Method for manufacturing mould and its structure

A mold manufacturing and mold technology, applied in the field of laminated mold manufacturing method and its structure, can solve the problems of time-consuming and money-consuming, complicated process, mold volume and weight cannot be reduced or reduced, etc., and achieve void elimination and volume reduction. , The effect of reducing production cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The mold manufacturing method of the present invention is different from the existing mechanical drilling method, and the mold manufacturing time, precision and cost are greatly improved. The mold structure and manufacturing process are explained below.

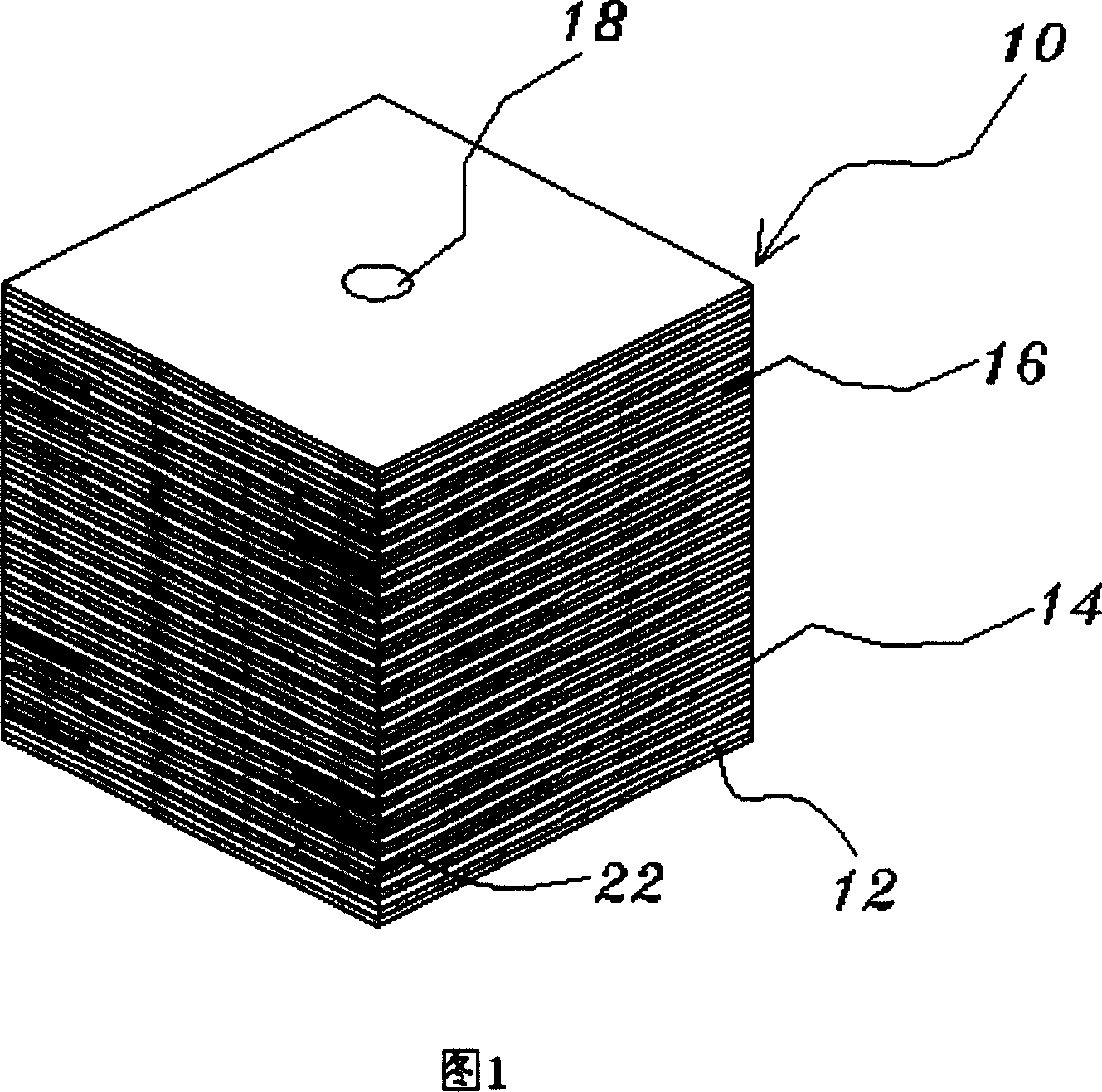

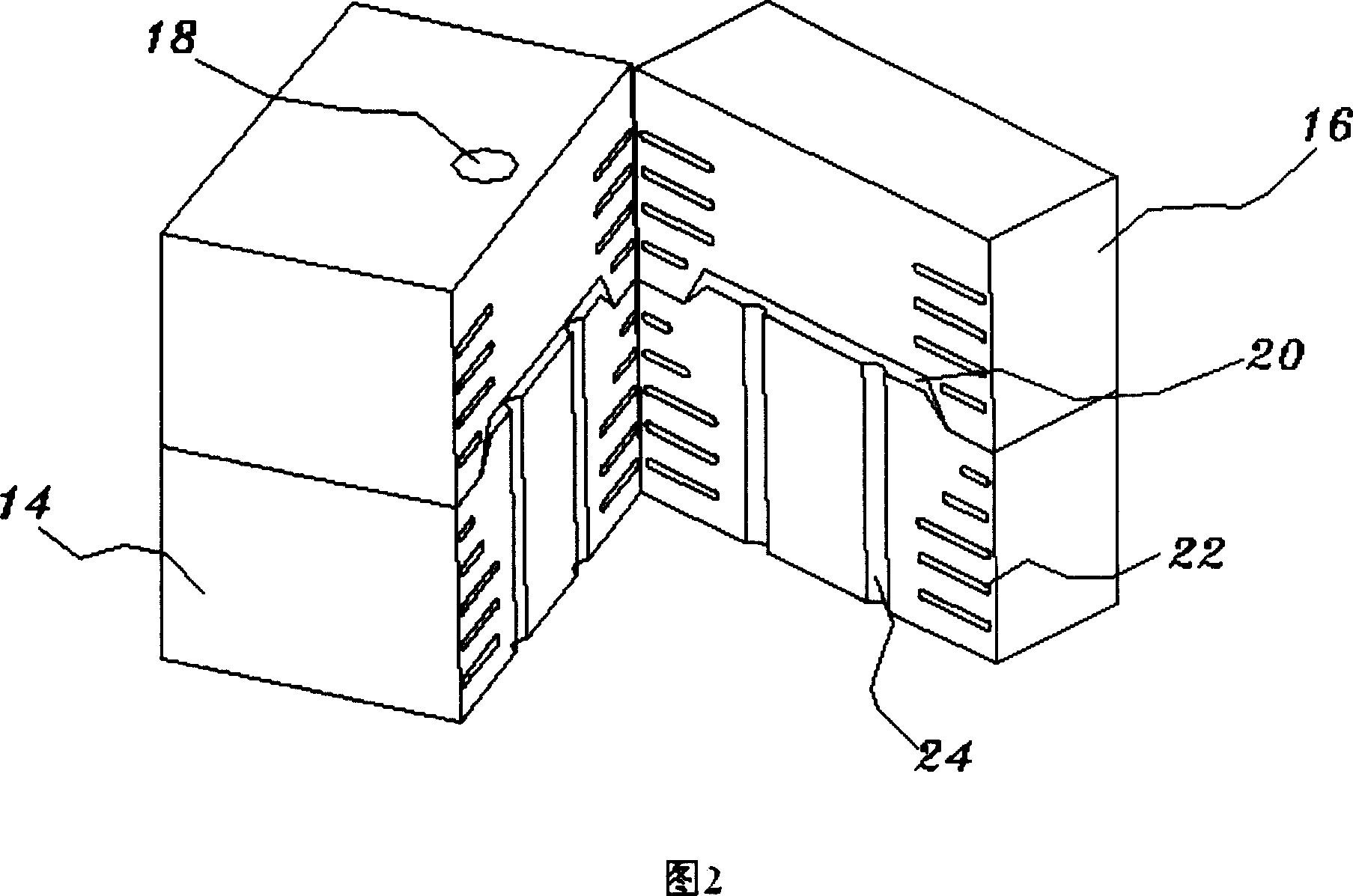

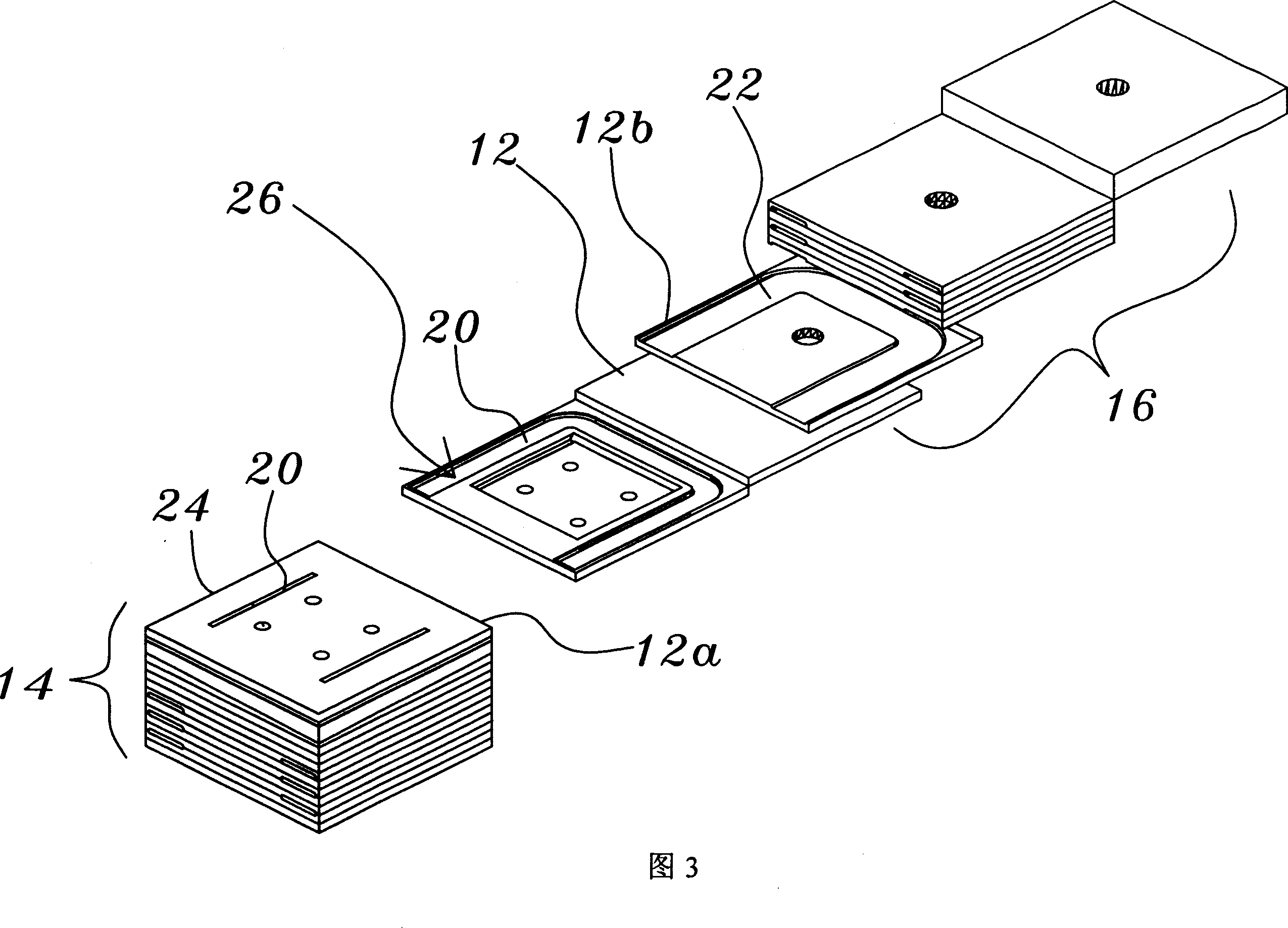

[0026] First introduce the structure of the present invention, with reference to shown in Fig. 1 and Fig. 2, this mold structure 10 is formed by stacking a plurality of thin plates 12, and the material of this thin plate 12 is metal material, and thin plate 12 also can be heat-resistant material in addition, This mold structure 10 comprises lower mold 14 and upper mold 16, and this lower mold 14 is provided with a filling hole 18, and is provided with a mold cavity 20 between lower mold 14 and upper mold 16, and filling hole 18 can be connected with this. The mold cavity 20 is connected, and the pouring hole 18 can be poured into and flow into the mold cavity 20 by molten molding liquid; in addition, a cooling system an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com