Patents

Literature

57results about How to "Reduce perforation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

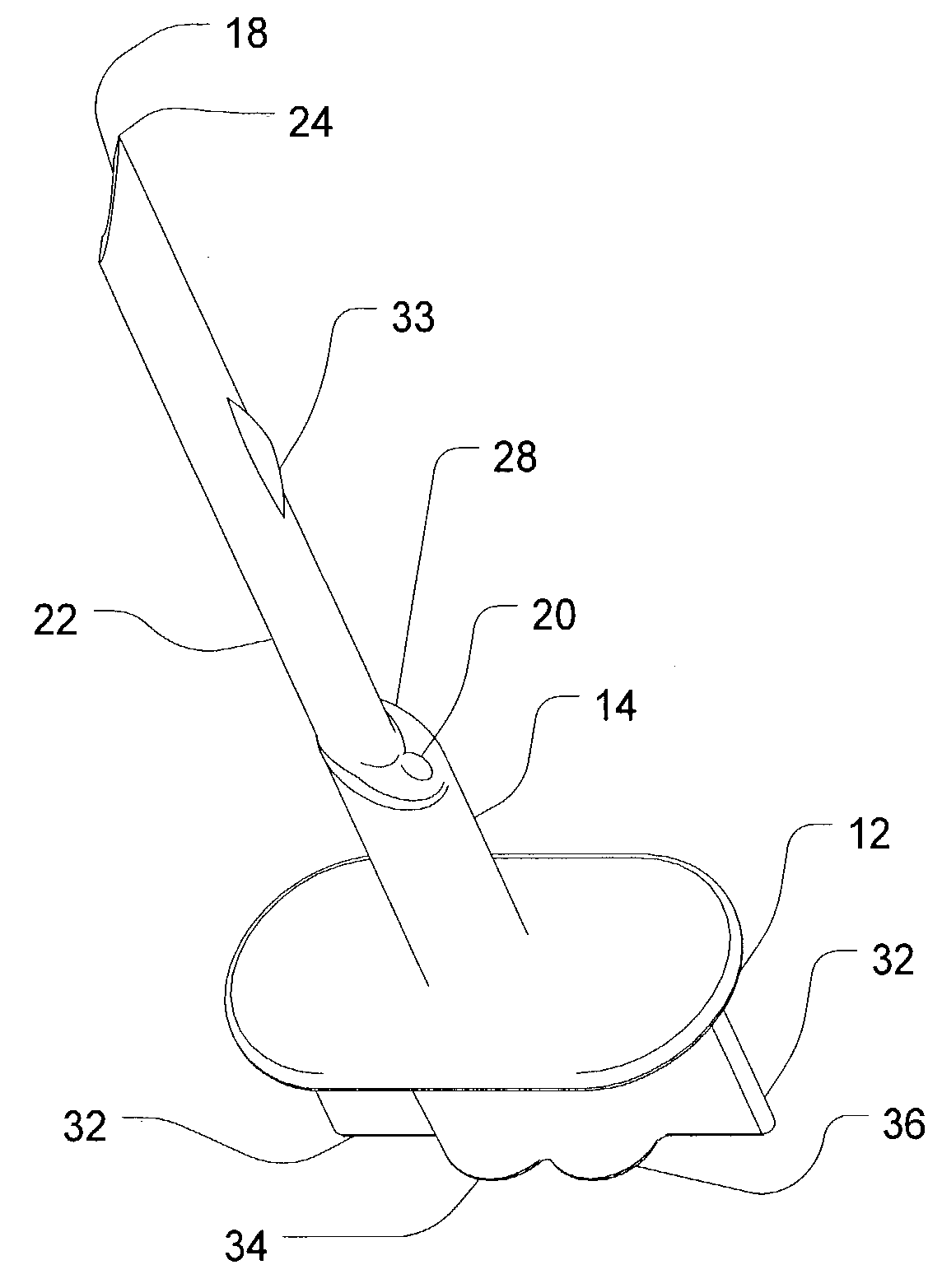

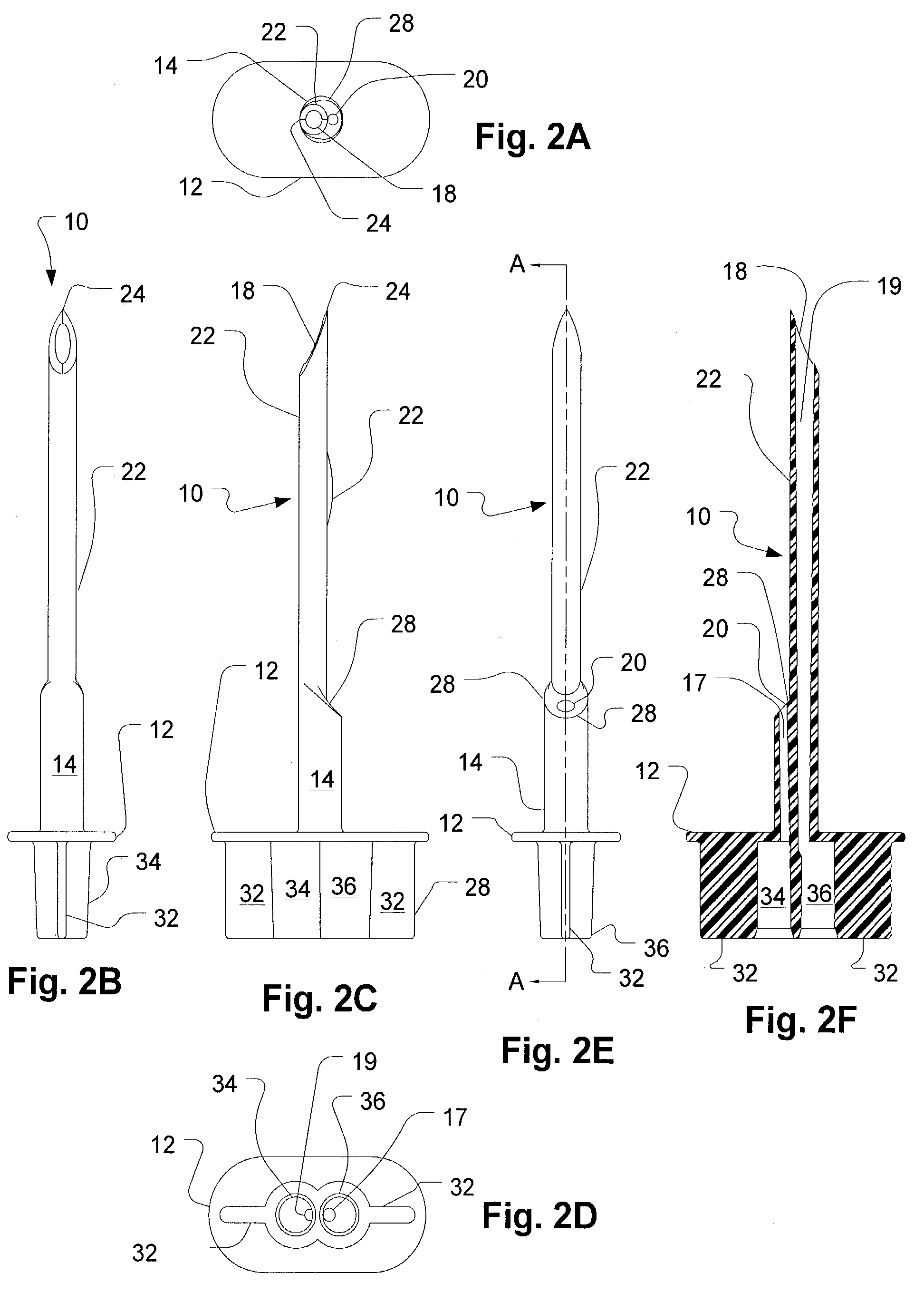

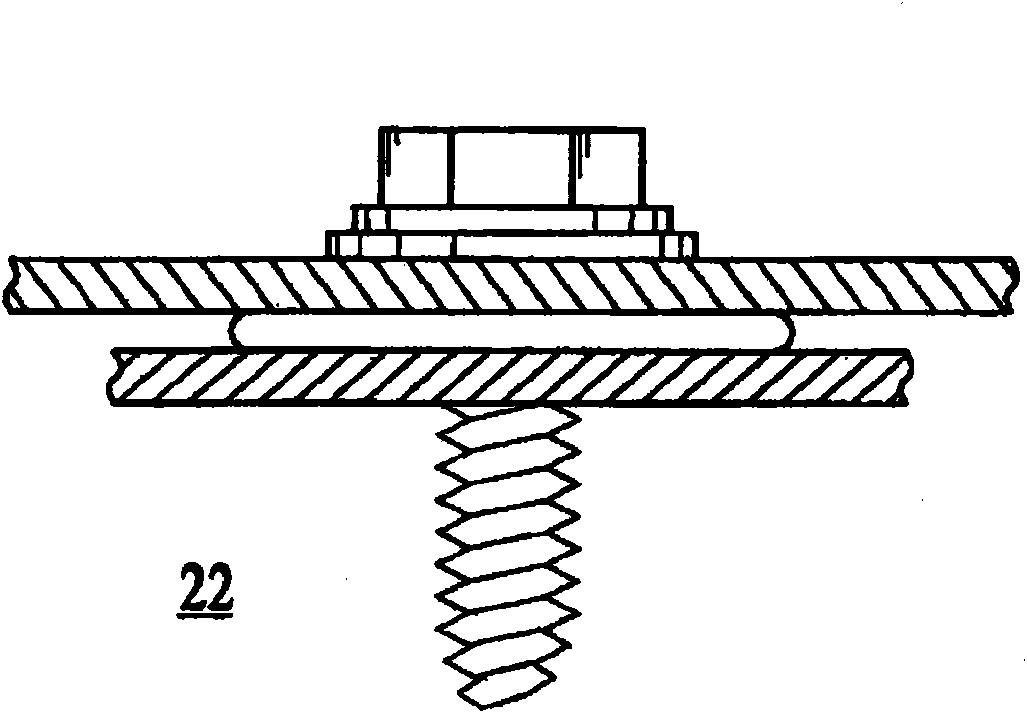

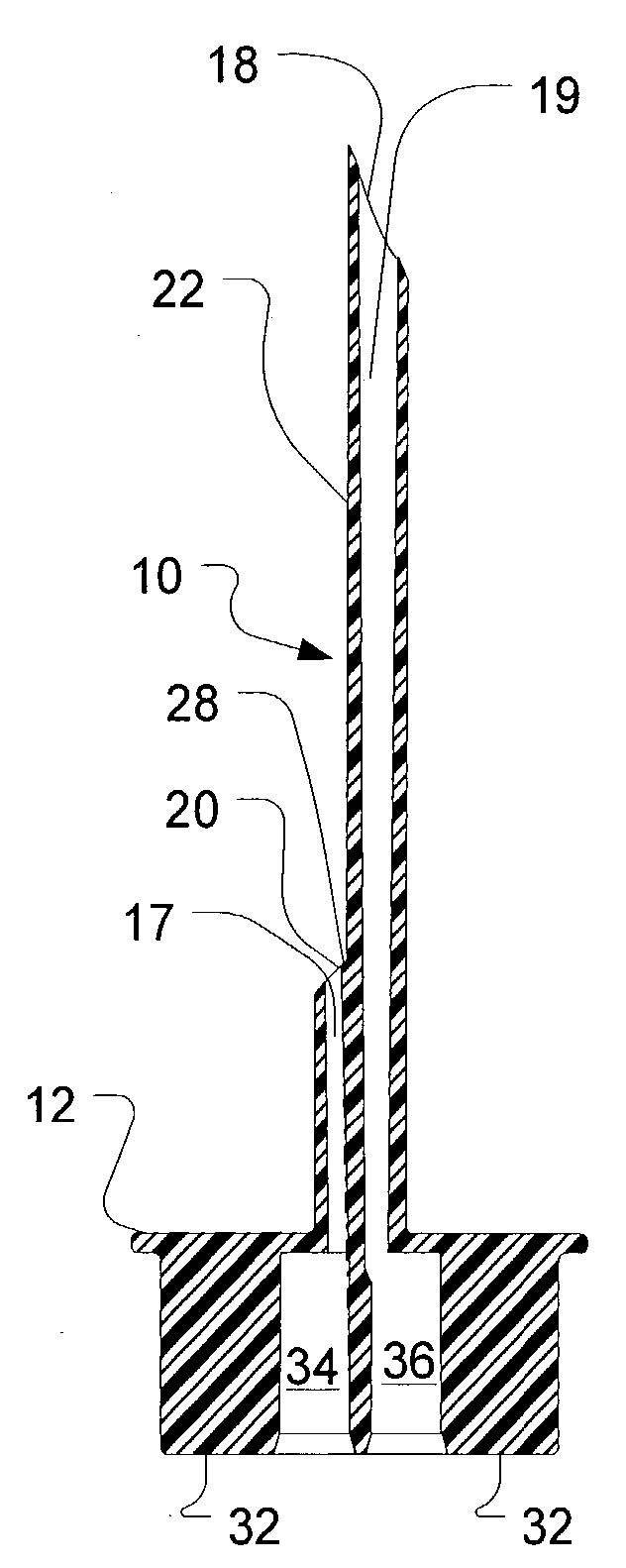

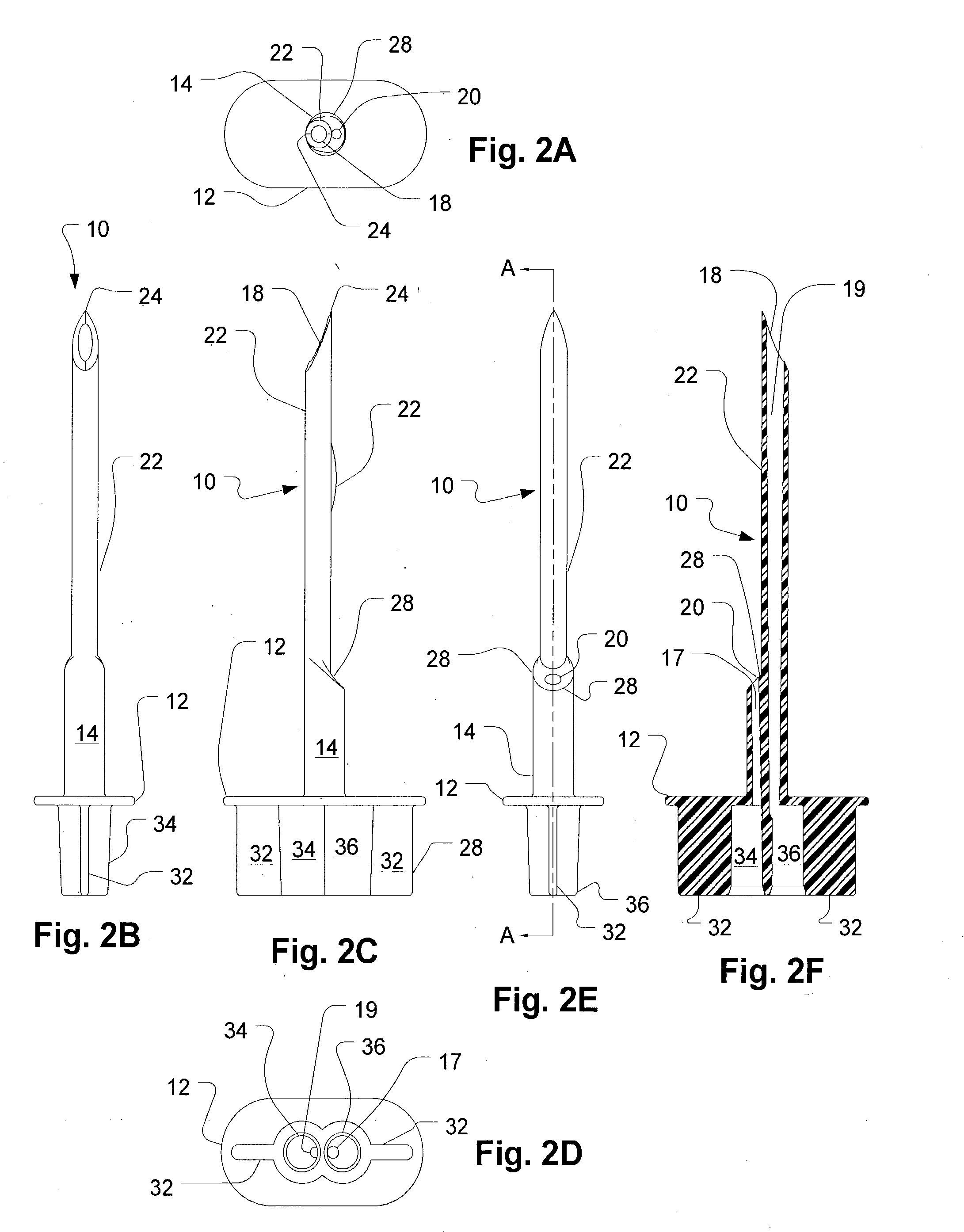

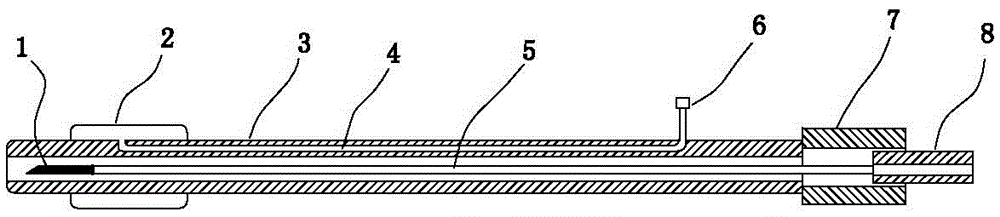

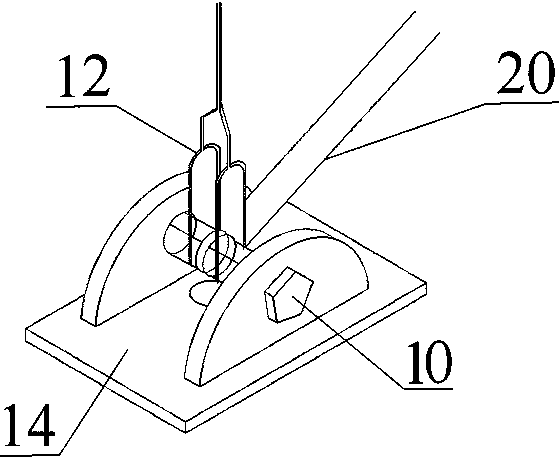

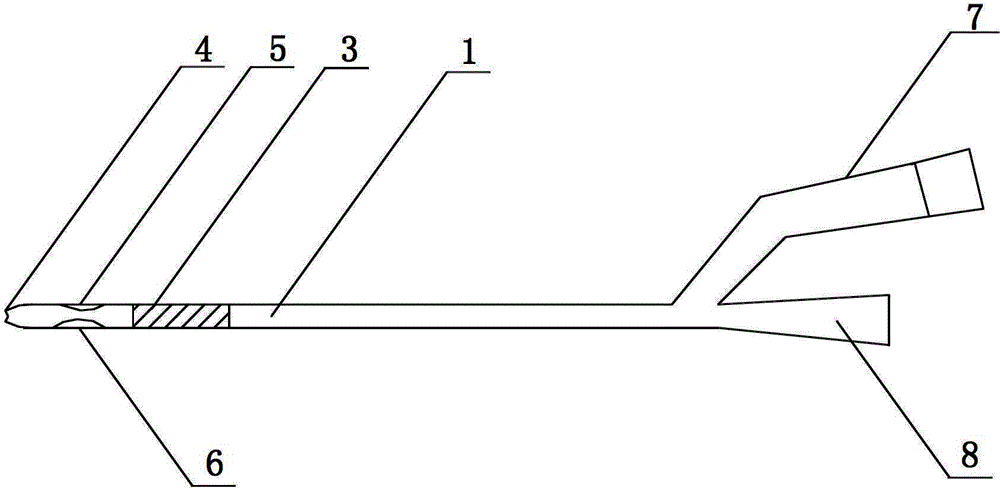

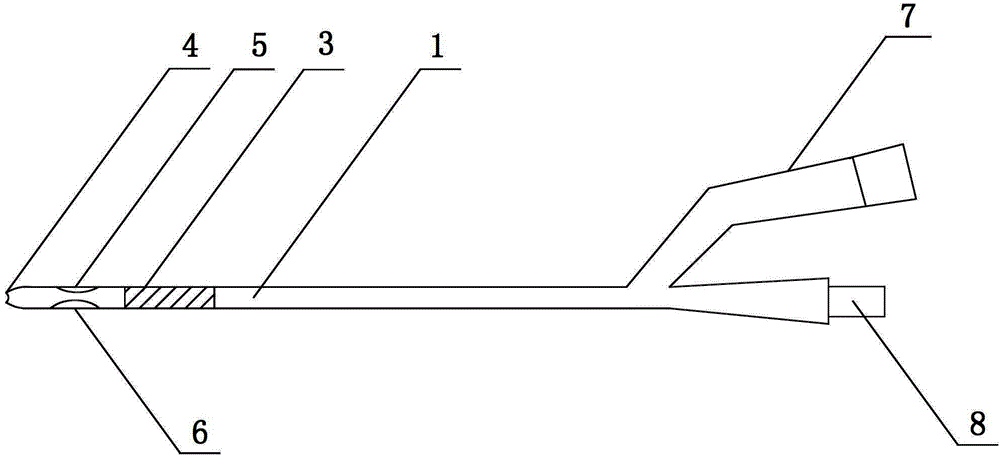

Dual access spike for infusate bags

ActiveUS7470265B2Reduce perforationEasy to insertDiagnosticsSurgeryDual accessMechanical engineering

Owner:NXSTAGE MEDICAL INC

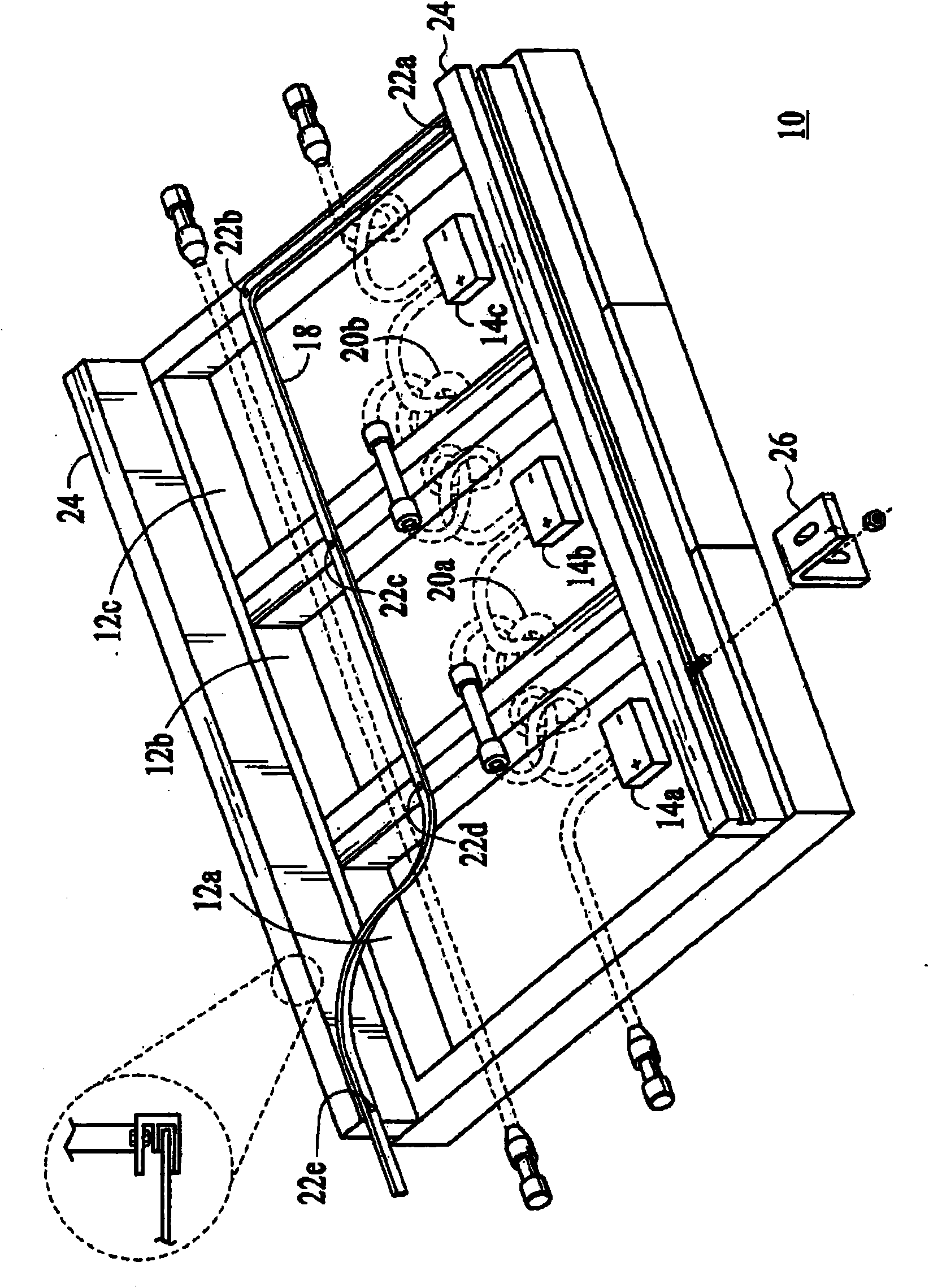

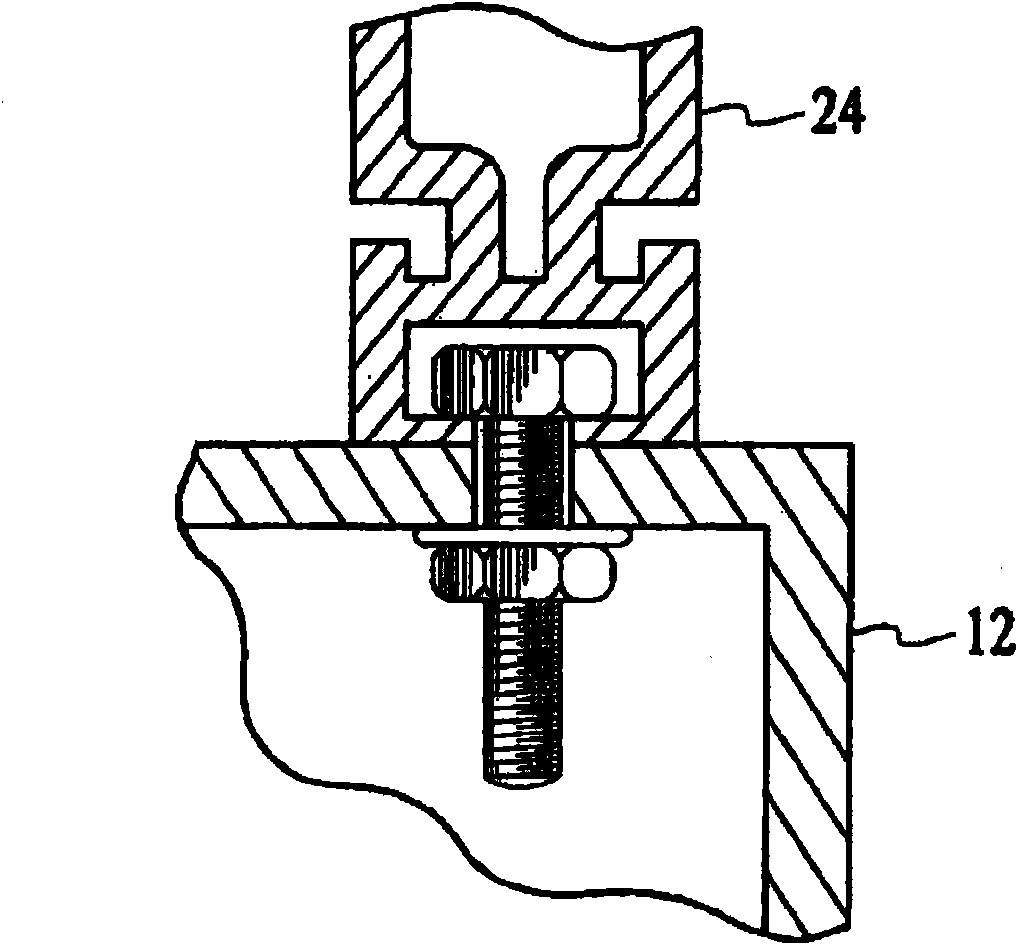

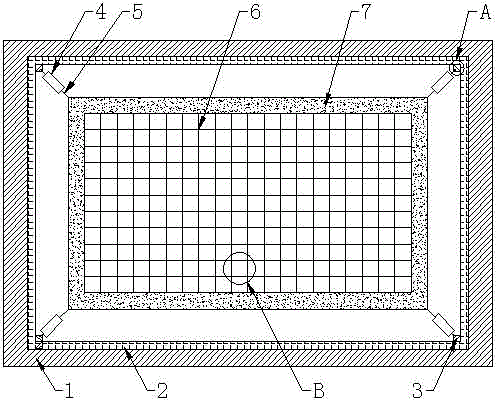

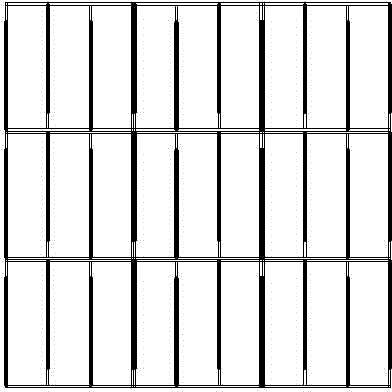

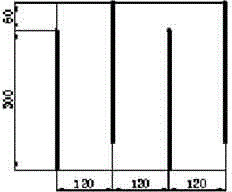

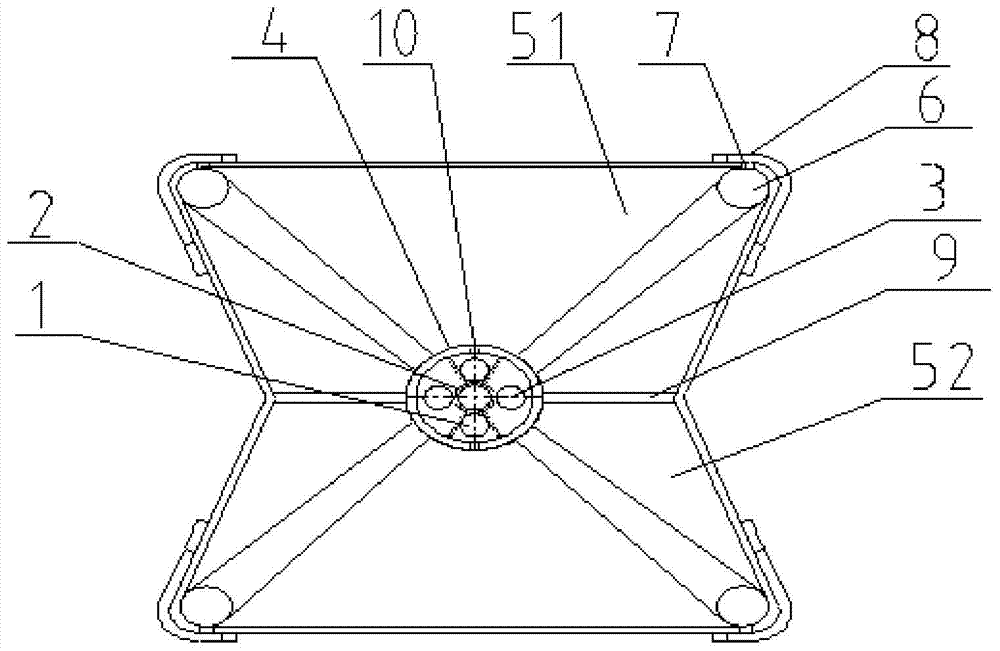

Mounting system for solar panels

InactiveCN101868860AReduce perforationClosely connectedPhotovoltaic supportsSolar heating energySupporting systemEngineering

Owner:ANDALAY SOLAR

Cutting method for digital controlled flame cutter

InactiveCN1928756AImprove appearance qualityIncrease profitTotal factory controlGas flame welding apparatusFlameoutEngineering

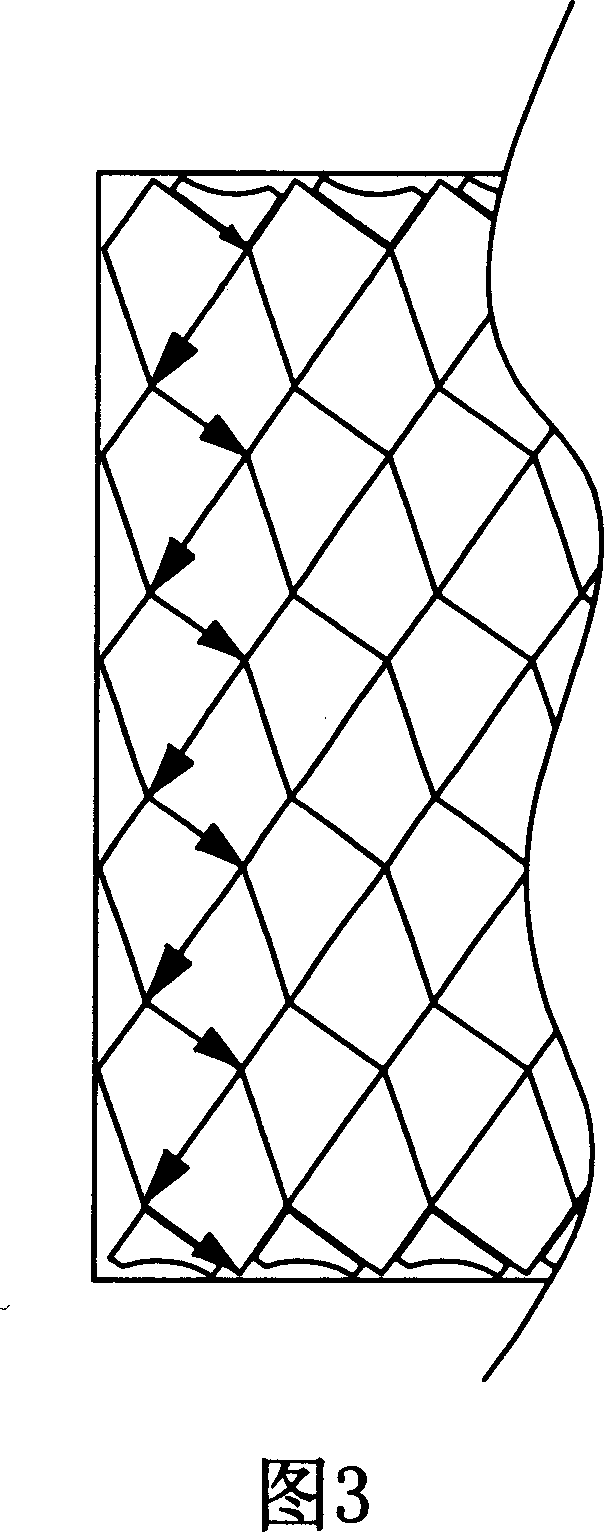

The disclosed cutting method with digital-control flame cutter comprises: a. designing pattern, which includes: according to product detail shape and target plate material, drawing the pattern figure with some closed ring figure element with same shape as the product; b. designing the cutting path and defining cutting processing codes; c. loading codes; d. cutting. During the procedure of startup, warm-up, perforating, cutting and flameout, this invention can process scores even hundreds details for one time.

Owner:陈晓坚

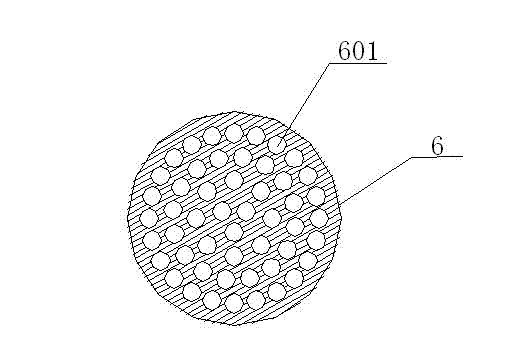

Heat pipe cold guide device and cold storage body and freezer with said device

InactiveCN1554920AReduce perforationReduce cooling energy lossDomestic cooling apparatusIndirect heat exchangersTubing setEngineering

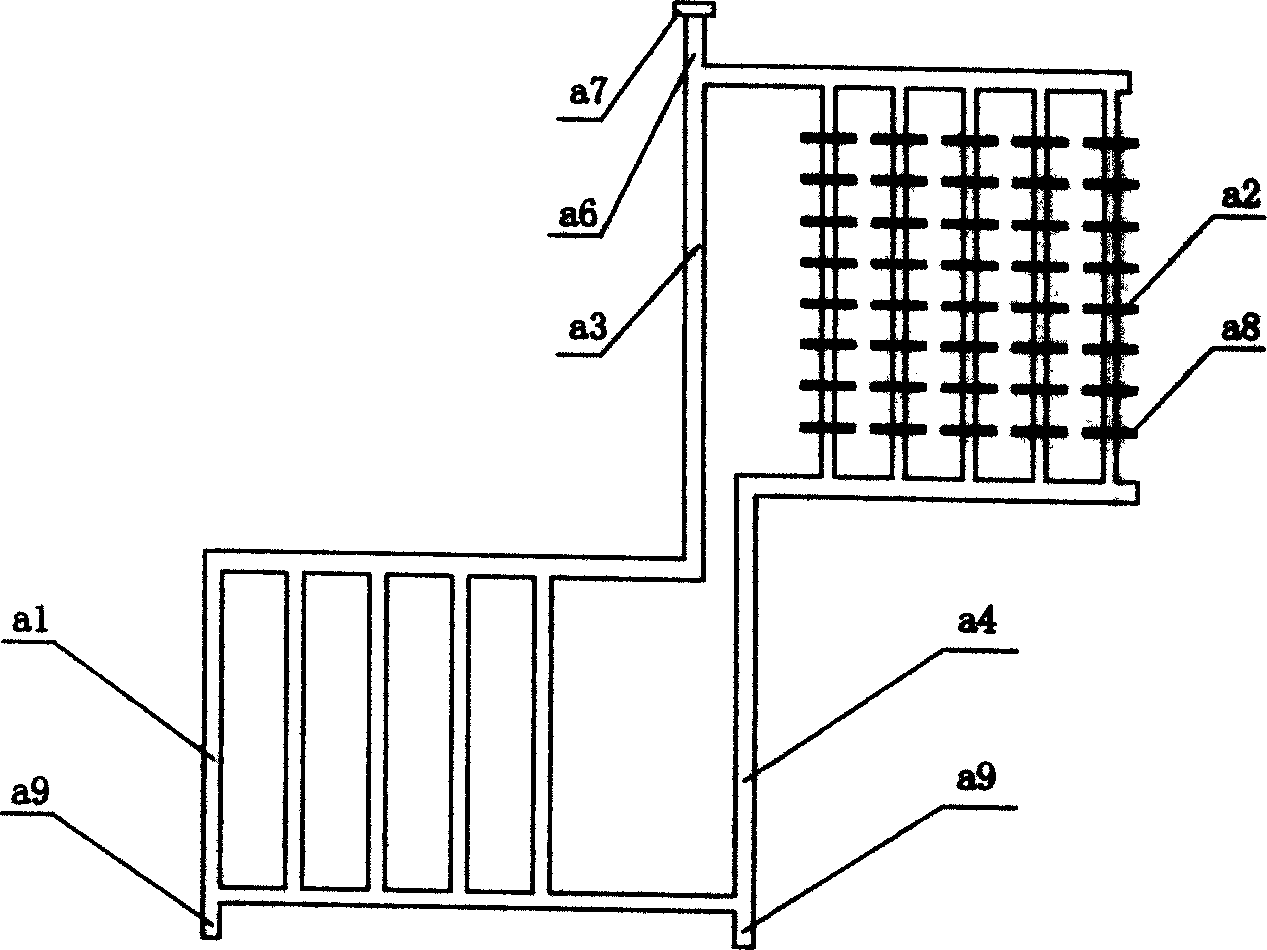

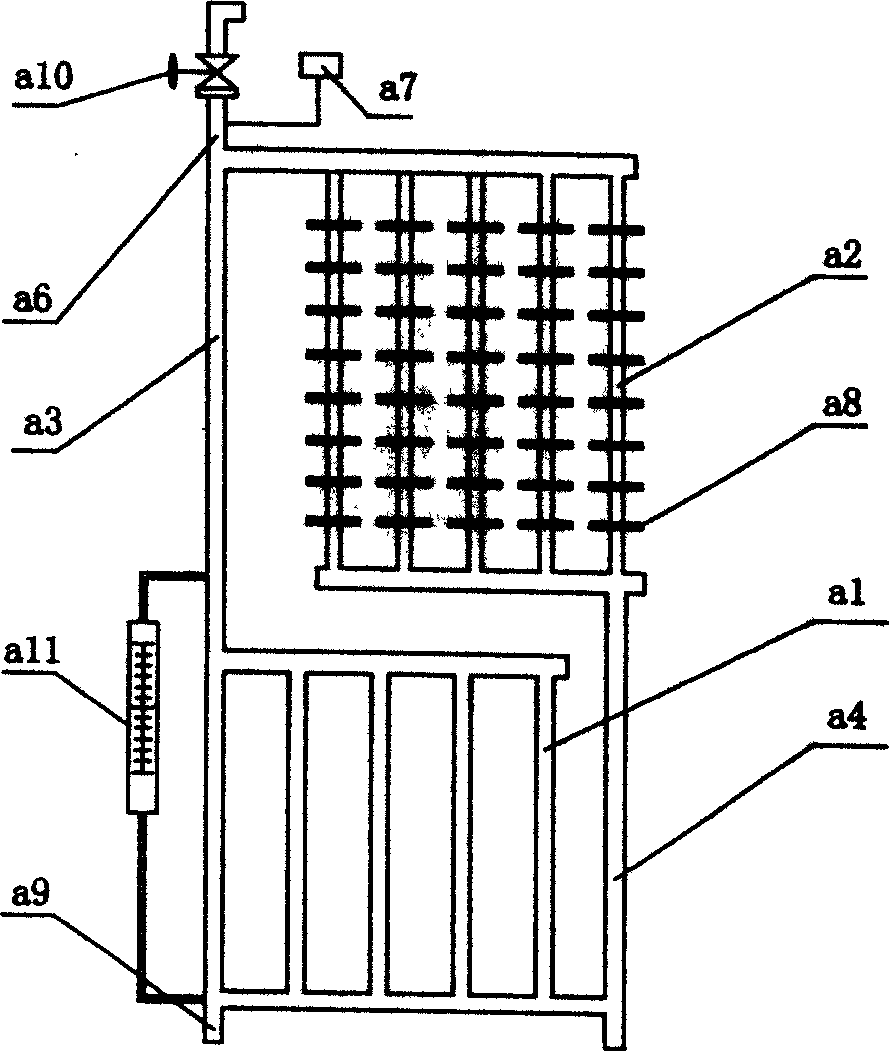

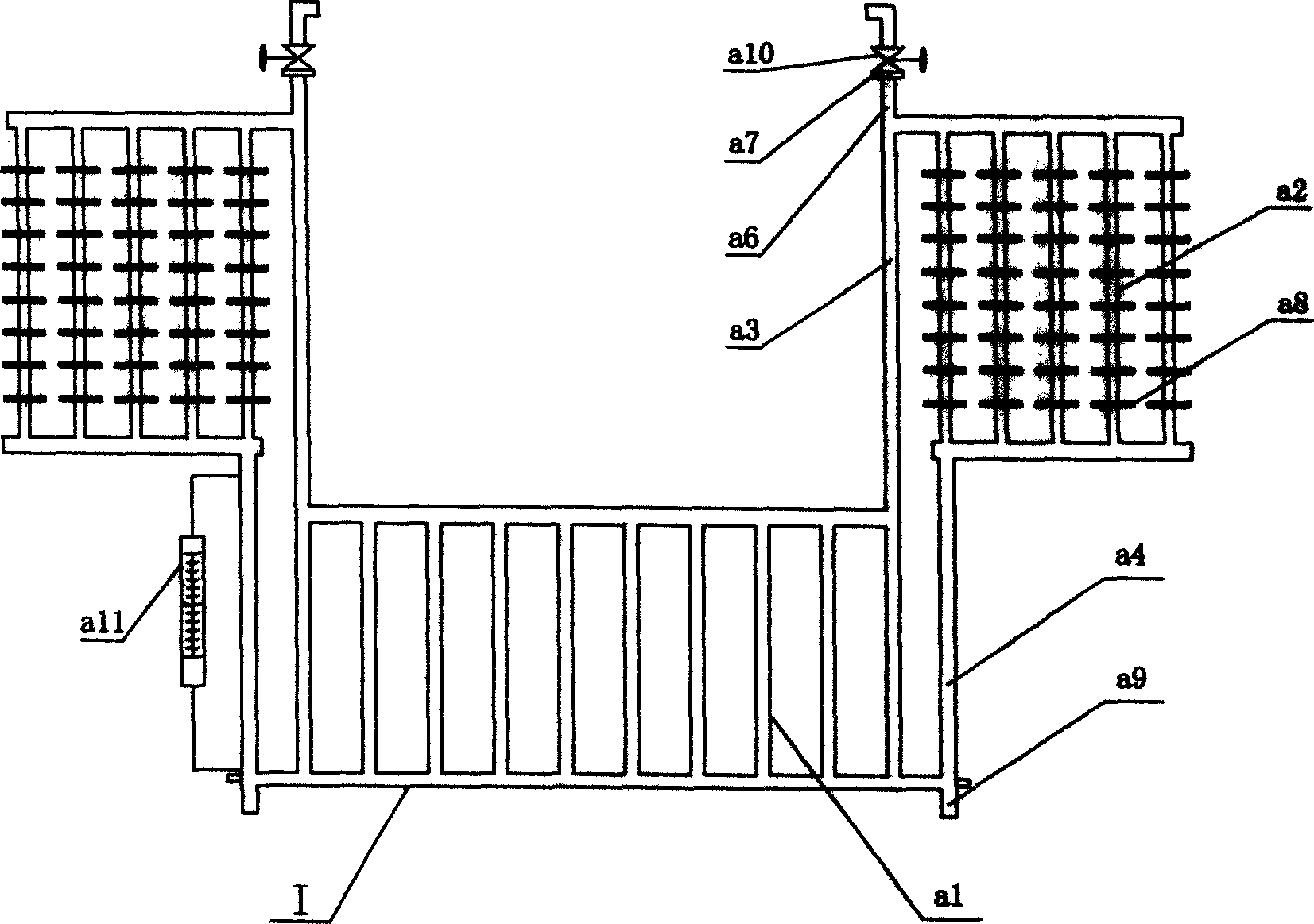

The cold-guiding heat pipe device includes at least two evaporating tubes and condensing tubes to form the evaporating tube set and the condensing tube set separately via parallel connection with the connecting tubes. The upper connecting tubes for the evaporating tube set and the upper connecting tubes for the condensing tube set are communicated, and the lower connecting tubes for the evaporating tube set and the lower connecting tubes for the condensing tube set are communicated to form the circulating loop. Inside the closed container holding cold storing medium, the evaporating tube set is soaked. The refrigerated warehouse includes heat insulator and cold storing body as the cold source. The present invention has heat pipe with high heat conductance and ring circulating loop so that it has high efficiency, high stability, low cost, low power consumption and high performance / cost ratio.

Owner:尹学军 +1

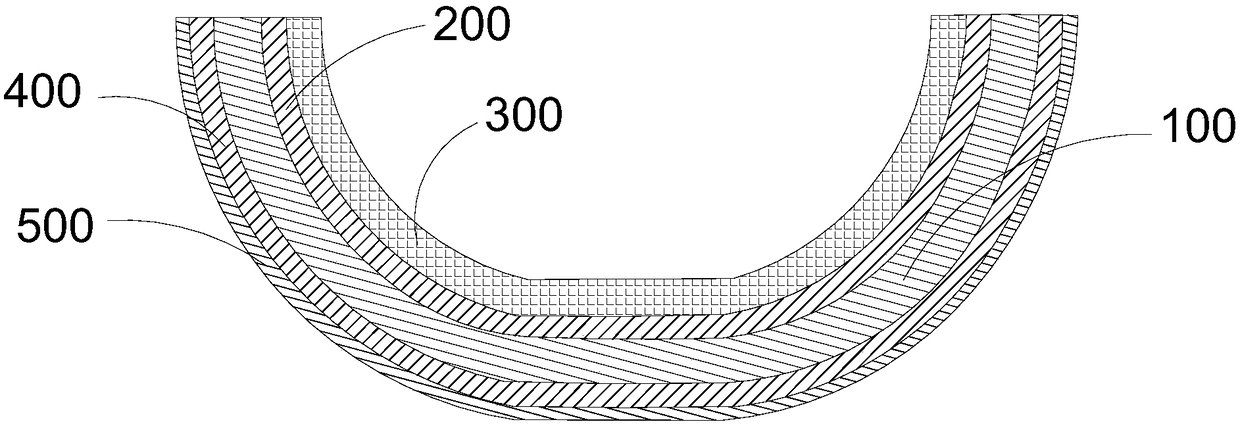

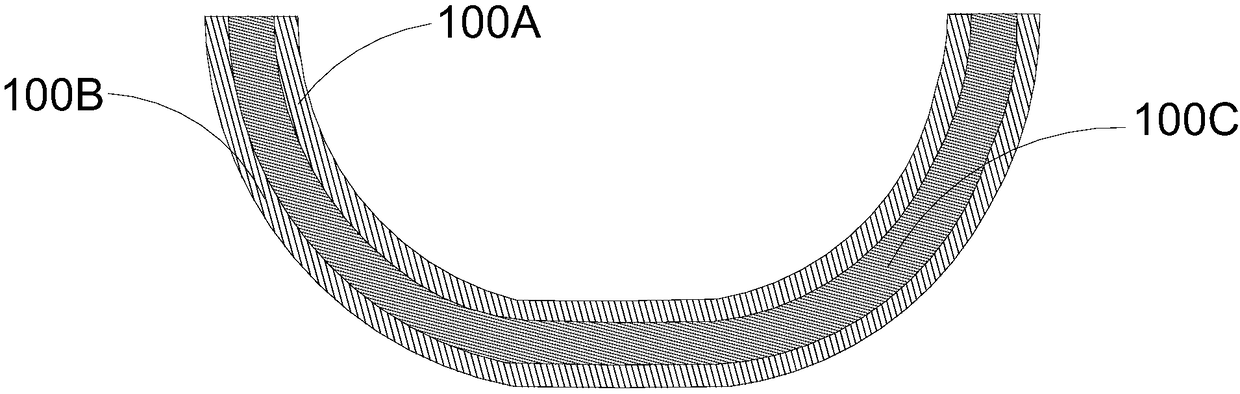

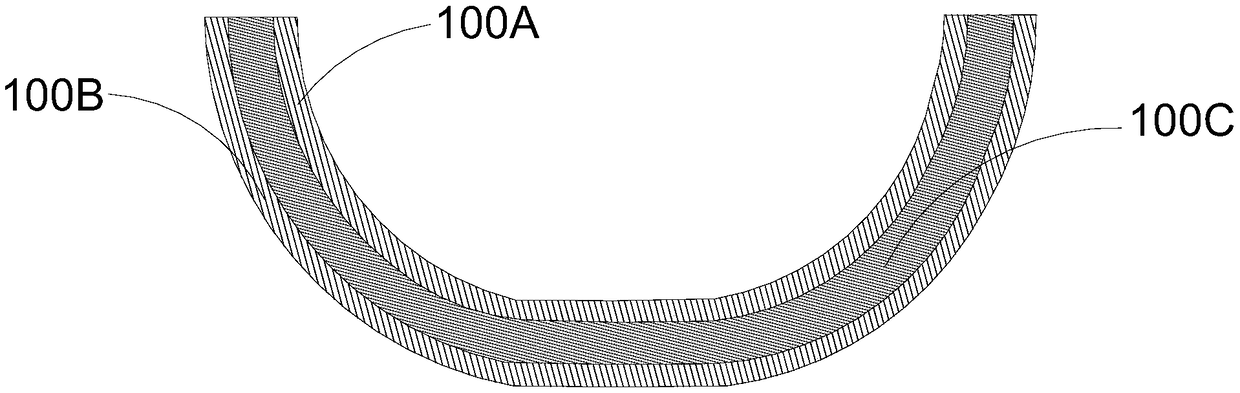

Stainless iron pan acid-proof material, preparation method of stainless iron pan acid-proof material and stainless iron container

InactiveCN108504975AImprove acid resistanceReduce trachomaCooking-vessel materialsMolten spray coatingThermal sprayingNitrogen

The invention belongs to the technical field of iron pan preparation, and particularly relates to a stainless iron pan acid-proof material, a preparation method of the stainless iron pan acid-proof material and a stainless iron container. The inner surface of a pan body is coated with a titanium nitride layer. The inner surface of the pan body is coated with titanium and / or titanium alloy layer through a thermal spraying method, and the pan body is subjected to nitriding treatment or nitrocarburizing treatment. According to the prepared stainless iron pan acid-proof material, the acid resistance of stainless iron pans subjected to nitriding treatment is improved, the problems of sand holes and punch holes in the application process of nitrided iron pans are reduced, and the influence of base material surface structure defects on the performance of iron pans is reduced.

Owner:武汉安在厨具有限公司 +1

Preparation technology of high-water-absorption breathable tissue raw paper material for puerperae

InactiveCN110172856AImprove creping efficiencyReduce wearDryer sectionReinforcing agents additionWater basedAbsorption capacity

The invention relates to the technical field of tissue processing, in particular to a preparation technology of a high-water-absorption breathable tissue raw paper material for puerperae. The preparation technology comprises the following steps of pulping, residue removal, pulp grinding, pulp preparing, sizing, papermaking and rewinding. By softening a coating and adding a water-based stripping agent, the wrinkling efficiency of a drying cylinder in the papermaking process is improved, so that the elongation rate of raw paper reaches 20-25%, the air permeability is improved by 30% or above, the horizontal liquid absorption height is increased by 10-15%, and the liquid absorption capacity can reach 3.0 g per gram of water; meanwhile, a wet strength promoter and a wet strength agent are added, so that the wet strength of the raw paper is enhanced; the prepared base paper has high water absorption and air permeability and good wet strength.

Owner:HENGAN (CHINA) PAPER IND CO LTD

Submucosal injection solution

InactiveCN107456612AGood liquidityLow viscositySurgeryPharmaceutical delivery mechanismSodium hyaluronatePhysiological function

Owner:SHANDONG WEIGAO PHARM CO LTD

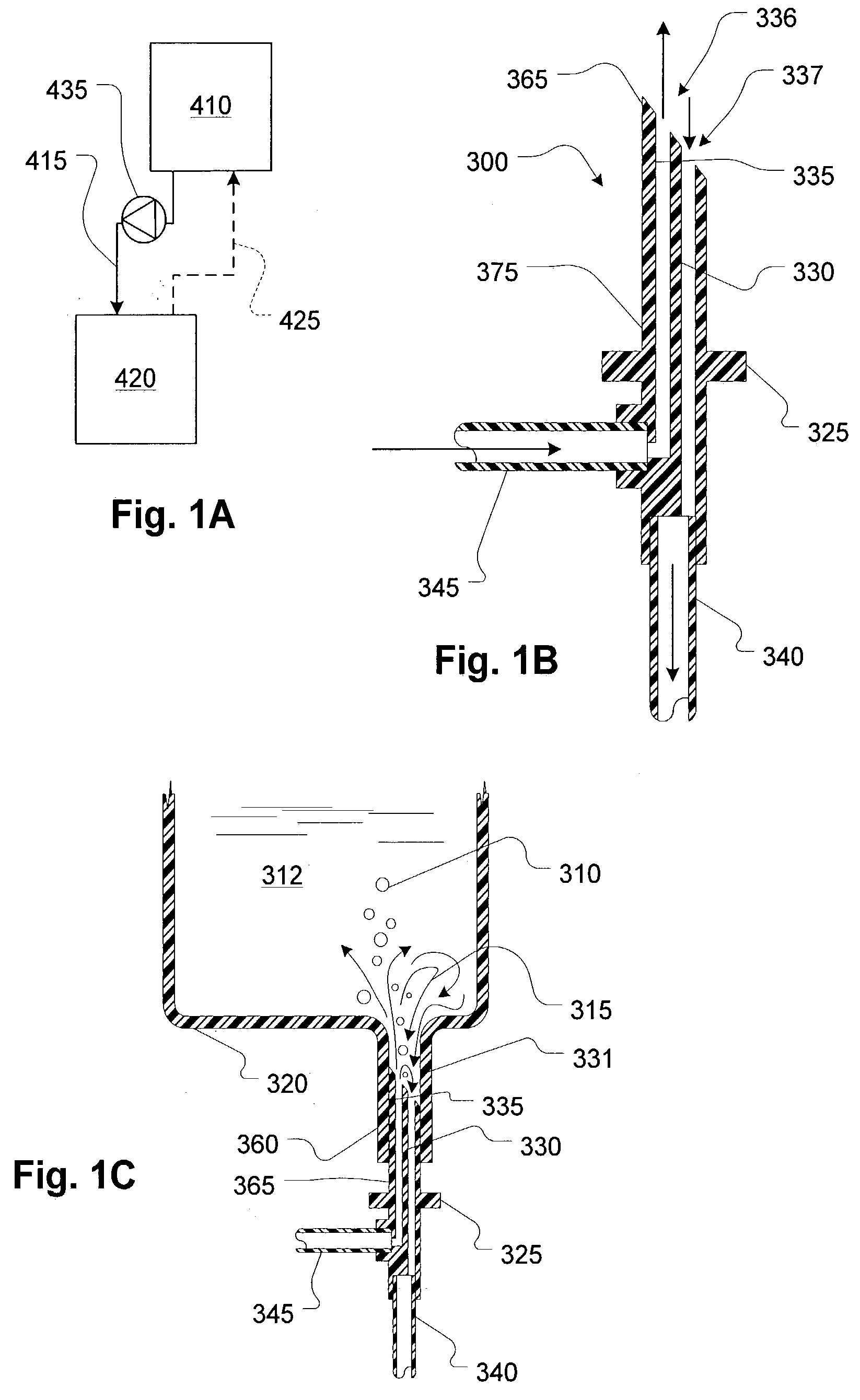

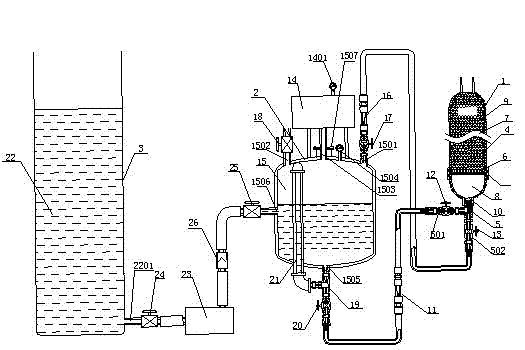

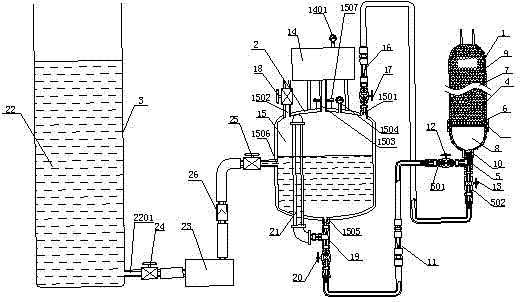

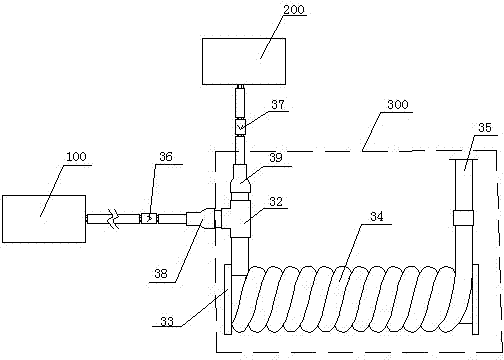

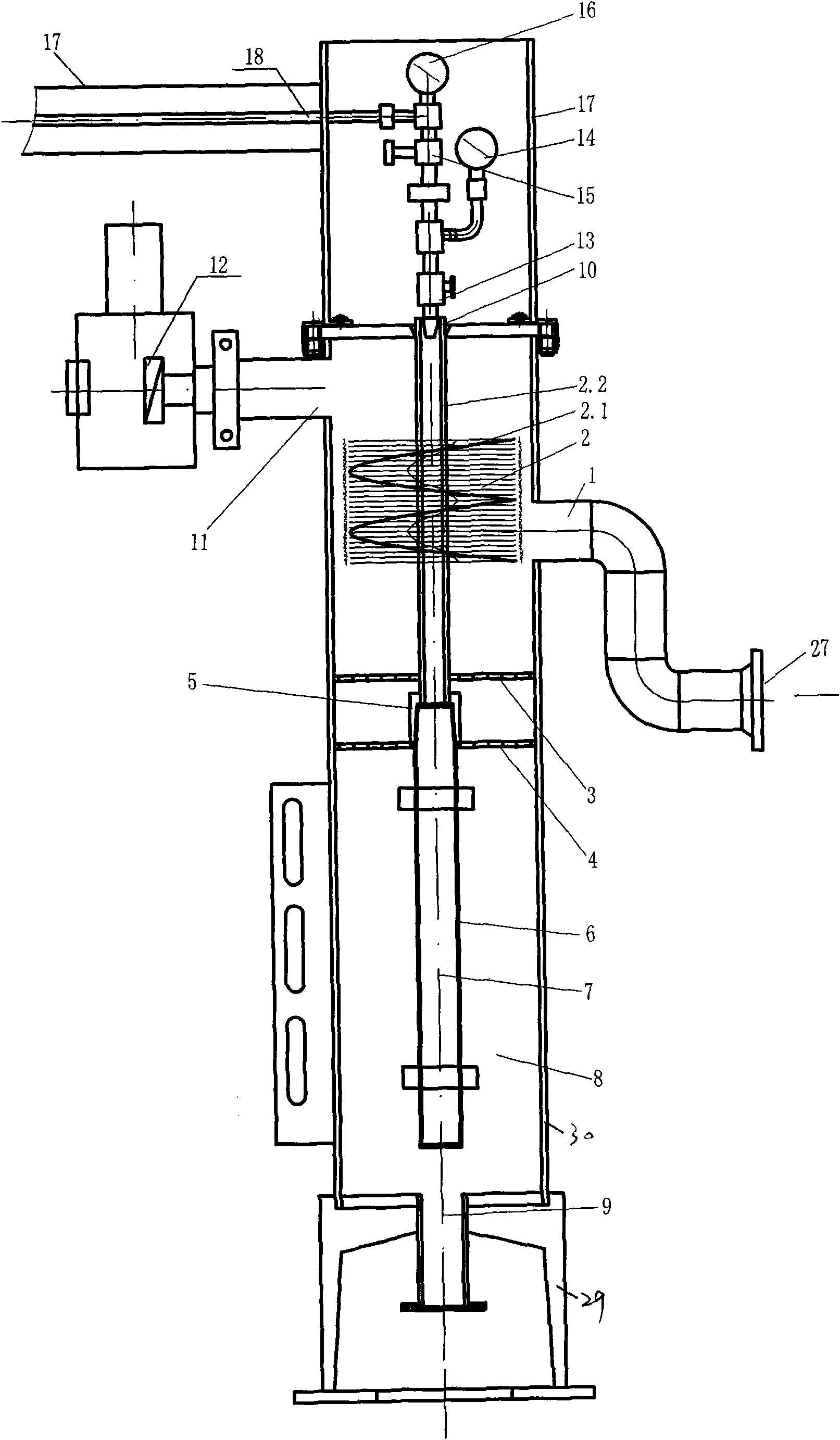

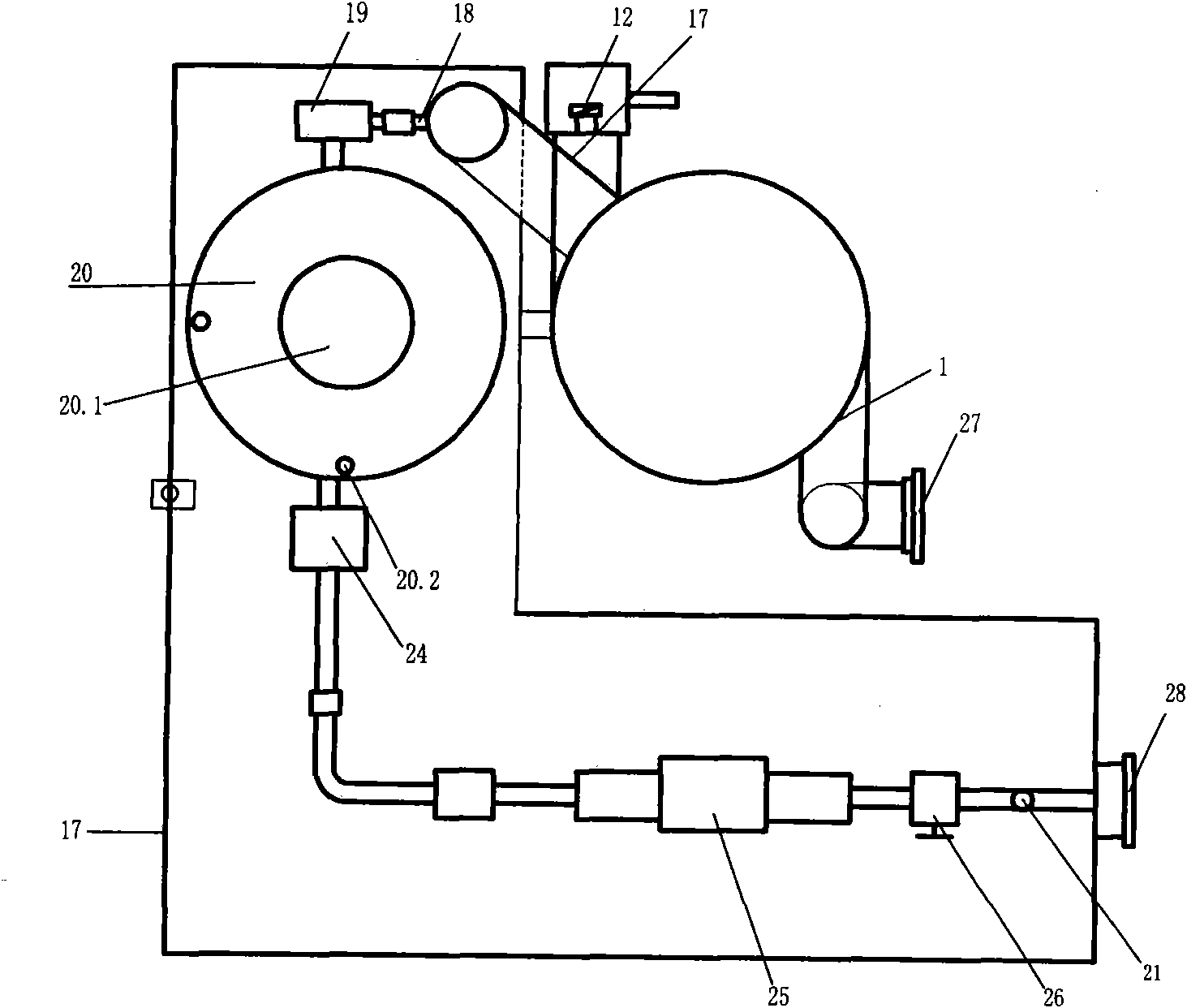

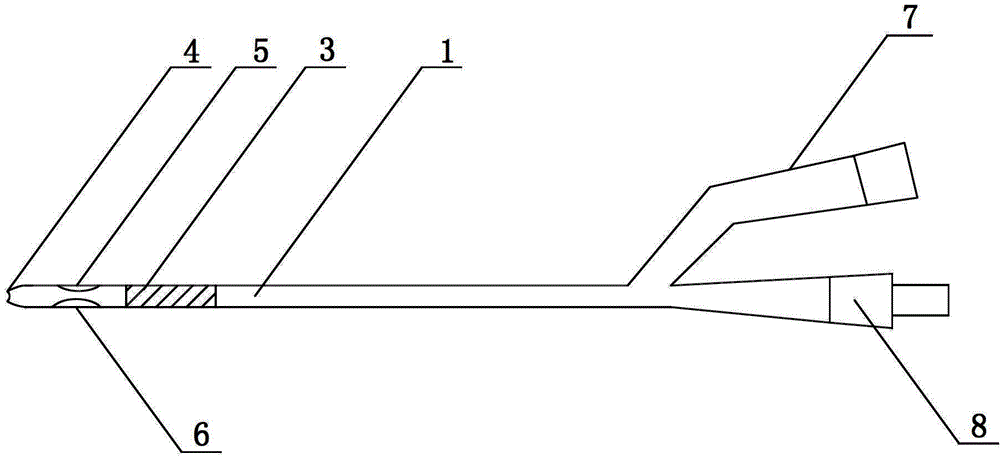

A high-efficiency foam concrete foaming agent foaming machine

ActiveCN102267165AHigh trafficUnlimited dilution factorFlow mixersTransportation and packagingFoam concreteFoaming agent

The invention provides a high efficient foam concrete foaming agent foaming machine which comprises a foaming device, an air driving device and a foaming agent diluent feeding device, wherein the foaming device comprises a foaming pipe and a spraying mechanism; the air driving device comprises an air compressor and a foaming agent diluent storage tank; and the foaming agent diluent feeding deviceis connected with a liquid inlet pipe of the foaming agent diluent storage tank via a worm pump. By using the high efficient foam concrete foaming agent foaming machine provided by the invention, thedilution ratio of the foaming agent and the ratio of the diluent to the air can be randomly adjusted according to the instructions of the foaming agent and the hardness degree of the made foam so that the usage of the foaming agent is saved, compressed air is reduced and more stable foam with a larger diameter is formed.

Owner:LUOYANG NORMAL UNIV

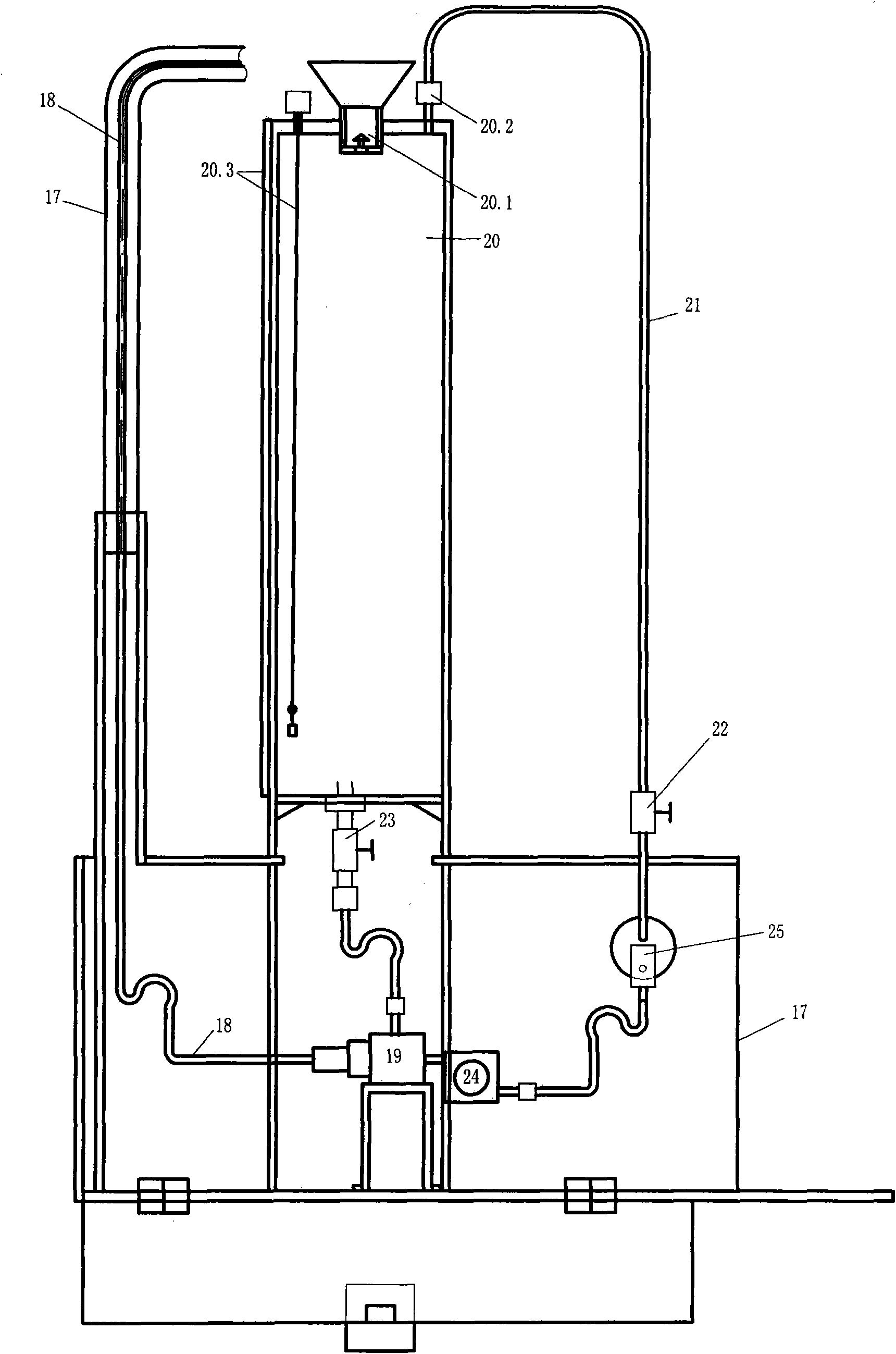

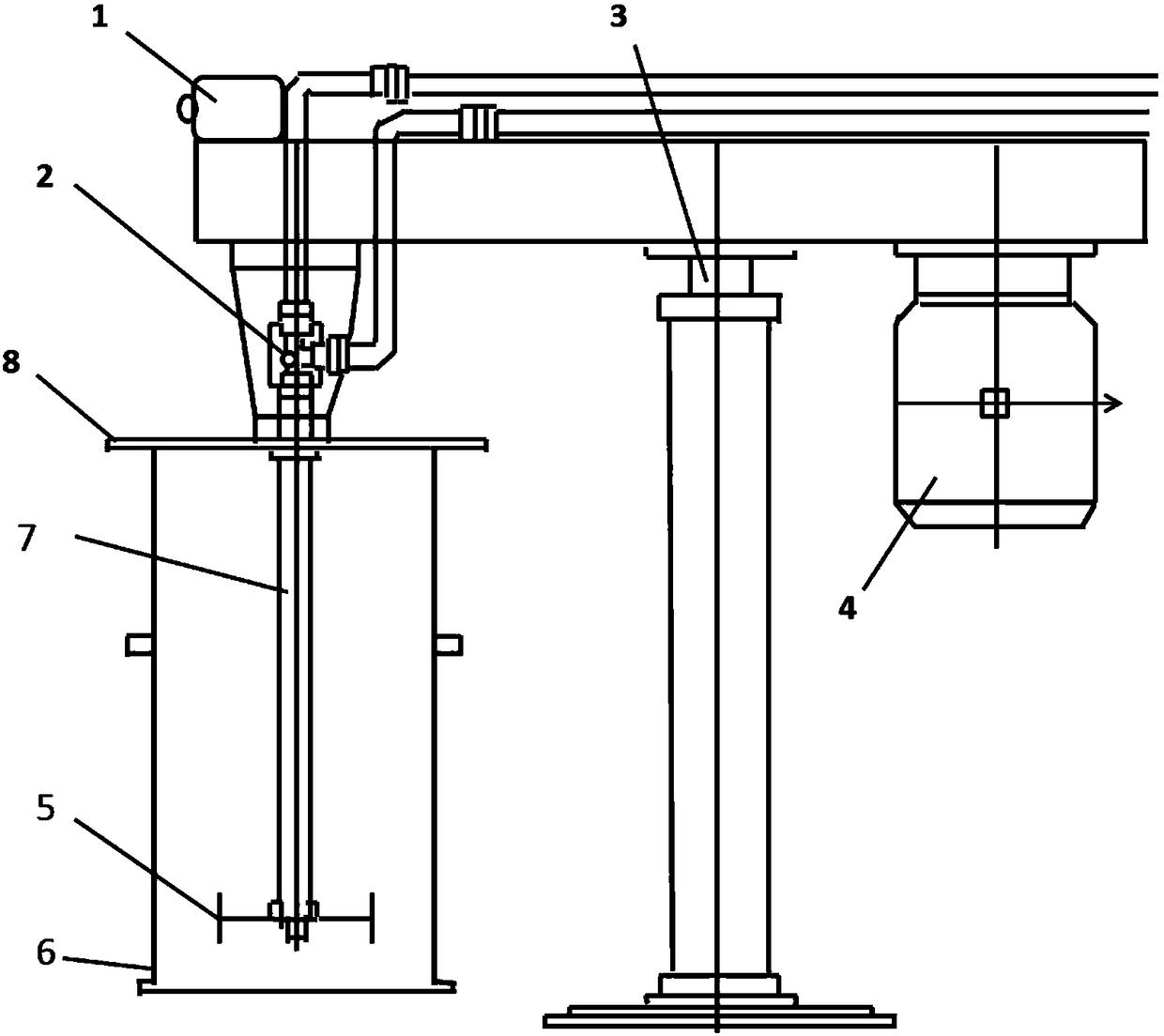

Novel foam concrete slurry producing and conveying machine

InactiveCN102514098AIncrease productionUnlimited dilution factorCement mixing apparatusMixing operation plantFoam concreteFiber

The invention relates to a novel foam concrete slurry producing and conveying machine, which comprises a foaming machine foaming system, a concrete slurry producing system and a mixing pipe mixing system, wherein the mixing pipe mixing system is respectively communicated with the foaming machine foaming system and a concrete slurry producing system. The equipment has the advantages that the concrete slurry water-cement ratio and the slurry and foam mixing ratio of specified volume-weight foam concrete products can be conveniently determined, foams are not easy to crack and cannot be influenced by conveying pressure, the continuous production can be realized, and in addition, anti-crack short fibers are allowed to be used, so the pressure resistance intensity and the anti-crack performance of the foam concrete products are obviously improved, and simultaneously, the utilization rate of foaming agents and compressed air can also be improved.

Owner:LUOYANG NORMAL UNIV

Dual access spike for infusate bags

ActiveUS20050277906A1Increase the cross-sectional areaSlow forceDiagnosticsSurgeryDual accessMechanical engineering

Owner:NXSTAGE MEDICAL

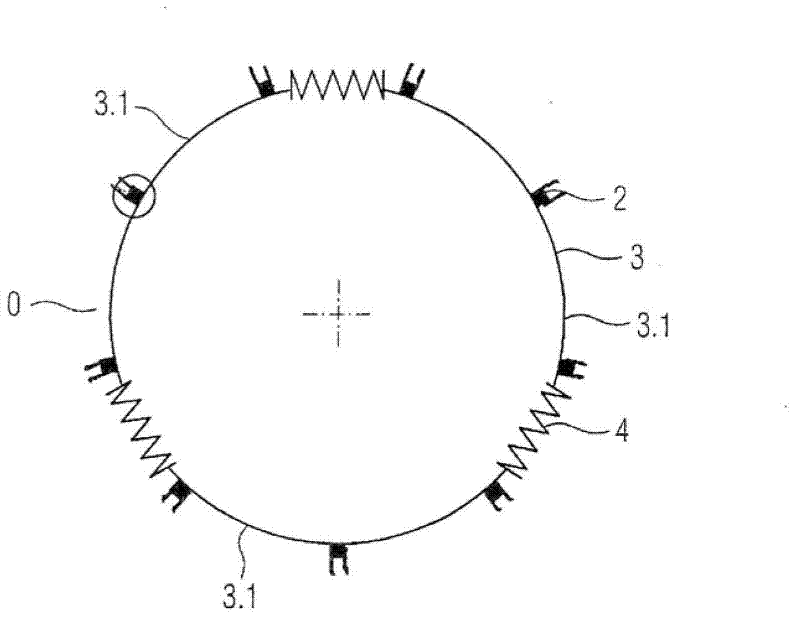

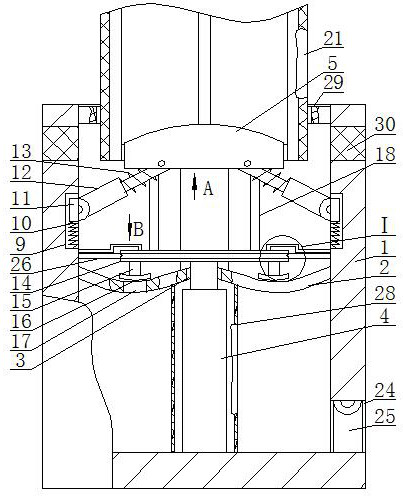

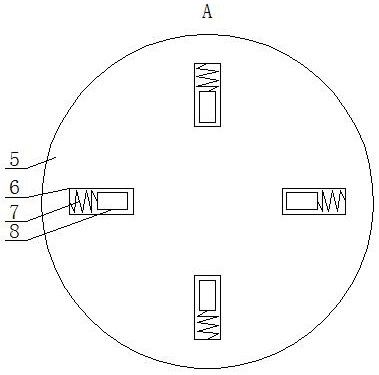

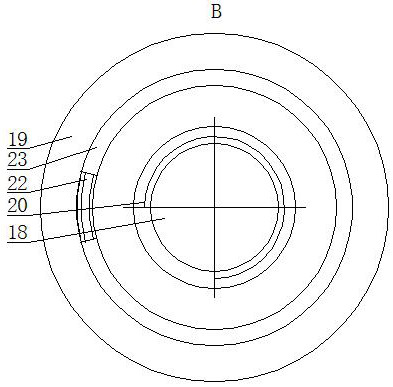

Oscillation impact damping device for liquid goods carrying

The invention aims to provide an oscillation impact damping device for liquid goods carrying. By means of the oscillation impact damping device, the angle does not need to be increased for oscillation reduction for a cargo space, and reduction of locating capacity is avoided, the effect of lowering the oscillation impact can be achieved flexibly under the condition of non-stand loading, and the oscillation impact damping device is used for liquid goods carrying. According to the technical scheme, the oscillation impact damping device for liquid goods carrying comprises heat preservation materials, sliding rails, connection ropes, an oscillation reduction assembly, sliding blocks and rails. The goods bin wall is provided with the heat preservation materials. The sliding rails are arranged on the four corners of the goods bin wall, and the sliding blocks in the sliding rails are connected with a main frame of the oscillation reduction assembly through the connection ropes.

Owner:SHENYANG AEROSPACE UNIVERSITY

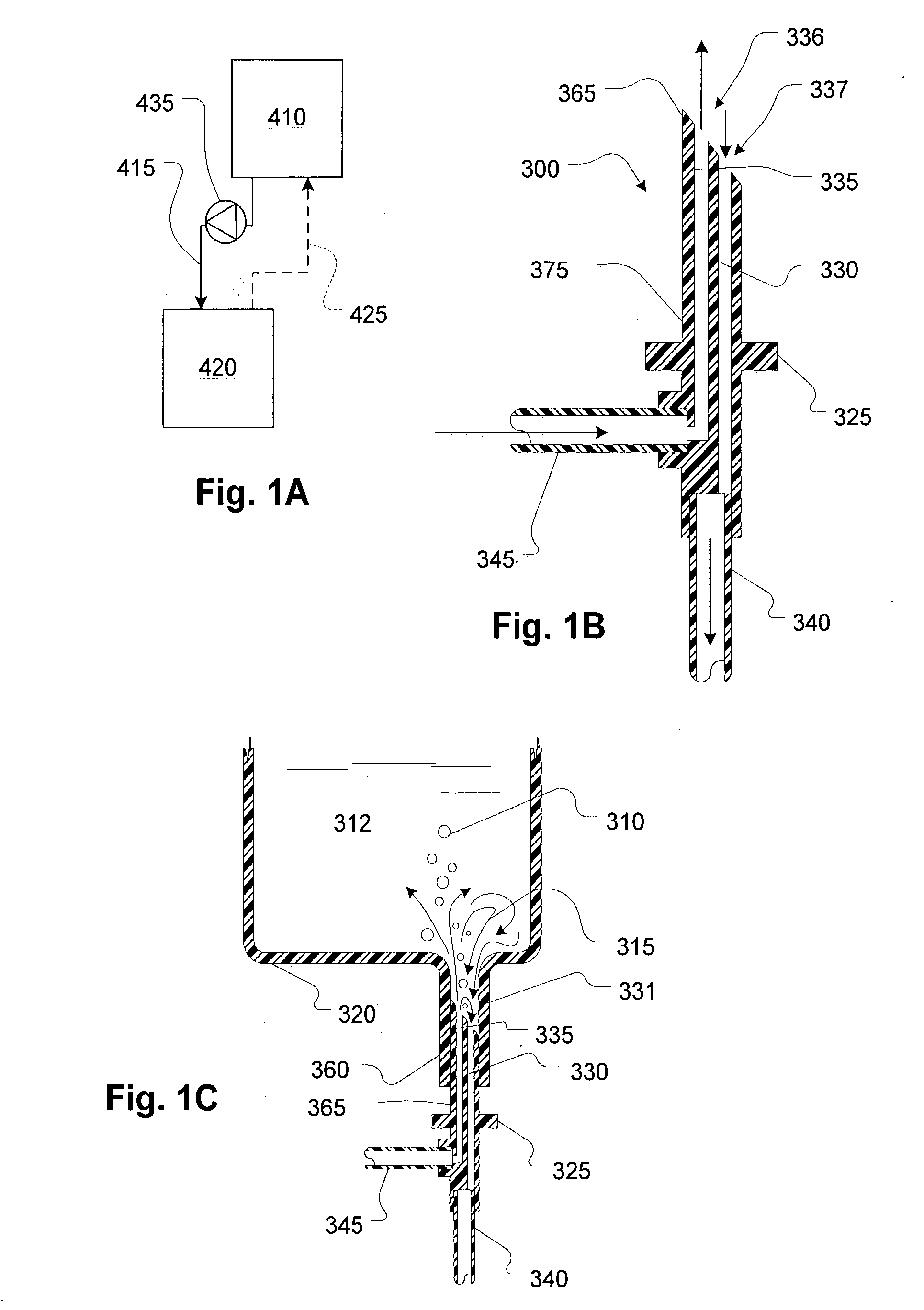

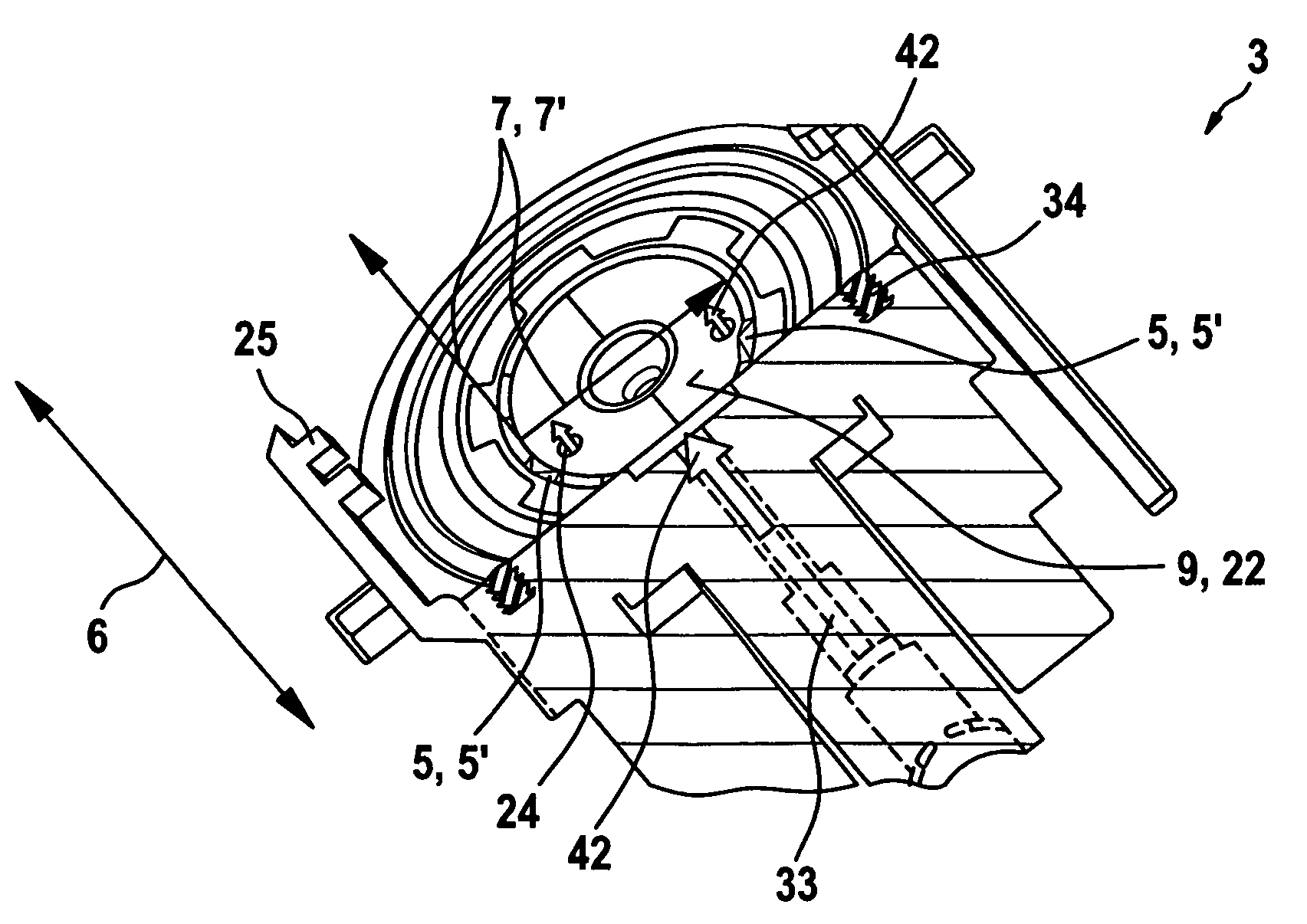

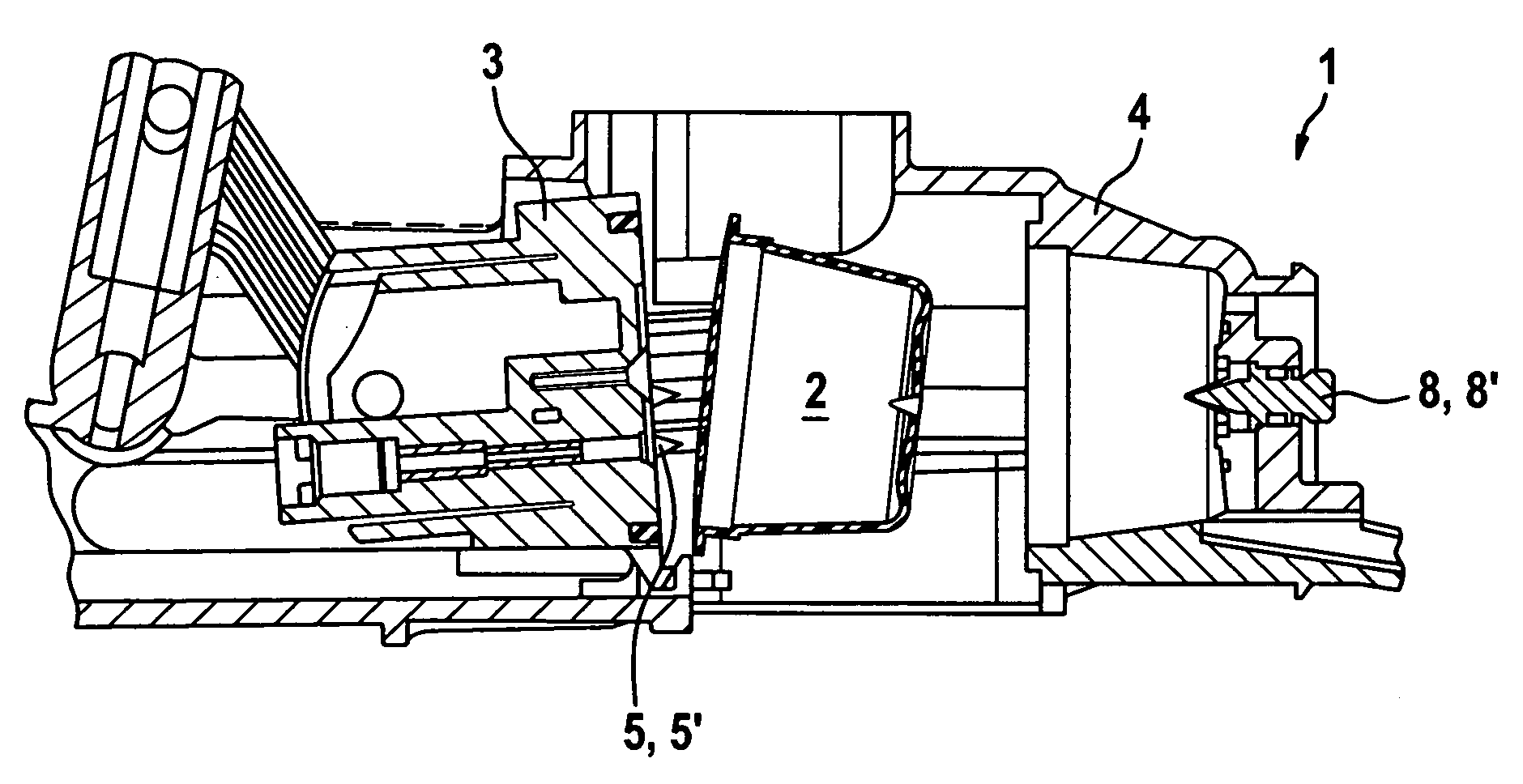

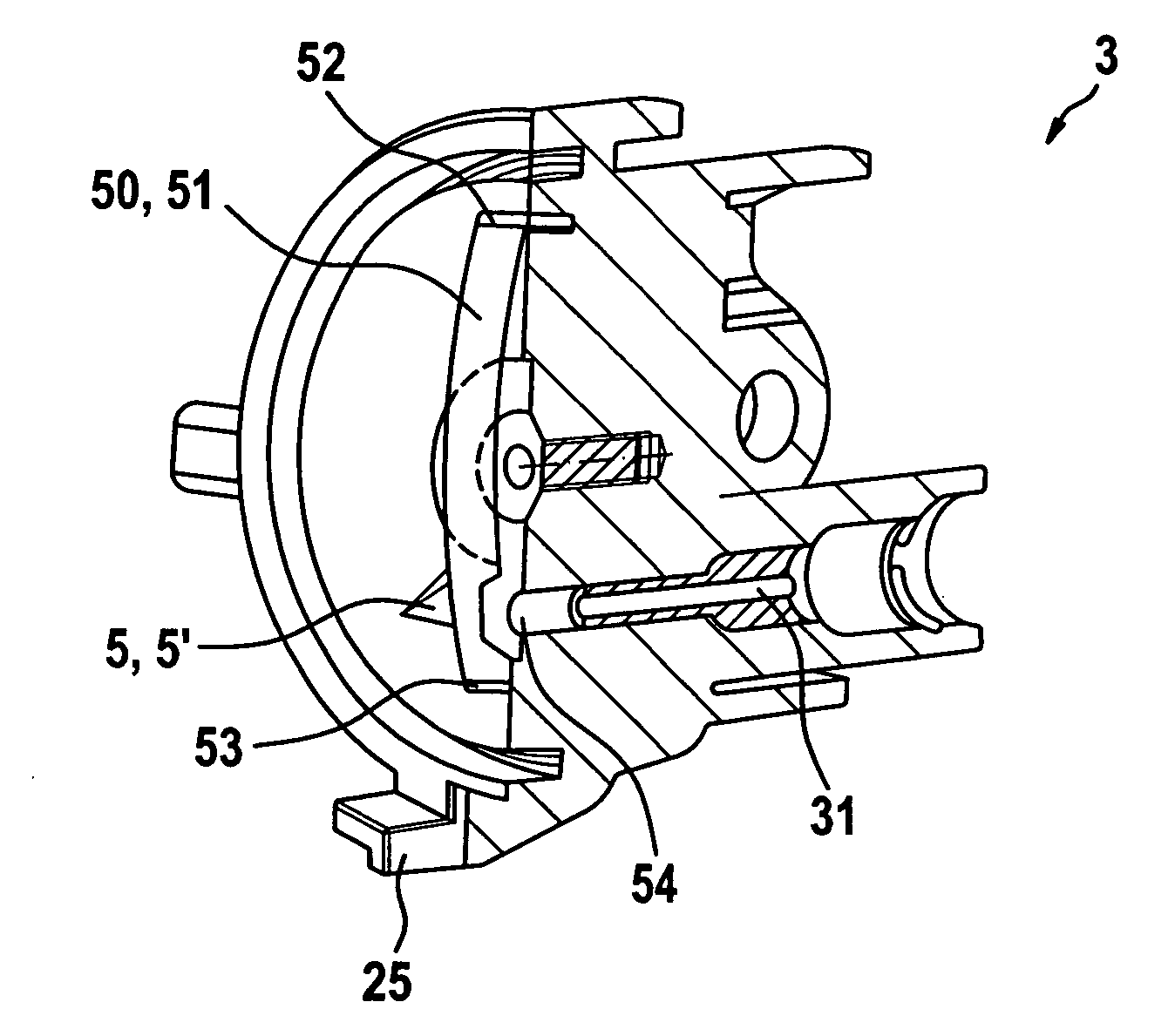

Brewing apparatus for extracting a portion capsule

ActiveCN103200849AReduce the risk of injuryReduce the risk of direct contactBeverage vesselsMaterial PerforationMechanical engineering

The present invention relates to a brewing apparatus for extracting a portion capsule, having a first brewing chamber element and a second brewing chamber element, wherein the first and / or the second brewing chamber element can be moved in an axial direction between a loading position, in which the first and the second brewing chamber element are spaced apart from each other, and an extraction position, in which the first and the second brewing chamber elements form a substantially closed brewing chamber, and wherein the first brewing chamber element has at least one first perforation means for perforating the portion capsule, which perforation means is arranged along a gravitational field of the Earth below a horizontal plane extending substantially at right angles to the gravitational field and centrally through the brewing chamber.

Owner:奥伊格斯特/弗里斯马格家用电器股份公司

Injection and expansion integrated device

The invention relates to an integrated device for injection and expansion, which comprises a hollow outer tube, and a movable socketed inner tube is arranged inside the outer tube; the front end of the inner tube is connected with an injection needle, and the rear end is connected with a hollow handle; The front end of the outer tube is covered with an expansion balloon, and the rear end is connected with the cylindrical shell; the expansion balloon is connected with the gas injection pipeline inside the outer tube; the handle is movably set in the shell. The invention has reasonable design, simple structure, convenient and safe operation, can quickly establish a submucosal tunnel, saves operation time, and can greatly reduce the risk of perforation or bleeding, creating favorable conditions for improving operation quality.

Owner:NANJING GENERAL HOSPITAL NANJING MILLITARY COMMAND P L A

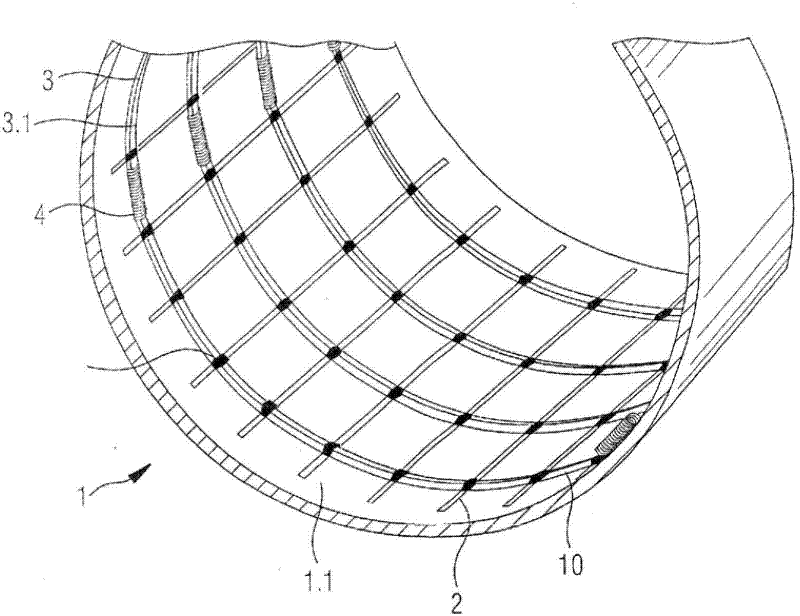

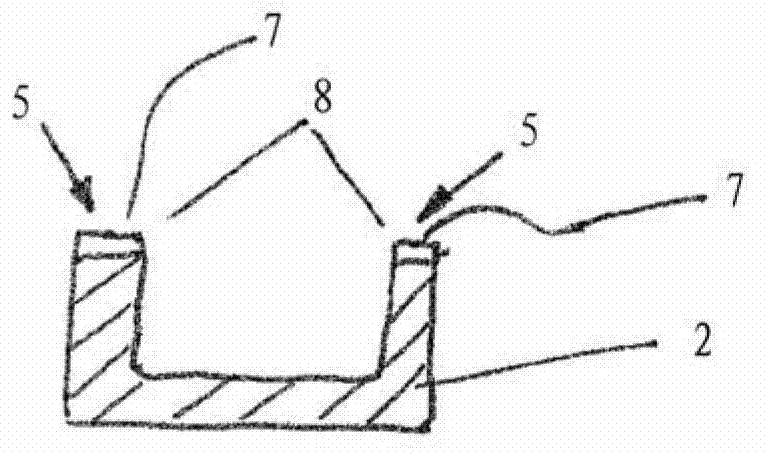

Device and method for producing a material web

InactiveCN102686797AEasy to install and fixPrevent slippingDryer sectionCardboardBiomedical engineering

The invention relates to a drying device (1) for drying a material web, in particular a paper, cardboard, or tissue web, comprising a steam-heatable cylinder (1.1) with an interior that has a lateral face (1.2). The drying device also comprises a device (10) lying in the interior for increasing the heat transfer from the interior to the lateral face (1.2). The device (10) comprises at least one disrupting strip (2), which lies axially and which has a contact surface (8) that is in contact with the lateral face (1.2), and at least one pressing element (3) for pressing the at least one disrupting strip onto the lateral face (1.2). The invention is characterized in that the lateral face (1.2) and / or the contact surface (8) of the disrupting strip (2) has means for increasing the friction coefficient between the lateral face (1.2) and the disrupting strips (2).

Owner:VOITH PATENT GMBH

Preparation of liquid collagen submucosal filler

InactiveCN107686517AWon't hurtNo need for multiple injectionsConnective tissue peptidesSurgeryMucosal resectionHydroxyproline

The invention discloses preparation of a liquid collagen submucosal filler. Collagen is of type I and has a complete natural triple helix structure, and a hydroxyproline content is greater than 11%. The type I collagen and type I collagen powder prepared from the type I collagen are particularly applicable to preparation of the liquid collagen submucosal filler; and the obtained liquid collagen submucosal filler can serve as a rising agent of a focus in endoscopic mucosal resection or endoscopic submucosal decollement and a repair material of a wound in an operation process, is reasonable in support time span, can be absorbed by a tissue completely, has hemostasis and repair functions at the same time, and has a very good application effect.

Owner:BEIJING HOTWIRE MEDICAL TECH DEV CO LTD

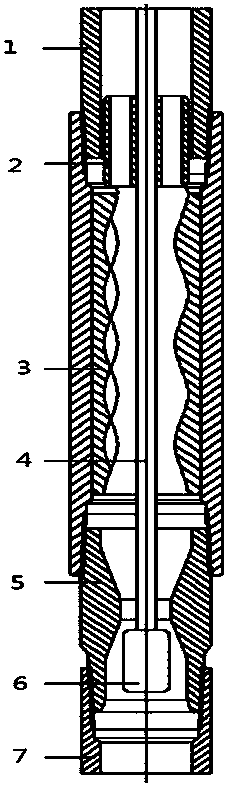

Underground screw pump and construction method for penetrating underground screw pump

PendingCN110242559AAvoid wear and tearSolve the problem of not being able to pass through construction cablesFluid removalRotary piston pumpsDepth in a wellArchitectural engineering

The invention discloses an underground screw pump and a construction method for penetrating the underground screw pump. The underground screw pump comprises a positioning pin, the positioning pin is connected to the lower end of a stator, and a center hole allowing a construction instrument or a tool to pass through is formed in the positioning pin. During construction, the lower end of the stator is connected to the positioning pin, the upper end of the stator is connected to a pump upper pipe column, the lower end of the positioning pin is connected to a pump lower pipe column, and the lower end of the positioning pin is lowered to a preset depth in a well; the construction instrument or the tool is connected to the lower end of a construction cable or a rod pipe, and a sliding centralizer is installed on the construction cable or the rod pipe above the construction instrument or the tool; and the construction cable or the rod pipe are lowered to enable the construction instrument or the tool to pass through the stator and the positioning pin, and the construction cable or the rod pipe are lowered to a preset position for construction. According to the underground screw pump and the construction method for penetrating the underground screw pump, the periods of test oil and production operation can be greatly shortened, the operation cost can be reduced to a largest extent, the construction operation range of the combined use of the screw pump and other tools is enlarged, the construction efficiency is improved, and meanwhile, the protection of reservoir is facilitated.

Owner:中石化石油工程技术服务有限公司 +2

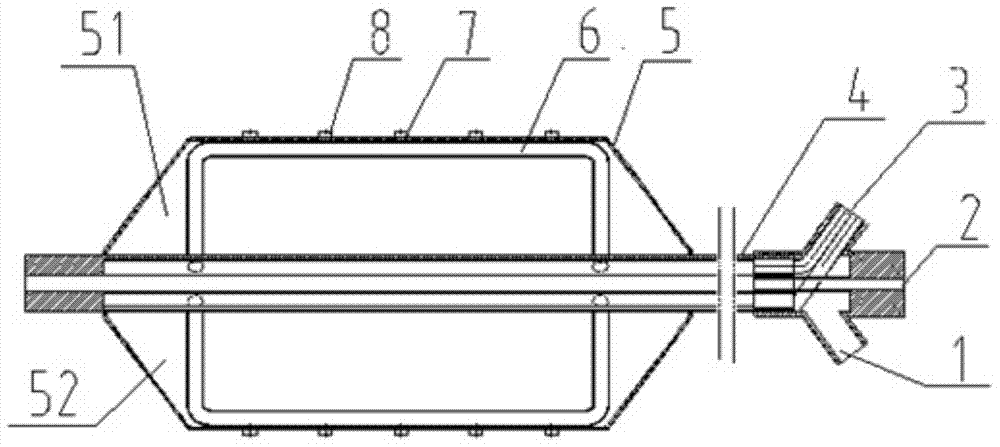

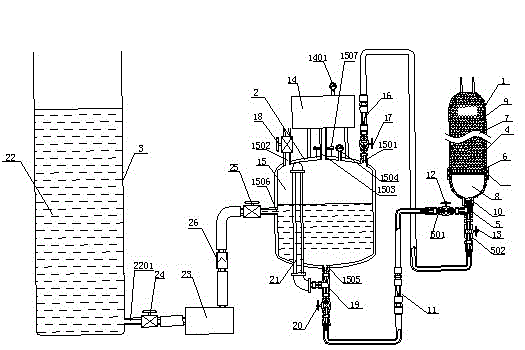

Tunnel support for endoscopic submucosal dissection

The invention provides a tunnel support for endoscopic submucosal dissection. The tunnel support comprises an air bag, a tubing, a negative pressure tube, a lead guide tube and an inflatable tube; the negative pressure tube, the lead guide tube and the inflatable tube are located in the tubing; the air bag is located at the front end of the tubing; the negative pressure sucking tubes are lengthways arranged on two sides of the upper wall and the lower all of the air bag; outward negative pressure sucking holes which pass through the air bag wall to communicate with the outside are uniformly formed in the negative pressure sucking tubes at the two sides of the upper wall and the lower wall of the air bag; the inflatable tube communicates with the air bag; the negative pressure tube is connected with a negative pressure generator. The tunnel support is simple in structure, convenient and reliable to operate, and effective to support a tunnel during the endoscopic submucosal dissection, so as to greatly reduce perforation and injury on muscularis propria and other complications; in addition, the difficulty at surgery can be greatly reduced, the cutting efficiency can be improved, and meanwhile, the safety of the surgery can be improved.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

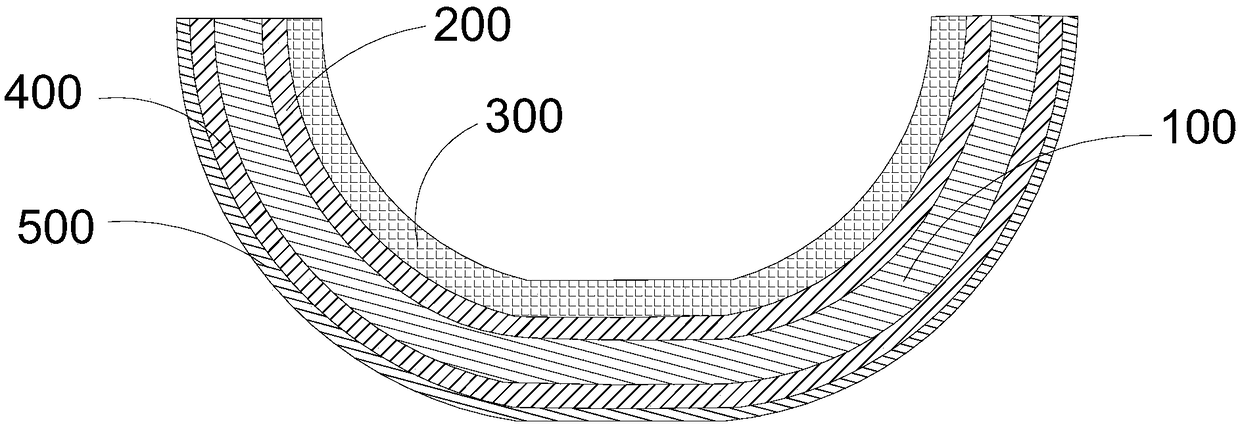

Stainless cooking utensil material, stainless cooking utensil and preparation method thereof

PendingCN109124371AImprove acid resistanceReduce corrosionCooking-vessel materialsMolten spray coatingTitaniumAlloy

The invention belongs to the technical field of pot body preparation, in particular to a stainless cooking utensil material, comprising a substrate, wherein the first surface of the substrate is an iron substrate; the first surface of the substrate is provided with a dense protective layer and a protective layer of a titanium compound, and the dense protective layer is located between the substrate and the protective layer. The method for preparing a stainless cooking utensil comprises nitriding a substrate provided with a titanium layer and / or a titanium alloy layer on an inner surface of a pot to obtain a protective layer and a dense protective layer which are laminated in sequence on the inner surface of the pot. The prepared stainless cooking utensil material improves the acid resistance of the nitriding true stainless pot, reduces the problems of sand holes and perforations in the use of the nitriding pot, and reduces the influence of the surface microstructure defects of the substrate on the performance of the iron pot.

Owner:武汉安在厨具有限公司 +1

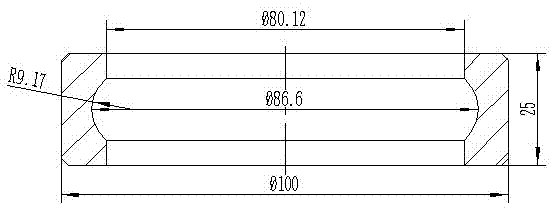

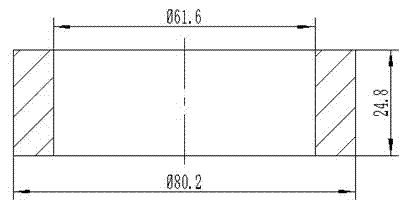

Method for directly producing ring parts by centrifugal casting and cold rolling

The invention discloses a method for directly producing ring parts by centrifugal casting and cold rolling, which belongs to the technology field of production of the ring parts. The method is characterized in that the technology process is as follows: (1) melting alloy by an intermediate frequency furnace at the temperature of 1700 DEG C; (2) externally refining by a low frequency (LF) ladle refining furnace at the temperature of 1680-1700 DEG C, carrying out bottom blowing argon, and stirring, deoxidizing and desulfurizing; (3) pouring the refined molten steel of 1550-1560 DEG C into a horizontal centrifuge for the centrifugal casting; (4) sawing by a steel pipe blanking machine and blanking; (5) rolling ring blanks at the room temperature on a precise cold rolling machine, wherein during rolling, the feed rate of each turn must be not less than the minimum feed rate v min of each turn needed by forging penetration of the ring parts, and is also not more than the maximum feed rate v max of each turn allowed by biting of the ring parts, the rolling ratio of the ring parts is selectable for 1.1 to 1.5, and the ring parts are processed into the required shape and dimension; (6) quenching and tempering conventionally the ring parts; and (7) precisely shaping the ring parts conventionally. The method can improve production efficiency, and save the energy and materials.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

A graphene-containing static-electricity-conducting polystyrene foaming material and a preparing method thereof

A graphene-containing static-electricity-conducting polystyrene foaming material and a preparing method thereof are disclosed. The weight of graphene in the material is 0.4-1 wt% of the total weight of a styrene monomer and graphene before polymerization. Prepared graphene / polystyrene beads are subjected to foaming, plate pressing and molding to obtain a foam plate. The surface resistance of the foam plate is 10<6>-10<8> [omega], the antistatic requirement is met, the flame retardance grade of the foam plate can be the B1 grade, the heat conductivity decreases from original 0.039-0.042 W / (m.K) to 0.030-0.034 W / (m.K), and the drawing performance increases from original 90 KPa to 220-260 KPa.

Owner:无锡兴达泡塑新材料股份有限公司 +1

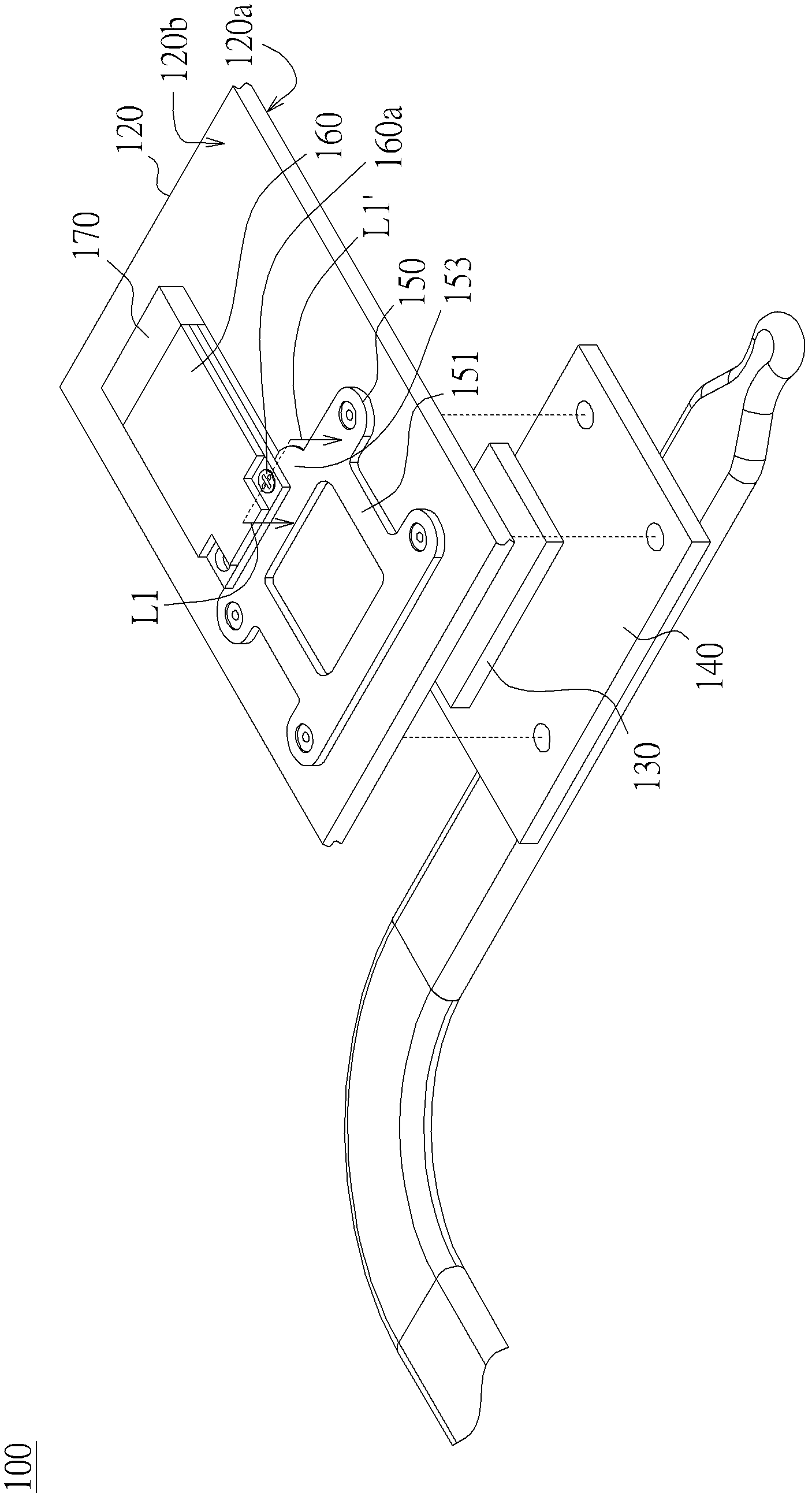

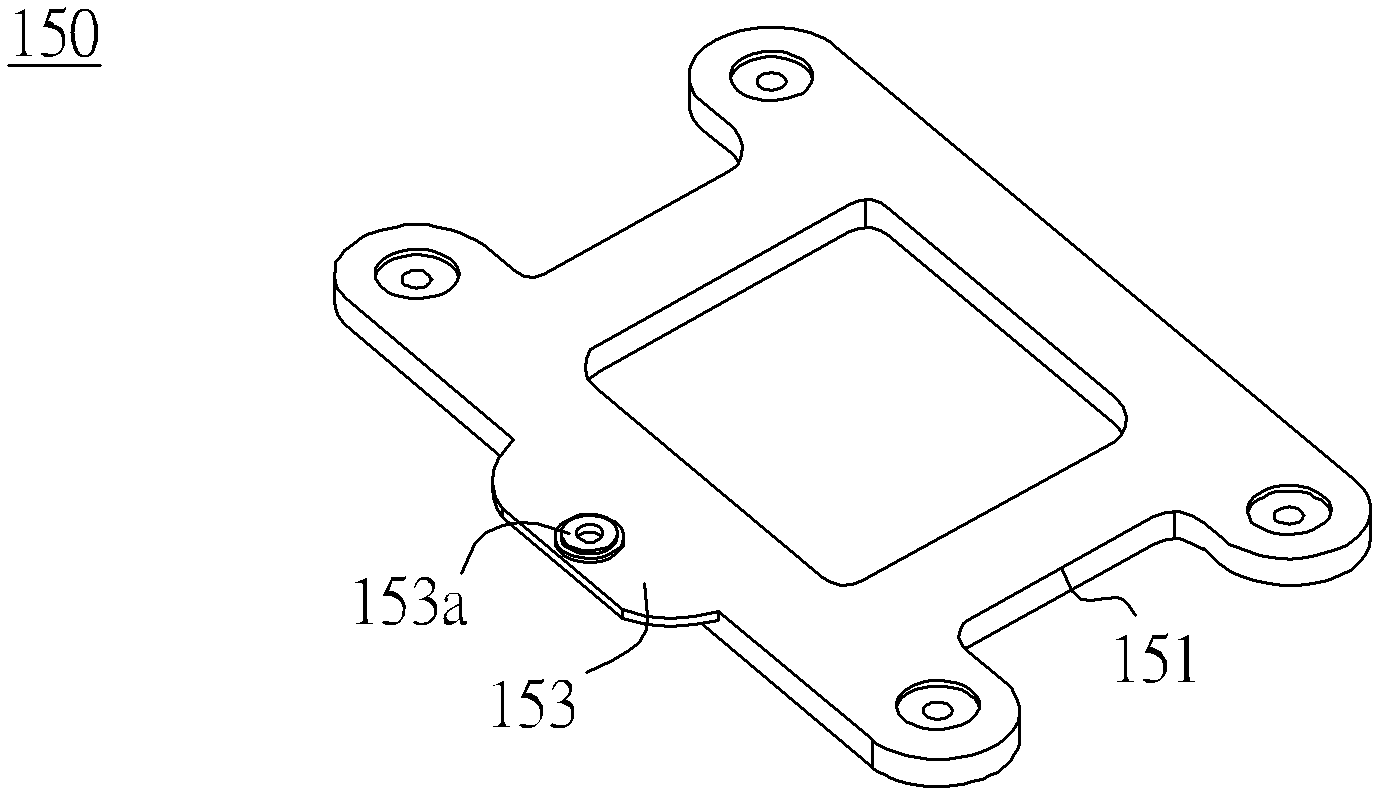

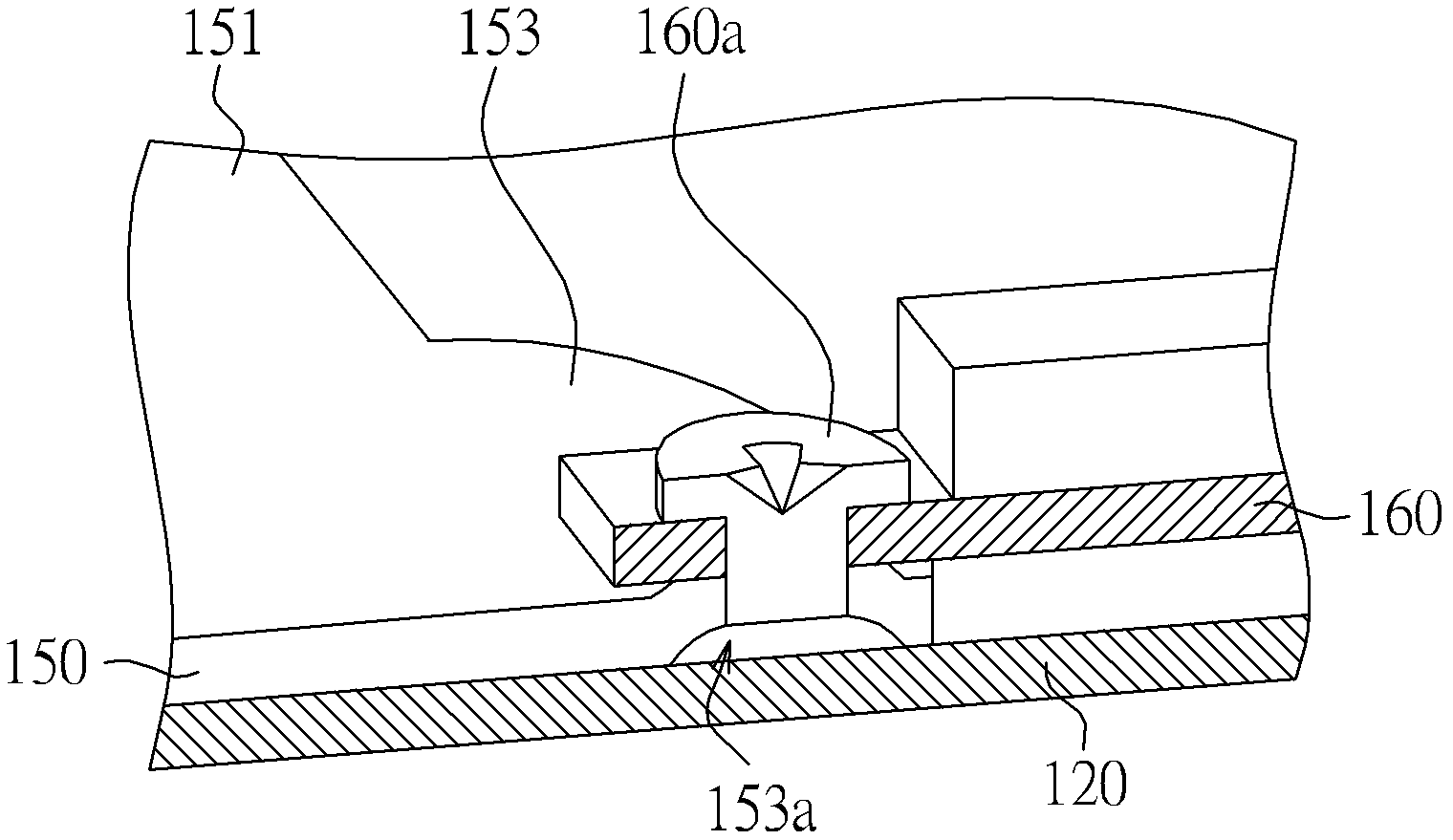

Electronic device

InactiveCN103105912AReduce perforationIncrease the areaDigital data processing detailsComputer moduleFunctional module

An electronic device comprises a circuit board, a chip, a heat dissipation module, a fixing plate, a functional module and a connector. The circuit board is provided with a first surface and a second surface, the chip is arranged on the first surface, the heat dissipation module is arranged on the chip, and the fixing plate corresponding to the chip is arranged on the second surface and connected with the heat dissipation module. One end of the functional module is fixed on the fixing plate in a locking mode, the connector is arranged on the second surface of the circuit board, and the functional module is in electric connection with the circuit board through the connector.

Owner:INVENTEC CORP

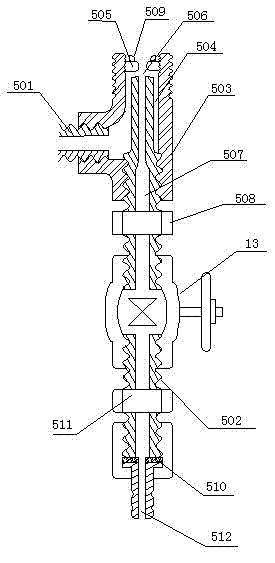

Passive type multifunctional well head backflow dredging compensating device

InactiveCN101608536AReduce resistancePrevent reverse accessFluid removalSealing/packingWater storageElectricity

The invention relates to a passive type multifunctional well head backflow dredging compensating device for petroleum industry, mainly comprising a separating backflow assembly and a medicament carrying unit, wherein the separating backflow assembly mainly comprises a well fluid separating unit, a filter, a sand and water storage chamber and a backflow flow rate control unit; the medicament carrying unit mainly comprises a medicament carrier, a medicament can and an air balancing connection pipe, wherein the medicament carrier is respectively communicated with a fluid returning pipe and the medicament can; and after well fluid is separated and filtered by the separating backflow assembly, a part of polluted water enters the medicament carrier through a well fluid backflow pipe column along the fluid returning pipe and is mixed with medicament inside the medicament can by a water power spray principle to flow back to a passage dredging submergence depth air in an oil sleeve ring in the air. The invention reduces the resisting force of the air which upwards flows from submergence depth, prevents the air reversely entering an electric pump, ensures the separating effect of an electric pump separator, prolongs the exemption period of an electric pump well and saves a great amount of operation expense and operation time.

Owner:SHENGLI OILFIELD SANLI GASOLINEEUM TECH DEV

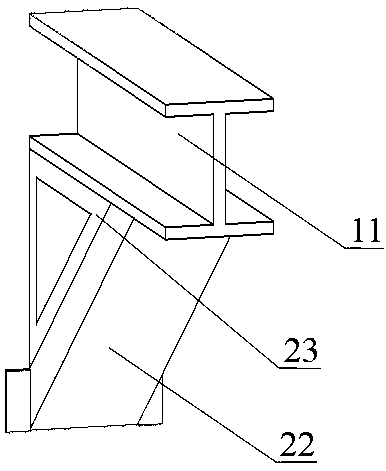

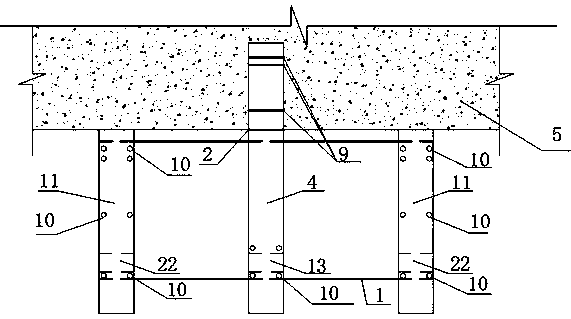

Upper-air formwork support and outer scaffold shared cantilever structure

PendingCN111236640AHigh strengthEasy to obtainForms/shuttering/falseworksScaffold accessoriesFalseworkFloor slab

The invention discloses an upper-air formwork support and outer scaffold shared cantilever structure, and belongs to the technical field of buildings. The upper-air formwork support and outer scaffoldshared cantilever structure comprises cantilever steel beams, a horizontal rectangular steel plate, a U-shaped pull ring and the like. The cantilever steel beams comprise a first cantilever steel beam and a second cantilever steel beam, the first cantilever steel beam is in lap joint to a floor, the lap-joint end of the first cantilever steel beam and the floor is connected through the U-shaped pull ring, the horizontal rectangular steel plate is mounted on the bottoms of the first cantilever steel beam and the second cantilever steel beam, the second cantilever steel beam is connected with the side of the floor, and rectangular hollow braces and triangular steel plate are mounted between the lower portion of the horizontal rectangular steel plate at the bottoms and the side wall of the floor. Through the structure system, the horizontal rectangular steel plate is mounted, the first cantilever steel beam and the second cantilever steel beam are better stressed, it is ensured that a formwork support and an outer scaffold are erected at the same time, bearing capacity is high, all cantilever steel beams adopt brace types, a traditional single steel wire rope is not adopted for inclined bracing, the stability of the cantilever steel beams is improved, and stability and safety of a cantilever scaffold can be improved.

Owner:张延年

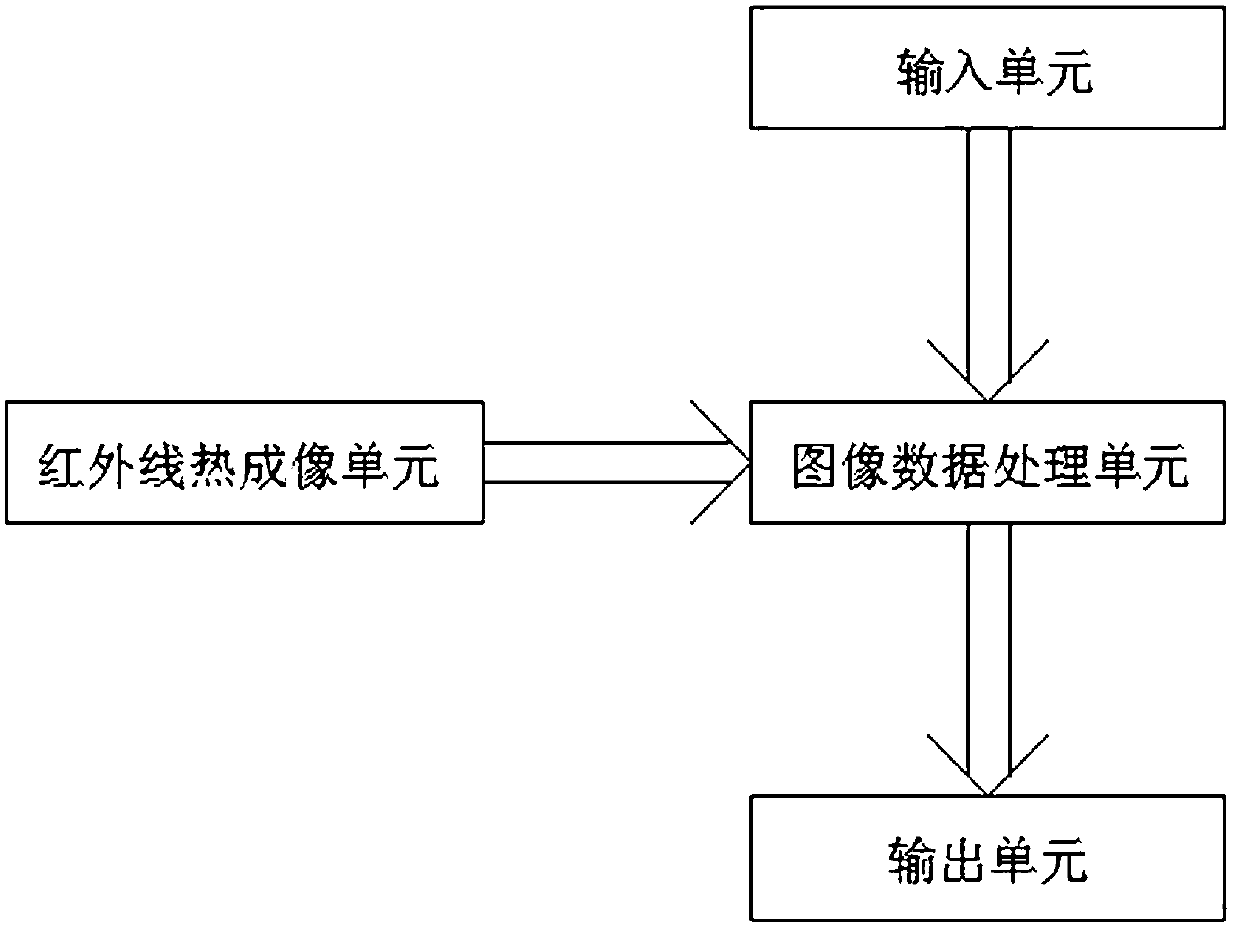

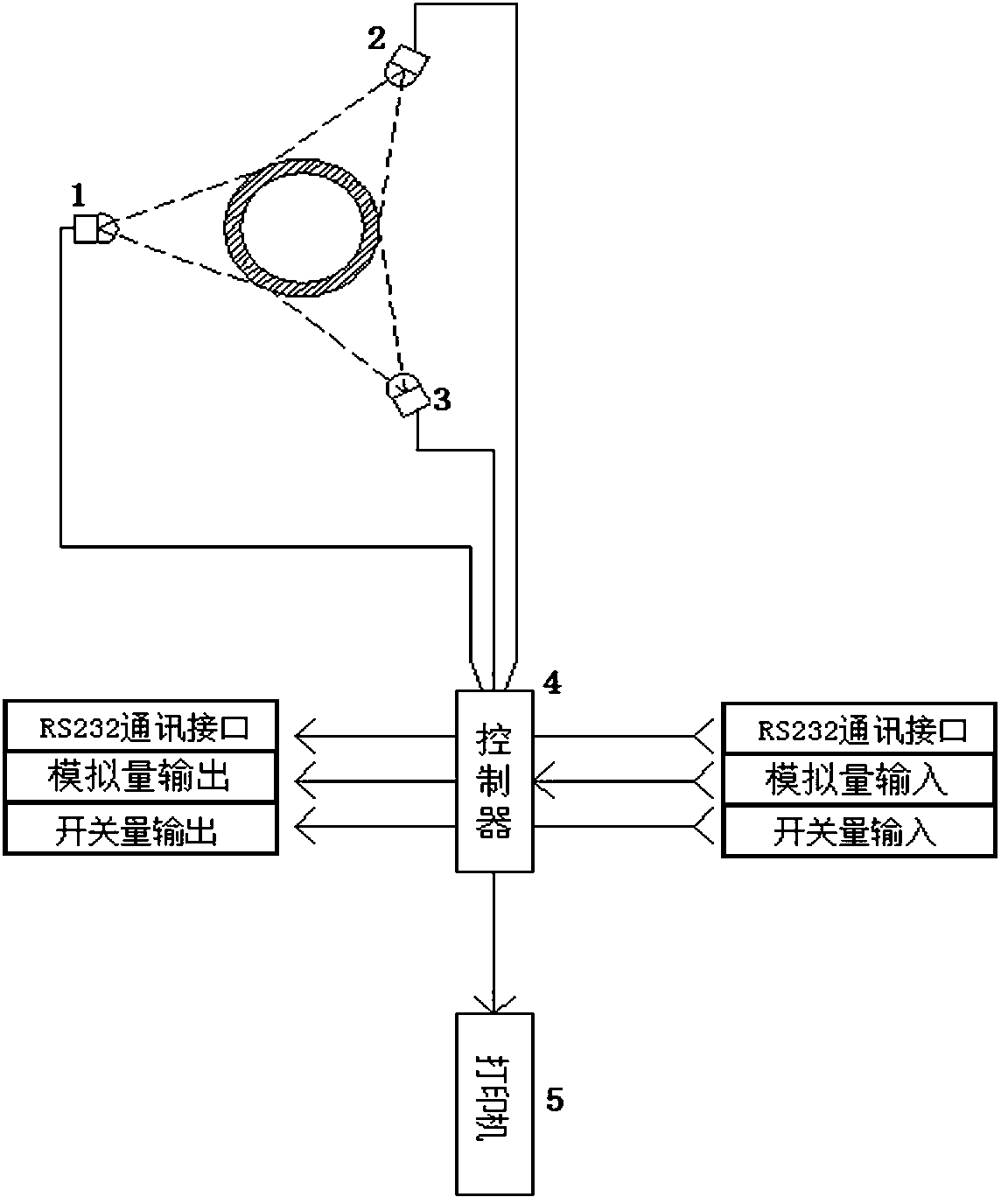

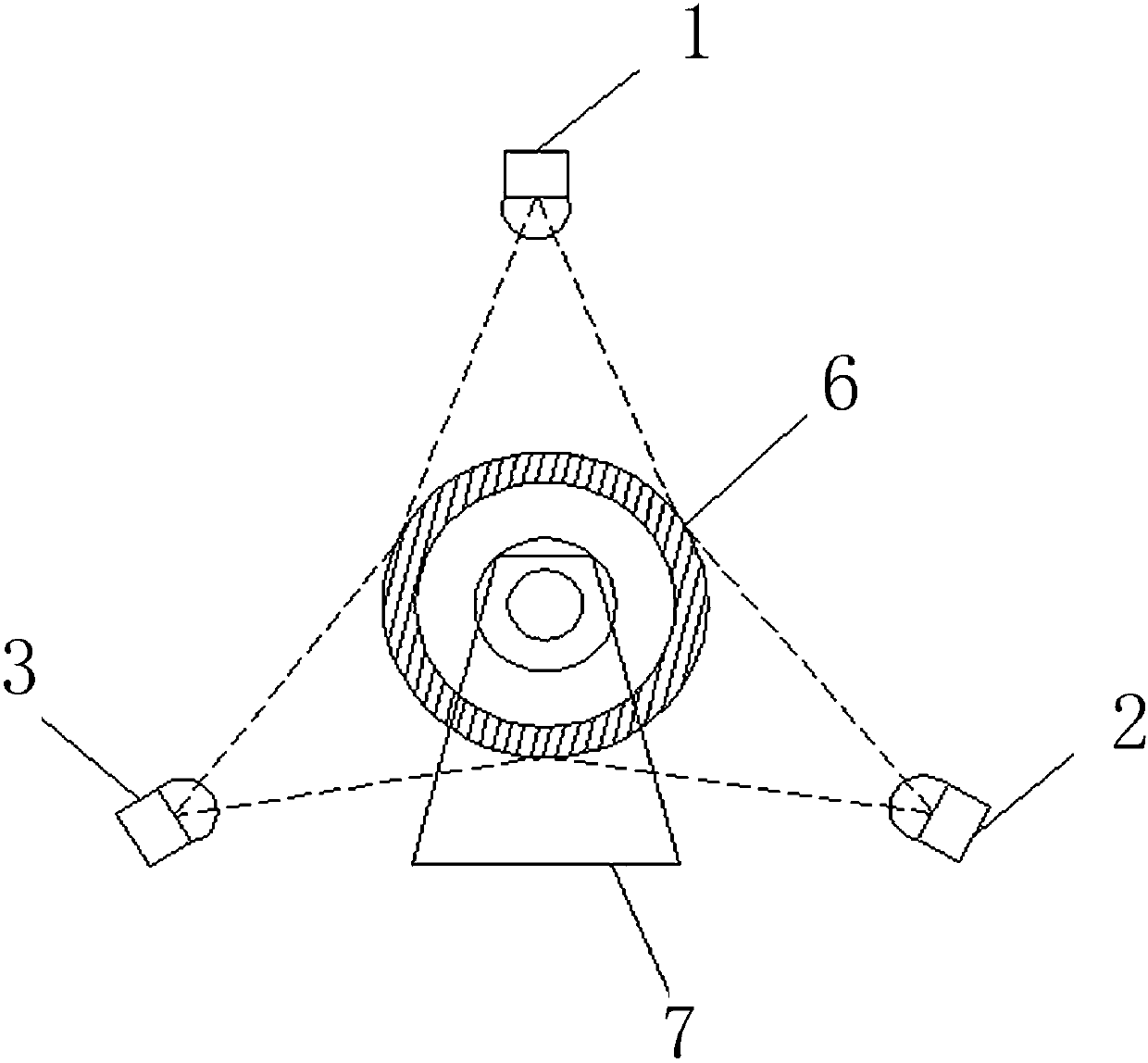

Device and method for testing temperature rising characteristics of nonlinear resistors of generator de-excitation systems

ActiveCN102998570AReduce short circuitReduce perforationRadiation pyrometryDynamo-electric machine testingElectrical resistance and conductanceNonlinear resistor

The invention belongs to the technical field of industrial automation, and particularly relates to a device and a method for testing temperature rising characteristics of nonlinear resistors of generator de-excitation systems. An infrared thermal imaging lens A, an infrared thermal imaging lens B and an infrared thermal imaging lens C are connected with a controller through communication cables; the controller is connected with input signals and output signals of other external controllers through communication cables in a RS232, switching value and analog quantity mode; the controller is connected with a printer through a cable; and a nonlinear resistor element is connected with a fixed support frame through insulated screws. The device and the method have the advantages of being safe and reliable, the occurrence rate of accidents of short circuit, perforation, breakage and the like of resistance valve plates can be reduced, and nonlinear resistors are guaranteed to operate stably and reliably.

Owner:STATE GRID CORP OF CHINA +2

Thermoplastic sheet, a radiation mask of thermoplastic sheet and method for providing said sheet and said mask

ActiveUS20140206924A1Reduce perforationObstruct patientCosmetic preparationsImpression capsVitrificationAcrylonitrile

The present invention relates to a thermoplastic composition suitable for manufacturing a thermoplastic sheet for producing a medical cast, such as a radiation mask. The composition has a polymeric component comprising a mixture of a styrene acrylonitrile copolymer and polycaprolactone, optionally together with a cross-linker and / or a filler, wherein the polymeric component comprises, 20 to 40 weight % of a styrene acrylonitrile copolymer and 80 to 60 weight % of a polycaprolactone, expressed in weight % of the polymeric component, wherein the thermoplastic composition has a glass transition temperature of 35° C.-80° C. The invention further relates to a thermoplastic sheet and to a medical cast, in particular a radiation mask, obtainable from said composition. In a final aspect, the invention relates to a method for producing said sheet and said radiation mask.

Owner:T TAPE

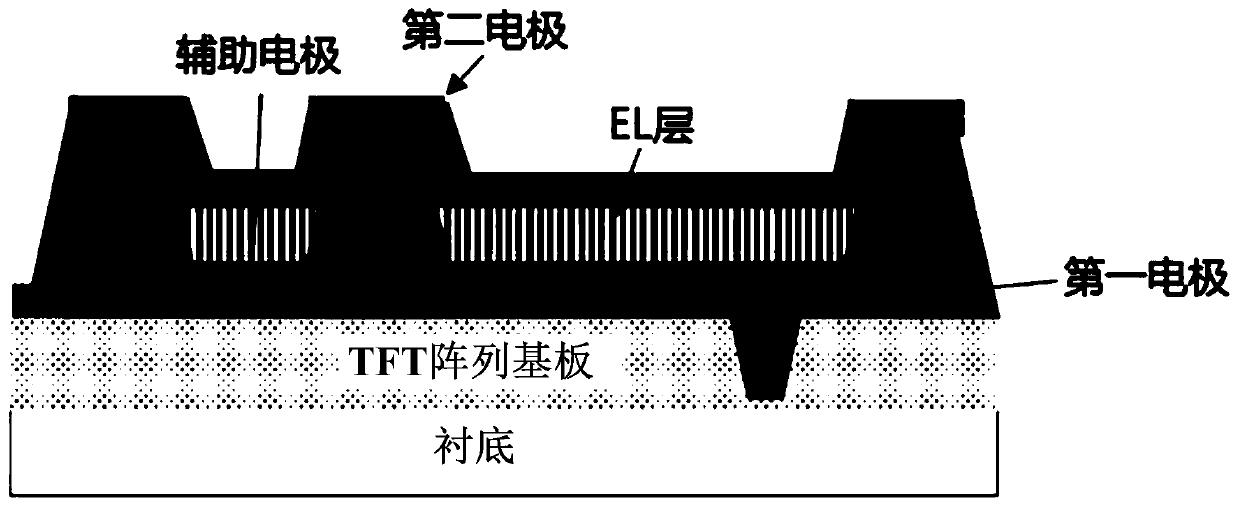

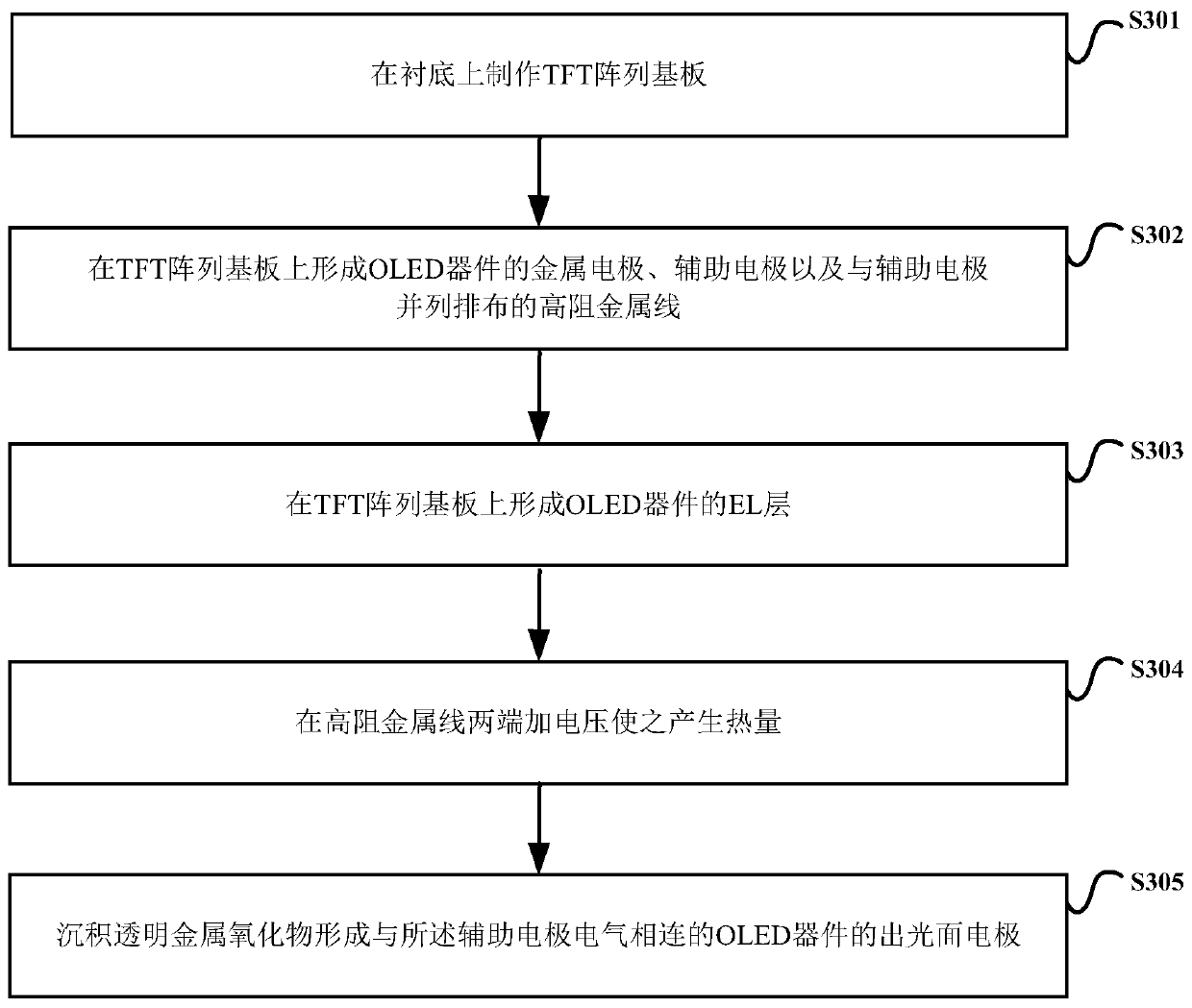

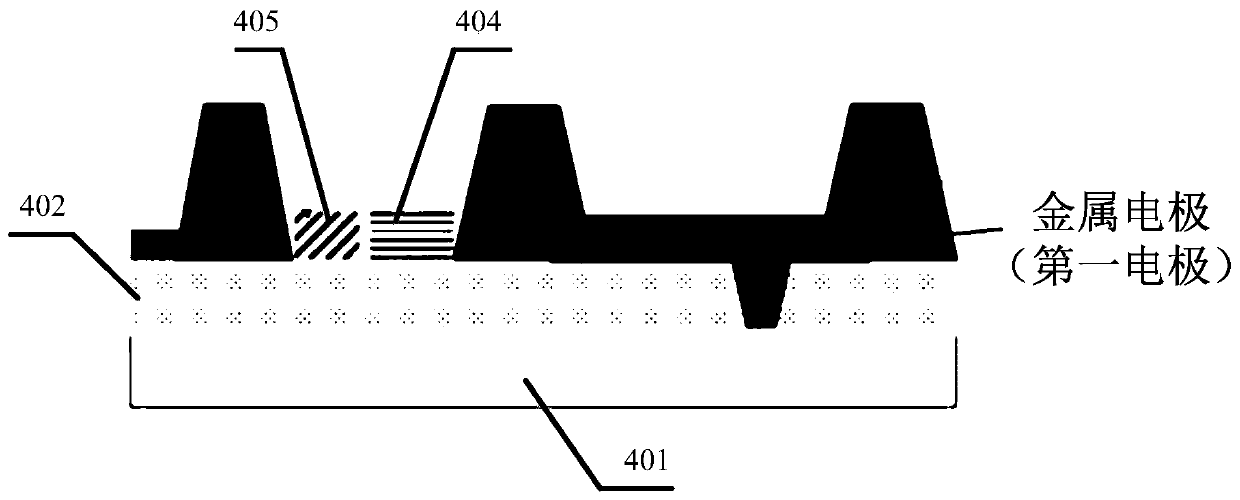

OLED display screen, display panel, and manufacturing method thereof

ActiveCN110416262AReduce perforationShorten process manufacturing timeSolid-state devicesSemiconductor/solid-state device manufacturingHigh resistancePunching

The present invention discloses an OLED display screen, a display panel, and a manufacturing method thereof. The method comprises: forming, on a TFT array substrate, a high-resistance metal wire thatis parallel to an auxiliary electrode and has a spacing less than a threshold; after forming an EL layer of an OLED device, applying voltage to both ends of the high-resistance metal wire, to enable the high-resistance metal wire to generate heat; and after the heat makes a temperature of the auxiliary electrode rise, and makes a organic material of the high-resistance metal wire and the EL layeron the top of the auxiliary electrode evaporated and eliminated, depositing a transparent metal oxide to form a light-exiting surface electrode of the OLED device electrically connected to the auxiliary electrode. According to the manufacturing method, when a technique of connecting the light-exiting surface electrode of the OLED and the auxiliary electrode in a manufacturing process is performed,a punching operation is no longer needed, so that a process manufacturing time is shortened, and production efficiency is improved. Further, production costs may be further reduced because a high-precision laser puncher is not needed.

Owner:BOE TECH GRP CO LTD

A bottom anti-shake dust filter bag

A bottom rocking prevention type dedusting filter bag comprises a barrel body, the top surface of the barrel body is open, a separator plate is arranged in the barrel body, the outer circumference ofthe separator plate is fixedly connected with the inner wall of the barrel body, the top surface of the separator plate is provided with a first through hole, the first through hole is colinear with the center line of the separator plate, the inner bottom surface of the barrel body is fixedly connected with the lower end of an electric push rod, the movable rod of the electric push rod goes through the first through hole, the upper end of the electric push rod is fixedly connected with the bottom surface of a cylindrical plug, the cylindrical plug is colinear with the center line of the electric push rod, the bottom surface of the cylindrical plug is provided with a plurality of sliding slots, the outer end of every sliding slot is fixedly connected with one end of a first spring, and theother end of every first spring is fixedly connected with one side of a first sliding block. The bottom rocking prevention type dedusting filter bag can effectively inhibit the lower end of a filter bag from rocking, also can clean dusts in the filter bag by an ingenious design, and can work only by providing electric power required by the electric push rod, so the energy consumption is minimal; and dust removal is completed through the self-vibration of the filter bag and airflow, so energy saving and environmental protection are achieved.

Owner:江苏蓝天环保集团股份有限公司

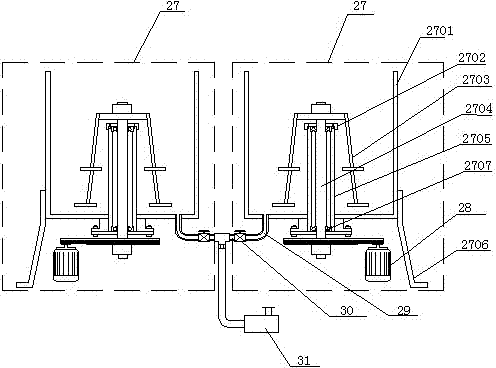

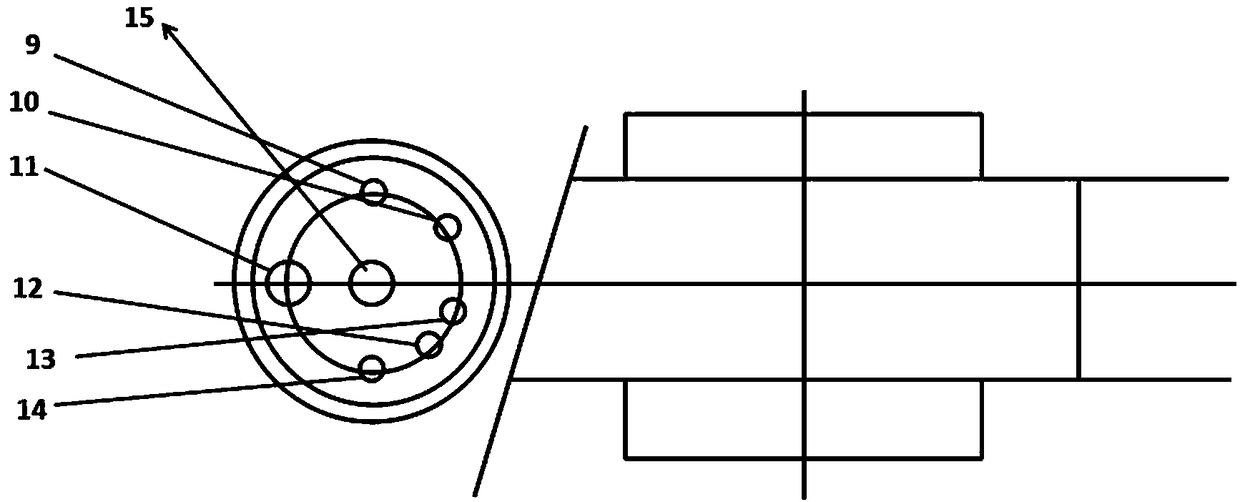

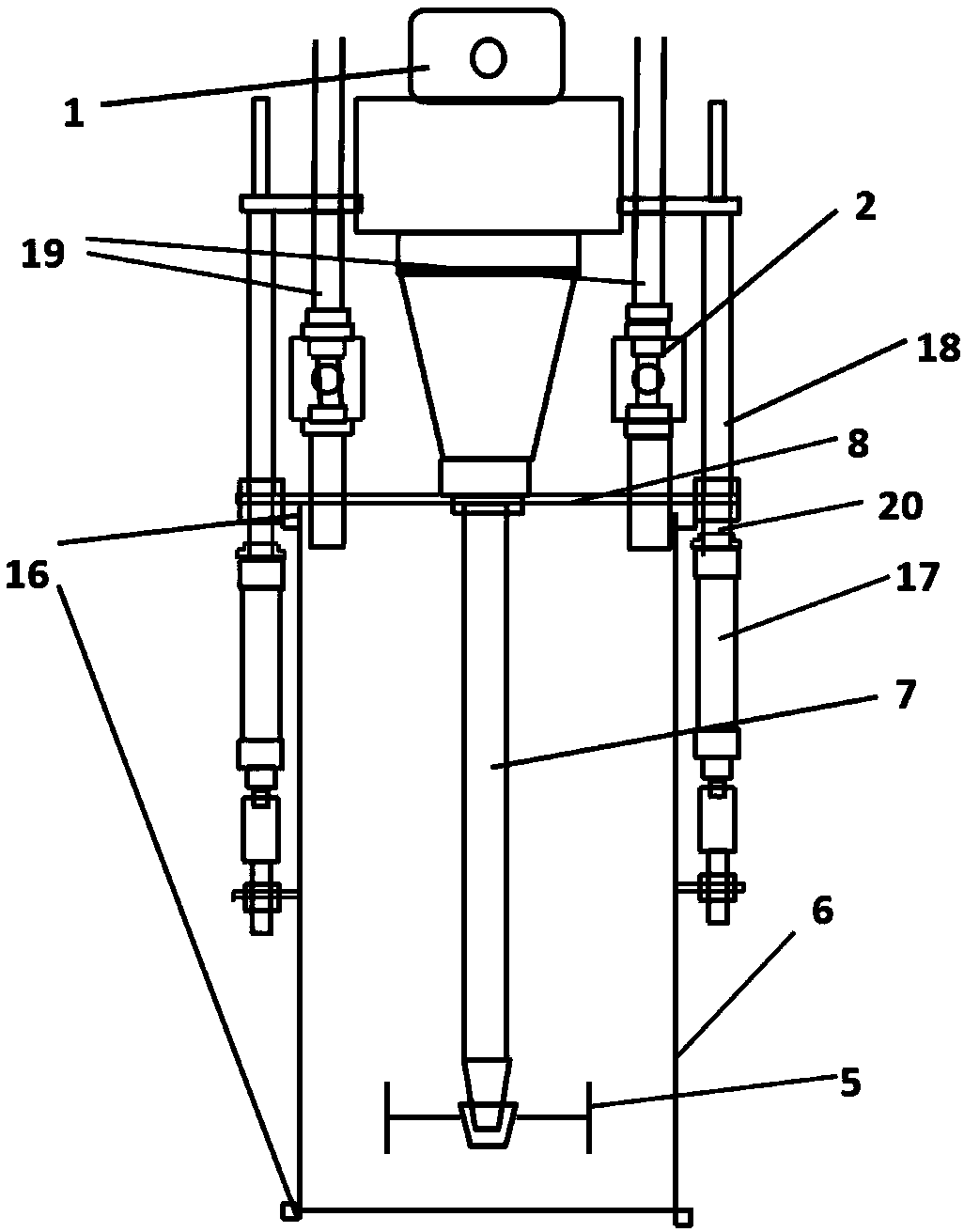

Separable negative pressure foaming machine with bottomless bucket, and preparation method thereof

The invention discloses a separable negative pressure foaming machine with a bottomless bucket, and a preparation method thereof. The separable negative pressure foaming machine comprises a stirring device, a hydraulic lifting device, a negative pressure air extraction device, a separable stirring bucket and a discharge device, wherein the separable stirring bucket comprises the bottomless bucketand a sealing cover; the hydraulic lifting device is fixedly connected with the sealing cover through an upper pull rod; the sealing cover is movably connected with the bottomless bucket through a cylinder and a lower pull rod; and the cylinder realizes the closure and separation of the sealing cover and the bottomless bucket. The separable negative pressure foaming machine disclosed by the invention overcomes the technical problems that the internal structure defects of a product are caused due to air mixing during stirring, and the inner wall of a bucket bottom cannot be self-cleaned and residues exist, so that the production efficiency is reduced, in the prior art, and the provided foaming equipment with the polyurethane bottomless bucket and a negative pressure defoaming stirring device realizes that the next foaming can be carried out without the need of cleaning for a bucket body, and continuous industrial production is efficient and rapid; and meanwhile, the foam holes of foam are fine and uniform, so that the perforation and structure defects are greatly reduced, the mechanical strength of the product is increased, and the appearance quality of the product is improved.

Owner:浙江华江科技股份有限公司

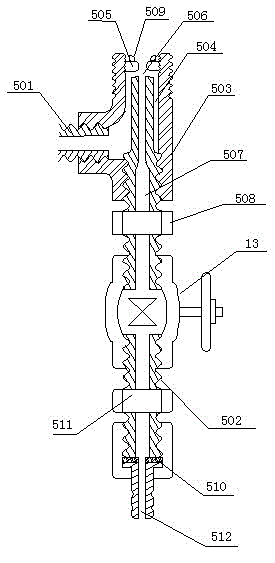

Fallopian tube recanalization assembly

InactiveCN103932763AShorten the lengthSimple structureBalloon catheterObstetrical instrumentsObstetricsBalloon catheter

The invention relates to instruments and apparatuses for the gynaecology and obstetrics department, in particular to a fallopian tube recanalization assembly. The fallopian tube recanalization assembly comprises a dual-cavity sacculus catheter and a guide wire, wherein the dual-cavity sacculus catheter is provided with a sacculus cavity and a guide wire cavity. A deflection sacculus is arranged at the front portion of the dual-cavity sacculus catheter. The top end of the dual-cavity sacculus catheter is in a smooth arc shape. Three holes are formed in the front end of the dual-cavity sacculus catheter, and the three holes include a guide wire through hole in the top end, and a first liquid outlet and a second liquid outlet which are symmetrically distributed in the two sides. The tail end of the dual-cavity sacculus catheter is forked into a sacculus cavity tail section and a guide wire cavity tail section. A check valve is fixedly connected with the tail end of the sacculus cavity tail section, and a guide wire is a straight-head guide wire. According to the fallopian tube recanalization assembly, the liquid outlets are formed in the two sides, and therefore positioning is accurate during operations; the straight-head guide wire can smoothly enter the fallopian tube during operations, and therefore the pain degree of a patient and damage to the uterine cavity are reduced; an eccentric air bag is used in cooperation with the liquid outlets in the two sides, the length of the guide wire is accurately controlled, and therefore operability can be better achieved during operations, operation time is shortened to 0.3 hour to 0.5 hour compared with traditional operation time of 1 hour to 1.5 hours, and the operation success rate is greatly increased to 85%.

Owner:徐中华 +1

High efficient foam concrete foaming agent foaming machine

ActiveCN102267165BHigh trafficUnlimited dilution factorFlow mixersTransportation and packagingFoam concreteFoaming agent

A high-performance foaming machine for a foam concrete foaming agent comprises a foaming device (1), an air-driving device (2) and a foaming agent dilute solution supply device (3). The foaming device (1) comprises a foaming tube (4) and a spray mechanism (5). The air-driving device (2) comprises an air compressor (14) and a foaming agent dilute solution storage tank (15). The foaming agent dilute solution supply device (3) is connected to a liquid inlet tube (1506) of the foaming agent dilute solution storage tank (15) through a worm pump (23). The foaming machine can adjust the dilution ratio of the foaming agent and the proportion of the dilute solution and air arbitrarily according to the use instruction of the foaming agent and the desired hardness of the foam, thereby reducing the required amount of the foaming agent, saving the compressed air, and forming foam which is stable and has a large diameter.

Owner:LUOYANG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com