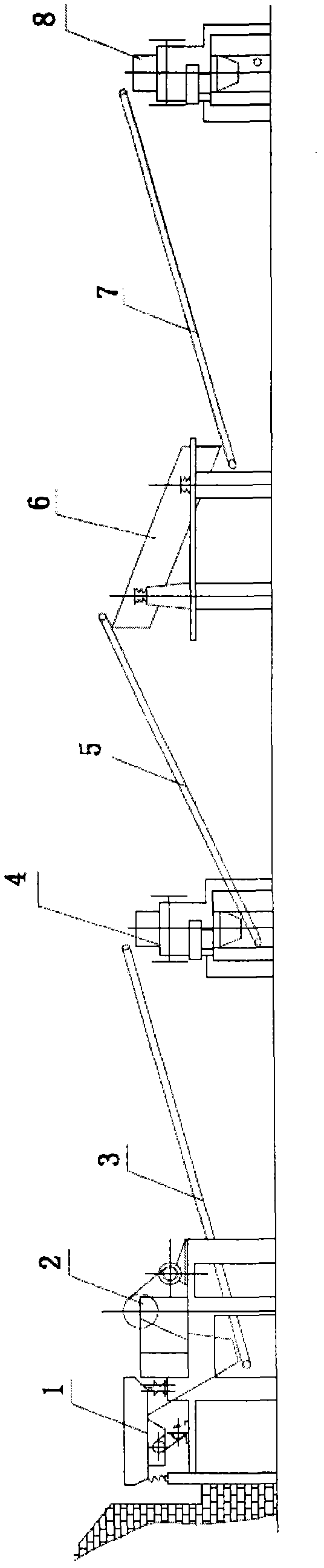

One-machine crushing production line

A production line and stand-alone technology, applied in grain processing and other directions, can solve the problems of high cost, poor economy, complex structure of crushing production line, etc., and achieve the effect of improving crushing efficiency, avoiding over-crushing and improving crushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

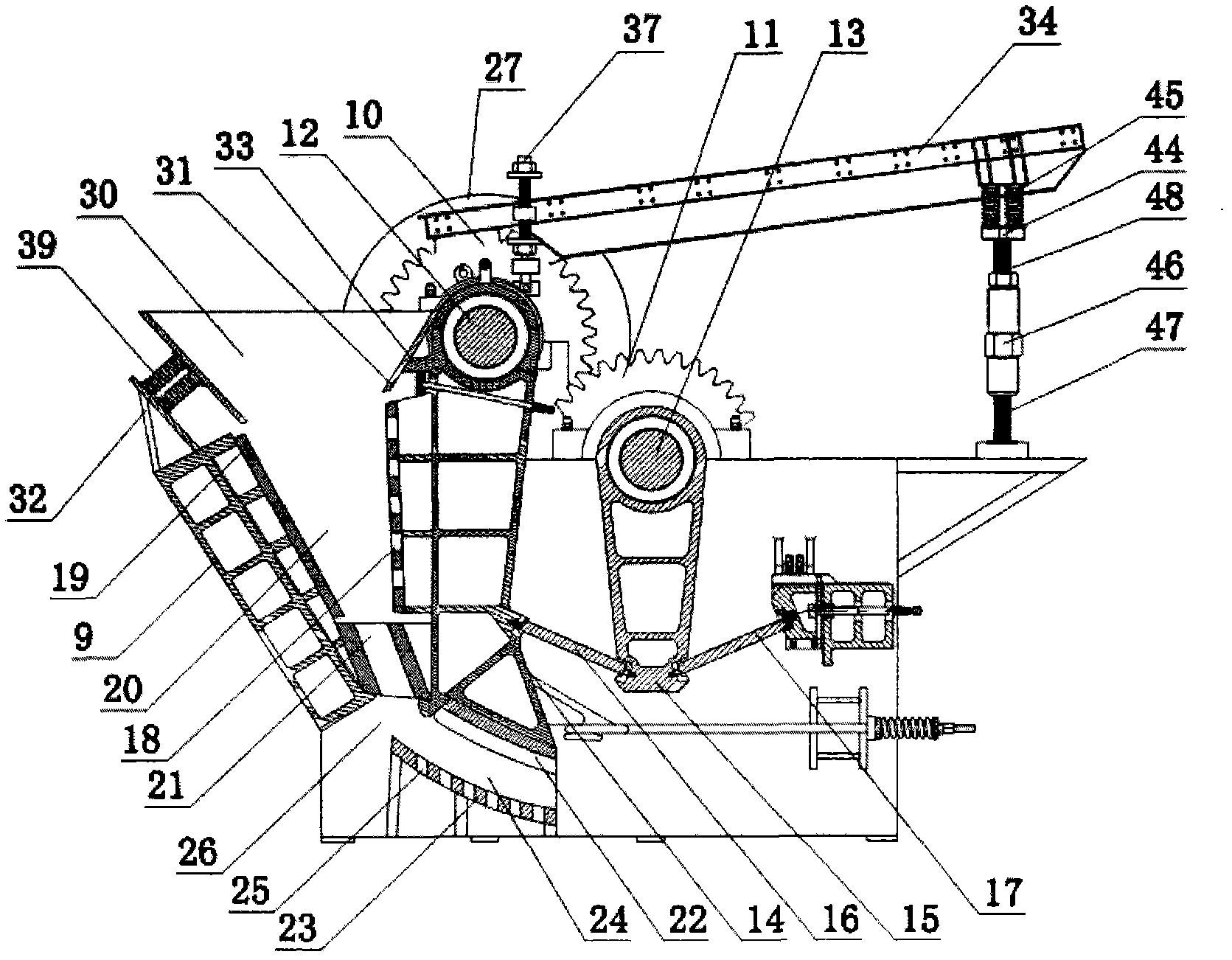

[0081] Embodiment 1: as figure 2 As shown, a single-machine crushing production line includes a frame 9 and a transmission device. The transmission device includes a front transmission gear 10, a rear transmission gear 11 and a transmission wheel 27. The front transmission gear 10 and the rear transmission gear 11 are meshed with the transmission wheel 27 connected.

[0082] The frame 1 is provided with a biaxial double crank rocker mechanism. The biaxial double crank rocker mechanism includes a front crank rocker mechanism and a rear crank rocker mechanism. The front crank rocker mechanism includes a front movable jaw 14, a front toggle plate 16 and The front eccentric drive shaft 12; the rear crank rocker mechanism includes a rear movable jaw 15, a rear toggle plate 17 and a rear eccentric drive shaft 13; the front eccentric drive shaft 12 is connected with the front transmission gear 10, and the rear eccentric drive shaft 13 is connected with the rear transmission gear 11...

Embodiment 2

[0093] Embodiment 2: as Figure 4 As shown, the lower movable jaw plate and the lower fixed jaw plate are provided with vertical rows of holes 50 at the valleys.

Embodiment 3

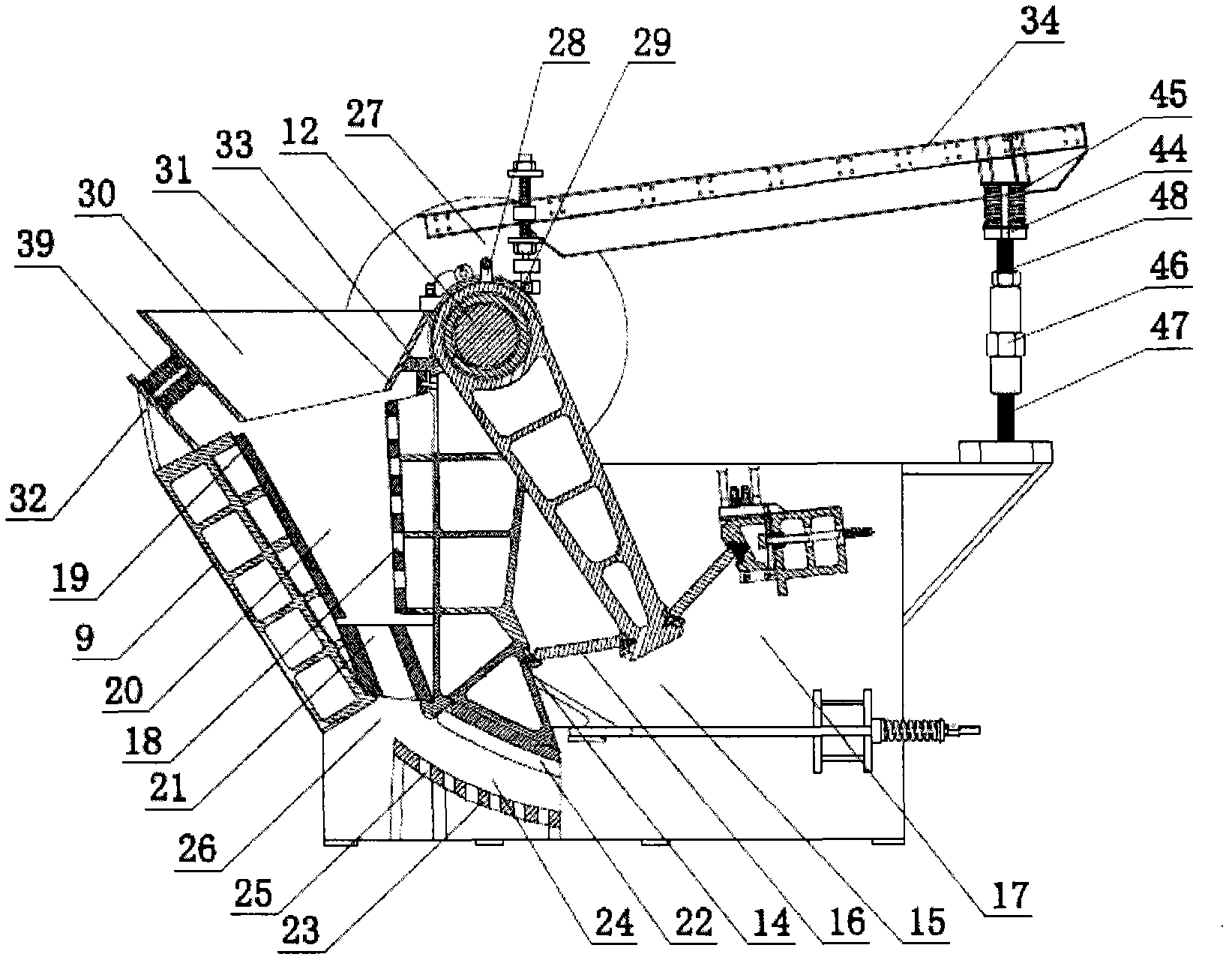

[0094] Embodiment 3: as image 3 As shown, the frame 1 is provided with a single-axis double-crank rocker mechanism, the single-axis double-crank rocker mechanism includes a front crank-rocker mechanism and a rear crank-rocker mechanism, and the front crank-rocker mechanism includes a front movable jaw 14, a front elbow Plate 16 and front eccentric drive shaft 12; rear crank rocker mechanism includes rear movable jaw 15, rear toggle plate 17 and front eccentric drive shaft 12; front eccentric drive shaft 12 is connected with drive wheel 27. The front eccentric drive shaft 12 is covered with a bearing block 28 and a bearing pad 29, the bearing pad 29 is located on the middle section of the front eccentric drive shaft 12, and the bearing block 28 is located on the front eccentric drive shaft 12 on both sides of the bearing pad 29; the front movable jaw 14 is hung on the bearing block 28, and the rear movable jaw 15 is hung on the bearing shoe 29. One end of the front toggle pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com