Patents

Literature

169 results about "Non wetting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

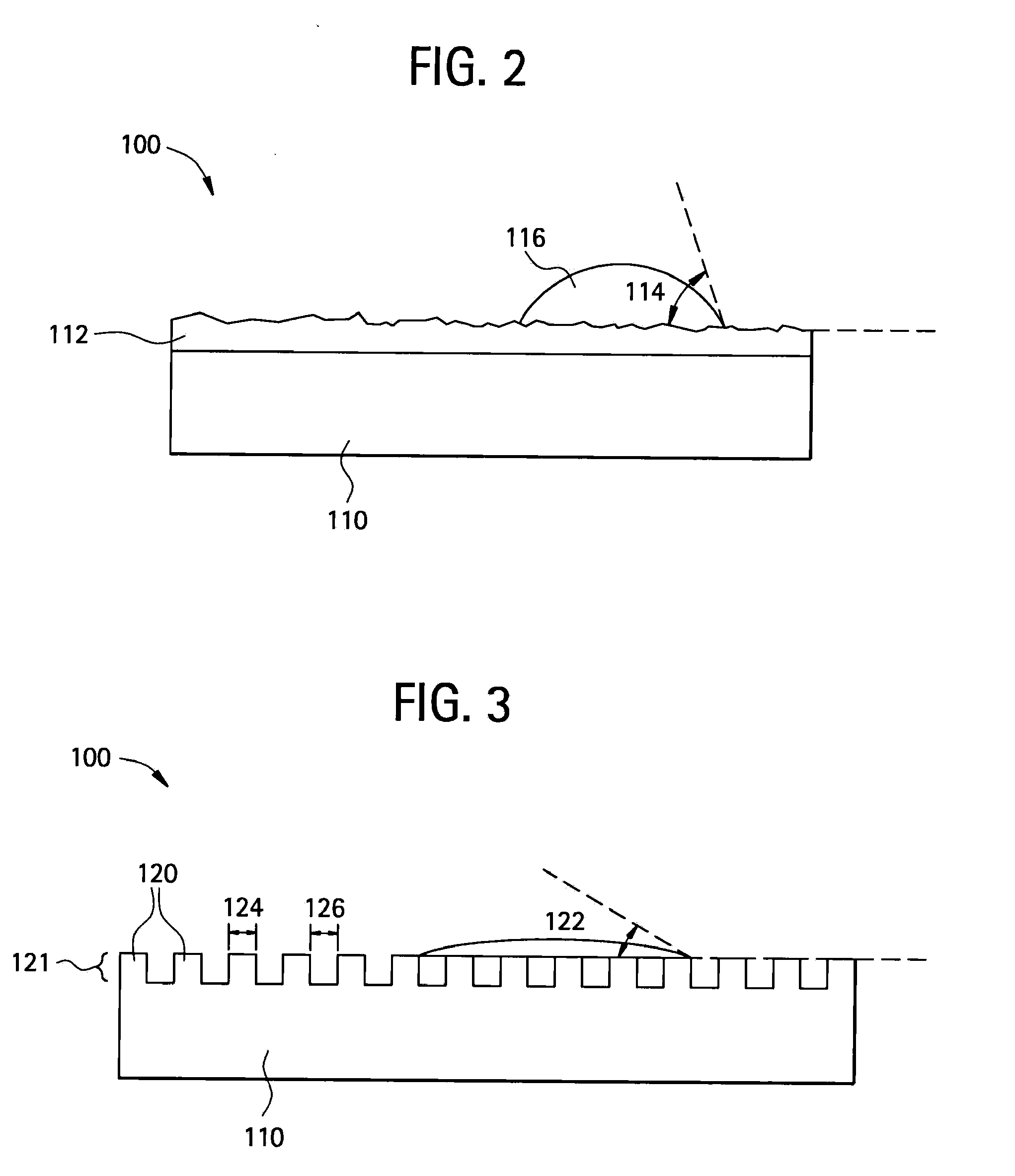

Liquid-Impregnated Surfaces, Methods of Making, and Devices Incorporating the Same

InactiveUS20130032316A1Improve skidReduce resistanceFouling preventionDe-icing equipmentsNon wettingFrost

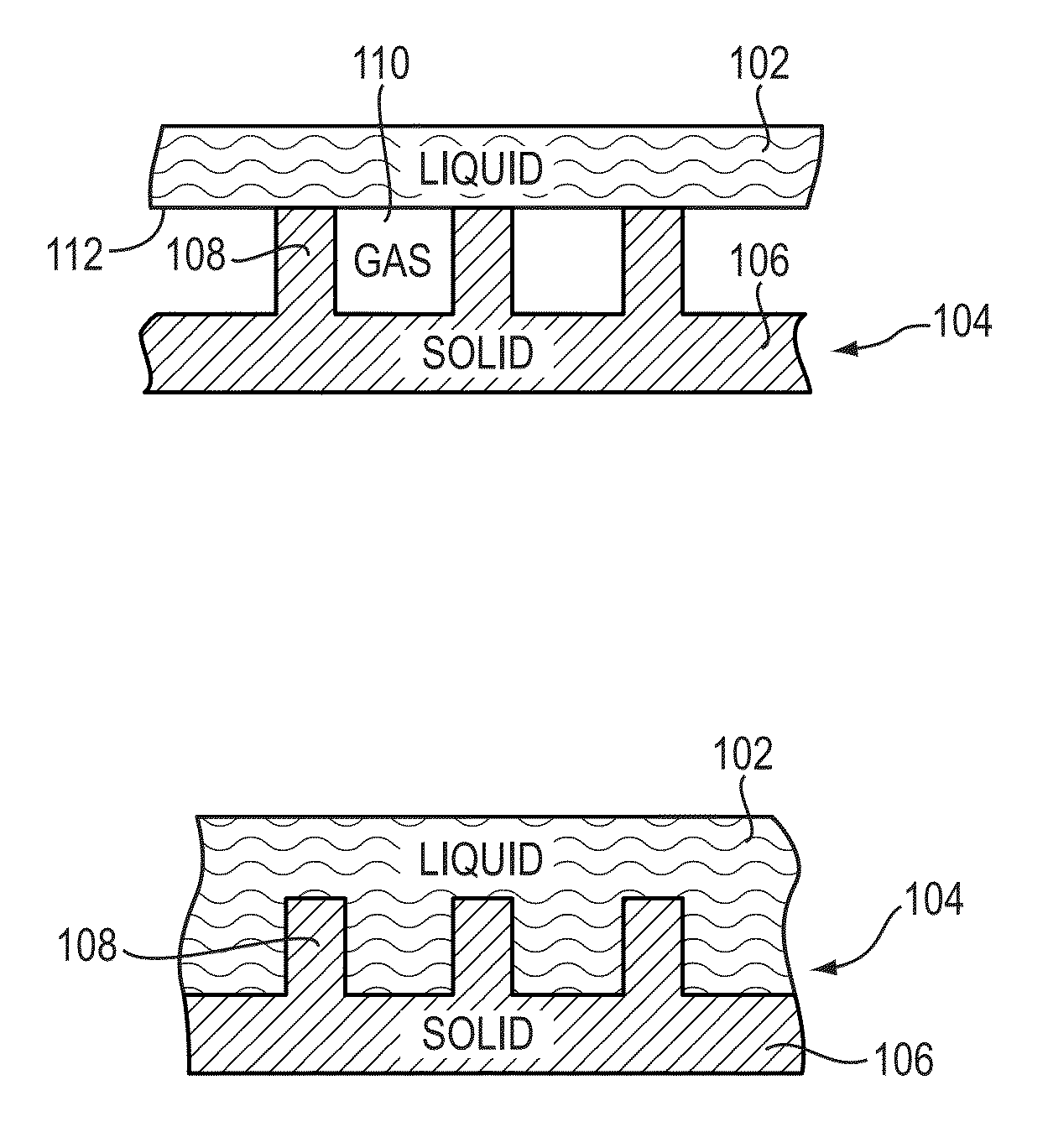

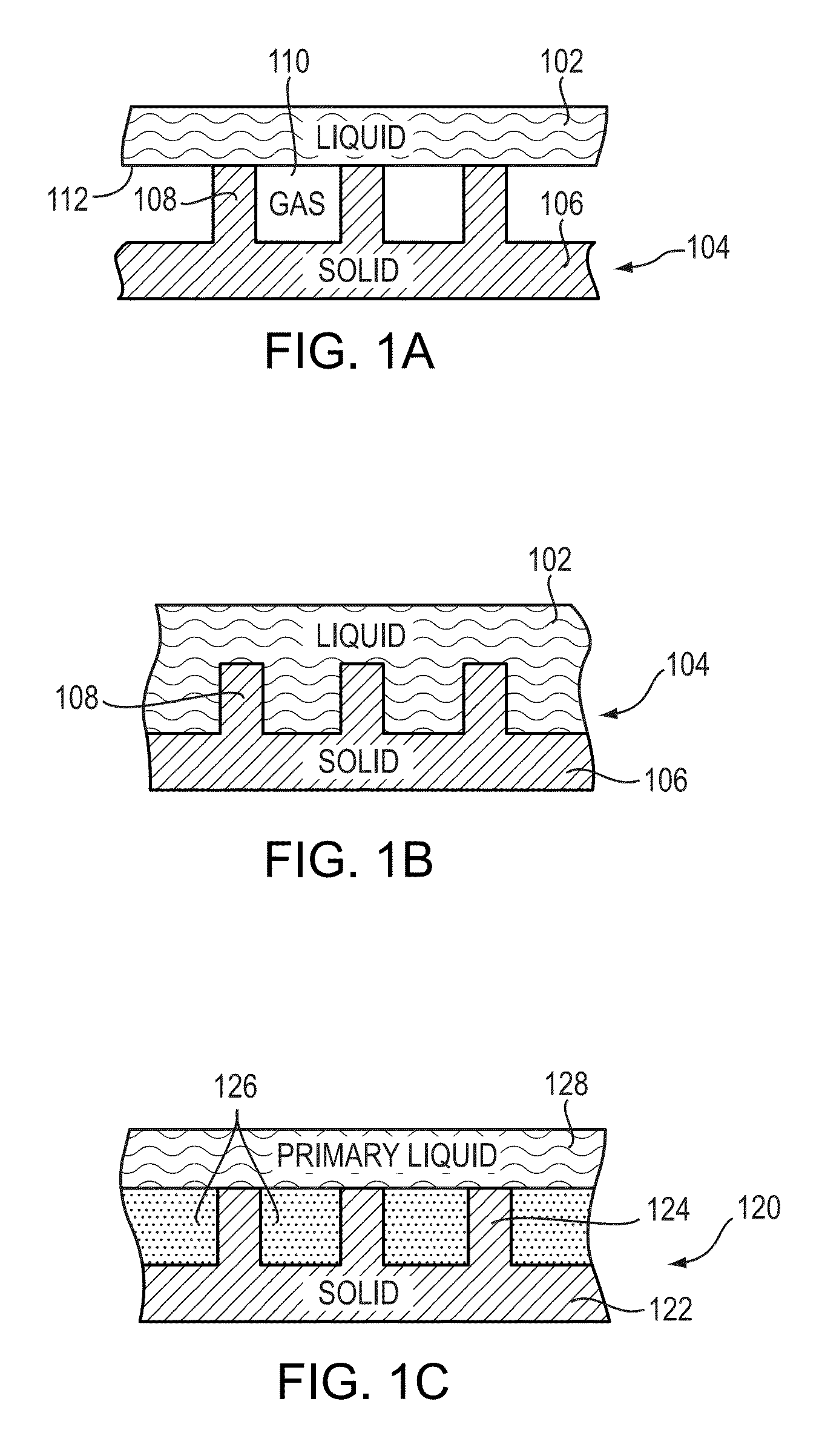

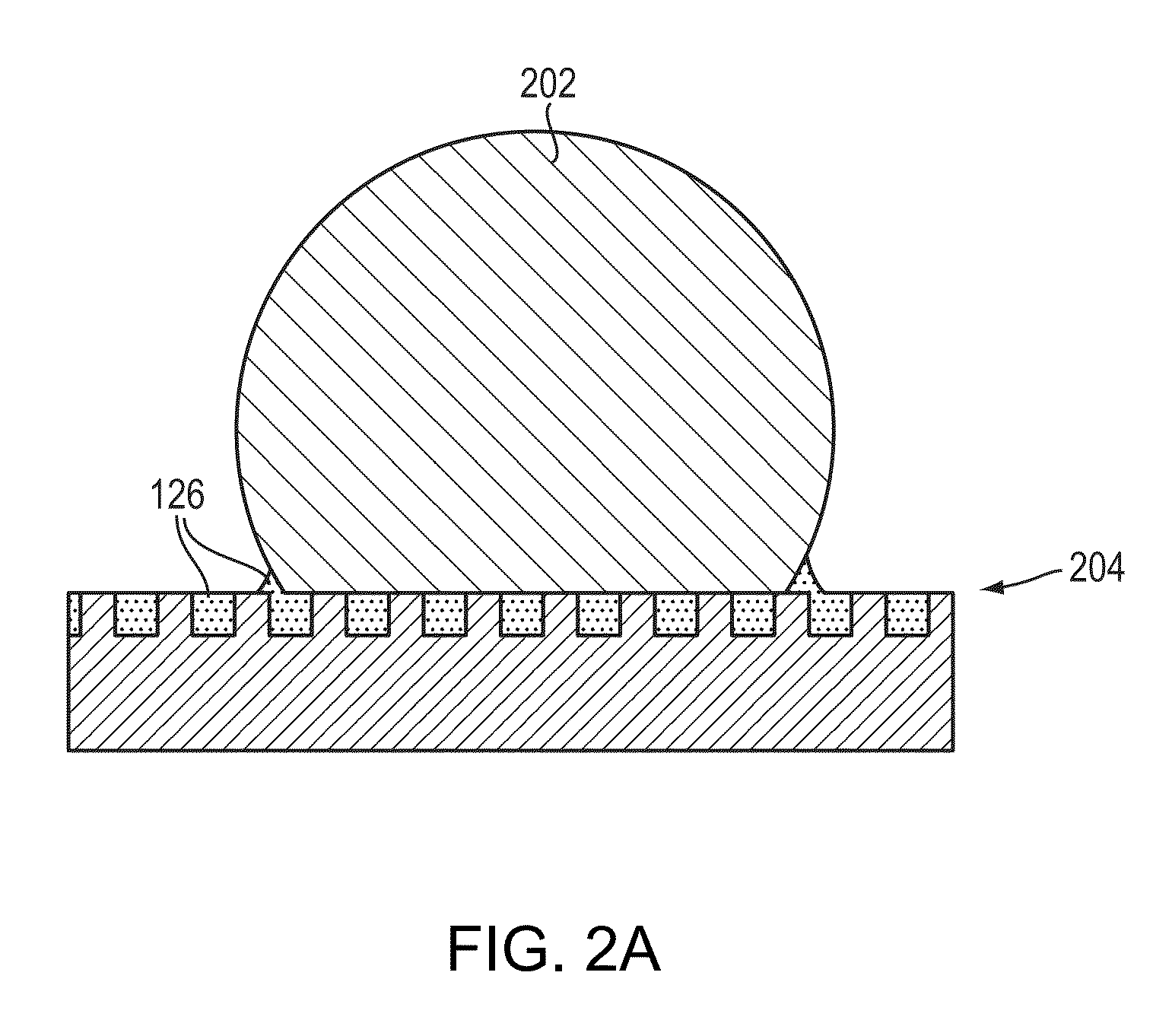

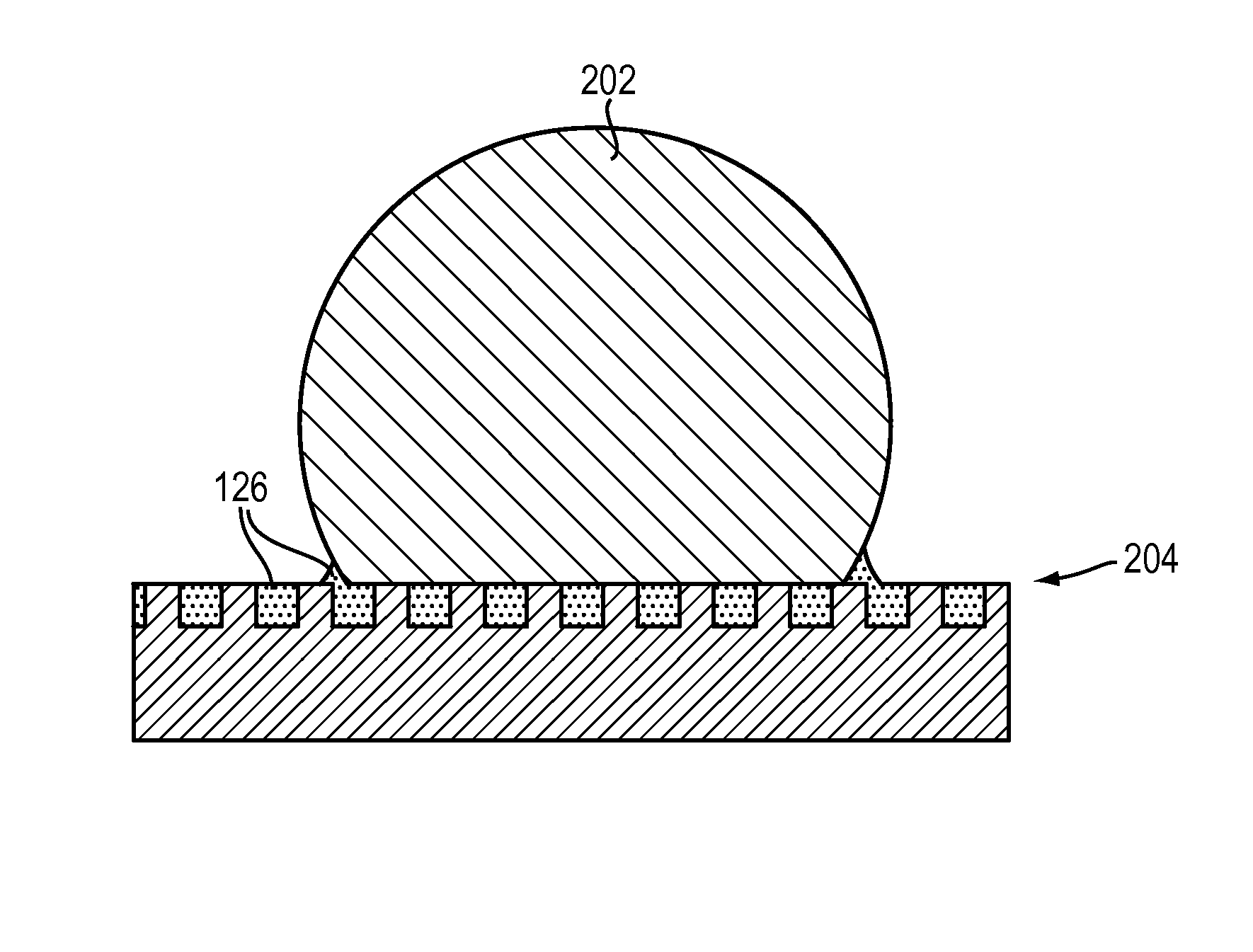

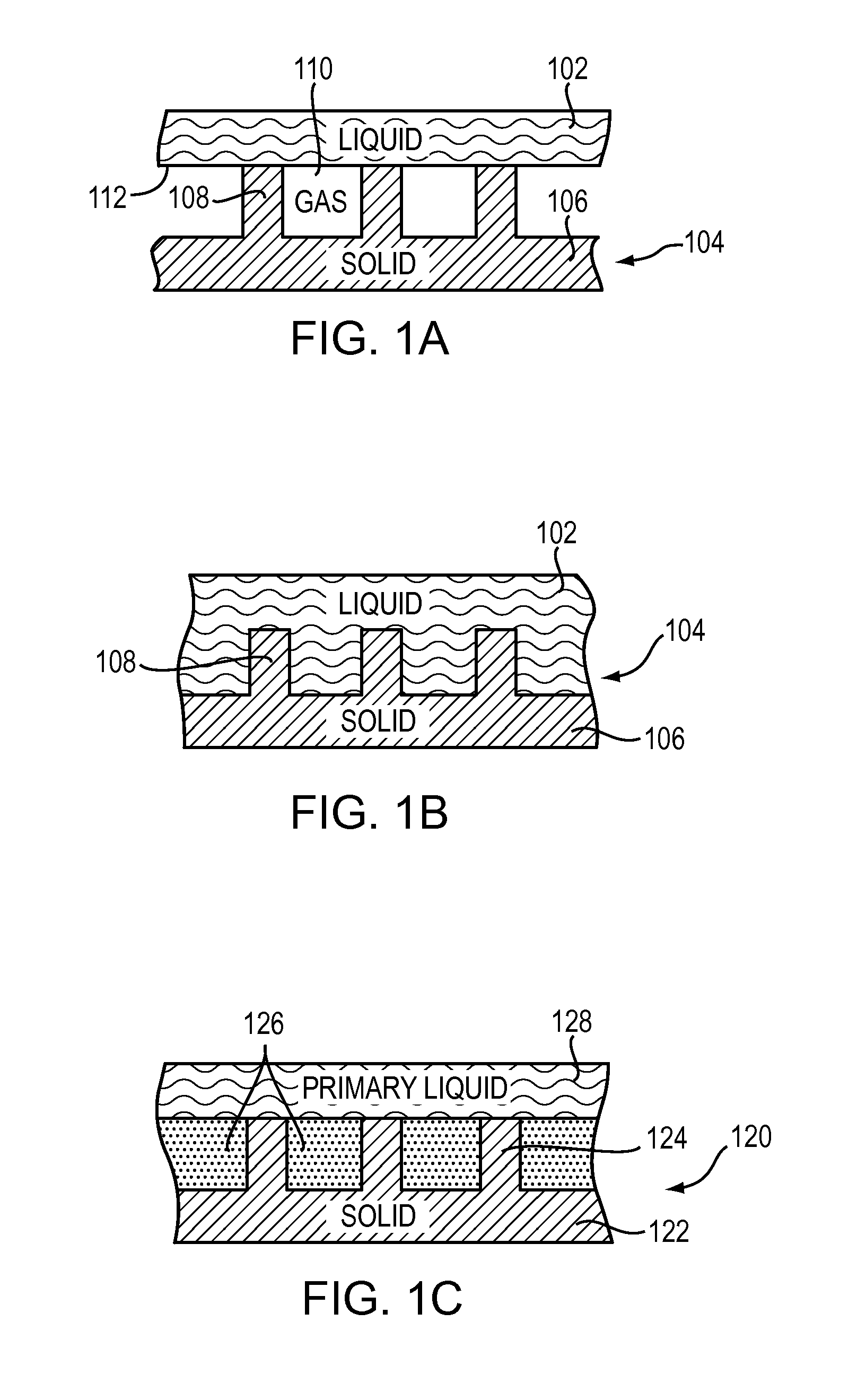

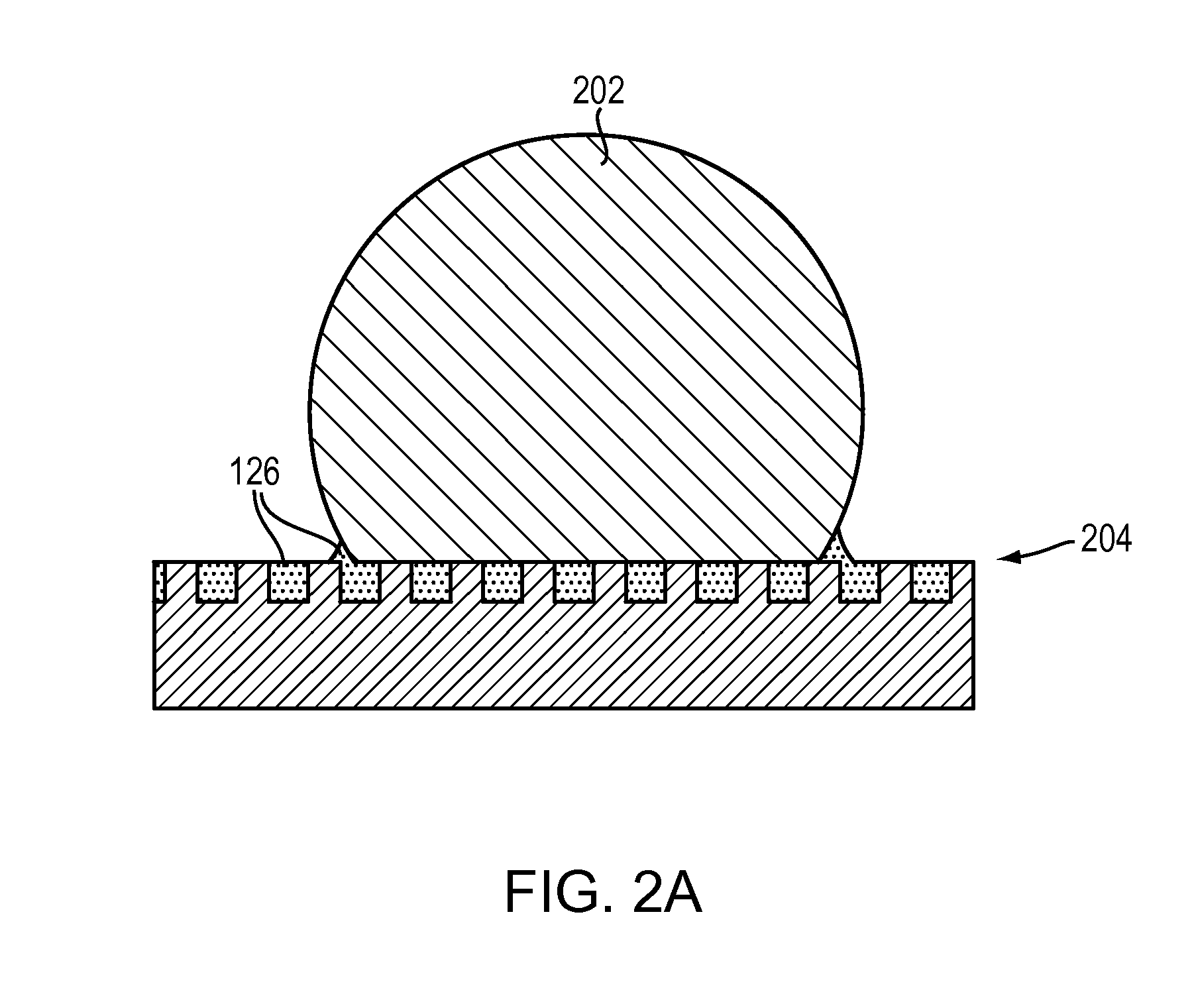

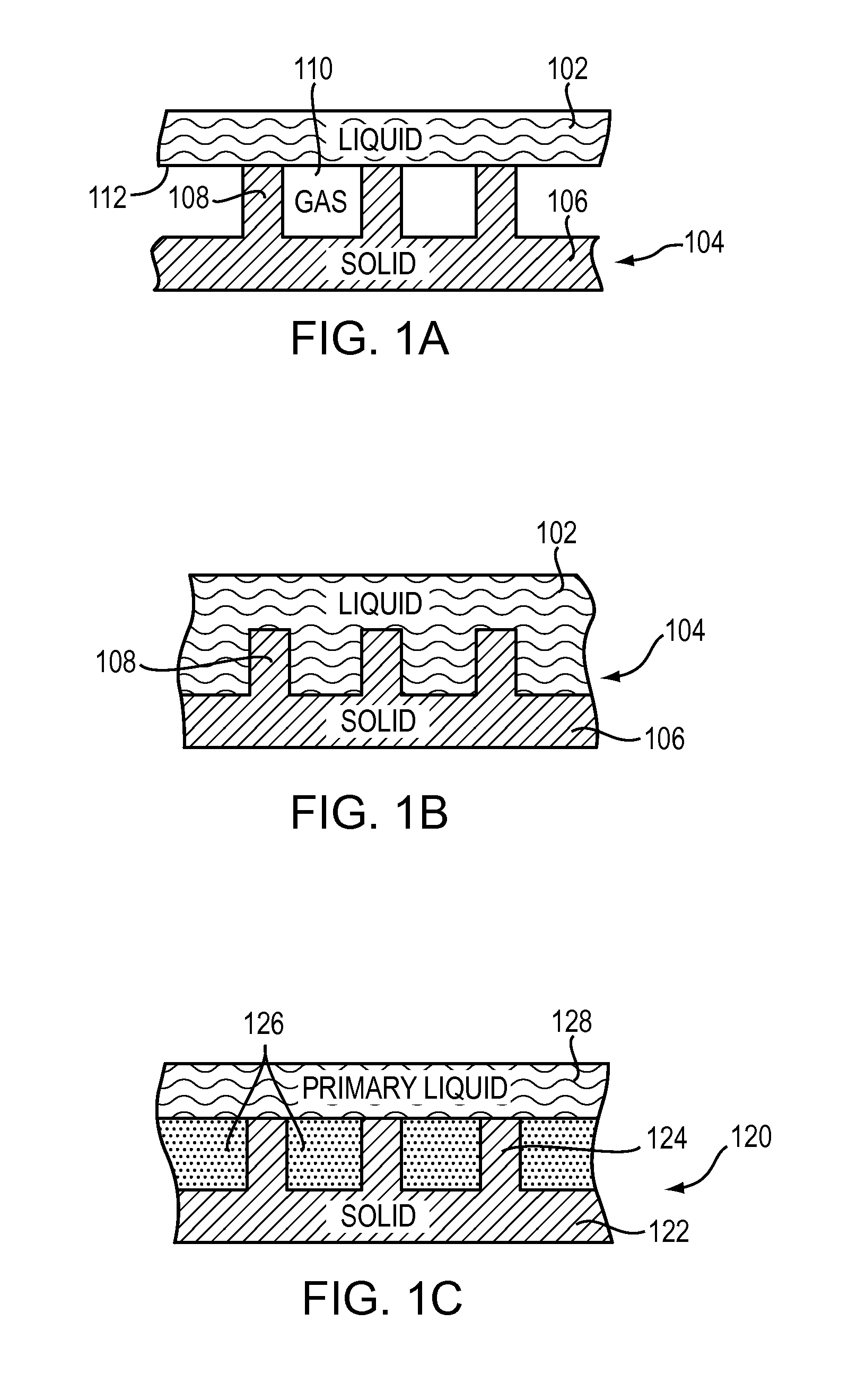

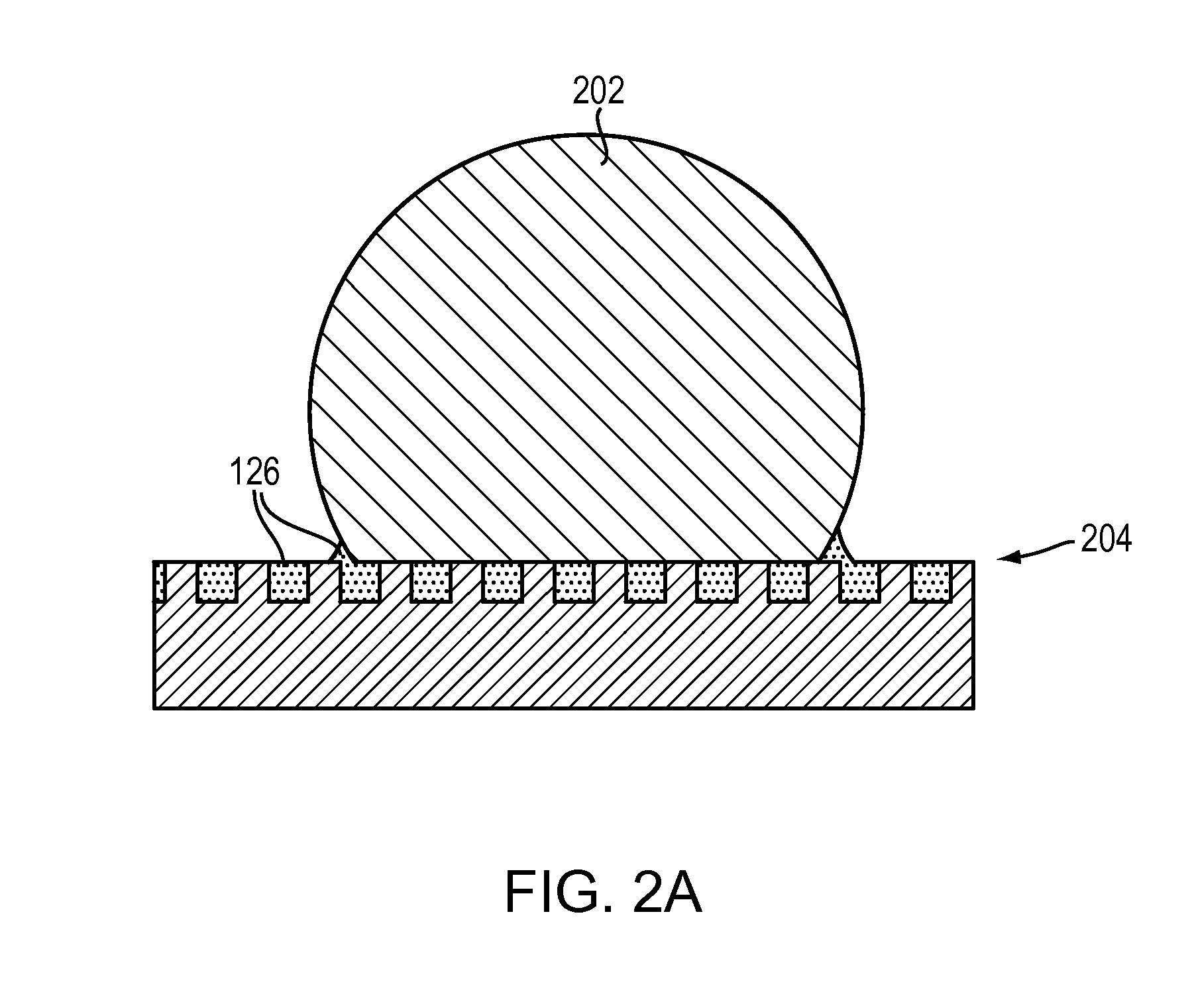

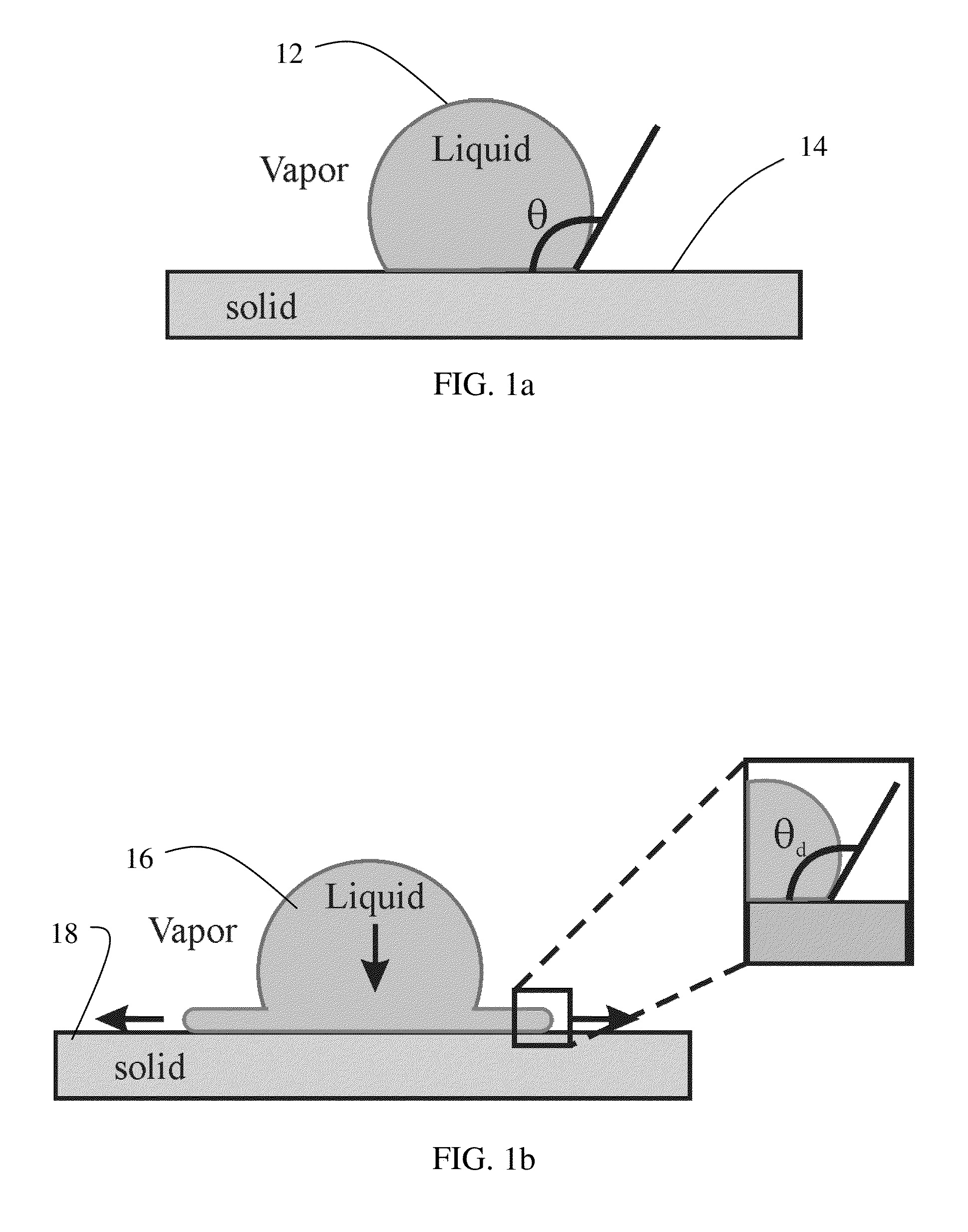

The invention is directed to an article with a liquid-impregnated surface, the surface having a matrix of features thereupon, spaced sufficiently close to stably contain a liquid therebetween or therewithin, and preferable also a thin film thereupon. The surface provides the article with advantageous non-wetting properties. Compared to previous non-wetting surfaces, which include a gas (e.g., air) entrained within surface textures, these liquid-impregnated surfaces are resistant to impalement and frost formation, and are therefore more robust.

Owner:MASSACHUSETTS INST OF TECH

Free flowing dry back-up insulating material

Disclosed is a free flowing dry back-up material which comprises:from 67 to 96% by weight of fly-ash;from 2 to 15% by weight of a heat sensitive binder such as boric acid;from 2 to 7% by weight of a non-wetting agent such as calcium fluoride;from 0 to 10% by weight of a heat expandable material, viz. a material expandable as a function of the temperature such as vermiculite or graphite; andfrom 0 to 1% by weight of a dust suppressant such as kerosene.This material which is useful in particular in the aluminum industry has the advantages of being water free and free flowing, such avoiding the use of vibrator to position it into a shell. It also has a low density and a low thermal conductivity. Moreover, it is organic free as compared to the existing materials which use an organic binder to ensure a low temperature set; and it sets at a temperature lower than 400° F.

Owner:LES PROD CHIMS INDS DE HAUTE TEMPERATURE PYROTEK

Free flowing dry back-up insulating material

ActiveUS20050116398A1Reduce the temperatureSolid waste managementThermal insulationKeroseneNon wetting

Disclosed is a free flowing dry back-up material which comprises: from 67 to 96% by weight of fly-ash; from 2 to 15% by weight of a heat sensitive binder such as boric acid; from 2 to 7% by weight of a non-wetting agent such as calcium fluoride; from 0 to 10% by weight of a heat expandable material, viz. a material expandable as a function of the temperature such as vermiculite or graphite; and from 0 to 1% by weight of a dust suppressant such as kerosene. This material which is useful in particular in the aluminum industry has the advantages of being water free and free flowing, such avoiding the use of vibrator to position it into a shell. It also has a low density and a low thermal conductivity. Moreover, it is organic free as compared to the existing materials which use an organic binder to ensure a low temperature set; and it sets at a temperature lower than 400° F.

Owner:LES PROD CHIMS INDS DE HAUTE TEMPERATURE PYROTEK

Liquid-impregnated surfaces, methods of making, and devices incorporating the same

ActiveUS8574704B2Reduce viscous dragMinimizes accumulationLayered productsDe-icing equipmentsNon wettingFrost

The invention is directed to an article with a liquid-impregnated surface, the surface having a matrix of features thereupon, spaced sufficiently close to stably contain a liquid therebetween or therewithin, and preferable also a thin film thereupon. The surface provides the article with advantageous non-wetting properties. Compared to previous non-wetting surfaces, which include a gas (e.g., air) entrained within surface textures, these liquid-impregnated surfaces are resistant to impalement and frost formation, and are therefore more robust.

Owner:MASSACHUSETTS INST OF TECH

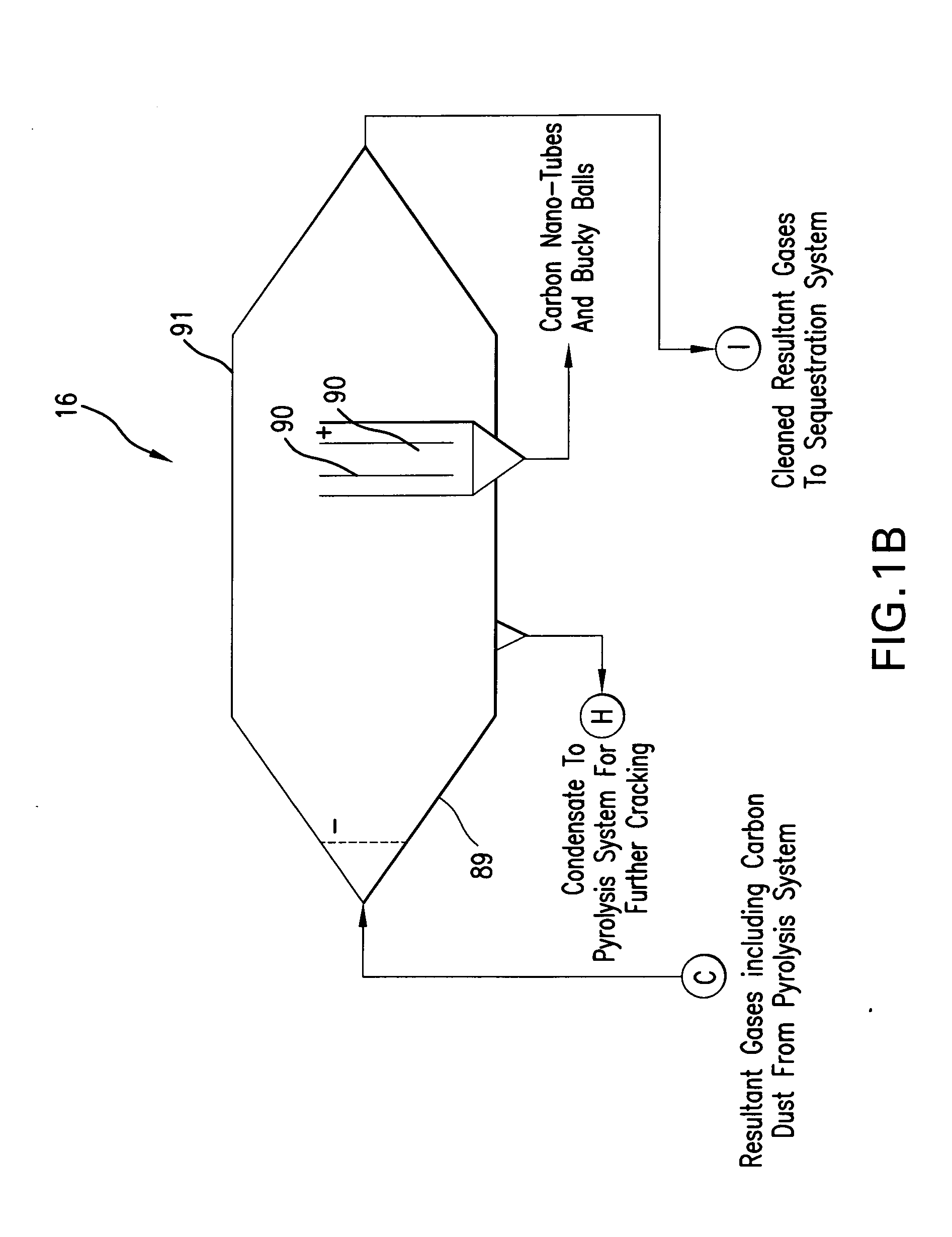

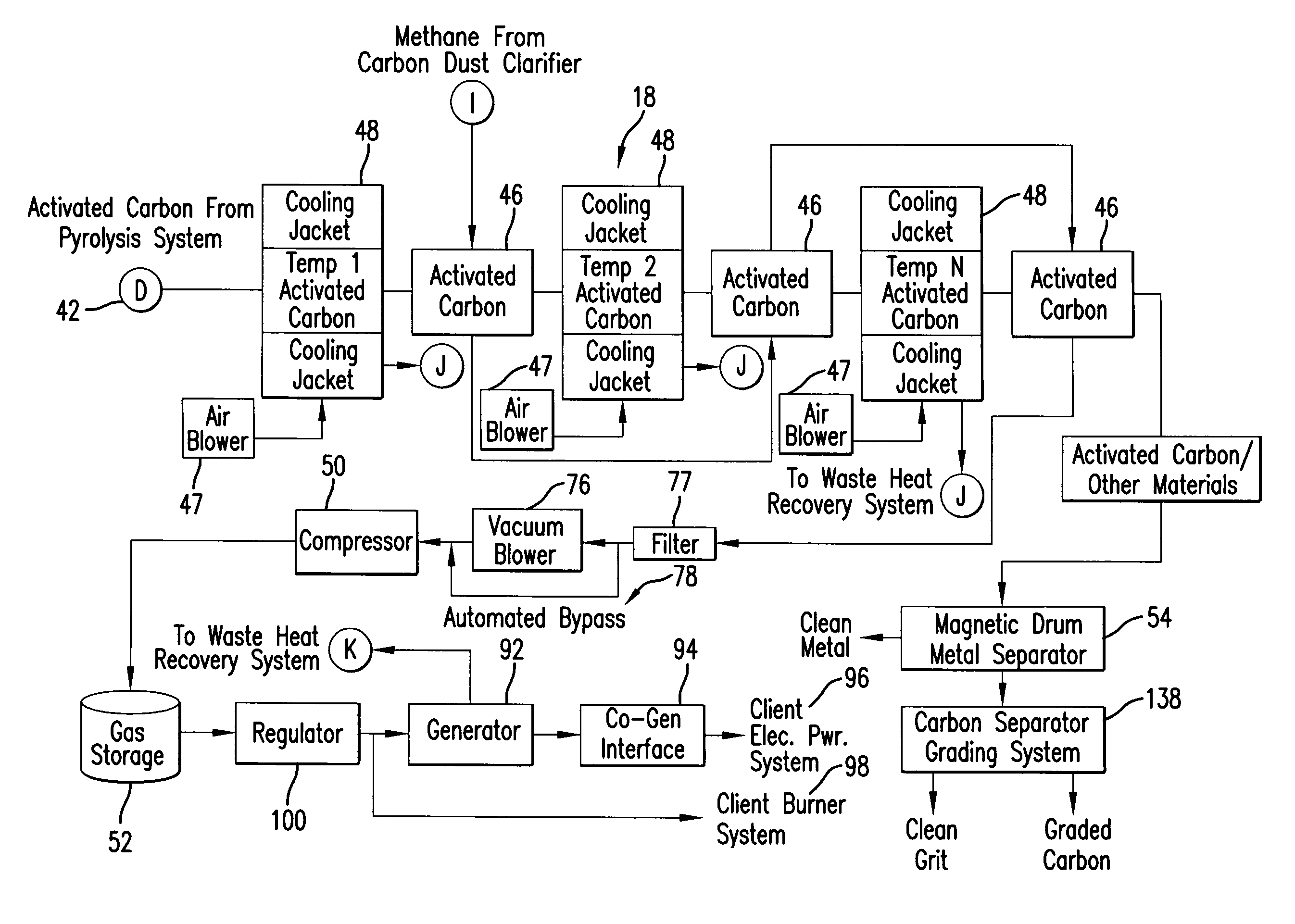

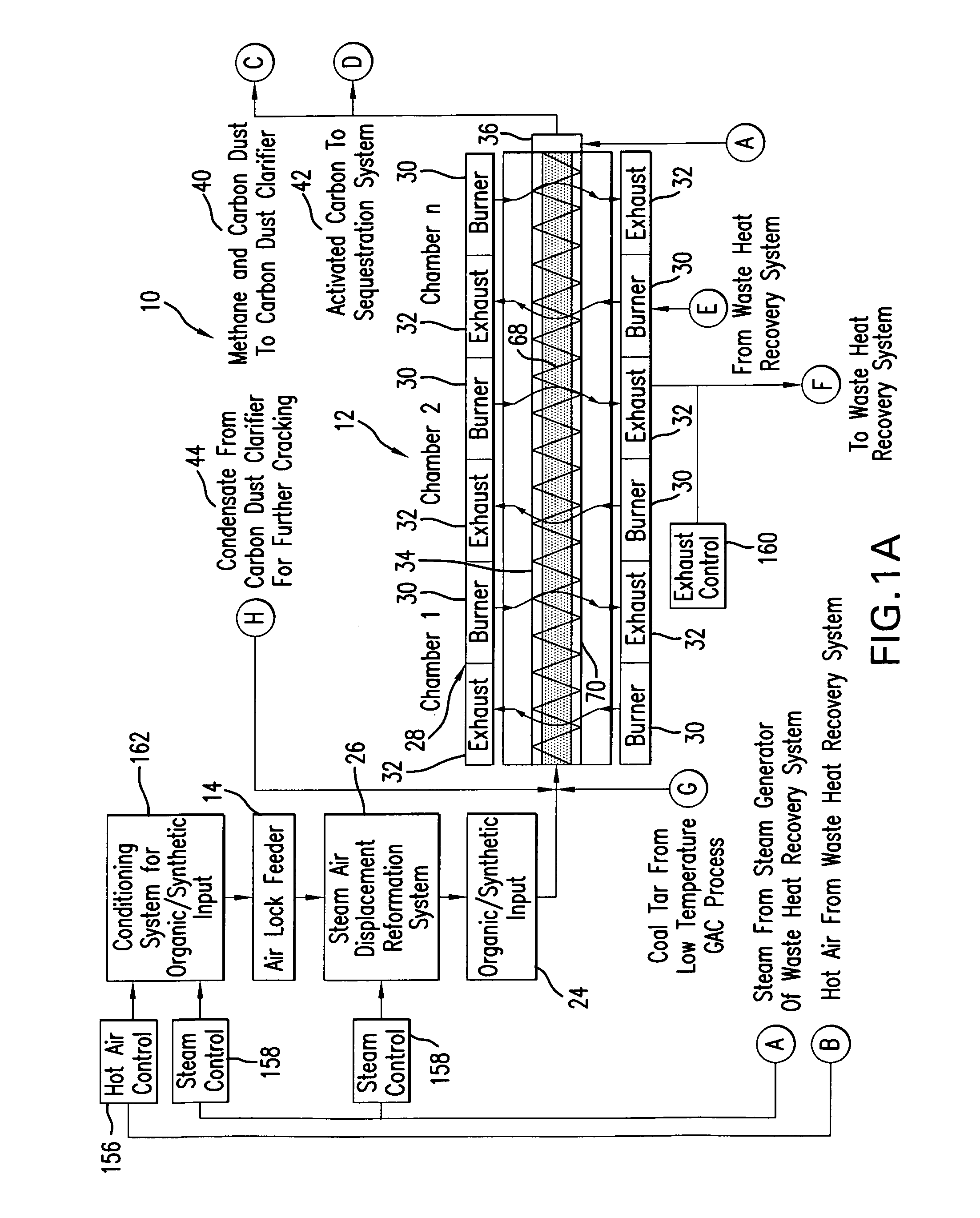

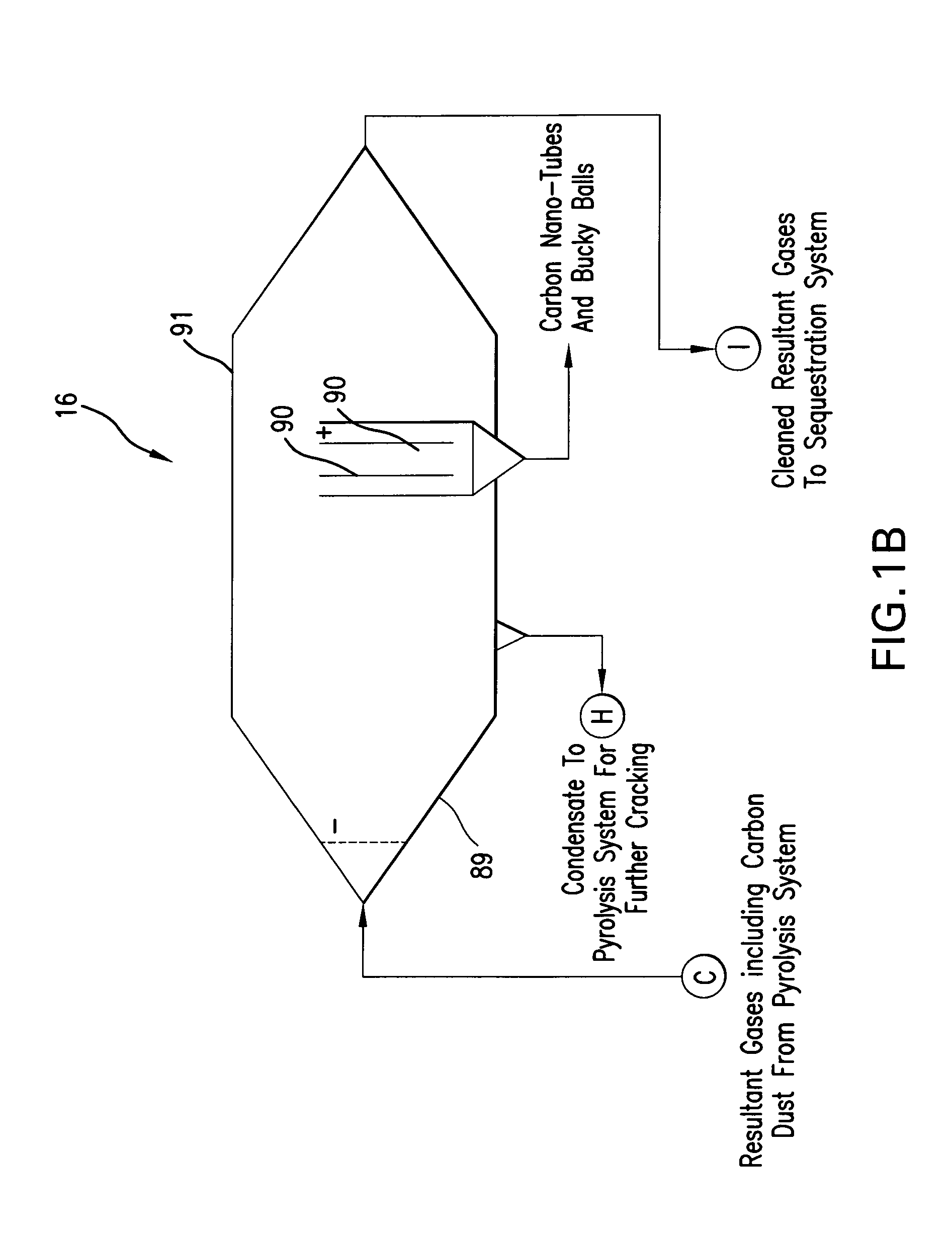

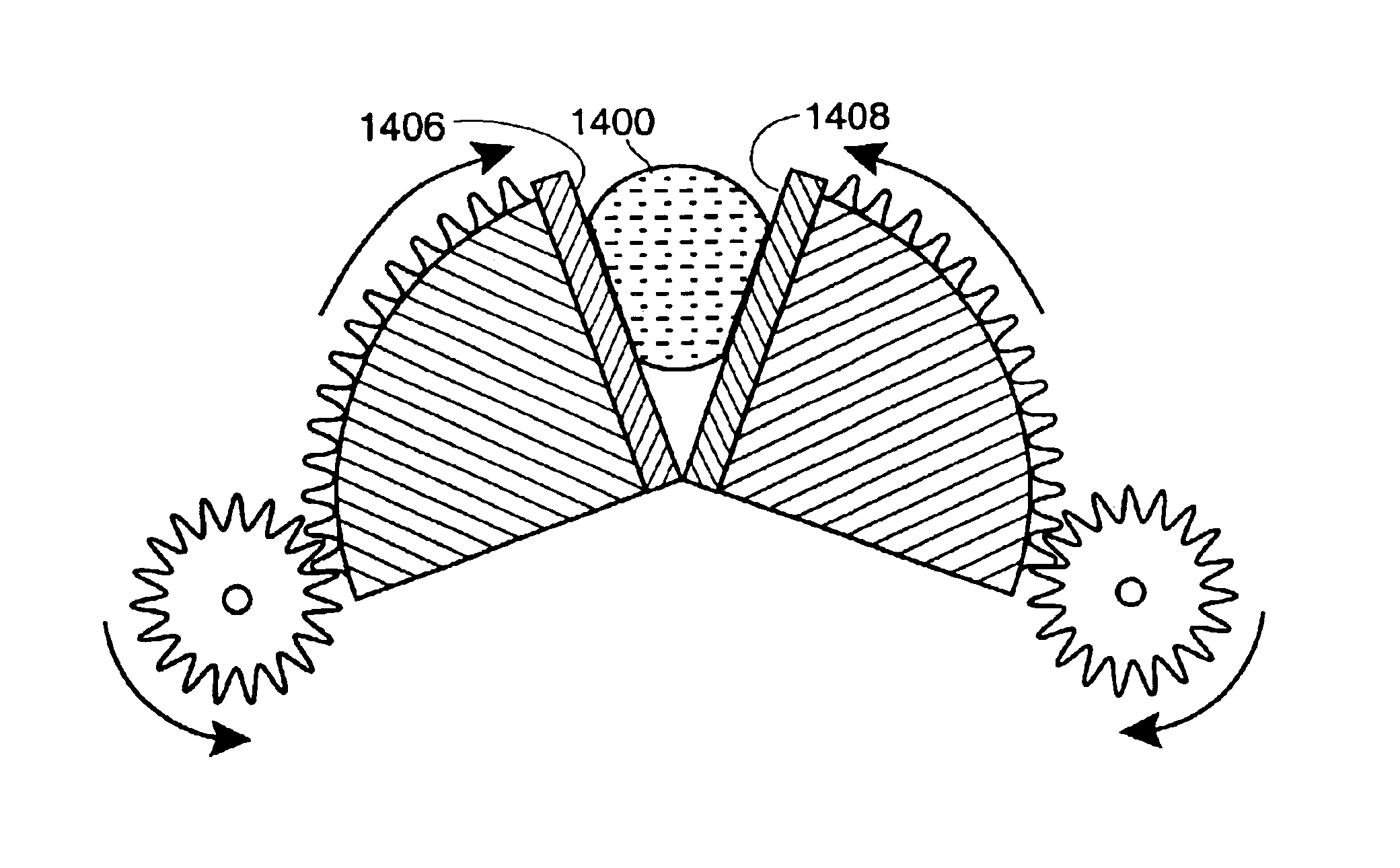

Pyrolysis Systems, Methods, and Resultants Derived Therefrom

ActiveUS20080286557A1Fit closelyWithout undesired degradation of communication system performanceLayered productsUsing liquid separation agentActivated carbon filtrationSilicon dioxide

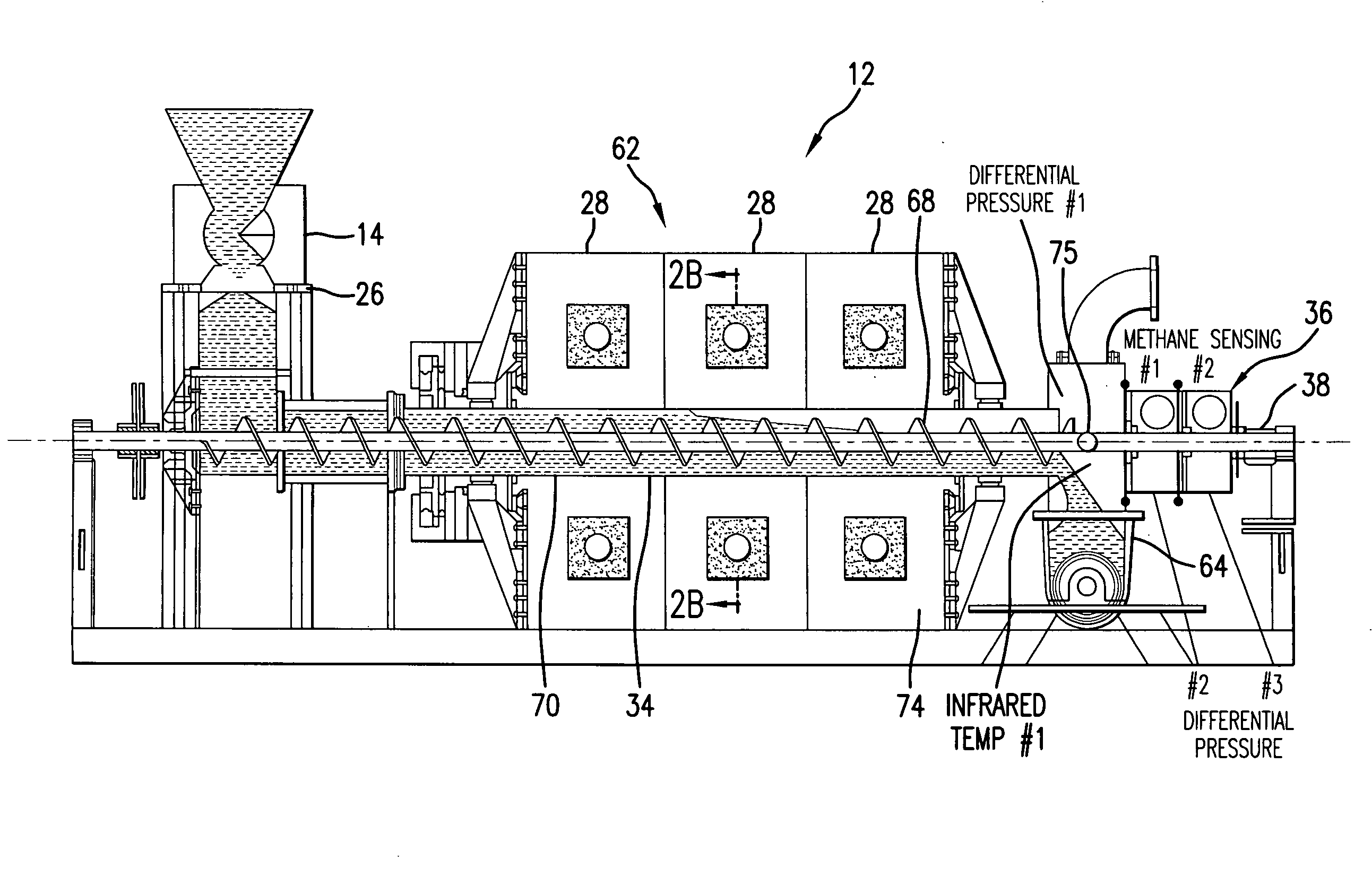

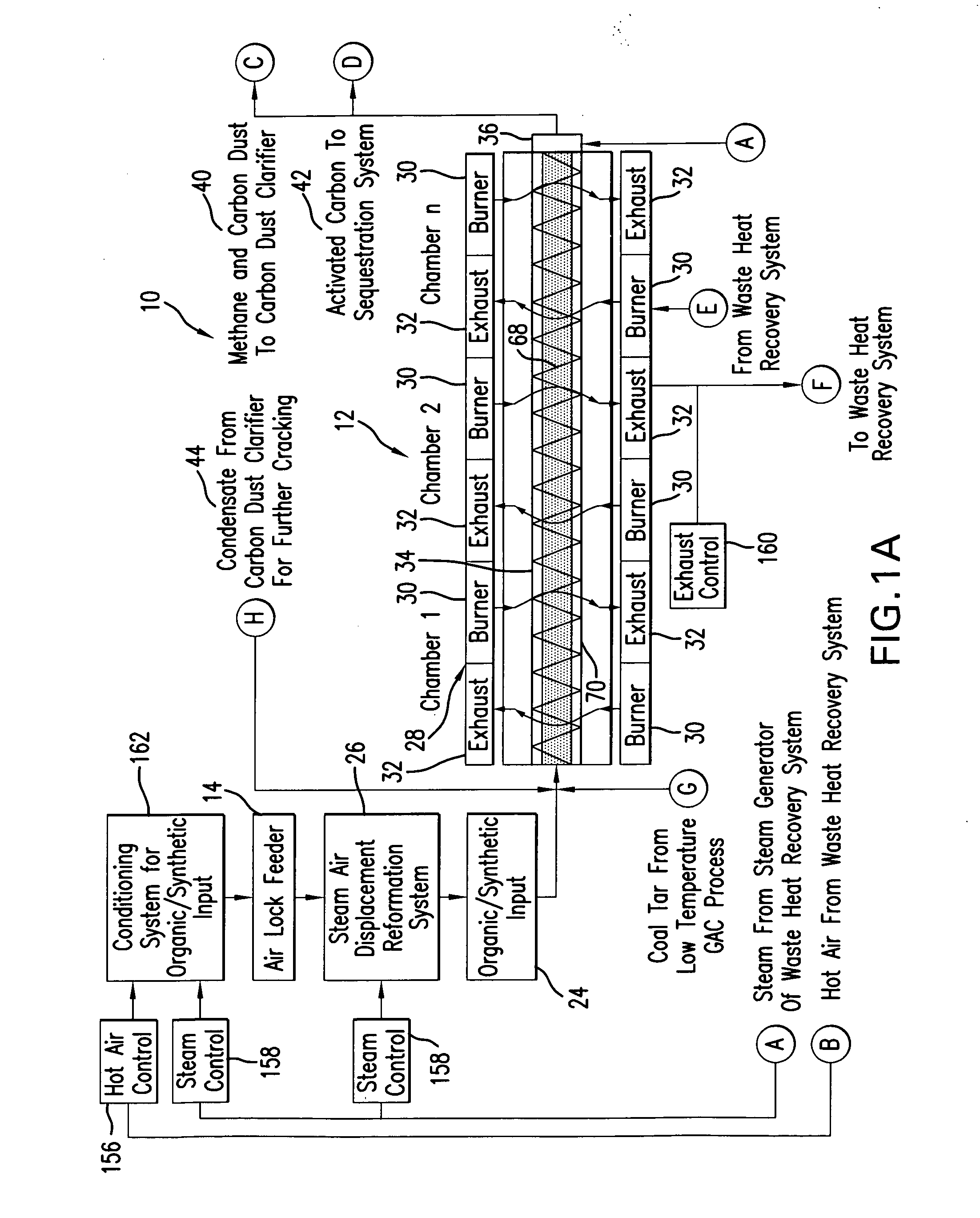

A system and process for gasification of a carbonaceous feedstock uses pyrolysis to produce a gas product, which may include methane, ethane, and other desirable hydrocarbon gases, and a solids product, which includes activated carbon or carbon. The gas product may then be filtered using at least a portion of the activated carbon from the solids product as a filtering medium. In an embodiment, at least some of the noxious chemicals are sequestered or removed from the gas product in one or more filtering steps using the activated carbon as a filtering medium. In a further embodiment, the filtering steps are performed in stages using activated carbon at different temperatures. A high-temperature pyrolysis system that produces activated carbon may be combined with another high-temperature pyrolysis system that does not produce activated carbon to provide filtering of noxious compounds using activated carbon from the first high-temperature pyrolysis system. A high-temperature pyrolysis system may be combined with one or more low-temperature feedstock conversion processes such that waste heat from the high-temperature pyrolysis system is used to operate the low-temperature process. A novel non-wetting carbon having pores fused with silica can be produced from using the system and process.

Owner:TUCKER RICHARD D

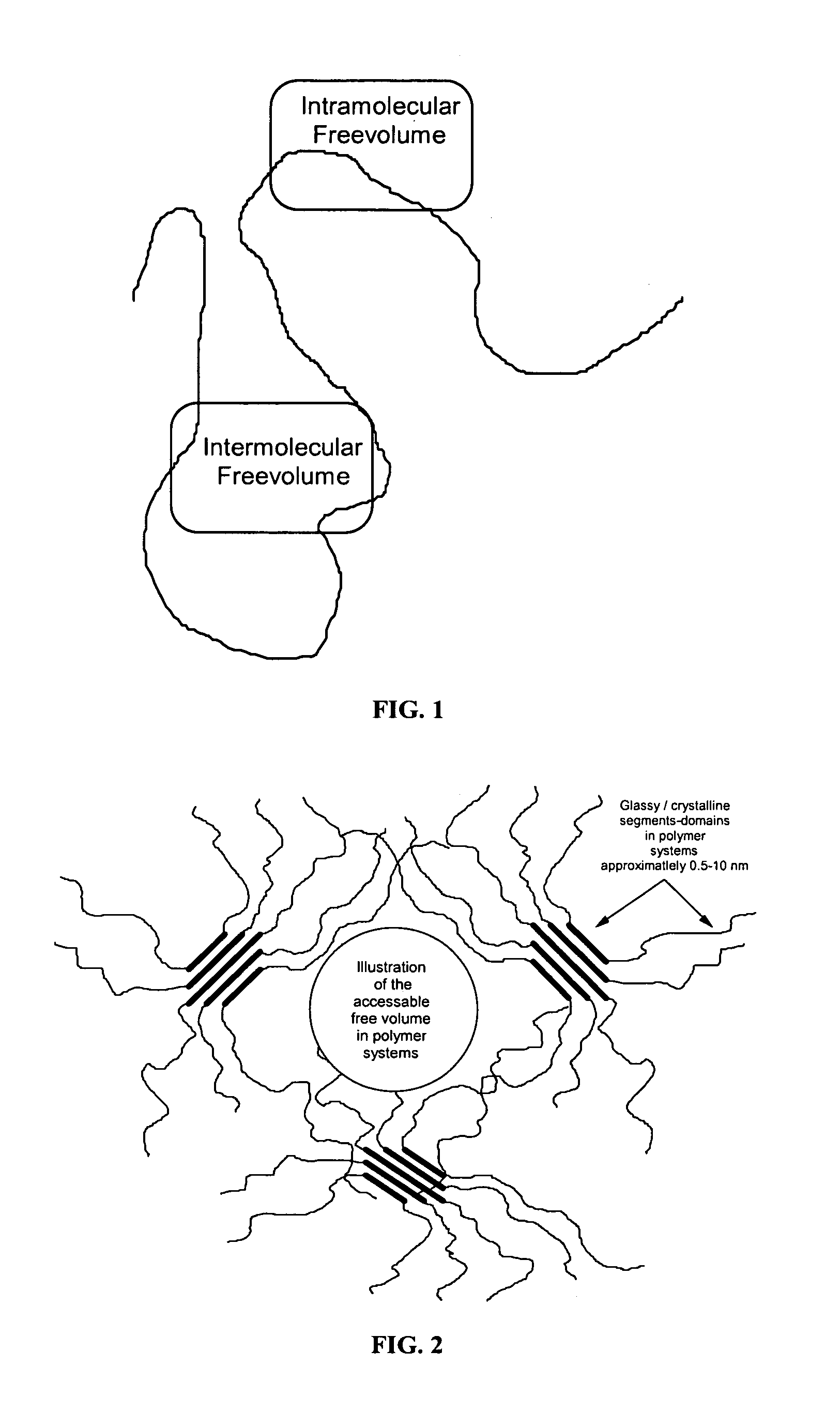

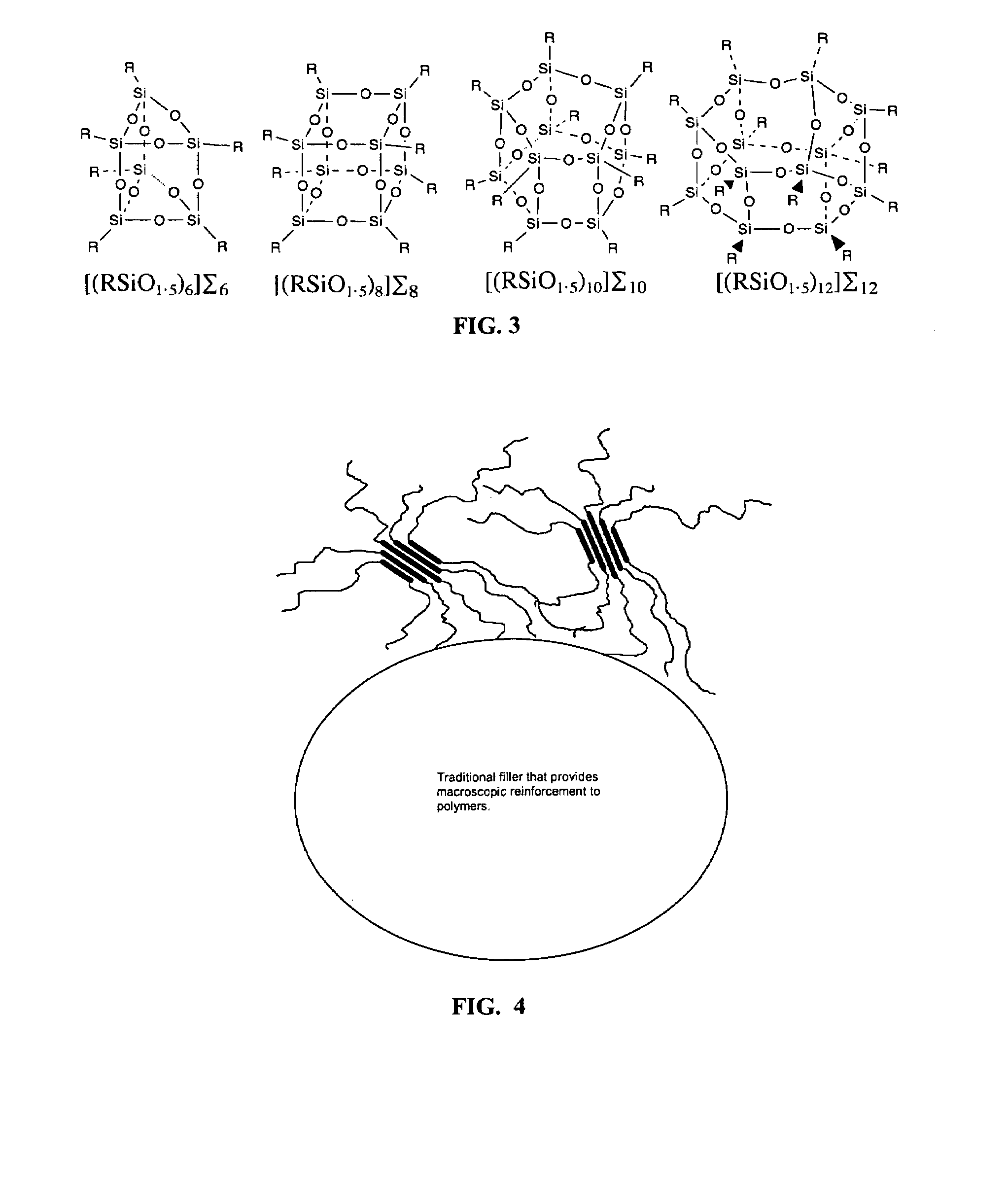

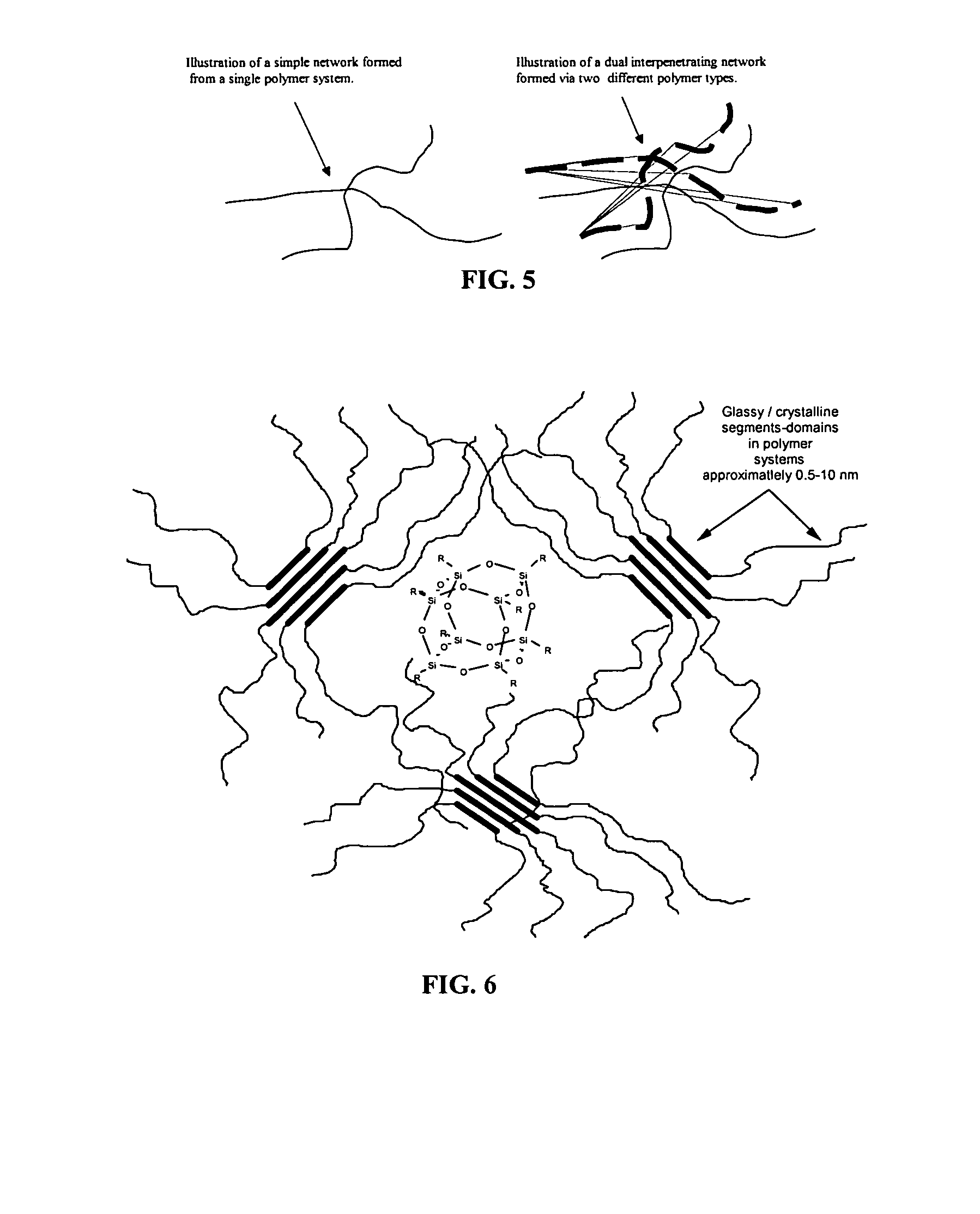

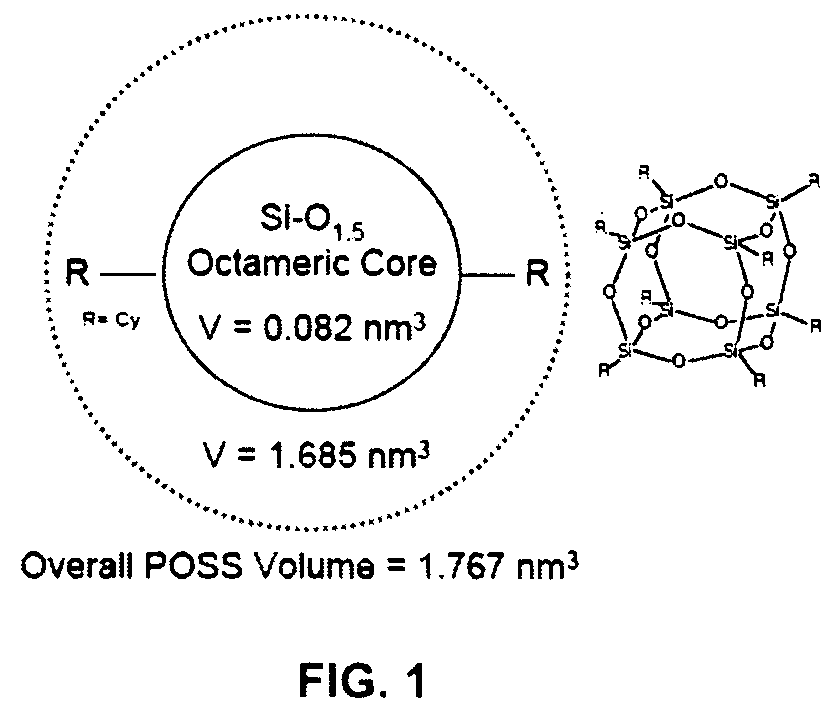

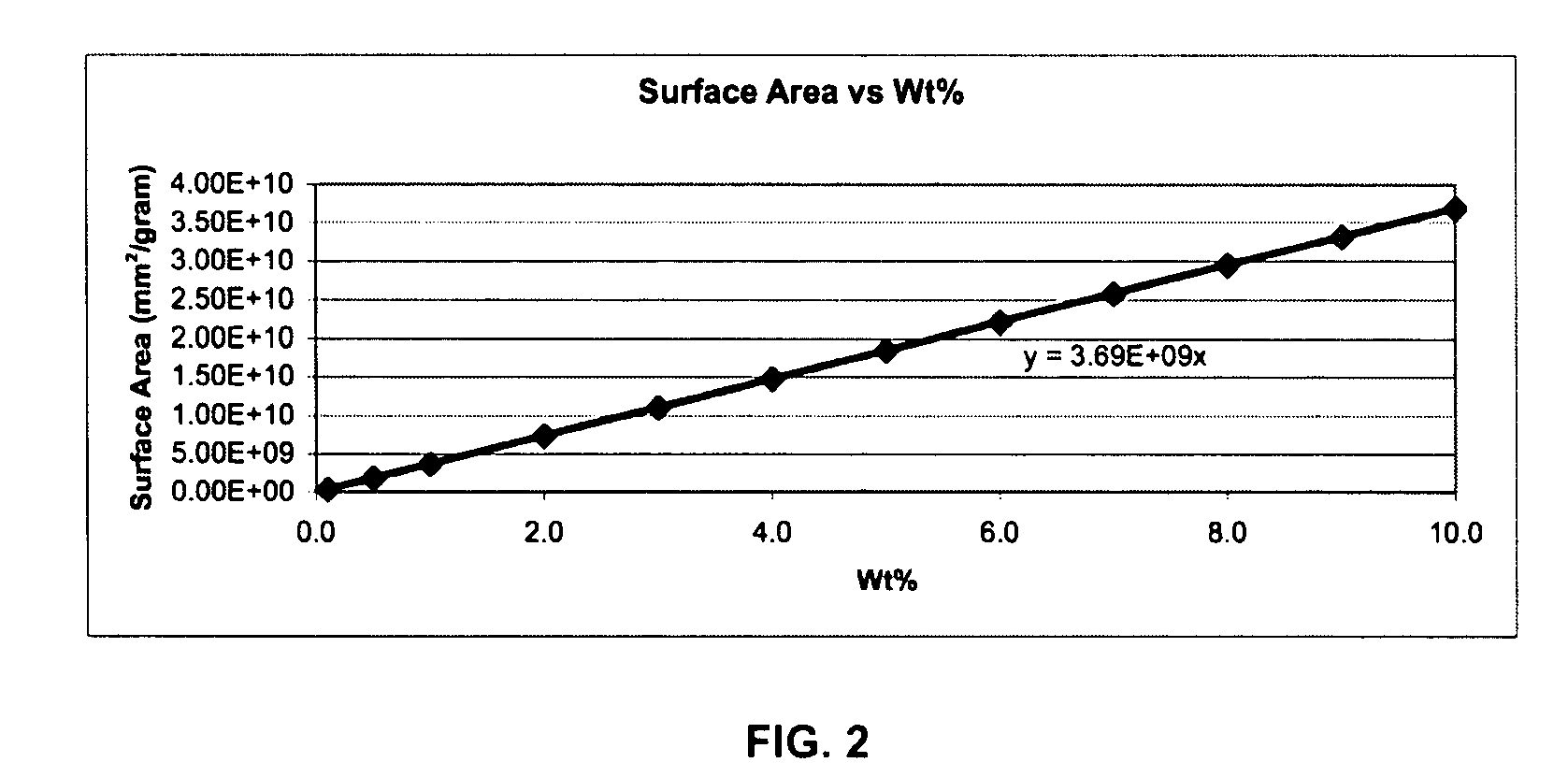

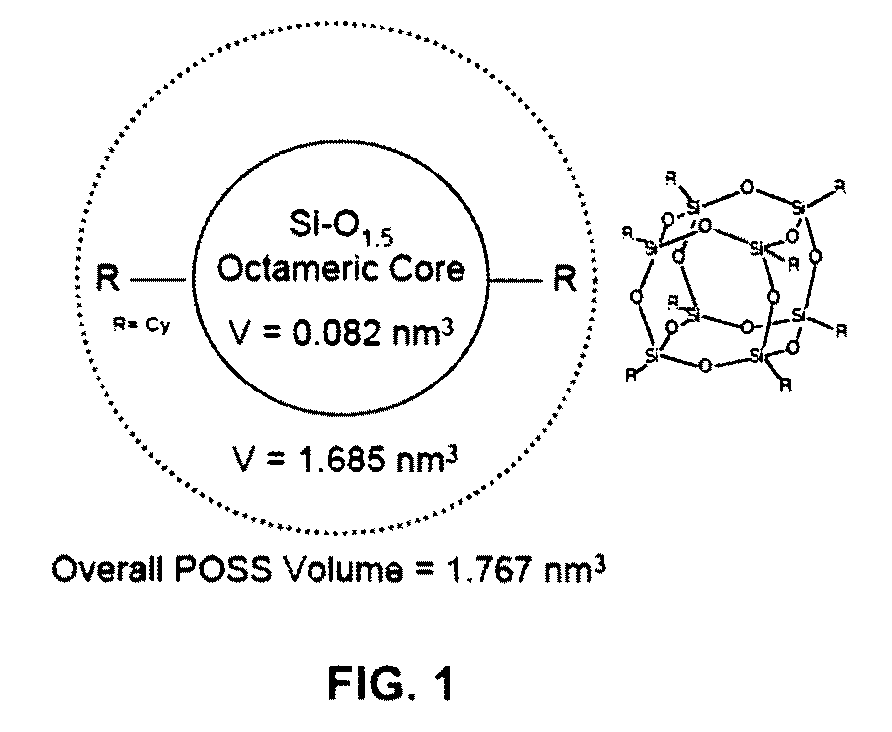

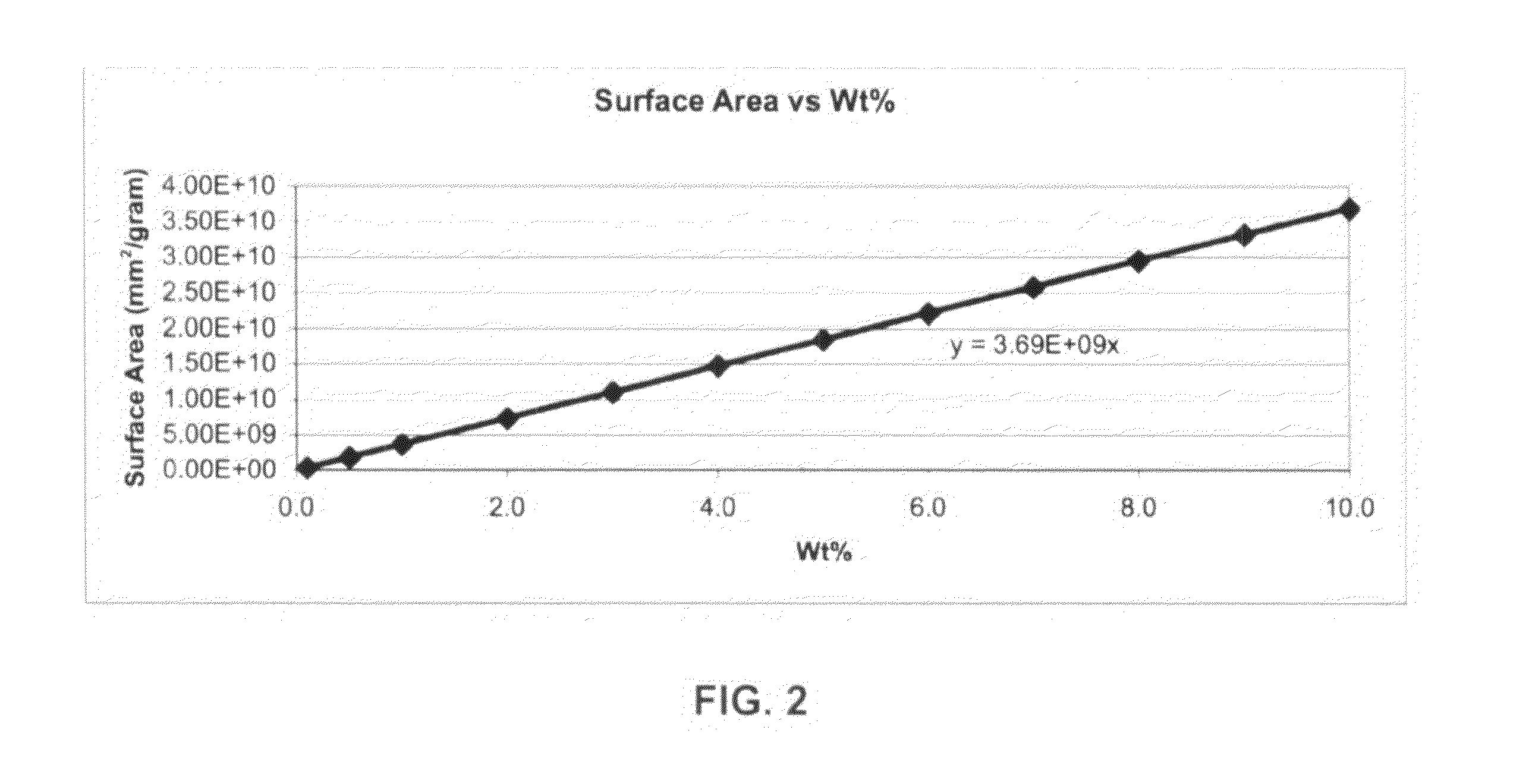

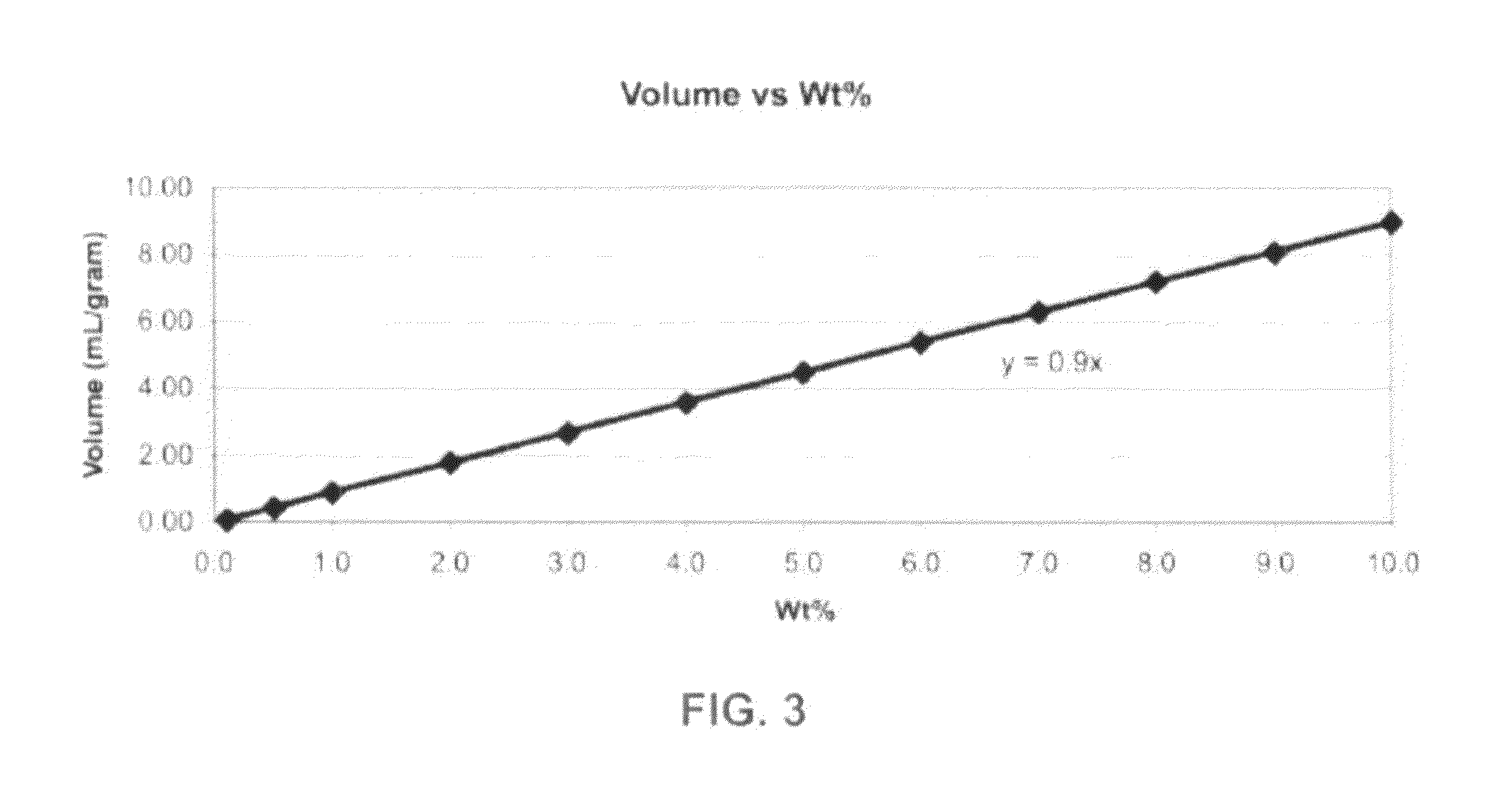

Nanostructured chemicals as alloying agents in fluorinated polymers

InactiveUS7193015B1Reduce melt viscosityLow dielectric constantMaterial nanotechnologyMolecular levelCompression set

A method of using nanostructured chemicals as alloying agents for the reinforcement of flouropolymer microstructures, including polymer coils, domains, chains, and segments, at the molecular level. Because of their tailorable compatibility with fluorinated polymers, nanostructured chemicals can be readily and selectively incorporated into polymers by direct blending processes. Properties most favorably improved are time dependent mechanical and thermal properties such as heat distortion, creep, compression set, shrinkage, modulus, hardness and abrasion resistance. In addition to mechanical properties, other physical properties are favorably improved, including lower thermal conductivity, fire resistance, and improved oxygen permeability. These improved properties may be useful in a number of applications, including space-survivable materials and creep resistant seals and gaskets. Improved surface properties may be useful for applications such as anti-icing or non-wetting surfaces or as low friction surfaces.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Liquid-impregnated surfaces, methods of making, and devices incorporating the same

ActiveUS20130034695A1Improve skidReduce resistanceDe-icing equipmentsRecord information storageNon wettingFrost

The invention is directed to an article with a liquid-impregnated surface, the surface having a matrix of features thereupon, spaced sufficiently close to stably contain a liquid therebetween or therewithin, and preferable also a thin film thereupon. The surface provides the article with advantageous non-wetting properties. Compared to previous non-wetting surfaces, which include a gas (e.g., air) entrained within surface textures, these liquid-impregnated surfaces are resistant to impalement and frost formation, and are therefore more robust.

Owner:MASSACHUSETTS INST OF TECH

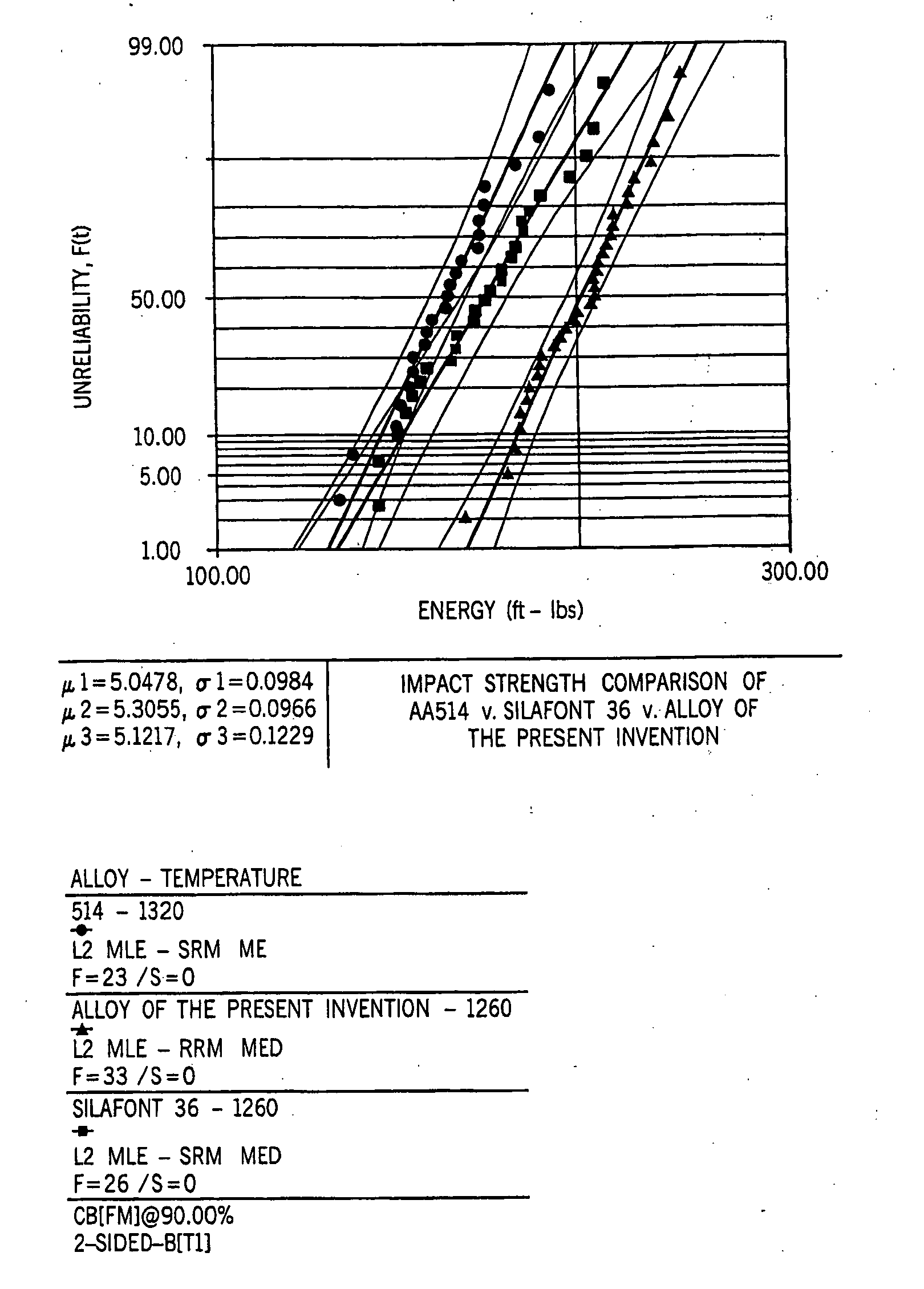

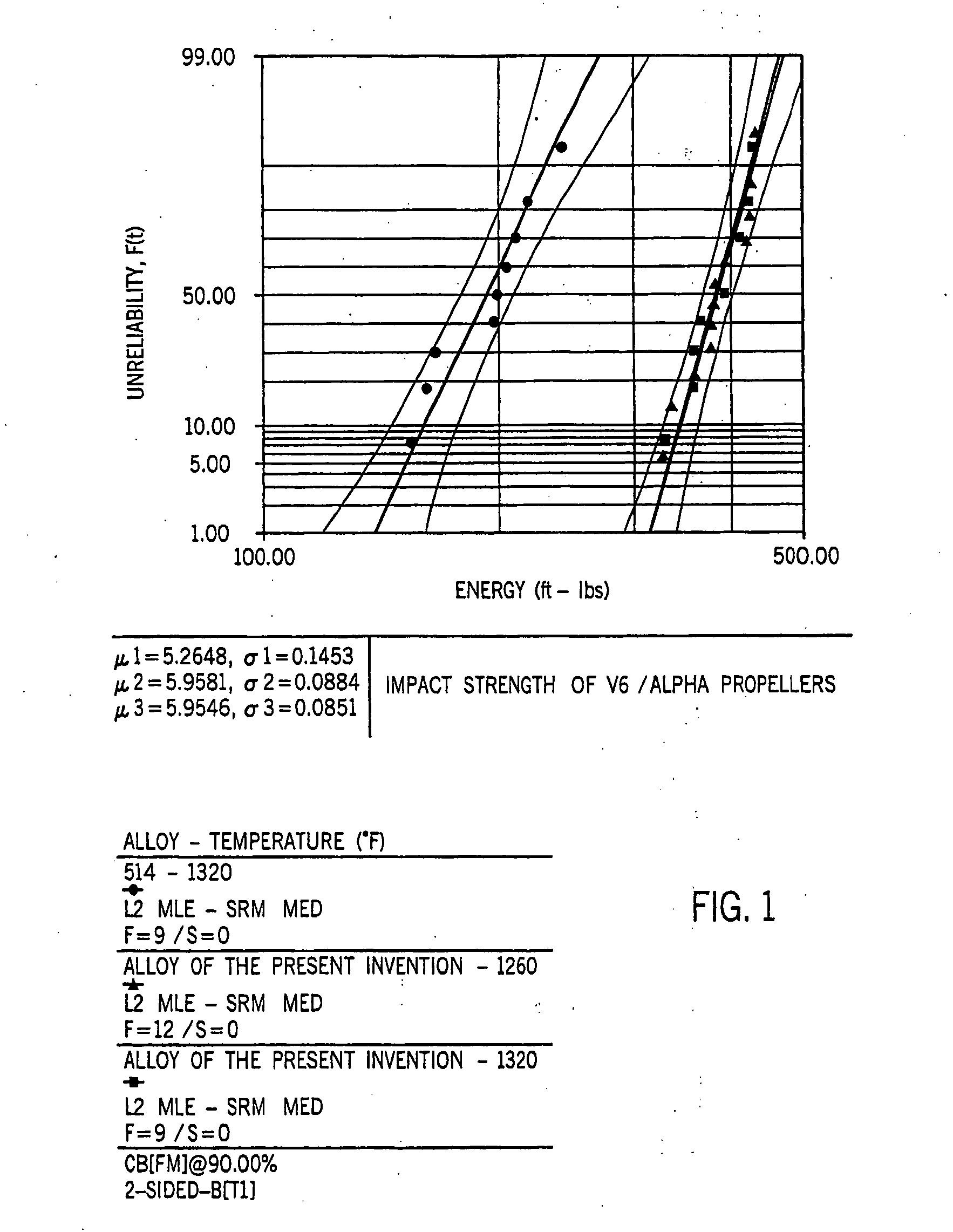

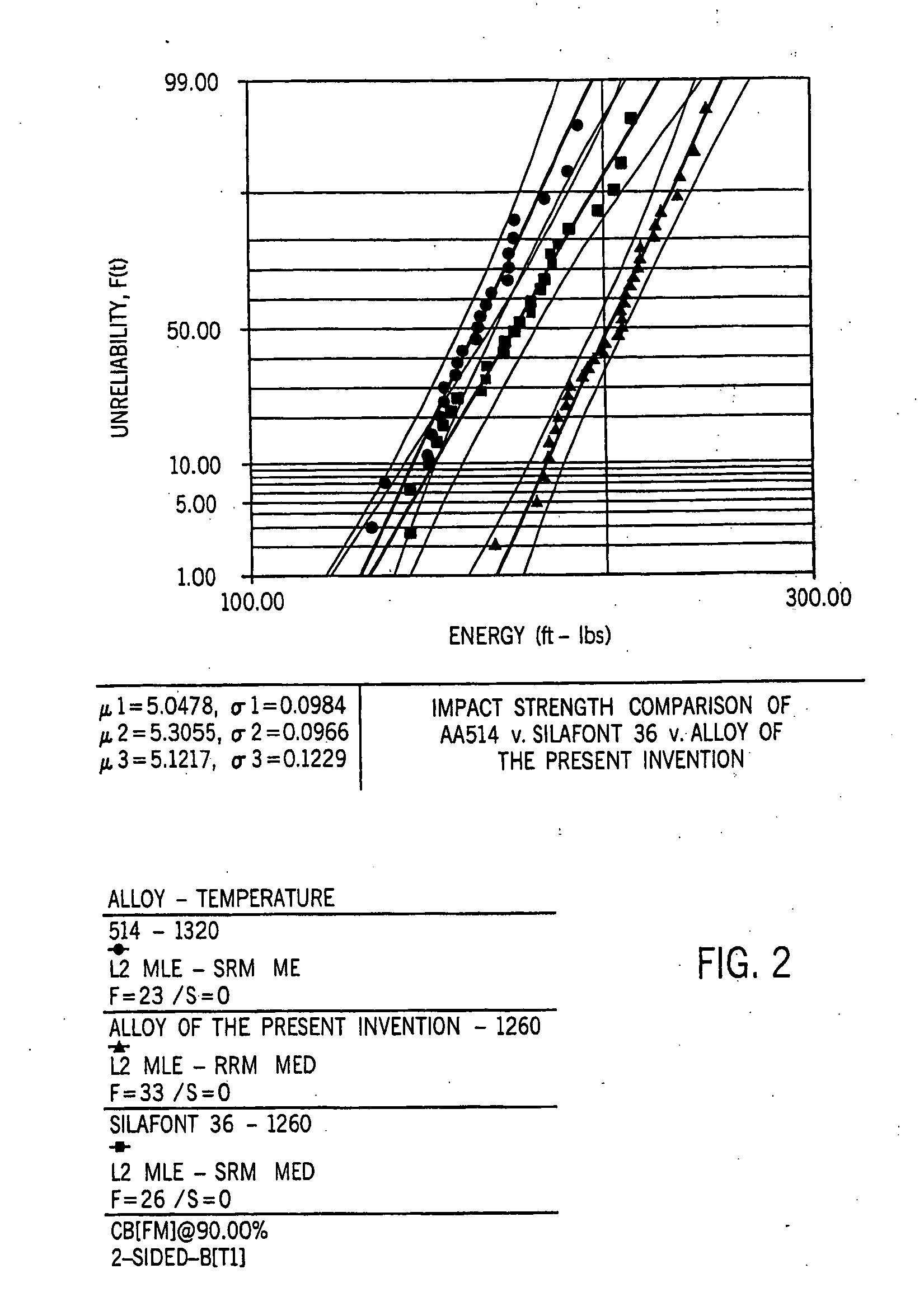

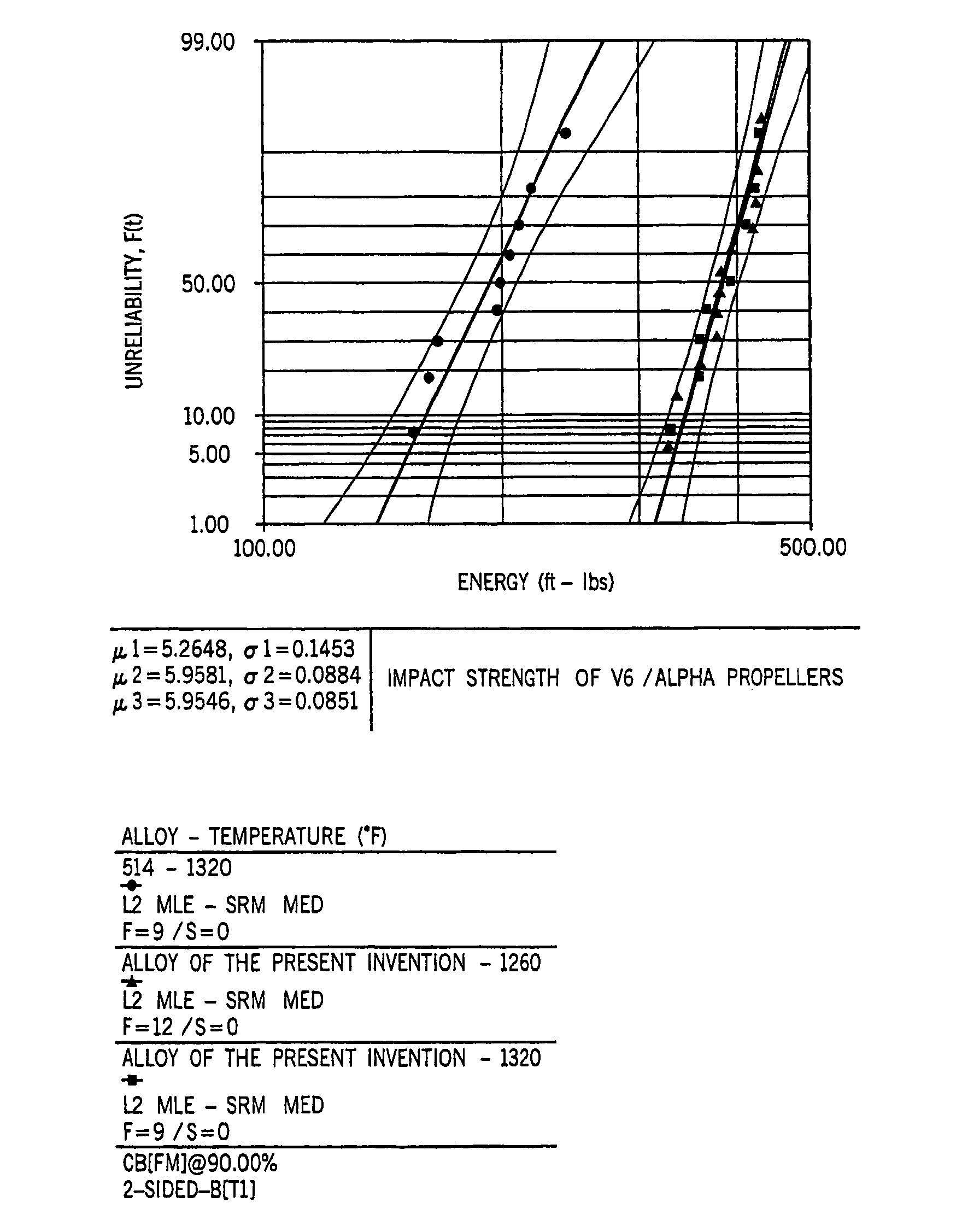

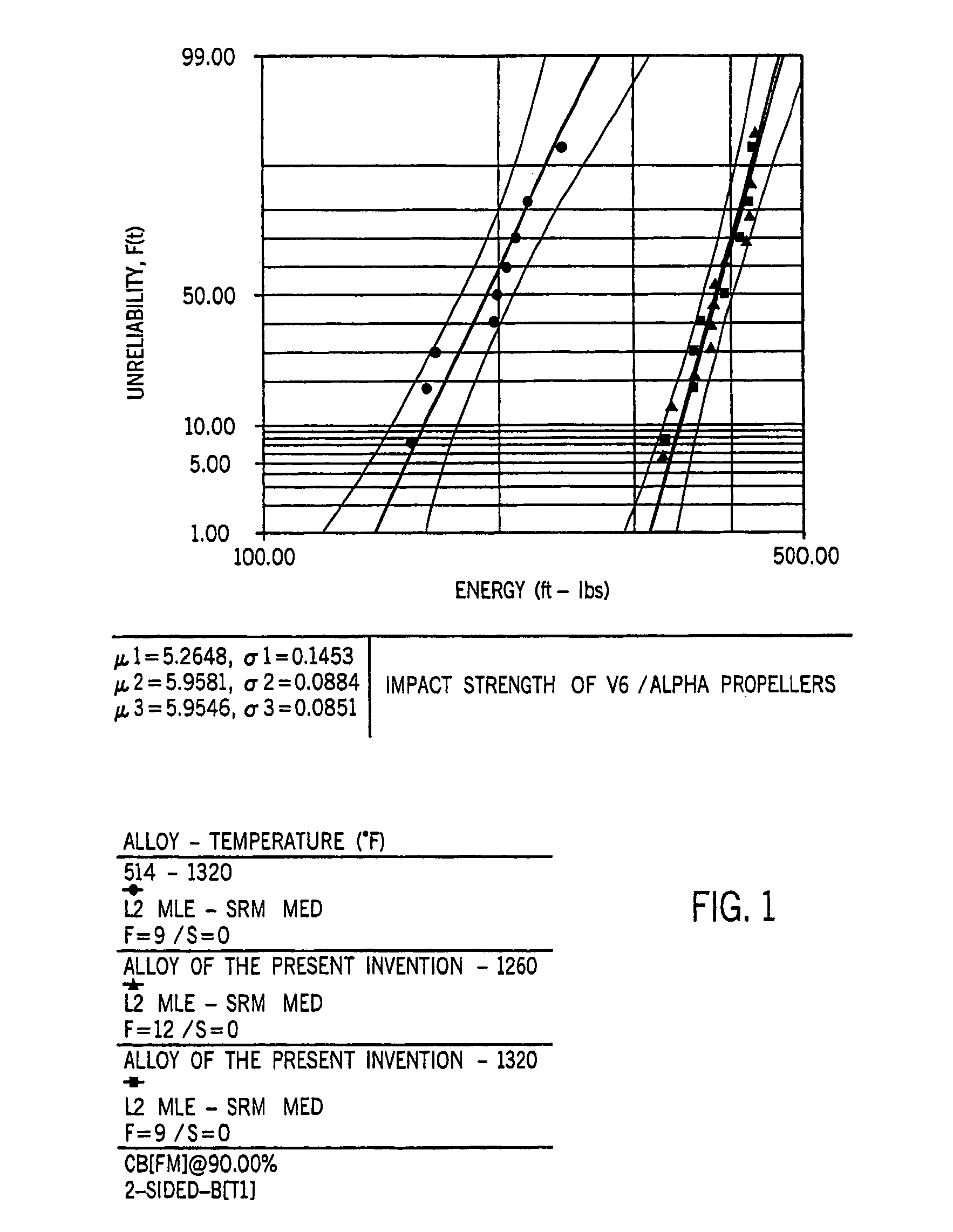

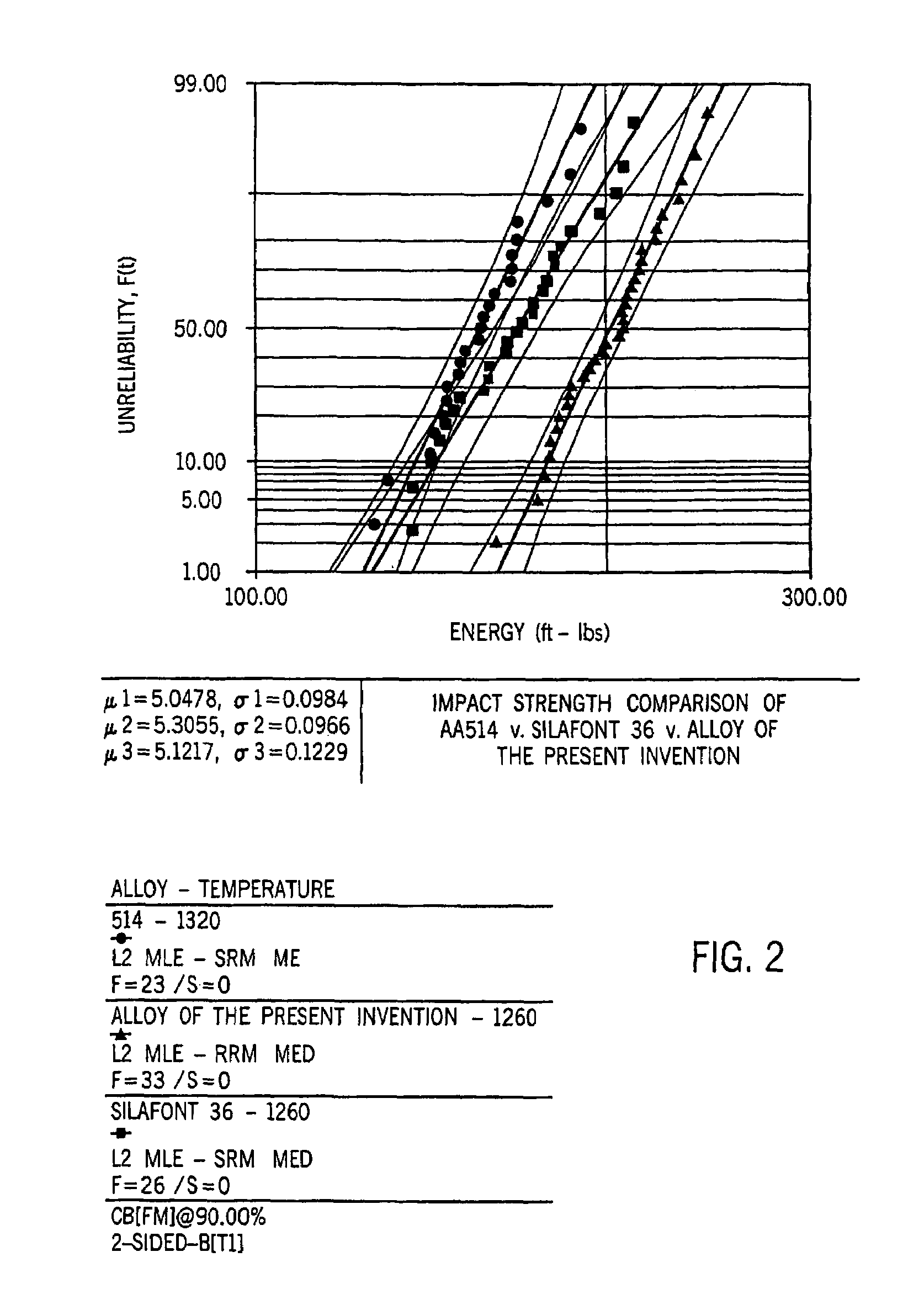

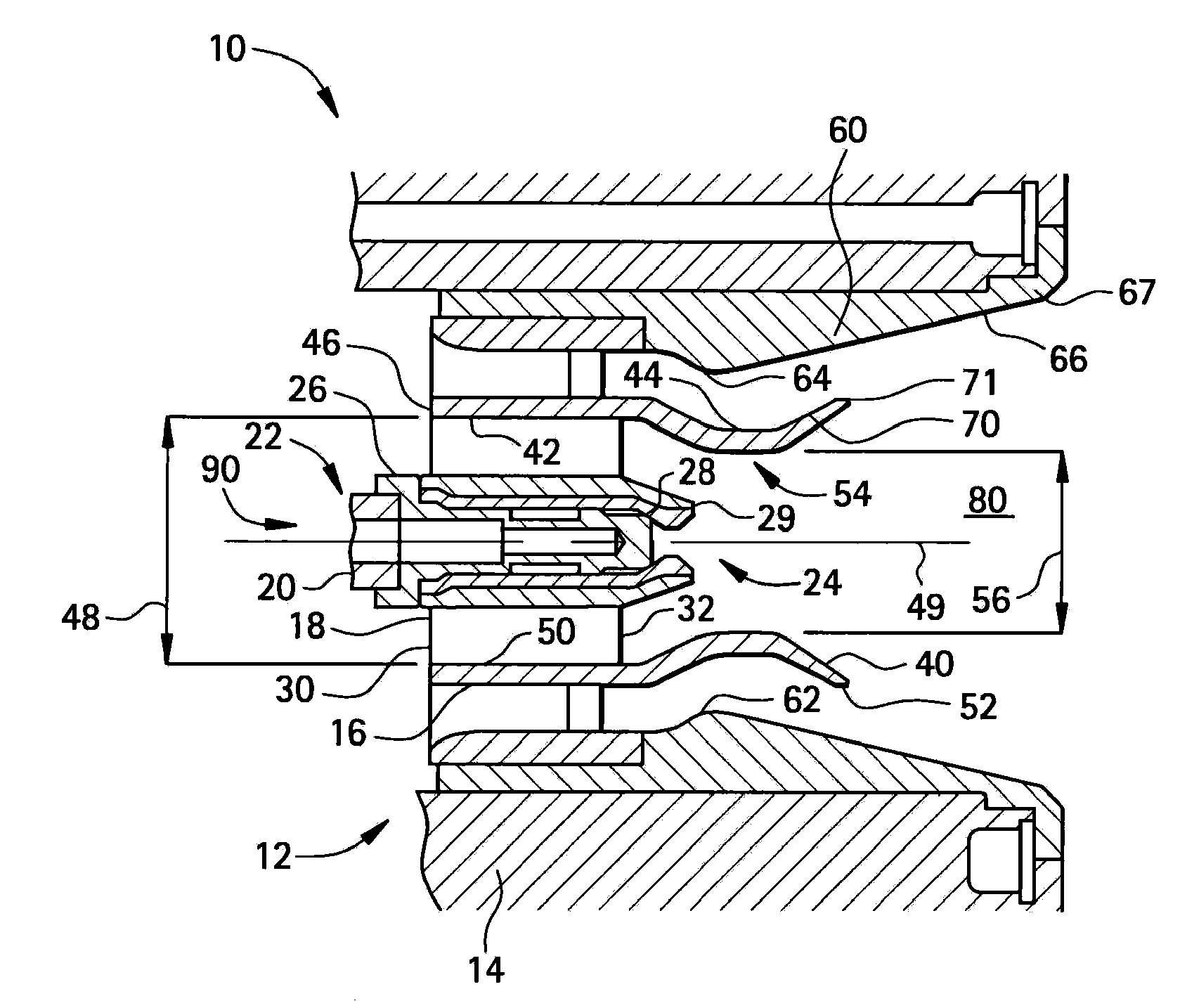

Aluminum-silicon alloy having reduced microporosity

An aluminum silicon die cast alloy having a very low iron content and relatively high strontium content that prevents soldering to dies into die casting process. The alloys of the present invention also have a modified eutectic silicon and modified iron morphology, when iron is present, resulting in low microporosity and high impact properties. The alloy comprises 6-22% by weight silicon, 0.05 to 0.20% by weight strontium and the balance aluminum. Preferably, the alloy of the present invention contains in weight percent: 6-20% silicon, 0.05-0.10% strontium, 0.40% maximum iron and most preferably 0.20% maximum iron, 4.5% maximum copper, 0.50% maximum manganese, 0.60% maximum magnesium, 3.0% maximum zinc, balance aluminum. On cooling from the solution temperature, the strontium serves to modify the eutectic silicon structure as well as create an iron phase morphology change if iron is present, facilitating feeding through the aluminum interdendritic matrix. This, in turn, creates a finished die cast product with extremely low levels of microporosity defects. The strontium content also appears to create a non-wetting monolayer of strontium atoms on the surface of a molten casting, preventing die soldering, even at very low iron contents. The alloy may be used to cast any type of object and is particularly suited for casting outboard marine propellers, driveshaft housings, gear case housings, Gimbel rings and engine blocks.

Owner:BRUNSWICK CORPORATION

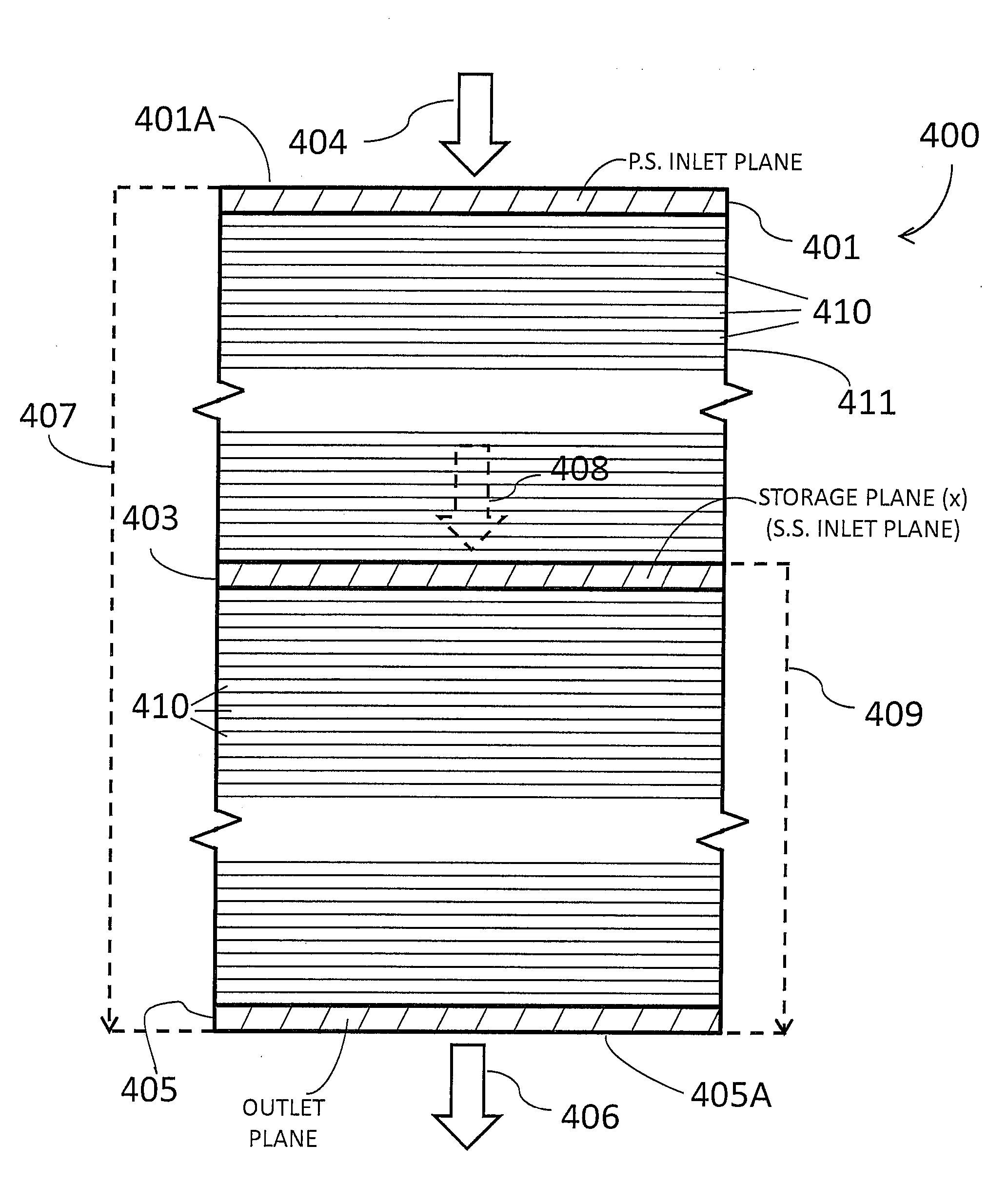

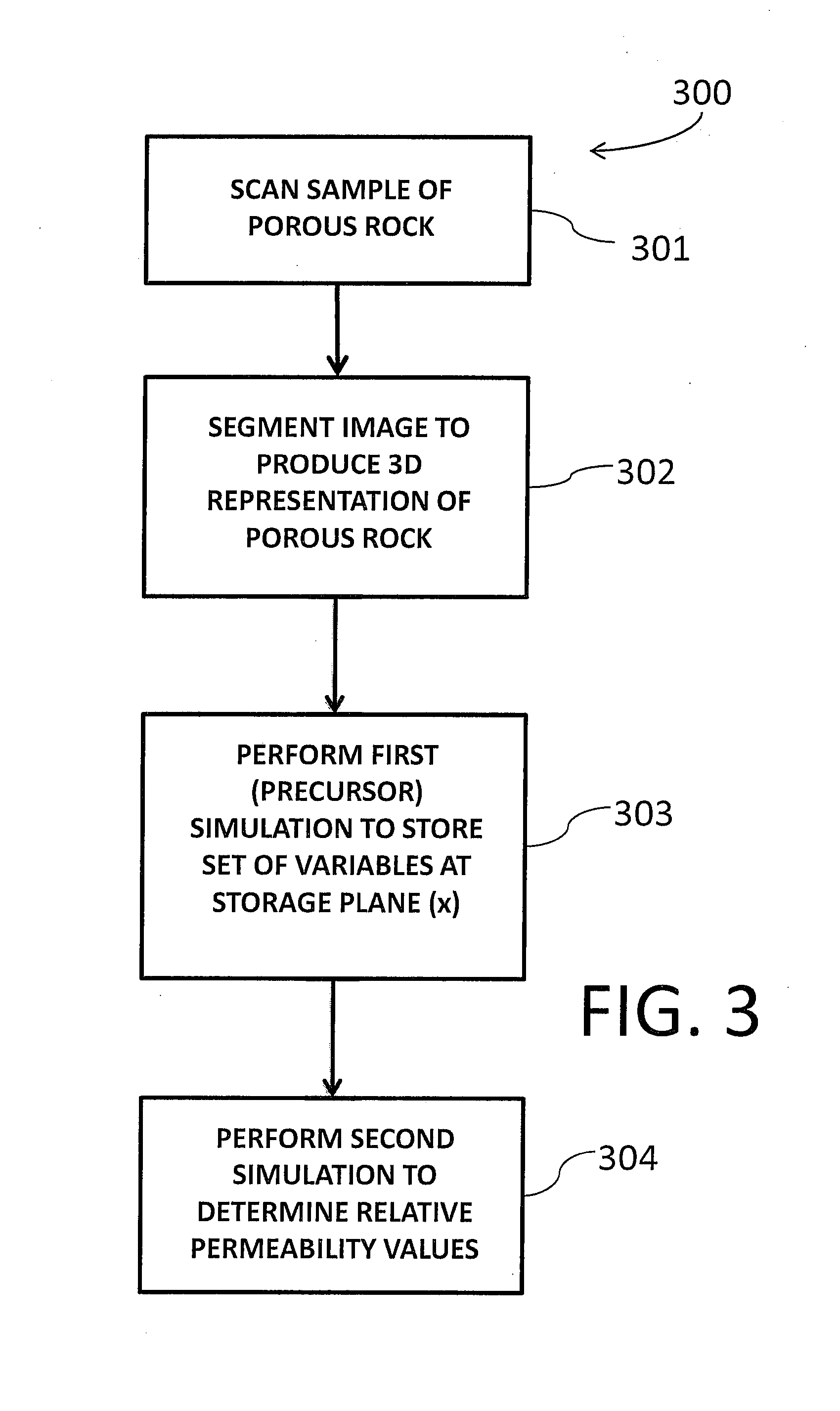

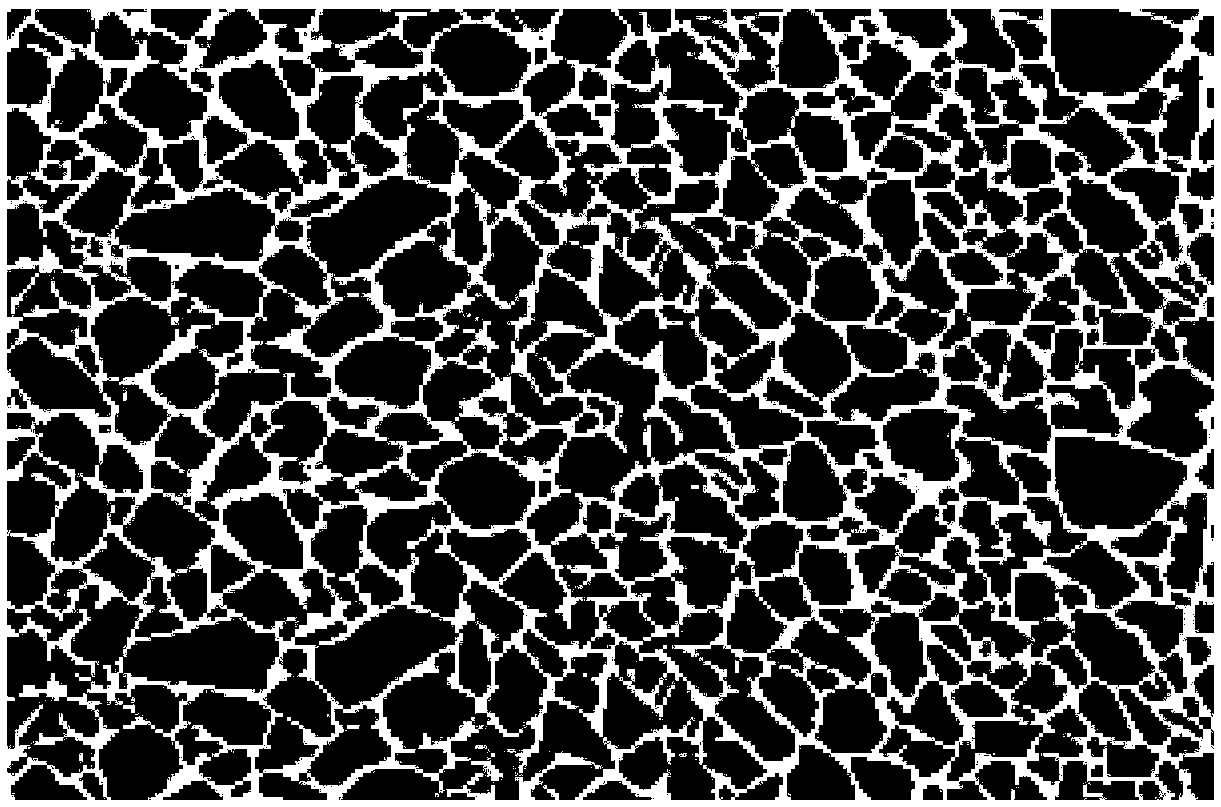

Method For Evaluating Relative Permeability For Fractional Multi-Phase, Multi-Component Fluid Flow Through Porous Media

ActiveUS20140019053A1Improved evaluation and estimateElectric/magnetic detection for well-loggingDesign optimisation/simulationDynamic methodFluid transport

A method for computing or estimating relative permeability for fractional multi-phase, multi-component fluid flow through a porous medium, which employs a 3D digital representation of a porous medium and a computational fluid dynamics method to calculate flow rates, pressures, saturations, velocities and other flow parameters, is described. The method employs a unique method which integrates a precursor simulation used to generate a set of variables like pressure, saturation and velocity distribution associated with a selected storage plane in the 3D digital representation of a porous medium, which variables are used as inlet condition in the workflow of a second simulation that can generate values of fractional flow rates, pressures, saturations, velocities, or other parameters of wetting and non-wetting phases, which can be used to compute or estimate relative permeability values or other fluid transport properties of the porous medium. Computerized systems and programs for performing the method are also provided.

Owner:HALLIBURTON ENERGY SERVICES INC

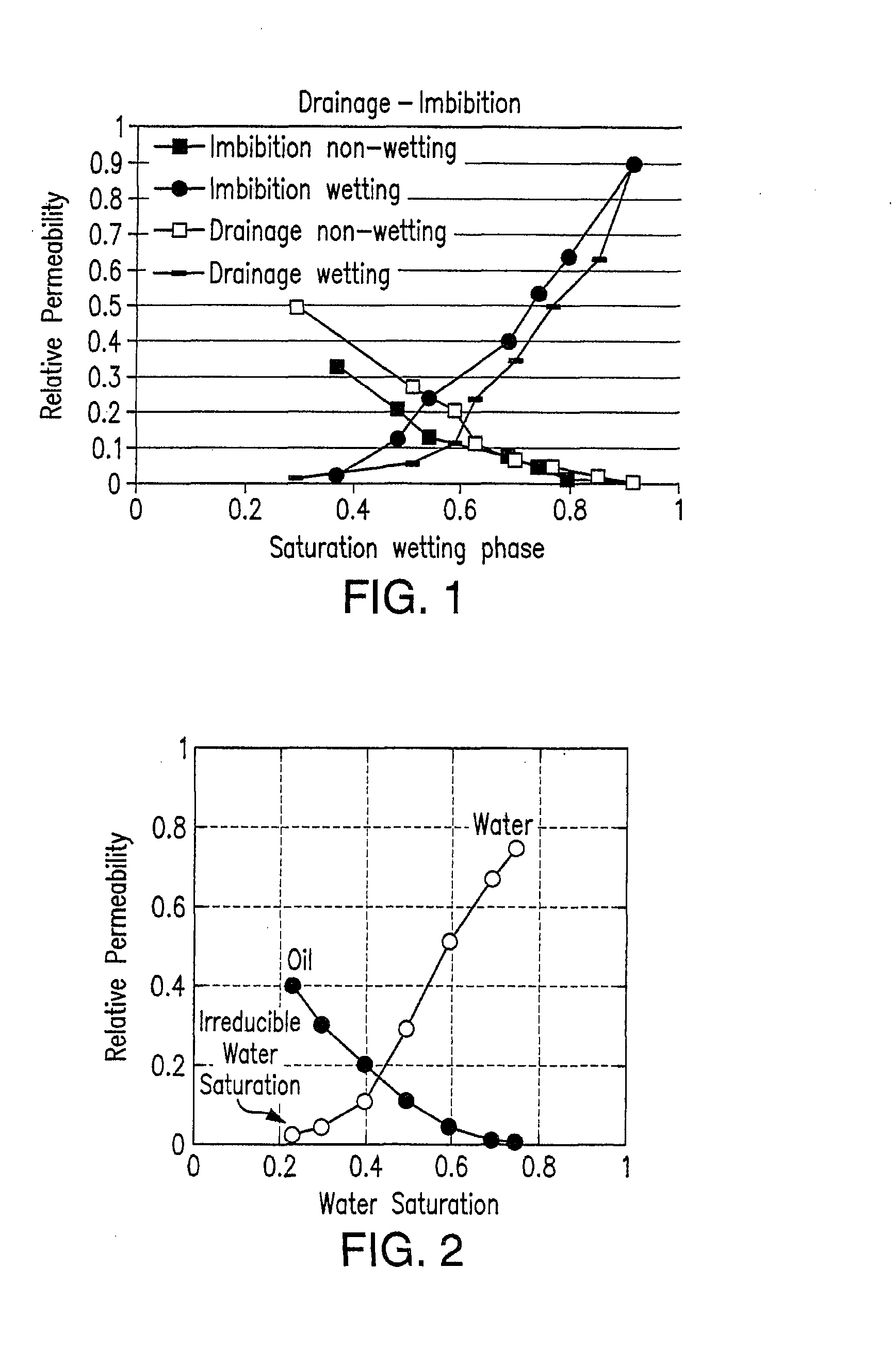

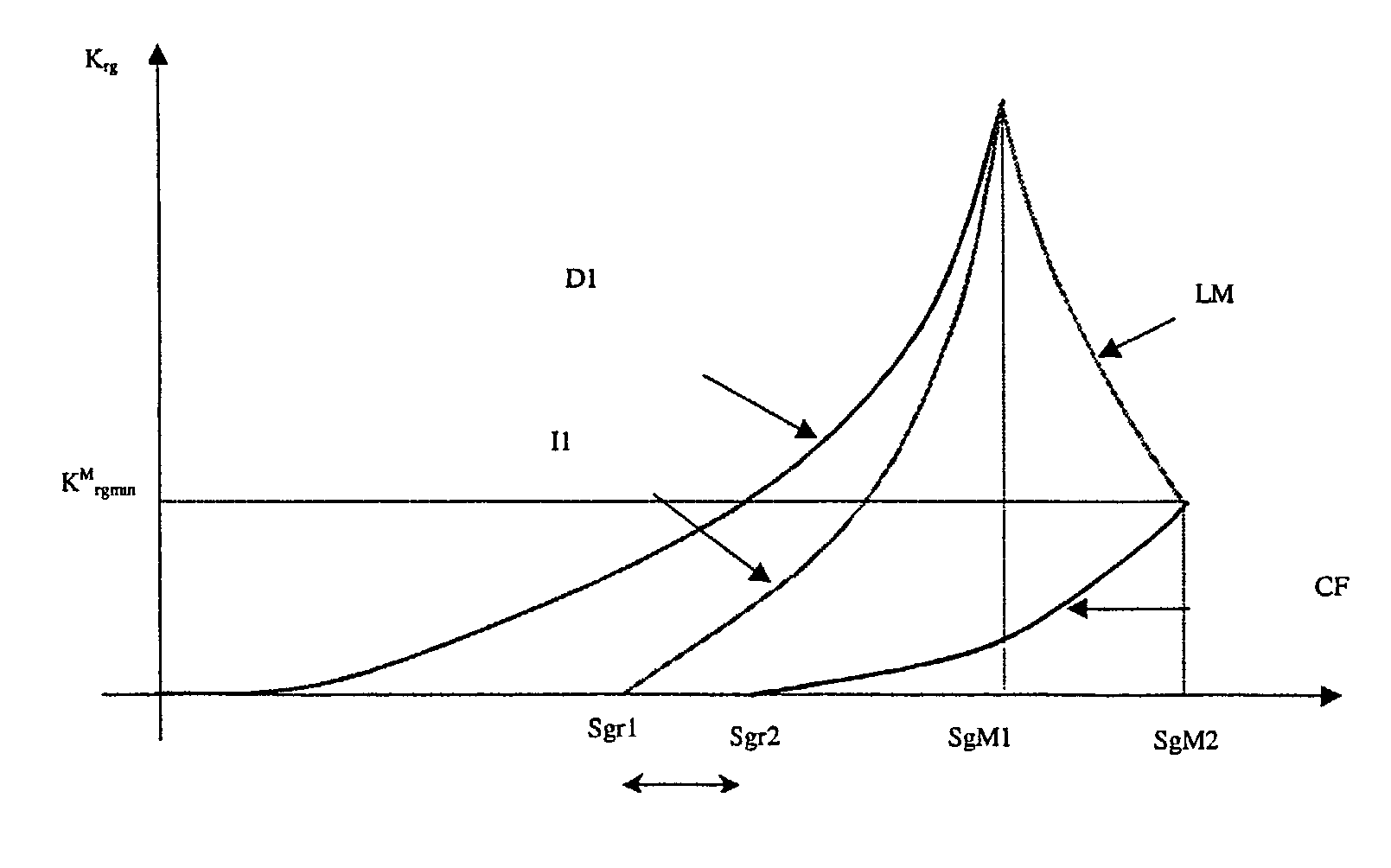

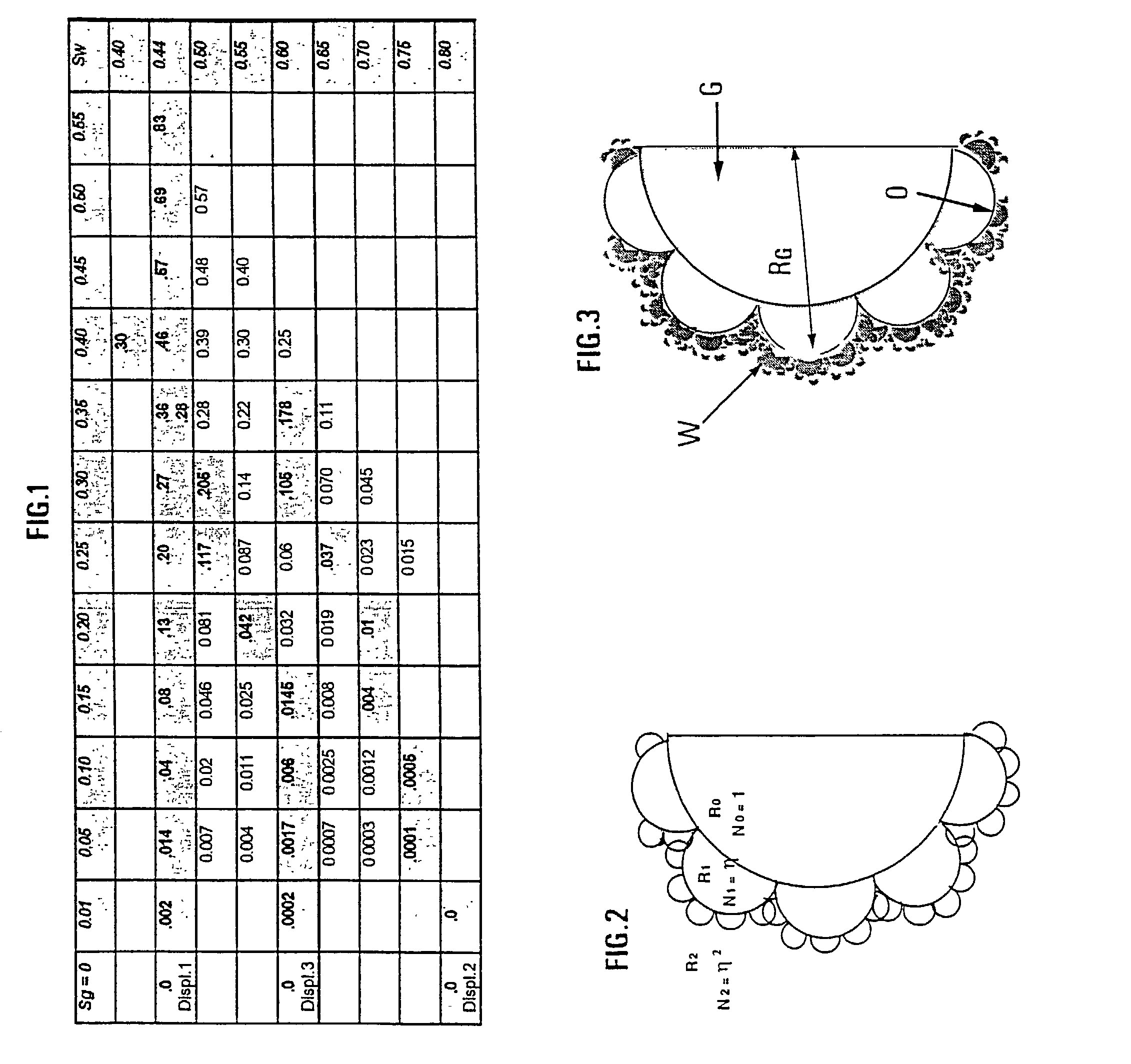

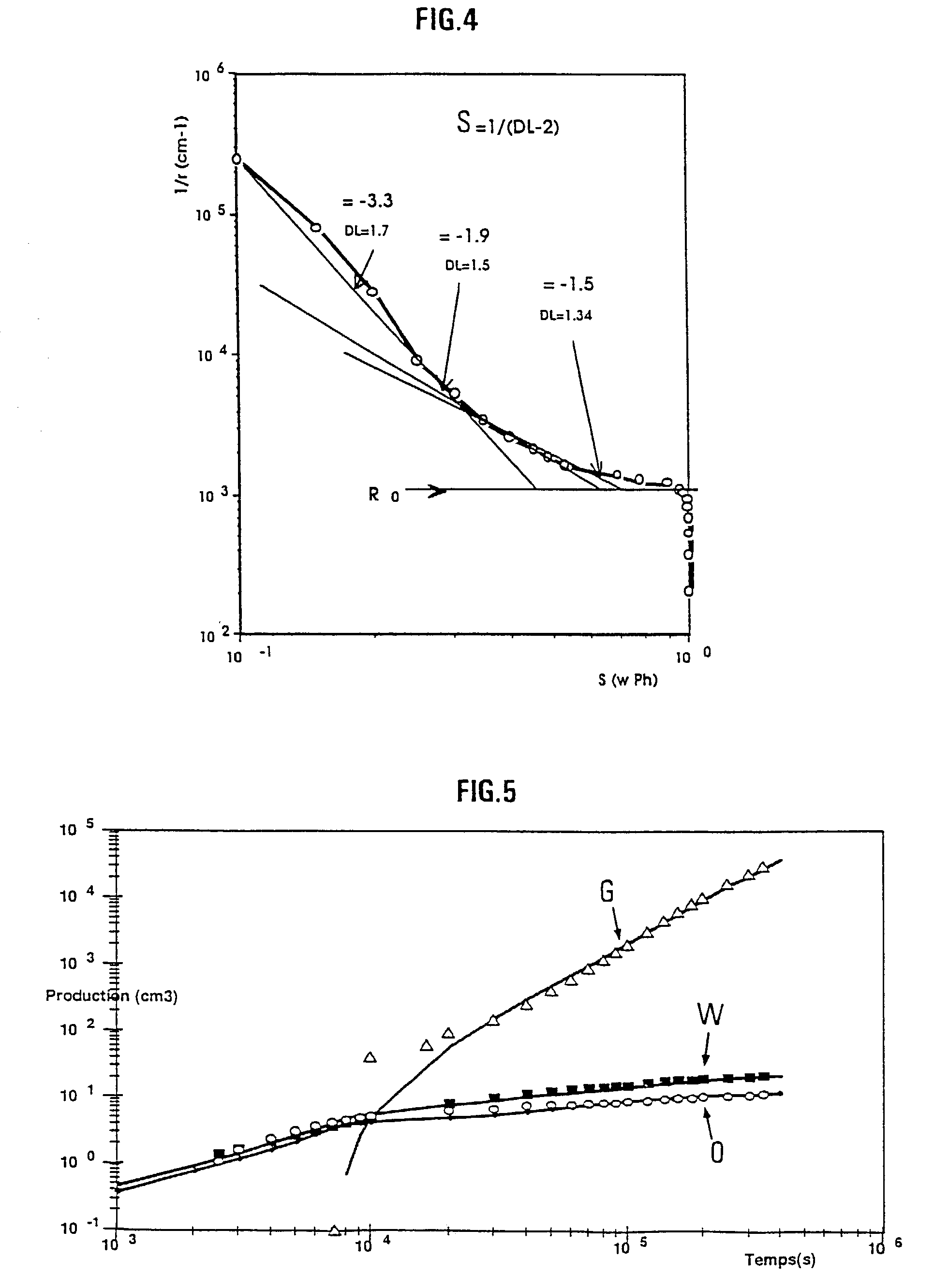

Method for modelling fluid displacements in a porous environment taking into account hysteresis effects

InactiveUS7072809B2The process is convenient and fastMore and more conditionElectric/magnetic detection for well-loggingEarth material testingHysteresisNon wetting

A modelling method having application to petroleum production, soil cleaning, etc. for optimizing faster and more realistically the displacement conditions, in a porous medium wettable by a first fluid (water for example), of a mixture of fluids including this wetting fluid, another, non-wetting fluid (oil for example) and a gas. The method comprises experimental determination of the variation curve of the capillary pressure in the pores as a function of the saturation in the liquid phases, modelling the pores of the porous medium by means of a distribution of capillaries with a fractal distribution by considering, in the case of a three-phase water (wetting fluid)-oil-gas mixture for example, a stratification of the constituents in the pores, with the water in contact with the walls, the gas in the center and the oil forming an intercalary layer, determination, from this capillary pressure curve, of the fractal dimension values corresponding to a series of given values of the saturation in the liquid phase, modelling the hysteresis effects that modify the mobile saturations of the fluids effectively displaced in the sample, that vary during drainage and imbibition cycles.

Owner:GAZ DE FRANCE +1

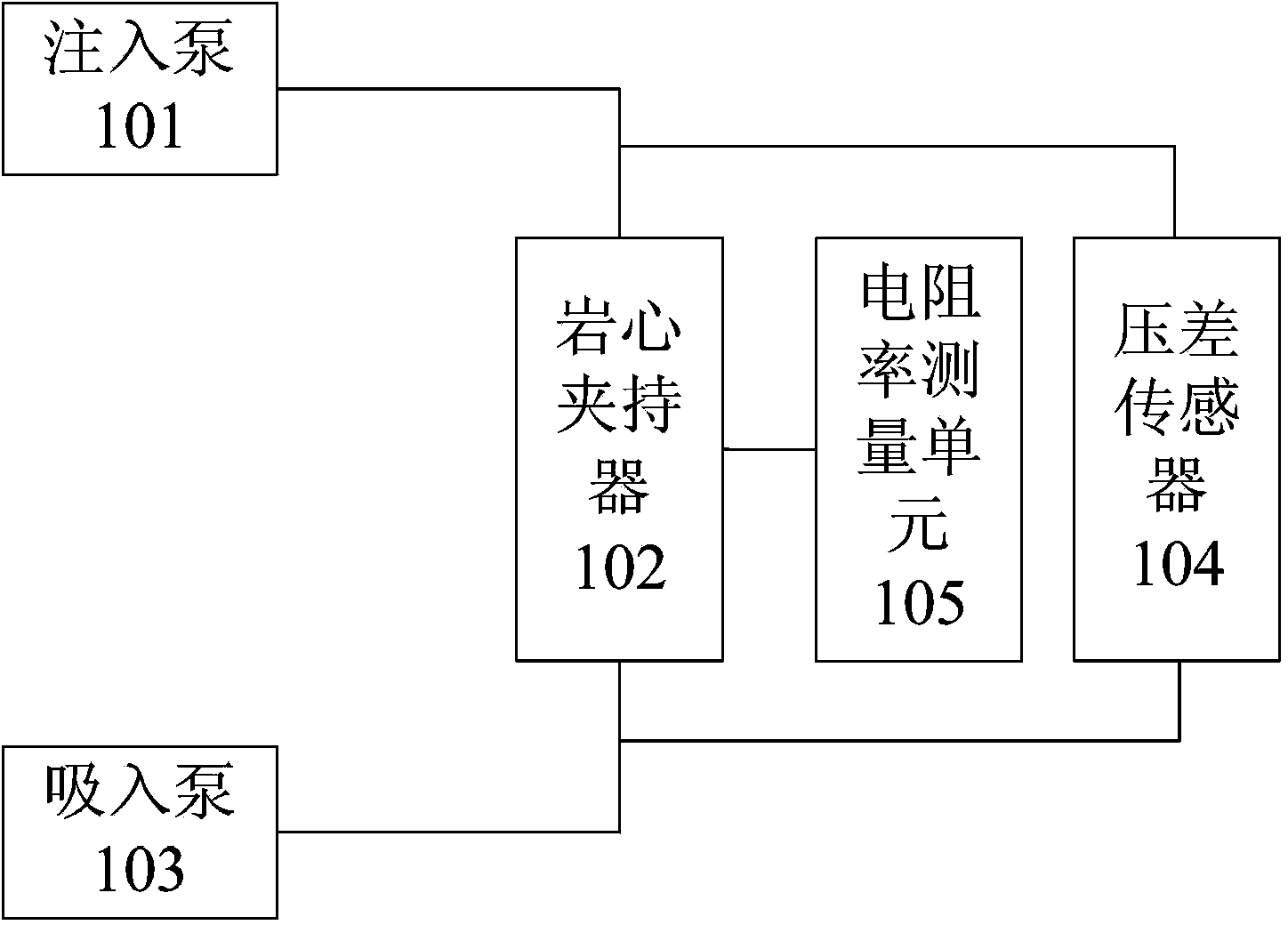

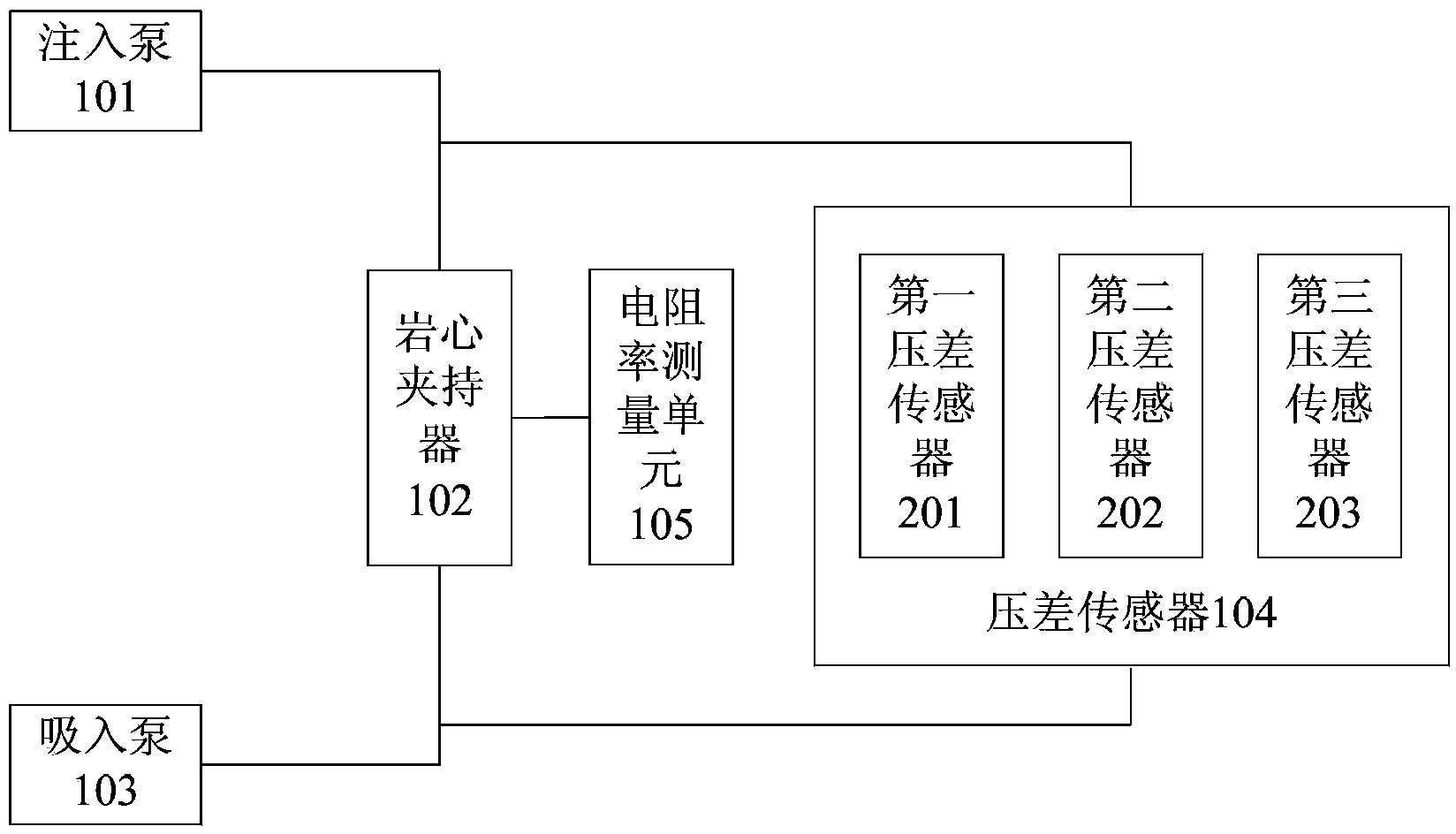

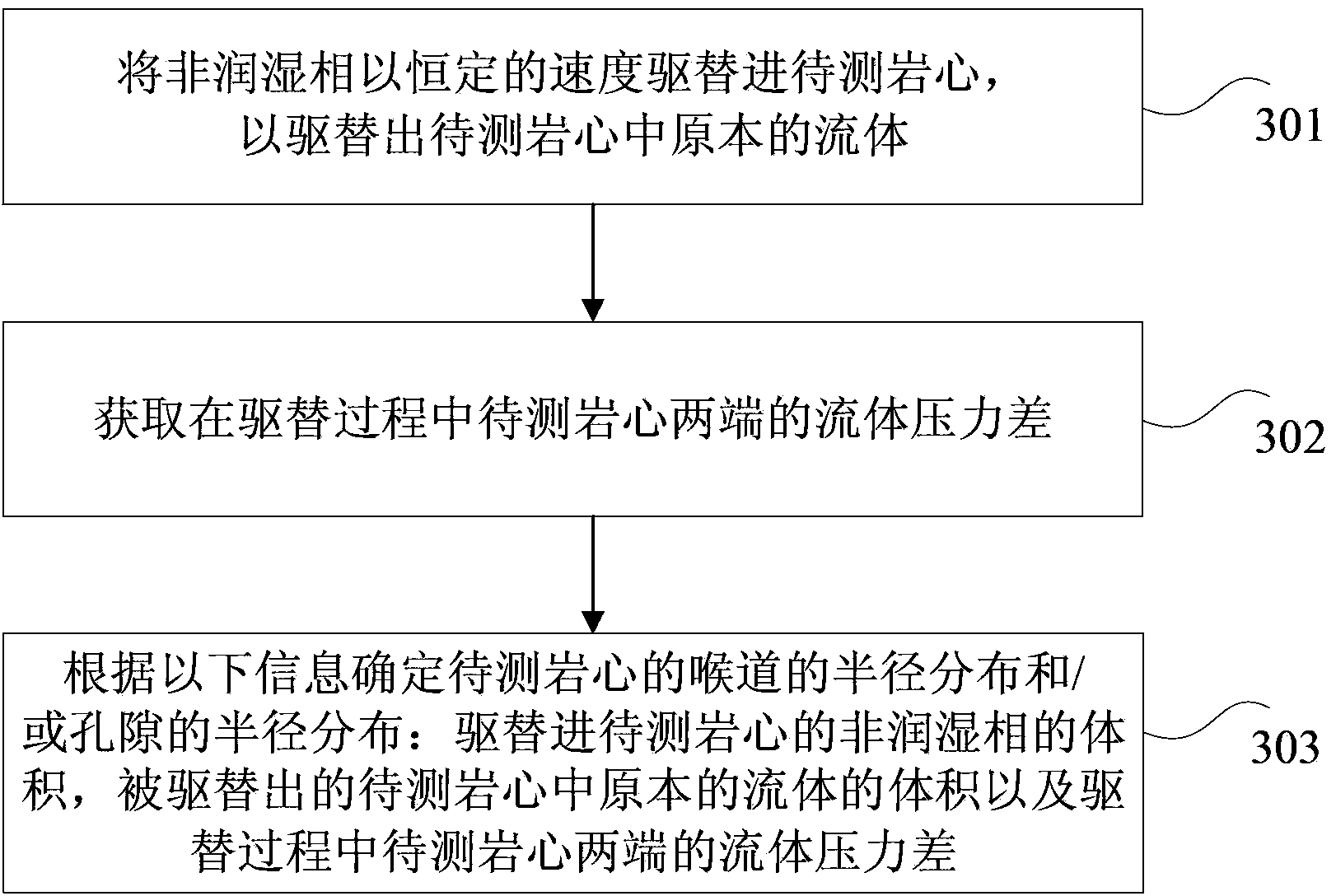

Rock core measuring system and method

ActiveCN103412111ARealize measurementShort measuring cycleEarth material testingPermeability/surface area analysisNon wettingRock core

The invention provides a rock core measuring system and method. The system comprises a core holder, an injection pump, a suction pump, a pressure difference sensor and a resistivity measuring unit, wherein the injection pump is connected with a fluid injection port of the core holder and used for displacing a non-wetting phase entering into a to-be-measured rock core fixed in the core holder at a constant speed; the suction pump is connected with a fluid output port of the core holder and used for collecting the original fluid which is in the to-be-measured rock core and is displaced out from the to-be-measured rock core; two ends of the pressure difference transducer are connected with the fluid injection port and the fluid output port respectively, and the pressure difference transducer is used for measuring the pressure difference of fluid at the two ends of the to-be-measured rock core in the displacement process of the to-be-measured rock core; the resistivity measuring unit is connected with the to-be-measured rock core and used for measuring the resistivity of the to-be-measured rock core in the displacement process of the to-be-measured rock core. The system and the method provided by the invention solve the technical problems that when a constant-pressure difference method is adopted for measuring a rock core, the resistivity of the rock core and the information of a pore connected with a throat can not be determined at the same time, and the number of obtained data points is small; meanwhile, the measurement period is shortened compared with that of the constant-pressure difference method.

Owner:PETROCHINA CO LTD

Dry water cosmetic compositions that change color upon application

A powdered water cosmetic composition comprising activatable pigments, a water phase comprised of water droplets, and a particulate phase comprised of non-wetting particulates operable to surround and sequester the individual water droplets from each other in the composition, wherein said activatable pigments prior to activation provide a composition having a first resting color and, upon activation by application to a keratinous surface, a second application color which is visually distinct from the first color, and a method for applying color to keratinous surfaces using the composition of the invention.

Owner:REVLON CONSUMER PROD CORP

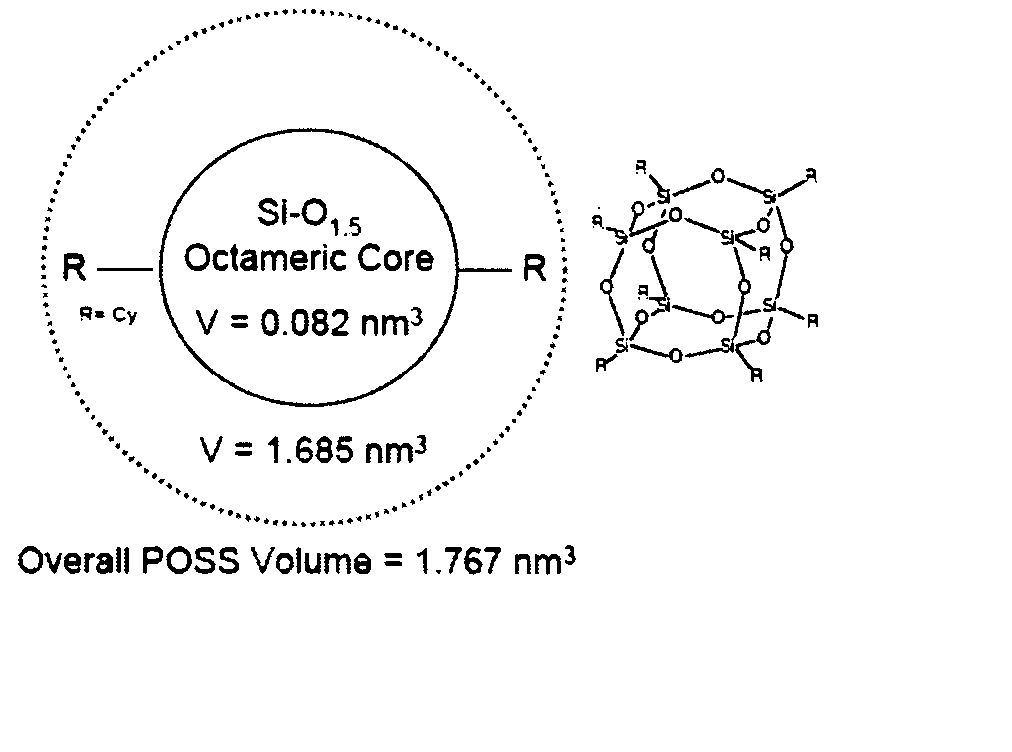

Fluorinated POSS as alloying agents in nonfluorinated polymers

ActiveUS20080221262A1Improve impactImprove surface propertiesMaterial nanotechnologyPersonal careMolecular level

A method of using fluorinated-nanostructured POSS chemicals as alloying agents for the reinforcement of polymer microstructures, including polymer coils, domains, chains, and segments, at the molecular level. Because of their tailorable compatibility with nonfluorinated polymers, nanostructured chemicals can be readily and selectively incorporated into polymers by direct blending processes. The incorporation of a nanostructured chemical into a polymer favorably impacts a multitude of polymer physical properties. Properties most favorably improved are surface properties, such as lubricity, contact angle, water repellency, deicing, surface tension, and abrasion resistance. Improved surface properties may be useful for applications such as anti-icing surfaces, non-wetting surfaces, low friction surfaces, self cleaning. Other properties improved include time dependent mechanical and thermal properties such as heat distortion, creep, compression set, shrinkage, modulus, hardness and biological compatibility. In addition to mechanical properties, other physical properties are favorably improved, including lower thermal conductivity, dielectric properties, fire resistance, gas permeability and separation. These improved properties may be useful in a number of applications, including space-survivable materials and seals, gaskets, cosmetics, and personal care.

Owner:HYBRID PLASTICS INC +1

Pyrolysis systems, methods, and resultants derived therefrom

ActiveUS8282787B2Fit closelyWithout undesired degradation of communication system performanceLayered productsUsing liquid separation agentNon wettingActivated carbon filtration

A system and process for gasification of a carbonaceous feedstock uses pyrolysis to produce a gas product, which may include methane, ethane, and other desirable hydrocarbon gases, and a solids product, which includes activated carbon or carbon. The gas product may then be filtered using at least a portion of the activated carbon from the solids product as a filtering medium. In an embodiment, at least some of the noxious chemicals are sequestered or removed from the gas product in one or more filtering steps using the activated carbon as a filtering medium. In a further embodiment, the filtering steps are performed in stages using activated carbon at different temperatures. A high-temperature pyrolysis system that produces activated carbon may be combined with another high-temperature pyrolysis system that does not produce activated carbon to provide filtering of noxious compounds using activated carbon from the first high-temperature pyrolysis system. A high-temperature pyrolysis system may be combined with one or more low-temperature feedstock conversion processes such that waste heat from the high-temperature pyrolysis system is used to operate the low-temperature process. A novel non-wetting carbon having pores fused with silica can be produced from using the system and process.

Owner:TUCKER RICHARD D

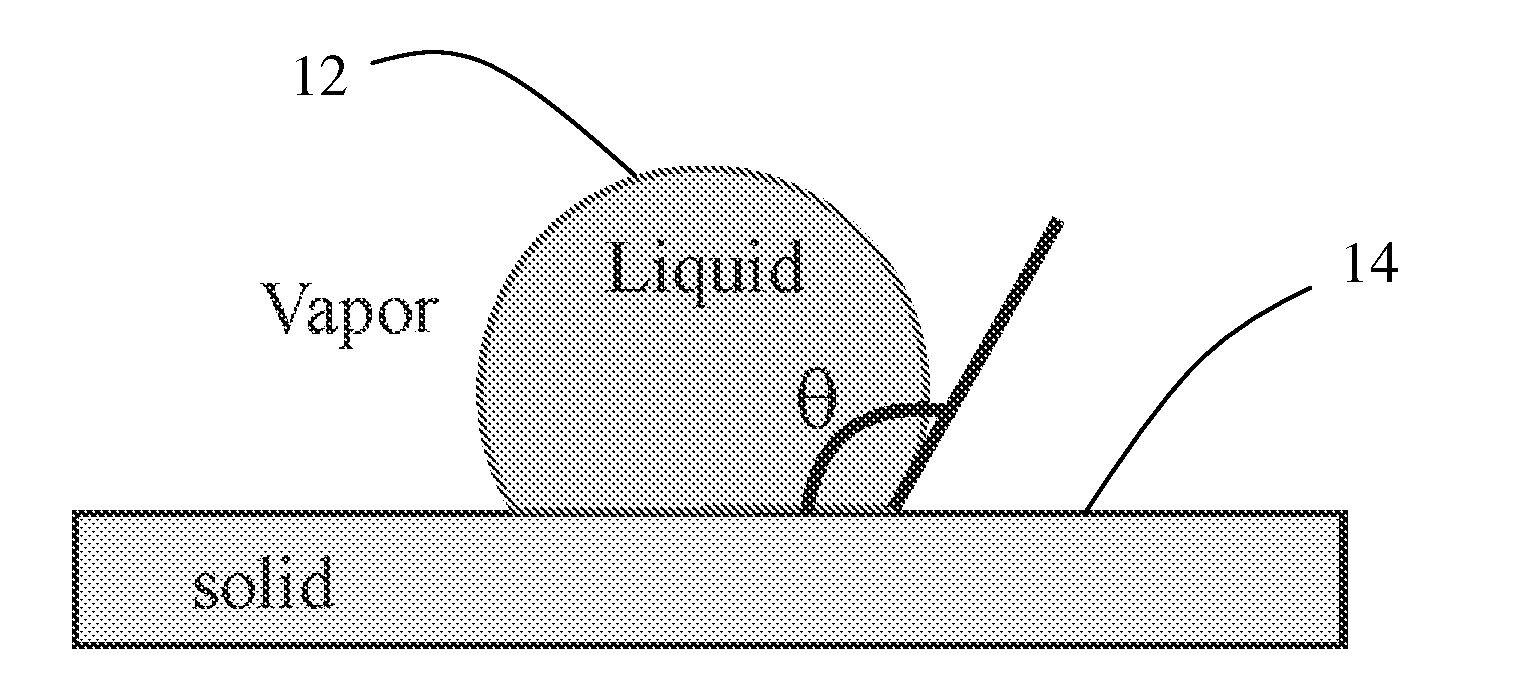

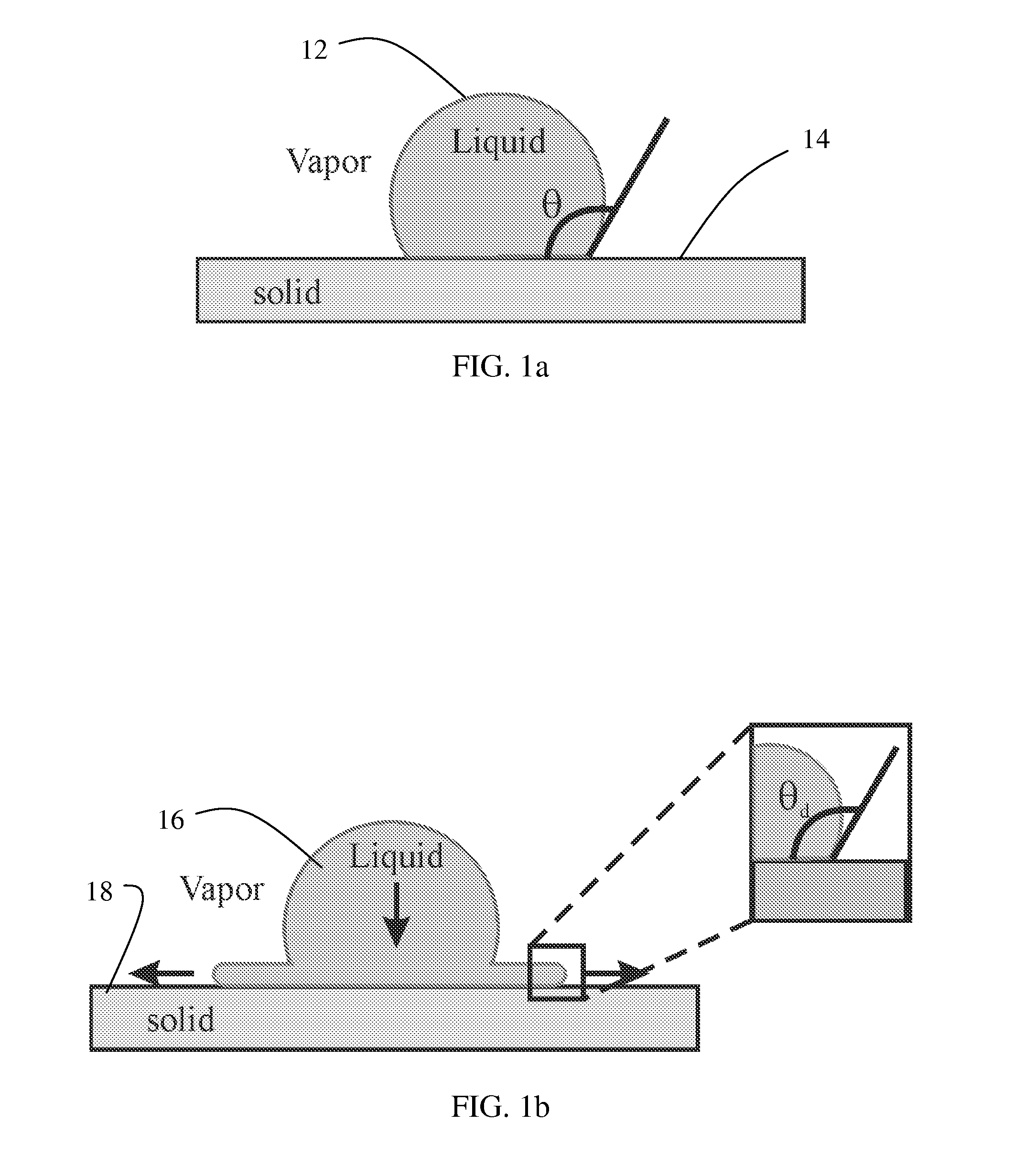

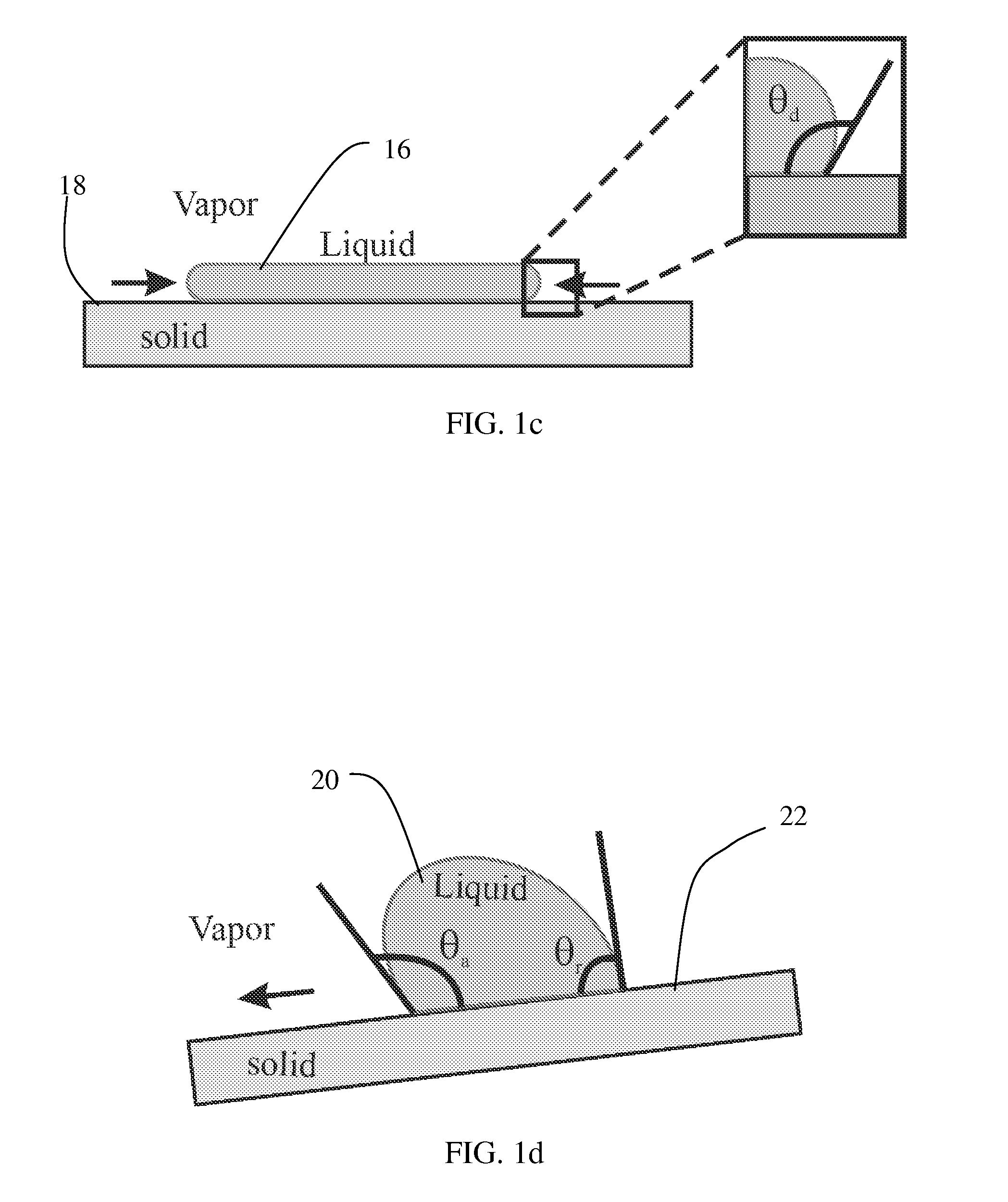

Articles for manipulating impinging liquids and methods of manufacturing same

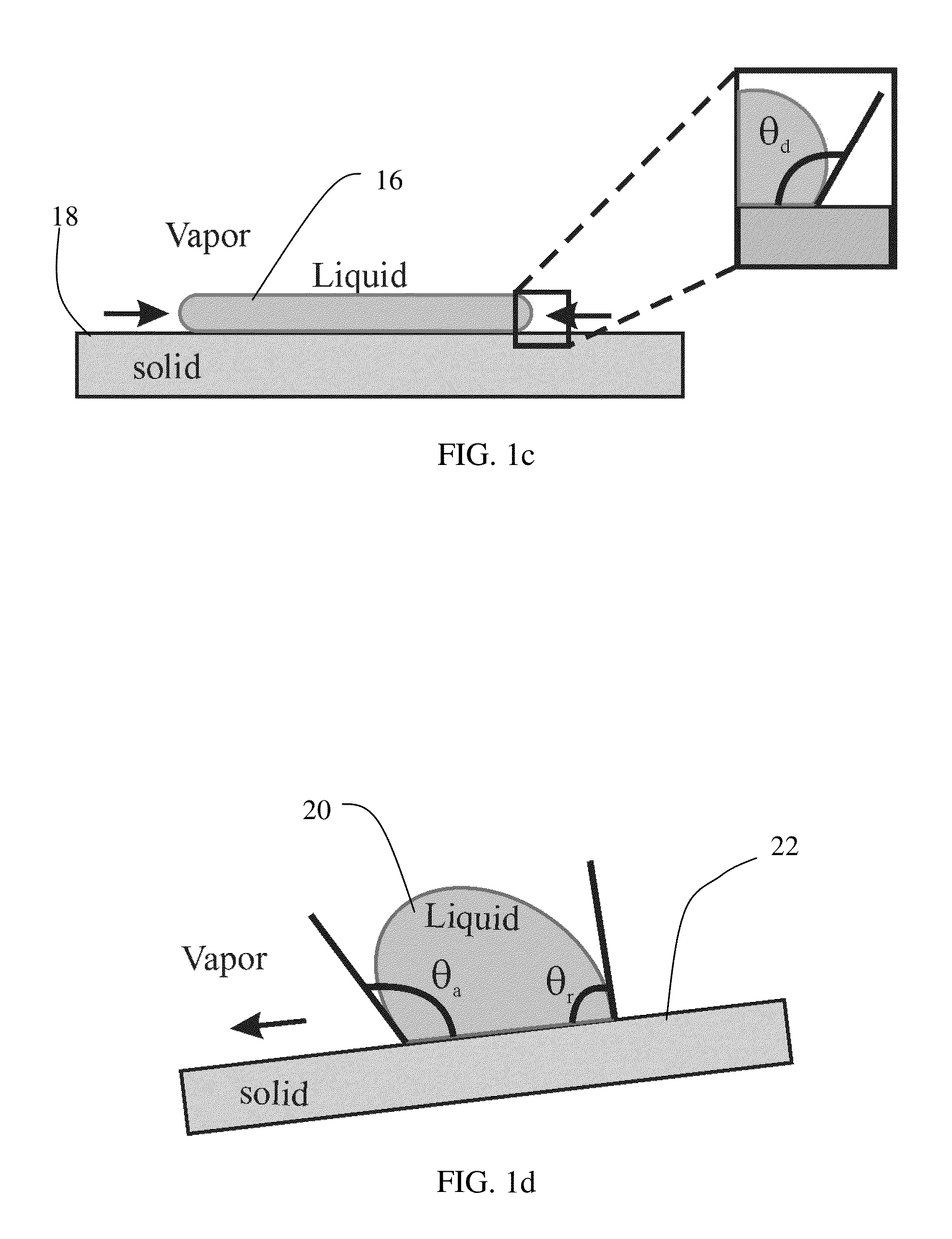

ActiveUS20130032646A1Improve performanceMore practicalMaterial nanotechnologyLayered productsNon wettingMacroscopic scale

This invention relates generally to an article that includes a non-wetting surface having a dynamic contact angle of at least about 90°. The surface is patterned with macro-scale features configured to induce controlled asymmetry in a liquid film produced by impingement of a droplet onto the surface, thereby reducing time of contact between the droplet and the surface.

Owner:MASSACHUSETTS INST OF TECH

Aluminum-silicon alloy having reduced microporosity

An aluminum silicon die cast alloy having a very low iron content and relatively high strontium content that prevents soldering to dies into die casting process. The alloys of the present invention also have a modified eutectic silicon and modified iron morphology, when iron is present, resulting in low microporosity and high impact properties. The alloy comprises 6-22% by weight silicon, 0.05 to 0.20% by weight strontium and the balance aluminum. Preferably, the alloy of the present invention contains in weight percent: 6-20% silicon, 0.05-0.10% strontium, 0.40% maximum iron and most preferably 0.20% maximum iron, 4.5% maximum copper, 0.50% maximum manganese, 0.60% maximum magnesium, 3.0% maximum zinc, balance aluminum. On cooling from the solution temperature, the strontium serves to modify the eutectic silicon structure as well as create an iron phase morphology change if iron is present, facilitating feeding through the aluminum interdendritic matrix. This, in turn, creates a finished die cast product with extremely low levels of microporosity defects. The strontium content also appears to create a non-wetting monolayer of strontium atoms on the surface of a molten casting, preventing die soldering, even at very low iron contents. The alloy may be used to cast any type of object and is particularly suited for casting outboard marine propellers, driveshaft housings, gear case housings, Gimbel rings and engine blocks.

Owner:BRUNSWICK CORPORATION

Surface treatments and coatings for atomization

InactiveUS20090283611A1Promote atomizationReduce mean drop sizeLiquid spraying apparatusMedical atomisersNon wettingInstability

An atomizer, comprising a pre-filming region comprising a surface configured to reduce a mean drop size of a liquid to be atomized, wherein the surface has an effective contact angle, with reference to the liquid, of less than about 30 degrees; and a lip portion disposed at an end of the pre-filming region and configured to create hydrodynamic instabilities in a liquid film, wherein the lip portion comprises an alternating pattern of wetting and non-wetting surfaces, wherein the non-wetting surface comprises a contact angle, with reference to the liquid, of greater than 90 degrees, and the wetting surface comprises a contact angle, with reference to the liquid, of less than 90 degrees.

Owner:GENERAL ELECTRIC CO

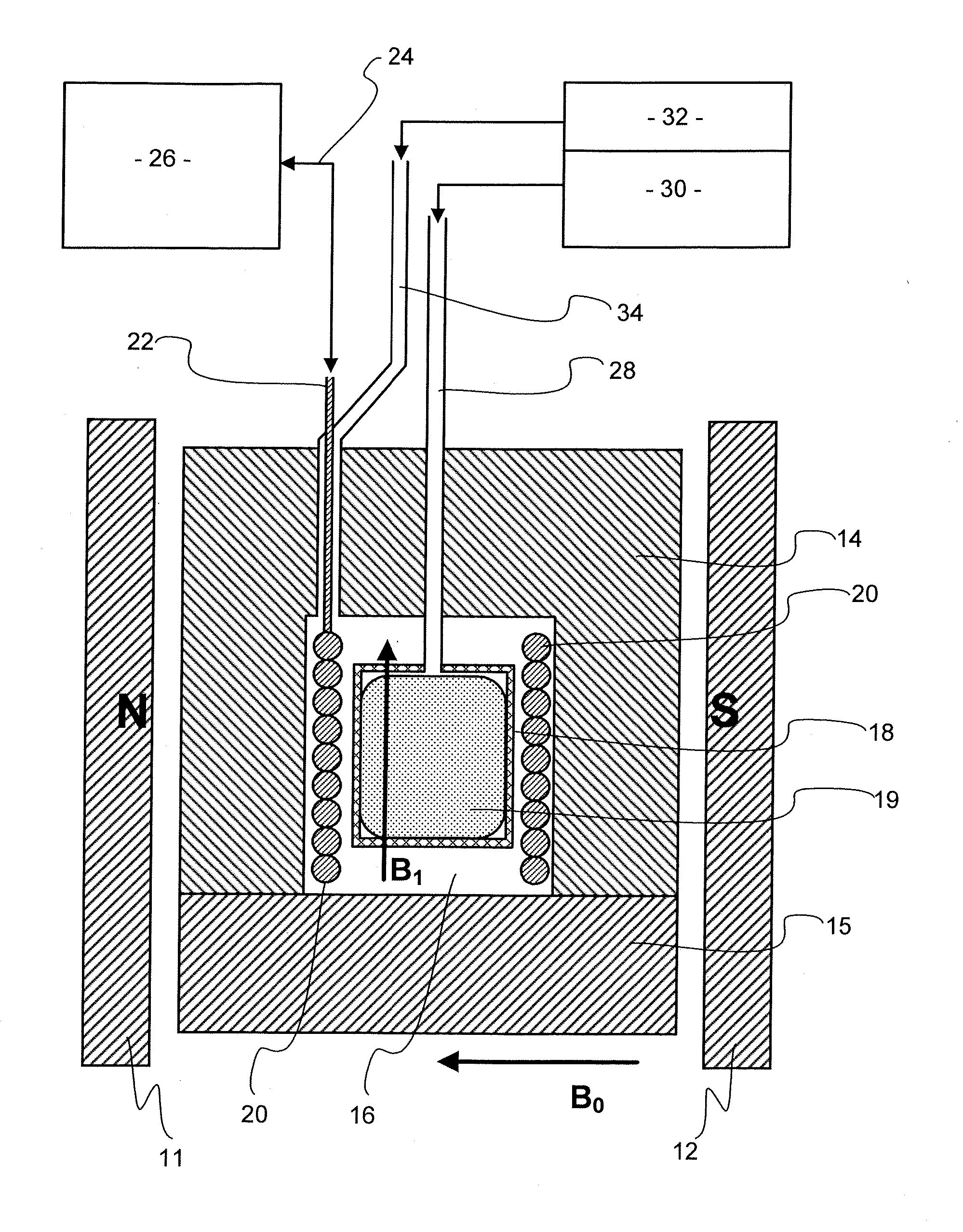

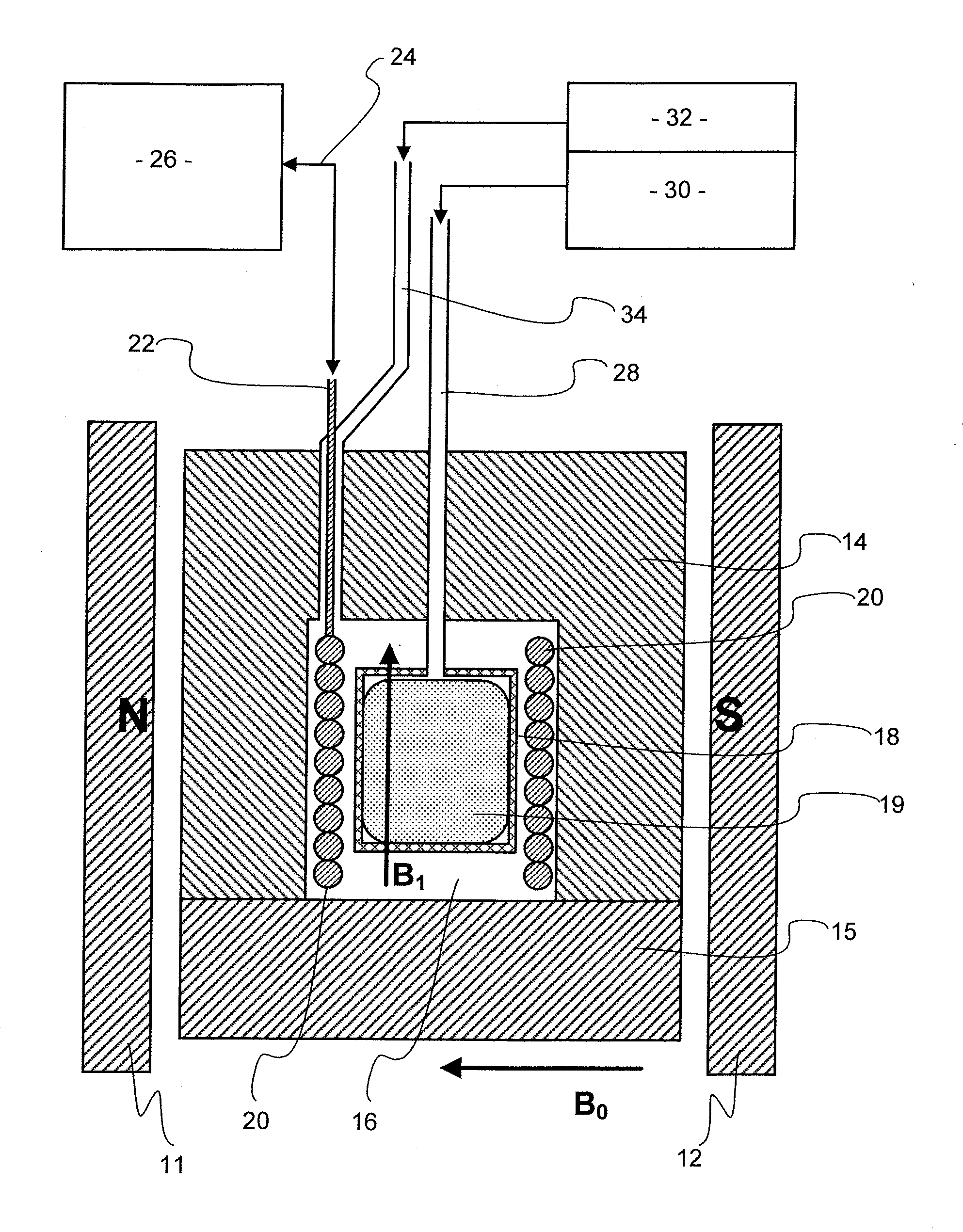

Examination of porosity by NMR and intrusion porosimetry

ActiveUS20140002081A1Analysis using nuclear magnetic resonanceElectric/magnetic detectionElectromagnetic radiationSpherical equivalent

Properties of a porous solid sample 19, which may be a core of rock taken from below ground are carried out using apparatus which performs both nuclear magnetic resonance (NMR) and porosimetry measurements. The apparatus has a magnet 11,12 providing a magnetic field and a radio frequency coil 20 for transmitting and / or receiving electromagnetic radiation so as to bring about NMR in the magnetic field, a pressure vessel 14, 15 to hold a sample 19 within the magnetic field, a supply of a non-wetting liquid connected to the vessel, means to apply pressure to the non-wetting liquid to force liquid into pores of the sample 19 means to measure applied pressure of the non-wetting liquid and means to measure volume thereof taken up by the sample. The pressure of non-wetting liquid may be increased in steps, using intruded liquid volume at each step to give a measurement of pore throat size using NMR at each step to give a measure of pore size such as diameter of equivalent sphere. The non-wetting liquid may be mercury and NMR may observe the Knight shift of 99 Hg.

Owner:SCHLUMBERGER TECH CORP

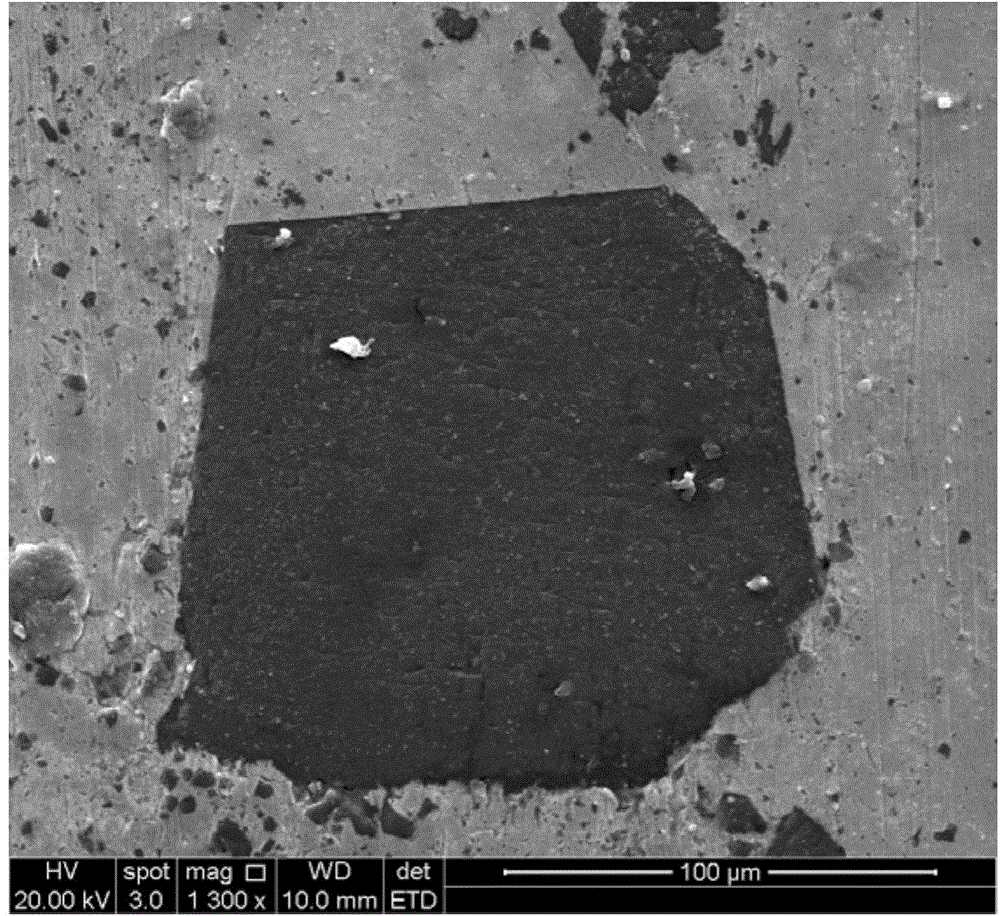

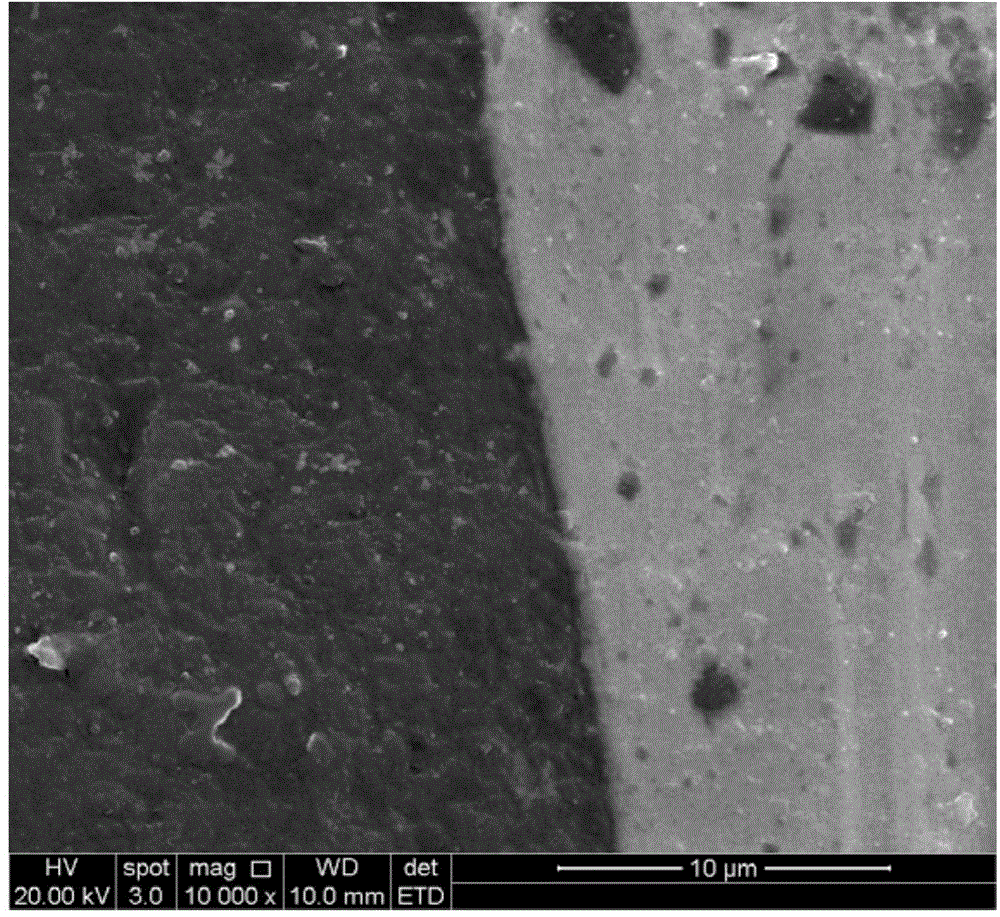

Preparation method of high heat-conducting diamond/copper-based composite material

InactiveCN103981382AHigh thermal conductivityImprove interfaceSuperimposed coating processNon wettingChemical plating

The invention relates to a preparation method of a high heat-conducting diamond / copper-based composite material which consists of matrix copper, diamond powder and a molybdenum coating, wherein the volume fraction of molybdenum is 1-2%, the balance of diamond particles and copper. In diamond and copper, the volume fraction of the diamond powder is 15-50%. The preparation method provided by the invention can solve the problem that in methods of infiltration, powder metallurgy and the like, diamond powder and copper are non-wetting to lead to sintering densification. The preparation method comprises the following steps: I, plating molybdenum on the surfaces of the diamond particles by adopting a magnetron sputtering method to prepare molybdenum-coated diamond powder; II, plating copper on the surface of the molybdenum-coated diamond powder by a chemical plating method to prepare copper and molybdenum-coated diamond powder; III, mixing the composite powder obtained in step II and pure copper powder in a certain proportion by a mechanical mixing manner; and IV, hot pressing and sintering the mixed powder prepared in step III in vacuum to obtain the diamond / copper-based composite material. The material has a good interface bonding condition, high density and heat conductivity.

Owner:WUHAN UNIV OF TECH

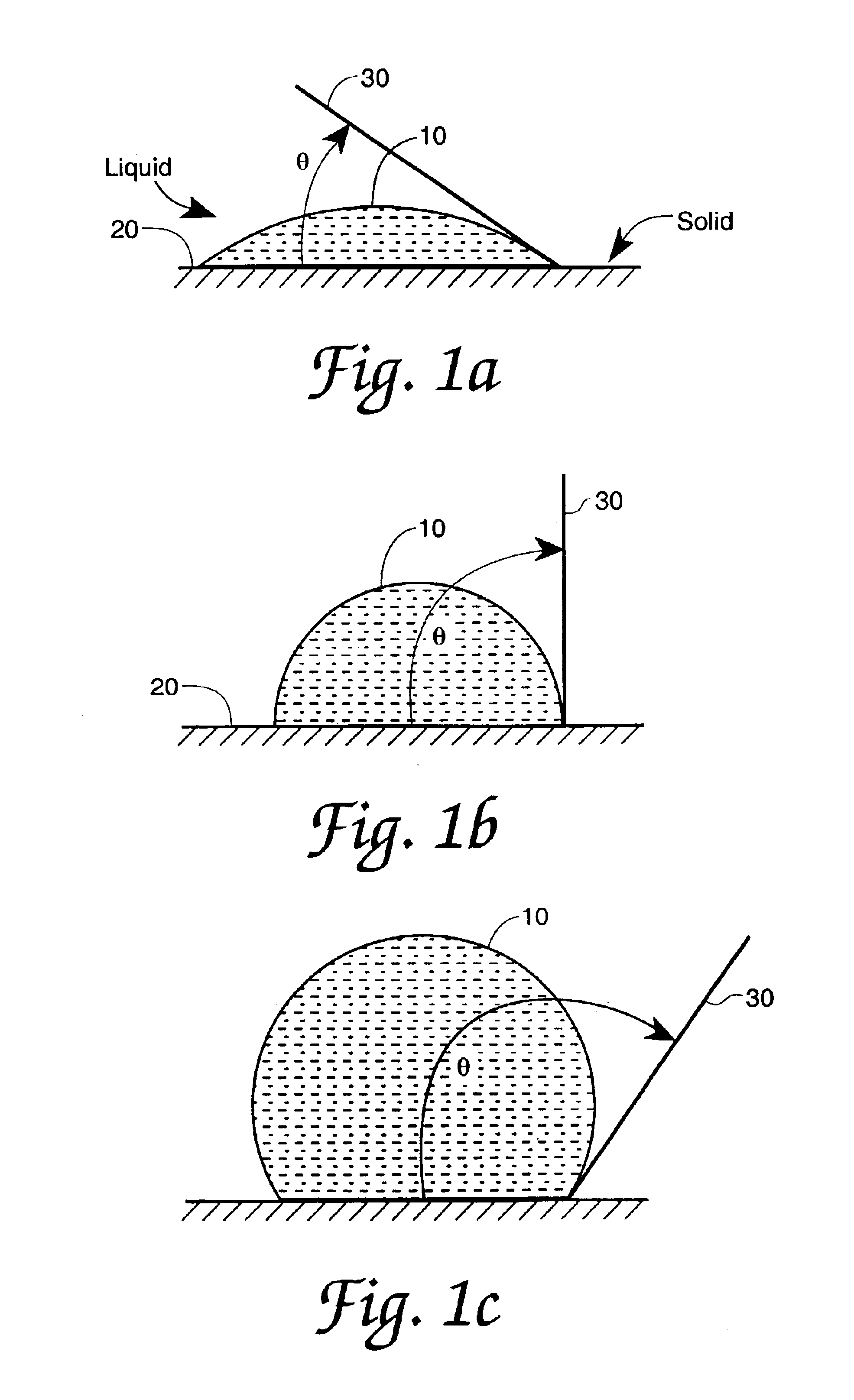

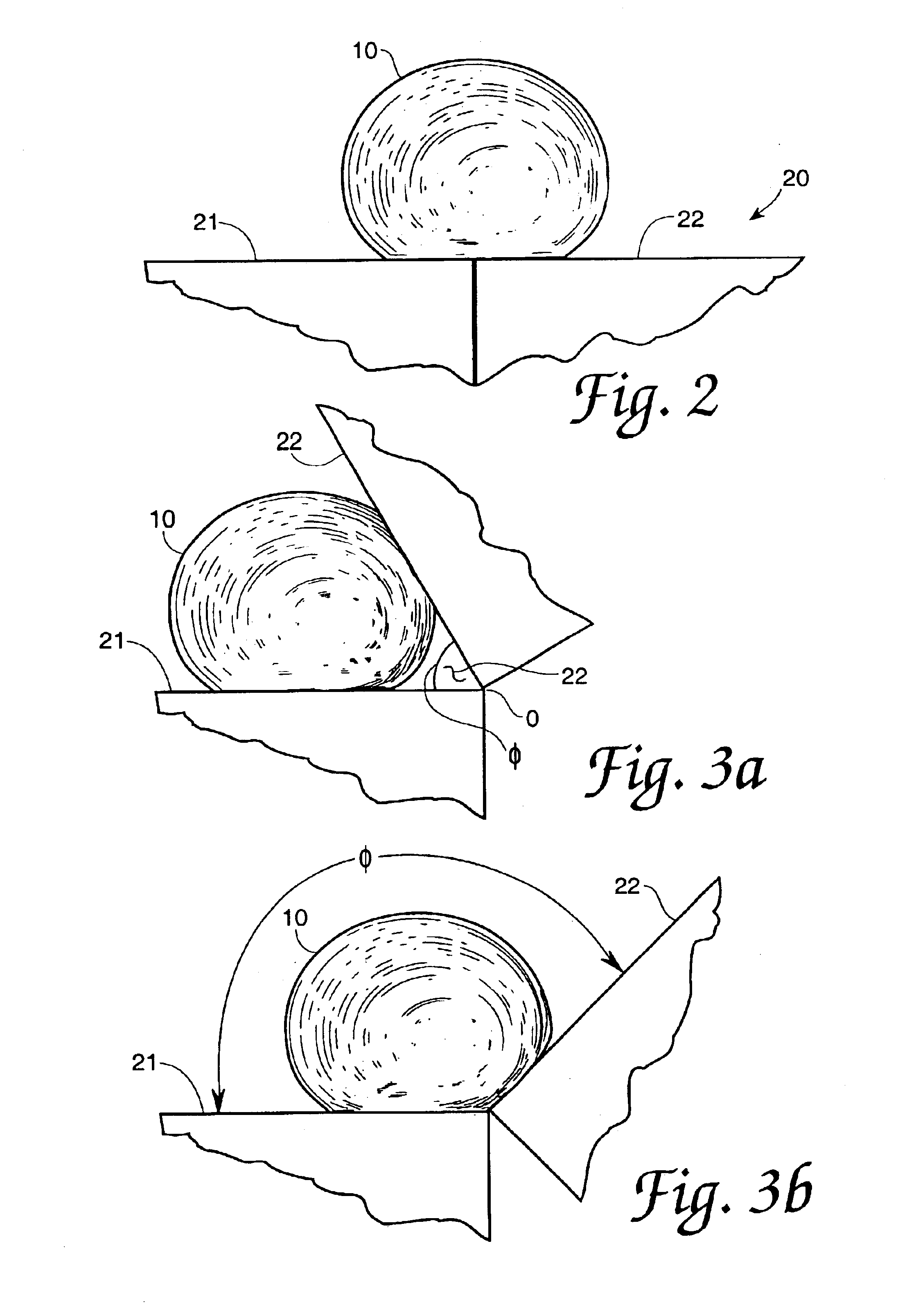

Liquid to solid angle of contact measurement

InactiveUS6867854B1Navigation by terrestrial meansChemical vapor deposition coatingNon wettingSolid angle

A liquid to solid material surface contact angle measurement system operating by way of detecting a transition in the behavior of a liquid sample with the solid material in a changing angular confinement environment along with use of a mathematical algorithm to then determine contact angle. Measurement of the angle at which the tested liquid transitions between apparent wetting and apparent non-wetting behavior, regardless of whether the liquid and solid material are truly classified as wetting or non-wetting, provides a measurement from which disclosed mathematical algorithms can predict the surface wetting characteristics of the liquid on the solid material. Automated performance of the confinement environment measurement and examples are included.

Owner:US SEC THE AIR FORCE THE

Articles for manipulating impinging liquids and methods of manufacturing same

ActiveUS20140291420A1Improve performanceMore practicalMaterial nanotechnologyFouling preventionNon wettingEngineering

This invention relates generally to an article that includes a non-wetting surface having a dynamic contact angle of at least about 90°. The surface is patterned with macro-scale features configured to induce controlled asymmetry in a liquid film produced by impingement of a droplet onto the surface, thereby reducing time of contact between the droplet and the surface.

Owner:MASSACHUSETTS INST OF TECH

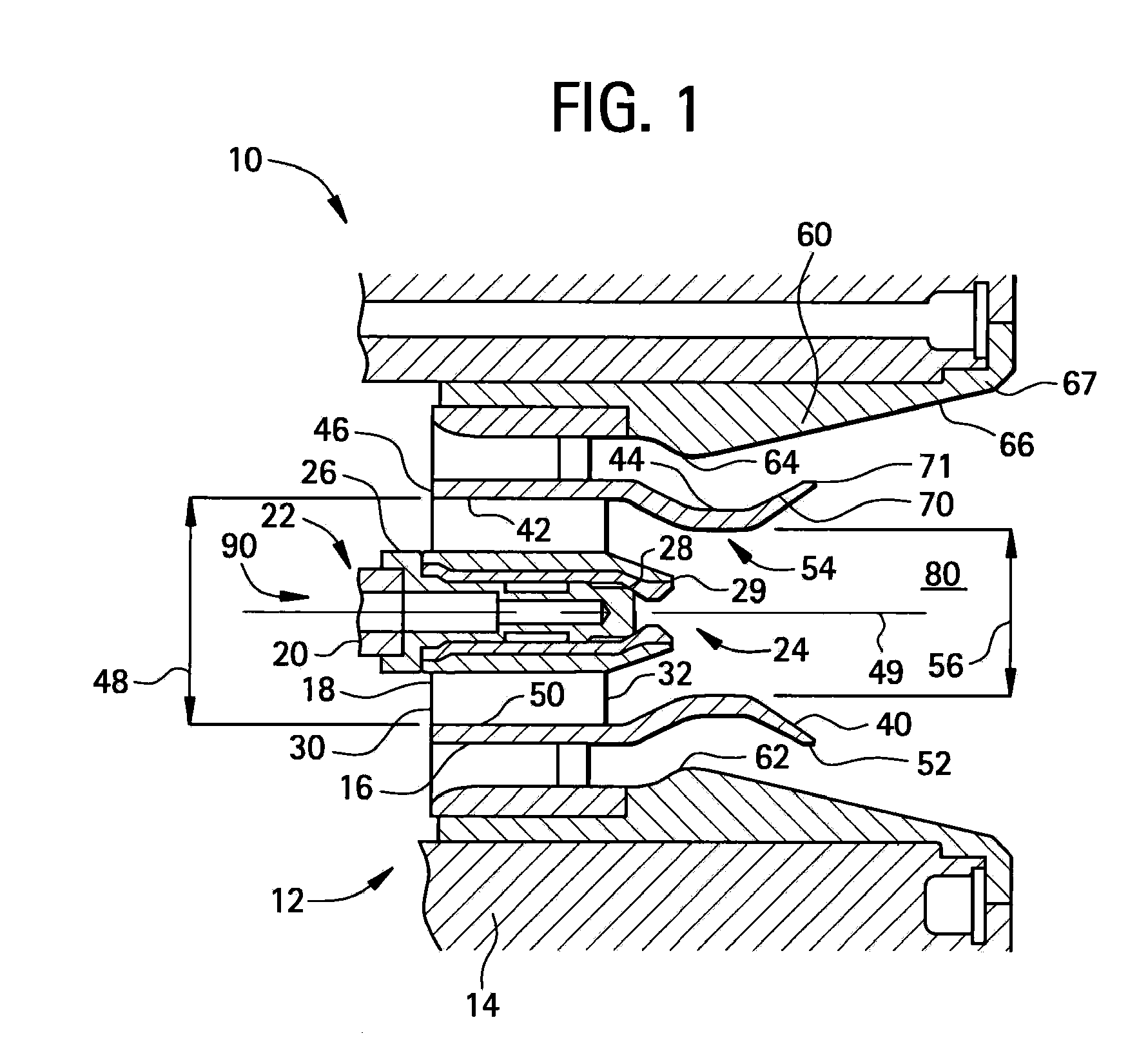

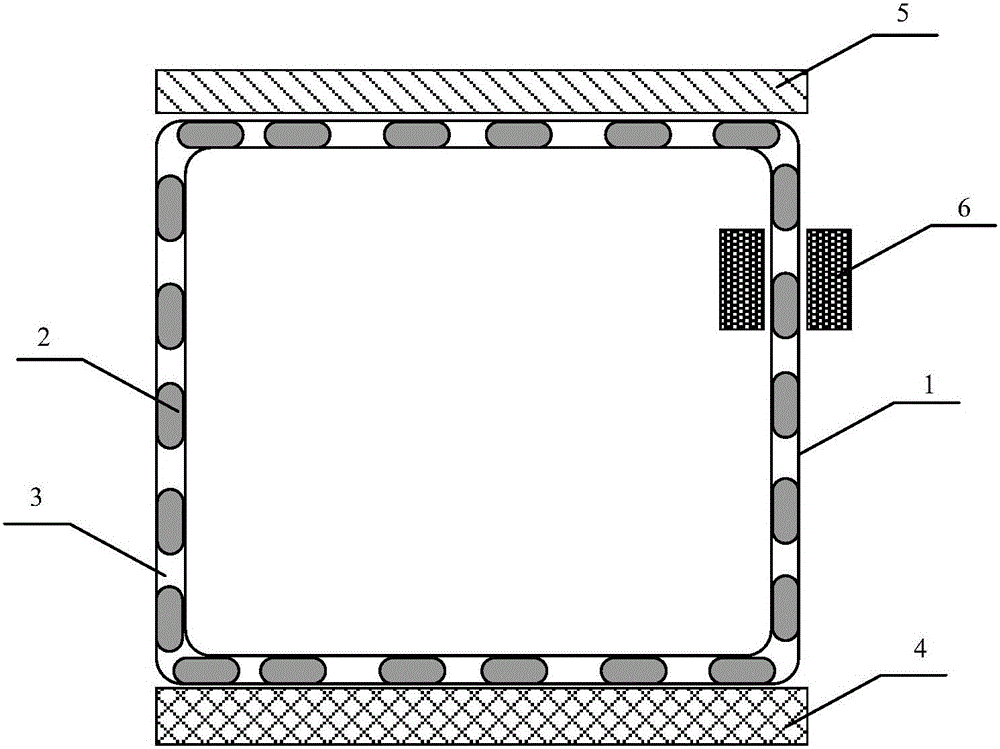

Microchannel heat exchanger system

InactiveCN106197117AImprove heat transfer efficiencyImprove reliabilityIndirect heat exchangersNon wettingEngineering

The invention relates to the field of application of microchannel heat exchangers, and particularly discloses a microchannel heat exchanger system. The microchannel heat exchanger system comprises a closed flowing channel located between a cold source and a heat source and a magnet outside the channel. Two or multiple phases of non-wetting fluid are closed in the channel. The flowing state of the multiple phases of fluid is bubble flow or slug flow. At least one phase of fluid in the multiple phases of fluid is magnetic fluid. Microchannel fluid drives the multiple phases of fluid to cyclically flow in the channel through the thermomagnetic effect of the magnetic fluid or with extra electromagnetic field force as drive force. The microchannel heat exchanger system is simple in structure; mixing and separating of multiple phases of fluid at an inlet and an outlet in conventional design are avoided; no rotary component is arranged in the system, and high reliability is achieved; and the system fully utilizes the heat transfer enhancement mechanism of heat convection of the multiple phases of non-wetting fluid in a microchannel, and the heat exchange efficiency of a microchannel heat exchanger is greatly improved.

Owner:SUZHOU NUSSELT TECH CO LTD

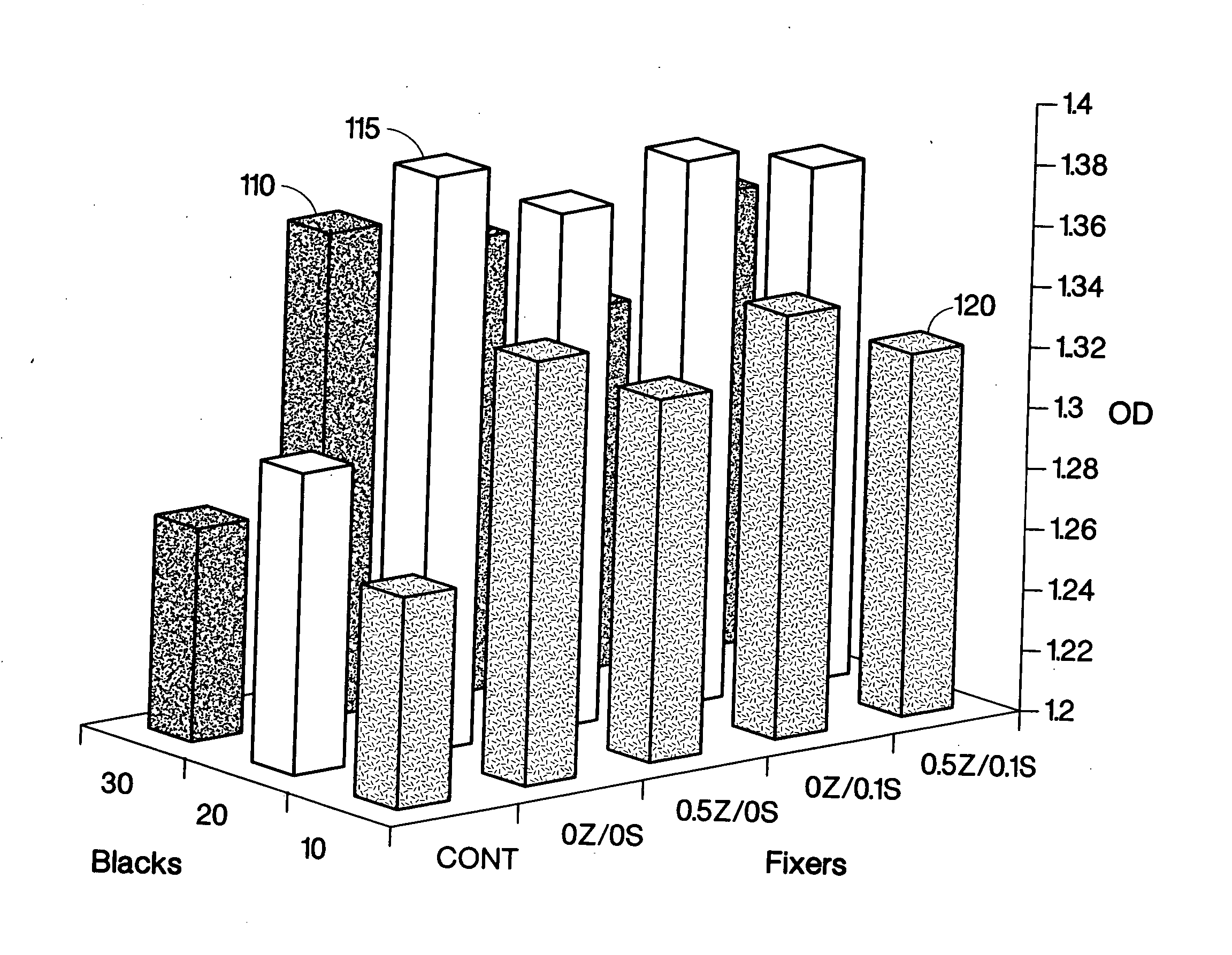

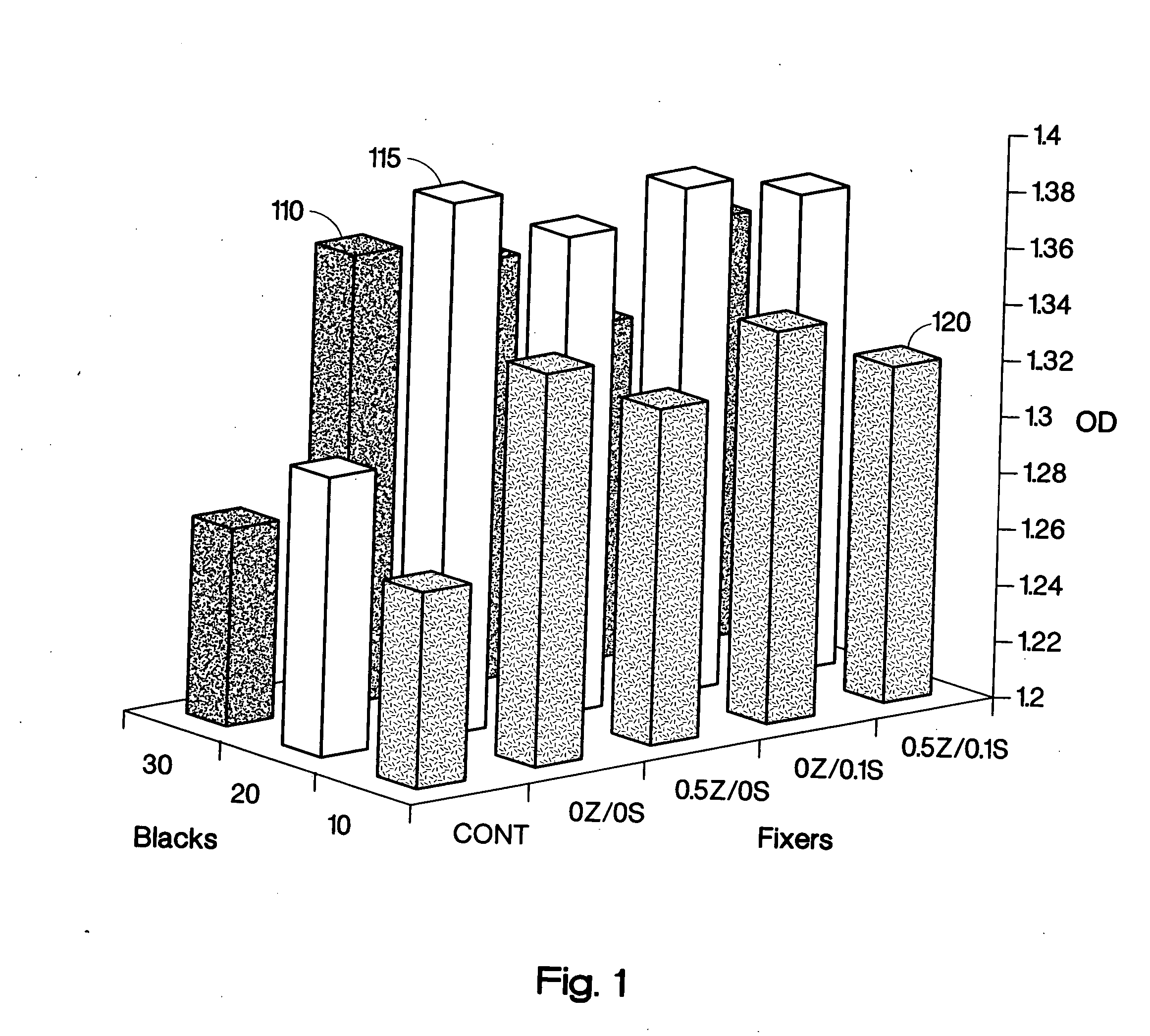

Slow-penetrating inkjet fixer composition and methods and systems for making and using same

The invention relates to an inkjet fixer composition and a printing method and system used with the composition, the composition comprising: a) from 1 to 8 weight percent cationic polymer; and b) from 0 to 2 weight percent of at least one surfactant selected from the group consisting of nonionic surfactant, cationic surfactant and combinations thereof; c) an aqueous liquid vehicle wherein the fixer composition is non-wetting in relation to the substrate; wherein, upon overprinting the fixer composition with an ink-jet ink on a substrate, the fixer composition vehicle and the ink-jet ink vehicle form a vehicle mixture on the substrate after which the vehicle mixture penetrates into the substrate, and an ink image is formed on the substrate.

Owner:HEWLETT PACKARD DEV CO LP

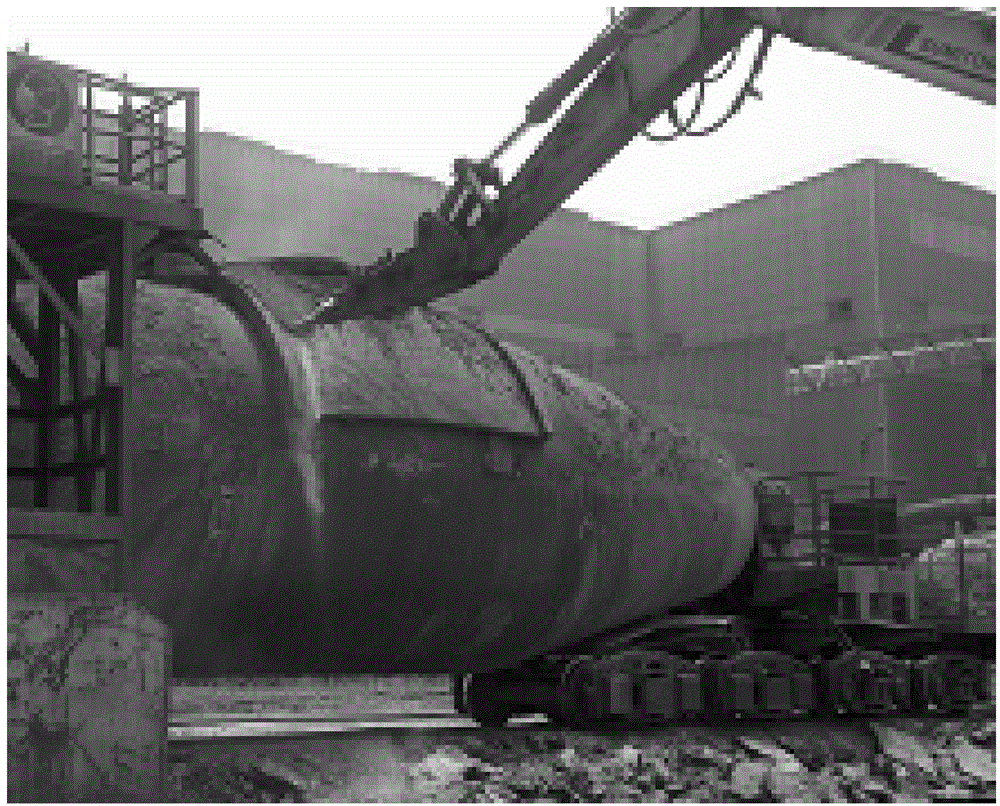

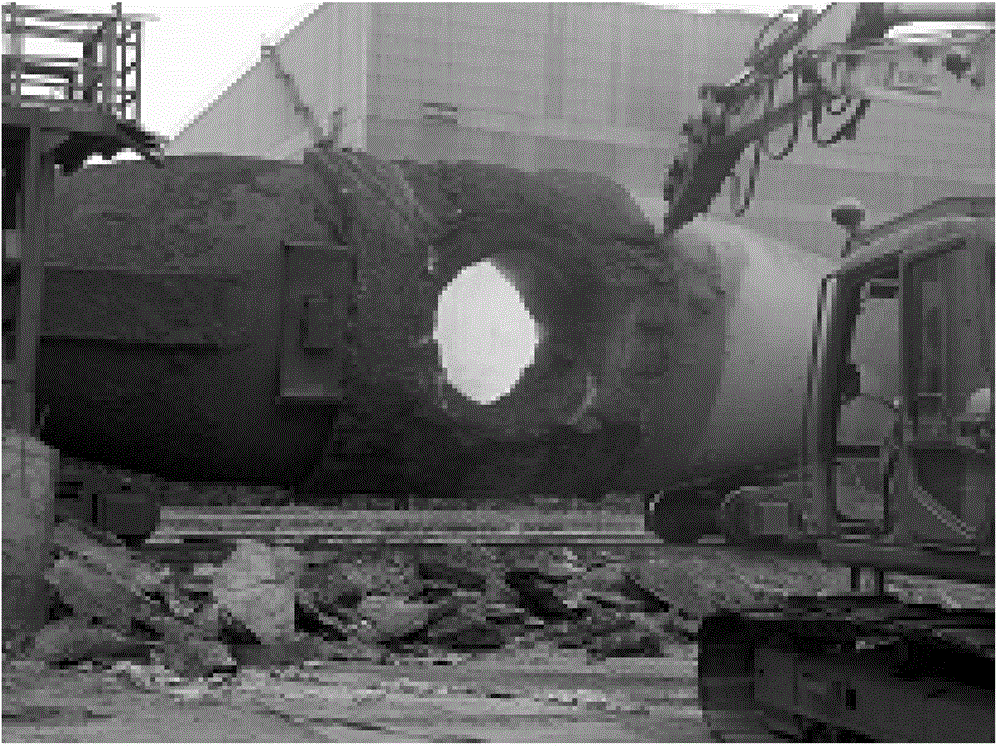

Spray coating capable of preventing slag adhesion

The invention relates to a coating capable of preventing slag adhesion. The coating is characterized by being prepared from, by mass, 8-15 parts of MgO, 15-25 parts of Al2O3, 12-20 parts of SiC, 20-30 parts of SiO2, 2-6 parts of Si, 10-20 parts of C and 0.5-2 parts of Fe2O3, and the coating is prepared by additionally adding 22%-28% of water and conducting stirring through an emulsifying machine. According to the coating capable of preventing the slag adhesion, waste materials of the fire-resistant material industry and the solar energy industry are fully utilized to serve as the main raw materials, and the slag adhesion is prevented by utilizing the non-wetting property of carbon, silicon carbide and the like in the waste raw materials to slags; reactions that metallic silicon is reacted with oxygen to form silicon dioxide, and then the silicon dioxide is reacted with magnesium oxide to form forsterite or reacted with aluminum oxide to form mullite are utilized, and looseness of the materials is caused along with volume expansion, so that the materials are automatically disengaged or easily removed. The coating is used for Baosteel torpedo iron mixing vehicles, Baosteel hot metal ladles, VD shielding caps of the Shanghai steel fifth-factory and LAST immersion covers of the Shanghai steel first factory to enable the service life of fire-resistant materials to be prolonged; the service life is prolonged by 50 percent or above except the hot metal ladles.

Owner:上海柯瑞冶金炉料有限公司

Fluorinated POSS as alloying agents in nonfluorinated polymers

InactiveUS7897667B2Reduce contactWeaken energyMaterial nanotechnologyPlastic/resin/waxes insulatorsPersonal careMolecular level

Owner:HYBRID PLASTICS INC +1

Silver tungsten carbide graphite contact material and preparation method thereof

InactiveCN101976615AImprove distributionImprove physical bond strengthContactsChemical platingHigh energy

The invention discloses a novel silver tungsten carbide graphite contact material and a preparation method thereof, which belong to the technical field of electric engineering material. The preparation method comprises the following steps of: putting tungsten carbide powder, graphite powder and tungsten into a reaction vessel; adding deionized water and 40% hydrazine hydrate into the reaction vessel; spraying 50-500 g / l silver ammonia complex solution into the reaction vessel at a flow rate of 5 to 500 ml / min with stirring at a rotating speed of 50 to 200 r / min to coat silver powder on the tungsten carbide graphite, the graphite powder and the tungsten particles; and performing high-energy ball milling, destressing, initial-pressing forming, sintering, re-pressing forming, annealing and re-pressing forming to obtain the contact material, wherein the weight percents of silver, tungsten carbide and graphite in the contact material are 72 to 85 percent, 13 to 24 percent and 2 to 5 percent respectively, and the weight of tungsten is 0.5 to 1.5 percent of the total weight of the silver, the tungsten carbide and the graphite. By using a coating process with a chemical plating principle,the invention improves the physical bonding strength between non-wetting materials, improves chemical properties and physical properties of the materials, greatly optimizes the conductivity and improves the arc erosion resistance.

Owner:YANGZHOU LEYIN ALLOY TECH

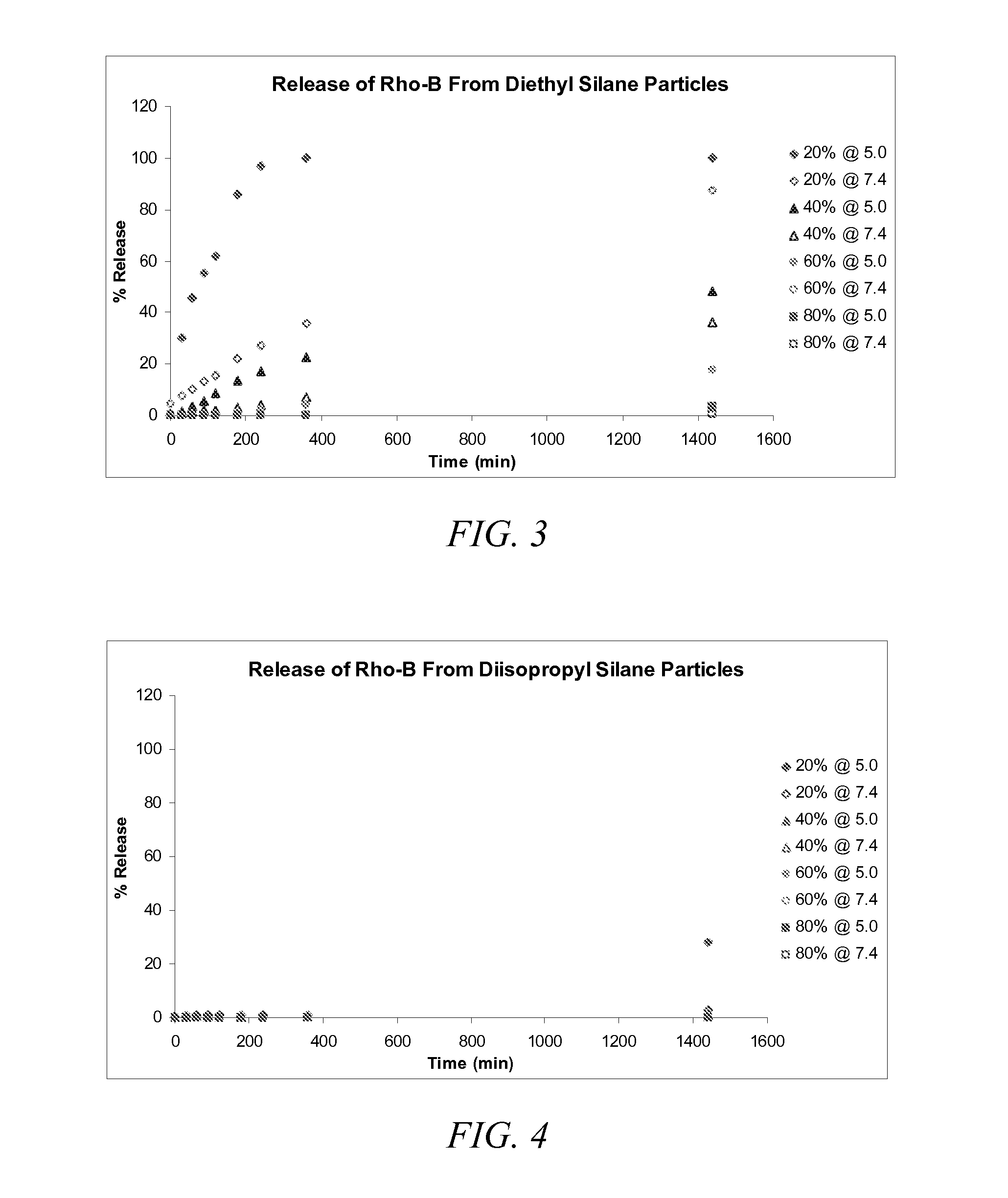

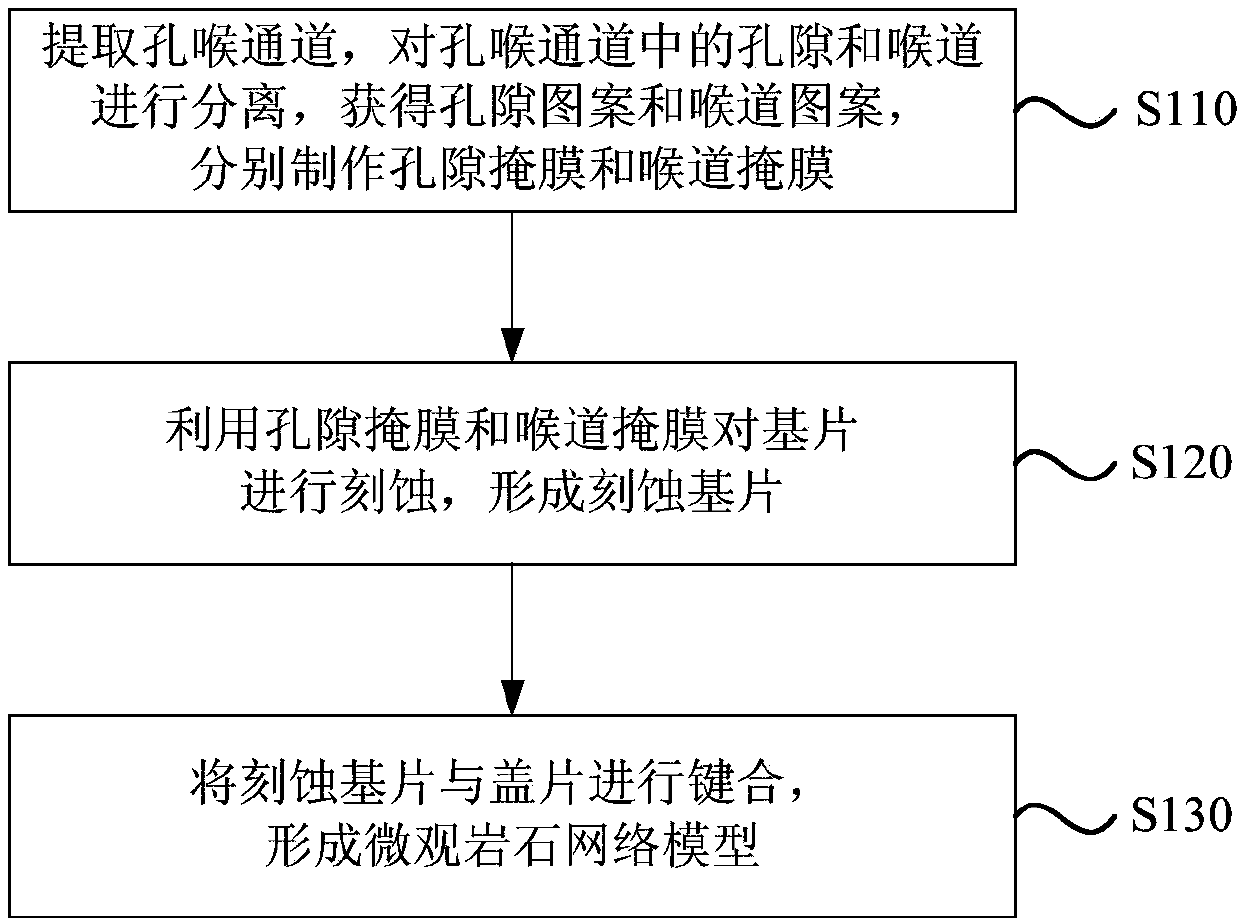

Degradable compounds and methods of use thereof, particularly with particle replication in non-wetting templates

The present invention provides compounds that will degrade under specified conditions, methods of using such compounds, and compositions comprising such compounds. The degradable compounds of the invention may be characterized by the labile —Si-A-C— groups present in the compounds (A representing an atom, such as O, N, or S, or a group, such as C═O). The compounds may be incorporated into a composition that further may include a polymeric matrix and / or a cargo component. A wide variety of cargo components may also be used in the present invention. In particular embodiments, the cargo component comprises a drug or other therapeutic agent. Accordingly, the invention particularly provides pharmaceutical formulations and methods of delivering a drug or other therapeutic material.

Owner:LIQUIDIA TECH +1

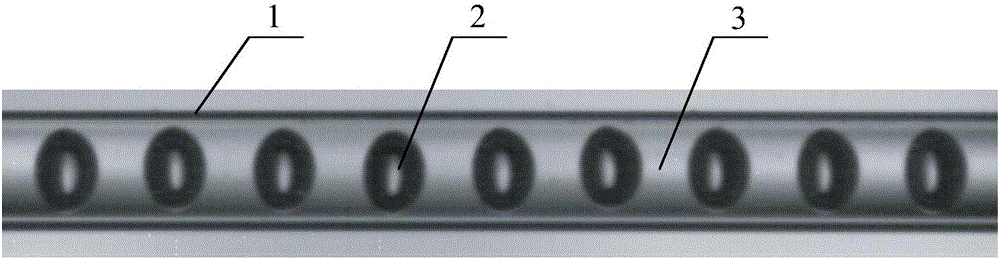

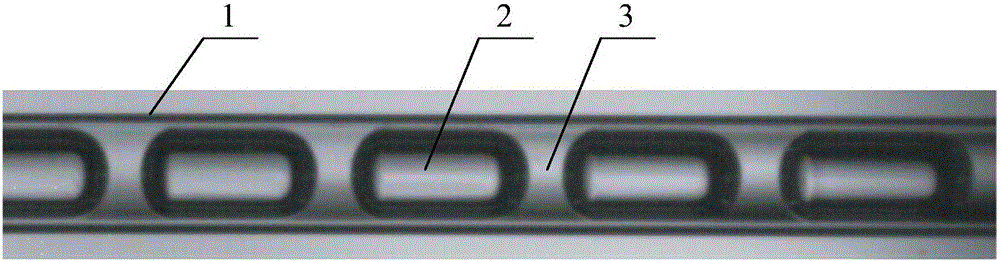

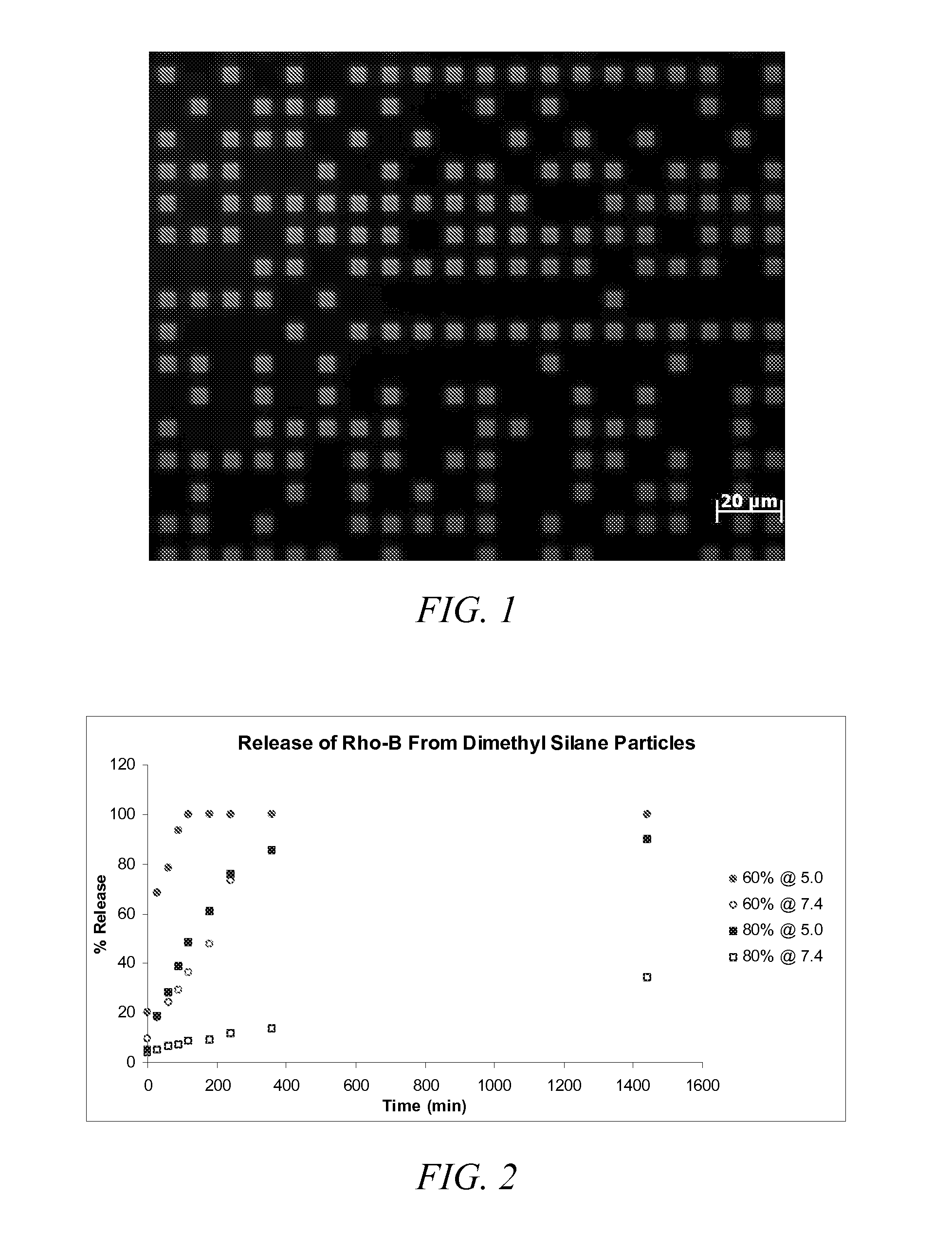

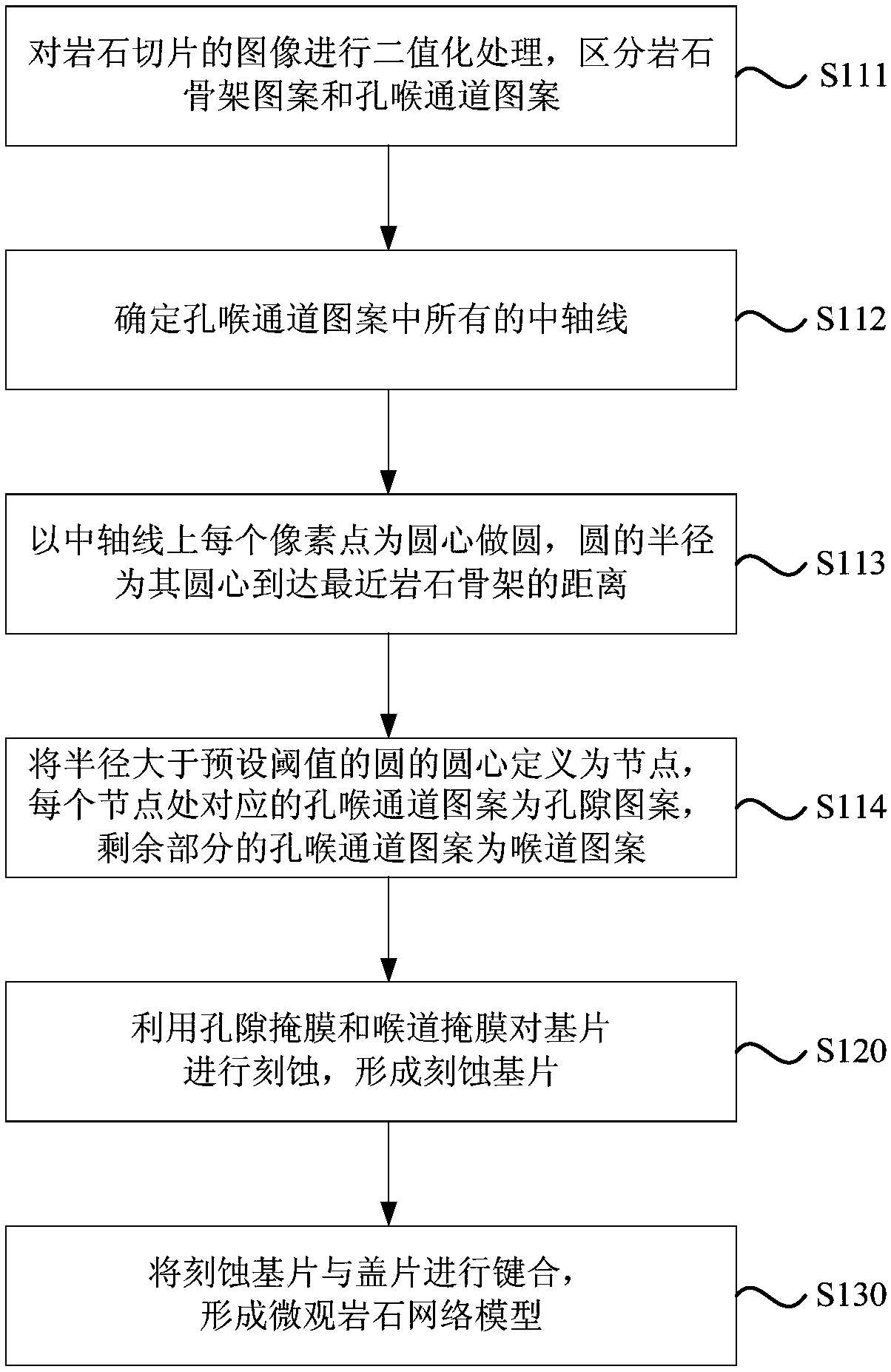

Microscopic rock network model manufacturing method

The invention discloses a microscopic rock network model manufacturing method. The microscopic rock network model manufacturing method comprises the steps that a pore-throat passage is extracted, pores and throat ways in the pore throat passage are separated, pore patterns and throat way patterns are obtained, and pore masks and throat way masks are manufactured correspondingly; through the pore masks and the throat way masks, base pieces are etched to form etched base pieces; and the etched base pieces are in key fit with cover pieces to form a microscopic rock network model. According to themicroscopic rock network model manufacturing method, through pore-throat separating, image aligning and repeated photoetching, a micro-nano oil gas flowing passage which is closer to the reality of an oil reservoir is achieved in the microscopic glass model, control over the reaction time in the etching technique is accurate, the depth-width ratio, smoothness and flatness of the passage are good,pressure does not need to be provided in the key fit process, the nano passage can be better protected, key fit of the real sand rock microscopic models of the micron pores and the nano throat ways is achieved, and microscopic dynamic change, such as Haines phase step and non-wetting phase coalescence, which cannot occur on a two-dimensional planar model is taken on.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

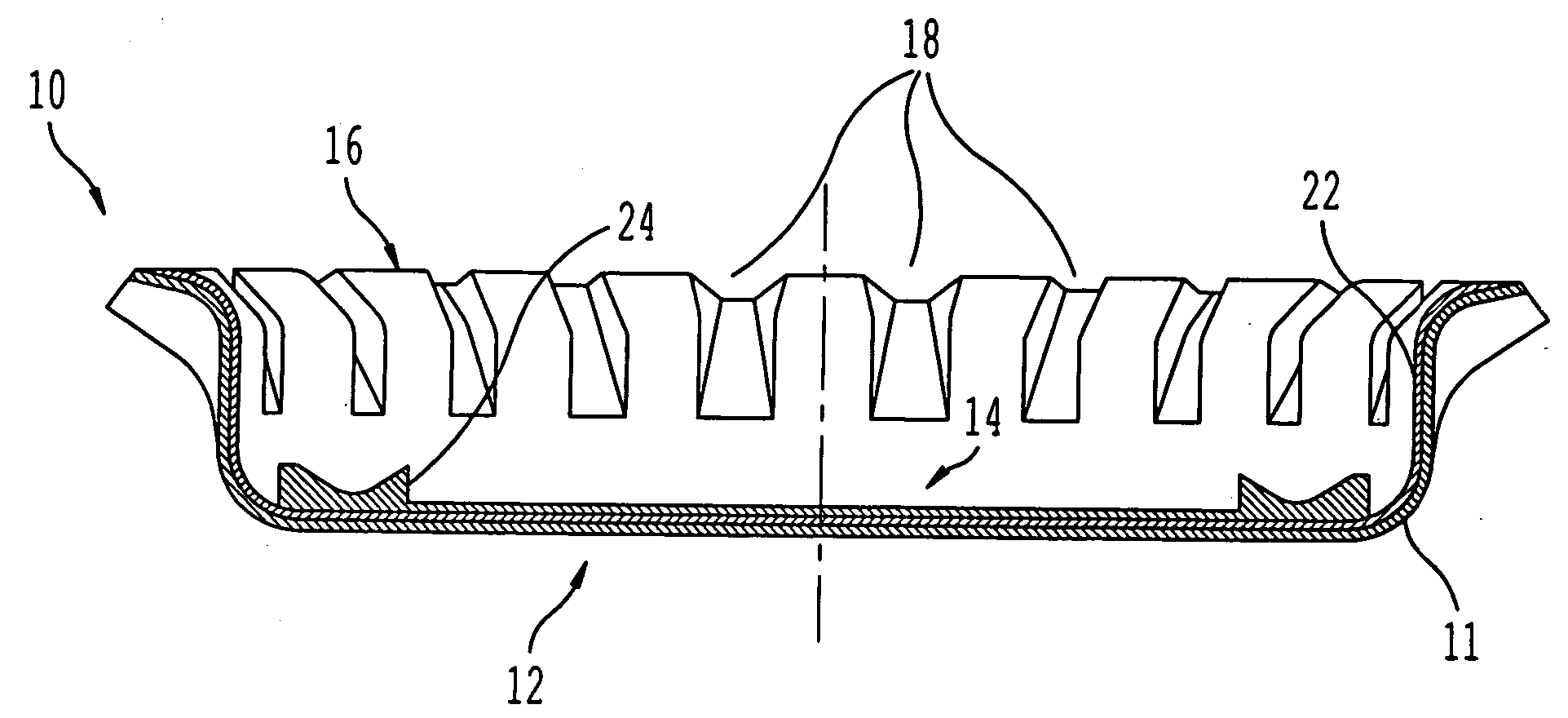

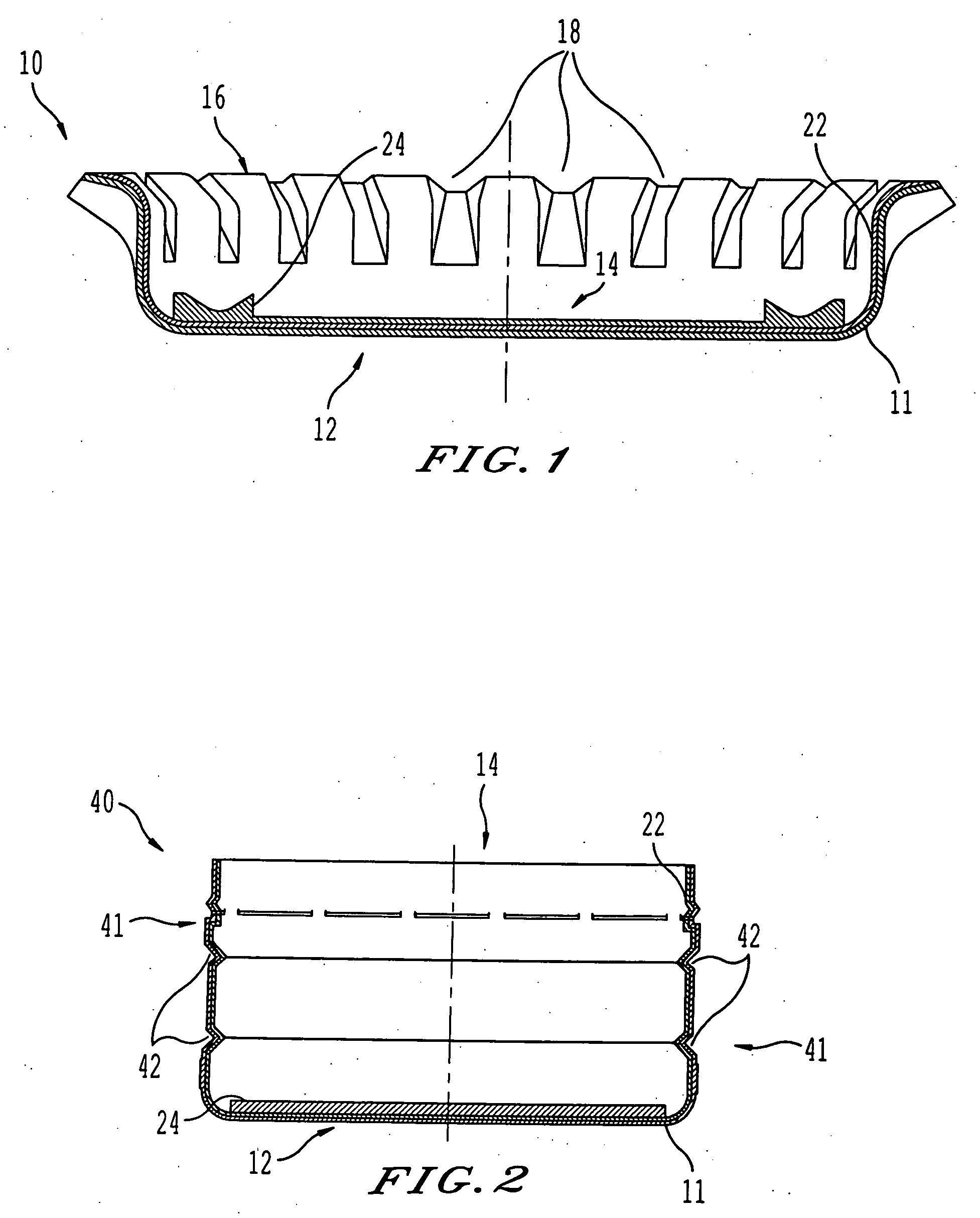

Metallic cap closure having water repelling properties and method of fabricating the same

A metallic closure having water repelling properties, and methods of manufacturing the same, includes a metallic closure shell, as for example, the type used for crown caps or roll-on caps, and a non-wetting material layer deposited on at least a portion of an inside surface of the closure such that, when the closure is disposed over the rim and opening of a container, the opening is hermetically sealed and moisture is repelled from confined regions between an inside surface of the shell and an outside surface of the container.

Owner:FABS MONTERREY S A DE

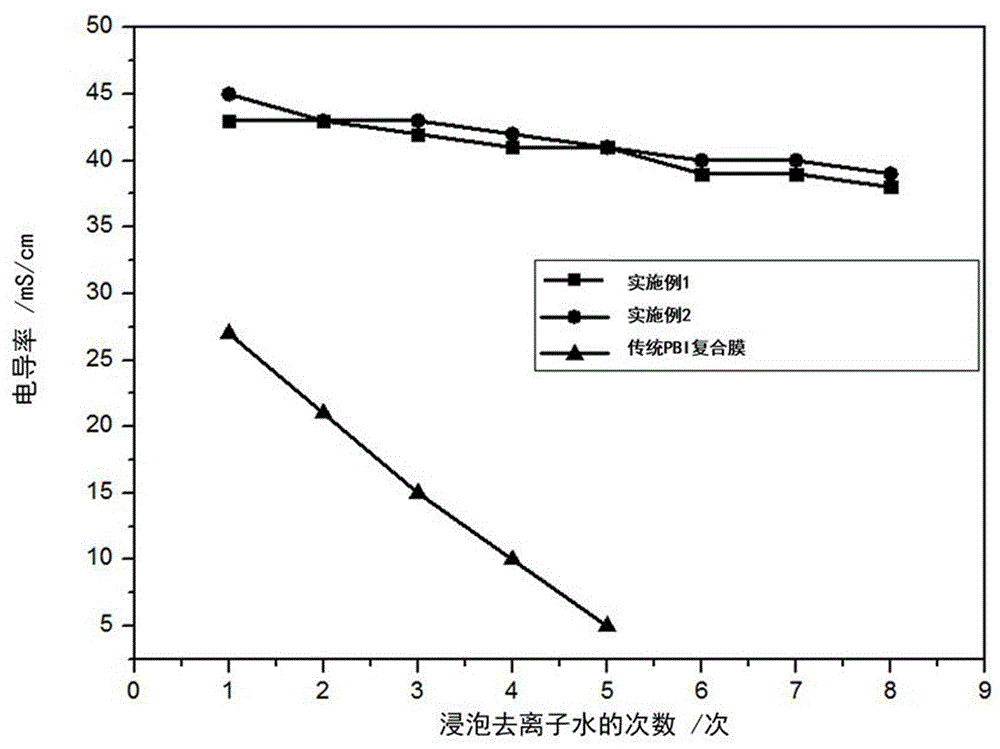

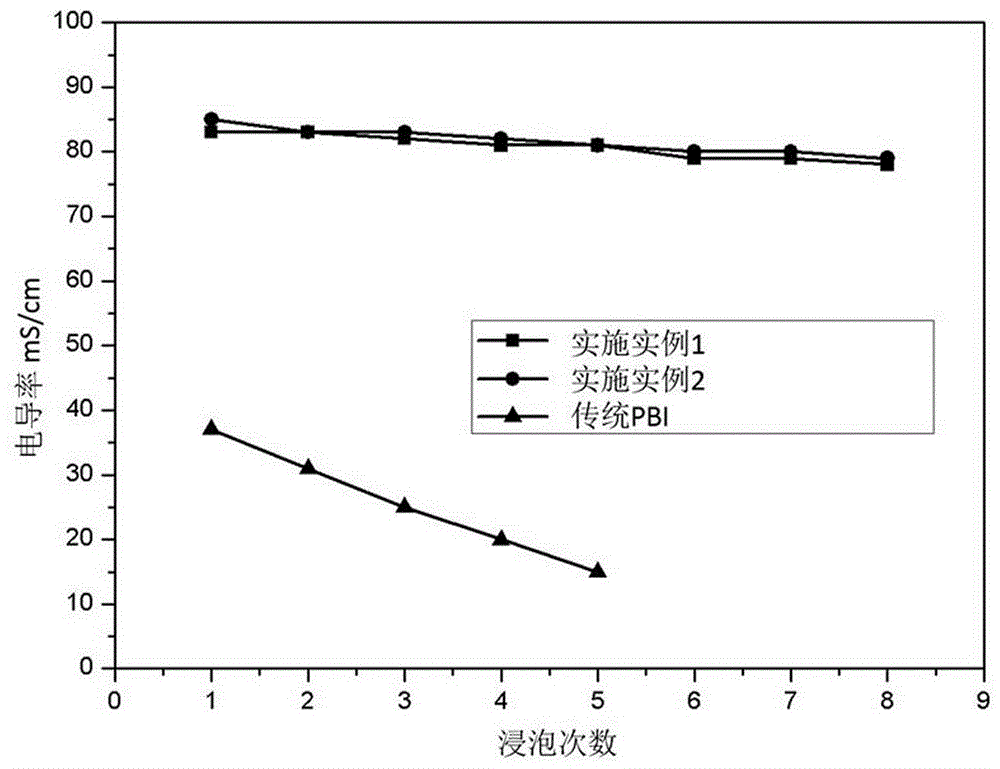

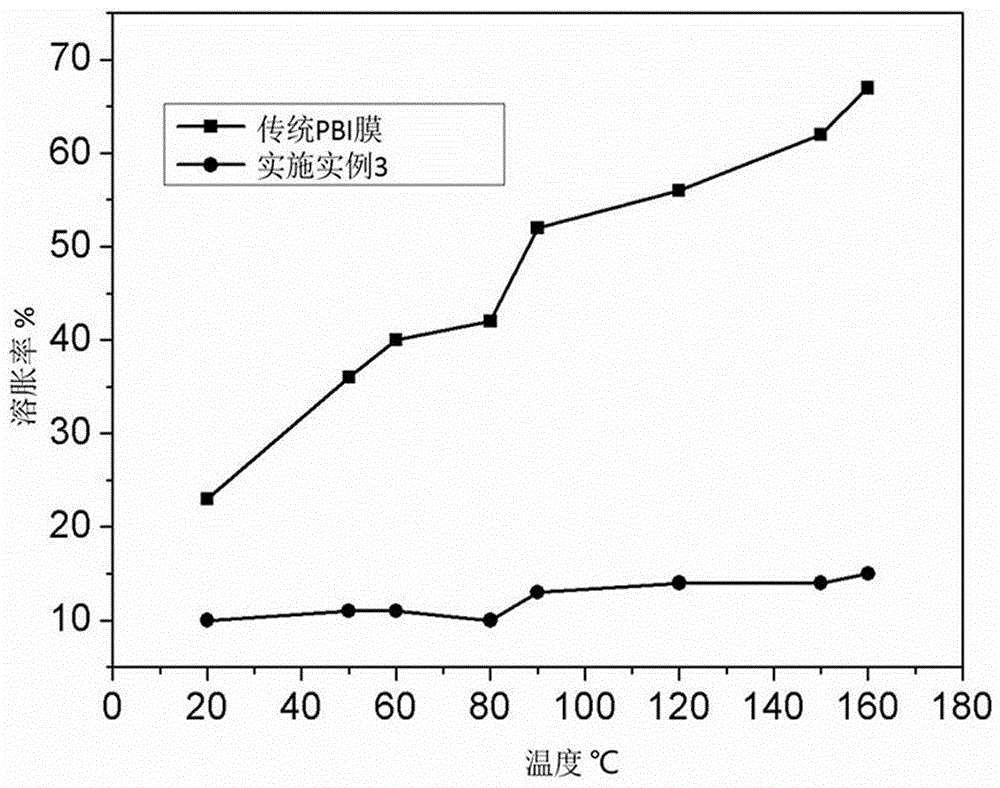

High conductivity cross-linked organic phosphate polybenzoimidazole high temperature proton exchange membrane and preparation method thereof

The invention discloses a high conductivity cross-linked organic phosphate polybenzoimidazole high temperature proton exchange membrane and preparation method thereof. The polybenzoimidazole is adopted as the polymer substrate. Through polymerization reaction and the adoption of vinyl benzyl chloride as the cross-linking agent, the self-cross-linking of polybenzoimidazole and Vinyl phosphate is conducted to form the membrane, which can be adopted for the preparation of homogeneous phase high temperature proton exchange membrane. The membrane not only can enhance the adsorption site of phosphoric acid, thus enhancing the conductivity of the membrane, but also can hugely reduce the phosphoric acid loss of polybenzoimidazole / phosphoric acid film, effectively enhance the conductivity stability of the membrane. Under non-wetting condition the membrane has the advantages of excellent proton conductive capability, and low air permeability. The membrane can be adopted for the high temperature proton exchange membrane fuel cell, direct alcohol fuel cell, electrochemical sensor and other electrochemical devices.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com