Novel foam concrete slurry producing and conveying machine

A foamed concrete, production and conveyor technology, which is applied in clay preparation devices, mixing operation control, mixing plants, etc., can solve problems such as inability to continuous production, and achieve the effects of increasing foam output, reducing length-diameter ratio, and mixing uniformly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

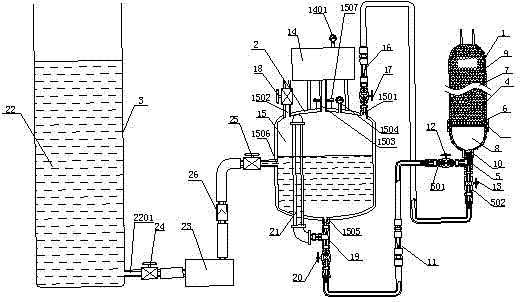

Embodiment 1

[0090] LC-01 foam concrete foaming agent, the expansion ratio is 4.0m 3 / kg, the dilution factor is 1:100.

[0091] The parameters of the present invention are as follows.

[0092] ①Air compressor: the maximum pressure is 0.6MPA, and the displacement is 50L / min.

[0093] ② Foaming agent diluent storage tank: the volume is 100L.

[0094] ③Foaming liquid dilution tank: the volume is 600L.

[0095] ④ Foam tube: the length L of the tube waist is 600mm; the inner diameter of the outlet is 20mm, the inner diameter of the middle part is 50mm, and the inner diameter of the inlet is 20mm.

[0096] ⑤Spray mechanism: The outer diameter of the upper opening of the tee pipe is matched with the inner diameter of the spray port inlet of the foam pipe, and is connected with a screw; the outer diameter of the wrench bayonet 505 of the space adjustment screw 508 of the atomization chamber is 8mm, and the outlet diameter of the atomization chamber 4mm, air injection pipe 507 outlet diameter ...

Embodiment 2

[0132] LC-03 foam concrete foaming agent, the expansion ratio is 6.0m 3 / kg, the dilution factor is 1:100.

[0133] The parameters of the present invention are as follows.

[0134] ①Air compressor: the maximum pressure is 1.0MPA, and the displacement is 400L / min.

[0135] ② Foaming agent diluent storage tank: the volume is 400L.

[0136] ③Foaming liquid dilution tank: the volume is 1200L.

[0137]④ Foam tube: the length L of the tube waist is 1200mm; the inner diameter of the outlet is 40mm, the inner diameter of the middle part is 120mm, and the inner diameter of the inlet is 40mm.

[0138] ⑤Spray mechanism: The outer diameter of the upper opening of the tee pipe is matched with the inner diameter of the spray port inlet of the foam pipe, and is connected with a screw; the outer diameter of the wrench bayonet 505 of the space adjustment screw 508 of the atomization chamber is 16mm, and the outlet diameter of the atomization chamber 8mm, the outlet diameter of air injectio...

Embodiment 3

[0174] A foam concrete foaming agent in a factory in my country, the expansion ratio is 1.6m 3 / kg, the dilution factor is 1:30.

[0175] The parameters of the present invention are as follows.

[0176] ①Air compressor: the maximum pressure is 1.0MPA, and the displacement is 400L / min.

[0177] ② Foaming agent diluent storage tank: the volume is 400L.

[0178] ③Foaming liquid dilution tank: the volume is 1200L.

[0179] ④ Foam tube: the length L of the tube waist is 1200mm; the inner diameter of the outlet is 40mm, the inner diameter of the middle part is 120mm, and the inner diameter of the inlet is 40mm.

[0180] ⑤Spray mechanism: The outer diameter of the upper opening of the tee pipe is matched with the inner diameter of the spray port inlet of the foam pipe, and is connected with a screw; the outer diameter of the wrench bayonet 505 of the space adjustment screw 508 of the atomization chamber is 16mm, and the outlet diameter of the atomization chamber 8mm, the outlet d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com