High-voltage discharge lamp and its manufacture

A high-pressure discharge lamp and manufacturing method technology, applied in the manufacture of discharge tubes/lamps, discharge lamps, gas discharge lamps, etc., can solve the problems of different thermal expansion coefficients, insufficient bonding force, etc., to prevent cracks, increase bonding force, The effect of suppressing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

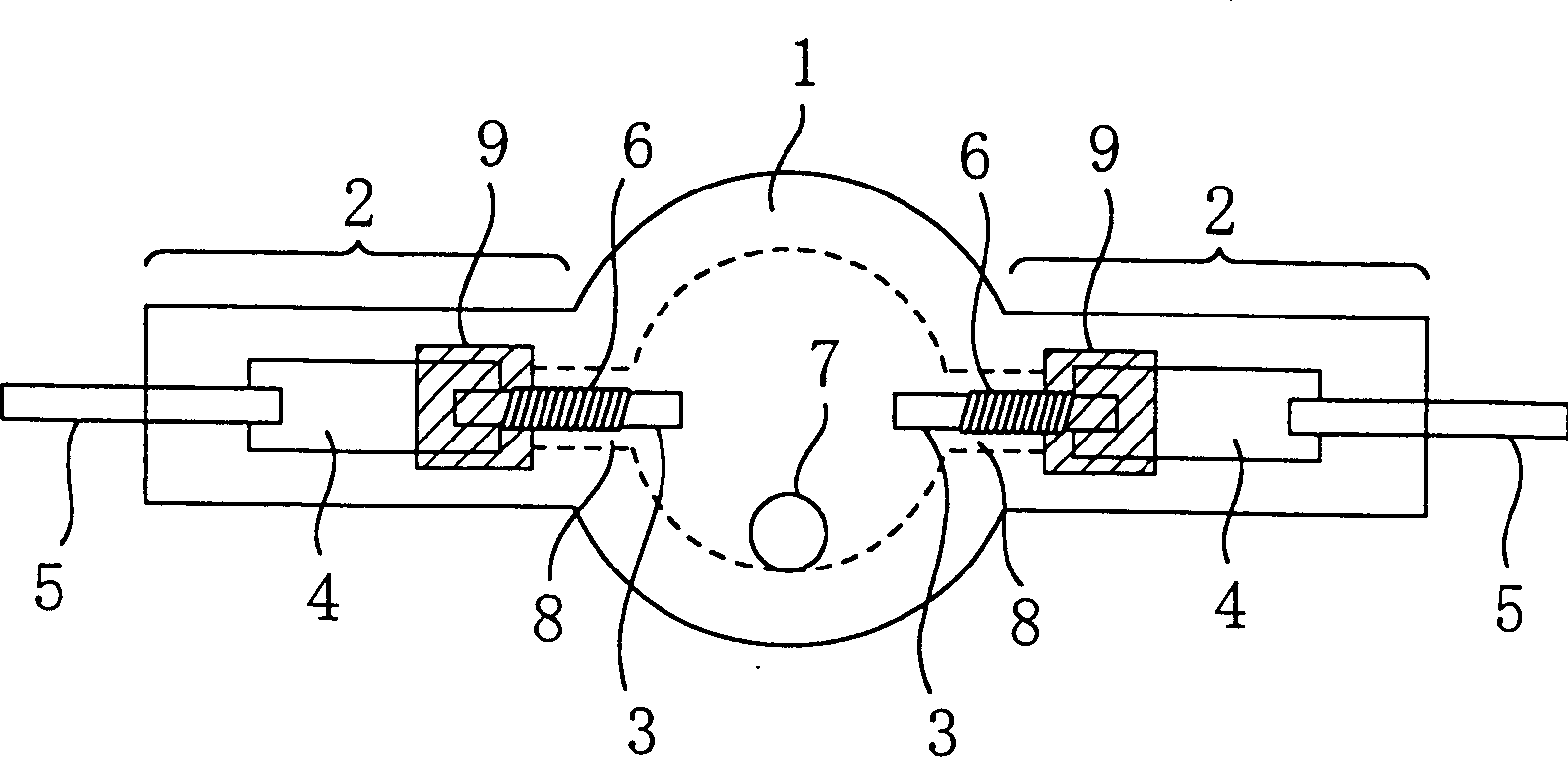

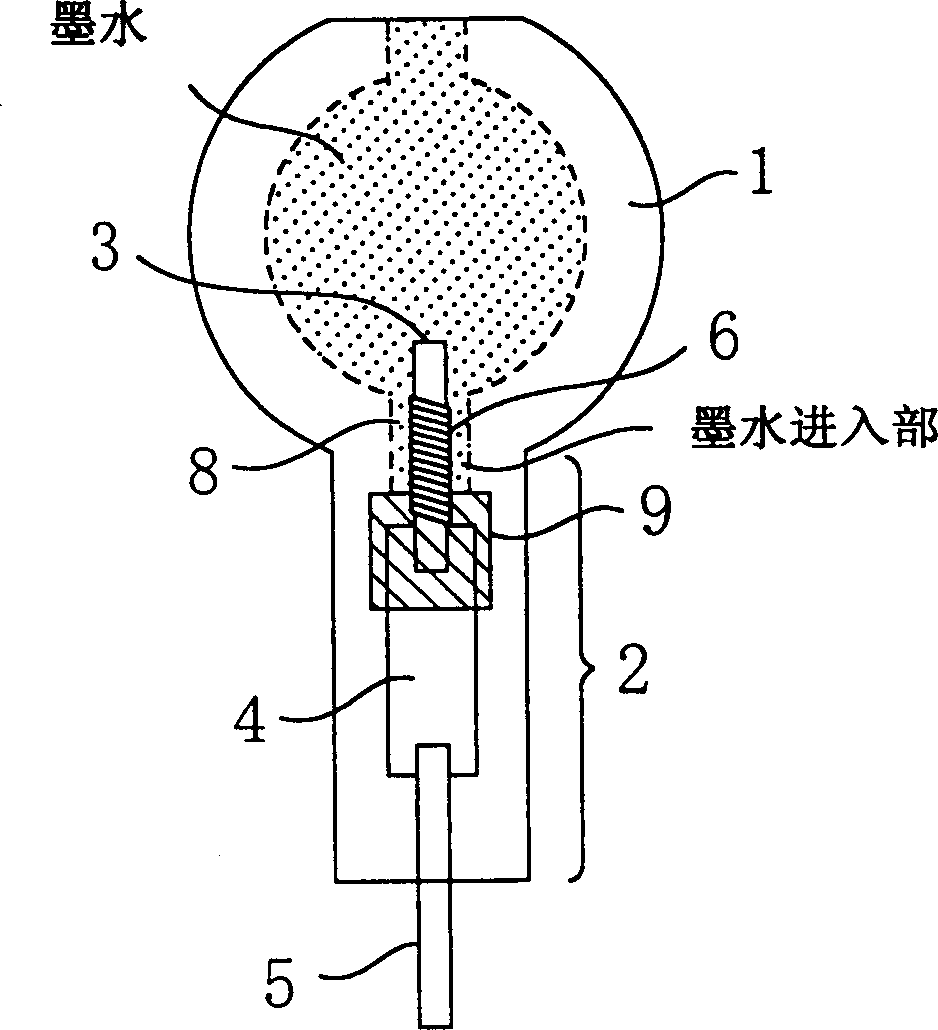

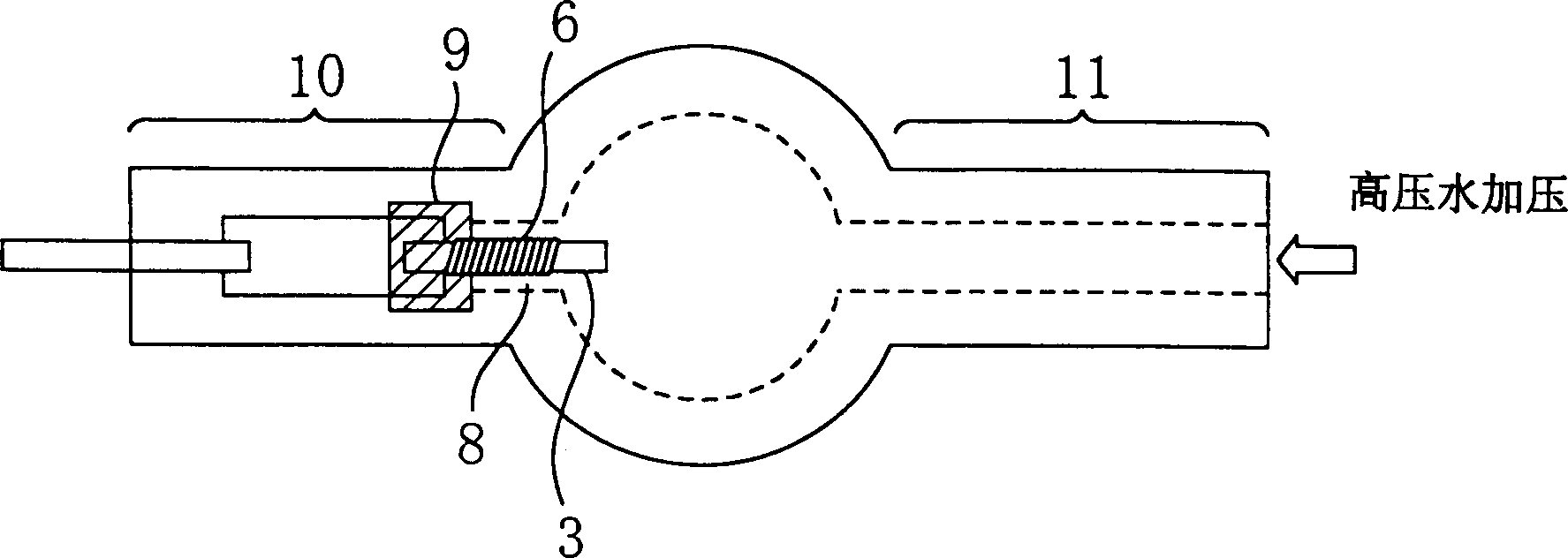

[0073] figure 1 The simulation shows the structure of the high-pressure discharge lamp according to Embodiment 1 of the present invention. In addition, a high-pressure discharge lamp is a discharge lamp whose internal pressure is 1 atmosphere or more when emitting light. A high-pressure discharge lamp is generally called a HID lamp (high-intensity lamp), and examples thereof include a high-pressure mercury lamp and a metal halide lamp.

[0074] figure 1 The shown high-pressure discharge lamp consists of a light-emitting part 1 and a container (hereinafter sometimes referred to as "tube") constituted by side tubes 2 extending from both sides of the light-emitting part 1 . The main component of the material constituting the container is quartz (more specifically, quartz glass). At least mercury 7 is sealed in the light emitting unit 1 . and, figure 1 The side tube 2 of the high pressure discharge lamp shown in , has a portion (sealing portion) that maintains the airtightnes...

Embodiment approach 2

[0109] Next, a method of manufacturing the lamp according to Embodiment 1 described above will be described with reference to the drawings.

[0110] Figure 8 A tungsten coil 6 welded to the electrode rod 3 is shown. The tungsten coil in this embodiment has a diameter of about 60 μm and is wound with a winding inner diameter of about 0.25 mm. The total length of the tungsten coil 6 is about 3 mm.

[0111] The tungsten coil 6 is inserted into the electrode rod 3 for welding. Figure 9 The electrode rod 100 is shown with a tungsten coil 6 after welding. The electrode rod 3 in this embodiment has an outer diameter of about 0.25 mm and a length of about 9 mm. The tungsten coil 6 is provided on the electrode rod 3 in a space about 1 mm away from the end formed by the welded portion of the metal foil 4 and the electrode rod 3 .

[0112] Figure 10 An electrode assembly member 101 used in a lamp is shown. The metal foil 4 is, for example, a foil made of molybdenum, and the met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com