Method for measuring and calculating radius-thickness ratio of fine sheet mineral

A technology of diameter-thickness ratio and lamella, which is applied in the field of industrial testing and research of powder materials, can solve problems such as heavy workload, high testing cost, and large testing error, and achieve the effects of reduced workload, short testing time and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

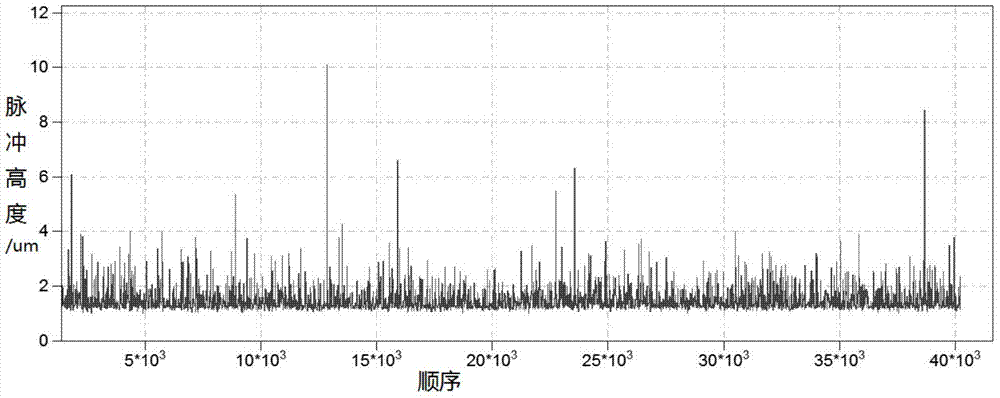

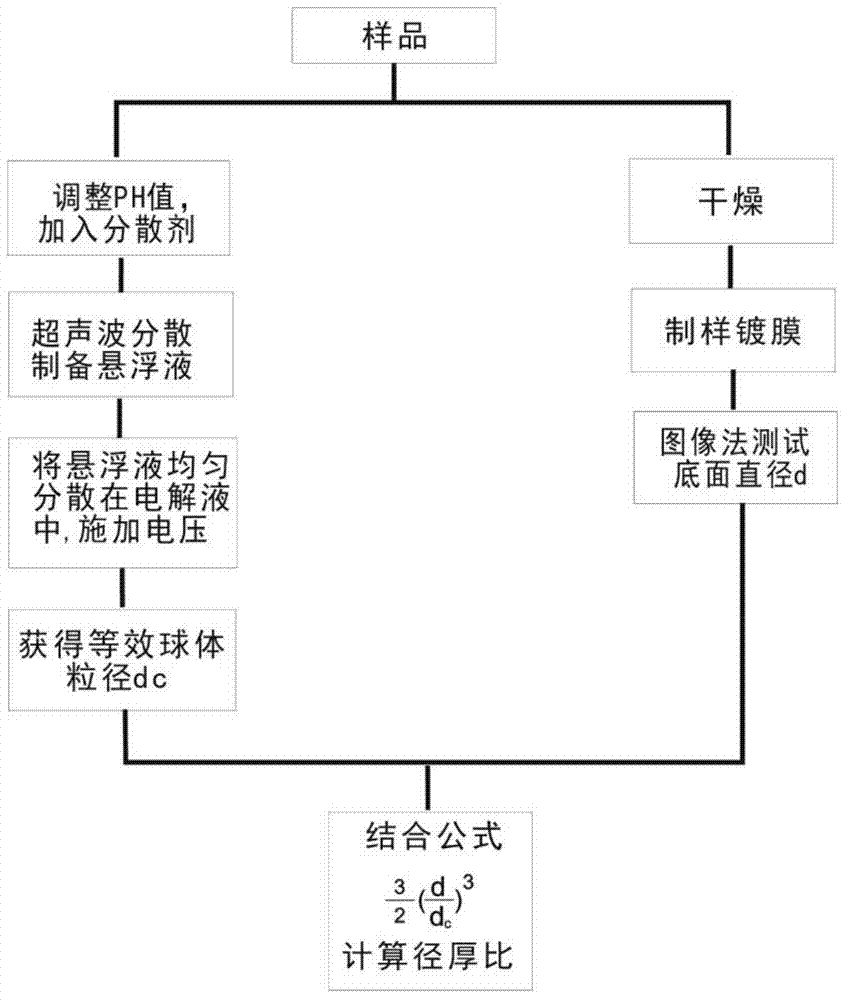

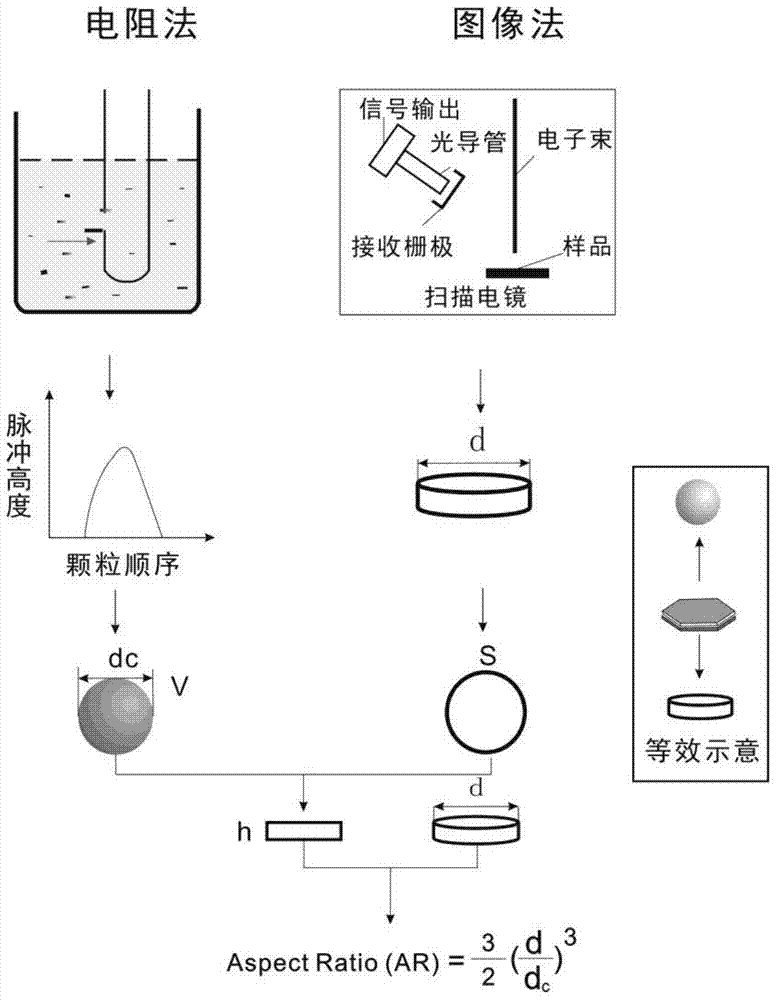

[0056] Taking the Zhangjiakou kaolinite sample as an example, the average pulse height of the kaolinite (value equal to the particle size) dc = 1.009 μm was measured by a Coulter multisizer3 particle size analyzer. The SEM image of kaolinite was obtained by Hitachi S-4800 scanning electron microscope. By observing and marking 100 kaolinite particles in the SEM image, the average bottom surface diameter d=2.12μm was obtained, and the result brought into the formula was 13.91.

example 2

[0060] Taking the Xuanhua kaolinite sample as an example, the average pulse height of the kaolinite (the value is equal to the particle size) dc = 1.65 μm was measured by a Coulter multisizer3 particle size analyzer. The SEM image of kaolinite was obtained with a Hitachi S-4800 scanning electron microscope. By observing and marking 100 kaolinite particles in the SEM image, the average bottom diameter d=4.23 μm was obtained, and the result brought into the formula was 25.27.

example 3

[0064] Taking a mica sample as an example, the average pulse height of the mica (the value is equal to the particle diameter) dc=3.23 μm is obtained by testing with a Coulter multisizer3 particle size analyzer. The SEM image of mica was obtained by using a Hitachi S-4800 scanning electron microscope. By observing and marking 100 mica particles in the SEM image, the average bottom diameter d=11.22 μm was obtained, and the result brought into the formula was 62.87.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com