, and particularly provides a laser processing method for sand covering of the surface of a glass material. A drawing document of aspecific pre-processing disordered dot matrix bitmap is drawn and guided into a laser controller, the laser controller controls laser beams to carry out scanning and ablation along the drawing document according to the path of the disordered dot matrix bitmap, random dot irradiation of the beams onto the disordered dot matrix bitmap is achieved by adjusting the focusing positions of the light beams and processing parameters of a laser device, and therefore the sand covering effect is achieved on the surface of a to-be-processed workpiece. Specific laser device parameters are combined with a software bitmap disordered dotting mode, laser grain generated on the surface of the glass workpiece after processing can be effectively controlled, and meanwhile roughness and transmittance of the sample surface are guaranteed by laser spots under a certain overlapping rate; and in addition, the laser processing manner is adopted, the influence on glass strength is small, and the environment cannot be polluted.

Owner:WUHAN HGLASER ENG CO LTD

Safety energy-saving hollow glass and coating film as well as preparation method

InactiveCN101705781AImprove glass strengthPurify indoor airClimate change adaptationWindows/door improvementBenzeneRadioactive gas

The invention discloses safety energy-saving hollow glass, which comprises an internal layer of glass and an external layer of glass between which a cavity is kept; a coating film with the function of heat insulation and preservation is arranged outside the external layer glass; coating films with the functions of enhancing glass strength are arranged inside the external layer of glass and outside the internal layer of glass, insulating sound wave and filtering ultraviolet rays; and a coating film with the functions of absorbing, purifying and decomposing indoor radioactive and poisonous gases is arranged inside the internal layer of glass. The structure of the invention has the functions of obviously improving heat insulation and preservation property, increasing anti-seismic and anti-impact intensity, purifying indoor air, and absorbing, purifying, and decomposing radioactive gas radon, volatilizing gases of methyl aldehyde, benzene and methylbenzene, and bacterial viruses in building decoration materials.

Owner:HEBEI RUIHUI GLASS PRODS

Composite packaging adhesive film for solar packaging material and preparation method of composite packaging adhesive film

ActiveCN109294455AInhibitionAchieving high efficiency of cross-linking and curingNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveElastomerCross-link

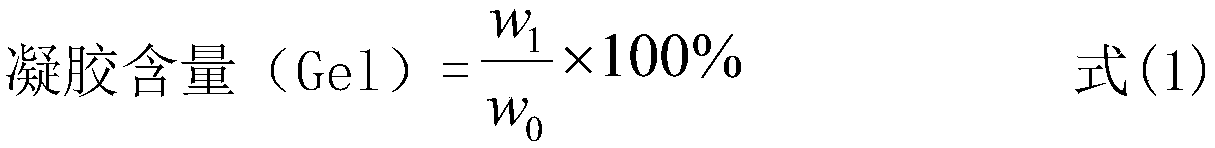

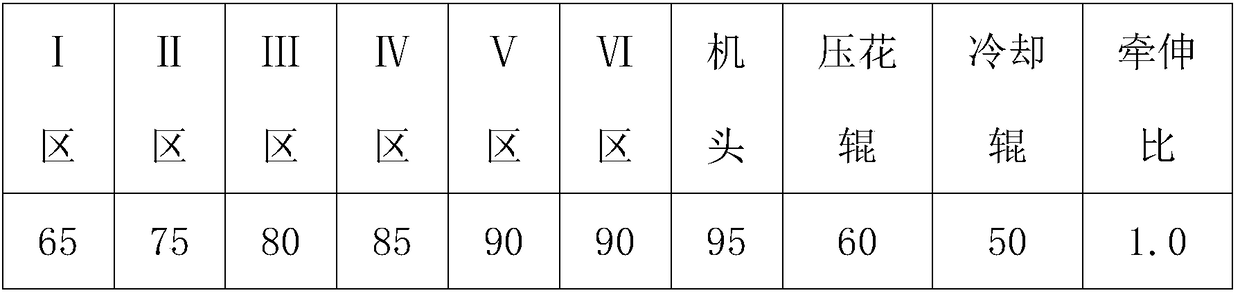

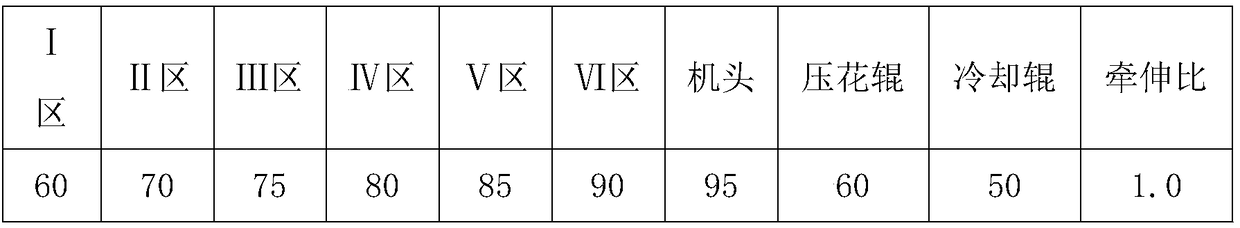

The invention discloses a composite packaging adhesive film for a solar packaging material. The composite packaging adhesive film is composed of an ethylene vinyl acetate (EVA) adhesive film layer anda polyolefin elastomer (POE) adhesive film layer, and the EVA adhesive film layer is prepared from the following raw materials in parts by weight: 100 parts of EVA resin, 0.5-1.6 parts of a compositecross-linking agent, 0.5-1 part of a co-crosslinking agent, 0.05-0.2 part of an ultraviolet absorbent, 0.03-0.1 part of an antioxidant and 0.1-0.5 part of a tackifier, wherein the composite cross-linking agent comprises a peroxide and an crosslinking control agent. The invention further discloses a preparation method of the composite packaging adhesive film for the solar packaging material, and the preparation method comprises the following steps: melt extrusion of POE resin, melt extrusion of EVA resin and co-extrusion. According to the composite packaging adhesive film disclosed by the invention, the problems of bubbles and too low gel content of a cured film are solved, and meanwhile, the composite packaging adhesive film has the characteristics of good light transmittance and high glass strength. The preparation method can meet the requirements of process stability, laminating process stability and cross-linking curing efficiency during film preparation by casting at a same time.

Owner:JIANGSU LUSHAN PHOTOVOLTAIC TECH +1

Online surface enhancing method of flotation-process aluminum silicate flat glass

ActiveCN103601360AHigh strengthReduce thicknessGlass tempering apparatusGlass productionFlat glassPhysical chemistry

The invention relates to an online surface enhancing method of flotation-process aluminum silicate flat glass. According to the method, high-temperature Li<+>-containing fused salt is adopted to carry out spraying treatment onto formed aluminum silicate flat glass between a tin slot and a pre-annealing zone in a process of preparing aluminum silicate flat glass by the flotation process. The enhancing method disclosed by the invention is adopted, so that enhanced aluminum silicate flat glass which is 3mm thick replaces common soda-lime-silica glass which is 5mm thick to satisfy glass strength requirements in fields of building and traffic; moreover, cost can be lowered and working hours can be saved.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

High-strength glass and preparation technology thereof

The invention discloses a high-strength glass. The high-strength glass comprises the following raw materials in parts by weight: 60-80 parts of quartz sand, 10-20 parts of alumina, 5-10 parts of sodaash, 3-8 parts of dolomite, 2-6 parts of calcium carbonate, 3-6 parts of bauxitic clay, 7-16 parts of anorthite, 5-15 parts of high-purity magnesium oxide, 3-8 parts of nano silica, 2-8 parts of zincoxide, 5-10 parts of sodium nitrate, 8-15 parts of calcite, 3-8 parts of yttrium oxide, 2-6 parts of boron oxide, 1-5 parts of titanium dioxide, 4-10 parts of a composite colouring agent, and 1-5 parts of a clarificant. The method comprises the following steps: 1) weighing raw materials; 2) crushing the raw materials; 3) melting and moulding the raw materials; 4) performing annealing; 5) performing surface pretreatment; 6) performing strengthening treatment; and 7) performing drying treatment. The high-strength glass solves the disadvantages of the insufficient glass intensity in the prior art, the preparation technology is simple, and realization is easy.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

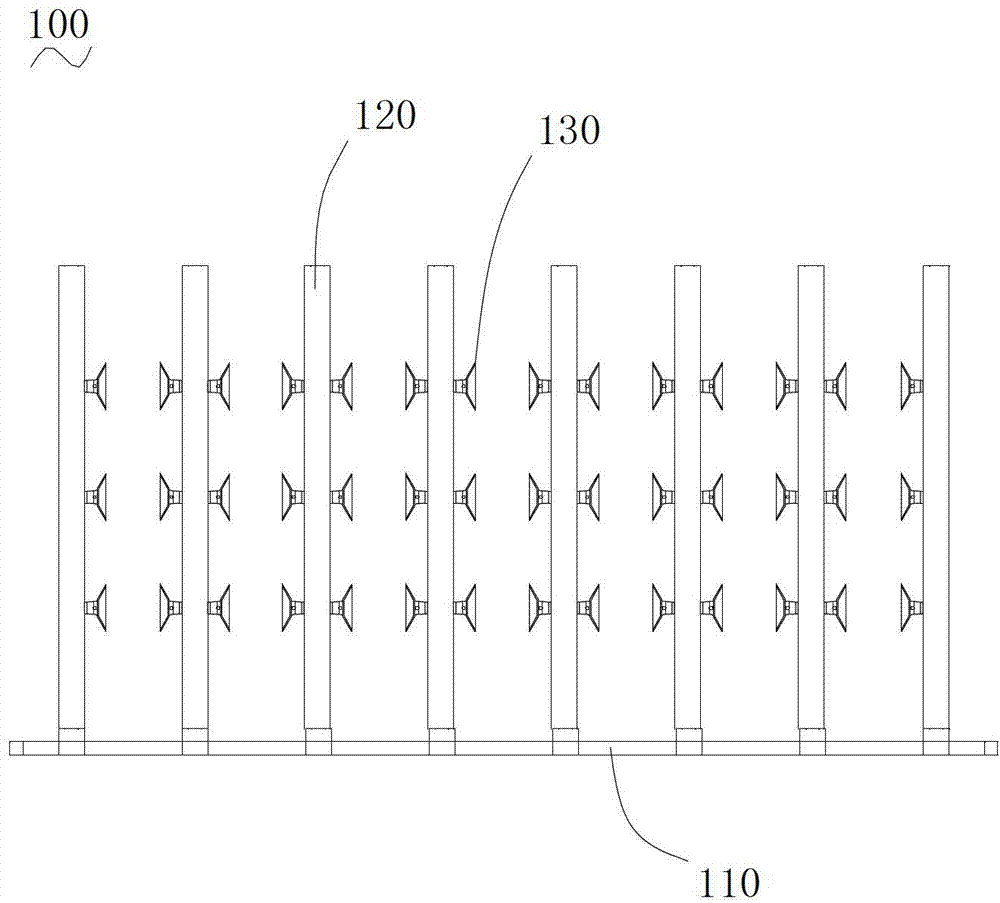

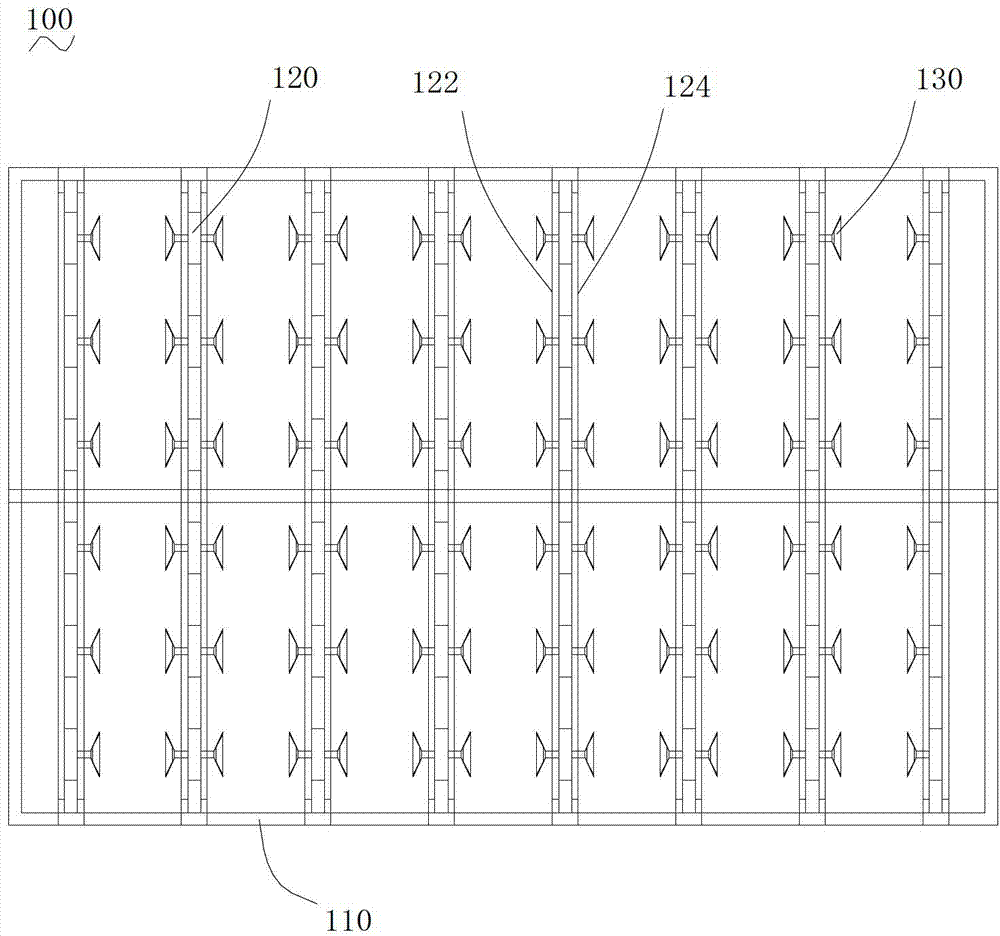

Device used for enhancing strength of tempered glass

ActiveCN102923964AChemical treatment is easy to operateImprove efficiencyChemical treatmentEngineering

The invention relates to a device used for enhancing strength of tempered glass. The device comprises a jig and a bearing plate, wherein a rabbet for fixing the bearing plate is arranged on the jig, the bearing plate is provided with a front surface and a back surface, and at least one of the front surface and the back surface is fixed with a sucking disc used for adsorbing the tempered glass. According to the device used for enhancing the strength of the tempered glass, the glass is adsorbed by the sucking disc on the bearing plate, and the bearing plate is arranged in the jig and then is put into chemical corrosive liquid, so that chemical treatment operation for the glass is convenient, and efficiency is improved.

Owner:WGTECH JIANGXI

Window glass for vehicle

ActiveUS20070128448A1Reduced strengthReduce tensile stressWindowsWindscreensElectrical conductorElectronic component

To provide a window glass for vehicles, which is obtained by fixing a conductor formed on the glass plate, and an electronic material, by means of a lead-free solder, thereby to secure sufficient adhesive strength and glass strength. A window glass for vehicles, which comprises a glass plate, a conductor formed on the glass plate, and an electronic component electrically connected to the conductor by means of a solder, wherein the solder comprises a buffer component and a conductive component containing no lead, and the proportion of the volume of the conductive component based on the volume of the entire solder is from 58 to 93%, or the proportion of the specific gravity of the entire solder based on the specific gravity of the conductive component is from 70 to 93%.

Owner:ASAHI GLASS CO LTD

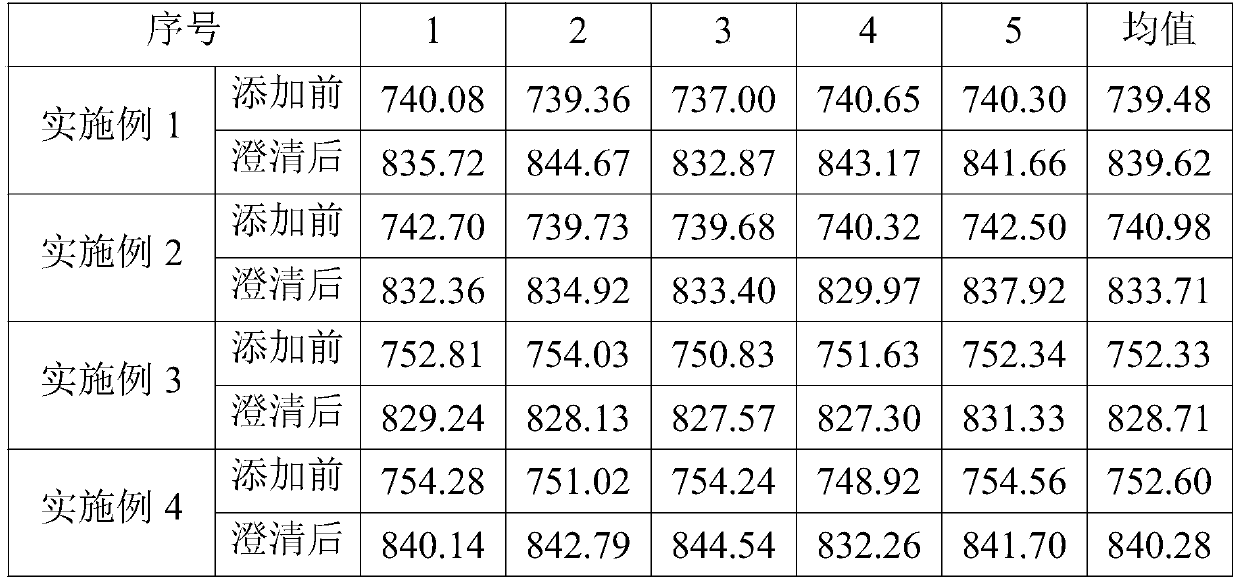

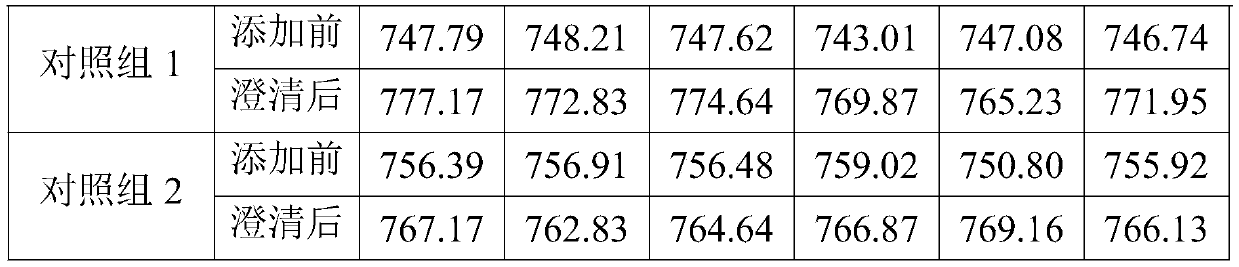

Molten salt impurity removal method suitable for chemical tempering production and method for improving glass strength

ActiveCN111099840AEasy to operateRaise the stress valueAlkali metal nitrate purificationGlass productionSorbentPhysical chemistry

The invention relates to a molten salt impurity removal method suitable for chemical tempering production and a method for improving glass strength. The molten salt impurity removal method suitable for chemical tempering production comprises the following steps: adjusting the pH value of molten salt to 9-14; adding a precipitant into the molten salt, performing mixing treatment to enable the precipitant to react with impurity ions in the molten salt to generate precipitate, and adjusting the pH value of the molten salt to 6.8-7.2; and adding an adsorbent, and standing to clarify the molten salt. The molten salt impurity removal method for chemical tempering production is simple to operate, and experiments prove that the effect of removing impurities from molten salt by adopting the methodis obviously better than that of a traditional molten salt impurity removal method.

Owner:VITALNK IND SHENZHEN

Special formula for lightweight glass packaging material

The invention discloses a special formula for a lightweight glass packaging material. The lightweight glass packaging material is prepared from the following raw materials in parts by weight: 900-1100 parts of quartz sand, 110-150 parts of lepidolite, 260-360 parts of soda, 260-360 parts of limestone, 4000-4300 parts of cullet, 18-22 parts of barite, 4-7 parts of chromite ore powder, 28-32 parts of anhydrous sodium sulfate, 17-21 parts of sodium fluosilicate, 0.8-1.2 parts of chrome green and 0.8-1.2 parts of carbon powder. According to the special formula disclosed by the invention, with sodium-calcium-silicate glass as a basic skeleton, alumina, magnesium oxide and barium oxide are auxiliary filled, and a part of sodium oxide is replaced by lithia and potassium oxide, so that the structure is ensured to be stable, and the strength of the glass is strengthened; by virtue of the evenness of a batch of above 95.8 percent, a lightweight bottle (L=0.44*bottle weight / brimful capacity (0.81)), produced by the special formula, with the lightweight degree to be small than or equal to 1 has the impact resistance to be larger than or equal to 0.4J, the internal pressure resistance to be larger than or equal to 1.4MPa and the vertical load to be larger than or equal to 4000N and exceeds the European standard.

Owner:SHANDONG JINGYAO GLASS GRP

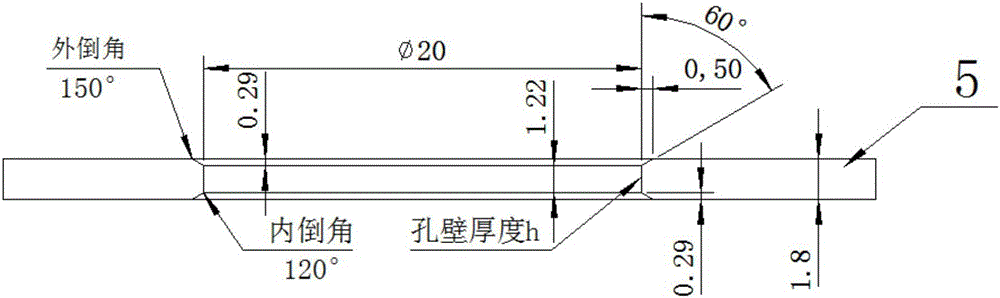

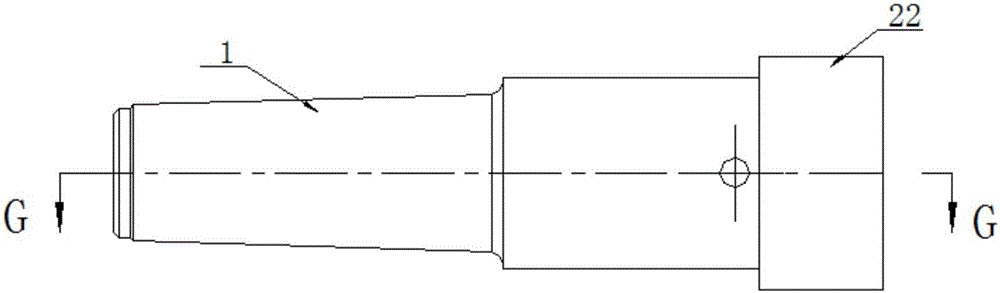

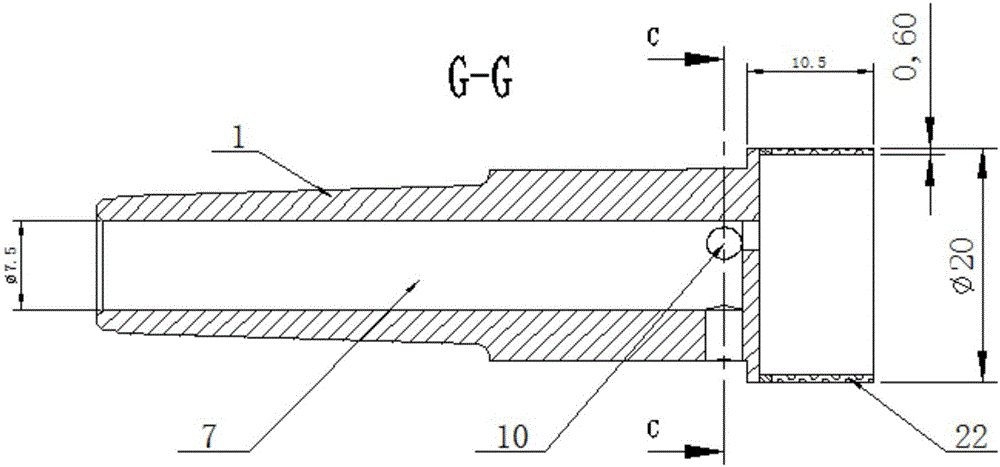

Method for reducing machining stress concentration of glass hole

ActiveCN105856429APromote repairReduce the difficulty of productionStone-like material working toolsStress concentrationGlass strength

The invention relates to a method for reducing machining stress concentration of a glass hole. The method comprises the following steps: assembling a chamfer bit, enabling the end with external diameter smaller than the aperture of the glass hole to get close to a drill bit working ring; arranging a chamfer ring at the rear side of the drill bit working ring and assembling the chamfer ring on a drill bit basal body; carrying out drilling-down machining, wherein the drill bit drills through a transitional slot at the lower end face of the glass, and the drill slot depth at the external diameter of the drill bit working ring is smaller than the set chamfer depth of the lower end face of the glass; carrying out drilling-up machining, wherein the drill bit carries out hole drilling and outer chamfer drilling at the upper end face of the glass, corresponding to the transitional slot, and drills at the external diameter part of the end face of the drill bit working ring until reaching the bottom of the transitional slot or running through the bottom of the transitional slot; carrying out secondary drilling-down machining, wherein the drill bit carries out inner chamfer drilling at the transitional slot of the glass, and thus completing machining of the glass hole. The method can realize little edge breakage of the end face and the inner chamfer, can avoid forming of junction gaps, can form a uniform and smooth hole wall, and can ensure that the inner chamfer is an obtuse angle, thus solving or relieving the problem of stress concentration in machining of the glass hole, and ensuring the strength of the glass.

Owner:GUILIN CHAMPION UNION DIAMOND CO LTD

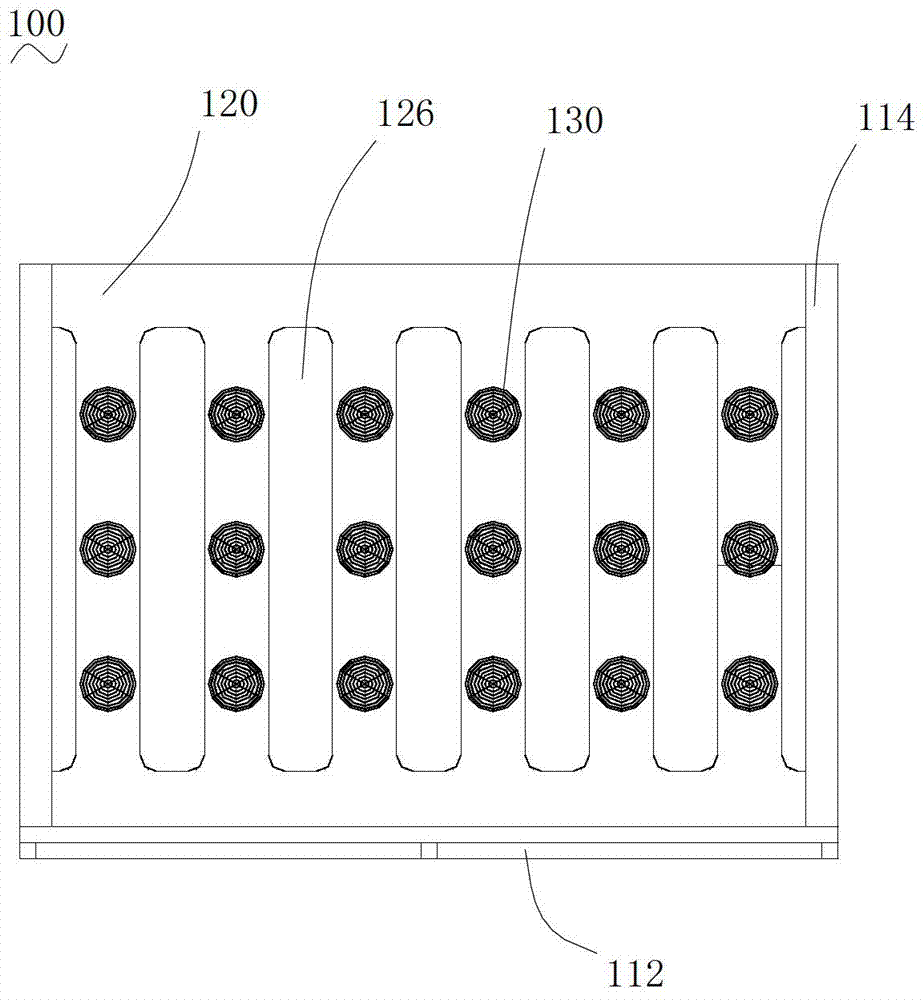

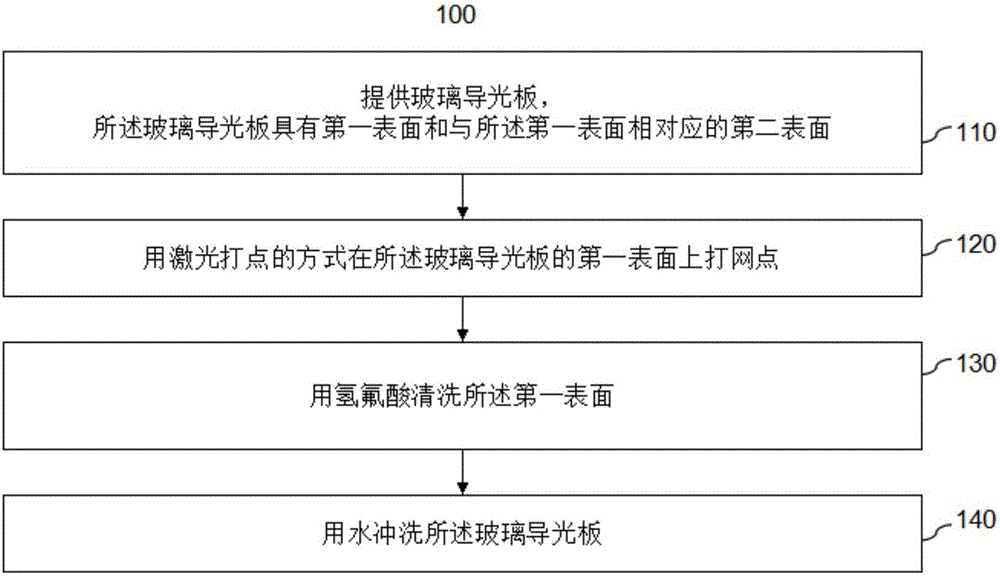

Processing technique of glass light guide plate

InactiveCN105044834ANo color differenceNo sheddingPlanar/plate-like light guidesHydrofluoric acidLight guide

The invention provides a processing technique of a glass light guide plate. The processing technique includes the following steps that: a glass light guide plate is provided, wherein the glass light guide plate is provided with a first surface and a second surface opposite to the first surface; lattice points are marked on the first surface of the glass light guide plate through adopting a laser point marking mode; the first surface is washed through hydrofluoric acid; and the glass light guide plate is washed through water. The glass light guide plate with lattice points which is prepared through the processing technique has the advantages of no chromatic aberration, excellent lattice point effects, no crack, high glass strength, little possibility of being fractured and high light guide performance, and can be produced in a batch manner. With the processing technique adopted, lattice points of which the sizes are smaller than 0.1mm can be produced on the glass light guide plate. According to the glass light guide plate prepared through the processing technique of the invention, ink has little possibility of falling off from the glass light guide plate.

Owner:SUZHOU DONGSHAN PRECISION MANUFACTURING CO LTD

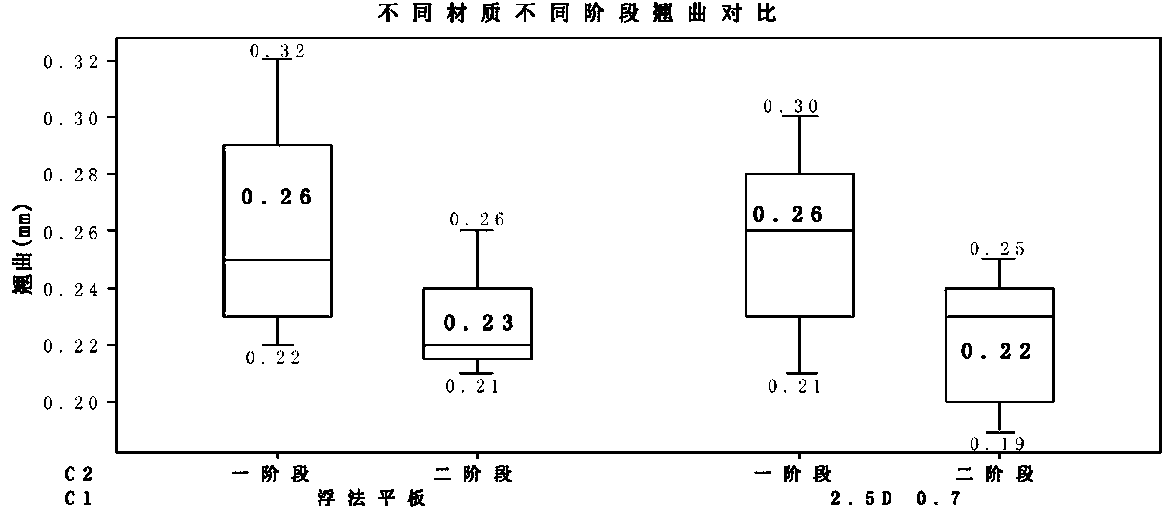

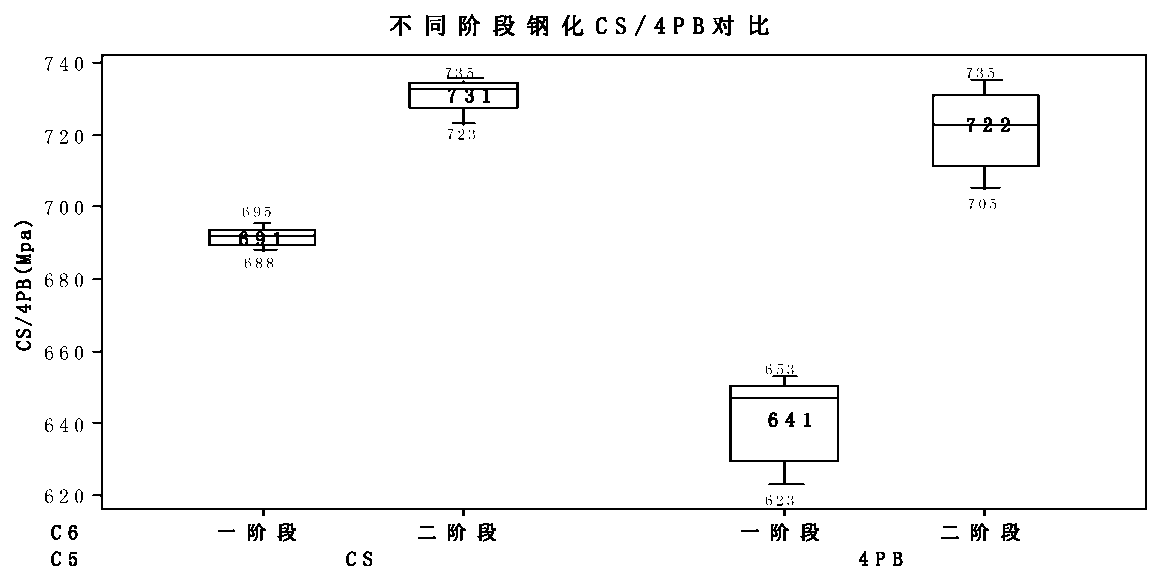

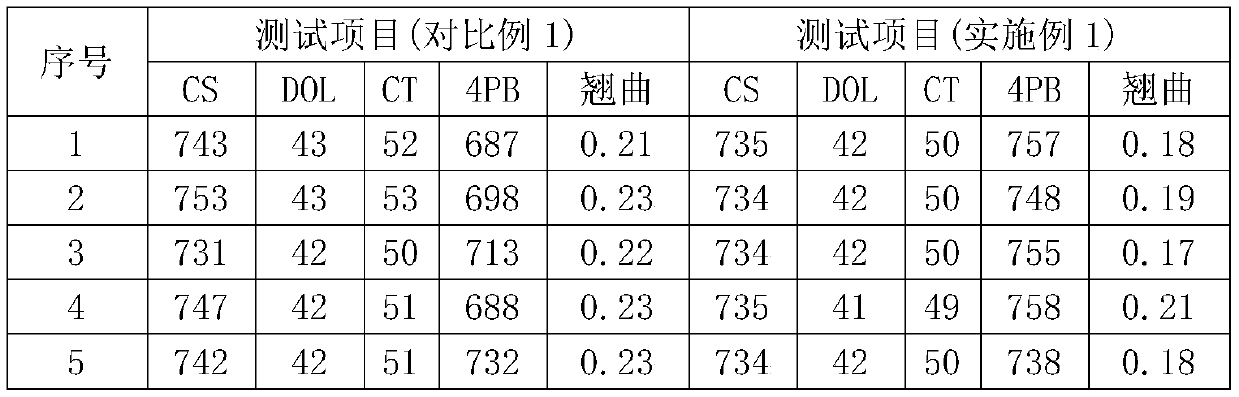

Chemical tempering treatment method of glass

The invention discloses a chemical tempering treatment method of glass. The method includes the steps of: 1) selecting glass containing alkali metal ions, and immersing the glass in a first salt bathat 400-460DEG C for more than or equal to 1h, and then conducting rapid annealing at room temperature; 2) immersing the obtained annealed glass in a second salt bath at 350-420DEG C for at least 5min,and then conducting rapid annealing at room temperature, wherein the concentration of the first salt bath is less than or equal to the concentration of the second salt bath, and the concentration ofthe second salt bath is less than or equal to twice the concentration of the first salt bath. Through the above operations, chemical tempering treatment of the glass can be completed. The method can improve the glass strength, and also can improve the glass warpage.

Owner:XIANNING NANBO PHOTOELECTRIC GLASS CO LTD +1

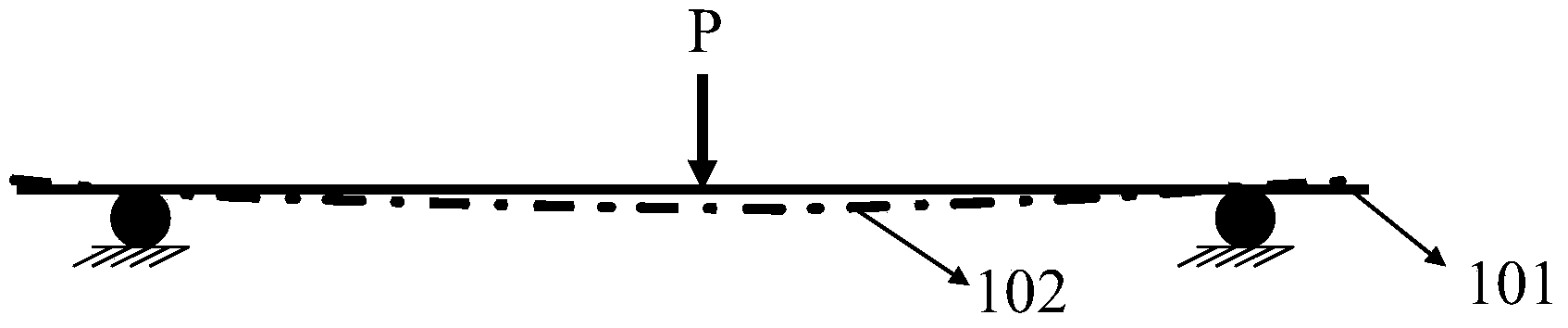

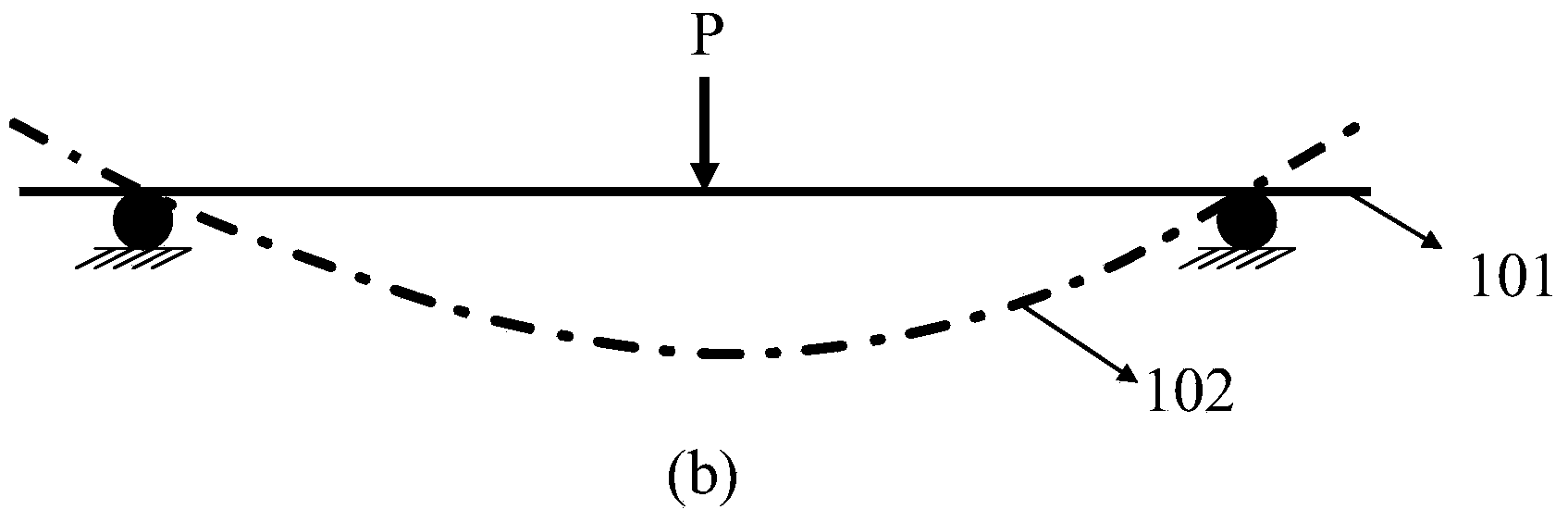

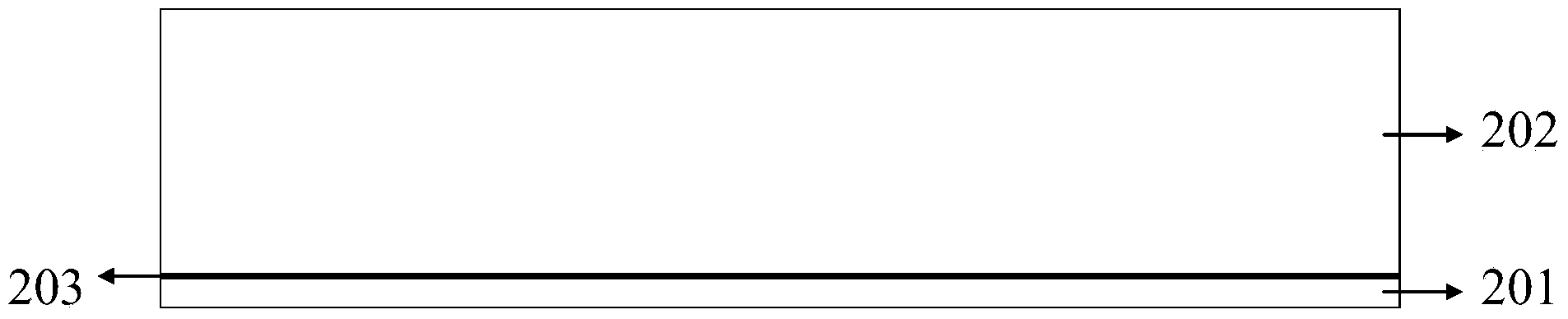

Method for testing bending strength of ultra-thin glass

ActiveCN104316415AEasy to manufactureThe experimental method is simpleMaterial strength using steady bending forcesExperimental methodsTest sample

The invention discloses a method for testing strength of ultra-thin glass. The method comprises the following steps: obtaining elasticity modulus of an object; fixing the object with to-be-tested ultra-thin glass together, and forming a combined object sample; measuring the corresponding force value of the combined object sample at glass breakage moment through an existing glass strength testing method, substituting the force value into a given calculation formula, thereby obtaining the bending strength of the ultra-thin glass, wherein the object refers to a standard beam or a block. The experimental method disclosed by the invention is simple, easy in sample preparation, accurate in test data and high in operability. With the adoption of a test sample prepared by the method, the strength test can be directly finished according to the existing glass strength testing method and instrument.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

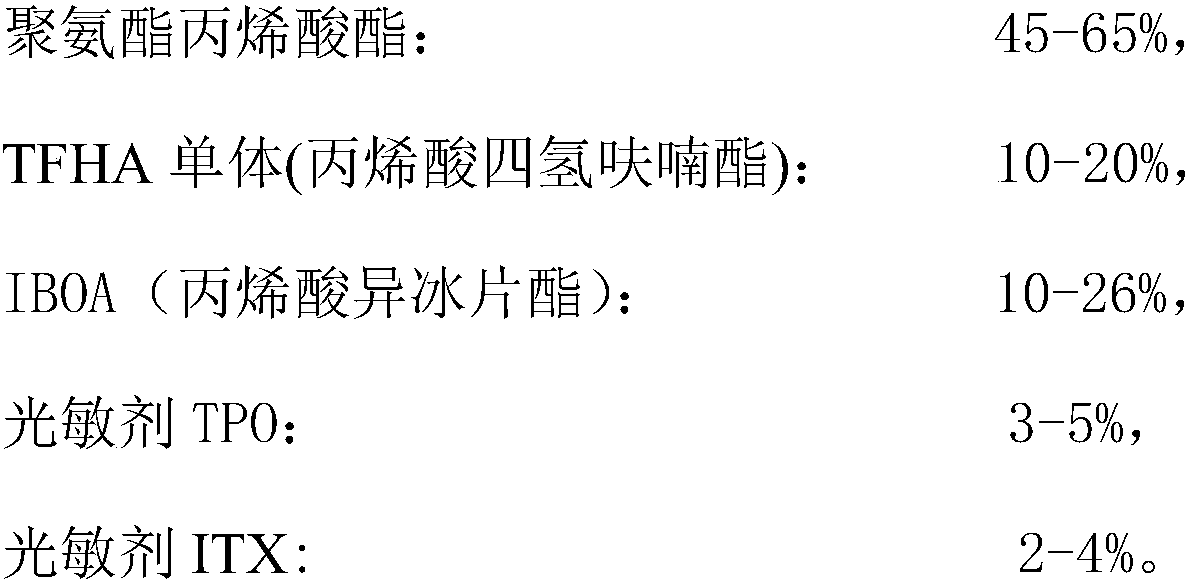

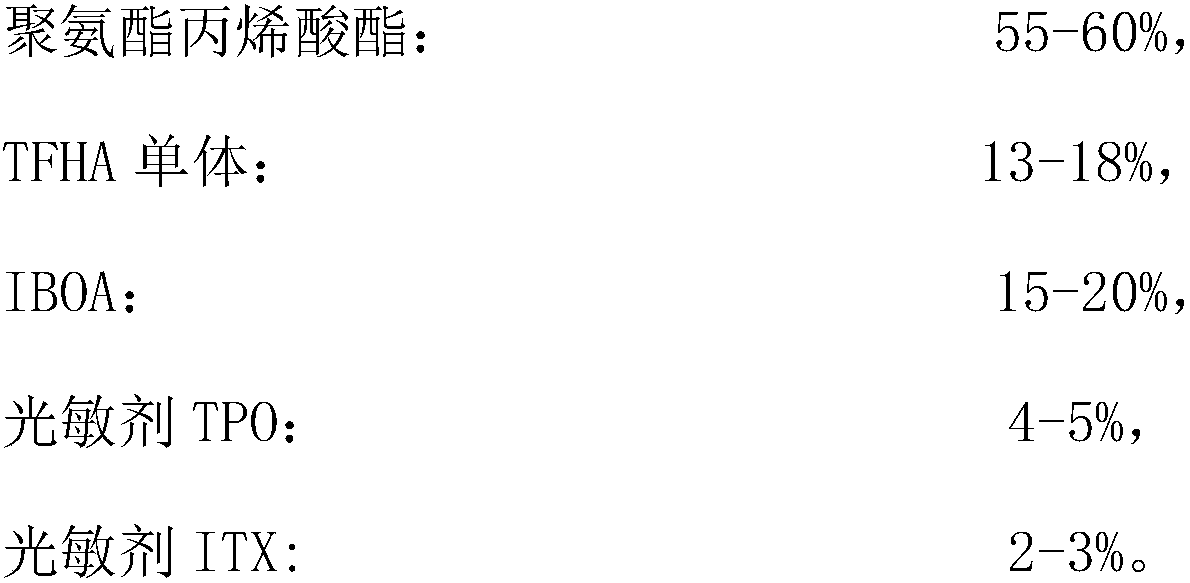

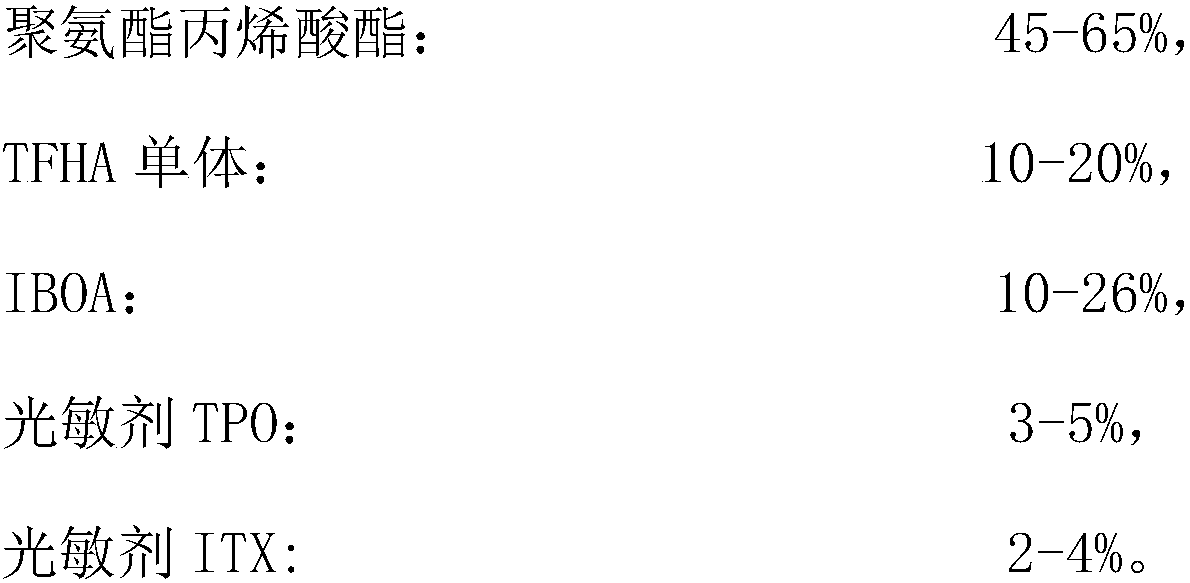

Environment-friendly UV glue applied to flexible packaging film

InactiveCN108441164AShort curing timeIncrease productivityPolyureas/polyurethane adhesivesPhotosensitizerSolvent free

The invention relates to environment-friendly UV glue applied to a flexible packaging film. The environment-friendly UV glue is prepared from components in percentage by weight as follows: 45%-65% ofurethane acrylate, 10%-20% of TFHA (tetrahydrofurfuryl acrylate) monomers, 10%-26% of IBOA (isobornyl acrylate), 3%-5% of a photosensitizer TPO and 2%-4% of a photosensitizer ITX. The invention further provides a preparation method and a use method of the environment-friendly UV glue. Appearance, glass strength and heat sealing strength of a composite structural film prepared from the UV glue arecomparable with those of a composite structural film prepared from solvent-free compound glue, the using requirement of the flexible packaging film industry can be met, besides, the glue can be curedrapidly, so that production efficiency is obviously improved, and quality accidents and accident cost are reduced; further, an overlong heating oven is not needed, therefore, size of a compound machine can be reduced, and a production spot is reduced.

Owner:中山市康和化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com