Patents

Literature

31 results about "Spherical equivalent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Spherical Equivalent is a set of two numbers, one value for each eye, that gives you an estimate of your eyes' refractive error. It is not the most accurate number for most people as it does not include the astigmatism component. The Spherical Equivalent is calculated as follows:

Method for determining the power of an intraocular lens used for the treatment of myopia

InactiveUS7044604B1Improve predictabilityCorrection of myopiaEye diagnosticsIntraocular lensCorneal curvatureIntraocular lens

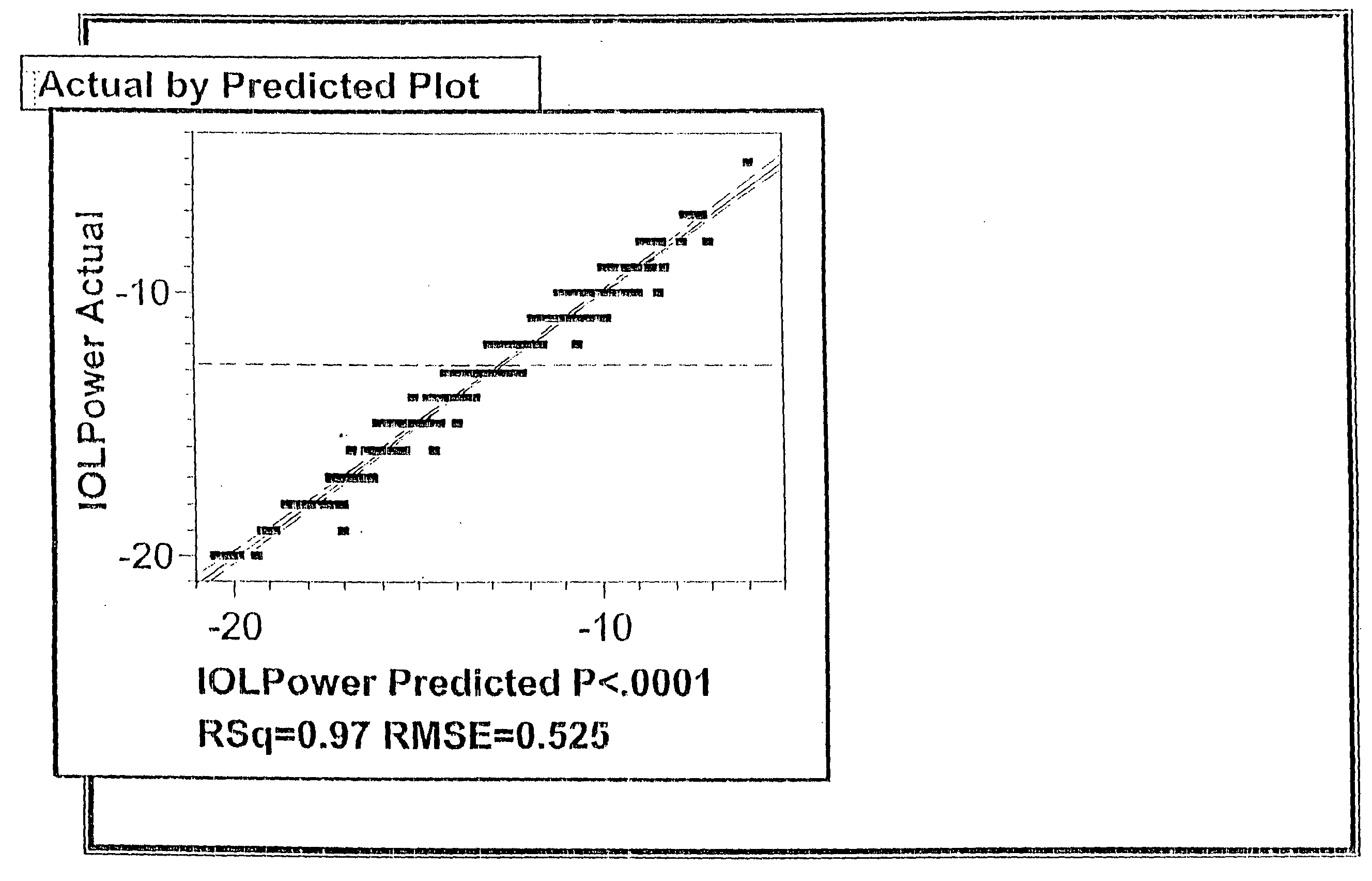

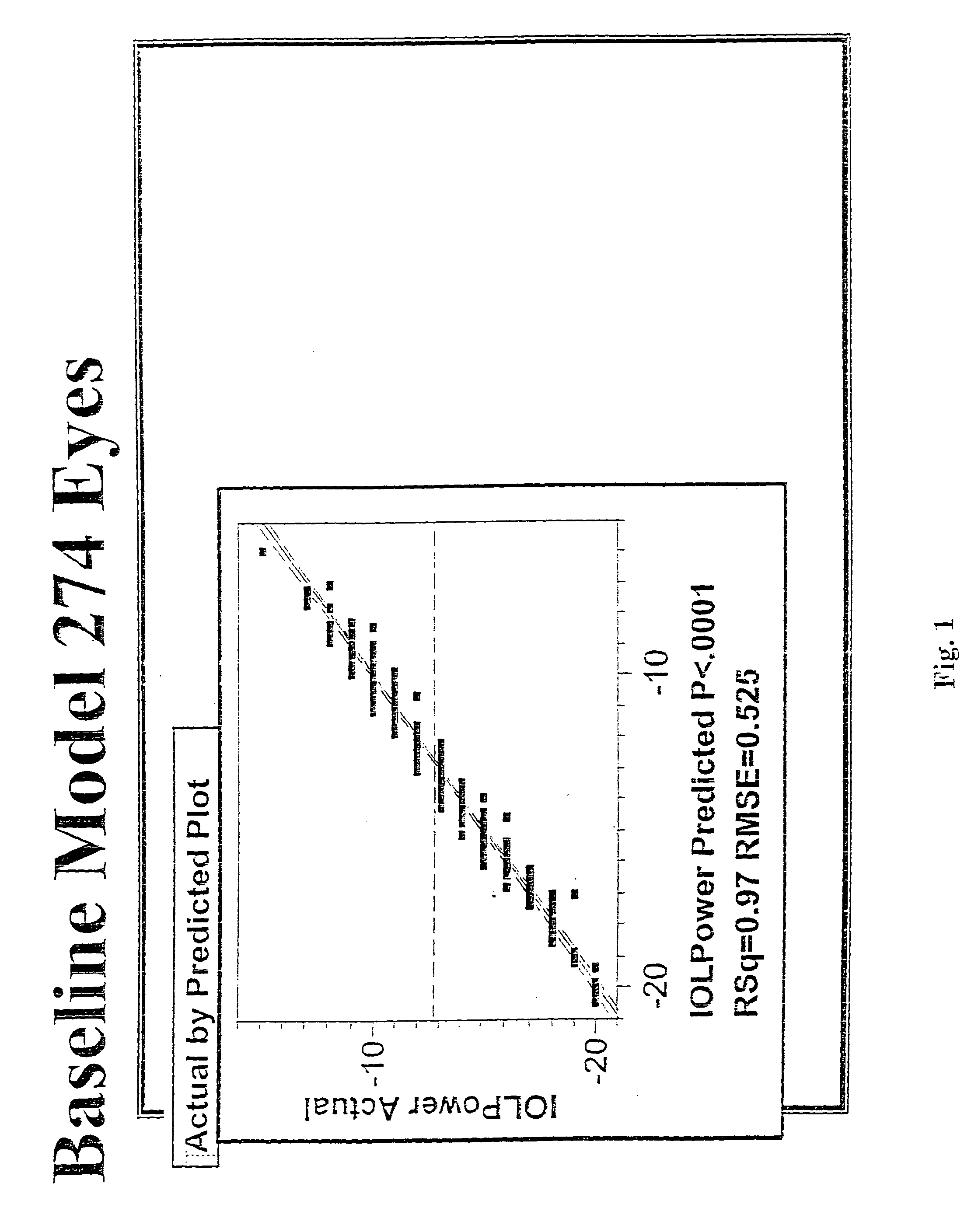

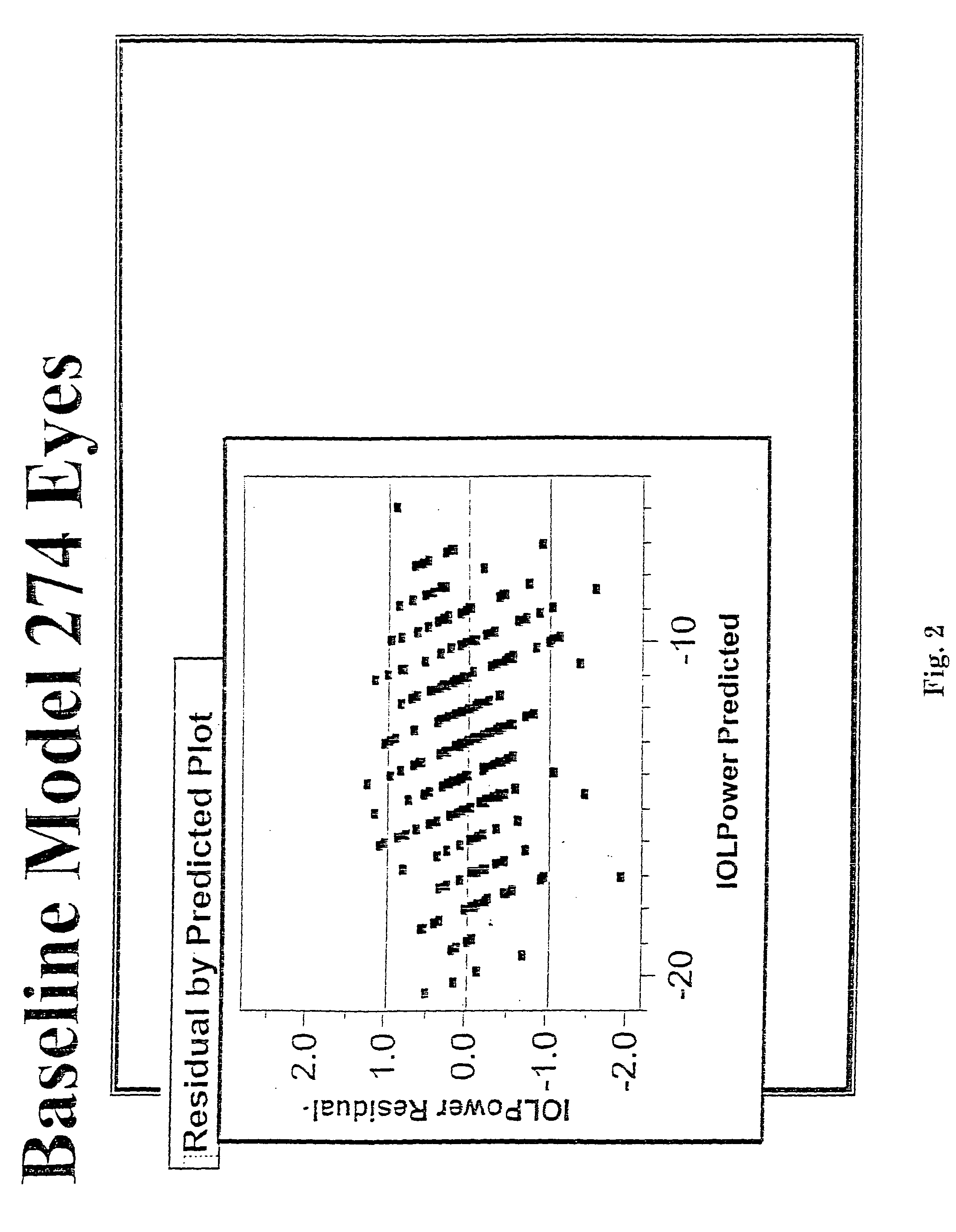

A method of deriving a prediction model and calculating a predicted lens power to provide a desired post-operative spherical equivalent to correct myopia in a phakic eye of a patient using an intraocular lens includes measuring and determining the predictive significance of certain pre-operative characteristics of the eye, including cycloplegic and manifest spherical equivalent, vertex distance, anterior chamber depth, axial length, and keratometry. The prediction model is derived using multiple regression analysis on the pre-operative and post operative data. Measured data corresponding to a particular patient is used in the lens power prediction model to calculate the predicted lens power for implantation in the patient.

Owner:ARROWSMITH PETER N

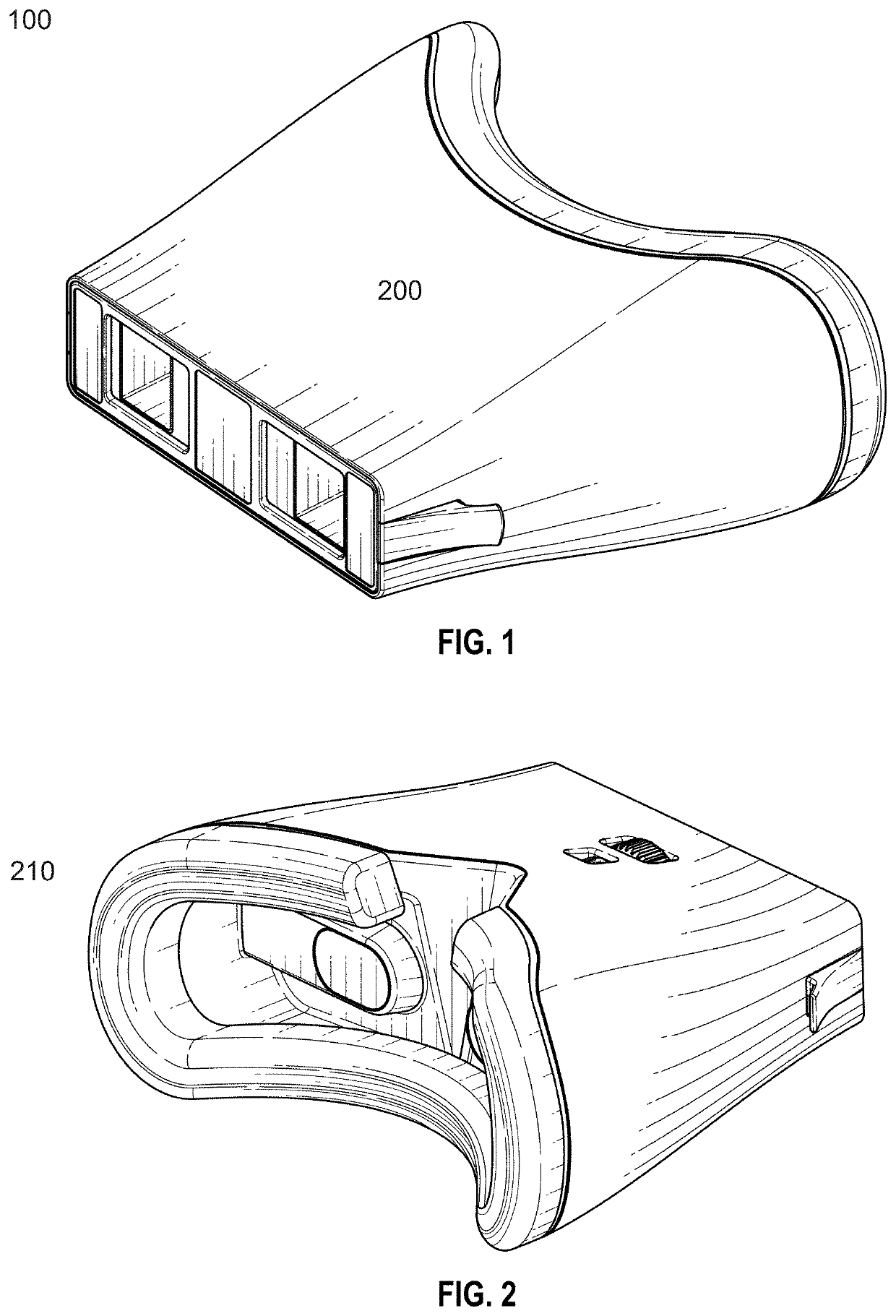

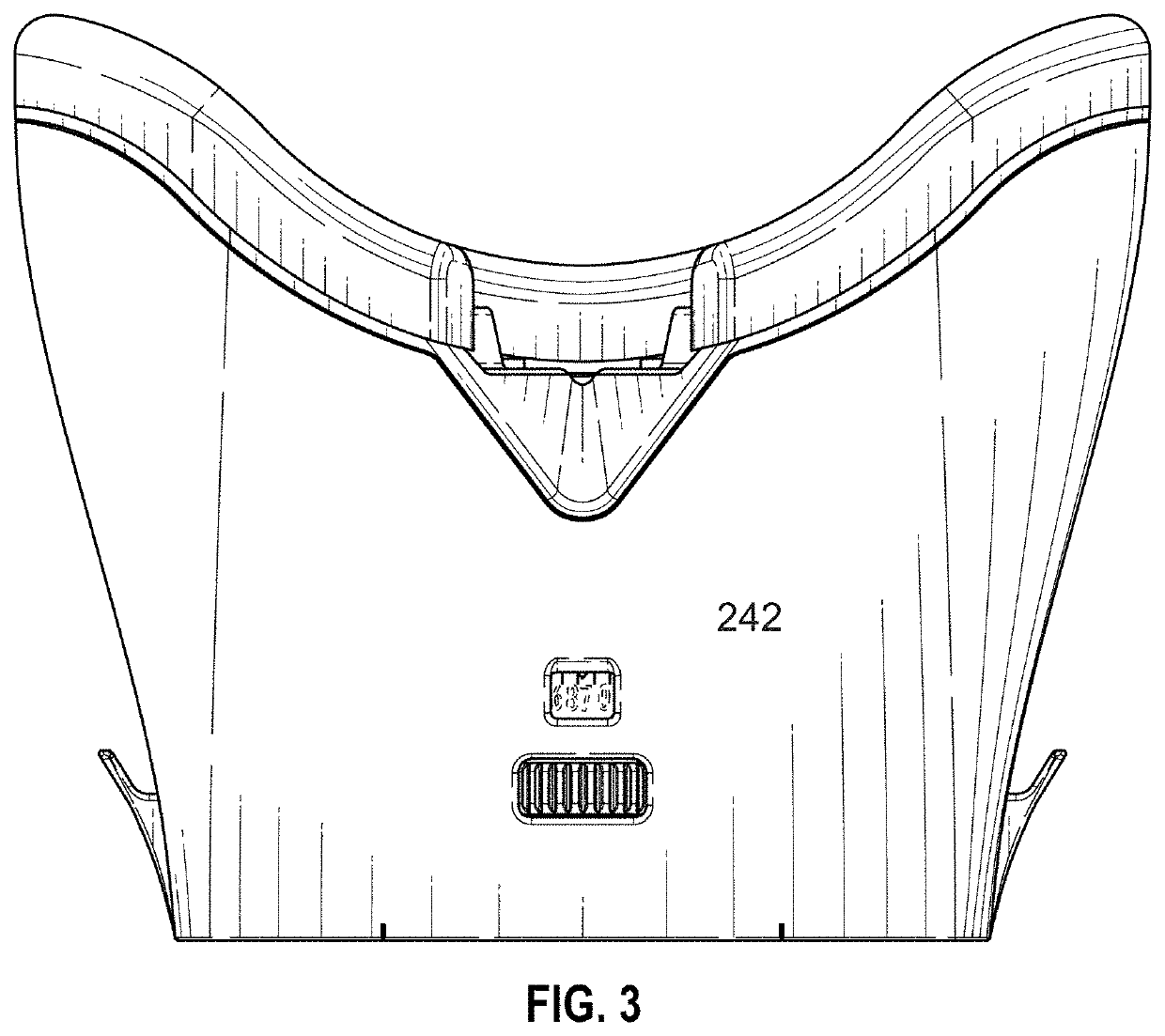

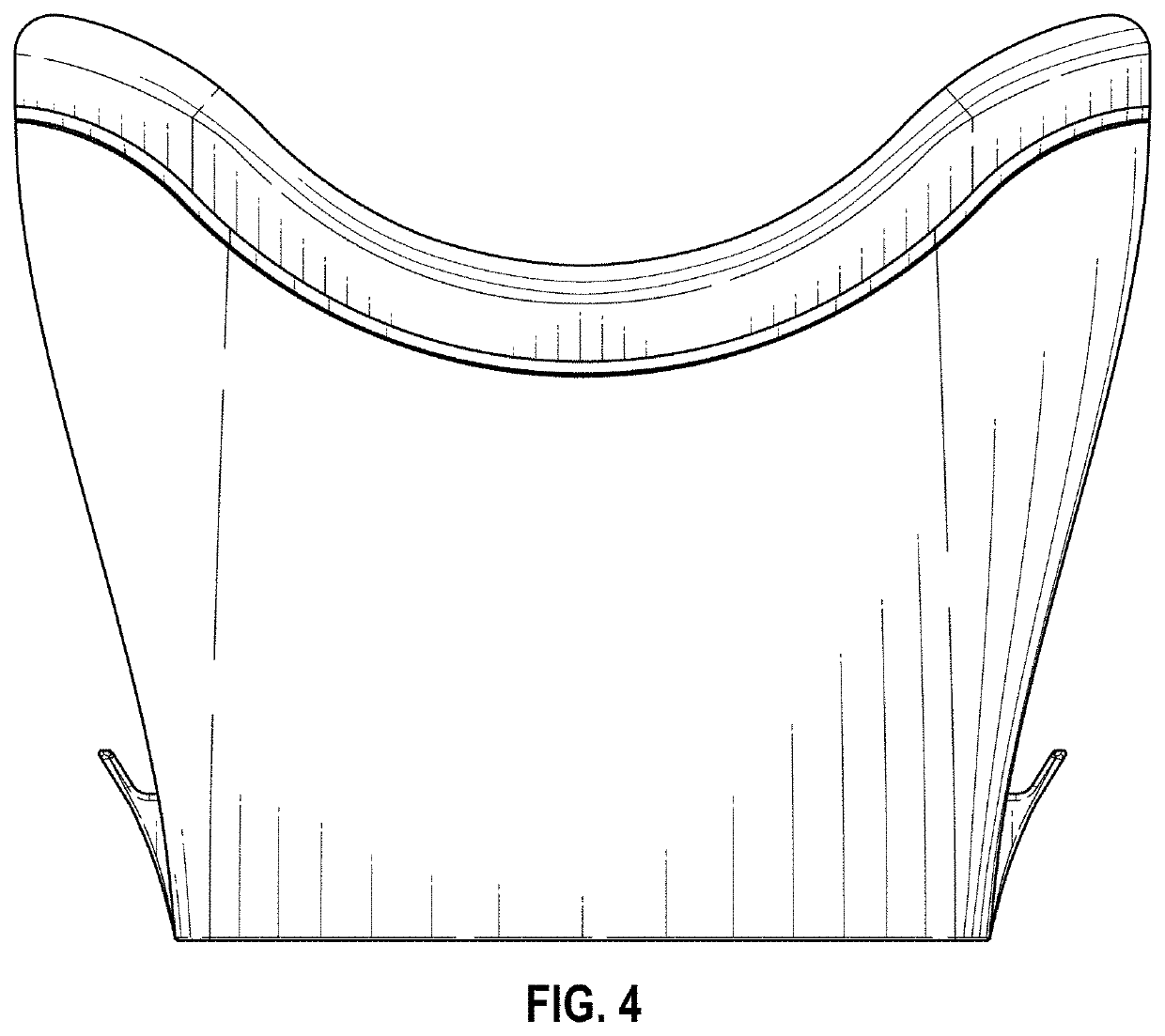

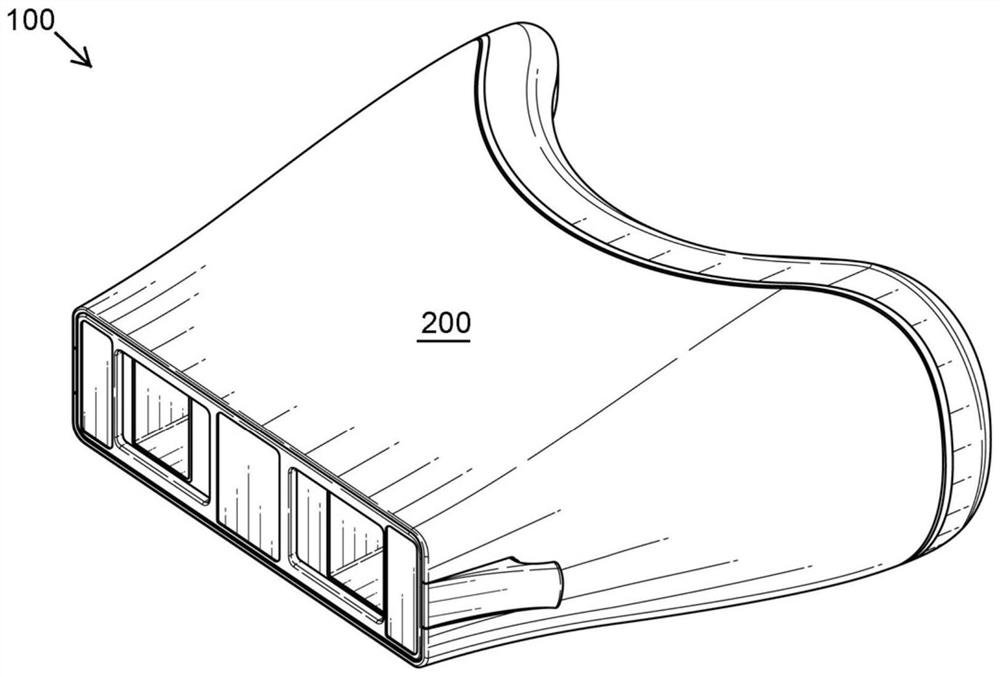

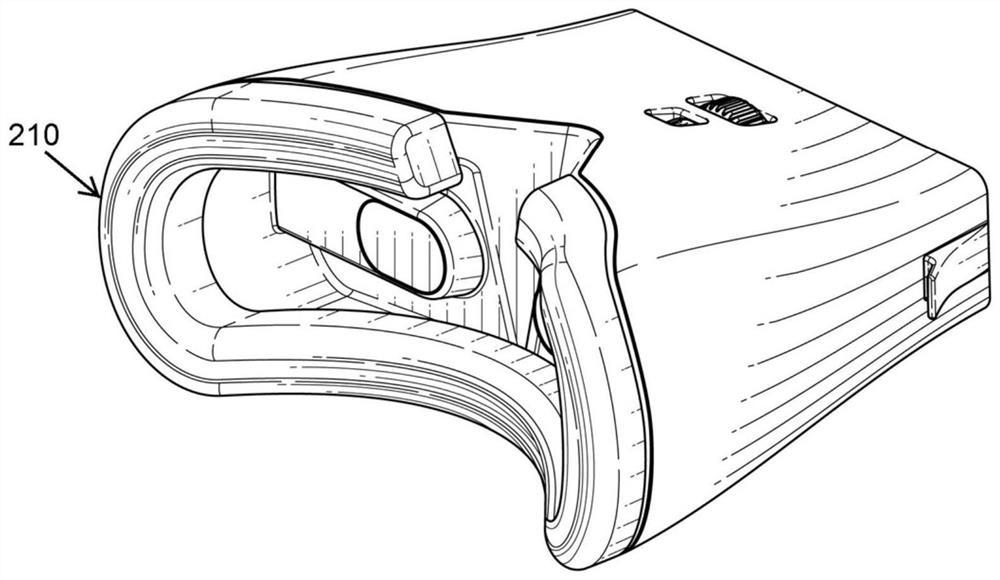

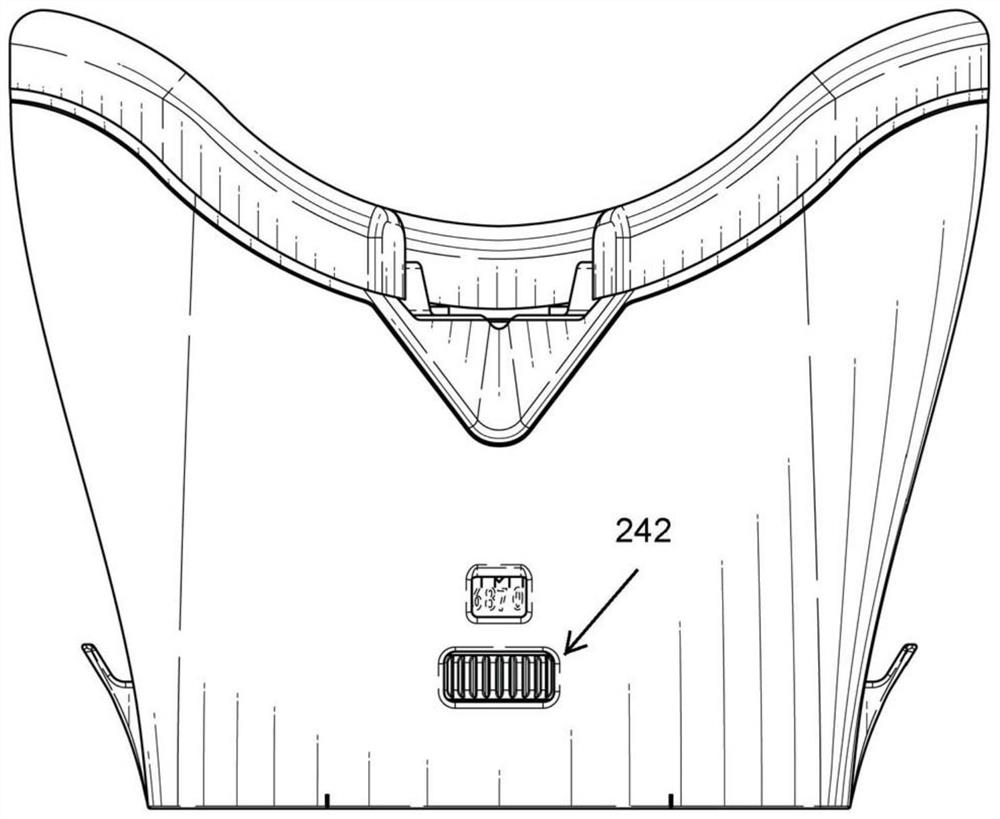

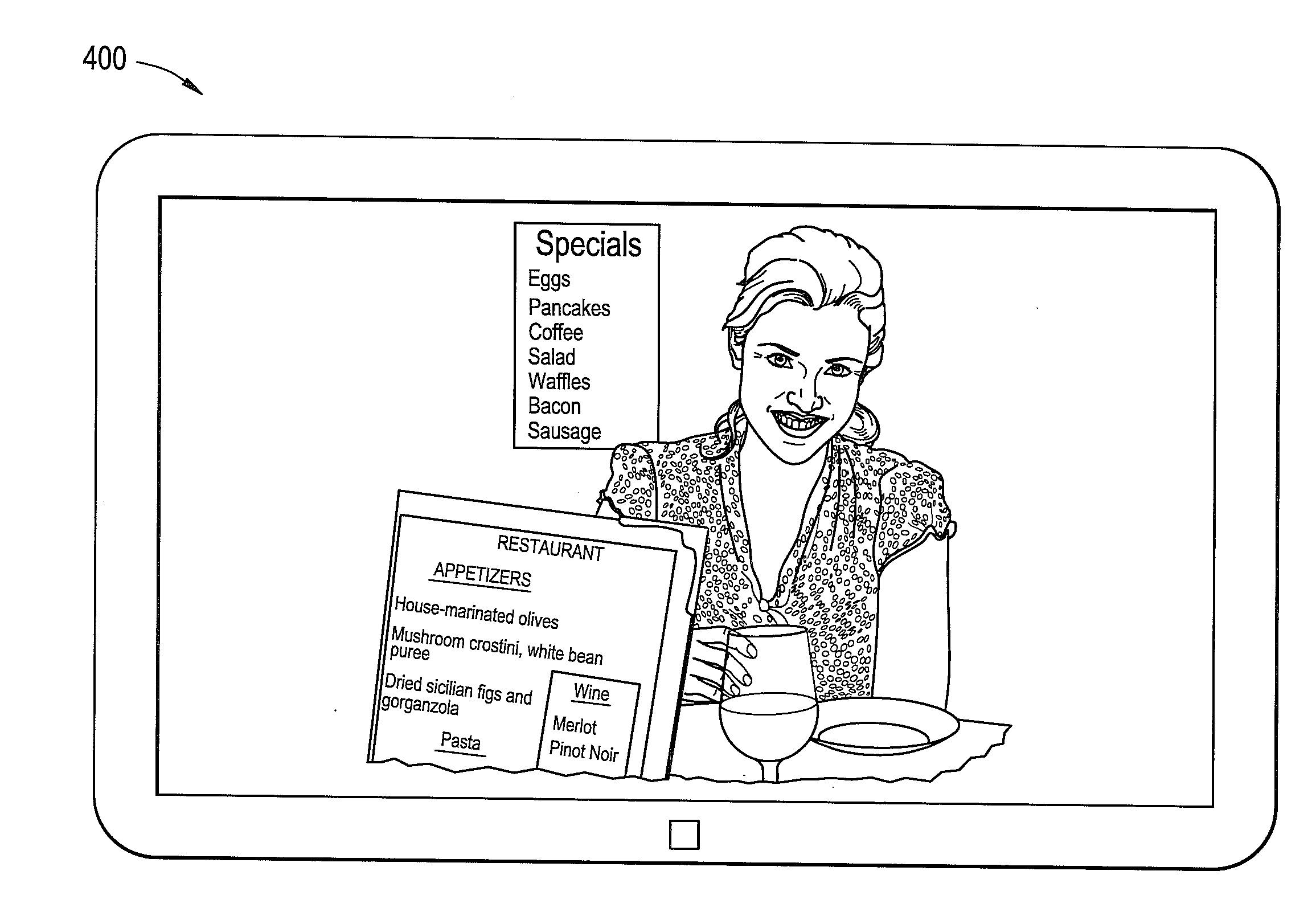

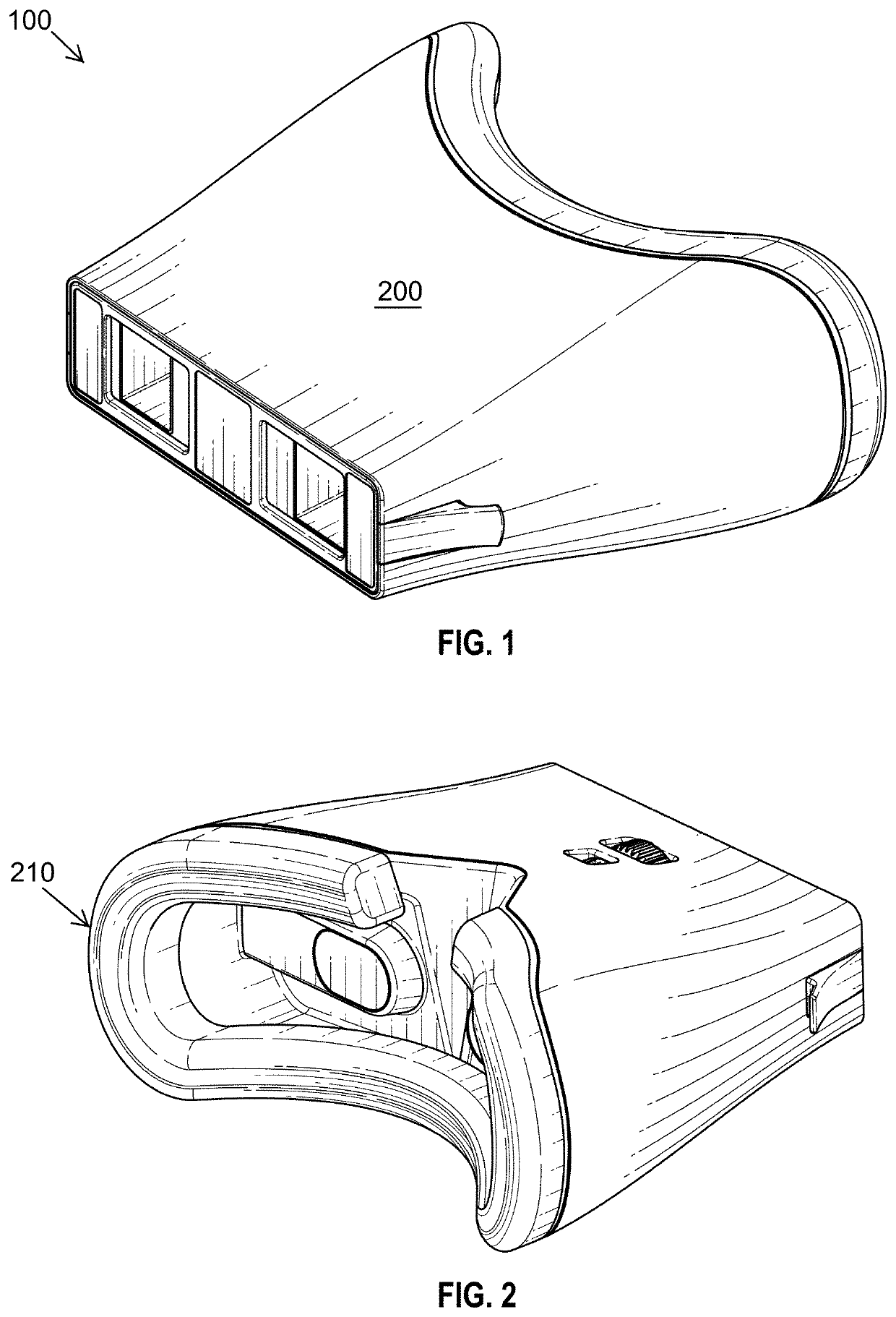

Smart Phone Based Virtual Visual Charts for Measuring Visual Acuity

ActiveUS20190125179A1Improve eyesightReduce communication costsRefractometersSkiascopesOphthalmic refractometerVisual perception

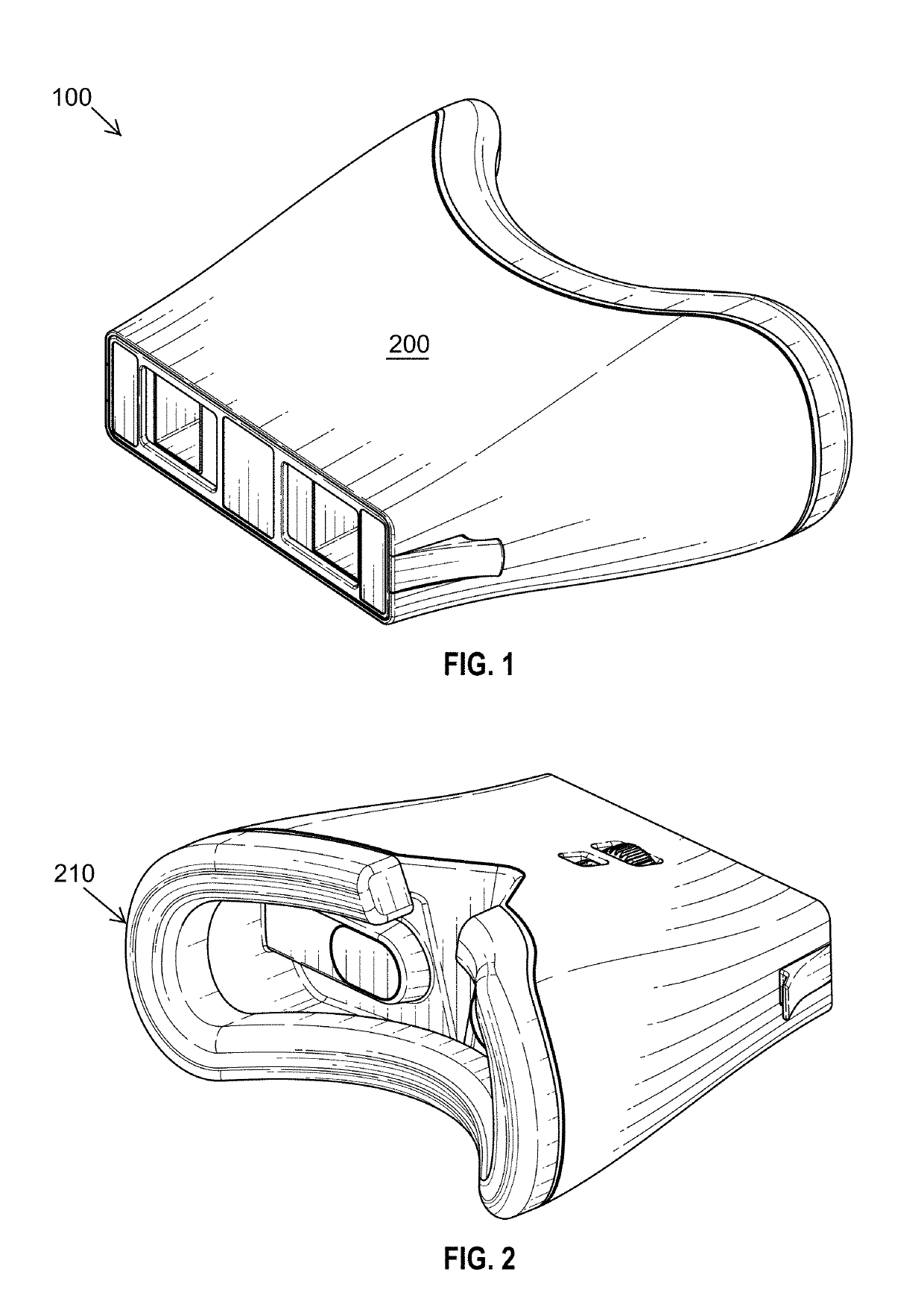

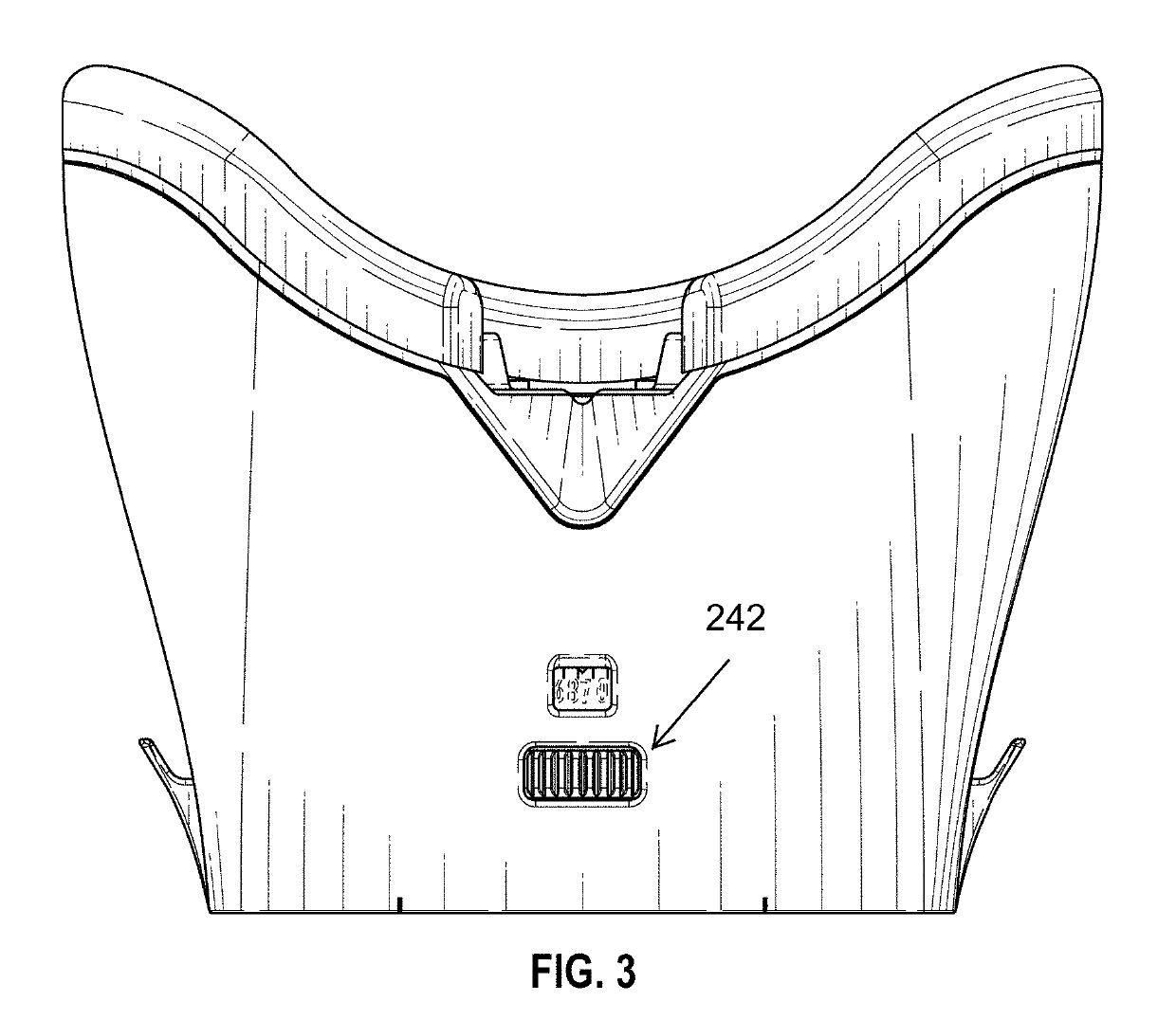

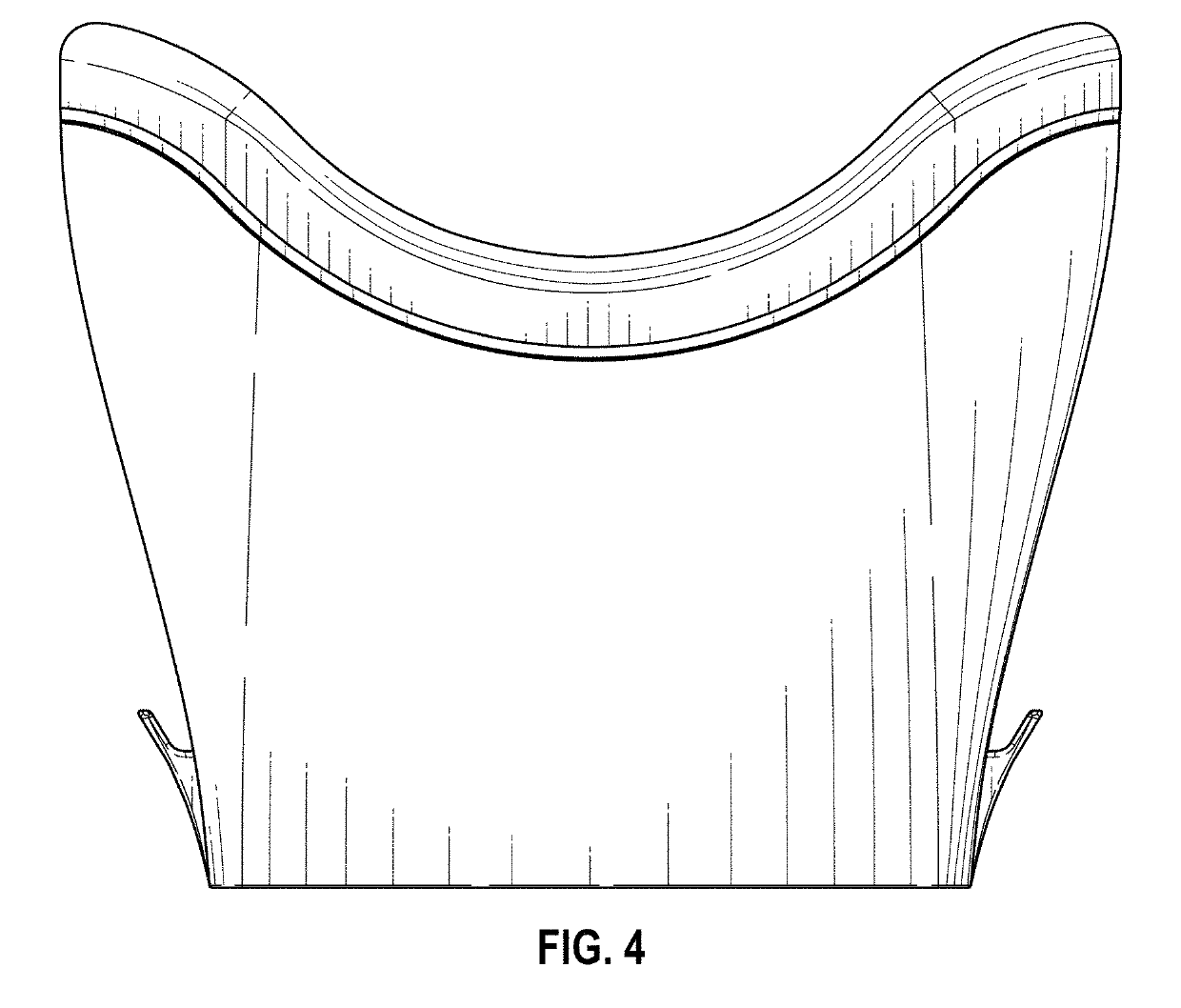

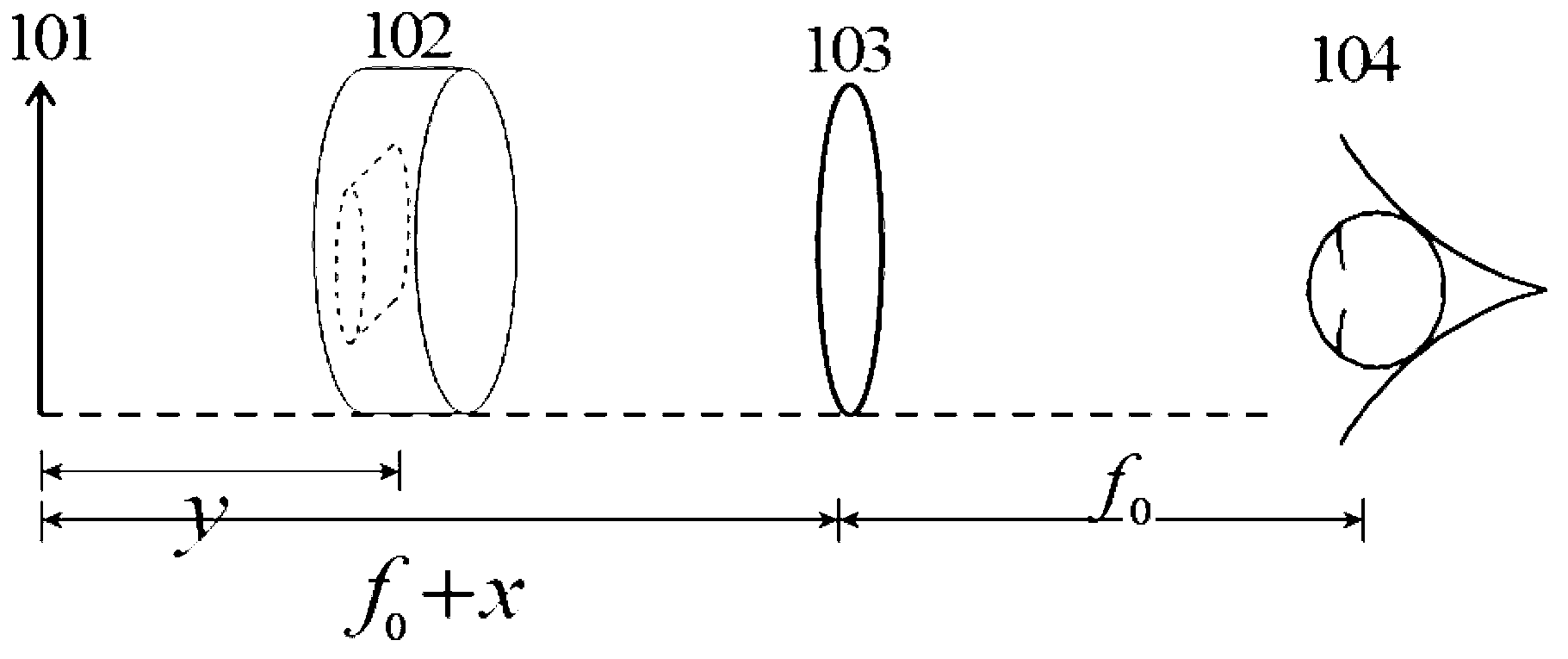

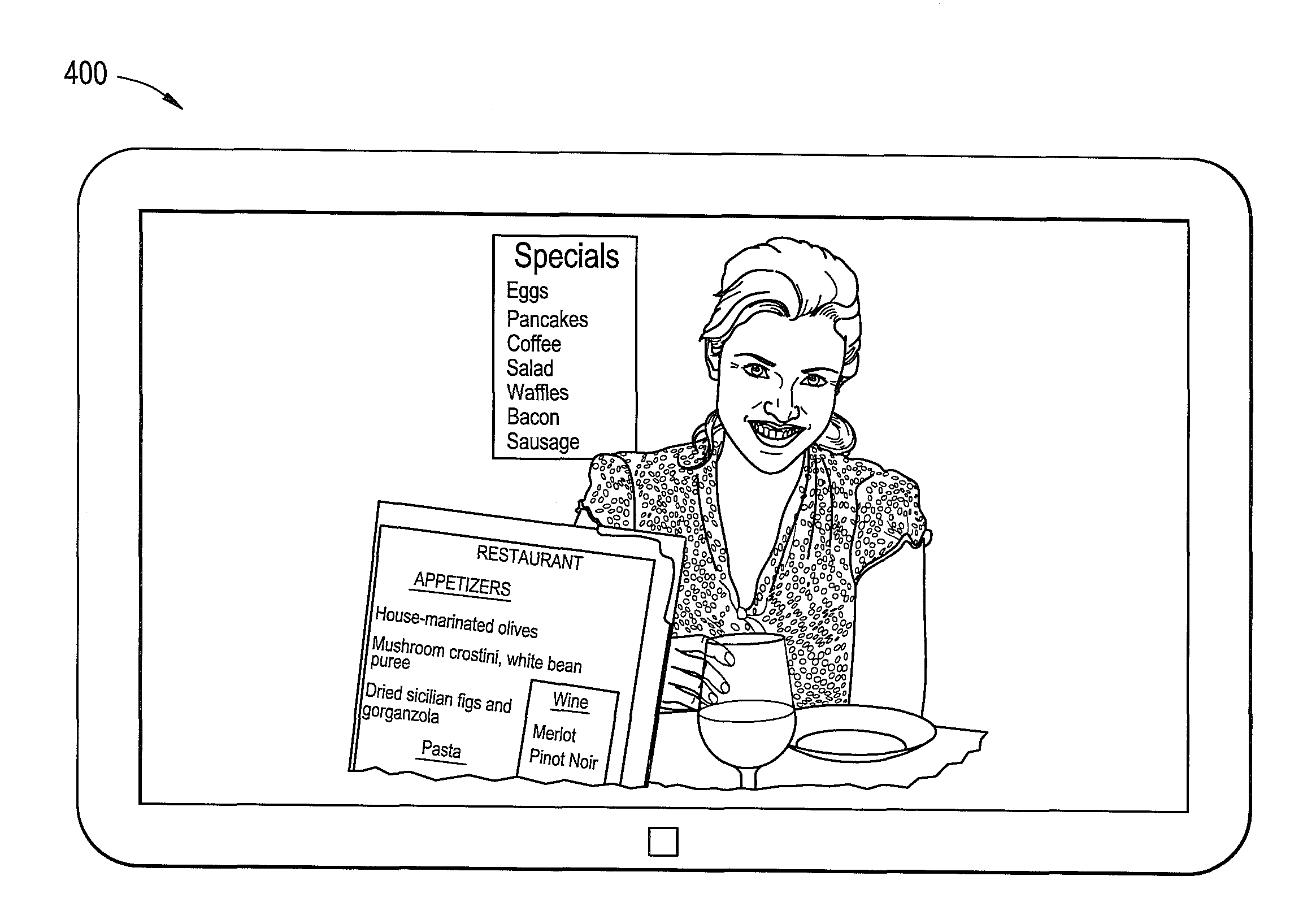

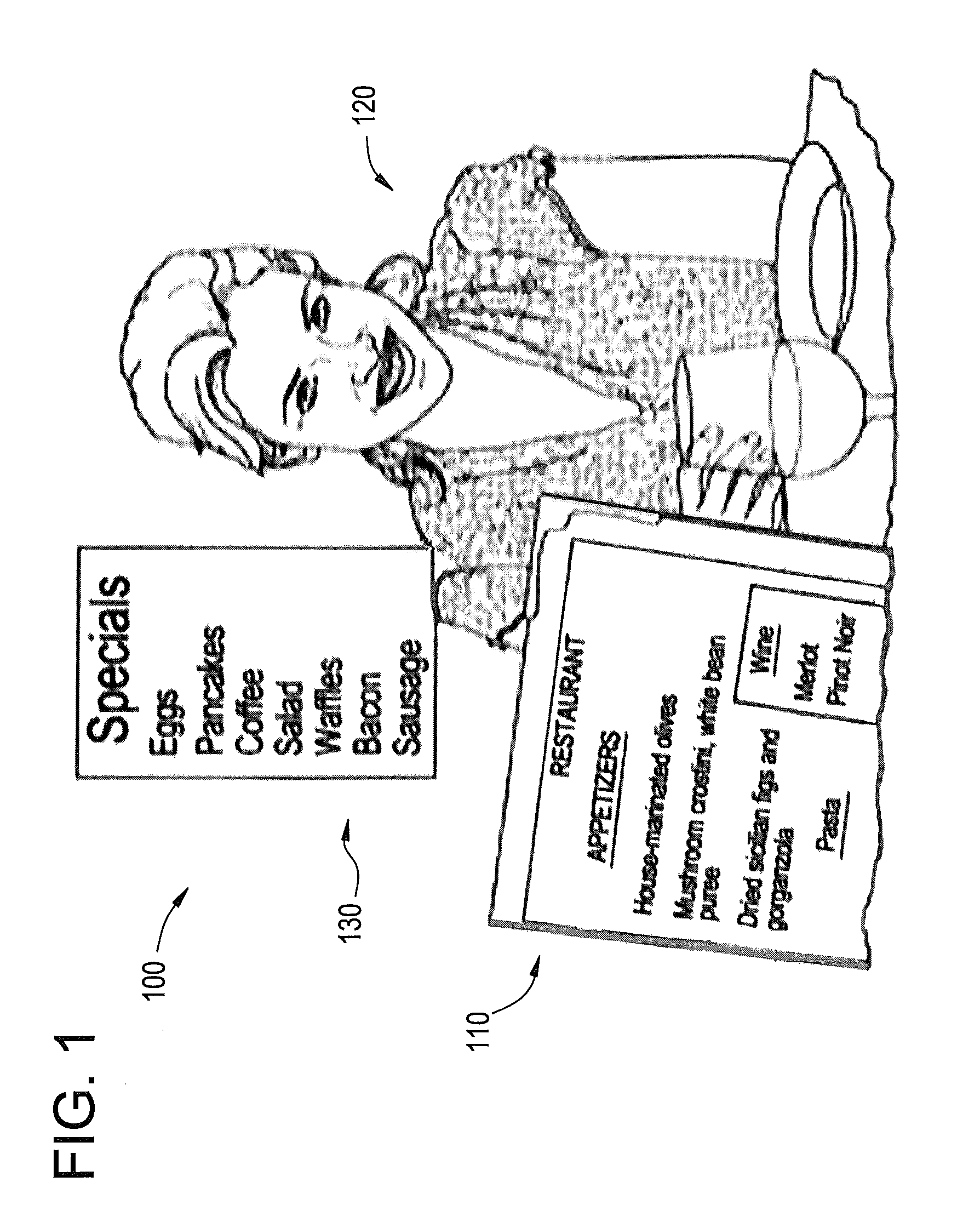

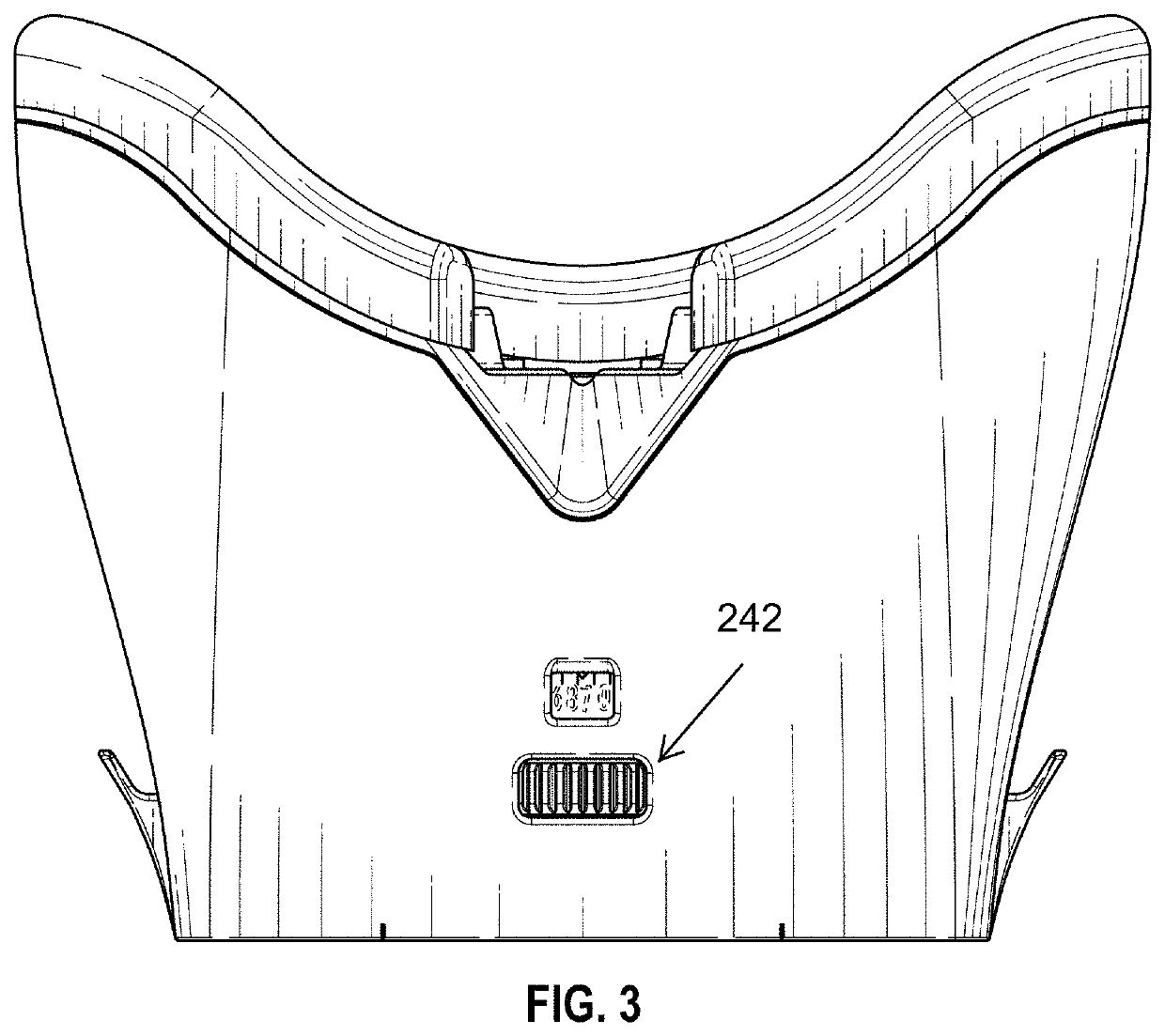

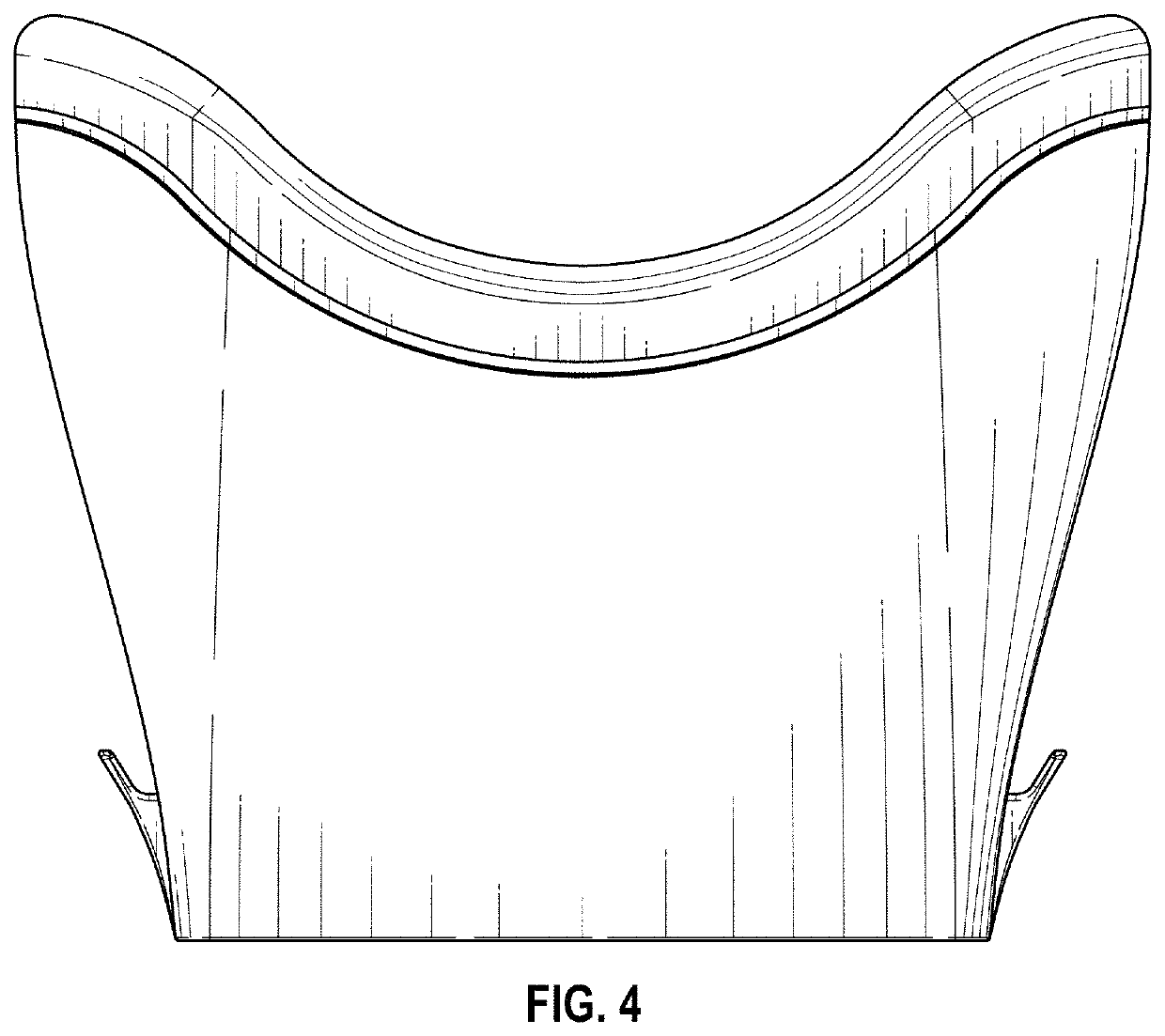

A system for replicating a standardized visual acuity test, such as the 20′ Snellen test may comprise a binocular viewer attached to a smartphone. A binocular viewer may comprise a housing comprising a pair tube covers having voids allowing for viewing through a pair of lens tubes with each lens tube in visual communication with a second lens a first lens an aperture and a front cover. The optical systems use an artful combination of front and back lens surfaces, demagnification and other systems to faithfully replicate the sight lines perceived by a user of a traditional 20′ test. The system also allows for the incorporation of other tests conducted with both eyes including Color Sensitivity and Contrast, furthermore by placing a deformable, tunable lens between the second lens and the eye the device serves as an ophthalmic refractometer, allowing a Spherical Equivalent refraction estimate for each eye.

Owner:EYEQUE INC

Examination of porosity by NMR and intrusion porosimetry

ActiveUS20140002081A1Analysis using nuclear magnetic resonanceElectric/magnetic detectionElectromagnetic radiationSpherical equivalent

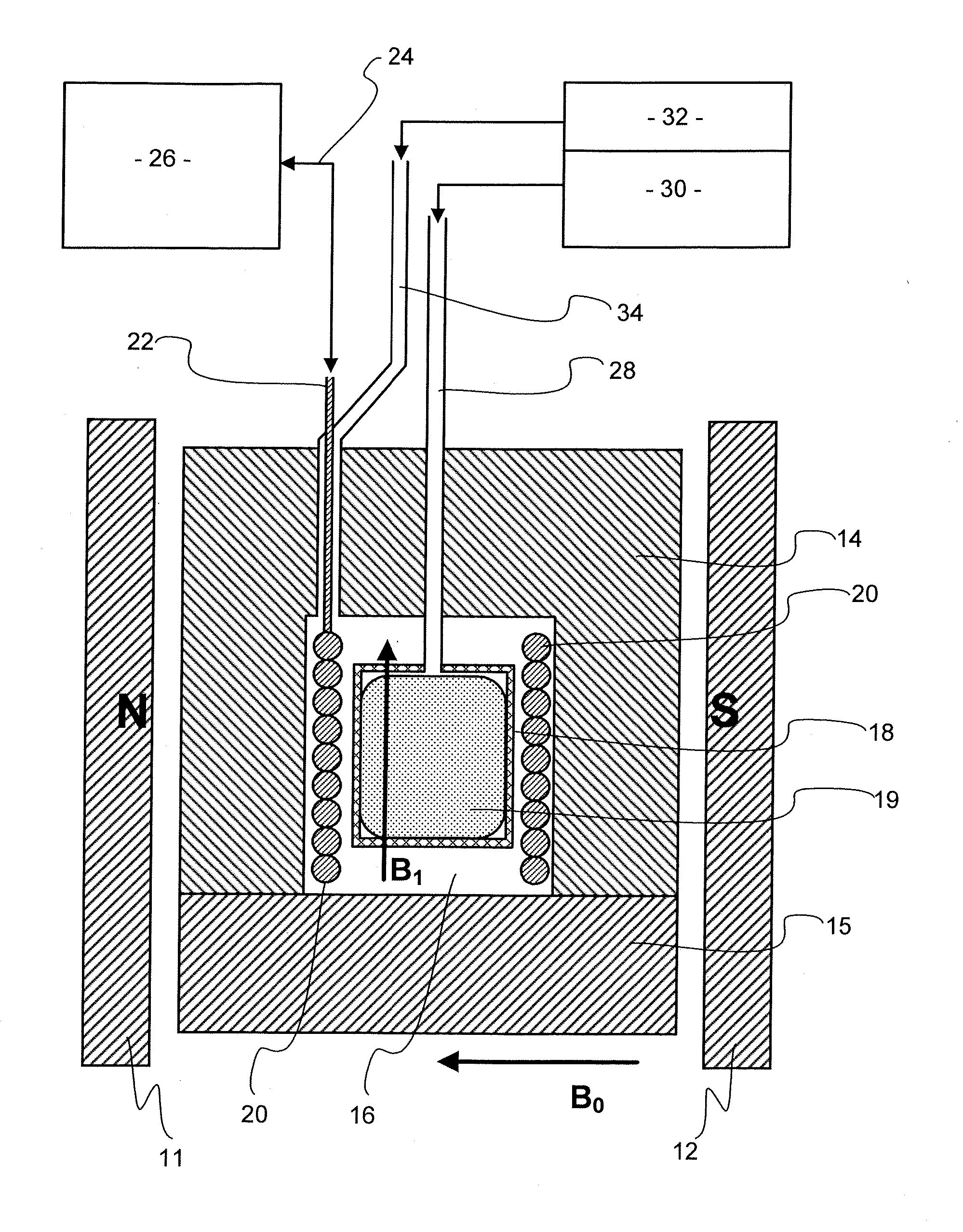

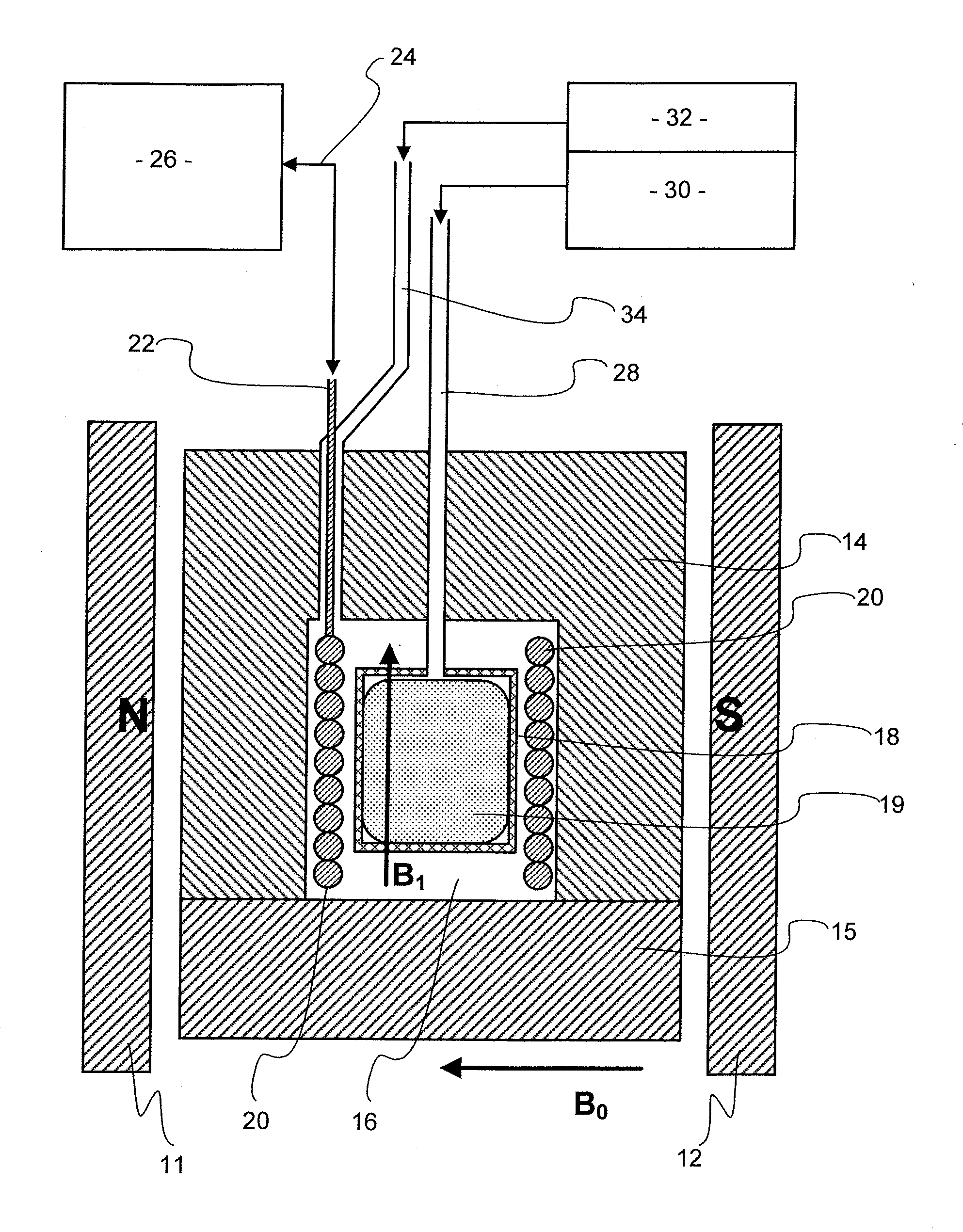

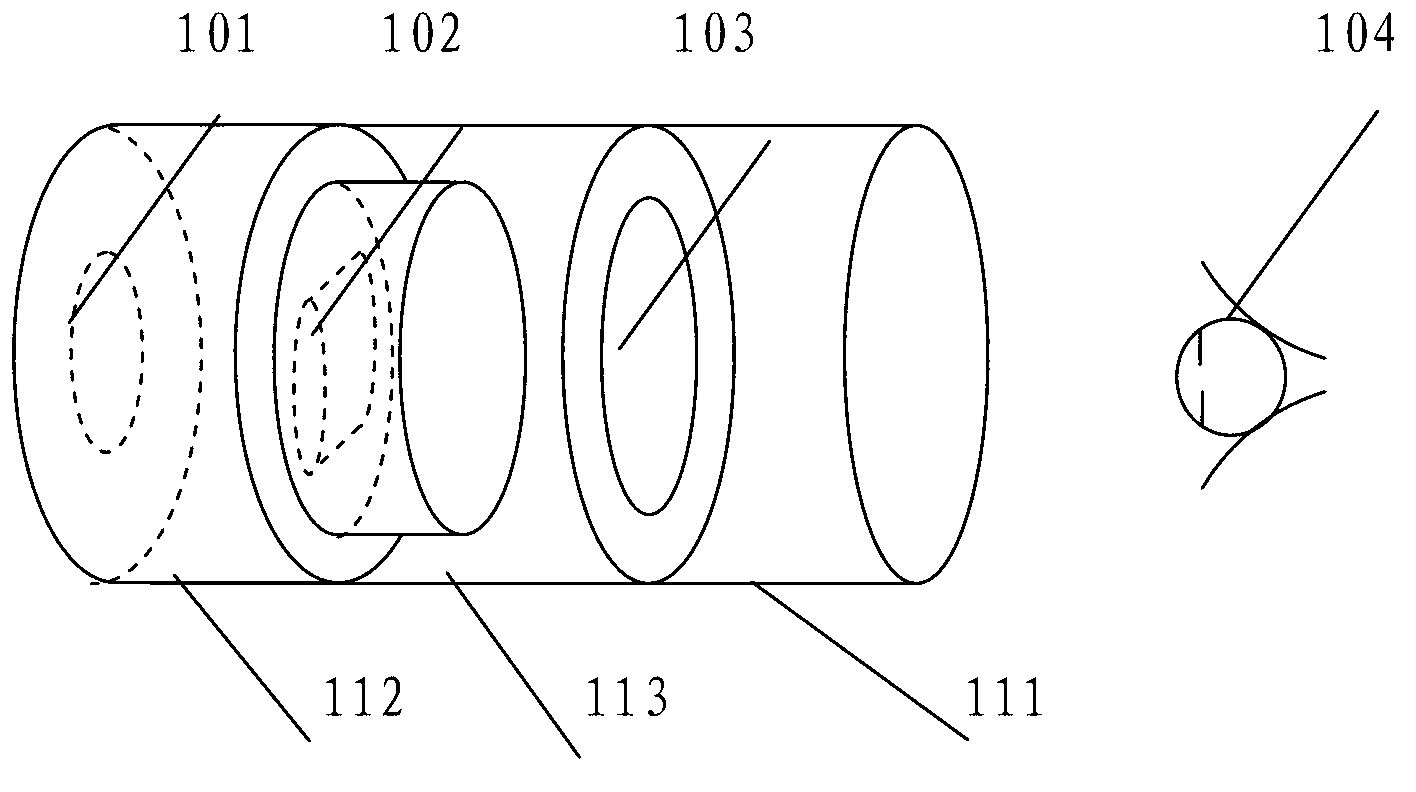

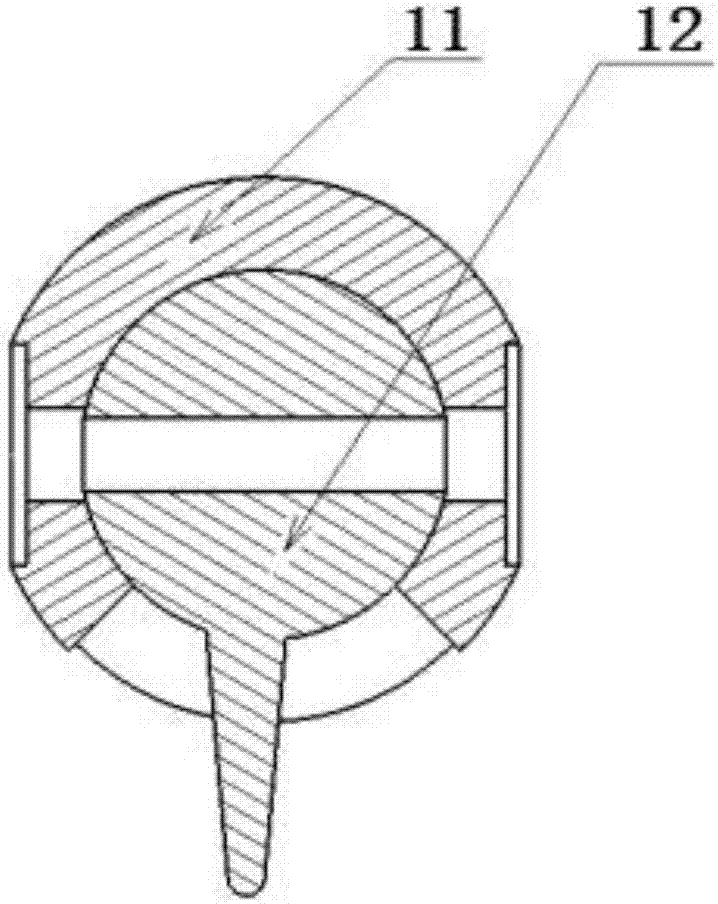

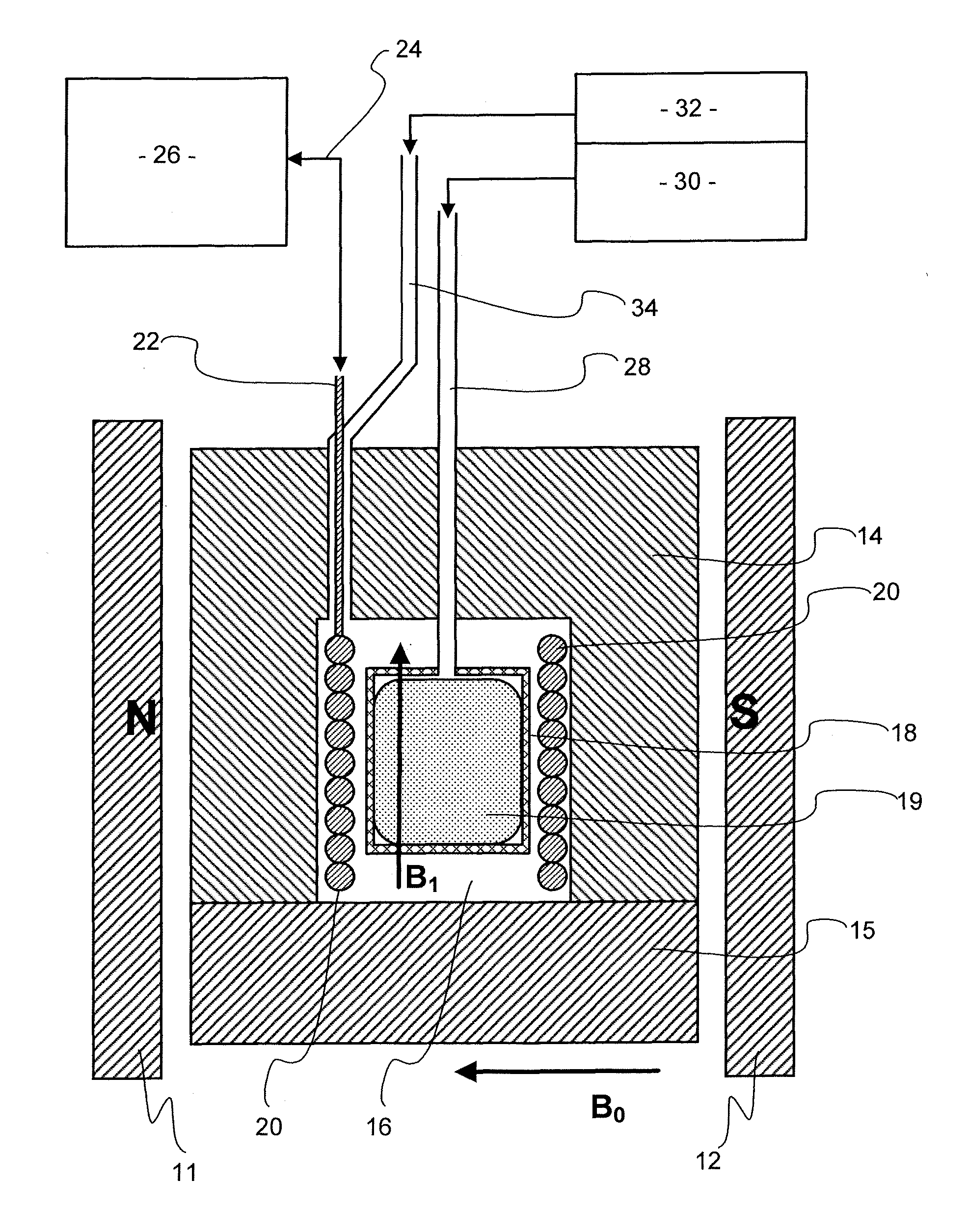

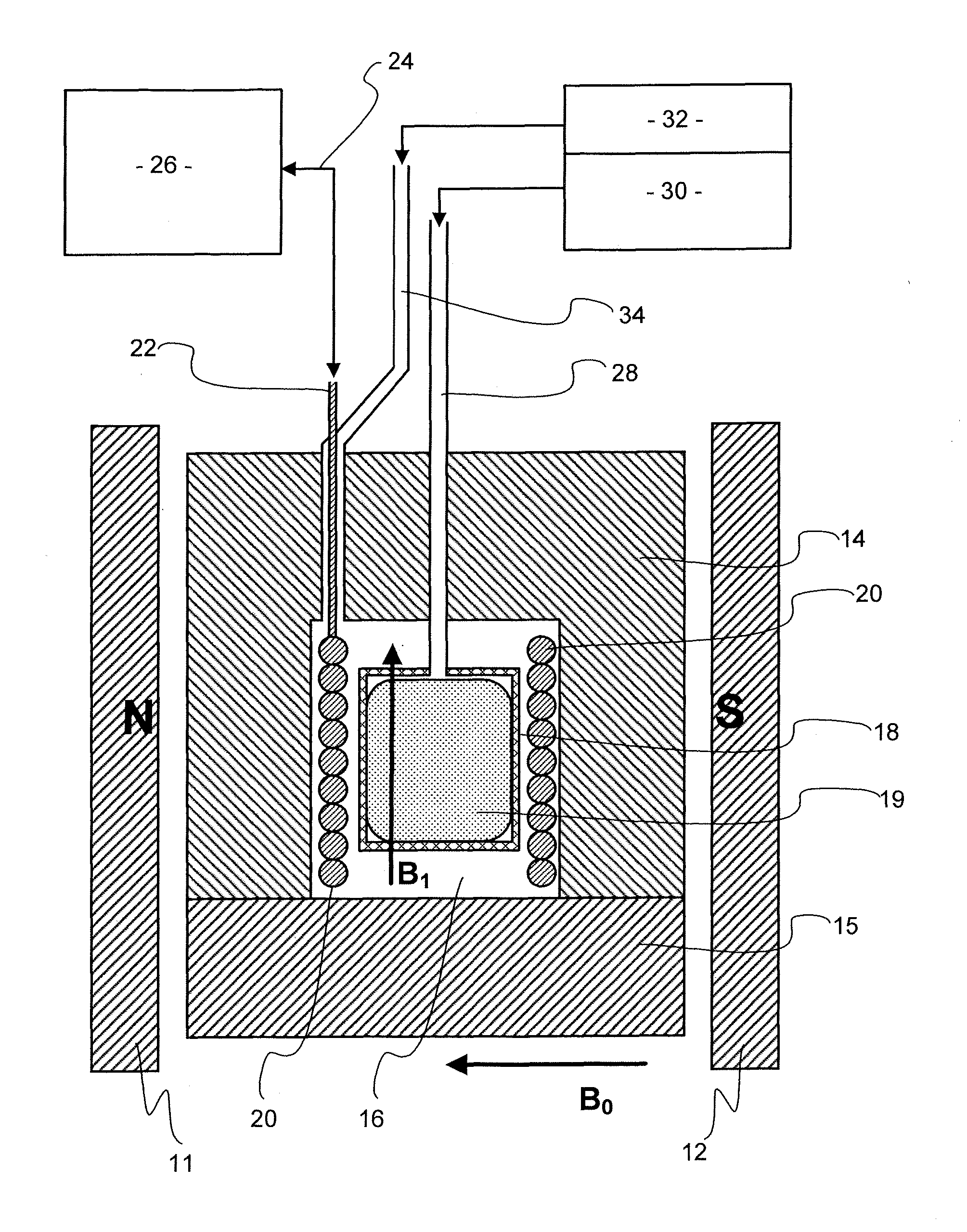

Properties of a porous solid sample 19, which may be a core of rock taken from below ground are carried out using apparatus which performs both nuclear magnetic resonance (NMR) and porosimetry measurements. The apparatus has a magnet 11,12 providing a magnetic field and a radio frequency coil 20 for transmitting and / or receiving electromagnetic radiation so as to bring about NMR in the magnetic field, a pressure vessel 14, 15 to hold a sample 19 within the magnetic field, a supply of a non-wetting liquid connected to the vessel, means to apply pressure to the non-wetting liquid to force liquid into pores of the sample 19 means to measure applied pressure of the non-wetting liquid and means to measure volume thereof taken up by the sample. The pressure of non-wetting liquid may be increased in steps, using intruded liquid volume at each step to give a measurement of pore throat size using NMR at each step to give a measure of pore size such as diameter of equivalent sphere. The non-wetting liquid may be mercury and NMR may observe the Knight shift of 99 Hg.

Owner:SCHLUMBERGER TECH CORP

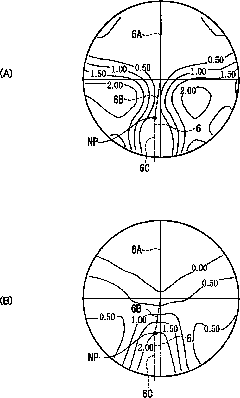

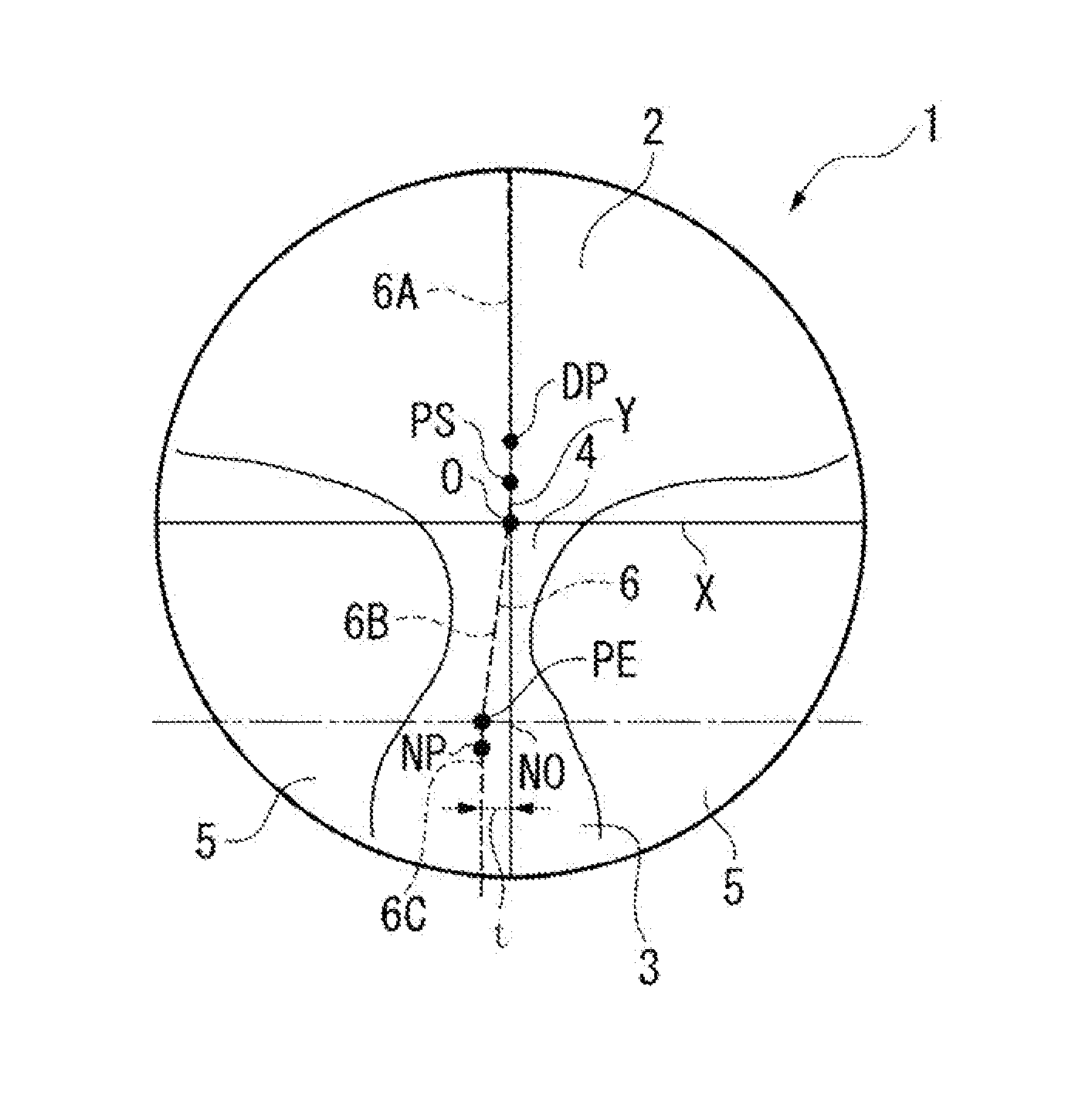

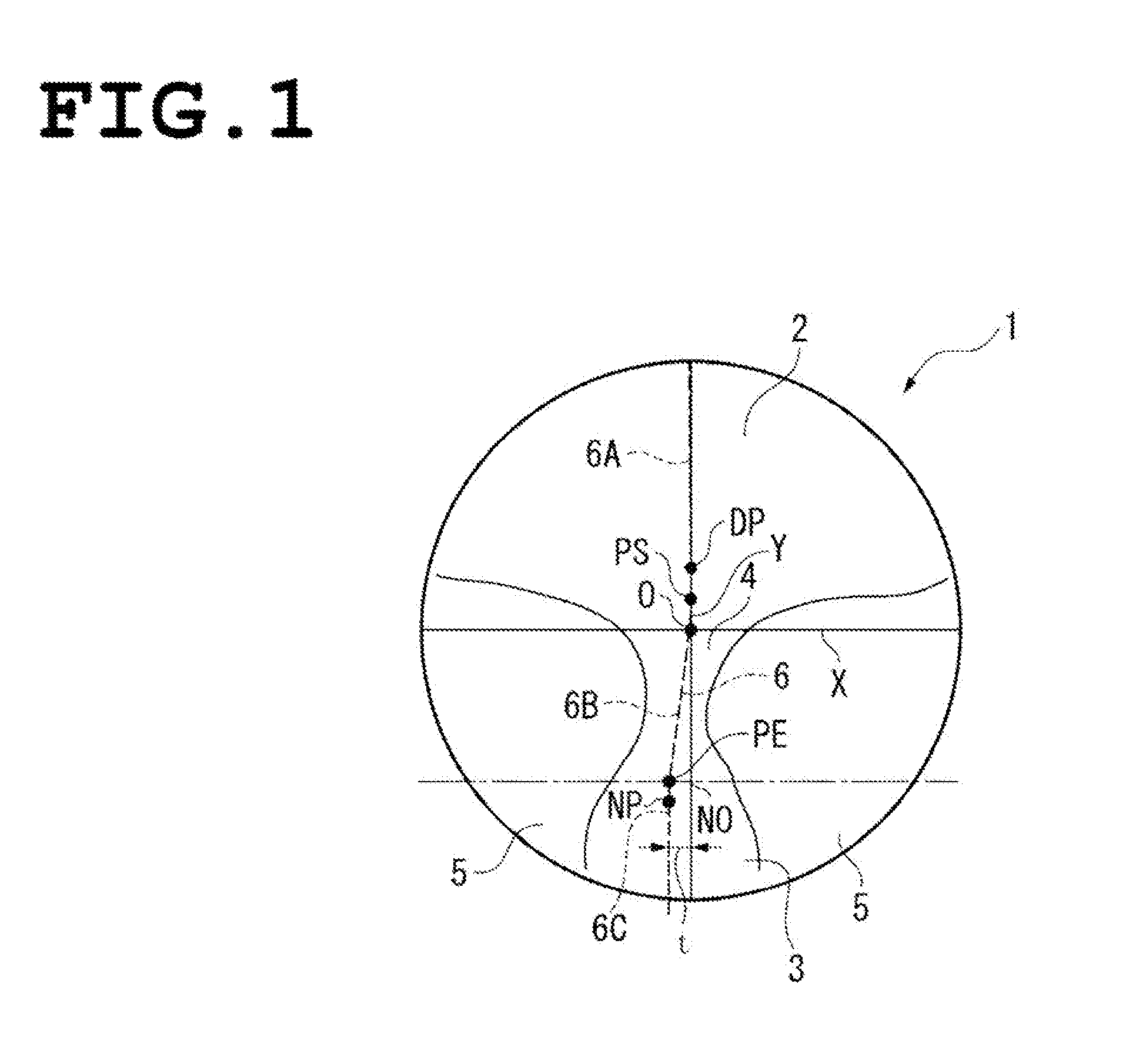

Spectacle Lens and Method for Designing the Same

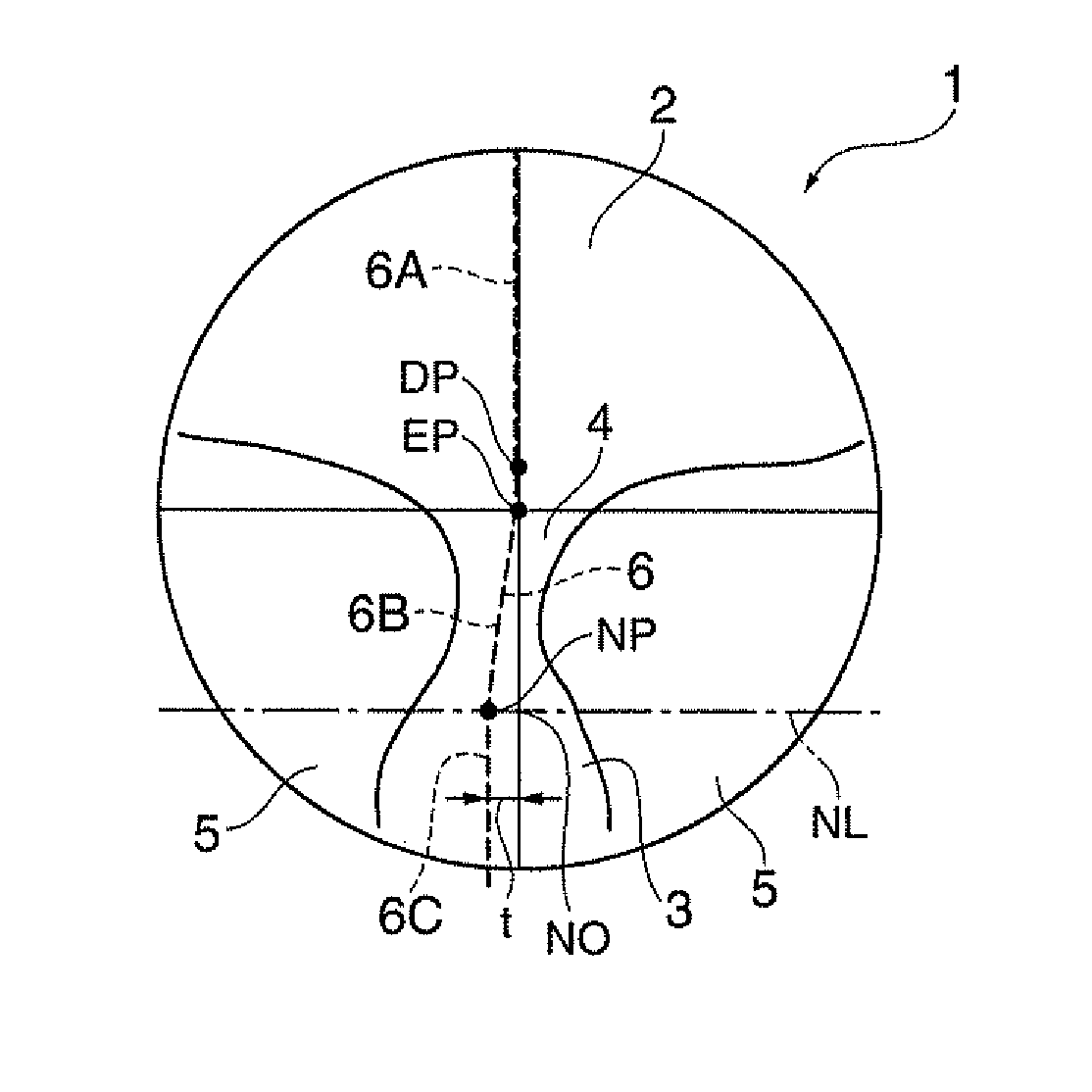

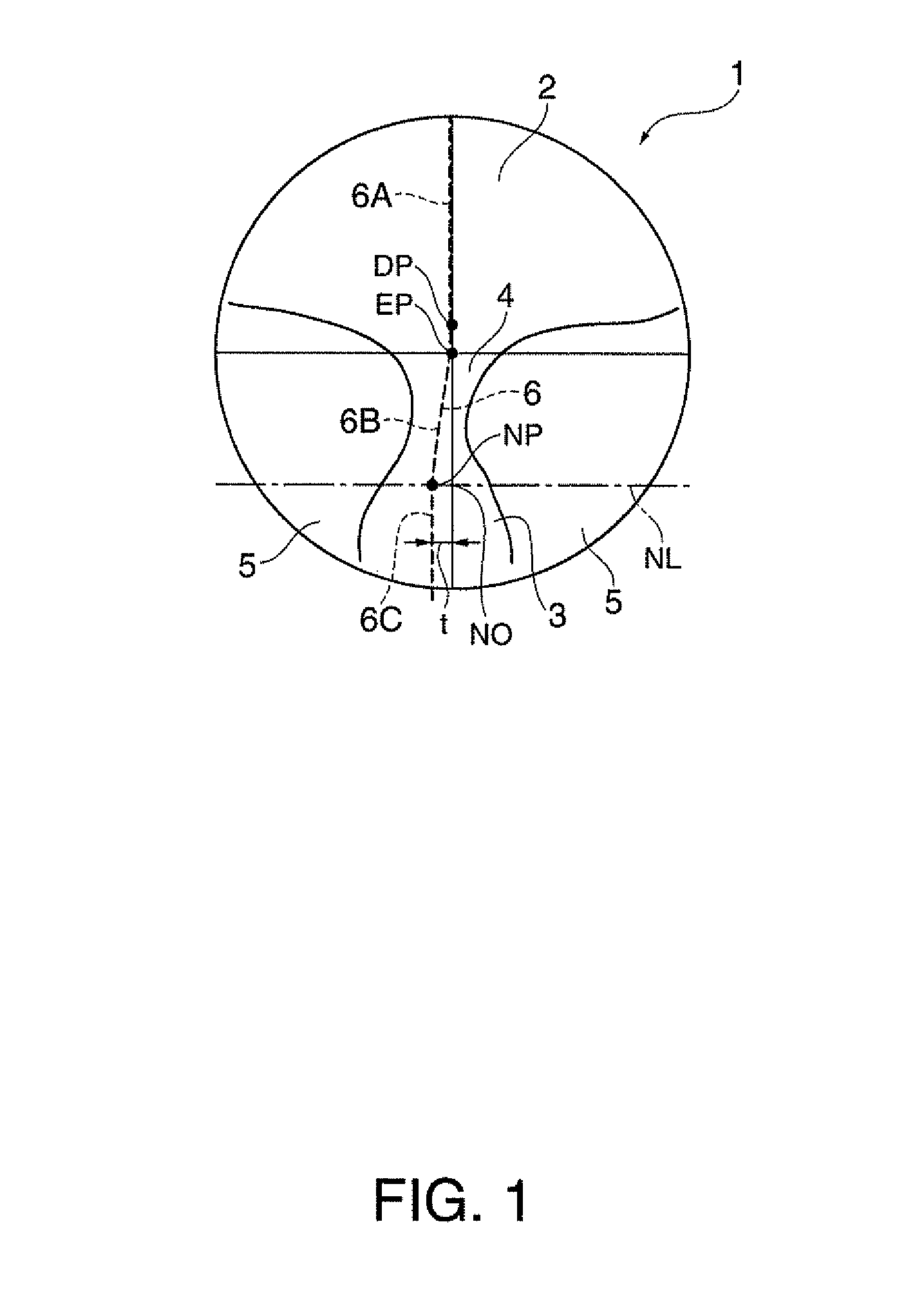

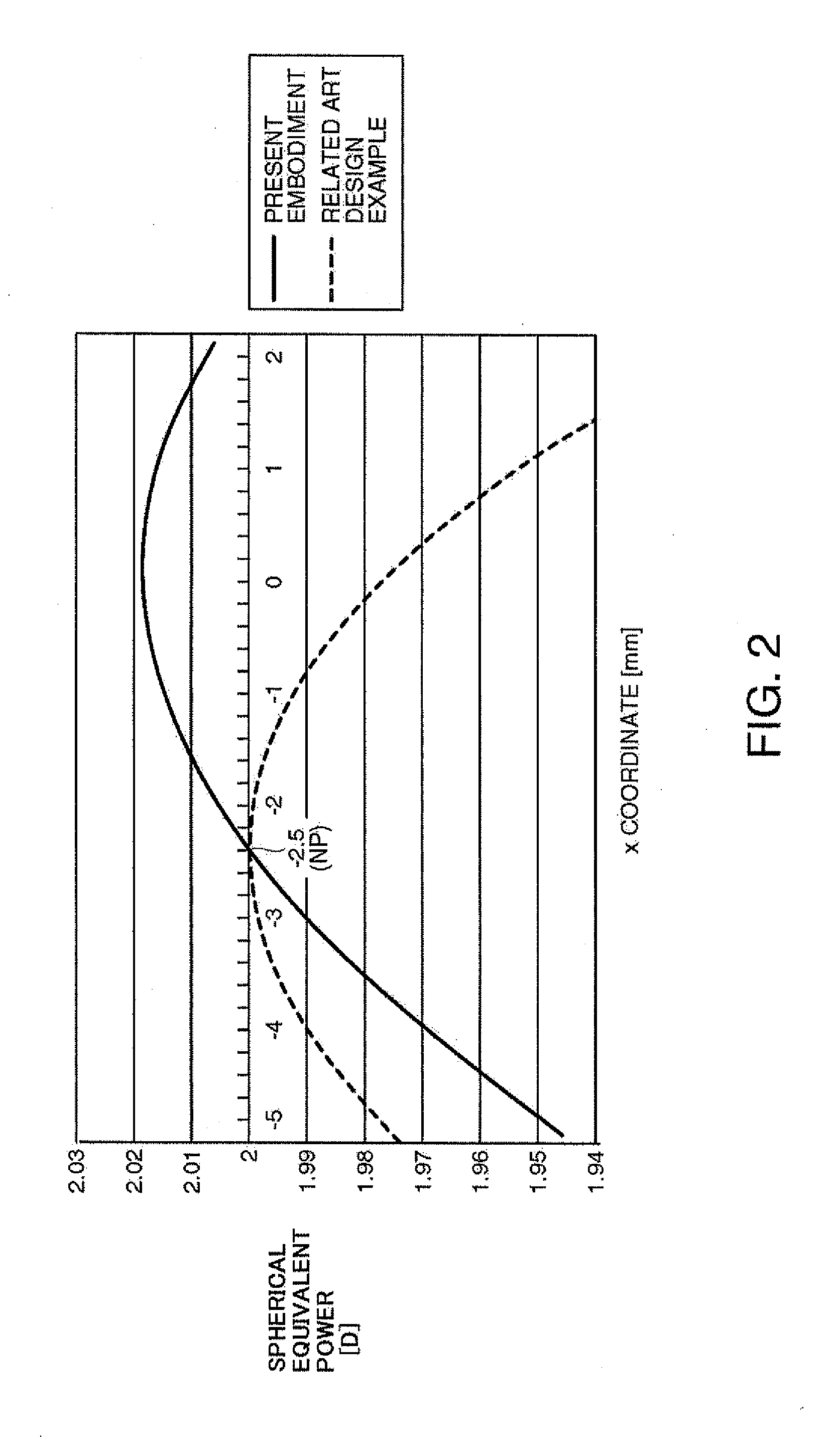

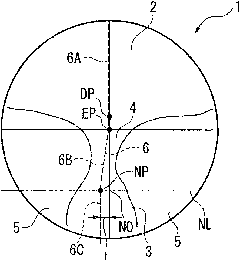

A spectacle lens includes: a near region corresponding to near vision, wherein a spherical equivalent power at a point located on a principal line of fixation in the near region is larger than the spherical equivalent power in a region away from the point toward the nose, in a horizontal direction with reference to a spectacle wearer but smaller than the spherical equivalent power in a region away from the point toward the ear in the horizontal direction.

Owner:HOYA LENS MFG PHILIPPINES

Subjective optometry instrument and optometry method

Owner:SHENZHEN CERTAINN TECH CO LTD

Spectacle lens and method for designing the same

The present invention relates to a spectacle lens and a method for designing the spectacle lens. The invention provides spectacle lenses that allow the wearer to comfortably view a near object in binocular vision by using near regions of the spectacle lenses irrespective of the horizontal position of a target portion of the object. The spectacle lens is set that: compared with the spherical equivalent power at the near dioptric power measuring point on the main visual line in the near dioptric area of the spectacle lens, the spherical equivalent power at a point away from the near dioptric power measuring point NP horizontally toward the nose with reference to the spectacle wearer is set to decrease continuously, whereas the spherical equivalent power at a point away from the near dioptric power measuring point NP horizontally toward the ear is set to increase continuously.

Owner:HOYA LENS MFG PHILIPPINES INC

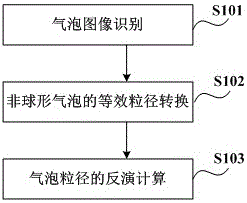

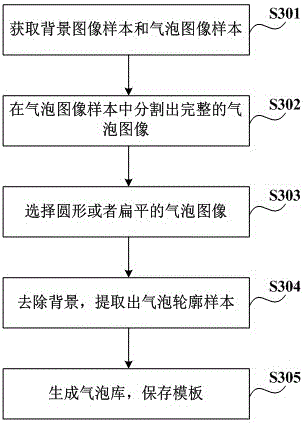

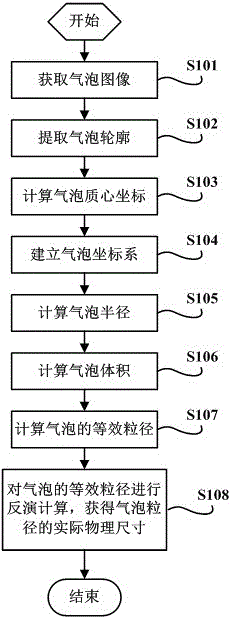

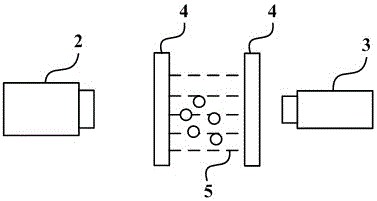

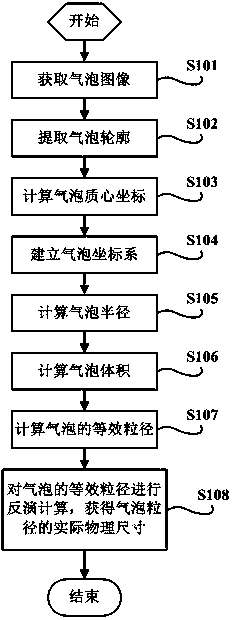

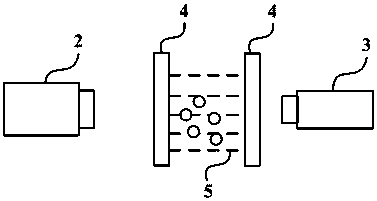

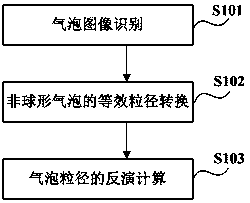

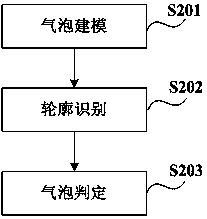

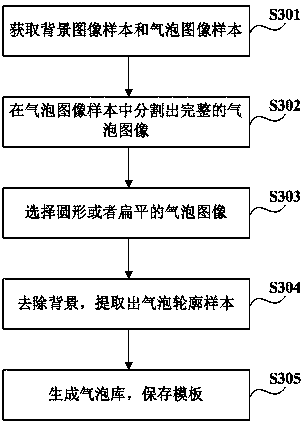

Method for measuring bubbles in water body

ActiveCN106023153AAccurate Bubble ContourReduce mistakesImage enhancementImage analysisImage calibrationComputer science

The invention discloses a method for measuring bubbles in a water body. The method comprises a bubble image identification process, a non-spherical bubble equivalent particle size conversion process and a bubble particle size inversion calculation process. By use of the bubble image identification process, bubble images and suspension images in the water body can be accurately distinguished from each other, and accurate bubble contours are obtained. By use of the non-spherical bubble equivalent particle size conversion process, errors in an equivalent conversion process can be reduced, and the calculation precision of equivalent spherical bubble particle sizes is improved. By use of the bubble particle size inversion calculation process, physical dimensions of bubble particle sizes are generated through combination of image calibration and inversion calculation. The precision is high, the real-time performance is good, original-position real-time measurement of physical parameters of the bubbles can be realized, and the method is suitable for wide application in such fields as scientific research, teaching, seawater monitoring and the like.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Ametropia treatment tracking methods and system

ActiveUS20170209036A1Shorten the progressMedical simulationSpectales/gogglesRefractive errorMedicine

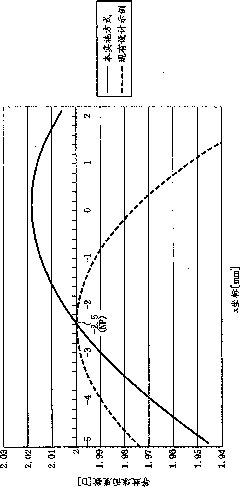

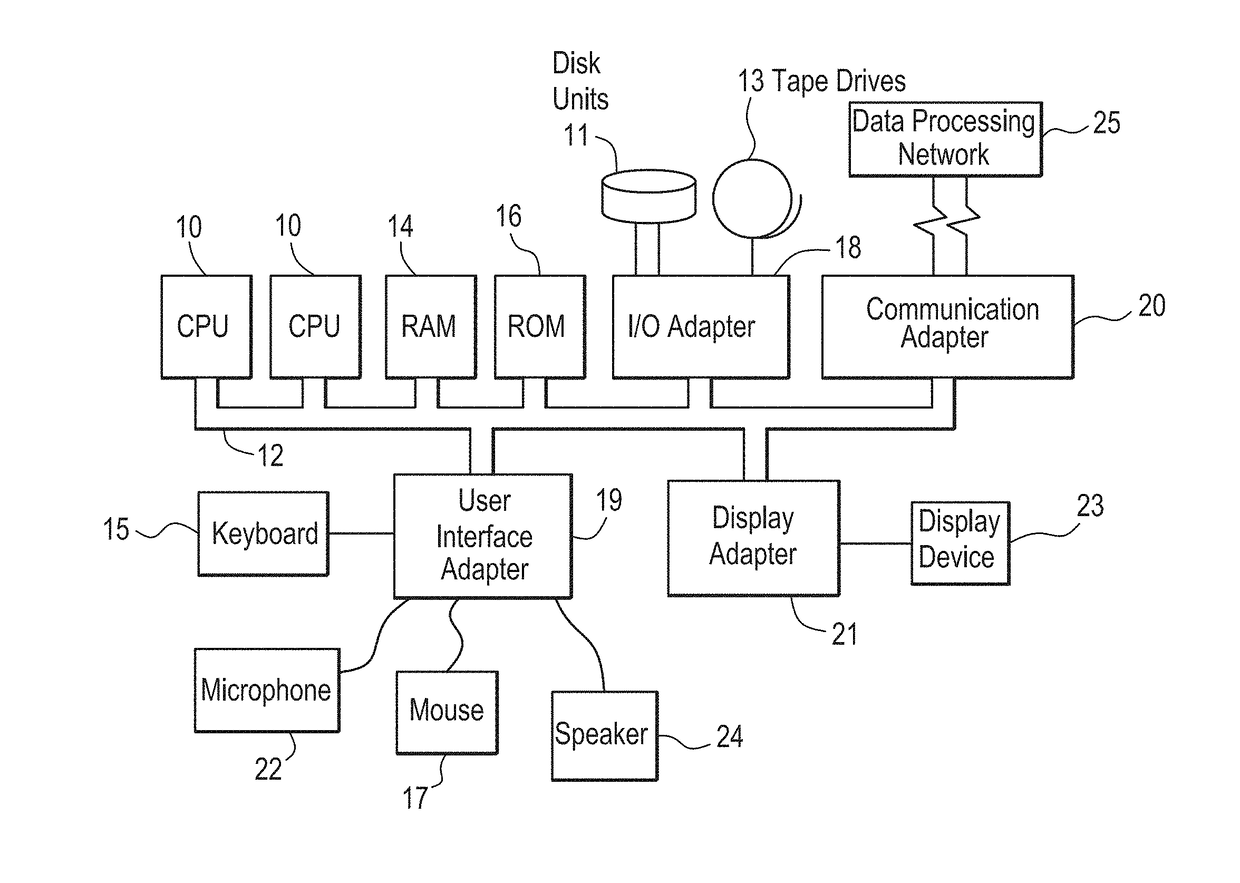

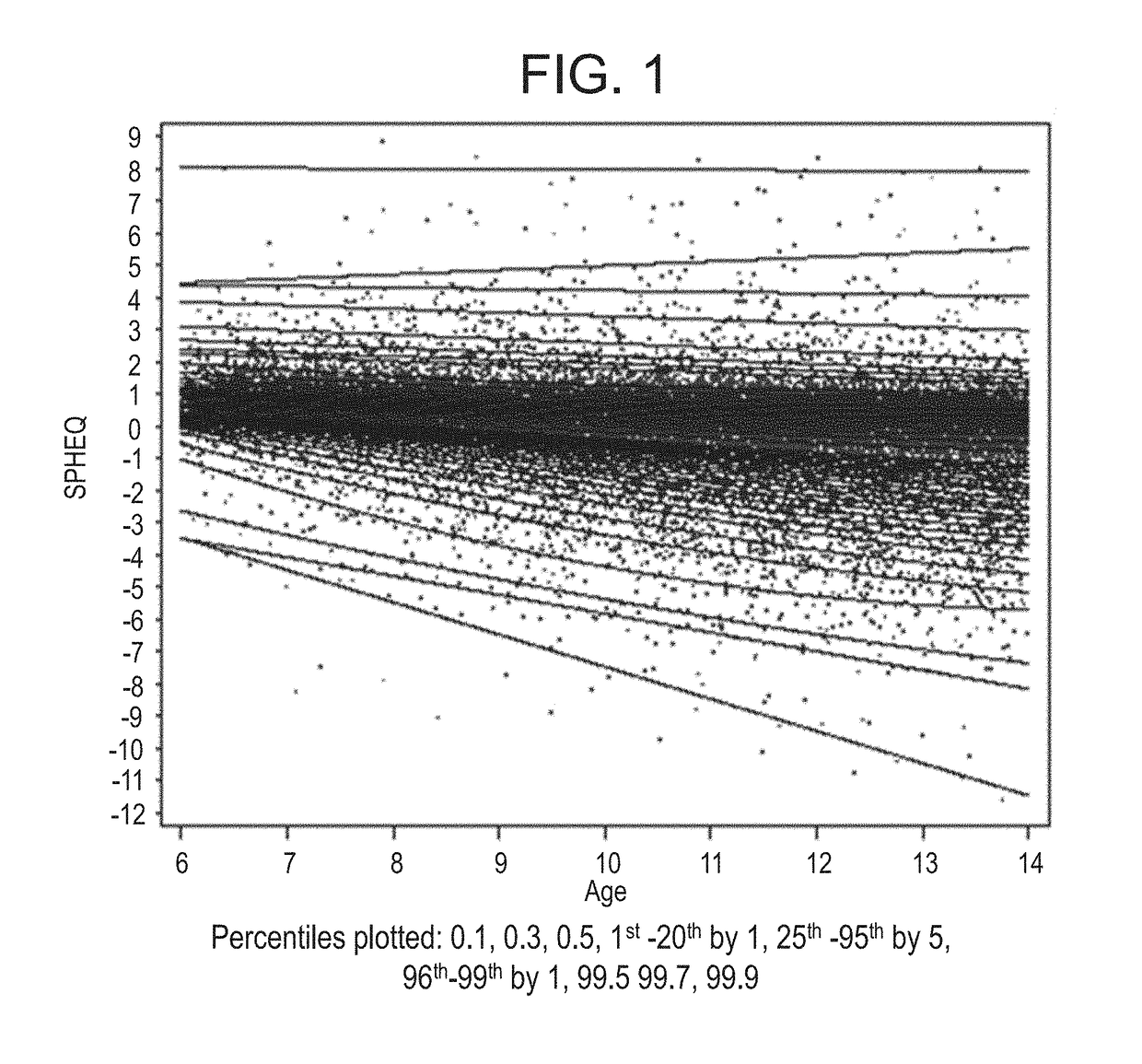

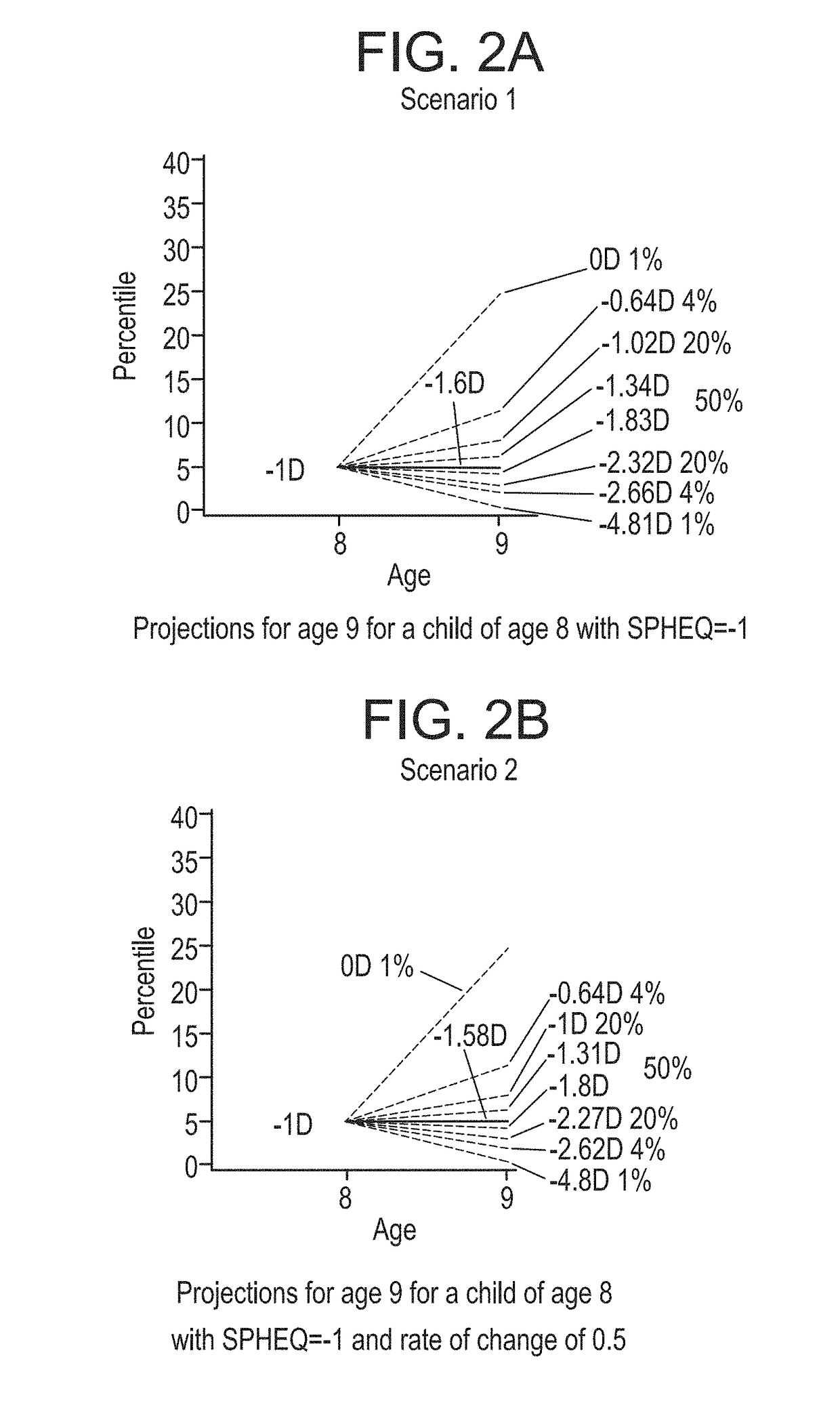

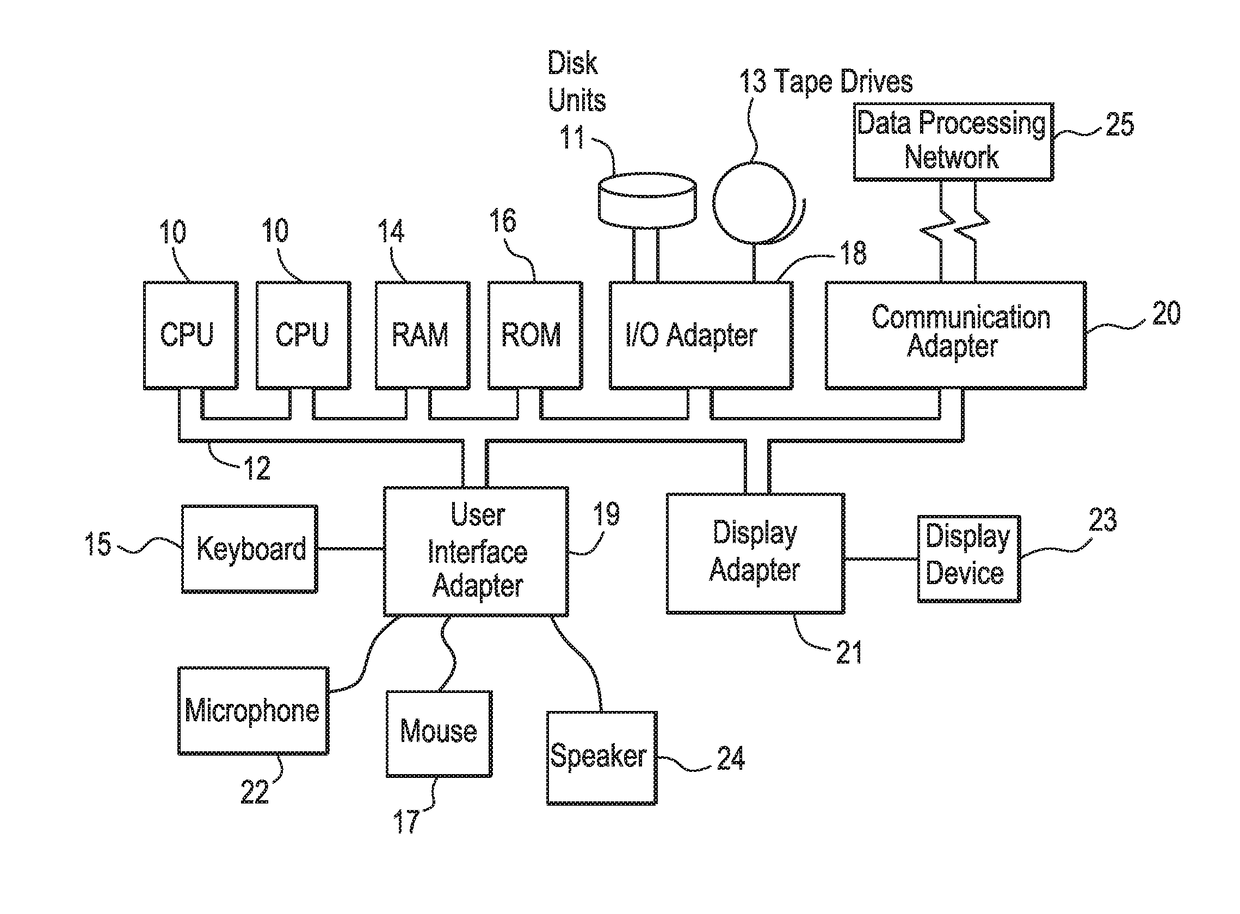

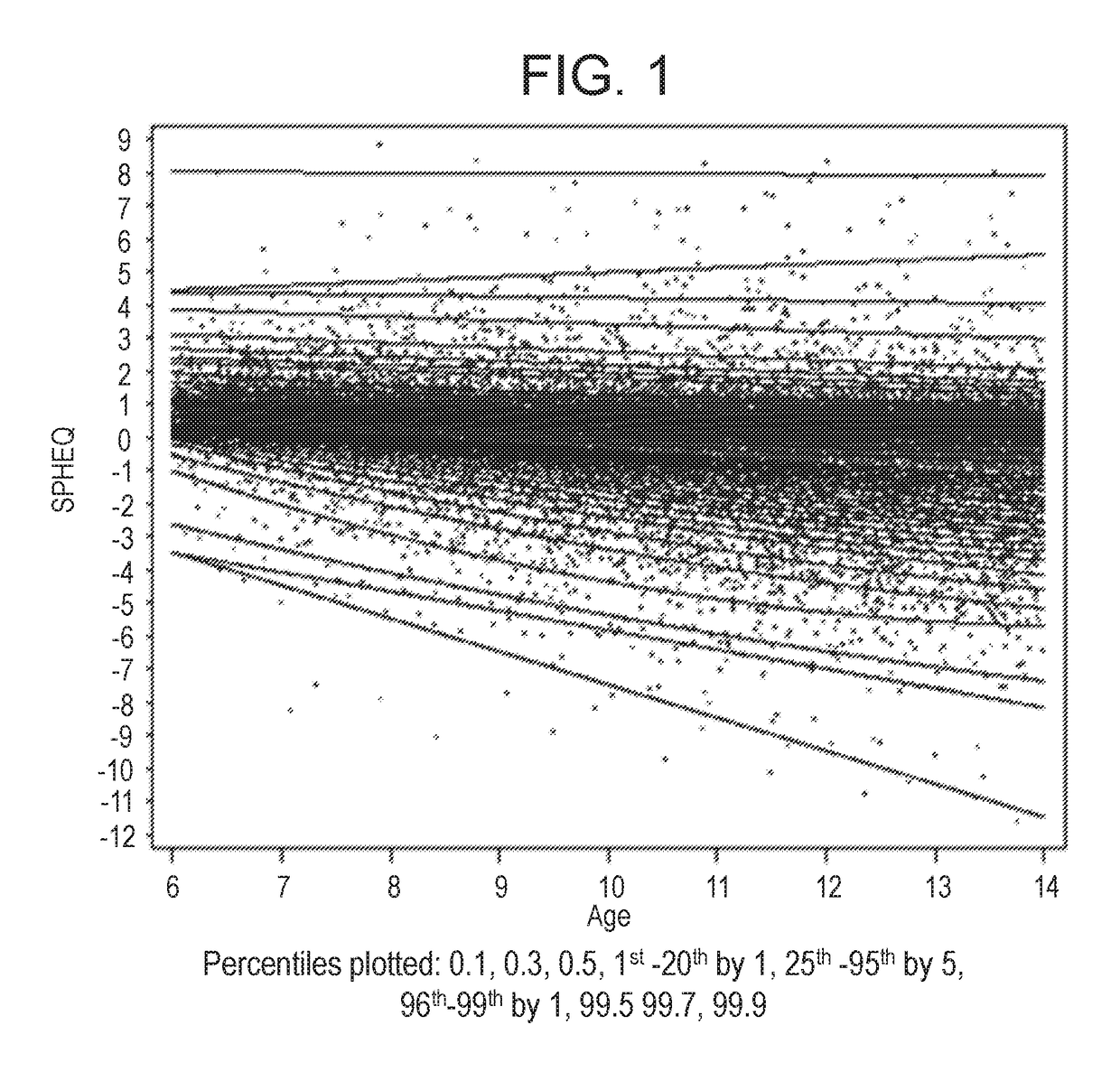

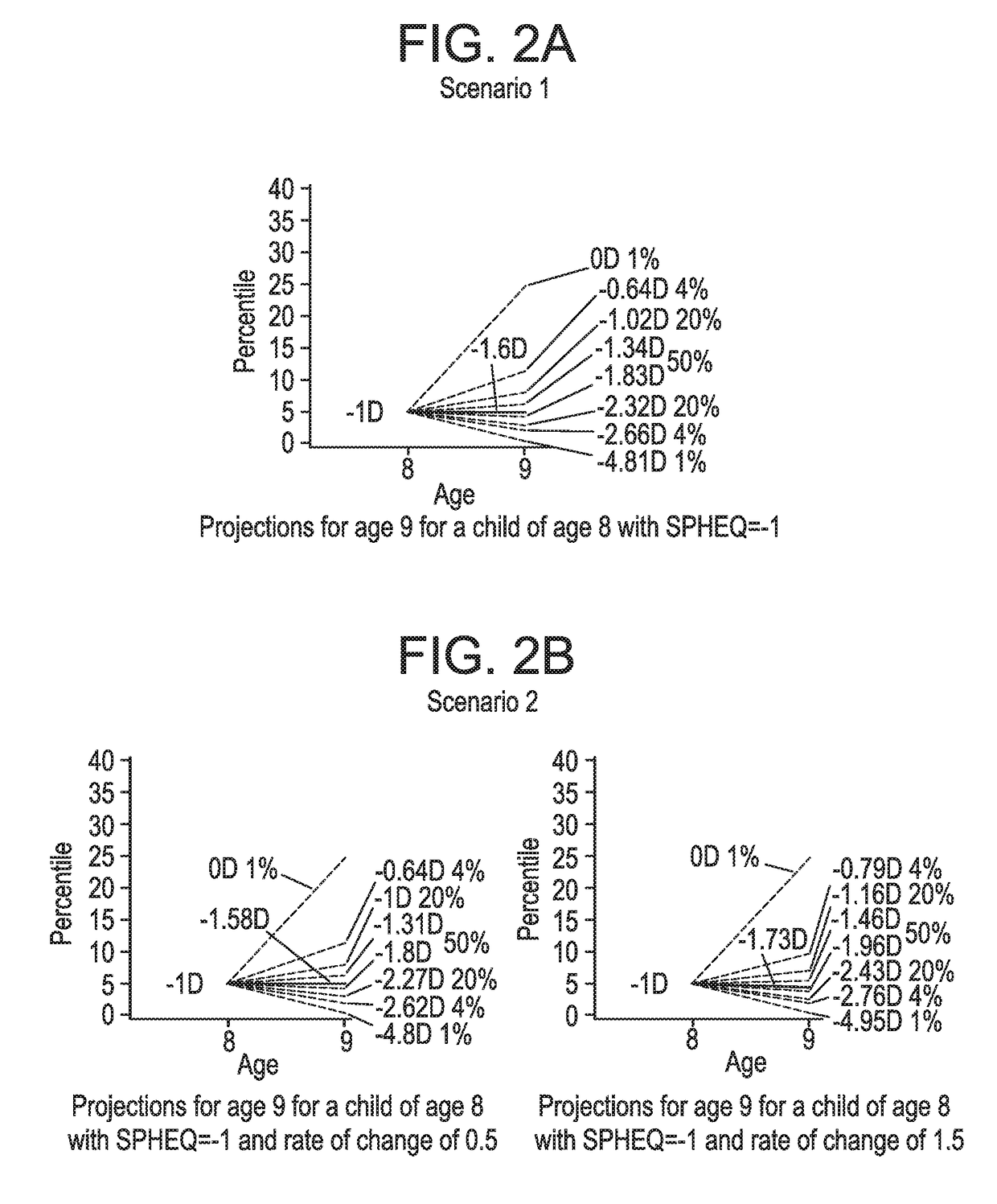

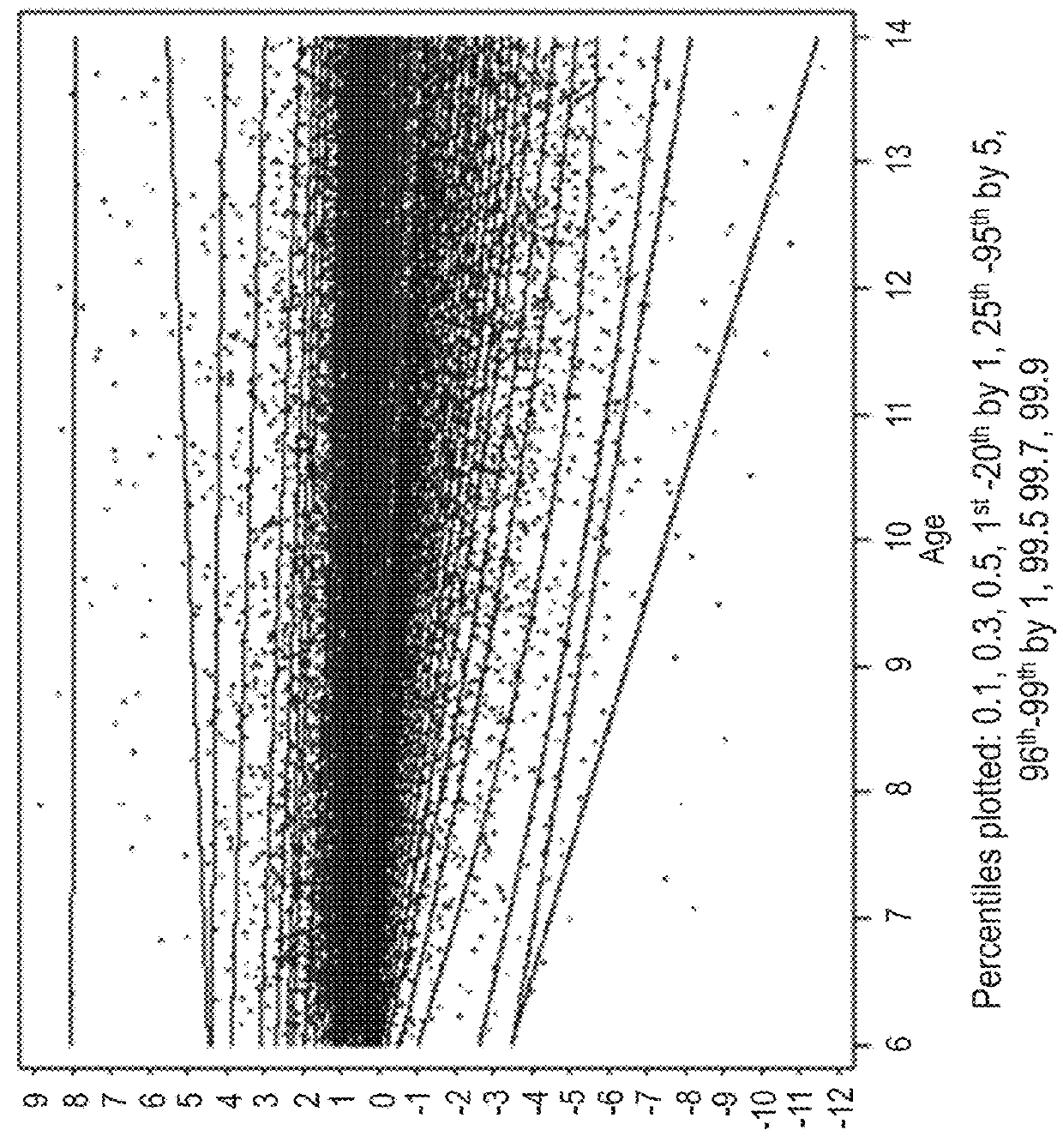

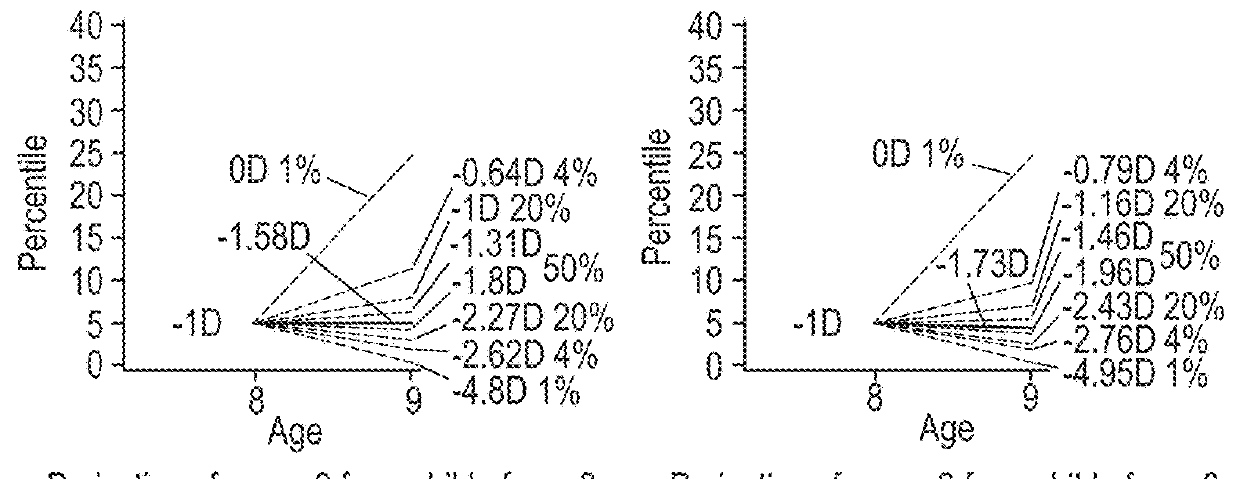

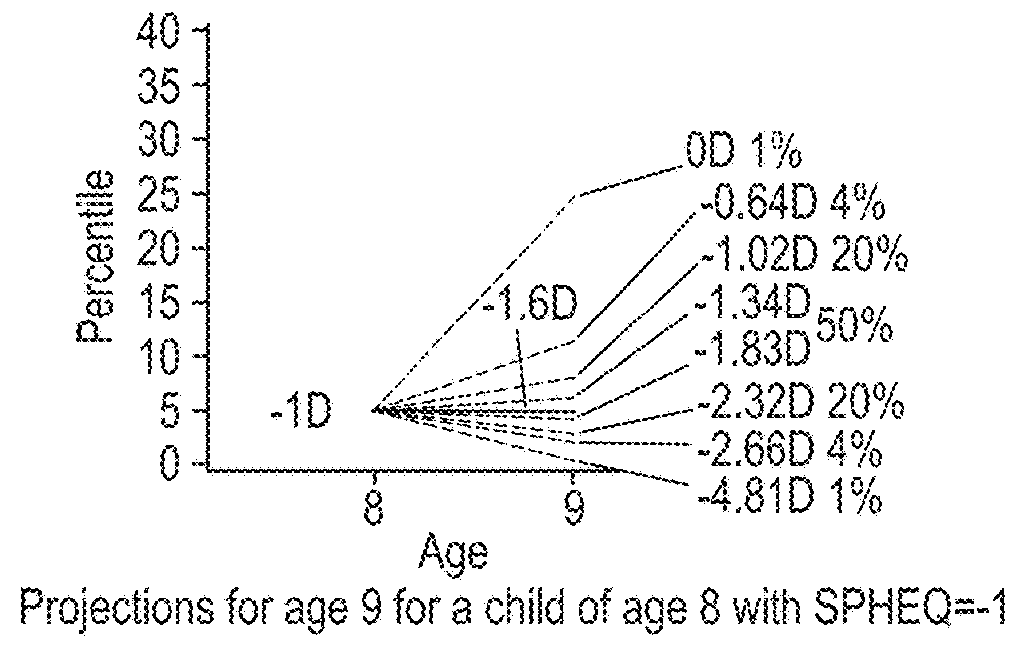

A method for estimating and tracking refractive error progression of an individual includes estimating a percentile of Spherical Equivalent Refraction (SPHEQ) as a function of at least the individual's age by comparison to a reference population; estimating an expected SPHEQ trajectory over a future predetermined period of time; comparing the expected SPHEQ trajectory with the reference population; and comparing the expected SPHEQ trajectory with an expected SPHEQ trajectory using an ametropia control treatment, thereby showing a possible treatment benefit over the predetermined period of time.

Owner:JOHNSON & JOHNSON VISION CARE INC

Ametropia treatment tracking methods and system

ActiveUS20180140181A1Shorten the progressSpectales/gogglesMedical simulationRefractive errorMedicine

Owner:JOHNSON & JOHNSON VISION CARE INC

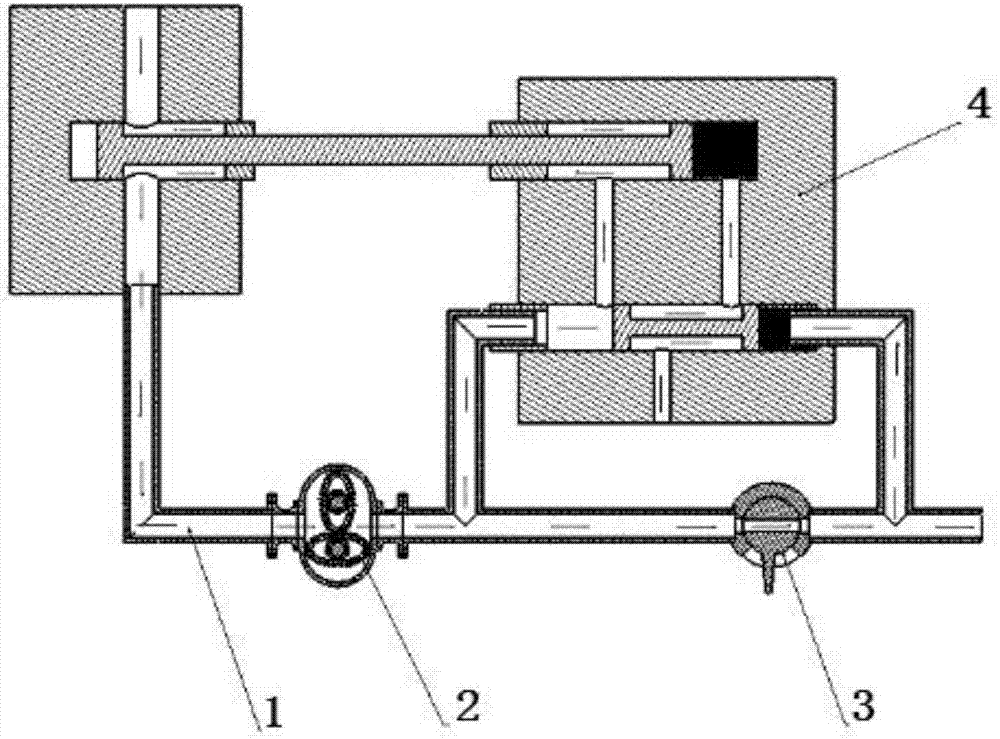

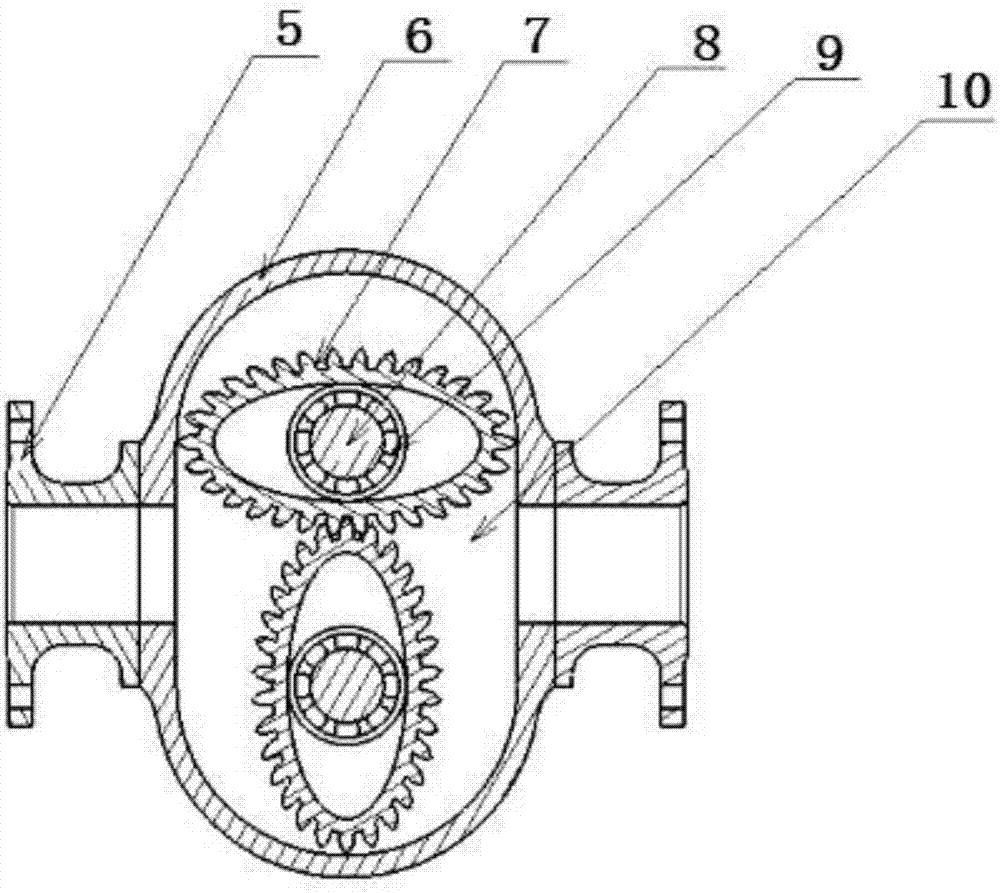

Indirect effect type fuel metering device and metering method thereof

PendingCN107063363AImprove reliabilitySimple structureVolume/mass flow by differential pressureDifferential pressureStreamflow

The invention discloses an indirect effect type fuel metering device which comprises a pipeline delivery system, a high-temperature oval gear flowmeter system, an equivalent valve metering system and an indirect constant differential pressure valve control system. The indirect effect type fuel metering device is simple in structure and small in opening degree stroke, steady-state errors are effectively decreased, and the indirect effect type fuel metering device is high in reliability. In addition, the high-temperature oval gear flowmeter system is adopted, the control precision is high, and outside influence factors are small. Furthermore, when the spherical equivalent valve metering system and the indirect constant differential pressure valve control system are matched to control pressure and flow of fuel, meanwhile fuel flow control mainly relies on that the stroke of a main piston is controlled by a differential pressure valve, accordingly input flow of an oil port is changed, the purpose of stably metering previous and later differential pressures of the valve, the opening stroke of the differential pressure valve is smaller in the mode, and accordingly steady-state errors can be effectively decreased. The device can be widely applied to aero-engines needing high precision.

Owner:西安成立航空制造有限公司

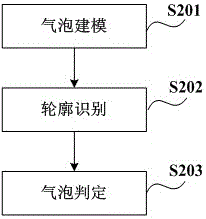

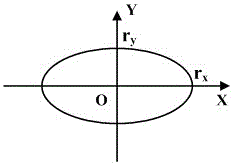

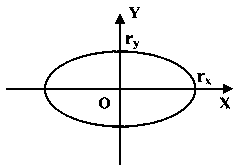

Method for converting equivalent grain size of non-spherical bubble

ActiveCN105931250AReal-time measurementReduce mistakesImage enhancementImage analysisComputer scienceSpherical equivalent

The invention discloses a method for converting equivalent grain size of a non-spherical bubble. The method comprises the following steps: calculating a coordinate of the center of mass for each bubble contour, establishing a plane right angle coordinate system with the center of mass as an origin of coordinates, separately calculating the numbers of pixels corresponding to radiuses in an X-axis direction and a Y-axis direction of the bubble contour and separately marking as rx, ry; separately selecting the rx and ry as the number of pixels rz corresponding to a radius in a Z-axis direction of a spatial right angle coordinate system of the bubble contour, calculating the volumes of two ellipsoids in accordance with an ellipsoid calculation formula, and solving a mean value of the volumes of the two ellipsoids as the volume of the non-spherical bubble; calculating the equivalent grain size of the non-spherical bubble by using a spherical volume formula. According to the invention, the method can implement 3D equivalent volume calculation of a 2D micro non-spherical bubble image, and can reduce errors in the course of equivalent conversion, increase precision of volume calculation, and further increase precision of equivalent spherical bubble grain size.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Preparation method of nano-CaCO3-coated brucite composite material

InactiveCN104892980AEnhanced interface bindingRealize interphase reactionChemical LinkageDepolymerization

The invention relates to a preparation method of a nano-CaCO3-coated brucite composite material, which firmly and uniformly coats nano CaCO3 on the brucite particle surface by the following steps: carrying out wet-process ultrafine grinding to refine brucite particles used as the core, and carrying out depolymerization dispersion on the nano CaCO3 particles used as the coating until the brucite particles and nano CaCO3 particles are respectively refined to the matched particle size range, wherein the ratio of the brucite diameter (spherical equivalent diameter) to the CaCO3 particle diameter is about (8-10):1. The brucite particles subjected to ultrafine grinding generate the mechanical force surface activation effect, thereby promoting the interface combination between the brucite particles and nano CaCO3; and the brucite particles are subjected to ultrafine grinding and activation to form more structural hydroxy groups on the surface, the nano CaCO3 forms secondary hydroxy groups under the hydration actions of Ca<2+> and CO3<2->, and the reaction between the brucite particles and nano CaCO3 particles is implemented by chemical linkage among the surface hydroxy groups.

Owner:HULUDAO SHOUCHUANG TECH CO LTD

Photosensitive image-forming element containing internally modified silver halide crystals

InactiveUS6159679ABetter sensitivity-gradation-relationshipSimple methodSilver halide emulsionsSedSilver halide

A photosensitive image-forming element comprising on a support at least one photosensitive layer containing silver halide crystals internally doped in the center of the crystal volume with a transition metal complex while satisfying equation (I): 0<FORM<10+5(I) where and where d1 represents a spherical equivalent diameter (SED), expressed in mu m, corresponding with a central crystal part doped with the said transition metal complex, d expressed in mu m represents the SED of the whole crystalvolume, while Q represents the concentration of the transition metal complex, expressed in 10-9 mole per mole of silver halide and wherein the said transition metal complex has the following general formula (1): [MXnYmLq]r-(1) wherein: M represents a metal selected from the group consisting of an element from Group 5 up to Group 10 of the Periodic System of the Elements; X and Y, which are different from each other, each represents one of the elements from the group consisting of Cl, Br and I; L represents any anorganic or organic ligand but preferably a ligand selected from the group consisting of NO, NS, OH, H2O, CN, CO, CH3CN, CNS, NCS, NO2, F, SeCN, CNSe, TeCN, CNTe, OCN, CNO, N3 and COO; n and m each equals an integer having a value from 0 to 6 while n+m equals 4, 5 or 6; q equals 0, 1 or 2 while n+m+q=6 and r equals 1, 2, 3 or 4.

Owner:AGFA-GEVAERT NV

Method for measuring and calculating radius-thickness ratio of fine sheet mineral

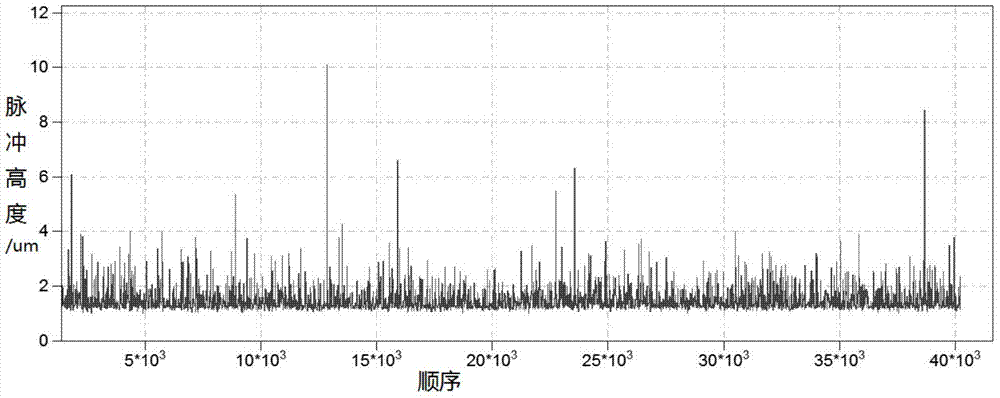

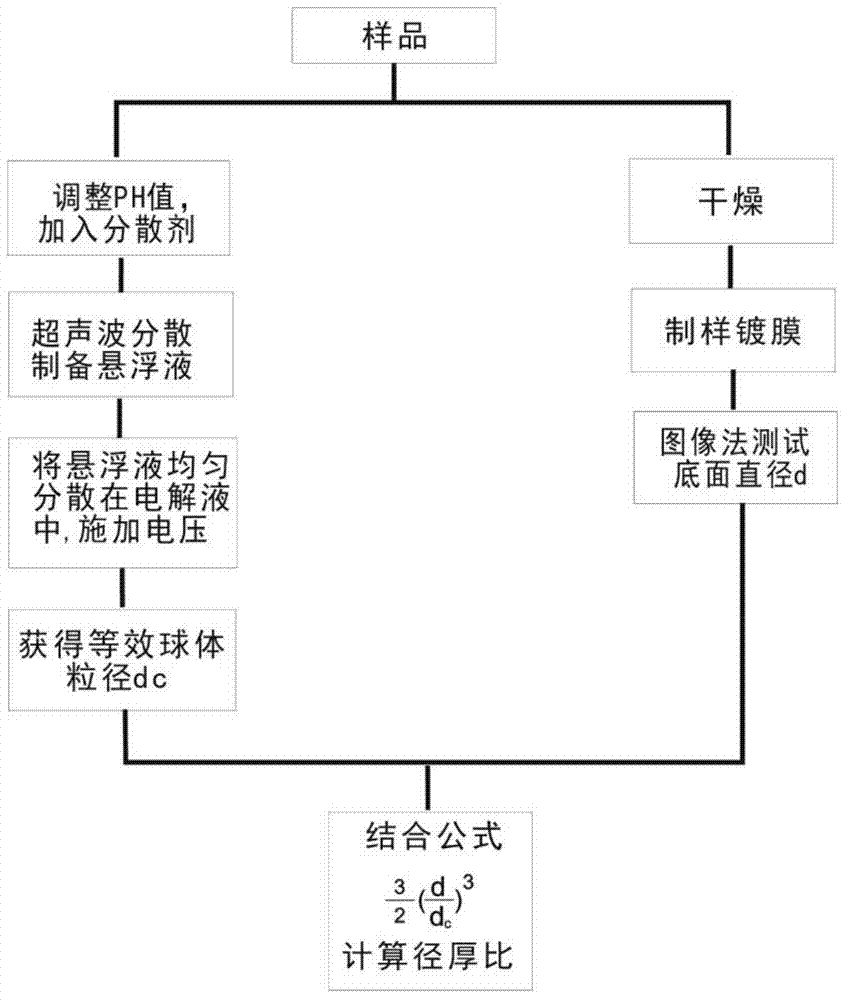

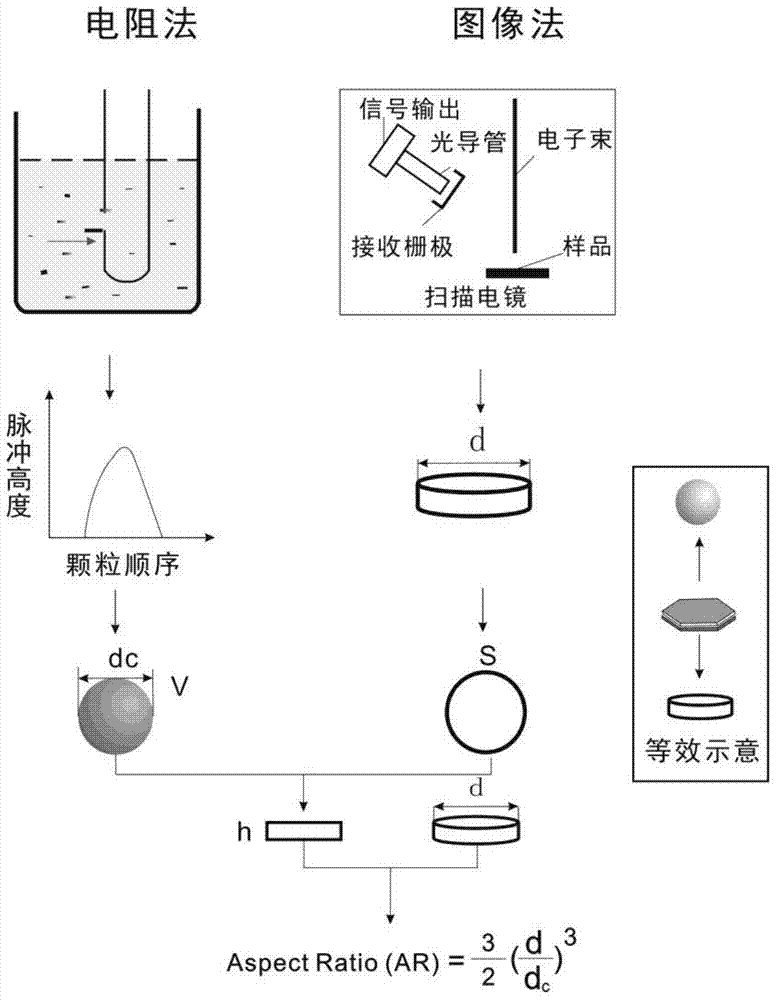

InactiveCN104777079ARigorous mathematical derivation processReduce workloadParticle size analysisElectrical resistance and conductancePulse height

The invention provides a method for measuring and calculating the radius-thickness ratio of fine sheet mineral. The method comprises the following steps: preparing a solution of a sample, dispersing, preparing a suspension, and measuring and calculating the radius-thickness ratio. The particle size dc of an equivalent sphere is obtained according to the pulse height through adopting a resistance method principle. The diameter d of the bottom of the sample is obtained by adopting an image technology. A formula derivation process comprises the following steps: obtaining the volume V of the sample according to the particle size dc of the equivalent sphere and a spherical formula; allowing the sheet sample to be equivalent to a circular disk shape (column with a very small height), and obtaining the bottom area S according to the diameter d of the bottom of the circular disk; obtaining the thickness h of the circular disk according to a column volume formula; and obtaining the radius-thickness ratio of 3(d / dc)<3> / 2 according to a radius-thickness ratio definition that the radius-thickness ratio is a ratio of the bottom diameter of the sheet mineral to the thickness of the sheet mineral. The method has the advantages of simple work mode, small workload, clear principle, small artificial factors, simple formula and high popularization.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

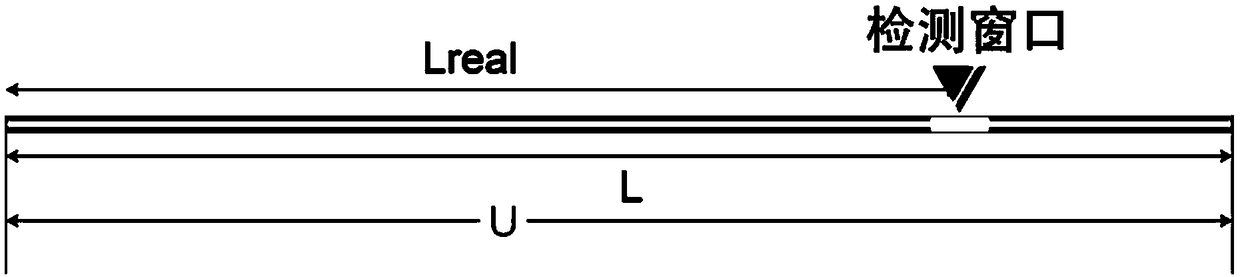

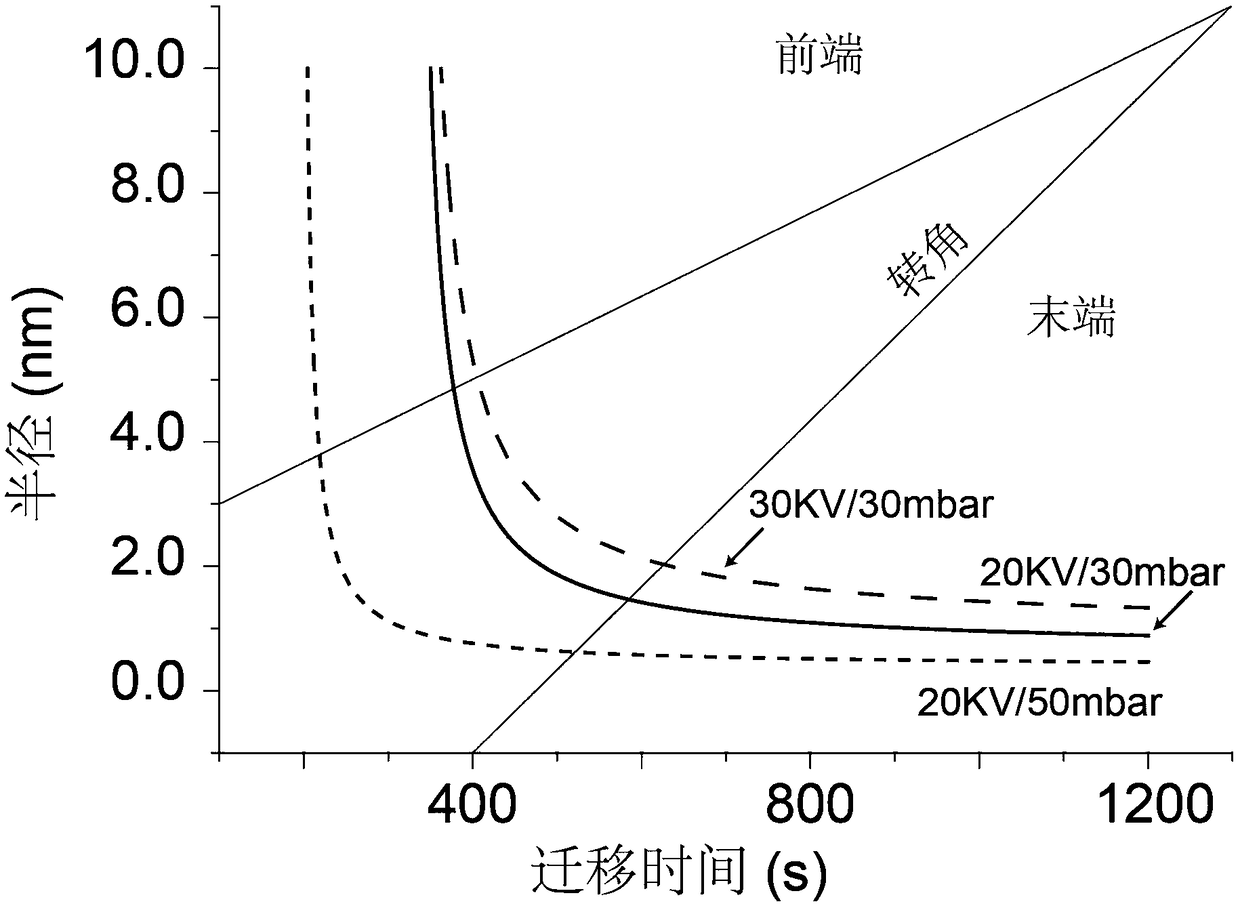

Mobility electrophoresis based method for measuring size of material

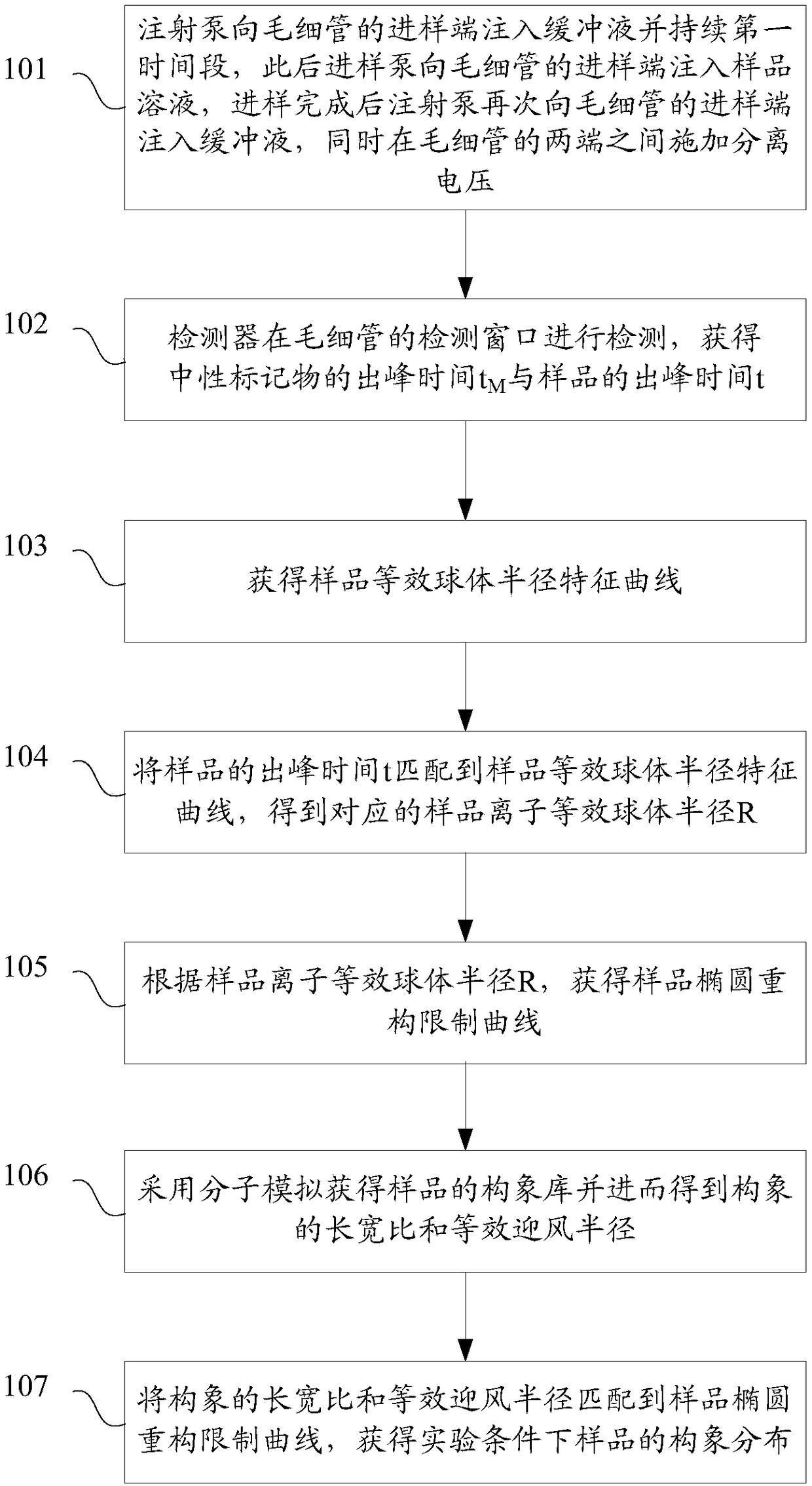

PendingCN108663428AEasy to understandMaterial analysis by electric/magnetic meansEllipseBuffer solution

The invention relates to the technical field of mobility electrophoresis and discloses a mobility electrophoresis based method for measuring the size of a material. The method comprises using an injection pump to inject a buffer solution into a sampling end of a capillary tube, maintaining for a first period of time, then using a sampling pump to inject a sample solution into the sampling end of the capillary tube, using the injection pump to inject the buffer solution into the sampling end of the capillary tube again after finishing sampling, applying a separation voltage between the two endsof the capillary tube at the same time; using a detector to detect a detection window of the capillary tube, acquiring the appearance time tM of a neutral marker and the appearance time t of a sample; acquiring a characteristic curve of the equivalent sphere radius of the sample, further acquiring the ionic equivalent sphere radius R of the sample; acquiring the ellipse reconstruction limit curveof the sample according to the ionic equivalent sphere radius R of the sample, and further acquiring the conformation distribution of the sample under the experiment condition. The operation of the method is convenient, the analysis speed is fast, and the analysis can be conducted together with the separation of the mixture.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

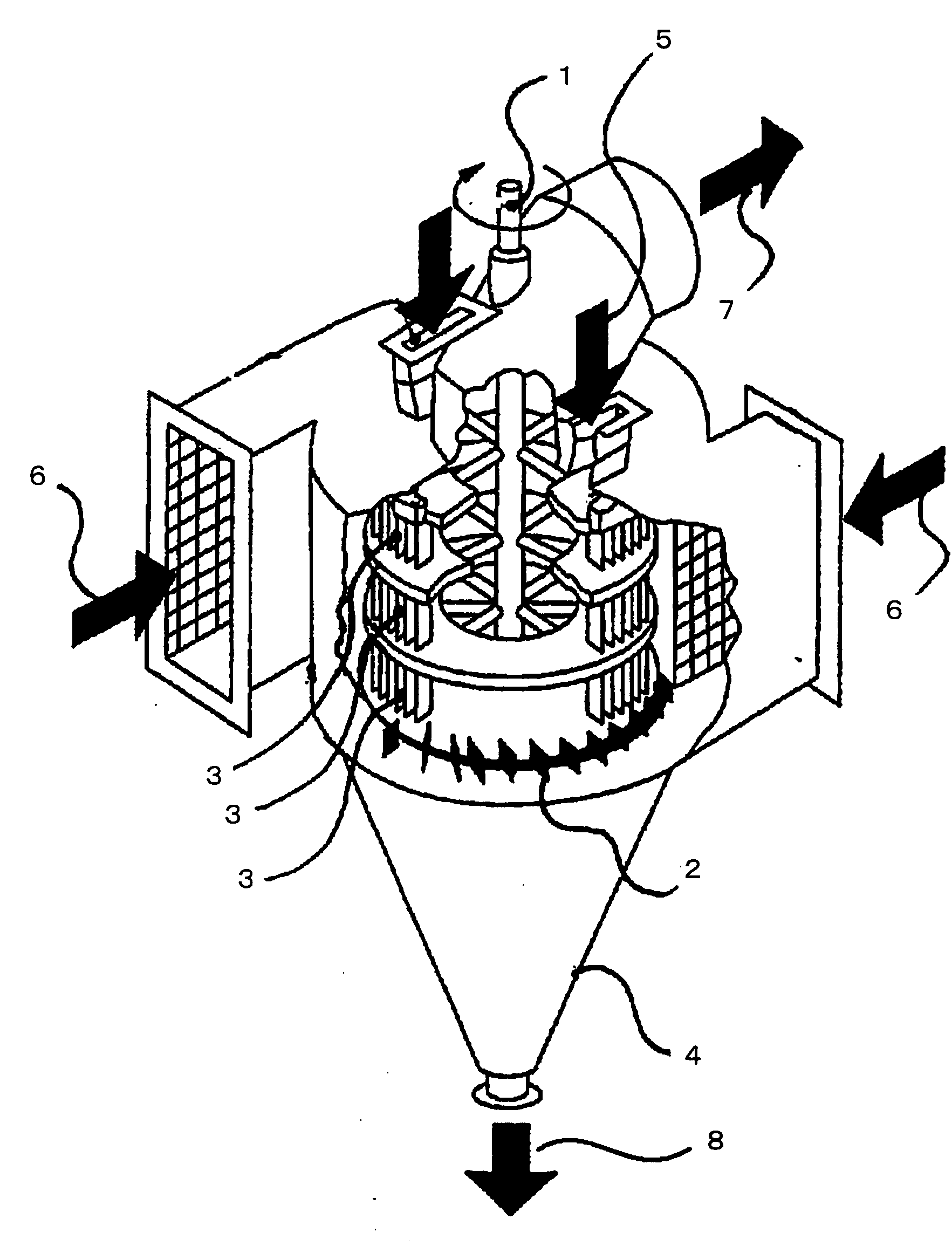

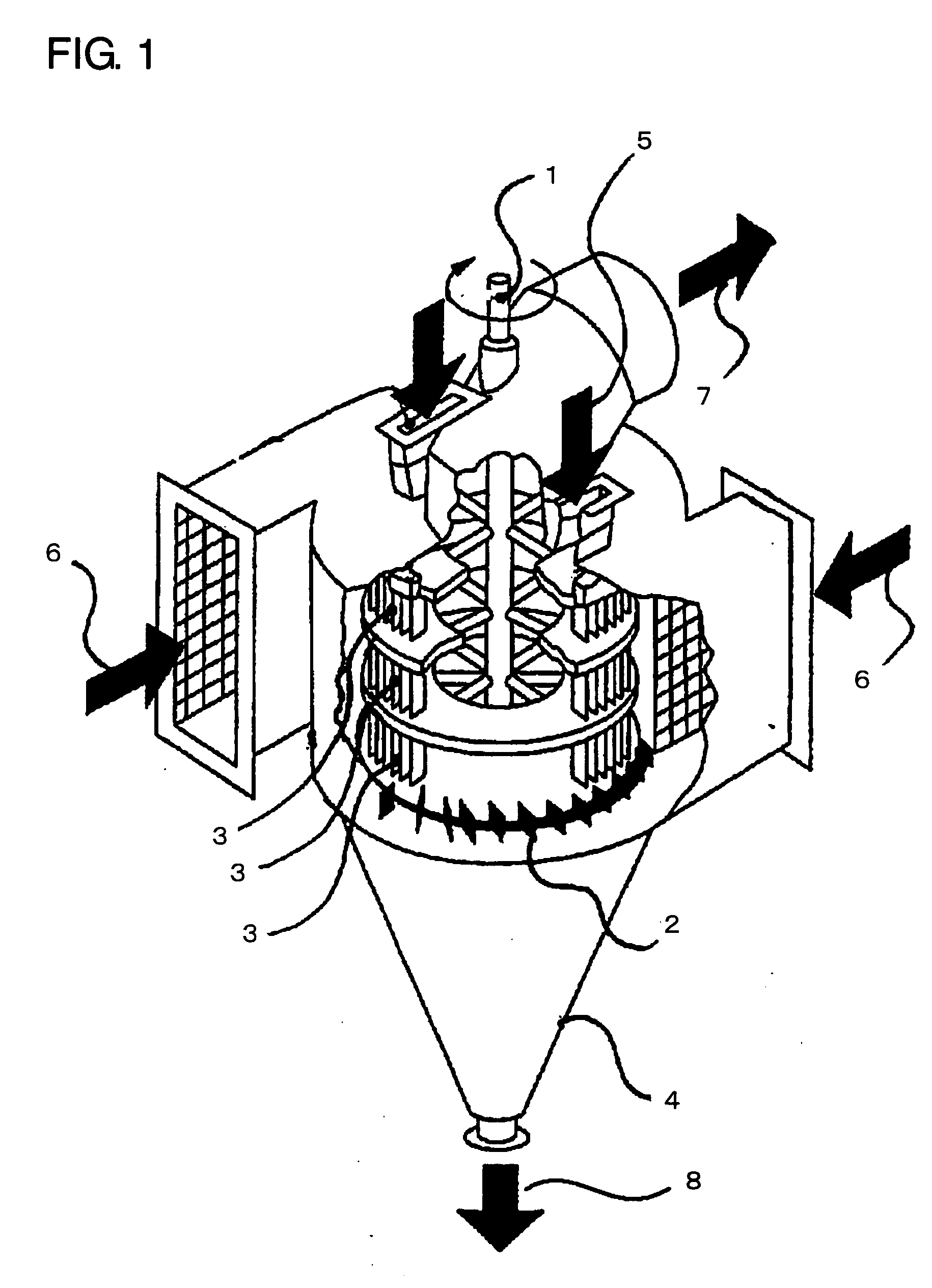

Method of Separating Foreign Particles

ActiveUS20080135459A1Easy to useHigh purityGas current separationElectrostatic separationForeign matterElectrostatic separation

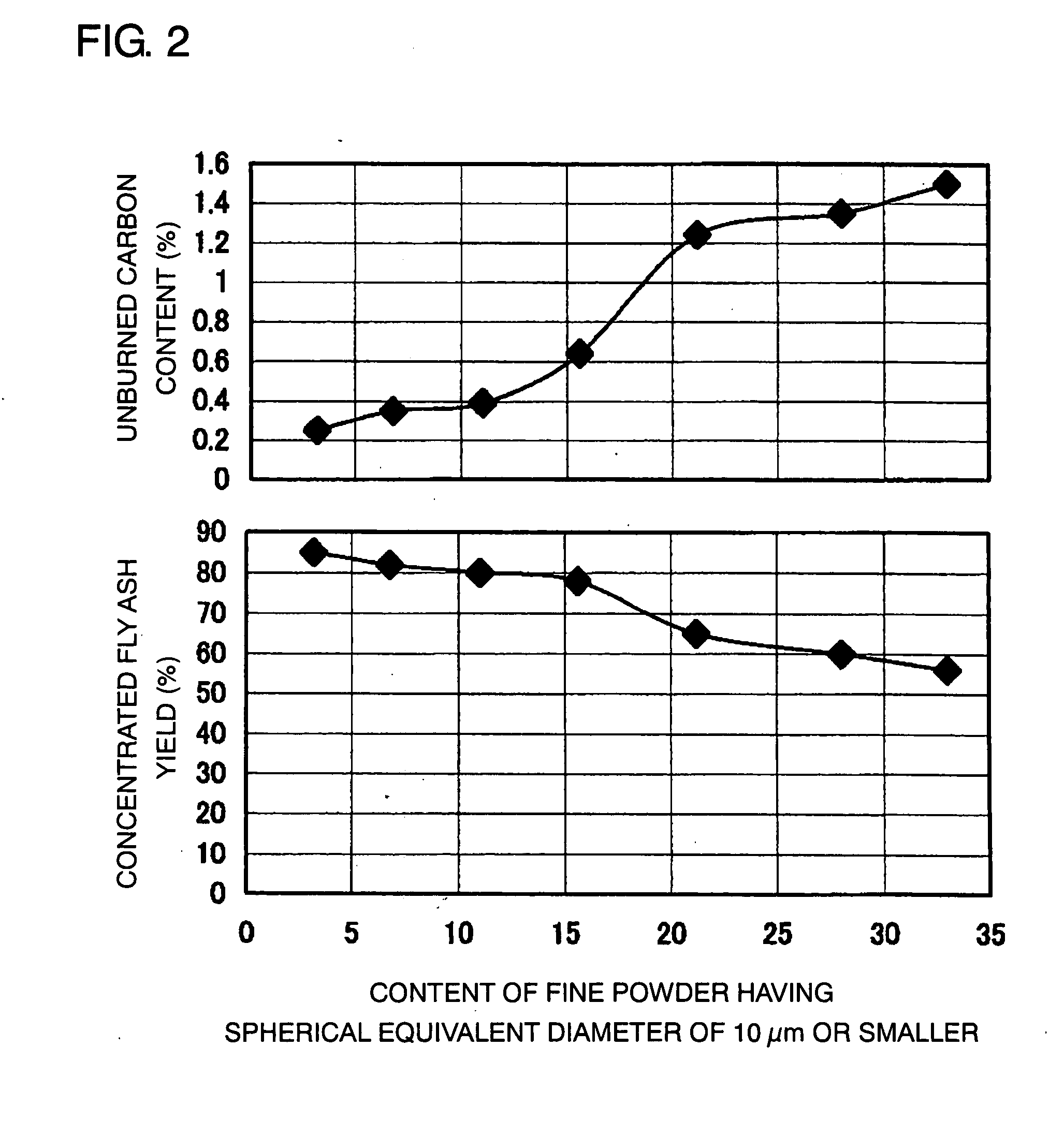

In an electrostatic separator or a magnetic separator, prior to electrically charging or magnetization of particles in order to carry out separation of mixed powder of particles having different properties from each other, classification is performed by a classifier so that the content of fine powder having a spherical equivalent diameter of 10 μm or smaller is 15 mass % or less. After the classification, prior to electrostatic separation or magnetic separation, an operation of dispersing the mixed powder of particles may be carried out.

Owner:TAIHEIYO CEMENT CORP

Ametropia treatment tracking methods and system

ActiveUS10042181B2Shorten the progressSpectales/gogglesMedical simulationRefractive errorControl treatment

A method for estimating and tracking refractive error progression of an individual includes estimating a percentile of Spherical Equivalent Refraction (SPHEQ) as a function of at least the individual's age by comparison to a reference population; estimating an expected SPHEQ trajectory over a future predetermined period of time; comparing the expected SPHEQ trajectory with the reference population; and comparing the expected SPHEQ trajectory with an expected SPHEQ trajectory using an ametropia control treatment, thereby showing a possible treatment benefit over the predetermined period of time.

Owner:JOHNSON & JOHNSON VISION CARE INC

Method and Apparatus for Measuring Vision Function

PendingUS20220304570A1Facilitates instant analysisOvercome deficienciesEye diagnosticsContrast levelOphthalmology department

Owner:EYEQUE INC

Method and apparatus for measuring vision function

PendingCN111616672AFor instant analysisInstant messagingPhoroptersInstrumentsOphthalmic refractometerContrast level

A system for replicating a standardized visual acuity test, such as the 20' Snellen test may comprise a binocular viewer attached to a smartphone. A binocular viewer may comprise a housing comprisinga pair tube covers having voids allowing for viewing through a pair of lens tubes with each lens tube in visual communication with a second lens, a first lens, an aperture and a front cover. The optical systems use an artful combination of front and back lens surfaces, demagnification and other systems to faithfully replicate the sight lines perceived by a user of a traditional 20' test. The system also allows for the incorporation of other tests conducted with both eyes including Color Sensitivity and Contrast, furthermore by placing a deformable, tunable lens between the second lens and theeye the device serves as an ophthalmic refractometer, allowing a Spherical Equivalent refraction estimate for each eye.

Owner:艾科股份有限公司

Patient interactive fit tool and methodology for contact lens fitting

An interactive fit tool and methodology which may be utilized by an eye care professional to improve the efficiency and final outcome in selecting a pair of contact lenses targeted towards a specific patient visual need in the treatment of presbyopia. The interactive fit tool comprises an application which includes images that would allow a patient to decide if he or she desires balanced visual acuity, near biased visual acuity, or distance biased visual acuity. In addition, the interactive fit tool comprises fit guide tables and performs the calculations for vertex distance and spherical equivalent.

Owner:JOHNSON & JOHNSON VISION CARE INC

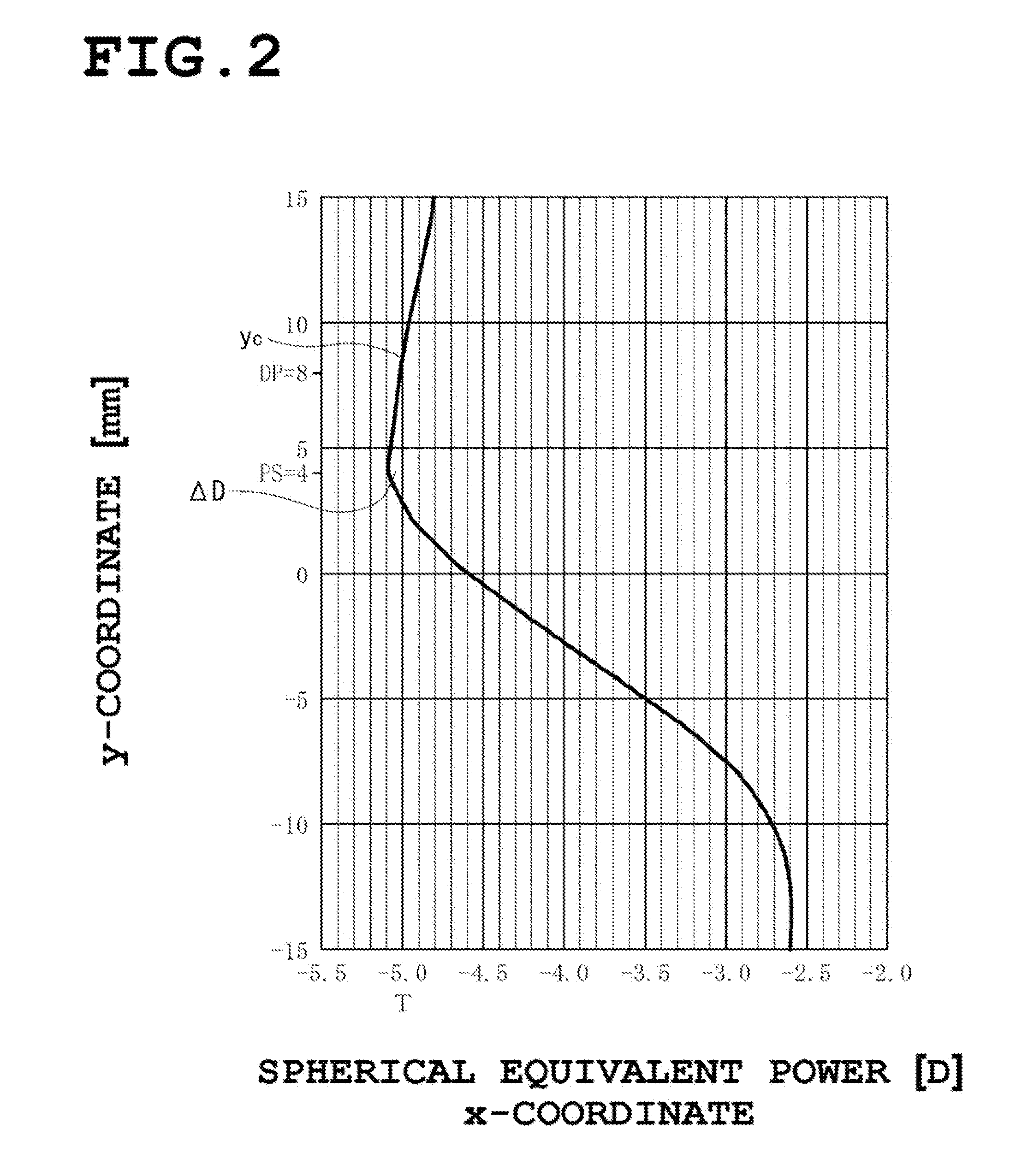

Progressive addition lens

ActiveUS20140240662A1Good optical performanceReduce generationOptical partsSpherical powerProgressive addition lenses

There is provided a progressive addition lens capable of improving both of astigmatism and power error on a peripheral part of a distance area, including a distance area used for a distance vision, and other area different from the distance area, wherein at least one of an eyeball side surface of a wearer and an object side surface in the progressive addition lens is formed into an aspheric form, and when a prescription value T to be obtained from formula “S+C / 2” expressed by a prescribed spherical power S and a cylindrical power C, is minus, the area where a power deviation ΔD of a spherical equivalent power D from the prescription value T goes negative, exists on principal sight line in the distance area.

Owner:EHS LENS PHILIPPINES

Patient interactive fit tool and methodology for contact lens fitting

An interactive fit tool and methodology which may be utilized by an eye care professional to improve the efficiency and final outcome in selecting a pair of contact lenses targeted towards a specific patient visual need in the treatment of presbyopia. The interactive fit tool comprises an application which includes images that would allow a patient to decide if he or she desires balanced visual acuity, near biased visual acuity, or distance biased visual acuity. In addition, the interactive fit tool comprises fit guide tables and performs the calculations for vertex distance and spherical equivalent.

Owner:JOHNSON & JOHNSON VISION CARE INC

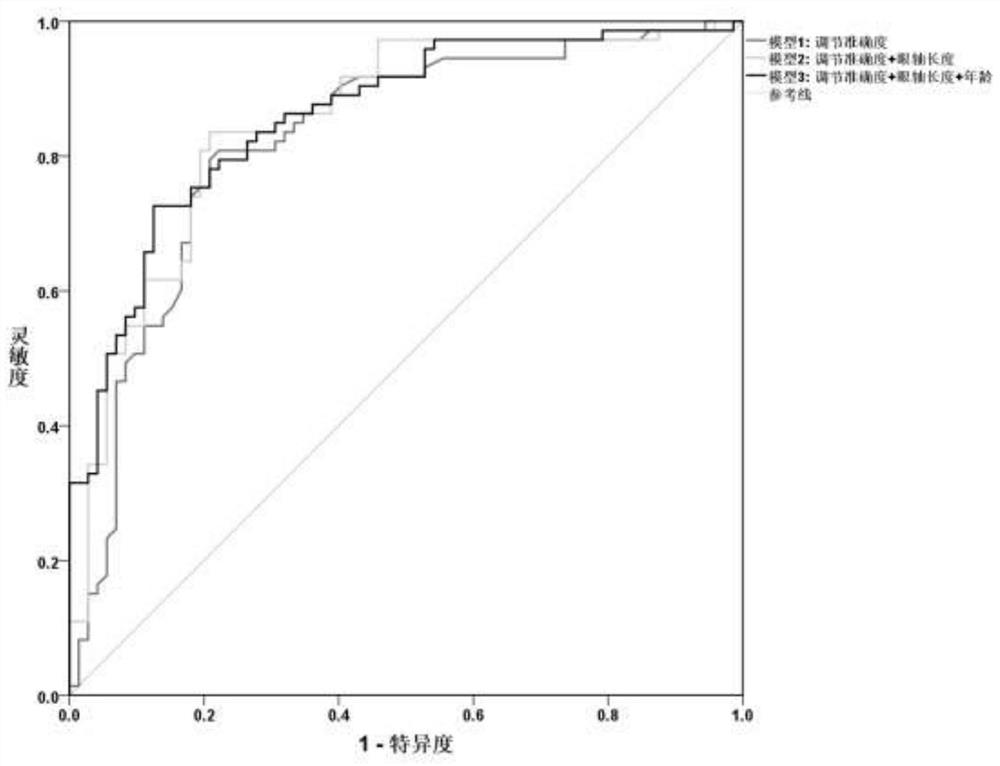

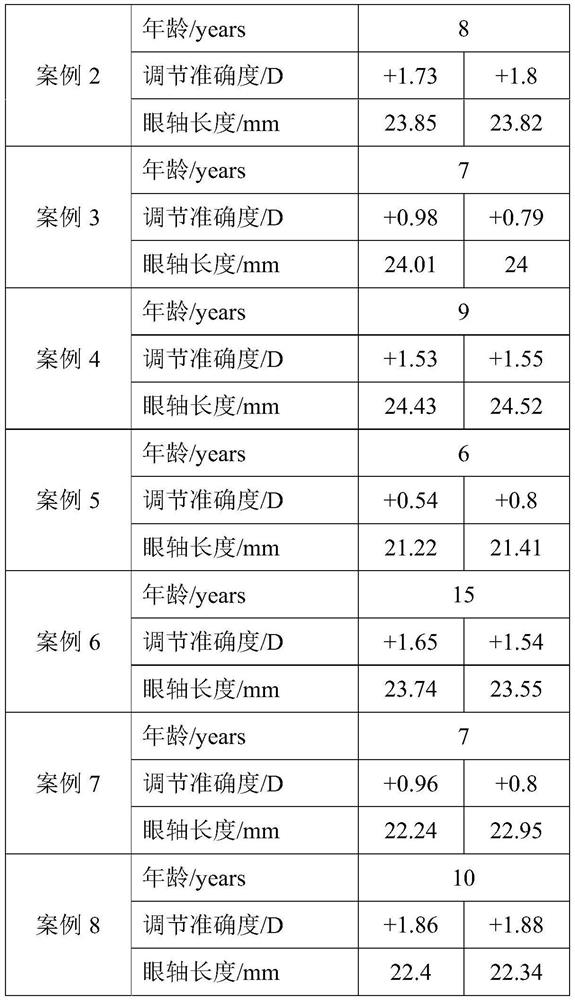

A method for predicting the change of spherical equivalent power before and after cycloplegia

ActiveCN111145899BReduce exposure to related drug side effectsEffective forecastMedical data miningMedical automated diagnosisEye SurgeonCILIARY MUSCLE PARALYSIS

The invention relates to a method for estimating spherical equivalent change degree before and after cycloplegia. The spherical equivalent change degree is estimated by measuring and adjusting an accuracy numerical value; in order to further improve the prediction accuracy, the eye axis length and the subject age can be increased to serve as reference factors, and a prediction result is obtained through a calculation model. The beneficial effects of the invention are that the method can achieve the effective estimation of the spherical equivalent change degree before and after cycloplegia; themethod is higher in predictability and can provide a new clinical standard for clinical ophthalmologists to evaluate whether children patients need to use a cycloplegia agent or not, so the diagnosisand treatment efficiency is improved, medical resources are saved, and related drug side effects borne by the patients due to unnecessary cycloplegia are reduced.

Owner:天津医科大学眼科医院

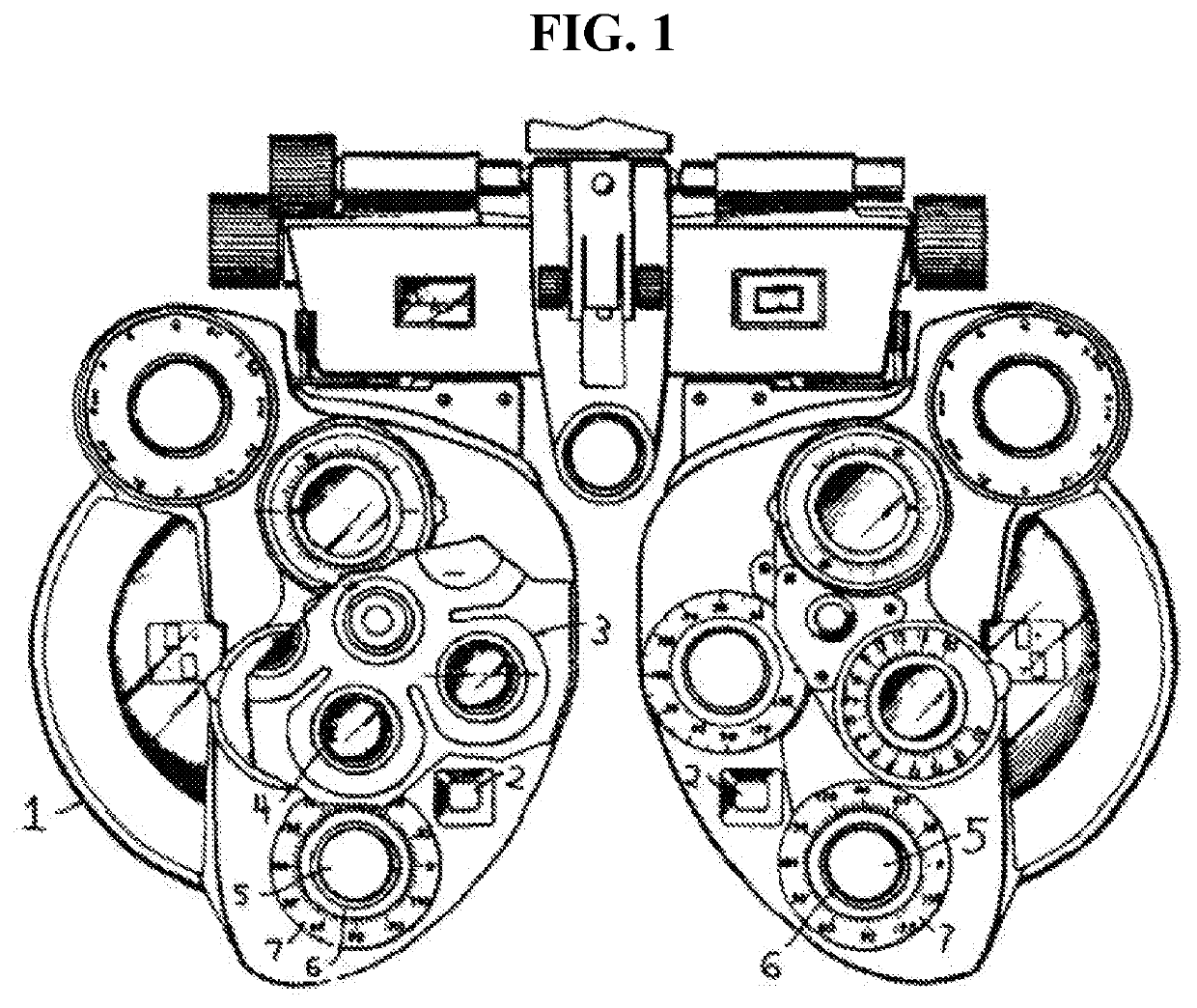

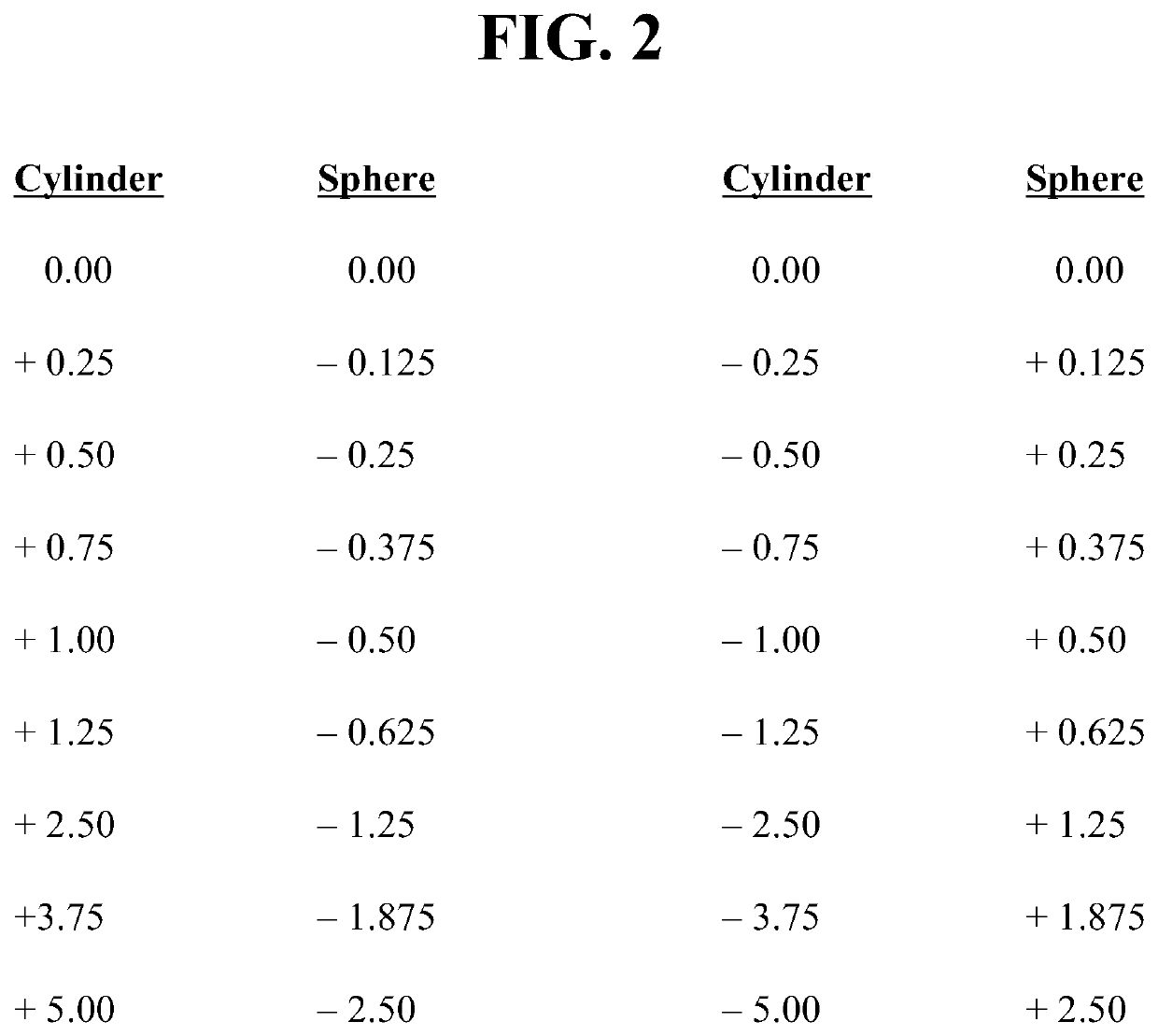

Neutral cylinder refractor

The present invention is a neutral cylinder refractor, which is a refractor that uses spherical power in combination with cylinder lenses to render them spherically neutral. Every cylinder lens in the refractor, excluding the Jackson Cross Cylinder, has corresponding spherical power added to it to neutralize the spherical equivalent of the cylindrical lenses. The invention can be used to measure the refractive error of a patient's eye, and specifically the cylinder aspect can be measured more easily due to a lack of interference from spherical equivalent.

Owner:ZANDER NATHANIEL SCOTT

Smart phone based virtual visual charts for measuring visual acuity

ActiveUS11432718B2Facilitates instant analysisOvercome deficienciesRefractometersSkiascopesOphthalmic refractometerContrast level

A system for replicating a standardized visual acuity test, such as the 20′ Snellen test may comprise a binocular viewer attached to a smartphone. A binocular viewer may comprise a housing comprising a pair tube covers having voids allowing for viewing through a pair of lens tubes with each lens tube in visual communication with a second lens a first lens an aperture and a front cover. The optical systems use an artful combination of front and back lens surfaces, demagnification and other systems to faithfully replicate the sight lines perceived by a user of a traditional 20′ test. The system also allows for the incorporation of other tests conducted with both eyes including Color Sensitivity and Contrast, furthermore by placing a deformable, tunable lens between the second lens and the eye the device serves as an ophthalmic refractometer, allowing a Spherical Equivalent refraction estimate for each eye.

Owner:EYEQUE INC

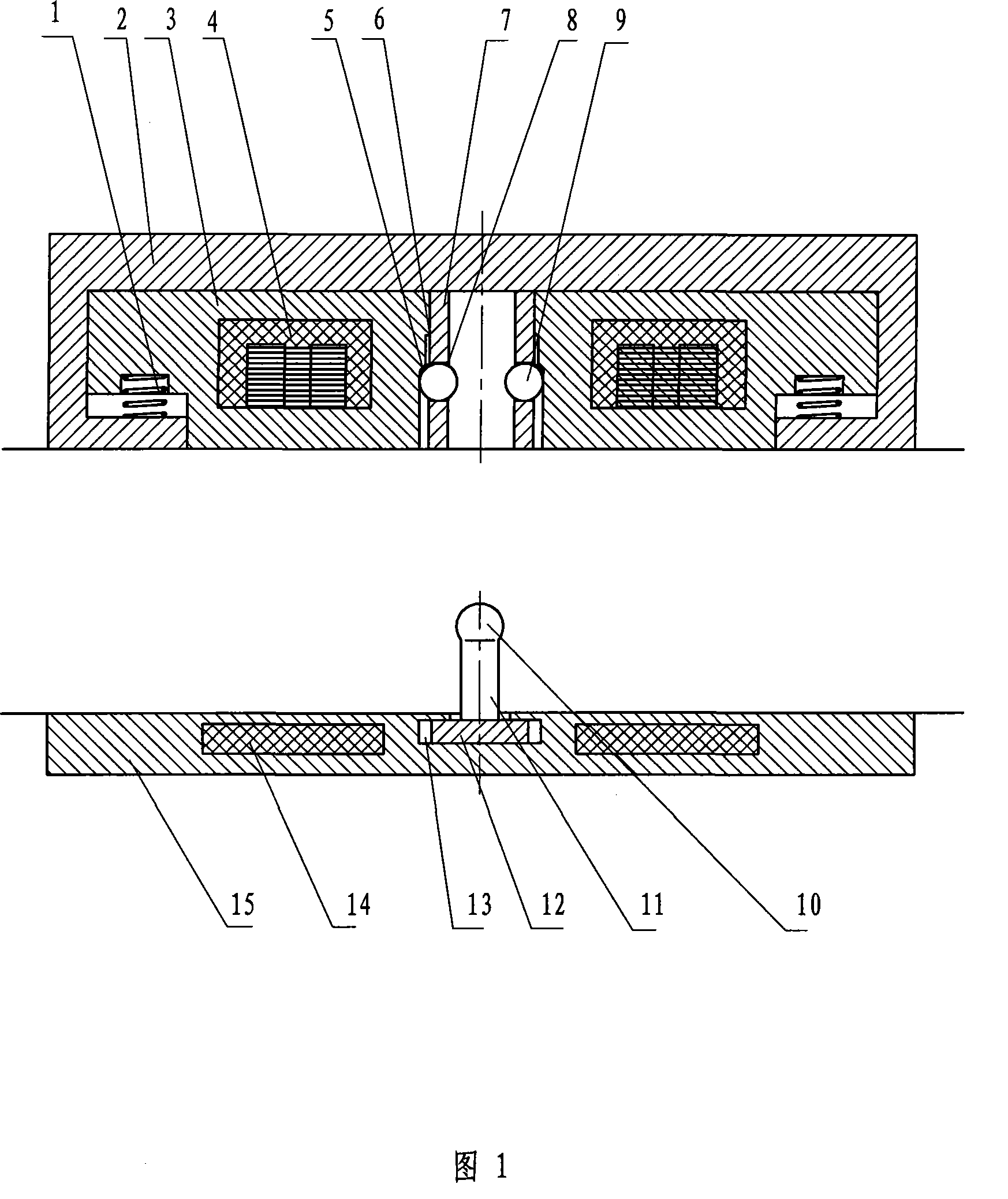

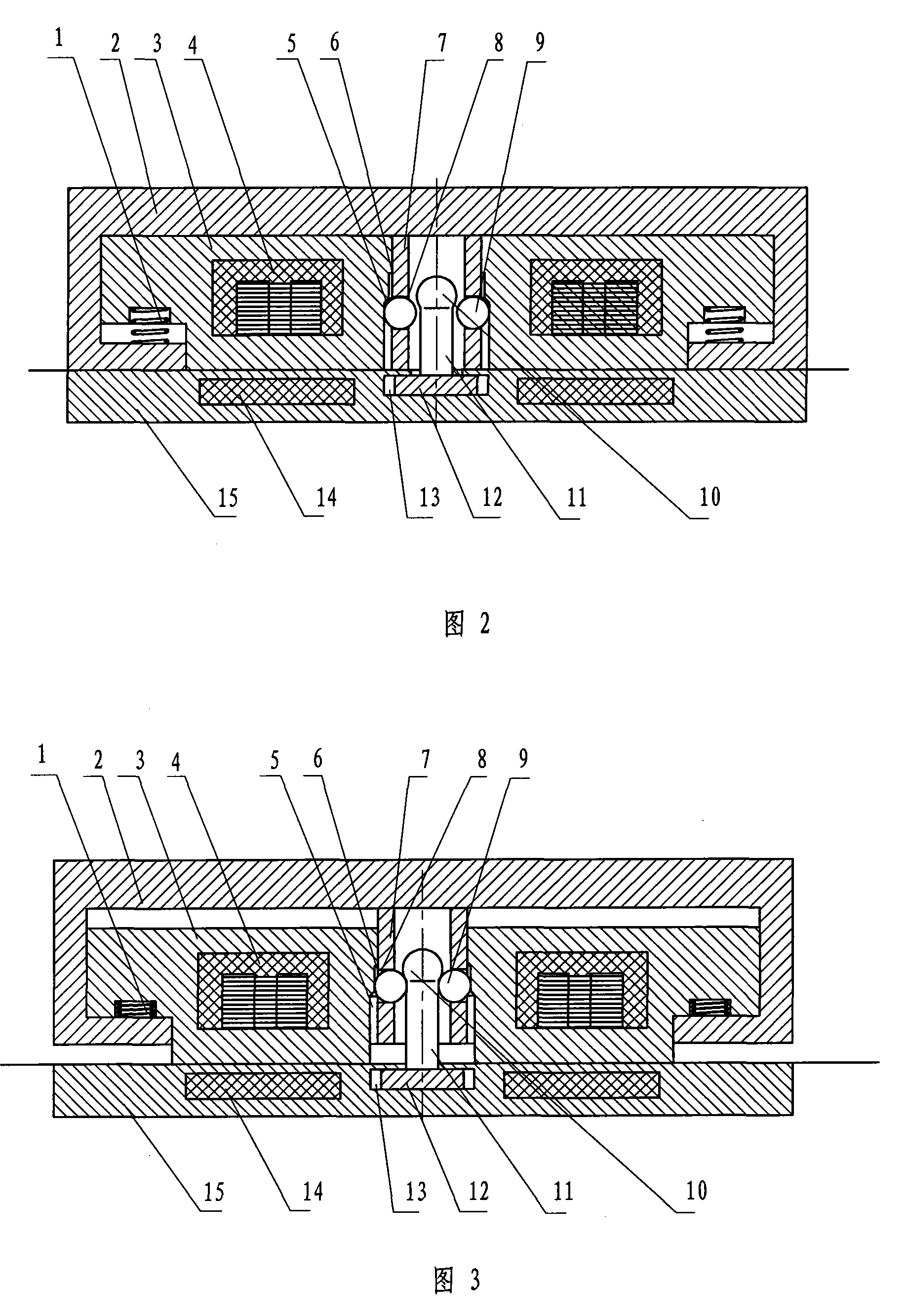

Examination of porosity by NMR and intrusion porosimetry

ActiveUS9500608B2Analysis using nuclear magnetic resonancePermeability/surface area analysisNon wettingThroat

Properties of a porous solid sample 19, which may be a core of rock taken from below ground are carried out using apparatus which performs both nuclear magnetic resonance (NMR) and porosimetry measurements. The apparatus has a magnet 11,12 providing a magnetic field and a radio frequency coil 20 for transmitting and / or receiving electromagnetic radiation so as to bring about NMR in the magnetic field, a pressure vessel 14, 15 to hold a sample 19 within the magnetic field, a supply of a non-wetting liquid connected to the vessel, means to apply pressure to the non-wetting liquid to force liquid into pores of the sample 19 means to measure applied pressure of the non-wetting liquid and means to measure volume thereof taken up by the sample. The pressure of non-wetting liquid may be increased in steps, using intruded liquid volume at each step to give a measurement of pore throat size using NMR at each step to give a measure of pore size such as diameter of equivalent sphere. The non-wetting liquid may be mercury and NMR may observe the Knight shift of 99 Hg.

Owner:SCHLUMBERGER TECH CORP

A Conversion Method of Equivalent Particle Size of Non-spherical Bubbles

ActiveCN105931250BReal-time measurementReduce mistakesImage enhancementImage analysisComputer scienceSpherical equivalent

The invention discloses a method for converting equivalent grain size of a non-spherical bubble. The method comprises the following steps: calculating a coordinate of the center of mass for each bubble contour, establishing a plane right angle coordinate system with the center of mass as an origin of coordinates, separately calculating the numbers of pixels corresponding to radiuses in an X-axis direction and a Y-axis direction of the bubble contour and separately marking as rx, ry; separately selecting the rx and ry as the number of pixels rz corresponding to a radius in a Z-axis direction of a spatial right angle coordinate system of the bubble contour, calculating the volumes of two ellipsoids in accordance with an ellipsoid calculation formula, and solving a mean value of the volumes of the two ellipsoids as the volume of the non-spherical bubble; calculating the equivalent grain size of the non-spherical bubble by using a spherical volume formula. According to the invention, the method can implement 3D equivalent volume calculation of a 2D micro non-spherical bubble image, and can reduce errors in the course of equivalent conversion, increase precision of volume calculation, and further increase precision of equivalent spherical bubble grain size.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

A method for measuring air bubbles in water body

ActiveCN106023153BAccurate Bubble ContourReduce mistakesImage enhancementImage analysisImage calibrationComputer science

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Coating nano-caco on the surface of brucite 3 Preparation method of composite material

InactiveCN104892980BEnhanced interface bindingRealize interphase reactionChemical LinkageDepolymerization

The invention relates to a preparation method of a nano-CaCO3-coated brucite composite material, which firmly and uniformly coats nano CaCO3 on the brucite particle surface by the following steps: carrying out wet-process ultrafine grinding to refine brucite particles used as the core, and carrying out depolymerization dispersion on the nano CaCO3 particles used as the coating until the brucite particles and nano CaCO3 particles are respectively refined to the matched particle size range, wherein the ratio of the brucite diameter (spherical equivalent diameter) to the CaCO3 particle diameter is about (8-10):1. The brucite particles subjected to ultrafine grinding generate the mechanical force surface activation effect, thereby promoting the interface combination between the brucite particles and nano CaCO3; and the brucite particles are subjected to ultrafine grinding and activation to form more structural hydroxy groups on the surface, the nano CaCO3 forms secondary hydroxy groups under the hydration actions of Ca<2+> and CO3<2->, and the reaction between the brucite particles and nano CaCO3 particles is implemented by chemical linkage among the surface hydroxy groups.

Owner:HULUDAO SHOUCHUANG TECH CO LTD

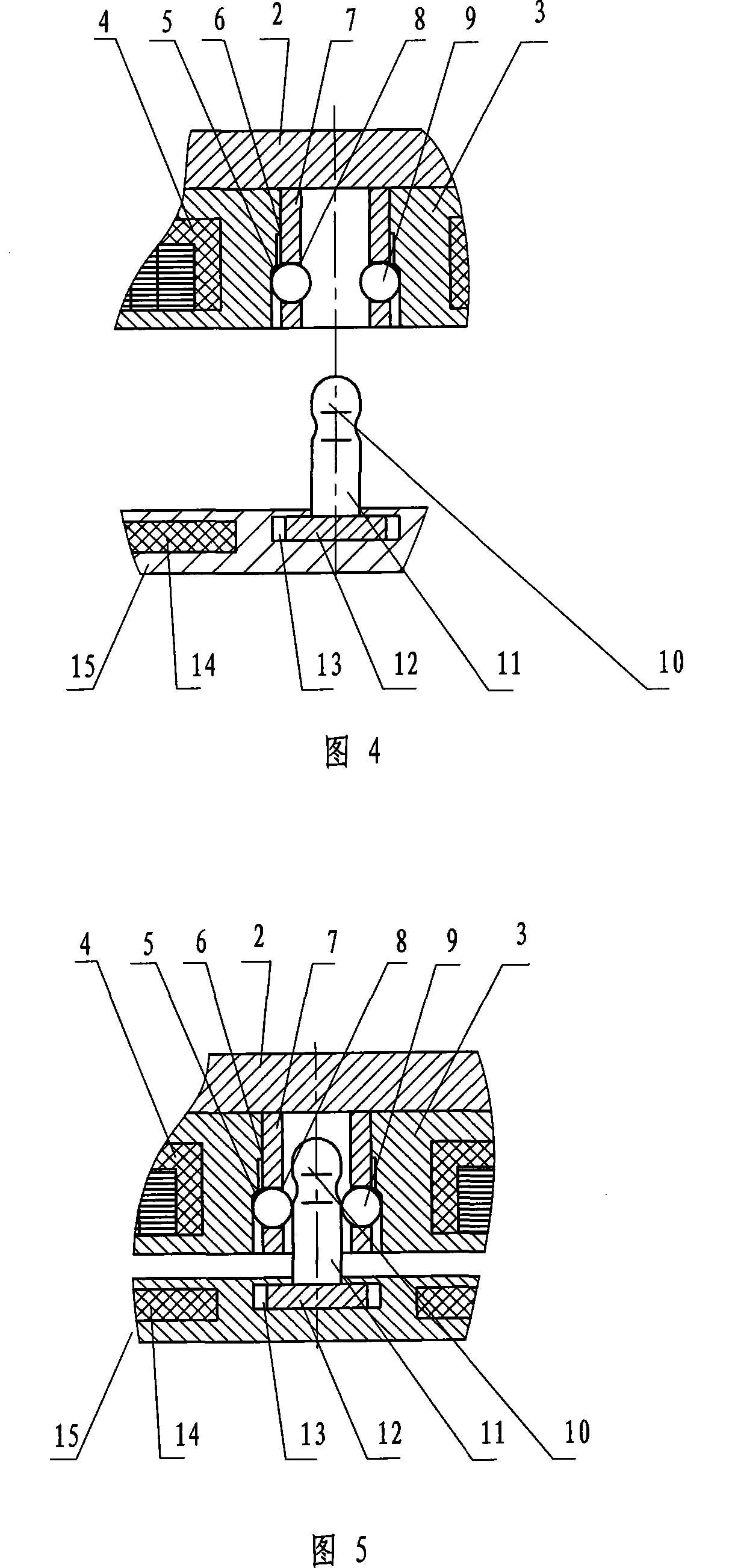

Door lock jointing construction

InactiveCN101240676BImprove joint forceEasy to operateNon-mechanical controlsBall bearingEngineering

The invention is a counterblow door lock structure which is opposite direction motion between door and doorframe. Door lock connecting structure, the one end of the convex area which is perpendicular to the cardinal plate of the door board is the cylinder stick, the stick whose spherical equivalent diameter is bigger than cylinder diametric is a knuckling stick, and other door board is installed movable block ball mechanism. A ball cavity whose middle is hollow space is perpendicular to the base of the flat-plate, the interior diameter of the ball cavity is bigger than that of the knuckling stick, a limit ball control mechanism whose caliber size is changeable is installed at the mouth of the ball cavity. The limit ball control mechanism is: at least two round holes are radial at the wallpart of the ball cavity, ball bearing is placed in the round hole, a slipper block which can move along the axial cord of the ball cavity around the ball cavity and the inner wall has vary in size step hole is configured at the base of the ball cavity, the technical project achieves that the little electromagnetic force transforms to the large door leaves engaging force; after the door leaves closed, the door leaves is permitting opened through the method of the electromagnetic control etc; and its operations is smooth, steady and convenience.

Owner:上海欧意机电五金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com