Patents

Literature

38results about How to "Avoid over breaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

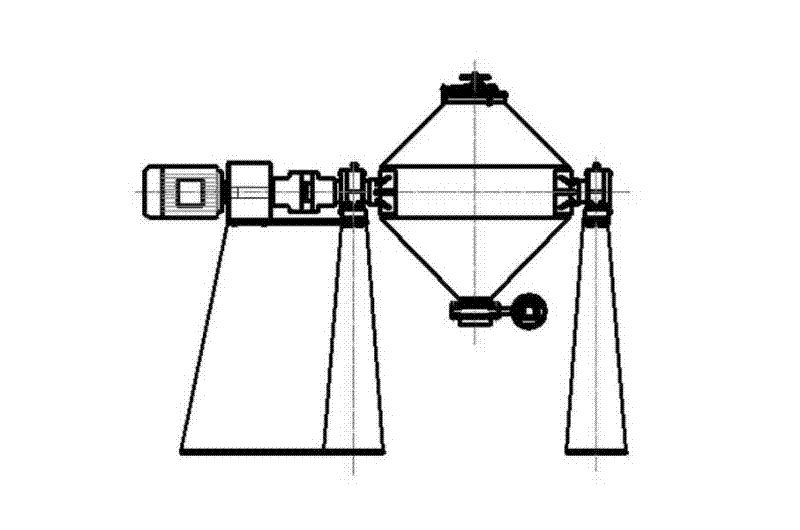

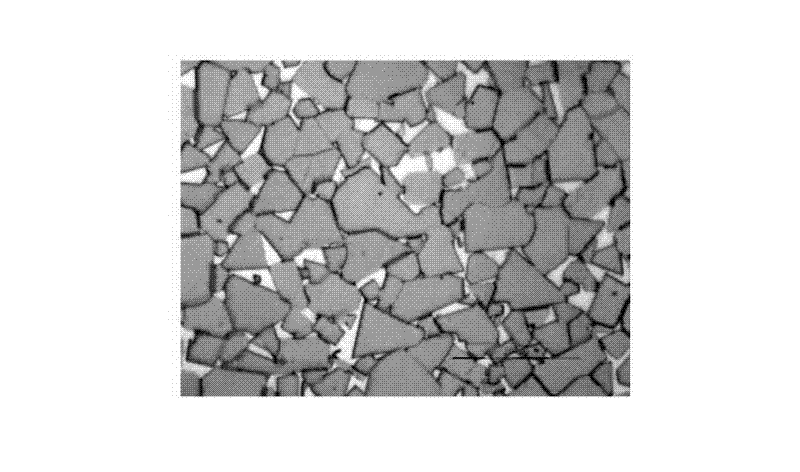

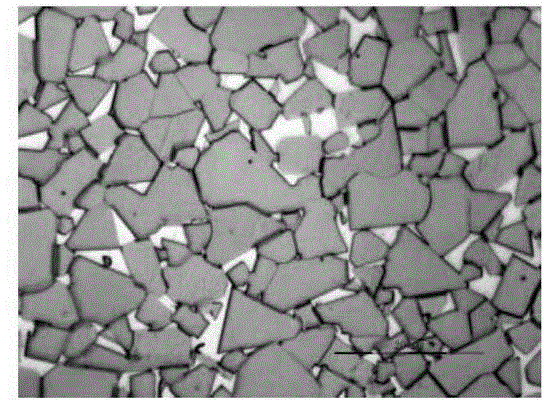

Method for preparing ultra-coarse grain cemented carbide by flexible ball milling technology

The invention discloses a method for preparing ultra-coarse grain cemented carbide by flexible ball milling technology, which comprises the following steps: firstly premixing ultra-coarse WC powder and Co powder for 0.5-2 h with a rotating speed of 6-12 rpm, wherein the Fisher particle size of the WC powder is 18.0-22.0 microns; performing mild ball milling of the premixed powder, adding liquid grinding mediums and a forming agent, wherein the grinding ball material is WC-Co cemented carbide with a diameter of 6-10 mm, the ball milling time is 8-24 h, the ball-to-powder ratio is 1.5-3.0:1, the rotating speed is 20-55% of a critical rotating speed; then discharging the slurry in the ball mill, preparing a mixture by spray drying, performing pressing and molding, sintering at a temperature of 1390-1500 DEG C, wherein the prepared ultra-coarse grain cemented carbide has a grain size of 6.0-10.0 microns, a hardness HV 30 of 740-1240, and a porosity of less than A04B00. The invention is simple in process, short in flow, low in production cost, and suitable for industrial production.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY +1

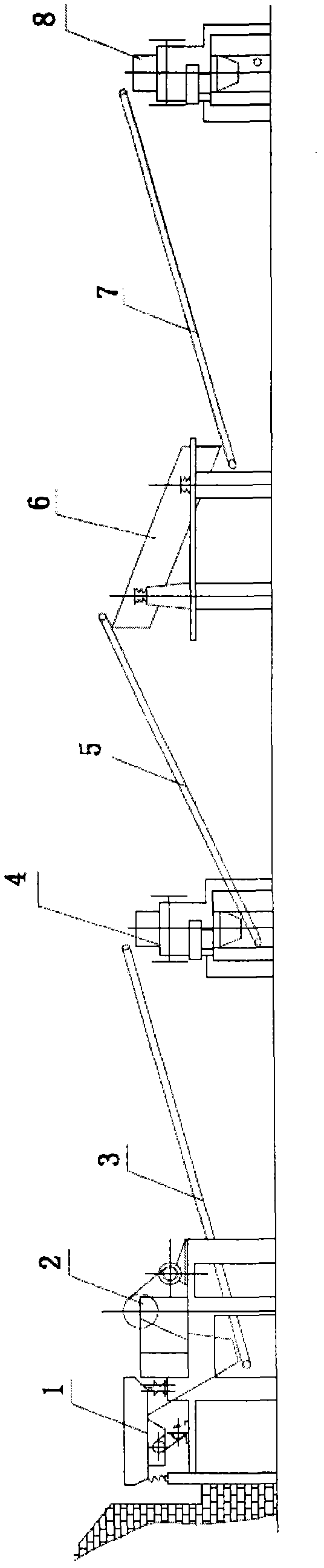

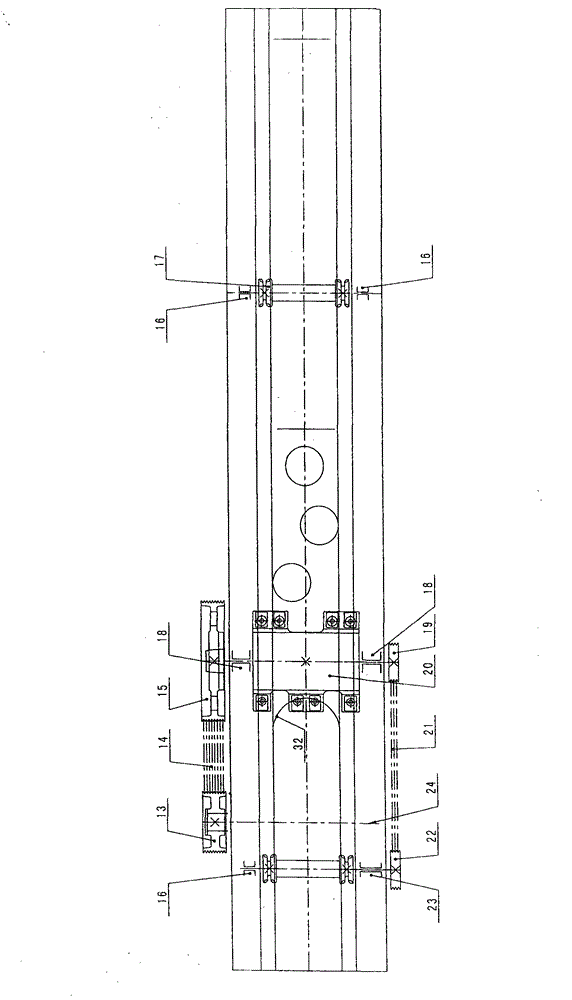

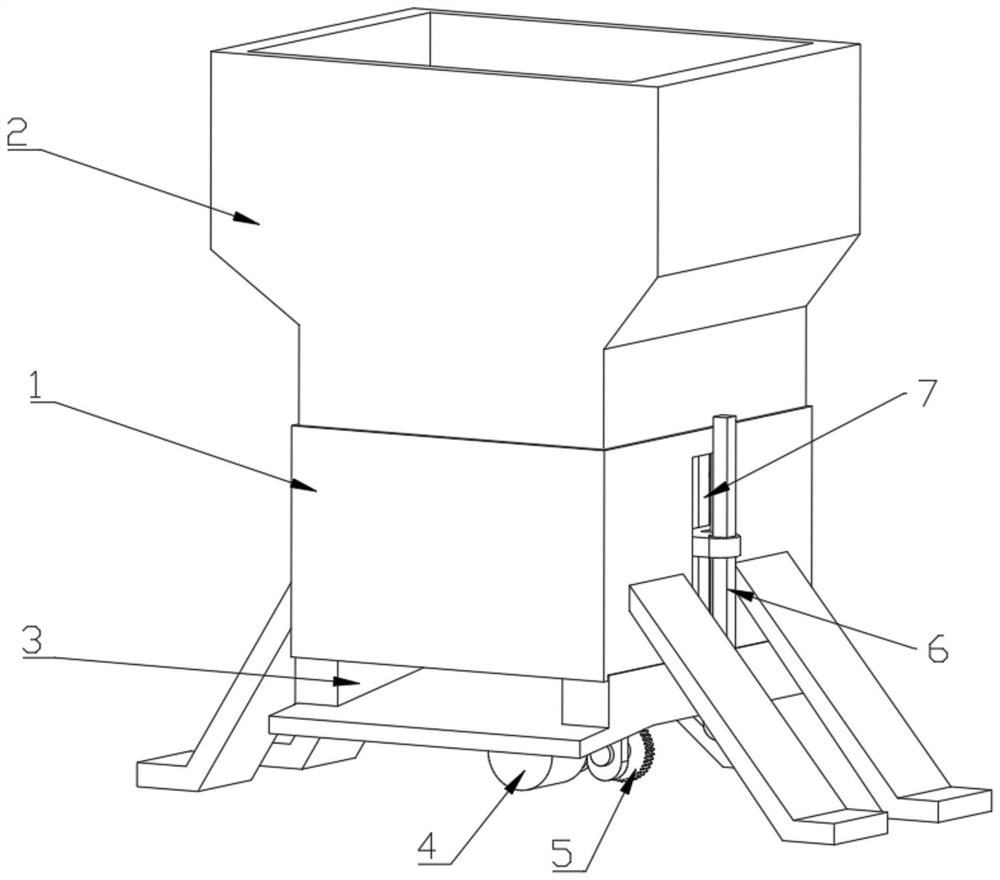

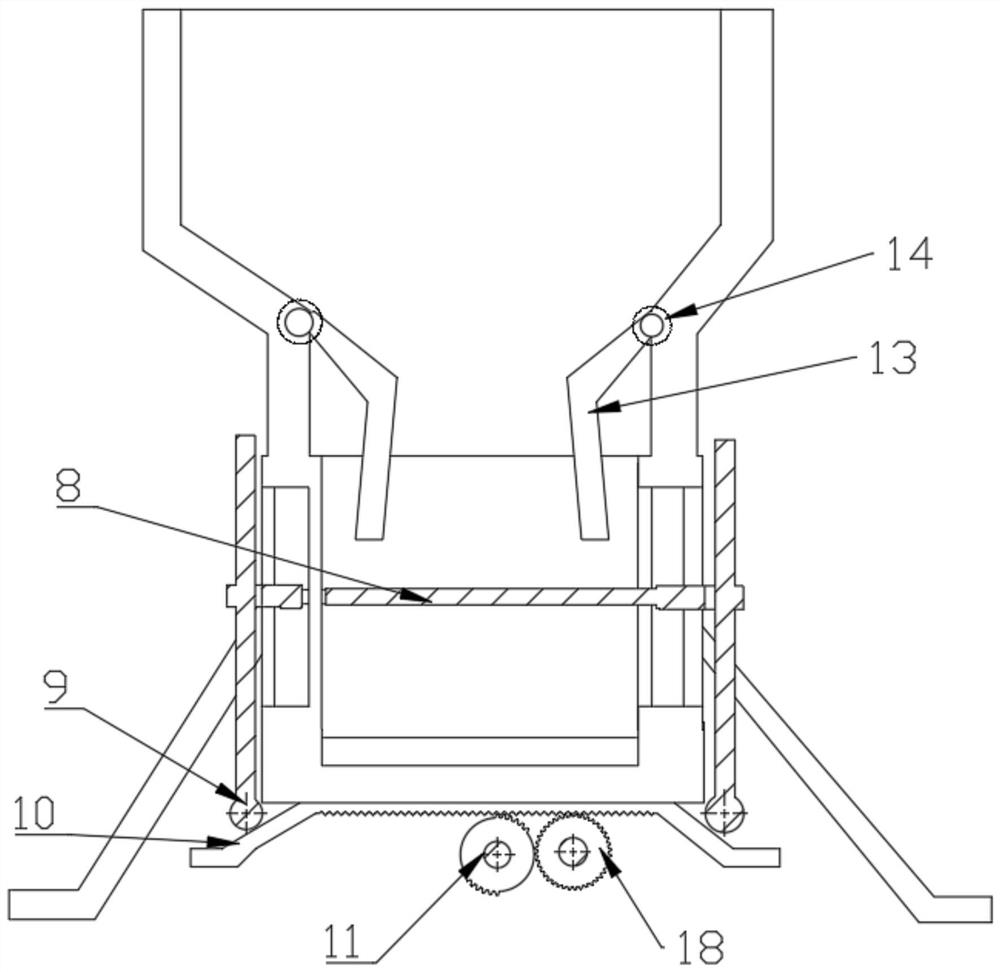

One-machine crushing production line

The invention discloses a one-machine crushing production line. The one-machine crushing production line breaks through the conventional thinking that the crushing production line is composed of a plurality of machines in the prior art, and achieves the function of the conventional crushing production line by ingenious and reasonable internal structural configuration and multifunctional combination of the single machine. The function achieved by the single machine provided by the invention is equal to the combined functions of eight machines in the crushing production line in the prior art (one feeder, three crushers, one vibrating screen and three conveyors). The design of multi-machine combined production line is replaced by the design of one-machine crushing production line is a major breakthrough in the technical field of crushers and the technical field of crushing production lines.

Owner:YIWU BLACK AND WHITE MINING MACHINERY

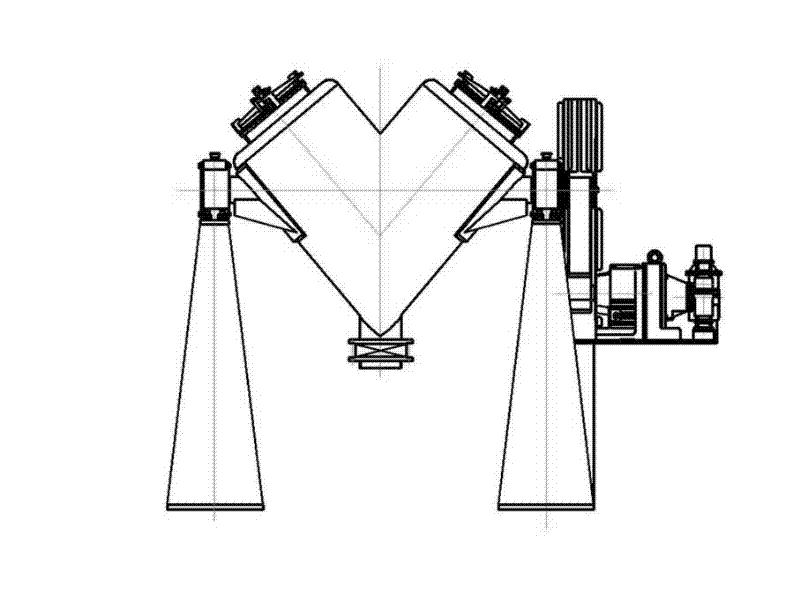

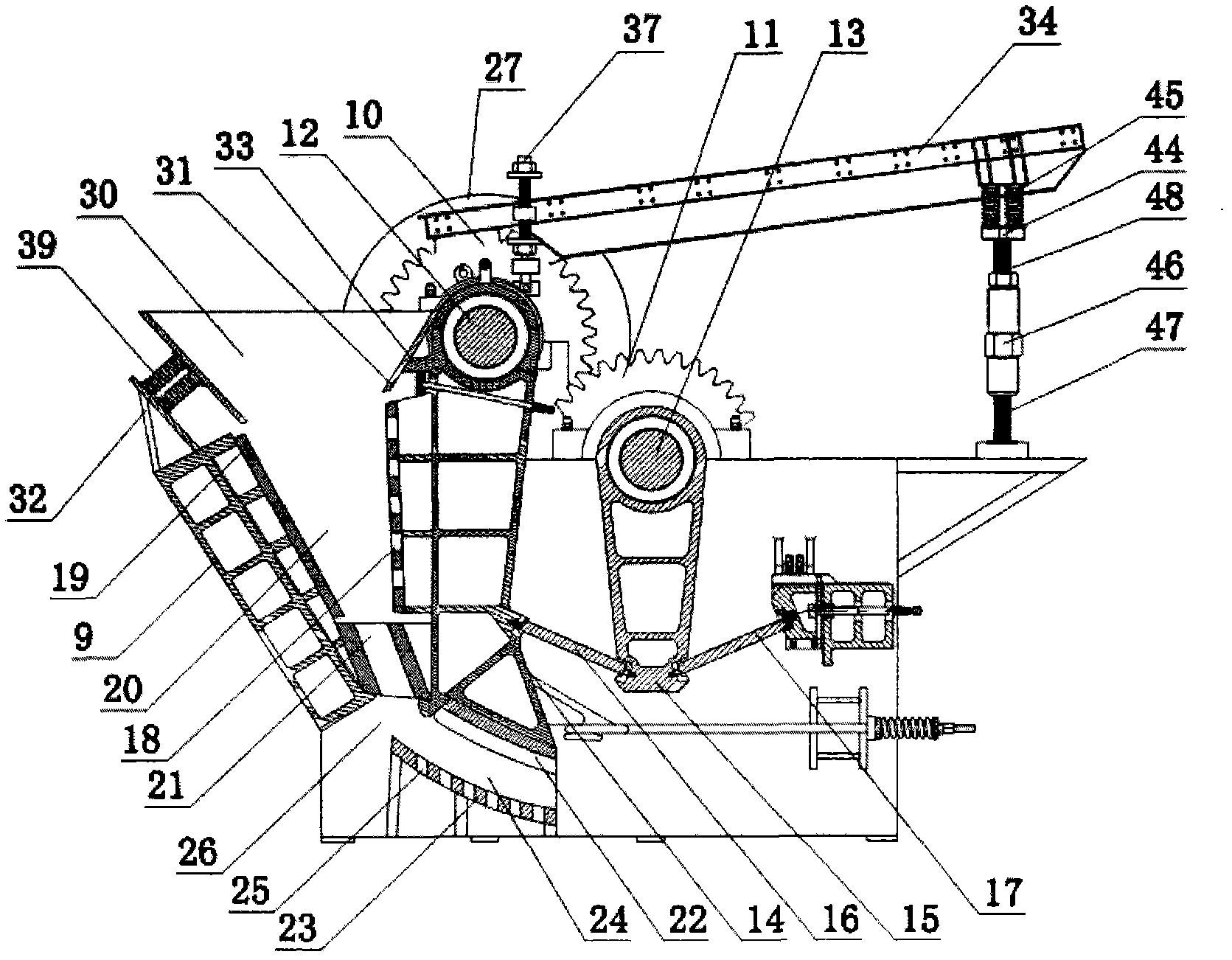

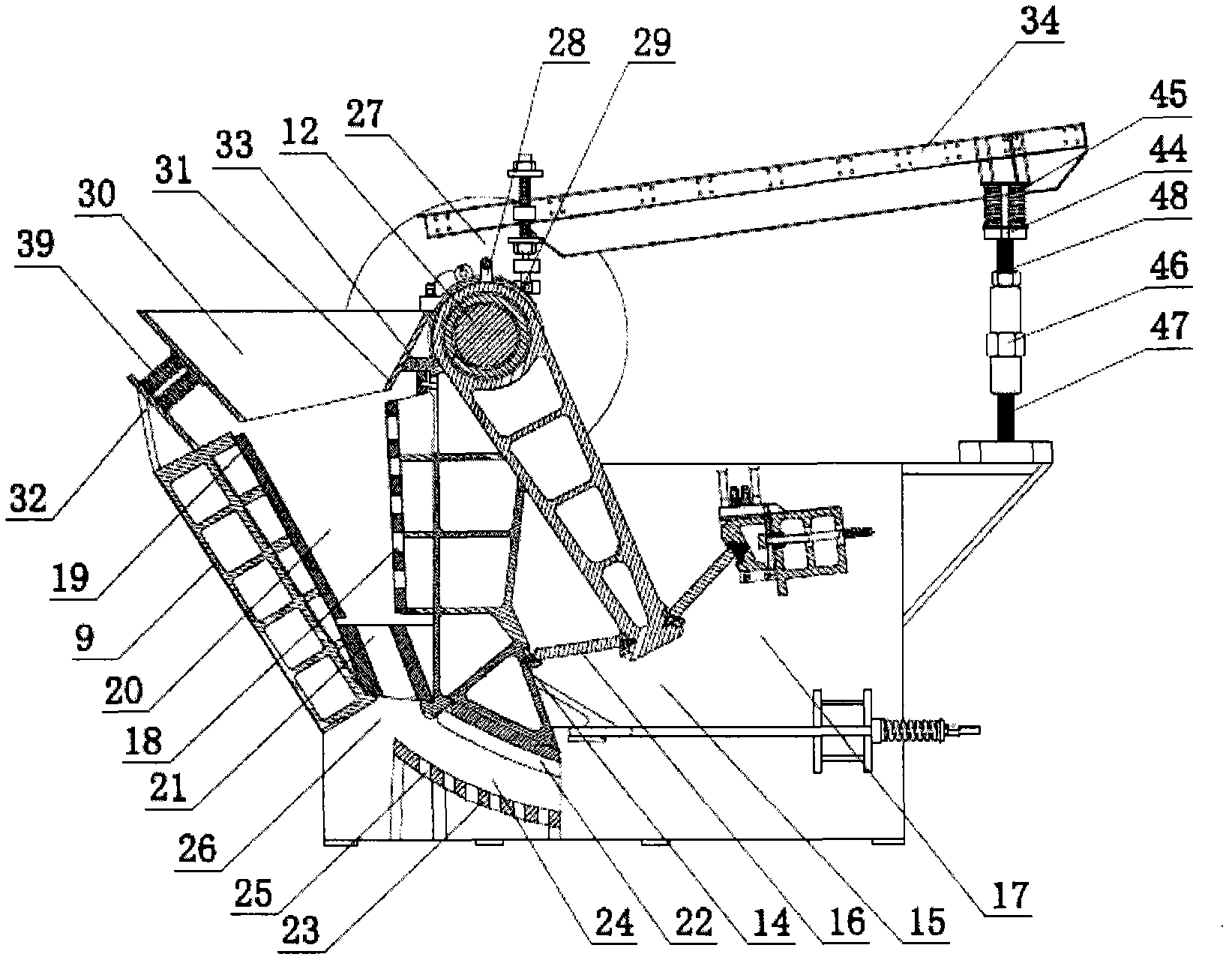

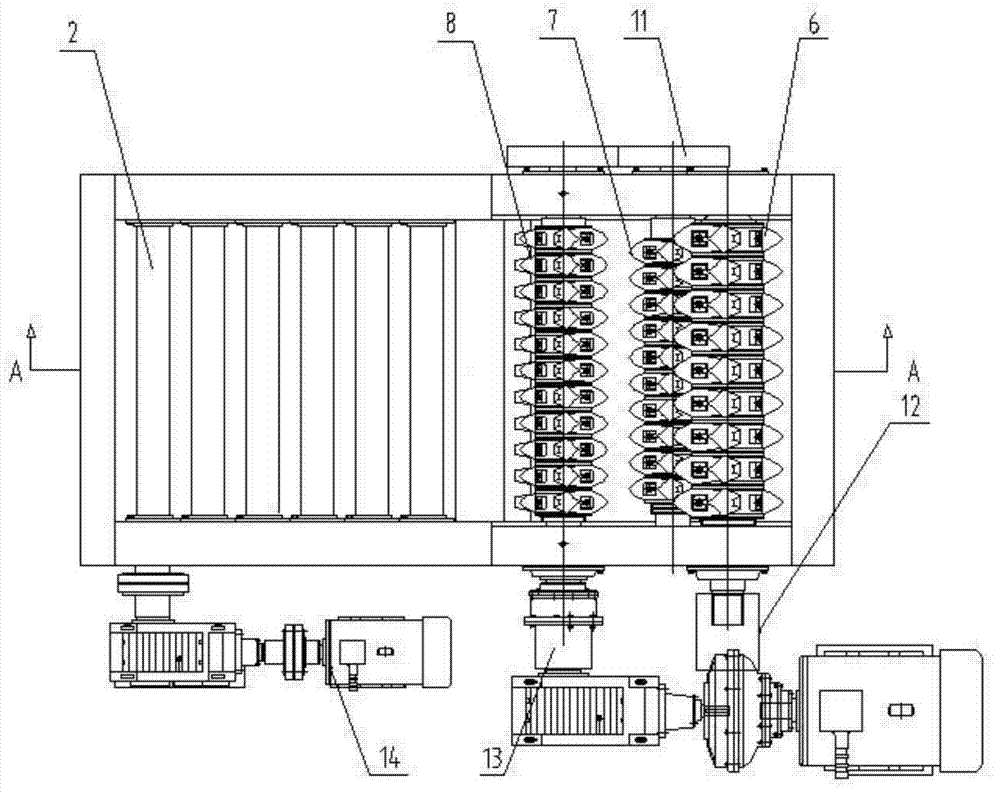

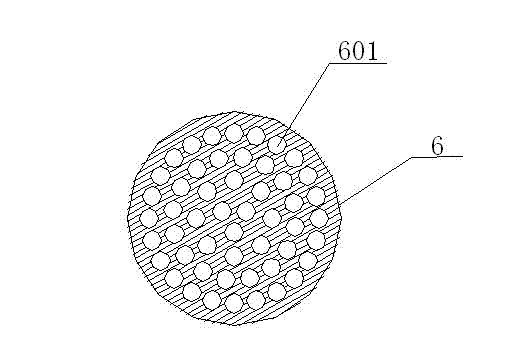

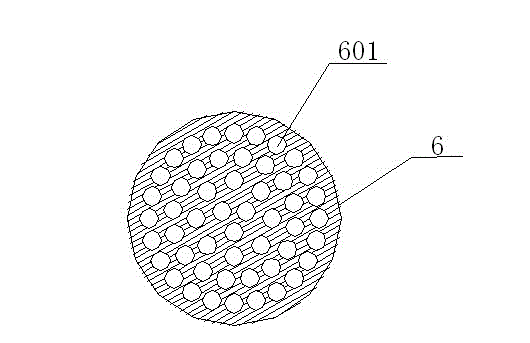

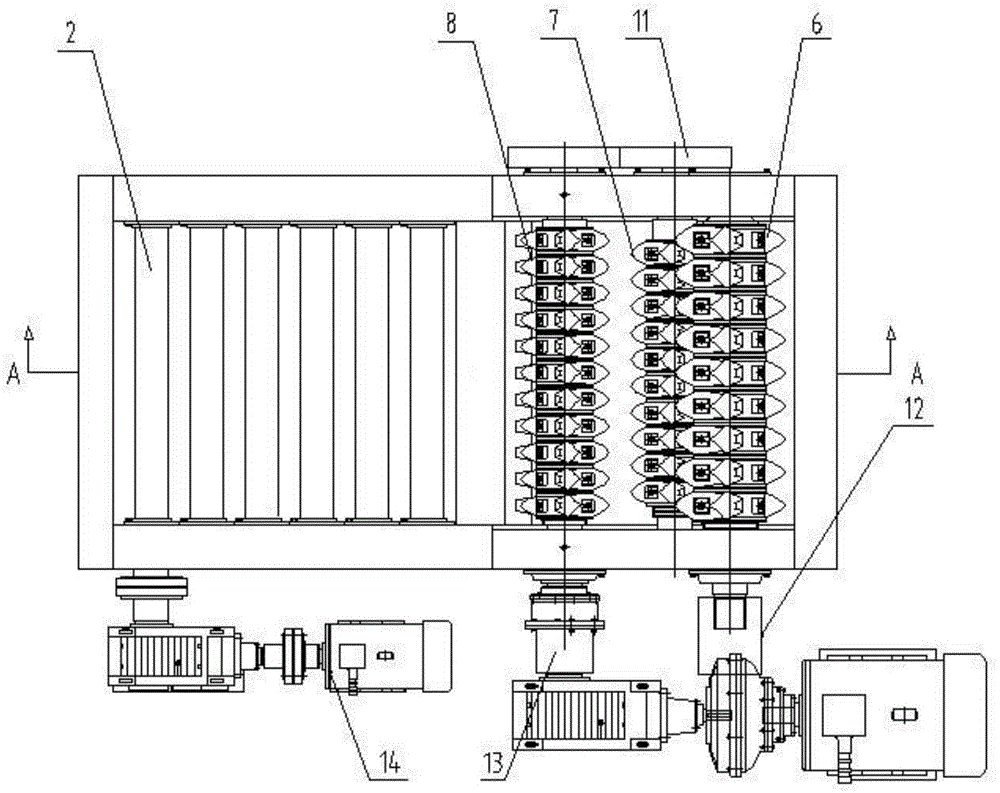

Mining differential three-roller tooth crusher

The invention discloses a mining differential three-roller tooth crusher, which comprises a front roller screen, a large tooth roller (6), a small driven tooth roller (7), a small driving tooth roller (8), a small tooth roller transmission gear (11) and a driving device, wherein the front roller screen is provided with six rollers (2) with wear-proof shaft sleeves; transmission between every two adjacent rollers (2) is realized through a roller idle wheel (3); each roller (2) is arranged according to a uniform thickness probability screening principle; materials are subjected to probability uniform-thickness screening after entering the roller screen from a feed end, a great amount of small materials are rapidly screened, and a small amount of large materials are rapidly conveyed to a three-roller crushing cavity; the three-roller crushing cavity is provided with a large crushing tooth roller and two small crushing tooth rollers; the materials are crushed through the three rollers in multiple stages under the comprehensive action of shearing, stretching and bending crushing mechanisms. The mining differential three-roller tooth crusher has the characteristics of high working efficiency, high processing capacity, high reliability, low energy consumption, no blocking, capability of avoiding excessive crushing of the materials and the like.

Owner:中国矿业大学盱眙矿山装备与材料研发中心

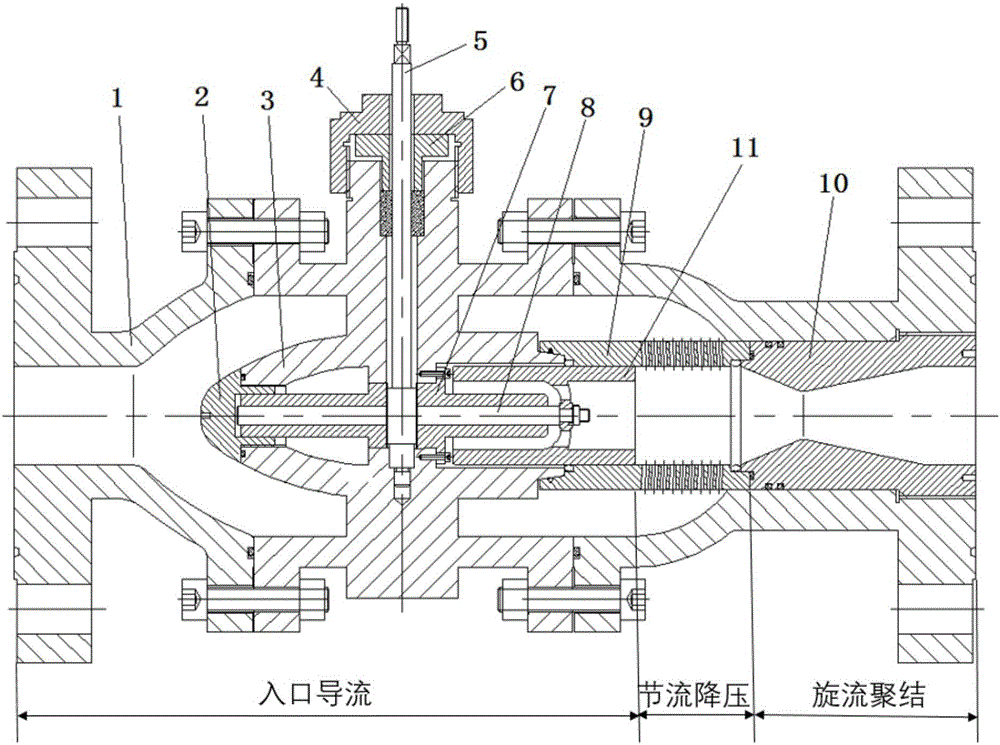

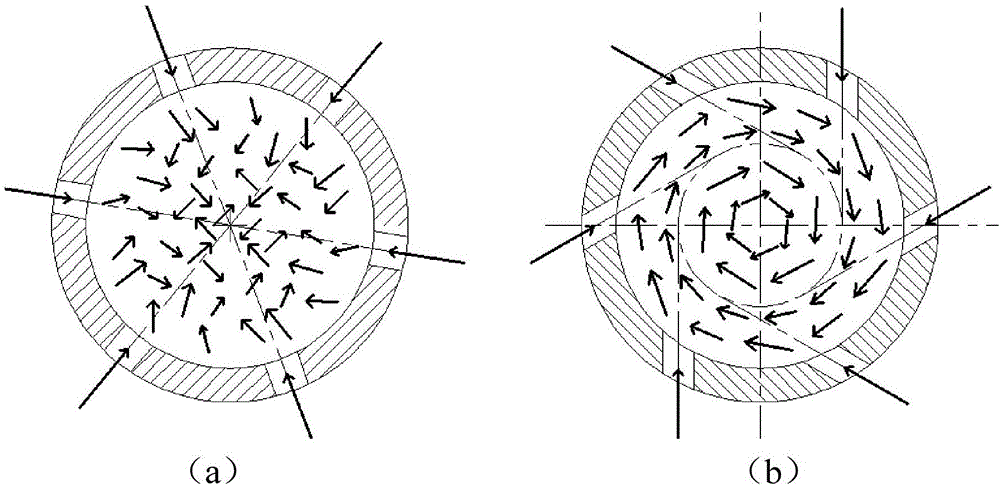

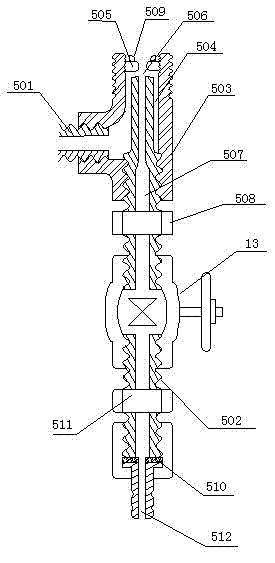

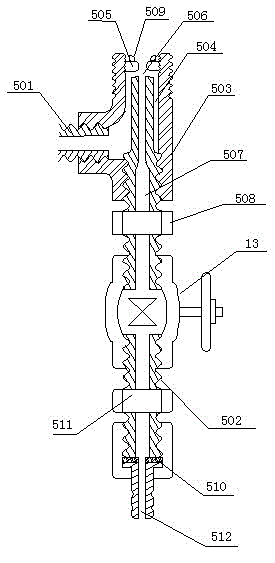

Low shearing plunger type throttling valve used for oil production gathering and transporting

InactiveCN106439137AEnhance swirl effectReduce random vortex motionEqualizing valvesSafety valvesBase functionOil water

The invention discloses a low shearing plunger type throttling valve used for oil production gathering and transporting. Based on a rotational flow agglomeration and unit mass energy dissipation rate control technology, orifices of a valve cage are designed to be in the tangential direction, a rotational flow chamber which is converged firstly and expanded afterwards is connected behind the orifices, the basic function of flow and pressure adjustment can be achieved on the plunger type throttling valve, meanwhile, the velocity gradient and the turbulence energy dissipation rate in a flow field are reduced, the shearing force of the orifices for fluid is reduced, the liquid drop breaking degree is lowered, and the subsequent oil water separation difficulty is lowered.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

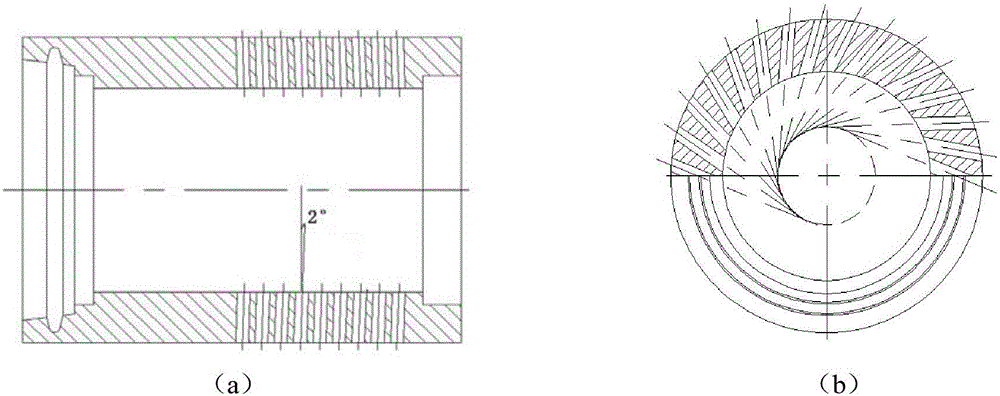

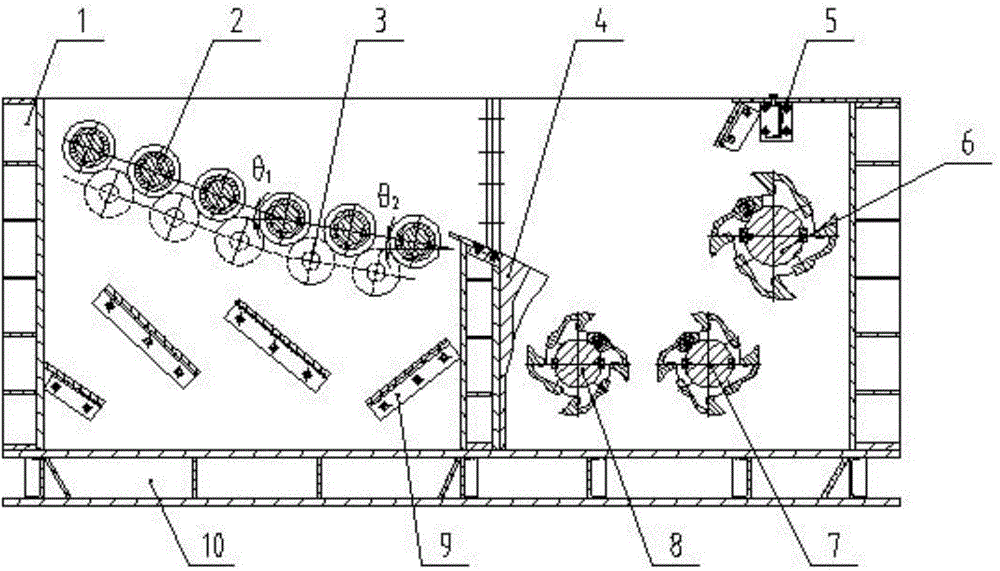

Hammer crusher with screening structure

InactiveCN104096616AReduce energy consumptionChange the installation locationGrain treatmentsPulp and paper industryCrusher

The invention specifically relates to a hammer crusher with a screening structure, which belongs to the technical field of coal mine machinery. The hammer crusher is used for working face crossheading of an underground coal mine and comprises a bottom groove body, a crushing rack body, a drive unit, a hammer shaft assembly and a below-sieve conveying mechanism. Coal conveyed from the tail of a loading machine is conveyed to sieve meshes in the upper middle plate of the crusher through the scraper plate chain of the loading machine for screening; coal with a size smaller than the size of the sieve meshes falls down to the below-sieve conveying mechanism, is then transferred to a U-shaped port and enters coal flow on the scraper plate chain of the loading machine, which enables crushing of the coal when the coal passes through the hammerhead of the crusher to be avoided; coal with a size greater than the size of the sieve meshes is conveyed to the hammerhead of the crusher by the scraper plate chain of the loading machine for crushing, and coal which is crushed to a size smaller than the size of the sieve meshes falls down through the sieve meshes or is transferred by the scraper plate chain of the loading machine so as to prevent secondary crushing; coal with a size greater than the size of the sieve meshes is further crushed with the hammerhead of the crusher, and above-mentioned operation is repeated. The objective of the invention is to crush large coal transported by the loading machine to desired specifications during transporting.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

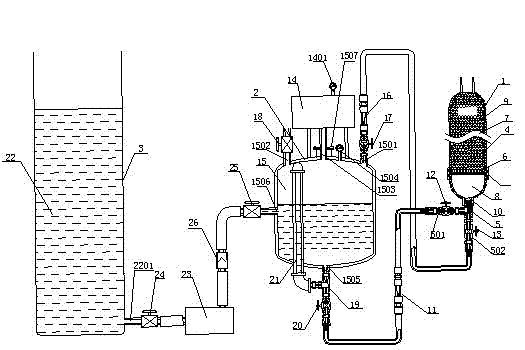

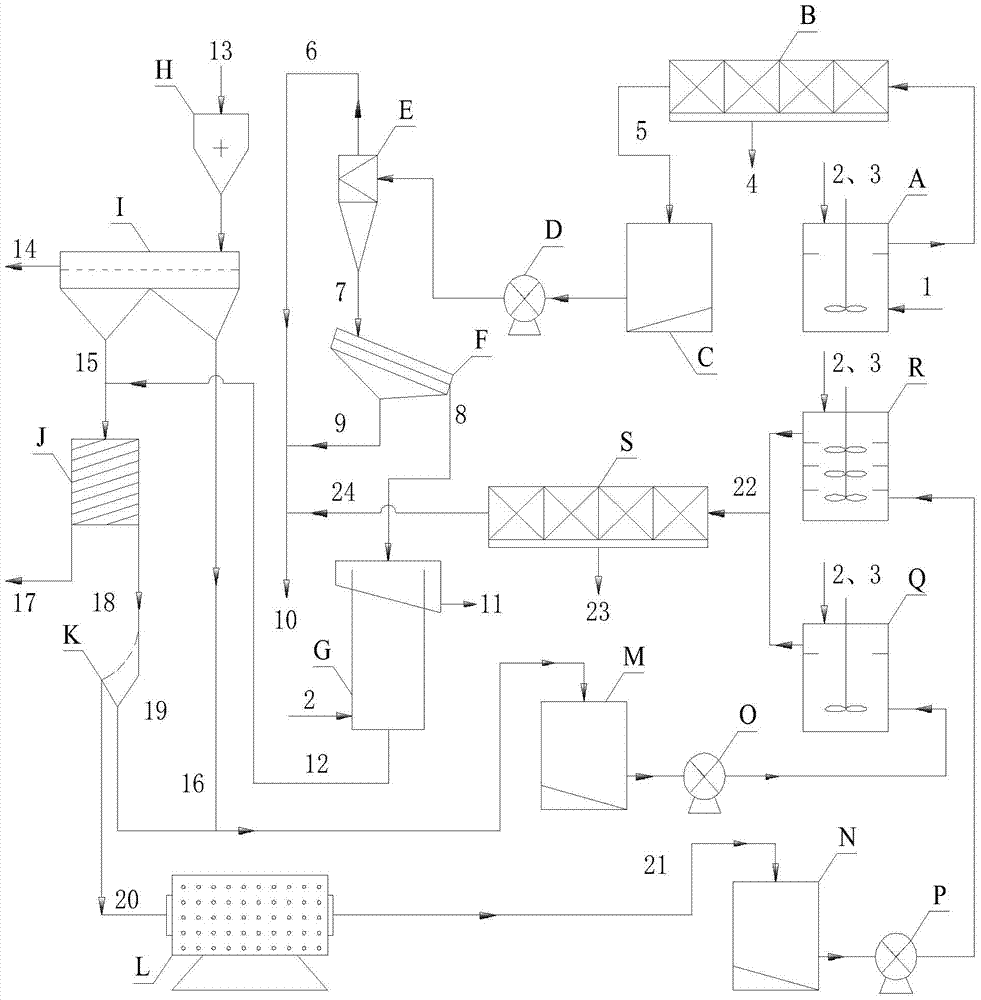

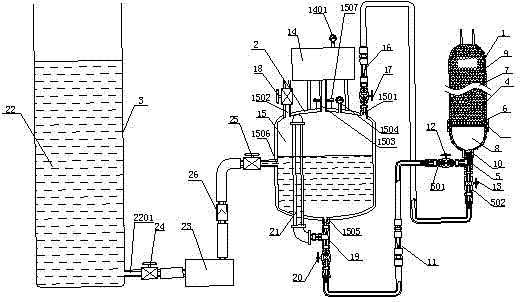

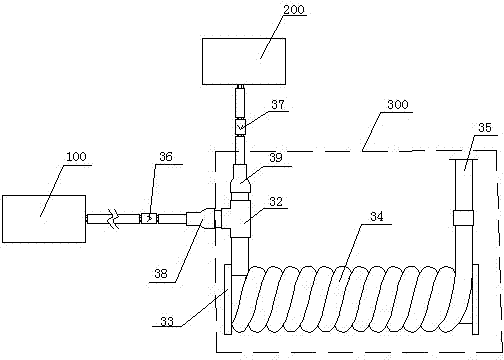

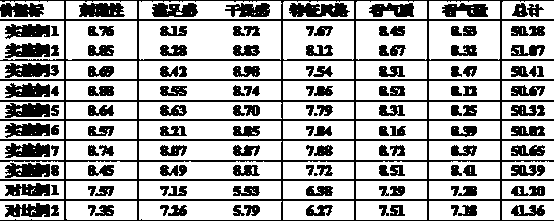

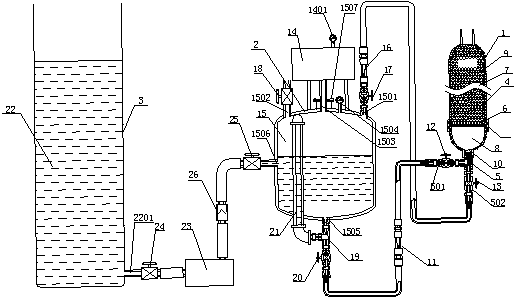

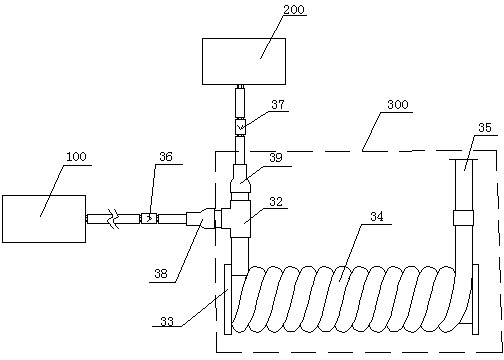

A high-efficiency foam concrete foaming agent foaming machine

ActiveCN102267165AHigh trafficUnlimited dilution factorFlow mixersTransportation and packagingFoam concreteFoaming agent

The invention provides a high efficient foam concrete foaming agent foaming machine which comprises a foaming device, an air driving device and a foaming agent diluent feeding device, wherein the foaming device comprises a foaming pipe and a spraying mechanism; the air driving device comprises an air compressor and a foaming agent diluent storage tank; and the foaming agent diluent feeding deviceis connected with a liquid inlet pipe of the foaming agent diluent storage tank via a worm pump. By using the high efficient foam concrete foaming agent foaming machine provided by the invention, thedilution ratio of the foaming agent and the ratio of the diluent to the air can be randomly adjusted according to the instructions of the foaming agent and the hardness degree of the made foam so that the usage of the foaming agent is saved, compressed air is reduced and more stable foam with a larger diameter is formed.

Owner:LUOYANG NORMAL UNIV

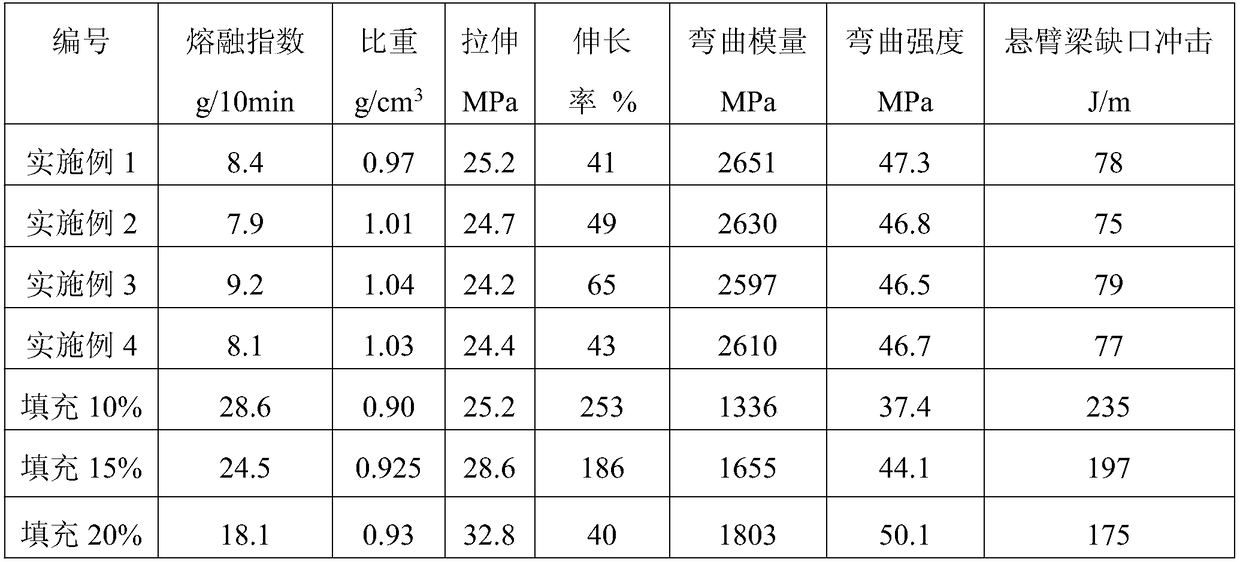

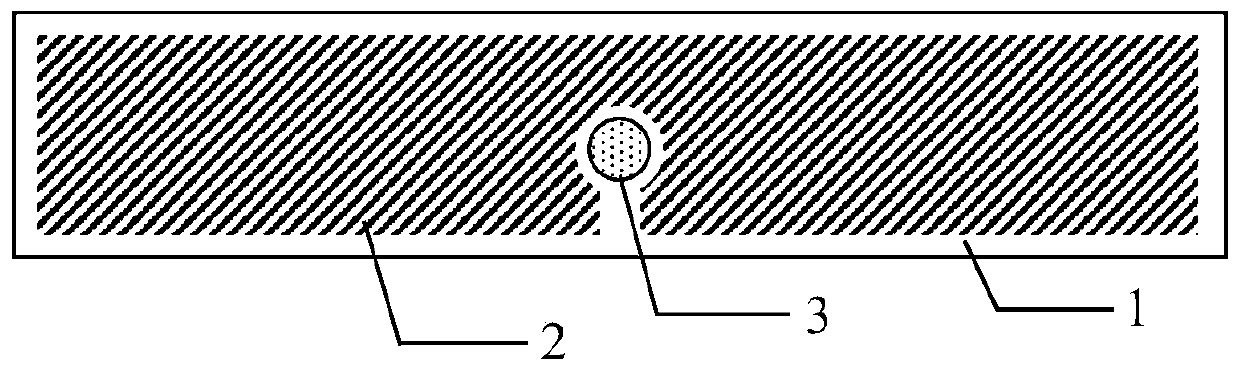

Low specific density filling master batch for polypropylene injection molding and preparation method of low specific density filling master batch

The invention discloses a low specific density filling master batch for polypropylene injection molding and a preparation method of the low specific density filling master batch. The low specific density filling master batch is applied to direct injection molding of lightened components such as automobile interior and exterior door plates, consoles, dashboards and bumpers. Every 100 weight parts of the low specific density filling master batch for polypropylene injection molding comprises the following components in parts by weight: 35-50 parts of polypropylene, 20-40 parts of hollow glass beads, 20-25 parts of talcum powder1, 3-5 parts of a compatilizer, 0.5-1 part of an antioxidant and 1-2 parts of carbon black. By adopting the master batch, the operation that powder hollow glass beads are added in polypropylene injection molding is avoided, flying dust can be avoided, in addition, the problems that the powder hollow glass beads are hard to disperse and liable to layer in polypropylene, and an excessive number of hollow glass beads can be broken in double-screw rod shearing, can be solved.

Owner:SHANXI HAINUO TECH CO LTD

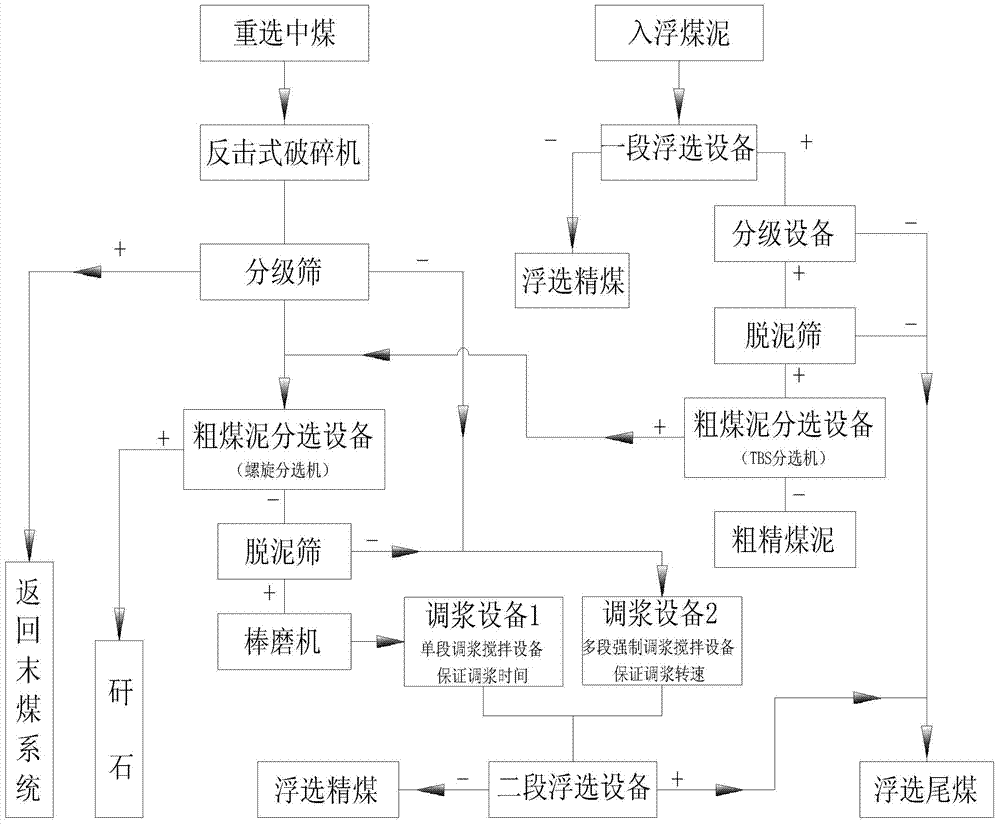

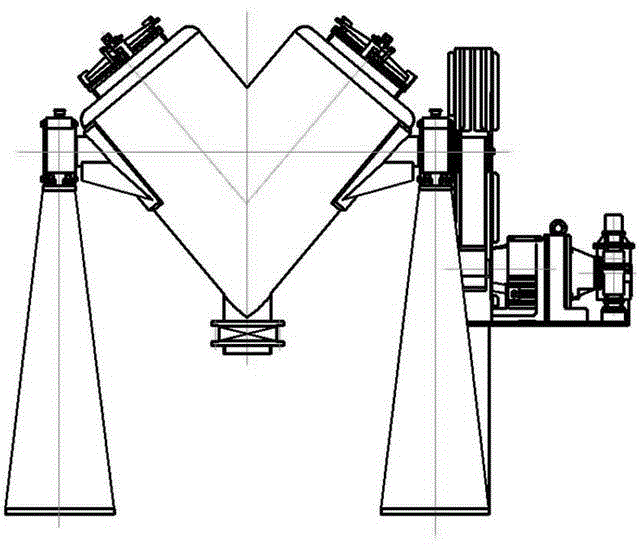

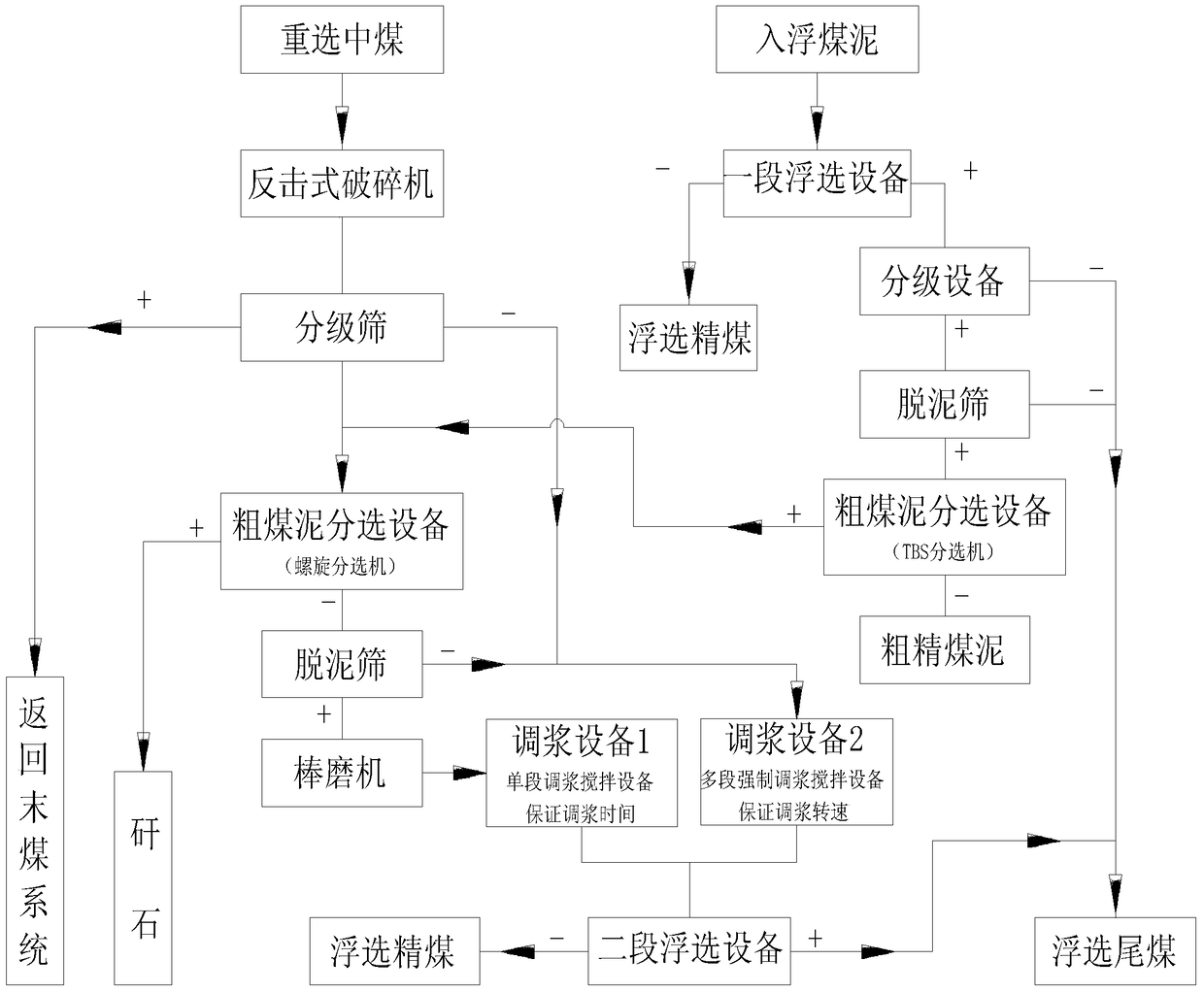

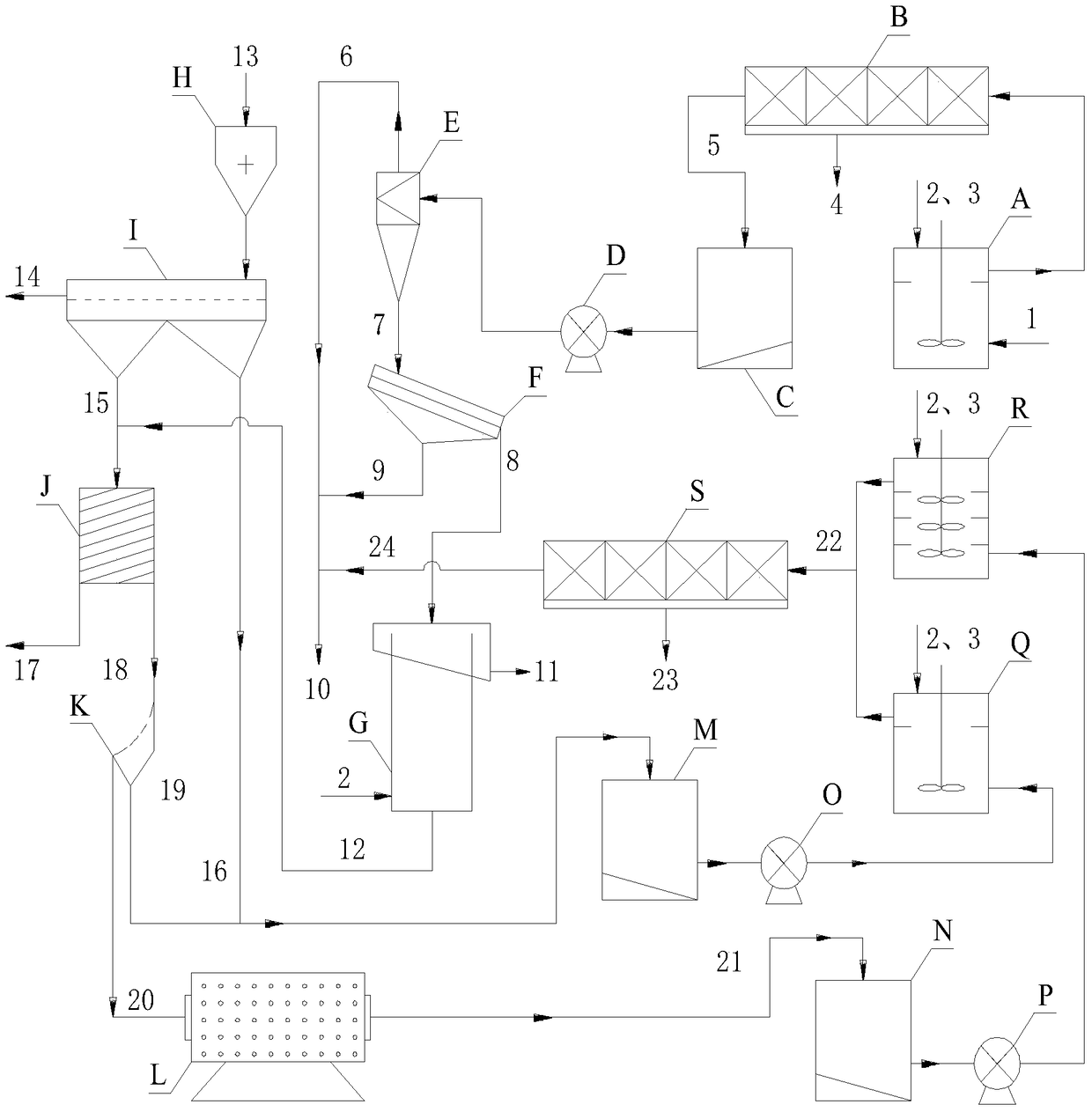

Coking middling coal dms-flotation combined separation process

The invention discloses a coking middling coal dms-flotation combined separation process, and belongs to the technical field of coking middling coal separation. The process comprises the steps of 1, primary size mixing flotation operation, 2, hierarchical dewatering operation, 3, crushing and screening operation, 4, coarse slime separation operation, 5, desliming operation, 6, ore grinding dissociation operation, 7, secondary size mixing operation and 8, secondary flotation operation. The coking middling coal dms-flotation combined separation process is simple in procedure, small in investment, low in energy consumption, little in operation cost, high in separation efficiency and remarkable in economic benefit.

Owner:CHINA UNIV OF MINING & TECH

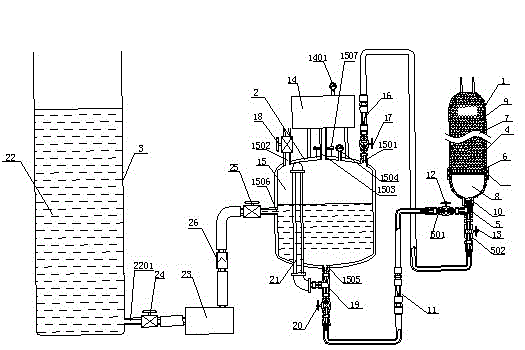

Novel foam concrete slurry producing and conveying machine

InactiveCN102514098AIncrease productionUnlimited dilution factorCement mixing apparatusMixing operation plantFoam concreteFiber

The invention relates to a novel foam concrete slurry producing and conveying machine, which comprises a foaming machine foaming system, a concrete slurry producing system and a mixing pipe mixing system, wherein the mixing pipe mixing system is respectively communicated with the foaming machine foaming system and a concrete slurry producing system. The equipment has the advantages that the concrete slurry water-cement ratio and the slurry and foam mixing ratio of specified volume-weight foam concrete products can be conveniently determined, foams are not easy to crack and cannot be influenced by conveying pressure, the continuous production can be realized, and in addition, anti-crack short fibers are allowed to be used, so the pressure resistance intensity and the anti-crack performance of the foam concrete products are obviously improved, and simultaneously, the utilization rate of foaming agents and compressed air can also be improved.

Owner:LUOYANG NORMAL UNIV

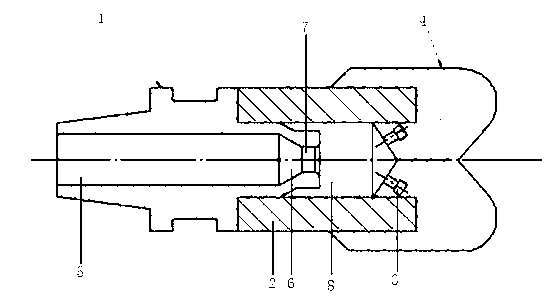

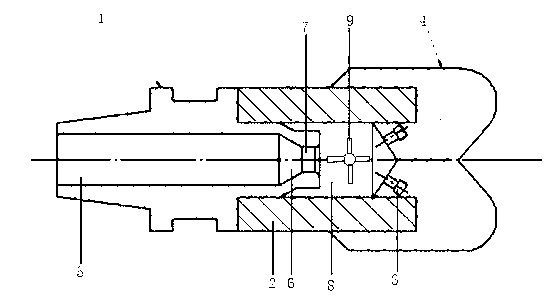

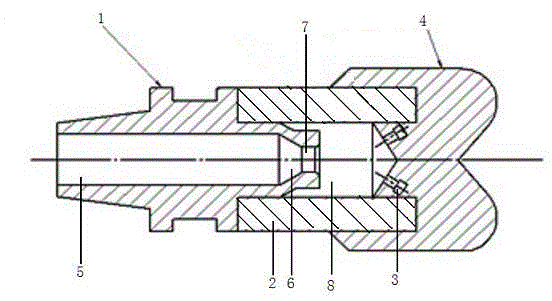

Self-excitation type pulse polycrystalline diamond compact (PDC) drill bit

ActiveCN103277051AIncrease hydraulic rock breaking capacityAvoid over breakingDrill bitsPolycrystalline diamondSpray nozzle

A self-excitation type pulse polycrystalline diamond compact (PDC) drill bit comprises a drill bit upper body at the upper portion, wherein an inner spray nozzle is installed inside a drill bit body, a drill bit blade is fixed outside the drill bit body, a diamond compact is inlayed on the drill bit blade, a central hole is formed on the axis of the drill bit upper body, and the diameter of the central hole is 55-80mm. A contracting taper hole is formed at the lower end of the central hole, the inner spray nozzle is arranged at the lower end of the contracting taper hole, the lower end of the inner spray nozzle is a self-excitation pulse cavity in the drill bit body, and the lower portion of the self-excitation pulse cavity is communicated with 4-6 spray nozzles. A rotating wheel can be further installed in the self-excitation pulse cavity at the lower portion of the inner spray nozzle inside the drill bit body, and liquid in a drill rod forms self-excitation pulse in the self-excitation pulse cavity and then is sprayed out through the spray nozzles at the lower portion to produce pulse oscillation, so that water pressure at the bottom of the drill bit is varying, the hydraulic rock breaking capacity of the drill bit at the bottom of a well is improved, meanwhile excessive breaking of rocks at the bottom of the well is also avoided, and the impact effect is more than two times of the effect of common steady pressure jet flows.

Owner:TIANJIN BANGPU PETROLEUM TECH EQUIP

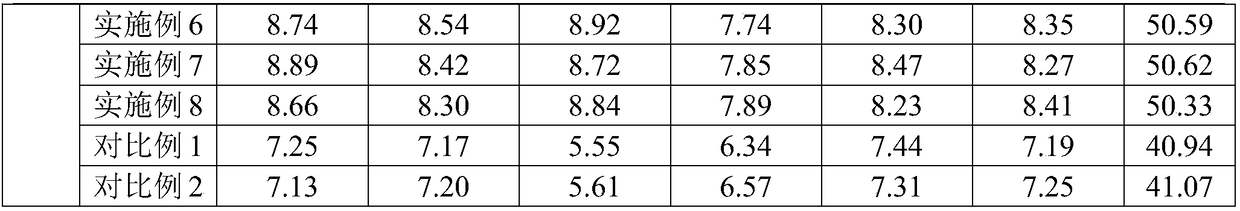

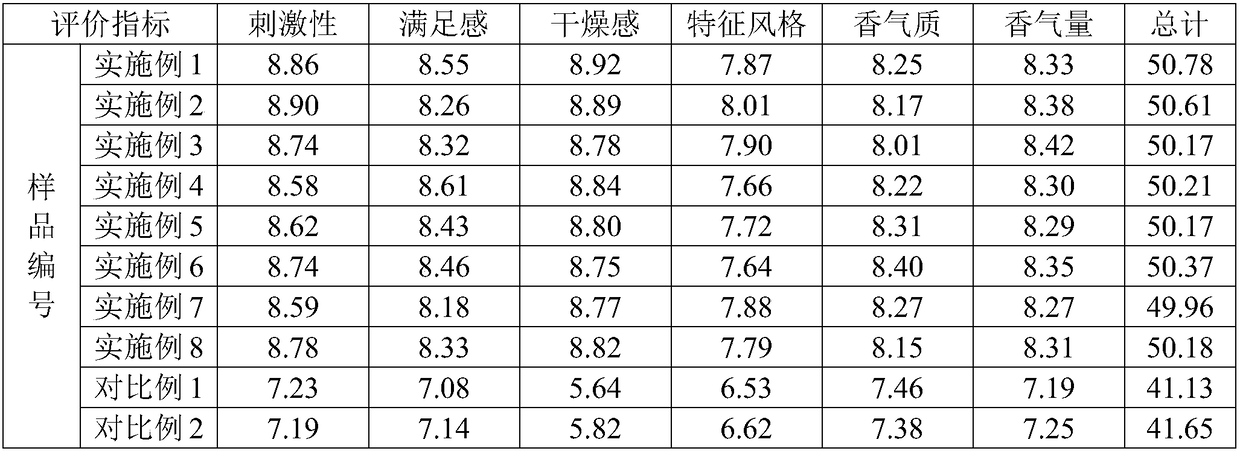

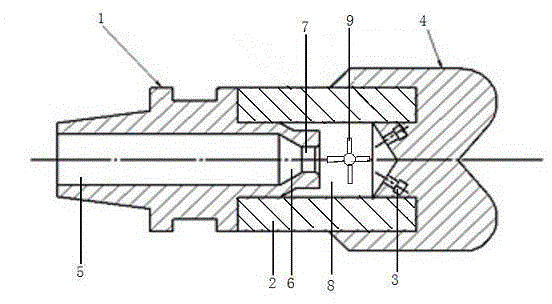

Wet grinding preparation method of electronic smoke oil with tobacco flavor

The invention provides a wet grinding preparation method of electronic smoke oil with tobacco flavor. The method comprises the steps of S1, accurately weighing and taking a certain mass of dry tobacco, conducting primary grinding, passing the ground tobacco through a 5-50 mesh net, adding a certain proportion of solution into the ground tobacco, mixing the solution uniformly, adding the solution into a high speed cutting wet grinder, grinding the solution in a certain reaction condition, taking out the solution after the reaction, wherein the solution taken out is the base oil of the electronic smoke oil with the tobacco flavor; S2, mixing the base oil of the electronic smoke oil with tobacco flavor with the mass percent of 50-100% and the essence and perfume with the mass percent of 0-50% uniformly to obtain the electronic smoke oil with tobacco flavor. Compared with the prior art, the electronic smoke oil with tobacco flavor prepared by mixing the base oil with tobacco flavor according to the method has a substantial elevation of sensual quality, can effectively reduce the mouth sweat and sticky feeling brought by the electronic smoke oil, and alleviate the symptoms of drying mouth and dry tongue after smoking.

Owner:ETABONG QINGDAO INDAL

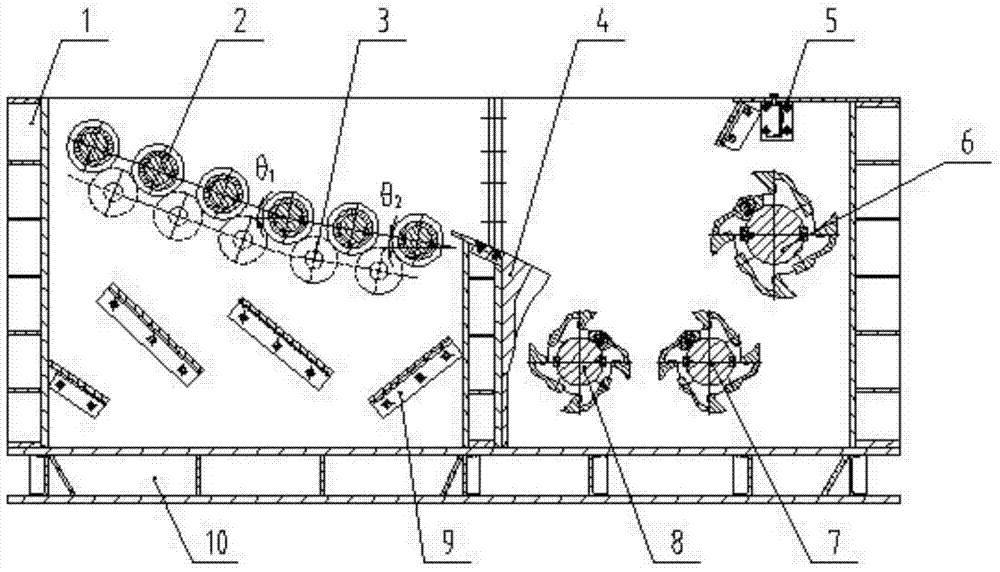

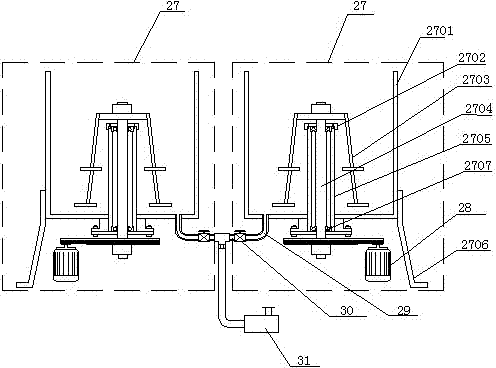

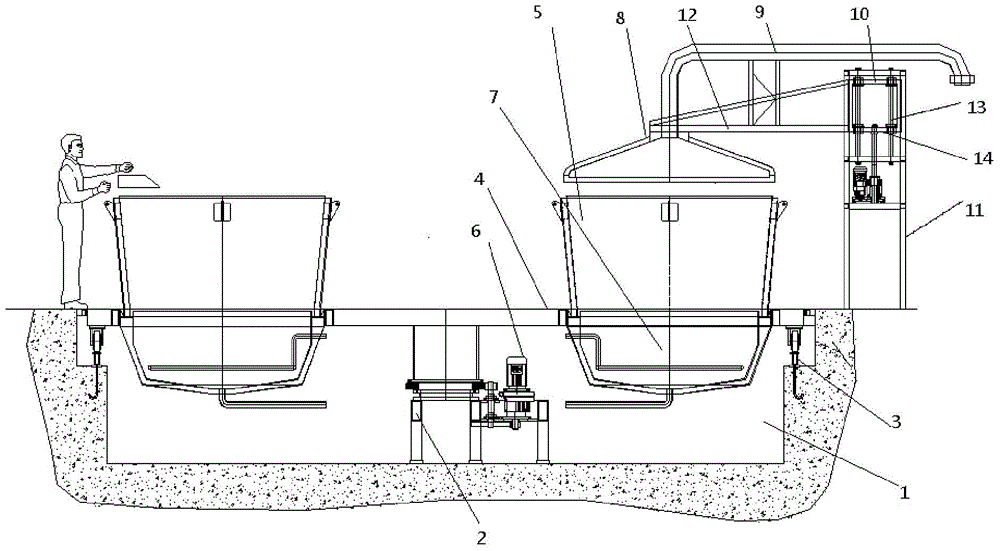

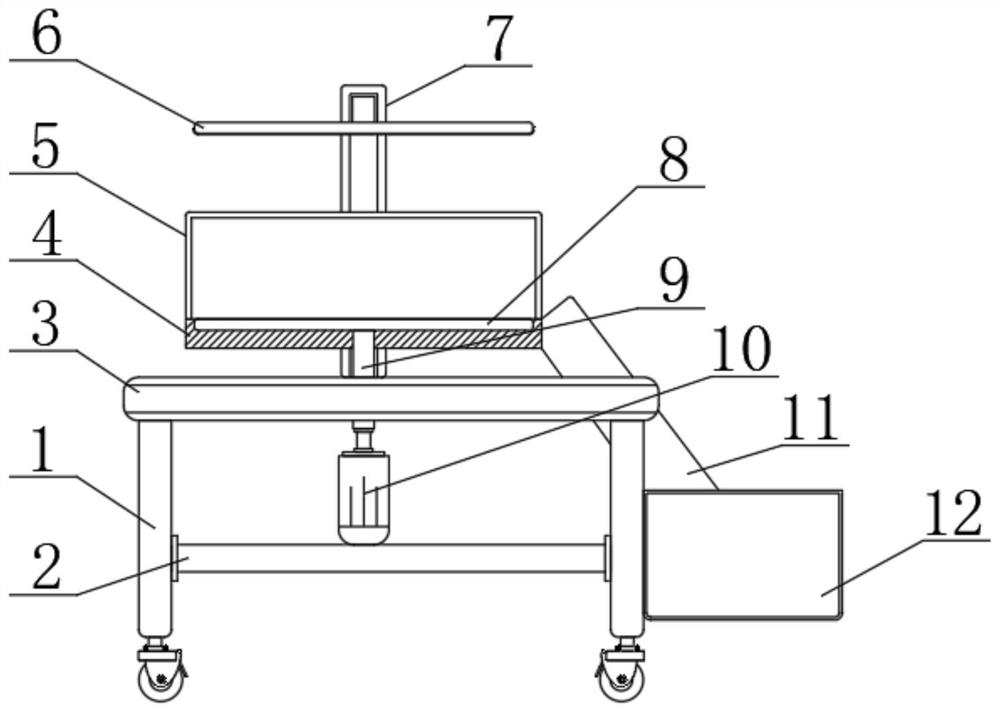

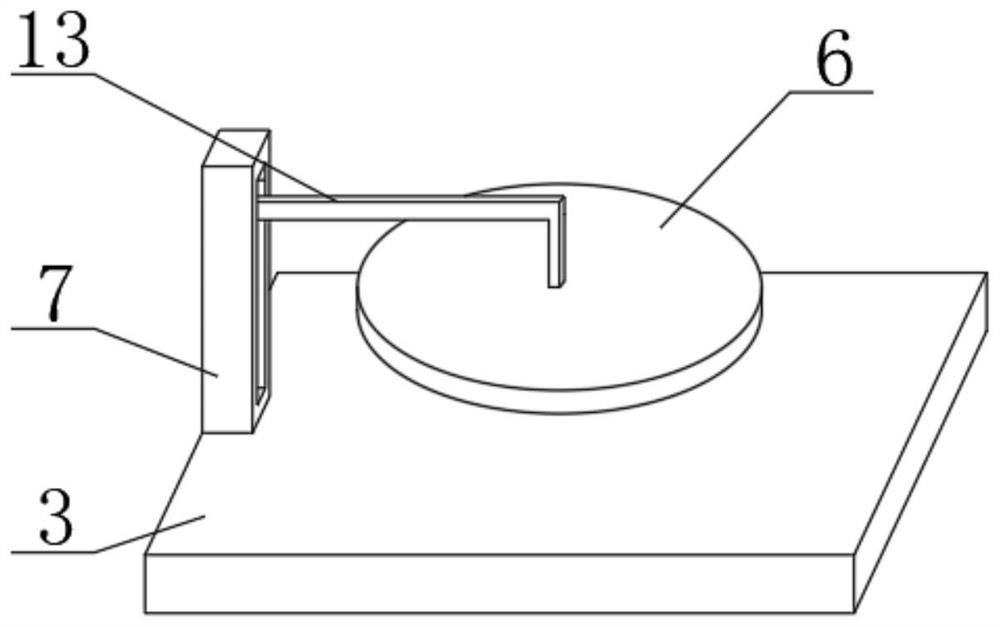

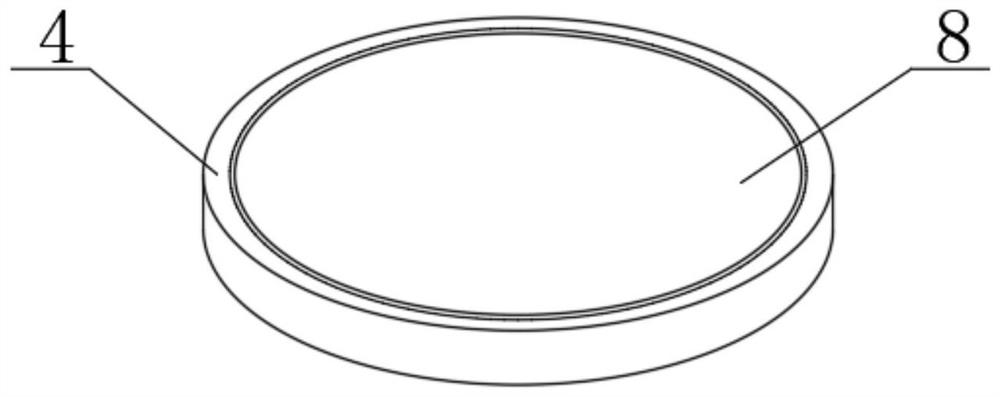

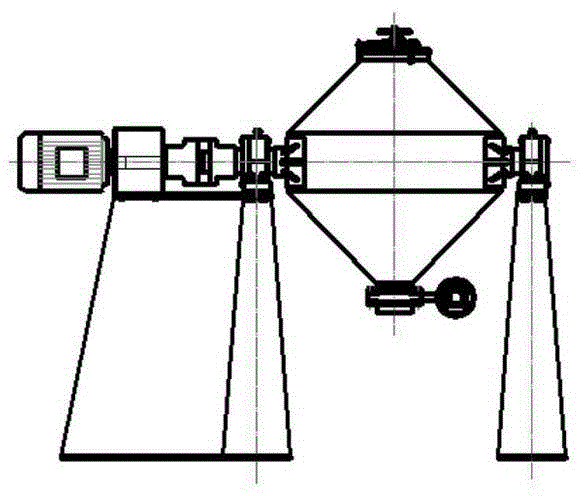

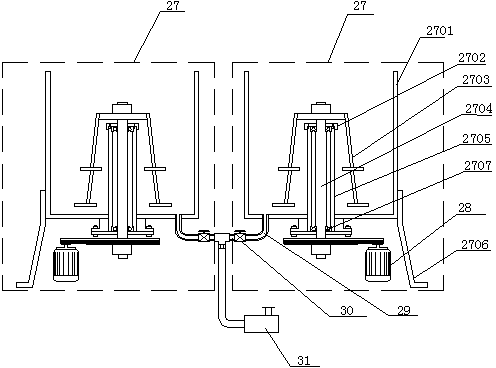

Quadruplet rotating disk movable steaming bucket

InactiveCN104988027AImprove fermentation qualityReduce workAlcoholic beverage preparationEngineeringUltimate tensile strength

The invention discloses a quadruplet rotating disk movable steaming bucket. The bucket comprises a sinking groove formed on the ground, and a step surface is formed on the groove opening of the sinking groove. A round supporting ground rail is arranged on the step surface. A rotating supporting table is arranged in the center of the sinking groove and rotationally provided with a rotating disk body. A steaming bucket body is installed on the rotating disk body. A driving mechanism is installed on the side face of the rotating supporting table and is in transmission connection with the rotating disk body through a gear. A bottom pot is installed in the steaming bucket body. Steaming quality, liquor storage according to quality, cooking gelatinization and large-vapor acid discharge can be effectively controlled easily. A travelling trolley is fully used for fast discharge, and excessive adhesion and excessive smash caused by other discharging manners are avoided. It is guaranteed that white wine brewing fermentation quality and wine base quality are improved, labor intensity is low, and cost performance of investment is high.

Owner:ANHUI GOLDEN SEED WINERY CO LTD

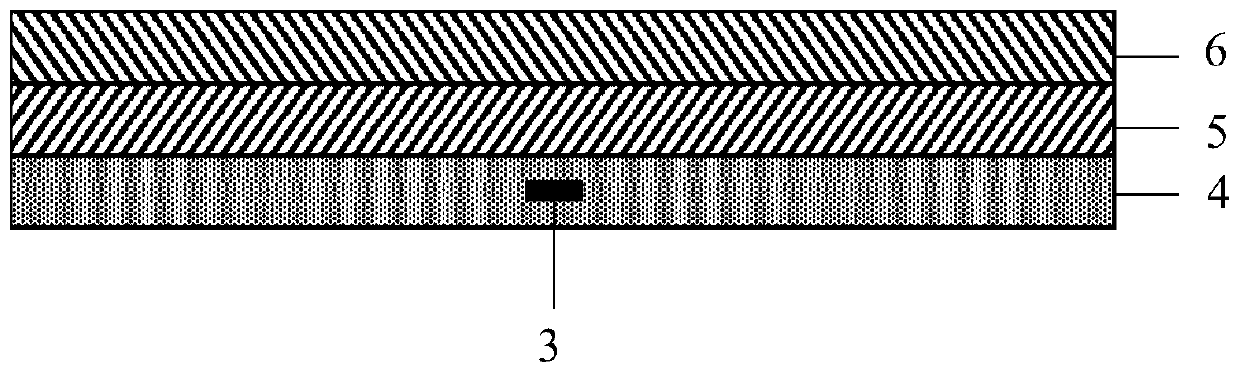

Graphite nanosheet conductive ink as well as preparation method and application thereof

InactiveCN111004546AFully dispersedGood and stable conductivityGraphiteRadiating elements structural formsHigh humidityGraphite

The invention discloses graphite nanosheet conductive ink as well as a preparation method and application thereof. The graphite nanosheet conductive ink comprises the following components in percentage by weight: 7%-30% of graphite nanosheets, 1%-20% of an auxiliary conductive carbon material, 10%-30% of a bonding agent, 40%-80% of a solvent and 0.1%-5% of an auxiliary agent. The method comprisesthe following steps: (1) uniformly mixing the bonding agent, the solvent and the auxiliary agent; and (2) grinding the mixture obtained in the step (1), the graphite nanosheet and the auxiliary conductive carbon material in a colloid mill to obtain the graphite nanosheet conductive ink. The graphite nanosheet conductive ink is good and stable in conductivity and can be used for preparing RFID linen labels, and the prepared RFID linen labels can meet the requirements of the linen industry for high temperature resistance, high humidity resistance, bending resistance and torsion resistance of RFID washing labels.

Owner:HUARUIMOSHI DANYANG CO LTD

Drug for treating asthma and preparation method thereof

InactiveCN107596175ARetain bioactive ingredientsNo localized overheatingPill deliveryRespiratory disorderActive componentBetel

The invention relates to a drug for treating asthma and a preparation method thereof. The drug is prepared from the following traditional Chinese medicine as active pharmaceutical ingredients in partsby weight: ginkgo nuts, snakegourd peel, radix ophiopogonis, wolfberry, black soybeans, bamboo shavings, exocarpium citri rubrum, semen armeniacae amarae, folium perillae, fructus schisandrae chinensis, herba ephedra, bulbus fritillariae ussuriensis, betel nut, smoked plum pulp, radix peucedani, rhizoma pinelliae preparatum, pine pollen, rhizoma anemarrhenae, raw gypsum, fructus chebulae, bulbusallii macrostemonis, herba asari, rhizoma belamcandae and radix glycyrrhizae preparata. The preparation method comprises the following steps: putting folium perillae, semen armeniacae amarae, ginkgo nuts and black soybeans into an extracting tank, and extracting filtrate; concentrating the filtrate so as to obtain an extract, and drying the extract by virtue of a microwave drying machine; sterilizing, drying and mixing the other components, crushing the mixture and the dried extract by virtue of an ultrafine powder crushing machine, and mixing medical powder, so as to obtain pharmaceutical active components; and preparing the active pharmaceutical ingredients into the drug in required dose form by virtue of a conventional method. The active pharmaceutical ingredients of the drug can supplement each other, so that the treatment effect of the drug can be enhanced, untoward effects can be reduced, and asthma can be fundamentally treated.

Owner:山西振东五和堂制药有限公司

Tobacco stem pulping process

ActiveCN103653231ASimple and reliable process controlStable feed controlTobacco preparationMacromolecular SubstancesHigh concentration

Disclosed is a tobacco stem pulping process. The process includes the following steps: delivering a mixture of tobacco stems 10-18% in mass concentration and water to a middle-concentration pulping machine in two-stage series for defibering pulping; delivering pulp after being defibered to a high-concentration hydrapulper, wherein mass concentration of the pulp is 10-18%, pulping temperature is maintained to be at 60-80 DEG C, and pulping time is 15-30min; entering a leaching stage after pulping is completed, and manufacturing paper with the pulp after retreatment. The tobacco stems are properly defibered, so that uniformity in tobacco stem pulping is realized, and smooth extraction of soluble substances in the process of leaching is facilitated; due to adoption of high-concentration grinding and high-concentration hydrodynamic pulping, overmuch tiny broken tobacco stems cannot be generated as high-concentration pulping does, and macromolecular substances like pectin cannot be dissolved out too much, so that purification of leaching liquid and improvement of sensory quality are facilitated, favorable factors in two aspects are combined, products are enabled to be good in bulk, higher in softness and excellent in liquid absorbing performance, and physical quality and sensory quality are improved.

Owner:HENAN CIGARETTE IND TOBACCO SLICE

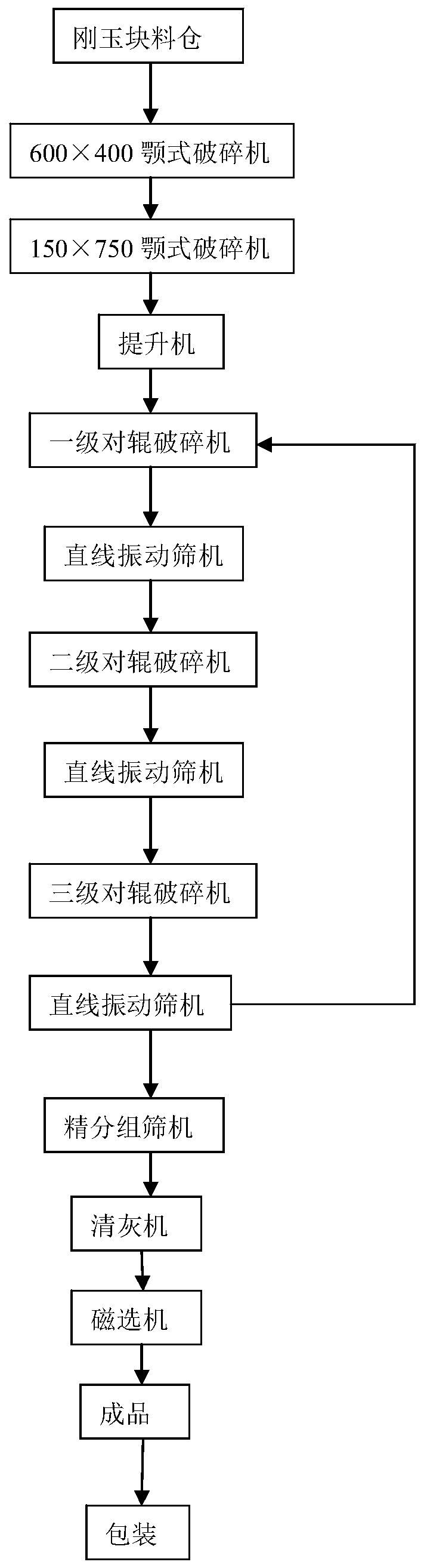

Preparation process of corundum powder

InactiveCN110180662AIncrease productivityImprove efficiencyMagnetic separationGrain treatmentsThree stageClosed loop

The invention belongs to the technical field of corundum powder, and particularly relates to a preparation process of corundum powder. The process comprises the following steps of (1) coarse crushing,crushing a corundum block to obtain a fine crushing material with the particle size of less than 20 mm and a crushed material with the particle size of more than or equal to 20 mm and less than 50 mmin particle size; (2) fine crushing, crushing the fine crushing material and crushed material obtained in the step (1) through a three-stage closed-loop circulating pair roller, screening and gradingto obtain a particle material with the particle size being more than or equal to 0.106 mm and less than 0.5 mm in particle size; (3) fine grouping sieving, the granules obtained in the step (2) are screened into two-section materials with the particle size of 0.0106-0.180 mm and 0.180-0.5 mm; (4) finishing product, the two-section materials obtained in the step (3) are subjected to dust removal,magnetic separation and fine screening to obtain a corundum powder finished product. The prepared corundum powder particles are more uniform in particles, high in yield, short in efficiency, short inperiod, low in cost and clean in materials.

Owner:山东英格瓷四砂泰山磨料有限公司

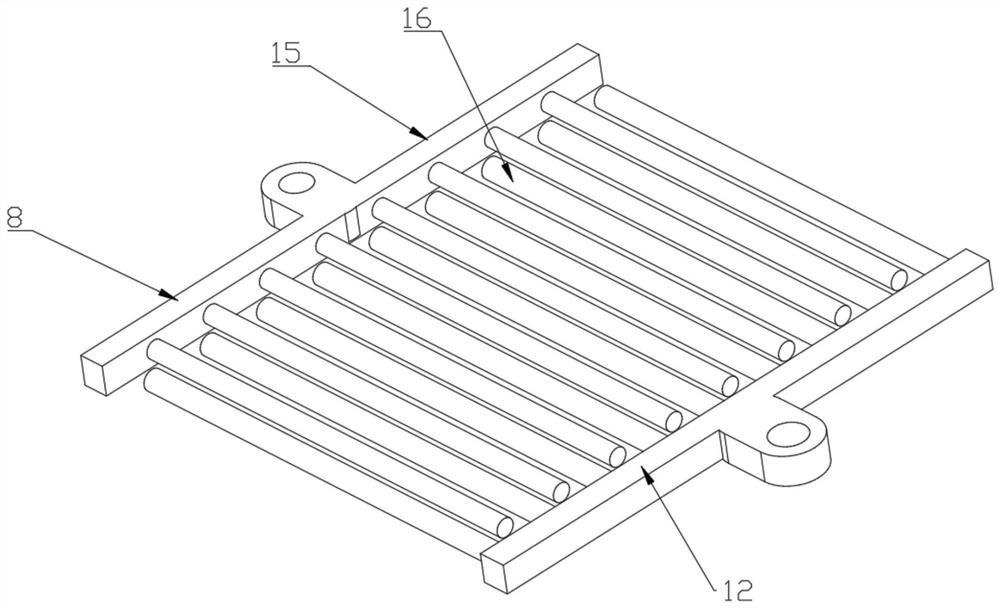

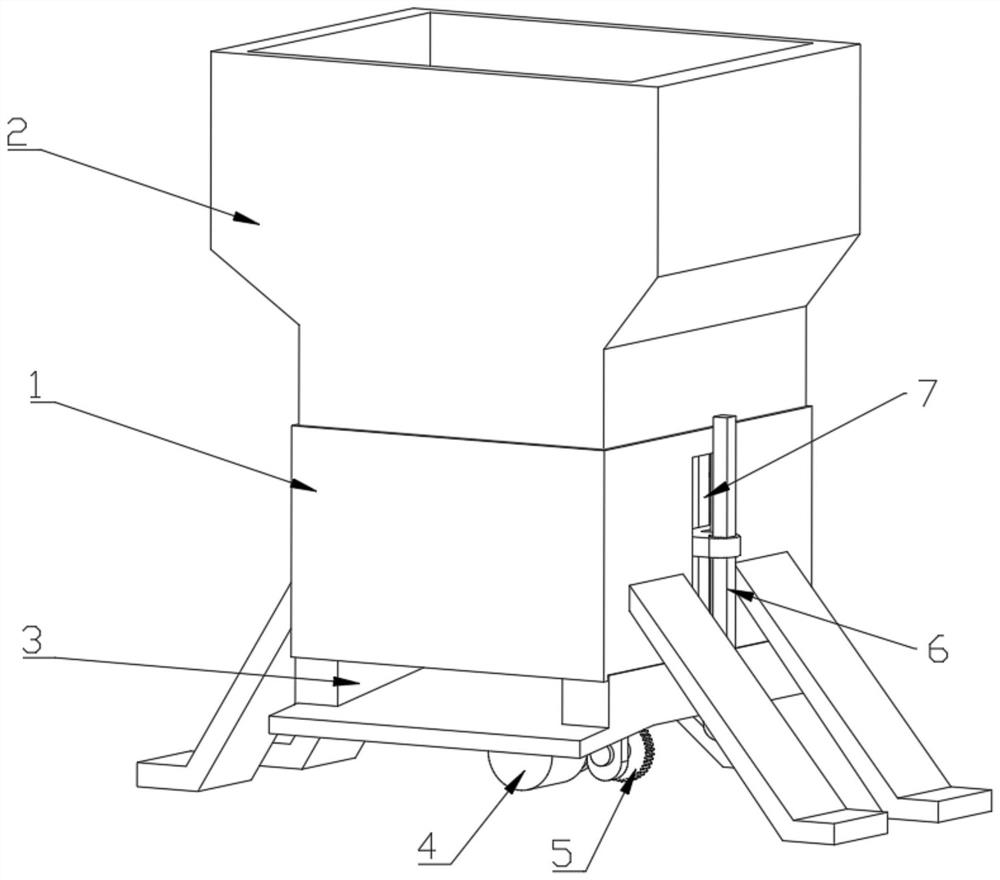

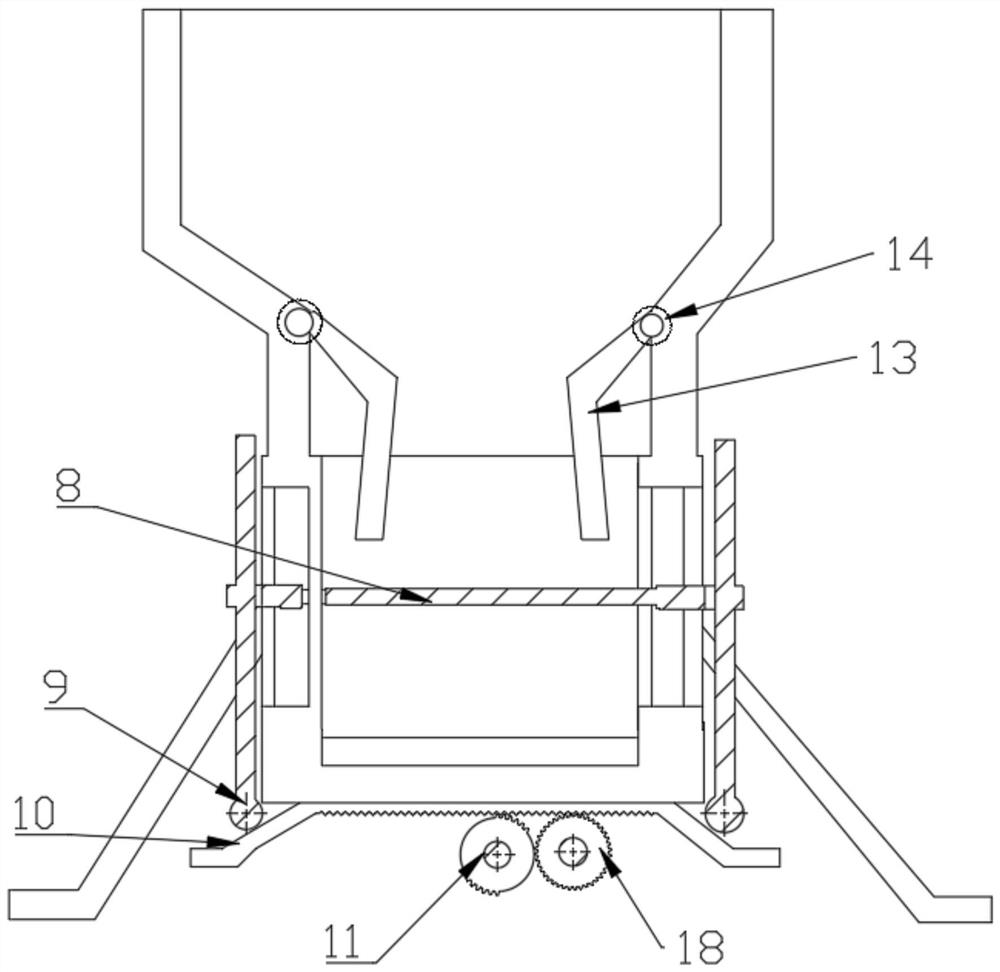

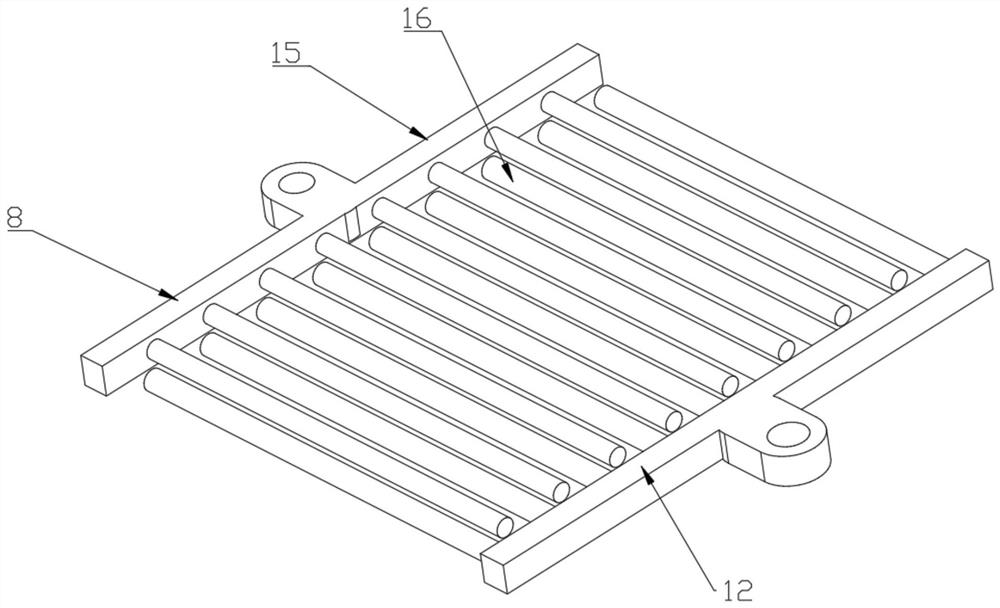

A kind of ore crushing and screening device

ActiveCN112718218BEasy to pass throughImprove screening efficiencyGrain treatmentsHigh energyStructural engineering

The present invention is applicable to the technical field of ore mining, and provides an ore crushing and screening device, comprising: a shell with a discharge opening at the bottom, forming a crushing and filtering space inside; a hopper connected to the top of the shell; In the inside of the housing; the first rack is liftable and arranged inside the housing; the second rack is opposite and liftable and is arranged inside the housing, and is spaced apart from the first rack; wherein, the first rack The outer ends of the first socket and the second socket are fixedly connected with support rods, and the bottom of the hopper is slidingly provided with support bridge rods. The support bridge rods have a structure with a high center and low ends. At both ends of the hopper, reciprocating drive parts are installed on the bottom of the hopper, and the reciprocating drive parts drive the supporting bridge rod to reciprocate and slide, pushing the first frame and the second frame to alternately lift and screen the ore. The invention has the advantages of simple structure, high screening efficiency, high energy utilization rate, uniform crushing quality and good synchronization.

Owner:柞水县宝华矿业有限公司

Ore crushing and screening device

ActiveCN112718218AEasy to pass throughImprove screening efficiencyGrain treatmentsEngineeringStructural engineering

The invention is applicable to the technical field of ore extraction, and provides an ore crushing and screening device. The ore crushing and screening device comprises: a shell, wherein a discharge port is formed in the bottom of the shell, and a crushing and filtering space is formed inside the shell; a hopper, communicated with the top of the shell; a crushing part, arranged in the shell; a first insertion frame, arranged in the shell in a liftable manner; and a second inserting frame, oppositely arranged in the shell in a liftable mode and spaced from the first inserting frame. Supporting rods are fixedly connected to the outer ends of the first inserting frame and the second inserting frame, a supporting bridge rod is arranged at the bottom of the hopper in a sliding mode, the supporting bridge rod is of a structure with the high middle and the low two ends, and the bottoms of the supporting rods are erected at the two ends of the supporting bridge rod under the action of gravity. A reciprocating driving piece is mounted at the bottom of the hopper, the reciprocating driving piece drives the supporting bridge rod to slide in a reciprocating mode, and the first inserting frame and the second inserting frame are pushed to alternately ascend and descend to screen ores. The invention has the advantages of simple structure, high screening efficiency, high energy utilization rate, uniform crushing quality and good synchronism.

Owner:柞水县宝华矿业有限公司

High efficient foam concrete foaming agent foaming machine

ActiveCN102267165BHigh trafficUnlimited dilution factorFlow mixersTransportation and packagingFoam concreteFoaming agent

A high-performance foaming machine for a foam concrete foaming agent comprises a foaming device (1), an air-driving device (2) and a foaming agent dilute solution supply device (3). The foaming device (1) comprises a foaming tube (4) and a spray mechanism (5). The air-driving device (2) comprises an air compressor (14) and a foaming agent dilute solution storage tank (15). The foaming agent dilute solution supply device (3) is connected to a liquid inlet tube (1506) of the foaming agent dilute solution storage tank (15) through a worm pump (23). The foaming machine can adjust the dilution ratio of the foaming agent and the proportion of the dilute solution and air arbitrarily according to the use instruction of the foaming agent and the desired hardness of the foam, thereby reducing the required amount of the foaming agent, saving the compressed air, and forming foam which is stable and has a large diameter.

Owner:LUOYANG NORMAL UNIV

A kind of rotating and striking walnut shell breaking equipment

Owner:TARIM UNIV

A kind of Chinese herbal medicine electronic cigarette oil and the method for preparing Chinese herbal medicine electronic cigarette oil by wet pulverization

ActiveCN106617276BEasy to manufactureEnergy-efficient preparationTobacco treatmentTobacco devicesFlavorDrying mouth

Owner:ETABONG QINGDAO INDAL

A tea-flavored electronic cigarette oil and its preparation method by wet pulverization

ActiveCN106617277BEasy to manufactureEnergy-efficient preparationTobacco treatmentFlavorElectronic cigarette

Owner:ETABONG QINGDAO INDAL

Self-excitation type pulse polycrystalline diamond compact (PDC) drill bit

ActiveCN103277051BIncrease hydraulic rock breaking capacityAvoid over breakingDrill bitsPolycrystalline diamondSpray nozzle

Owner:TIANJIN BANGPU PETROLEUM TECH EQUIP

A method for preparing tobacco-flavored electronic cigarette oil by wet pulverization

ActiveCN106723303BEasy to manufactureEnergy-efficient preparationTobacco treatmentFlavorDrying mouth

The invention provides a wet grinding preparation method of electronic smoke oil with tobacco flavor. The method comprises the steps of S1, accurately weighing and taking a certain mass of dry tobacco, conducting primary grinding, passing the ground tobacco through a 5-50 mesh net, adding a certain proportion of solution into the ground tobacco, mixing the solution uniformly, adding the solution into a high speed cutting wet grinder, grinding the solution in a certain reaction condition, taking out the solution after the reaction, wherein the solution taken out is the base oil of the electronic smoke oil with the tobacco flavor; S2, mixing the base oil of the electronic smoke oil with tobacco flavor with the mass percent of 50-100% and the essence and perfume with the mass percent of 0-50% uniformly to obtain the electronic smoke oil with tobacco flavor. Compared with the prior art, the electronic smoke oil with tobacco flavor prepared by mixing the base oil with tobacco flavor according to the method has a substantial elevation of sensual quality, can effectively reduce the mouth sweat and sticky feeling brought by the electronic smoke oil, and alleviate the symptoms of drying mouth and dry tongue after smoking.

Owner:ETABONG QINGDAO INDAL

A method for preparing pipe fittings from polyolefin masterbatch

A method of preparing pipe fittings from polyolefin master batch is provided. The method includes: A) a step of preparing the master batch, wherein the master batch comprises 40-70% by weight of polyolefin, 0.5-1% by weight of an antioxidant, 5-15% by weight of hollow glass beads, 2-10% by weight of an organic compatibilizer, 5-20% by weight of nanometer calcium carbonate, 1-5% by weight of a lubricant, and 3-10% by weight of a polyolefin elastomer; B) a step of mixing raw materials at a high speed to obtain a primary material mixture; C) a step of mixing raw materials at a low speed to obtain a secondary material mixture; D) a step of granulating by a granulating machine to obtain granulated master batch; and E) a step of injection molding of the pipe fittings, namely a step of mixing the obtained granulated master batch and polyolefin (different color master batch) and performing injection molding to obtain the pipe fittings.

Owner:YONGGAO CO LTD

Method for preparing ultra-coarse grain cemented carbide by flexible ball milling technology

The invention discloses a method for preparing ultra-coarse grain cemented carbide by flexible ball milling technology, which comprises the following steps: firstly premixing ultra-coarse WC powder and Co powder for 0.5-2 h with a rotating speed of 6-12 rpm, wherein the Fisher particle size of the WC powder is 18.0-22.0 microns; performing mild ball milling of the premixed powder, adding liquid grinding mediums and a forming agent, wherein the grinding ball material is WC-Co cemented carbide with a diameter of 6-10 mm, the ball milling time is 8-24 h, the ball-to-powder ratio is 1.5-3.0:1, the rotating speed is 20-55% of a critical rotating speed; then discharging the slurry in the ball mill, preparing a mixture by spray drying, performing pressing and molding, sintering at a temperature of 1390-1500 DEG C, wherein the prepared ultra-coarse grain cemented carbide has a grain size of 6.0-10.0 microns, a hardness HV 30 of 740-1240, and a porosity of less than A04B00. The invention is simple in process, short in flow, low in production cost, and suitable for industrial production.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY +1

A tobacco stem pulping process

ActiveCN103653231BUniform pulpingAvoid over breakingTobacco preparationHigh concentrationPulp and paper industry

Disclosed is a tobacco stem pulping process. The process includes the following steps: delivering a mixture of tobacco stems 10-18% in mass concentration and water to a middle-concentration pulping machine in two-stage series for defibering pulping; delivering pulp after being defibered to a high-concentration hydrapulper, wherein mass concentration of the pulp is 10-18%, pulping temperature is maintained to be at 60-80 DEG C, and pulping time is 15-30min; entering a leaching stage after pulping is completed, and manufacturing paper with the pulp after retreatment. The tobacco stems are properly defibered, so that uniformity in tobacco stem pulping is realized, and smooth extraction of soluble substances in the process of leaching is facilitated; due to adoption of high-concentration grinding and high-concentration hydrodynamic pulping, overmuch tiny broken tobacco stems cannot be generated as high-concentration pulping does, and macromolecular substances like pectin cannot be dissolved out too much, so that purification of leaching liquid and improvement of sensory quality are facilitated, favorable factors in two aspects are combined, products are enabled to be good in bulk, higher in softness and excellent in liquid absorbing performance, and physical quality and sensory quality are improved.

Owner:HENAN CIGARETTE IND TOBACCO SLICE

A Coking Coal Heavy Floatation Combined Separation Process

ActiveCN104722390BAvoid running roughImprove sorting efficiencyWet separationEconomic benefitsEngineering

Owner:CHINA UNIV OF MINING & TECH

A mine-used differential three-roller gear crusher

Owner:中国矿业大学盱眙矿山装备与材料研发中心

Foam concrete slurry producing and conveying machine

InactiveCN102514098BIncrease productionUnlimited dilution factorCement mixing apparatusMixing operation plantFoam concreteFiber

The invention relates to a novel foam concrete slurry producing and conveying machine, which comprises a foaming machine foaming system, a concrete slurry producing system and a mixing pipe mixing system, wherein the mixing pipe mixing system is respectively communicated with the foaming machine foaming system and a concrete slurry producing system. The equipment has the advantages that the concrete slurry water-cement ratio and the slurry and foam mixing ratio of specified volume-weight foam concrete products can be conveniently determined, foams are not easy to crack and cannot be influenced by conveying pressure, the continuous production can be realized, and in addition, anti-crack short fibers are allowed to be used, so the pressure resistance intensity and the anti-crack performance of the foam concrete products are obviously improved, and simultaneously, the utilization rate of foaming agents and compressed air can also be improved.

Owner:LUOYANG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com