Pyrite cinder separation, recovery and recycling method

A pyrite slag, separation and recovery technology, applied in chemical instruments and methods, magnesium sulfate, iron oxide and other directions, can solve the problems of increasing the cost of waste residue separation, difficult to separate water-soluble salt mixture, and difficult separation and recovery of waste residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

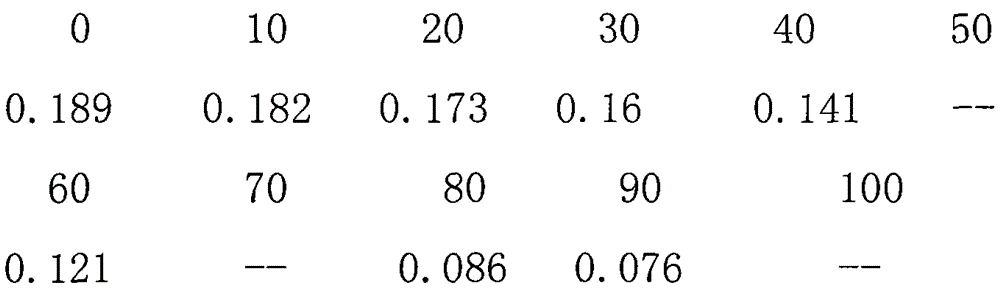

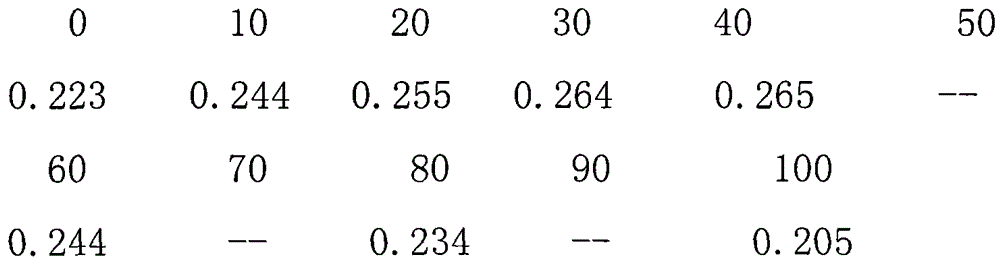

Image

Examples

Embodiment

[0110] 1. Soak pyrite slag, i.e. sulfuric acid slag, with sufficient water, and stir at a speed of 30-50 rpm for 1-2 hours to convert the alumina and calcium oxide in the sulfuric acid slag into hydrated Aluminum oxide, calcium hydroxide, and become suspension emulsion, stand still, make ferric oxide or / and ferrous oxide, magnesia, silicon dioxide, a small amount of aluminum oxide, sulfur (comprising elemental sulfur and iron disulfide FeS 2 ), apatite (calcium phosphate), magnesium phosphate, calcium sulfate and trace copper oxide, lead oxide, zinc oxide, cobalt oxide, gold and silver oxide and other trace metal elements or mixtures of their oxides are immediately precipitated and separated; at the same time Separation of hydrated alumina and calcium hydroxide suspension emulsion; in this step, the water is recycled, and the pyrite slag, namely sulfuric acid slag, is soaked in multiple cycles, and most of the hydrated alumina and all calcium hydroxide are separated by precipit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com