Patents

Literature

127results about How to "Increase low speed torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

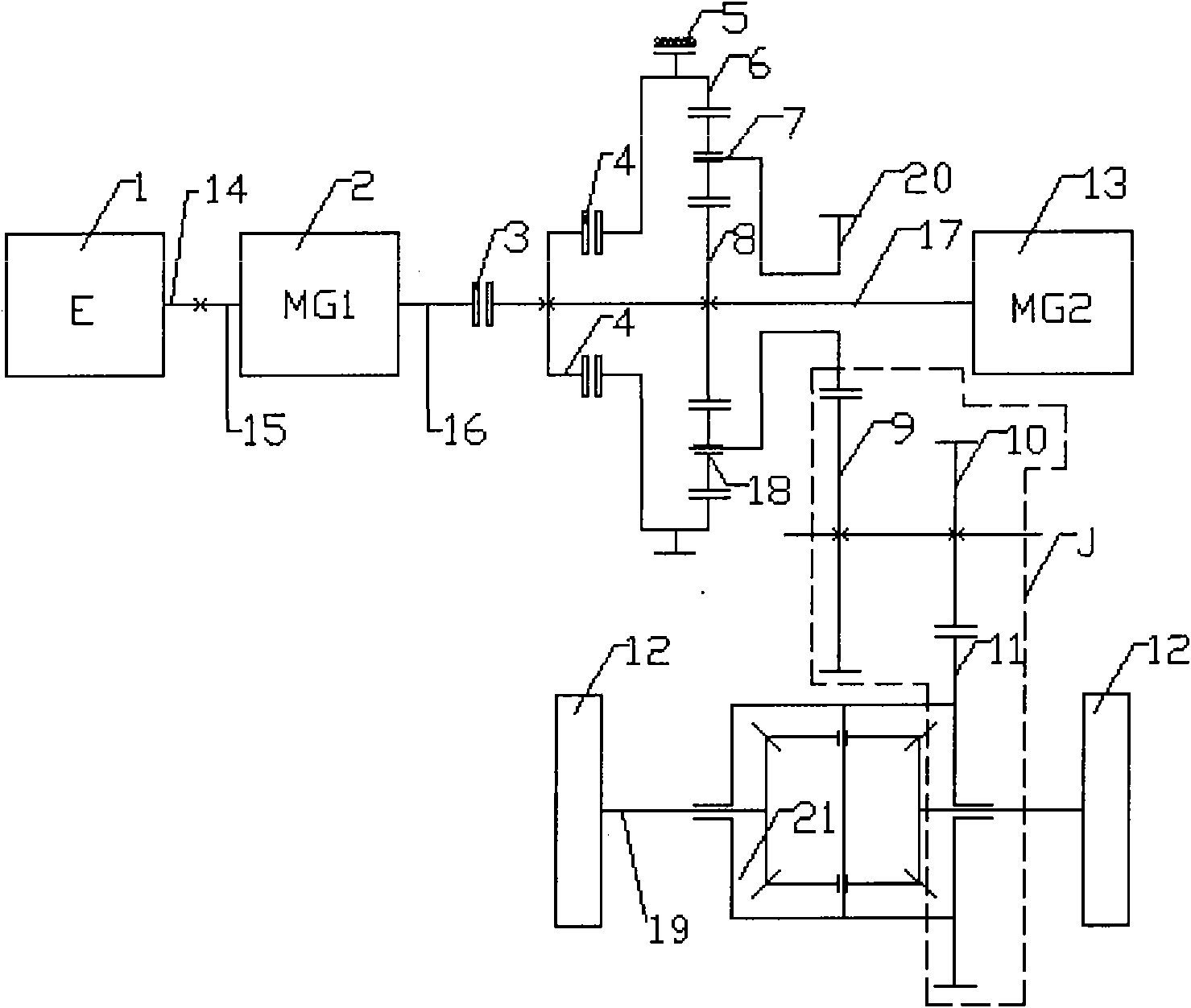

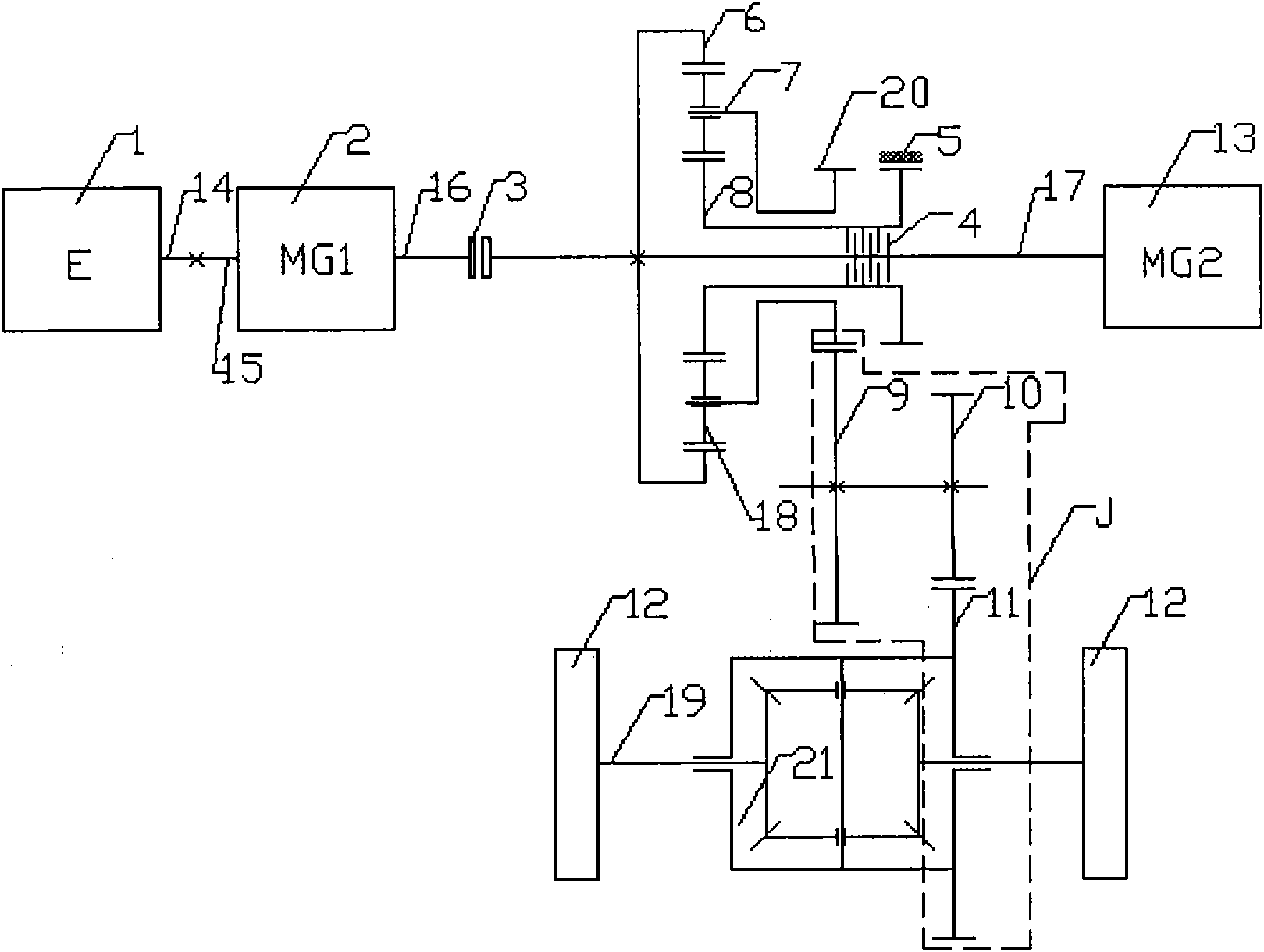

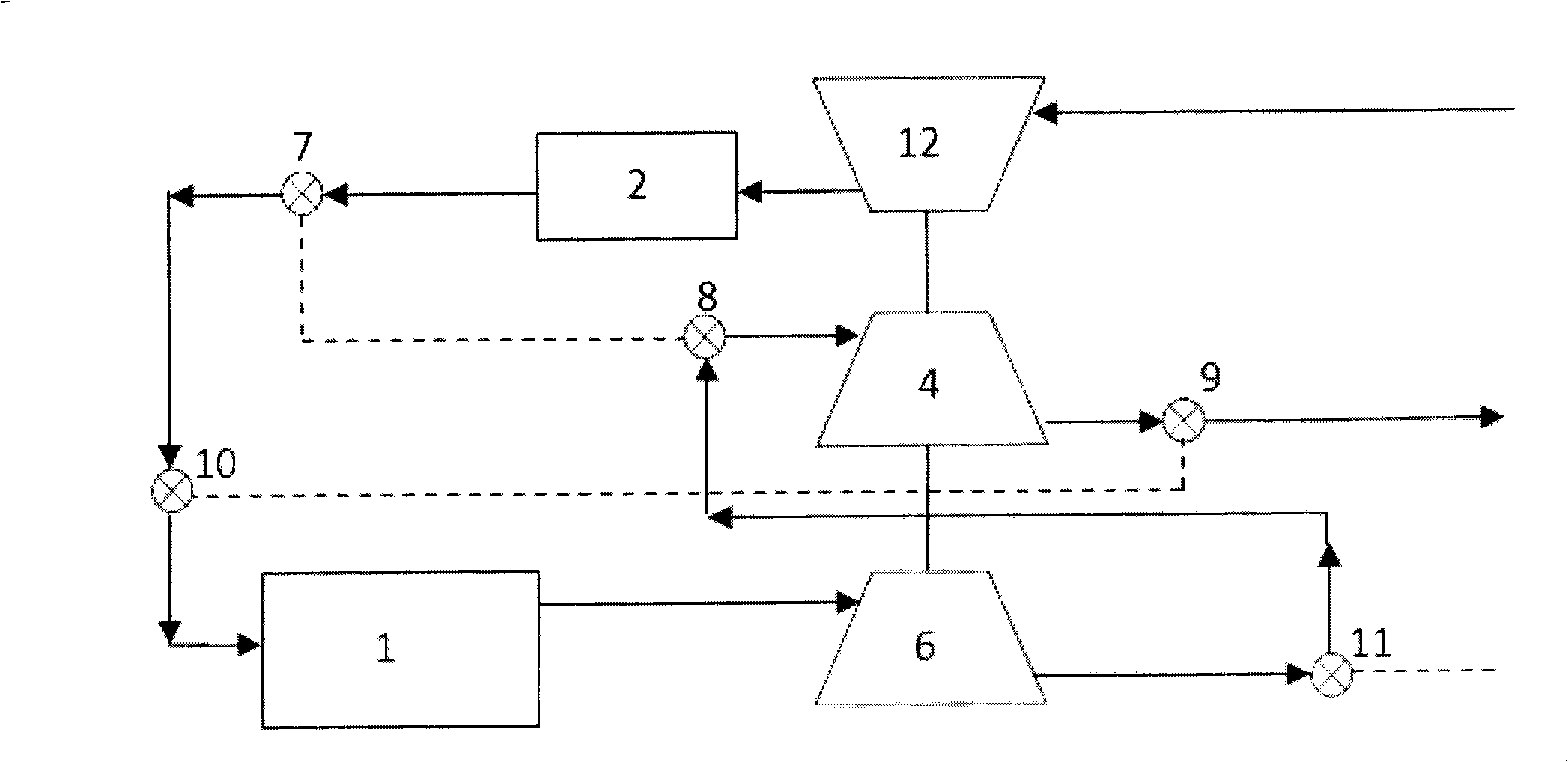

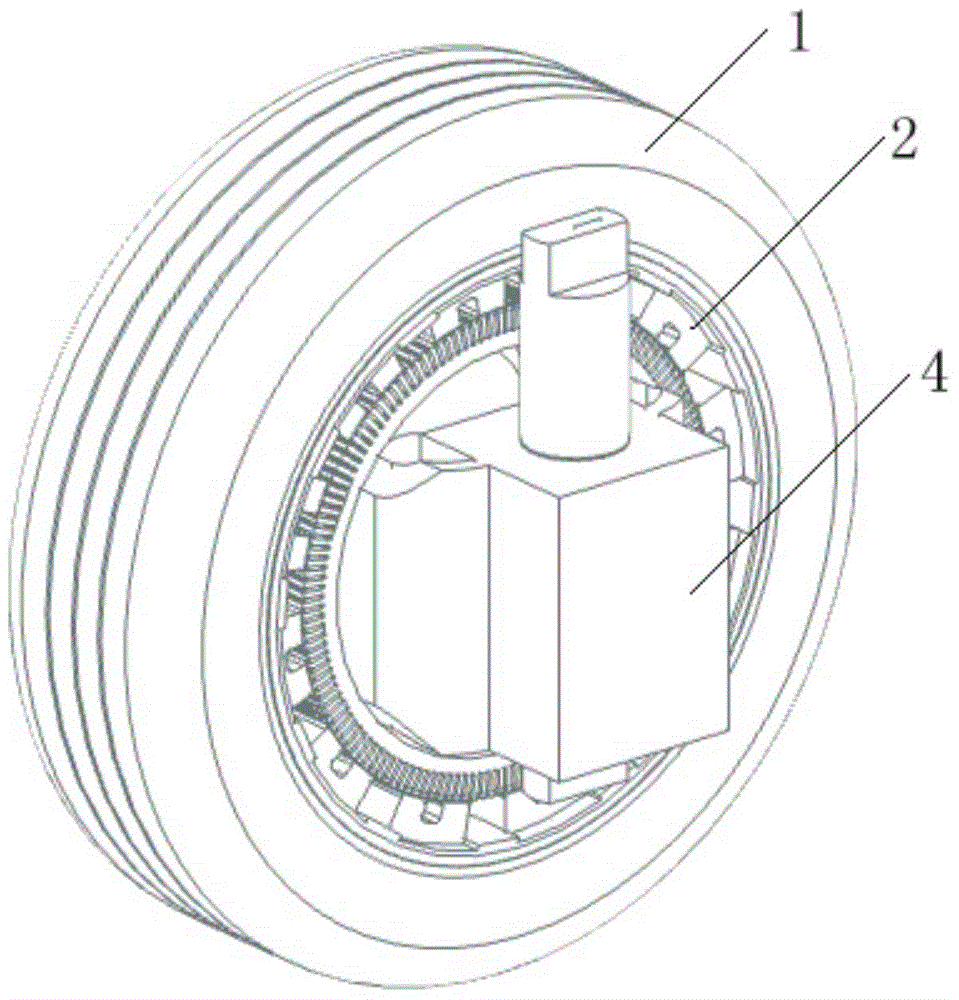

Hybrid driving system for automobile and gear operating method thereof

ActiveCN102107604ASmall reduction ratioReduce in quantityHybrid vehiclesToothed gearingsCouplingInternal combustion engine

The invention relates to a hybrid driving system and a gear operating method thereof. The system comprises an internal-combustion engine, a first motor, a second motor, a planet coupling mechanism, a retarding mechanism and a differential mechanism, wherein an output shaft of the internal-combustion engine is connected with an input shaft of the first motor; an output shaft of the first motor is connected with an output shaft of the second motor by a first clutch; and the output shaft of the second motor is connected with one of a sun wheel and a gear ring of the planet coupling mechanism at the position of the axial direction of the output shaft, and output shaft of the second motor is connected with the other one of the sun wheel with a brake and the gear ring by a second clutch at the other position of the axial direction of the output shaft. In the hybrid driving system, two gear levels of forward gears of an automobile are formed by adjusting the planet coupling mechanism, so that operating modes and corresponding gears are selected flexibly according to different running work conditions of the automobile to achieve the effects of low emission and oil consumption, high kinetic energy and the like of the integral automobile.

Owner:BYD CO LTD

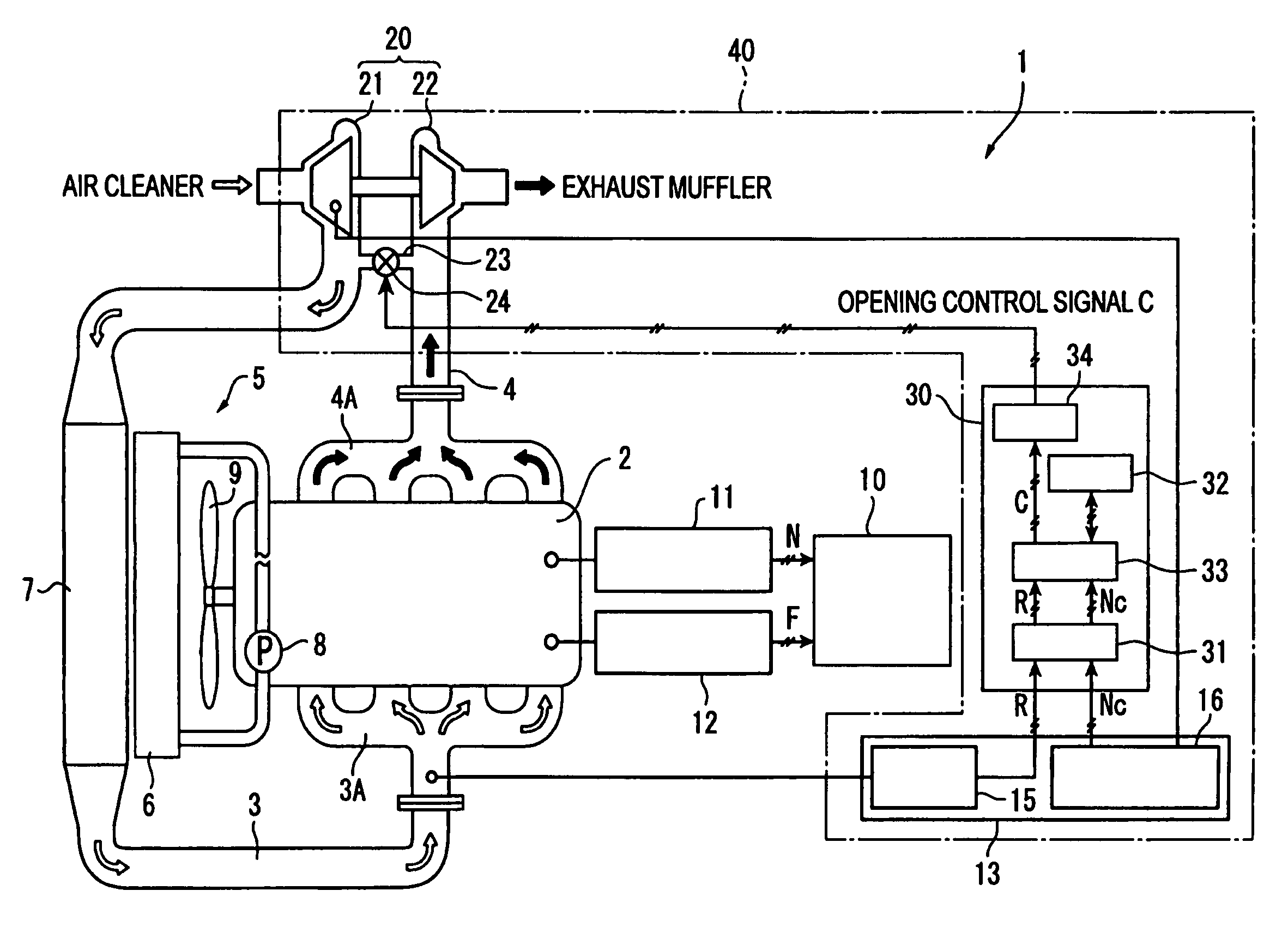

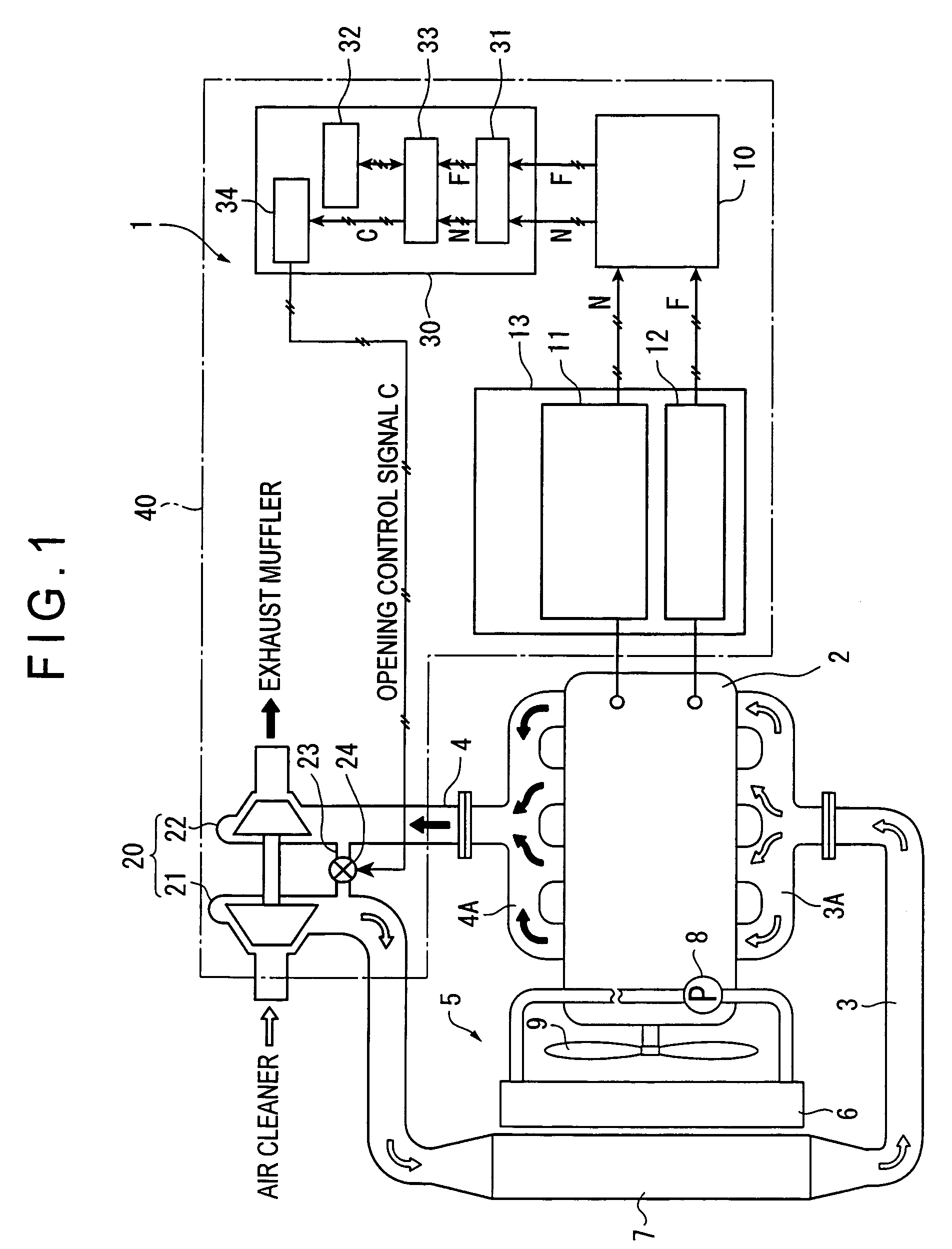

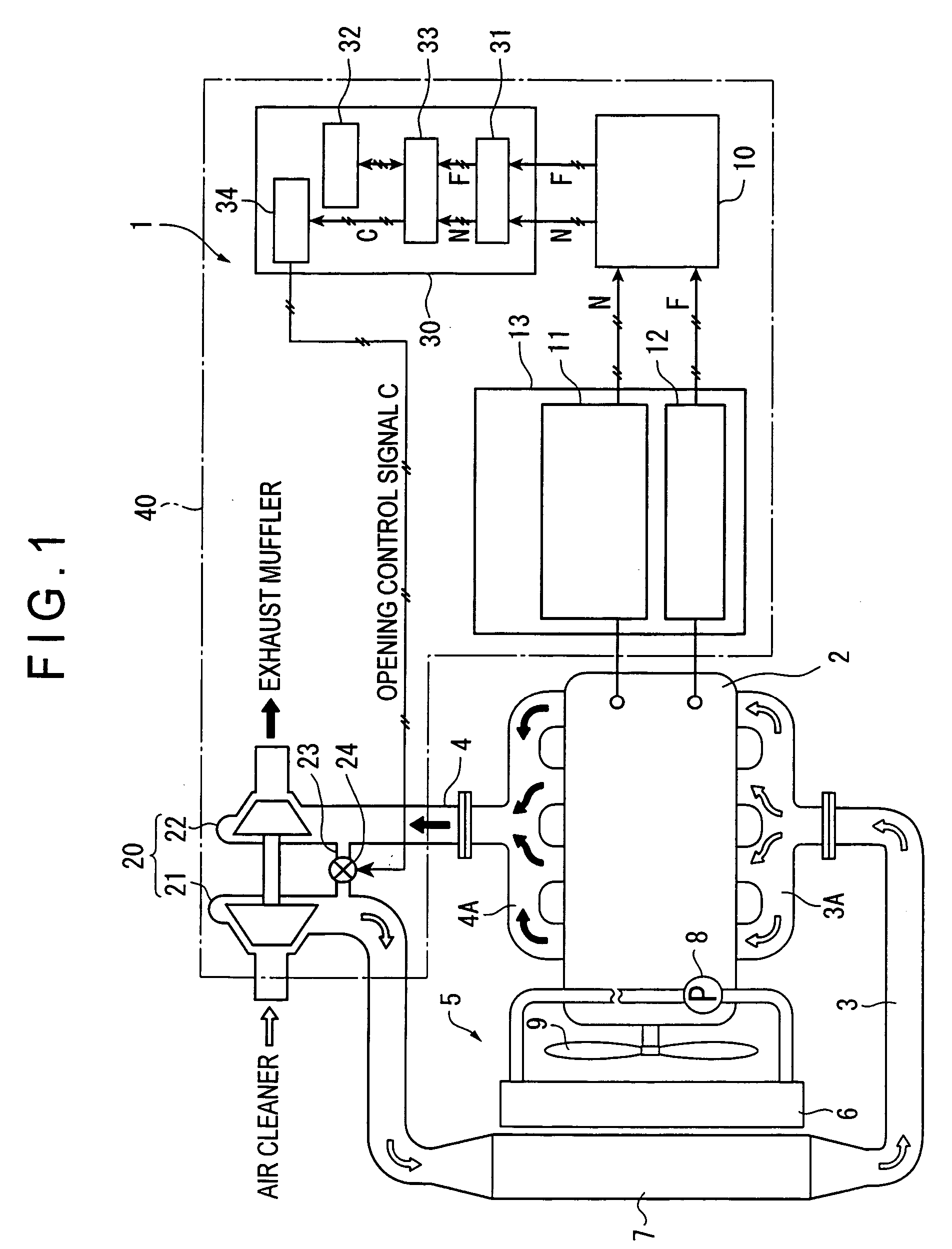

Internal combustion engine provided with intake bypass control device

InactiveUS7032382B2Prevent surgeIncrease pressure ratioElectrical controlInternal combustion piston enginesTurbochargerDieseling

A bypass conduit (23) connects an outlet passage of a compressor (21) of an exhaust gas turbocharger (20) and an inlet passage of an exhaust turbine (22), and a bypass valve (24) is provided therein. When the operating condition of a diesel engine (1) is found to be in a low-speed and high-load region, the bypass valve (24) is controlled by means of a valve controller to adjust the bypass conduit (23) so as to open it. Then, the charge air partly flows into an exhaust conduit (4) to increase the rotational speed of the exhaust turbine (22) and hence the charge air flow rate raises the output of the diesel engine (1). Additionally, as the charge air flow rate is increased, the operating condition of a compressor (21) is prevented from approaching the surging range.

Owner:KOMATSU LTD

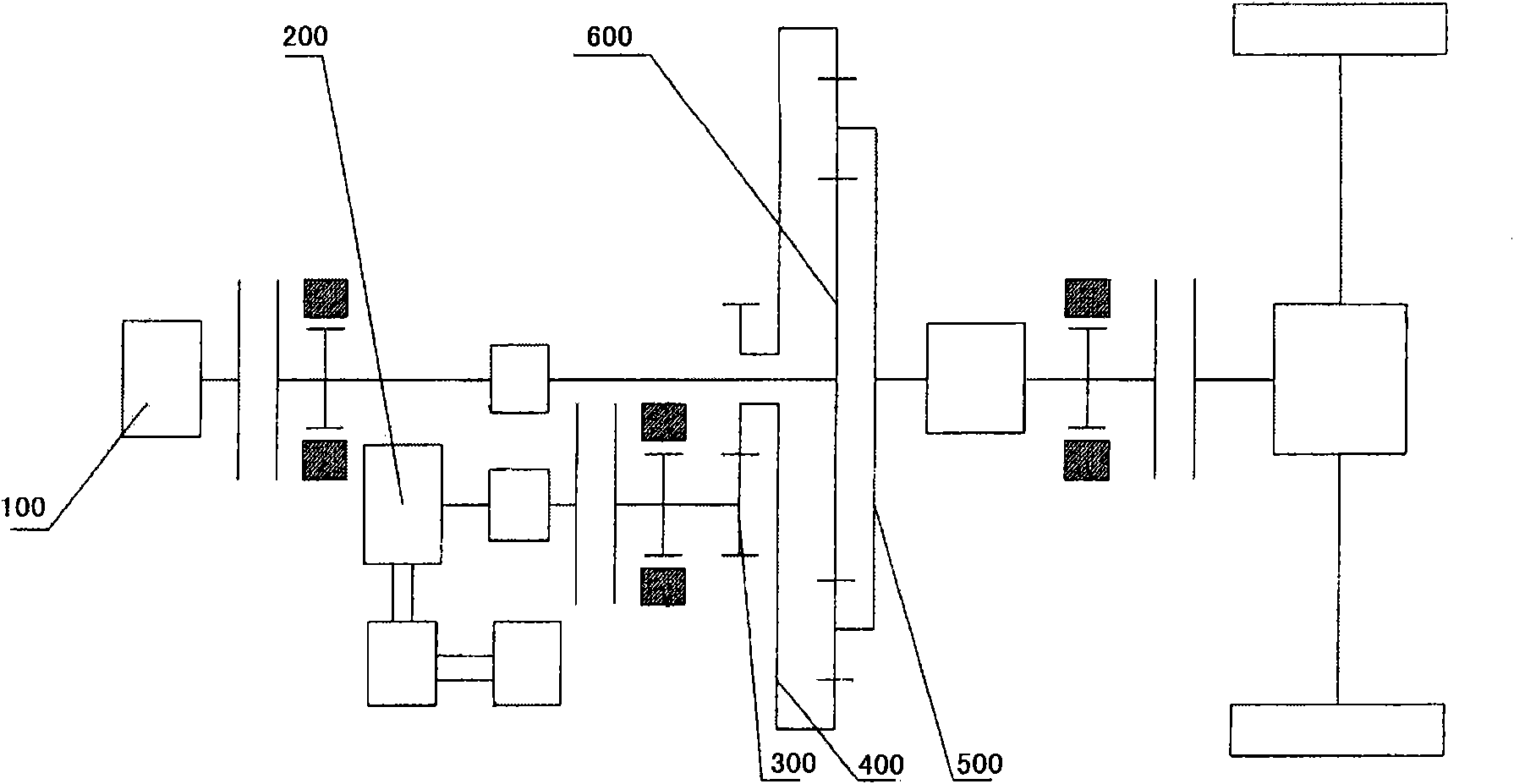

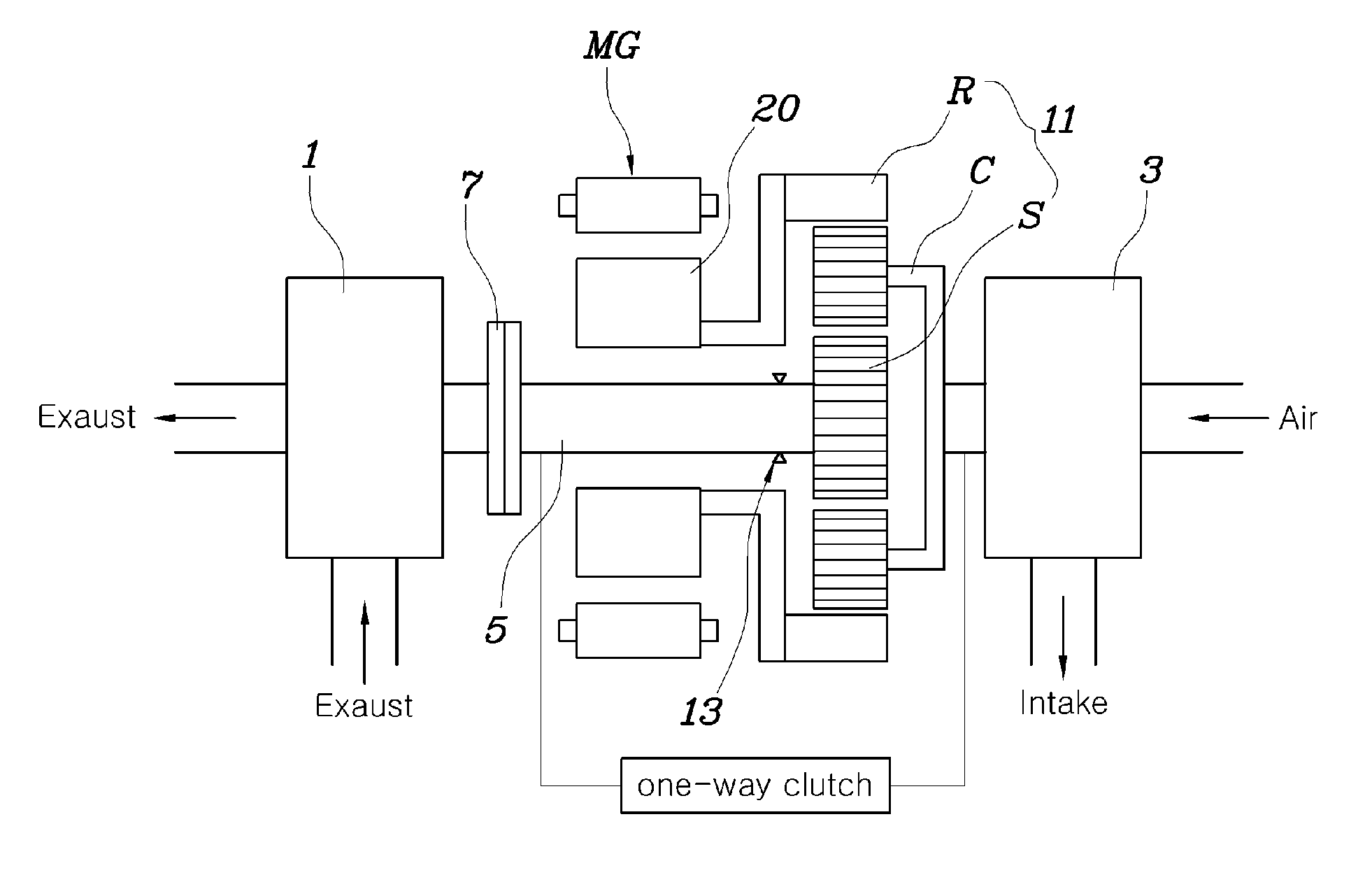

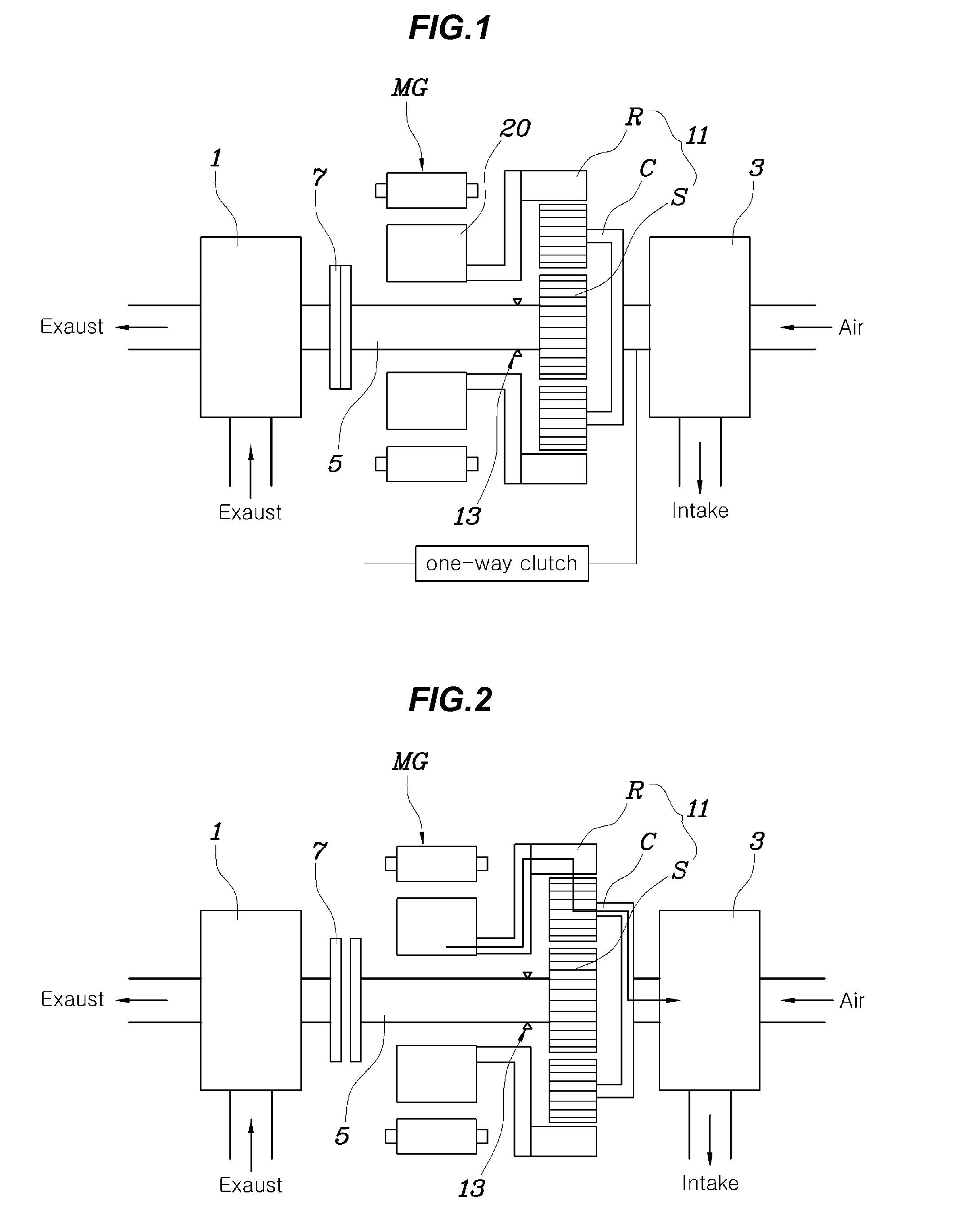

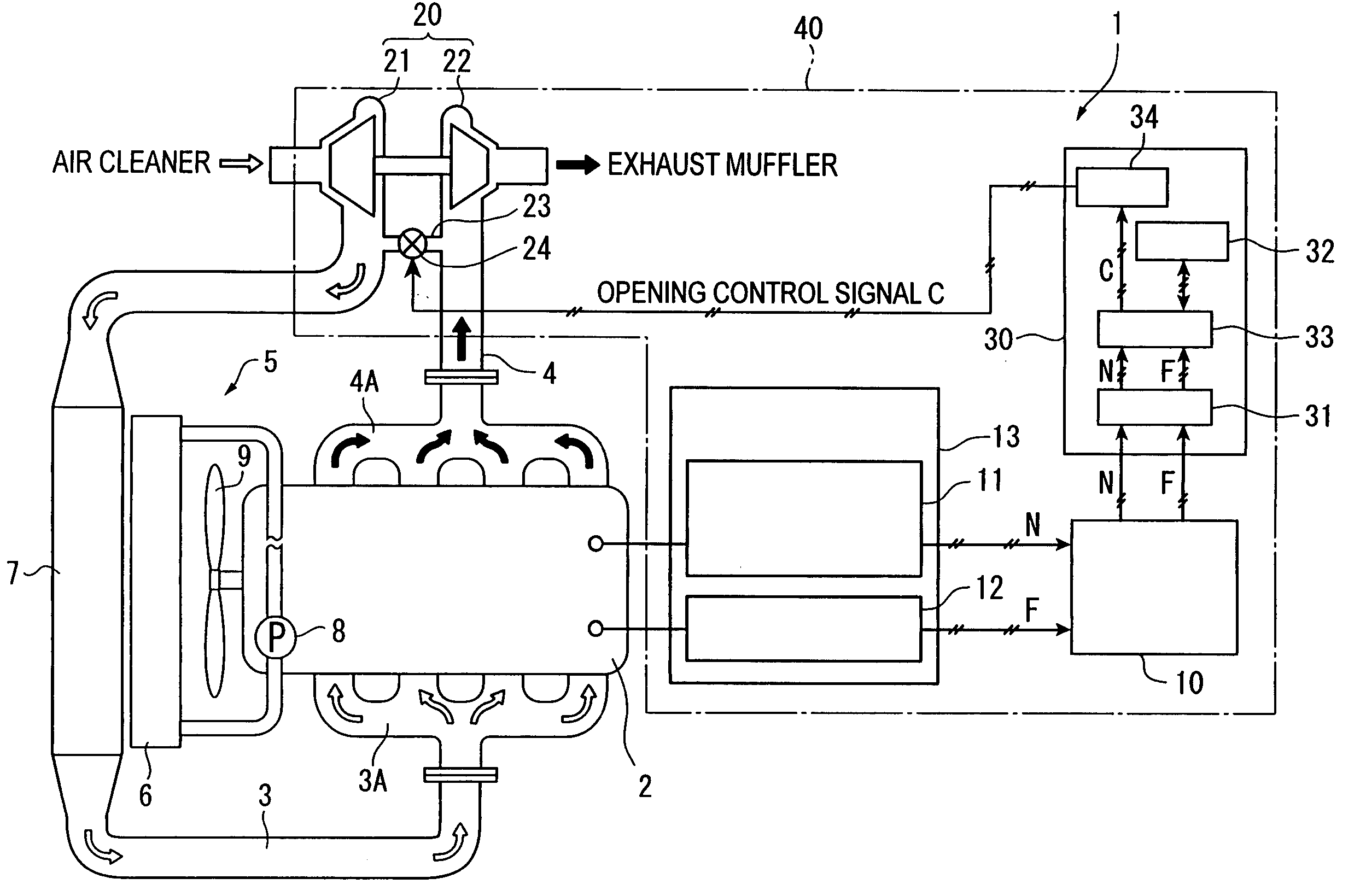

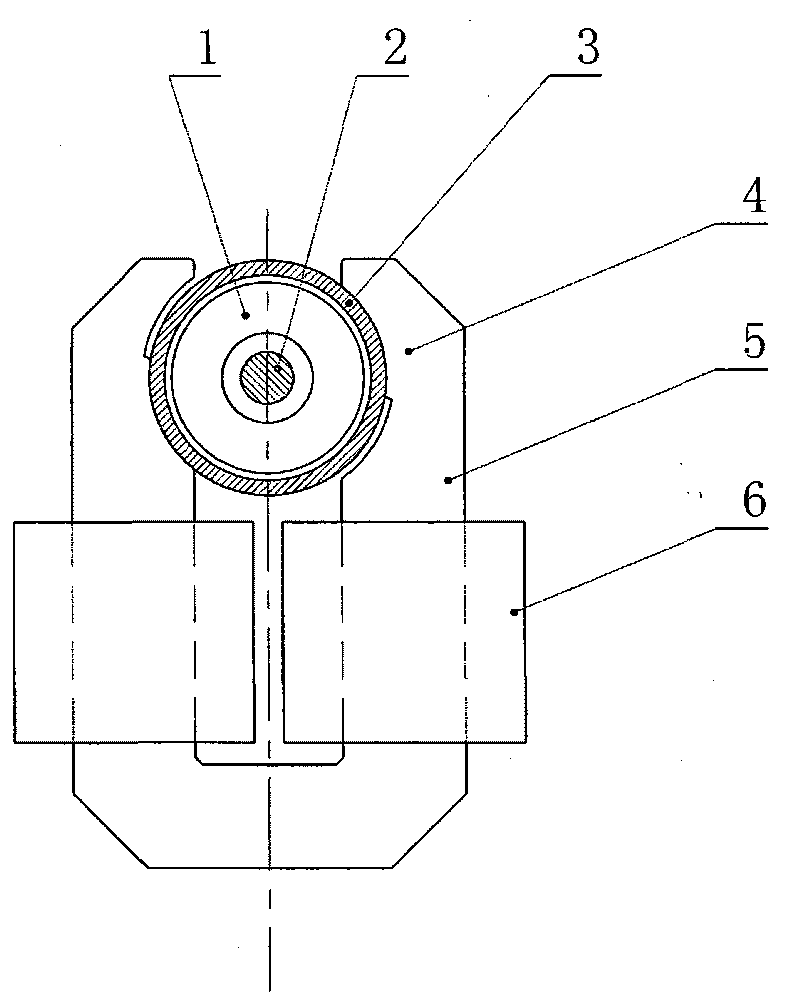

Turbocharger of engine

InactiveUS20130269342A1Increase low speed torqueLow costInternal combustion piston enginesExhaust apparatusExhaust gasClutch

A turbocharger apparatus of an engine may include a turbine installed to generate a rotating force from an exhaust gas flow of the engine, a compressor selectively coupled to the turbine to be rotated for compressing air which is to be supplied into an engine combustion chamber of the engine, a shaft installed to transfer the rotating force of the turbine to the compressor, a clutch installed to the shaft to control the transfer of the rotating force between the turbine and the compressor, a planetary gear unit connected to the compressor, and a motor generator mounted onto the shaft and coupled to the planetary gear unit to receive the rotating force of the compressor through the planetary gear set.

Owner:HYUNDAI MOTOR CO LTD

Internal combustion engine provided with intake bypass control device

InactiveUS20050160733A1Avoid rangePrevent surgeElectrical controlNon-fuel substance addition to fuelExhaust gasOperant conditioning

A bypass conduit (23) connects an outlet passage of a compressor (21) of an exhaust gas turbocharger (20) and an inlet passage of an exhaust turbine (22), and a bypass valve (24) is provided therein. When the operating condition of a diesel engine (1) is found to be in a low-speed and high-load region, the bypass valve (24) is controlled by means of a valve controller to adjust the bypass conduit (23) so as to open it. Then, the charge air partly flows into an exhaust conduit (4) to increase the rotational speed of the exhaust turbine (22) and hence the charge air flow rate raises the output of the diesel engine (1). Additionally, as the charge air flow rate is increased, the operating condition of a compressor (21) is prevented from approaching the surging range.

Owner:KOMATSU LTD

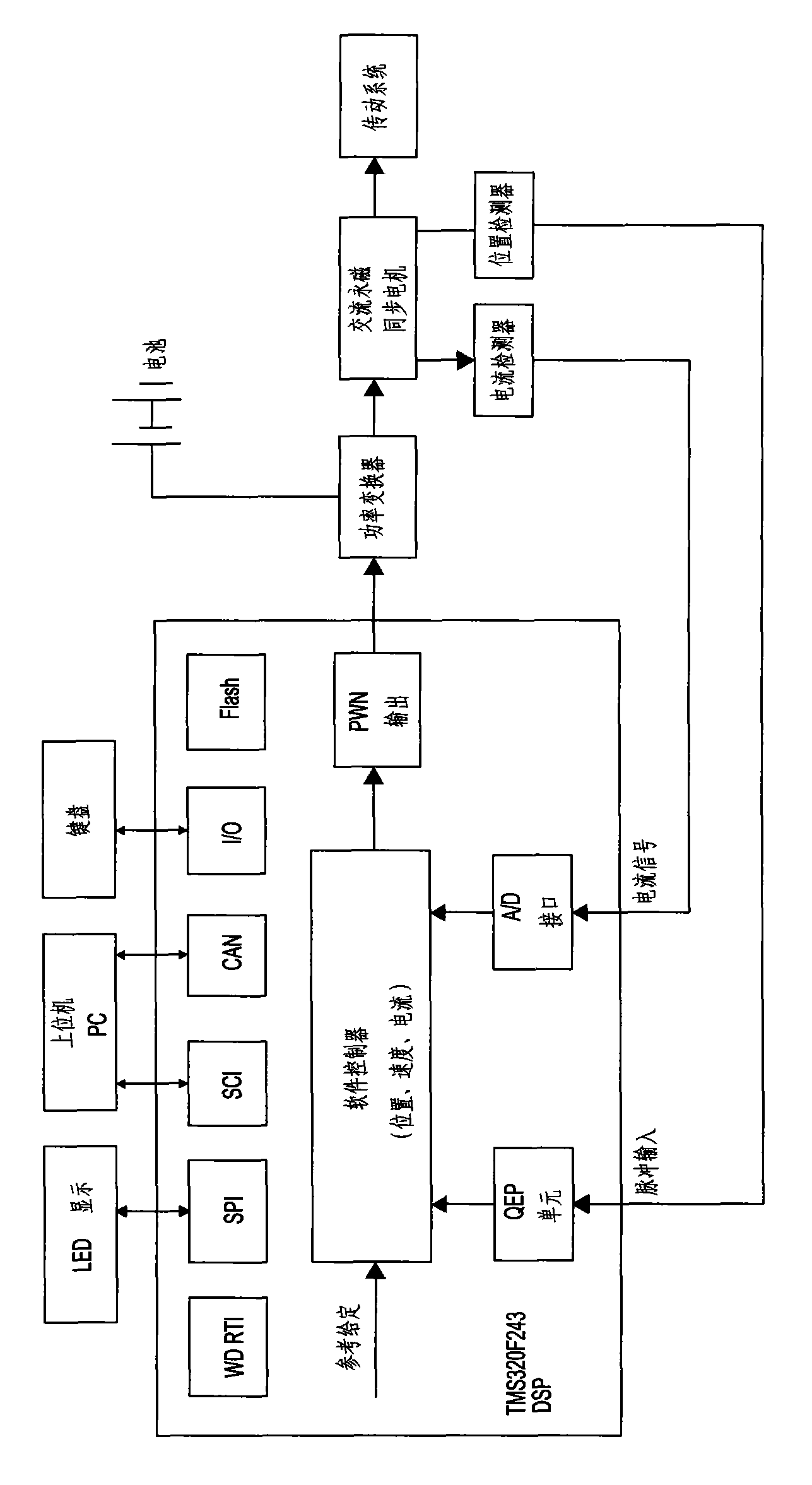

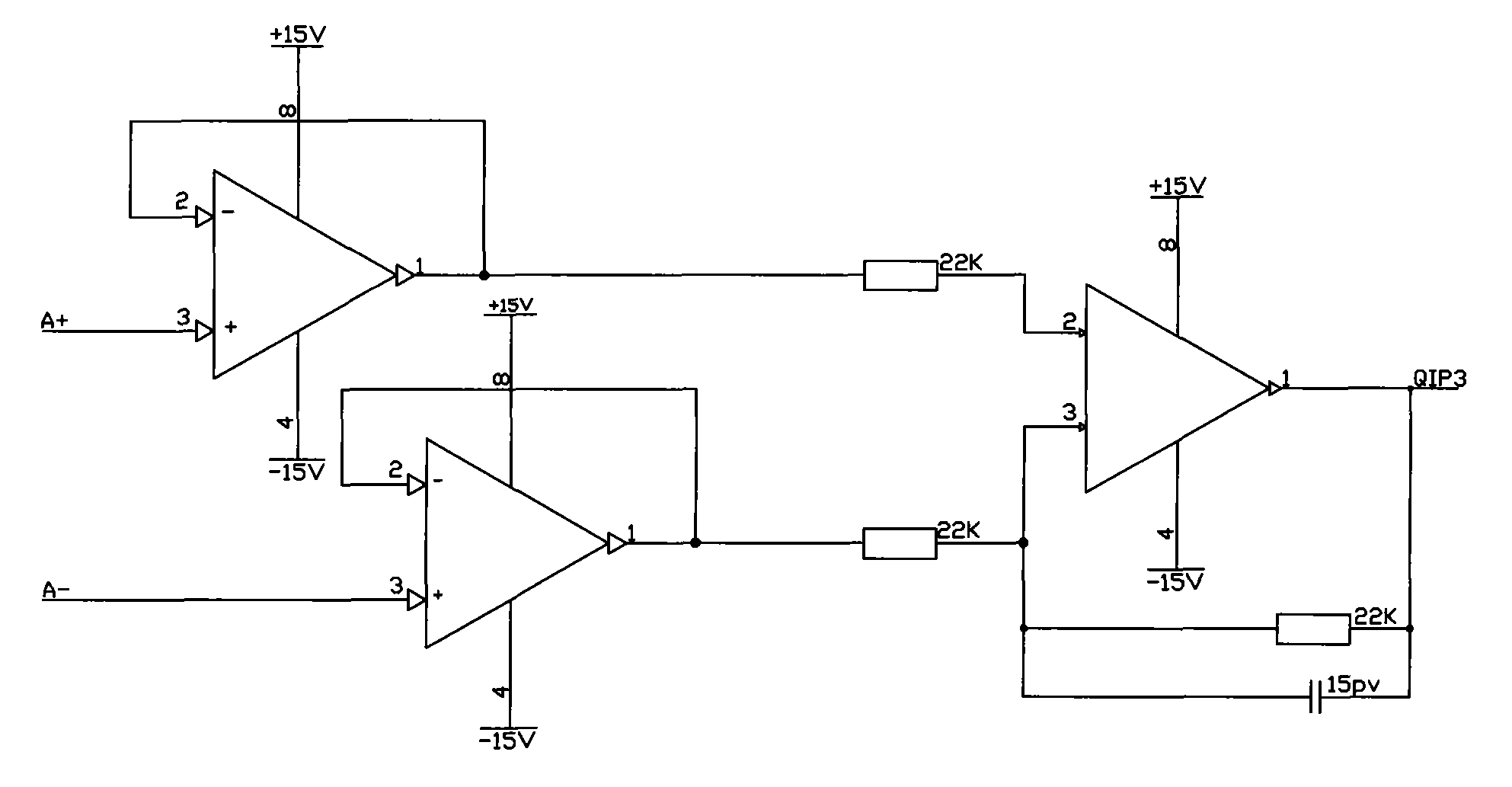

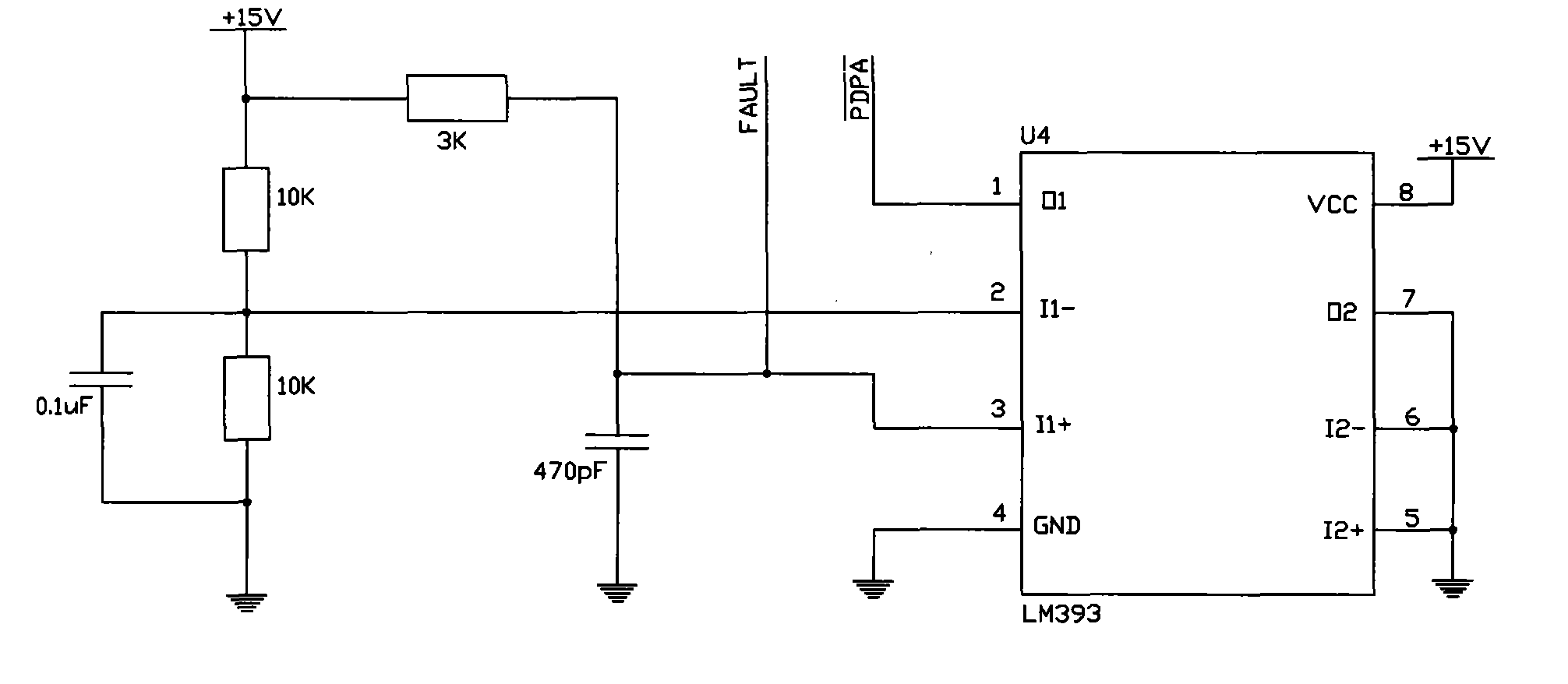

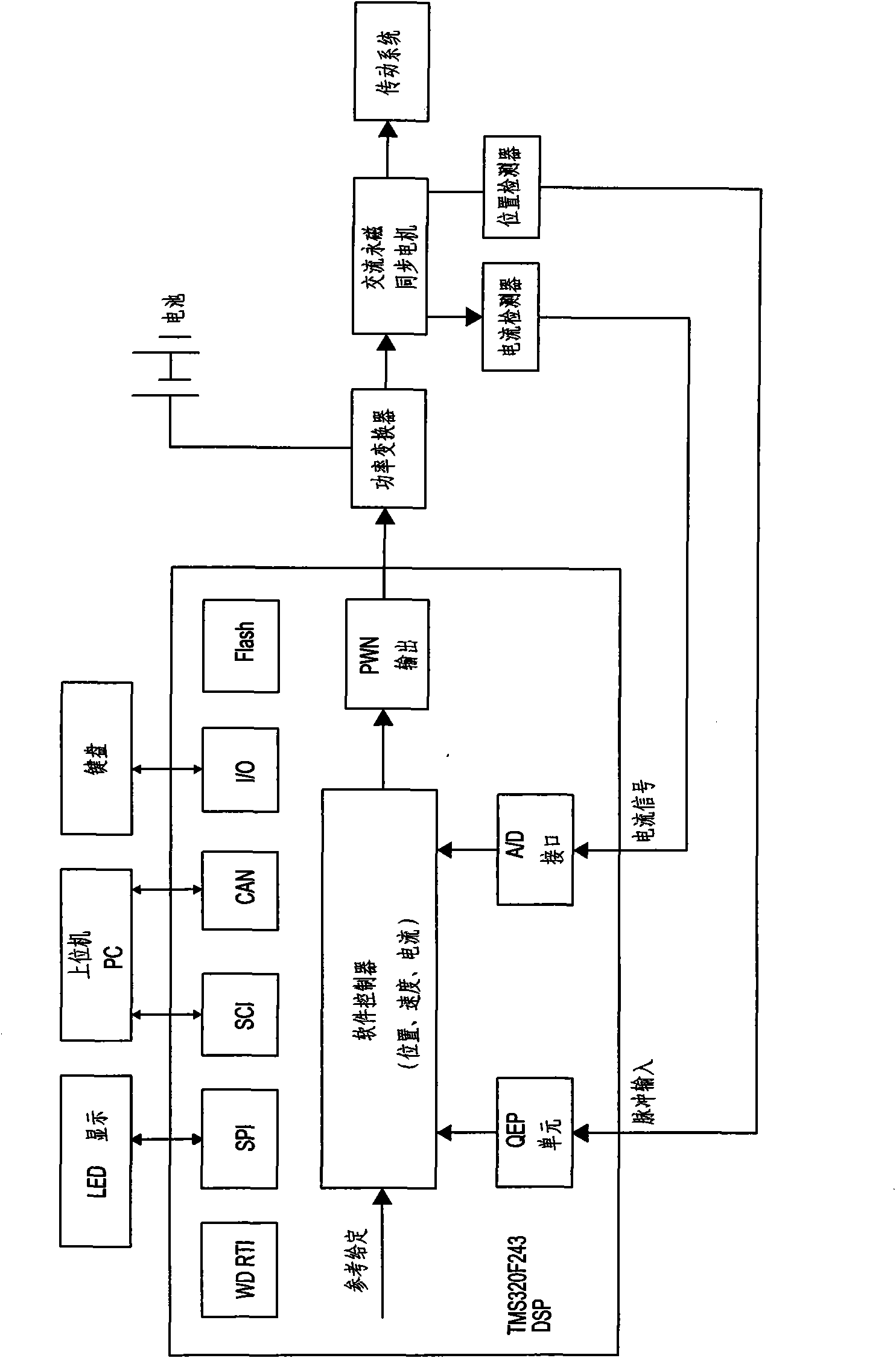

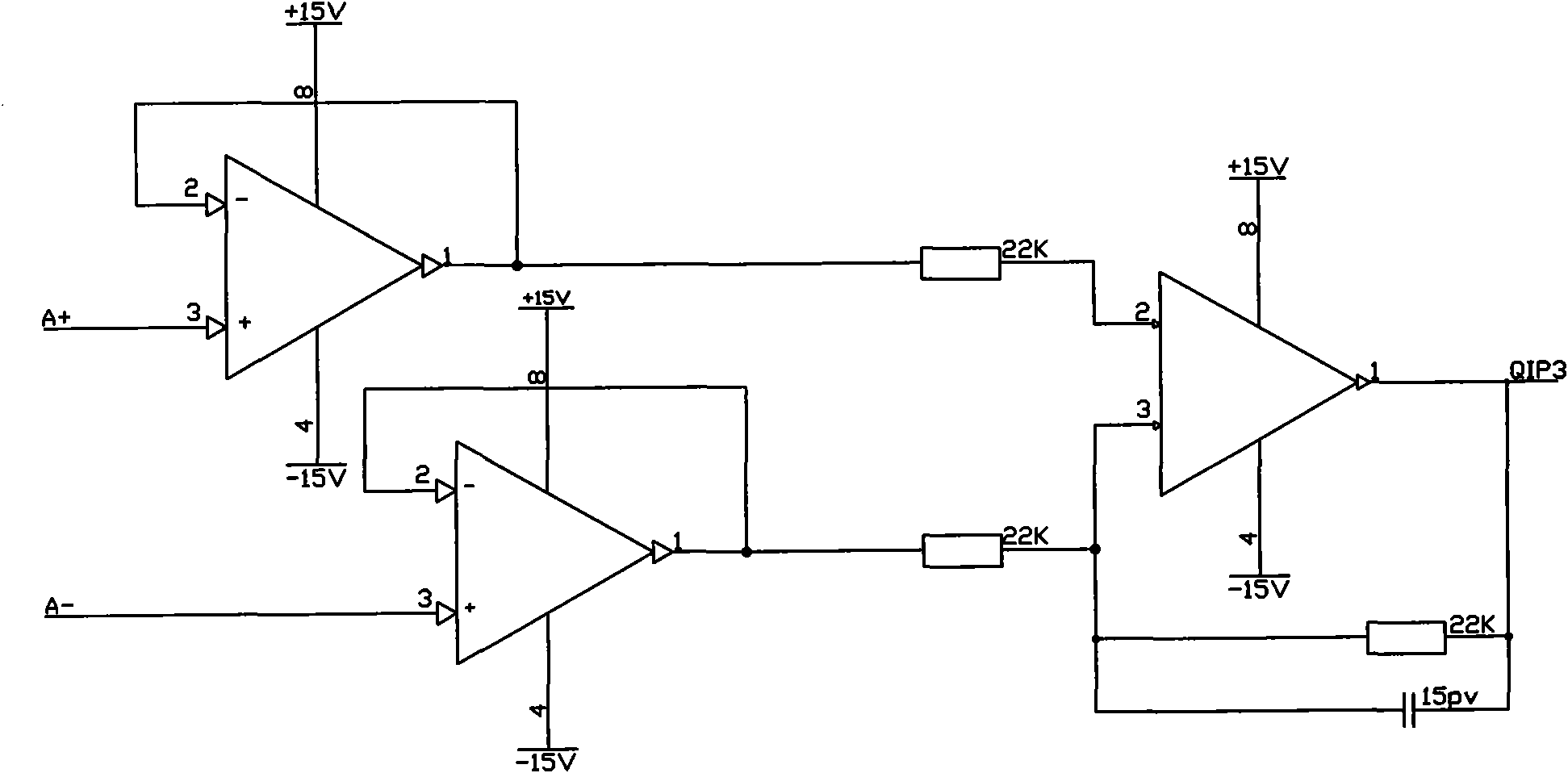

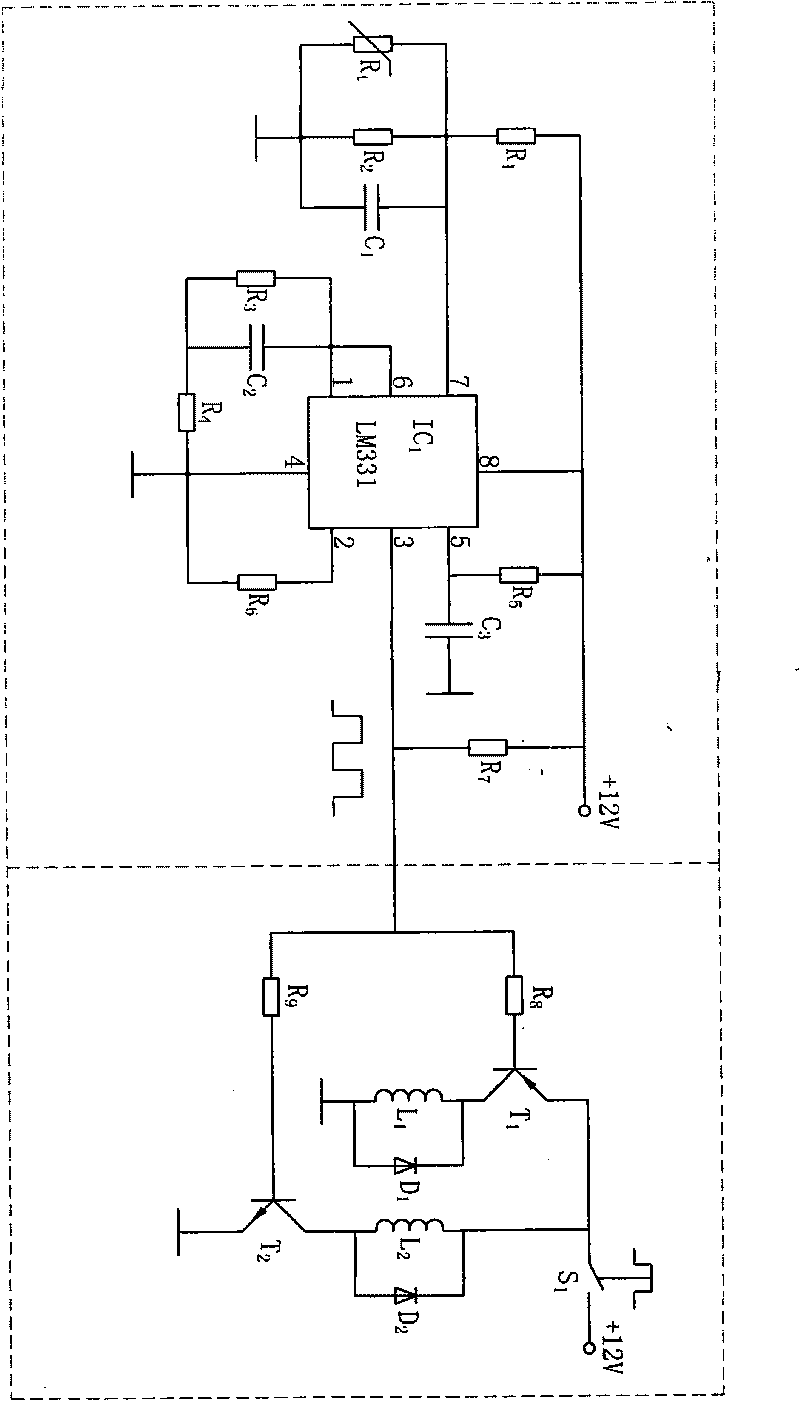

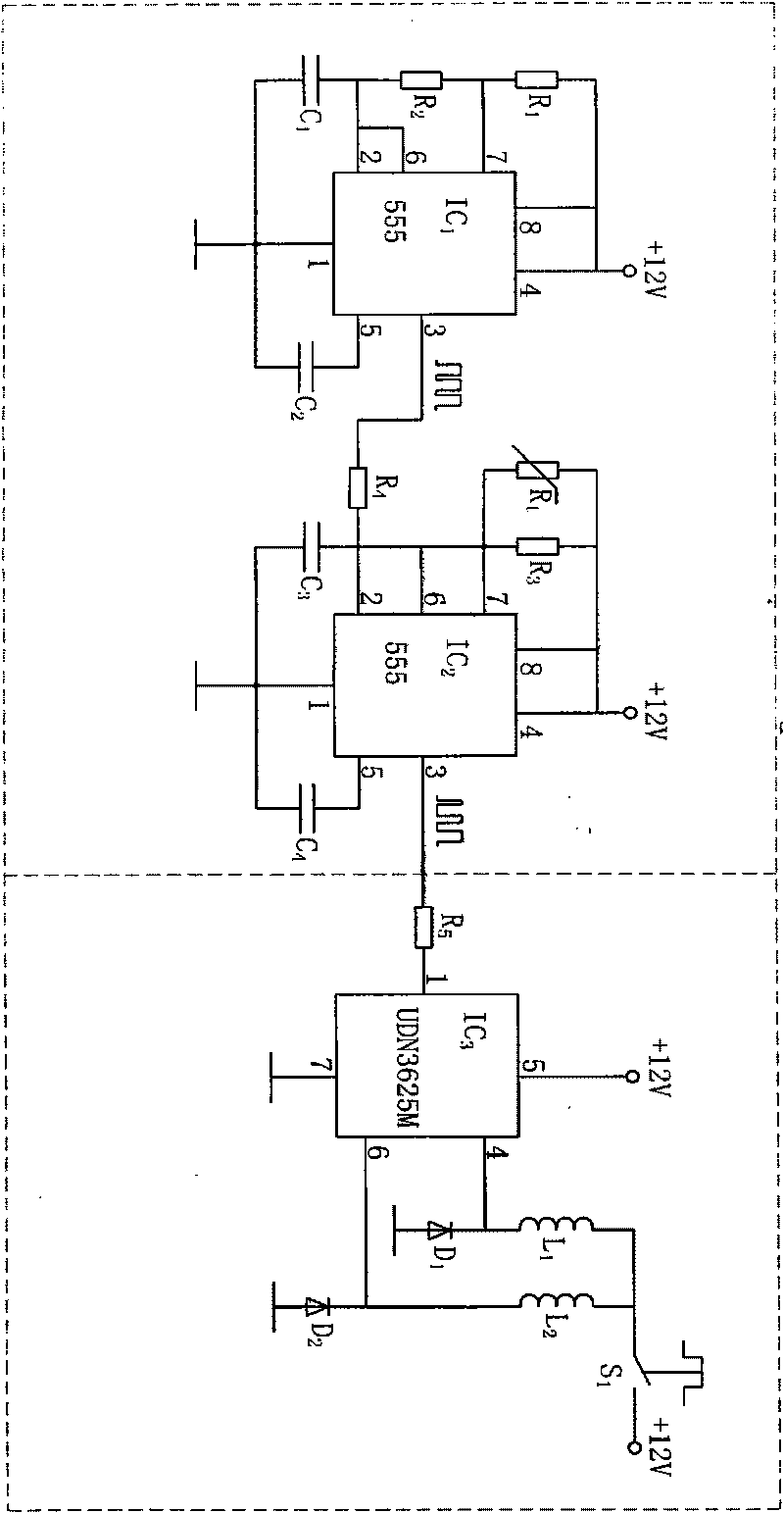

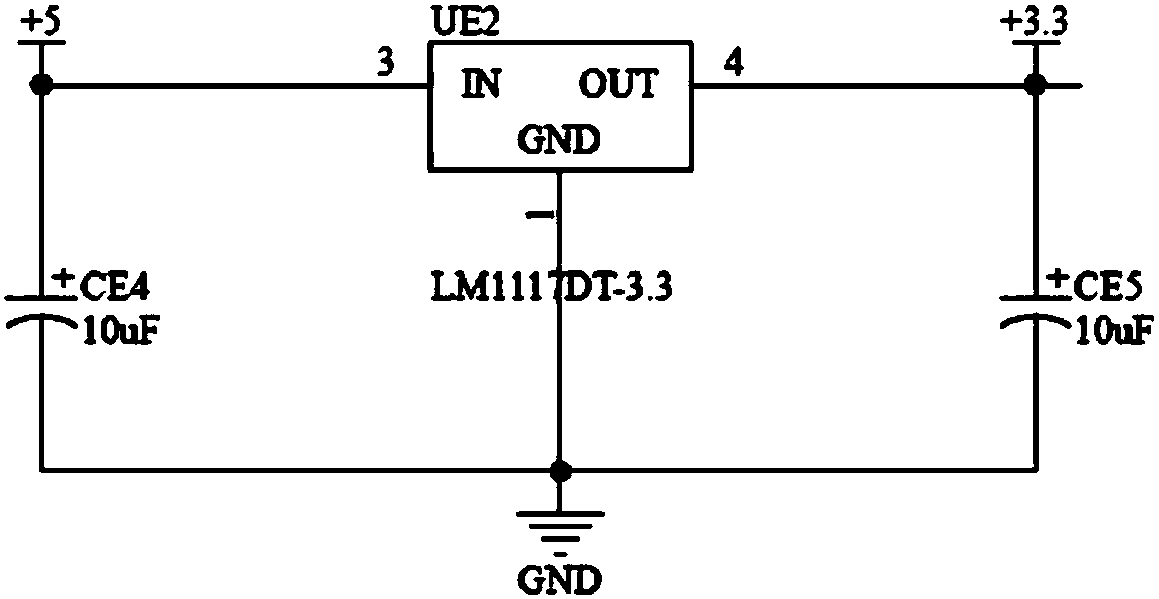

Alternating current permanent-magnet synchronous machine controller

InactiveCN102064753AIncrease low speed torqueNo current shock phenomenonAC motor controlSingle motor speed/torque controlPhysicsDigital signal processing

The invention relates to an alternating current permanent-magnet synchronous machine controller which comprises a digital signal microprocessor (DSP), a power converter, an alternating current permanent-magnet synchronous machine, a position detector and a current detector, wherein the position detector inputs the detected rotor position signal and rotor speed signal of the alternating current permanent-magnet synchronous machine by a quadrature encoder pulse (QEP) unit of the DSP; the current detector inputs the detected current signal of the alternating current permanent-magnet synchronous machine by an analog to digital (A / D) conversion interface of the QEP of the DSP; the DSP calculates the given value of current according to the input rotor position signal and rotor speed signal, and compares the given value of current with the input detected value of current to obtain the corresponding control signal for controlling the width of the pulse-width modulation (PWM) pulse; and the PWM signal drives the alternating current permanent-magnet synchronous machine by the power converter. The invention has the advantages of compact and firm structure, simple circuit, low cost, reliable performance, stable operation, wide speed adjusting range, high efficiency, high accuracy and the like.

Owner:程基江

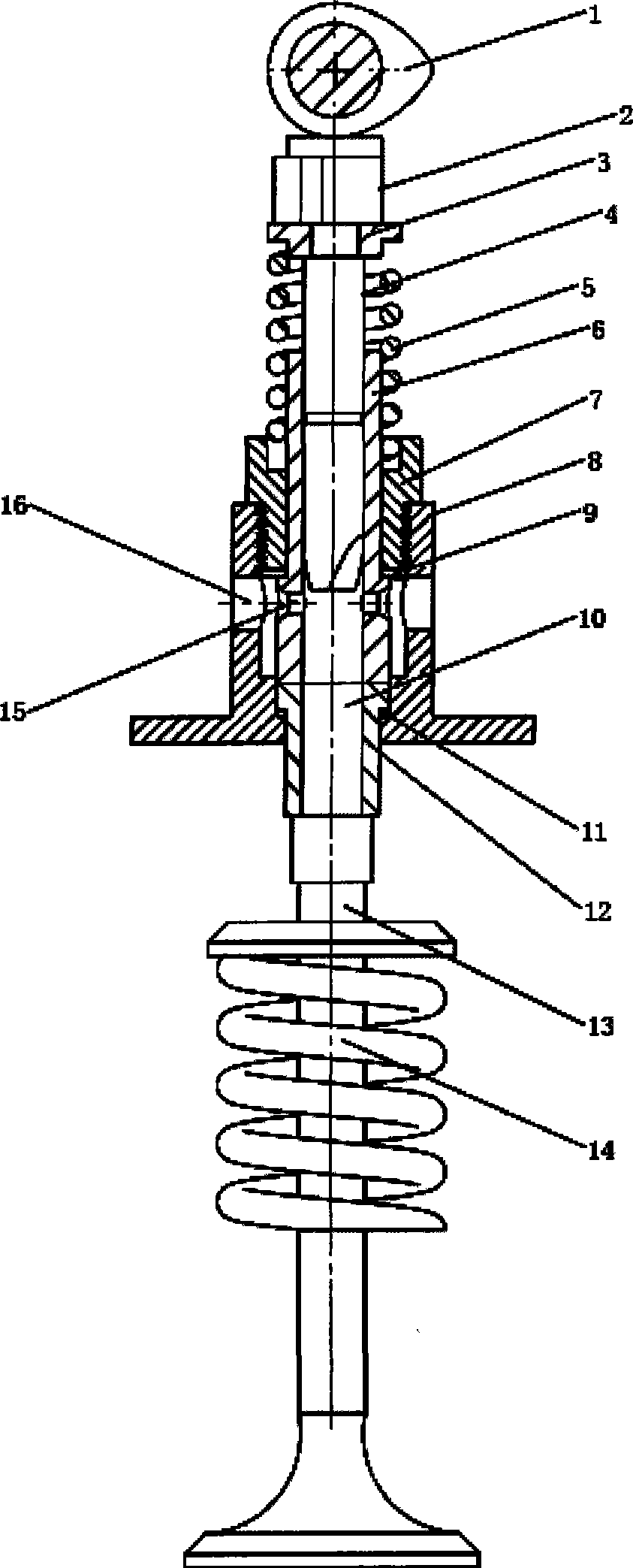

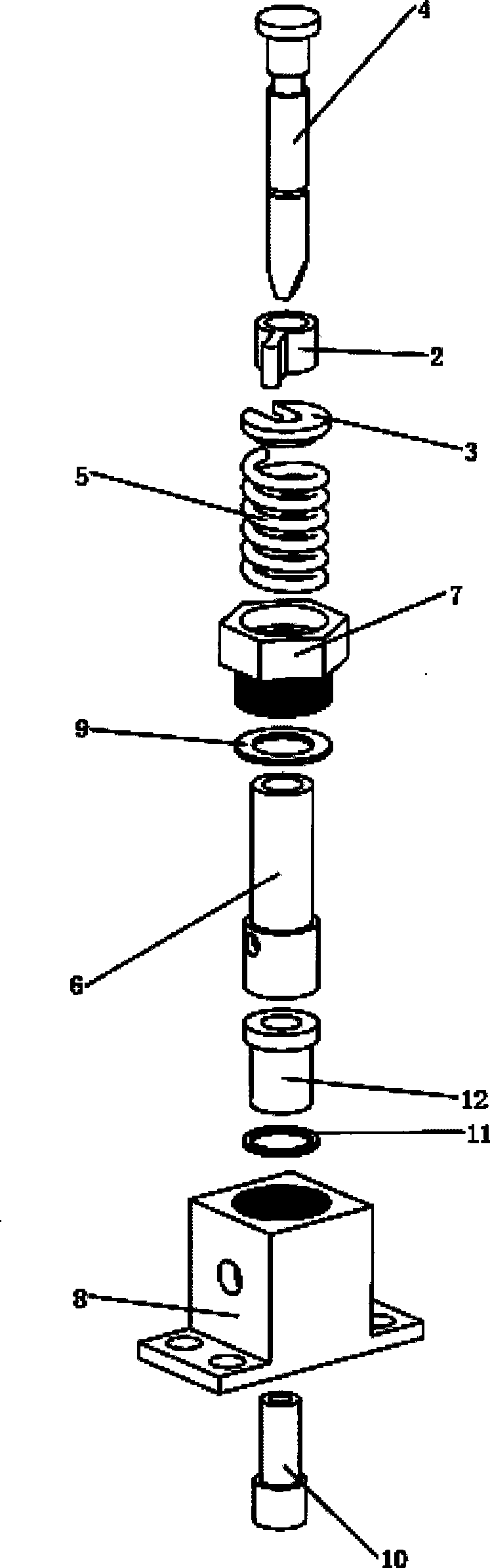

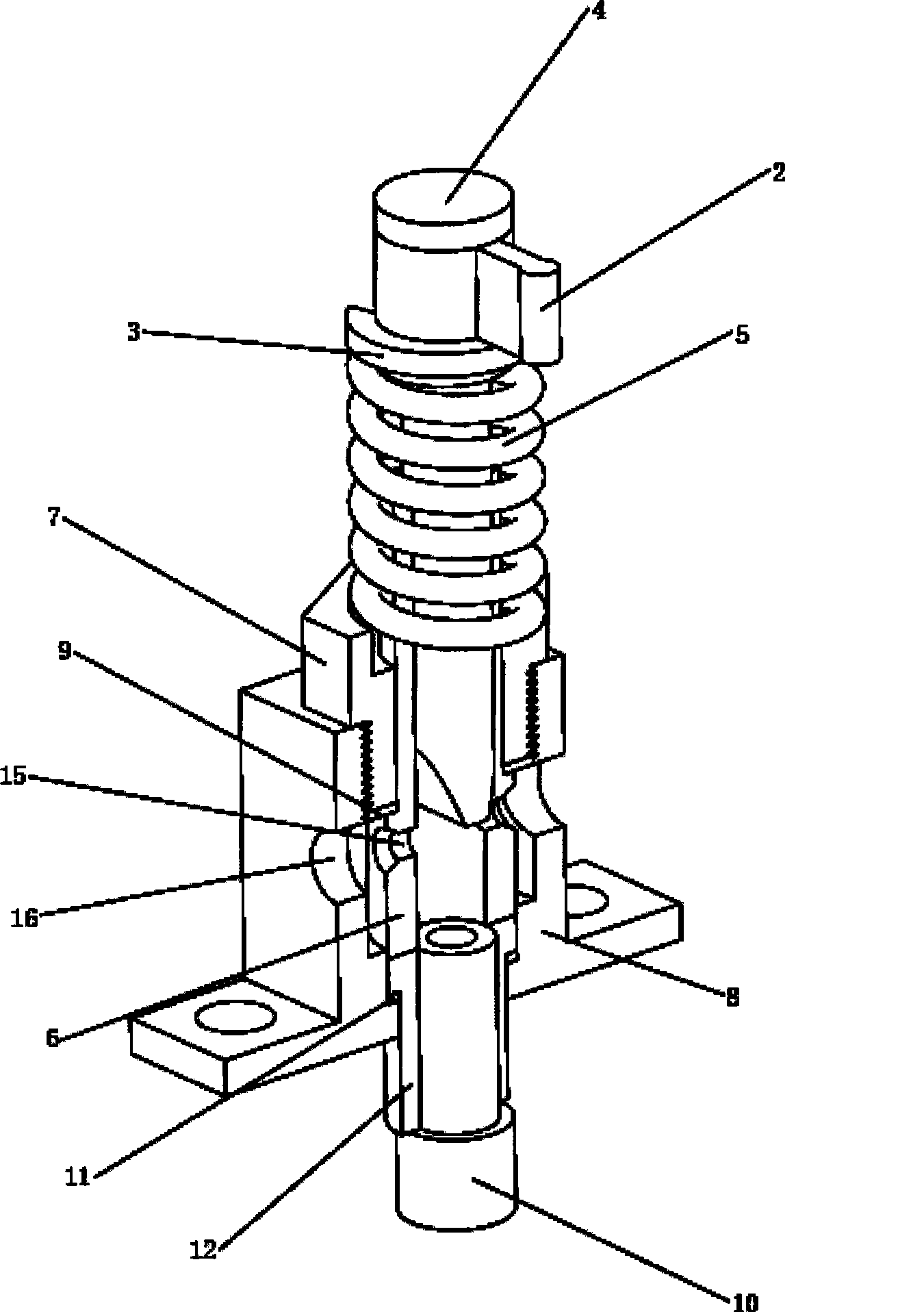

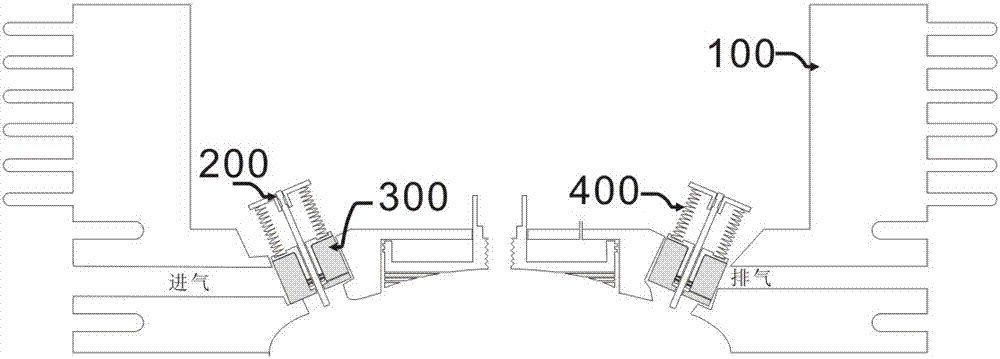

Continuously adjustable mechanical hydraulic valve lift device

InactiveCN101446214AReduce lossesImprove economyMachines/enginesNon-mechanical valveEngineeringInternal combustion engine

The invention relates to a continuously adjustable mechanical hydraulic valve lift device which belongs to the technical field of internal combustion engine. The continuously adjustable mechanical hydraulic valve lift device comprises a valve cam, a valve, a valve spring, a plunger piston adjusting arm, a plunger piston spring base, a tappet plunger piston, a plunger piston spring, a tappet plunger barrel, a retaining nut, a low pressure oil cylinder, a first gasket, a second gasket, an executing plunger piston and an executing plunger barrel. The lift range is decided by the relative position of the tappet plunger piston and a first oil hole at the tappet plunger barrel. The symmetrical plane of the plunger piston adjusting arm is coincident with the symmetrical plane of a diclinic section at the head of the tappet plunger piston, and the symmetrical plane of the plunger piston adjusting arm along the axial line is considered as a reference plane. When maximum lift is required, the plunger piston adjusting arm is rotated to ensure that the reference plane is parallel with the axial line of the first oil hole. When minimum lift is required, the plunger piston adjusting arm is rotated to ensure that the reference plane is vertical to the axial line of the first oil hole. When medium lift is required, the plunger piston adjusting arm is rotated to ensure that the reference plane and the axial line of the first oil hole form any angle between 0 to 90 degrees. The device has simple structure and can adjust valve lift, valve right timing and duration continuously.

Owner:SHANGHAI JIAO TONG UNIV

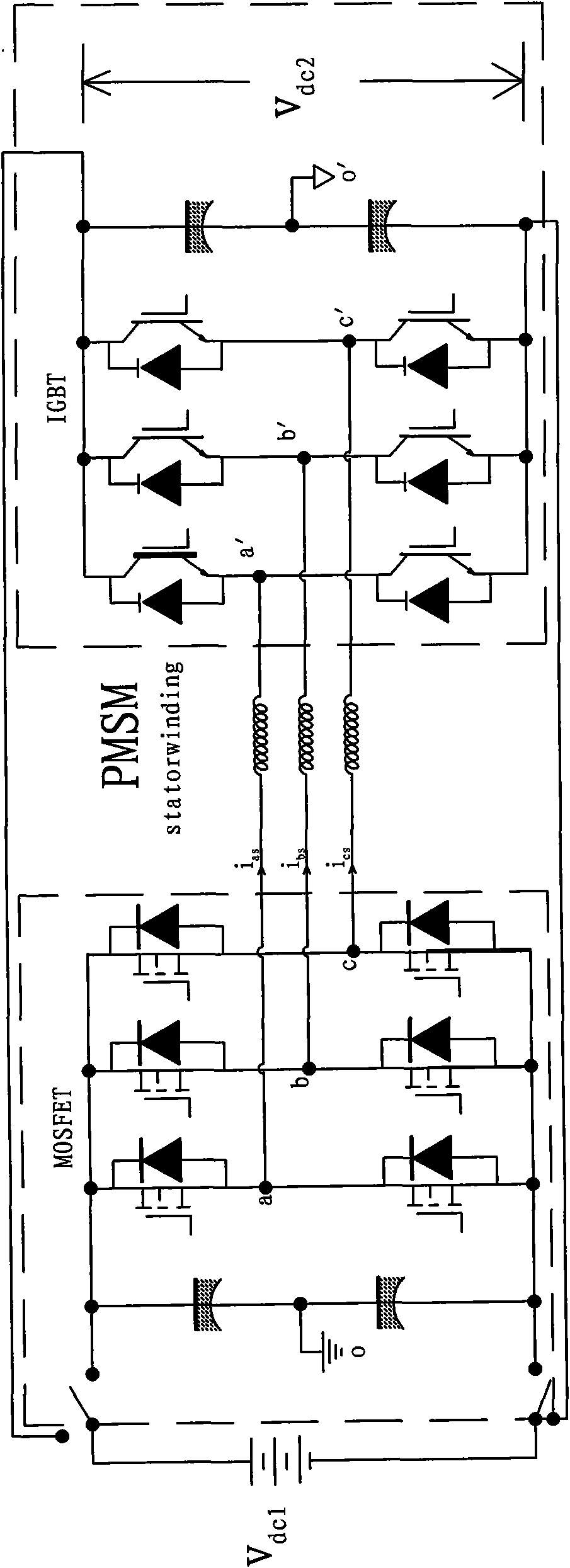

Alternating current permanent magnet synchronous machine control system for electric vehicle

InactiveCN102377380AIncrease low speed torqueNo current shock phenomenonAC motor controlSingle motor speed/torque controlMOSFETPermanent magnet synchronous machine

The invention discloses an alternating current permanent magnet synchronous machine control system for an electric vehicle. The system comprises an alternating current permanent magnet synchronous machine, a power convertor, a controller and detectors; the controller is a digital signal processor (DPS); the detectors comprise a position detector and a current detector; the position detector and the current detector input rotor positions / speed signals and current signals, which are detected by the position detector and the current detector respectively, of the alternating current permanent magnet synchronous machine to the DSP; the DSP calculates the given value of the current according to the input rotor positions / the speed signals and compares the given value and the input current detection value to obtain a corresponding control signal, and the alternating current permanent magnet synchronous machine is driven by the power convertor; and the power convertor has a three-phase double-inversion bridge structure consisting of a metal-oxide-semiconductor field effect transistor (MOSFET) inverter and an insulated gate bipolar transistor (IGBT) inverter. The system has the advantages of compact and firm structure, reliable performance, high control efficiency and accuracy and the like and runs stably and a circuit is simple.

Owner:程基江

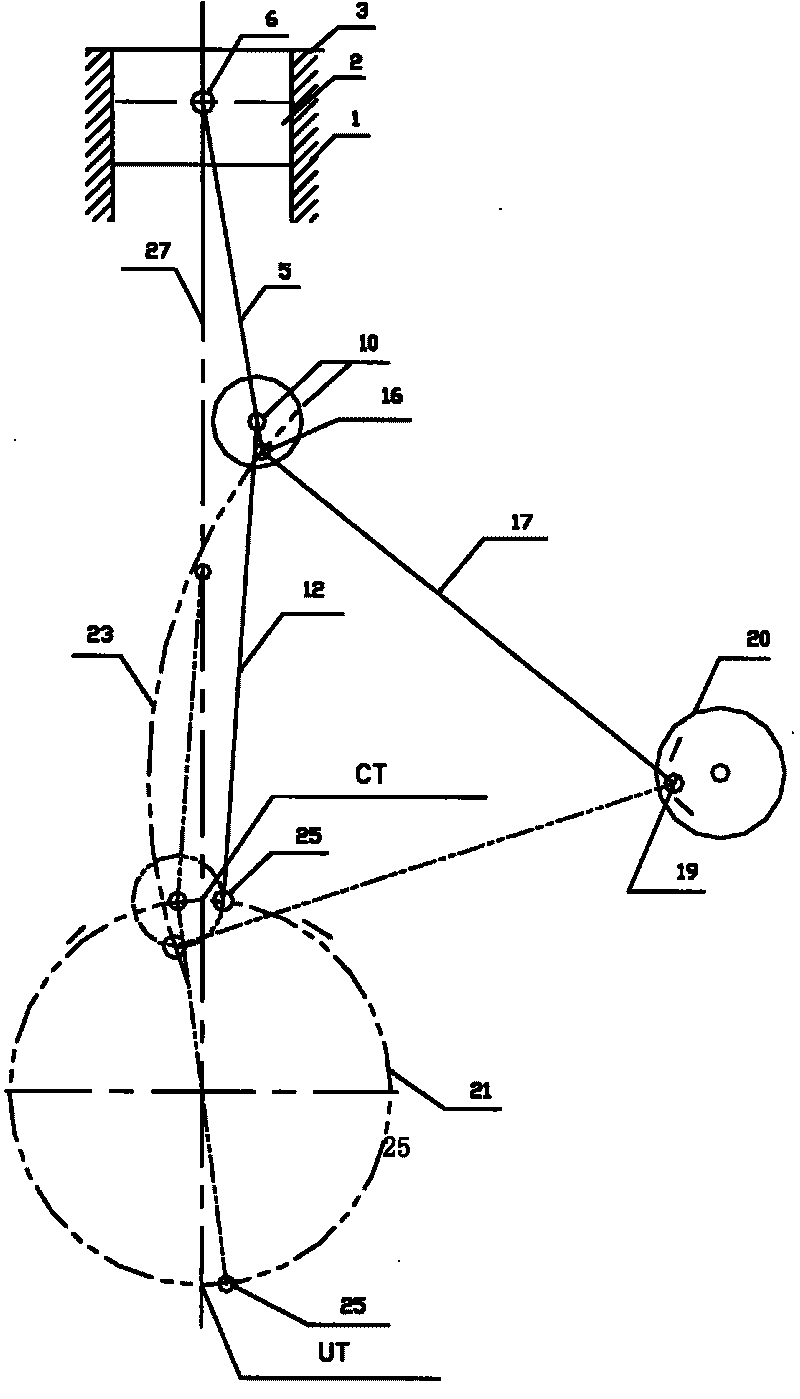

Engine with adjustable compression ratio

InactiveCN101701548AReduce the overall heightSolution to short lifeMachines/enginesDrive wheelLow speed

The invention discloses an engine with adjustable compression ratio, comprising a cylinder, a piston arranged in the cylinder and an upper connecting rod of which the upper end socket is articulated with the piston pin and the lower end socket is articulated with the eccentric pin; the eccentric pin is integrally formed with a first pin which is fixedly connected with one or two auxiliary driving wheels; the auxiliary driving wheels are coaxial with the first pin and are provided with an oscillating bar; one end of the oscillating bar is articulated on the first pin, and the other end is supported on a second pin on the engine cylinder and is coaxially connected with one or two active driving wheels which are parallel to the auxiliary driving wheels and rotate under control; the active driving wheels drive the auxiliary driving wheels to rotate; the middle part of the oscillating bar is provided with articulating points and is articulated with a lower connecting rod which is connected with a crank. The engine has low height of the complete machine of the engine, good rigidity of the crankshaft, long service life, low cost, good dynamic property, simple and convenient adjustment of compression ratio, great output low speed torque, high power, little fuel consumption and low discharge pollution.

Owner:TIANJIN UNIV

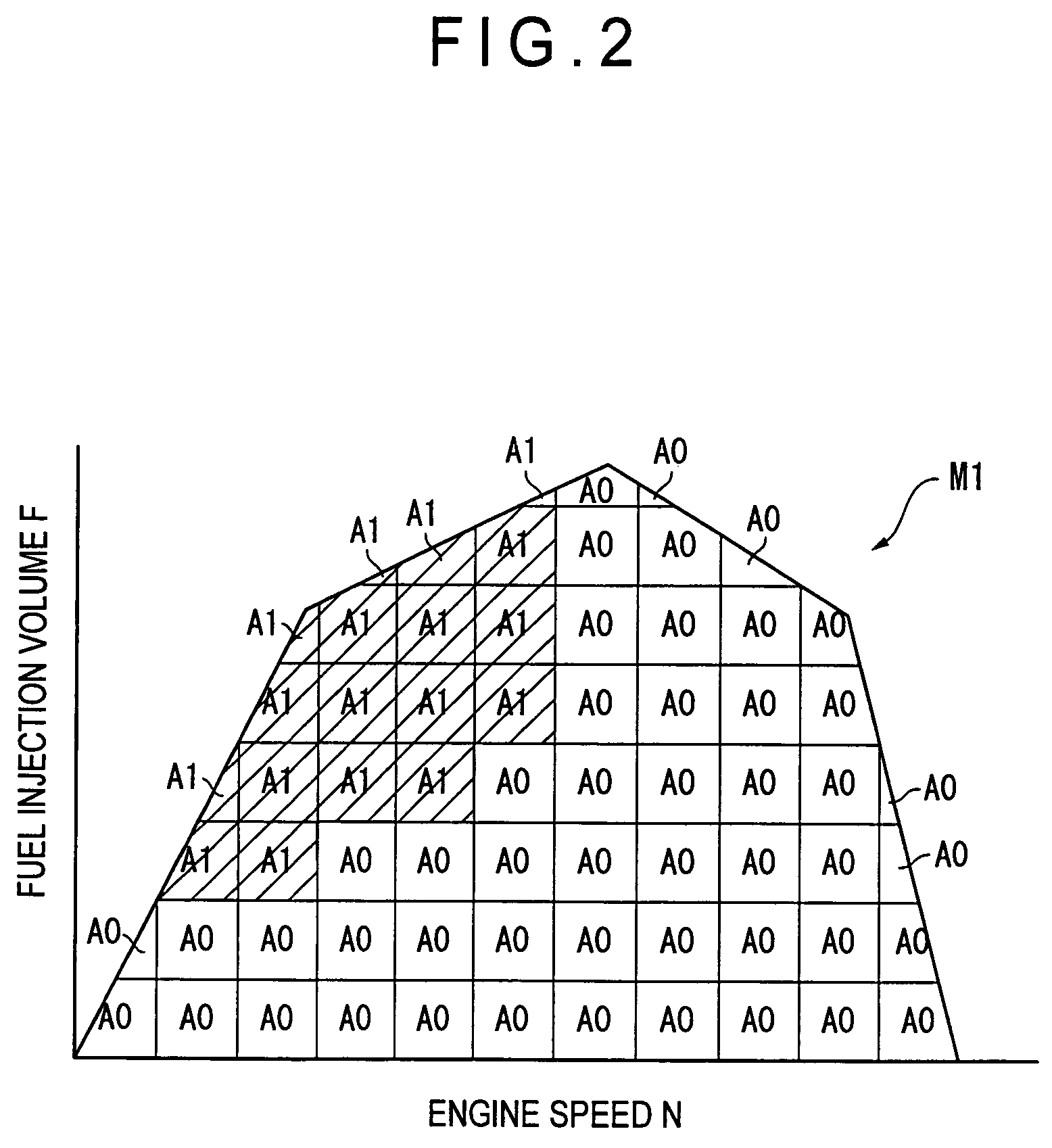

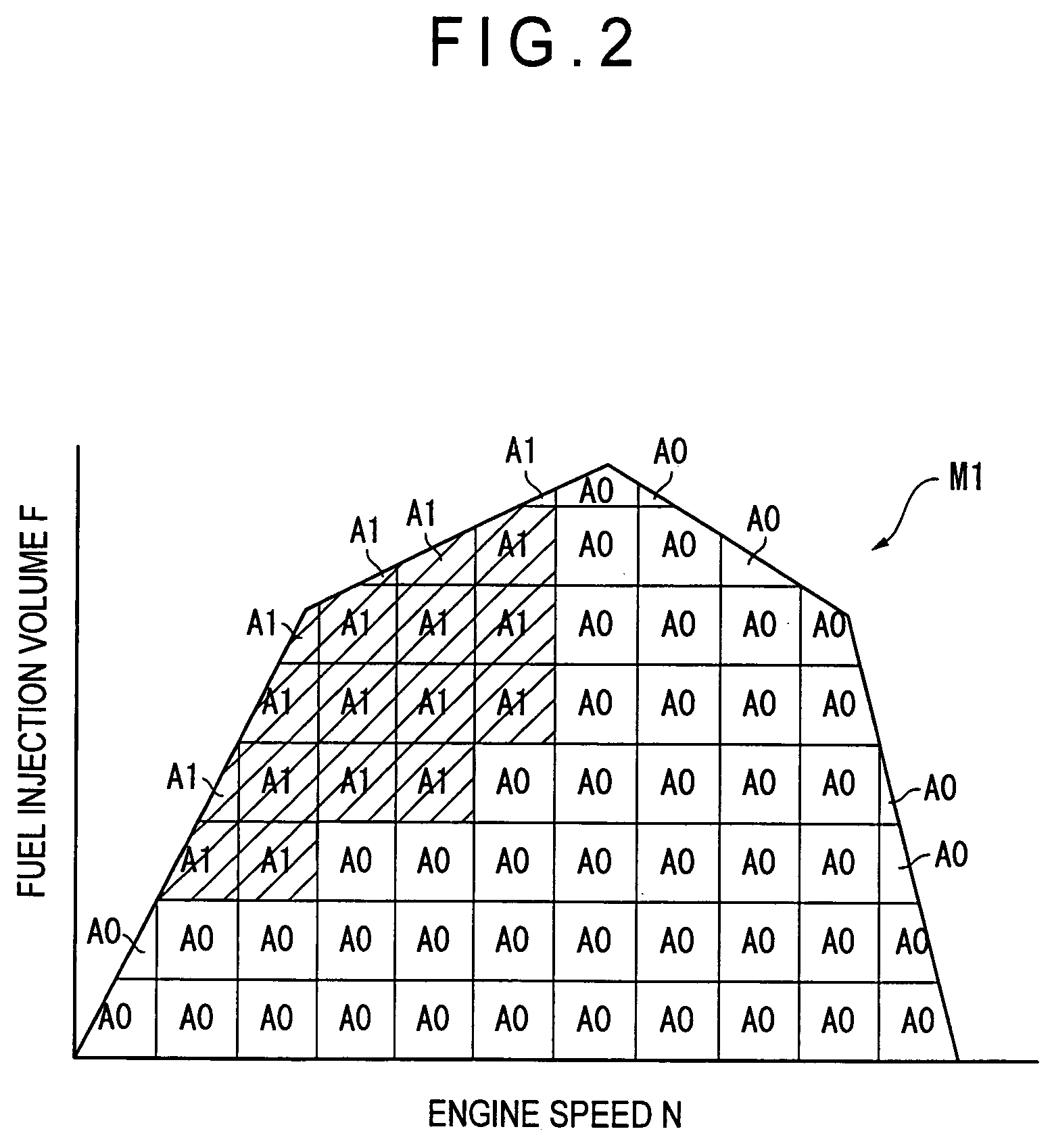

Engine performance modification or tuning kit

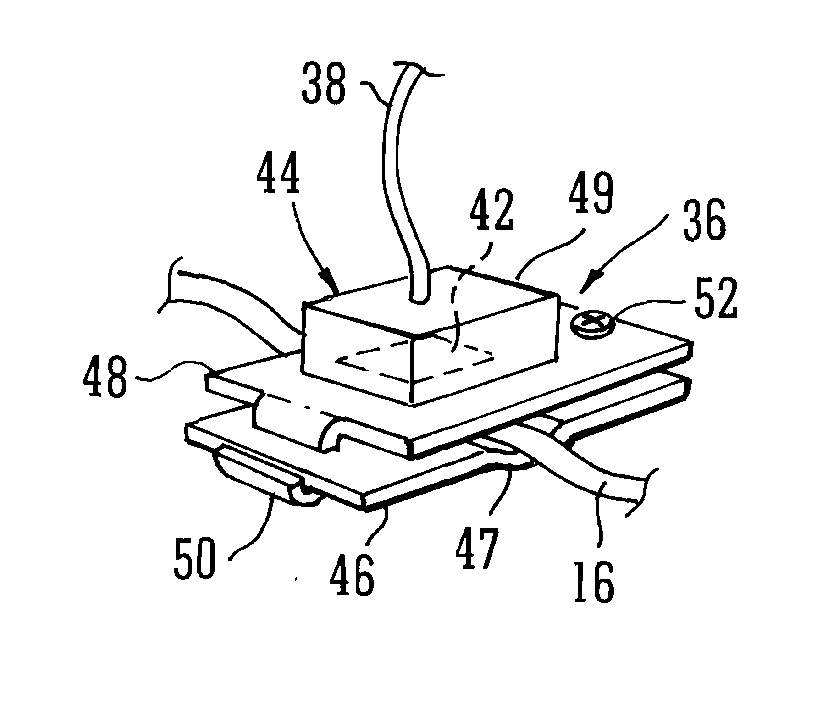

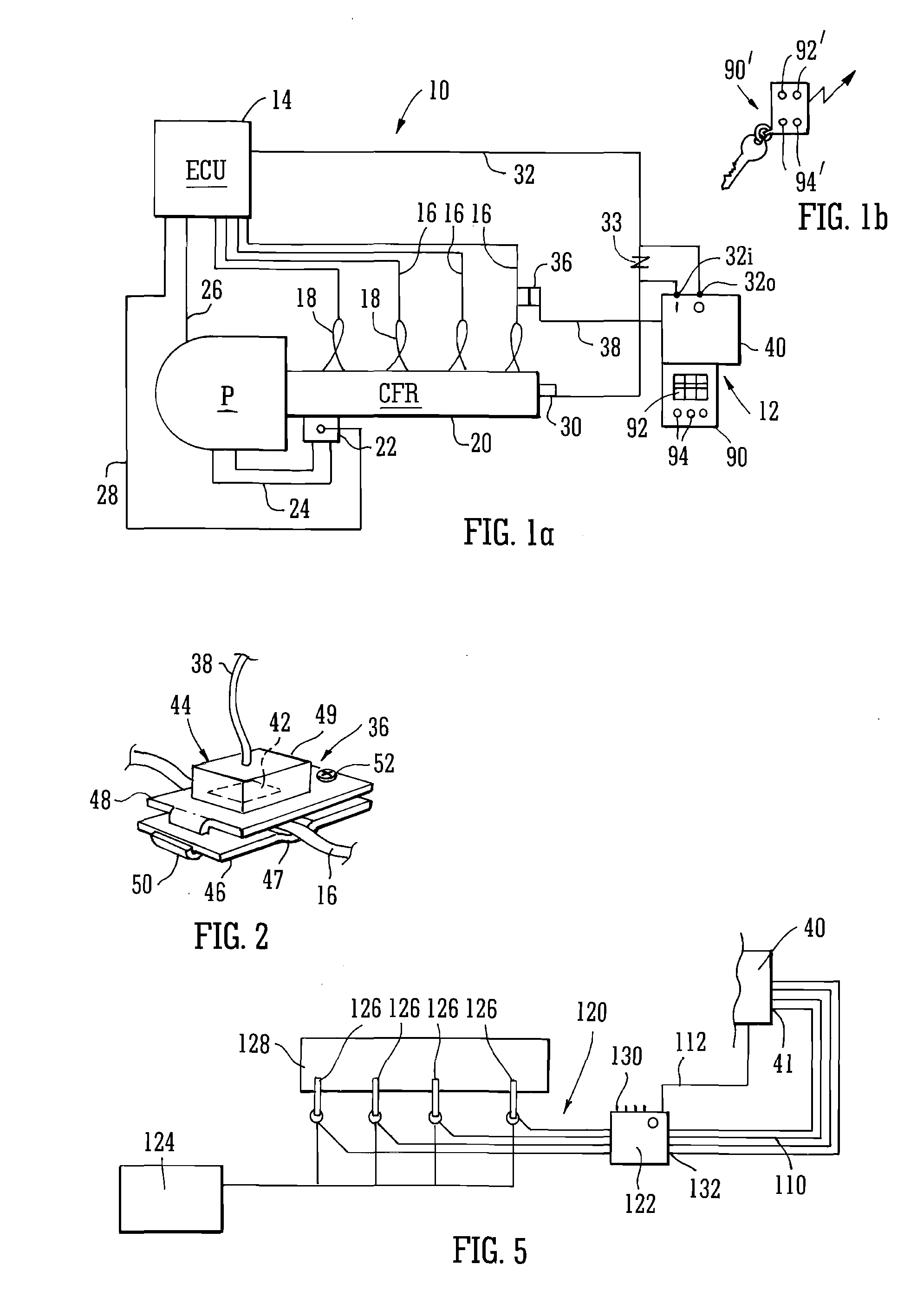

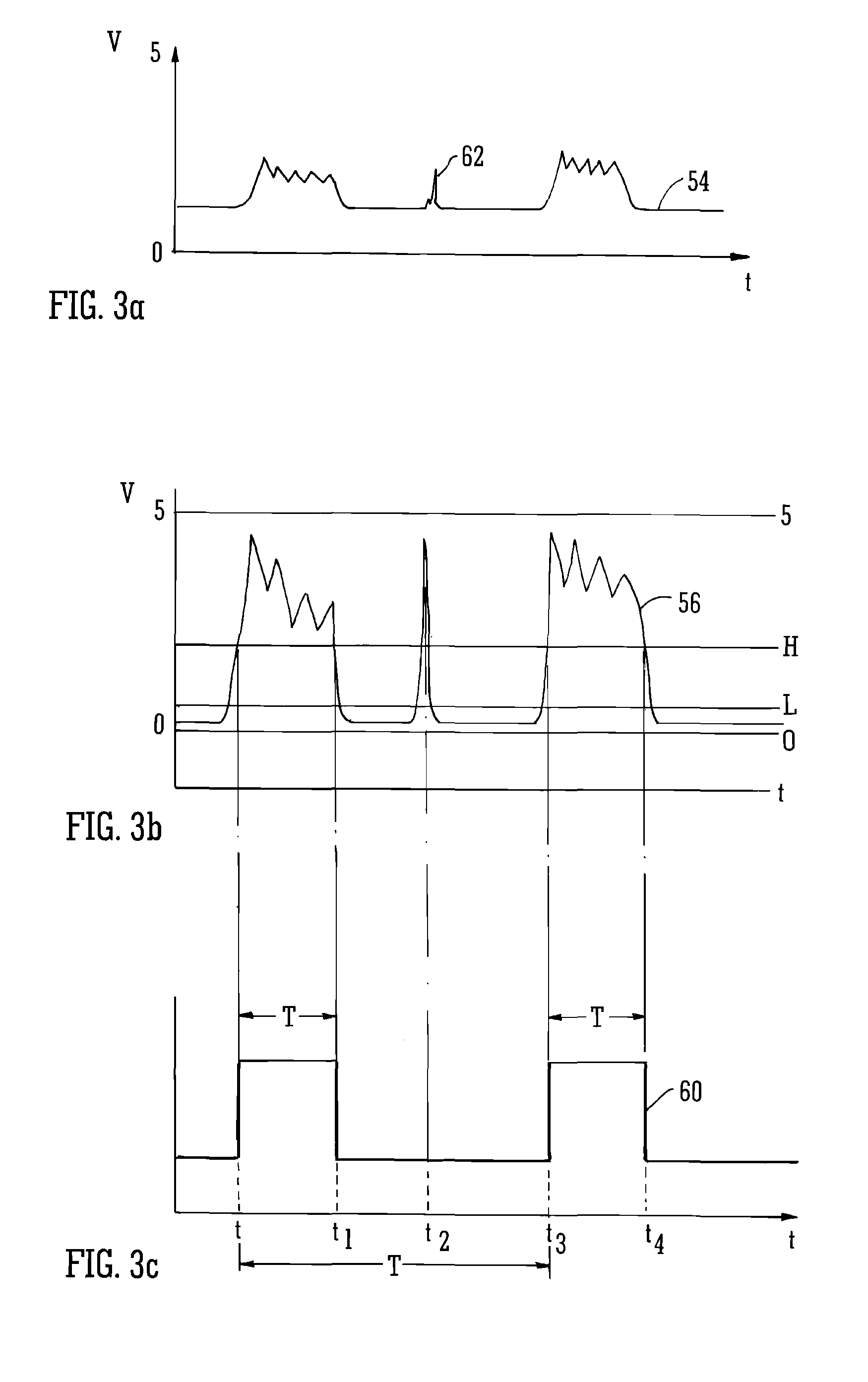

InactiveUS20130345951A1Reduce the amount of solutionImprove engine performanceElectrical controlInternal combustion piston enginesExternal combustion engineControl line

A performance modification / tuning kit for an internal combustion engine of the type comprises a kit control unit. An electrical sensor is adapted to detect the opening and closing signals of a control line to one of the injectors of the engine and connected through a sensor line to the control unit. An input receives the signal from a pressure sensor of the common fuel rail of the engine and an output report a generated pressure signal to the engines ECU. A selectively changeable modification map, comprising modification values for a range of different engine speeds and fuel loads demanded by the ECU is used by the kit control unit to generate the generated pressure signal. That is generated in dependence upon the value in the modification map for the engine fuel load Q currently demanded by the ECU and the engine speed currently pertaining from time to time.

Owner:MOBILIZER

Internal-combustion engine cooling system based on integrative permanent magnet synchronous motor water pump and electronic speed regulation technology

InactiveCN101709664AIncrease temperatureStable temperatureCoolant flow controlMachines/enginesPermanent magnet rotorTemperature control

The invention discloses an internal-combustion engine cooling system based on an integrative permanent magnet synchronous motor water pump and an electronic speed regulation technology, belonging to the (electronic control) technical field of internal-combustion engine. The internal-combustion engine cooling system can be used for small water-cooled internal-combustion engine cooling systems and can be used for cooling other mechanical, electronic and electrical equipment. The purpose of the invention is to bring simple system, improve cooling control performance and temperature control precision, lower power consumption and obviously improve reliability and practicality. The internal-combustion engine cooling system is characterized in that the internal-combustion engine cooling system comprises a single circulation path cooling circulation system; a permanent magnet rotor operating in a water pump case forms an integrative permanent magnet synchronous motor water pump; the permanent magnet synchronous motor water pump, a temperature sensor and an electronic speed regulation driving circuit form an automatic cooling control system which can realize required temperature-water pump flow characteristic and engine body temperature-heat dissipating characteristics and can keep the engine body temperature stable.

Owner:SHANDONG UNIV OF SCI & TECH

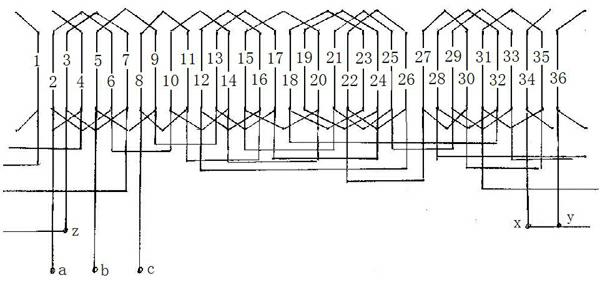

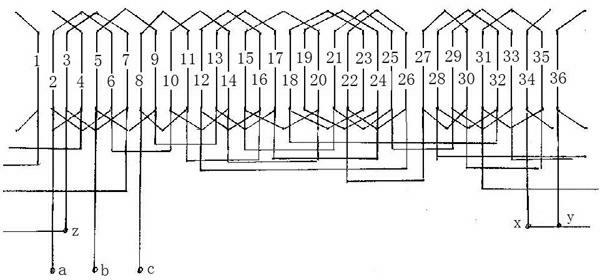

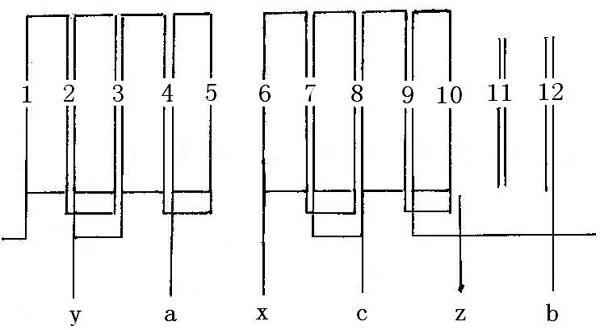

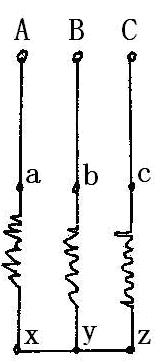

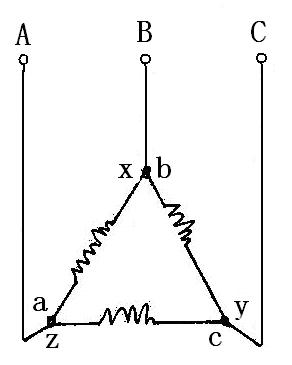

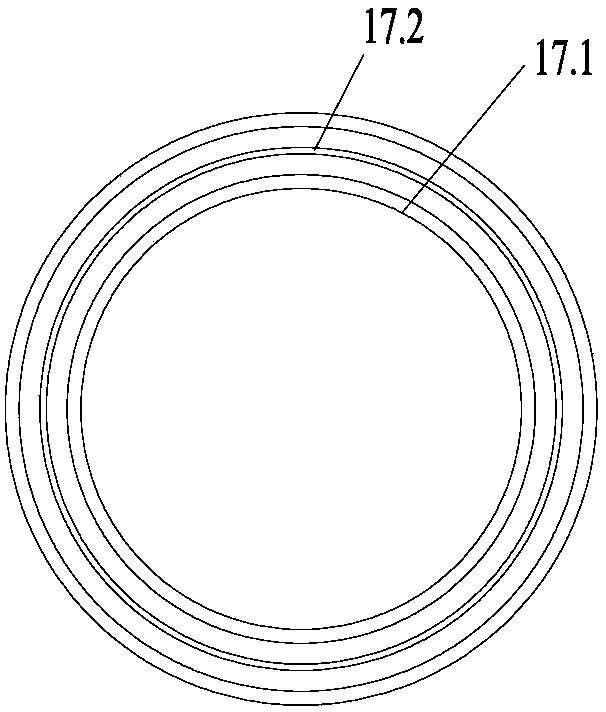

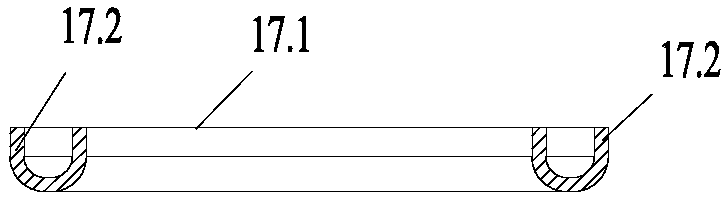

Permanent magnetism servo synchronous motor three-phase winding

InactiveCN102306991AIncrease low speed torqueImprove running qualitySynchronous machine detailsMagnetic circuit stationary partsSynchronous motorPole number

The invention provides a permanent magnetism servo synchronous motor three-phase winding, wherein a motor stator core has 36 slots, pole number is 8, phase number is 3, and a stator core adopts a skewed slot. A three-phase single layer winding is arranged in the 36 slots of a stator: an a phase winding ax is composed of 6 coils, a is led out from a second slot, and x is led out from a 34th slot; a b phase winding by is composed of 6 coils, b is led out from a fifth slot, and y is led out from a 36th slot; a c phase winding cz is composed of 6 coils, c is led out from a eighth slot, and z is led out from a third slot. According to the three-phase single layer winding, an average pitch is 4, number of turns of each coil is equal, and the windings in each slot all are single layers. Coil leading-out wire adopts a Y connection method, i.e., x, y and z of the three windings are connected together without leading out and are led out by a, b and c. The three phases of the three-phase single layer winding differ by 120 degrees mutually to form the symmetrical three-phase winding. The three-phase winding is suitable for permanent magnetism servo synchronous motor stator winding structure.

Owner:江西省迪普安数字功率技术发展有限公司

High-quality three-phase alternating current permanent magnet servo synchronous motor

InactiveCN102355108AReduce inertiaIncrease the axial wind pathMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous motorElectric machine

The invention relates to a high-quality three-phase alternating current permanent magnet servo synchronous motor, which comprises a stator and a rotor, wherein a stator core of the motor has 12 slots, the stator core is inclined for 7 / 32 pitches, the pole number is 10, and the phase number is 3; and a stator core three-phase winding is a fractional slot concentrated winding, the pitch of winding coils is 1, the number of turns of each coil is equal, and the difference of the three-phase winding is 120-degree electrical angles. The three-phase winding has 6 lead-out wires and provides two wiring methods. A rotor permanent magnet structure is in a built-in type, N and S poles of neodymium iron boron permanent magnets are alternately embedded into a ladder-shaped groove stacked into a rotor core by a rotor stamping piece, the rotor core is axially divided into two sections equally, and the central line of two sections of magnets with the same polarity is axially deflected for 4mm; and the excircle and the axle hole of a pole shoe of the rotor core are not concentric, ununiform air gaps are formed between the pole shoe of each pole and the inner circle of the stator core, and a plurality of measures are adopted to greatly improve the sine property of a phase voltage waveform of the motor and motor quality. The invention is suitable for the three-phase alternating current permanentmagnet servo synchronous motor.

Owner:江西省迪普安数字功率技术发展有限公司

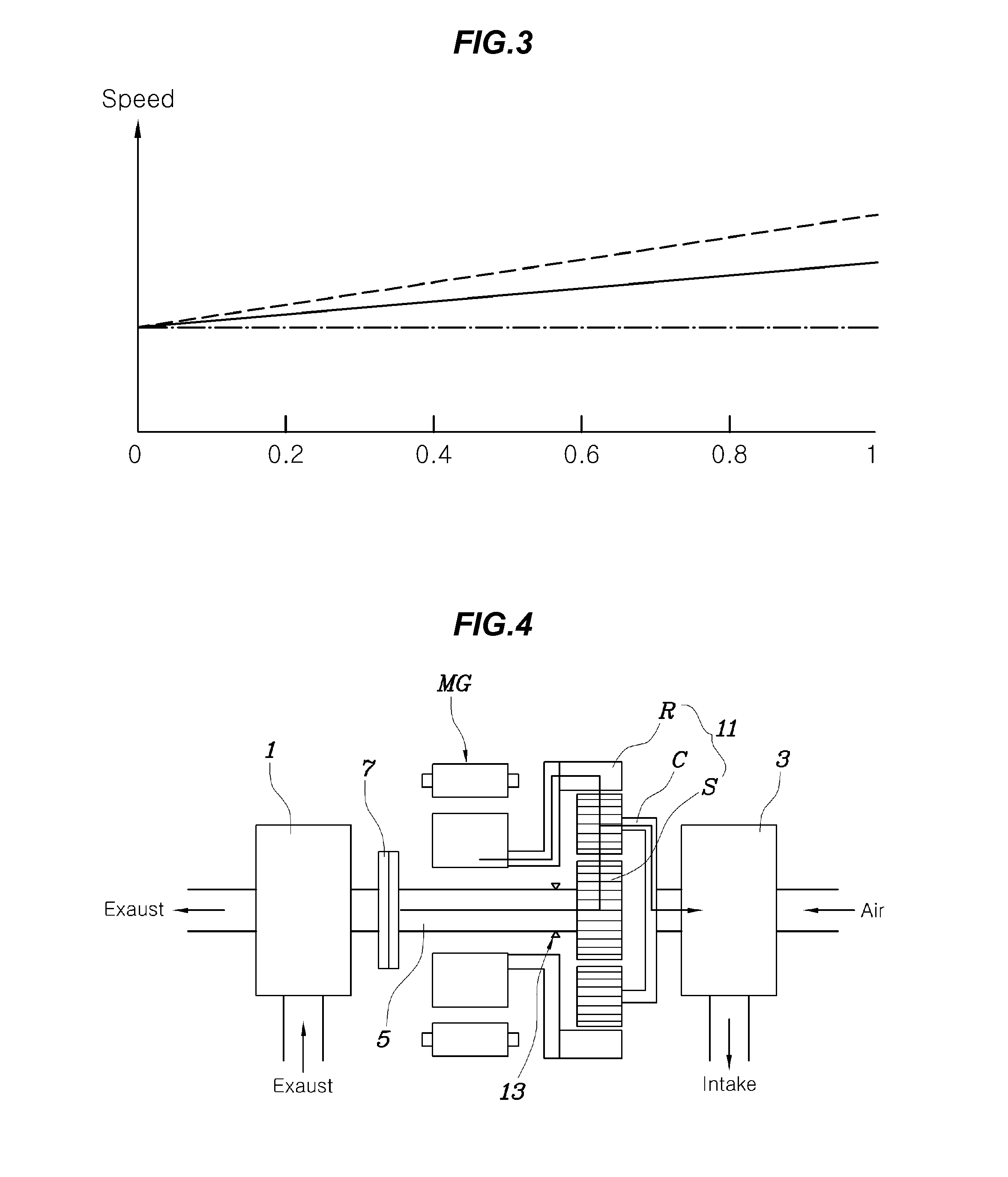

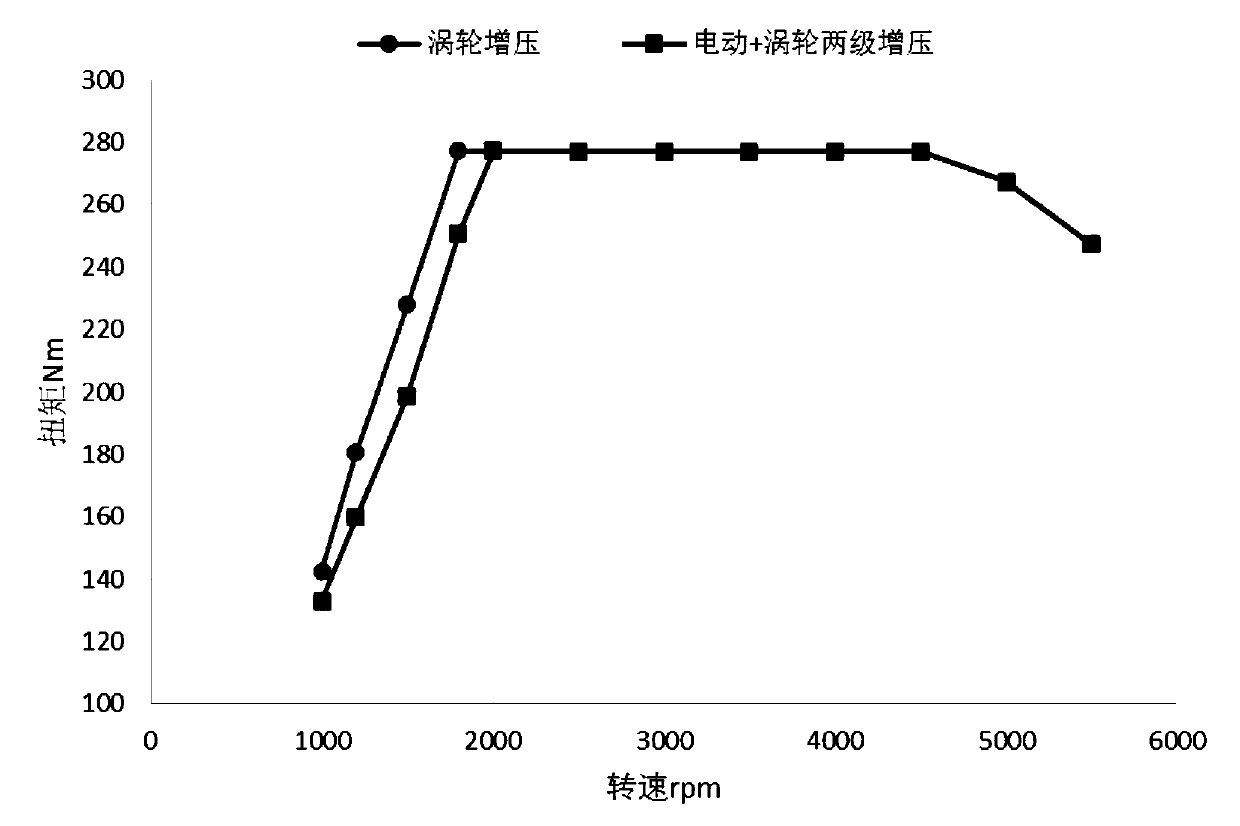

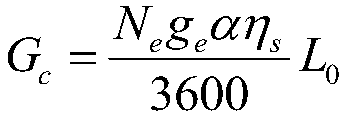

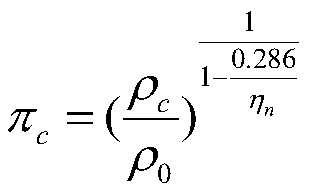

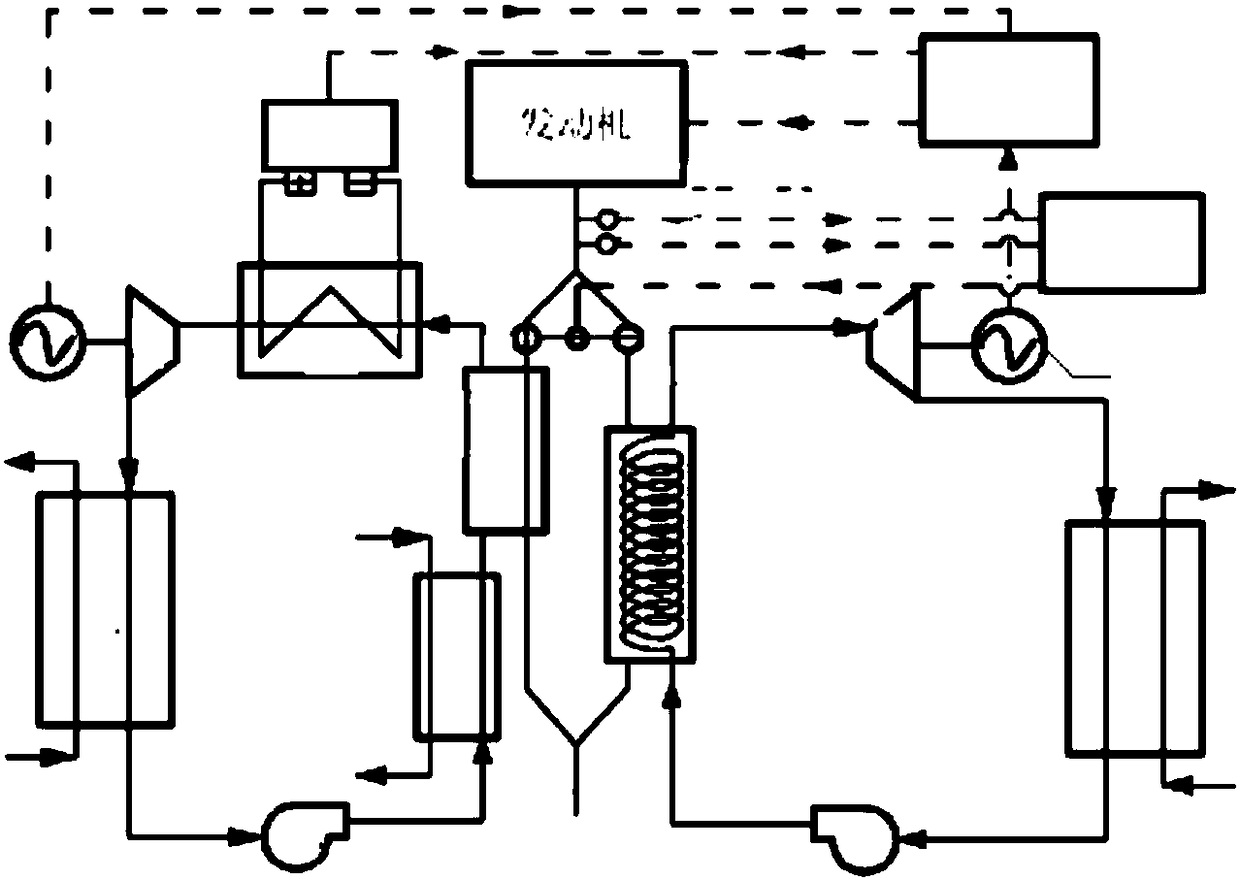

Two-stage supercharging system matching method based on simulation calculation

ActiveCN110543715AIncrease low speed torqueExpand the scope ofSpecial data processing applicationsLow speedTurbocharger

The invention discloses a two-stage supercharging system matching method based on simulation calculation, first-stage electric supercharging and second-stage turbocharging which are arranged in seriesare adopted in two-stage supercharging, and an electric supercharger is provided with a bypass pipeline. During two-stage supercharging matching, firstly, according to the performance development target of an engine, the air inlet flow and pressure requirements of the engine are obtained through analysis, the actual measurement performance Map of a turbine and an air compressor is matched according to the requirements, and the scheme that the low-speed torque, the maximum torque section, the rated power and the plateau power of the engine are comprehensively optimal is selected. On the basis,the bypass branch is closed, two-stage supercharging joint matching is conducted, the rotating speed of the electric supercharger is adjusted to conduct first-stage supercharging, the inlet air pressure of the turbocharger is increased, second-stage supercharging is conducted through the turbocharger, and therefore the effects of increasing the low-speed torque of the engine and expanding the range of the maximum torque section are achieved. And the simulated electric supercharging rotating speed and turbocharging waste gas bypass valve data are used for rack calibration development.

Owner:DONGFENG MOTOR CORP HUBEI

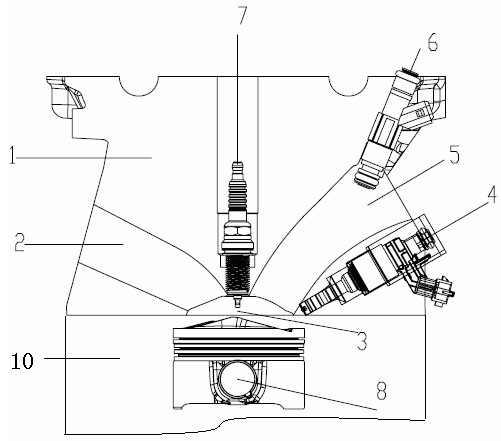

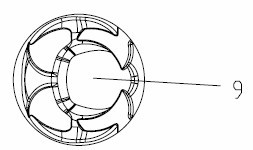

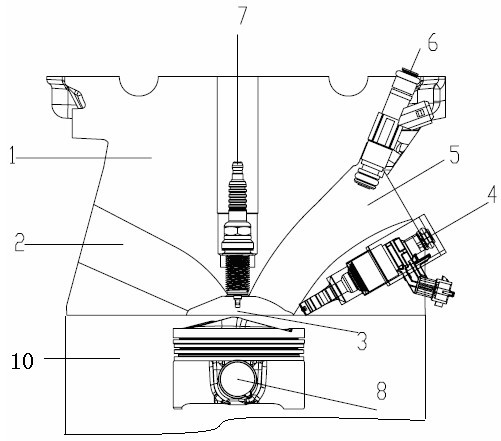

Dual-fuel engine combustion system and control method thereof

InactiveCN102155307ASimple structureLow retrofit costInternal combustion piston enginesEngine controllersCombustion systemLow speed

The invention aims at providing a dual-fuel engine combustion system capable of giving consideration to performance and emission and a control method thereof. The dual-fuel engine combustion system comprises a cylinder body, a cylinder cover and a piston, wherein the cylinder body, the cylinder cover and the piston form a combustion chamber, and the combustion chamber is provided with an air intake channel and an exhaust channel and is also internally provided with a spark plug. The dual-fuel engine combustion system is characterized in that the air intake channel is internally provided with a first gasoline nozzle communicated with a gasoline supply system, and the combustion chamber is internally provided with a first alcohol nozzle communicated with an alcohol supply system. The dual-fuel engine combustion system has simple structure and low reconstruction cost, and can be applied by only little reconstructing the traditional combustion system. By adopting the control method of the dual-fuel engine combustion system, the problems of low ignition success rate and overproof emission of the cold-starting stage are solved, the dual-fuel engine combustion system is driven under different load states by adopting different kinds of fuels, and oil consumption and emission are reduced on the premise of improving high-speed power and low-speed torque of the engine.

Owner:CHERY AUTOMOBILE CO LTD

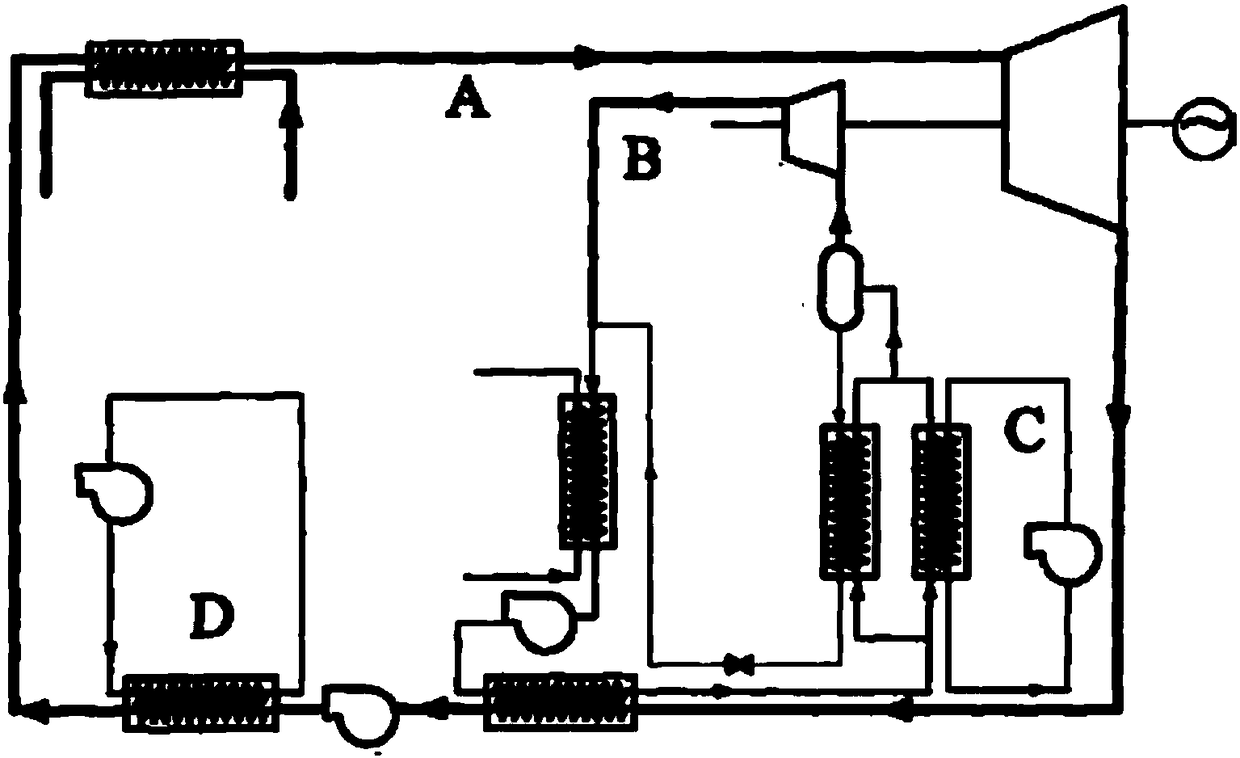

Engine residual heat recovery system for equipment electromechanical coupling supercharger

InactiveCN108457744AHigh thermal efficiencyIncrease low speed torqueInternal combustion piston enginesExhaust apparatusLow speedTurbocharger

The invention discloses an engine residual heat recovery system for an equipment electromechanical coupling supercharger. The electromechanical coupling supercharger, a supercharger controller, a high-voltage battery, an ISG (Integrated Starter and Generator) and an ISG controller are connected in series to a same high-voltage bus, by means of control of an ECU (Electronic Control Unit), electricenergy is made to flow between all components through the high-voltage bus, the electromechanical coupling supercharger comprises a turbine supercharger and a motor-generator integrated to the turbinesupercharger, the turbine supercharger comprises a turbine machine and an air compressor, the turbine machine is connected to an air exhaust pipe of an engine, the air compressor conveys fresh air after compression to an air inlet total pipe of the engine through an intercooler in working, and the ISG is connected with the engine. Compared with the prior art, the engine residual heat recovery system for the equipment electromechanical coupling supercharger has the beneficial effects that the whole system does not require work involvement of third working media, thus a series of pipeline systems are omitted, the system is simple and comprises energy recovery and energy feedback functions, the heat efficiency of the engine can be improved, and the low speed torque and transient response capability of the engine are improved.

Owner:CHINA FIRST AUTOMOBILE

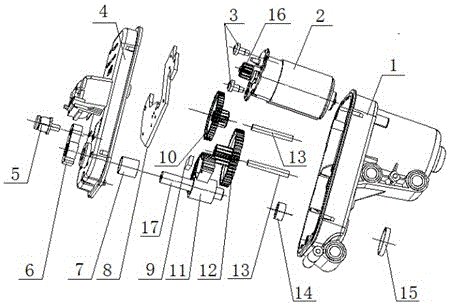

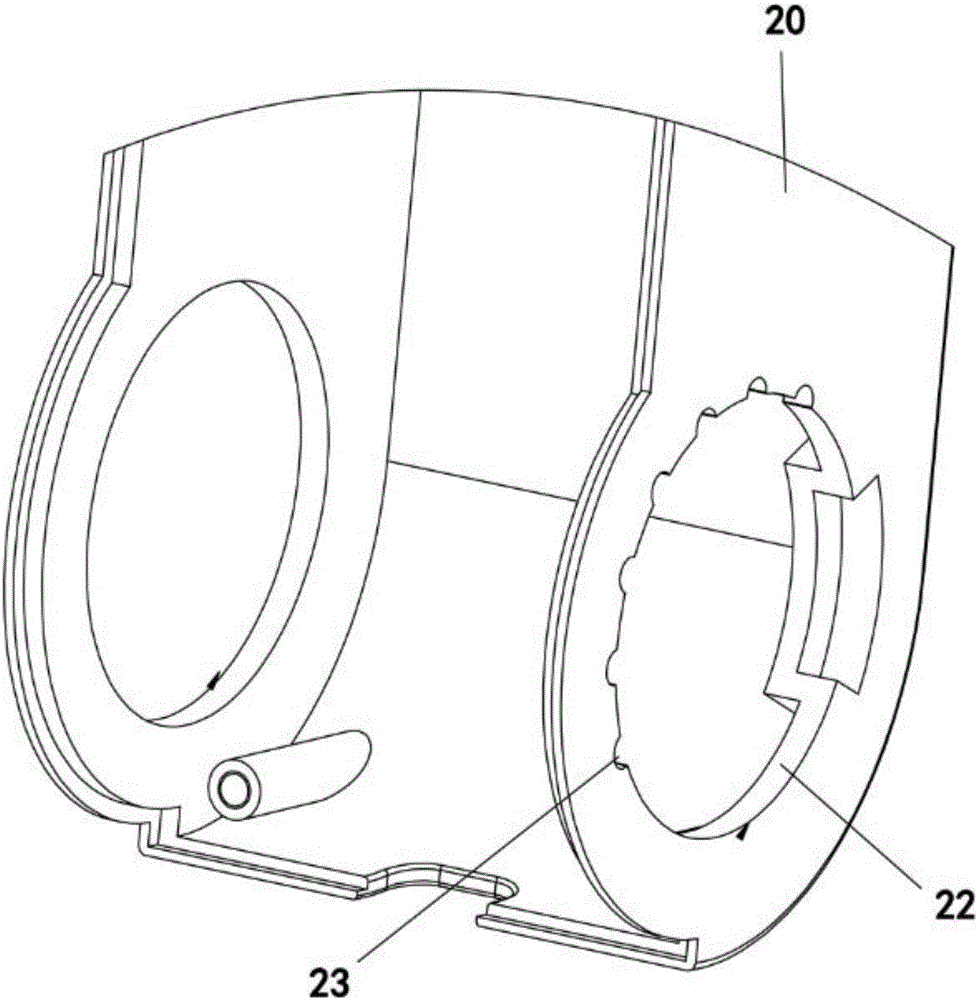

Turbocharging electronic actuator and mounting method thereof

ActiveCN106089408AGreat assembly optionsEasy to installInternal combustion piston enginesMotor driveLow speed

The invention relates to a turbocharging electronic actuator and a mounting method thereof, and belongs to the field of electronic actuators. The turbocharging electronic actuator comprises a shell, a motor, an upper cover, a connecting plate, a PCBA circuit board, a magnet, a gear II, a fan-shaped gear, a gear I, a shaft, a dustproof cover, a motor driving gear, an output shaft and a connecting mechanism. The turbocharging electronic actuator is compact in structure, high in control precision, sensitive in control and quick in response, and solves the defects of response lag phenomenon and low precision of a traditional mechanical air release valve. The electronic actuator, provided by the invention, can provide quicker, more stable and more sensitive control to a diesel turbocharger and a gasoline waste gas bypass turbocharger when being applied to a passenger car and a commercial vehicle. Under the condition of the same rated power, the electronic actuator can improve the fuel economy and increase low-speed torque. The electronic actuator realizes the control target through programming the motor driving problem, and uses a sensor for a feedback value of an actuator output position.

Owner:锋宏海力汽车技术(昆山)有限公司

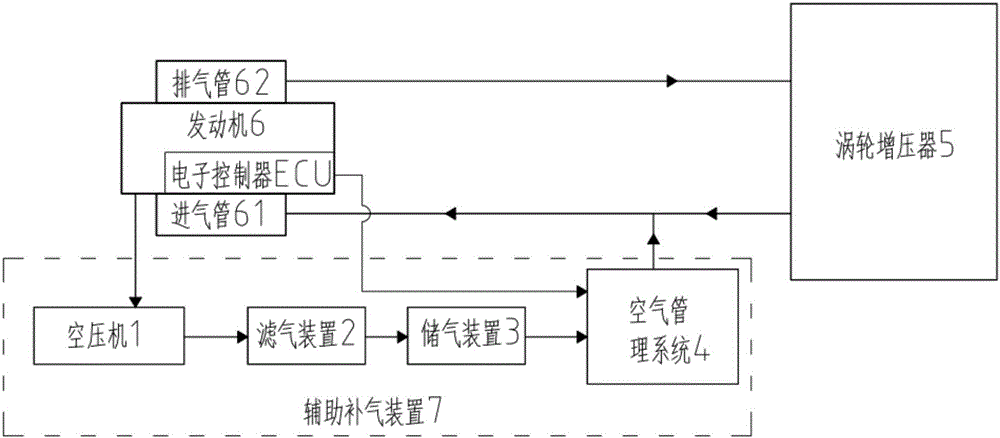

Method and device for improving low-speed dynamic property and acceleration responsiveness of turbocharged engine

InactiveCN106194403AImprove powerReduce acceleration response timeInternal combustion piston enginesEngine componentsElectronic controllerLow speed

The invention discloses a method and device for improving the low-speed dynamic property and the acceleration responsiveness of a turbocharged engine. On the one hand, according to the method for improving the low-speed dynamic property and the acceleration responsiveness of the turbocharged engine, gas is supplied to the engine through a turbocharger; and on the other hand, the method further comprises an auxiliary gas supplementation device used for supplementing gas to the engine, and when the engine needs gas supplementation, the auxiliary gas supplementation device is driven to supplement gas to the engine by means of detection of an electronic controller of the engine. The device for implementing the method is further provided. According to the method and device, the dynamic property of low-speed operating of the turbocharged engine can be improved, and the acceleration response time of the turbocharged engine can be shortened.

Owner:GUANGXI YUCHAI MASCH CO LTD

Motor vehicle

InactiveCN106948896ARelieve stressExtended service lifeValve arrangementsMachines/enginesCylinder headEngineering

The invention proposes a motor vehicle, comprising: an engine, and a cylinder head installed on the engine, one end of the valve spring withstands the pressure plate of the valve spring, and the other end withstands the lifting seat, and the lifting seat is installed on the cylinder head. On the valve seat; there is a balance weight and at least one lifter inside the lifting seat. Wherein, adjusting the pressure of the inner spring of the valve includes adjusting the electric control connected with the lifter. Includes electrical control that adjusts to the lifter based on engine speed. Adjust the pressure of the valve inner spring when the engine speed is high and adjust the pressure of the valve inner spring to be small when the engine speed is low. Realize increasing the pressure of the inner spring of the valve when the engine speed is high and reducing or canceling the pressure of the inner spring of the valve when the engine speed is low.

Owner:NANAN FENGZHOU GAOJIE MOTORCYCLE ENERGY SAVING PRACTICAL TECH PROD SALES CENT

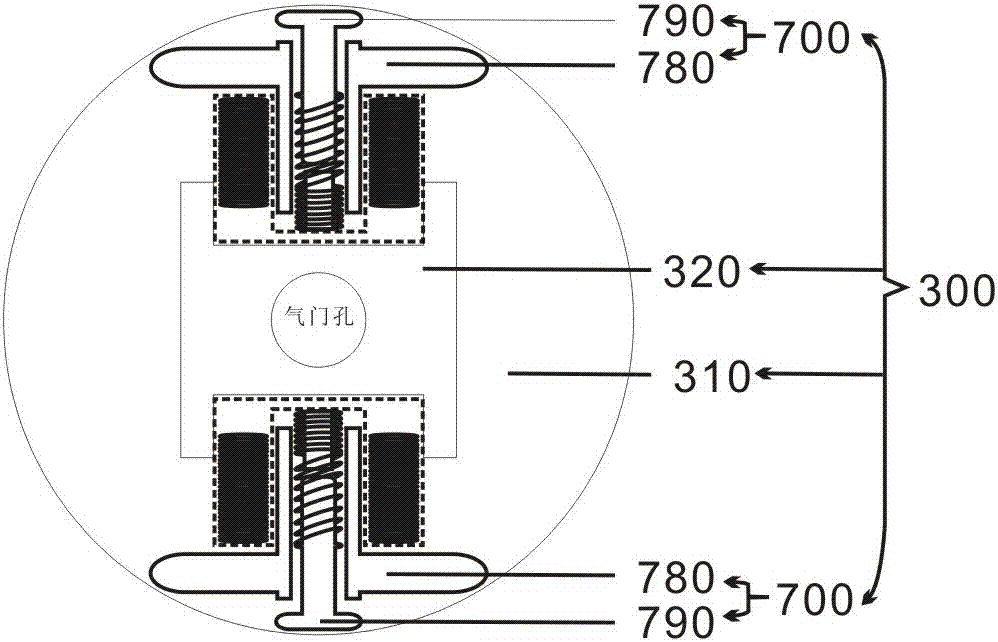

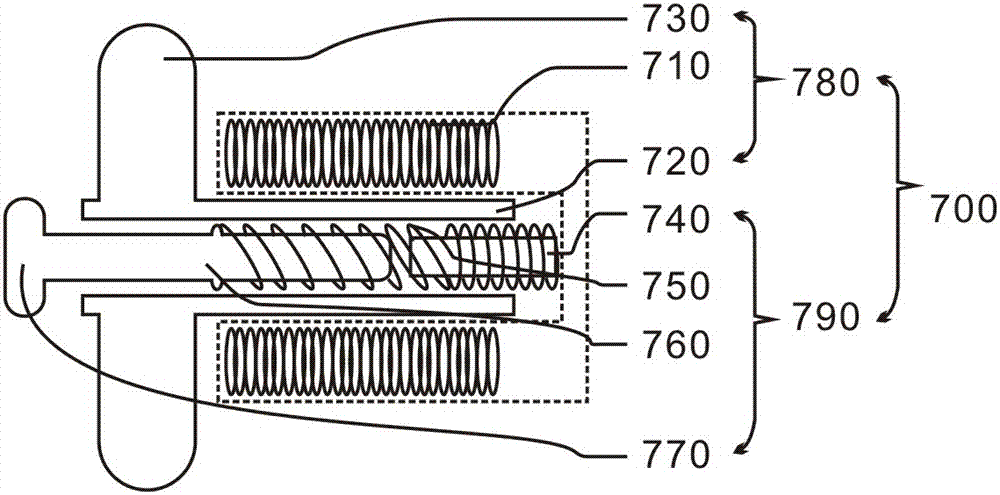

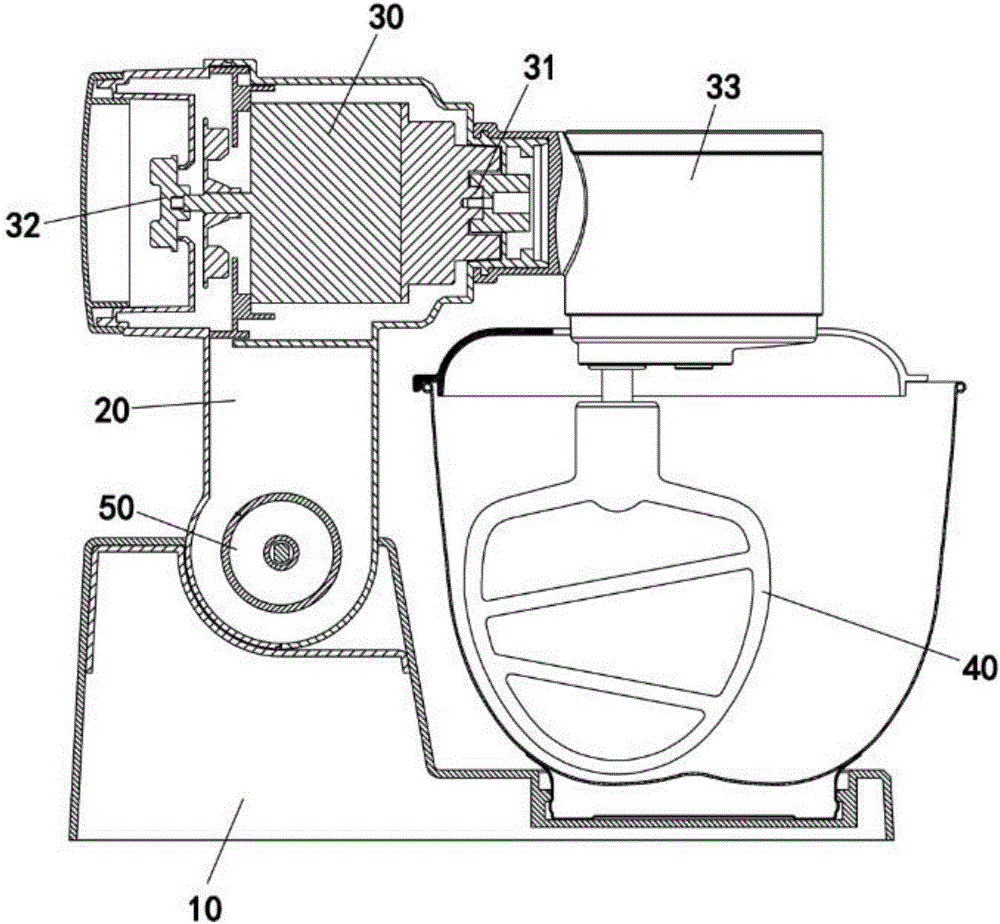

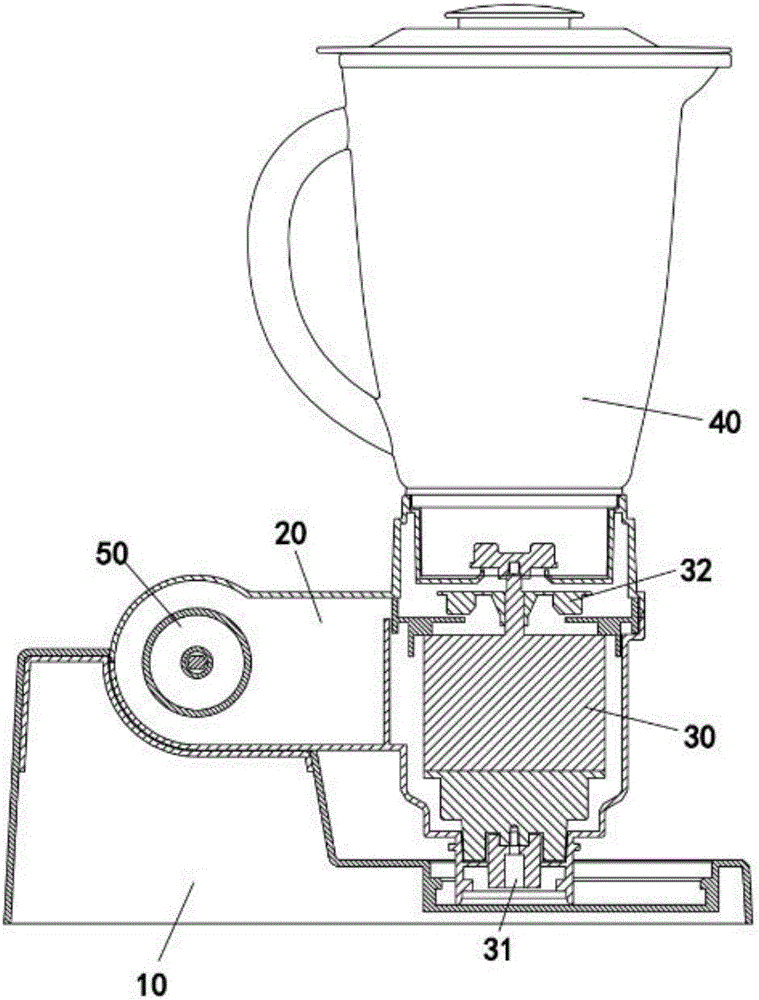

Folding type blender

ActiveCN106037528ARich use requirementsImprove ease of useKitchen equipmentLow speedMechanical engineering

The invention relates to the technical field of the blender, especially to a folding type blender comprising a pedestal, a support connected to the pedestal, a motor arranged in the support, and a processing assembly in transmission connection with the motor. A fixed hole is formed in the pedestal and a connecting hole is formed in the support; a rotating shaft is inserted into the fixed hole and the connecting hole, so that the pedestal and the supported are hinged; and the rotating shaft and the fixed hole in the pedestal are connected. A first locking delocking mechanism is arranged between the rotating shaft and the connecting hole, so that the rotating shaft and the support can rotate relatively or are locked to avoid rotation. Besides, a rotatable adjusting shaft is arranged in the rotating shaft and is used for changing the state of the first locking delocking mechanism. According to the invention, the nose support and the pedestal can be folded in a rotating mode, so that the storage space is saved effectively. When low-speed stirring is carried out, the blender can be placed in or taken out of any container with any size conveniently; and food spilling is avoided.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

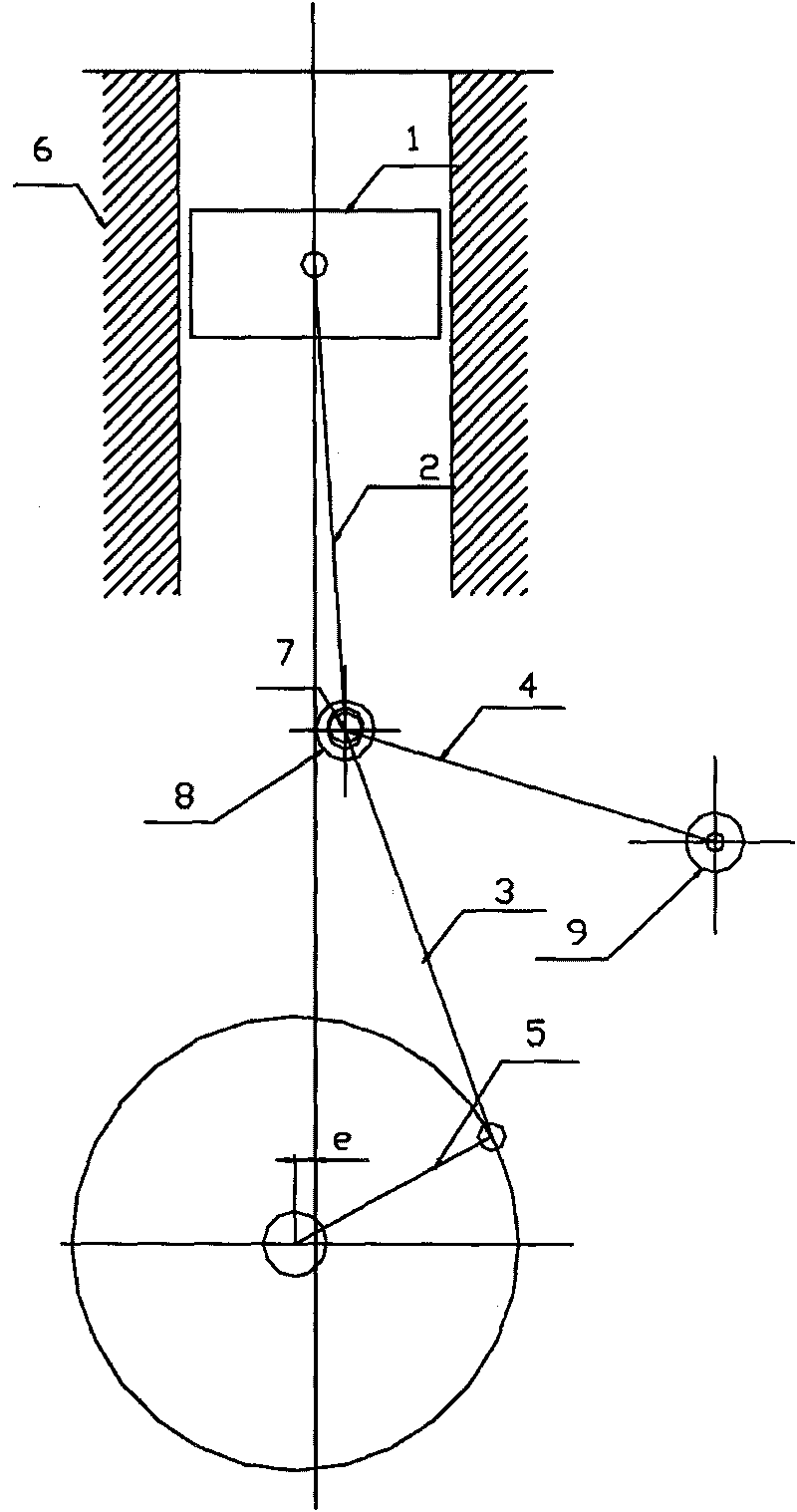

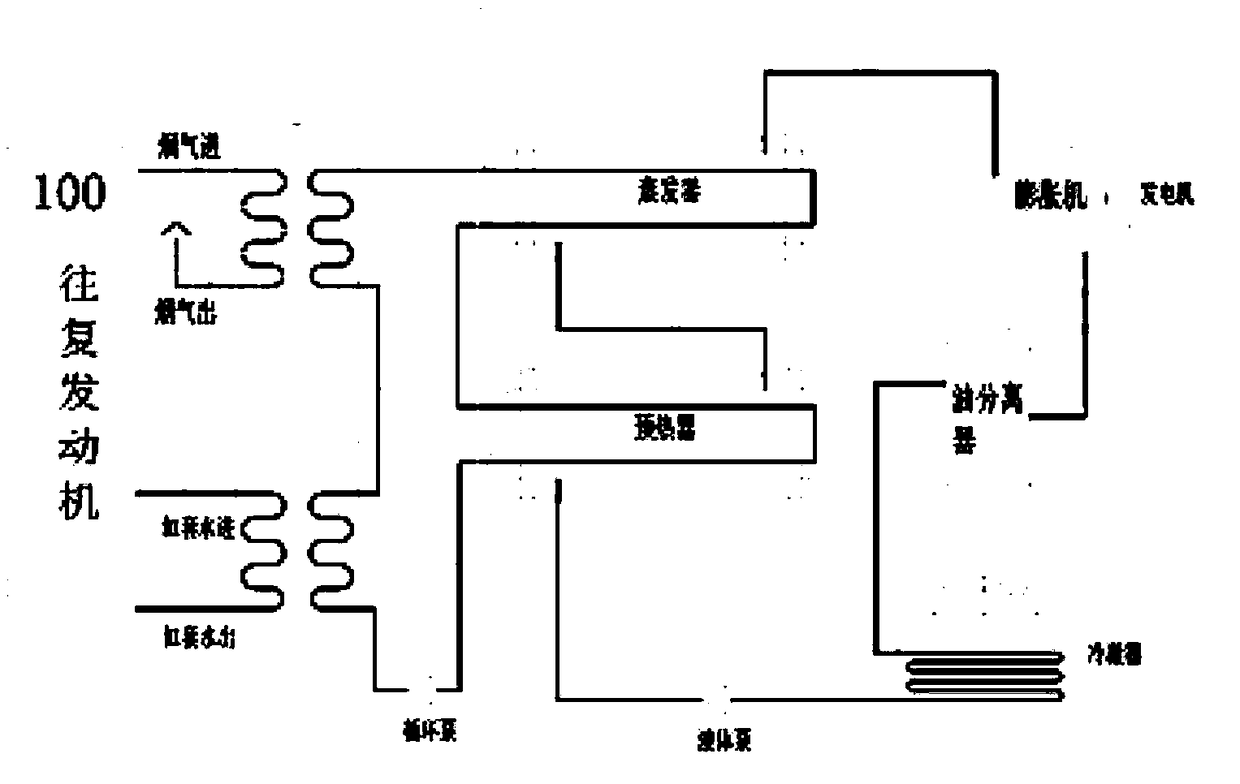

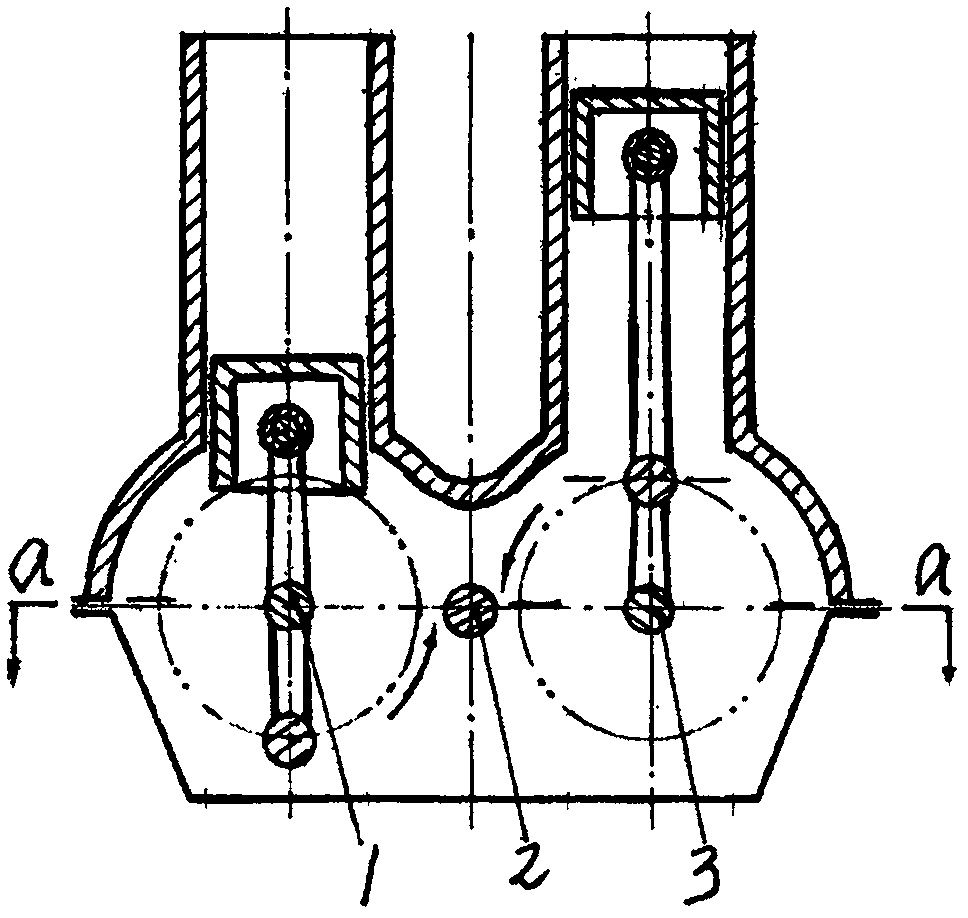

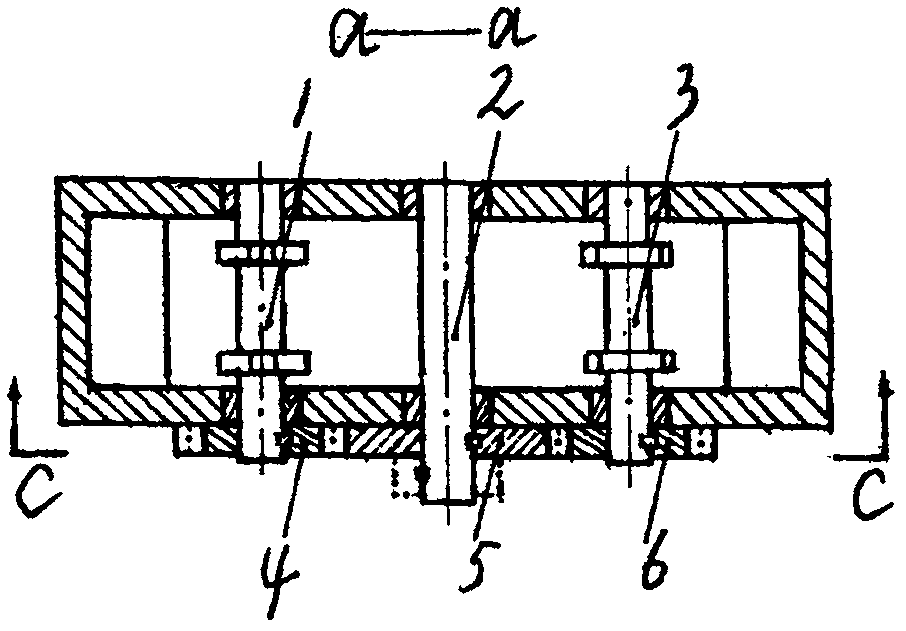

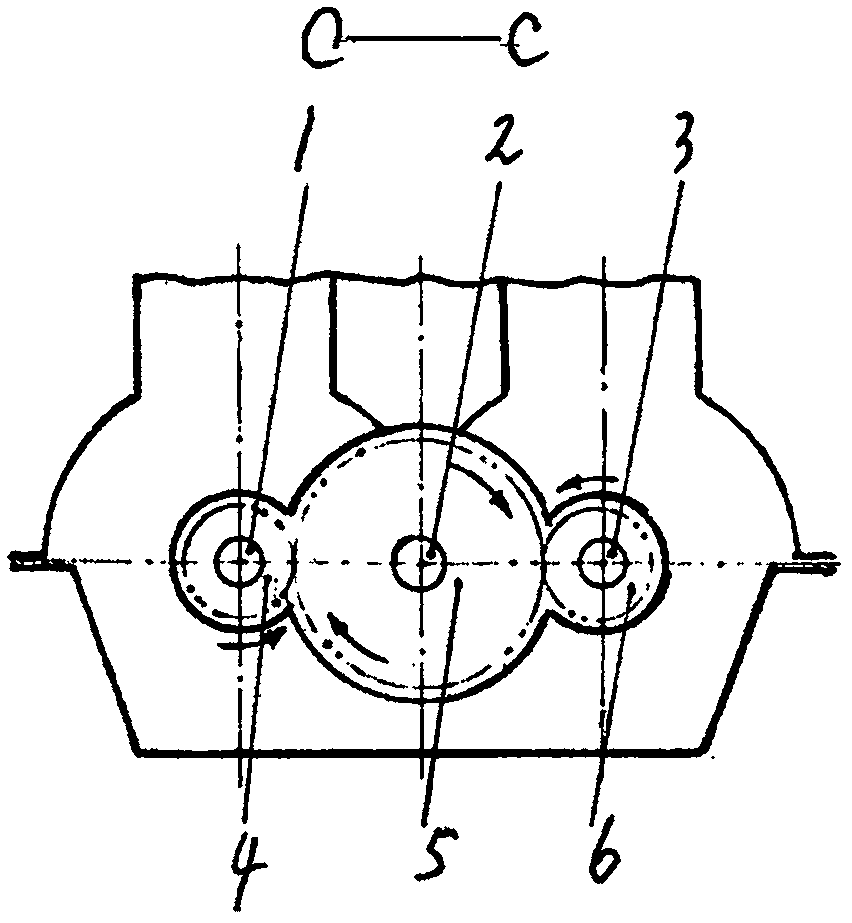

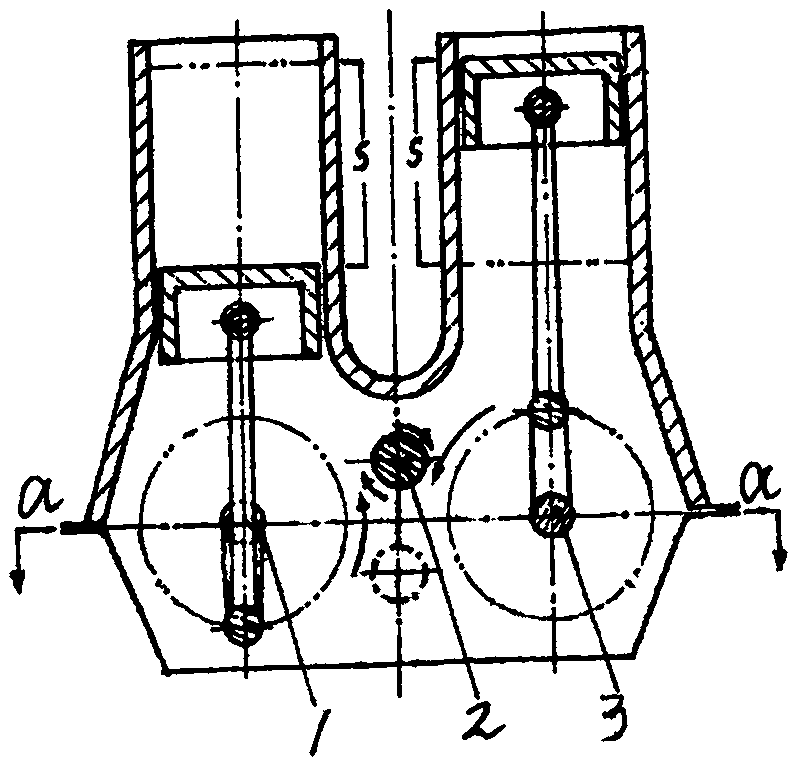

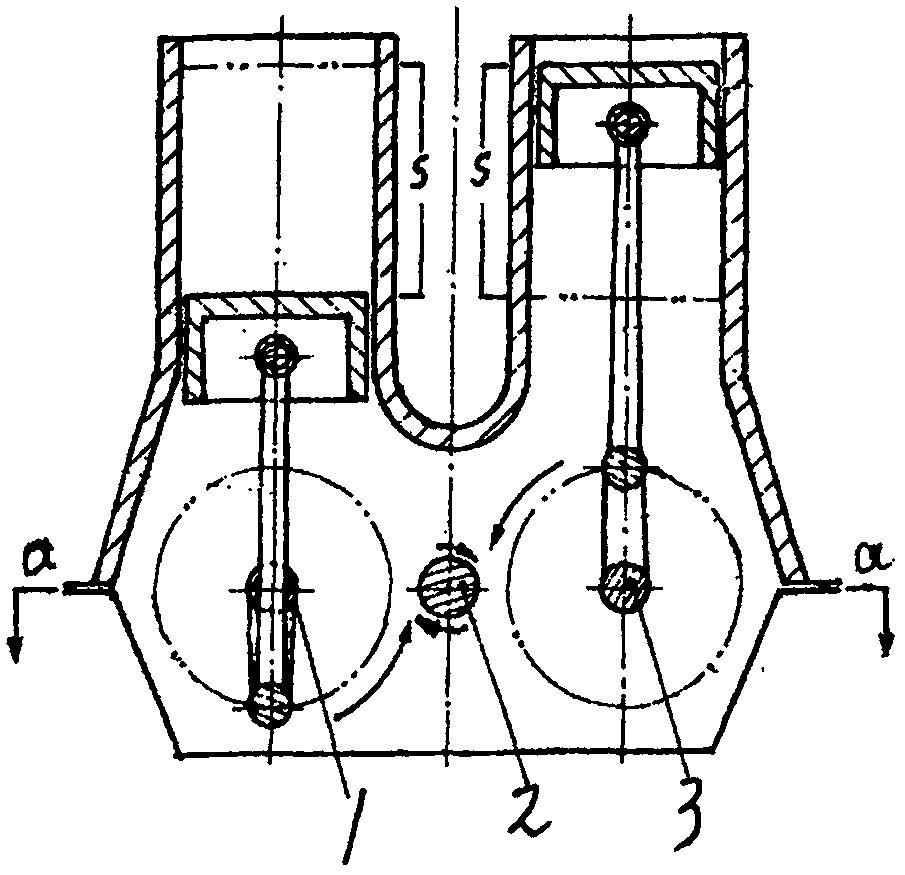

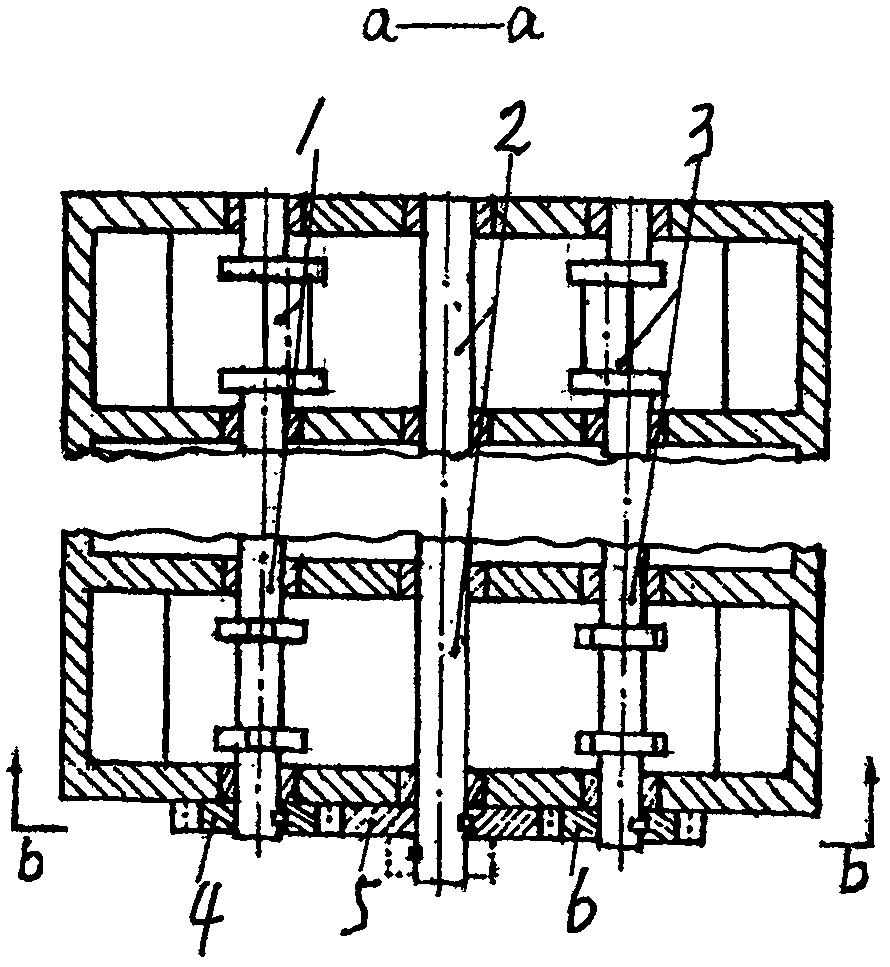

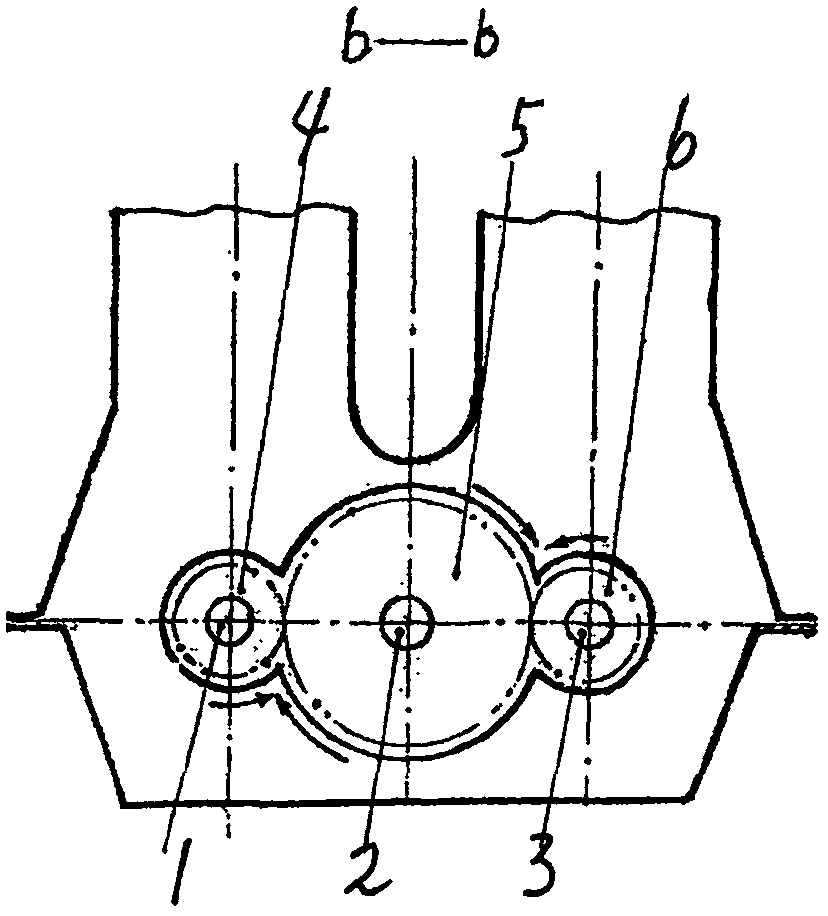

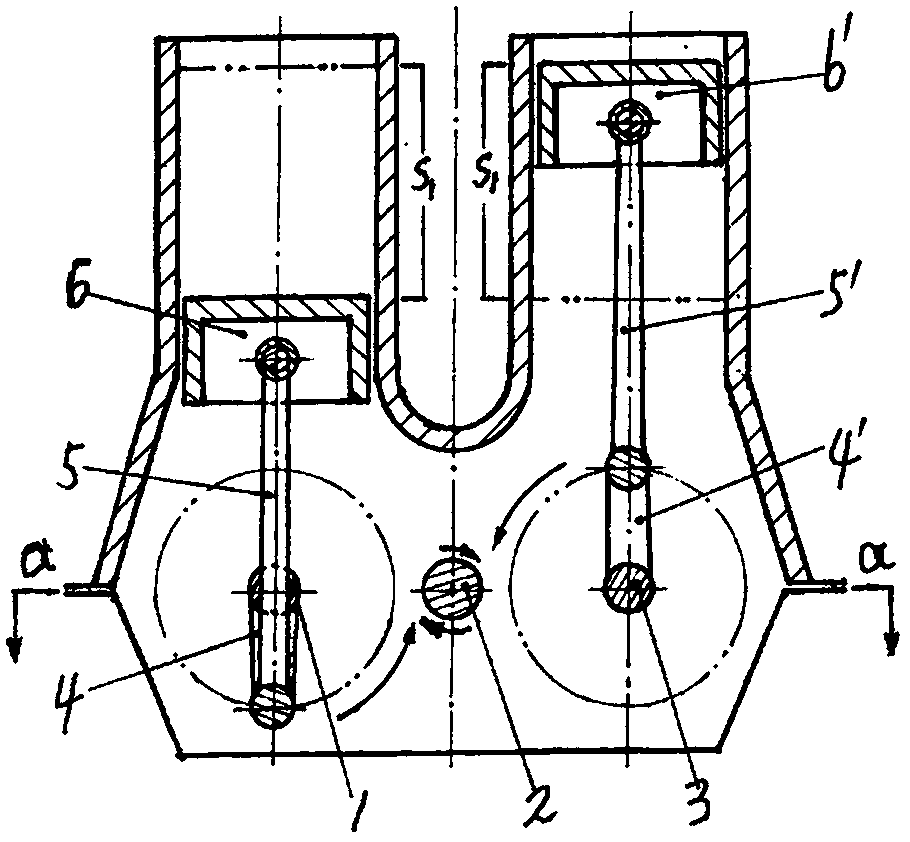

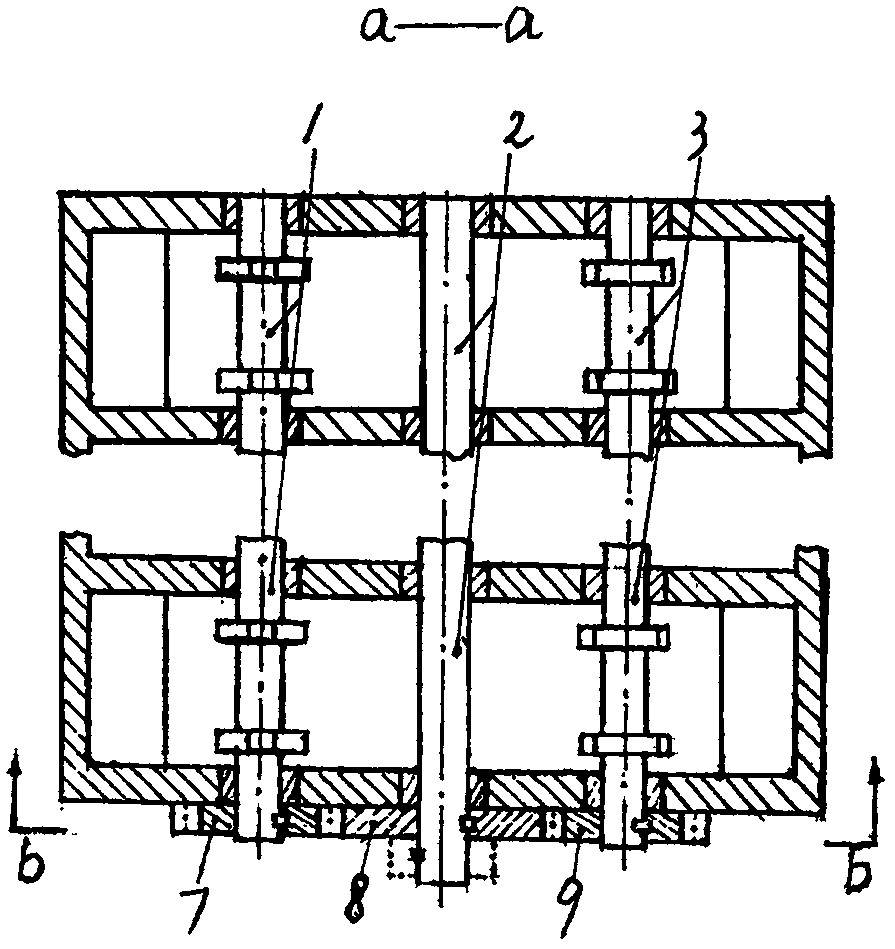

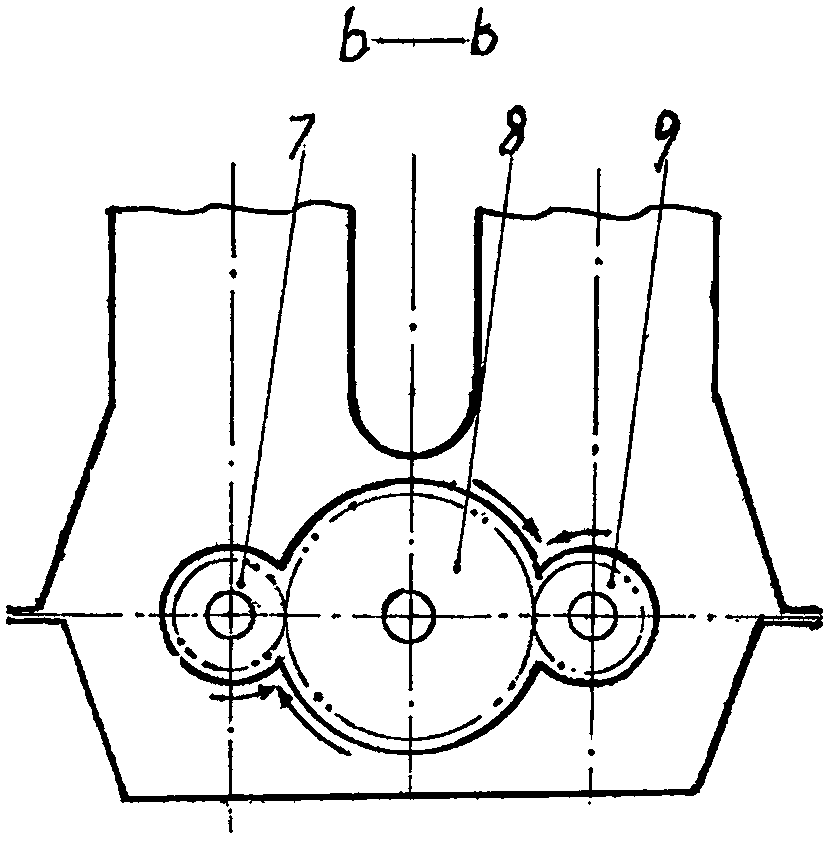

Piston reciprocating double-cylinder engine

InactiveCN107237689AIncrease the lengthMeet the requirements of the rated speedMachines/enginesLow speedEngineering

The invention discloses a piston reciprocating double-cylinder engine which is formed by paralleling L-shaped engine double cylinders, and the declared speeds of a left crankshaft (1) and a right crankshaft (2) are the same and equal to the declared speed of an existing engine; the declared speed of an output shaft (2) is the declared speed output by the engine to the outside and can be equal to, smaller than or larger than the declared speeds of the crankshafts according to the requirements of the outside; thus, the working property is optimized, the application range of the engine is enlarged, auxiliary devices additionally arranged among devices are omitted or simplified, and the cost of occupied by the auxiliary devices and the device bearing and assembly spaces are saved; meanwhile, the piston reciprocating double-cylinder engine has the advantages that the structures of the L-shaped engine double cylinders and the crankshafts are simple, the manufacturing cost is low, stability is high, the low-speed torque characteristic is good, and the total length of the V-shaped engine is small, so that the space is saved, and arrangement is facilitated; and the disadvantages that a V-shaped engine is complex in structure, high in manufacturing cost and difficult to maintain and repair, and an L-shaped engine is long, so that arrangement is difficult are overcome.

Owner:肖光宇

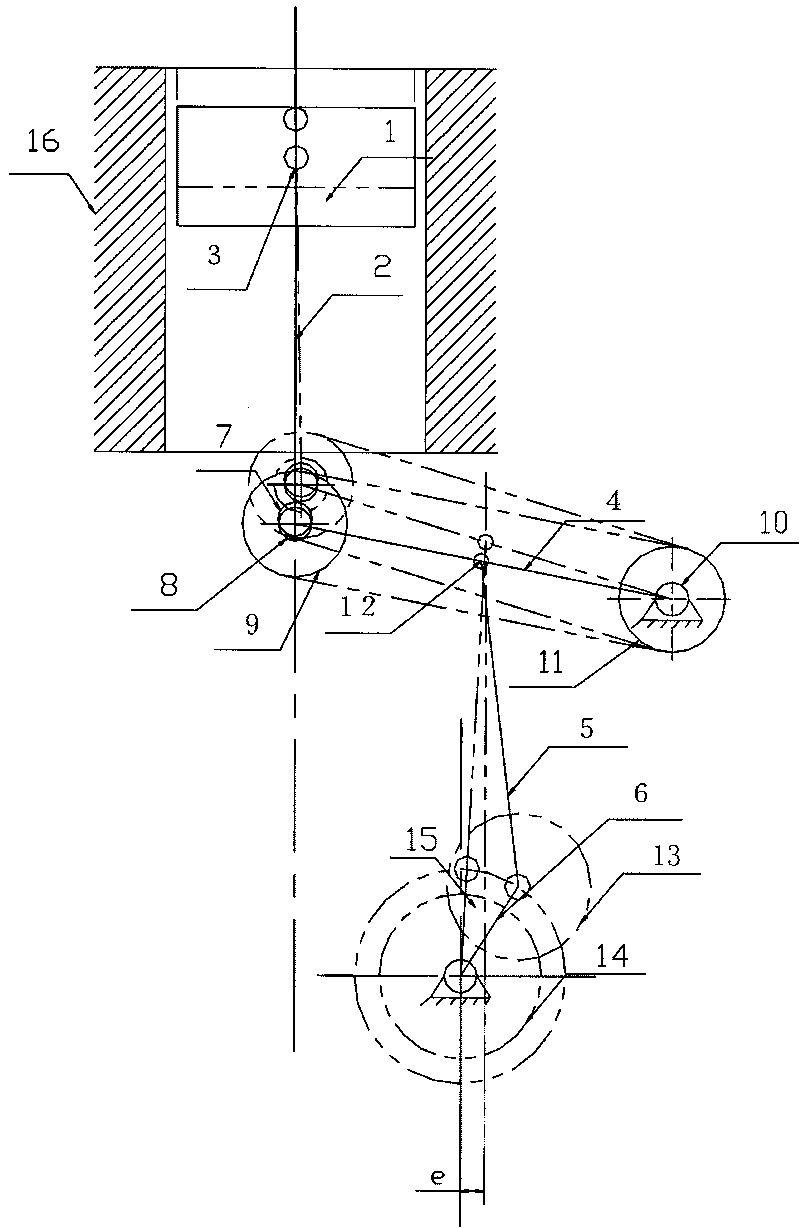

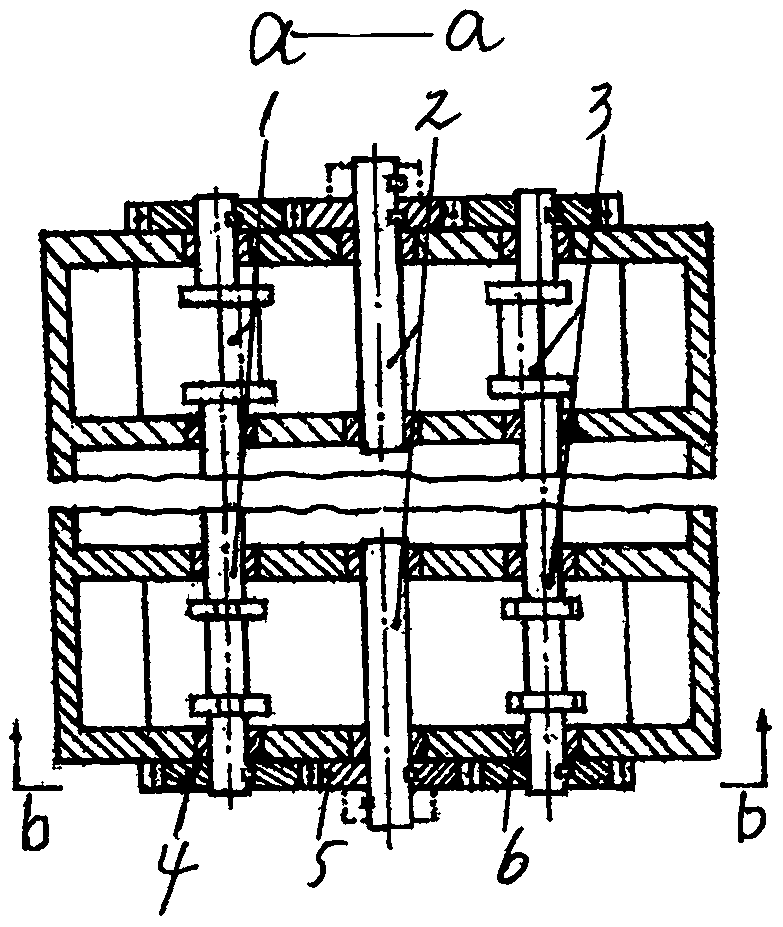

U-shaped piston reciprocating engine

PendingCN107989694ASimple structureImprove thermal efficiencyMachines/enginesEngineeringCylinder block

The invention discloses a U-shaped piston reciprocating engine. The U-shaped piston reciprocating engine is mainly characterized in that only a front row and a rear row of cylinders are equipped withconcentric output shafts (2); two corresponding same gear sets are separately arranged at the front part and the rear part of an engine body; two crankshafts (1, 3) have the same rated rotating speedwhich is equal to a certain fixed value; the rated rotating speed of the crankshafts is equal to the rated rotating speed outputted outwards by the crankshafts of an existing engine; the rated rotating speed of each output shaft is the rated rotating speed outputted outwards by the engine; in each gear set, the diameter of a reference circle of an output shaft gear (5) can be larger than or equalto or smaller than the diameter of the reference circle of a corresponding crankshaft gear, namely the rated rotating speed outputted by the engine is smaller than or equal to or larger than the ratedrotating speed of the crankshafts; so the engine can output a plurality of different rated rotating speeds for use of different equipment, and the application range of a single engine is widened. Besides, the U-shaped piston reciprocating engine also has the advantages that an existing L-shaped engine cylinder body and the crankshafts are simple in structure and easy to manufacture and maintain;the thermal efficiency is high; good stability is realized; and the engine body is short and convenient to arrange when the quantity of the cylinders of the engine is increased.

Owner:肖光宇

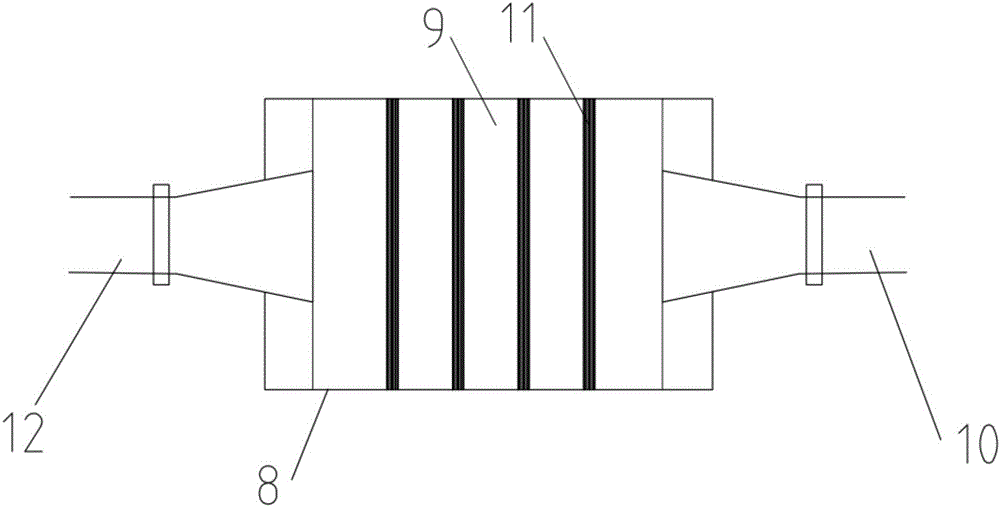

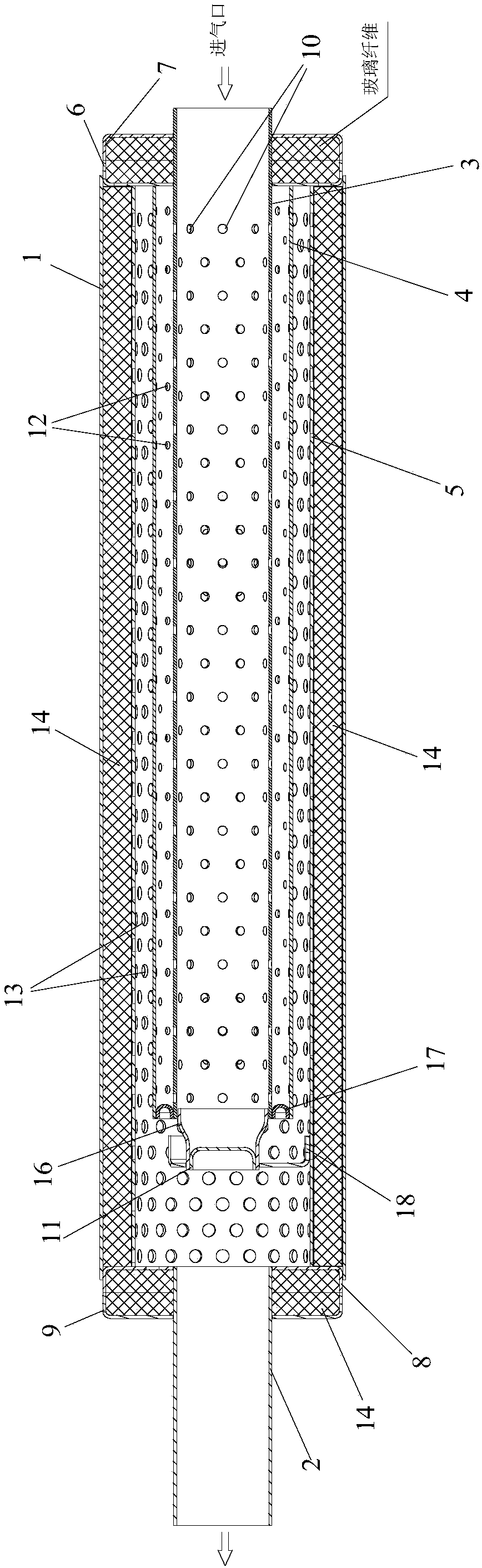

Gasoline engine exhaust silencer composed of porous pipes

PendingCN108278141ASoft and steady soundReduce noise pollutionSilencing apparatusMachines/enginesNoise pollutionPorous pipe

The invention provides a gasoline engine exhaust silencer composed of porous pipes. The gasoline engine exhaust silencer comprises a front end cover, an outer barrel body, a tail cover and a tail pipewhich are connected in sequence. The gasoline engine exhaust silencer further comprises a silencing assembly arranged inside the outer barrel body. The silencing assembly comprises the first porous pipe, the second porous pipe and the glass fiber supporting porous pipe. The pipe wall of the first porous pipe is provided with a plurality of first silencing holes, and the first porous pipe is arranged in the second porous pipe. The pipe wall of the second porous pipe is provided with a plurality of second silencing holes. The pipe wall of the glass fiber supporting porous pipe is provided witha plurality of first sound absorption holes. A glass fiber layer is arranged between the glass fiber supporting porous pipe and the outer barrel body. A glass fiber layer is arranged inside the tail cover. The end face, facing towards the interior of the outer barrel body, of the tail cover is provided with a plurality of second sound absorption holes. The silencing effect and silencing performance are good so as to reduce noise pollution caused by operation of a gasoline engine, and the gasoline engine is large in largest power, high in highest speed and small in power loss.

Owner:陈秀祯

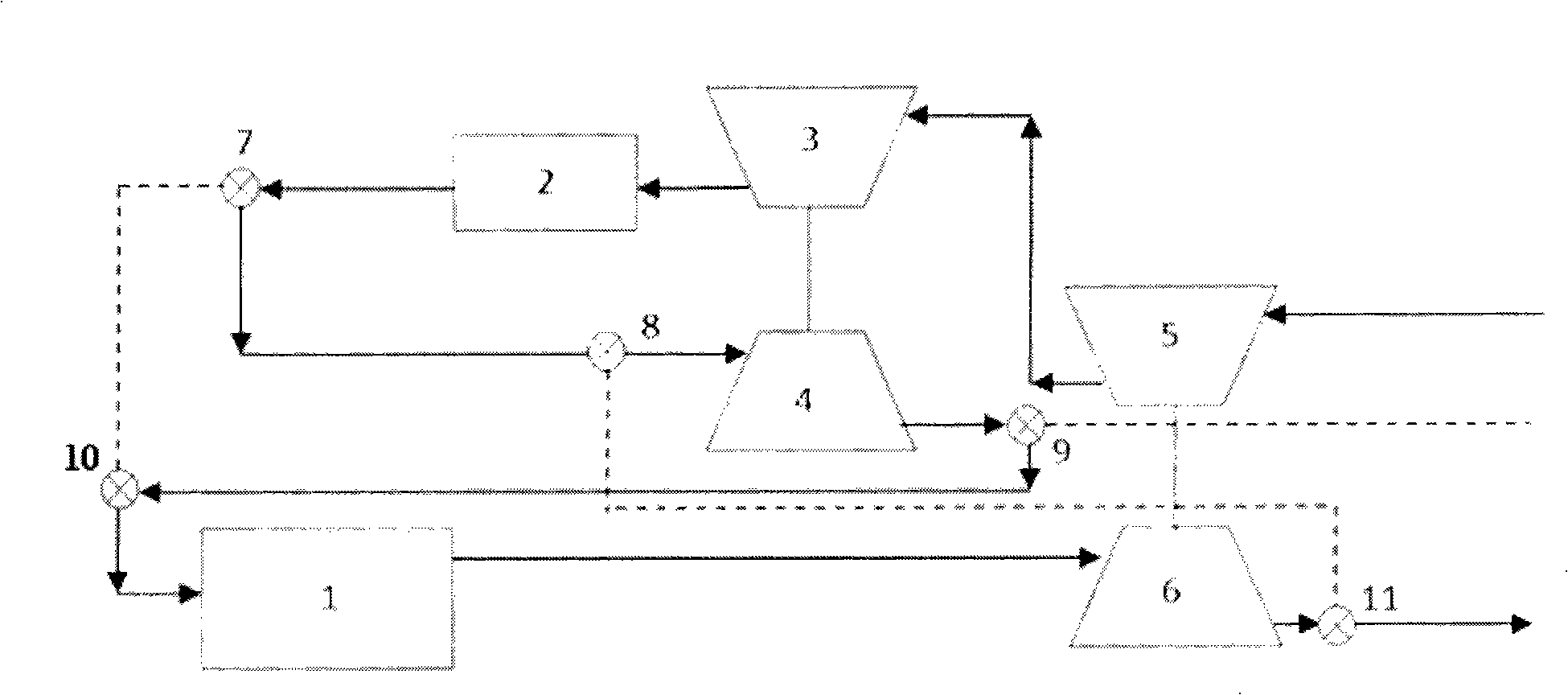

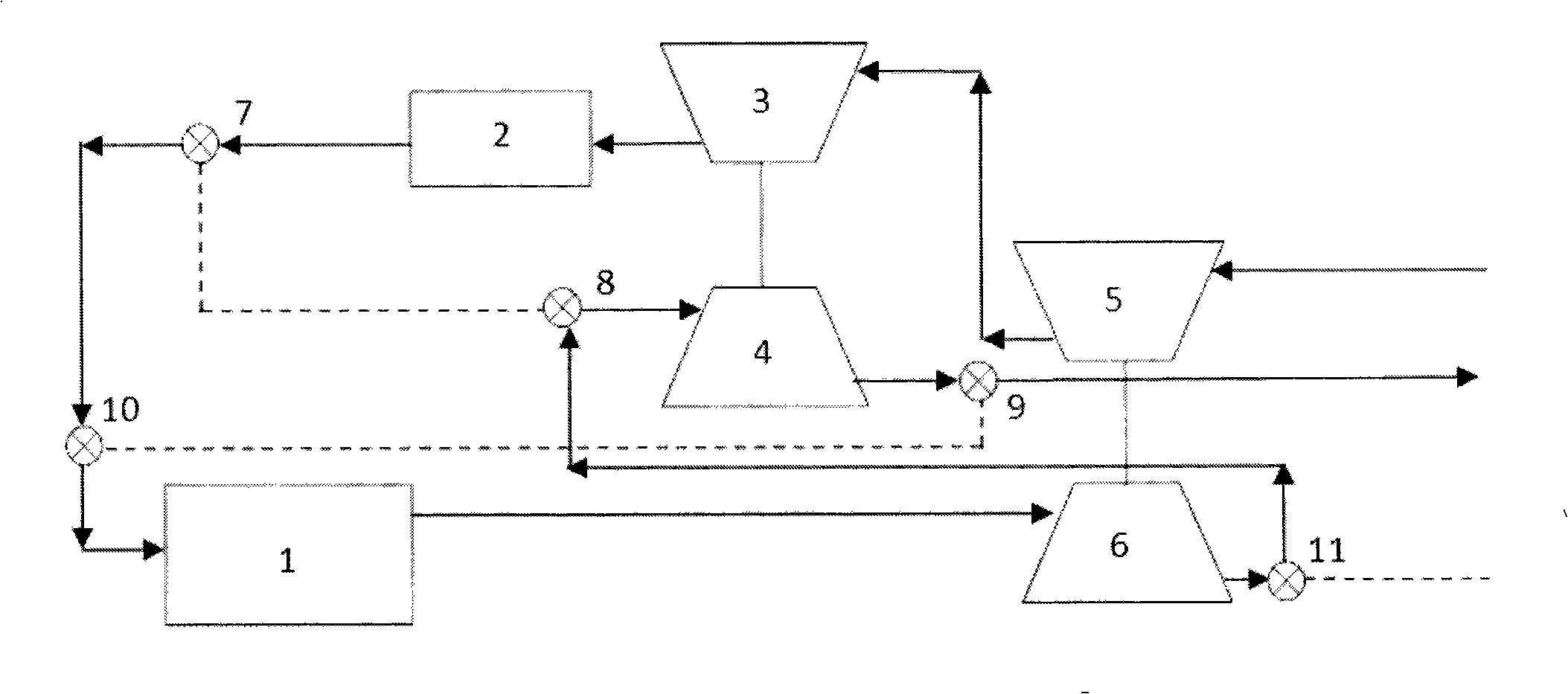

Supercharging gasoline engine air administrative system

InactiveCN101333959AControl intake air temperatureIncrease boost ratioInternal combustion piston enginesAir managementLow speed

The invention belongs to the gasoline engine field, in particular to an air management system of a supercharger gasoline engine, which comprises an air compressor, an intercooler, a main turbine and a double-effect turbine; in the medium or high speed operating condition, the double-effect turbine is serially connected behind the intercooler; the a cylinder and a main turbine are serially and sequentially connected behind the double-effect turbine; the double-effect turbine acts the turbine cooling effect; in the low speed operating condition, the intercooler, the cylinder and the main turbine are serially connected, and then the double-effect turbine is serially connected; the double-effect turbine acts the effect of improving the output torque. The air management system of a supercharger gasoline engine has the advantages of realizing the functions of turbine cooling and the double turbo supercharging, well controlling the inlet gas temperature, allowing higher supercharging ratio and improving the low-speed torque, adopting different operation modes under the high, medium and low rotation speeds, enabling the operation state of the system to be optimized under different operating conditions.

Owner:TSINGHUA UNIV

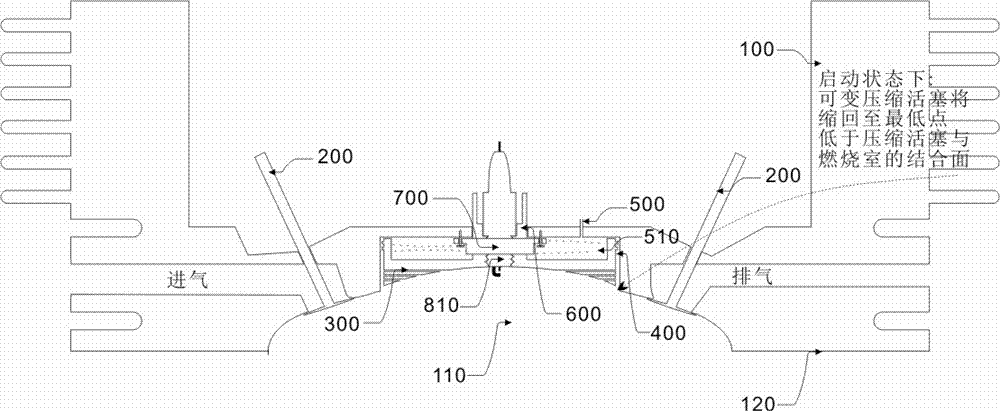

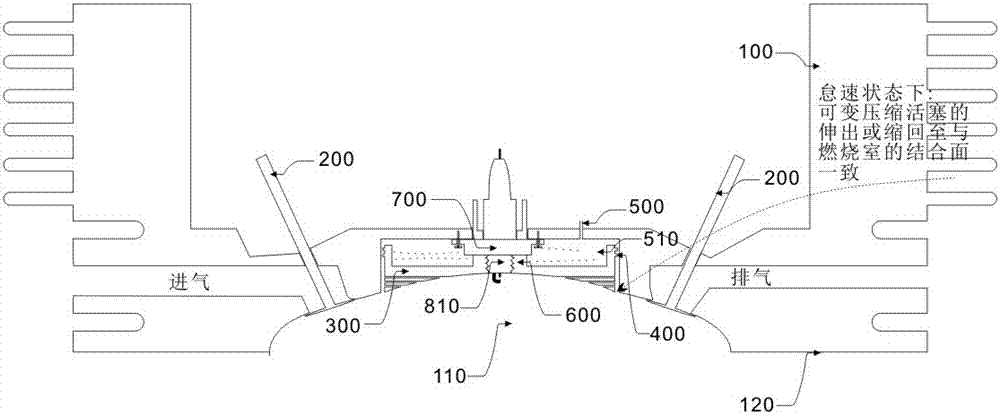

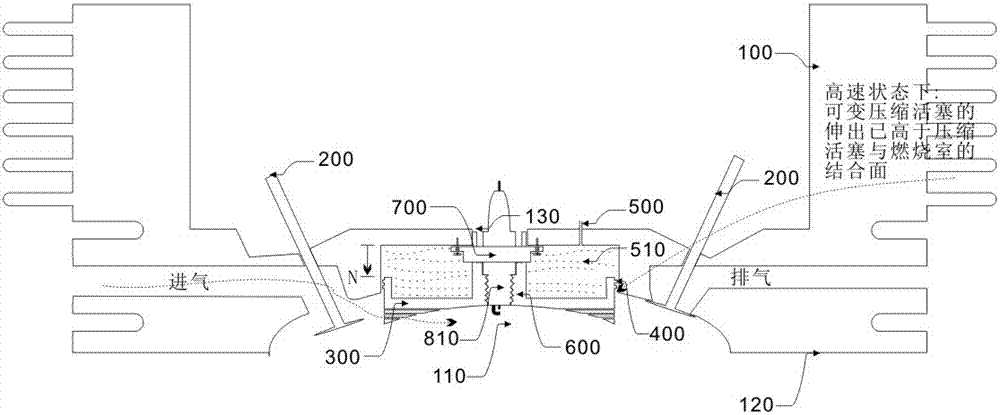

Spark plug position based on engine work condition

InactiveCN106988917ASolve the compression ratioExtended service lifeMechanical controlElectrical controlMomentumCombustion chamber

The invention provides a variable compression engine. The problem about the unified compression ratio of different engine loads in the prior art is solved. The technical scheme is achieved in the manner that the variable compression engine comprises an air cylinder head, a motor and a variable compression piston. The variable compression piston is installed at the position of a combustion chamber of the air cylinder head and is connected with the motor. Due to a vehicle-mounted ECU control motor, the compression ratio of the engine during low-load running and the compression ratio of the engine during medium-load running and high-load running are completely different, the ignition position is also changed along with different compression ratio states, and the requirement for different compression ratios and different ignition positions when different engine loads and different engine rotating speeds are adopted is met, and therefore the power and the momentum of the engine are improved by improving the combustion efficiency of fuel.

Owner:JINJIANG LUOSHAN YONGMING COMP SOFTWARE DEV SERVICE DEPT

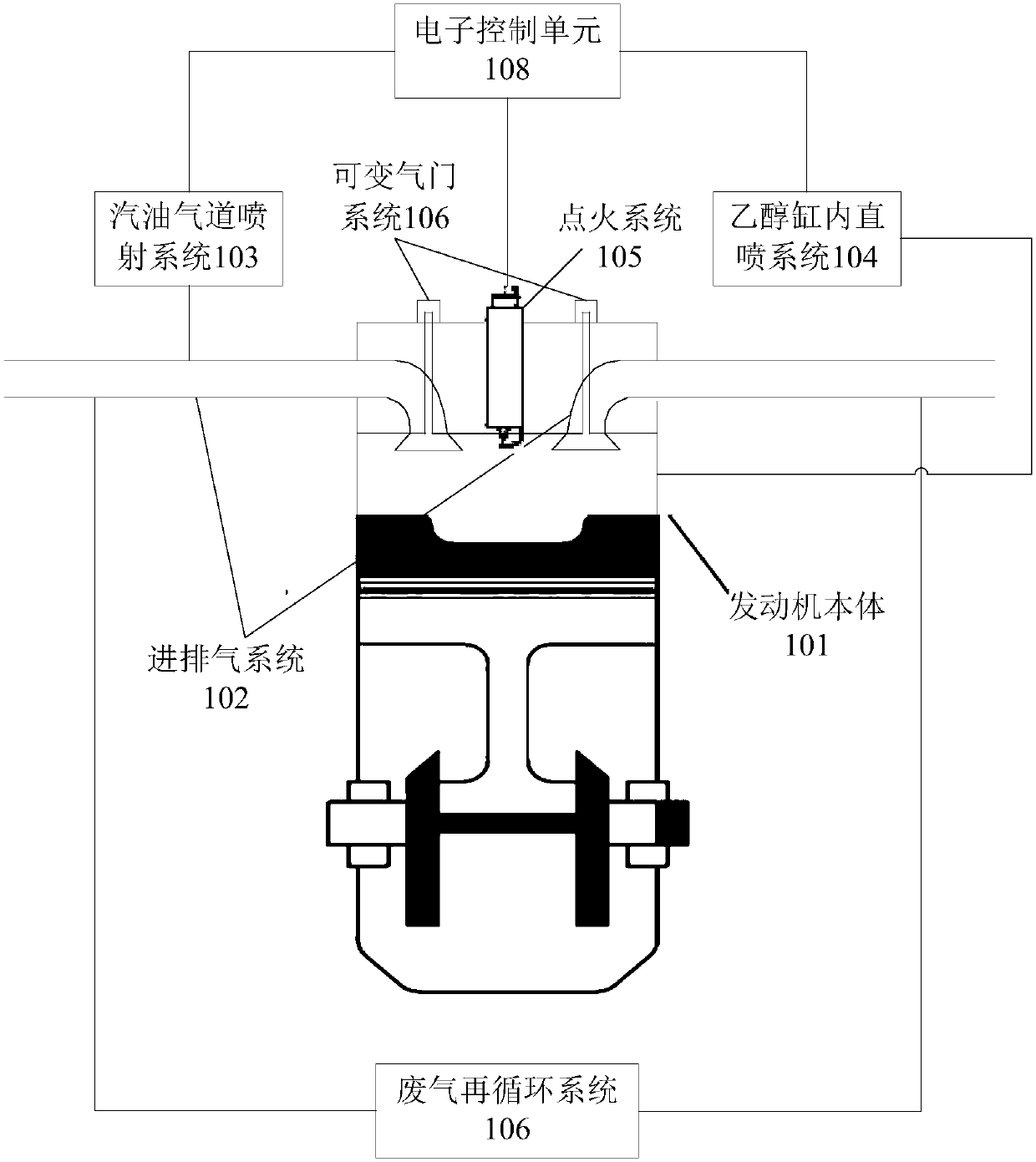

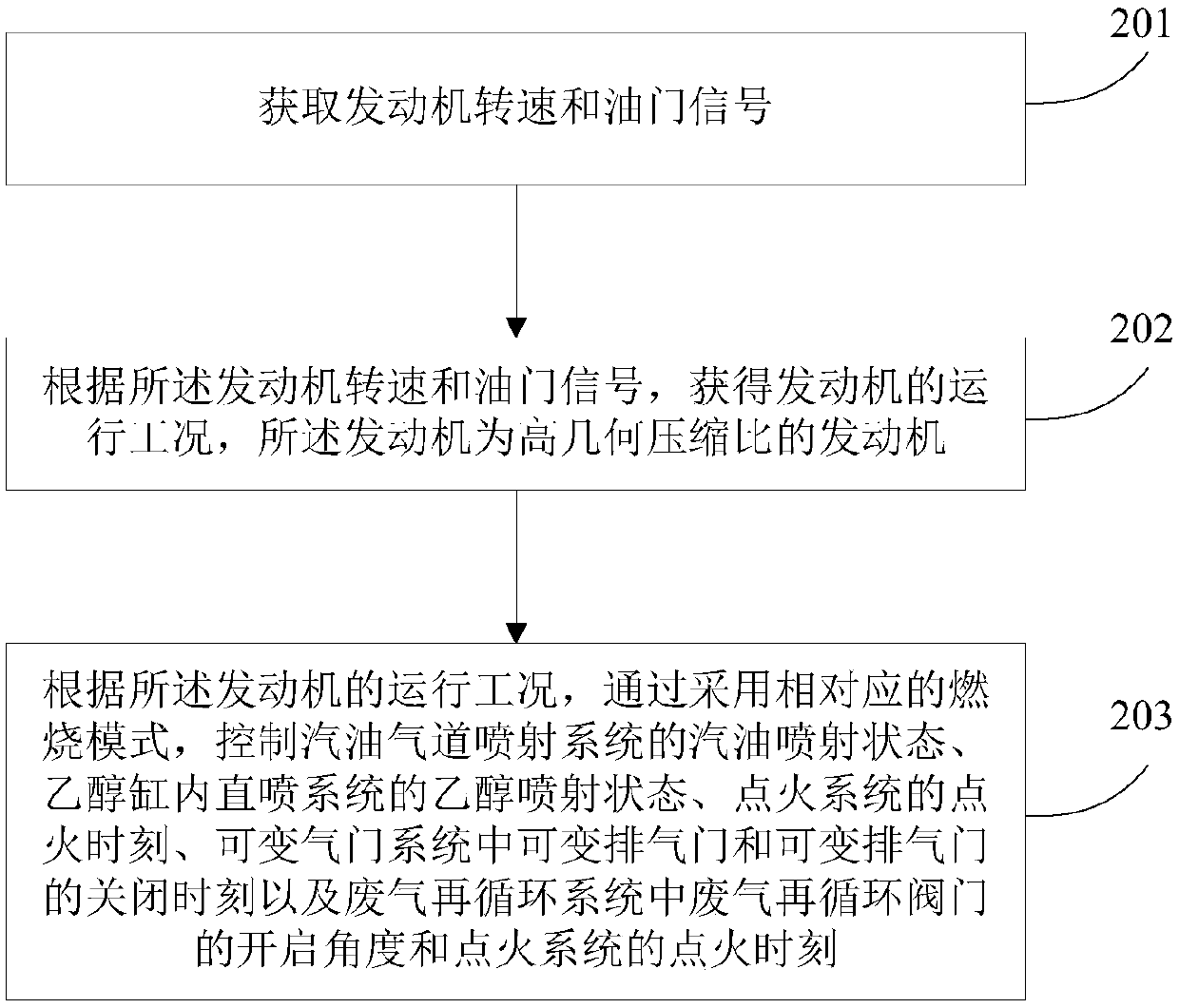

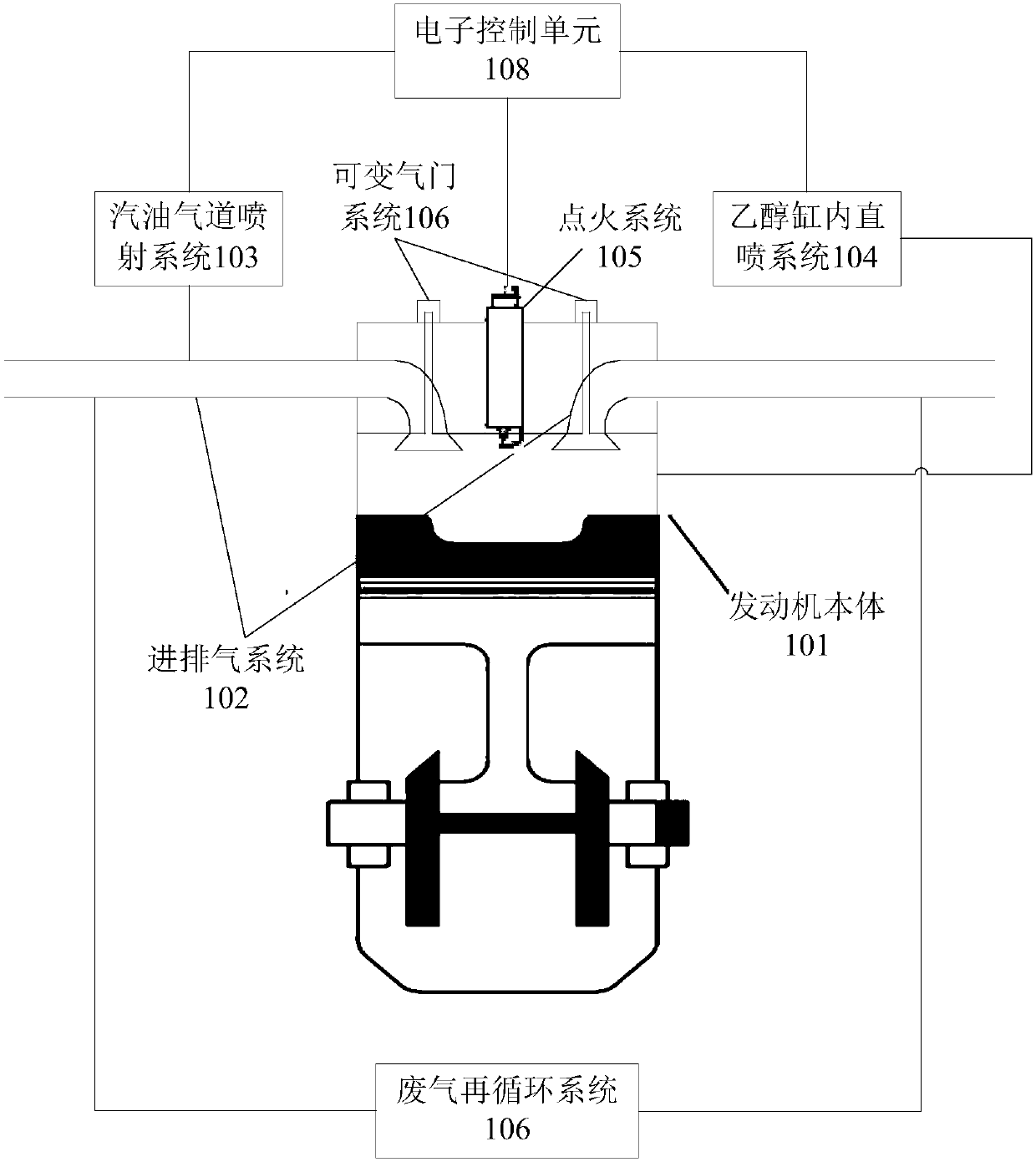

Engine combustion system and control method thereof

InactiveCN109838319AIncrease low speed torqueImprove power densityElectrical controlMachines/enginesCombustion systemDetonation

The invention discloses an engine combustion system and a control method thereof. The system comprises an engine body, an air inlet and exhaust system, a gasoline air channel injection system, an ethanol cylinder direct injection system, an ignition system, a variable valve system, an exhaust gas recirculation system and an electronic control unit; the engine body is connected with the air inlet and exhaust system, the ethanol cylinder inner direct injection system, the ignition system and the variable valve system, the air inlet and exhaust system is connected with the gasoline gas channel injection system and the waste gas recirculation system, the gasoline air channel injection system, the ethanol cylinder direct injection system, the ignition system, the variable valve system and the exhaust gas recirculation system are connected with the electronic control unit, and a high-geometric compression ratio is adopted by the engine body. Therefore, the gasoline and ethanol dual-fuel composite combustion is realized through the corresponding combustion mode, and the early combustion and detonation tendency of a large-load working condition region are inhibited, the low-speed torque and the power density of an engine are improved, and the combustion efficiency and the heat efficiency are improved.

Owner:SAIC MOTOR

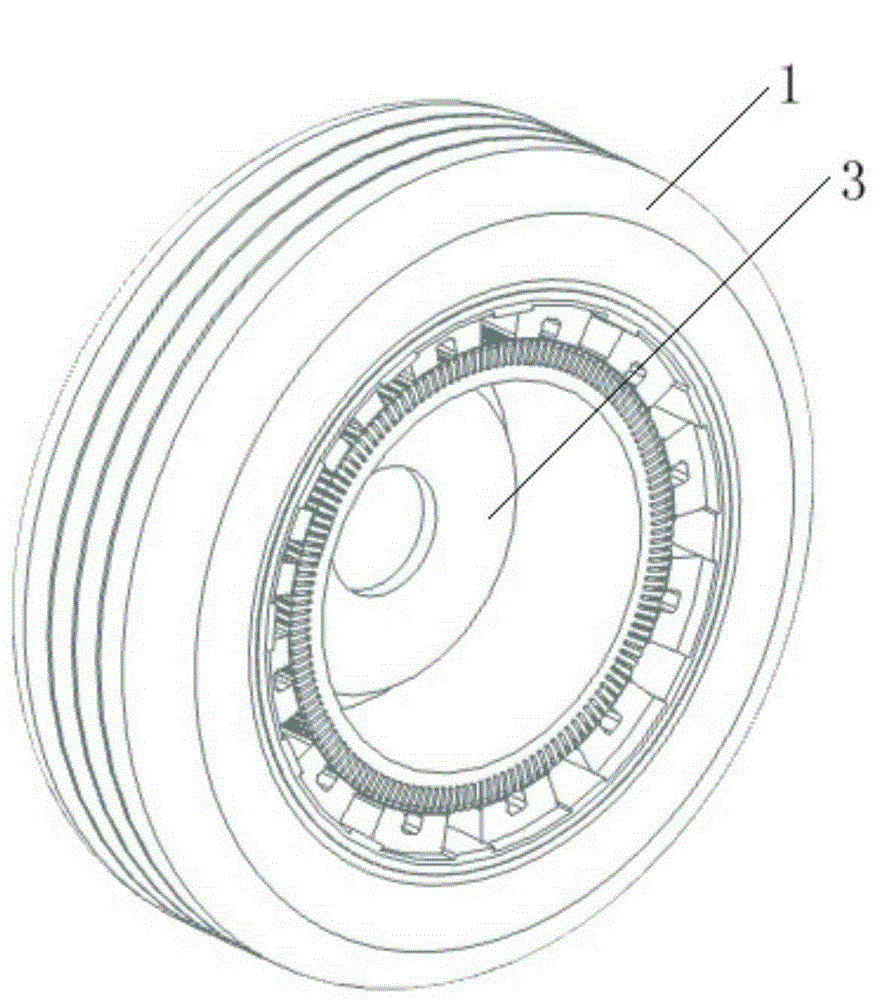

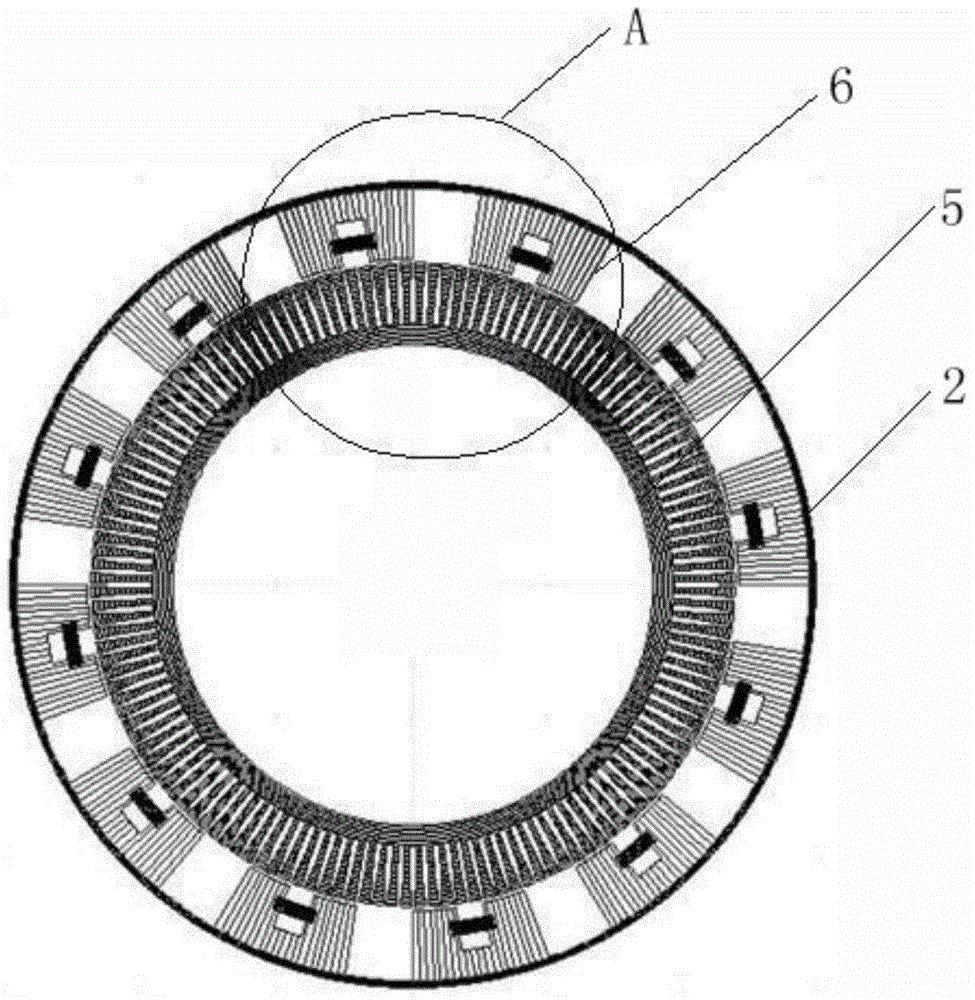

Direct-drive wheel device based on magnetic resistance switch motor and achieving method

ActiveCN105128649ASimplify complex transmission structureImprove fatigue strengthElectric machinesFluid steeringDrive wheelCombustion

The invention discloses a direct-drive wheel device based on a magnetic resistance switch motor. The device comprises a tire and a magnetic resistance outer rotor direct-drive motor arranged in the tire. A speed reduction device and a steering device are arranged in the magnetic resistance outer rotor direct-drive motor. An achieving method of the direct-drive wheel device based on the magnetic resistance switch motor comprises the following steps that 1, dynamic pole adjustment is carried out on stators in the magnetic resistance outer rotor direct-drive motor; 2, all poles of outer rotors of the magnetic resistance outer rotor direct-drive motor are excited at the same time; 3, multiple groups of voltage and current are dynamically communicated with windings; 4, air is compressed to control speed reduction or steering. The cost of the magnetic resistance switch motor is largest, the cost of materials and a driver is low, and therefore the cost of a carrying robot, a remote driving electric automobile and the like composed of the device is greatly lower than that of a traditional internal combustion automobile.

Owner:中科厚载地理信息科技盐城有限公司

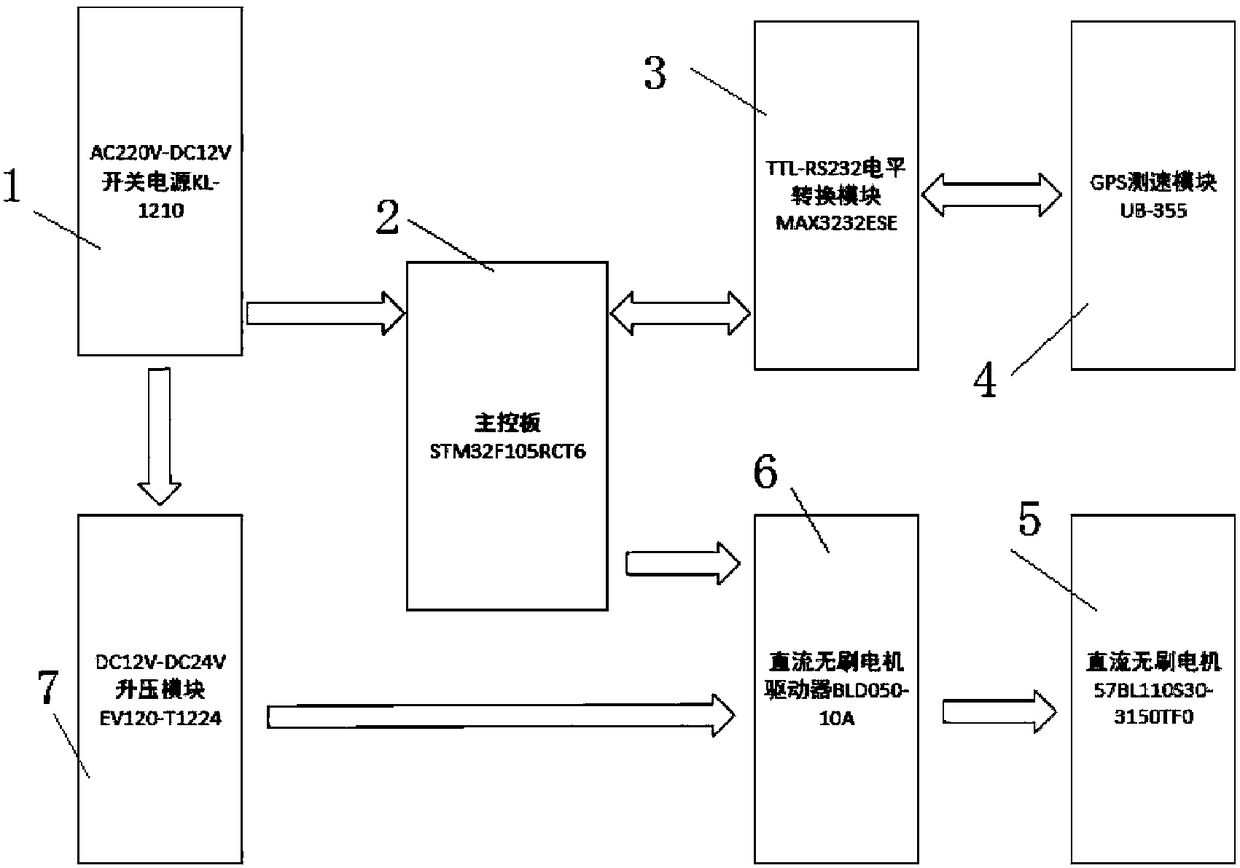

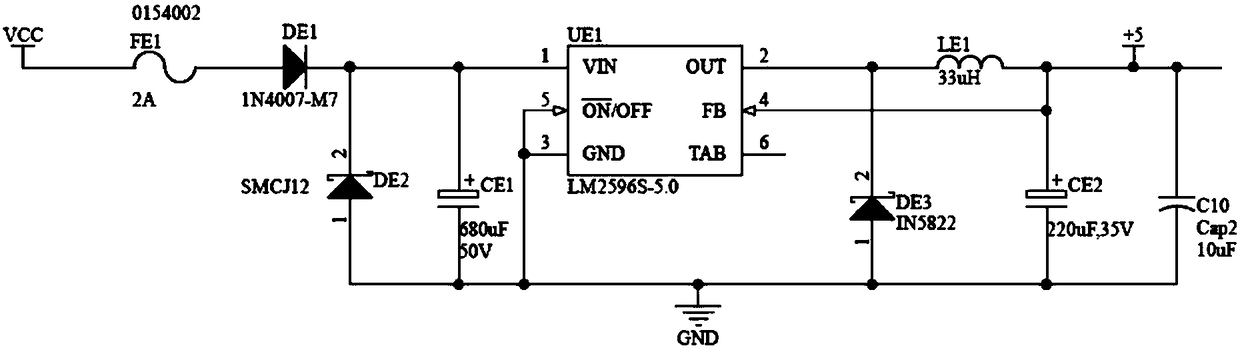

Electric driving type seed sowing device control system based on GPS (global position system)

PendingCN108207213ALittle wind and rainSolve slippageProgramme controlComputer controlBrushless motorsSeeder

The invention discloses an electric driving type seed sowing device control system based on a GPS (global position system). The control system comprises a power supply, a main control board, a level switching circuit, a GPS speed measuring module, a direct current brushless motor, a direct current brushless motor driver and a boost module, wherein the power supply supplies power to the main control board and the booster module; power is supplied to the GPS speed measuring module through the main control board; the boost module supplies power to the direct current brushless motor driver; the direct current brushless motor is driven by the direct current brushless motor driver. The control system effectively solves the problem of slipping of a tachometer wheel, and improves the sowing quality at a high speed state; the tachometer wheel is not required to be additionally mounted onto a seeder, and the complexity degree of a machine structure is reduced; the requirements on the environmentare reduced, and the influence on the GPS by dust, wind and rain is smaller than that on a coder; a GPS module can collect more effective information, which is beneficial to the expansion of future system functions.

Owner:CHINA AGRI UNIV

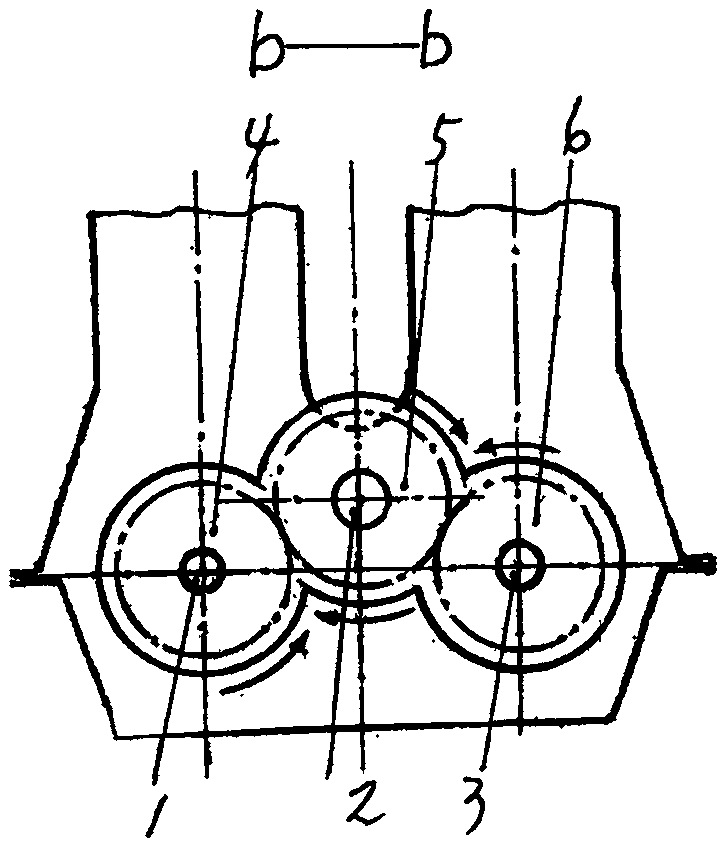

Piston reciprocating tank engine

InactiveCN107747514ASimple structureReduce manufacturing costMachines/enginesLow speedControl theory

The invention discloses a piston reciprocating tank engine. It is characterized in that two rows of L-shaped engine cylinders connected vertically and parallelly in parallel replace the engine cylinders of multiple rows of V-shaped engines; the output shaft (2) is arranged in the middle of the left and right crankshafts (1, 3); the left and right crankshaft gears (4, 6 ) with the same rotating speed and opposite rotation directions, and respectively mesh with the output shaft gear (5) to form a gear set; adjusting the ratio of the diameter of the pitch circle diameter of the crankshaft gear to the pitch circle diameter of the output shaft gear can adjust the output of the output shaft (2) to the outside world. calibrated speed. It has the advantages of L-type engine engine cylinder and crankshaft with simple structure, low cost, easy maintenance, stable operation, high thermal efficiency, and V-type engine body length is short, easy to arrange, etc., and can also reduce the rated speed of the engine output, several times Increase the low-speed torque of the engine.

Owner:肖光宇

Large piston-reciprocating low-speed engine

The invention discloses a high-power piston-reciprocating low-speed engine for large ships. The piston diameter and the average speed of an existing large high-power piston-reciprocating low-speed engine (hereinafter referred to as a contrast engine) are kept basically unchanged, the rated rotating speed of crankshafts (1,3) is increased to be three times that of the contrast engine, and the piston travel is 1 / 3 of that of the contrast engine, so that the rated power of the engine is identical with that of the contrast engine, and the size of the engine is only 1 / 4 of that of the contrast engine; then the ratio of the crankshaft gear reference circle diameter to the output shaft gear reference circle diameter is set as 1:3, so that the rated rotating speed output by the engine is identicalwith that output by the contrast engine; after the engine has the unchanged functions but the smaller size, a lot of expensive steel materials are saved, the technical difficulty in manufacturing andmaintenance of large working components is overcome, a lot of manufacturing and maintenance costs are saved, the gravity center of the engine is lowered, and the working performance is more excellent.

Owner:肖光宇

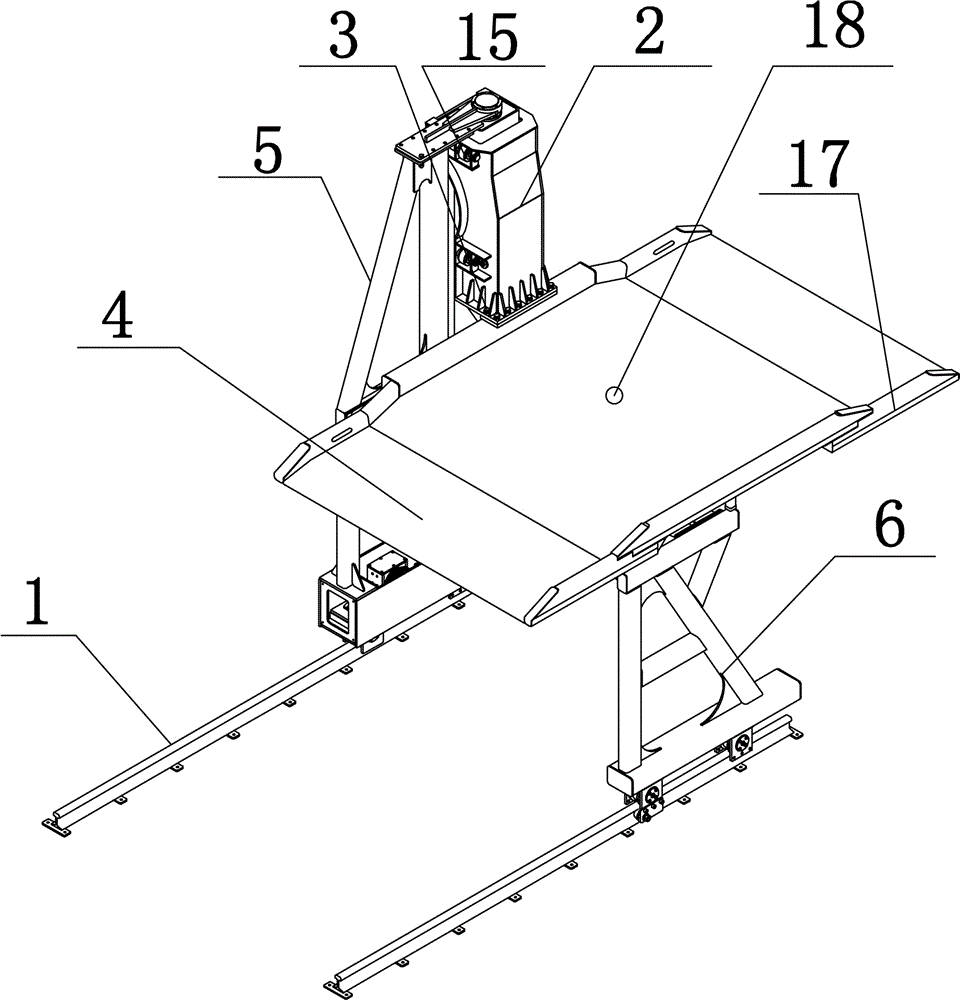

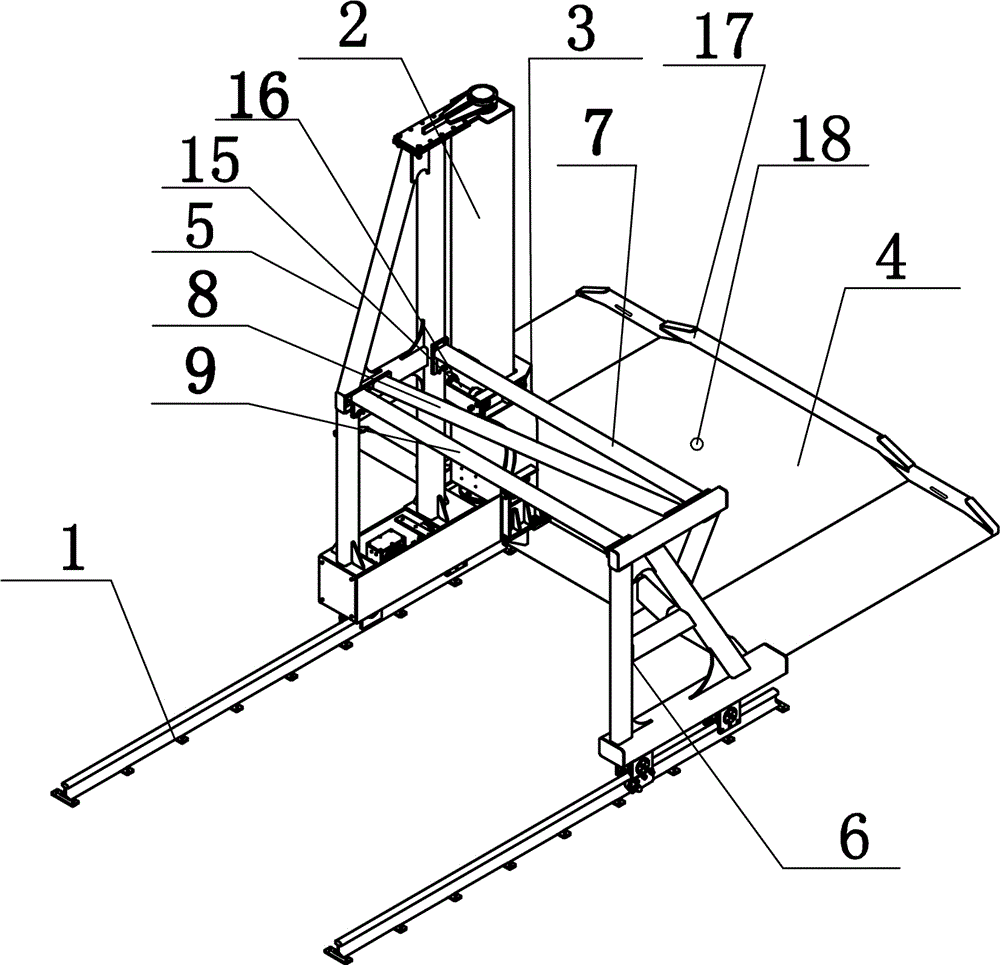

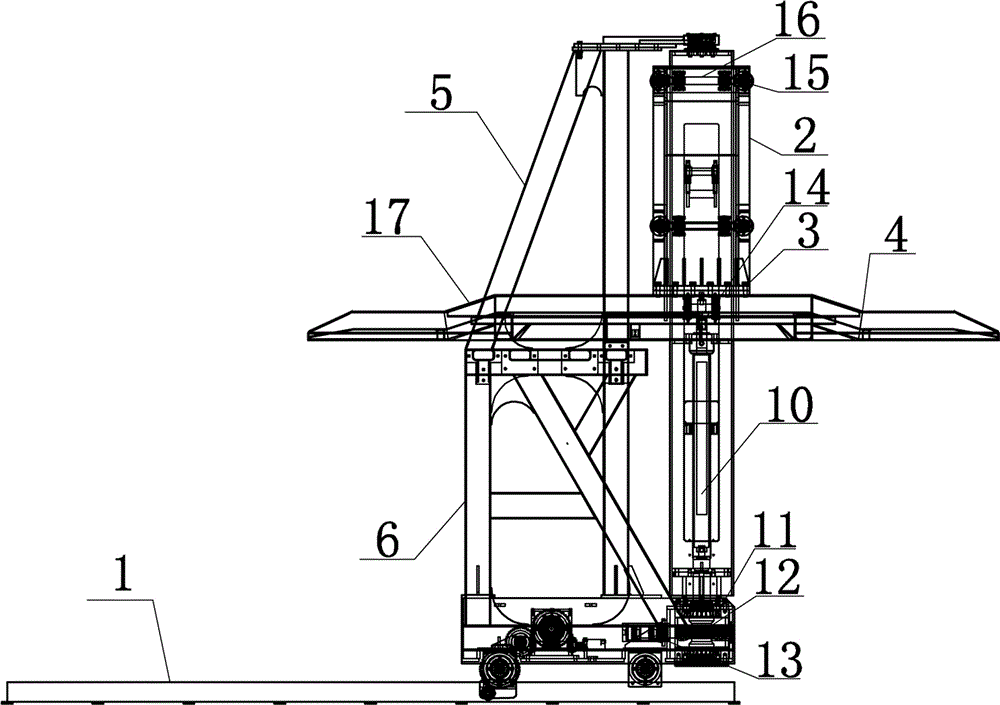

Frame-type interference-free three-dimensional parking equipment

ActiveCN105649387AEnergy efficient operationIncrease low speed torqueParkingsPulse controlEnvironmental noise

The invention relates to frame-type interference-free three-dimensional parking equipment. A storage battery and a direct-current motor are connected in sequence and directly connected with a hydraulic mechanism to control each action mechanism to act, so that an integrated frame moves forwards, a rotary frame rotates, a lifting seat is lifted, and the interference-free parking work is finished together with a sensing mechanism, a limiting mechanism and a controller. The frame-type interference-free three-dimensional parking equipment takes the hydraulic mechanism as a power driving source and is small in volume, simple in structure, low in cost, smooth in action and low in noise; all actions of the equipment are driven by adopting hydraulic parts, so that the operation is stable and the dynamic speed adjustment range is large; each motion displacement position is matched with the hydraulic dynamic length, so that the phenomena of top pushing and the like during failure of a system control part do not occur and the safety is improved; and a power source of the hydraulic mechanism selects and uses a direct-current drive source, the direct-current motor is powered by adopting the storage battery, the parking equipment is energy-saving and efficient through a pulse control technology, the environmental noise is lower when the equipment runs, the motor is large in low-speed torque and stable to start, and the vehicle parking and getting processes are not influenced by power failure.

Owner:ZHEJIANG E STRONG COMM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com