Patents

Literature

499results about "Magnesium chlorides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

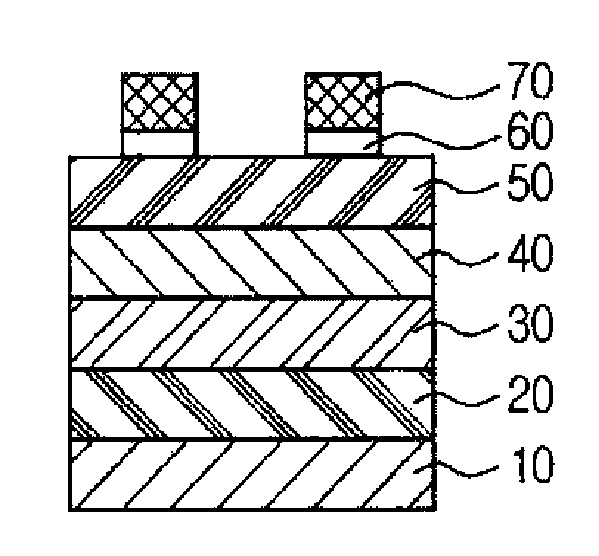

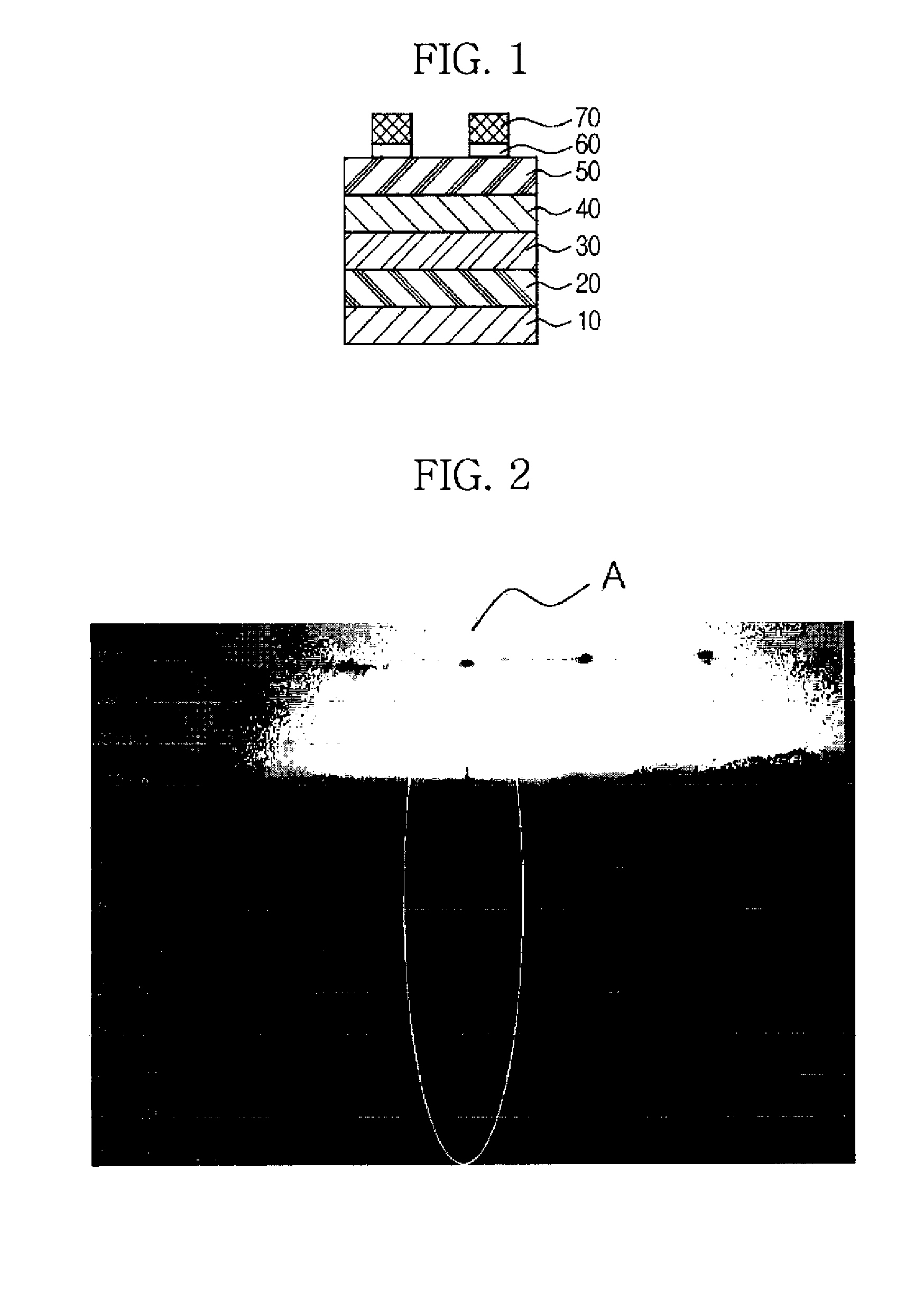

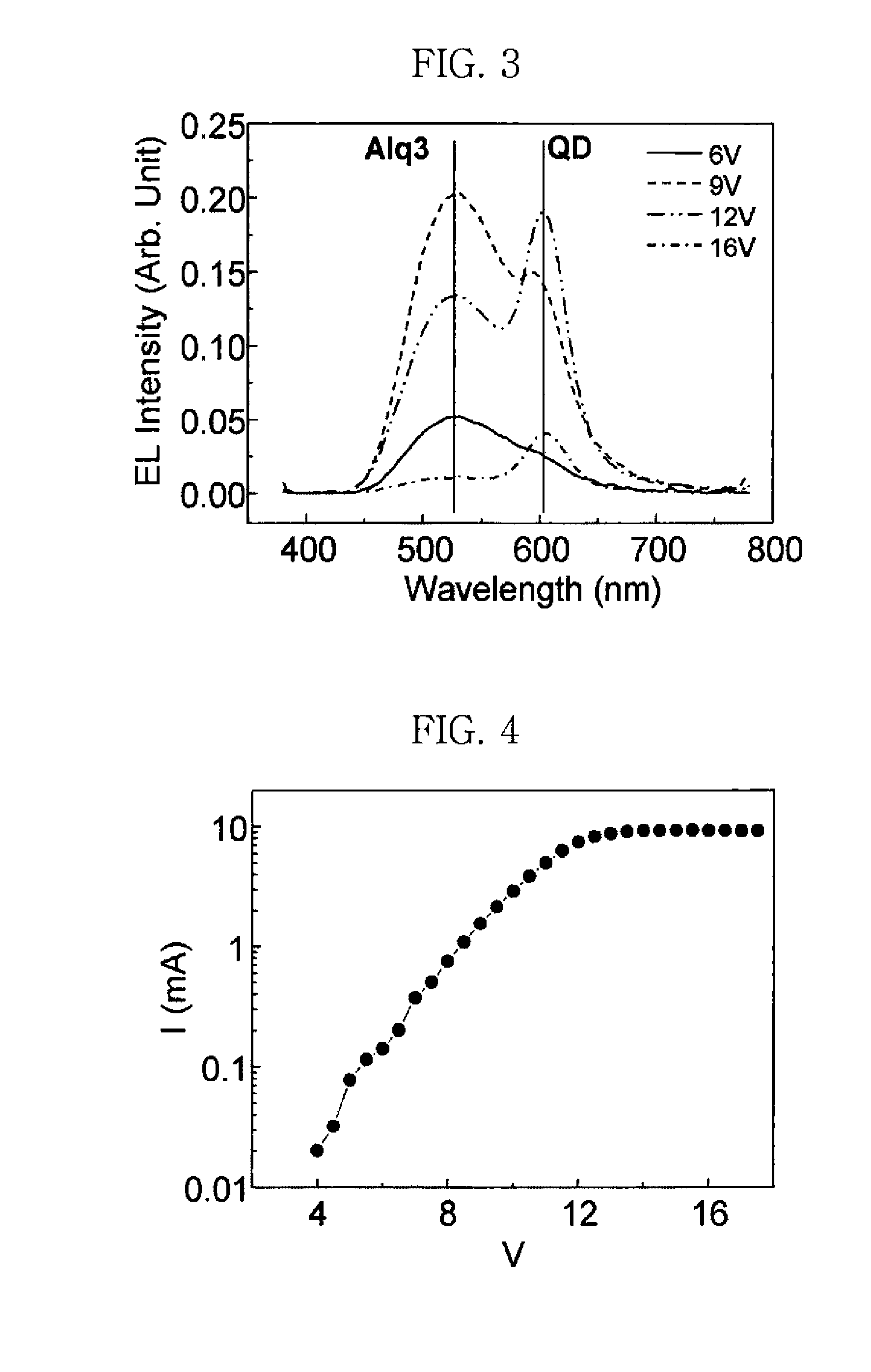

Quantum dot ink composition for inkjet printing and electronic device using the same

Owner:SAMSUNG ELECTRONICS CO LTD

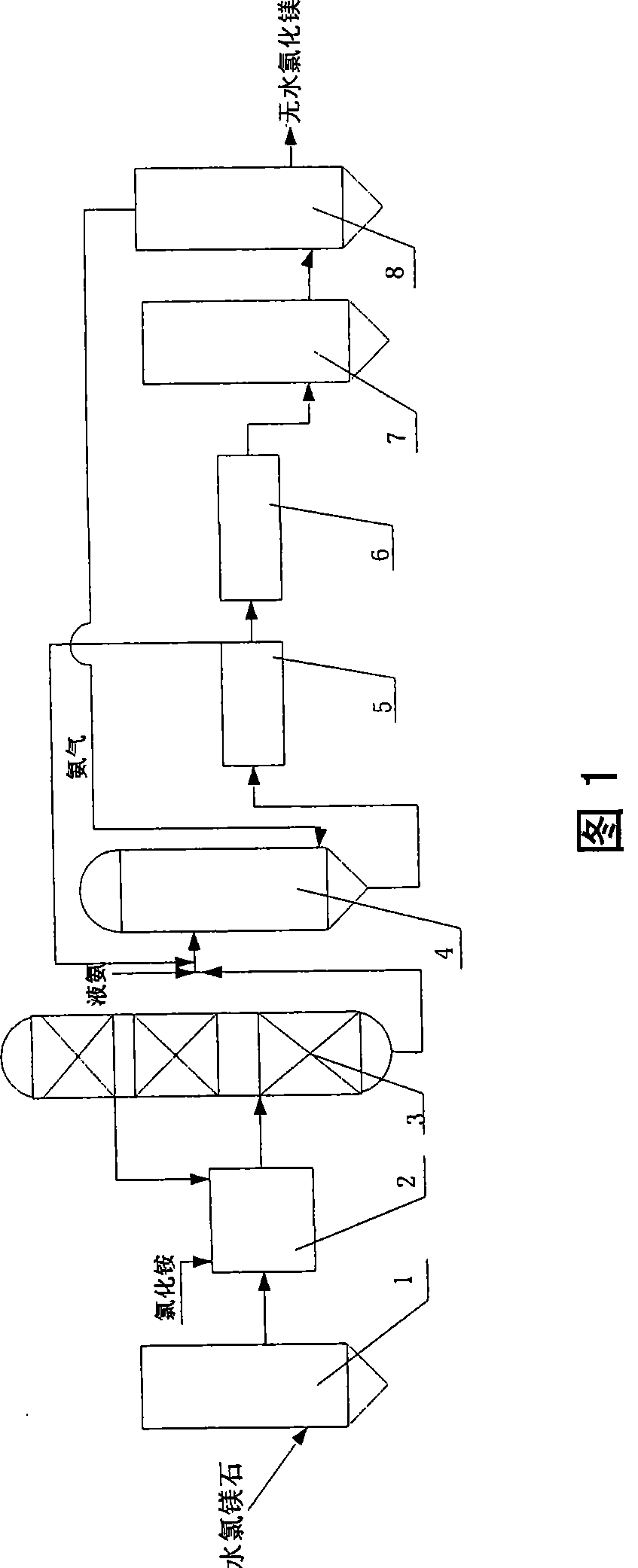

Process for producing high purity magnesia

InactiveCN1704337ANo pollutionShort technical routeChlorine/hydrogen-chlorideMagnesium chloridesSulfate radicalsPhysical chemistry

The invention discloses a process for preparing high purity magnesium oxide products, which consists of using brine containing magnesium chloride from sea, lakes or crude magnesium chloride hexahydrate as raw material, purifying the brine through vacuum crystallization method, removing boron, sulfate radicals, calcium ions and soluble impurity substance in the raw material, finally carrying out dynamic calcinations.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

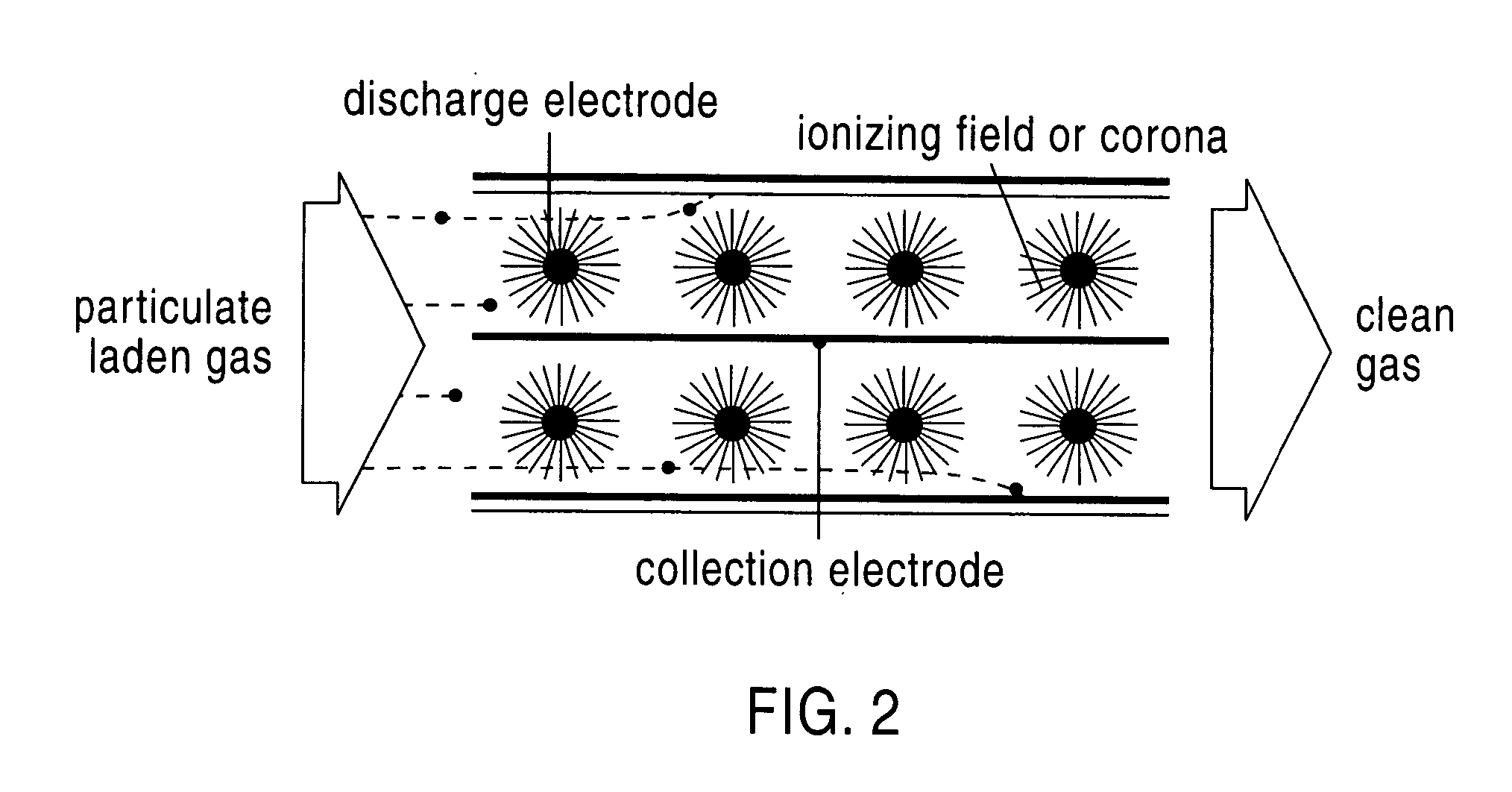

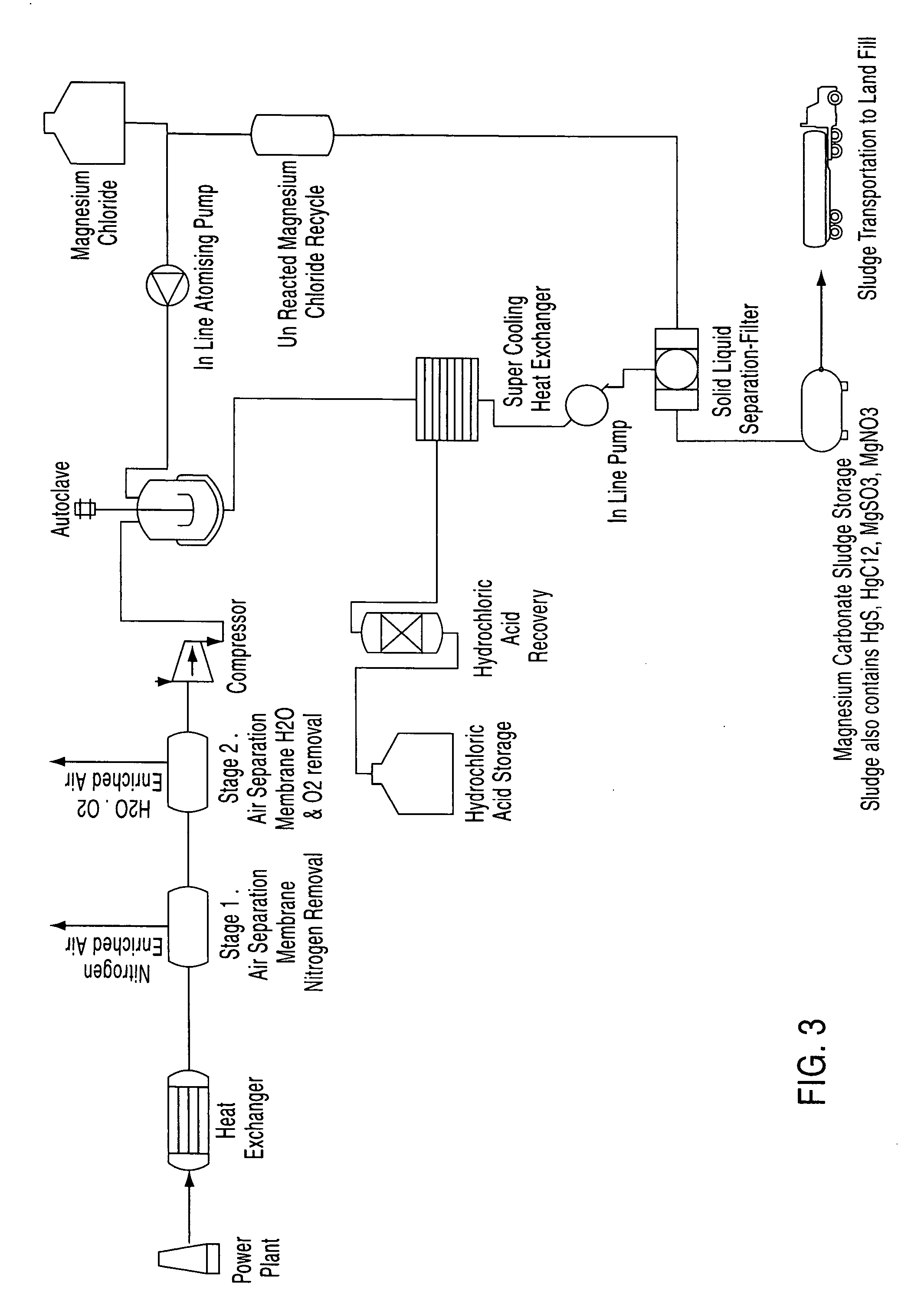

Process for removal of pollutants

A process for the removal of pollutants from a combustion process and, more particularly, a process for removing pollutants such as carbon dioxide, mercury, sulphur dioxide, nitrogen compounds and oxygen compounds from a combustion process. The process includes the removal of pollutants from a combustion process that produces an emission comprising: cooling the emission to a temperature of about 200° C.; removing nitrogen, water and oxygen from the emission to produce a gas containing a concentration of pollutants; contacting the gas with an aqueous magnesium chloride solution, wherein a slurry mixture is formed; and cooling the gas and the slurry mixture, wherein hydrochloric acid vapour and a sludge are formed.

Owner:CLEAN WORLD STRATEGIES CORP

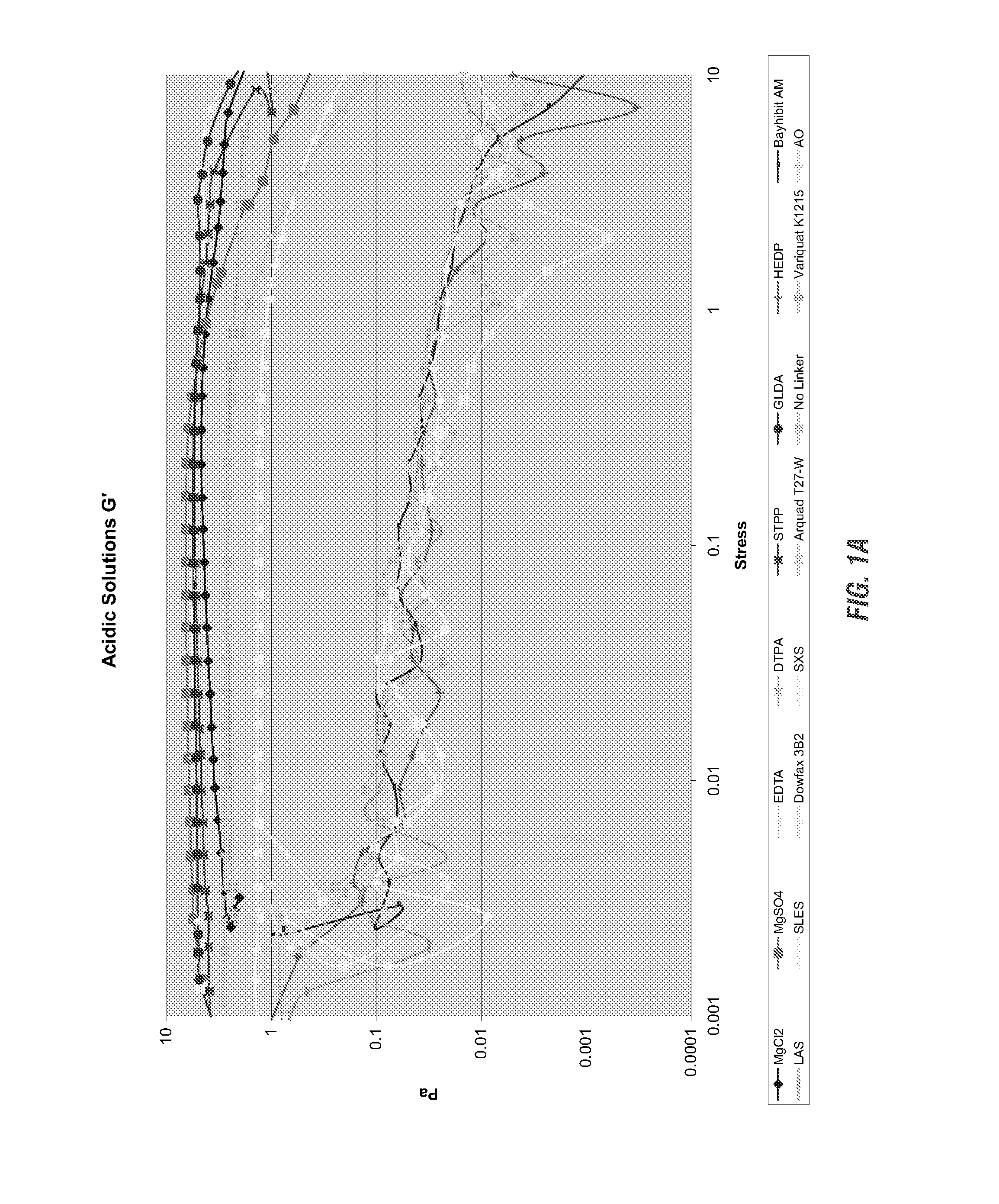

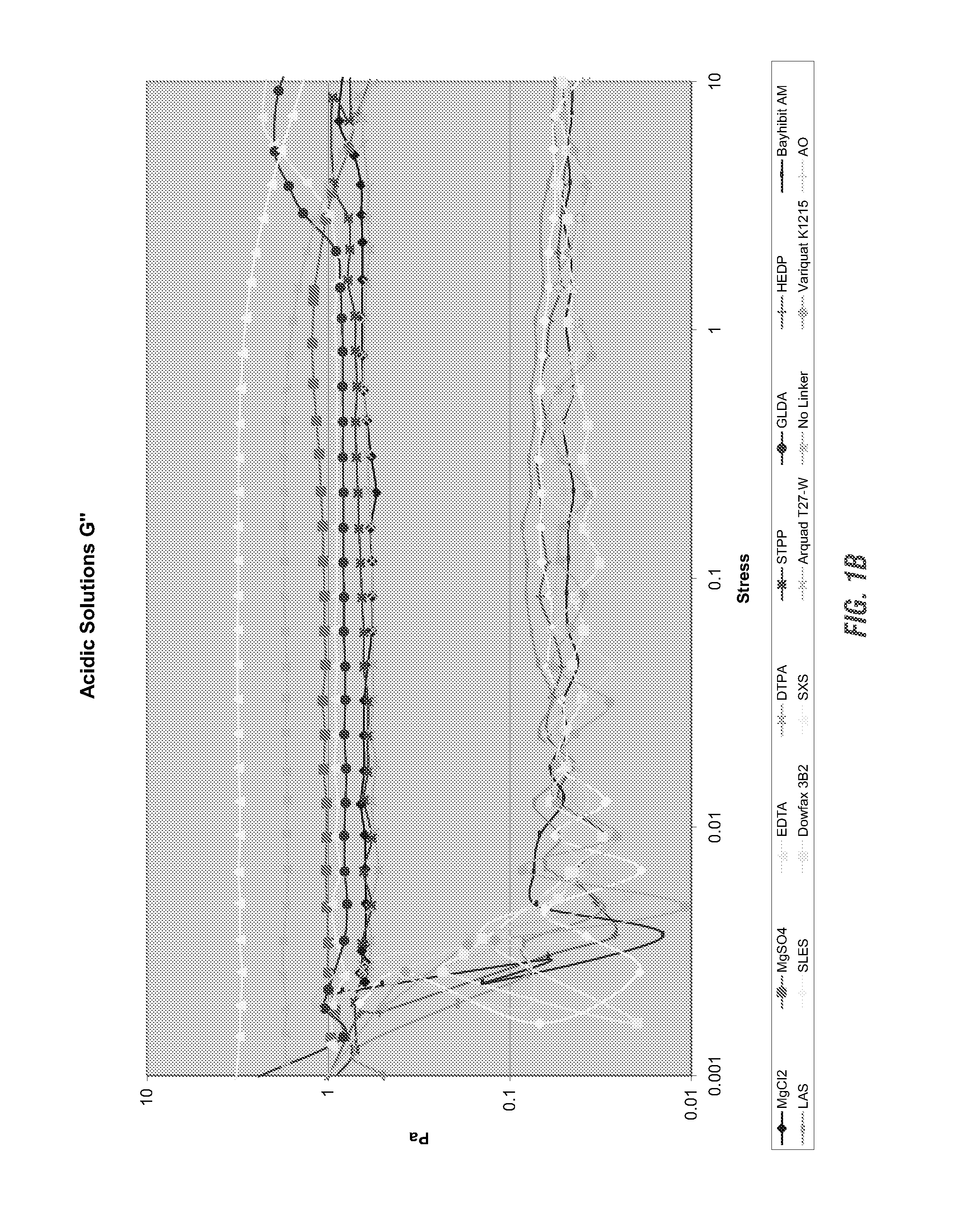

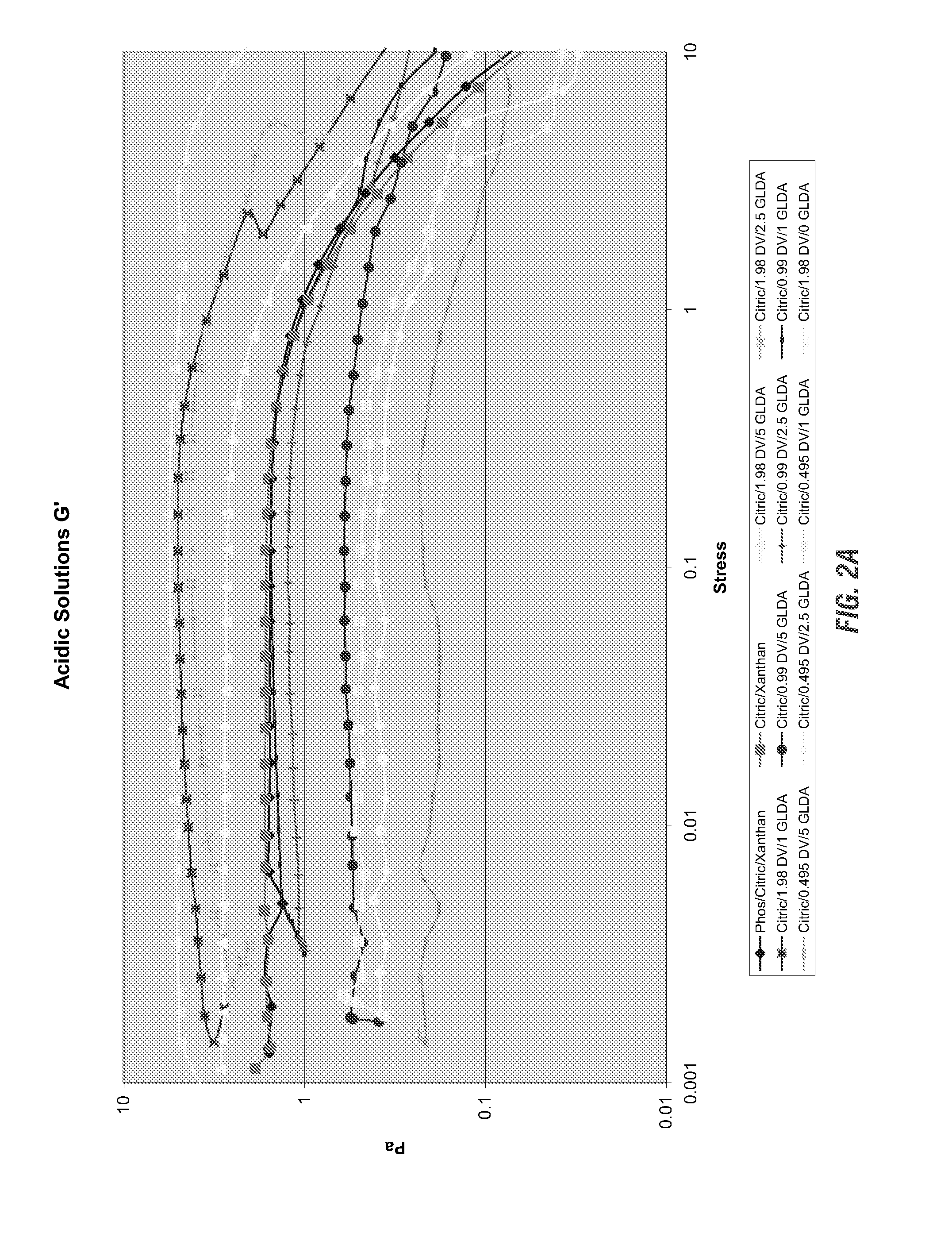

Acidic viscoelastic surfactant based cleaning compositions

ActiveUS20140148372A1Better clingReduce foggingInorganic/elemental detergent compounding agentsCationic surface-active compoundsViscoelasticitySURFACTANT BLEND

Owner:ECOLAB USA INC

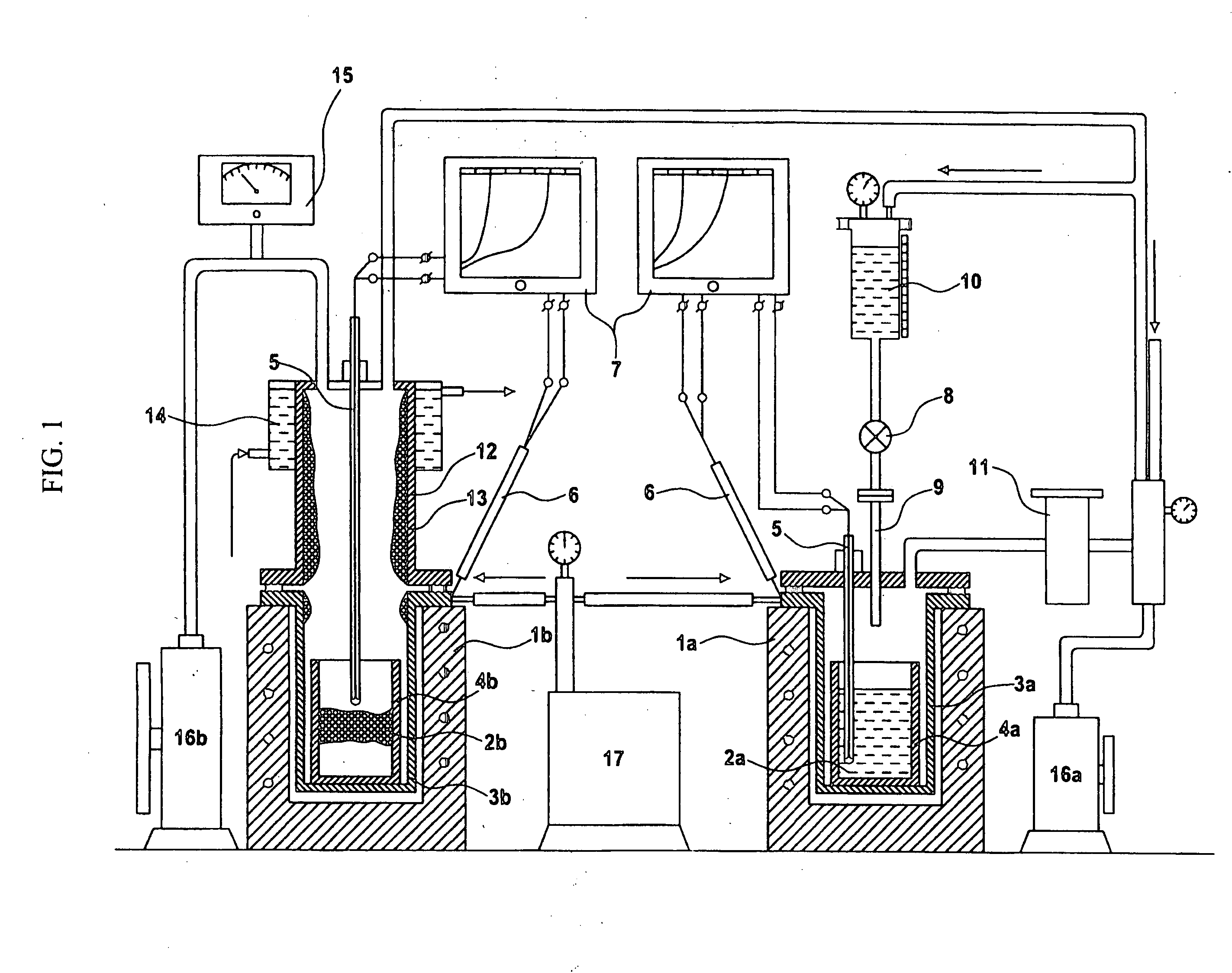

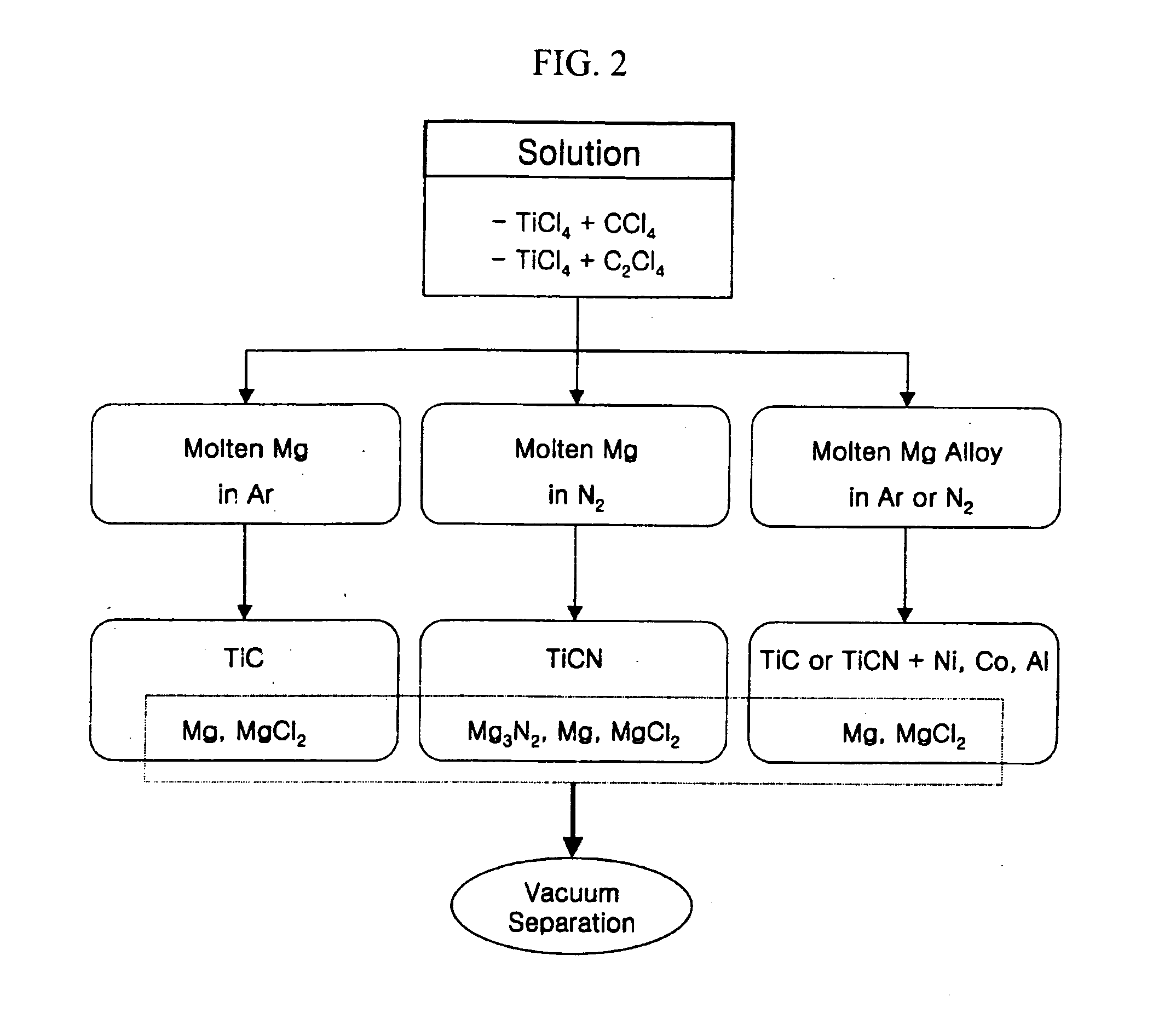

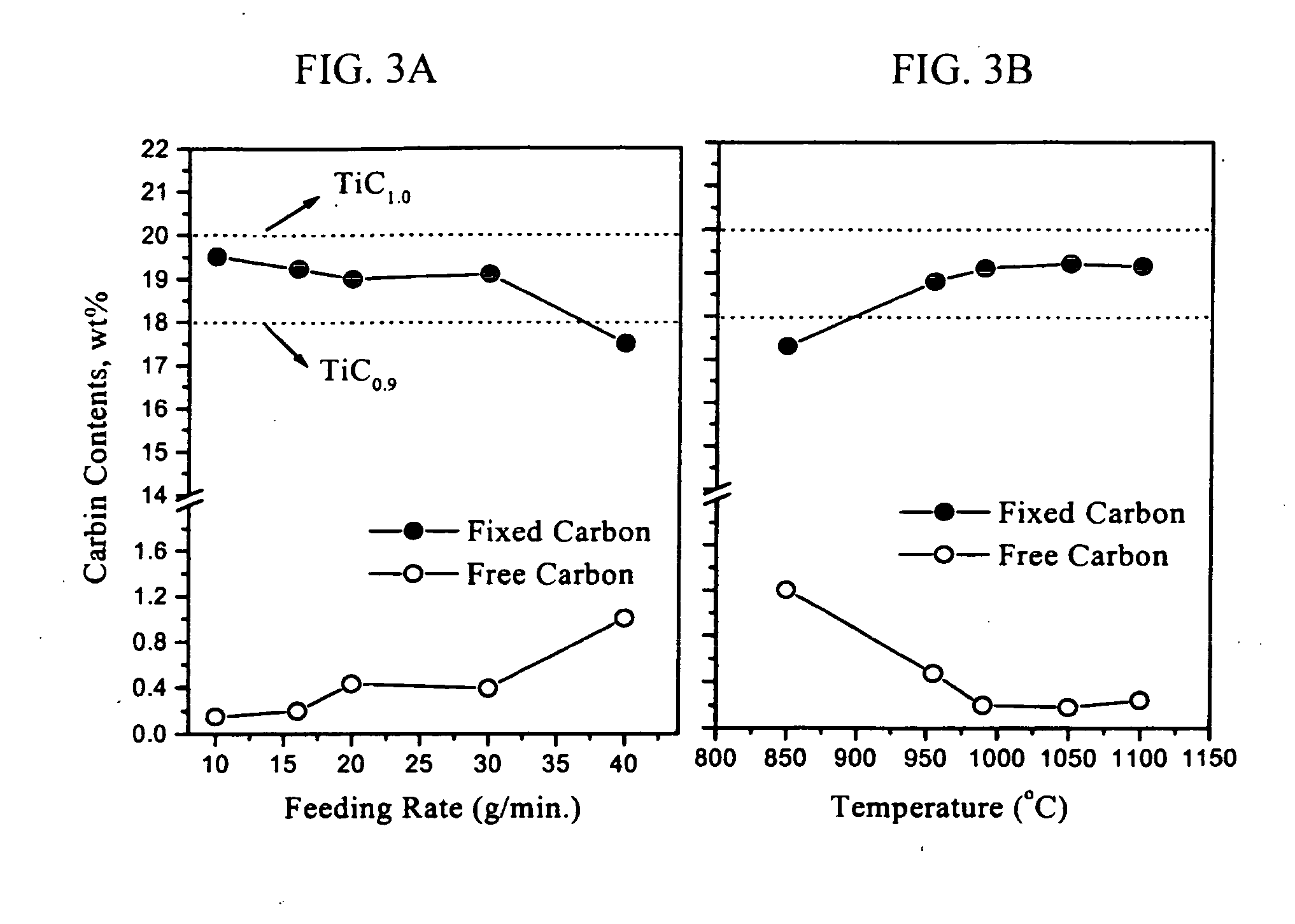

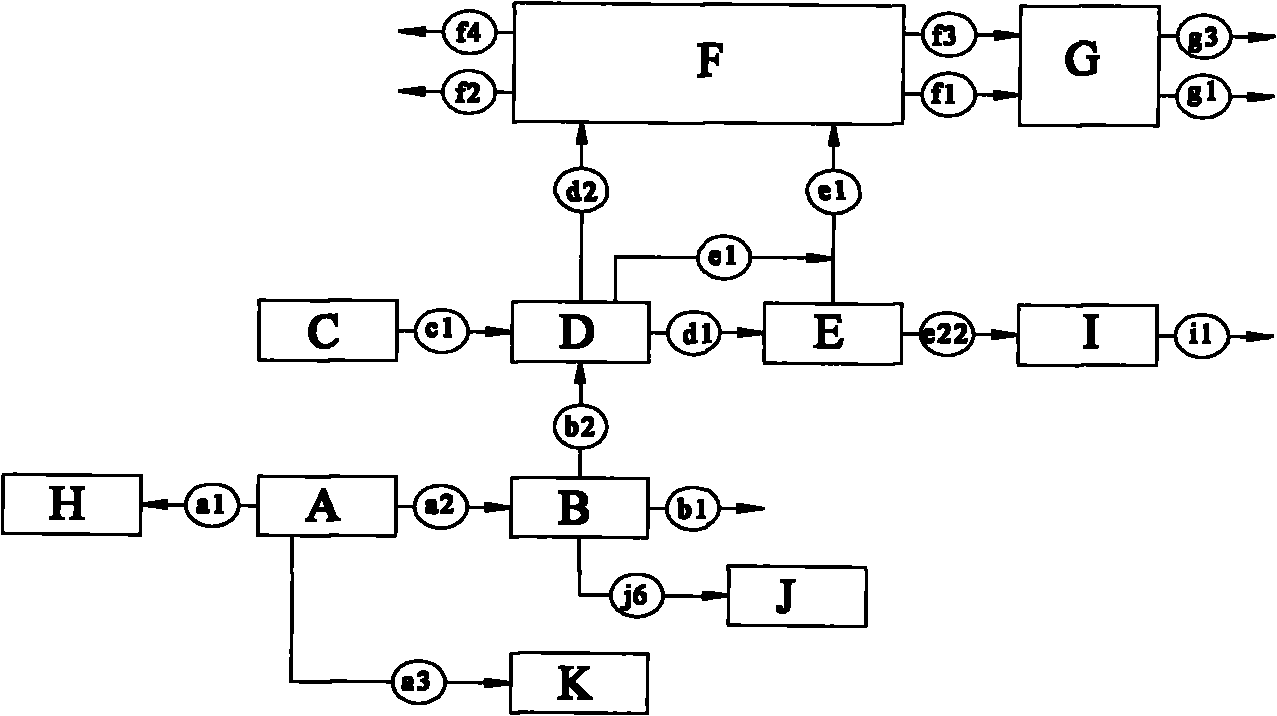

Method for manufacturing nanophase TiC-based composite powders by metallothermic reduction

Disclosed herein is a method for economically manufacturing high quality TiC powder, TiCN powder or ultrafine nanophase TiC+Ni (Co, Al) and TiCN+Ni (Co, Al) composite powders by means of metallothermic reduction. The method comprises the steps of preparing a starting solution of titanium tetrachloride (TiCl4) in a carbon chloride, feeding the starting solution into a closed container containing molten magnesium (Mg) under inert atmosphere, vacuum-separating unreacted liquid-phase Mg and magnesium chloride (MgCl2) remaining after reduction of magnesium from the closed container, and collecting a TiC compound from the closed container. TiC powder, TiCN powder or ultrafine nanophase TiC+Ni (Co, Al) and TiCN+Ni (Co, Al) composite powders having a particle size of a few tens nm can be manufactured in a simpler manner using economically advantageous starting materials such as titanium tetrachloride and carbon chlorides.

Owner:KOREA INST OF MASCH & MATERIALS

Method for mining and machining water-soluble potassium salt mine

InactiveCN102251759APromote recoveryReduce collapseMagnesium chloridesFluid removalSodium saltPollution

The invention discloses a method for mining and machining a water-soluble potassium salt mine. The method disclosed by the invention comprises the following steps: firstly, exploiting the potassium salt mine by adopting a well drilling water soluble method; evaporating and crystallizing the exploited brine to sequentially precipitate a sodium salt and a potassium salt; refrigerating and crystallizing the residual feed liquid to further precipitate potassium chloride; and respectively filtering and drying the precipitated sodium salt and potassium salt to obtain finished sodium salt and potassium salt, wherein a part of mother liquor after the sodium salt and potassium salt are precipitated is used for preparing magnesium chloride, and the other part is used for preparing magnesium oxide. The method disclosed by the invention is particularly suitable for the exploitation of a potassium mine having the defects of complicated geological and hydrologic conditions, over-shallow or over-deep burial, poor quality and high carnallite content, can reduce ground collapse, improves the exploitation rate, can prepare a potassium fertilizer in a large scale and has the advantages of low energy consumption and little pollution and waste discharge.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Simultaneous recovery of potassium chloride and KCL enriched edible salt

The present invention relates to recovery of industrial grade potassium chloride and low sodium edible salt from bittern as part of an integrated process. The process comprises, mixing low sulphate concentrated feed bittern (a by-product of salt industry) of density 31.5 to 32.5° Be (sp.gr. 1.277-1.289) with high density end bittern of density 36.5 to 37.5° Be′ (sp.gr. 1.336-1.35), thereby producing low sodium carnallite, from which industrial grade potassium chloride is produced. The resultant bittern is evaporated in forced evaporation system, thereby producing crude carnallite, from which low sodium salt that would be beneficial to persons suffering from hypertension is produced. When sulphate-rich bittern is used, such bittern is desulphated with CaCl2 that is generated from carnallite decomposed liquor through reaction with lime, and wherein low B2O3-containing Mg(OH)2 is a by-product. The entire content of potassium in feed bittern is recovered in the process of the invention.

Owner:COUNCIL OF SCI & IND RES

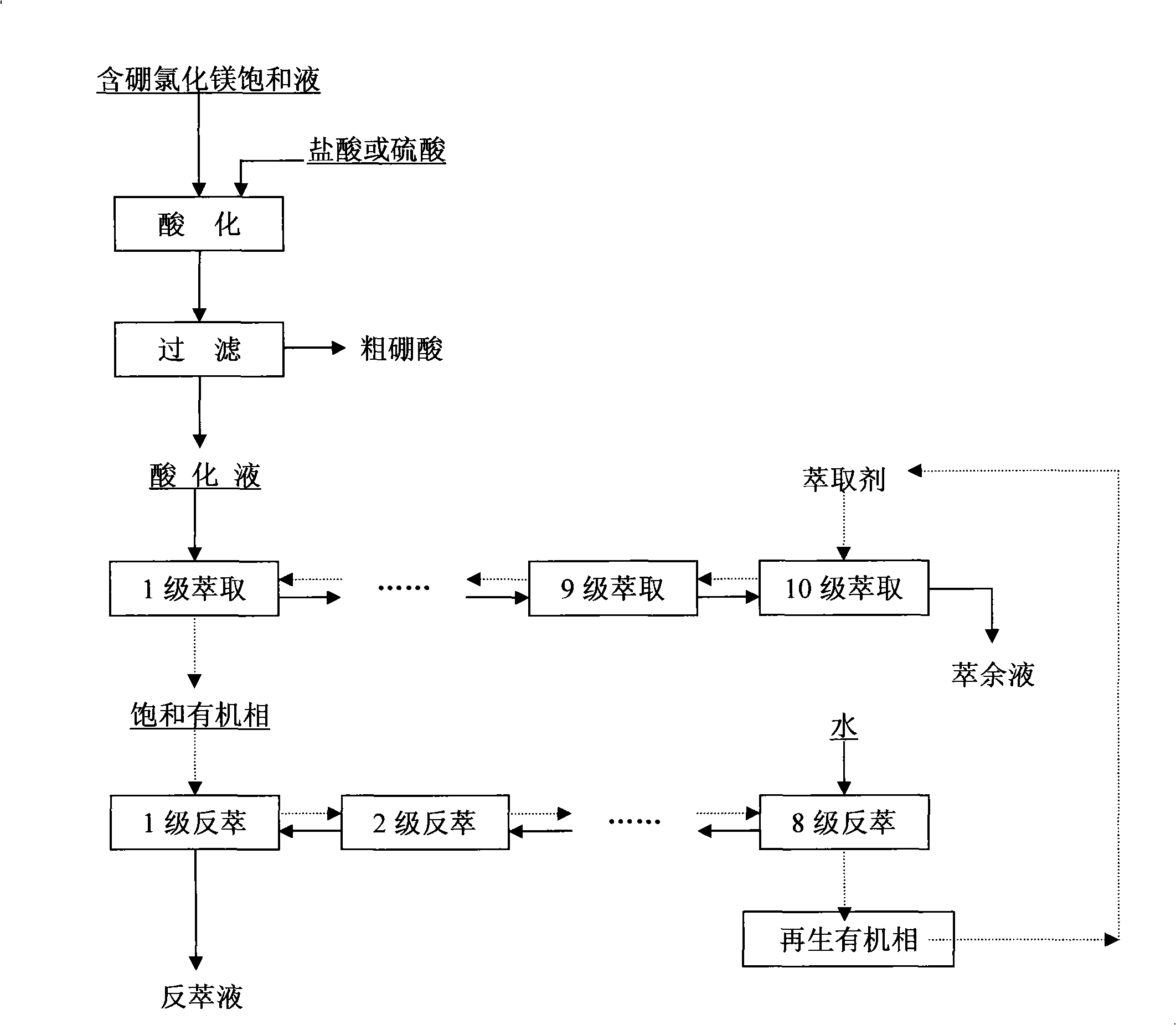

Method for removing boron and iron from boron containing magnesium chloride saturated liquid

InactiveCN101318675ASolve the problem of large melting lossShort processMagnesium chloridesInorganic saltsAlcohol

The invention pertains to the technical field of inorganic salt chemical industry, and in particular relates to a method for removing boron and iron from a saturated boron-bearing magnesium chloride solution. The method is a coordinate process integrating acidification and extraction which aims at solving the deficiency of the present process for removing boron and iron from the saturated boron-bearing magnesium chloride solution in salt lakes, and the technological process includes an acidification and boron extraction section, a filtration section, an extraction section and a reverse extraction section. The saturated boron-bearing magnesium chloride solution is taken as the raw material in the method, to which hydrochloric acid or sulfuric acid is added to acidify and precipitate boric acid, the remnant boric acid in the acidizing solution is extracted and removed by a mixed alcohol, the contents of B2O3 and Fe2O3 can be reduced to be less than 25mg / l, and the recovery ratio of boric acid reaches more than 99%; owing to the adoption of the mixed alcohol extraction technology, the method not only solves the problem of great extractant loss in the extraction method effectively, but also removes iron from the saturated magnesium chloride solution, and has the advantages of short technological process, simple operation and high yield.

Owner:青海中信国安科技发展有限公司

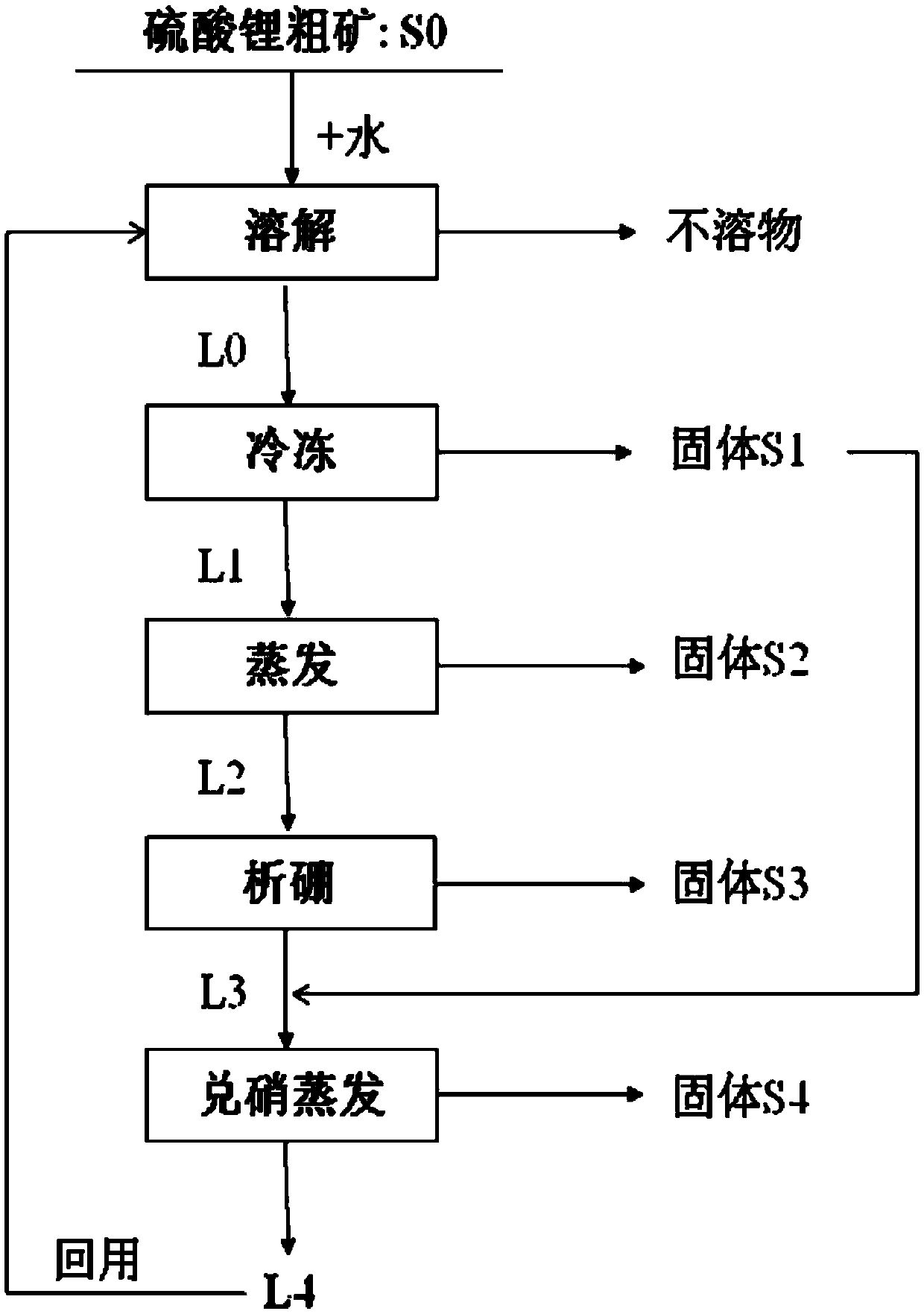

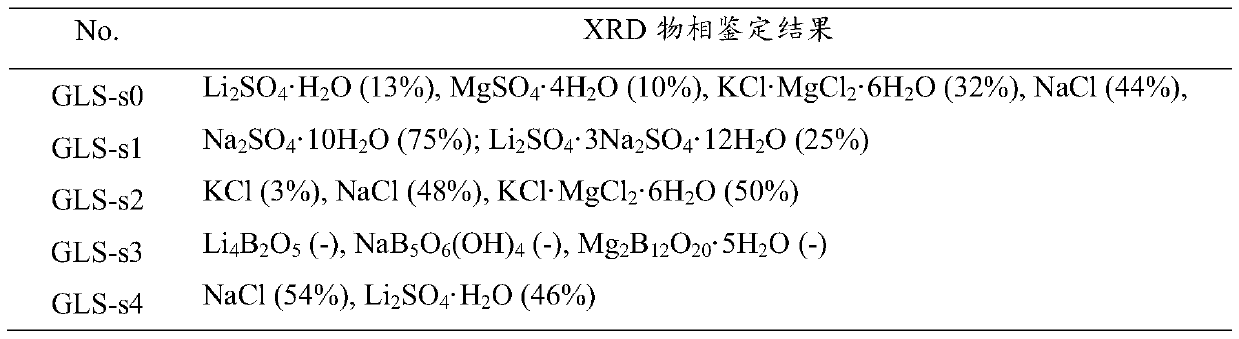

Method for purifying lithium sulfate crude ore

ActiveCN105502440AHigh yieldSimple process routeMagnesium chloridesAlkali metal chloridesLithium sulphateMirabilite

The invention provides a method for purifying lithium sulfate crude ore. The method comprises the following steps: step I, mixing the lithium sulfate crude ore S0 with excessive water to ensure that soluble ingredients in the lithium sulfate crude ore are just dissolved completely, and carrying out solid-liquid separation to obtain a solution L0; step II, freezing the solution L0 to separate out mirabilite, and carrying out solid-liquid separation to obtain a solution L1 and a solid S1; step III, evaporating the solution L1 to separate out a solid phase, and carrying out solid-liquid separation to obtain a solution L2 and a solid S2; step IV, allowing the solution L2 to stand still in a sealed condition for 7 to 50 days at 0 to 40 DEG C to separate out borate, and carrying out solid-liquid separation to obtain a solution L3; step V, mixing the solid S1 obtained in the freezing process in the step II with the solution L3, and evaporating the mixture at 0 to 40 DEG C to separate lithium sulfate concentrate.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method for producing potassium chloride, sodium chloride and magnesium sheet from bittern extracted from carnallite mine

ActiveCN102491373AReduce consumptionReduce dosageMagnesium chloridesAlkali metal chloridesSolubilityEvaporation

The invention discloses a method for producing potassium chloride, sodium chloride and a magnesium sheet from bittern extracted from a carnallite mine. The method provided by the invention comprises the following steps of 1, decomposing carnallite, 2, carrying out evaporation concentration, 3, separating carnallite, 4, preparing a mining injection agent, 5, carrying out heating dissolution and crystallization to obtain potassium chloride, 6, carrying out salt-leaching and drying to obtain sodium chloride, and 7, carrying out magnesium sheet processing. The method provided by the invention has the advantages that the hot mining injection agent is utilized for ore dissolution and thus a yield of sodium chloride and magnesium chloride is greatly reduced in production of per unit amount of potassium chloride because the solubility of potassium chloride is far greater than the solubility of sodium chloride and the solubility of magnesium chloride; a waste salt discharge amount of a follow-up process is reduced; a backfill amount is reduced obviously; a cost is reduced; comprehensive utilization of potassium and magnesium resources of carnallite is realized; and the economic benefits are high.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN +1

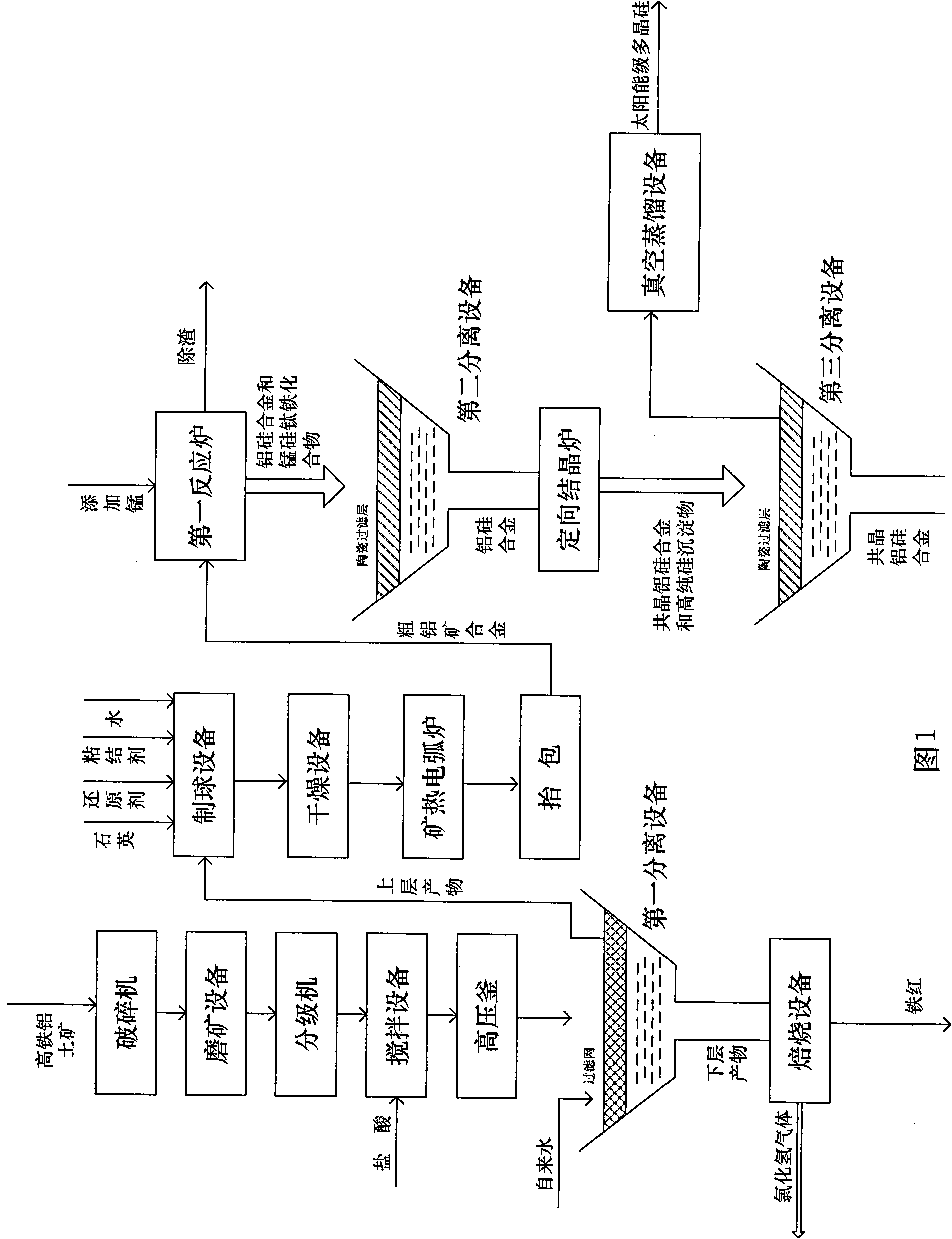

Combination production method for obtaining multi-products using high iron bauxite as raw material

The invention discloses a combination production method for industrially producing a plurality of products by using high-iron alumyte as a material. The combination production method comprises the steps of performing pressure-leaching the high-iron alumyte by using hydrochloric acid as a leaching medium, iron enters the hydrochloric acid in the form of ion to form the chloride of iron, aluminum is left in solid alumyte, thereby separating iron from aluminum; roasting a hydrochloric acid leaching fluid to obtain iron oxide red and a chlorine hydride gas, wherein the chloride hydride gas is absorbed by washing water and becomes hydrochloric acid, which can be recycled; and melting the upper layer of products, conducting directional crystallization to prepare a cocrystallized Al-Si alloy with silica content below 14wt%. Therefore, the high-iron alumyte which cannot be utilized currently, can be comprehensively utilized.

Owner:辽宁建元投资发展有限公司 +1

Method for teating heavy alkali filter liquid in synthesizing alkali producing method

InactiveCN1944291AReduce energy consumptionIncrease profitChlorine/hydrogen-chlorideCarbon compoundsChlorideAmmonia

The method of treating heavy alkali filtering liquid from alkali synthesizing production process includes evaporating ammonia to decompose NH4HCO3 and recover NH3 and CO2, adding MgO and evaporating ammonia to recover NH3, separating NaCl and returning to salt dissolving step, crystallizing magnesium chloride, hydrolyzing magnesium chloride to obtain MgO and HCl, reusing MgO while obtaining HCl. The present invention can raise the utilization rate of NaCl greatly, lower power consumption and cost.

Owner:自贡鸿鹤化工股份有限公司

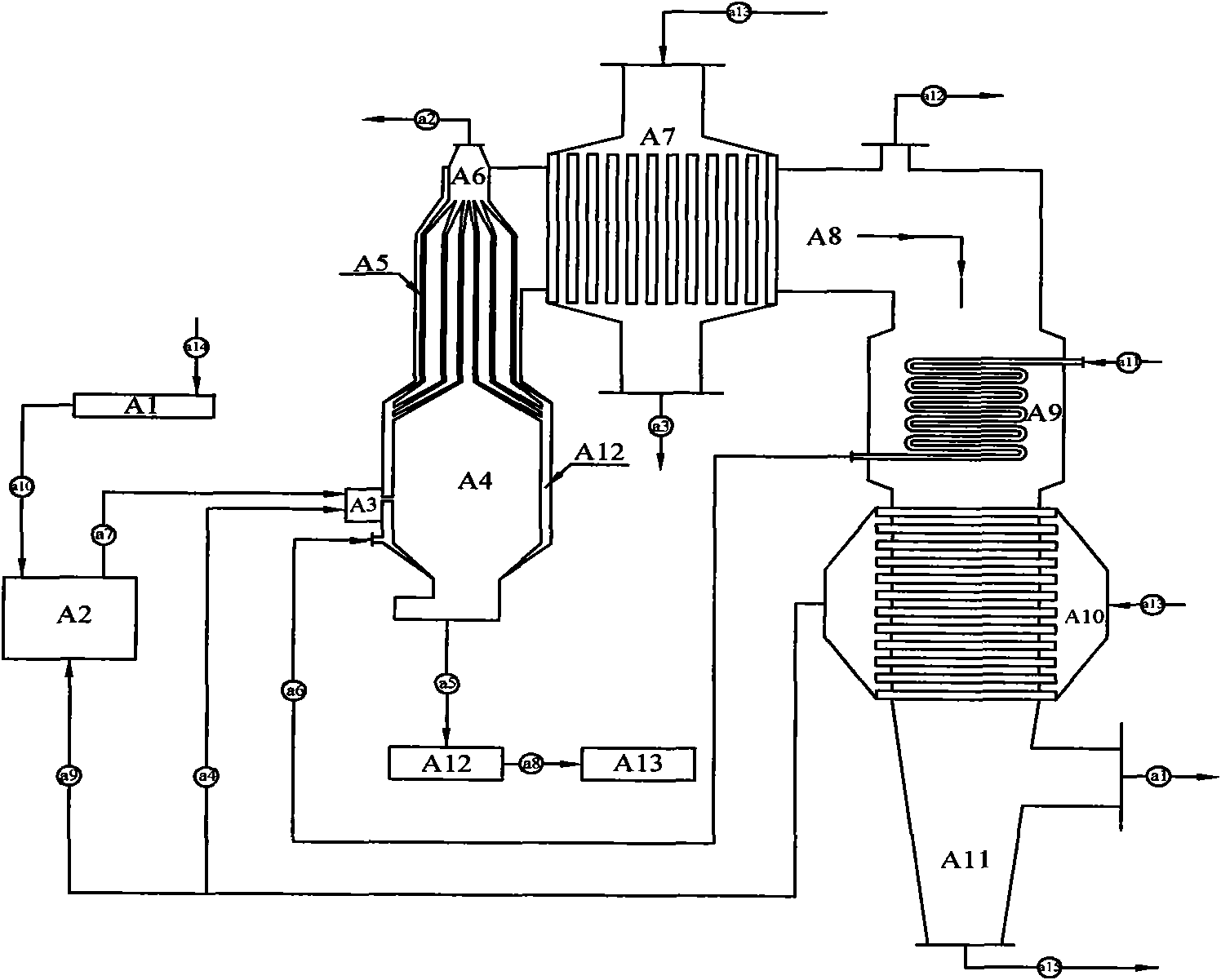

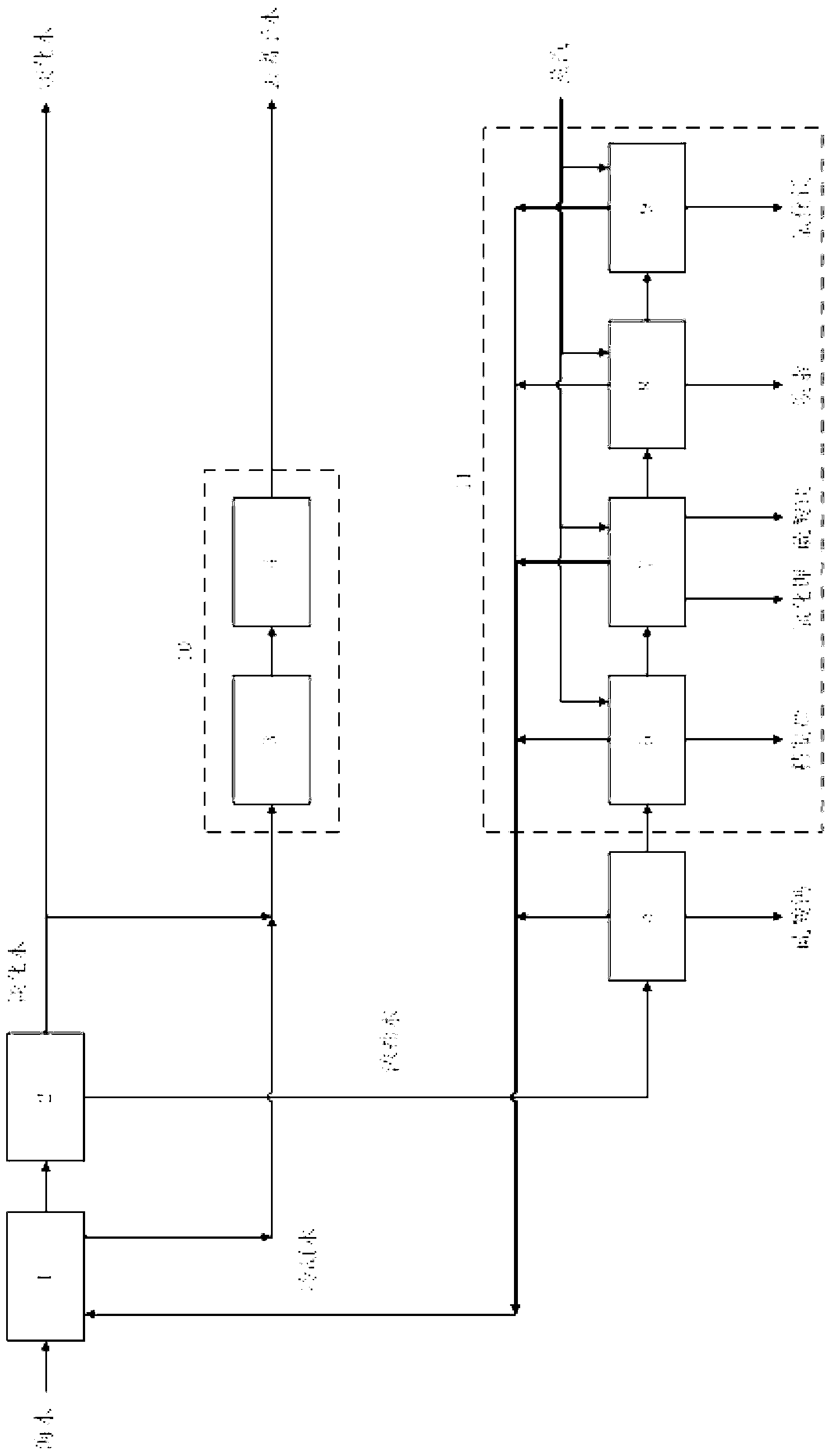

Seawater desalination, resource comprehensive utilization and zero discharge processing system

InactiveCN103253818ASave energyCreate pollutionGeneral water supply conservationSeawater treatmentUF - UltrafiltrationSeawater

The invention discloses a seawater desalination, resource comprehensive utilization and zero discharge processing system. The system comprises an ultrafiltration (UF) system, a seawater reverse osmosis (SWRO) system, a deionized water processing system, namely an UPW system, a mechanical compression system capable of preventing scaling and a salt manufacturing and salt chemical engineering system, wherein the UF system is used for generating pure seawater; the SWRO system is used for generating desalted water and concentrated seawater; the concentrated seawater can be produced into calcium sulfate, sodium chloride, potassium chloride, magnesium sulfate, bromine, magnesium chloride and steam condensed water by virtue of the mechanical compression system and the salt manufacturing and salt chemical engineering system; and the steam condensed water and a part of desalted water flow into the UPW system to generate deionized water. According to the processing system, the relevant projects of seawater desalination, energy source utilization, industrial salt manufacturing and salt chemical engineering are organically combined, so that reasonable allocation and utilization of resources are realized, and the aims of energy conservation, emission reduction, circular economy and zero discharge are fulfilled.

Owner:金逹行有限公司

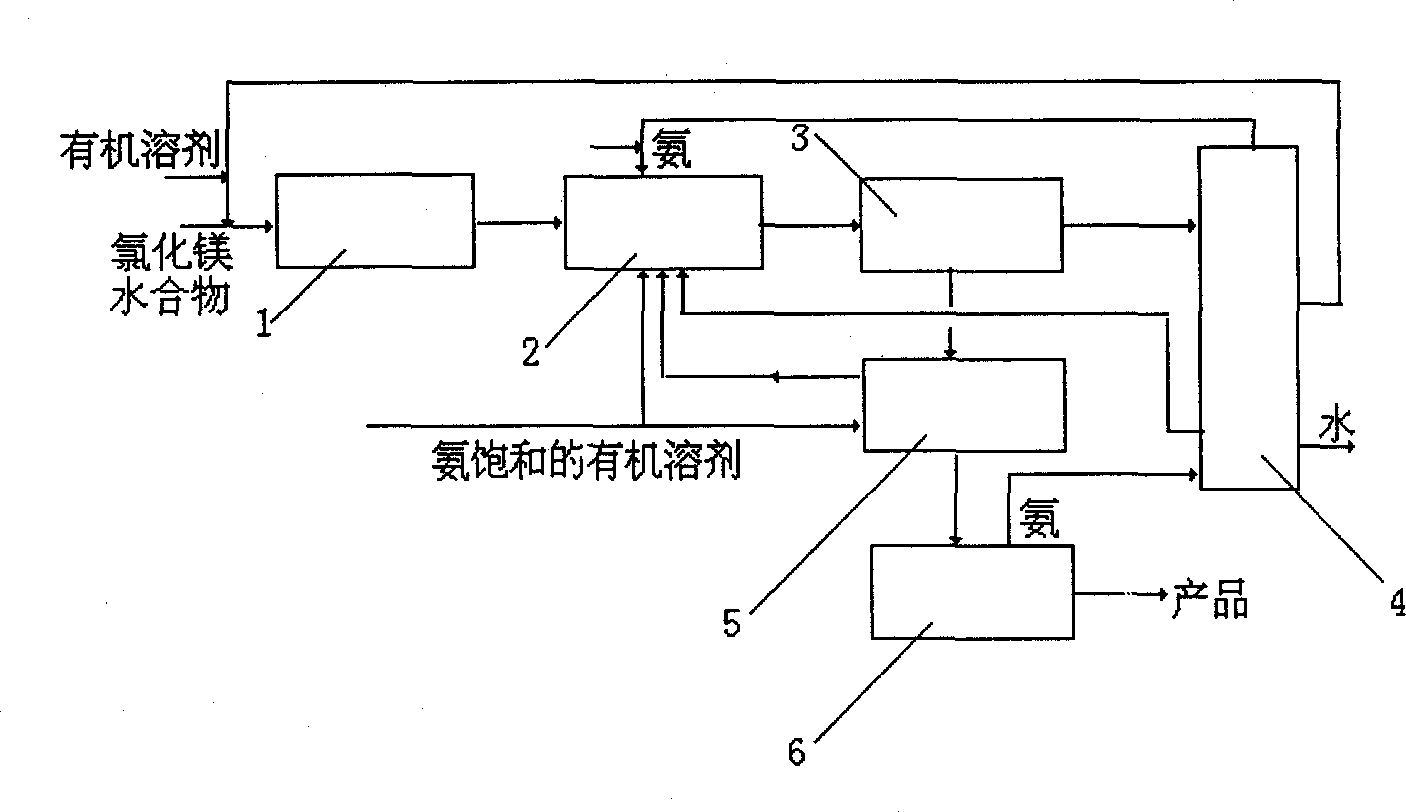

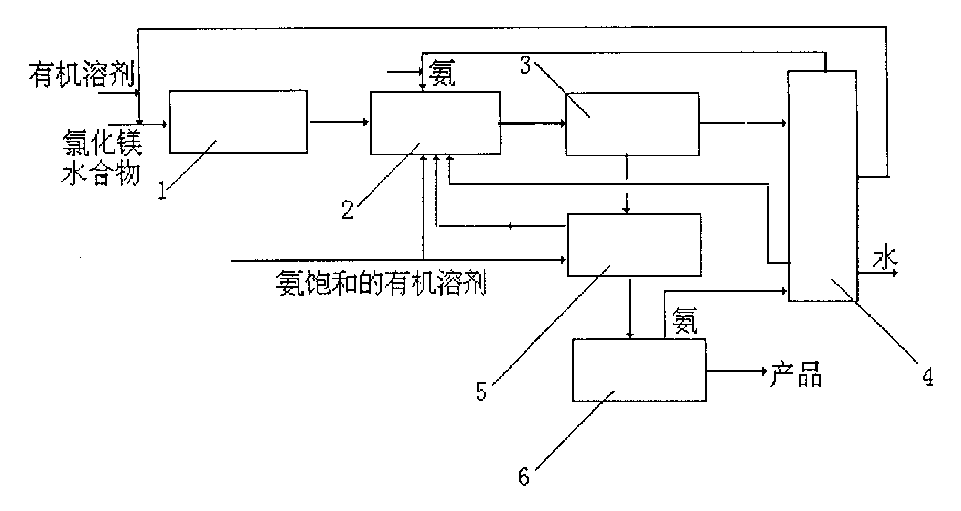

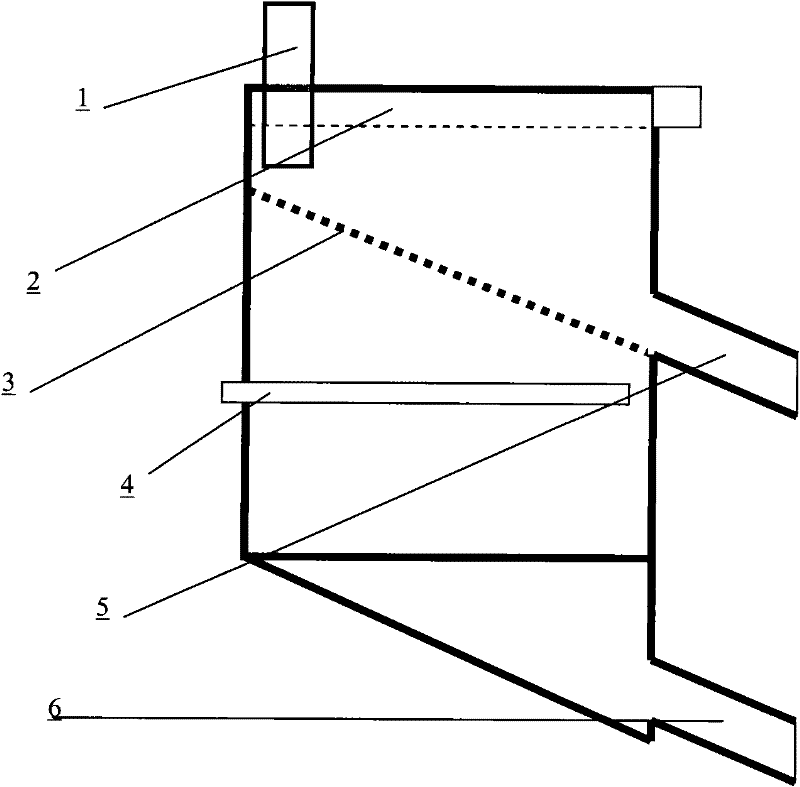

Methodf or preparing anhydrous magnesium chloride

InactiveCN1333183AIncrease sedimentation rateReduce generationMagnesium chloridesAmmonia preparation/separationOrganic solventChloride

The method for preparing anhydrous magnesium chloride includes the following steps: 1. preparation of organic hydrated magnesium chloride; 2. reaction, crystallization and coupling reaction to prepare anhydrous magnesium chloride complex; 3. solid-liquid separation and washing; 4. crystallizing mother liquor and circular utilization of precipitant; and 5. heat treatment of complex intermediate product to obtain the anhydrous magnesium chloride. Said invention adopts mixed organic solvent to prepare hydrated magnesium chloride solution, can reduce production of alkoxide in the course of crystallization, and can return the washing liquor containing saturated hexamine magnesium chloride into crystallization reaction procedure, and can raise rate of deposition of magnesium chloride and utilization rate of ammonia, and can reduce the running load of recovery tower. Said invention also adopts the reaction cold-crystallization process, and is favorable for implementing industrial production.

Owner:青海盐湖镁业有限公司

Simultaneous recovery of potassium chloride and KCL enriched edible salt

The present invention relates to recovery of industrial grade potassium chloride and low sodium edible salt from bittern as part of an integrated process. The process comprises, mixing low sulphate concentrated feed bittern (a by-product of salt industry) of density 31.5 to 32.5° Be (sp.gr. 1.277–1.289) with high density end bittern of density 36.5 to 37.5° Be′ (sp.gr. 1.336–1.35), thereby producing low sodium carnallite, from which industrial grade potassium chloride is produced. The resultant bittern is evaporated in forced evaporation system, thereby producing crude carnallite, from which low sodium salt that would be beneficial to persons suffering from hypertension is produced. When sulphate-rich bittern is used, such bittern is desulphated with CaCl2 that is generated from carnallite decomposed liquor through reaction with lime, and wherein low B2O3-containing Mg(OH)2 is a by-product. The entire content of potassium in feed bittern is recovered in the process of the invention.

Owner:COUNCIL OF SCI & IND RES

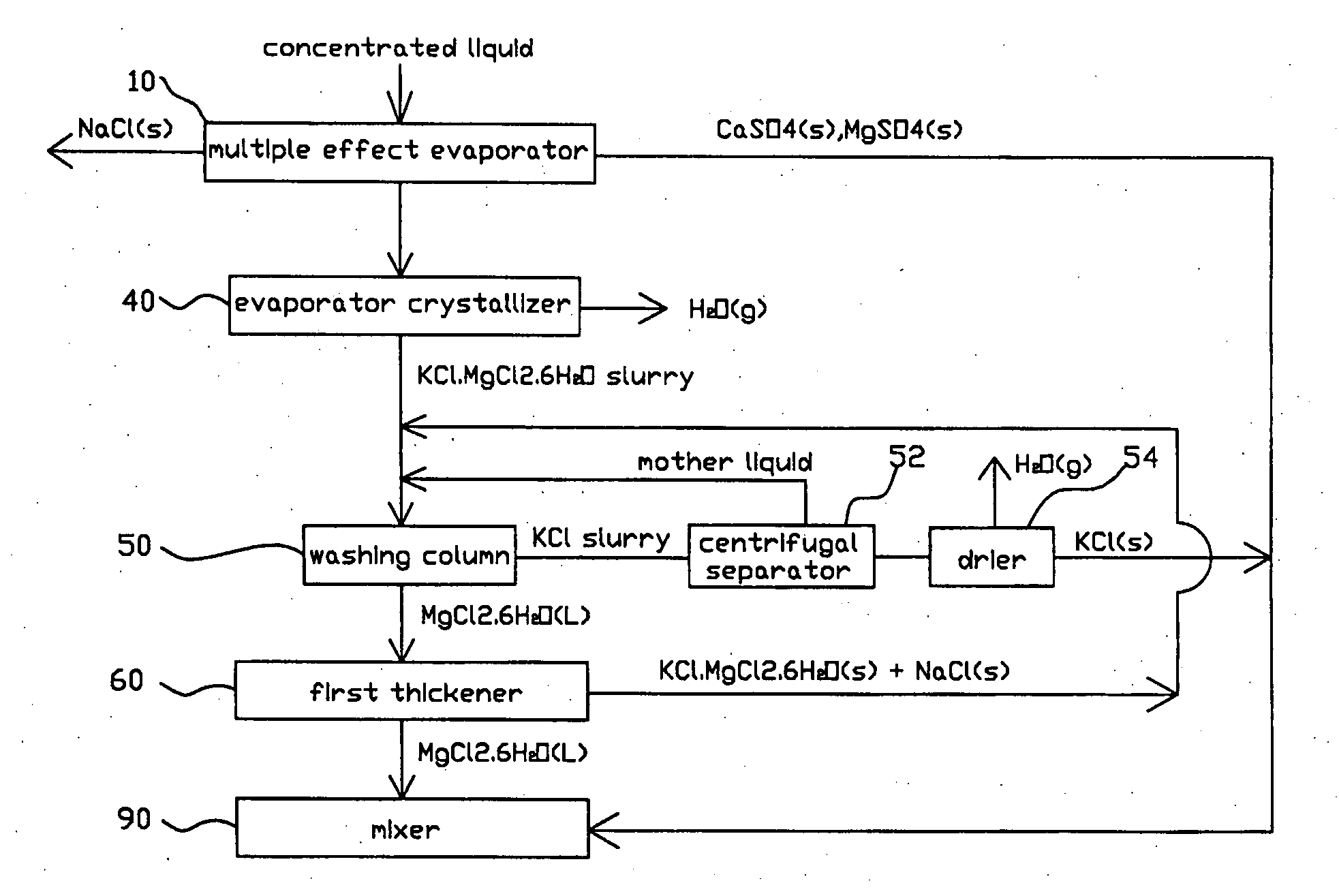

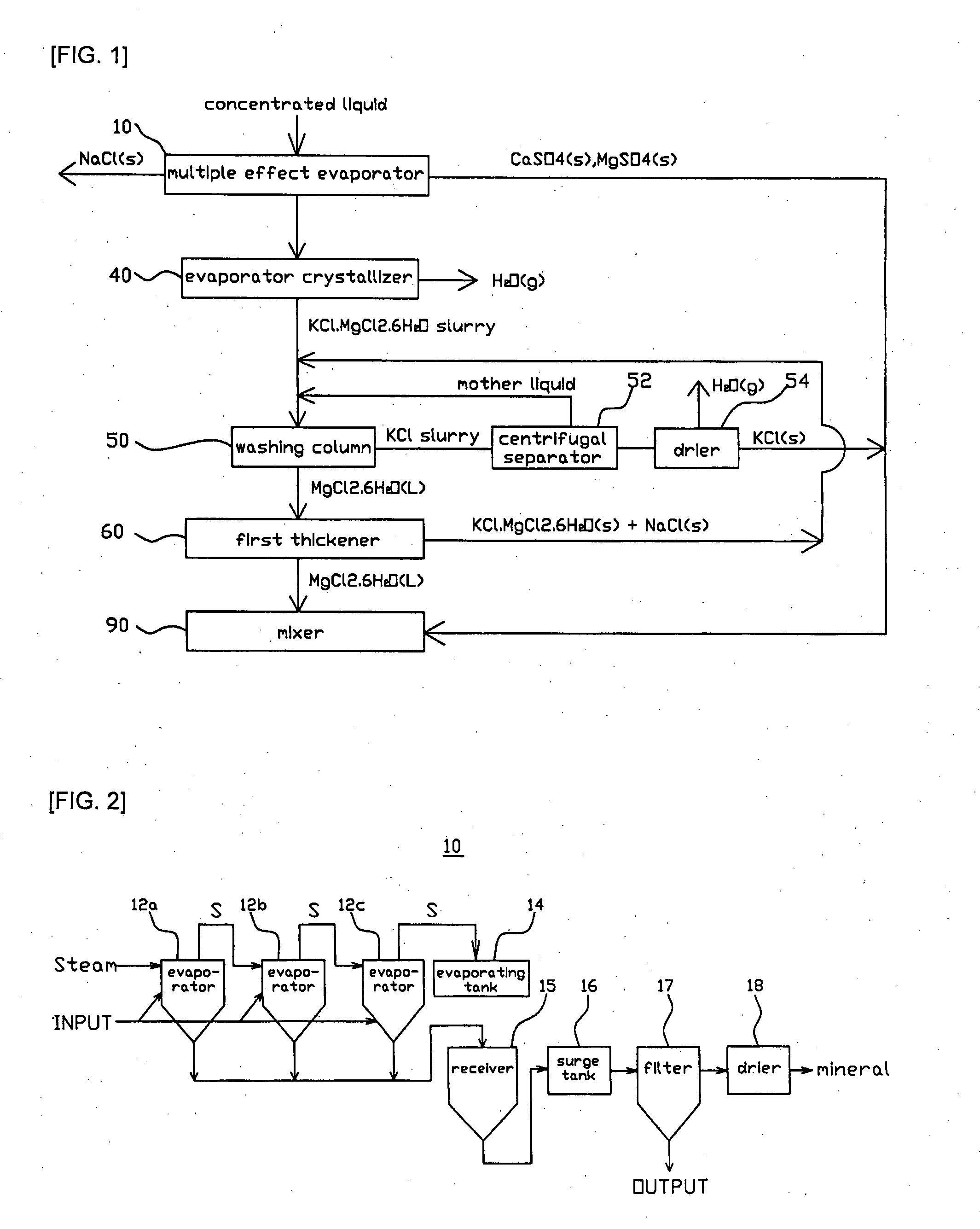

Method for extracting minerals with high purity from deep ocean water

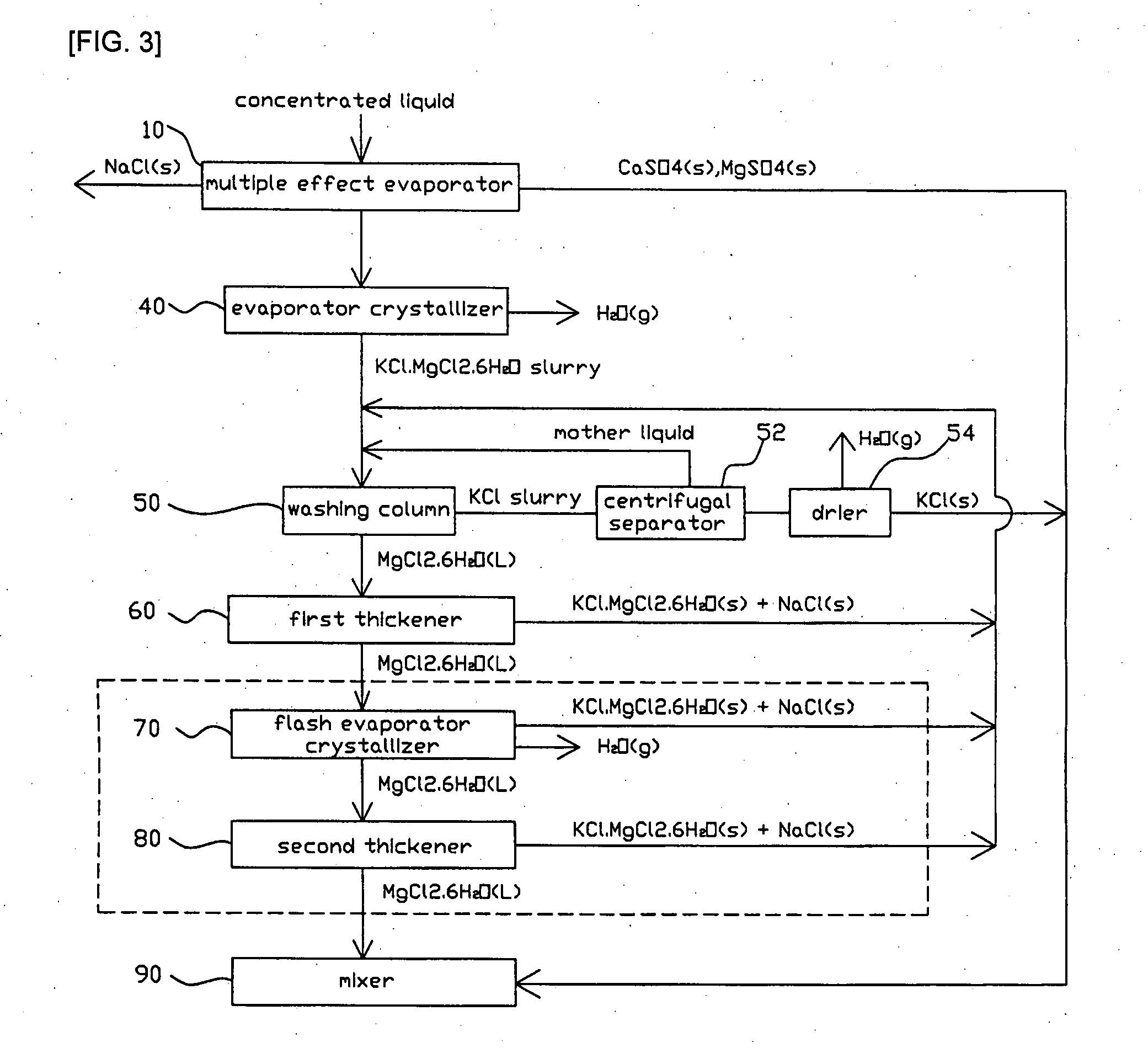

A method for efficiently extracting minerals of high purity from deep ocean water by using low temperature vacuum crystal is disclosed. The method comprises the steps of: obtaining concentrated liquid containing ion components and fresh water without the ion components by freshening the deep ocean water; separating crystals of a calcium salt, a sodium salt, and a sulfate from the concentrated liquid by heat-concentrating and filtering the concentrated liquid; obtaining a mixed salt slurry of a potassium salt and a magnesium salt by concentrating the concentrated liquid from which a calcium salt, a sodium salt, and a sulfate are removed; obtaining a solution in which a magnesium salt is dissolved and a crystal of a potassium salt by washing the mixed salt slurry with water; and obtaining a mixed crystal of a potassium salt and a magnesium salt by concentrating the solution in which a magnesium salt is dissolved, and then separating a magnesium salt solution with improved purity by filtering the concentrated solution in which a magnesium salt is dissolved.

Owner:WATERVIS

Method for preparing anhydrous magnesium chloride from bischofite

The invention relates to a method for preparing anhydrous magnesium chloride from bischofite, which uses the bischofite as a raw material for preparing the anhydrous magnesium chloride. The method comprises the following technical processes: (1) firstly, drying the bischofite for dewatering most crystallization water; (2) dissolving the dried magnesium chloride in glycol for preparing a glycol solution of the magnesium chloride and using a vacuum distillation method for dewatering water in the glycol solution of the magnesium chloride; (3) reacting the dewatered glycol solution of the magnesium chloride with ammonia for crystallizing so as to generate magnesium chloride hexammoniate crystals; (4) washing, filtering and drying for obtaining the magnesium chloride hexammoniate crystals; and (5) heating, decomposing and deaminating the dried magnesium chloride hexammoniate crystals for preparing the anhydrous magnesium chloride. In each process, ammonia gas, detergent and a crystallization mother liquor are recycled. The process has the characteristics of convenient operation, easy large-scale production, low energy consumption, low product cost and no pollution to environment and the prepared anhydrous magnesium chloride can be used as a raw material for producing magnesium metal by an electrolysis method.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

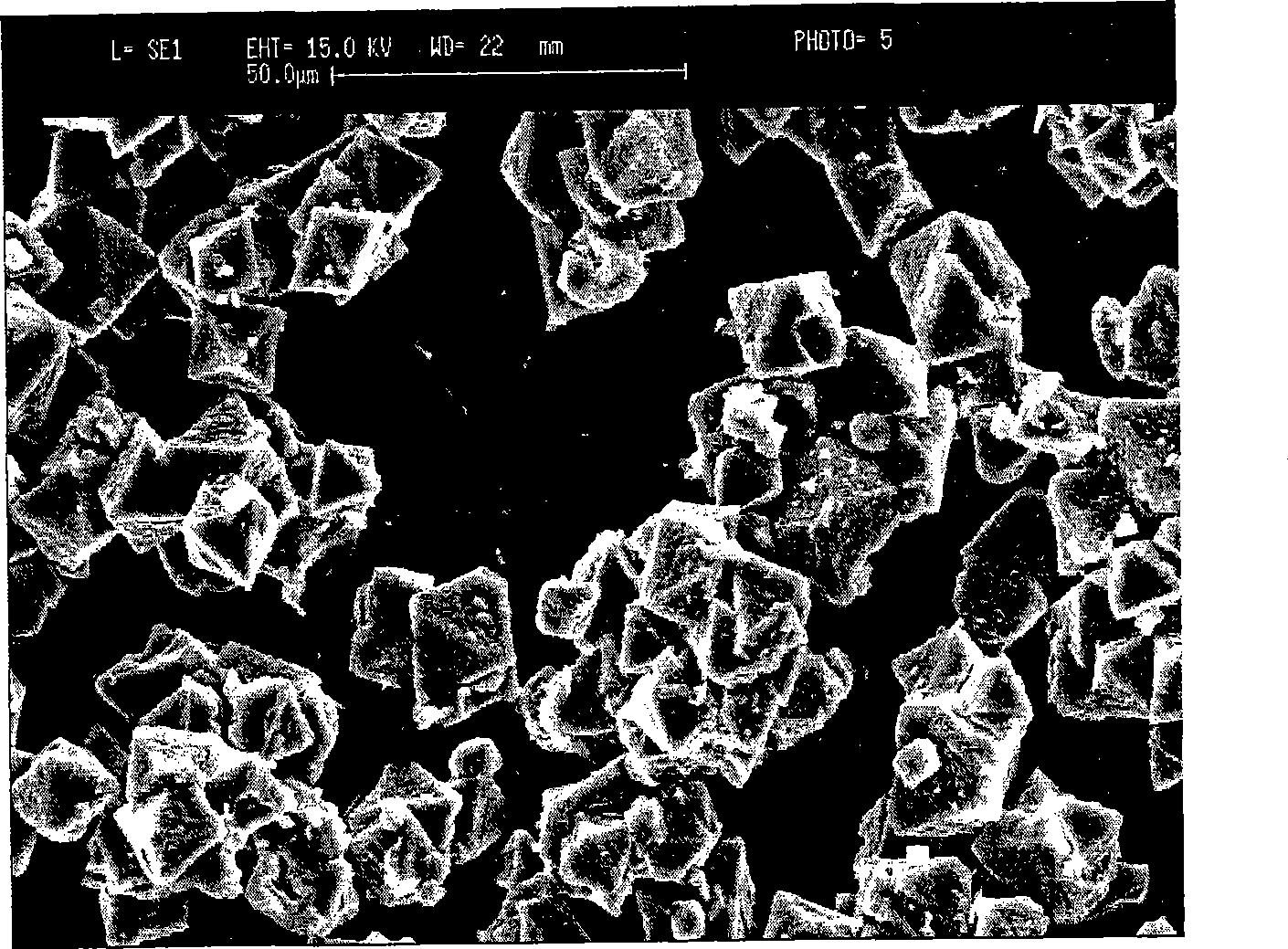

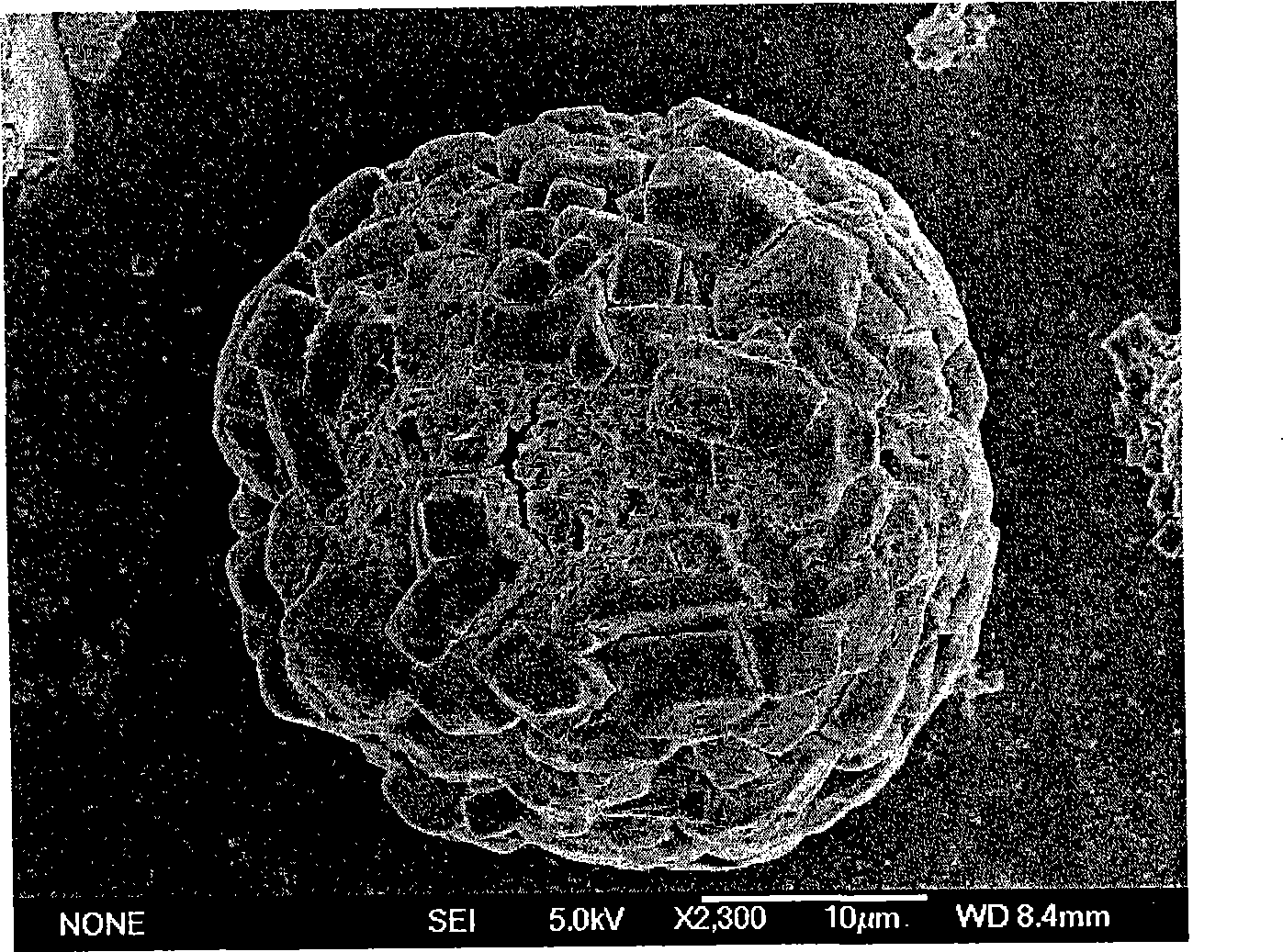

Method for producing fibrous basic magnesium chloride Mg2(OH)3Cl.4H2O3monocrystal

InactiveCN101381890AAvoid askingSimple processPolycrystalline material growthFrom normal temperature solutionsCalcium hydroxideChloride

The invention relates to a method for preparing fibrous alkali magnesium chloride Mg2(OH)3Cl.4H2O single crystal. The single crystal is prepared by the following compounds in weight percentage: 80.53 to 85.13 percent of crystal magnesium chloride, 9.3 to 13.87 percent of calcium chloride, and 5.29 to 5.58 percent of calcium hydroxide. The method for preparing the fibrous alkali magnesium chloride Mg2(OH)3Cl.4H2O single crystal by the compounds comprises the following steps: preparing the magnesium chloride and the calcium chloride into aqueous solution; adding calcium hydroxide powder to the aqueous solution; heating the mixed solution to the temperature of between 50 and 90 DEG C under the condition of continuously stirring, and controlling the pH value of the solution to between 8 and 9; stopping heating the solution and keeping the solution stand after the reacting solution is completely changed into white suspension; placing the suspension in an oven for boiling for 2 to 4 days at a temperature of between 50 and 90 DEG , after the suspension is deposited; and washing and filtering the deposition to obtain the fibrous alkaline magnesium chloride which has the diameter of between 0.2 and 3 microns and the length of between 10 and 100 microns, and has the advantages of high purity, good uniformity of crystal shape and stable composition.

Owner:XIDIAN UNIV

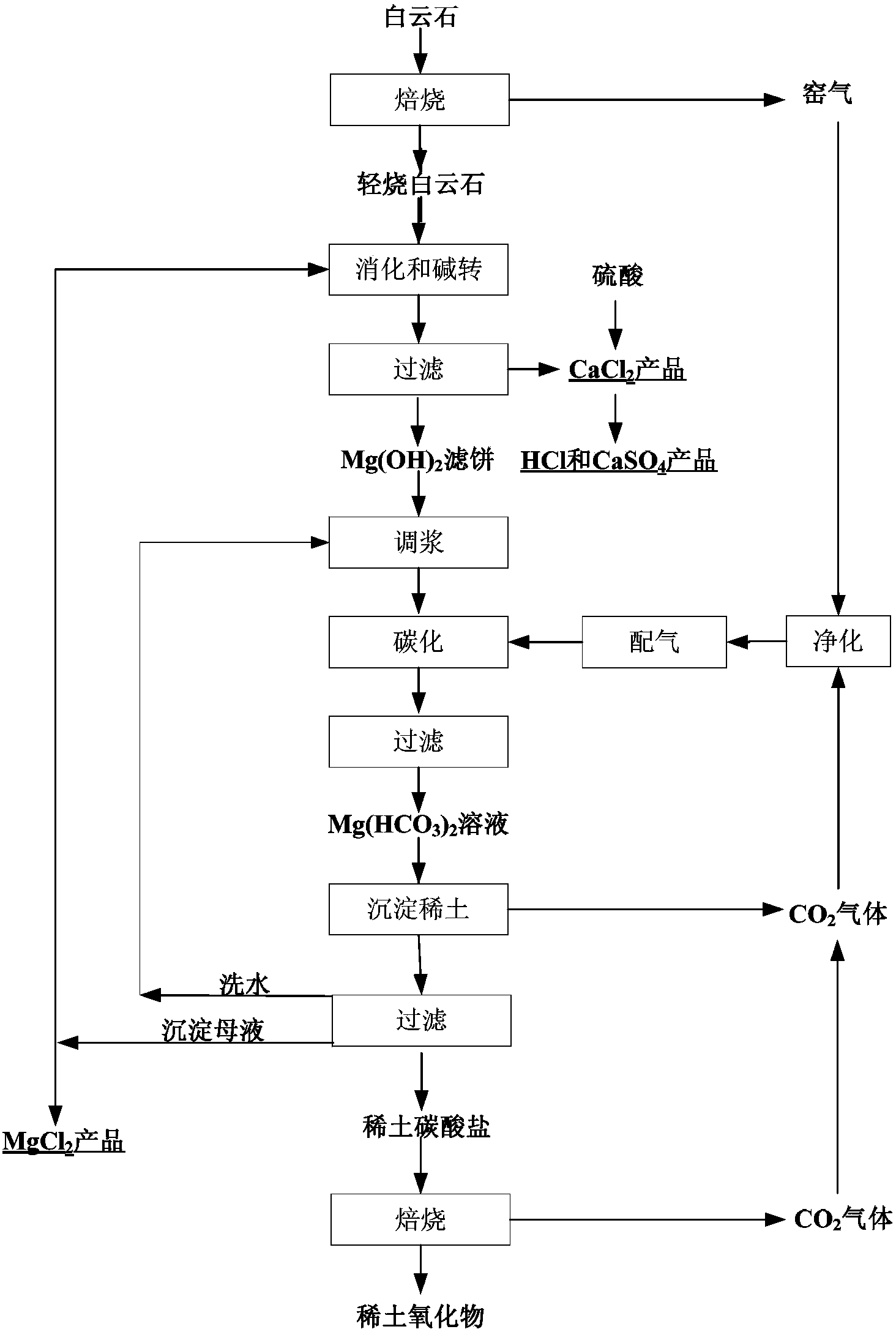

Preparation and comprehensive utilization method of magnesium bicarbonate solution

ActiveCN103382034ARealize comprehensive utilizationAchieve emissionsChlorine/hydrogen-chlorideCalcium/strontium/barium chloridesCarbonizationSlurry

The invention relates to a preparation and comprehensive utilization method of a magnesium bicarbonate solution. The method is used to prepare the magnesium bicarbonate solution used for deposition, crystallization and recovery of rare earth ions, and comprehensive recovery of calcium-compound products and magnesium-compound products by taking dolomite as a raw material. The method specifically comprises: roasting dolomite to obtain a powder containing calcium oxide and magnesium oxide, directly mixing with a magnesium chloride solution for digestion and alkali transformation at the same time to prepare a magnesium hydroxide secondary-product and a calcium compound secondary-product, and further to realize effective separation of calcium and magnesium; performing slurry mixing on magnesium hydroxide, introducing carbon dioxide gas for a carbonization reaction to prepare the magnesium bicarbonate solution; applying obtained magnesium bicarbonate to deposition and crystallization of the rare earth ions to produce rare-earth carbonate or rare-earth oxide products; and recycling one part of the filtrate to prepare magnesium bicarbonate, and evaporating one part of the filtrate for crystallization to produce the magnesium compound product.

Owner:GRIREM ADVANCED MATERIALS CO LTD

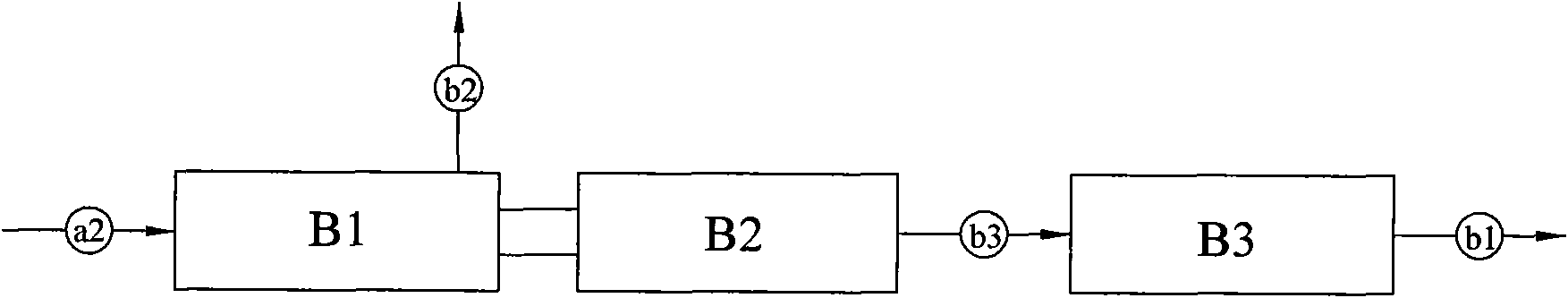

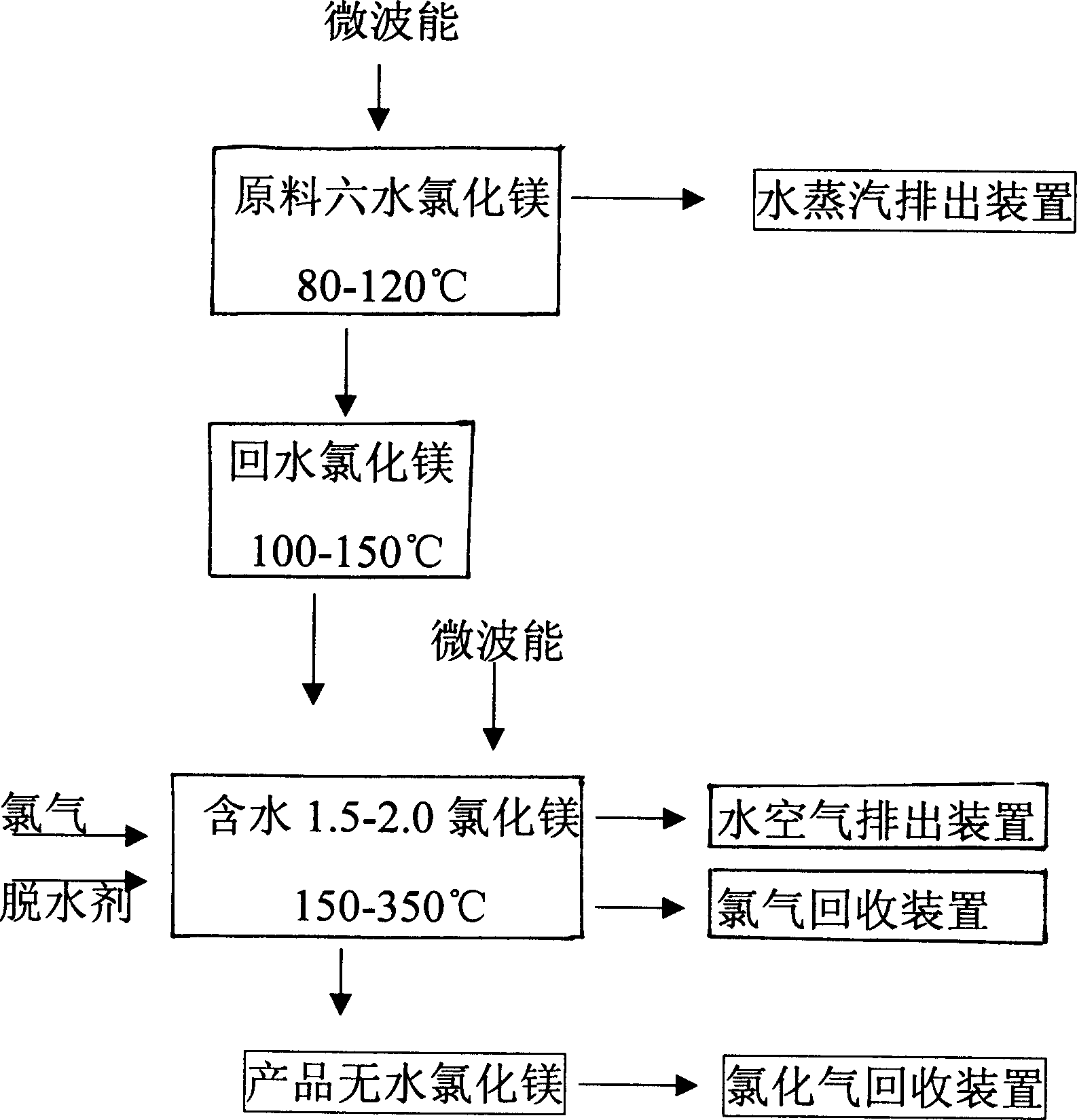

Process for producing anhydrous magnesium chloride by microwave energy

InactiveCN1613770AImprove heating efficiencyShorten heating timeMagnesium chloridesPhysical chemistryChloride

Anhydrous magnesium chloride production by microwave energy is disclosed. It is carried out by dehydrating hexhydrated magnesium chloride to obtain magnesium chloride with 1.5-2.0 water content in the first microwave heater, dehydrating hexhydrated magnesium chloride to obtain tetrahydrated magnesium chloride at temperature 100-120deg.C, dehydrating tetrahydrated magnesium chloride to obtain magnesium chloride with 1.5-2.0 water content at temperature 100-150deg.C, and realizing magnesium chloride with 1.5-2.0 water content to obtain anhydrous magnesium chloride at temperature 150-350deg.C. It achieves low dehydrating temperature and short time.

Owner:陈瑜

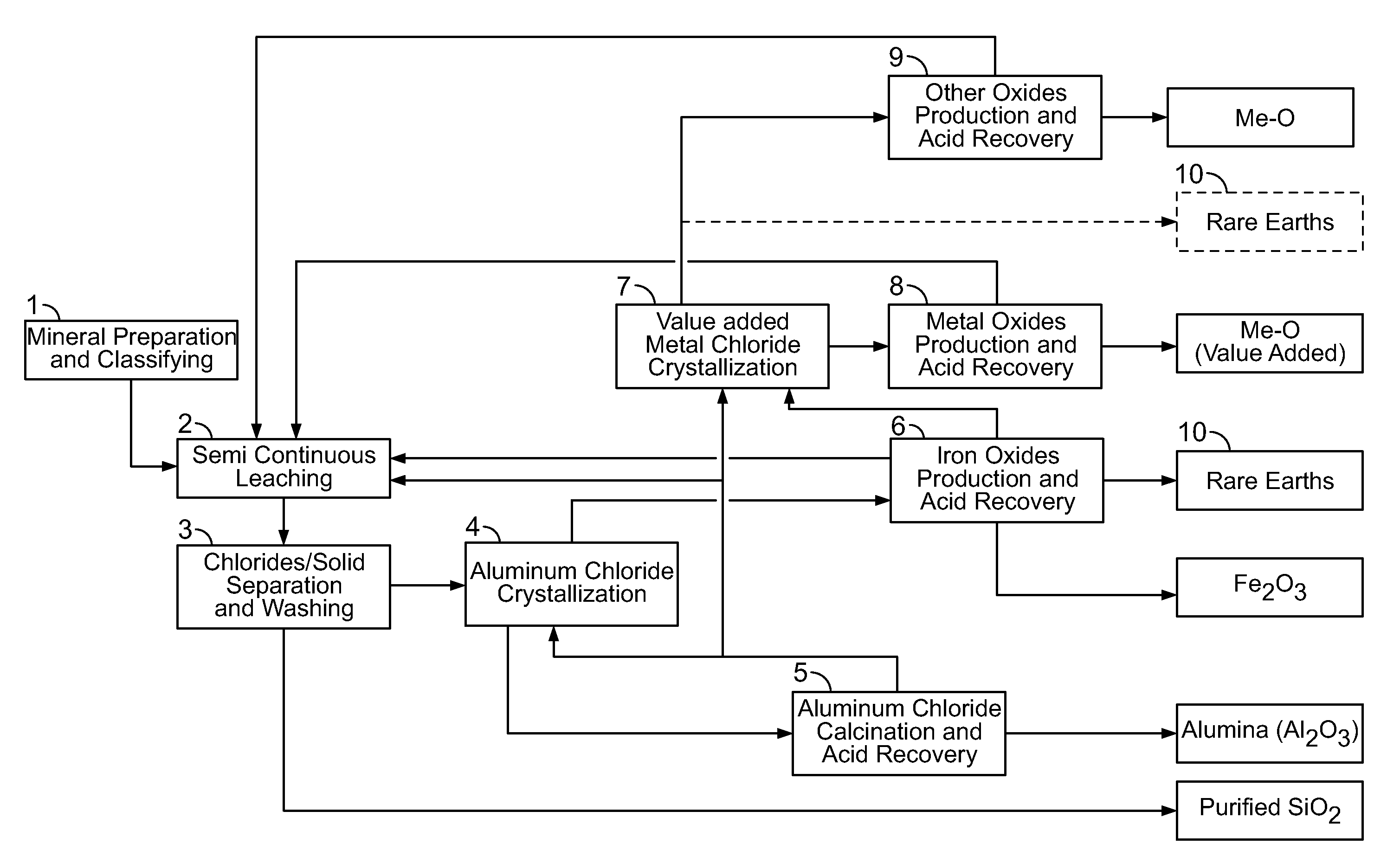

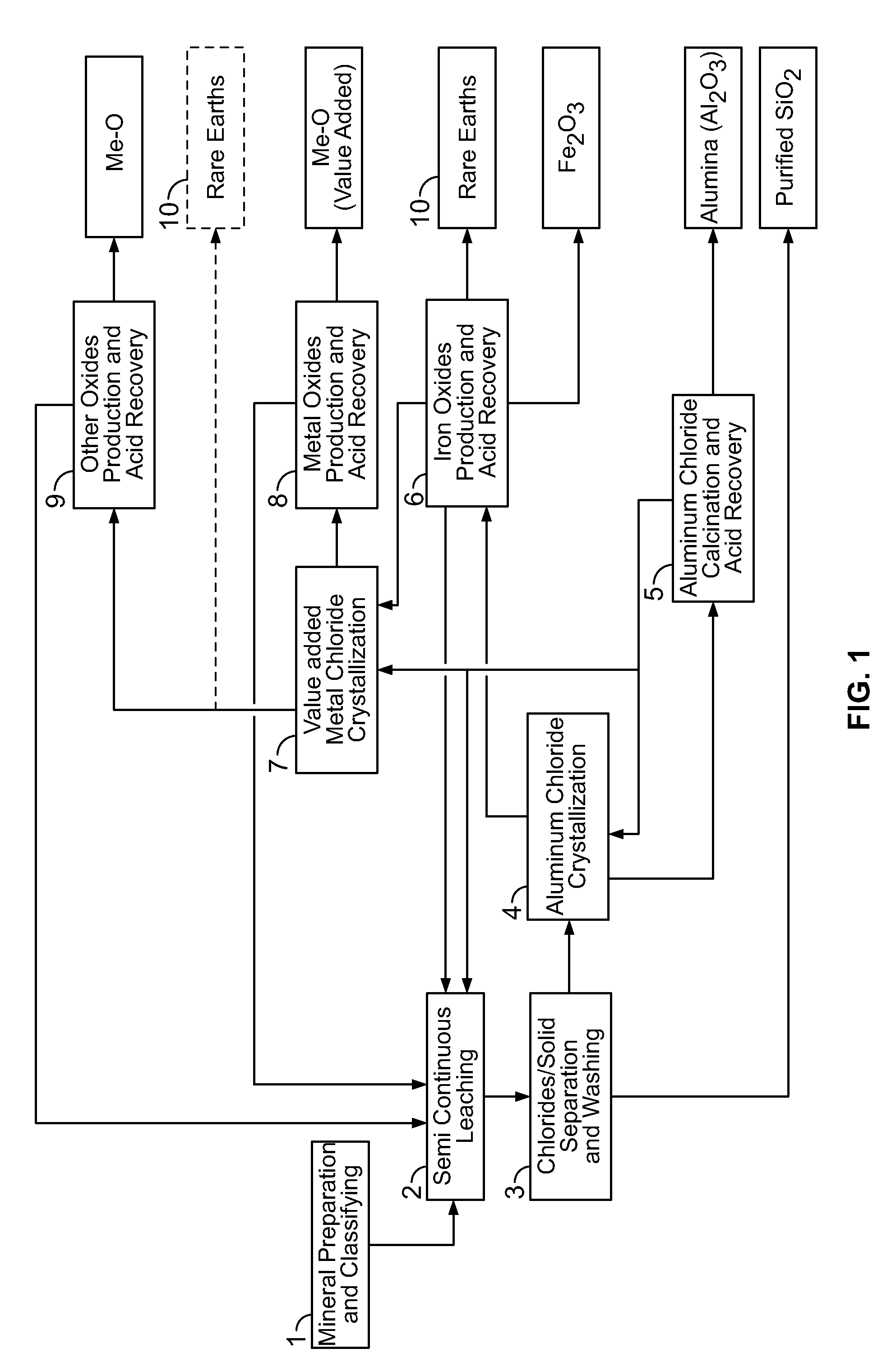

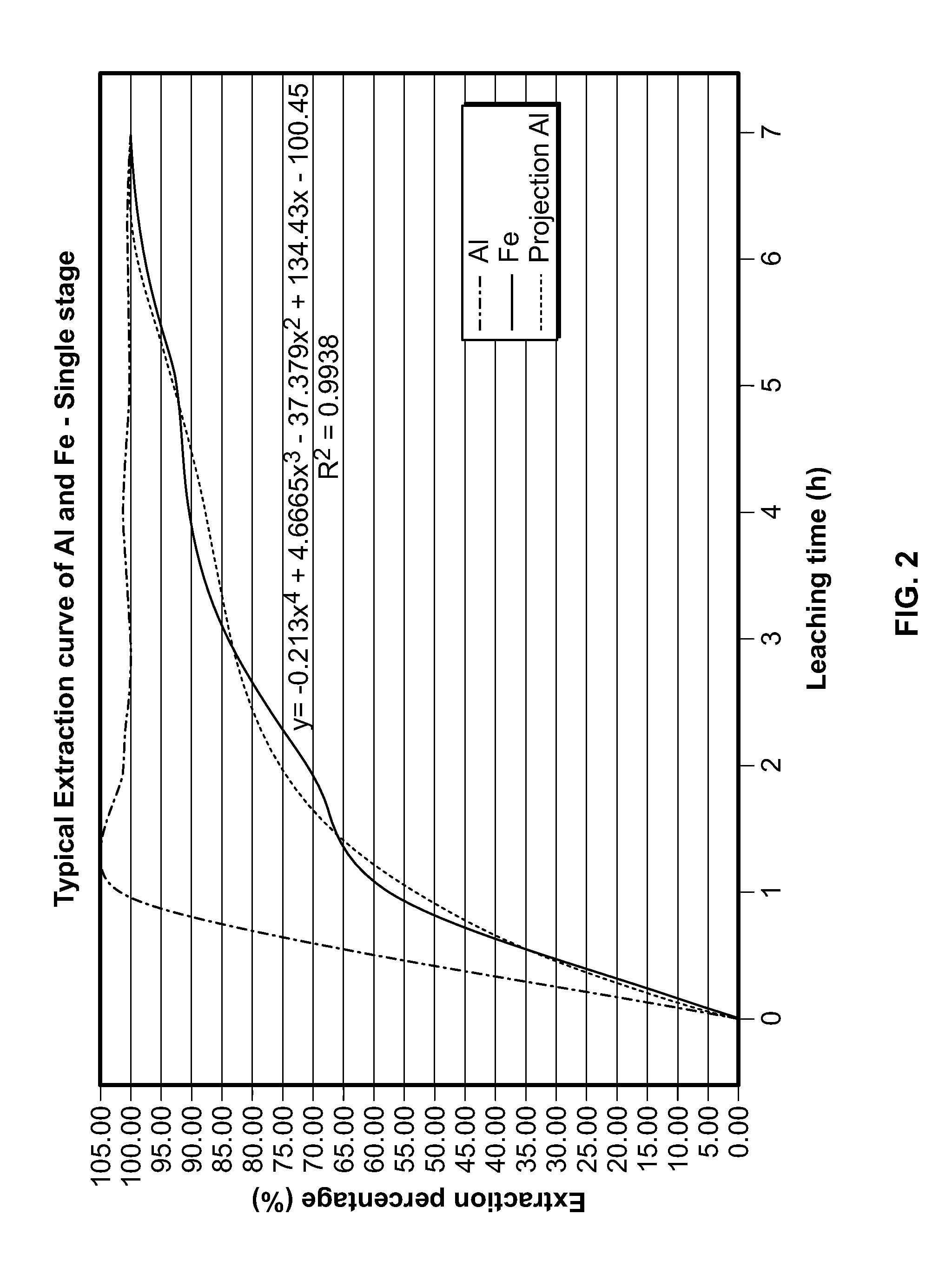

Processes for preparing alumina and various other products

There are provided processes for preparing alumina. These processes can comprise leaching an aluminum-containing material with HCl so as to obtain a leachate comprising aluminum ions and a solid, and separating said solid from said leachate; reacting said leachate with HCl so as to obtain a liquid and a precipitate comprising said aluminum ions in the form of AlCl3, and separating said precipitate from said liquid; and heating said precipitate under conditions effective for converting AlCl3 into Al2O3 and optionally recovering gaseous HCl so-produced. These processes can also be used for preparing various other products such as hematite, MgO, silica and oxides of various metals, sulphates and chlorides of various metals, as well as rare earth elements, rare metals and aluminum.

Owner:ORBITE ALUMINAE INC

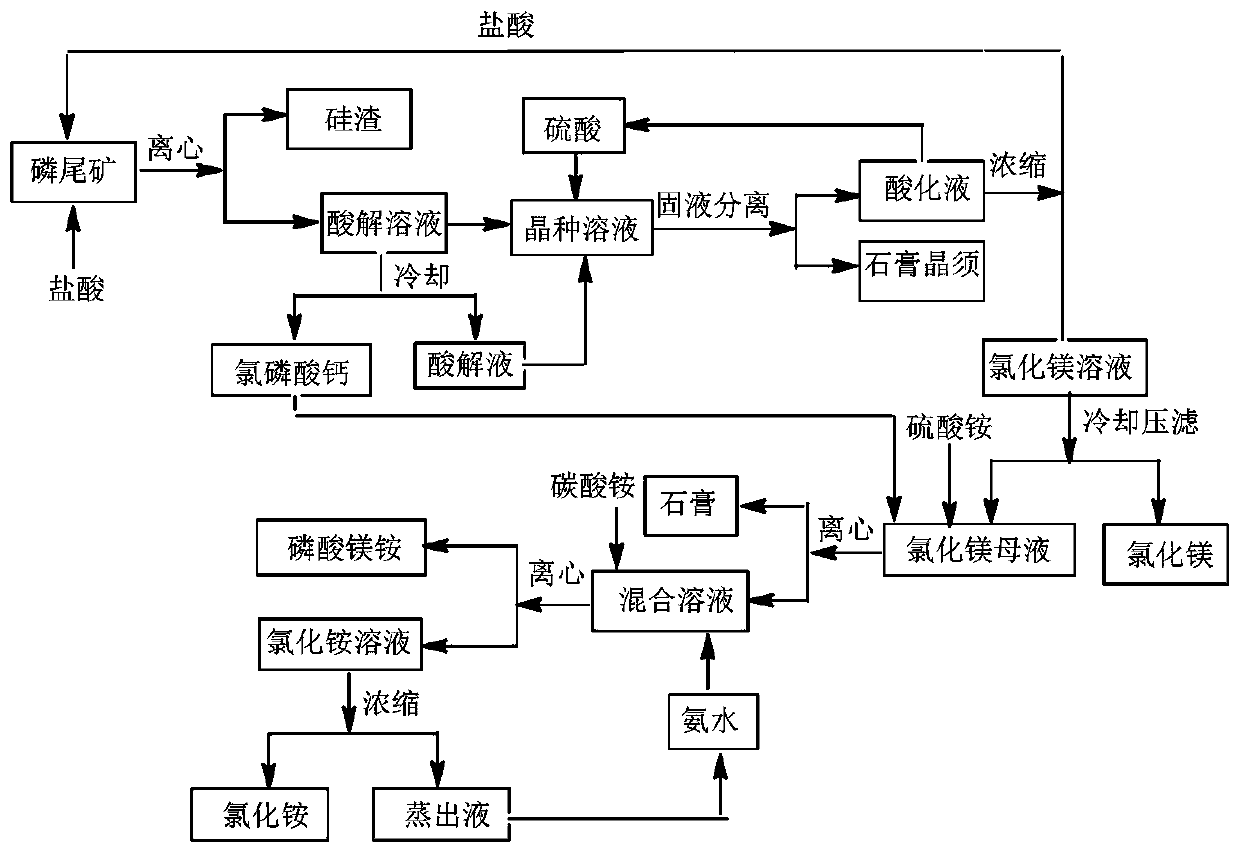

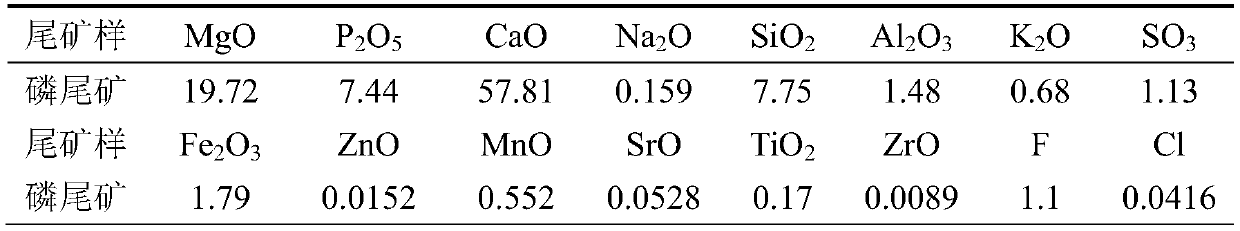

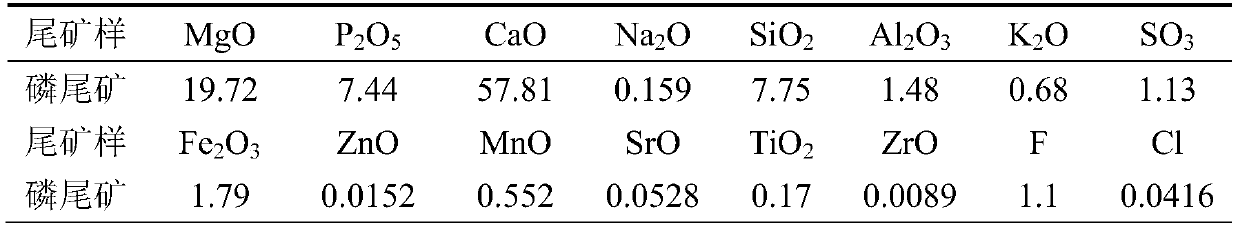

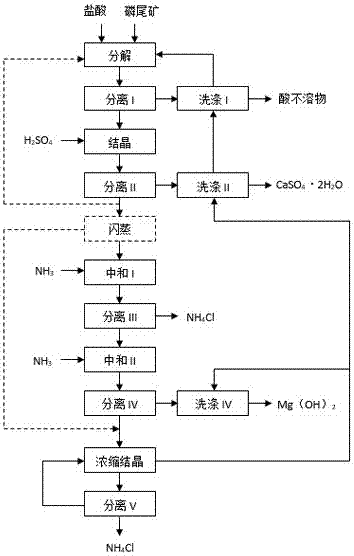

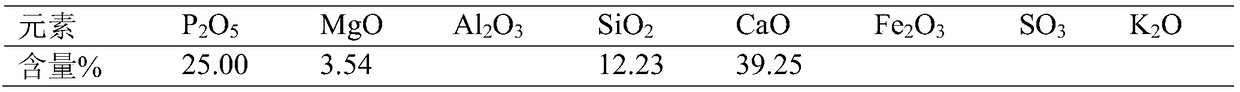

Method for preparing gypsum whiskers, magnesium chloride, ammonium magnesium phosphate and ammonium chloride from phosphate tailings

ActiveCN110817911AHigh recovery rateSolve the bottleneck problem that cannot be consumed in large quantitiesPolycrystalline material growthFrom normal temperature solutionsMagnesium phosphatePhosphoric acid

The invention provides a method for preparing gypsum whiskers, magnesium chloride, ammonium magnesium phosphate and ammonium chloride from phosphate tailings. The method comprises the following steps:adding an acidizing fluid into phosphate tailings in batches, dropwise adding hydrochloric acid to react, separating silicon slag and an acidolysis solution, and cooling and crystallizing the acidolysis solution to obtain calcium chlorophosphate and acidolysis solution; adding concentrated sulfuric acid into the acidizing fluid, dropwise adding the acidolysis fluid for reaction, and performing centrifugal separation after reaction to obtain gypsum whiskers and the acidizing fluid; heating and concentrating the acidizing fluid, crystallizing to obtain a magnesium chloride solution, and centrifugally separating the magnesium chloride solution to obtain magnesium chloride hexahydrate and a magnesium chloride mother liquor; adding ammonium sulfate and calcium chlorophosphate into the magnesium chloride mother liquor for reaction, filtering to obtain gypsum and a filtrate after the reaction is finished, dropwise adding ammonia water into the filtrate, cooling and filtering to obtain ammonium magnesium phosphate and an ammonium chloride solution; heating, concentrating, and cooling the ammonium chloride solution to obtain ammonium chloride crystals and a crystallization mother liquor, and after centrifugal separation, preparing a 5 to 20% ammonia water solution from the crystallization mother liquor and ammonia water. According to the technical scheme, the recovery rate of phosphorus reaches 99%, and the recovery rate of calcium reaches 95%.

Owner:三峡公共检验检测中心

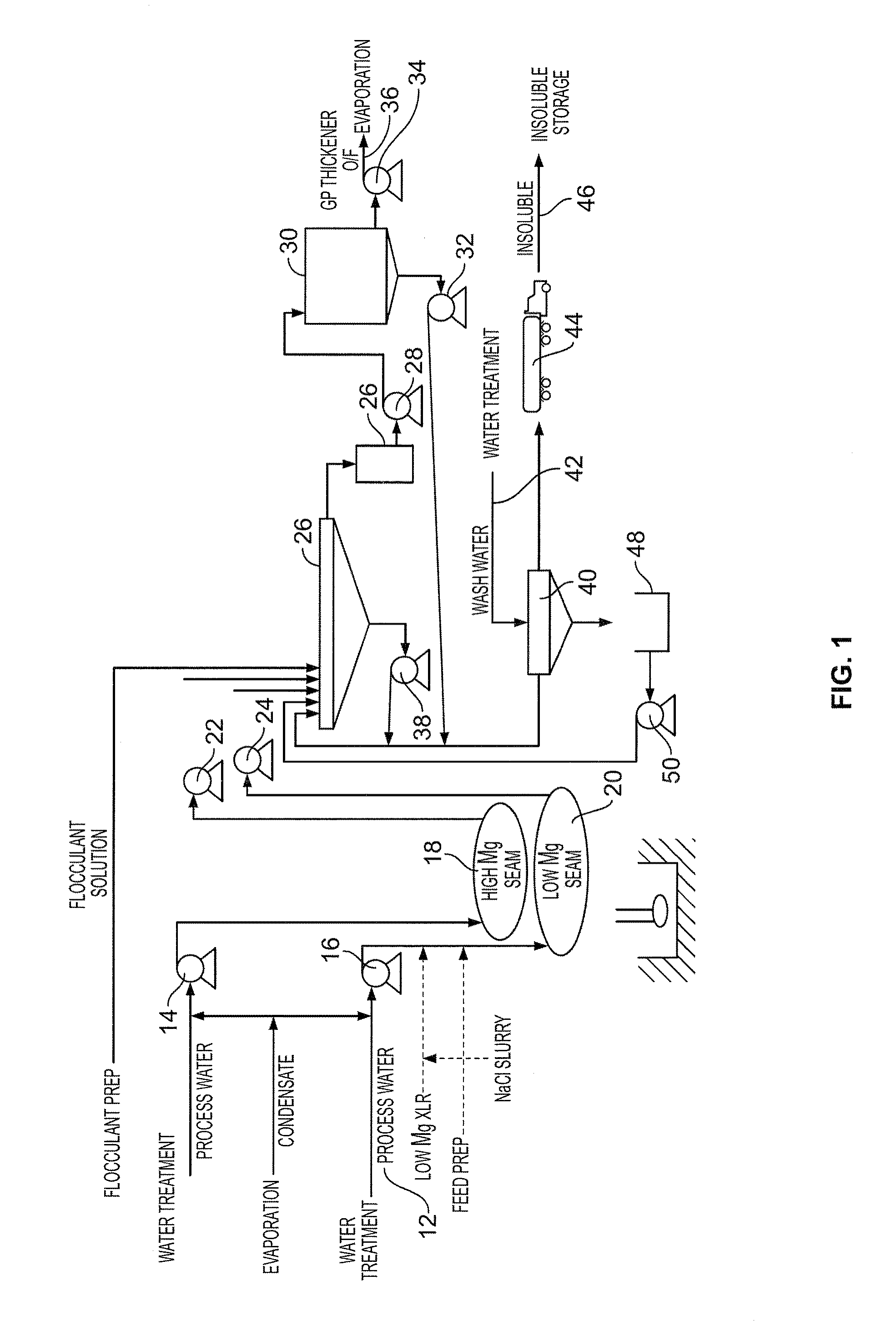

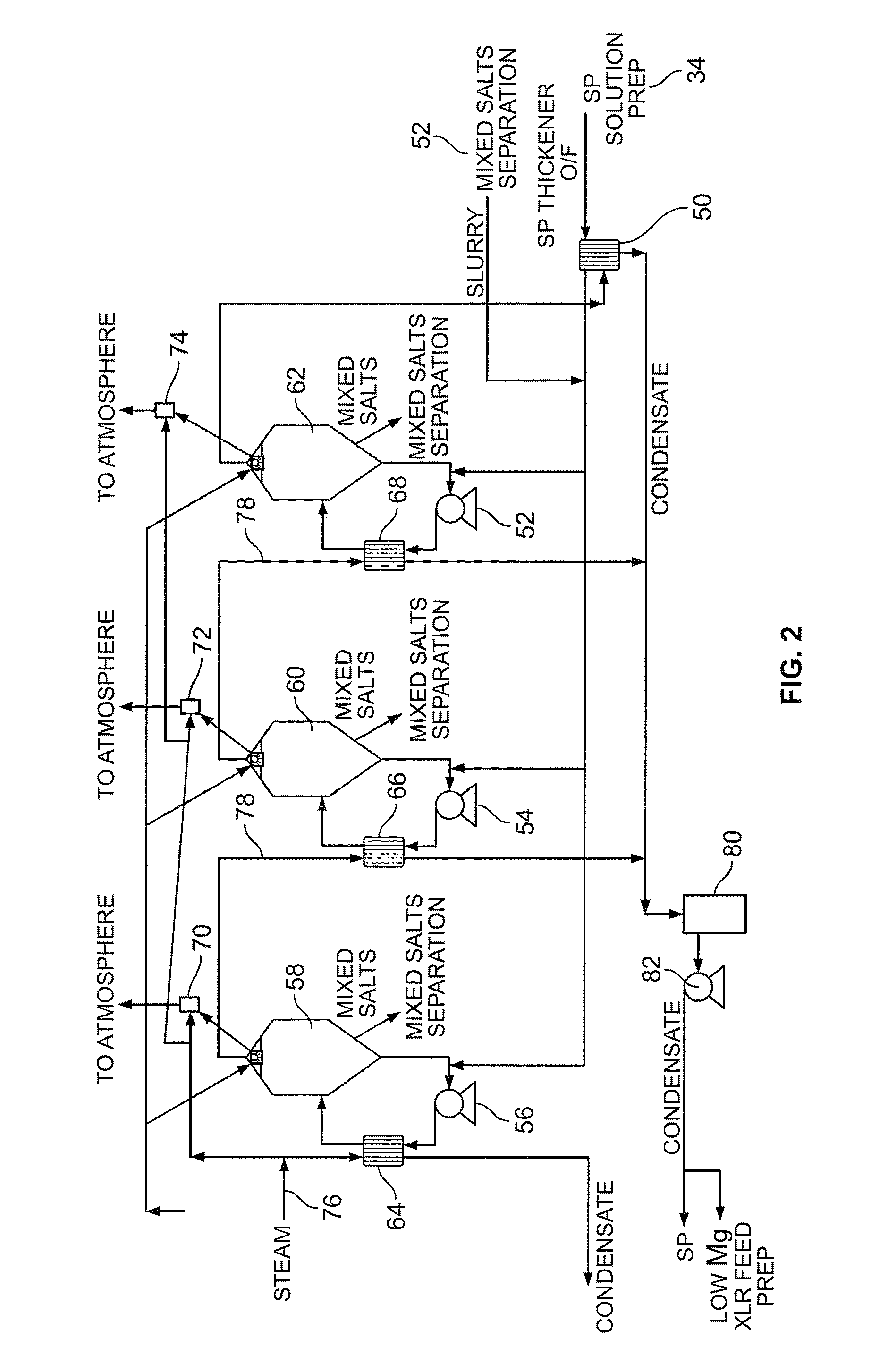

Process for the formulation of potassium chloride from a carnallite source

A process for formulating high purity potassium chloride from a carnallite source. The process takes advantage of solubility differences and saturation levels in a multiple salt system generated upon dissolution of carnallite. In the system, the sodium chloride is kept in solution and the magnesium chloride present in the system is controlled to be in a concentration range of between 12% and 25% by weight. This avoids co-precipitation of sodium chloride with the potassium chloride during crystallization and therefore prevents the sodium chloride from contaminating the potassium chloride. The result is high grade potassium chloride.

Owner:KARNALYTE RESOURCES

Method for preparing calcium sulfate whiskers and magnesium hydroxide by decomposing phosphate tailings through hydrochloric acid

InactiveCN107098372ASolve unhandled problemsMitigating the security concerns of stockpilingMagnesium chloridesCalcium/strontium/barium sulfatesSlurryToxic industrial waste

The invention relates to a method for preparing calcium sulfate whiskers and magnesium hydroxide by decomposing phosphate tailings through hydrochloric acid. The method comprises the following steps: adding phosphate tailings and hydrochloric acid into a decomposing tank to adequately react in the decomposing tank, and carrying out solid-liquid separation I on reacted slurry, so as to separate first mother solution and solid waste residues, wherein the solid waste residues are acid-insoluble substances; adding sulfuric acid into the first mother solution to react for crystallization, so as to generate the calcium sulfate whiskers; carrying out solid-liquid separation on crystallized slurry, so as to separate calcium sulfate dihydrate whiskers, wherein the mother solution is a mixed mother solution containing magnesium chloride and hydrochloric acid; after magnesium chloride in the mixed mother solution reaches a certain concentration, starting to take out a part of mixed mother solution, carrying out flash evaporation to evaporate HCl in the mother solution so as to obtain the mother solution mainly containing magnesium chloride, and returning the rest part of the mixed mother solution to the decomposing tank; introducing ammonia gas into the magnesium chloride mother solution, and carrying out solid-liquid separation, so as to obtain a relatively pure magnesium chloride mother solution and magnesium ammonium chloride solids containing a small amount of impurities; and absorbing HCl gas in the front stage by a magnesium ammonium chloride solution to enable the pH value of the magnesium ammonium chloride solution to be close to neutrality, and carrying out concentration and crystallization, so as to obtain magnesium ammonium chloride crystals. The method has the advantage that magnesium hydroxide and the calcium sulfate whiskers which have relatively high quality can be produced from industrial waste and the cheap raw materials.

Owner:HUBEI SANNING CHEM

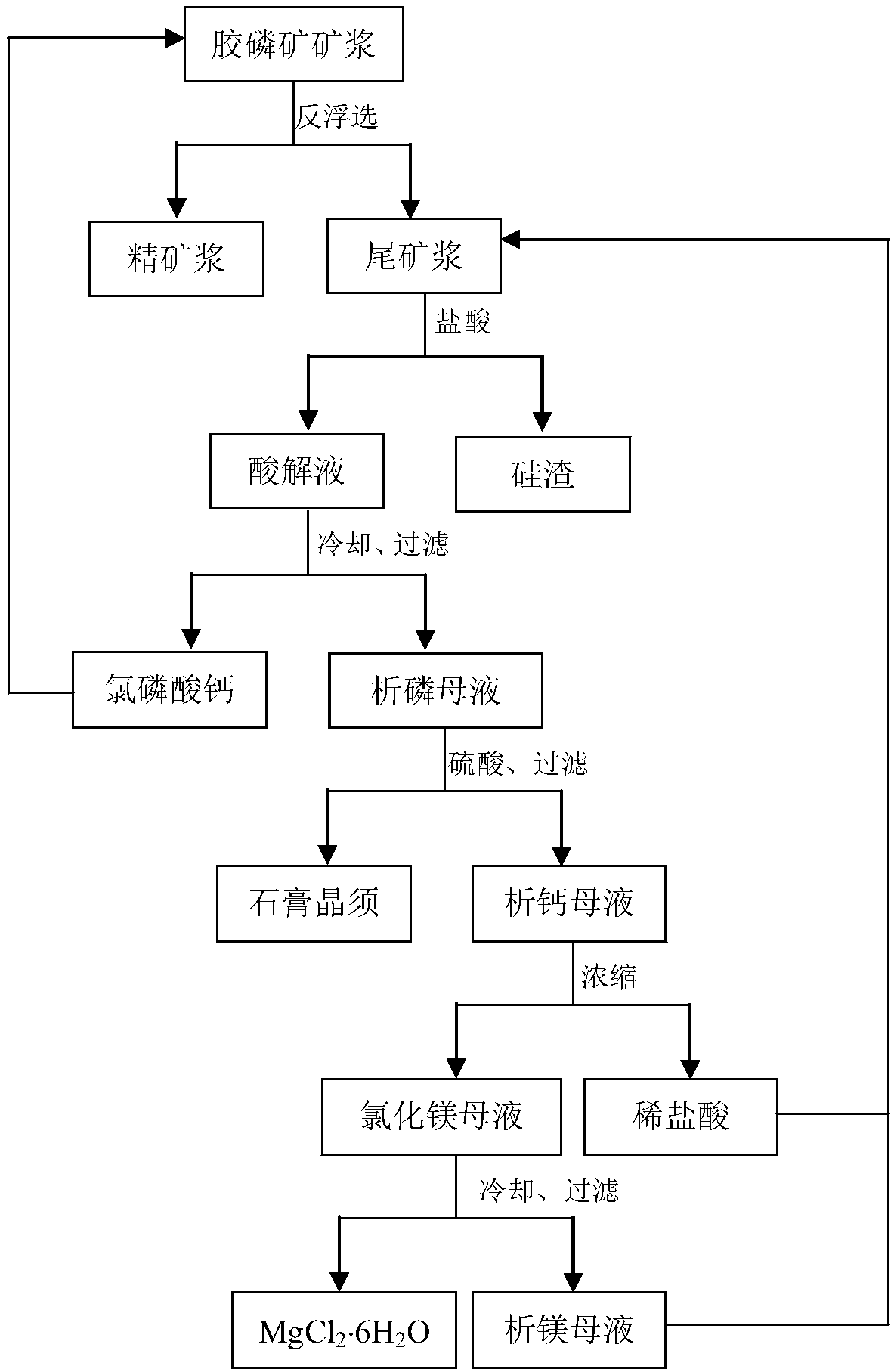

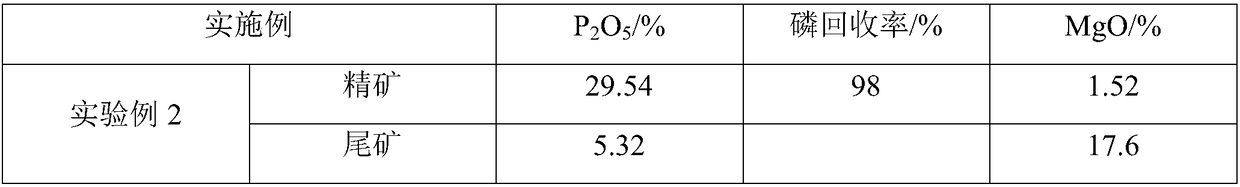

Reprocessing method of phosphate ore flotation tailings and phosphate ore flotation method

InactiveCN109290060AAdvantages of reprocessing methodsAchieve reuseMagnesium chloridesFlotationLand resourcesSlag

The invention provides a reprocessing method of phosphate ore flotation tailings and a phosphate ore flotation method. The reprocessing method comprises the following steps that firstly, acidolysis onthe phosphate ore flotation tailings is conducted, then floating coupling, precipitation and filtering are conducted for several times to separate silicon, phosphorus, Ca<2+> and Mg<2+> in the phosphate ore flotation tailings in the form of silicon slag, calcium chloride calcium phosphate, gypsum whisker and MgCl2.6H2O from each other. According to the reprocessing method, separated outcomes canbe used for producing industrial products, no waste residue is generated in the whole process, reutilization of the phosphate ore flotation tailings is realized, the resource utilization rate of the phosphate ore flotation tailings is improved, therefore the problems that the phosphorus tailings occupy land resources and pollute environment are solved, and the method has good economic benefits andimportant environmental protection significance.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

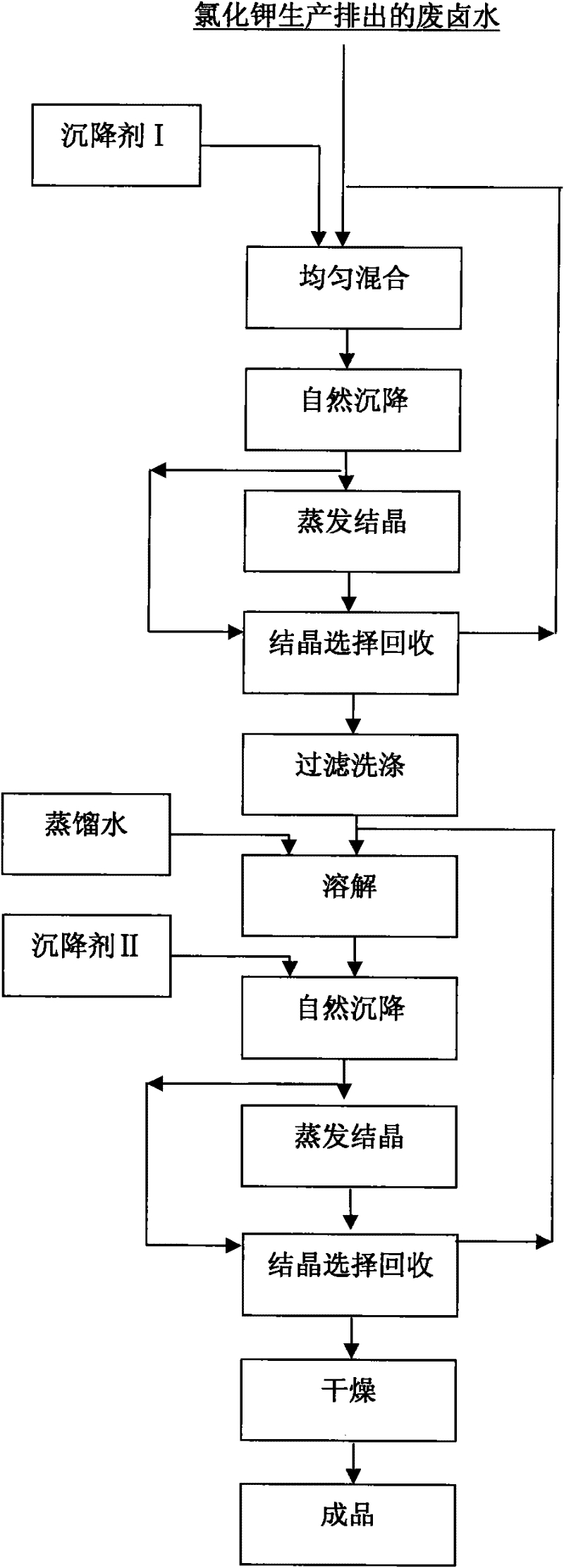

Method for preparing high-purity magnesium chloride hexahydrate from waste brine

The invention provides a method for removing trace impurities in magnesium chloride by using waste brine discharged in potassium chloride production as a raw material by an improved two-stage recrystallization technique. Each stage of the crystallization technique comprises the following steps: 1) free settling, 2) natural evaporation and crystallization, 3) size-grading selective recycling, 4) filtration, (5) saturated magnesium chloride solution washing and the like. By using the method, trace impurities, such as boron, sulfur, ferrum and the like, in magnesium chloride can be reduced to less than 5 ppm, and the purity of the product magnesium chloride hexahydrate is higher than 99.5%. The invention has the characteristics of low energy consumption and low cost, is simple to operate, and is applicable to refining magnesium metal, flame retardant, magnesium hydroxide or any other raw material by an electrolytic process.

Owner:张英才

Pyrite cinder separation, recovery and recycling method

InactiveCN105984893ASave landSaving and efficient useCalcium/strontium/barium carbonatesSolid waste disposalIron(II) oxideAluminium hydroxide

The invention discloses a pyrite cinder separation, recovery and recycling method and belongs to the technical field of an inorganic chemistry industry. The method comprises carrying out suspended separation on calcium hydroxide and alumina through water, dissolving and separating alumina through an ammonium salt, dissolving iron sesquioxide / ferrous oxide in the pyrite cinder through strong phosphoric acid, filtering to separate the mixture of sulfur, phosphorus and silica insoluble with strong phosphoric acid from iron sesquioxide / ferrous oxide, and separating and recovering resource materials such as iron sesquioxide / ferrous oxide and alumina or aluminum hydroxide. The separated product can be used for an industrial raw material and agricultural fertilizer.

Owner:耿兆翔

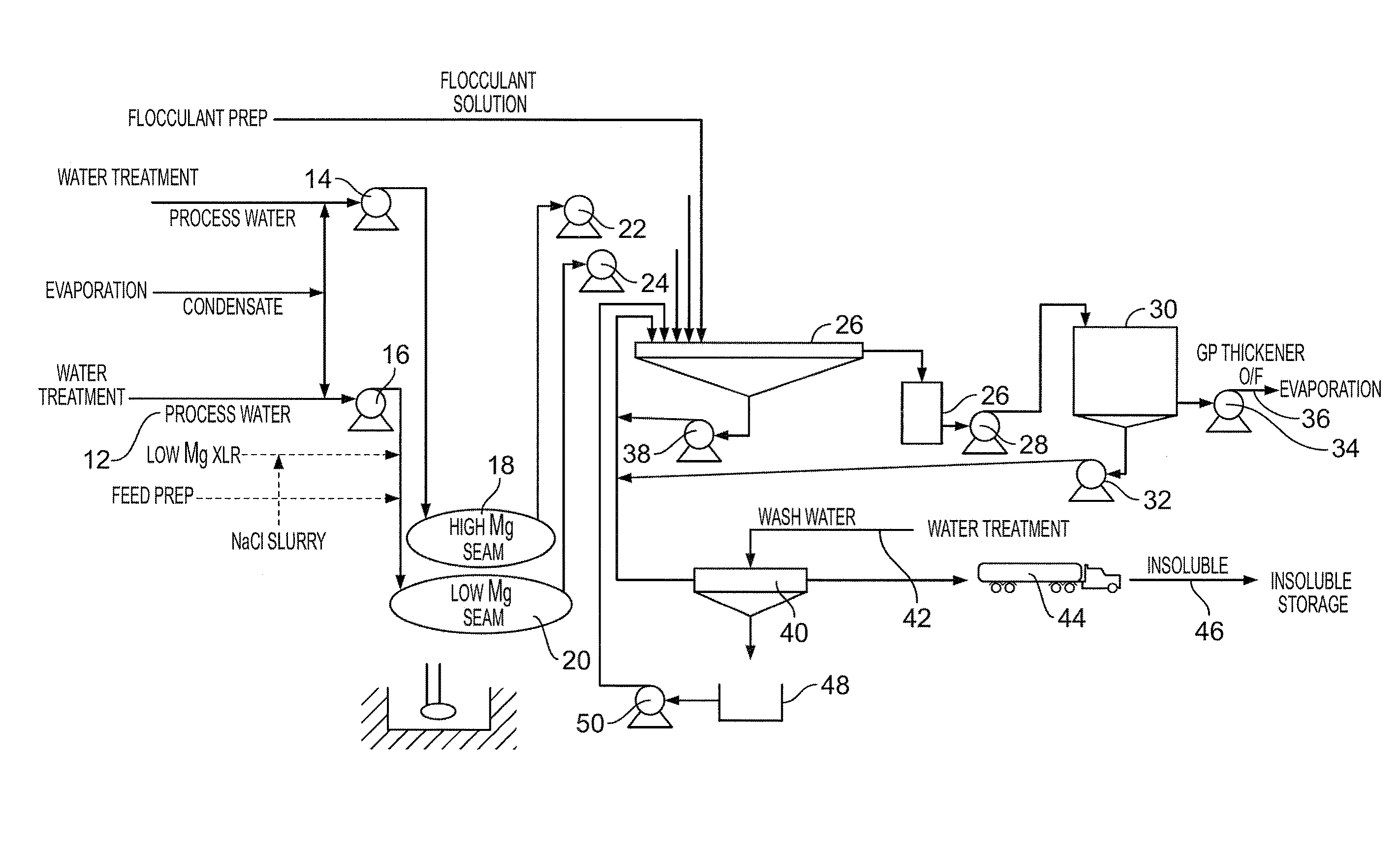

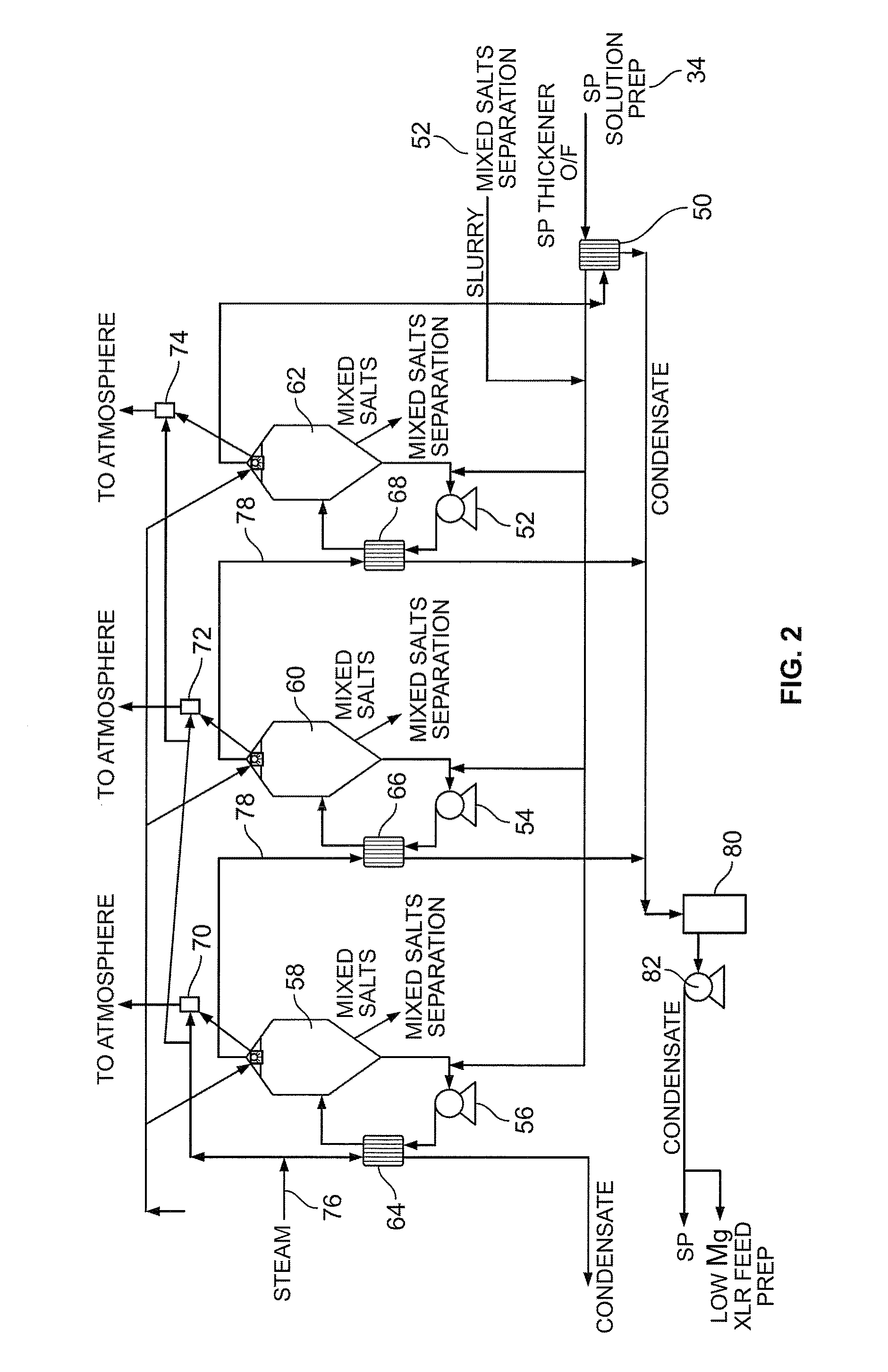

Process for the formulation of potassium chloride from a carnallite source

ActiveUS20110123420A1Speed up the processSolvent extractionCrystallization separationSolubilitySaturated Level

A process for formulating high purity potassium chloride from a carnallite source. The process takes advantage of solubility differences and saturation levels in a multiple salt system generated upon dissolution of carnallite. In the system, the sodium chloride is kept in solution and the magnesium chloride present in the system is controlled to be in a concentration range of between 12% and 25% by weight. This avoids co-precipitation of sodium chloride with the potassium chloride during crystallization and therefore prevents the sodium chloride from contaminating the potassium chloride. The result is high grade potassium chloride.

Owner:KARNALYTE RESOURCES

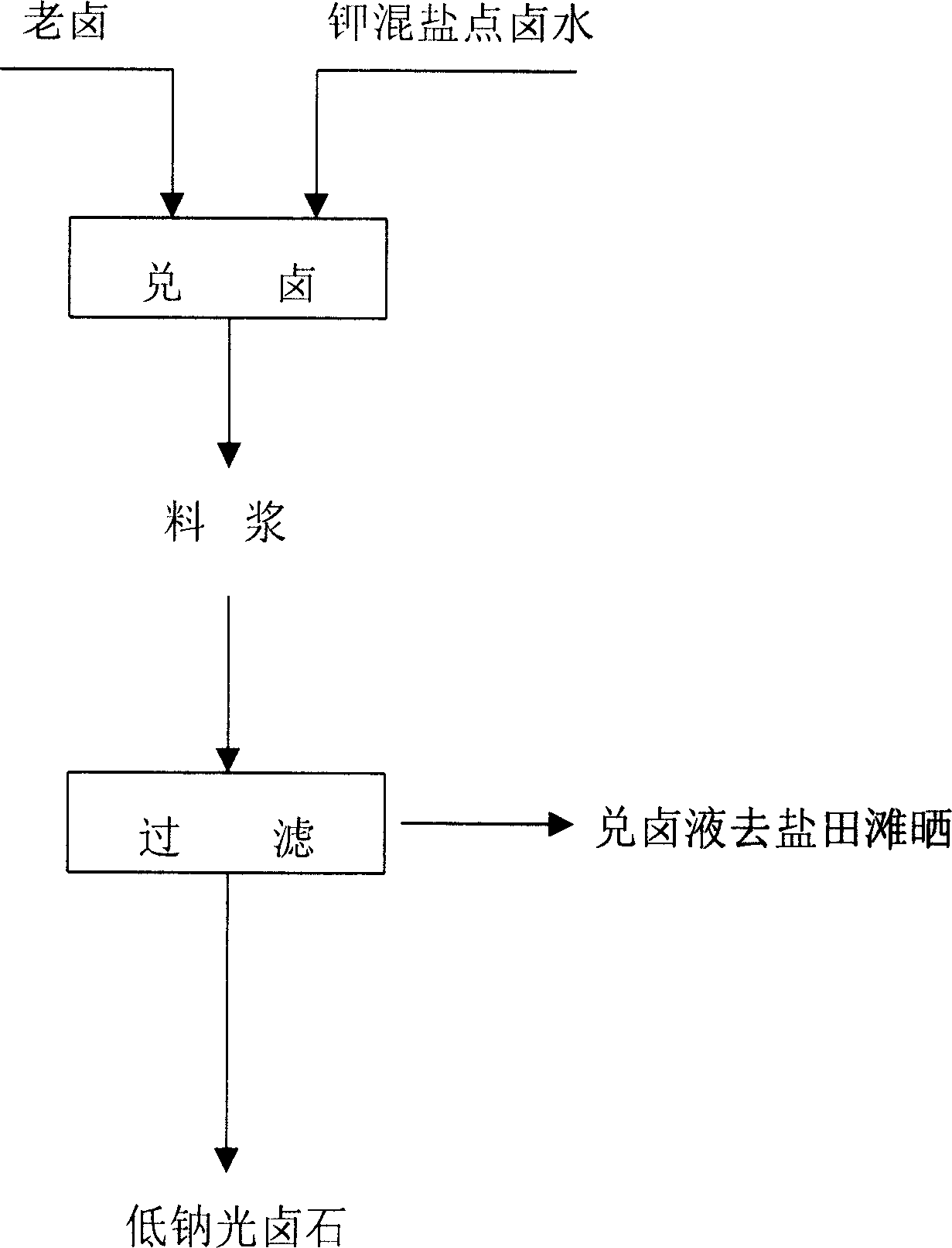

Halogen-blended process of preparing low-sodium carnallite

ActiveCN1608995ANo pollution in the processEasy to buildMagnesium chloridesAlkali metal chloridesHalogenEvaporation

The preparation process of low-sodium carnallite features that the subtype magnesium sulfate bittern as material is prepared into low-sodium carnallite through natural evaporation in saltern to separate out solid salt and to obtain bittern with Mg ion content not less than 7.0 %, subsequent blending with mixed potassium salt in the weight ratio of 1-3 to produce crystallization reaction, and filtering. The present invention has simple process and convenient operation, and the low-sodium carnallite product produced directly from bittern has sodium chloride content of 1.35 %, purity up to 98 % and no floatation chemical contained. The blending process has single time potassium ion recovering rate up to 66.50 %. The said technological process has no environmental pollution.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com