Patents

Literature

122results about "Alkali metal nitrate purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recycling dimethyl sulfone and sodium nitrate from dimethyl sulfoxide waste slag

ActiveCN101195595AIncrease added valueEmission reductionOrganic chemistryOrganic compound preparationDimethyl SulphoneSlag

The invention relates to a method for recovering dimethyl sulfone and sodium nitrate from dimethyl sulfoxide waste slag, which comprises arranging waste slag waste slag in a decompression autoclave at 120-160DEG C to decompress and distill, distilling out the dimethyl sulfoxide and dimethyl sulfone from dimethyl sulfoxide waste slag to be arranged into an another autoclave to be cooled to obtain crystallized solid, arranging the distilled dimethyl sulfoxide and dimethyl sulfone into enough hydrogen dioxide solution to be oxidized and dried in vacuum to obtain dimethyl sulfone product, dissolving leavings in water to be discharged, adding concentrated nitric acid into the filtered mother liquid to adjust pH till 2-3 and convert sodium nitrite to sodium nitrate, neutralizing over nitric acid via soda, to neutralize the mother liquid, heating the solution to 120-125DEG C, evaporating at normal pressure, cooling to 50-70DEG C, crystallizing, separating and drying to obtain sodium nitrate product. The invention can reduce discharge of industrial waste slag and reduce environment pollution, with simple process and low energy consumption.

Owner:HUBEI XINGFA CHEM GRP CO LTD

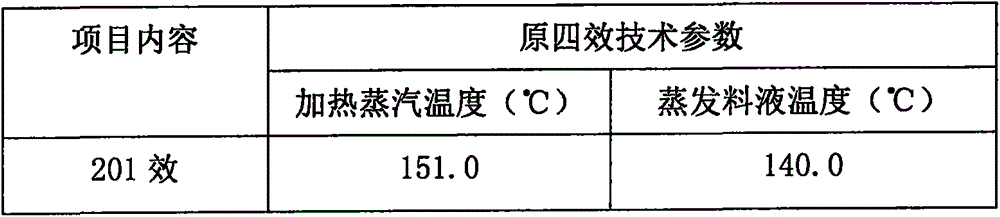

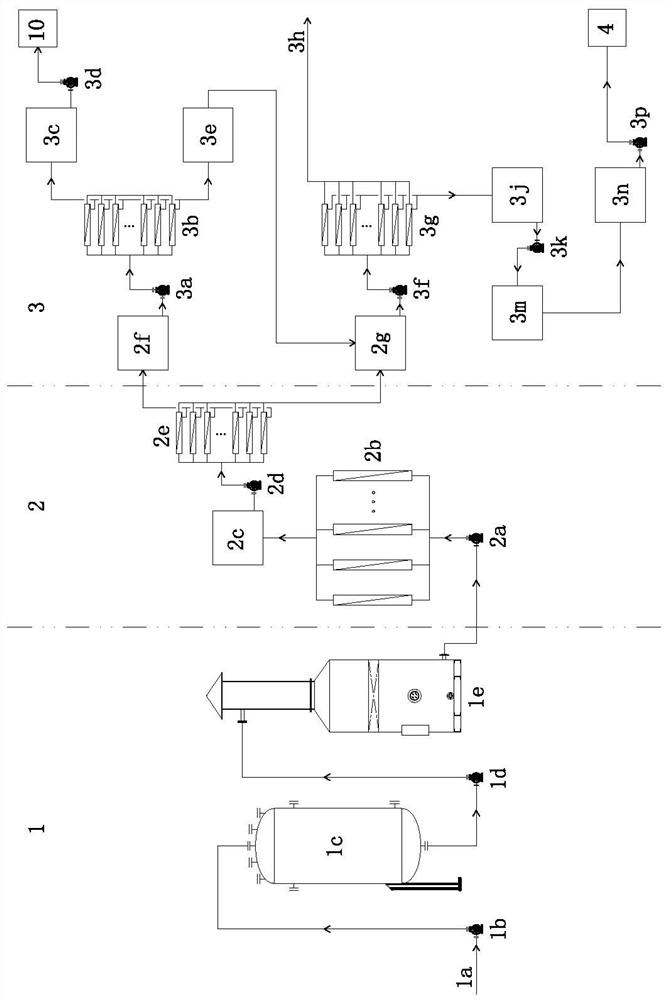

Treatment method and device for coal chemical industry high-concentration brine

ActiveCN105502438AAchieving zero emissionsRealize comprehensive utilizationAlkali metal nitrate purificationAlkali metal sulfite/sulfate purificationHigh concentrationResource utilization

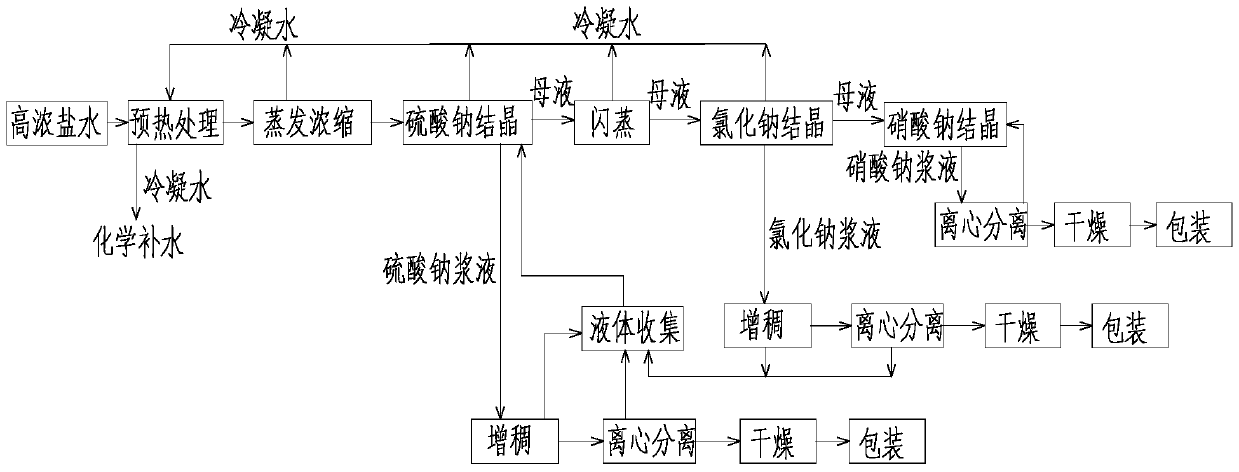

The invention discloses a treatment method and device for coal chemical industry high-concentration brine. The treatment method for the coal chemical industry high-concentration brine includes the following steps that 1, preheating and evaporating concentration are conducted on the coal chemical industry high-concentration brine in sequence; 2, sodium sulfate crystallization is carried out on the high-concentration brine concentrated in an evaporation mode to obtain sodium sulfate slurry and mother liquor, and the sodium sulfate slurry is thickened, treated in a crystal growth mode and centrifugally separated to obtain sodium sulfate crystal; 3, sodium chloride crystallization is carried out on the mother liquor obtained in the step 2 to obtain sodium chloride slurry and mother liquor, and the sodium chloride slurry is thickened, treated in a crystal growth mode and centrifugally separated to obtain sodium chloride crystal; 4, sodium nitrate crystallization is carried out on the mother liquor obtained in the step 3 to obtain sodium nitrate slurry and mother liquor, and the sodium nitrate slurry is centrifugally separated to obtain sodium nitrate crystal. Zero emission of the coal chemical industry high-concentration brine and resource utilization of crystalline salt are achieved.

Owner:深圳能源资源综合开发有限公司

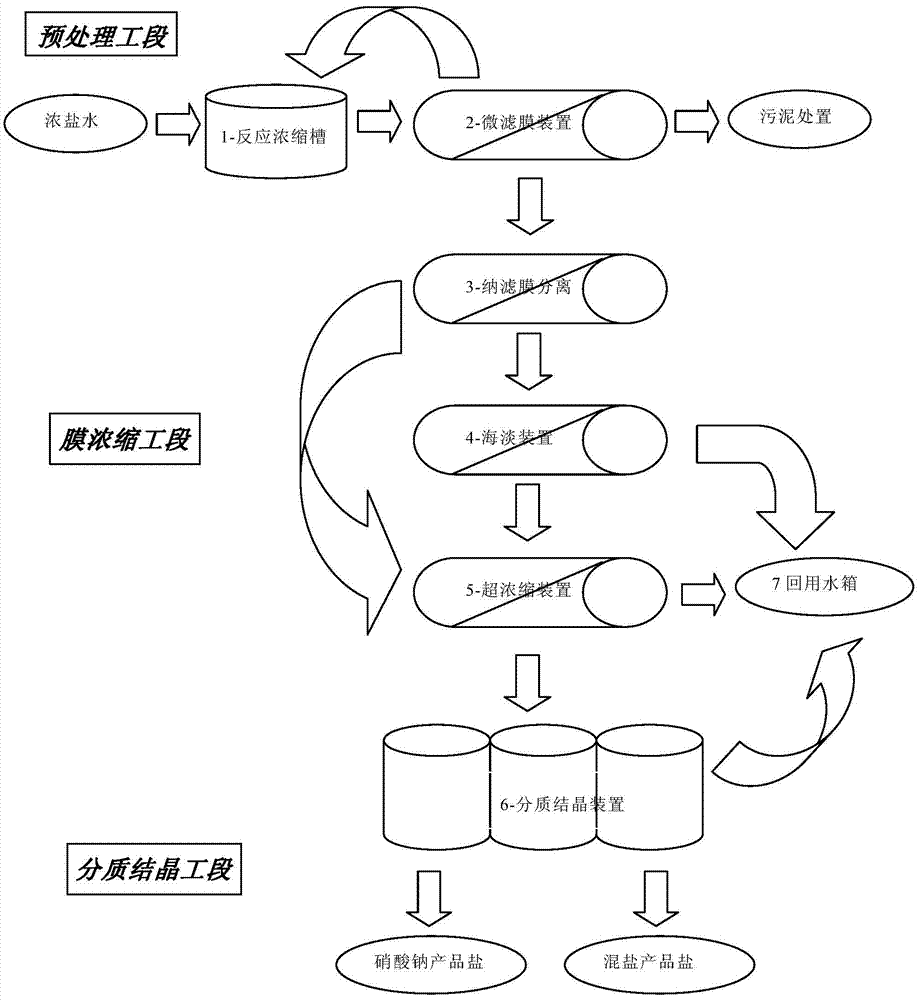

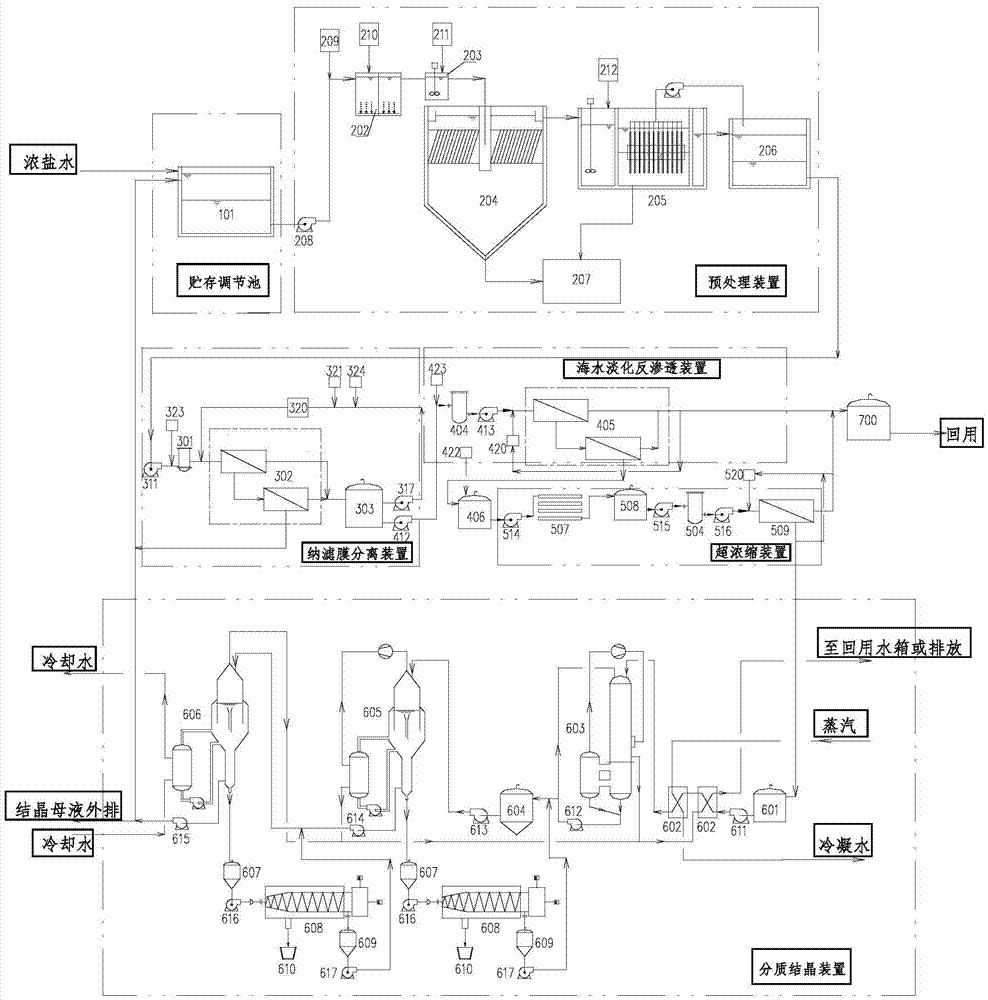

Concentrated salt water zero discharging membrane concentration and quality grading crystallization process and concentrated salt water zero discharging membrane concentration and quality grading crystallization equipment

PendingCN106966535AAchieve reductionAchieving zero emissionsGeneral water supply conservationSeawater treatmentSaline waterSalt water

The invention relates to a concentrated salt water zero discharging membrane concentration and quality grading crystallization process and concentrated salt water zero discharging membrane concentration and quality grading crystallization equipment. The concentrated salt water zero discharging membrane concentration and quality grading crystallization process comprises a pretreatment step, a membrane concentration treatment step, and a quality grading crystallization treatment step, wherein a pretreatment device comprises a high-grade oxidation unit and a softening microfiltration unit, the membrane concentration treatment step comprises nano-filtration membrane separation, seawater desalination reverse osmosis membrane separation and super-concentration separation, and the quality grading crystallization process comprises separating a sodium chloride and sodium sulfate mixing salt and a sodium nitrate product salt. According to the present invention, by combining a variety of concentration processes, the concentrated salt water treatment efficiency of the equipment can be effectively improved, the purpose of reduction and zero discharging of the concentrated salt water can be achieved, and the running cost of the concentrated salt water treatment equipment can be reduced.

Owner:MAIWANG INT BUSINESS SHANGHAI

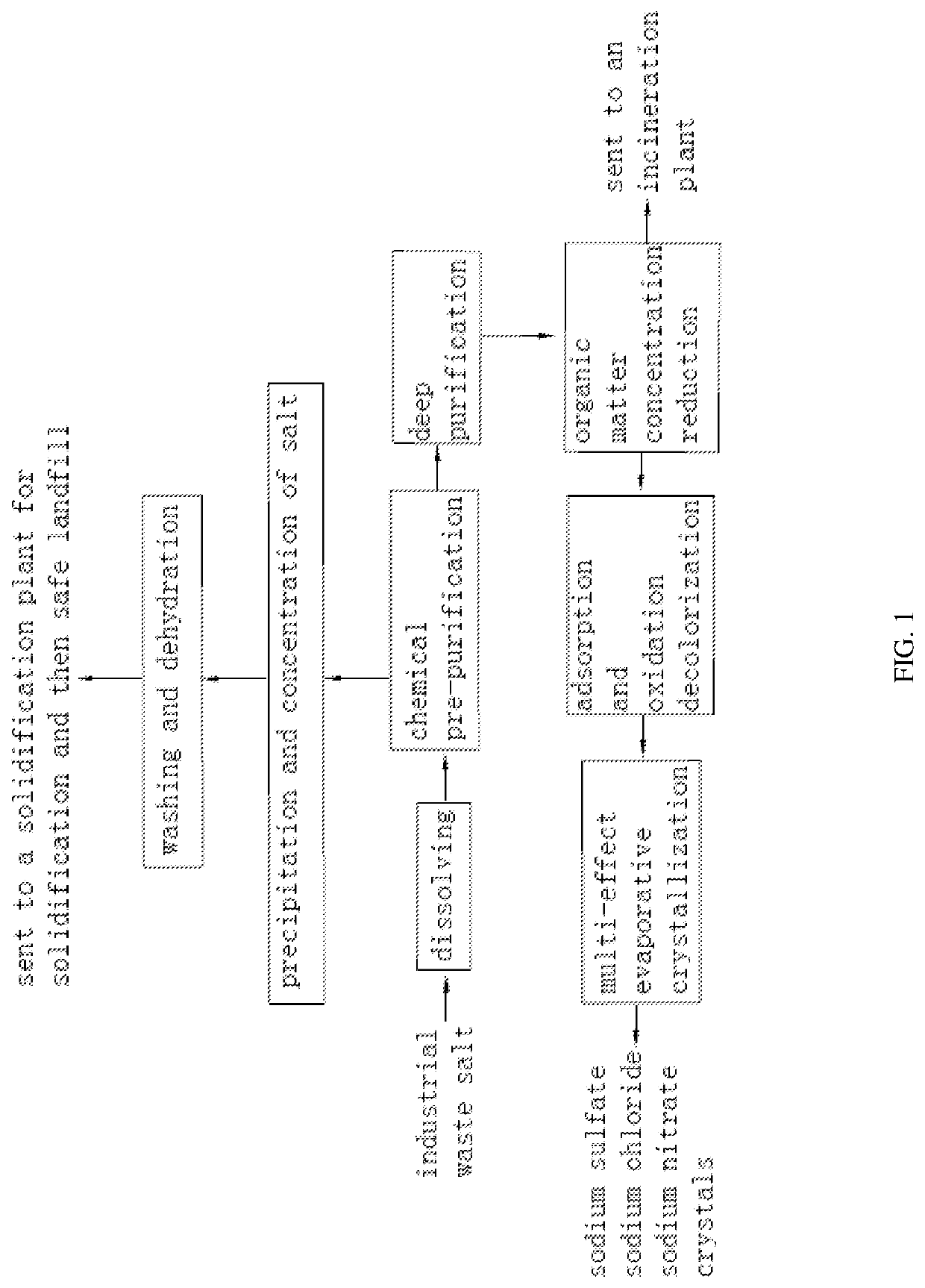

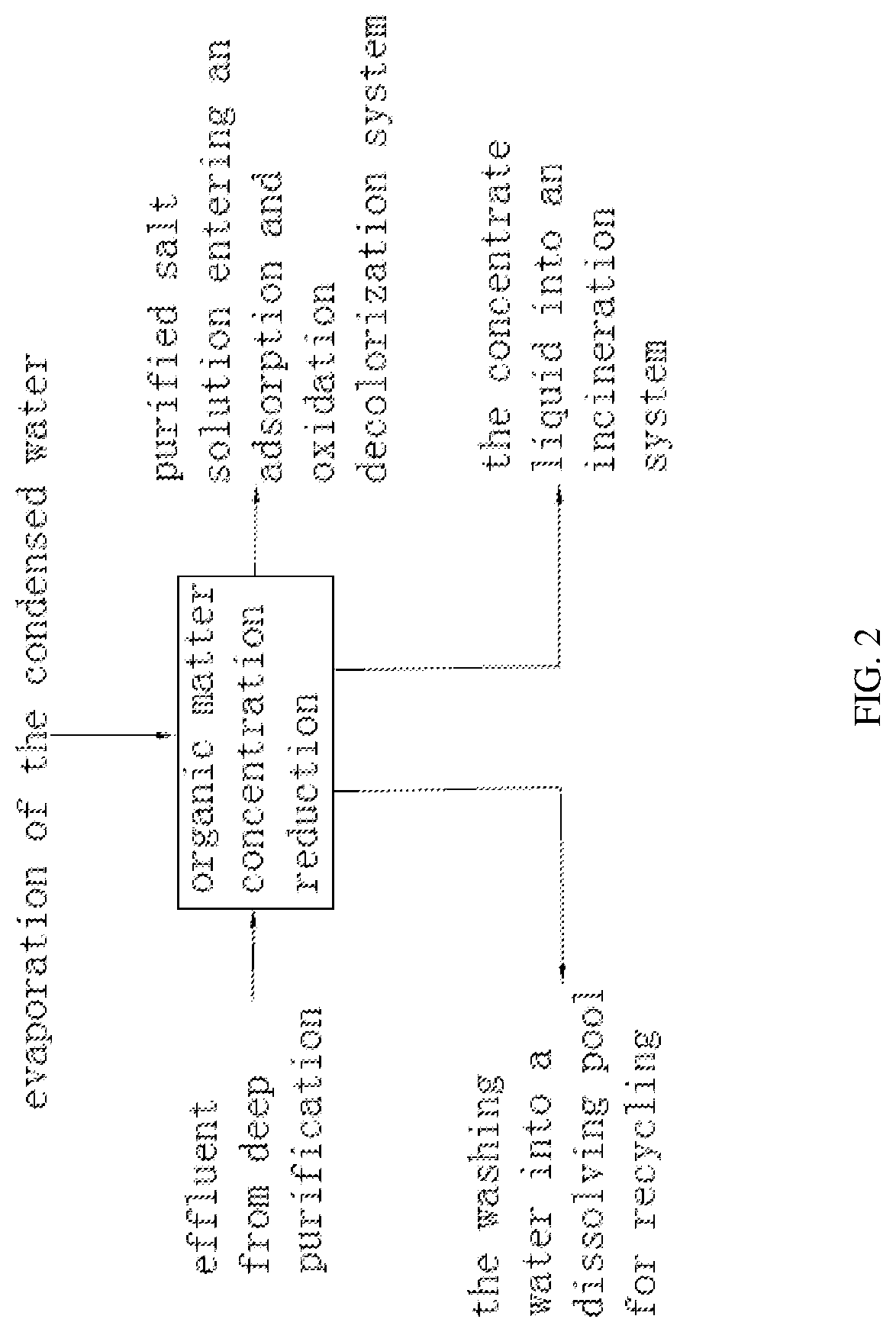

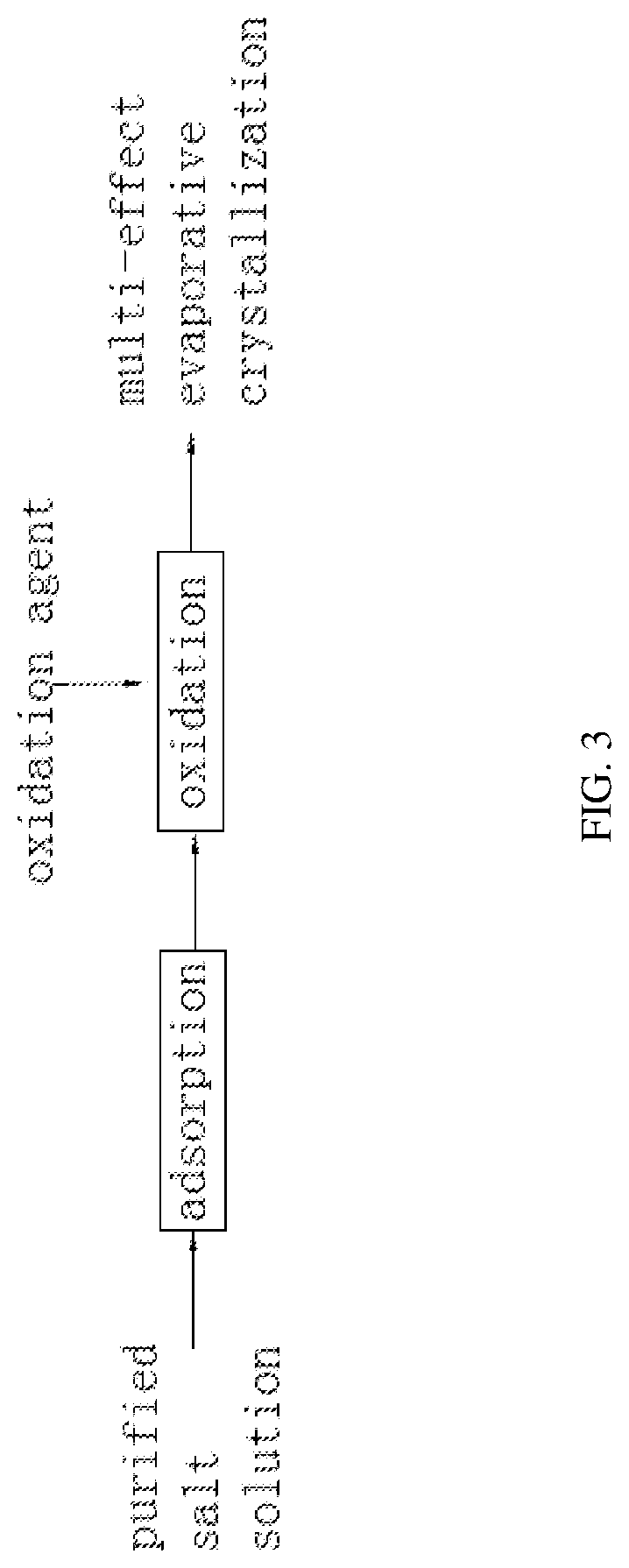

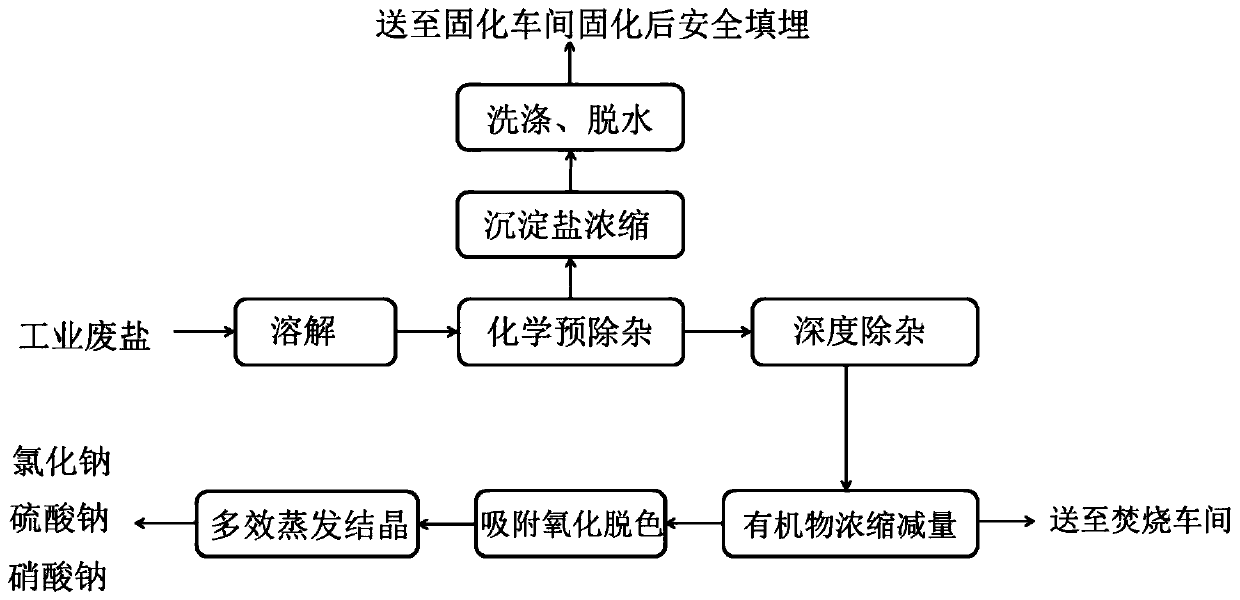

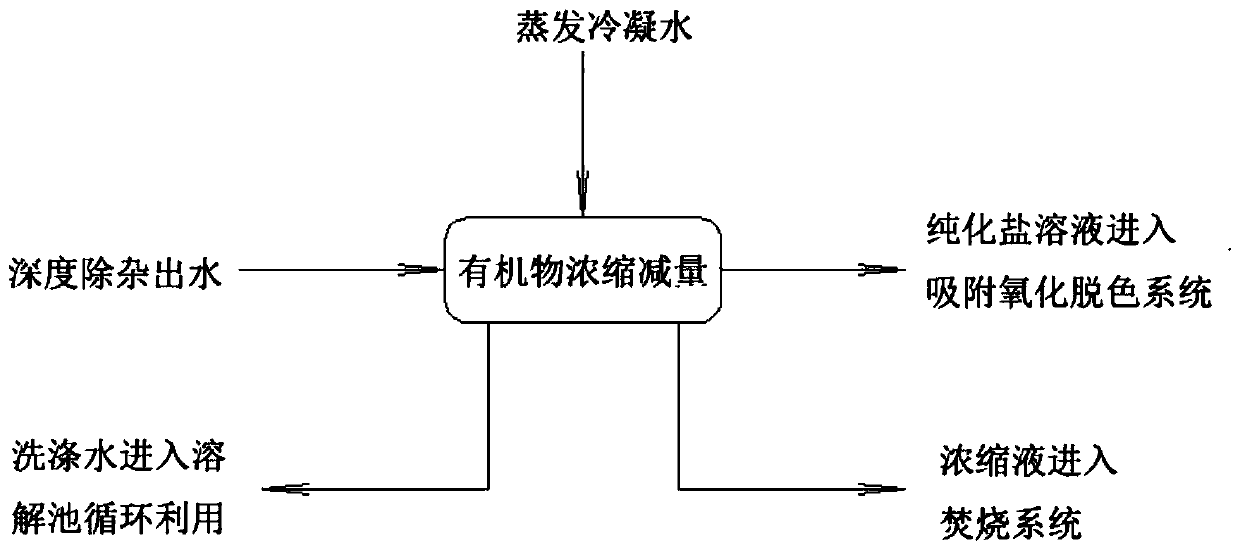

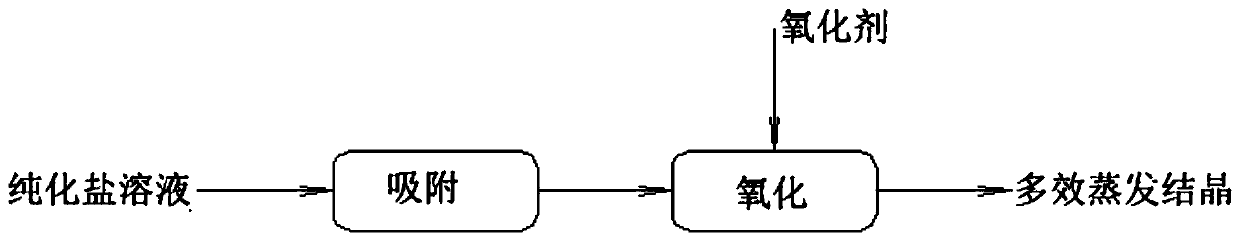

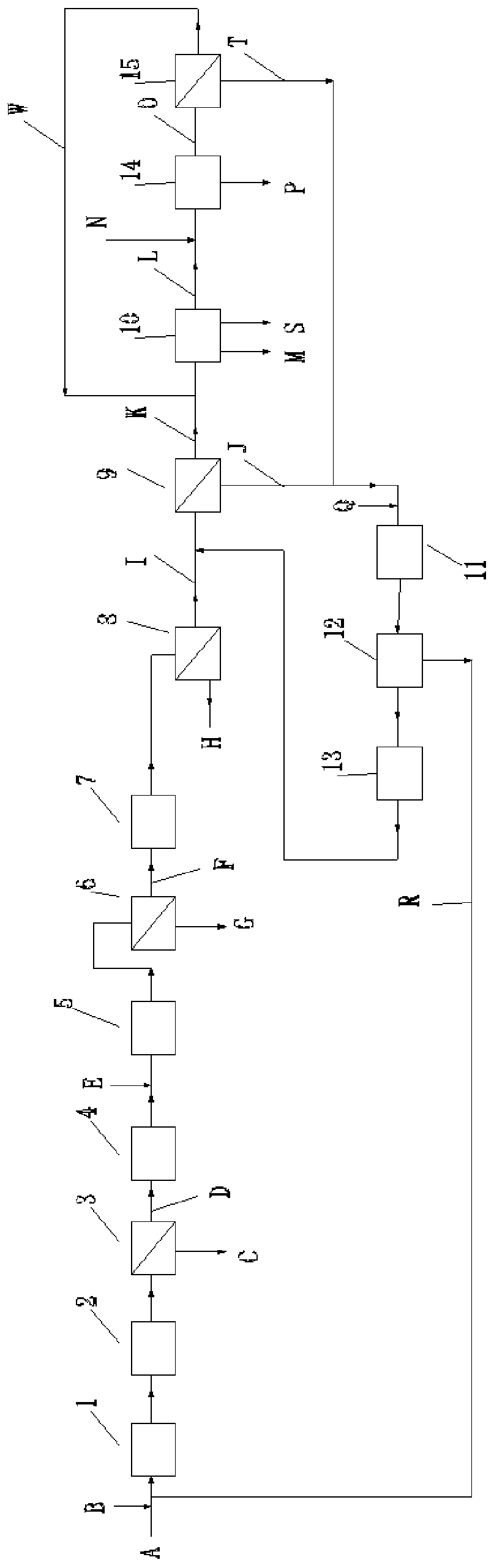

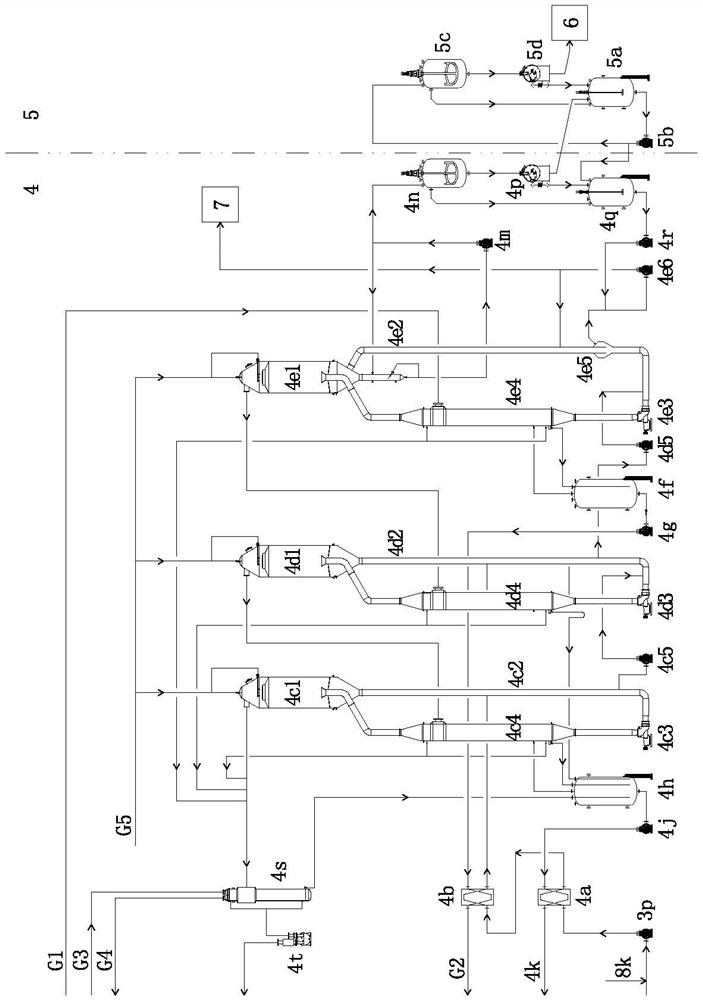

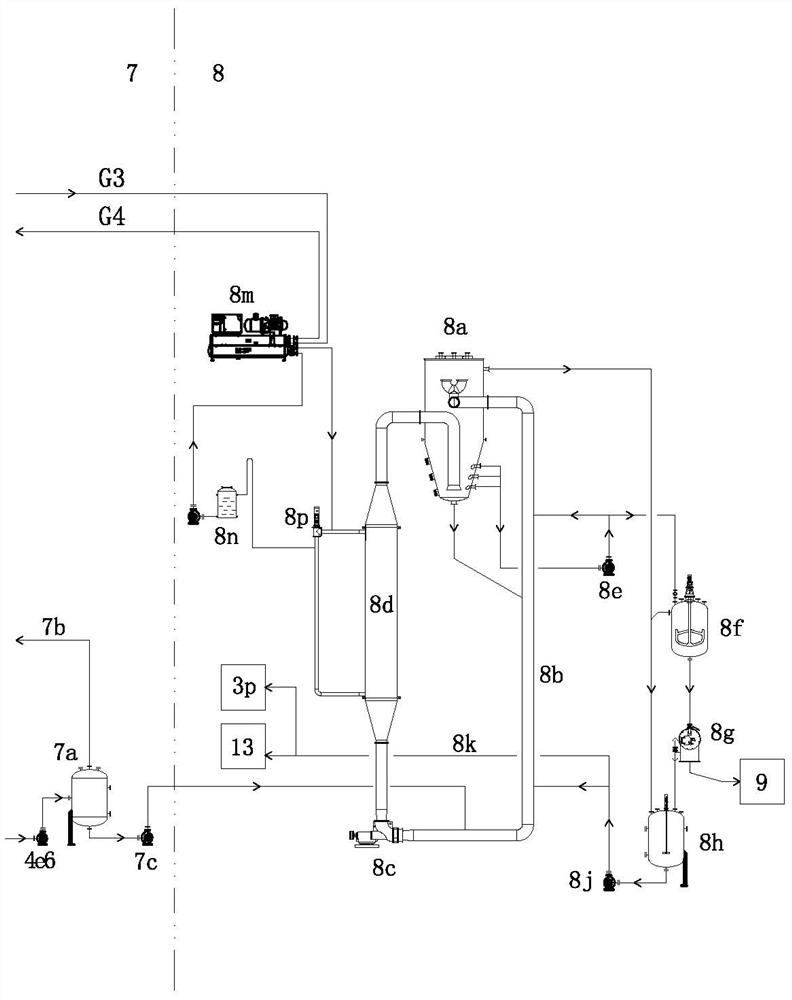

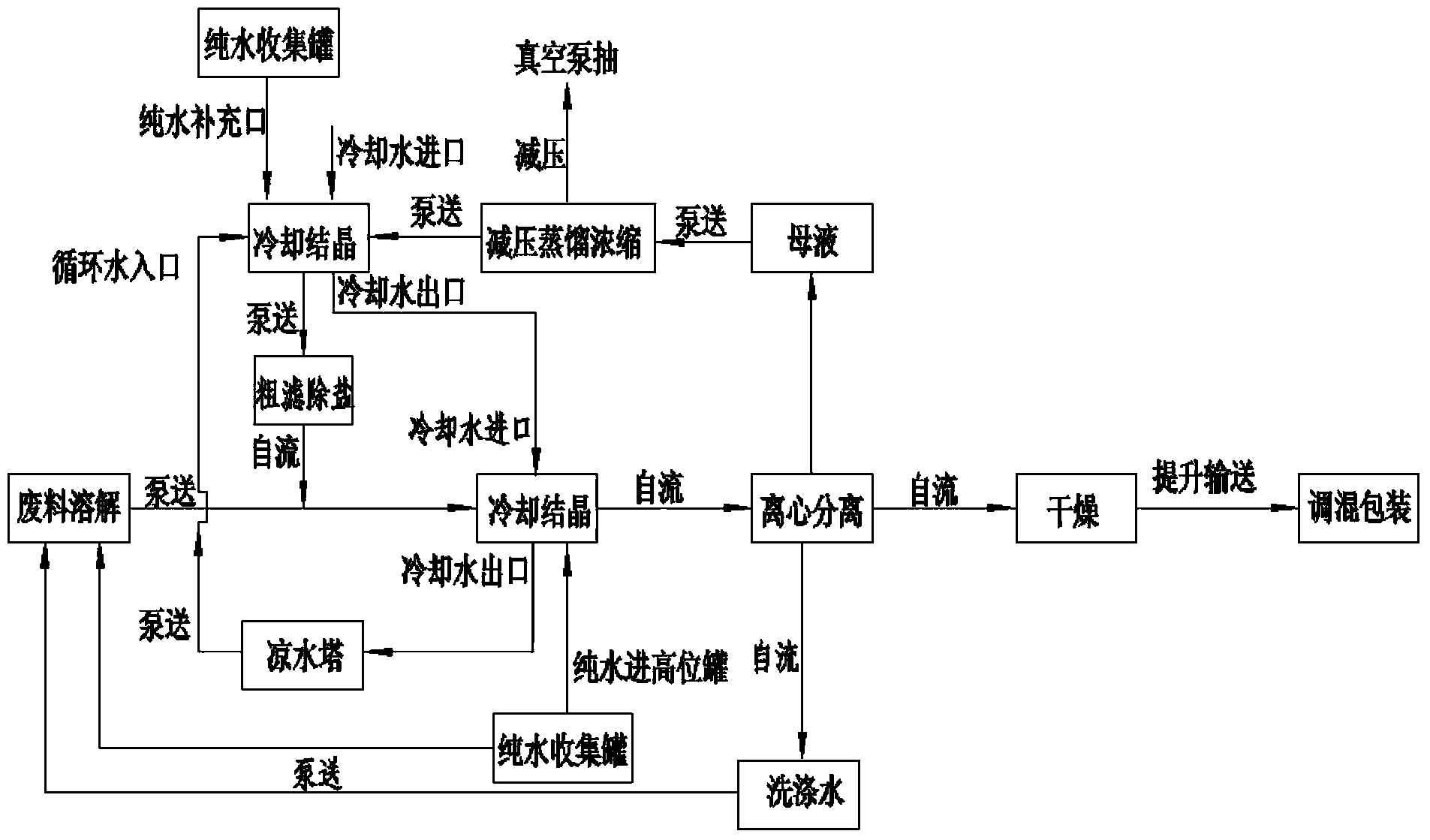

Industrial waste salt resourceful treatment method and device

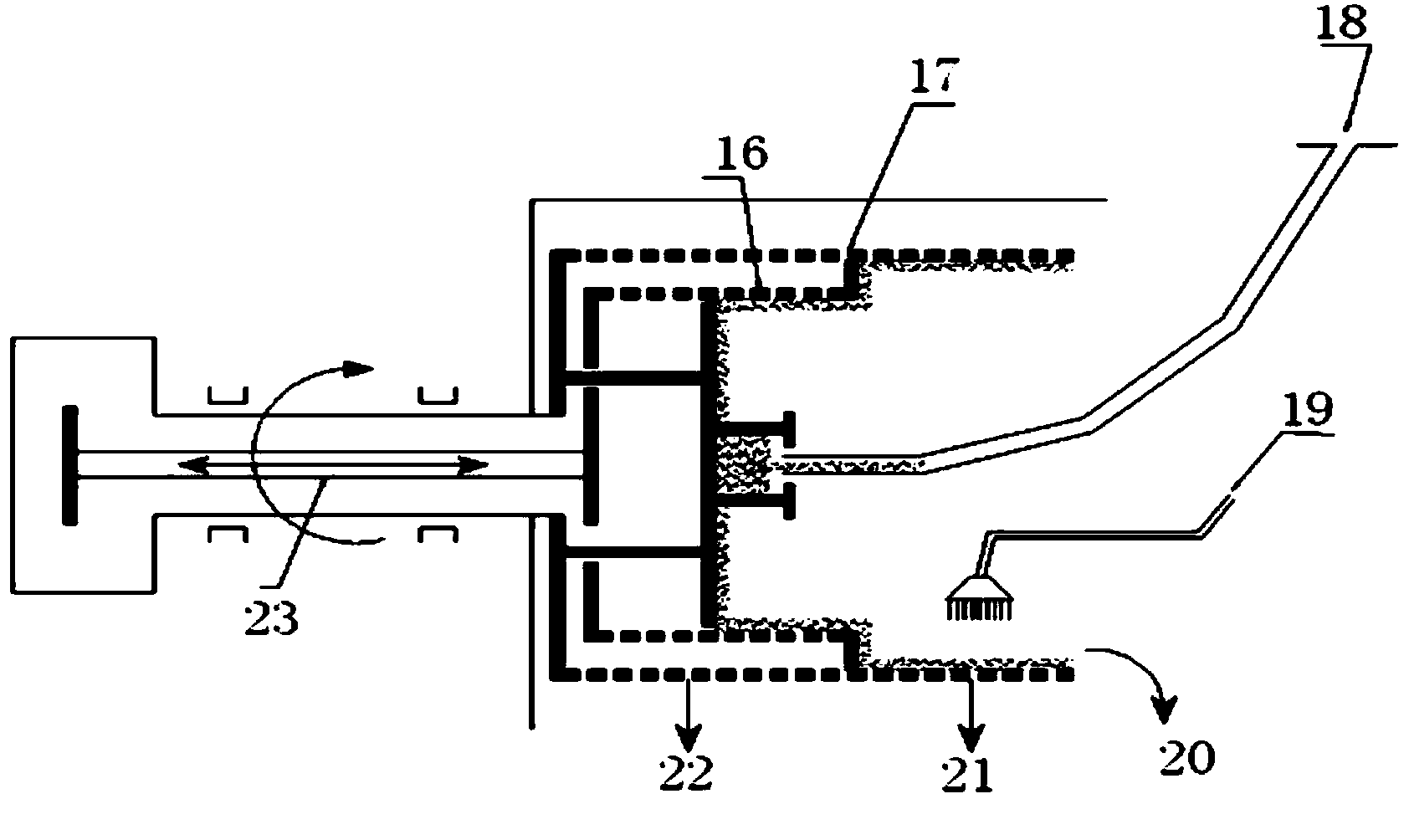

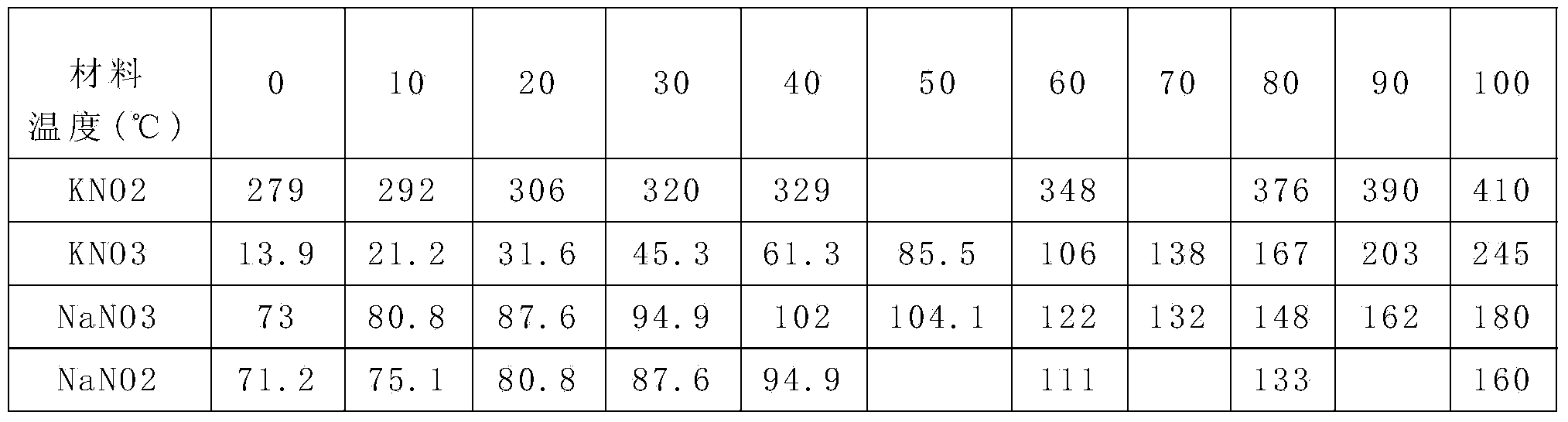

ActiveUS20210347649A1Reduce difficultyReduce pretreatment costsSludge treatmentUltrafiltrationEnvironmental engineeringCrystallization temperature

An industrial waste salt resourceful treatment method comprises the following steps: the industrial waste salt is sequentially subject to dissolving, chemical pre-purification, deep purification, organic matter concentration reduction, adsorption and oxidation decolorization and multi-effect evaporative crystallization to respectively obtain sodium sulfate, sodium chloride and sodium nitrate crystals; the crystallization temperature of sodium sulfate is in a range of 75° C. to 85° C.; the crystallization temperature of sodium chloride is in a range of 60 to 70° C.; and the crystallization temperature of sodium nitrate is in a range of 45° C. to 55° C. An industrial waste salt resourceful treatment device is further provided.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

Method for producing sodium nitrate

InactiveCN101070168AIncrease profitHigh recovery rateAlkali metal nitrate purificationInorganic ChemicalEvaporation

The invention offers a kind of method of producing sodium nitrate which belongs to technique field of inorganic chemical industry. This method uses the following raw material and steps to make sodium nitrate: 1. vaporize and dispose bittern solution and sodium nitrate vaporization mother liquor with certain volumetric ratio to get sodium nitrate mixture in the form of plasm; 2.separate solid and liquid, get salt-mixture of sodium sulfate and sodium chloride or sodium sulfate or sodium chloride and vaporization mother liquor to make salt; 3. vaporize and dispose vaporization mother liquor to make salt and get vaporization mother liquor to make salt in the form of plasm; 4. Separate solid and liquid, get vaporization mother liquor which continues to circulate and join in working procedure of salt preparation at high temperature using evaporation in step 1 and finished product of sodium nitrate. Utilizing ratio of raw material in this invention is high, quality of products is also high, with low energy consumption and production cost and it has no discharge of the three wastes.

Owner:CHINA LIGHT IND INT ENG CO LTD

Industrial waste salt resourceful treatment method and equipment

PendingCN110844922AEfficient use ofReduce difficultyAlkali metal nitrate purificationAlkali metal sulfite/sulfate purificationEnvironmental engineeringCrystallization temperature

The invention provides an industrial waste salt resourceful treatment method and equipment. The method comprises the following steps: sequentially dissolving industrial waste salt, chemically pre-removing impurities, deeply removing impurities, concentrating and reducing organic matters, and carrying out adsorption oxidation decolorization and multiple-effect evaporative crystallization to respectively obtain sodium sulfate, sodium chloride and sodium nitrate crystals; wherein the crystallization temperature of the sodium sulfate is 75-85 DEG C; the crystallization temperature of sodium chloride is 60-70 DEG C; and the crystallization temperature of sodium nitrate is 45-55 DEG C. According to the industrial waste salt resourceful treatment method provided by the invention, the organic matters and other impurities in the industrial waste salt are firstly removed by adopting the steps, then salt separation and crystallization are realized by controlling the temperature in the evaporationprocess, and the industrial waste salt is obtained by utilizing the difference of three-phase co-saturation points of the sodium chloride, sodium nitrate and sodium sulfate at different temperaturesand the solubility of each salt. And the purity and whiteness of the sodium chloride, sodium nitrate and sodium sulfate obtained by salt separation crystallization all reach industrial-grade standards, and the sodium chloride, sodium nitrate and sodium sulfate can be directly applied.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

Salt-containing wastewater salt recycling system and method, salt-containing wastewater treatment system and method

PendingCN109734238ARealize resource processingAchieving zero emissionsWater contaminantsAlkali metal nitrate purificationRecovery methodFiltration

The invention provides a salt-containing wastewater salt recycling system which is used for recycling salt in salt-containing wastewater containing sodium chloride, sodium sulfate and sodium nitrate acquired after salt-containing wastewater is desalted. The salt recycling system comprises a first nano-filtration unit, an ozone oxidation unit, a chelating resin adsorption unit, a sodium sulfate freezing crystallization unit, a sodium chloride evaporative crystallization unit, a sodium nitrate freezing crystallization unit and a second nano-filtration unit. The invention further provides a salt-containing wastewater salt recycling method. The invention further provides a salt-containing wastewater treatment system and method. According to the system and method, high-purity products such as sodium chloride, sodium nitrate and mirabilite can be effectively recycled from the salt-containing wastewater, unserviceable mixed salt is omitted, resourceful treatment of the salt-containing wastewater is achieved, zero discharge of the salt-containing wastewater is really achieved, scaling and blocking of devices such as nano-filtration units can be effectively relieved, so that long-time, stable and reliable operation of the salt recycling system and a wastewater treatment system can be ensured.

Owner:美景(北京)环保科技有限公司

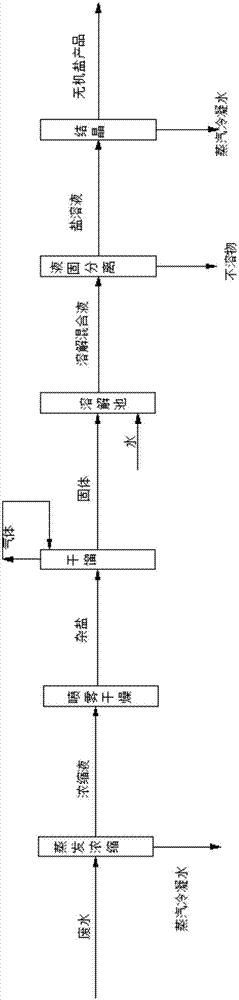

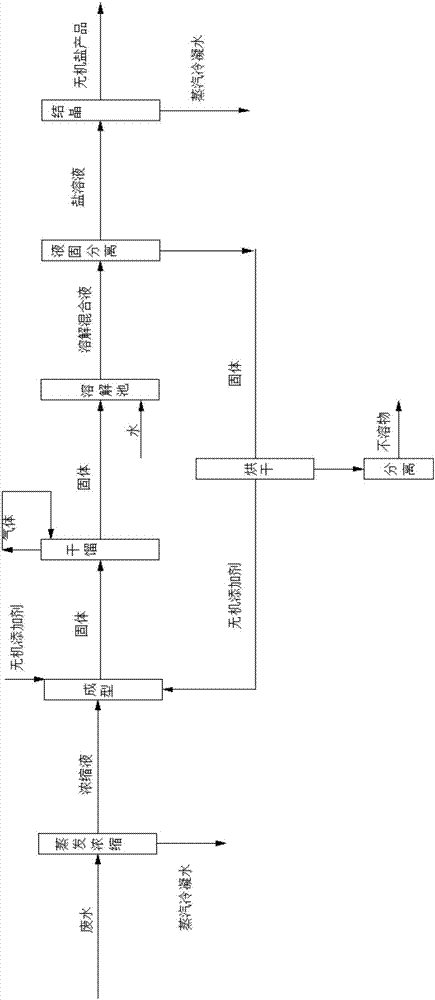

Method for removing organic matters from high organic matter carnallite and recycling inorganic salt

InactiveCN107140703ALow costHigh recovery rateAlkali metal nitrate purificationAlkali metal sulfite/sulfate purificationSecondary emissionEvaporation

The invention relates to a method for removing organic matters from high organic matter carnallite and recycling inorganic salt, and belongs to the field of treatment of waste water and hazardous waste. The method for removing organic matters from high organic matter carnallite and recycling inorganic salt comprises the following steps: step 1, introducing high organic matter carnallite waste water into an evaporator to conduct normal pressure or reduced pressure evaporation until the mass percent of the inorganic salt is 20%-25%, or conducting evaporative crystallization to obtain inorganic salt and a small amount of mother solution; step 2, preparing the concentrated solution or mother solution in the step 1 into a shaped solid; step 3, loading the solid in the step 2 into a dry distillation furnace, and conducting treatment at 300-700DEG C for 30-300min; step 4, adding water to the solid after dry distillation, conducting stirring and liquid solid separation, removing insoluble solid to obtain a saline solution; and step 5, crystallizing the saline solution in the step 4 to obtain the inorganic salt. The method for removing organic matters from high organic matter carnallite and recycling inorganic salt has high removal rate (above 99%) of organic matters, innocent treatment of the technical process, no secondary emission of hazardous waste and low cost.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

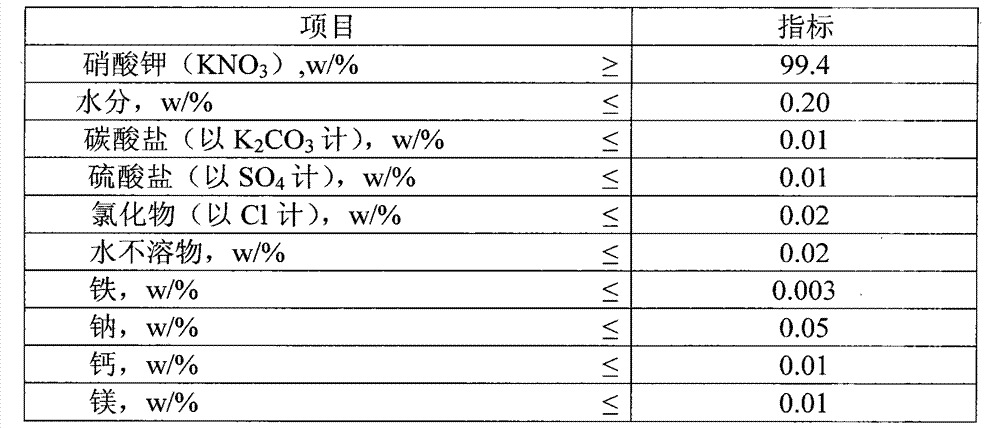

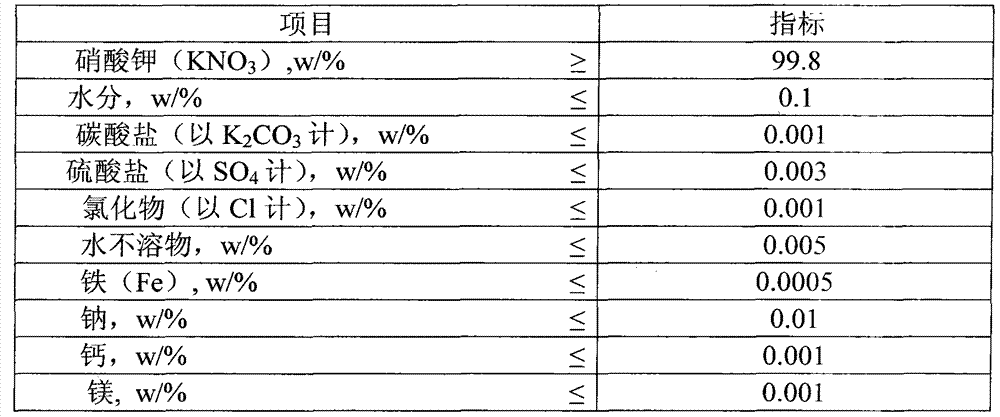

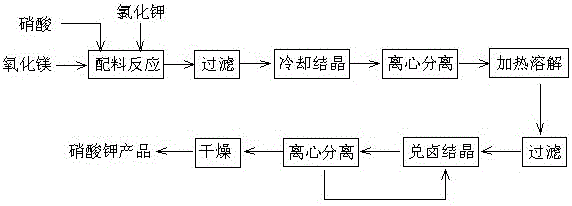

Preparation method of high-purity mass potassium nitrate

InactiveCN103204522AHigh purityReduce contentAlkali metal nitrate purificationPotassium nitratePurification methods

The invention relates to a preparation method of potassium nitrate. The preparation method comprises steps of dissolving, crystallizing, washing, dehydrating and drying. By utilizing the preparation method, the purity of the potassium nitrate is greatly improved, contents of various impurities in the potassium nitrate are greatly reduced, and the requirements on the high-purity potassium nitrate by various industries are met. By utilizing a one-step purification method for purified water production, the investment is greatly reduced, the energy consumption is reduced, the production cost is reduced, large-scale industrial production can be formed, and mass requirements on the high-purity potassium nitrate in a market are met.

Owner:潍坊昌盛硝盐有限公司 +2

Treatment method for potassium nitrate wastes

InactiveCN104609448AHigh purityTake advantage ofAlkali metal nitrate purificationPotassium nitrateChemical treatment

The invention relates to the technical field of chemical industry, in particular to a treatment method for potassium nitrate wastes. The method comprises the following steps: (a) collecting the potassium nitrate wastes generated during chemical enhanced treatment of glass, and adding water for mixing to obtain dilute waste liquor, wherein the concentration of potassium nitrate in the dilute waste liquor is 40-70%; (b) heating the dilute waste liquor to 50-100 DEG C for fully dissolving, performing filtration treatment on dissolved liquor to remove sodium nitrate and other impurities, cooling filter liquor obtained by filtering to lower than a room temperature, crystallizing, dewatering, and drying to obtain potassium nitrate powder. The potassium nitrate wastes are treated with the method for diluting and heating for dissolving, and then the filtration treatment is adopted for removing a relatively large amount of sodium nitrate, impurities and the like in the potassium nitrate wastes, so that the concentration of potassium nitrate in a potassium nitrate solution can be increased, a purification effect is achieved, and the obtained potassium nitrate powder can be sold as a product; specifically, the market price of existing potassium nitrate byproduct wastes is 1,000 yuan / ton, and the price of the potassium nitrate powder obtained after the potassium nitrate wastes are treated with the method disclosed by the invention is 10,000 yuan / ton.

Owner:XUANCHENG HENGTAI ELECTRONICS CHEM MATERIAL

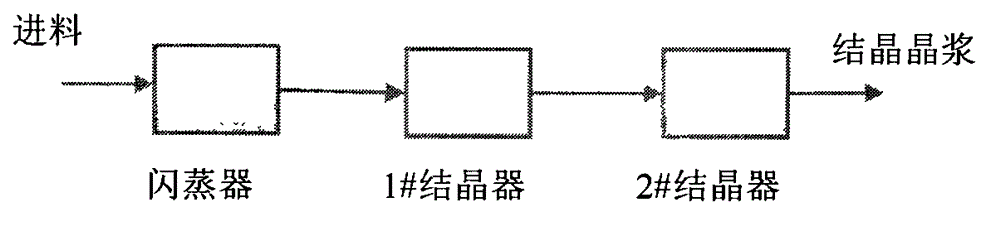

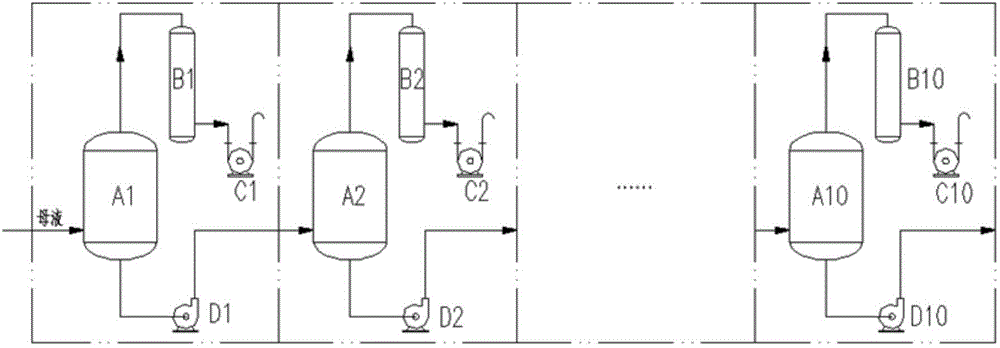

Method for preparing industrial potassium nitrate by virtue of recrystallization method

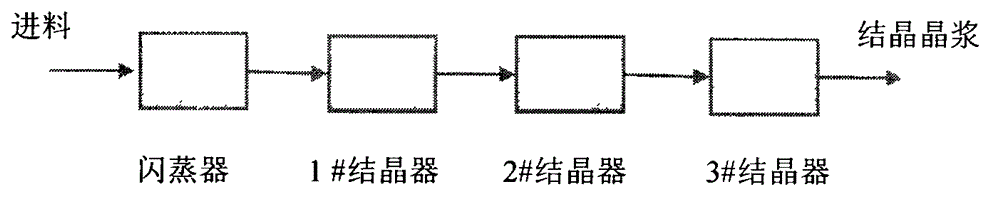

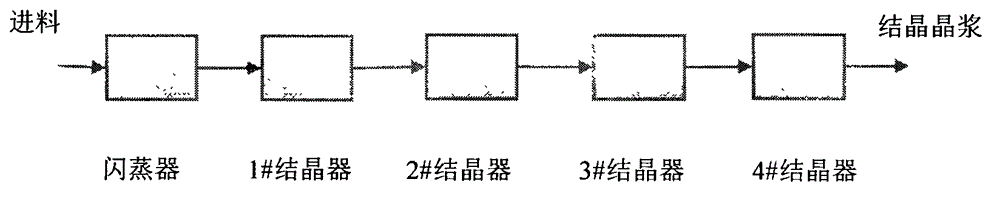

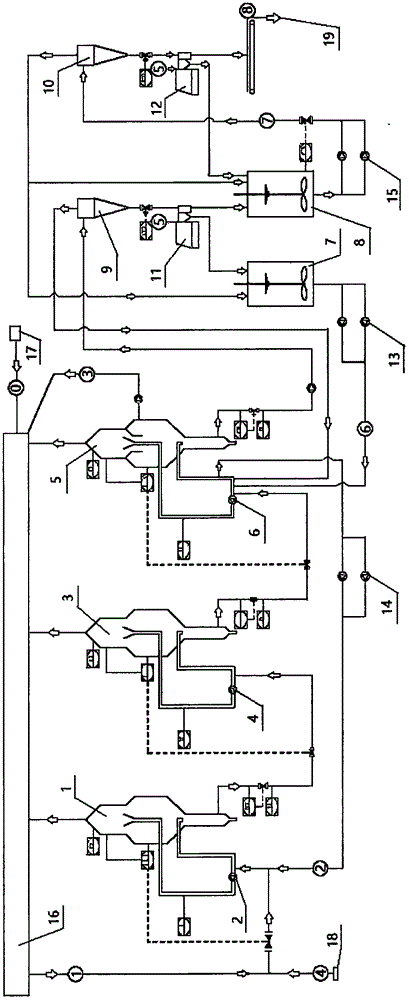

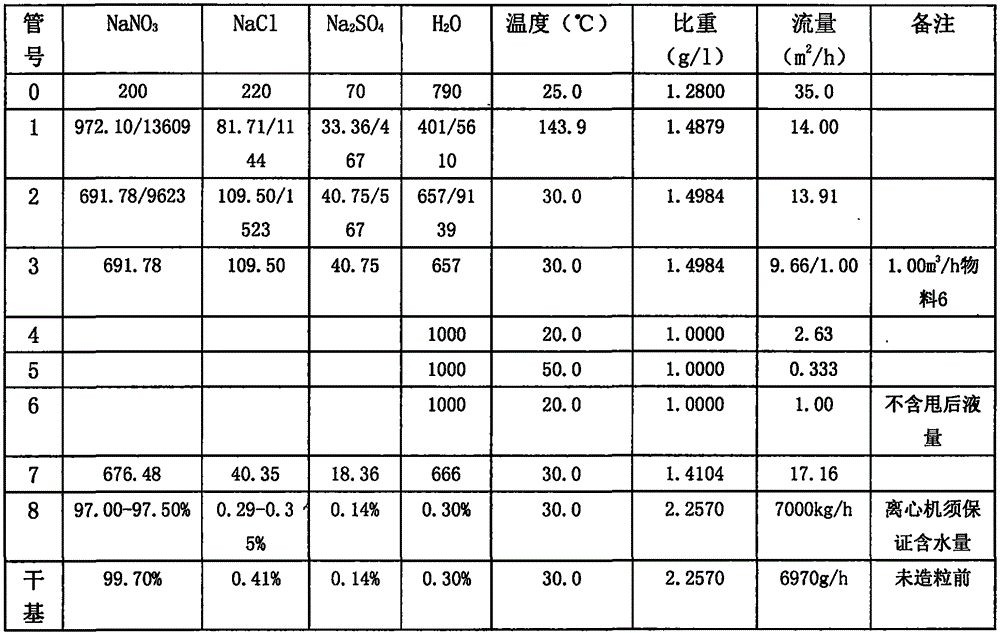

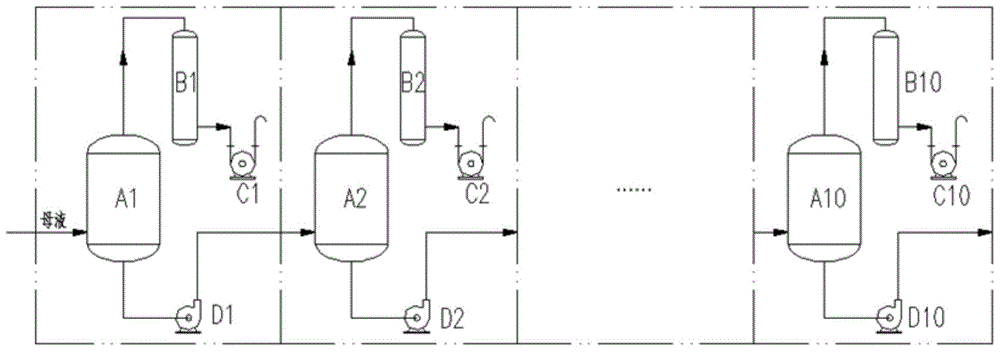

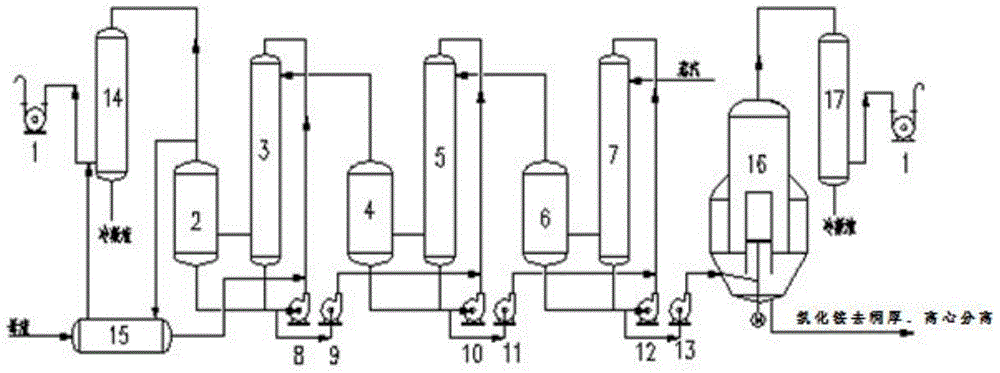

The invention discloses a method for preparing industrial potassium nitrate from a potassium nitrate crude product by virtue of the recrystallization method, and relates to the technical field of inorganic chemical industry. A 2 to 5-stage continuous crystallization manner is adopted, and a crystallization device is formed by connecting a flash evaporator and liquid phases of 2 to 5 crystallizers in series, wherein the temperature of a potassium nitrate crude product solution is 70 to 78 DEG C, and the saturation of the potassium nitrate crude product solution is 90 to 91 percent; the temperature of a flash evaporator solution is 59 to 67 DEG C, the corresponding flash steam temperature is 54 to 61 DEG C, and the flash steam pressure is 112 to 156 mm Hg; the temperature of a liquid phase outlet of the final crystallizer is 17 to 19 DEG C, the corresponding flash steam temperature is 16 to 18 DEG C, and the flash steam pressure is 14 to 15 mm Hg; the flash steam rate is 22 to 27 percent, and the potassium nitrate crystallization rate is 79 to 84 percent. The industrial potassium nitrate state standard GB 1918-2011 is executed to produce high-class and first-class industrial potassium nitrate.

Owner:四川米高化肥有限公司

Potassium nitrate preparing technology

InactiveCN101070167AWide variety of sourcesReduce manufacturing costAlkali metal nitrate purificationAlkali metal nitrate preparationSolubilityChemical reaction

The invention relates to a kind of technique field of inorganic chemical industry, which is a kind of preparation craft of niter. To solve such problems existing preparation craft of niter as that sources of raw material is restricted, production cost and energy consumption is high and quality of products is inferior, the invention uses potassium chloride and dilute nitric acid react to form potassium chloride, dilute nitric acid, niter and hydrochloric acid, take a great of hydrochloric acid and nitric acid out through distillation, then heat and concentrate them to make the mixture turn into saturated solution which becomes neutral when put into sodium carbonate and regulated, the solution reacts with surplus little hydrochloric acid and form sodium chloride at the same time. Finally, it separates niter out making use of different solubility of niter, sodium chloride and potassium chloride at the same temperature. Sources of raw material in this invention are extensive, the production cost is relatively low; Operations such as chemistry reaction, distillation and concentration are finished at the same reaction equipment, process of operation goes on under normal atmosphere and save investment of equipment; it is easy to operate and separate; get finished product using method of mechanism filter-pressing, it is simple to operate with little investment.

Owner:上海文通化工有限公司 +1

Balanced circulating mother liquor purification method based on evaporation salt making system

ActiveCN106430253AIncrease profitReduce consumptionAlkali metal nitrate purificationAlkali metal chloridesChloride sodiumSodium sulfate

The invention discloses a balanced circulating mother liquor purification method based on an evaporation salt making system. Three stages of evaporation are adopted for mother liquor of the salt making system, a high-purity sodium nitrate intermediate product is produced, sodium sulfate and sodium chloride are separated out by crystallization, the high-temperature mother liquor is conveyed back to the evaporation salt making system for continuous circulating balance, sodium nitrate circulating mother liquor circulates, and sodium nitrate circulating mother liquid components are balanced by adding fresh water and discharging the mother liquor. Three stages of evaporation are adopted for the salt making system, the sodium nitrate circulating mother liquor components are balanced by adding the fresh water and discharging the fresh water, in this way, discharging of three wastes does not exist, product quality is high, the utilization rate of raw materials is high, reaction time is obviously shortened, equipment investment and process operating cost are saved, the total steam consumption is lowered by 20% or above per ton of sodium nitrate, energy is saved, environmental protection is achieved, flashing intensity can be reduced, the production period can be effectively prolonged, the utilization rate of heat energy can be increased, and system productivity can be improved. Meanwhile, the method has the advantages of being high in purification efficiency and low in energy consumption.

Owner:TURPAN BRANCH OF SINKIANG NITRATE MINERALS

Resourceful treatment method of TDI industrial wastewate

ActiveCN112079515AReduced risk of foulingSafety Film Concentration SystemGeneral water supply conservationWater contaminantsIndustrial waste waterPhysical chemistry

The invention relates to a resourceful treatment method of TDI industrial wastewater. The resourceful treatment method sequentially comprises the following steps: (1) removing calcium and magnesium ions and bicarbonate radicals from mixed miscellaneous salt wastewater rich in sodium nitrate, sodium chloride and sodium sulfate through a pretreatment unit; (2) realizing separation of divalent salt and monovalent salt through a salt separation unit; (3) re-concentrating the divalent salt to enable the concentration of the sodium sulfate solution to reach 9.86%, and performing freezing crystallization in a sodium sulfate freezing crystallization unit at 0 DEG C; re-concentrating the monovalent salt mixed solution to enable the concentration of sodium chloride to reach 4% and the concentrationof sodium nitrate to reach 9.9%; (4) the monovalent salt mixed solution enters a sodium chloride evaporative crystallization unit for multiple-effect evaporation so that sodium chloride is crystallized and separated out and is separated from a sodium nitrate solution; and (5) cooling the sodium nitrate solution by flash evaporation of the sodium nitrate flash evaporation unit, and cooling to normal temperature in the sodium nitrate cooling crystallization unit to crystallize sodium nitrate, and carrying out hot melting crystallization on sodium sulfate, and drying to obtain sodium sulfate withthe purity of 99%. Mixed miscellaneous salt is classified and recycled, the productivity is high, and the quality of crystalline salt is good.

Owner:JIANGSU MYANDE ENERGY SAVING EVAPORATION EQUIP CO LTD

Method for quickly converting NOx tail gas into potassium nitrate

InactiveCN105858688AEasy to operateReduce investmentDispersed particle separationAlkali metal nitrate purificationPotassium nitrateChloride

The invention discloses a method for quickly converting NOx tail gas into potassium nitrate, and solves the problems of the conventional tail gas treatment for existing enterprises in the prior art, such as high tail gas treatment cost, environmental pollution and the like. The method is characterized in that a nitrogen oxide and a potassium chloride solution (or a mixed solution) are rapidly converted into potassium nitrate in an absorption tower. The purity of potassium nitrate is controlled through controlling the concentration of dilute nitric acid, the volume of dilute nitric acid and the added amount of potassium chloride, and the purity of potassium nitrate is further improved through adopting the saturated solution of potassium nitrate as a scrubbing solution. Meanwhile, the yield of potassium nitrate is judged based on the concentration of Cl. Specifically, the method comprises the steps of (1) absorbing the industrial tail gas containing NOx, and converting the tail gas into nitric acid, wherein a 1% salt crystallization inhibitor is previously added in an absorbent; (2) reacting nitric acid with potassium chloride to convert the tail gas into potassium nitrate; (3) separating the HCl gas and dissolving out the potassium nitrate; (4) washing and separating the potassium nitrate; (5) drying the potassium nitrate and recycling the filtrate. The above method has the advantages of convenient operation, environmental protection, energy saving and the like. Based on the method, the NOx-contained tail gas of a chemical enterprise is directly converted into the potassium nitrate. Therefore, the method has wide popularization and application value.

Owner:HUANGGANG NORMAL UNIV

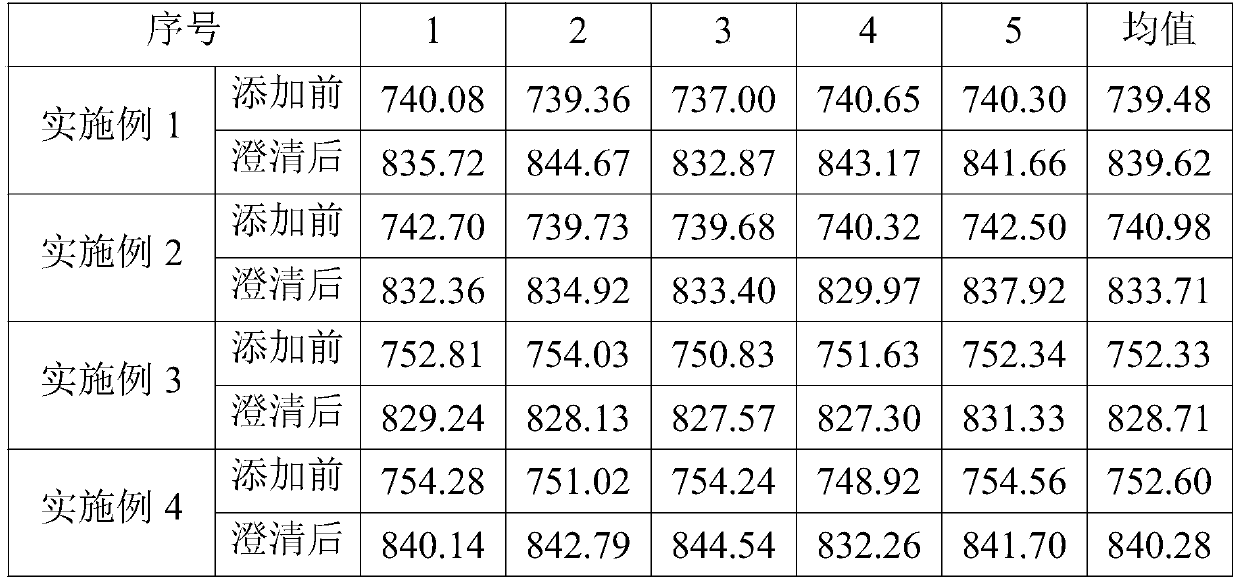

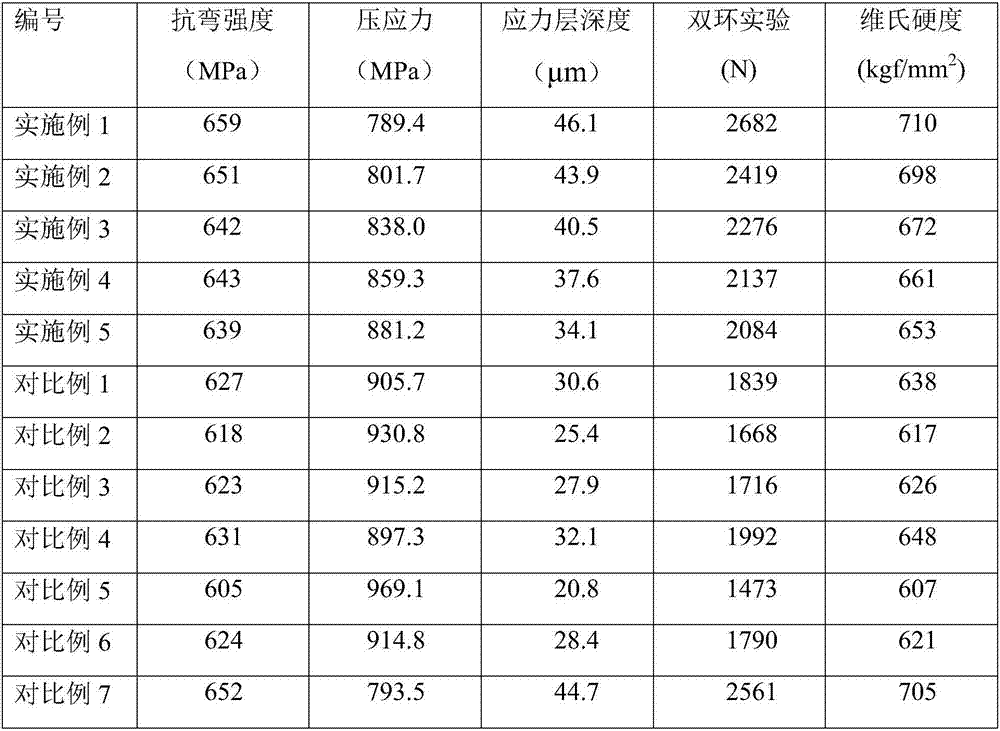

Molten salt impurity removal method suitable for chemical tempering production and method for improving glass strength

ActiveCN111099840AEasy to operateRaise the stress valueAlkali metal nitrate purificationGlass productionSorbentPhysical chemistry

The invention relates to a molten salt impurity removal method suitable for chemical tempering production and a method for improving glass strength. The molten salt impurity removal method suitable for chemical tempering production comprises the following steps: adjusting the pH value of molten salt to 9-14; adding a precipitant into the molten salt, performing mixing treatment to enable the precipitant to react with impurity ions in the molten salt to generate precipitate, and adjusting the pH value of the molten salt to 6.8-7.2; and adding an adsorbent, and standing to clarify the molten salt. The molten salt impurity removal method for chemical tempering production is simple to operate, and experiments prove that the effect of removing impurities from molten salt by adopting the methodis obviously better than that of a traditional molten salt impurity removal method.

Owner:VITALNK IND SHENZHEN

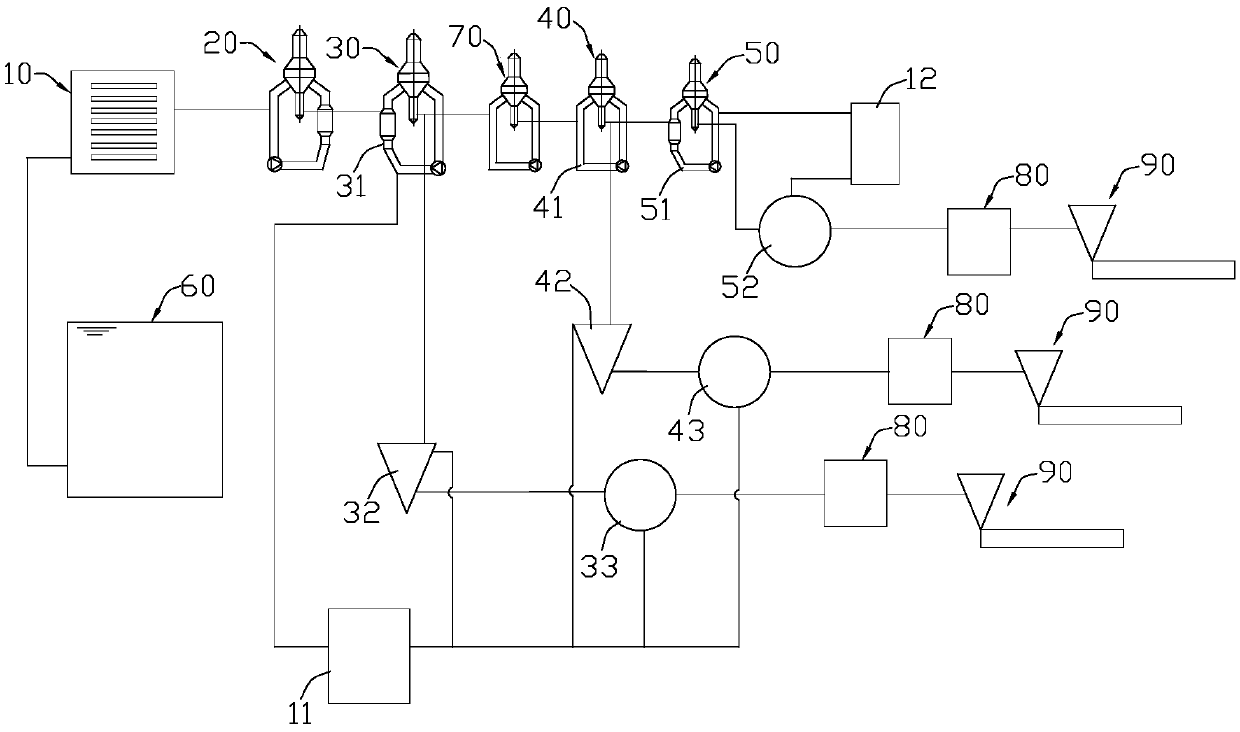

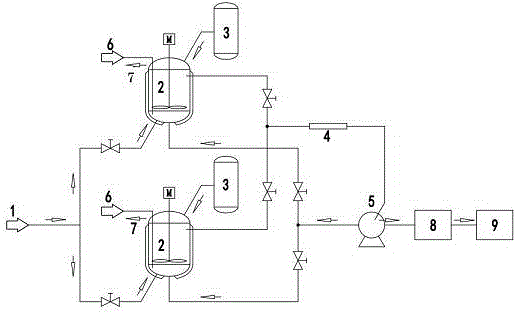

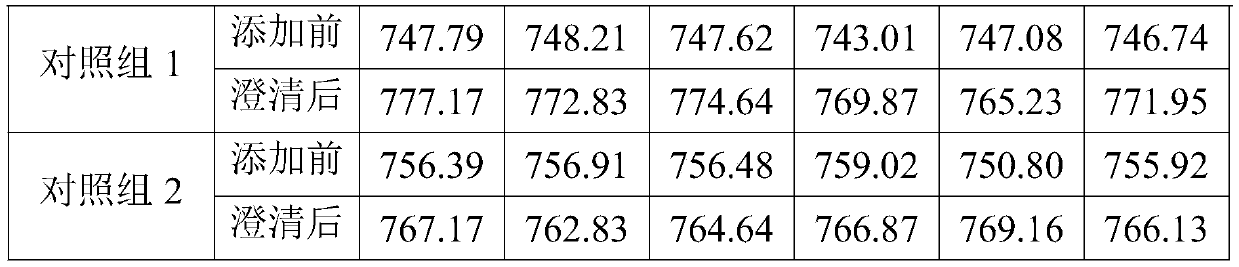

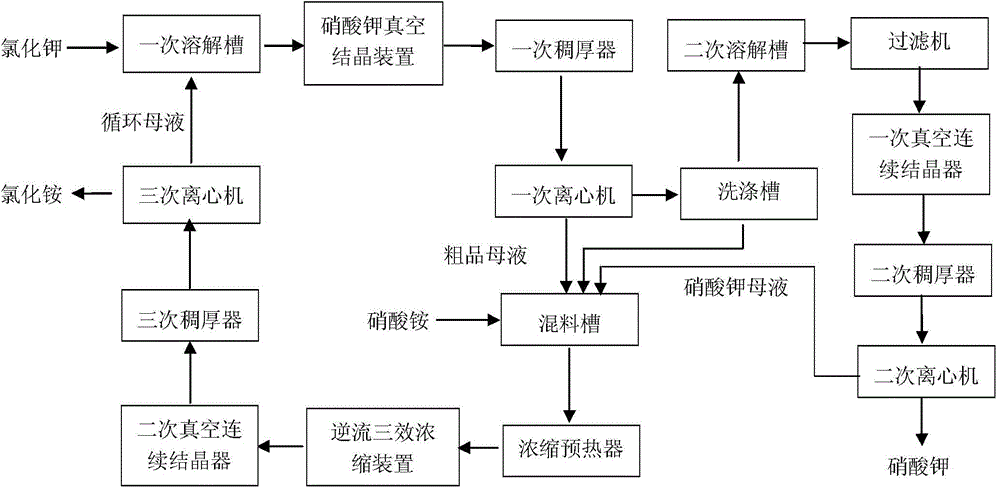

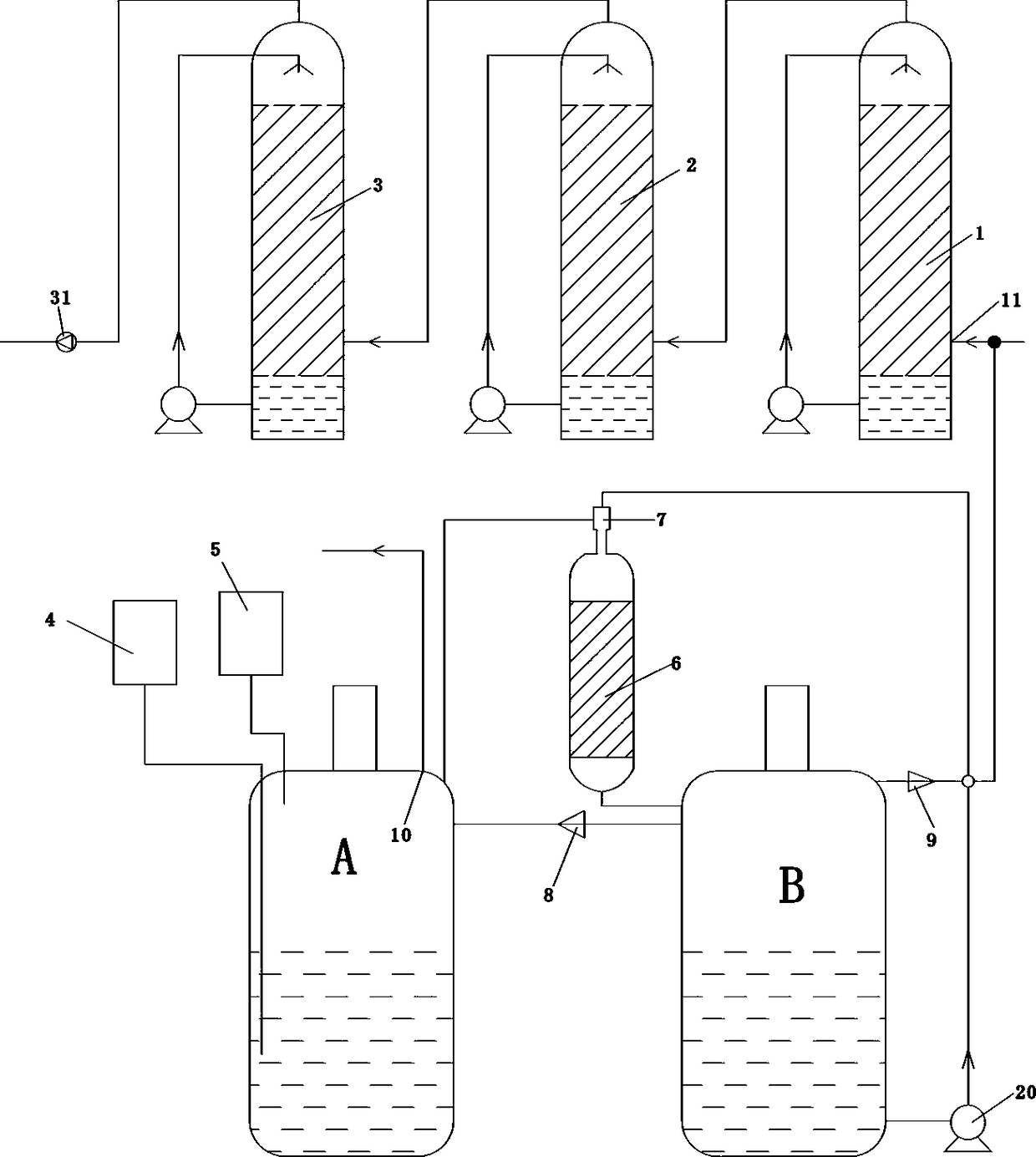

Continuous potassium nitrate production system and production method combined with production of liquid ammonium nitrate

ActiveCN104310443AIncrease productivityAvoid buyingAmmonium nitratesAlkali metal nitrate purificationPotassium nitrateGaseous ammonia

The invention relates to a continuous potassium nitrate production system and a production method combined with production of liquid ammonium nitrate. The system comprises a potassium nitrate production system and a liquid ammonium nitrate production system, wherein the potassium nitrate production system comprises a dissolving tank, a potassium nitrate vacuum crystalizing device, a primary thickener, a primary centrifugal machine, a mixing tank, a concentration preheater, a reflux triple effect concentrating device, a vacuum continuous crystalizing device, a secondary thickener, and a secondary centrifugal machine, wherein the liquid ammonium nitrate production system comprises an ammonia evaporator, a gaseous ammonia filter, an ammonia preheater, a tubular reactor, a neutralizing scrubbing tower and a flash tank. The invention develops the new continuous potassium nitrate production system combined with production of liquid ammonium nitrate, so that the efficiency of potassium nitrate production technology is improved, the crystalizing process is controlled more accurately, and the potassium nitrate crystalline quality and yield are more stable.

Owner:KINGENTA ECOLOGICAL ENG GRP

Method for separation and collection of purified alkali metal salt

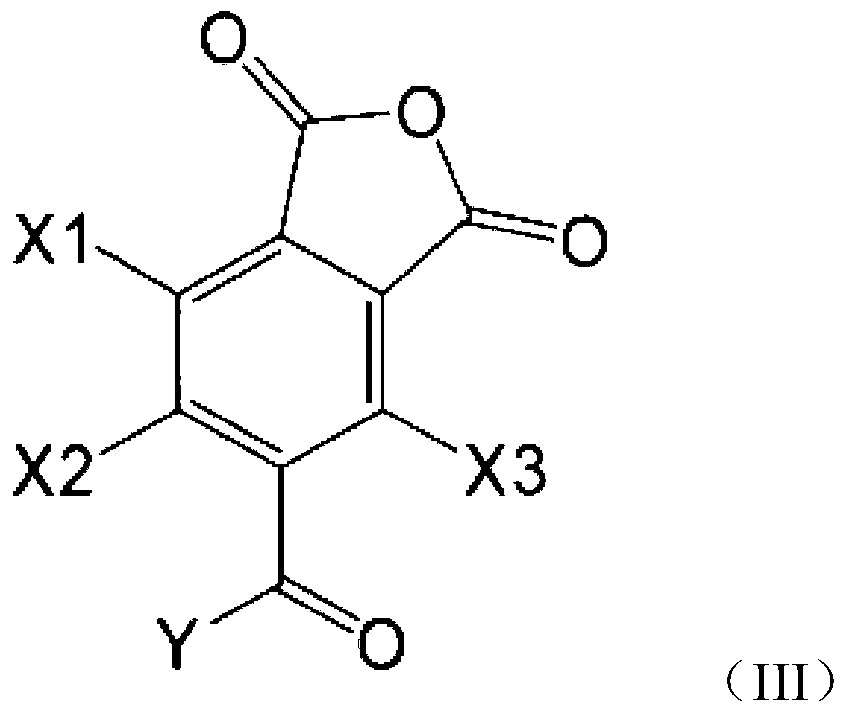

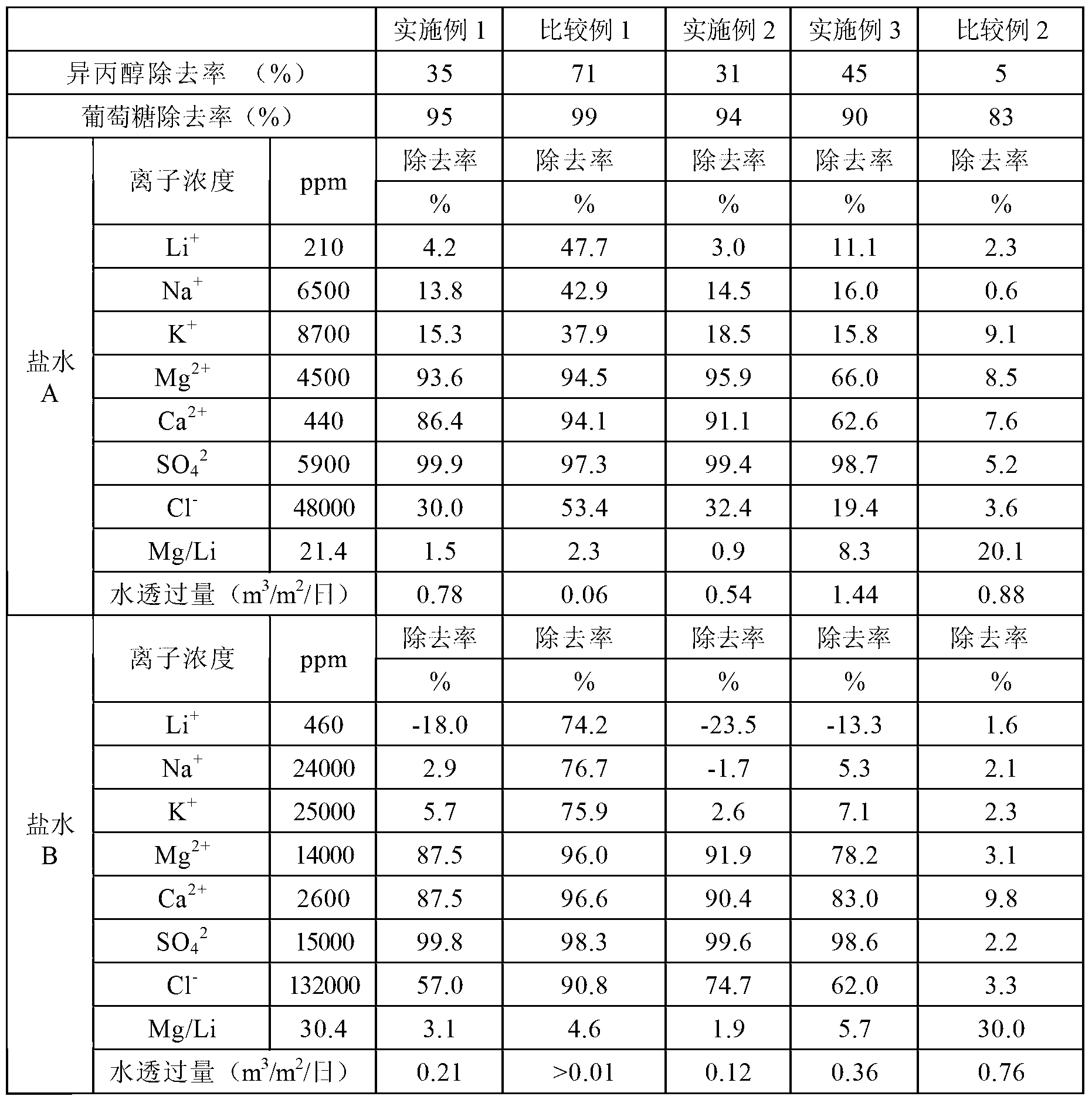

ActiveCN103237760AEfficient recyclingCalcium/strontium/barium chloridesSeawater treatmentSalt waterGlucose polymers

The present invention relates to a method for separating and recovering a purified alkali metal salt from an aqueous alkali metal salt solution, the method including a treatment step of removing a purification-inhibiting substance from an aqueous alkali metal salt solution with a separation membrane having a glucose removal ratio and an isopropyl alcohol removal ratio simultaneously satisfying the following expressions (I) and (II) when each of a 1000 ppm aqueous glucose solution having a temperature of 25° C. and pH of 6.5 and a 1000 ppm aqueous isopropyl alcohol solution having a temperature of 25° C. and pH of 6.5 is permeated through the separation membrane at an operating pressure of 0.75 MPa: Glucose removal ratio>=90% . . . (I), Glucose removal ratio-Isopropyl alcohol removal ratio>=30% . . . (II).

Owner:TORAY IND INC

Method for recycling waste potassium nitrate generated in glass toughening into potassium nitrate reagent

The invention discloses a method for recycling waste potassium nitrate generated in glass toughening into a potassium nitrate reagent. The method comprises the following steps: (1) crushing waste potassium nitrate generated in chemical toughening of glass into small pieces, adding into a solvent, and heating to 80-100 DEG C to completely dissolve the waste potassium nitrate to obtain a waste potassium nitrate solution; (2) adding ammonium salt into the waste potassium nitrate solution to ensure that the mole ratio of NH<4+> to NO<2-> in the waste potassium nitrate solution is (1-1.05):1, reacting for 1-2 hours, detecting the concentration of NH<4+> ions in the solution, and regulating the pH value to be 5-7 by adding a nitric acid reagent when the concentration of the NH<4+> ions is smaller than 10ppm so as to transform potassium hydroxide and potassium carbonate in the solution into potassium nitrate; keeping the temperature for 0.5-1 hour; filtering, cooling and crystalizing to obtain a crystal product; and (3) centrifuging, washing and drying the crystal product to obtain the potassium nitrate reagent, retaining and storing a centrifuged mother liquid obtained after centrifugation and a washing liquid obtained after washing.

Owner:CHANGSHA XINBEN CHEM

Preparation method of guaranteed-reagent potassium nitrate

InactiveCN105314657AThe process steps are simpleEasy to operate and controlAlkali metal nitrate purificationPotassium nitrateDistilled water

The invention relates to a preparation method of guaranteed-reagent potassium nitrate, which includes the following steps: 1) purification and iron impurity removal of industrial potassium nitrate: placing the industrial potassium nitrate in a glass beaker, dissolving the industrial potassium nitrate in distilled water, heating the solution on an electric stove at 85 DEG C to dissolve the industrial potassium nitrate, adding potassium carbonate and heating the solution to 110 DEG C to generate precipitate with continuous stirring, allowing the solution to stand for 2 h and filtering the solution to obtain a solution A; 2) re-crystallization to prepare the guaranteed-reagent potassium nitrate: concentrating the solution A obtained in the step 1) at 170 DEG C to separate crystal out, cooling and spin-drying the crystal, performing re-crystallization, spin-drying the crystal, and drying the crystal in an electric dry oven at 75 DEG C for 5 h to obtain the guaranteed-reagent potassium nitrate. In the method, the guaranteed-reagent potassium nitrate is dissolved in hot water to form a solution which is then boiled with addition of the potassium carbonate to remove the iron impurity. The solution is then cooled and filtered, and finally is dried and crystallized to obtain the guaranteed-reagent potassium nitrate.

Owner:TIANJIN CHEM REAGENT RES INST

Method for recovering sodium nitrate from silver waste water

ActiveCN101913629ATake advantage ofEasy to operateAlkali metal nitrate purificationMultistage water/sewage treatmentCyanideWastewater

The invention relates to a method for recovering sodium nitrate from silver waste water, belonging to the technical field of environmental protection. The method for recovering the sodium nitrate from the silver waste water is characterized by comprising the following steps of: carrying out alkaline oxidation cyanide breaking on the silver waste water; adding acids for neutralization, and then filtering a solution for evaporation and concentration; and cooling and crystallizing to obtain the sodium nitrate. The method for recovering the sodium nitrate from the silver waste water has the advantages of simple operation method, economy and environmental protection and can sufficiently utilize the resources, thereby enhancing the economic benefits to a certain degree.

Owner:烟台招金励福贵金属股份有限公司

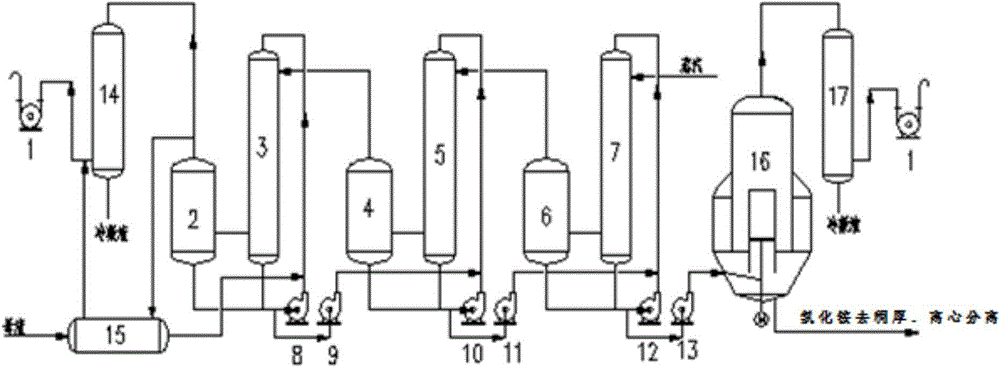

System and method for producing potassium nitrate by adopting continuous double-decomposition method

ActiveCN104310440AIncrease productivityIncrease production capacityAlkali metal nitrate purificationAlkali metal nitrate preparationPotassium nitrateTriple effect

Owner:KINGENTA ECOLOGICAL ENG GRP

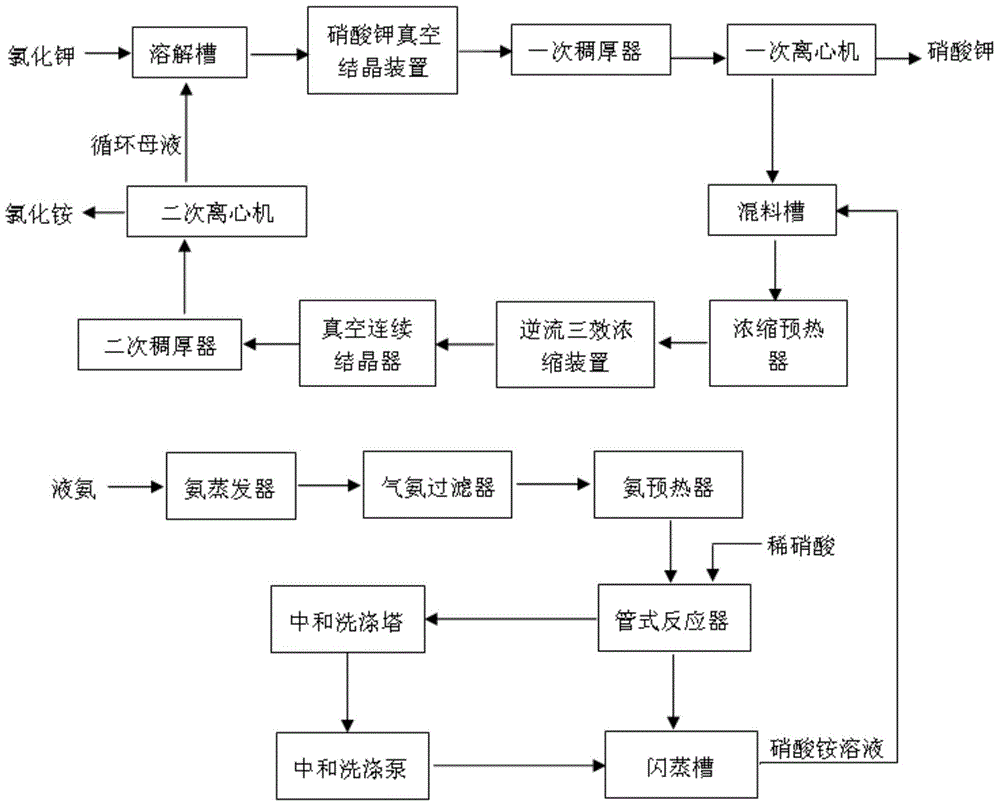

Method for purification of potassium nitrate in toughened glass waste liquid

ActiveCN107311205AEfficient removalPlay a catalytic roleAlkali metal nitrate purificationLiquid wastePotassium nitrate

Relating to the field of purification of toughened glass waste liquid, the invention discloses a method for purification of potassium nitrate in toughened glass waste liquid. The method includes the steps of: (1) cooling toughened glass waste liquid containing potassium nitrate, then adding water for dissolving, and conducting filtering to obtain a solid impurity removed solution; (2) carrying out adding of potassium carbonate and potassium sulfate and solid-liquid separation repeatedly on the solution to obtain a clarified solution; (3) conducting ion exchange and filtration for impurity removal on the clarified solution repeatedly to obtain an impurity removed solution; (4) adding an HCl solution into the impurity removed solution, and performing centrifugal separation to obtain a potassium nitrate-containing solution; and (5) carrying out aftertreatment on the potassium nitrate-containing solution to obtain purified potassium nitrate powder. The method provided by the invention can effectively remove solid impurities, Ca<2+>, Mg<2+>, Ba<2+>, Sr<2+> and the like from the toughened waste liquid, also can fully convert NaNO3 in the solution into KNO3 and enable reuse of the toughened waste liquid, and has the advantages of cost saving and environmental friendliness.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

Method for recovering reagent grade sodium nitrate from waste liquid generated in citric acid bismuth production

ActiveCN102020293AEfficient removalReduce pollutionAlkali metal nitrate purificationAmmonium nitrateSodium nitrite

The invention provides a method for recovering reagent grade sodium nitrate from waste liquid generated in a production process of citric acid bismuth prepared by the reaction of nitric acid bismuth solution with citric acid and sodium carbonate solution. The method comprises the following steps: heating and concentrating the collected waste liquid until the proportion of the heat solution is 1.15-1.20; adding 5-8% of ammonium nitrate into the waste liquid, wherein the molar ratio of the ammonium nitrate is equal to that of the sodium nitrite in the waste liquid; heating to microboil to remove the impurities of nitrite; adding calcium hydroxide to remove a small amount of residual citric acid in the reaction; adding the sodium carbonate to regulate the pH value of the waste liquid; preserving the temperature to remove the heavy metal impurities and excessive calcium; regulating the pH value of the filtrate by nitric acid; and concentrating and crystallizing to obtain the reagent grade sodium nitrate. The method for recovering the sodium nitrate is simple in operation and moderate in process condition, can be used for effectively removing various purities in the waste liquid; the comprehensive recovery rate is up to 75-85%; and the obtained product conforms to the analytically pure standard of GB / T 636-1992 chemical reagent. In the invention, the waste liquid is comprehensively processed and utilized to recover the reagent grade sodium nitrate, thus achieving the purposes of saving the energy, reducing the emission, lowering the environment pollution and lowering the production cost.

Owner:GUANGDONG GUANGHUA SCI TECH +1

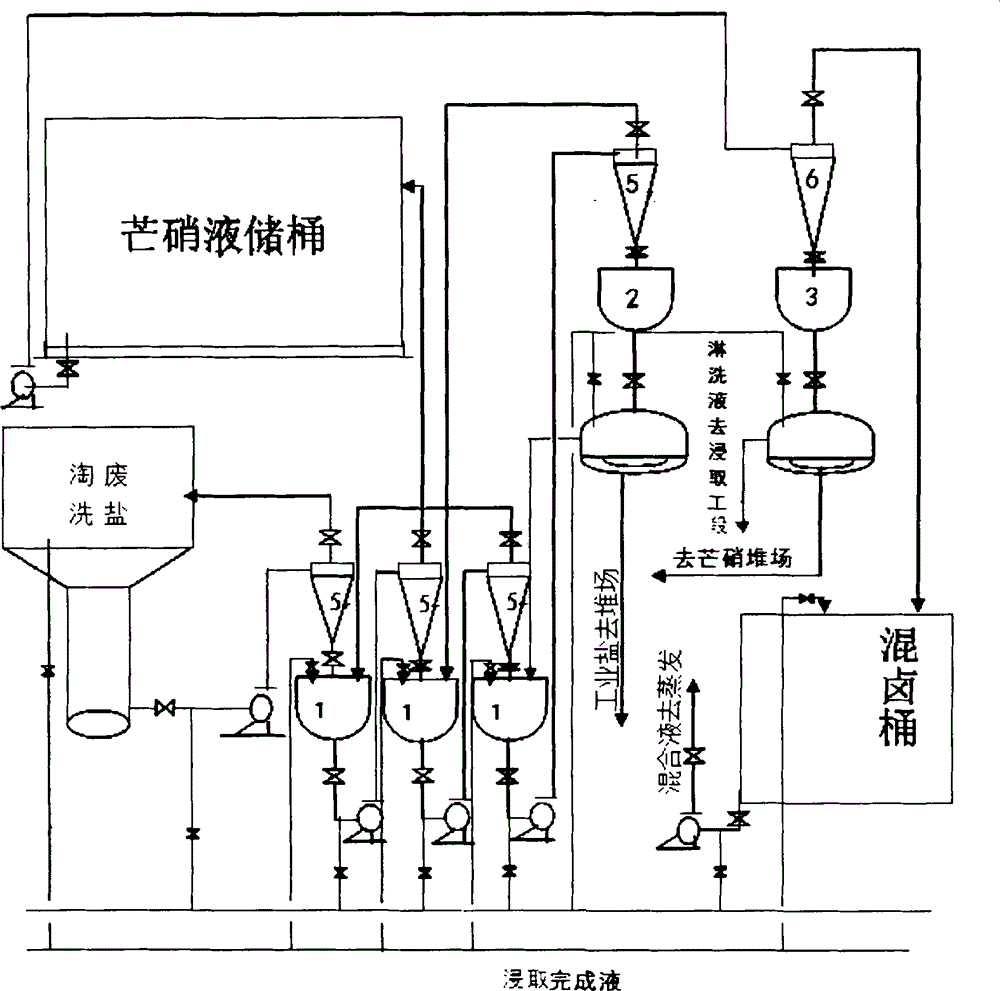

Process for producing rice-shaped crystalline potassium nitrate by brine mixing method

ActiveCN106629784AHigh purityLarge particle sizeAlkali metal nitrate purificationAlkali metal nitrate preparationSeed crystalImpurity

The invention discloses a process for producing rice-shaped crystalline potassium nitrate by a brine mixing method. The process comprises the following steps: reacting nitric acid, magnesium oxide and potassium chloride serving as raw materials; cooling for crystallization to obtain crude potassium nitrate; mixing a high-temperature solution and a low-temperature solution of the potassium nitrate according to a certain proportion by the brine mixing method; adding a potassium nitrate seed crystal at the same time; controlling the temperature and stirring speed of a mixed solution; crystalizing to obtain the rice-shaped crystalline potassium nitrate. In the production process, a reaction solution is heated by heat produced in a reaction of the nitric acid and the magnesium oxide, so that the reaction speed is high, and energy is saved; cooling crystallization is performed in a way of mixing brine and adding the seed crystal, so that the crystallization speed is high, the efficiency is high, and the obtained potassium nitrate product is an elliptical rice-shaped crystal, and has the advantages of high purity, low impurity content, large crystal particle size, uniform granularity, high fluidity, no tendency to agglomeration, convenience in use and wide application.

Owner:浙江联大化工股份有限公司

Preparation method of potassium nitrate

InactiveCN110862101ALarge particle sizeUniform particlesAlkali metal nitrate purificationAlkali metal nitrate preparationPotassium nitratePtru catalyst

The invention discloses a preparation method of potassium nitrate. The preparation method comprises the following steps: adding nitric acid and magnesium oxide to a reactor, carrying out a reaction for 2-3 h, then adding potassium chloride, and carrying out a reaction for 1.5-3 h to obtain a reaction mixture; cooling and crystallizing the reaction mixture for the first time, and carrying out separating to obtain coarse potassium nitrate crystals and first mother liquor; carrying out secondary cooling crystallization and tertiary cooling crystallization on the first mother liquor, and performing separating to obtain wet potassium nitrate crystals and second mother liquor; and drying the wet potassium nitrate crystals to obtain potassium nitrate crystals. According to the preparation methodof potassium nitrate, nitric acid, potassium chloride and magnesia are used as raw materials, and the raw materials are cheap, easy to obtain and low in cost; the technological process of the method is simple; the reactions are performed at normal temperature and normal pressure, does not use any catalyst, produces no corrosive strong acid, and has small corrosion to equipment; and the produced potassium nitrate crystals are good in quality, high in purity and large in particle size.

Owner:安徽胜达化工科技有限公司

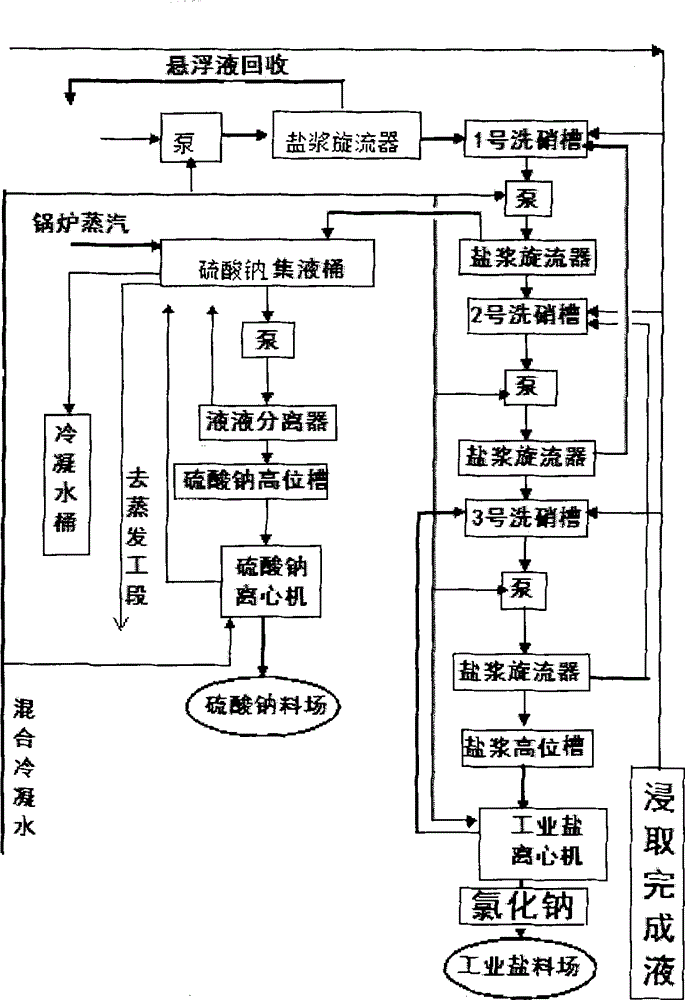

Production process of temperature-controlled cyclic layer-by-layer sodium nitrate separation

ActiveCN104591229ASave heatReduce water consumptionAlkali metal nitrate purificationAlkali metal sulfite/sulfate purificationTemperature controlEvaporation

The invention discloses a production process of temperature-controlled cyclic layer-by-layer sodium nitrate separation. The production process comprises the following steps: soaking nitronatrite ore with water to form a three-salt system liquid of sodium chloride NaCl, sodium nitrate NaNO3 and sodium sulfate Na2SO4; producing sodium chloride by low-temperature salt slurry whirl in the heating treatment process; extracting sodium sulfate from high-temperature salt slurry by virtue of a liquid-liquid separator; and returning a mother liquid to an evaporation system to use in cycle, and gradually separating and washing a salt slurry separator, so that heat energy is reduced; the water consumption is reduced; industrial pollution is reduced; the production process is mainly applied to comprehensive utilization of nitronatrite ore resources; production of the sodium nitrate is achieved; by-production of the sodium chloride and the sodium sulfate is achieved; waste salt is divided into two products, namely the sodium sulfate and the sodium chloride, so that the production value is increased; and the comprehensive economic benefits are improved.

Owner:TURPAN BRANCH OF SINKIANG NITRATE MINERALS

Fully-automatic production line type potassium nitrate recovering process

ActiveCN103466664AIncrease production capacityMeet the needs of large glass tempering plantsAlkali metal nitrate purificationPotassium nitrateProduction line

The invention discloses a fully-automatic production line type potassium nitrate recovering process. The wastes are potassium nitrate wasted after glass strengthening, the wastes are crushed, added into water, heated to dissolve, and cooled and crystallized after being dissolved, crystals are washed by water and centrifugally separated, and the centrifugally separated solids are subjected to drying and dehumidifying, so as to obtain a finished product potassium nitrate. The fully-automatic production line type potassium nitrate recovering process provided by the invention has high yield, high recovering rate and high quality of a recovered product.

Owner:LENS TECH

Nitrogen oxide absorption device and method for realizing separation of absorption products by using device

ActiveCN108380018ASimple structureEasy to operateDispersed particle separationAlkali metal nitrate purificationNitrogen oxidesHydrogen

Owner:XILONG SCI CO LTD

Method for treating potassium element in aluminum electrolyte by using acid process

ActiveCN104445327AAlkali metal nitrate purificationAluminium fluoridesPotassium nitrateMolecular sieve

The invention discloses a method for treating a potassium element in aluminum electrolyte by using an acid process. The method is characterized by comprising the following steps of (1) adding aluminum electrolyte containing the potassium element into a concentrated acid solution to react, filtering the material after reacting to obtain filtrate and a filtered solid, and drying to remove water in the filtered solid to obtain cryolite; (2) introducing the filtrate to a molecular sieve for adsorbing potassium ions to separate the potassium ions and sodium ions, desorbing the absorbed molecular sieve by using an ammonium nitrate solution, and carrying out evaporative crystallization on the desorbed solution to obtain potassium nitrate; and (3) carrying out evaporative crystallization on the adsorbed filtrate to obtain sodium nitrate. By using the method, a series of problems of superheat, carbon material damage, electrolytic tank service life loss and the like generated in the aluminum electrolysis production process because of the existence of the potassium element in the aluminum electrolysis industry are solved, the production benefit is increased, and a feasible method is provided for realizing electrolytic aluminum production under a complex electrolyte system.

Owner:NORTHEASTERN UNIV LIAONING

Popular searches

Water/sewage treatment by heating Alkali metal halide purification Water/sewage treatment by neutralisation Water/sewage treatment by flocculation/precipitation Water/sewage treatment by oxidation Water treatment parameter control Water treatment compounds Specific water treatment objectives Water/sewage treatment by ion-exchange Crystallization by component evaporation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com