Method for separation and collection of purified alkali metal salt

A technology of alkali metal salt and separation membrane, which is applied to the purification of alkali metal nitrate, alkali metal chloride, alkali metal compound, etc., and can solve the problems of high cost, difficult to effectively recover, difficult to apply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

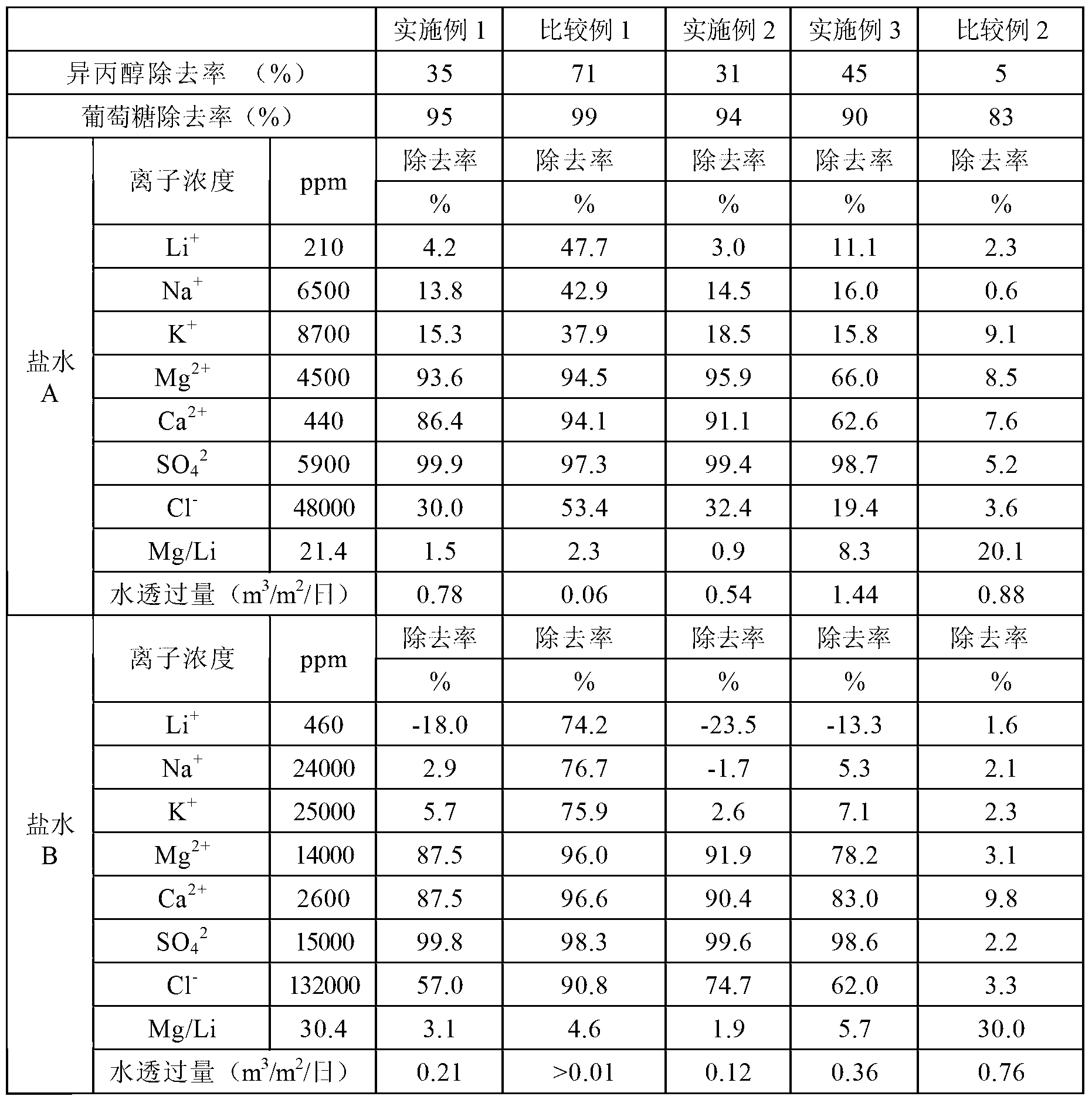

[0079] Using UTC-60 (cross-linked aramid nanofiltration membrane, manufactured by Toray Industries, Ltd.) as a separation membrane, and brine A and B as raw water, respectively, the ion removal rate and water permeability were evaluated. The results are shown in Table 1 together with the isopropanol removal rate and the glucose removal rate.

Embodiment 2)

[0083] Evaluation was performed in the same manner as in Example 1, except that the separation membrane B was used as the separation membrane. The results are shown in Table 1.

Embodiment 3)

[0085] Evaluation was performed in the same manner as in Example 1, except that the separation membrane C was used as the separation membrane. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com