Super-fine TiC0.7N0.3 base metal ceramic and preparing method

A cermet and composition technology, applied in the field of ultrafine TiC0.7N0.3-based cermet and its preparation, can solve the problems of unstable product performance, insufficient strength and toughness, etc., to reduce defect formation, improve material density, inhibit The effect of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

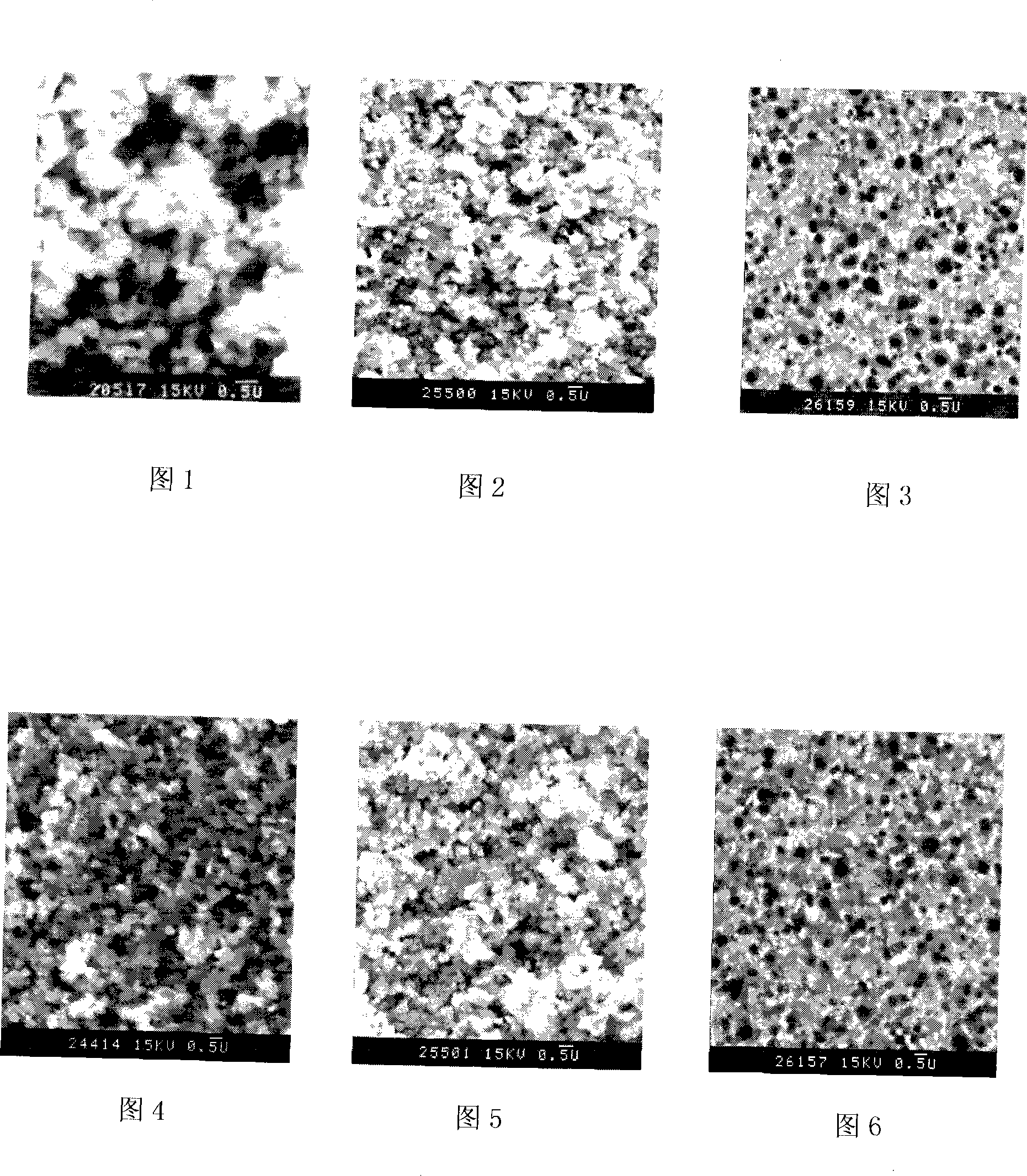

[0038] Example 1: The particle size of each component is: TiC 0.7 N 0.3 : 0.05~0.13μm; WC: 0.2~0.4μm; Mo 2 C: 0.4 0.7 μm; TaC: 0.8-1 μm; Ni / Co: 2 C: 10wt%; WC: 15wt%; TaC: 7wt%; NiCo: 14.5wt% (and Co:Ni=60:40); the rest is TiC 0.7 N 0.3 solid solution. Ultrafine TiC 0.7 N 0.3 The deoxidation treatment of powder in H 2 It is carried out in a protected continuous propulsion type moss calcination furnace. Ultrafine TiC 0.7 N0.3 The powder is placed on a clean graphite boat and sent into the H 2 Deoxidation treatment is carried out in a protected continuous propulsion type moss calciner, the boat pushing speed is 20 boats / min, the high temperature zone temperature is 400°C, H 2 Velocity 2m 3 / Hour. The morphology after treatment is shown in Figure 1, and the composition analysis is shown in Table 3. Then mix various carbides, carbonitrides and metal powders according to the weight percentage of the composition, and grind them in a drum type wet mill. The wet grinding m...

example 2

[0045] Example 2: The particle size of each component is: TiC 0.7 N 0.3 : 0.05~0.13μm; WC: 0.2~0.4μm; Mo 2 C: 0.4-0.7 μm; TaC: 0.8-1 μm; Ni / Co: 2 C: 13wt%; WC: 15wt%; TaC: 8wt%; NiCo: 13wt% (and Co:Ni=60:40); the rest is TiC 0.7 N 0.3 solid solution. Ultrafine TiC 0.7 N 0.3 The deoxidation treatment of other powders is carried out in a vacuum sintering furnace. Ultrafine TiC 0.7 N 0.3 Put the powder on a clean graphite boat, send it into a vacuum sintering furnace for deoxidation treatment, and keep it warm at 1500°C for 1 hour with a vacuum degree of 0.5Pa. The morphology after treatment is shown in Figure 4, and the component analysis is shown in Table 5. Then mix various carbides, carbonitrides and metal powders according to the weight percentage of the composition, and grind them in a drum type wet mill. The wet grinding medium is hexane, and the grinding balls are WC-8wt% Co cemented carbide balls. The grinding speed is 68r / min, the grinding time is 48h, the dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com