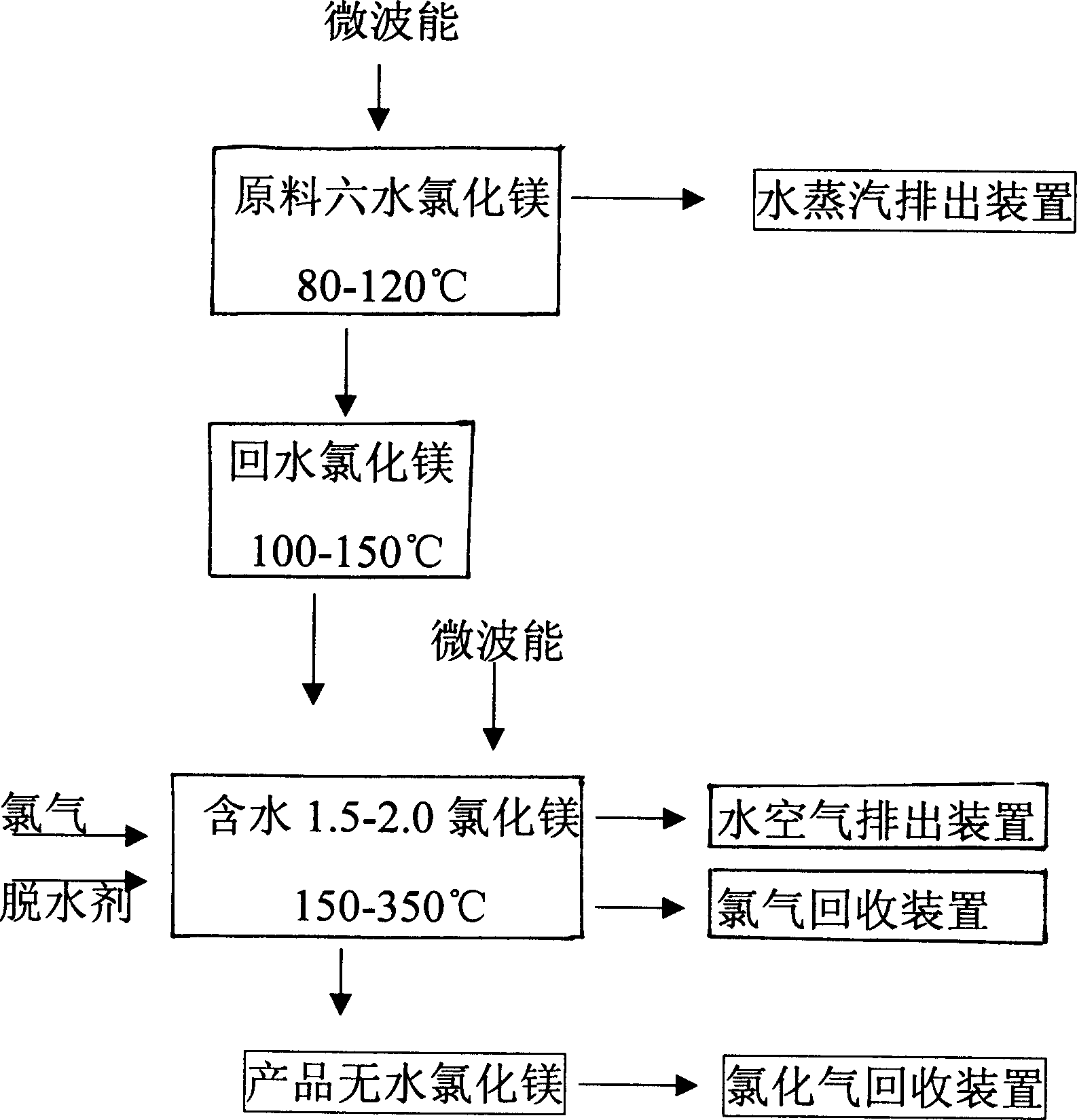

Process for producing anhydrous magnesium chloride by microwave energy

A technology of anhydrous magnesium chloride and magnesium chloride hexahydrate, which is applied in the direction of magnesium chloride, magnesium halide, etc., can solve the problems of uncontinuous production process, large relative material flow, and low recovery rate, and achieve simple processing, low tax water temperature, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Mix 200 grams of magnesium chloride hexahydrate MgCl 2 .6H 2 O is placed in a microwave heater, the container is opened and stirred, the temperature is controlled at 100°C, the exhaust machine is working, and after the two crystal waters are removed, magnesium chloride tetrahydrate MgCl is formed 2 .4H 2 O; then increase the temperature to 150°C to form magnesium chloride dihydrate MgCl 2 .2H 2 O, the process time is 5 minutes.

[0042] 2. Move magnesium chloride dihydrate into a closed microwave heater with an air inlet and outlet, add 5% dehydrating agent activated carbon of the material weight at this time, pass in chlorine gas covering the surface area of the material, and heat the temperature to 230°C after fully stirring. The time course is 5 minutes, obtains electrolytic anhydrous magnesium chloride, wherein magnesium oxide MgO2 O<0.3%.

Embodiment 2

[0044] 1. Put 500 grams of magnesium chloride hexahydrate into a microwave heater equipped with a scraper for stirring and conveying, heat to 100°C with microwaves, and the exhaust machine works at the same time, and the temperature is increased to 150°C. After 5 minutes, magnesium chloride dihydrate MgCl is obtained 2 .2H 2 O.

[0045] 2. Send magnesium chloride dihydrate to a tubular microwave heater with stirring, add 4.5% dehydrating agent charcoal and 20ml chlorine gas respectively at this time, heat to 240°C by microwave, and obtain electrolytic non-alcoholic acid after 10 minutes Magnesium chloride hydrate, the content of which is MgO2 O<0.2%.

Embodiment 3

[0047] 1. Put 500 grams of magnesium chloride hexahydrate into a semicircular microwave heater with stirring, and heat it to 100°C with microwaves. The exhaust machine works at the same time, and the temperature is increased to 150°C. After 5 minutes, magnesium chloride dihydrate is obtained.

[0048] 2. Magnesium chloride dihydrate is delivered to the tubular microwave heater with stirring, and 4.5% carbon and 20ml chlorine gas of the material weight are added respectively at this time, and anhydrous magnesium chloride is obtained after 10 minutes, and the magnesium oxide content2 O<0.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com