Blade for a turbo device with a vortex-generator

一种涡轮叶片、涡轮机的技术,应用在发动机控制、发动机元件、发动机制造等方向,能够解决难以加工使用时间等问题,达到改善可加工性、可覆层性延长、低效率损失的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

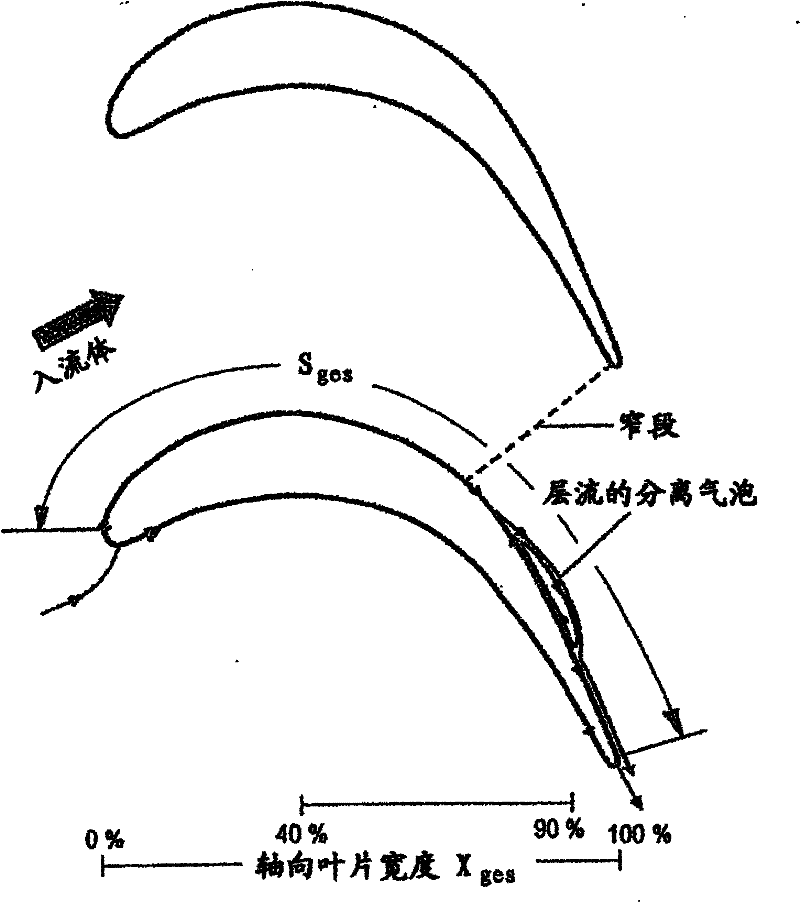

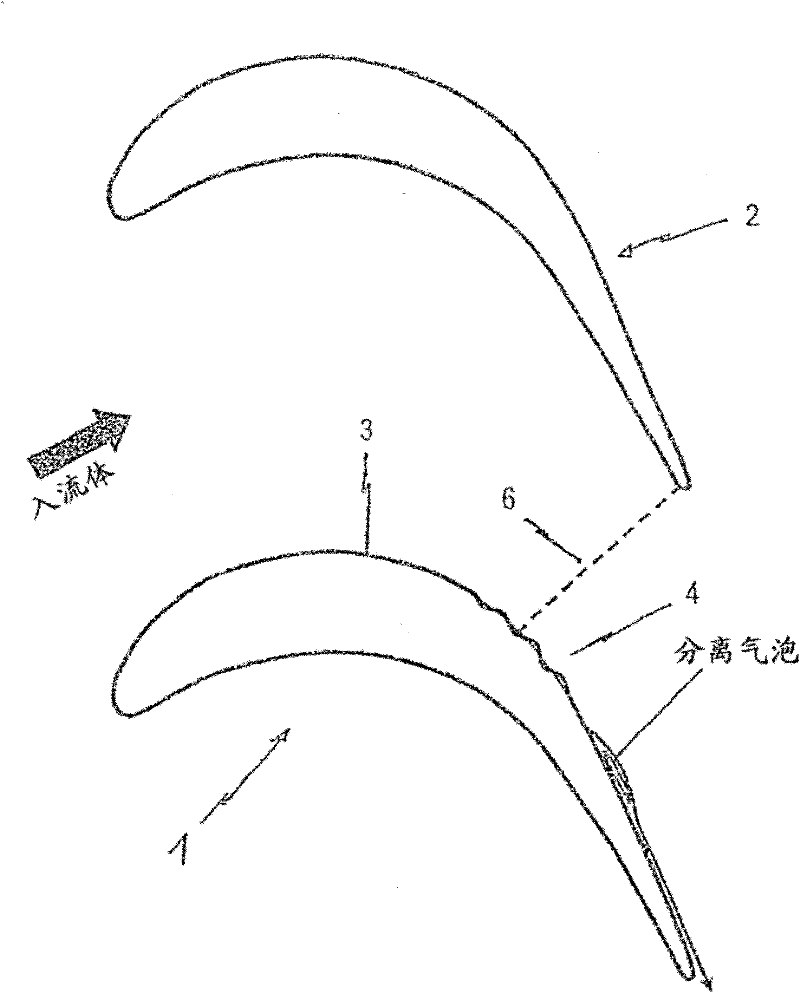

[0028] exist image 3Two adjacent blades 1 , 2 of a turbine are shown in , on their suction-side profiled surface 3 , downstream of the maximum speed, a vortex generator 4 is arranged. In a preferred embodiment, the vortex generator 4 is formed by a plurality of edgeless surface waves, whose wave tails (Wellenrüken) 5 are mainly distributed in the shape of troughs and crests in the blade height direction h, as it is also Figure 4 as shown in. Said wave 4 is also arranged along the blade suction side 3 in such a way that the fluid rises and falls alternately on this wave 4, i.e. the wave 4 is mainly distributed in the direction of the flow (see Figure 4 ) and at least in the blade height direction h according to Figure 4 The core fluid region extends between 20% and 80% of the blade height.

[0029] as by image 3 It can also be seen that the wave 4 has a sinusoidal shape, the maximum amplitude of which is constant in the flow direction. However, it is also possible for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com