Patents

Literature

379results about How to "Eliminate voids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

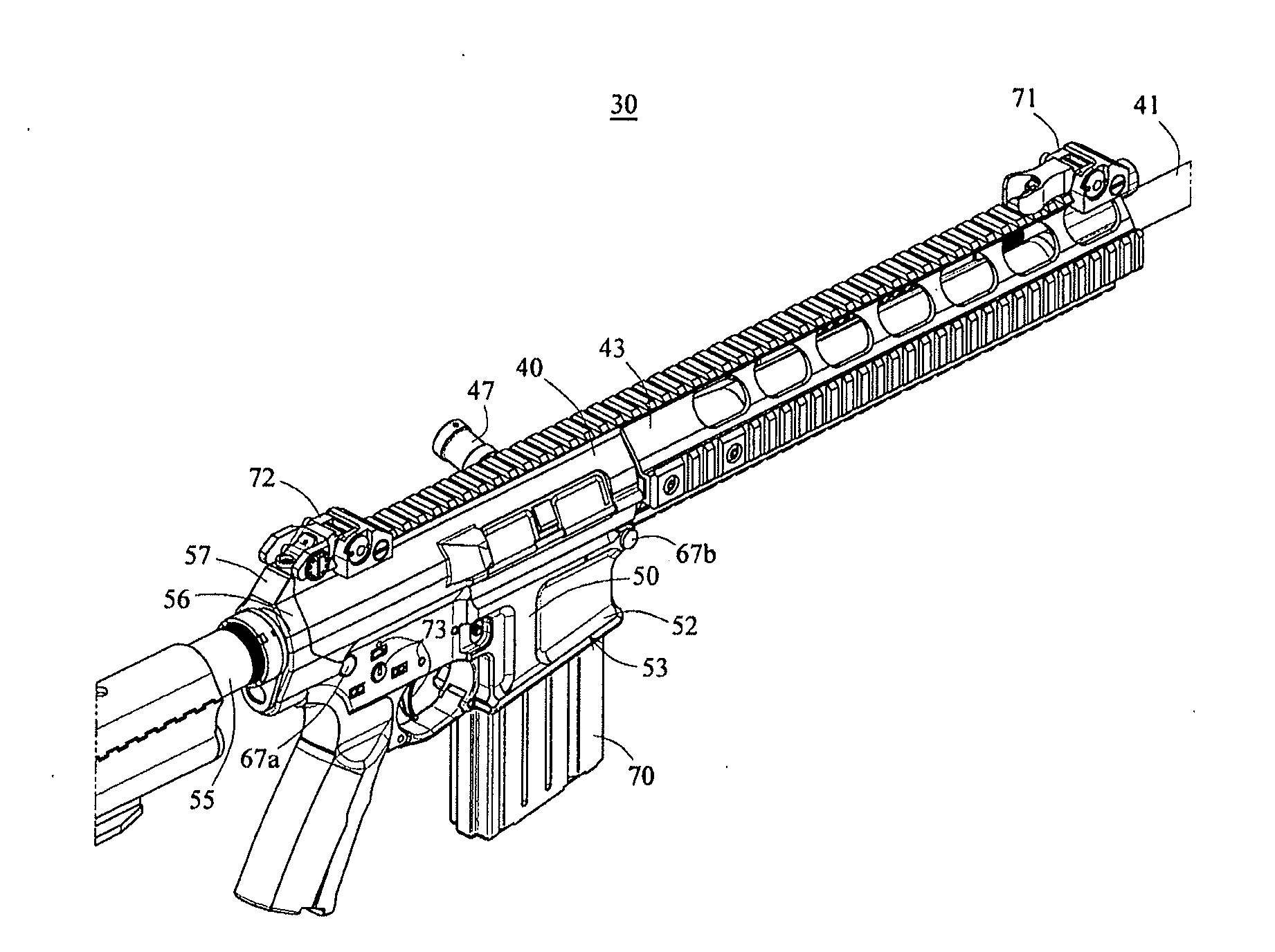

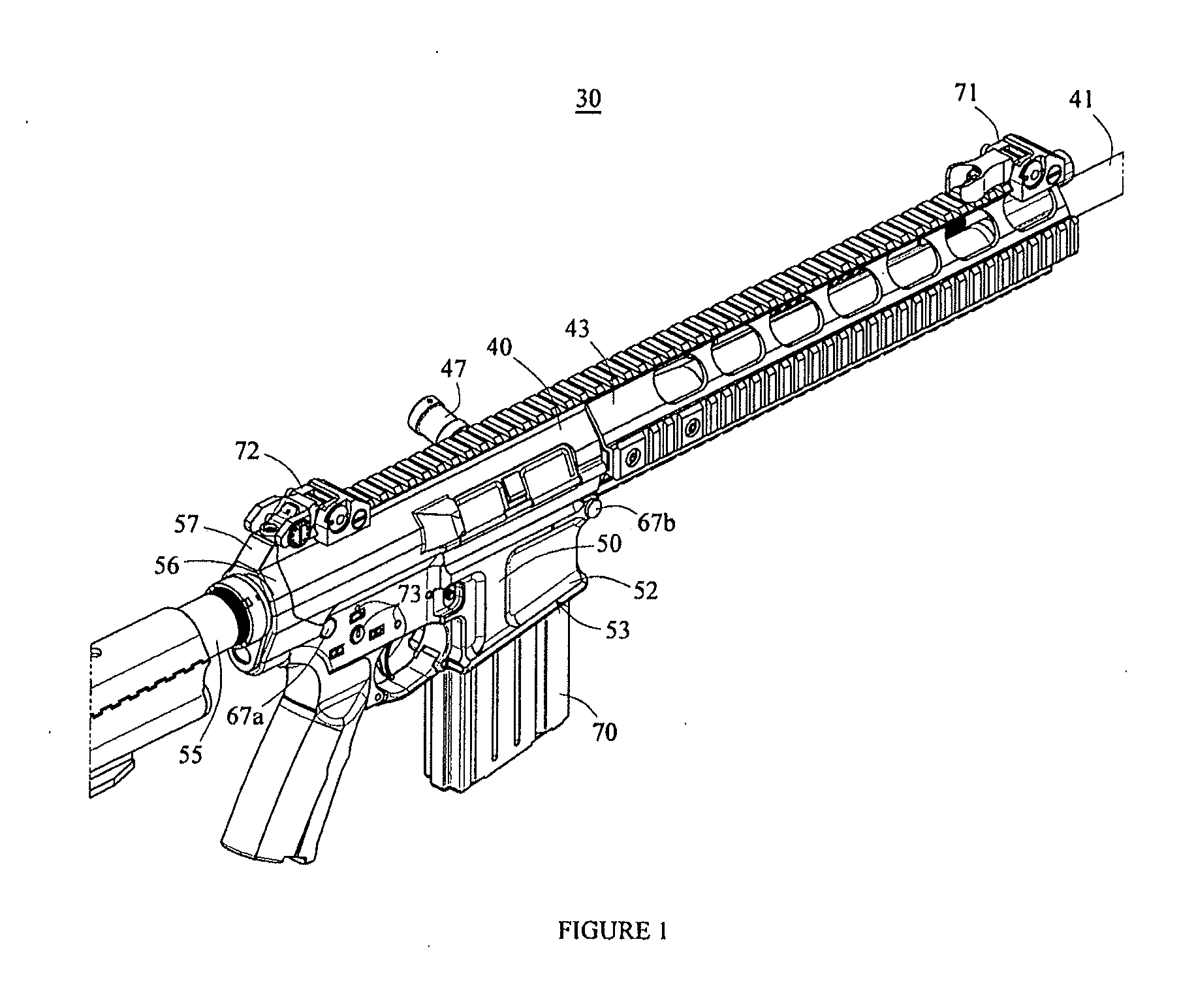

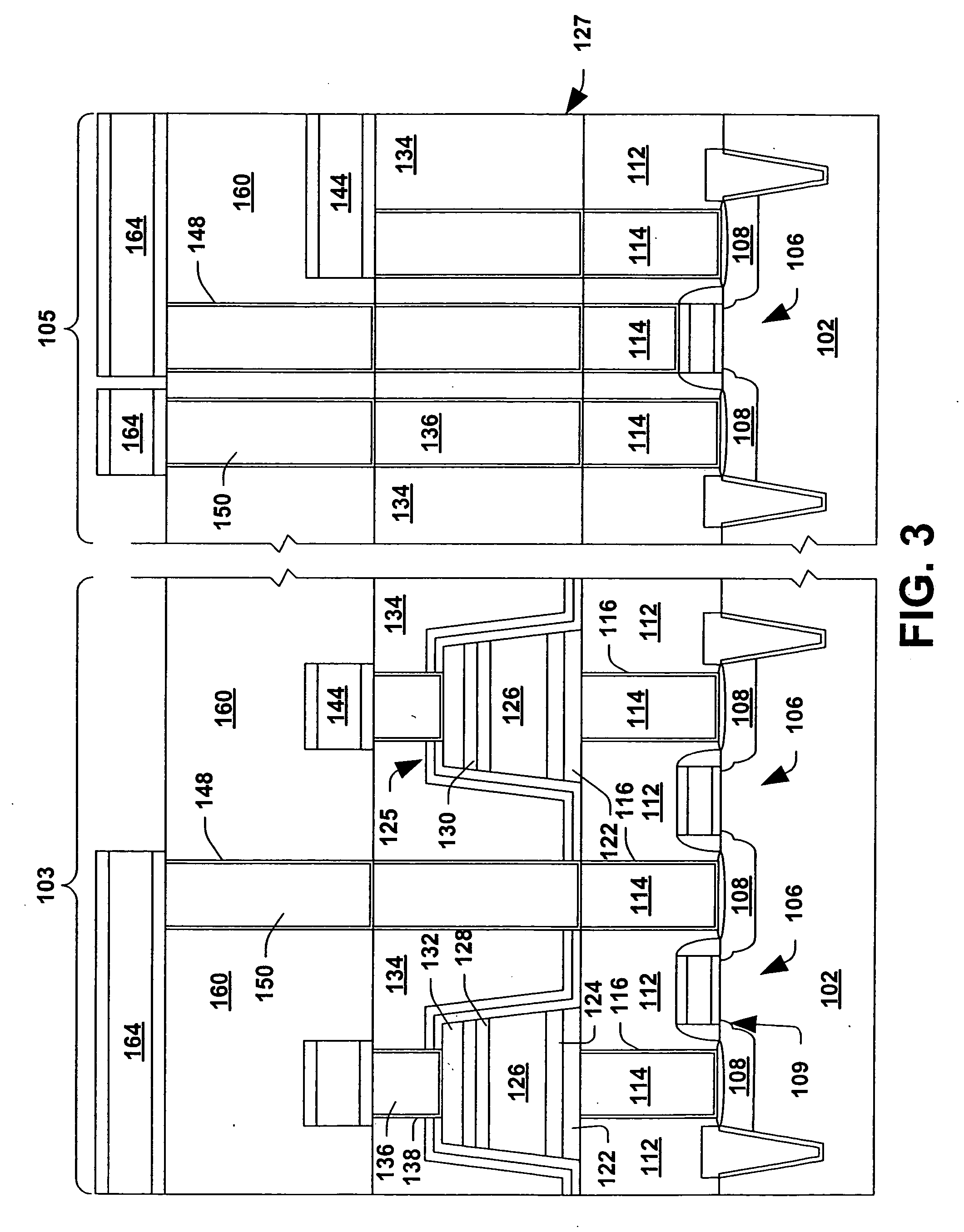

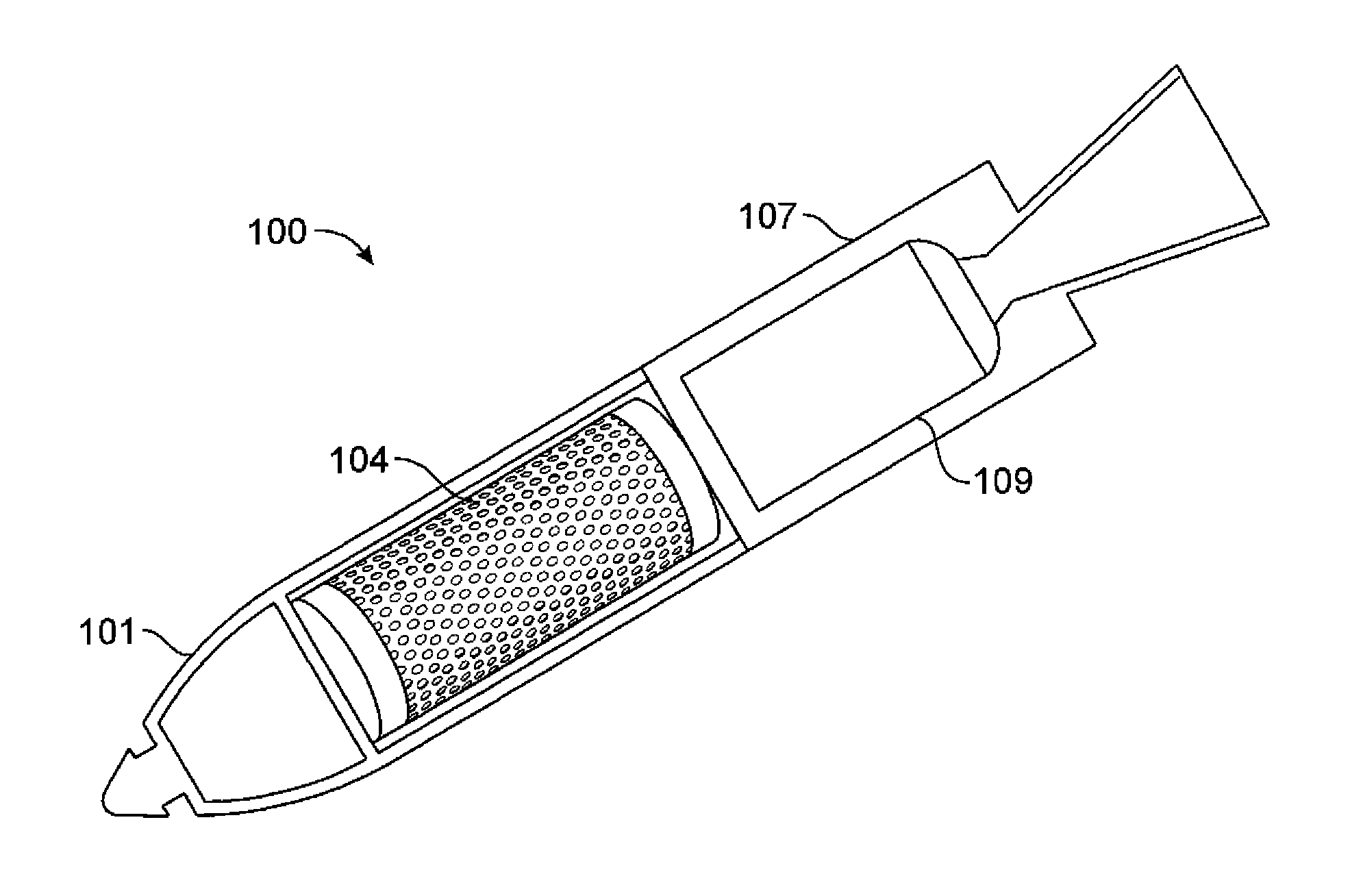

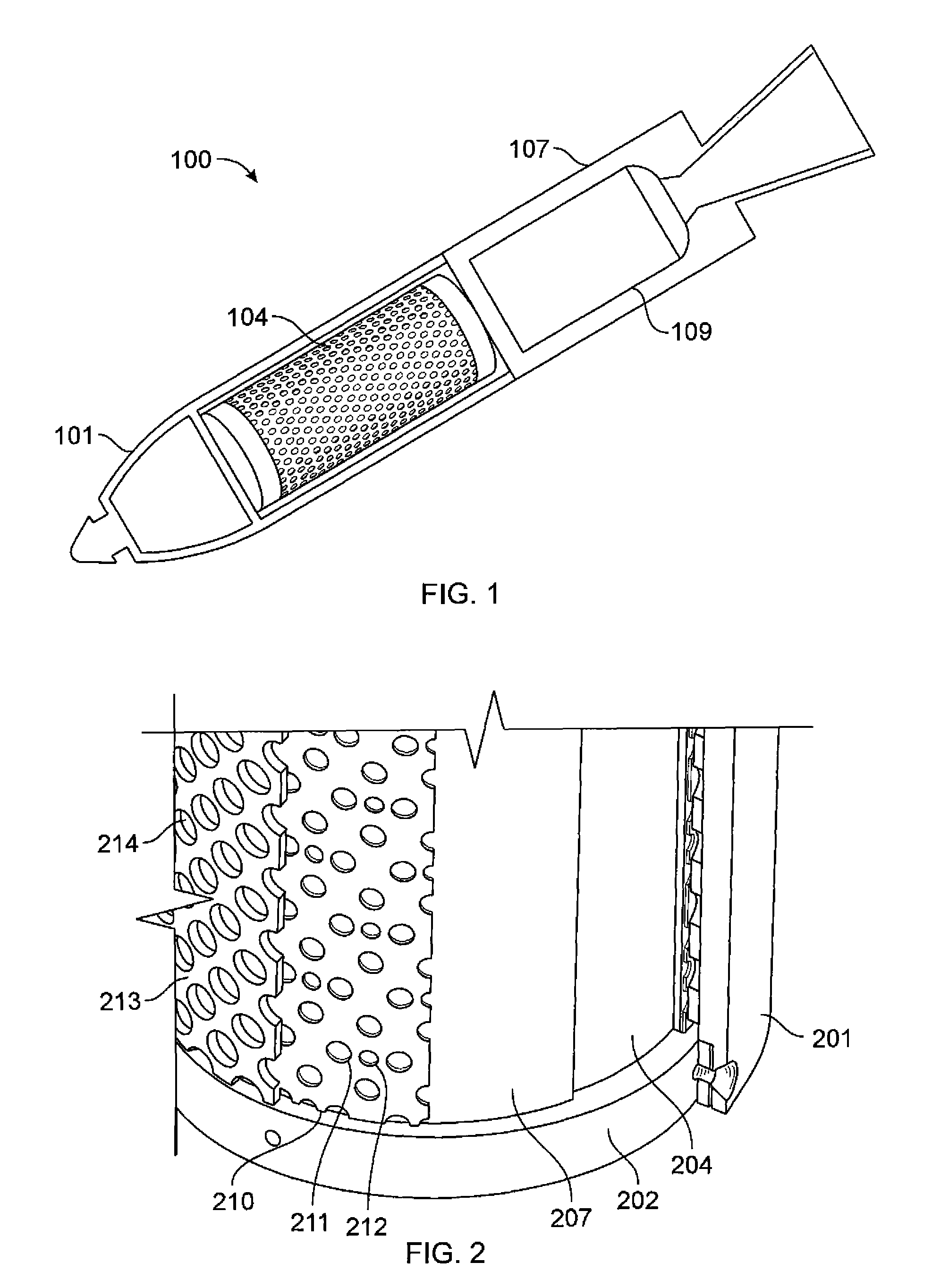

Receiver for an autoloading firearm

ActiveUS20120260793A1Quick insertIncreased margin of errorBreech mechanismsElectrical and Electronics engineeringEngineering

Improved receiver set for an indirect or direct gas operated firearm wherein the charging handle has been moved to the side of the upper receiver, the magazine well has been flared open to better receive a magazine, and the lower receiver has a semi-circular shelf in the rear which supports the proximal end of the bolt carrier as it is longitudinally displaced due to firing of the weapon.

Owner:LWRC INTERNATIONAL

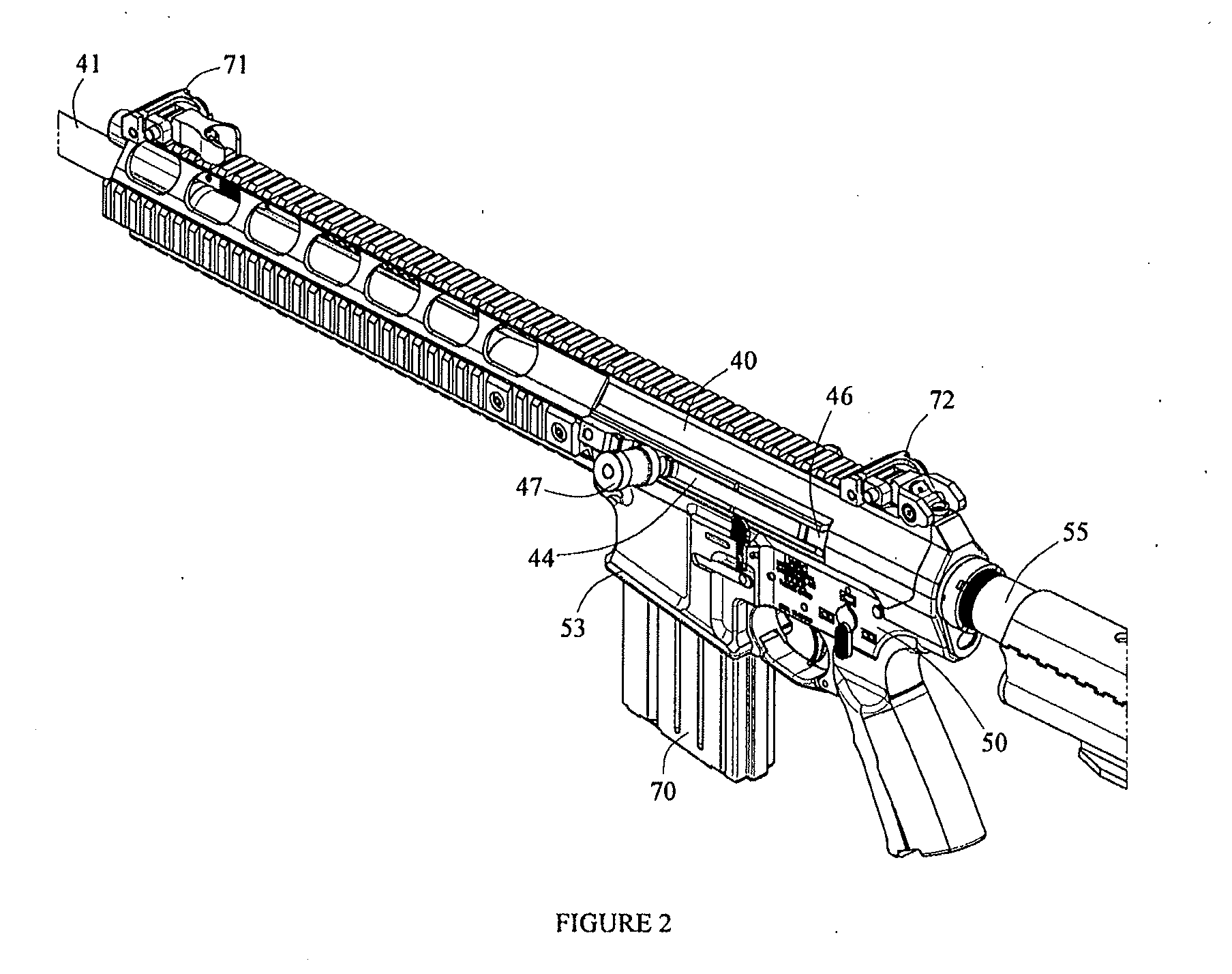

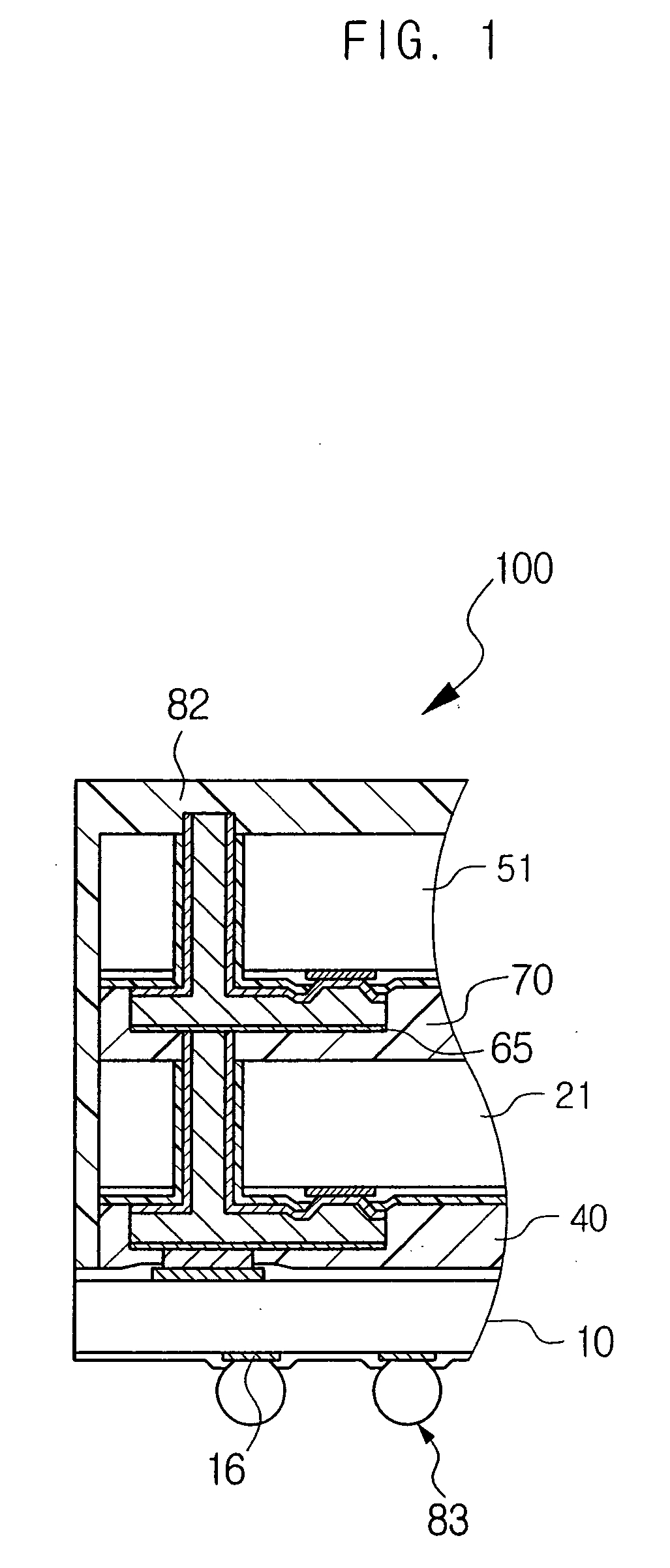

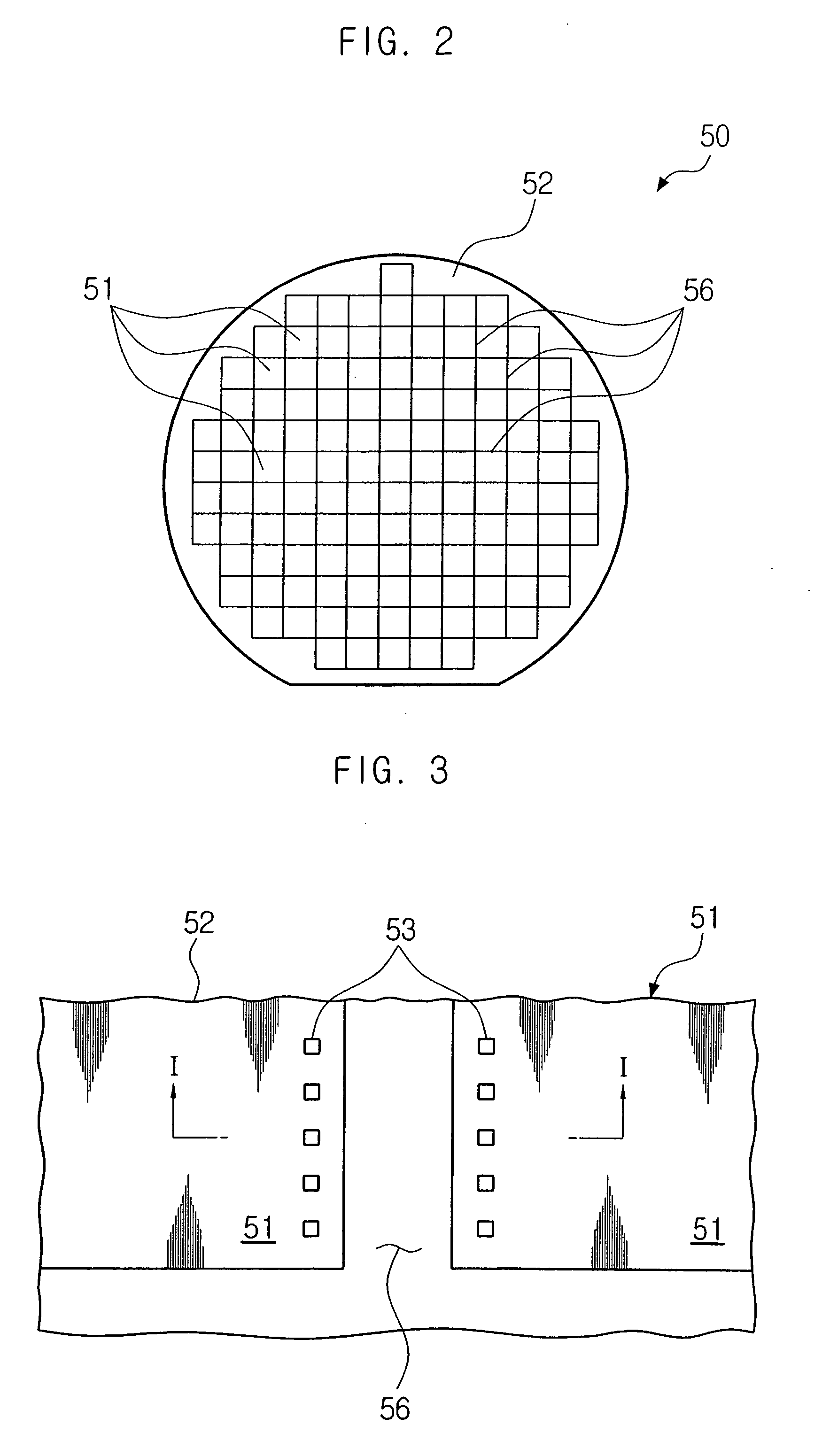

Stacked chip package using photosensitive polymer and manufacturing method thereof

ActiveUS20070048969A1Reduce decreaseImprove device reliabilitySemiconductor/solid-state device detailsSolid-state devicesMechanical reliabilityPhotosensitive polymer

In a stacked chip configuration, and manufacturing methods thereof, the gap between a lower and an upper chip is filled completely using a relatively simple process that eliminates voids between the lower and upper chips and the cracking and delamination problems associated with such voids. The present invention is applicable to both chip-level bonding and wafer-level bonding approaches. A photosensitive polymer layer is applied to a first chip, or wafer, prior to stacking the chips or stacking the wafers. The photosensitive polymer layer is partially cured, so that the photosensitive polymer layer is made to be structurally stable, while retaining its adhesive properties. The second chip, or wafer, is stacked, aligned, and bonded to the first chip, or wafer, and the photosensitive polymer layer is then cured to fully bond the first and second chips, or wafers. In this manner, adhesion between chips / wafers is greatly improved, while providing complete gap fill. In addition, mechanical reliability is improved, alleviating the problems associated with cracking and delamination, and leading to an improvement in device yield and device reliability.

Owner:SAMSUNG ELECTRONICS CO LTD

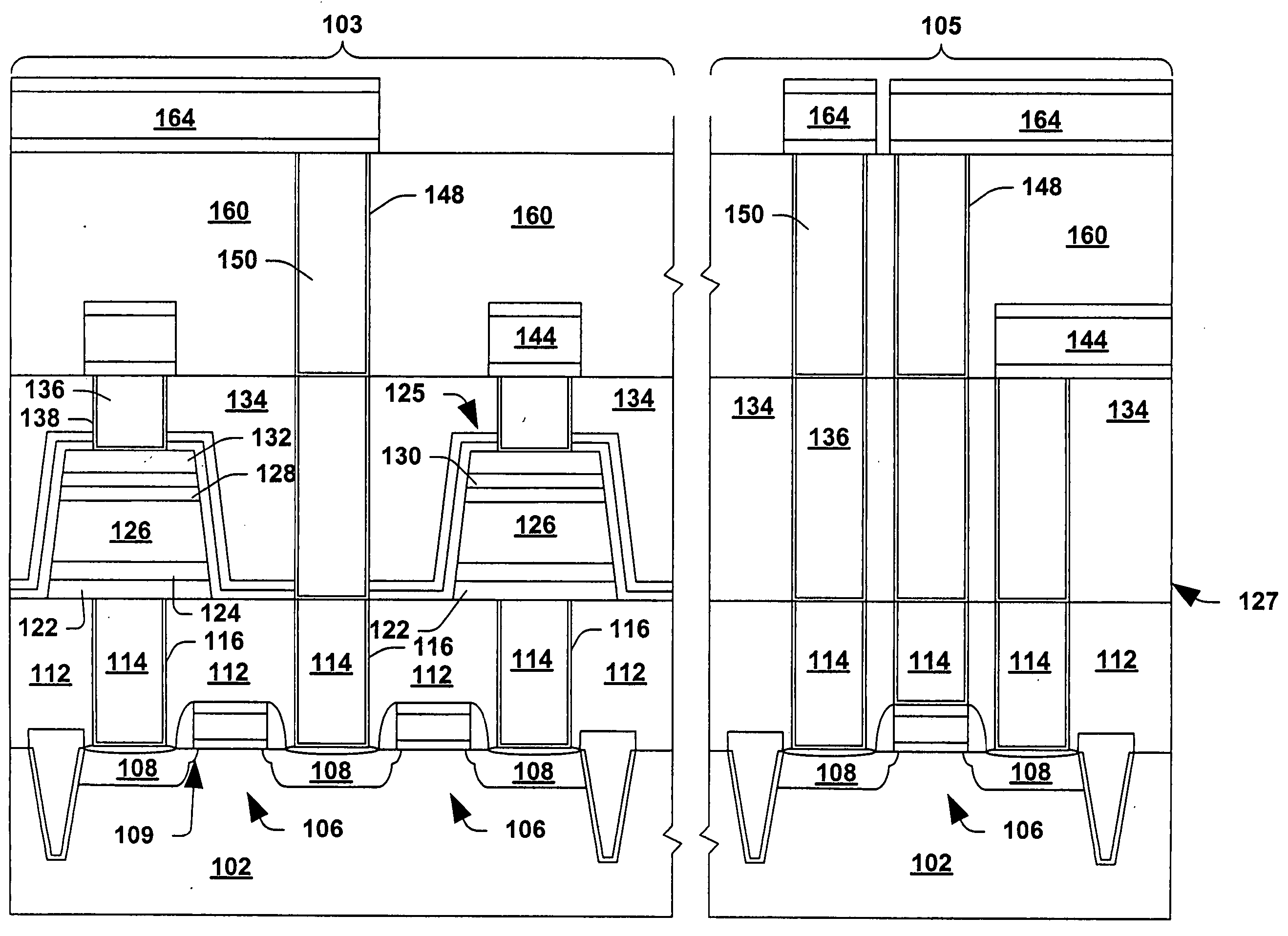

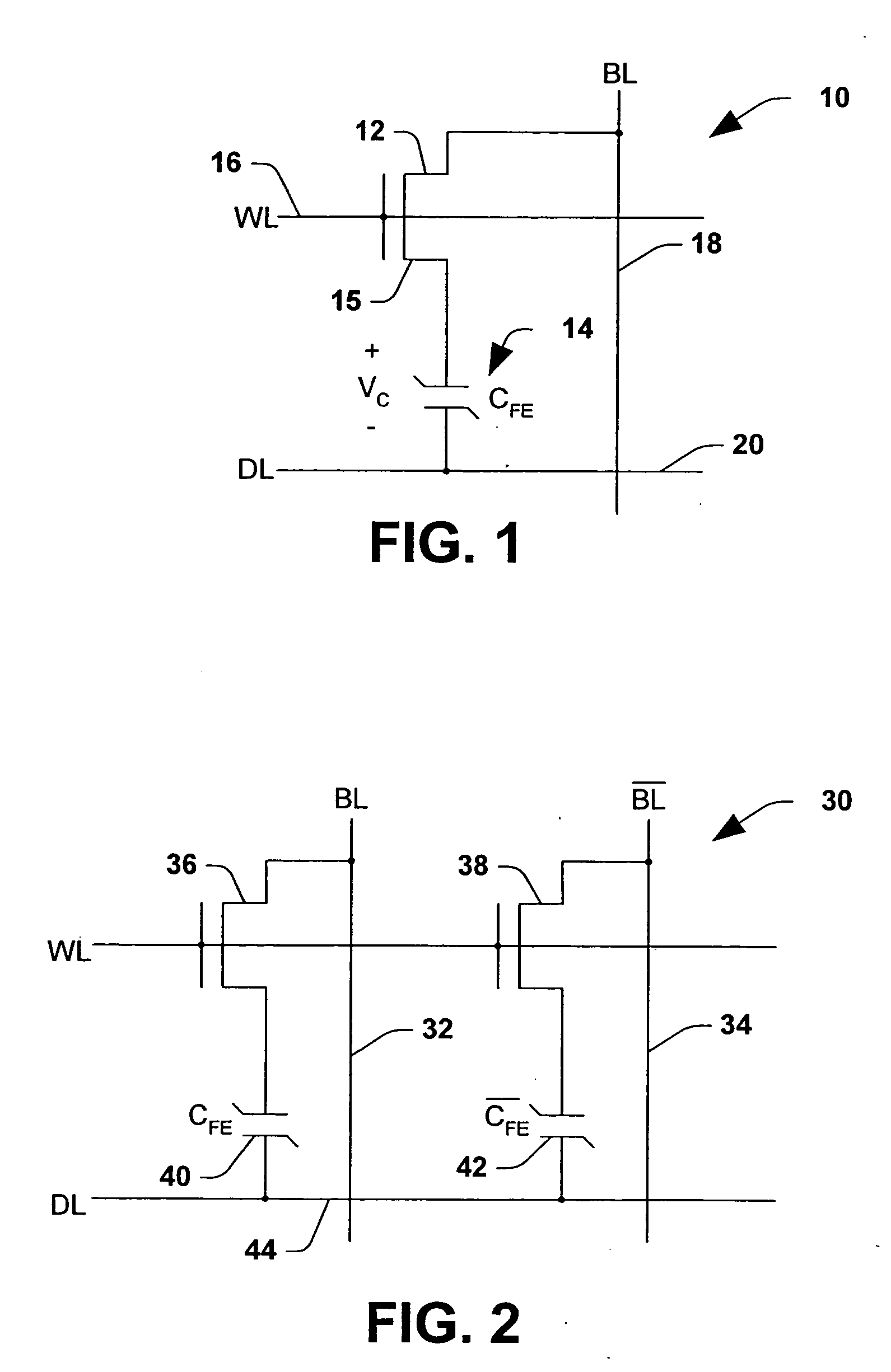

FeRAM capacitor stack etch

InactiveUS20050054122A1Minimize cell sizeCost advantageSolid-state devicesSemiconductor/solid-state device manufacturingConductive materialsCapacitor

The present invention is directed to a method of forming an FeRAM integrated circuit, which includes performing a capacitor stack etch to define the FeRAM capacitor. The method comprises etching a PZT ferroelectric layer with a high temperature BCl3 etch which provides substantial selectivity with respect to the hard mask. Alternatively, the PZT ferroelectric layer is etch using a low temperature fluorine component etch chemistry such as CHF3 to provide a non-vertical PZT sidewall profile. Such a profile prevents conductive material associated with a subsequent bottom electrode layer etch from depositing on the PZT sidewall, thereby preventing leakage or a “shorting out” of the resulting FeRAM capacitor.

Owner:TEXAS INSTR INC

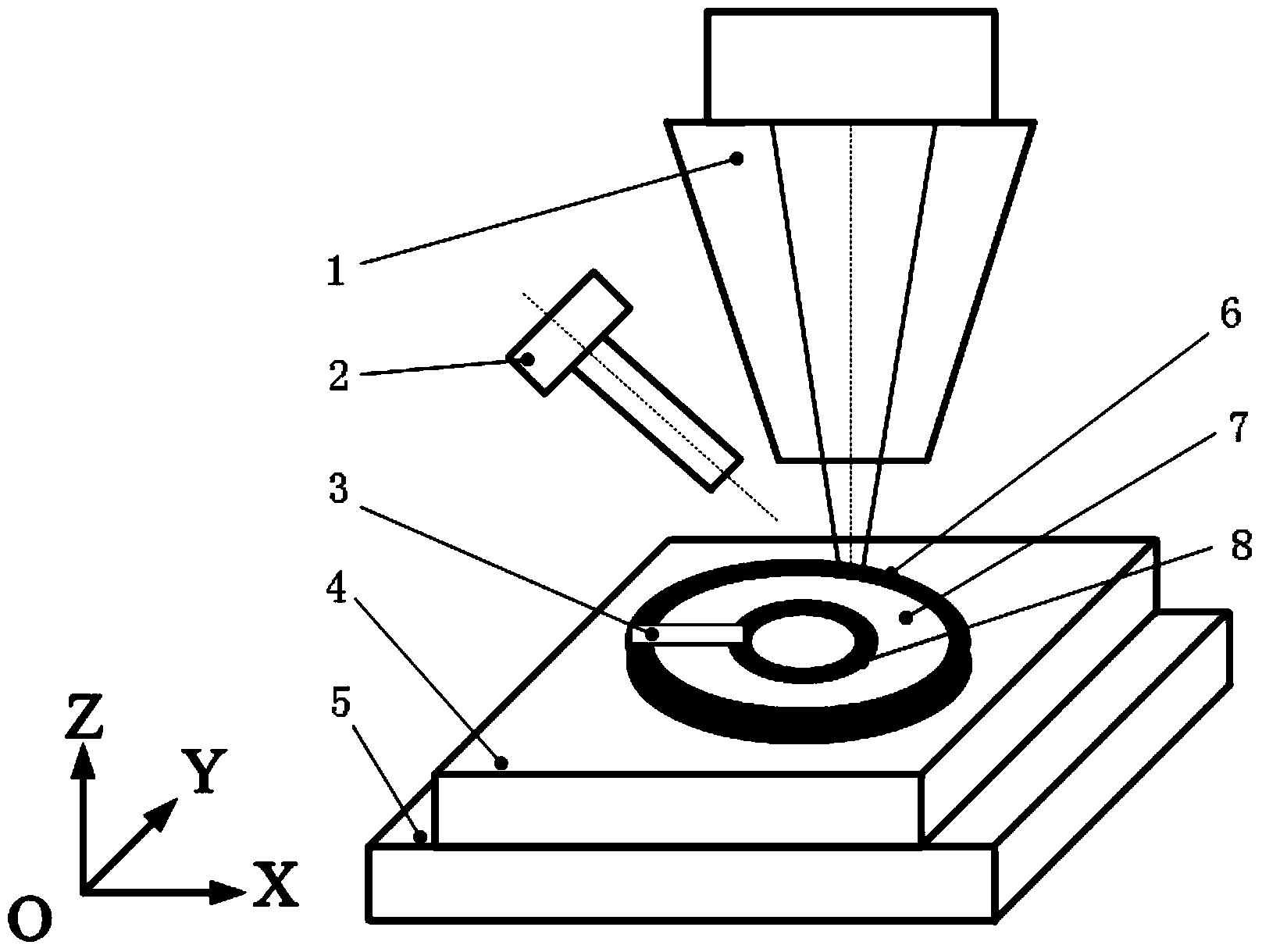

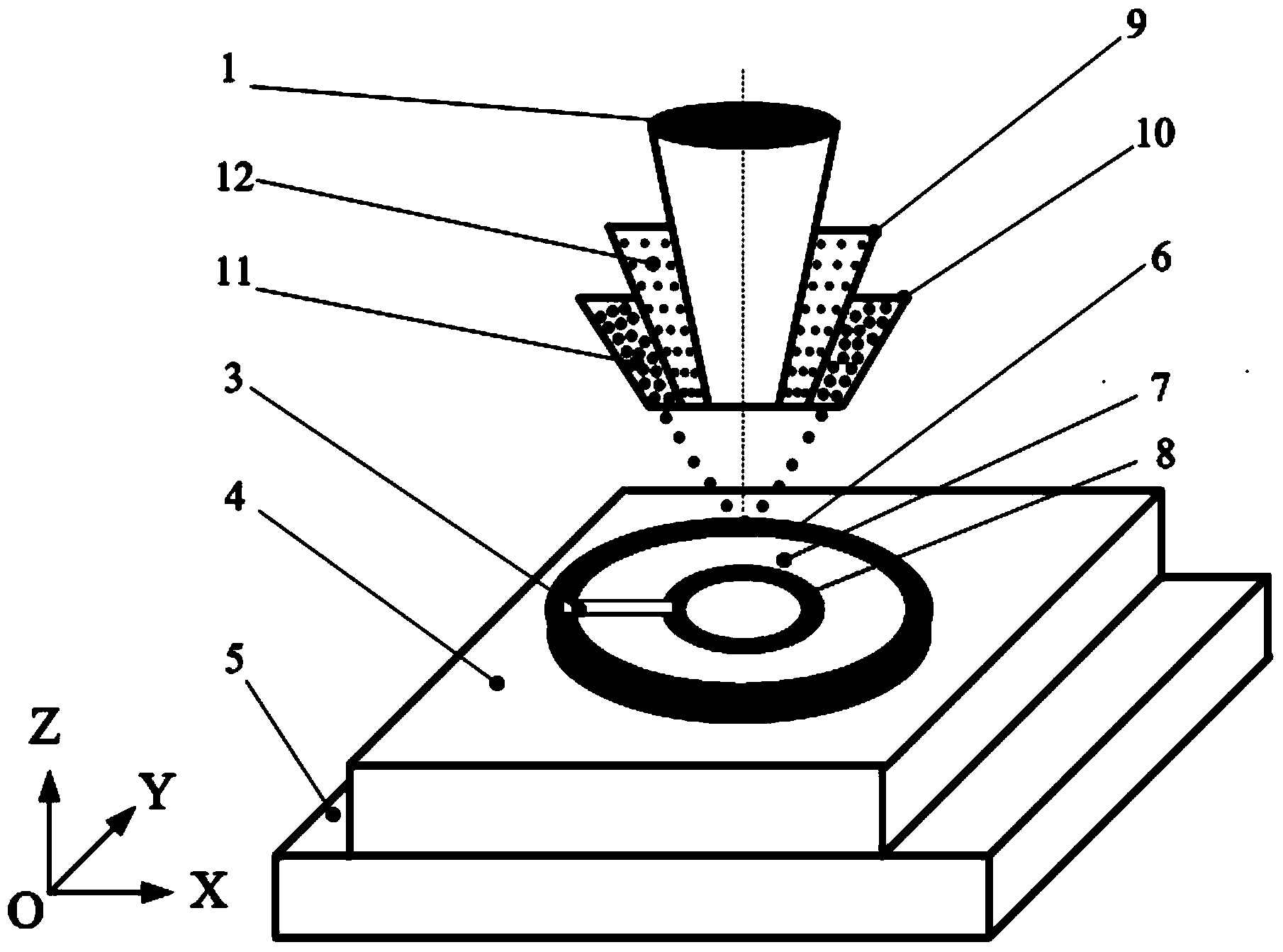

Metal 3D printer based on interlayer shock processing process and printing method thereof

The invention discloses a technique for improving the mechanical performance of a printed piece through shock processing in the process of metal part 3D printing. The technique is characterized in that shock processing is conducted on the upper surfaces of cladding layers after a certain number of layers are cladded, so that defects such as cavities, looseness and microcracks in the cladding layers are eliminated, and the density of a formed part is improved; in the shock processing process, heating and reasonable partitioned technology planning are conducted on the cladding layers, the shock processing angle can be changed according to different areas on the same layer and the change of the number of the layers, and therefore it is guaranteed that the density and the mechanical performance are improved, stress concentration is prevented, and the forming precision of the metal 3D printed part is ensured.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

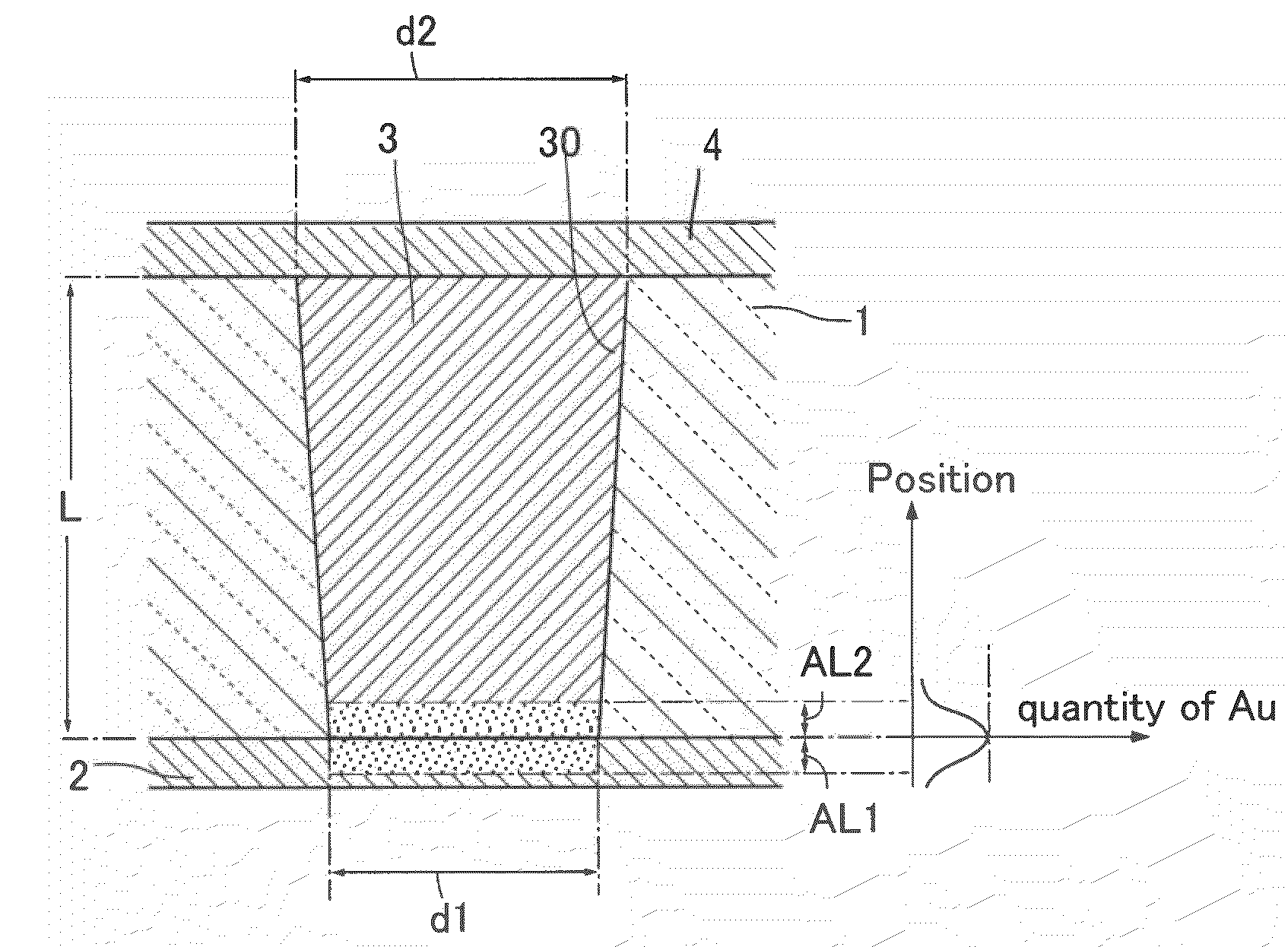

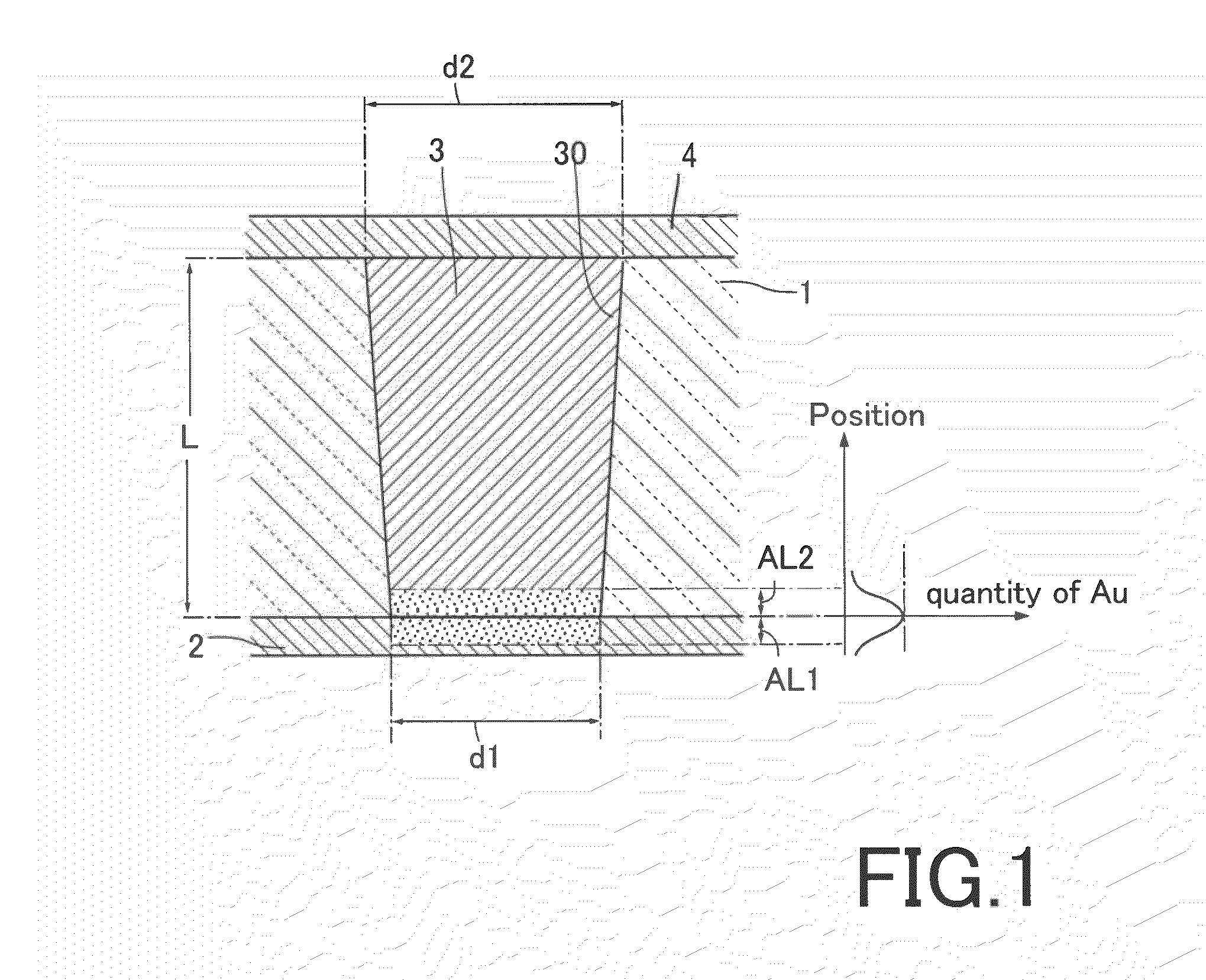

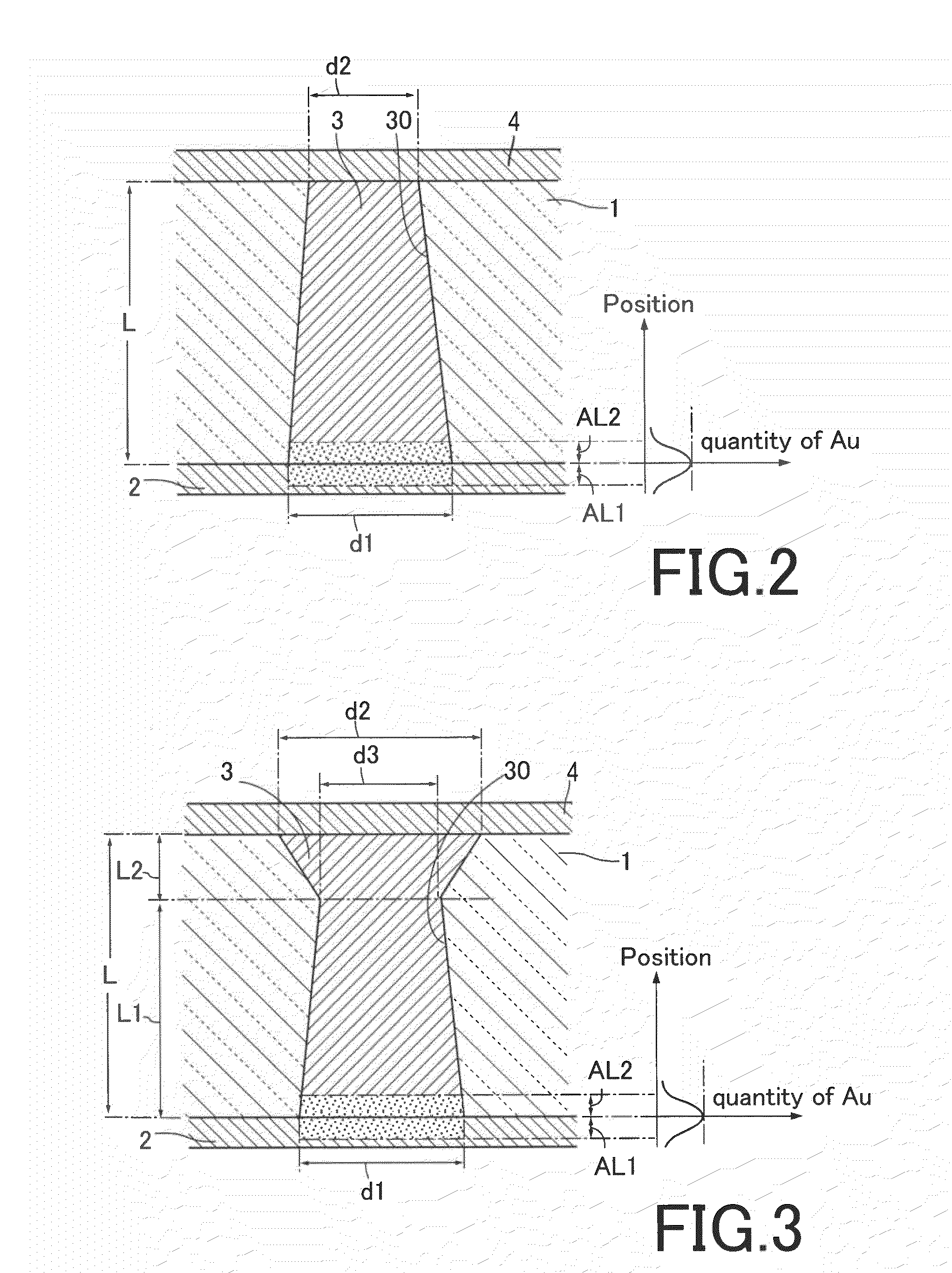

Circuit board, electronic device and method for manufacturing the same

InactiveUS20090084588A1Prevent void formationInhibition formationSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrode

A circuit board includes a substrate, a circuit pattern and a through electrode. The circuit pattern is disposed on one side of the substrate in a thickness direction thereof. The through electrode is filled in a through-hole formed in the substrate with one end connected to the circuit pattern. The circuit pattern and the through electrode each have an area containing a noble metal component (e.g., Au component) and are connected to each other therethrough.

Owner:NAPRA

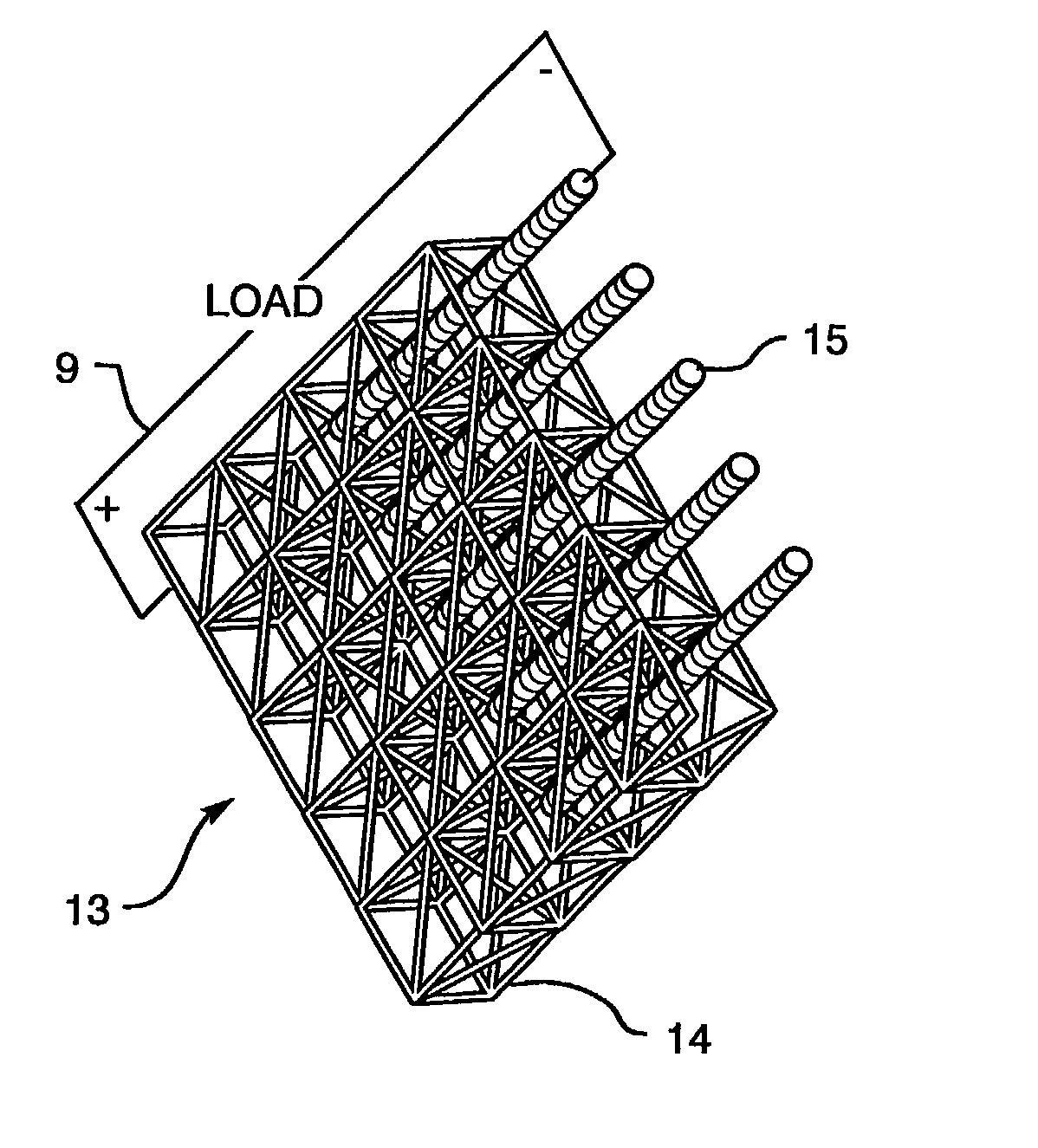

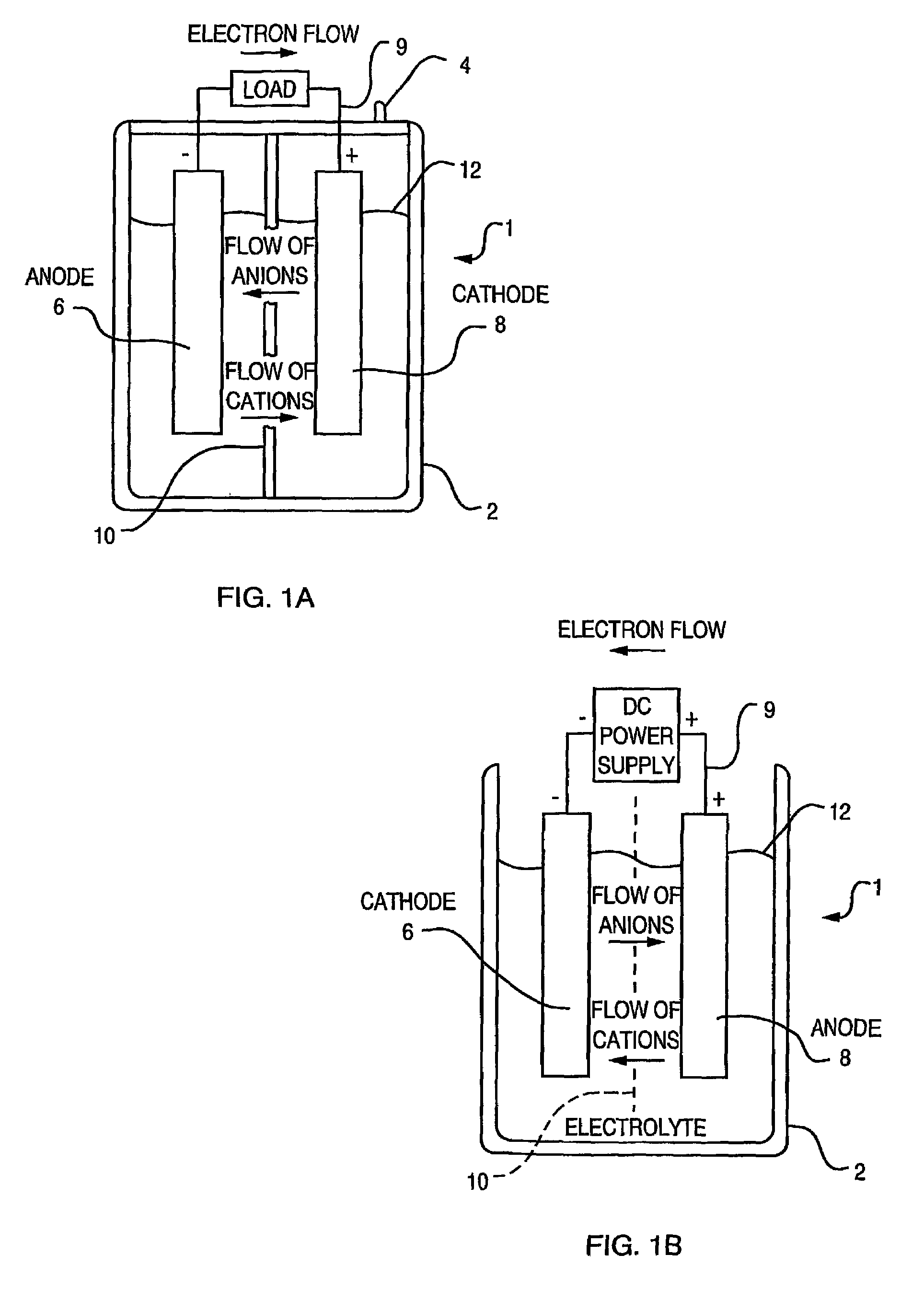

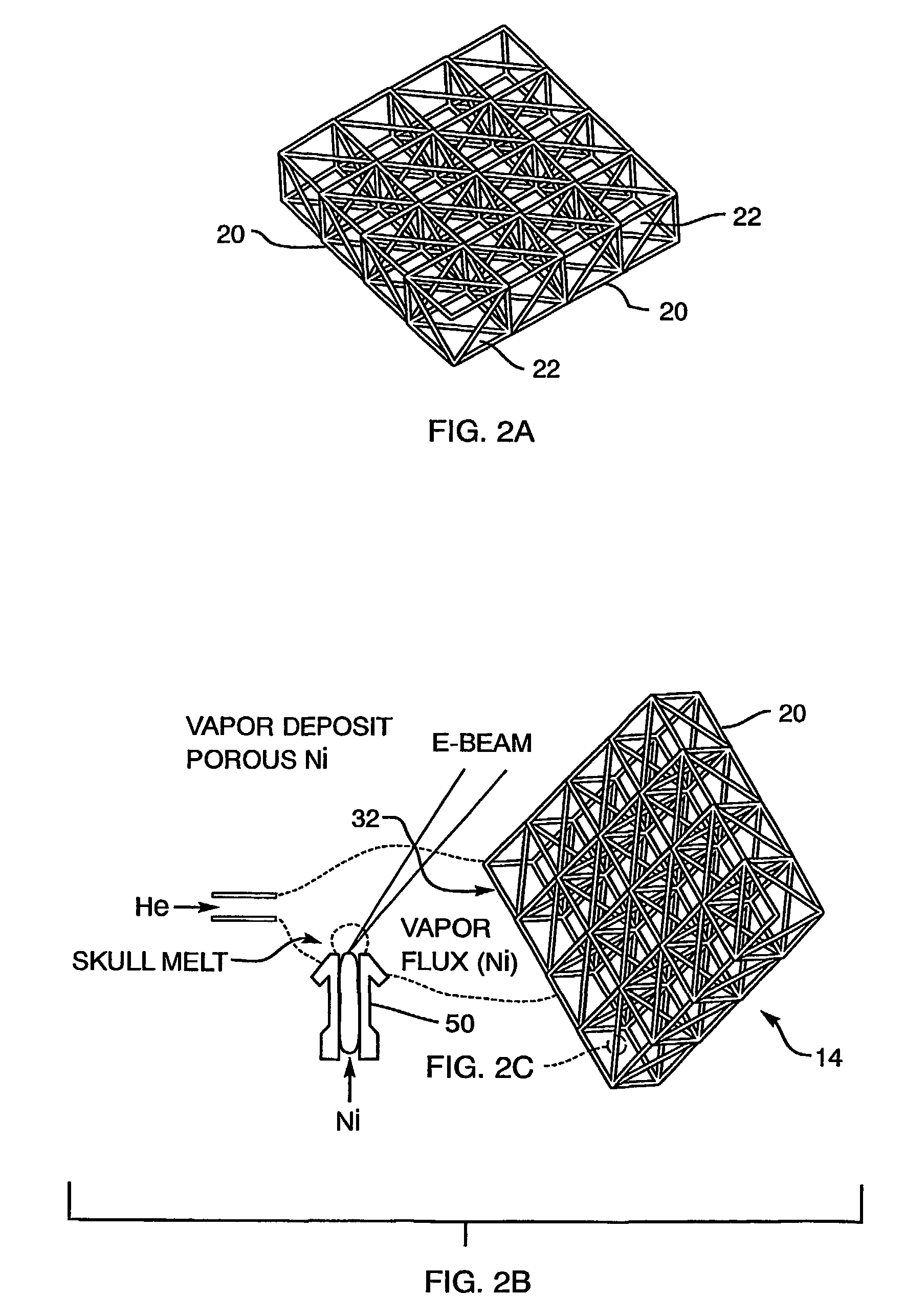

Multifunctional battery and method of making the same

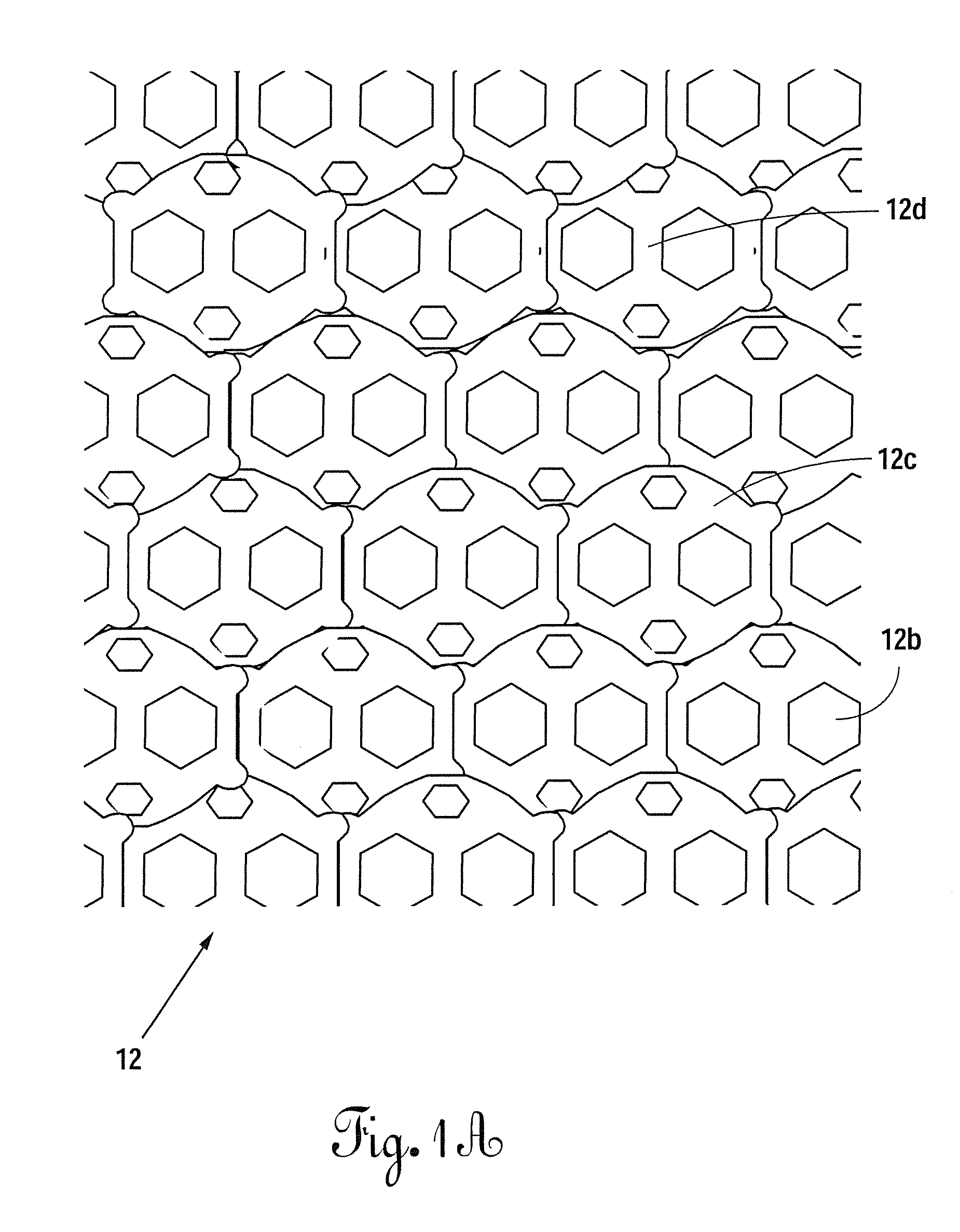

InactiveUS7211348B2Efficiently assembleEliminate voidElectrode manufacturing processesFinal product manufactureMultiple functionOpen cell

Disclosed herein is a multifunctional battery for supplying power to an electrical circuit, and the related method of making the same. Use of the multifunctional battery permits structural integrity and versatility, while maximizing power output of the cells and minimizing the overall weight of the structure. The multifunctional battery includes an open cell interconnected structure comprised of a plurality of open cells so as to provide a structural electrode. The structural electrode is configured to be a load bearing member. The battery also includes interstitial electrodes that are counter electrodes to the structural electrode. The interstitial electrodes are at least partially received within a predetermined number of the cells of the interconnected structure. Additionally, a separator portion is disposed between the structural electrode and interstitial electrodes to serve as an electrical insulator.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND +1

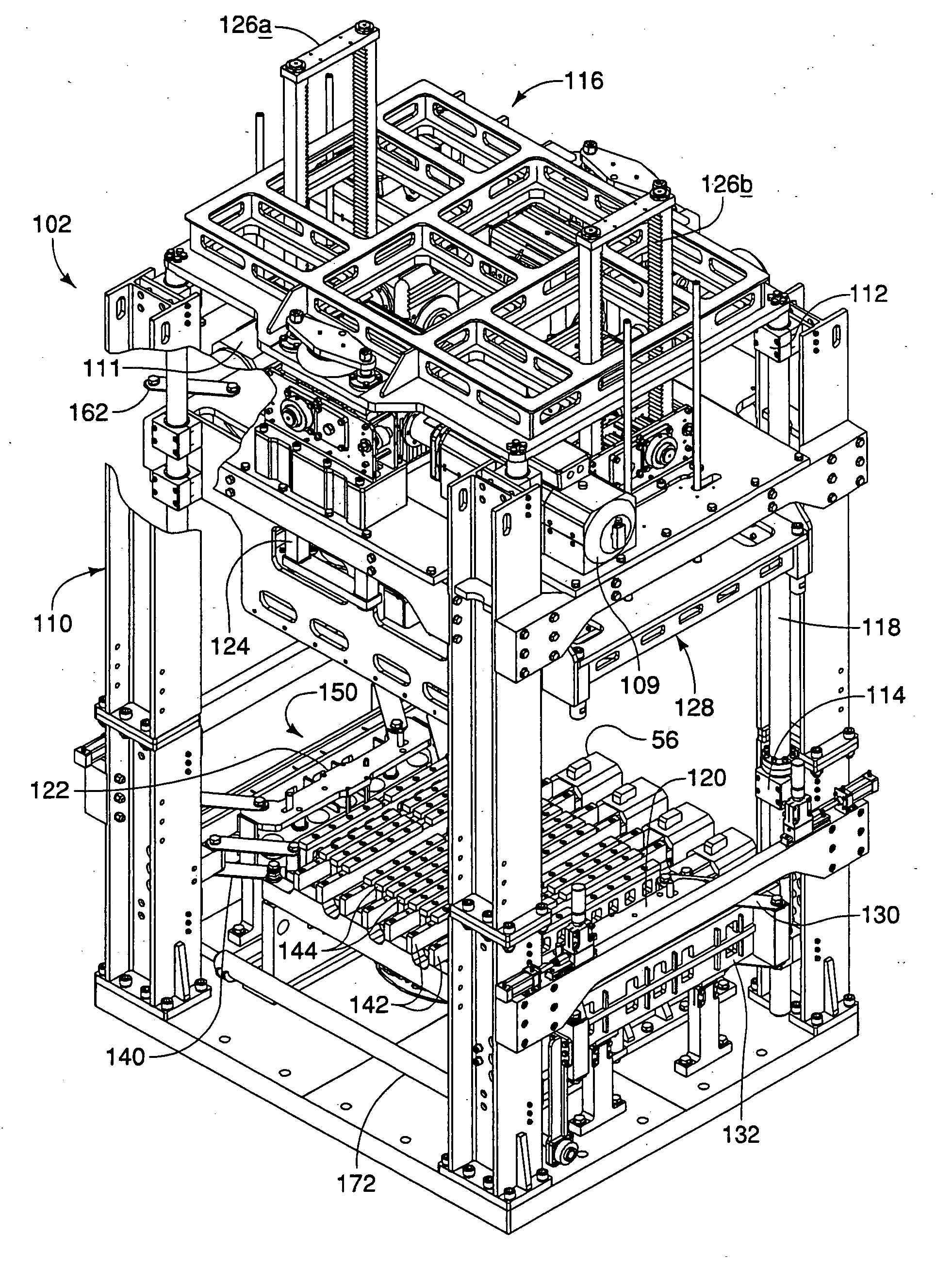

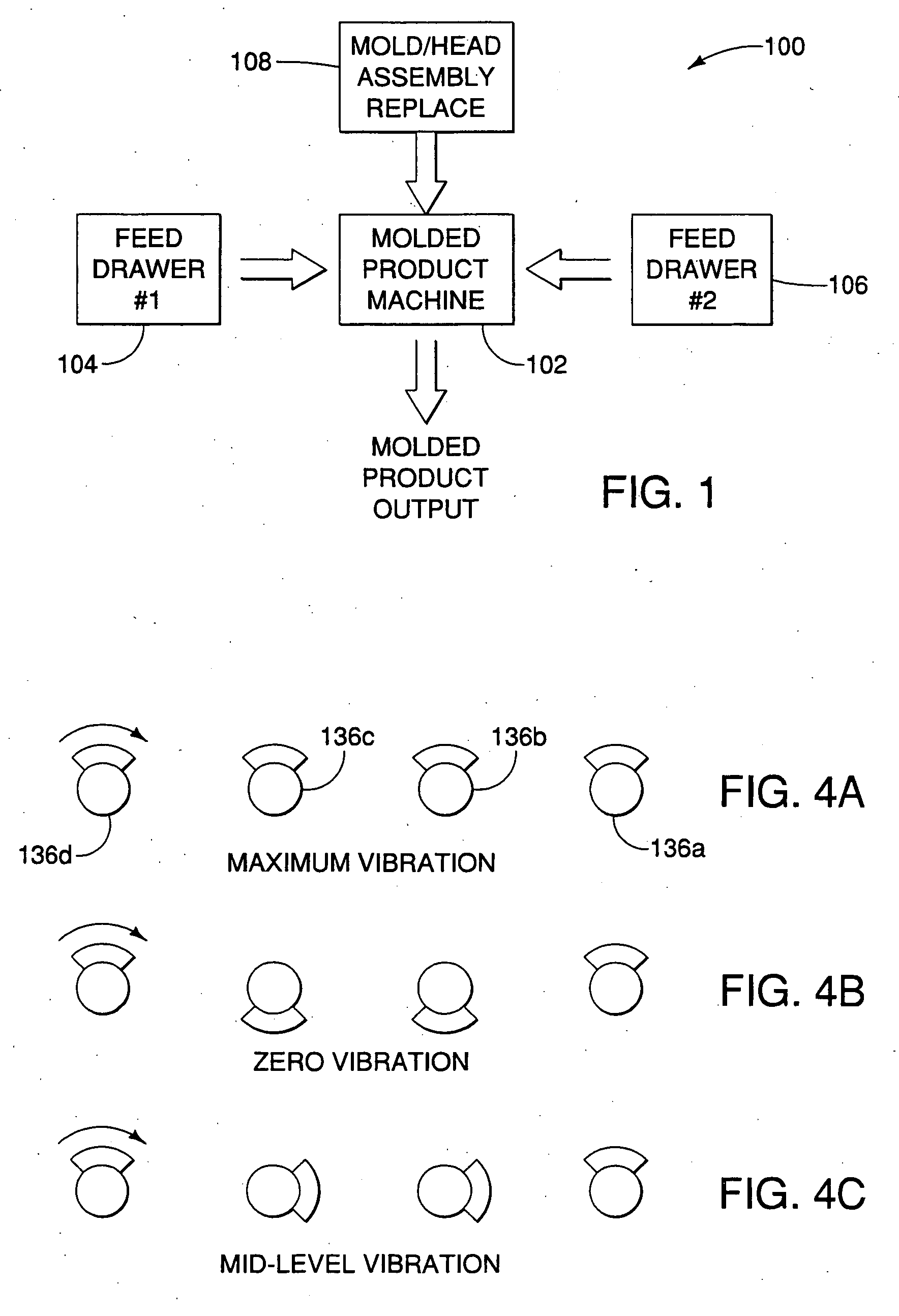

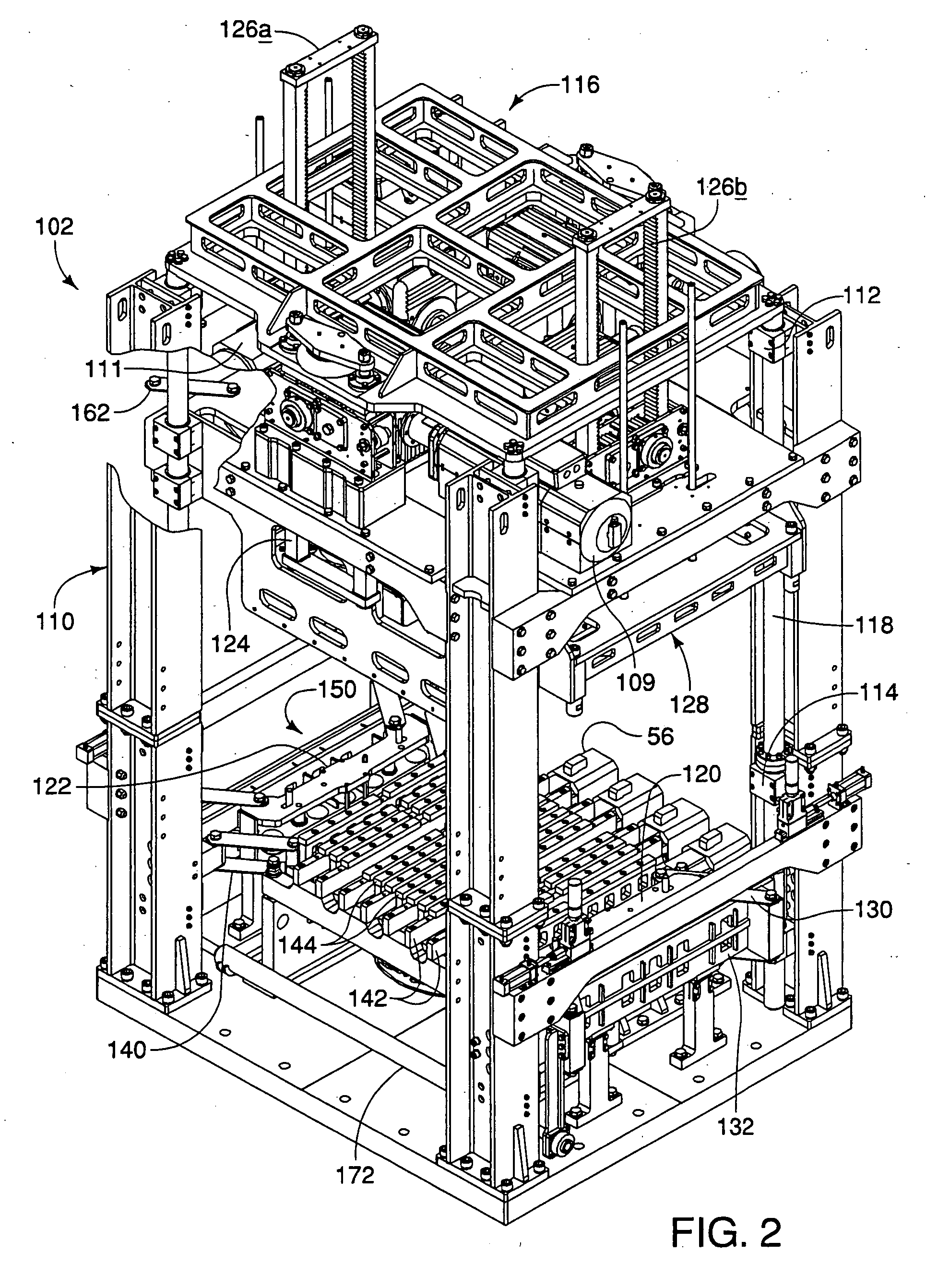

Large pallet machine for forming molded products

ActiveUS20060182840A1Minimize scalpingEasy to installConfectioneryCeramic shaping plantsMolding machineEngineering

A concrete products forming machine including a main frame, feed drawers, die supports and mold and head assemblies. The feed drawer is moved into position over the mold using an electric belt drive system and includes a vibrating strike off plate to improve surface quality of the molded product, zoned agitators to control movement and placement of concrete, a spring loaded seal system between the walls and floor of the feed box, and quick-release agitator design with urethane sleeves to effect easy and clean removal, replacement and cleaning of the agitators. The concrete products forming machine includes torque tube and leaf spring supports to effect substantially vertical vibrational movement of the mold with air inflatable springs for controlled force between the mold bottom and the pallet. The pallet itself is vibrated from below using phased, counter rotating shafts coupled to the pallet table on which the pallet rests. Vibration induced into the pallet by the vibrating pallet table is transferred to the mold resulting in material compaction. After the molding process, the mold is lifted in a stripping process to remove the molded product for curing or drying.

Owner:KORONBIA MACH

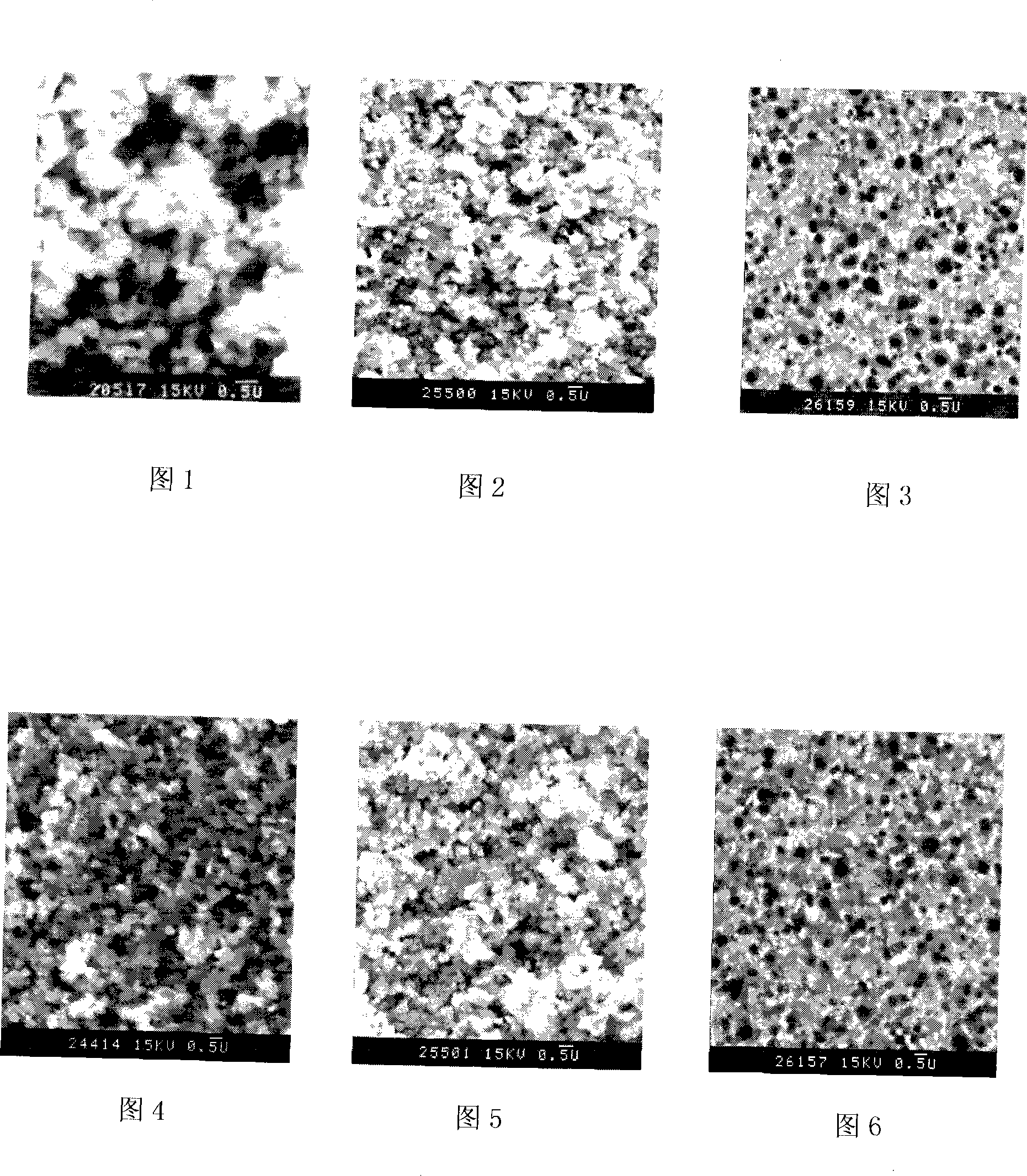

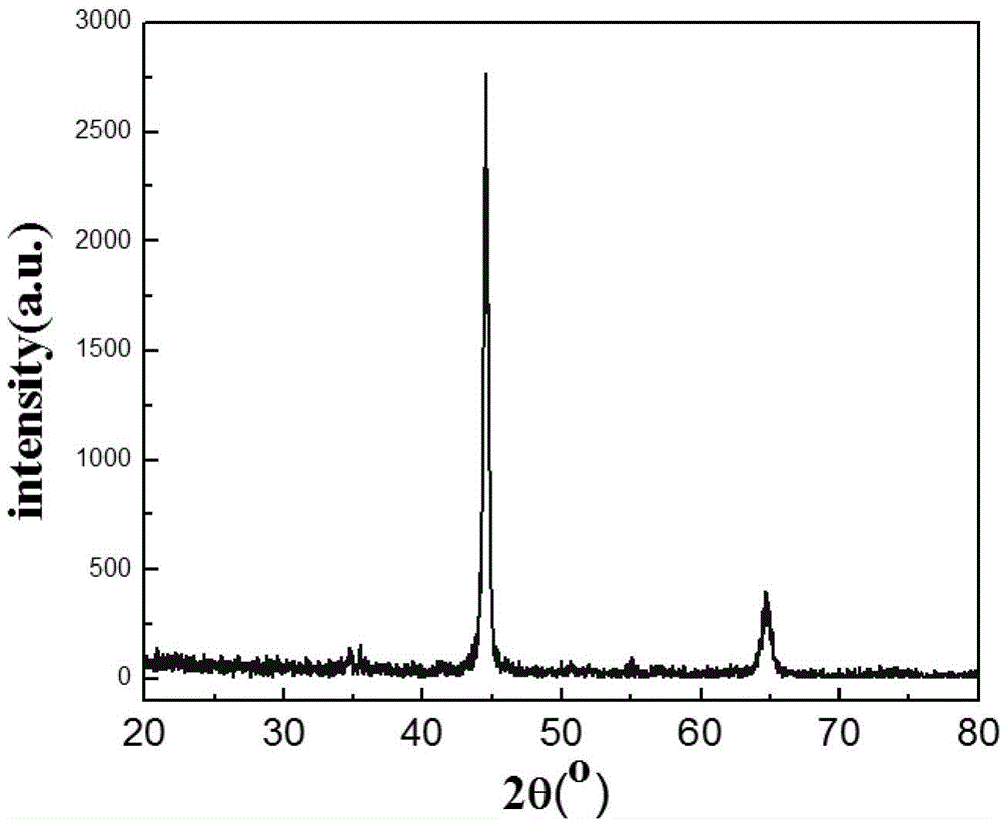

Super-fine TiC0.7N0.3 base metal ceramic and preparing method

This invention has publicized one kind of superfine cermet and its preparation method. Each composition ingredient weight percent of this cermet is: Mo2C: 8-13wt %; WC: 10-15wt %; TaC: 5-8wt %; NiCo:10.5-14.5wt % (also Co: Ni = 60: 40); the reminder is TiC0.7N0.3. This cermet uses the superfine TiC0.7N0.3 solid solution as raw material powder, and deoxidation process the superfine powder, it solved the technical difficult problems of preparation superfine cermet such as wet milling easy to to be agglomeration, compaction easy to dehiscence and easy to form holes after being sintered because powder granularity thin and breath. The processed powder adopt optimization wet milling craft, and add stearic acid mountain ash grain fat dispersing agent; Suppressed under 300 -400MPa pressure to shape; do dewaxing under 10-15Pa higher than vacuum degree; sinter vacuum degree is higher than 1-5X10-2Pa, sinter temperature is 1400degree C-1,480degree C, then holding 1-1.5h; do the hot isostatic pressing processing at 1,350degree C, holding 90-120min, the argon pressure is 70-120MPa. The prepared cermet has crystal grain size 0.5mum and the typical core - link structure, its hardness is>=93HRA, anti-curved intensity>=2200MPa, it may used as half precision work and precision work cutting tool material.

Owner:SICHUAN UNIV

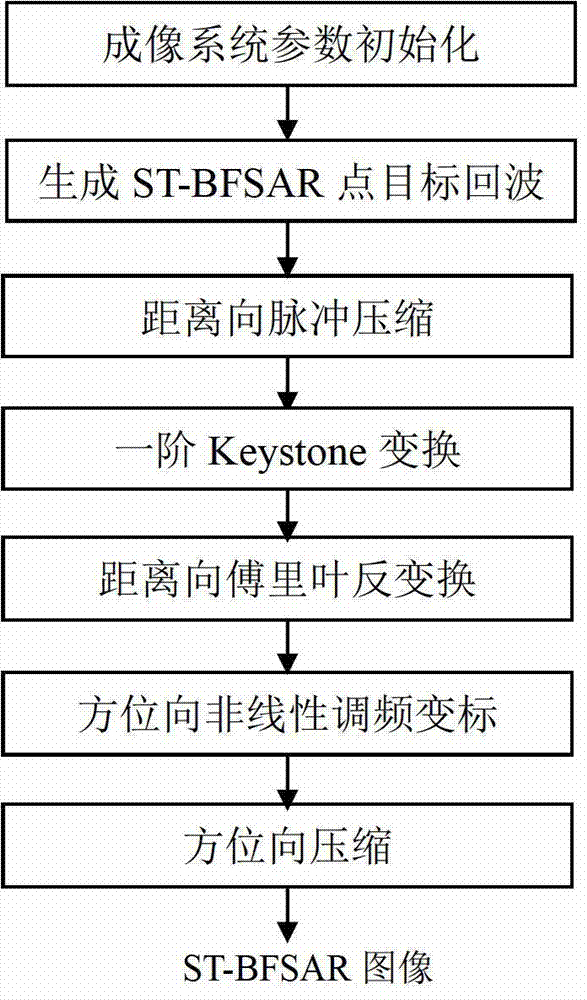

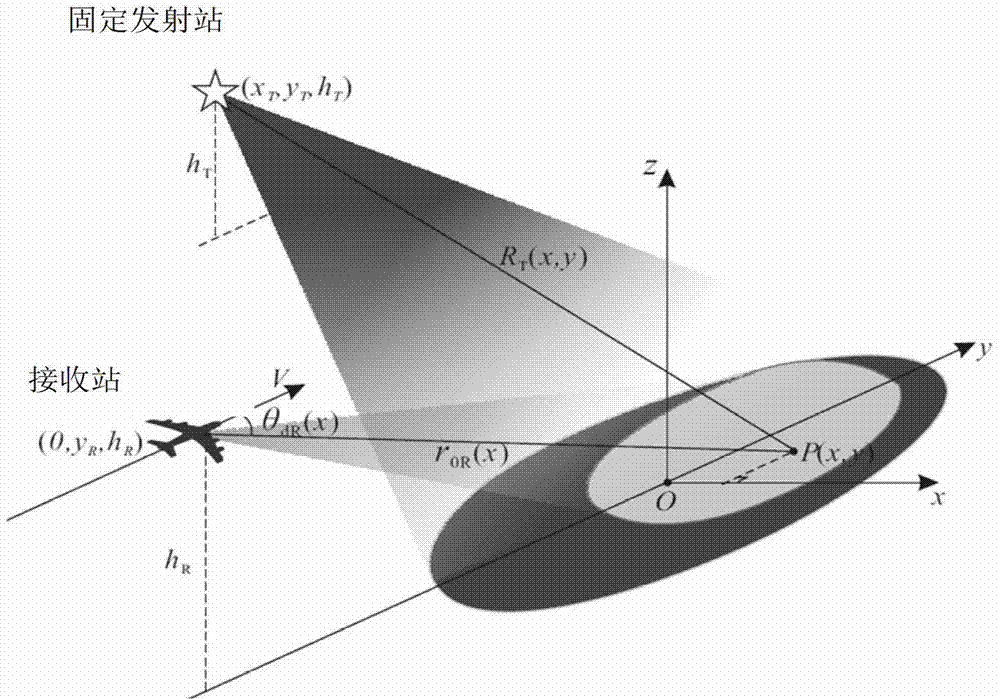

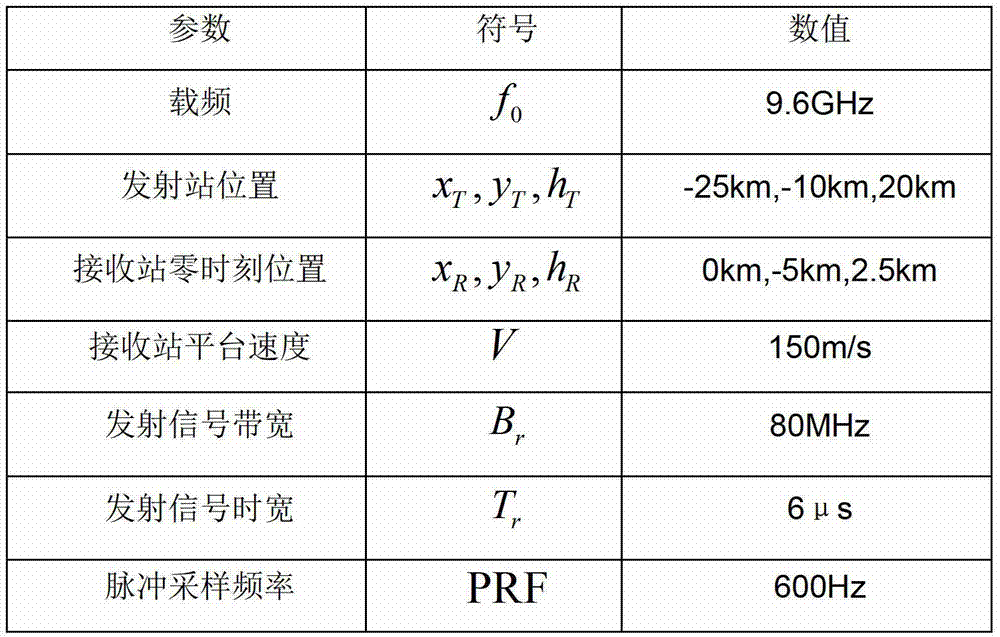

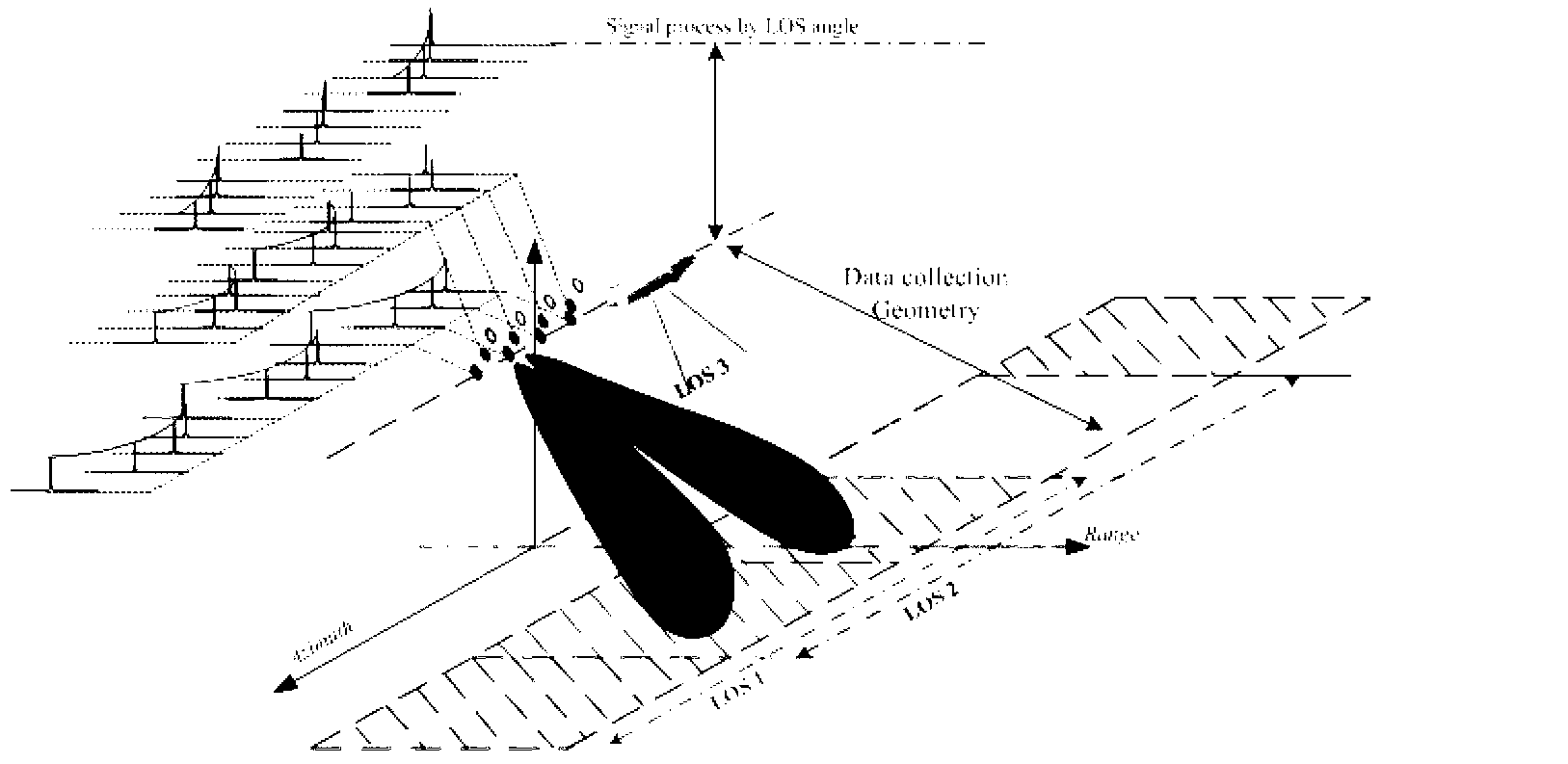

Method for imaging stationary transmitter bistatic foresight synthetic aperture radar (ST-BFSAR)

ActiveCN102778681AEliminate voidsAchieve precise focusRadio wave reradiation/reflectionRadarSynthetic aperture radar

The invention discloses a method for imaging a stationary transmitter bistatic foresight synthetic aperture radar (ST-BFSAR). The method comprises the following specific steps: after obtaining a target echo, rectifying a two-dimensional space variant of a distance migration of the ST-BFSAR by using first-order Keystone transform, wherein an object which has a same bistatic distance sum at a slow time zero moment is moved to a same distance gate during the operation; and after the distance migration rectification is accomplished, balancing the Doppler chirp scaling of an object in the same distance gate by using a non-linear chirp scaling variant object so as to eliminate the space variant of the Doppler chirp scaling along a directional bit and accomplishing the directional bit compression, so that the precise focusing of the ST-BFSAR is realized, and the problem that the two-dimensional space variant during the data treatment of the ST-BFSAR cannot be solved by using a traditional SAR (Synthetic Aperture Radar) imaging method and an existing bistatic foresight SAR imaging method is solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

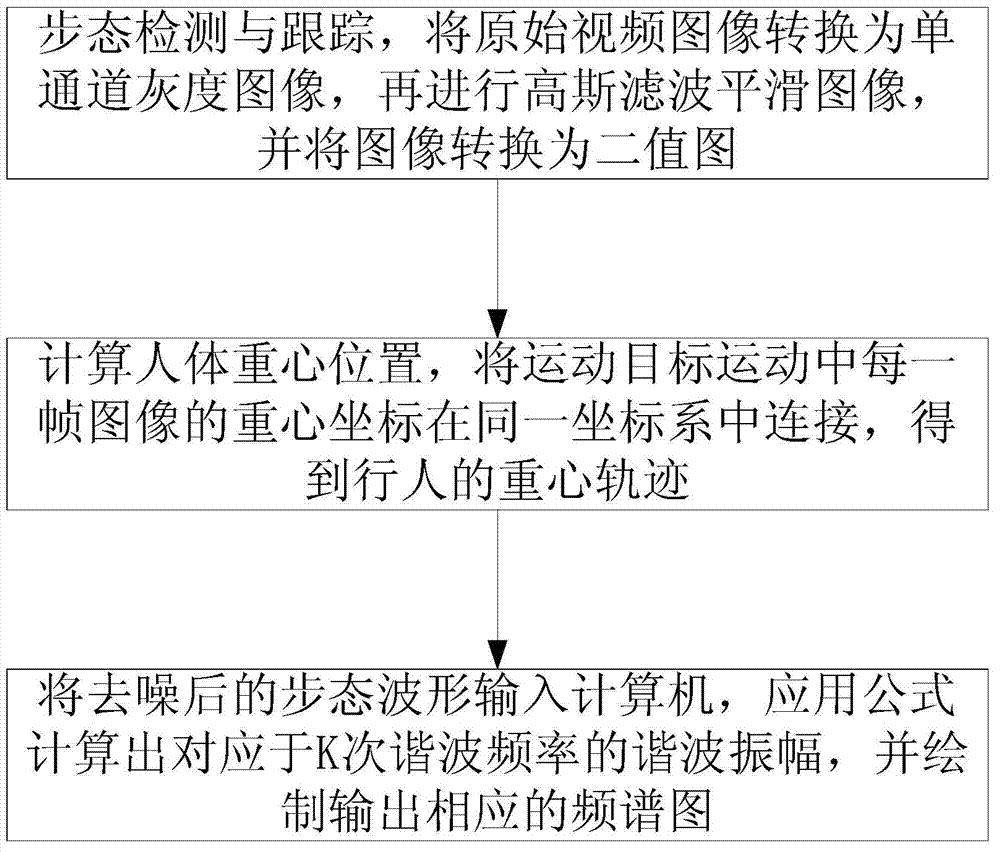

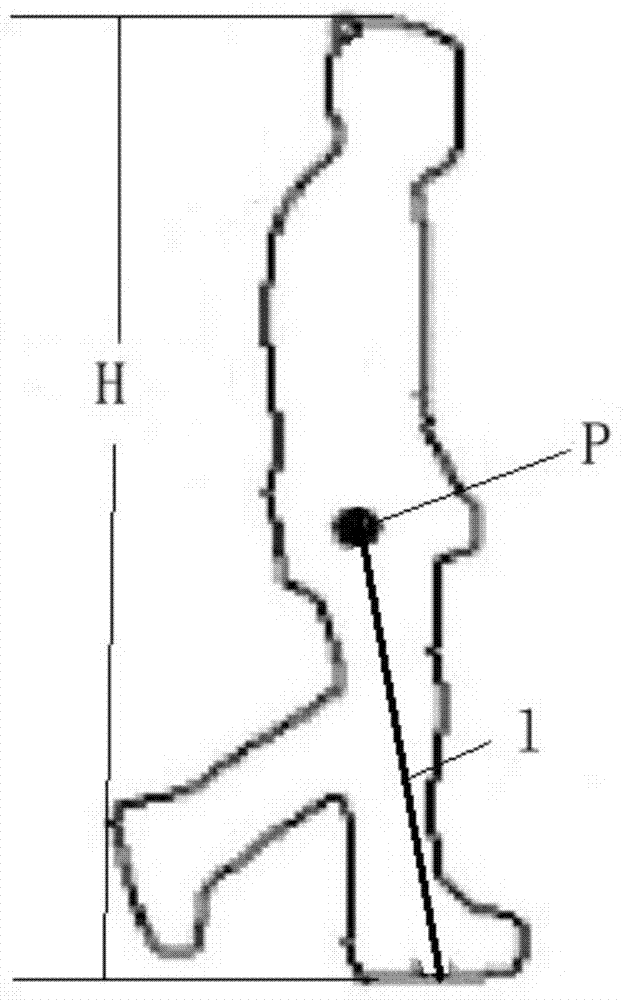

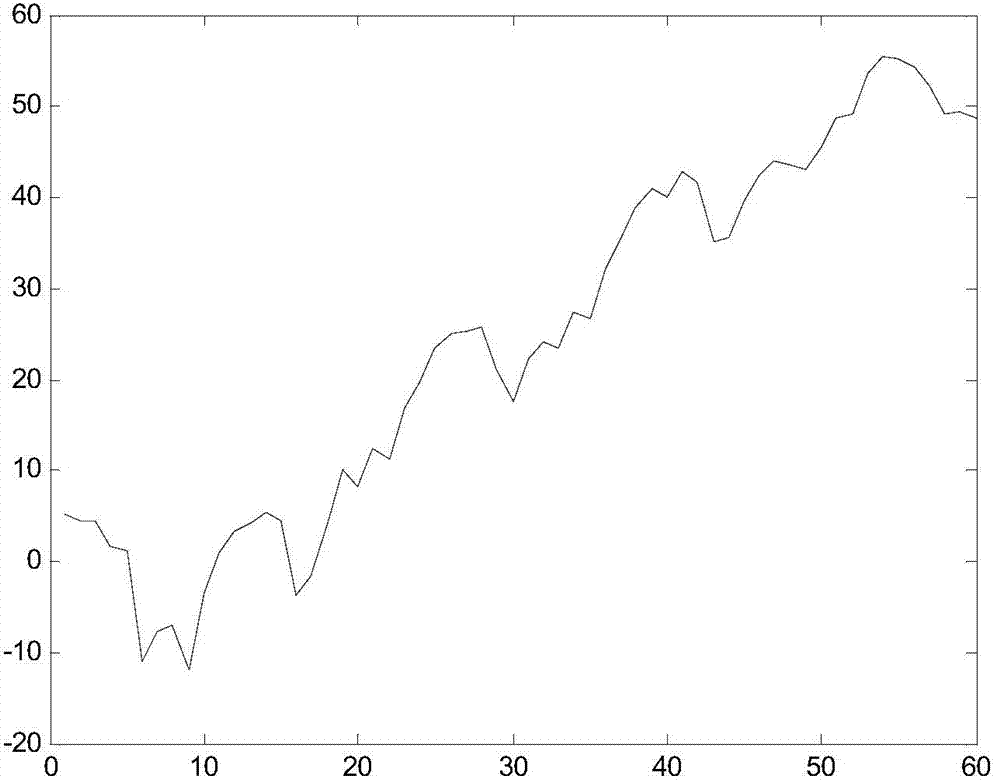

A gait feature extraction method based on human body gravity center track analysis

InactiveCN103679171AEasy to analyzeEasy to trainImage enhancementImage analysisHuman bodyFrequency spectrum

The invention discloses a gait feature extraction method based on human body gravity center track analysis. The method comprises the steps of: S1, gait detection and tracking: original video images are converted into single channel gray scale images, and the images are smoothed through Gauss filtering, and the images are further converted into binary images; S2, positions of human body gravity centers are calculated, and gravity center coordinates of the image of each frame in a moving object in motion are connected in a same coordinate system to obtain a gravity center track of a pedestrian; and S3, gait waveforms after being subjected to denoising are input into a computer, and a harmonic wave amplitude corresponding to a K subharmonic frequency is calculated through the utilization of a formula, and a corresponding frequency spectrogram is drawn and output. According to the invention, problems encountered in present feature extraction can be solved, and a one-dimensional gait characteristic vector can be extracted from the complex gait images, so that further analysis, training and identification are convenient.

Owner:JINAN UNIVERSITY

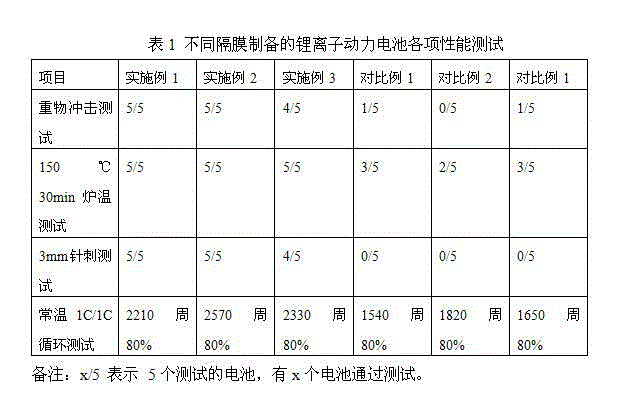

A preparing method of a lithium ion battery composite separating membrane

ActiveCN104681762AImprove mechanical propertiesImprove heat resistanceCell seperators/membranes/diaphragms/spacersPolyamide coatingsHeat resistanceResin coating

A preparing method of a lithium ion battery composite separating membrane is disclosed. A common PP or PE separating membrane is coated with an oxide coating, an aramid fiber resin coating and a PVDF-HFP copolymer layer to obtain the composite separating membrane. The composite separating membrane enhances mechanical performance and heat resistance of the separating membrane and enhances safety performance of batteries.

Owner:WANXIANG 123 CO LTD

Pattern quartz composite board and production method thereof

The invention relates to a pattern quartz composite board and a production method thereof. The pattern quartz composite board mainly comprises a main ingredient mixture and a pigment mixture, wherein the pigment mixture is sprayed and molded on the surface of the main ingredient mixture; the main ingredient mixture is prepared from quartz stone, unsaturated polyester resin, a toner, a curing agent, an accelerant and a coupling agent; the pigment mixture is prepared from a toner and quartz powder. The production method of the pattern quartz composite board comprises the following steps: putting the quartz stone, the unsaturated polyester resin, the toner, the curing agent, the accelerant and the coupling agent into an agitator to well agitate and mix, and then putting into the mixture a die frame; evenly spraying the pigment mixture on each surface; feeding to a vacuum pressure molding machine to press; and heating and curing, positively and reversely thickening, and polishing and cutting. The pattern quartz composite board has relatively high compactness; grains which are the same as those of a natural stone are formed on the surface of the composite board; the quality of the pattern quartz composite board is improved; the increasingly upgraded building decoration requirements can be met.

Owner:廖荣刚

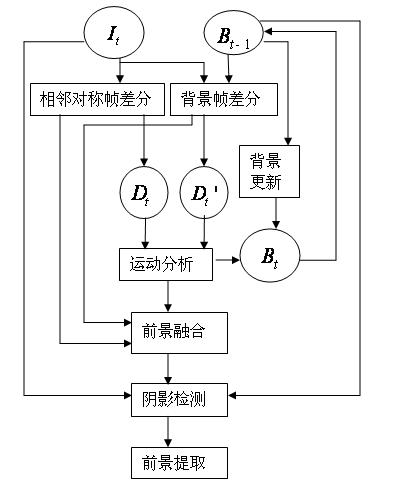

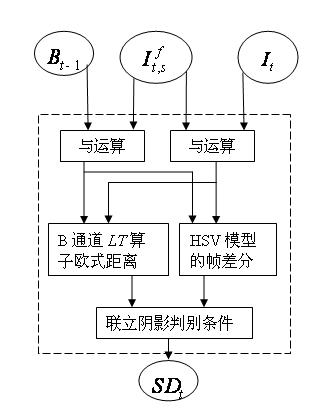

Method for extracting foreground in piggery monitoring video

InactiveCN102024146AEasy to identifyAccurate detectionCharacter and pattern recognitionClosed circuit television systemsFrame differenceFrame sequence

The invention discloses a method for extracting foreground in piggery monitoring video. The method comprises the steps of firstly acquiring an initial background frame containing no foreground and a background frame sequence containing the foreground, then carrying out adjacent symmetric frame difference and background frame difference, carrying out foreground motion analysis according to the adjacent symmetric frame difference and the background frame difference, acquiring a status code, updating background and fusing the two frame differences by utilizing the status code so as to acquire a shade containing foreground, calculating background Euclidean distance of local texture operators and S (saturation) and H (hue) channel background frame difference of HSV (hue-saturation-value) colour space, combining shade discriminating conditions, and finally extracting a foreground frame according to result of pixel attribute values. The invention is applicable to piggery monitoring of large-scale piggery farms, has adaptability, robustness and higher foreground target segmentation accuracy and creates favorable conditions for subsequent work which is pig video intelligent analysis.

Owner:JIANGSU UNIV

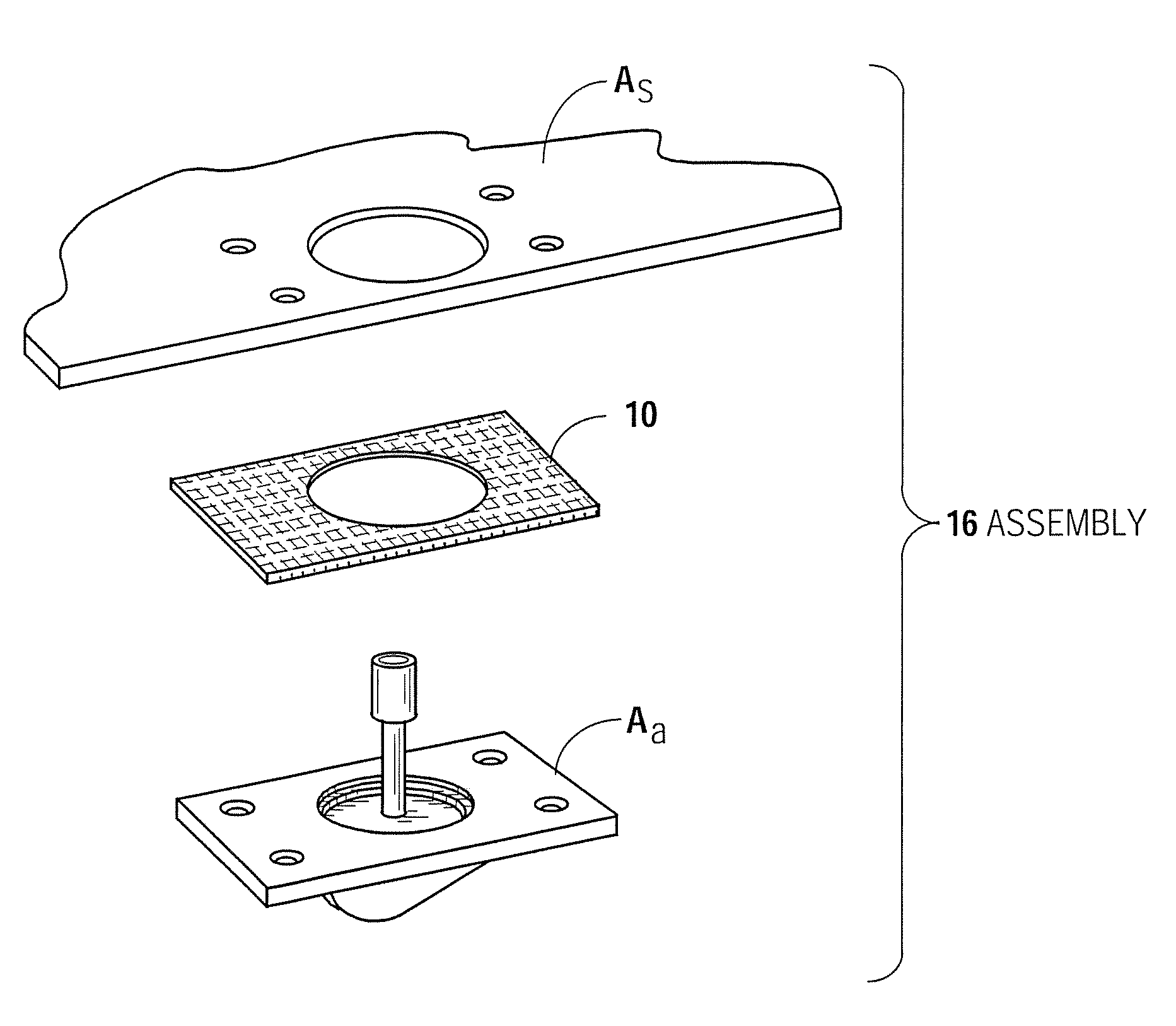

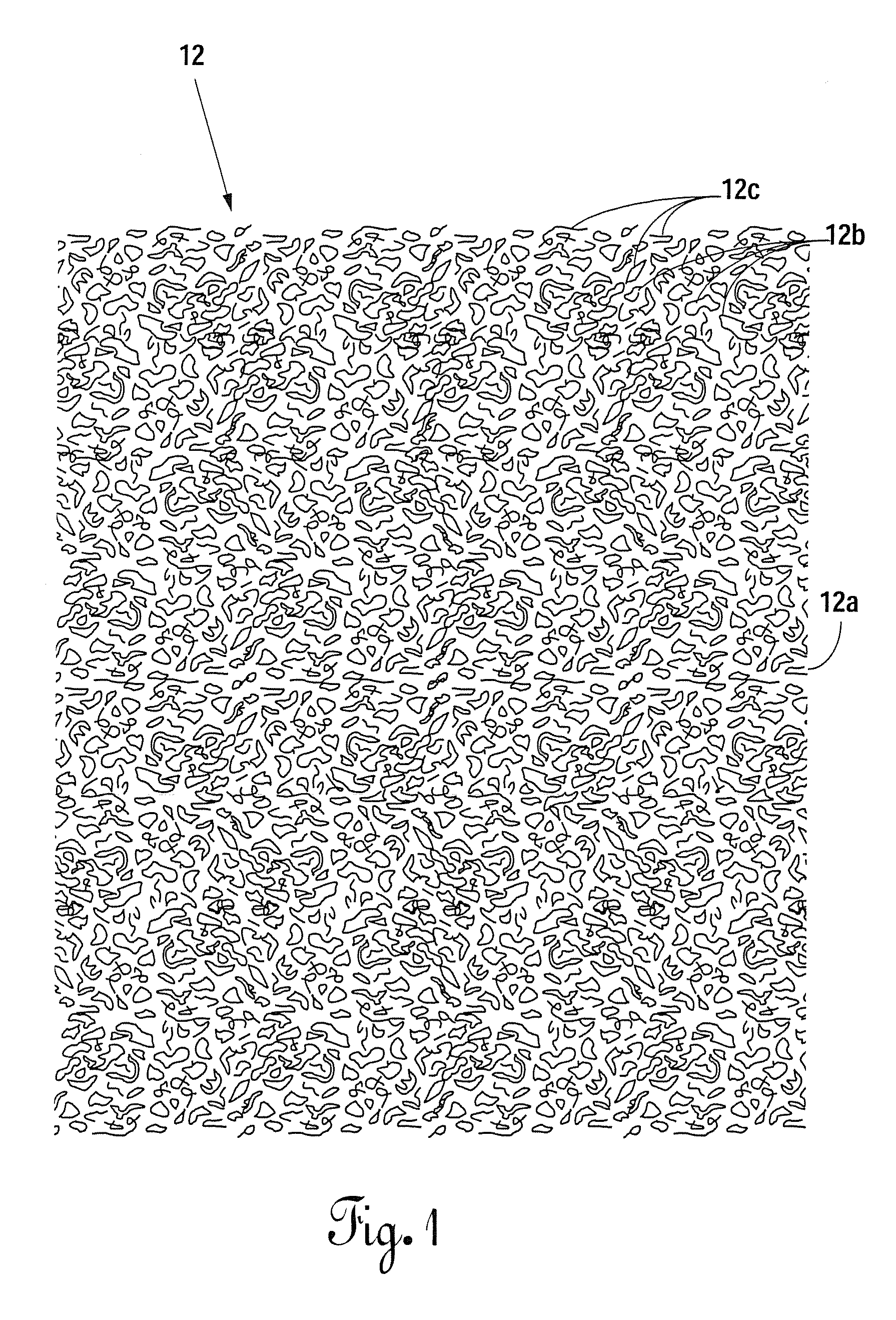

Elastomeric gasket having a foam metal skeletal member

InactiveUS20160017999A1Good environmental sealImprove sealingEngine sealsAircraft lighting protectorsBiomedical engineeringPolymer

A gasket for compressible placement between a first surface and a second surface is disclosed. In one embodiment, the gasket has a cellular metal skeleton embedded in a viscoelastic, pliable, deformable tacky polymer body. The skeleton has multiple strands, which connect to form multiple interconnected cells or pores. The skeleton, prior to being encapsulated in the tacky polymer body, is typically about 75% or more void space. The void space is substantially filled in the manufacture of the gasket, with the tacky uncured polymer. The uncured polymer will set up or cure, and then the gasket may be used.

Owner:THE PATENT WELL LLC

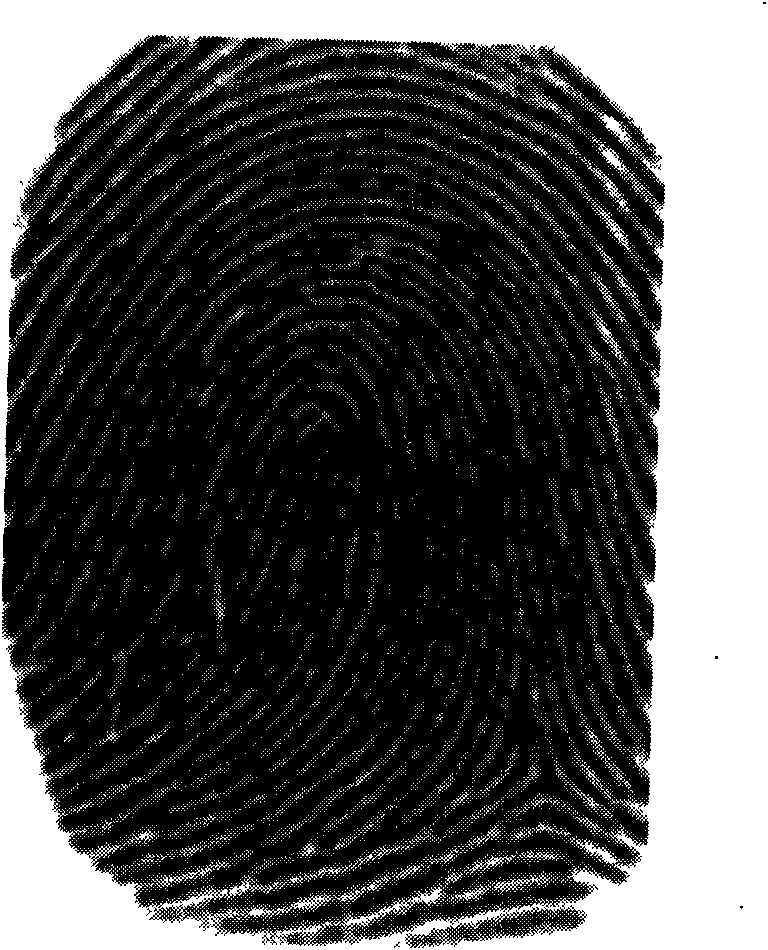

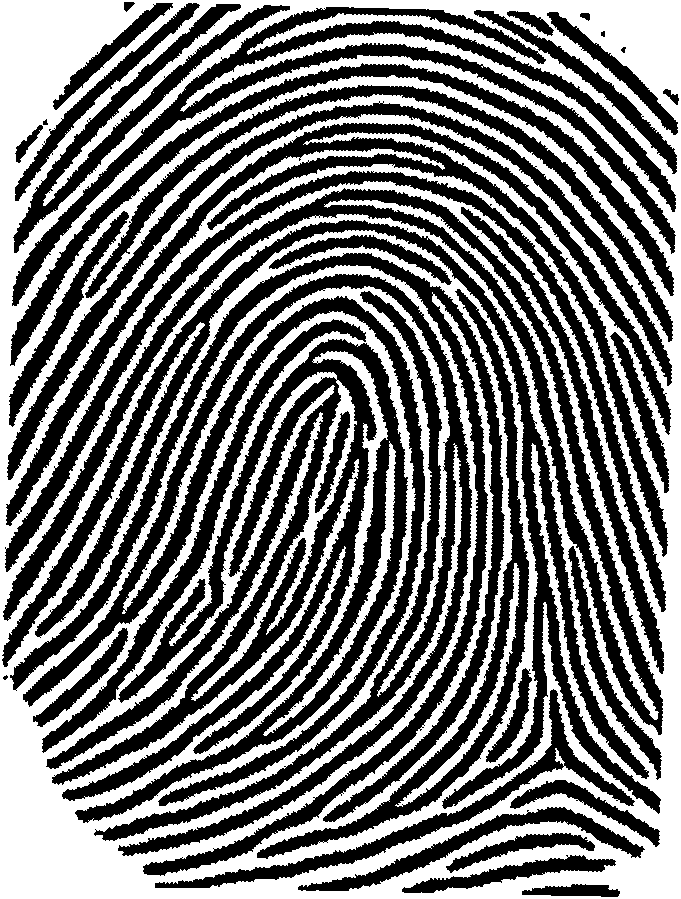

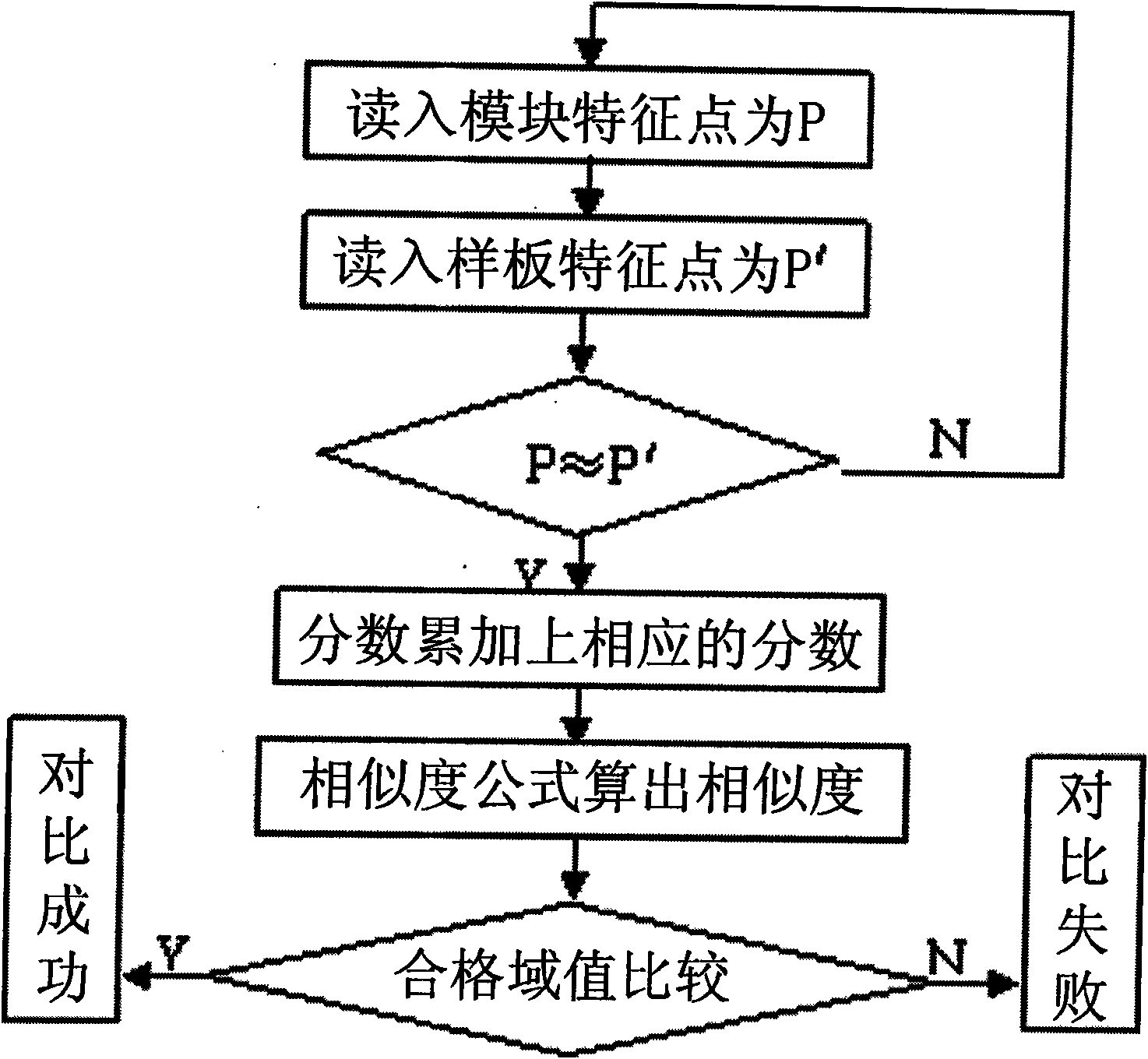

Individualized fingerprint identification method

InactiveCN101604384AHigh speedAccurate extractionCharacter and pattern recognitionPersonalizationFeature extraction

The invention relates to an individualized fingerprint identification method, which comprises the following steps of fingerprint acquisition and image preprocessing. The method is characterized by also comprising the following steps: in the image preprocessing, adopting the matrix type binaryzation processing method as the binaryzation processing method: after the characteristic extraction step, judging whether the intelligent updating is needed or not first, if so, performing the intelligent updating step, otherwise performing the next step which is the study matching step. The method has the advantages that: due to the adoption of the matrix type binaryzation processing method, the characteristic points of the fingerprint can be accurately extracted, and the speed of the image preprocessing is improved; the fingerprint which is hurt, crimpled, cracked, stained with oil and esquamate can be identified at high efficiency; and the fingerprint data can be intelligently added, repaired, improved and updated, so that the identification rate is improved.

Owner:周易

Iron-based non-crystalline composite coating for protecting heat exchange pipes in flue gas waste heat recovery system of power station boiler and laser re-melting and moulding technology thereof

The invention discloses an iron-based non-crystalline composite coating for protecting heat exchange pipes in the flue gas waste heat recovery system of a power station boiler, and a laser re-melting and moulding technology thereof. The iron-based non-crystalline composite coating is composed of the following elements in percentage by weight: 55.1 to 66.2 wt% of Fe, 24.4 to 34.3 wt% of Cr, 2.4 to 3.4 wt% of B, 1.5 to 2.9 wt% of Si, 1.7 to 3.9 wt% of Mo, and 1.6 to 3.8 wt% of Nb. The moulding technology comprises the following steps: preparing iron-based non-crystalline cored wires, adopting an ultrasonic electric arc spraying method to prepare an iron-based thermally-sprayed alloy coating on the surface of a heat exchange pipe; and then adopting neodymium-doped yttrium aluminium garnet (YAG) laser as the heat source to carry out laser re-melting and moulding on the positions, which are prone to low-temperature acid dew point corrosion, on the thermally-sprayed coating so as to form compact iron-based non-crystalline composite coating; wherein the coating and the substrate are combine through metallurgy, and no crack and gap exists between the substrate and the coating. The provided coating prevents the transfer of the low-temperature acid dew point corrosion, thus prominently improves the service life of the flue gas waste heat recovery system, relieves the symptom of low-temperature acid dew point corrosion, and has a great application potential.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

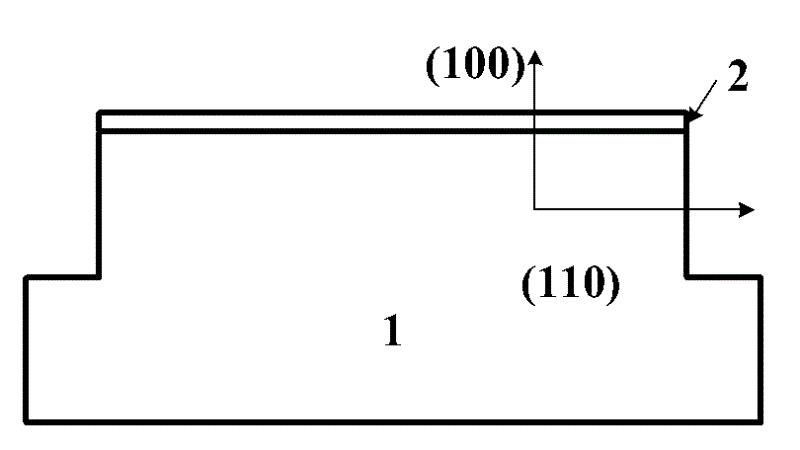

Semiconductor device and manufacturing method thereof

ActiveCN102623487AEliminate voidsHigh carrier mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricEdge effects

The invention provides a semiconductor device, comprising: a substrate; a shallow trench isolation means embedded in the substrate, and forming at least one open area; a channel region positioned in the open area; a gate stack, positioned on top of the channel region, comprising a gate dielectric layer and a gate electrode layer; a source-drain area, positioned on the two sides of the channel region, comprising a stress layer for providing a strain to the channel region. There is a liner between the shallow trench isolation means and the stress layer. By inserting a liner of a material same or similar to that of the stress layer of the source-drain area between the STI and the stress layer of the source-drain area, wherein the liner acts asa crystal seed layer or a nucleating layer for epitaxial growth an edge effect of STI during the source-drain area process is eliminated, that is a gap between the STI and the stress layer of the source-drain area is eliminated, the reduction of the channel stress caused by the source-drain area is prevented, and a mobility of the current carriers of the metal-oxide semiconductor (MOS) device is improved, thus improving a driving capability of the device.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Preformed liner adhered to a pipe with an adhesive

InactiveUS20070089797A1Eliminate voidsImprove shrinkageUnderground chambersSynthetic resin layered productsParaffin waxAdhesive

The present invention relates to a preformed liner adhered to the surface of a pipe, and in particular, an oil well pipe, by an adhesive. The liner comprises a polymer, preferably a fluoropolymer. The present invention also relates to a process for adhering the preformed liner to the interior surface of a pipe, and in particular by applying adhesive to the preformed liner. The liner is preferably treated prior to applying the adhesive. A suitable treatment includes etching. The pipe is heated to adhere the preformed liner to the interior surface of the pipe, without buckling the liner. The interior surface of the preformed fluoropolymer liner reduces the deposition of at least one of 1) asphaltenes, 2) paraffin wax, and 3) inorganic scale by at least 40% as compared to the interior surface of the oil pipe without the preformed liner being present.

Owner:EI DU PONT DE NEMOURS & CO

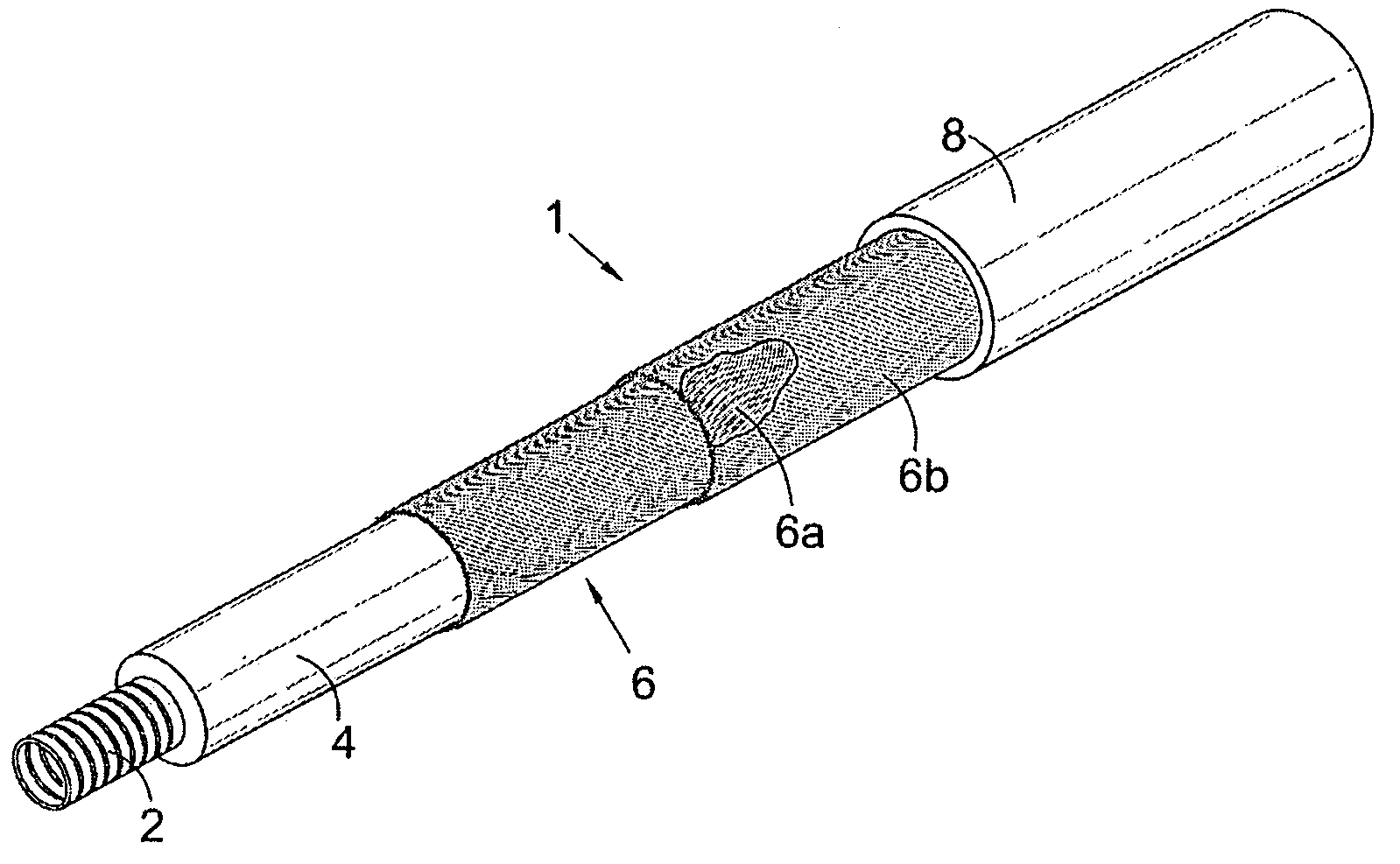

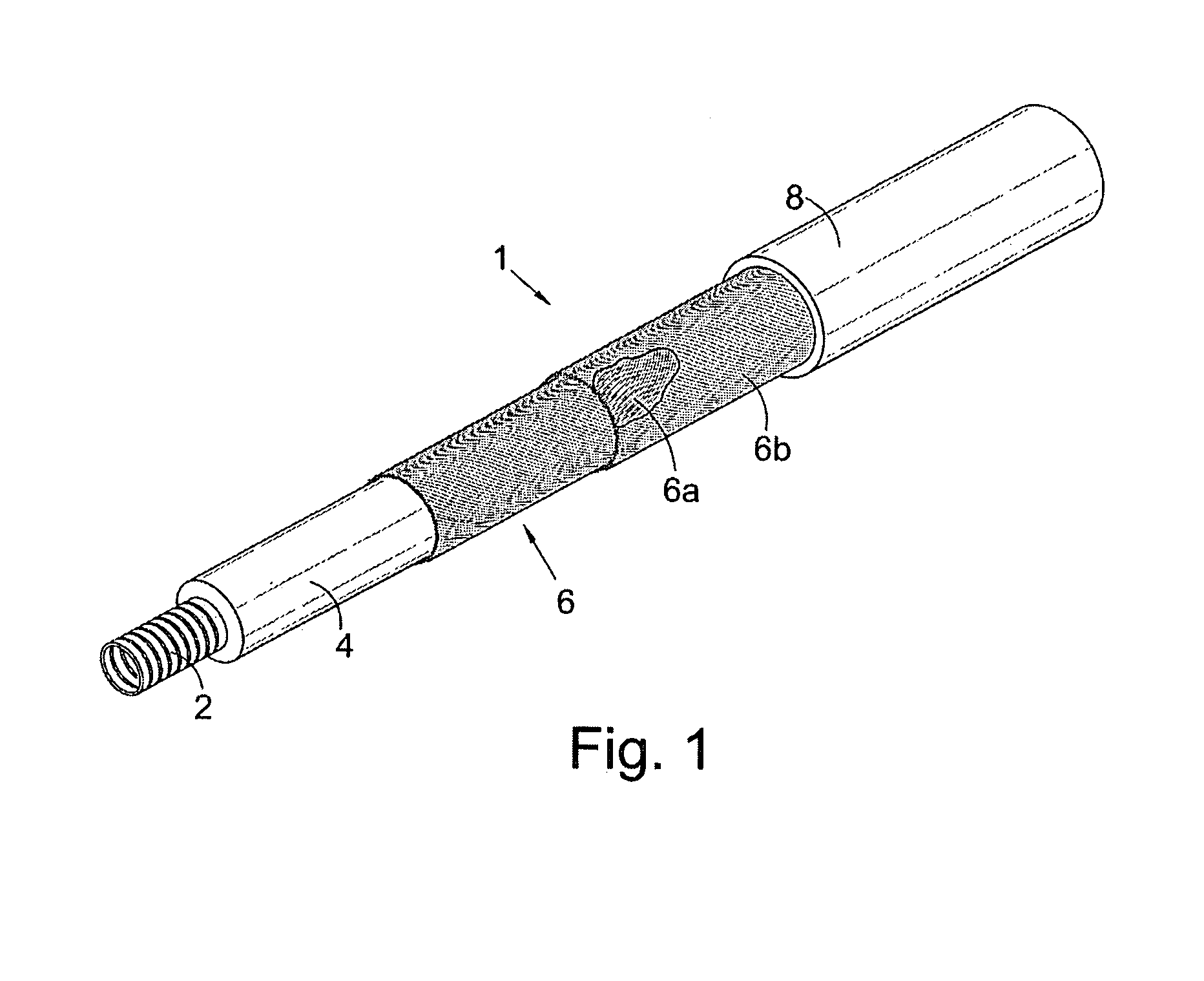

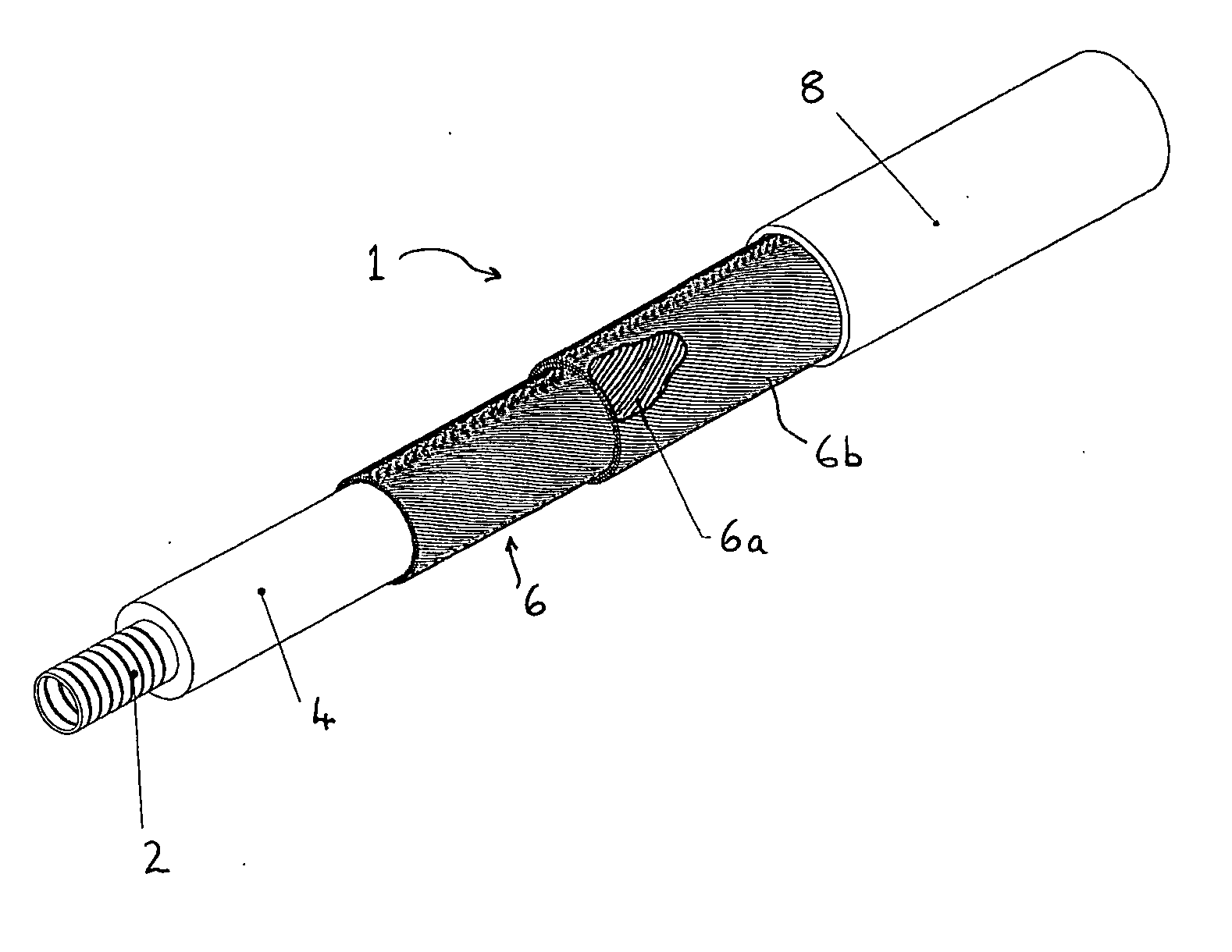

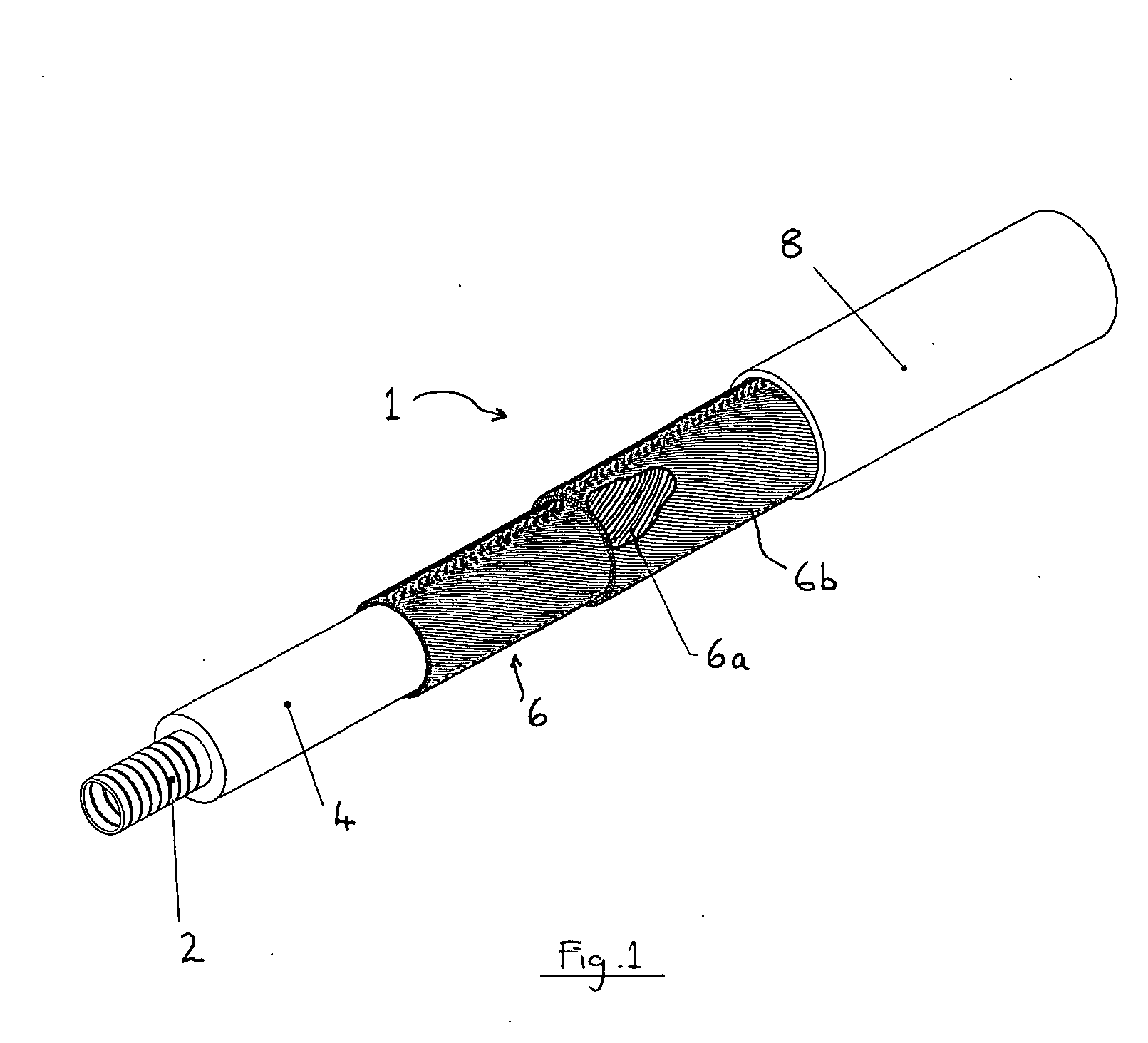

Fluid conduit

ActiveUS7493918B2Eliminate voidsEnhanced inhibitory effectFlexible pipesRigid pipesWorking fluidCatheter

The present invention relates to fluid conduit (1) suitable for use in the transportation of working fluids to a wellhead or the like from a topside location or the like. The fluid conduit (1) is suitable for use in a multi-conduit umbilical. The conduit comprises an inner flexible collapse resistant hose (2) surrounded by a hose liner (4), and at least one pair of helically contra-wound high tensile wires (6a, 6b). Each turn of each wire (6a, 6b) is in substantially close contact with adjacent turns thereof. A multi-conduit umbilical comprising a plurality of the fluid conduits bundled together and provided with an outer sheath is also described.

Owner:OCEANEERING INT SERVICES

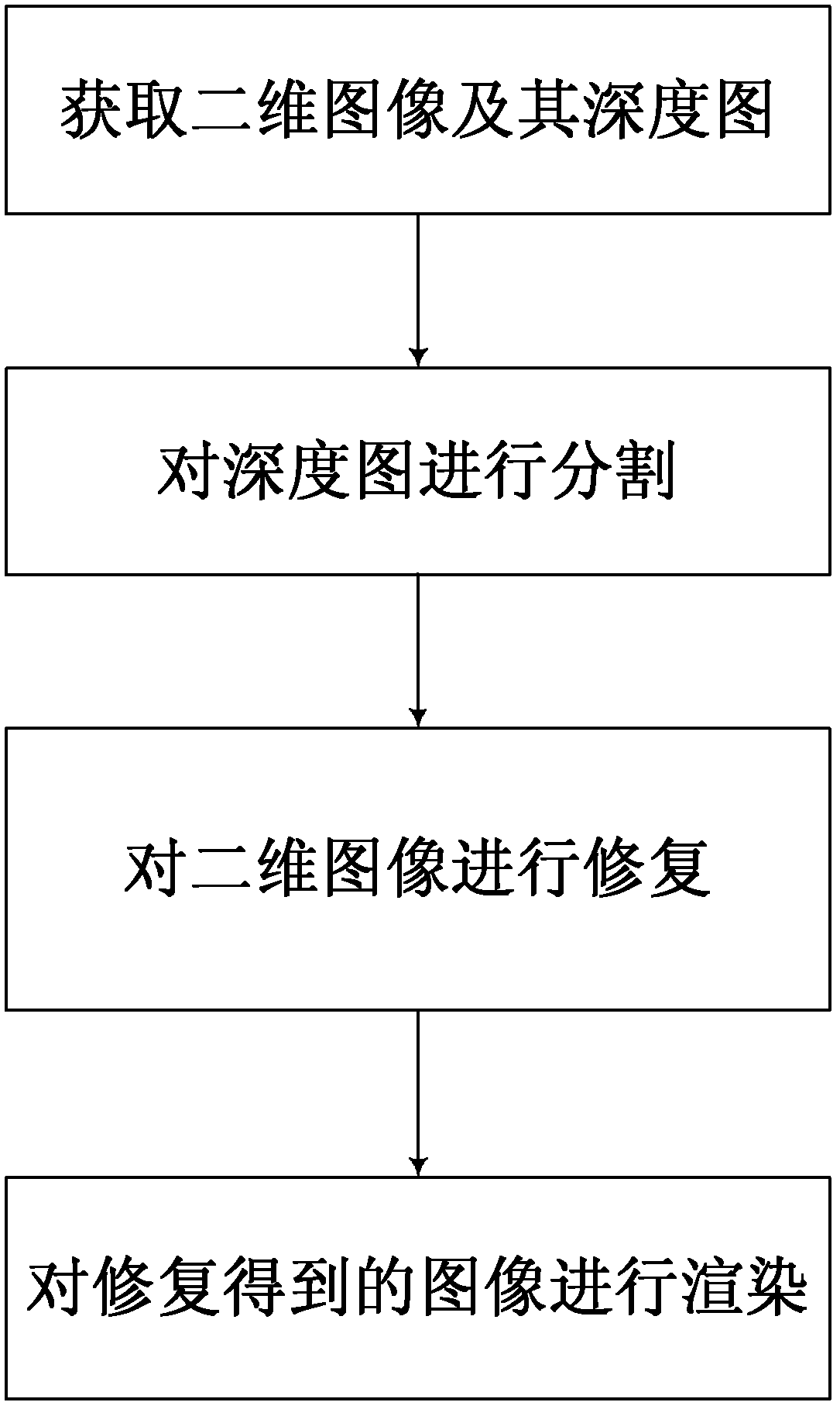

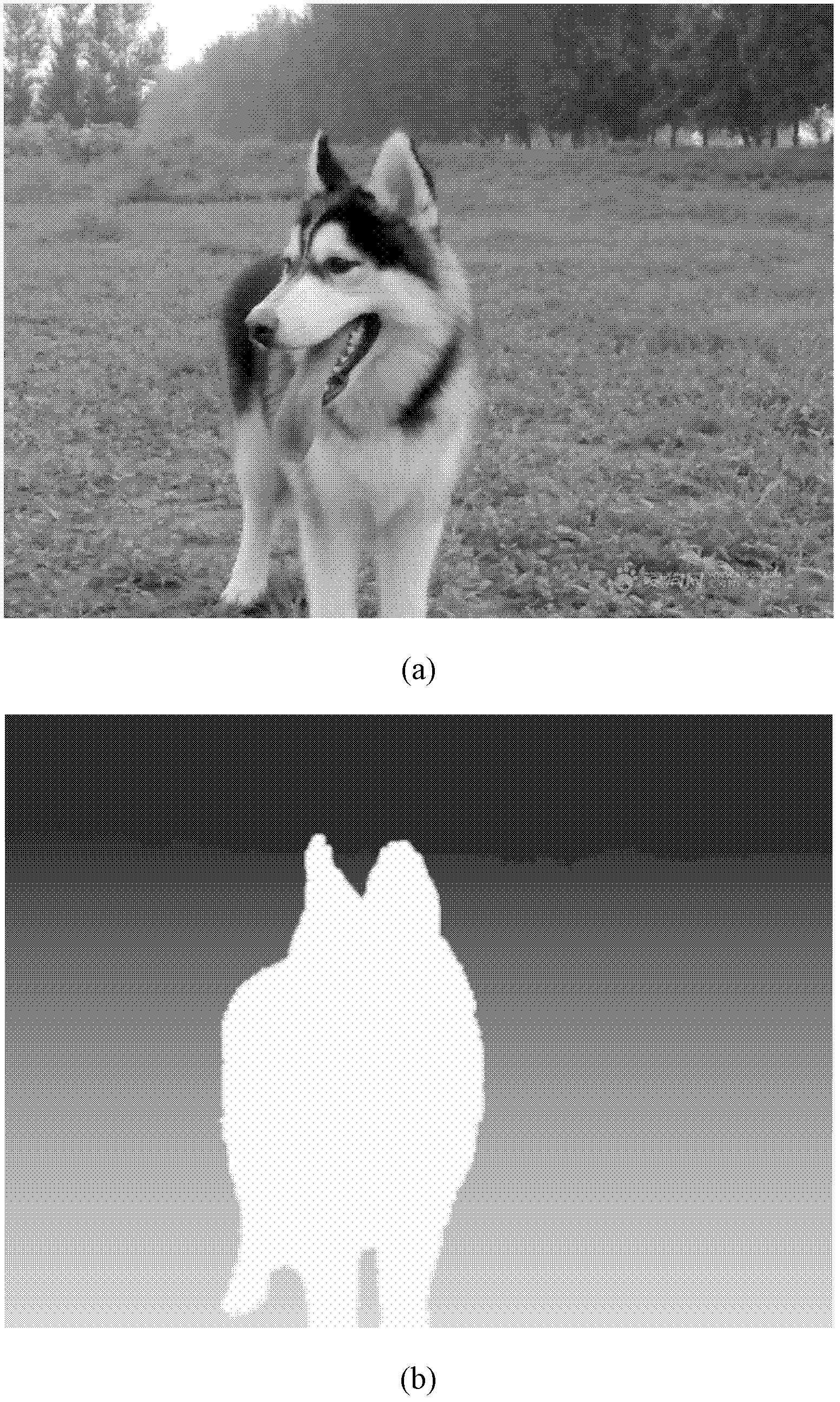

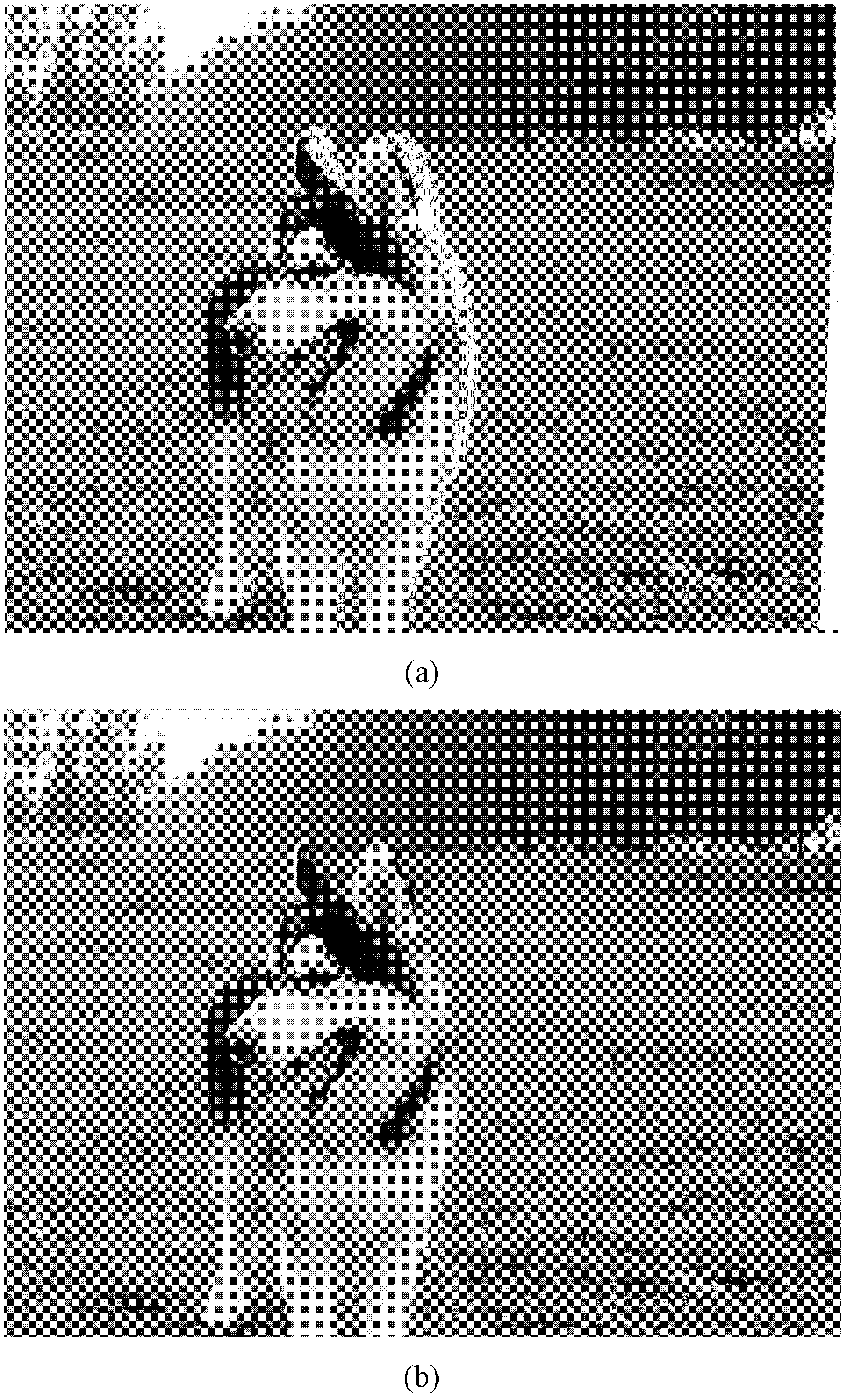

Virtual viewpoint image generation process on basis of depth map segmentation and rendering

InactiveCN102609974AEliminate voidsImprove computing efficiencySteroscopic systems3D-image renderingPersonal computerViewpoints

The invention discloses a virtual viewpoint image generation process on the basis of depth map segmentation and rendering, which includes: (1) acquiring two-dimensional images and a depth map thereof; (2), segmenting the depth map; (3), recovering the two-dimensional images; and (4), rendering the recovered images. By the generation process on the basis of depth map segmentation and rendering, virtual viewpoint images can be synthesized according to the original two-dimensional images and the corresponding depth map, and holes in the synthesized virtual viewpoint images can be eliminated thoroughly. Meanwhile, the virtual viewpoint image generation process can be implemented on hardware systems such as general PC (personal computers) or work stations and the like, higher computation efficiency can be achieved, and the virtual viewpoint images generated are obvious in stereoscopic effect.

Owner:四川和鼎昇泰信息技术有限公司

Fluid conduit

The present invention relates to fluid conduit (1) suitable for use in the transportation of working fluids to a wellhead or the like from a topside location or the like. The fluid conduit (1) is suitable for use in a multi-conduit umbilical. The conduit comprises an inner flexible collapse resistant hose (2) surrounded by a hose liner (4), and at least one pair of helically contra-wound high tensile wires (6a, 6b). Each turn of each wire (6a, 6b) is in substantially close contact with adjacent turns thereof. A multi-conduit umbilical comprising a plurality of the fluid conduits bundled together and provided with an outer sheath is also described.

Owner:OCEANEERING INT SERVICES

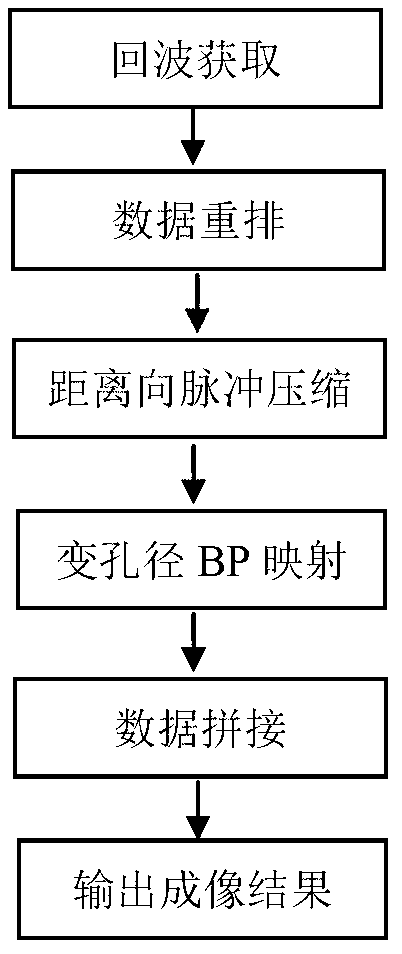

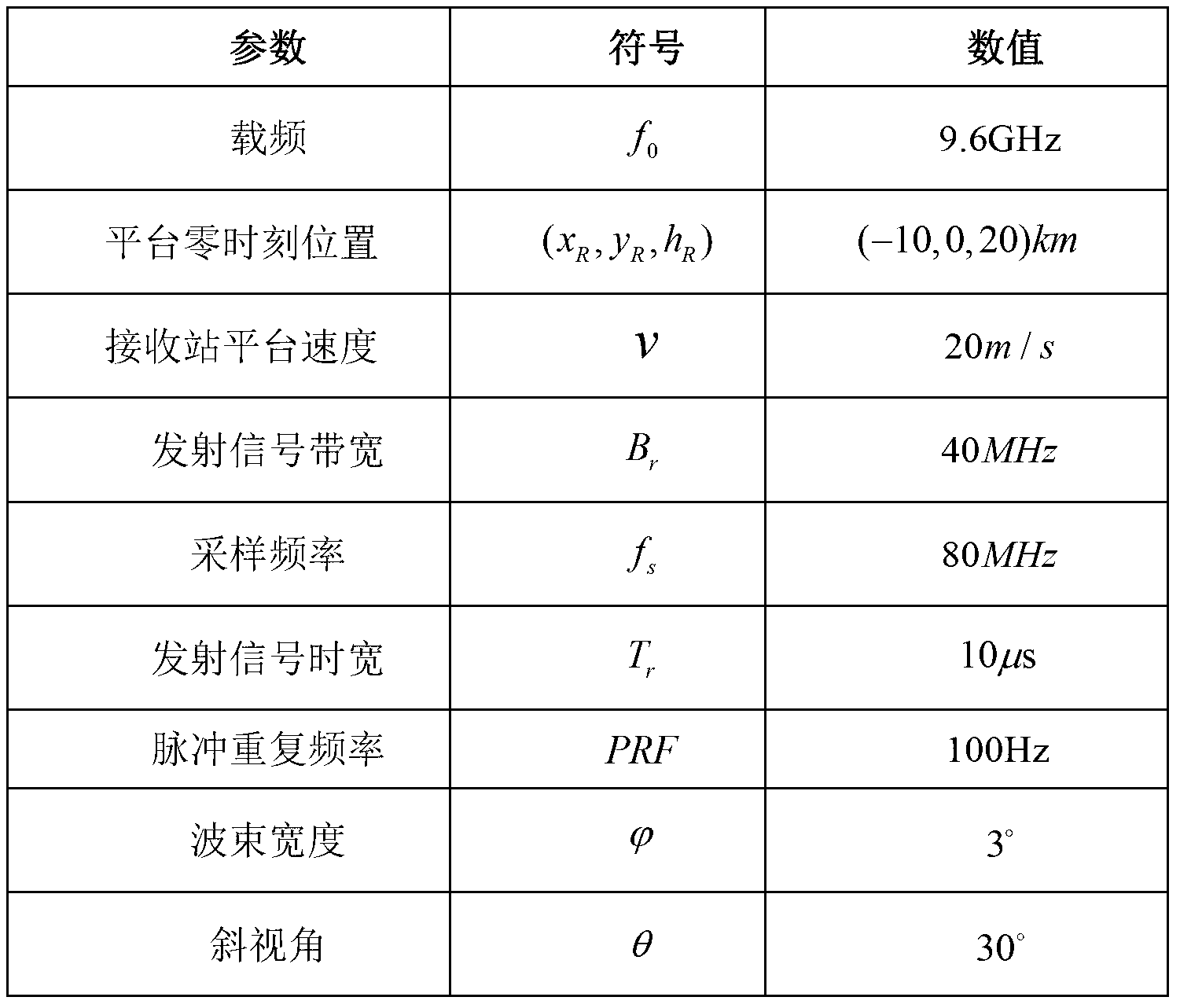

Near space low-speed platform SAR (Synthetic Aperture Radar) imaging method

ActiveCN103235309ARealize large scene imagingEliminate voidsRadio wave reradiation/reflectionSynthetic aperture sonarLow speed

The invention discloses a near space low-speed platform SAR (Synthetic Aperture Radar) imaging method, which specifically comprises the following steps: acquiring target echo; rearranging data; performing pulse compression in range dimension; performing variable-aperture back projection imaging; and performing data splicing and outputting an imaging result. The solution of the invention is that a wide view field and common aperture working mode is adopted, and large-scene imaging is realized on the basis of a gradient aperture back projection method; the space-variant problem of range migration is solved by using the back projection method; a gradient aperture is used in the azimuth direction, so that the space-variant and image distortion problems caused by different resolutions in the azimuth direction of an image in case of different view angles are solved; and finally near space low-speed platform SAR large-scene imaging is realized.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

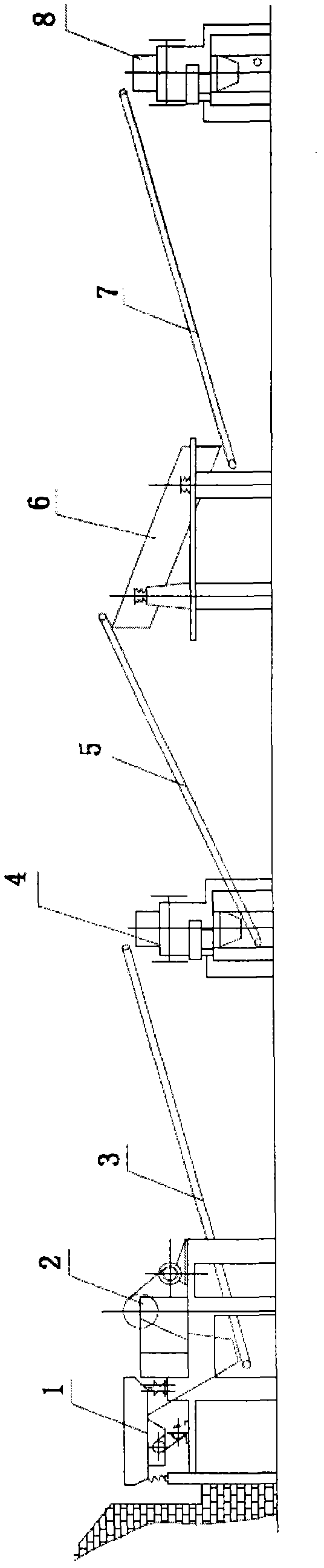

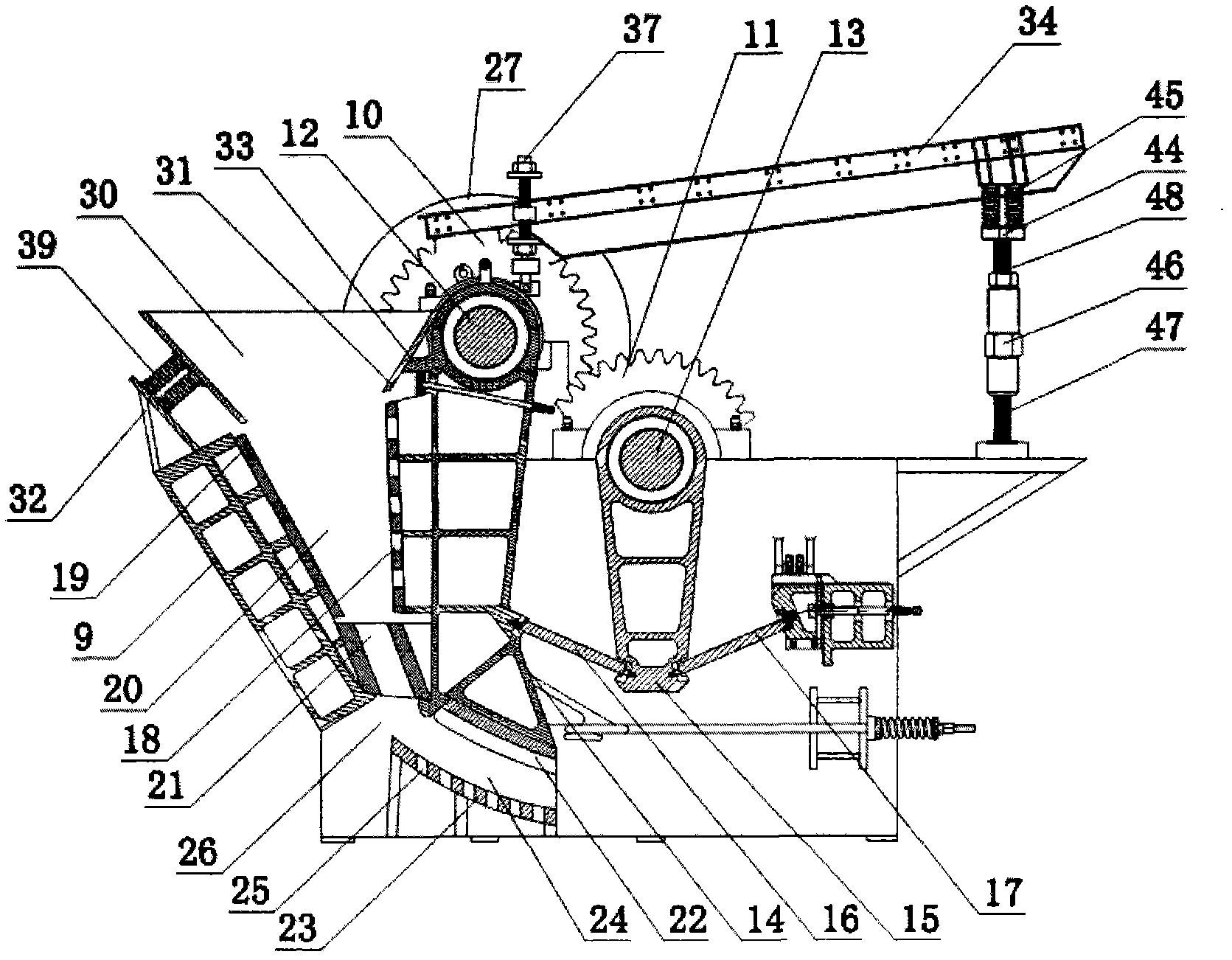

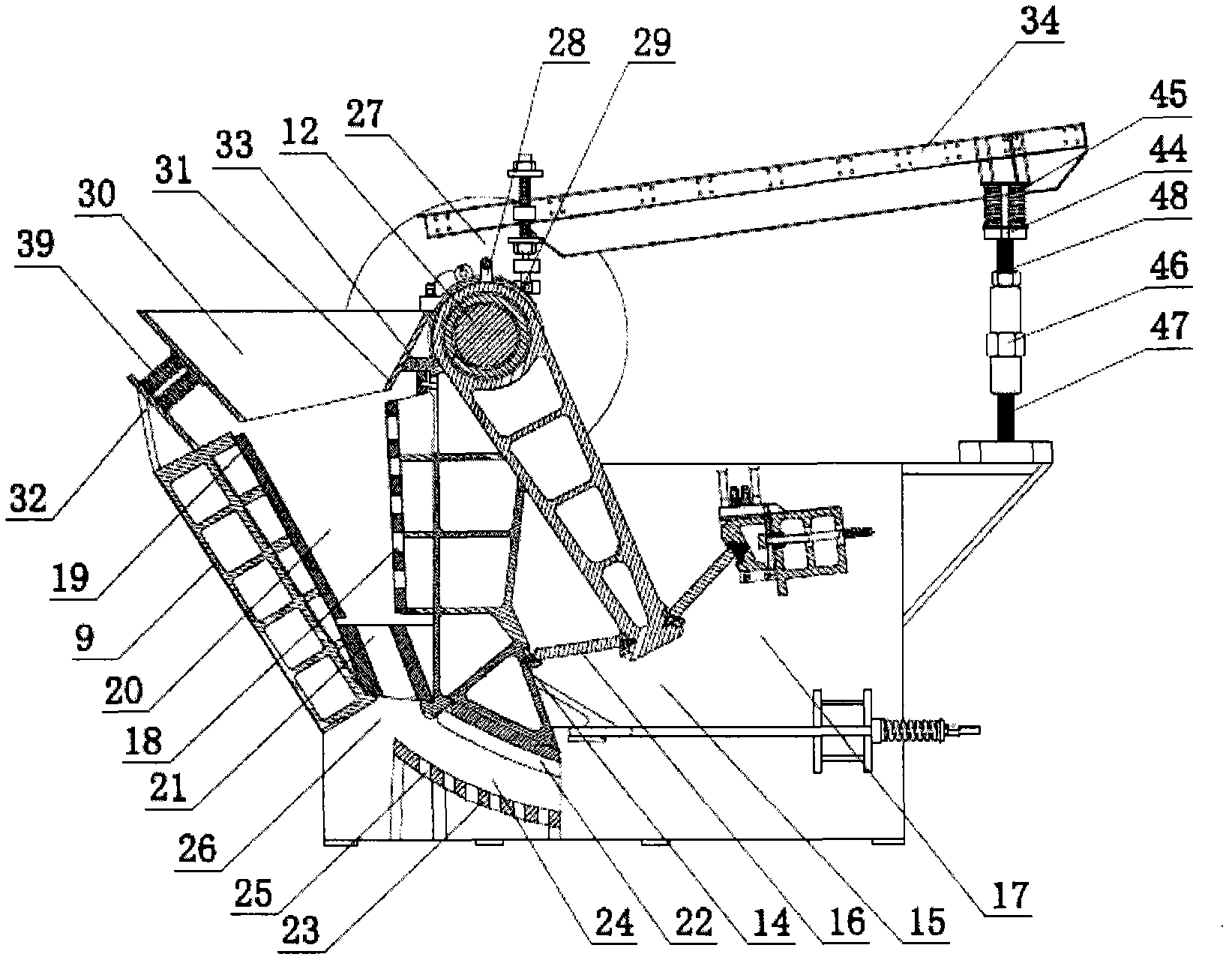

One-machine crushing production line

The invention discloses a one-machine crushing production line. The one-machine crushing production line breaks through the conventional thinking that the crushing production line is composed of a plurality of machines in the prior art, and achieves the function of the conventional crushing production line by ingenious and reasonable internal structural configuration and multifunctional combination of the single machine. The function achieved by the single machine provided by the invention is equal to the combined functions of eight machines in the crushing production line in the prior art (one feeder, three crushers, one vibrating screen and three conveyors). The design of multi-machine combined production line is replaced by the design of one-machine crushing production line is a major breakthrough in the technical field of crushers and the technical field of crushing production lines.

Owner:YIWU BLACK AND WHITE MINING MACHINERY

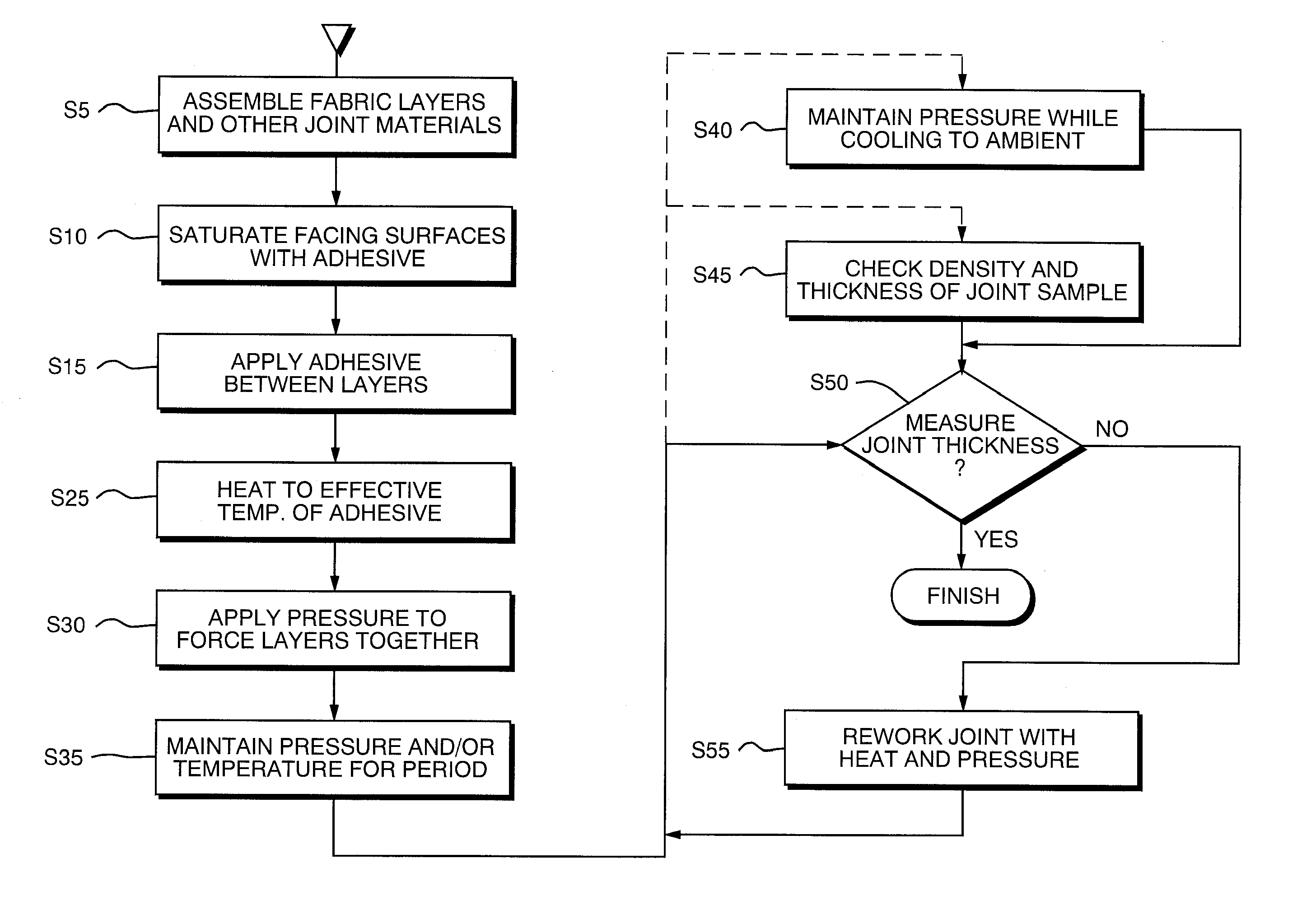

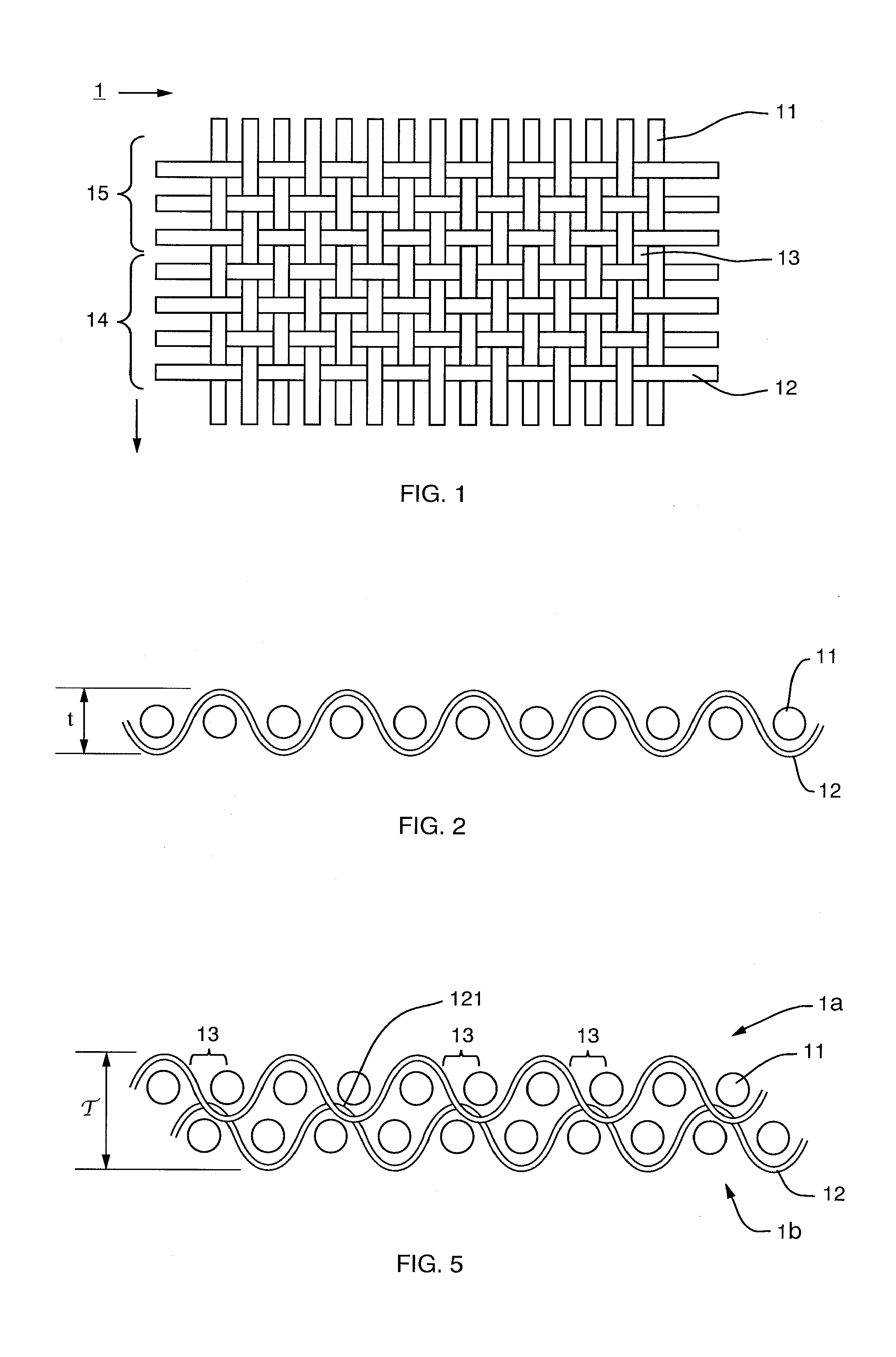

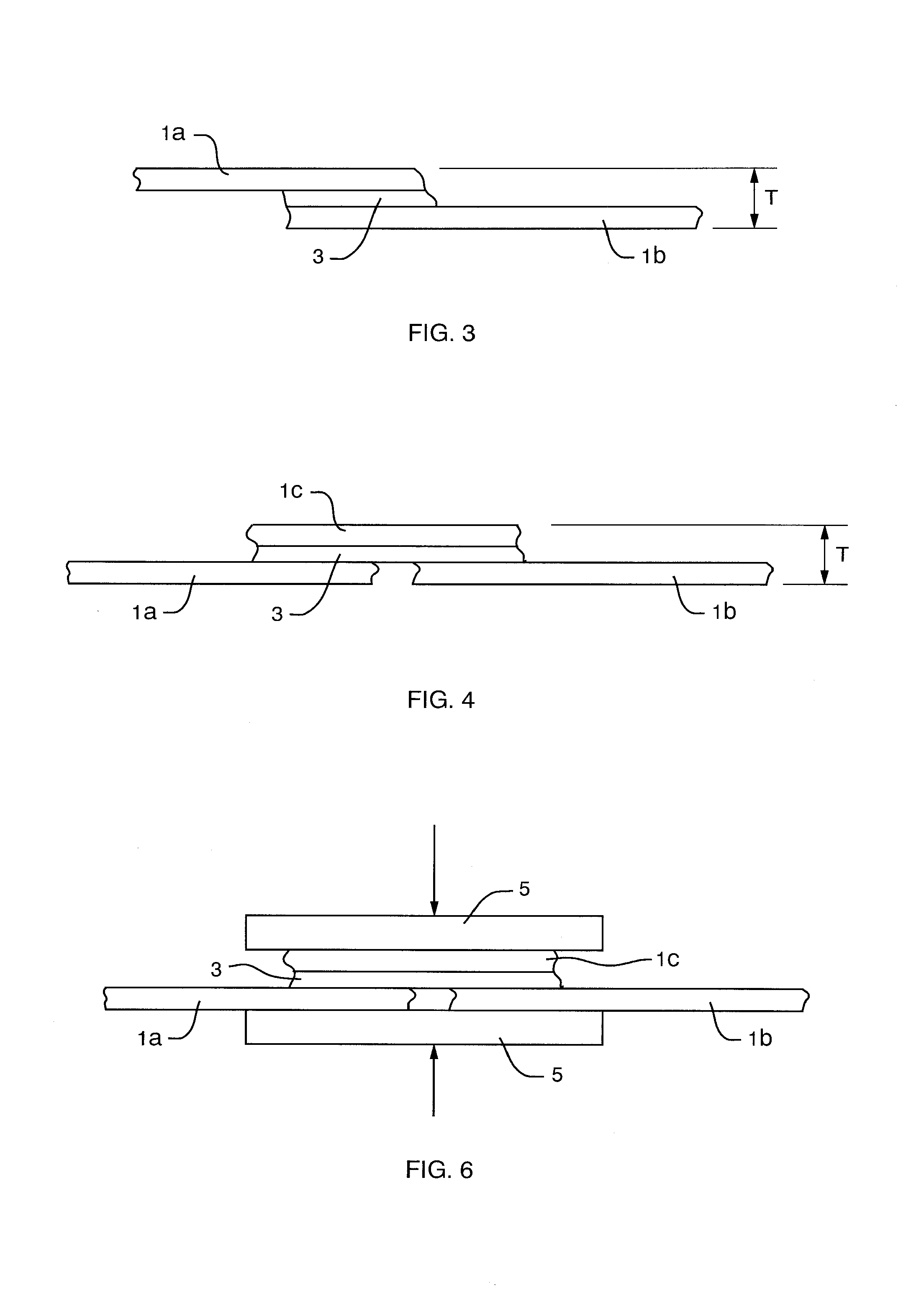

Method for making adhesive fabric joints with heat and pressure by comparing actual joint parameters to pre-calculated optimal joint parameters

ActiveUS7192498B2Improve adhesionImprove efficiencyLamination ancillary operationsControlling laminationAdhesiveQuality control

A method for joining fabrics, particularly high strength fabrics such as airship hull fabrics, including the steps of: measuring selected parameters of two fabric layers to be joined and the adhesive and any tape or other materials intended to be included in the joint; calculating therefrom an optimal value of a quality control parameter of an ideal joint, such as joint thickness, specific gravity or opacity; assembling the two fabric layers and other materials in the desired order; and applying heat and pressure to the assemblage until the selected quality control parameter of the joint, such as joint thickness, specific gravity or opacity, is satisfied.

Owner:WARWICK MILLS INC

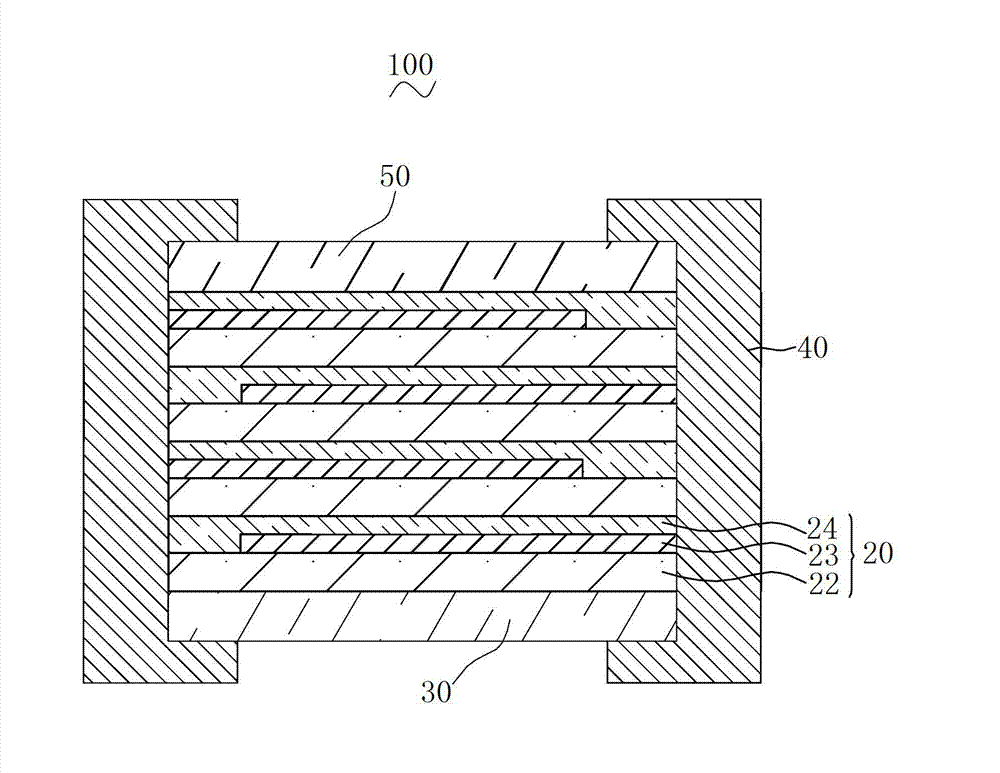

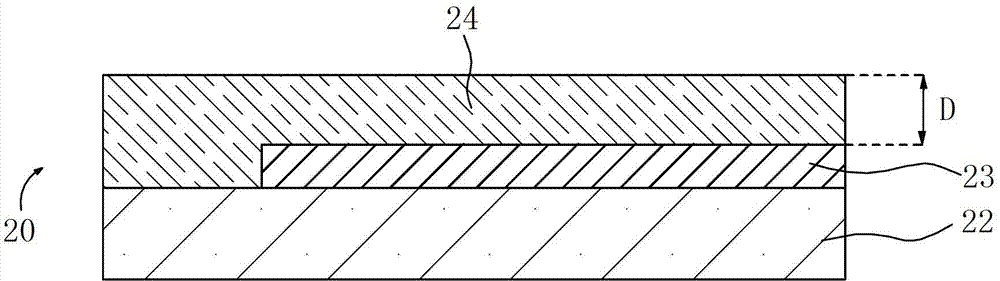

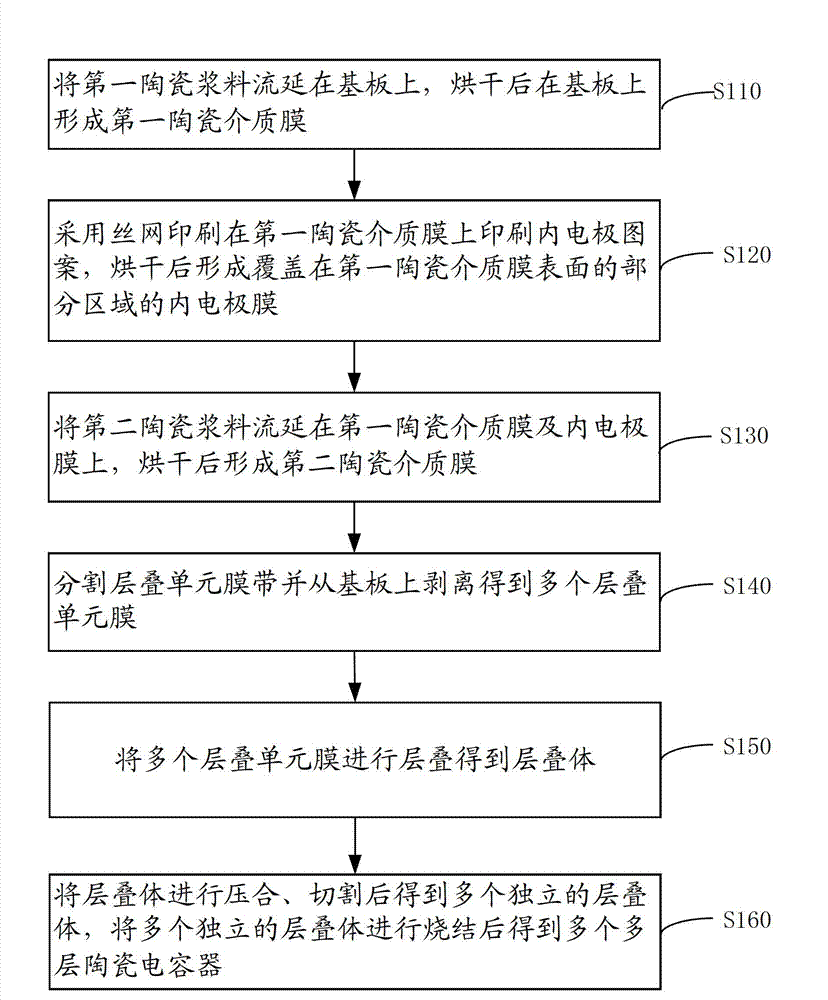

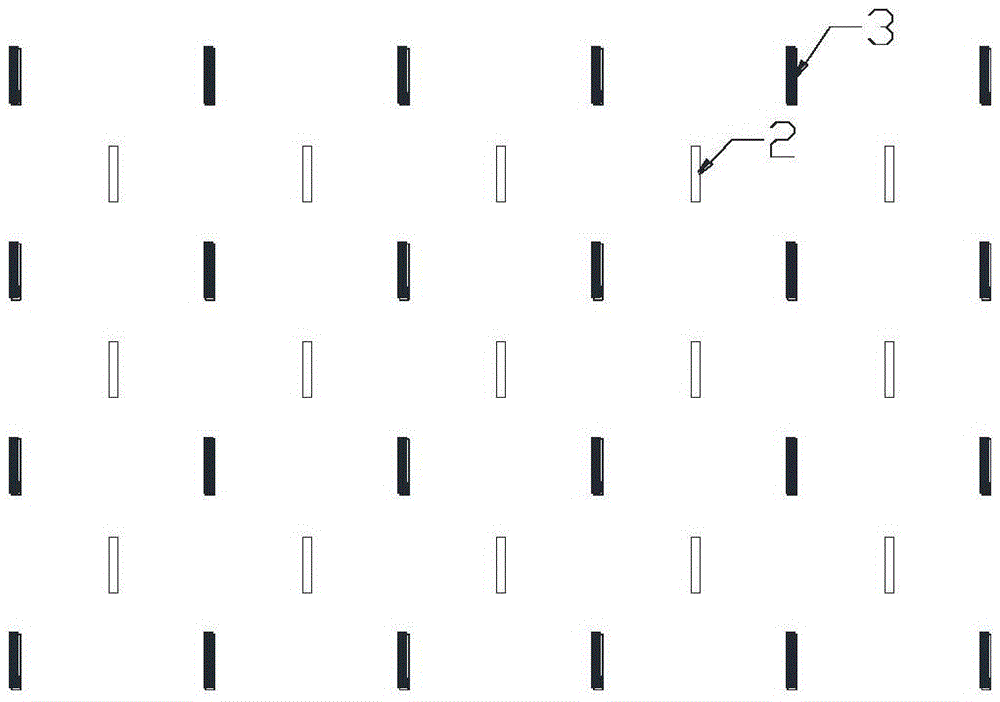

Multilayer ceramic capacitor and preparation method thereof

ActiveCN103050278AGuaranteed capacityIncrease effective capacityFixed capacitor electrodesFixed capacitor dielectricMicrometerMetallurgy

The invention provides a multilayer ceramic capacitor, which comprises a plurality of superposed superposing units, wherein each superposing unit comprises a first ceramic dielectric layer and an inner electrode layer formed in a partial area on the surface of the first ceramic dielectric layer; each superposing unit also comprises a second ceramic dielectric layer which covers the inner electrode layer and an area which is not covered by the inner electrode layer on the surface of the first ceramic dielectric layer; and a distance from the surface of the second ceramic dielectric layer far from the first ceramic dielectric layer to the surface of the inner electrode layer far from the first ceramic dielectric layer is 0.56 to 2.1 micrometers. By the multilayer ceramic capacitor with the structure, height difference and gaps are eliminated, inner electrode layers of two adjacent superposing units can be accurately aligned, and the reliability and effective capacity of the multilayer ceramic capacitor are higher. Furthermore, the invention provides a preparation method for the multilayer ceramic capacitor.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

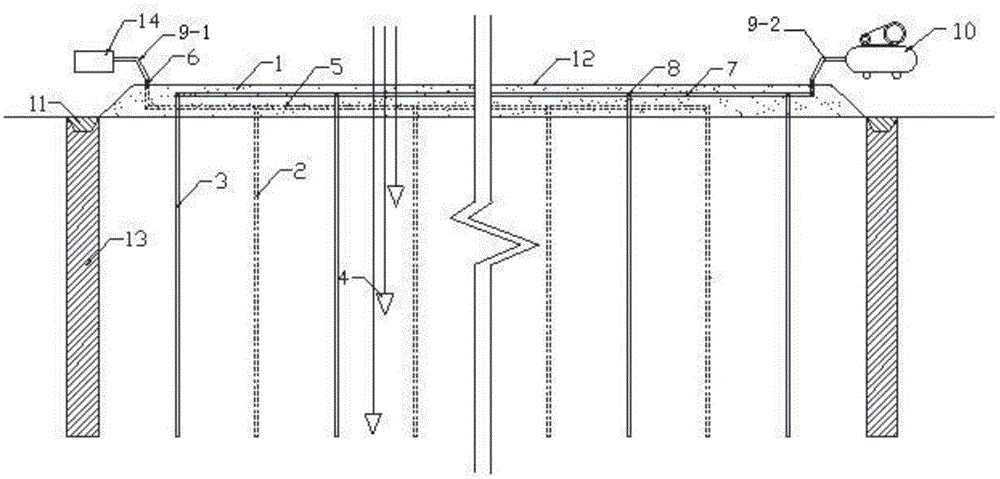

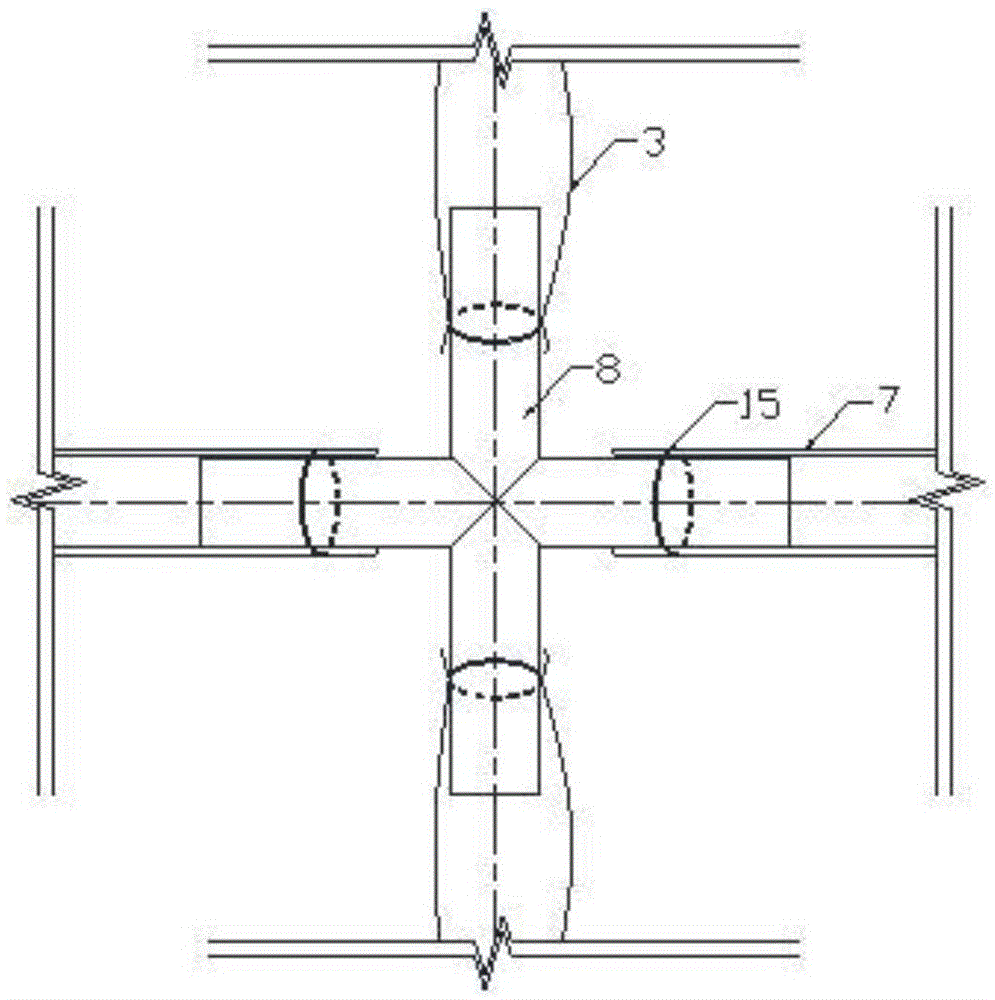

Flat belt lateral swelling combined vacuum pre-pressing foundation processing device and method

InactiveCN105603963AIncrease the permeability coefficient and consolidation coefficientSpeed up horizontal consolidationSoil preservationCushionProduct gas

The invention discloses a flat belt lateral swelling combined vacuum pre-pressing foundation processing device. A sand cushion layer is arranged above a construction region. A sealing film is arranged on the upper surface of the sand cushion layer. A plastic water drainage plate and a plastic flat belt are arranged in the construction region in a driving mode. A filtering pipe is embedded in the sand cushion layer. The plastic water drainage plate and the filtering pipe are connected. The filtering pipe is connected with a film outlet device. The film outlet device is connected with a jet pump through a first connecting pipe. An air injection pipe is embedded in the sand cushion layer. The plastic flat belt is connected with the air injection pipe which is connected with the film outlet device. The film outlet device is connected with an air compressor through a second connecting pipe. Film pressing ditches are formed around the construction region. A clay sealing wall is arranged below the film pressing ditches, the four edges of the sealing film are laid in the film pressing ditches and pressed compact with clay. Construction starts, the jet pump and the air compressor are started, vacuumizing is performed on the construction region, the plastic flat belt is filled with gas so that the plastic flat belt can laterally swell and have a squeezing effect on the peripheral edges. The technical scheme is applied to reinforcing of a soft soil foundation, the flat belt laterally swells and can generate fractures and accelerate soil solidification, additional loads in the horizontal direction are applied, the bearing force of the reinforced foundation is further improved and can reach 80 kPa or above.

Owner:TIANJIN PORT ENG INST LTD OF CCCC FIRST HARBOR ENG +2

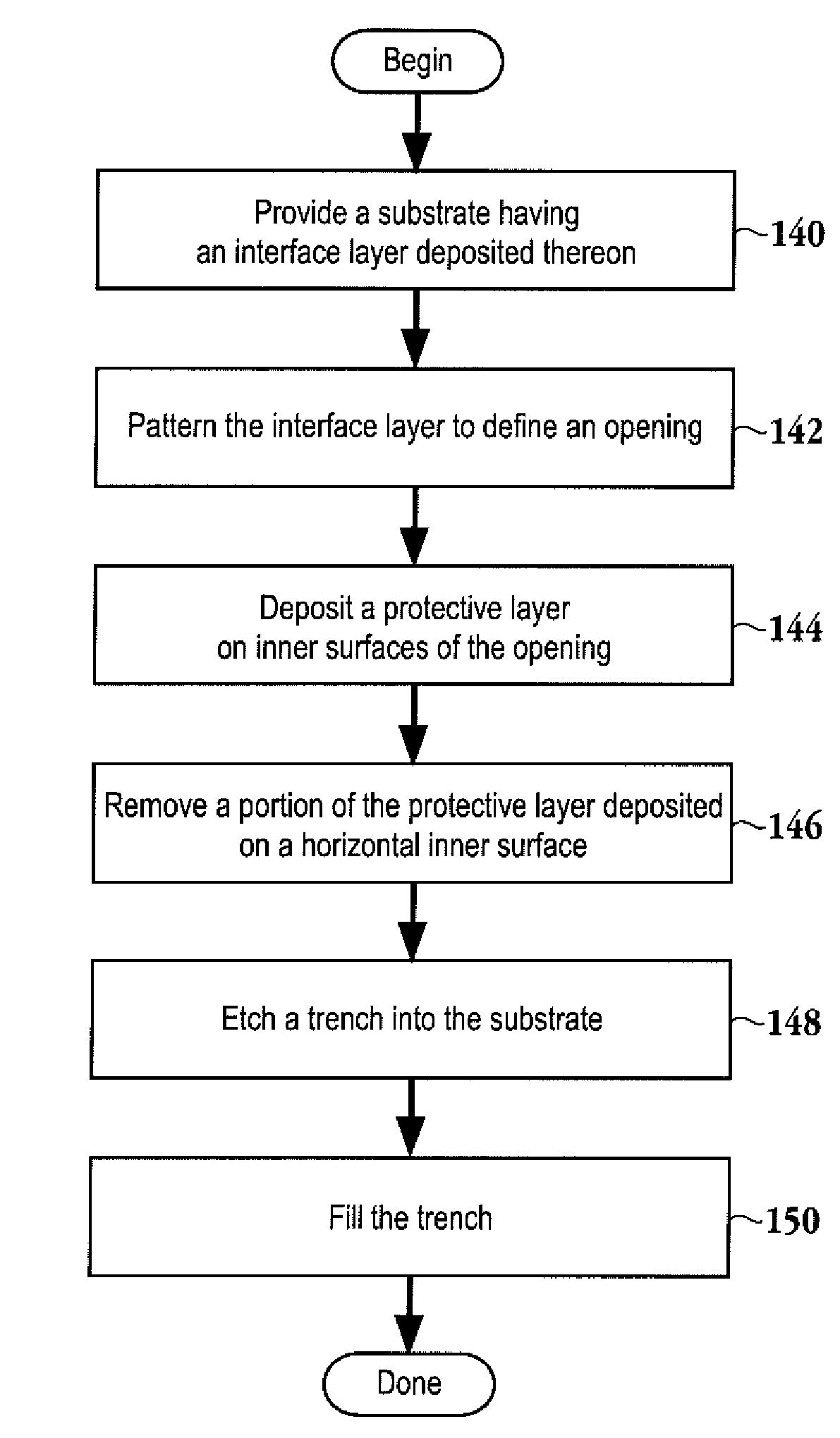

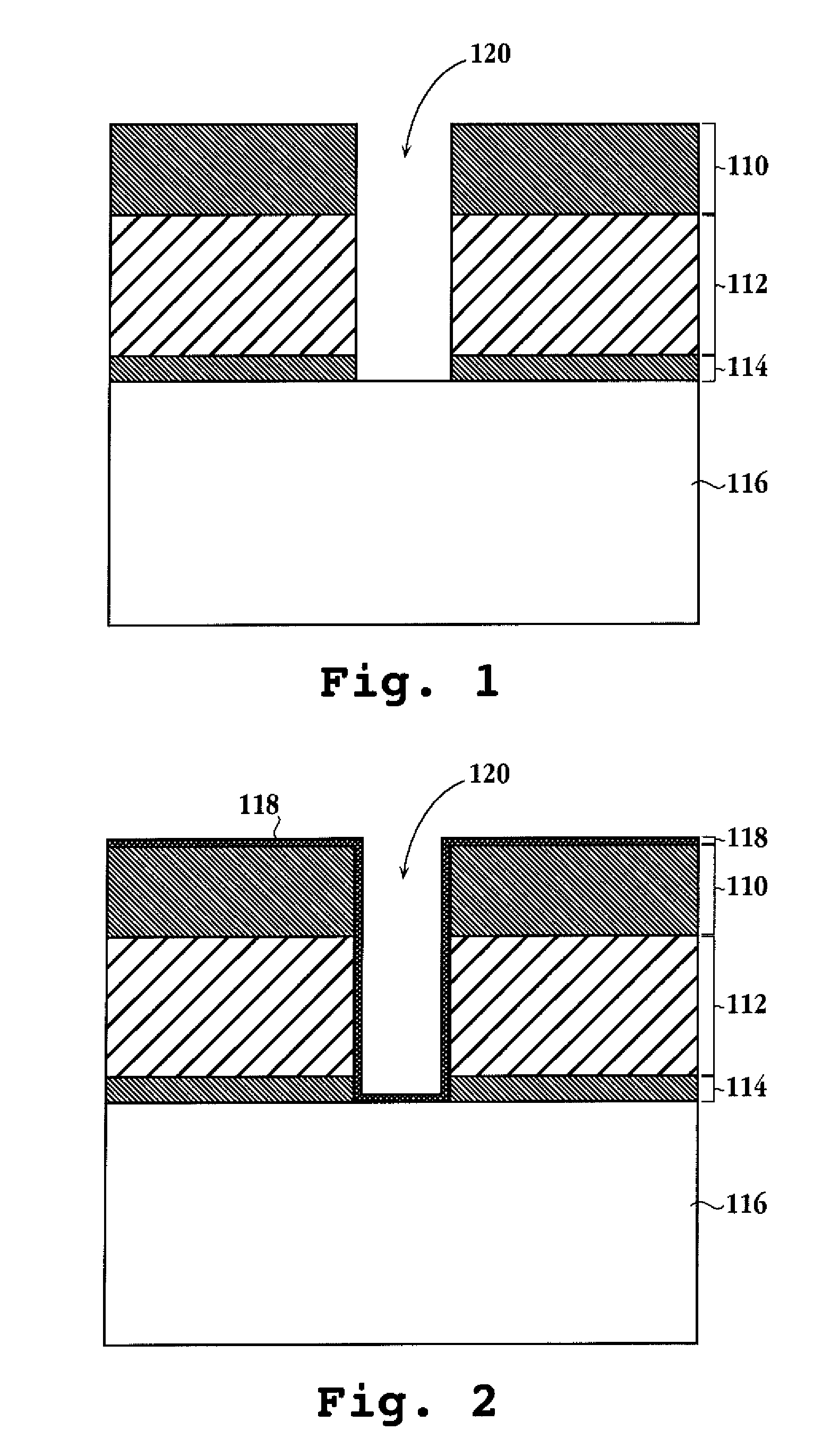

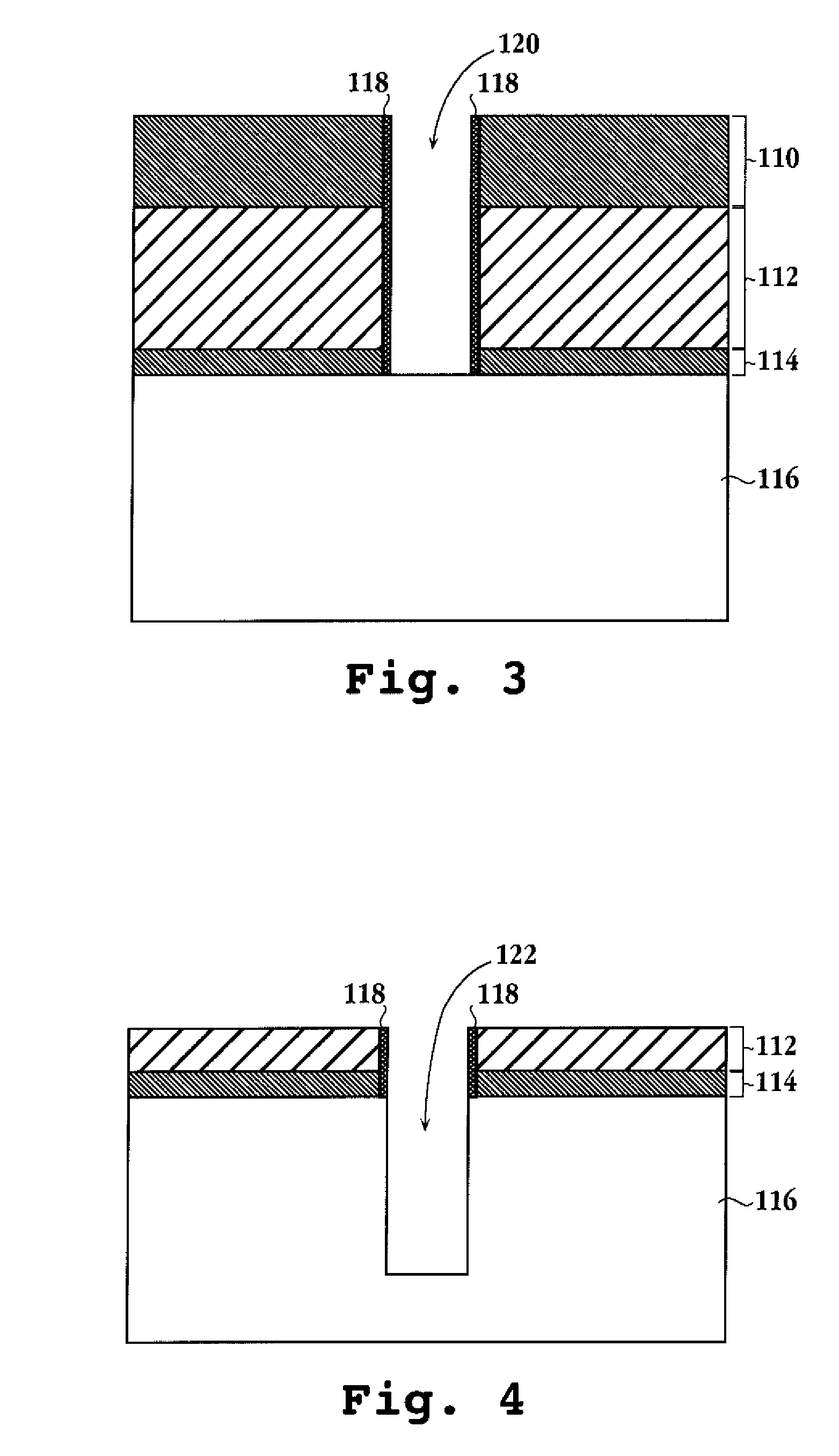

Sacrificial layer for protection during trench etch

ActiveUS7205226B1Eliminate voidsSemiconductor/solid-state device manufacturingEtchingDeposition process

A method for etching a trench is provided. The method initiates with providing a substrate having a patterned feature. The method includes alternating between deposition of a protective layer onto inner surfaces of the patterned feature and etching the trench into the substrate. The alternating may be achieved through a gas modulation technique and in one embodiment, the deposition and the etching are performed in the same chamber, i.e., the substrate does not move to a different chamber between the etch and deposition processes. The alternating is continued until the trench is completed and then the trench is filled. A semiconductor processing system is also provided.

Owner:LAM RES CORP

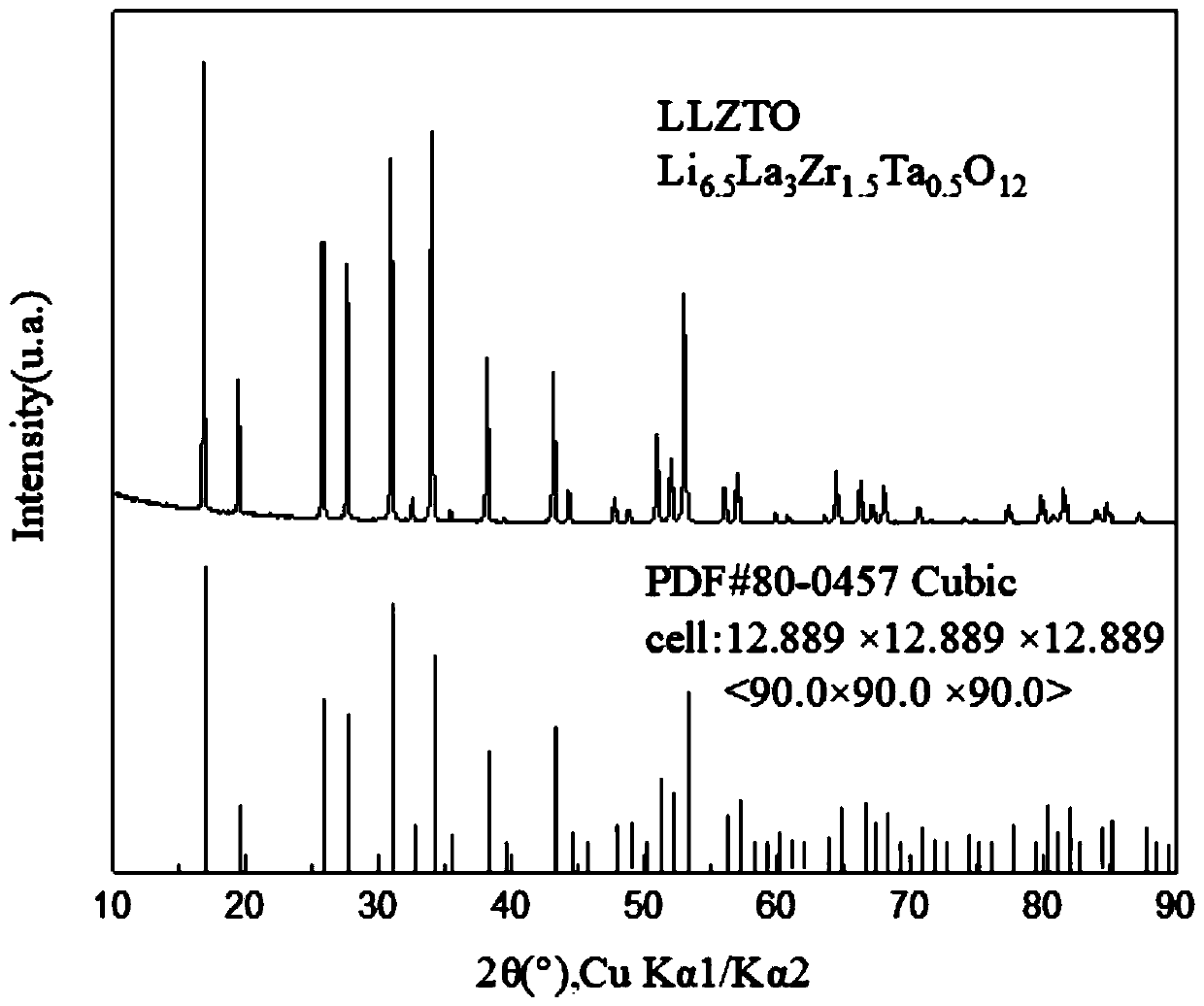

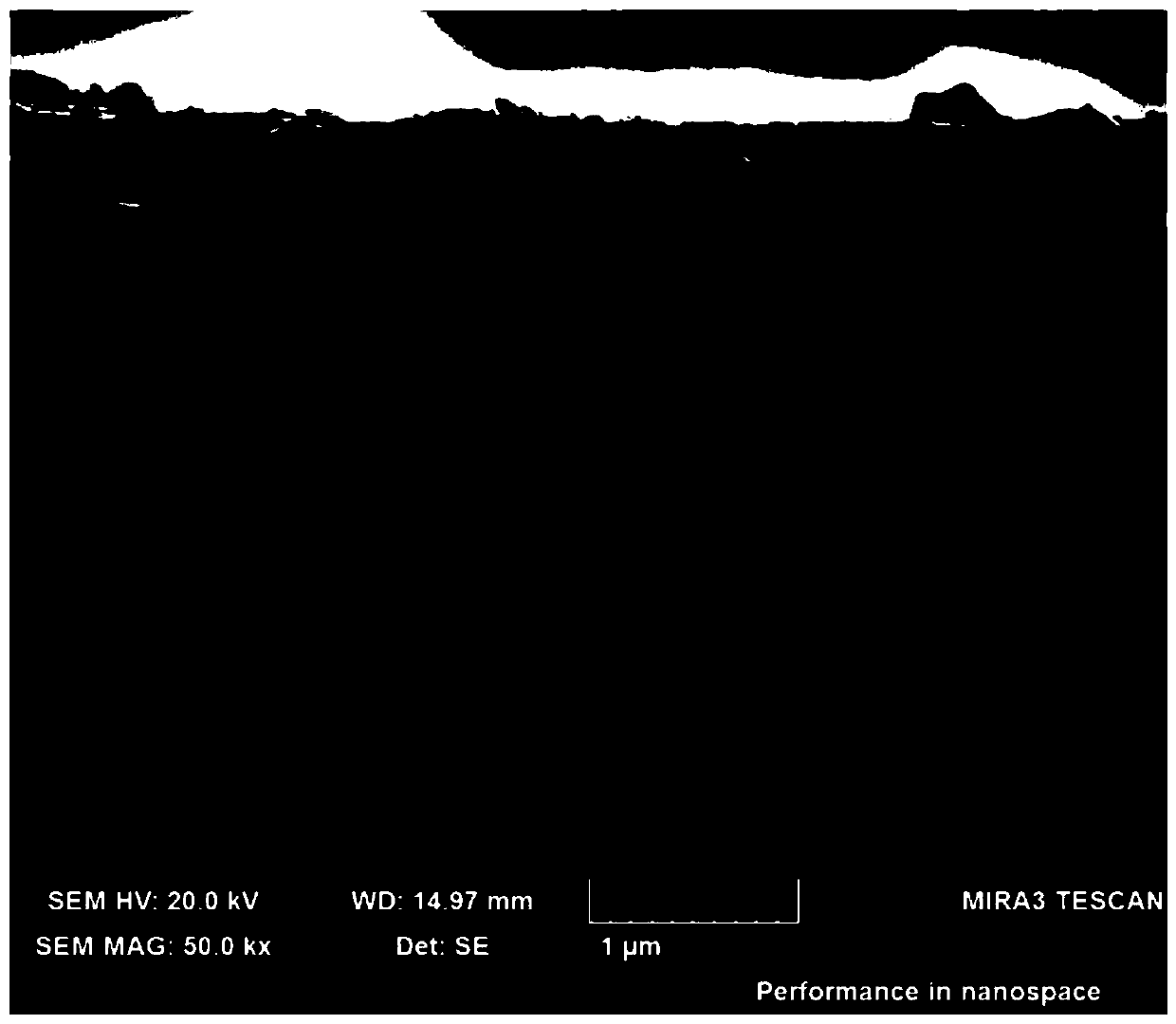

All-solid-state lithium battery, garnet solid-state electrolyte and preparation method thereof

ActiveCN110085910AImprove contact effectEliminate voidsFinal product manufactureElectrolytesAll solid stateElectrical conductor

The invention discloses an all-solid-state lithium battery, a garnet solid-state electrolyte and a preparation method thereof. The garnet solid-state electrolyte comprises a matrix, wherein the matrixa garnet-type fast ionic conductor LiaMbLacZrdNeO12, M includes one or more of Al, Sr, Sc, Ca, Ba and Y, and N includes one or more of Ta and Nb; the surface of the matrix is coated with a solid lubricant so as to modify the interface of the solid-state electrolyte, and the solid lubricant includes one or more of WS2, WSe2, NbSe2, NbS2, MoSe2, TaS2, TaSe2, TiS2 and TiTe2. The solid-state electrolyte is in full surface contact with the garnet-type fast ionic conductor via the solid lubricant, thereby being conducive to improving the interface between crystal grains of the solid-state electrolyte and between an electrode and the solid-state electrolyte, thus acquiring low interface impedance, and significantly improving the durability and cycle performance of the battery.

Owner:广州博粤新材料科技有限公司

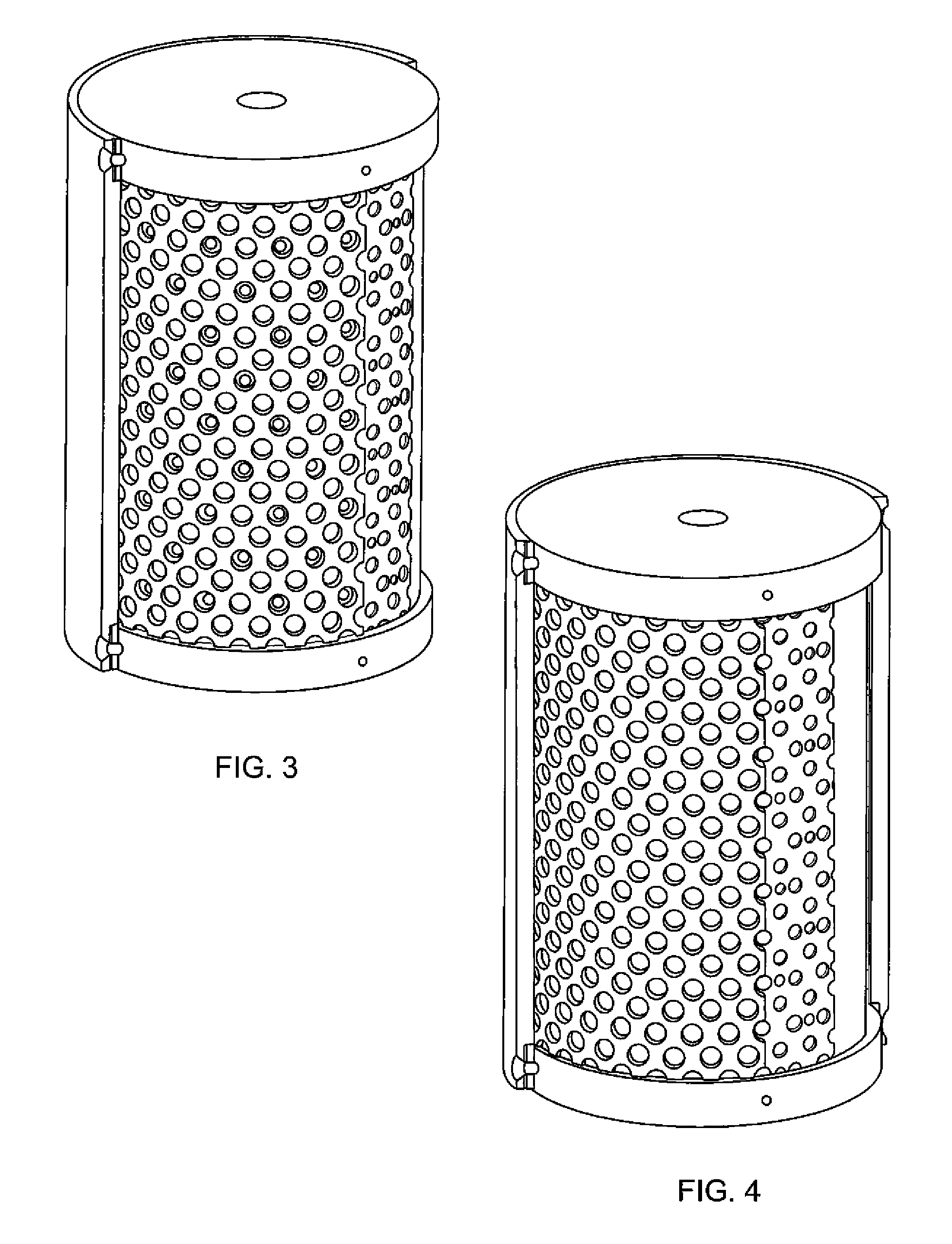

Selectable lethality warhead patterned hole fragmentation insert sleeves

InactiveUS8272329B1Strong penetrating powerEliminate voidsAmmunition projectilesFall bombsFragment sizeLarge fragment

The dynamically configurable controlled fragmentation insert mechanism of this invention includes an assembly of three or more sleeves with differing through hole patterns thereon, that fit inside the shell casing. The individual sleeves can move independently of one another and a simple pinning mechanism holds the parts in place for a selected configuration. The warfighter can realign the insert sleeves by to create different geometric patterns of holes, each designed to engage a different target set with optimally sized fragments. The aligned patterns of holes creates individual geometric shapes that focus high-velocity jets to cut into the steel shell casing to correlate to the through-holes in the aligned patterned sleeves. Realigning the insert sleeves changes the through-hole pattern to produce different fragment sizes and mass distributions. To defeat light armored vehicles for instance, a warfighter can deploy a sleeve hole pattern to produce larger fragments with greater penetrating power, while to engage enemy troops for instance, a warfighter can “dial in” another hole pattern through the fuze assembly to otherwise produce a much larger number of smaller, lighter fragments.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

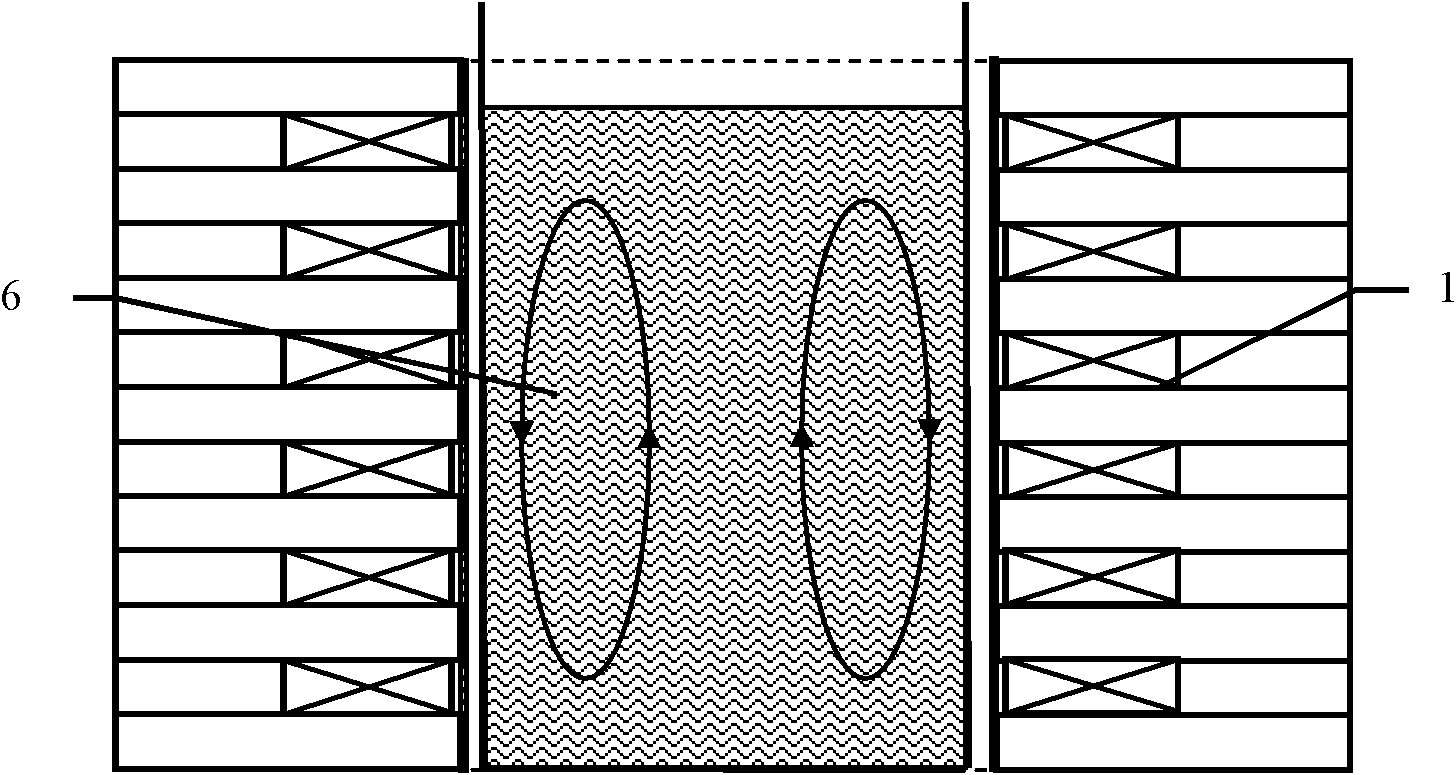

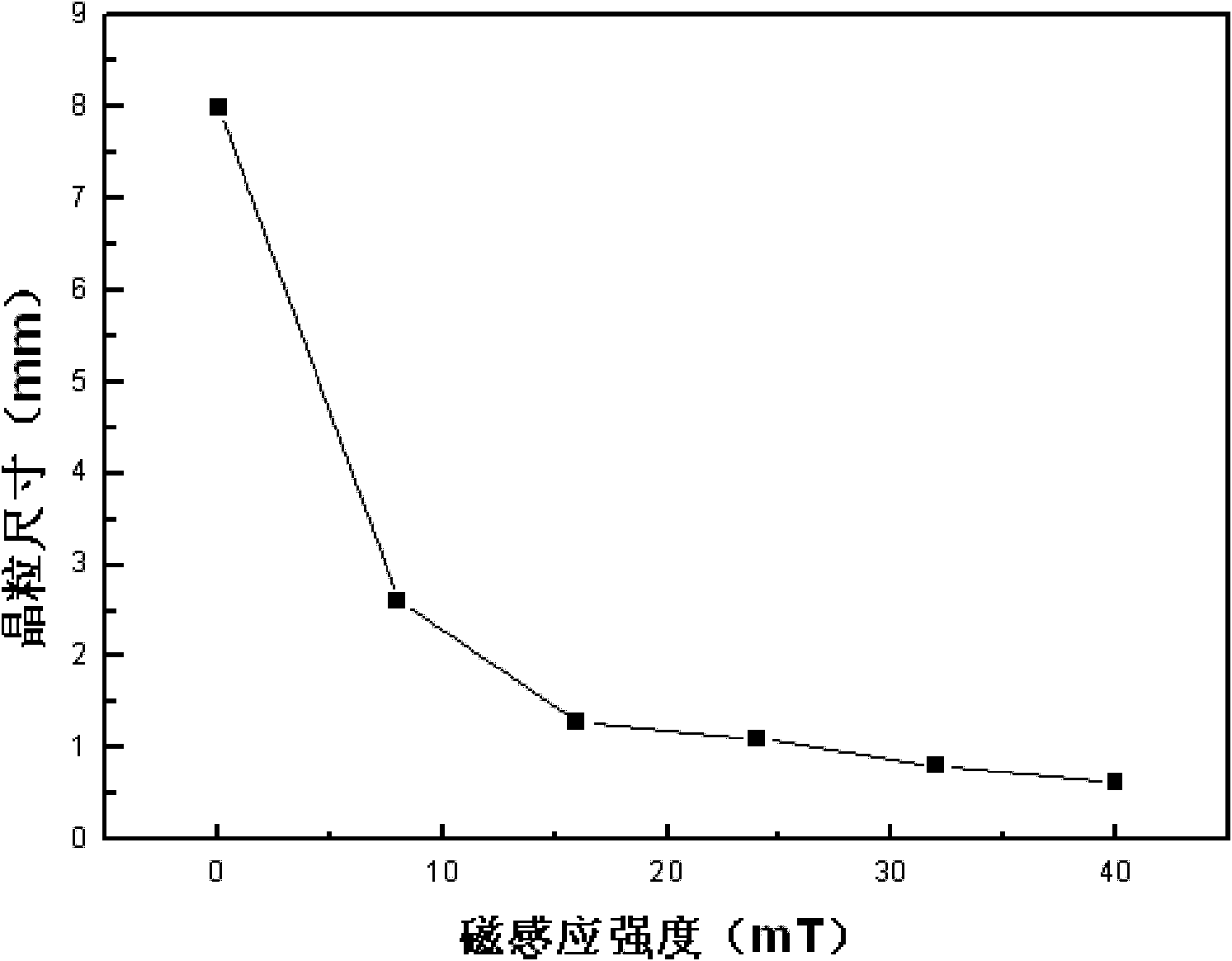

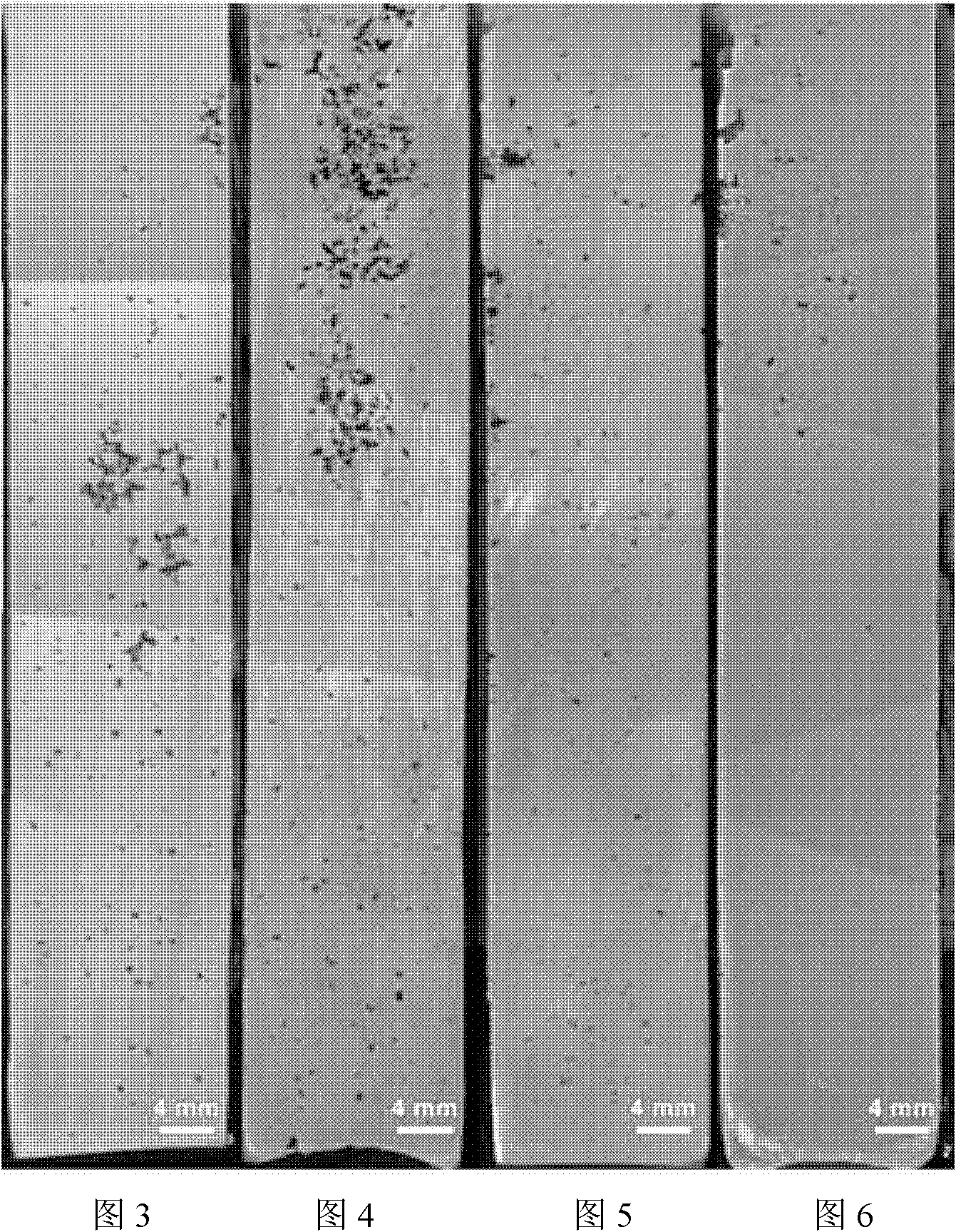

Precision casting method for refining aluminum alloy by using adjustable traveling wave magnetic field

The invention relates to a precision casting method for refining aluminum alloy by using an adjustable traveling wave magnetic field, belonging to the technical field of casting. The invention aims to solve the technical problems of high cost and difficulty in control in the process of grain refining and compacting for changing the properties of aluminum alloy in the prior art. The method provided by the invention comprises the following steps: 1. heating to melt aluminum alloy, and carrying out heat preservation,, thus obtaining an aluminum alloy molten mass; and 2. putting a casting mold, which is made of a non-magnetic material, in a traveling wave magnetic field inductor, turning on the traveling wave magnetic field inductor, adjusting the magnetic field intensity of the traveling wave magnetic field inductor, injecting the aluminum alloy molten mass obtained in the step 1 into the casting mold, and applying a traveling wave magnetic field, of which the magnetic field direction is vertically downward and the magnetic induction intensity is 32-500mT, onto the aluminum alloy molten mass to solidify the aluminum alloy under the traveling wave magnetic field, thereby completing the precision casting of the aluminum alloy. The method provided by the invention is easy to control and low in cost; and by utilizing the method provided by the invention, the obtained alloy crystal grains are fine, bubbles and voids can be effectively reduced, and the metal feeding capacity in the solidification process can be enhanced.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com