Gasoline engine exhaust silencer composed of porous pipes

An exhaust muffler, gasoline engine technology, applied in the direction of engine components, machines/engines, exhaust devices, etc., can solve problems such as unsatisfactory, low maximum engine power, large power loss, etc., achieve soft and stable sound, and reduce noise pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

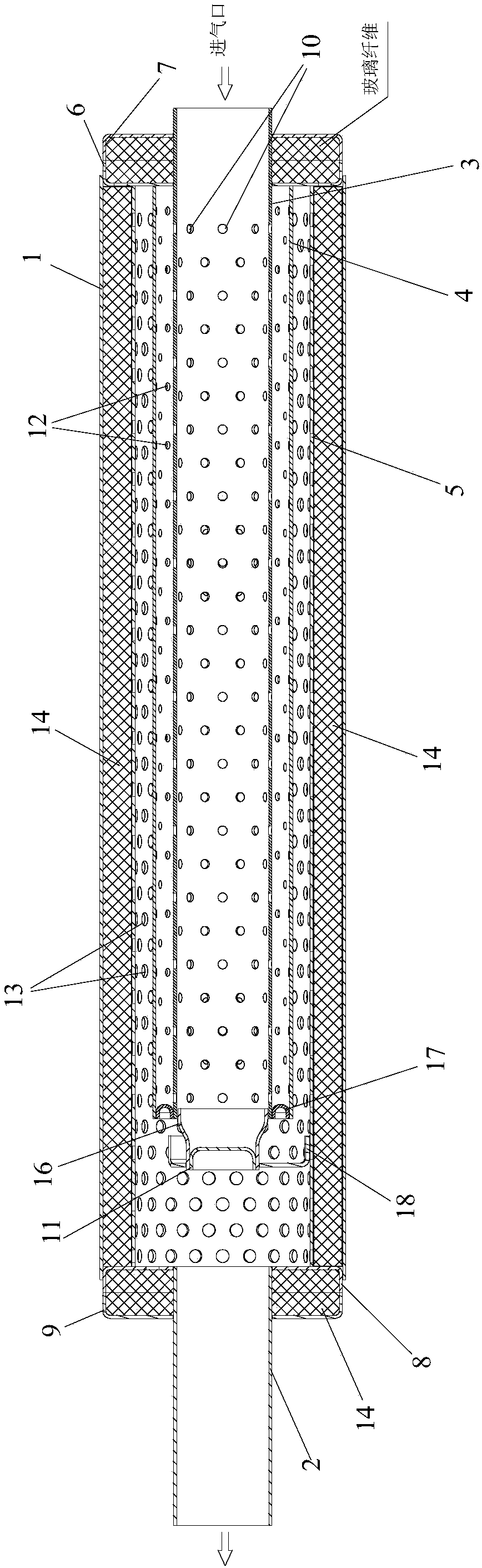

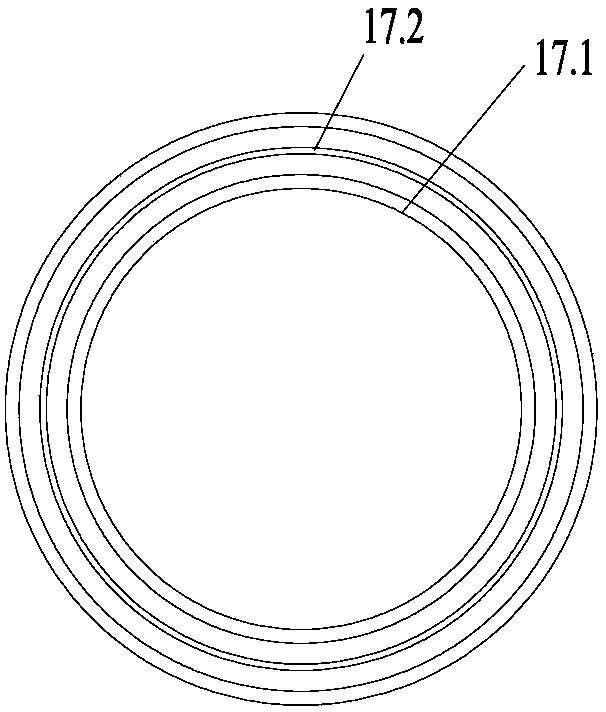

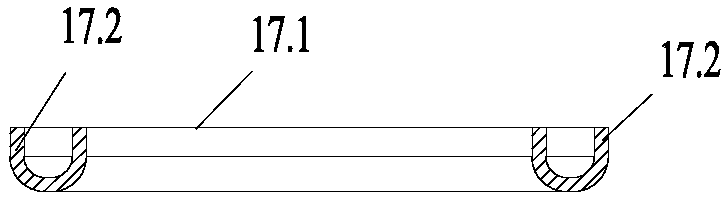

[0046] Such as Figure 1 to Figure 6 As shown, a gasoline engine exhaust muffler composed of porous pipes in the present invention includes a front end cover, an outer cylinder 1, a tail cover and a tail pipe 2 connected in sequence; , wherein the noise reduction assembly includes a first porous tube 3, a second porous tube 4 and a glass fiber support porous tube 5, the front end cover is composed of an inner front end cover 6 and an outer front end cover 7, and the tail cover is composed of an inner tail cover 8 It is combined with the outer tail cover 9.

[0047] Specifically, the pipe wall of the first porous pipe 3 in this embodiment is provided with 216 first silencing holes 10, and the diameter d1 of the first silencing holes 10 is 3.5mm, and two adjacent first silencing holes The hole center distance L1 of the hole 10 is 14.92mm. The first porous tube 3 is built inside the second porous tube 4, and one end thereof protrudes from the front end cover as an air inlet, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com