Oscillation impact damping device for liquid goods carrying

A technology of impact device and cargo, applied in the direction of bulk cargo, etc., can solve the problem of not reducing the sloshing impact, reducing the loading capacity of the tank, etc., reducing the sloshing impact, increasing the resistance loss along the way, and reducing the price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

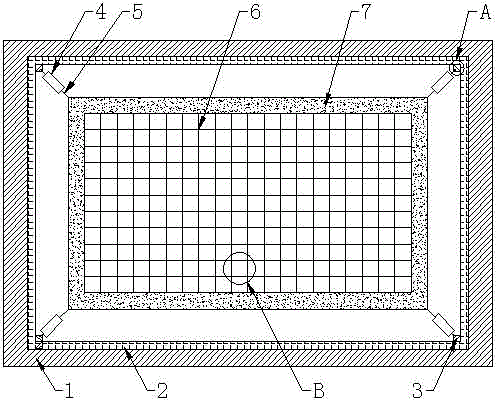

[0019] Such as figure 1 and Figure 4 Shown: a sloshing impact reduction device for liquid cargo transportation, including thermal insulation material 2, slide rail 3, connecting rope 5, sloshing reduction component 6, slider 10 and rail 11, the warehouse wall is provided with thermal insulation material 2, The slide rails 3 are arranged at the four corners of the cargo compartment wall 1 , and the slide blocks 10 arranged in the slide rails 3 are connected to the main frame of the sloshing reduction assembly 6 through connecting ropes 5 . The slide rails 3 are fixed at the four corners of the cargo hold, so that the floating device on the anti-sloshing assembly 6 will not be too close to the bulkhead.

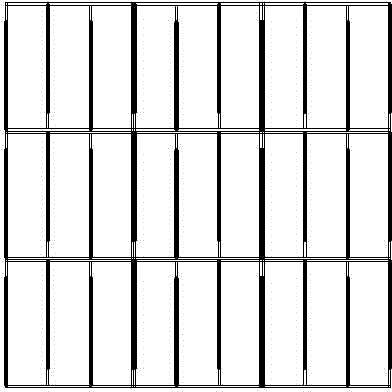

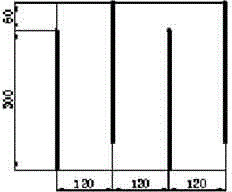

[0020] The anti-sloshing assembly 6 includes a frame unit 9 and baffles 8 , and the baffles 8 are arranged alternately in the frame unit 9 . The fluid flows in the channel defined by the baffles 8 . The specific setting method of the baffle plate 8 is: directly inserting it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com