Patents

Literature

870results about How to "Reduce kinetic energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

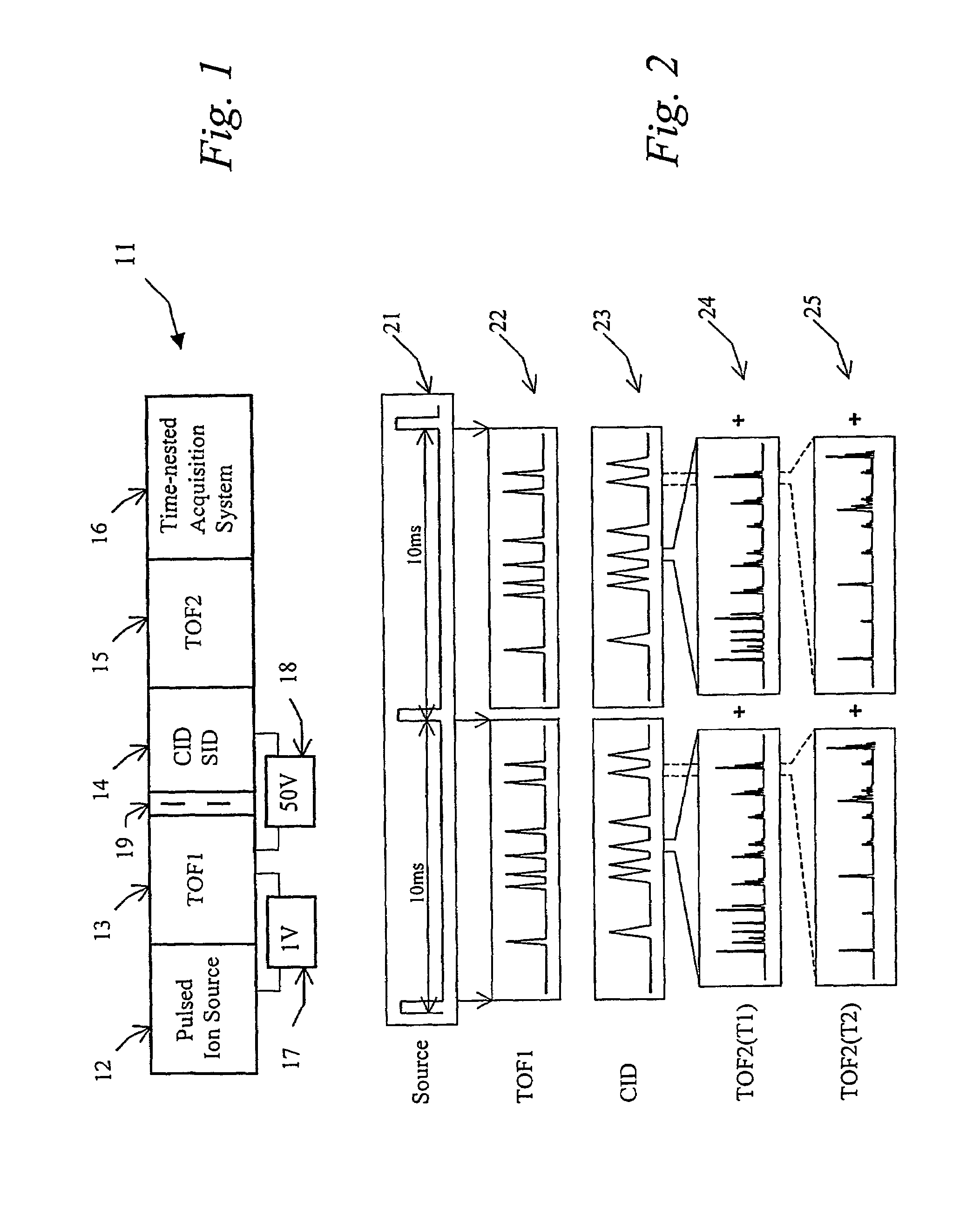

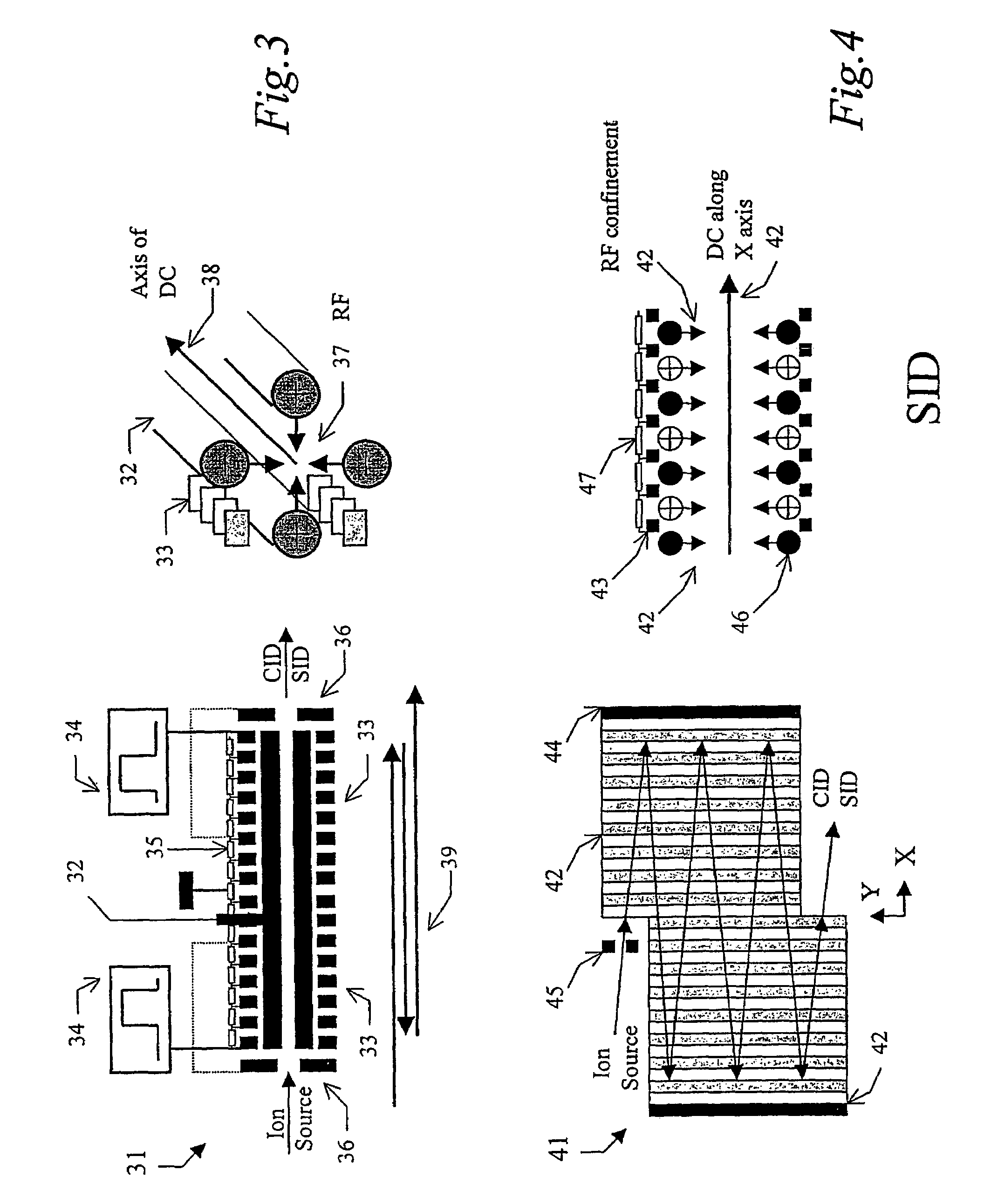

Tandem time of flight mass spectrometer and method of use

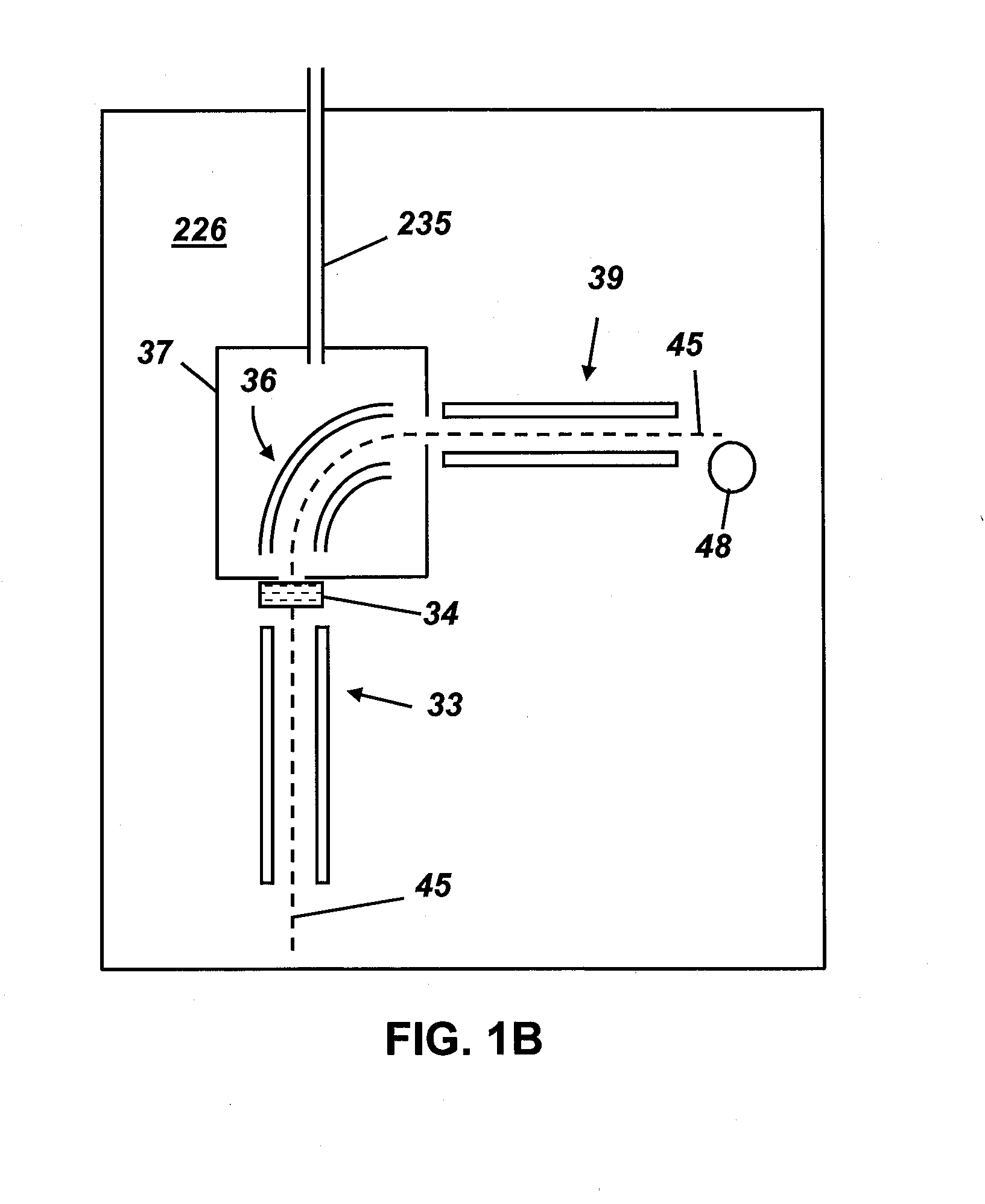

InactiveUS20050242279A1Rapid MS-MS analysisEasy to separateTime-of-flight spectrometersIsotope separationRelative energyMass analyzer

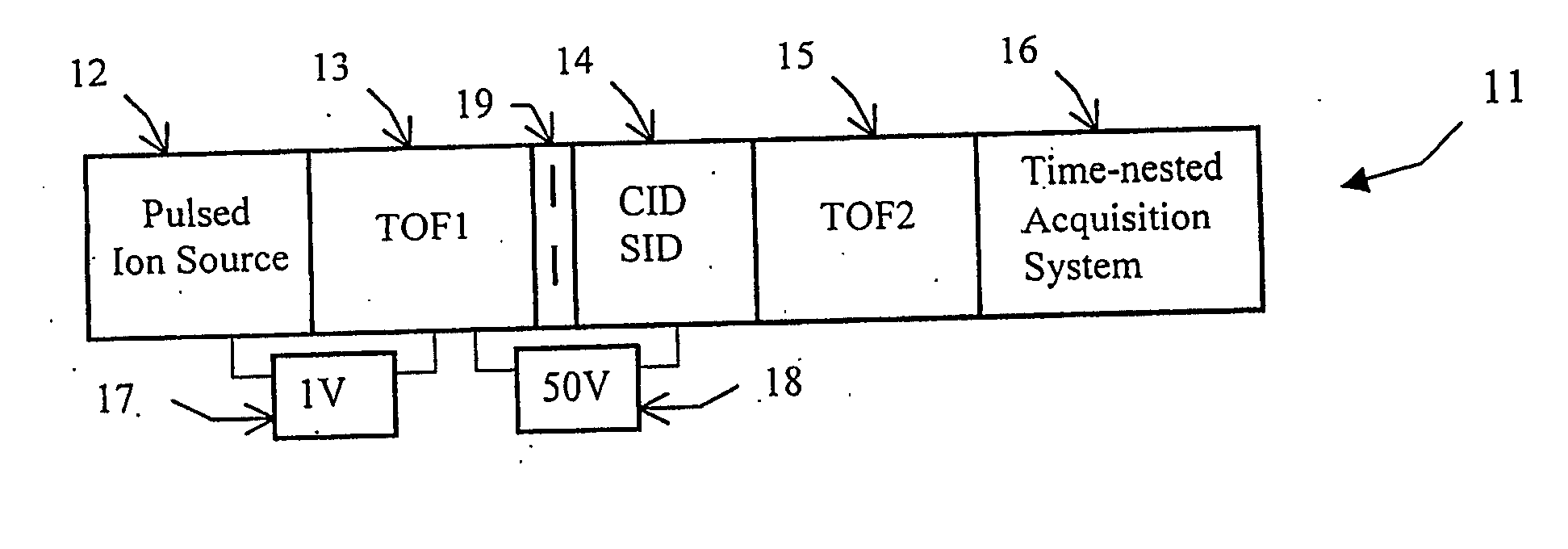

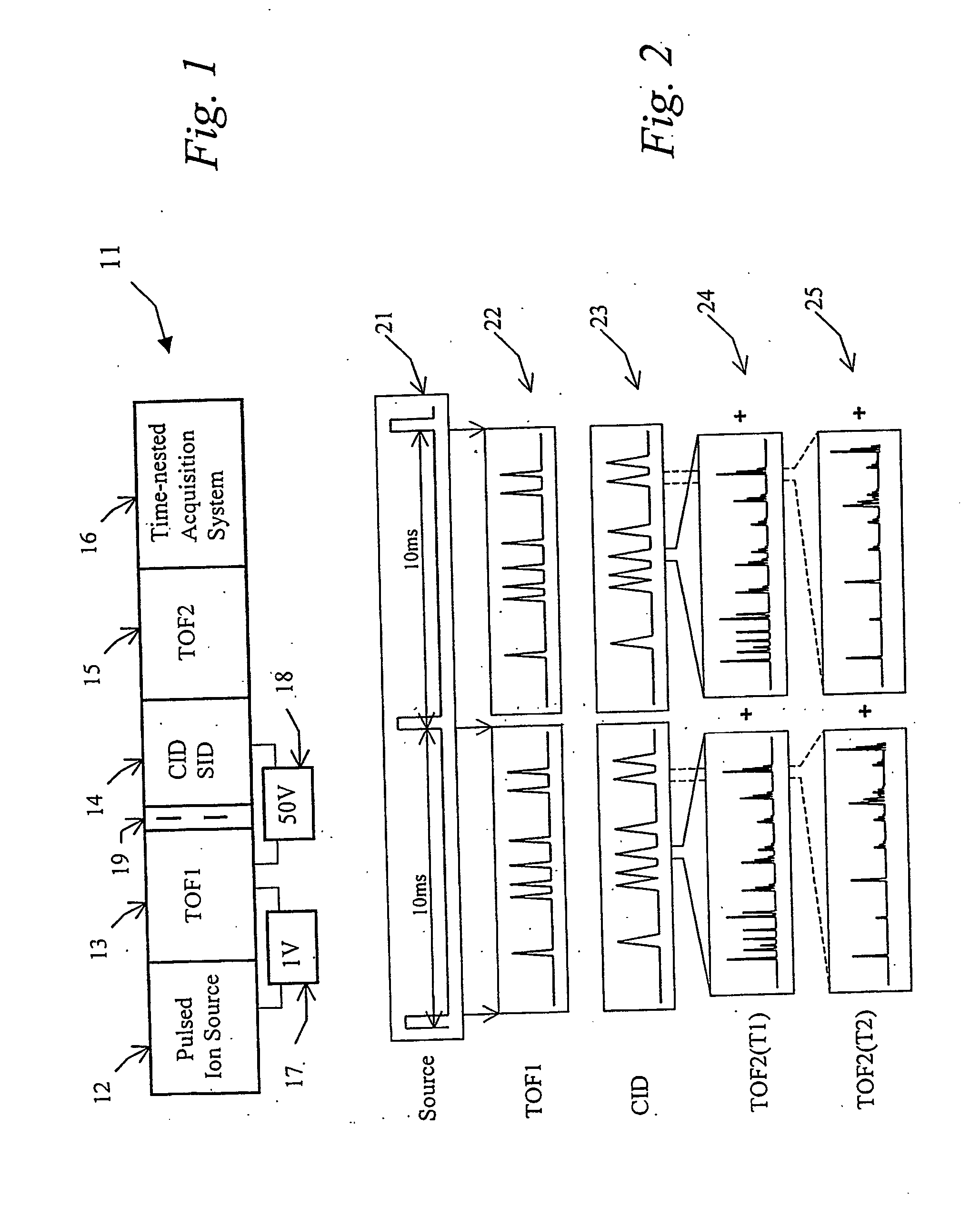

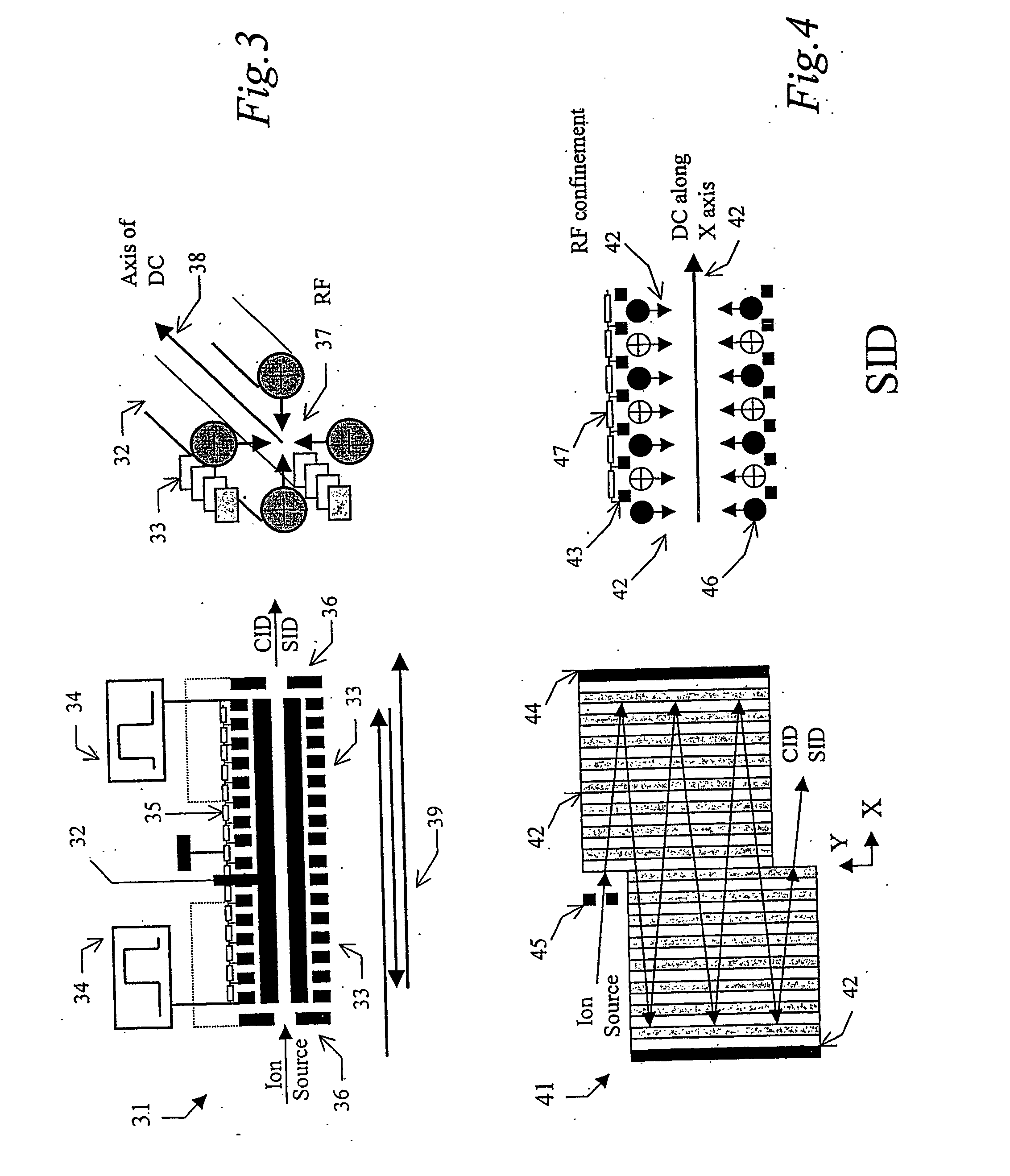

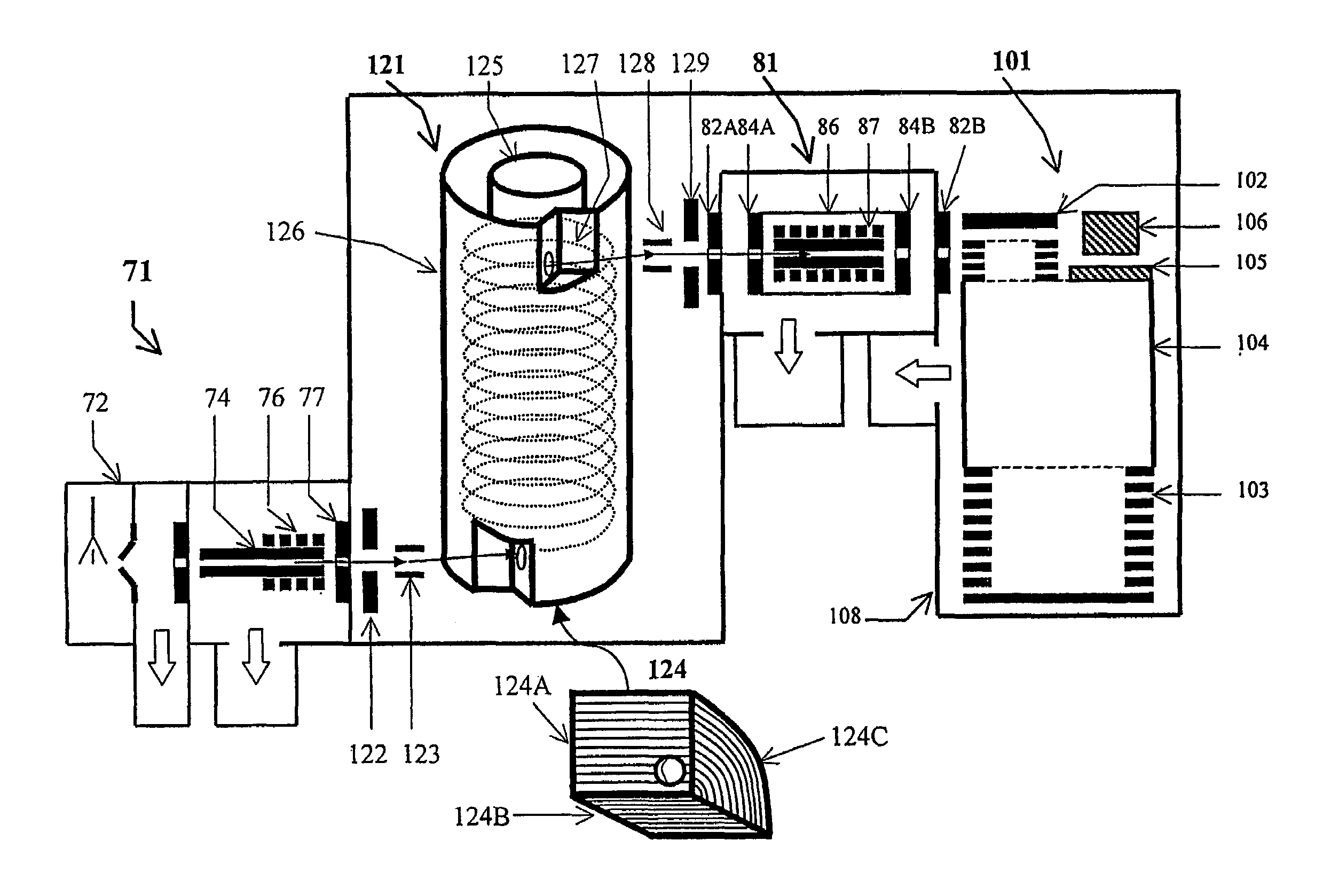

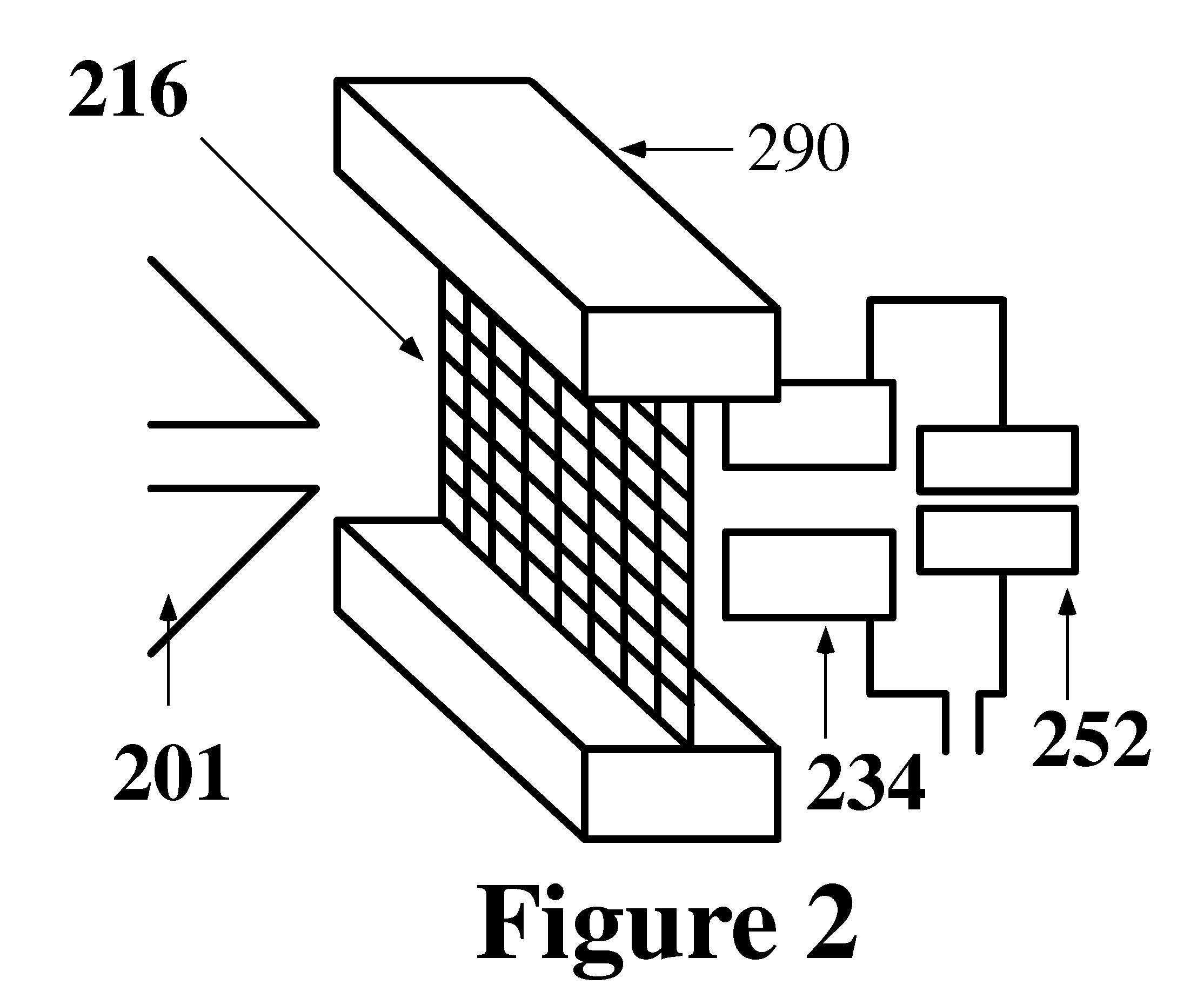

To provide comprehensive (i.e. rapid and sensitive) MS-MS analysis, the inventor employs a time-nested separation, using two time-of-flight (TOF) mass spectrometers. Parent ions are separated in a slow and long TOF1, operating at low ion energy (1 to 100 eV), and fragment ions are mass analyzed in a fast and short TOF2, operating at much higher keV energy. Low energy fragmentation cell between TOF1 and TOF2 is tailored to accelerate fragmentation and dampening steps, mostly by shortening the cell and employing higher gas pressure. Since separation in TOF1 takes milliseconds and mass analysis in TOF2—microseconds, the invention provides comprehensive MS-MS analysis of multiple precursor ions per single ion pulse. Slow separation in TOF1 becomes possible with an introduction of novel TOF1 analyzers. The TOF-TOF could be implemented using a static TOF1, here described on the examples of spiratron, planar and cylindrical multi-pass separators with griddles spatial focusing ion mirrors. Higher performance is expected with the use of novel hybrid TOF1 analyzers, combining radio frequency (RF) and quadratic DC fields. RF field retains low-energy ions within TOF1 analyzer, while quadratic DC field improves resolution by compensate for large relative energy spread.

Owner:LECO CORPORATION

Tandem time of flight mass spectrometer and method of use

InactiveUS7196324B2Quick analysisEasy to separateTime-of-flight spectrometersIsotope separationRelative energyMass analyzer

To provide comprehensive MS—MS analysis, a time-nested separation is employed using two time-of-flight (TOF) mass spectrometers. Parent ions are separated in a slow and long TOF1, operating at low ion energy (1 to 100eV), and fragment ions are mass analyzed in a fast and short TOF2, operating at much higher keV energy. A low energy fragmentation cell between TOF1 and TOF2 is tailored to accelerate fragmentation and dampening steps, mostly by shortening the cell and employing higher gas pressure. Slow separation in TOF1 becomes possible with an introduction of novel TOF1 analyzers. Higher performance is expected with the use of novel hybrid TOF1 analyzers, combining radio frequency (RF) and quadratic DC fields. An RF field retains low-energy ions within a TOF1 analyzer, while a quadratic DC field improves resolution by compensating for a large relative energy spread.

Owner:LECO CORPORATION

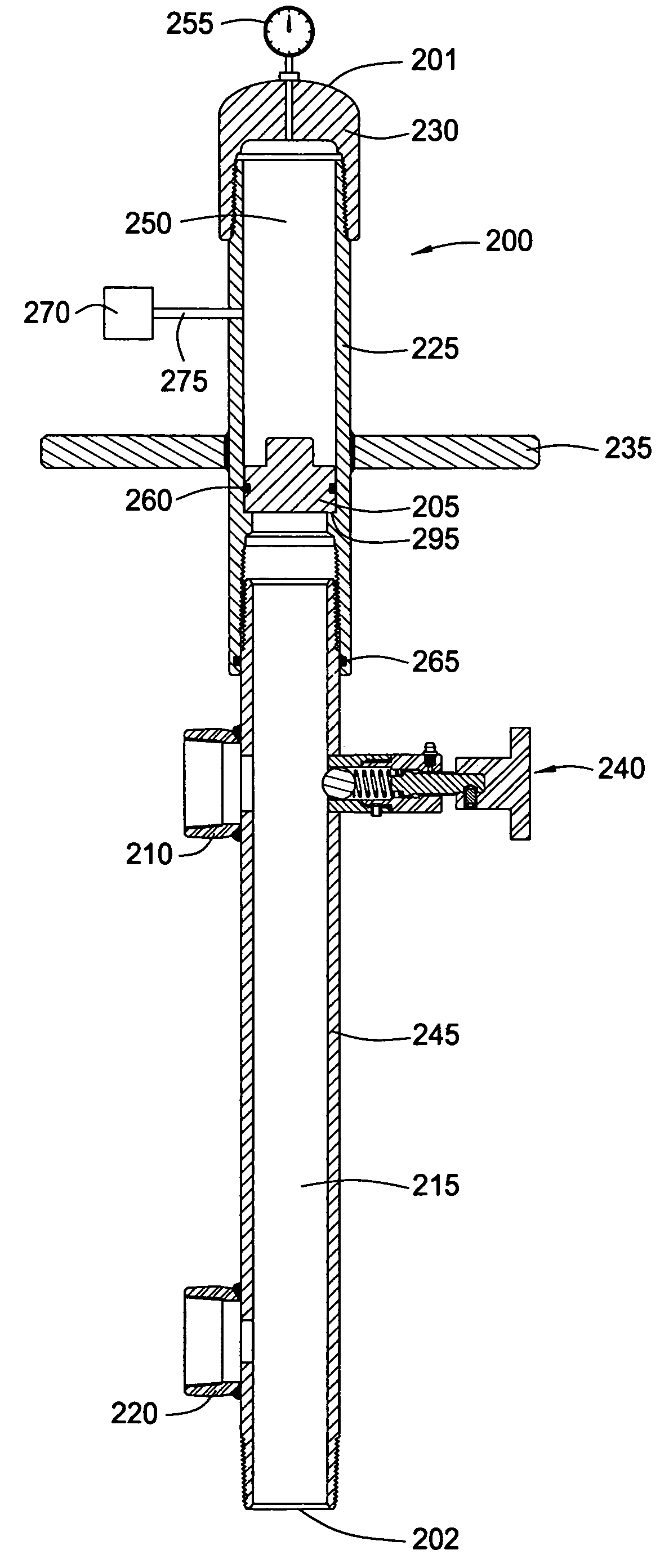

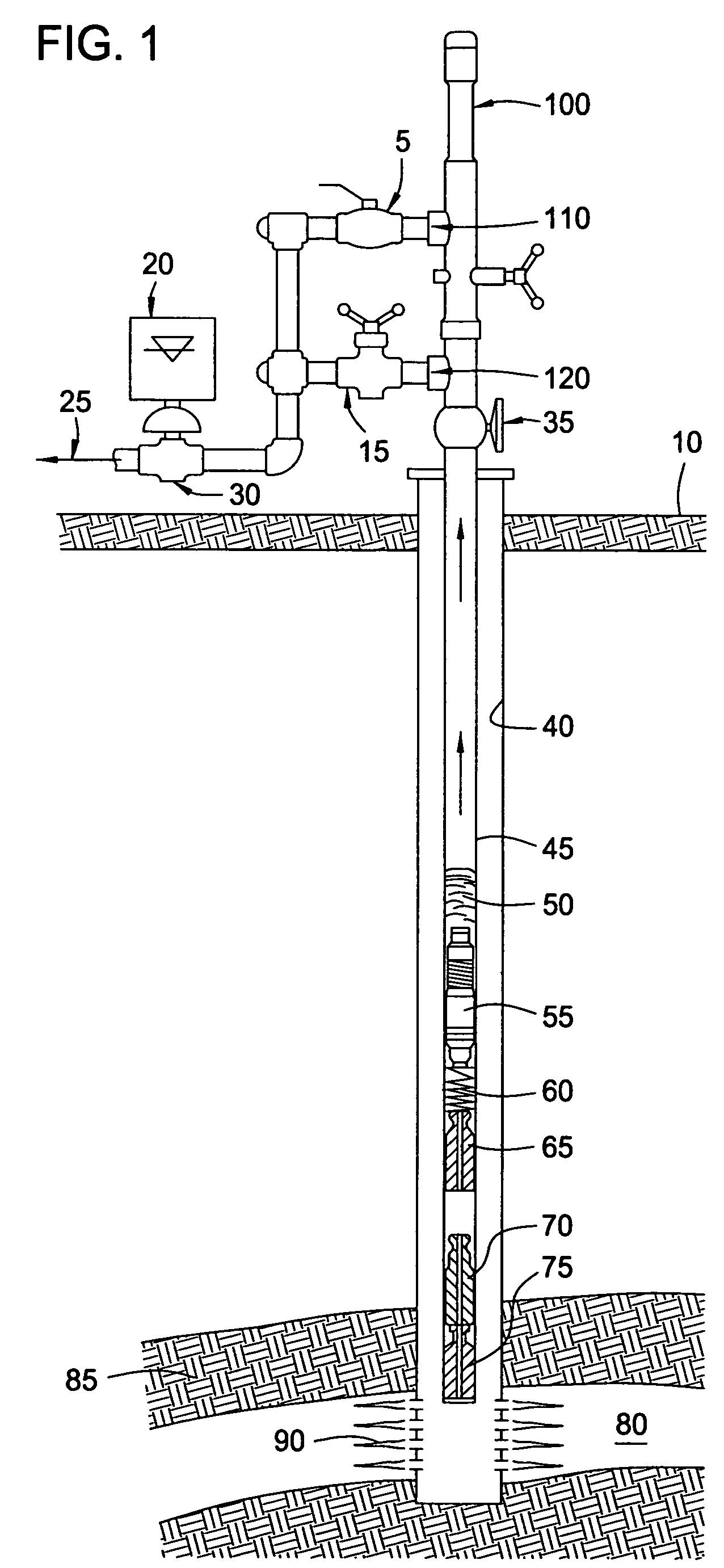

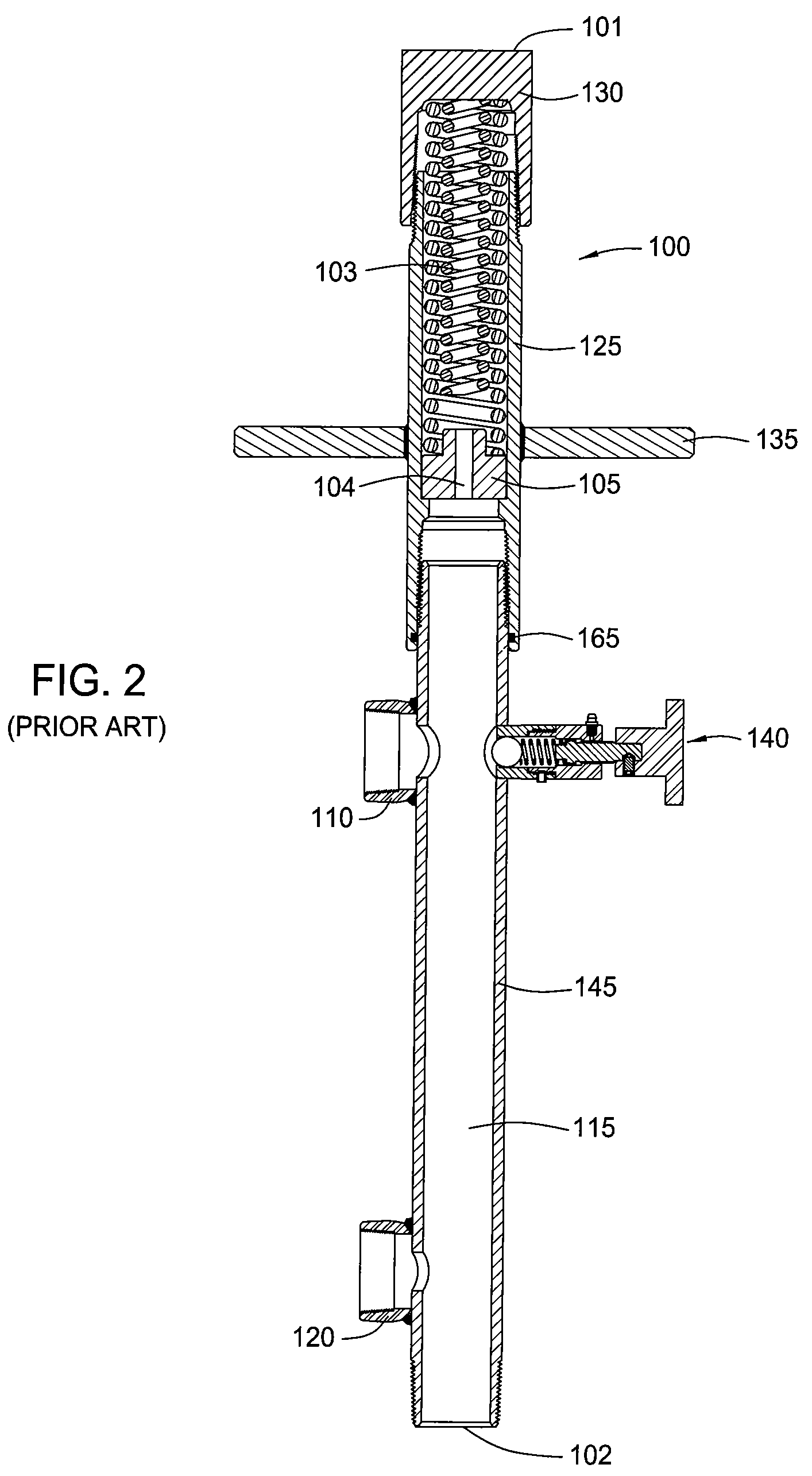

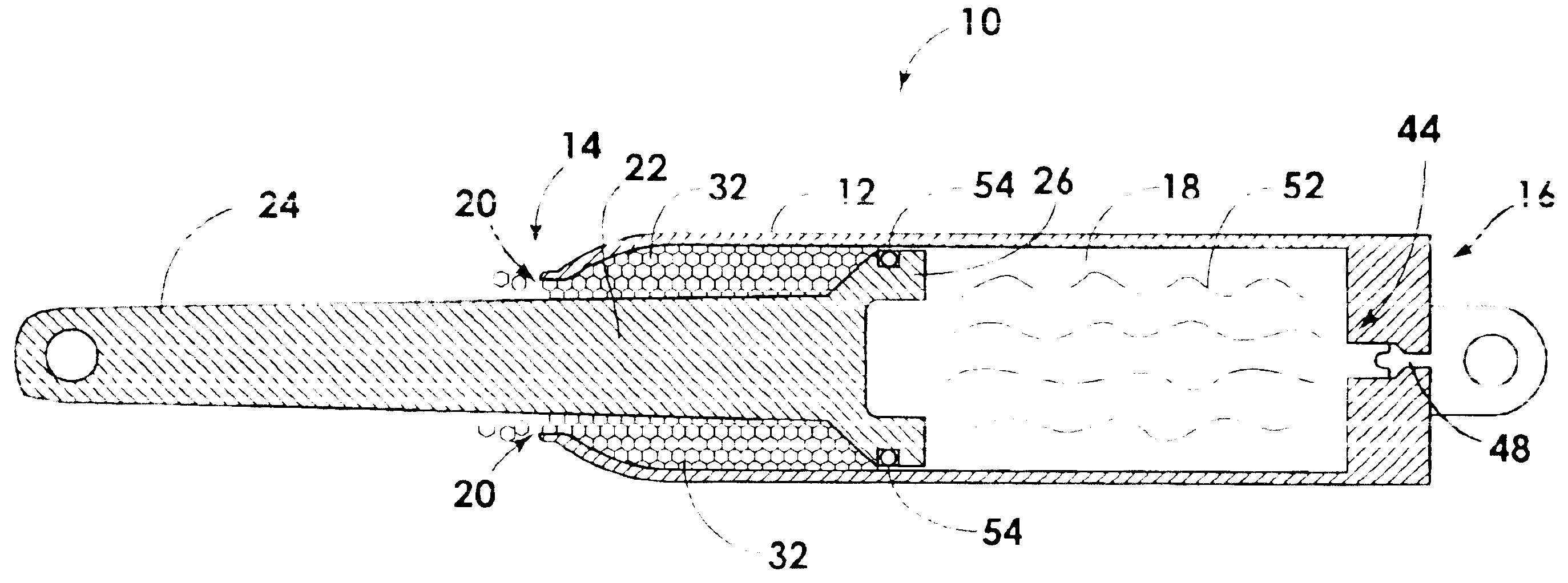

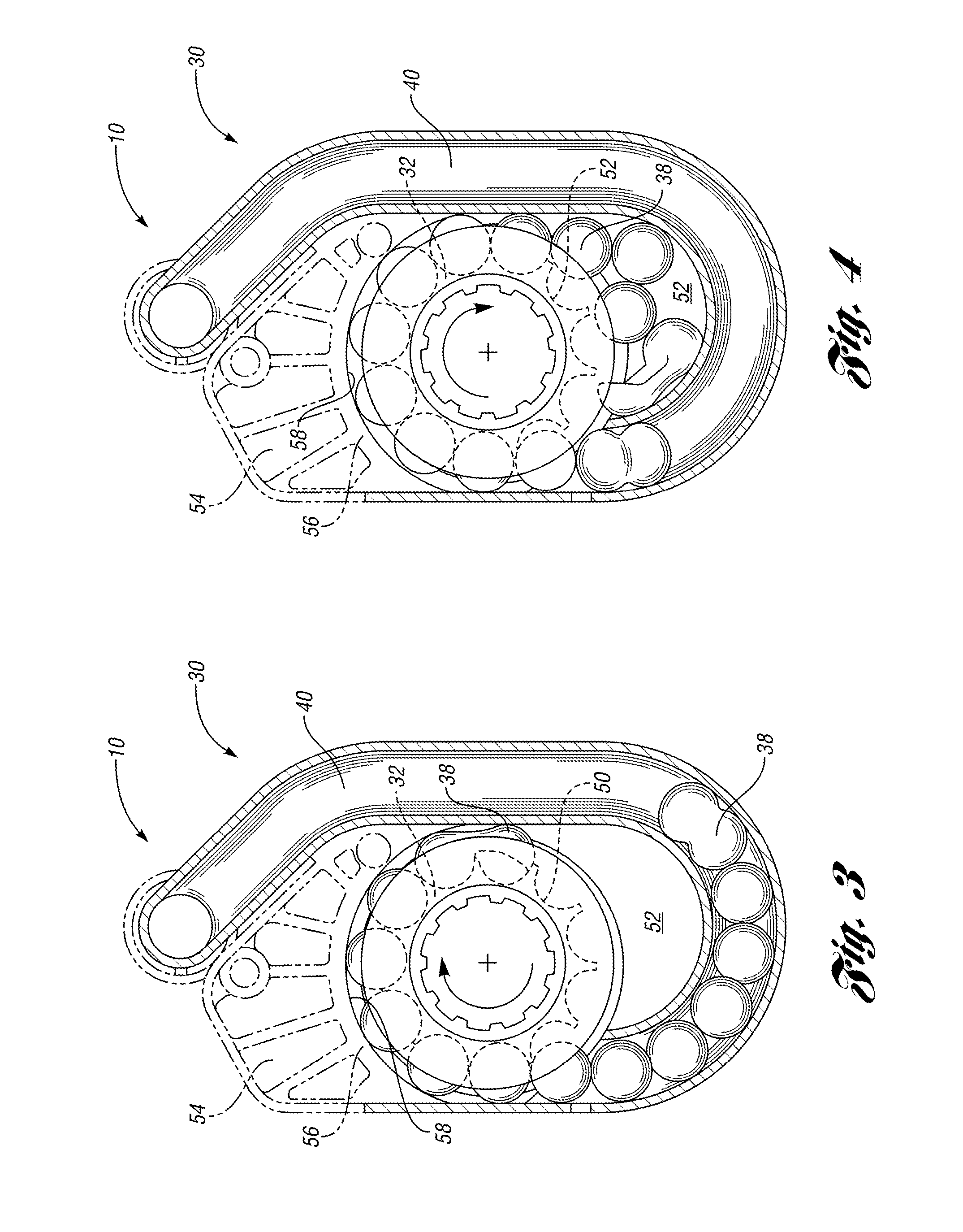

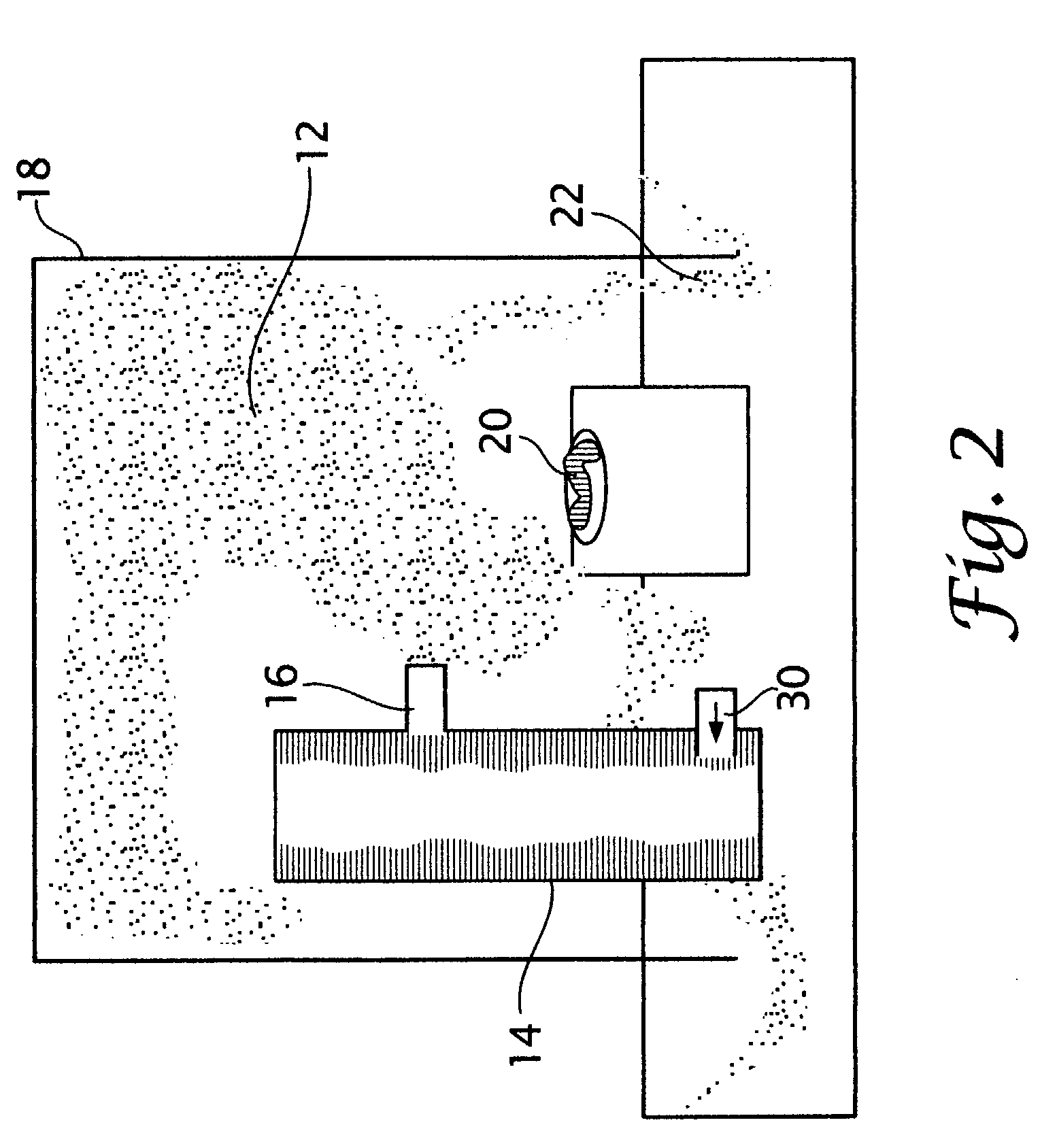

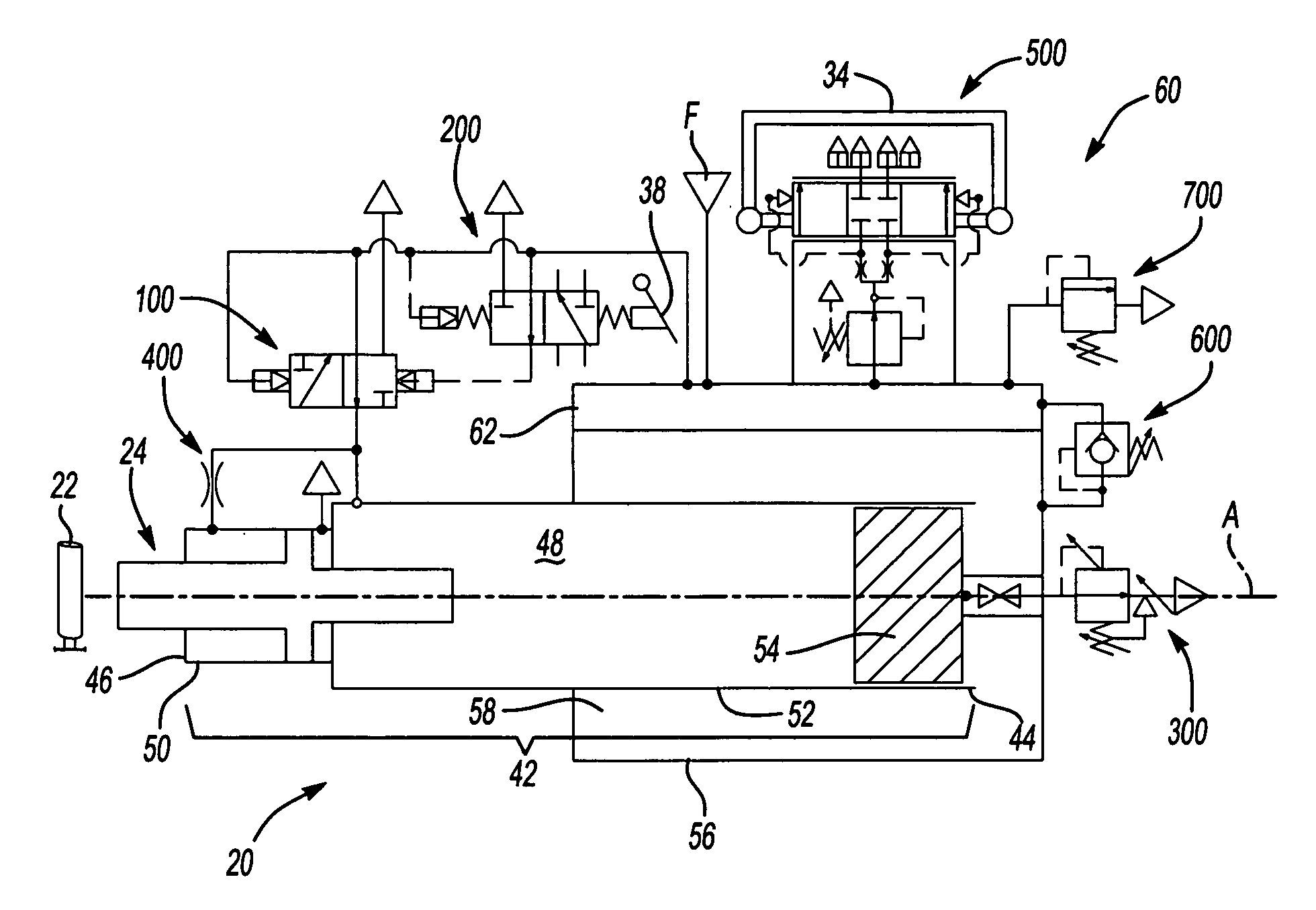

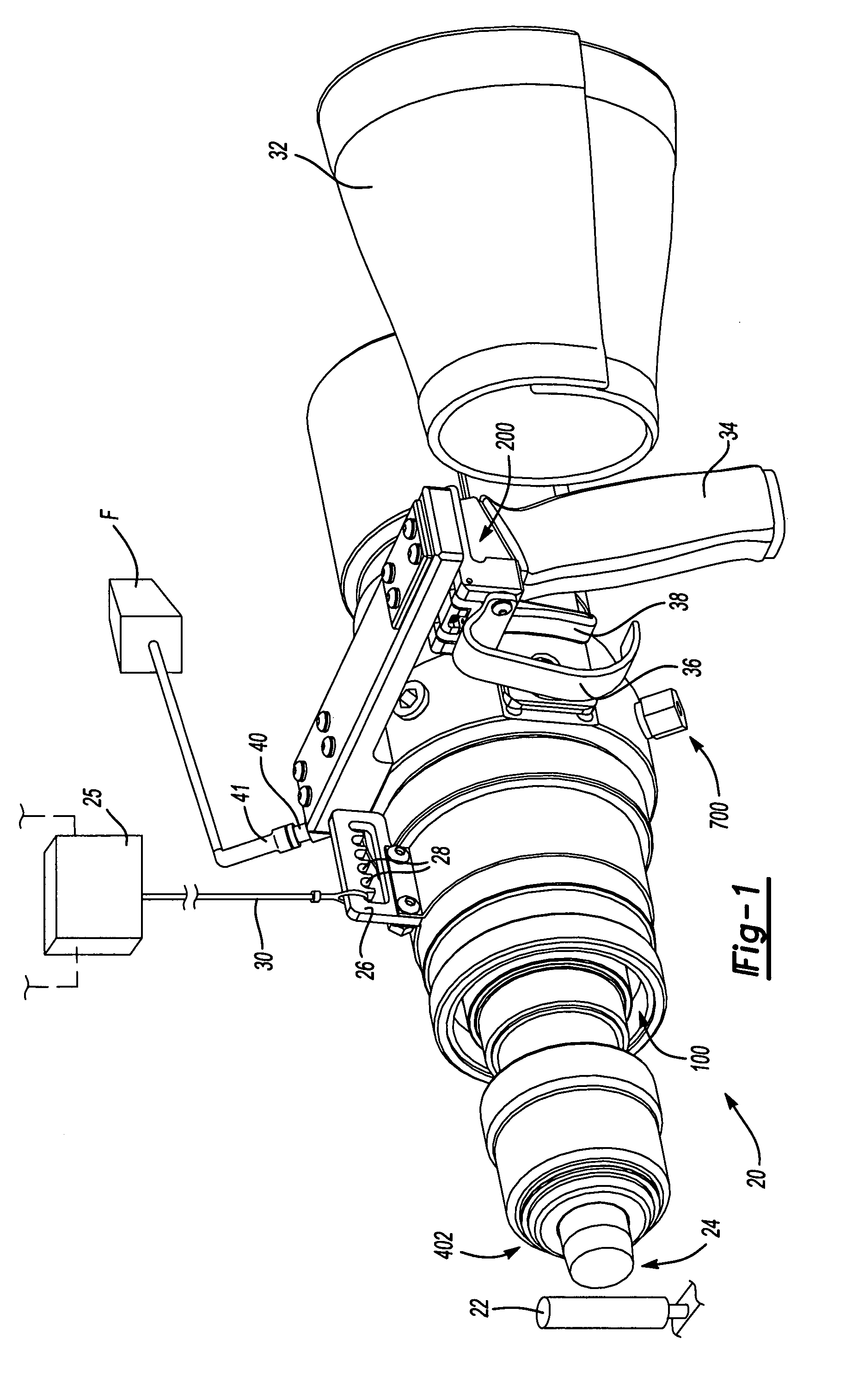

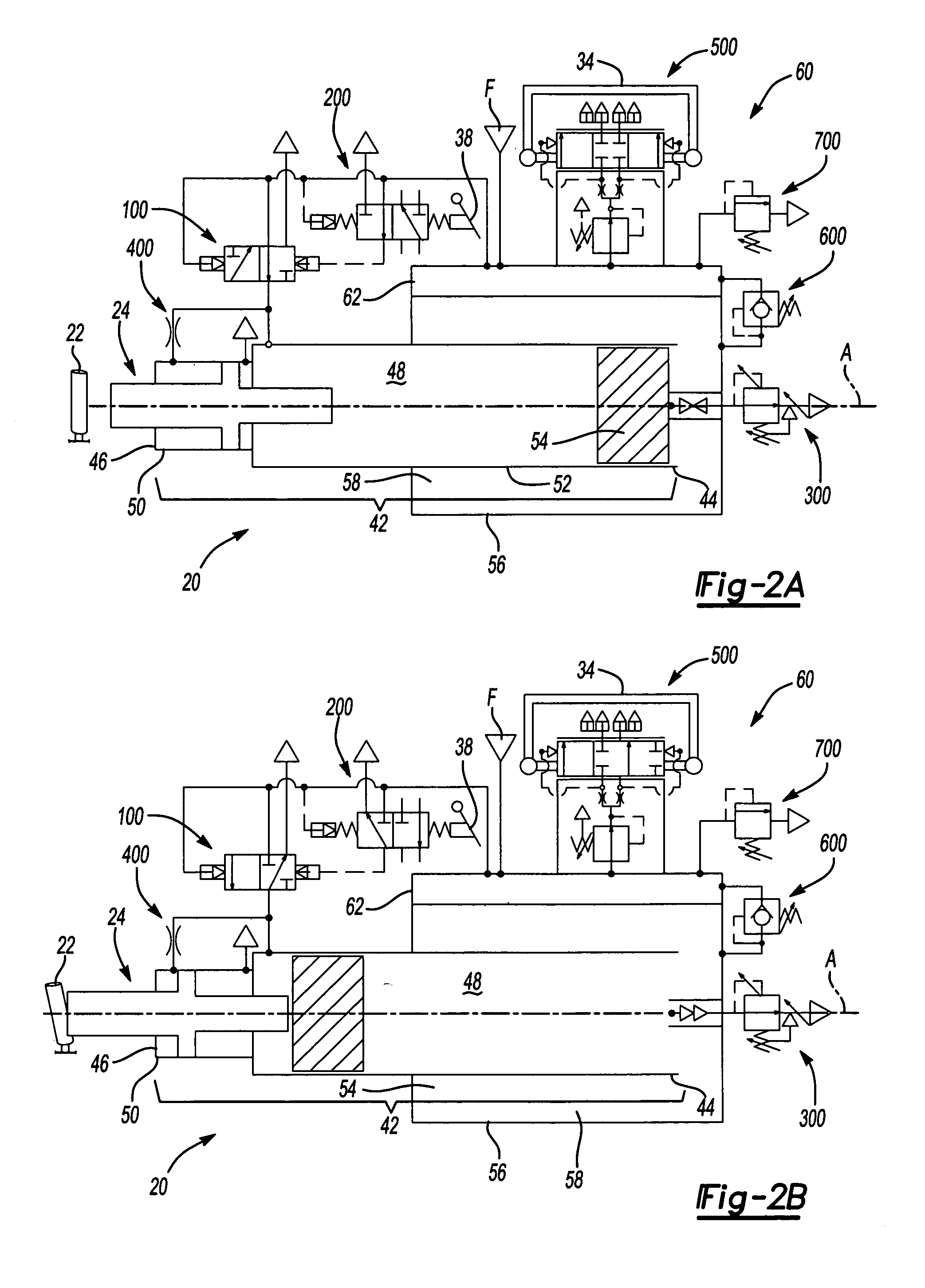

Gas-pressurized lubricator and method

InactiveUS7337854B2Reduce kinetic energyReduce shockFlexible member pumpsFluid removalEngineeringGas chamber

Embodiments of the present invention provide methods and apparatus for reducing kinetic energy of a plunger within a plunger lift system. In one aspect, a lubricator is provided at a surface of a wellbore, the lubricator having a sealed, pressurized chamber therein to cushion the plunger upon impact. In another aspect, a method is provided for reducing the kinetic energy of the plunger by providing a compressed gas chamber within a lubricator, moving a kinetic energy-reducing surface which is partially bounding the chamber, and compressing the gas within the chamber to reduce kinetic energy of the plunger and cushion the impact force of the plunger.

Owner:WEATHERFORD TECH HLDG LLC

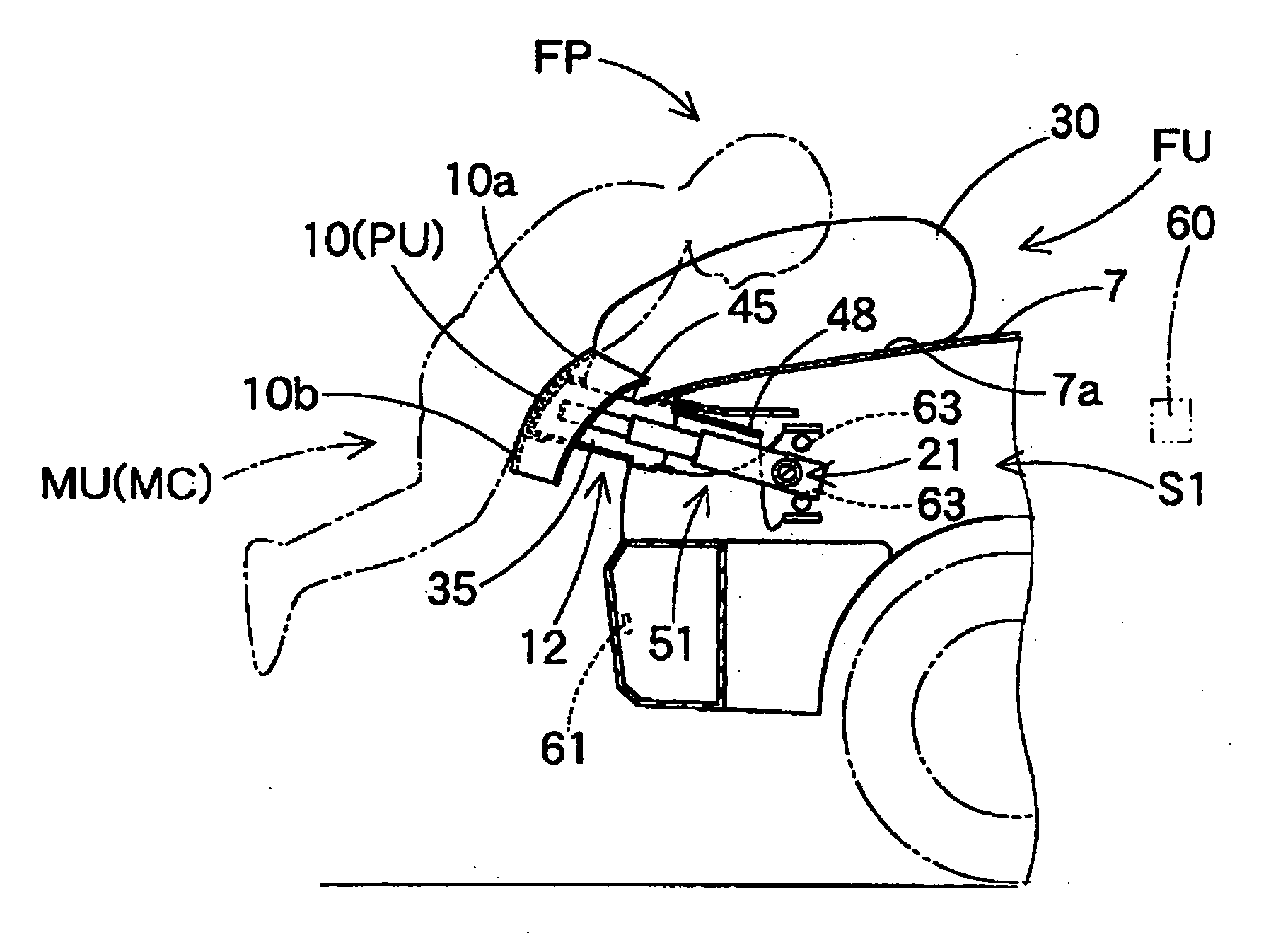

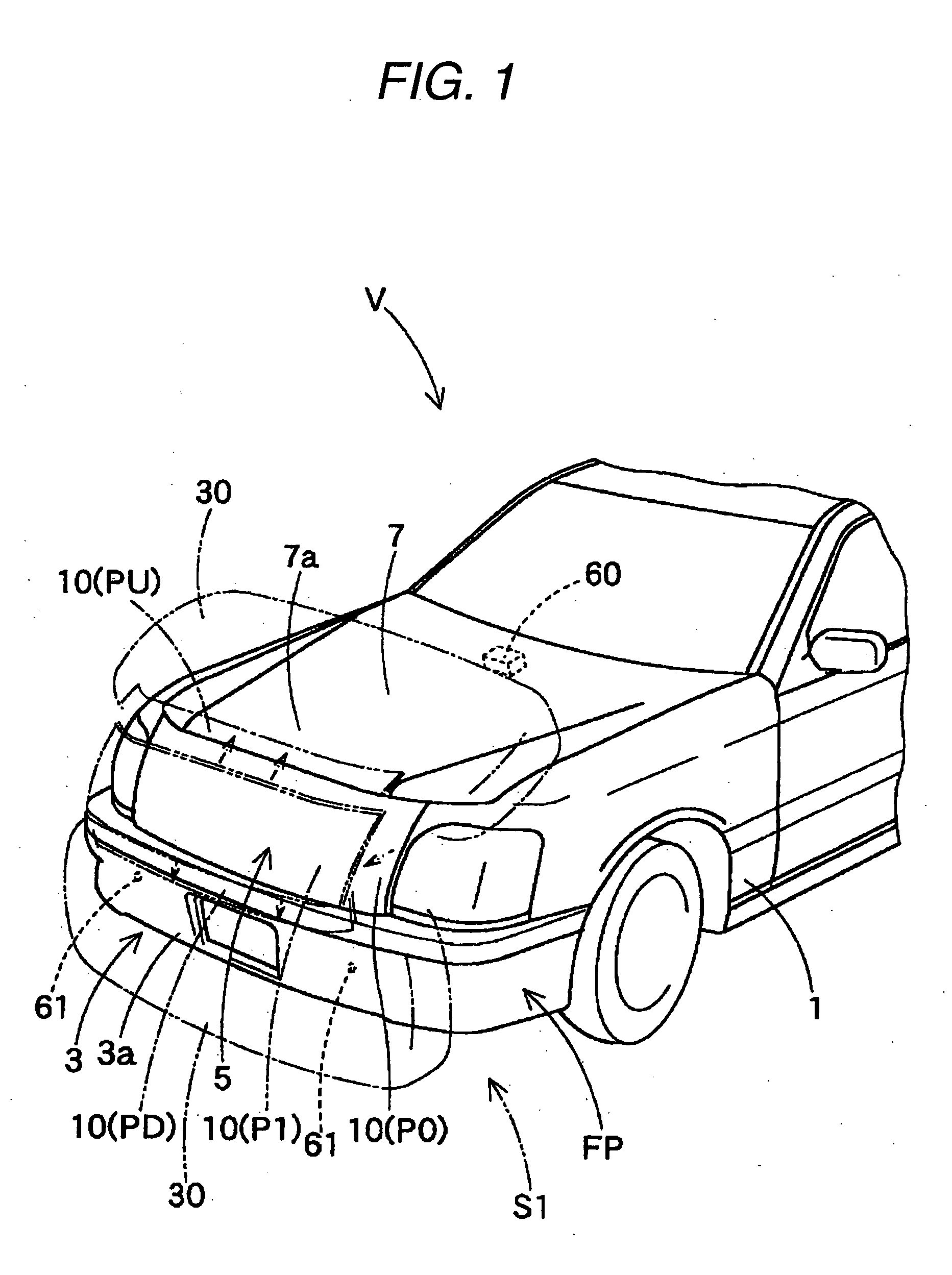

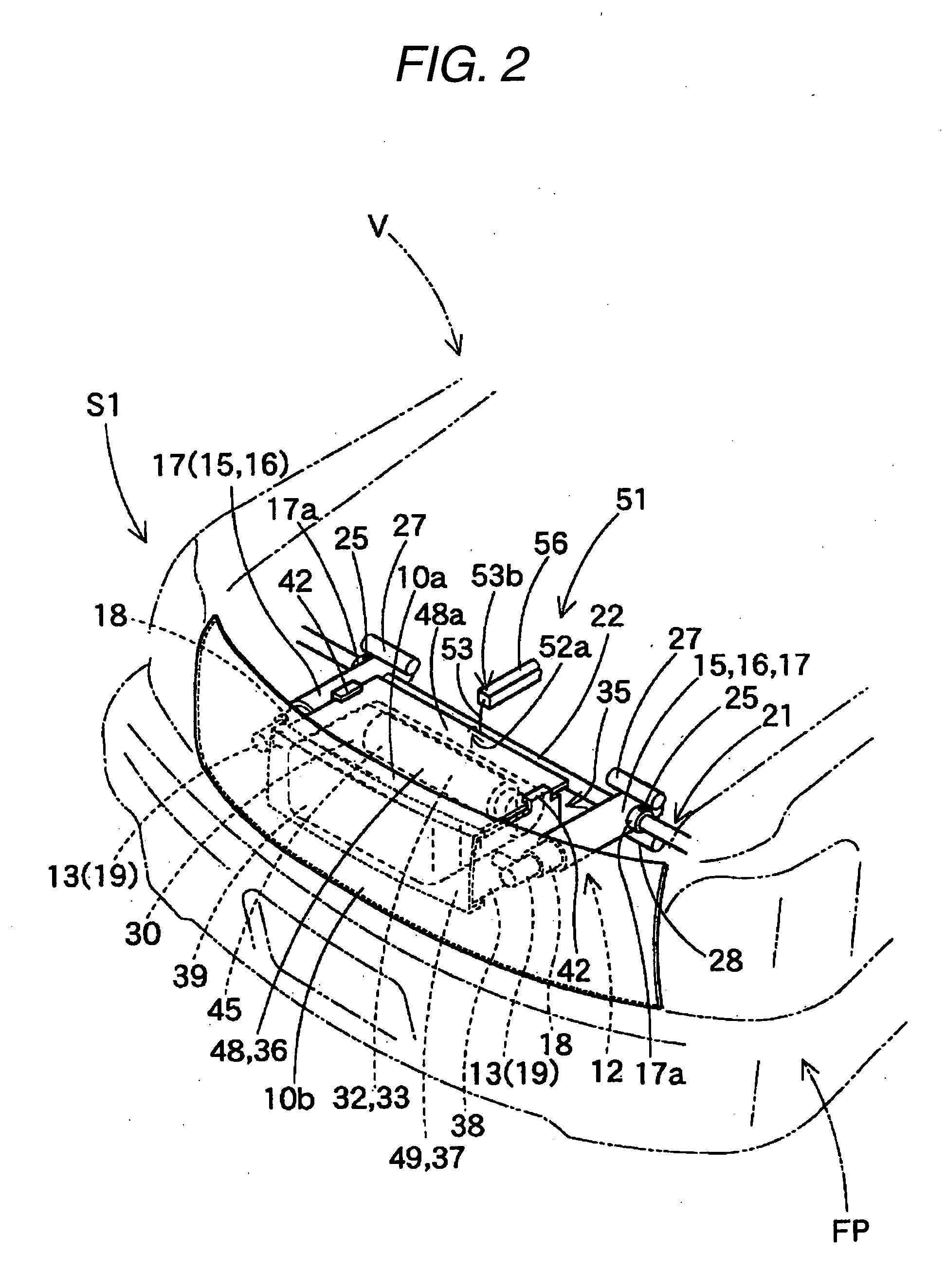

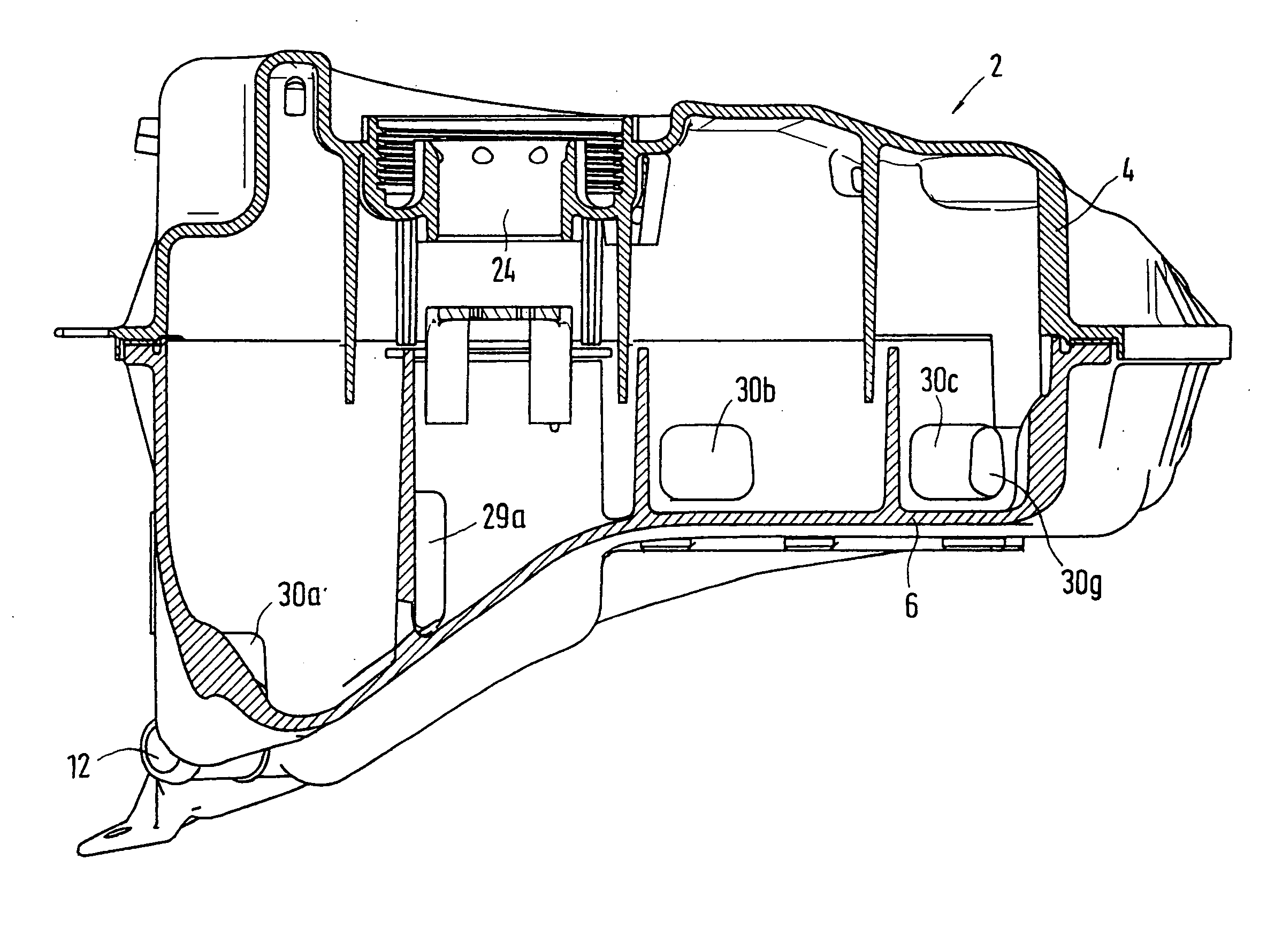

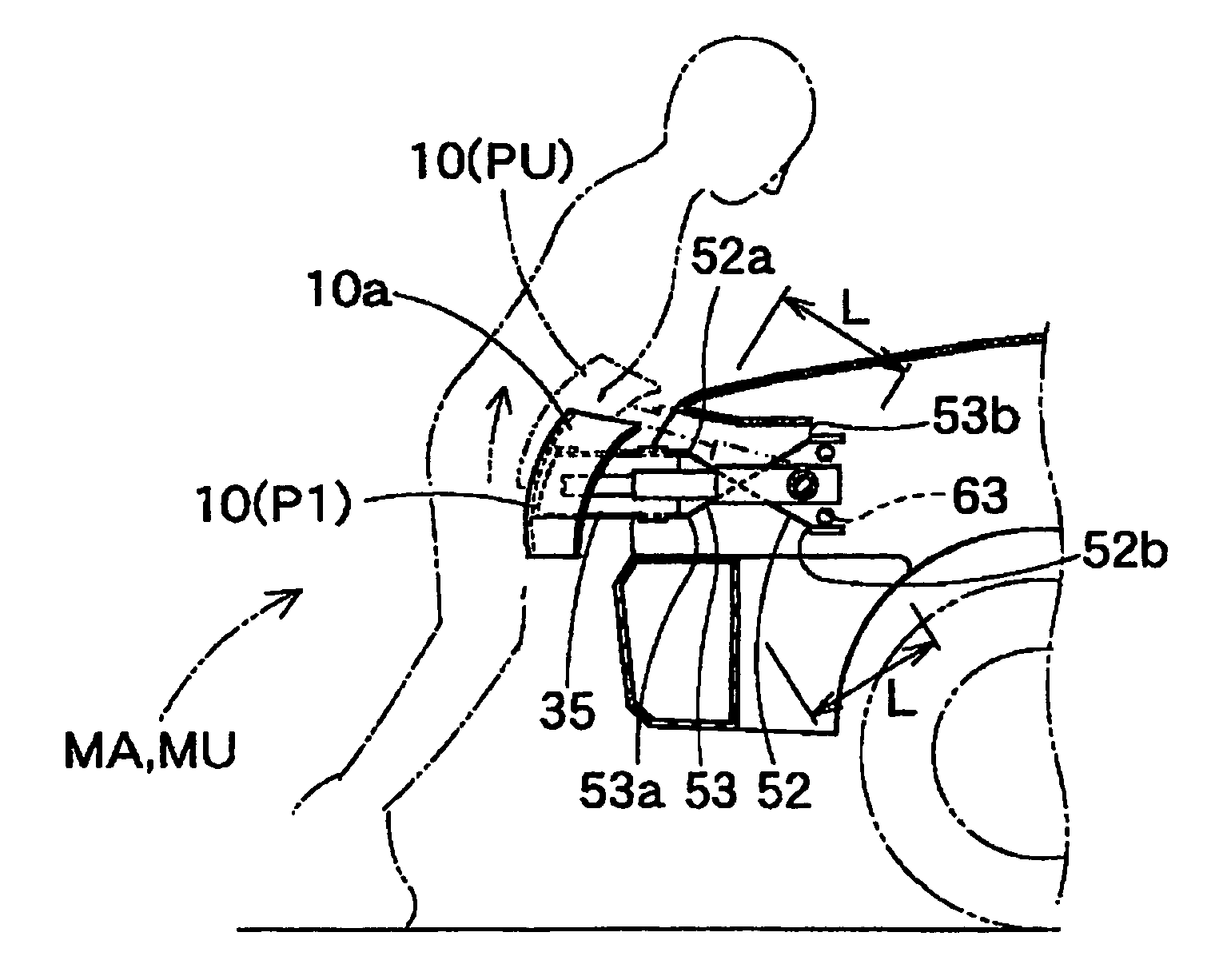

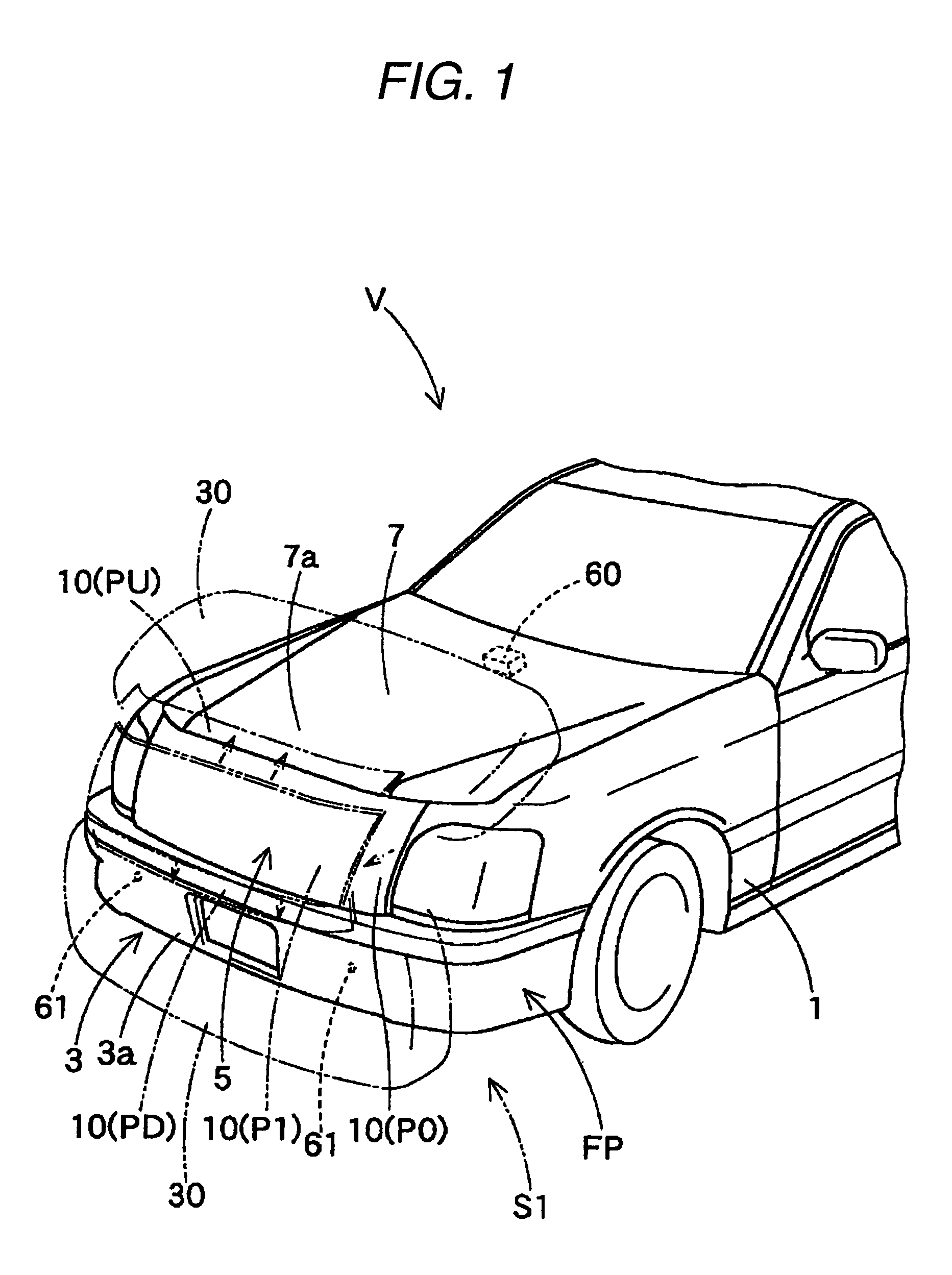

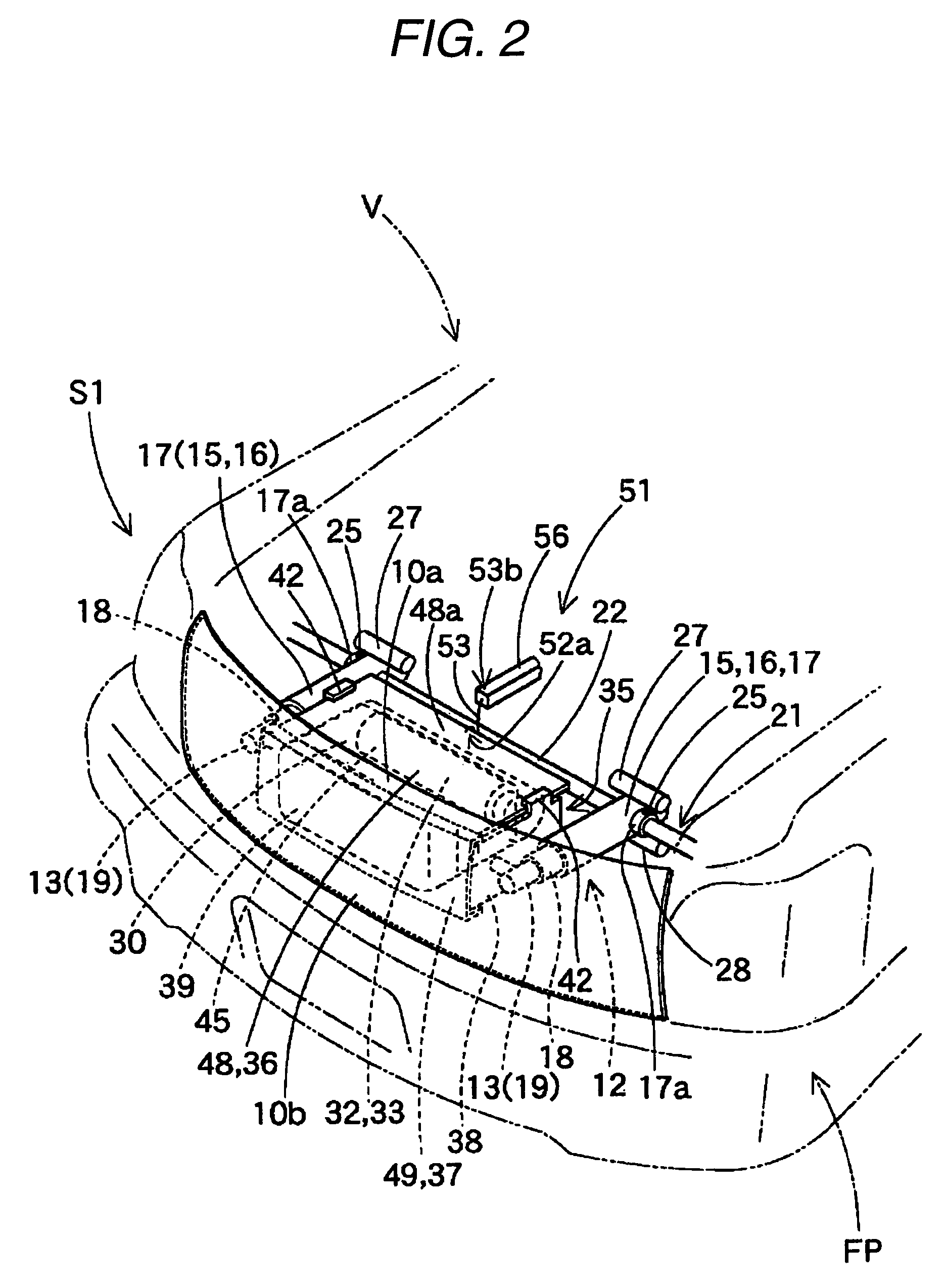

Pedestrian protection system

InactiveUS20090242308A1Accurate protectionEasy constructionElectric devicesPedestrian/occupant safety arrangementPedestrianMechanical engineering

A pedestrian protection system is mounted in the front portion of a vehicle, and includes a controller, a forward movement holding mechanism controlled in actuation by the controller, and a contact body that a pedestrian can contact. The controller, when having predicted a collision of a pedestrian with the vehicle based on a signal from a collision predicting sensor, actuates the forward movement holding mechanism to cause a forward movement of the contact body, and based on a signal from a turn sensor when the forward movement holding mechanism carries out an upward rotation or a downward rotation at the time of contact of the forwardly moved contact body with a pedestrian, controls actuation of the restraint body so as to correspond to a pedestrian moving to a front upper side of the vehicle and a pedestrian moving to a front lower side of the vehicle, respectively.

Owner:TOYODA GOSEI CO LTD

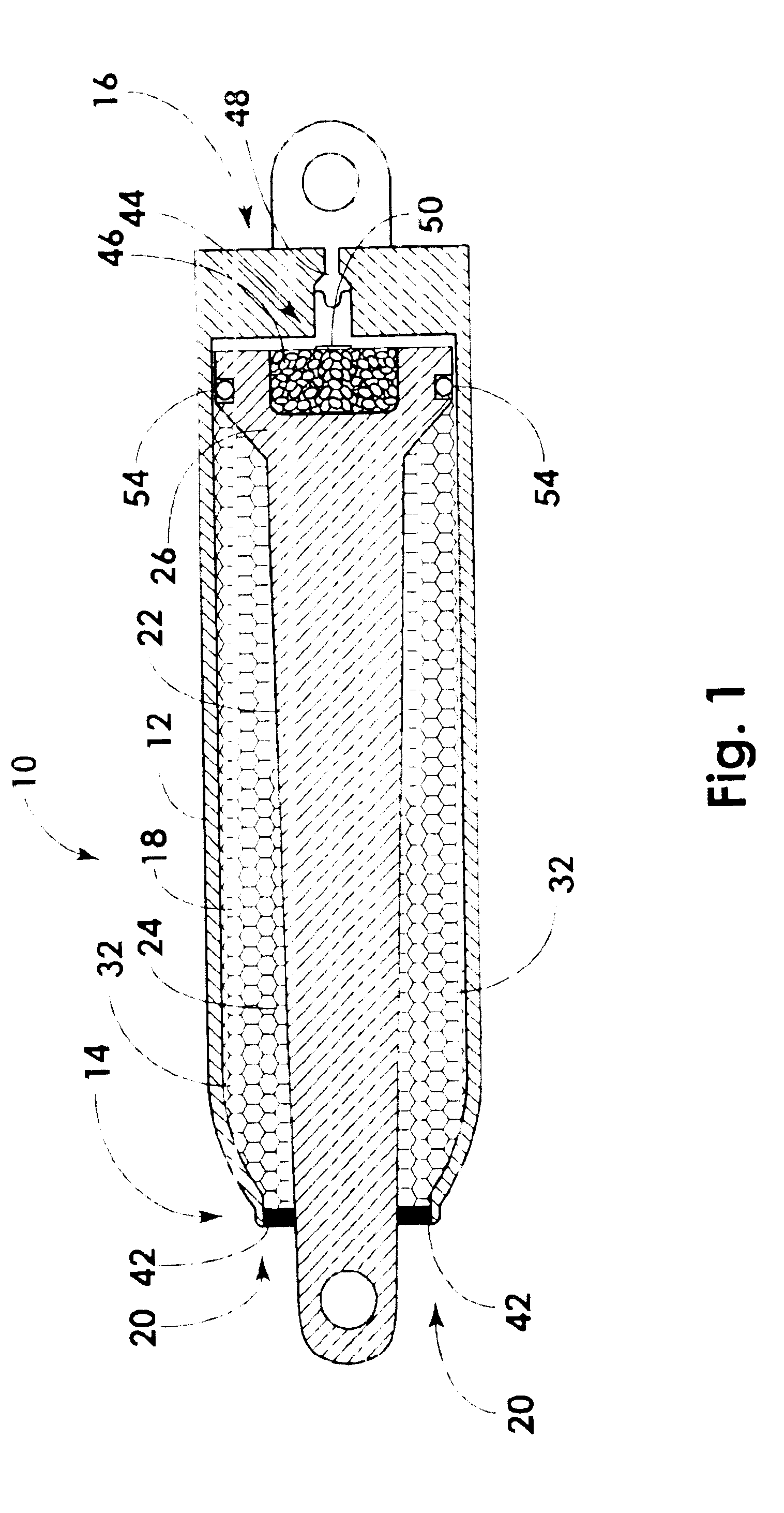

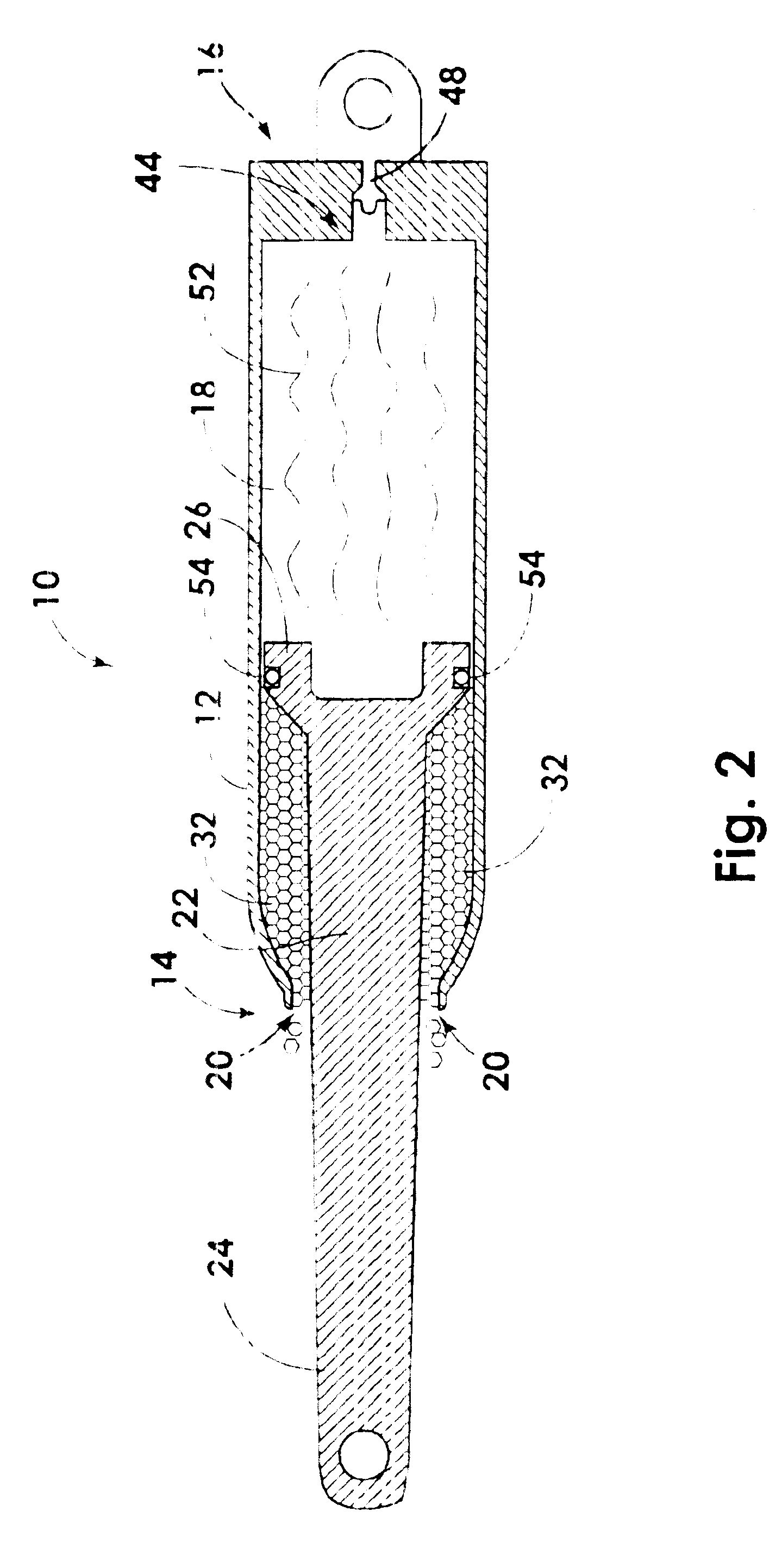

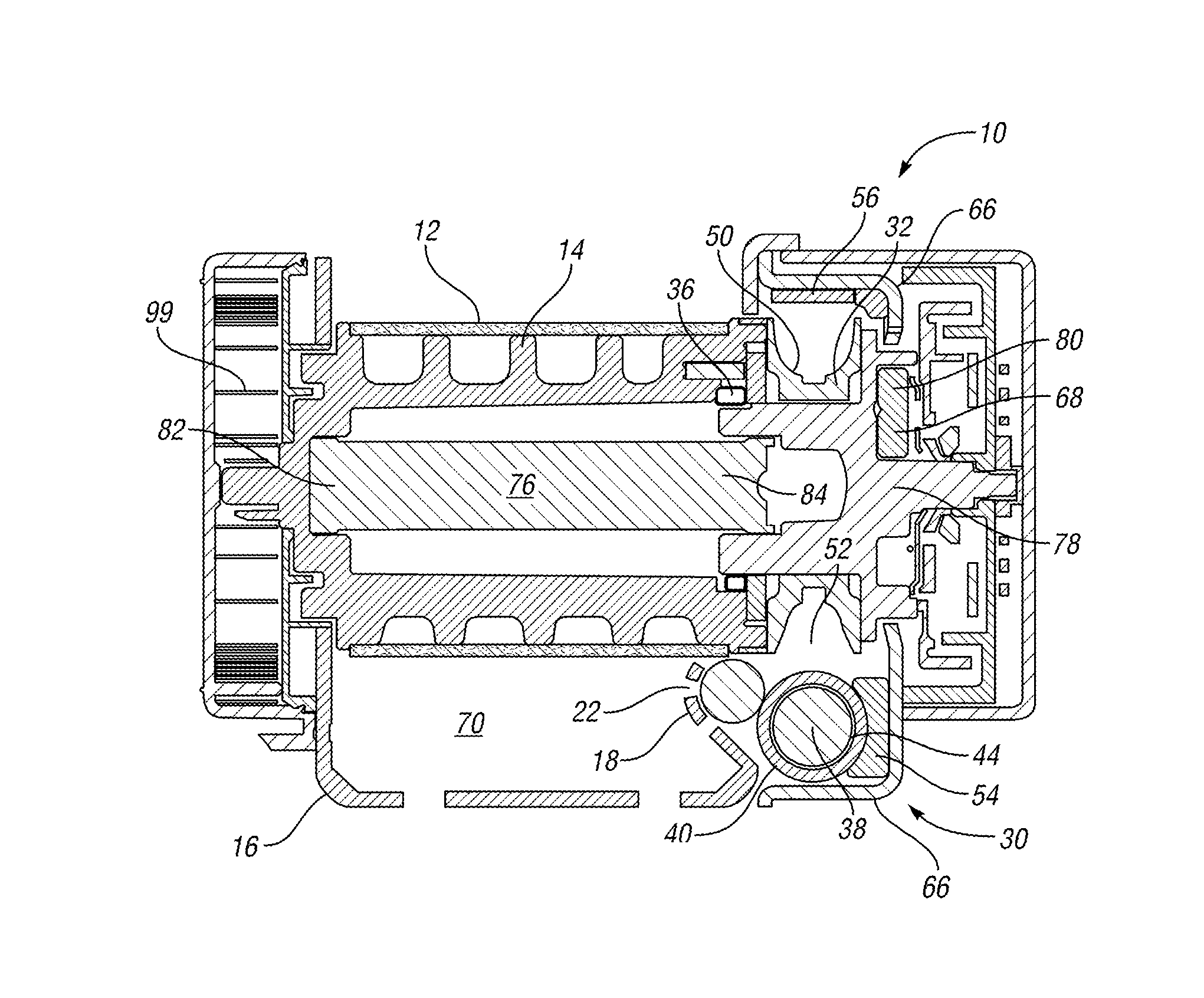

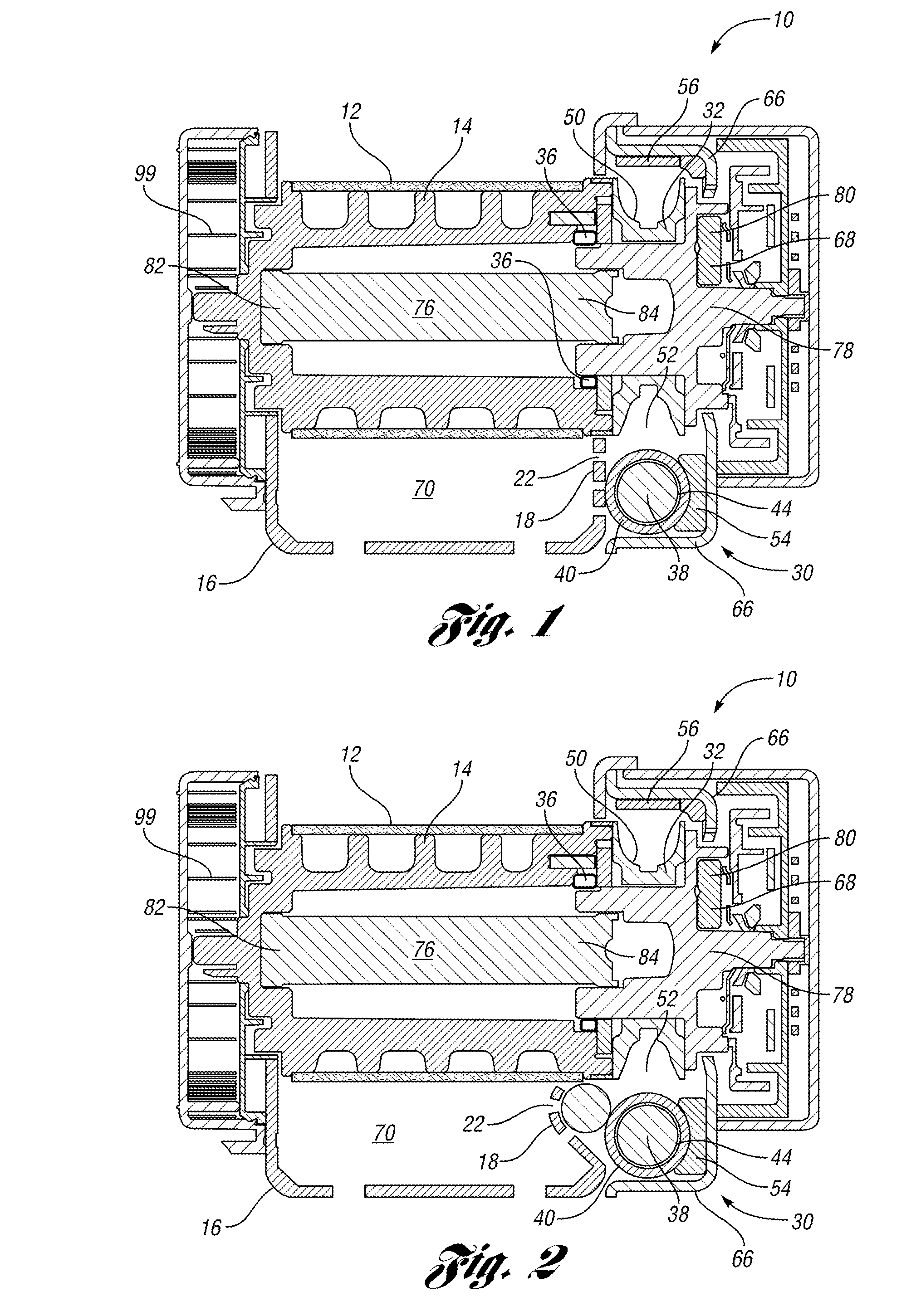

Linear actuator with an internal dampening mechanism

InactiveUS6942261B2Adequately dampeningIncrease pressurePyrotechnical actuatorsPedestrian/occupant safety arrangementEngineeringControl theory

A linear actuator with an internal dampening mechanism is disclosed. The actuator has a housing has a first end and a second end and forms an internal chamber. A constricted opening is also added to the actuator at the first end. A piston is disposed within the housing and is capable of sliding along the chamber. The piston has a head portion and a shaft portion. The shaft portion is slidable through the constricted opening whereas the head portion is not slidable through the constricted opening. A fluid is also added to the actuator. The fluid is disposed within the housing. In one embodiment, the actuator is constructed such that the sliding of the shaft portion forces a fluid through the constricted opening such that the movement of the piston is dampened. In an alternative embodiment, the actuator includes one or more second pistons and an orifice. In this embodiment, the actuator is constructed such that the sliding of the piston forces the fluid through the orifice and causes the second pistons to telescopically extend from the first piston.

Owner:AUTOLIV ASP INC

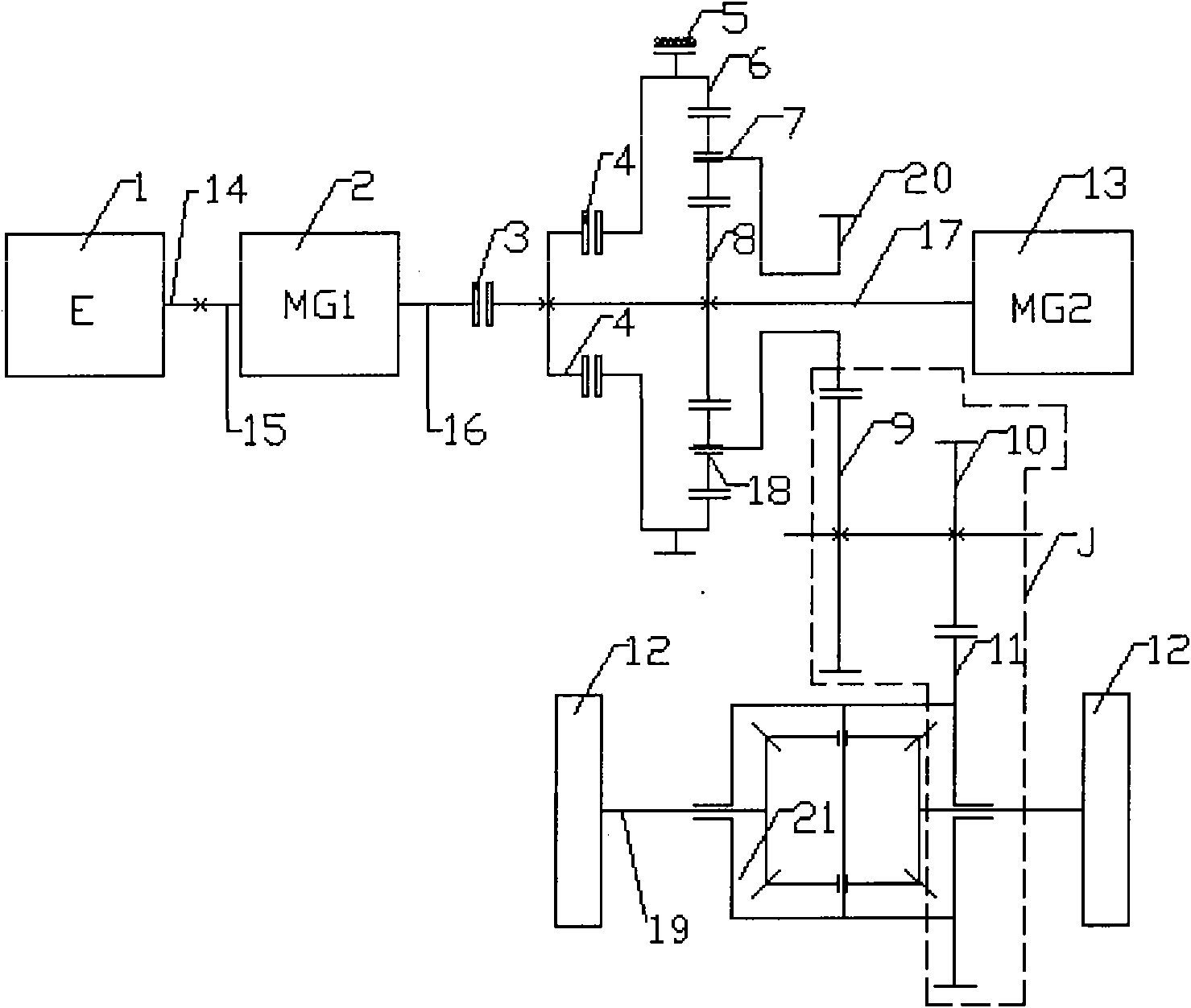

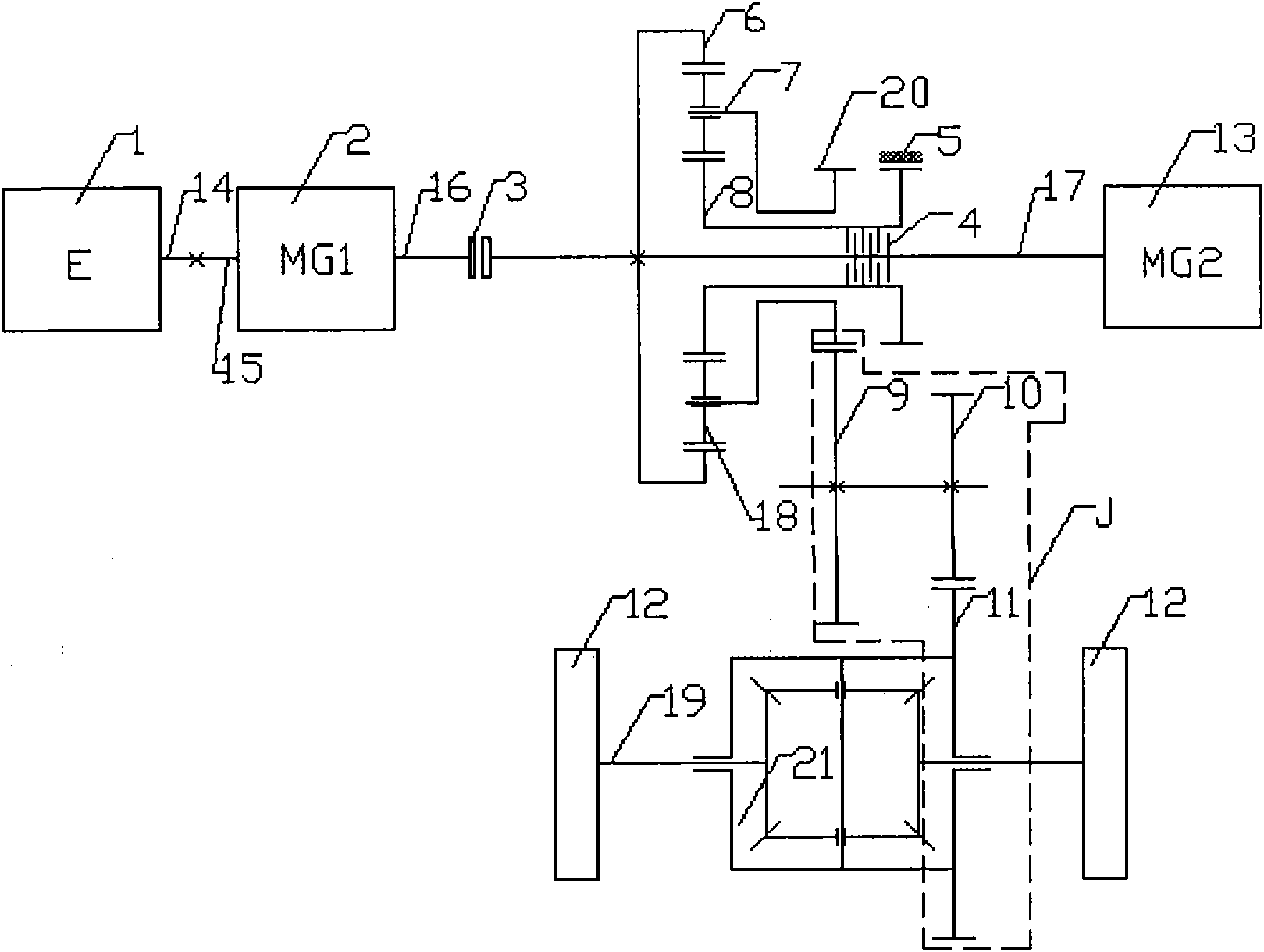

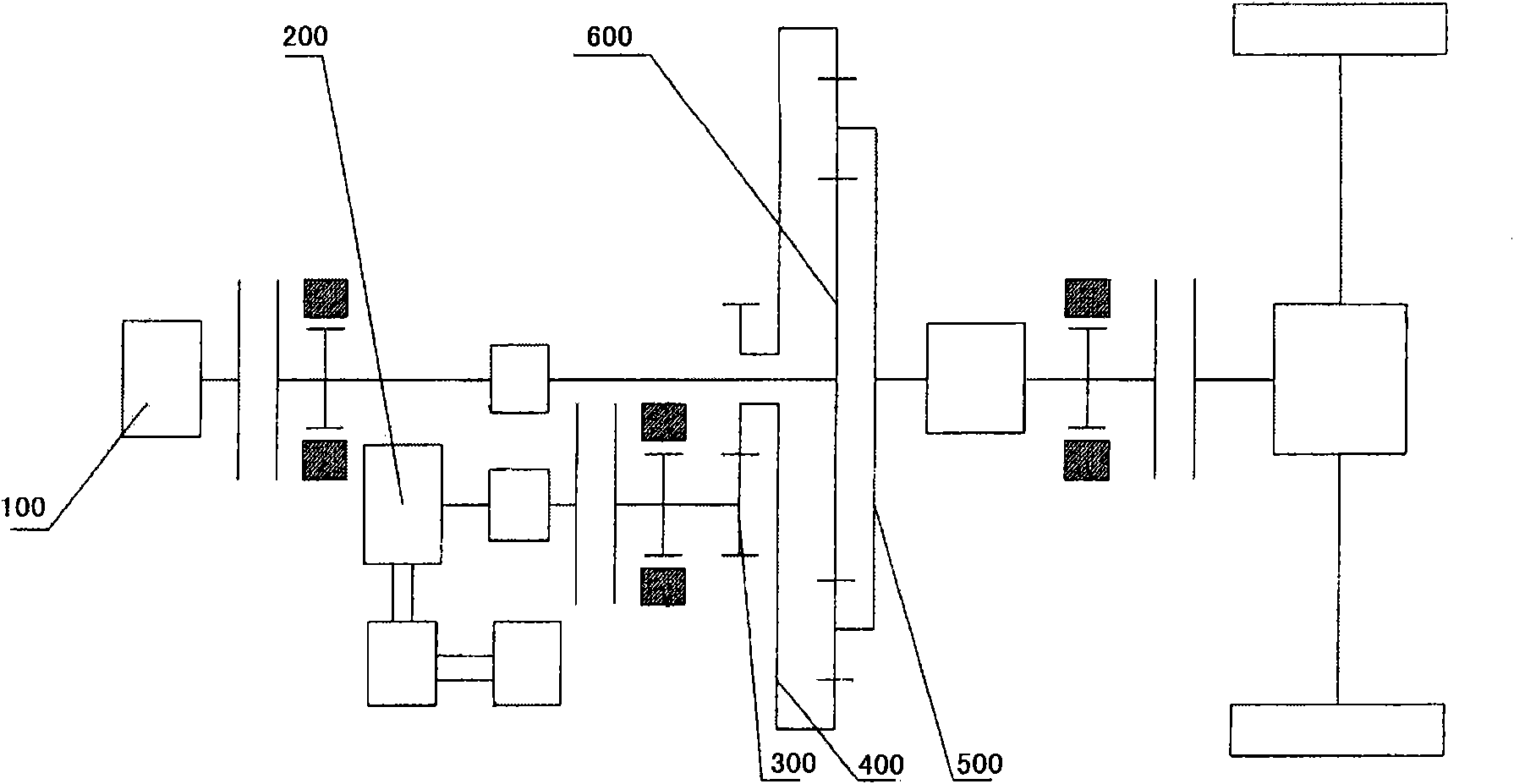

Hybrid driving system for automobile and gear operating method thereof

ActiveCN102107604ASmall reduction ratioReduce in quantityHybrid vehiclesToothed gearingsCouplingInternal combustion engine

The invention relates to a hybrid driving system and a gear operating method thereof. The system comprises an internal-combustion engine, a first motor, a second motor, a planet coupling mechanism, a retarding mechanism and a differential mechanism, wherein an output shaft of the internal-combustion engine is connected with an input shaft of the first motor; an output shaft of the first motor is connected with an output shaft of the second motor by a first clutch; and the output shaft of the second motor is connected with one of a sun wheel and a gear ring of the planet coupling mechanism at the position of the axial direction of the output shaft, and output shaft of the second motor is connected with the other one of the sun wheel with a brake and the gear ring by a second clutch at the other position of the axial direction of the output shaft. In the hybrid driving system, two gear levels of forward gears of an automobile are formed by adjusting the planet coupling mechanism, so that operating modes and corresponding gears are selected flexibly according to different running work conditions of the automobile to achieve the effects of low emission and oil consumption, high kinetic energy and the like of the integral automobile.

Owner:BYD CO LTD

Device for pretensioning a seatbelt

ActiveUS7988084B2Improve efficiencyHigh energyBelt retractorsEnergy-absorbing device incorporationEngineeringBelt safety

In at least one embodiment of the present invention, a device for pretensioning a seatbelt is provided. The device comprises a spindle for receiving a portion of the seatbelt. A retractor frame that has a weakened portion is supported by the spindle for rotational movement within the retractor frame. A pretensioner is operatively connected to the spindle for rotating the spindle to tighten the seatbelt. The pretensioner includes pretensioner balls. The pretensioner is configured to drive the pretensioner balls toward a ball collection area adjacent to the weakened portion. The weakened portion is deformed by the pretensioner balls to increase the size of the ball collection area.

Owner:AUTOLIV ASP INC

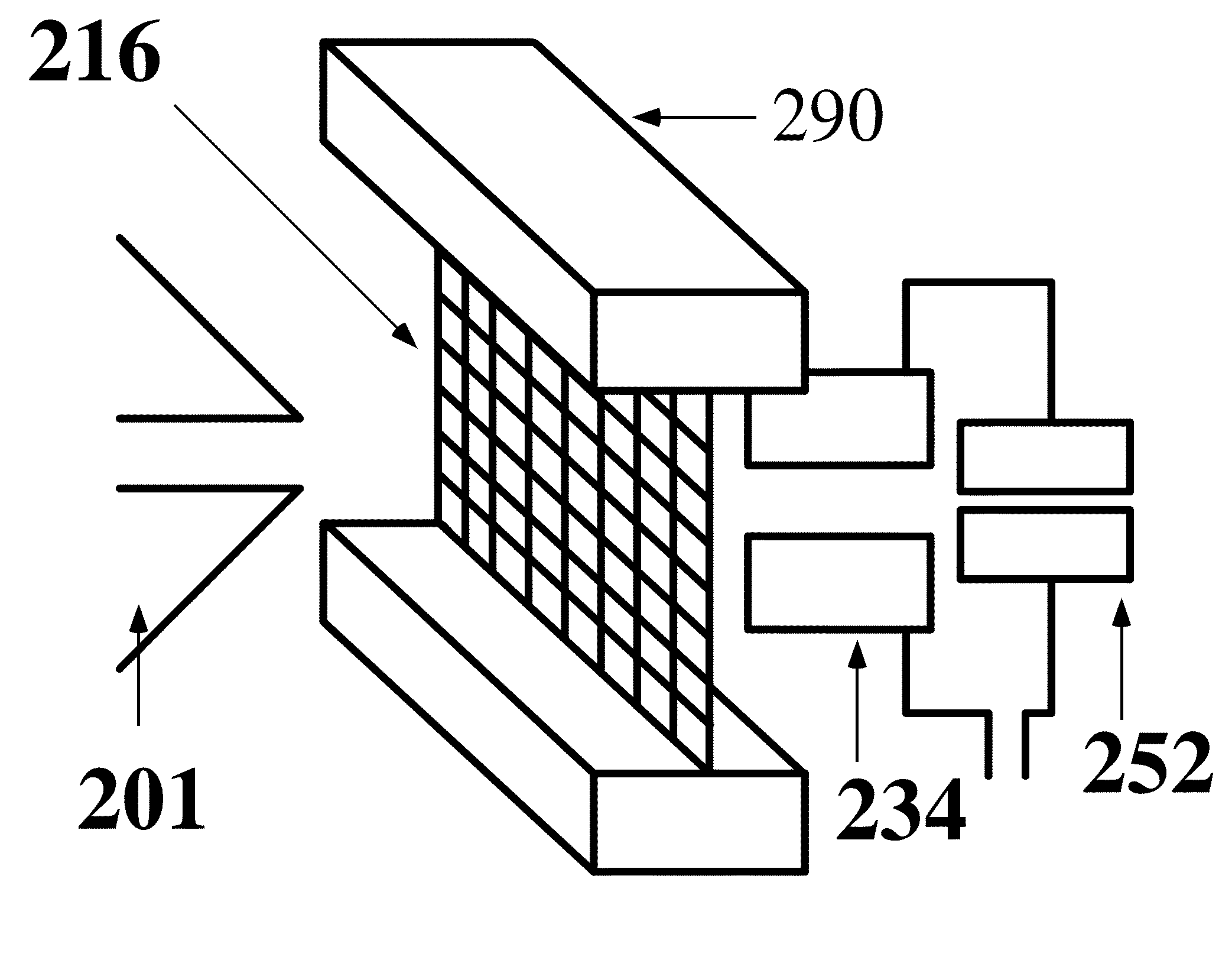

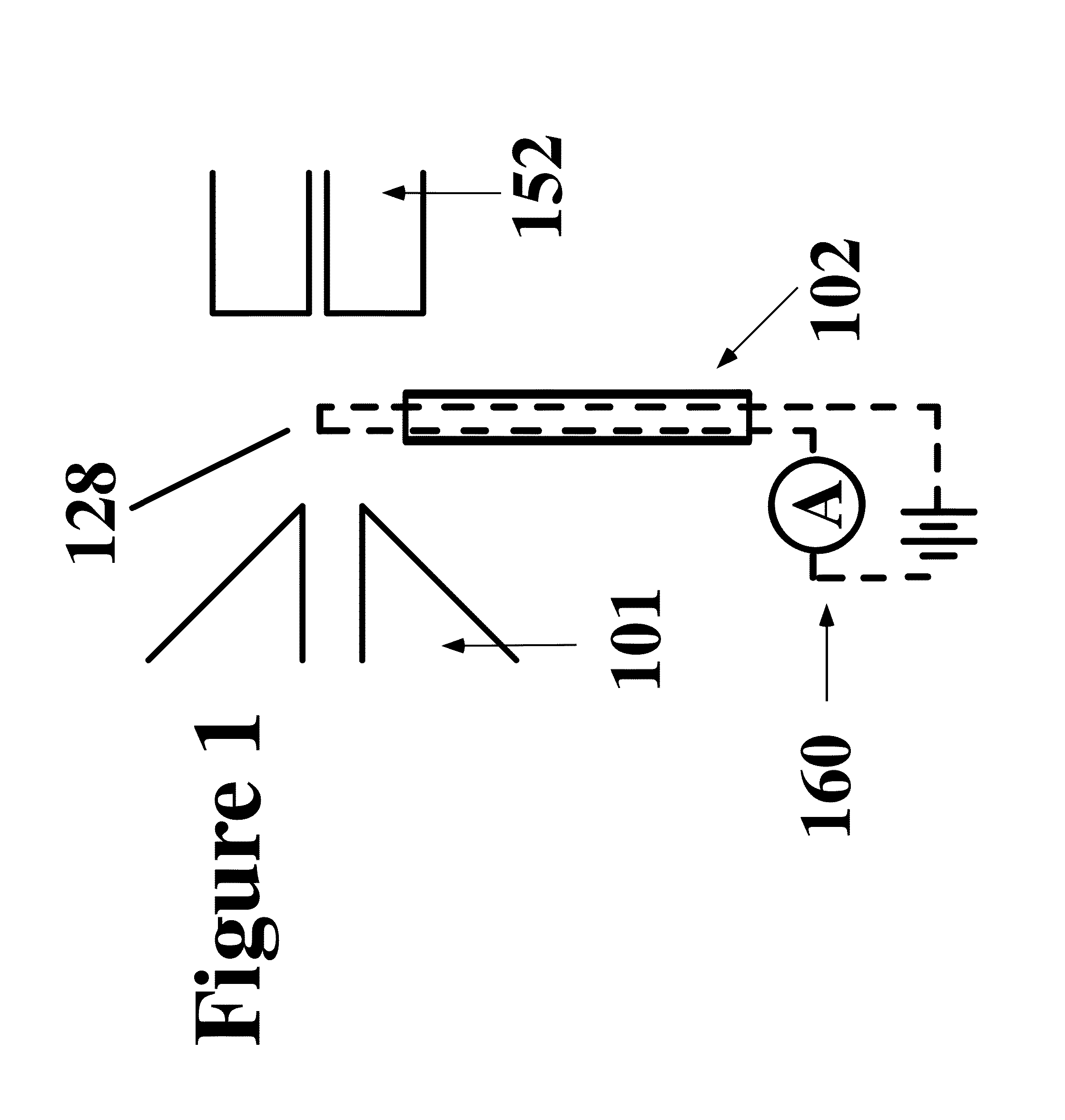

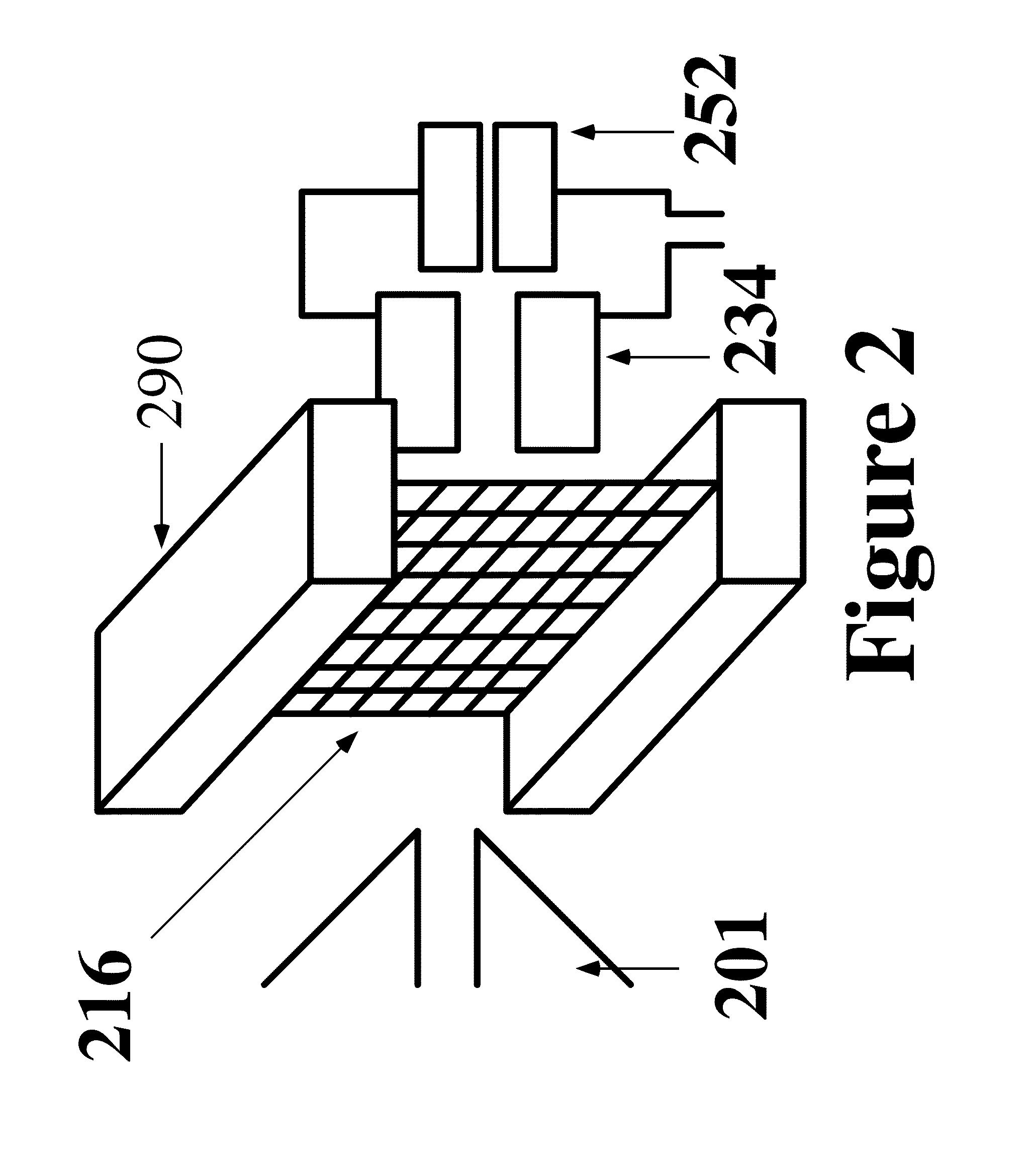

Apparatus and method for thermal assisted desorption ionization systems

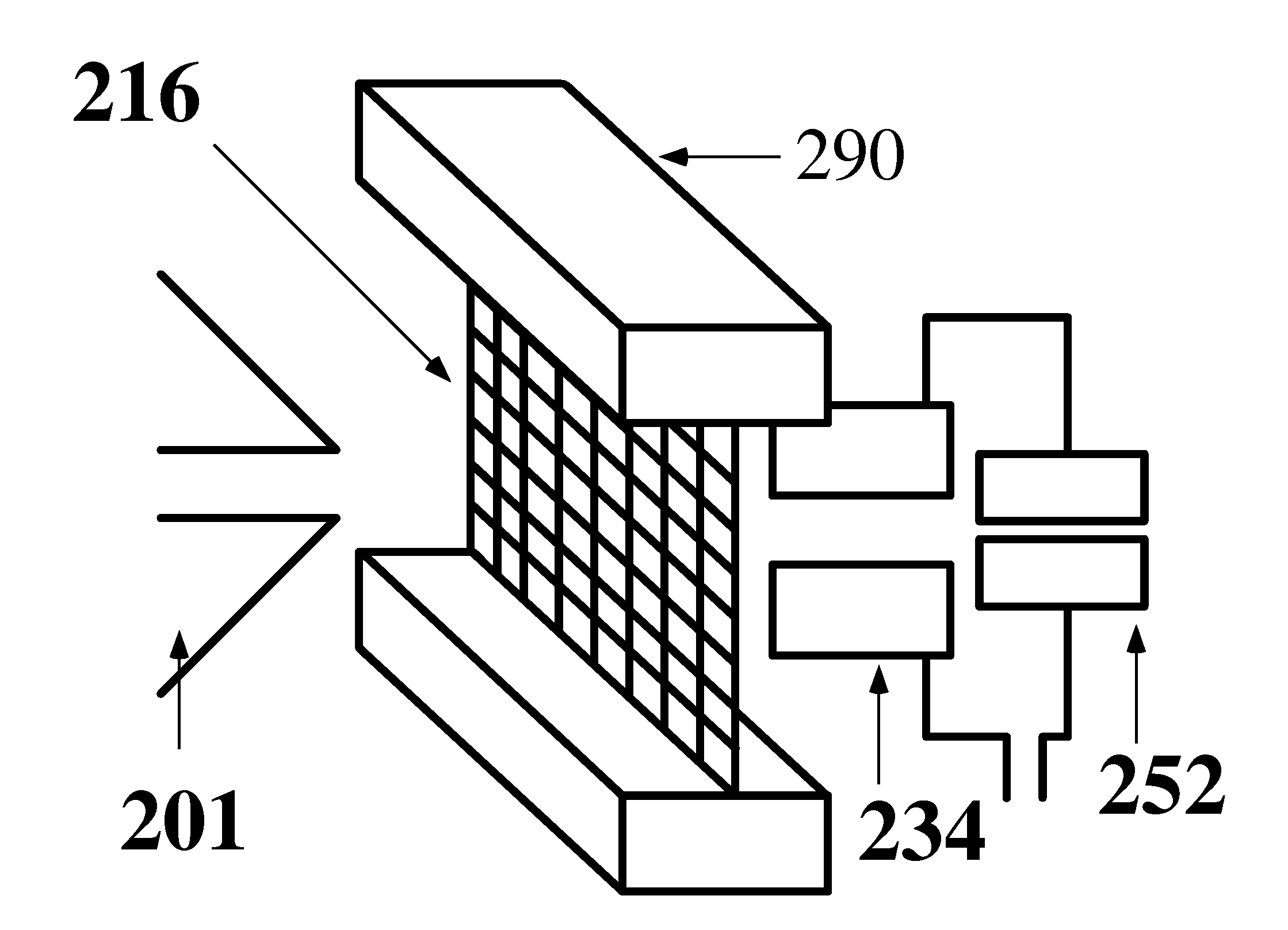

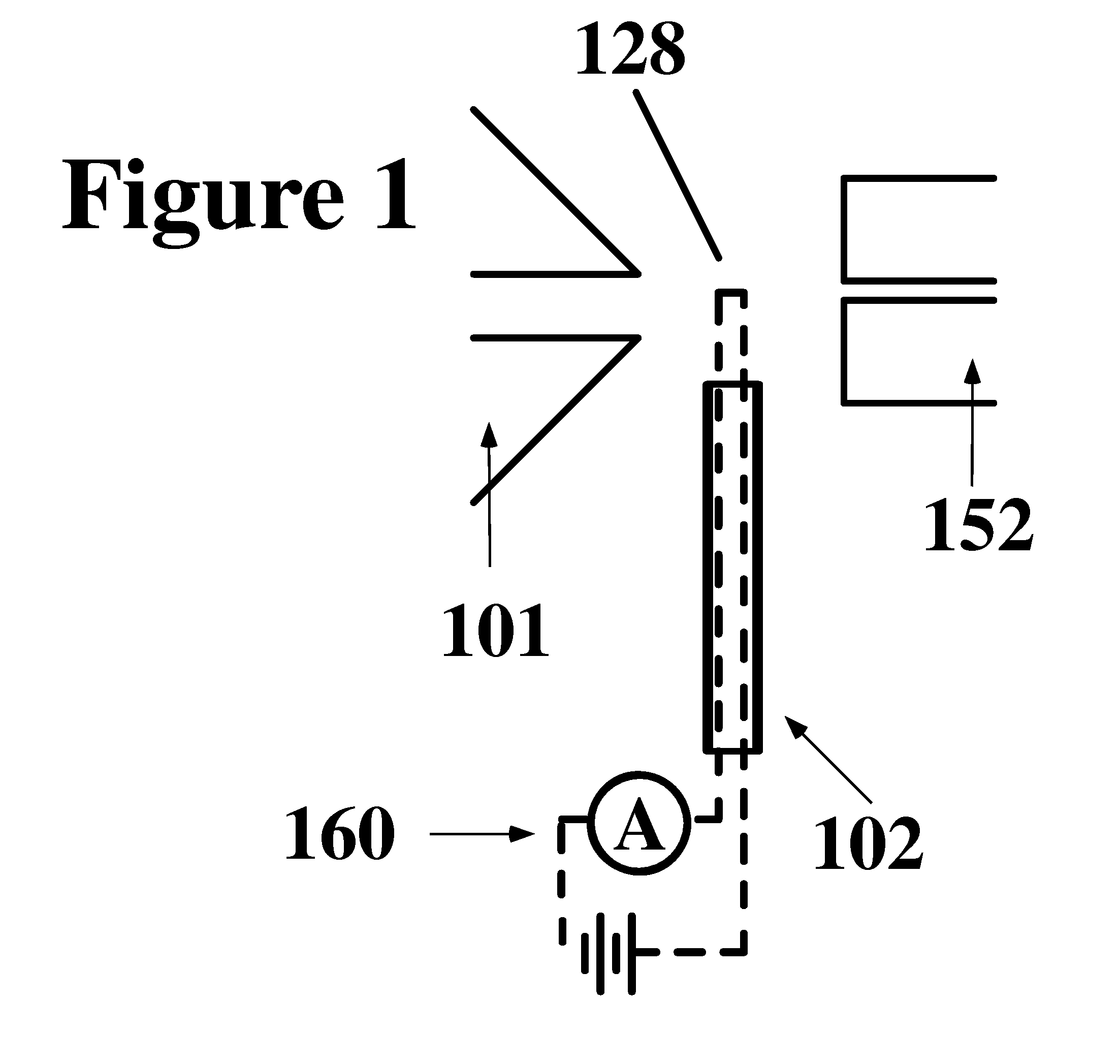

ActiveUS8754365B2Raise transfer toHigh resolutionSamples introduction/extractionMaterial analysis by electric/magnetic meansGas phaseDesorption

The present invention is directed to a method and device to desorb an analyte using heat to allow desorption of the analyte molecules, where the desorbed analyte molecules are ionized with ambient temperature ionizing species. In various embodiments of the invention a current is passed through a mesh upon which the analyte molecules are present. The current heats the mesh and results in desorption of the analyte molecules which then interact with gas phase metastable neutral molecules or atoms to form analyte ions characteristic of the analyte molecules.

Owner:BRUKER SCI LLC

Apparatus and method for thermal assisted desorption ionization systems

ActiveUS20120199735A1Easy to analyzeHigh resolutionTime-of-flight spectrometersSamples introduction/extractionPower flowDesorption

The present invention is directed to a method and device to desorb an analyte using heat to allow desorption of the analyte molecules, where the desorbed analyte molecules are ionized with ambient temperature ionizing species. In various embodiments of the invention a current is passed through a mesh upon which the analyte molecules are present. The current heats the mesh and results in desorption of the analyte molecules which then interact with gas phase metastable neutral molecules or atoms to form analyte ions characteristic of the analyte molecules.

Owner:BRUKER SCI LLC

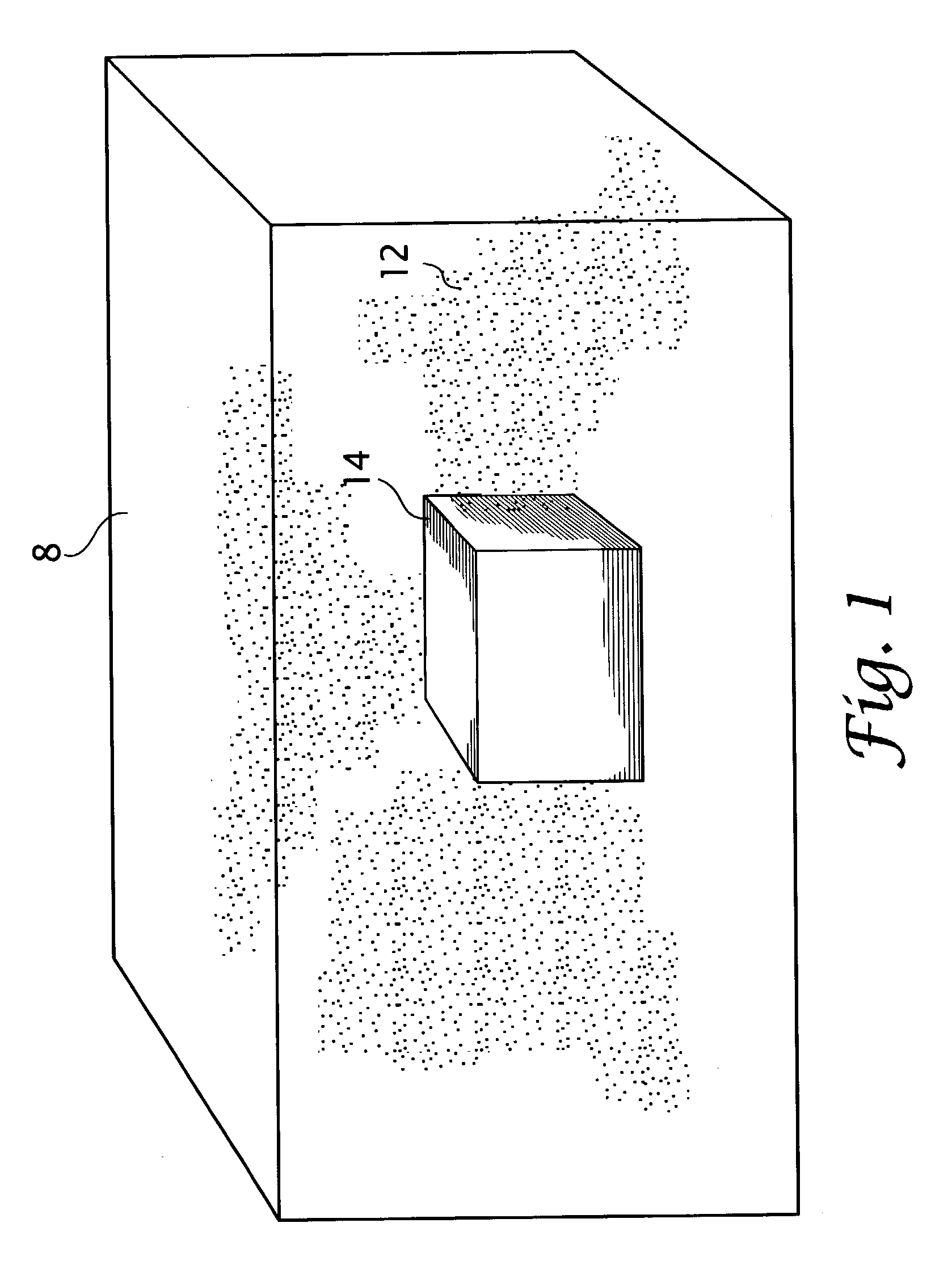

Apparatus and method for fine mist sterilization or sanitation using a biocide

A method of sterilizing a site or contained volume includes providing an aqueous biocide solution containing a biocide agent such as hydrogen peroxide. A mist of reactive biocide droplets is generated by atomization at ambient pressure from the biocide solution and a flow of carrier medium or air is provided in communication with the mist. The flow of carrier medium is controlled to generate a biocide mist comprising a concentration of stable mist droplets within the carrier medium. By controlling aersolization, extraction and delivery of the stable mist droplets, a sufficient portion of the stable mist droplets for a sterilizing treatment of a designated site do not coalesce prior to treatment interaction with the treatment site. The process of formation, stabilization and extraction are done in-situ so that droplets do not coalesce during transport.

Owner:NANOMIST SYST

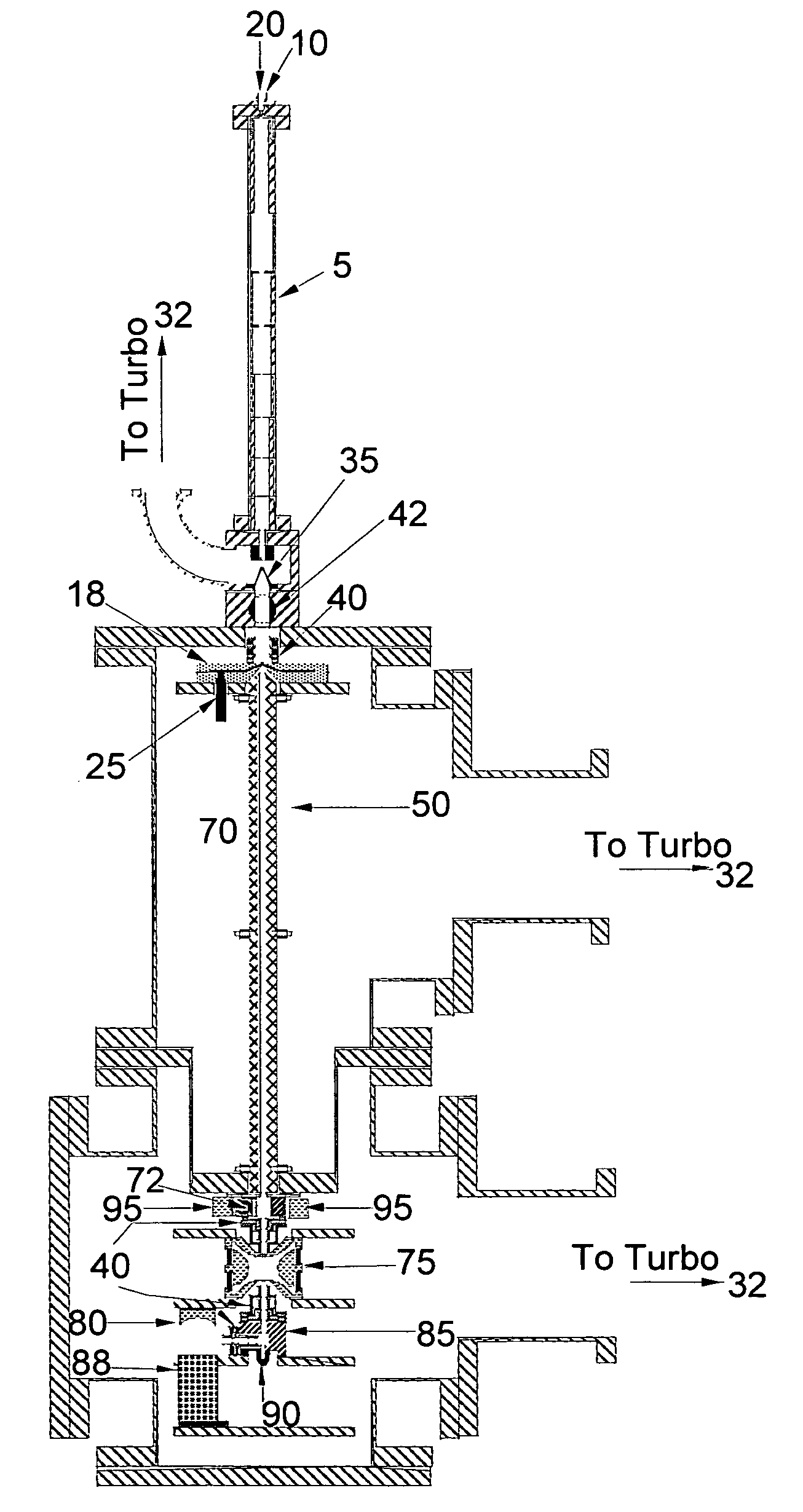

Ultra high mass range mass spectrometer systems

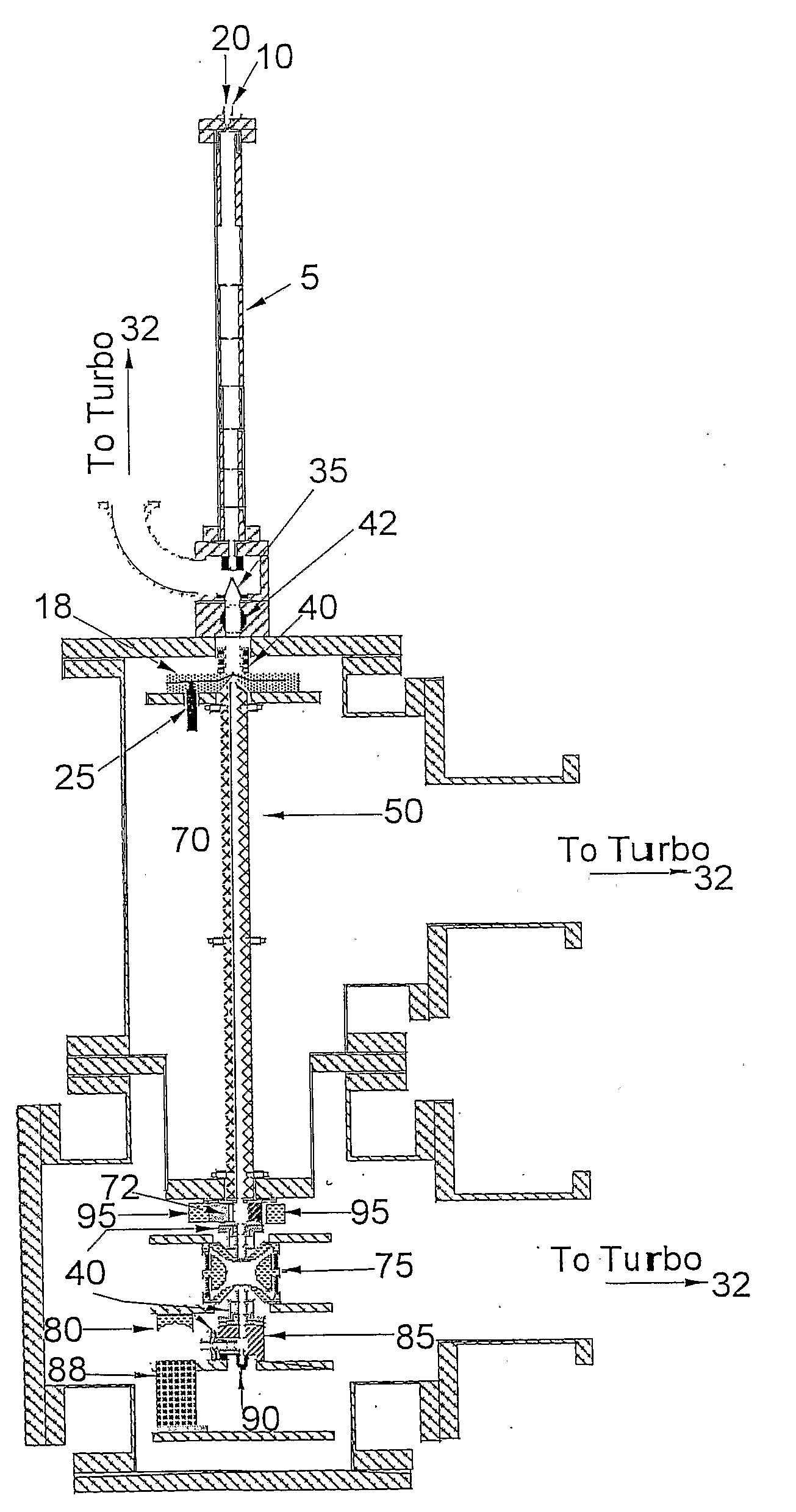

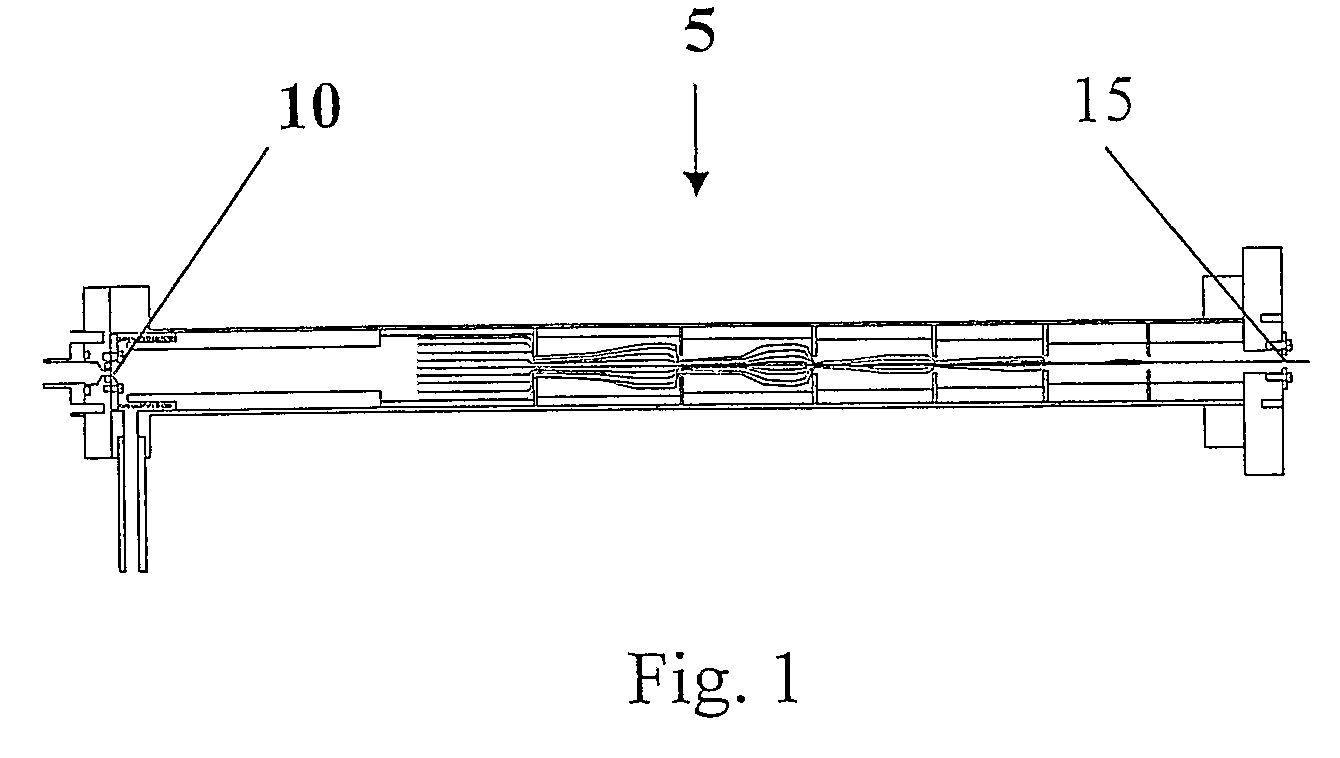

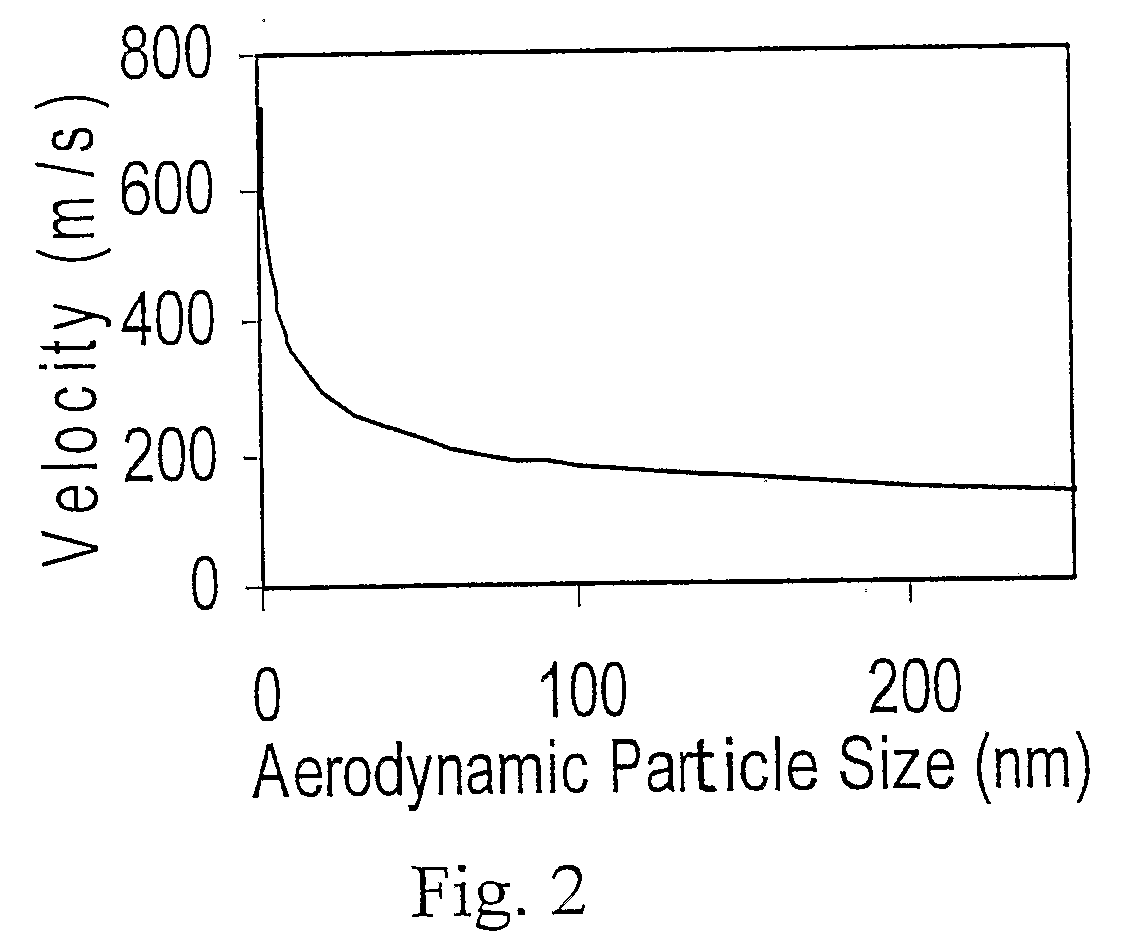

InactiveUS6972408B1Reduce kinetic energyPermit deliveryCombination devicesLaser detailsIon trap mass spectrometryMass analyzer

Applicant's present invention comprises mass spectrometer systems that operate in a mass range from 1 to 1016 DA. The mass spectrometer system comprising an inlet system comprising an aerodynamic lens system, a reverse jet being a gas flux generated in an annulus moving in a reverse direction and a multipole ion guide; a digital ion trap; and a thermal vaporization / ionization detector system. Applicant's present invention further comprises a quadrupole mass spectrometer system comprising an inlet system having a quadrupole mass filter and a thermal vaporization / ionization detector system. Applicant's present invention further comprises an inlet system for use with a mass spectrometer system, a method for slowing energetic particles using an inlet system. Applicant's present invention also comprises a detector device and a method for detecting high mass charged particles.

Owner:UT BATTELLE LLC

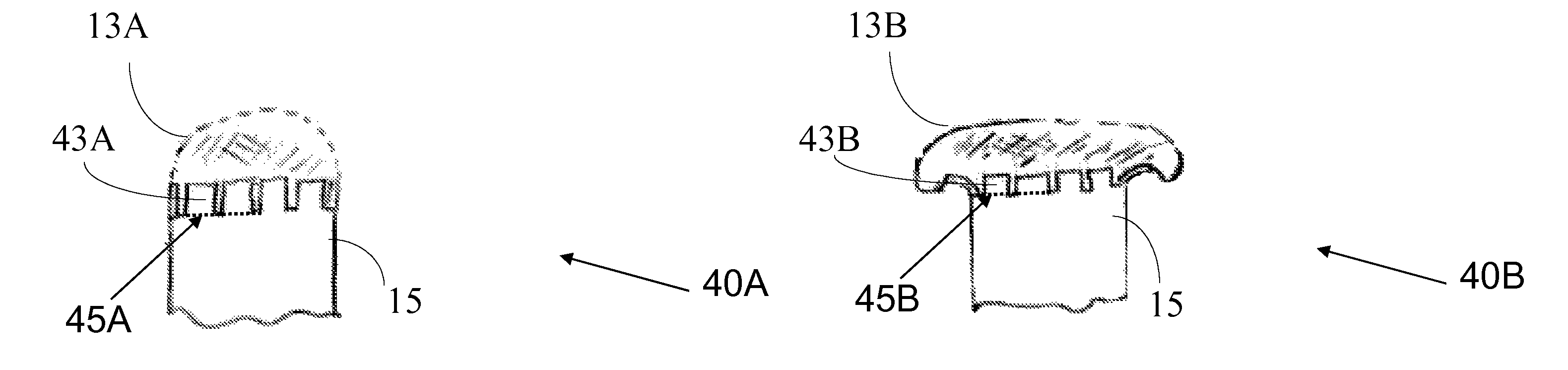

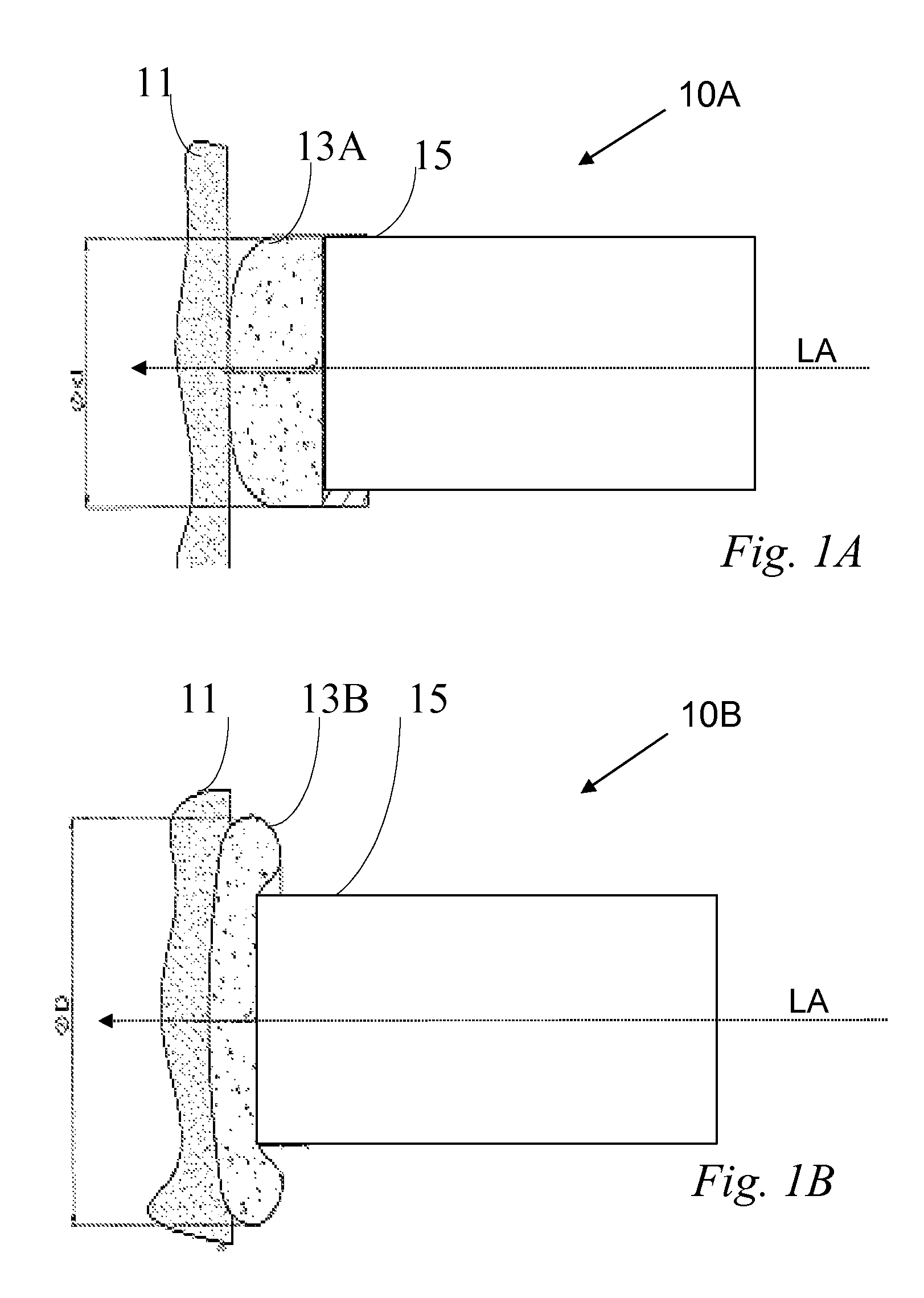

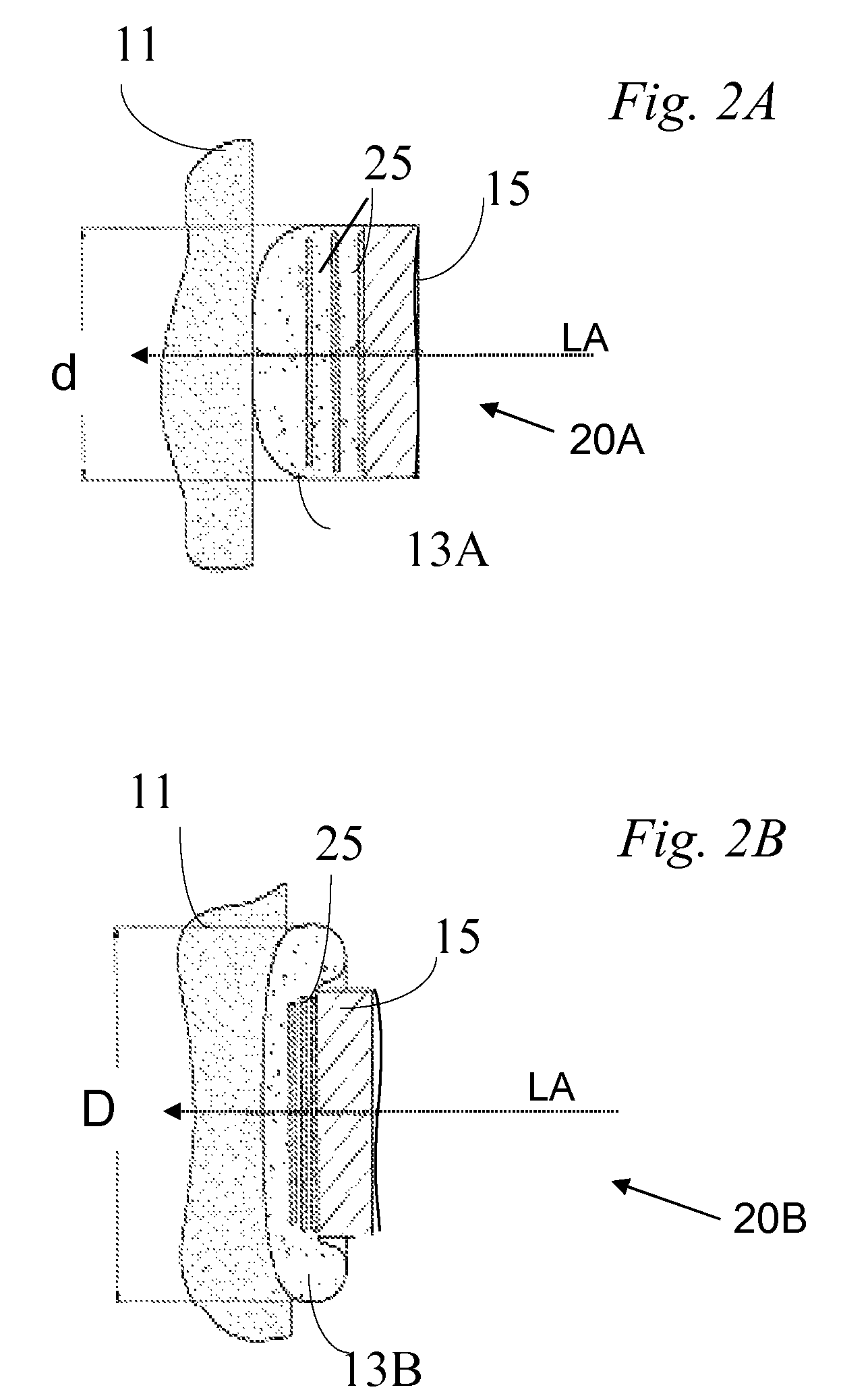

Non-lethal projectile

ActiveUS7861657B2Reduce the maximum forceInhibition releaseAmmunition projectilesTraining ammunitionLocking mechanismEngineering

A projectile is provided for use in a non-lethal weapon system. The projectile having kinetic energy is launched substantially along the longitudinal axis in the direction of a target. Upon impact of the projectile with the target an elastic mechanism absorbs elastically a first portion of the kinetic energy. A locking mechanism stores the first portion of the kinetic energy within the elastic mechanism; whereby the remaining kinetic energy of the impact is reduced to a non-lethal level of the target. The projectile preferably includes a deformable head attached to the first body. The deformable head is formed from a viscoelastic material which manifests both the elastic mechanism (with the elastic mechanical properties of the viscoelastic material) and further manifests the locking mechanism with the viscous properties of the viscoelastic material.

Owner:FACTA GLOBAL INC

Ultra High Mass Range Mass Spectrometer Systems

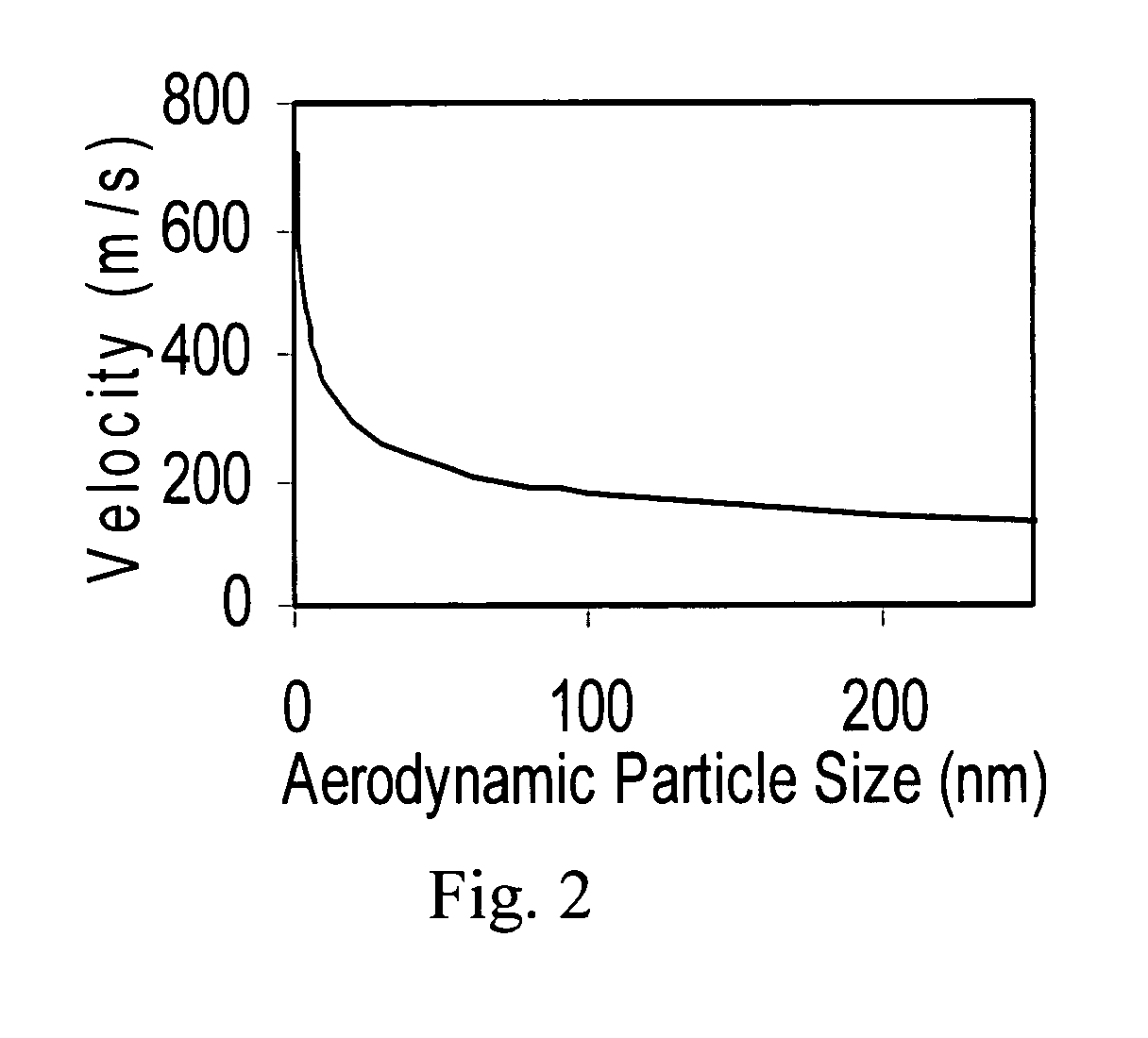

InactiveUS20080251711A1Reduce kinetic energyPermit deliveryCombination devicesLaser detailsMass analyzerHigh mass

A mass spectrometer system includes an inlet system having an aerodynamic lens system for collimating charged particles into a beam, and an aerodynamic kinetic energy reducing device for receiving and slowing the charged particles to near zero kinetic energy. A detection system receives and identifies a mass of the charged particles. The aerodynamic kinetic energy reducing device can be a reverse jet or a pathway through a stagnant volume of gas. Such mass spectrometer systems can operate in a mass range from 1 to 1016 DA.

Owner:UT BATTELLE LLC

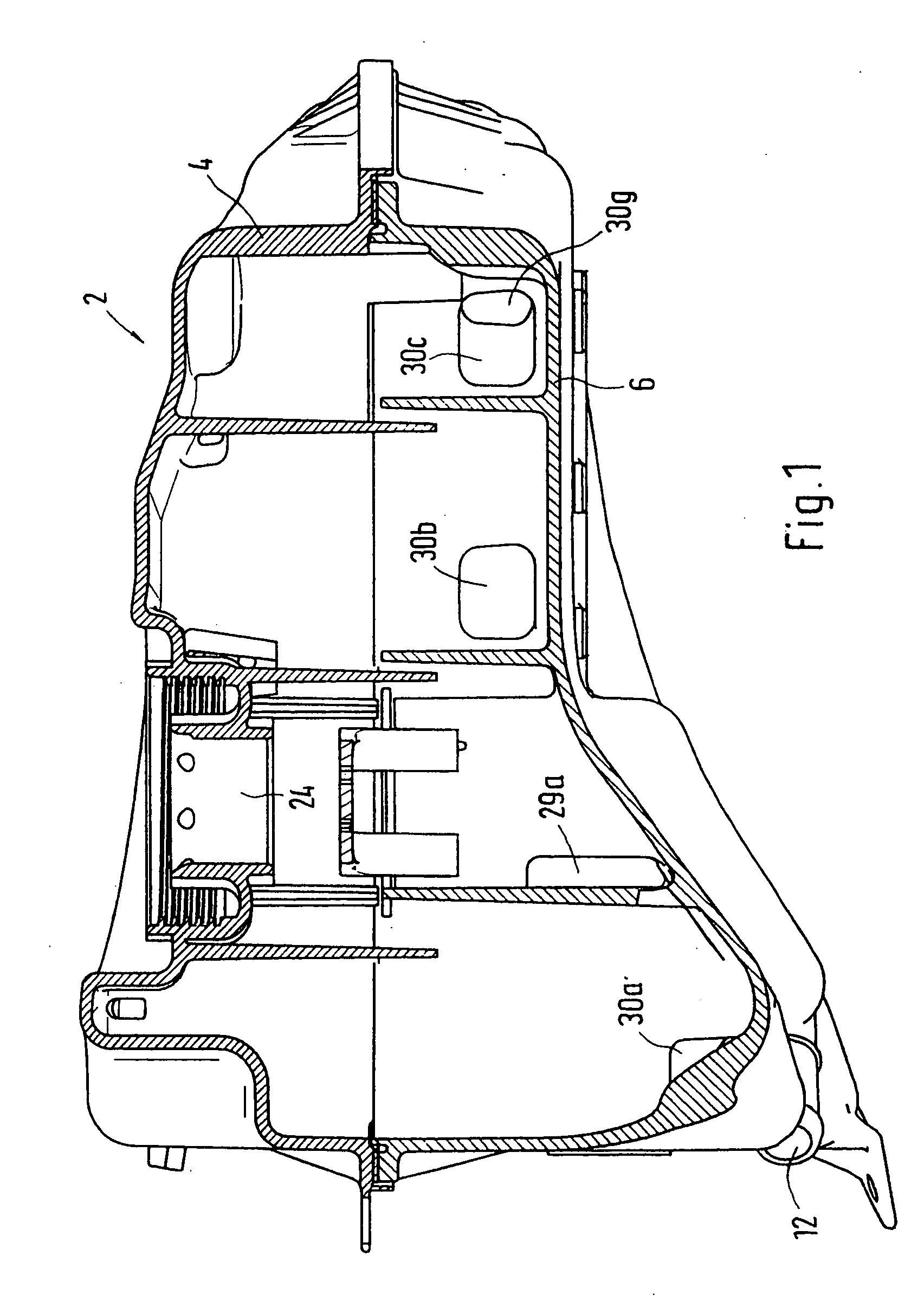

Compensation reservoir for a cooling circuit of an internal combustion engine

InactiveUS20050224021A1Reduce kinetic energyIncrease liquid viscosityLiquid coolingMachines/enginesCoolant flowInternal combustion engine

A compensating tank for a cooling circuit of an internal combustion engine has at least one inflow connection and one outflow connection, both of which are connected with the cooling circuit, a chamber system formed in the tank to receive the coolant, such that the individual chambers are at least partially interconnected via openings, and a coolant pipe connected with the inflow connection discharging into one of the chambers in which an impact element is provided for the inflowing coolant. The impact element is configured as a curved guiding wall along which the inflowing coolant is specifically guided. This inhibits, among other things, foaming of the coolant flowing into the compensating tank.

Owner:DR ING H C F PORSCHE AG

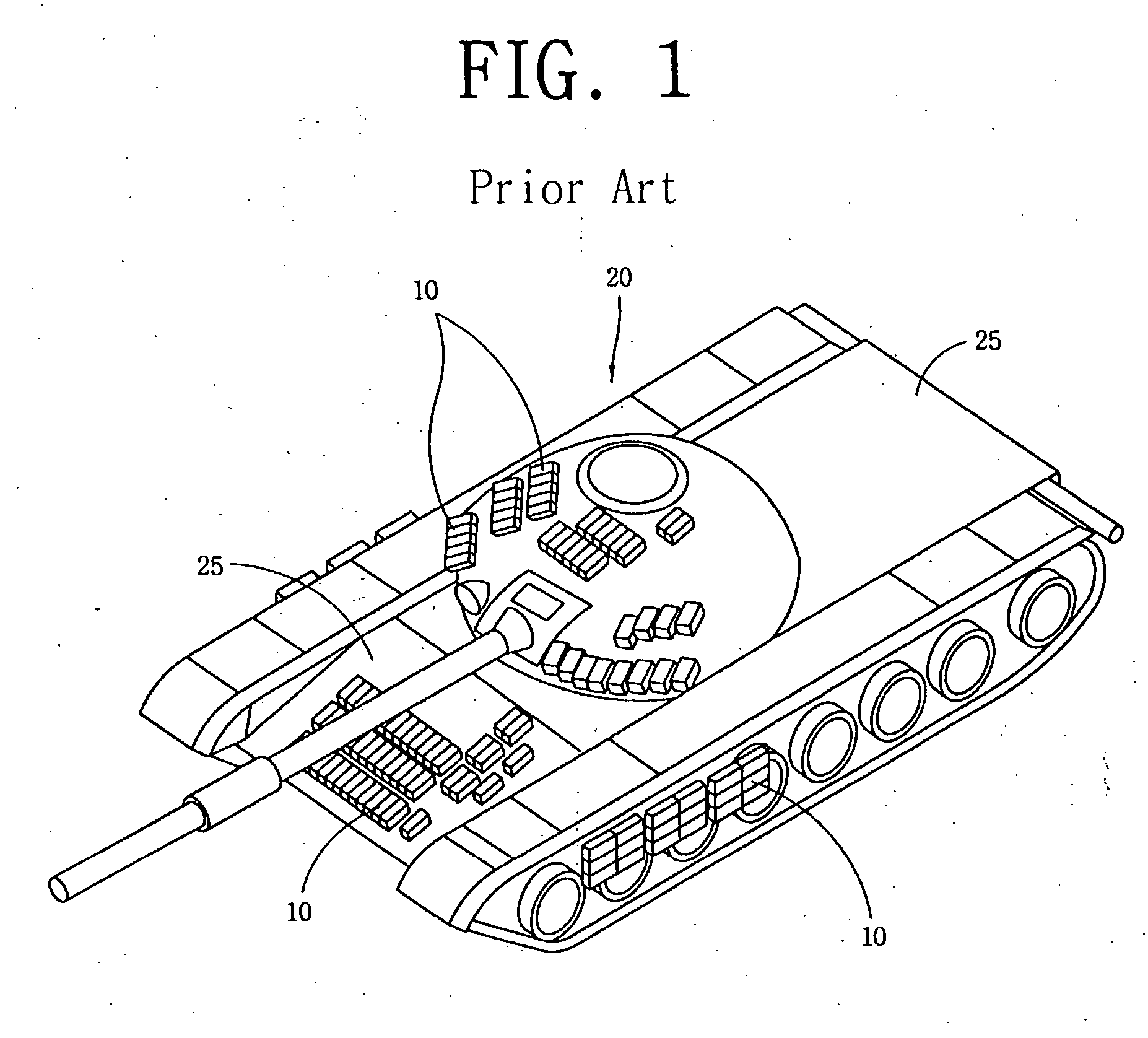

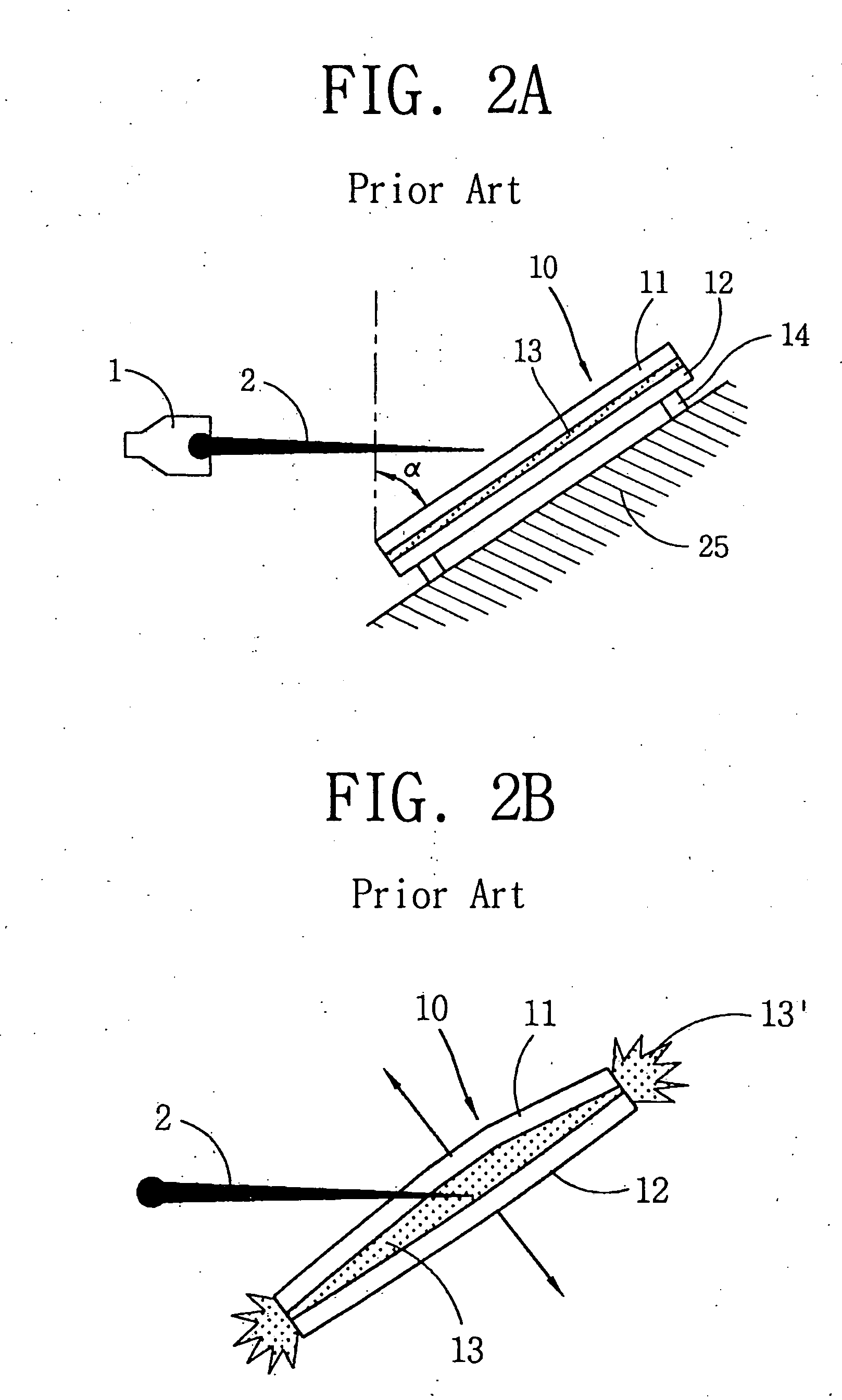

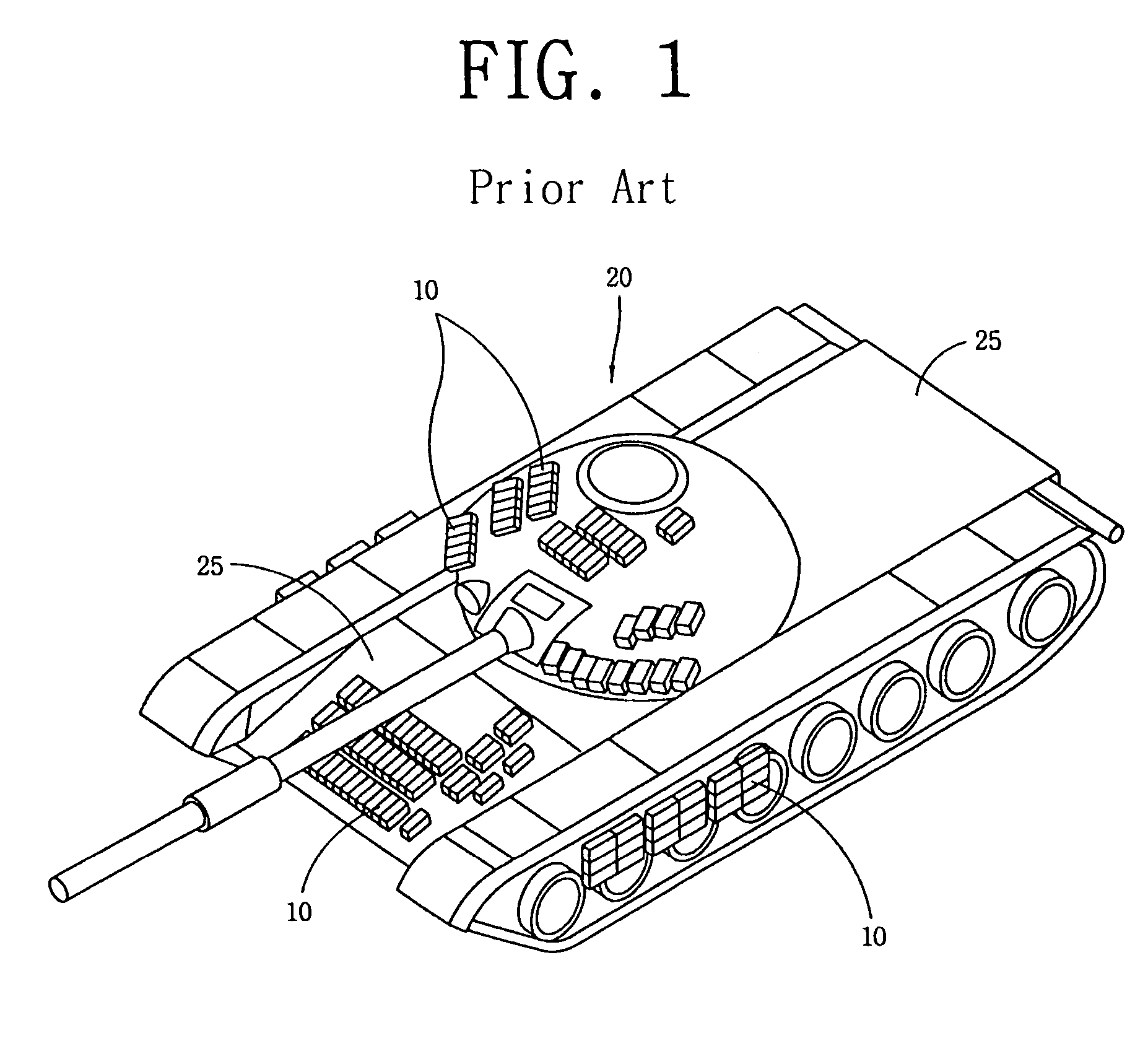

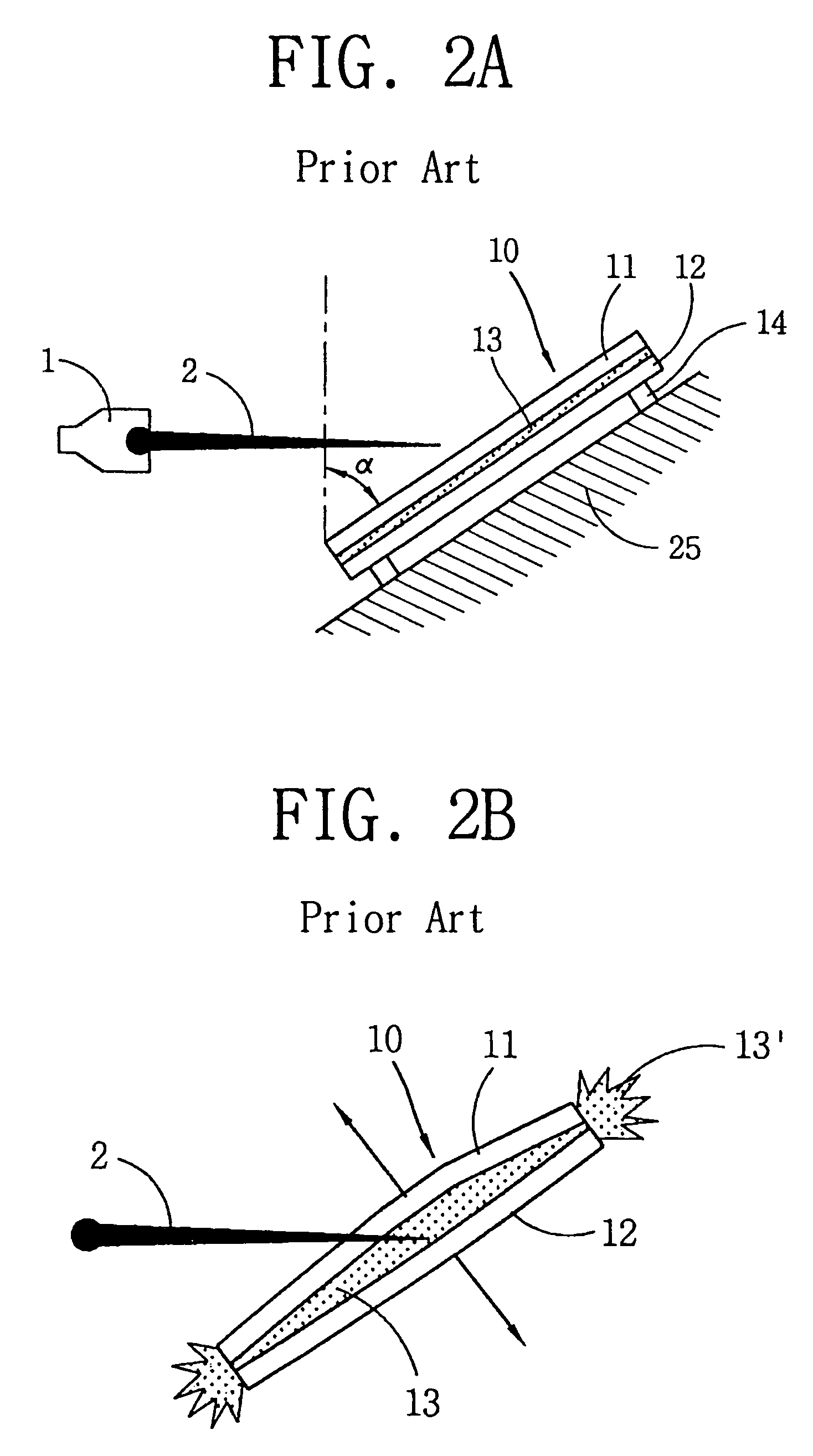

Explosive reactive armor with momentum transfer mechanism

ActiveUS20060086243A1Enhanced interactionImprove protectionDefence devicesArmoured vehiclesDetonationSlant angle

Disclosed is an explosive reactive armor with a momentum transfer mechanism by developing a new protection mechanism in which a momentum transfer mechanism by detonation of a reactive material is integrated with a thickness increase mechanism. In this explosive reactive armor with the momentum transfer mechanism, a flying element always travels with a vertical angle or a slant angle with respect to an ongoing direction of the threat such that a momentum of the flying element is transferred to the threat effectively. As a result of this, shear force is induced over an entire length of the threat and thus the threat can be destroyed. Therefore, a protection effect can always be achieved regardless of an impact angle of the threat. Also, a protection capability can be achieved even in case of a vertical impact which is the most vulnerable case for the existing explosive reactive armor.

Owner:AGENCY FOR DEFENSE DEV

Pedestrian protection system

InactiveUS7836996B2Easy constructionAccurate protectionVehicle seatsSuperstructure subunitsEngineeringProtection system

Owner:TOYODA GOSEI CO LTD

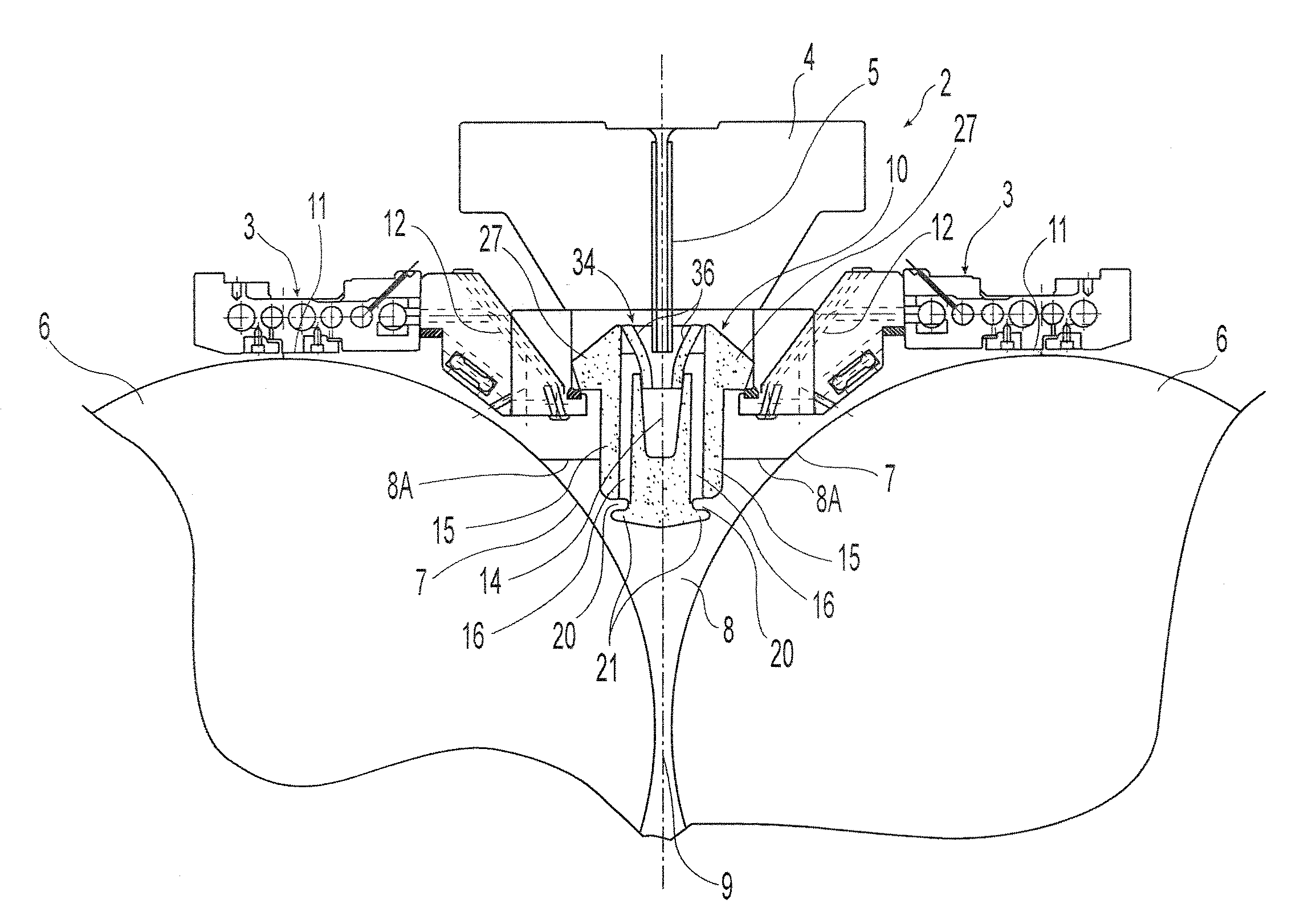

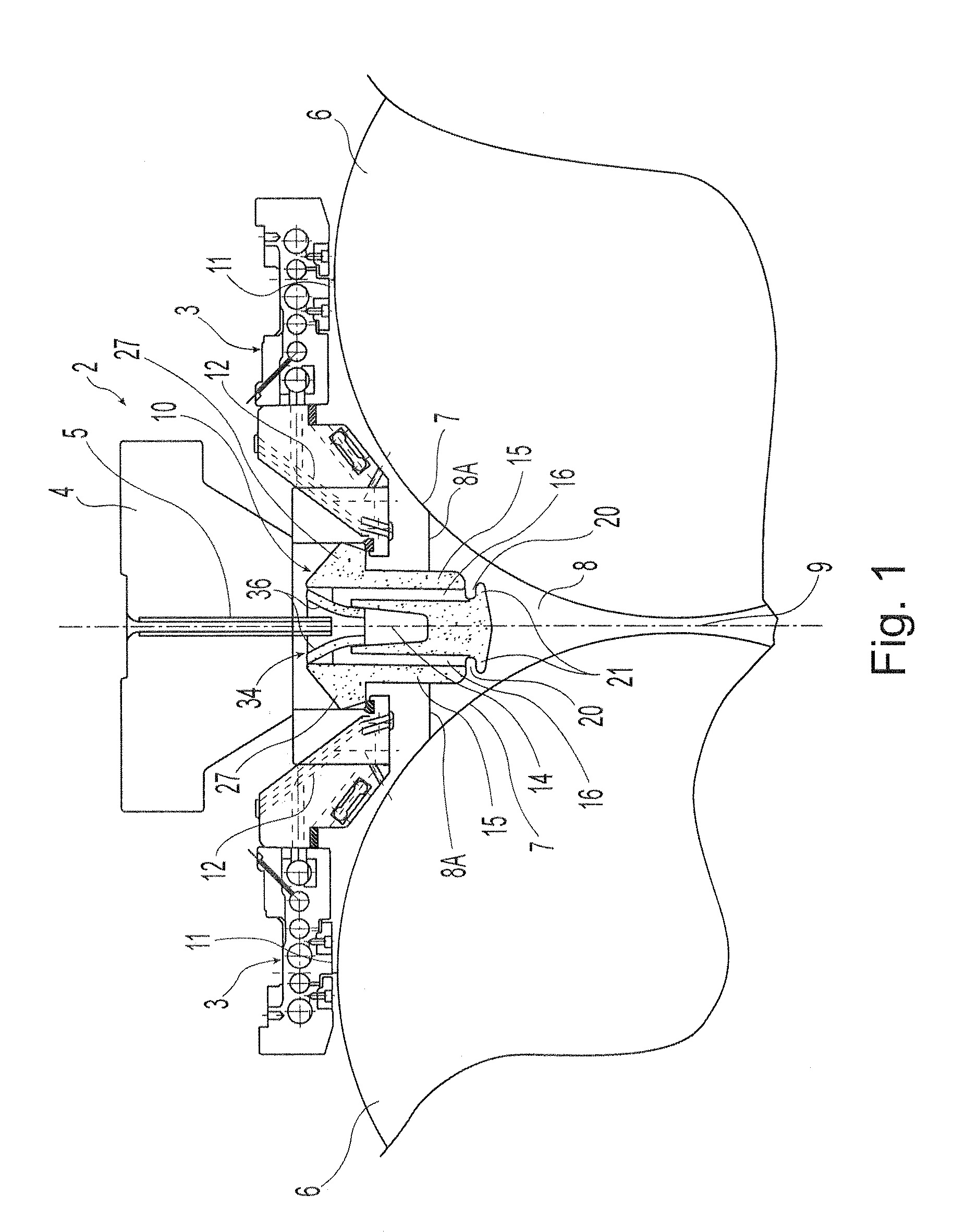

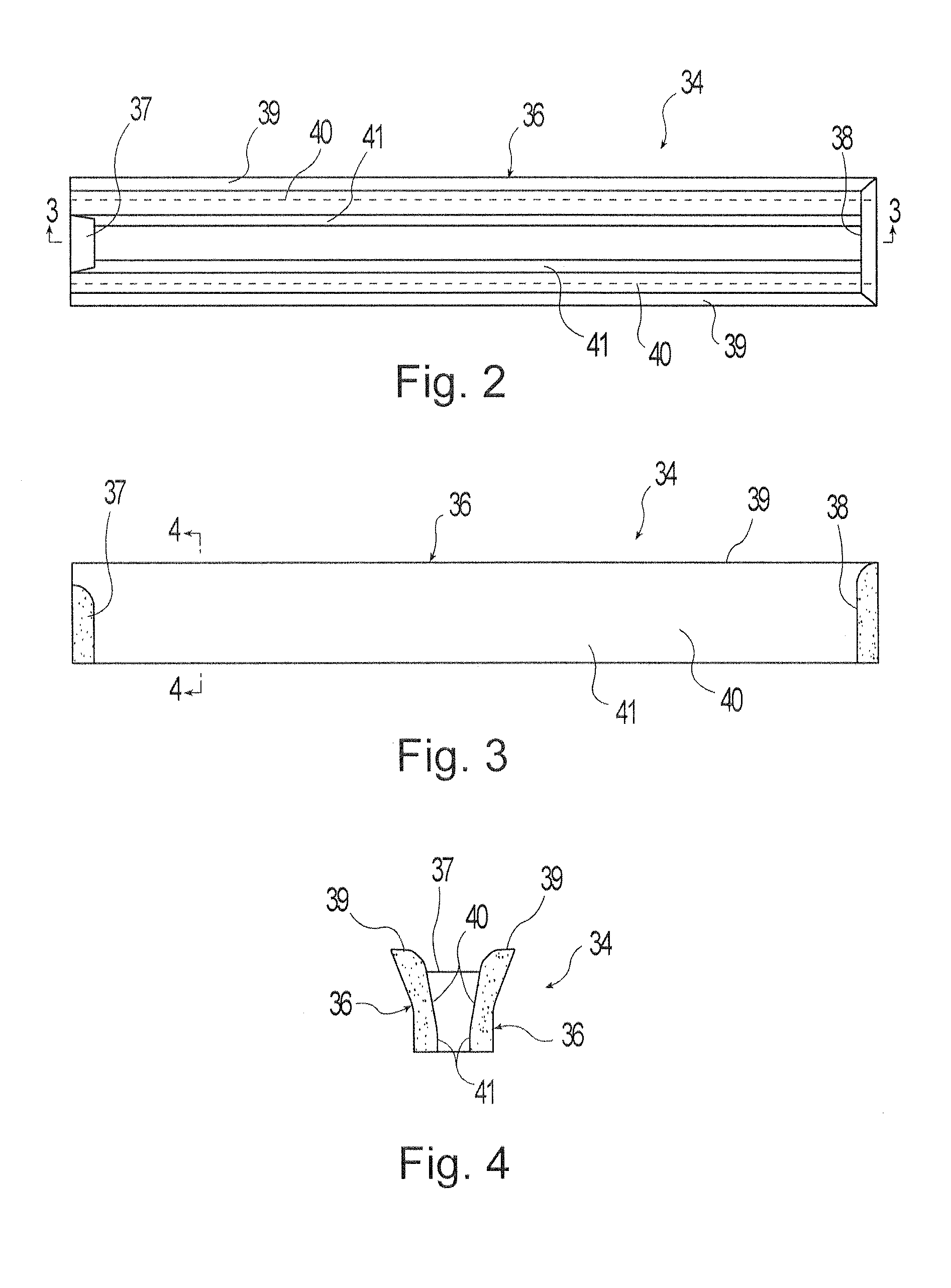

Casting delivery nozzle with insert

InactiveUS20080264599A1Easy to replaceReduces turbulence in flowMolten metal pouring equipmentsMolten metal supplying equipmentsMolten metalNozzle

A metal strip casting apparatus and a method of casting continuous metal strip includes assembling a pair of counter-rotatable casting rolls having casting surfaces positioned laterally forming a nip between for casting, and delivering molten metal through a delivery nozzle disposed above the nip capable to form a casting pool supported on the casting rolls. The delivery nozzle comprises segments each having elongate nozzle body with longitudinally extending side walls, end walls and a bottom part to form an inner trough, a nozzle insert disposed above bottom portions of the inner trough of each segment and supported relative to the nozzle body through which incoming molten metal may be delivered to the inner trough of each segment of the delivery nozzle, and the elongate nozzle body of each segment having passageways in fluid communication with the inner trough and outlet openings capable of discharging molten metal from the nozzle body outwardly into the casting pool.

Owner:NUCOR CORP

Explosive reactive armor with momentum transfer mechanism

ActiveUS7540229B2Enhanced interactionImprove protectionDefence devicesArmoured vehiclesDetonationSlant angle

Disclosed is an explosive reactive armor with a momentum transfer mechanism by developing a new protection mechanism in which a momentum transfer mechanism by detonation of a reactive material is integrated with a thickness increase mechanism. In this explosive reactive armor with the momentum transfer mechanism, a flying element always travels with a vertical angle or a slant angle with respect to an ongoing direction of the threat such that a momentum of the flying element is transferred to the threat effectively. As a result of this, shear force is induced over an entire length of the threat and thus the threat can be destroyed. Therefore, a protection effect can always be achieved regardless of an impact angle of the threat. Also, a protection capability can be achieved even in case of a vertical impact which is the most vulnerable case for the existing explosive reactive armor.

Owner:AGENCY FOR DEFENSE DEV

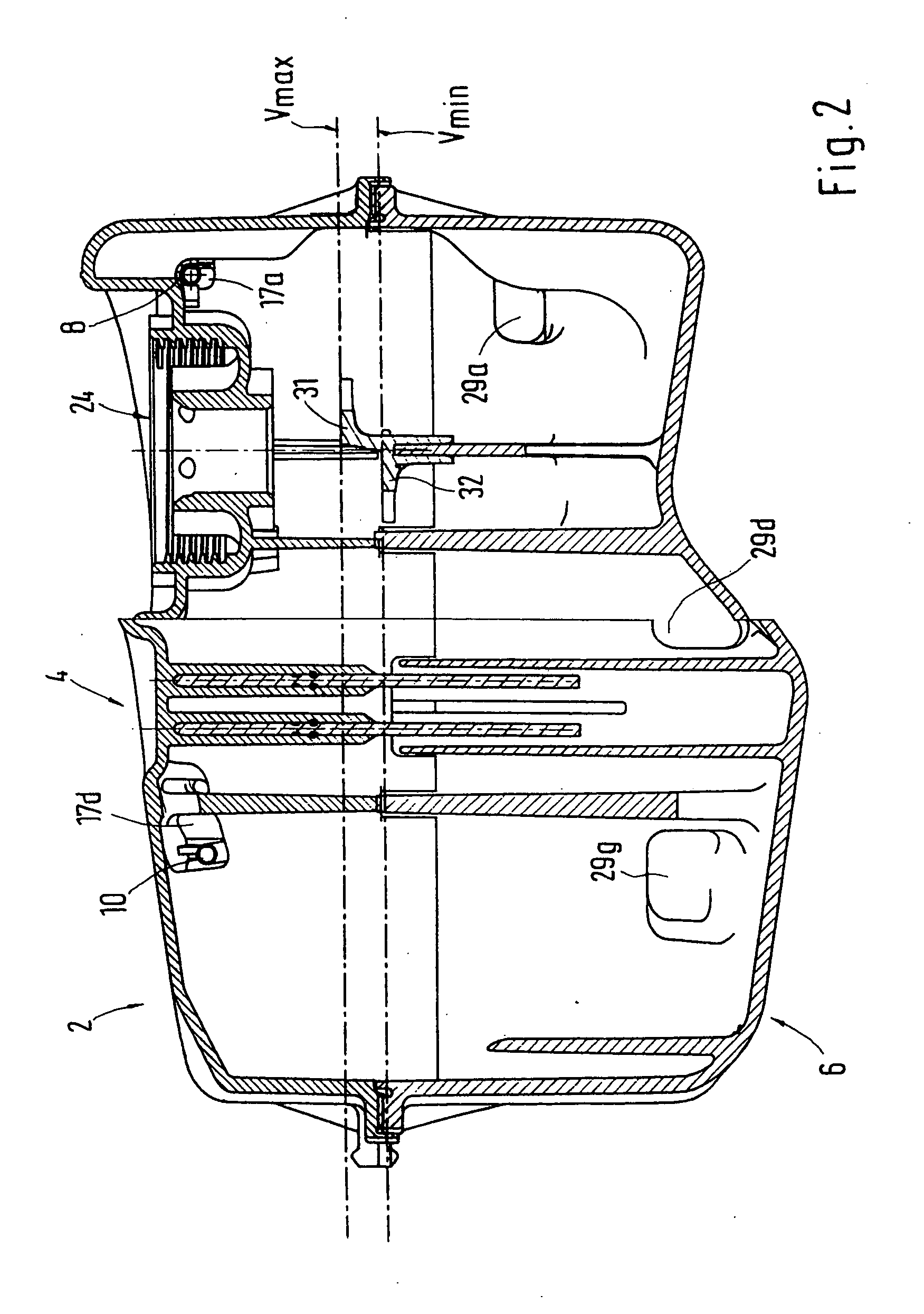

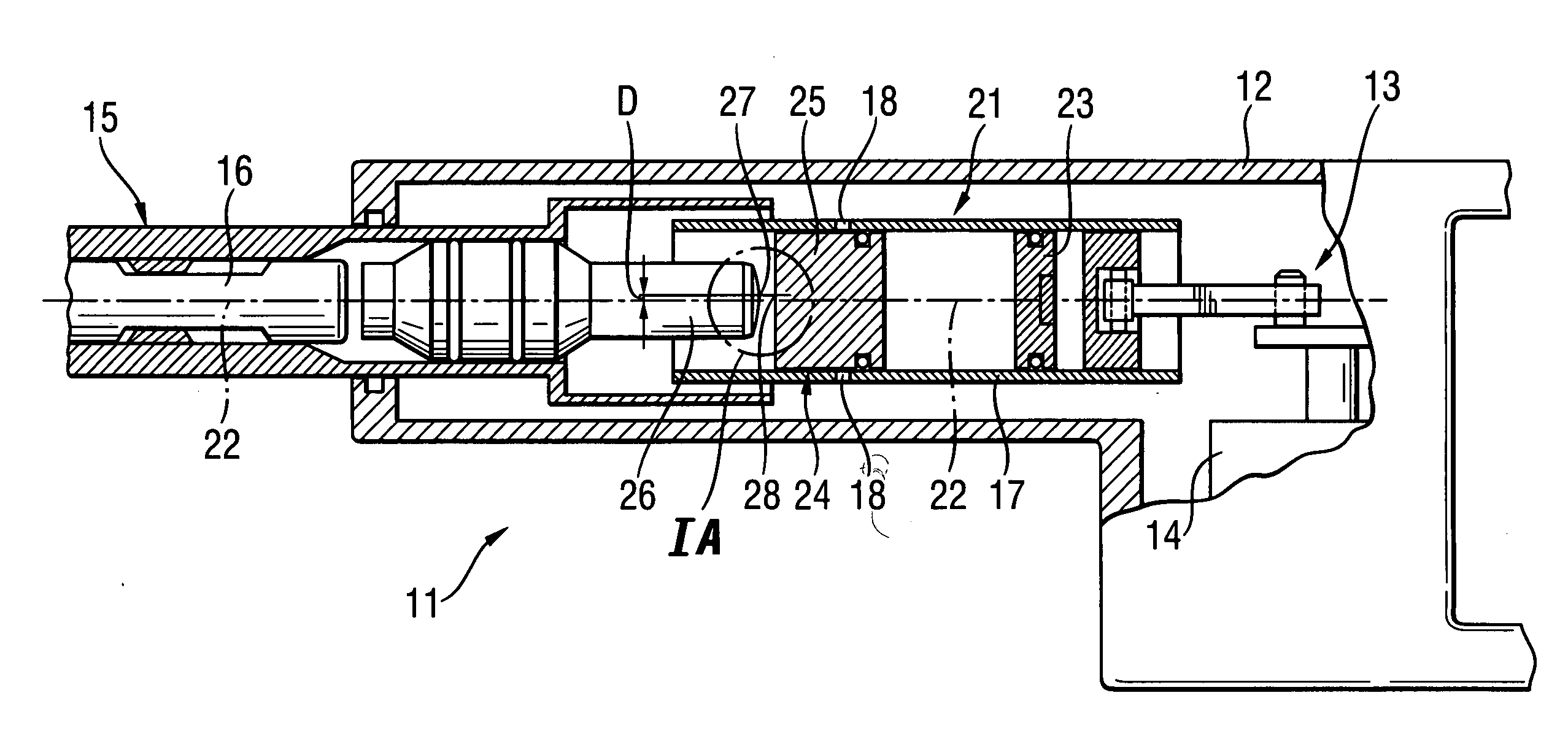

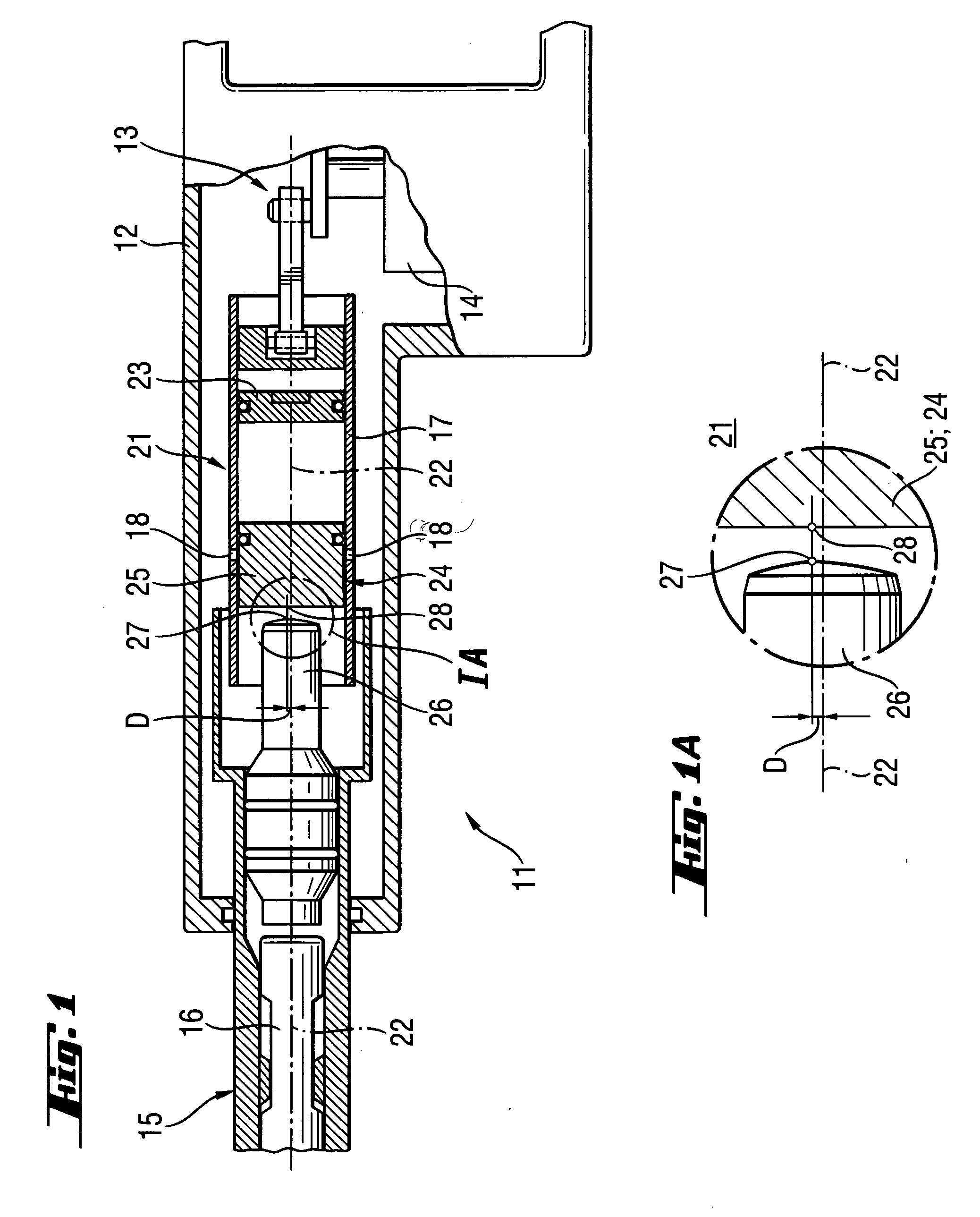

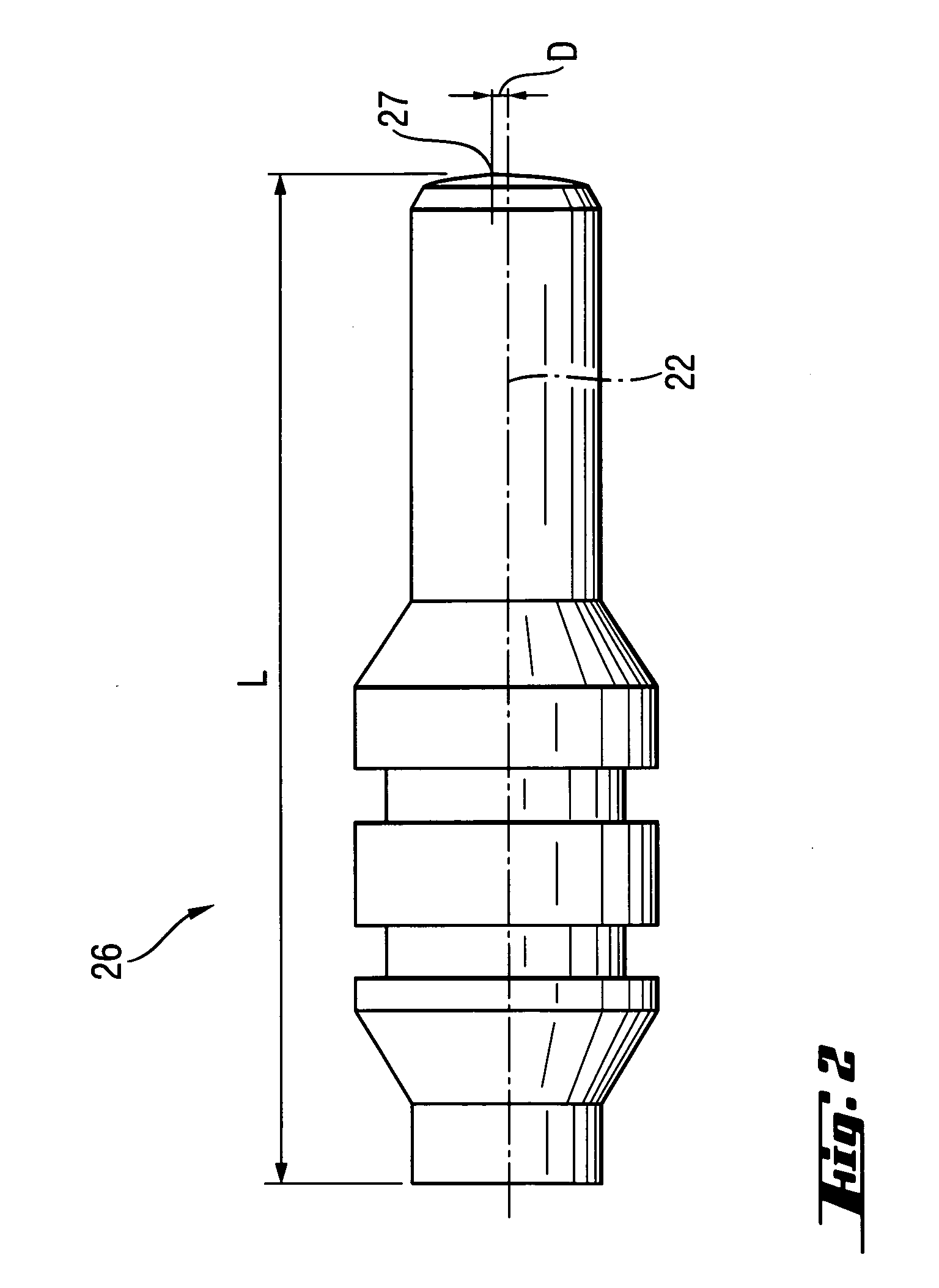

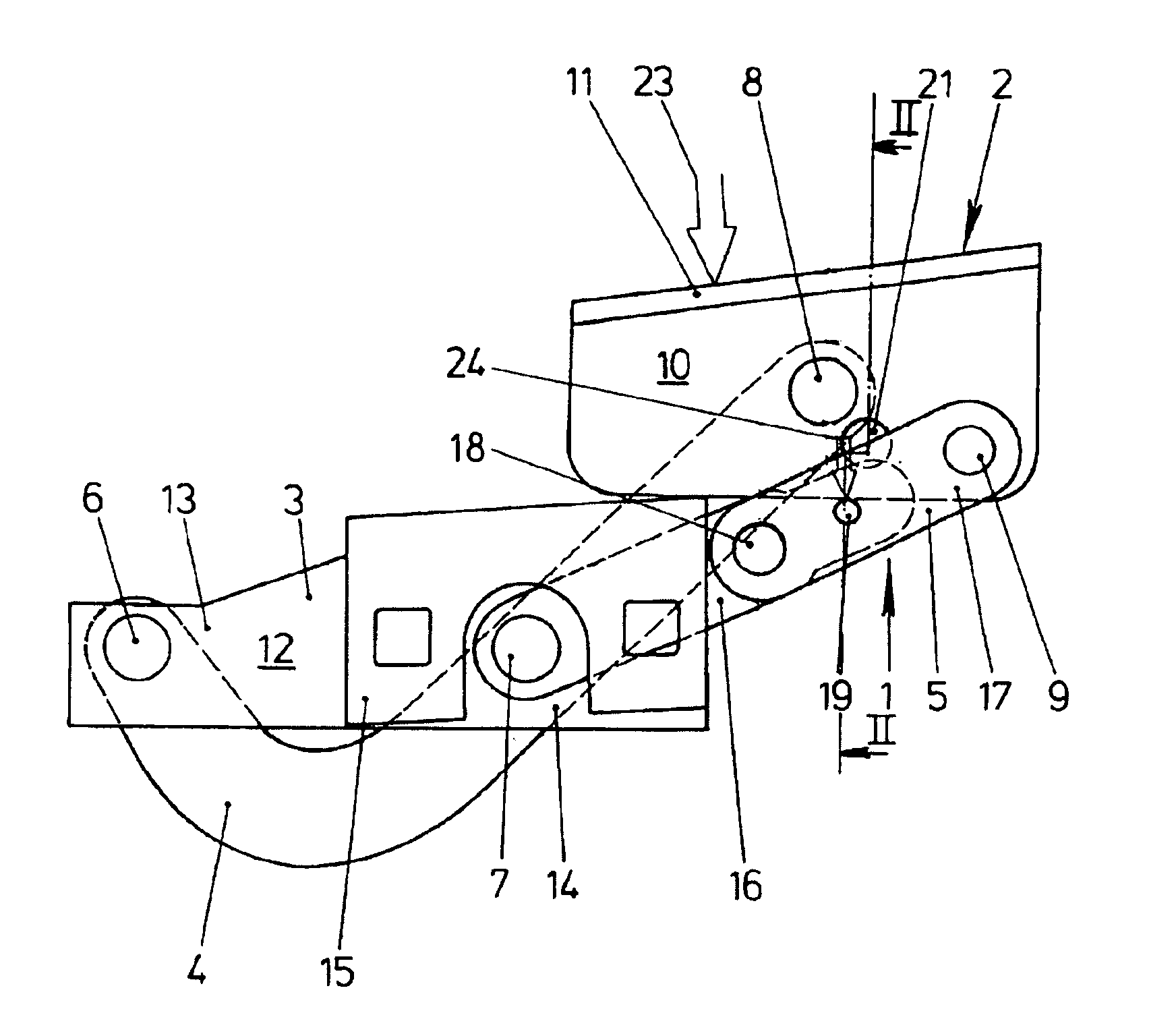

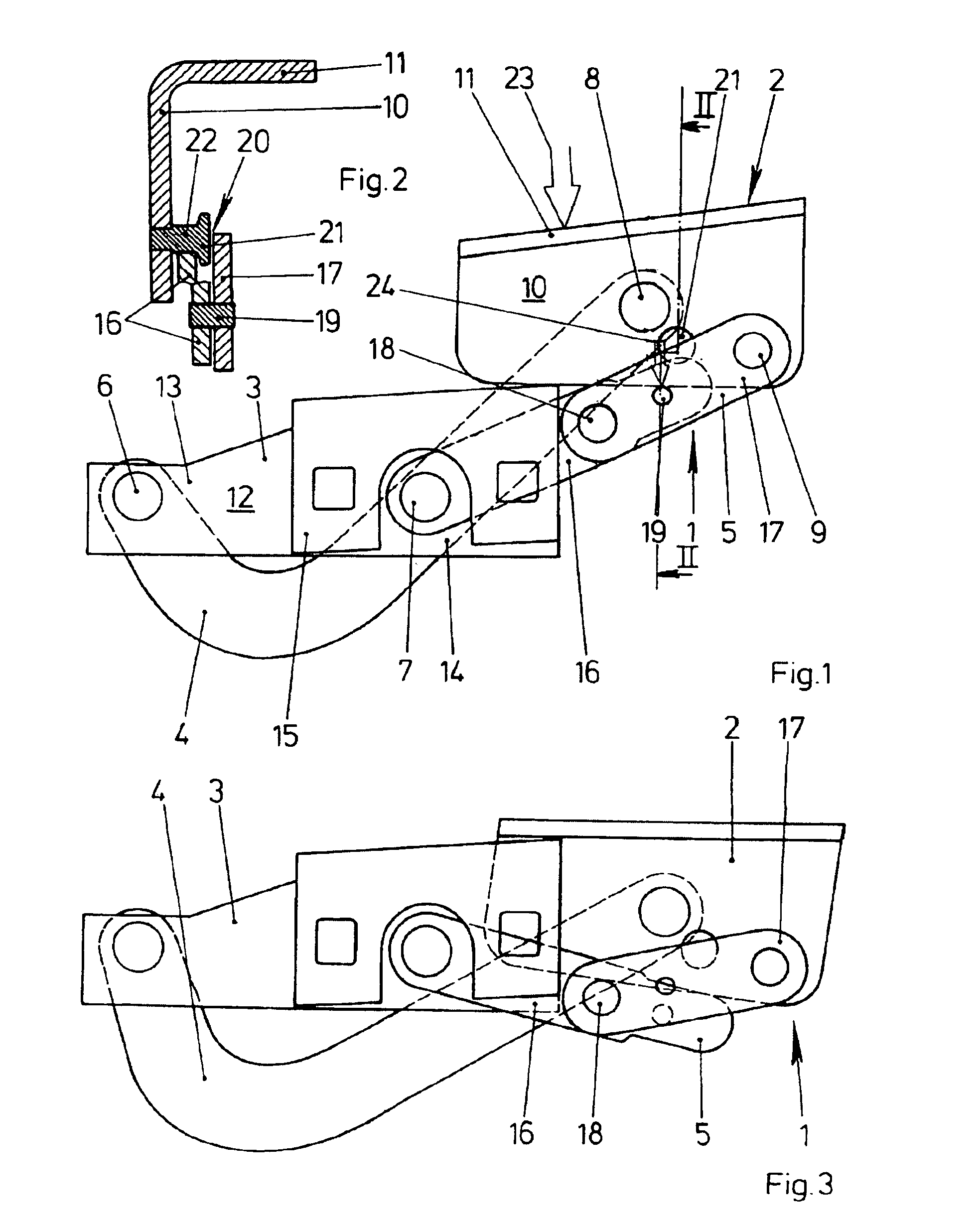

Percussion power tool

InactiveUS20060237206A1Reduce kinetic energyIncrease frictionReciprocating drilling machinesConstructionsReciprocating motionEngineering

A percussion mechanism (21; 41) for a percussion power tool includes an impact element (24; 44) reciprocating along a percussion axis (22; 42) of the percussion mechanism (21; 41) and acting on the striker (26, 46). The contact point (27, 47) and counter-contact point (28, 48) are provided between the striker (26, 46) and the impact element (24, 44), with the contact point (27, 47) being formed as an exposed contact point and being arranged outside of the percussion axis (22; 42).

Owner:HILTI AG

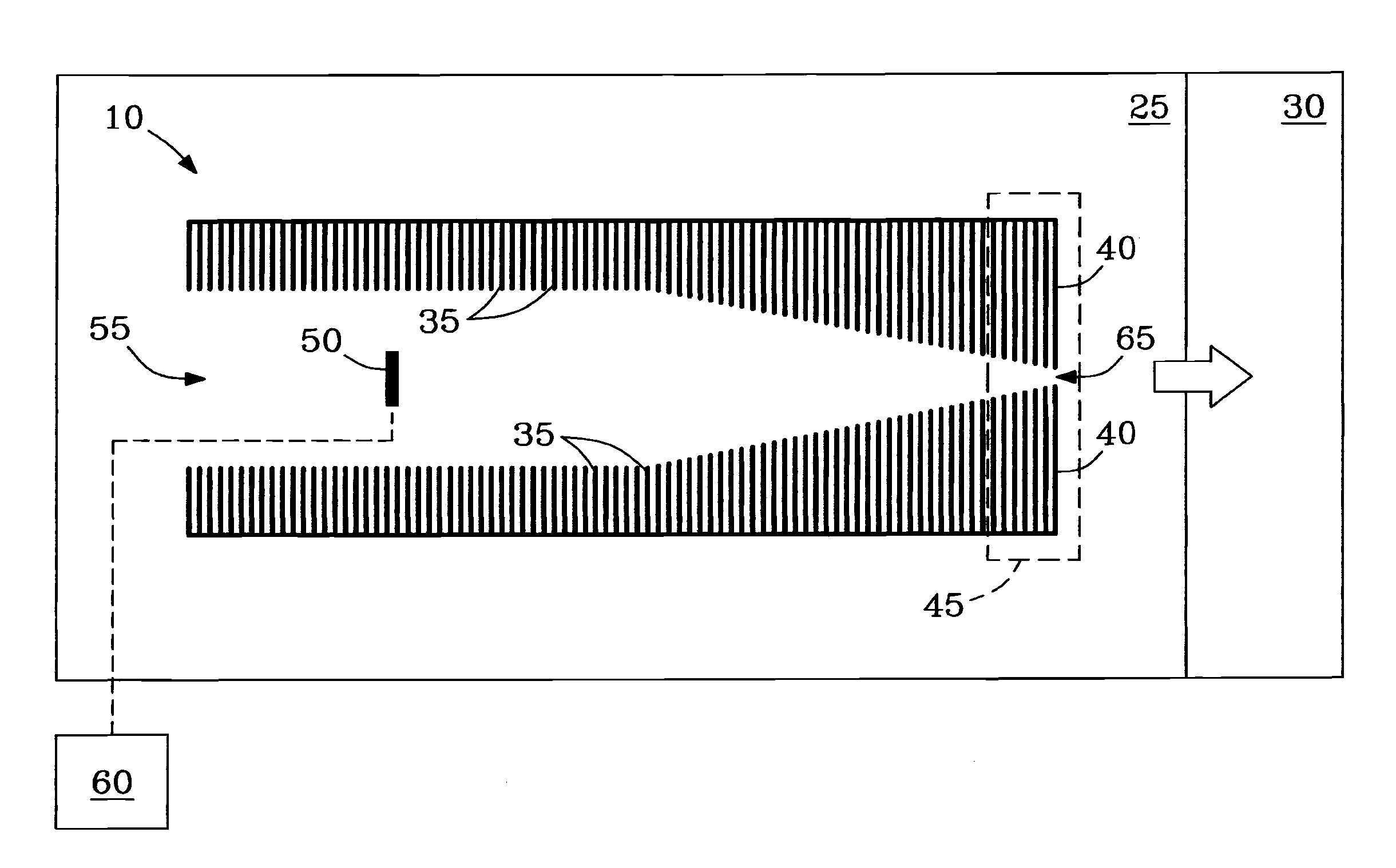

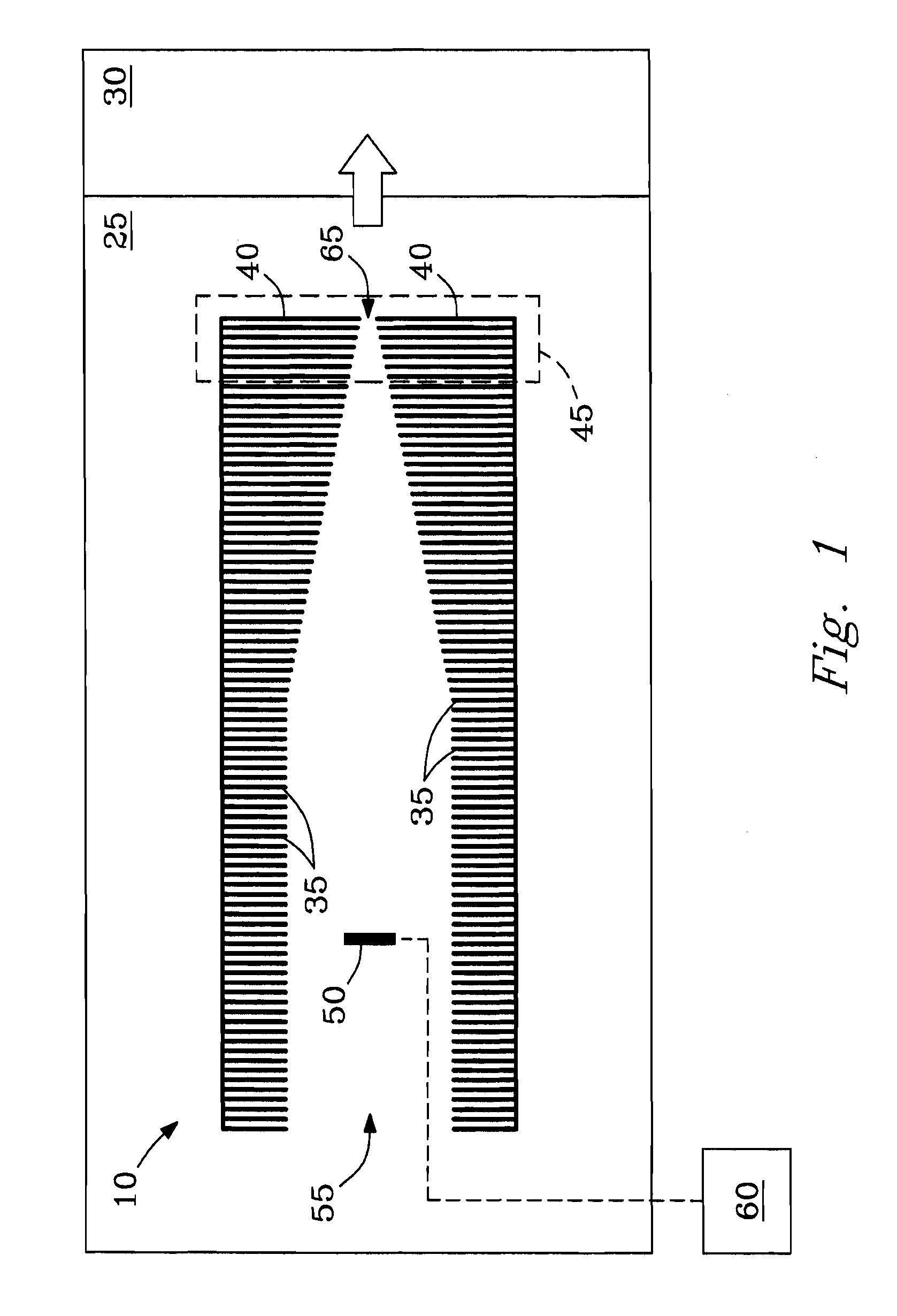

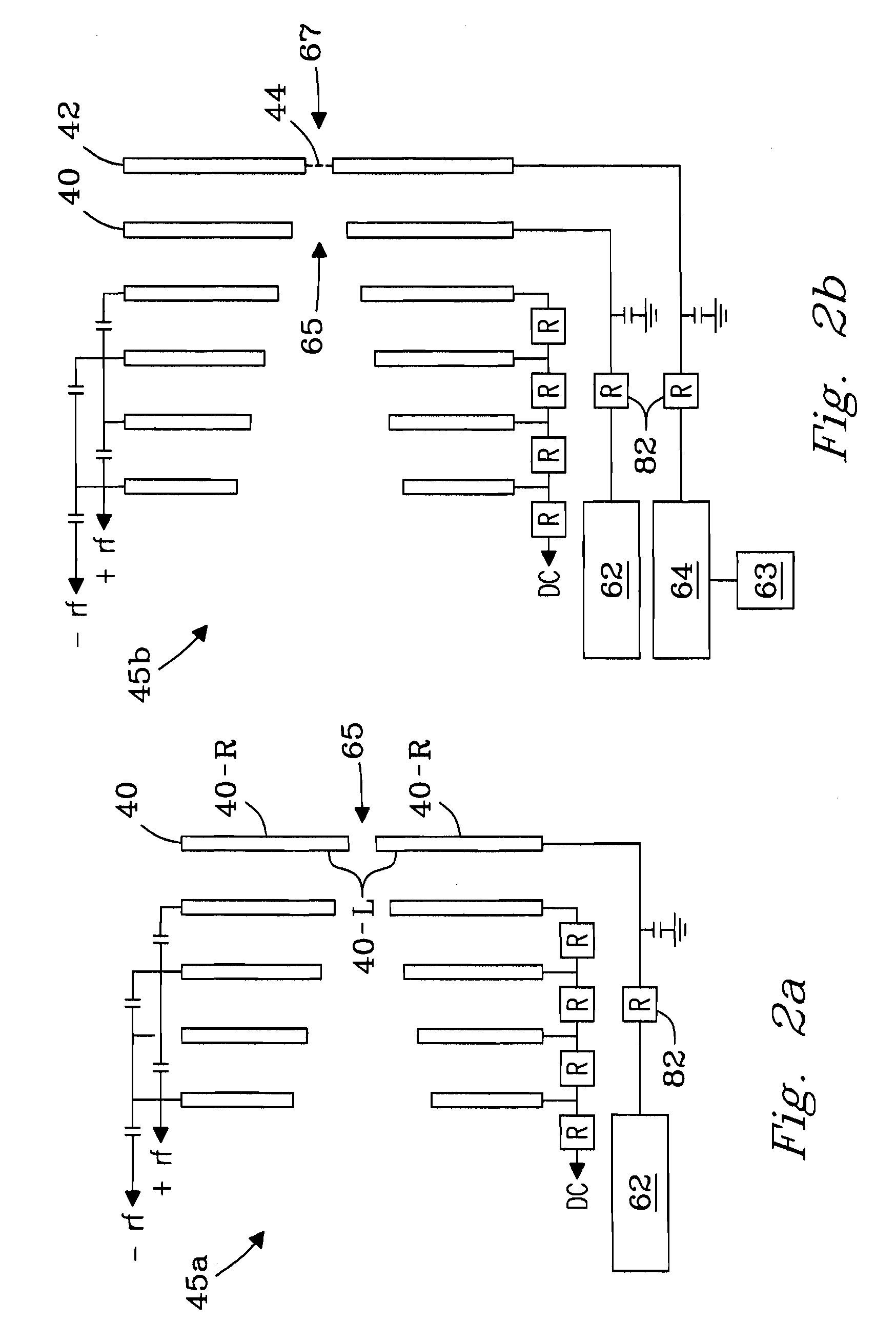

Method and apparatus for selective filtering of ions

ActiveUS7514676B1Reduce the impactReduce chargeStability-of-path spectrometersTime-of-flight spectrometersMass analyzerSpectrometer

An adjustable, low mass-to-charge (m / z) filter is disclosed employing electrospray ionization to block ions associated with unwanted low m / z species from entering the mass spectrometer and contributing their space charge to down-stream ion accumulation steps. The low-mass filter is made by using an adjustable potential energy barrier from the conductance limiting terminal electrode of an electrodynamic ion funnel, which prohibits species with higher ion mobilities from being transmitted. The filter provides a linear voltage adjustment of low-mass filtering from m / z values from about 50 to about 500. Mass filtering above m / z 500 can also be performed; however, higher m / z species are attenuated. The mass filter was evaluated with a liquid chromatography-mass spectrometry analysis of an albumin tryptic digest and resulted in the ability to block low-mass, “background” ions which account for 40-70% of the total ion current from the ESI source during peak elution.

Owner:BATTELLE MEMORIAL INST

Dual-arm articulated hinge for the front bonnet of a motor vehicle

InactiveUS6934999B2Reduce harmKinetic energyVehicle seatsPedestrian/occupant safety arrangementMobile vehicleEngineering

Owner:EDSCHA ENG GMBH +1

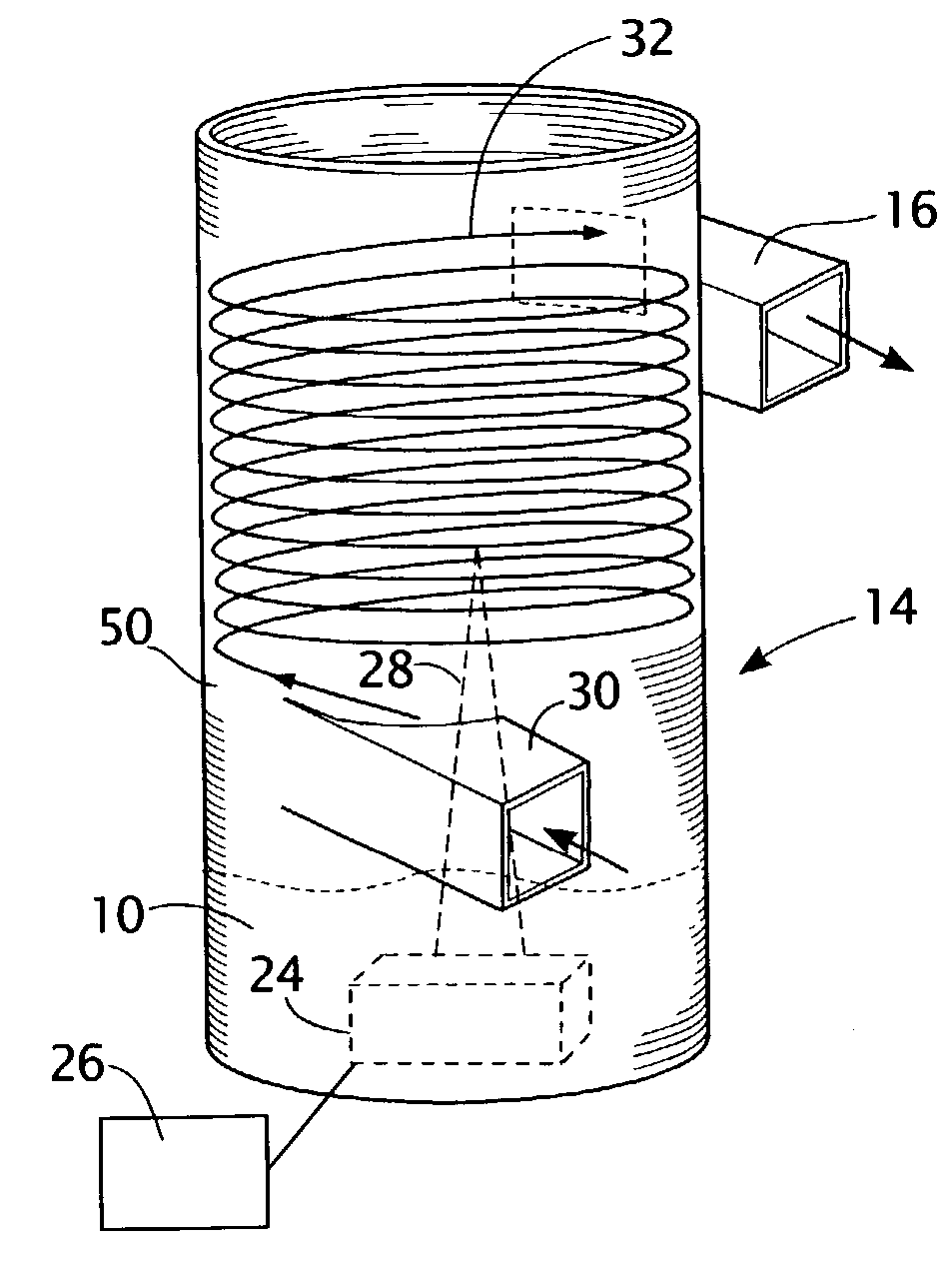

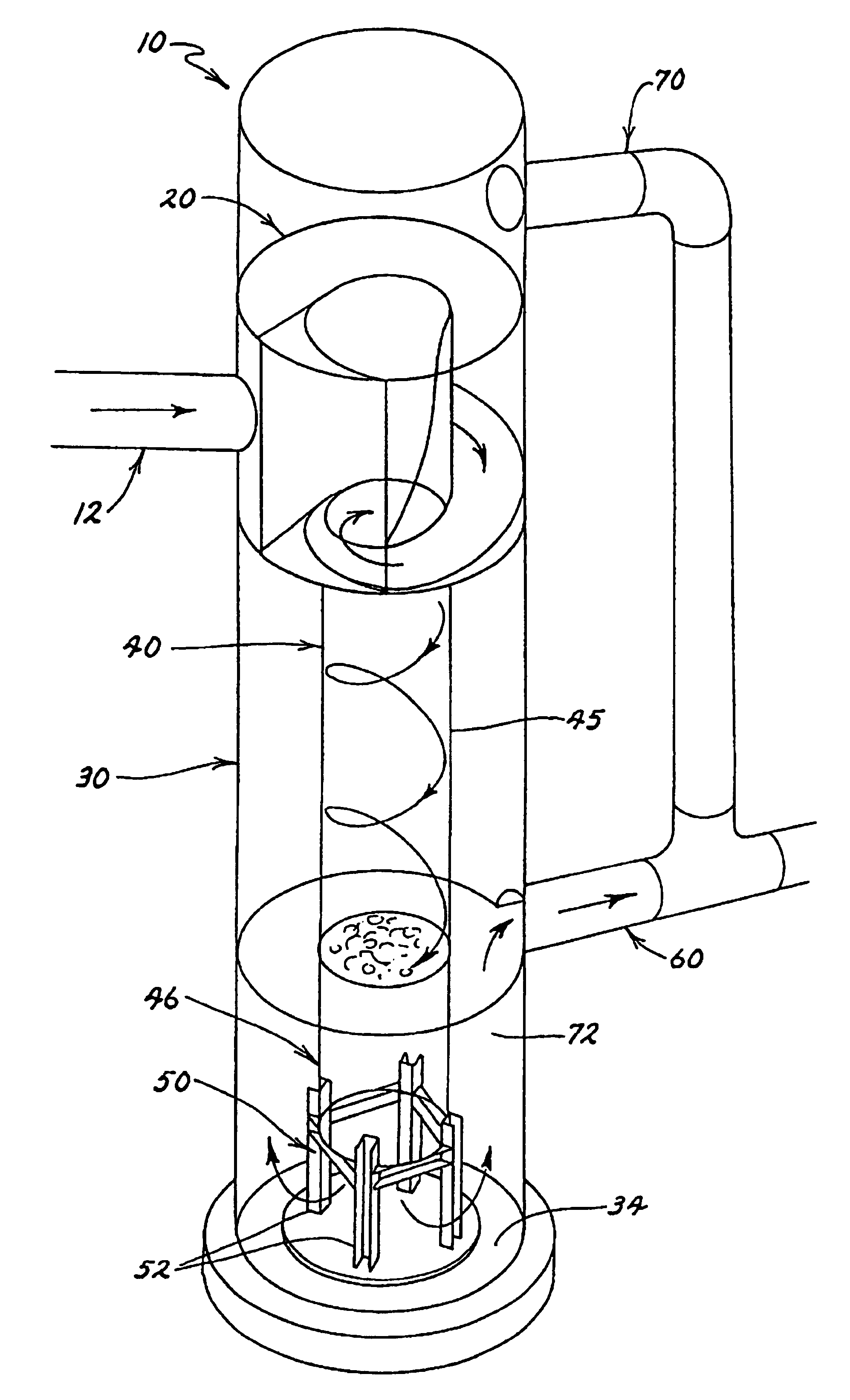

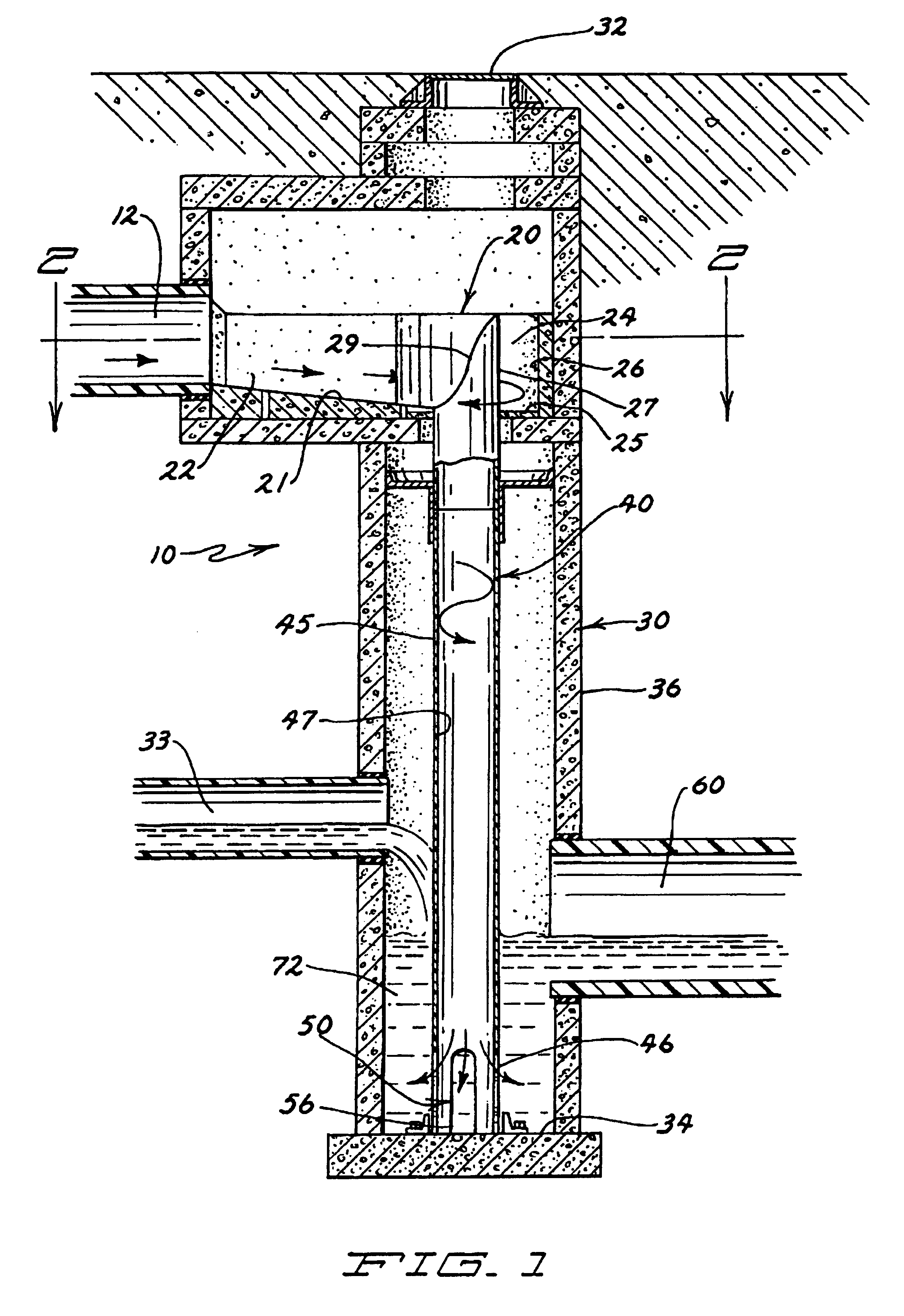

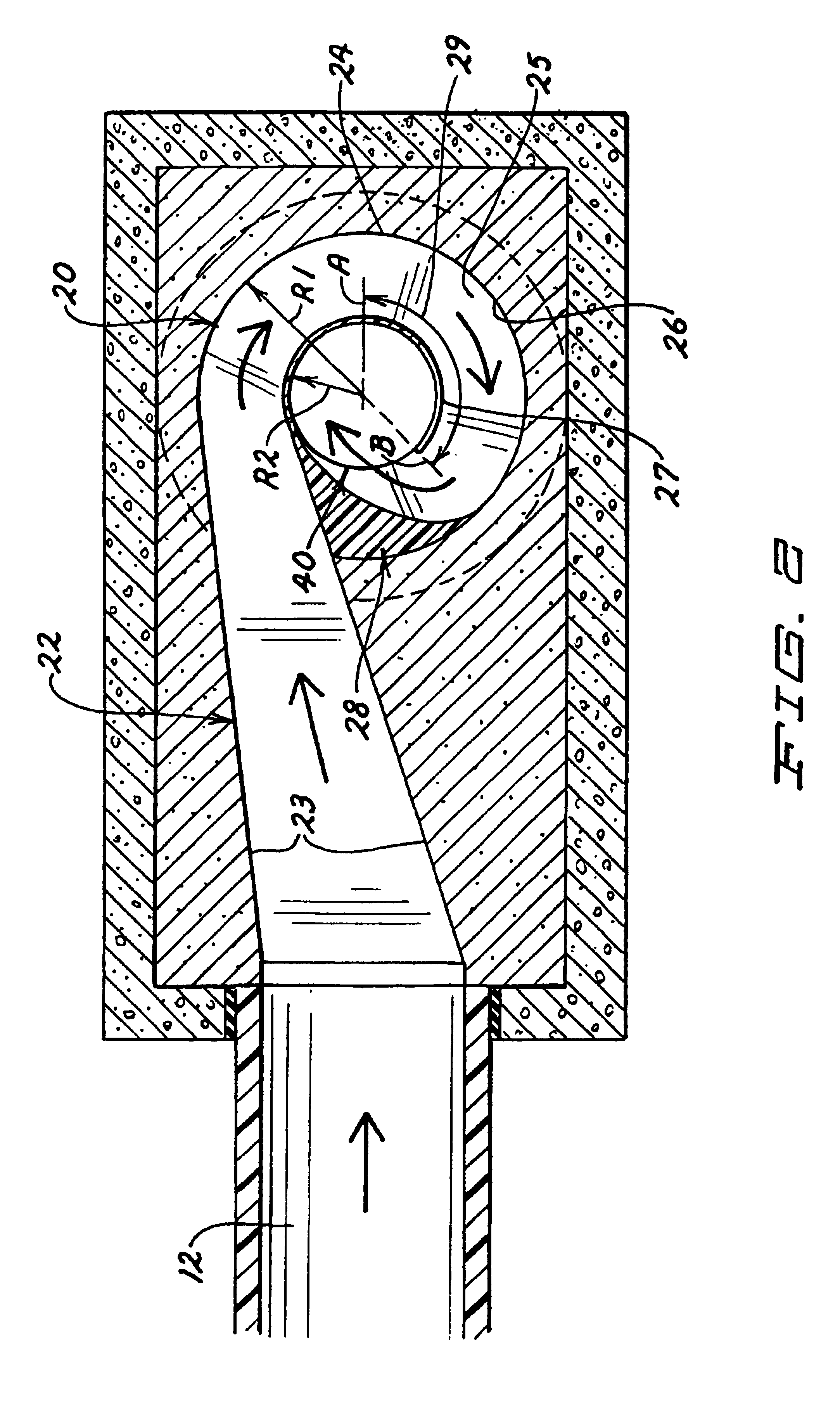

Method and apparatus for mixing fluids

InactiveUSRE40407E1Reduce gas emissionsReduces odorous gas emissionReversed direction vortexFlow mixersEngineeringDrop structure

A method for entraining and mixing gas with liquids within a conduit or drop structure, comprising the channeling of one or more liquid flows into spiral flows of predetermined radius (radii), reducing the predetermined radius (radii) to increase the centrifugal forces acting upon the spiral flow(s) as the spiral flow(s) enter the conduit, and allowing gas access to the conduit to mix with and entrain within the spiral flow within the conduit or drop structure. The method can facilitate the mixing of gas with one or more fluid flows and / or reduce the release of gas emissions from the fluid(s) into the surrounding environment.

Owner:VORTEX FLOW

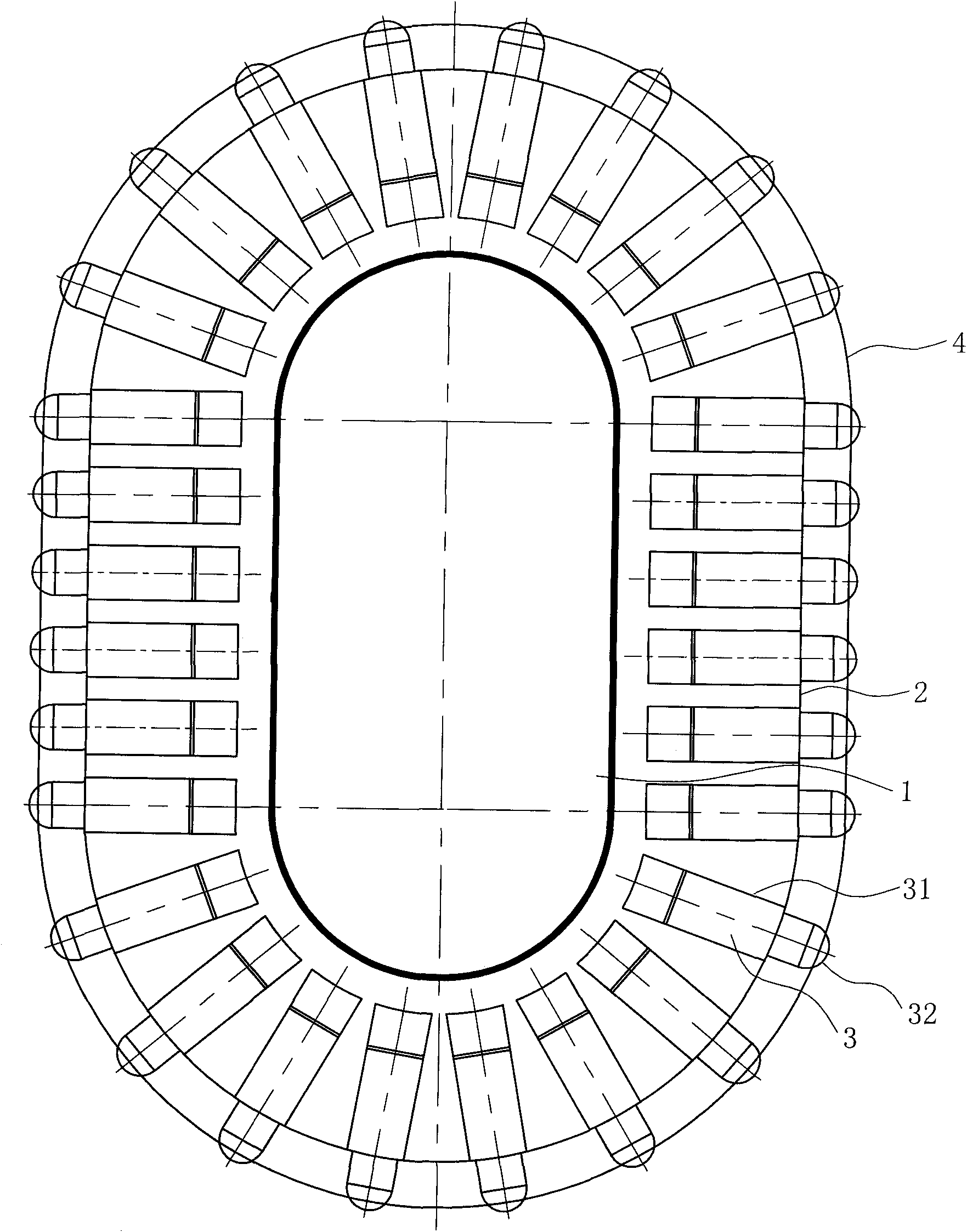

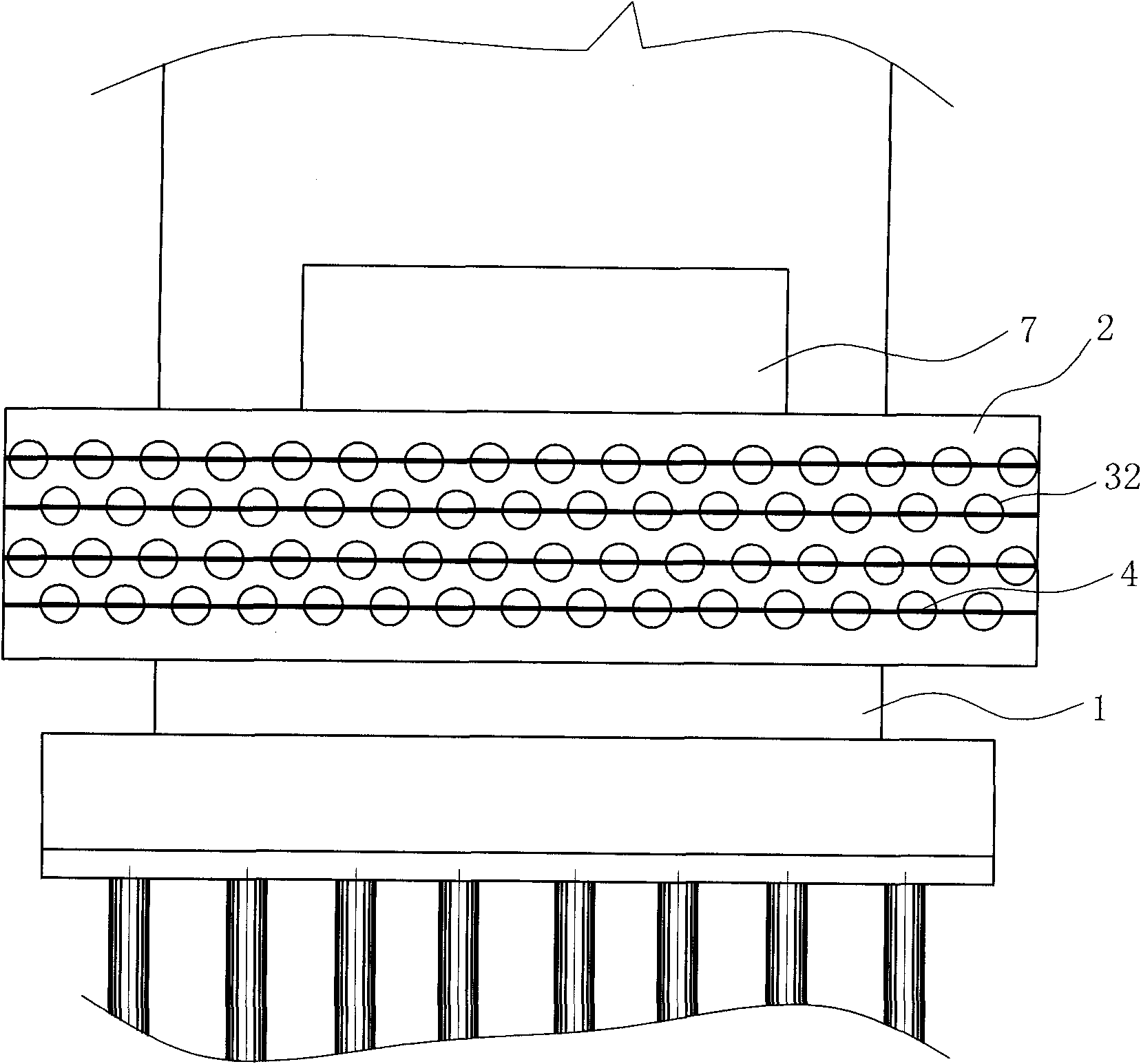

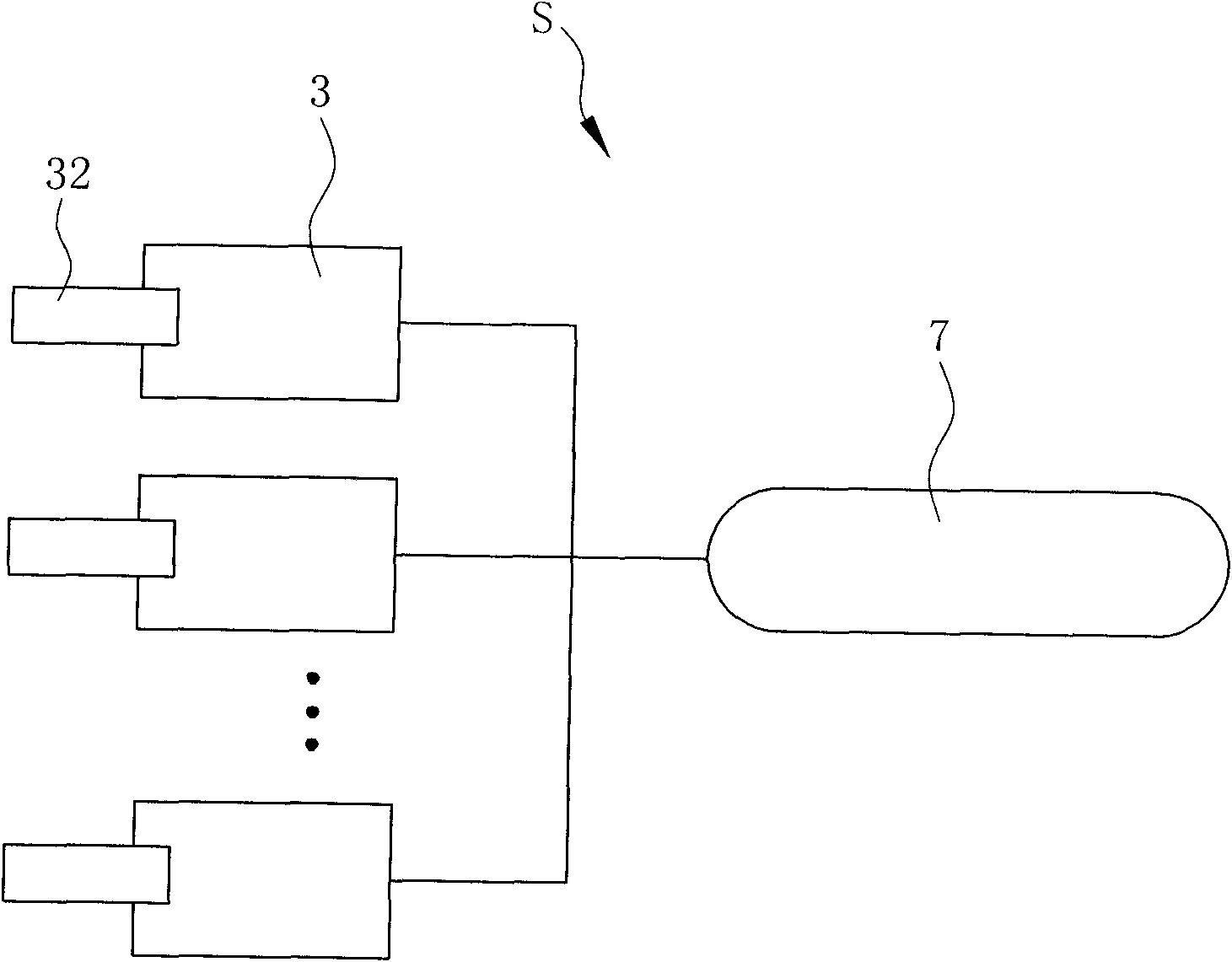

Multi-stage jet-type reaction force disc generating system

InactiveCN101813006AConsistent flow rateReduce kinetic energyHydro energy generationWind motor combinationsCircular discJet flow

The invention relates to a generating technology, in particular to a multi-stage jet-type reaction force disc generating system which mainly comprises a leak-off pipe, a jet-type reaction force disc generating set and a disc shell. The generating system is characterized in that the multi-stage jet-type reaction force disc generating set is arranged on a plurality of sections of the leak-off pipes which are connected. One or more than one jet flow pipe is arranged in a reaction force disc which rotates to generate power through tangential-jet reaction force. The system is powered by water, wind or steam. The invention breaks through the traditional generating technology and applies work by the reaction force of fluid, and meanwhile, the invention keeps original kinetic energy, static pressure energy and potential energy of the fluid undamaged to the largest extent to keep applying work to downstream machines, thereby using the kinetic energy, static pressure energy and potential energy of the fluid to apply work again and again; and therefore, by the invention, it is possible that more generating sets can be installed in the same leak-off pipe.

Owner:李贵祥

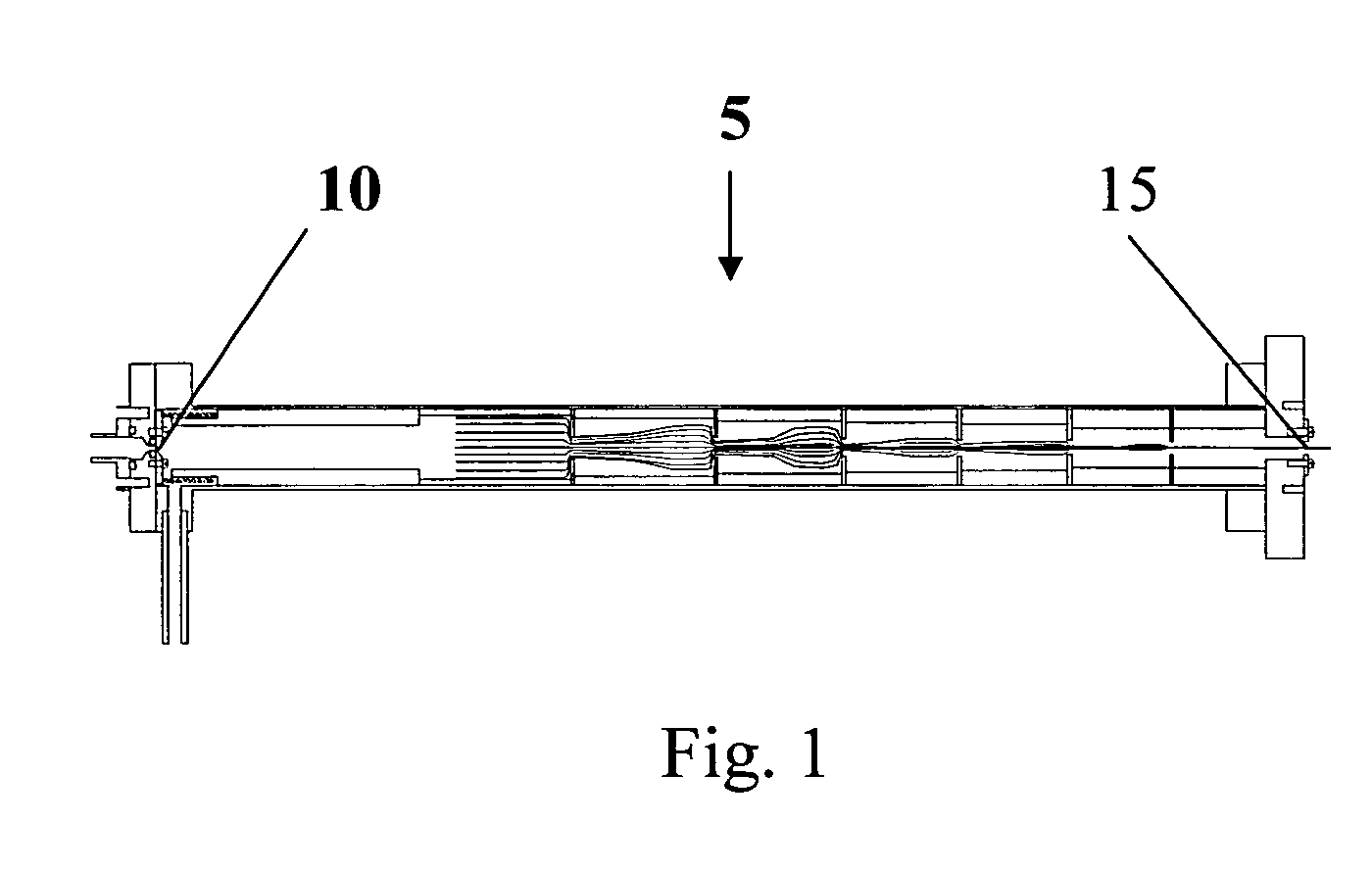

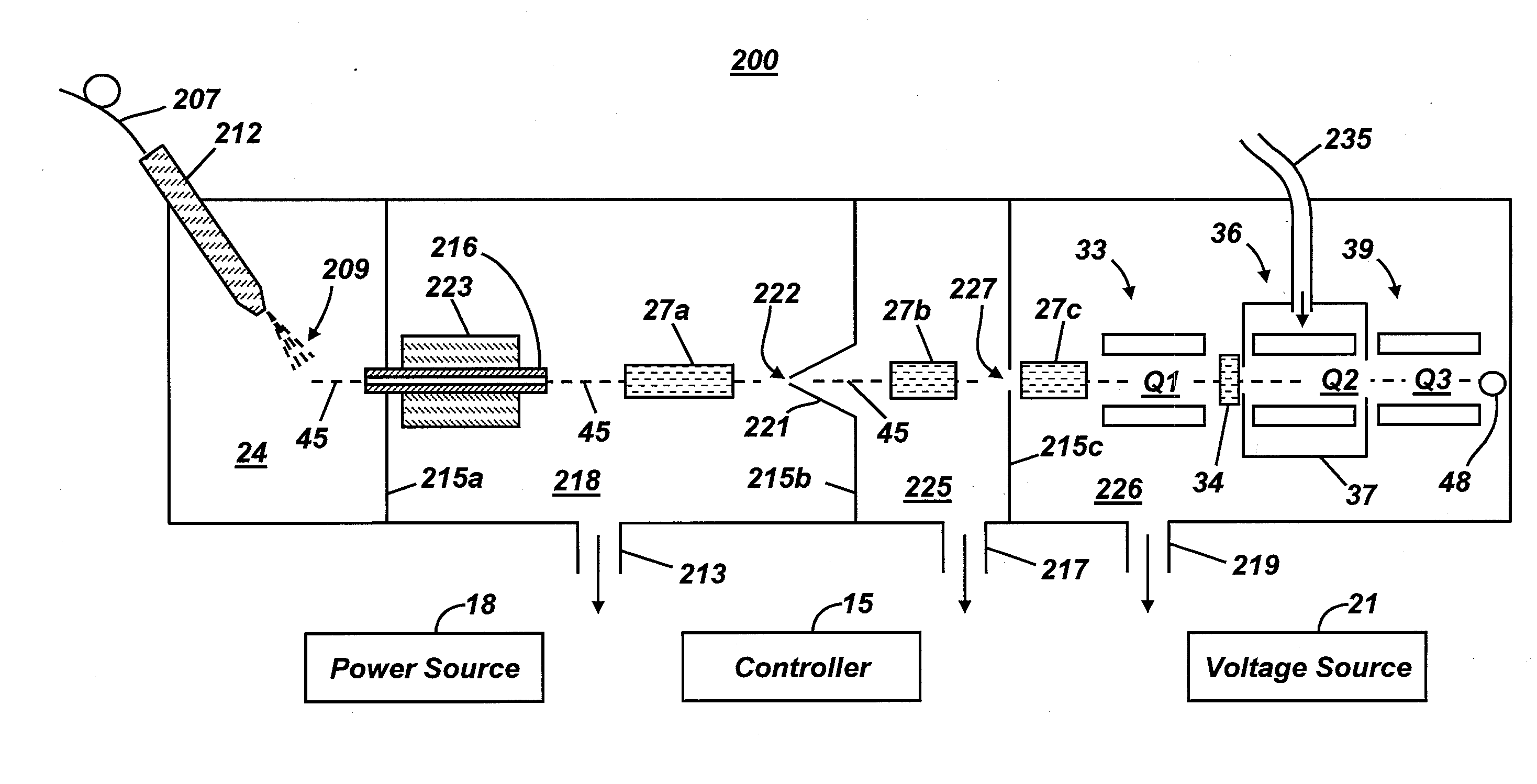

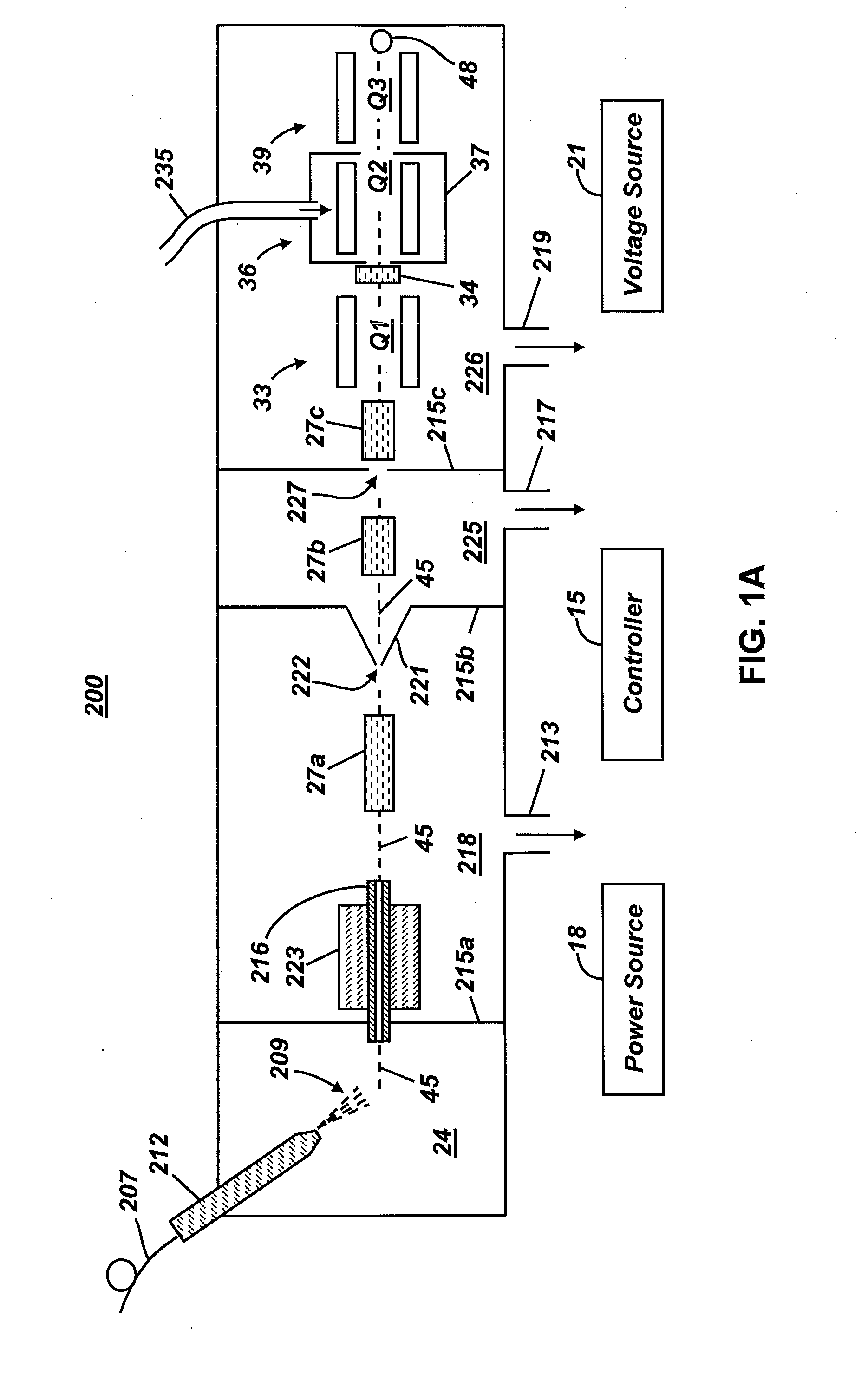

Method for Automated Checking and Adjustment of Mass Spectrometer Calibration

ActiveUS20140306106A1Reduce kinetic energyAvoid fragmentationIsotope separationMass spectrometersPhysicsCompound (substance)

A method for automatically checking and adjusting a calibration of a mass spectrometer having a first quadrupole (Q1), a fragmentation cell and a mass analyzer comprises: introducing a sample having at least one known chemical entity; decreasing a kinetic energy so as to prevent fragmentation of ions in the fragmentation cell; optionally applying a drag field to the fragmentation cell; ionizing the at least one known chemical entity sample to generate a set of ions; performing a mass scan of the set of ions using Q1; transmitting the scanned ions through Q1 to and through the fragmentation cell; detecting the scanned and transmitted ions by a detector of the mass analyzer; and comparing the results with expected results. Embodiments may include automatic recalibration or notification of possible errors, need for further data processing or an analysis of system performance.

Owner:THERMO FINNIGAN

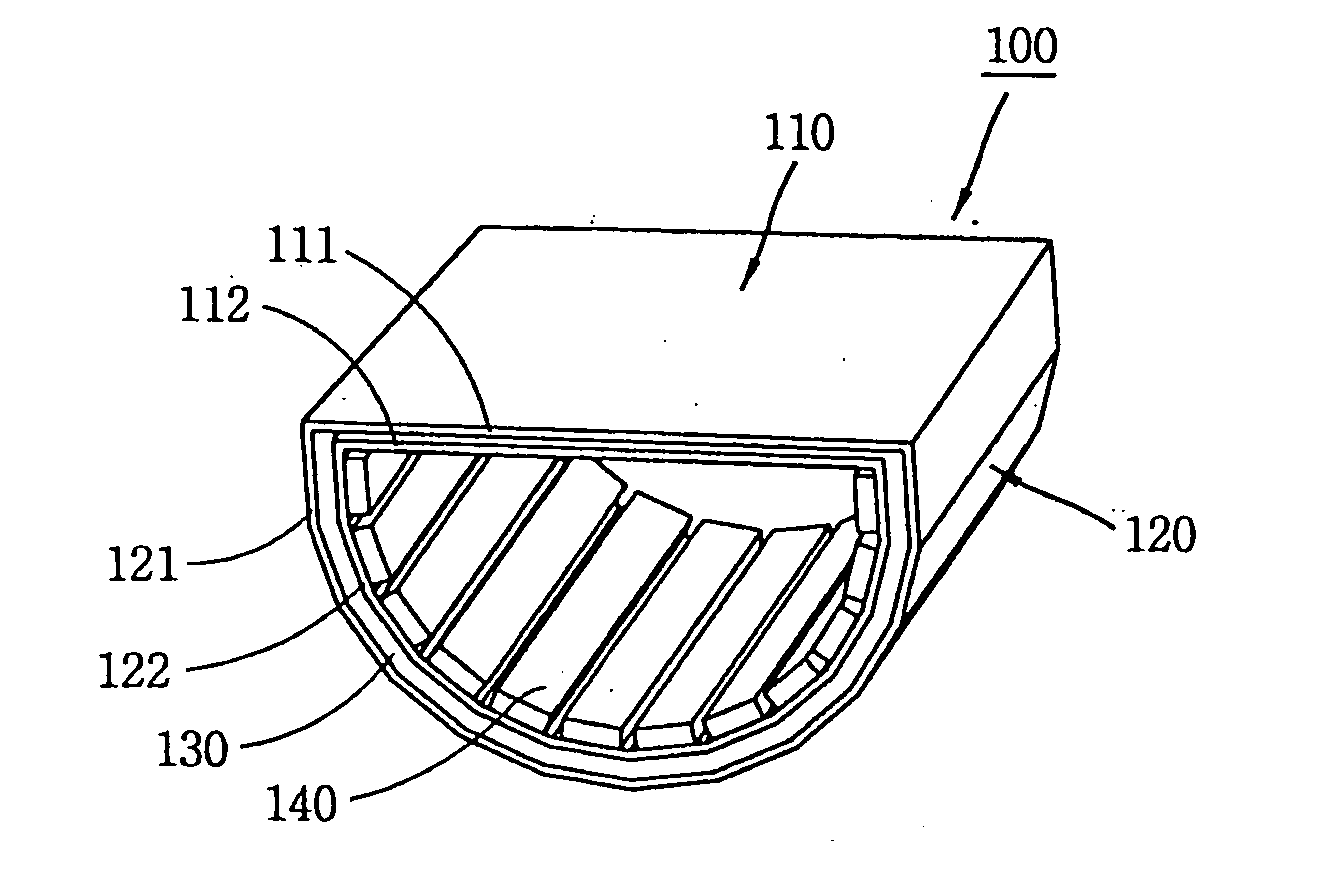

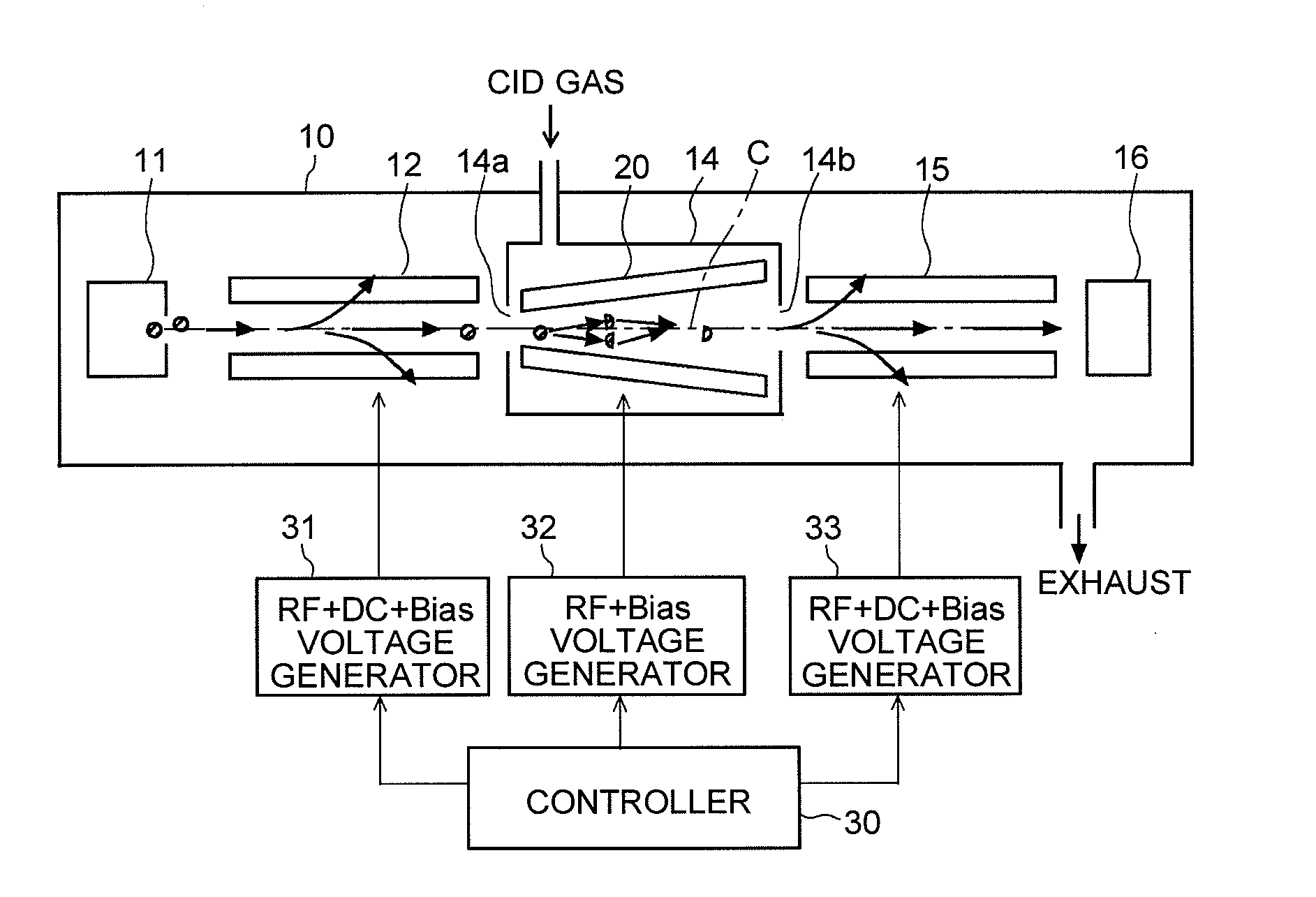

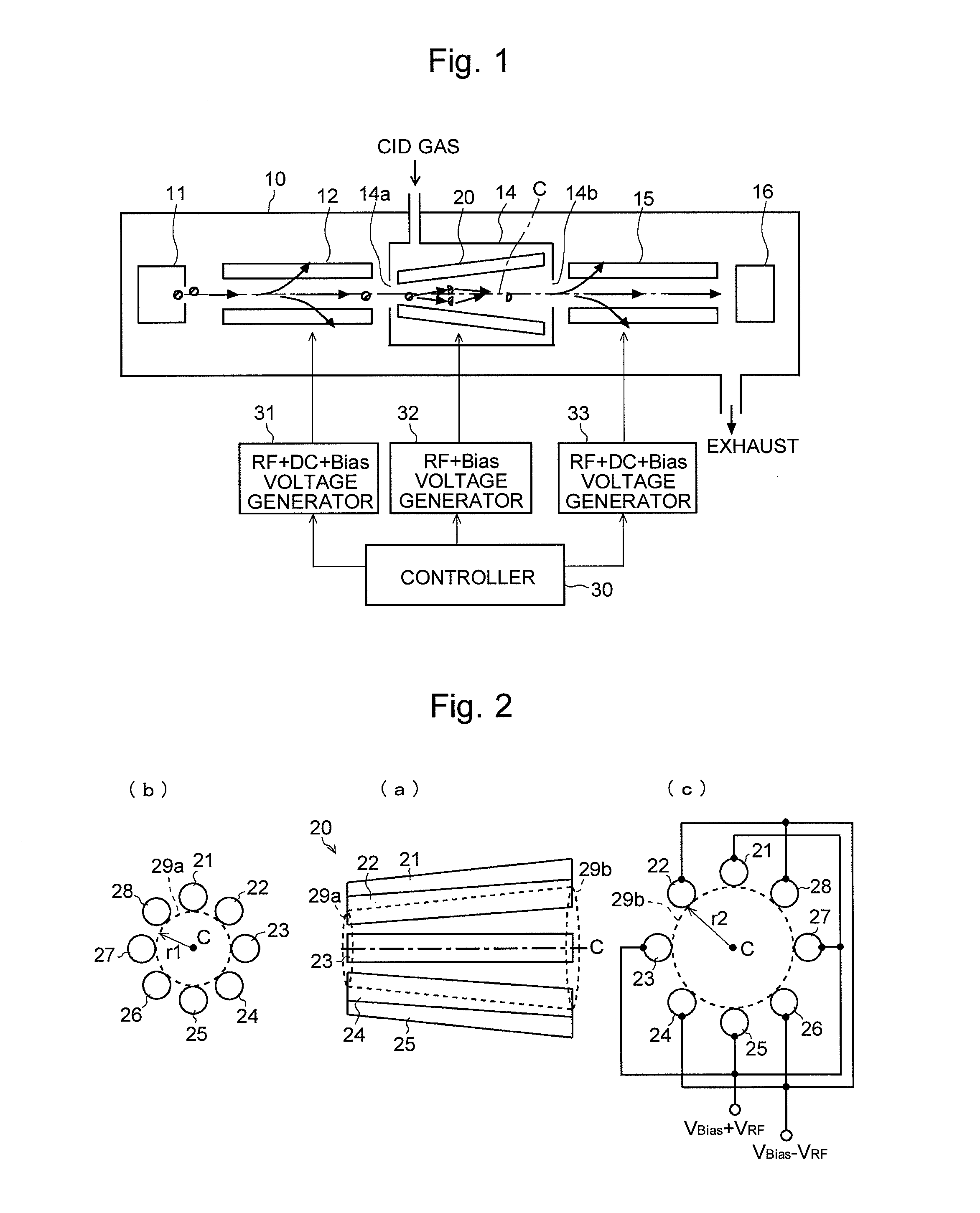

Mass spectrometer

ActiveUS20100171035A1Reduce kinetic energyImprove detection sensitivityElectron/ion optical arrangementsIsotope separationRadio frequencyPhysics

A radio-frequency ion guide (20) for converging ions by a radio-frequency electric field and simultaneously transporting the ions into the subsequent stage is composed of eight rod electrodes (21 through 28) arranged in such a manner as to surround an ion optical axis (C). Each of the rod electrodes (21 through 28) is disposed at a tilt with respect to the ion optical axis (C) so that the radius r2 of the inscribed circle (29b) at the end face of the ion exit side is larger than the radius r1 of the inscribed circle (29a) at the end face of the ion injection side. Accordingly, the gradient of the magnitude or depth of the pseudopotential is formed in the ion's traveling direction in the space surrounded by the rod electrodes (21 through 28). Ions are accelerated in accordance with this gradient. Therefore, even in the case where the gas pressure is relatively high and ions have many chances to collide with gas, it is possible to moderate the ions' slowdown and prevent the ions' delay and stop.

Owner:SHIMADZU CORP

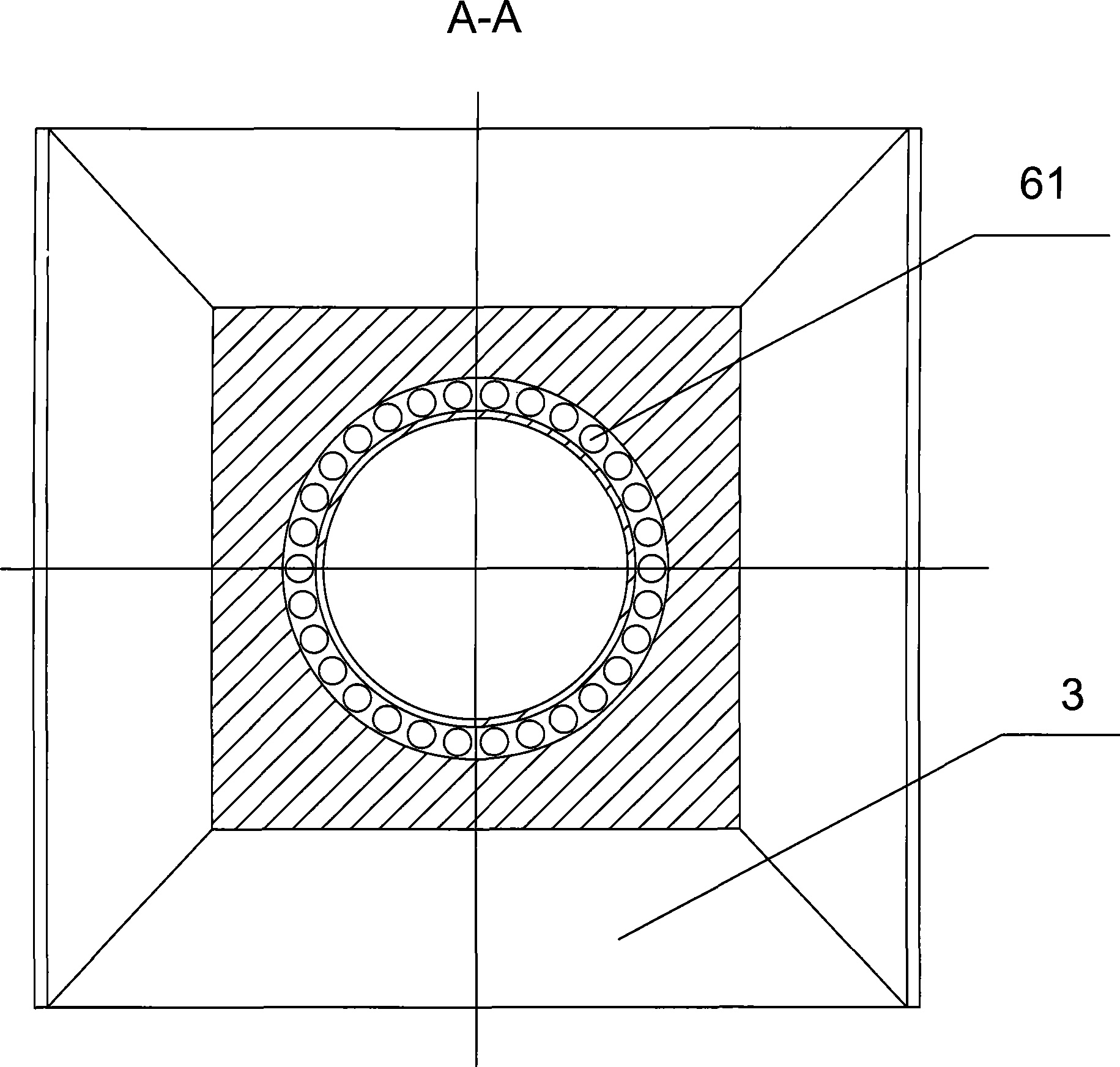

Safety protection device for bridge pier

InactiveCN101775777AReduce kinetic energyReduce speedBridge structural detailsHydraulic cylinderHydraulic pump

The invention relates to a safety protection device for a bridge pier. The safety protection device comprises a steel boxed cofferdam arranged at the periphery of the bridge pier and a hydraulic station fixed opposite to the steel boxed cofferdam. The steel boxed cofferdam is provided with a plurality of supporting hydraulic cylinders at least on the side close to a channel, wherein the cylinder body of each supporting hydraulic cylinder is fixed opposite to the steel boxed cofferdam; the head of a piston rod of each supporting hydraulic cylinder is exposed from the outer surface of the steel boxed cofferdam; a rodless cavity of each supporting hydraulic cylinder is communicated with the hydraulic station through a hydraulic pipeline; and the rodless cavities, the hydraulic pipelines and the hydraulic stations of all the supporting hydraulic cylinders are filled with a hydraulic medium so as to form a sealed hydraulic system. Compared with the prior art, the impact resistance of the bridge pier is greatly enhanced through the device of the invention; and the kinetic energy of an offending ship can be absorbed and converted into hydraulic energy for storage, so that the offending ship is quickly speeded down to reduce the kinetic energy, and the resultant force borne by the bridge pier tends to zero to protect the bridge pier.

Owner:杨光华

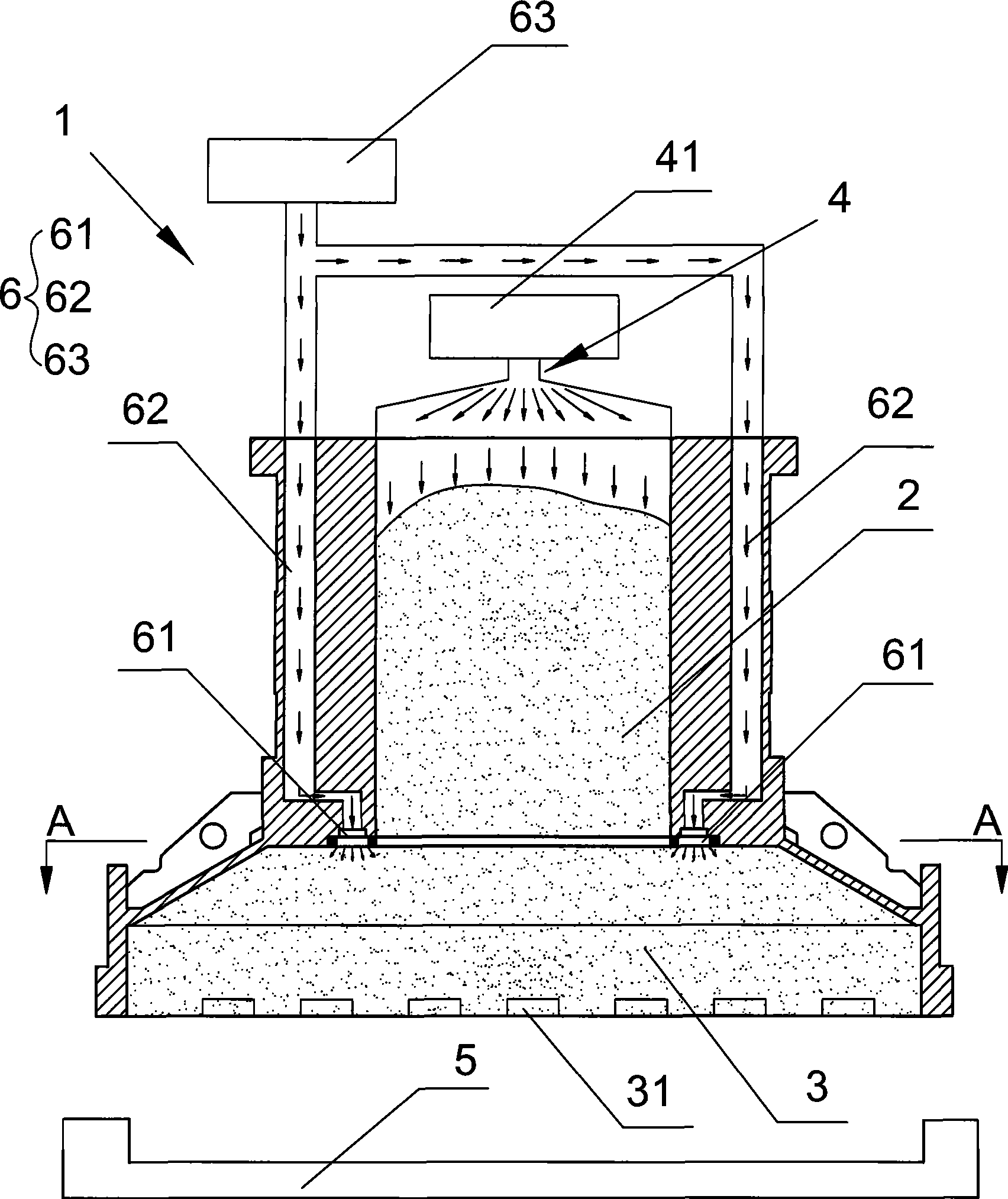

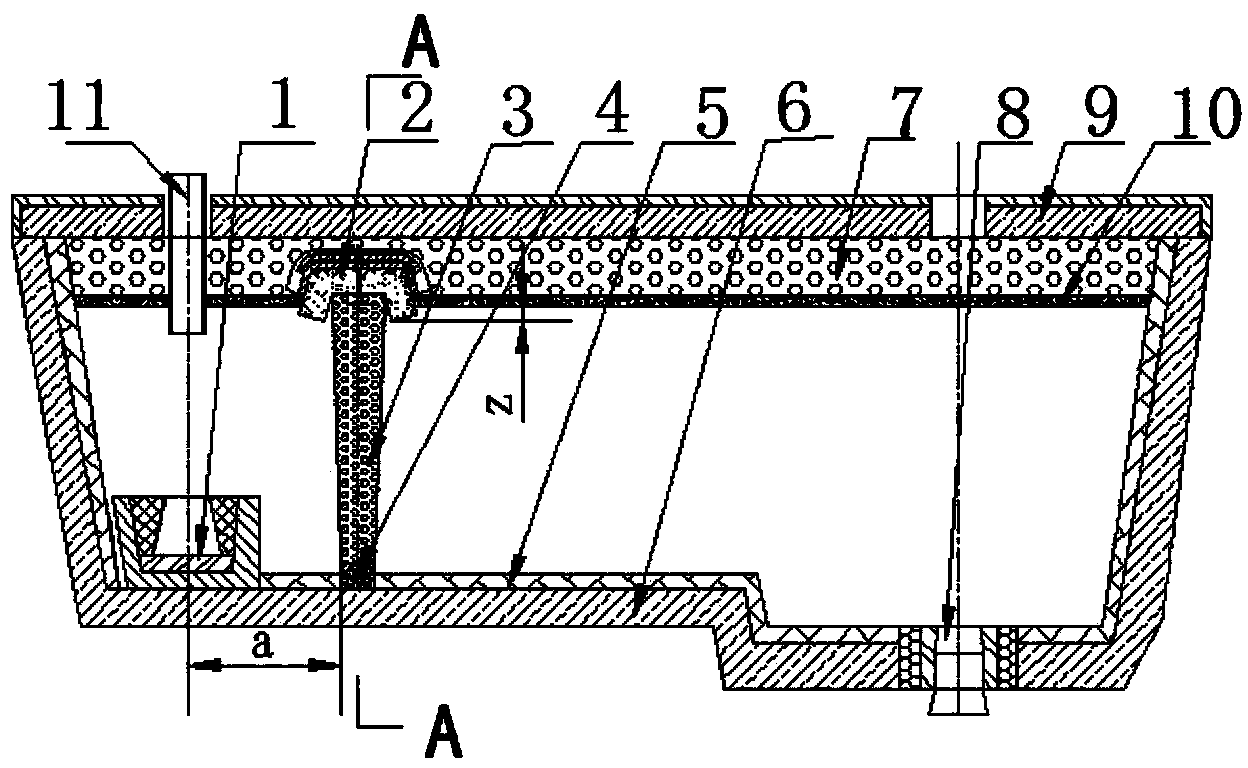

Sand-jetting mechanism sand core-molding method using the same

ActiveCN101462152AReduce lossGuaranteed tightnessFoundry mouldsMoulding machinesEngineeringKinetic energy

The invention relates to a sand shooting mechanism, which comprises a main sand shooting and air exhausting mechanism, a sand storage cylinder arranged below the main sand shooting and air exhausting mechanism and storing core sand inside, and a shooting head positioned under the sand storage cylinder and provided with a plurality of sand shooting holes, wherein the main sand shooting and air exhausting mechanism shoots downward sand shooting airflow into the sand storage cylinder, and the upper part of the shooting head is also provided with a shooting head sand-shooting mechanism which shoots the downward sand shooting airflow into the shooting head. Because a sand shooting initial stage carries out sand shooting and air admittance through the upper part of the shooting head to drive the core sand inside the shooting head, the required kinetic energy is smaller, correspondingly, the required sand shooting airflow pressure is lower; therefore, the air inlet amount is reduced, and abrasion of a mould is slowed down. Matched with sand shooting motion of the sand storage cylinder driven by the sand shooting airflow of the main sand shooting and air exhausting mechanism, the sand shooting mechanism effectively ensures compactness of the sand core.

Owner:SUZHOU MINGZHI TECH

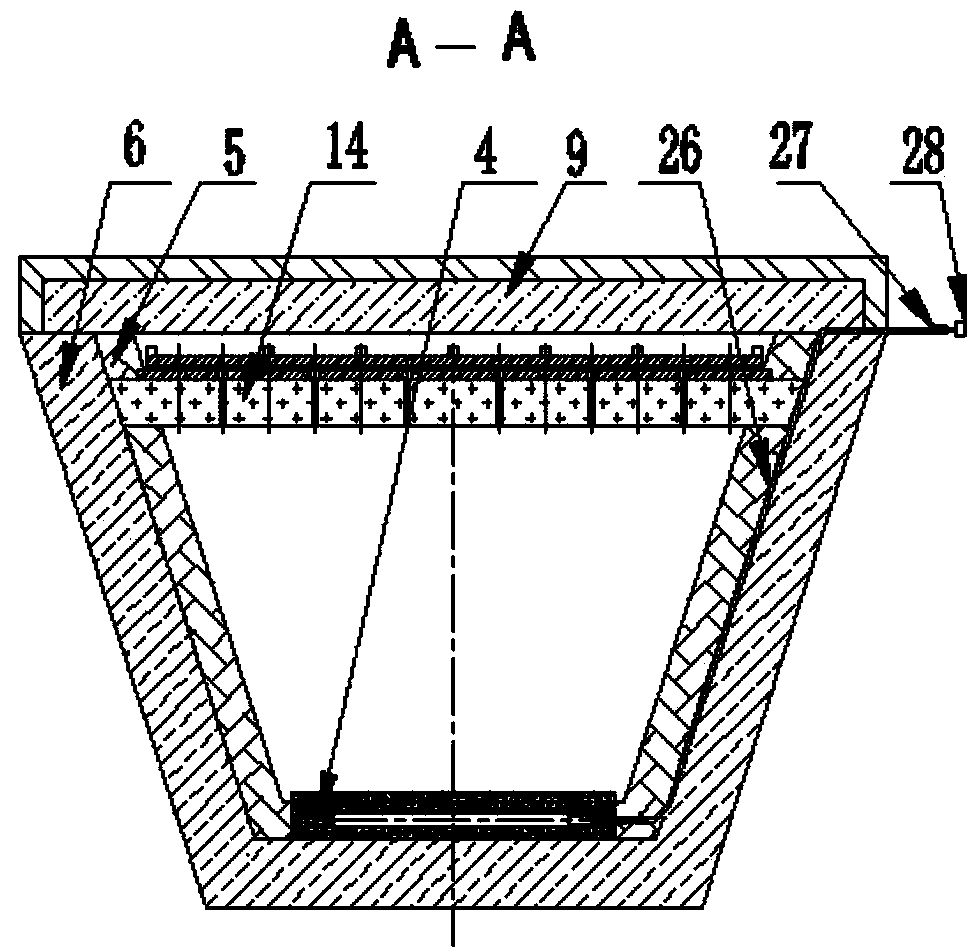

Refining device and method for removing liquid steel inclusions in continuous casting tundish

The invention relates to a refining device and method for removing liquid steel inclusions in a continuous casting tundish. The refining device comprises a turbulence controller, a refining cover and air curtain ventilation bricks. The two side ends of the refining cover are fixed to a permanent lining on the wall of the tundish, the lower end of the refining cover is immersed into liquid steel below a steel slag layer inside the tundish, the refining cover is located over the air curtain ventilation bricks and is opposite to the air curtain ventilation bricks, a gas channel is formed in the body of the refining cover, the two ends of the gas channel are communicated with a gap between a tundish cover and the steel slag layer inside the tundish, gas exhaust holes communicated with the gas channel are formed in the body of the refining cover and are opposite to the air curtain ventilation bricks, large-flow argon is blown in through the air curtain ventilation bricks, an air curtain barrier with the large continuous intensity is formed between the air curtain ventilation bricks and the refining cover, the inclusions are captured and are adsorbed and removed by the steel slag layer, the argon flows through the gas channel and forms argon seal between the steel slag layer inside the tundish and the tundish cover, the steel slag face is protected, secondary oxidation of liquid steel is avoided, the cleanliness of the liquid steel is greatly improved, and the 0.5 level of the four kinds of inclusions in LHG2 steel reaches more than 90%.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Pneumatic tool

InactiveUS6932166B1Reduce kinetic energyWeaken energyConstructionsReciprocating drilling machinesExhaust valveEngineering

A pneumatic tool (20) for impacting a workpiece (22) is provided. The tool (20) comprises a casing (42) defining a chamber (48). A piston (54) is slidable within the chamber (48) along an operational axis (A). An exhaust valve (100) controlled by a pilot valve (200) slides the piston (54) by selectively introducing and releasing pressurized fluid into and out from the chamber (48). A tool bit (24) is slidable within the chamber (48) to impact the workpiece (22). Kinetic energy is transferred to the tool bit (24) from the piston (54) via an impact from the piston (54) as the piston (54) slides within the chamber (48). An energy absorbing mechanism (402) reduces the kinetic energy of the tool bit (24) after impact by the piston (54). The energy absorbing mechanism comprises a sleeve (404) that slides along the casing (42) and first (412) and second (414) pressure chambers that dissipate the kinetic energy of the tool bit (24) in multiple stages.

Owner:KIRSCH PAUL

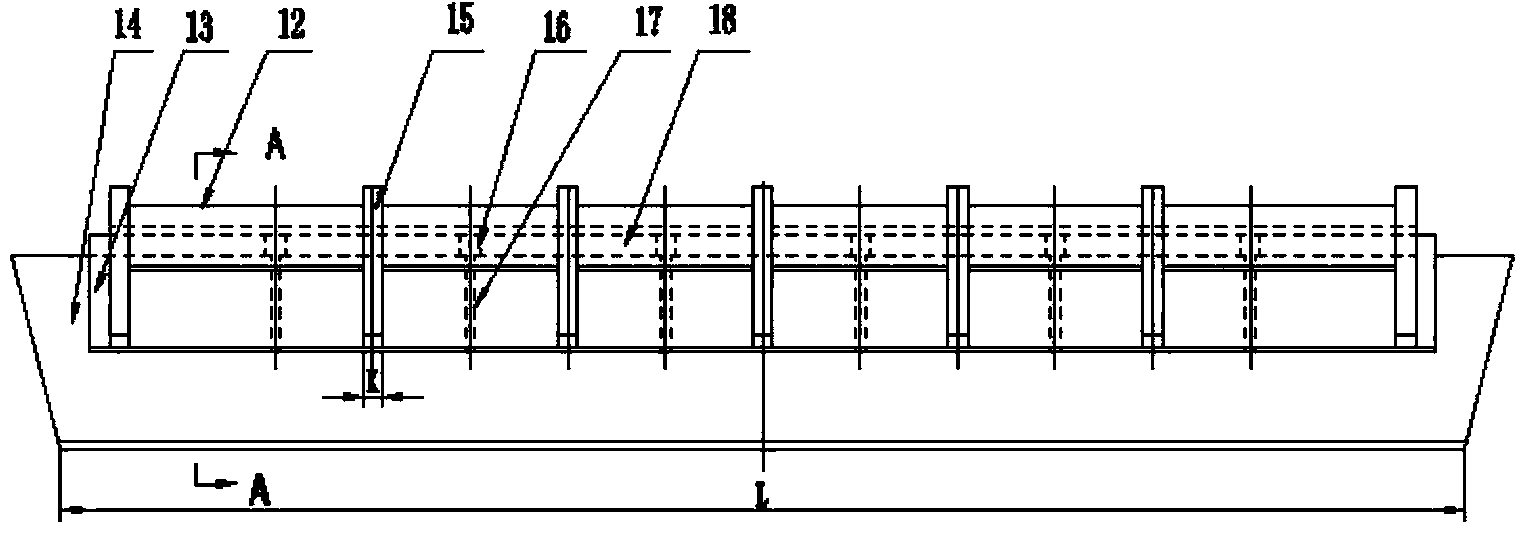

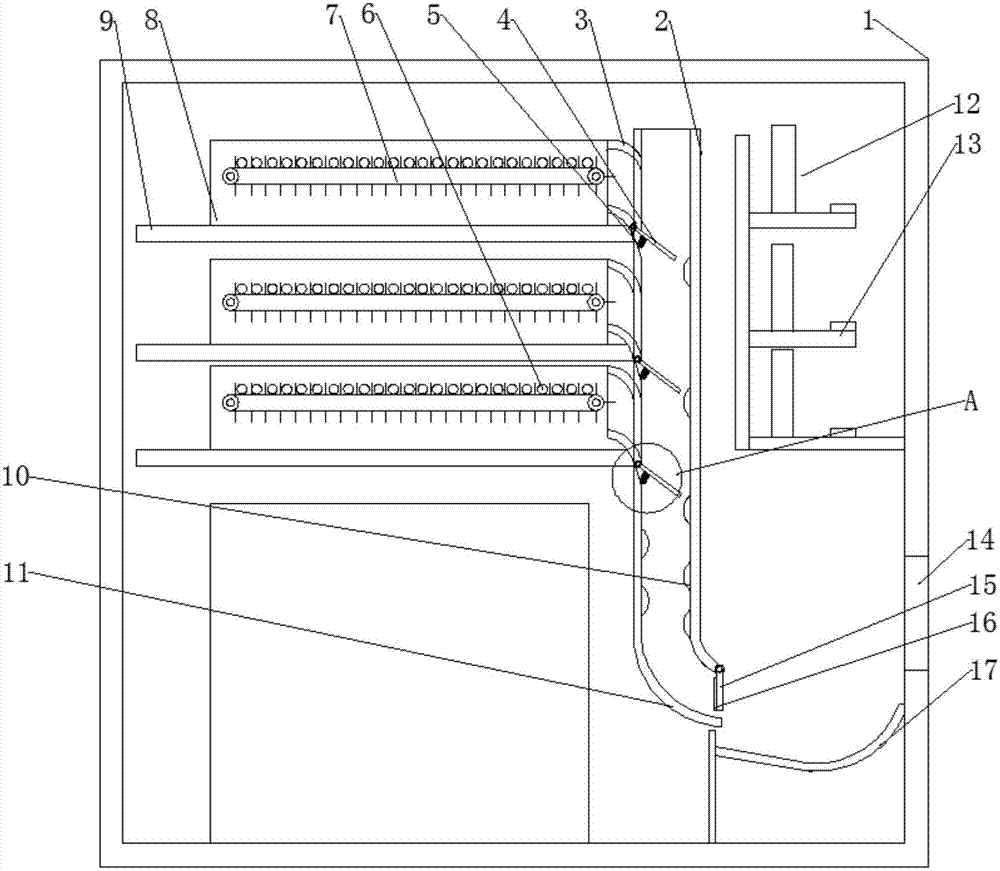

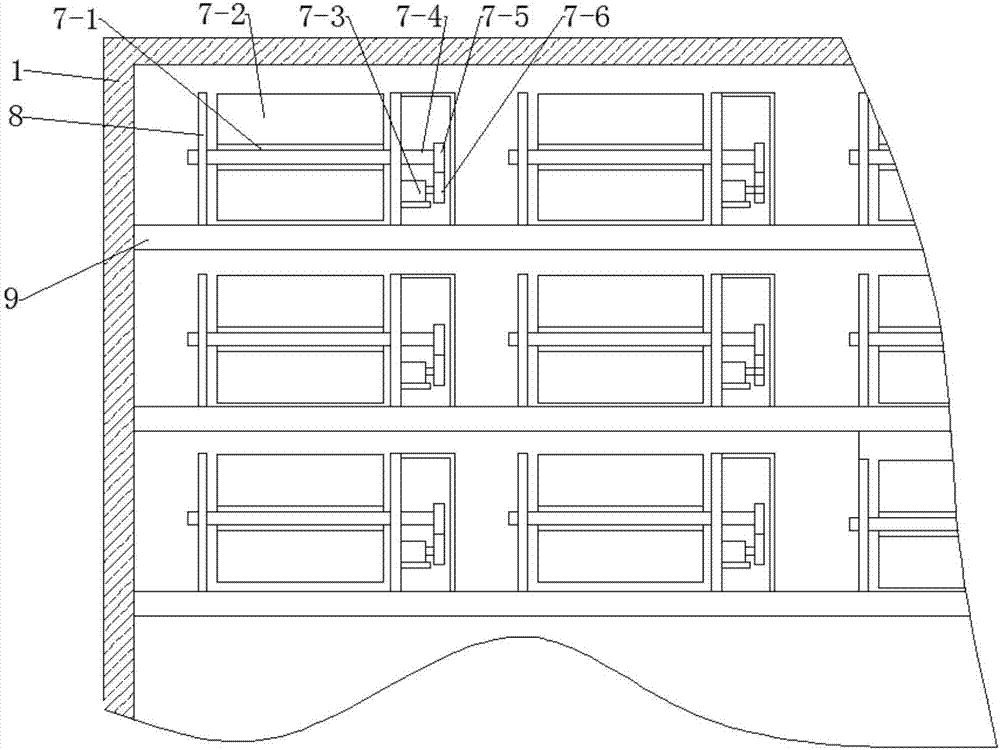

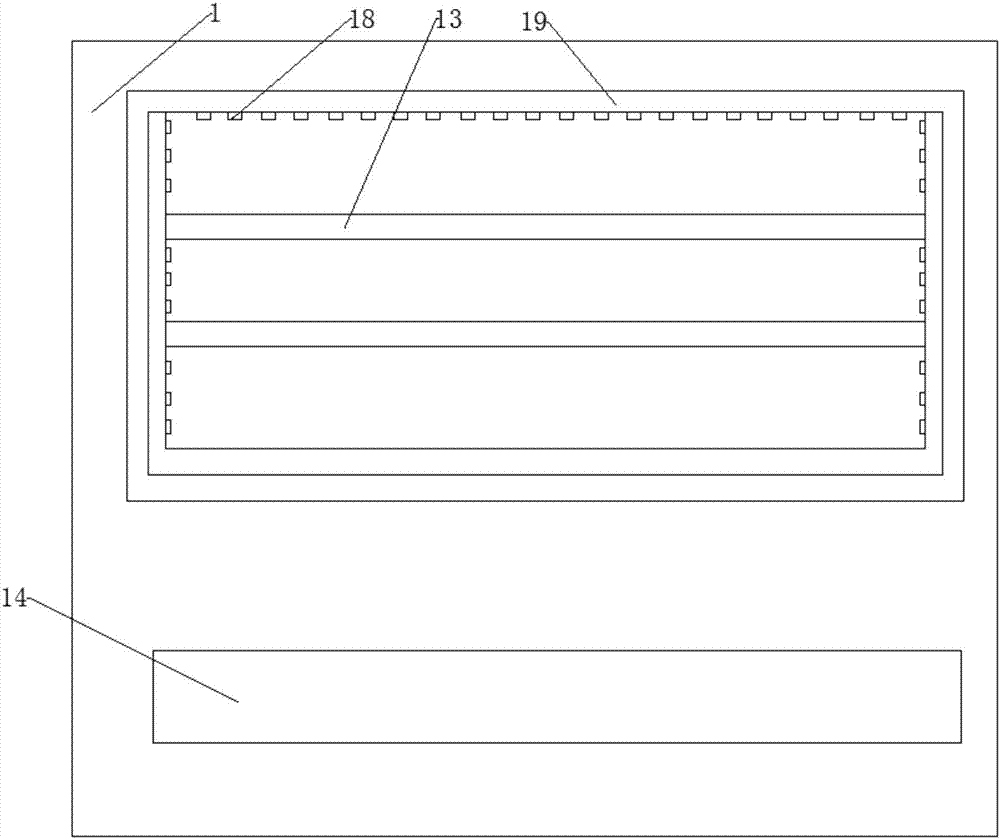

Automatic vending machine and material channel

InactiveCN107886631AReduce kinetic energyImprove accuracyCoin-freed apparatus detailsApparatus for dispensing discrete articlesElectric machineryIndustrial engineering

The invention discloses an automatic vending machine and a material channel, and relates to a vending machine. The vending machine comprises a vending machine body. The vending machine body is internally provided with goods storage channels and goods outlet material channels. The vending machine body is internally provided with a horizontal supporting plate. The supporting plate is provided with vertical stand plates. The two stand plates and the supporting plate form the goods storage channel used to install delivery mechanisms. The delivery mechanisms are corresponding to the goods storage channels in a one-to-one manner. The goods outlet material channel is formed by a goods inlet channel, a goods unloading channel, and a goods outlet channel. The delivery mechanisms and driving motorsare corresponding to each other in a one-to-one manner, and the goods inlet channels and the delivery mechanisms are corresponding to each other in a one-to-one manner, and goods outlet accuracy and goods outlet efficiency are improved, and the goods outlet material channels can effectively reduce kinetic energy of canned commodities in a falling process, so that the canned commodities are delivered to a pick-up port stably and gently, noise generated by collision of the canned commodities and the pick-up port is reduced. The vending machine body is protected to a certain extent.

Owner:安徽智佳信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com