Patents

Literature

284results about How to "Reduce efficiency loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

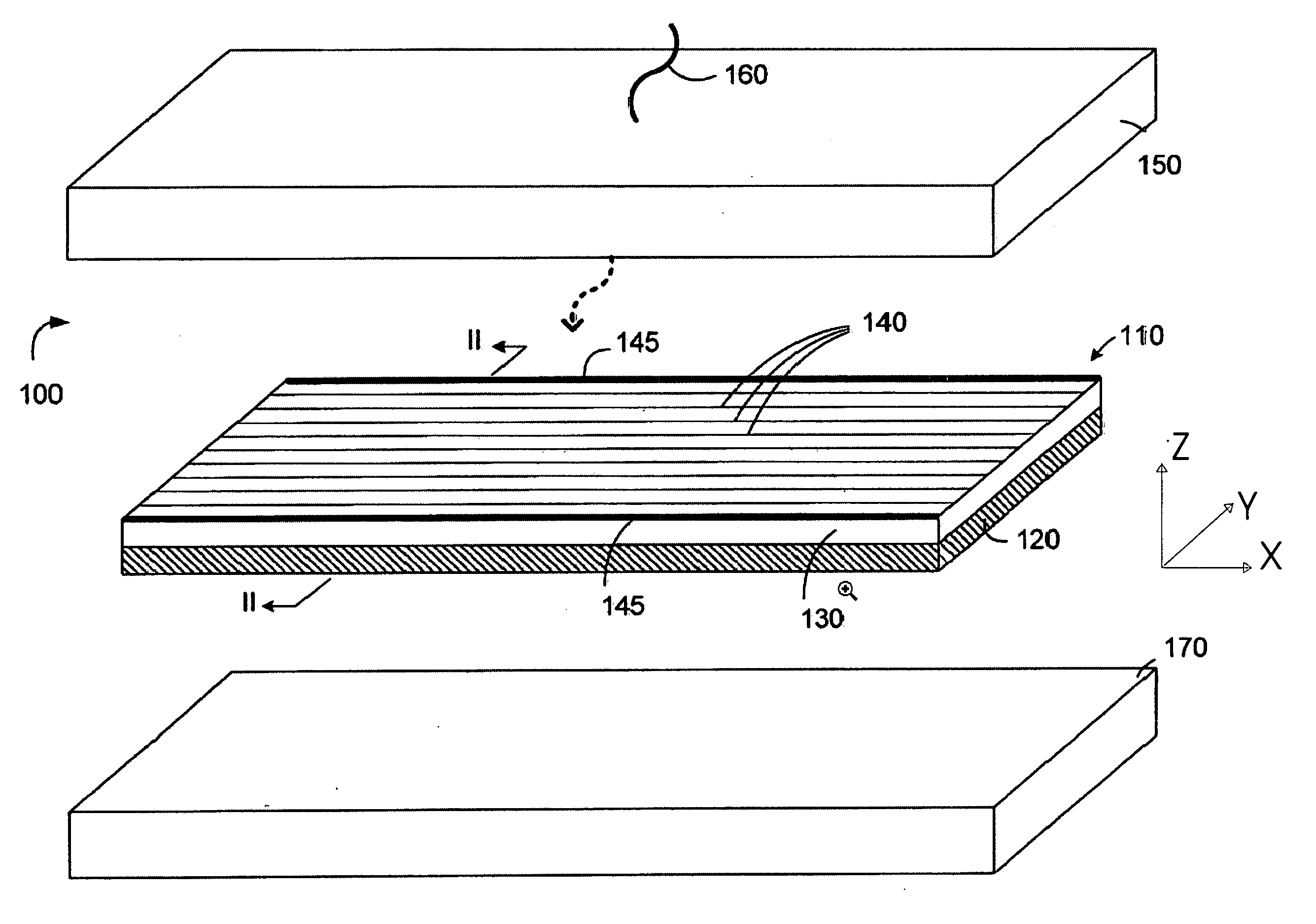

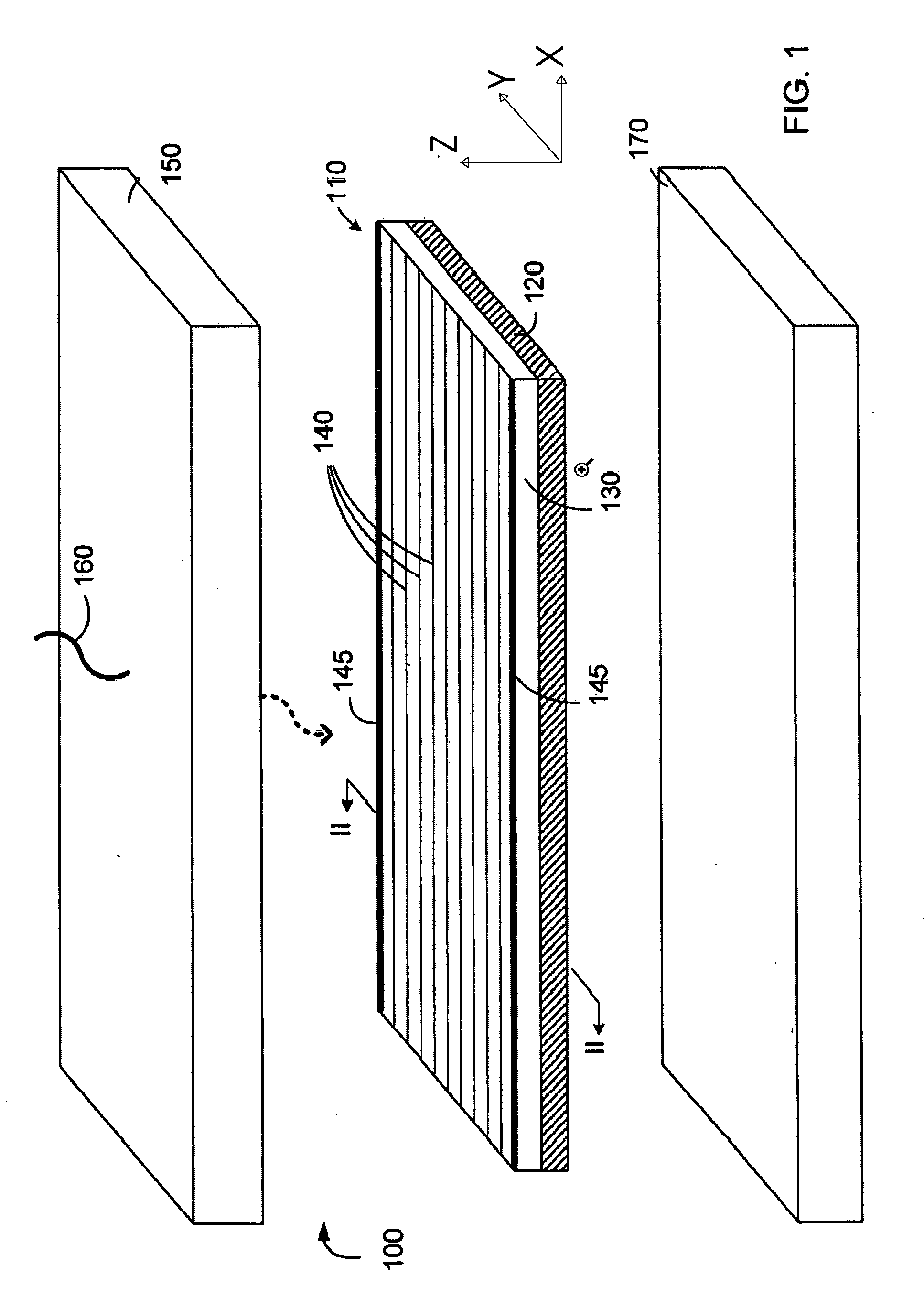

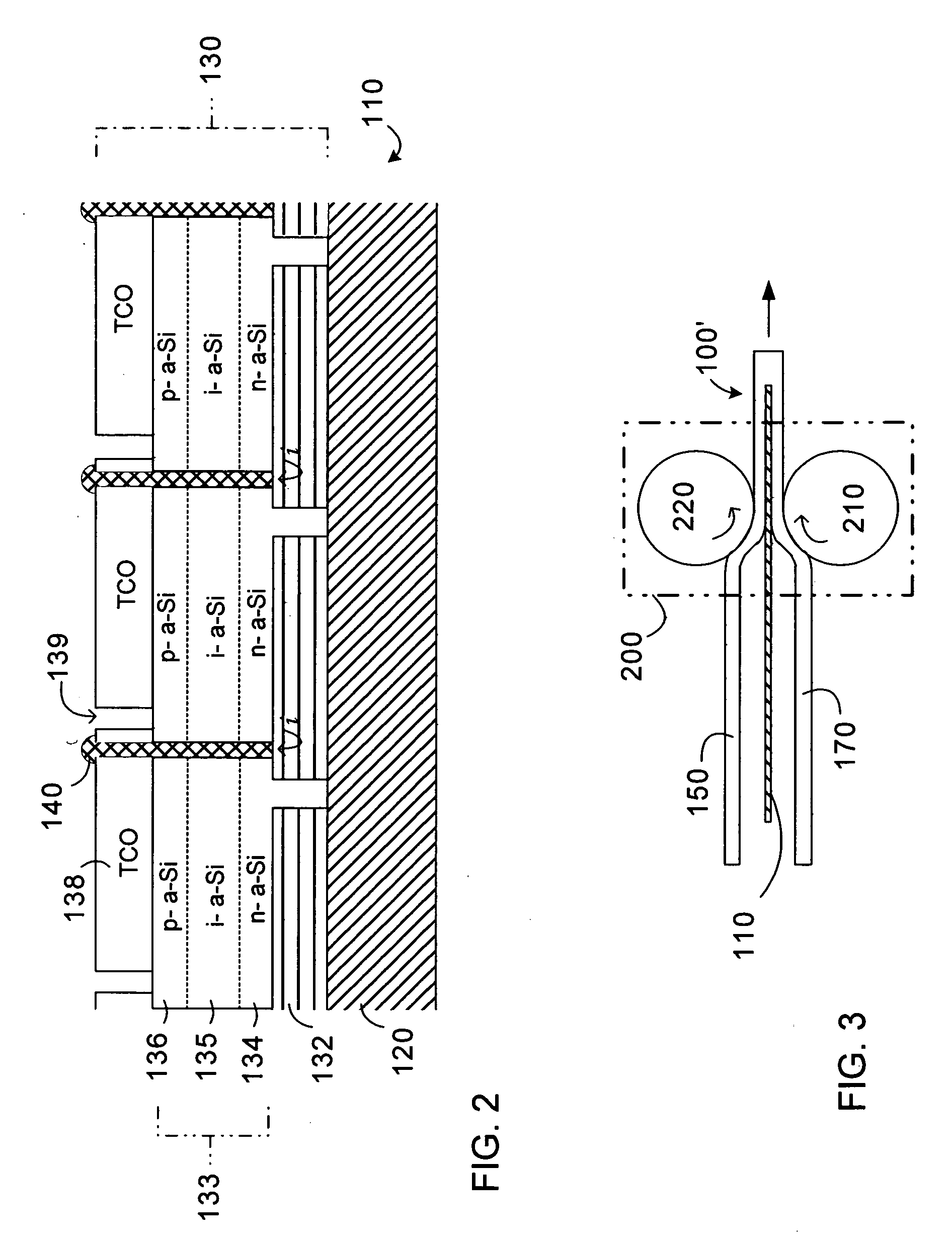

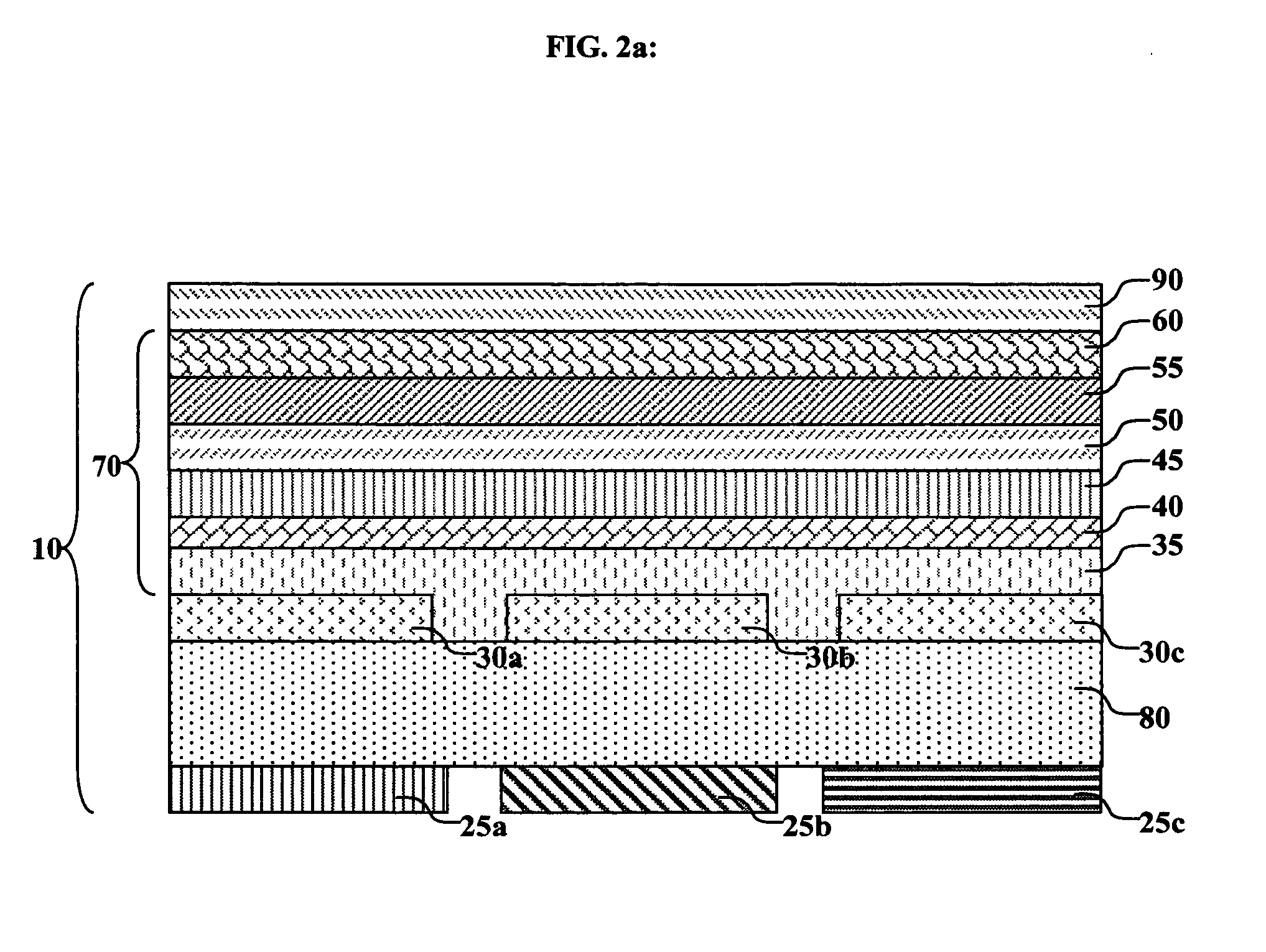

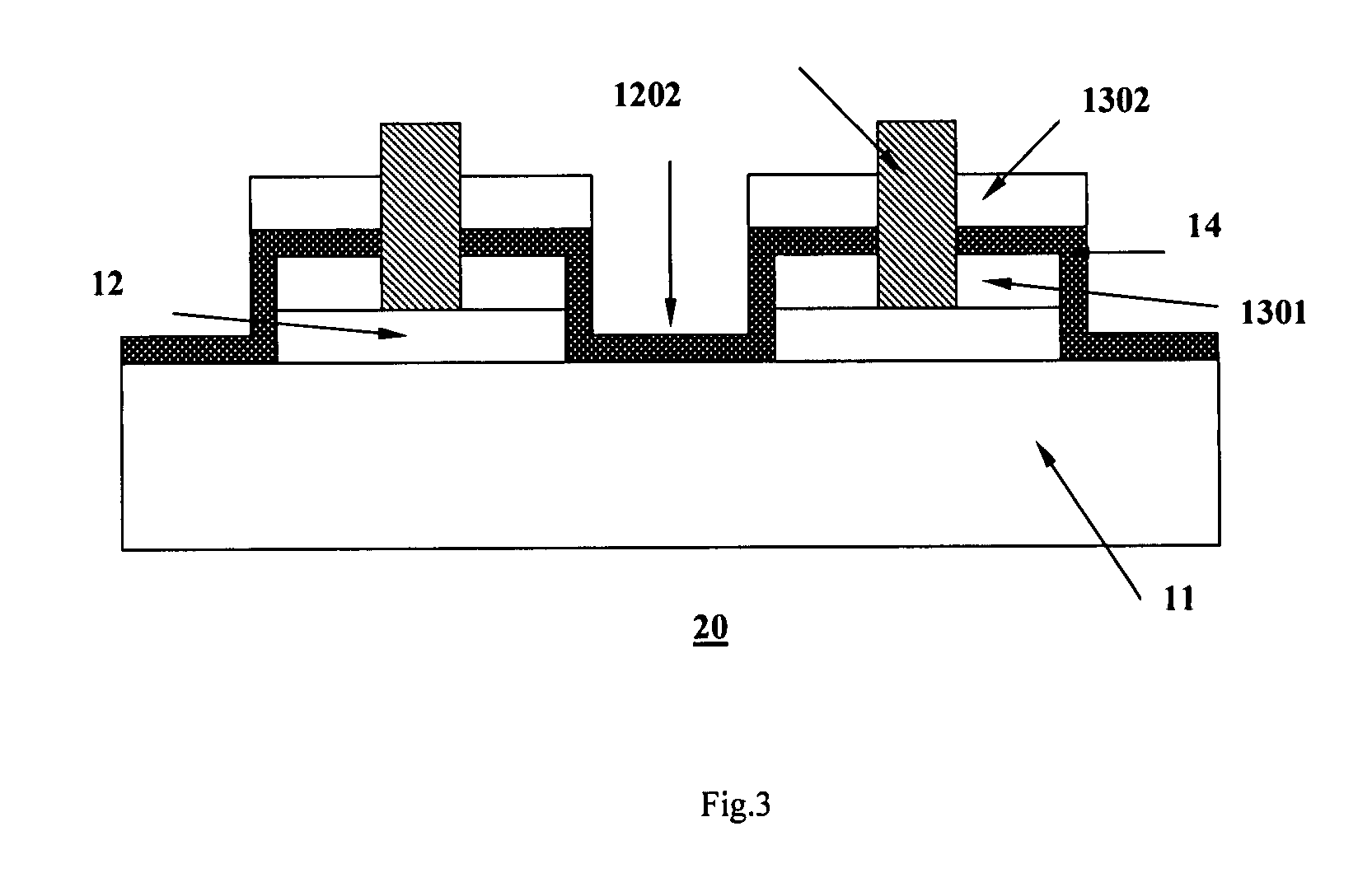

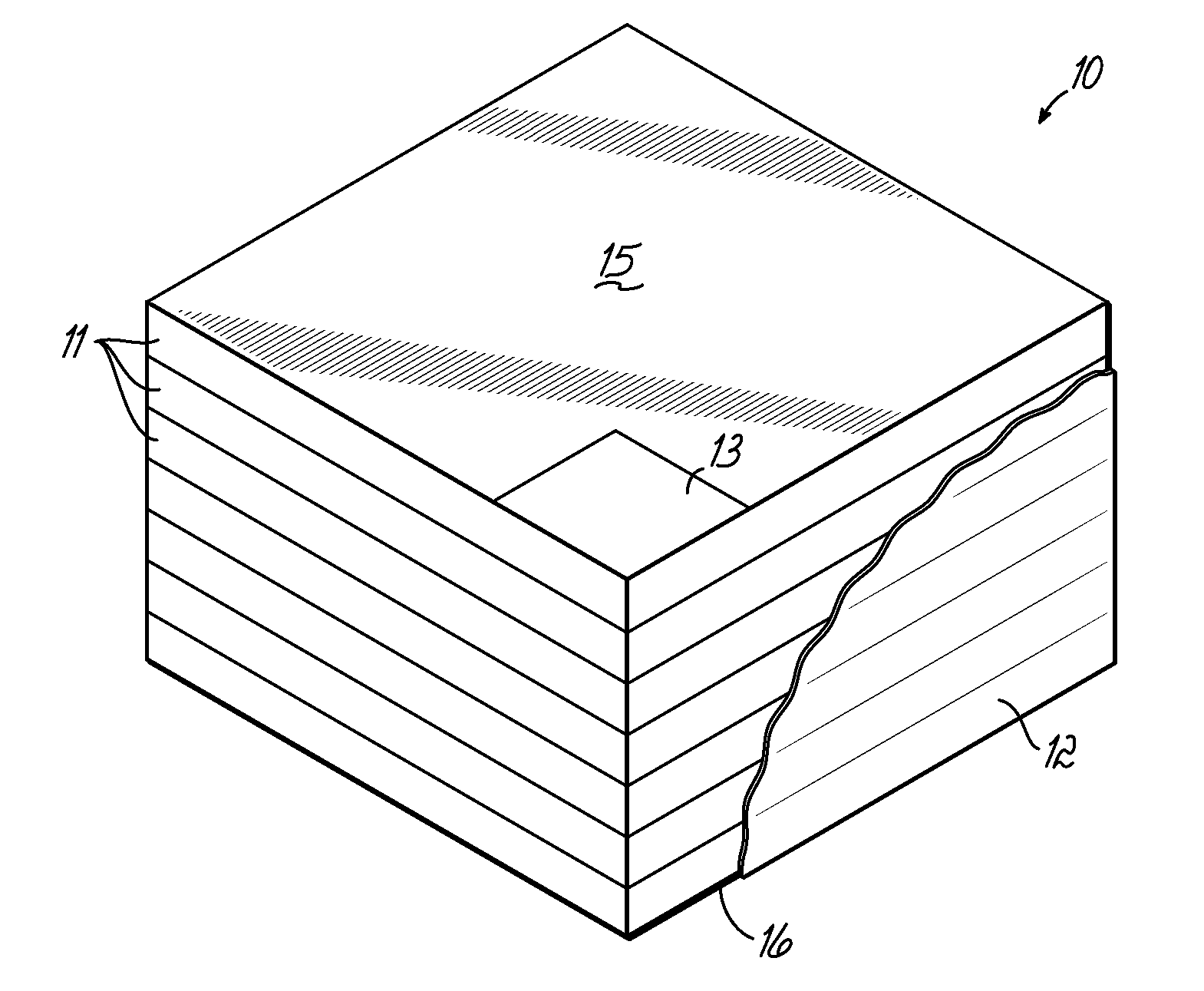

Electric energy generating modules with a two-dimensional profile and method of fabricating the same

InactiveUS20070012353A1Reduce efficiency lossImprove efficiencyPhotovoltaic supportsPV power plantsEngineeringRigid structure

An electric energy generating module is shaped to take on a desired two dimensional profile to match a non-flat surface or architectural element such as corrugated roofing. The module includes an electric energy generating film sealed between a top layer of encapsulant material and a bottom layer of encapsulant material. The type and quantity of the encapsulant materials are such that the shape of the encapsulant materials can be altered when a high temperature and / or pressure is applied to the module, but where the encapsulant materials provide a rigid structure around the electric energy generating film under ordinary (i.e., naturally occurring) temperature and pressure conditions. The module can therefore be shaped by applying a suitable pressure and / or a high temperature but, once placed under ordinary temperature and pressure conditions, the module has a rigid structure.

Owner:VHF TECH

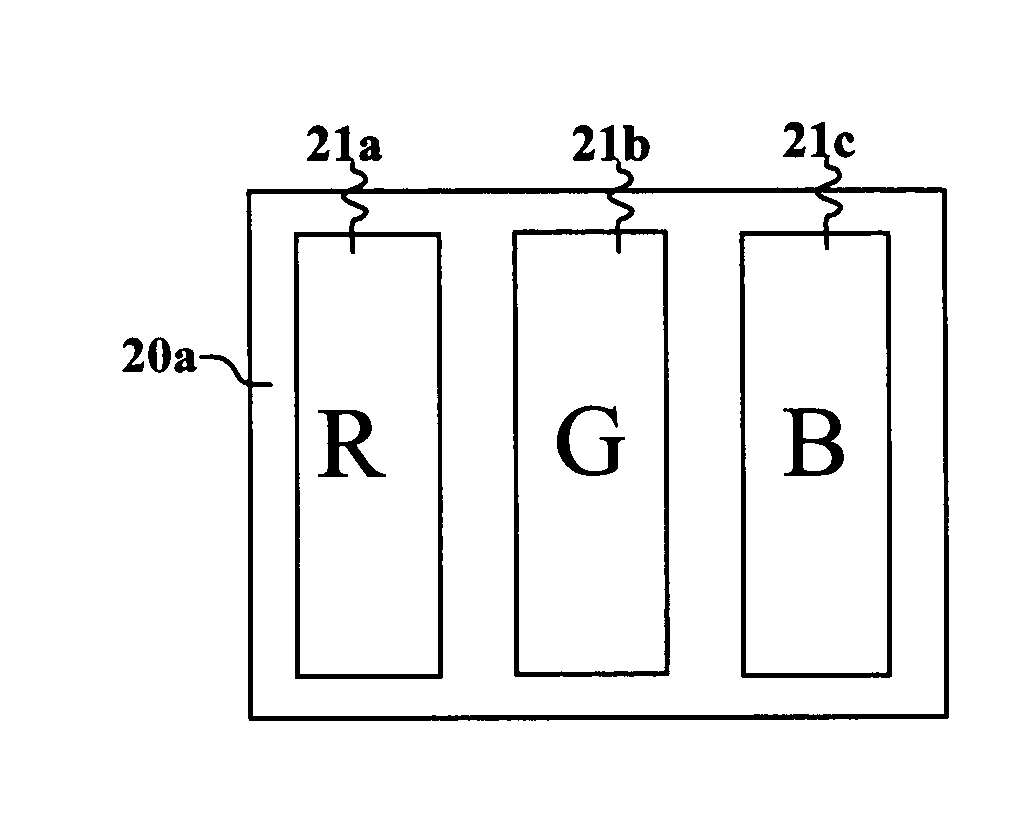

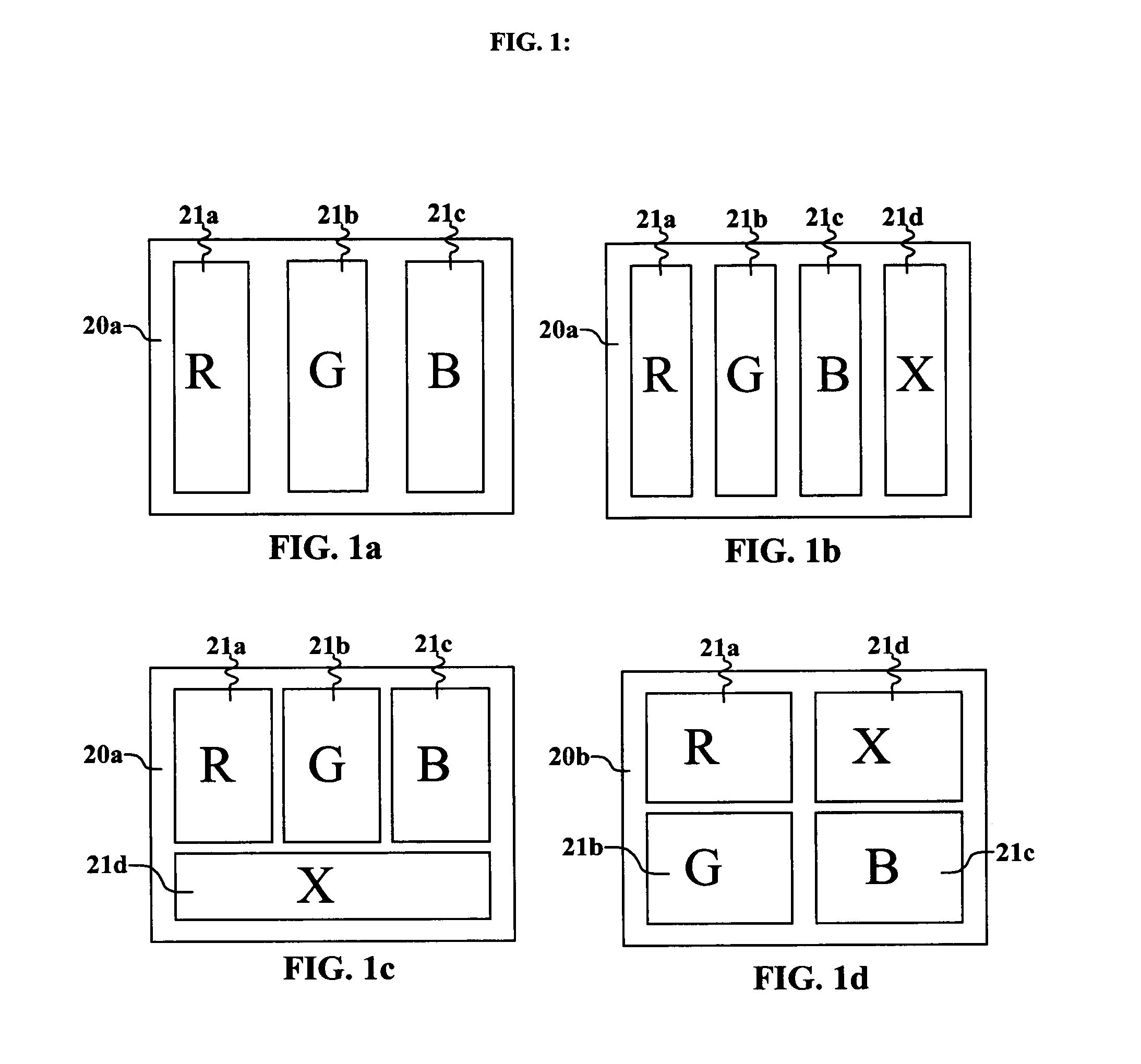

Display with RGB color filter element sets

ActiveUS20080112069A1Reduce efficiency lossWell color gamutOptical filtersSolid-state devicesPhysicsTransmittance

An electronic display containing a light source and a color filter set, the color filter set comprising: a green color filter having a green filter layer comprising a first pigment having its maximum absorption at a wavelength from 600 to 700 nm wherein at least 90 volume percent of the first pigment particles have a particle size less than 300 nm, and a second pigment having its maximum absorption at a wavelength from 400 to 500 nm wherein at least 90 volume percent of the second pigment particles have a particle size less than 300 nm, and wherein the green filter layer has a transmittance of 60% or more at a wavelength of 520 nm and of no more than 10% at a wavelength of 480 nm and of no more than 10% at a wavelength of 590 nm; a blue color filter having a blue filter layer; a red color filter having a red filter layer; and wherein the color gamut defined by the electronic display has a % NTSCx,y ratio greater than 88%.

Owner:GLOBAL OLED TECH

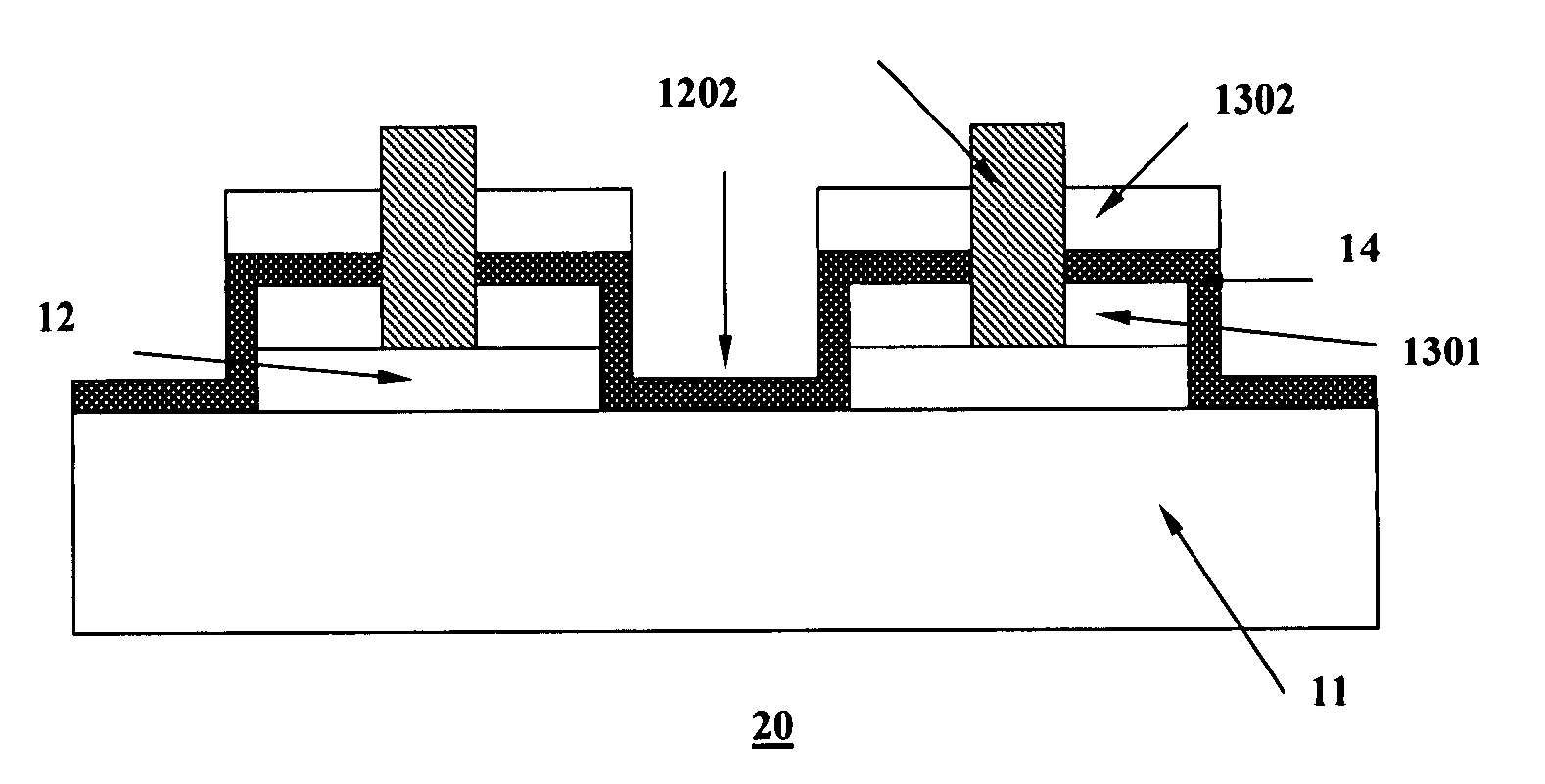

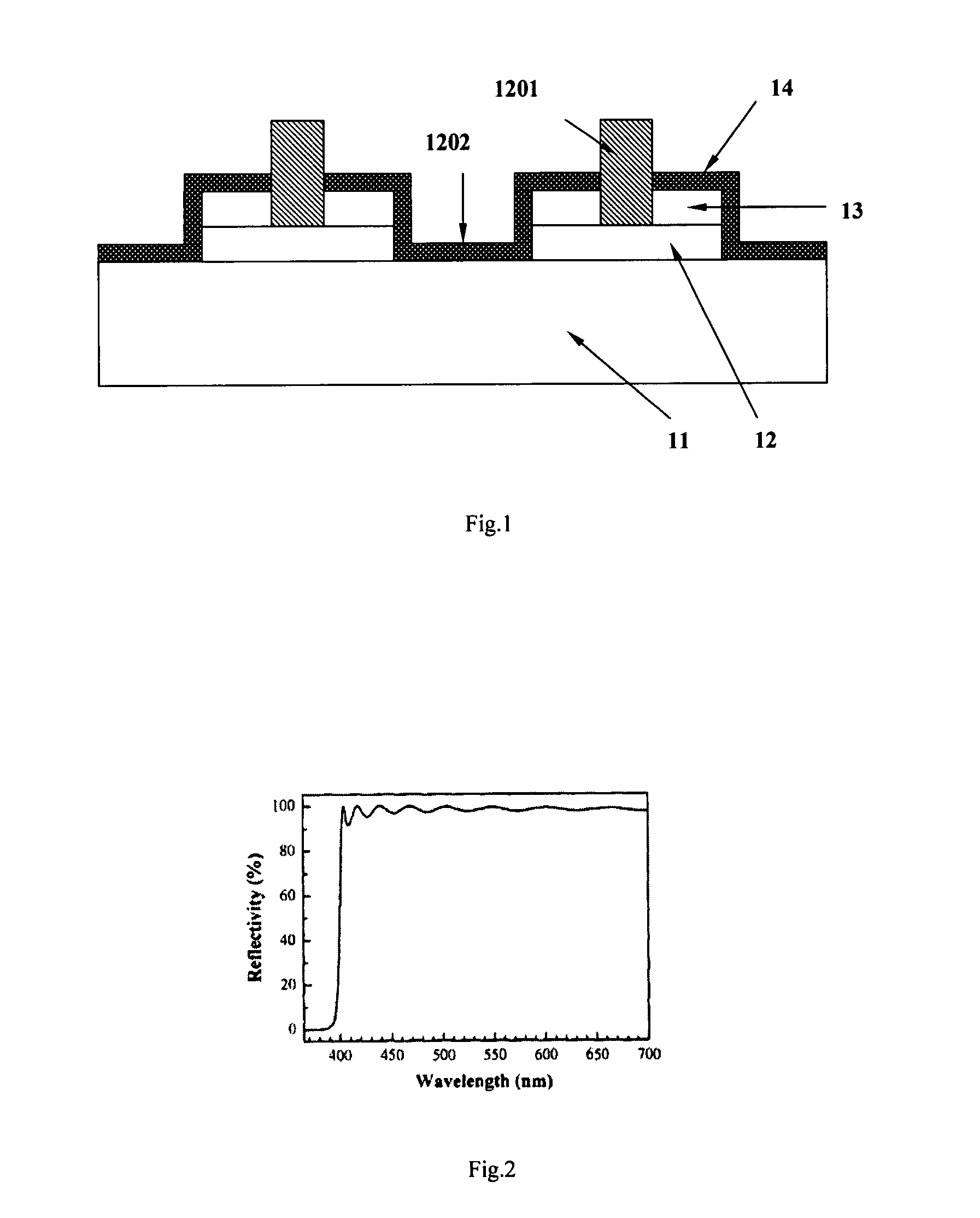

High efficient phosphor-converted light emitting diode

ActiveUS20080006815A1Improve overall light luminescence efficiencyAvoid disadvantagesSemiconductor/solid-state device manufacturingSemiconductor devicesPhosphorLight emitting device

A light-emitting device and manufacturing method thereof are disclosed. The light-emitting device includes a substrate, a semiconductor light-emitting structure, a filter layer, and a fluorescent conversion layer. The method comprises forming a semiconductor light-emitting structure over a substrate, forming a filter layer over the semiconductor light-emitting structure, and forming a fluorescent conversion layer over the filter layer.

Owner:EPISTAR CORP

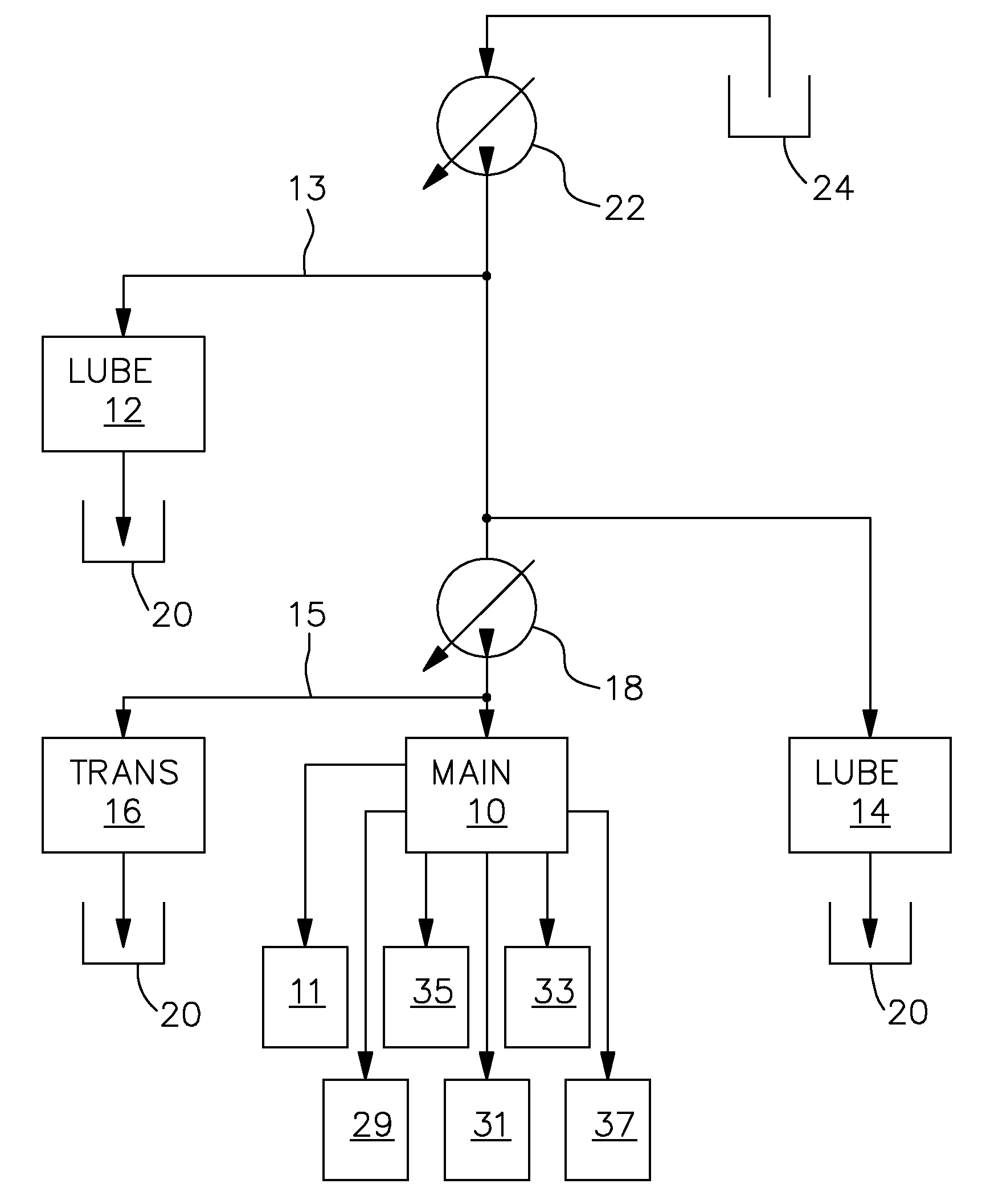

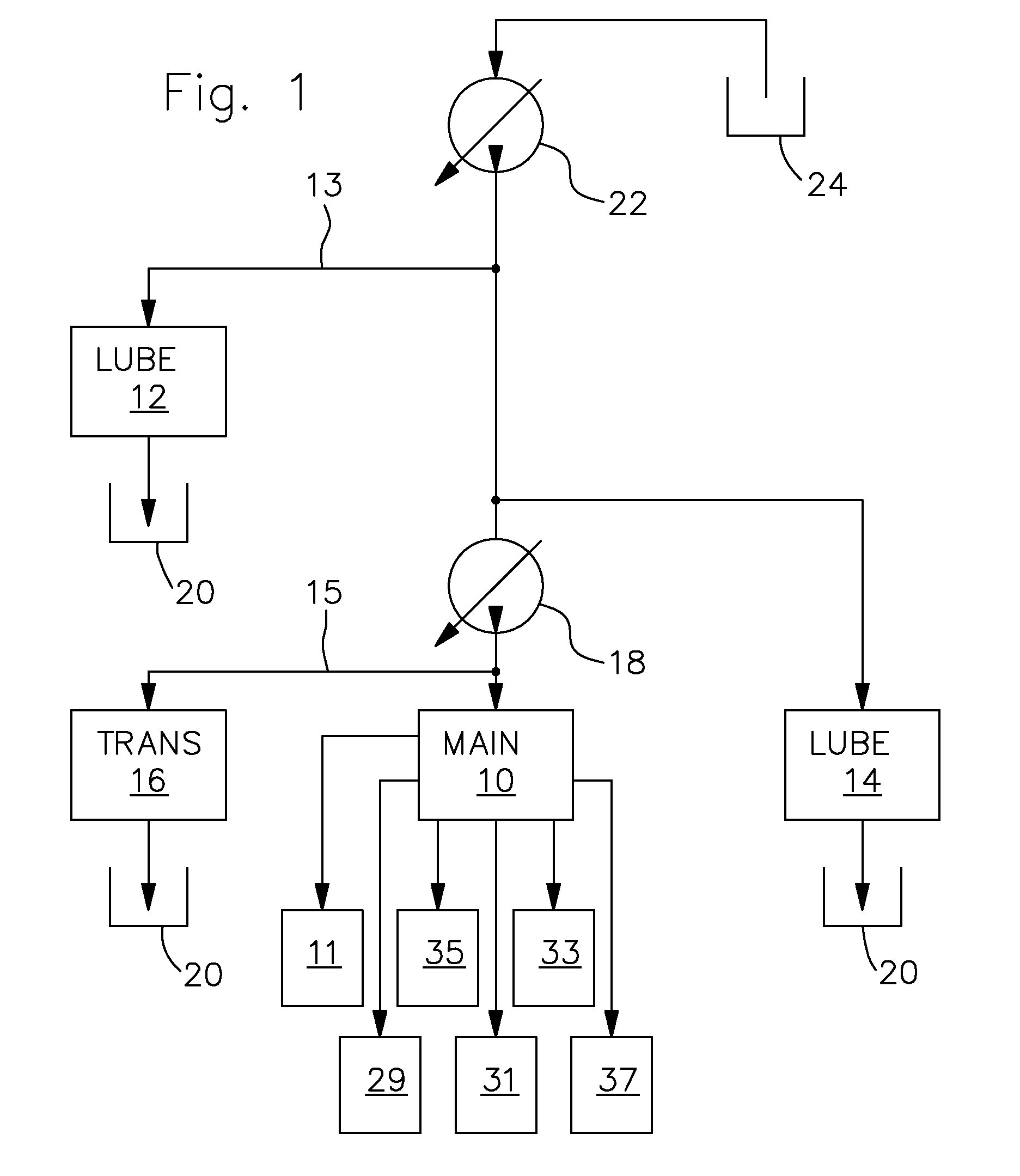

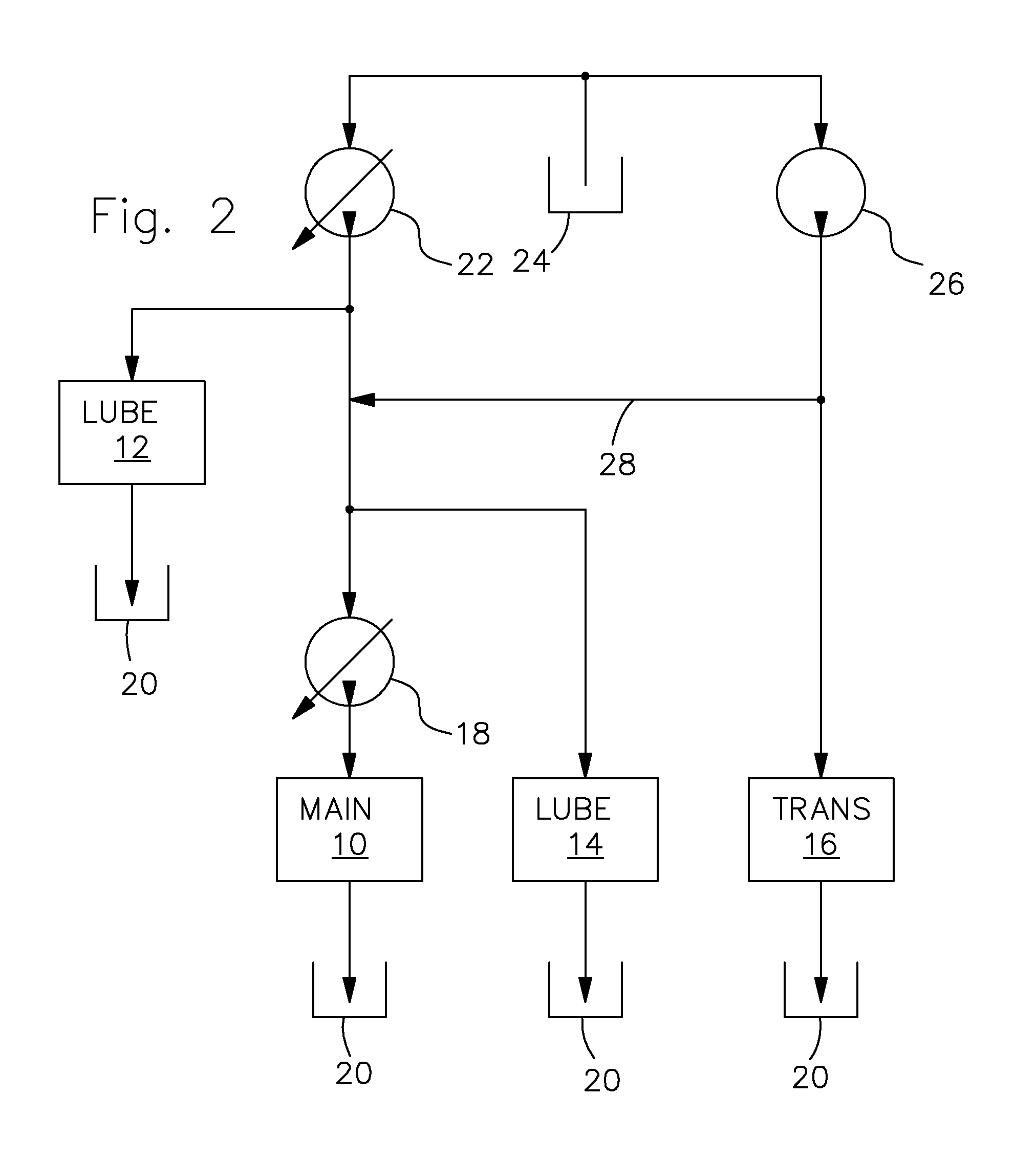

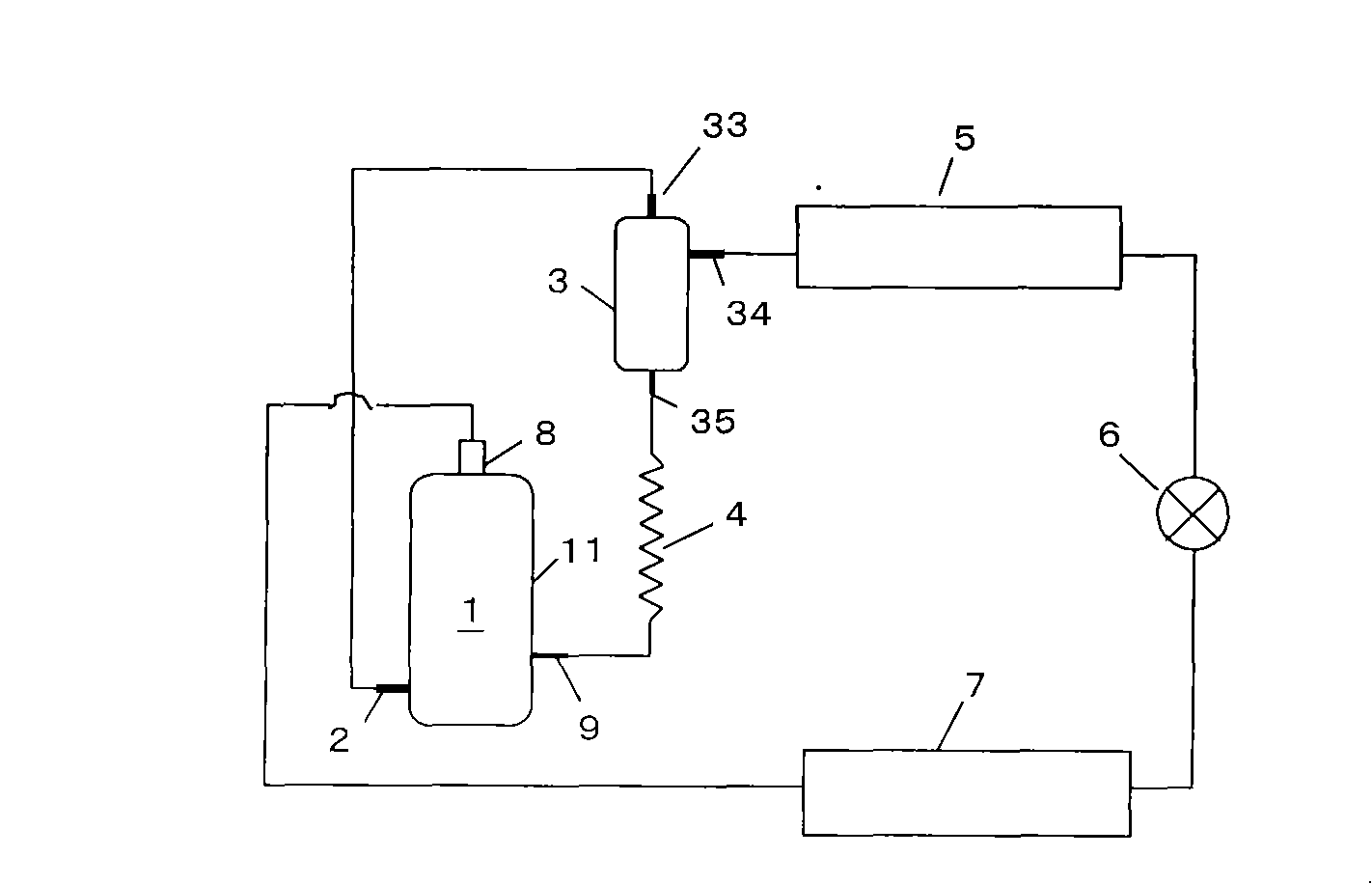

Hydraulic system

ActiveUS20090158727A1Advantage in of complexityDevelopment complexityFluid couplingsGearing controlHydraulic circuitHydraulic pump

A hydraulic system for an agricultural vehicle is proposed. The hydraulic system comprises a main hydraulic circuit, which is fed with hydraulic fluid by a main hydraulic pump, a variable displacement charge pump which supplies charge pressure to the main hydraulic pump, and a lubricating hydraulic circuits. In order to keep efficiency losses on the vehicle to a minimum, particularly at high engine speeds, part of the hydraulic fluid delivered by the charge pump can be diverted to the lubricating hydraulic circuit.

Owner:DEERE & CO

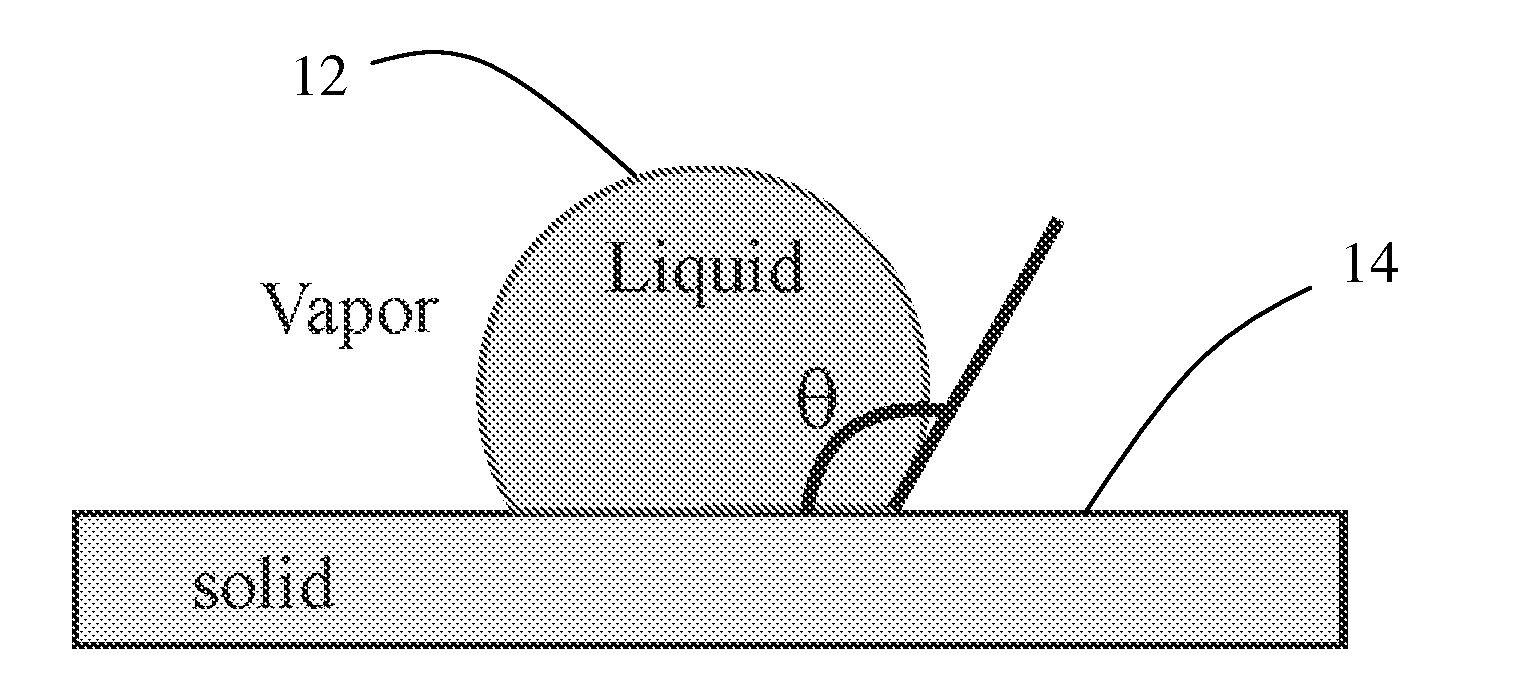

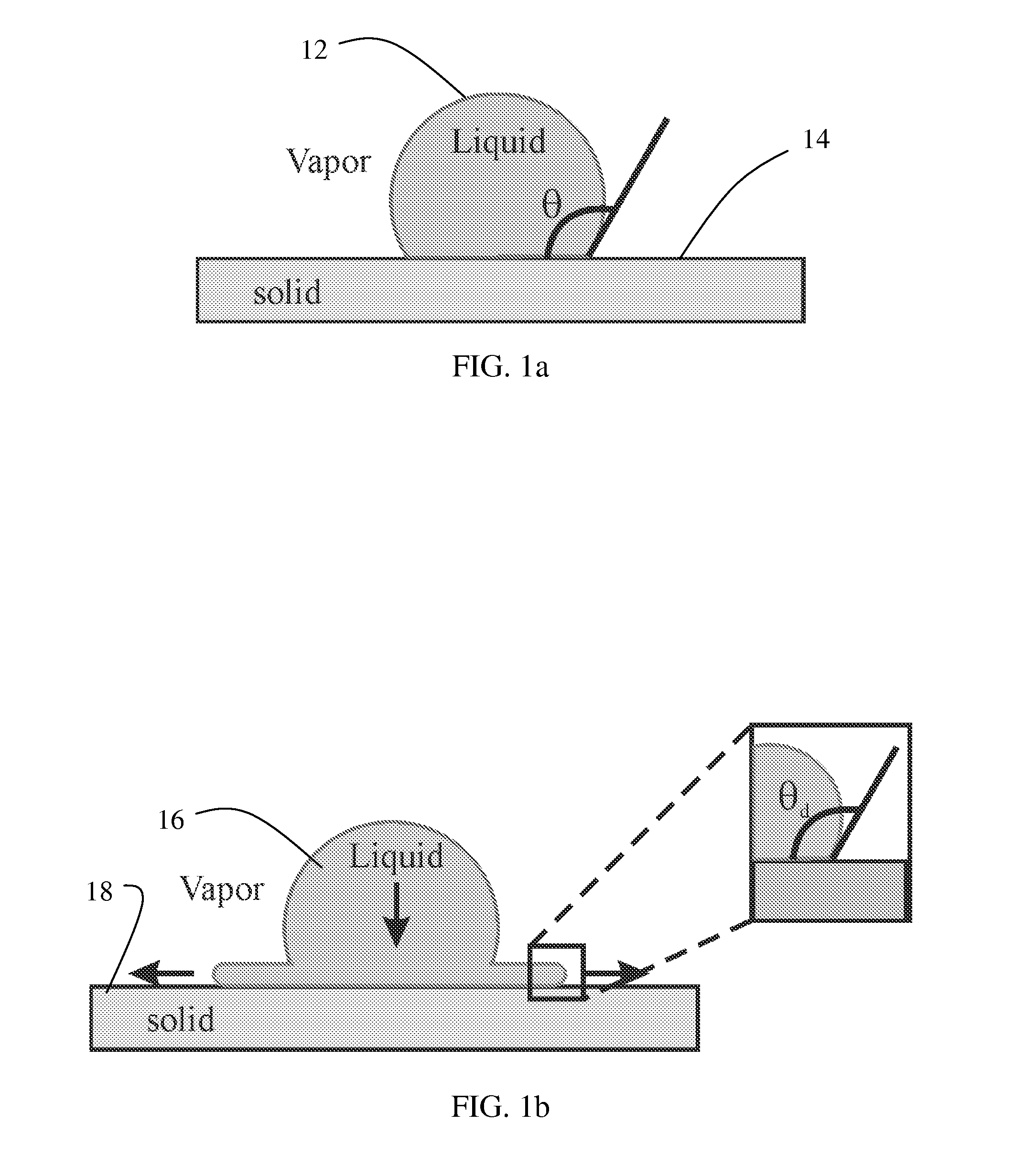

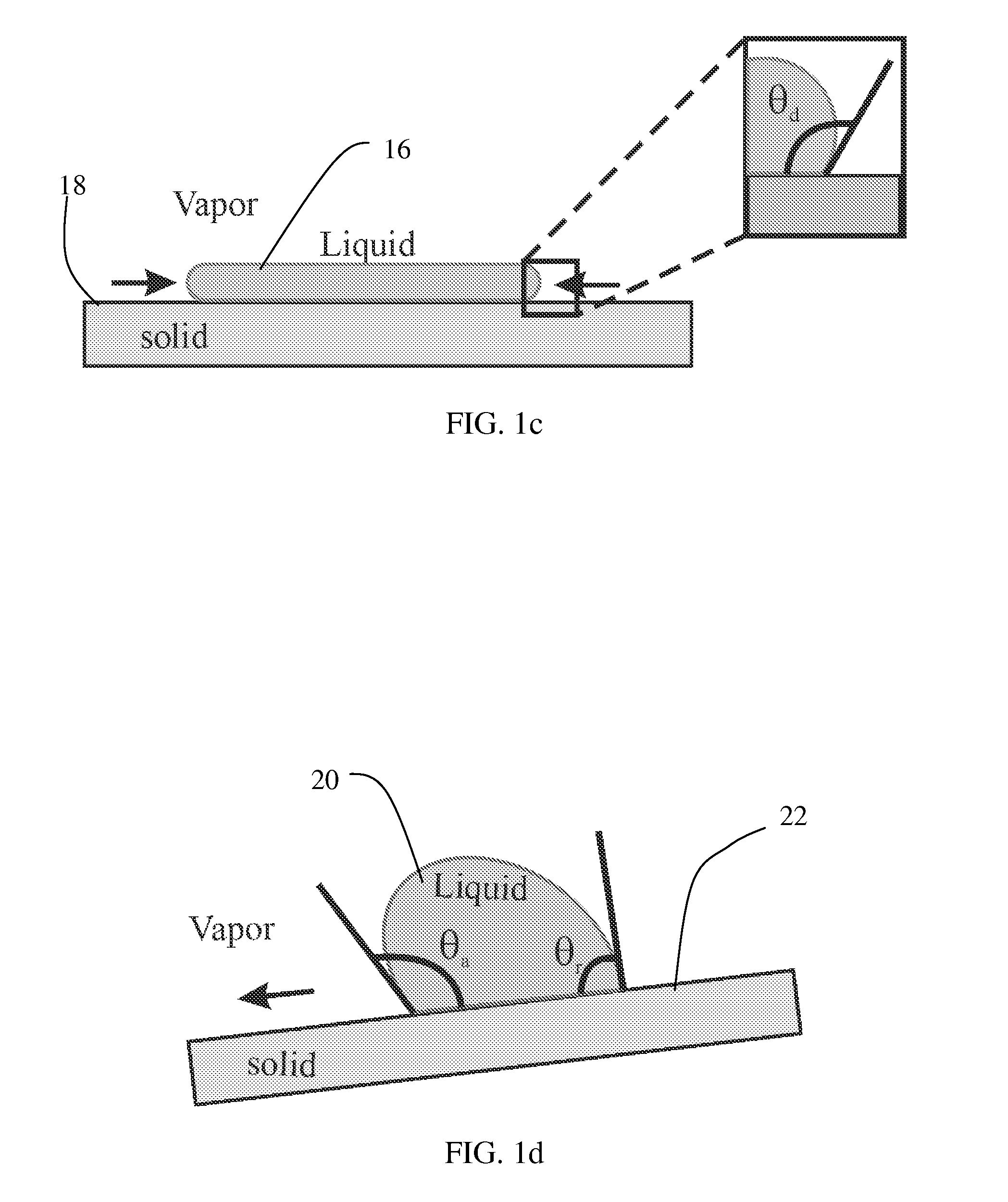

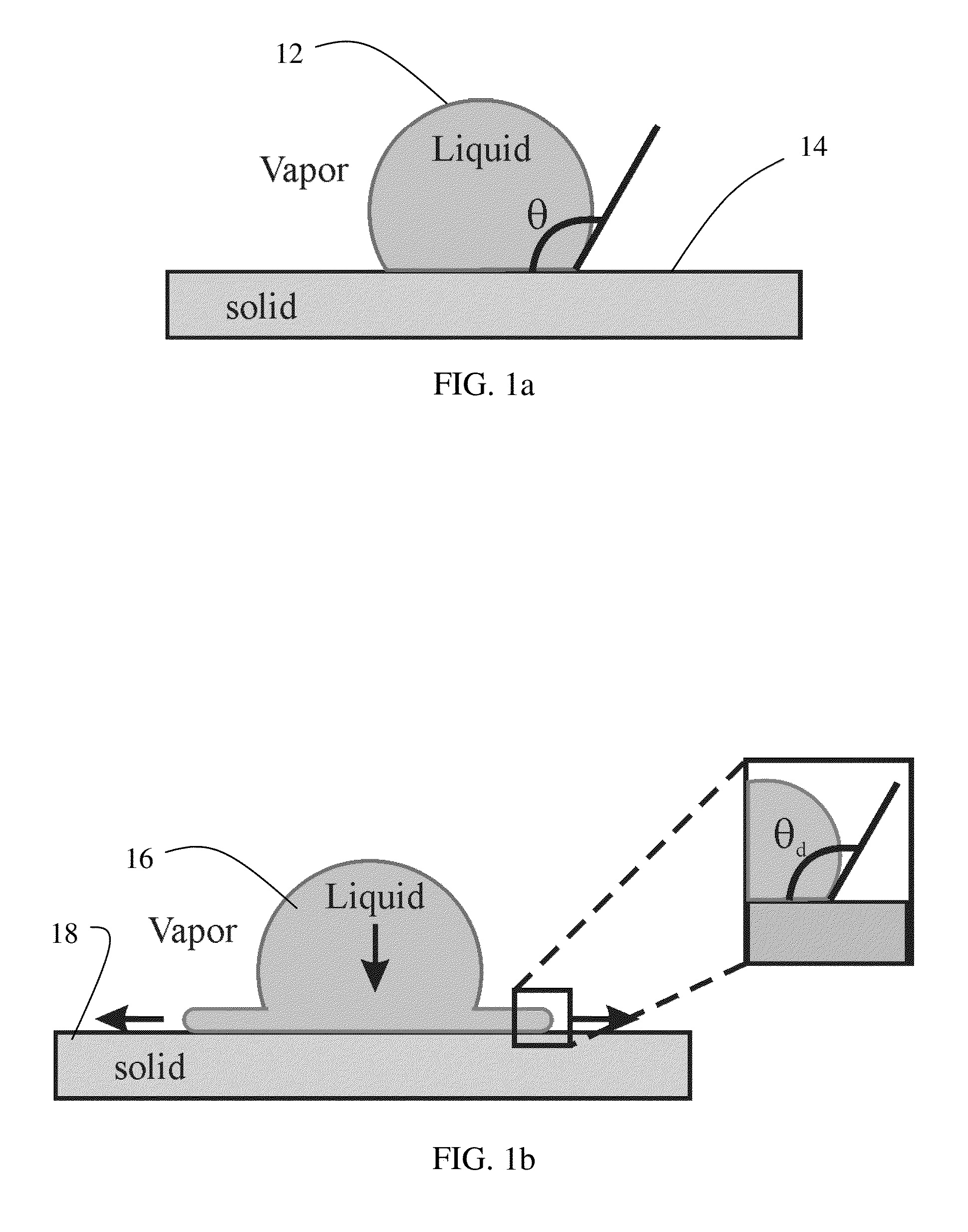

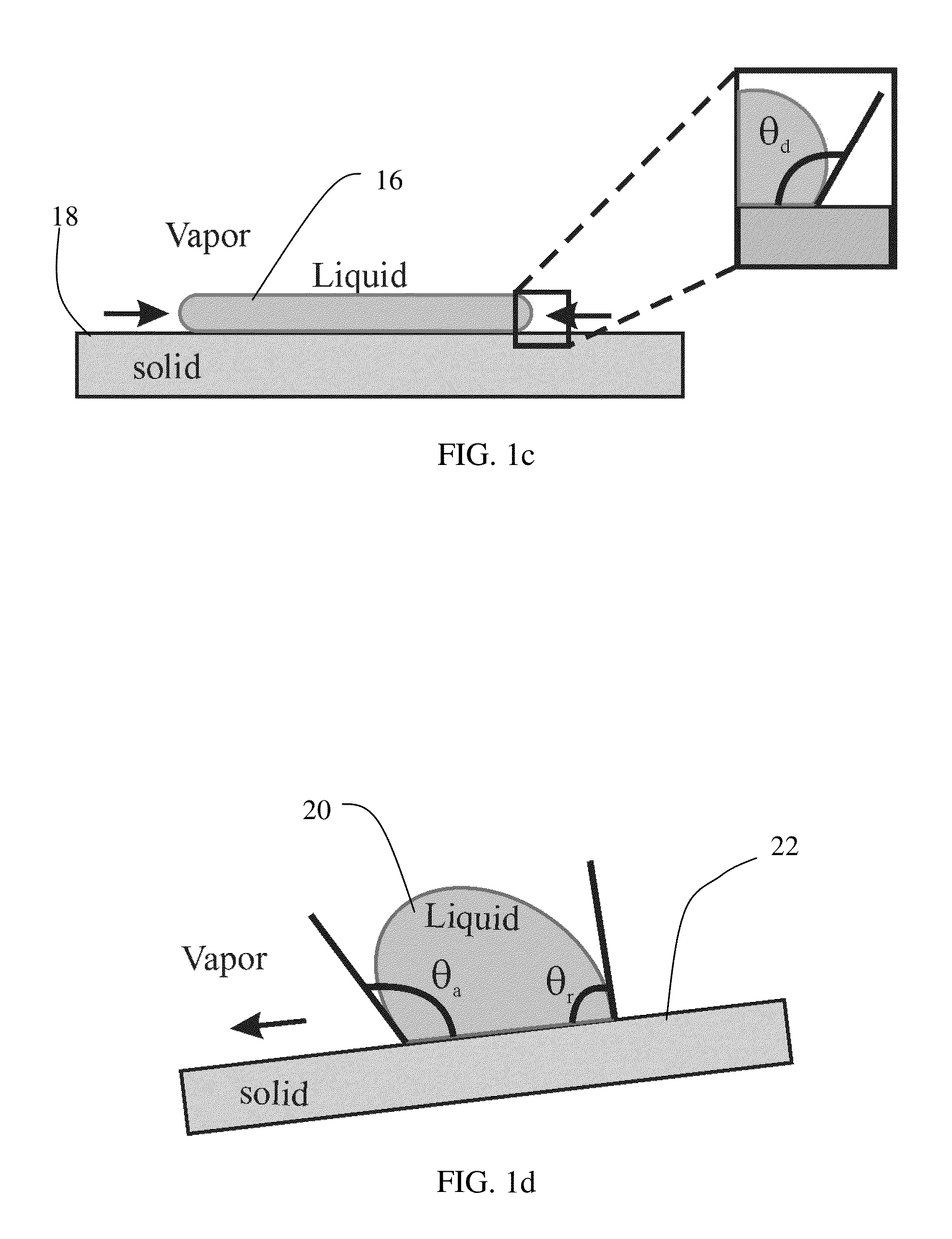

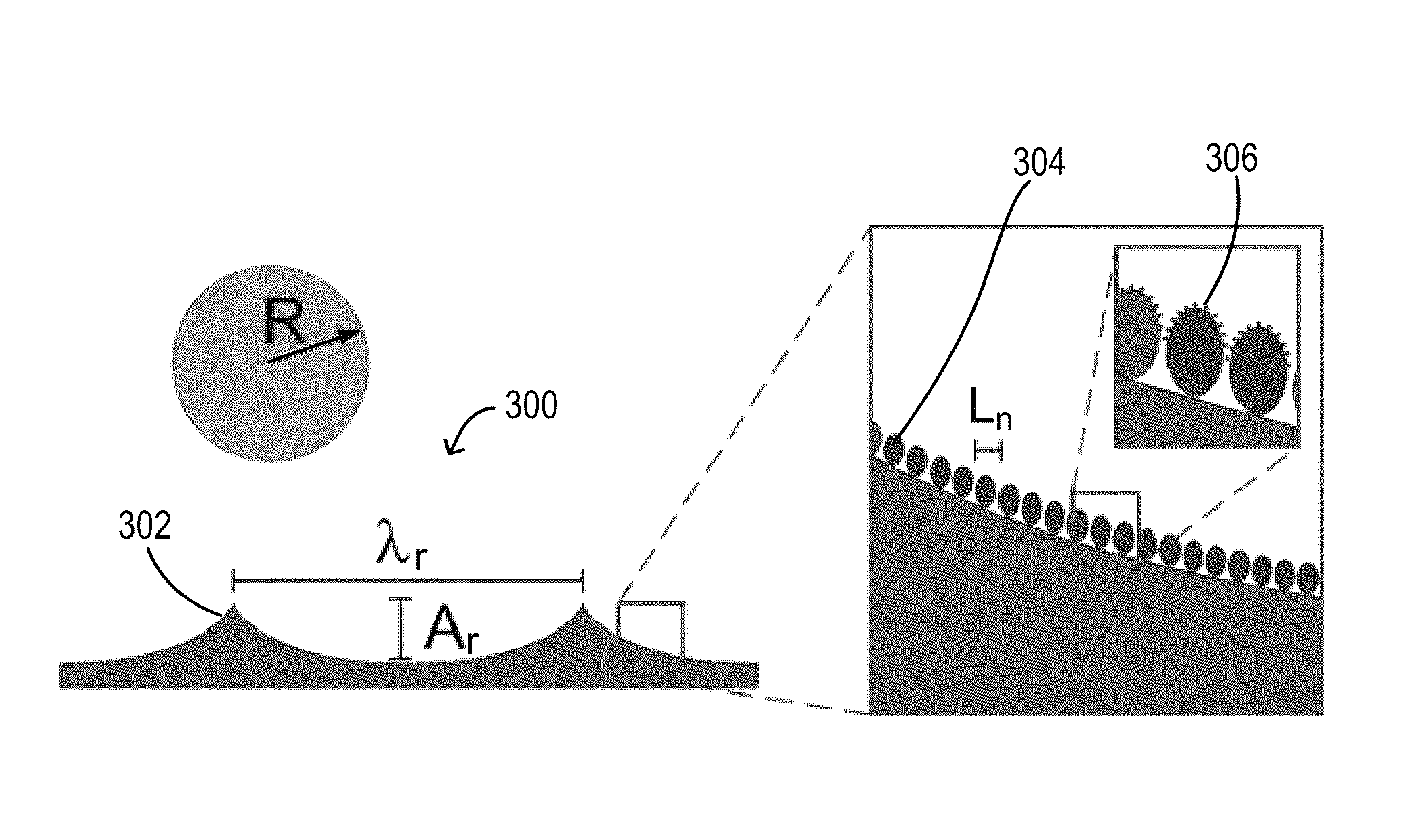

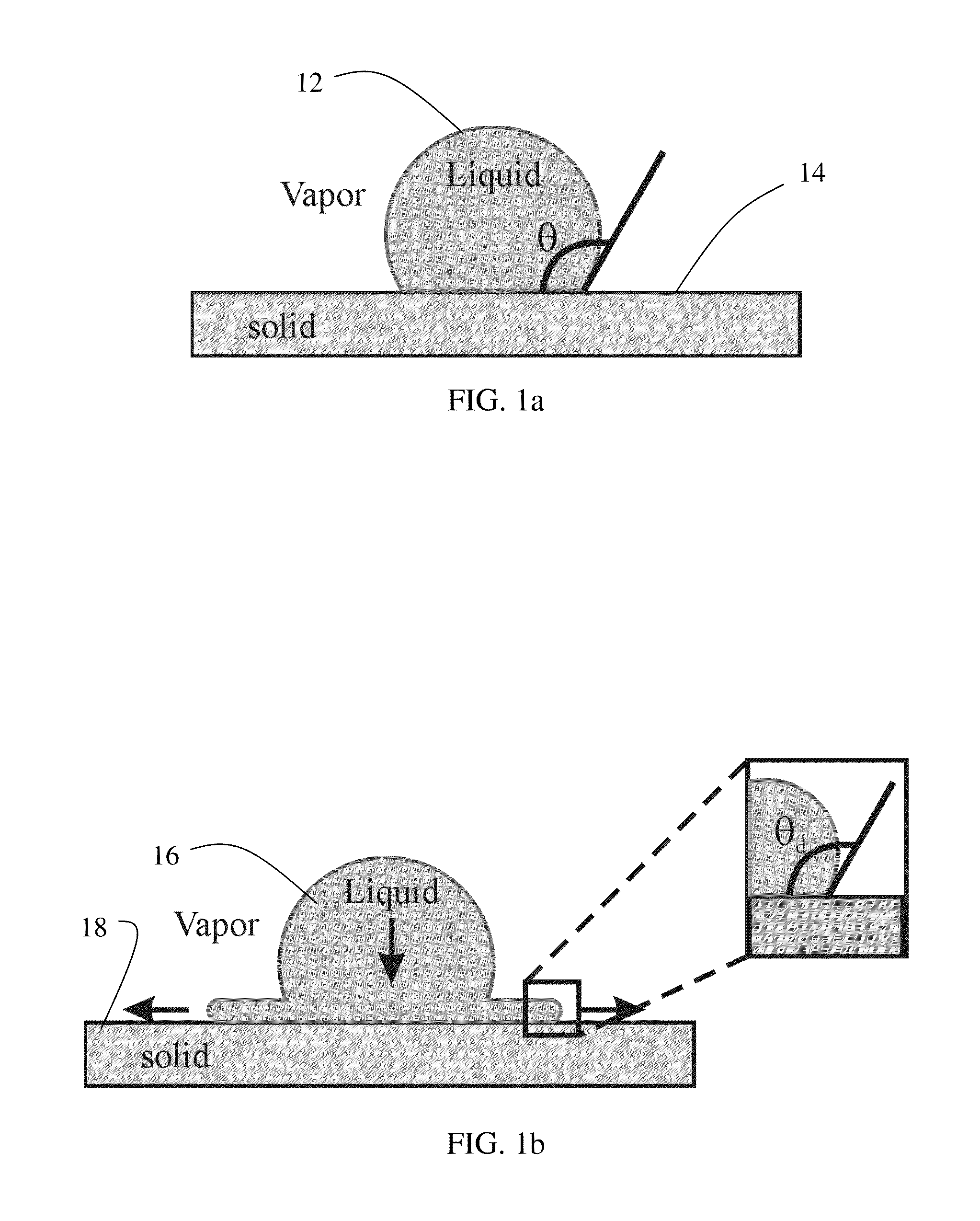

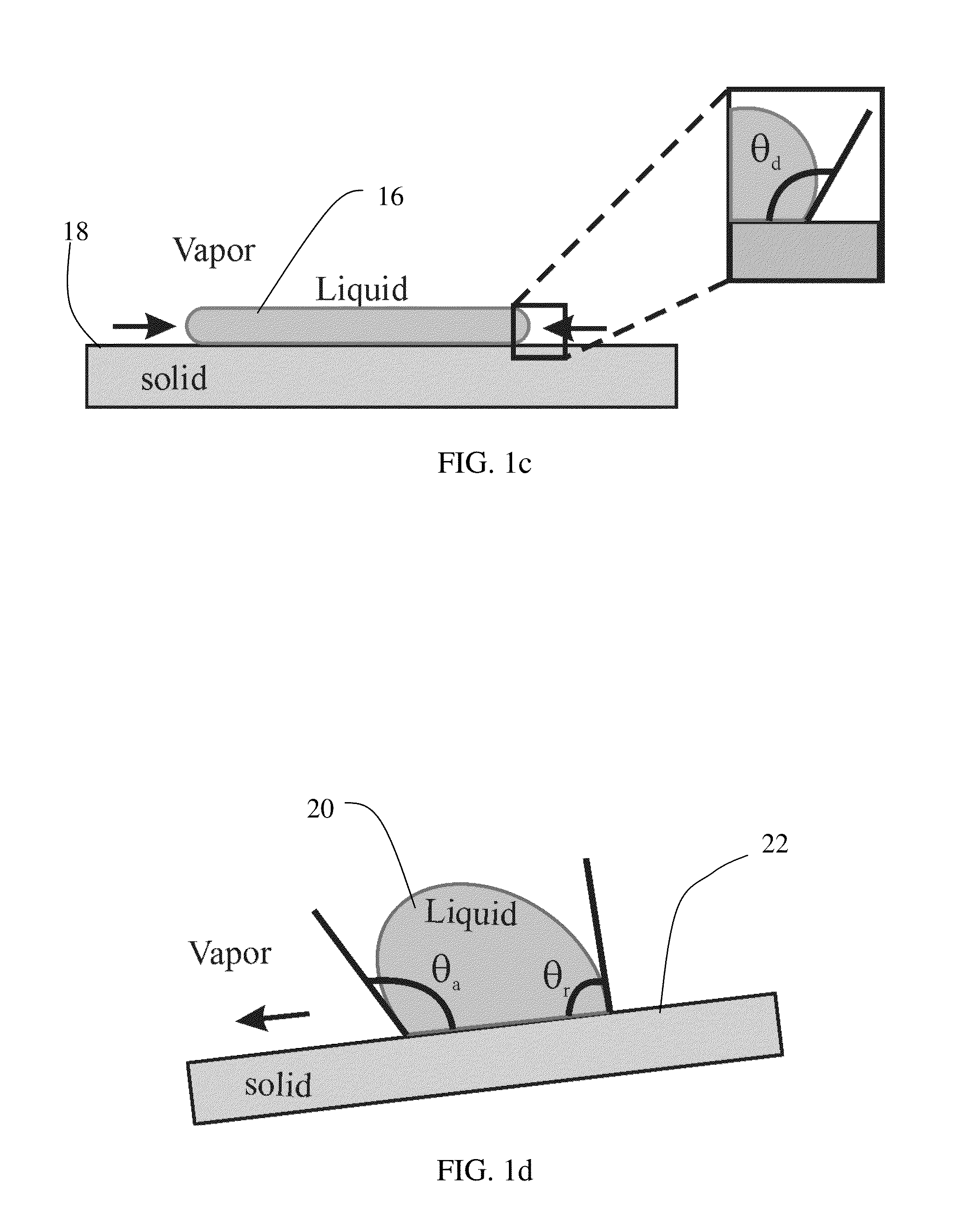

Articles for manipulating impinging liquids and methods of manufacturing same

ActiveUS20130032646A1Improve performanceMore practicalMaterial nanotechnologyLayered productsNon wettingMacroscopic scale

This invention relates generally to an article that includes a non-wetting surface having a dynamic contact angle of at least about 90°. The surface is patterned with macro-scale features configured to induce controlled asymmetry in a liquid film produced by impingement of a droplet onto the surface, thereby reducing time of contact between the droplet and the surface.

Owner:MASSACHUSETTS INST OF TECH

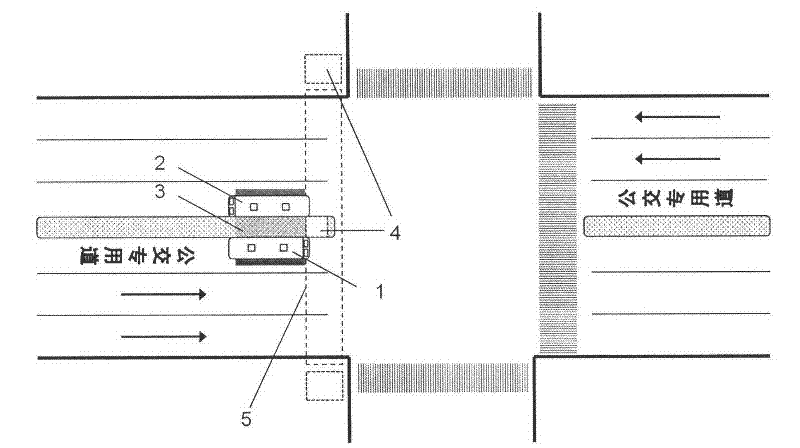

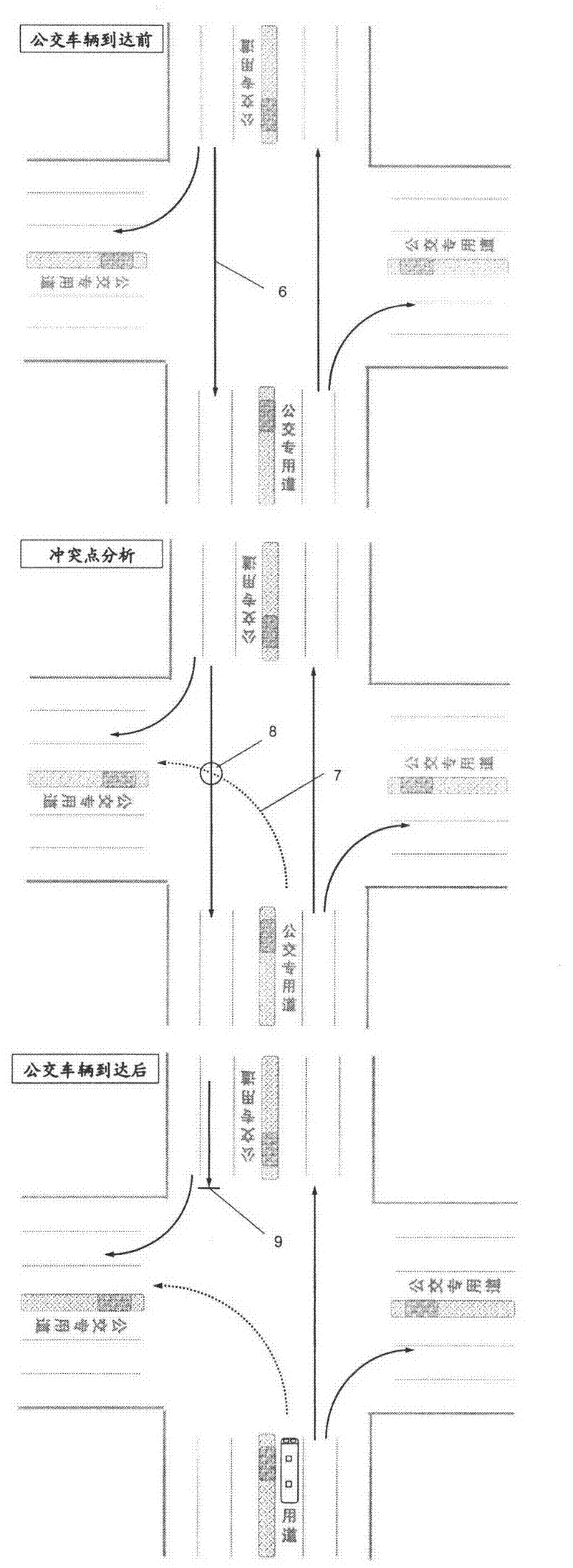

Cooperative control method of left-opened-door bus special phase setting and social traffic flow

InactiveCN102542817AReduce efficiency lossEasy to identifyControlling traffic signalsTransit networkTraffic flow

The invention discloses a cooperative control method of a left-opened-door bus special phase setting and social traffic flow, which comprises the following steps: setting a bus station and a stereo facility which help pedestrians to cross a street; detecting a bus; determining the running time of the bus; determining a signal phase of the bus which drives through an intersection; and setting the bus special phase and a cooperative control plan. According to the invention, the bus stations in two directions are combined and placed at a median strip of the intersection, so that not only the land is saved, but also the bus station points are easier to recognize, and meanwhile, a new concept for planning and constructing of a public transit network is provided, that is, the public transit network is connected based on the bus stations arranged at intersections. With the adoption of the method, the situation that the bus does not stop at an intersection without a bus station while stops at an intersection with a bus station can be basically realized, so that passengers waiting for a long time at an intersection with a bus station can be avoided, thereby shortening the whole driving time of the bus and improving the whole operation efficiency of the bus system. Moreover, the method is functioned as the cooperation of the social traffic flow, so that the passing efficiency of the whole intersections is guaranteed.

Owner:SOUTHEAST UNIV

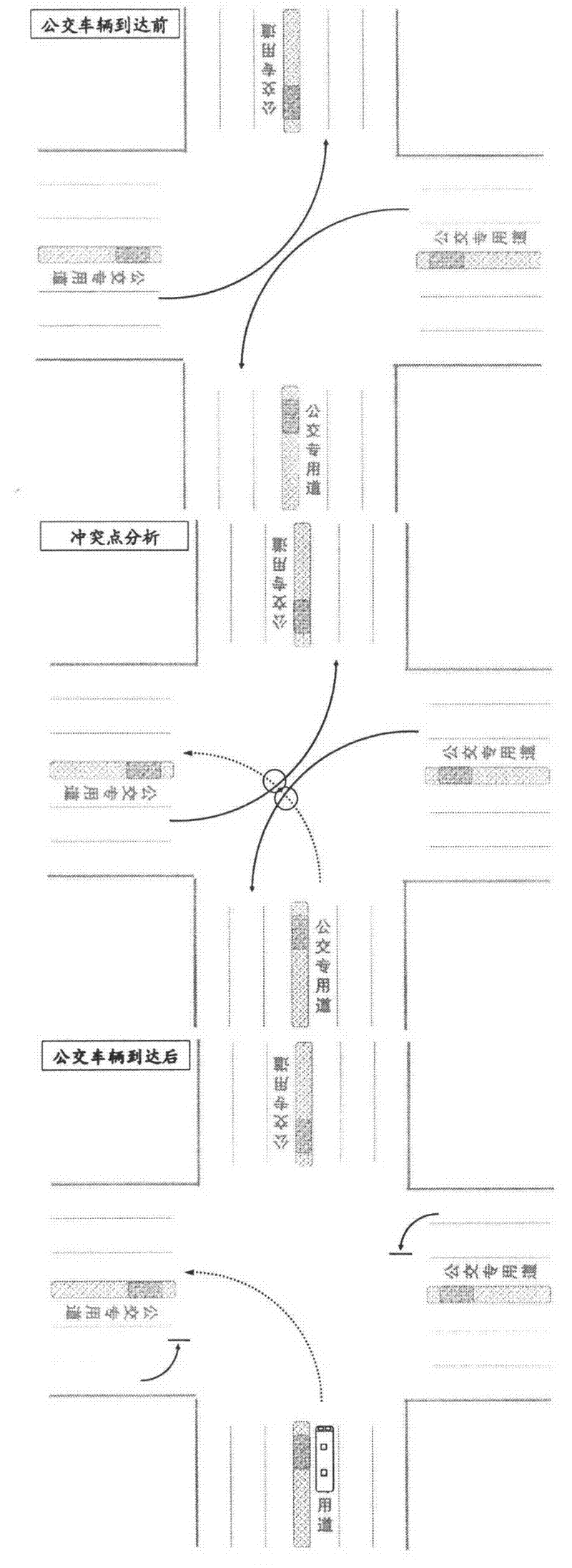

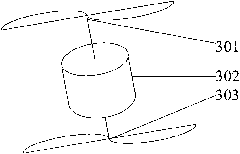

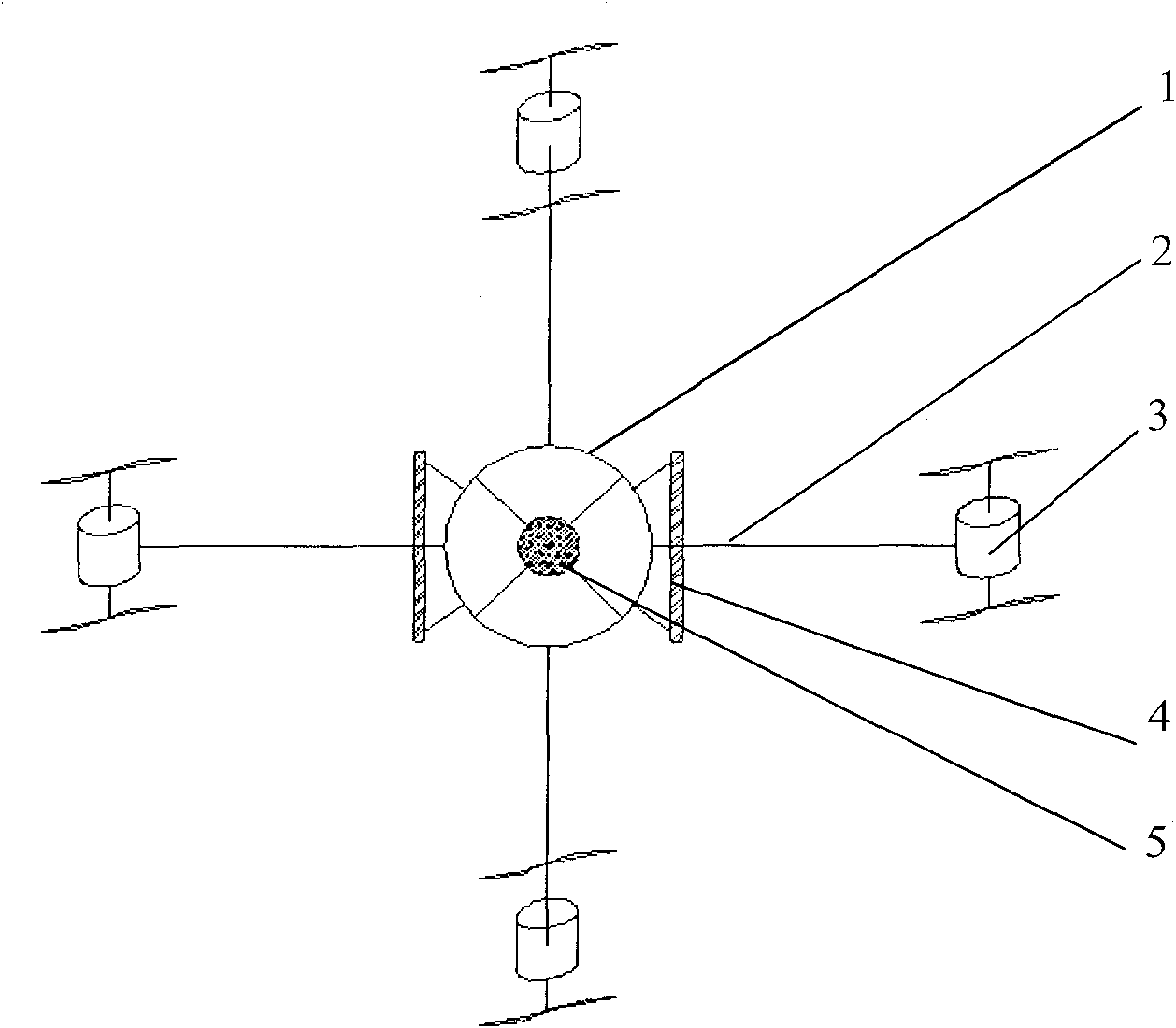

Coaxial contrarotation birotor twelve-rotary wing air vehicle

ActiveCN101823556AReduce efficiency lossImproved lift-to-weight ratioRotocraftElectric machineryElectric control

The invention provides a coaxial contrarotation birotor twelve-rotary wing air vehicle relating to the technical field of unmanned air vehicles. The air vehicle comprises an air vehicle body (1), six supporting arms (2), six birotors (3) and an electric control system (4), wherein the six supporting arms (2) are connected on the periphery of the air vehicle body (1), geometric center lines of thesix supporting arms (2) are on the same plane, and an included angle formed by the geometric center lines of two adjacent supporting arms (2) is 60 degrees; the six birotors (3) are respectively arranged at the end parts of the six supporting arms (2), and the electric control system (4) is arranged in the air vehicle body (1) to control and connect with the six birotors (3). The air vehicle has high maneuverability, and can realize vertical takeoff and landing, fast forward flight, inverted flight, hovering and change to any direction in flight; and the rotors are directly driven by an electric engine or an oil engine, thereby the energy loss of a transmission system is eliminated and the ratio of lift force to the weight of the air vehicle is increased.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

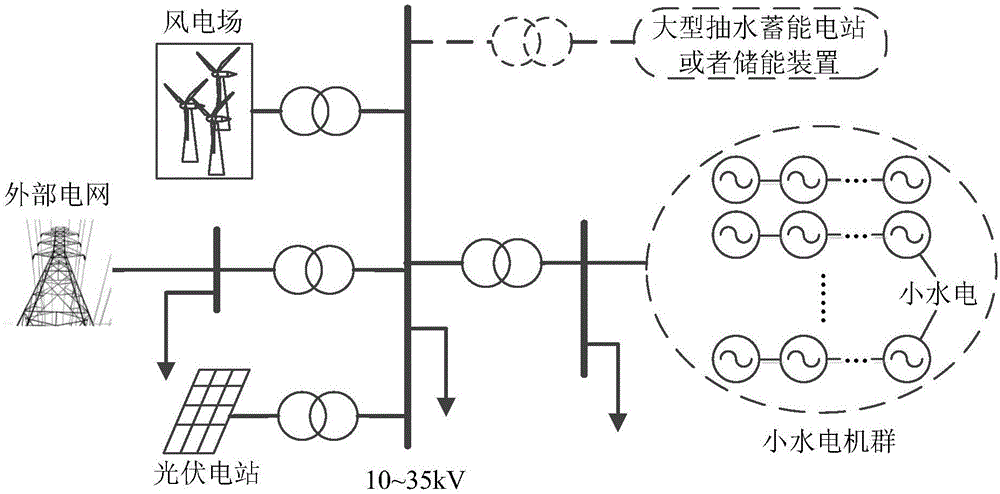

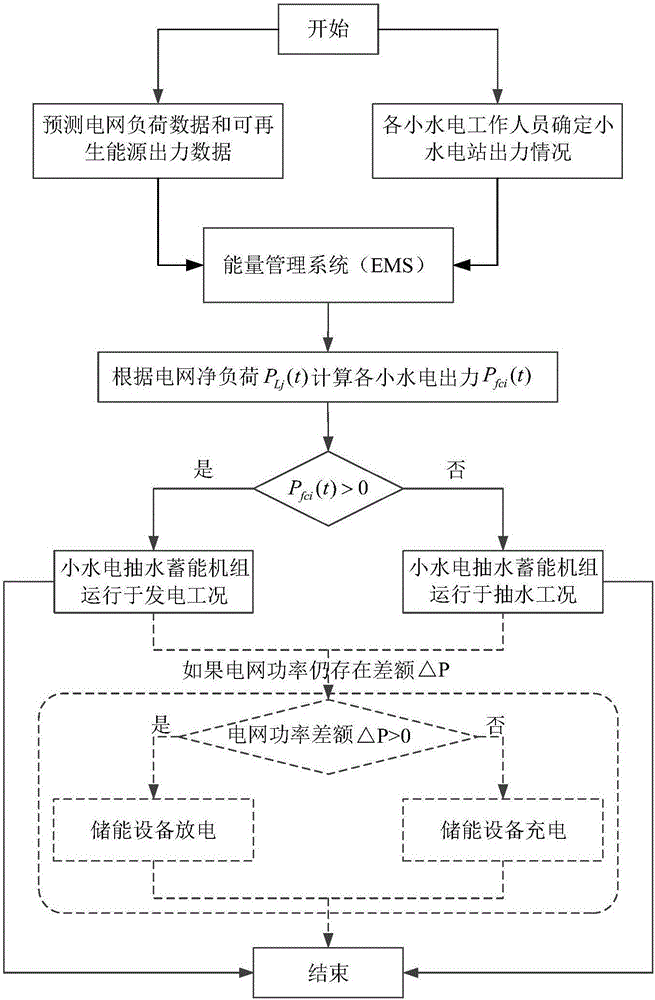

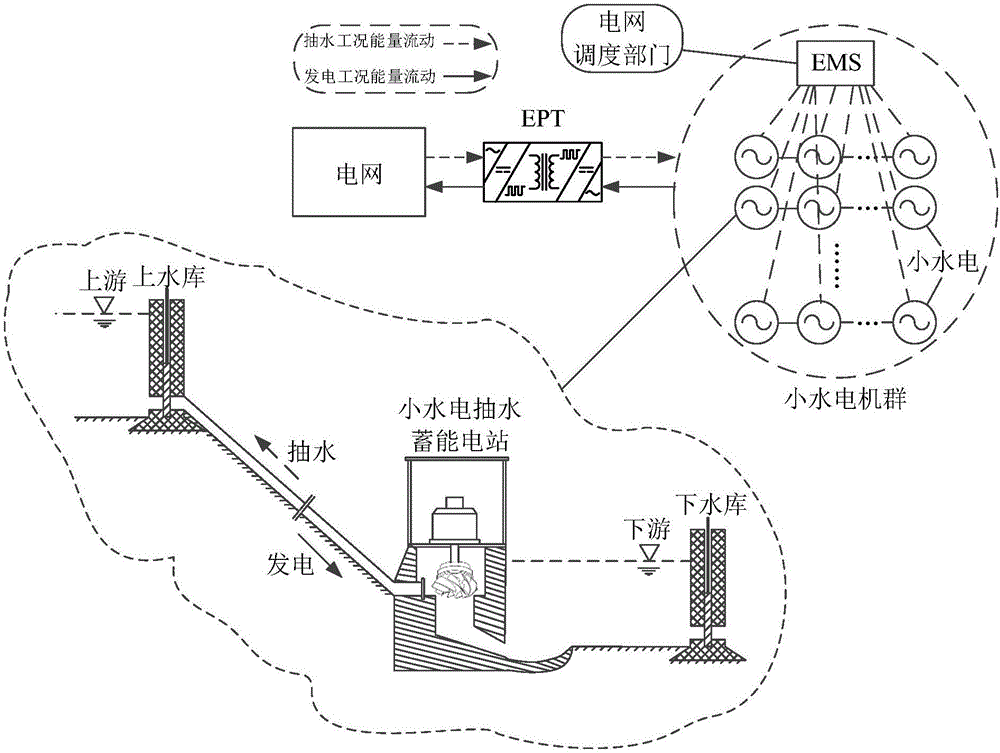

Method of forming distributed energy storage system by small hydropower cluster

ActiveCN106099960ALow costReduce construction difficultySingle network parallel feeding arrangementsHydro energy generationWater turbinePower grid

The invention discloses a method of forming a distributed energy storage system by a small hydropower cluster. The method comprises steps: a total net load value PLj(t) of all small hydropower stations at a tth time in an energy storage cycle T is acquired; according to an optimization objective, the total net load value PLj(t) and planned load pi(t) of an ith small hydropower station, the actual load pfci(t) of the ith small hydropower station is acquired; and according to the actual load pfci(t) of the ith small hydropower station, optimal efficiency control is carried out on a water pumping and water storing device of the ith small hydropower station, and the ith small hydropower station is made to operate under the optimal efficiency according to the actual load pfci(t), wherein the water pumping and water storing device is a hydraulic turbine, a water pump or a reversible hydraulic turbine. Through carrying out improvement on the small hydropower stations and using an energy management unit to manage the small hydropower stations in a unified mode, the multiple small hydropower stations can form a large energy storage system capable of power generation and energy storage, the problems of the operation efficiency and the utilization of the small hydropower stations can be solved, and the regulation capability of the power grid is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Articles for manipulating impinging liquids and methods of manufacturing same

ActiveUS20140291420A1Improve performanceMore practicalMaterial nanotechnologyFouling preventionNon wettingEngineering

This invention relates generally to an article that includes a non-wetting surface having a dynamic contact angle of at least about 90°. The surface is patterned with macro-scale features configured to induce controlled asymmetry in a liquid film produced by impingement of a droplet onto the surface, thereby reducing time of contact between the droplet and the surface.

Owner:MASSACHUSETTS INST OF TECH

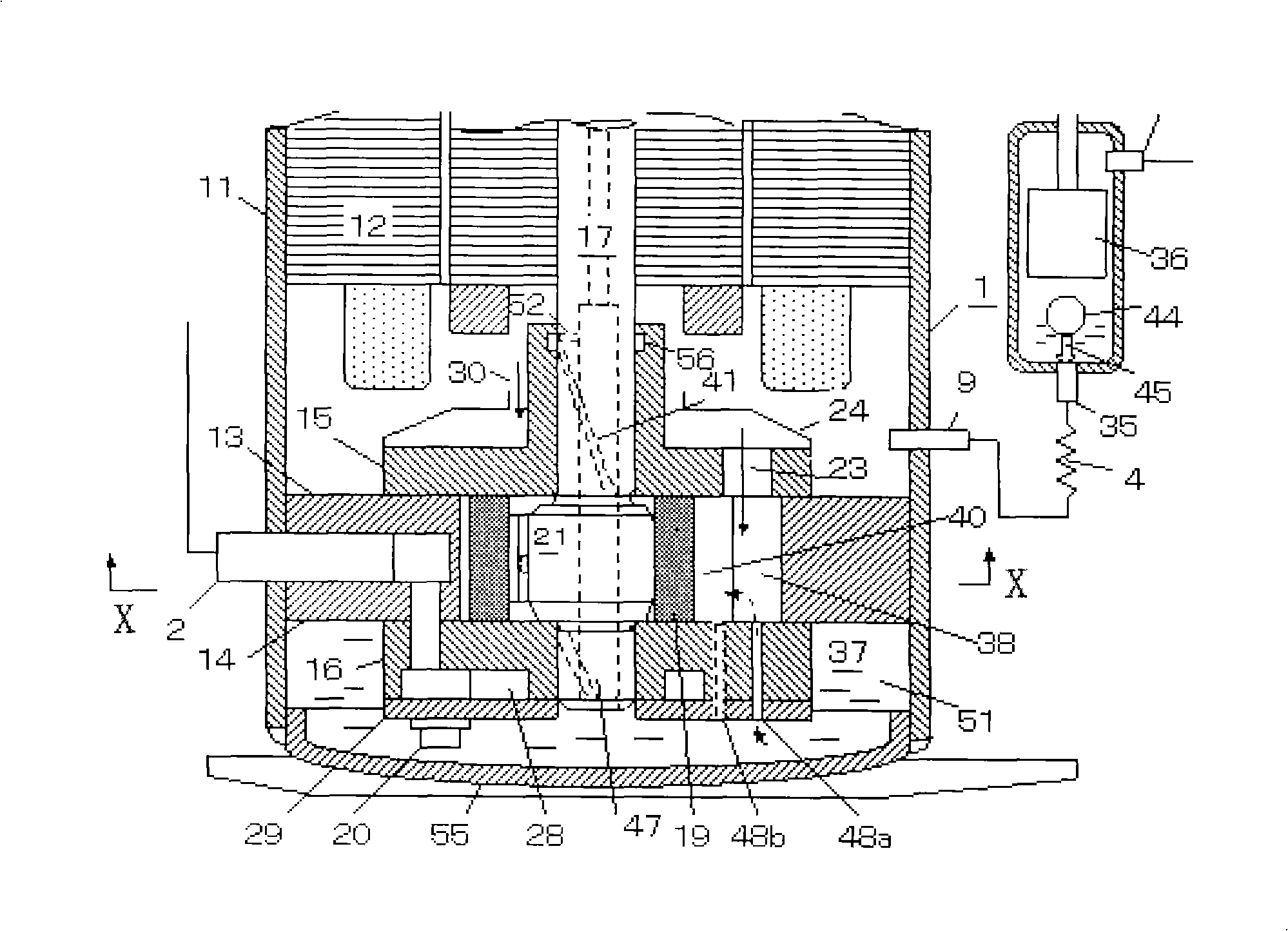

Shell low-pressure rotary compressor

InactiveCN101526084AReduce efficiency lossRotary piston pumpsRotary piston liquid enginesFree rotationEngineering

The invention relates to a shell low-pressure rotary compressor which comprises a compressor and an oil separator, wherein the pressure inside the shell of the compressor is a low pressure side; a motor and a compressor component connected with the motor are accommodated in the sealed shell; the compressor component comprises an air cylinder, an air cylinder compressor cavity accommodating a free rotary piston and arranged in the air cylinder, a crankshaft driving the piston, a main bearing and an auxiliary bearing which both support the crankshaft and are arranged on the upper part and the lower part of the air cylinder, and a sliding blade arranged in a sliding blade cavity; the end part of the sliding blade is supported on the outer edge of the piston, an exhaust pipe of the compressor is communicated with a gas inlet pipe arranged on the upper part of the oil separator, a gas outlet pipe arranged on the lateral side of the oil separator is communicated with a condenser, and an oil outlet pipe arranged on the bottom of the oil separator is communicated with the inner side of the integration or the inner side of the air cylinder compressor cavity. The compressor has simple and reasonable structure and low manufacture cost, can ensure the air cylinder compressor cavity to obtain optimal oil during compression, and can also ensure the lubrication of the sliding blade.

Owner:GUANGDONG MEIZHI COMPRESSOR

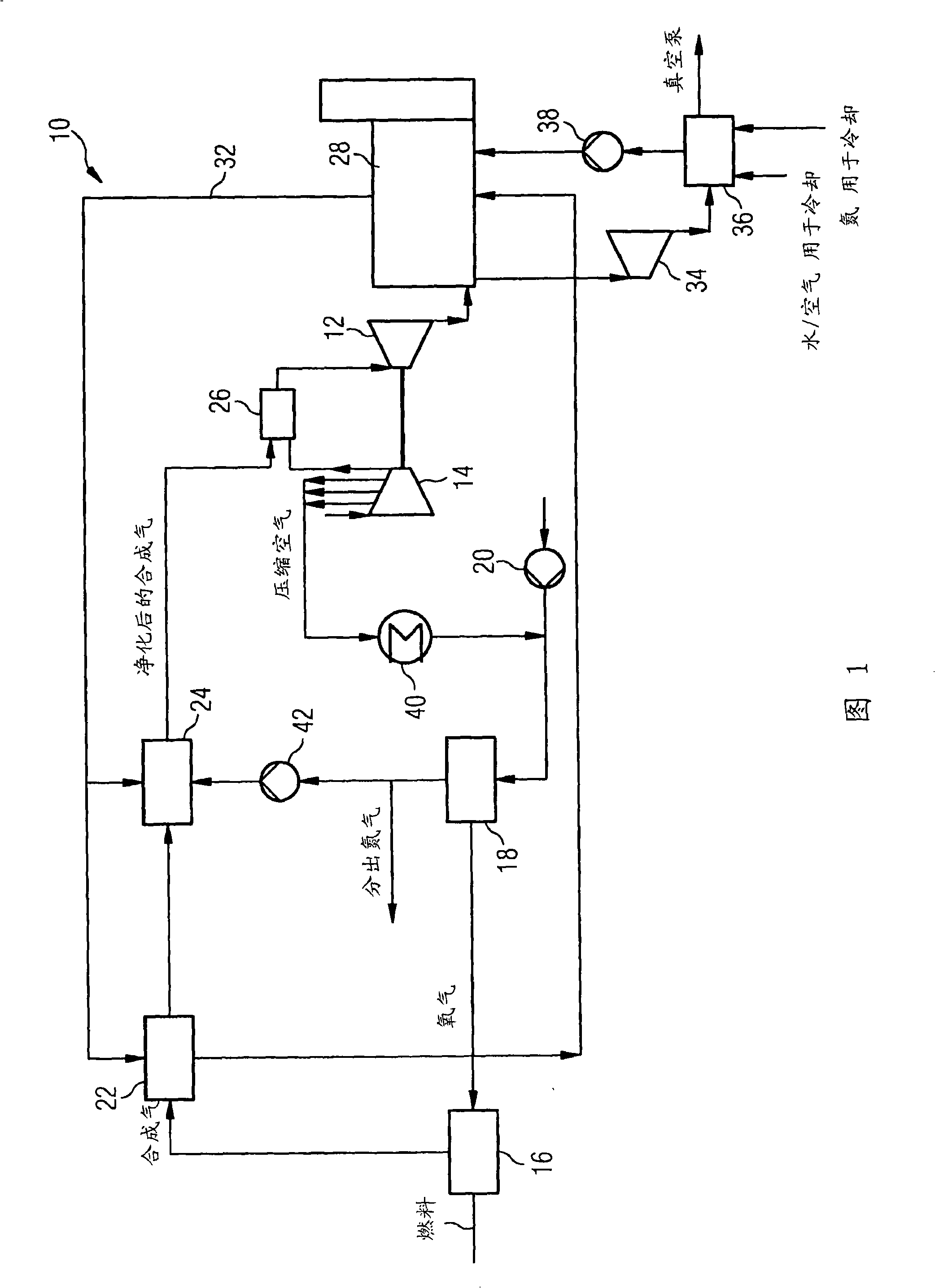

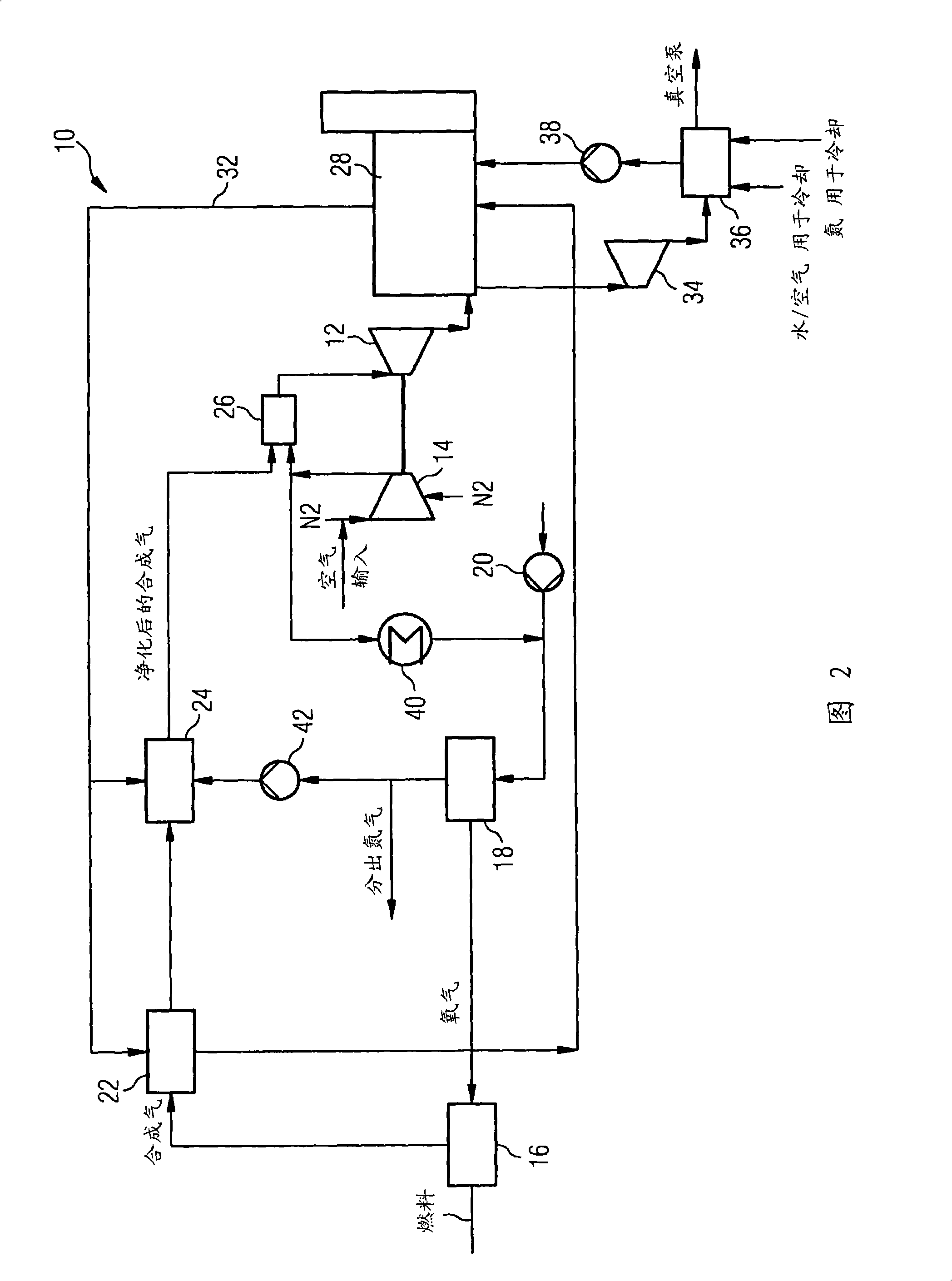

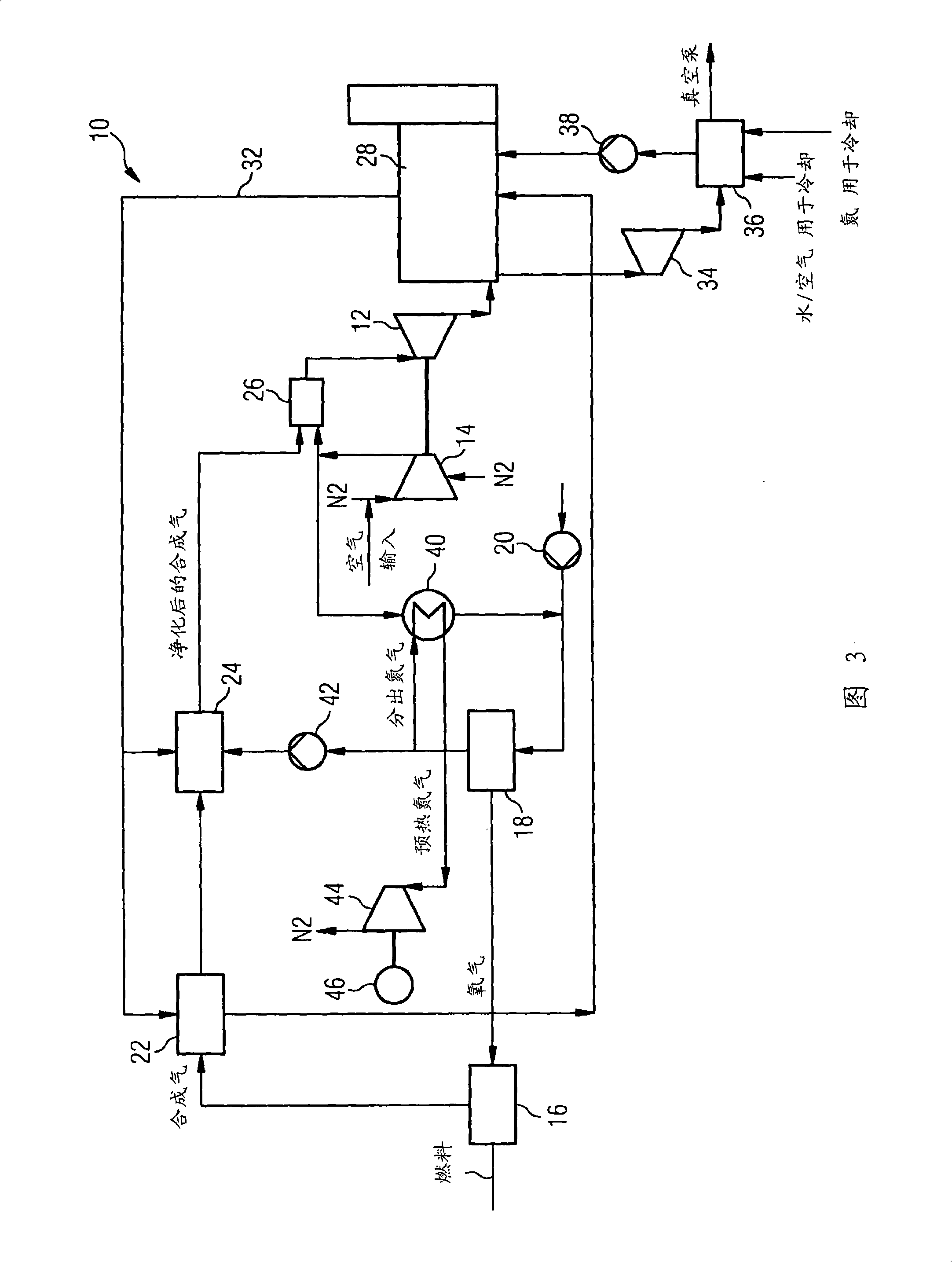

Method for increasing the efficiency of a combined gas/steam power station with integrated gasification combined cycle

InactiveCN101287893AReduce power lossReduce efficiency lossSolidificationLiquefactionEngineeringNitrogen gas

The present invention relates to a method for increasing the efficiency of a combined gas / steam power station (10) with integrated gasification combined cycle. Said power station comprises a gas turbine compressor (14) and an air-separation unit (18) having a defined working pressure. Compressed air is removed from the gas turbine compressor (14) at a pressure level that is adapted to the working pressure of the air-separation unit (18). The removed air is then supplied to the air-separation unit (18) where the air is broken down into its individual constituents, especially oxygen and nitrogen. The nitrogen produced in the air-separation unit (18) is removed from the air-separation unit and at least a part of the removed nitrogen quantity is used as a coolant in the gas / steam power station in order to improve its efficiency.

Owner:SIEMENS AG

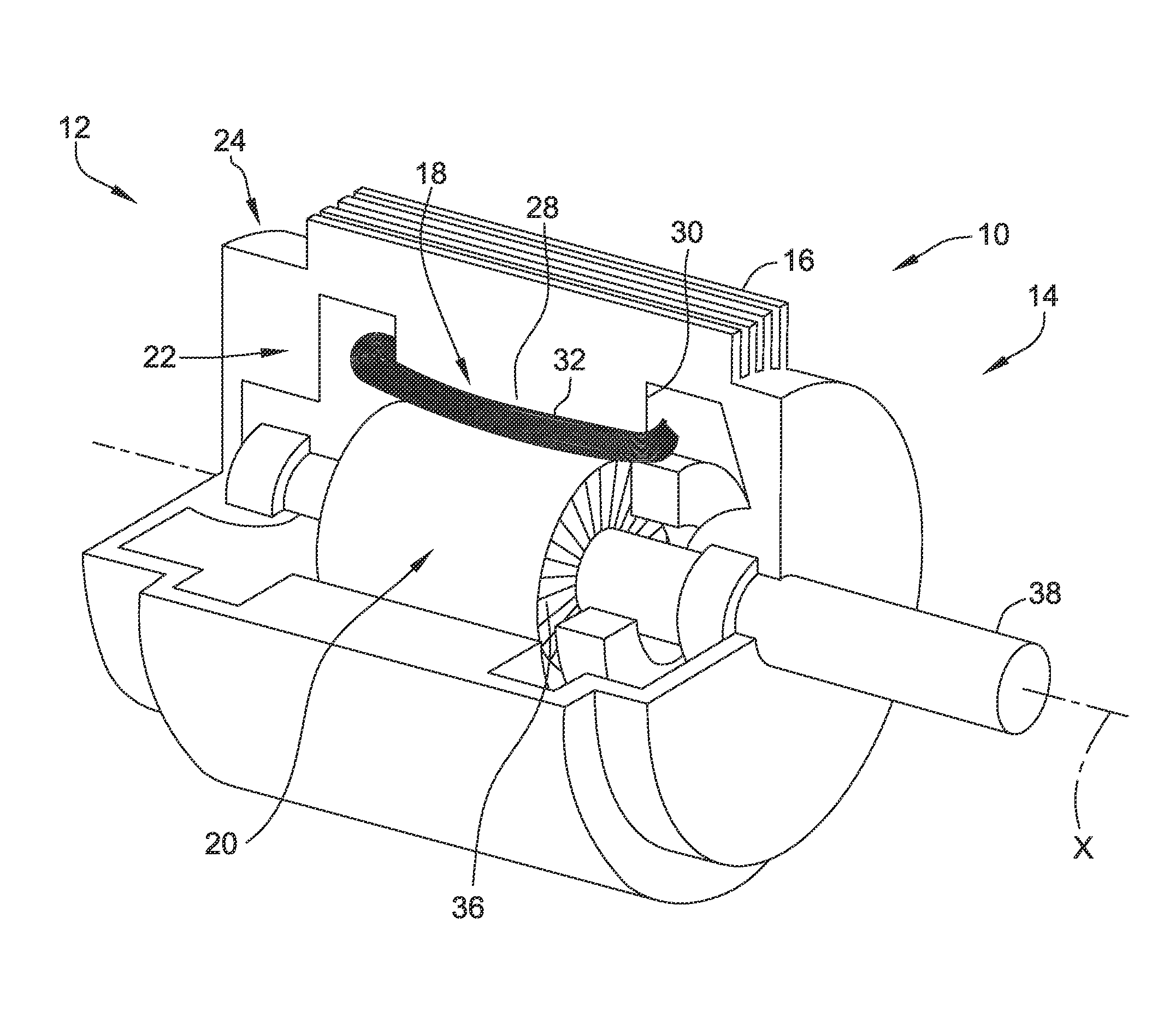

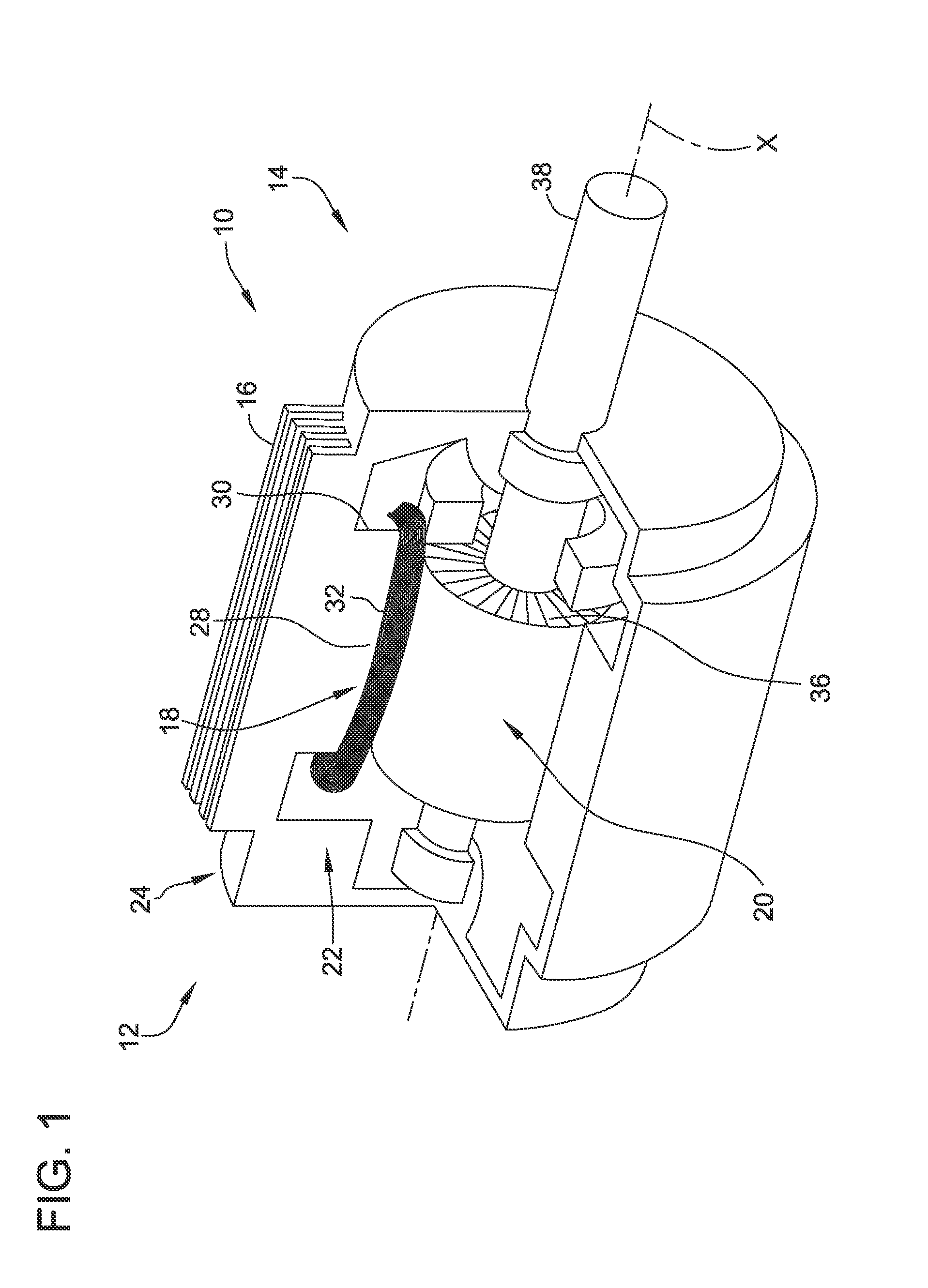

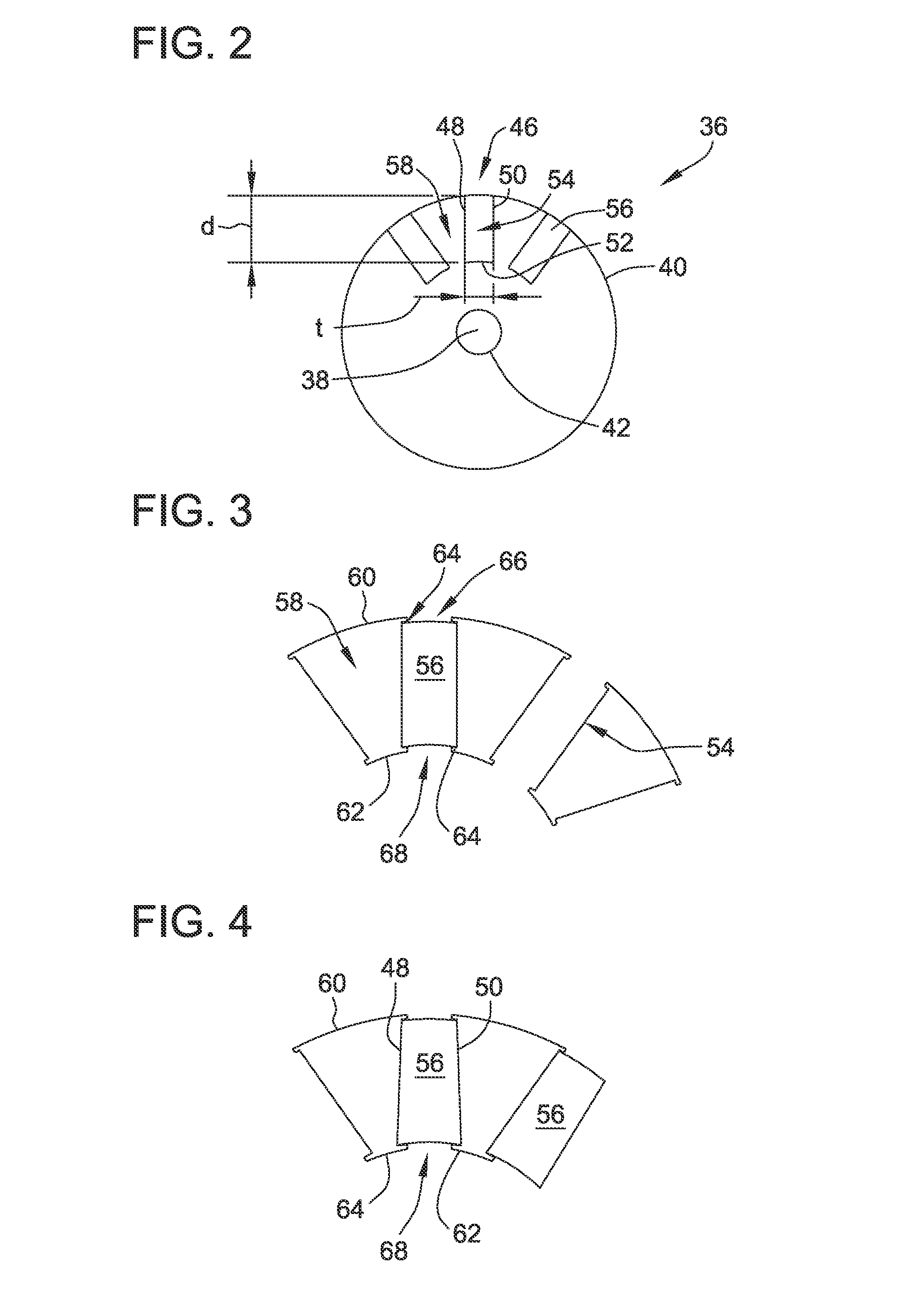

Permanent magnet rotor and methods thereof

ActiveUS20140103770A1Improve throughputLow efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet rotorMagnet

In one embodiment, an electric machine is provided. The electric machine includes a machine housing and a stator disposed at least partially within the housing, the stator comprising a plurality of teeth and an aluminum winding wound around at least one tooth of the plurality of teeth. The electric machine further includes a radially embedded permanent magnet rotor disposed at least partially within the housing, the rotor comprising at least one radially embedded permanent magnet and configured to provide increased flux to reduce motor efficiency loss compared to a copper winding.

Owner:REGAL BELOIT AMERICA

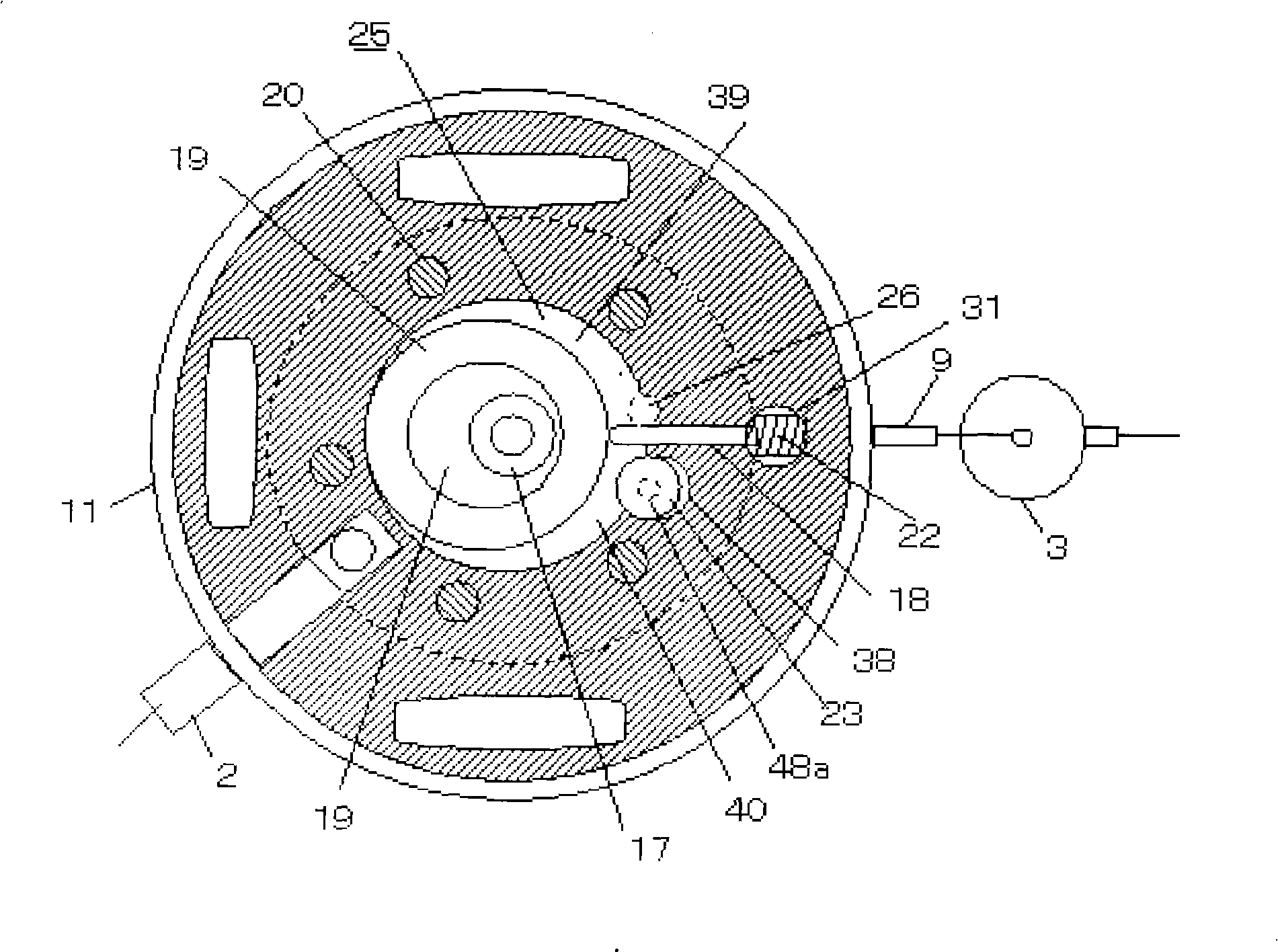

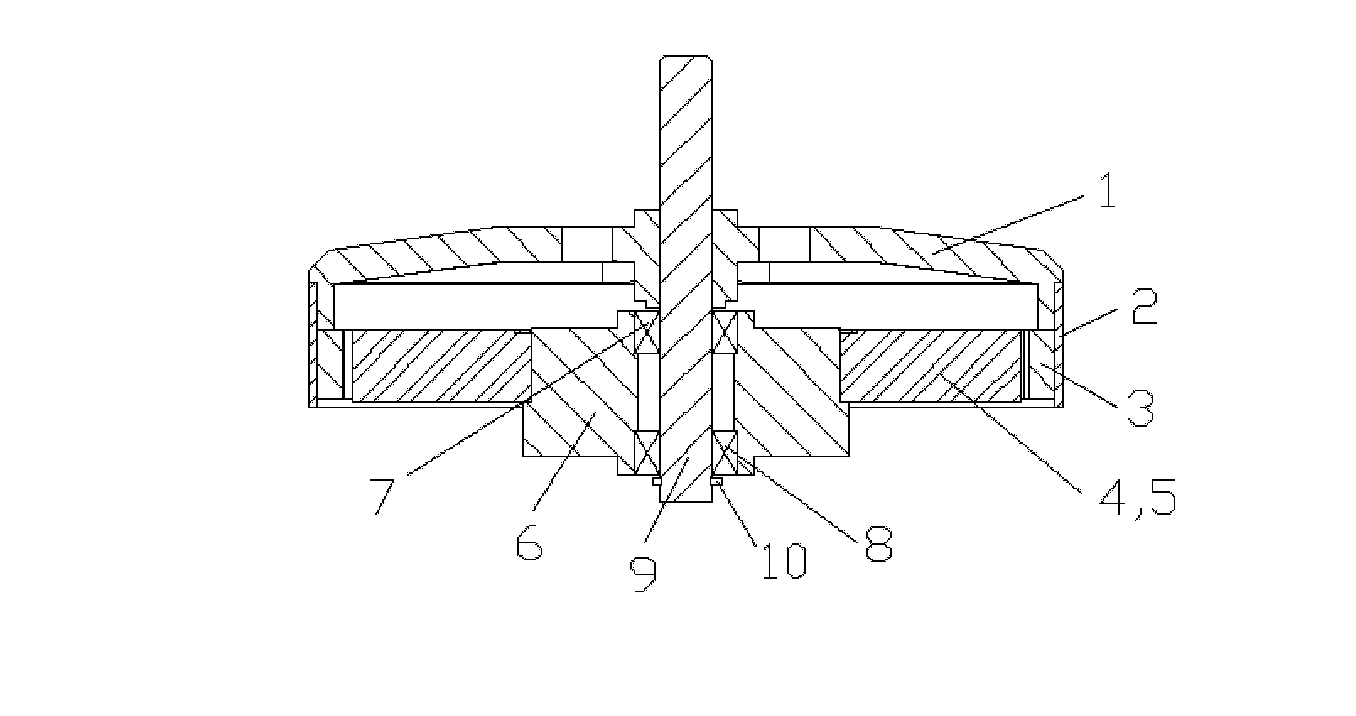

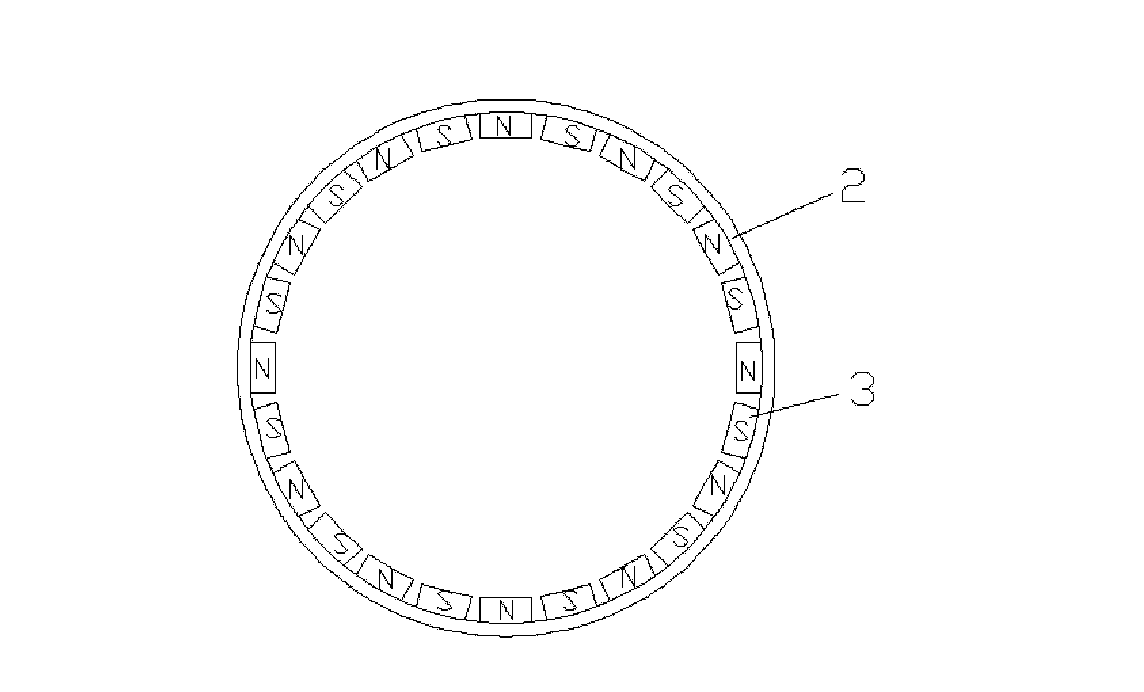

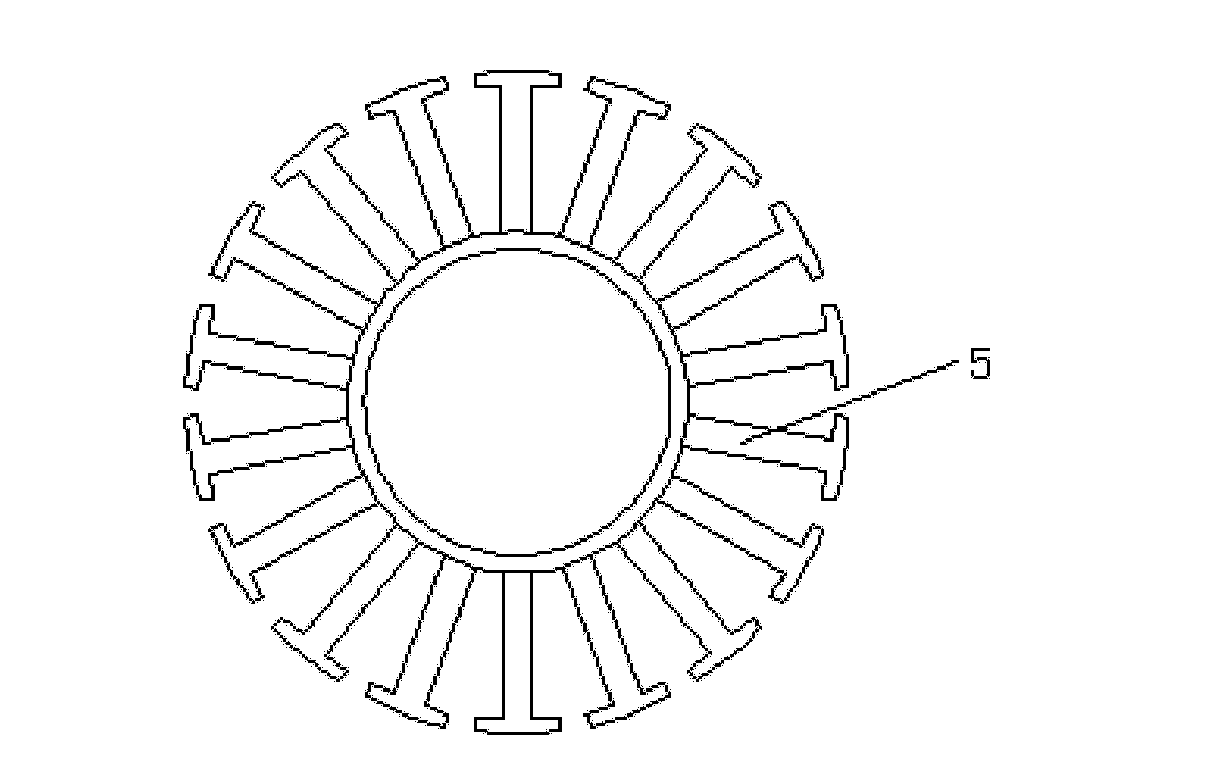

Brushless DC (Direct Current) motor for unmanned air vehicles

InactiveCN102130565AMany slotsImprove efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsMass ratioElectric machine

The invention relates to a brushless DC (Direct Current) motor for unmanned air vehicles, belonging to the technical field of unmanned air vehicle powerplants. The brushless DC motor comprises an external rotor composed of a rotor end cover, a rotor yoke and a permanent magnet, a stator composed of a winding, a stator iron core and a stator yoke, an upper bearing, a lower bearing, a rotation shaft and a stopper ring, wherein the outer diameter of the rotor yoke is the same as that of the rotor end cover, the rotor yoke is fixed at the lower end of the rotor end cover, the permanent magnet is fixed on the inner wall of the rotor yoke, and the number of magnetic poles of the permanent magnet is 24; the stator iron core comprises 18 slots, the stator yoke is sleeved on the inner wall of the stator iron core, and the winding is coiled on the outside of the stator iron core; the upper bearing and the lower bearing are respectively fixed on two ends of the rotation shaft; the stator is connected with the rotor through the rotation shaft, the stator is embedded inside the rotor end cover, and the stopper ring is sleeved on the rotation shaft. In the invention, by directly driving airscrews, the brushless DC motor is beneficial to elimination of efficiency loss of a driving system, and improvement of lift force / power consumption ratio and lift force / mass ratio of air vehicles.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

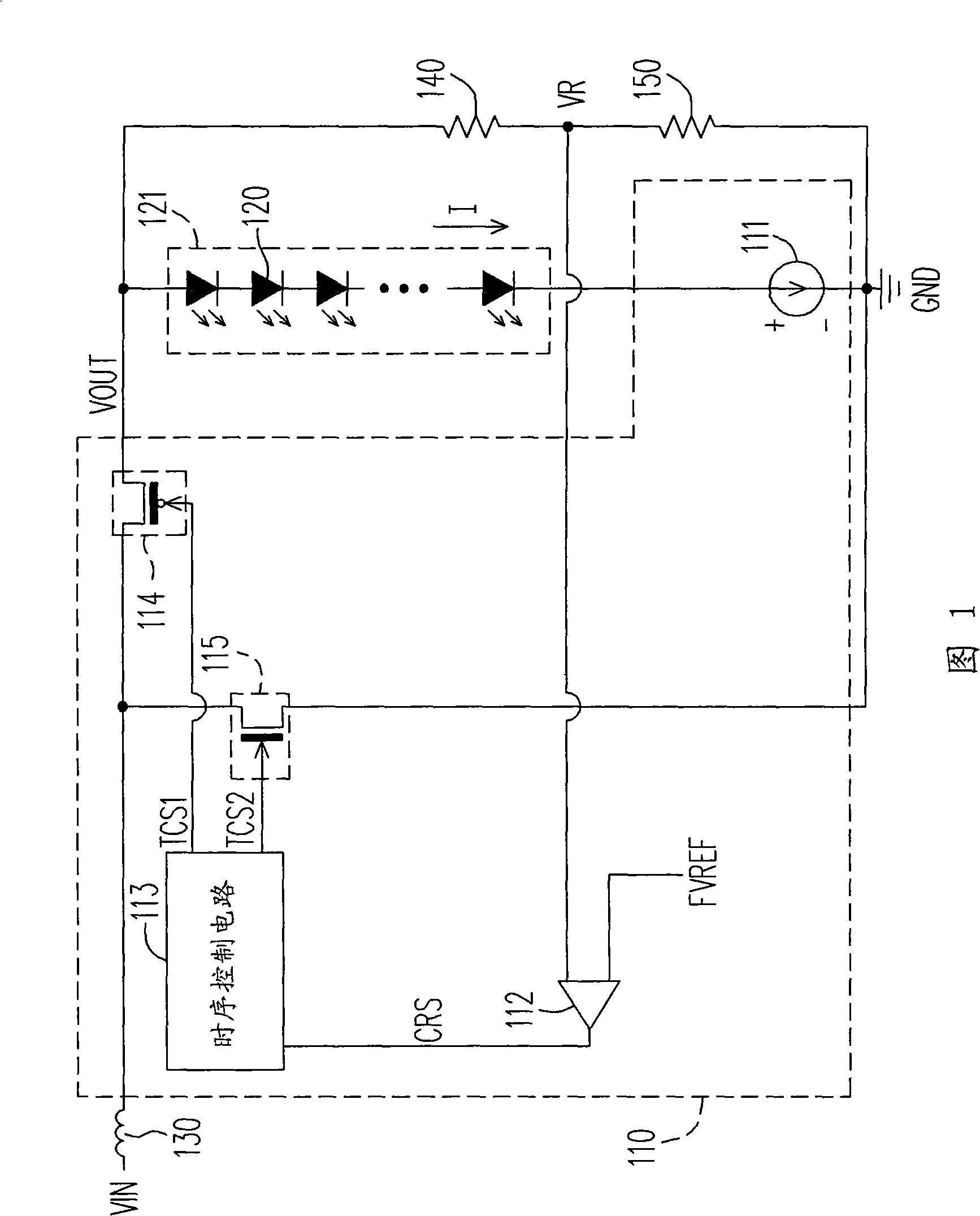

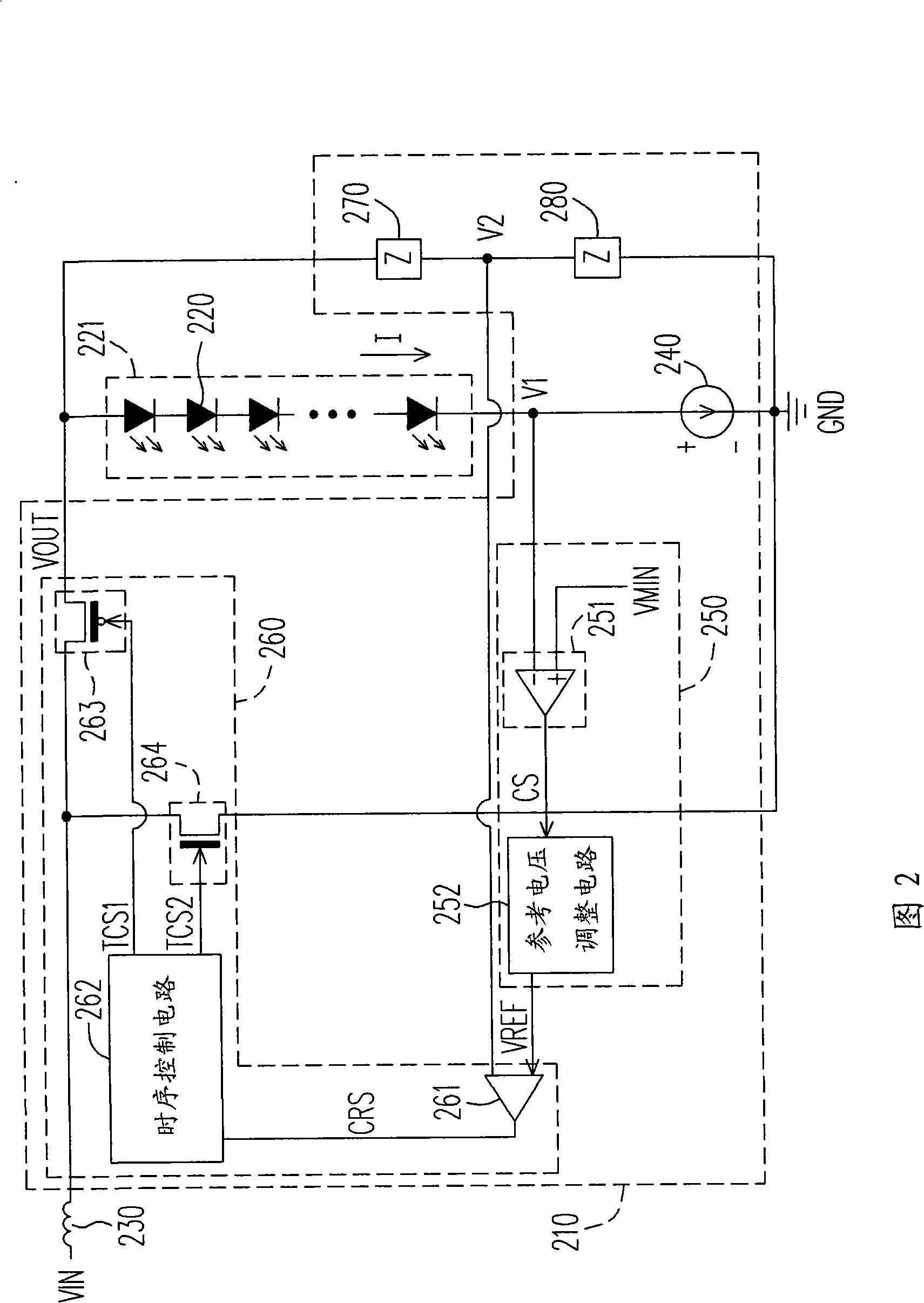

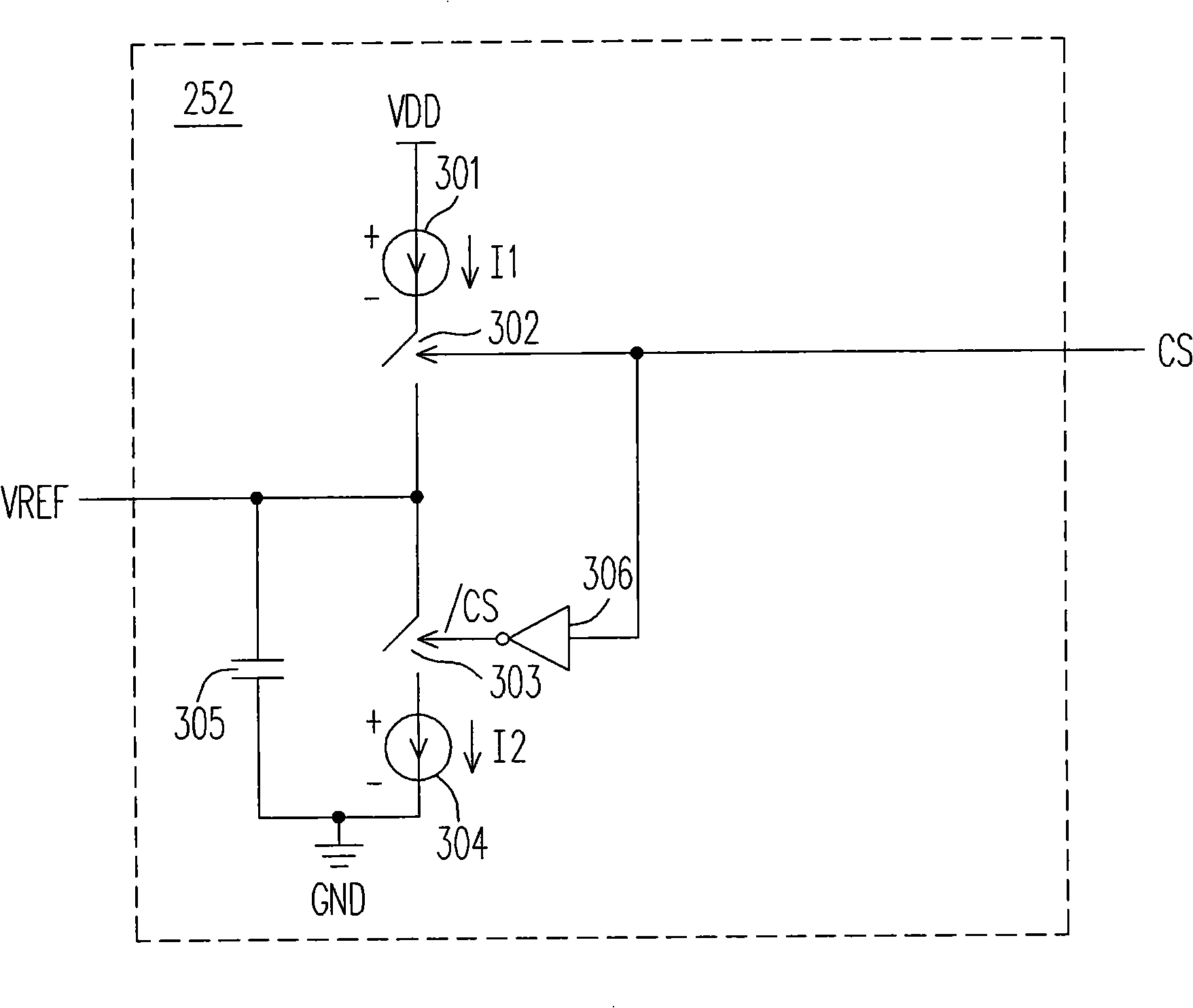

Constant-current driving circuit

ActiveCN101316466AReduce efficiency lossPoint-like light sourceElectric lightingPower flowEngineering

The invention provides a constant current drive circuit which comprises a first current supply, a reference voltage generation circuit and an output signal generation circuit. One end of the first current supply is coupled with one end of a first light-emitting component series, wherein, the end of the first power supply is provided with a first voltage; the reference voltage generation circuit is used for generating reference voltage and compares the first voltage with a first preset voltage to generate a first comparison signal and dynamically adjust the value of the reference voltage according to the first comparison signal; the output signal generation circuit is used for outputting output signals to the other end of the first light-emitting component series and receiving input signals and determining whether to output the input signals according to the result of the comparison between the reference voltage and a second voltage so as to form the output signals.

Owner:ITE TECH INC

Articles for manipulating impinging liquids and methods of manufacturing same

ActiveUS9254496B2Improve performanceMore practicalMaterial nanotechnologyLayered productsNon wettingBiomedical engineering

Owner:MASSACHUSETTS INST OF TECH

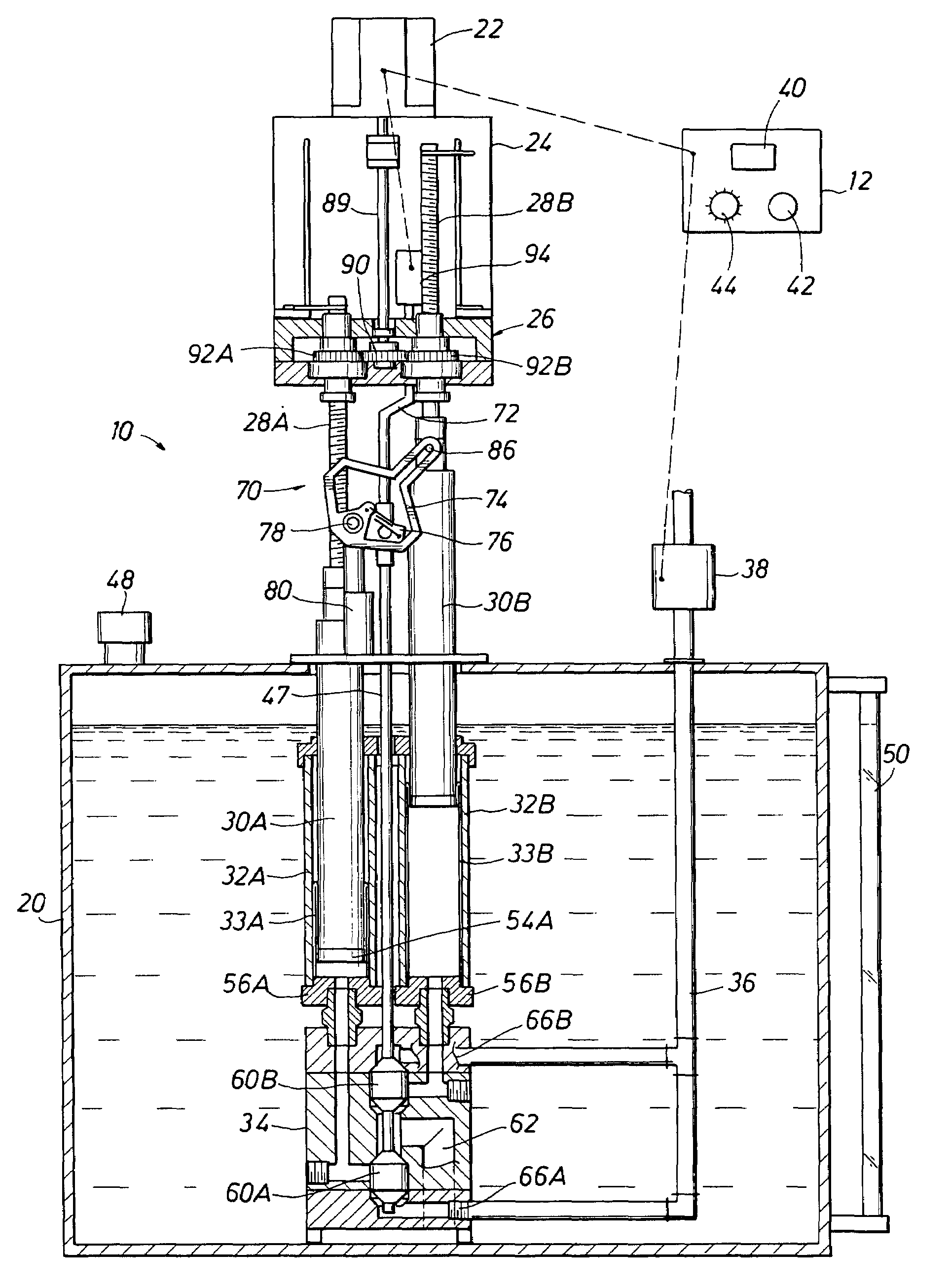

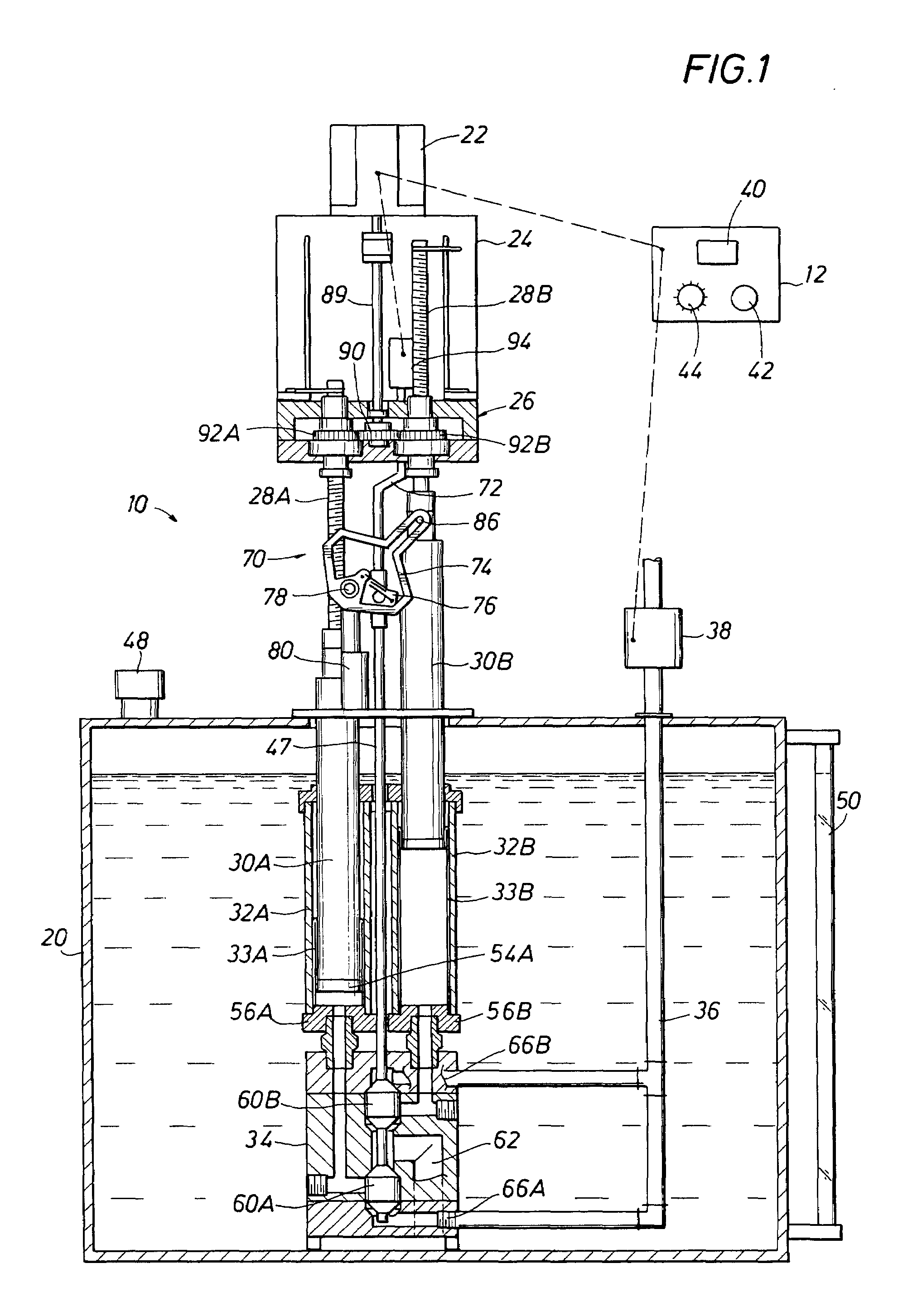

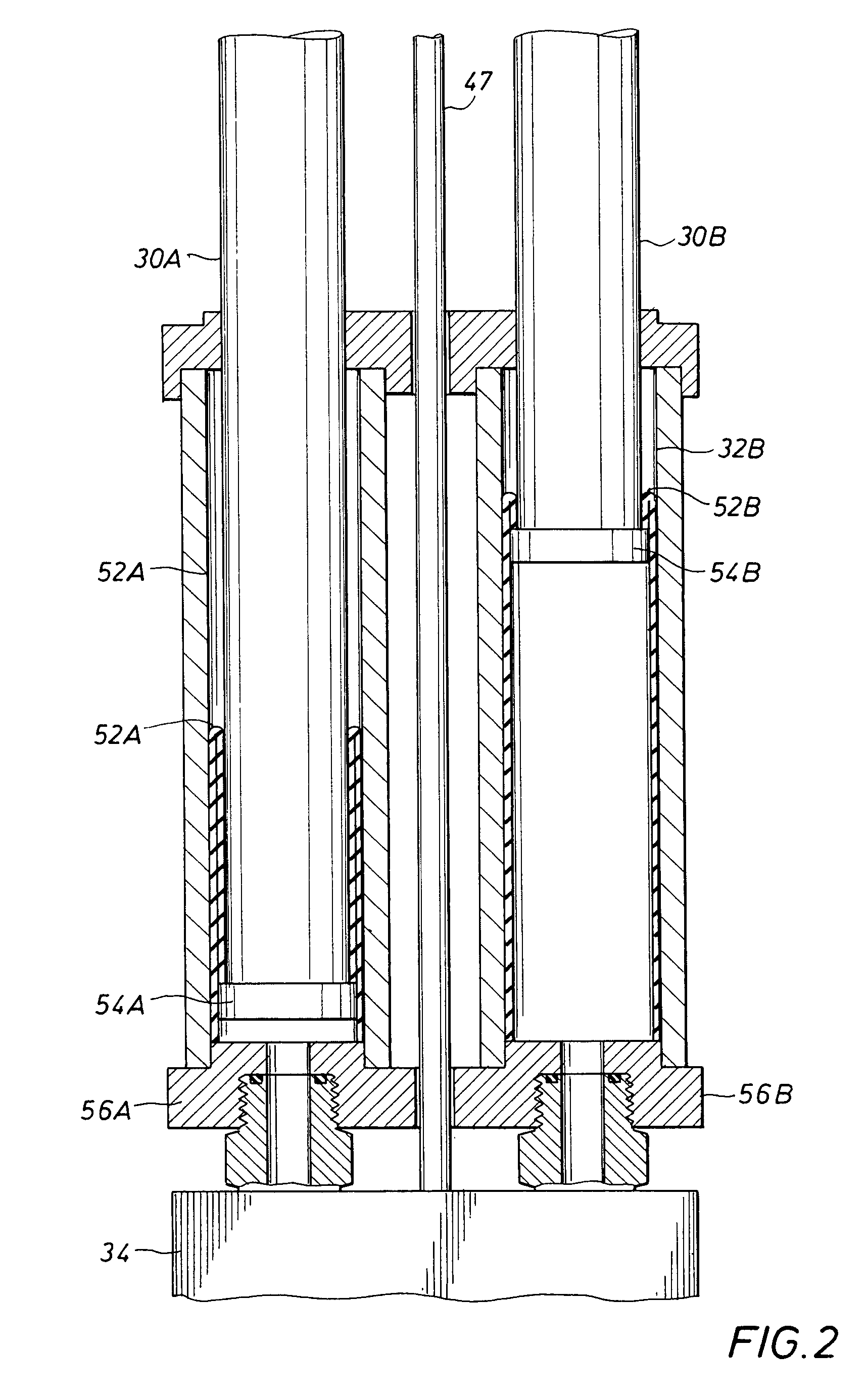

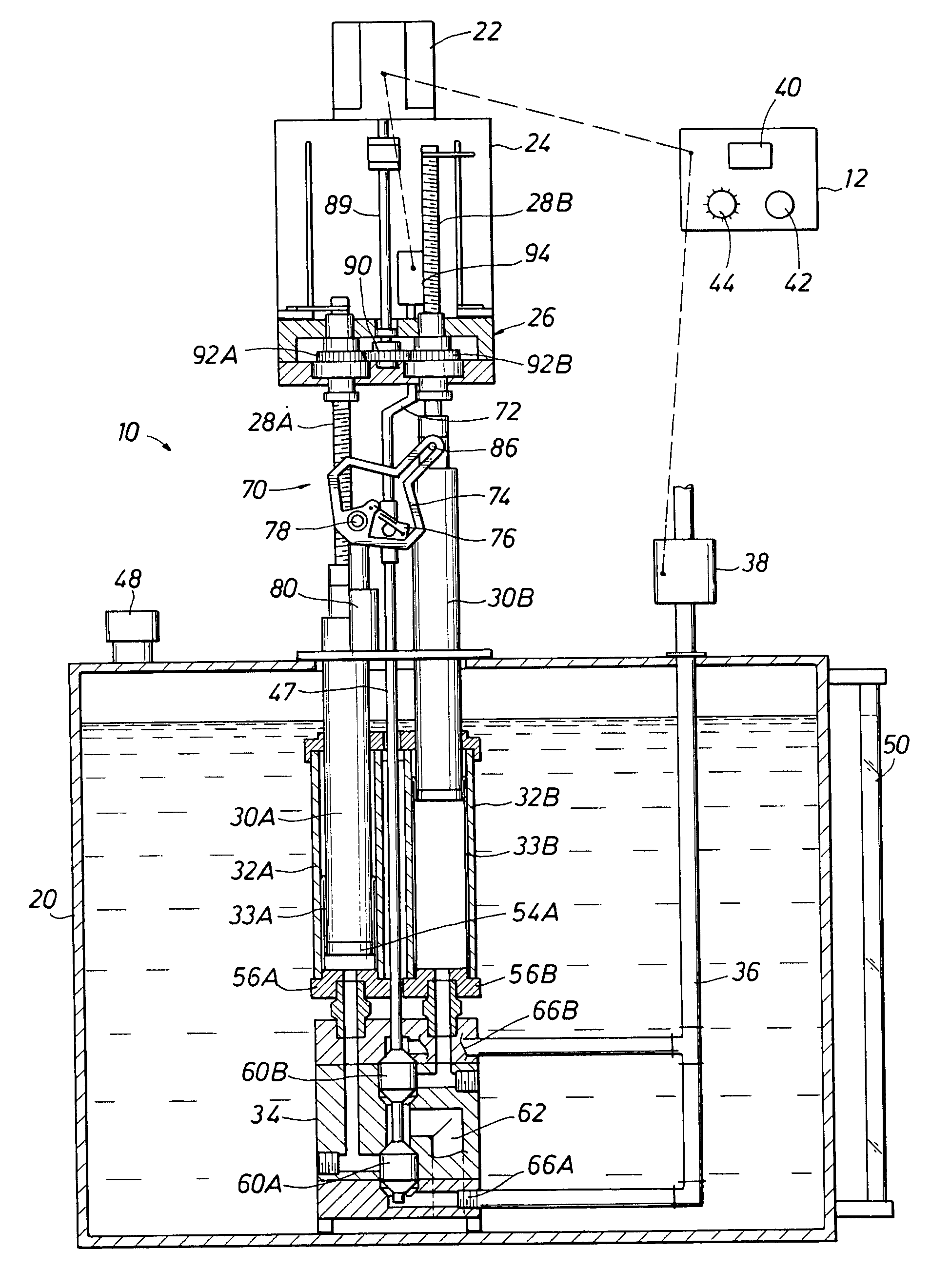

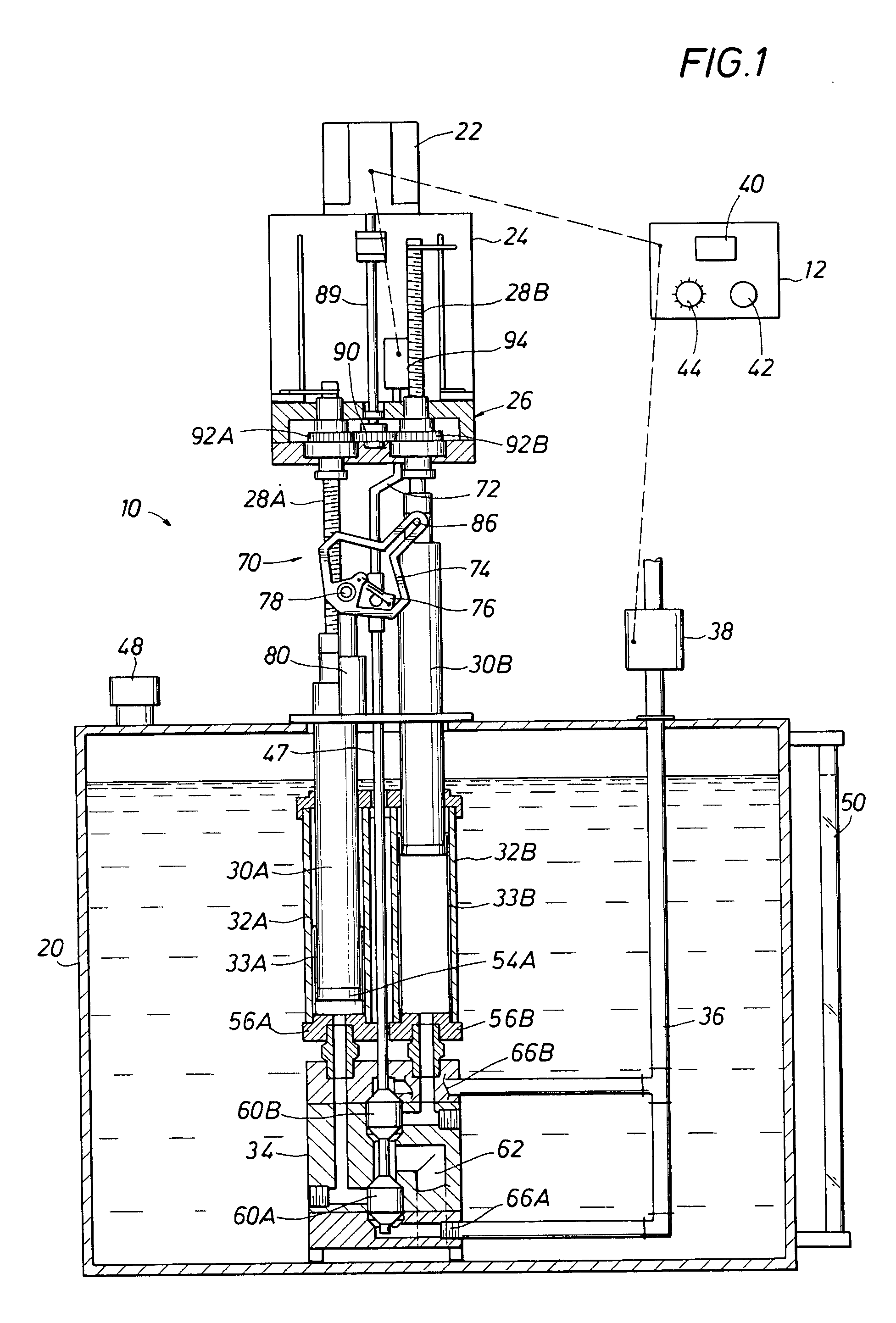

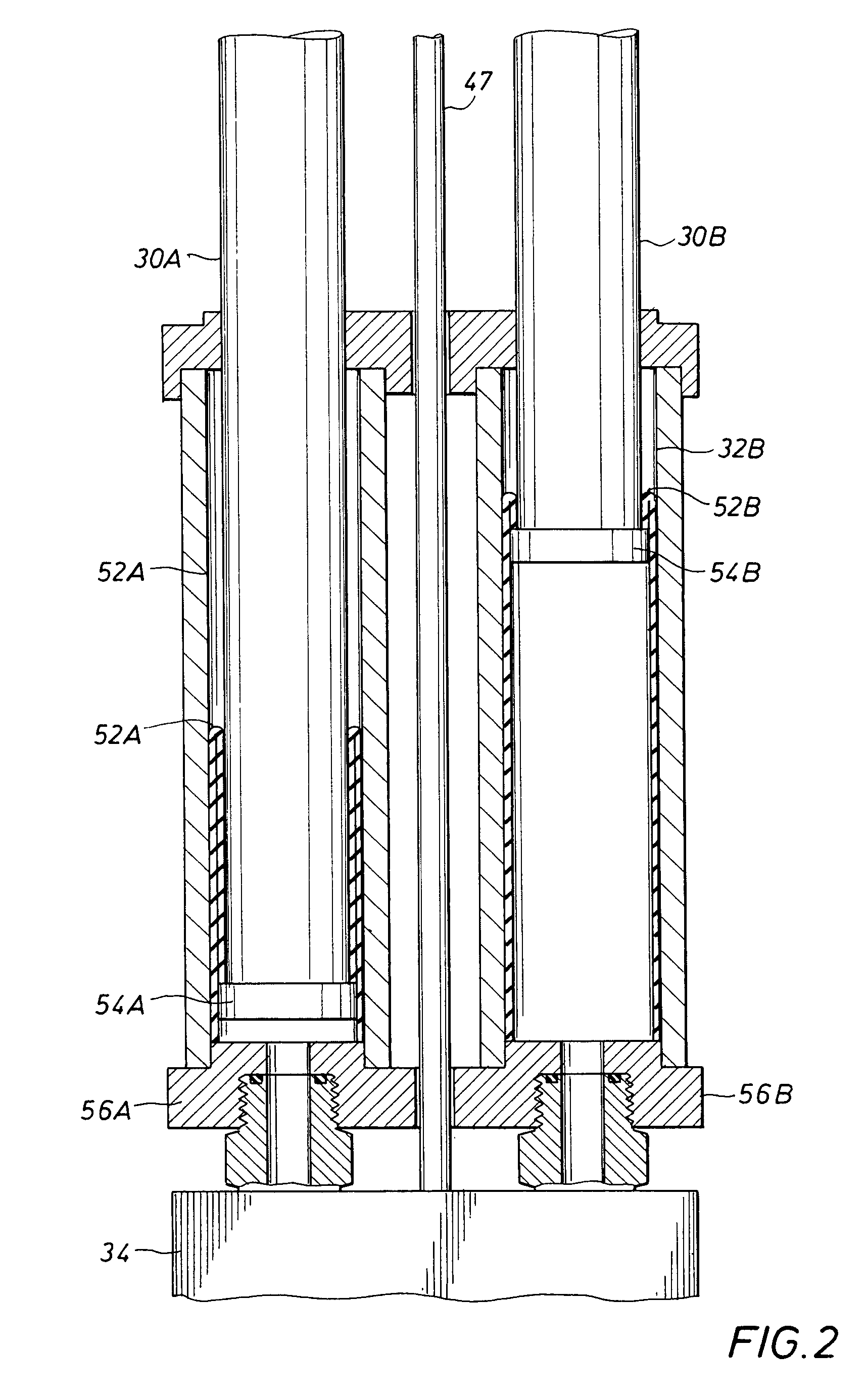

Metering pump

InactiveUS7278836B2Reduce efficiency lossPositive displacement pump componentsPiston pumpsPump chamberReciprocating motion

A metering pump that is capable of delivering a constant, rate of fluid over a wide range of viscosities at infinitely variable delivery rates. Two identical pumping chambers are provided with one operating in the suction mode, and the other in the discharge mode with each cylinder switching modes at each pumping cycle, thereby providing continuous delivery of fluid in and out of the pump. The displacement of the chamber is large in order to facilitate operation at a very slow cycle speed of only one to four reciprocations per minute. The fluid valves are mechanically operated providing for positive sealing thus enabling the pump to operate at very slow speeds without leakage.

Owner:HAMMONDS TECHN SERVICES

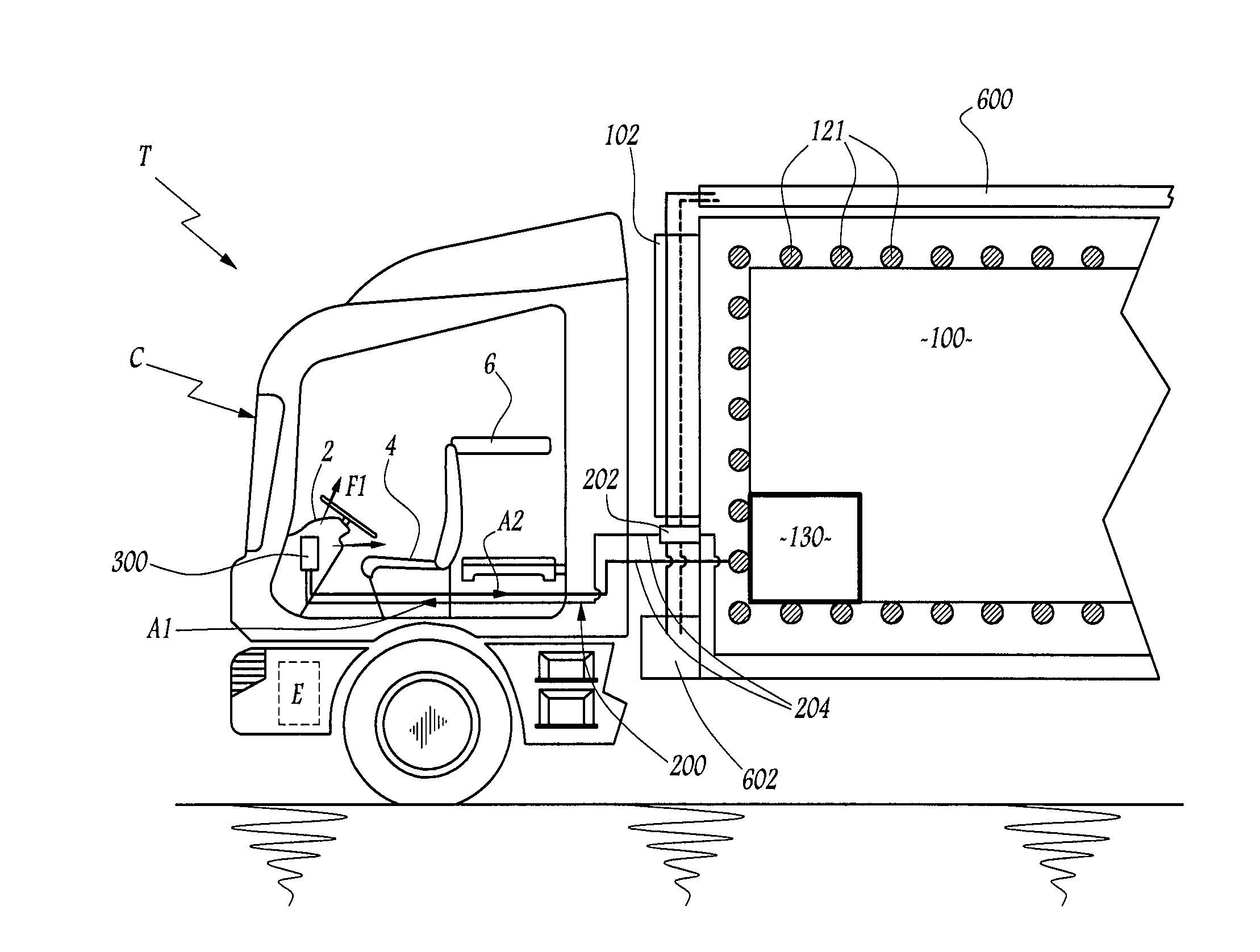

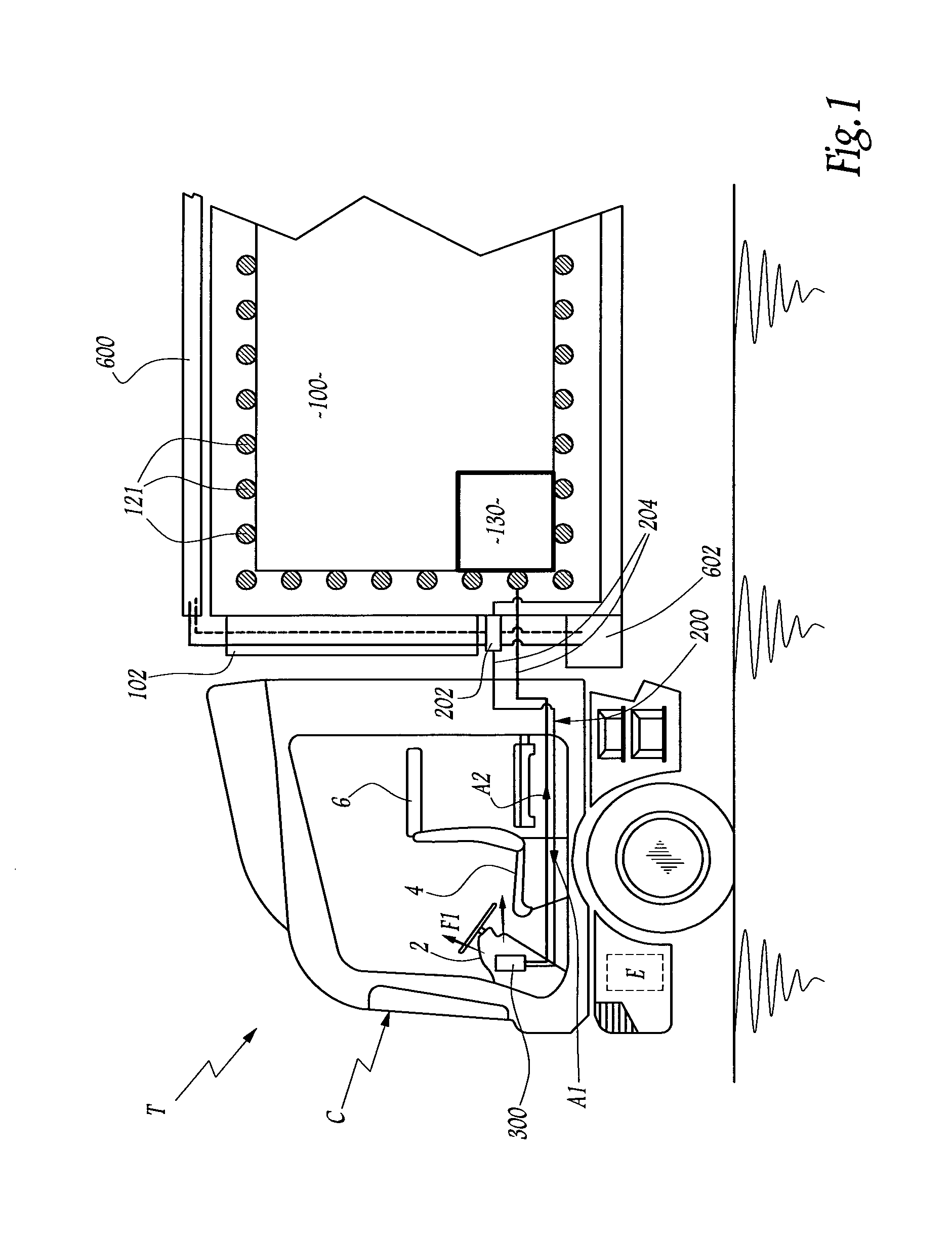

Truck with a refrigerated compartment

ActiveUS20130247605A1Easy to useReduce efficiency lossAir-treating devicesLighting and heating apparatusEngineeringTruck

A truck includes a refrigerated compartment that is equipped with a dedicated refrigerating system, and a driver cabin. The driver cabin is equipped with a least a first heat exchanger adapted to cool an air flow directed to the cabin. The truck further includes a compartment heat exchanger located in the refrigerated compartment and adapted to cool a heat transfer liquid sent to the first heat exchanger through a heat transfer liquid connecting the first heat exchanger to the compartment heat exchanger.

Owner:VOLVO LASTVAGNAR AB

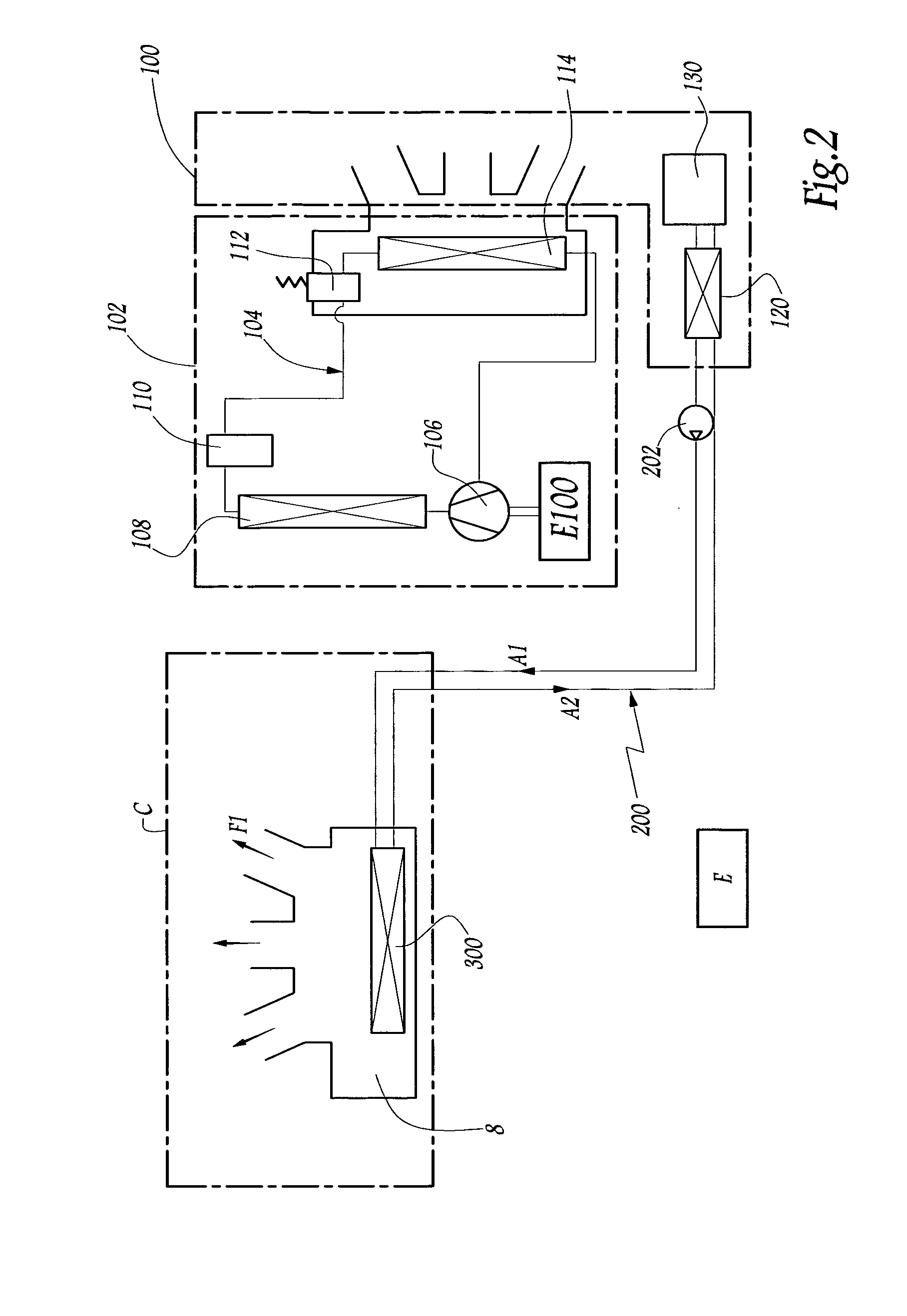

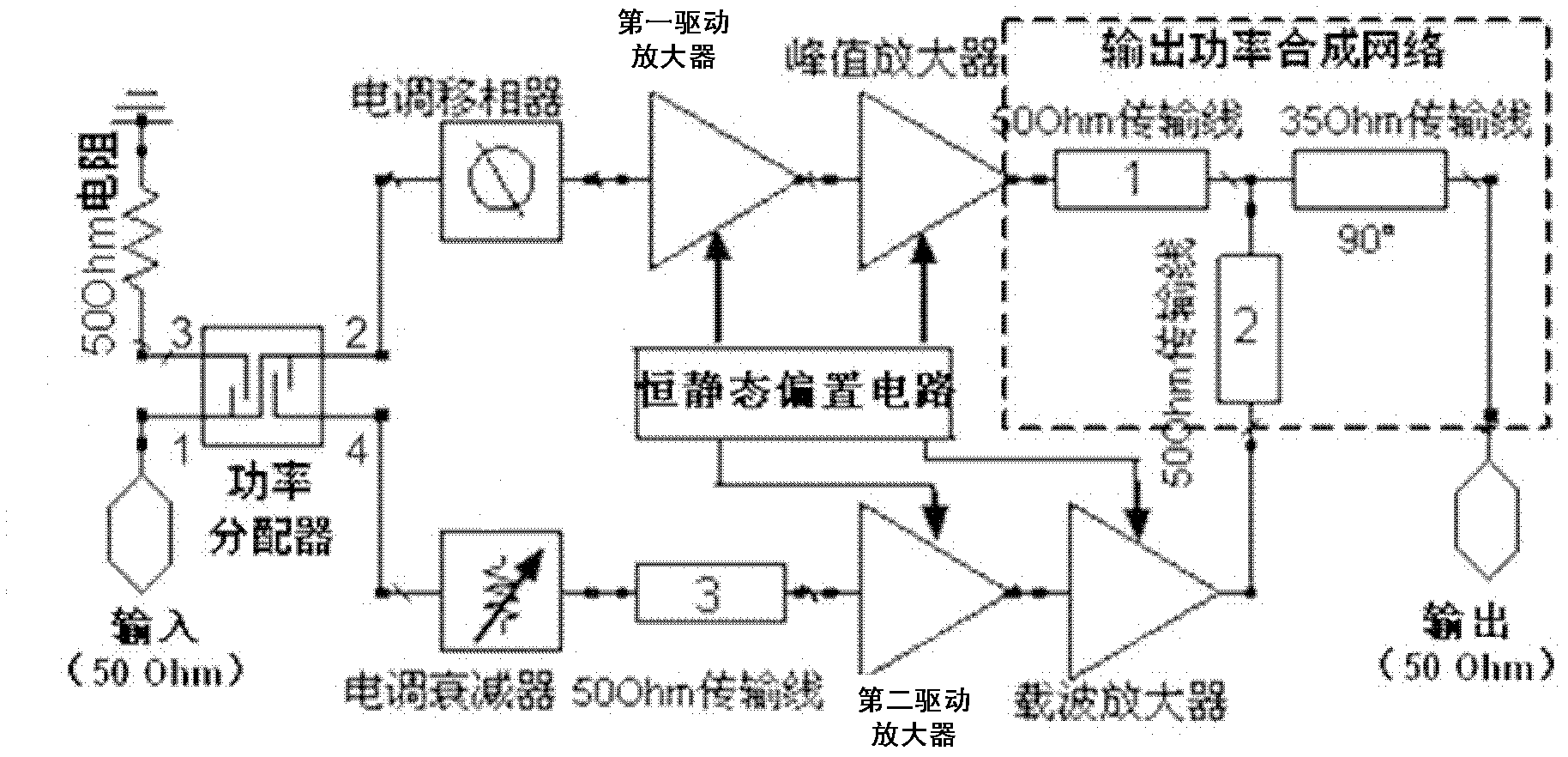

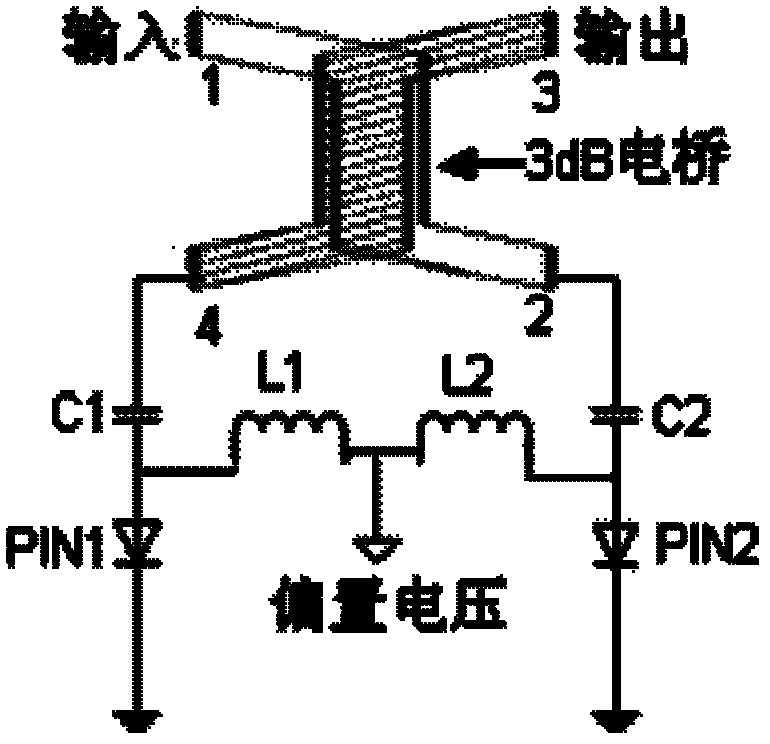

Electric adjusting Doherty power amplifier

InactiveCN102594265AReduce efficiency lossThe driving power distribution ratio of the power amplifier is goodAmplifier modifications to raise efficiencySatelliteElectricity

The invention discloses an electric adjusting Doherty power amplifier, which is applied to the fields of mobile base station power amplification and satellite communication and the like. In the electric adjusting Doherty power amplifier, driving power splitting ratio of a carrier amplifier and a peak amplifier and a synthetic phase of two branches of amplifiers can be adjusted electrically, therefore a best driving power splitting ratio of the Doherty power amplifier and a best synthetic phase are guaranteed.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

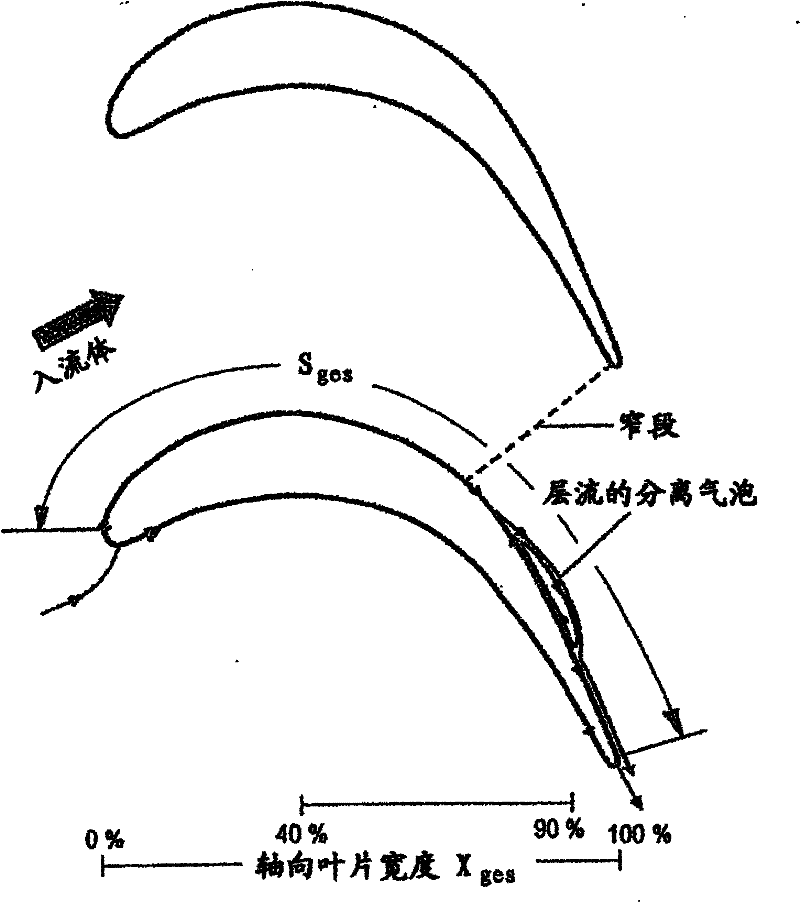

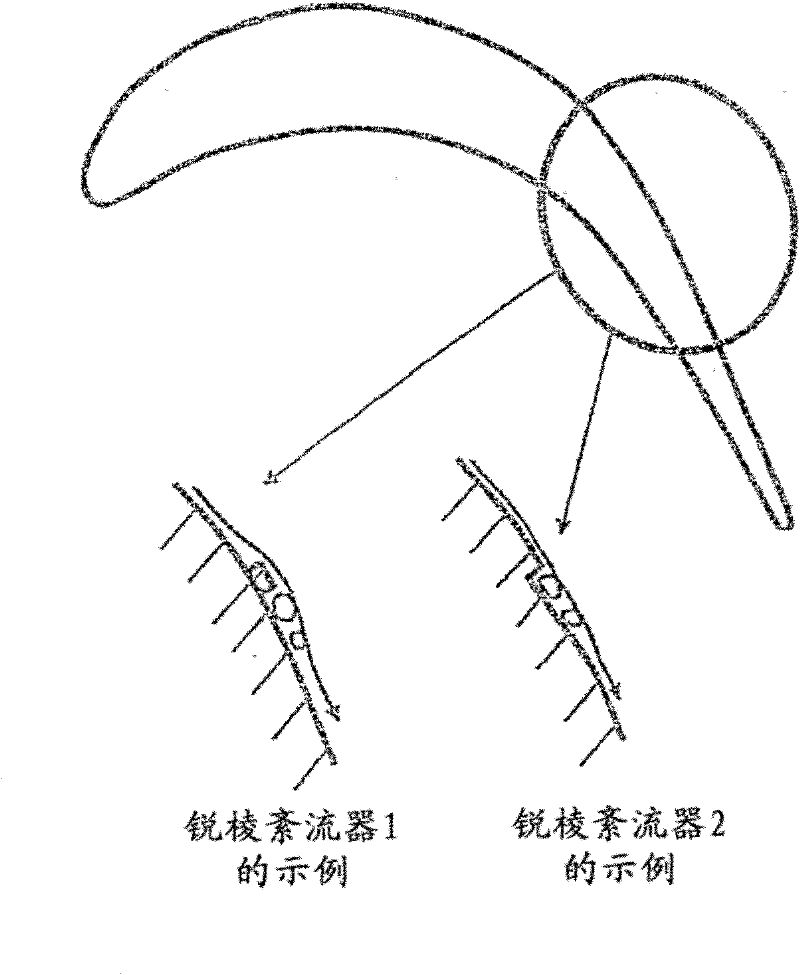

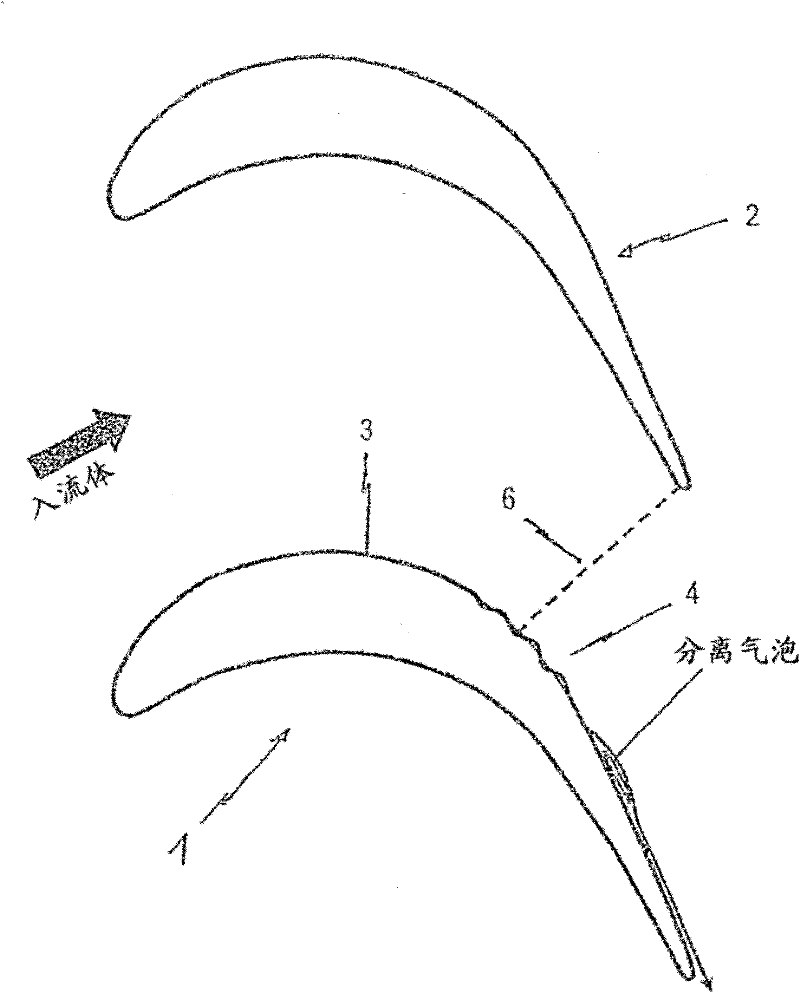

Blade for a turbo device with a vortex-generator

InactiveCN102099546AImprove machinabilityImprove claddingEngine manufactureBlade accessoriesEngineeringTurbine

The invention relates to a blade construction for a turbo device, preferably a blade array of a low-pressure turbine, on the inlet-side profile surface (3) of which a vortex generator (4) is arranged downstream of the speed maximum. The vortex generator is formed by a surface undulation with at least one wave, the wave back of which runs in the form of a wave trough and / or wave peak in the blade vertical direction.

Owner:MTU AERO ENGINES GMBH

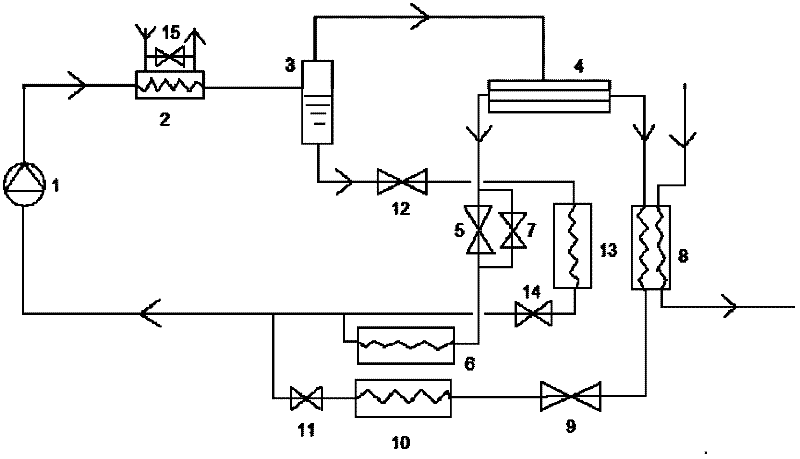

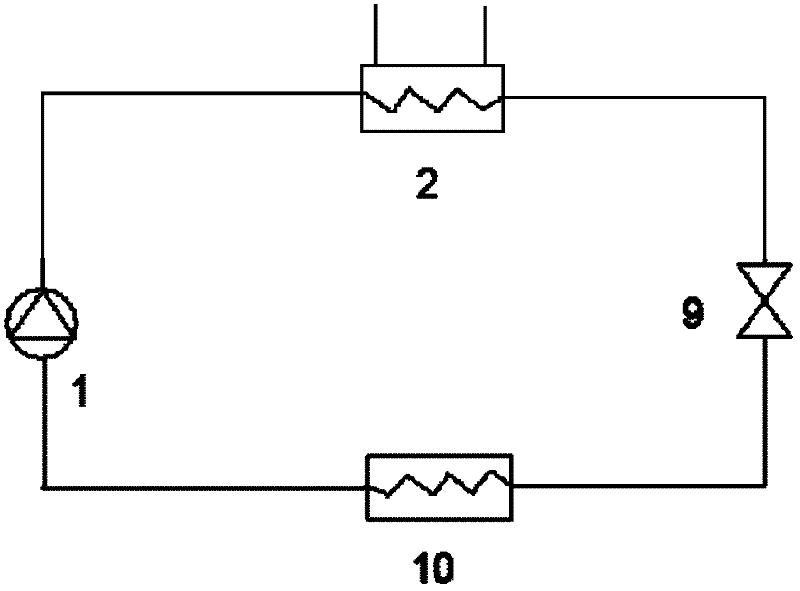

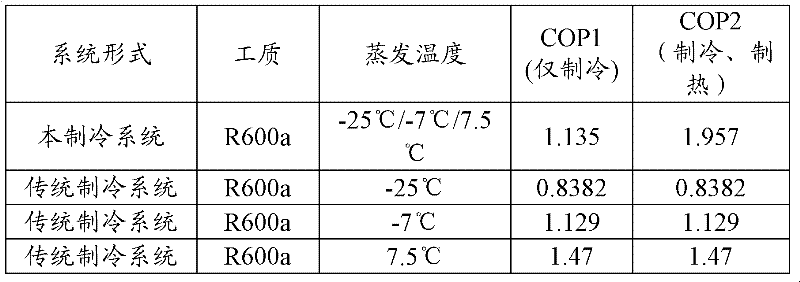

Multi-temperature-zone refrigeration system with vortex tube

ActiveCN102338496ASave energyGood energy savingCompression machinesFluid circulation arrangementEvaporatorRefrigeration temperature

The invention discloses a multi-temperature-zone refrigeration system with a vortex tube. A compressor is connected with a first condenser, the first condenser is connected with a gas-liquid separation device, a gas outlet of the gas-liquid separation device is connected with the vortex tube, and a hot end outlet of the vortex tube is sequentially connected in series with a second condenser, a first expansion valve, a first evaporator and a first pressure reducing valve; a cold end outlet of the vortex tube is sequentially connected in series with a second expansion valve and a second evaporator, and the outside of the second expansion valve is parallel to a first bypass valve; a liquid outlet of the gas-liquid separation device is sequentially connected in series with a third expansion valve, a third evaporator and a second pressure reducing valve; an outlet of the first pressure reducing valve, an outlet of the second evaporator and an outlet of the second pressure reducing valve are connected with the compressor after being connected into a circuit. By using the multi-temperature-zone refrigeration system with the vortex tube, the problem that different refrigeration devices are needed for different refrigeration temperatures and storage environments in some occasions such as hypermarkets and the like is solved. Multi-temperature-zone refrigeration is realized by adopting aset of refrigeration system and device through an energy separation effect of the vortex tube, and the system efficiency is increased by utilizing generated heat quantity.

Owner:ZHEJIANG UNIV

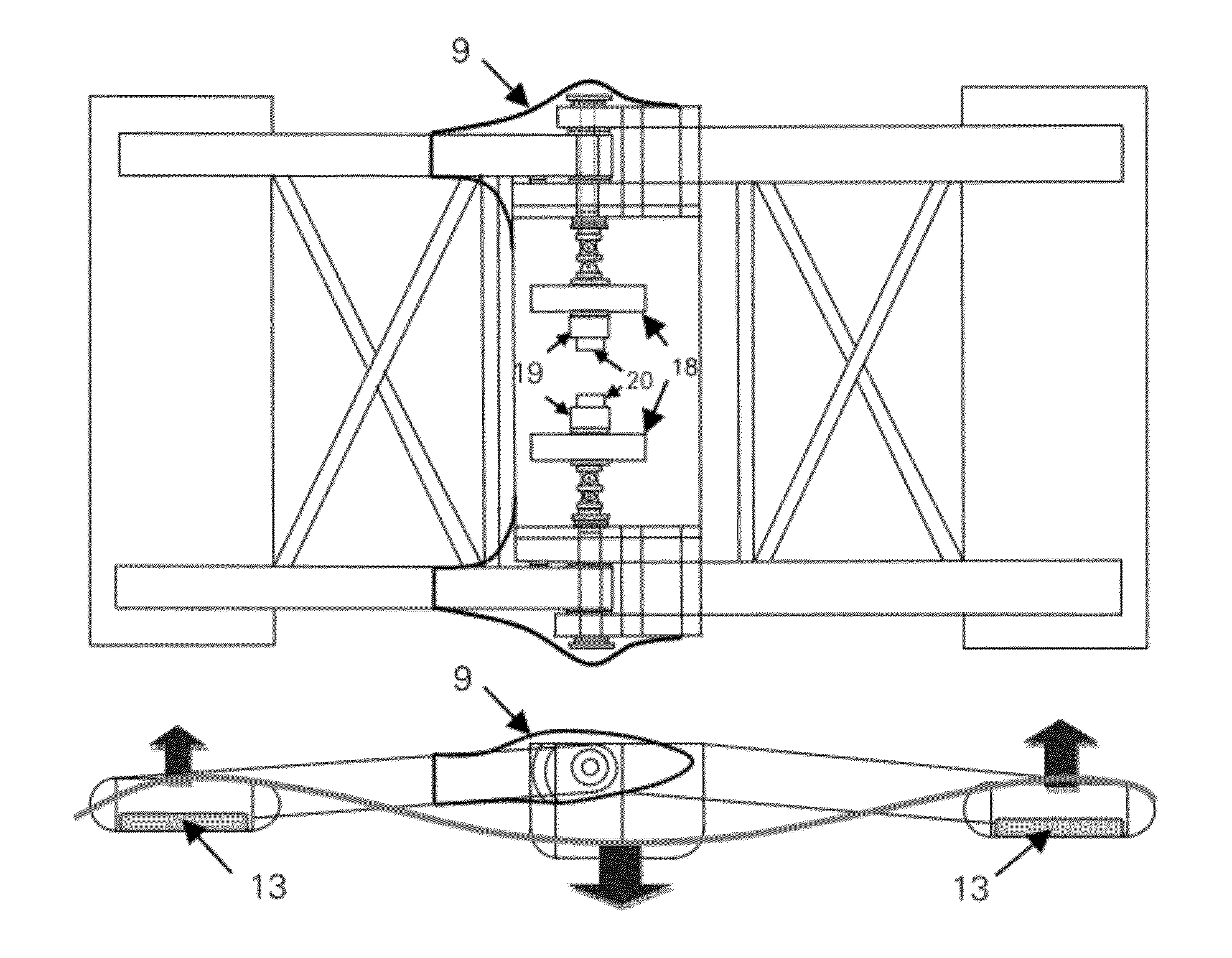

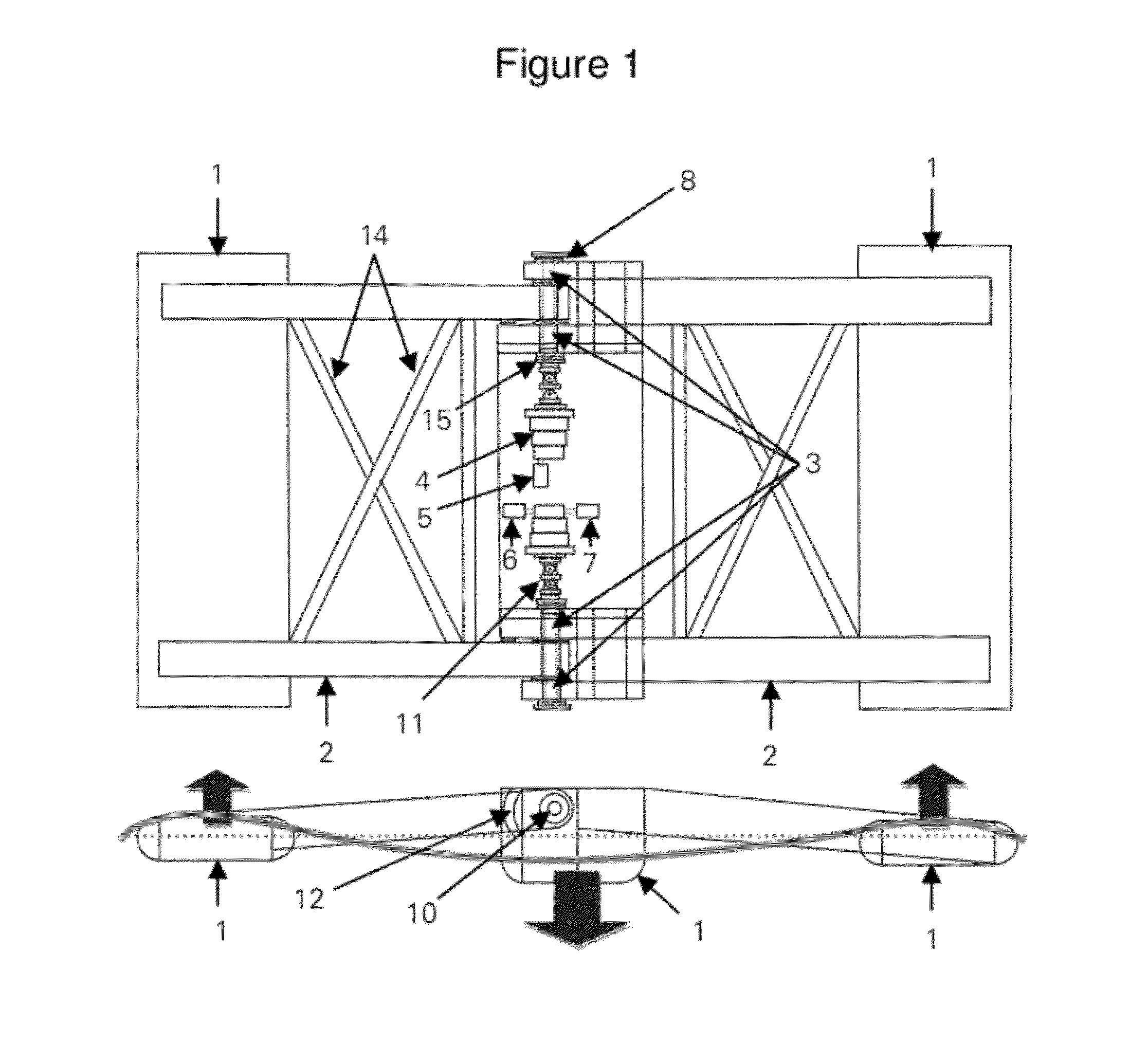

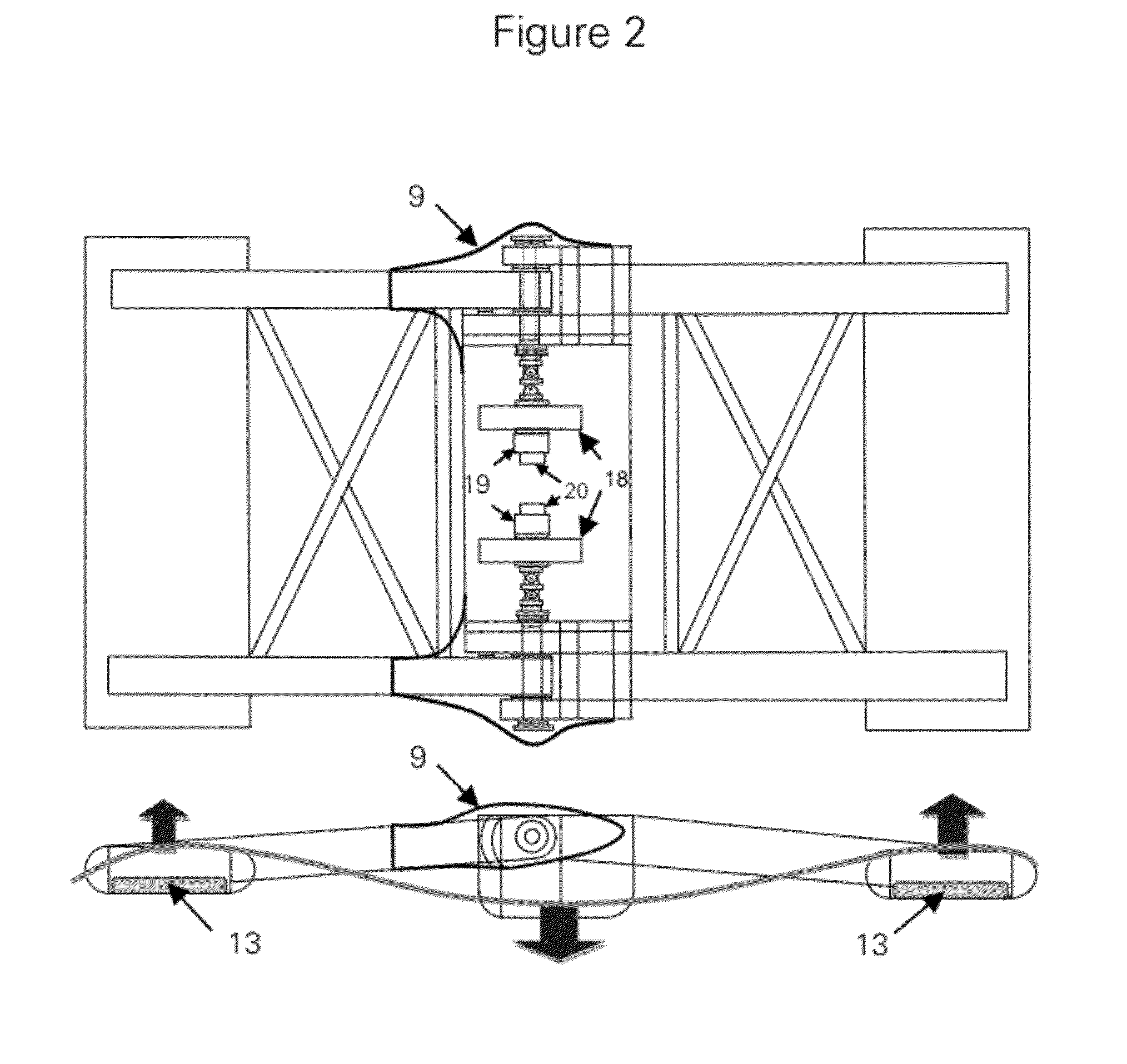

Simplified Wave Energy Device Without One-way Clutches

InactiveUS20120087732A1Increased mechanical advantageLower cost of capitalWater-power plantsMachines/enginesEngineeringBuoy

This invention is a greatly simplified device for transforming the energy of water waves into useable energy. The invention is a device for transforming the energy of water waves into useable energy comprising two or more buoys or buoys, and structural members connecting buoys, whereby motions of buoys relative to one another generates torque, and a means for transferring torque to one or more generators, and a means by which to enable all generator currents to flow in a single beneficial direction. Novel systems for interconnecting such devices are also described herein.

Owner:GRAY DENNIS JOHN

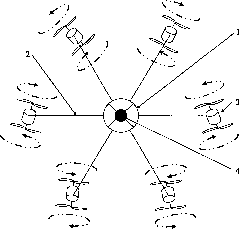

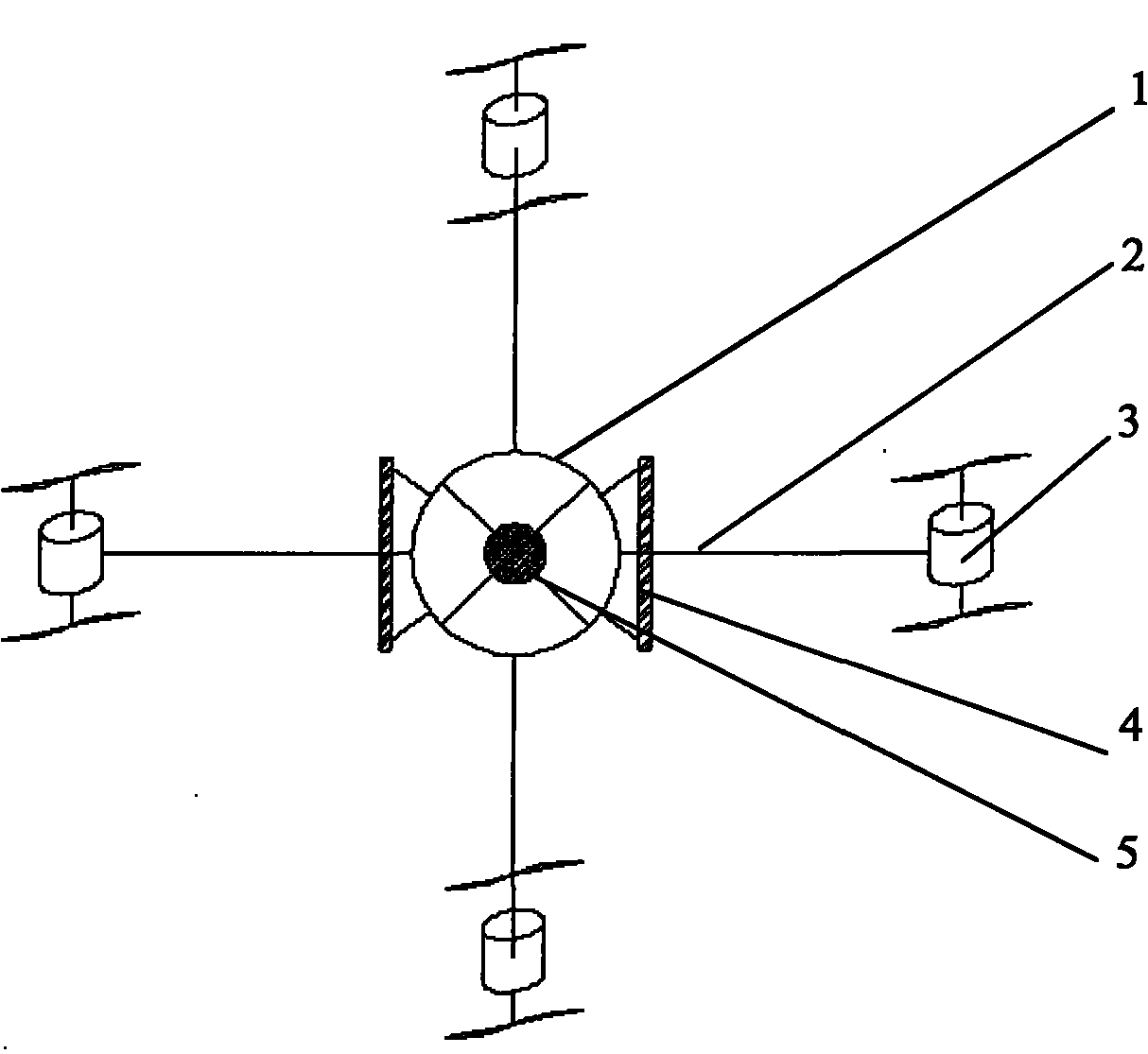

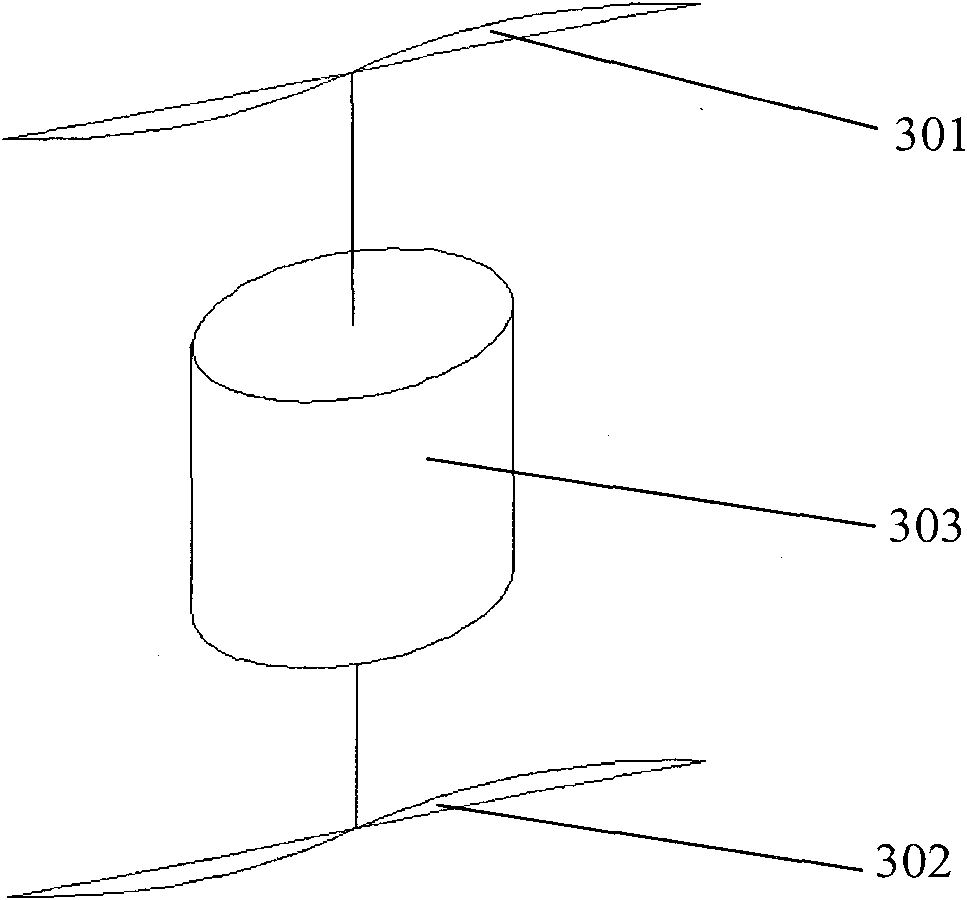

Coaxial-inversion birotor eight-rotary wing aircraft

InactiveCN101811572AReduce efficiency lossImproved lift-to-weight ratioRotocraftHigh liftElectric control

The invention provides a coaxial-inversion birotor eight-rotary wing aircraft, relating to the technical field of unmanned aircrafts and comprising an engine body (1), four supporting arms (2), four birotors (3), undercarriages (4) and an electric control system (5), wherein the four supporting arms (2) are connected to the periphery of the engine body (1), the geometrical center lines of the four supporting arms (2) are on the same plane, and the included angle of the geometrical center lines of the adjacent two supporting arms (2) is 90 degrees; the four birotors (3) are respectively arranged on the ends of the four supporting arms (2); the undercarriages (4) are symmetrically connected to the engine body (1); and the electric control system (5) is arranged in the engine body (1), controls and is connected with the four birotors (3). The aircraft has high lift force / weight ratio and loading capacity.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

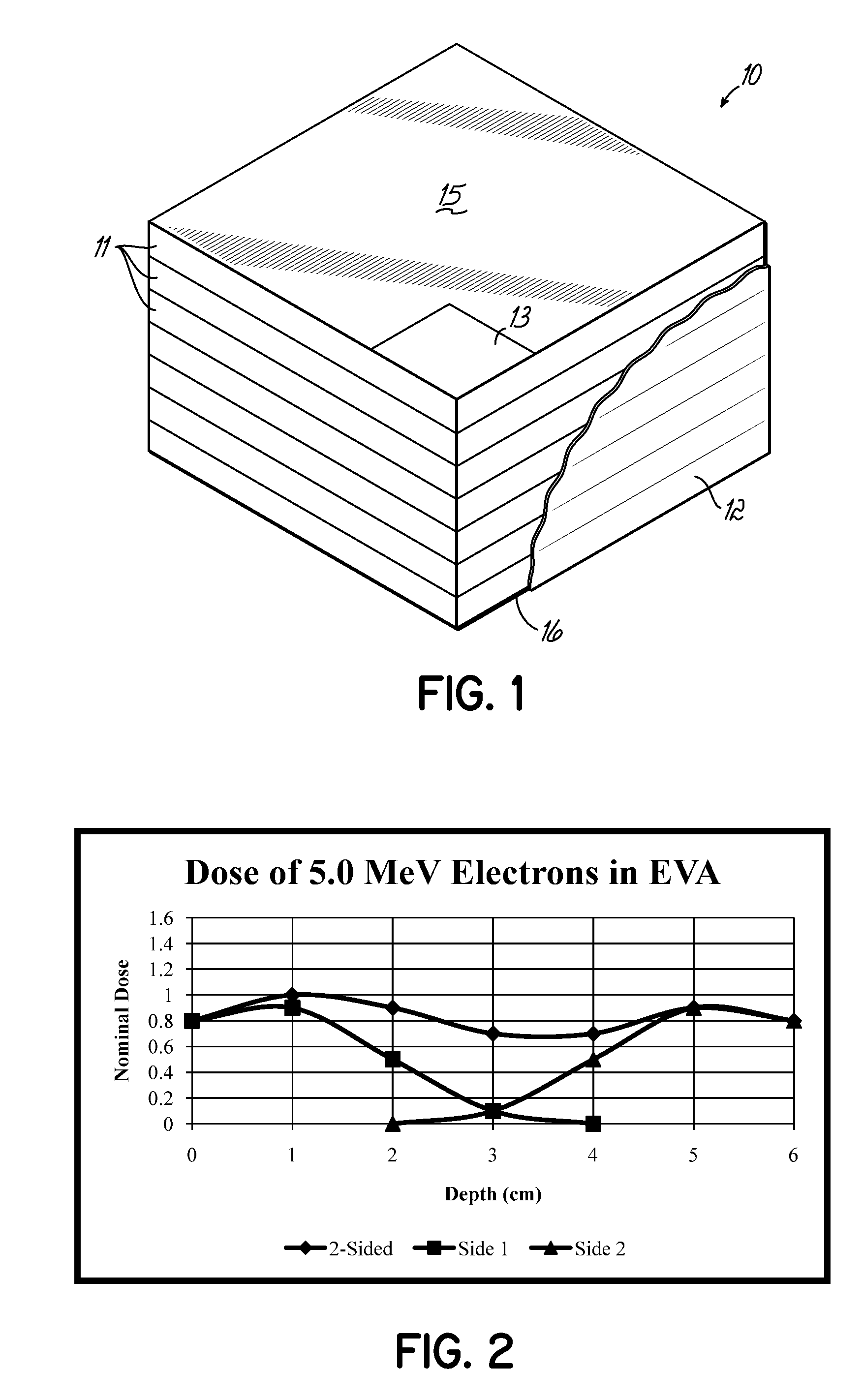

Electron Beam Irradiation of Bulk Material Solids

ActiveUS20110031657A1Easy to handleEasy disposalElectric discharge tubesSolid materialHigh energy electron beamElectron

Owner:E BEAM SERVICES

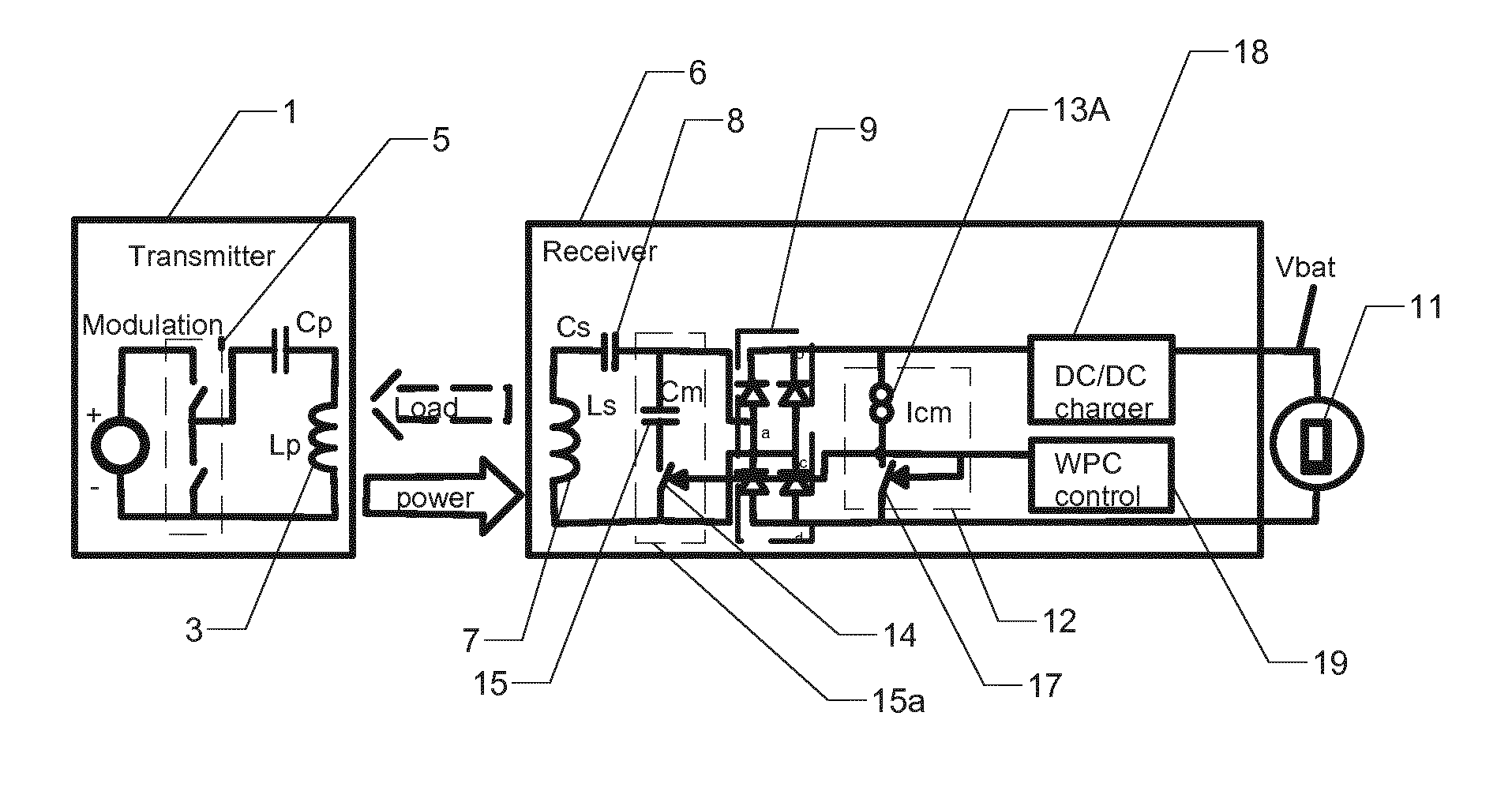

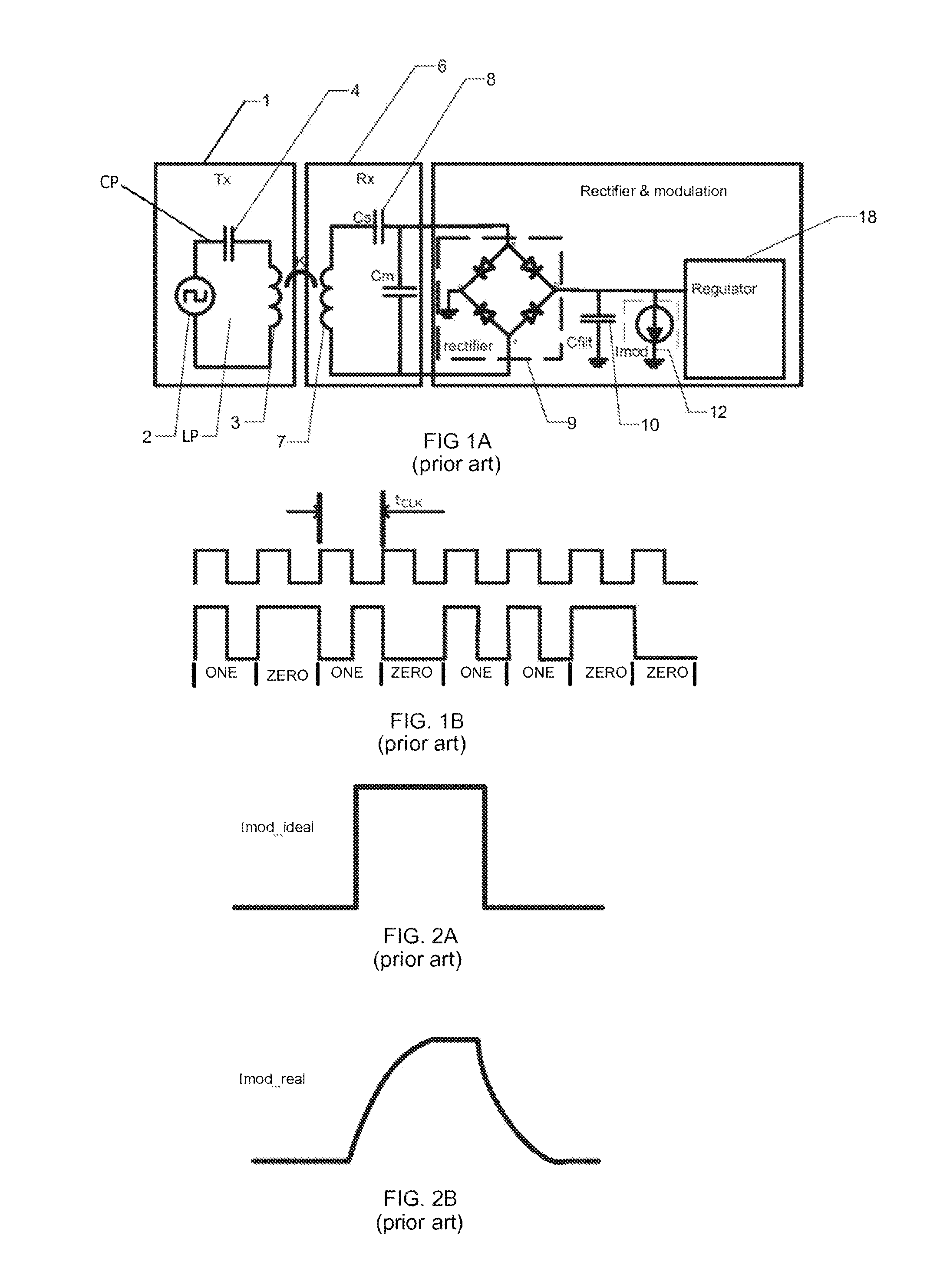

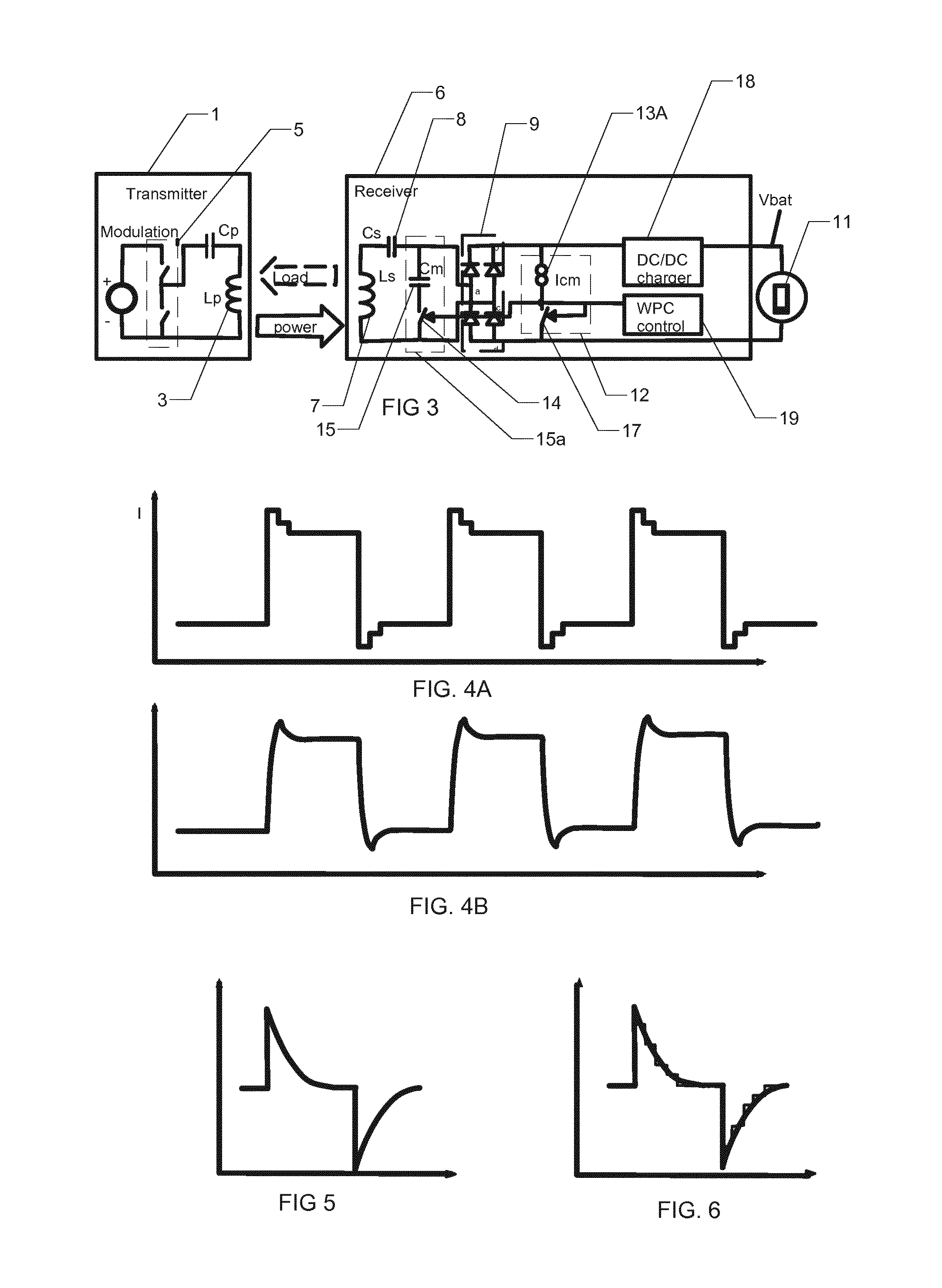

Method of and Receiver for Communication During Wireless Power Transmission

InactiveUS20150222330A1Reduce efficiency lossNear-field transmissionBatteries circuit arrangementsElectric power transmissionEngineering

In a wireless power charger a receiver (6) is inductively coupled to a transmitter (1) to receive power for charging an accumulator in a device (11). The receiver (6) communicates charging data to the transmitter (1) by imposing current pulses across the direct current output terminals of a rectifier (9) in the receiver. To enhance the performance of the receiver without reducing the signal to noise ratio of the current pulse receiver to transmitter communication the shape of unwanted transient currents in a filter capacitor (10) are sensed and the transient current shape added to an ideal rectangular step function pulse shape to produce a communication pulse shape. As a result the communication pulse shape seen at a secondary inductor (7) of the receiver closely approximates the ideal rectangular step function shape desired whereby the signal to noise ratio is kept high. The receiver is particularly useful in mobile devices such as cell phones, tablet PC's and laptops.

Owner:OPTIS CIRCUIT TECH LLC

Metering pump

InactiveUS20040076534A1Reduce efficiency lossPositive displacement pump componentsPiston pumpsPump chamberReciprocating motion

A metering pump that is capable of delivering a constant, rate of fluid over a wide range of viscosities at infinitely variable delivery rates. Two identical pumping chambers are provided with one operating in the suction mode, and the other in the discharge mode with each cylinder switching modes at each pumping cycle, thereby providing continuous delivery of fluid in and out of the pump. The displacement of the chamber is large in order to facilitate operation at a very slow cycle speed of only one to four reciprocations per minute. The fluid valves are mechanically operated providing for positive sealing thus enabling the pump to operate at very slow speeds without leakage.

Owner:HAMMONDS TECHN SERVICES

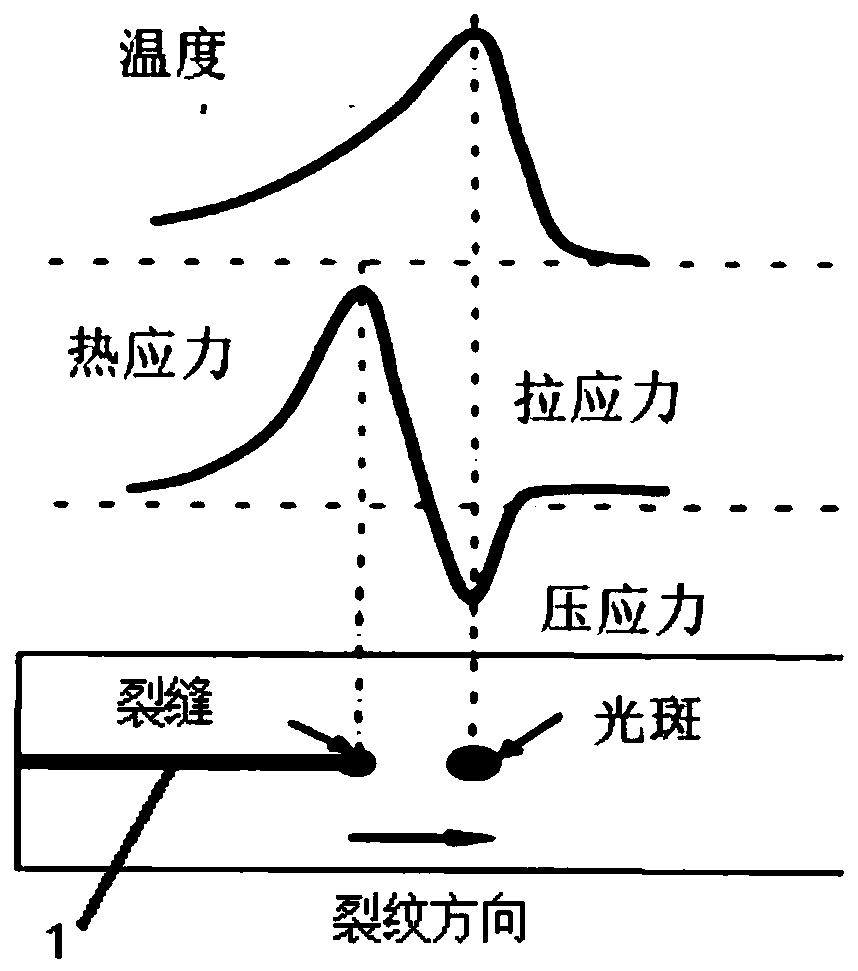

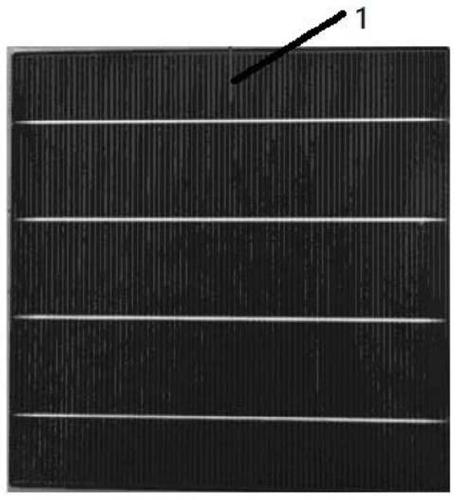

Photovoltaic cell cutting method and cell manufactured by method

InactiveCN111590214AReduce the temperatureLow efficiencySemiconductor/solid-state device manufacturingLaser beam welding apparatusLight spotAmorphous silicon

The invention discloses a photovoltaic cell cutting method, and further provides a battery piece which is obtained by cutting through the photovoltaic battery piece cutting method. The method comprises the steps of that 1, a cell to be cut is placed in a laser scribing area; 2, forming a first cutting line on the edge of the cutting position of the battery piece by using a first laser; and 3, a second laser is used, the light spot of the second laser is locally heated along the position in front of the crack of the first cutting line and moves and extends in the direction where the first cutting line is located and in the direction away from the edge, and meanwhile the heated position is cooled. The method has the advantages that the laser cutting temperature can be obviously reduced, no gasification or fusion is generated in the cutting process, so that no dust is generated, no slag chip or micro crack is generated on the cutting fracture surface, so that the mechanical properties ofthe battery and the assembly are improved, namely the mechanical strength is improved, for condition of an amorphous silicon film layer, the amorphous silicon film layer is prevented from being damaged, and efficiency loss of the battery piece is reduced.

Owner:RISEN ENERGY

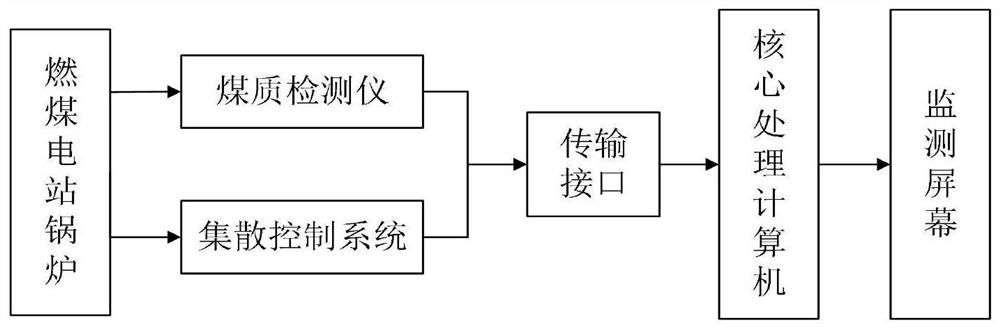

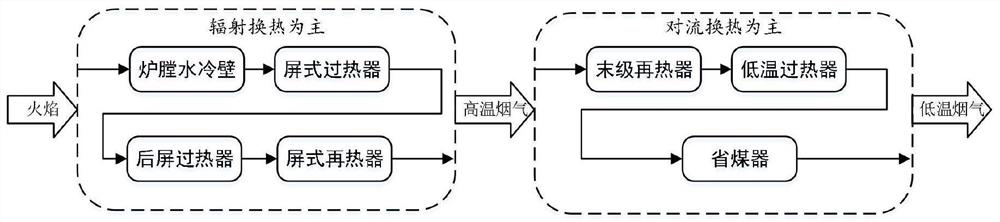

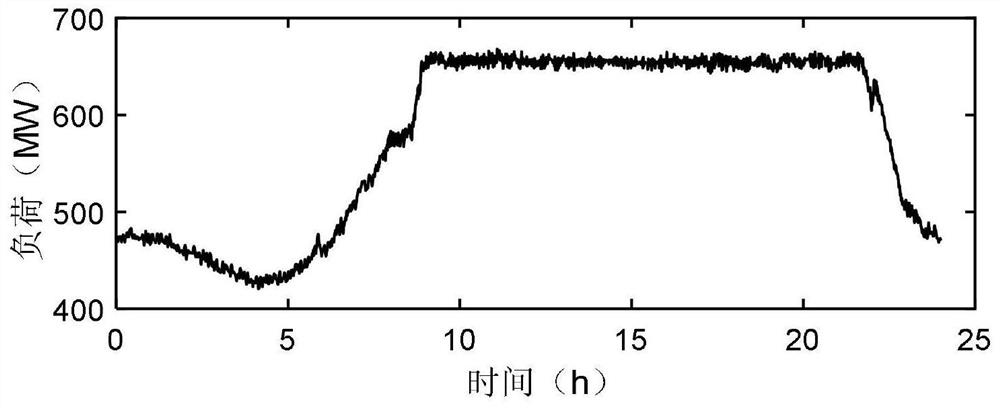

On-line monitoring system for heating surface ash deposition of coal-fired power plant boiler, and detection method of on-line monitoring system

ActiveCN112283689AReduce running timeSmall monitoring accuracyBoiler controlTotal factory controlReal-time dataDistributed control system

The invention relates to an on-line monitoring system for heating surface ash deposition of a coal-fired power plant boiler, and a detection method of the on-line monitoring system. The heating surface of the coal-fired boiler is divided into a radiation heating surface and a convection heating surface according to different heat transfer modes, corresponding ash deposition monitoring characterization parameters are selected according to the different heating surfaces, and the heating surface ash deposition degree is monitored in real time. According to the invention, real-time and historicaloperation parameters of a field distributed control system and a coal quality detector of a coal-fired power plant are downloaded, real-time data preprocessing and key parameter soft measurement are carried out, a database and an ash deposition monitoring model and a prediction model of each heating surface are built, offline data is applied to train each model, and online monitoring is realized after the target precision is reached. According to the invention, the ash deposition conditions of the different heating surfaces of the coal-fired power plant boiler can be monitored in real time, the ash deposition monitoring result of each the heating surface is output, a theoretical basis is provided for workers to judge ash blowing operation, and then the problem of steam waste caused by lowheat exchange efficiency of the boiler and excessive ash blowing due to insufficient ash blowing, is solved.

Owner:XIAN TECHNOLOGICAL UNIV

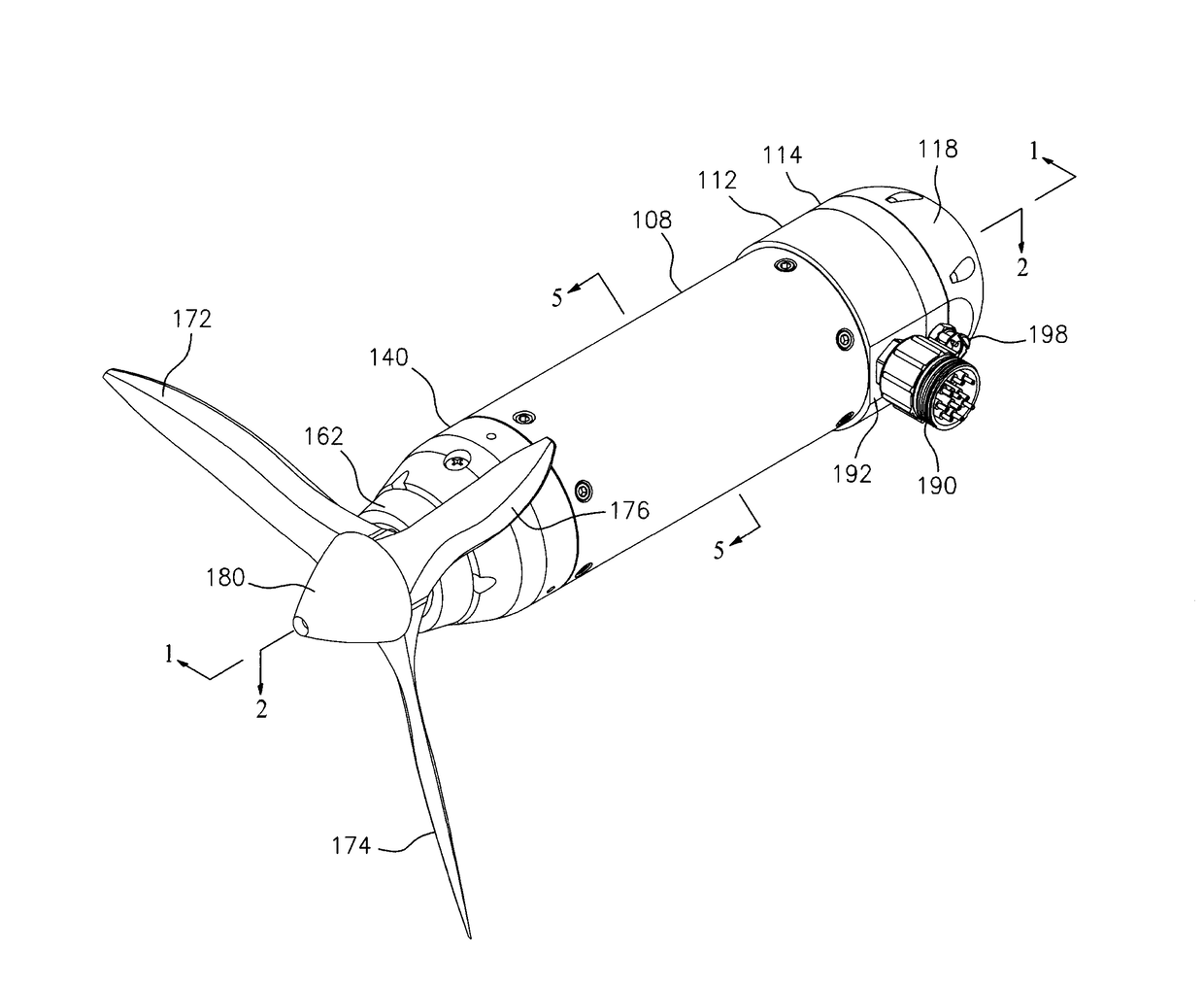

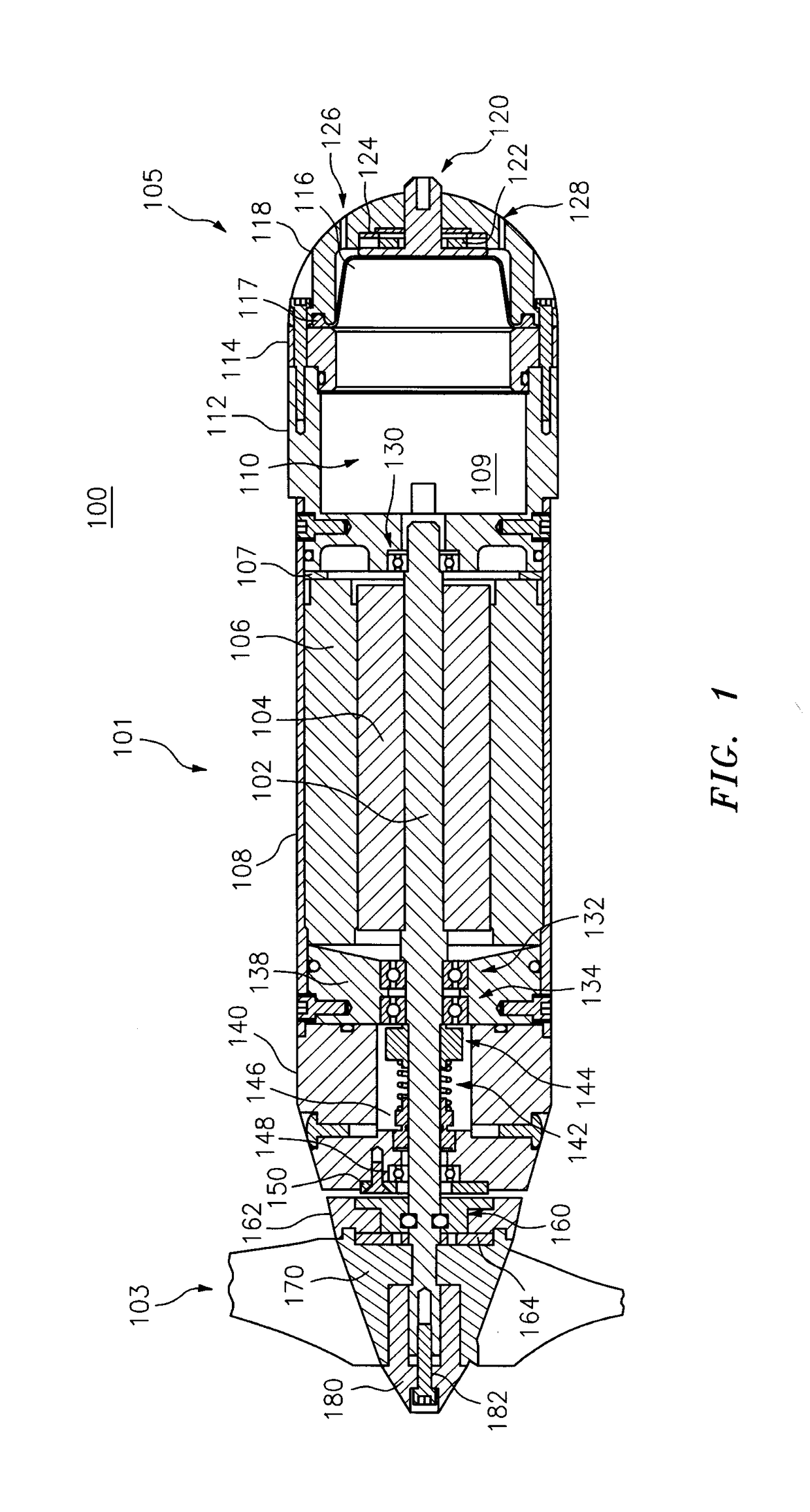

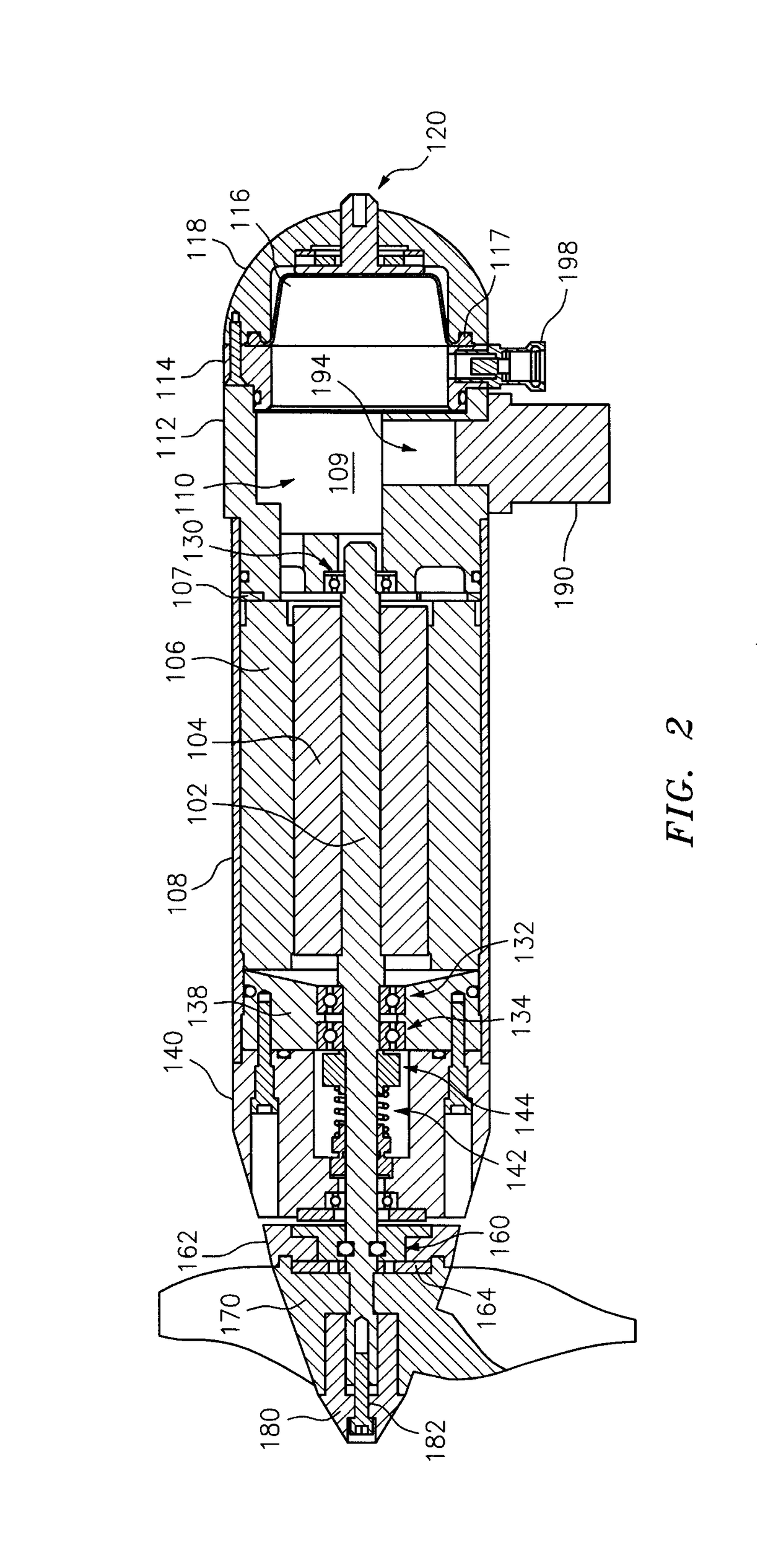

Improved-Efficiency Submersible Thruster

ActiveUS20170113773A1Reduce efficiency lossImprove efficiencyPropulsion power plantsUnmanned surface vesselsDrive shaftThrust efficiency

A submersible thruster, and methods of optimizing and using same, including selecting a motor with an efficiency of greater than 75 percent when operated at 250 rpm immersed in a pressure-resistant fluid, the motor having a drive shaft with a rotor and a stator matched to the rotor, the rotor and the stator being immersed in the pressure-resistant fluid and being separated by a gap less than or equal to 1 mm. The motor is disposed in a housing to isolate the motor components from a liquid environment. A rear portion of the drive shaft extends through a low-friction shaft seal beyond the housing to drive at least one propeller within the liquid environment. Movement of the drive shaft is constrained to a radial and axial play each of less than 0.75 mm. The method further includes operating the motor at less than 50 percent of peak power, wherein said thruster operates at greater than 30 percent end-to-end thrust efficiency within the liquid environment.

Owner:WOODS HOLE OCEANOGRAPHIC INSTITUTION

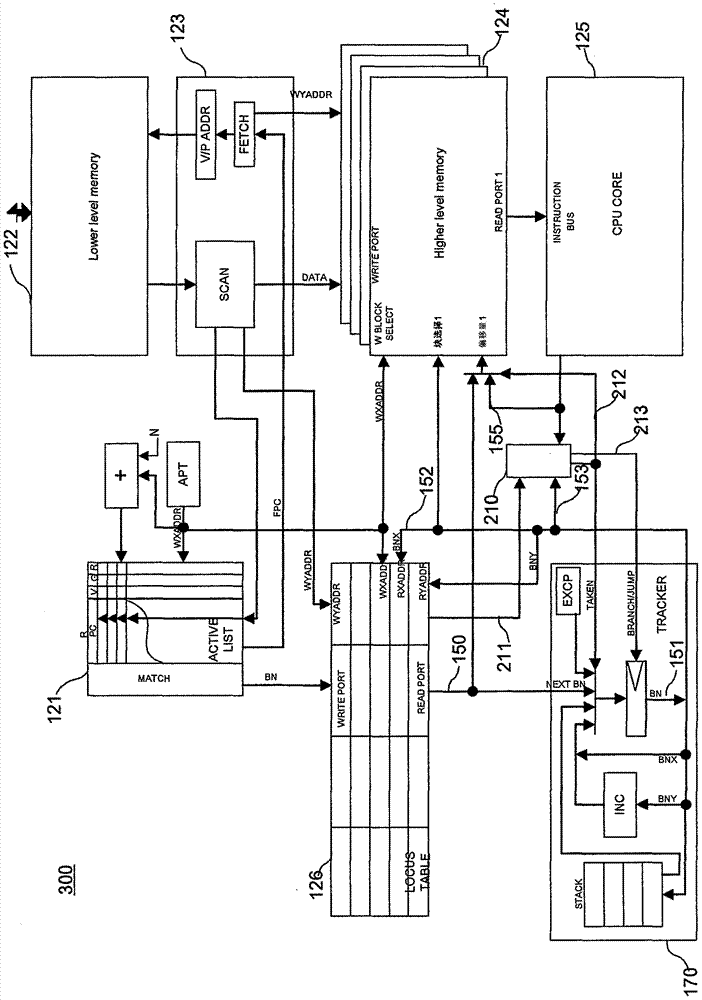

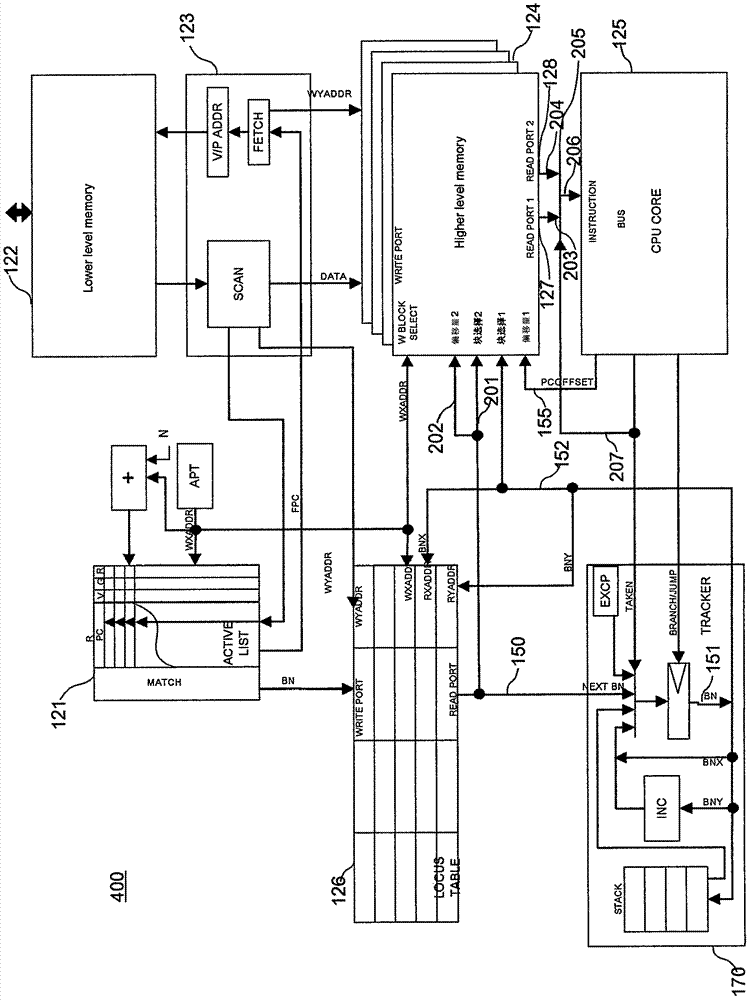

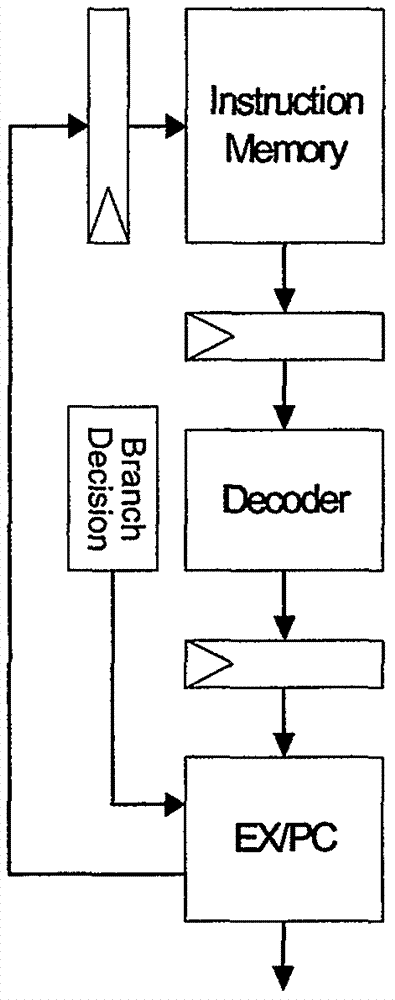

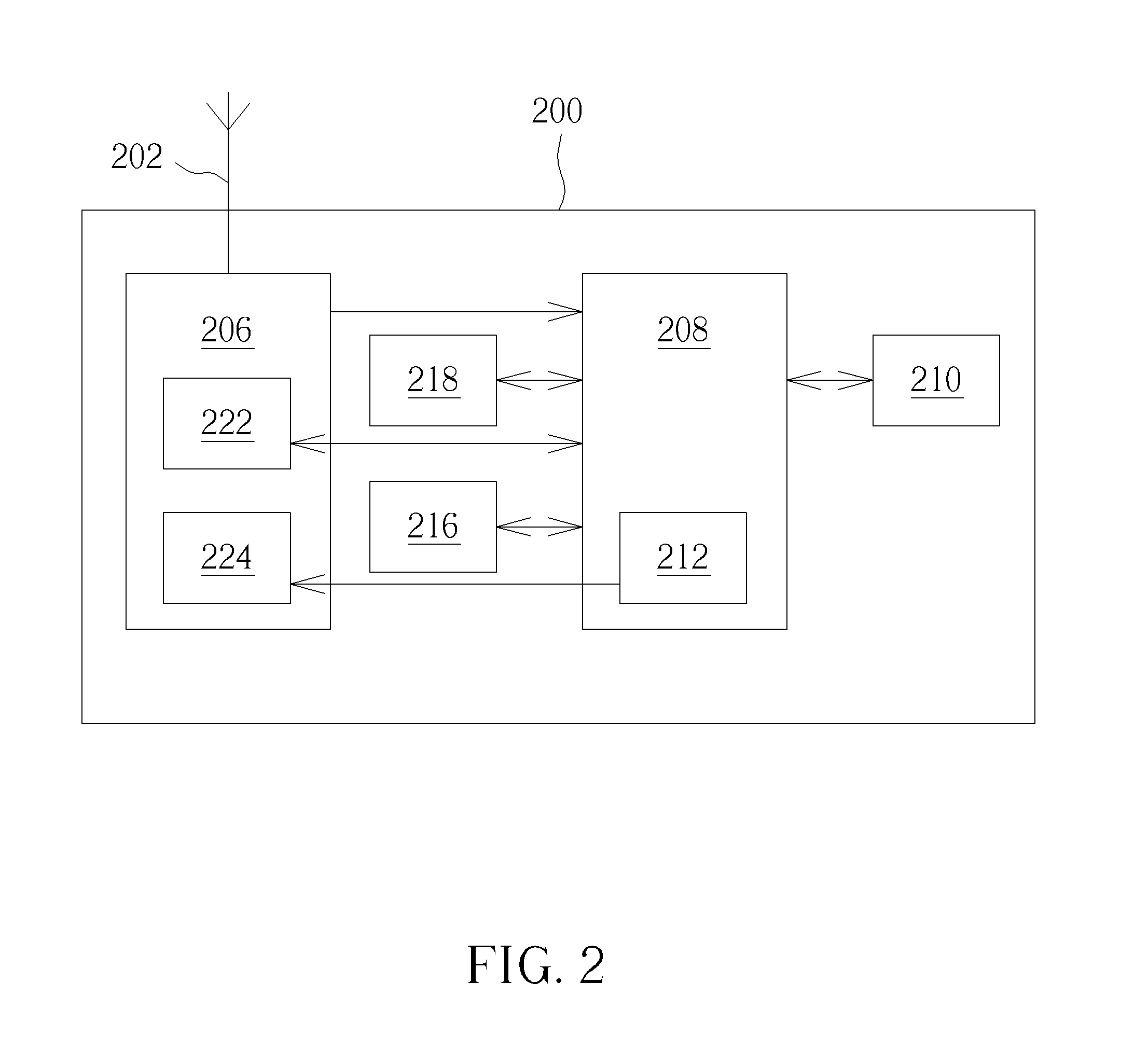

A branch processing method and system

InactiveCN106990942AReduce efficiency lossConcurrent instruction executionInstruction memoryControl signal

Owner:SHANGHAI XINHAO MICROELECTRONICS

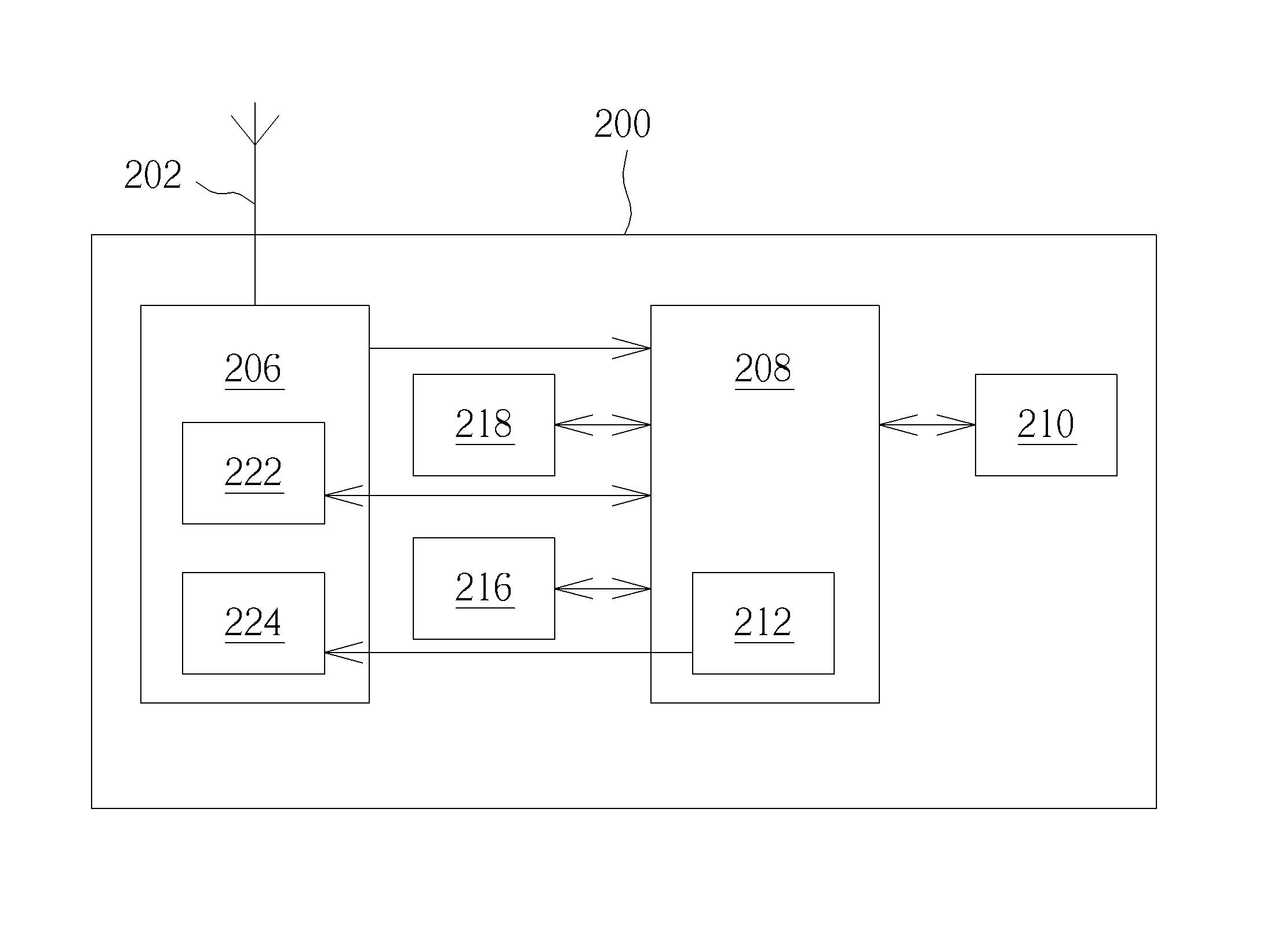

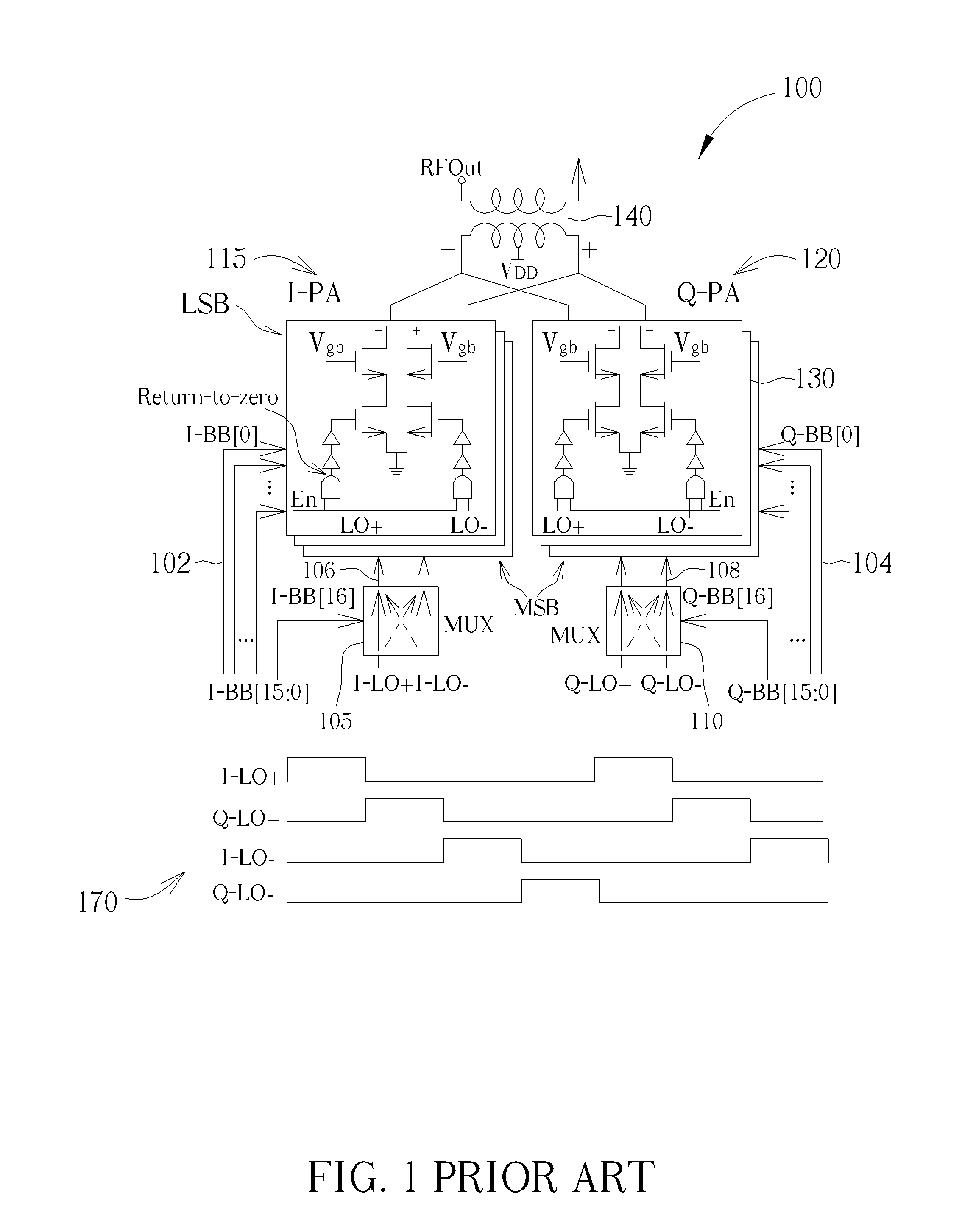

Transmitter circuit, communication unit and method for amplifying a complex quadrature signal

ActiveUS20160127164A1Improve efficiencyIncrease output powerPower amplifiersSecret communicationQuadrature modulatorQuadrature modulation

A transmitter circuit includes a frequency generation circuit configured to generate a local oscillator signal and a digital modulator configured to: receive data to be transmitted; quadrature modulate the received data to at least a first, Q, modulated value and a second, I, modulated value; examine the quadrature modulated data to determine if the first, Q, modulated value exceeds a limit, and in response thereto selectively modify the quadrature modulated values to a first modified, Q′, modulated value and a second modified, I′, modulated value thereby bringing only a value of the first modified, Q′, modulated value to within the limit. A local oscillator phase is selected in order to map the first modified, Q′, modulated value and second modified, I′, modulated value to desired quadrature values. A digital power amplifier, DPA, coupled to the digital quadrature modulator, is configured to amplify the quadrature modified modulated data.

Owner:XUESHAN TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com