Simplified Wave Energy Device Without One-way Clutches

a wave energy device and one-way clutch technology, applied in water-power plants, mechanical equipment, machines/engines, etc., can solve the problems of wave energy devices, generators that spin too slowly, generators that are too heavy and expensive, etc., to achieve the effect of adding mechanical advantages to power output, low capital cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

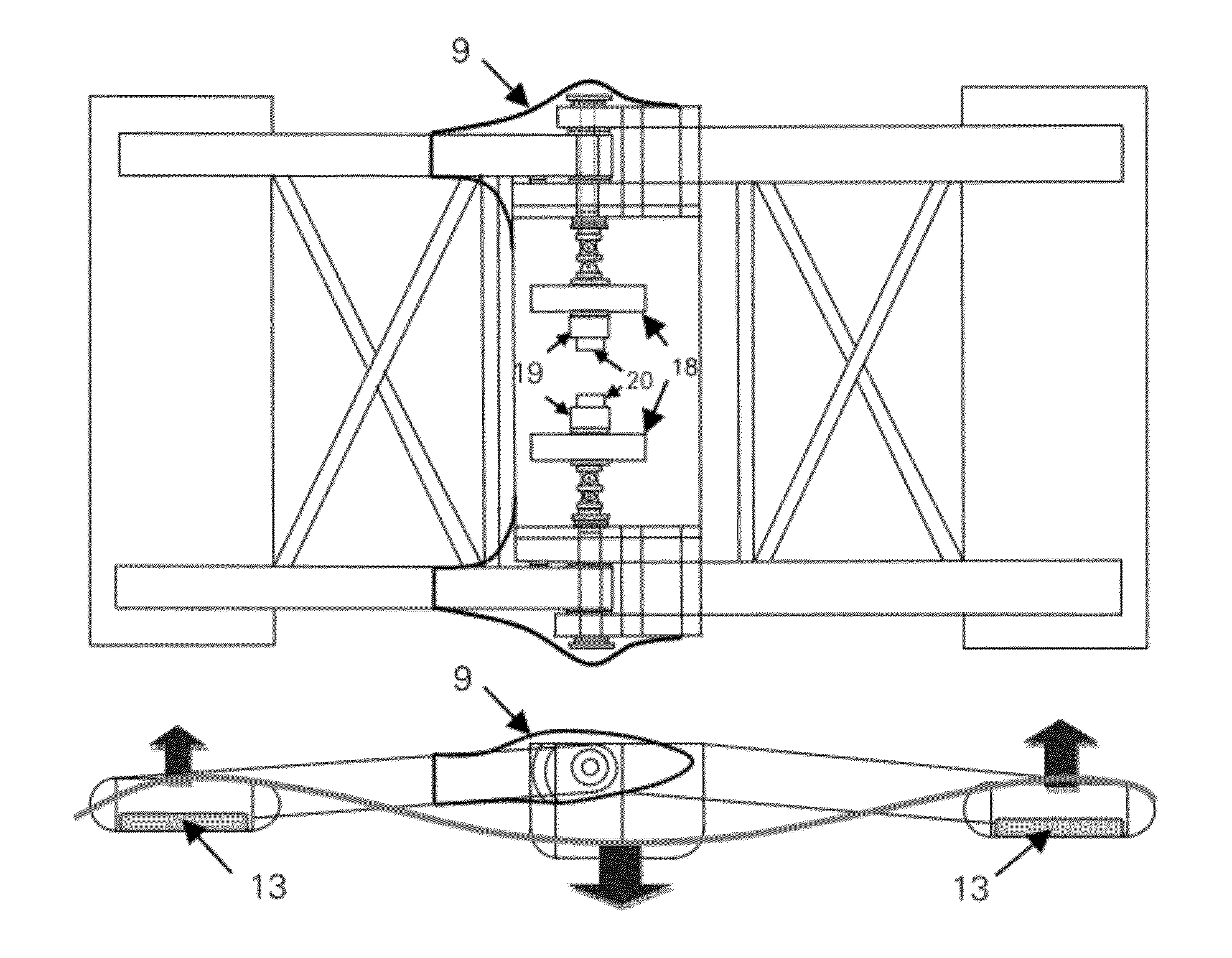

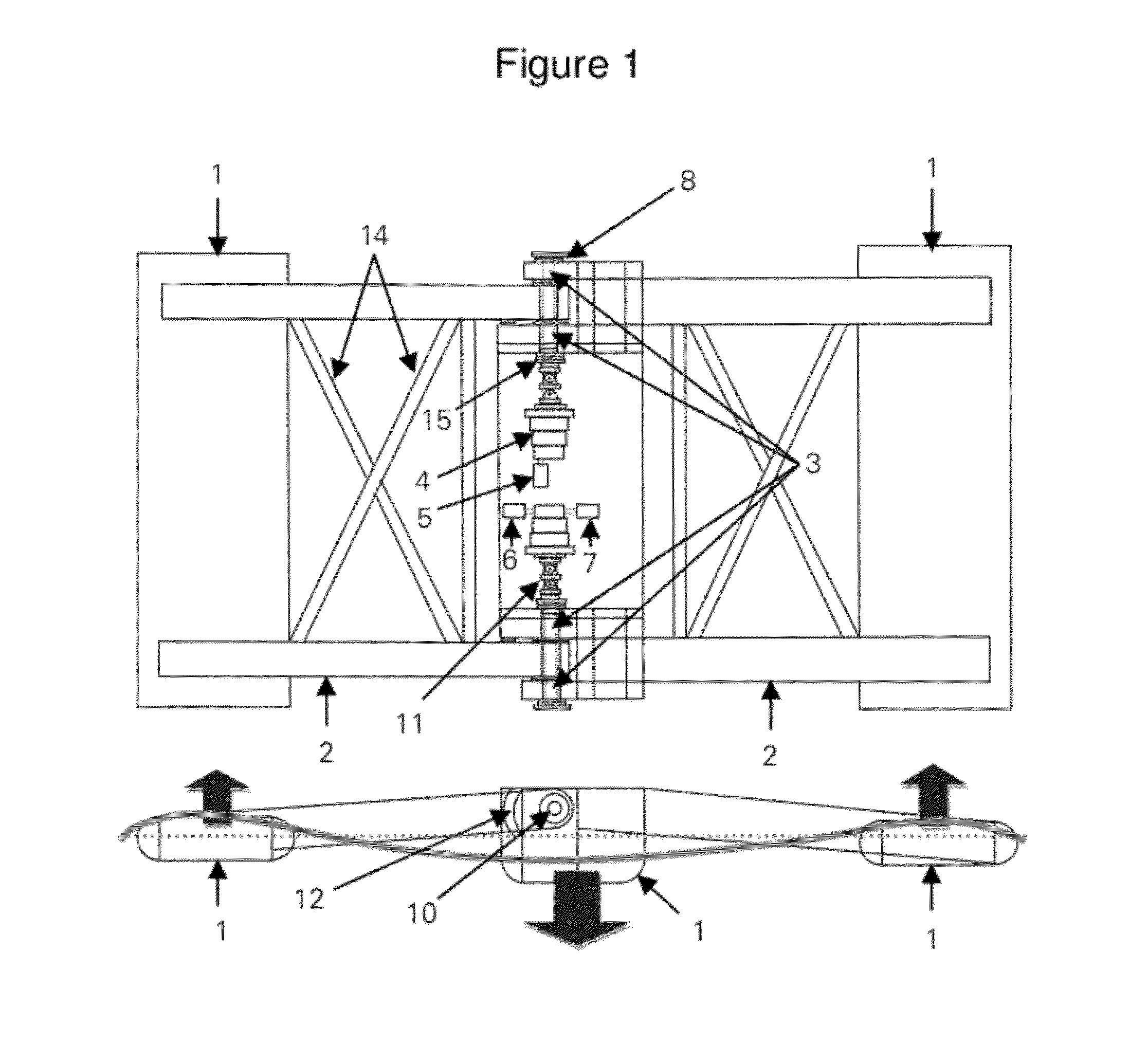

[0016]The invention can be designed and scaled for any size waves. A preferred embodiment would primarily be constructed of steel or other suitable marine materials. Components of the device include two or more buoys (1) connected by torque arms (2) whereby a pivoting motion is permitted at hinge points (3) that have bushing or bearings. The buoy movements generate torque which drive one or more gearboxes (4) which in turns drives one or more generators (5) at higher speeds for electrical output.

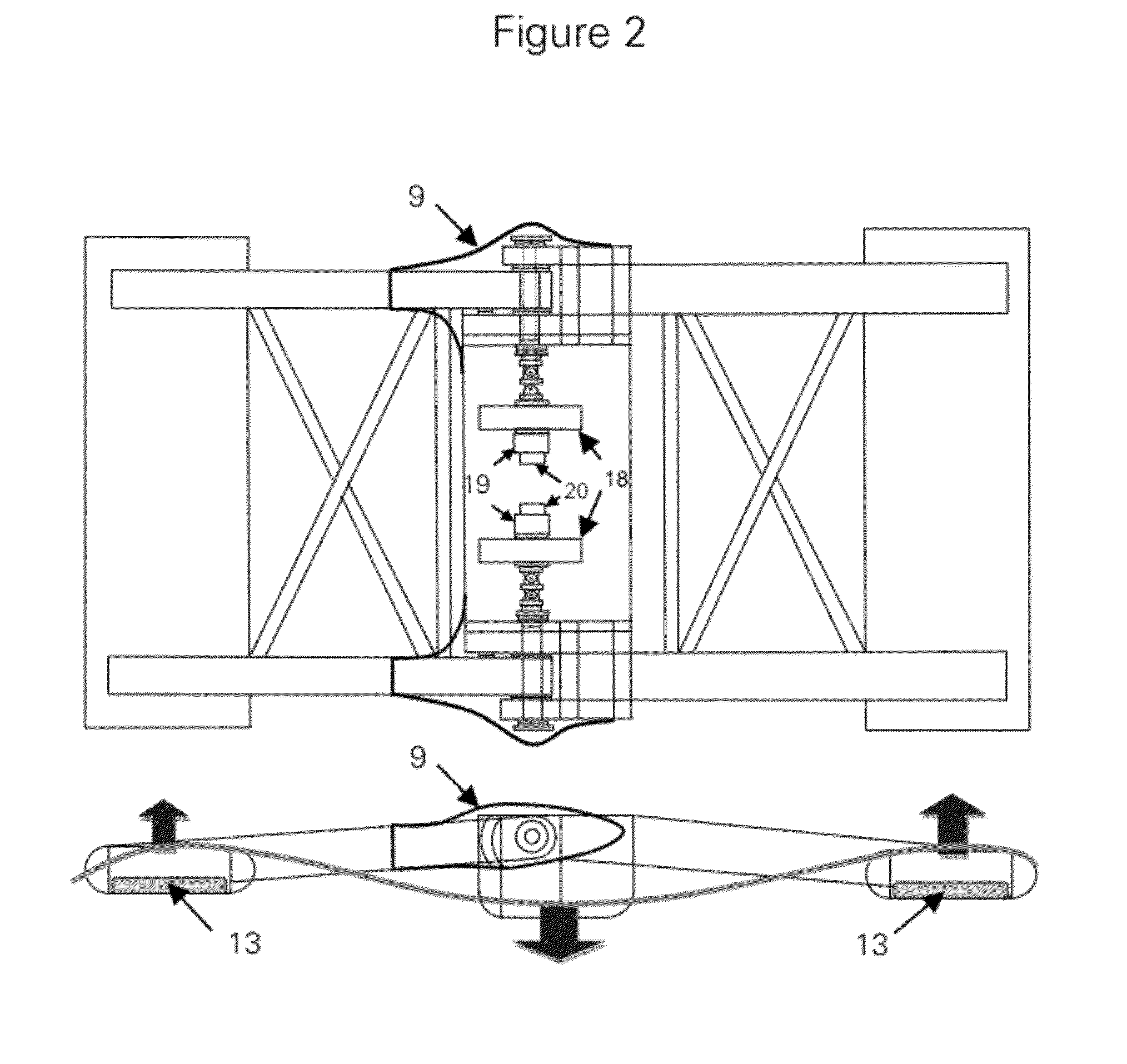

[0017]The complex transmission system described in U.S. Pat. No. 7,315,092 is too customized and expensive, reversing gears are not necessary, and reversing gears present unnecessary efficiency losses. Most importantly, the electrical load, or the amount a wave energy device is trying to power, can be controlled such that the moment of inertia of gearboxes and generators can be consumed before a wave reverses direction. For example, electrical load can be electronically increased just as a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com