Patents

Literature

154results about How to "Improve joint force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

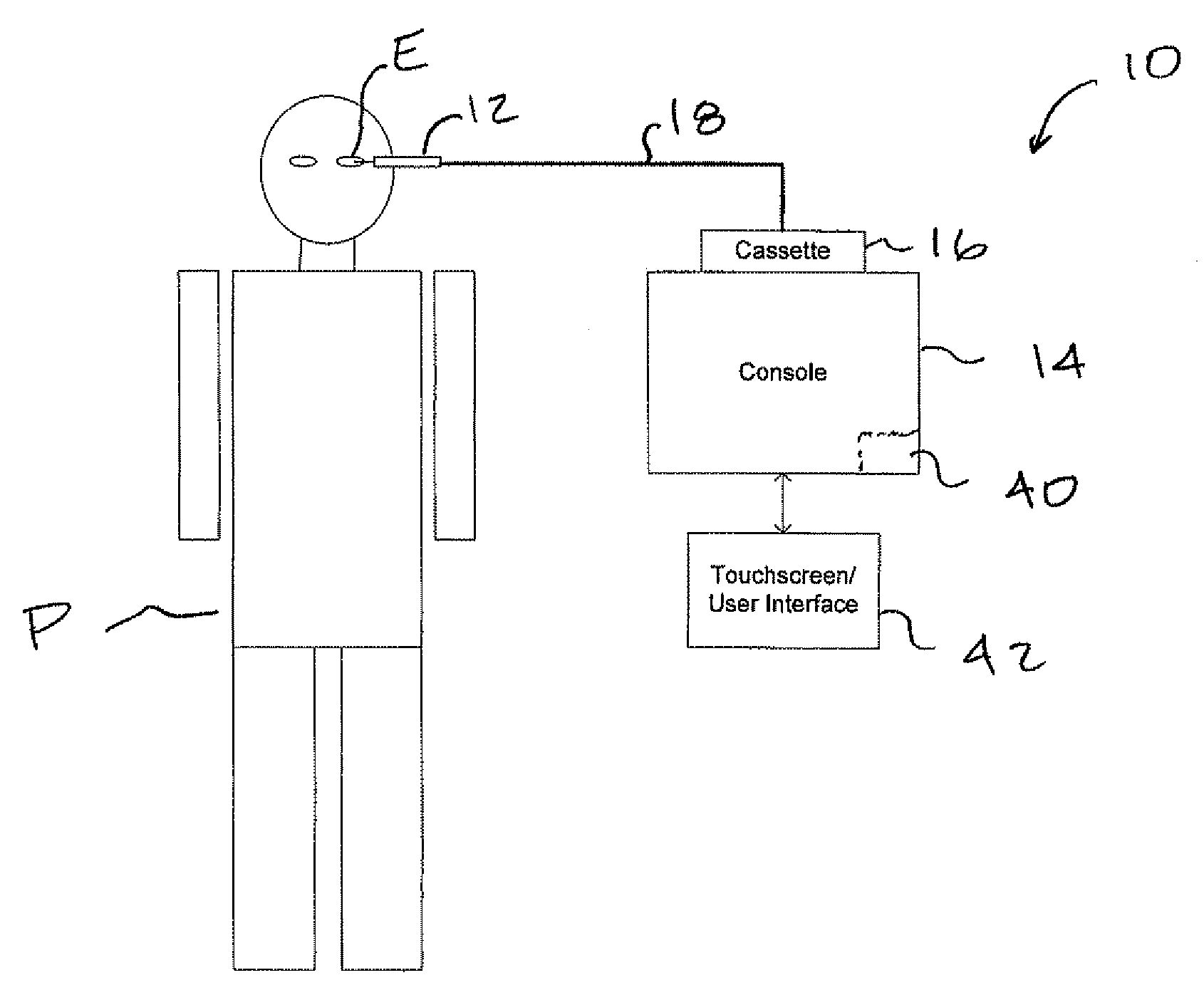

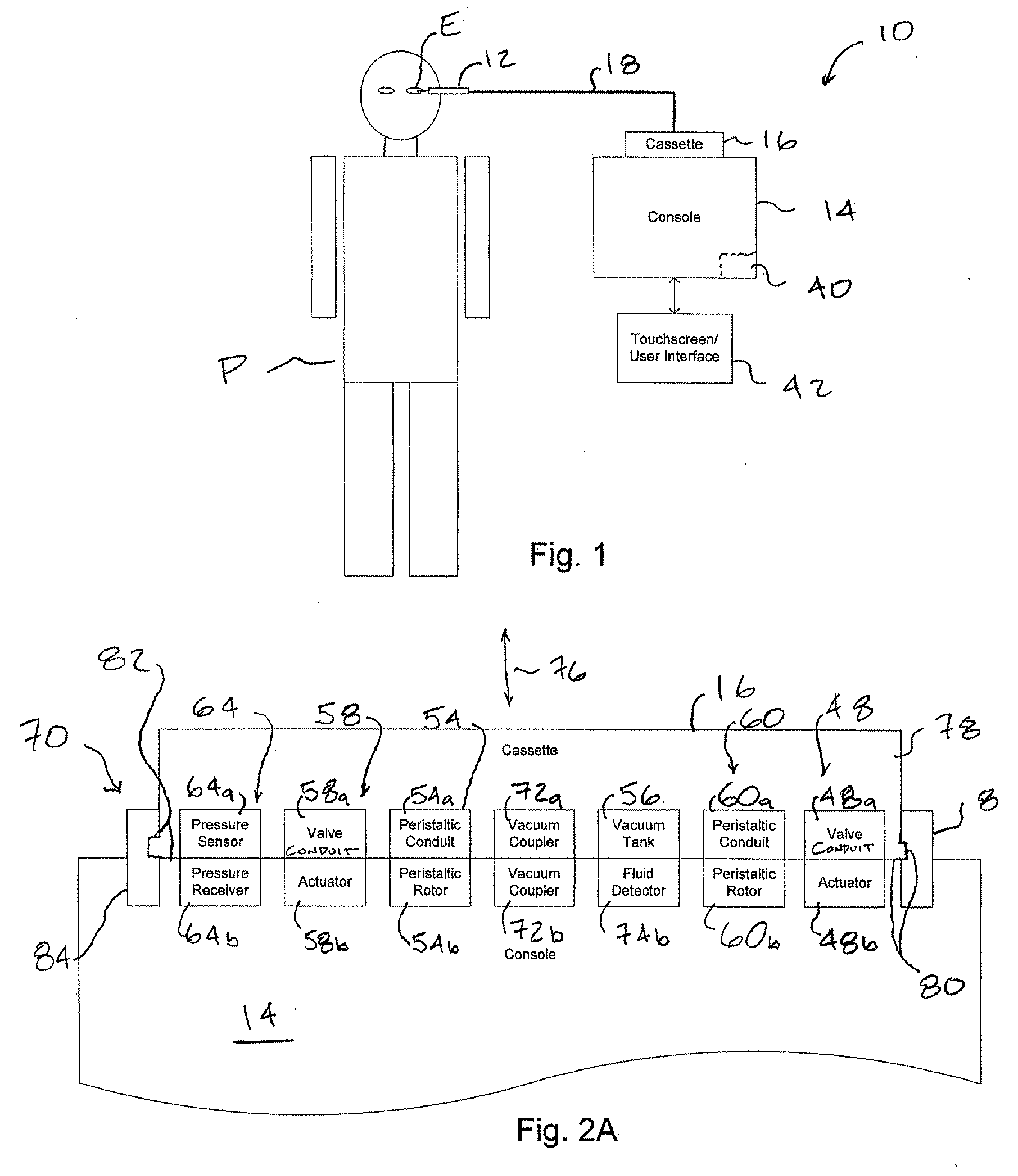

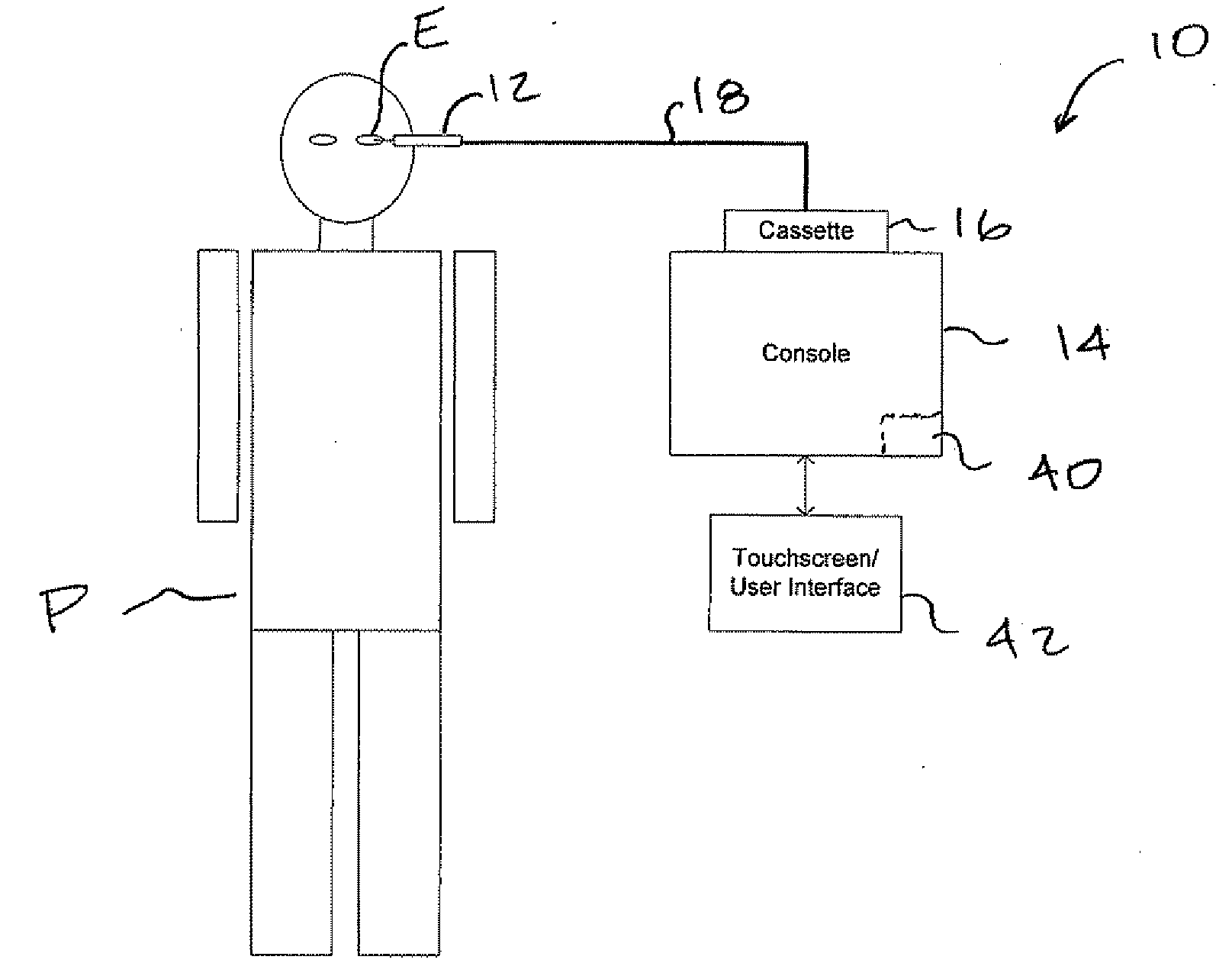

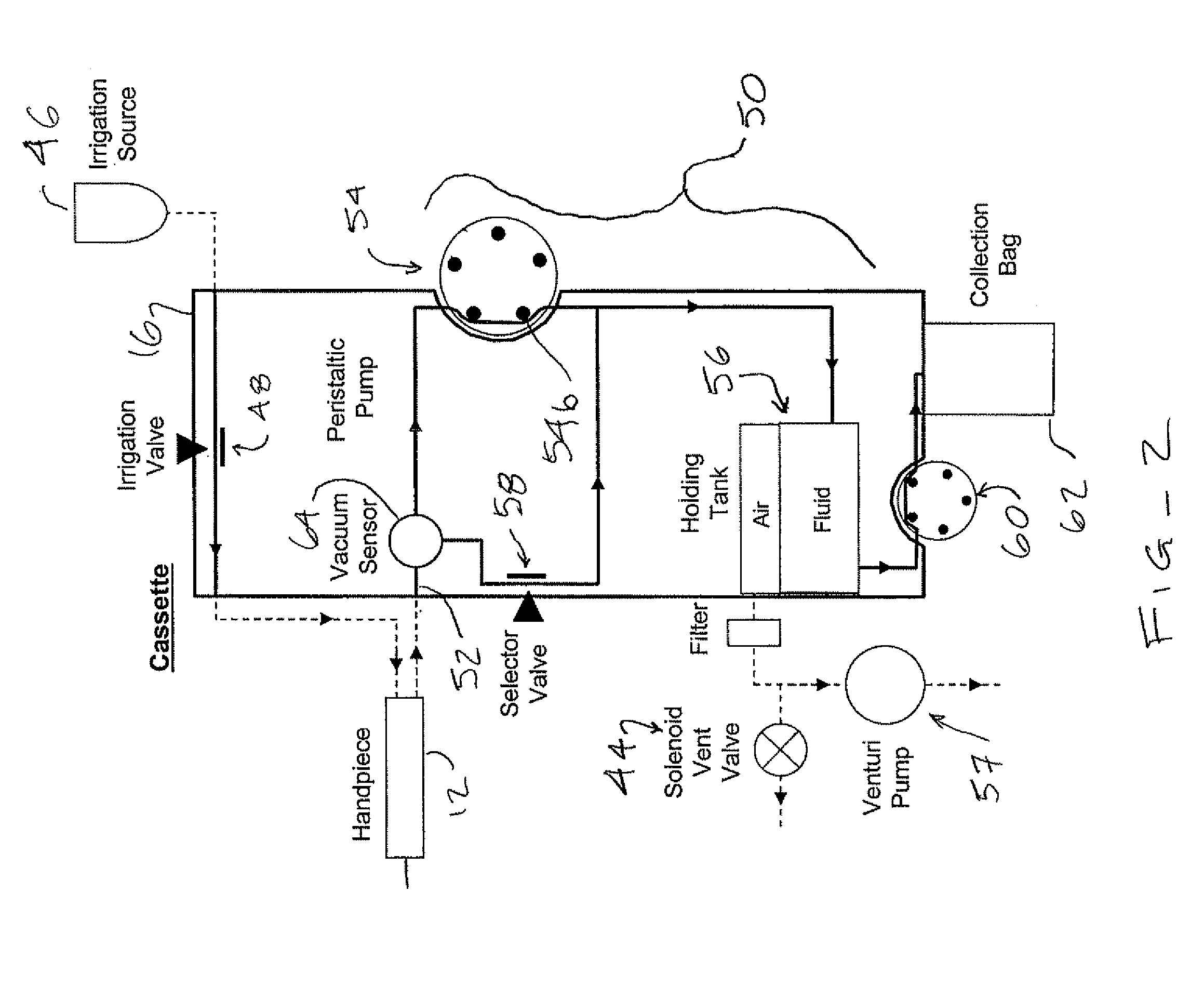

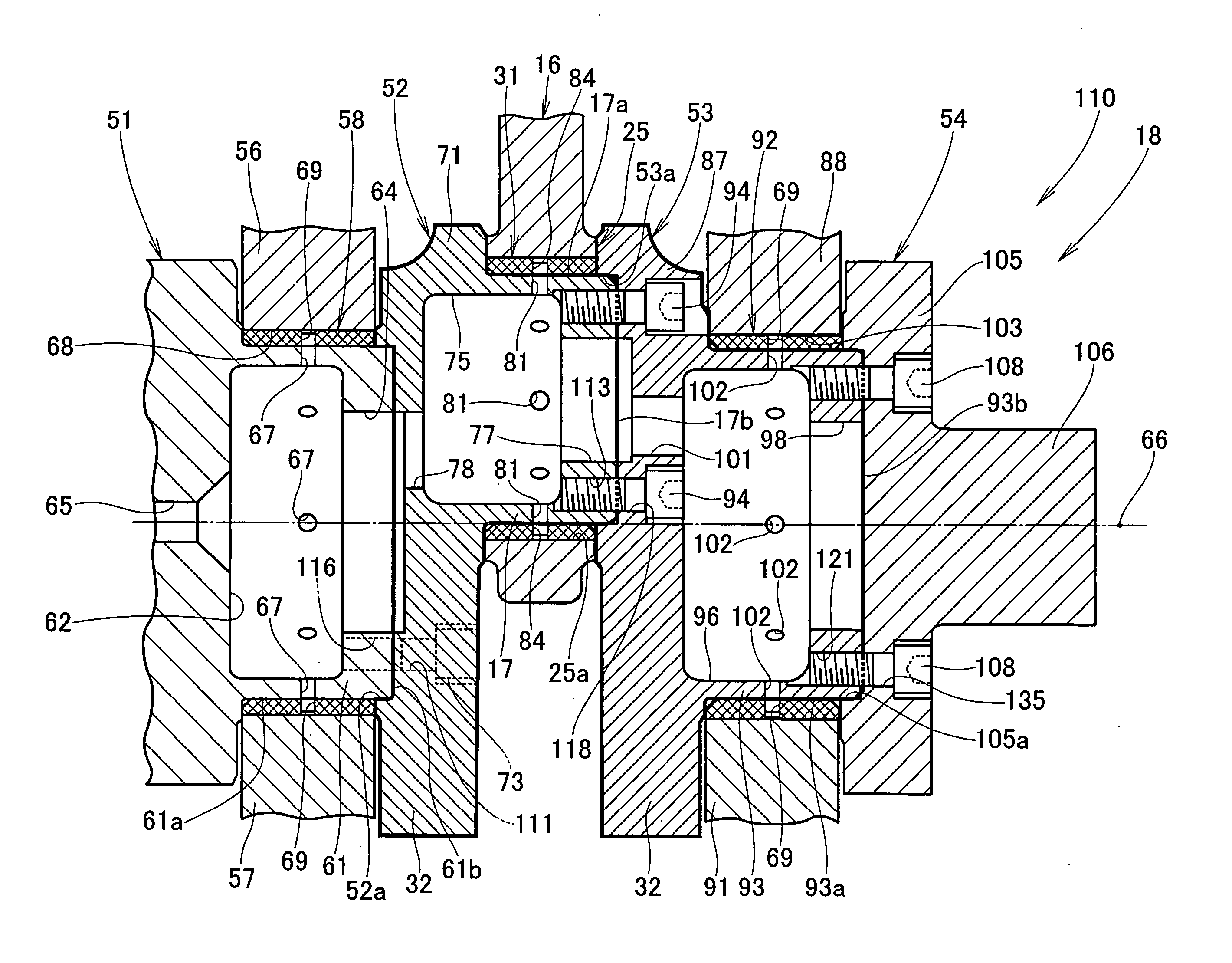

Loading system for alignment of fluidics cassette to console

ActiveUS20080114289A1Facilitate alignment and mountingImprove joint forceEye surgeryMedical devicesFluidicsBiomedical engineering

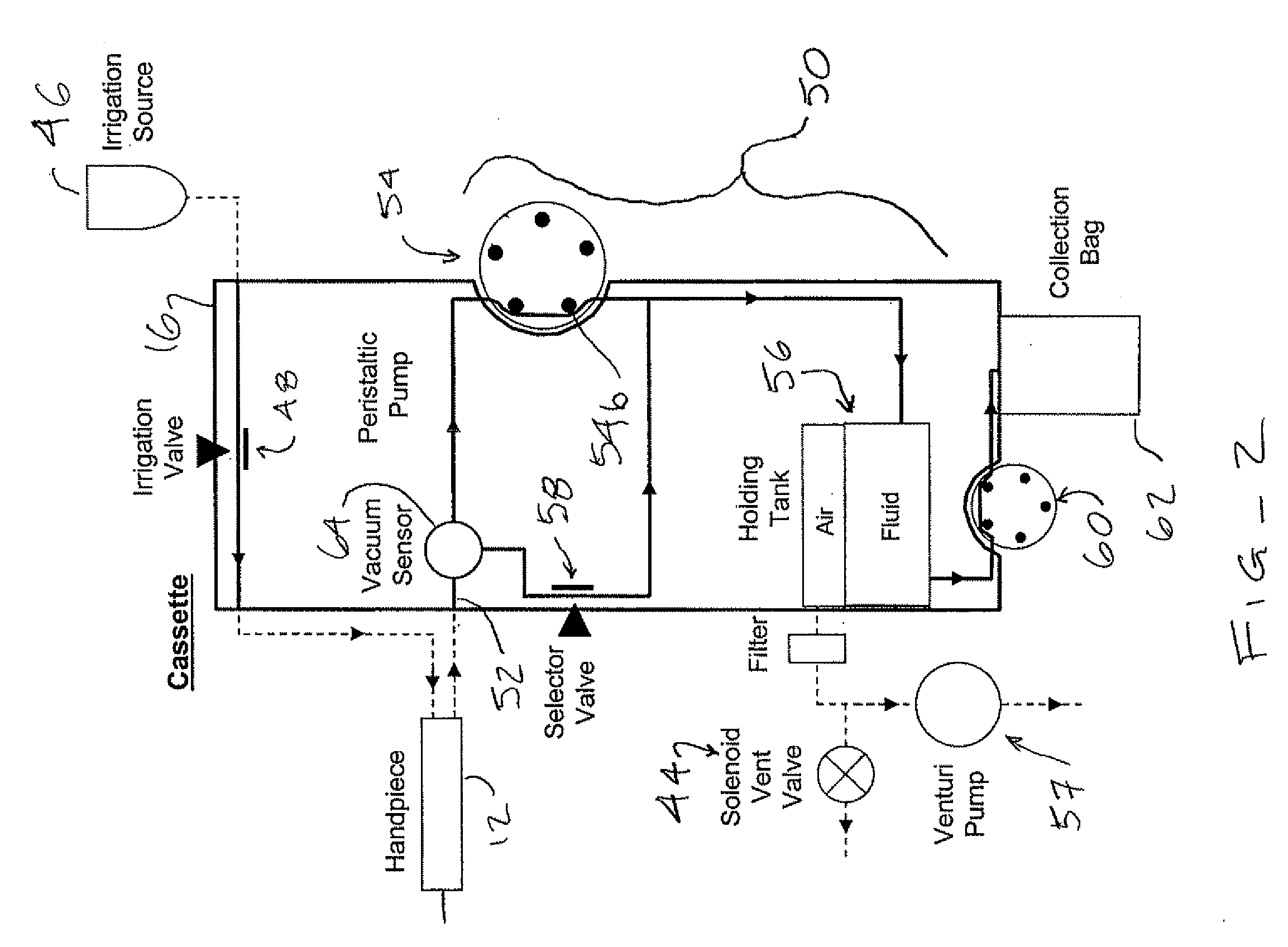

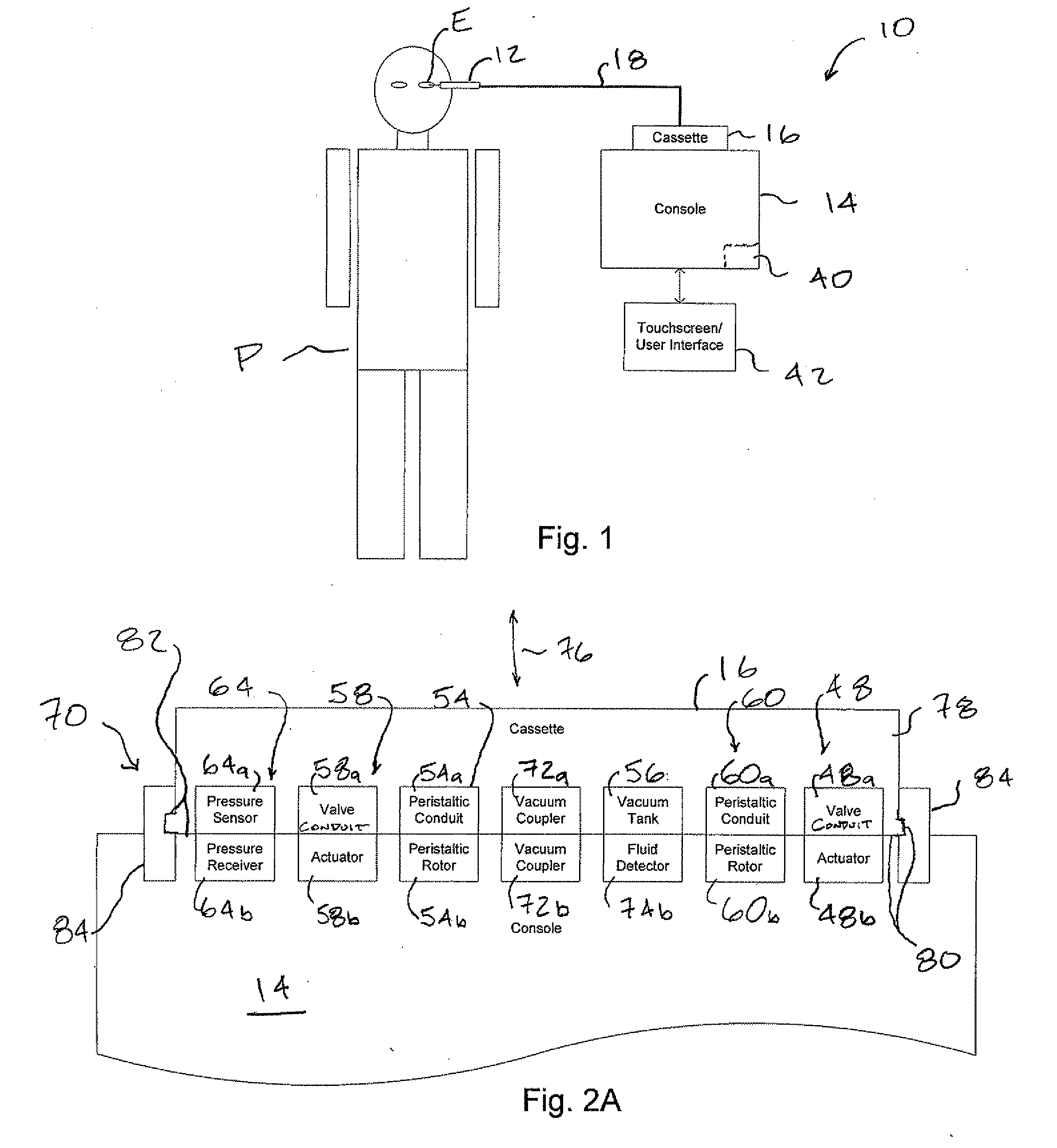

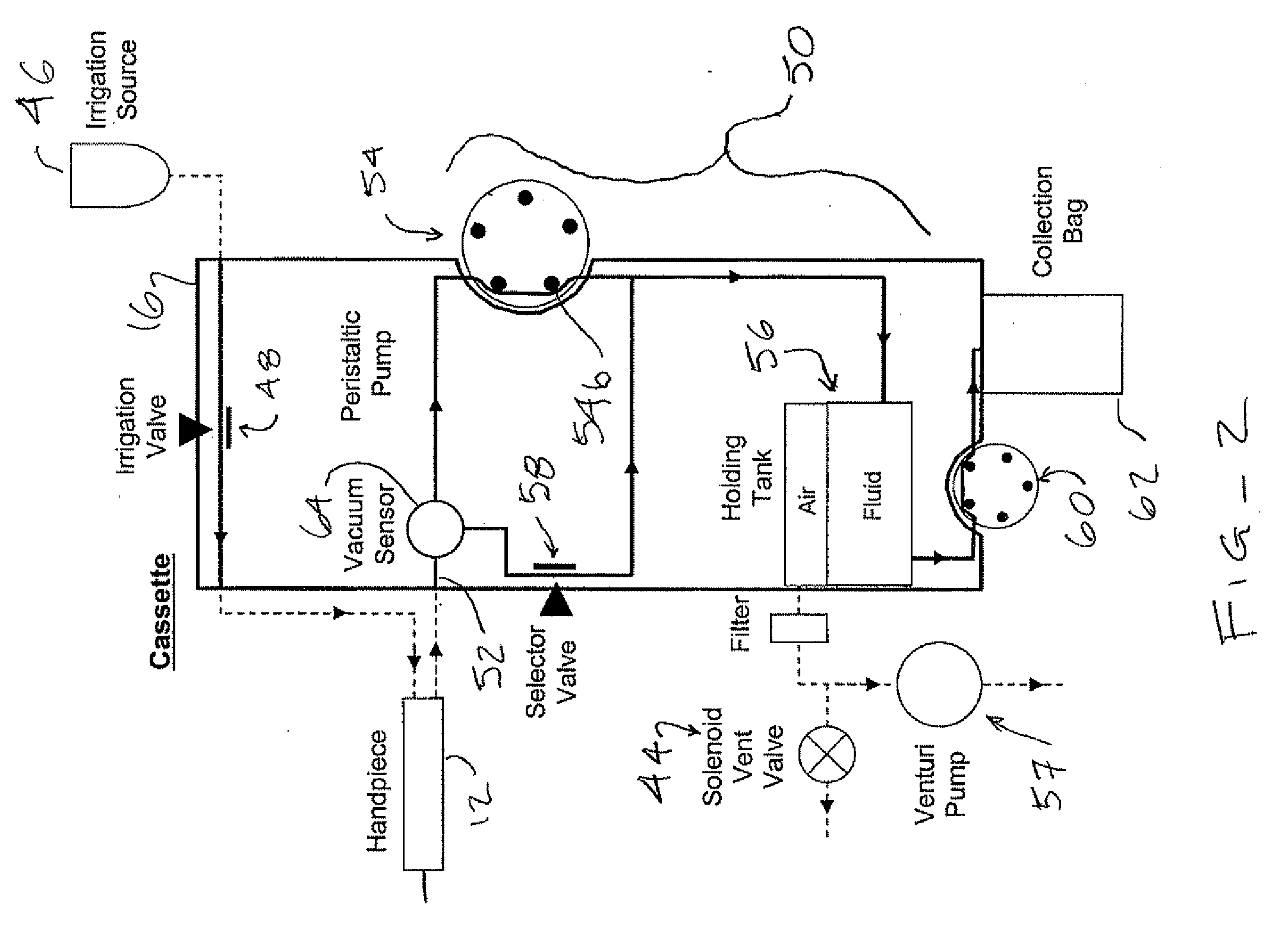

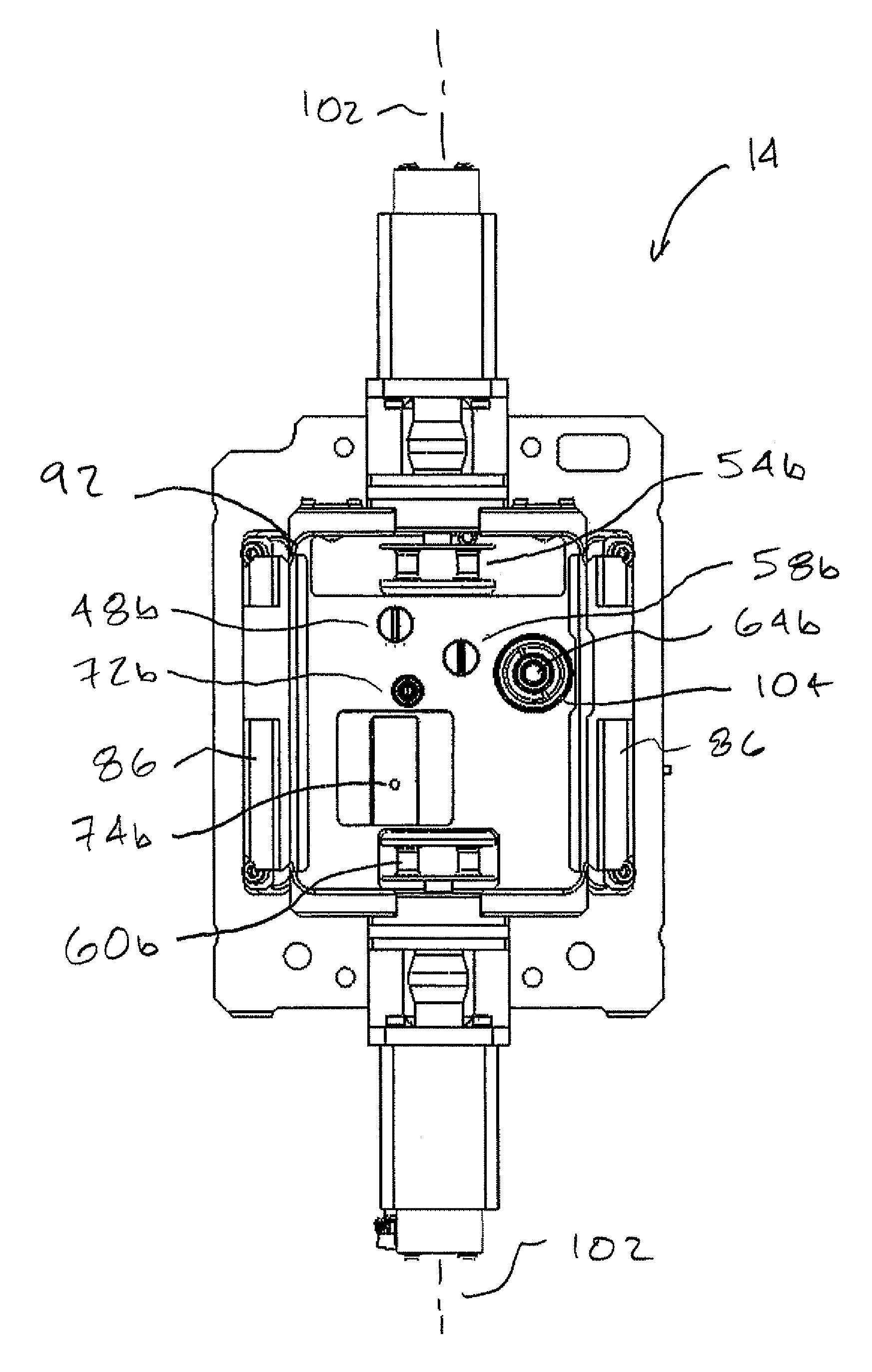

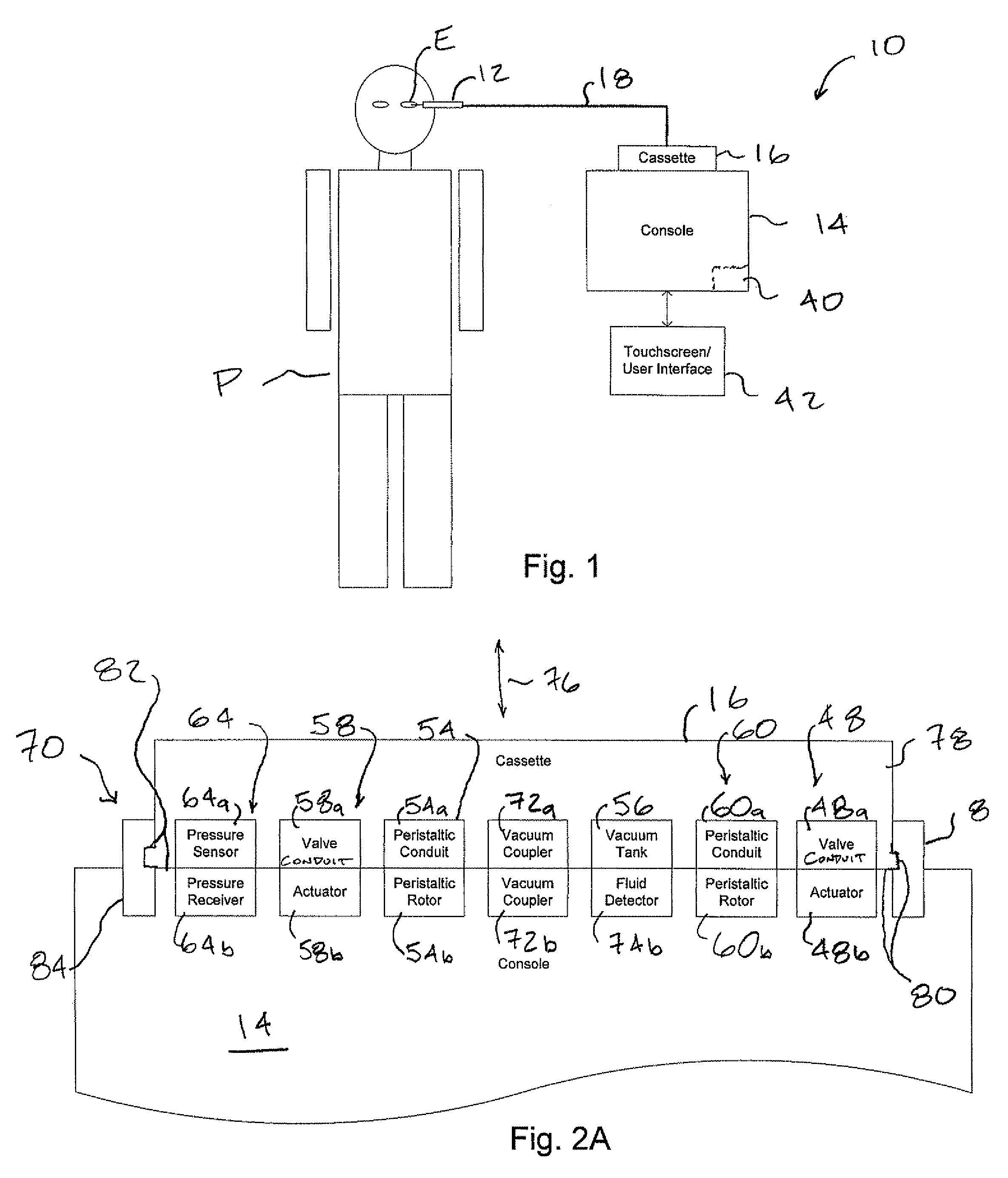

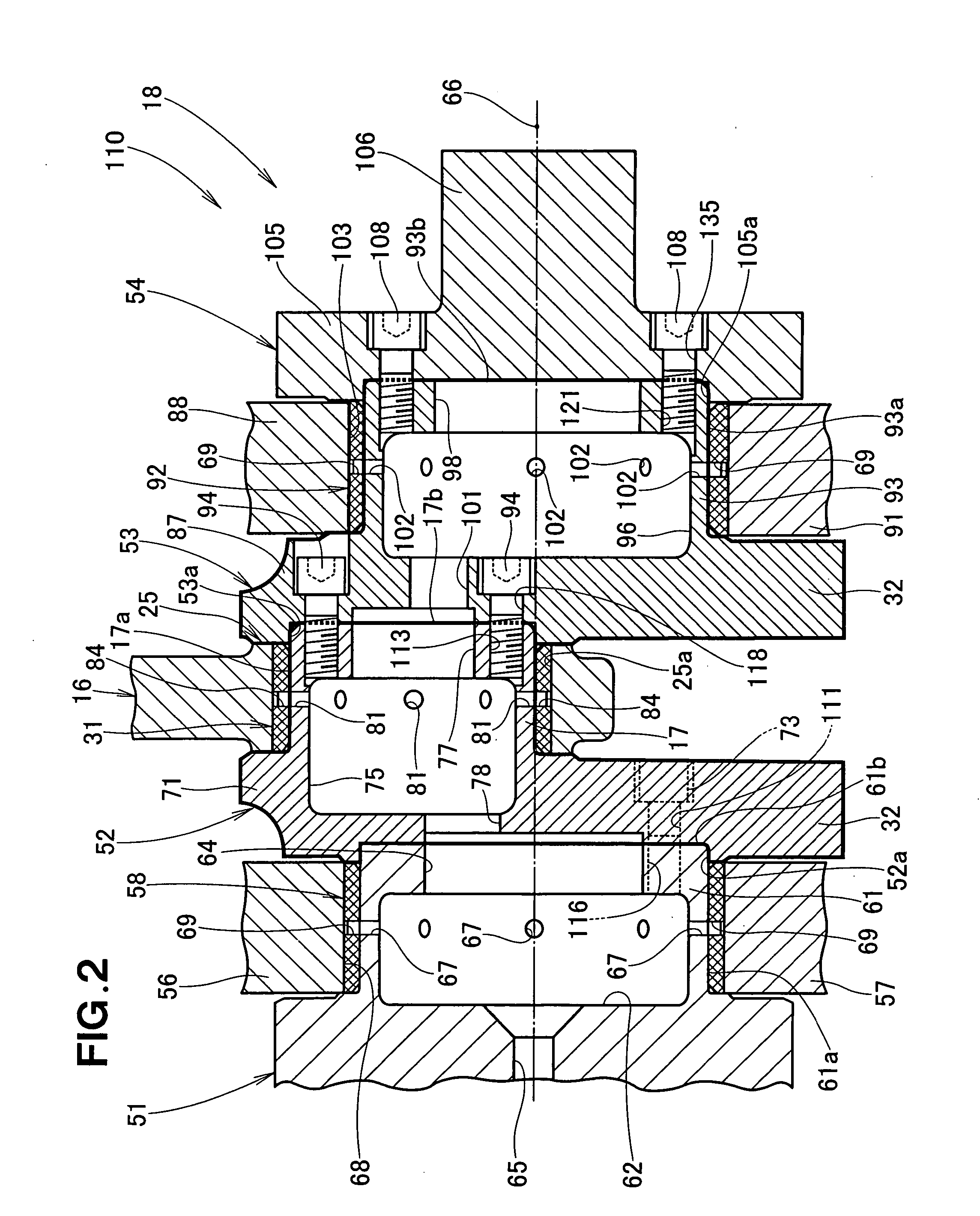

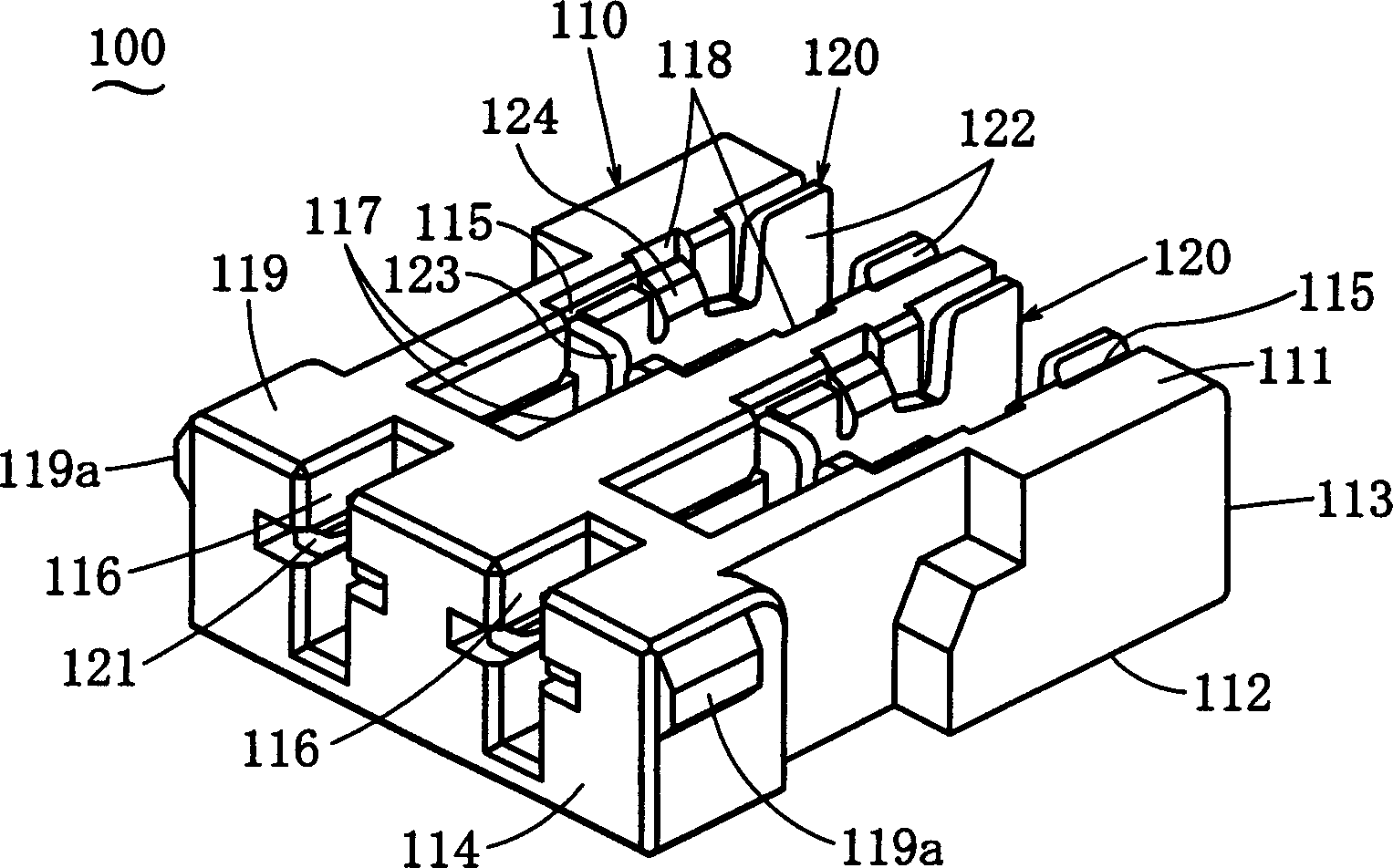

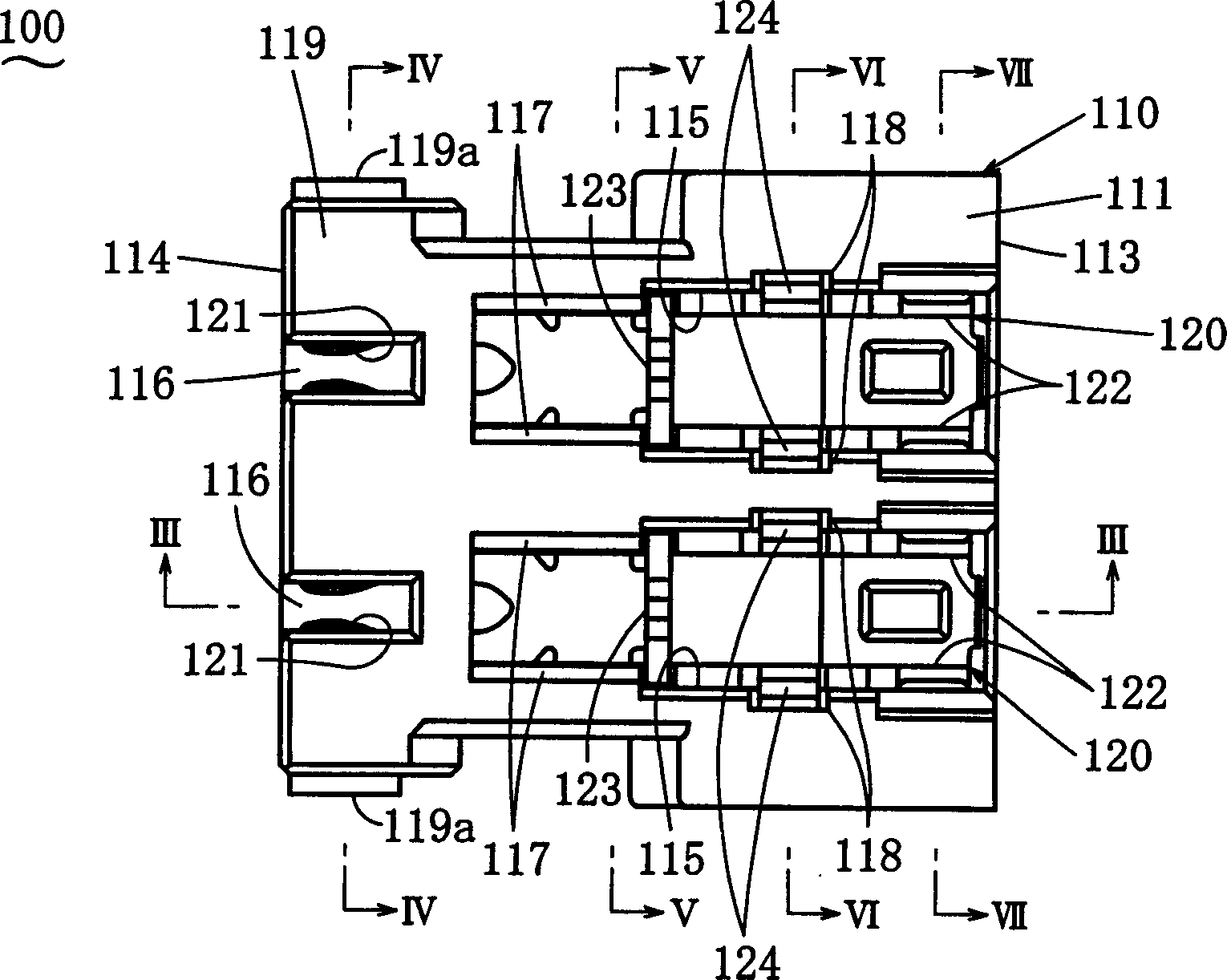

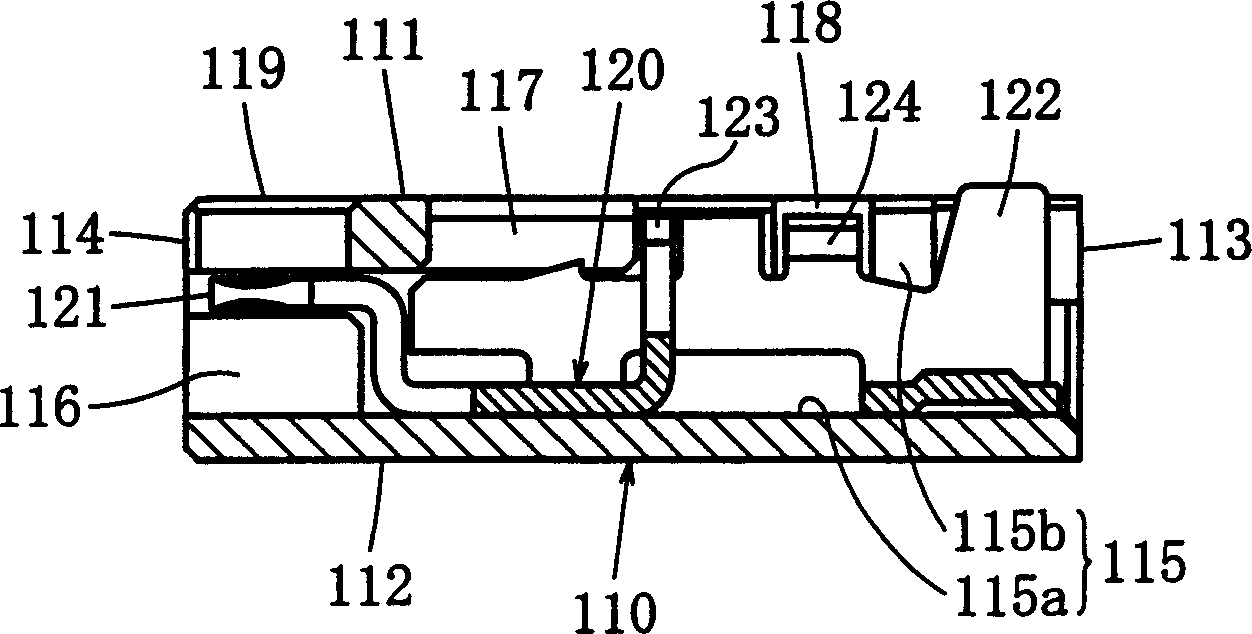

An eye treatment system includes an eye treatment probe and a console. The console has a cassette receptacle and a fluid drive system including a first peristaltic drive rotor and a second peristaltic drive rotor. The first and second drive rotors are exposed to the receptacle and are substantially coaxial. The cassette includes a cassette body and a fluid pathway network for coupling the fluid drive system of the console with the probe. The cassette body has cassette positioning surface for fittingly engaging the receptacle. The fluid pathway network has a first resilient tubing segment and a second resilient tubing segment, the first and second tubing segments are configured for peristaltic driving engagement by the first and second rotors, respectively, when the cassette is mounted to the console. Various elements of the cassette are configured for interfacing with the components of the console when the cassette is mounted to the console.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

Critical alignment of fluidics cassetts

ActiveUS20080114311A1Facilitate alignment and mountingImprove joint forceEye surgeryFlexible member pumpsFluidicsCoupling

Devices, systems, and methods interface a cassette with an eye treatment system console to provide coupling between the console and an eye treatment probe. The console may receive the cassette using a driven axial translation linkage that inhibits rotation of the cassette. The cassette may facilitate accurately positioning of a pressure sensor relative to a the console by allowing sliding movement between the sensor and a cassette body. Multiple peristaltic drives may be mounted to the console so that their rotors rotate about a common axis. An integrated mount structure may support and / or position components of the console which will interface with cassette, and an axially compressible vacuum connector of the console seal to a tapered vacuum coupler of the cassette.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

Loading system for alignment of fluidics cassette to console

ActiveUS8070712B2Facilitate alignment and mountingImprove joint forceEye surgeryMedical devicesFluidicsBiomedical engineering

An eye treatment system includes an eye treatment probe and a console. The console has a cassette receptacle and a fluid drive system including a first peristaltic drive rotor and a second peristaltic drive rotor. The first and second drive rotors are exposed to the receptacle and are substantially coaxial. The cassette includes a cassette body and a fluid pathway network for coupling the fluid drive system of the console with the probe. The cassette body has cassette positioning surface for fittingly engaging the receptacle. The fluid pathway network has a first resilient tubing segment and a second resilient tubing segment, the first and second tubing segments are configured for peristaltic driving engagement by the first and second rotors, respectively, when the cassette is mounted to the console. Various elements of the cassette are configured for interfacing with the components of the console when the cassette is mounted to the console.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

Electrode Assembly Having Tab-Lead Joint Portion of Minimized Resistance Difference Between Electrodes and Electrochemical Cell Containing The Same

InactiveUS20090317717A1Resistance differenceImprove reliabilityHybrid capacitor electrodesLarge-sized flat cells/batteriesEngineeringElectrochemical cell

Disclosed herein is a stacking or stacking / folding type electrode assembly of a cathode / separator / anode structure, wherein the electrode assembly is constructed in a structure in which tabs (electrode tabs), having no active material applied thereto, protrude from electrode plates constituting the electrode assembly, the electrode tabs are electrically connected to an electrode lead, and the pluralities of electrode tabs are joined to the top and the bottom of the electrode lead at an electrode lead-electrode tabs joint portion such that the resistance difference between electrodes at the electrode lead-electrode tabs joint portion is minimized. Also disclosed is an electrochemical cell including the electrode assembly.

Owner:LG CHEM LTD

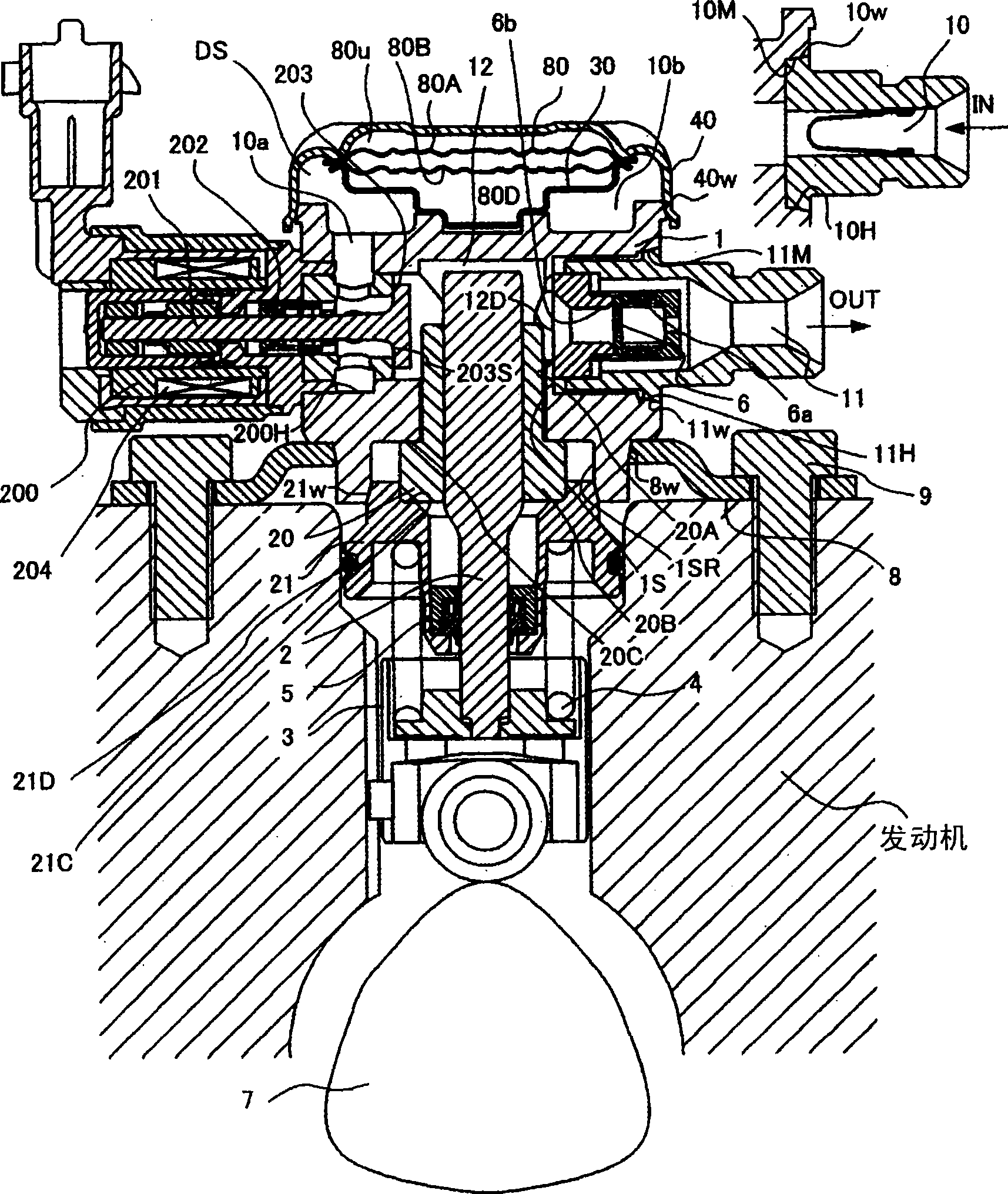

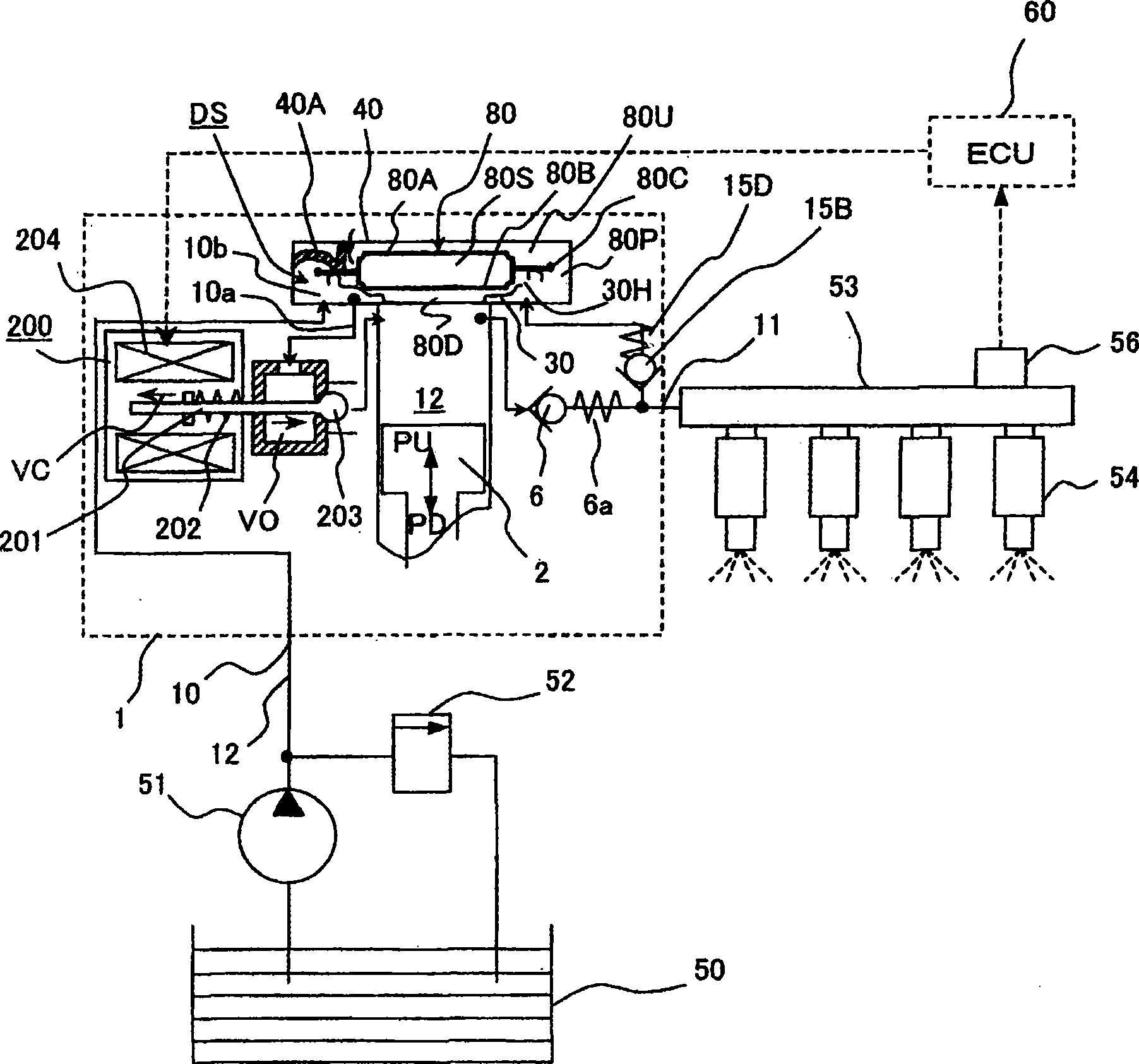

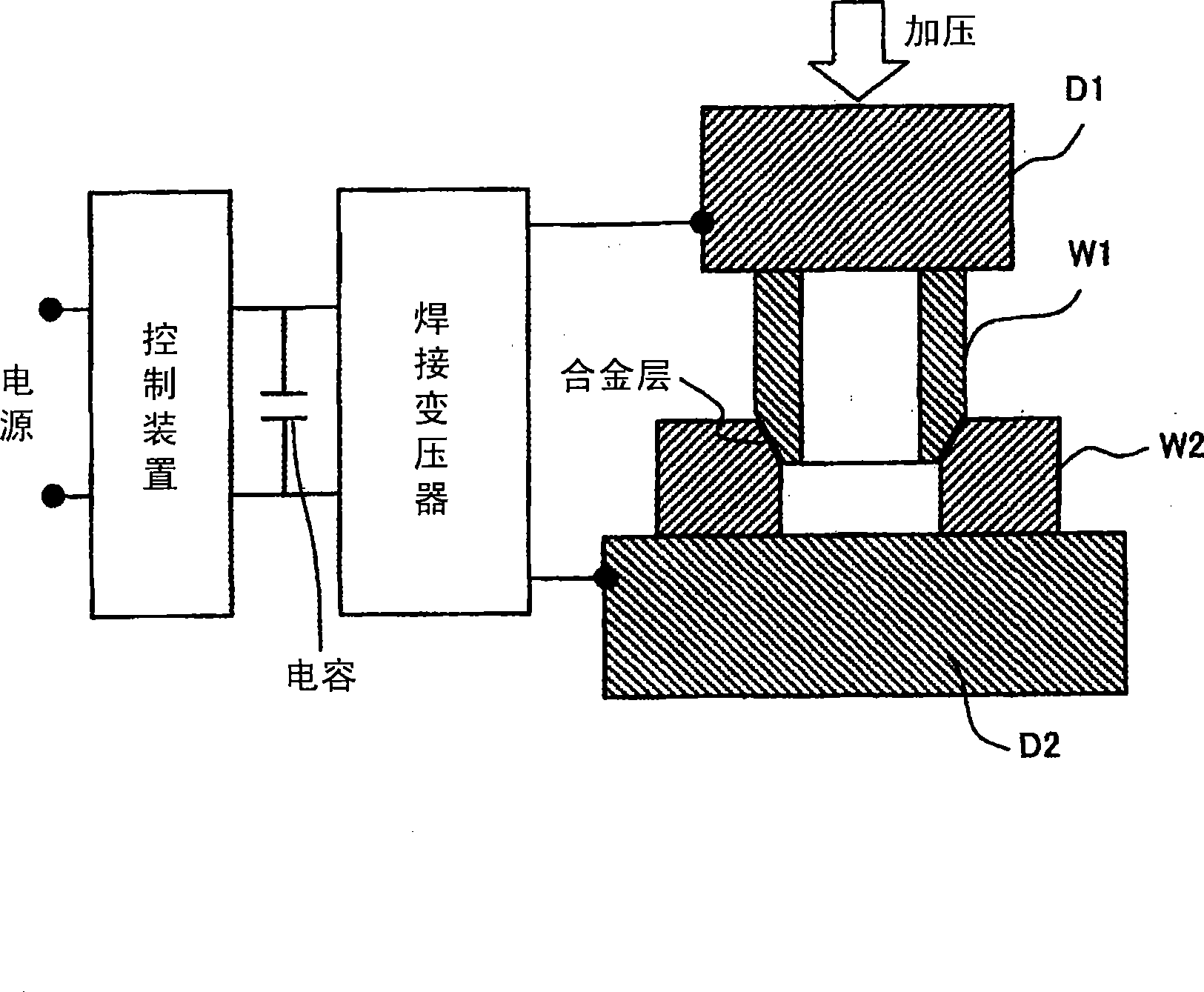

High-pressure fuel supply pump and the manufacturing method

InactiveCN101424235ARealize the joint functionRealize the sealing functionTubular articlesHollow articlesInlet valveMetallic materials

An object of this invention is to provide such a welded structure of and welding method for two metallic parts fitted together at a tubular section in a high-pressure fuel supply pump, that enables rapid joining of both metallic parts by staking (press-fitting included), screw fastening, and / or laser welding, offers high welding strength and sufficient fluid sealability, and keeps the metallic materials free from thermal changes in composition. While an electric current is supplied to any one of the welding connection surfaces formed between a pump housing and cylinder in a high-pressure fuel supply pump, between the pump housing and an installation flange, between the pump housing and an intake or discharge joint, between the pump housing and a pulsation-absorbing damper cover, between the pump housing and a relief valve mechanism, and between the pump housing and an electromagnetically driven intake valve mechanism, the particular two sections are pressed against each other to generate, along the connection surface, a plastic flow not causing melting or fusion due to heat, and form a diffusion-weld region at the connection surface by using the plastic flow and the application of the pressure.

Owner:HITACHI LTD

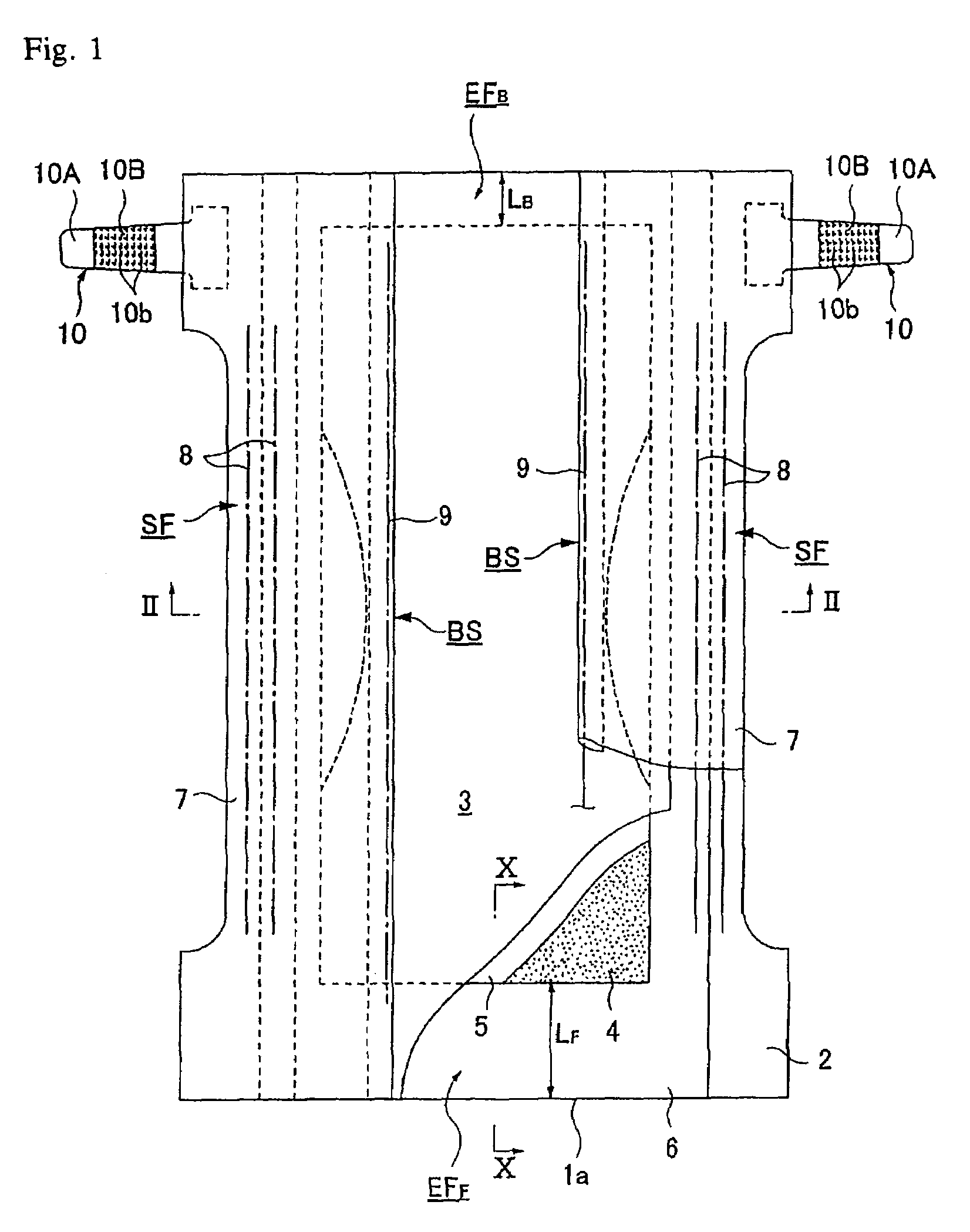

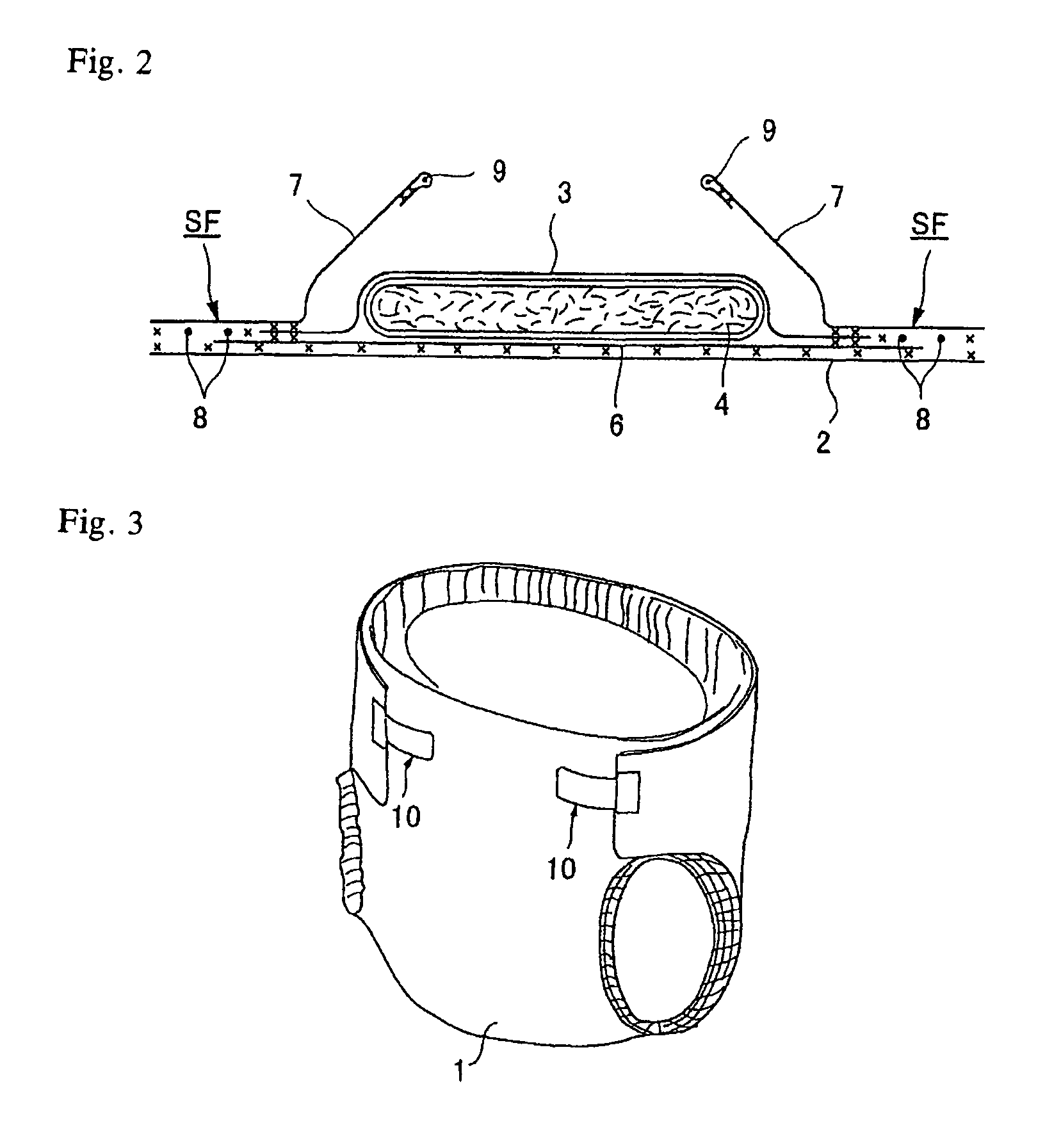

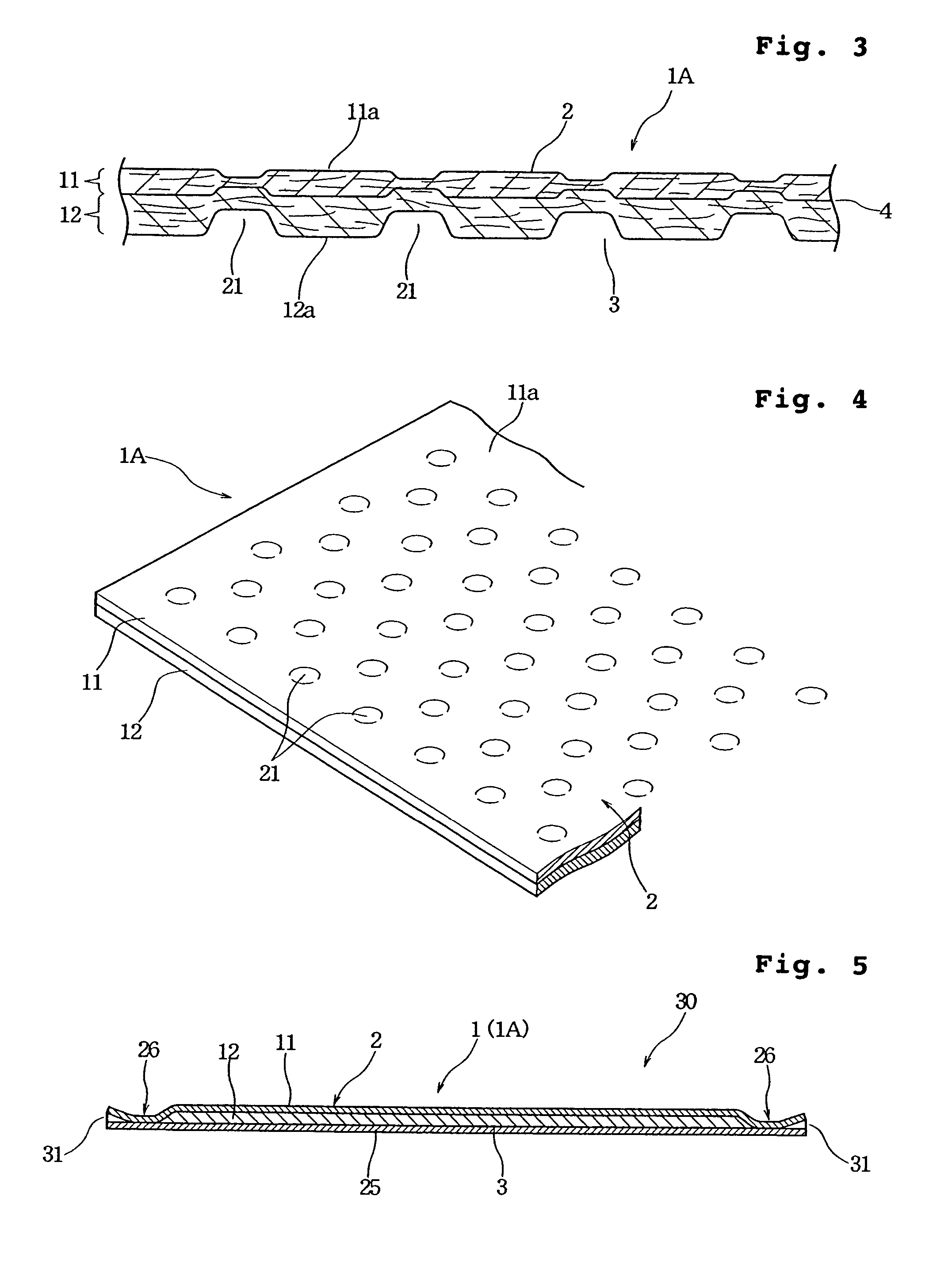

Disposable diaper having folded front-sided end flap portion

Provided is a disposable diaper, in which fastening tapes are brought into direct engagement with the surface of an outer-face back sheet made of a nonwoven fabric. The disposable diaper is enabled to adjust its size slightly according to the body shape of a baby, by improving the force of the fastening tapes to engage with the outer-face back sheet and the force to join the outer-face back sheet and a leakage-preventing sheet.The disposable diaper has its outer-face back sheet made of a nonwoven fabric prepared by an air-through method, in which fibers are thermally melted to each other at the time of manufacturing the nonwoven fabric by feeding hot air in a drum transfer process. This nonwoven fabric is arranged to have the aforementioned drum contacting face side on the inner face side of the diaper and the drum noncontact face side on the outer face side of the diaper, or the outer face side of the aforementioned outer-face back sheet is subjected to a raising treatment over a predetermined rangeset as at least the engaging range of the aforementioned fastening tapes. As a result, the engaging force of the fastening tapes can be improved, and at least the aforementioned front-side end flap portion EFF can be longitudinally folded back at an arbitrary position.

Owner:DAIO PAPER CORP

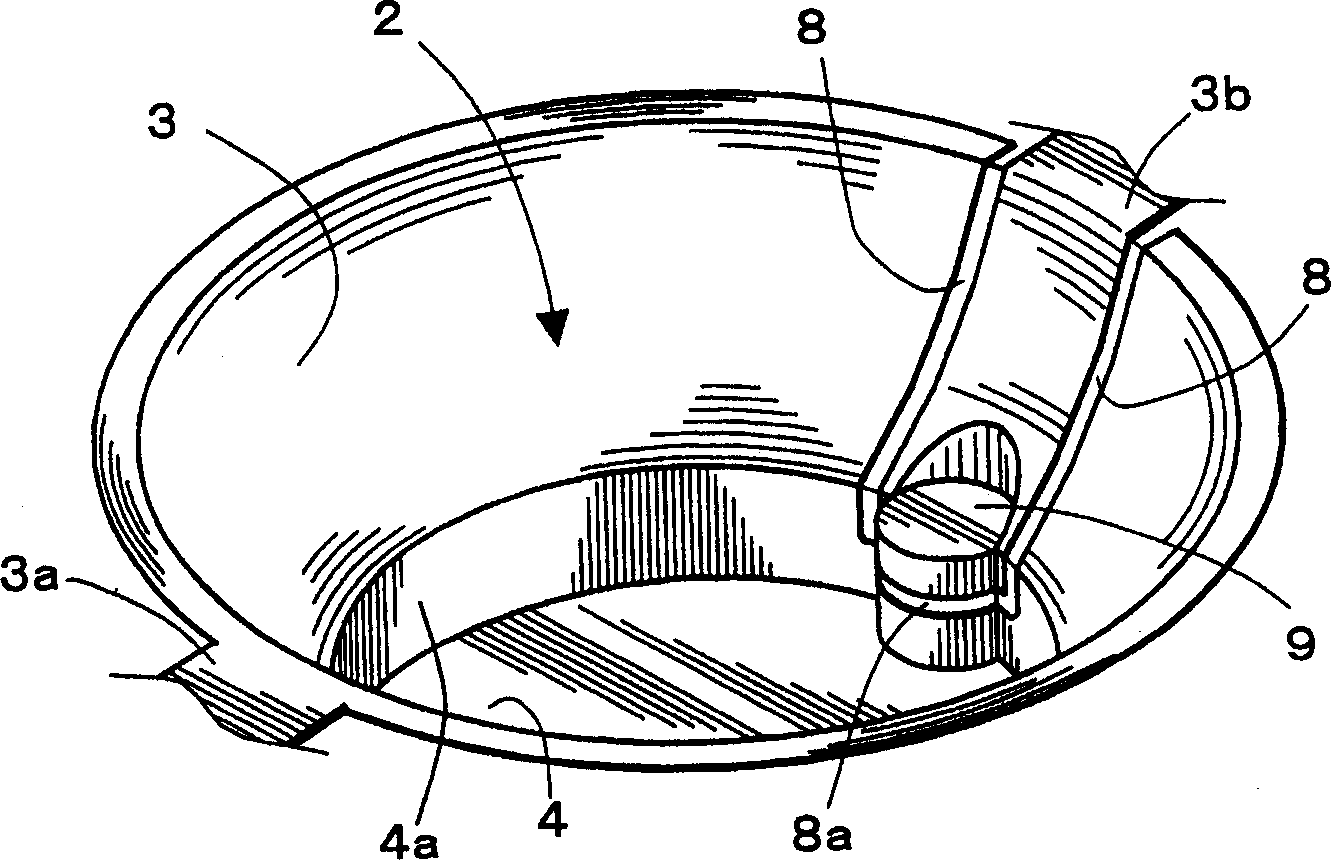

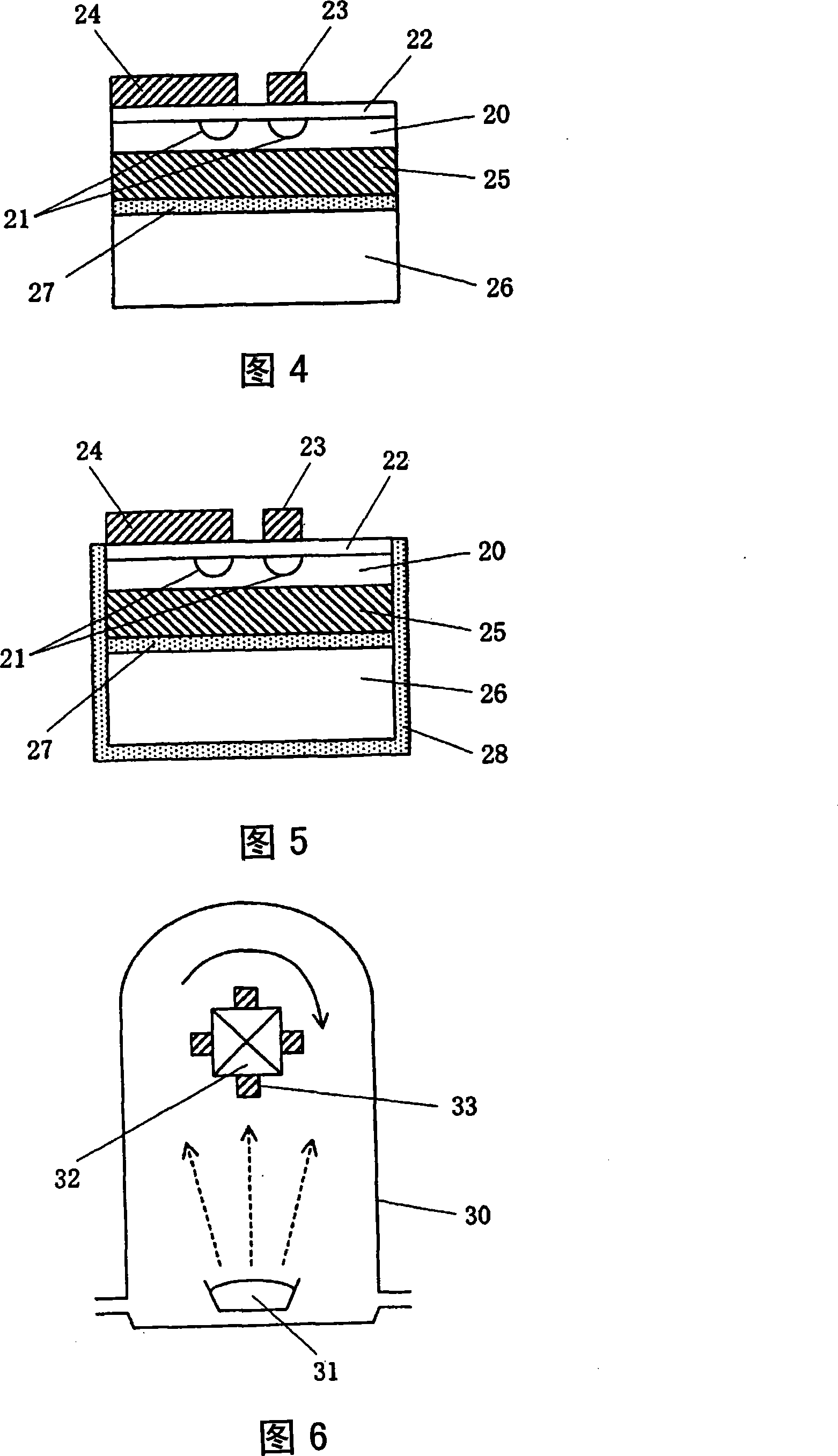

Photoelectric element assembly

InactiveCN1471178ASecure spaceMiniaturizationSolid-state devicesSemiconductor devicesMiniaturizationEngineering

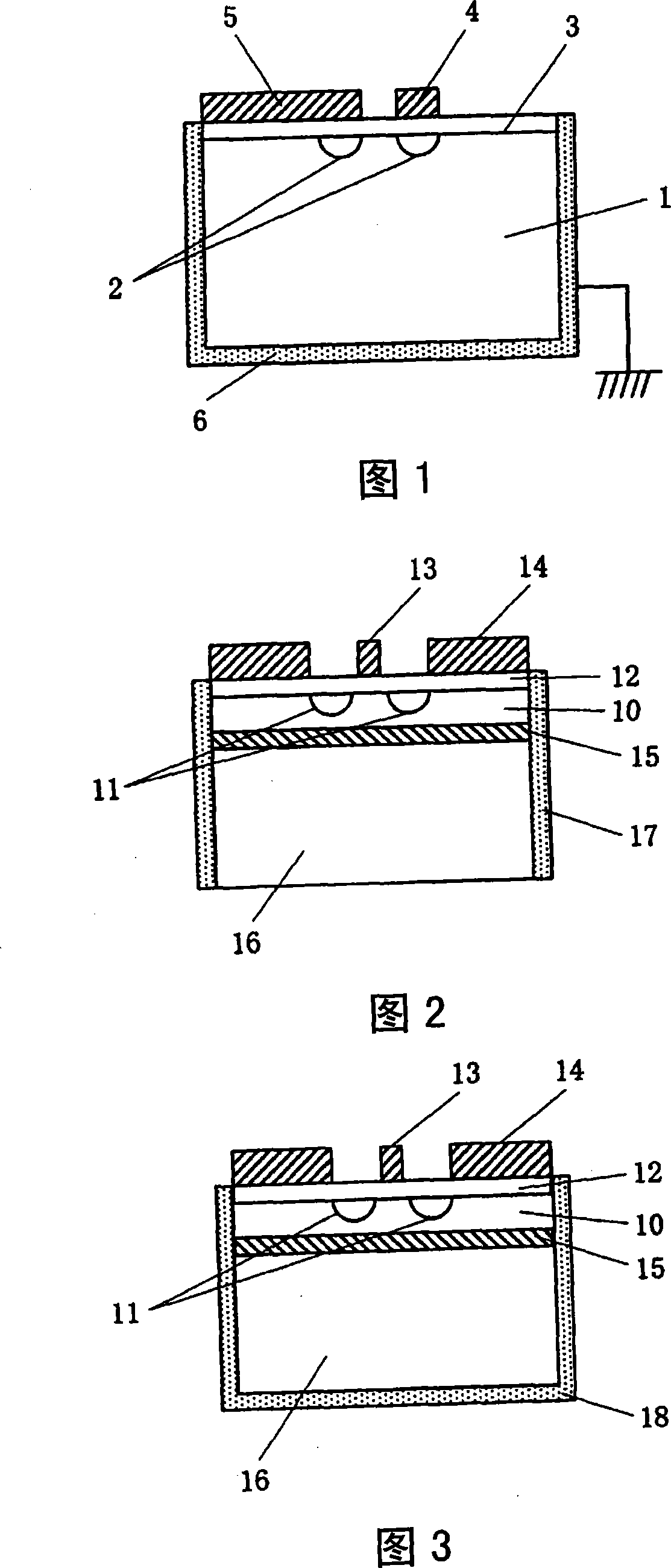

In a photoelectric device-part, a bonding pad is formed without increasing a plane area of a concave part for housing a photoelectric device to implement miniaturization and improvement of the light usability efficiency. A light reflecting surface 3 of nearly a parabola configuration or the like provided for light emission and reception by a photoelectric device 5 is formed on a slanting curved surface constituting a concave part 2 of a circuit substrate 1. A convex portion 9a projecting from the light reflecting surface 3 and a receding concave portion 9b are formed in the middle of the concave part 2. A stage 9 is formed by an upper and bottom surfaces of the convex and concave portions 9a and 9b, respectively. A bonding pad 7 for connecting circuits of the photoelectric device 5 is formed at the stage 9. Since a space for the bonding pad 7 is provided by both concave and convex portions, deformation of the light reflecting surface 3 caused by the receding concave portion 9b and a ratio of intrusion to the bottom surface of the concave part by the projecting convex portion 9a can be both minimized. As a result, the photoelectric device 5 can be mounted without largely lowering light emission efficiency or without decentering the light emitting and receiving center, whereby a photoelectric device-part 10 can be miniaturized.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Door lock jointing construction

InactiveCN101240676AImprove joint forceEasy to operateNon-mechanical controlsEngineeringSpherical equivalent

The invention is a counterblow door lock structure which is opposite direction motion between door and doorframe. Door lock connecting structure, the one end of the convex area which is perpendicular to the cardinal plate of the door board is the cylinder stick, the stick whose spherical equivalent diameter is bigger than cylinder diametric is a knuckling stick, and other door board is installed movable block ball mechanism. A ball cavity whose middle is hollow space is perpendicular to the base of the flat-plate, the interior diameter of the ball cavity is bigger than that of the knuckling stick, a limit ball control mechanism whose caliber size is changeable is installed at the mouth of the ball cavity. The limit ball control mechanism is: at least two round holes are radial at the wall part of the ball cavity, ball bearing is placed in the round hole, a slipper block which can move along the axial cord of the ball cavity around the ball cavity and the inner wall has vary in size step hole is configured at the base of the ball cavity, the technical project achieves that the little electromagnetic force transforms to the large door leaves engaging force; after the door leaves closed, the door leaves is permitting opened through the method of the electromagnetic control etc; and its operations is smooth, steady and convenience.

Owner:上海欧意机电五金有限公司

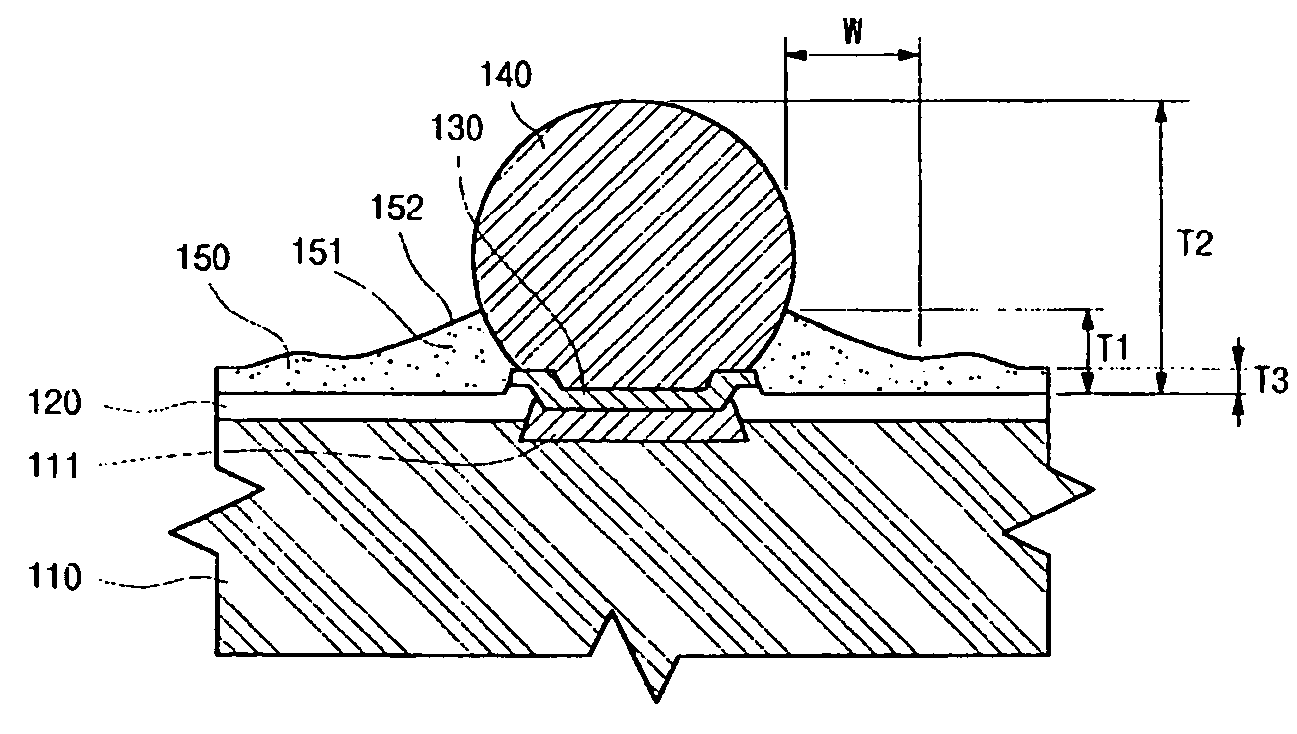

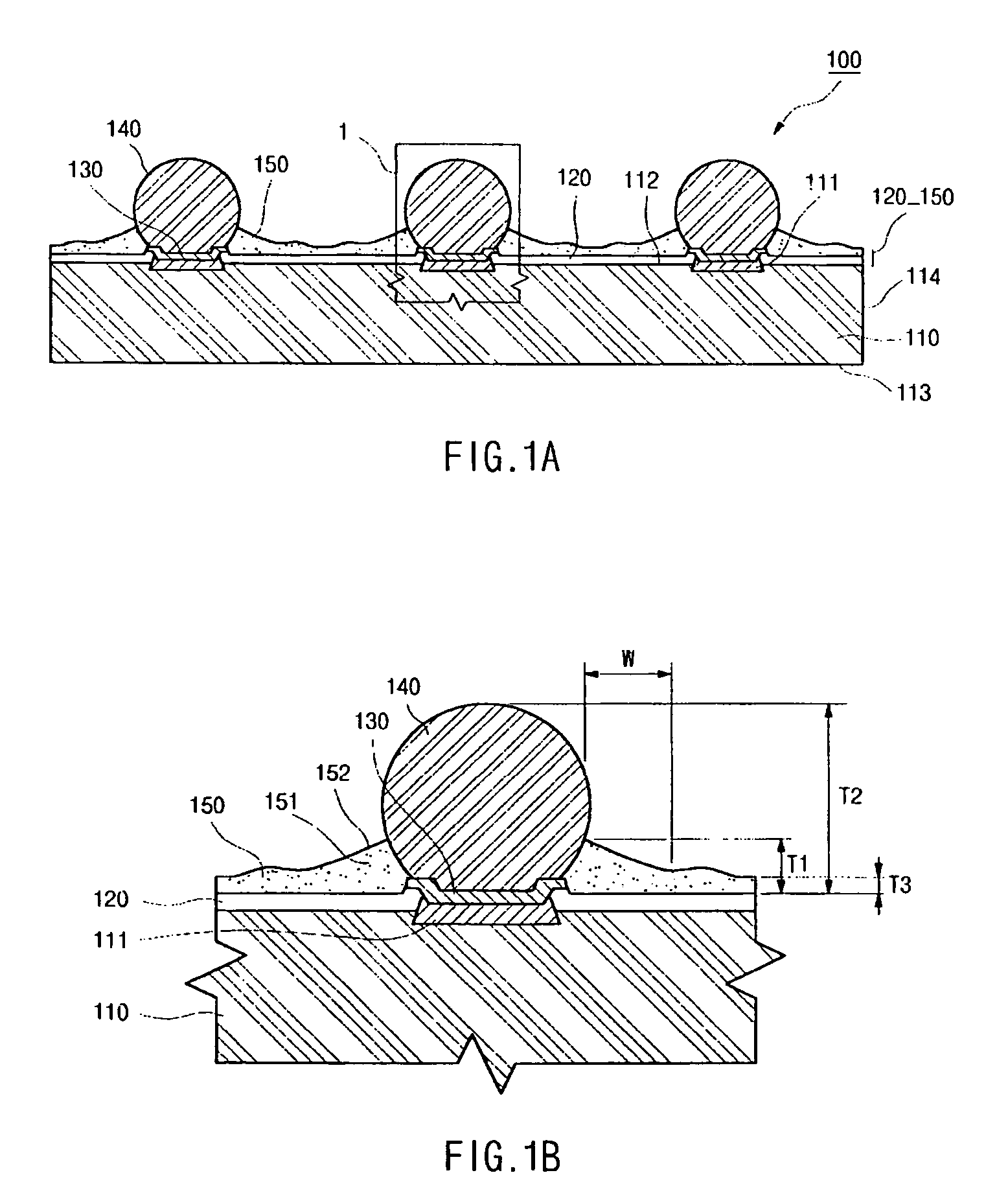

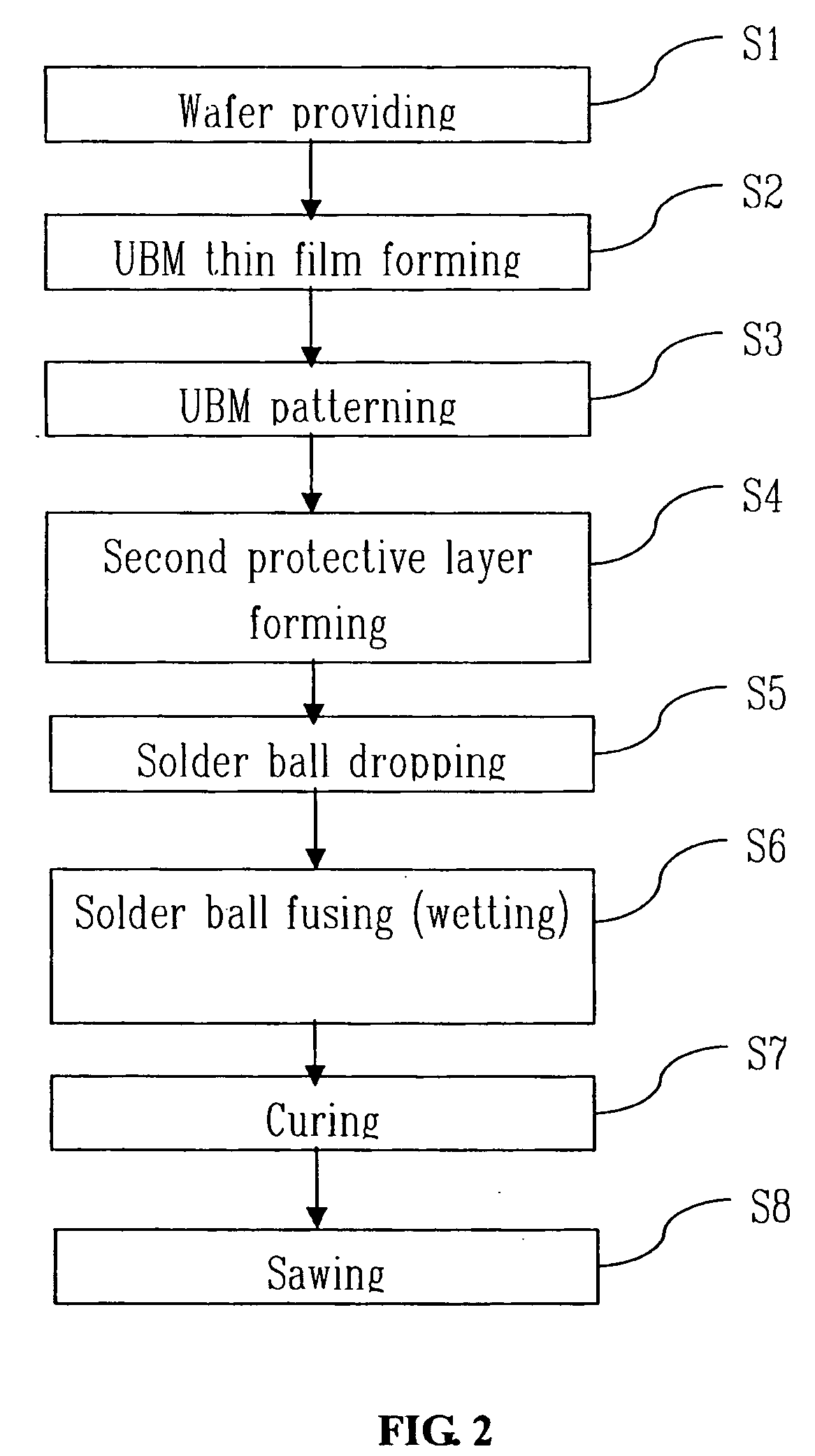

Wafer level package and its manufacturing method

InactiveUS20070018322A1Absorbs and alleviates external stressJoint force can be moreSemiconductor/solid-state device detailsSolid-state devicesSolder ballSemiconductor package

A semiconductor package includes a semiconductor die having a plurality of bond pads, a first protective layer formed at the periphery of the bond pads of the semiconductor die, UBM (Under Bump Metals) formed at the bond pads of the semiconductor die, a plurality of solder balls wetted to the UBM, and a second protective layer formed at the periphery of the solder balls. The second protective layer includes a thick collar, which is formed from the surface of the solder ball toward its periphery, so that the joint force of the solder ball can be more improved. Further, the second protective layer protects the surface of the wafer from the external environment, and absorbs and alleviates the external stress.

Owner:AMKOR TECH INC DW US

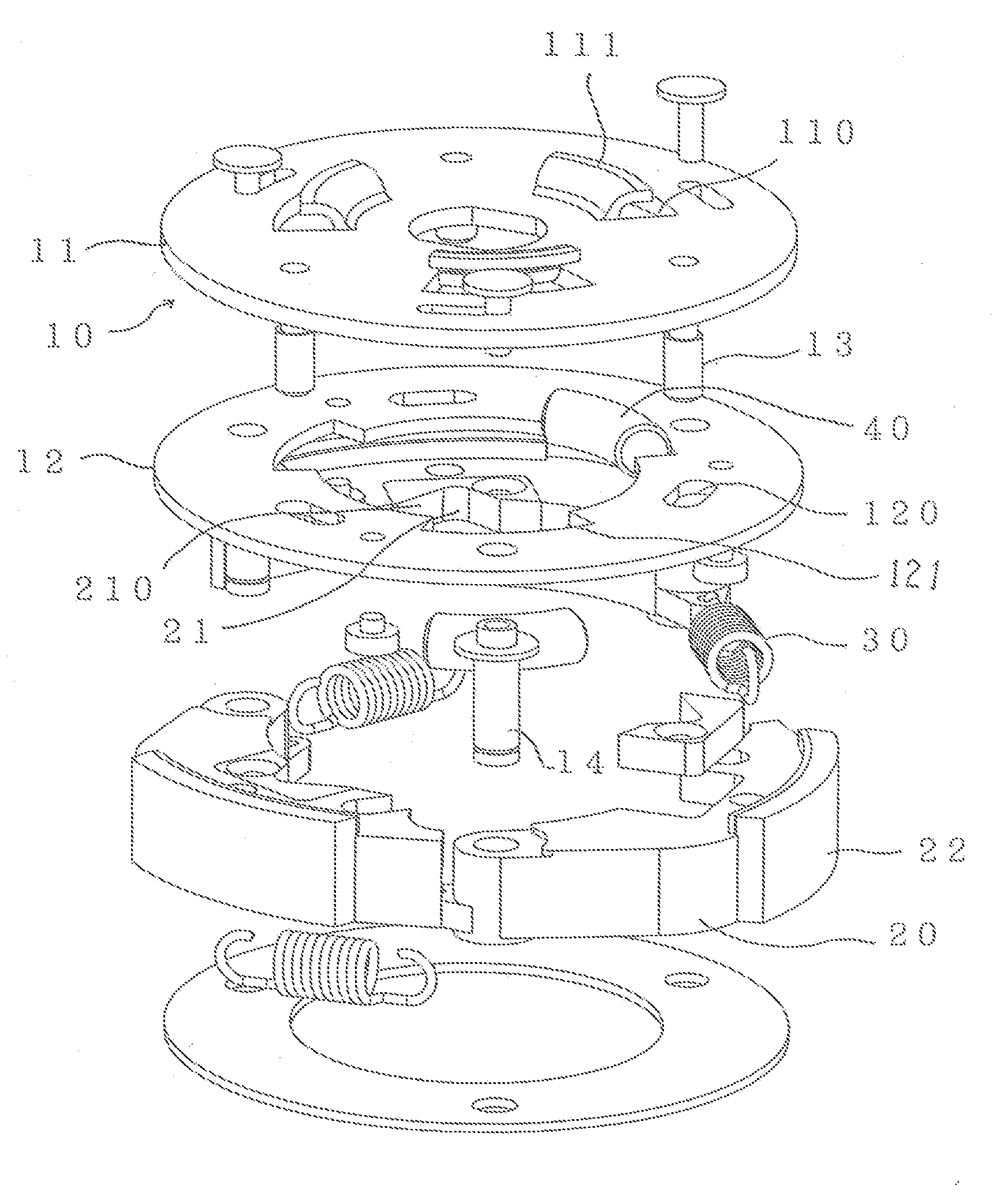

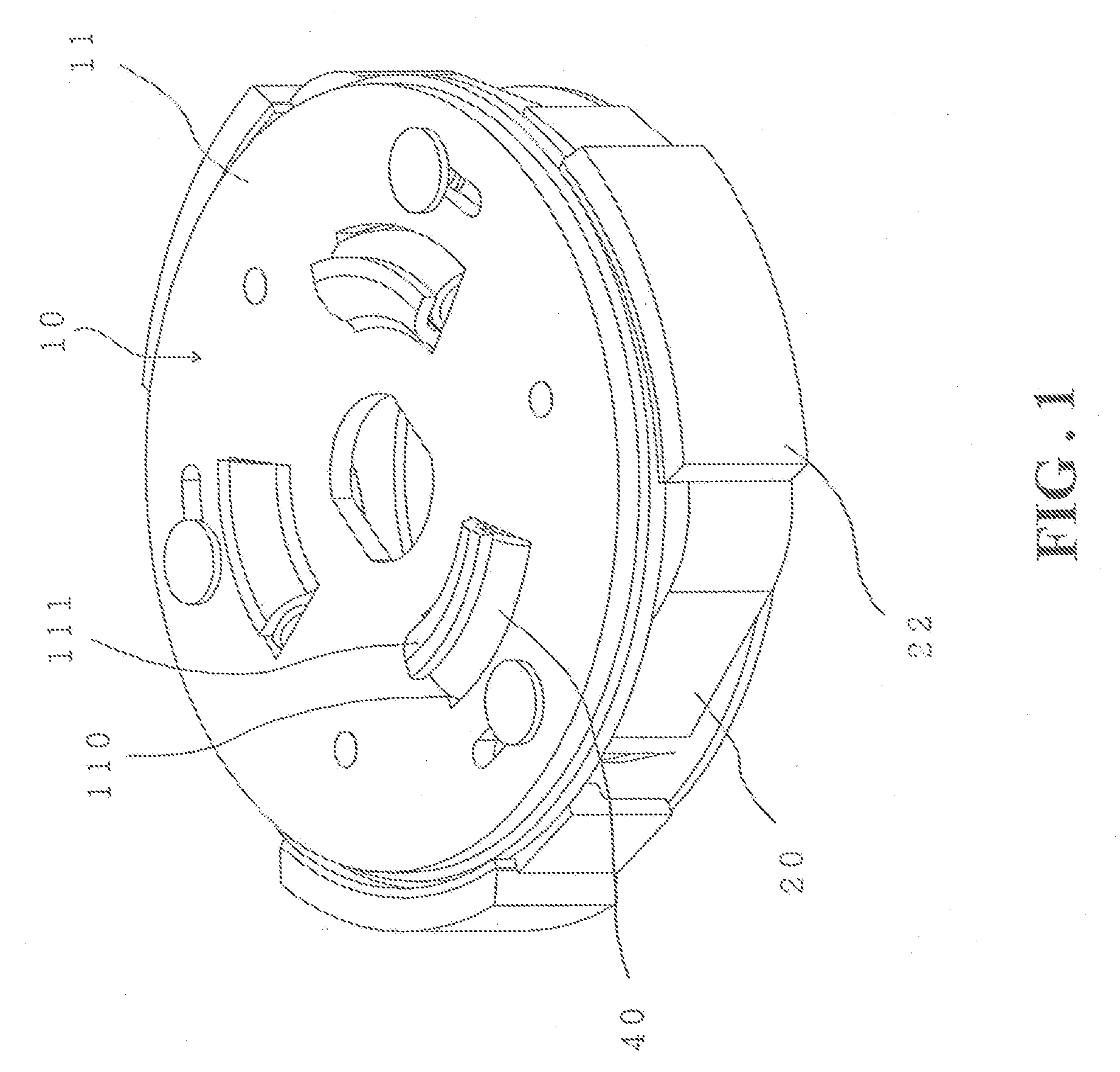

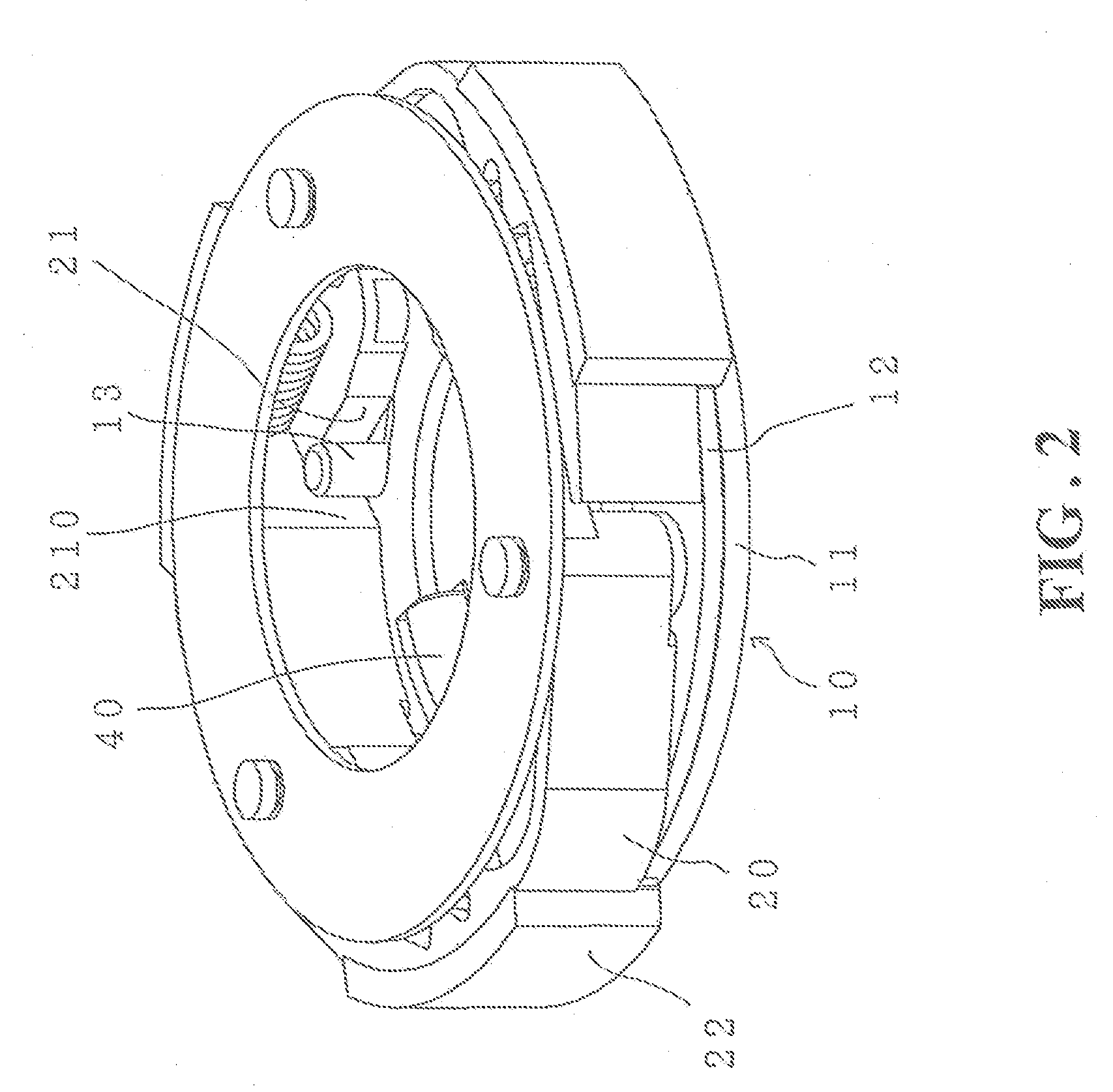

Clutch

ActiveUS20080053783A1Increase engagementFacilitates stability of powerAutomatic clutchesEngineeringUltimate tensile strength

A clutch having high engaging force and featuring of smooth operation, wherein clutch weights that are biased by return elements are subject to thrusting force caused by constraint sections of a main driving plate that receive and convert torque from an engine into the pressing action against engaging slots defined in the clutch weights so as to gain enhanced engaging force even when the minor difference or error existing on the response time of the clutch weight or the strength of the return elements and also provides anti-reversal function to reduced the oscillation and let the power output more smooth and more stable. Accordingly, slippage of clutch and wear of the clutch wear pad are both reduced and temperature rise of the wear pad is also reduced.

Owner:TUAN HEUI +2

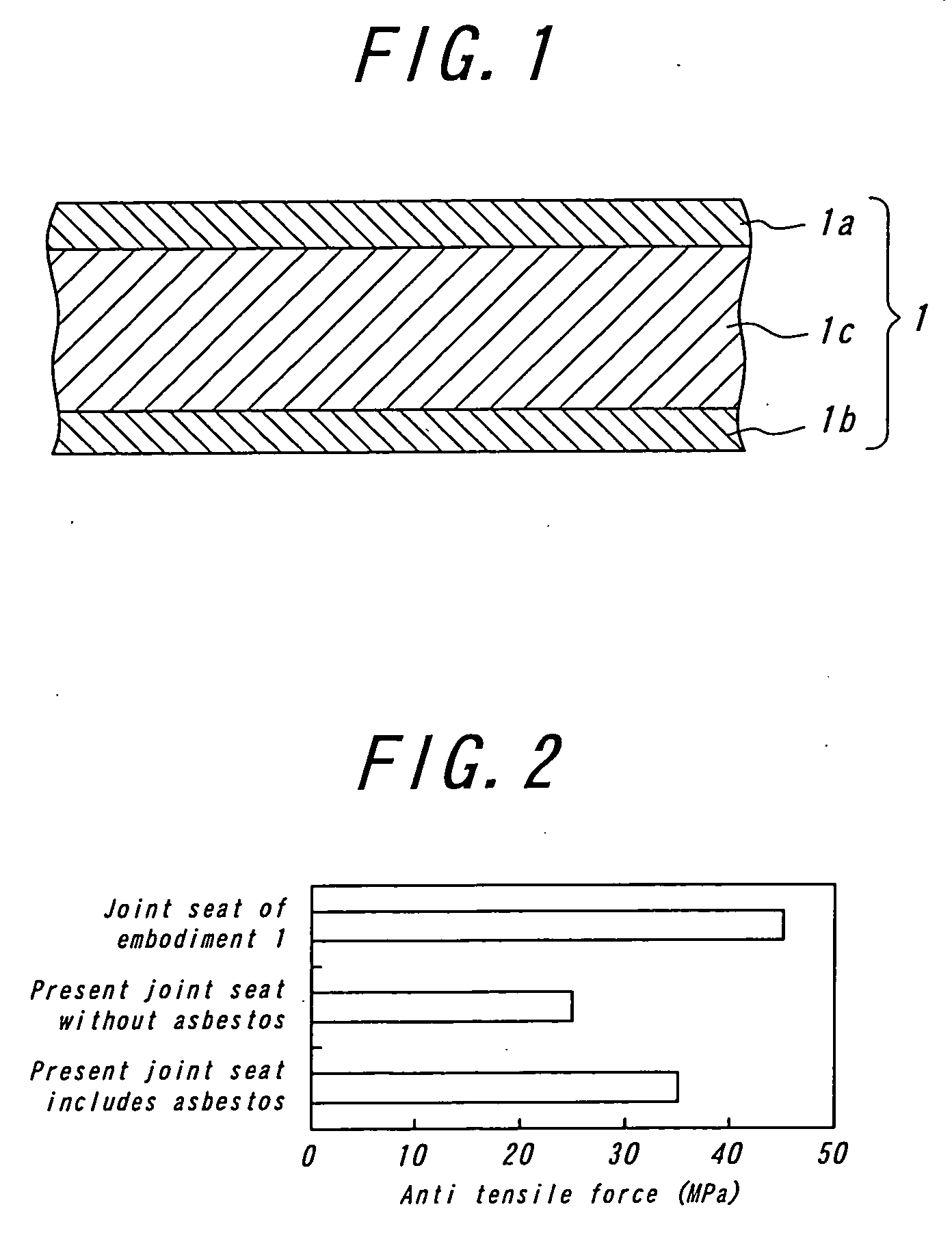

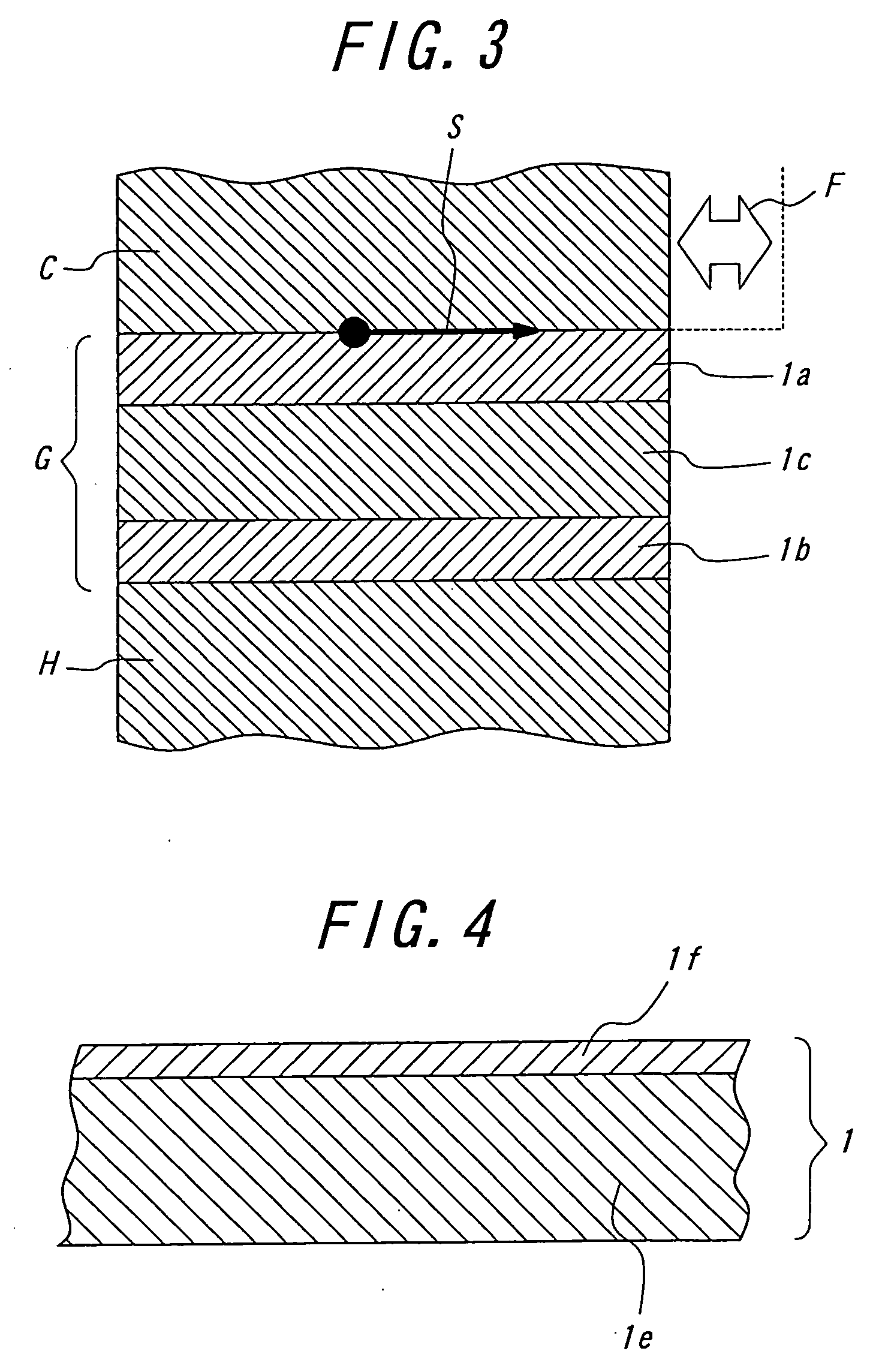

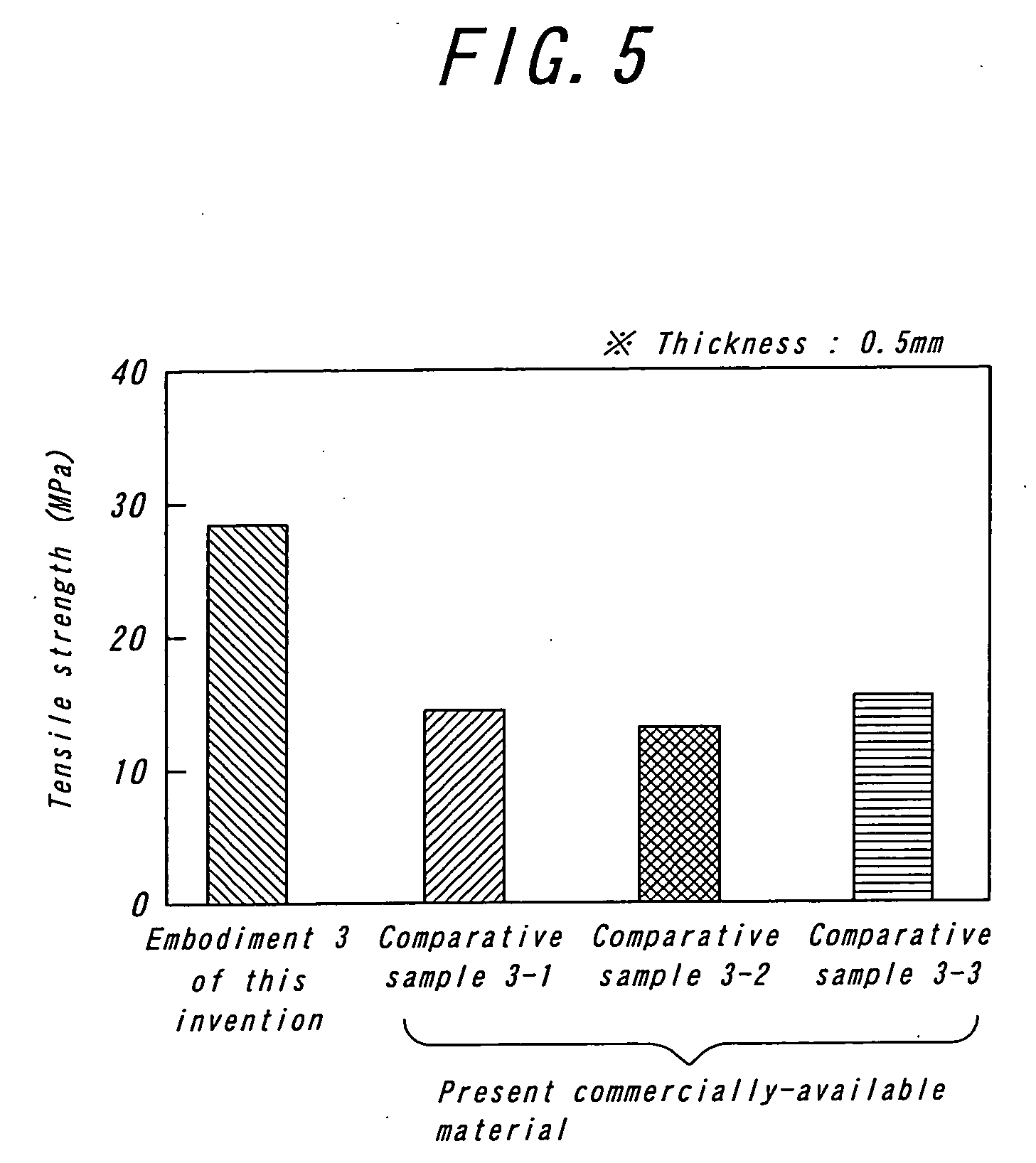

Gasket material

The gasket material that is manufactured from a joint seat which includes three layers, that is, a front surface layer (1a), a back surface layer (1b) and the middle layer (1c), and these layers have different composition of reinforced fiber and filler respectively, and this joint seat is made from an ingredient made by mixing and kneading rubber, reinforced fiber and filler, then pressurized laminating and vulcanizing the ingredient, this joint seat is characterized in that the reinforced fiber is as a sort of fibril which is composed from one or both of organic fiber and non-asbestos type inorganic fiber, and at least a part of the filler is spicular inorganic fiber and its composition is 10 wt %-45 wt %. According to this joint seat (1), a crack breakage of the gasket that the ingredient material is the joint seat (1) due to fretting is prevented.

Owner:NIPPON LEAKLESS IND CO LTD +1

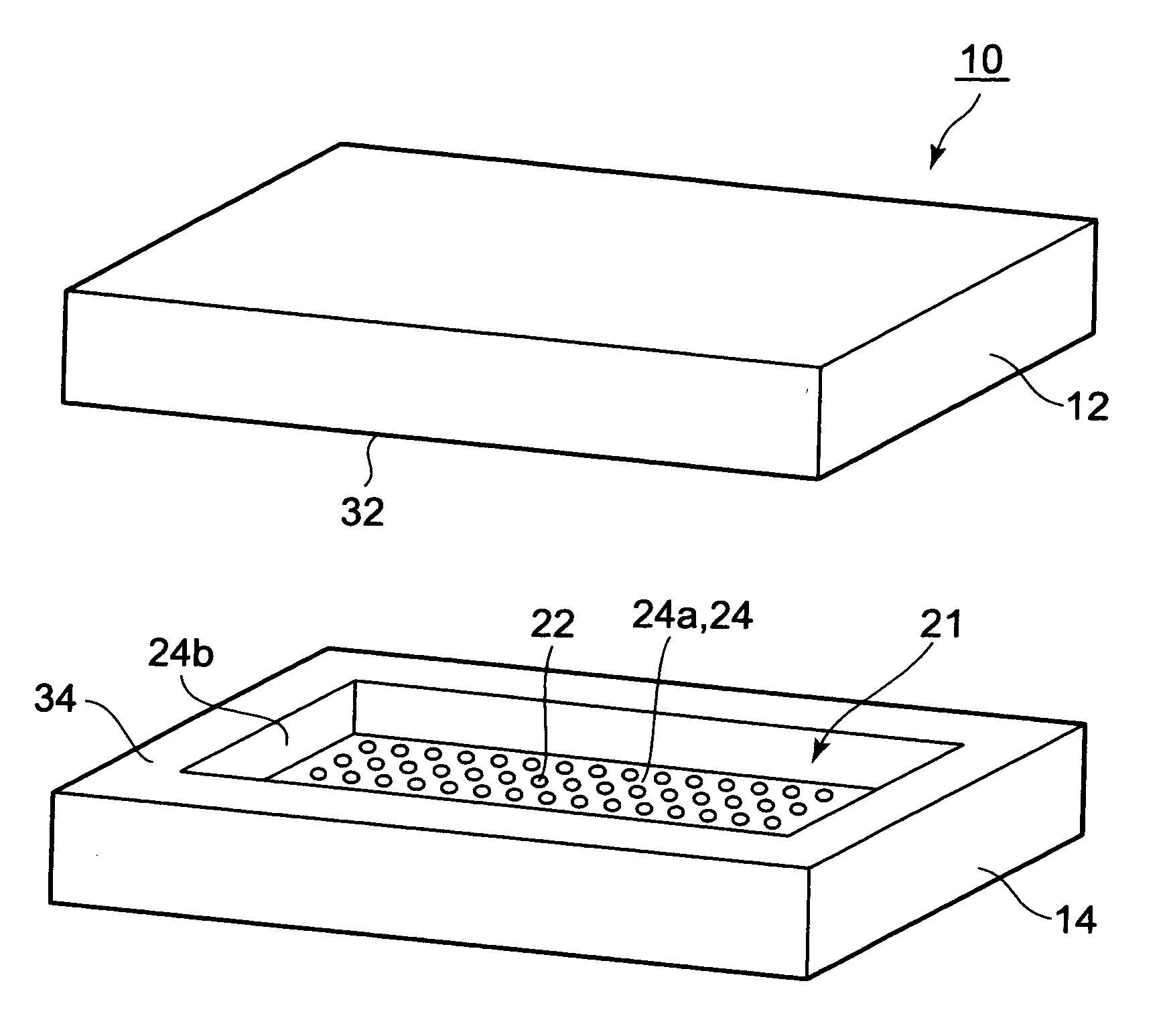

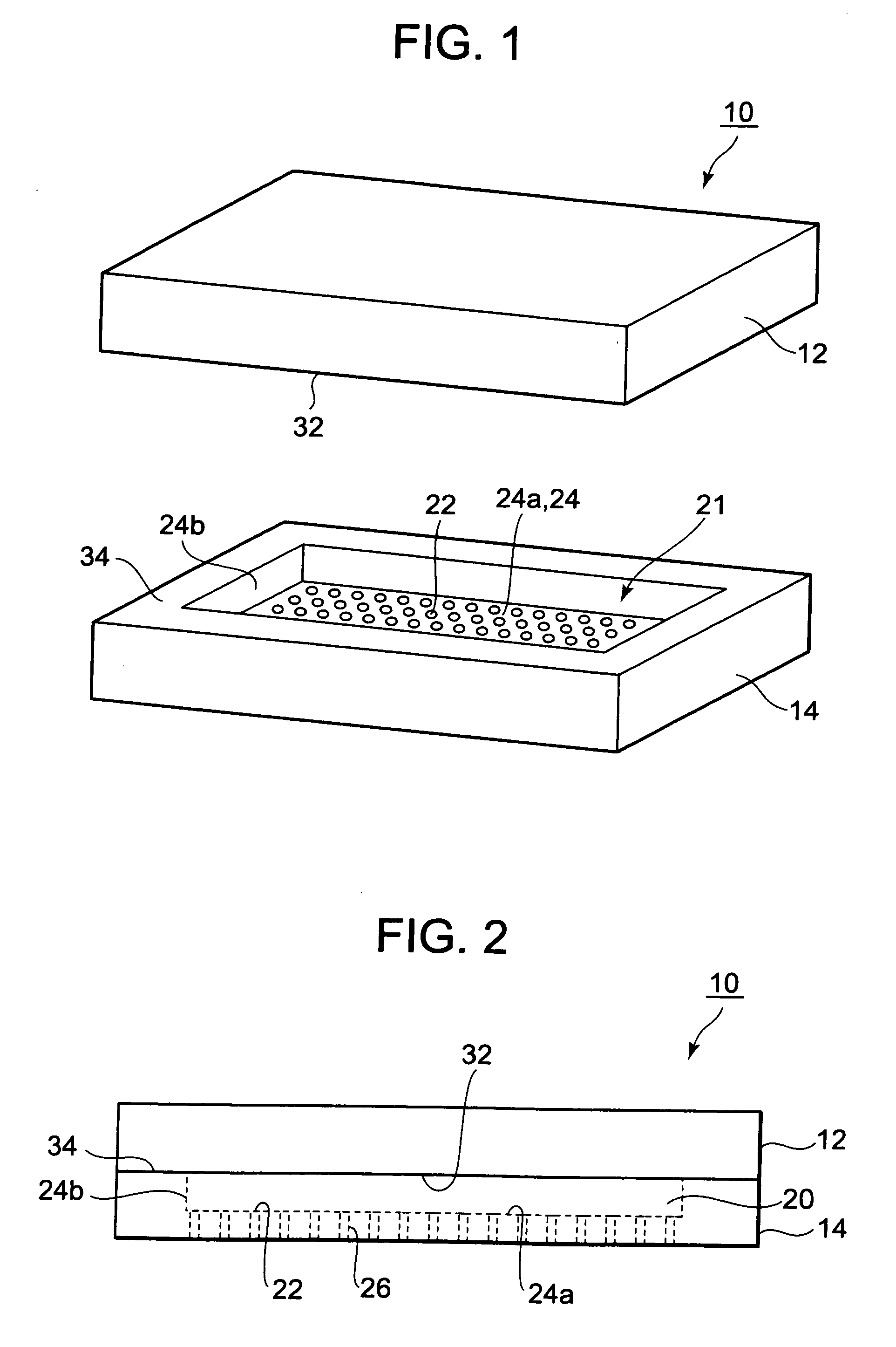

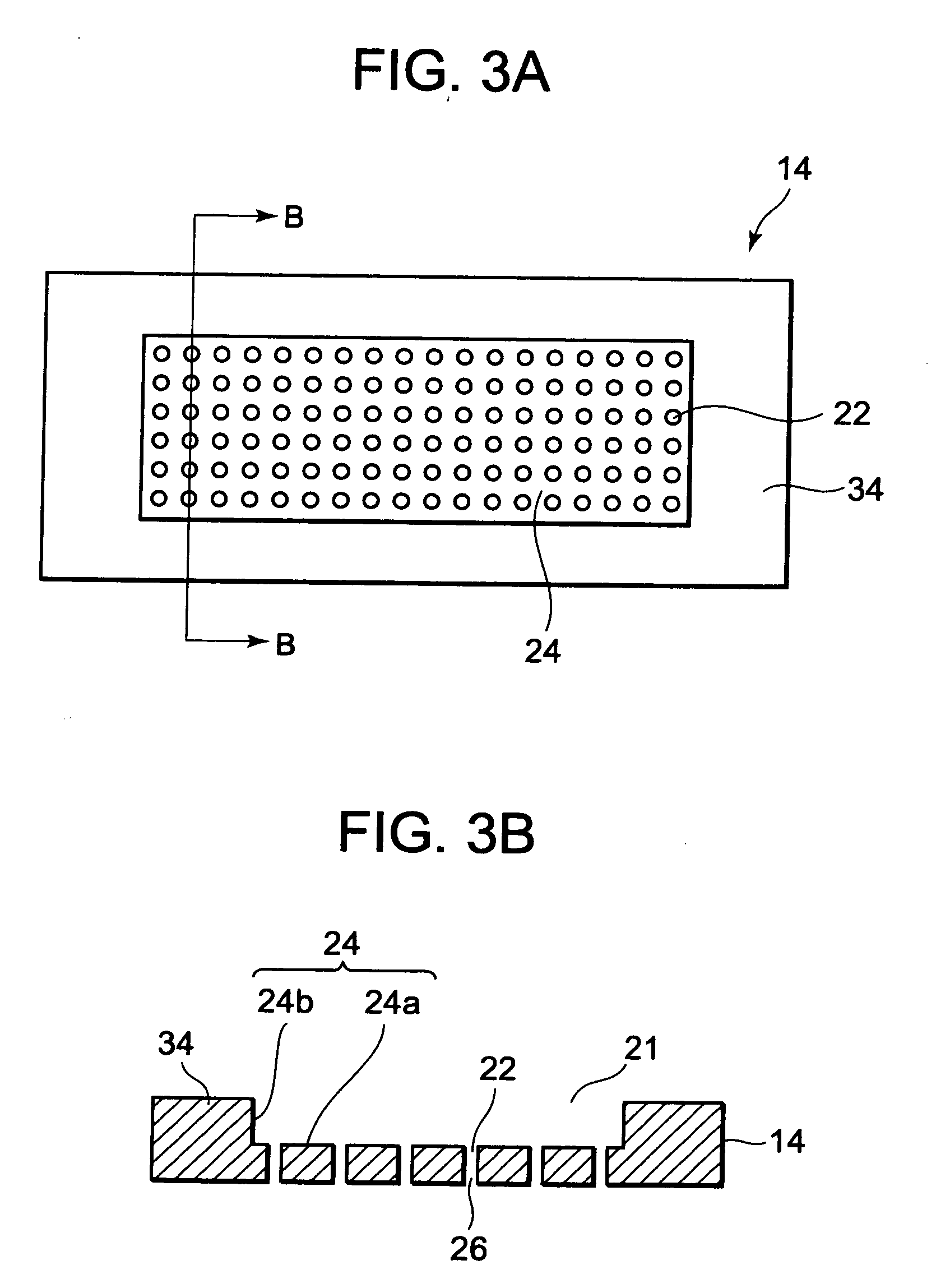

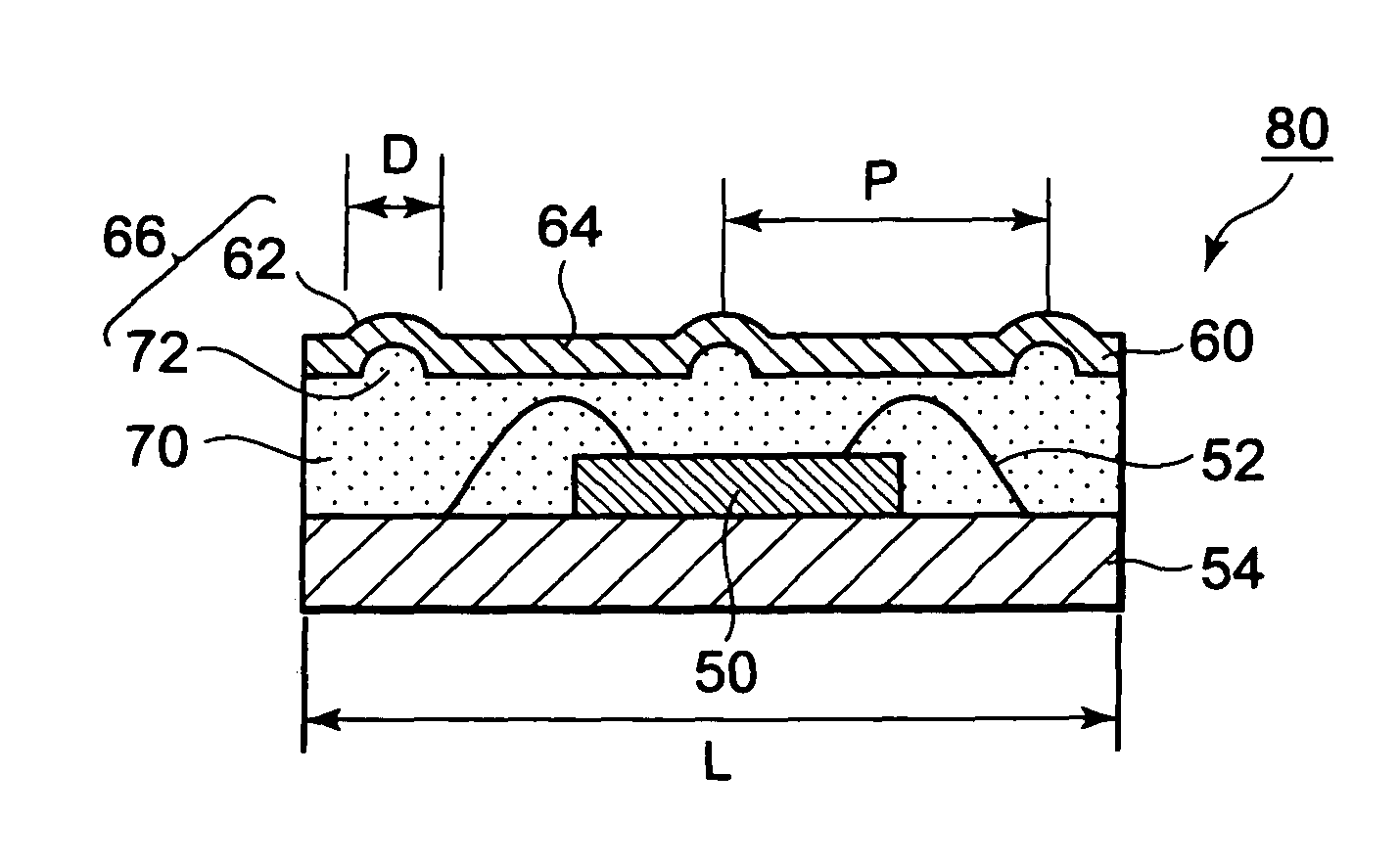

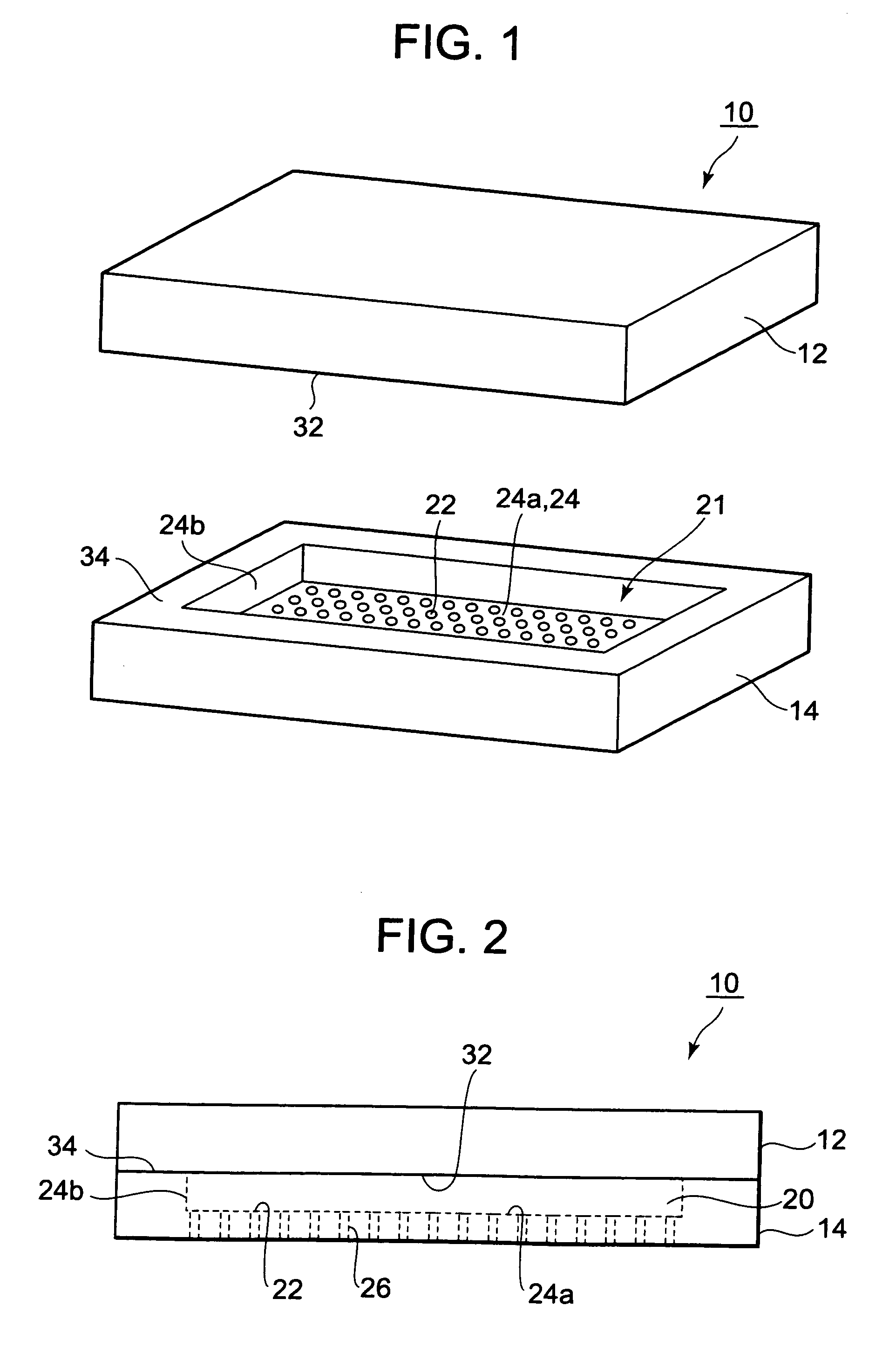

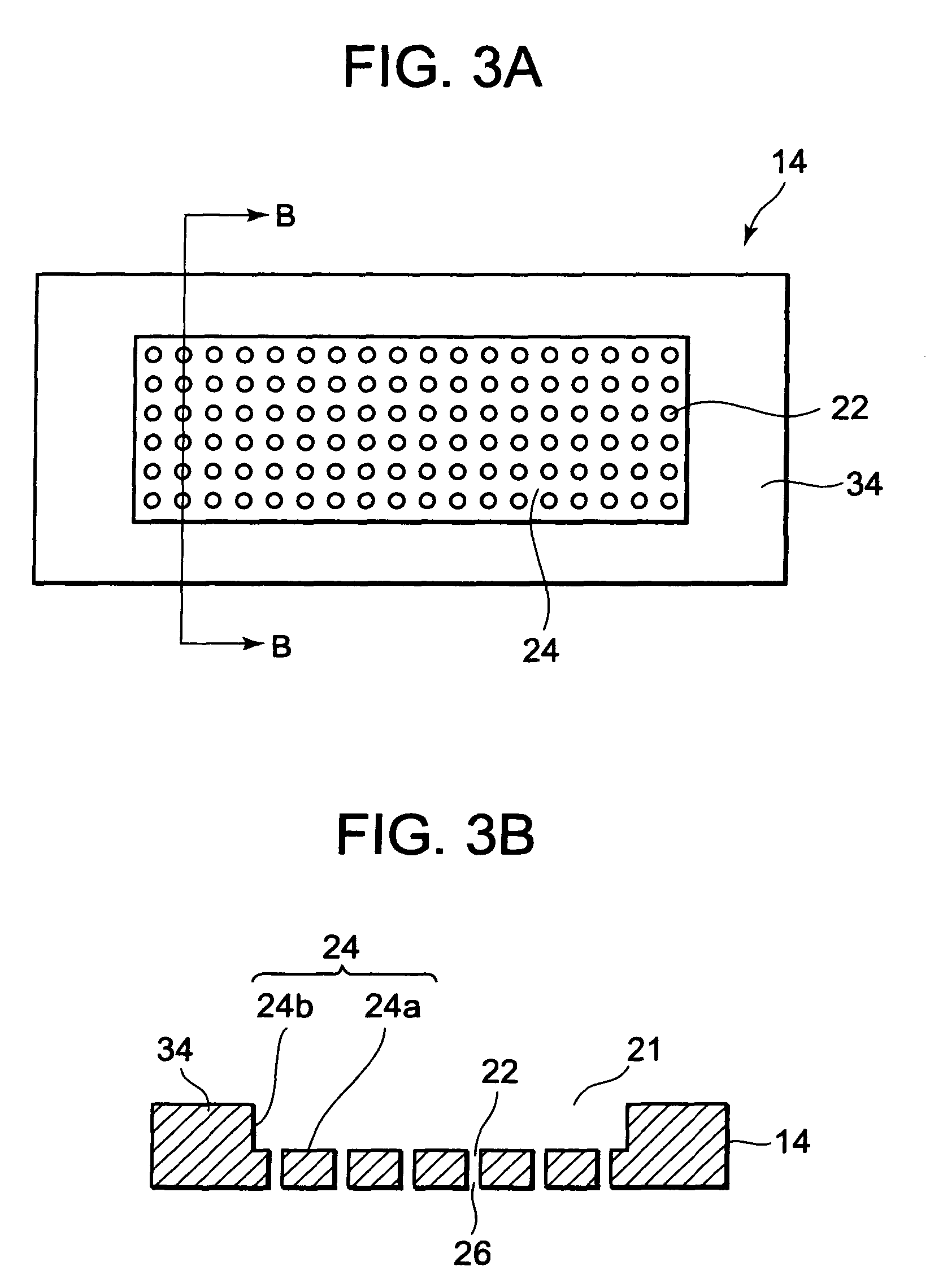

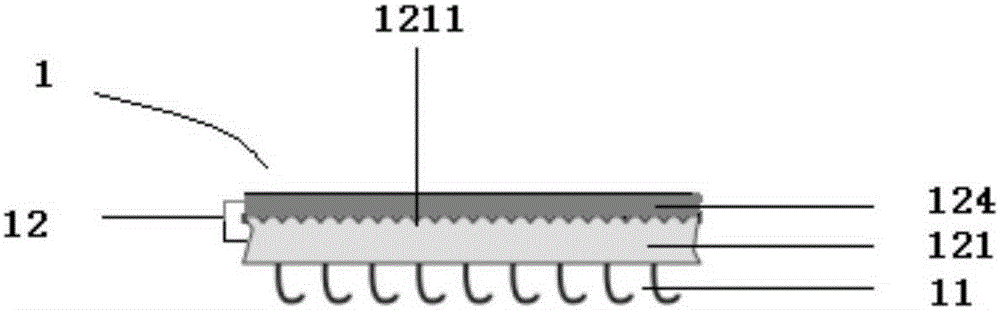

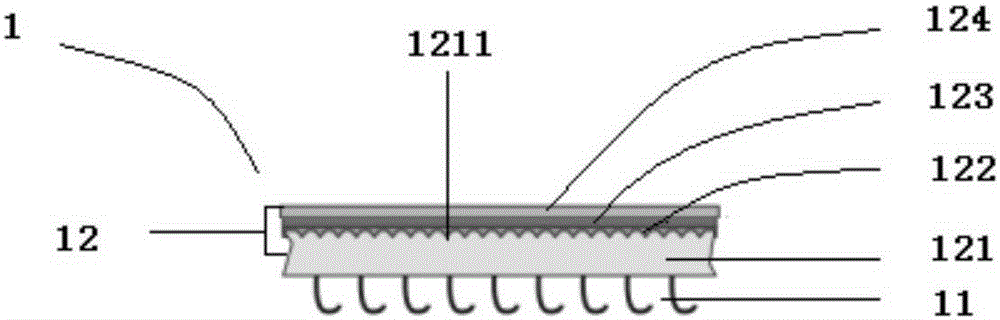

Method of manufacturing a semiconductor device and molding die

InactiveUS20090291531A1Resistant to peelingHeat be favorably diffusedSemiconductor/solid-state device detailsConfectioneryShell moldingSemiconductor chip

A method of manufacturing a semiconductor device capable of obtaining high joining force between a heat spreader and resin is provided. The method of manufacturing a semiconductor device according to the present invention includes: setting a heat spreader 60 on a face formed a plurality of apertures 22 in a cavity 21 of a first molding die 14; filling resin 20 into the cavity; setting a substrate 54 mounted with a semiconductor chip 50 a second molding die 12; and pressure-welding the first molding die 14 and the second molding die 12 so that the semiconductor chip is embedded in the resin 20, wherein a plurality of concave portion is formed on one face of the heat spreader 60, a plurality of convex portions is formed on the other face of the heat spreader 60, and the plurality of concave portions and the plurality of convex portions are overlapped in plan view.

Owner:RENESAS ELECTRONICS CORP

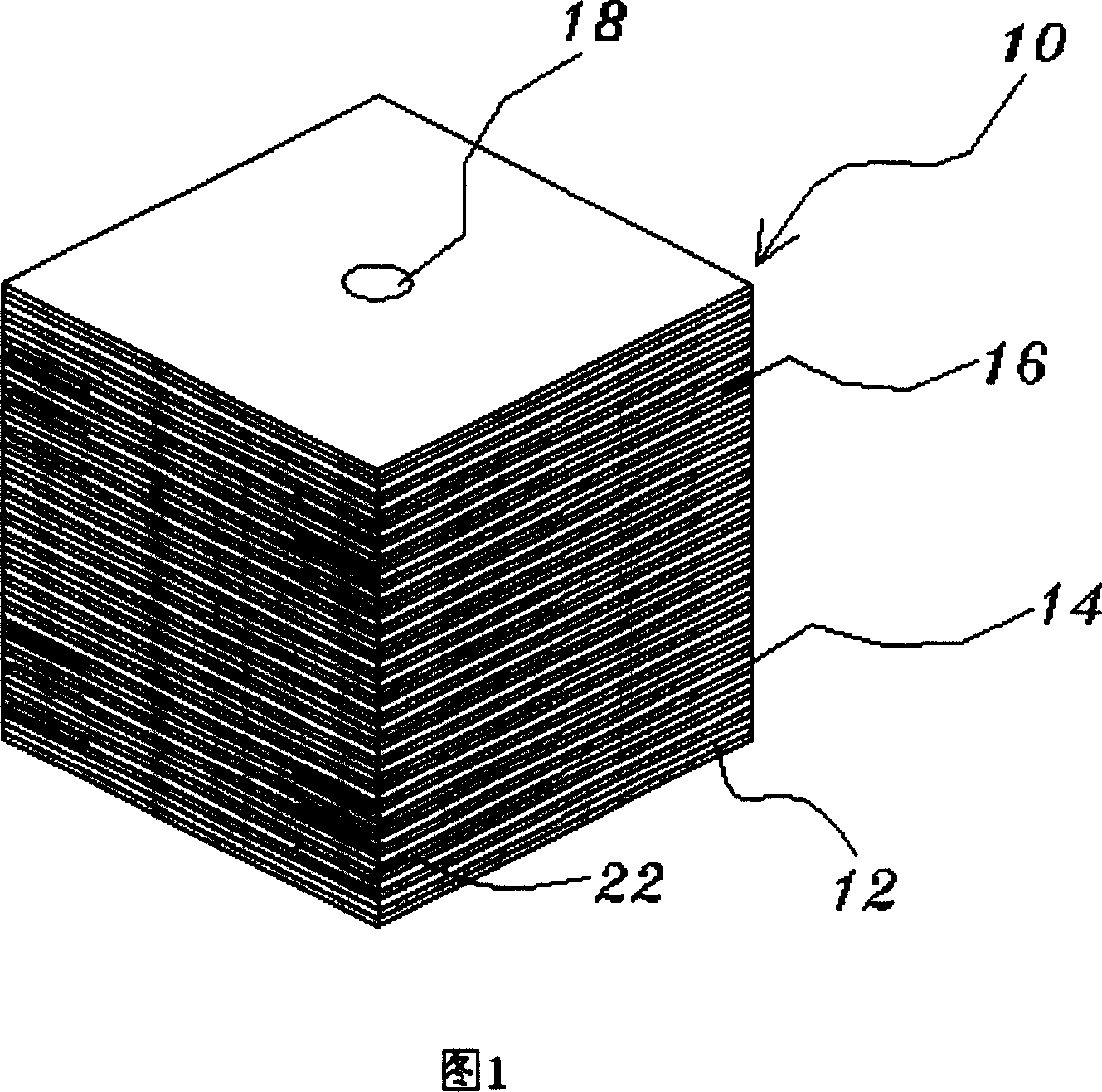

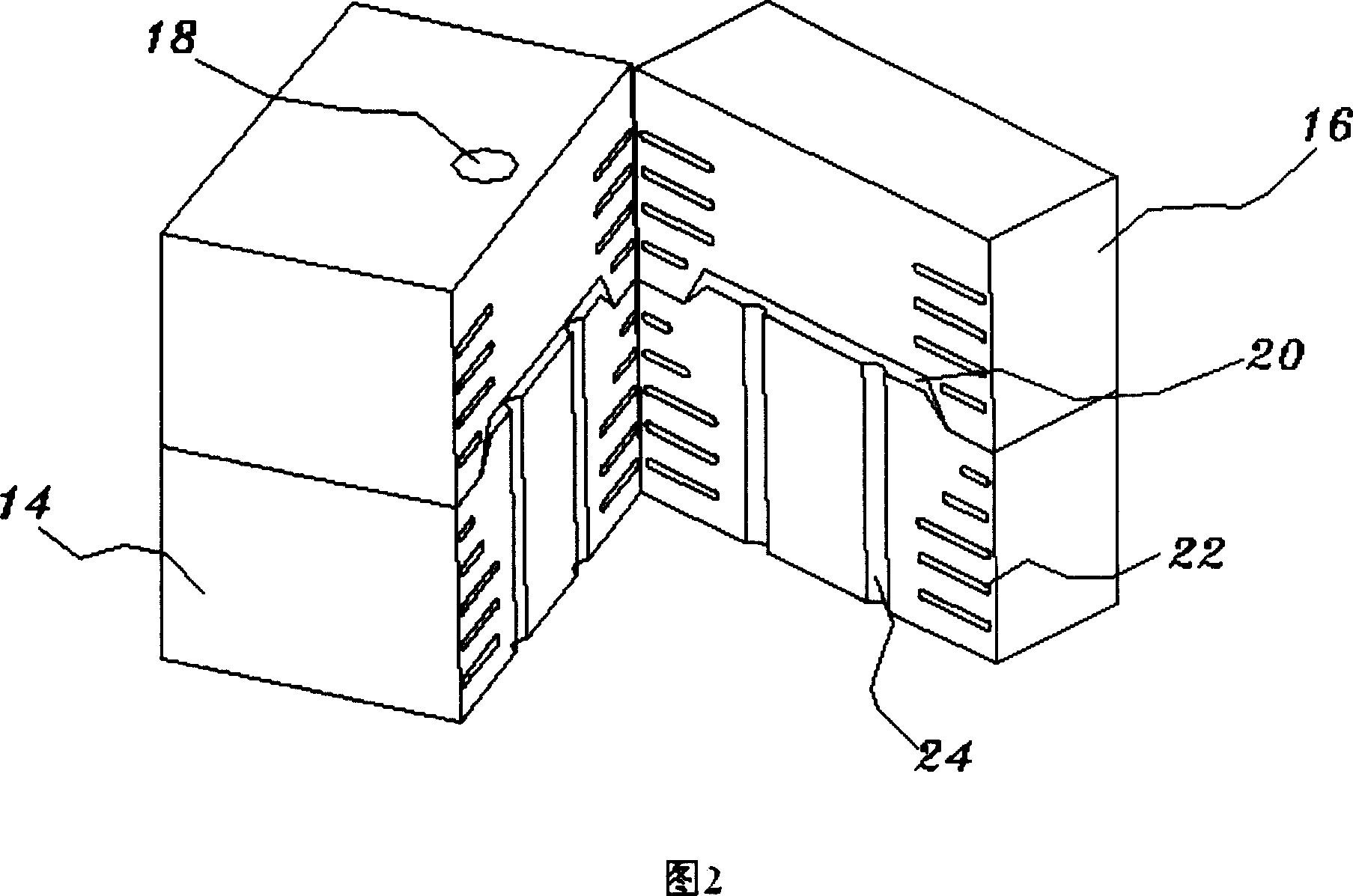

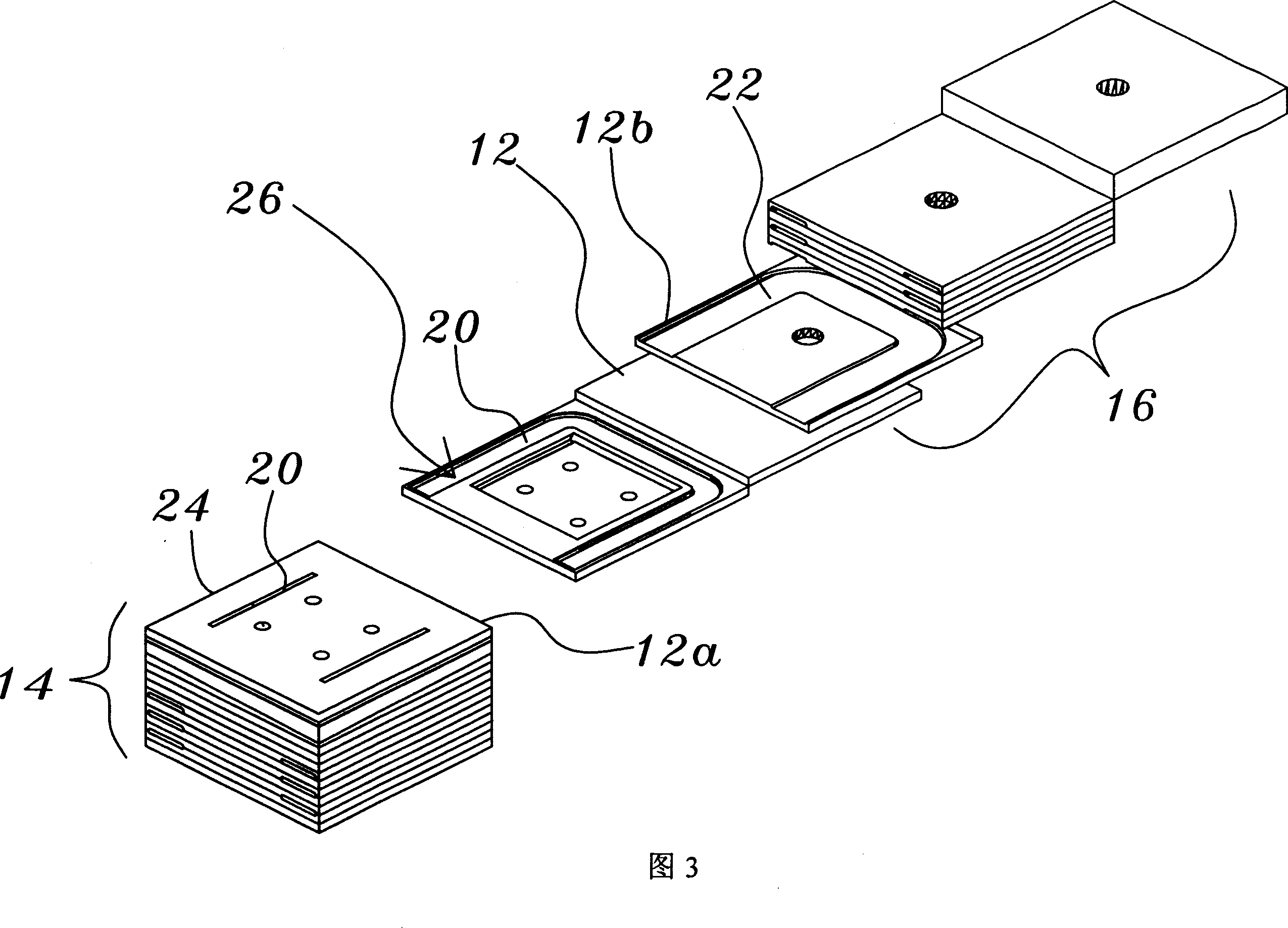

Method for manufacturing mould and its structure

InactiveCN101062538AReduce manufacturing costShorten production timeFoundry mouldsFoundry coresManufacturing engineering

The invention relates to a mold fabrication method by dividing at least one patterned notch on several thin plates, laminating machining on each cut plate, stacking them into the mold, with the notches formed into the mold cavity, cooling system and ejection system. It can greatly reduce the manufacturing cost and time of mold, getting rid of the extra size of the mold, shrinking it to achieve the goal of light mold.

Owner:林承洋

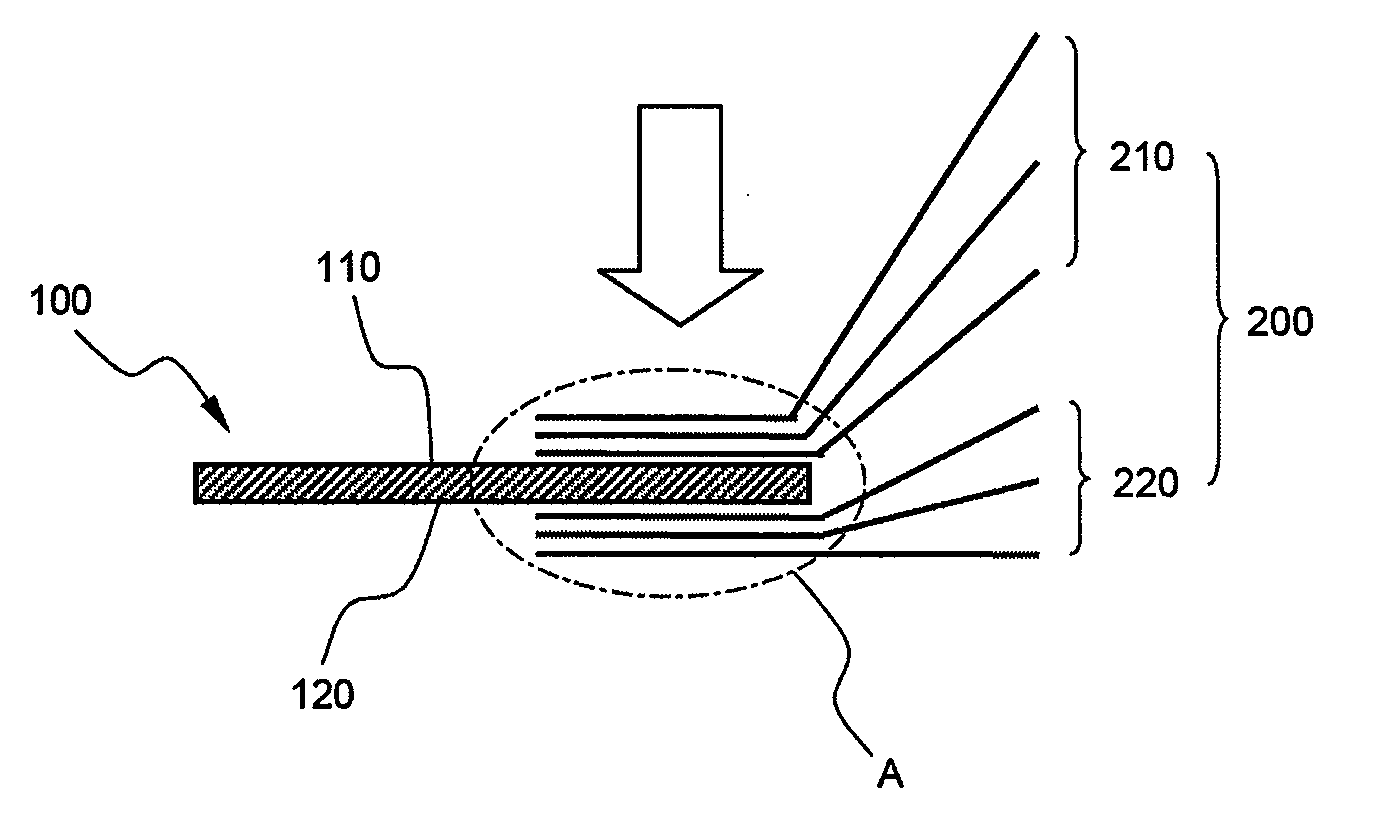

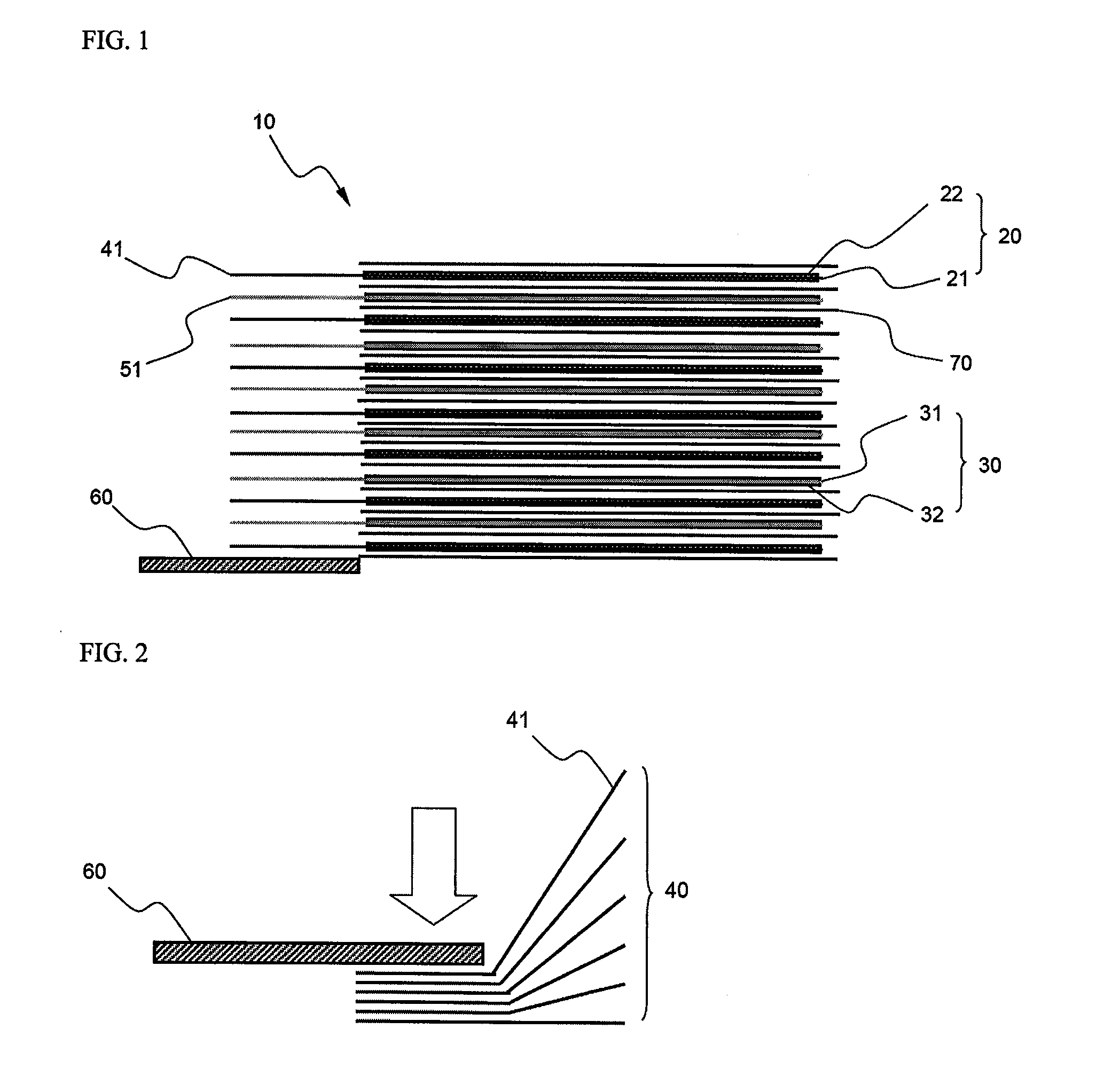

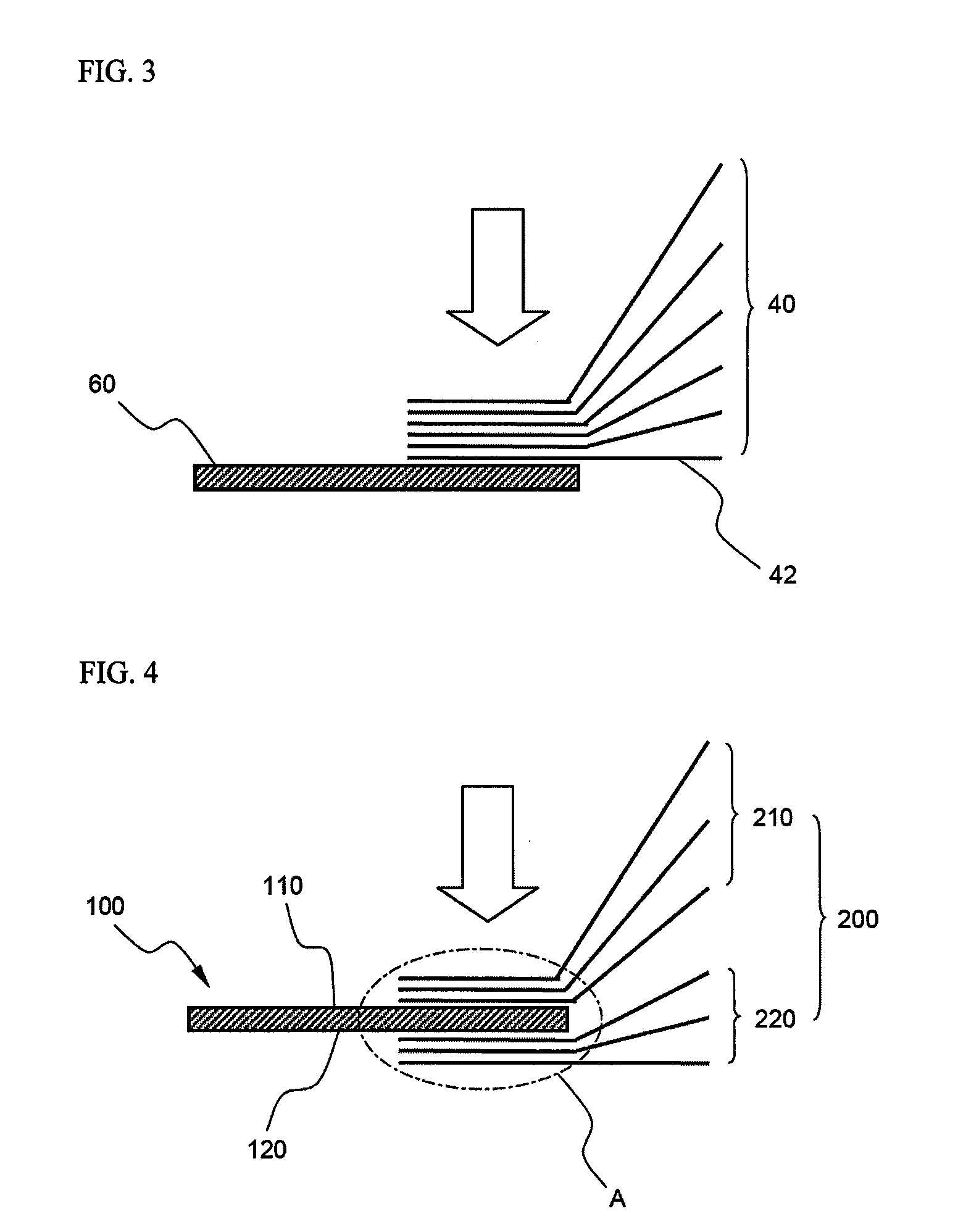

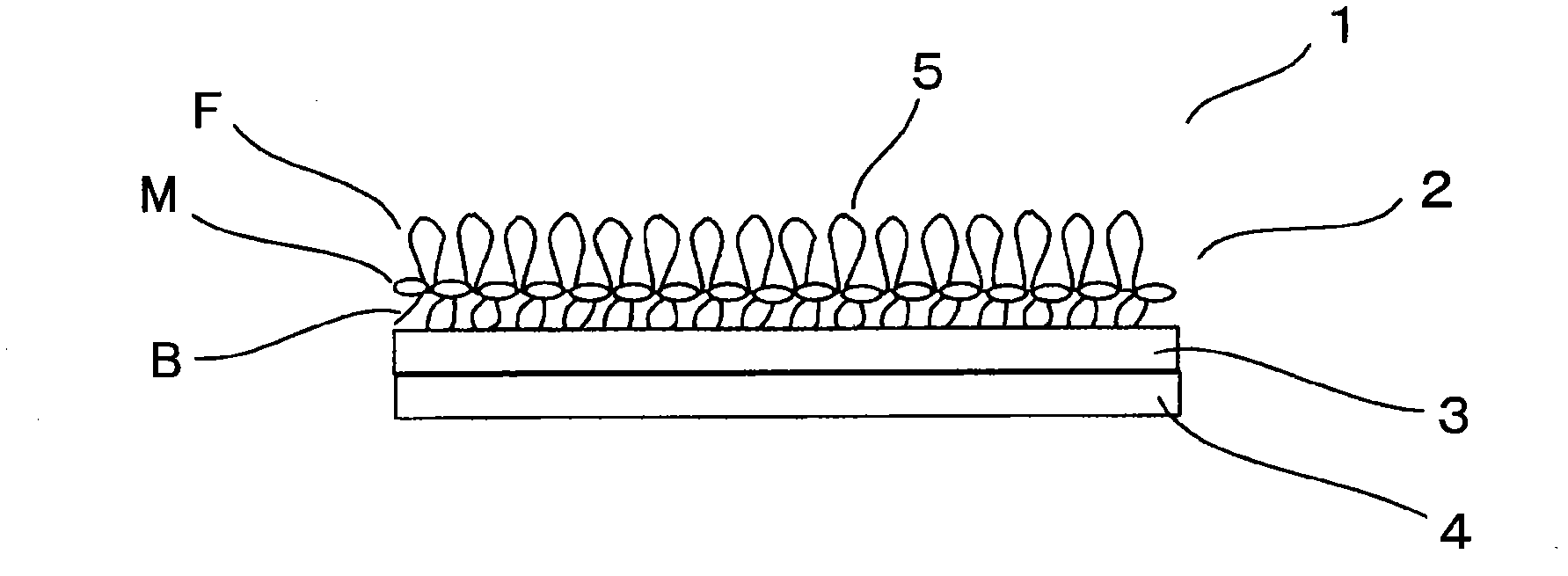

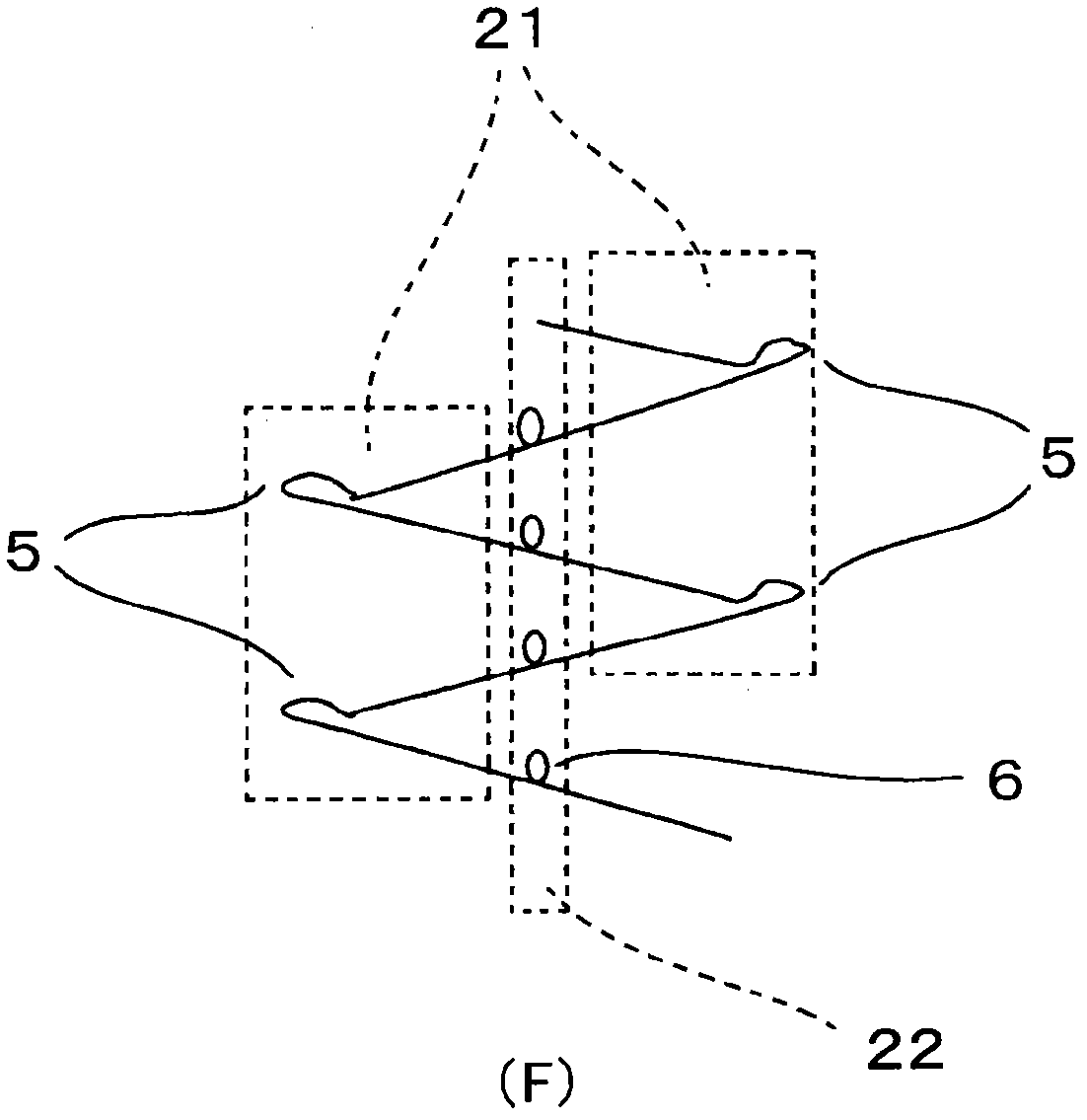

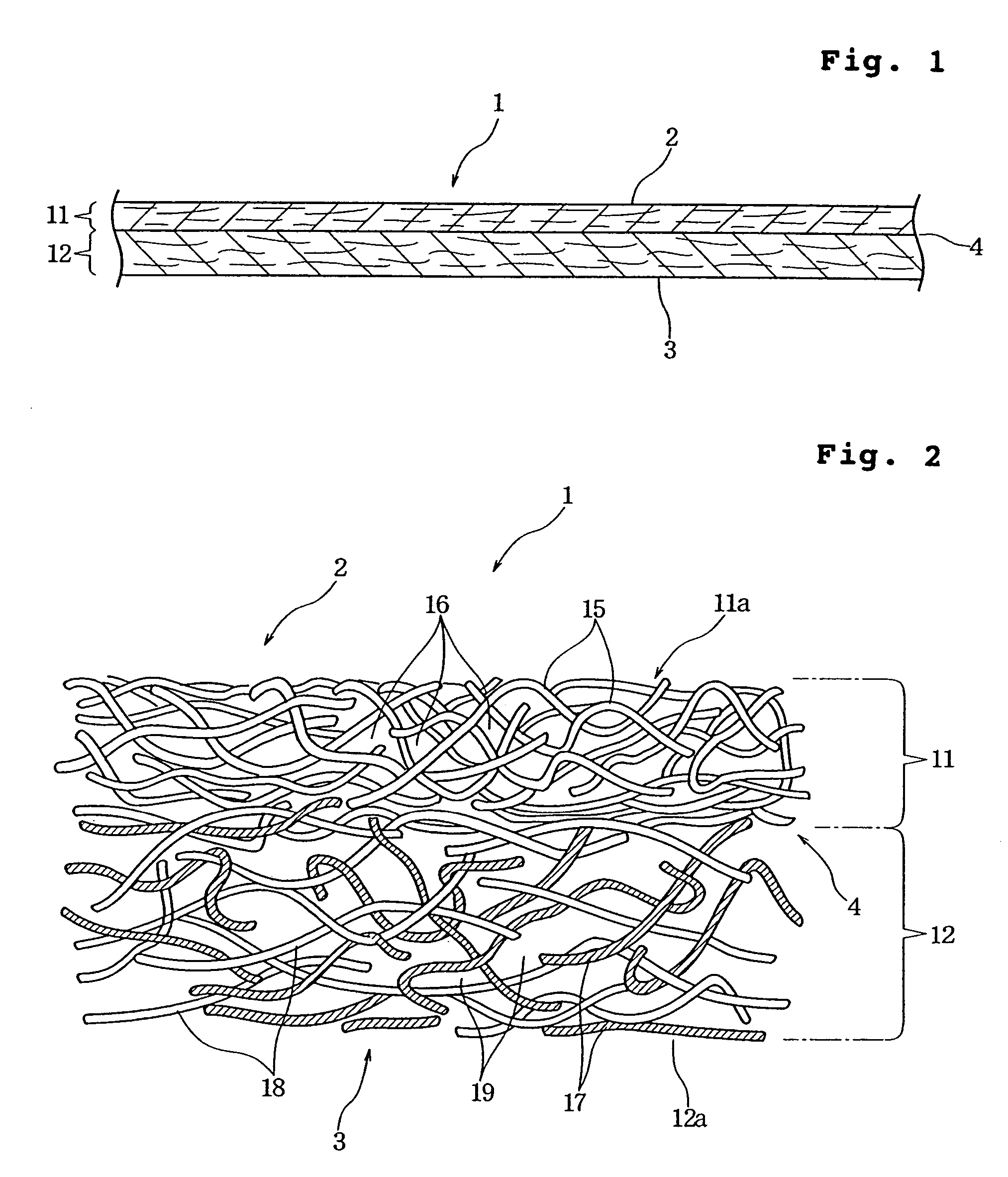

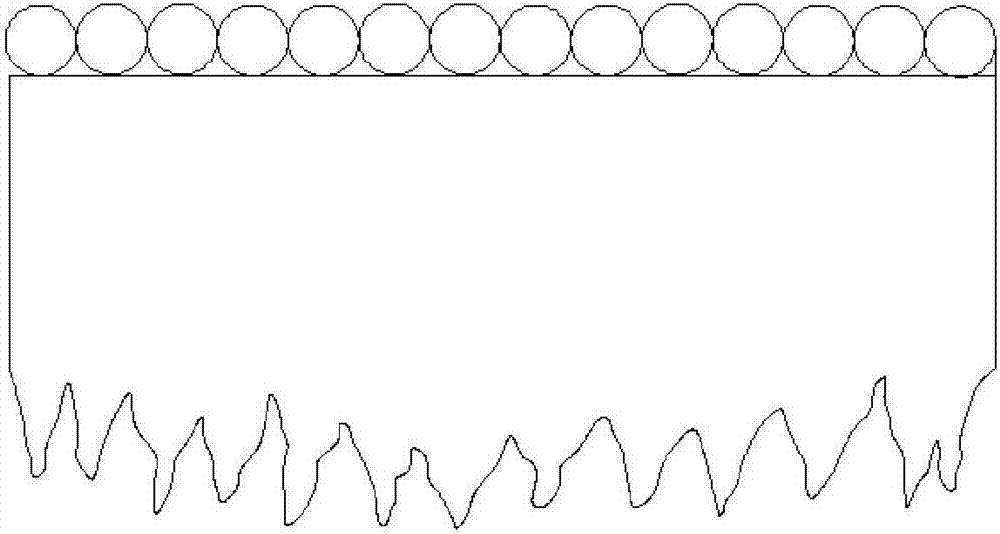

Knitted Fabric For Hook-and-loop Fastener

[Problem] To provide a knitted tricot fabric having a high fabric strength and a low cost, which is to be used in a female member of a hook-and-loop fastener, exhibits a large engagement force with an engaging element and, in the case where said knitted fabric is engaged with engaging elements located on both sides thereof, shows no difference between the engagement forces in both directions. [Solution] A knitted fabric for hook-and-loop fastener, which is a knitted tricot fabric consisting of a knitting yarn in the front face part, a knitting yarn in the middle part and a knitting yarn in the back face part, wherein the knitting yarn in the front face part, the knitting yarn in the middle part and the knitting yarn in the back face part are each provided with loops formed at definite intervals, the loops formed in the knitting yarn in the front face part are connected with the loops formed in the knitting yarn in the middle part, and the loops formed in the knitting yarn in the middle part are connected to the loops formed in the knitting yarn in the back face part. In the knitted tricot fabric, a same number of piles are formed by the knitting yarn in the front face part alternately from side to side, and the knitting direction of the loop-forming knitting yarn in the front face part is opposite to the knitting direction of the loop-forming knitting yarn in the middle part while the knitting direction of the loop-forming knitting yarn in the middle part is opposite to the knitting direction of the loop-forming knitting yarn in the back face part.

Owner:LU PU CO LTD

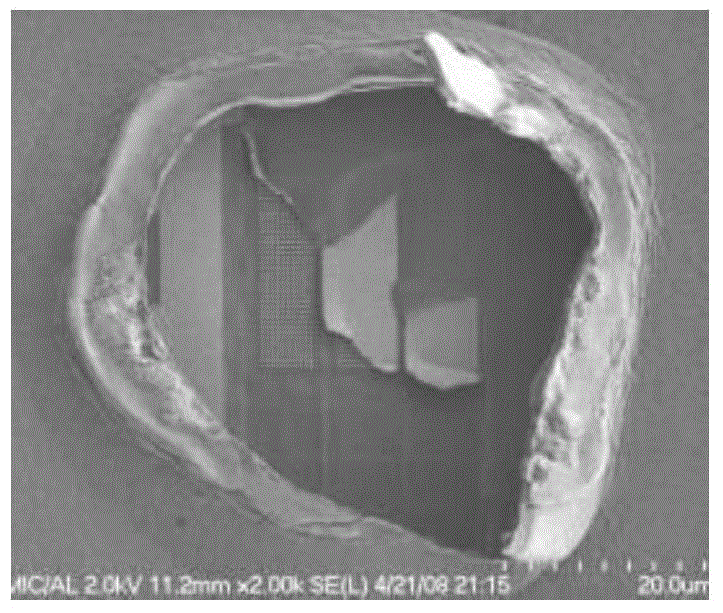

High-voltage discharge lamp and its manufacture

InactiveCN1407597AAvoid crackingCrack suppressionGas discharge lamp detailsCold cathode manufactureMetal foilPhysics

A high pressure discharge lamp includes a vessel made mainly of quartz including a luminous portion and side tube portions extending from both sides of the luminous portion; mercury enclosed in the luminous portion; a metal foil buried in each of the side tube portion; and an electrode rod, one end of which is connected to the metal foil and the other of which is extending to the luminous portion. The electrode rod has a surface area increase structure for increasing a surface area in at least a part of a portion buried in the side tube portion. A sealing portion glass containing at least one metal material selected from the group consisting of metals and metal oxides thereof is provided in a portion of the side tube portion including at least a part of the metal foil, a connection portion between the metal foil and the electrode rod and a part of the surface area increase structure.

Owner:PANASONIC CORP

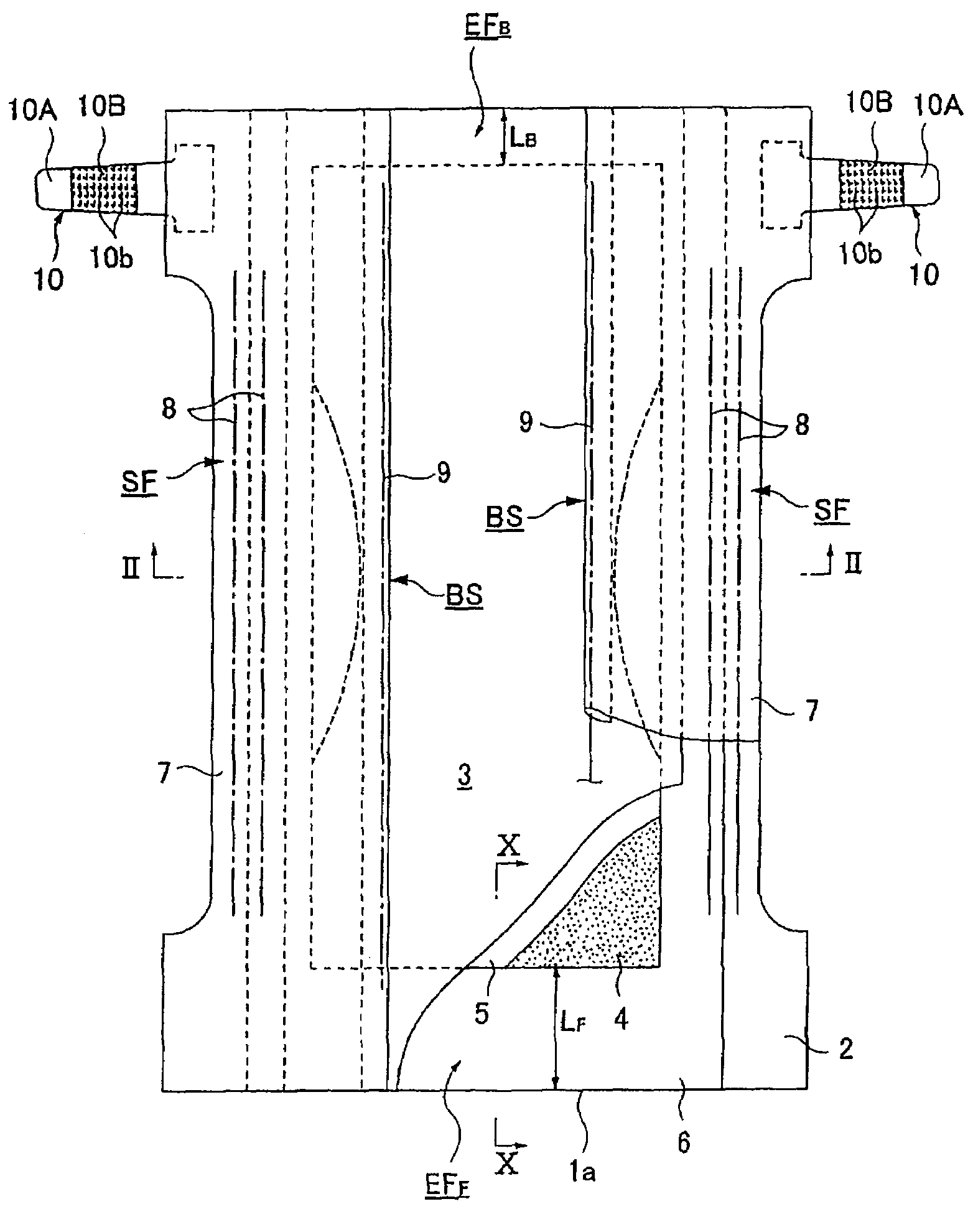

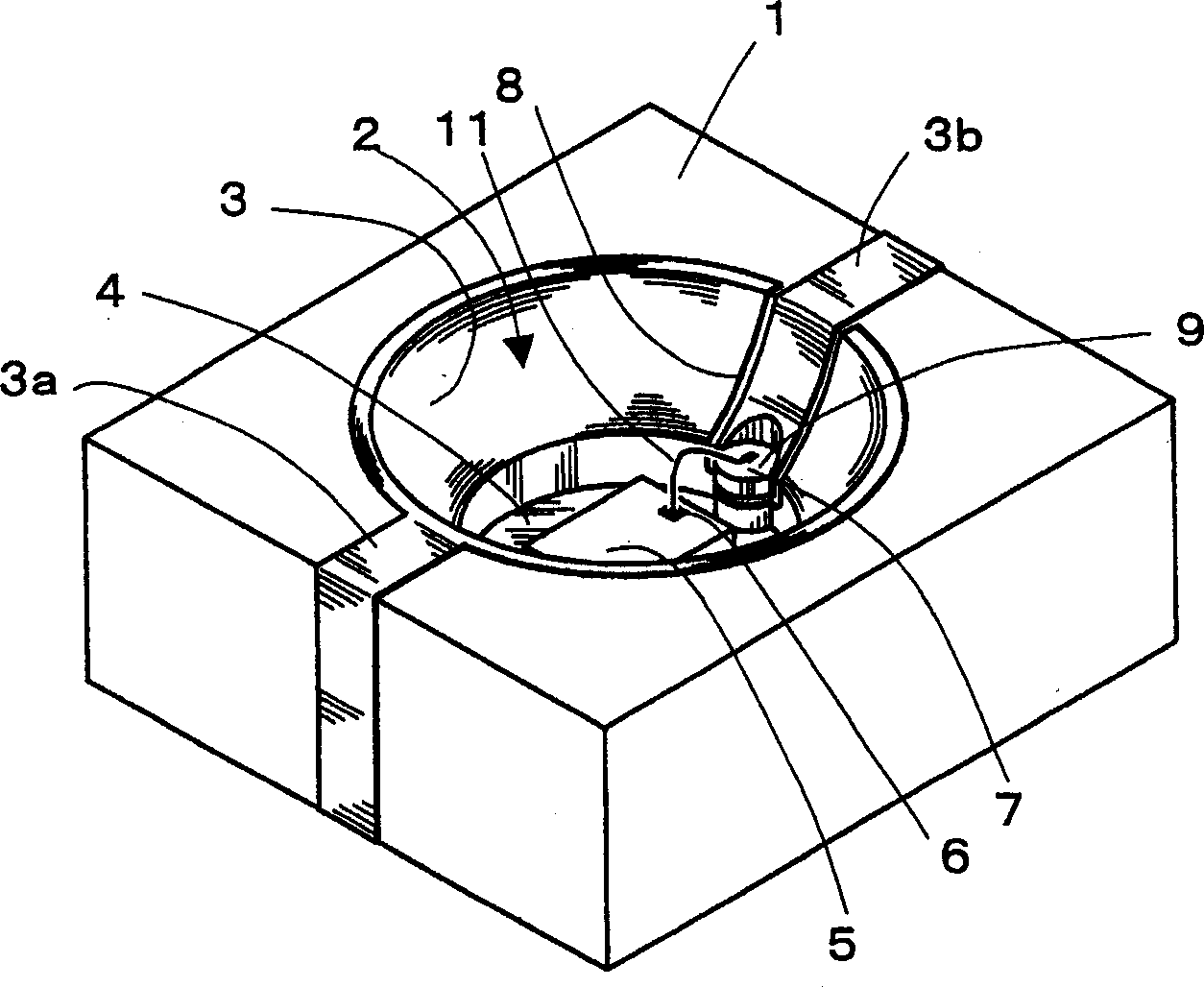

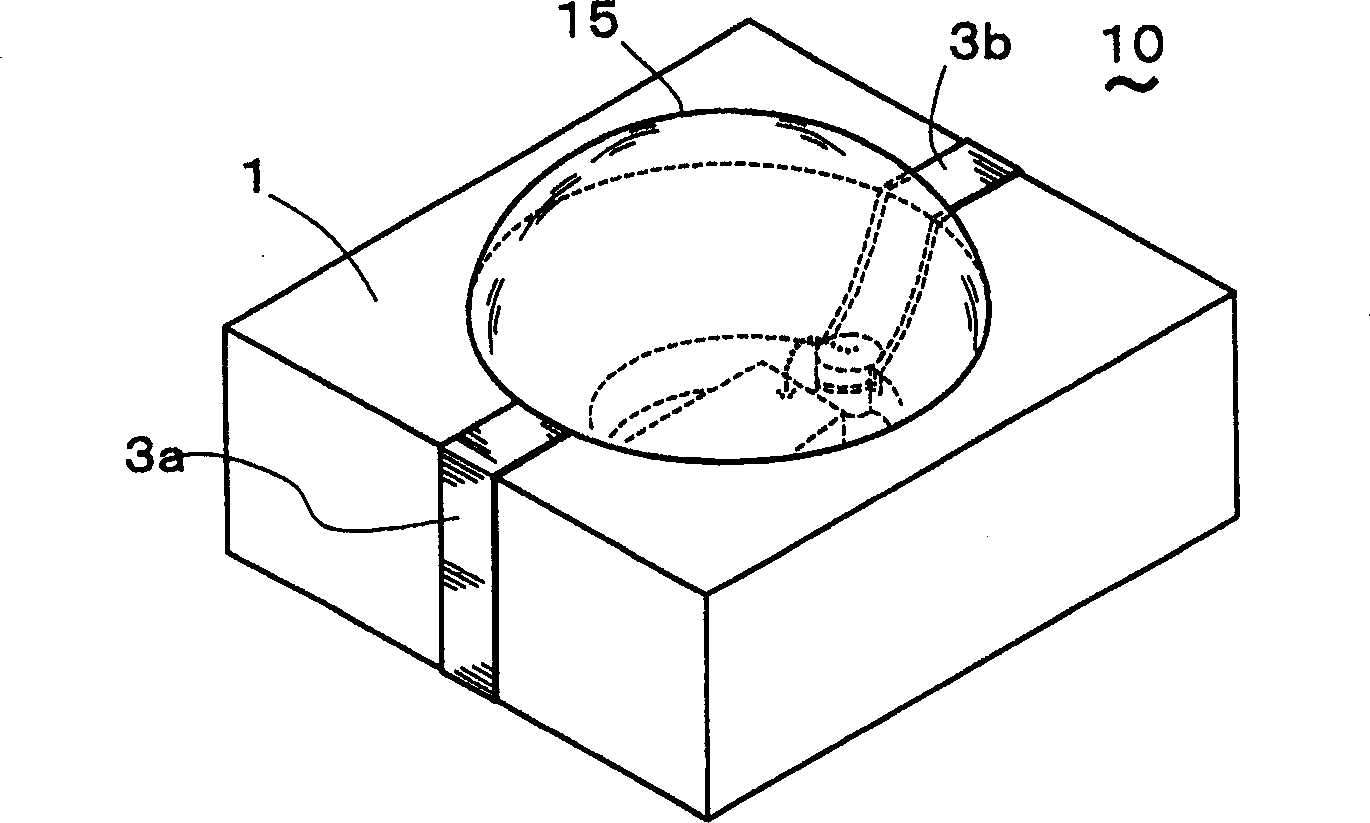

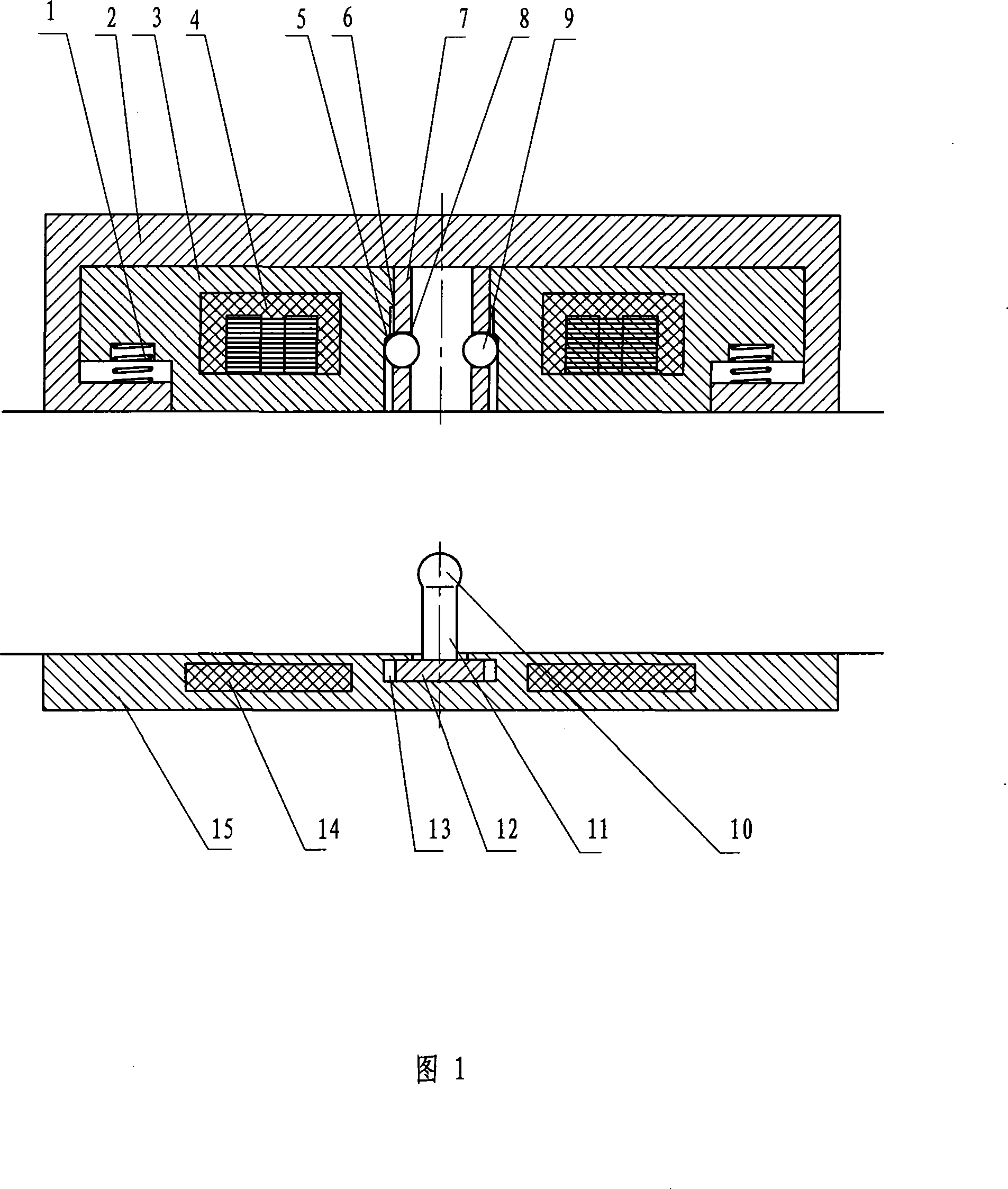

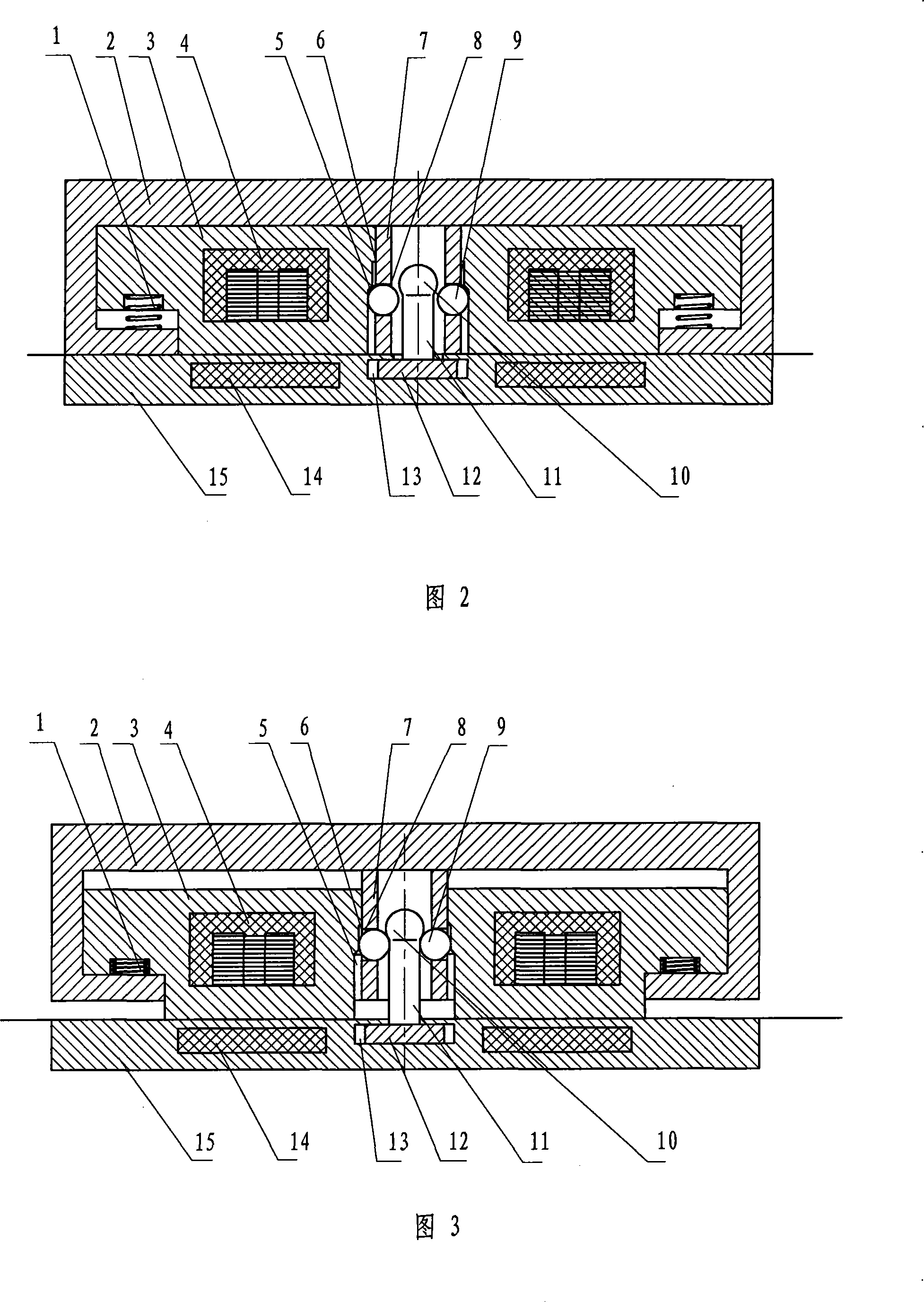

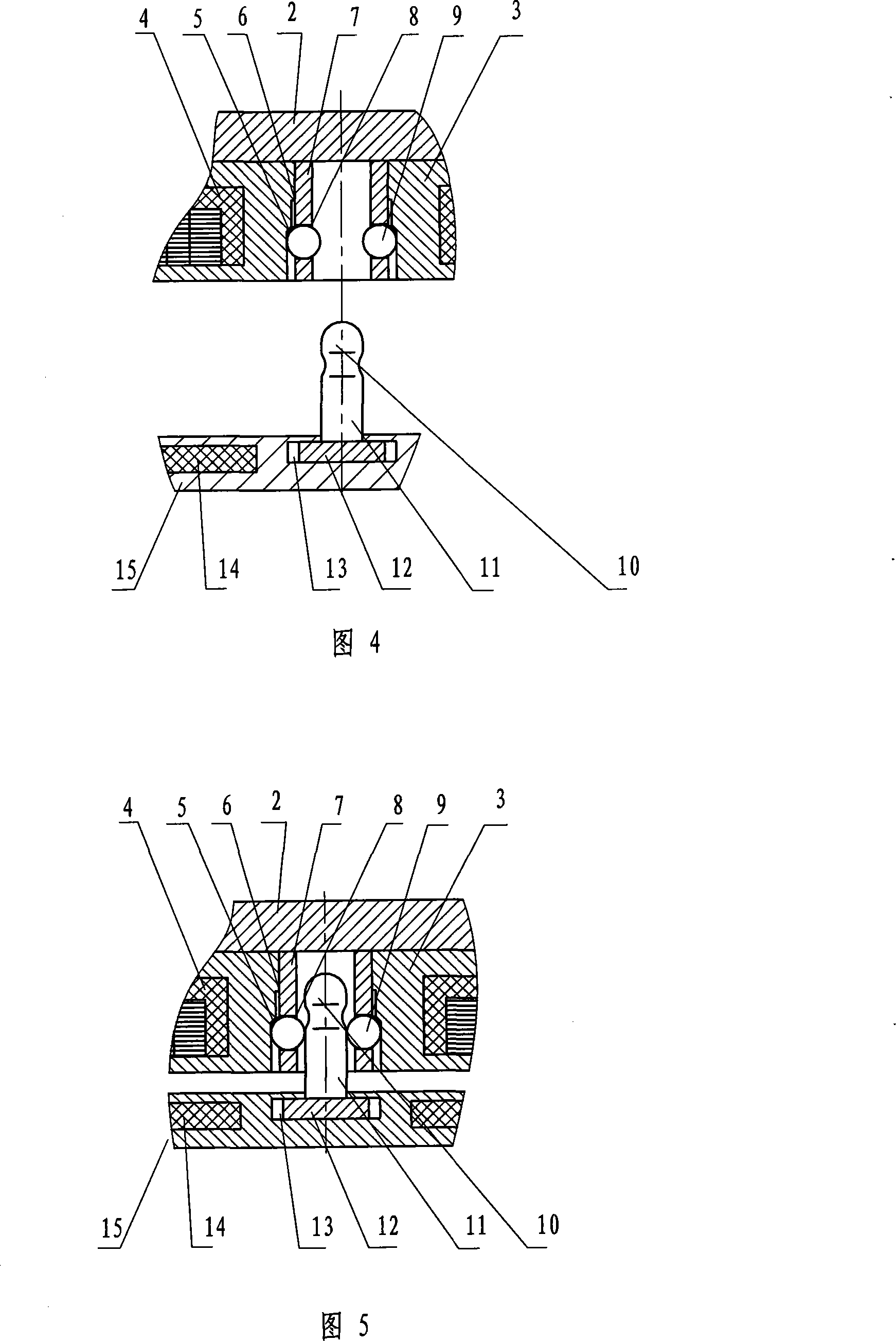

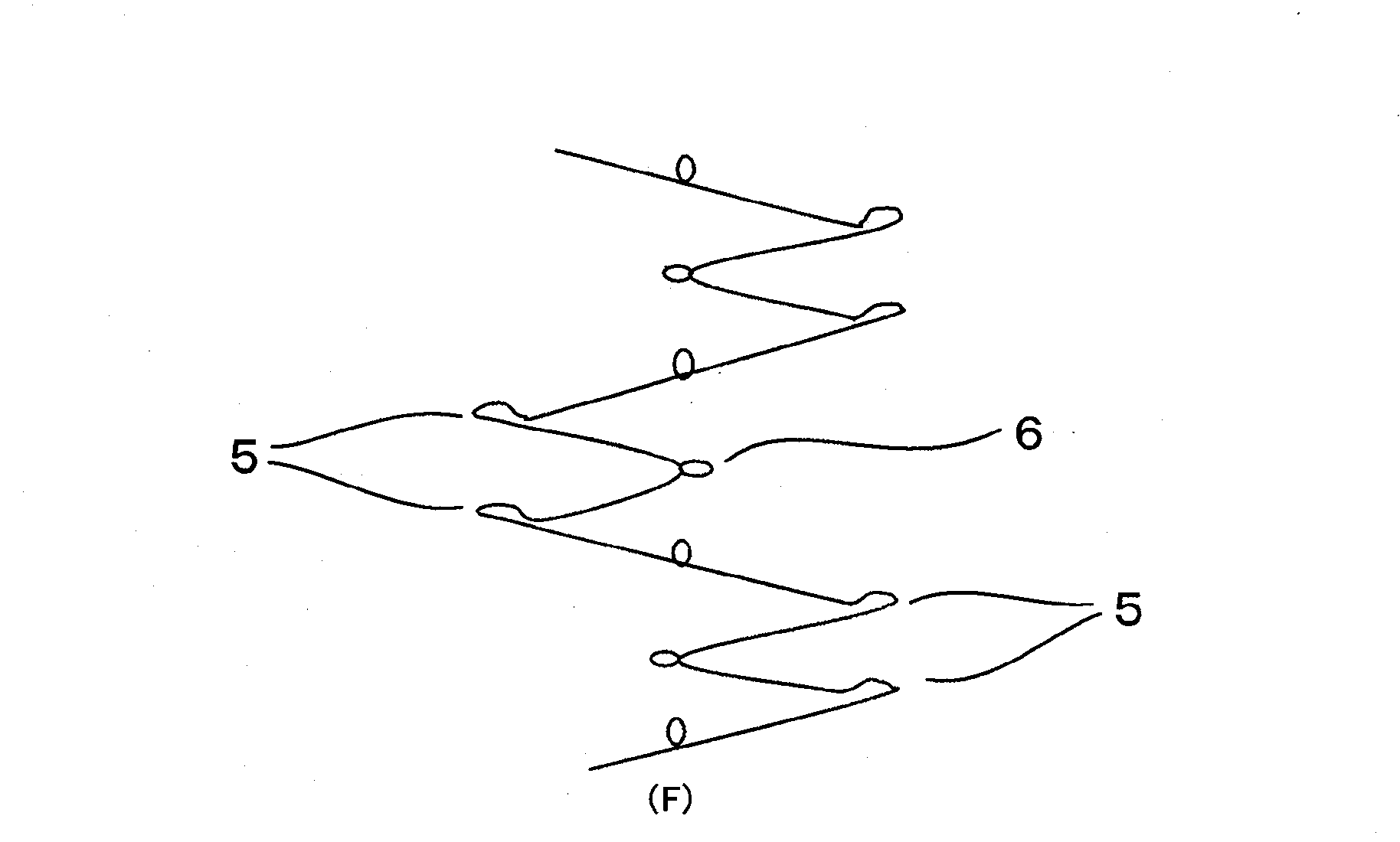

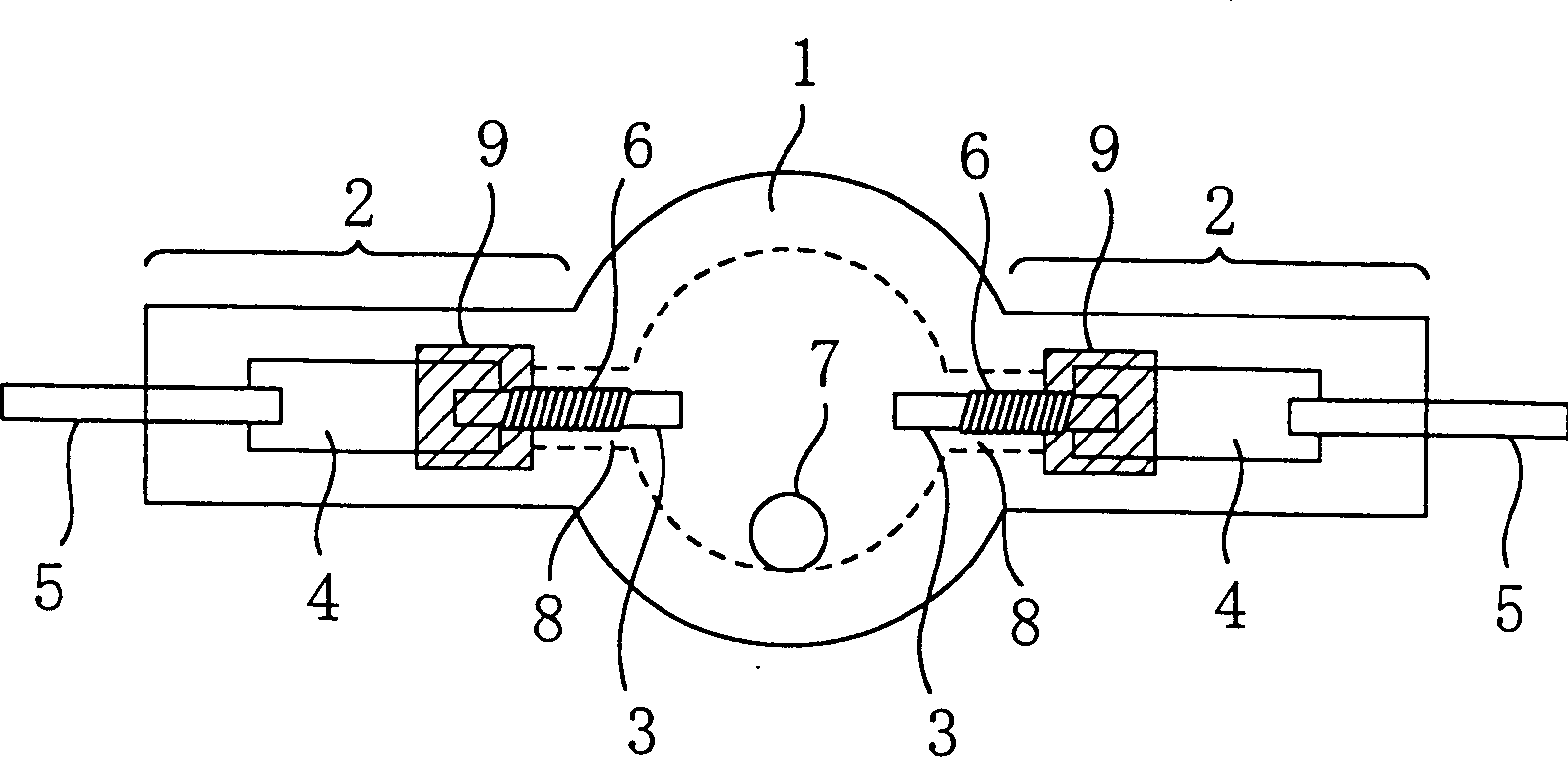

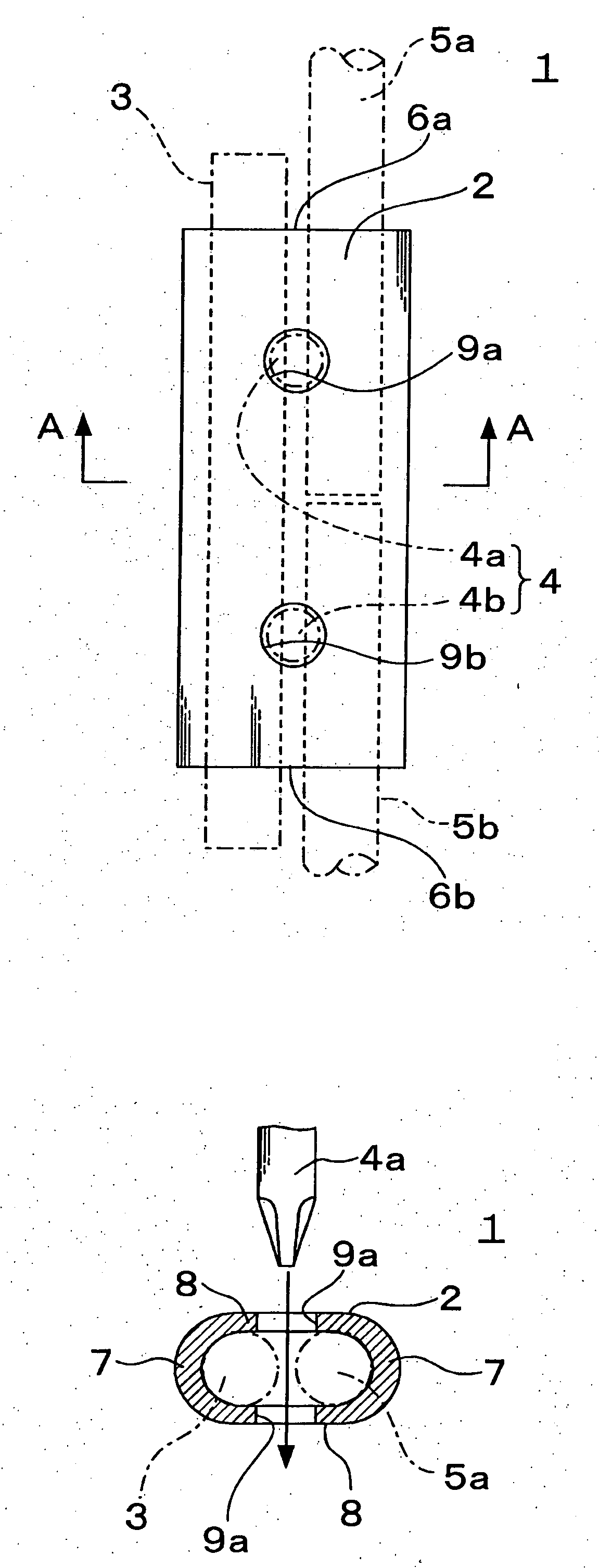

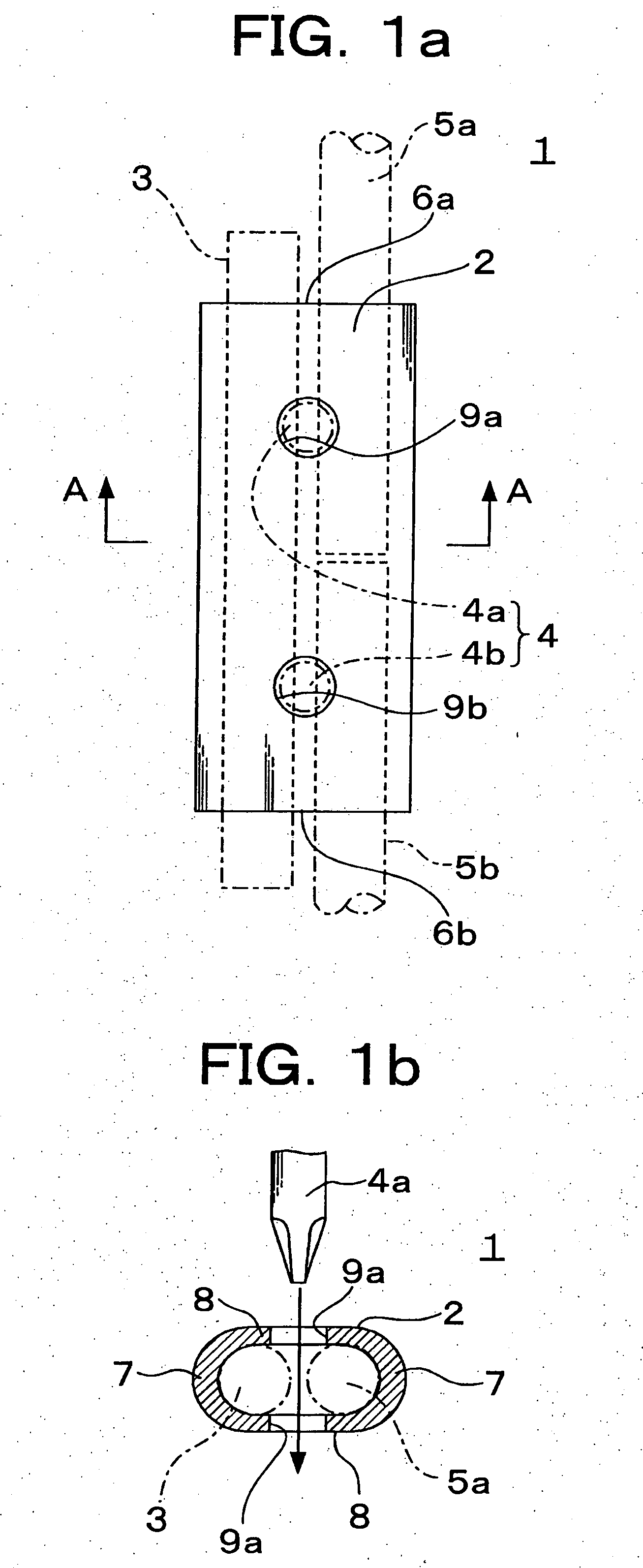

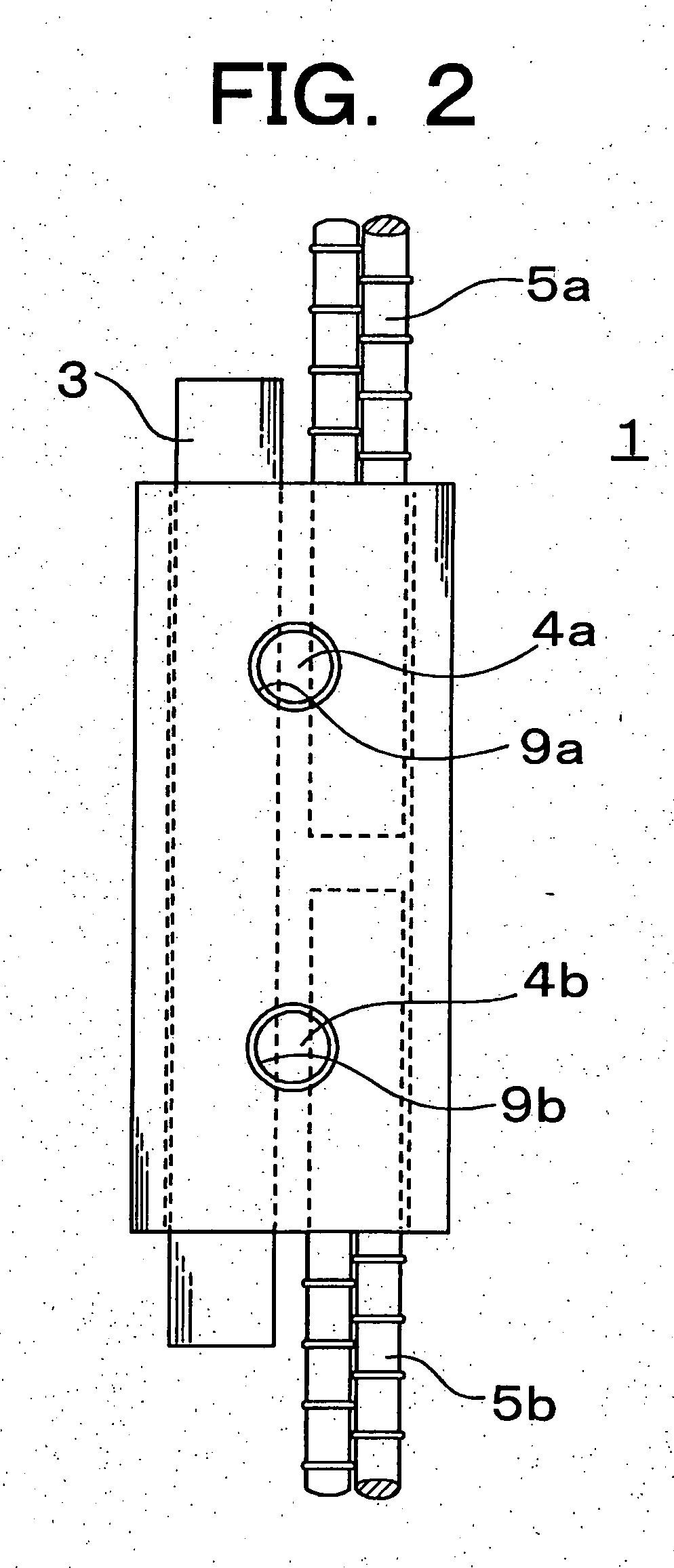

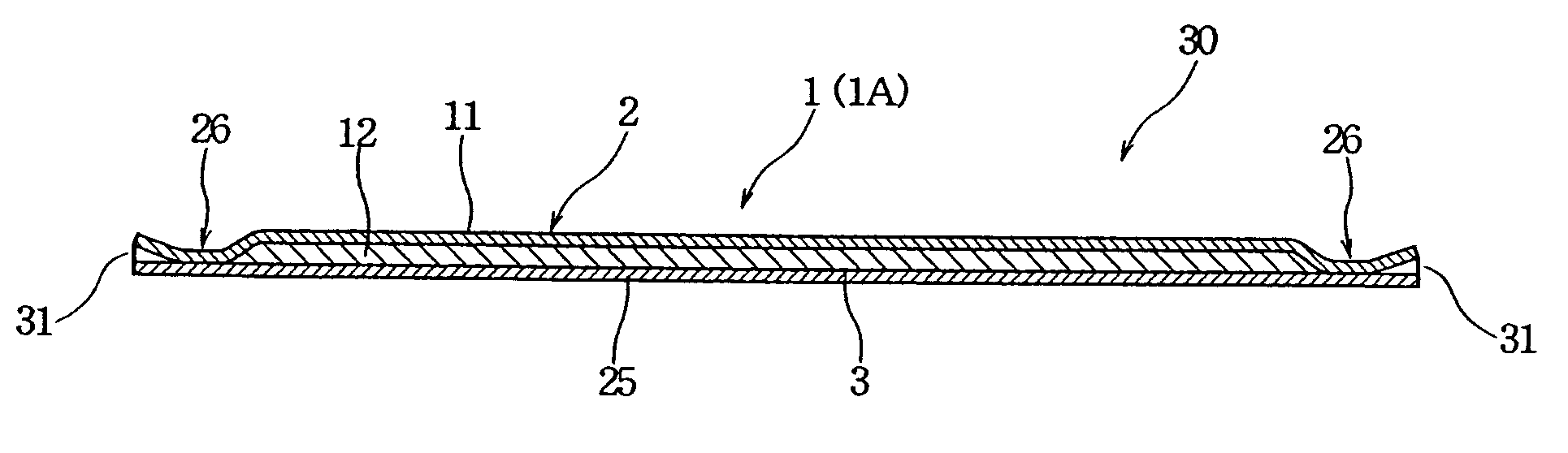

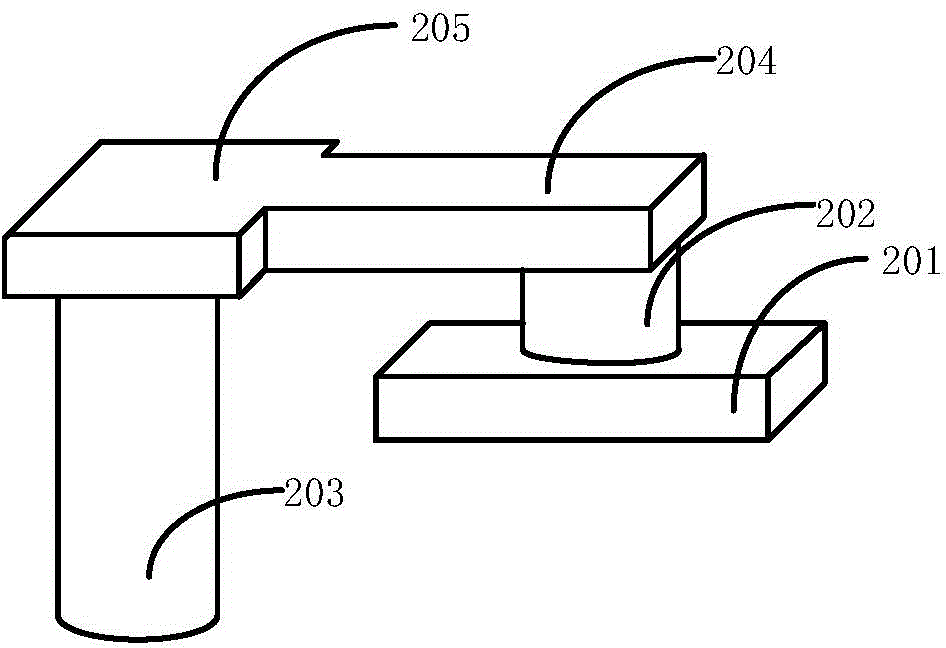

Reinforcing bar joint

InactiveUS20100088995A1Improve joint forcePrevent rotationLoad-supporting elementsBuilding reinforcementsStructural engineeringEngineering

To avoid the rotation of a sleeve, providing an enhanced joint force. A reinforcing bar joint 1 according to the present invention includes an elliptic-sectioned sleeve 2, a load transfer rod 3 to be inserted through the sleeve, and wedging means 4. The sleeve 2 is configured so that end portions of reinforcing bars 5a, 5b can be inserted into openings 6a, 6b formed in respective ends of the sleeve 2 so that the reinforcing bars are arranged in series along an identical line. The load transfer rod 3 can also be inserted therethrough in parallel with the end portions of the reinforcing bars 5a, 5b which are inserted into the sleeve 2.

Owner:OKABE CO LTD

Method of manufacturing a semiconductor device and molding die

InactiveUS7993978B2High peel strengthImprove thermal conductivitySemiconductor/solid-state device detailsConfectioneryPower semiconductor deviceSemiconductor chip

A method of manufacturing a semiconductor device capable of obtaining high joining force between a heat spreader and resin is provided. The method of manufacturing a semiconductor device according to the present invention includes: setting a heat spreader 60 on a face formed a plurality of apertures 22 in a cavity 21 of a first molding die 14; filling resin 20 into the cavity; setting a substrate 54 mounted with a semiconductor chip 50 a second molding die 12; and pressure-welding the first molding die 14 and the second molding die 12 so that the semiconductor chip is embedded in the resin 20, wherein a plurality of concave portion is formed on one face of the heat spreader 60, a plurality of convex portions is formed on the other face of the heat spreader 60, and the plurality of concave portions and the plurality of convex portions are overlapped in plan view.

Owner:RENESAS ELECTRONICS CORP

Absorbent composite sheet and absorbent article using the same

ActiveUS7081559B2Keep drySimple manufacturing processSynthetic resin layered productsSanitary towelsFiberCellulose

An absorbent composite sheet is thin and has a surface to be easily situated in dry condition. The absorbent composite sheet includes at least a first layer and a second layer. The first layer placed on the side of receiving a liquid is a non-woven fabric fabricated from thermoplastic synthetic resin fibers. The second layer stacked below the first layer is a non-woven fabric fabricated by entangling cellulose type fibers and thermoplastic synthetic resin fibers. The first layer and the second layer are joined by fuse bonding synthetic resin fibers of the first layer and synthetic resin fibers of the second layer. The liquid applied on a surface of the first layer is transferred to the second layer through gaps between synthetic resin fibers of the first layer.

Owner:UNI CHARM CORP

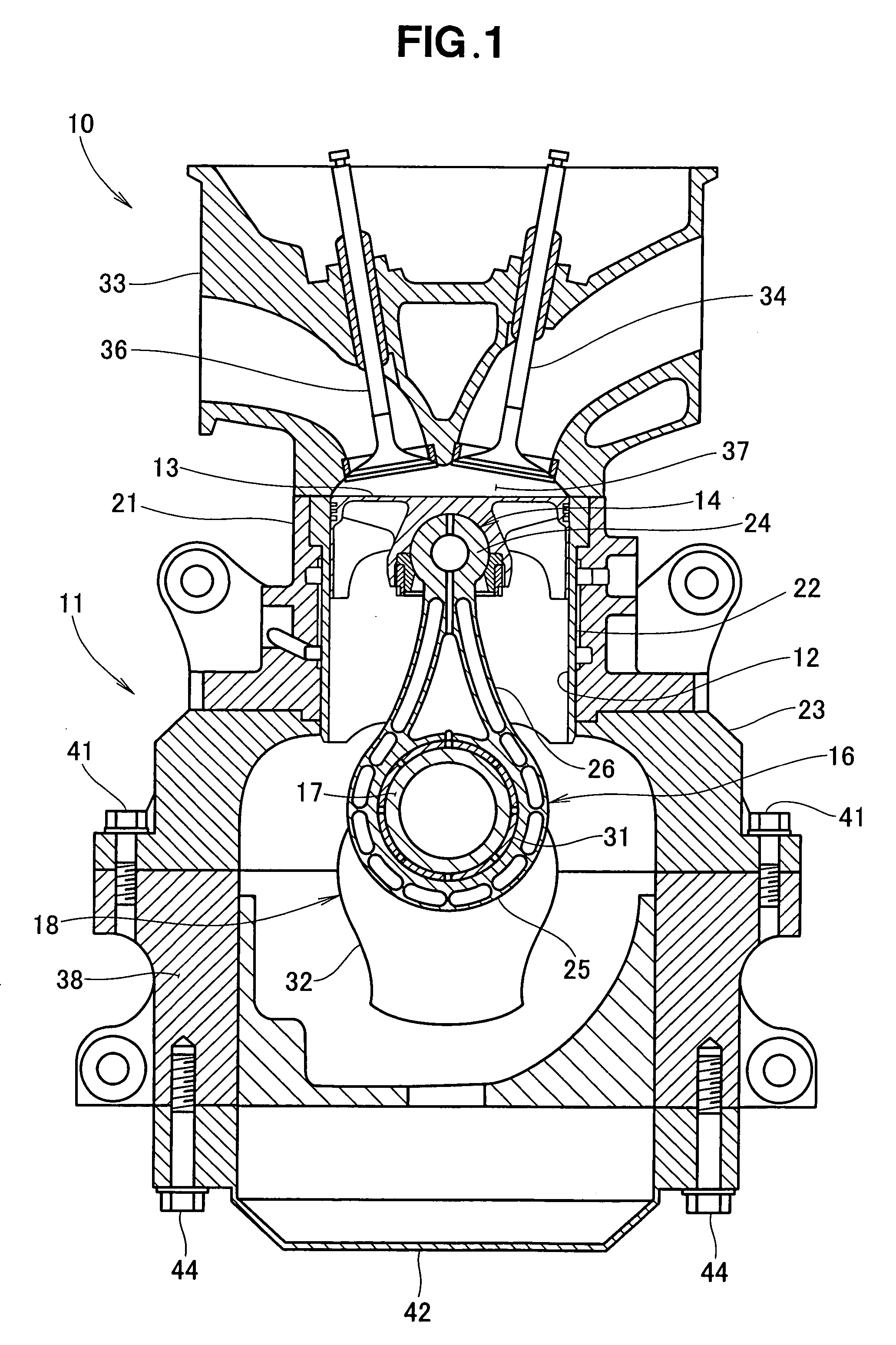

Assembled crankshaft and method for making crankshaft assembly

InactiveUS20050268879A1Accuracy be lowerEffective maintenanceCrankshaftsConnecting rodsMechanical engineeringCrankpin

Joint section is provided in a connection between a journal section and one of two arms supporting a crankpin and between the crankpin and the other of the arms. In each of the joint sections, a plurality of bolts are arranged along an imaginary circle substantially concentric to the axis of the journal section or crankpin, for fastening together the components. Radius of at least one of the journal section and crankpin is greater than a distance between axis lines of the journal section and crankpin. Blanks of shaft components are worked to provide thereon positioning sections, and the components are provisionally attached together to provide a crankshaft blank. The crankshaft blank is worked and then diassembled to attach thereto float bearings and a connecting rod integrally having a big end. Then, the crankshaft is re-assembled to make a crankshaft assembly.

Owner:HONDA MOTOR CO LTD

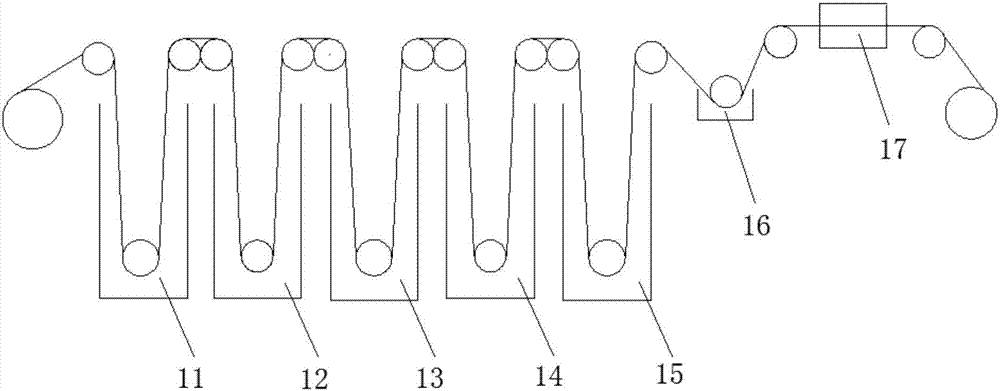

Micro-etching treatment process and equipment for shiny surface of copper foil

The invention discloses a micro-etching treatment process and equipment for a shiny surface of a copper foil. The process comprises the following steps: adding water into a liquid storage groove, adding 100g / L-400g / L sulfuric acid with a temperature of 10-80 DEG C into the liquid storage groove, cooling mixed liquid of water and sulfuric acid in the liquid storage groove to 10-50 DEG C, adding 50g / L-100g / L hydrogen peroxide and 20g / L-50g / L hydrochloric acid into the liquid storage groove, dissolving hydrogen peroxide, hydrochloric acid, water and sulfuric acid to obtain micro-etching liquid with a temperature of 10-50 DEG C, carrying out micro-etching on the shiny surface of the copper foil by virtue of a micro-etching process and equipment so as to generate an uneven shape, so that the specific surface area of the copper foil is increased; and carrying out treatments of solidification, heat-proof layer treatment, oxidation prevention and coupling agent coating, so that the bonding force between the shiny surface-treated copper foil and a base material is obviously increased.

Owner:建滔(连州)铜箔有限公司

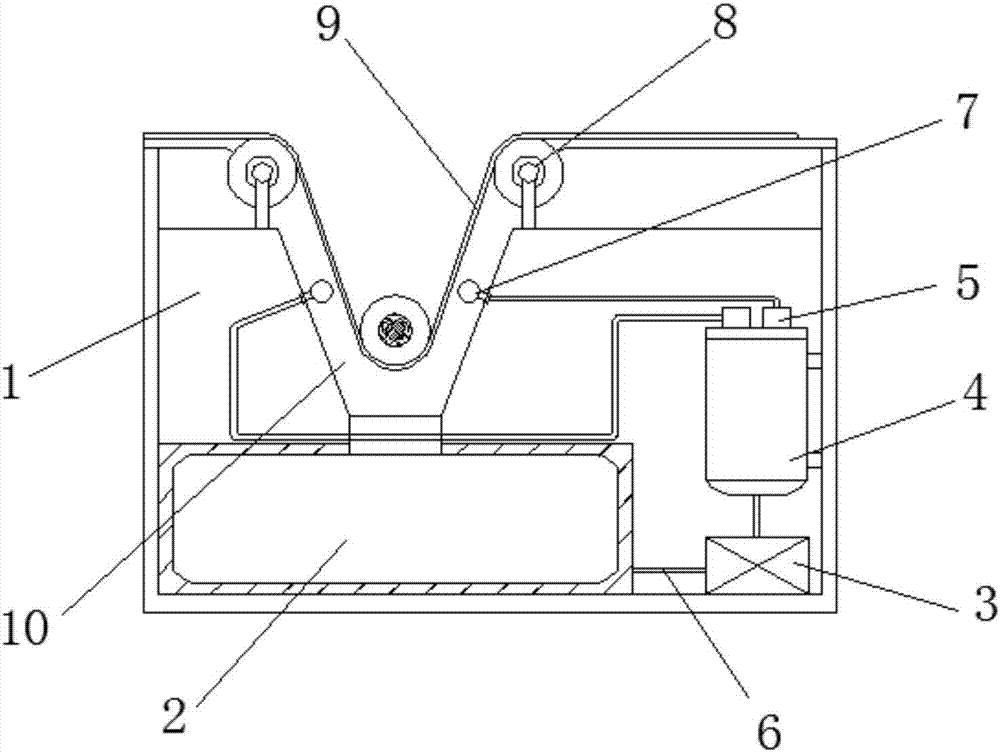

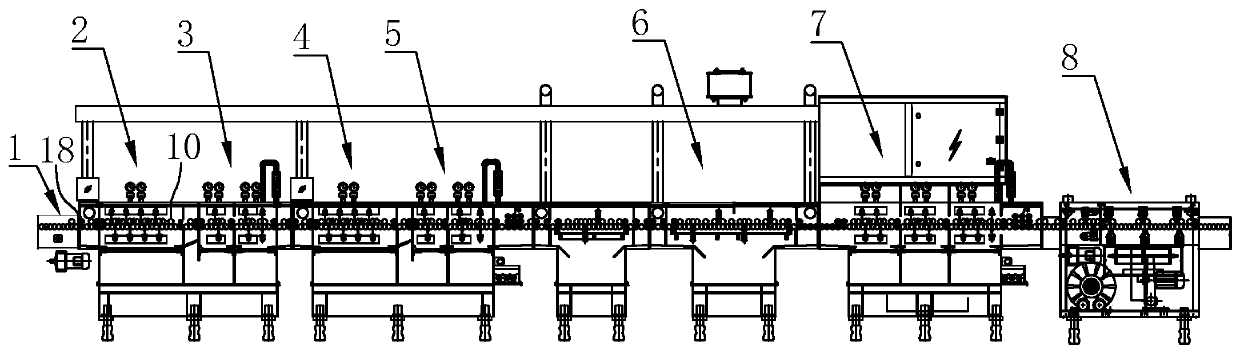

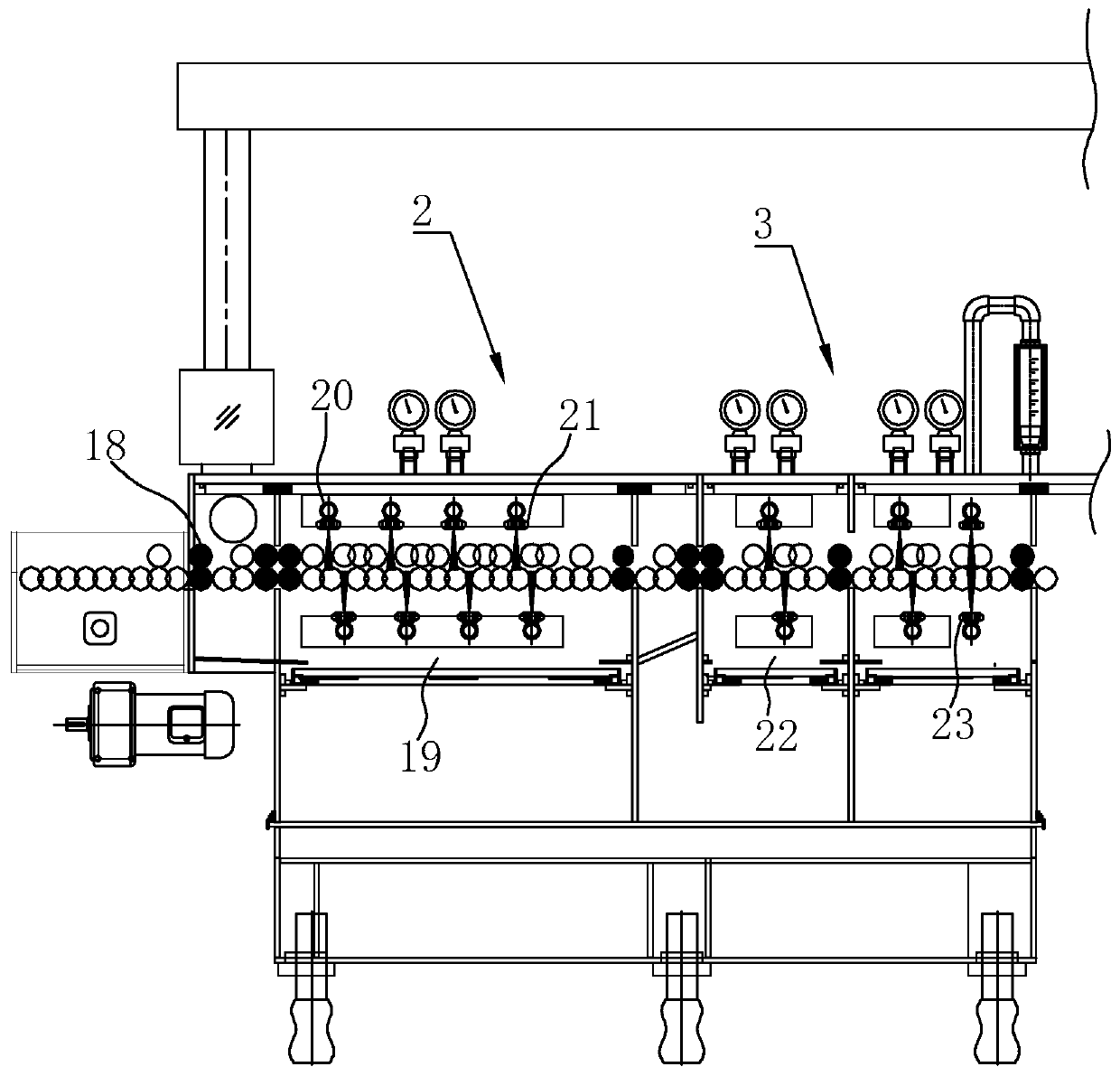

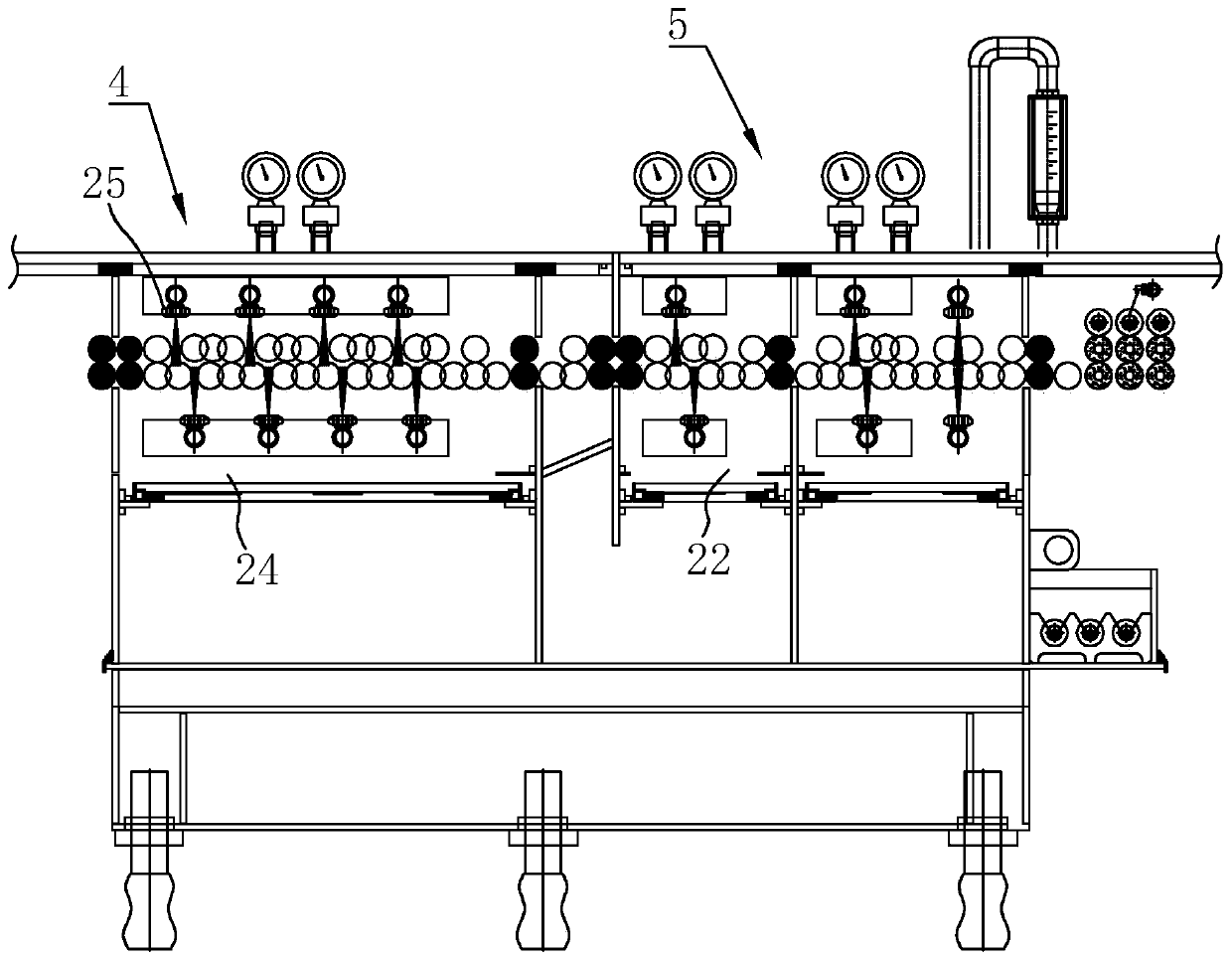

PCB cleaning line

ActiveCN110139493AEfficient removalImprove joint forceConductive pattern polishing/cleaningEpoxyCopper foil

The invention discloses a PCB cleaning line comprising a conveying platform. An alkali washing device, a first water washing device, a pickling device, a second water washing device, a browning device, a third water washing device and an air drying device are orderly arranged in a conveying direction on the conveying platform. Conveying rollers which are rotatingly connected to the conveying platform are arranged above and under the conveying platform, and a channel for passing a PCB is formed between the upper and lower conveying rollers. The PCB is placed on the conveying platform to be continuously conveyed forward during use, firstly the PCB passes the alkali washing device to be washed by alkali liquor, oxides and fingerprints on the surface of the PCB can be removed, then the PCB passes an acid solution of the pickling device to achieve the purposes of removing surface grease and a residual film, the PCB passes the browning device to perform micro-etch roughening treatment on a copper surface so as to improve the bonding force between a copper foil and epoxy resin when the circuit board is pressed, liquid adhering to the surface of the circuit board is washed and removed by the washing devices in the process and is avoided from being brought to a next cleaning link, and the purpose of a better cleaning result is achieved.

Owner:CIRCUIT TECH MACHINERY

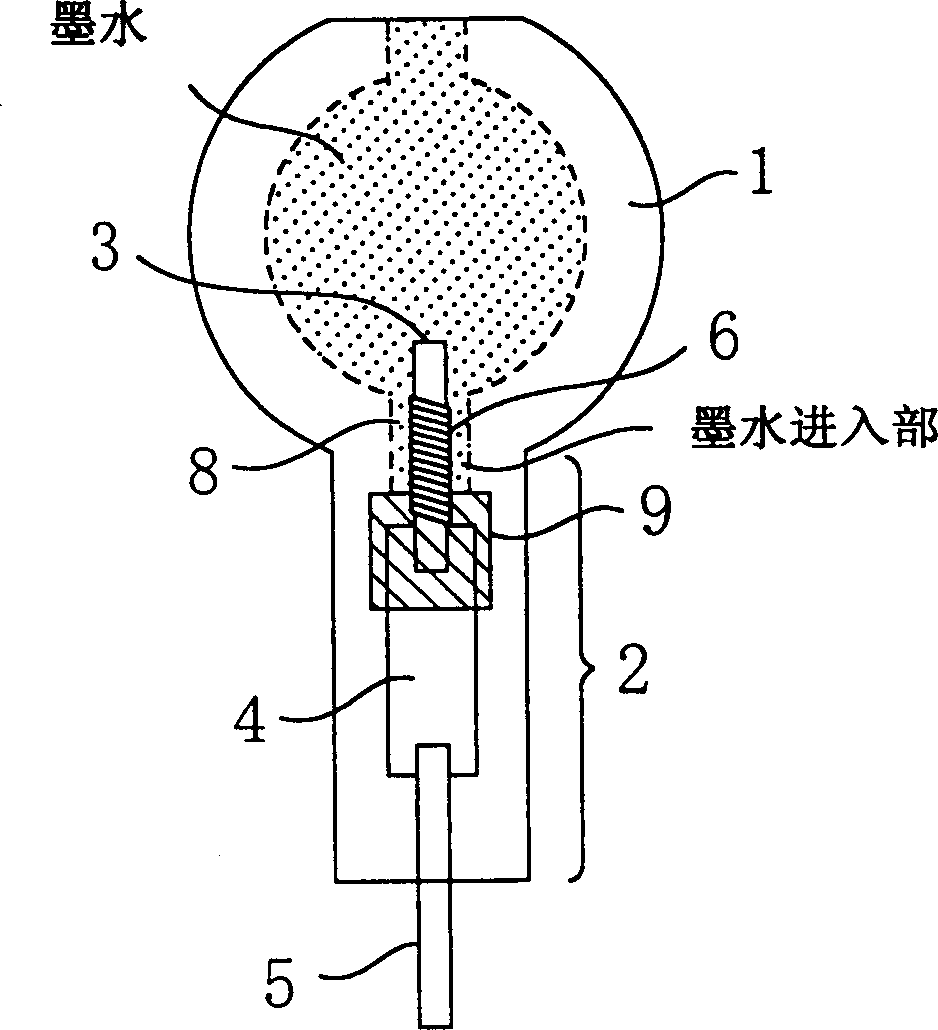

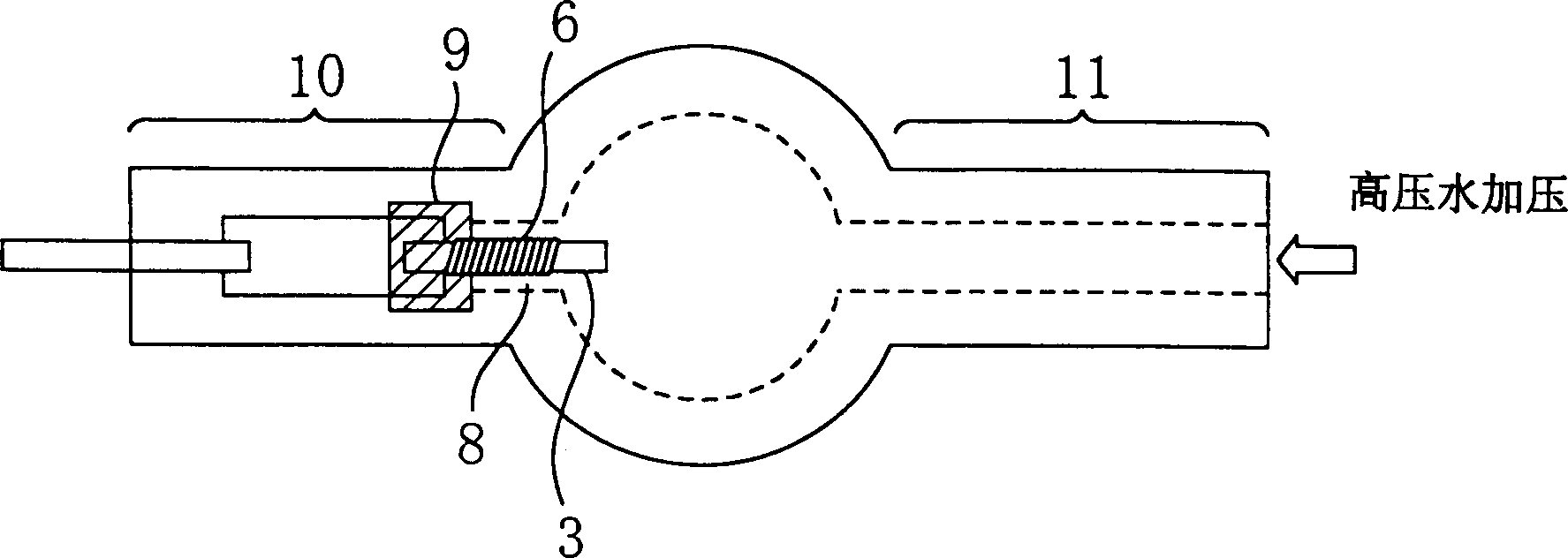

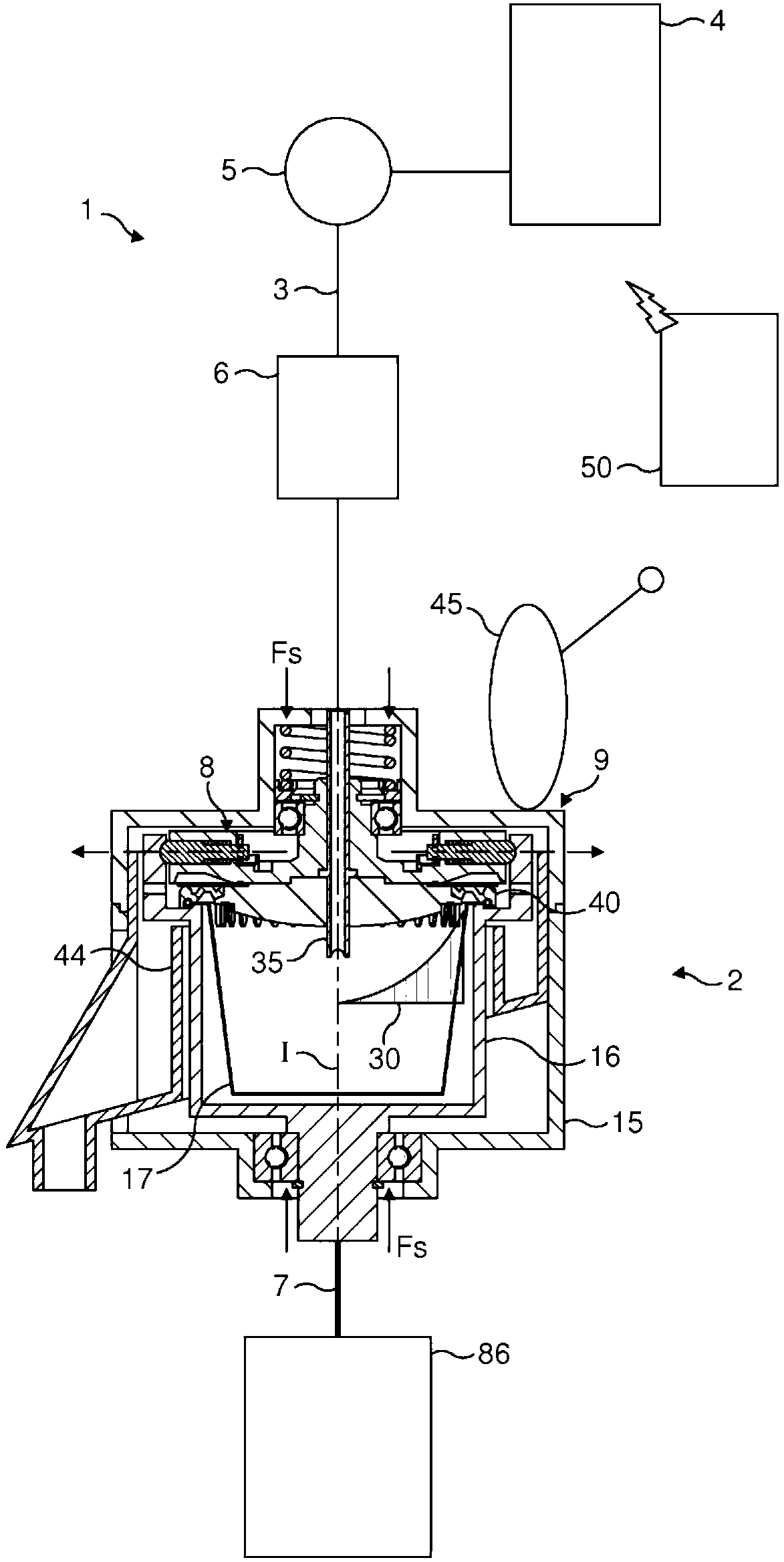

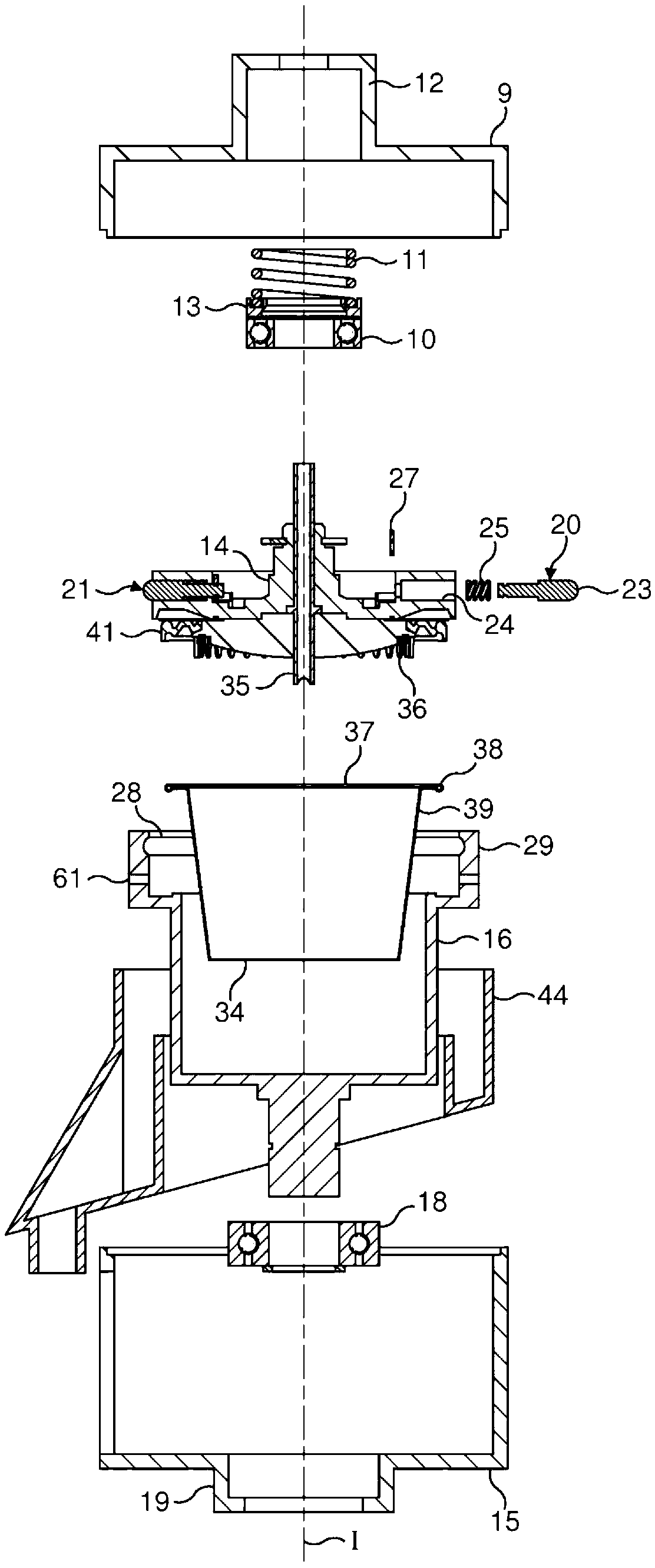

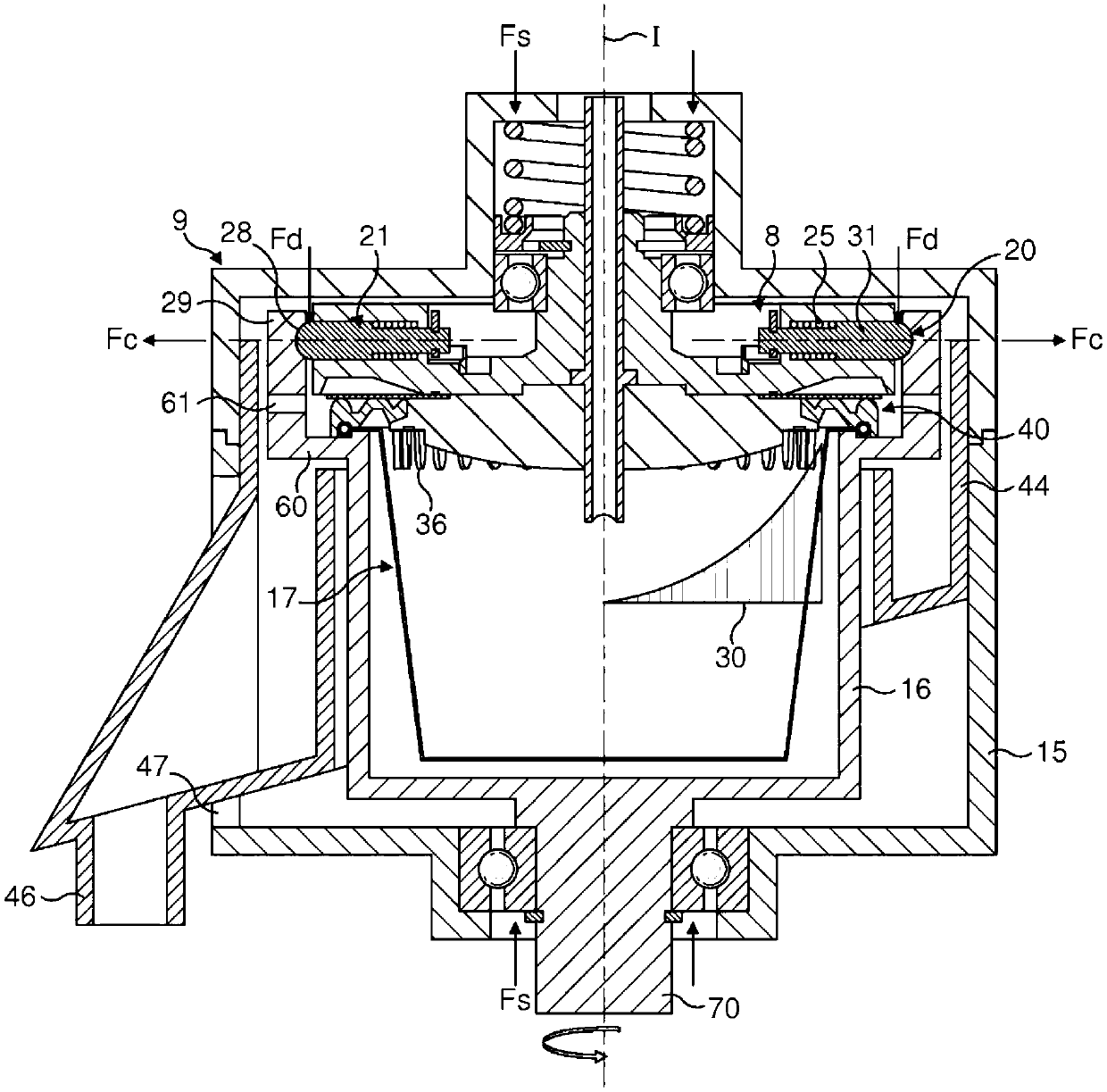

Device for preparing a beverage by centrifugation

ActiveCN103108577AFirmly closed connectionImprove joint forceBeverage vesselsAdditive ingredientCentrifugation

Device for preparing a beverage from a beverage ingredient contained in a receptacle (17) by driving the receptacle in centrifugation comprising:-a holding part (16) arranged for holding the receptacle in a position enabling it to be driven in rotation along a longitudinal axis of rotation (I),-a liquid interfacing part (8) arranged for supplying water in the receptacle and / or extracting the beverage from the receptacle,-a collecting part (44) for collecting the beverage obtained by the interaction between the ingredient and water in the receptacle, wherein the holding part and liquid interfacing part (8, 16) are connected together by connection means in such a manner that these parts (8, 16) rotate together with the receptacle during centrifugation, wherein the connection means comprise at least a first engaging surface (48; 86) of the holding part (16) and a second engaging surface (23; 87) of the liquid interfacing part (8) engaged in contact together during connection in a manner preventing the holding part (16) and the liquid interfacing part (8) from moving away from each other, at least in the axial direction of rotation (I), and the connection means further comprising at least one mass of inertia (20, 21, 31; 80) arranged to be moveably connected to at least one of the parts (8, 16) with at least one degree of freedom in a least one radial direction for enabling the engagement forces to increase between the two engaging surfaces as a result of the increase of the centrifugal forces.

Owner:SOC DES PROD NESTLE SA

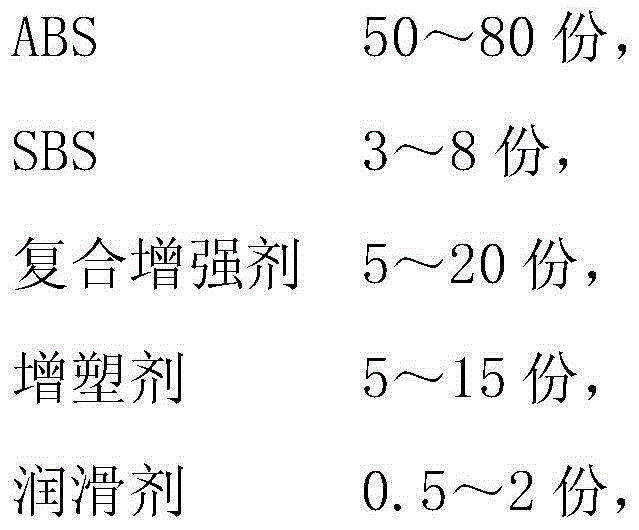

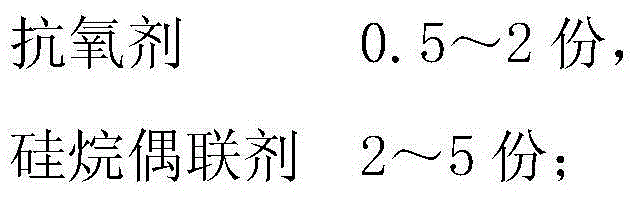

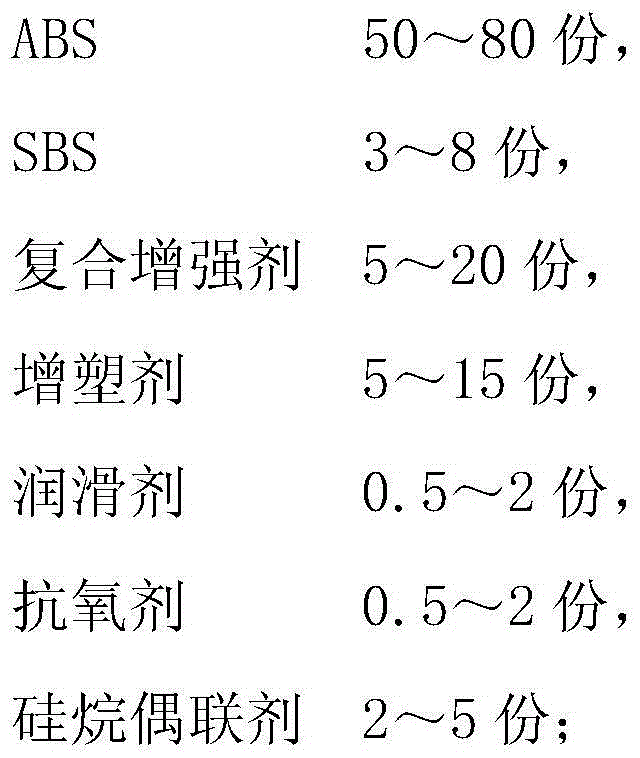

ABS composite material for plastic toys and preparation method thereof

The invention provides an ABS composite material for plastic toys, wherein the ABS composite material comprises the following components in parts by weight: 50-80 parts of ABS, 3-8 parts of SBS, 5-20 parts of a composite reinforcing agent, 5-15 parts of a plasticizer, 0.5-2 parts of a lubricant, 0.5-2 parts of an antioxidant, and 2-5 parts of a silane coupling agent, wherein the composite reinforcing agent is prepared by mixing ceramic micro-beads and glass fibers with the weight ratio of 2:1. The invention also discloses a preparation method of the ABS composite material for the plastic toys. The ABS composite material for the plastic toys has relatively good shock-resisting and wear-resisting properties.

Owner:SUZHOU WILDER IND & TRADE

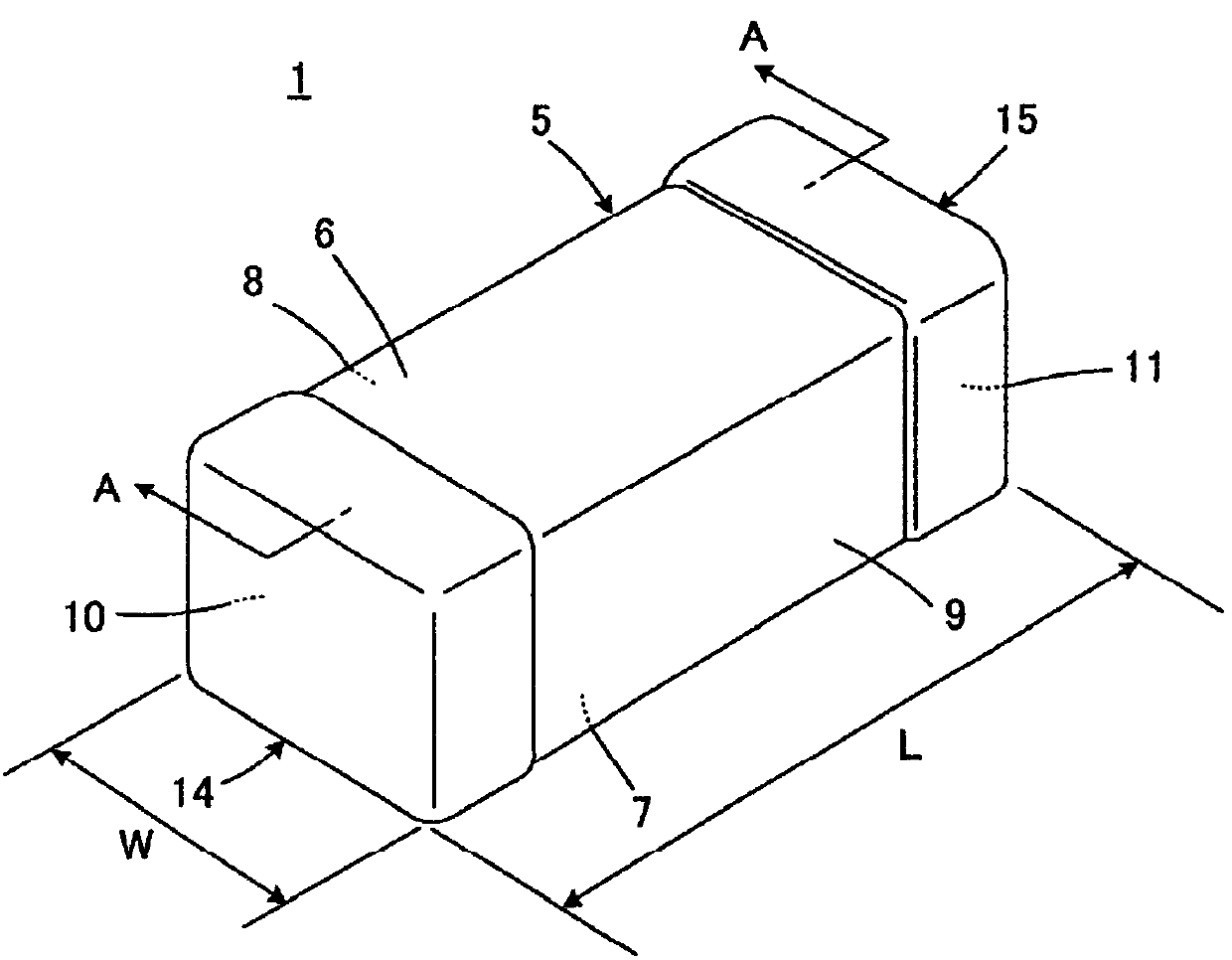

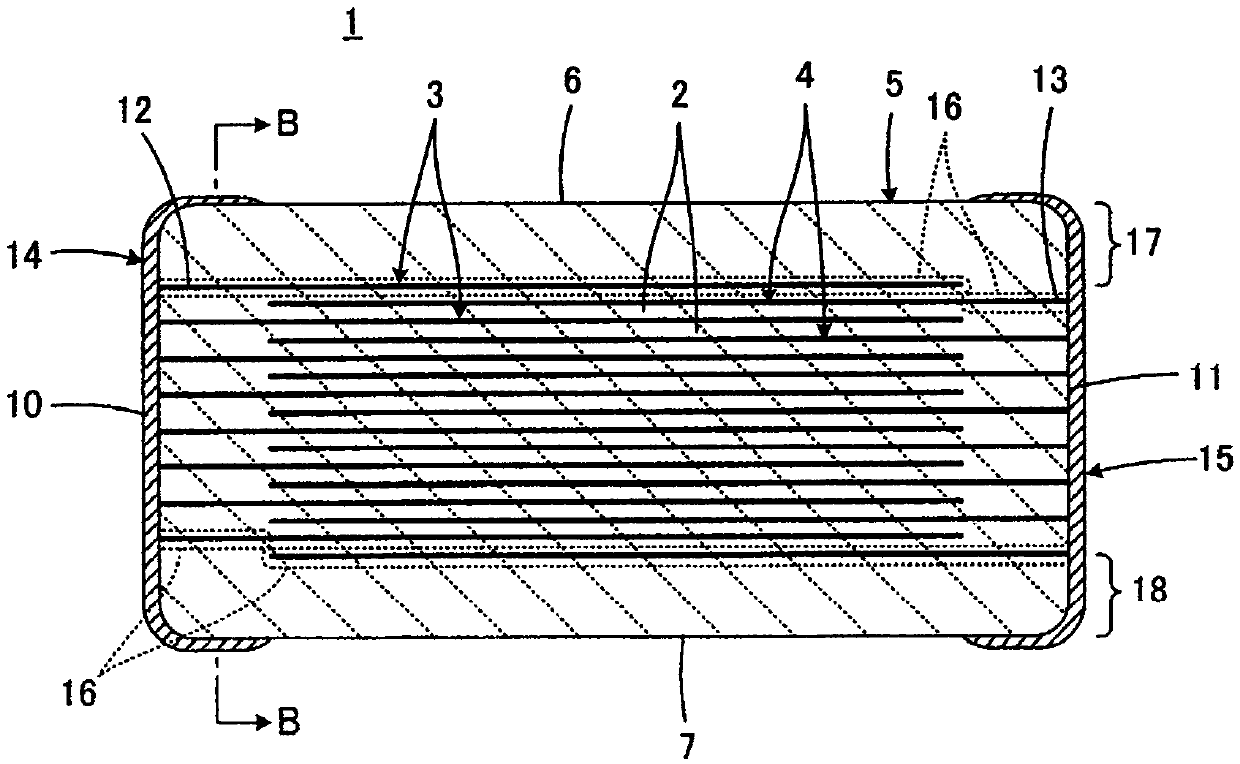

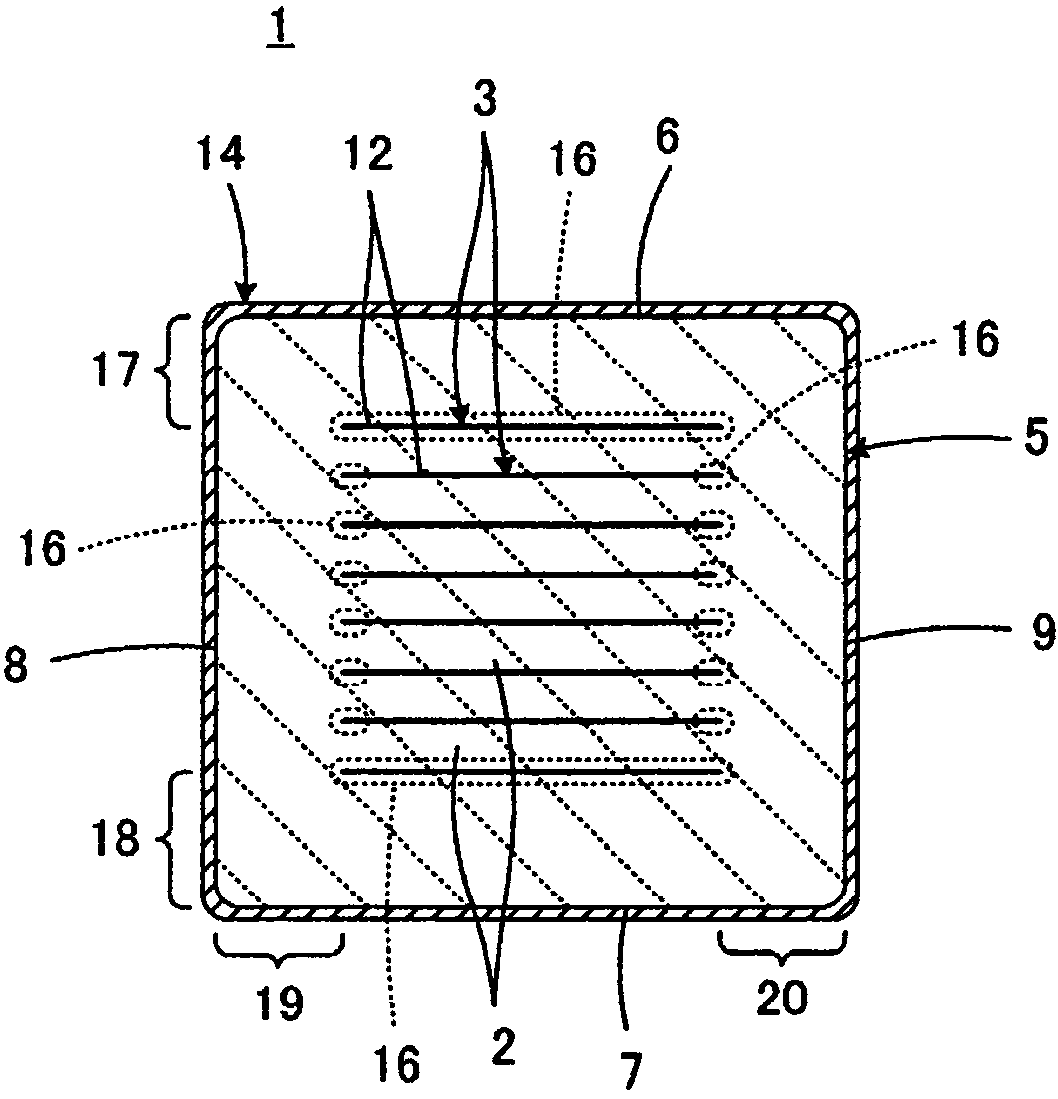

Monolithic Ceramic Electronic Component

ActiveCN103971932AImprove joint forceImprove moisture resistance reliabilityFixed capacitor electrodesFixed capacitor dielectricMetallurgyElectronic component

A monolithic ceramic electronic component includes a component body and outer electrodes. The component body includes a plurality of stacked ceramic layers and a plurality of inner electrodes which extend between the ceramic layers, which contain Ni, and which include exposed ends exposed on predetermined surfaces of the component body. The outer electrodes are electrically connected to the exposed ends of the inner electrodes and are formed on the predetermined surfaces of the component body by plating. The inner electrodes include Mg—Ni coexistence regions where Mg and Ni coexist.

Owner:MURATA MFG CO LTD

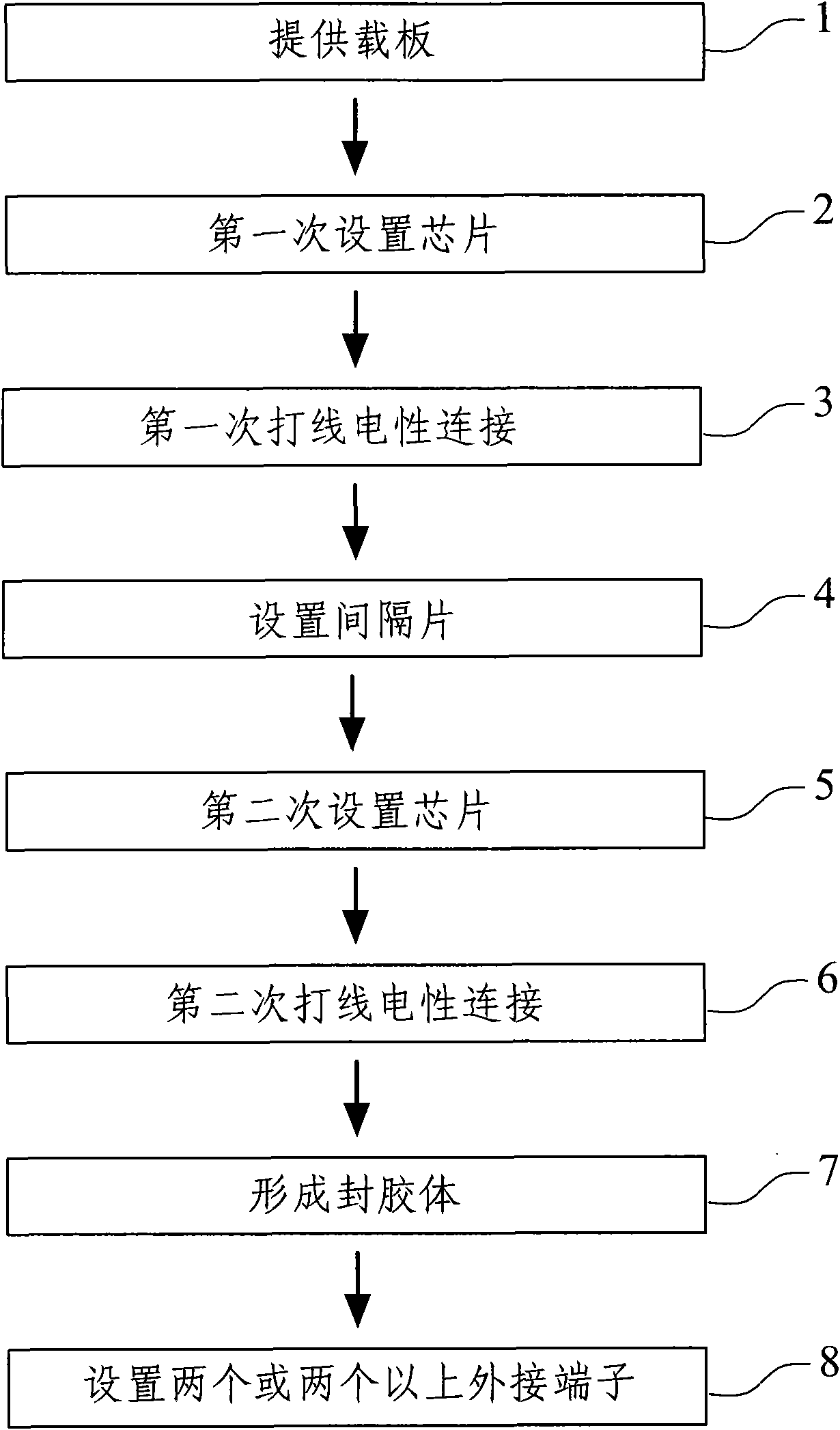

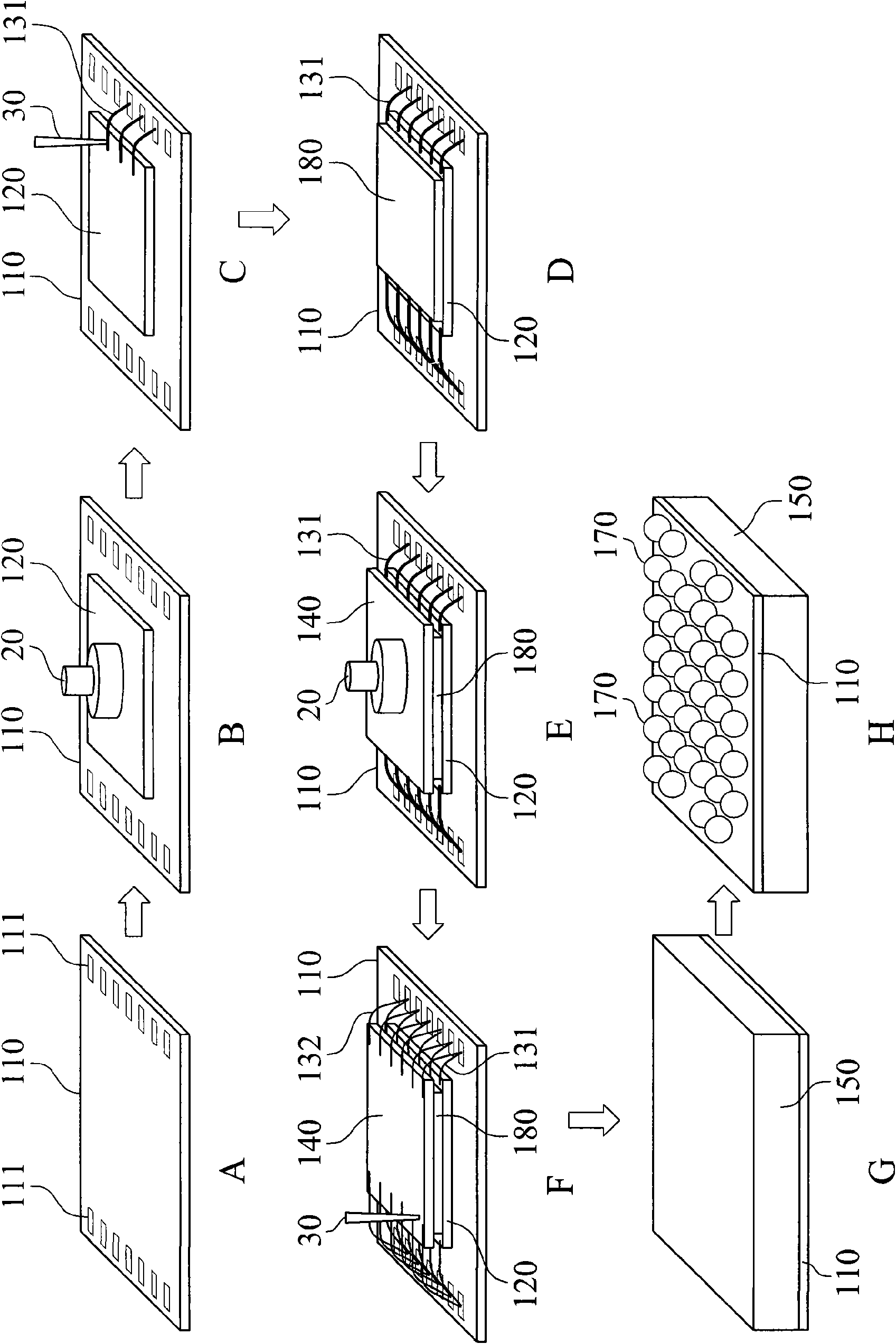

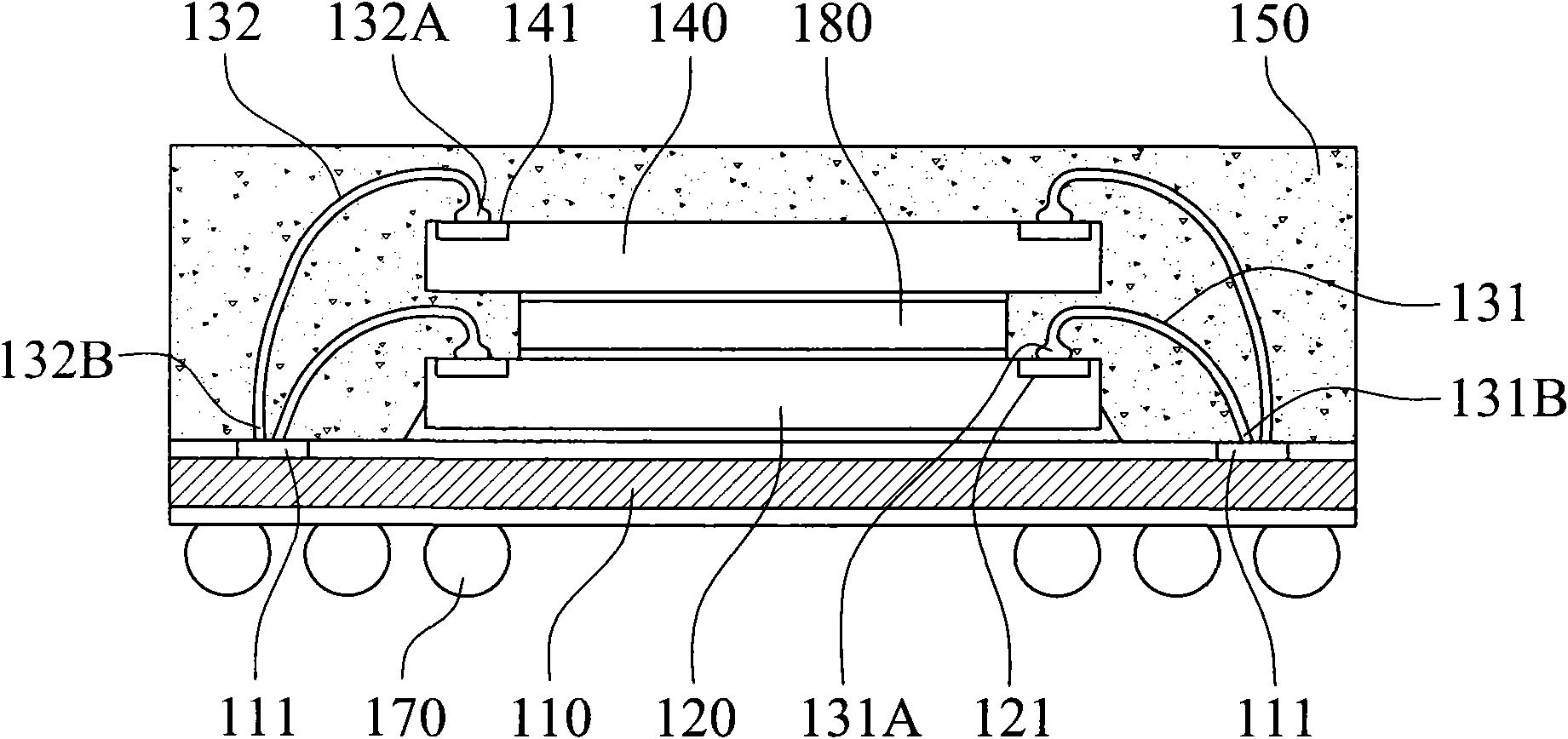

Multi-chip stacking method for halving routing procedure and structure thereof

InactiveCN101552214AReduce consumptionShorten the stacking processSemiconductor/solid-state device detailsSolid-state devicesFinger jointChip stacking

The invention discloses a multi-chip stacking method for halving routing procedure, comprising the following steps: firstly, providing a support plate having two or more finger joints and arranging at least one first chip on the support plate; then, routing to form two or more bonding wires to connect a first electrode of the first chip to the finger joints; arranging at least one second chip on the first chip face to face, and meanwhile, joining the second electrode of the second chip to one end of the bonding wires on the first electrodes, so that the second chip is electrically connected to the support plate through the bonding wires. The invention also discloses a multi-chip stacking structure for halving routing procedure. Therefore, the invention can shorten the procedure period and save cost, ensures that the bonding wires are located at the routing end on the chip and connected to the first electrode, and avoids line disconnection and line breasting.

Owner:POWERTECH TECHNOLOGY

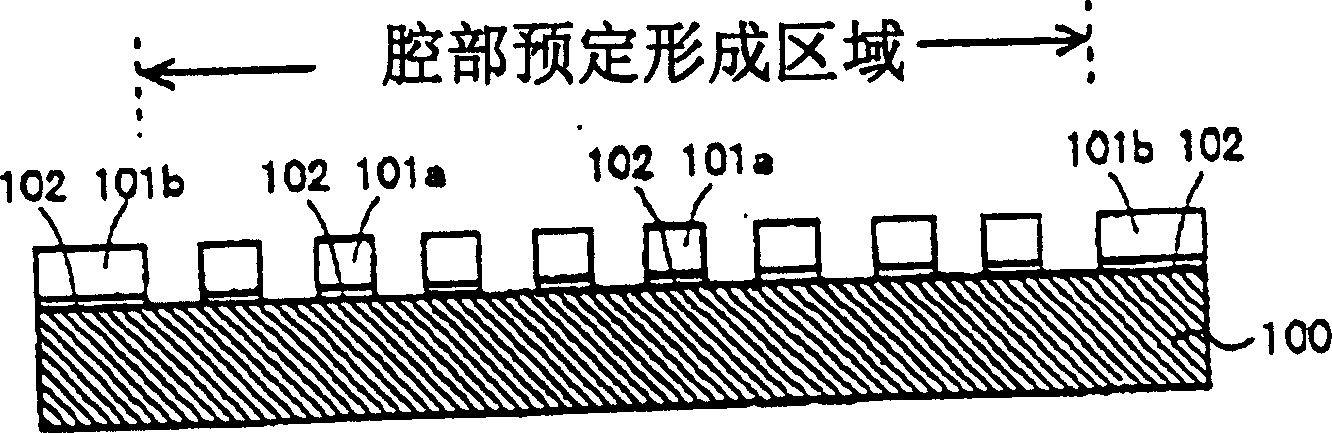

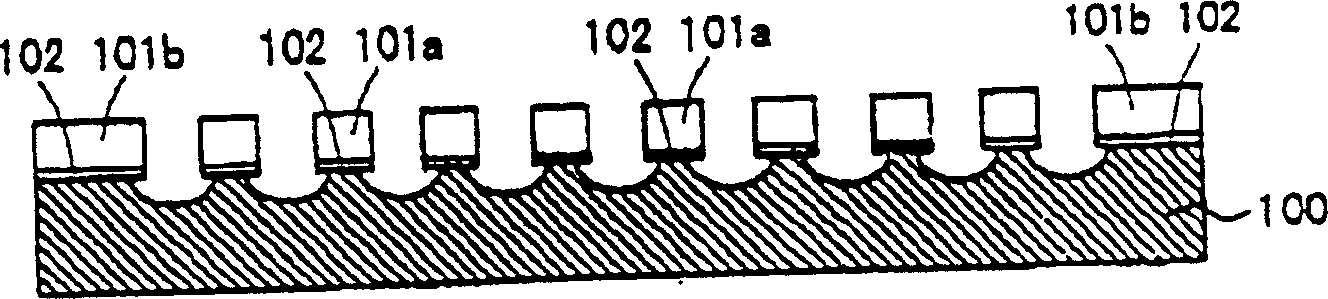

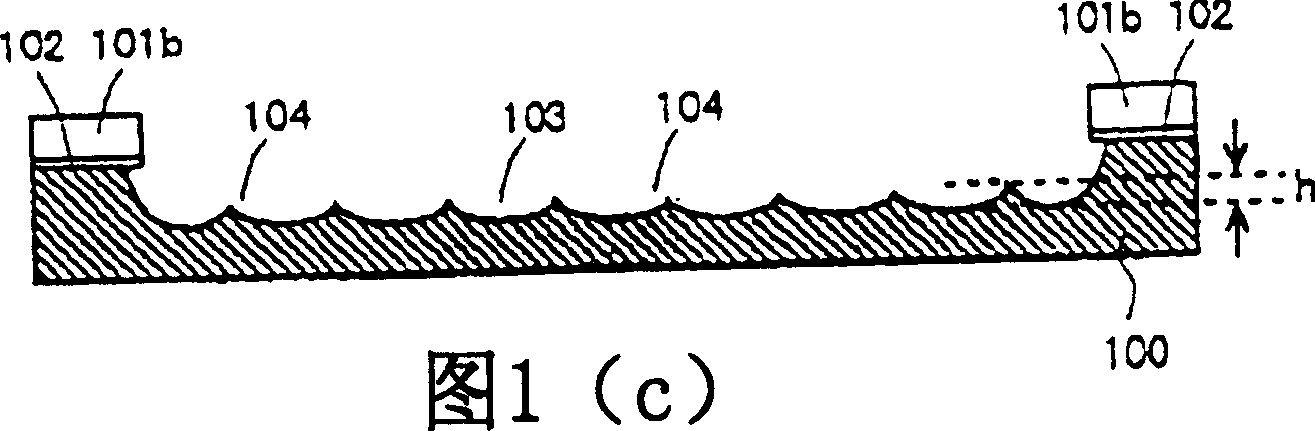

Electric field luminous display device and its mfg. method

InactiveCN1536937AImprove joint forceImprove reliabilityElectroluminescent light sourcesSolid-state devicesHydrofluoric acidDesiccant

Electroluminescent display device and manufacturing method thereof. To prevent exfoliation and rupture of a desiccant layer of an organic EL panel and improve the reliability to the temperature cycle. Using a plurality of resist patterns (101a) arranged in lattice shape as a mask, a sealing glass substrate (100) is etched with hydrofluoric acid, and a pocket part (103) is formed. An unevenness (104) is formed on the surface of the sealing glass substrate (100) on the bottom of the pocket part (103). Then, a desiccant layer (105) is formed. By this coarse surface making treatment, an anchor effect is demonstrated and adhesion of the desiccant layer to the sealing glass substrate is increased, and exfoliation or the like can be prevented.

Owner:SANYO ELECTRIC CO LTD

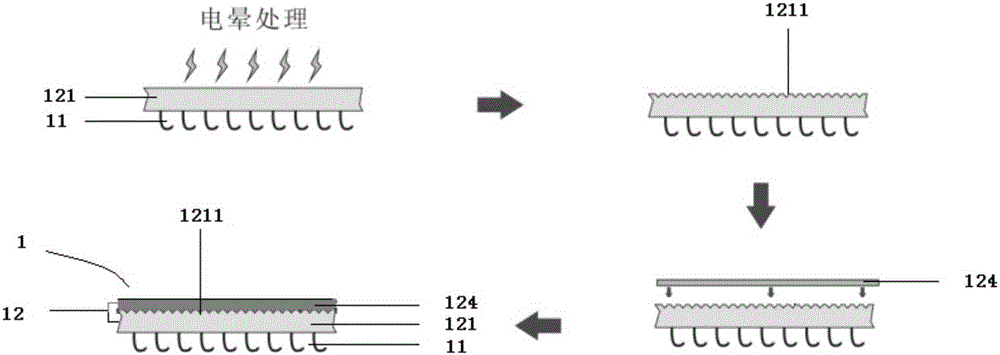

Velcro, Velcro work-piece, and preparation methods of Velcro and Velcro work-piece

InactiveCN106479391AImprove comfortThere will be no phenomenon such as perforationFilm/foil adhesivesHaberdasheryBiomedical engineering

The present invention belongs to the technical field of Velcro, and provides a Velcro, a Velcro work-piece and preparation methods of the Velcro and the Velcro work-piece. The Velcro comprises a hook surface and a back surface, wherein the back surface comprises a base material layer and a first adhesive layer, the base material layer comprises a roughened surface arranged opposite to the hook surface, and the first adhesive layer is adhered and connected to the roughened surface. The Velcro work-piece comprises a carrier and the Velcro, wherein the Velcro is adhered and connected to the carrier through the first adhesive layer, and the partial or all back surface of the Velcro is embedded into the carrier.

Owner:深圳德睿康科技有限公司

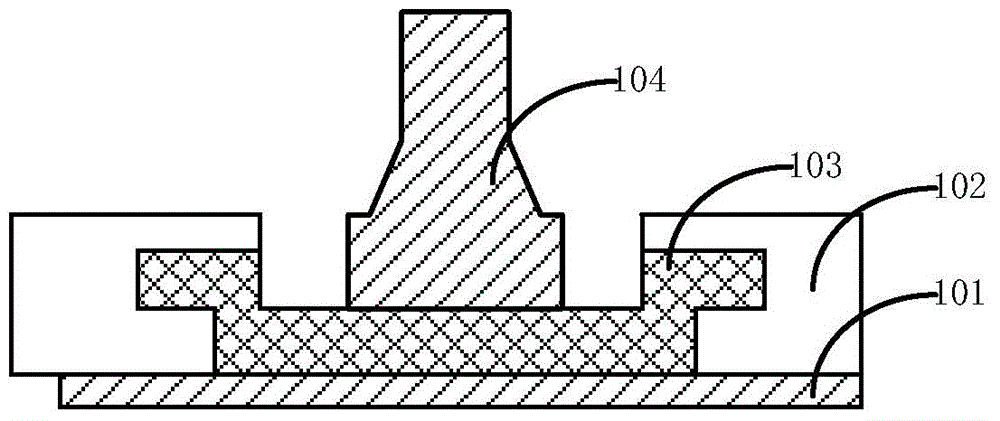

Pad structure and manufacturing method thereof

InactiveCN104952827AImprove joint forceInhibit sheddingSemiconductor/solid-state device detailsSolid-state devicesState of artMetal

The invention relates to a pad structure and a manufacturing method thereof. The pad structure comprises an isolation material layer, a metallic pad situated above the isolation material layer, a top metallic layer embedded in the isolation material layer and connected with the metallic pad through a metallic connecting line, and a nail pad situated under the metallic pad, tightly connected with the metallic pad and embedded in the isolation material layer while being spaced apart from the top metallic layer. The invention solves the problems in the prior art and provides a new pad structure. The nail pad is situated under the metallic pad, and the nail pad is integrated into one body with the metallic pad and embedded tightly in a passivation layer under the metallic pad. The bonding force of the metallic pad is thus increased to prevent falling off of the metallic pad.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Socket connector

InactiveCN1614827AHigh strengthNo relative movementRelieving strain on wire connectionCoupling contact membersElectric wireEngineering

A receptacle connector that improves strength against wire (W) stretching and enables flattening of the connection structure. It includes: a socket housing (110), with a wire insertion groove (115) recessed from the back side (111), and a support recess (116) that communicates with the wire insertion groove (115) and opens on the back side (111); The socket contact (120) that enters the wire insertion groove (115); the contact part (121) that contacts the contact (220) in the support recess (116); the insulating barrel (122) and the notch for crimping (123 ), press the electric wire (W) in the insertion groove (115) and crimp it on the cut groove (123), press the sheath of the electric wire (W) with the insulating tube (122), and the installation object (P) When the plug connector (200) is butted, the wire insertion groove (115) of the socket housing (110) is blocked by the installation object (P).

Owner:JST MFG CO LTD

Light modulator and its fabrication method

It is possible to provide a light modulator using a thin plate having a thickness of 20 mum or below capable of stably holding a conductive film suppressing troubles such as resonance phenomenon of microwaves in a substrate and pyro-electric phenomenon. It is also possible to provide a method for fabricating the light modulator. The light modulator includes: a thin plate (10) formed of a material having a photoelectric effect and having a thickness of 20 mum or below; light waveguide (11) formed on the front or rear surface of the thin plate; and modulation electrodes (13, 14) formed on the front surface of the thin plate for modulating light passing through the light waveguide. The light modulator further includes a reinforcing plate (16) bonded to the rear surface of the thin plate and a conductor film (17) formed on the side surface of the thin plate continuously to the side surface of the reinforcing plate.

Owner:SUMITOMO OSAKA CEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com